Patents

Literature

205results about "Phosphorus oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

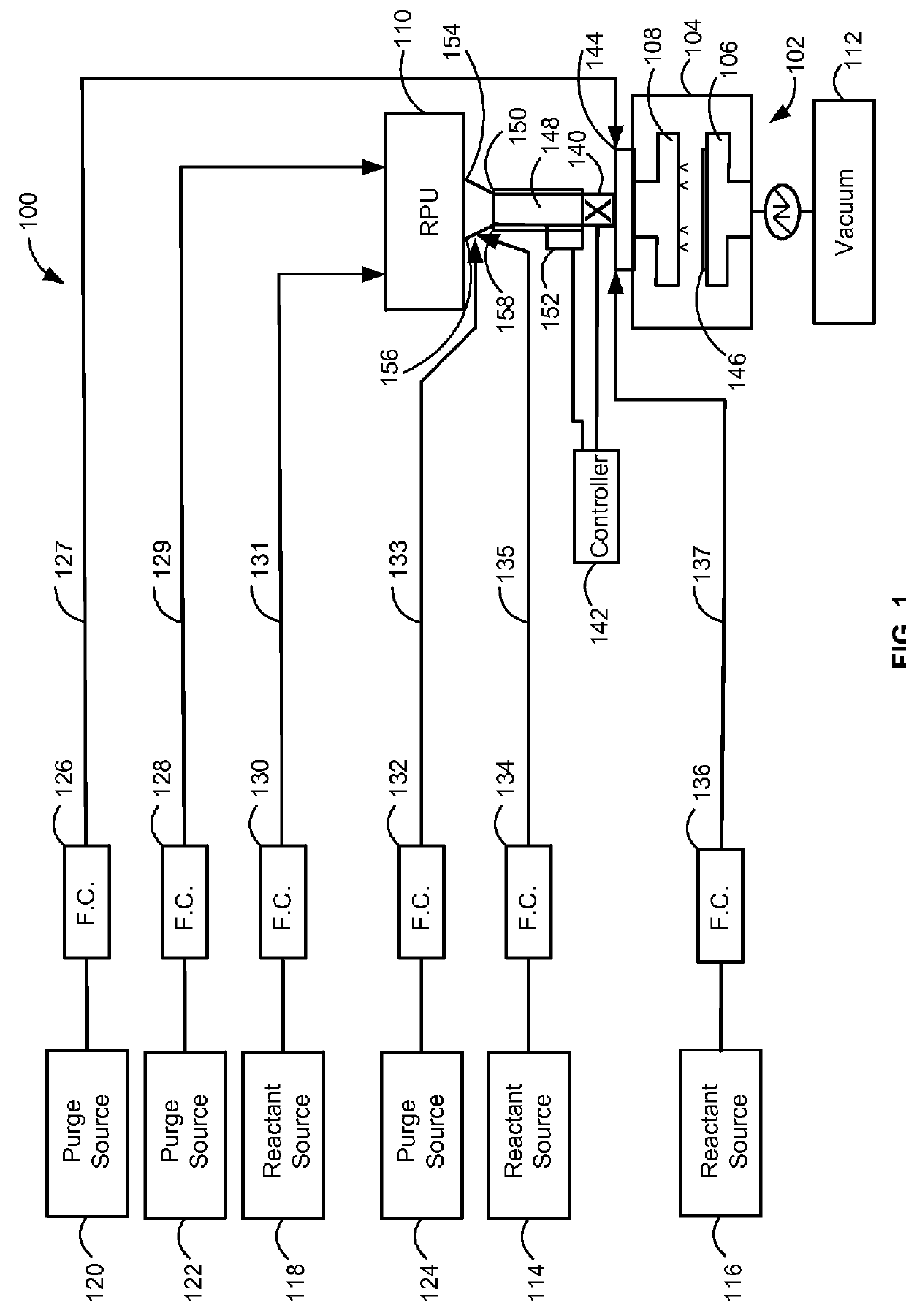

Method and system for in situ formation of gas-phase compounds

ActiveUS20160051964A1Process can be usedProcess control/regulationCell electrodesCompound aGas phase

A system and method for providing intermediate reactive species to a reaction chamber are disclosed. The system includes an intermediate reactive species formation chamber fluidly coupled to the reaction chamber to provide intermediate reactive species to the reaction chamber. A pressure control device can be used to control an operating pressure of the intermediate reactive species formation chamber, and a heater can be used to heat the intermediate reactive species formation chamber to a desired temperature.

Owner:ASM IP HLDG BV

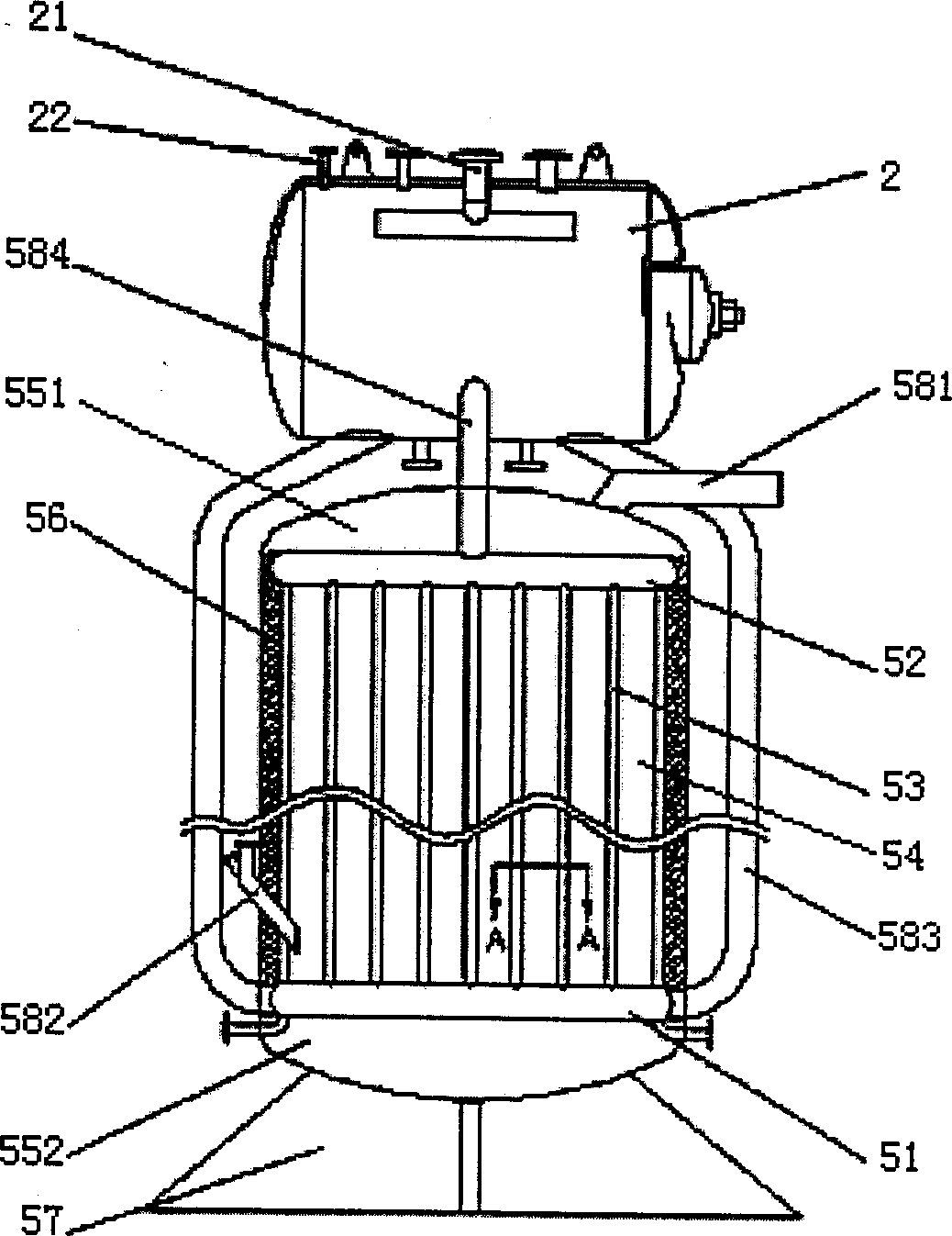

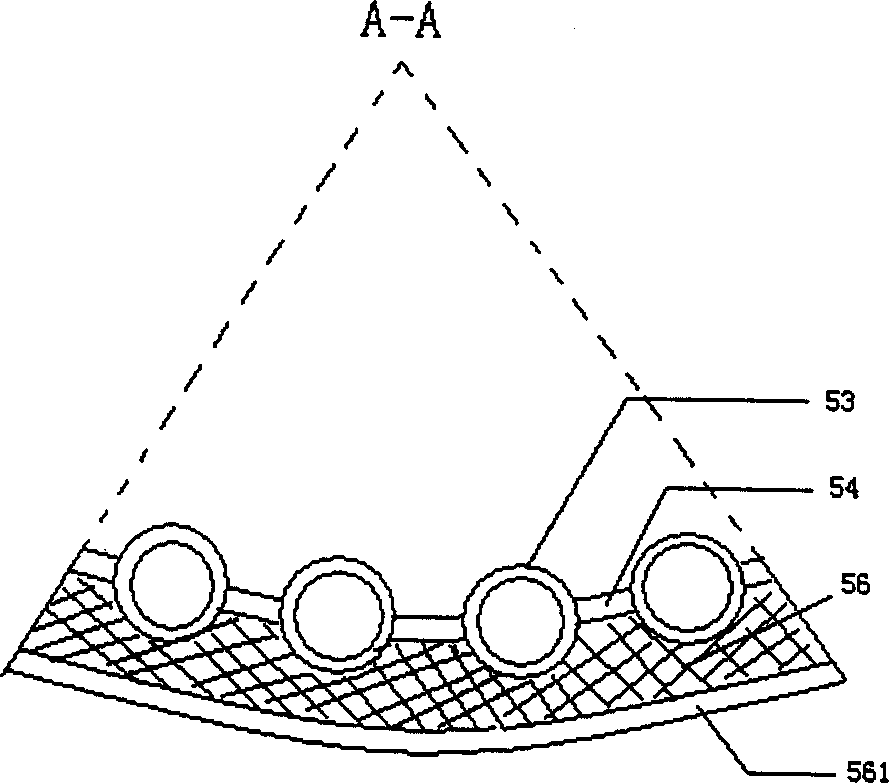

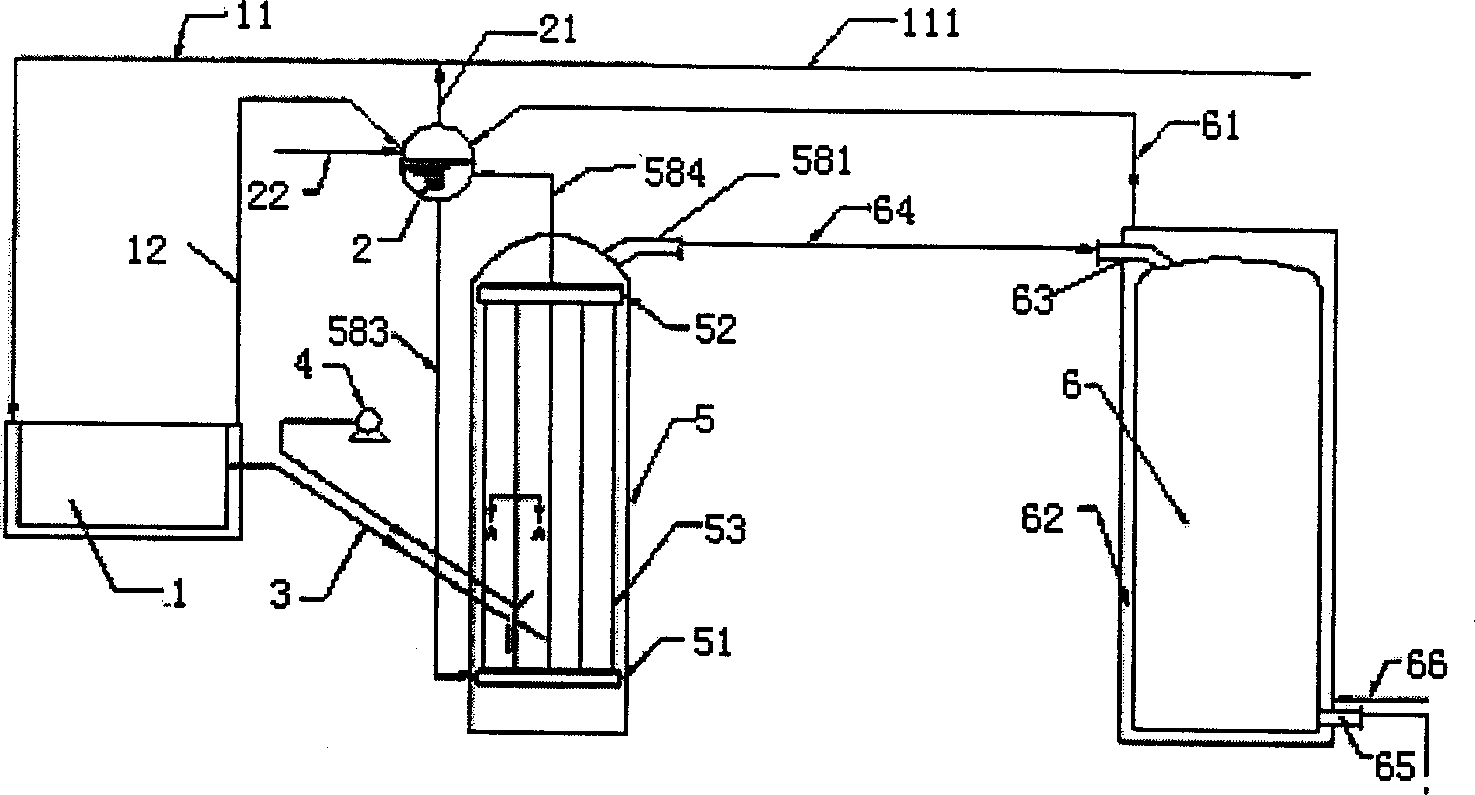

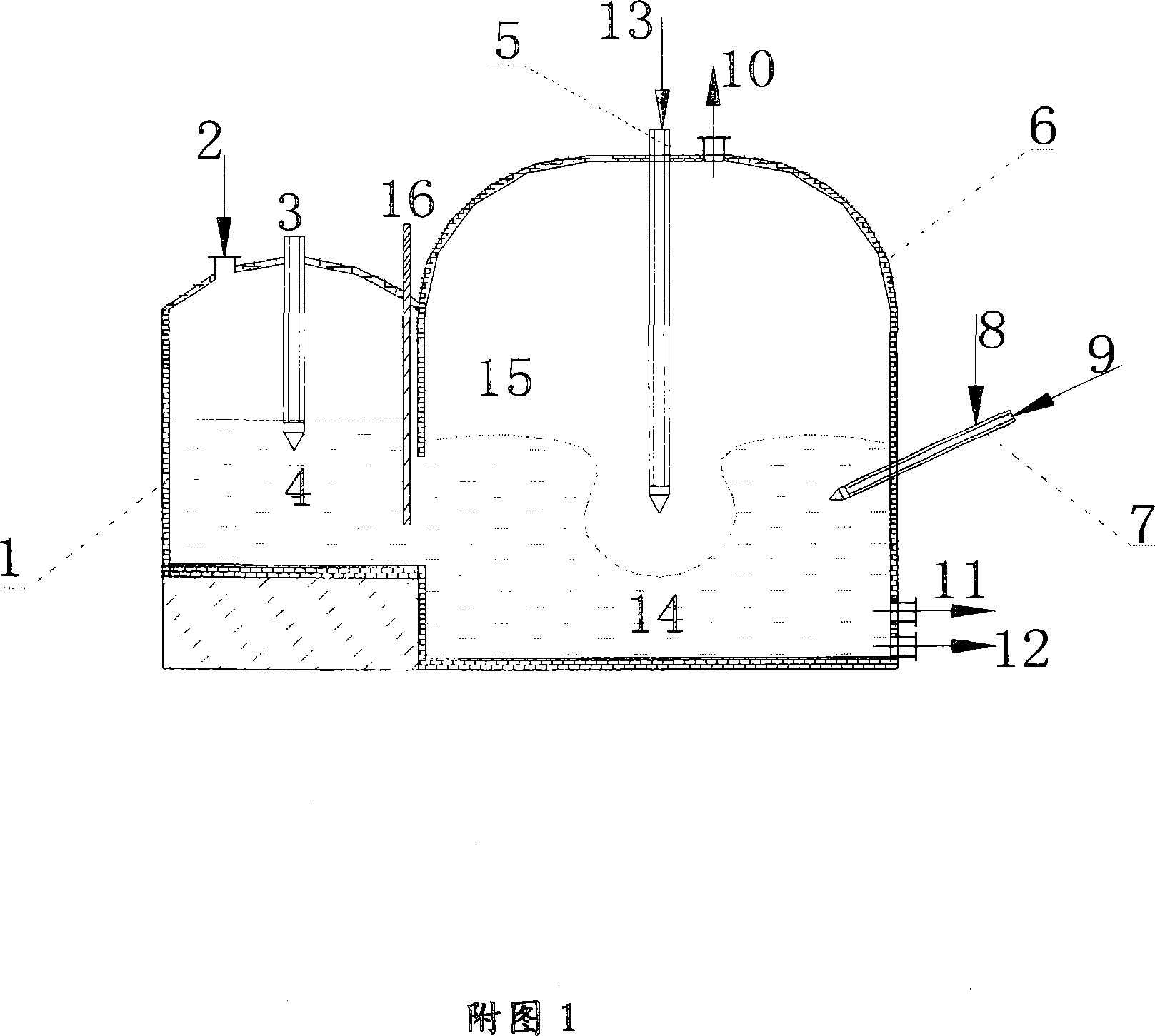

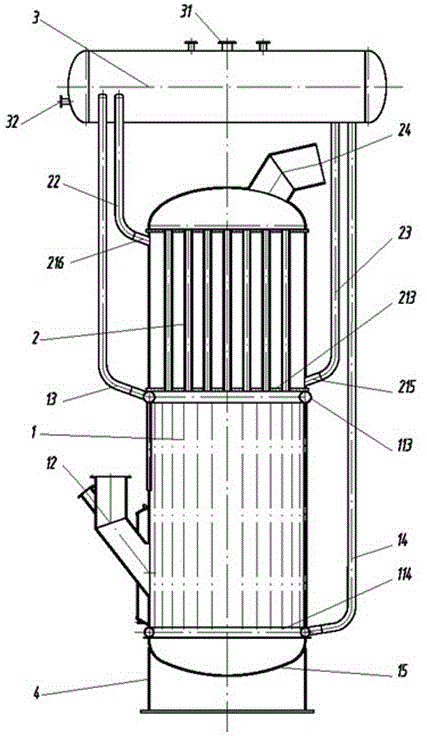

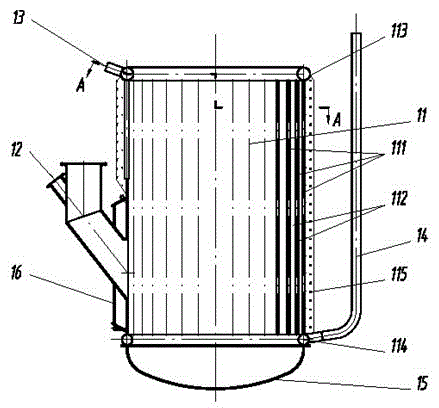

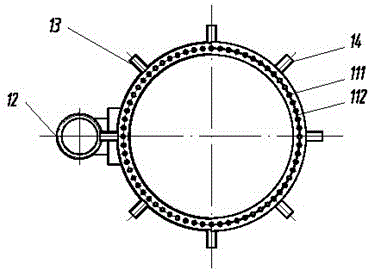

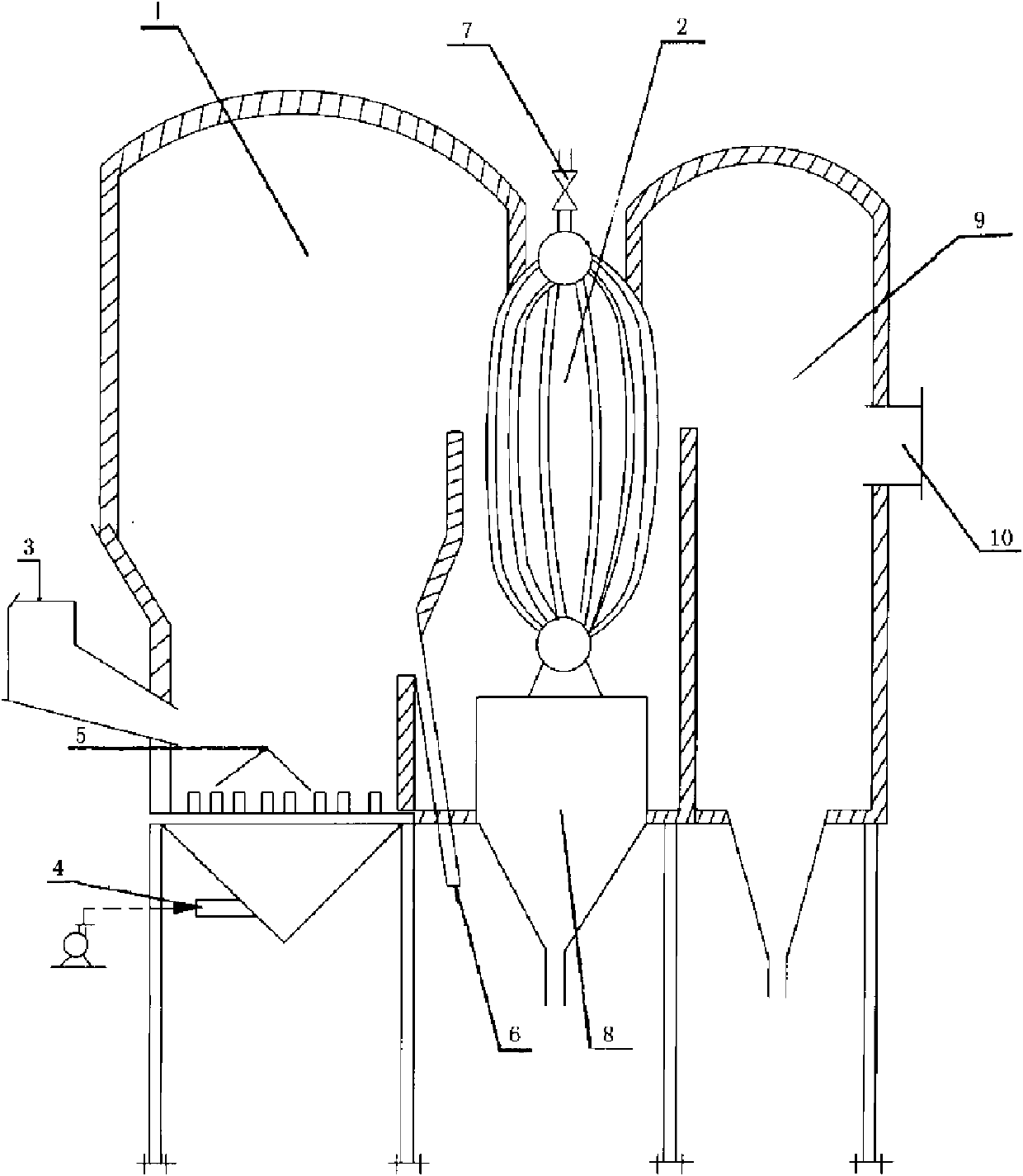

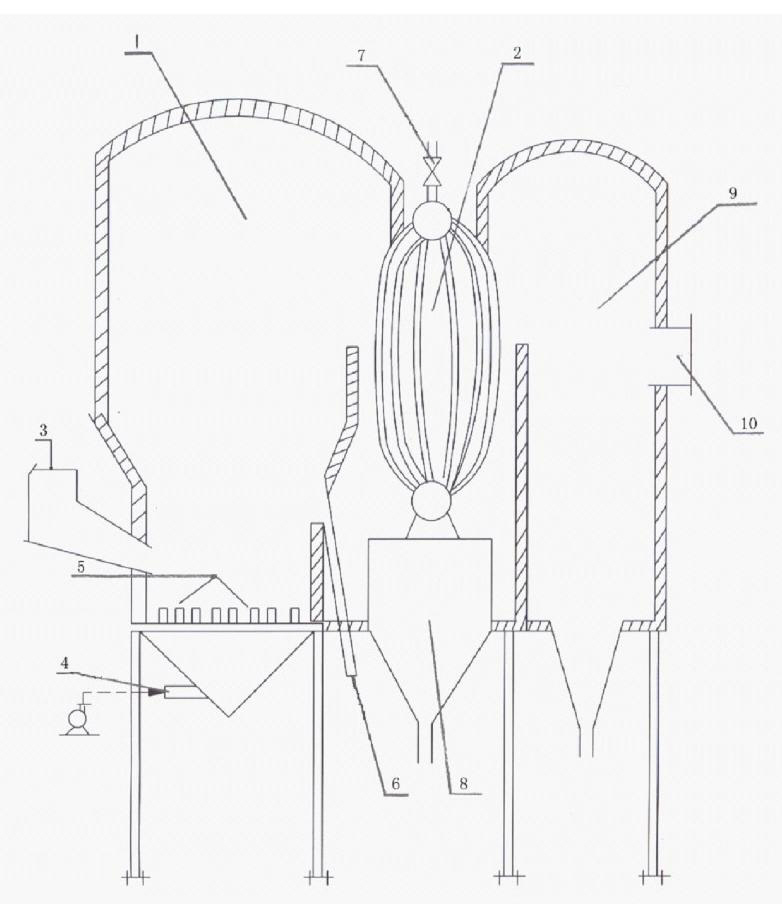

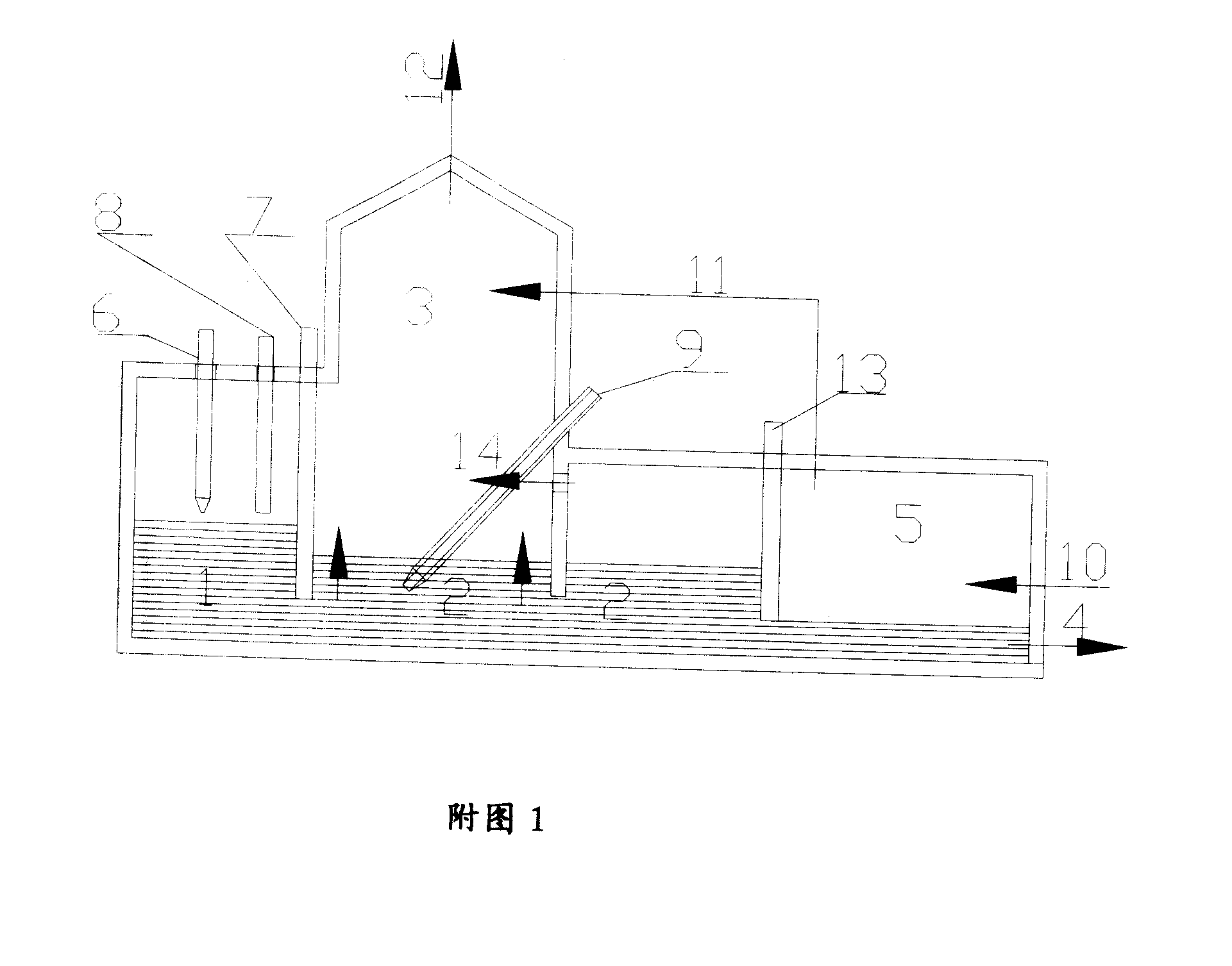

Equipment for recovering and utilizing heat energy generated by phosphor combustion and system for preparing phosphoric acid by hot method

An equipment for recovering and utilizing the heat energy generated by burning yellow phosphorus and a system for preparing phosphoric acid by the hot method are disclosed. It is composed of steam manifold and burning tower with heat energy recovering function. The burning tower consists of ring-shaped membrane heat exchanger with fins, heat-insulaitng enclosed casing, P2O5 gas outlet tube, connecting tube of phosphorus sprayer, etc.. Its advantages include low consumption of coal, water and energy, low cost and reduced environmental pollution.

Owner:TSINGHUA UNIV +1

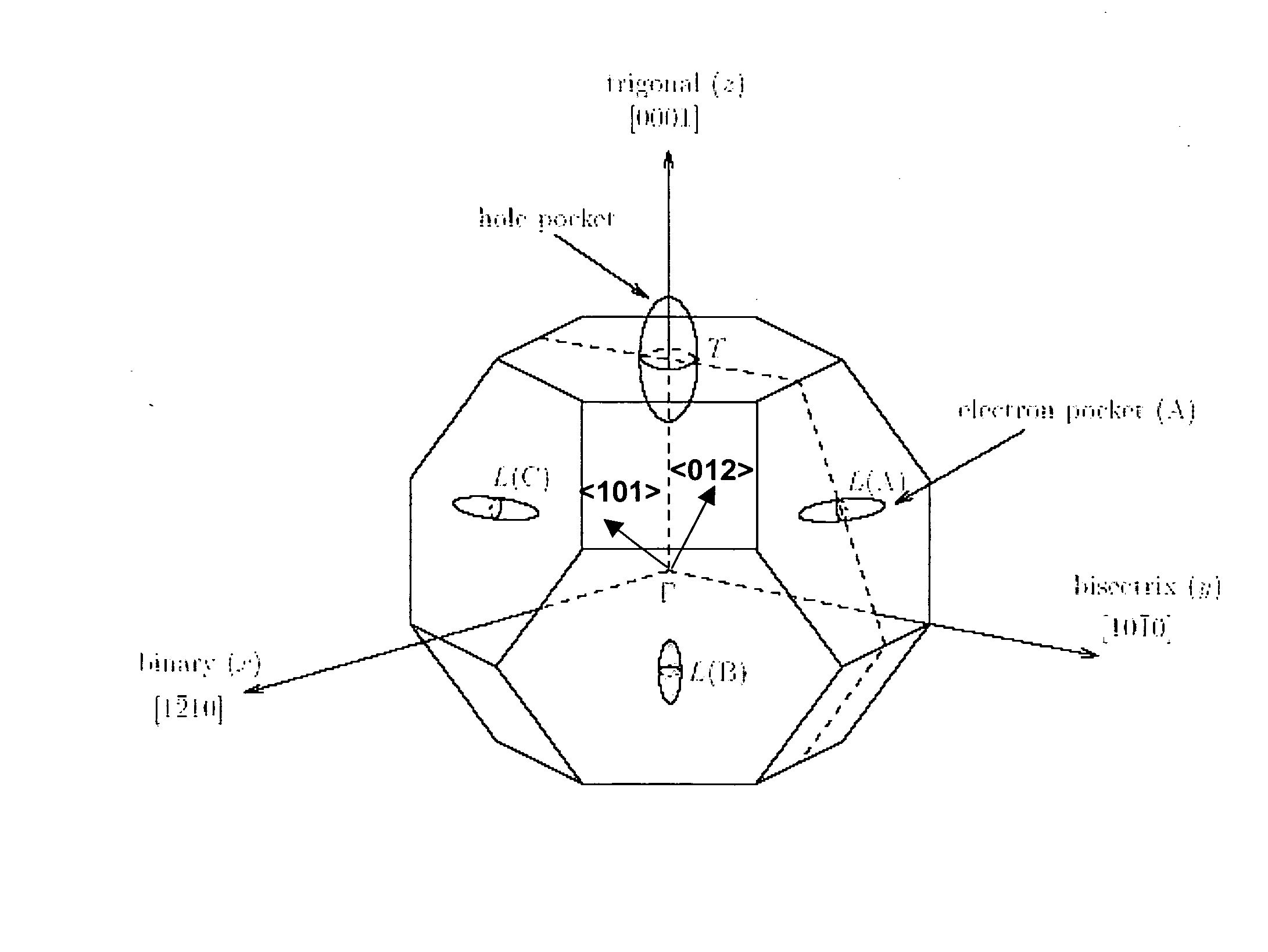

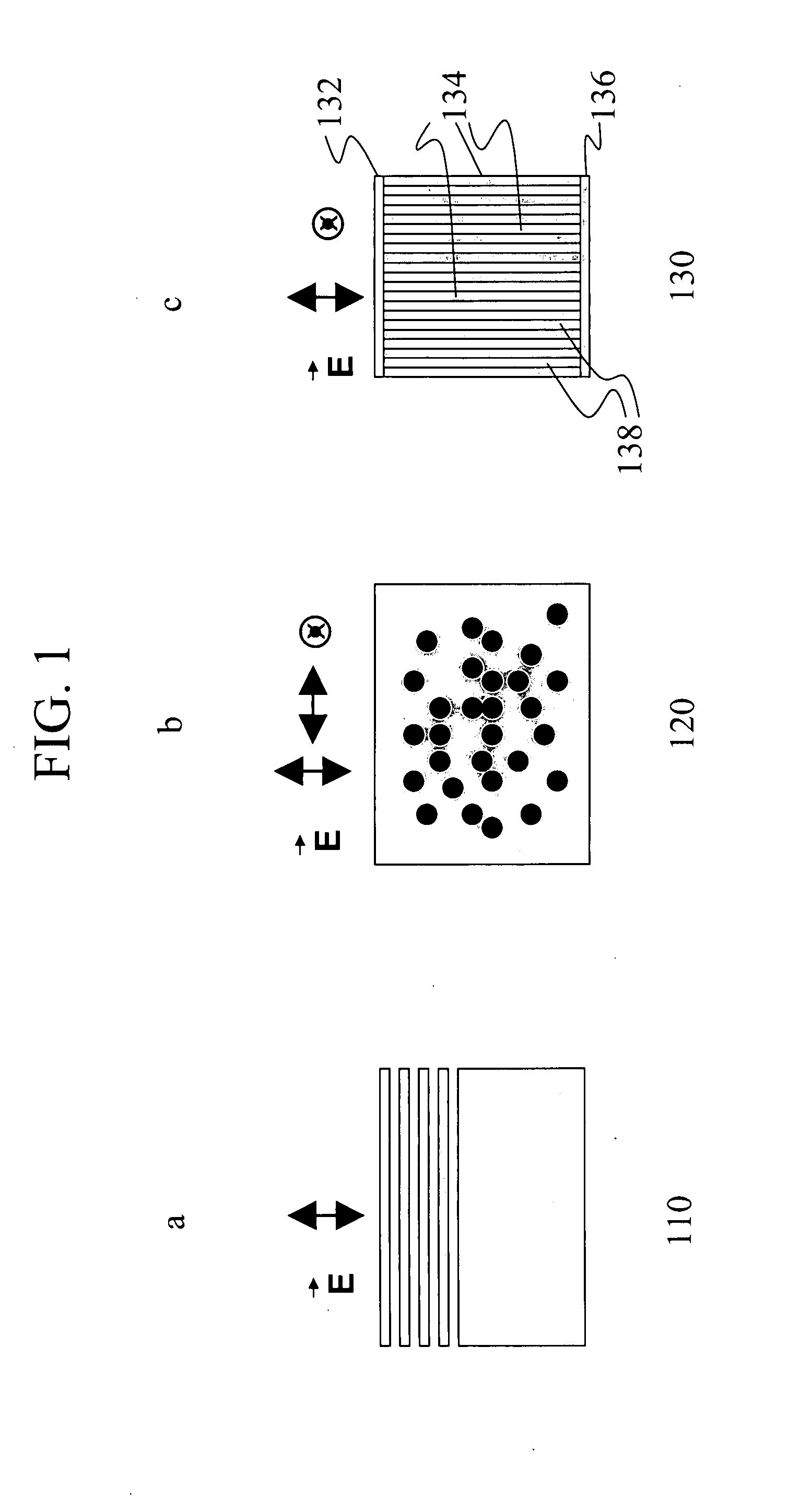

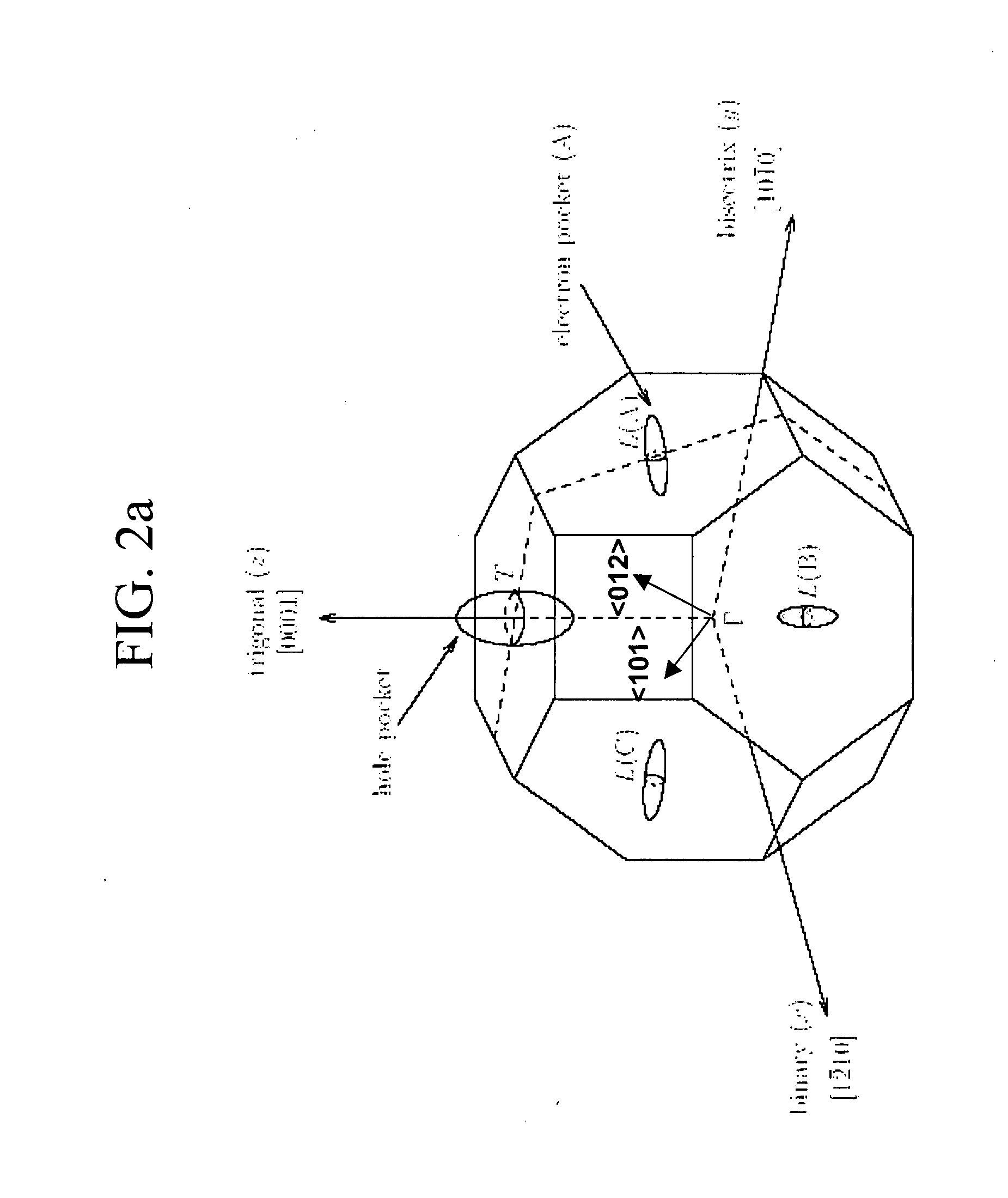

Optoelectronic devices utilizing materials having enhanced electronic transitions

An optoelectronic device that includes a material having enhanced electronic transitions. The electronic transitions are enhanced by mixing electronic states at an interface. The interface may be formed by a nano-well, a nano-dot, or a nano-wire.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

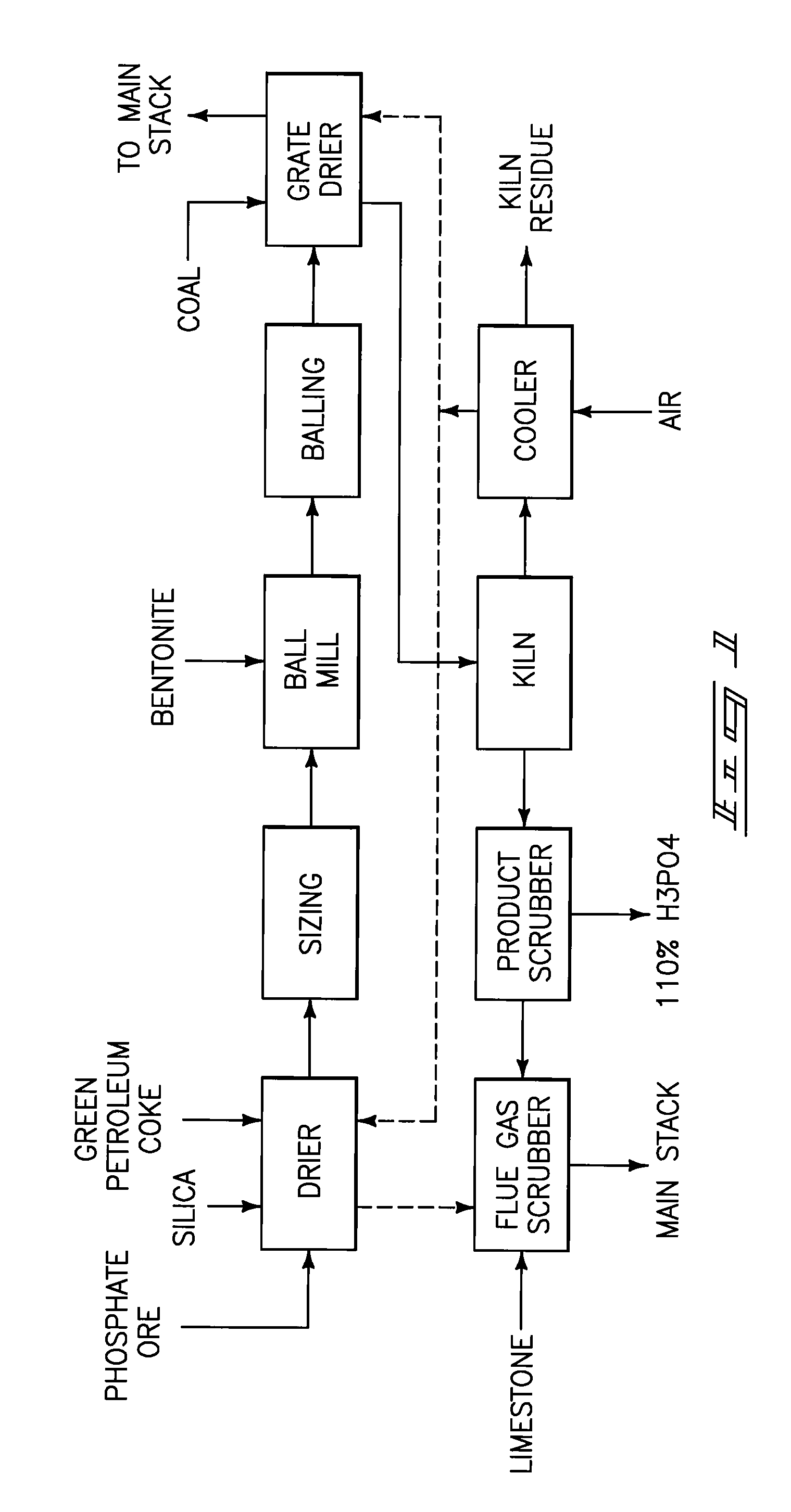

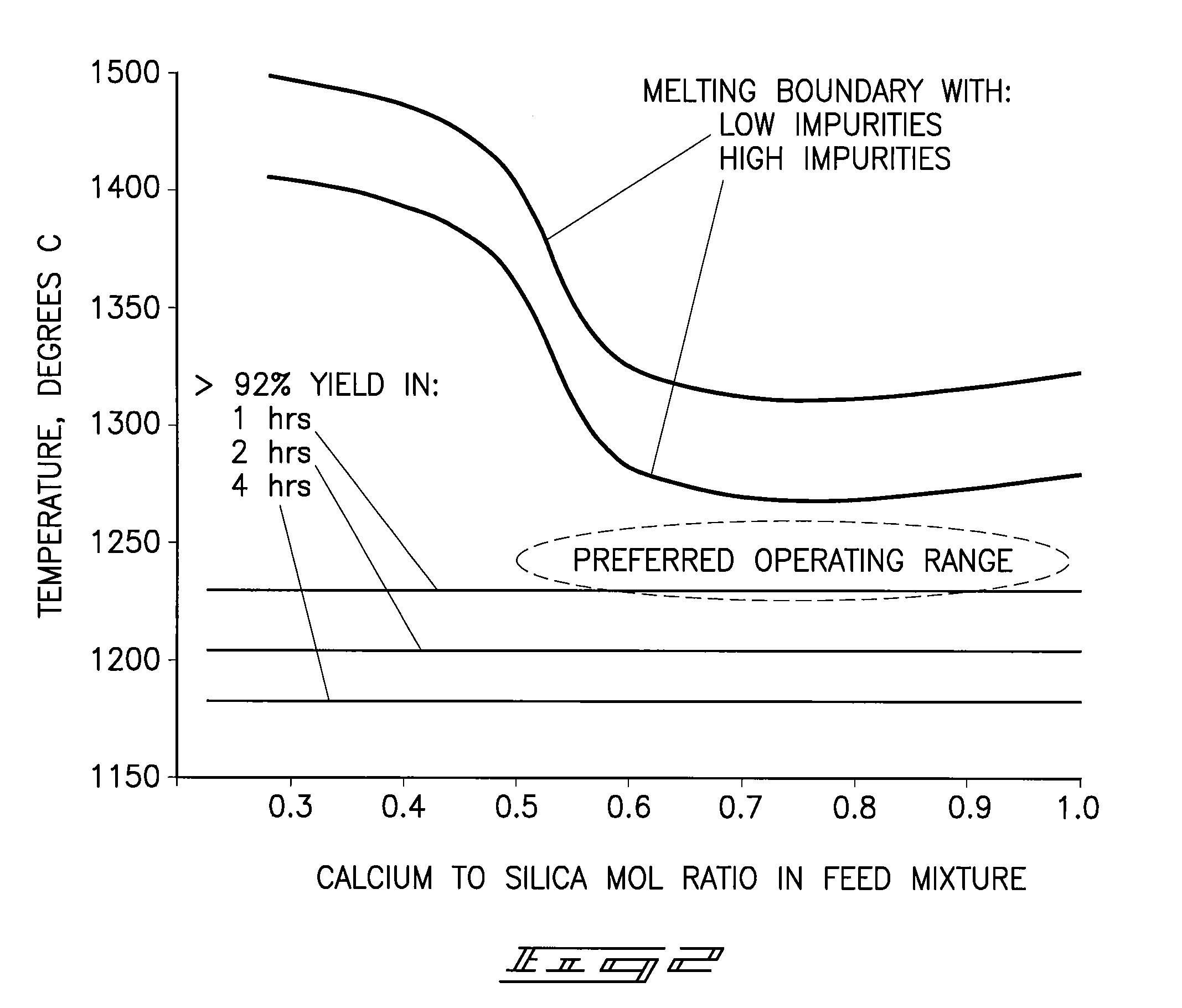

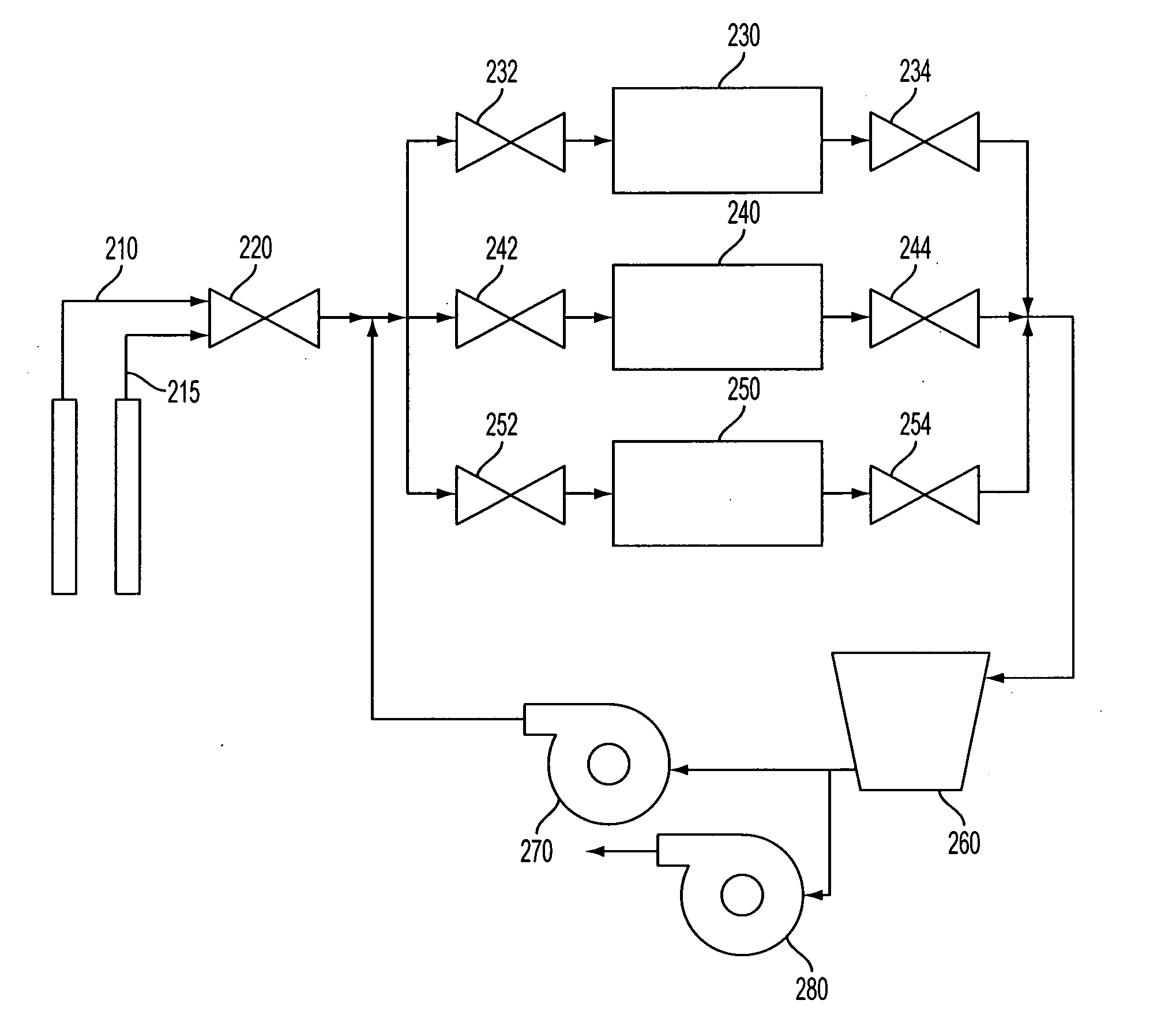

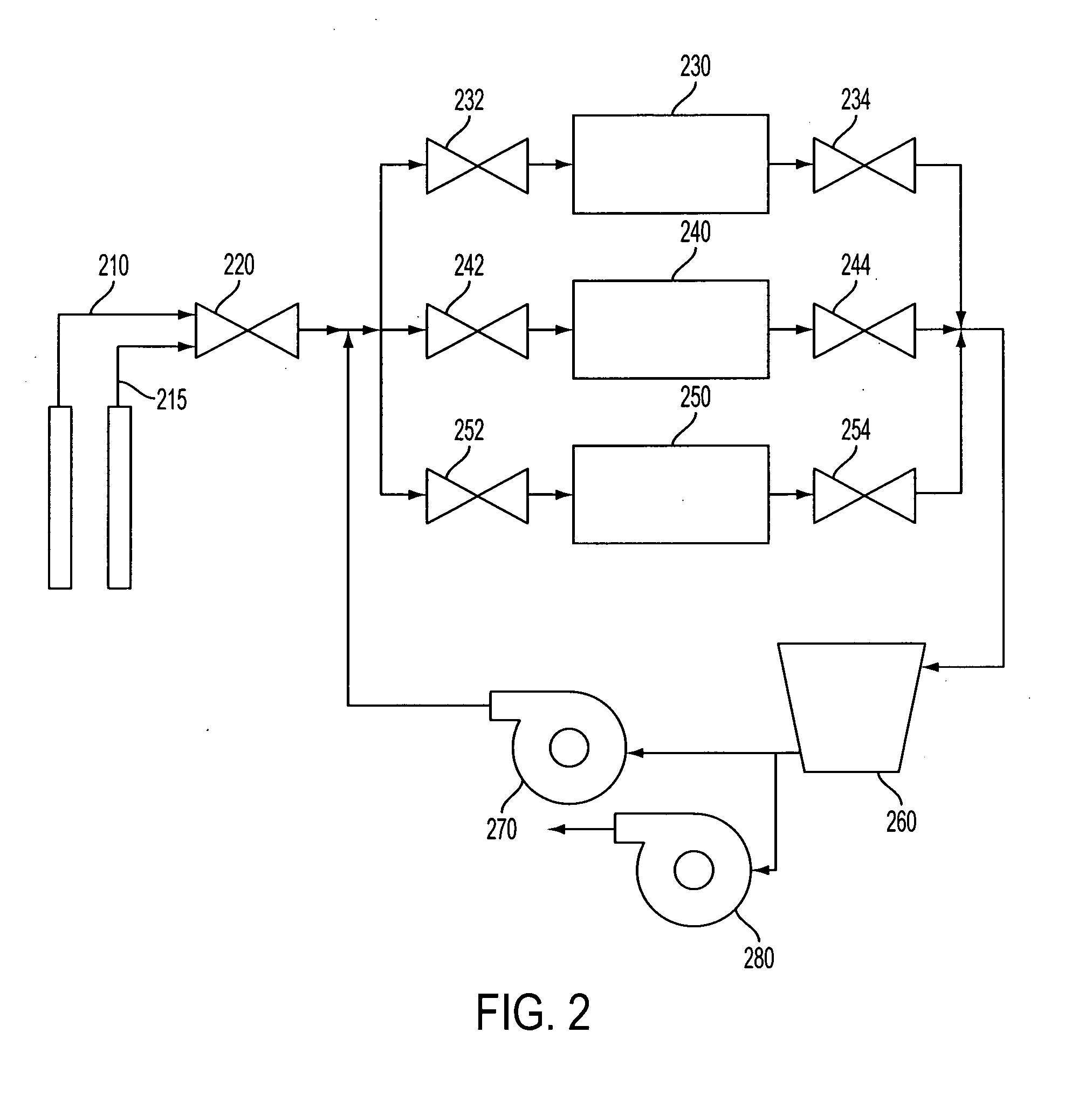

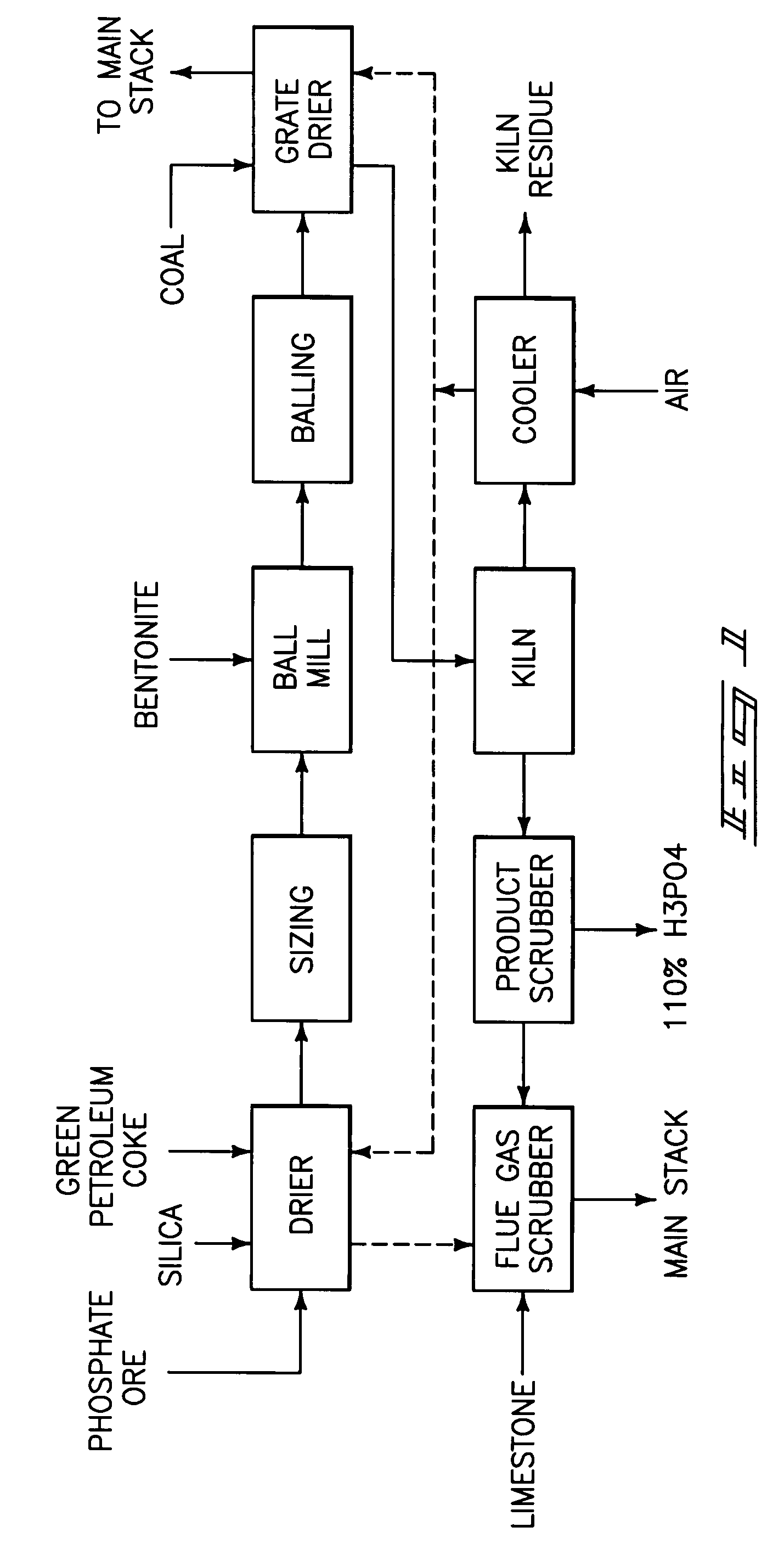

Phosphorous pentoxide producing methods

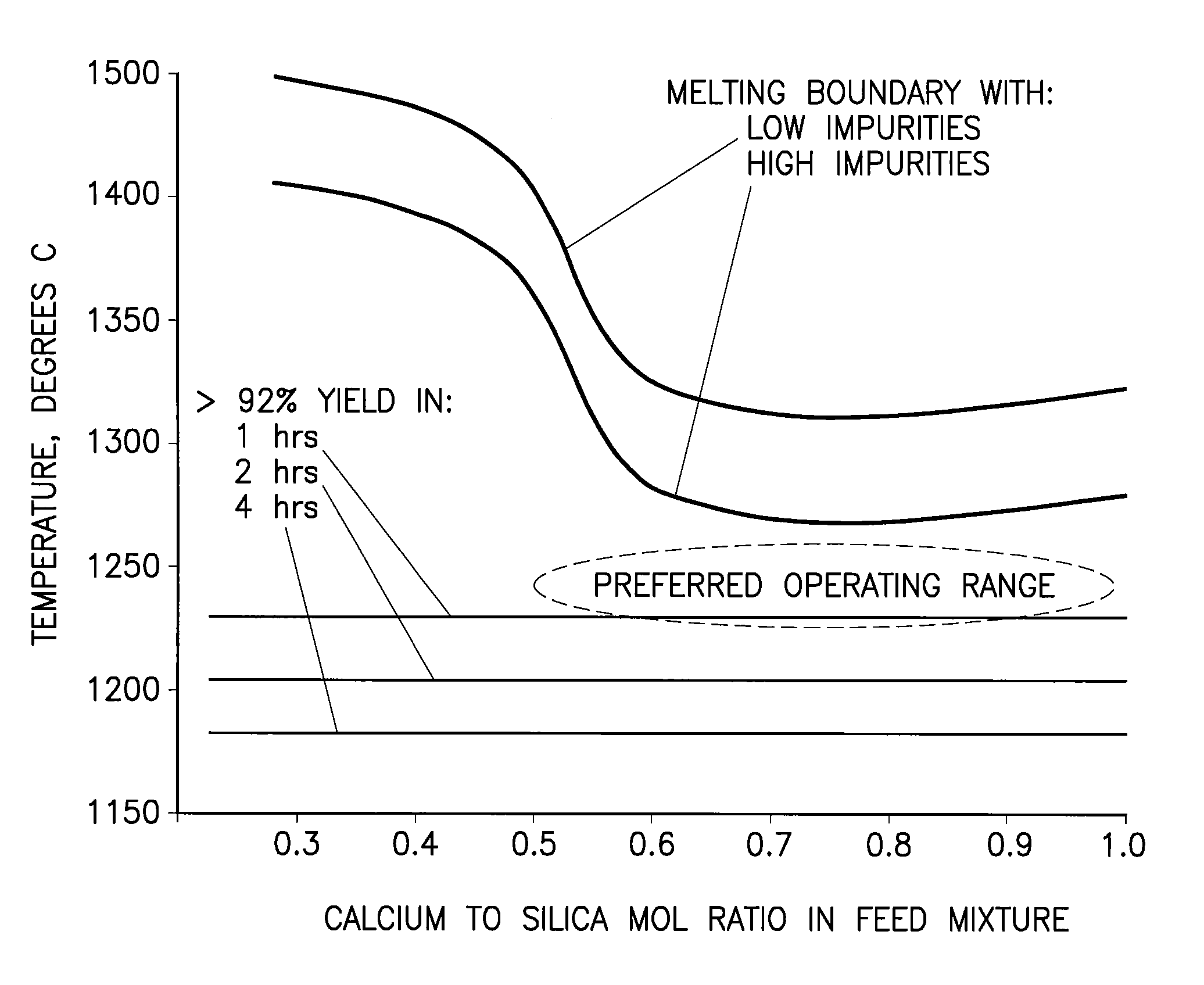

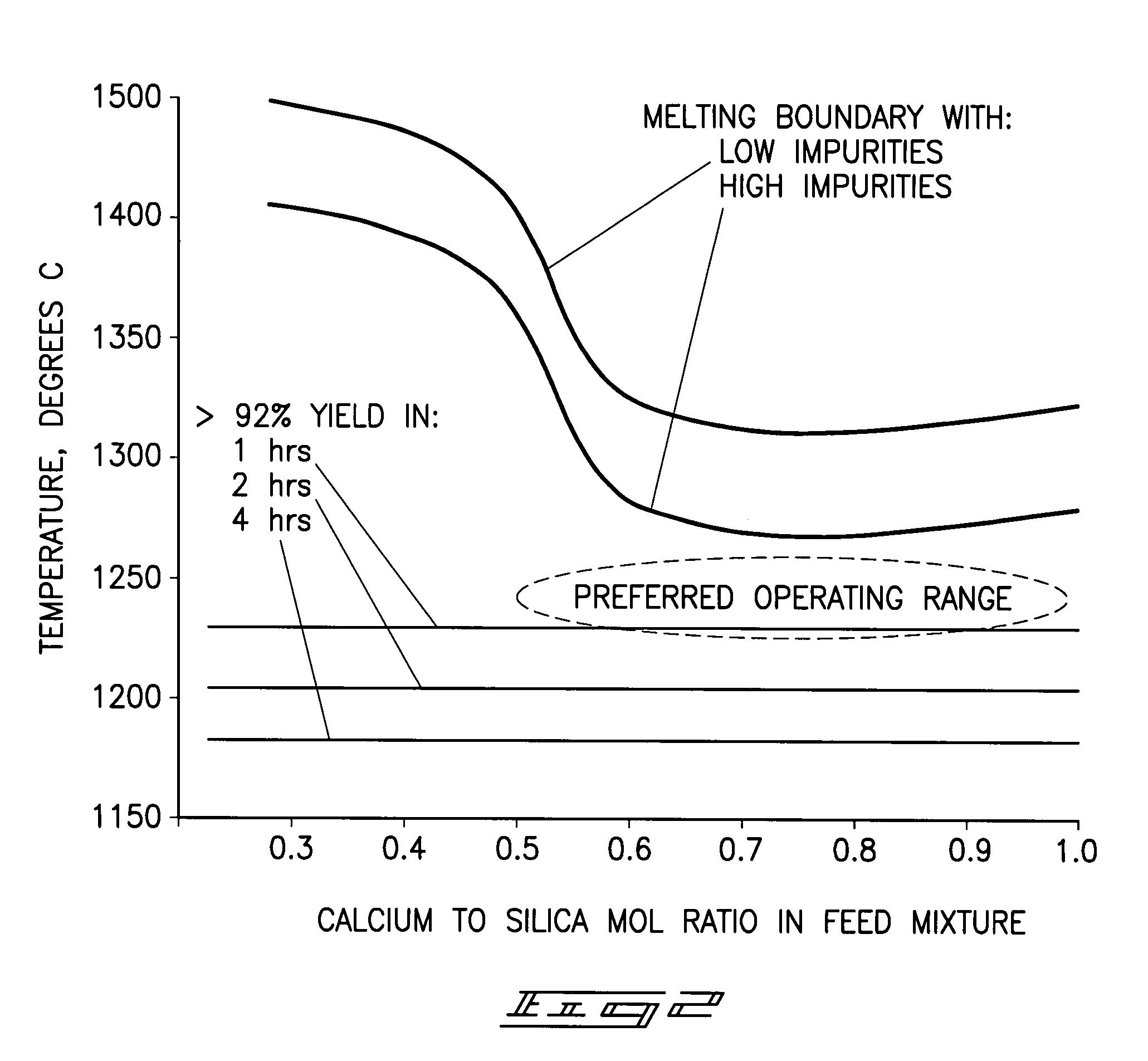

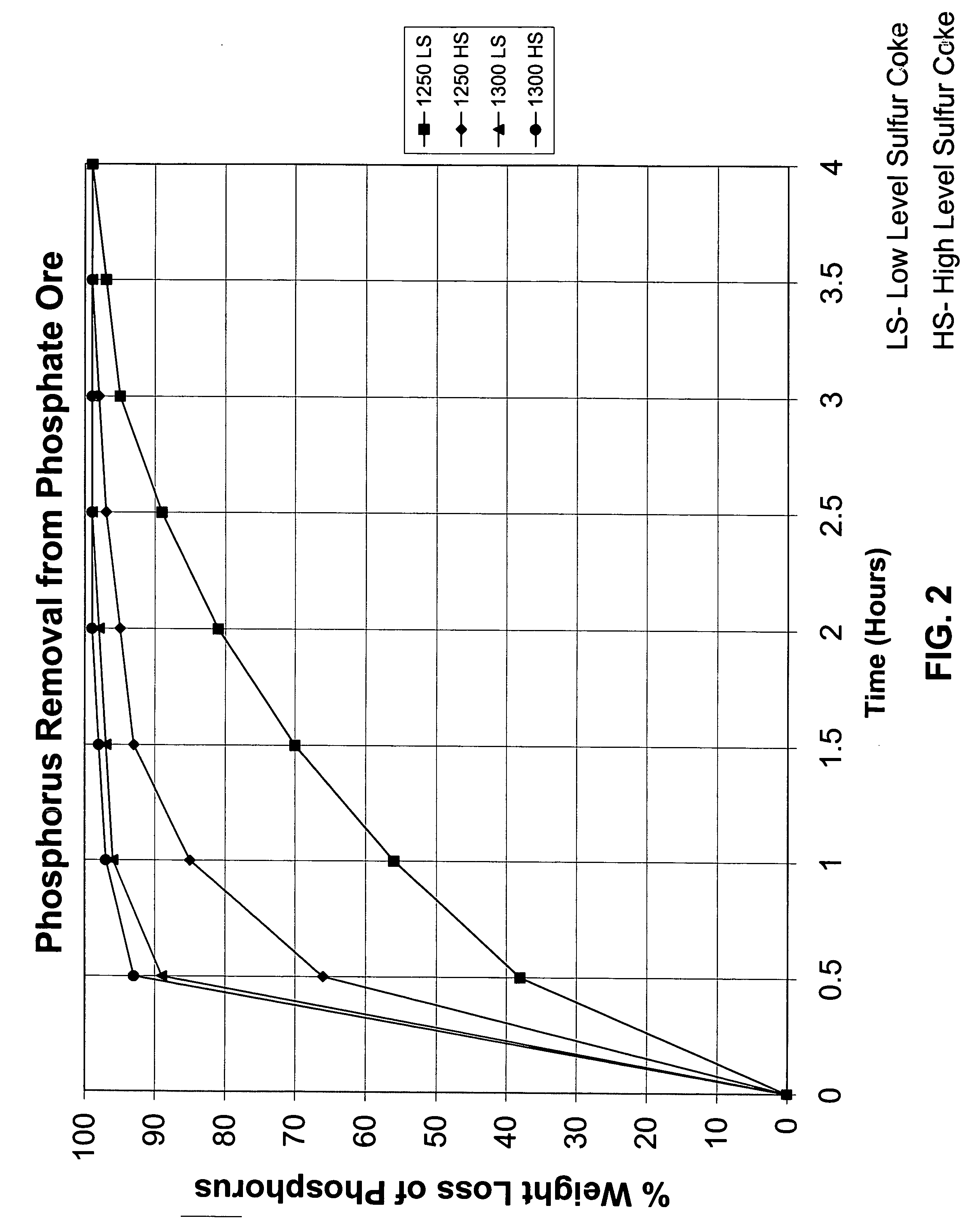

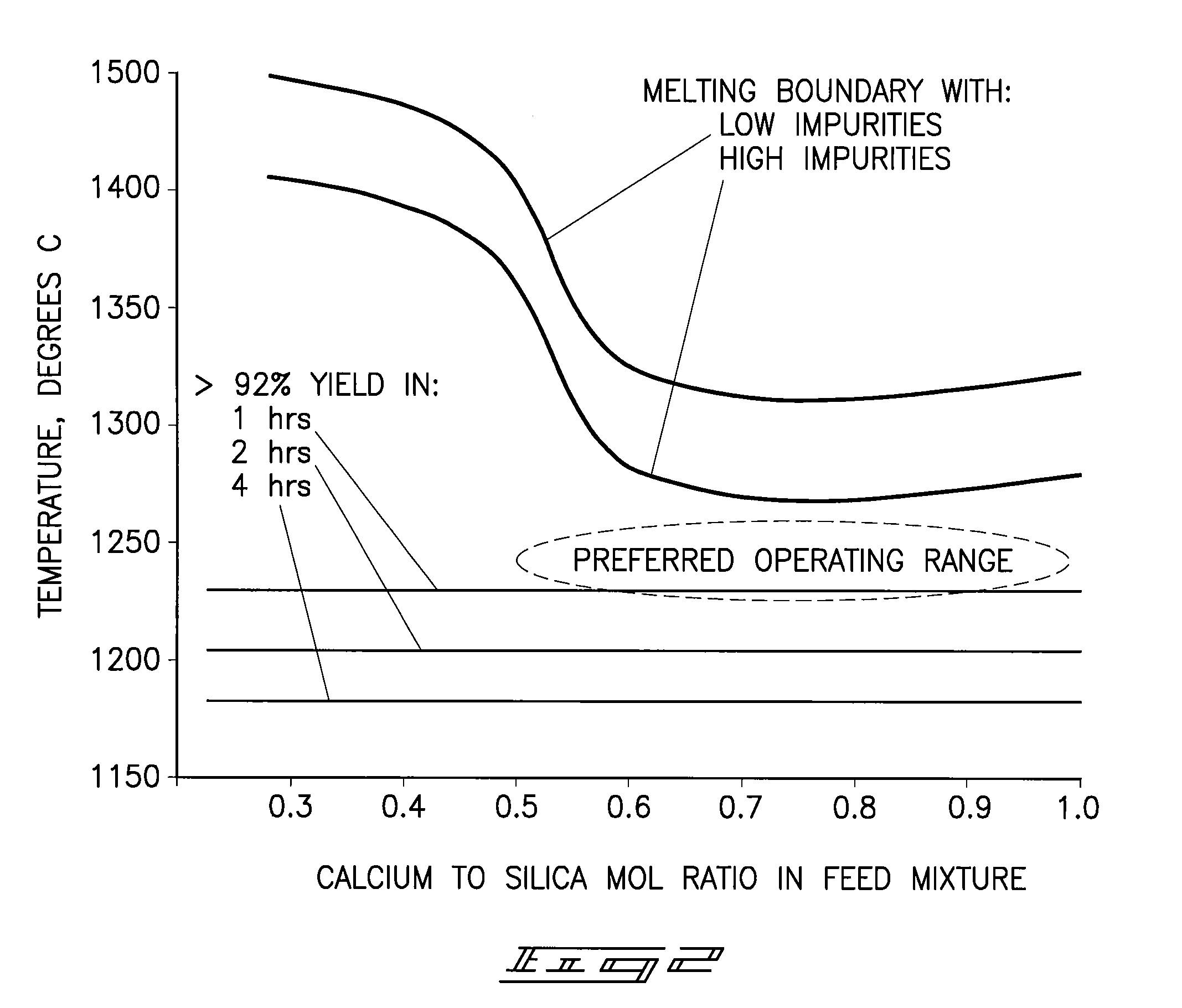

A phosphorous pentoxide producing method includes forming a kiln bed using feed agglomerates with a calcium-to-silica mole ratio of from 0.5 to 1.0 and maintaining a bed temperature at or above 1260° C. along a portion of the bed length without exceeding 1380° C. along the entire bed length. Less than 10% of the agglomerates' phosphate input to the kiln remains in the kiln residue as phosphate. Another method includes maintaining a bed temperature at or above 1180° C. along a portion of the bed length and establishing a bed surface-to-volume ratio multiplied by a time for bed heat up to 1180° C. of less than 50 minutes-ft2 / ft3.

Owner:NOVAPHOS INC

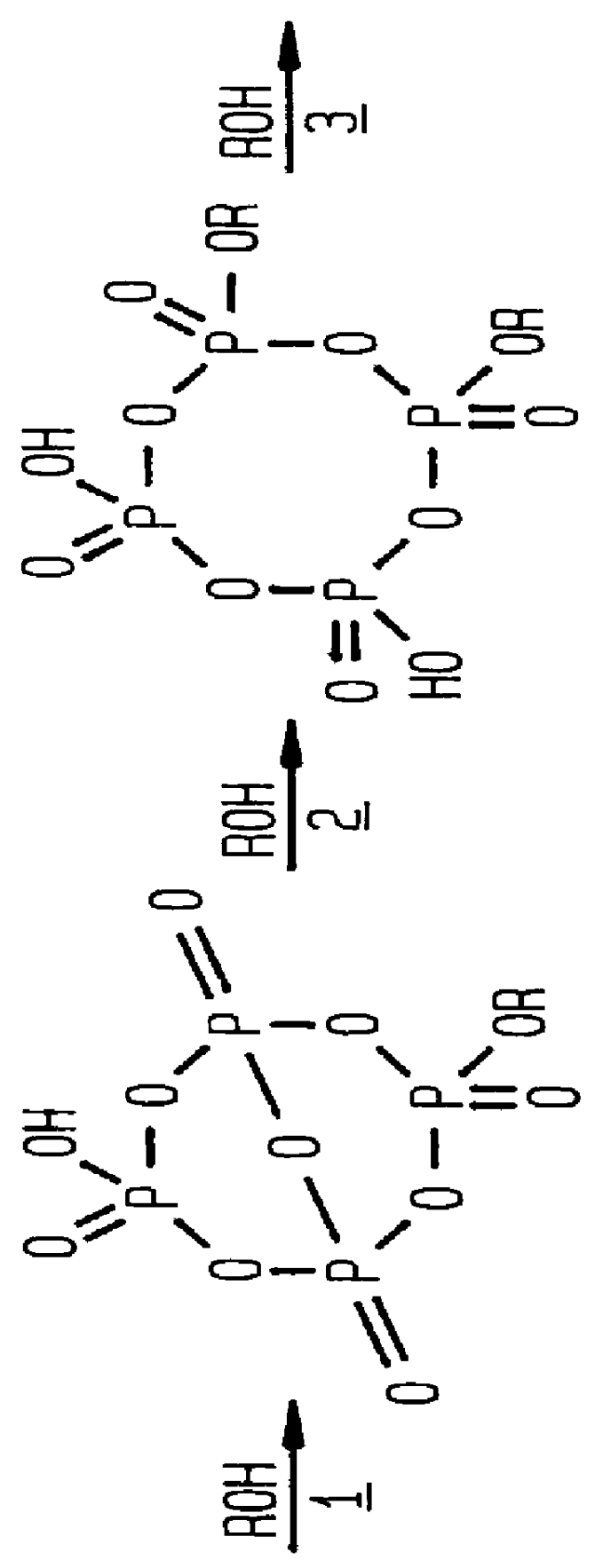

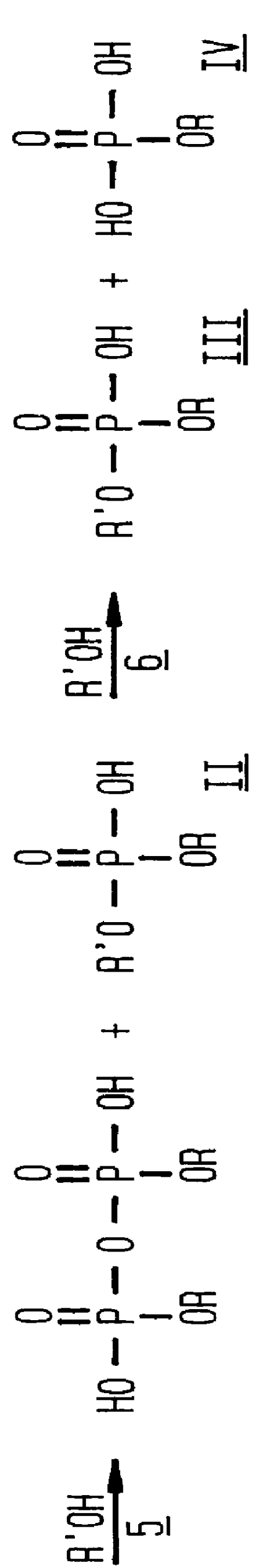

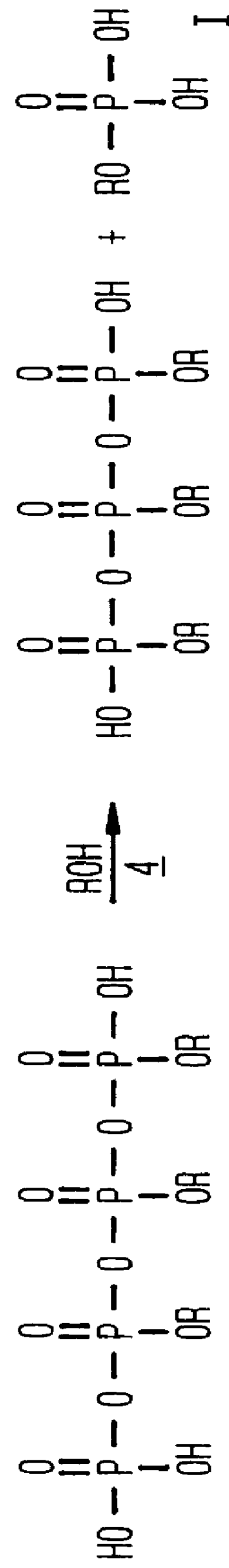

Phosphation reagent

The invention relates to a process for producing a unique phosphation reagent and to a simple, single-stage process utilizing is reagent to produce alkyl phosphate esters having high monoalkyl phosphate content in combination with low dialkyl phosphate, trialkyl phosphate, phosphoric acid and residual alcohol.

Owner:RHODIA OPERATIONS SAS

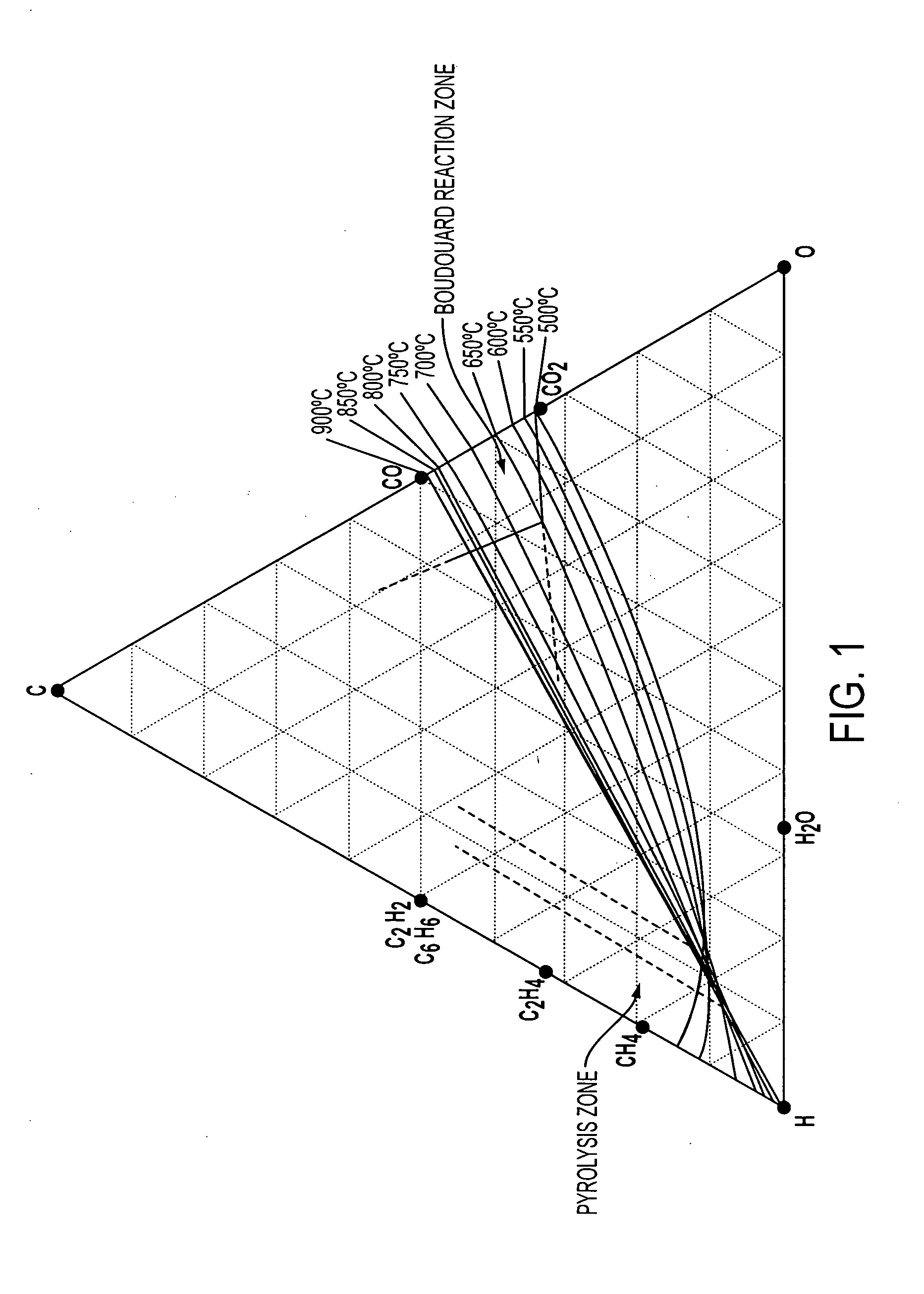

Methods and reactors for producing solid carbon nanotubes, solid carbon clusters, and forests

InactiveUS20150064092A1Promote lowerReduce metal oxideMaterial nanotechnologyOxygen-containing compound preparationSolid carbonBi modal

Methods of producing fibrous solid carbon forests include reacting carbon oxides with gaseous reducing agents in the presence of a catalyst having a predetermined grain size to cause growth of fibrous solid carbon forests upon a surface of the metal. The fibrous solid carbon forests are substantially perpendicular to the surface of the metal thus creating the “forests”. A bi-modal forest composition of matter is described in which a primary distribution of fibrous solid carbon comprises the forest and a secondary distribution of fibrous solid carbon is entangled with the primary distribution. A reactor includes a catalyst, a means for facilitating the reduction of a carbon oxide to form solid carbon forests on a surface of the catalyst, and a means for removing the solid carbon forest from the surface of the metal catalyst.

Owner:SEERSTONE

Processes for the separation of ores

InactiveUS20140110621A1Reduce the concentration of pollutantsPhosphorus oxidesDifferential sedimentationSlurryChemistry

Methods for purifying one or more value materials are provided. The method can include contacting an aqueous mixture comprising a value material and a contaminant with a dispersant and a depressant to produce a treated mixture. A weight ratio of the dispersant to the depressant can be from about 1:1 to about 30:1. The method can also include recovering a purified product comprising the value material from the treated mixture. The purified product can have a reduced concentration of the contaminant relative to the aqueous slurry.

Owner:INGEVITY SOUTH CAROLINA

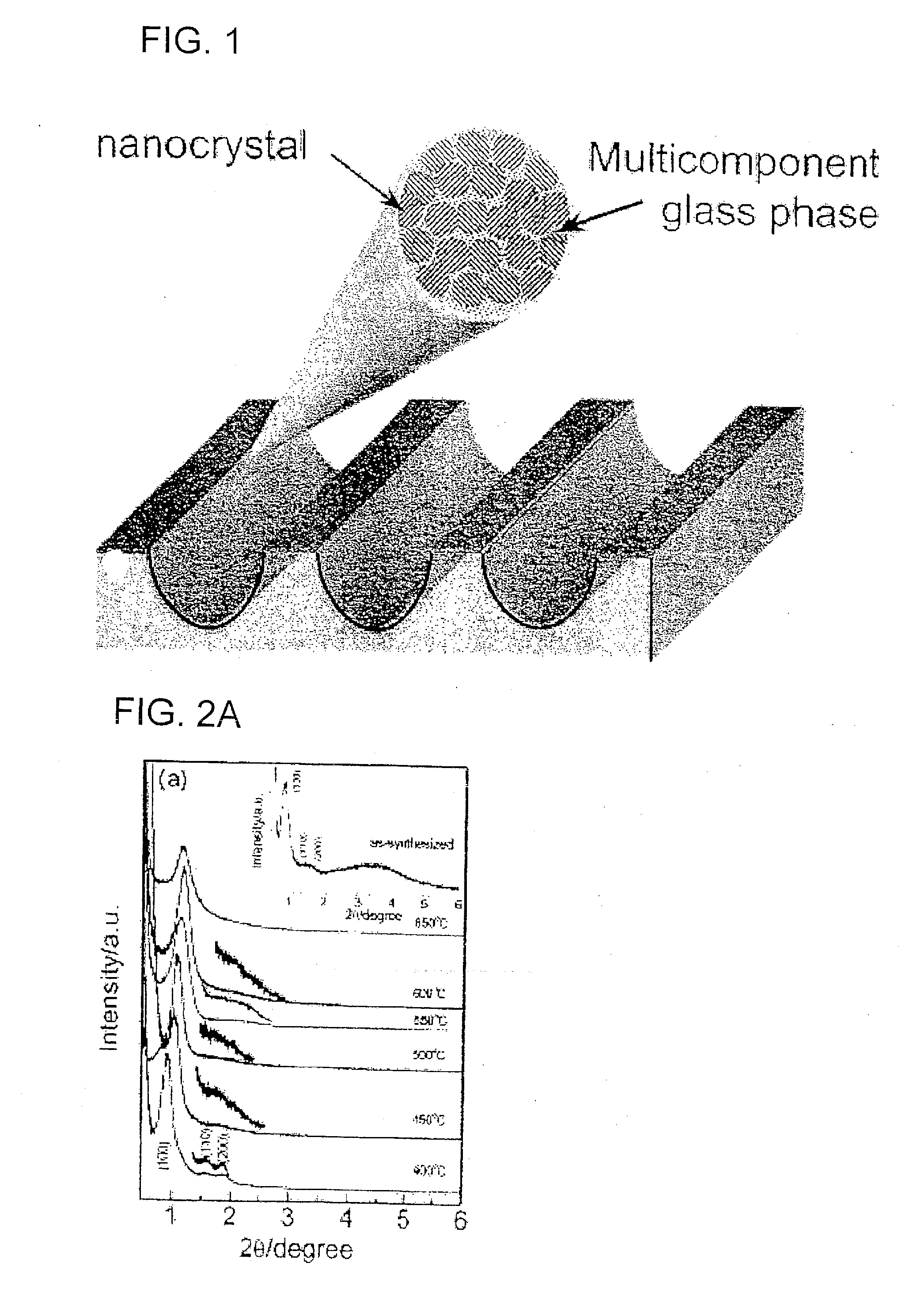

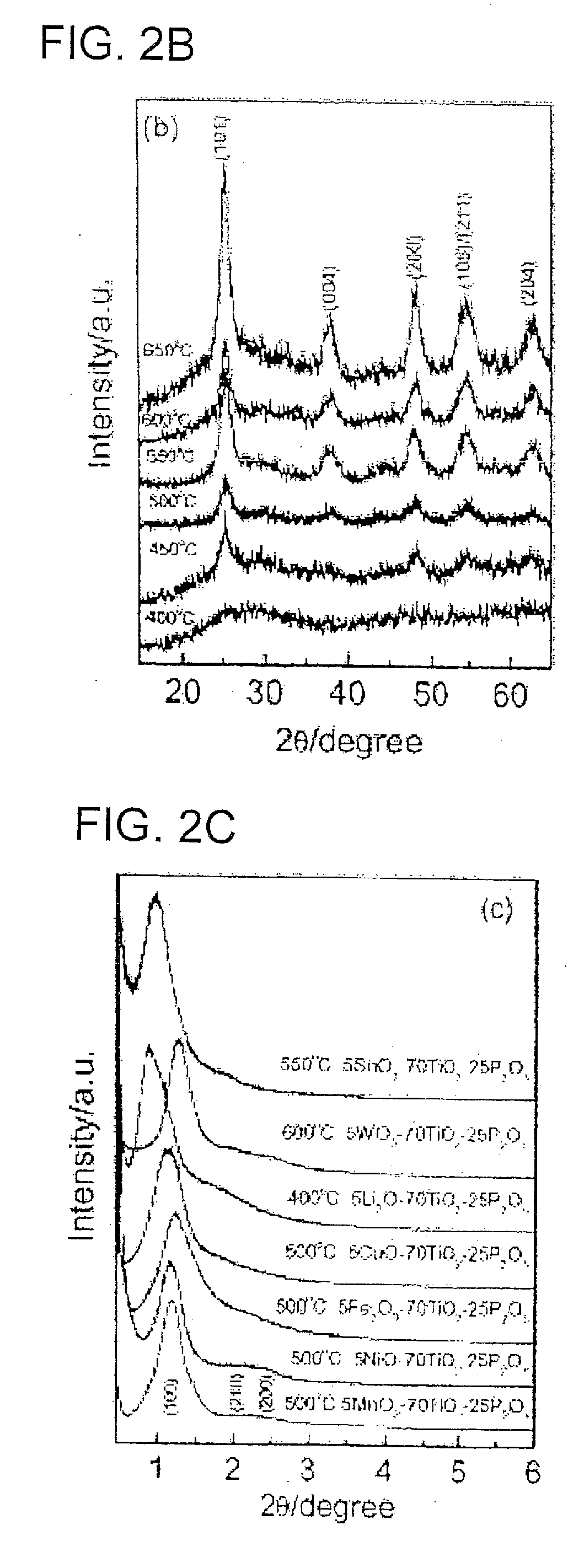

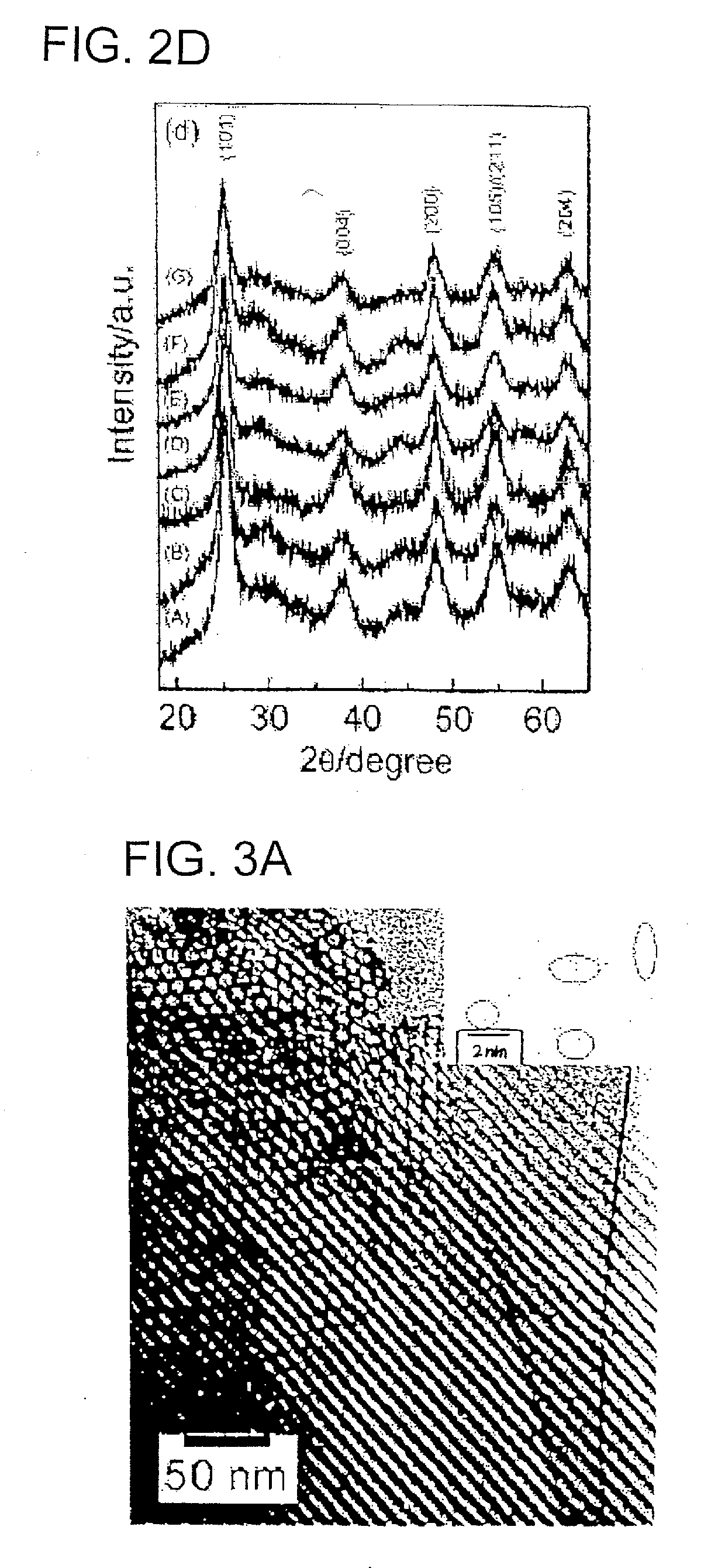

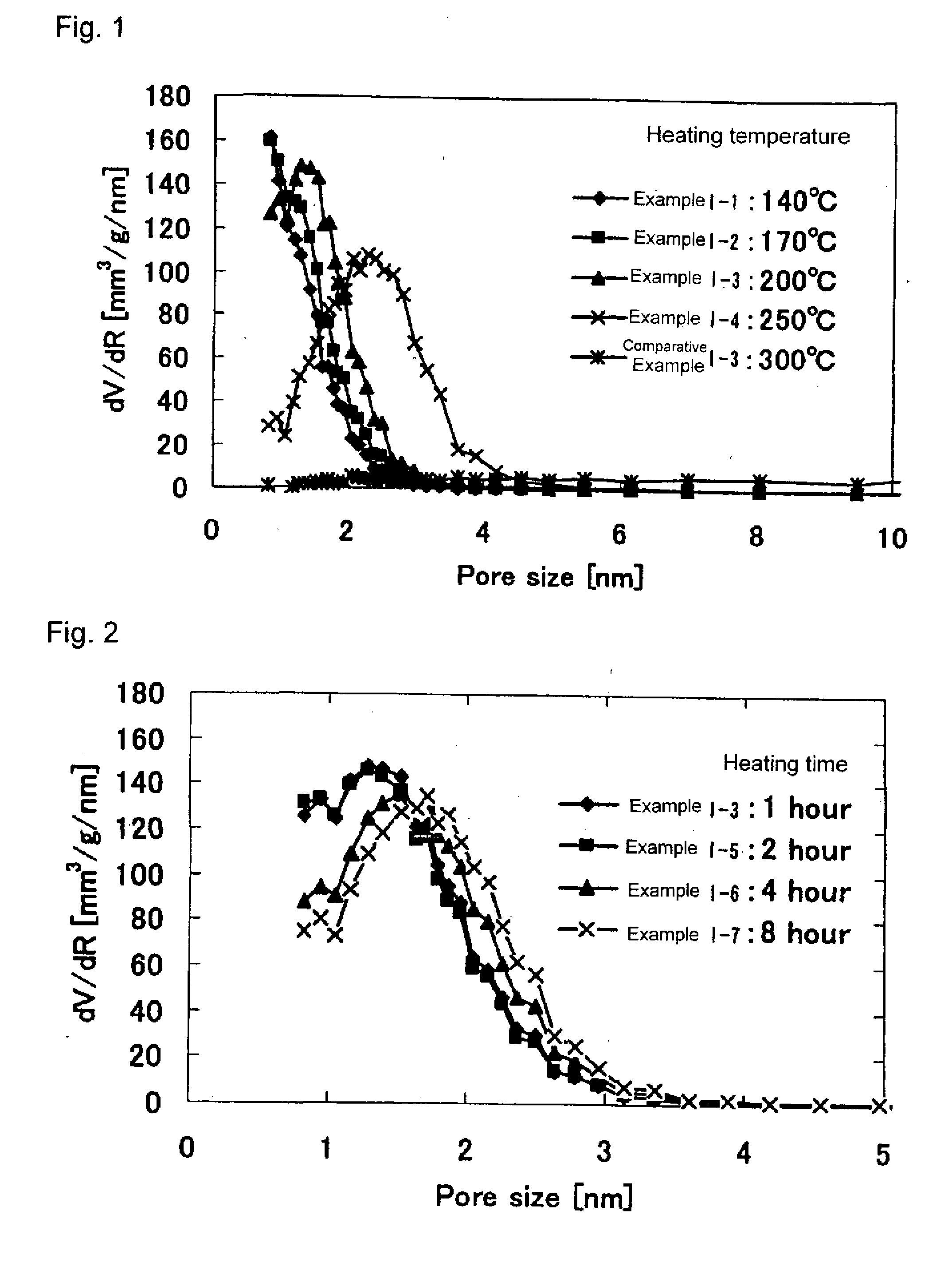

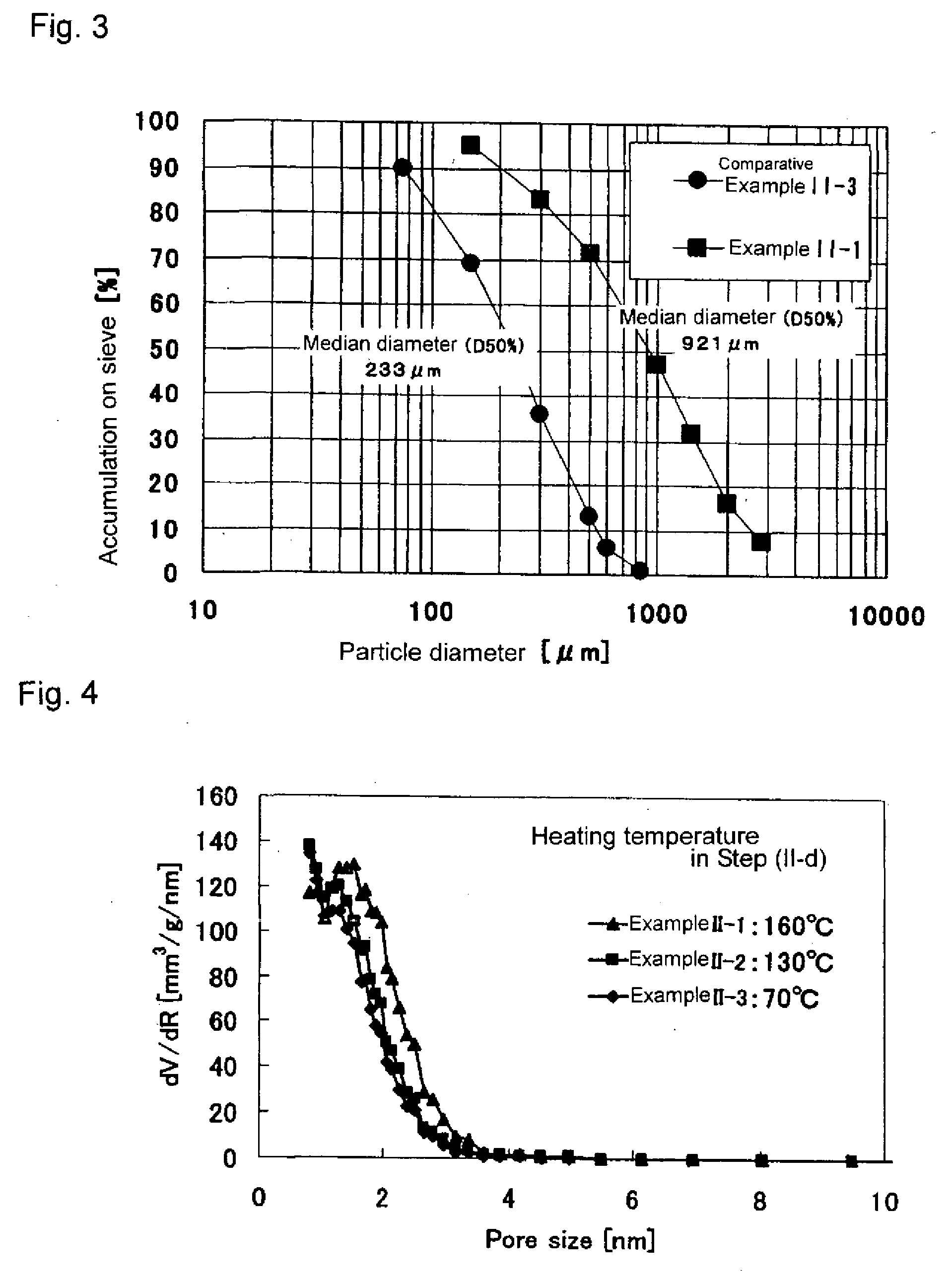

Nanocrystal oxide/glass composite mesoporous powder or thin film, process for producing the same, and utilizing the powder or thin film, various devices, secondary battery and lithium storing device

InactiveUS20070027015A1Simple methodLarge capacityPhosphorus oxidesMaterial nanotechnologyGlass compositesManufacturing technology

The present invention aims to realize (1) manufacture of a mesoporous composite powder or thin film composed of nanocrystalline metal oxide-glass having a three-dimensional structure with a large specific surface area, (2) construction of a porous structure framework with nanocrystalline metal oxide crystal and a slight amount of glass phase (SiO2 or P2O5, B2O3), (3) control of crystal growth of metal oxide with a slight amount of glass phase (SiO2 or P2O5, B2O3), (4) simplification of the manufacturing process, and (5) use thereof in manufacture of a lithium intercalation electric device, photocatalytic device, solar battery and energy storage device. Provided are a nanocrystal oxide-glass mesoporous composite powder or thin film having a three-dimensional structure with regularly arranged mesopores, and a secondary battery comprising the same.

Owner:NAT INST OF ADVANCED IND SCI & TECH

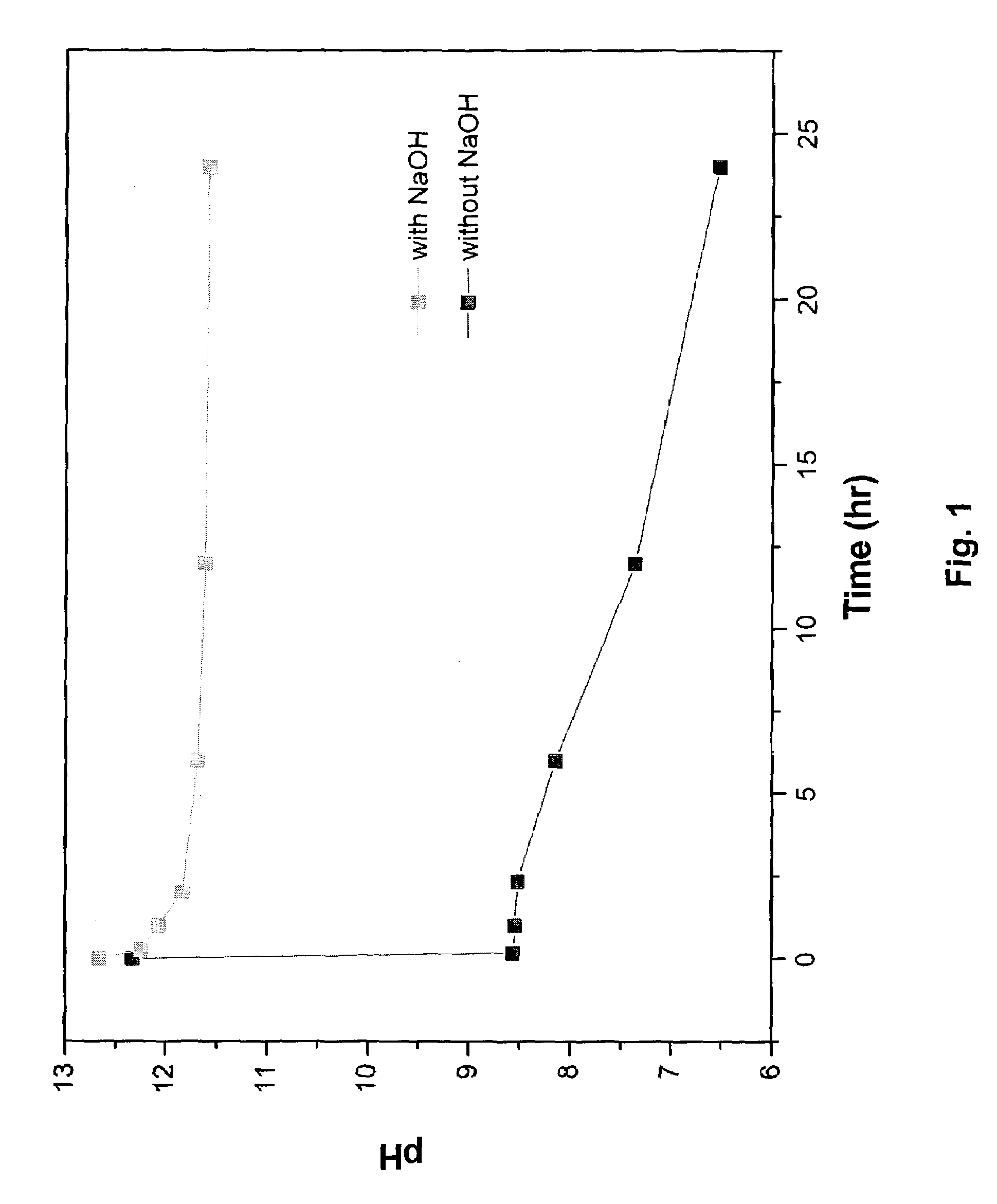

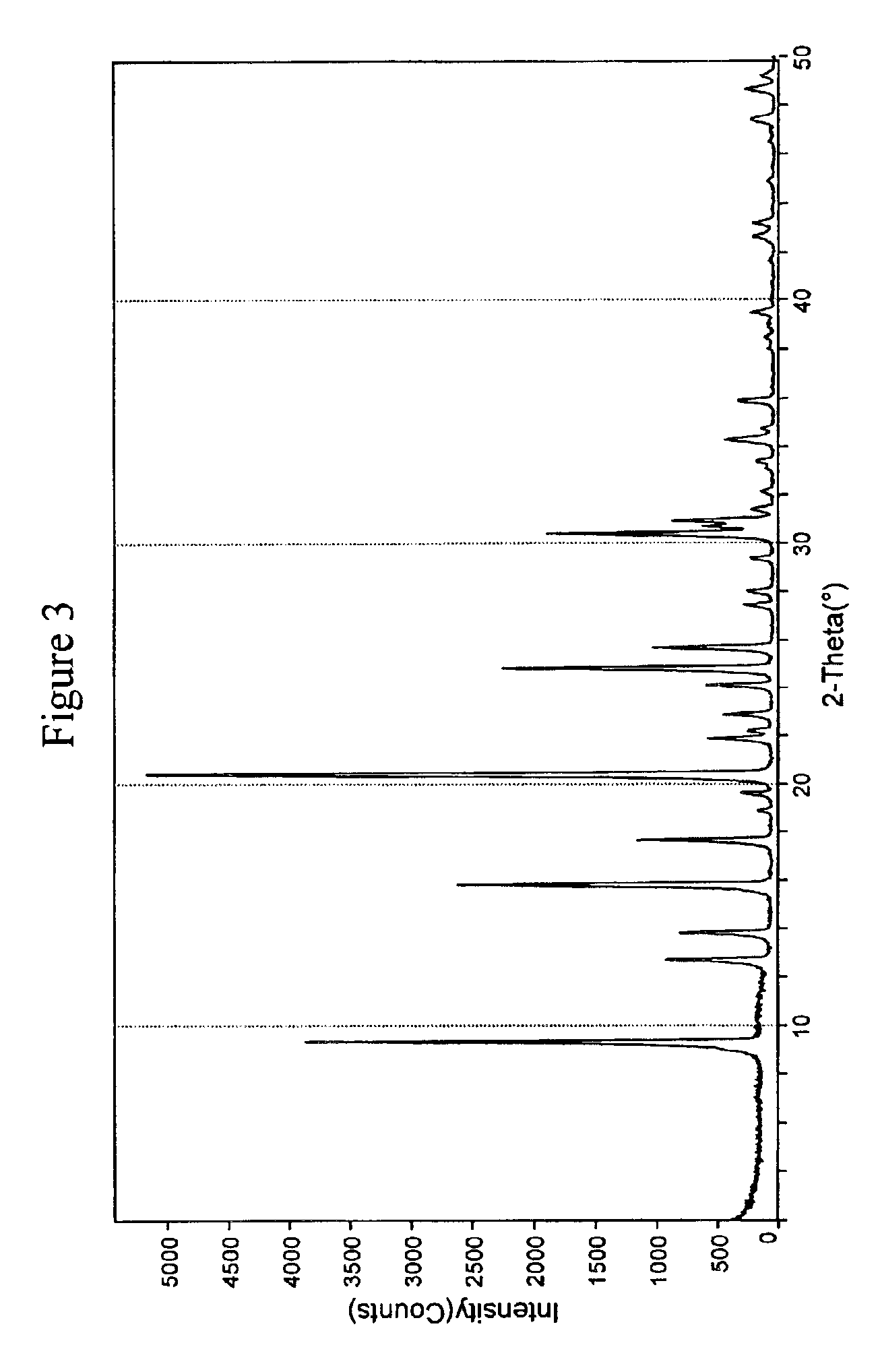

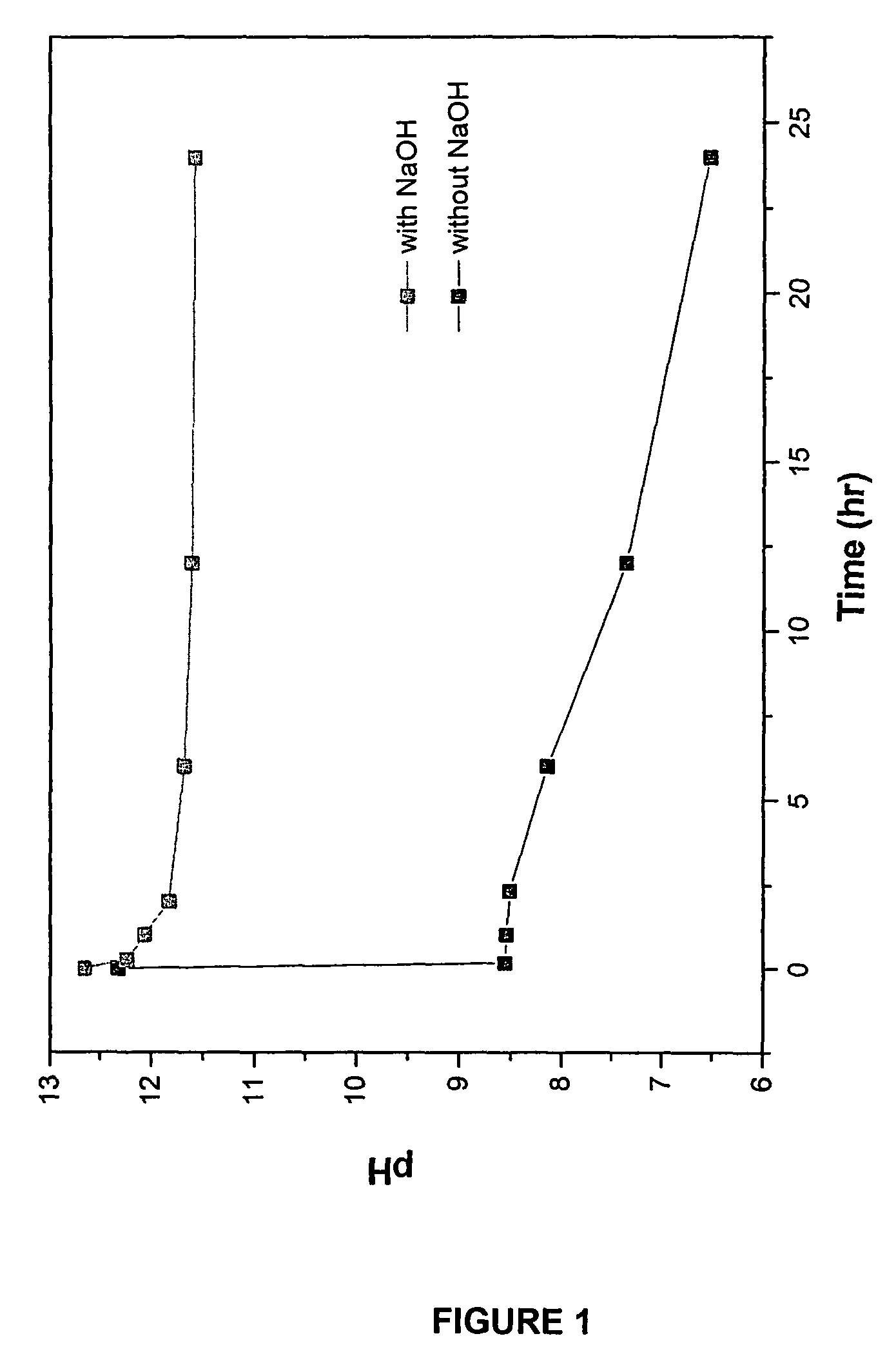

Method of manufacturing hydroxyapatite and uses therefor in delivery of nucleic acids

Provided is a method for production of nanocrystalline hydroxyapatite particles, and nanocrystalline hydroxyapatite particles produced according to the method. The nanocrystalline hydroxyapatite particles exhibit substantially superior cell transformation abilities as compared to known and commercially-available calcium phosphate kits. The nanocrystalline hydroxyapatite particles also find use in tissue engineering applications, for example bone and tooth engineering and repair applications.

Owner:CARNEGIE MELLON UNIV

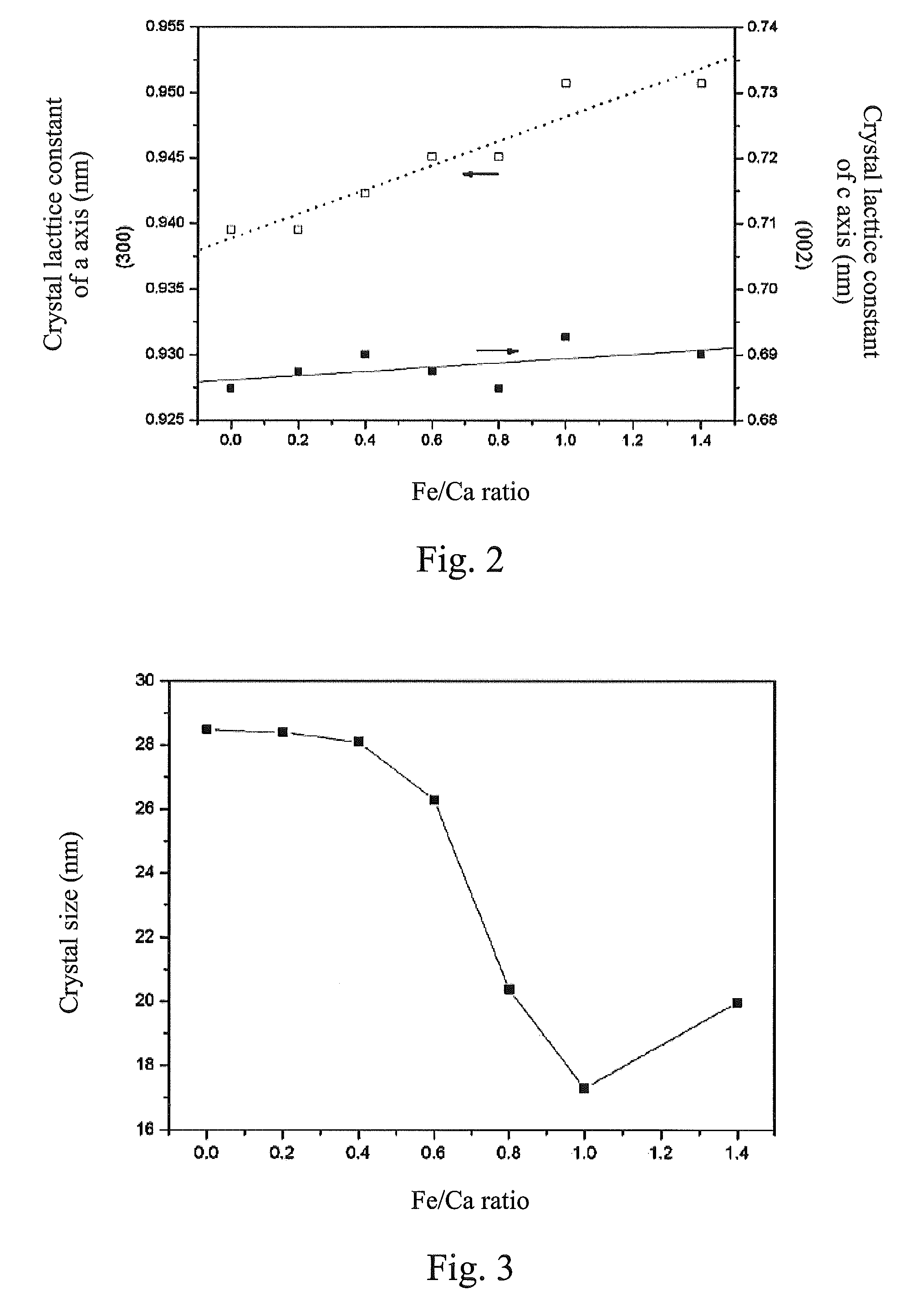

Magnetic nanoparticles of hydroxyapatite and preparation method thereof

This invention is related to magnetic nanoparticles of hydroxyapatite for biomedical applications and the preparation method thereof. The magnetic particles of hydroxyapatite are prepared by a wet chemical co-precipitation method at lower temperature, wherein the calcium ions originally existing in hydroxyapatite are replaced with divalent or trivalent metal ions, for example, Fe+2 ion, to form magnetic nanoparticles of hydroxyapatite.

Owner:NAT TAIWAN UNIV

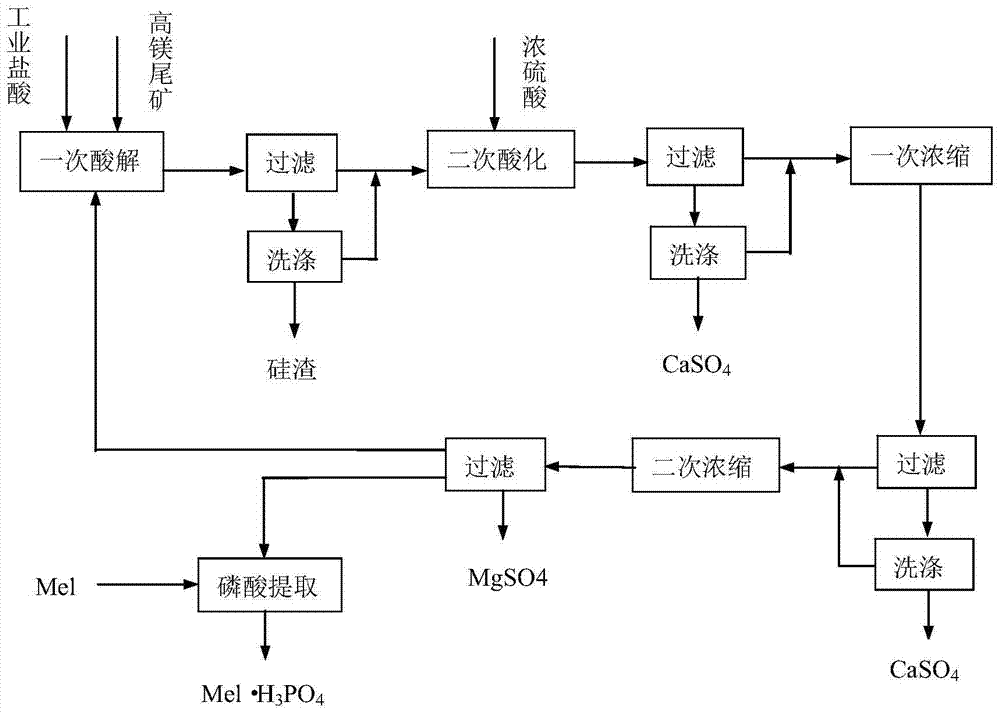

Method for recovering phosphorus in phosphate tailings with high magnesium content and preparing magnesium sulfate by adopting indirect sulfuric acid method

InactiveCN103922372AEfficient use ofEfficient recyclingPhosphorus oxidesSolid waste disposalSlagFiltration

The invention relates to a method for recovering phosphorus in phosphate tailings with high magnesium content and preparing magnesium sulfate by adopting an indirect sulfuric acid method. The method comprises the following steps: 1) mixing the phosphate tailings with high magnesium content with a hydrochloric acid to react, so as to obtain one-time acidolysis filtrate and silicon slag, carrying out insulated suction filtration and washing to obtain a one-time washing solution; 2) carrying out secondary acidification on obtained one-time acidolysis filtrate and a one-time washing solution by using a sulfuric acid, so as to obtain secondary acidified filtrate and calcium sulfate sediments, aging, carrying out suction filtration and washing; (3) concentrating the obtained secondary acidified filtrate and the one-time washing solution once to obtain one-time concentrated filtrate and one-time concentrated solid, carrying out suction filtration and washing after cooling; 4) concentrating the obtained one-time concentrated filtrate and one-time washing solution for the second time, so as to obtain secondary concentrated filtrate and secondary concentrated solid, carrying out suction filtration and drying after cooling, so as to obtain a magnesium sulfate product; 5) returning the secondary concentrated filtrate to be mixed with the hydrochloric acid, leaching the phosphate tailings with high magnesium content in cycle, and extracting after certain concentration is achieved. The method is short in flow, convenient to operate, and high in recovery rate of magnesium.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

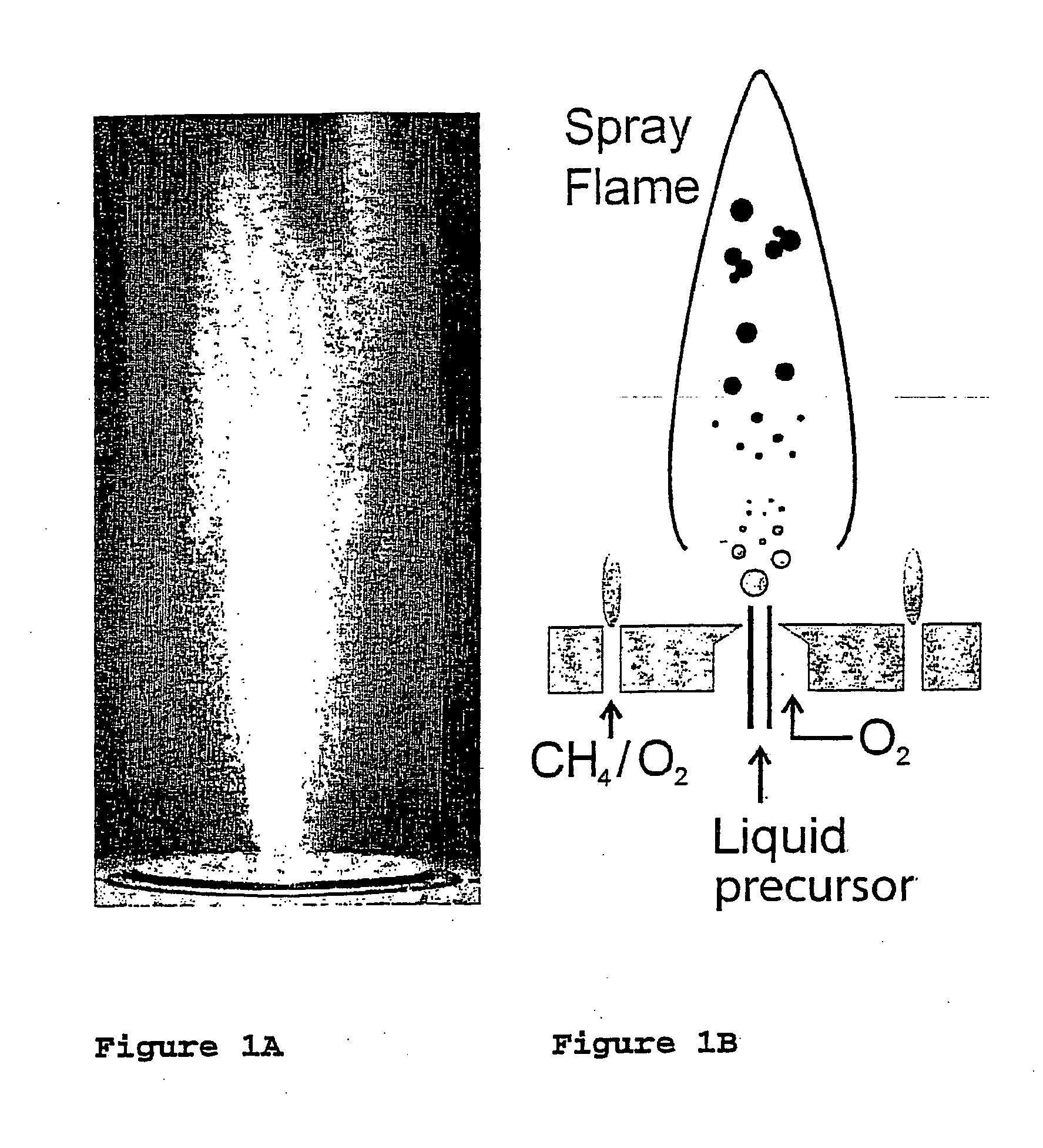

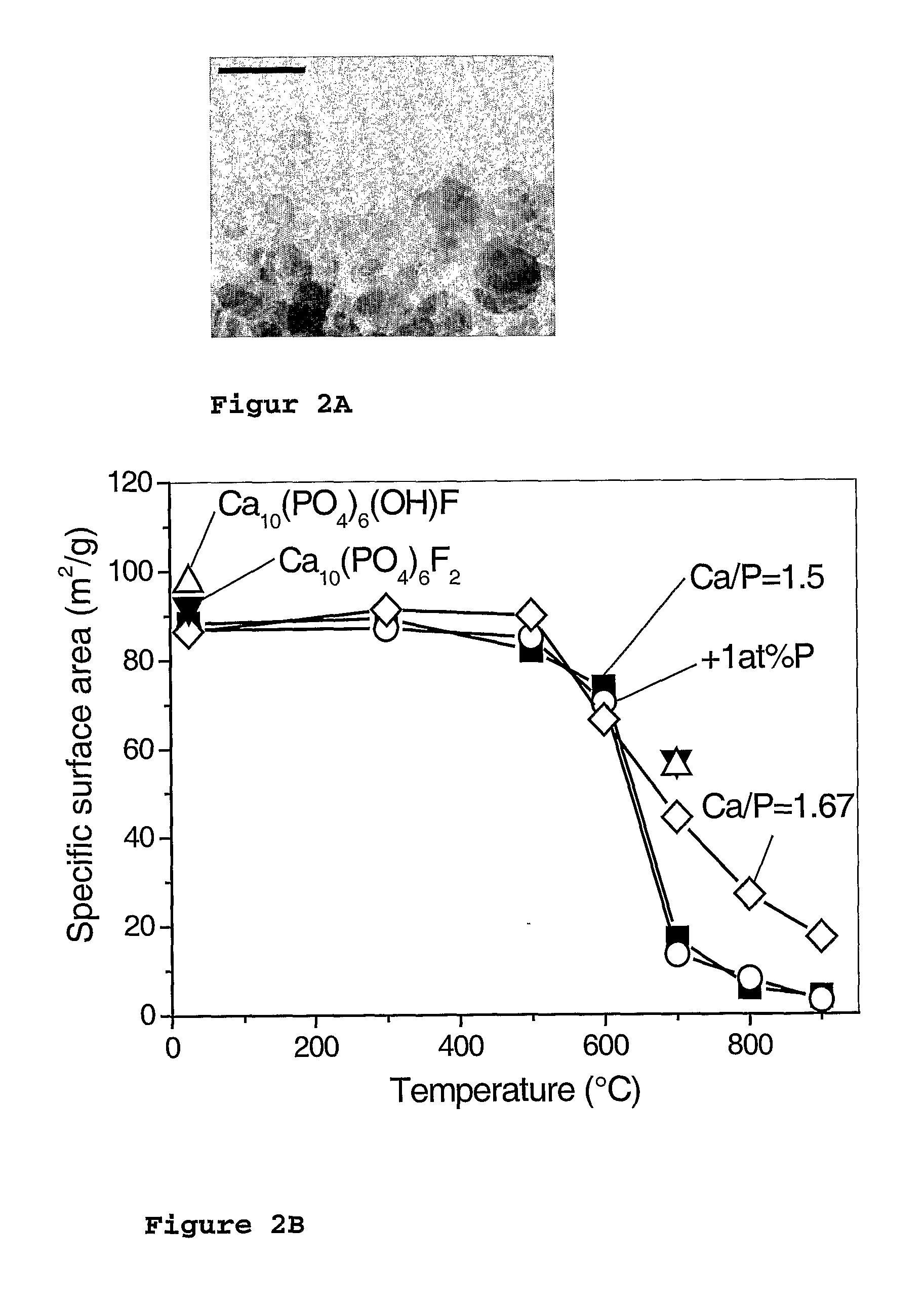

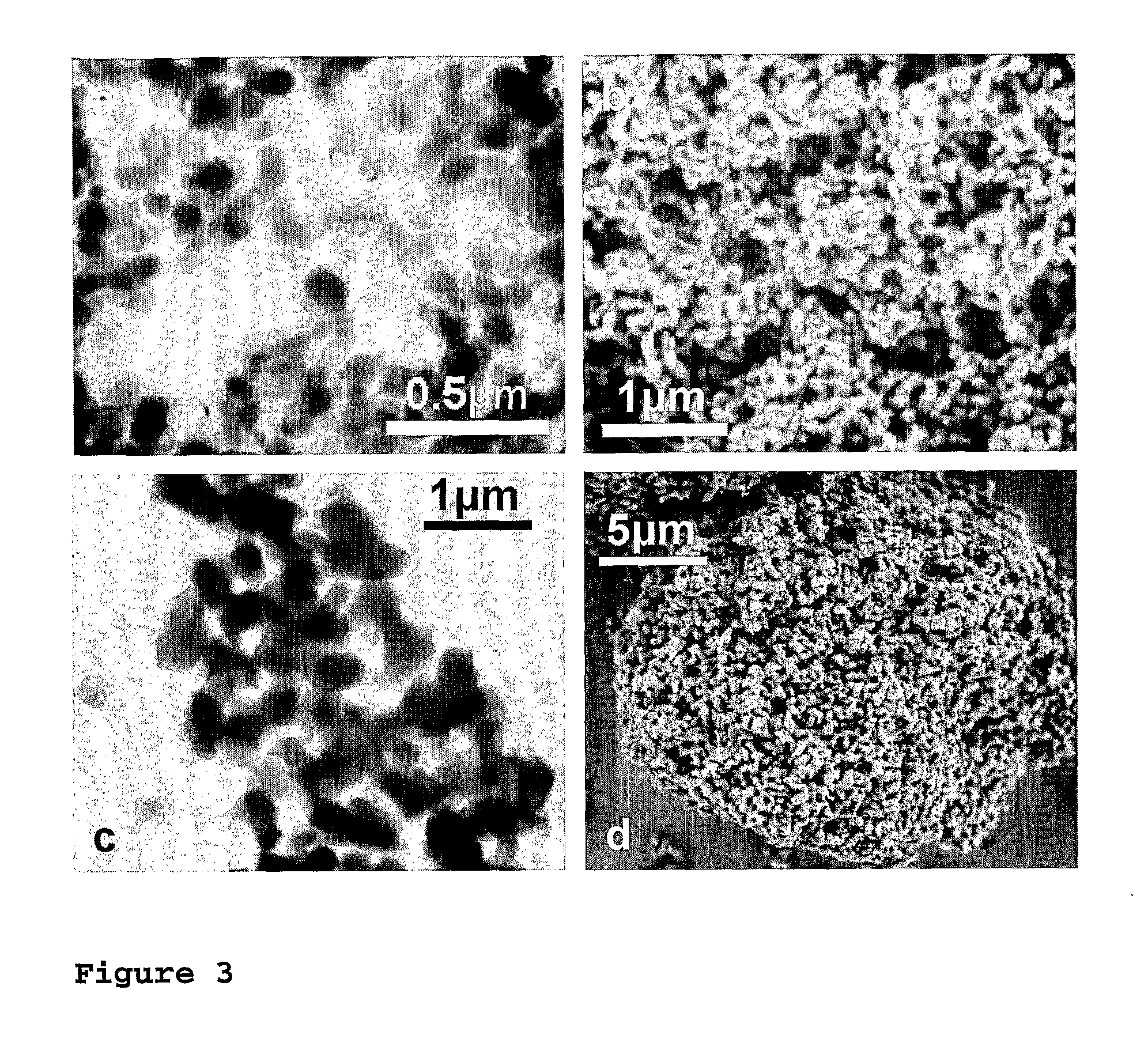

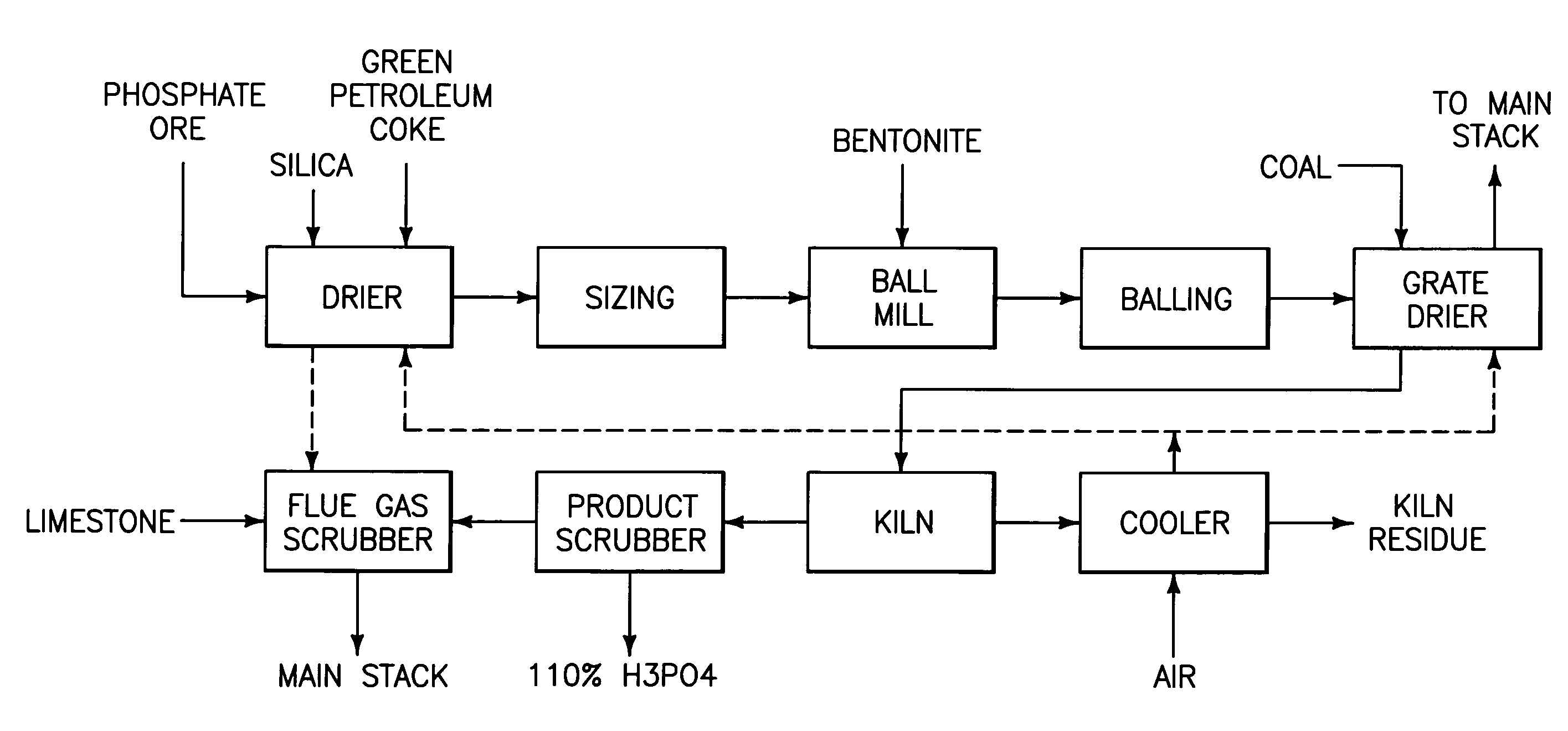

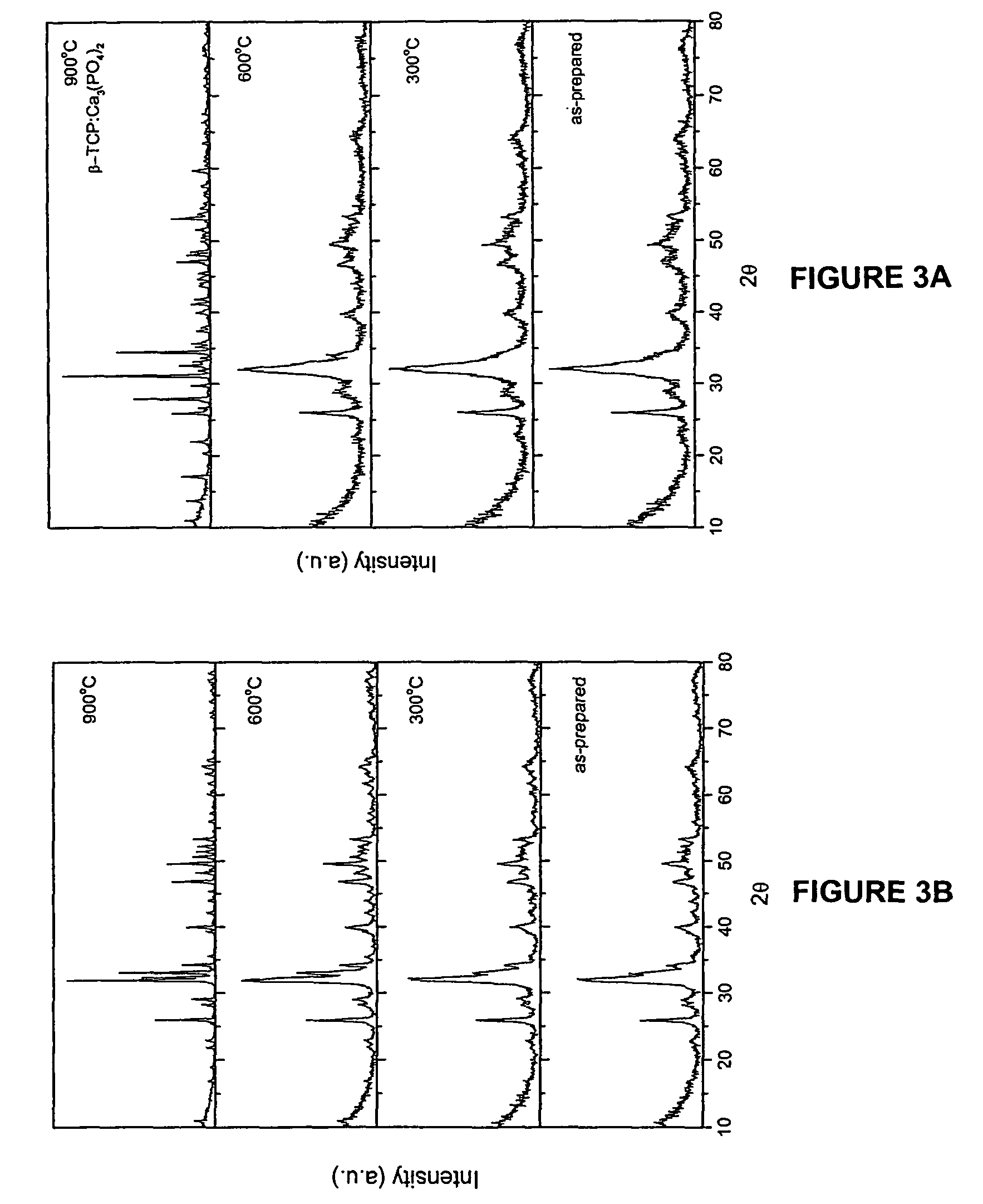

Flame synthesis of metal salt nanoparticles, in particular calcium and phosphate comprising nanoparticles

InactiveUS20070196259A1Increase chanceCalcium/strontium/barium carbonatesMaterial nanotechnologyBiocompatibility TestingMetallacarboxylic acid

Described is a method for the production of metal salts, wherein the cationic metal is preferably selected from Group I to IV metals and mixtures thereof and the anionic group is selected from phosphates, silicates, sulfates, carbonates, hydroxides, fluorides and mixtures thereof, and wherein said method comprises forming a mixture of at least one metal source that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3 and at least one anion source into droplets and oxiding said droplets in a high temperature environment, preferably a flame. This method is especially suited for the production of calcium phosphate biomaterials such as hydroxyapatite (HAp,Cal0(P04)6(OH)2) and tricalcium phosphate (TCP,Ca3(P04)2) that exhibit excellent biocompatibility and osteoconductivity and therefore are widely used for reparation of bony or periodontal defects, coating of metallic implants and bone space fillers.

Owner:EIDENGOSSICHE TECHN HOCHSCHULE ZURICH

Phosphorous pentoxide producing methods

A phosphorous pentoxide producing method includes forming a kiln bed using feed agglomerates with a calcium-to-silica mole ratio of less than 1.0 and maintaining a bed temperature at or above 1180° C. along at least 50% of the bed length without exceeding 1380° C. along the entire bed length. Less than 10% of the agglomerates' phosphate input to the kiln remains in the kiln residue as phosphate. Another method includes maintaining a bed temperature at or above 1180° C. along a portion of the bed length and establishing a bed surface-to-volume ratio multiplied by a time for bed heat up to 1180° C. of less than 50 minutes-ft2 / ft3.

Owner:NOVAPHOS PHOSPHATE TECH LLC

Method for recovering phosphorus from phosphorite tailings and preparing light magnesium oxide

The invention relates to a method for recovering phosphorus from phosphorite tailings and preparing light magnesium oxide. The method comprises the following steps of: calcining the phosphorite tailings; digesting calcined products to obtain digestion slurry and digestion products; separating the digestion products by using a table concentrator to obtain concentrates, middlings and tailings, wherein the concentrates are phosphorus concentrates and the middlings and the tailings are magnesium-enriched products; performing acid leaching on the magnesium-enriched products to obtain magnesium-enriched leachate and leaching slag; mixing the magnesium-enriched leachate and the digestion slurry, removing impurities, and carbonizing to prepare the light magnesium oxide; and recovering rich phosphorus pentoxide in the phosphorus concentrates and the leaching slag. By the method, phosphorus-containing ores in the phosphorite tailings are recovered effectively, and the light magnesium oxide is prepared, so that the aim of comprehensively utilizing the phosphorite tailings is fulfilled; and the total recovery rate of the phosphorus pentoxide is 98.88 percent, the content of magnesium oxide in the light magnesium oxide prepared by treating the leachate and the digestion slurry is 93.09 percent, and the quality of the light magnesium oxide meets the requirements for qualified products in the standard HG / T2573-94.

Owner:贵州贵达元亨环保科技有限公司

Phosphate recovery from sludge

A process for recovering reusable materials, in particular phosphate, from sewage sludge products, namely sewage sludge, sewage sludge ash or sewage sludge slag, by extraction, in which a suspension of the sewage sludge product is produced in water, alcohol, water-alcohol mixture or an aqueous solution, gaseous carbon dioxide (CO2) or supercritical carbon dioxide (scCO2) is introduced as an extraction agent into the suspension of the sewage sludge product, undissolved solids are separated from the liquid suspension agent, carbon dioxide is removed from the suspension agent, and reusable materials dissolved in the suspension agent are precipitated and separated from the suspension agent.

Owner:CHEM FAB BUDENHEIM AG

Method for producing iron oxyhydroxide and adsorbing material comprising iron oxyhydroxide

InactiveUS20090028770A1Improve adsorption capacityEfficient productionPhosphorus oxidesNitrogen compoundsIndustrial effluentHazardous substance

The present invention provides a method for advantageously producing an iron oxyhydroxide exhibiting excellent capability of adsorbing harmful substances, such as a phosphrous components and endocrine disrupting chemicals, which are contained in industrial wastewater, exhaust gases, etc., and an adsorbent material comprising the iron oxyhydroxide produced by the method as a main component. Specifically, the present invention provides an adsorbent material produced by a method comprising the steps of:(a) adding a base to an aqueous iron ion-containing solution, adjusting the pH of the resultant mixture to 9 or less, to form a precipitate that contains an iron oxyhydroxide;(b) drying the precipitate at a temperature of 100° C. or lower to obtain an iron oxyhydroxide;(c) contacting the resultant iron oxyhydroxide with water; and(d) subjecting the resultant iron oxyhydroxide to a heat treatment under a gas atmosphere having an inert gas concentration of 80% or greater at a temperature of 100 to 280° C.

Owner:JAPAN SCI & TECH CORP +2

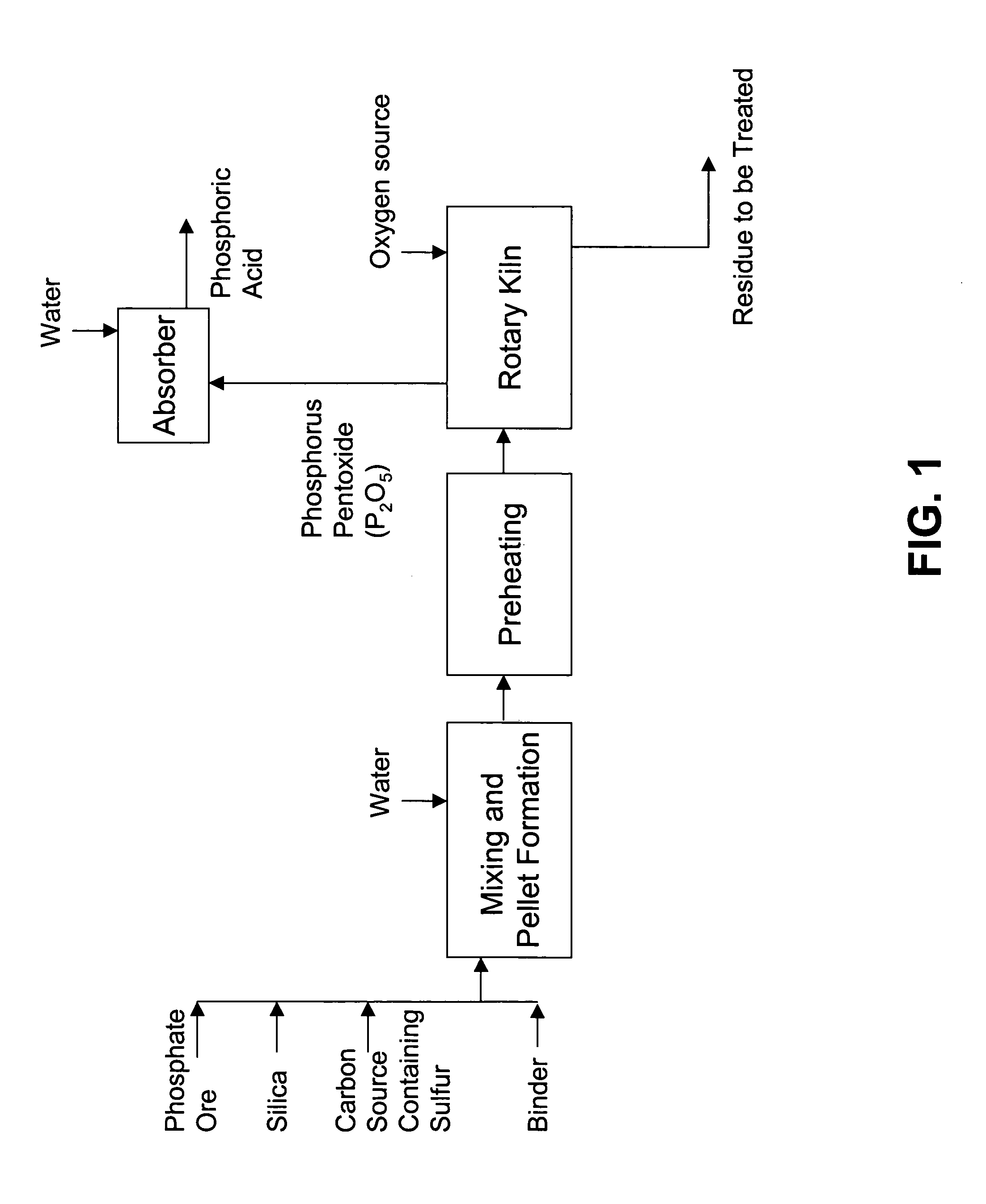

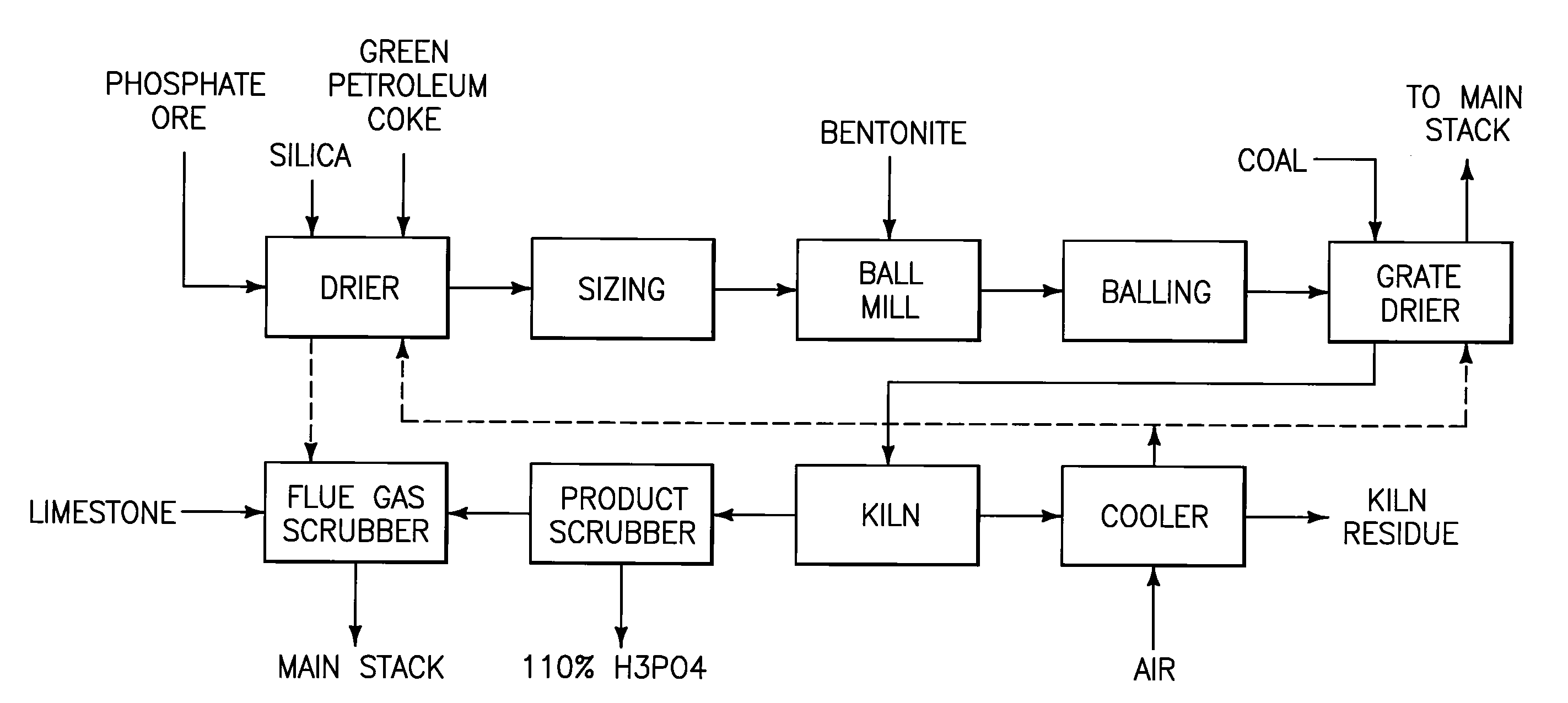

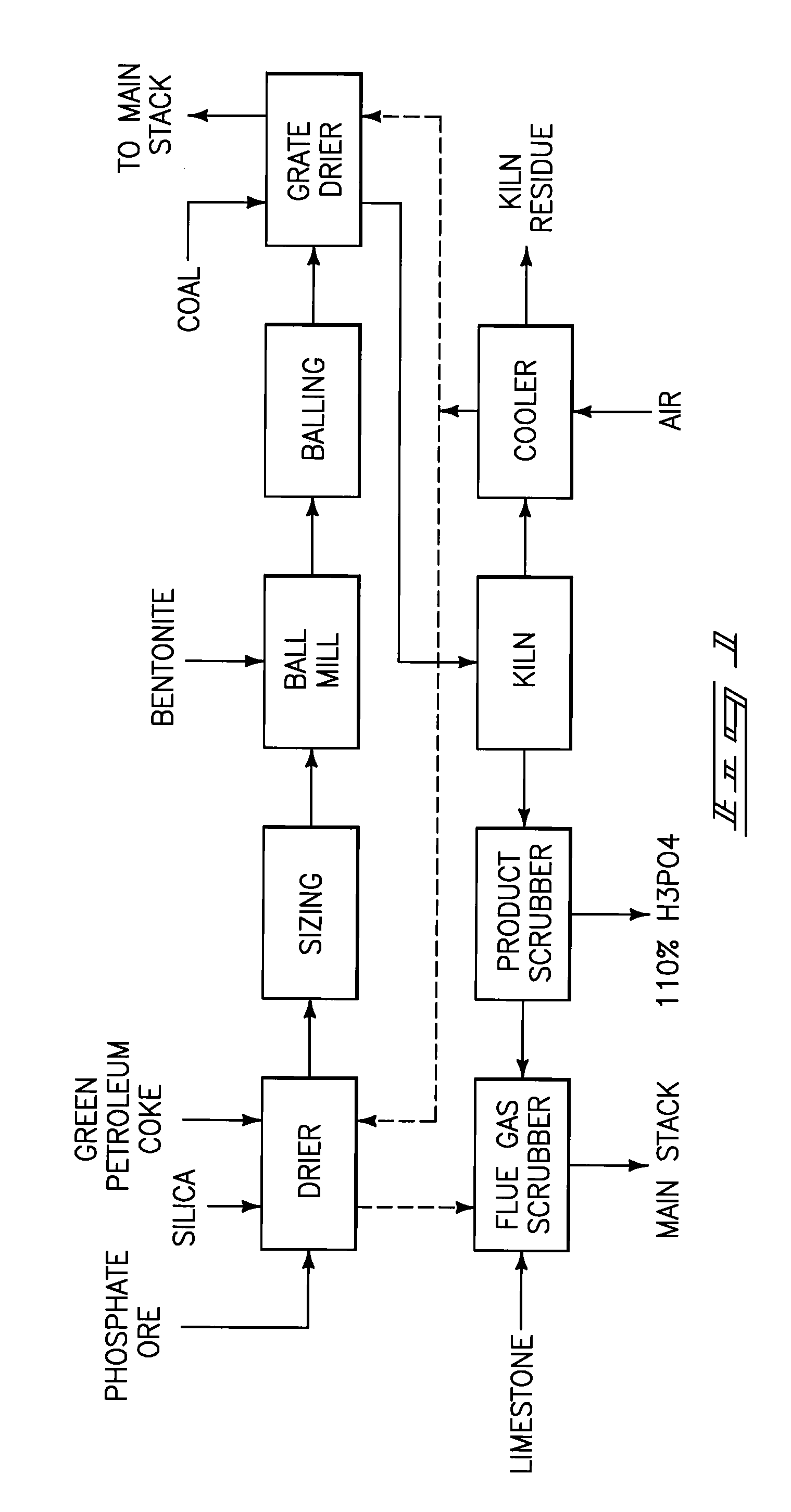

Method of forming phosphoric acid from phosphate ore

The process disclosed herein involves the high temperature processing of phosphate ore in a solid state using a ported rotary kiln. Prior to insertion into the kiln, the ore is pulverized and beneficiated to remove excessive quantities of unwanted materials such as clay, silica, iron, sodium, potassium, and alumina. The calcium oxide to silica ratio of the beneficiated is then adjusted to within a specific acceptable range, a carbon source containing sulfur such as petroleum coke is added and the resulting feed material is pelletized using a binding agent if necessary. The pelletized feed material is then dried, preheated, and fed into a ported rotary kiln. At the elevated temperature maintained in the reducing kiln, tricalcium phosphate undergoes a reduction reaction to produce phosphorus gas and carbon monoxide. Atmospheric air is injected into the rotating kiln chamber, which facilitates the oxidation of phosphorus gas to phosphorus pentoxide and the oxidation of carbon monoxide to carbon dioxide. The reducing kiln exhaust gas stream containing the phosphorus pentoxide and carbon dioxide gas components is processed in an absorption column in which the phosphorus pentoxide is hydrolyzed by water to phosphoric acid. The phosphoric acid is then recovered and concentrated to a commercial grade strength. The slag residue serves as a raw material for cement manufacture.

Owner:CAROLINA PROCESS ASSOC

Method for recovering P2O5 in phosphorus ore dressing mill tailings

InactiveCN101759165AEmission reductionSolve dissociation problemsPhosphorus oxidesCycloneResource recovery

The invention provides a method for recovering P2O5 in phosphorus ore dressing mill tailings, which relates to a method for utilizing mill tailings. The method uses a hydraulic cyclone for pre-treating and dividing the mill tailings into two parts (mill tailings smaller than 56 mum and mill tailings larger than 56 mum) by aiming at the mill tailings with the P2O5 content higher than 5 percent produced in the carbonate type phosphorite phosphorus ore dressing process, wherein the part of mill tailings smaller than 56 mum with a large amount of residual ore dressing agents directly enters the ore dressing step, and the part of mill tailings larger than 56 mum is milled again by a ball mill to present the size smaller than 56 mum for entering the ore dressing step. The method comprises the following steps: firstly, separating the mill tailings according to the coarse grain grade and the fine grain grade; and carrying out secondary milling by the coarse grain grade part. The invention solves the problem of ore monomer dissociation, the fine grain grade part does not participate in the ore milling, and the over-pulverization and the argillization of the ore are reduced. Through grading the mill tailings with a large amount of residual ore dressing agents, the ore dressing agents can be regenerated and reutilized through being separated with the fine grains from the coarse grains, and few collecting agents or no collecting agent can be added for secondary ore dressing of the mill tailings. The method improves the phosphorus ore recovery rate, reduces the discharge amount of the mill tailings, conforms to the requirements of circulation and economy, and is suitable for ore dressing enterprises.

Owner:WENGFU (GRP) CO LTD

Phosphorous Pentoxide Producing Methods

A phosphorous pentoxide producing method includes forming a kiln bed using feed agglomerates with a calcium-to-silica mole ratio of from 0.5 to 1.0 and maintaining a bed temperature at or above 1260° C. along a portion of the bed length without exceeding 1380° C. along the entire bed length. Less than 10% of the agglomerates' phosphate input to the kiln remains in the kiln residue as phosphate. Another method includes maintaining a bed temperature at or above 1180° C. along a portion of the bed length and establishing a bed surface-to-volume ratio multiplied by a time for bed heat up to 1180° C. of less than 50 minutes-ft2 / ft3.

Owner:NOVAPHOS INC

Method for direct production of phosphorus pentoxide with phosphorus ore

ActiveCN101172589ARealize continuous operationIncrease productivityPhosphorus oxidesChemical industryOxidation zoneEngineering industry

The invention discloses a production method of phosphorus pentoxide by directly using phosphorus ore. Phosphorus ore and silica are mixed pro rata, delivered to a heating furnace to be heated and molten, after the molten mass flows into a reaction furnace, carbon is directly added into the high temperature molten mass, the carbon is kept to be excess, the temperature of the molten mass is controlled above 1200 DEG C, thereby leading the molten mass to generate reducing reaction, high temperature and high speed oxygen is sprayed downward into the molten mass through an upper spray gun, thereby providing oxygen for the oxidation of phosphorus vapor and carbon monoxide generated in the reducing zone, and a dished high temperature zone can be formed on the surface of the center of the molten mass, therefore, the heat transfer rate of the mass transfer in the reduction oxidation zone is greatly intensified, the finished quality is ensured, the percent reduction of the phosphorus ore is improved, and the continuous phosphorus pentoxide and phosphonic acid production can be realized. The invention has the advantages that the flow is simplified, the cost is reduced, the finished quality is improved, the percent reduction of the phosphor reaches 98 percent, the energy and resource are saved, the three wastes are basically eliminated, therefore, the invention provides the epoch-making revolution for the phosphor chemical engineering industry.

Owner:GUIZHOU CHANHEN CHEM CO LTD

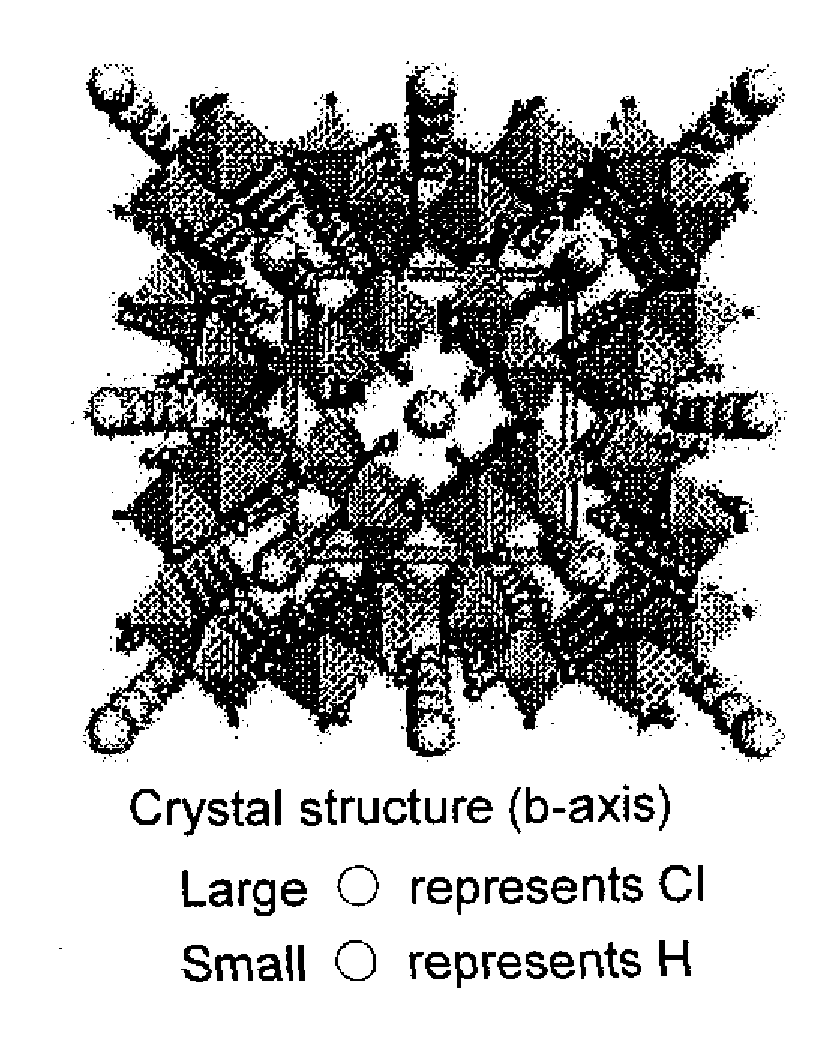

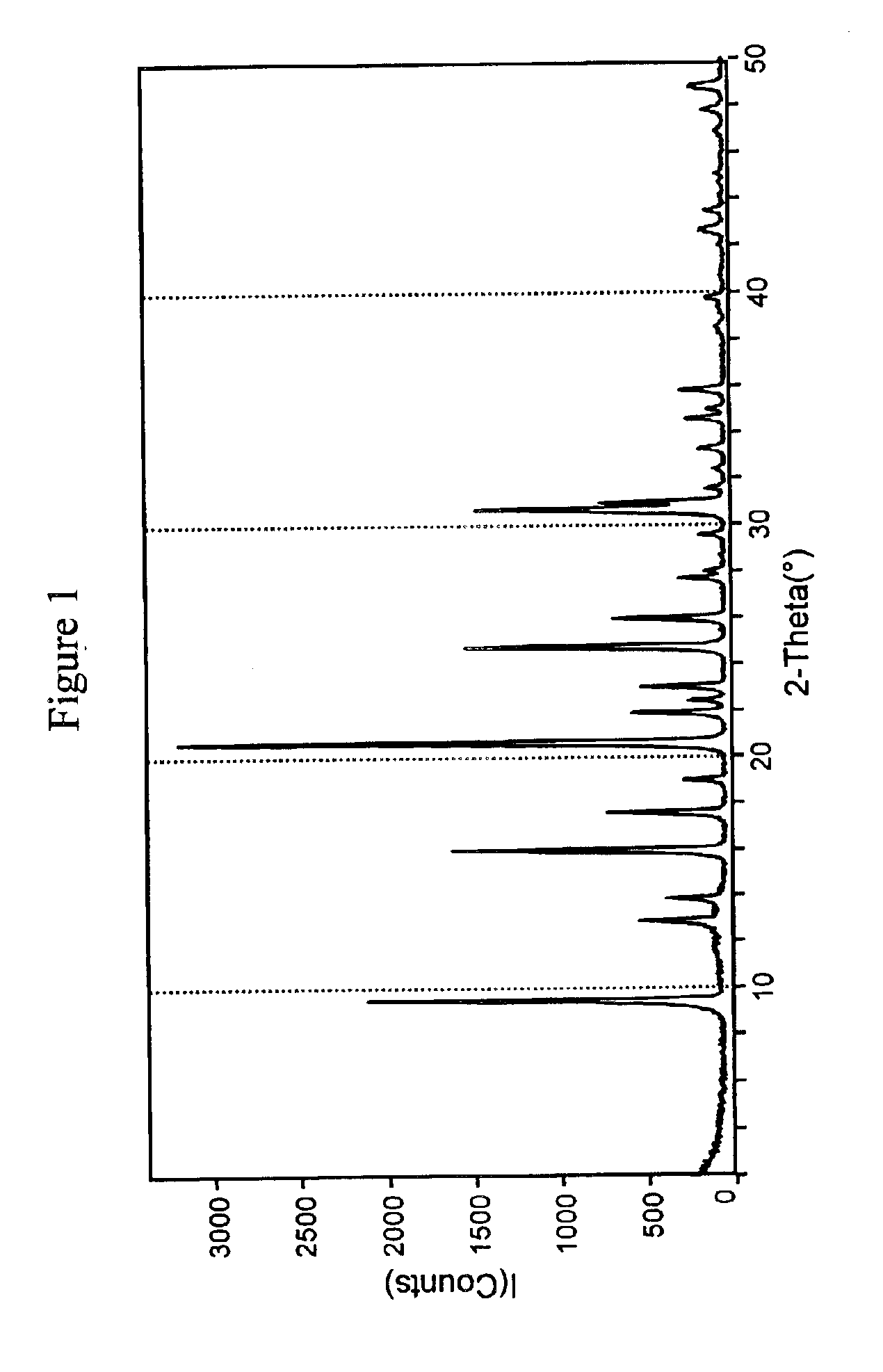

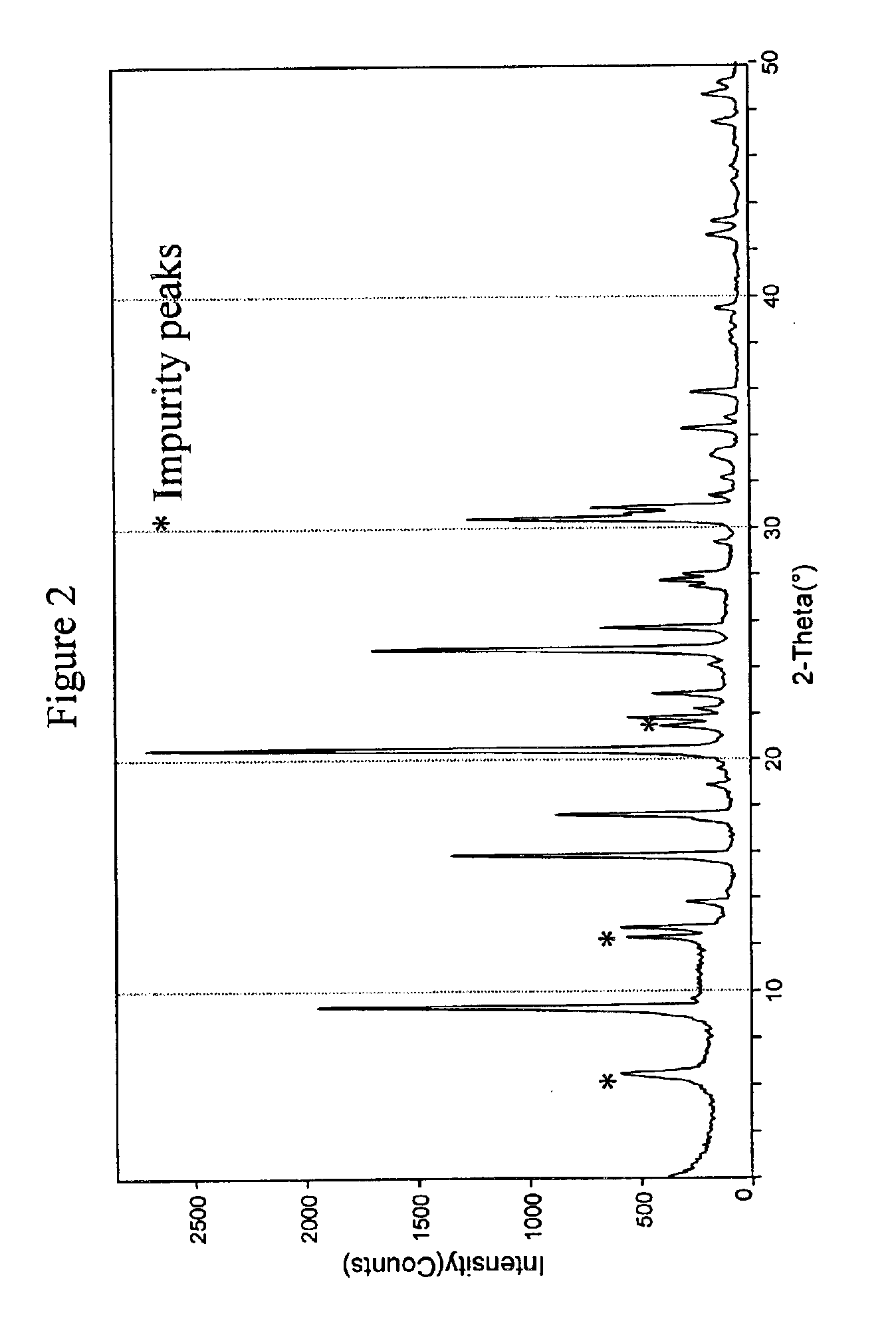

Synthesis of silicoaluminophosphates

The invention is directed to a method of synthesizing silicoaluminophosphate molecular sieves using synthesis templates that contain at least one dimethylamino moiety, selected from one or more of N,N-dimethylethanolamine, N,N-dimethylpropanolamine, N,N-dimethylbutanolamine, N,N-dimethylheptanolamine, N,N-dimethylhexanolamine, N,N-dimethylethylenediamine, N,N-dimethylbutylenediamine, N,N-dimethylheptylenediamine, N,N-dimethylhexylenediamine 1-dimethylamino-2-propanol, N,N-dimethylethylamine, N,N-dimethylpropylamine, N,N-dimethylpentylamine, N,N-dimethylhexylamine and N,N-dimethylheptylamine. The use of dimethylamino moiety containing templates results in good quality SAPO molecular sieves of CHA framework type.

Owner:EXXONMOBIL CHEM PAT INC

Diatomaceous earth products containing reduced soluble metal levels, processes for reducing soluble metal levels in diatomaceous earth products, and methods of using the same

Disclosed herein are diatomaceous earth products containing reduced soluble metal levels, processes for reducing soluble metal levels in diatomaceous earth products, and methods of using the same. In particular, diatomaceous earth products are disclosed that have been treated with at least one surface metal blocking agent, and then subjected to at least one thermal treatment process to reduce the level of soluble metals associated therewith. Such diatomaceous earth products containing reduced soluble metal levels may be useful for various applications including, but not limited to, as filter aid materials.

Owner:IMERYS FILTRATION MINERALS

Double-region device for efficiently recovering yellow phosphorus combustion heat

ActiveCN102910602AImprove recycling efficiencyImprove utilization efficiencyPhosphorus oxidesChemical industryProcess engineeringHeat of combustion

The invention discloses a double-region device for efficiently recovering yellow phosphorus combustion heat. The device comprises a support, a sufficient combustion region component, a convective heat transfer region component and a steam drum sequentially from bottom to top. One end of a sufficient combustion region down pipe is communicated with the steam drum while the other end of the sufficient combustion region down pipe is communicated with a lower header of the sufficient combustion region component. One end of a sufficient combustion region sufficient combustion region steam guide pipe is communicated with the steam drum while the other end of the sufficient combustion region steam guide pipe is communicated with an upper header of the sufficient combustion region component. One end of a convective heat transfer region down pipe is communicated with the steam drum while the other end of the convective heat transfer region down pipe is communicated with a cooling water inlet pipe of the convective heat transfer region component, one end of a convective heat transfer region steam guide pipe is communicated with the steam drum while the other end of the onvective heat transfer region steam guide pipe is communicated with a steam outlet pipe in the convective heat transfer region component, and a lower head of the sufficient combustion region component is connected with the support. The device is capable of achieving efficient recovery of the yellow phosphorus combustion heat, the theoretical recovery rate can reach more than 75%, energy saving and emission reduction of phosphoric-acid production by a hot method are promoted, and the device has wide application prospect in phosphoric-acid production by a hot method.

Owner:ZHEJIANG CHENGTAI CHEM MACHINERY

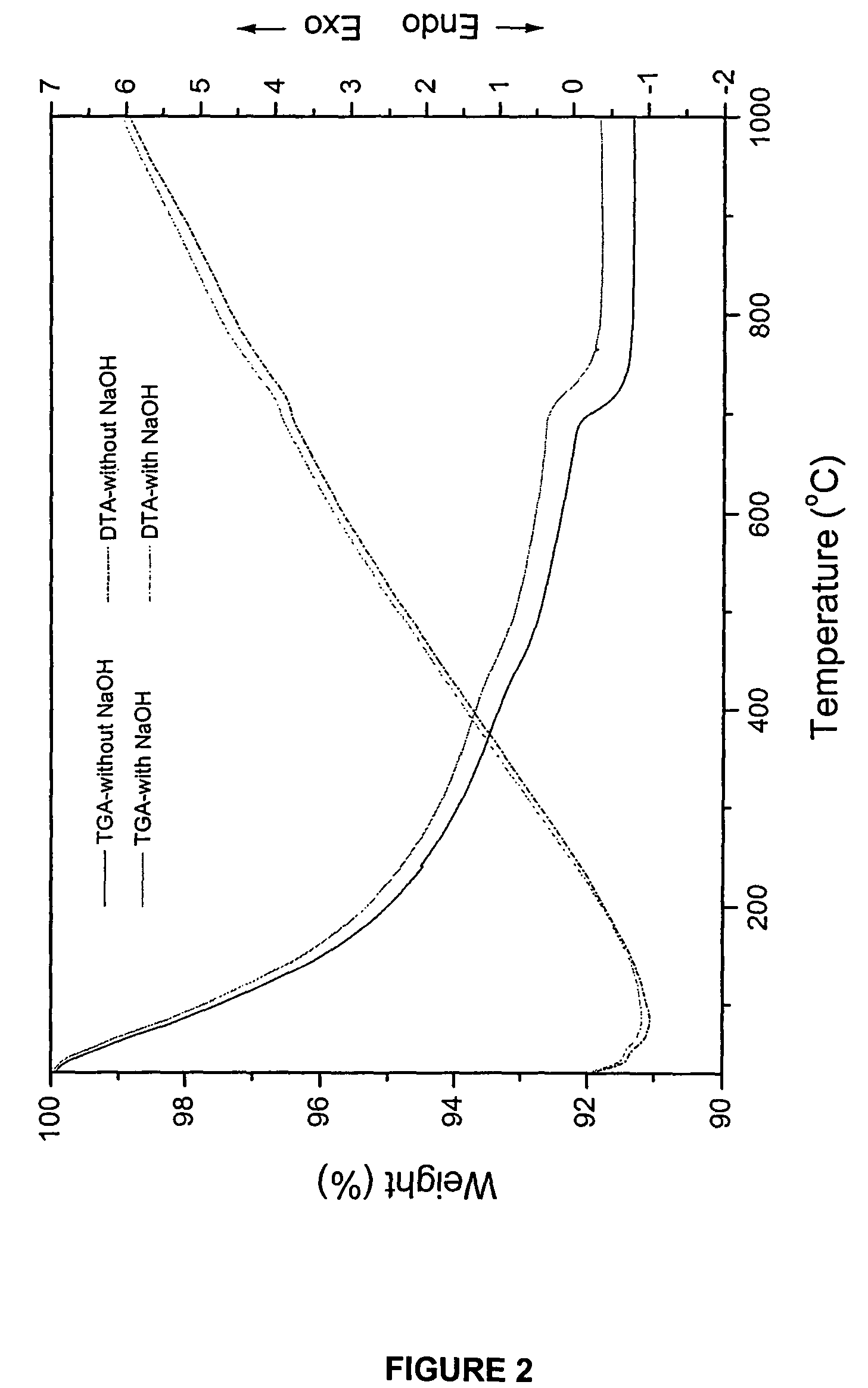

Calcium phosphate composition and method of preparing same

InactiveUS6849275B2Improve setting timeEasy to controlBiocidePowder deliveryCelluloseCalcium biphosphate

A method for controlling the formation of a hydroxyapatite bone filler from dry calcium phosphate precursors in an aqueous solution uses coated sodium phosphate powder. The sodium phosphate powder is coated with a water soluble cellulose. Until the cellulose dissolves in the aqueous solution setting of the calcium phosphate cements proceeds slowly but when the exposed sodium phosphate particles start to solubilize in the aqueous solution the setting rate increases.

Owner:HOWMEDICA OSTEONICS CORP

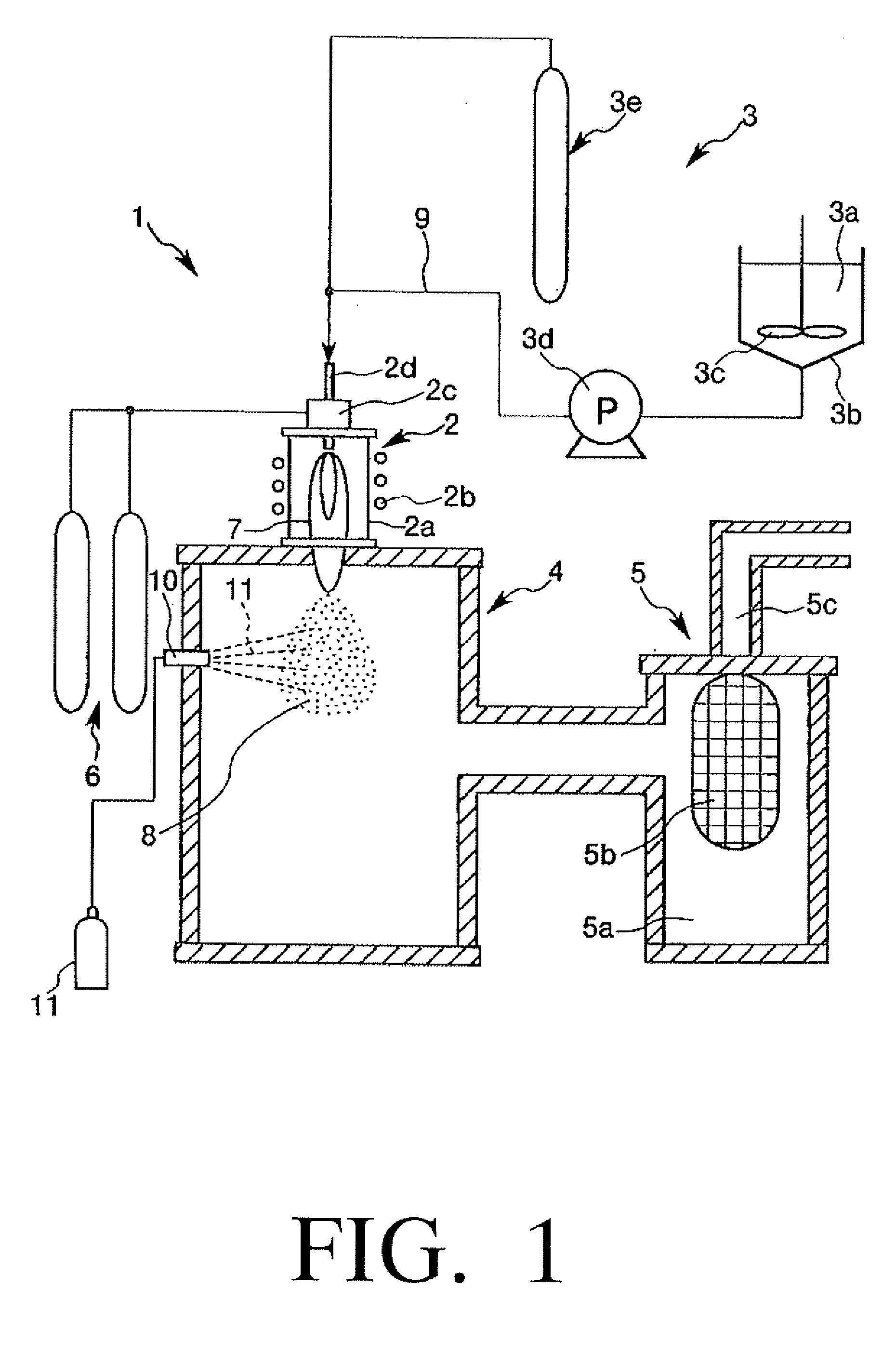

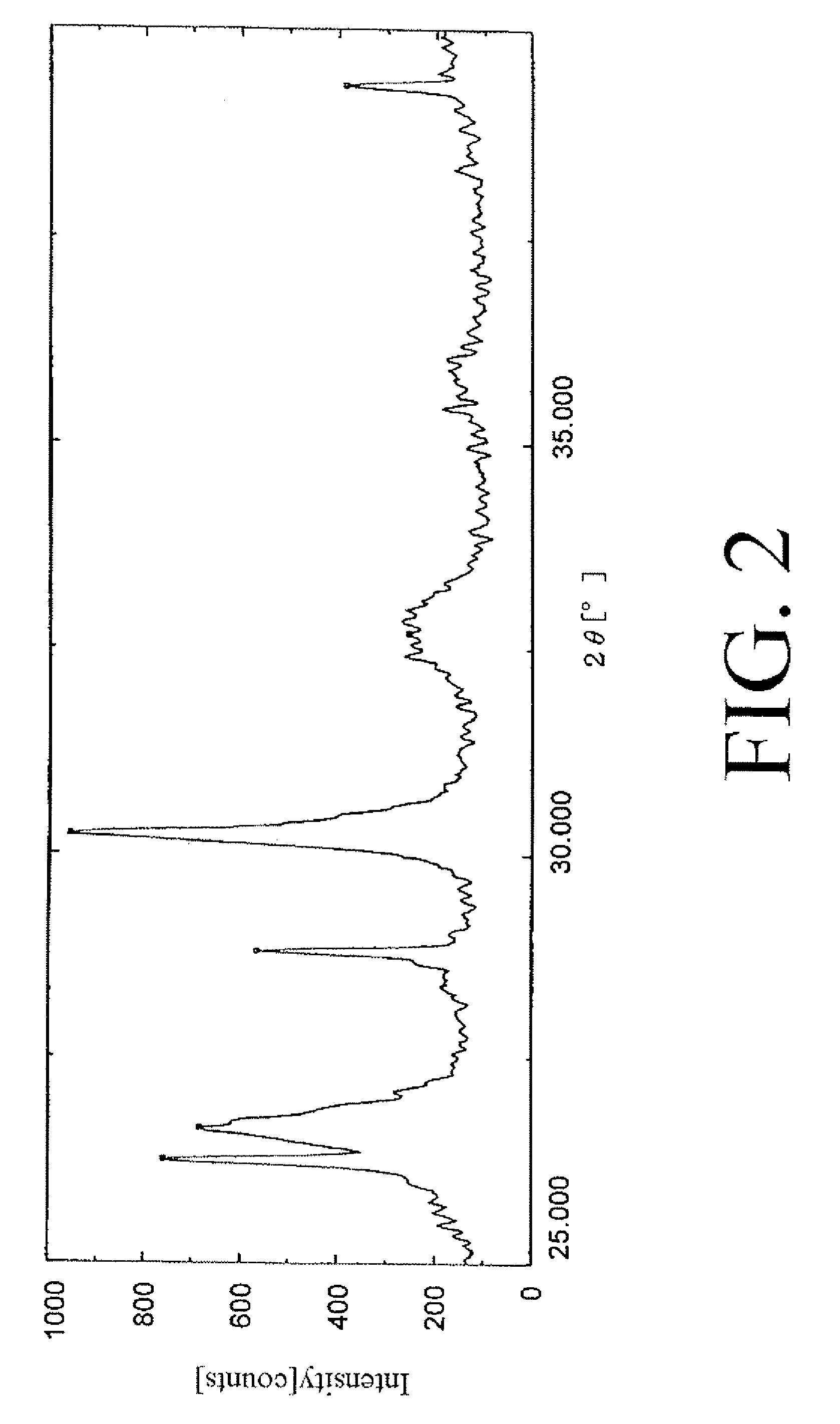

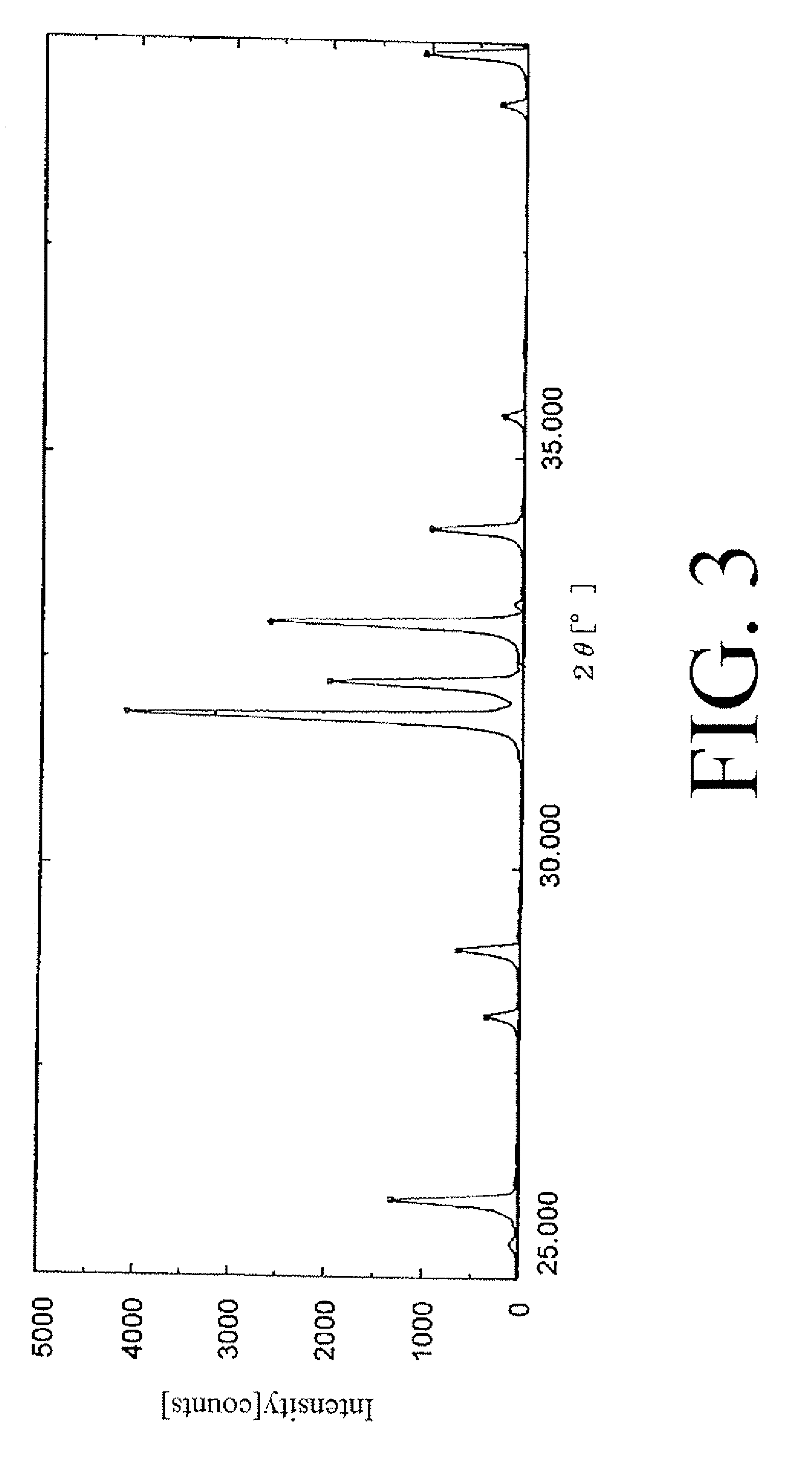

Method for producing particles, particles, and sintered body

ActiveUS20070053814A1High dimensional accuracyHigh strengthMaterial nanotechnologyPhosphorus oxidesCalcium biphosphateCompound (substance)

Disclosed herein are a particle production method whereby spherical fine particles of a crystalline calcium phosphate-based compound can be efficiently produced at low cost, fine particles (especially, spherical particles) with good flowability produced by the particle production method, and a high-quality sintered body obtained by sintering a molded body of the particles. The particle production method comprises a first step of mixing a first substance containing phosphorus and a second substance containing calcium so that the phosphorus and the calcium are present in a predetermined mole ratio and feeding, into a heated atmosphere, droplets of a slurry containing an amorphous reaction product, obtained by the reaction between the first substance and the second substance, to bring the reaction product into a gaseous state; and a second step of crystallizing the reaction product in the gaseous state to obtain particles mainly composed of a calcium phosphate-based compound containing phosphorus and calcium in the predetermined mole ratio. The heated atmosphere preferably contains plasma produced by ionization of an ambient gas.

Owner:NISSHIN ENG

Method for producing pyrophosphate

ActiveUS20130294994A1Efficiently provideHigh purityPhosphorus oxidesGroup 5/15 element organic compoundsPyrophosphateMelamine

A producing method of a high-purity pyrophosphate comprising a calcination of the orthophosphate under the condition of 120° C.-350° C.; and a producing method suitable for manufacturing effectively the high-purity melamine pyrophosphate.

Owner:ADEKA CORP

Method of manufacturing hydroxyapatite and uses therefor in delivery of nucleic acids

Provided is a method for production of nanocrystalline hydroxyapatite particles, and nanocrystalline hydroxyapatite particles produced according to the method. The nanocrystalline hydroxyapatite particles exhibit substantially superior cell transformation abilities as compared to known and commercially-available calcium phosphate kits. The nanocrystalline hydroxyapatite particles also find use in tissue engineering applications, for example bone and tooth engineering and repair applications.

Owner:CARNEGIE MELLON UNIV

Blast furnace phosphoric acid production method and equipment

ActiveCN101767779ASolve the problem of explosion during preferential oxidationHigh recovery ratePhosphorus oxidesChemical industrySludgeHigh energy

The invention provides a blast furnace phosphoric acid production and an equipment; phosphate ore is proportioned for blast-furnace processing, sludge phosphorus is recovered through blast furnace gas, the sludge phosphorus is oxidized and combusted to absorb P2O5 in circulation manner. Compared with prior art, the invention adopts the method of firstly receiving sludge phosphorus and subsequently oxidizing and combusting the sludge phosphorus, not only can utilize medium and low grade phosphorite to produce blast furnace phosphoric acid, but also can completely solve the explosion problem of prior oxidation of blast furnace phosphoric acid production, and also improves the reduced phosphor recovery rate to 98% in blast furnace phosphor acid production process; a boiling sludge phosphorus calcinator is combined with a vertical multi-smoke channel natural circulation boiler to recover heat generated by the sludge phosphorus combustion so that the invention has significant meanings on saving energy and reducing consumption of the high energy-consumption blast furnace phosphor acid process, also on further comprehensive development and utilization aspects.

Owner:GUIZHOU ZHONGYI LIANCHUANG TECH DEVCO

Composition and method for control of plant pathogenic bacteria and endophytic microorganisms using copper phosphite and nutrient-halo-phosphite compounds

ActiveUS8795736B2Facilitates absorption and translocation and distributionAlter nutritionBiocideInorganic phosphorous active ingredientsPathogenic microorganismBacteroides

The present disclosure is directed toward a composition and method of treating and preventing infection of pathogenic microorganisms and endopyhtic microorganisms in a plant through the use of phosphite compositions.

Owner:HUBER DON M

Method for producing phosphorus pentoxide by phosphorus ore fusion

ActiveCN101172587AIncrease productivityImprove practicalityPhosphorus oxidesChemical industryPhosphate

The invention discloses a method for producing phosphorus pentoxide by melting phosphate rock. The phosphate rock and silica are mixed in proportion and sent to a heating furnace for heating and melting. After flowing into the reaction furnace, carbon is added to the molten material and the temperature is controlled to 1200°C. Above, the molten material is reduced in the reduction zone of the reactor to produce a mixed gas of P4 steam and CO and absorb heat. This gas is directly oxidized with the added oxygen in the oxidation zone of the reactor to generate P2O5 and CO2 gases and release heat. The heat is supplied It is necessary to heat the molten material and reduce the heat required for the reduction reaction, control the oxygen addition method in the oxidation zone, maintain the reducing atmosphere on the molten liquid interface of the reactor, and make the reduction and oxidation reaction zones proceed smoothly. The generated P2O5 gas is cooled and purified to produce pentoxide. Phosphorus products. The advantages of the invention are: it simplifies the process, reduces the cost, improves the product quality, has a phosphorus reduction rate of 98%, saves energy and resources, basically eliminates "three wastes", and brings epoch-making changes to the phosphorus chemical industry.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com