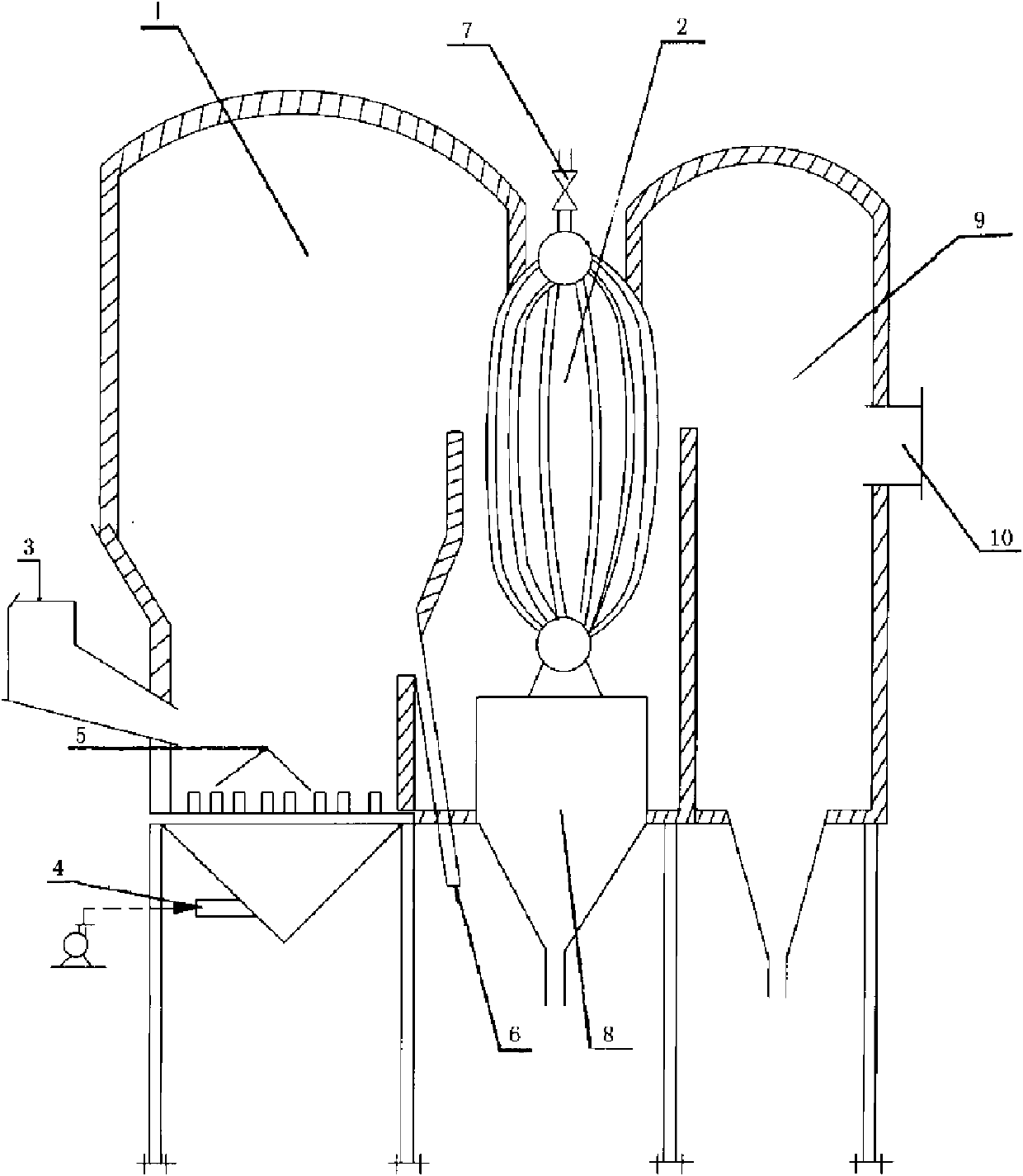

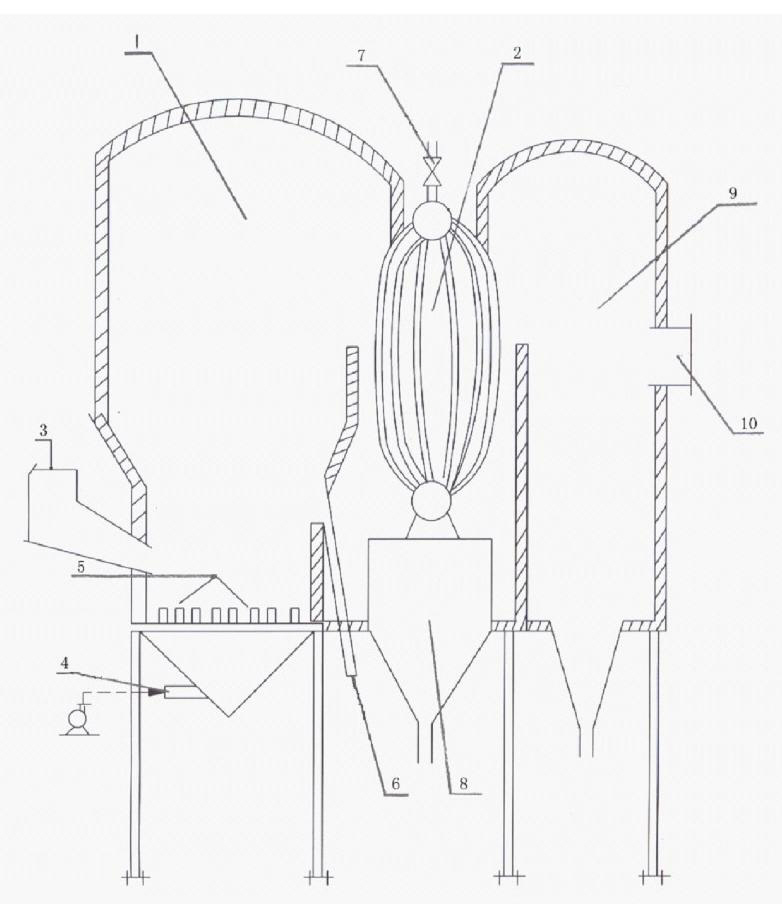

Blast furnace phosphoric acid production method and equipment

A technology of phosphoric acid and blast furnace, which is applied in the field of phosphoric acid and can solve problems such as blast furnace phosphoric acid explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] Preliminarily crush the phosphate rock, mix according to the weight ratio of coke or coal: phosphate rock: limestone: silica = 1:1:0.2:0.3, and send it to the blast furnace for smelting. The first level of mud phosphorus recovery, after the first level of mud phosphorus recovery, the phosphorus-containing dust in the blast furnace gas that has not been removed will enter the second level of mud phosphorus recovery device jet dust collector. The jet dust collector can further reduce the temperature of the blast furnace gas. In order to facilitate the further recovery of mud phosphorus dust, the fine mud phosphorus that has not been removed is then passed through the Venturi tube of the third-stage mud phosphorus recovery device, and the recovery effect can finally reach more than 98%. Collect and recover the tertiary sludge phosphorus, send it into the sludge phosphorus boiling roasting and heat recovery equipment from the feed port 3, and carry out the sludge phosphorus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com