Patents

Literature

526results about "Phosphoric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

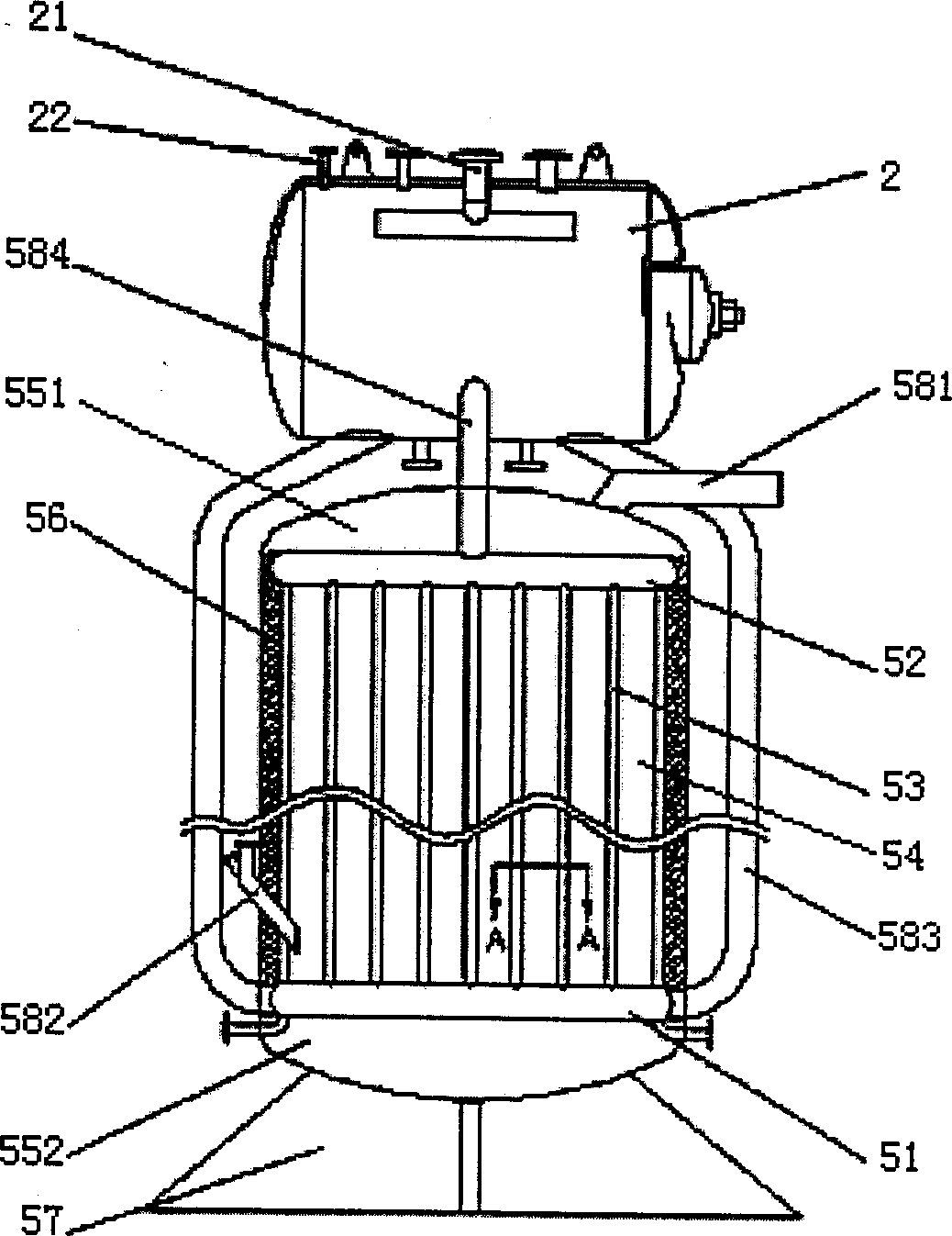

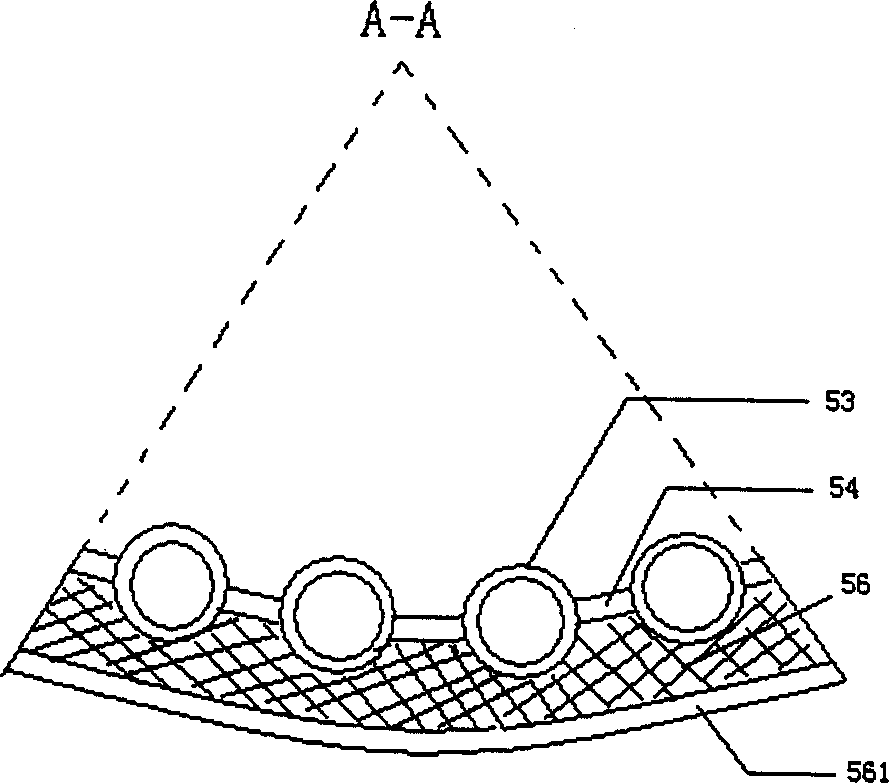

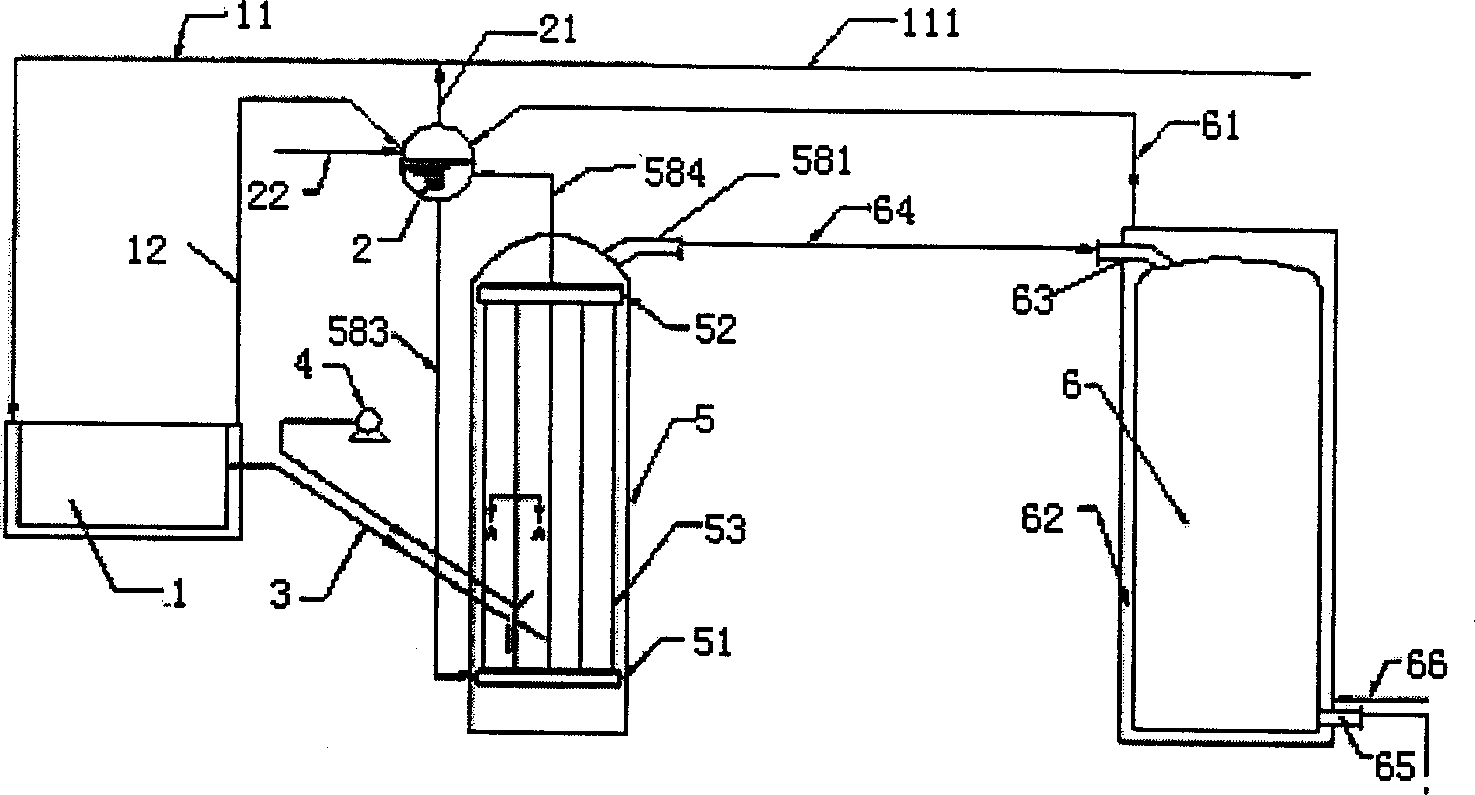

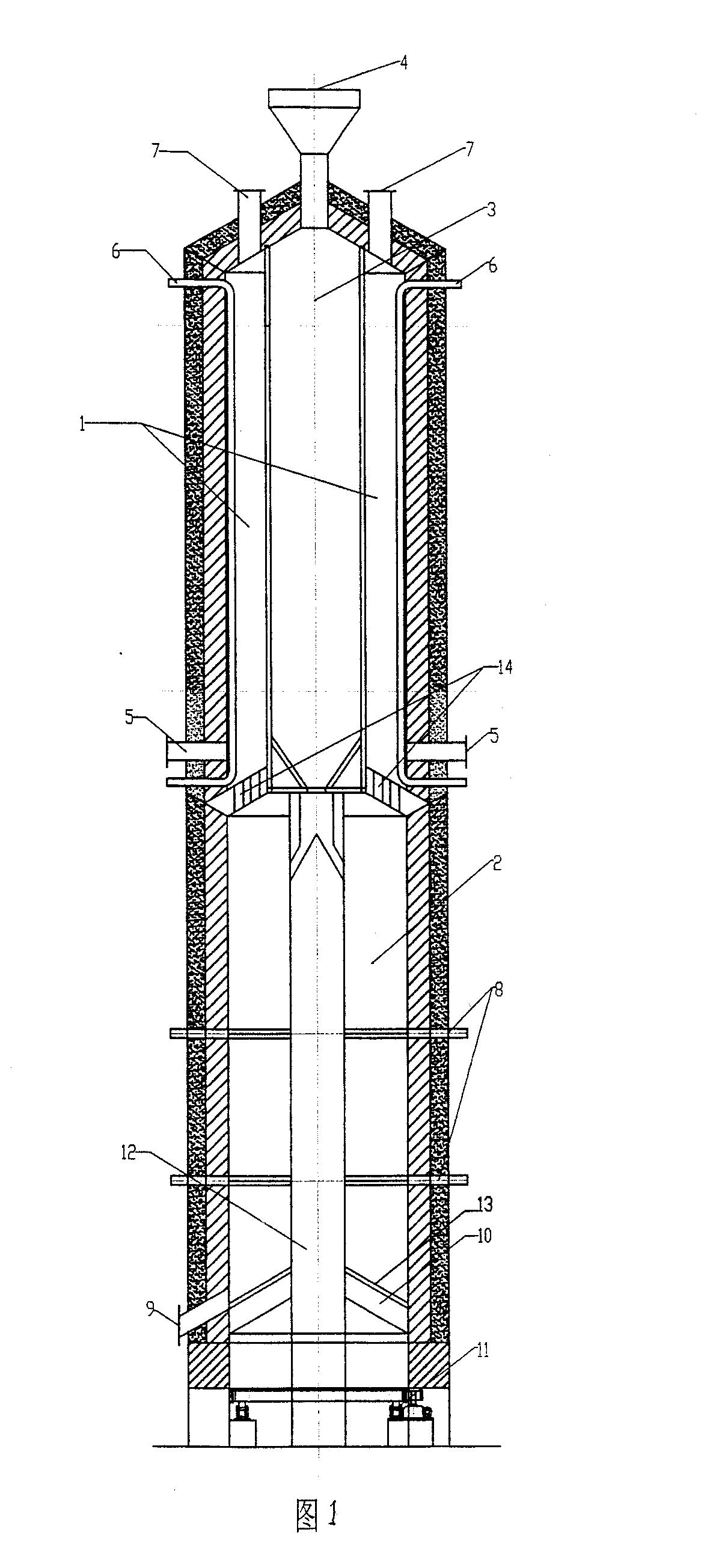

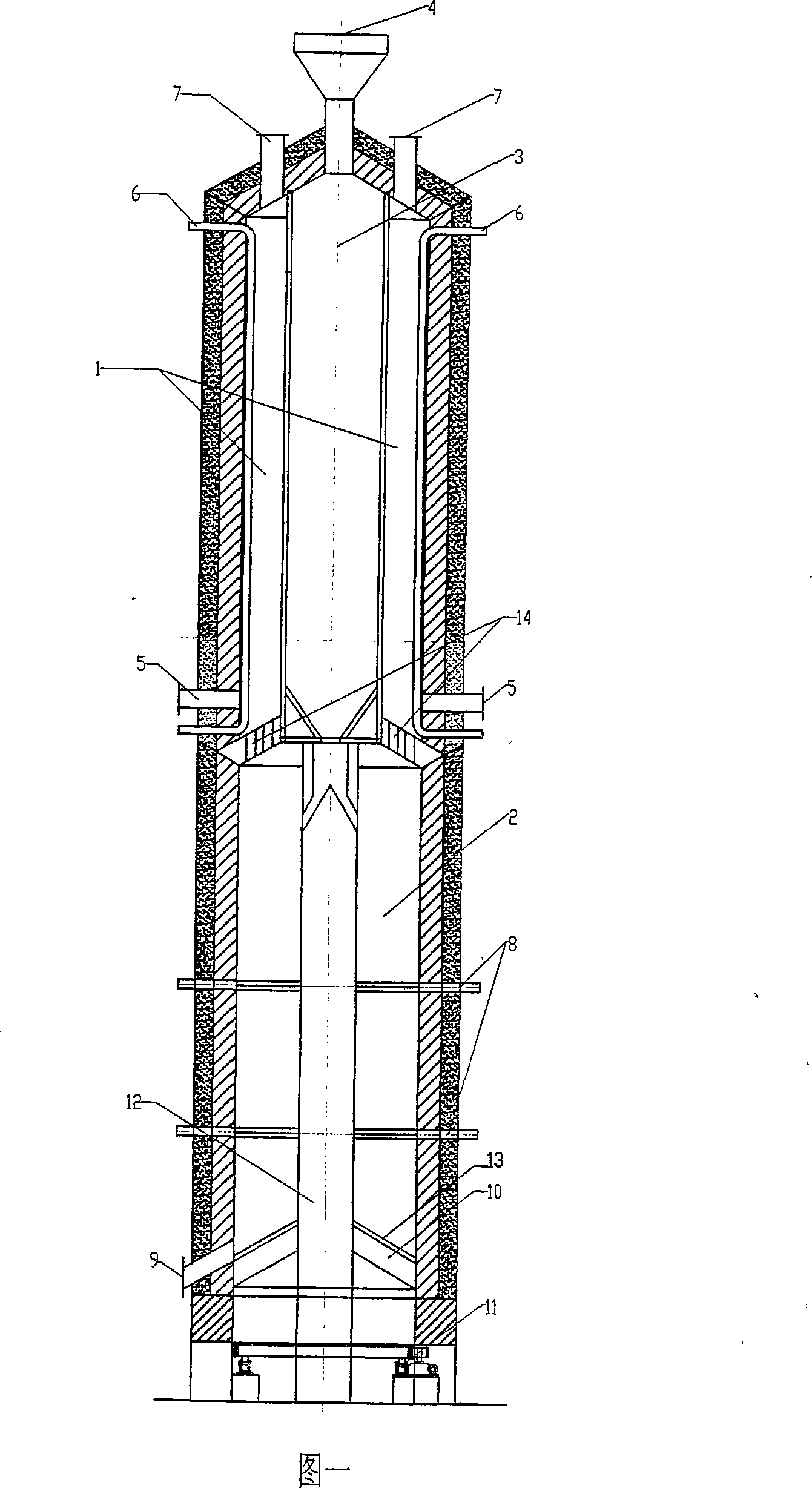

Equipment for recovering and utilizing heat energy generated by phosphor combustion and system for preparing phosphoric acid by hot method

An equipment for recovering and utilizing the heat energy generated by burning yellow phosphorus and a system for preparing phosphoric acid by the hot method are disclosed. It is composed of steam manifold and burning tower with heat energy recovering function. The burning tower consists of ring-shaped membrane heat exchanger with fins, heat-insulaitng enclosed casing, P2O5 gas outlet tube, connecting tube of phosphorus sprayer, etc.. Its advantages include low consumption of coal, water and energy, low cost and reduced environmental pollution.

Owner:TSINGHUA UNIV +1

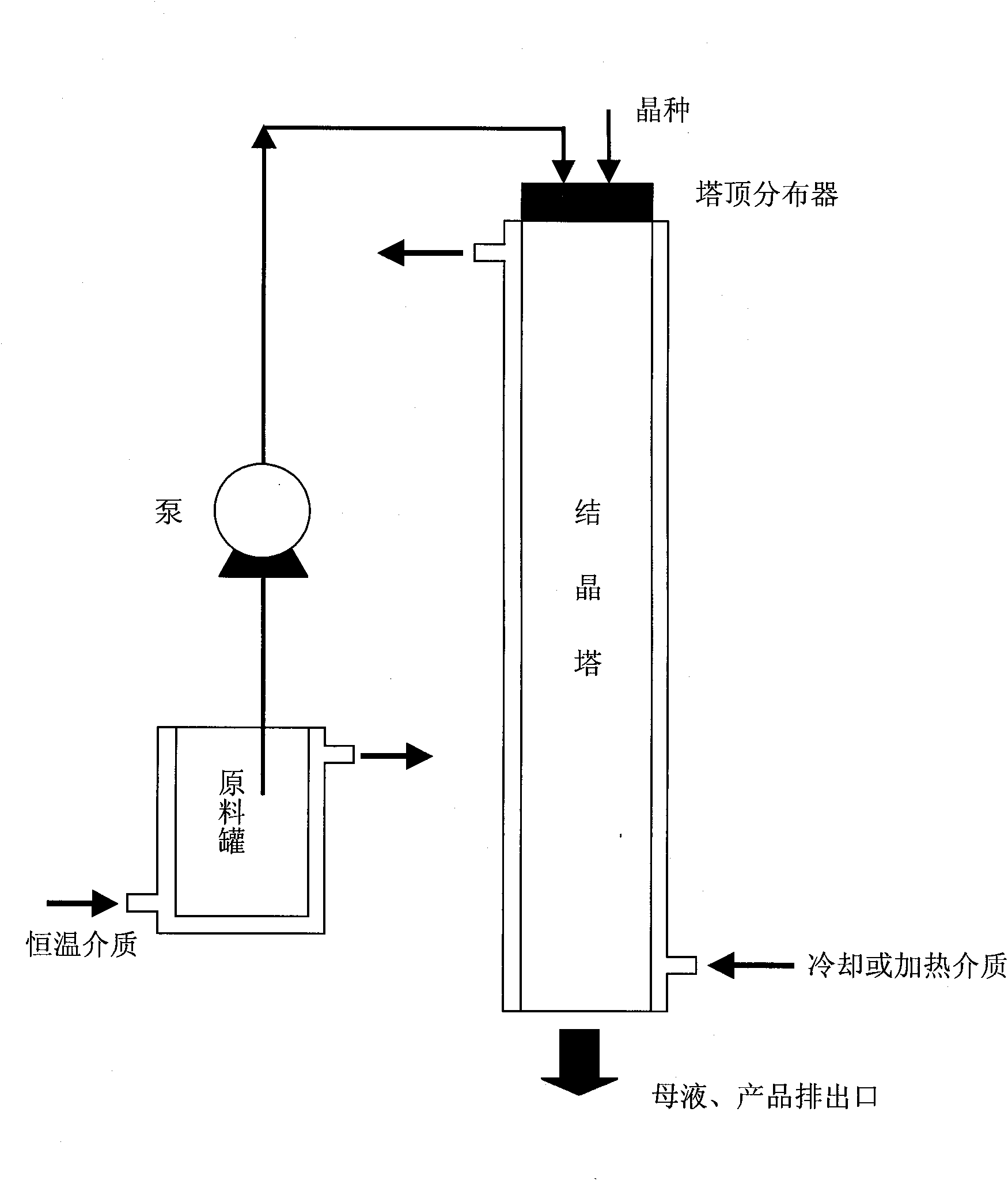

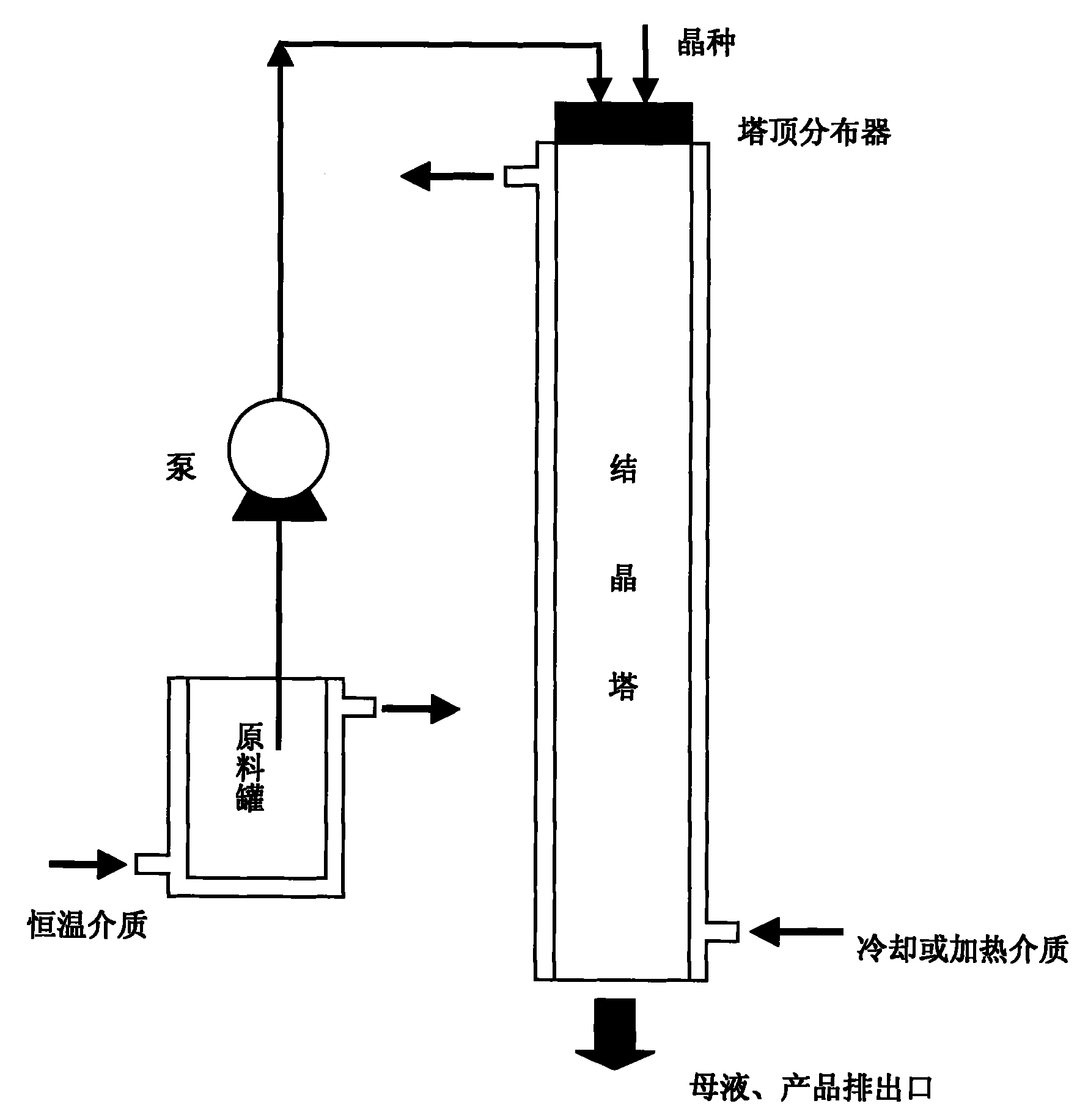

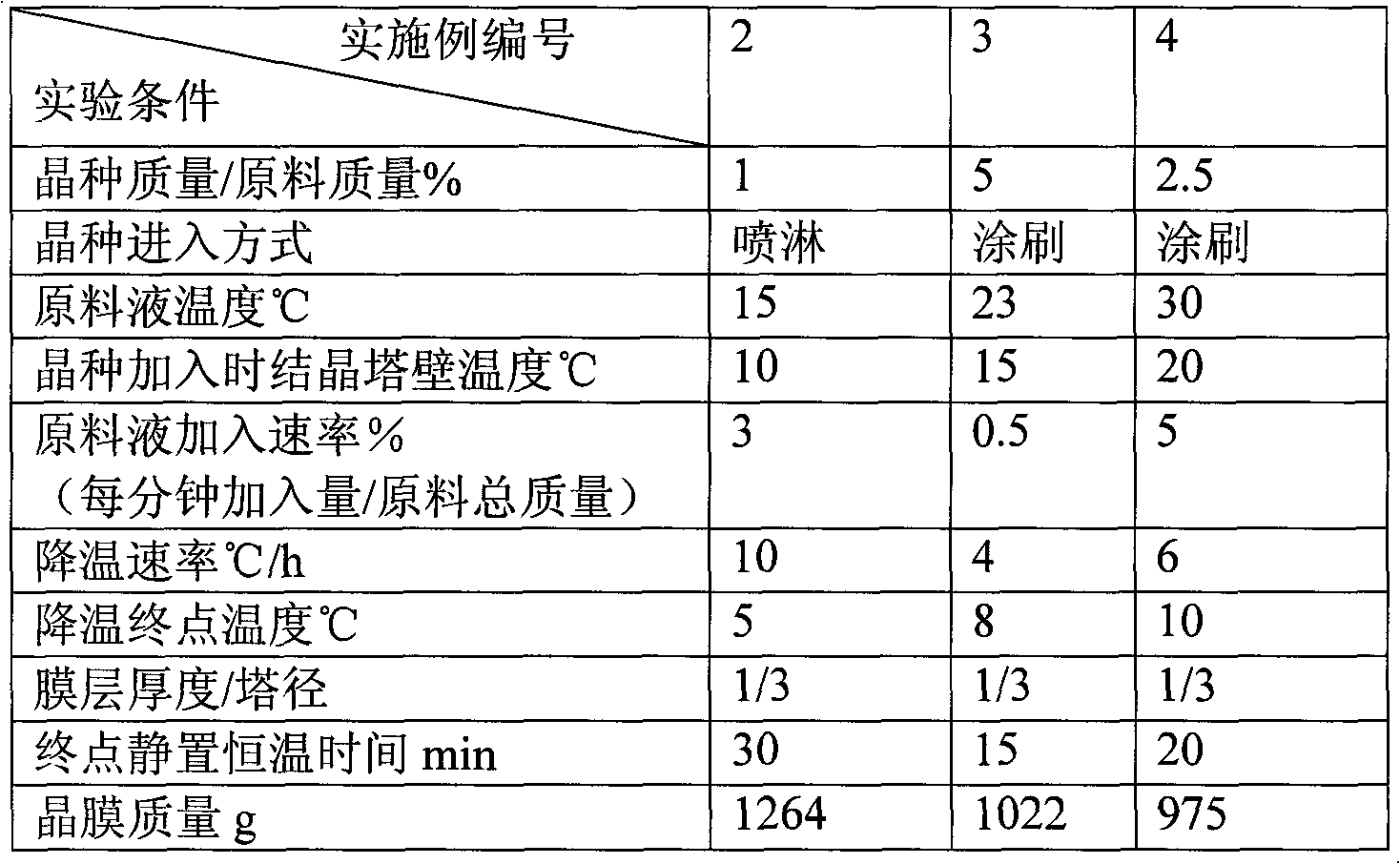

Method for preparing electronic grade phosphoric acid by fusion crystallization method

The invention relates to a process for preparaing electronic phosphoric acid with melt crystallization method. It comprises following steps: removing arsenic from industrial phosphoric acid; heating crystal tube to minus two Deg. C to ten Deg. C; putting phosphoric acid of 21-28 Deg. C into crystal tube for circultion, the crystal layer growing to 2-4 cm; stewing crystal tube for 15-25 minutes and keeping the temperature, then heating crystal tube at speed of 2-5 Deg. C per hour, stopping when quality of melted crystal is 10-40% of thant of initial one; cleaning crystal layer with cleaning liquid with its tempeature near at temperature of fusible point of phosphoric acid hemi-crystalline. The certificated electronic phosphoric acid can be got after crystallization and perspiration; and electronic phosphoric acid of high purity reaching to FCC4 standard can be got after cleaning. The invention is characterized by high removal rate for foreign matter, low energy consumtion, wide range for treating raw material with different purity, high purity of geot product and sound economic benefit.

Owner:朱健

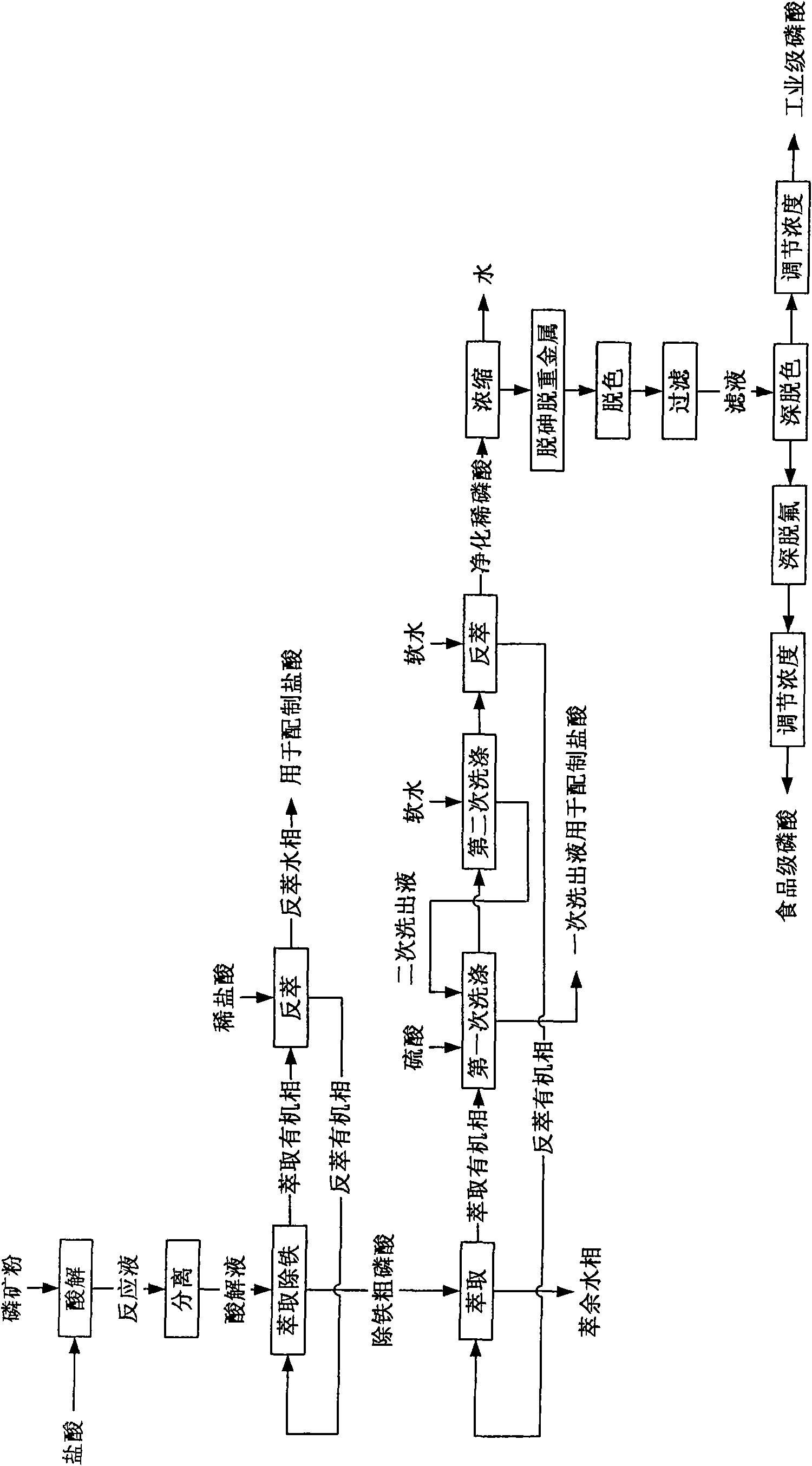

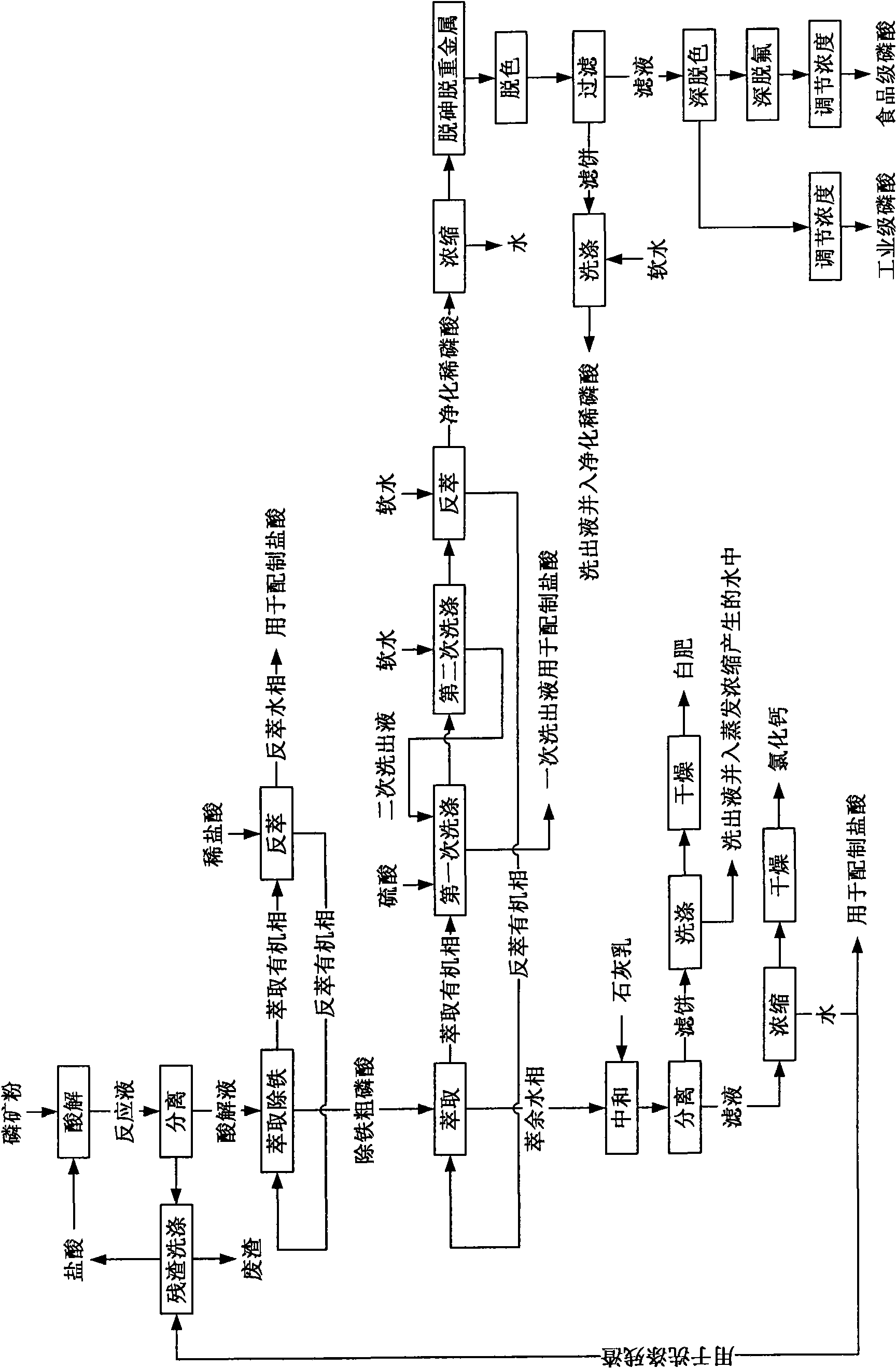

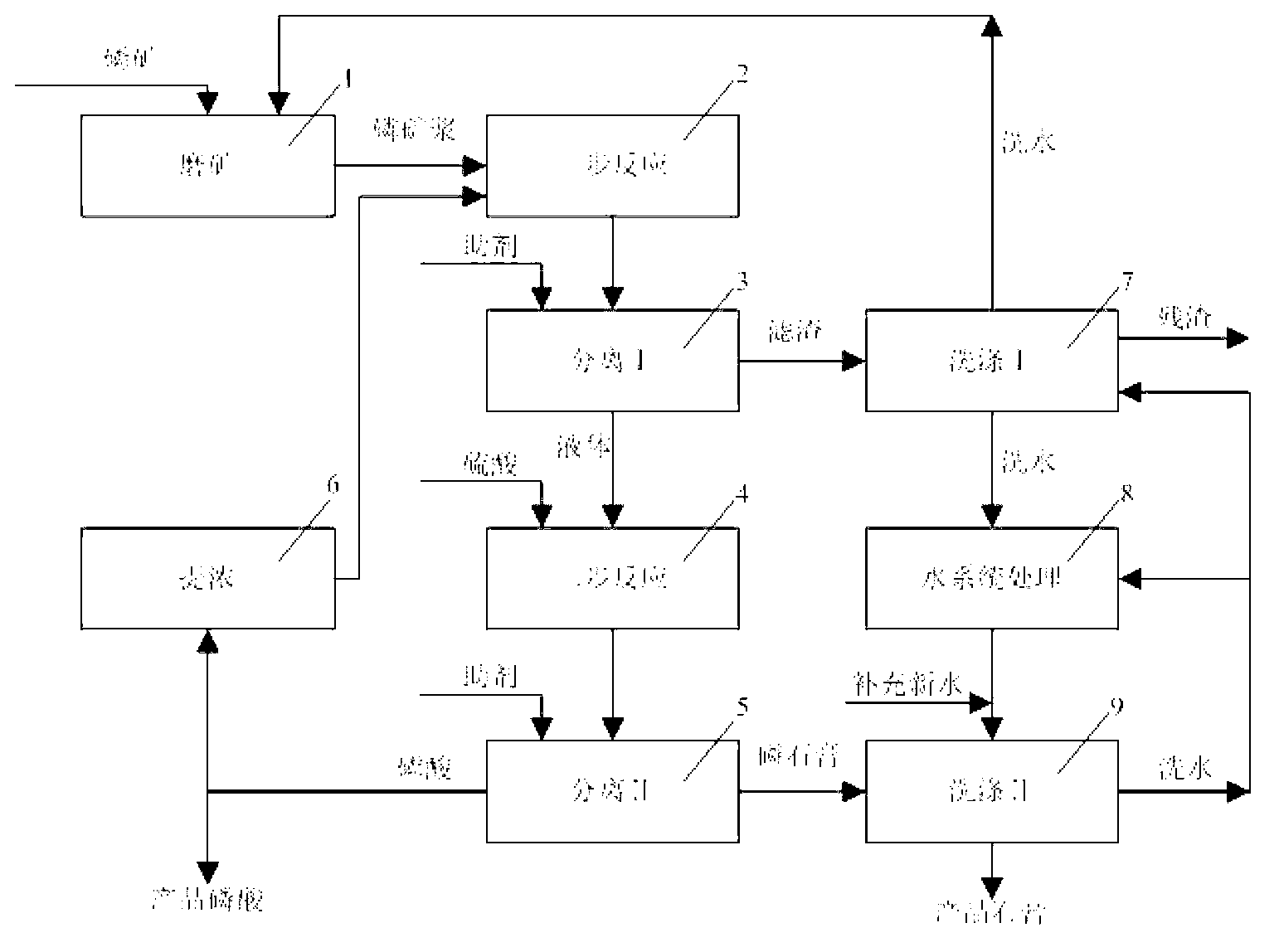

Method for preparing industrial grade and food grade phosphoric acid by decomposing low grade phosphate rocks with hydrochloric acid

The invention relates to a method for preparing industrial grade and food grade phosphoric acid by decomposing low grade phosphate rocks with hydrochloric acid. The method comprises the following processing steps: (1) decomposing phosphate rock powder with hydrochloric acid; (2) extracting to remove iron; (3) preparing dilute phosphoric acid; (4) preparing industrial grade phosphoric acid; and (5) preparing food grade phosphoric acid. Food grade phosphoric acid can be prepared only by adding deep defluorination process on the basis of the preparation steps of industrial grade phosphoric acid. The deep defluorination process adopts vacuum steam stripping process and the processing conditions are as follows: the vacuum degree is 0.075-0.090MPa, and the temperature is 95-110 DEG C. Industrial grade phosphoric acid prepared by the method of the invention meets the super grade or first-class product standards of GB / T 2091-2008; and food grade phosphoric acid meets the standards of GB 3149-2004.

Owner:SICHUAN UNIV

Method for preparing phosphoric acid and byproduct building brick by using phosphatic ore tailings after phosphate ore dressing

InactiveCN1837129AReduce consumptionReduce energy consumptionSolid waste managementPhosphoric acidBrickPhosphoric acid

The invention discloses a preparing phosphoric acid and by-product building brick method by debris with phosphor after phosphorus ore dressing ore, which comprises the following steps: adding in dinas rock powder, coking carbon powder (coal gangue powder), caoline to mix up; adding in water; ageing the mixture; modeling by vacuum extrusion machine or brick press; dipping after drying; putting mixture in kiln vehicle and entering tunnel oven; getting phosphor vapour and carbon monoxide after preheating and heating-up; getting concentrated phosphoric acid through hydrated tower; getting carrying brick production through heat transferring and cooling. The invention uses the mine and ore dressing fag-end to prepar acid and brick. We can use the ore when the P2O5 is not smaller than 6%.

Owner:HUBEI SANXIN PHOSPHORIC ACID

Method for preparing electronic grade phosphoric acid through liquid membrane crystallization

The invention relates to a method for preparing electronic grade phosphoric acid through liquid membrane crystallization. The method comprises the following steps: slowly pouring seed crystals which are prepared in advance, in a column crystallizer, wherein the temperature of the wall of the column crystallizer is controlled to 10-20 DEG C; (2) adding liquid phosphoric acid in the column crystallizer form the top of the crystallizer while using cooling medium in the jacket of the column crystallizer to reduce the temperature of the column crystallizer to 5-10 DEG C, wherein raw material crystallizes and grows on the seed crystals to form a crystal film and uncrystallized liquid flows out from the bottom of the column crystallizer; stopping adding materials when the thickness of the crystal film is 1 / 4-1 / 3 of the diameter of the column crystallizer, keeping temperature for 15-30min to discharge feed liquid which does not form film; heating the column crystallizer to 15-29 DEG C and keeping temperature for 0.5-2h so as to melt the film layer, collecting the discharged liquid as a product; and (4) repeating the step (1), (2) and (3) by using the obtained product as raw material to perform secondary liquid film crystallization and obtaining the electronic grade phosphoric acid product. The method has simple operation, short production time, low energy consumption and high impurity removal rate, and the electronic grade phosphoric acid product with a concentration of 87-90% can be directly obtained.

Owner:TIANJIN UNIV

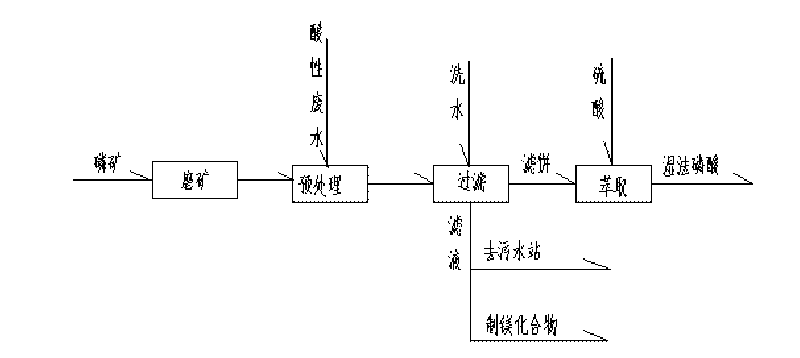

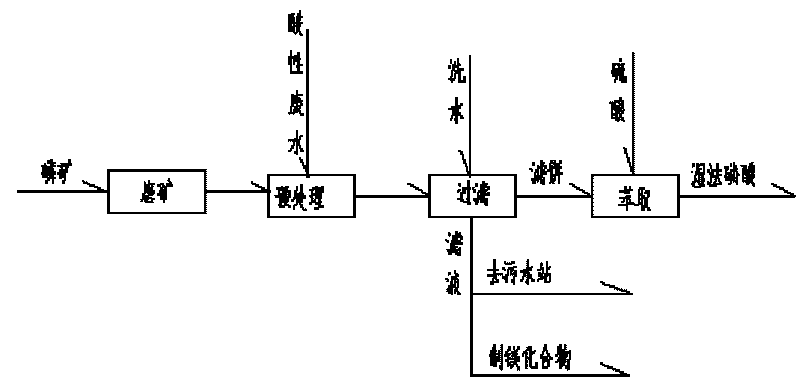

Method for pre-treating phosphorite by using acidic waste water in the production process of titanium pigment

ActiveCN101759166AReduce processing costsControl the strength of sulfuric acidPhosphoric acidPhosphoric acidSlurry

The invention discloses a method for pre-treating phosphorite of wet process phosphoric acid by using acidic waste water in the production process of titanium pigment, which comprises the following steps: (1), collecting the acidic waste water into an acidic waste water storage groove, controlling the acid degree to be 2 to 5 percent and the total iron concentration to be 0.3 to 0.5 percent; (2), adding the acidic waste water and the milled phosphorite in a solid-to-liquid ratio of 2-5:1 into a reaction groove for reaction; and (3), performing solid-liquid separation on the slurry which is obtained in the step (2) to obtain a solid phase, namely the required phosphorite. The content of magnesium in the phosphorite which is treated by the method is reduced by over 70 percent, the loss ratio of the phosphorus is controlled to be within 1 percent; when the phosphorite which is treated by the process is used for producing the phosphoric acid by a wet method, the consumption of the sulfuric acid for mine per ton is reduced by about 10 percent; and the acidic waste water pretreats phosphorite and then is delivered to a sewage station for treatment, the consumption of lime or other alkaline substance is reduced by 60 percent compared with the mode of directly delivering the waste water to the sewage station, so the economical efficiency of the process is high.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

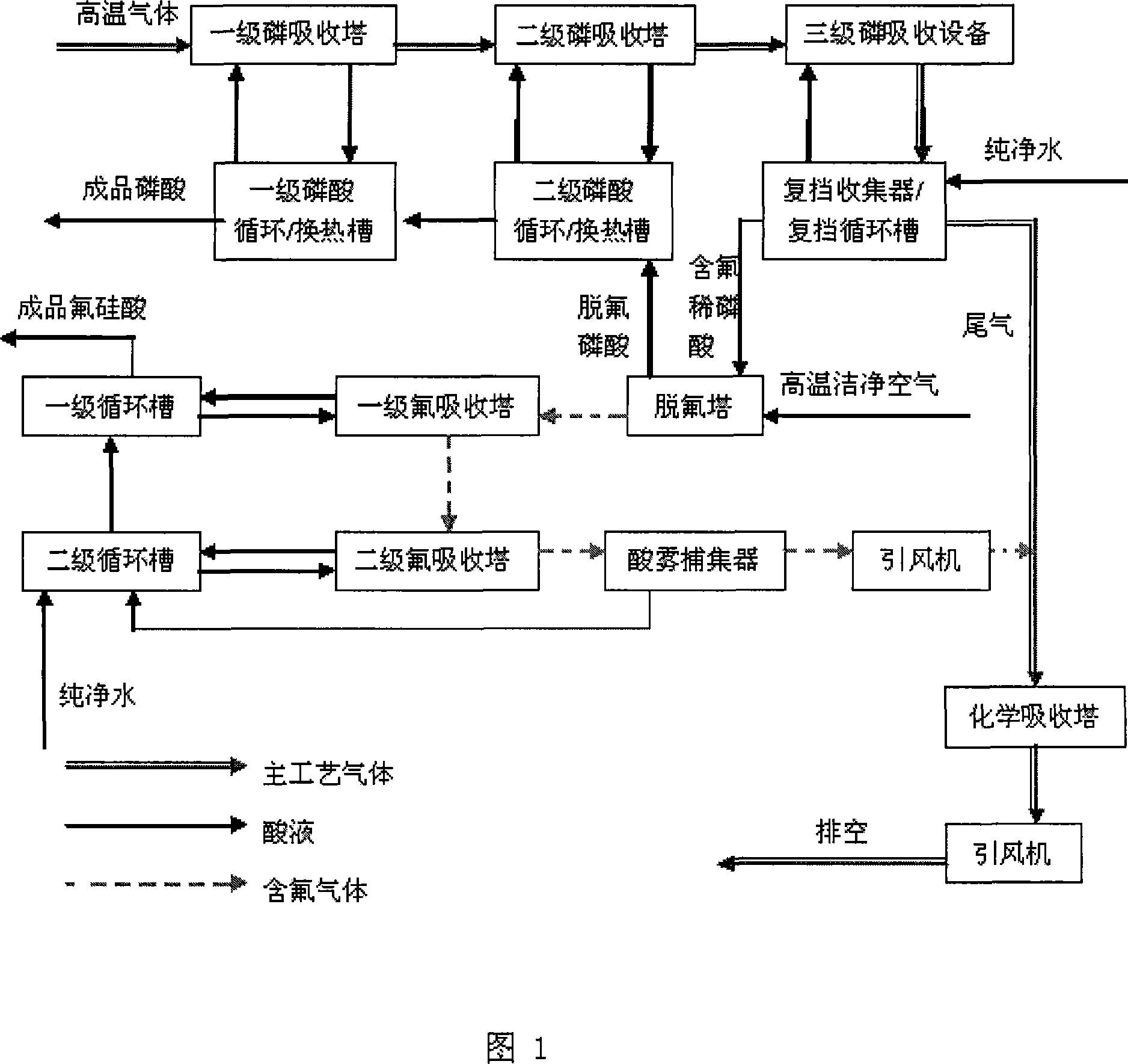

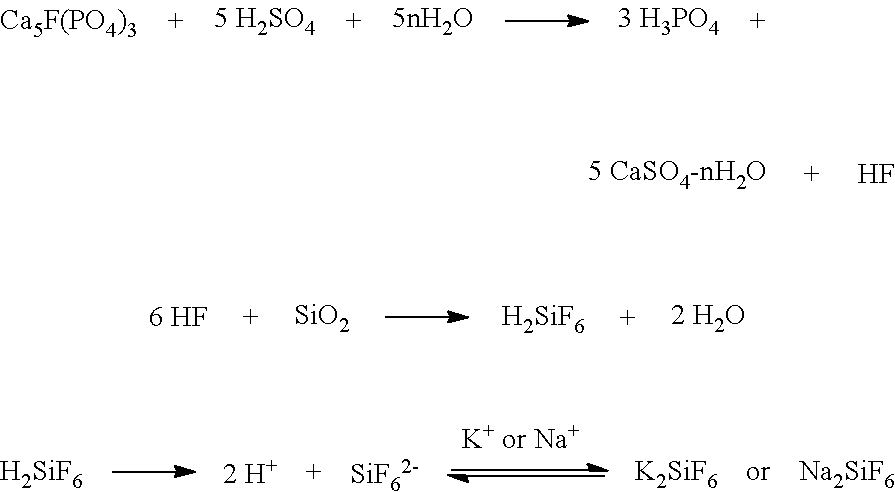

Method for absorbing and extracting phosphor and fluorin from phosphoric acid produced in kiln method

InactiveCN101049920AImprove separation rateHigh puritySilicon halogen compoundsPhosphoric acidHigh concentrationAbsorption column

This invention discloses a method for separating phosphorus and fluorine of kiln process phosphoric acid by absorption. The method comprises: sending relatively high temperature phosphoric acid after hydration in primary and secondary hydration columns to a circulation tank for cooling, pumping into the hydration columns for circulation, sending gases after primary and secondary absorption to a Venturi absorber for re-absorption, collecting the residual acid mist by a collector, sending the absorbed gas and tail gas after fluorine absorption together to a chemical absorption column, and exhausting the tail gas. Besides, qualified fluosilicic acid can be obtained from the fluorine-containing diluted H3PO4 in the collector. The method utilizes the air with residual heat in the kiln, and has such advantages as no extra energy consumption, high phosphorus and fluorine separation efficiency, high concentration and low fluorine content in obtained H3PO4, and low P2O5 content in obtained fluosilicic acid. The obtained fluosilicic acid has a wide concentration range and a high purity, and is easy to utilize.

Owner:HUBEI SANXIN PHOSPHORIC ACID

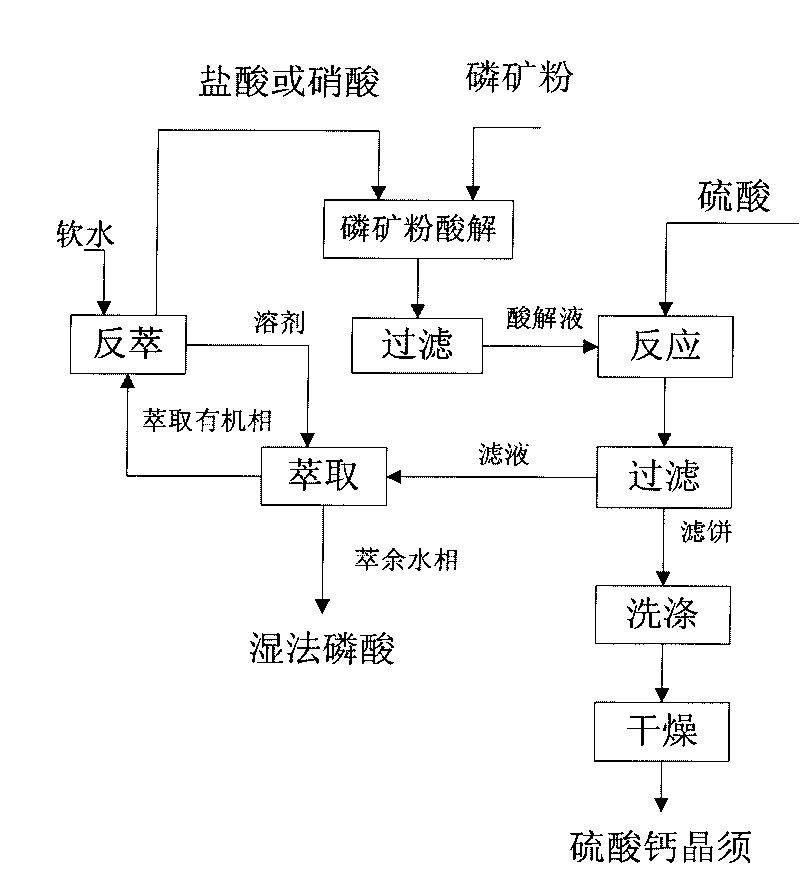

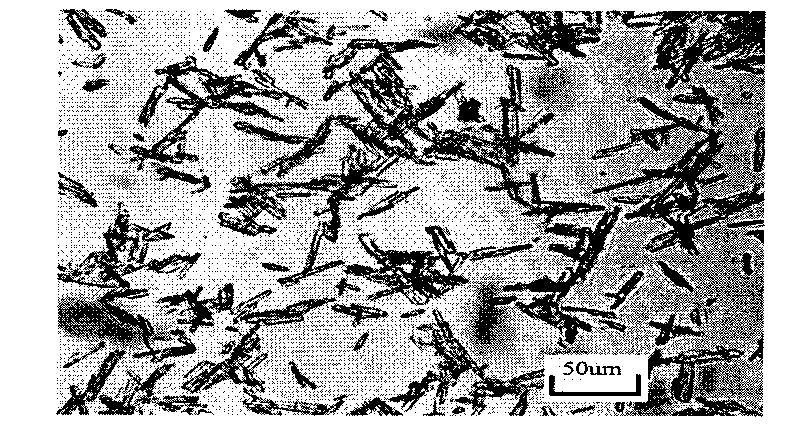

Co-production method of calcium sulfate whisker and phosphoric acid

ActiveCN101736404AIncrease contentSave energyPolycrystalline material growthSingle crystal growth detailsPhosphatePhosphoric acid

The invention relates to a co-production method of calcium sulfate whisker and phosphoric acid. The method comprises the following technical steps of: (1) acid-hydrolyzing phosphate rock powder by hydrochloric acid with the mass concentration of 15 to 26% or nitric acid with the mass concentration of 20 to 90%, filtering the acid-hydrolyzed slurry into the acid hydrolysis solution containing Ca2<+>; (2) using the acid hydrolysis solution containing Ca2<+> and the sulfuric acid with the mass concentration of 20 to 90% as the raw materials, wherein the use level of the sulfuric acid is 100% of the needed theoretical amount of the sulfuric acid when the Ca2<+> in the acid hydrolysis solution and the sulfuric acid react completely, adding the sulfuric acid to the acid hydrolysis solution containing Ca<2+> under the stirring condition, reacting the sulfuric acid with the acid hydrolysis solution containing Ca2<+> at the normal pressure and at 50 to 90 DEG, filtering and separating the calcium sulfate whisker after the reaction is finished, and then washing and drying the calcium sulfate whisker; and (3) carrying out the counter-current extraction on the filtrate obtained in the step (2), wherein the extracted water phase is the phosphoric acid, and acid-hydrolyzing the phosphate rock powder by using the hydrochloric acid obtained by the counter-extraction of the soft water to the extracted organic phase which is separated in the counter-current extraction.

Owner:SICHUAN UNIV

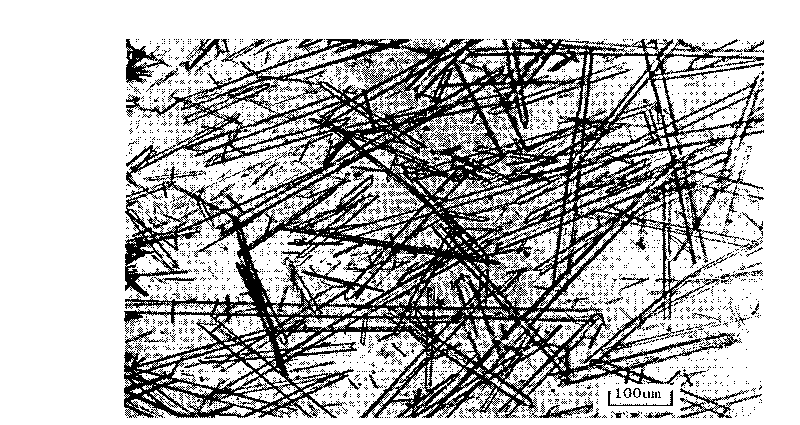

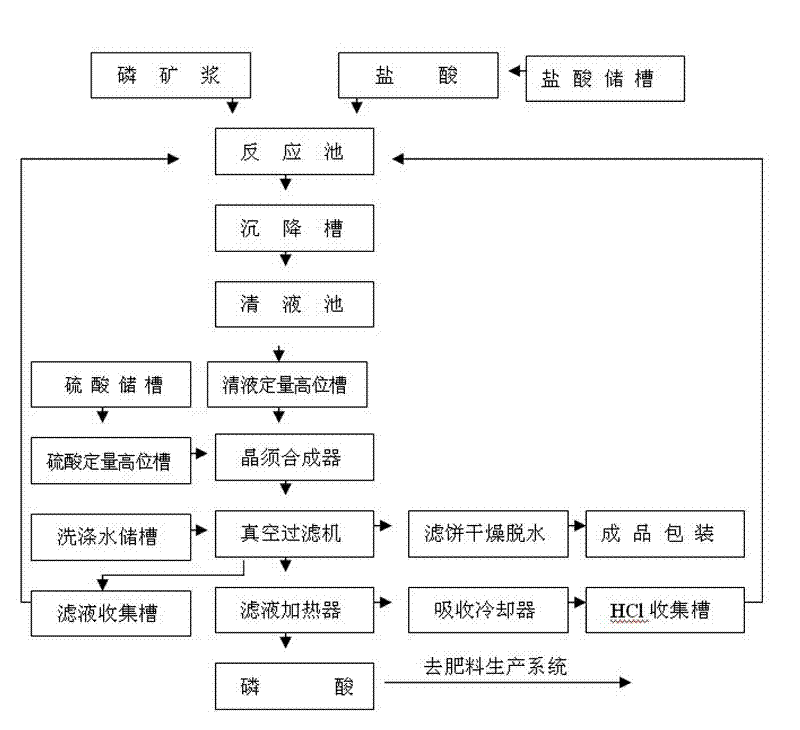

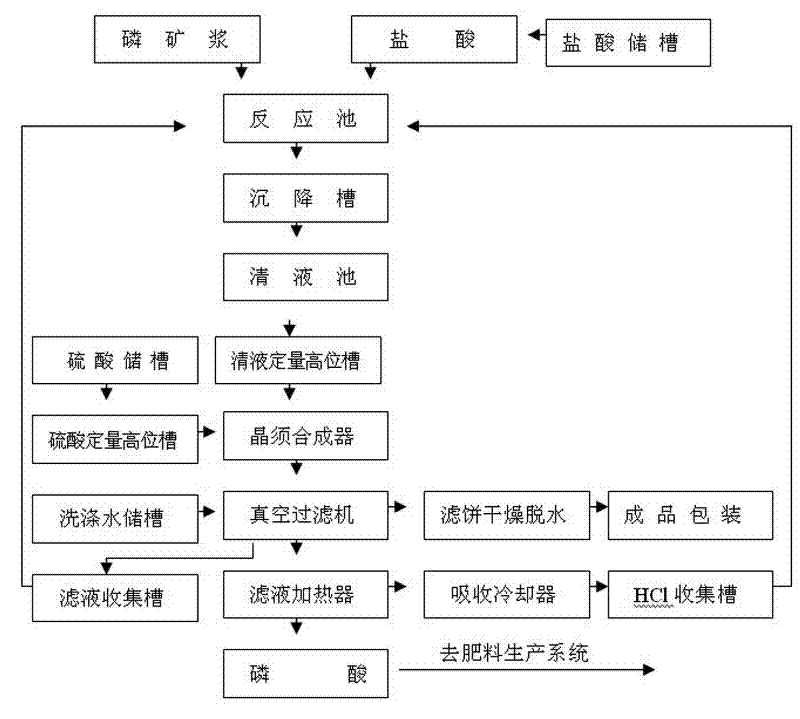

Method for producing phosphoric acid and gypsum whiskers by wet process

InactiveCN102303852ALarge specific surface areaTake advantage ofPolycrystalline material growthSingle crystal growth detailsPhosphate productChloride

The invention discloses a method for producing phosphoric acid and gypsum whiskers by a wet process, which is used in combination with a wet-process phosphoric acid production device. The method comprises: reacting hydrochloric acid with excessive phosphorus ore pulp to form calcium chloride solution containing hydrochloric acid; reacting the calcium chloride solution with solution of sulfuric acid to obtain a suspended matter; filtering, washing and obtaining dihydrate gypsum whiskers; and heating filtrate, cooling, and absorbing, wherein hydrogen chloride is circularly used, phosphoric acidis purified to be used for producing a phosphate product.

Owner:江苏瑞和化肥有限公司

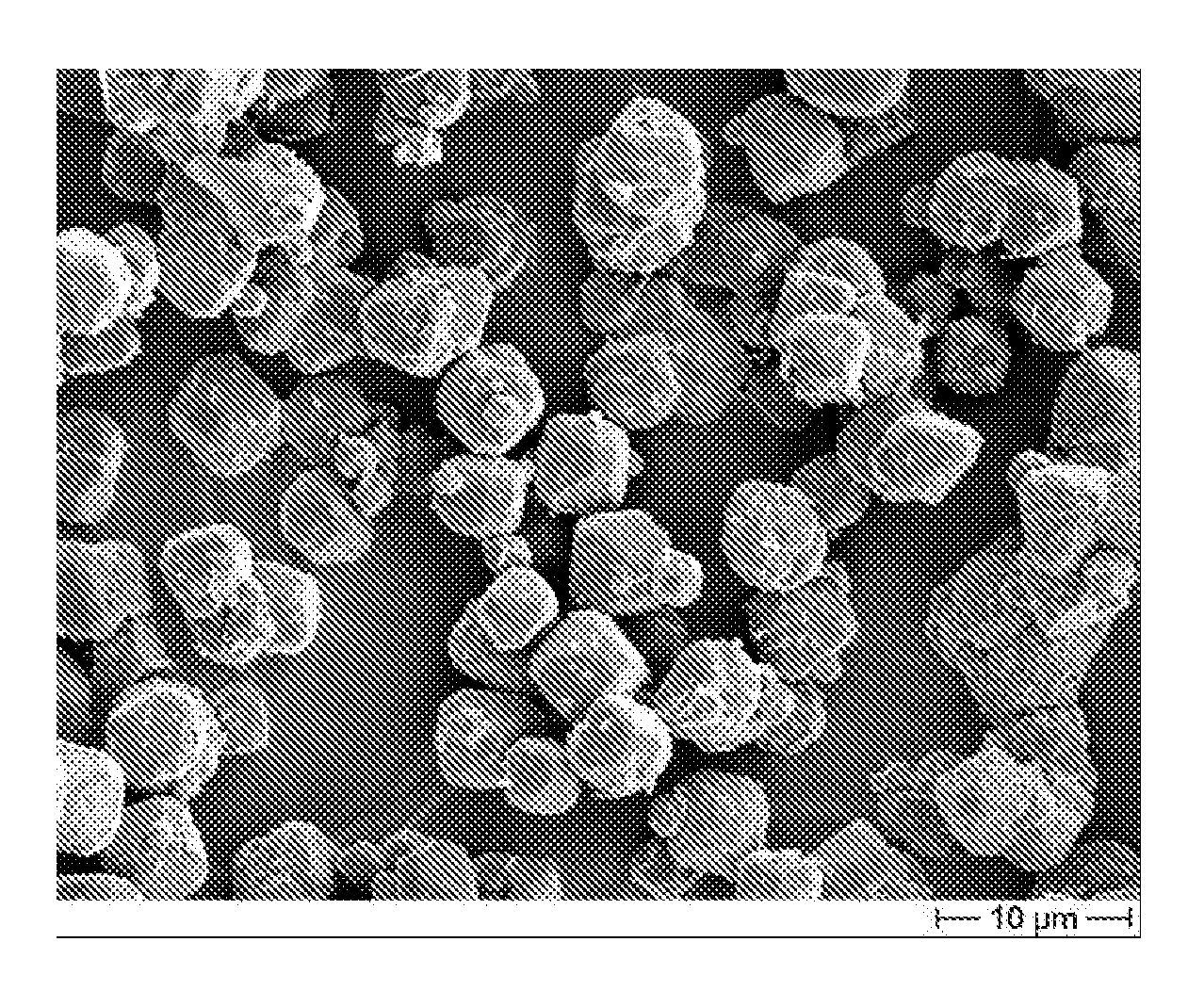

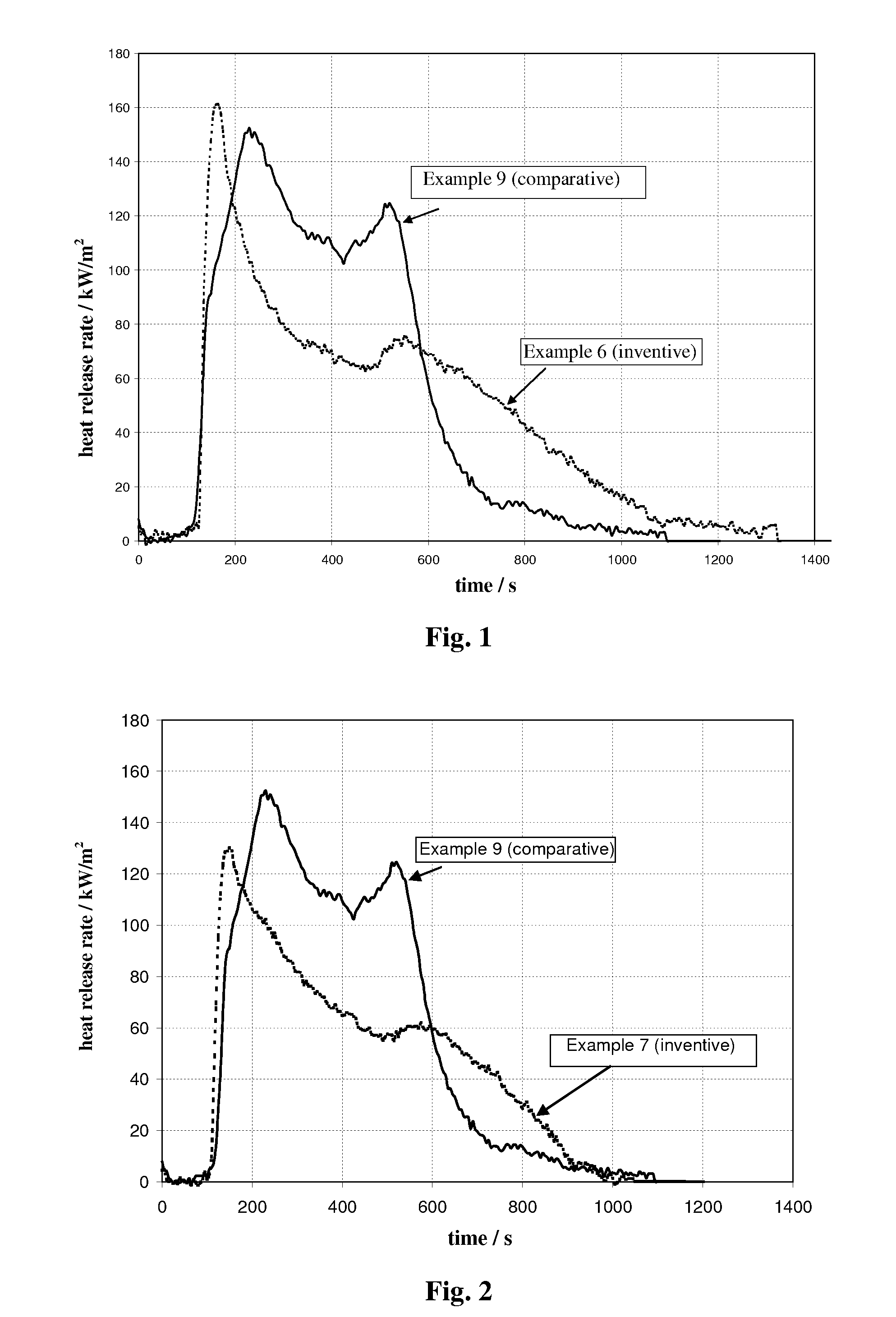

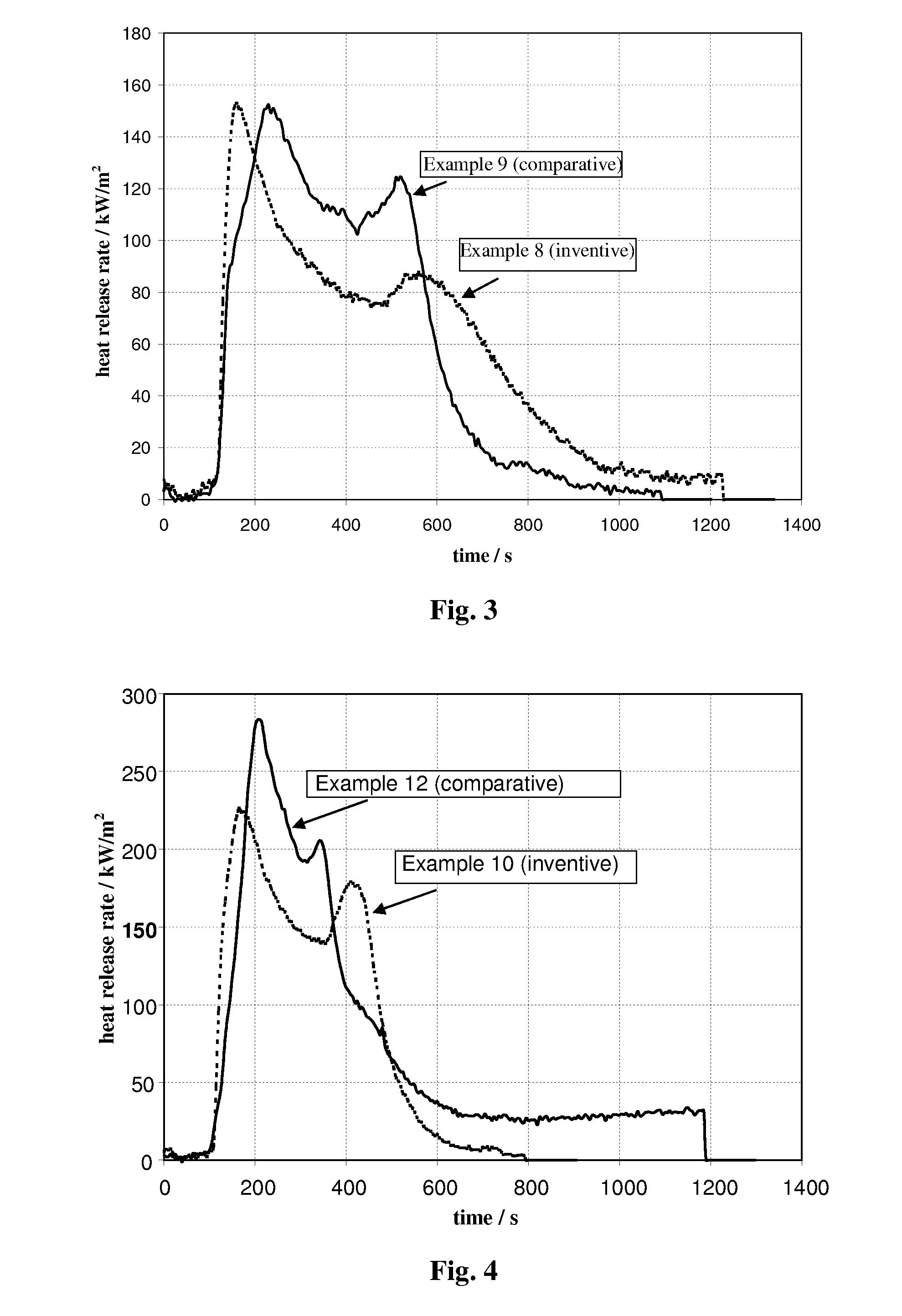

Synthetic inorganic flame retardants, methods for their preparation, and their use as flame retardants

InactiveUS20110213065A1High flame retardant efficiencyImprove thermal stabilitySilicaAlkali metal silicatesAlkaline earth metalPhosphate

Quite unexpectedly, by suitably modifying the crystal structure of hydrogarnets of the general formula MII3MrI-III2(OH)12 (where MII denotes divalent metal ions, especially alkaline earth metal ions, of Group IIA of the periodic table and MIII denotes trivalent metal ions of Group IIIA of the periodic table, especially aluminum) with suitable amounts of incorporated silicate and / or phosphate, flame retardants having both a higher flame retardant efficiency than such traditional mineral flame retardants as ATH and MDH, and a higher thermal stability than ATH can be produced. It has also been found that synthetic hydrogarnets of the general formula MII3MrIII2(OH)12(where MII and MIII are as defined above) having cubic crystal and these synthetic hydrogarnets also show high flame retardant efficiency.

Owner:ALBEMARLE CORP

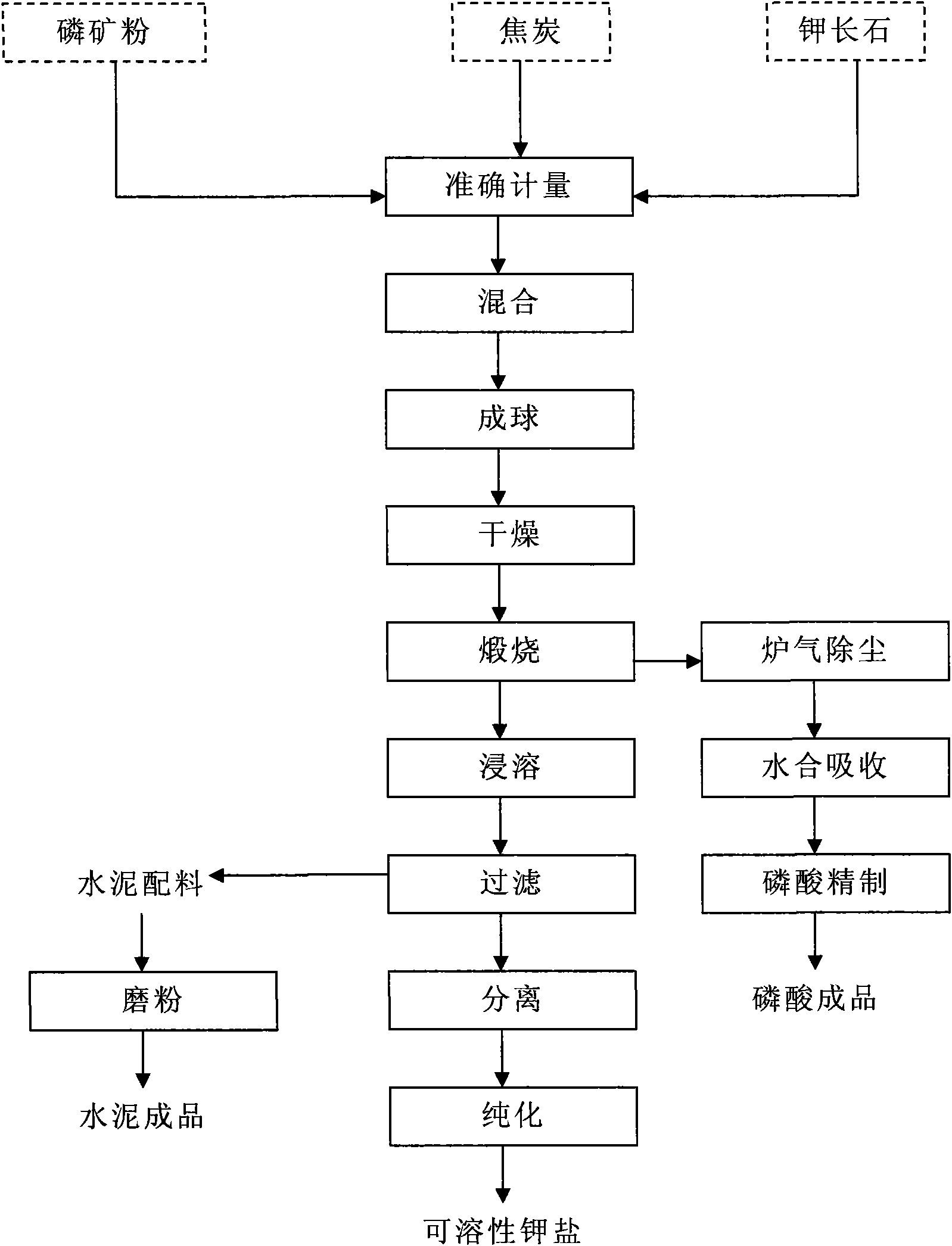

Method for producing phosphoric acid and soluble potassium salt by phosphorus ore and potash feldspar

InactiveCN101585521AReduce consumptionReduce external heating energyCement productionPhosphoric acidSlagPhosphor

The invention is a method for producing phosphoric acid and soluble potassium salt by phosphorus ore and potash feldspar, characterized in that, the method comprises: selecting phosphorus ore containing P2O5 15-30% and potash feldspar containing K2O 10-18% to mix with coke; crushing, ball milling, balling by adding water and drying; calcining for 10-30 minutes under temperature of 1100-1400DEG C; then soaking the calcined product in 1-5% citric acid solution for 12 hours, wherein, the soaking temperature is between room temperature and 60 DEG C; crystallizing and purifying the separated filtering solution; obtaining the soluble potassium salt; P2O5 in the phosphorus ore is reduced into phosphor vapor to be volatilized, the phosphor vapor above the material layer can be oxidized into P2O5 gas by the air introduced into the furnace, in the hydration apparatus, P2O5 gas can be absorbed to obtain the phosphoric acid. the invention solves the problems of waste slag and waste gas emissions during producing phosphoric acid, also alleviates the existing state that in our country, the soluble kalium resources are depended on importation, the method of the invention is economical and environment-protecting.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing phosphoric acid with low and medium grade phosphorous mine ore

InactiveCN1683239AIncrease profitEconomical and rational development and utilizationPhosphoric acidPhosphoric acidAqueous solution

The present invention relates to method of producing phosphoric acid with low and medium grade phosphorous ore. The low and medium grade phosphorous ore is used to produce phosphoric acid through the acidifying reaction with water solution of phosphoric acid, solid-liquid separation and phosphoric acid crystallization reaction. The method has the advantages of high phosphoric acid purity and low production cost.

Owner:CHENGYUAN CHEM SICHUAN

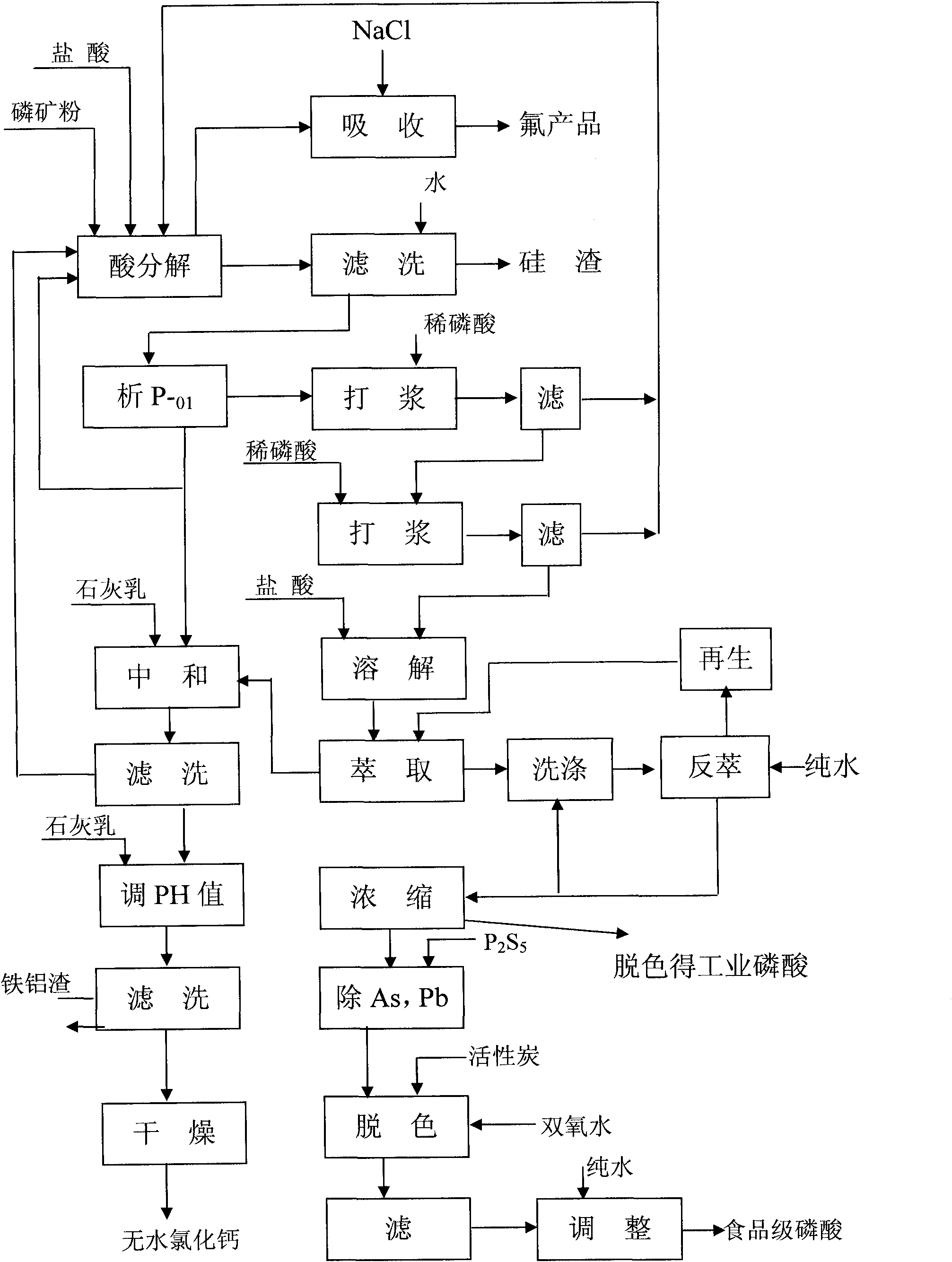

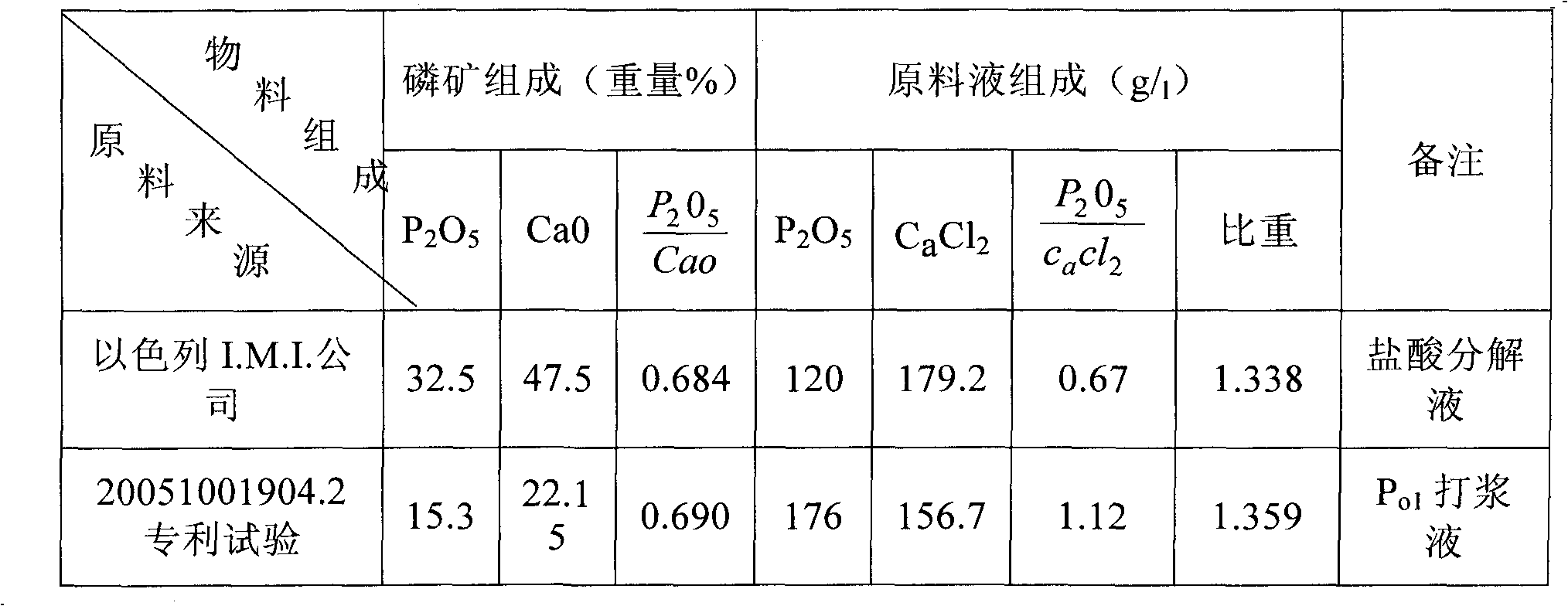

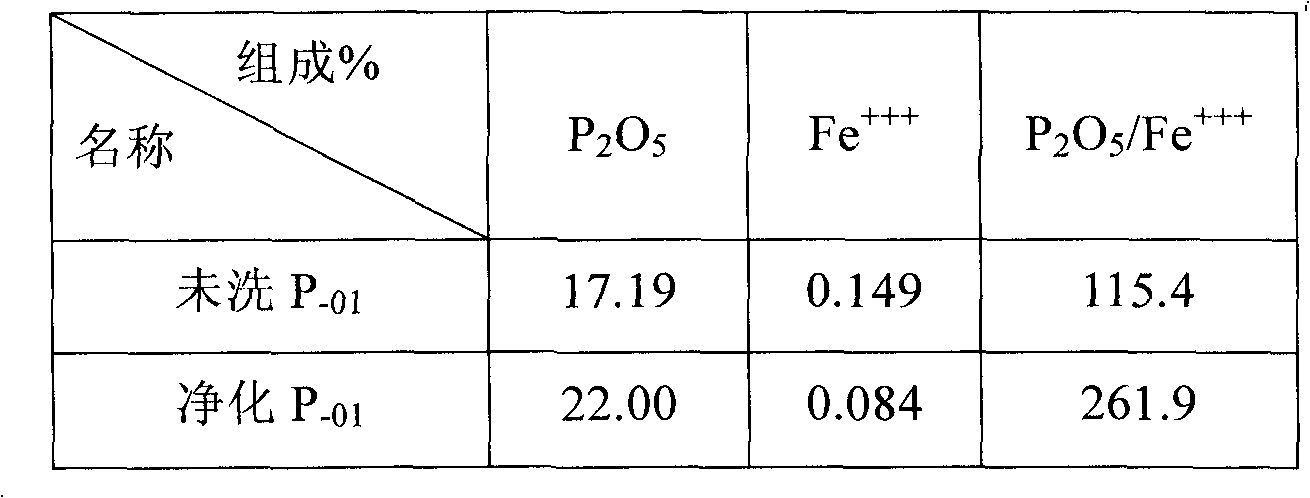

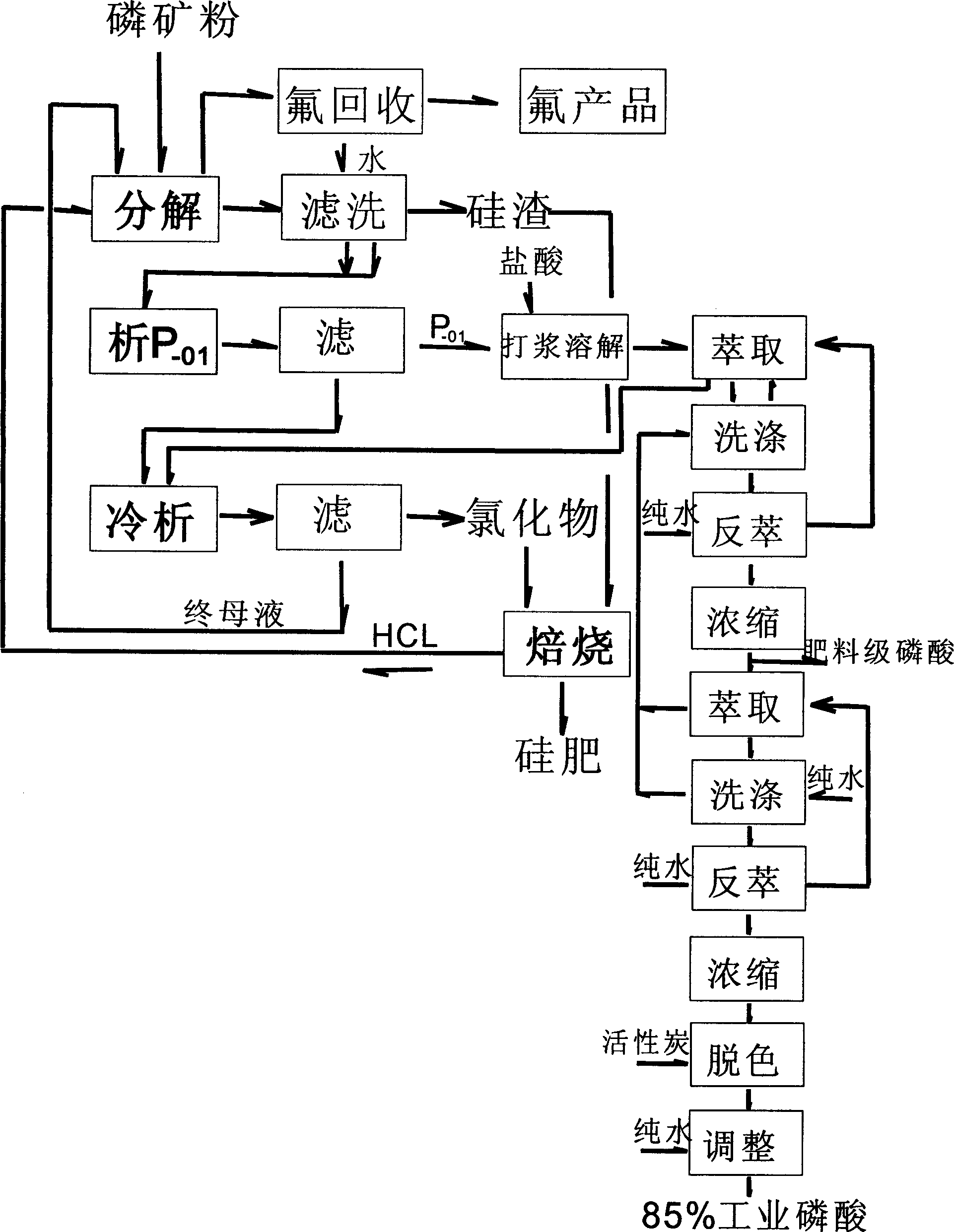

Method for manufacturing industrial phosphoric acid, industrial ammonium phosphate and food-grade phosphoric acid from medium and low-grade phosphorite by one-step extraction of hydrochloric acid method

InactiveCN102134063AHigh energy consumptionCalcareous fertilisersPhosphatesPhosphoric acidHydrogen peroxide

The invention discloses a method for manufacturing industrial phosphoric acid, industrial ammonium phosphate and food-grade phosphoric acid from medium and low-grade phosphorite by one-step extraction of a hydrochloric acid method. The method is characterized by comprising the following steps of: decomposing any phosphorite (the P2O5 of which is more than or equal to 6 weight percent) by using hydrochloric acid, preparing calcium chloride dihydrogen phosphate CaClH2PO4.H2O (P-01 for short), adding dilute phosphoric acid, pulping, filtering and purifying the P-01, pulping and dissolving the P-01 with hydrochloric acid, performing extraction by using tributyl phosphate, performing concentration and decolorization to obtain the industrial phosphoric acid, adding ammonia into the industrial phosphoric acid to obtain the industrial ammonium phosphate, or adding P2S5 into the concentrated industrial phosphoric acid to remove arsenic and heavy metal, performing decolorization by using active carbon and hydrogen peroxide and removing easily oxidized substances to reach the index requirement of the food-grade phosphoric acid.

Owner:上海协达精细化工研发有限公司

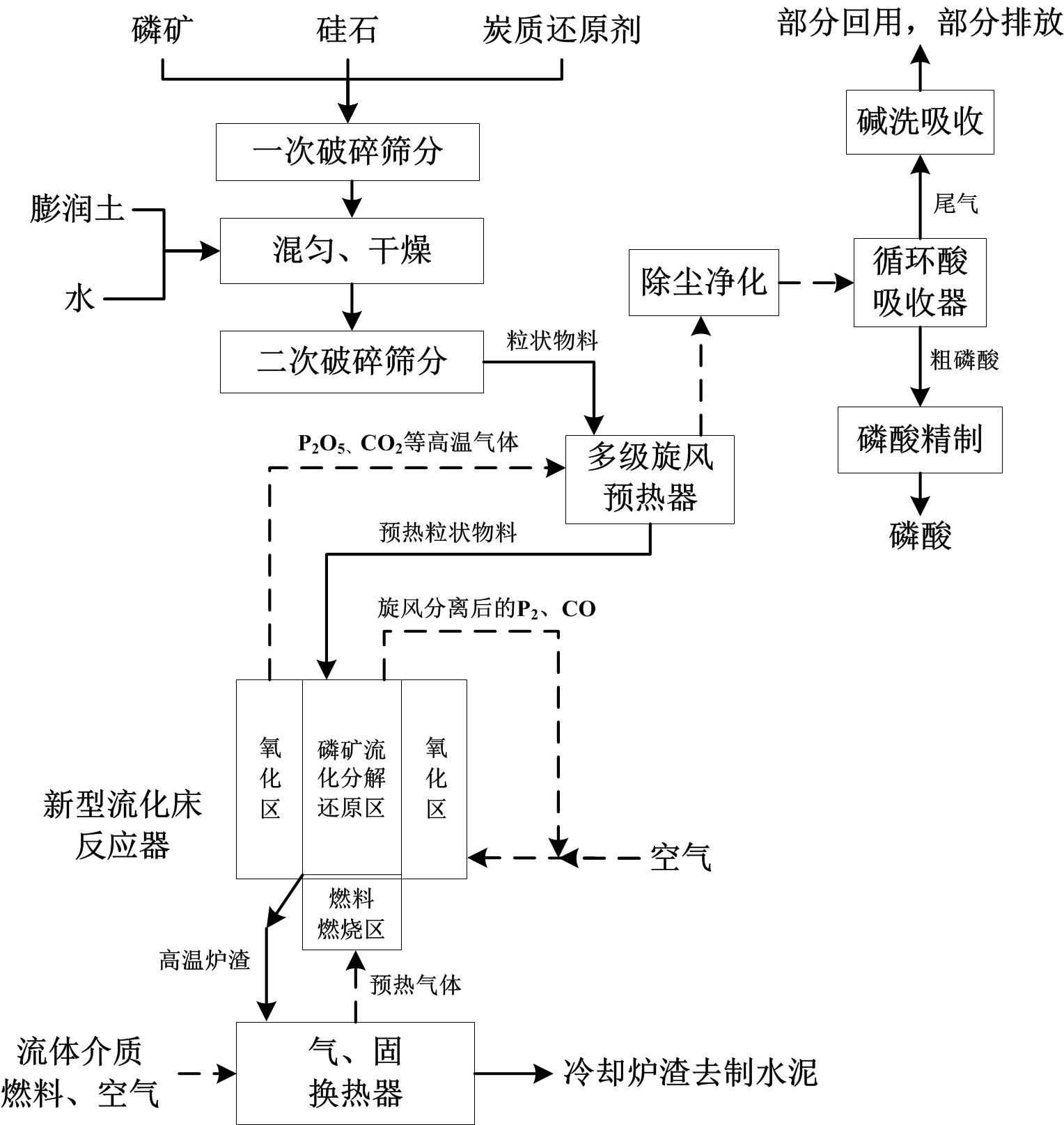

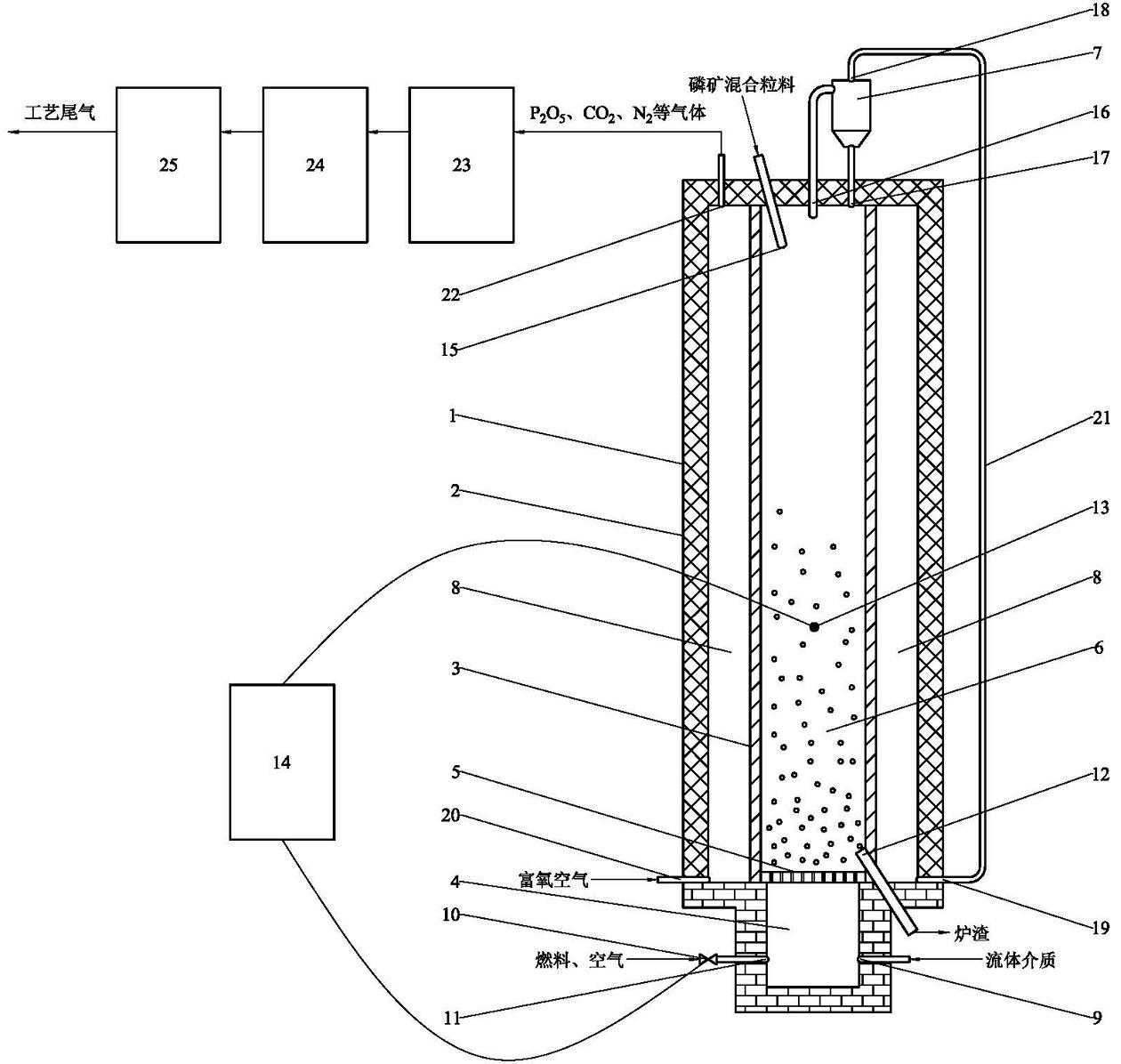

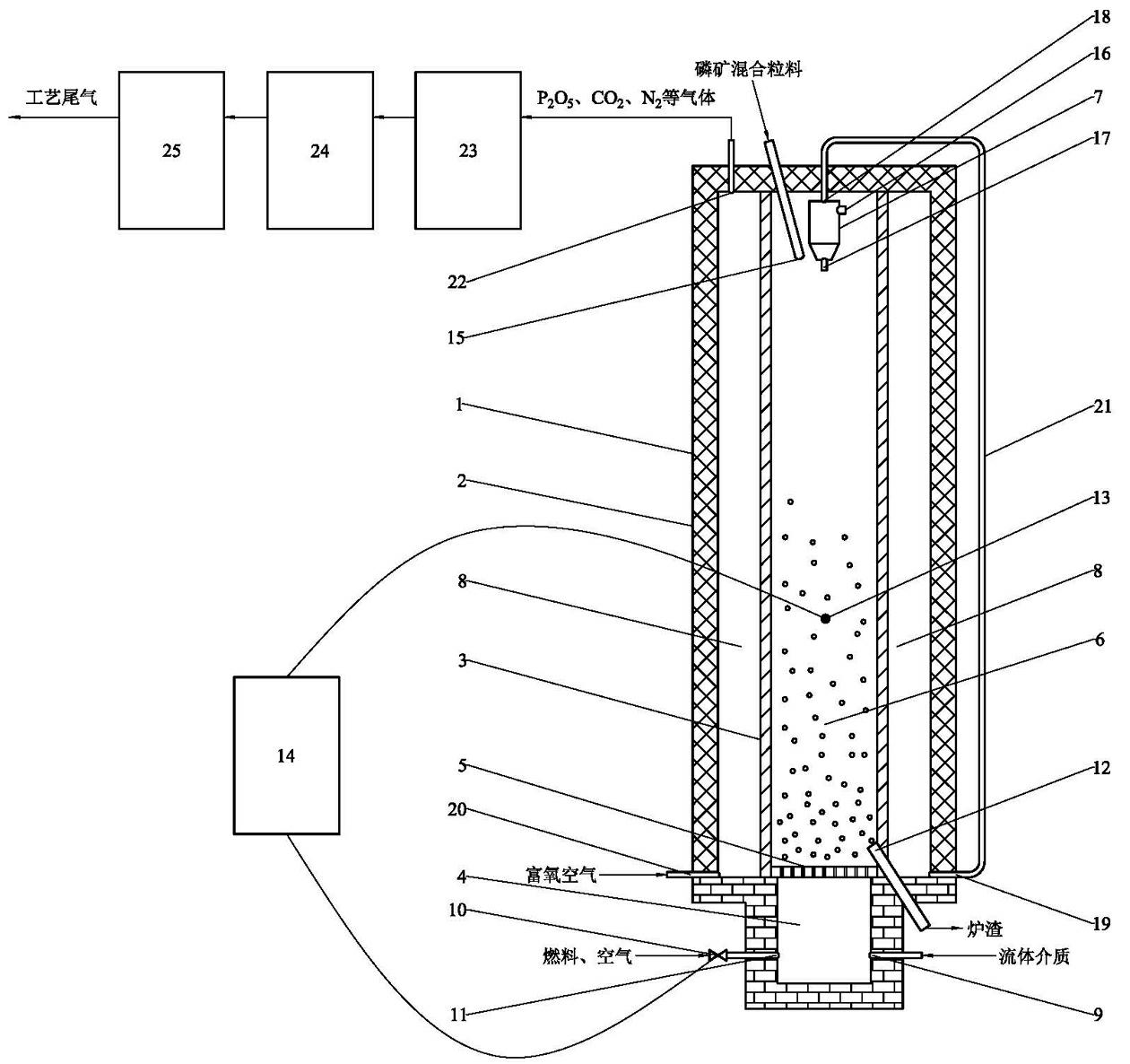

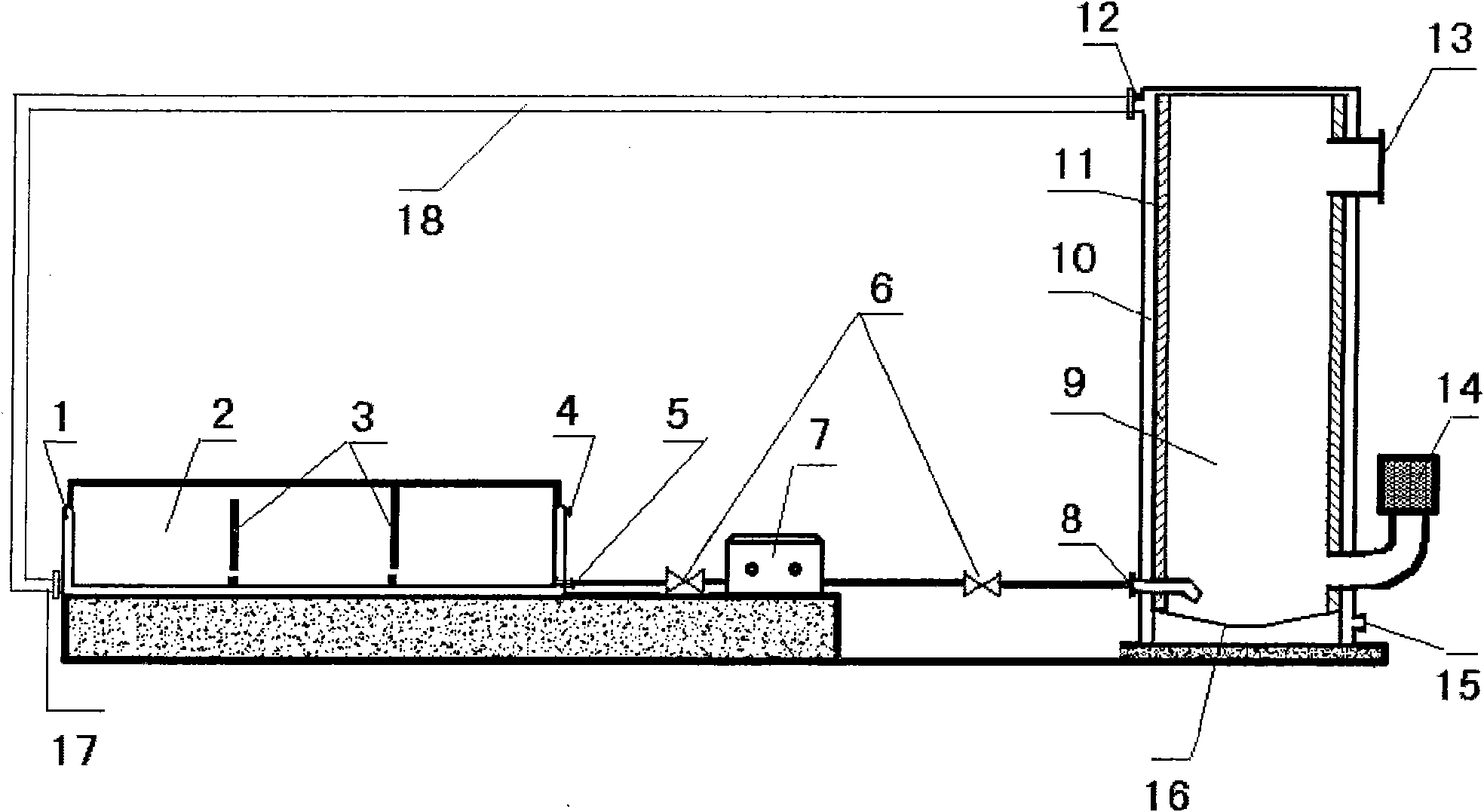

Technique and device for preparing phosphoric acid by fluidized bed reactor

InactiveCN102616759ALower the initial reduction temperatureEnhance heat and mass transferPhosphoric acidO-Phosphoric AcidHeat conducting

The invention discloses a technique and device for preparing phosphoric acid by a fluidized bed reactor. The technique mainly comprises the following steps: crushing phosphorite, silica and carbon reducer, screening, adding bentonite, adding water, evenly mixing, drying to solidify, recrushing, screening into a granular material, putting the granular material into a fluidized bed reactor, heating to 1100-1350 DEG C by fuel burning and high-temperature gas heat exchange in the oxidizing zone, and fluidizing and reducing under the actions of N2 and reflux technique tail gas; and after the generated P2 and CO enter the oxidizing zone together with external oxygen-enriched air and are burnt to generate P2O5 and CO2 and the P2O5 gas is purified by dust removal, absorbing with recycle acid to obtain H3PO4. The fluidized bed reactor is effectively divided into a reducing zone and an oxidizing zone through a heat conducting plate, and implements heat coupling; and the phosphorite is fluidized, reduced, and subjected to forced heating and mass transfer, thereby greatly lowering the reduction temperature, shortening the reaction time and solving the problems of plugging and ringing in the rotary kiln, and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Safe phosphorus supply device for thermal phosphoric acid production

The invention discloses a safe phosphorus supply device for thermal phosphoric acid production. A melting material, namely yellow phosphorus is safely conveyed through water level difference in a low melting slot, and then enters a furnace from the bottom of the combustion furnace, so that a dangerous operation step that the melting yellow phosphorus in the high risk state is conveyed to a high slot through a high pressure pump or compressed air, and then is bunt by high pressure spraying in the traditional production line is avoided; and the effects of energy consumption reduction, equipment investment reduction and stable quality are achieved. The safe phosphorus supply device for the thermal phosphoric acid production has the advantages of strong practicability and better economic benefit.

Owner:GUANGXI MINGLI CHEM

Direct phosphate rock reducing process for preparing high concentration phosphoric acid and coproducing silicate and aluminate products

InactiveCN101020574AImprove recovery rateSkip the glazing processCement productionPhosphoric acidHigh concentrationTunnel kiln

The present invention discloses direct phosphate rock reducing process for preparing high concentration phosphoric acid and coproducing silicate and aluminate products, and may be used in the comprehensive utilization of medium and low grade phosphate rock and phosphate rock tailings with P2O5 content not less than 6 %. The direct phosphate rock reducing process includes mixing phosphate rock powder with silica powder, coke powder, coal powder, kaolin or other additive and water; shaping the mixture and stoving; setting into container of refractory material and heating in a tunnel kiln to obtain phosphorus vapor and CO; absorbing in a hydrating tower to obtain concentrated phosphoric acid and cooling the product inside the container to obtain various kinds of side product. The present invention has simple production process and raised phosphorus reducing rate, and is suitable for industrial production.

Owner:HUBEI SANXIN PHOSPHORIC ACID

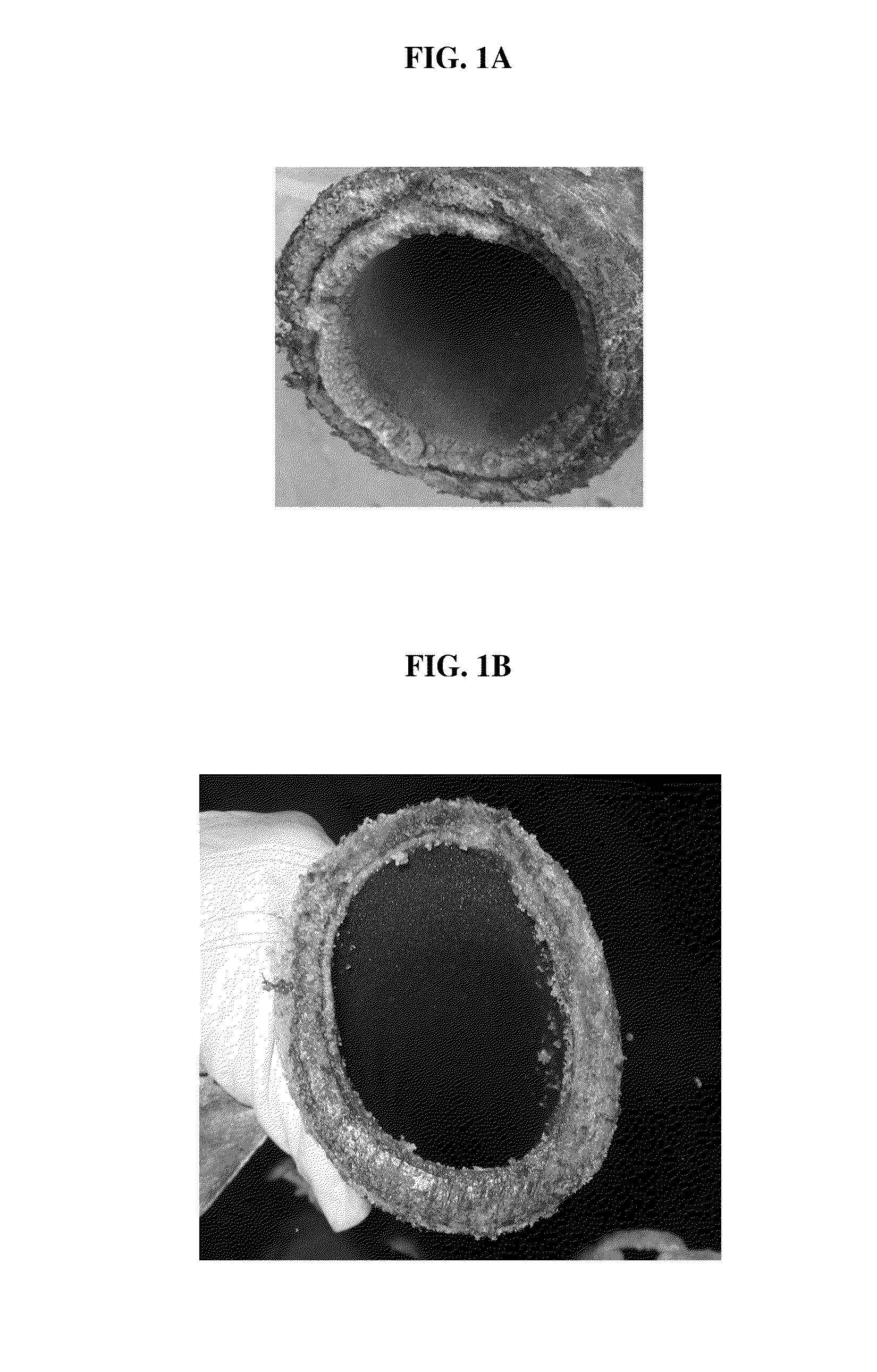

Process and Reagents for the Inhibition or Reduction of Scale Formation During Phosphoric Acid Production

ActiveUS20110076218A1Reduce and eliminate scalingLow treatment concentrationPhosphoric acidPhosphoric acidHydroxy group

Processes and reagents for inhibiting or eliminating scale formation during wet-process phosphoric acid production are provided and include adding to a wet-process phosphoric acid production stream a scale inhibiting amount of a reagent having an aliphatic or aromatic compound containing at least two hydroxy groups, and at least one amine.

Owner:CYTEC TECH CORP

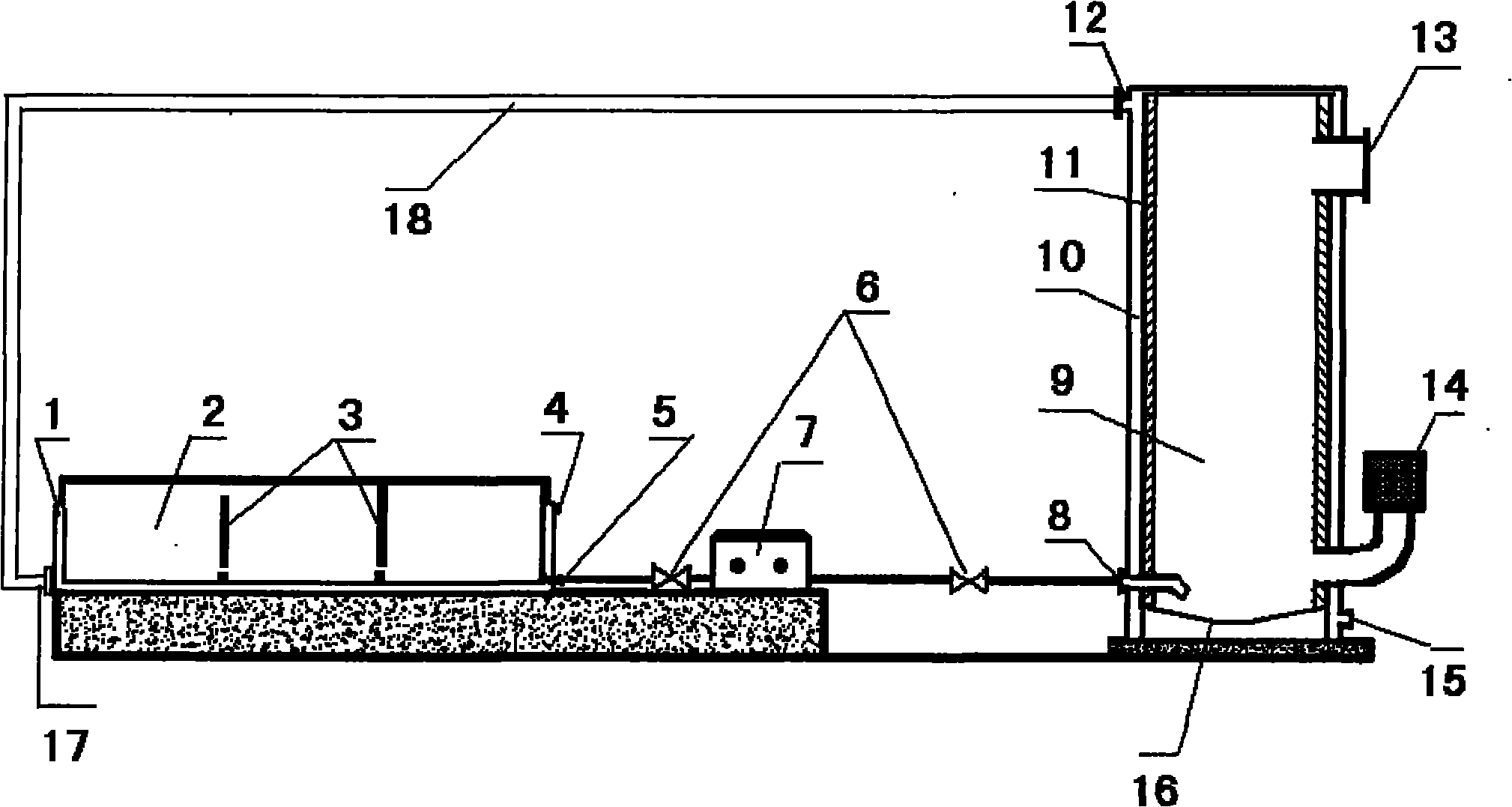

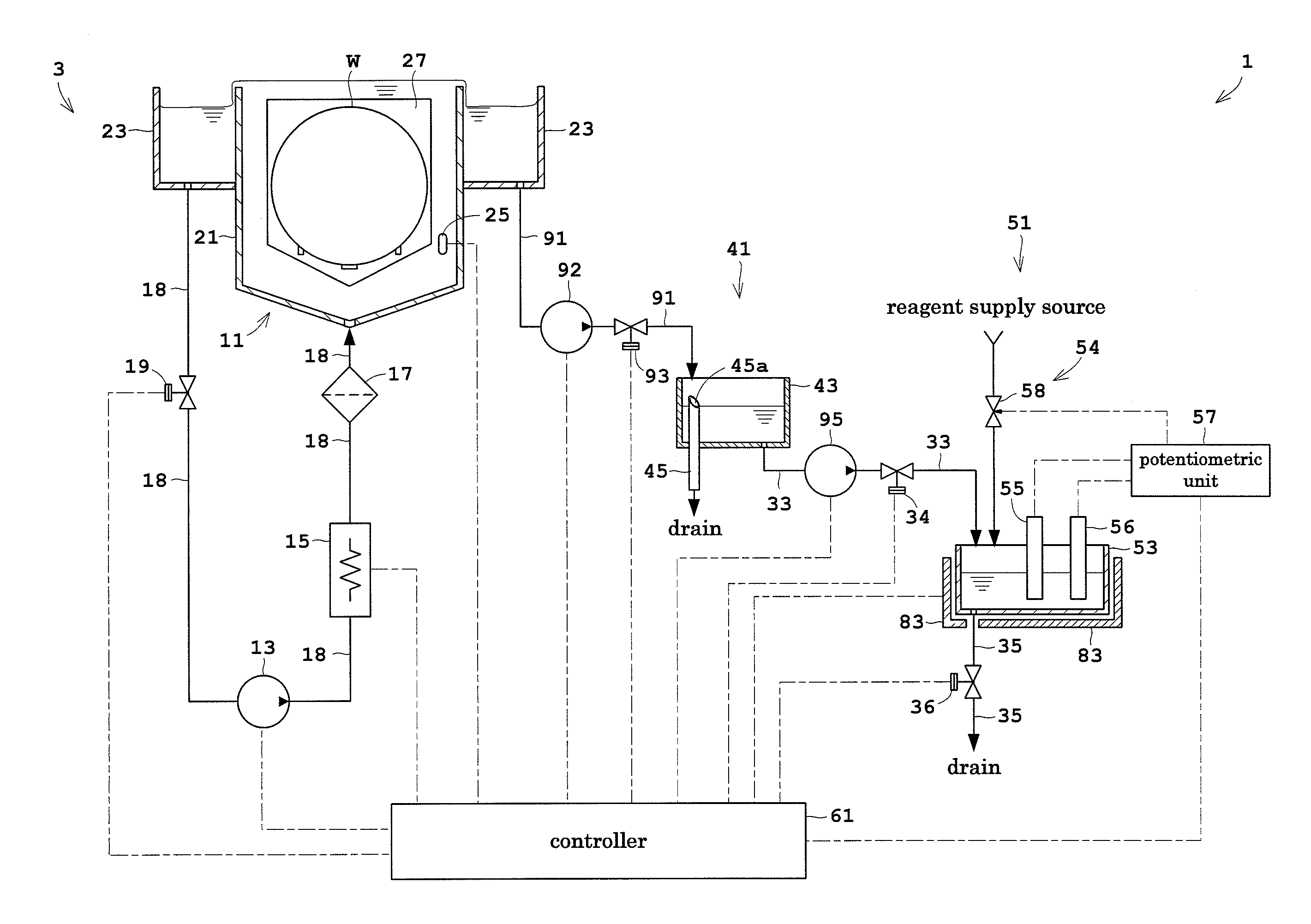

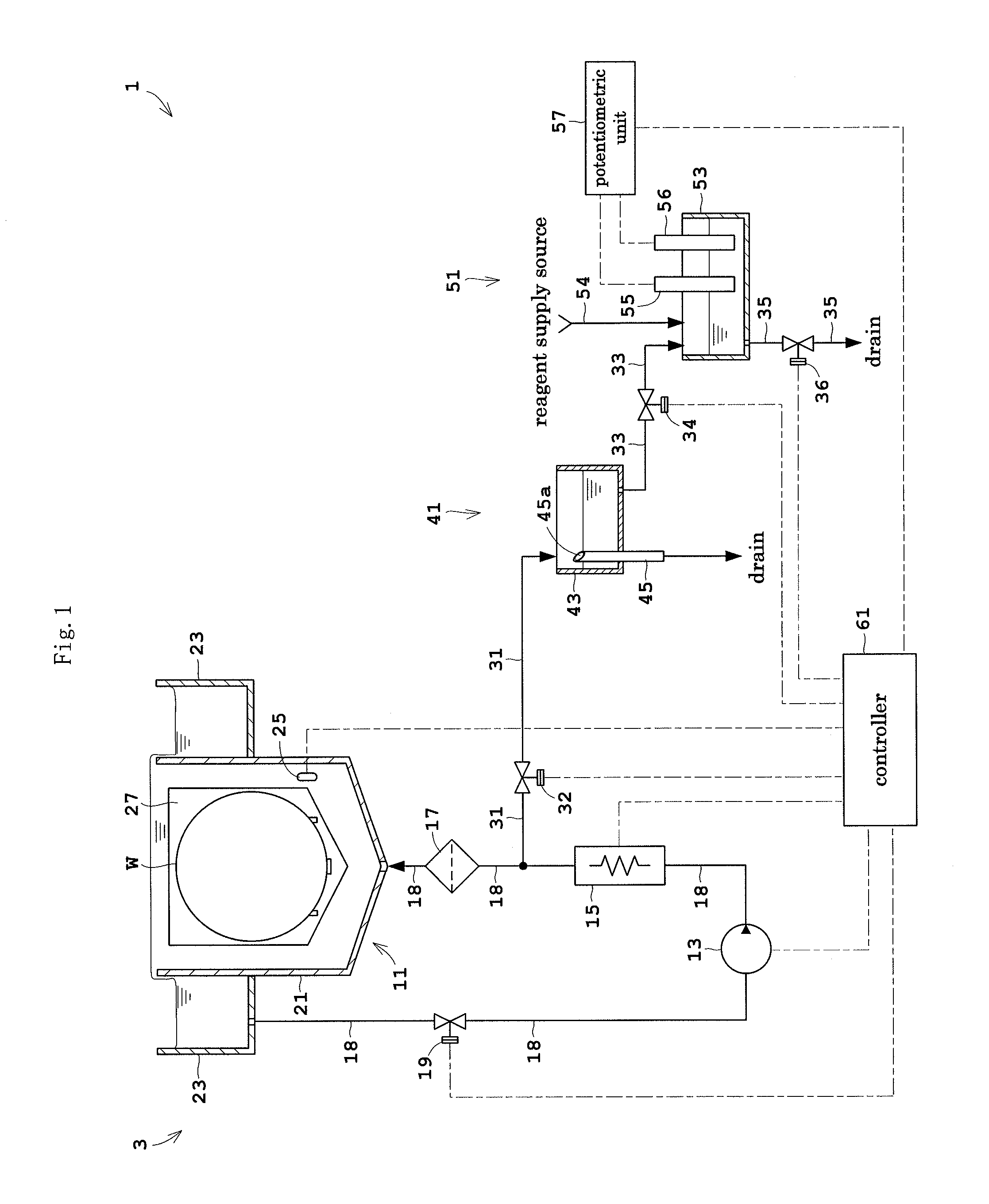

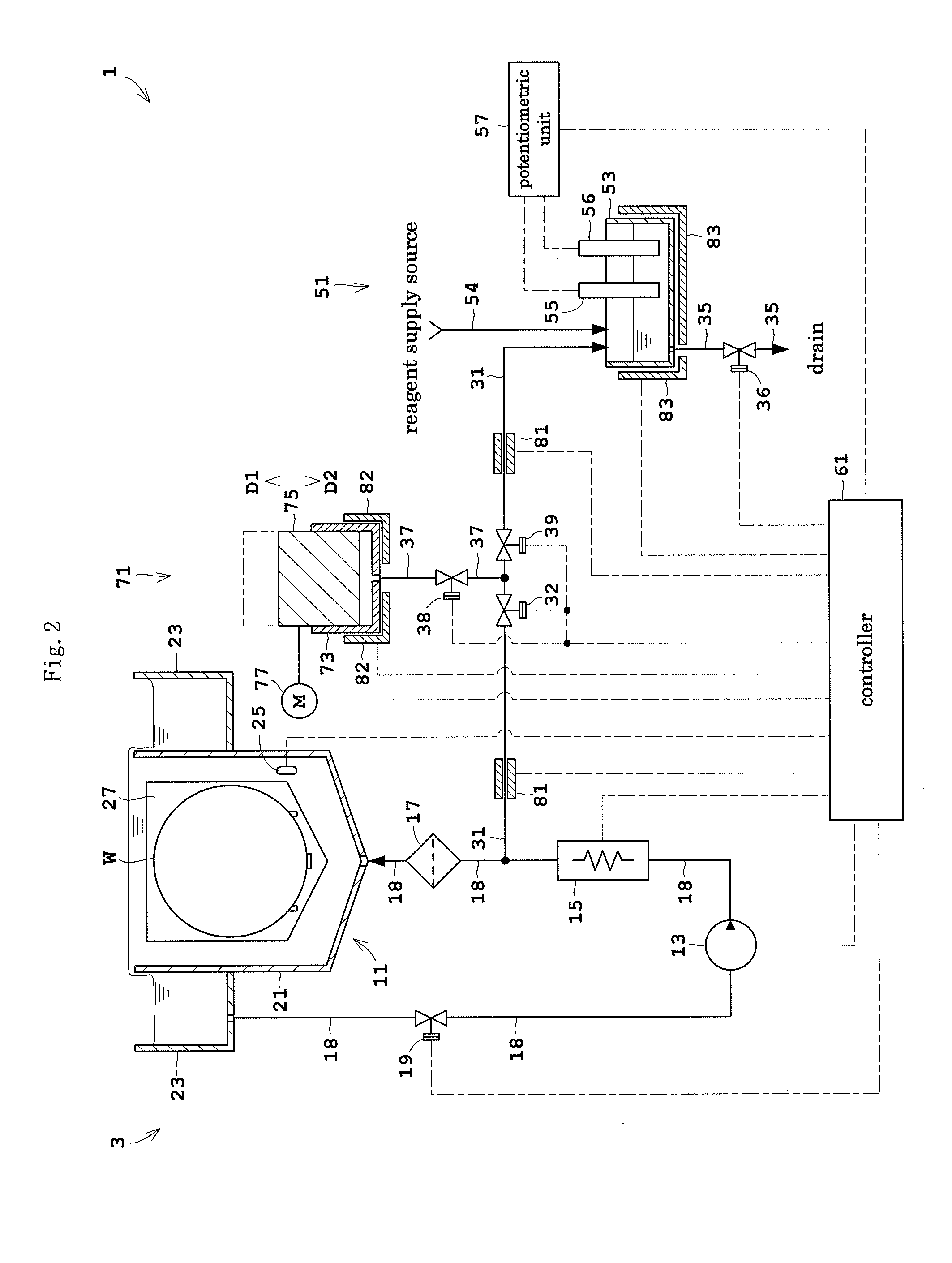

Substrate treating apparatus

InactiveUS20130255882A1Conveniently disposedImprove accuracyDetergent mixture composition preparationMaterial analysis by electric/magnetic meansPhosphoric acidPotentiometric titration

A substrate treating apparatus includes a circulating line having a treating tank for storing a phosphoric acid aqueous solution, a circulating pump for feeding the phosphoric acid aqueous solution, a heater for circulation for heating the phosphoric acid aqueous solution, a filter for filtering the phosphoric acid aqueous solution, the circulating line causing the phosphoric acid aqueous solution discharged from the treating tank to flow in order of the circulating pump, the heater for circulation and the filter, and returning the phosphoric acid aqueous solution from the filter to the treating tank. The apparatus also includes a branch pipe branching from the circulating line between the heater for circulation and the filter for extracting the phosphoric acid aqueous solution from the circulating line, and a concentration measuring station connected to the branch pipe for measuring silicon concentration in the phosphoric acid aqueous solution by potentiometry.

Owner:DAINIPPON SCREEN MTG CO LTD

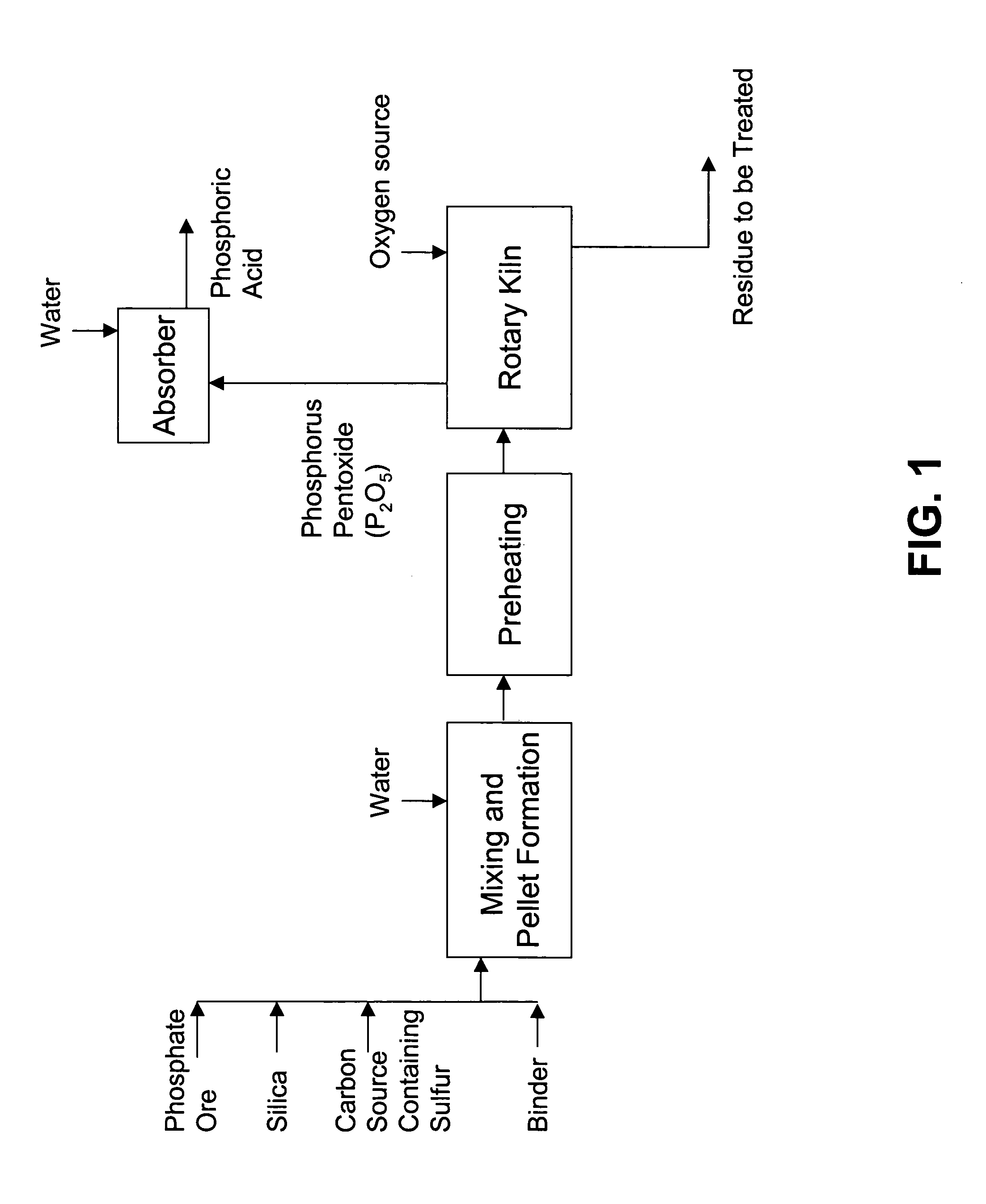

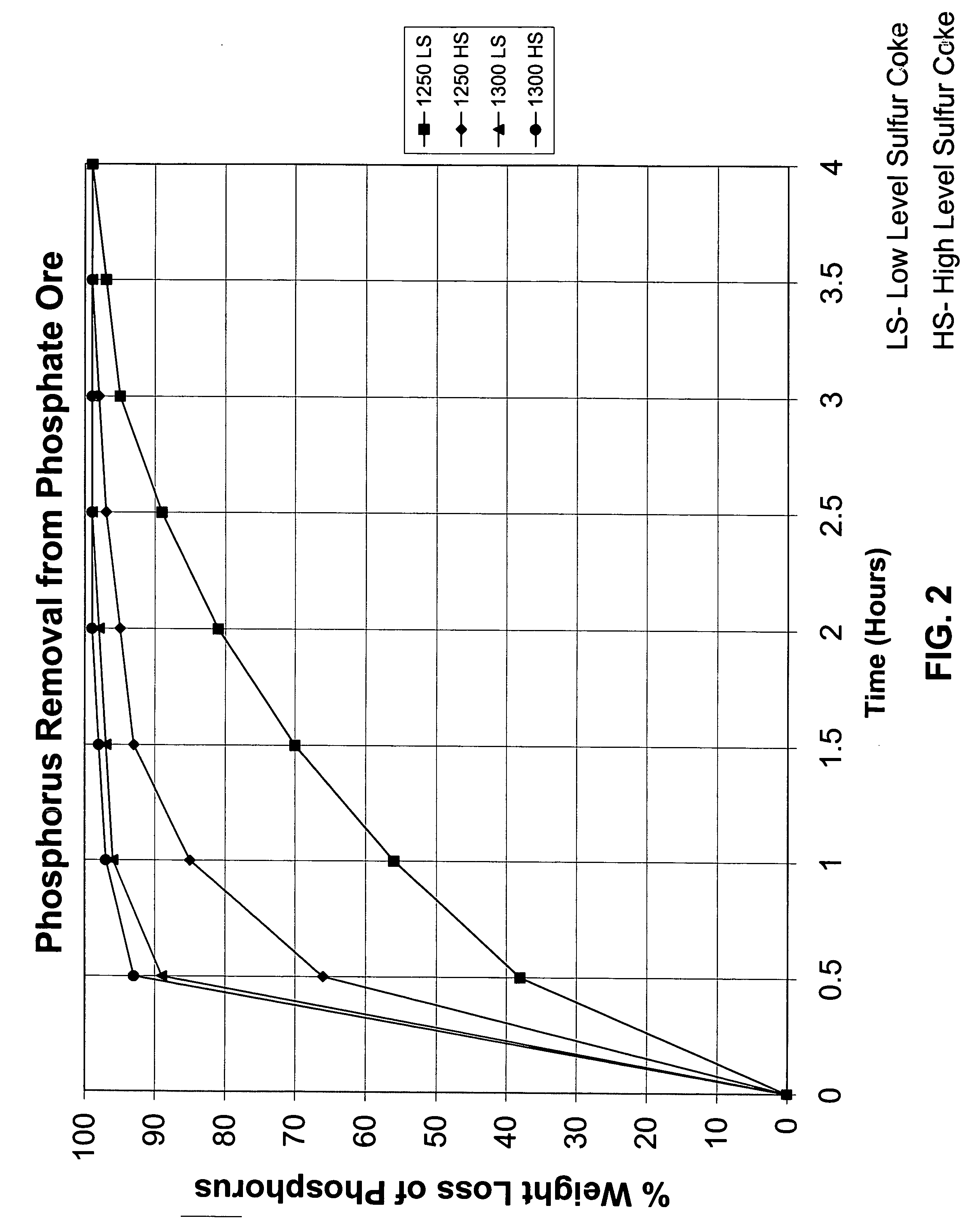

Method of forming phosphoric acid from phosphate ore

The process disclosed herein involves the high temperature processing of phosphate ore in a solid state using a ported rotary kiln. Prior to insertion into the kiln, the ore is pulverized and beneficiated to remove excessive quantities of unwanted materials such as clay, silica, iron, sodium, potassium, and alumina. The calcium oxide to silica ratio of the beneficiated is then adjusted to within a specific acceptable range, a carbon source containing sulfur such as petroleum coke is added and the resulting feed material is pelletized using a binding agent if necessary. The pelletized feed material is then dried, preheated, and fed into a ported rotary kiln. At the elevated temperature maintained in the reducing kiln, tricalcium phosphate undergoes a reduction reaction to produce phosphorus gas and carbon monoxide. Atmospheric air is injected into the rotating kiln chamber, which facilitates the oxidation of phosphorus gas to phosphorus pentoxide and the oxidation of carbon monoxide to carbon dioxide. The reducing kiln exhaust gas stream containing the phosphorus pentoxide and carbon dioxide gas components is processed in an absorption column in which the phosphorus pentoxide is hydrolyzed by water to phosphoric acid. The phosphoric acid is then recovered and concentrated to a commercial grade strength. The slag residue serves as a raw material for cement manufacture.

Owner:CAROLINA PROCESS ASSOC

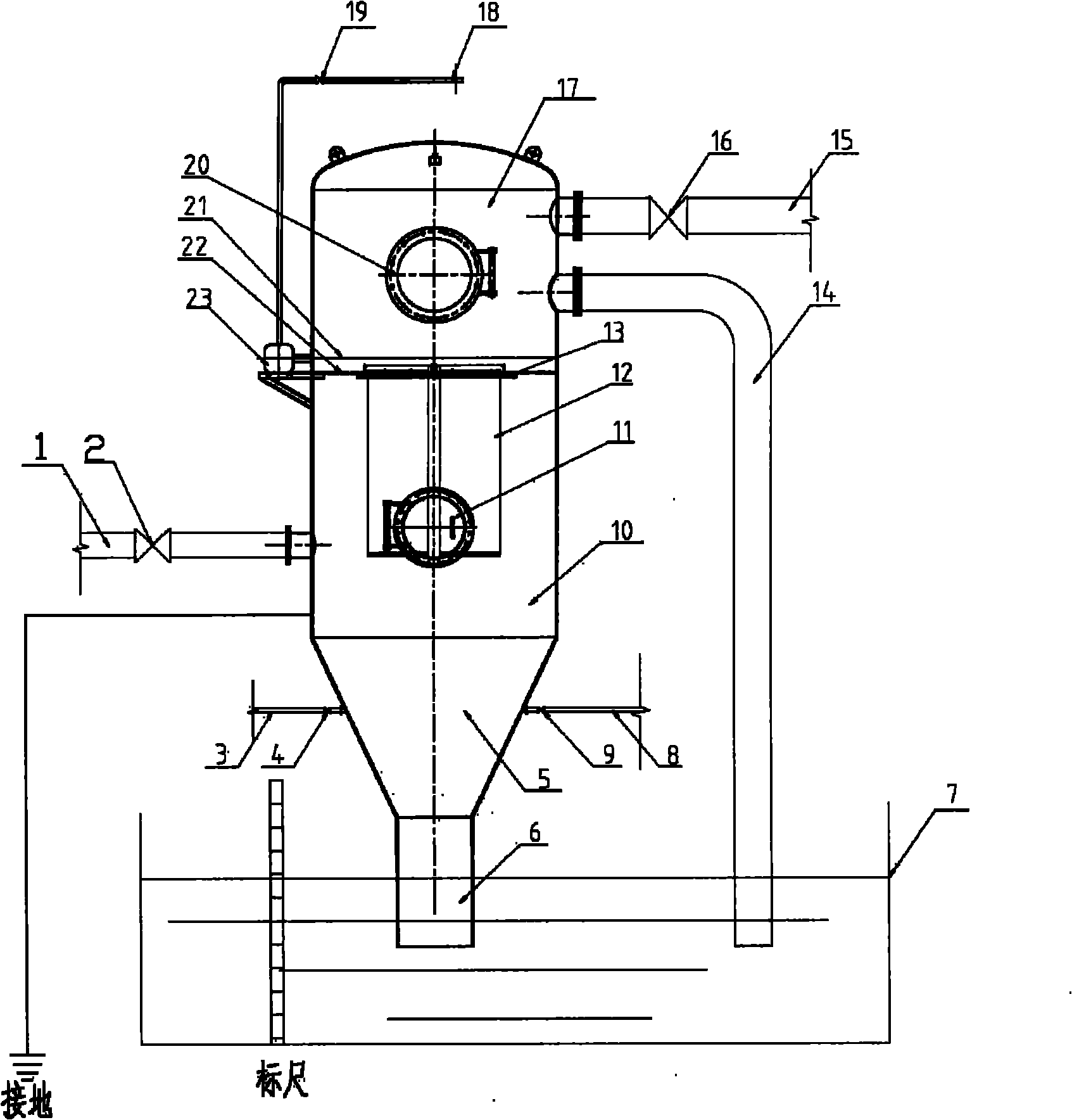

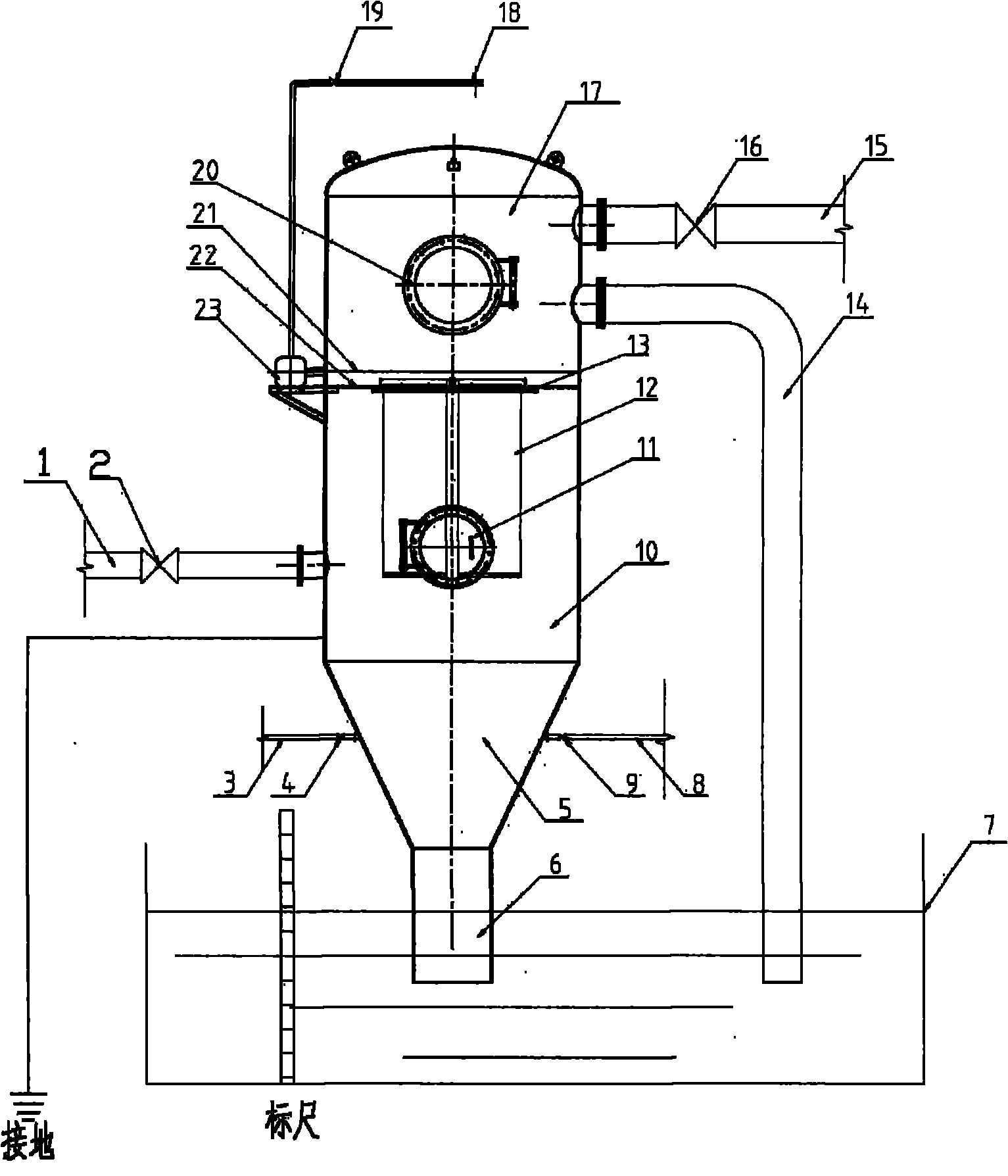

Method and device for purifying furnace gas generated by producing phosphoric acid through blast furnace process

ActiveCN101829461AEnsure safetyHuman health protectionDispersed particle filtrationPhosphoric acidHeat energy

The invention discloses a method for purifying phosphoric acid furnace gas generated by producing phosphoric acid through a blast furnace process and a purification device using the method. The purification device comprises a gas inlet, a sintering plate dust remover and a gas outlet, wherein the gas inlet and the gas outlet are respectively communicated with the sintering plate dust remover; andthe gas inlet is used for supplying furnace gas generated by producing phosphoric acid through the blast furnace process for the sintering plate dust remover. The sintering plate dust remover takes asintering plate as a filtering element; the sintering plate is made of porous filtering materials with favorable permeability, which is prepared from a high polymer material by adopting a sintering process and is used for carrying out dust removal and purification on the furnace gas. The gas outlet is used for supplying the purified gas furnace for a heat energy recovery device.

Owner:BEIJING CLEAN AIR TECH INNOVATION

Process for mfg. industrial phosphoric acid by low-grade phosphorus deposit in hydrogen chloride decomposition

A process for preparing industrial phosphoric acid by use of hydrochloric acid to decompose the low-and medium-grade phosphorus ore includes such steps as using hydrochloric acid to decompose phosphorus ore to obtain calcium chlorophosphate, using hydrochloric acid to prepare slurry, dissolving the calcium chlorophosphate in it, extracting by tri-butyl phosphate, concentrating, extracting by tri-butyl phosphate and isopropyl ether, concentrating, and de-coloring to obtain 85% industrial phosphoric acid. Its advantage is no environmental pollution.

Owner:湖北中磷科技有限公司

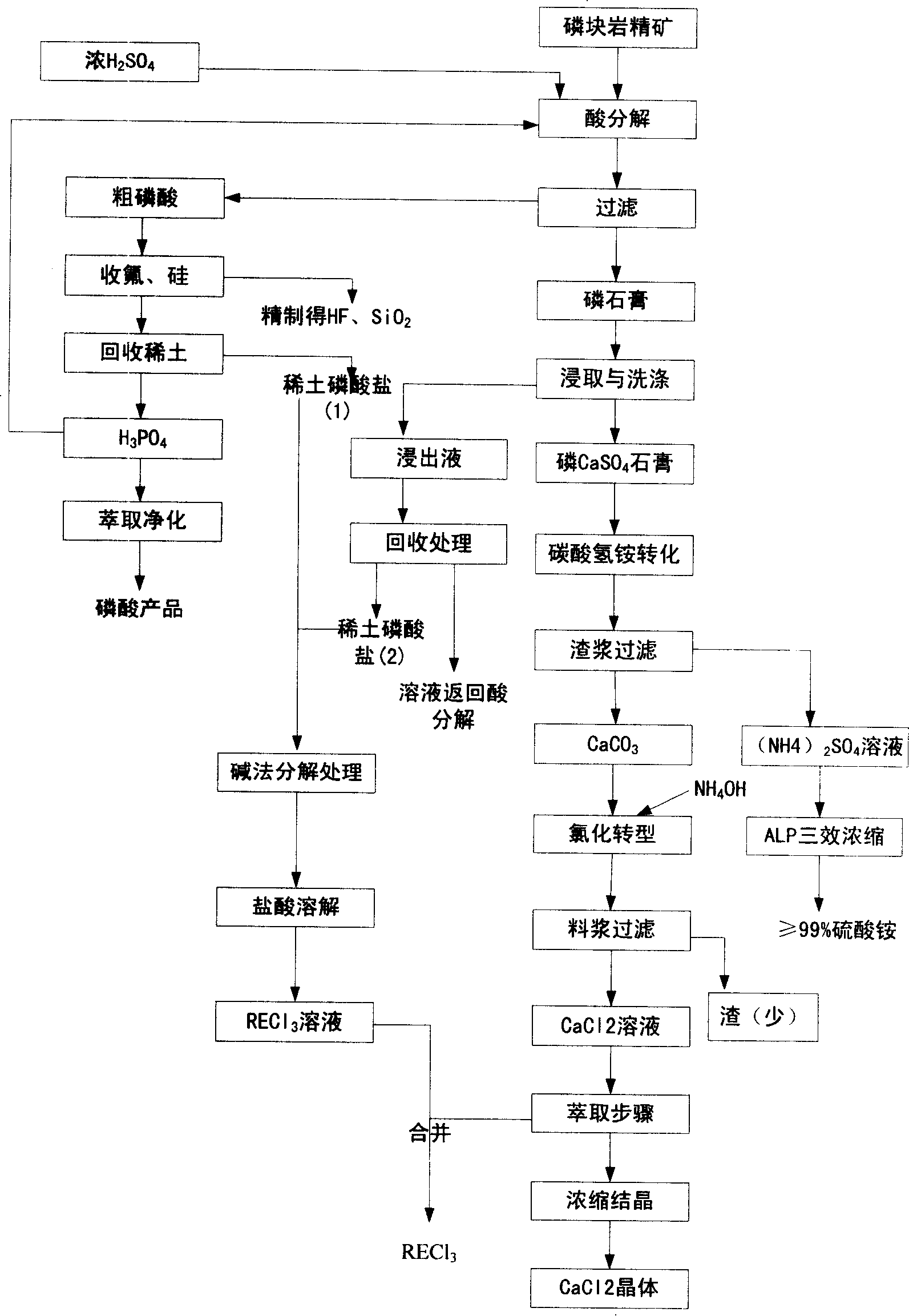

Technique for comprehensive utilization clean production of phosphorus block ore and extracting rare earth form the phosphorus block ore

InactiveCN101186967ASolve the use problemImplement resourcesProcess efficiency improvementPhosphoric acidRare-earth elementPhosphoric acid

The invention relates to a technology for carrying on comprehensive utilization and clean production of phosphorus rock mine and extracting rare earth from the phosphorus rock mine. By improving the existing technology for extracting phosphoric acid in wet method, the technology process of the invention can be carried on further treatment through the recovering and treating process of normal fluorine and silicon, thereby realizing precipitate of rare-earth microcosmic salt and achieving single rare-earth products by further normal treatment. Simultaneously, phosphogypsum in the existing technique is used through recycling and deep processing, thereby achieving the purpose of clean production. The invention has the advantages that the clean production can be achieved with relatively low cost, rare-earth element in mineral products is fully recycled, and the realization of industrial production and the deepening of the comprehensive utilization of the phosphogypsum are easily achieved.

Owner:贵州蓝天科大矿业发展有限公司 +1

Method of producing phosphoric acid by directly reducing phosphorus ore and co-producing Portland cement grog

InactiveCN101033061AIncrease concentrationReduce consumptionPhosphoric acidPhosphoric acidMaterials science

This invention discloses a method for recovering phosphorite to prepare highly concentrated phosphoric acid and by-product Portland cement clinkers, which increases proportion of Ca and Si of various levels of phosphorite P2O5>=6%, utilizes the Ca, Si, Al and Fe oxides contained in the phosphorite and adds carbon reducers and small amount of Si or Si correction material to be mixed and added with water to process balls or other shapes to be dried and put into a container of fireproof material then enters into a tunnel stove to get phosphor vapour and CO to be asorbed by a hydrate tower to get densed phosphor, and materials in the container are cooled to become Portland cement clinkers.

Owner:HUBEI SANXIN PHOSPHORIC ACID

Method for preparing high-concentration phosphoric acid by direct-reduction of phosphate ore

The invention relates to a high concentration phosphoric acid producing method by directly deoxidized phosphorite. The process that the stock produced by phosphorus ore, diatomite, coke or coal accomplishes a reduction-oxidation to produce phosphoric acid consists of a preheating zone, a reducing zone and an oxidation combustion zone which are composed of different equipment modules. The preheating zone is under 1150 DEG C to 1200 DEG C; the reducing zone is under 1250 DEG C to 1450 DEG C, the coke or the coal in the stock performs a reduction reaction with phosphorite; phosphorus vapor that is P4 and carbon monoxide gas which are produced enter into the oxidation combustion zone again; air is added into the oxidation combustion zone, thus the phosphorus vapor that is P4 and the carbon monoxide gas are oxidized to produce a mixed kiln gas which is composed of P2O5 and CO2; the mixed kiln gas with high temperature is sucked out and led into a hydration absorption tower after dust abatement, and the phosphoric acid is produced by recycle acid absorption. The stock after the reduction reaction is exported from the reducing zone, and is formed into cement clinker or building materials after cooling and heat transfer. The invention has the innovative points that the processes of preheating, deoxidizing and oxidizing of reducing gas of the stock are separated, and the reactions are not mutually interfered. The control of the action process is simple, in addition, the percent reduction of the phosphorite is high, and the high yield of total phosphorus can be gained.

Owner:云南常青树化工有限公司

Method for producing phosphoric acid by decomposing low-grade phosphate rock with wet-process phosphoric acid

InactiveCN103213960AImpurity content is not requiredImprove universalityPhosphoric acidSulfatePhosphoric acid

The invention discloses a method for producing phosphoric acid by decomposing a low-grade phosphate rock with wet-process phosphoric acid, which is characterized by using a two-step reaction, additive addition and separation. The method comprises the following steps: step one, decomposing the low-grade phosphate rock using phosphoric acid in an extraction tank, and removing residues through solid-liquid separation, so as to obtain a clear solution; and step two, reacting the extracted clear solution with sulfuric acid in a reactor to generate crystals of calcium sulfate dehydrate (phosphogypsum) and the phosphoric acid solution, so as to obtain the phosphoric acid solution and a phosphogypsum after solid-liquid separation, concentrating the phosphoric acid solution, thus finally partial concentrated phosphoric acid solution is returned to continuously decompose the phosphate rock, and partial phosphoric acid solution is output as finished products. By using the method, the relatively high quality phosphoric acid can be obtained and the yield of phosphoric acid is high, thus the method has wide prospect in industrial application; and at the same time, a white plaster as the by-product of method also has wide application value.

Owner:成都川科化工有限公司

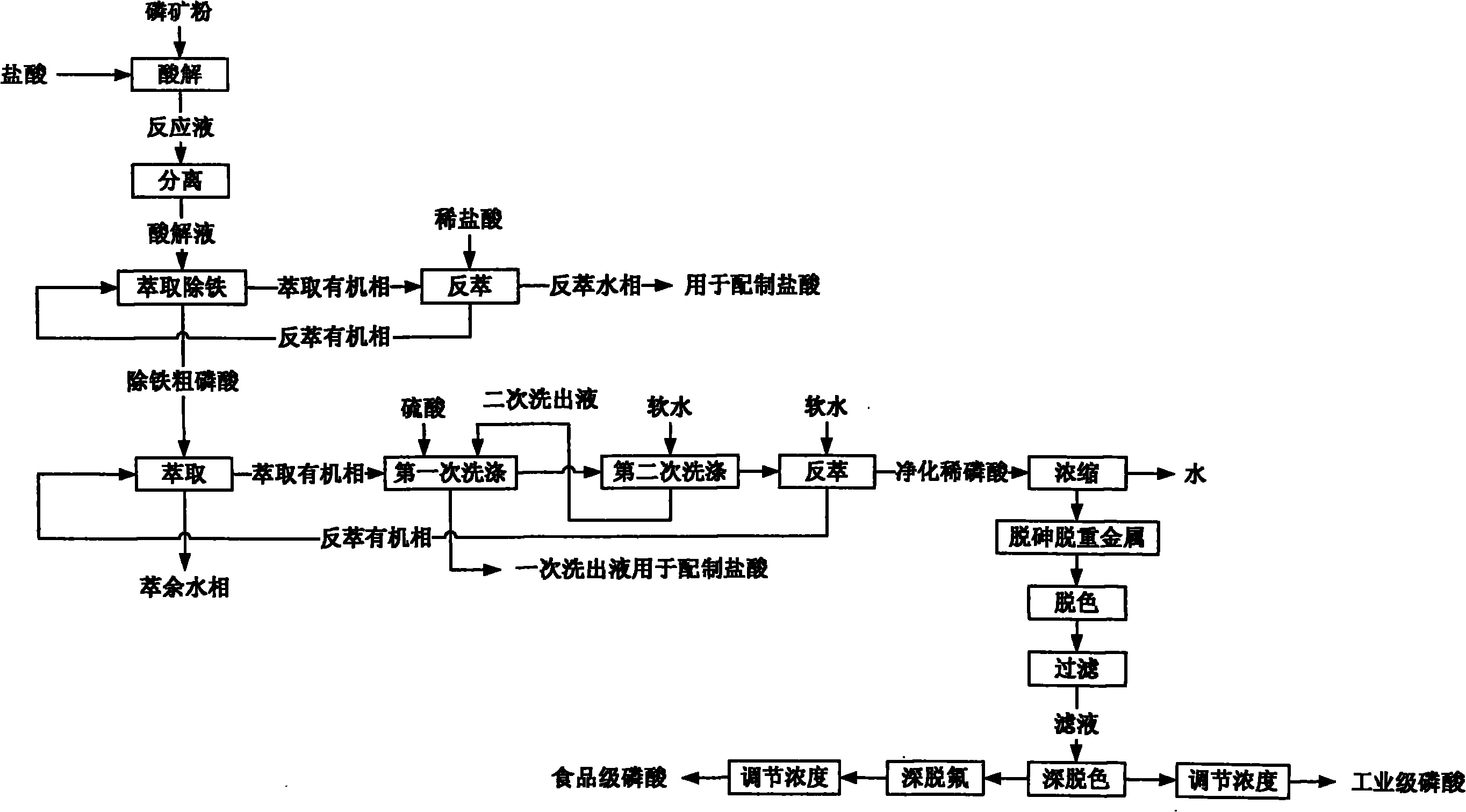

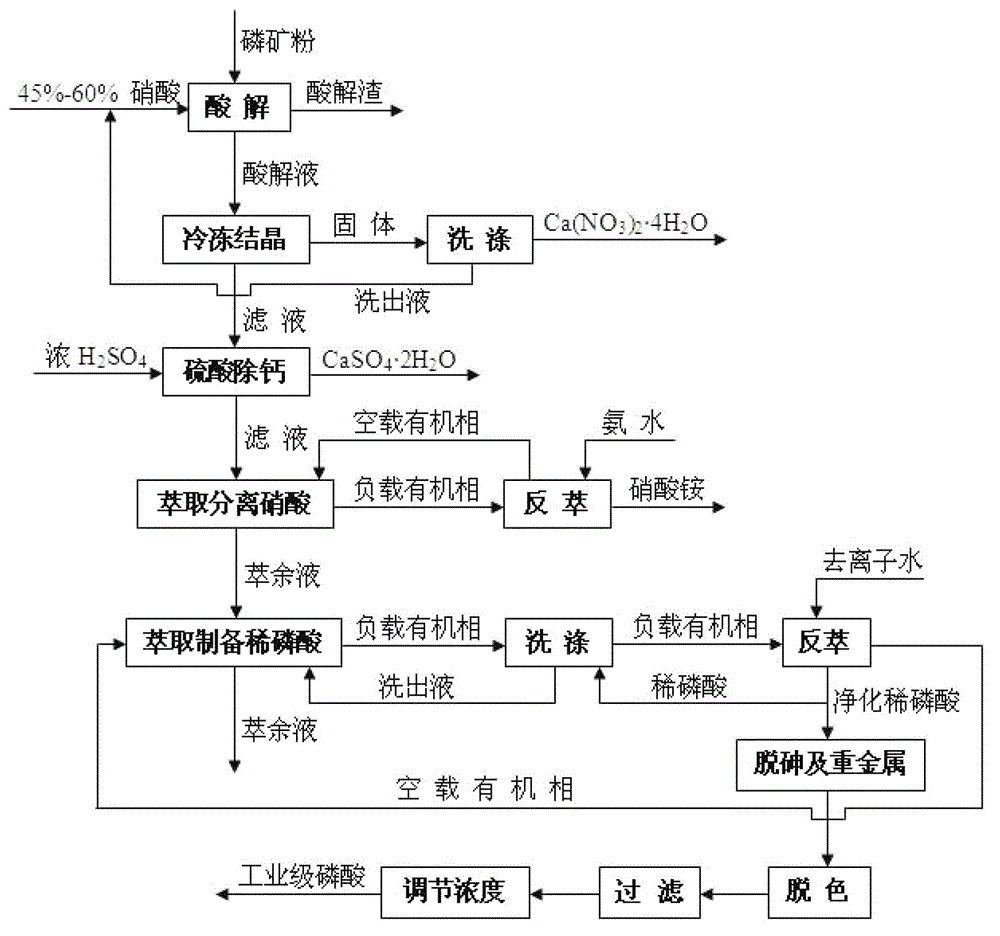

Method for preparing industrial-grade phosphoric acid by decomposing mid-low-grade phosphorite with nitric acid

The invention relates to a method for preparing industrial-grade phosphoric acid by decomposing mid-low-grade phosphorite with nitric acid. The method comprises the following processing steps: (1) decomposing phosphorite with nitric acid; (2) separating calcium nitrate through freezing crystallization; (3) carrying out deep deliming with sulfuric acid; (4) conducting countercurrent or cross current extraction of filtrate obtained in the step (3) by using a first mixed extractant to obtain raffinate which is coarse phosphoric acid; (5) conducting countercurrent or cross current extraction of the coarse phosphoric acid obtained in the step (4) by using a second mixed extractant, carrying out countercurrent washing on the load organic phase obtained by the countercurrent or cross current extraction by using dilute phosphoric acid for at least two times, and then conducting countercurrent reverse extraction by using deionized water to obtain strip liquor which is purified dilute phosphoric acid after removing impurities such as iron, magnesium, aluminum, calcium and fluorine; and (6) sequentially conducting evaporation concentration, dearsenification, heavy metal removal, decoloring, filtration and concentration adjustment on the purified dilute phosphoric acid obtained in the step (5) to obtain industrial-grade phosphoric acid.

Owner:CHINA BLUECHEMICAL +1

Hemi-hydrate process wet process phosphoric acid production process

ActiveCN103332664ASolve processing problemsSolve the biggest problem of resource utilizationCalcium/strontium/barium sulfatesPhosphoric acidO-Phosphoric AcidPhosphate

The invention discloses a hemi-hydrate process wet process phosphoric acid production process which comprises the following steps of: 1) crushing commercial-grade phosphate ore to be 60% ground phosphate rock and screening by using a sieve of 100 meshes; 2) adding the crushed phosphate ore into phosphoric acid which is 50-55% in mass concentration, controlling the liquid-solid ratio to be 12:1 and the reaction temperature to be 60-80 DEG C, carrying out decomposition reaction for 60-90 minutes; 3) adding reaction slurry into concentrated sulfuric acid (93-98%) to carry out rapid chemical reaction to generate hemi-hydrate gypsum and phosphoric acid; 4) filtering the generated hemi-hydrate gypsum by using a filtering machine, washing by using hot water, drying and grinding so as to obtain a product hemi-hydrate building gypsum powder; 5) using the filtrate obtained through filtration as another objective product, i.e., the wet process phosphoric acid. By using the process, the problem that the hemi-hydrate gypsum is hard to filter and wash is solved, and moreover the cost on ardealite resource application is greatly lowered.

Owner:WENGFU (GRP) CO LTD

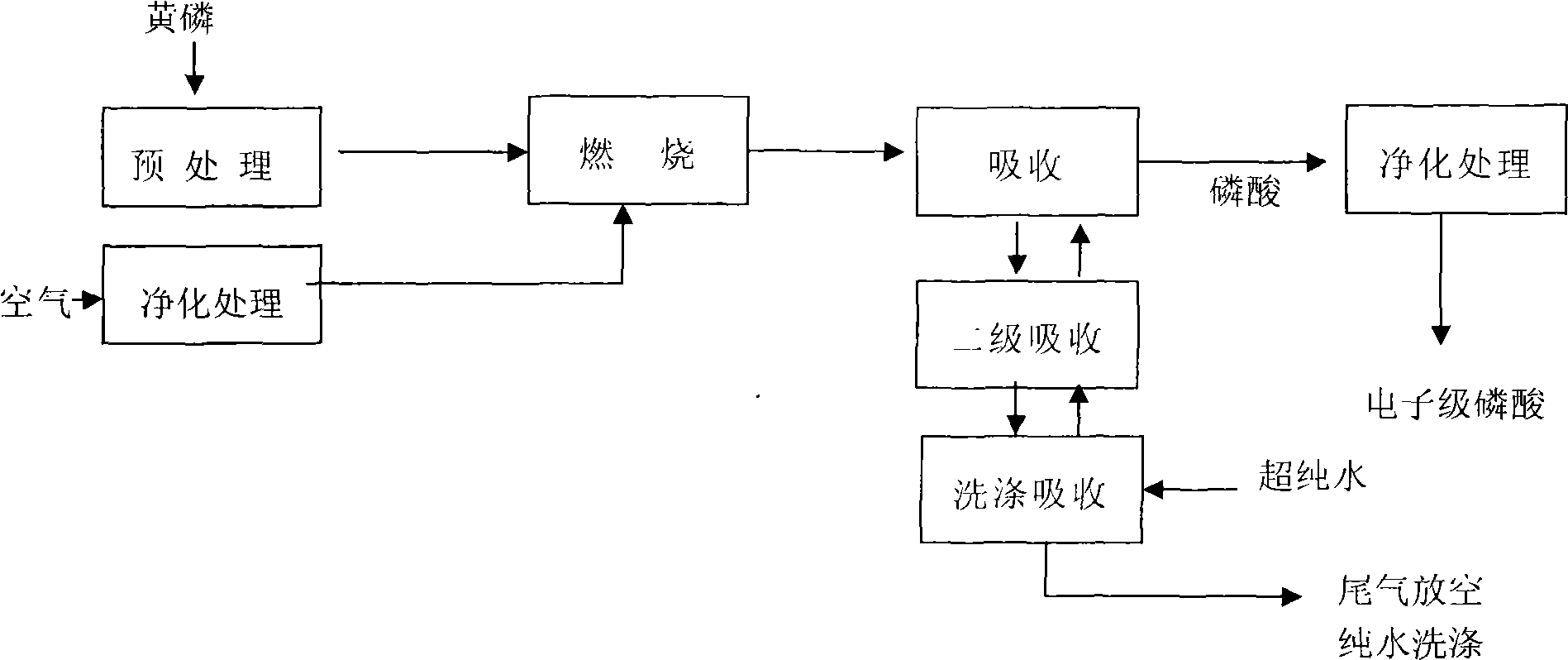

Method for directly preparing electronic grade phosphoric acid by yellow phosphorus

The invention provides a method for directly preparing electronic grade phosphoric acid by yellow phosphorus, relating to a preparation method of phosphoric acid, in particular to the preparation method of electronic grade phosphoric acid applied to the electronic industry; in the invention, industrial yellow phosphorus is used as the raw material, the method has the following steps: a. placing the industrial yellow phosphorus going through purifying pretreatment in a combustion tower; b. injecting air going through multilevel oil removal, edulcoration and humidity control into the industrial yellow phosphorus to facilitate sufficient burning thereof; c. sending P2O5 air generated by burning into an absorption tower, using ultrapure water for cycling absorption; d. sending a phosphoric acid purifying post treatment equipment for carrying out anion and cation desorption, aeration and multi-stage filtration purifying treatment after the concentration of the phosphoric acid generated by absorption reaches 85.0-87.0%; and d. purifying the processed phosphoric acid in the 10000-level or 1000-level air purification environment and packing product acid with a clean pail pack. The invention features easy control of production operation, good and relatively stable quality and low production cost.

Owner:YUNNAN CHEM RES INST

Method for extracting phosphorite co-production gypsum whisker by utilizing nitric acid

ActiveCN102352528AReduce utilizationIncrease profitPolycrystalline material growthFrom normal temperature solutionsCalcium nitrate tetrahydrateSulfate

The invention discloses a method for extracting a phosphorite co-production gypsum whisker by utilizing nitric acid, which comprises leaching phosphorite powder by taking a nitric acid solution of which the mass percent concentration is 50-60 percent as a raw material, wherein the mass ratio of the nitric acid to the phosphorite powder is 0.9-1.31; reacting for 50-70 minutes at the temperature of50-55 DEG C at the stirring speed of 350 turns per minute to obtain mixed liquor, filtering the mixed liquor, and then, performing freeze crystallization on the mixed liquor at the temperature of minus 5-0 DEG C for 280-300 minutes to obtain a product: tetrahydrated calcium nitrate; and adding a sulfuric acid solution and magnesium sulfate to a tetrahydrated calcium nitrate solution under the conditions of controlling the reaction temperature to be 40-90 DEG C, the stirring speed to be 150-250 turns per minute and the reaction time to be 30-60 minutes to obtain mixed liquor, filtering the mixed liquor, and then, drying filter residues at the temperature of 60 DEG C for 2 hours to obtain the product: a calcium sulfate whisker. The method for extracting the phosphorite co-production gypsum whisker by utilizing the nitric acid can improve the use ratio of the raw material, has low energy consumption and low production cost and is green and environmentally friendly.

Owner:WENGFU (GRP) CO LTD

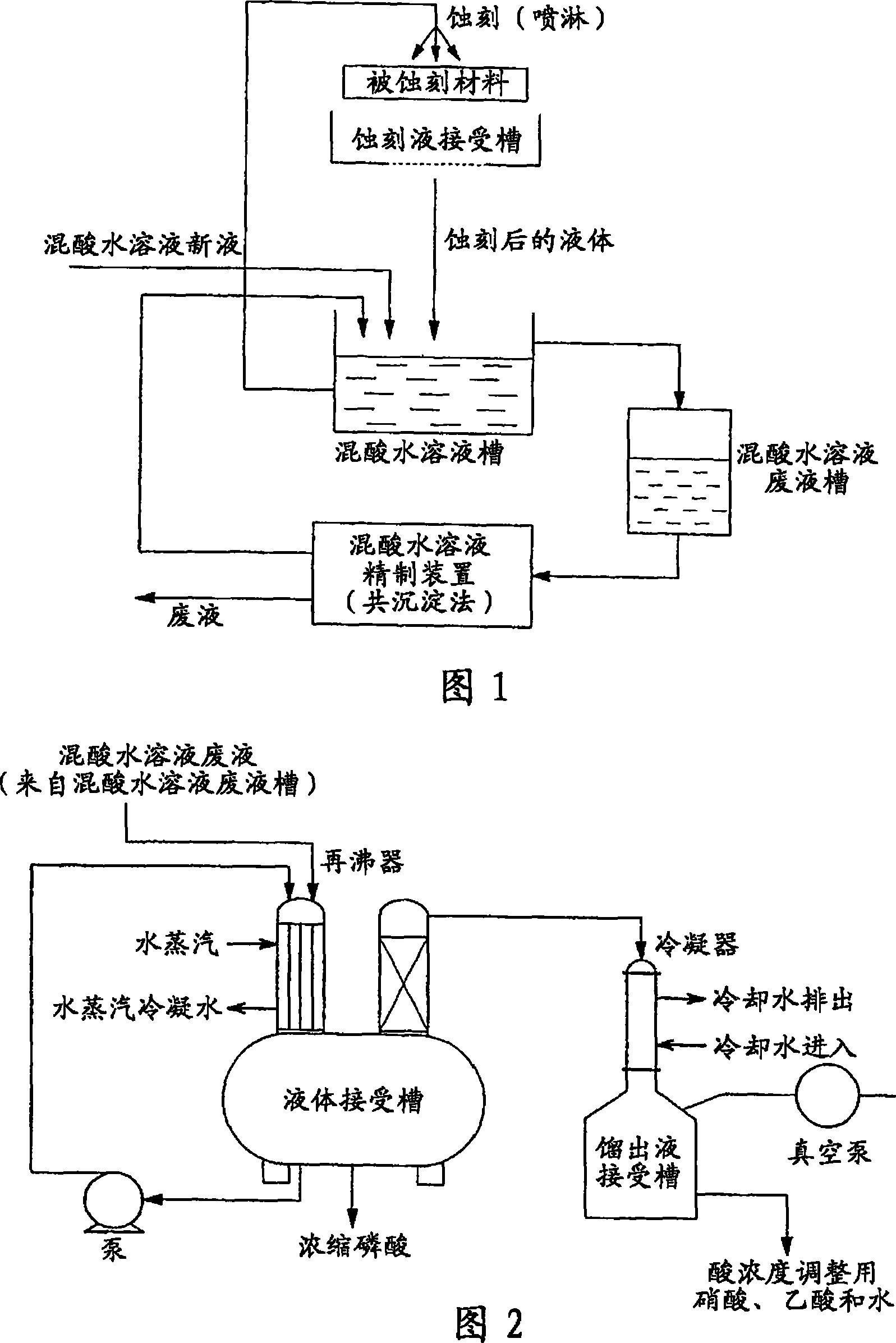

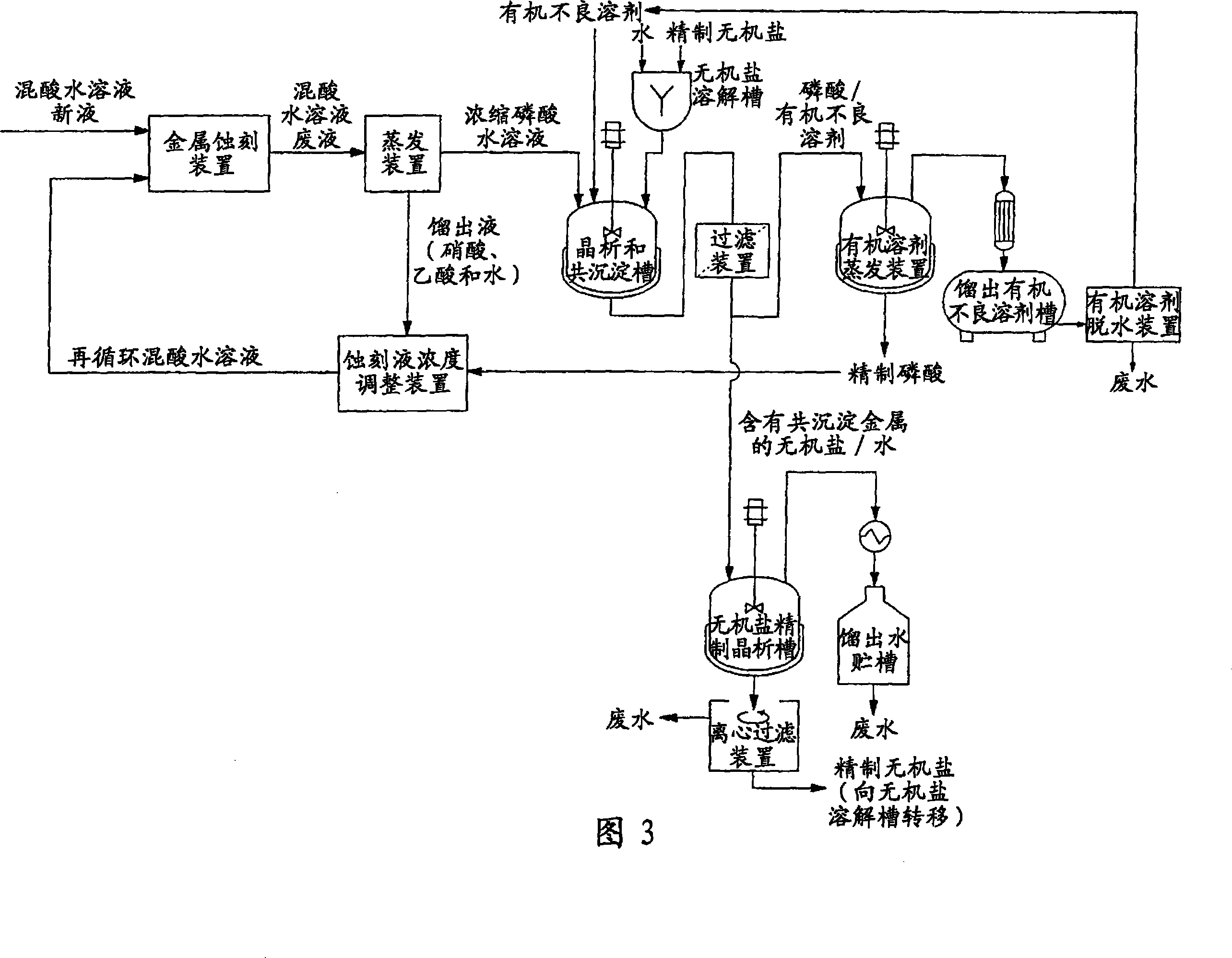

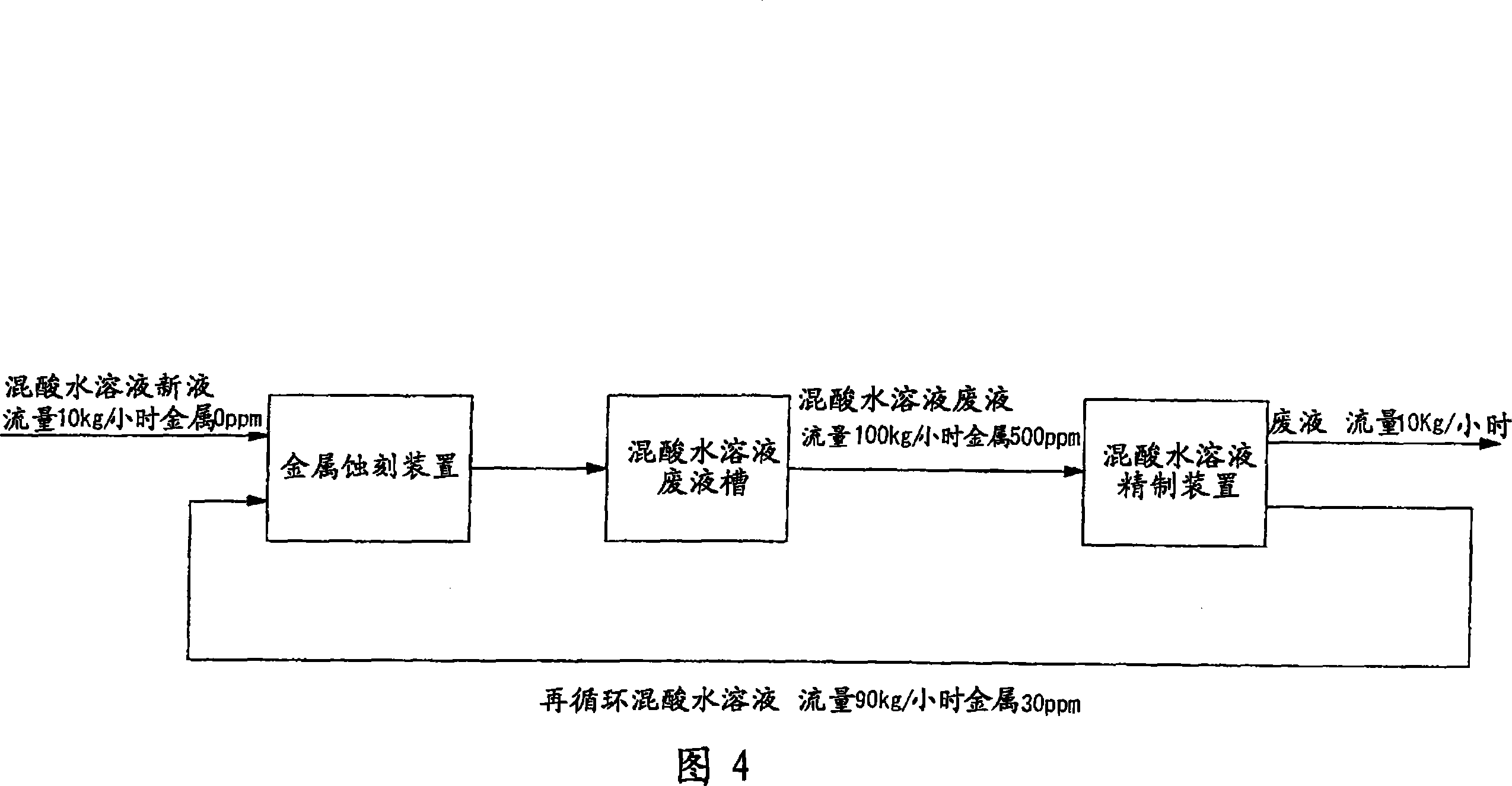

Method and apparatus for obtaining purified phosphoric acid from phosphoric acid aqueous solution containing plural metal ions

Method and apparatus for obtaining purified phosphoric acid from phosphoric acid aqueous solution containing plural metal ions A method for obtaining purified phosphoric acid from a phosphoric acid aqueous solution containing a plurality of metal ions includes: [1] crystallizing and coprecipitating that separate out an inorganic salt crystal from a phosphoric acid aqueous solution containing a plurality of metal ions and coprecipitate metal ions including: (a) mixing a phosphoric acid aqueous solution containing a plurality of metal ions with an inorganic salt aqueous solution; (b) separatingout an inorganic salt crystal and coprecipitating simultaneously the metal ions by further mixing an organic poor solvent which is soluble in phosphoric acid and does not dissolve an inorganic salt with the above resultant mixture; and (c) solid-liquid separating by filtering the inorganic salt crystal containing the metal ions; and [2] evaporating that obtains purified phosphoric acid by evaporating an organic poor solvent and water in a filtrate obtained by the filtration, wherein the amount of metal ions dissolved in the phosphoric acid / organic poor solvent mixture in the separating is less than the amount of metal ions in the phosphoric acid solution used in the mixing.

Owner:NIPPON REFINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com