Technique for comprehensive utilization clean production of phosphorus block ore and extracting rare earth form the phosphorus block ore

A phosphorite and clean technology, applied in the field of rare earth extraction, achieves high recycling rate, reduced process production cost and environmental treatment cost, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

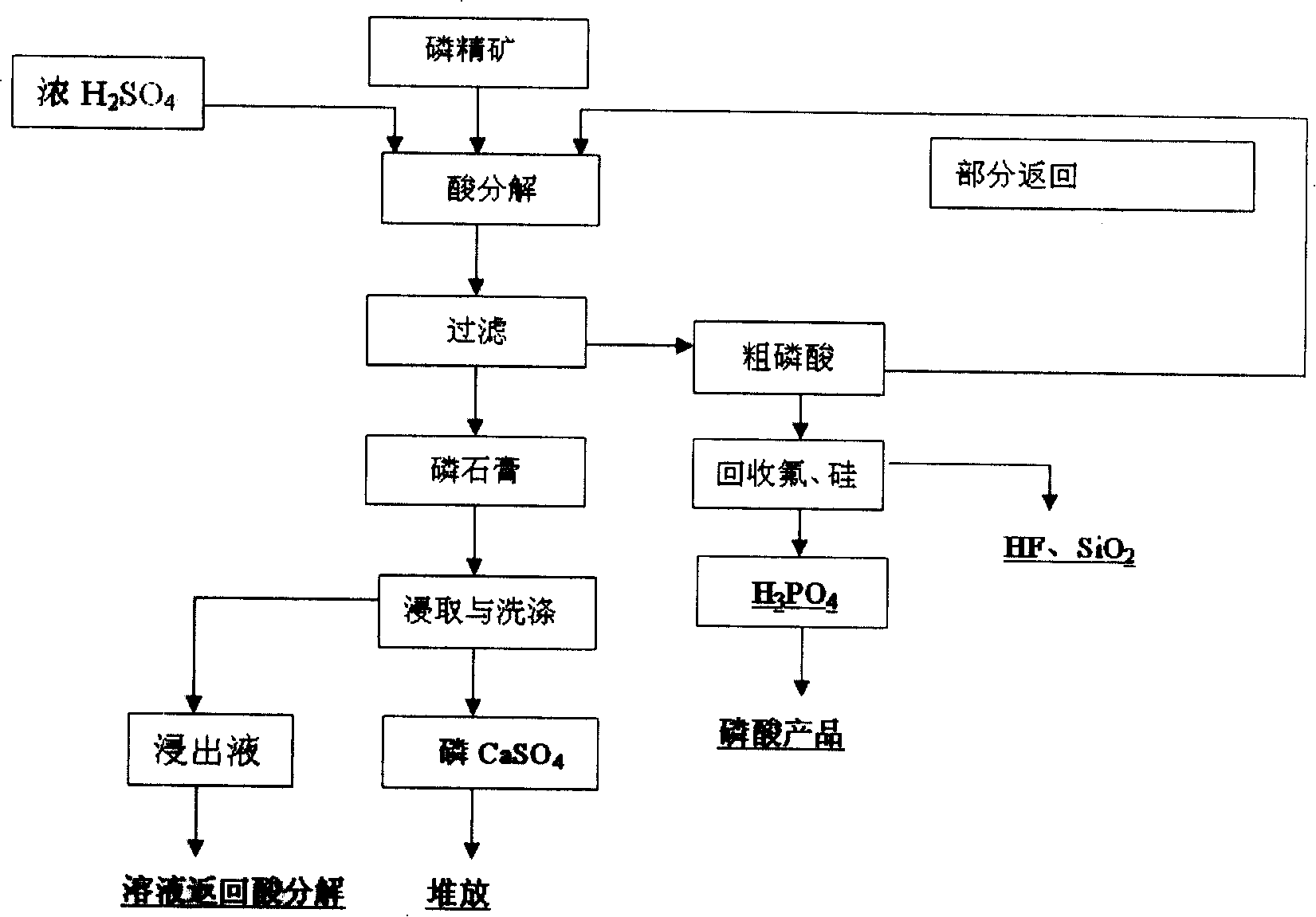

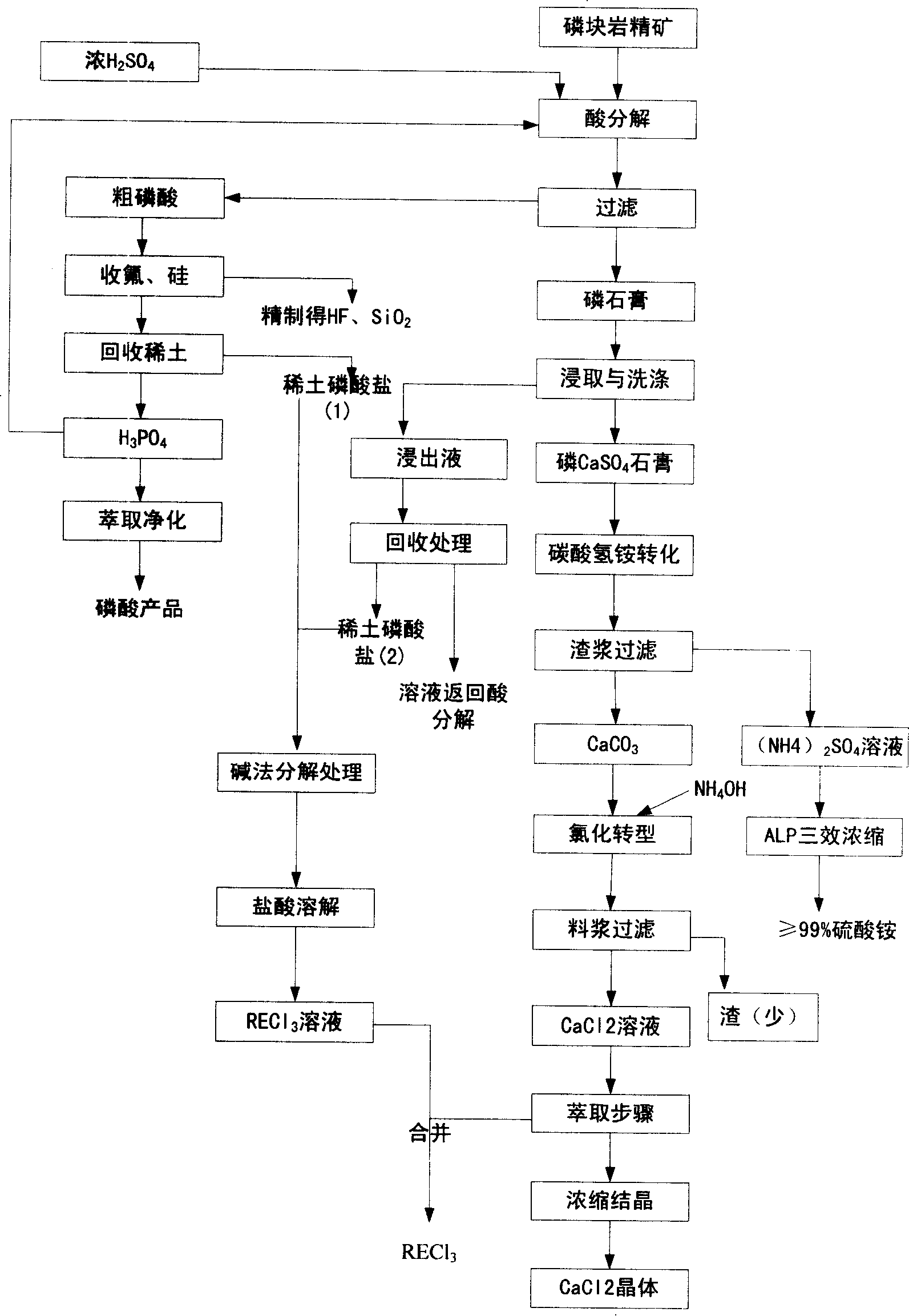

Method used

Image

Examples

Embodiment 1

[0043] Unless otherwise specified, the percentages involved in the following examples are all mass percentages.

[0044] Follow the steps below:

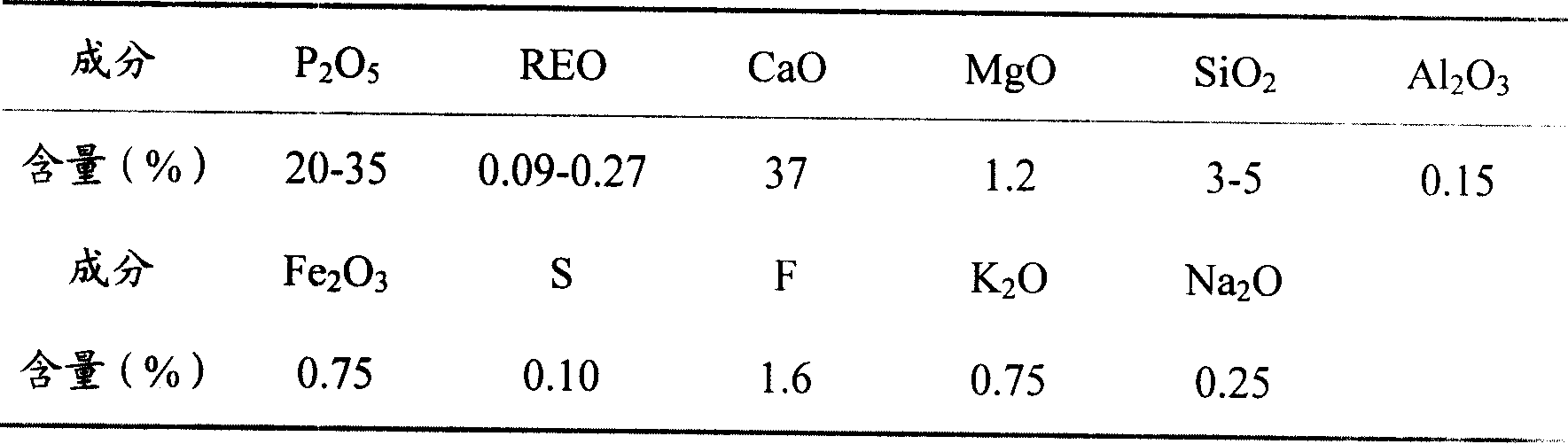

[0045] Step (1) According to the conventional wet-process phosphoric acid production process, take 10Kg of phosphorite concentrate, crush it to 100 mesh, and add it at a reaction temperature of 80±5°C at a ratio of 4:1 to liquid-solid ratio (mass ratio) 40kg of phosphoric acid with a concentration of 20wt% to 23wt% was reacted, and the reaction time was 2 hours; then, concentrated sulfuric acid with a concentration of at least 97% was added to continue the reaction, and the amount added was until the SO in the liquid phase 3 The concentration is 35±2g / L, and the reaction time is 5 hours. After the reaction is complete, filter to obtain crude phosphoric acid and phosphogypsum. The crude phosphoric acid solution concentration (P 2 o 5 ) is 29%; concentrate decomposition rate is 98%; P 2 o 5 The extraction rate is 96%; the extract...

Embodiment 2

[0060] Follow the steps below:

[0061] Step (1) According to the process of conventional wet phosphoric acid production, take 20Kg of phosphorite concentrate, crush it to 100 mesh, and add 80kg concentration React with 21wt% phosphoric acid, and the reaction time is about 2 hours; then add concentrated sulfuric acid with a concentration of at least 97% to continue the reaction, until the amount of SO in the liquid phase is 3 The concentration is 35±2g / L, and the reaction time is about 5 hours. After the reaction is complete, filter to obtain crude phosphoric acid and phosphogypsum. The crude phosphoric acid solution concentration (P 2 o 5 ) is 27.5%; concentrate decomposition rate is 98%; P 2 o 5 The extraction rate is 96%; the extraction rate of rare earth oxide is 43.1%.

[0062] (2) the crude phosphoric acid obtained in the step (1) is evaporated and concentrated, and fluorine and silicon are reclaimed from the escaped gas through a conventional process to obtain hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com