Aluminum-chromium-zirconium composite air bricks and manufacturing method thereof

A production method and technology of air-permeable bricks, which are applied in the direction of manufacturing tools, lighting and heating equipment, furnace components, etc., can solve problems such as waste of resources, poor comprehensive performance, and improper material selection, and achieve reduced economic losses, small thermal expansion coefficients, and improved use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

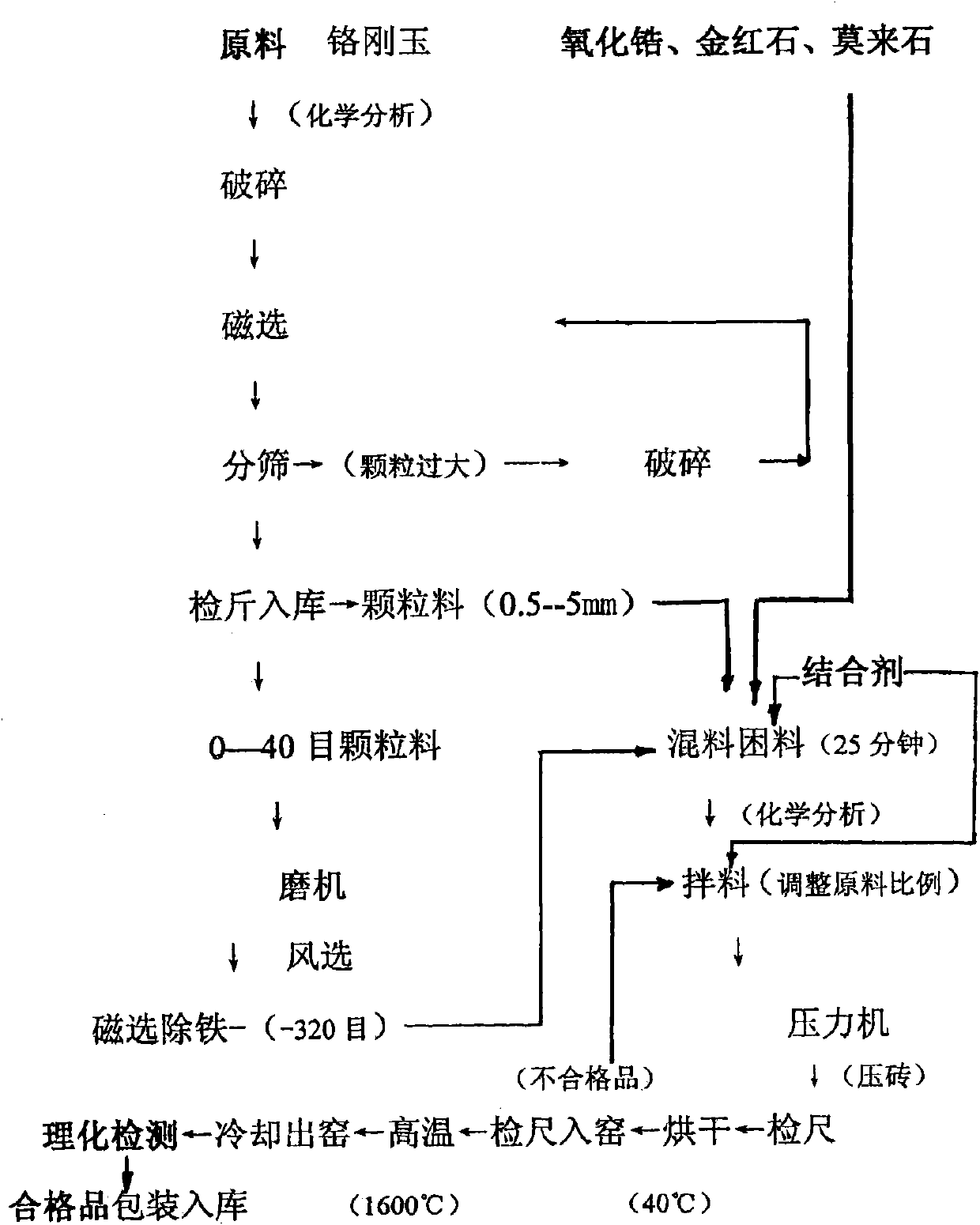

[0017] The present invention is described in detail below with reference to accompanying drawing:

[0018] The aluminum-chromium-zirconium composite air-permeable brick raw material of the present invention is by (Al 2 o 3 .C r2 o 3 ) and Z r o 2 and corundum mullite (SiO 2 ) and composition, which improves the corrosion resistance and thermal shock resistance, and also improves the FeO slag resistance of the permeable brick.

[0019] Its chemical composition (W) is:

[0020] Alumina (aluminum oxide) Al 2 o 3 ≥72%; (chromium trioxide) C r2 o 3 ≥15%; Zirconia Z r o 2 ≥4%; mullite ≥5%; rutile (titanium dioxide) TiO 2 ≥3%; Fe2O3 2 o 3 ≥1%.

[0021] Compared with materials with the same chemical composition but different production and preparation processes, the microstructure of the raw materials of the present invention is different from them.

[0022] Preparation method of the present invention:

[0023] al 2 o 3 , C r2 o 3 A new eutectic raw material prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com