Patents

Literature

81results about How to "Little change in thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

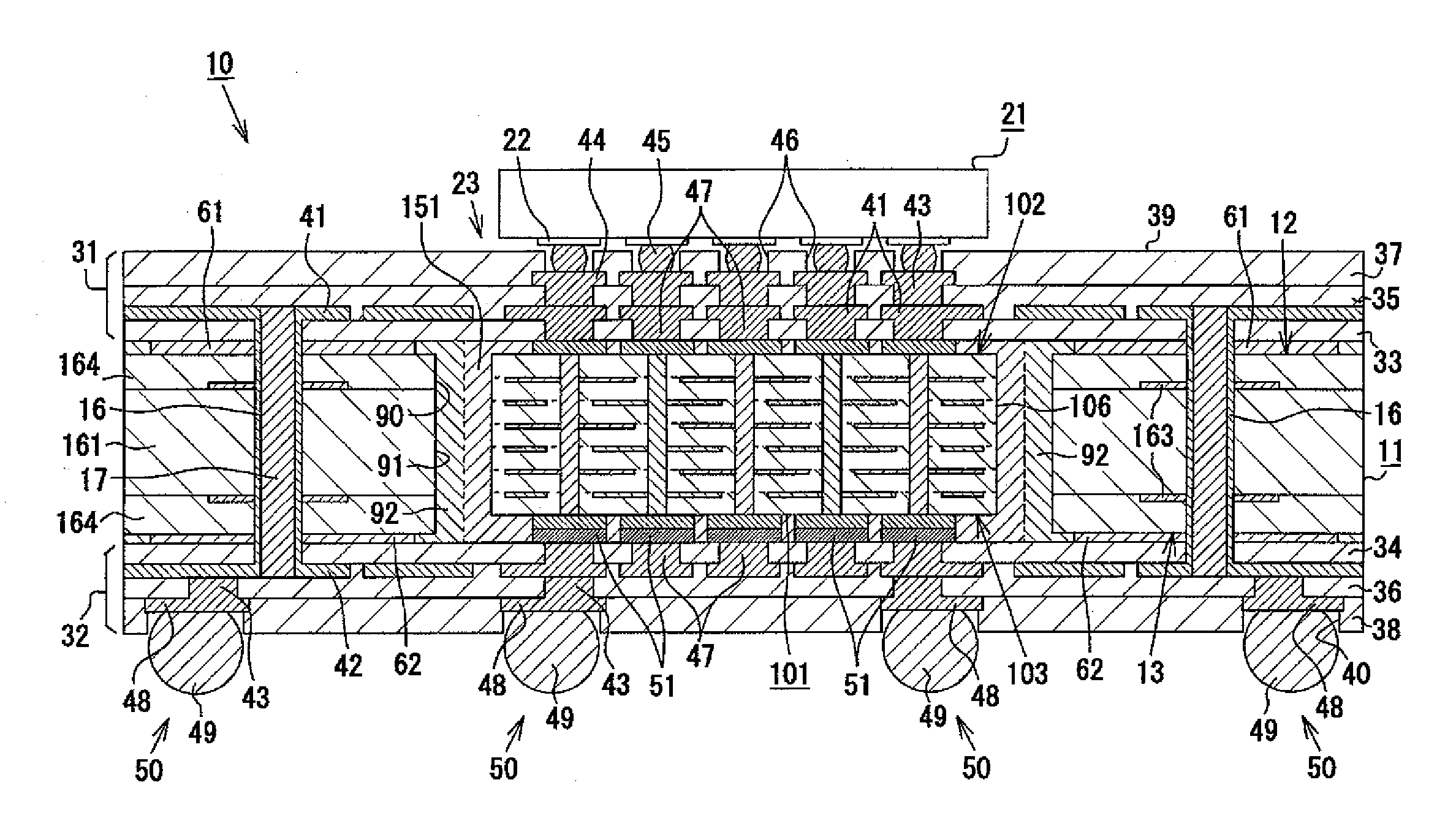

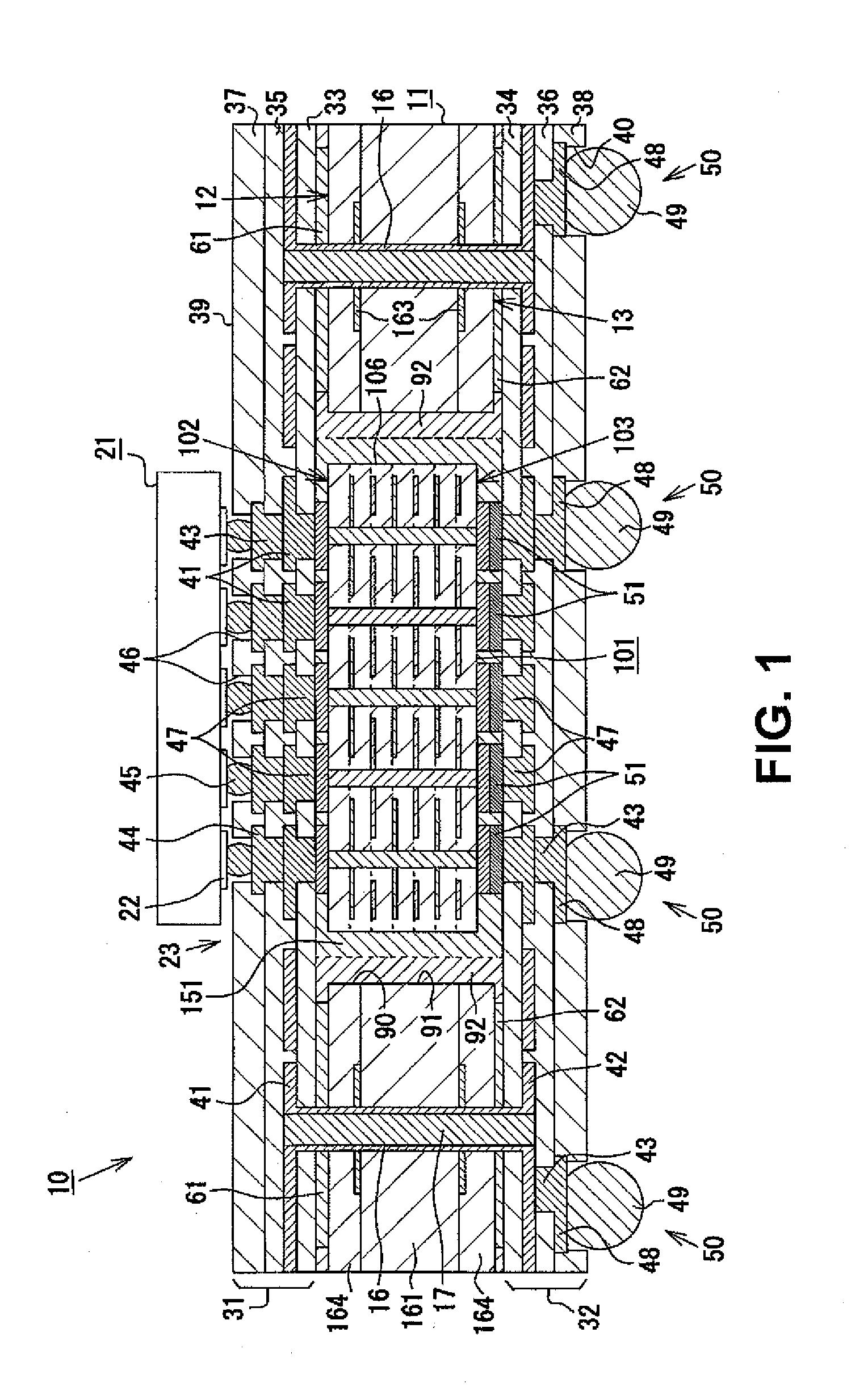

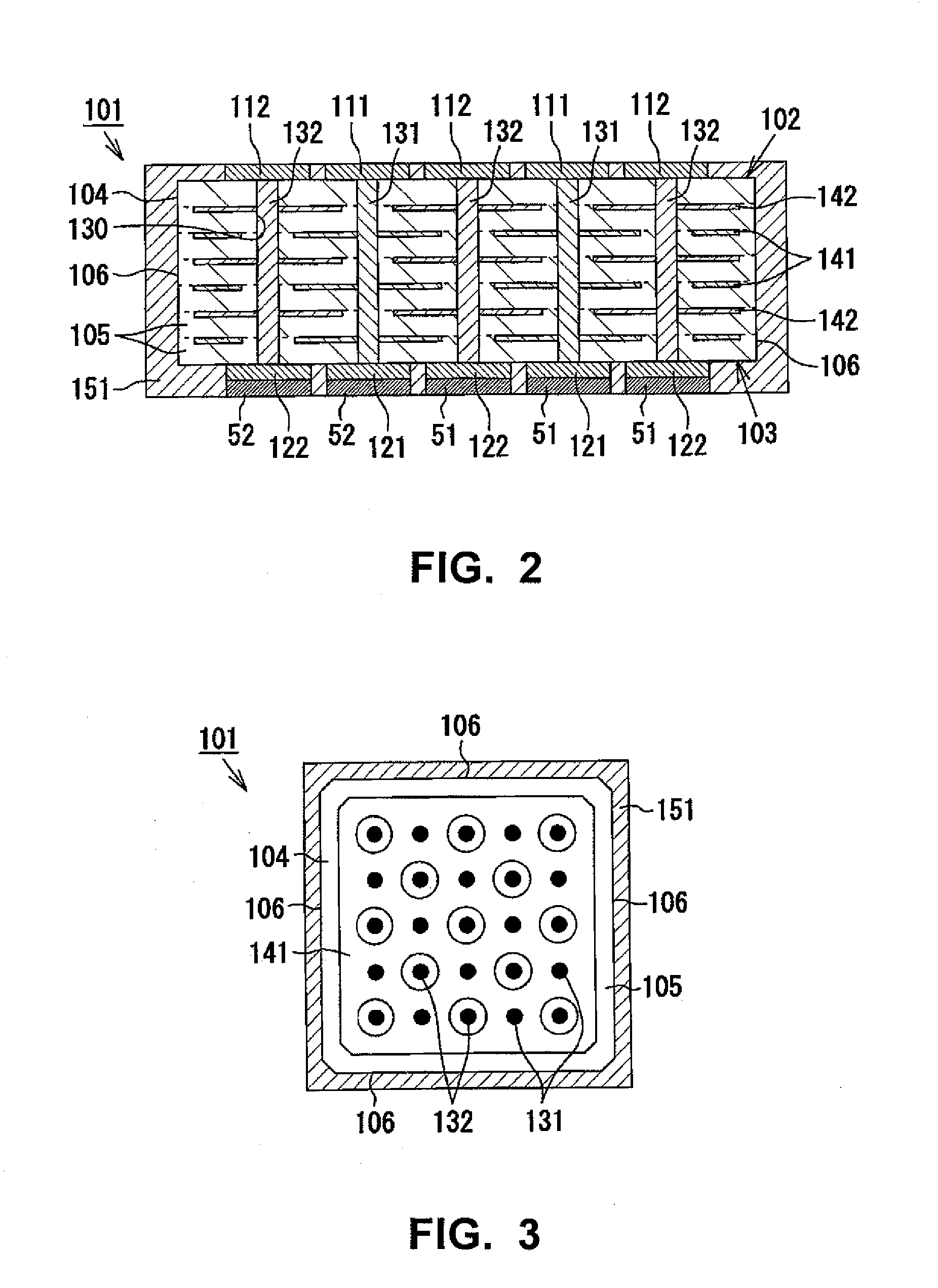

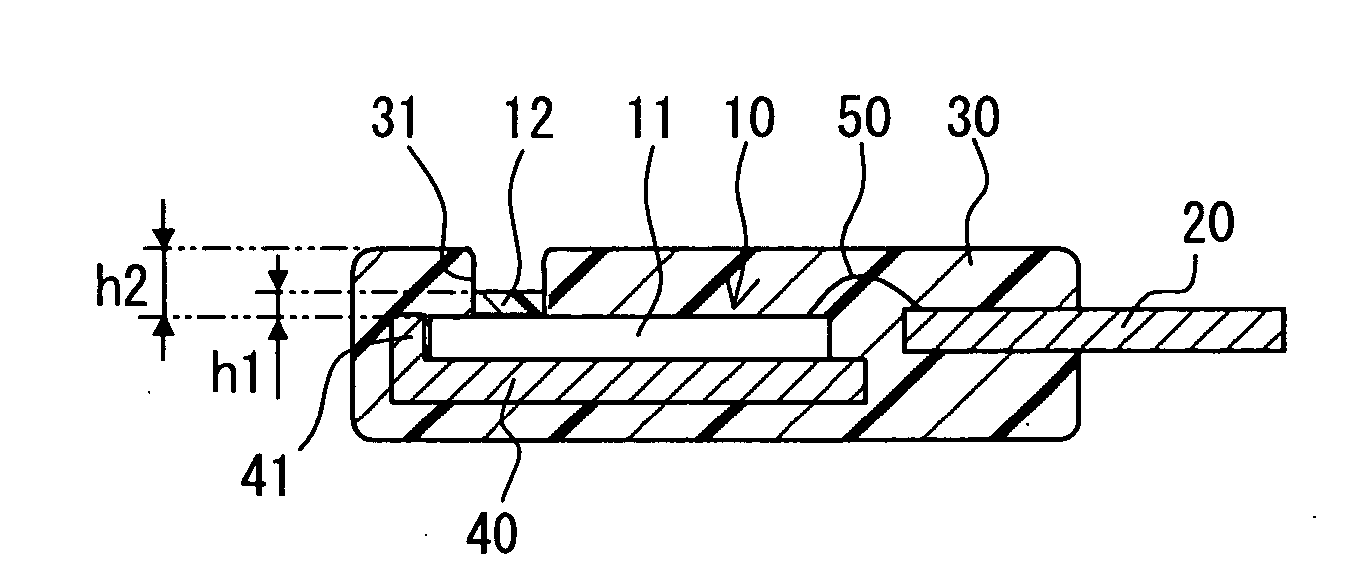

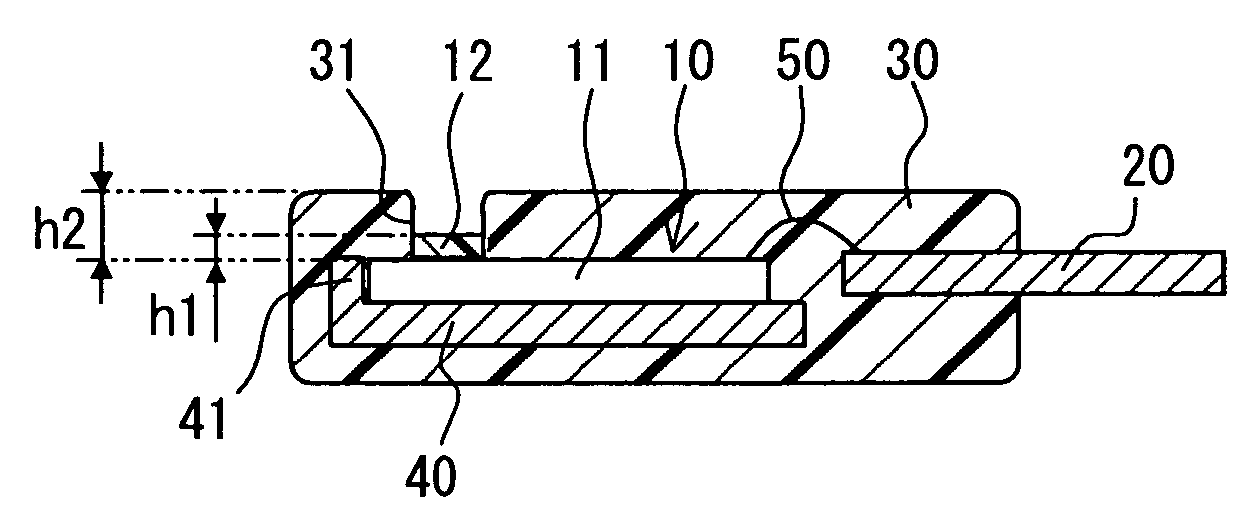

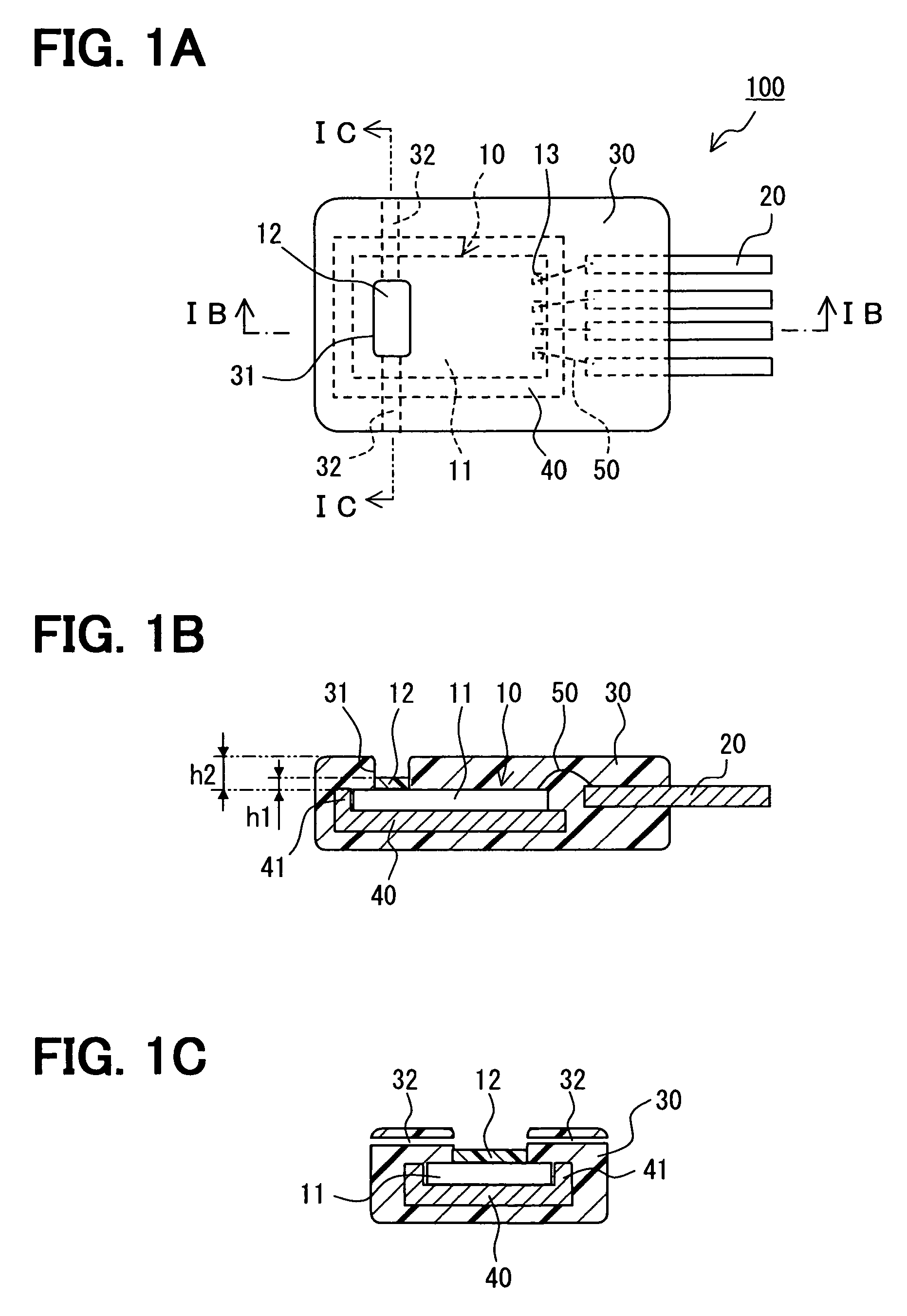

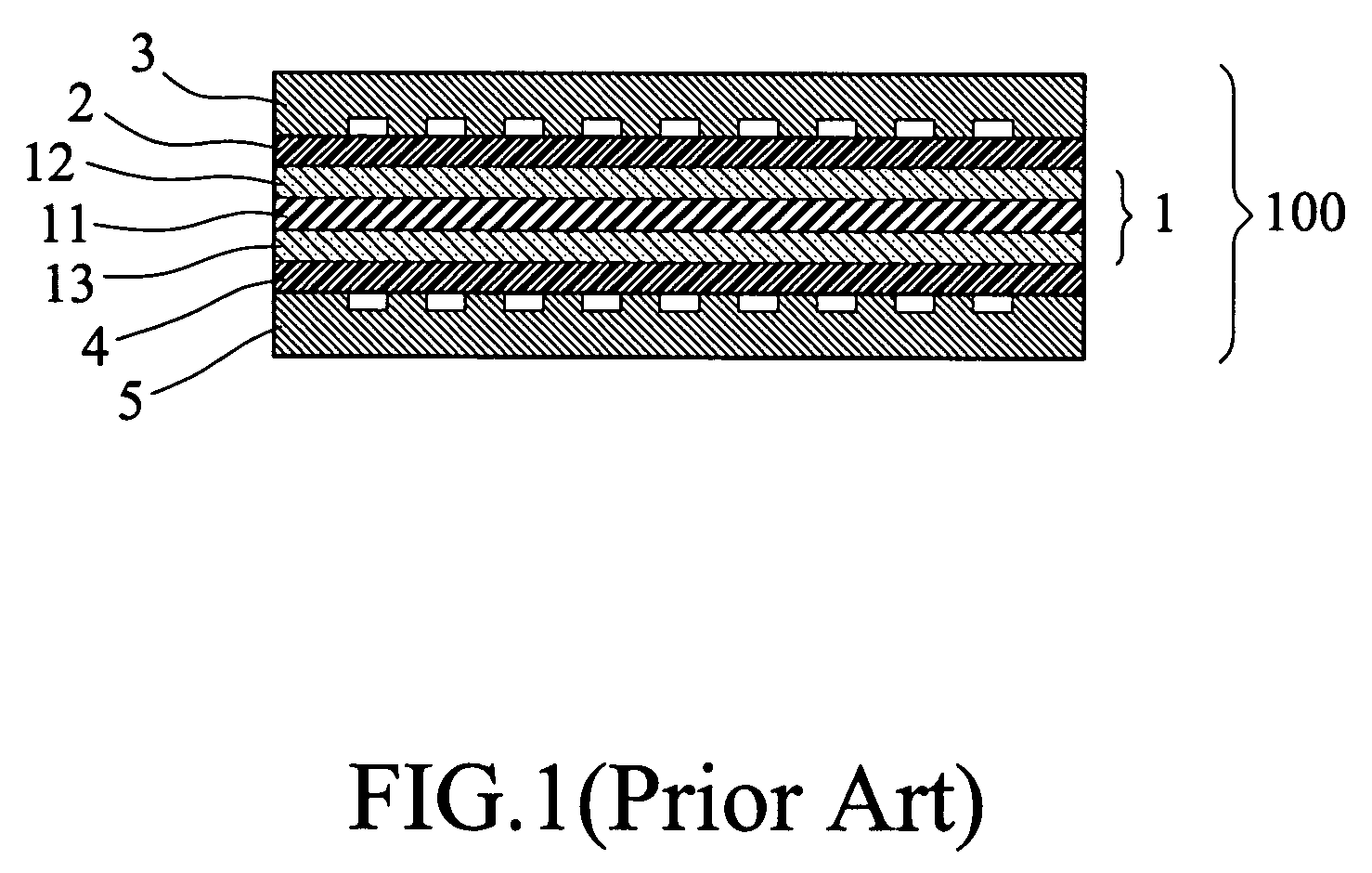

Wiring board with built-in component and method for manufacturing the same

InactiveUS20080277150A1Avoid defectsImprove reliabilityPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorCeramic capacitor

A method for manufacturing a wiring board with built-in component. The method provides a secure connection between a component and interlayer insulating layers so that the wiring board with built-in component has excellent reliability. The wiring board is manufactured through a core board preparation step, a component preparation step, an accommodation step and a height alignment step. In the core board preparation step, a core board having an accommodation hole therein is prepared. In the component preparation step, a ceramic capacitor having therein a plurality of protruding conductors which protrudes from a capacitor rear surface is prepared. In the accommodation step, the ceramic capacitor is accommodated in the accommodation hole with the core rear surface facing the same side as the capacitor rear surface. In the height alignment step, a surface of a top portion of the protruding conductor and a surface of a conductor layer formed on the core rear surface are aligned to the same height.

Owner:NGK SPARK PLUG CO LTD

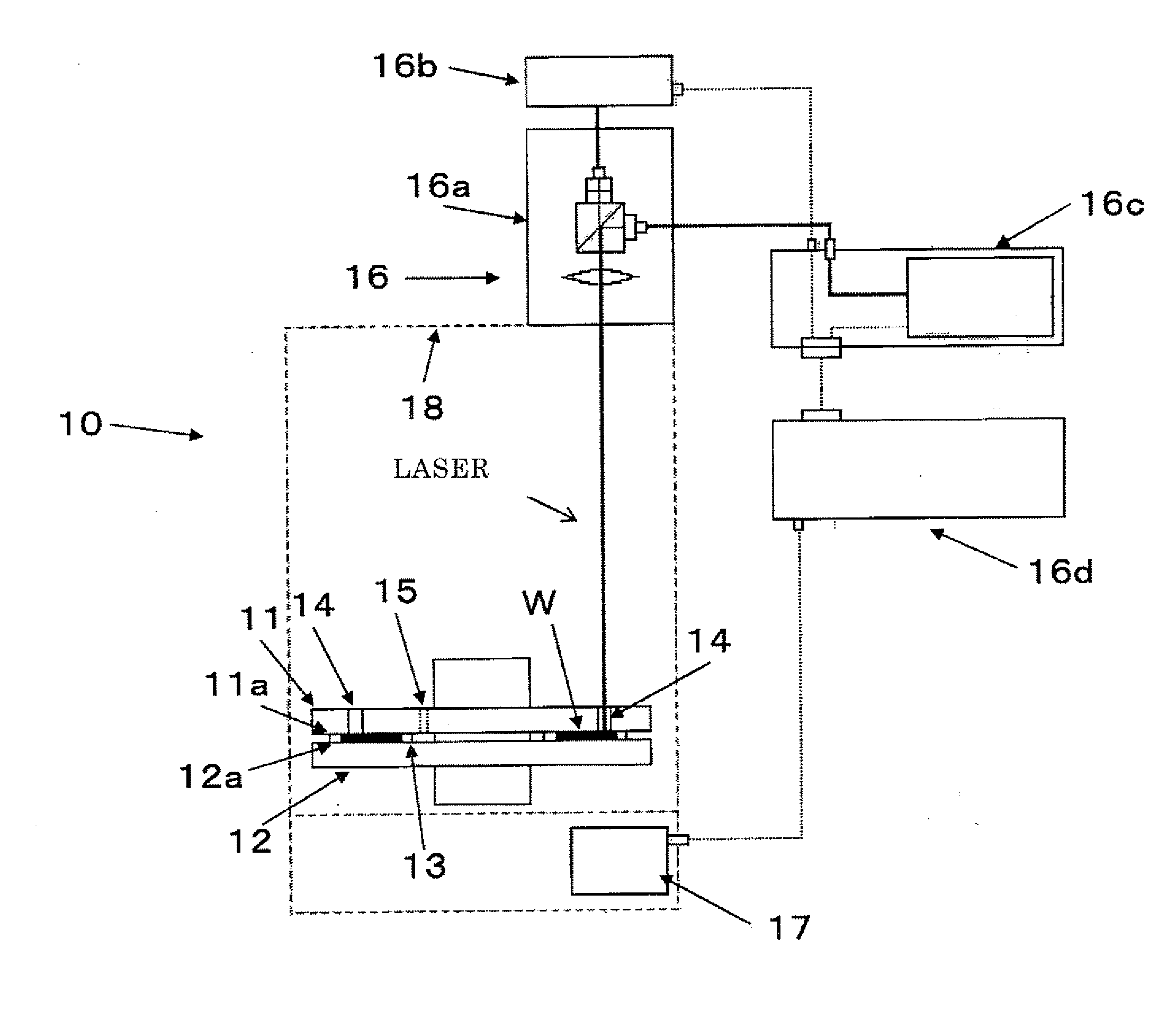

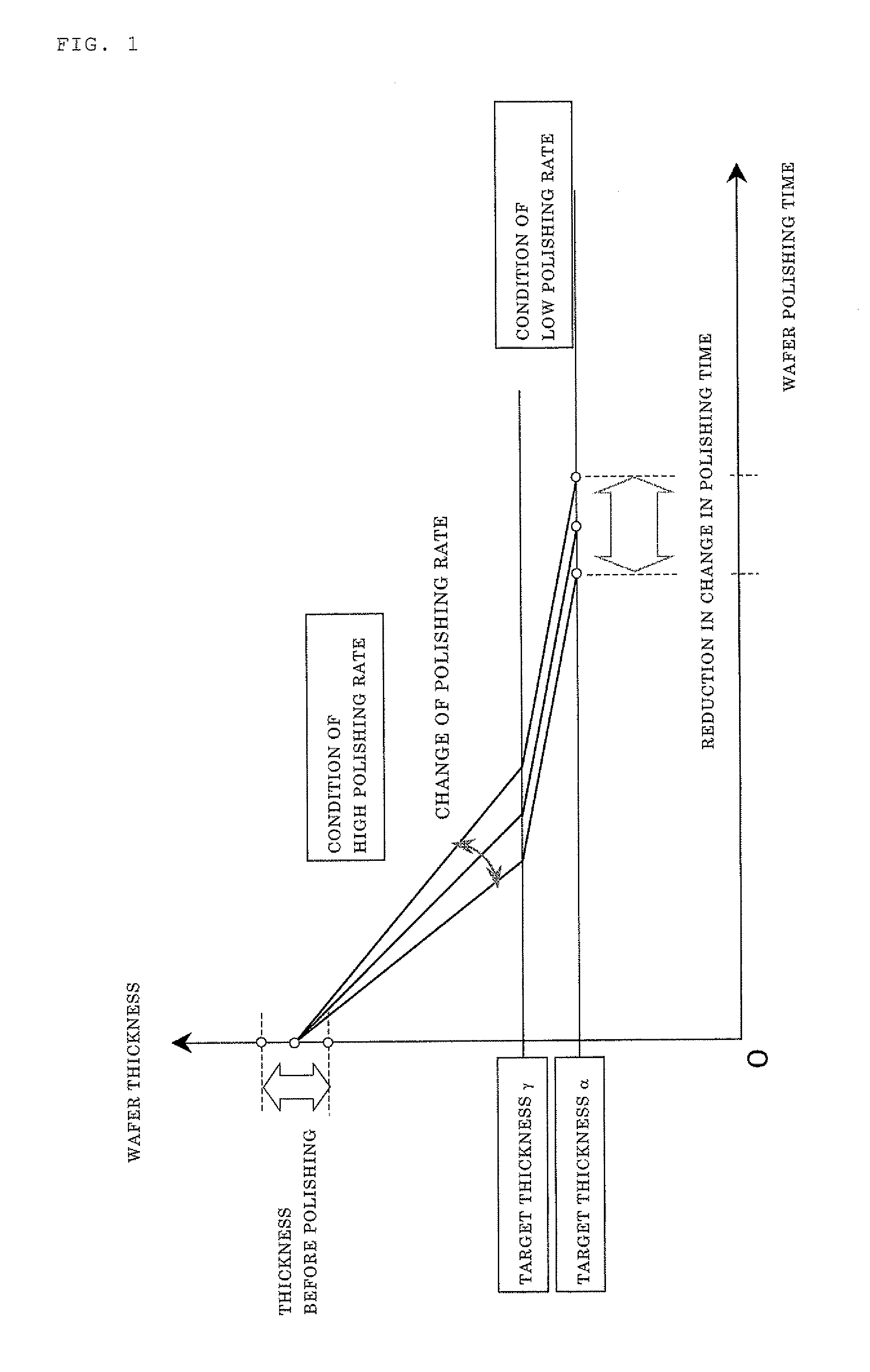

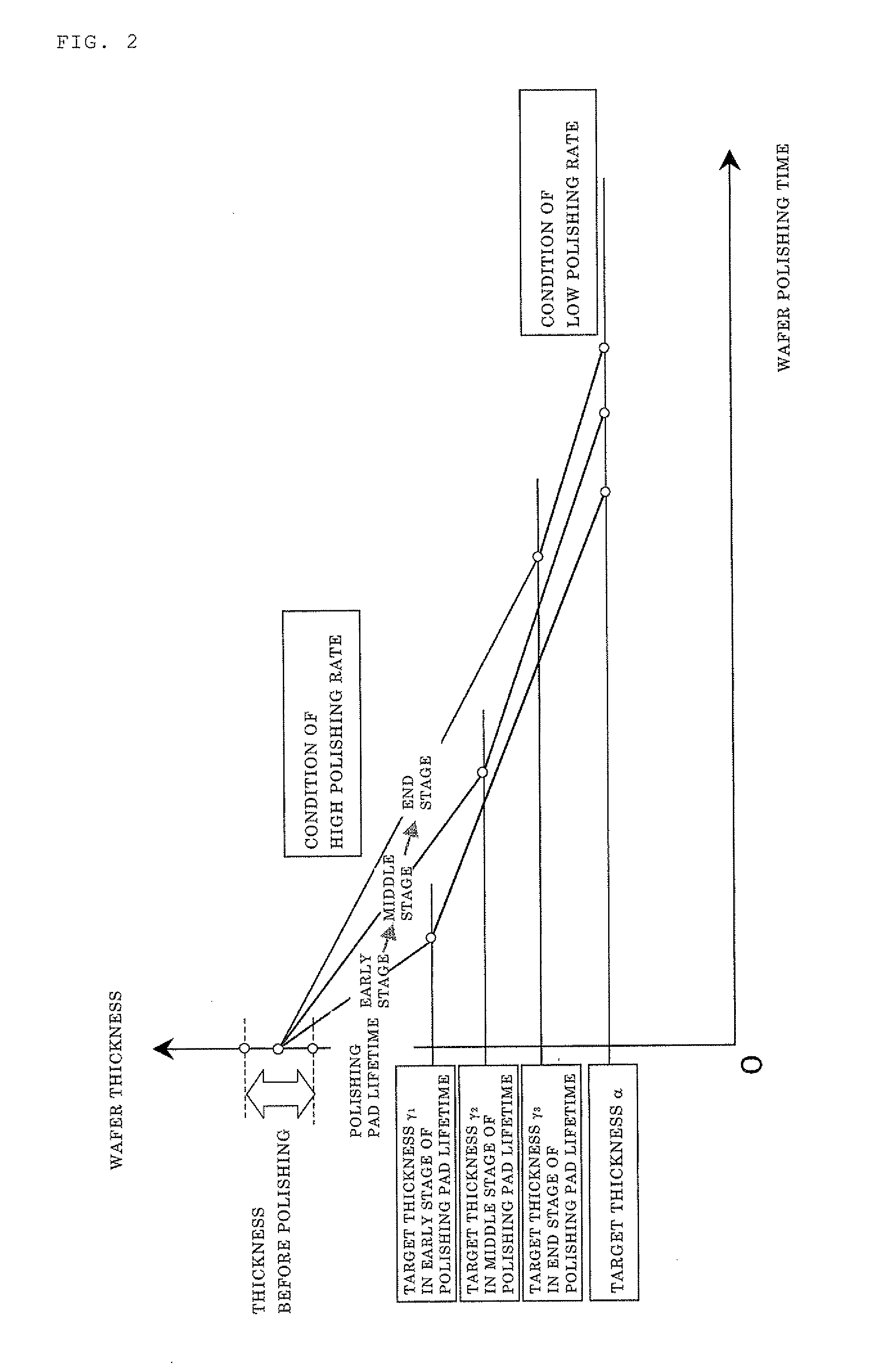

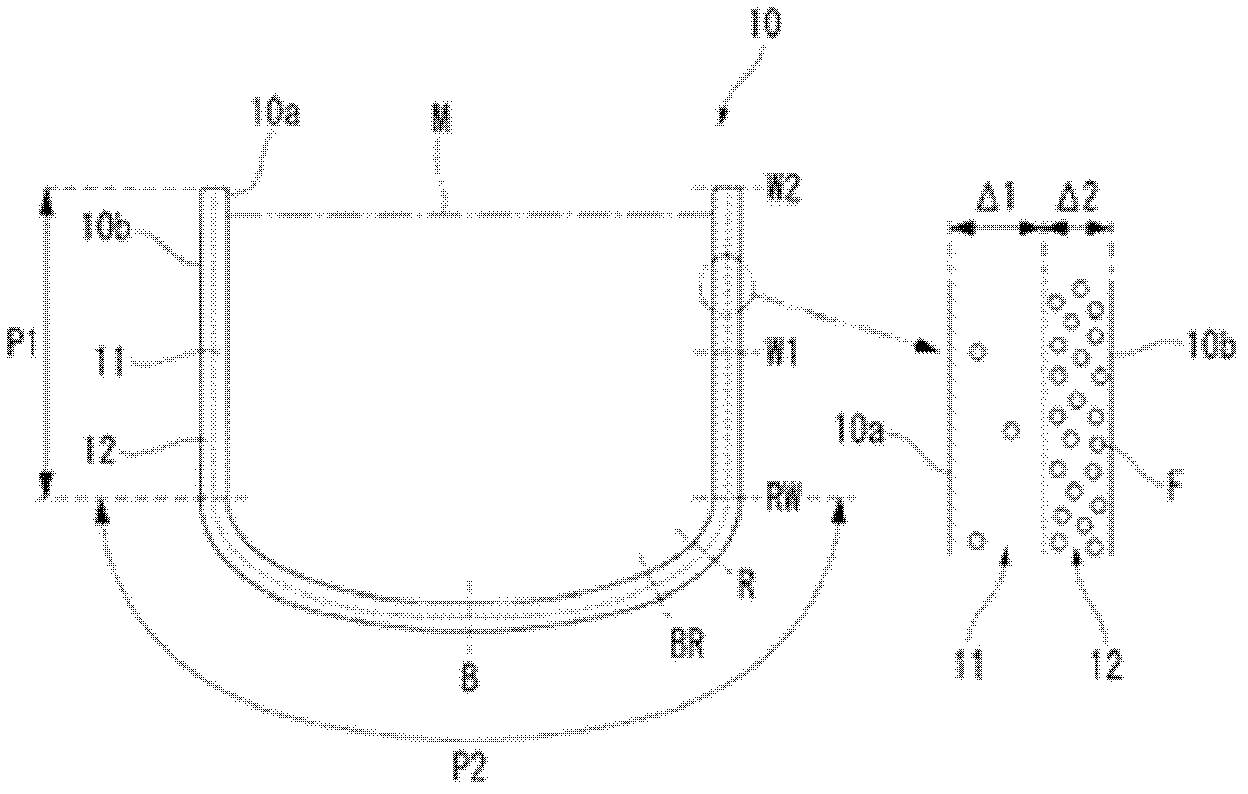

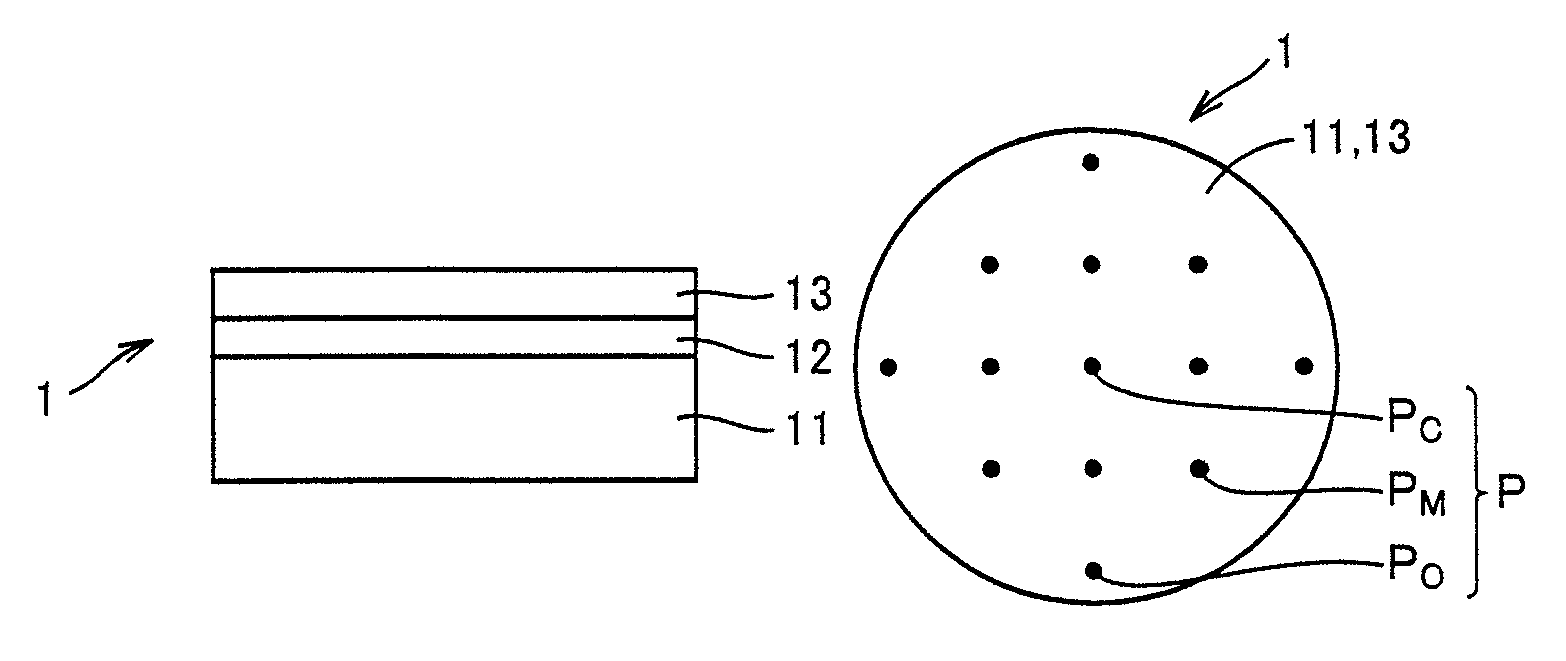

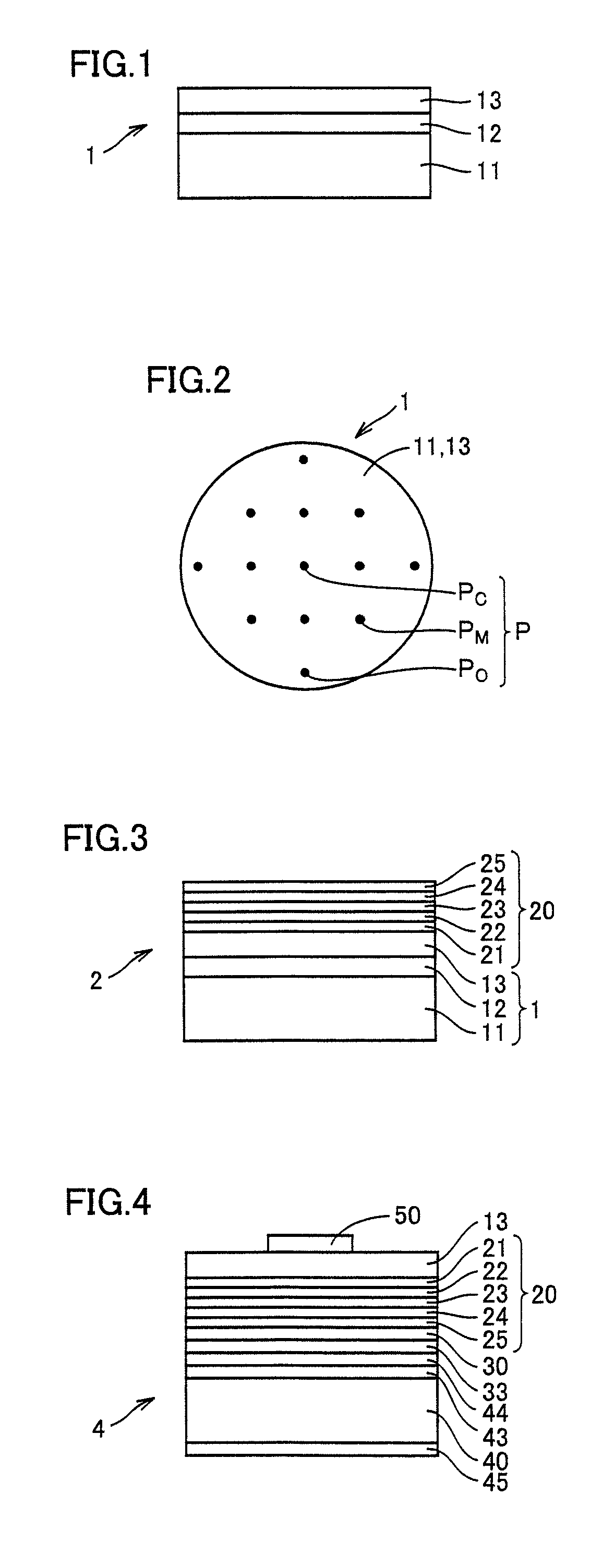

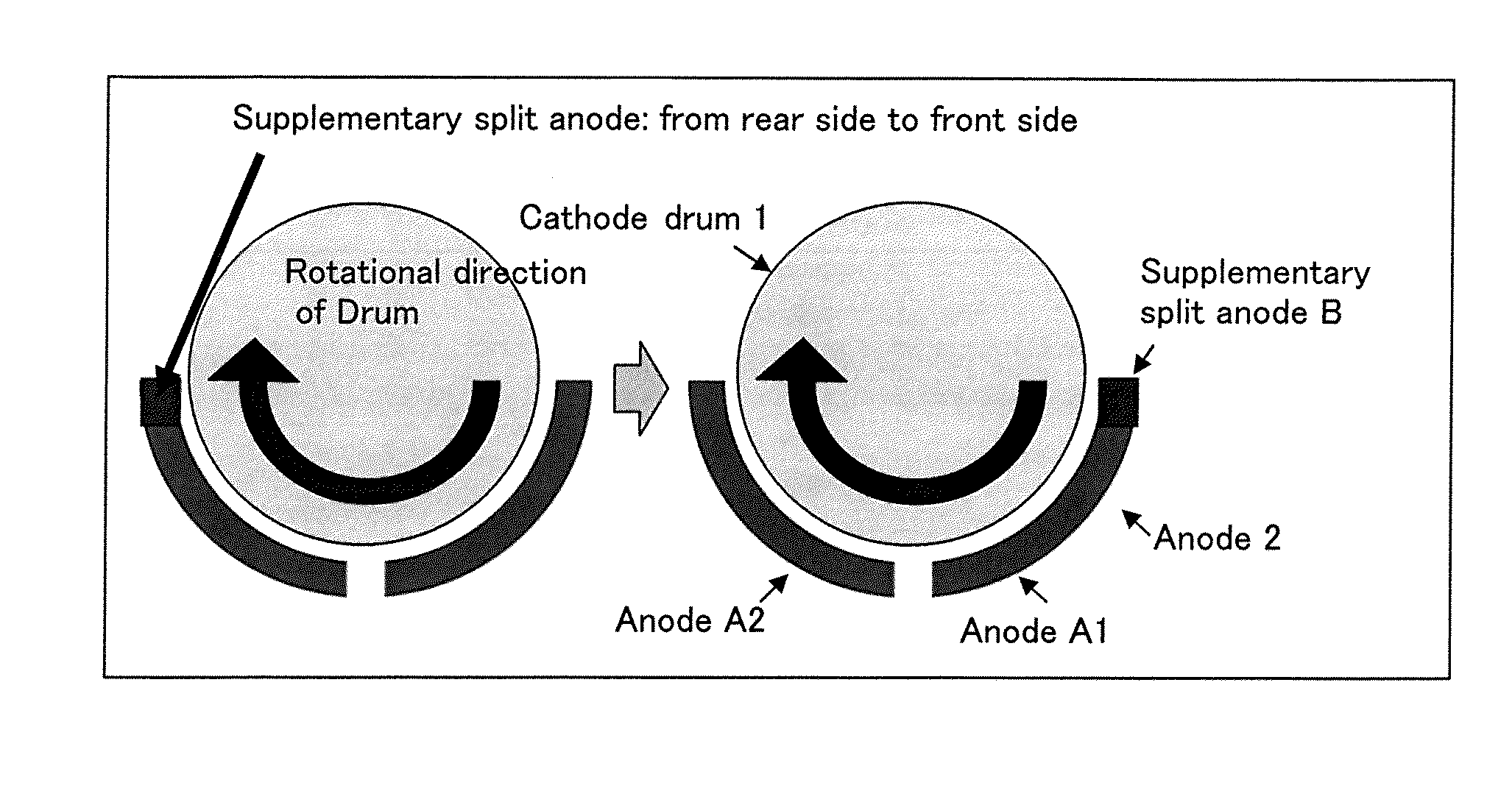

Wafer polishing method and double-side polishing apparatus

ActiveUS20110130073A1Easy to getImprove flatnessEdge grinding machinesSemiconductor/solid-state device testing/measurementWaferingPolishing

The present invention is a wafer polishing method including simultaneously polishing both surfaces of a wafer by pressing and rubbing the wafer, while holding the wafer with: a lower turn table having a flat polishing-upper-surface rotationally driven; an upper turn table having a flat polishing-lower-surface rotationally driven, the upper turn table being arranged with facing to the lower turn table; and a carrier having a wafer-holding hole for holding the wafer, wherein the polishing is performed while measuring a thickness of the wafer through a plurality of openings provided between a rotation center and an edge of the upper turn table or the lower turn table, and switching a polishing slurry with a polishing slurry having a different polishing rate during the polishing of the wafer. As a result, there is provided a wafer polishing method that can manufacture a wafer having a high flatness and a high smoothness at high productivity and high yield.

Owner:SHIN-ETSU HANDOTAI CO LTD

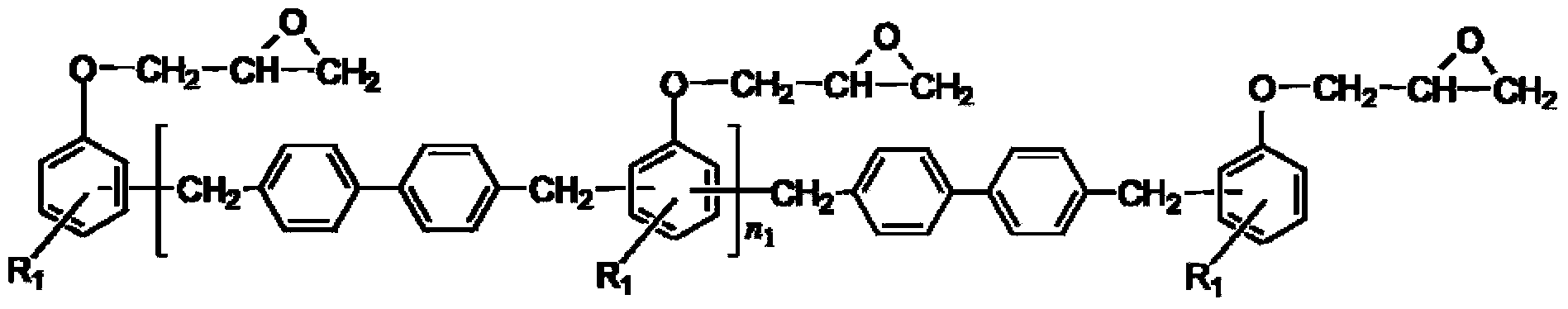

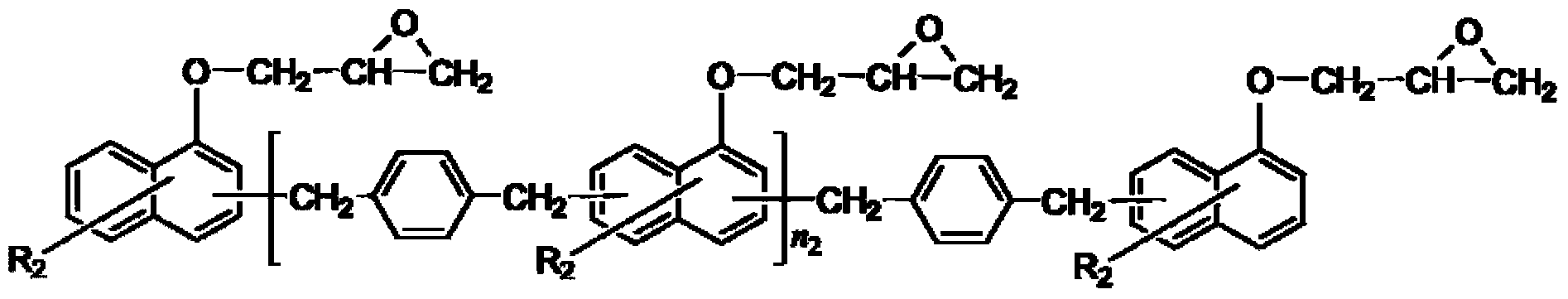

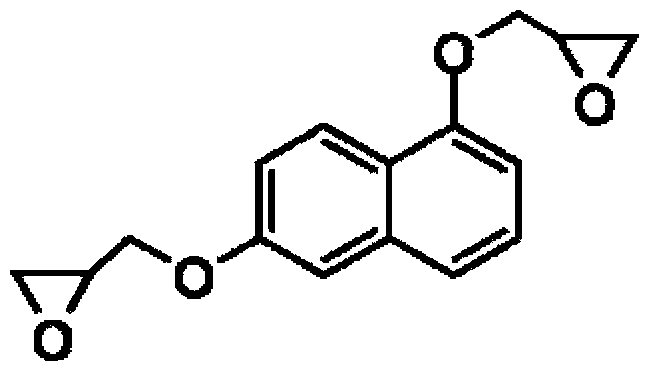

Resin composition used for forming dielectric layer of dielectric substrate for antenna and application of resin composition

ActiveCN103351578ASmall coefficient of thermal expansionLittle change in thicknessSynthetic resin layered productsMetal layered productsEpoxyDielectric substrate

The invention relates to a resin composition used for forming a dielectric layer of a dielectric substrate for an antenna. The resin composition comprises (A), epoxy resin containing a naphthalene nucleus or diphenyl structure, (B), any one of or a mixture of at least two of tri(4-hydroxyphenyl) methane type epoxy resin, o-cresol type novolac epoxy resin and phenol type novolac epoxy resin, (C), a resin fusion viscosity modifier, and (D), spherical ceramic powder after presintering treatment. With the adoption of the resin composition, the obtained dielectric substrate has a high dielectric constant, high peeling strength, a low thermal expansion coefficient and very good thickness consistency, and can meet a performance requirement of the high dielectric constant antenna substrate.

Owner:江苏生益特种材料有限公司

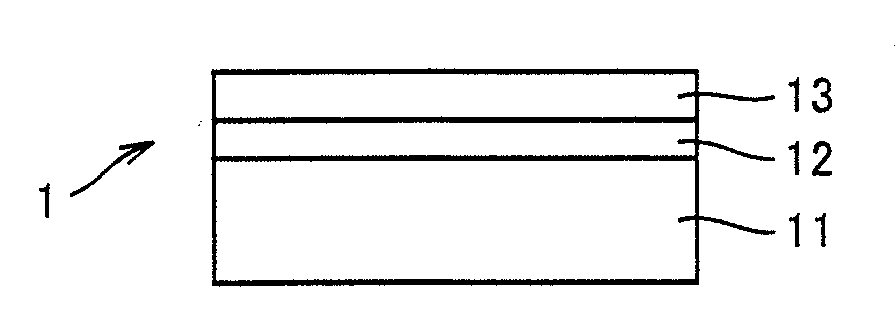

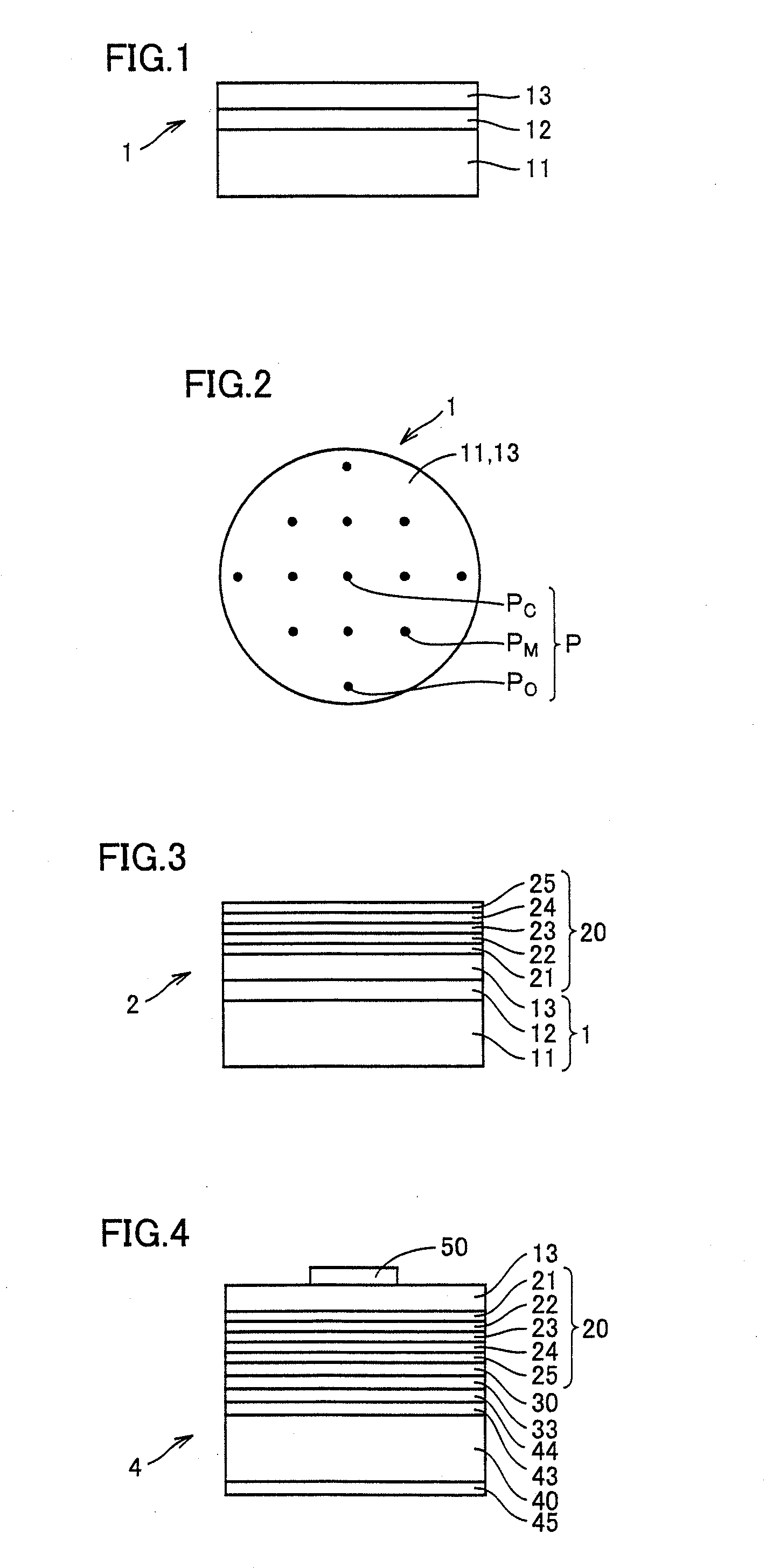

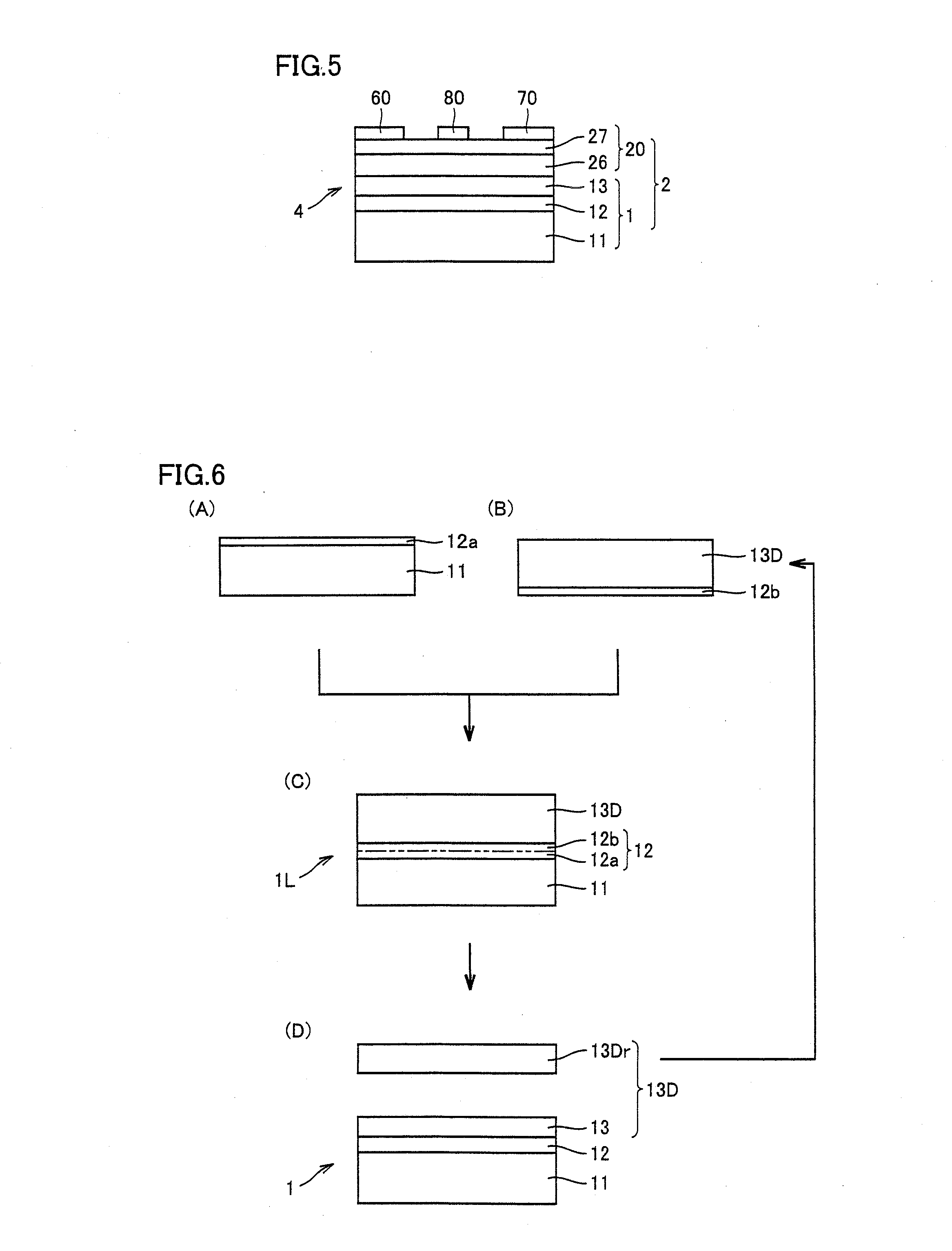

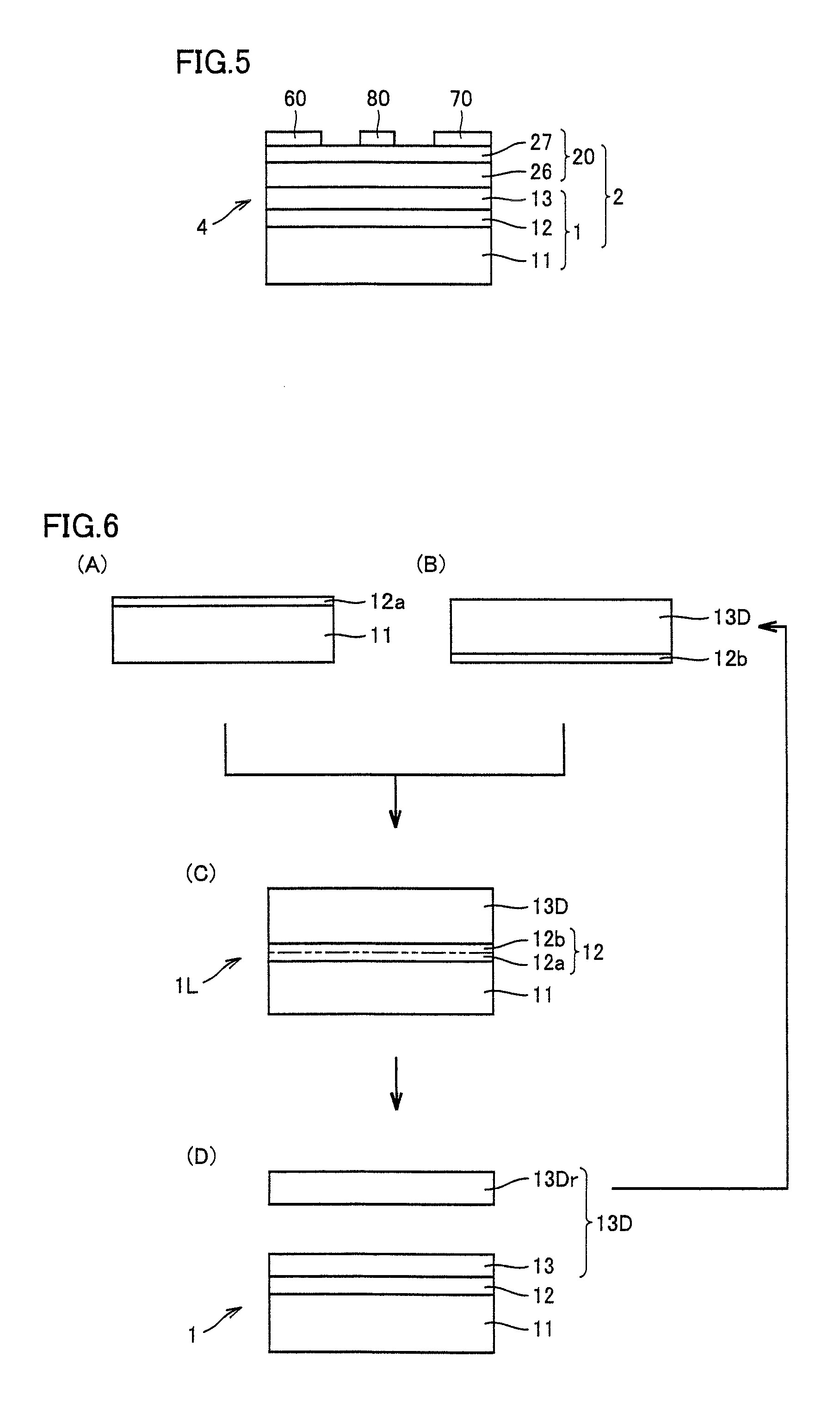

Group iii nitride composite substrate and method for manufacturing the same, laminated group iii nitride composite substrate, and group iii nitride semiconductor device and method for manufacturing the same

ActiveUS20140103353A1Large thicknessLittle change in thicknessSolid-state devicesSemiconductor/solid-state device manufacturingComposite substratePlane orientation

A group III nitride composite substrate includes a support substrate and a group III nitride film. A ratio st / mt of a standard deviation st of the thickness of the group III nitride film, to a mean value mt of the thickness thereof is 0.001 or more and 0.2 or less, and a ratio so / mo of a standard deviation so of an absolute value of an off angle between a main surface of the group III nitride film and a plane of a predetermined plane orientation, to a mean value mo of the absolute value of the off angle thereof is 0.005 or more and 0.6 or less. Accordingly, there is provided a low-cost and large-diameter group III nitride composite substrate including a group III nitride film having a large thickness, a small thickness variation, and a high crystal quality.

Owner:SUMITOMO ELECTRIC IND LTD

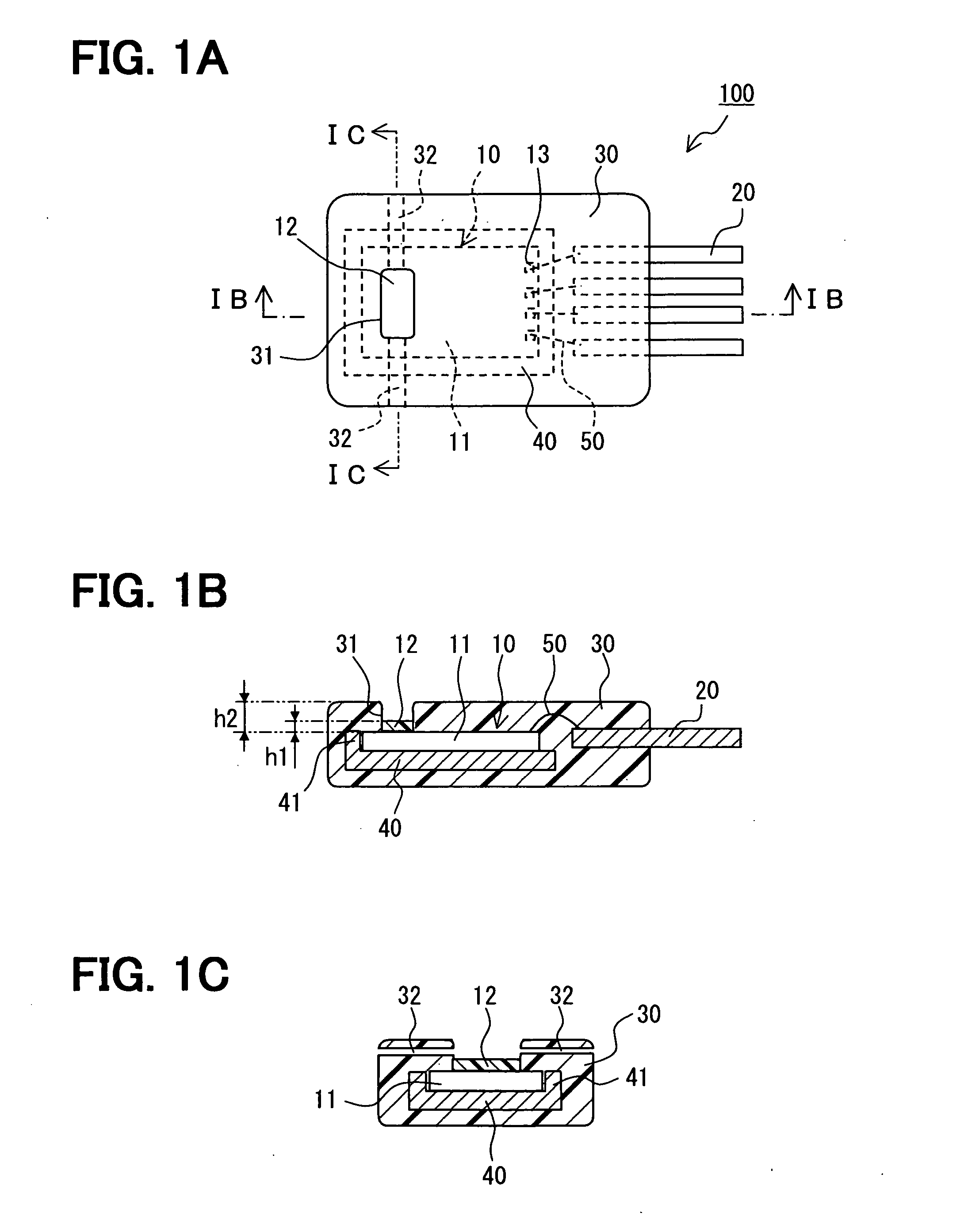

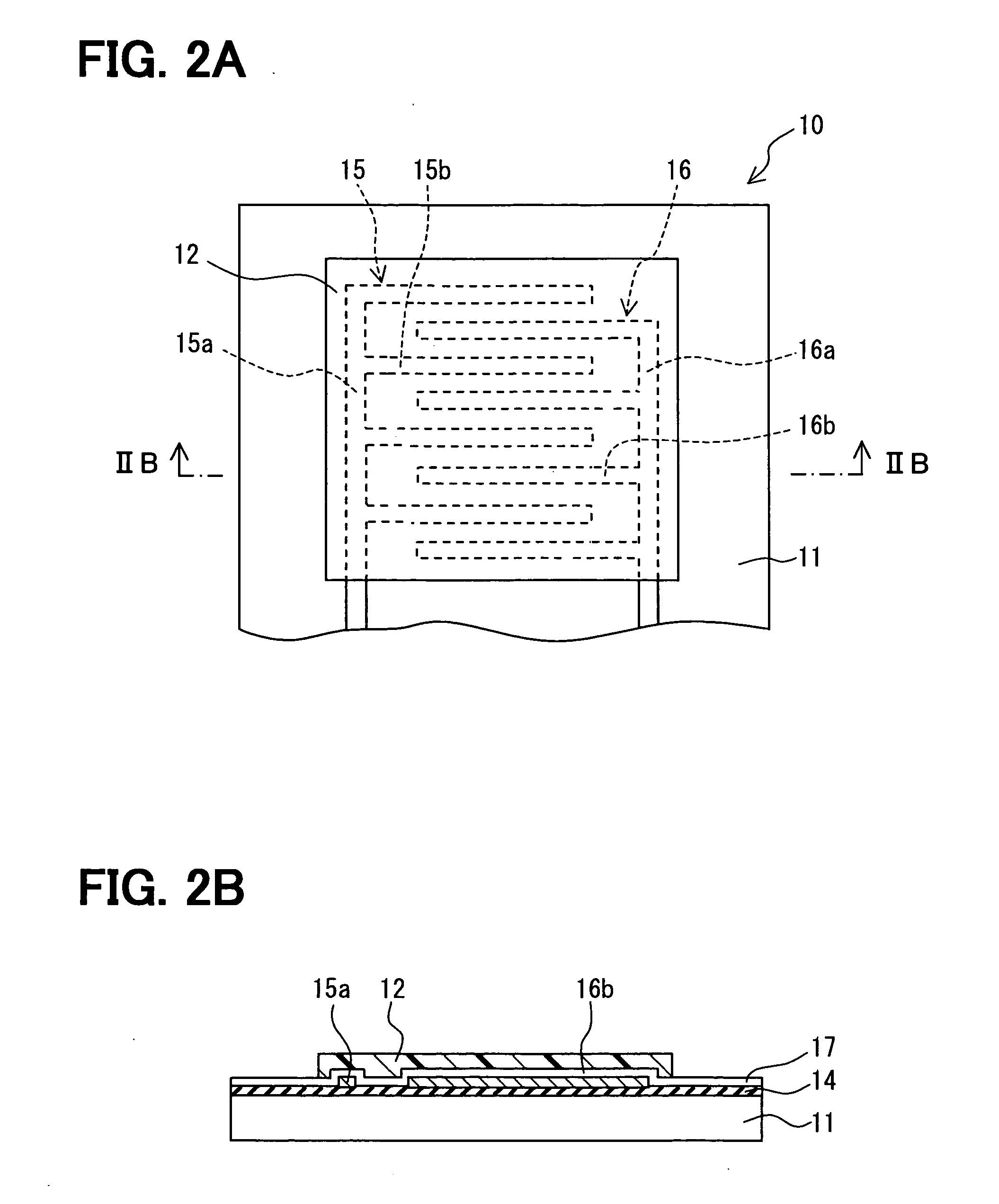

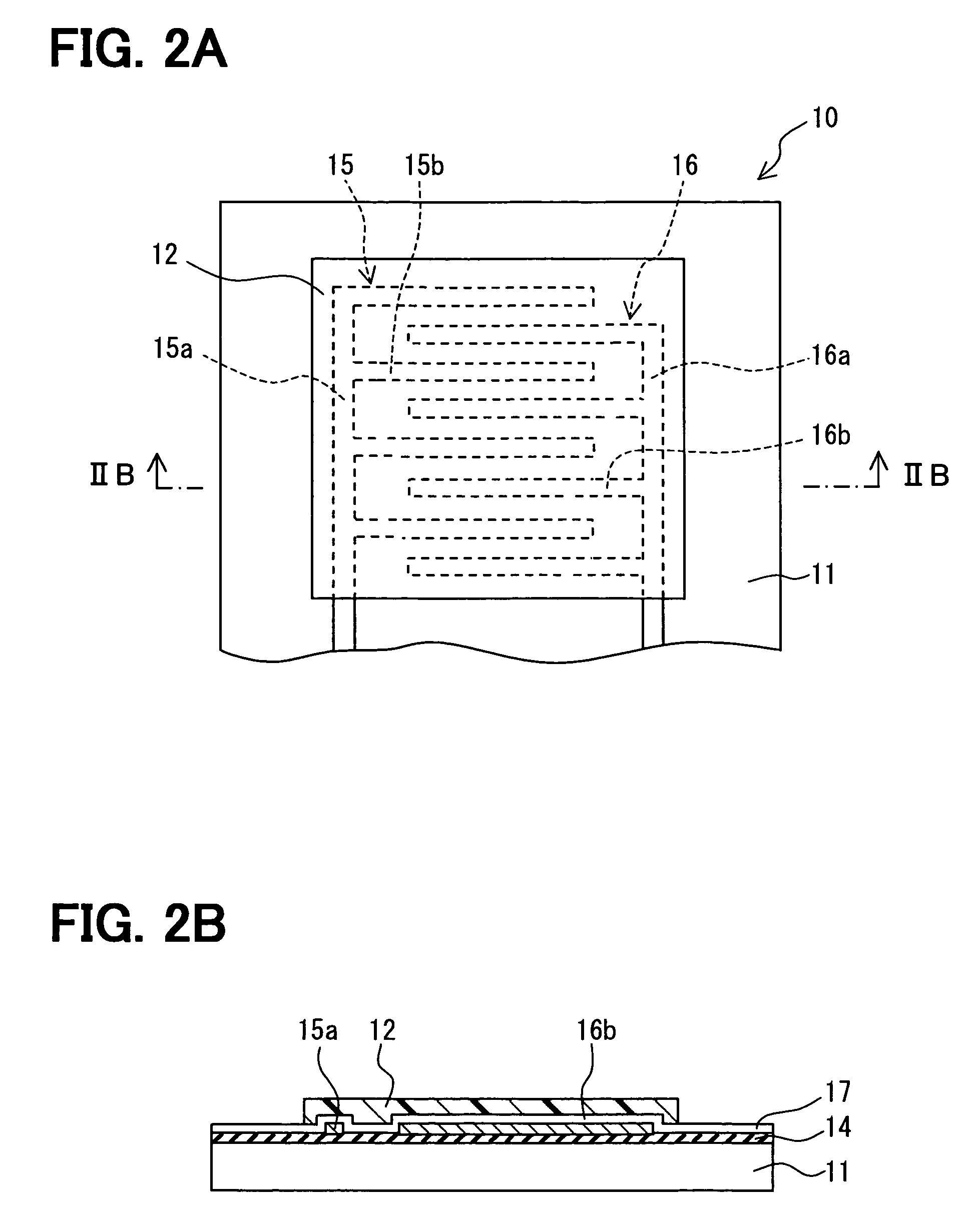

Humidity sensor having humidity sensitive film and method for manufacturing the same

InactiveUS20070113648A1Reduce variationReduce sensor costSolid-state devicesUsing mechanical meansMoisture sensorRelative permittivity

A humidity sensor includes: a sensor chip including a capacitive humidity sensor element and a connection electrode, wherein the capacitive humidity sensor element includes a humidity sensitive film having relative permittivity changeable in accordance with humidity, and wherein the connection electrode is electrically connected to the humidity sensor element; a lead plate electrically connected to the connection electrode; and a mold for covering a connection portion between the connection electrode and the lead plate. The mold is disposed on the sensor chip and includes a groove. The humidity sensitive film is disposed in the groove. The humidity sensitive film has a height in the groove, the height equal to or lower than a surface of the mold. The height of the humidity sensitive film in the groove is homogeneous.

Owner:DENSO CORP

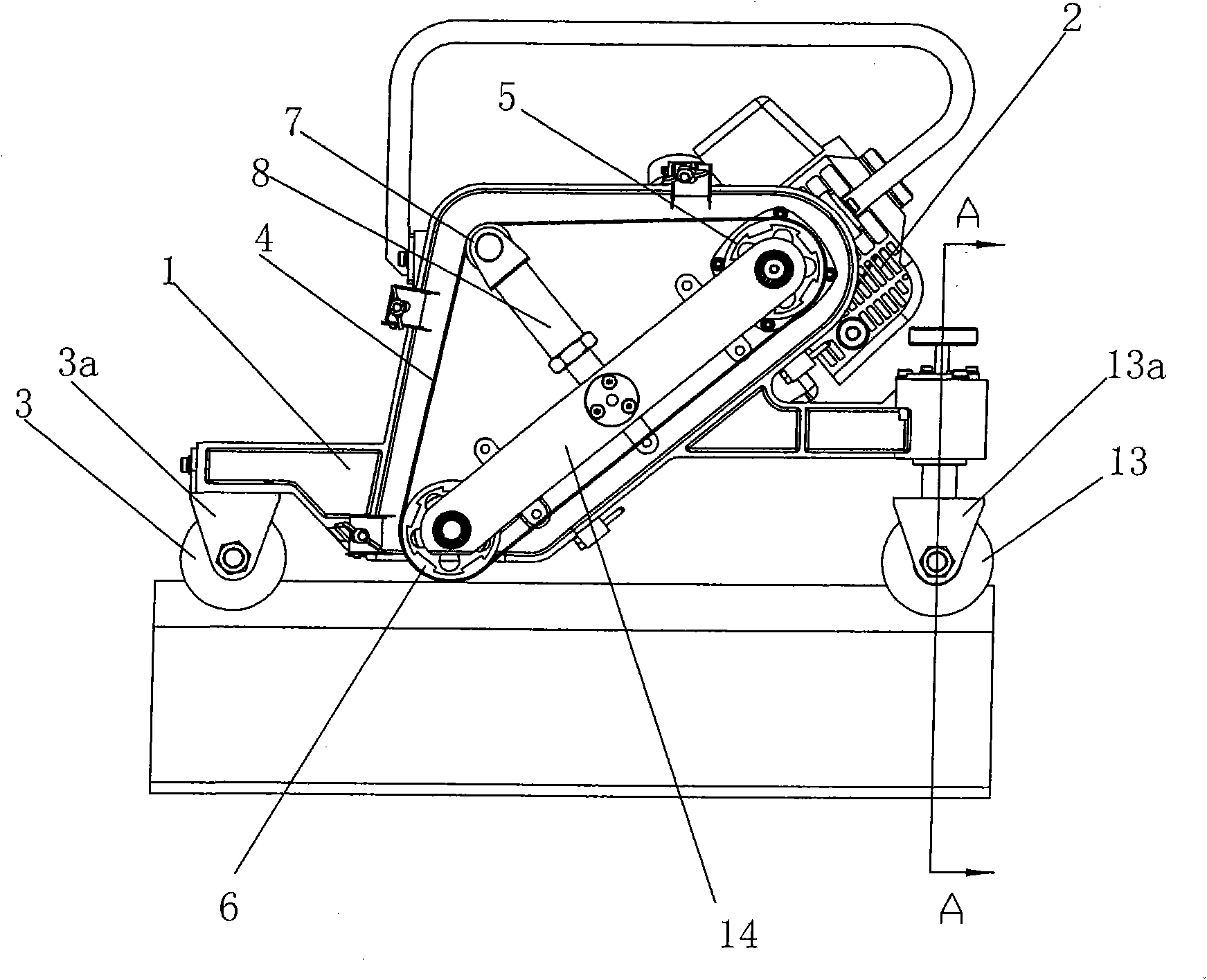

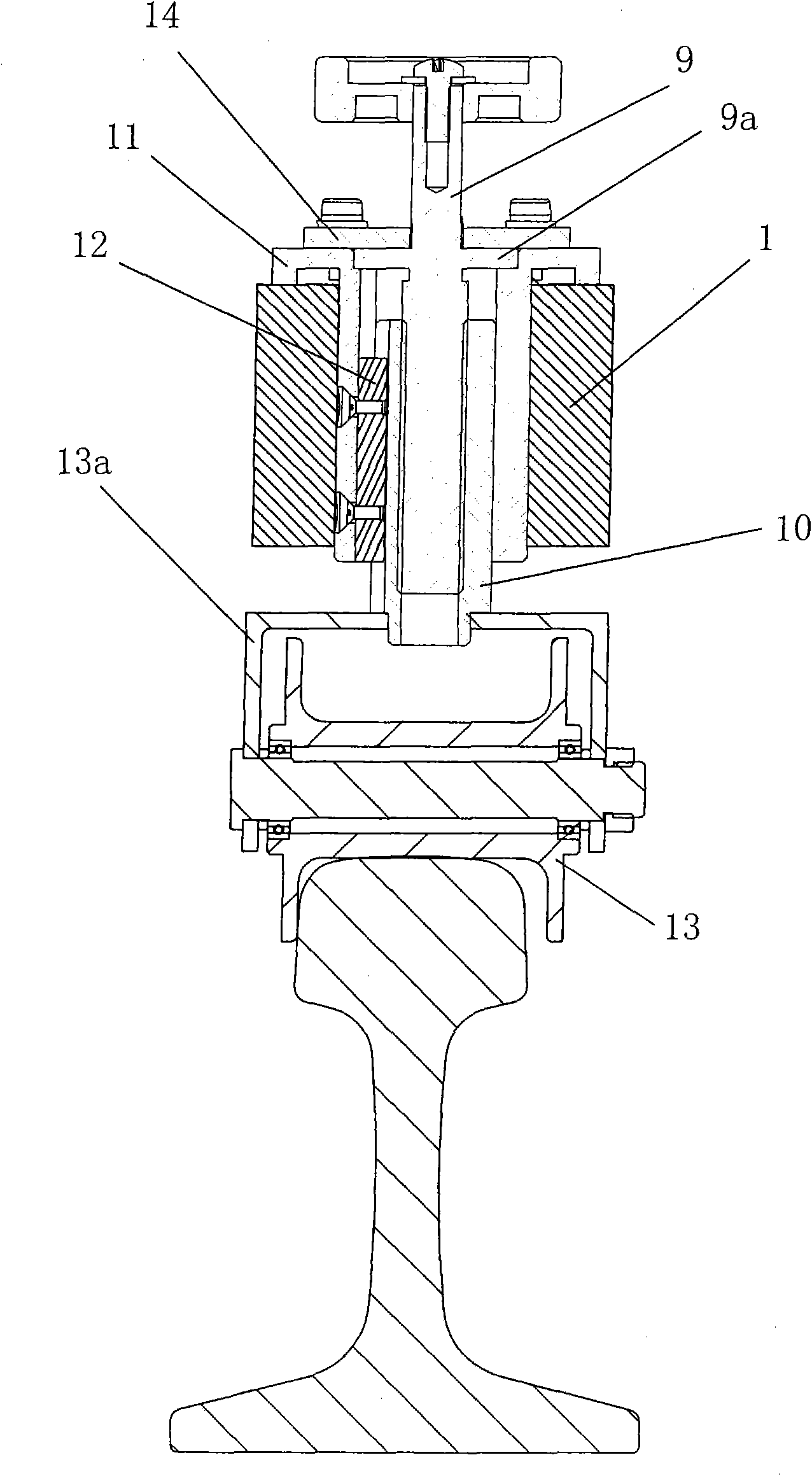

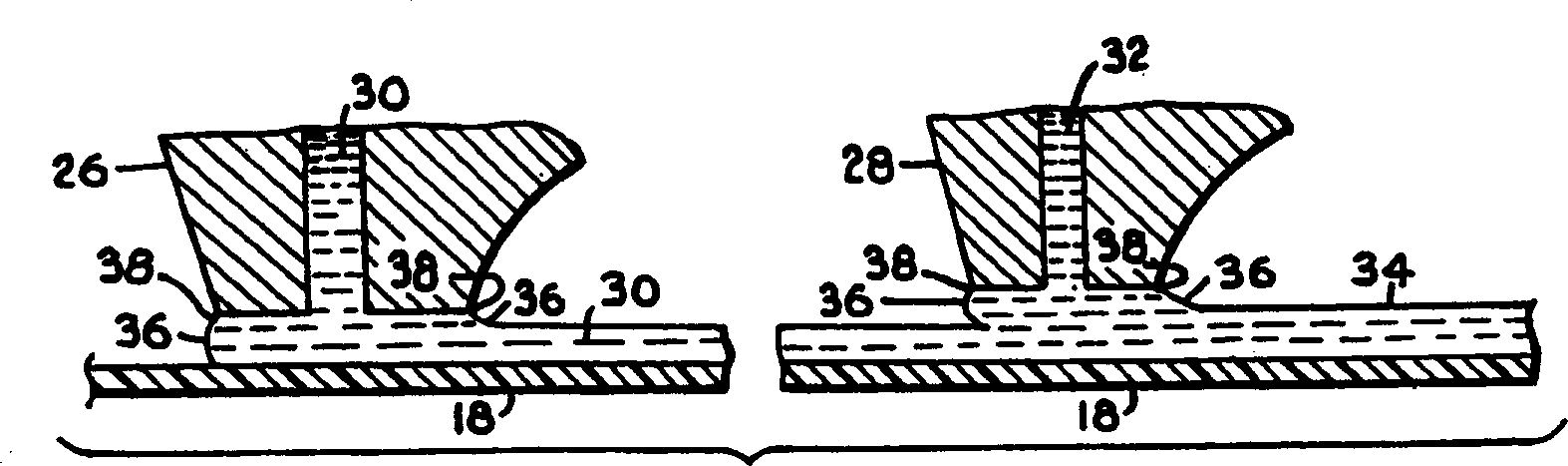

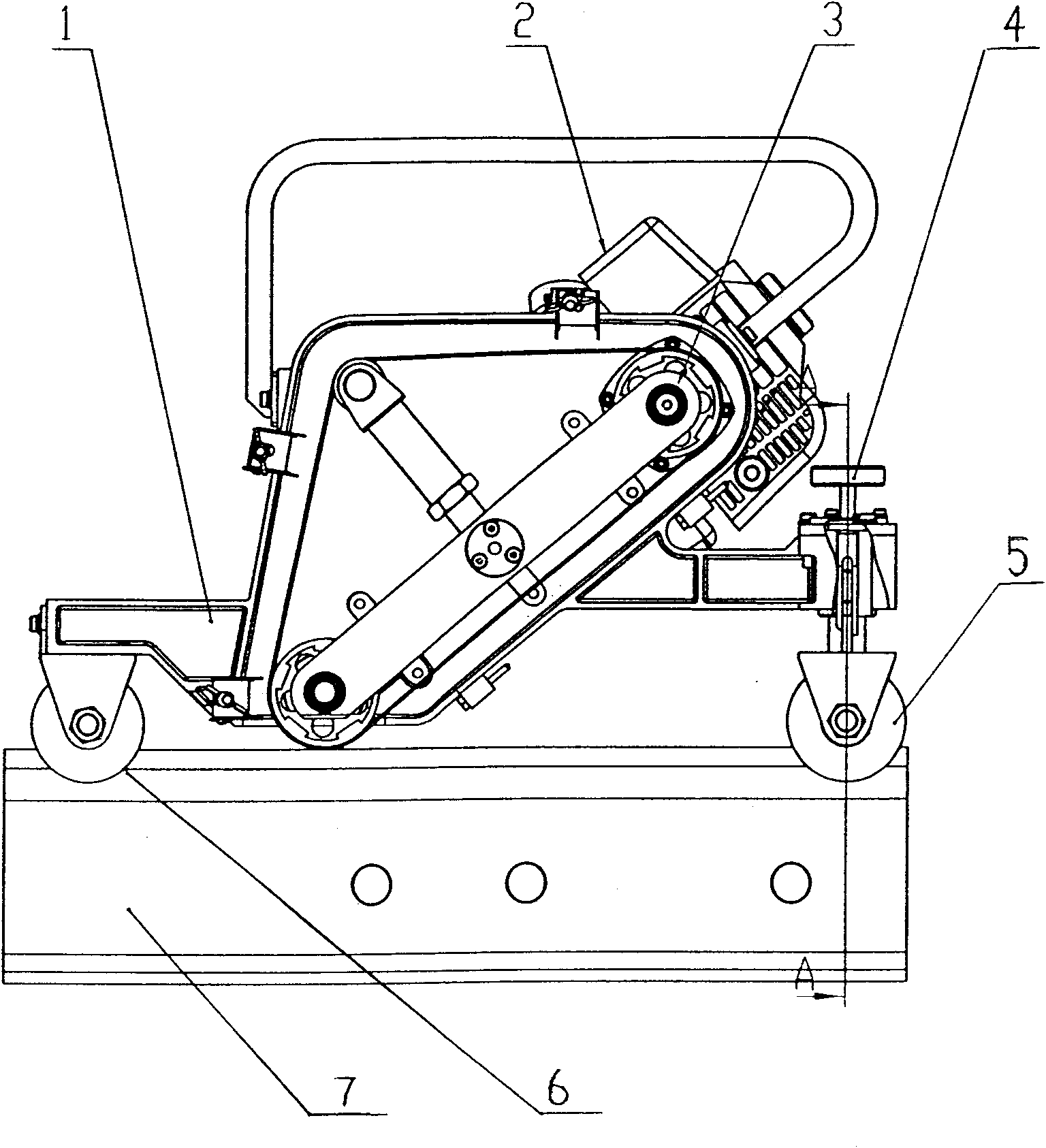

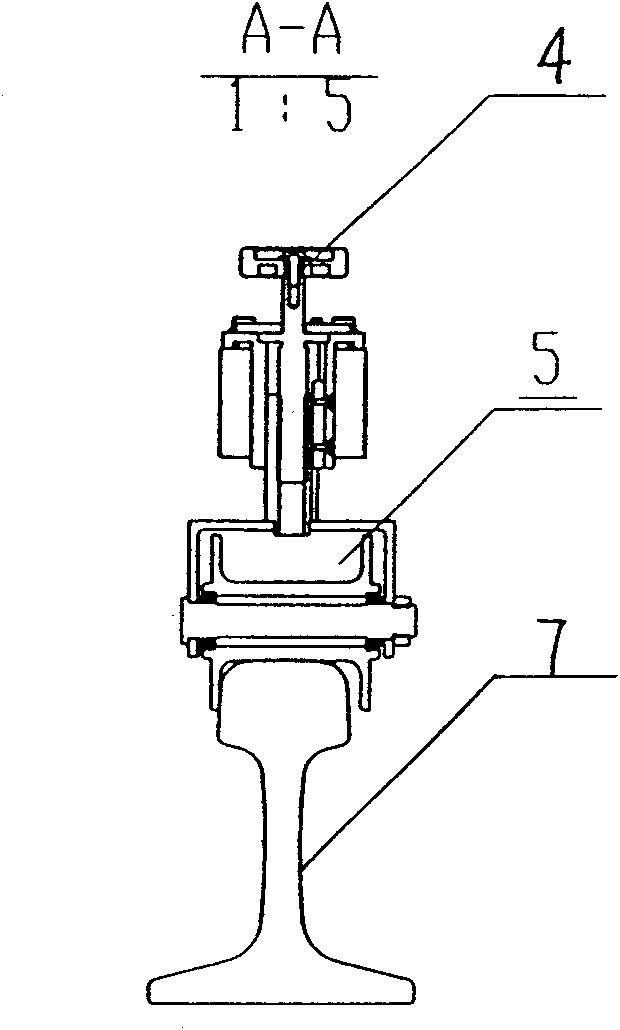

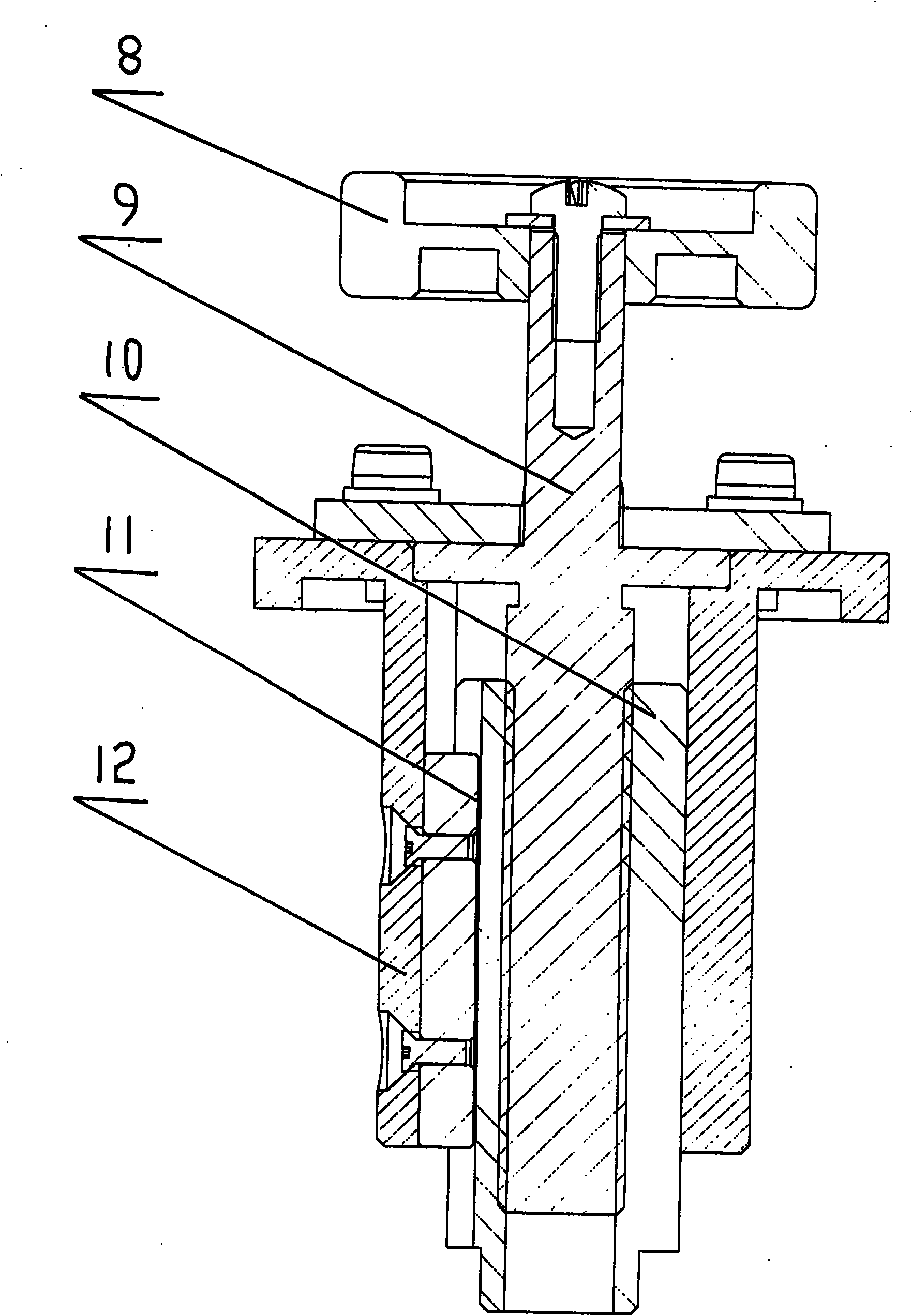

Internal combustion type rail belt grinder

InactiveCN101838956ACompact structureSimple structureRailway track constructionCombustionDrive wheel

The invention discloses an internal combustion type rail belt grinder, comprises a rack, a sanding belt, a driving wheel, a contact wheel, a tension pulley, a front travel contour wheel, a rear travel contour wheel and an explosive motor, wherein the front travel contour wheel and the rear travel contour wheel are arranged on the rack; the explosive motor is arranged on the rack and drives the driving wheel to rotate; the sanding belt is orderly wound on the excircles of the driving wheel, the contact wheel and the tension wheel; and a regulation mechanism for regulating the height of the rack is arranged between the rack and the front travel contour wheel or between the rack and the rear travel contour wheel. In the invention, the sanding belt is adopted to grind; the excircle of the contact wheel pressing the sanding belt on a welding line is provided with annular rubbers; the sanding belt is contacted with the welding line in a flexible mode, and the contact area is large, and the grinding efficiency is high; the variation in sanding belt thickness is small during grinding, thus the regulating operation of the grinding height is less, and the work efficiency is high; the regulation mechanism of the invention is simple, and the regulation is convenient and reliable; the driving wheel, the contact wheel and the tension wheel are all arranged on the support plate and the mounting and the debugging are convenient; and the explosive motor is suitable for field electroless operation.

Owner:李洪彬

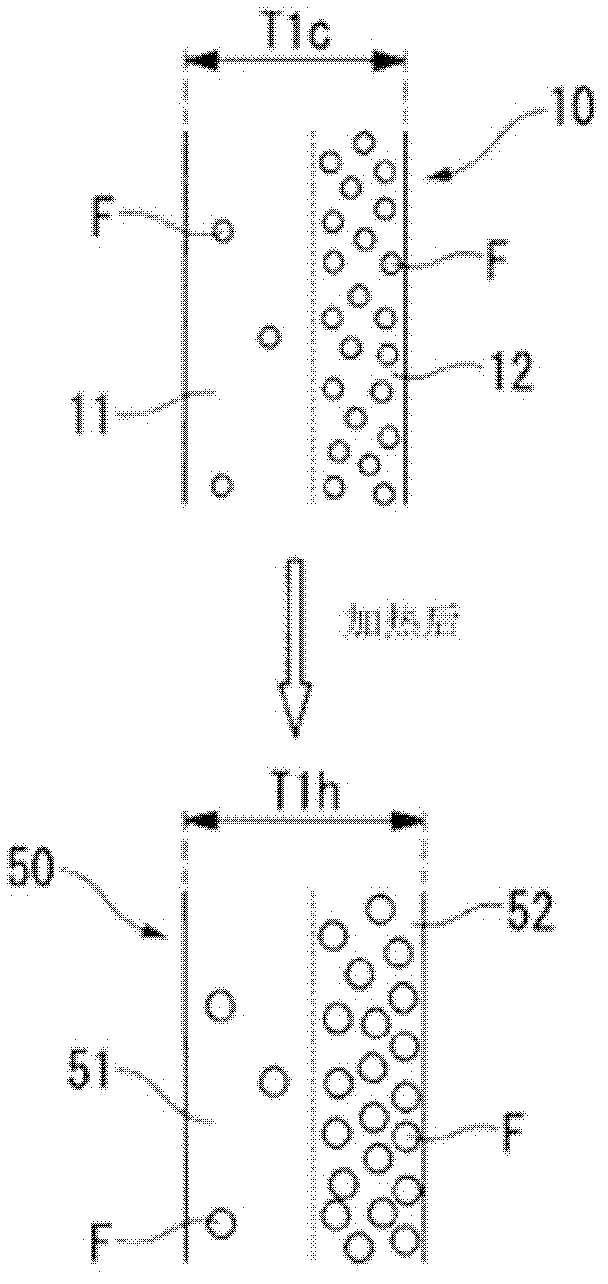

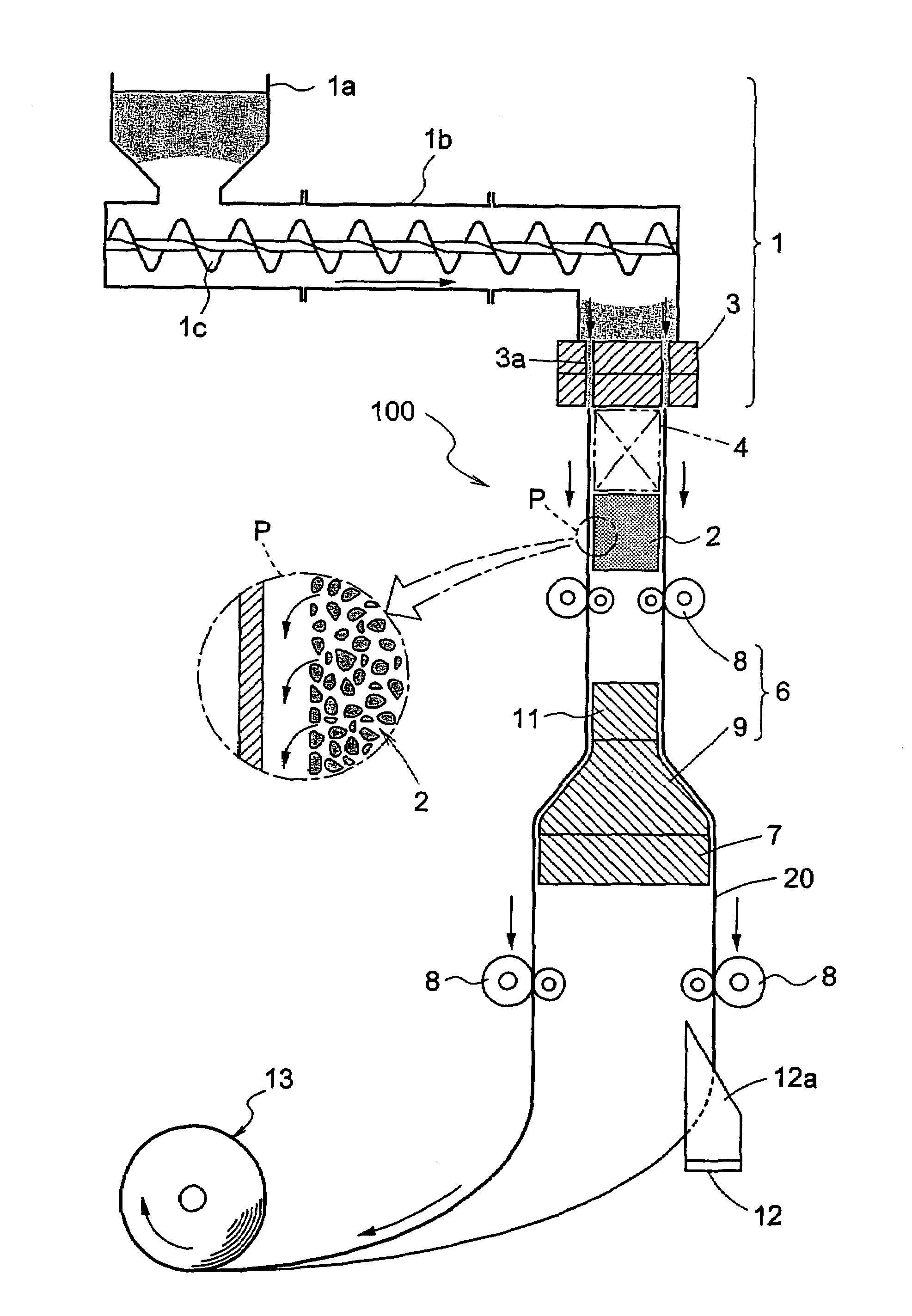

Method for producing gas diffusion electrodes

InactiveUS6838408B2Improve homogeneityLittle change in thicknessActive material electrodesElectrode shape/formsPowder mixtureElectrolysis

A method for producing gas diffusion electrodes, in particular for use in electrolysis cells, as well as electrodes and their uses are described. A method of the present invention involves first, a sheet-like structure is produced by means of a pair of rolls by rolling a powder mixture containing at least one catalyst or a catalyst mixture and a binder, and then the sheet-like structure is connected to an electrically conductive catalyst support by rolling by means of a pair of rolls. In one embodiment the clamping force of the rolls is preferably kept constant in the range from 0.2 kN / cm to 15 kN / cm.

Owner:COVESTRO DEUTSCHLAND AG

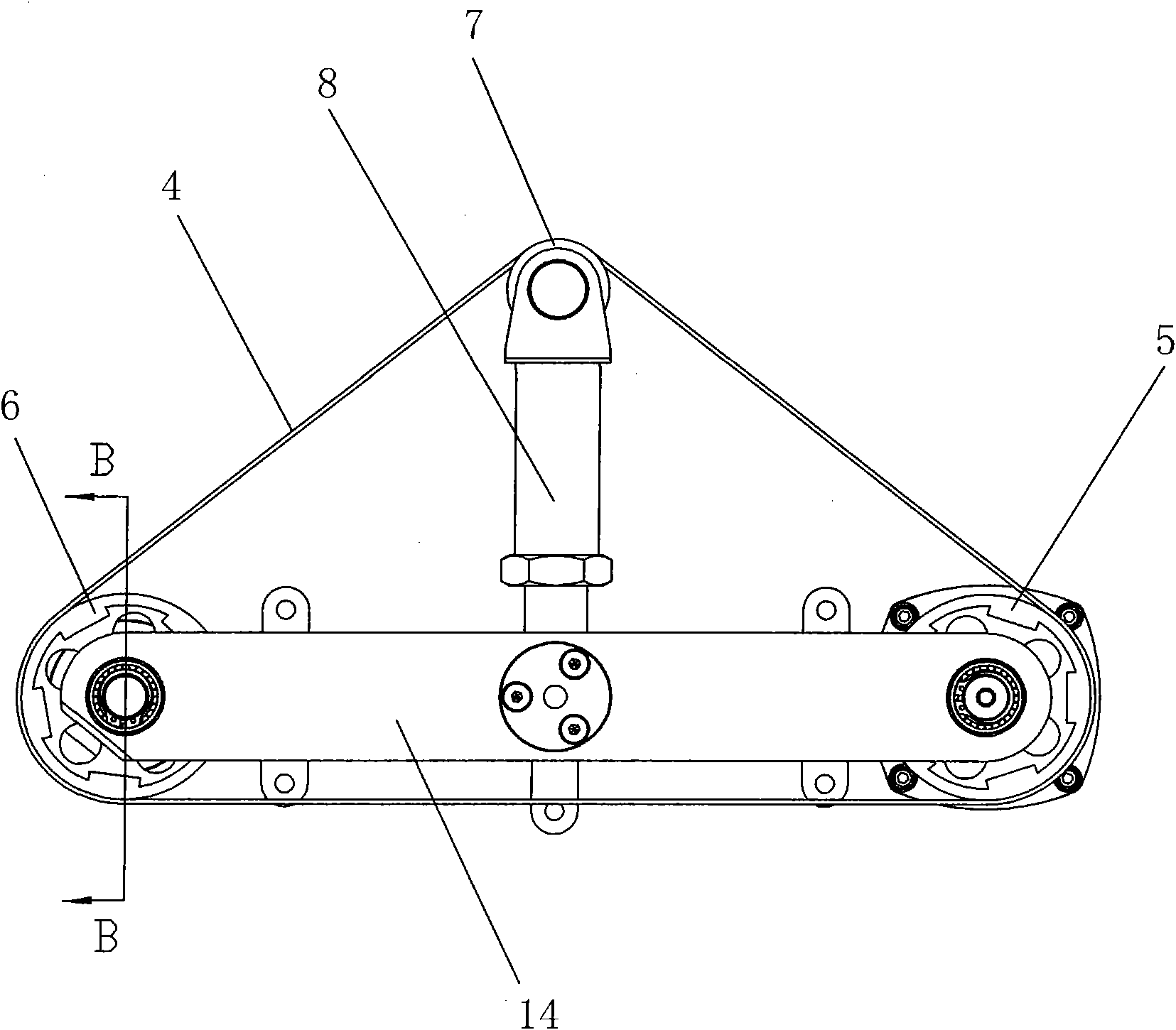

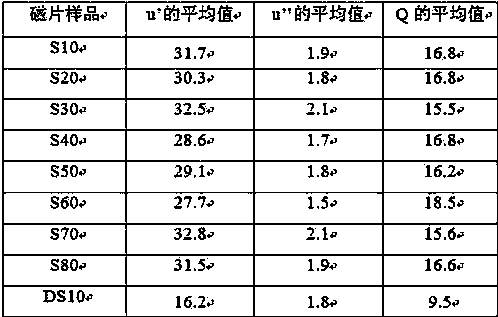

Sizing agent for near field communication (NFC) magnetic sheet, manufacturing method thereof and NFC magnetic sheet

ActiveCN103377787AShorten the production cycleImprove permeabilityMagnetsOrganic/organic-metallic materials magnetismState of artHigh humidity

The invention provides a sizing agent for a near field communication (NFC) magnetic sheet and a manufacturing method thereof. The sizing agent for the NFC magnetic sheet is composed of magnetic powder and organic carriers. The organic carriers contain 15-20wt% of adhesives, 75-83.8wt% of solvents, 0.1-1wt% of defoaming agents, 0.1-1wt% of dispersing agents and 1-5wt% of plasticizers. The adhesives are polyvinyl butyral and / or ethyecellulose. The invention further provides an NFC magnetic sheet manufactured by the sizing agent. The adhesives made of the powder polyvinyl butyral and / or ethyecellulose can replace resin and rubber in the prior art, so that production cycle of the NFC magnetic sheet can be shortened. Magnetic conductivity of the NFC magnetic sheet manufactured by the sizing agent is improved, magnetic powder is evenly distributed, and the magnetic sheet is small in thickness changing in a high-temperature high-humidity environment.

Owner:BYD CO LTD

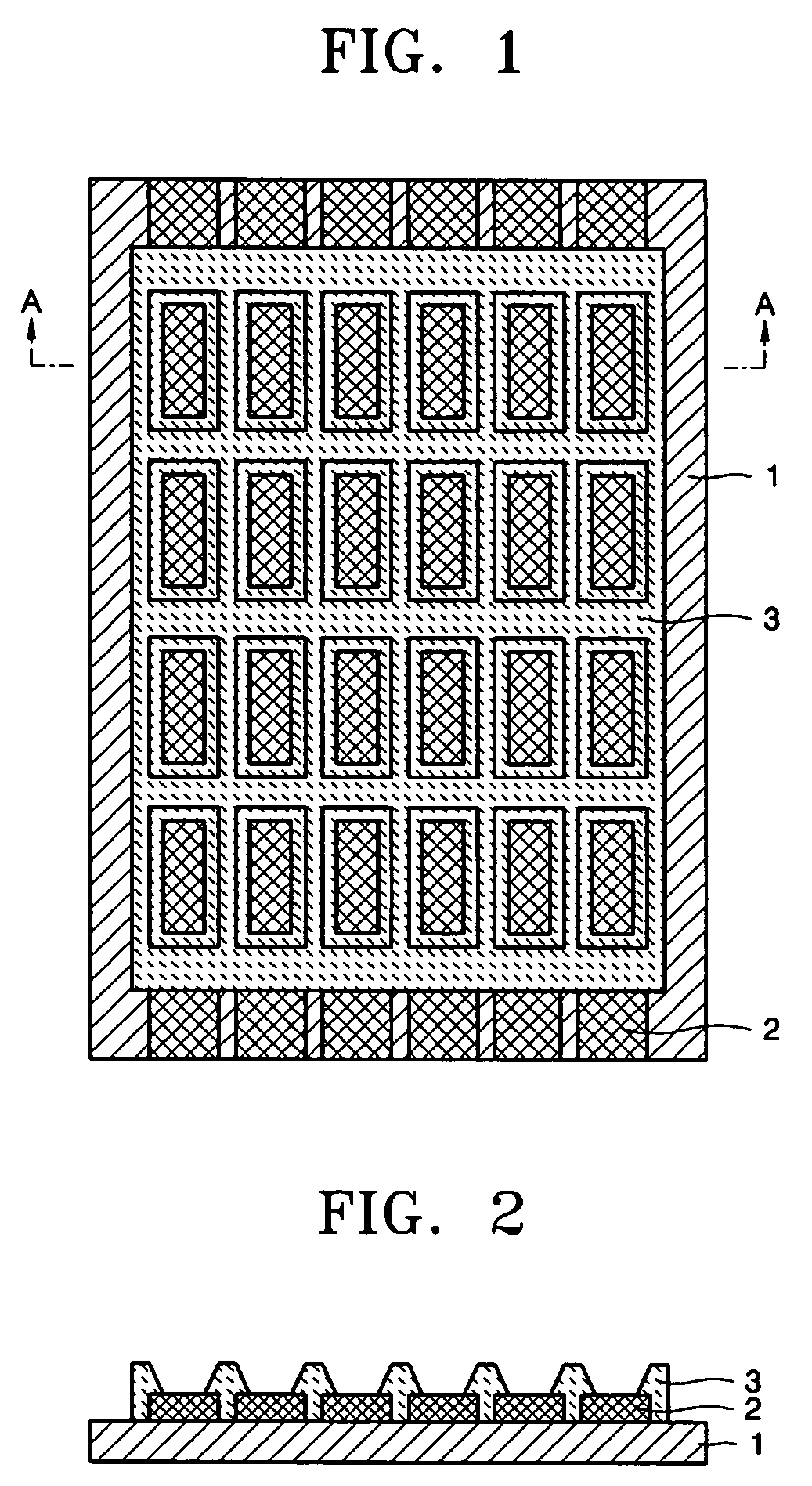

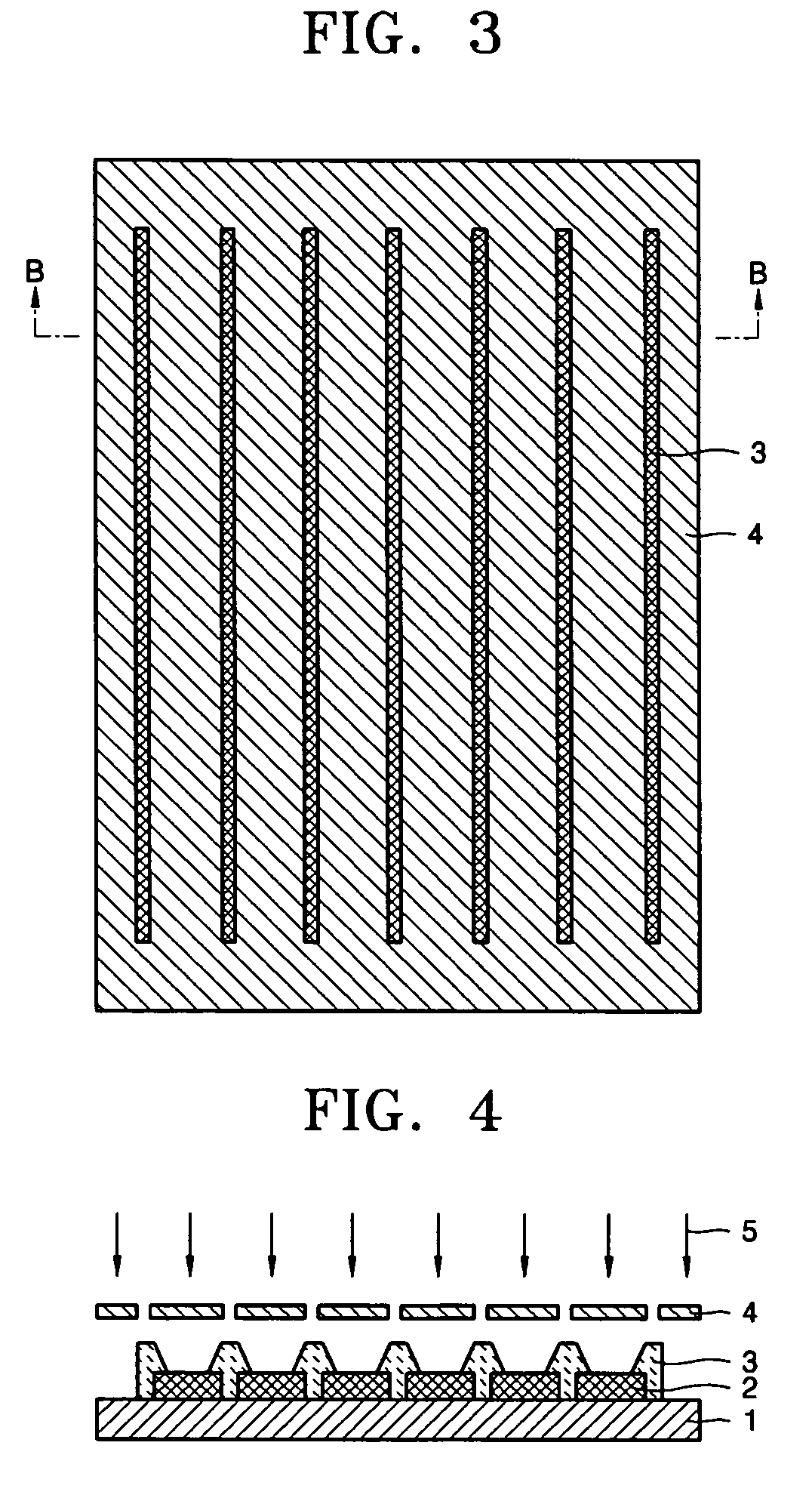

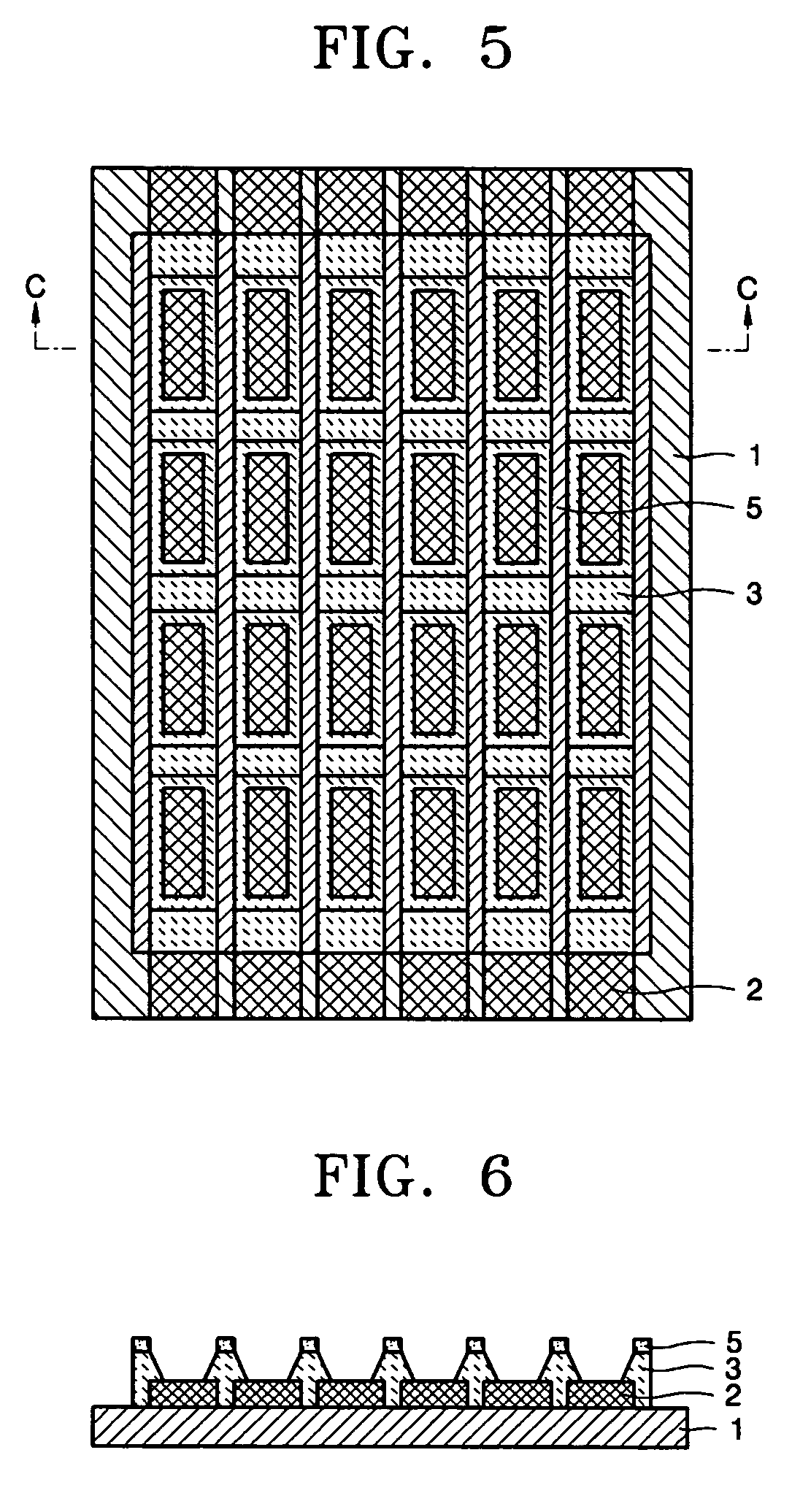

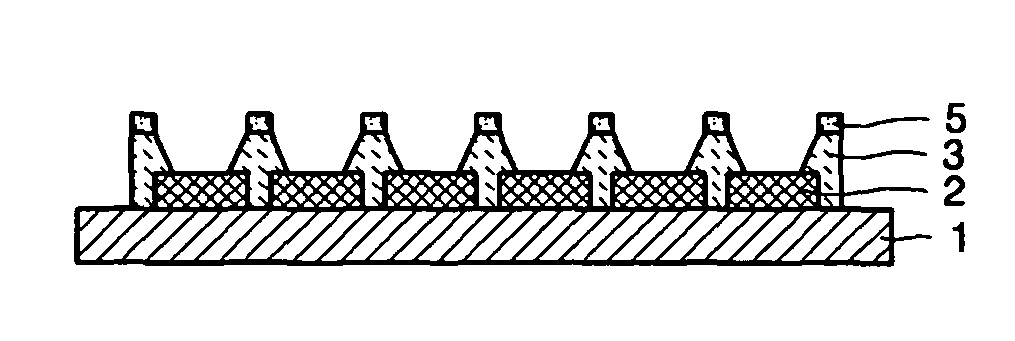

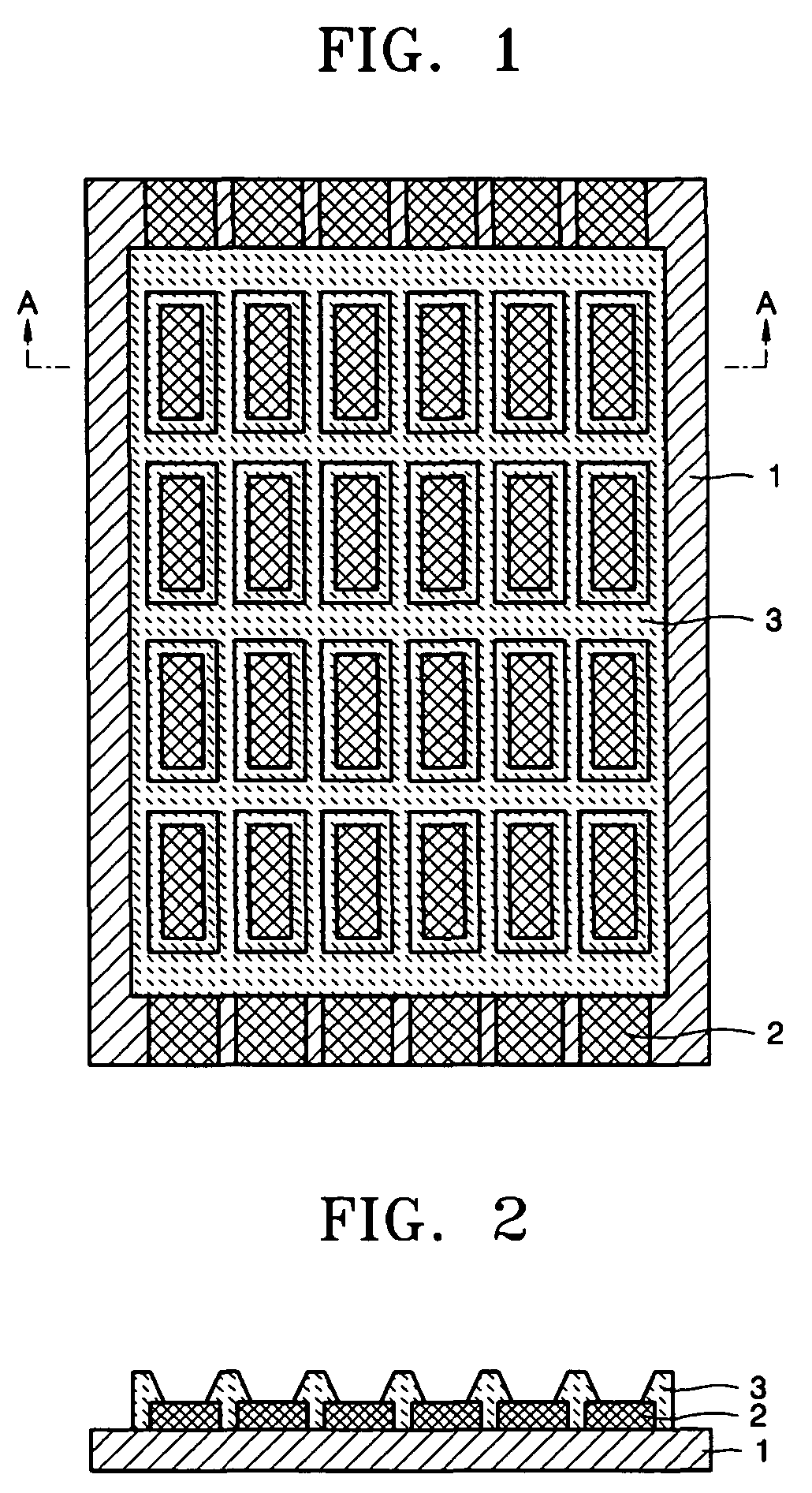

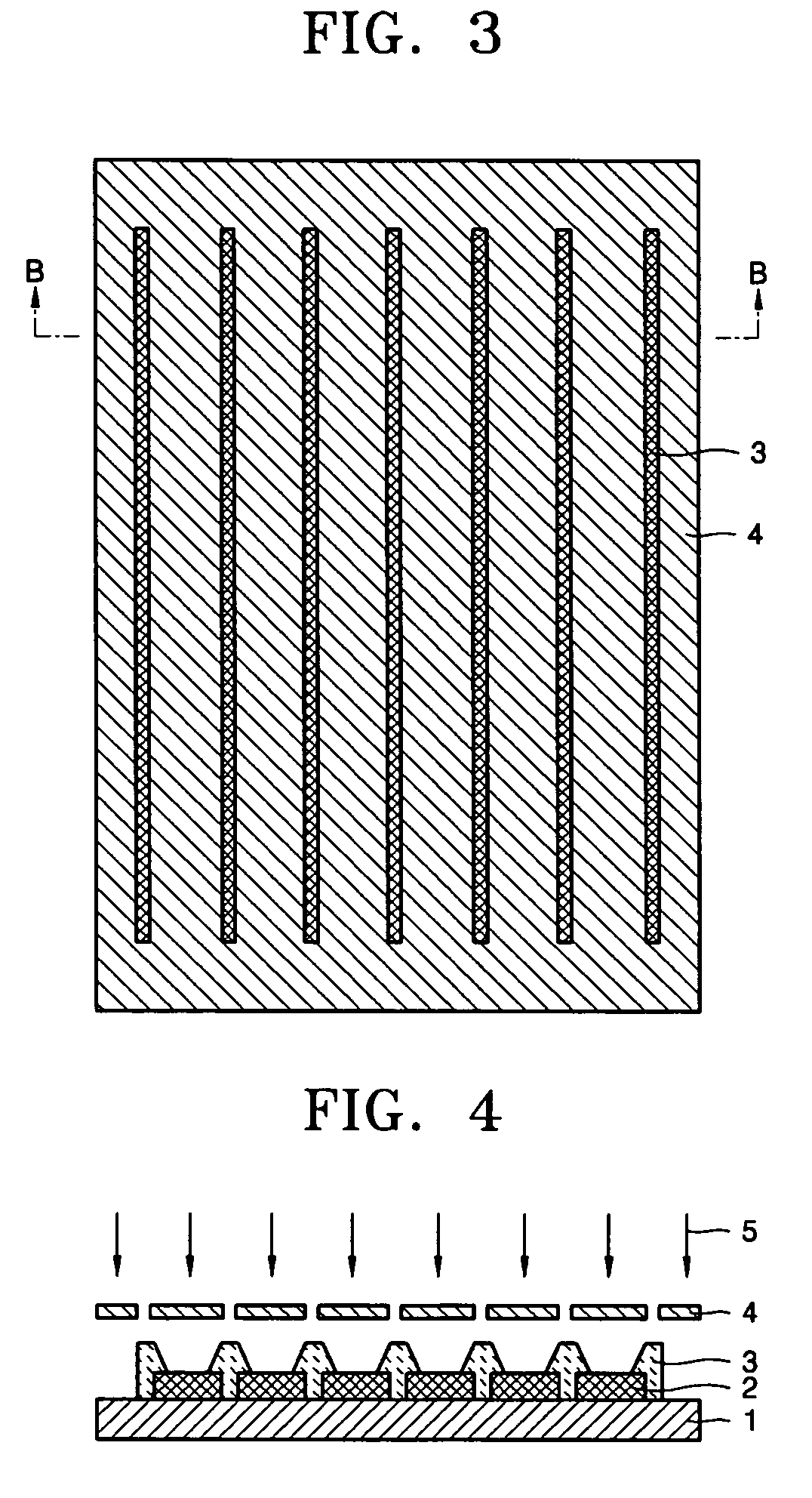

Substrate for inkjet printing and method of manufacturing the same

ActiveUS20050058785A1Low manufacturing costLarge variation of tensionDuplicating/marking methodsElectroluminescent light sourcesPhotoresistFluorinated hydrocarbons

A substrate for inkjet printing, which includes a photoresist layer structure on a base substrate, and a method of manufacturing the same are provided. The substrate, which has high surface tension variation and slight thickness variation, may be manufactured at a low cost. The substrate includes a discontinuous organic layer structure made of a fluorinated hydrocarbon or a polysiloxane on the photoresist layer structure.

Owner:SAMSUNG DISPLAY CO LTD

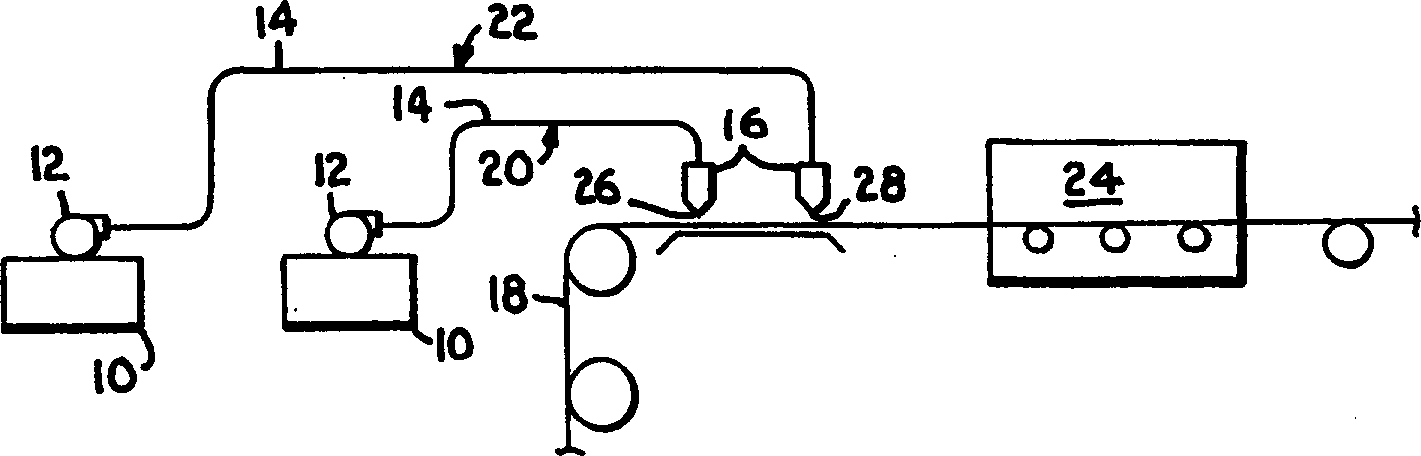

High performance composite membrane

InactiveCN1304329ALittle change in thicknessImprove effectivenessSemi-permeable membranesLiquid surface applicatorsPorous substrateCross-link

A process for producing high quality reverse osmosis, nanofiltration, and ultrafiltration membranes in a high speed process provides membranes which have excellent rejection characteristics coupled with high flux capabilities. The process employs tandem coating techniques to coat a microporous substrate with a thin membrane on the order of 25 ANGSTROM to 1.0 microns. The tandem coating process comprises tandem offset gravure and subsequent slot die coating applicators, or alternatively comprises tandem slot die coating applicators. For reverse osmosis and nanofiltration membranes, a wet-on-wet coating process is used to coat a porous substrate first with an aqueous solution, and then with an organic solution to produce a cross-linked, interfacially polymerized composite membrane. Single slot coating applicators are utilized to produce ultrafiltration membranes.

Owner:科克梅姆布莱尼系统公司

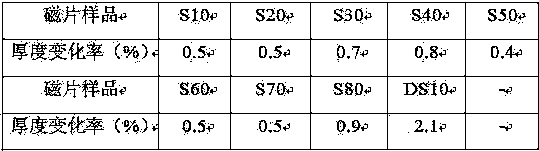

Grinding machine of internal combustion abrasive belt of small-sized steel rail

InactiveCN101864708AEasy for in-line solderingReduce weightRailway track constructionDrive wheelCombustion

The invention provides a grinding machine of an internal combustion abrasive belt of a small-sized steel rail, which is provided with a rack, a transmission device of an abrasive belt, walking contour wheels and an internal combustion engine or a high-speed motor, wherein the transmission device of the abrasive belt and the walking contour wheels are installed on the rack, and the internal combustion engine or the high-speed motor is installed on the transmission device of the abrasive belt. The rack is spanned on a steel rail by a front walking contour wheel and a back walking contour wheel. The transmission device of the abrasive belt comprises a driving wheel, a driven wheel, a tensioning wheel, a tensioning device and an abrasive belt; and the abrasive belt is tightly sleeved on the driving wheel, the driven wheel and the tensioning wheel which are in triangular distribution, and is tensioned by the tensioning device connected with the tensioning wheel. A grinding depth adjustment device adopts a screw adjustment structure and comprises an adjustment hand wheel, a screw, nuts, a fixed sleeve and a guidance key. The grinding machine of the abrasive belt has simple and compact structure, good miniaturization, light weight and high repair welding efficiency and is convenient for the works department of railways to finish the on-line welding and repair welding operation of steel rails within a shorter window time.

Owner:重庆运达机电设备制造有限公司

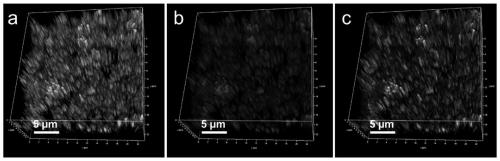

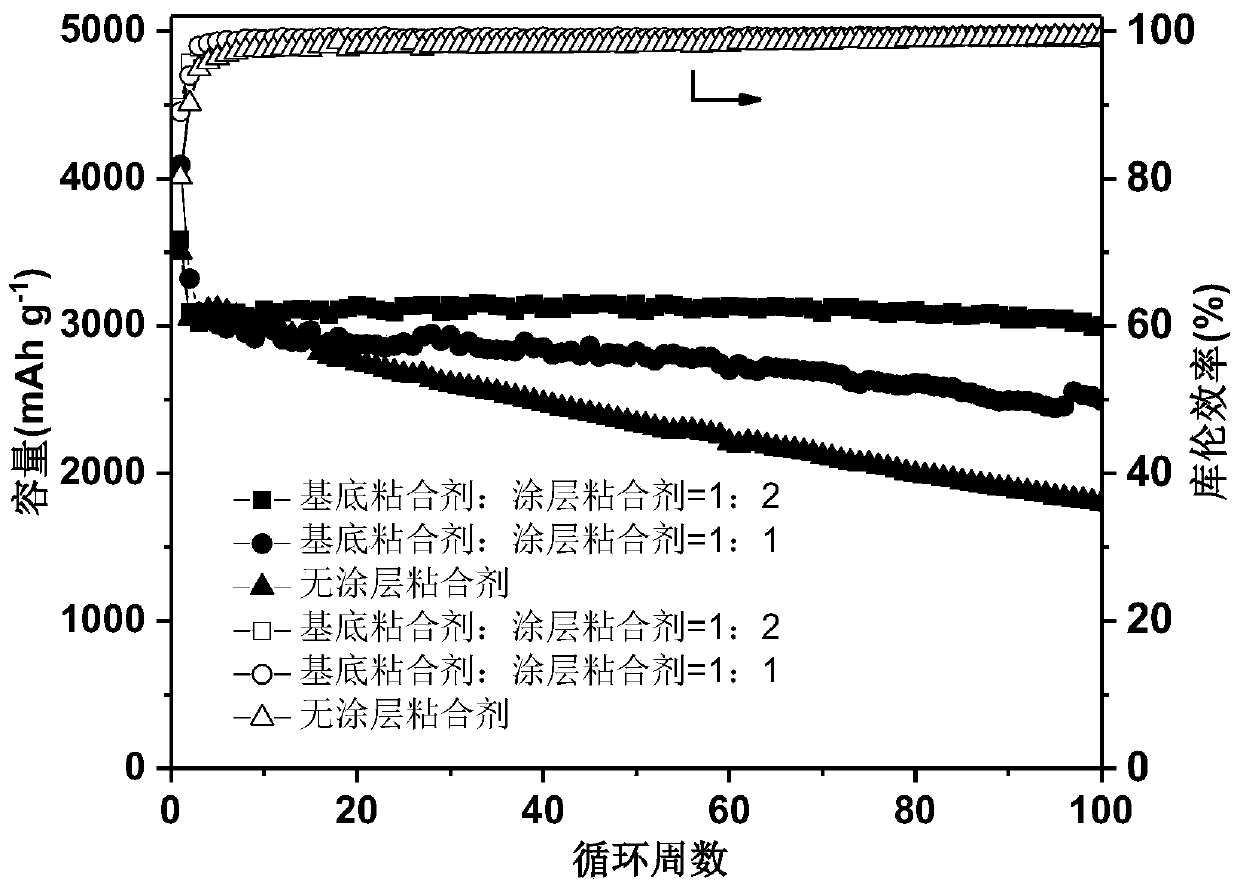

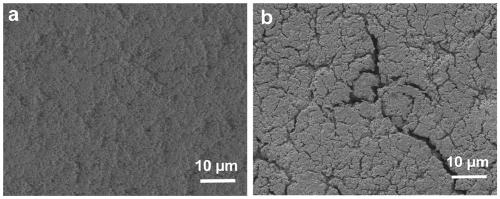

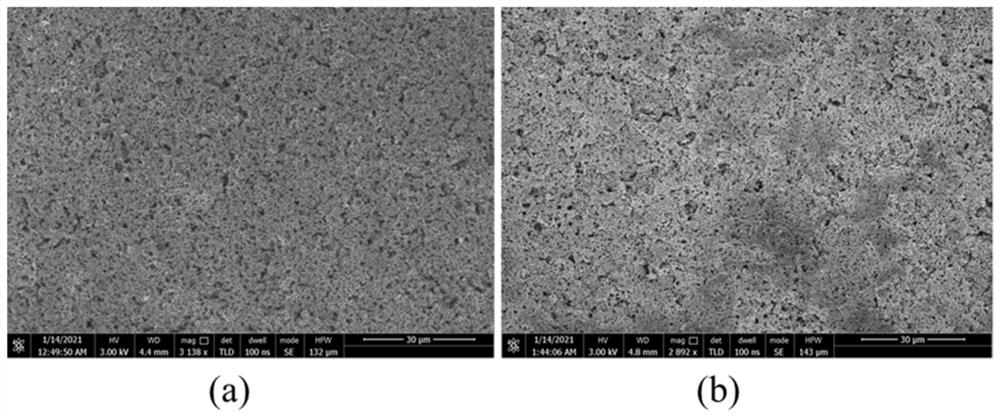

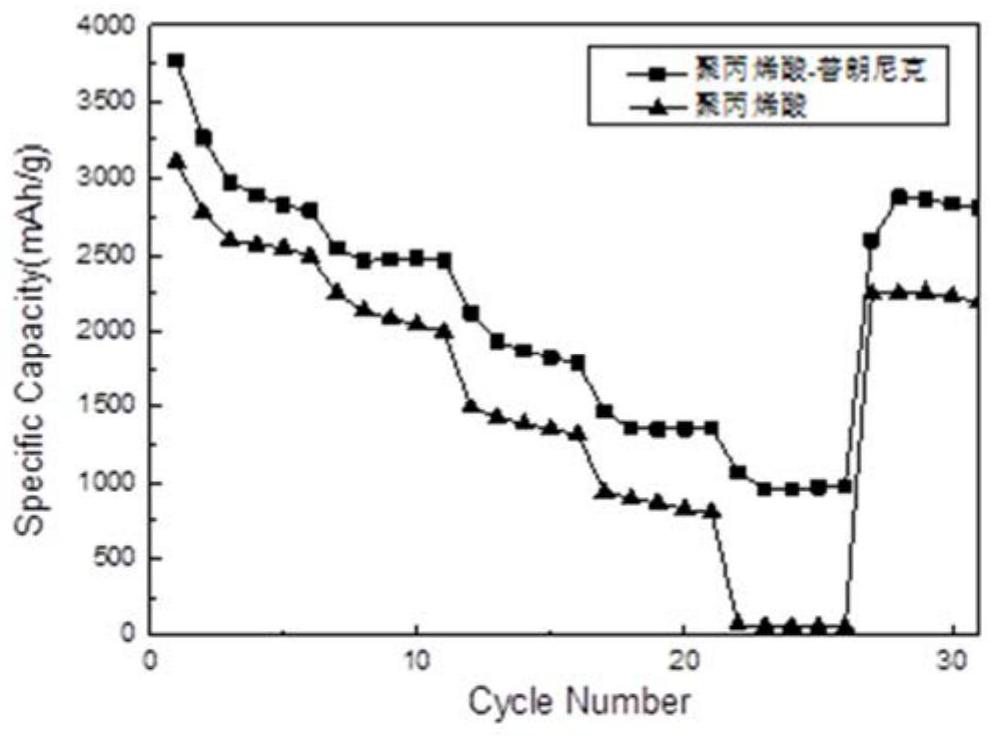

Lithium ion battery negative electrode, preparation method and application thereof

ActiveCN111261874AImprove structural stabilityImprove electrochemical stabilityNegative electrodesSecondary cellsElectrolytic agentPhysical chemistry

The invention discloses a lithium ion battery negative electrode and a preparation method and application thereof. The lithium ion battery negative electrode with stable structure and performance is constructed through a simple method, and the problems of electrode structure degradation and solid-phase electrolyte interface instability are effectively improved. In the preparation of the negative electrode, a substrate adhesive and a coating polymer are used; the substrate adhesive firmly bonds a negative electrode active material through chemical interaction; on one hand, the coating polymer permeates into the electrode to wrap the active material particles for the second time; on the other hand, due to good elasticity, ion conductivity and other functions of the coating polymer, mechanical and chemical protection is provided for the electrode, the construction of an SEI film and the effective transmission of lithium ions between the electrode and an electrolyte can be effectively improved, and the electrochemical stability of the electrode is improved.

Owner:XI AN JIAOTONG UNIV

Humidity sensor having humidity sensitive film and method for manufacturing the same

InactiveUS7644615B2Reduce variationReduce sensor costSolid-state devicesUsing mechanical meansMoisture sensorRelative permittivity

A humidity sensor includes: a sensor chip including a capacitive humidity sensor element and a connection electrode, wherein the capacitive humidity sensor element includes a humidity sensitive film having relative permittivity changeable in accordance with humidity, and wherein the connection electrode is electrically connected to the humidity sensor element; a lead plate electrically connected to the connection electrode; and a mold for covering a connection portion between the connection electrode and the lead plate. The mold is disposed on the sensor chip and includes a groove. The humidity sensitive film is disposed in the groove. The humidity sensitive film has a height in the groove, the height equal to or lower than a surface of the mold. The height of the humidity sensitive film in the groove is homogeneous.

Owner:DENSO CORP

Vitreous silica crucible

ActiveCN102485971ALittle change in thicknessAvoid thermal expansionPolycrystalline material growthBy pulling from meltCrucibleCorrosion

Provided is a vitreous silica crucible which is resistant to deformation and corrosion even when heated at high temperature for a long time. There is provided a vitreous silica crucible of the present invention including a substantially cylindrical straight body portion, a curved bottom portion, and a corner portion smoothly connecting the straight body portion and the bottom portion, wherein a wall of the vitreous silica crucible includes, from an inner surface side, a transparent layer and a bubble-containing layer, and a ratio of a thickness of the bubble-containing layer with respect to a thickness of the transparent layer at an intermediate position between an upper end and a lower end of the straight body portion is 0.7 to 1.4.

Owner:SUMCO CORP

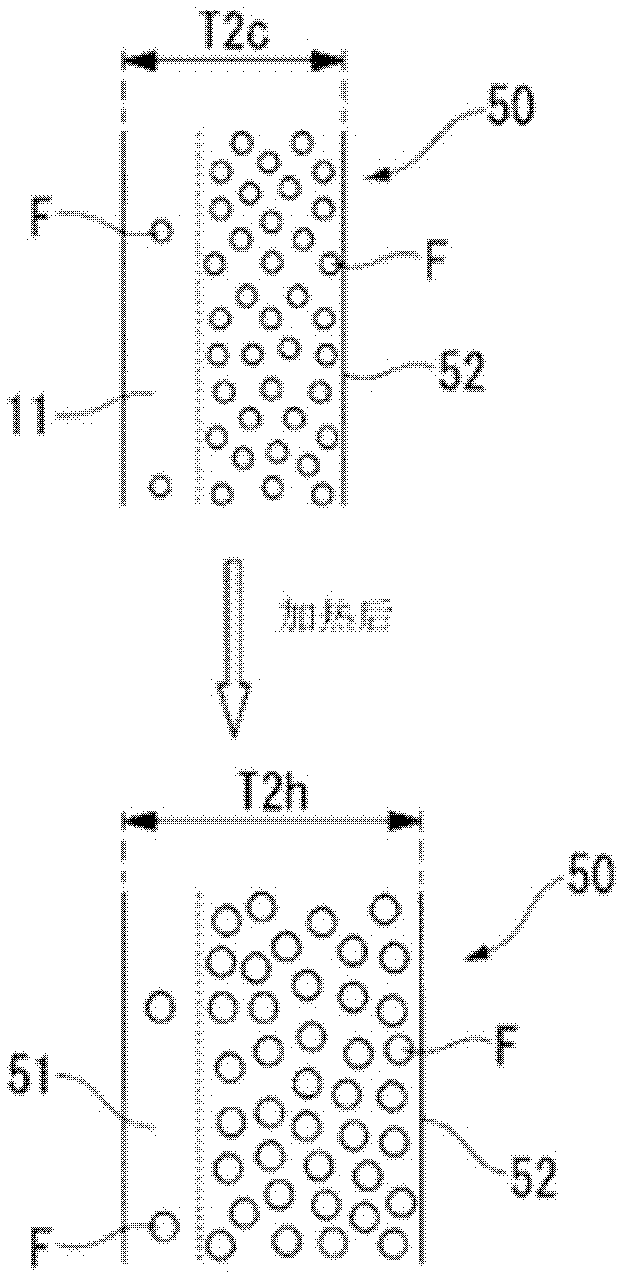

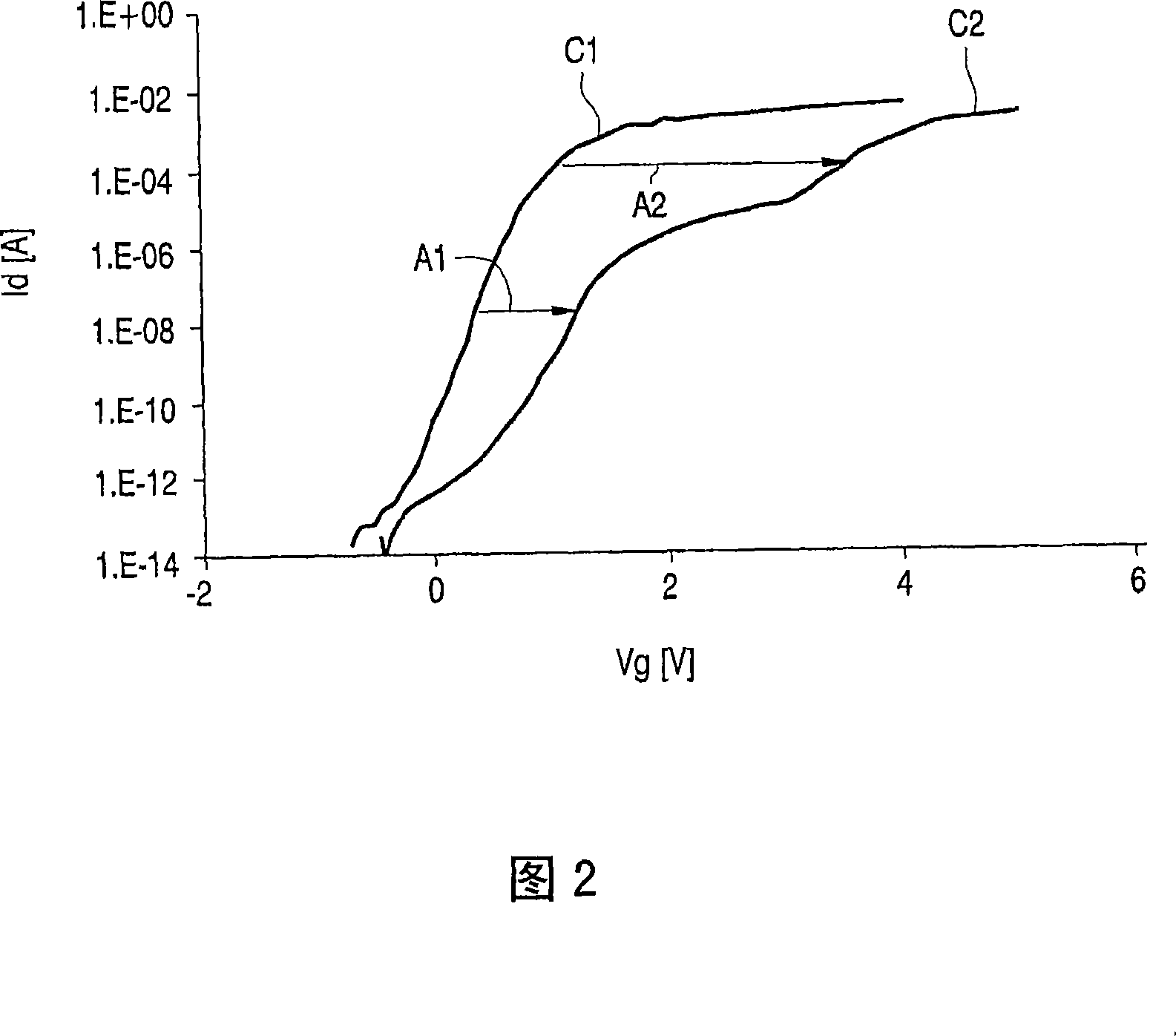

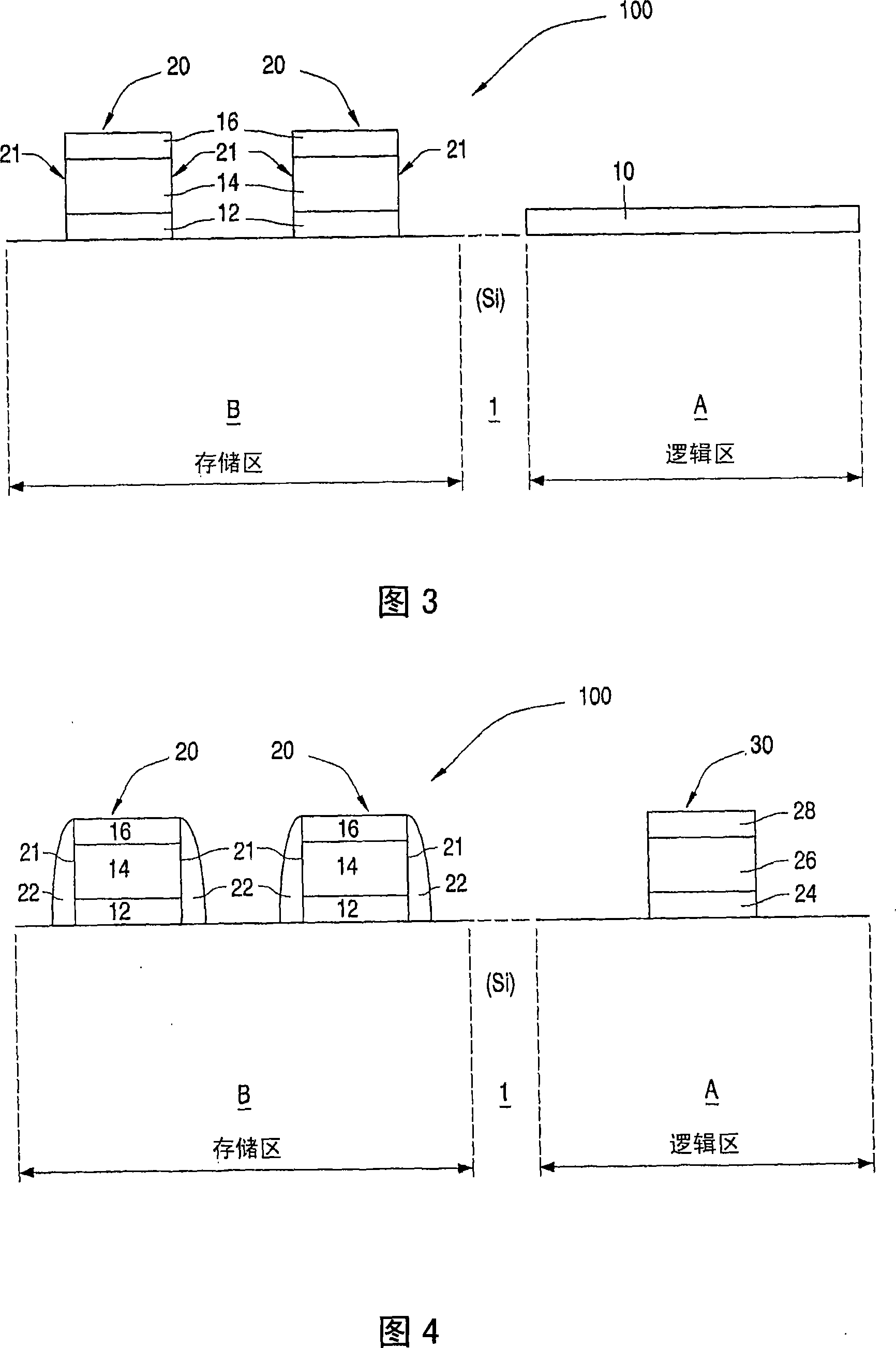

A sonos memory device with optimized shallow trench isolation

ActiveCN101019232ALittle change in thicknessImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingInter layerTrapping

Method of manufacturing a non-volatile memory device on a semiconductor substrate in a memory area, said non-volatile memory device comprising a cell stack of a first semiconductor layer, a charge trapping layer and an electrically conductive layer, the charge trapping layer being the intermediate layer between the first semiconductor layer and the electrically conductive layer, the charge trapping layer comprising at least a first insulating layer; the method comprising: providing the substrate having the first semiconductor layer; depositing the charge trapping layer; depositing the electrically conductive layer; patterning the cell stack to form at least two non-volatile memory cells, and creating a shallow trench isolation in between said at least two non-volatile memory cells.

Owner:NXP BV

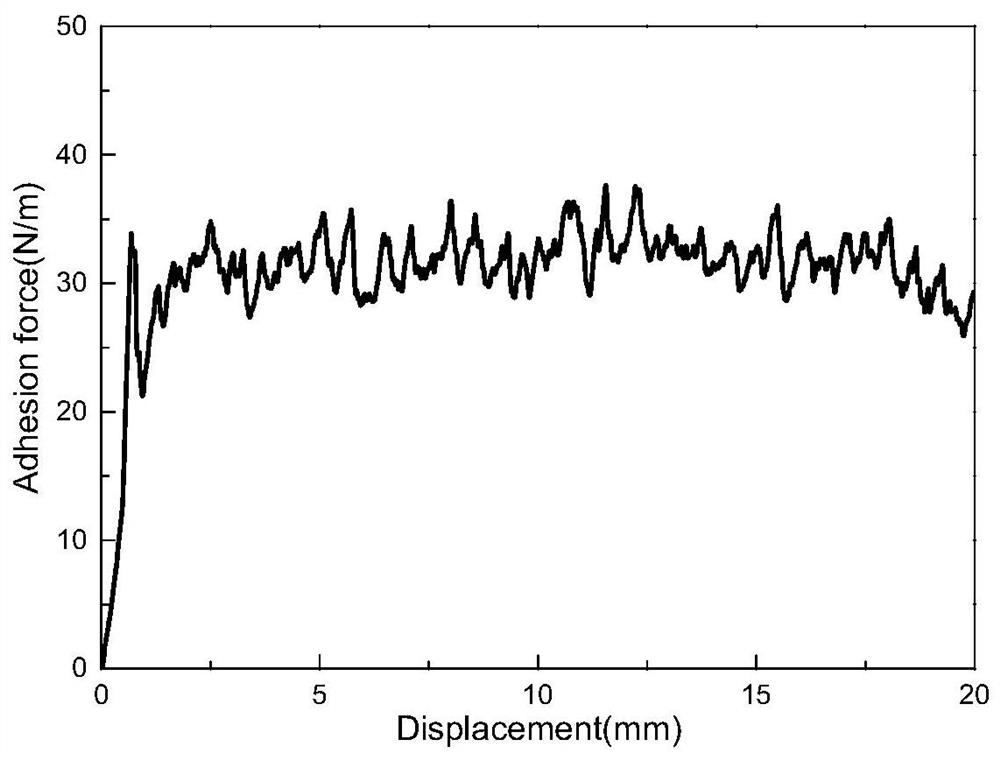

Network structure ionic conductive adhesive as well as preparation method and application of ionic conductive adhesive

ActiveCN113113605ARaw materials are readily availableLow costCell electrodesSecondary cellsElectrical batteryAdhesive

The invention discloses a network structure ionic conductive adhesive as well as a preparation method and an application thereof. The adhesive is synthesized through a 'one-pot method', the preparation process is simple, and the adhesive combines the excellent adhesion performance of polyacrylic acid to an active material and the good ionic conductivity of a polyoxyethylene polyoxypropylene ether block copolymer chain segment; and meanwhile, a three-dimensional cross-linked network structure is formed through condensation reaction. When the adhesive is applied to a lithium ion battery negative electrode, the problem of electrode structure degradation in the charging and discharging process can be effectively solved, and the electrochemical performance of the electrode is improved; by the three-dimensional network structure, the adhesive has excellent mechanical properties, and stress generated by an active material in the charging and discharging process can be effectively relieved; and the ionic conductivity provides a lithium ion migration channel for the electrode, so that the transportation of lithium ions is promoted, and the ionic conductivity has important significance for improving the rate capability of the electrode.

Owner:XI AN JIAOTONG UNIV

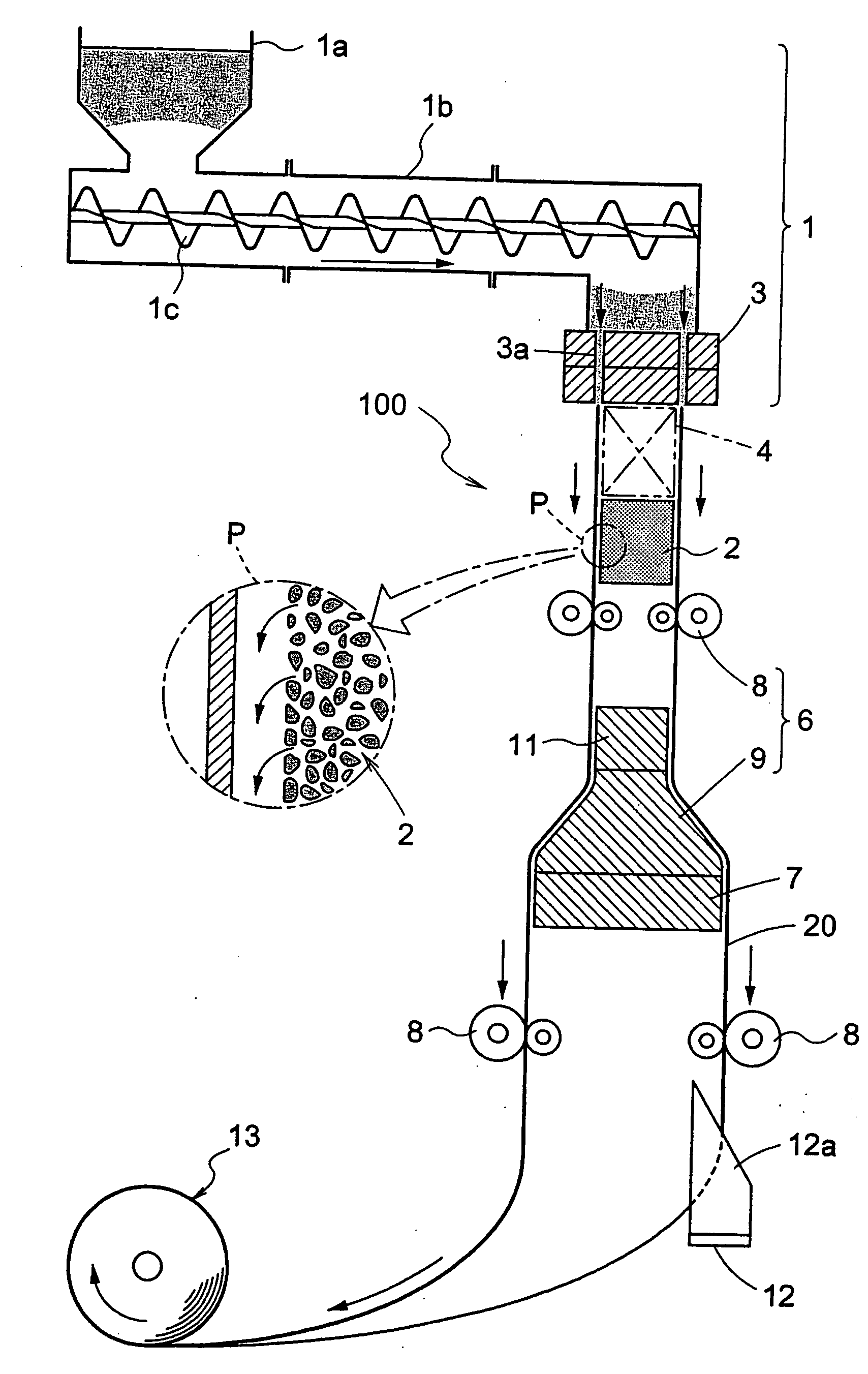

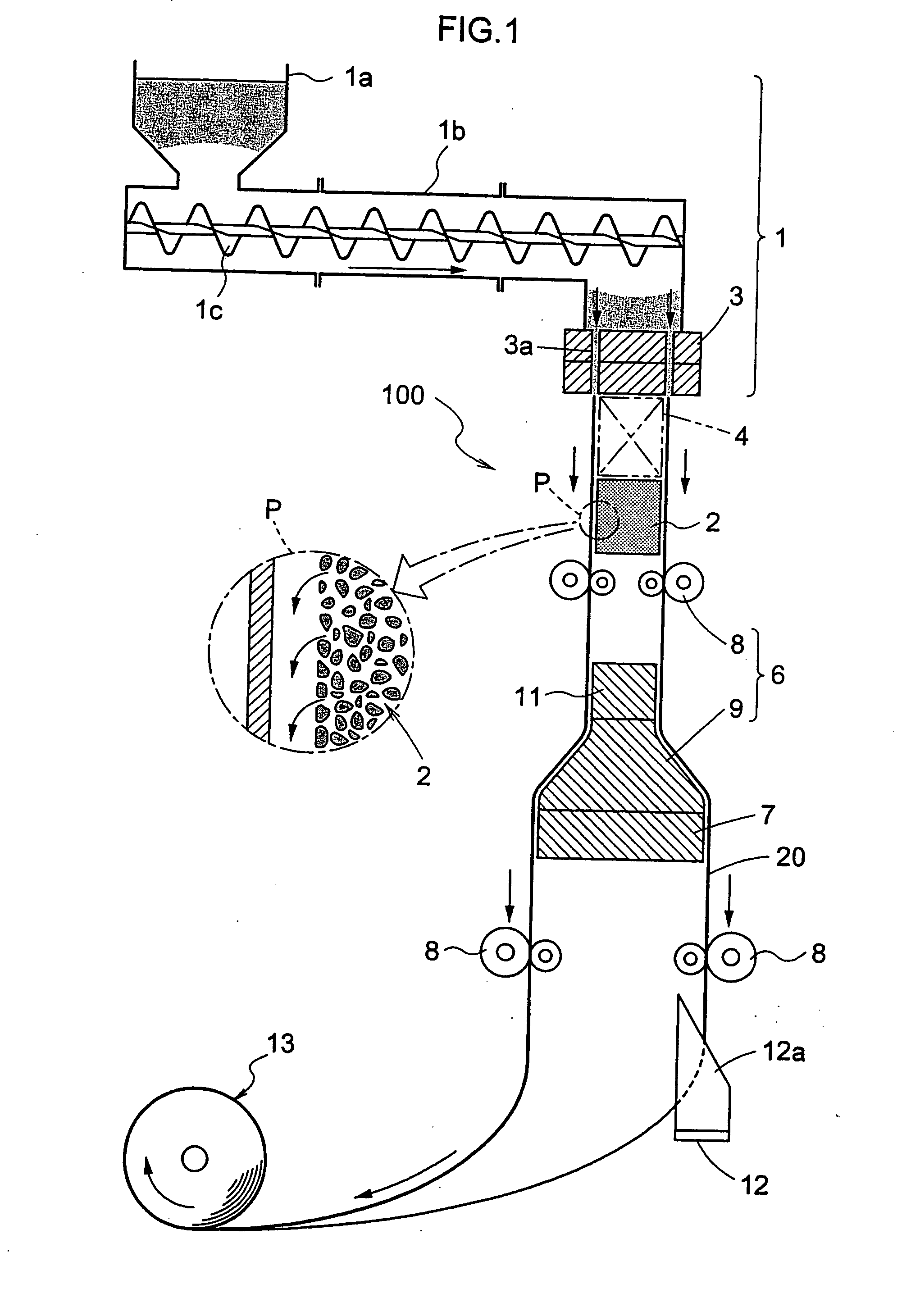

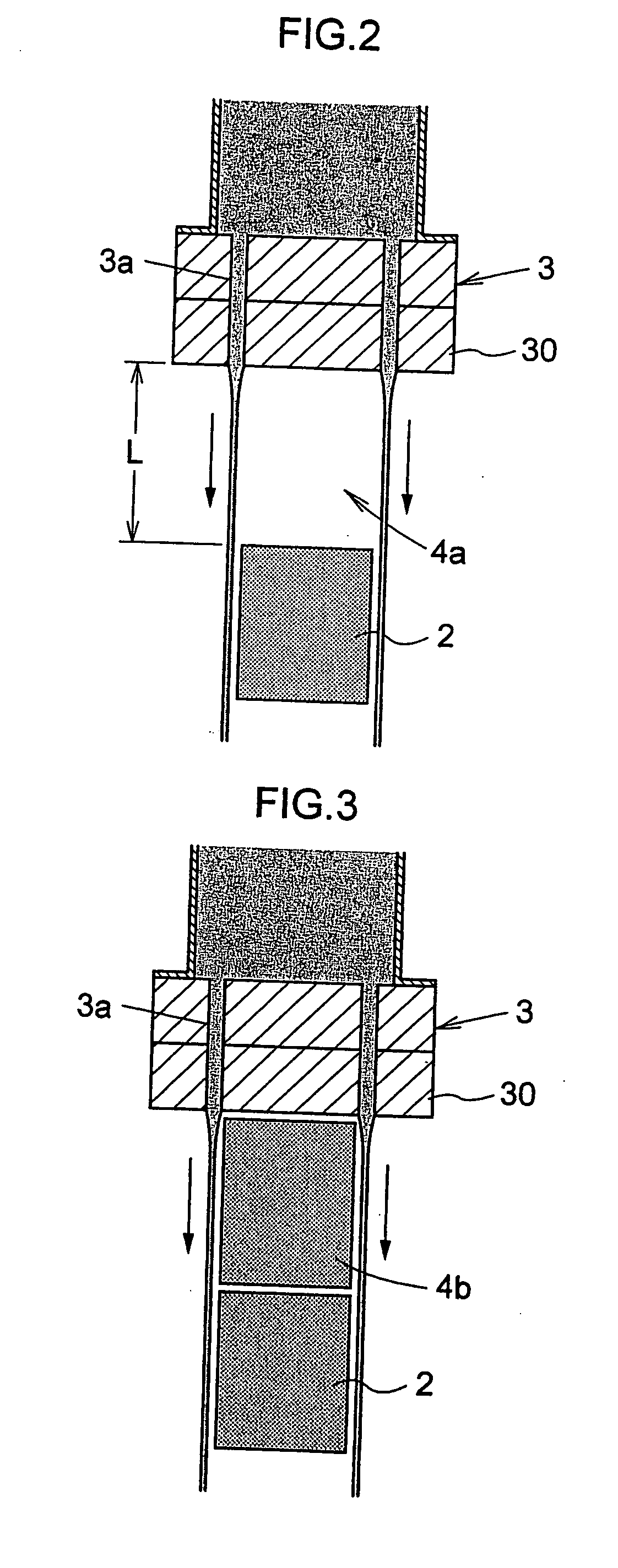

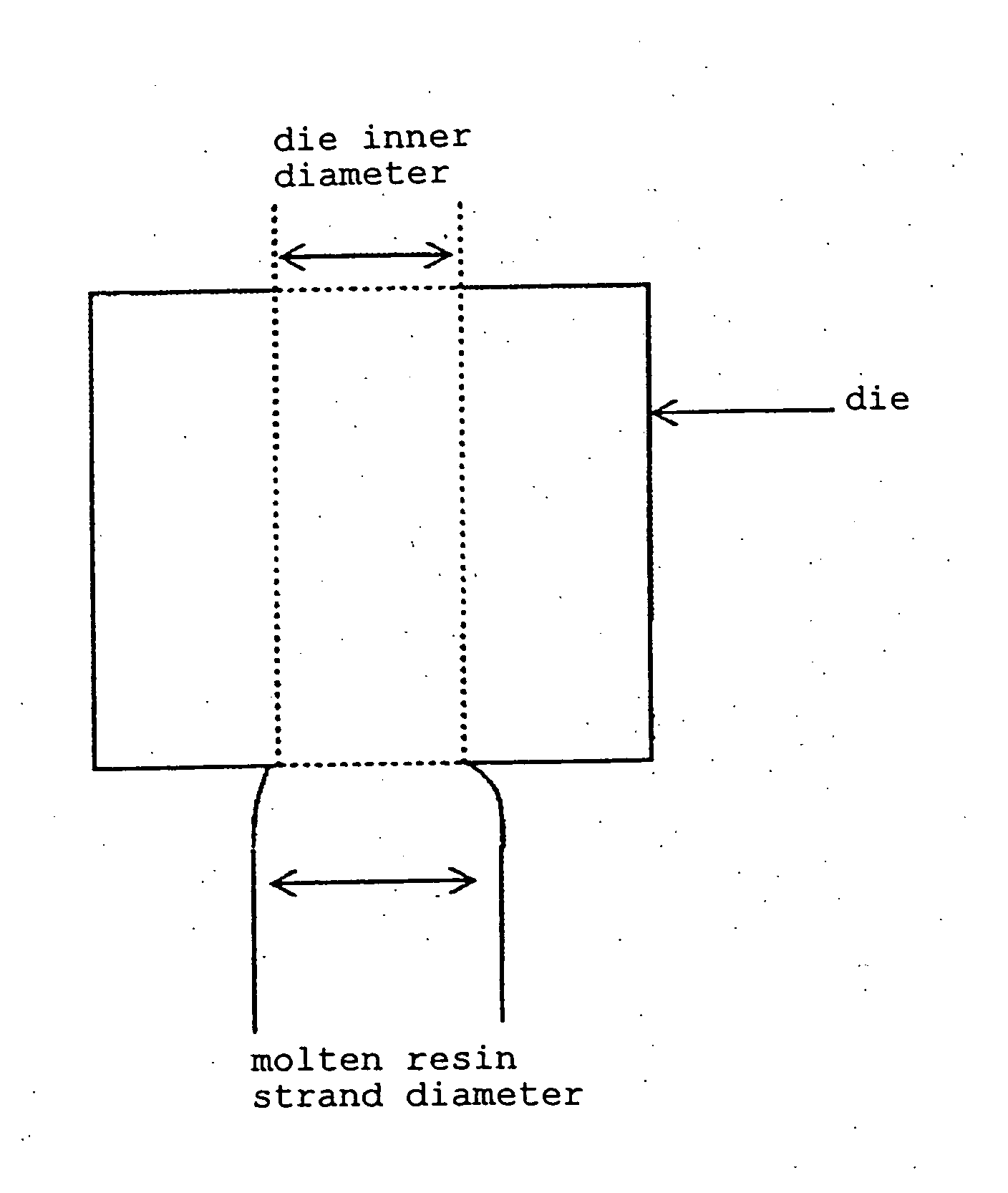

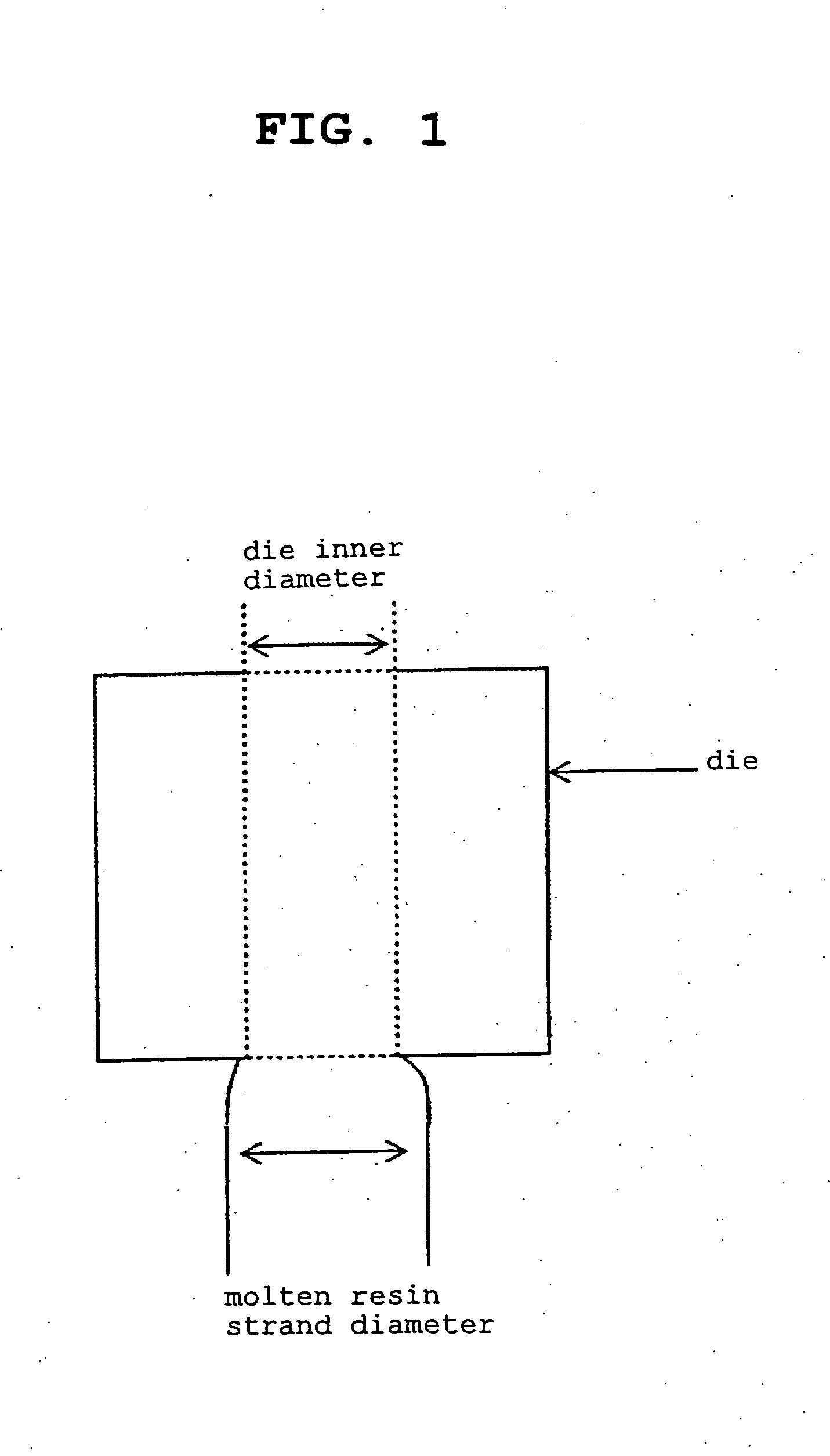

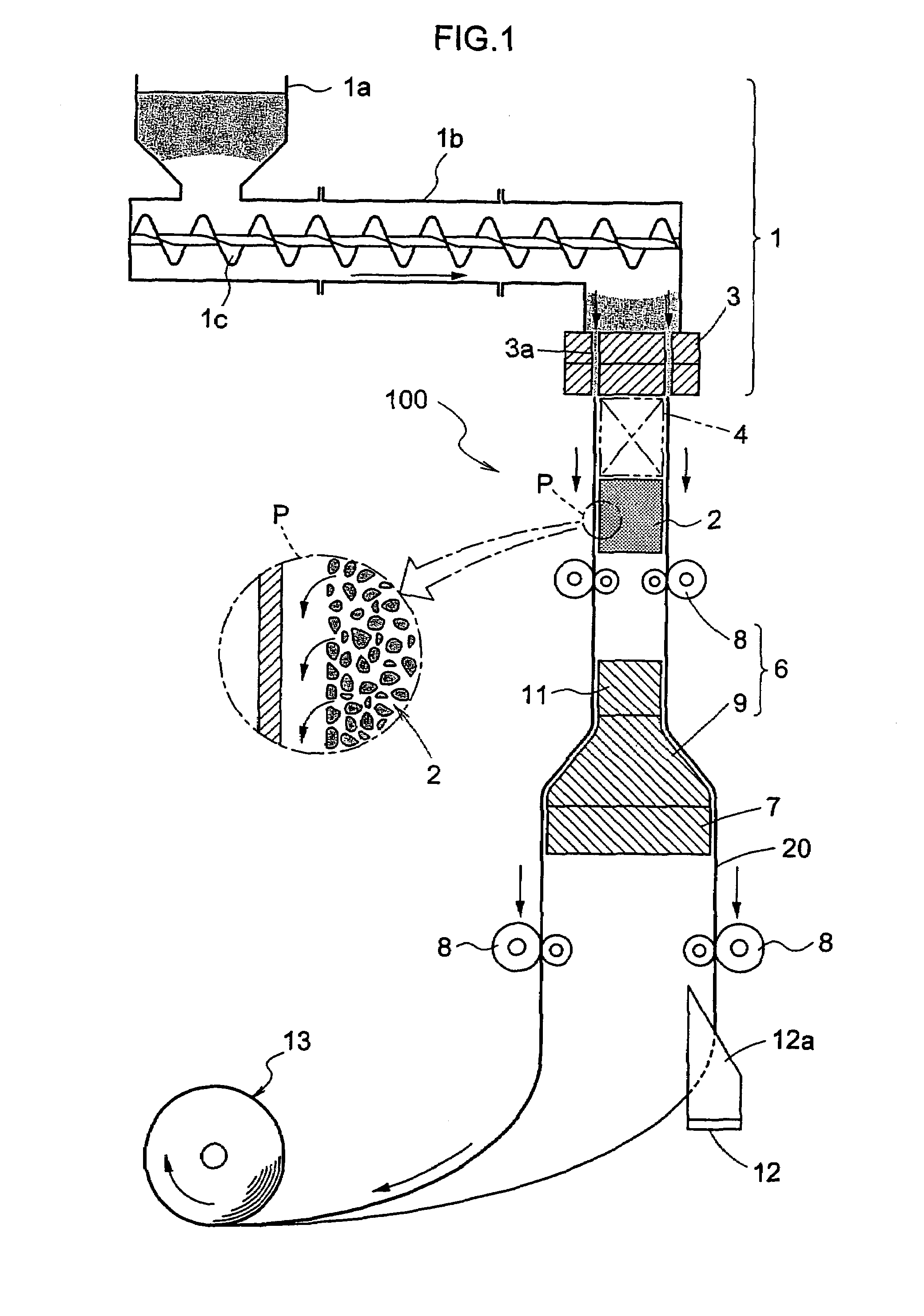

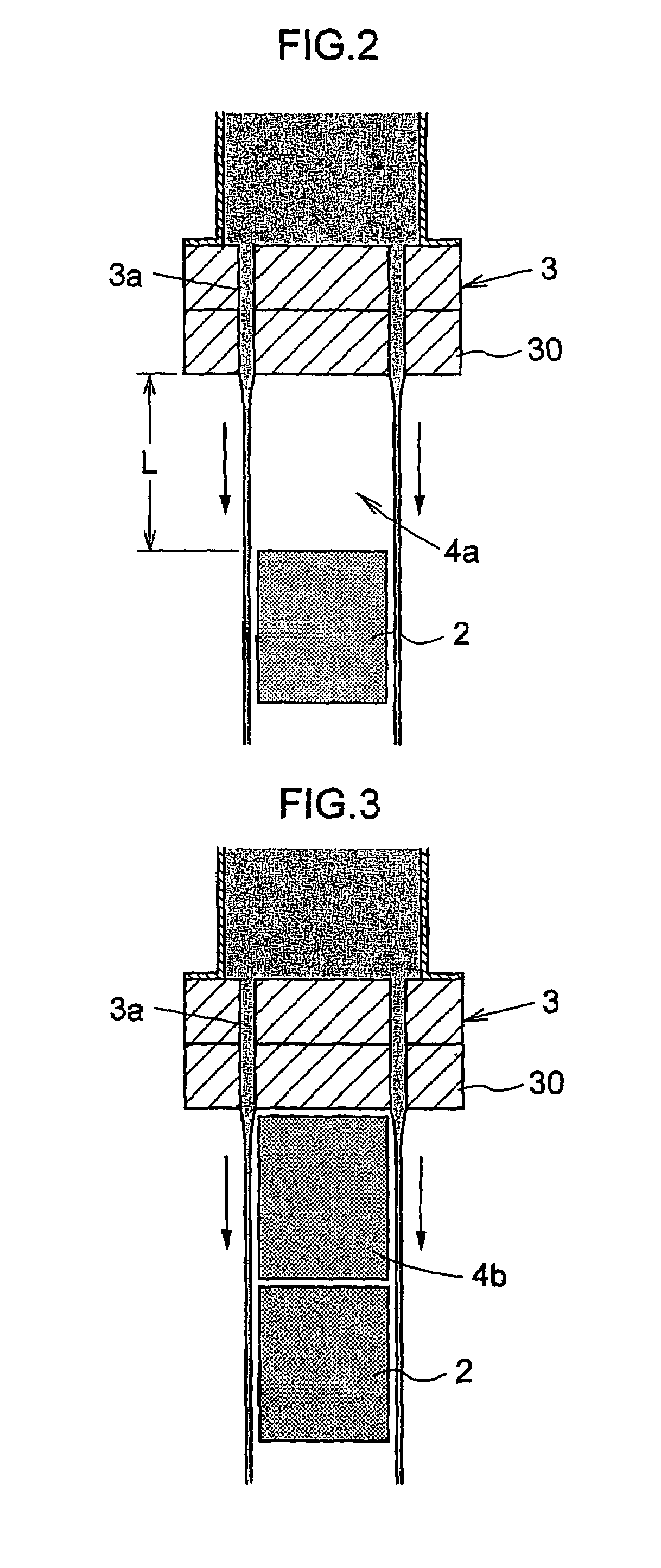

Unit for production of tubular resin film

Owner:SUMITOMO BAKELITE CO LTD

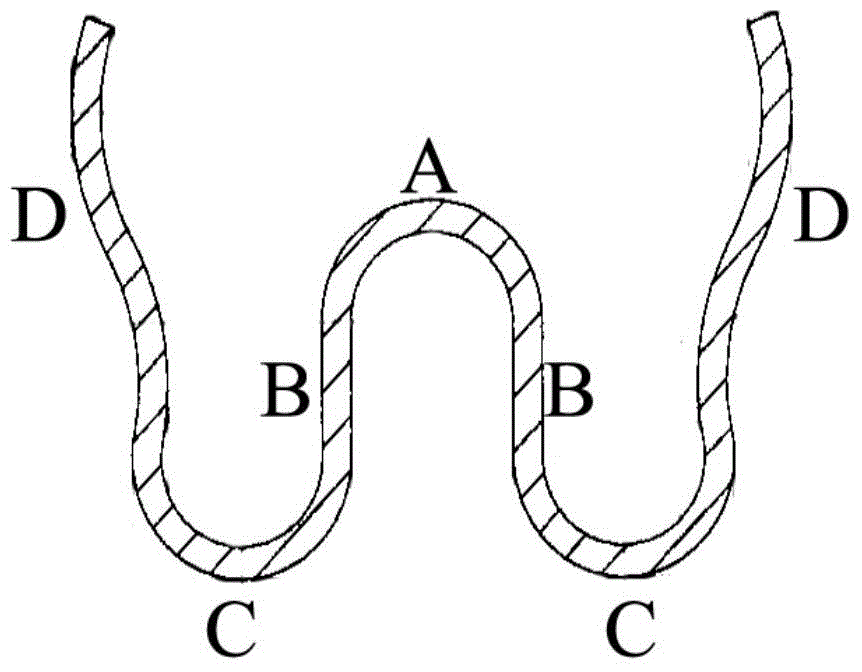

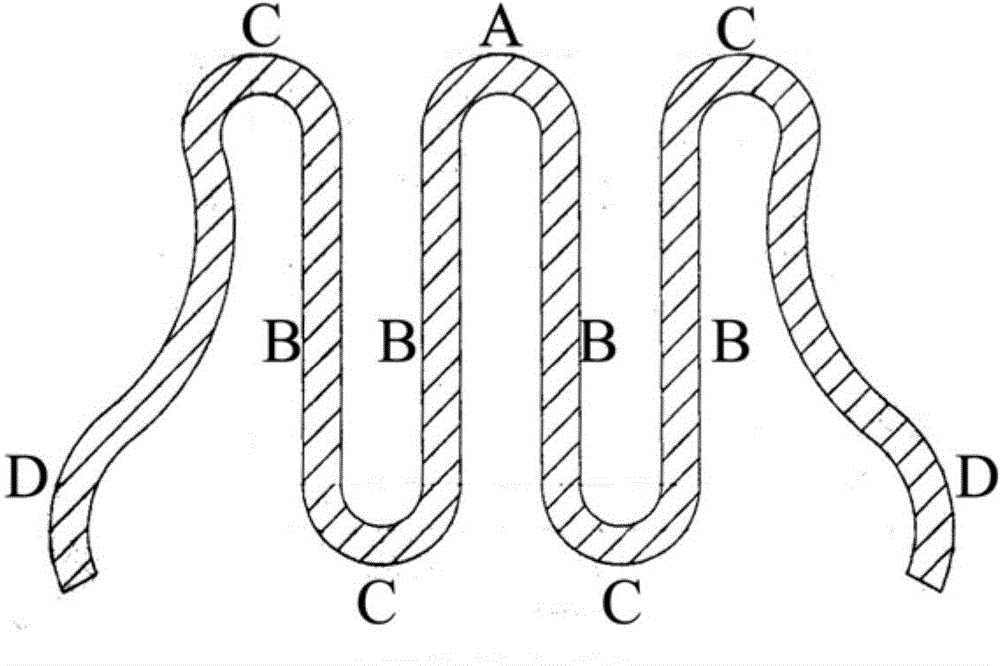

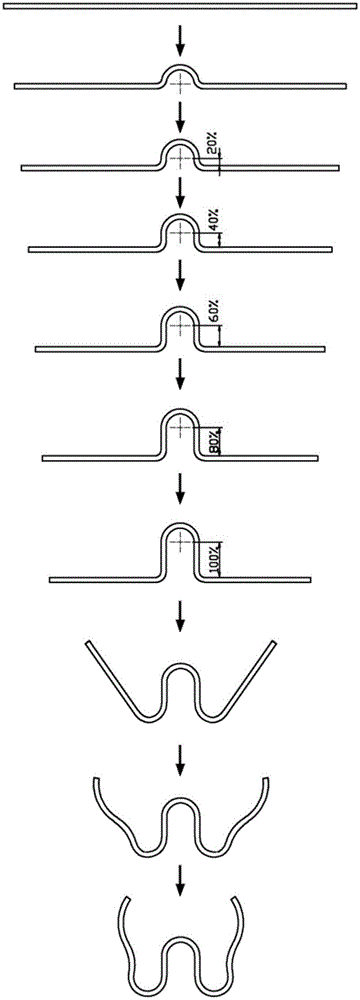

Forming technology for metal elastic sealing ring

The invention discloses a forming technology for a metal elastic sealing ring and belongs to the technical field of cold roll forming. The forming technology includes the following specific technology steps that a strip is cut to be in a corresponding width and a corresponding length according to the finished product size demand and welded to be in a ring shape; a strip ring is fixed, and spinning is conducted on the strip ring through a set of cold rolling rollers; the two sides of a circular arc are downwards extruded and deformed, a central bent circular arc (A) and a flat and straight connecting part (B) connected with the central bent circuit arc (A) are obtained, materials on the two sides of a section are bent upwards through a forming roller, and two elastic bent circular arcs (C) are formed; the obtained ring piece is arranged in a die roller, the two wings of the section are bent to form a left outwards-convex circular arc contact face (D) and a right outwards-convex circular arc contact face (D), and the ring piece is deformed after rotating by a circle; the left outwards-convex circular arc contact face (D) and the right outwards-convex circular arc contact face (D) are extruded from the two sides and are gathered in face-to-face mode and are deformed after rotating by a circle. The forming technology has the advantages that the surface quality of a product is good, the size deviation is small, and the variation of thicknesses of all parts of the section is small.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Group III nitride composite substrate and method for manufacturing the same, laminated group III nitride composite substrate, and group III nitride semiconductor device and method for manufacturing the same

InactiveUS9136337B2Large thicknessLittle change in thicknessSolid-state devicesSemiconductor/solid-state device manufacturingComposite substratePlane orientation

A group III nitride composite substrate includes a support substrate and a group III nitride film. A ratio st / mt of a standard deviation st of the thickness of the group III nitride film, to a mean value mt of the thickness thereof is 0.001 or more and 0.2 or less, and a ratio so / mo of a standard deviation so of an absolute value of an off angle between a main surface of the group III nitride film and a plane of a predetermined plane orientation, to a mean value mo of the absolute value of the off angle thereof is 0.005 or more and 0.6 or less. Accordingly, there is provided a low-cost and large-diameter group III nitride composite substrate including a group III nitride film having a large thickness, a small thickness variation, and a high crystal quality.

Owner:SUMITOMO ELECTRIC IND LTD

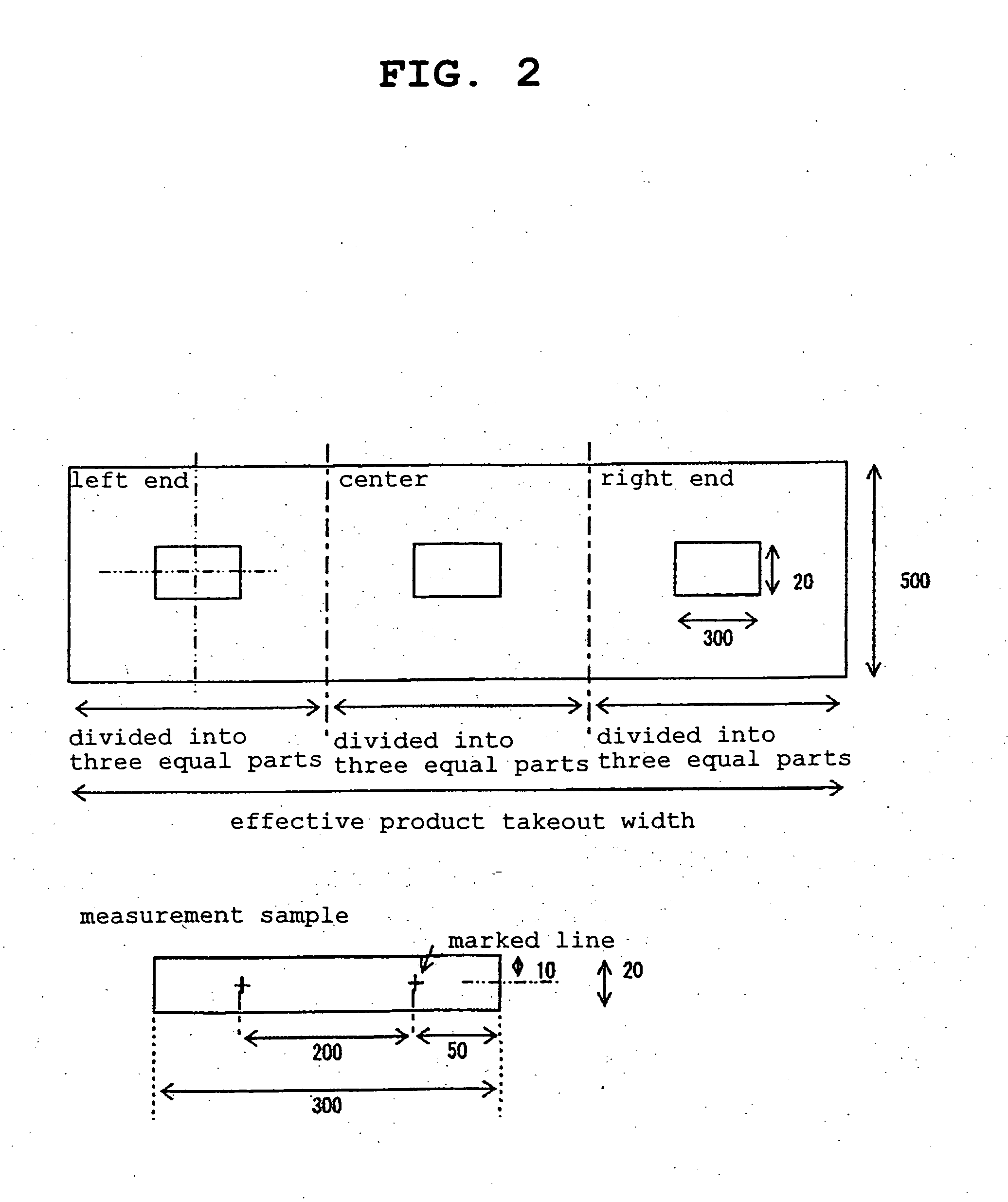

Polypropylene Laminate Film, and Package Comprising the Same

InactiveUS20080003386A1Little change in thicknessLayered product treatmentSynthetic resin layered productsPolyolefinEngineering

A wide polyolefin film may be made by high-speed film forming, which has uniform properties over its whole width and is free of thickness irregularities, and provides a packaging film applicable to large-scale production which has good gloss and bag-making property, as well as a package made from the film. A polyolefin laminate film includes an oriented base layer that is mainly made up of a polypropylene resin and a sealing layer mainly made up of a polyolefin resin which is formed on at least one surface of the base layer, which film has an effective product takeout width of not less than 5500 mm and satisfies the following relational formula of the thickness variation rate Y (%) of the film and the product takeout width X (mm) of the film: Y≦0.001X+4.

Owner:TOYOBO CO LTD

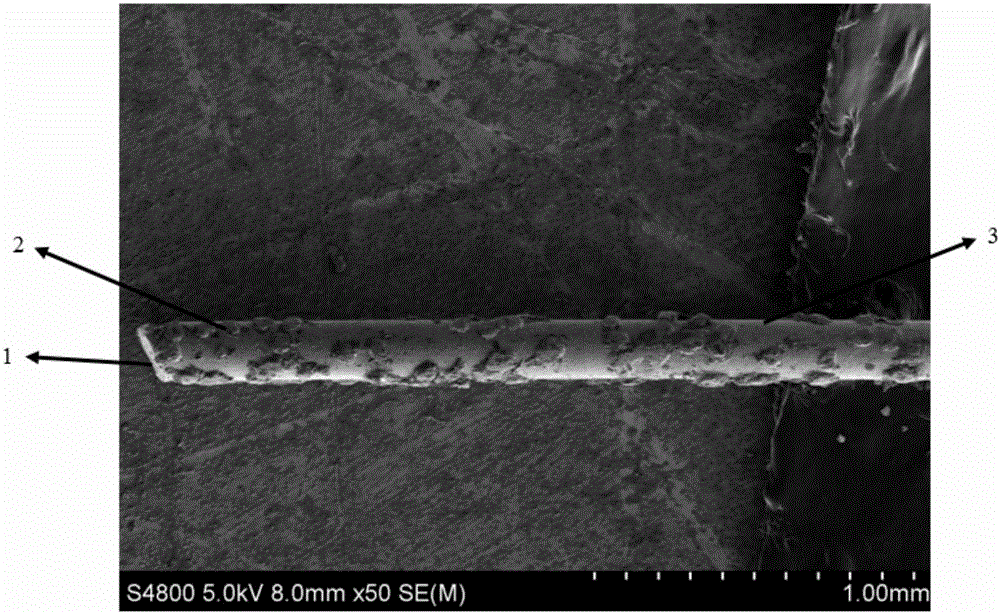

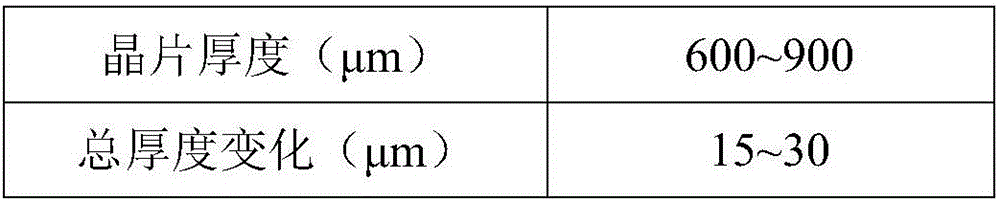

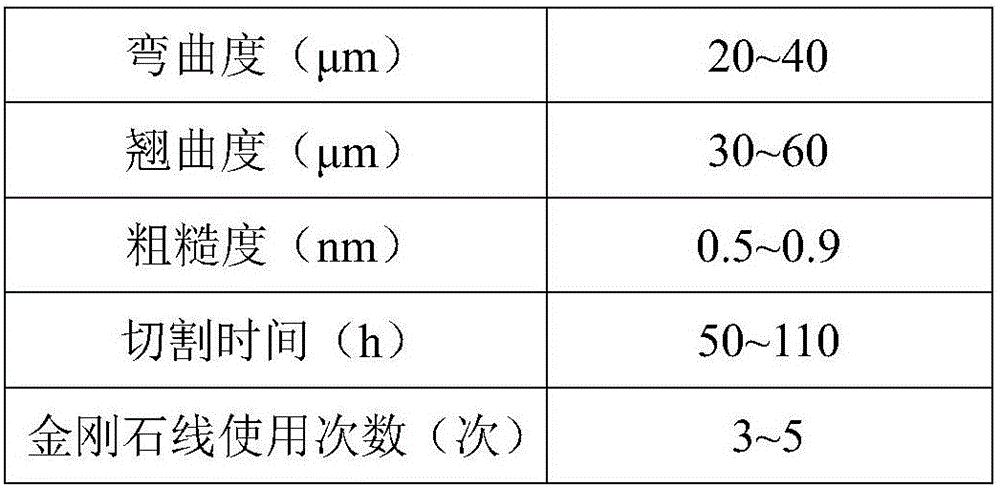

Method for cutting SiC monocrystal with size being six inches or larger through diamond wire and diamond mortar at same time

ActiveCN105818284AAchieve high-quality cuttingNo significant increase in economic costGrinding machinesFine working devicesSingle crystalElectroplating

A method for cutting a SiC monocrystal with the size being six inches or larger through a diamond wire and diamond mortar at the same time includes the steps that the diamond wire dipped in the diamond mortar is adopted for cutting the SiC monocrystal. In the method, a cutting wire is electrically plated with diamond particles on the diamond wire, the diamond particles cannot be thrown out along with high-speed movement of the diamond wire and can make contact with the SiC crystal all the time, and the profile quality of a SiC cutting disk is guaranteed; and meanwhile, diamond abrasive particles in the diamond mortar are clamped and embedded at the positions of gaps between the diamond particles solidified on the surface of the diamond wire and are brought into the SiC crystal at high speed along with the diamond wire, the SiC crystal is cut by the diamond wire and the diamond mortar, and therefore the cutting efficiency is improved.

Owner:SHANDONG UNIV

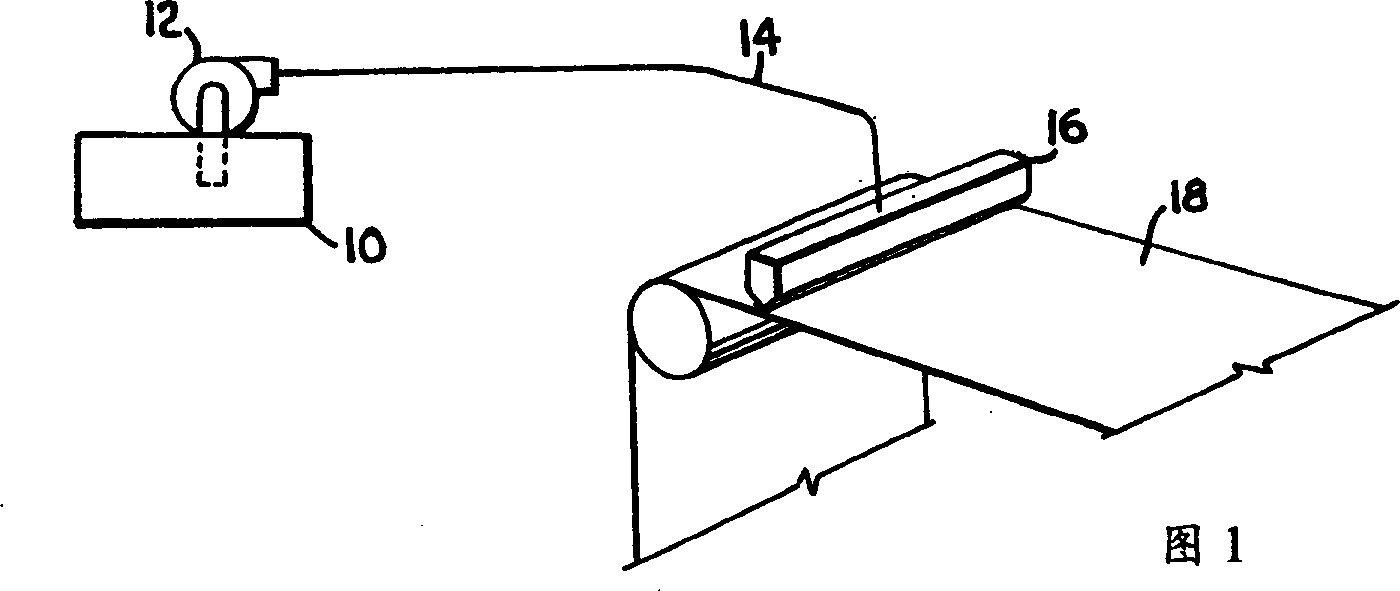

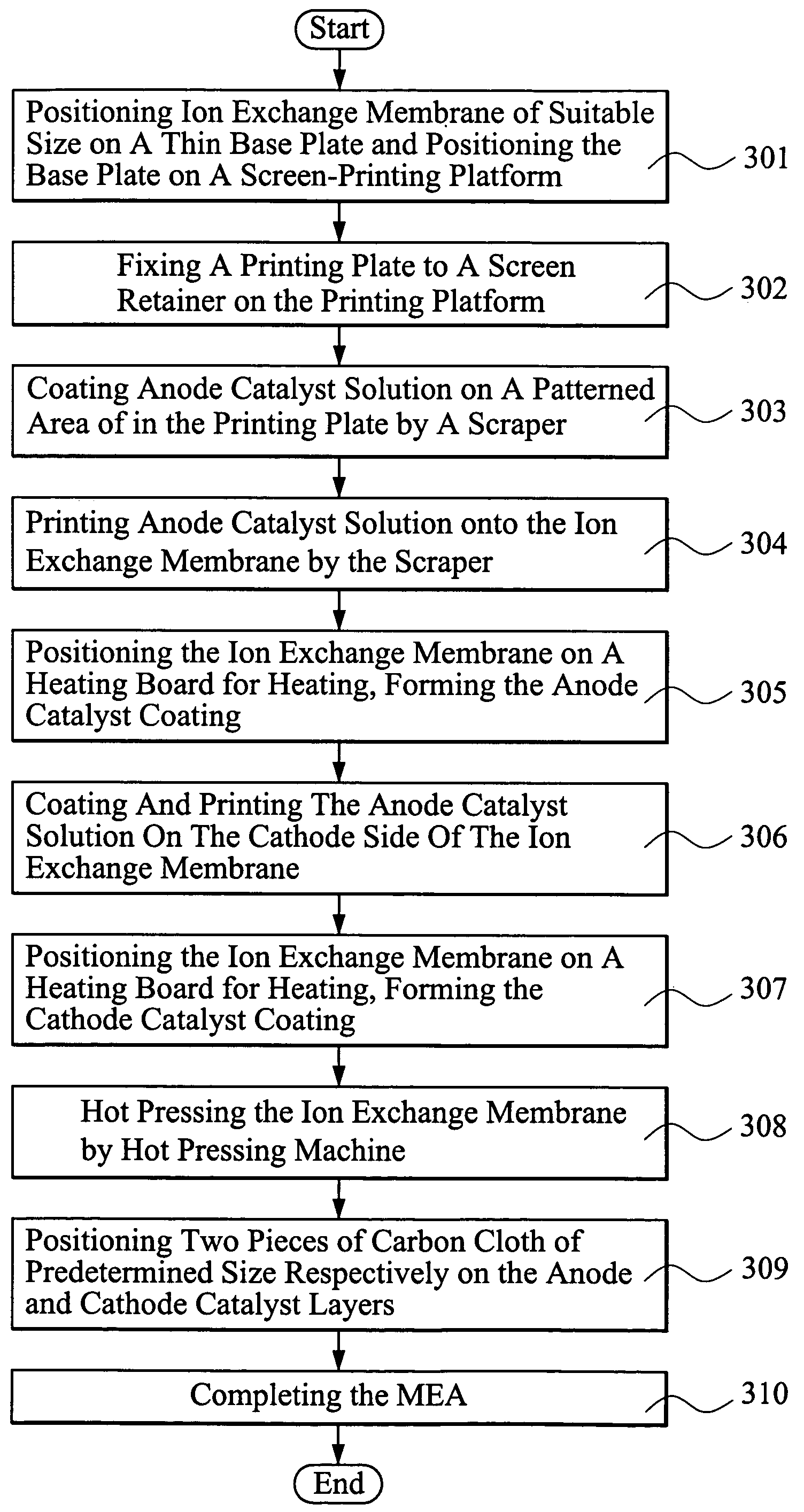

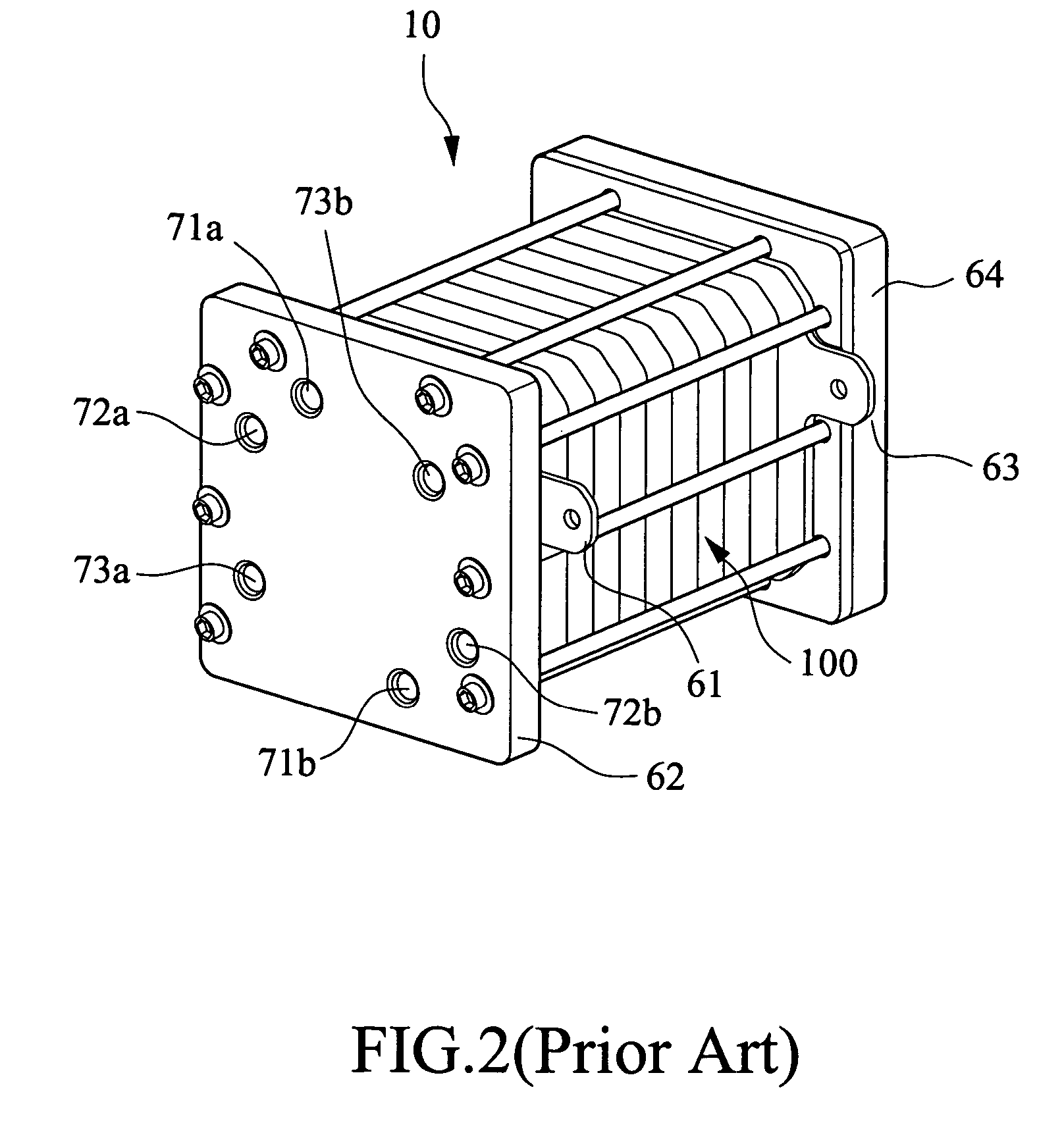

Method for manufacturing membrane electrode assembly of fuel cell by printing processes

InactiveUS7041191B2Easy to controlReduce thickness variationLamination ancillary operationsIon-exchanger regenerationFuel cellsEngineering

A method for manufacturing membrane electrode assembly of fuel cell includes positioning an ion exchange membrane that is cleaned and trimmed to a predetermined size in advance to a base plate, mounting the base plate to a printing platform, attaching a printing plate to the platform, coating a catalyst solution on the printing plate with a scraper, printing the catalyst solution onto the ion exchange membrane with the scraper, heating the ion exchange with a heating board to a temperature of 70–80° C., and waiting for the ion exchange membrane to return flat to complete the coating of the catalyst solution on the ion exchange membrane. The printing and heating steps are repeated for both anode and cathode of the ion exchange membrane. The ion exchange membrane is further subject to hot pressing and then a piece of carbon cloth is positioned on the catalyst coating to serve as a diffusion layer. This completes the manufacturing of the membrane electrode assembly.

Owner:INST NUCLEAR ENERGY RES ROCAEC

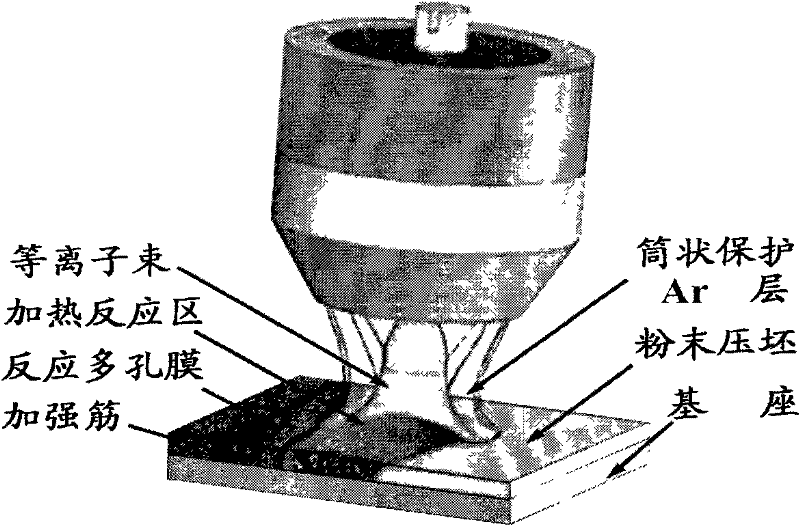

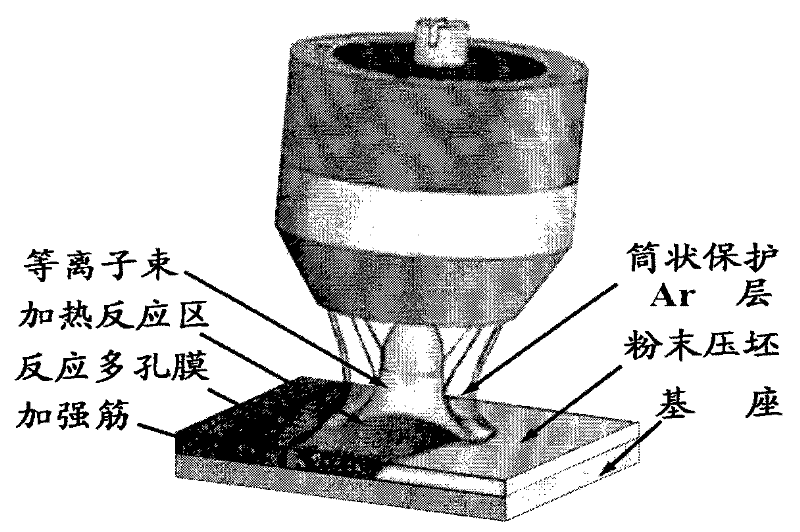

NiAl-TiB2-TiC-Al2O3 porous membrane and its synthetic method with plasma heating reaction

The invention discloses an NiAl-TiB2-TiC-Al2O3 porous membrane and a method for synthesizing the porous membrane with a plasma heating reaction. The method is that a composite material porous membrane is obtained through treating a plasma beam as a heat source, Ni powder, Al powder, Ti powder, B4C powder and B2O3 powder as raw materials, and argon as a plasma generation gas and a protective gas, and carrying out a reaction on the raw materials of powders under the effects of heating by a plasma beam flow and protecting by argon. The composite porous material integrates performance advantages of an Ni-Al intermetallic compound material and ceramic materials of TiB2, TiC, and Al2O3, and allows applications of the materials in aspects of catalysis, filtration, separation and the like to be enlarged.

Owner:SHANDONG UNIV OF SCI & TECH

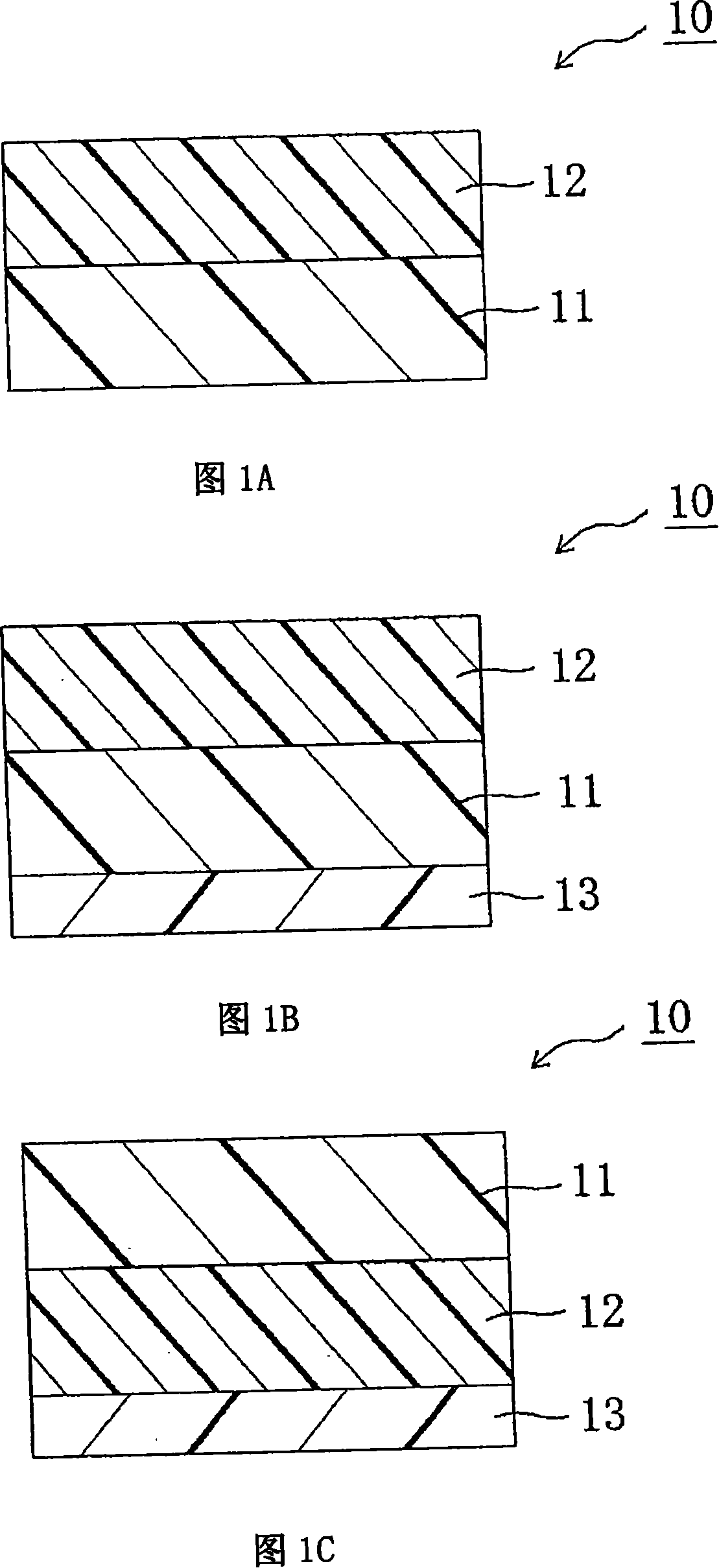

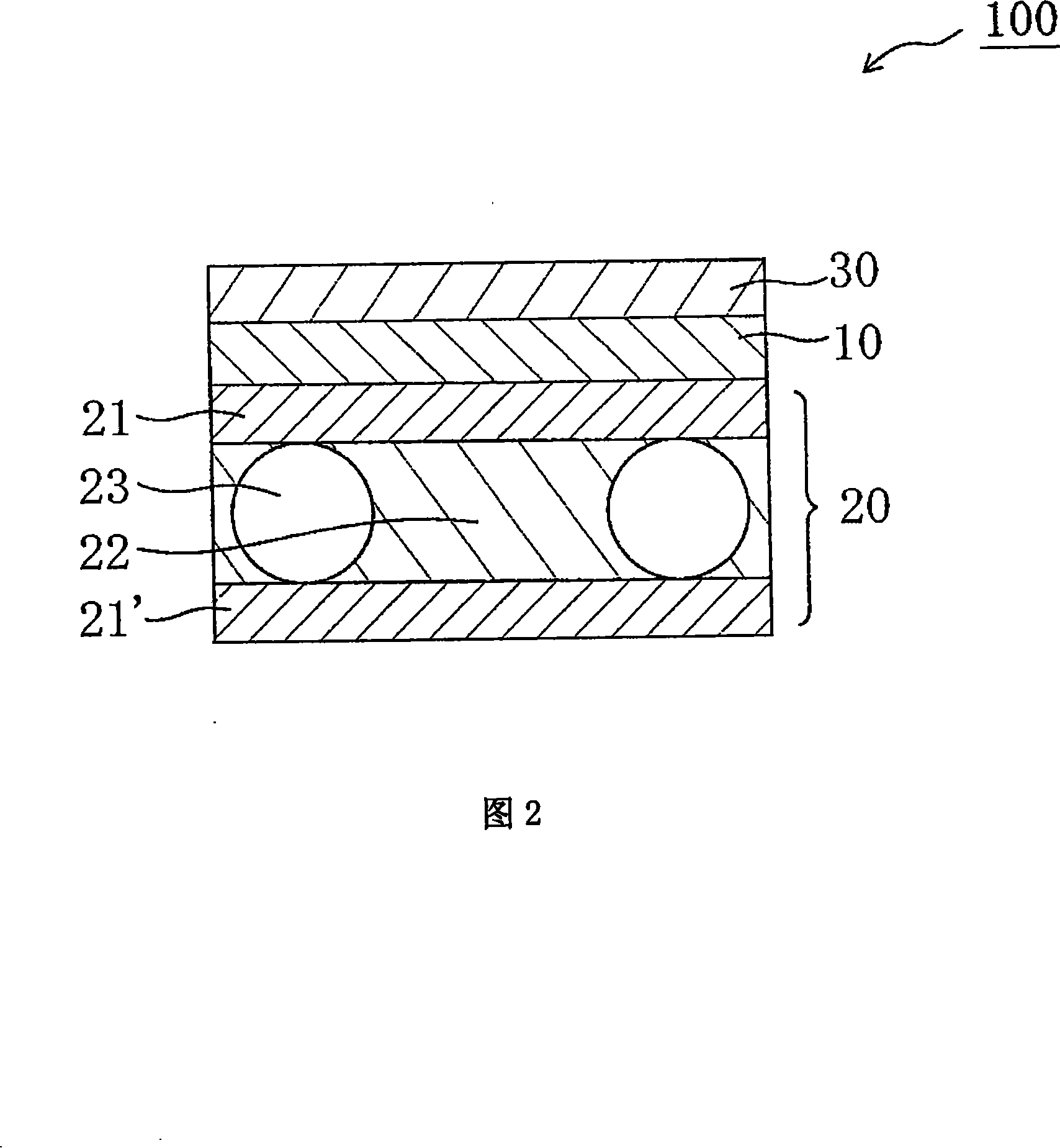

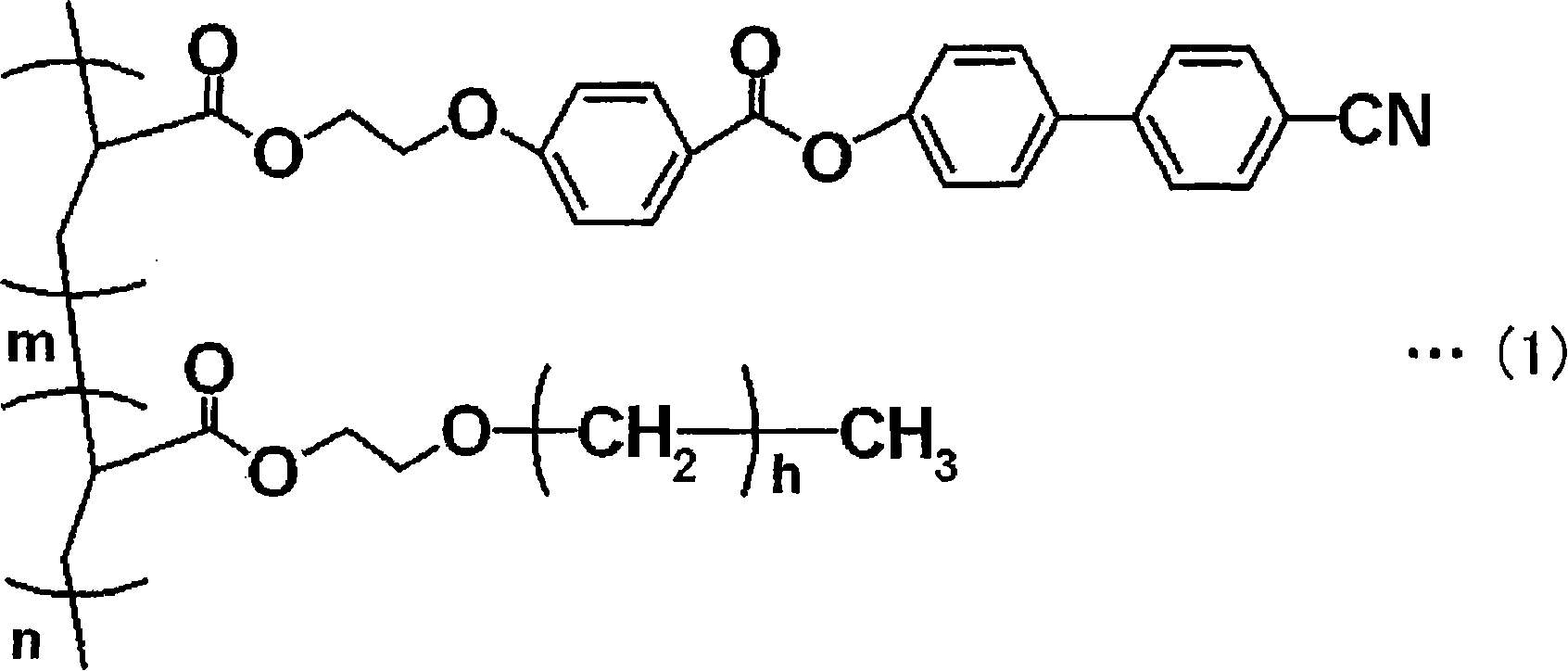

Laminate, liquid crystal panel, and liquid crystal display apparatus

InactiveCN101210975ALittle change in thicknessStatic indicating devicesDiffusing elementsLiquid-crystal displayAcrylate polymer

A laminate according to one embodiment of the present invention includes: a substrate; and a birefringent layer formed on the substrate and satisfying the relationship of nz>nx=ny, wherein the birefringent layer Contains acrylate polymers.

Owner:NITTO DENKO CORP

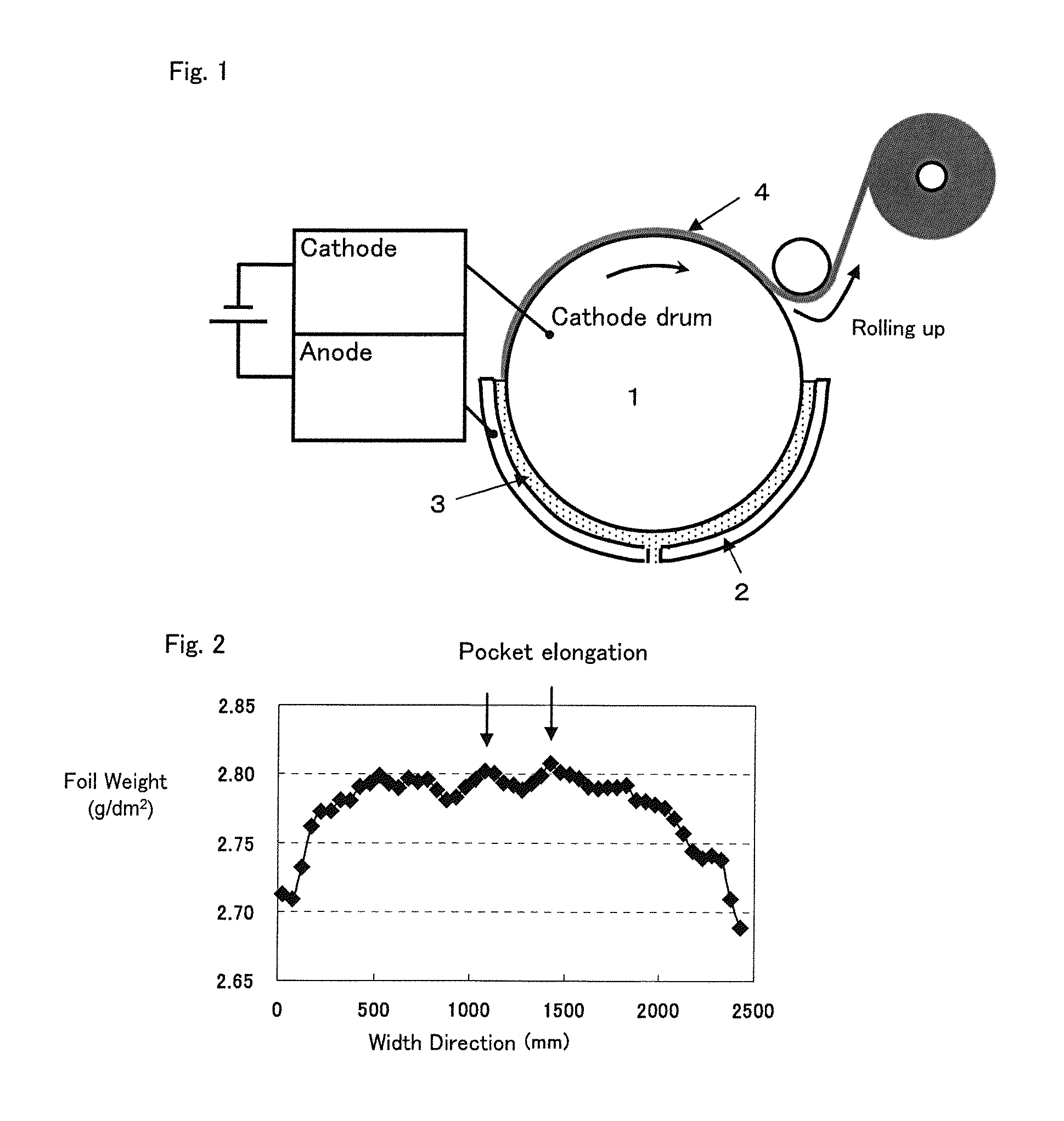

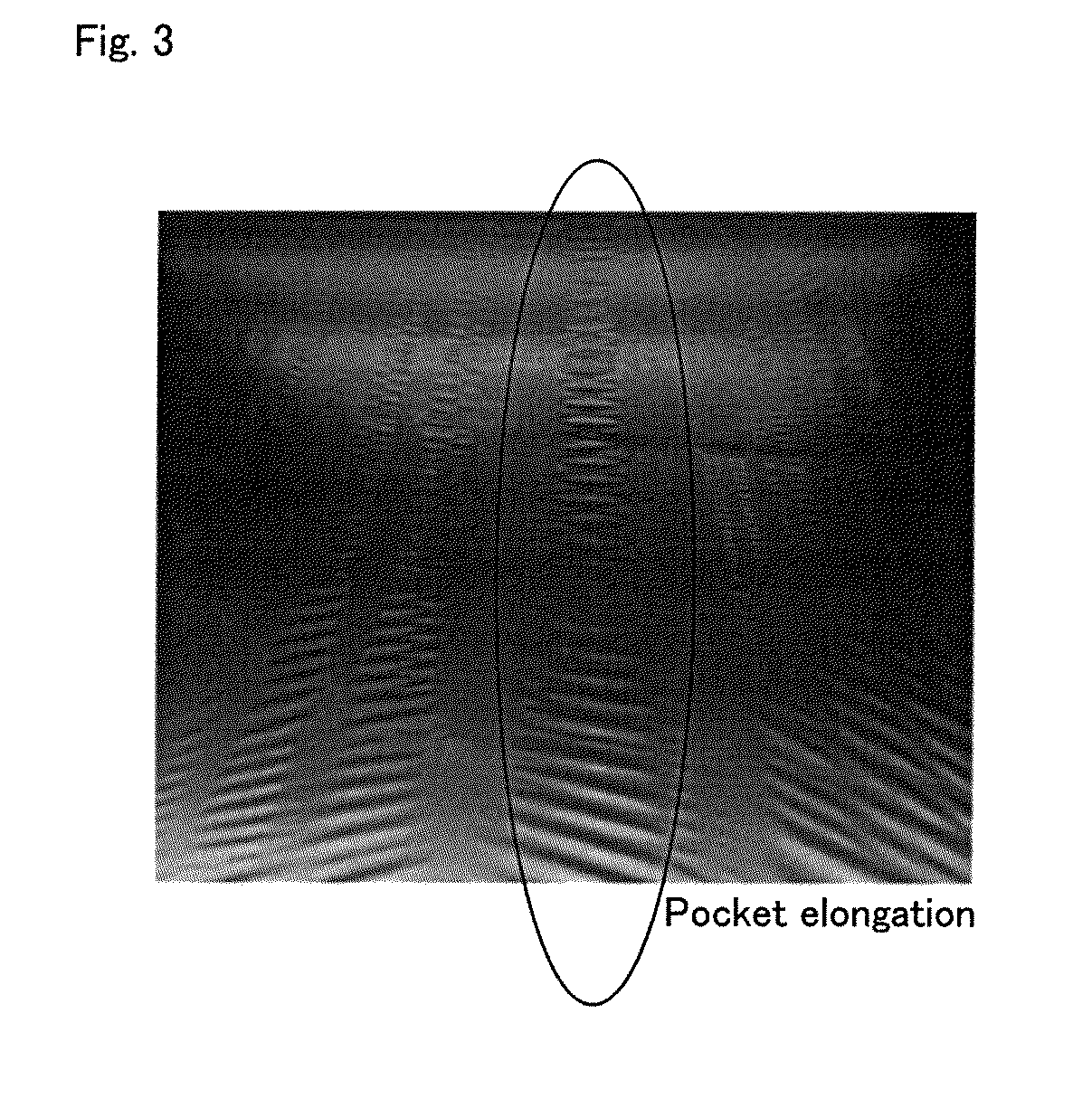

Electrolytic copper foil

InactiveUS20130256140A1Reduce surface roughnessLittle change in thicknessDuplicating/marking methodsPrinted circuit aspectsCopper foilMetallurgy

Provided is an electrolytic copper foil having a surface roughness Rz of 2.0 μm or less, wherein a foil thickness difference in the width direction is 1.5% or less. Also provided is the electrolytic copper foil, wherein the foil thickness difference in the width direction is 1.3% or less. Further provided is the electrolytic copper foil, wherein a variation in the roughness in the width direction (Rzmax−Rzmin) / Rzavg is 15% or less. An object of the present invention is to provide an electrolytic copper foil having low surface roughness, wherein the formation of an “elongation wrinkle” and a discolored streak along the length direction is suppressed by allowing the thickness to be uniform in the width and length directions.

Owner:JX NIPPON MINING& METALS CORP

Porous, electrically conductive sheet and method for production thereof

InactiveCN1338126ALower resistanceHigh fluid permeabilityCell electrodesFibre treatmentElectrical resistance and conductanceFiber

A porous, electrically conductive sheet, which (a) comprises a sheet formed with a number of carbon fibers having an organic substance adhered thereto, (b) has an electrical resistance in the direction of thickness of 50 m OMEGA cm<2> or less, (c) has a maximum diameter for causing fracture of 25 mm or less, and (d) has a compression ratio (the ratio of a thickness of a compressed sheet to that of an original sheet) of 40 % or less. The porous, electrically conductive sheet can be produced by a method comprising (a) a sheet-forming step of scooping a number of carbon fibers being dispersed in a liquid up onto a net to thereby form a carbon fiber sheet, (b) an organic substance adhesion step of rendering an organic substance to adhere to the formed carbon fiber sheet as a binder for carbon fibers, (c) a drying step of drying the sheet having the organic substance adhered thereto, and (d) a pressing step of pressing the dried sheet with a face pressure of 0.49 to 9.8 Mpa and / or of subjecting the sheet to a roll pressing with a clearance of 300 mu m or less.

Owner:TORAY IND INC

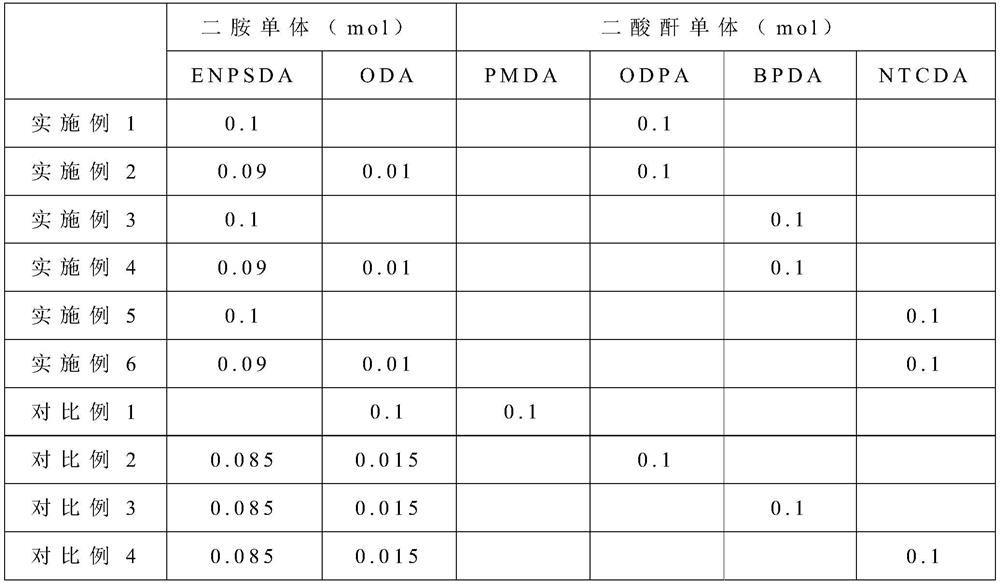

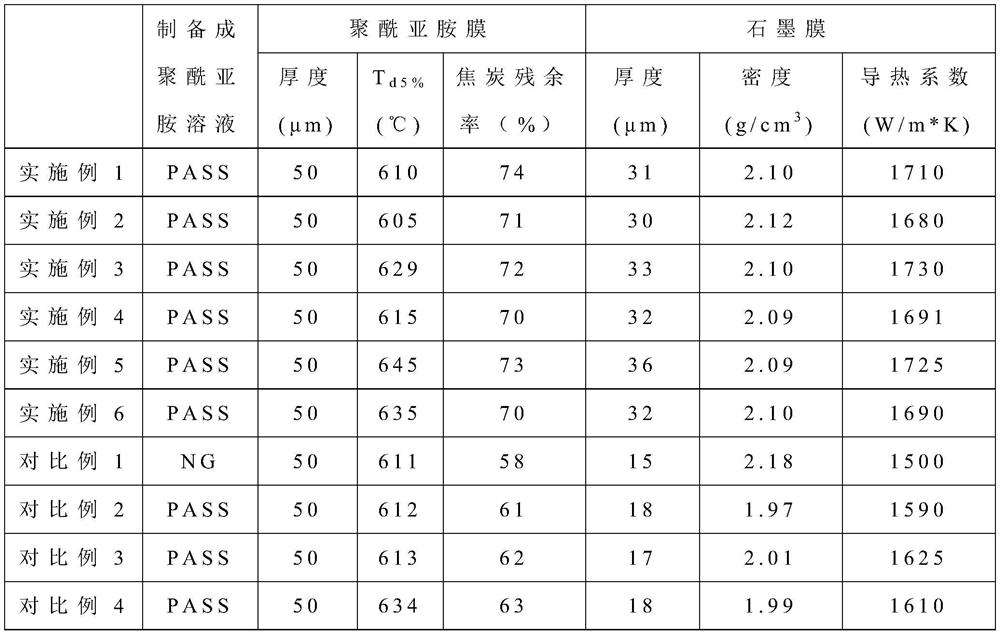

Polyimide film, preparation method thereof and graphite film

ActiveCN114437349AHigh degree of cyclizationHigh carbon residual rateCarbon compoundsImidePolymer science

The present application provides a polyimide film comprising a polyimide polymer. The polyimide polymer comprises a reaction product of a diamine monomer and a dianhydride monomer, and the diamine monomer comprises N, N-bis (4-aminophenyl)-N, N-diphenyl-1, 4-phenylenediamine. The polyimide film provided by the invention can be used for preparing a thick graphite film. The invention also provides a graphite film prepared from the polyimide film and a preparation method of the polyimide film.

Owner:广东鸿翔瑞材料科技有限公司

Substrate for inkjet printing and method of manufacturing the same

ActiveUS7833612B2Reduce manufacturing costLarge variation of tensionStatic indicating devicesLayered productsOrganic layerHigh surface

A substrate for inkjet printing, which includes a photoresist layer structure on a base substrate, and a method of manufacturing the same are provided. The substrate, which has high surface tension variation and slight thickness variation, may be manufactured at a low cost. The substrate includes a discontinuous organic layer structure made of a fluorinated hydrocarbon or a polysiloxane on the photoresist layer structure.

Owner:SAMSUNG DISPLAY CO LTD

Unit for production of tubular resin film

InactiveUS7625194B2Small variationQuality improvementHollow filament manufactureConfectioneryEngineering

Owner:SUMITOMO BAKELITE CO LTD

Vapor chamber semi-shearing forming method

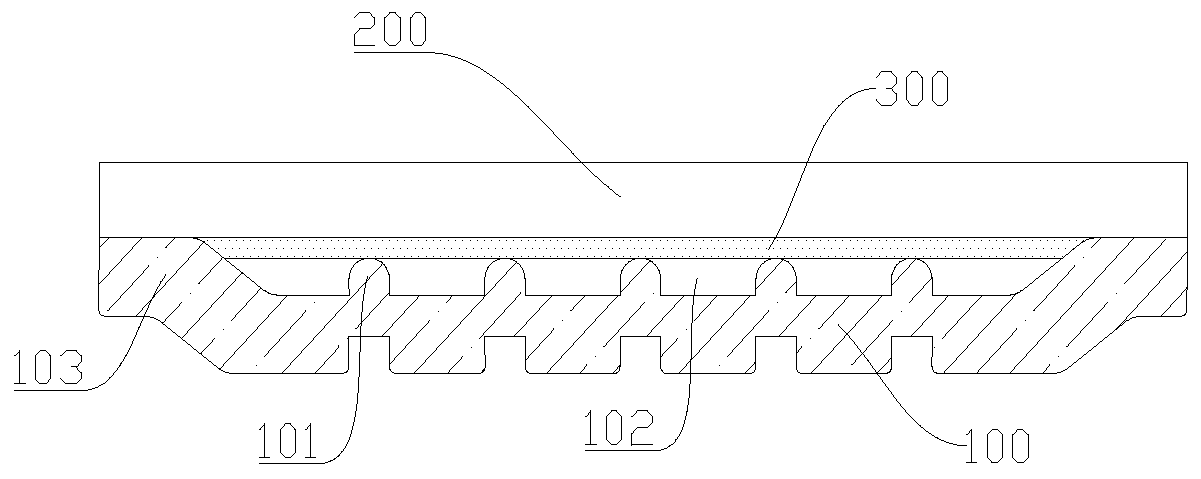

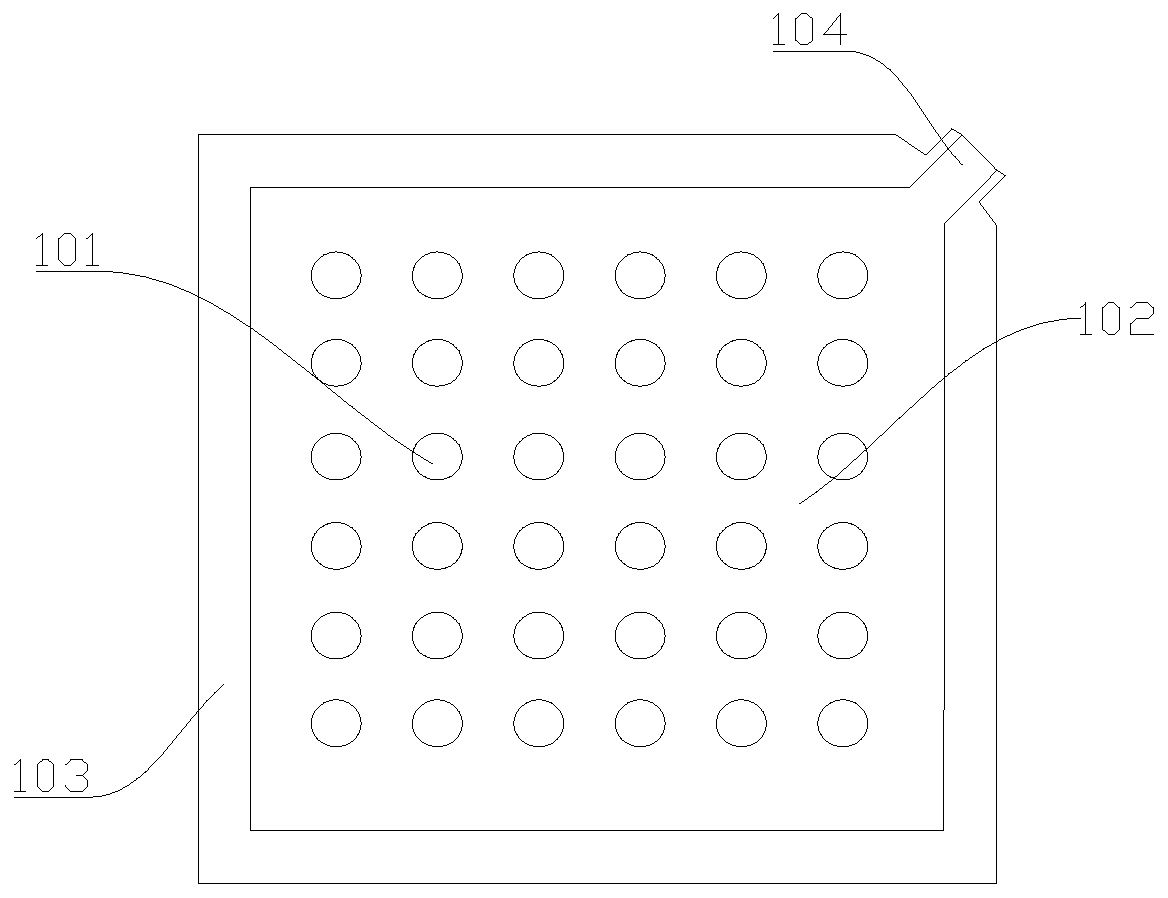

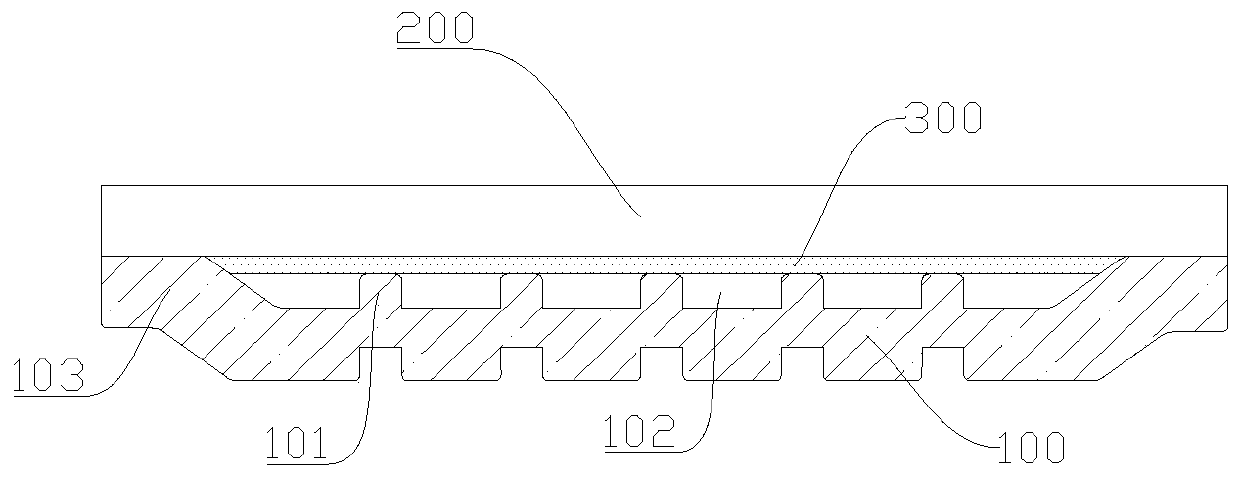

ActiveCN110779362AAvoid pollutionLittle change in thicknessSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

The invention discloses a vapor chamber semi-shearing forming method. The vapor chamber semi-shearing forming method includes the following steps of providing a first cover plate and a second cover plate, forming a plurality of supporting columns in the middle of the first cover plate in a semi-shearing stamping mode, performing semi-shearing on the edge to form a welding flange edge, reserving anair outlet, buckling the second cover plate on the first cover plate and performing sealing along the welding flange edge after a heat adsorption core body is adsorbed into the first cover plate or the second cover plate to form a cavity, vacuumizing the cavity after injecting working fluid into the cavity through the air outlet to form negative pressure, and finally sealing the air outlet to prepare a vapor chamber. The vapor chamber cover plates are manufactured in the semi-shearing stamping mode, production cost is reduced, and the environmental protection is facilitated; by arranging positioning blocks, the positioning precision is ensured, and the percent of pass of the product is improved; and through a welding mode, the production cycle of the whole technological process is greatlyshortened, and efficient production is realized.

Owner:DONGGUAN LINGJIE PRECISION MACHINING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com