Patents

Literature

2324 results about "Powder mixture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A powder is an assembly of dry particles dispersed in air. If two different powders are mixed perfectly, three theoretical powder mixtures can be obtained: the random mixture, the ordered mixture or the interactive mixture.

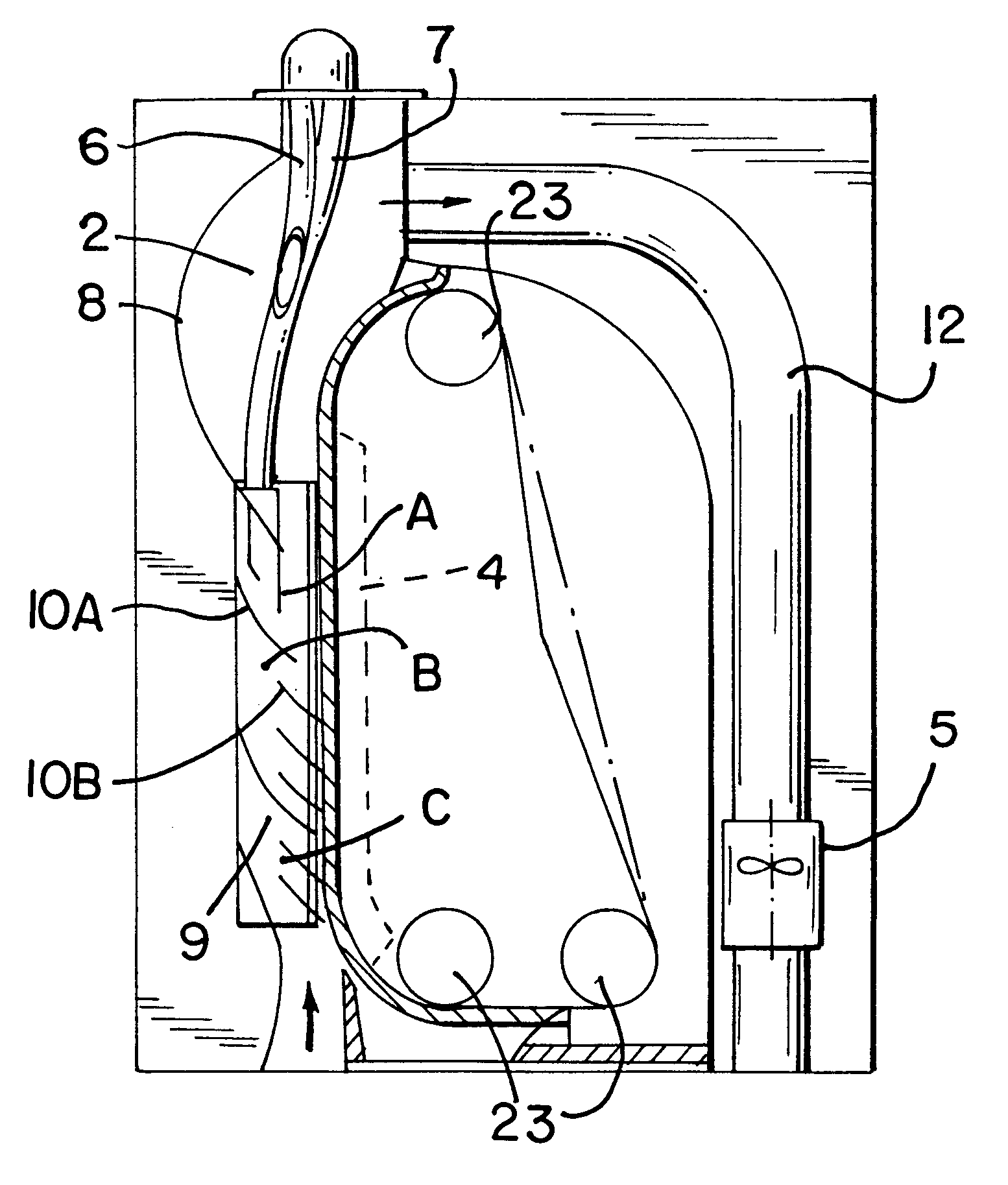

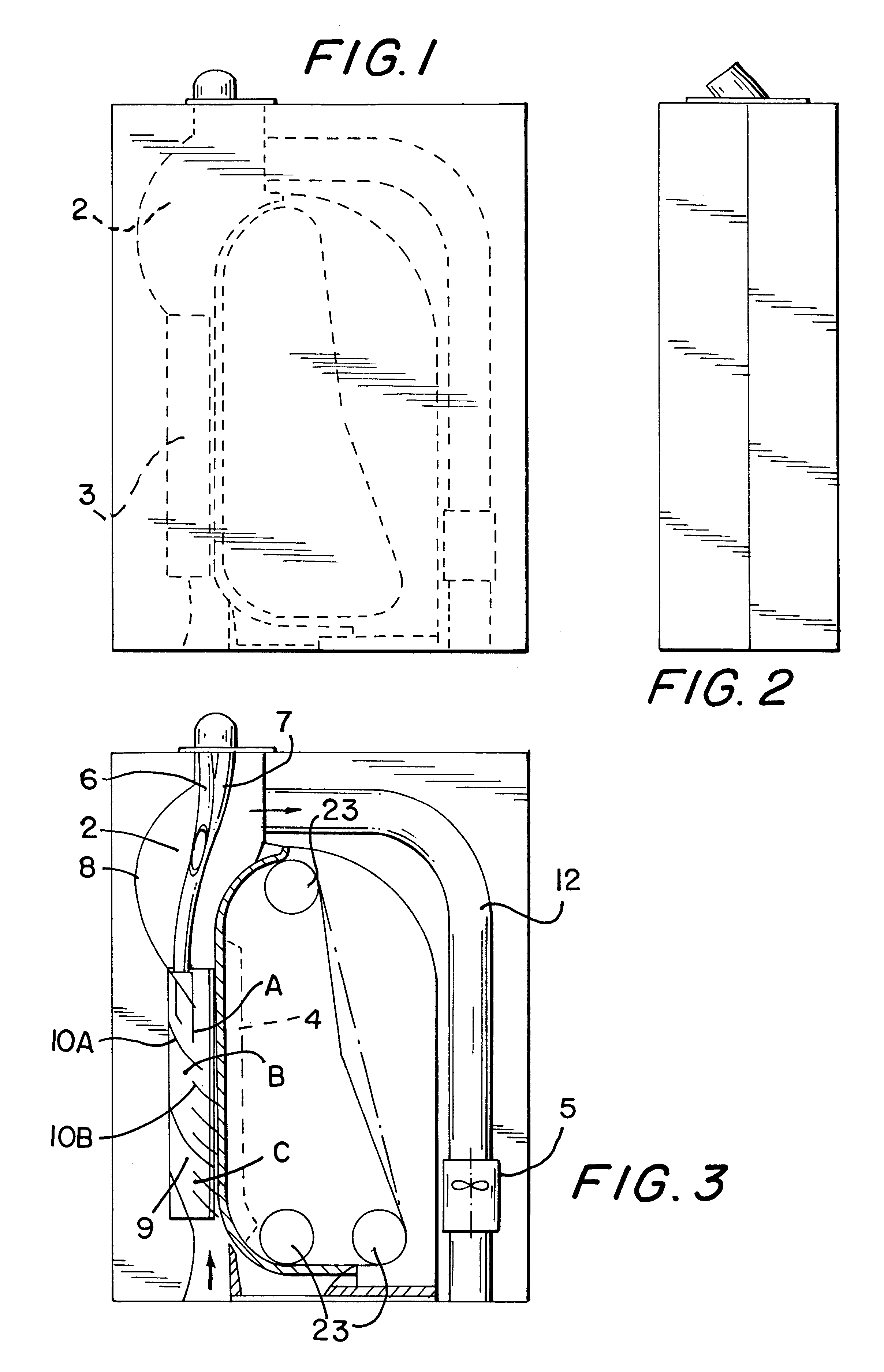

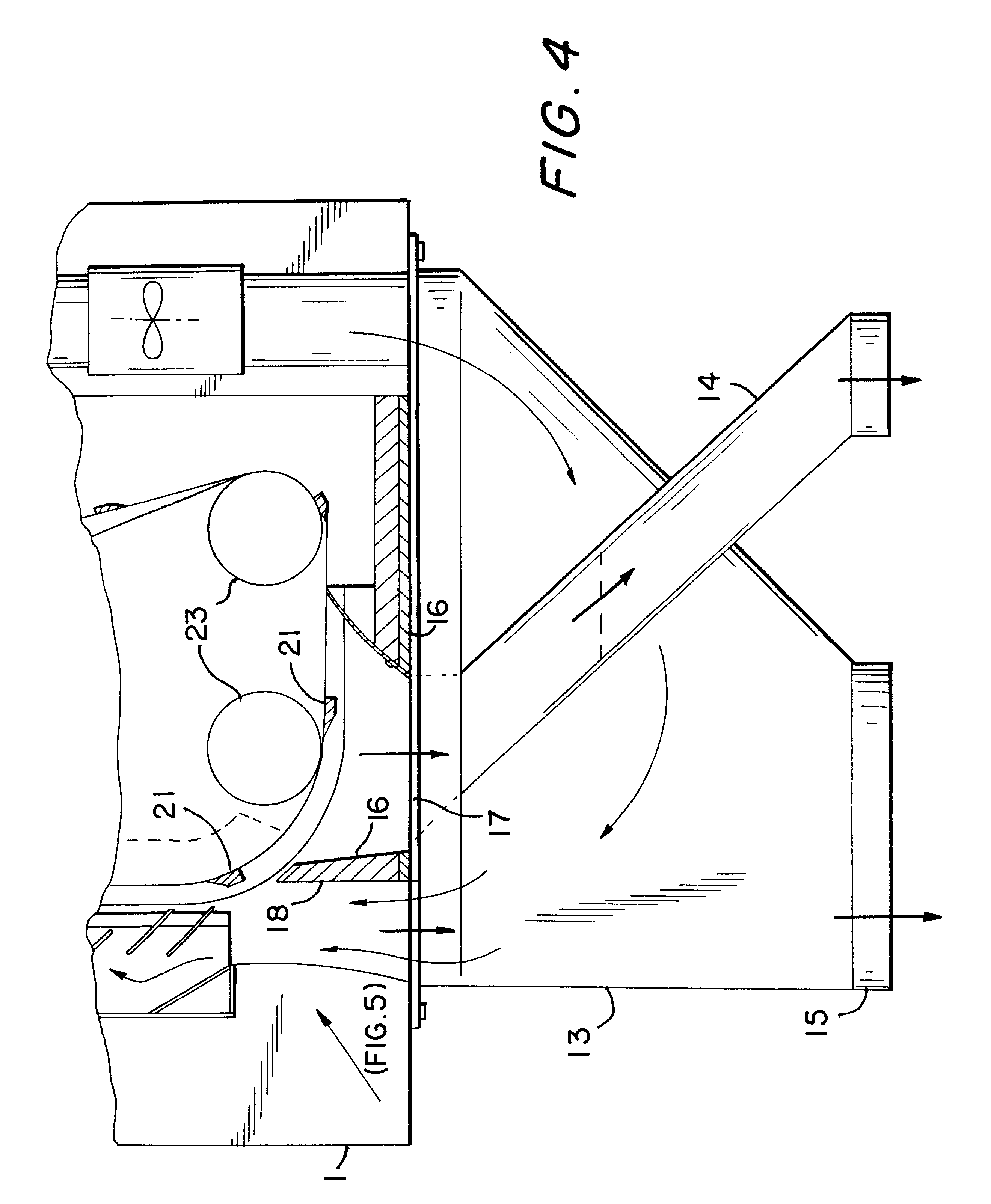

Magnetic decontamination device and method

InactiveUS6350296B1Water/sewage treatment by magnetic/electric fieldsFiltration separationPowder mixtureStream flow

A device and method for removing metalliferous particles from a powder so that the powder can be reused. A contaminated powder fluid stream flows down tube (6 / 7) into zones A, B and C adjacent the surface of a magnet (4). The flow flows past the surface of the magnet (4) and is directed towards the surface of the magnet (4) by baffles (10A, 10B). The magnet (4) separates metallic particles from powder particles and these metallic particles are removed from the face of the magnet (4) by scraper bars (21) conveyed by endless belts (22) supported by roller sets (23). The device can also include a fan (5) for promoting the movement of air in a counter direction to the delivered powder mixture.

Owner:WARNER CLIFFORD ROY

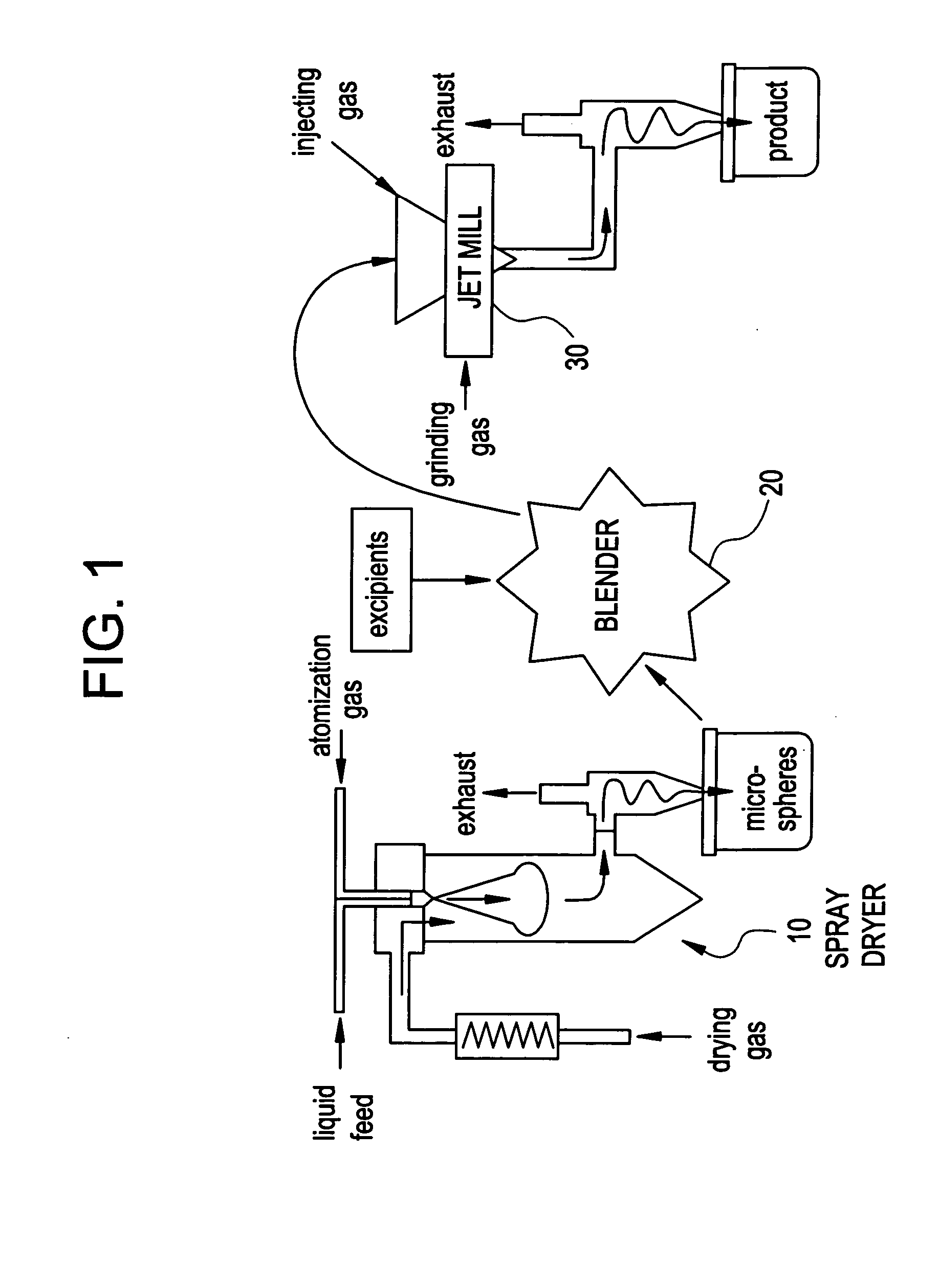

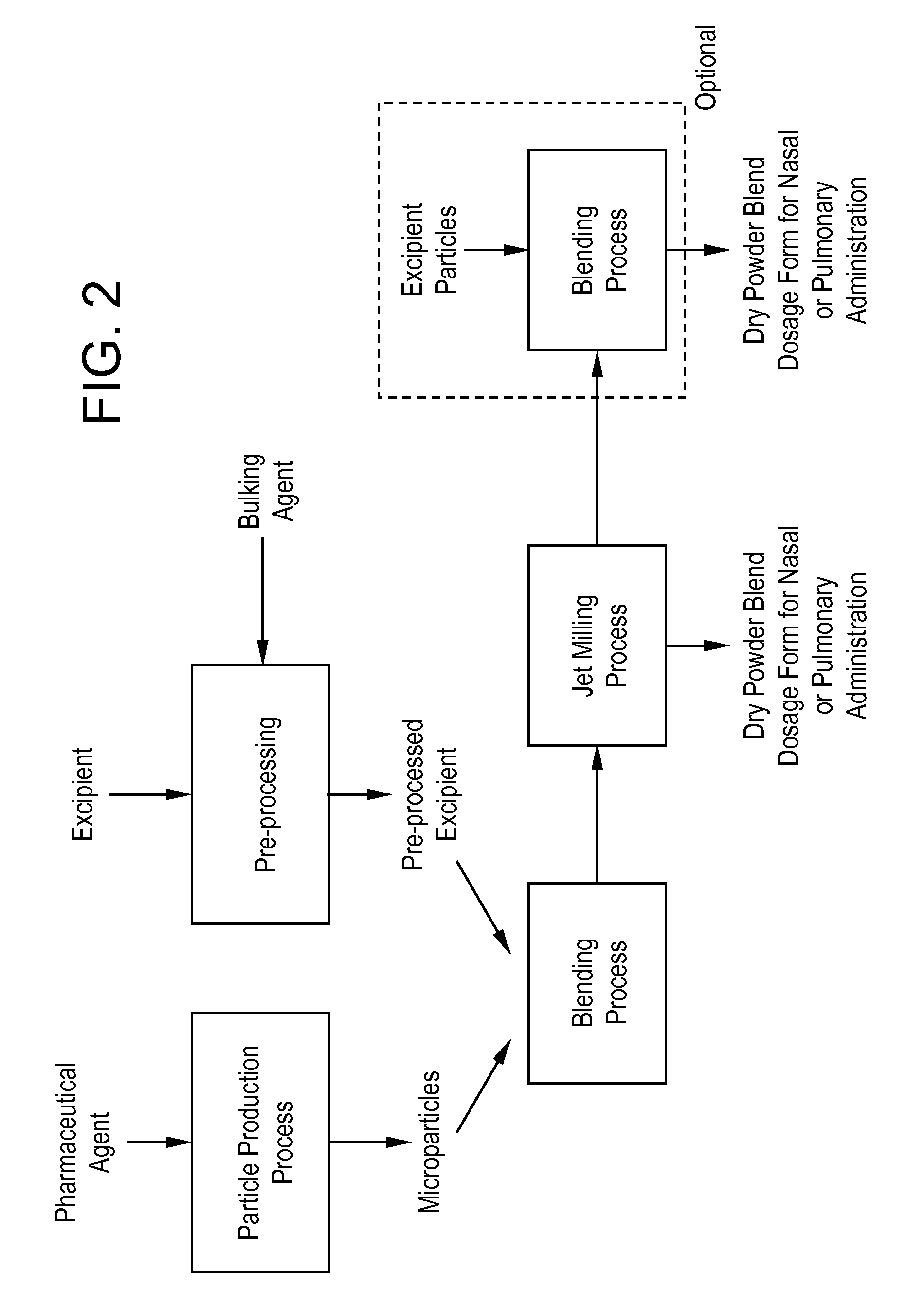

Methods for making pharmaceutical formulations comprising microparticles with improved dispersibility, suspendability or wettability

InactiveUS20050079138A1Good dispersibilityImproved suspendabilityPowder deliveryGranulation by liquid drop formationPowder mixtureMicroparticle

Methods are provided for making a dry powder blend pharmaceutical formulation, comprising the steps of: (a) providing microparticles which comprise a pharmaceutical agent; (b) blending the microparticles with at least one excipient in the form of particles to form a powder blend; and (c) jet milling the powder blend to form a dry powder blend pharmaceutical formulation having improved dispersibility, suspendability, or wettability as compared to the microparticles of step (a) or the powder blend of step (b). The method can further include dispersing the dry powder blend pharmaceutical formulation in a liquid pharmaceutically acceptable vehicle to make an formulation suitable for injection. Alternatively, the method can further include processing the dry powder blend pharmaceutical formulation into a solid oral dosage form. In one embodiment, the microparticles of step (a) are formed by a solvent precipitation or crystallization process.

Owner:ACUSPHERE INC

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS20050142211A1Facilitated releaseTo promote metabolismBiocideSurgical adhesivesO-Phosphoric AcidPowder mixture

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

Smooth, flexible powder coatings

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

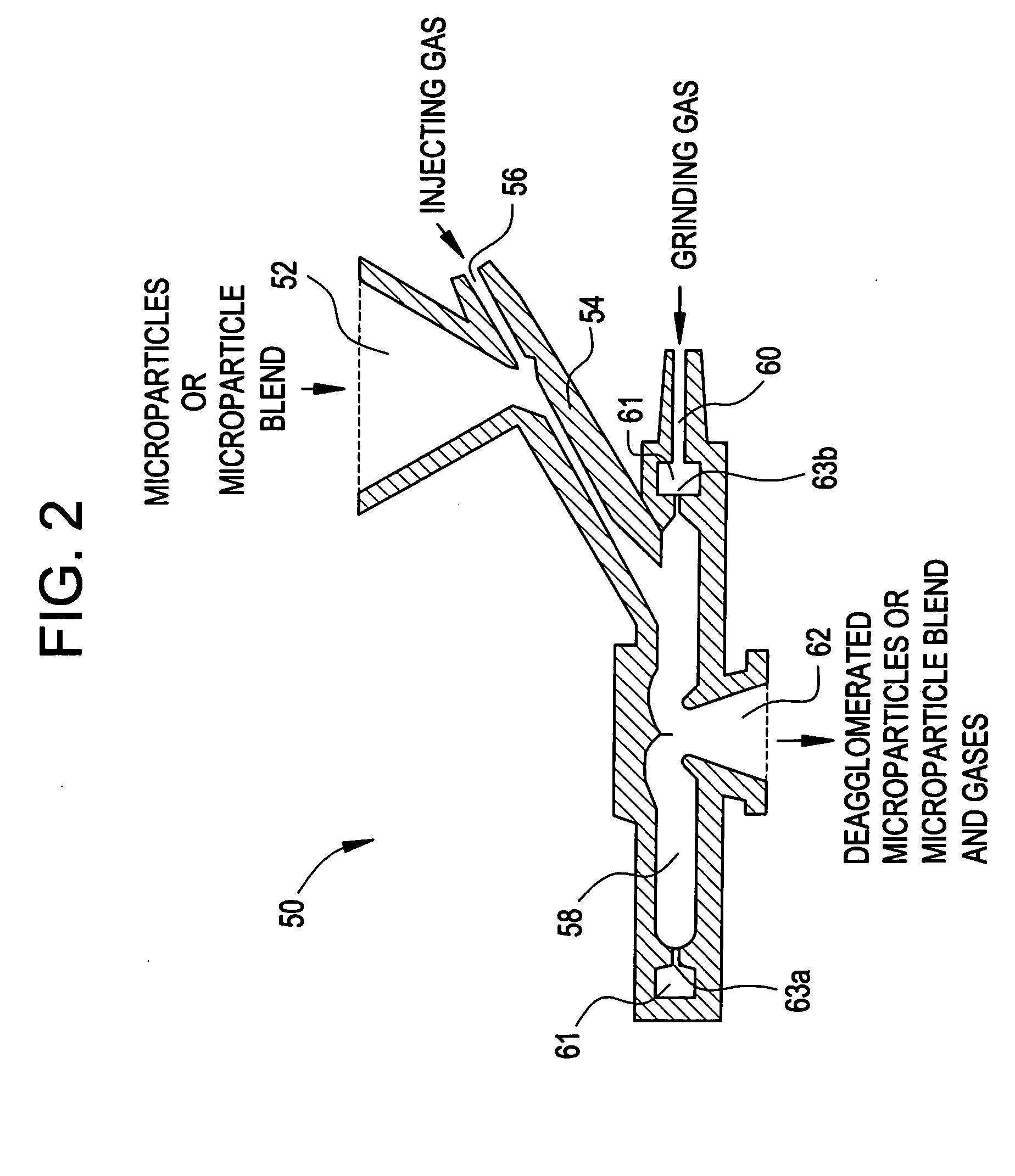

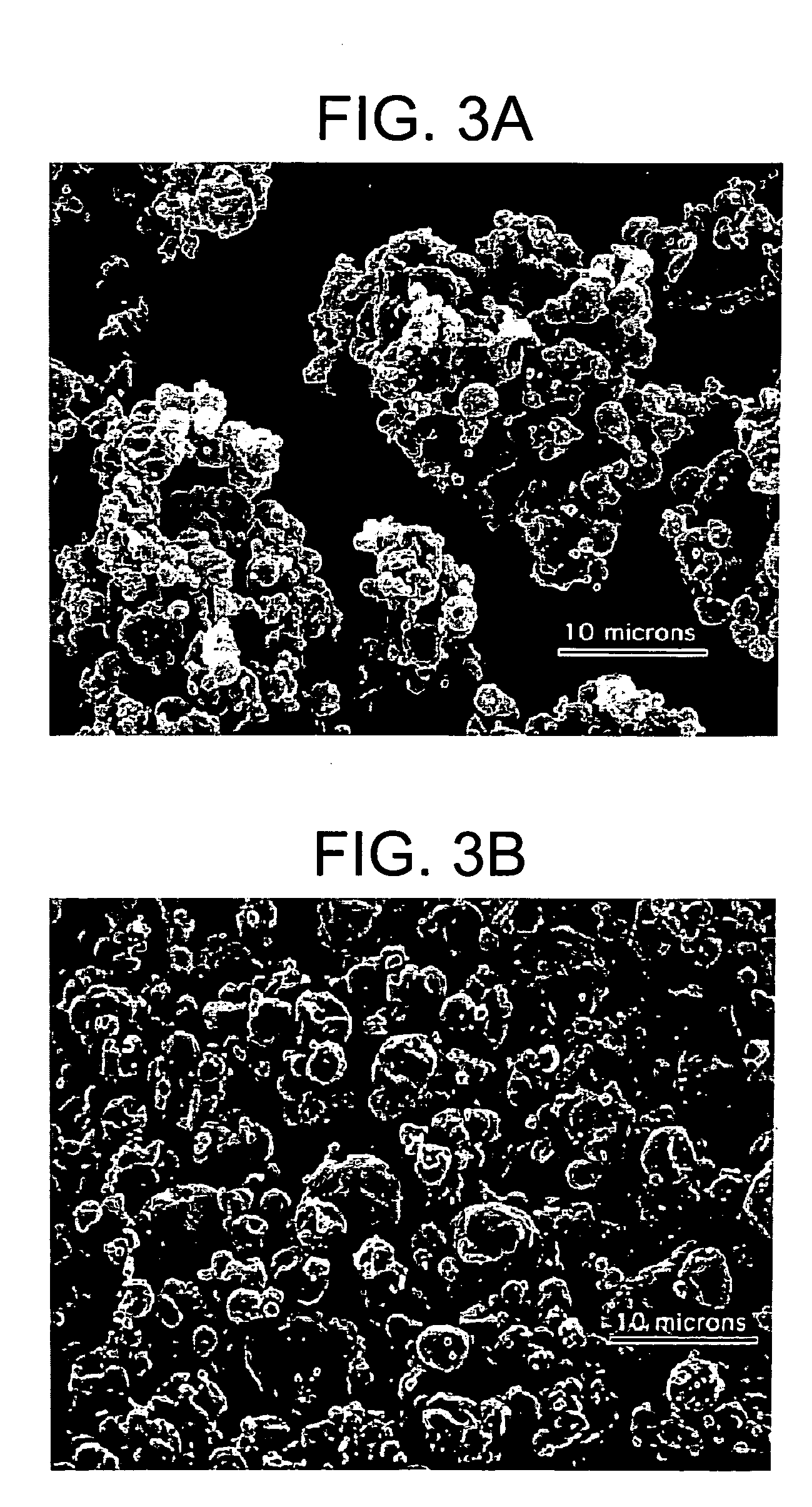

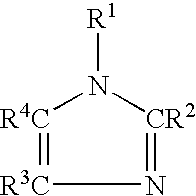

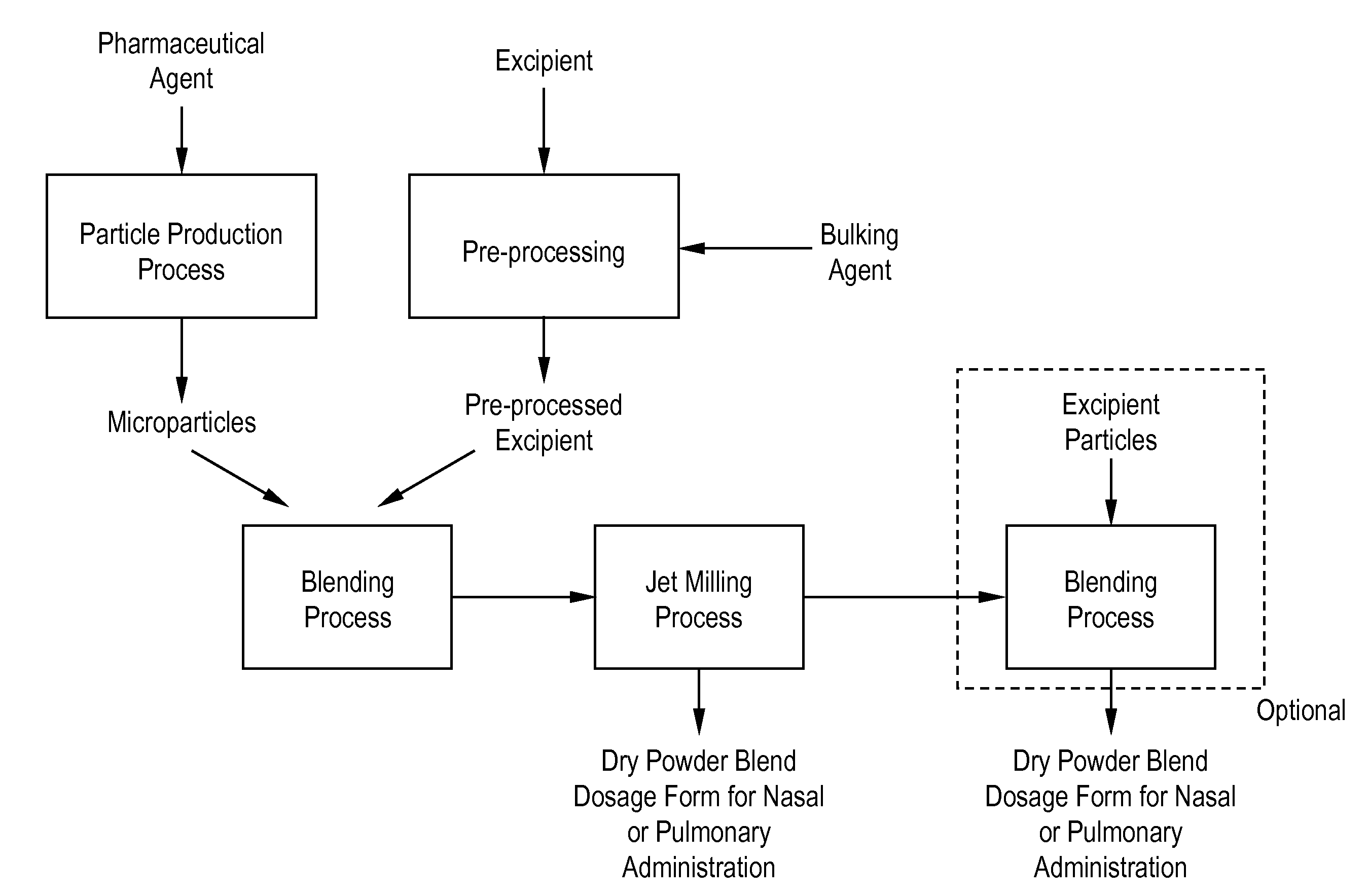

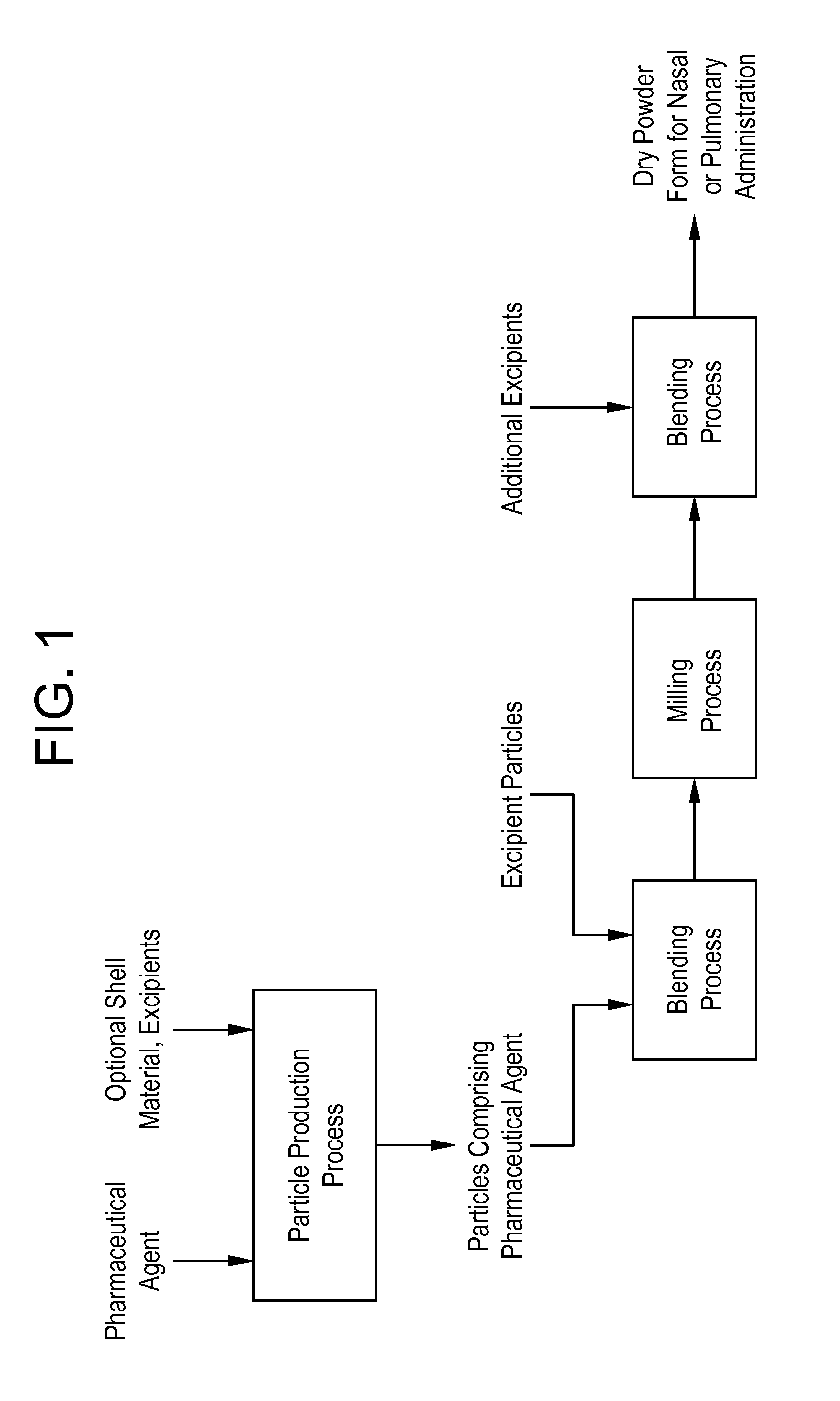

Processes for making particle-based pharmaceutical formulations for pulmonary or nasal administration

InactiveUS20070178166A1Improve stabilityStability storage conditionPowder deliverySpray deliveryPowder mixtureNanoparticle

Dry powder pharmaceutical formulations for pulmonary or nasal administration are made to provide an improved respired dose. These formulations may be blends of milled blends and may include a phospholipid, alone or in combination with other excipient materials. In one case, the process includes the steps of (a) providing particles which comprise a pharmaceutical agent, (b) blending the particles with particles of at least one first excipient to form a first powder blend; (c) milling the first powder blend to form a milled blend which comprises microparticles or nanoparticles of the pharmaceutical agent; and (d) blending the milled blend with particles of a second excipient to form a blended dry powder blend pharmaceutical formulation suitable for pulmonary or nasal administration.

Owner:ACUSPHERE INC

Process for preparing a catalyst

InactiveUS6342465B1Uniform penetrationConsiderable energy savingOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPowder mixtureActive component

A process for preparing a catalyst which has a catalytically active coating of high surface area finely divided materials and catalytically active components on an inert carrier structure. A powder mixture of the finely divided materials used is impregnated with a solution of precursor compounds of the catalytically active components. By suitable combination of the finely divided materials and the precursor compounds and appropriate management of the impregnation process, a highly dispersed deposition and adsorption of the catalytically active components is ensured on the finely divided materials. Then ai aqueous coating dispersion is produced using the impregnated powder mixture and the carrier structure is coated therewith. The coating is then dried and calcined.

Owner:UMICORE AG & CO KG +1

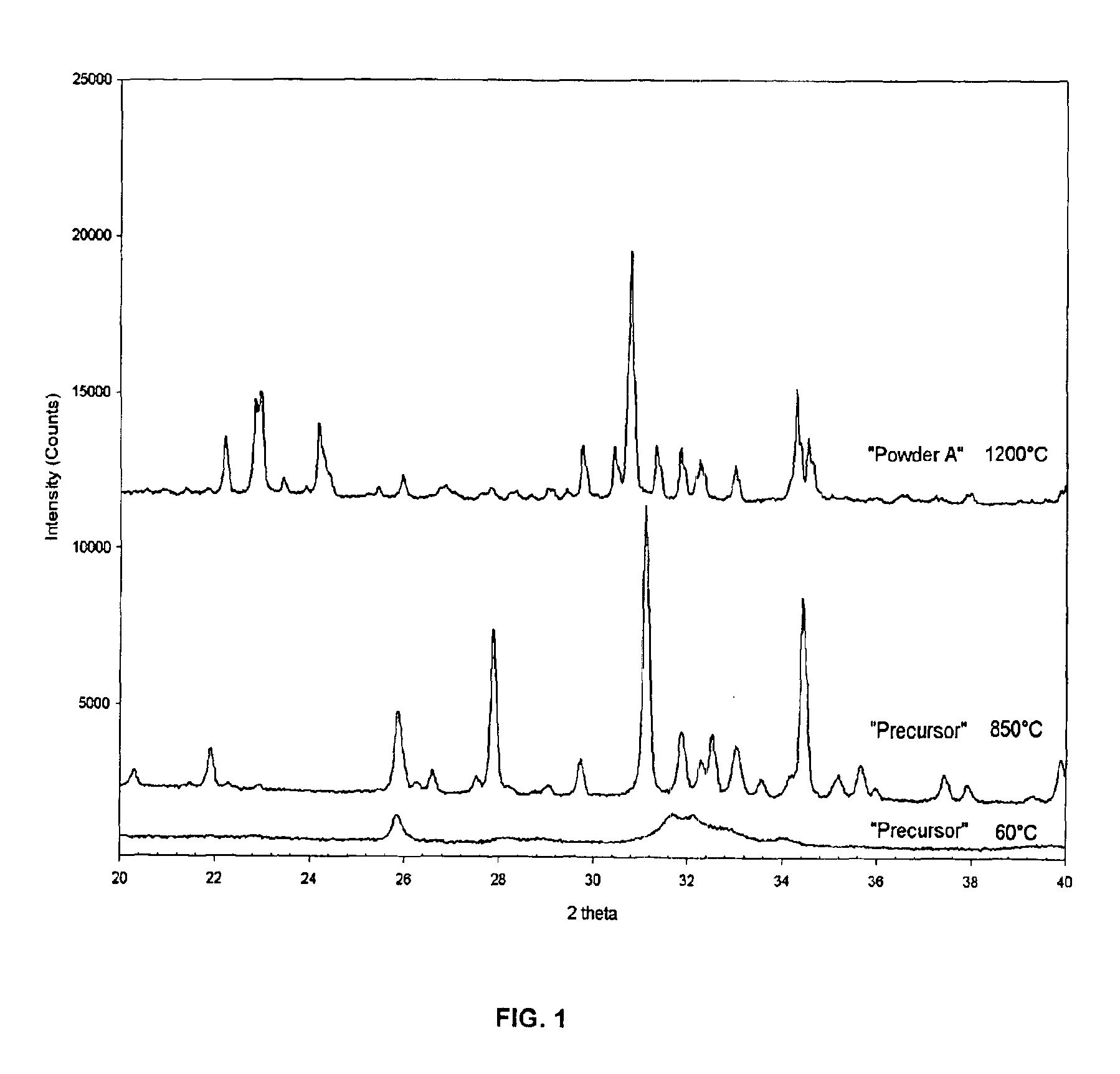

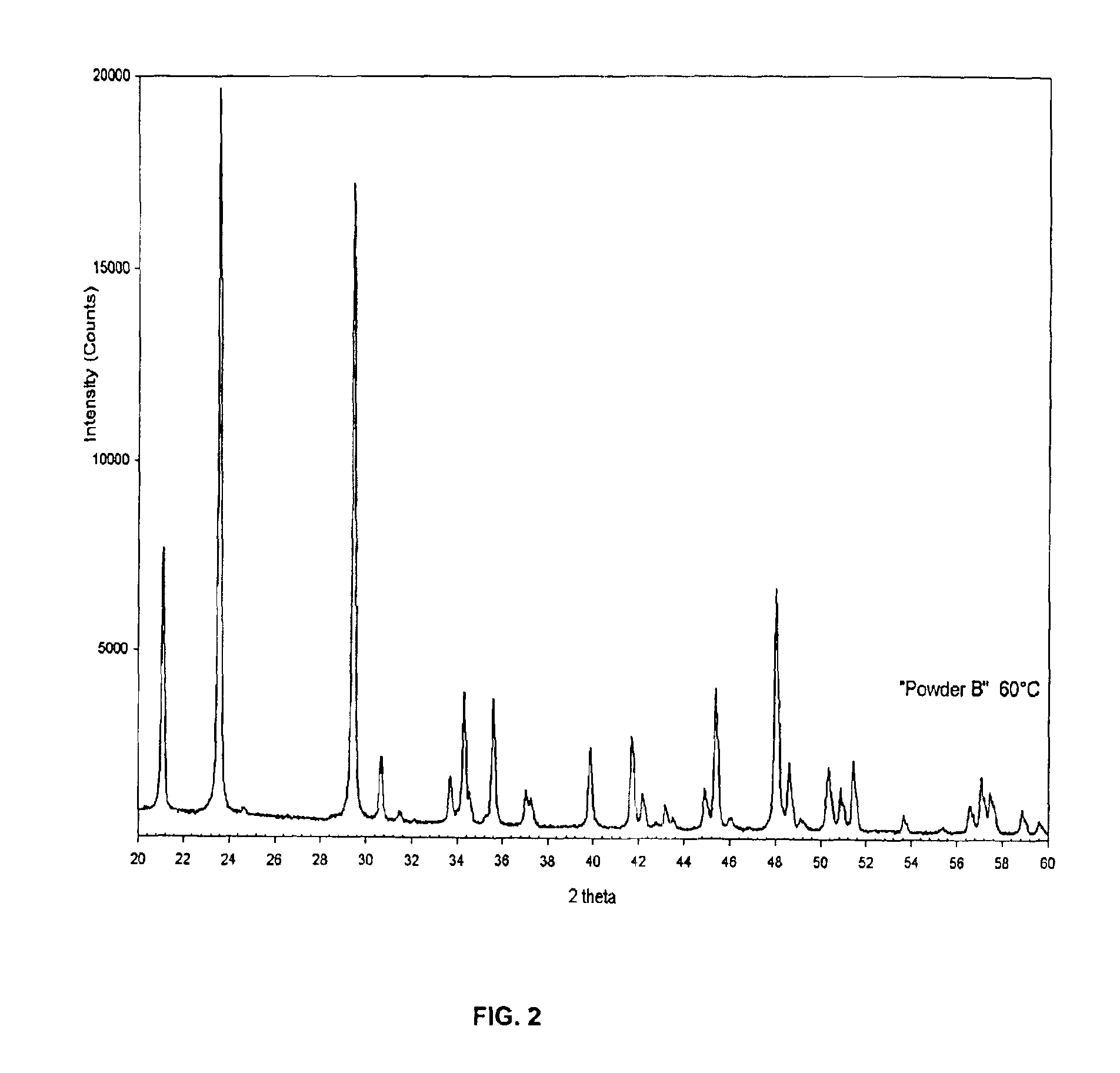

Calcium phosphate cement composition and a method for the preparation thereof

ActiveUS6929692B2Good water solubilityIncreased formationOther chemical processesBone implantChemical synthesisCalcium biphosphate

The invention describes a new calcium phosphate cement powder, whose composition can best be described over the Ca / P molar ratio range of 1.35 to 1.40, most preferably 1.39, and whose two components were prepared by wet chemical synthesis procedures. One component is chemically-synthesized, bi-phasic alpha-TCP (Ca3(PO4)2, 95 wt %)+HA (Ca10(PO4)6(OH)2, 5 wt %) powder, while the second component is again a chemically-synthesized, single-phase DCPD (CaHPO4·2H2O) powder. A setting solution (Na2HPO4·2H2O) is used to form a self-setting calcium phosphate cement from the powder mixture. This cement can be used as bone filler or bone substitute in applications, which require higher rates of resorption.

Owner:DR AHMET CUNEYT TAS

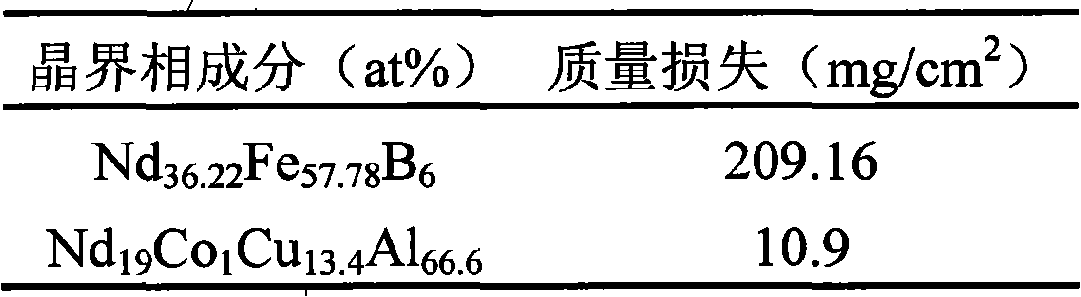

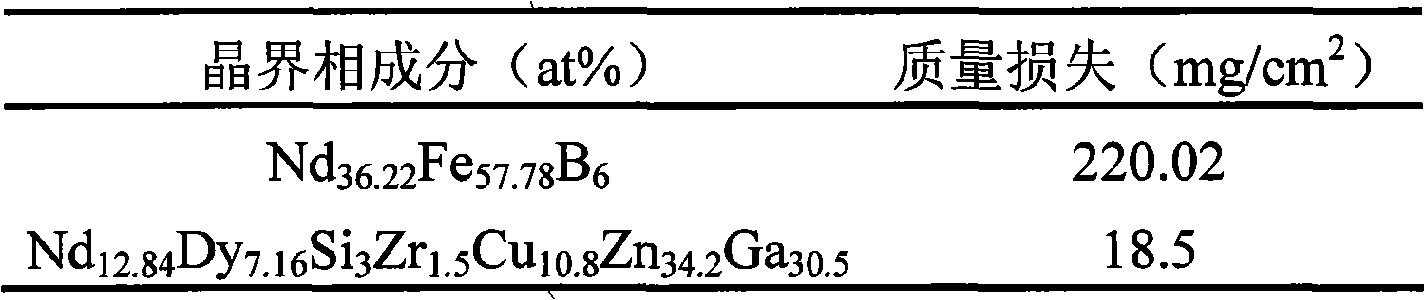

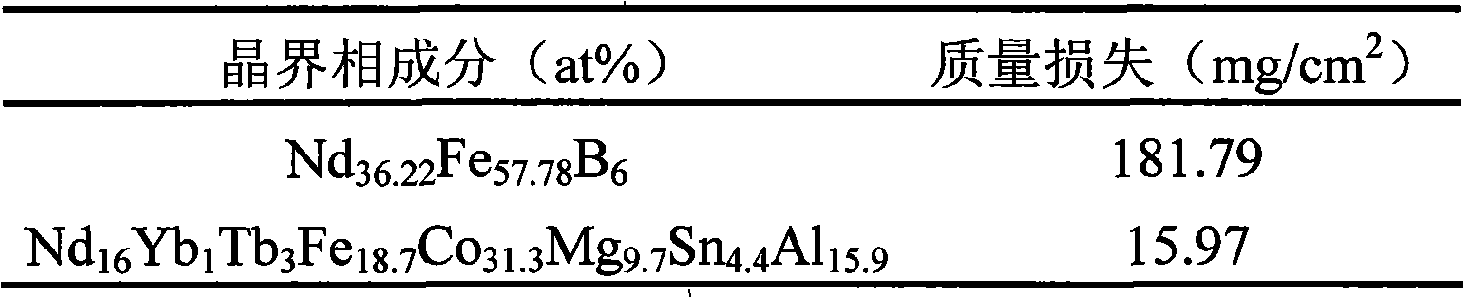

Grain boundary phase-reconstructed high-corrosion resistance Sintered NdFeB magnet and preparation method thereof

ActiveCN101320609ALow melting pointGuaranteed MagneticInorganic material magnetismInductances/transformers/magnets manufactureElectrode potentialPowder mixture

The invention discloses a sintered Nd-Fe-B magnet with high corrosion resistance and the grain boundary reconstruction and a preparation method thereof. The composition of the invention is that: NdeFe100-e-f-gBfMg, wherein, e is greater than or equal to 6 and equal to or less than 24, f is greater than or equal to 5. 6 and equal to or less than 7, g is greater than or equal to 0.03 and equal to or less than 8, M is one or some of elements Dy, Tb, Pr, Sm, Yb, La, Co, Ni, Cr, Nb, Ta, Zr, Si, Ti, Mo, W, V, Ca, Mg, Cu, Al, Zn, Ga, Bi, Sn and In; The method is that: main phrase alloy and reconstructed grain boundary phase alloy are respectively pulverized and mixed uniformly; the powder mixture is pressed to a mould in the magnetic field, and fabricated into a sintering magnet in a high vacuum sintering furnace. By the reconstruction of the grain boundary phase composition, the invention can obtain the grain boundary phase alloy with low melting point and high electrode potential, decrease the potential difference between the main phase and the grain boundary phase on the basis of ensuring the magnetic properties, promote the intrinsic corrosion resistance of magnet, and has the advantages of simple process, low cost and being suitable for the batch production. Therefore, by combining the grain boundary reconstruction and double alloy method, the sintered Nd-Fe-B magnet with high intrinsic corrosion resistance can be prepared.

Owner:ZHEJIANG UNIV

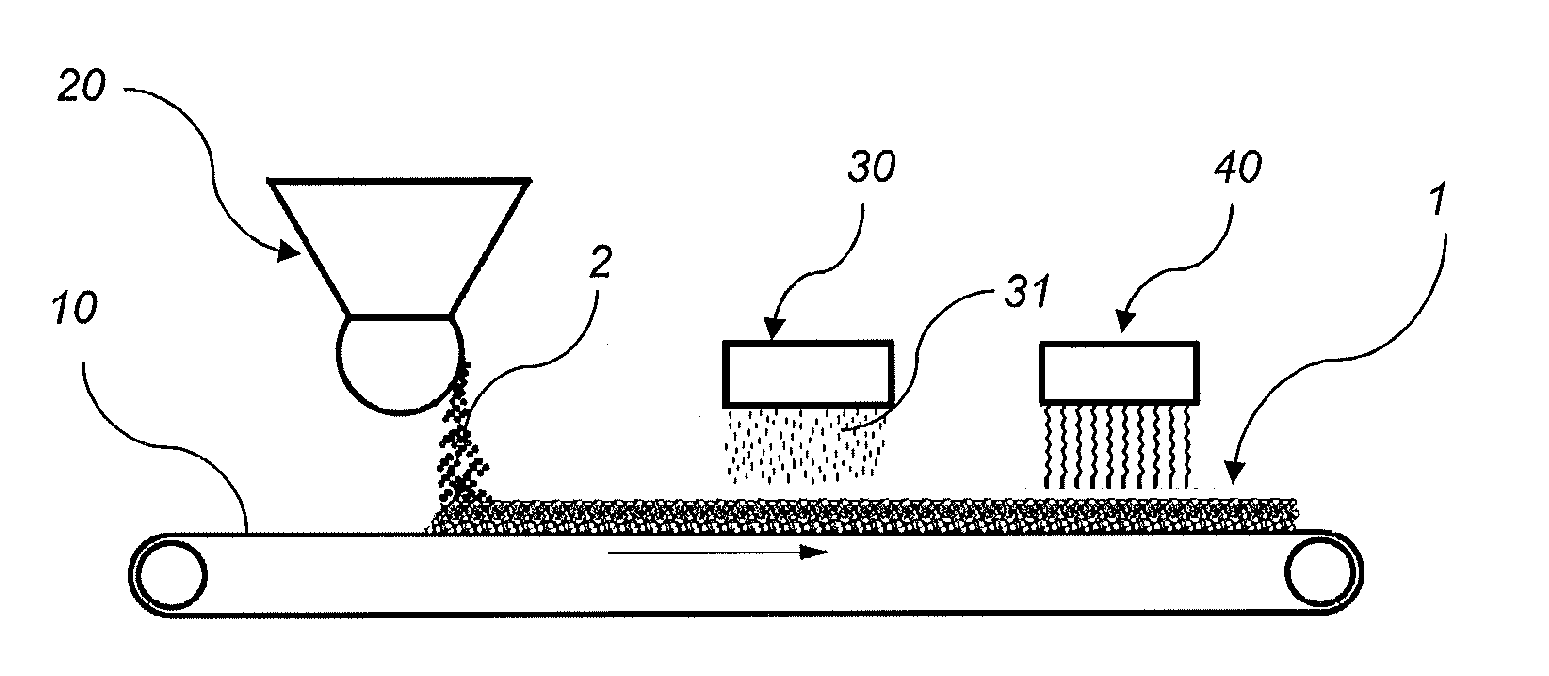

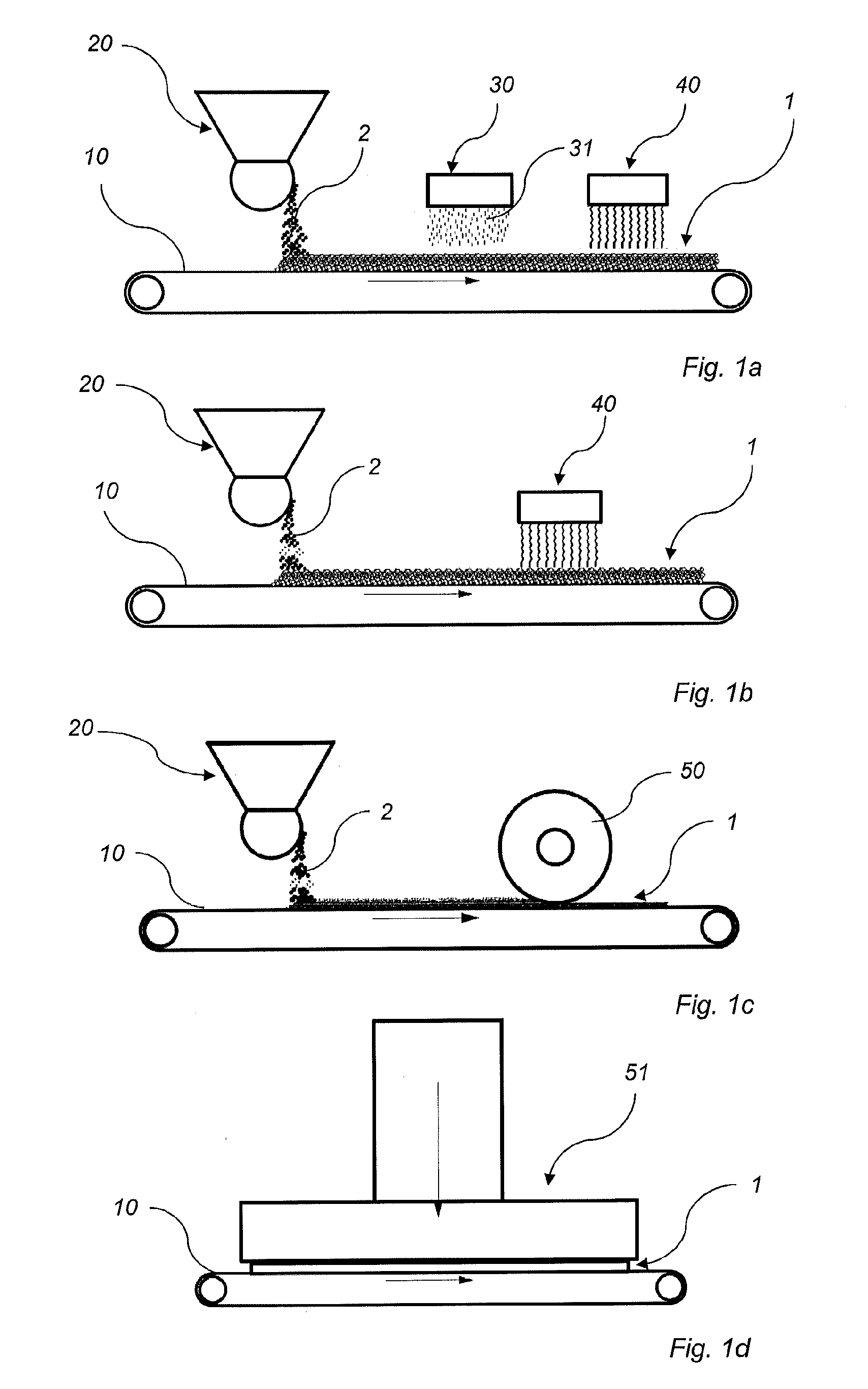

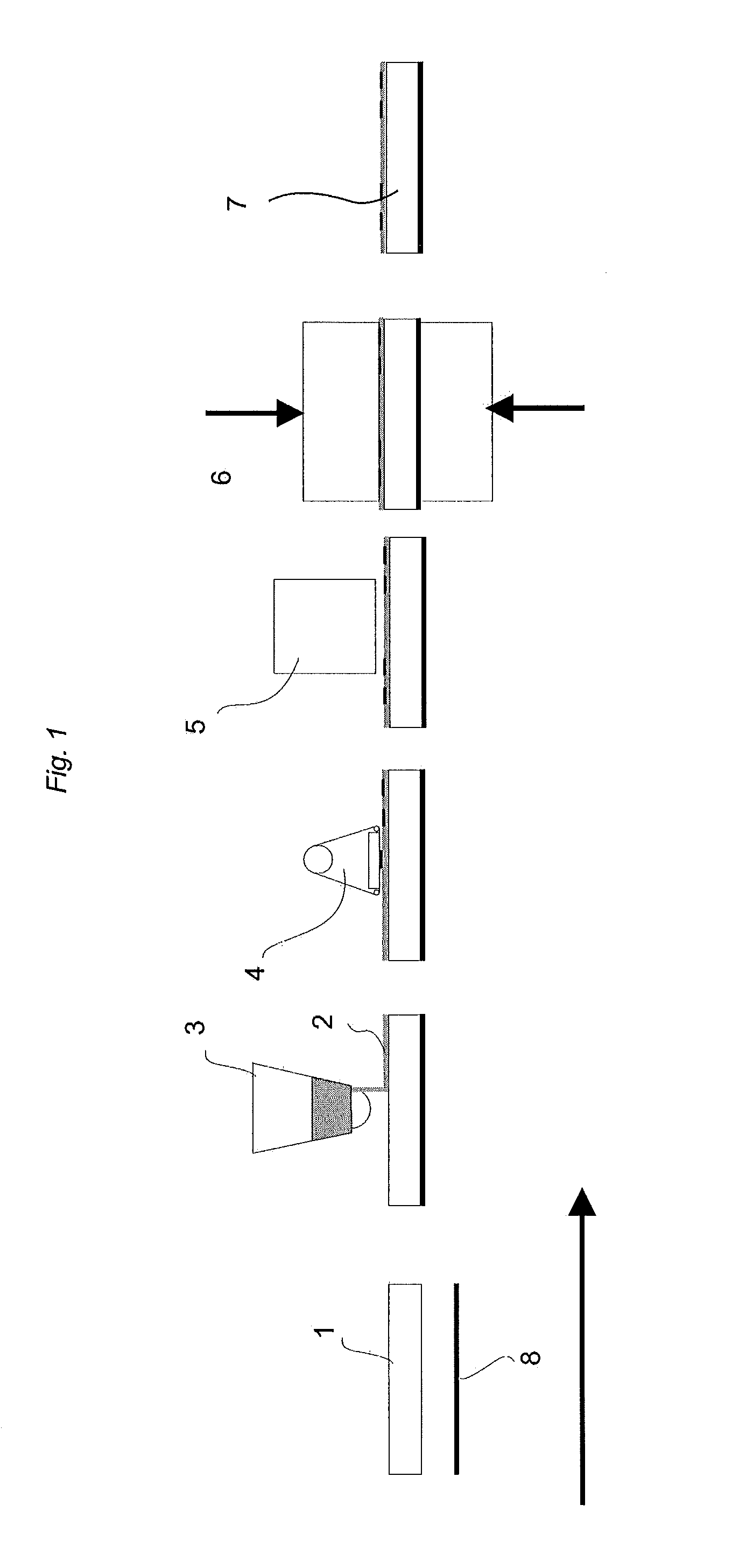

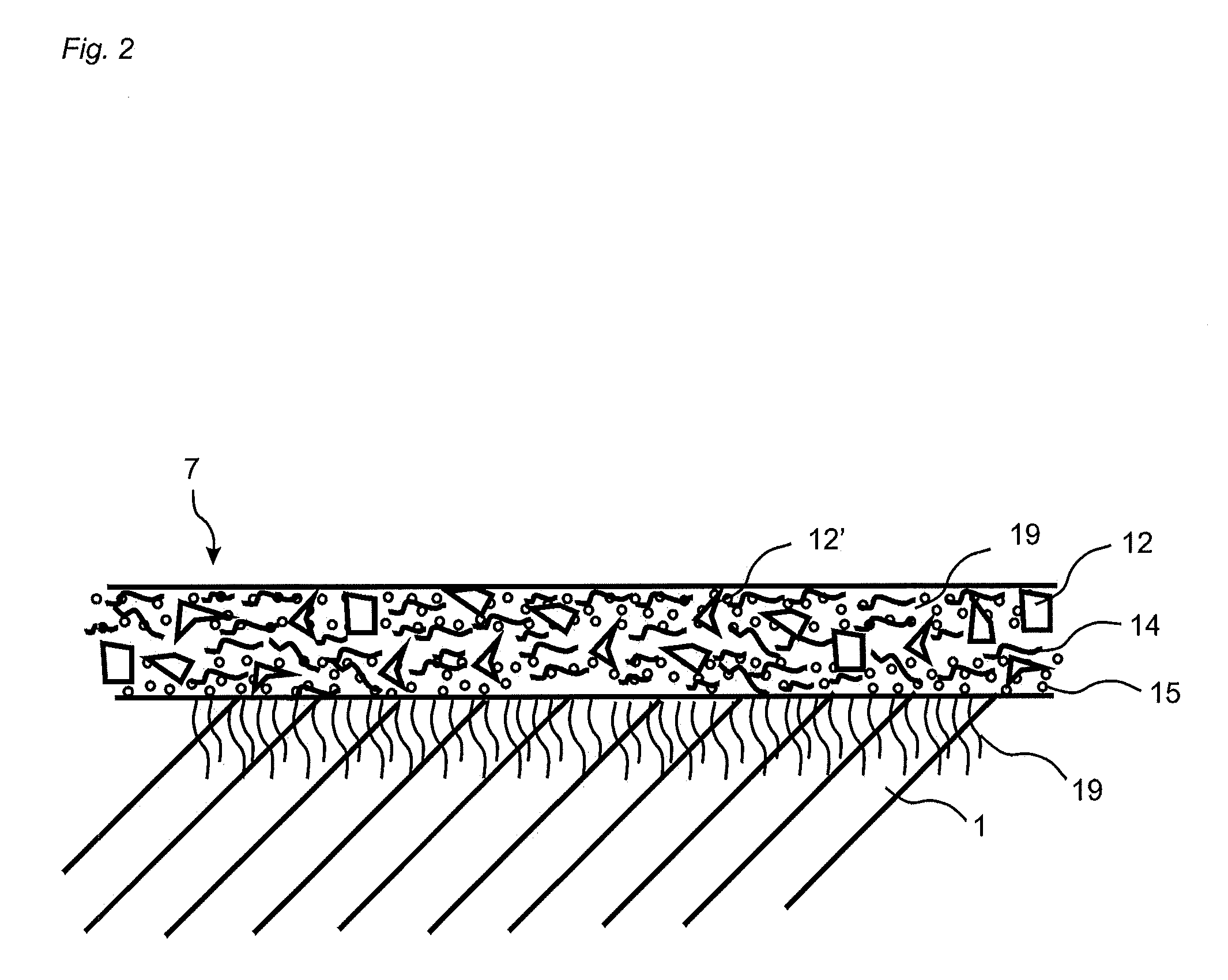

Method of manufacturing a layer

ActiveUS20120264853A1Less brittleReduce riskSynthetic resin layered productsPretreated surfacesFiberPowder mixture

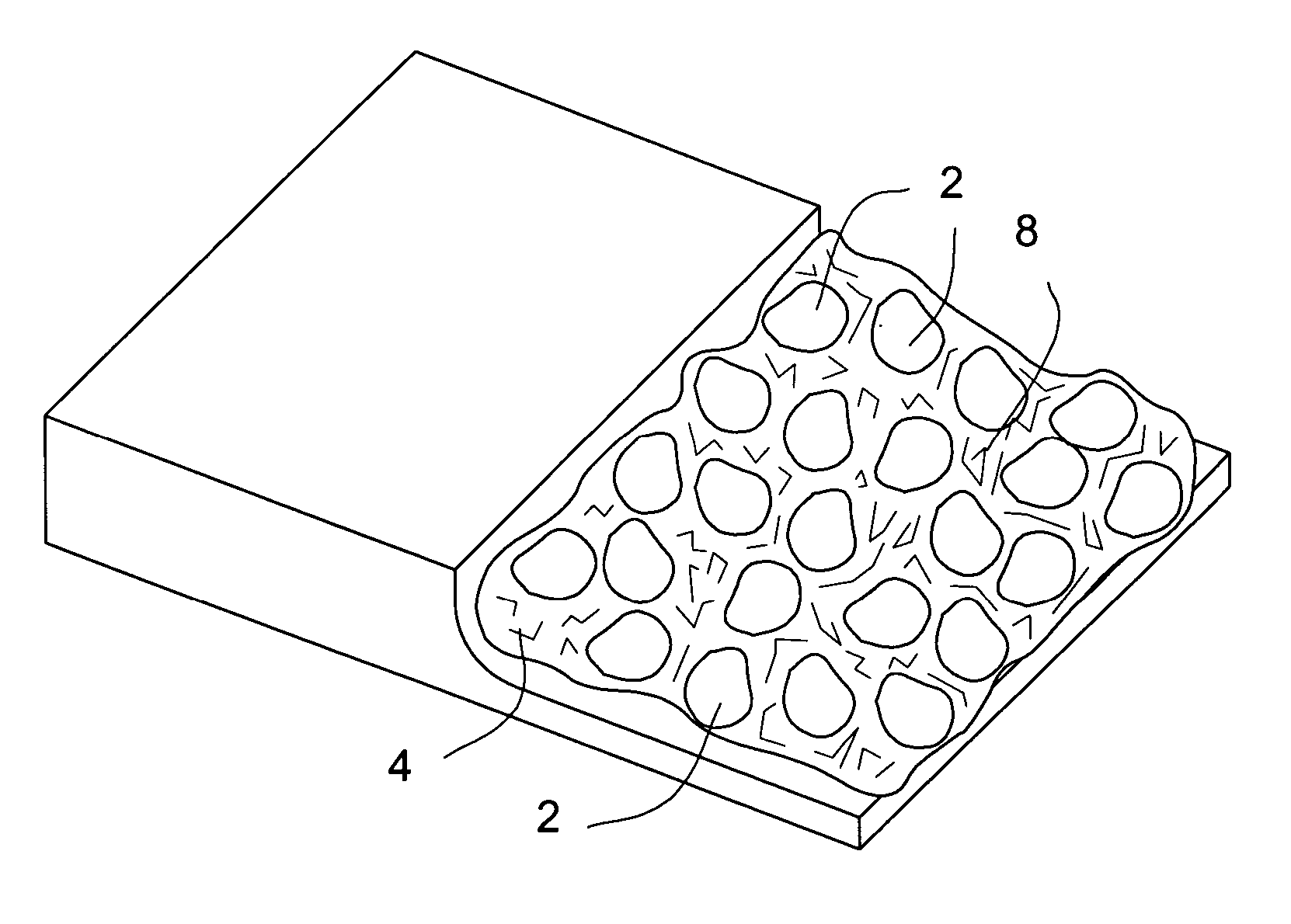

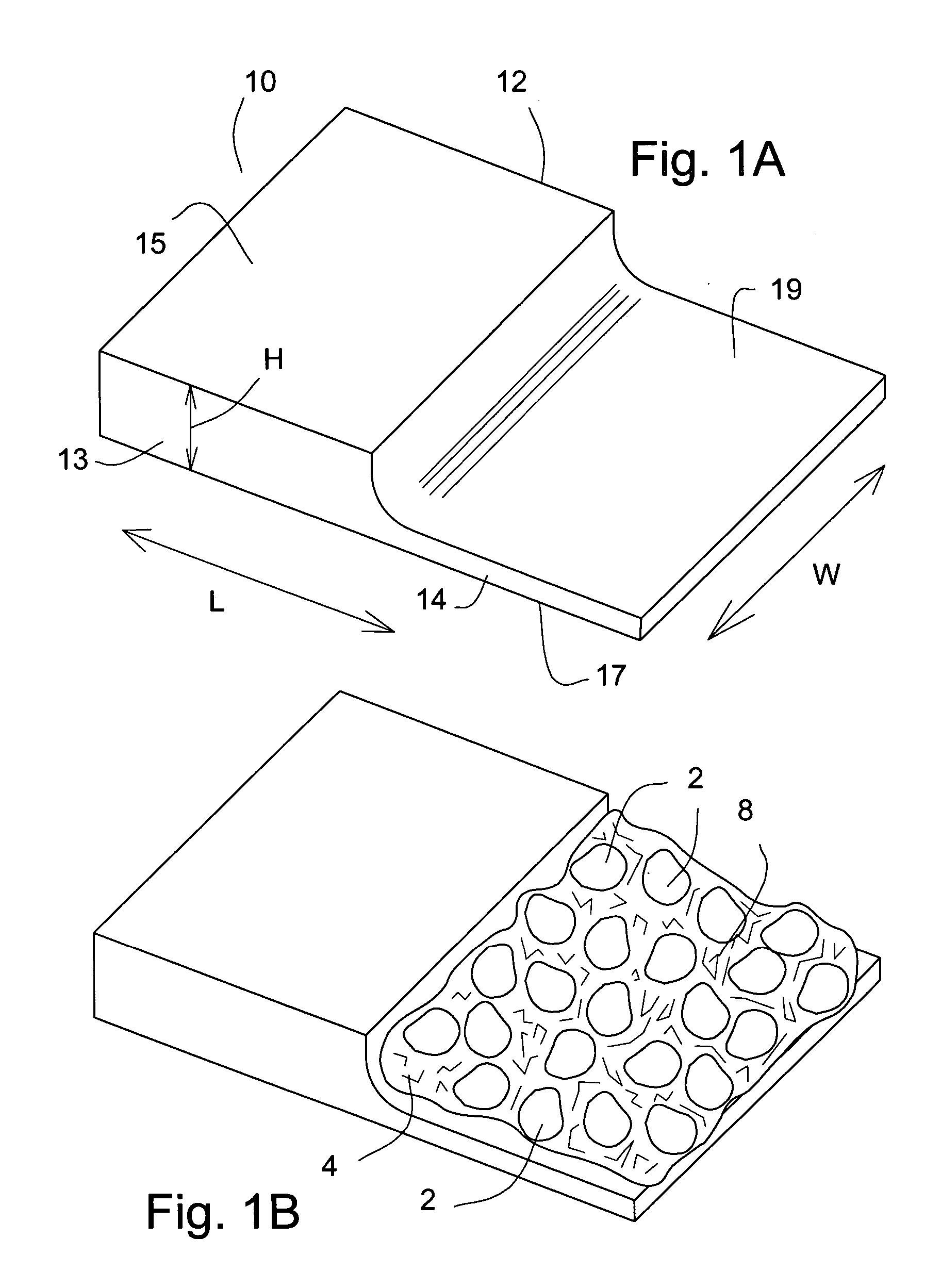

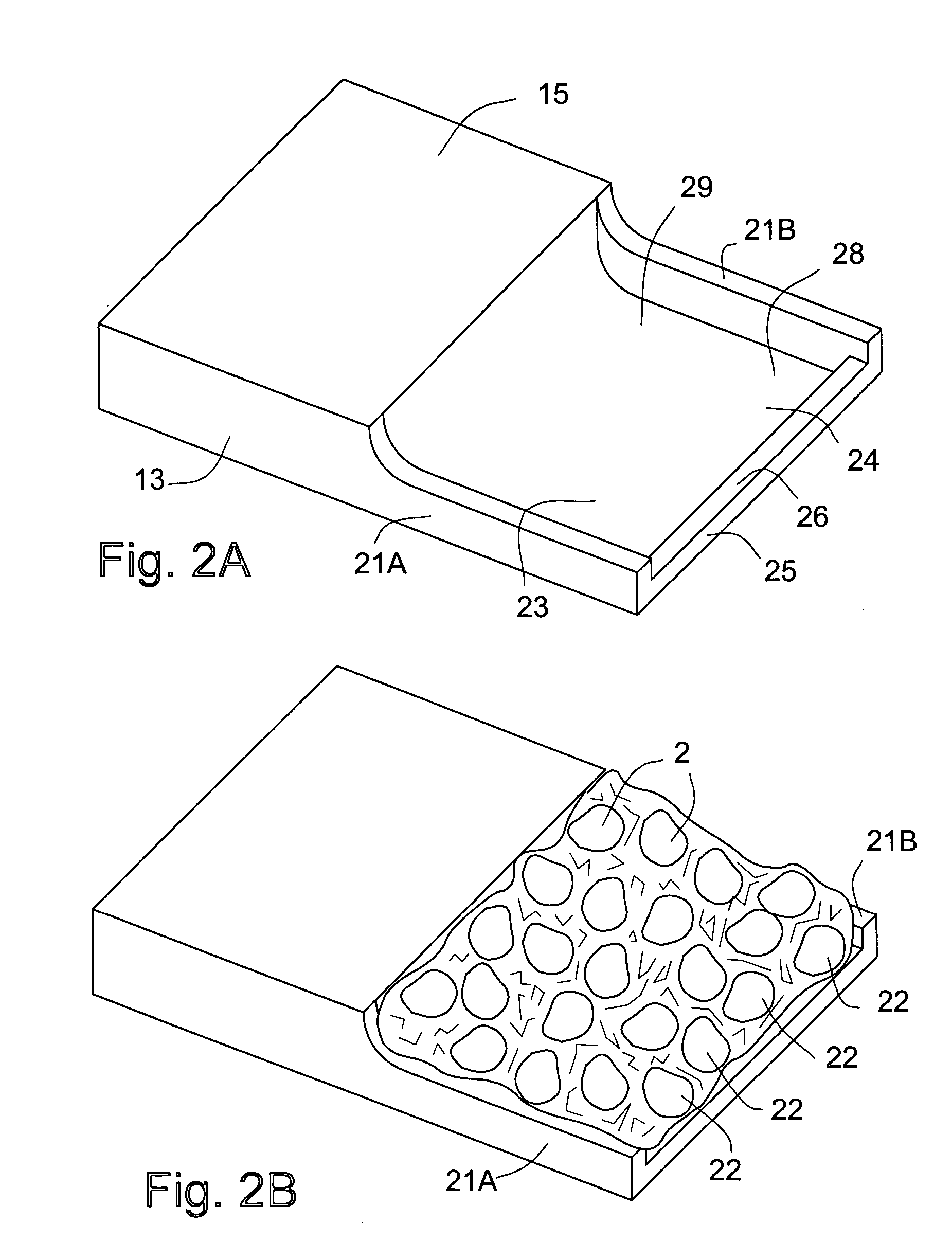

A method of manufacturing a separate and continuous layer being essentially uncured. The method includes applying a powder mix including fibres and a thermosetting binder on a carrier, forming a powder mix layer, wherein the powder mix is connected together such that the powder mix layer is obtained and wherein the powder mix layer is essentially uncured, and releasing the powder mix layer from the carrier. Also, a layer and a method for manufacturing a building panel.

Owner:VÄLINGE INNOVATION AB

Coating process for manufacture or reprocessing of sputter targets and x-ray anodes

ActiveUS20080216602A1Low heat introductionWide applicabilityLiquid surface applicatorsMolten spray coatingPowder mixtureNiobium

Disclosed is a process for the reprocessing or production of a sputter target or an X-ray anode wherein a gas flow forms a gas / powder mixture with a powder of a material chosen from the group consisting of niobium, tantalum, tungsten, molybdenum, titanium, zirconium, mixtures of two or more thereof and alloys thereof with at least two thereof or with other metals, the powder has a particle size of 0.5 to 150 μm, wherein a supersonic speed is imparted to the gas flow and the jet of supersonic speed is directed on to the surface of the object to be reprocessed or produced.

Owner:H C STARCK SURFACE TECH & CERAMIC POWDERS GMBH

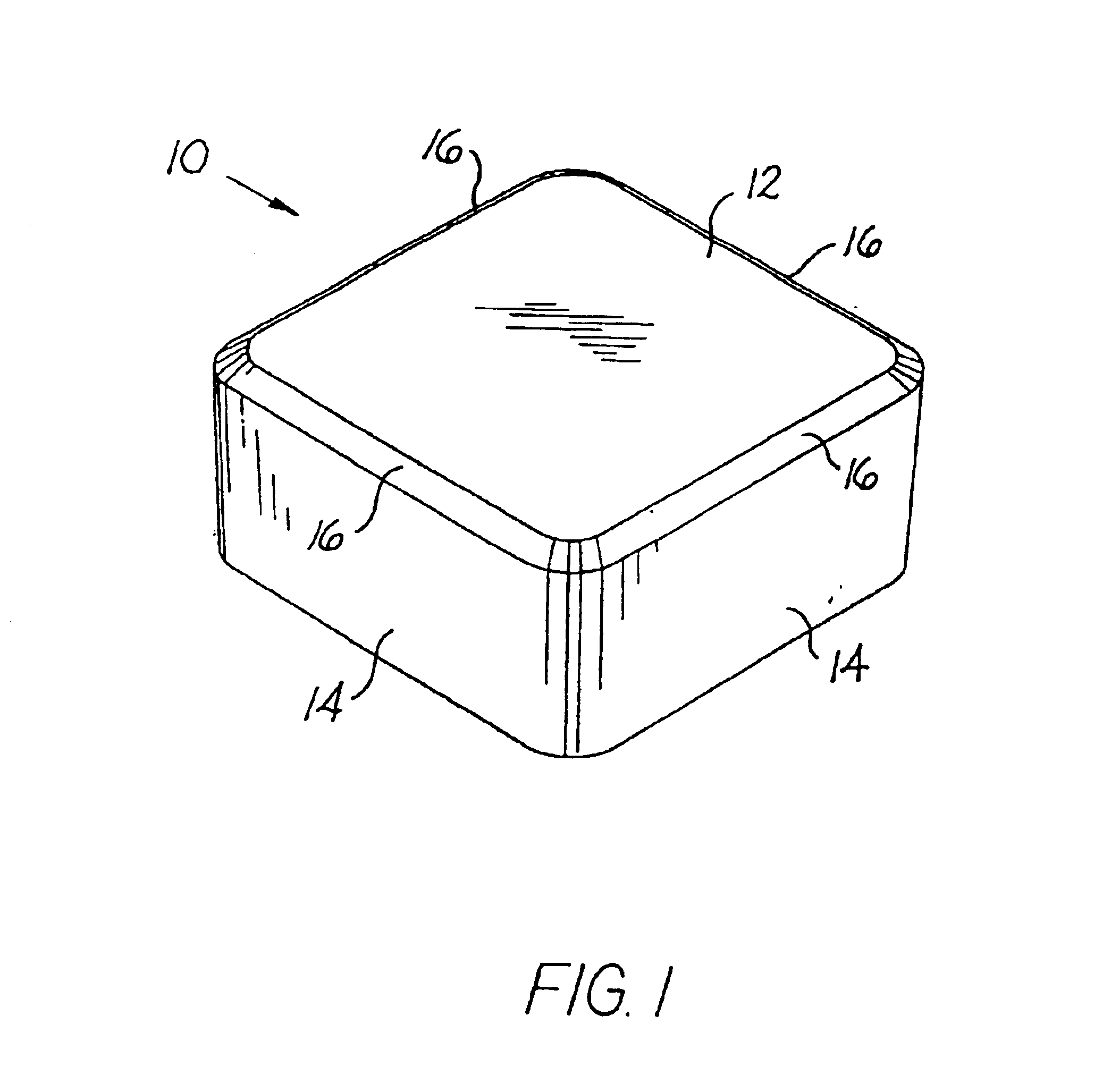

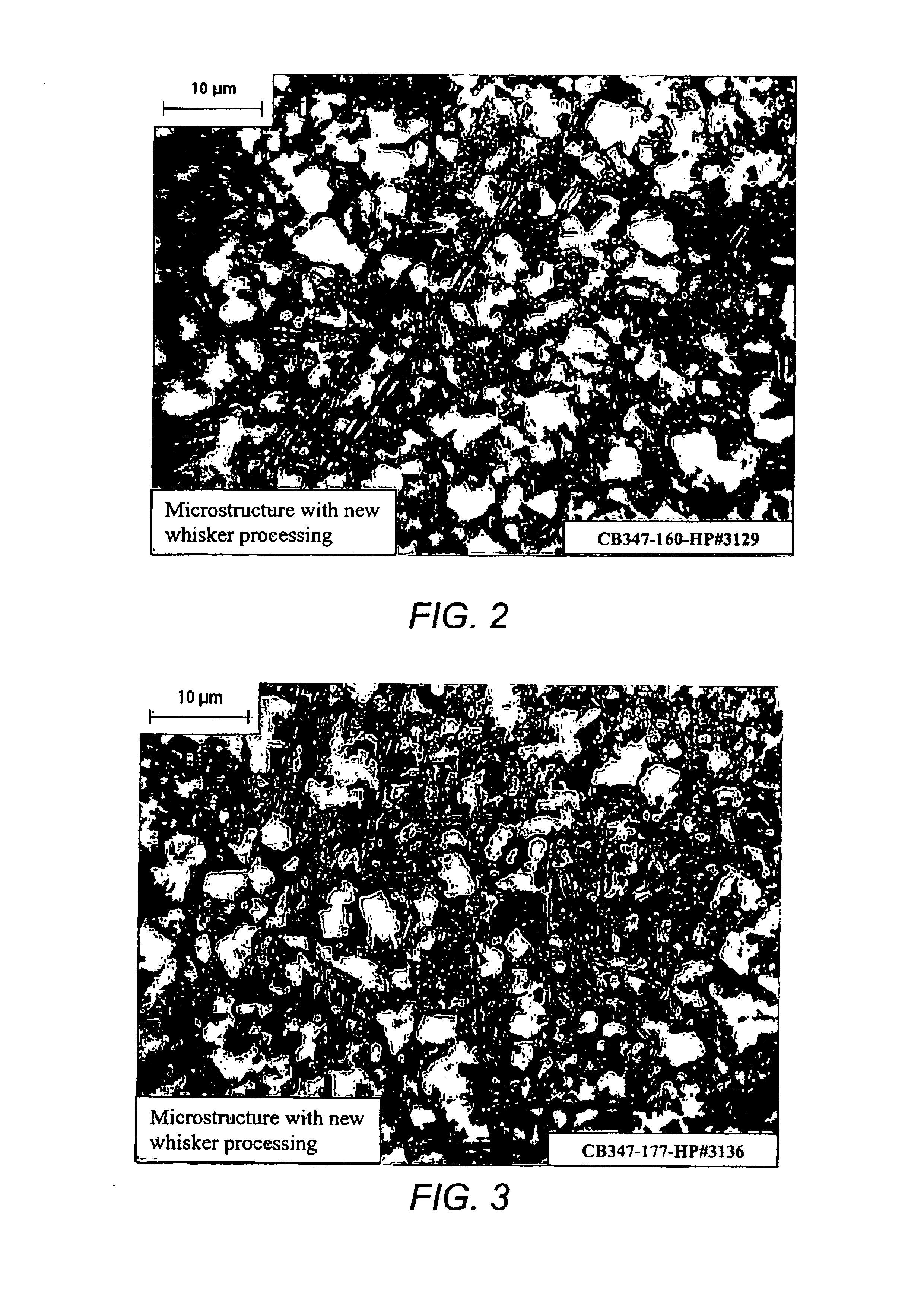

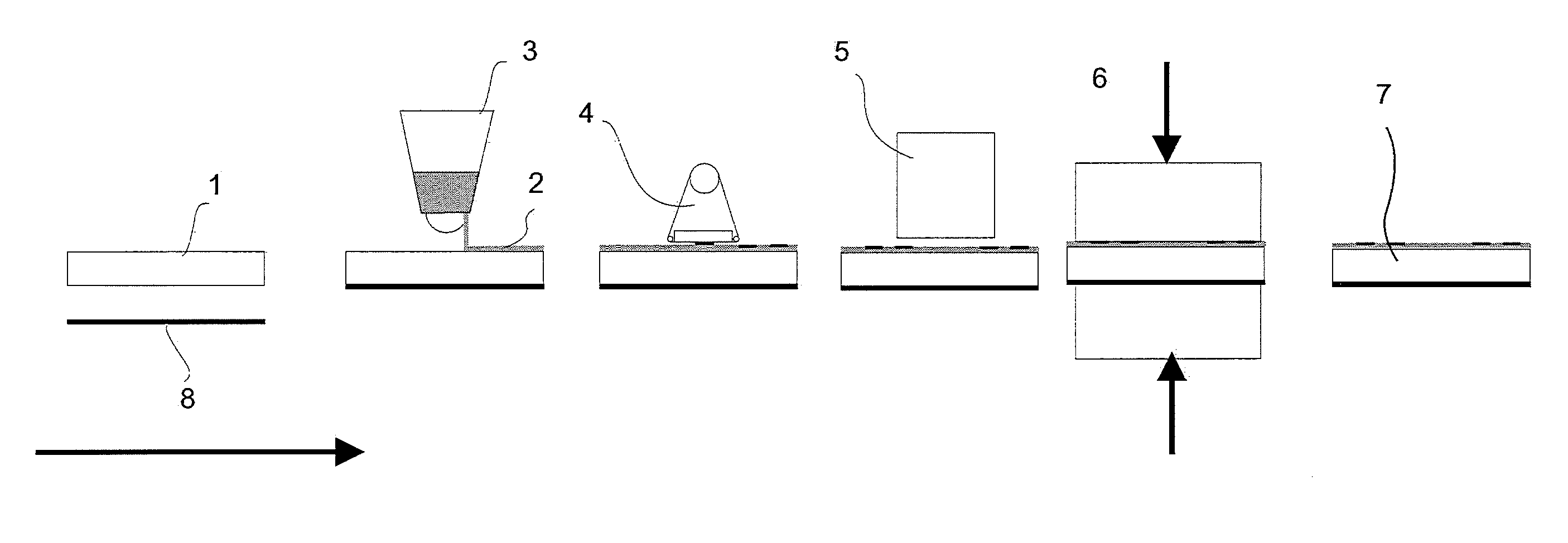

Ceramic body reinforced with coarse silicon carbide whiskers and method for making the same

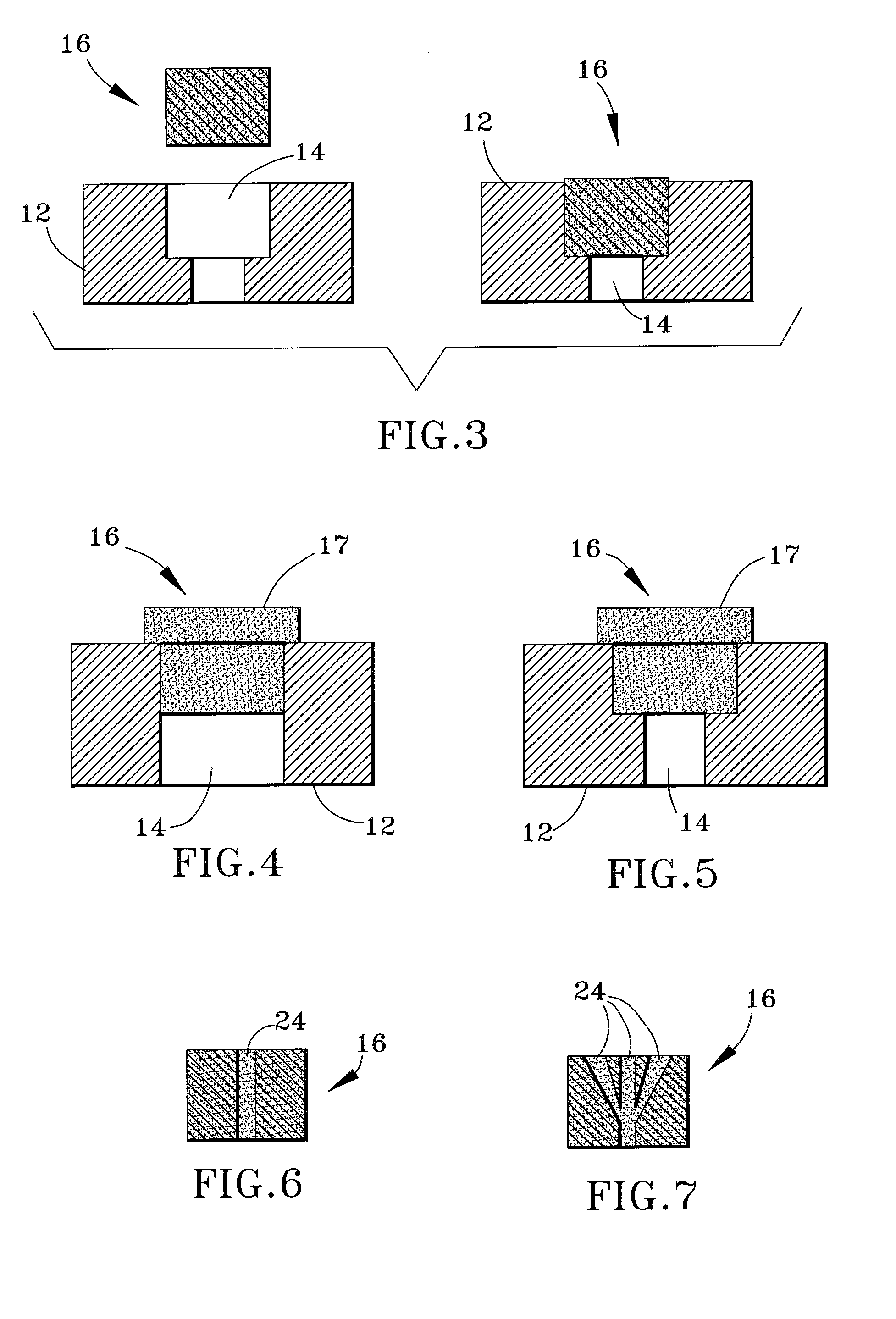

InactiveUS6905992B2Solve the lack of densityThin material handlingMetal layered productsPowder mixtureSquare Millimeter

A ceramic composite made by compacting a starting powder blend. The composite includes between about 50 volume percent and about 99 volume percent of a ceramic matrix; and between about 1 volume percent and about 50 volume percent as-processed silicon carbide whiskers. The ceramic composite having a fracture toughness (KIC) of greater than about 4.0 MPam1 / 2. The ceramic has a silicon carbide whisker density as measured in whiskers per square millimeter equal to or less than about 1500 times the volume percent of silicon carbide whiskers, but in a density sufficient for the ceramic composite to have the fracture toughness.

Owner:KENNAMETAL INC

Chlorinated vinyl resin/cellulosic blends: composition, processes, composites, and articles therefrom

InactiveUS7030179B2High expansion rateEasy squeezeLavatory sanitoryRadiationCellulosePolymer science

Compositions and processes for preparing extrudable powder blends containing at least one vinyl chloride resin and a cellulosic material are provided. More specifically, compositions and processes for preparing extrudable free-flowing powder blends containing PVC and wood flour (WF) are also provided for preparing foamed or nonfoamed extrudates. The processes provided herein incorporate components which may contain up to a total of 25 weight percent water. Processes for preparing foamed extrudates are also provided wherein a cooling fluid is used to increase the expansion ratio of the foam. Finally provided are composites having an extrudable thermoplastic substrate and at least one capstock layer disposed thereon containing a PVC / WF composition.

Owner:ROHM & HAAS CO

Powder mix and a method for producing a building panel

ActiveUS20120263878A1Enhanced control of lossEasy to controlPretreated surfacesWood working apparatusPowder mixtureComposite material

Owner:VÄLINGE INNOVATION AB

Fixed bed catalysts

InactiveUS6284703B1Promote hydrogenationHigh activityOrganic compound preparationPreparation by hydrogenationRheniumPowder mixture

A shaped, activated, fixed-bed Raney metal catalyst prepared by a method comprising preparing a mixture of powders comprising at least one catalyst alloy of (1) at least one catalytically active Raney process metal, a leachable alloy component and optionally a promoter, (2) at least one binder containing at least one pure Raney metal and (3) a moistening agent. Shaping, calcining and activating said catalyst and doping said catalyst with rhenium.

Owner:DEGUSSA AG

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS7273523B2Facilitated releaseTo promote metabolismBiocideSurgical adhesivesPowder mixturePhosphate

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

Dietetic nutritive powder

InactiveCN1647696APrevent cancerPromote absorptionUnknown materialsFood preparationWheat germPowder mixture

The diatotherapeutic nutritive powder as a kind of health food is powdered mixture produced with over forty kinds of grains, vegetable, fruit, sea food material and Chinese medicinal materials, including rice, red bean, peanut, Chinese cabbage, apple, shelled fresh shrimp, glossy ganoderma, lily, etc. It has comprehensive, balanced and reasonable nutritive components.

Owner:孙天福

Method of producing target material of Mo alloy

InactiveUS20050191202A1High bulk densityReduce materialTransportation and packagingMetal-working apparatusPowder mixtureAlloy

Disclosed is a method of producing a target material of a Mo alloy, which includes the steps of (a) preparing a green compact by compressing a raw material powder blend consisting of a Mo powder having an average particle size of not more than 20 μm and a transition metal powder having an average particle size of not more than 500 μm; (b) pulverizing the green compact to produce a secondary powder having an average particle size of from not less than an average particle size of the raw material powder blend to not more than 10 mm; (c) filling the secondary powder into a container for pressurizing; and (d) subjecting the secondary powder with the container for pressurizing to sintering under pressure thereby obtaining a sintered body of the target material.

Owner:HITACHI METALS LTD

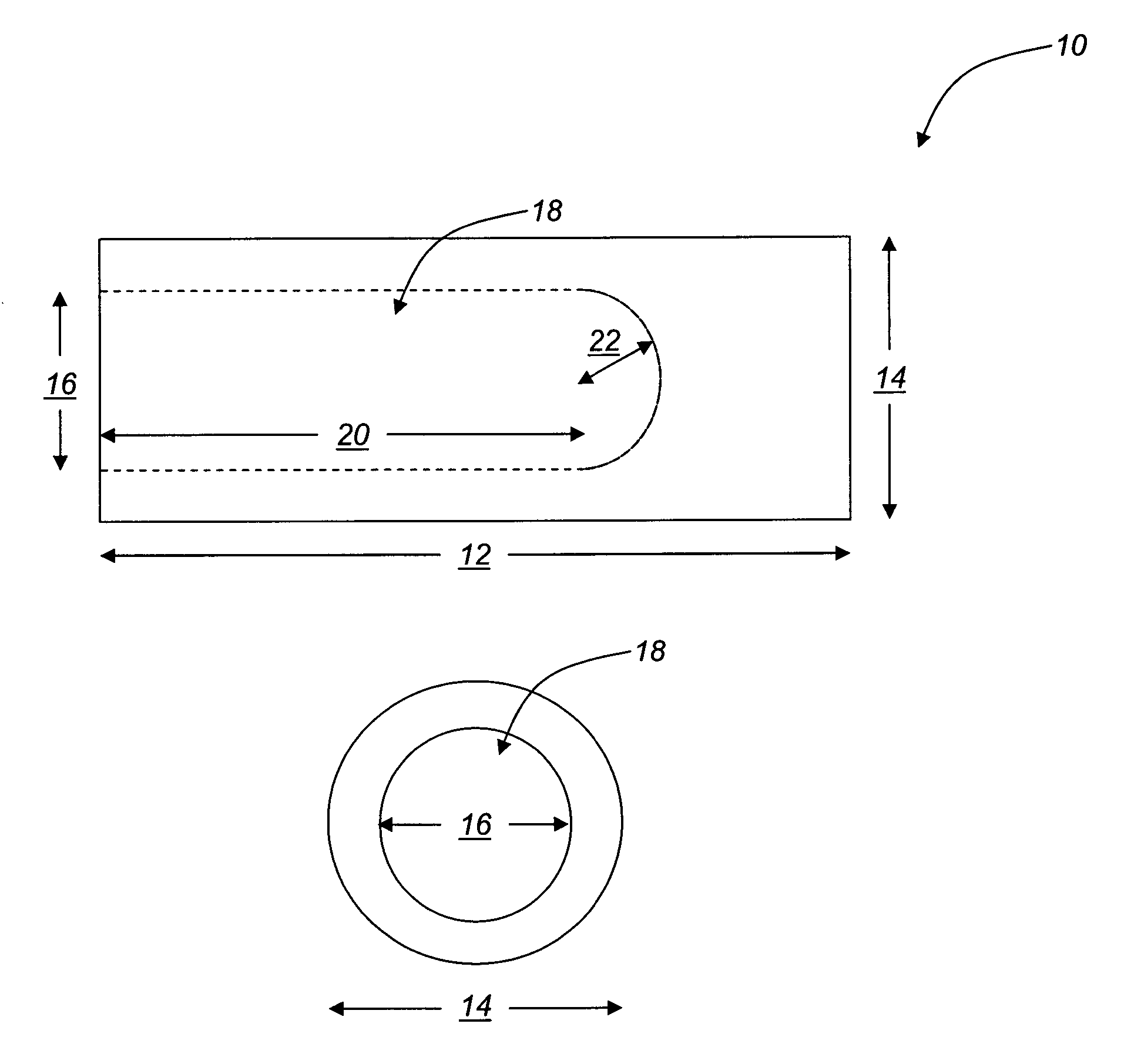

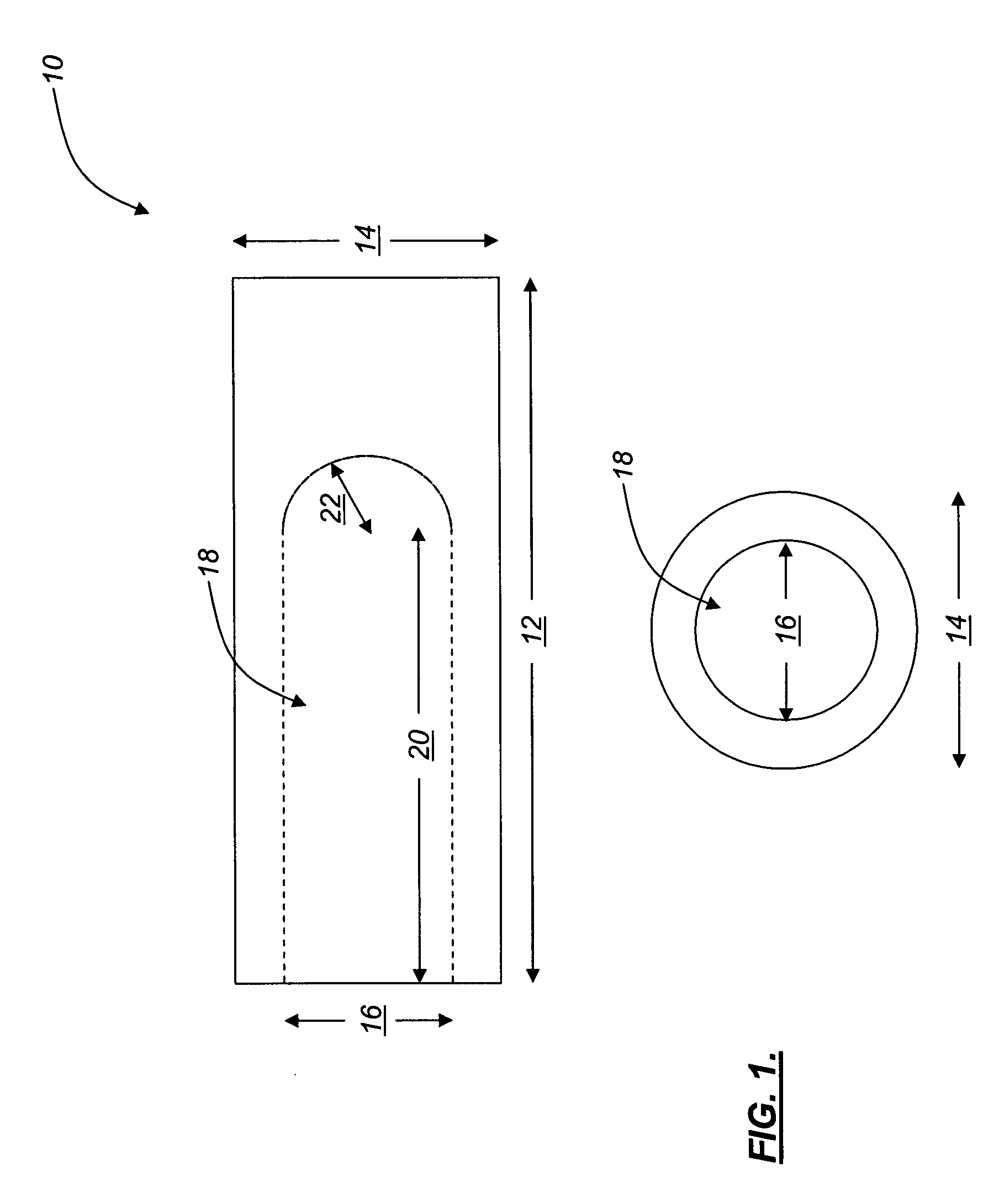

Brazed diamond dressing tool

A dressing blade for finishing and reconditioning new and used abrasive grinding and cutting tools has a slab-shaped shank with an extension protruding longitudinally from the shank. Superabrasive grains are disposed on the surface of the extension and held in place by a brazed metal composition. This composition is formed by brazing a powdered mixture of brazing metal components and active metal components. Specific extension configurations are provided which allow aligning the superabrasive grains in single layer arrangement for precise dressing and simple fabrication of the tool. The novel dressing tool exhibits excellent wear characteristics.

Owner:SAINT GOBAIN ABRASIVES INC

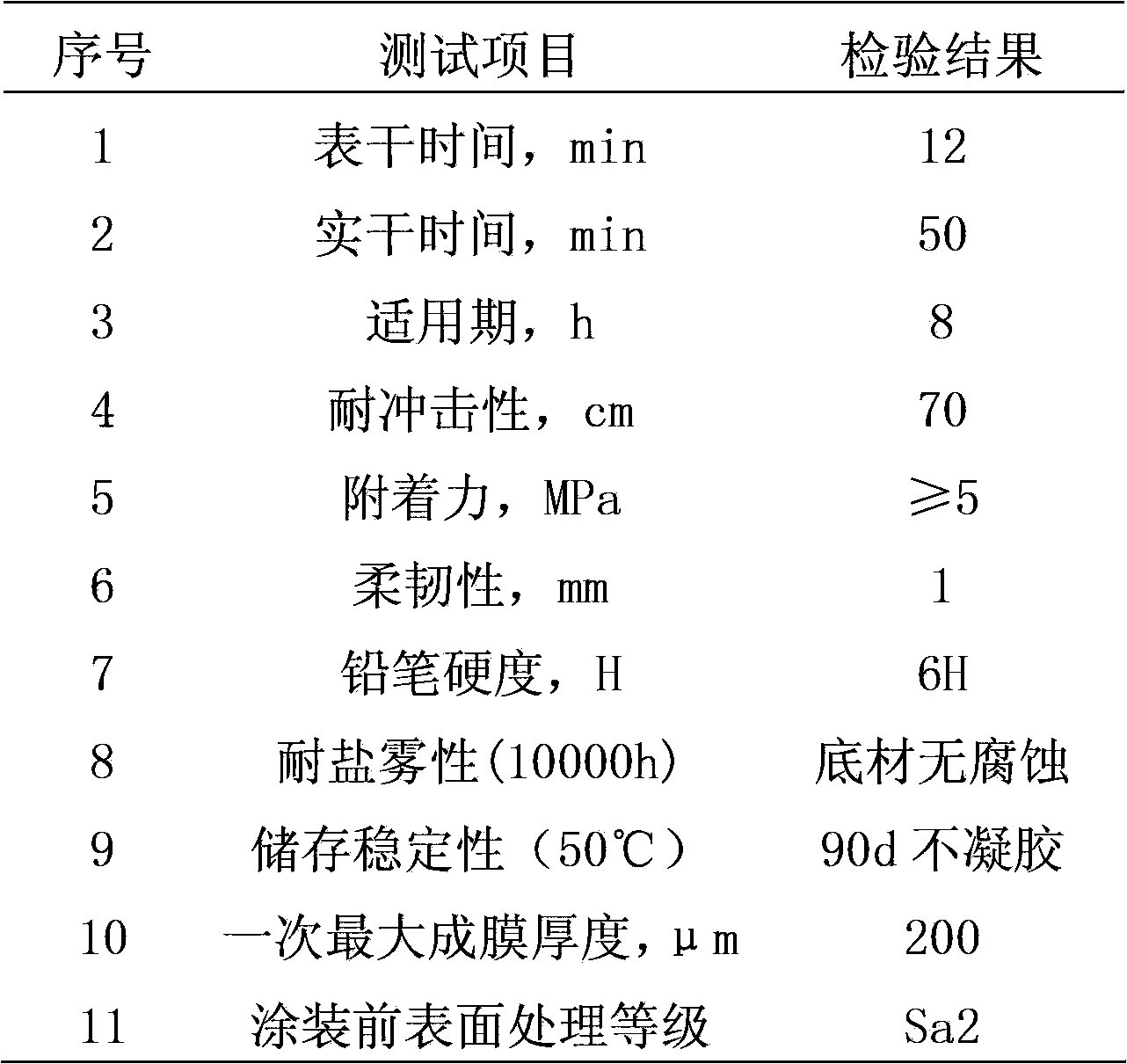

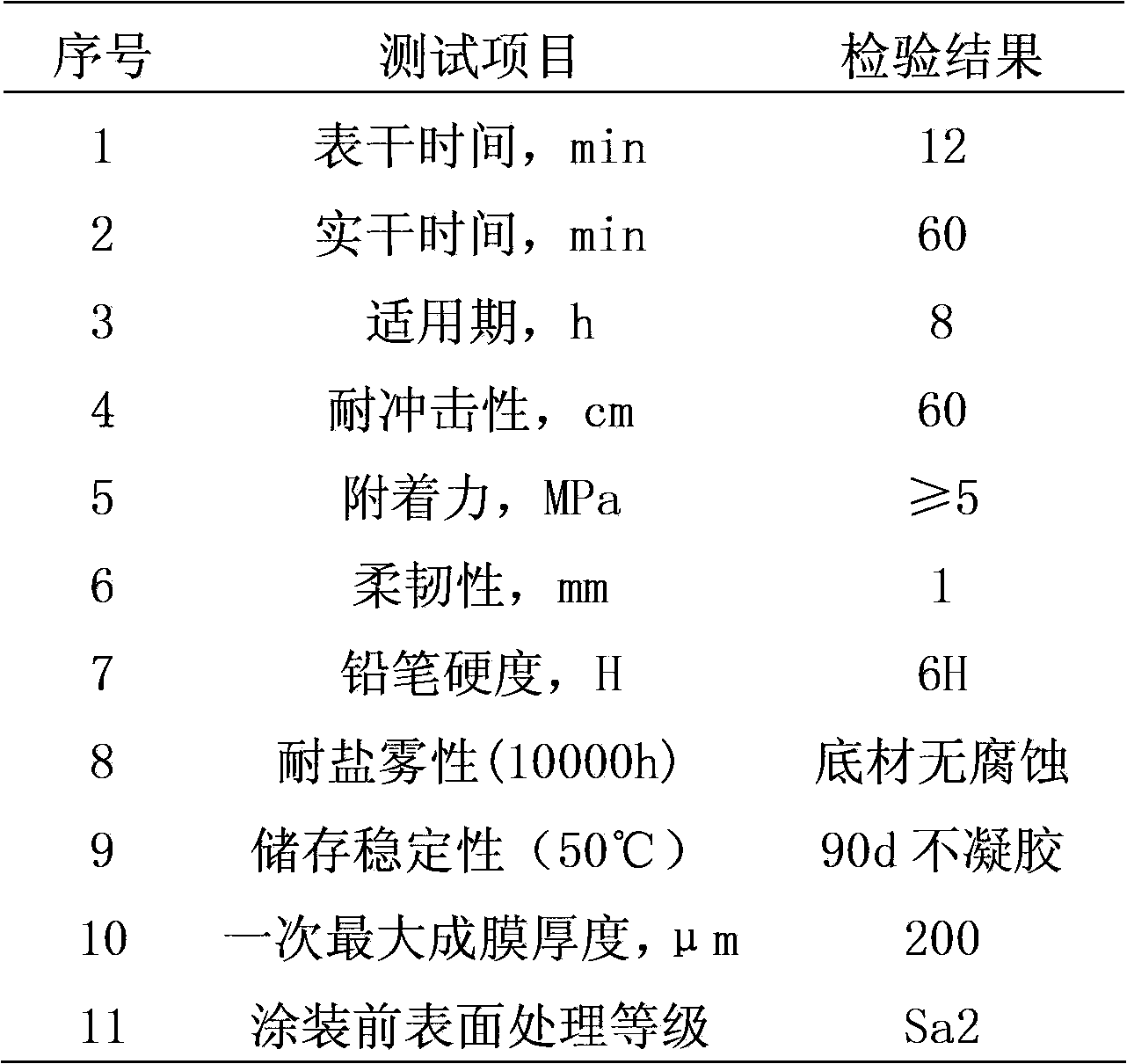

Water-soluble inorganic zinc-rich paint and preparation method thereof

ActiveCN103788734AUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsStress concentrationPowder mixture

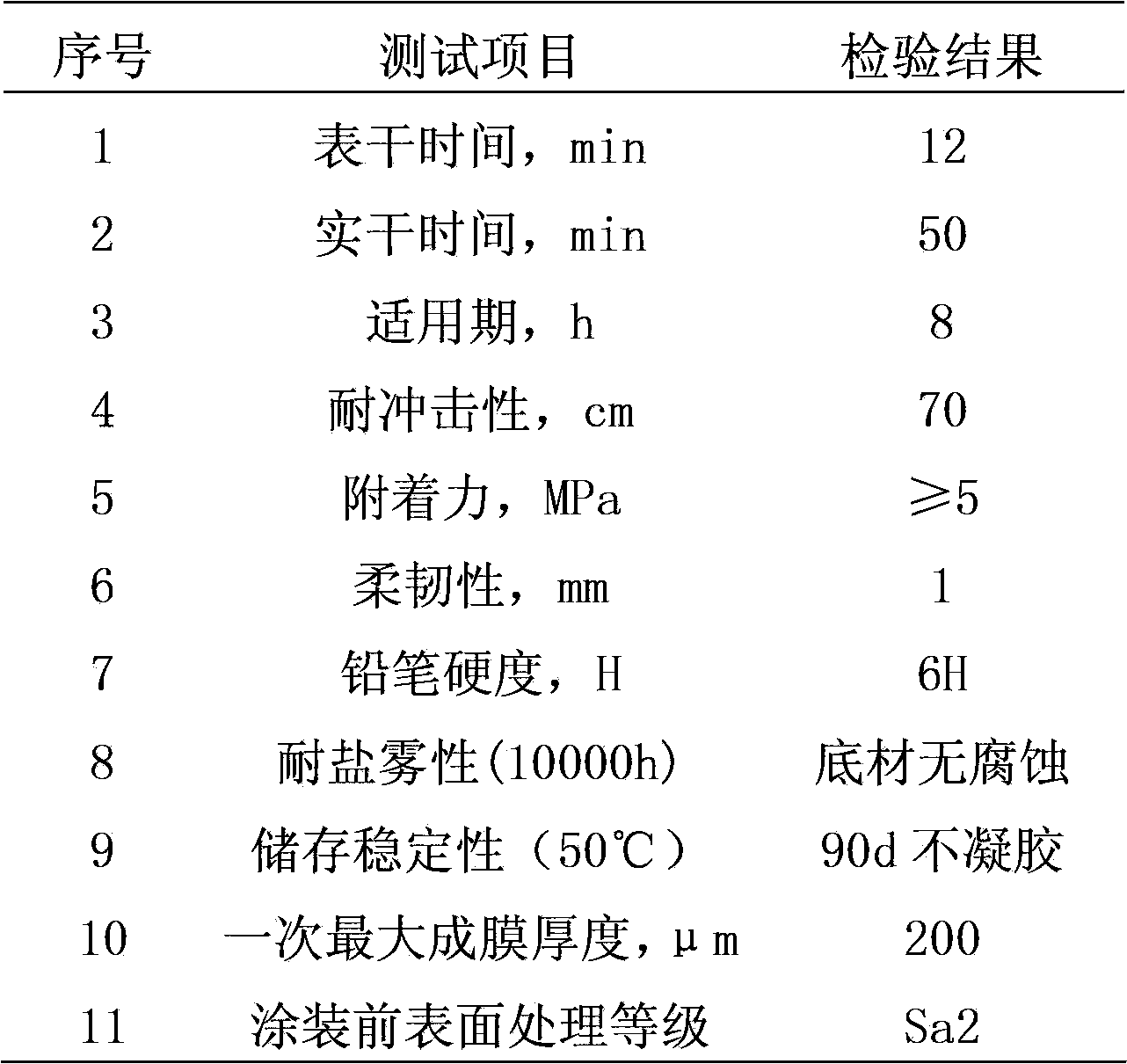

The invention provides a water-soluble inorganic zinc-rich paint and a preparation method thereof. The preparation method comprises the following steps: dropwise adding aluminum-modified silica sol into potassium silicate solution with low modulus, so as to obtain a high-modulus potassium silicate solution as a binder; and adding a catalyst, a siloxane oligomer and a modifier to ensure that the high-modulus potassium silicate solution are uniform in size distribution, and does not have gelatinization reaction for a long time, wherein after the high-modulus potassium silicate solution and a zinc powder mixture are stirred uniformly, the zinc-rich paint has the advantages that reaction rates of all parts of a coating are uniform, and no stress concentration phenomenon exist. Proved by experiments, the zinc-rich paint provided by the invention has no gel after being stored for 90 days at 50 DEG C, the thickness of a film formed once can reach 200 mu m, no cracking or bubbling phenomenon exists, construction can be carried out after the treatment level of the steel surface reaches Sa2, and the salt fog resistance of the coating can reach 10000 hours.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

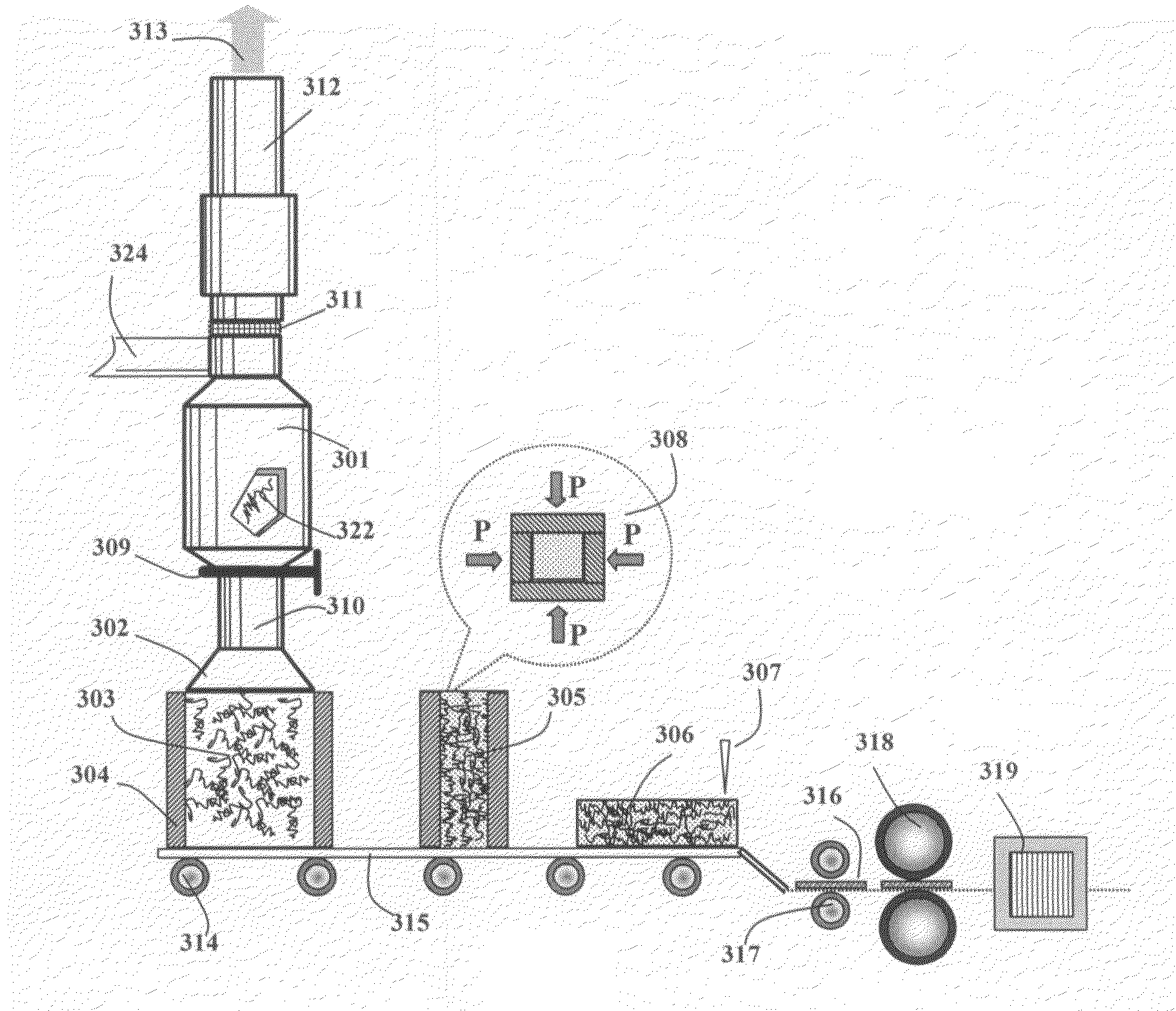

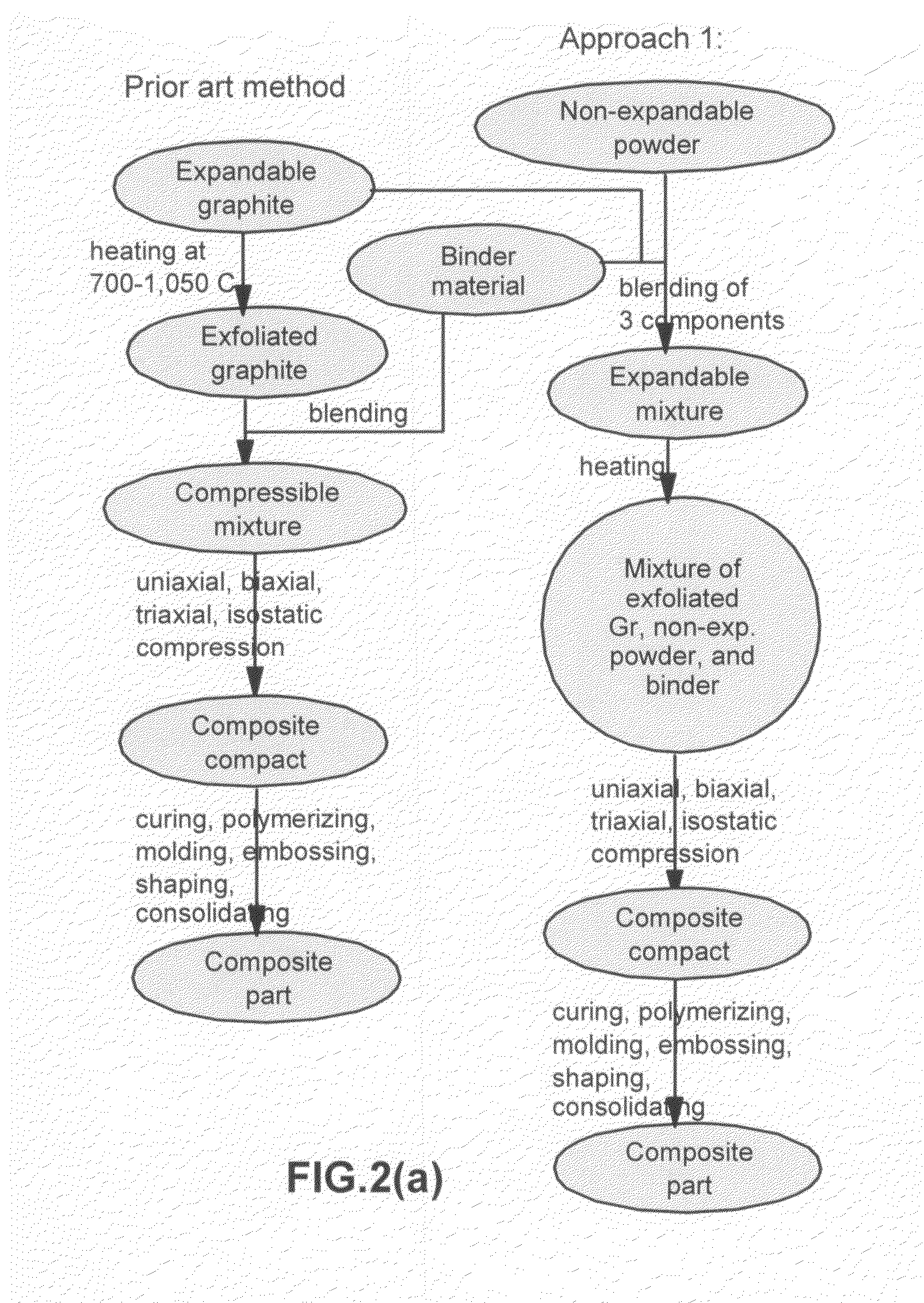

Method of producing exfoliated graphite composite compositions for fuel cell flow field plates

ActiveUS20080279710A1Improve adhesionEliminate or reduce this further anisotropyTransportation and packagingMetal-working apparatusFuel cellsPowder mixture

A method of producing an electrically conductive composite composition, which is particularly useful for fuel cell bipolar plate applications. The method comprises: (a) providing a supply of expandable graphite powder; (b) providing a supply of a non-expandable powder component comprising a binder or matrix material; (c) blending the expandable graphite with the non-expandable powder component to form a powder mixture wherein the non-expandable powder component is in the amount of between 3% and 60% by weight based on the total weight of the powder mixture; (d) exposing the powder mixture to a temperature sufficient for exfoliating the expandable graphite to obtain a compressible mixture comprising expanded graphite worms and the non-expandable component; (e) compressing the compressible mixture at a pressure within the range of from about 5 psi to about 50,000 psi in predetermined directions into predetermined forms of cohered graphite composite compact; and (f) treating the so-formed cohered graphite composite to activate the binder or matrix material thereby promoting adhesion within the compact to produce the desired composite composition. Preferably, the non-expandable powder component further comprises an isotropy-promoting agent such as non-expandable graphite particles. Further preferably, step (e) comprises compressing the mixture in at least two directions. The method leads to composite plates with exceptionally high thickness-direction electrical conductivity.

Owner:NANOTEK INSTR GRP LLC

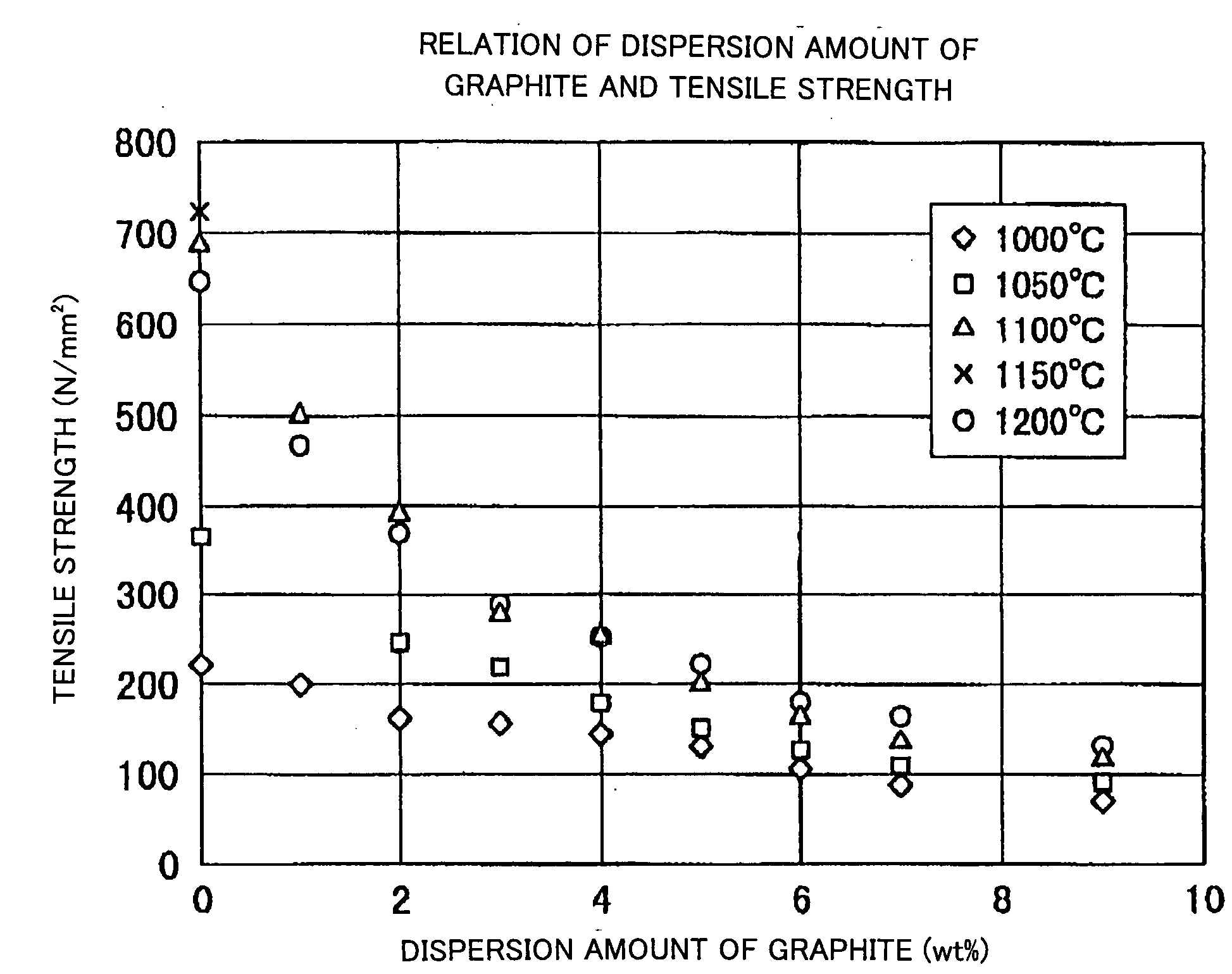

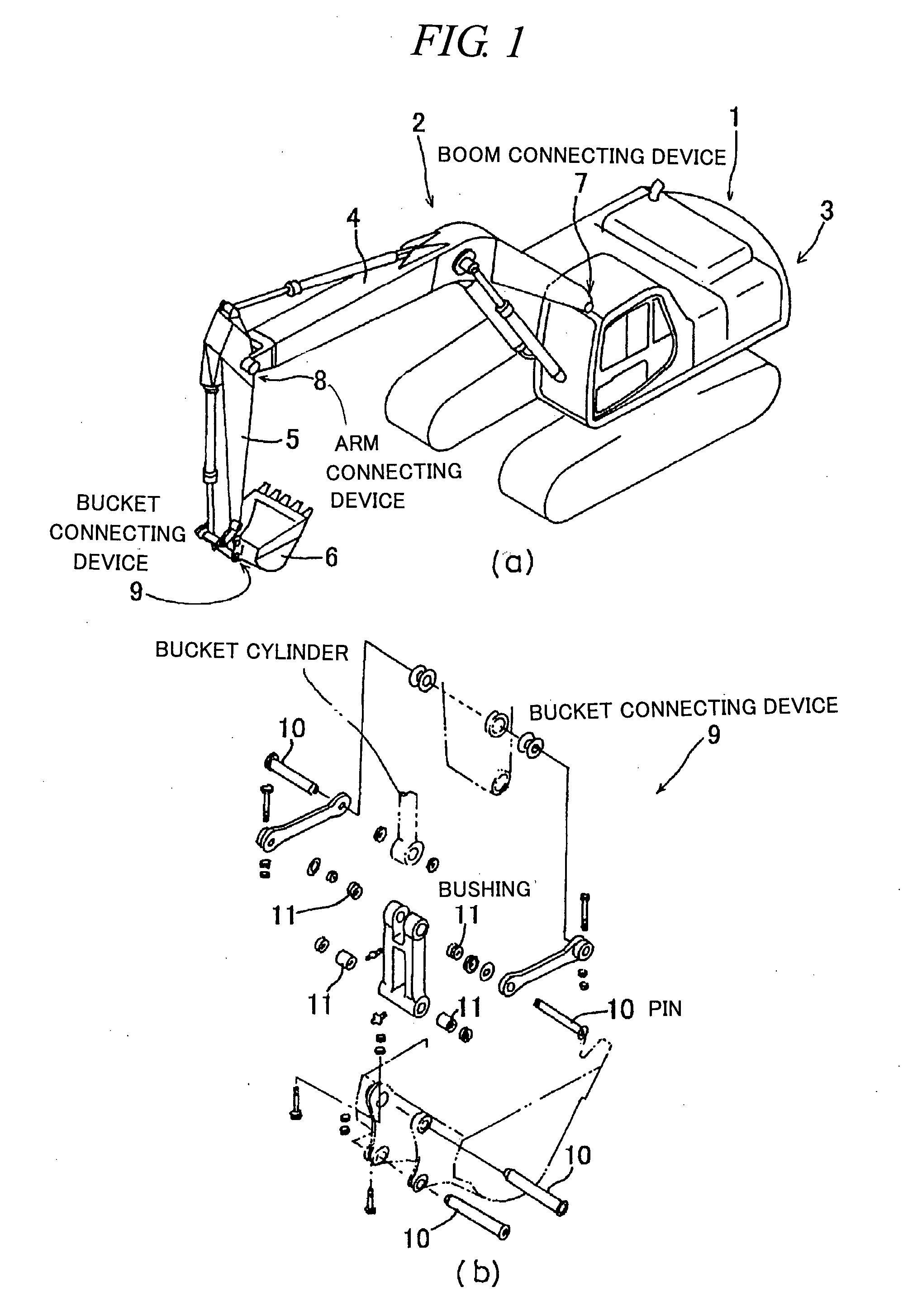

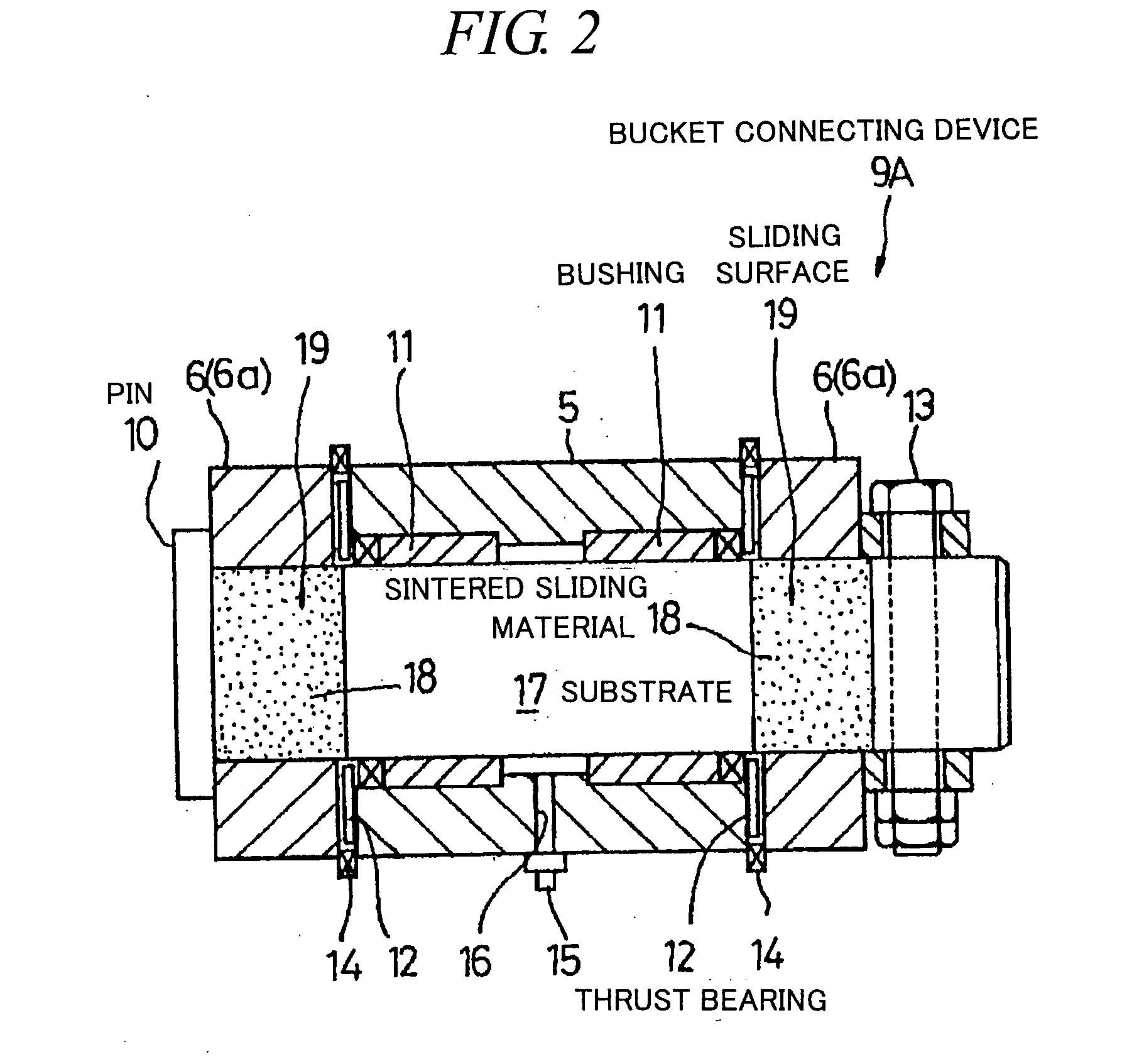

Sintered Material, Ferrous Sintered Sliding Material, Producing Method of the Same, Sliding Member, Producing Method of the Same and Coupling Device

InactiveUS20080146467A1Excellent abrasion resistanceReduce necessityBearing componentsPowder mixtureGraphite particle

The iron-based sintered sliding material comprises: a sintered structure which contains 10-50 wt. % copper and 1-15 wt. % carbon and has been formed by sintering a powder mixture obtained by mixing at least one of an Fe—Cu alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and an Fe—Cu—C alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and containing carbon in an amount of 0-5 wt. %, excluding 0 wt. %, with a graphite powder and at least one of a copper powder and a copper alloy powder; and graphite particles dispersed in the sintered sliding material in an amount of 1-14 wt. % or 3-50 vol. %.

Owner:KOMATSU LTD

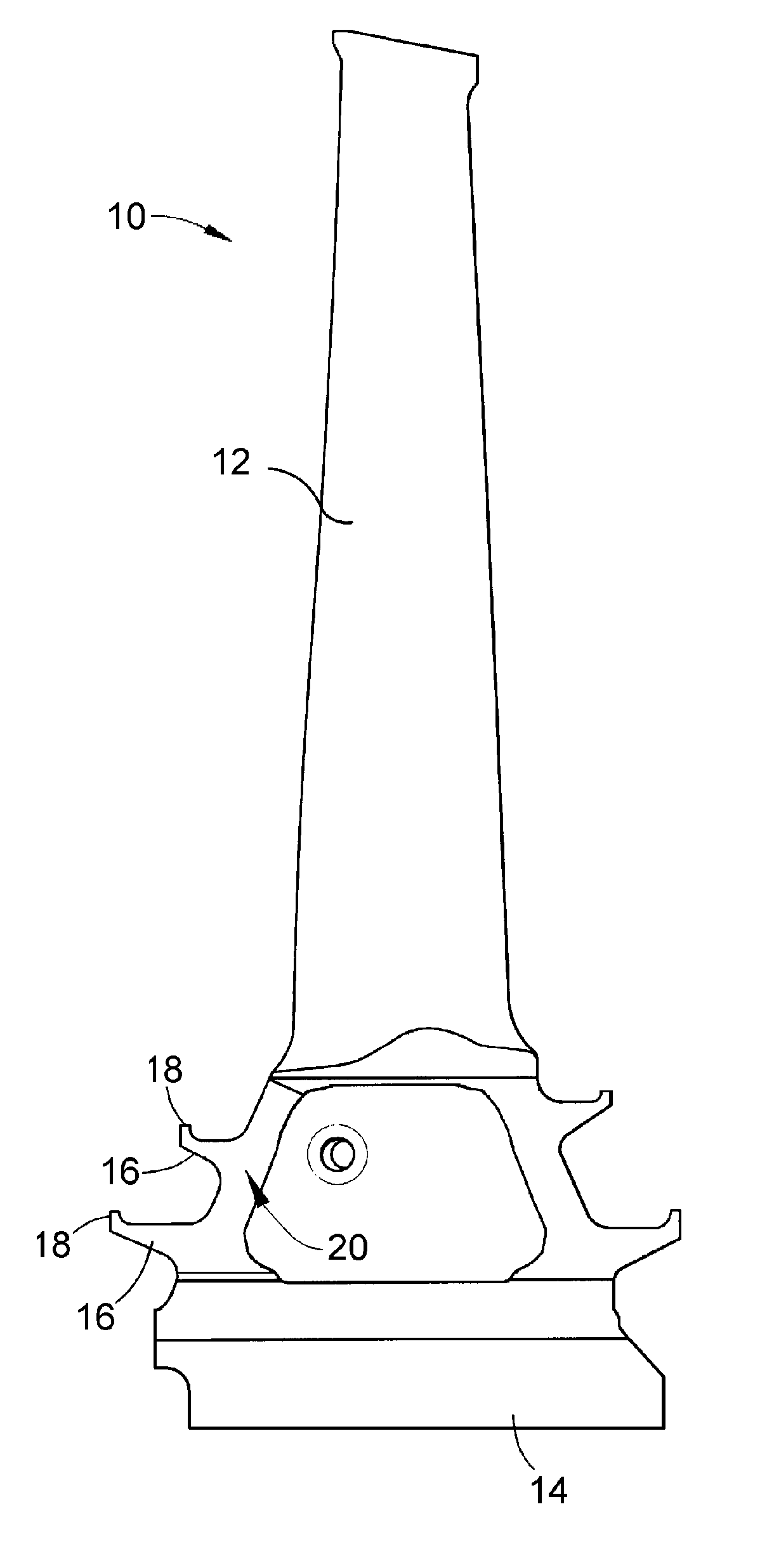

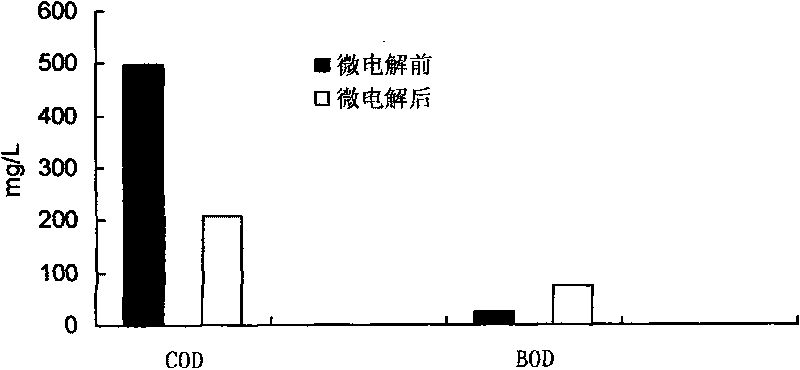

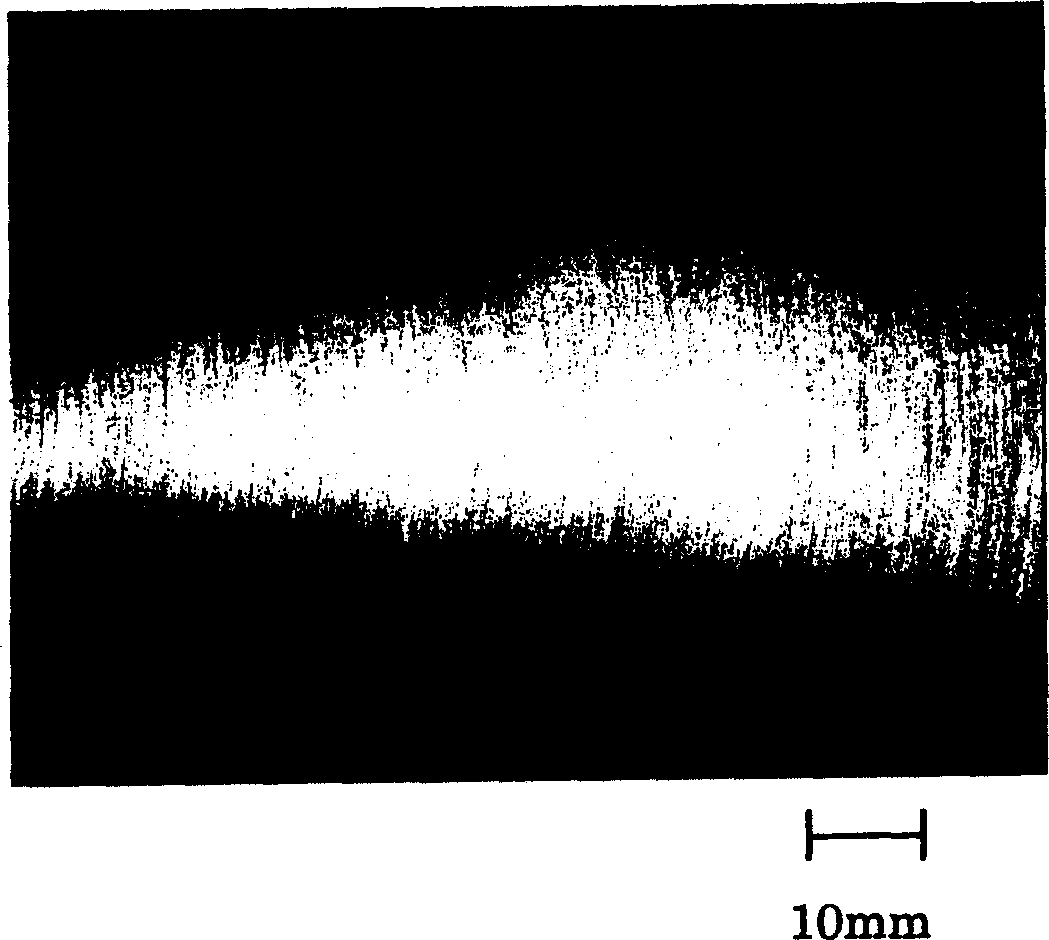

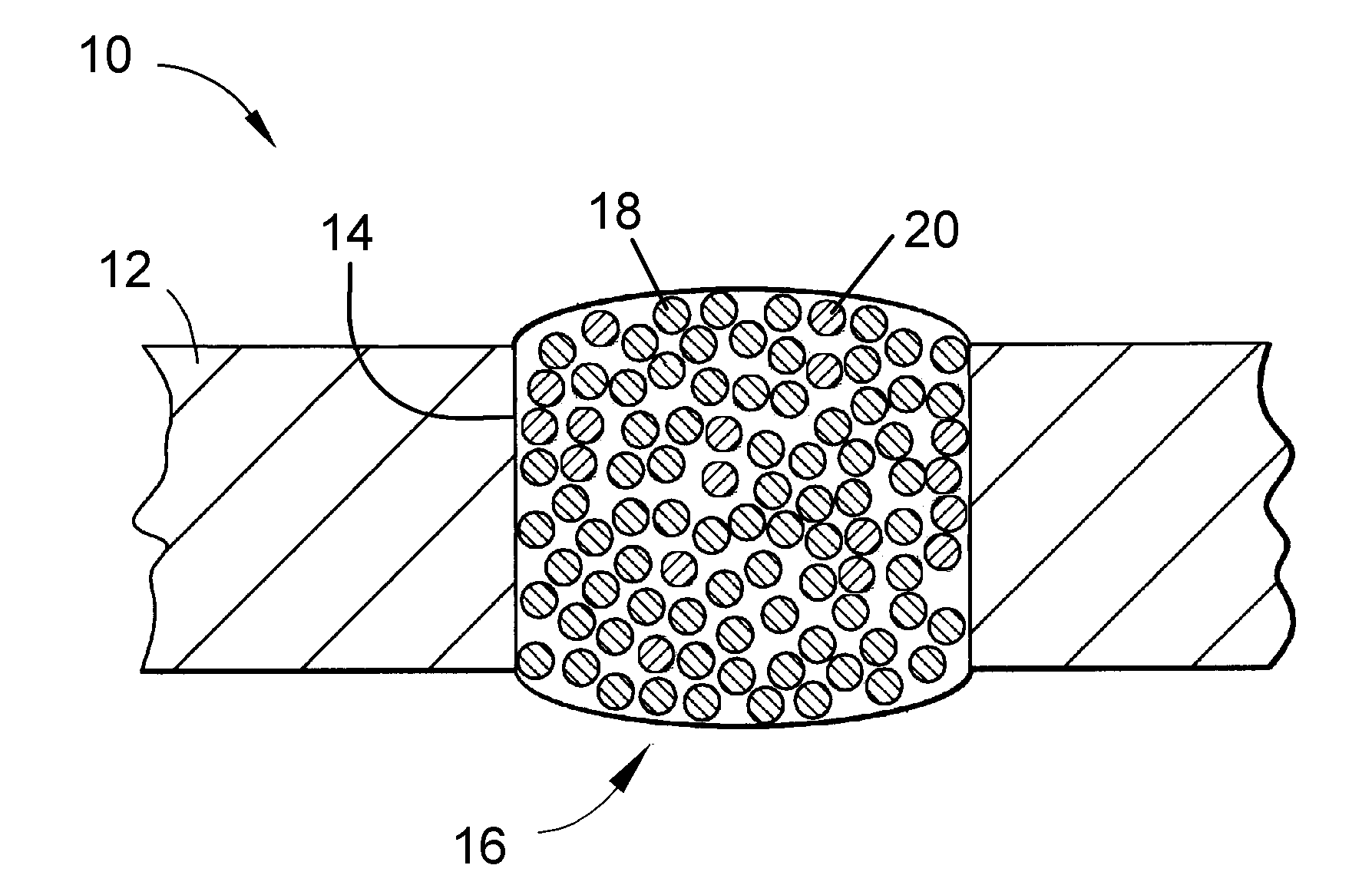

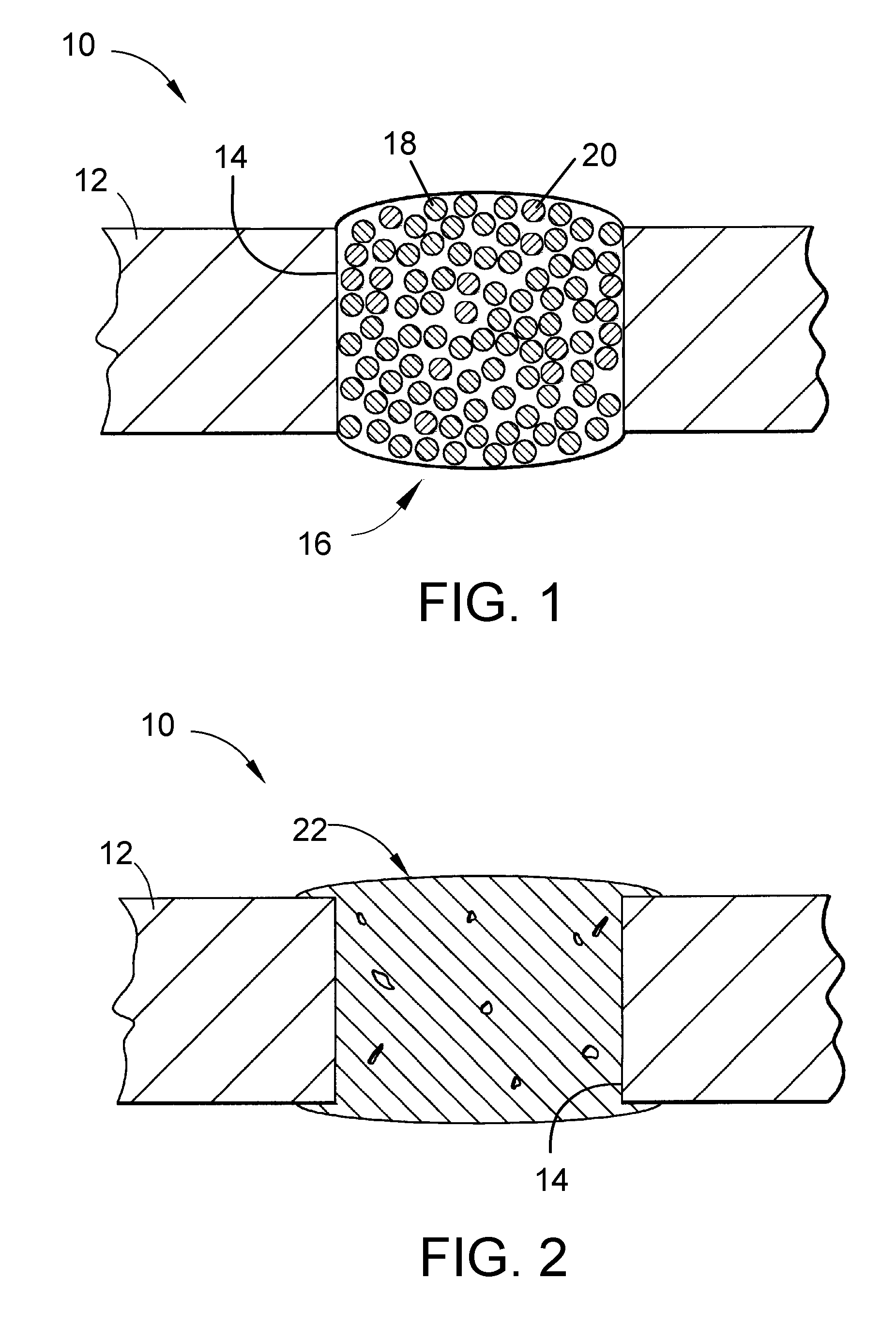

Preform and method of repairing nickel-base superalloys and components repaired thereby

InactiveUS20060134454A1Minimize distortionEasy to crackBlade accessoriesSolid state diffusion coatingPowder mixtureWear resistant

A process for repairing a turbine component of a turbomachine, as well as a sintered preform used in the process and a high gamma-prime nickel-base superalloy component repaired thereby. The sintered preform contains a sintered mixture of powders of a cobalt-base braze alloy and a cobalt-base wear-resistant alloy. The braze alloy constitutes at least about 10 up to about 35 weight percent of the sintered preform and contains a melting point depressant such as boron. The preform is formed by mixing powders of the braze and wear-resistant alloys to form a powder mixture, and then sintering the powder mixture. To use the preform, a surface portion of the turbine component is removed to expose a subsurface portion, followed by diffusion bonding of the preform to the subsurface portion to form a wear-resistant repair material containing the braze alloy dispersed in a matrix of the wear-resistant alloy.

Owner:GENERAL ELECTRIC CO

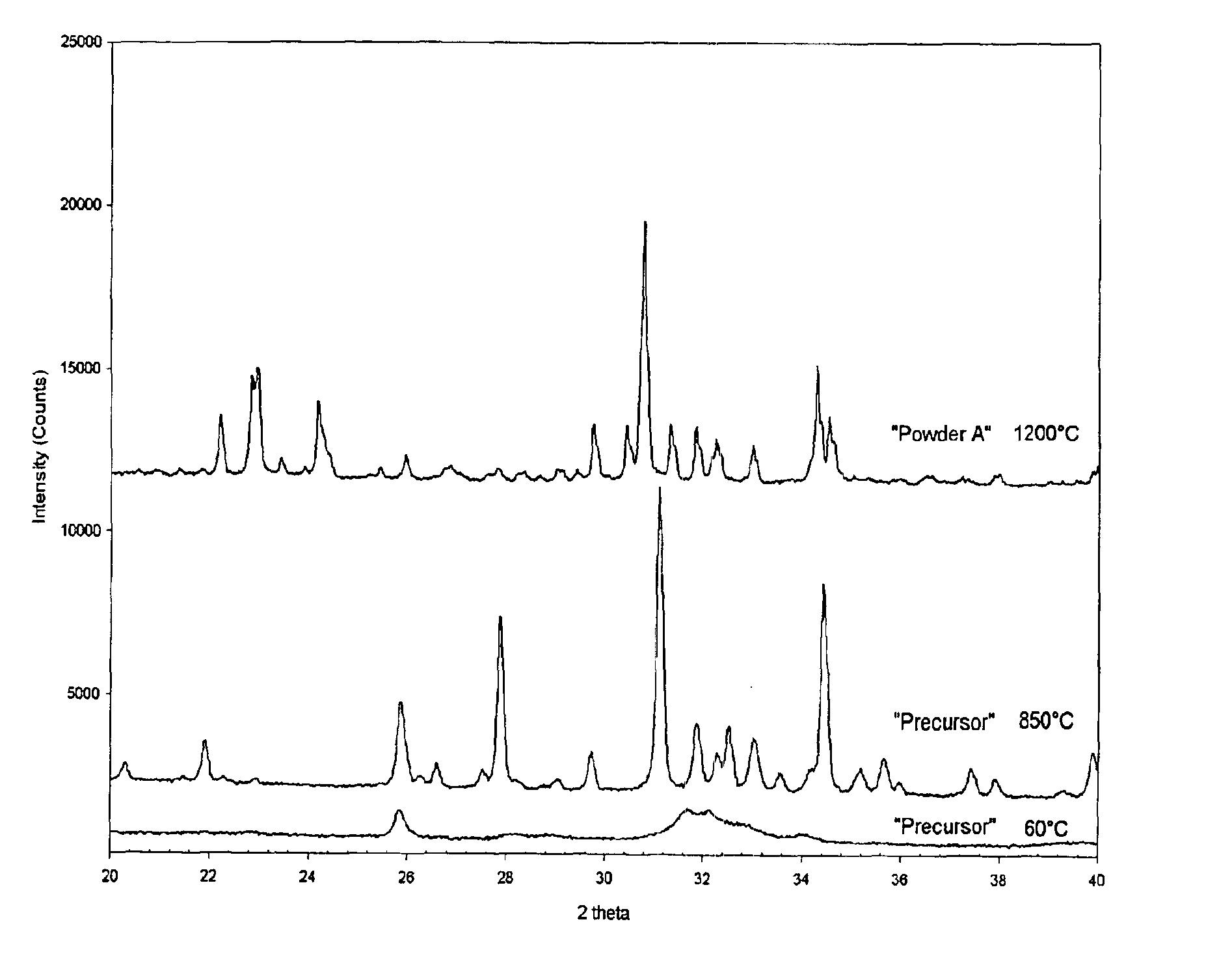

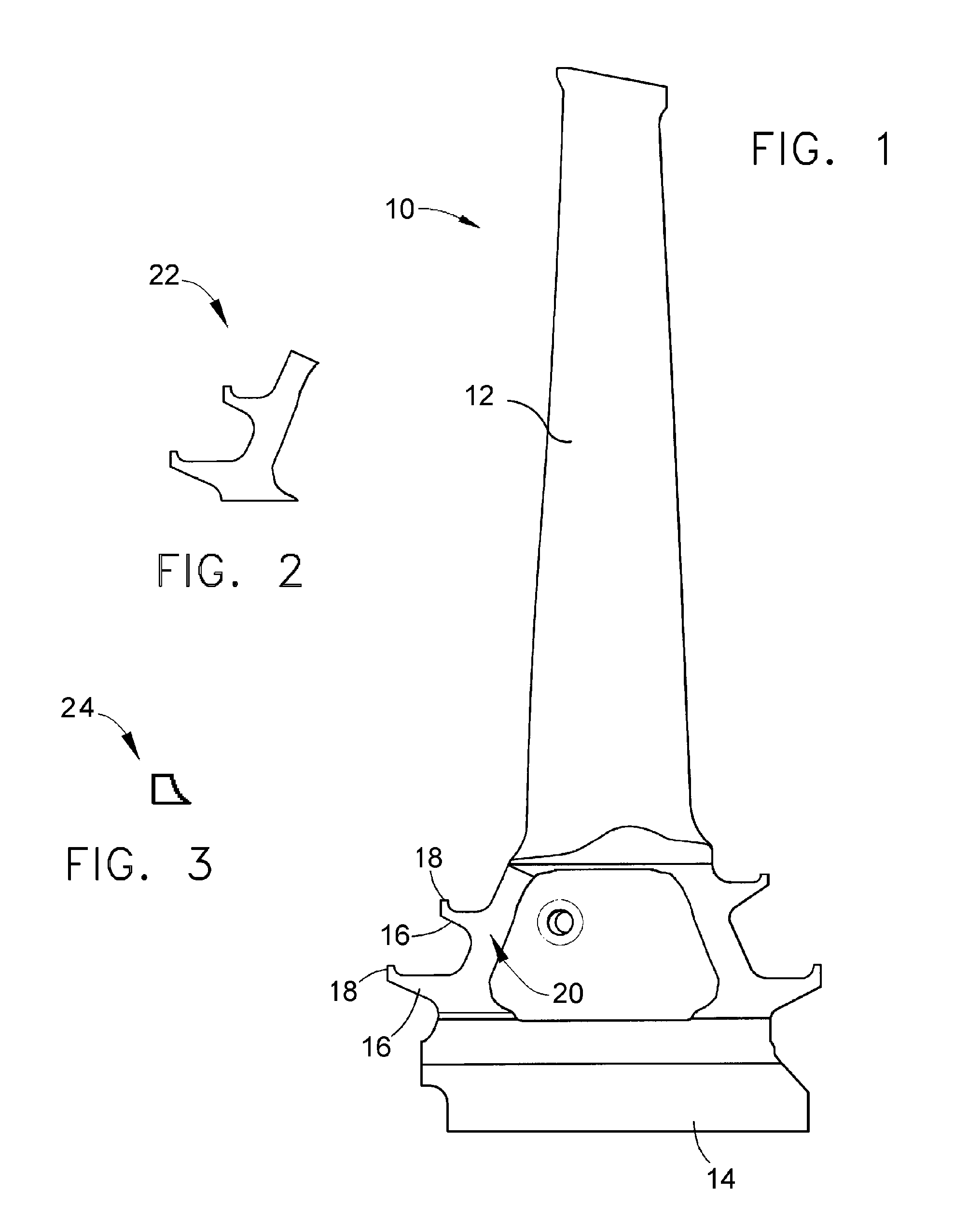

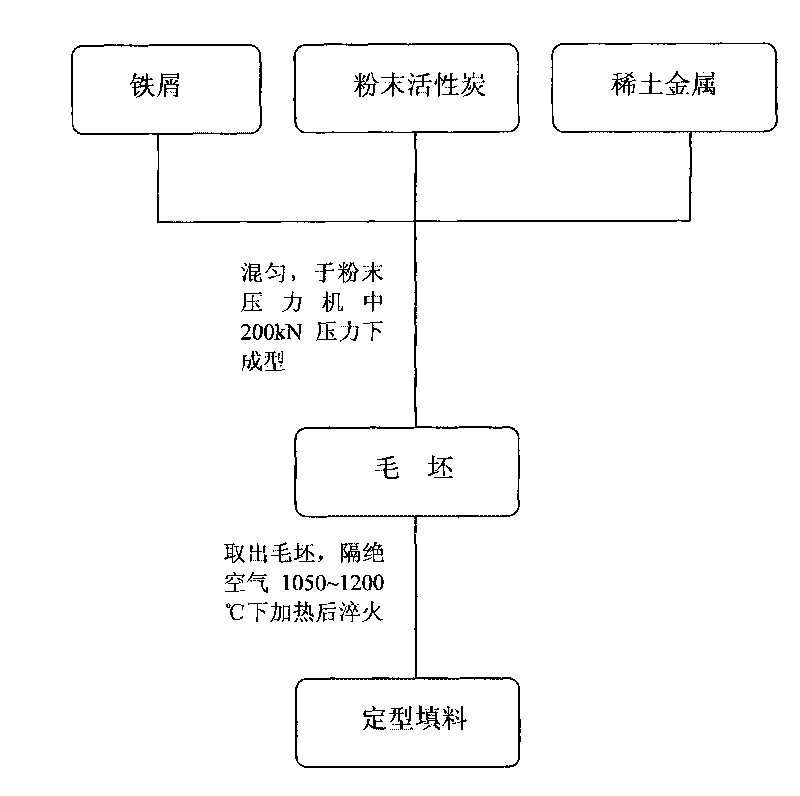

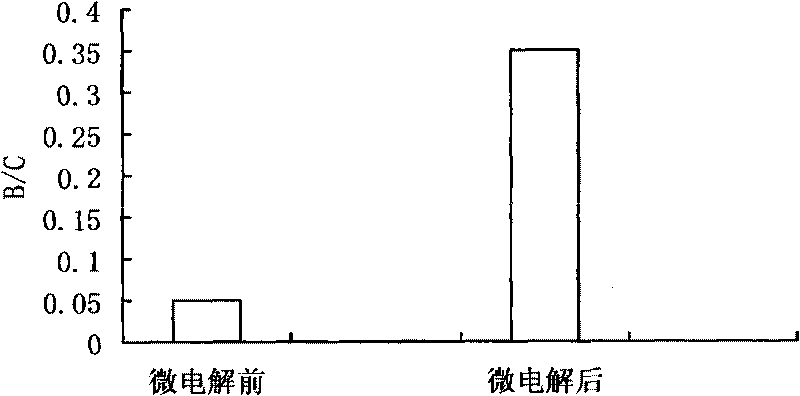

Preparation method of iron-carbon micro-electrolytic filler

InactiveCN101704565ALarge specific surface areaImprove responseWater contaminantsWater/sewage treatmentActivated carbonPowder mixture

A preparation method of iron-carbon micro-electrolytic filler relates to a preparation method of the micro-electrolytic filler for treating wastewater, comprising the following steps: using scrap iron with grain diameter of less than 60 meshes, active carbon powder with grain diameter of less than 100 meshes and rare-earth metal powder as raw materials; using hydrochloric acid solution with mass percentage of 5% for acid washing the scrap iron to activate the scrap iron; mixing the scrap iron with the active carbon powder and the rare-earth metal powder on mass percent of 85%: (14.91-14.00)%: (0.01-0.09)%; using a press machine to add the powder mixture to a Bauer ring-shaped mould for molding at 200 kN; demolding to obtain rough product; heating the rough product for 90-100 min at 1050-1200 DEG C in the absence of air; and then annealing to obtain the iron-carbon micro-electrolytic filler. The iron-carbon micro-electrolytic filler has good specific surface, excellent micro-electrolytic effect and simple technique, and is capable of effectively preventing passivation of the filler surface and hardening of the filler; moreover, the preparation method is easy to promote and suitable for industrial production.

Owner:TONGJI UNIV

Shield type coating composition and preparation process of coating thereof

InactiveCN101817058APrevent sulfidation defectsGuaranteed qualityFoundry mouldsFoundry coresPowder mixtureCarrier fluid

The invention discloses a shield type coating composition, comprising a fire-proof powder mixture, a suspending agent, a binder and a carrier fluid, wherein the fire-proof powder composition consists of high temperature resistant components and functional components, and has a particle size of 200-325 meshes. The invention selects a reasonable fire-proof powder composition to prepare the shield type sand coating, thus achieving good sand burning resistance, and preventing the defects of recarburization on extra-low-carbon stainless steel piece surface and desulphurization on nodular cast iron piece surface, thereby realizing the aim of ensuring casting quality.

Owner:深圳市景鼎现代科技有限公司

High-temperature composite articles and associated methods of manufacture

The present invention provides a method for forming a refractory metal-intermetallic composite. The method includes providing a first powder comprising a refractory metal suitable for forming a metal phase; providing a second powder comprising a silicide precursor suitable for forming an intermetallic phase; blending the first powder and the second powder to form a powder blend; consolidating and mechanically deforming the powder blend at a first temperature; and reacting the powder blend at a second temperature to form the metal phase and the intermetallic phase of the refractory metal-intermetallic composite, wherein the second temperature is higher than the first temperature.

Owner:GENERAL ELECTRIC CO

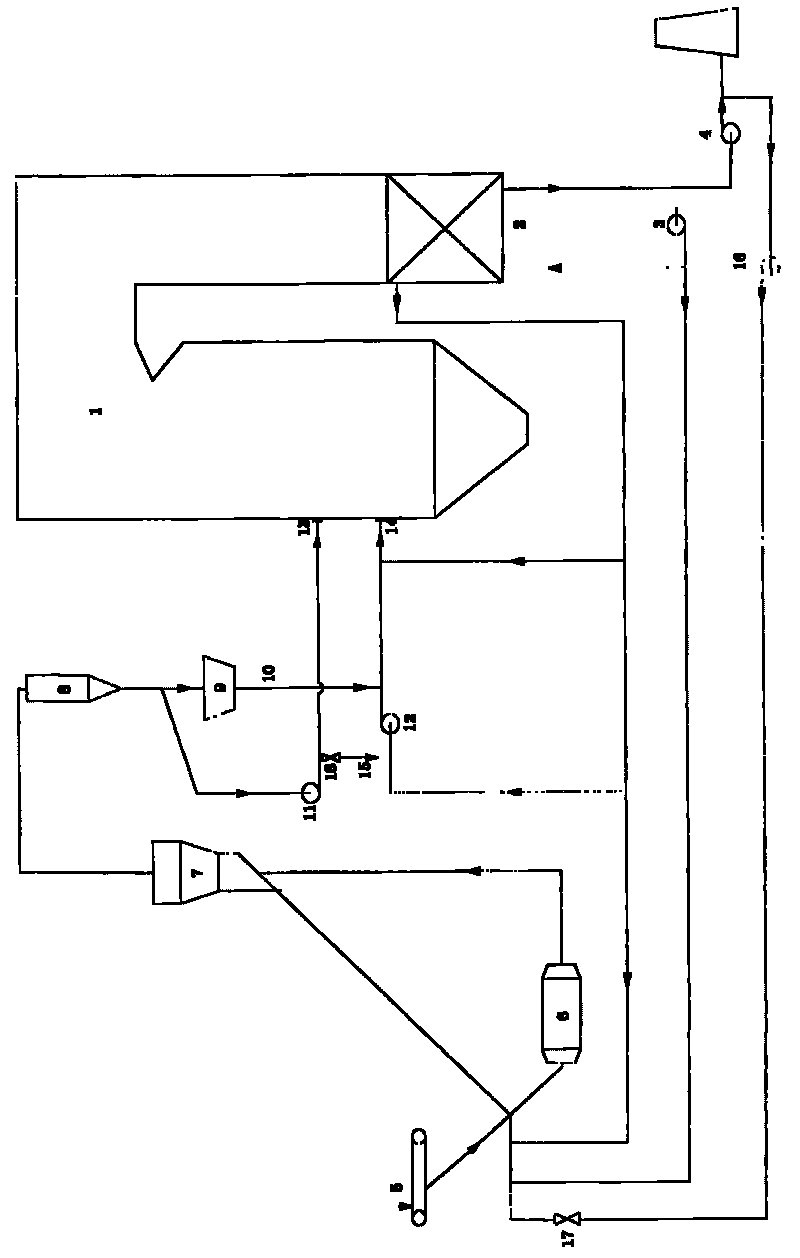

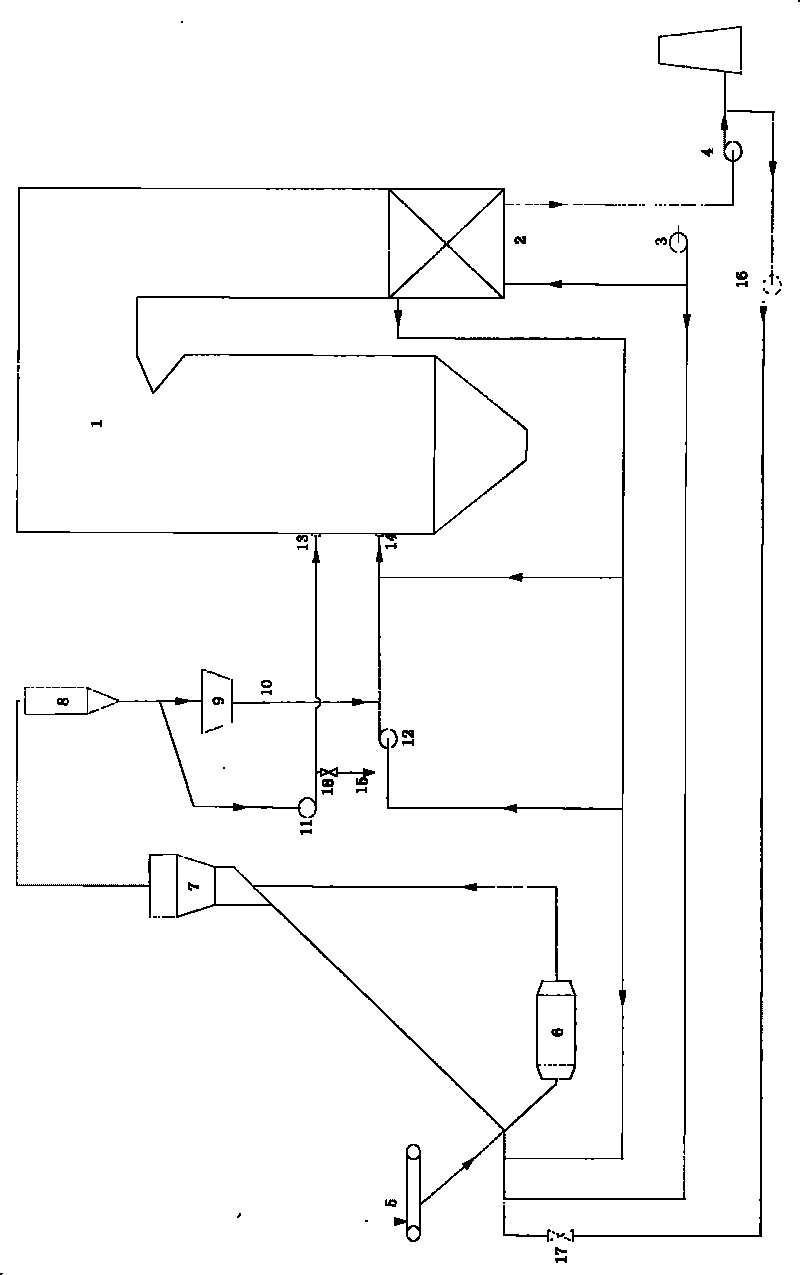

Low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system

ActiveCN101761933ALow oxygenReduce the temperatureGrain treatmentsLump/pulverulent fuel feeder/distributionAir preheaterPowder mixture

The invention relates to a low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system. A middle bin storage type steel ball coal mill hot air power feeding and meagre coal power preparation system is adopted as a prototype, and part of low-temperature furnace smoke is sucked from an outlet of a suction fan by a furnace smoke fan as an inert medium and part of drying mediums to be mixed with hot air taken from an outlet of an air preheater to enter a coal mill for drying and delivering coal powder; the oxygen content of the powder preparation system is reduced, and the explosion preventing requirement on grinding bituminous coal can be met. In addition, part of exhaust gas at an outlet of a power exhauster is led to an inlet of a heat primary fan by an exhaust gas transfer pipeline to be mixed with hot air to enter a primary bellows for delivering the coal powder; the temperature of a primary air and powder mixture and the oxygen concentration of the system are effectively reduced, and the combustion and explosion preventing requirement of bituminous coal delivery is met. Isolating doors are both installed on a furnace smoke system and an exhaust gas transfer system; by the switch control of the isolating doors, the switching of a typical hot air power feeding meagre coal system and a low-temperature furnace smoke exhaust gas and hot air drying composite powder feeding bituminous coal system is realized, and the invention is not only suitable for the meagre coal, but also suitable for the bituminous coal.

Owner:XIAN THERMAL POWER RES INST CO LTD

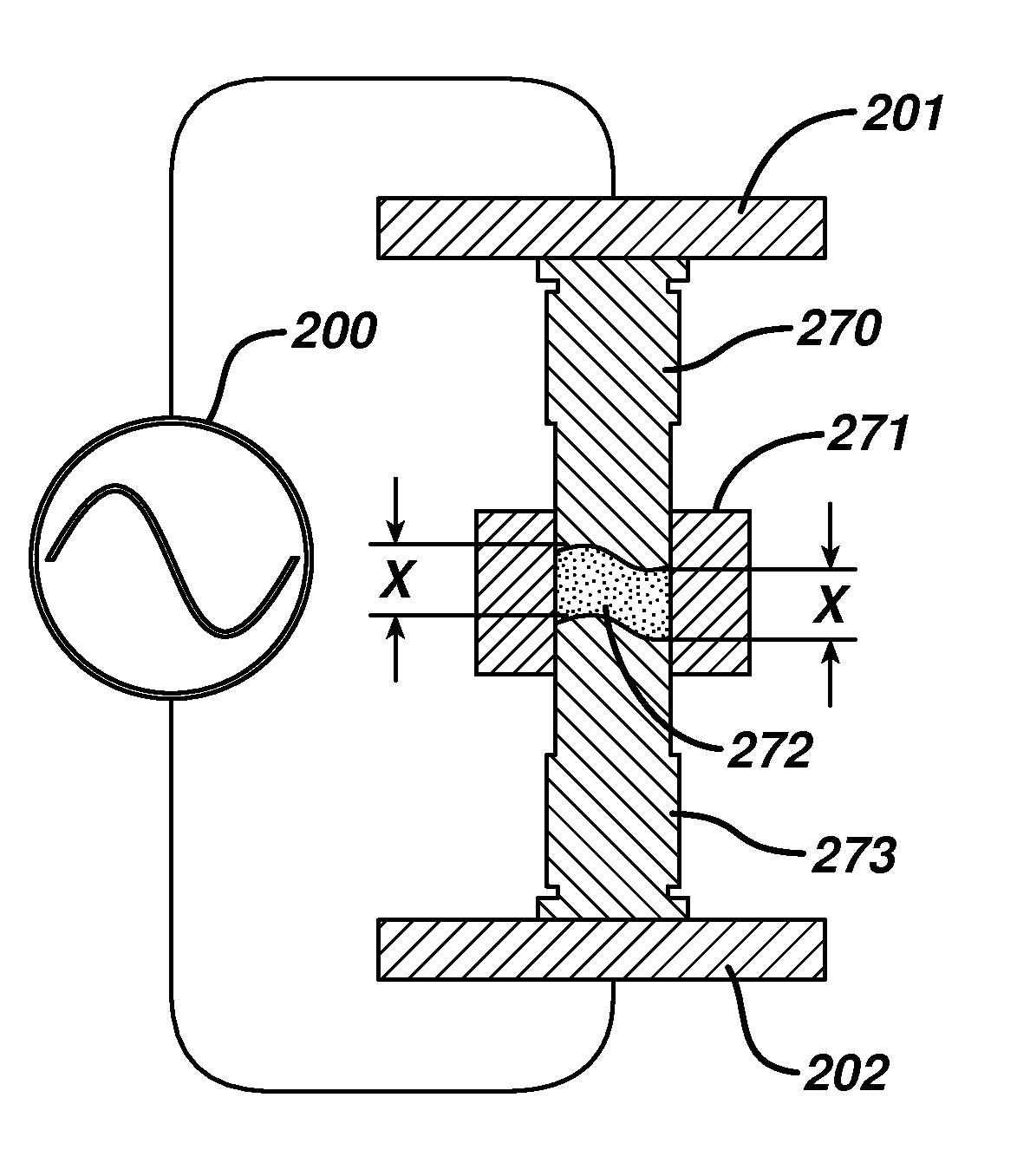

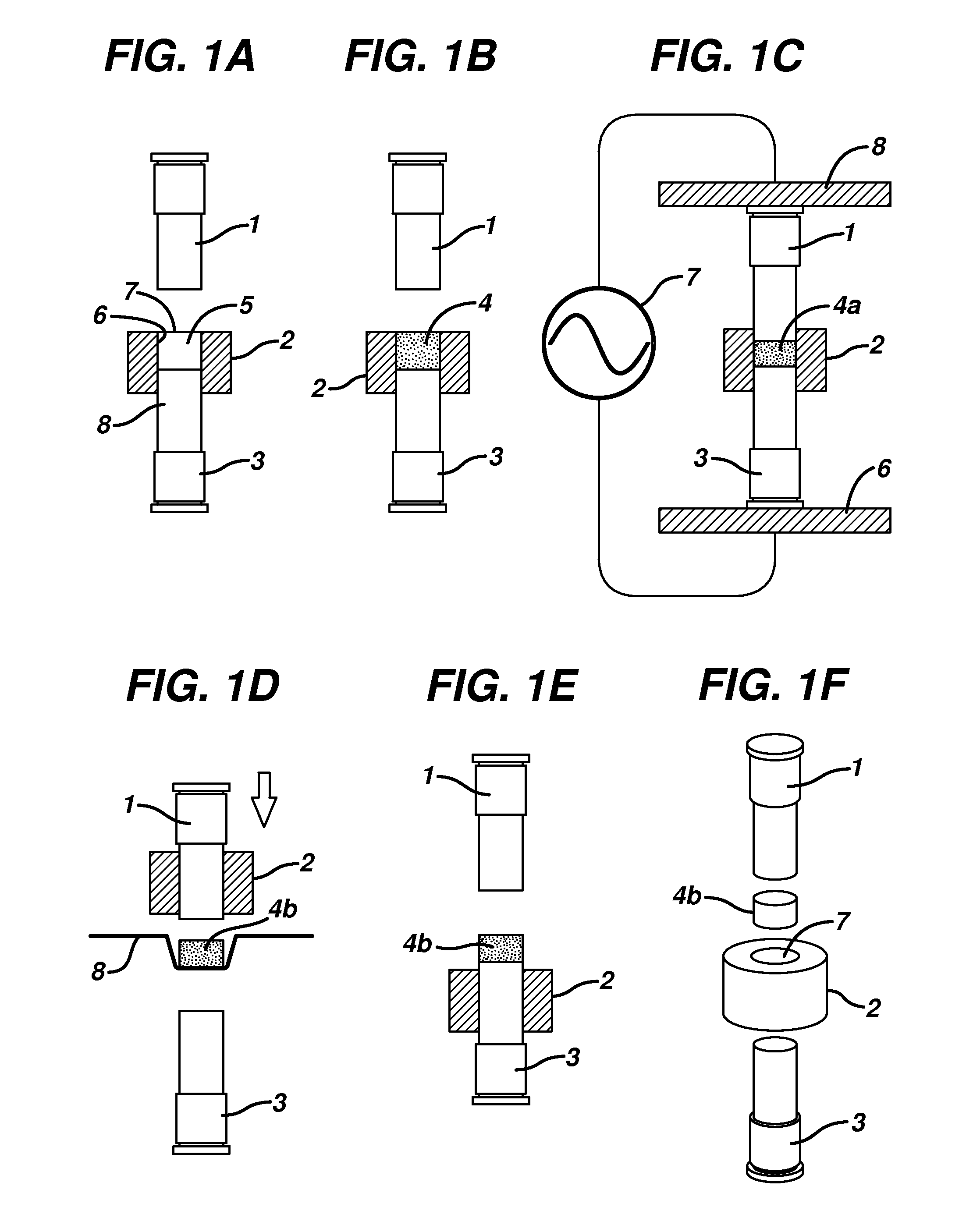

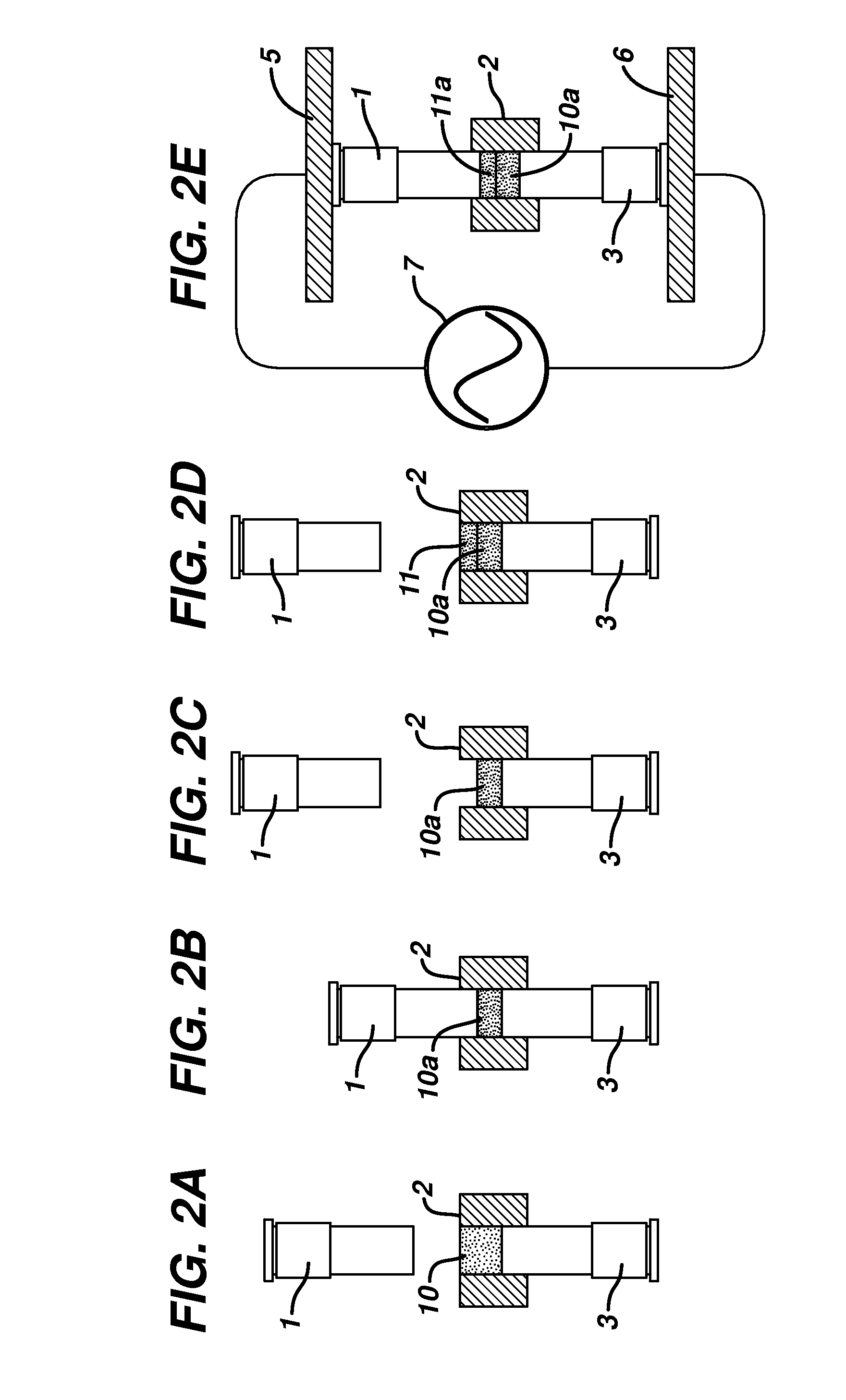

Manufacture of tablet in a die utilizing radiofrequency energy and meltable binder

The present invention features a process for making a tablet by (i) compacting a powder blend in a die to form a tablet shape, wherein the powder blend contains a pharmaceutically active agent and a meltable binder and (ii) applying radiofrequency energy to the tablet shape for a sufficient period of time to soften or melt the binder within said tablet shape to form the tablet.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

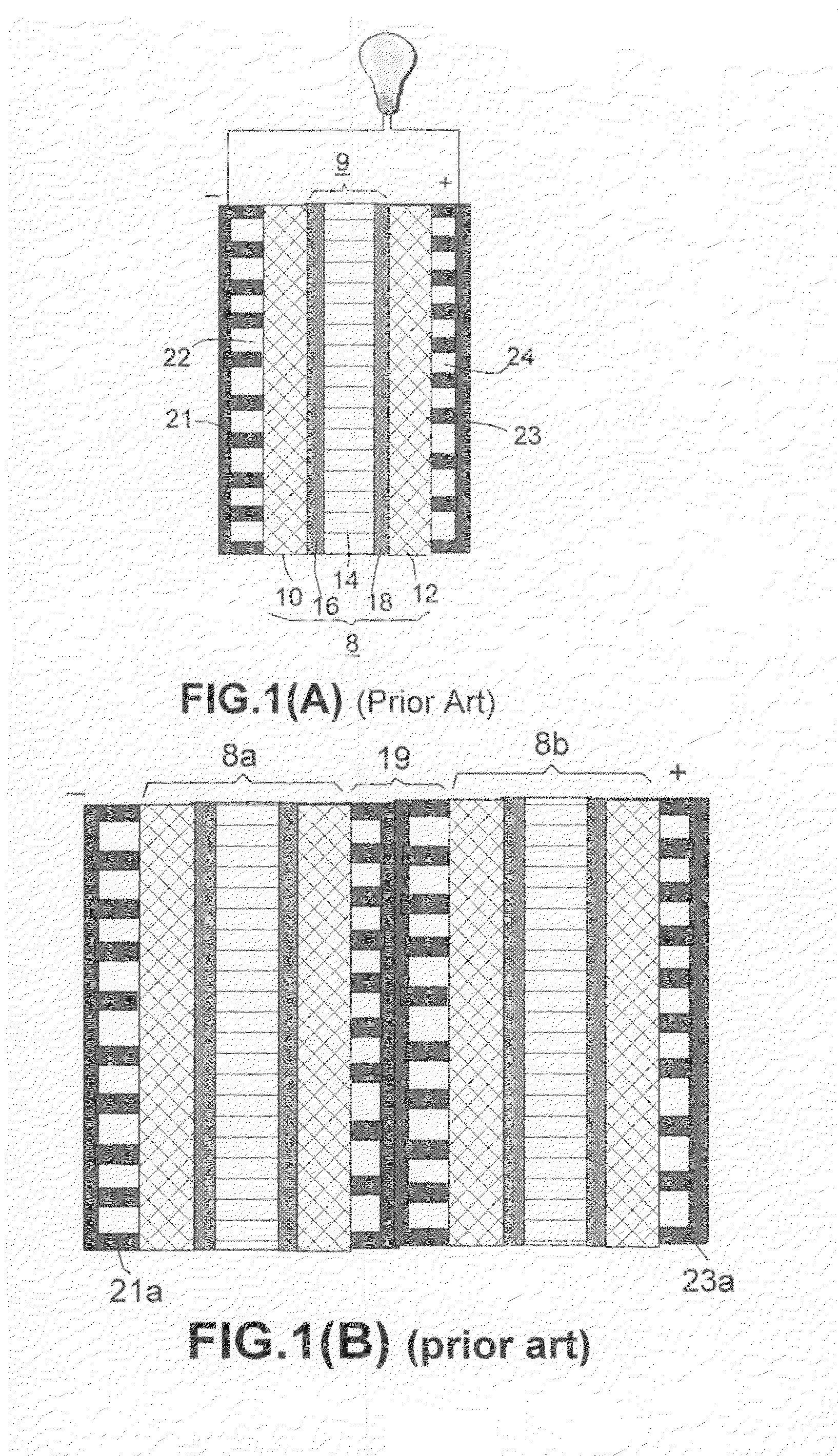

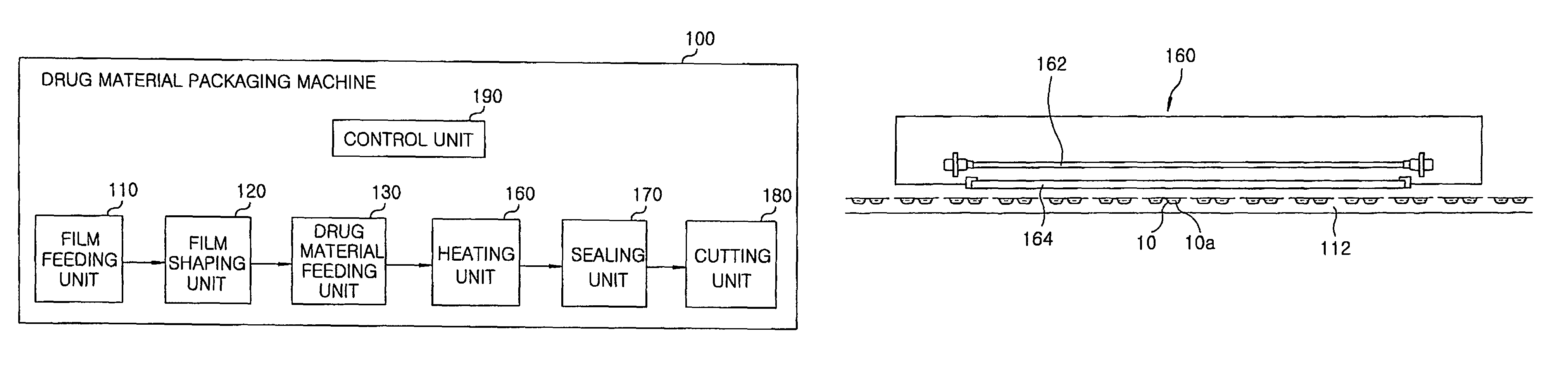

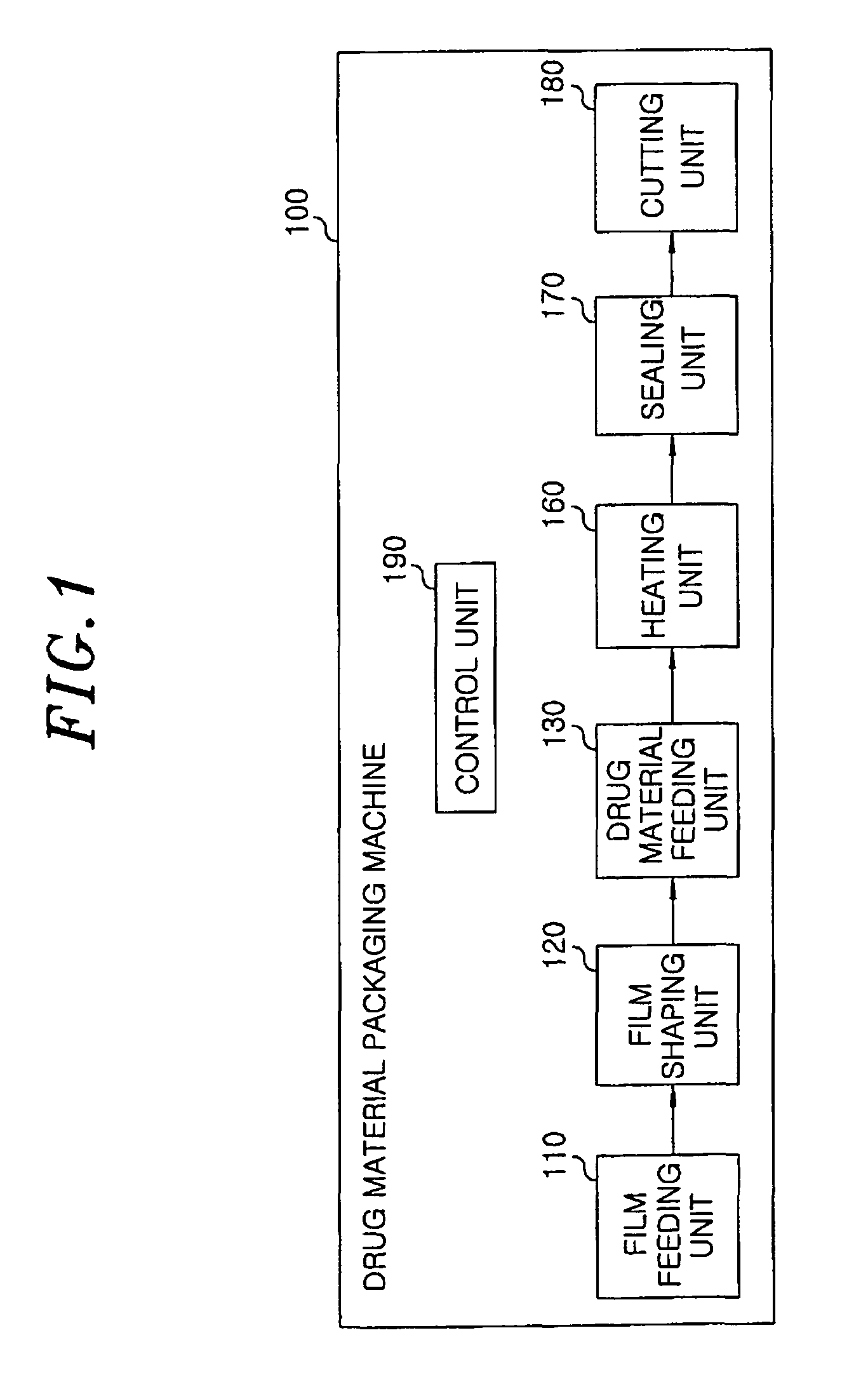

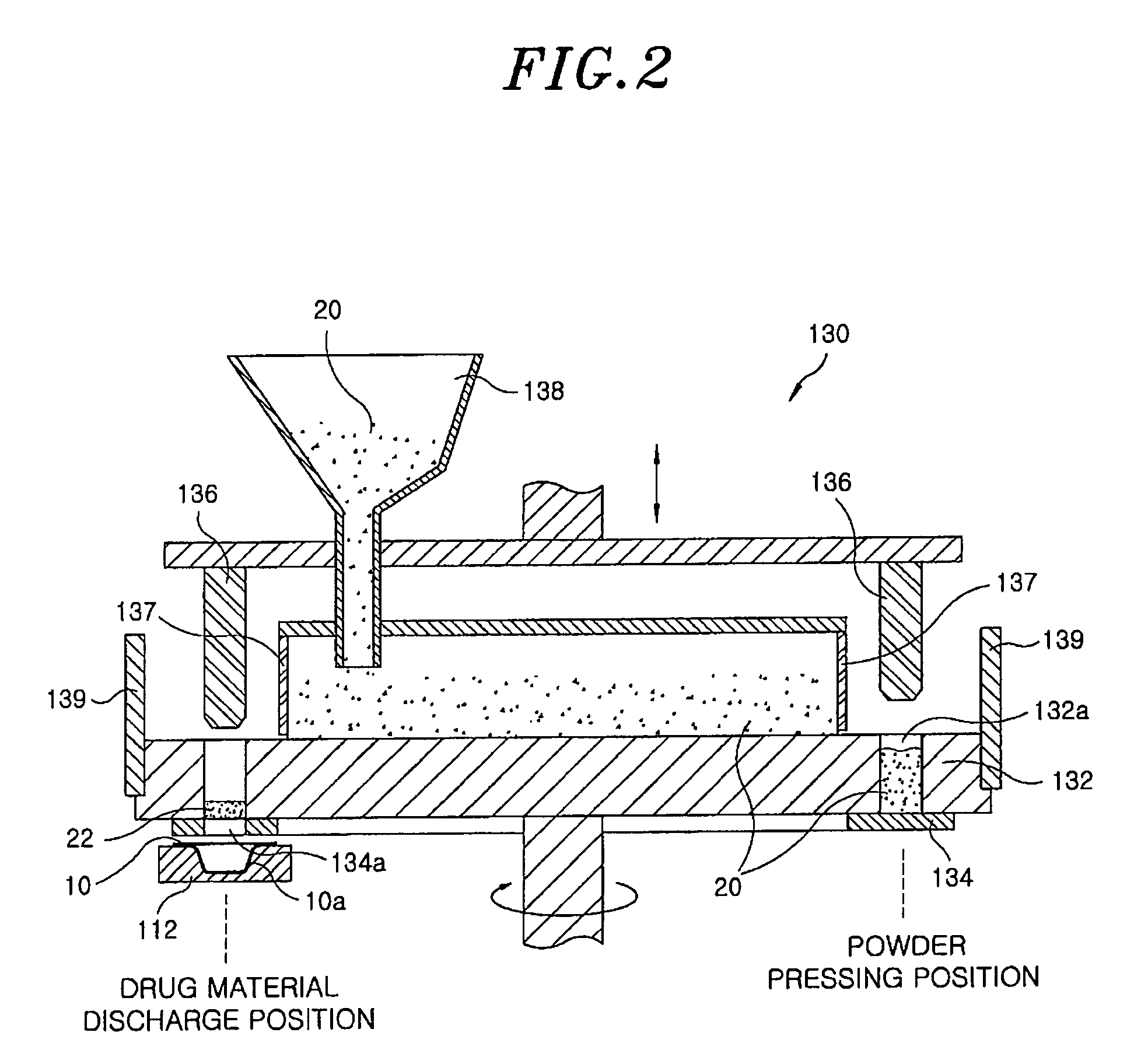

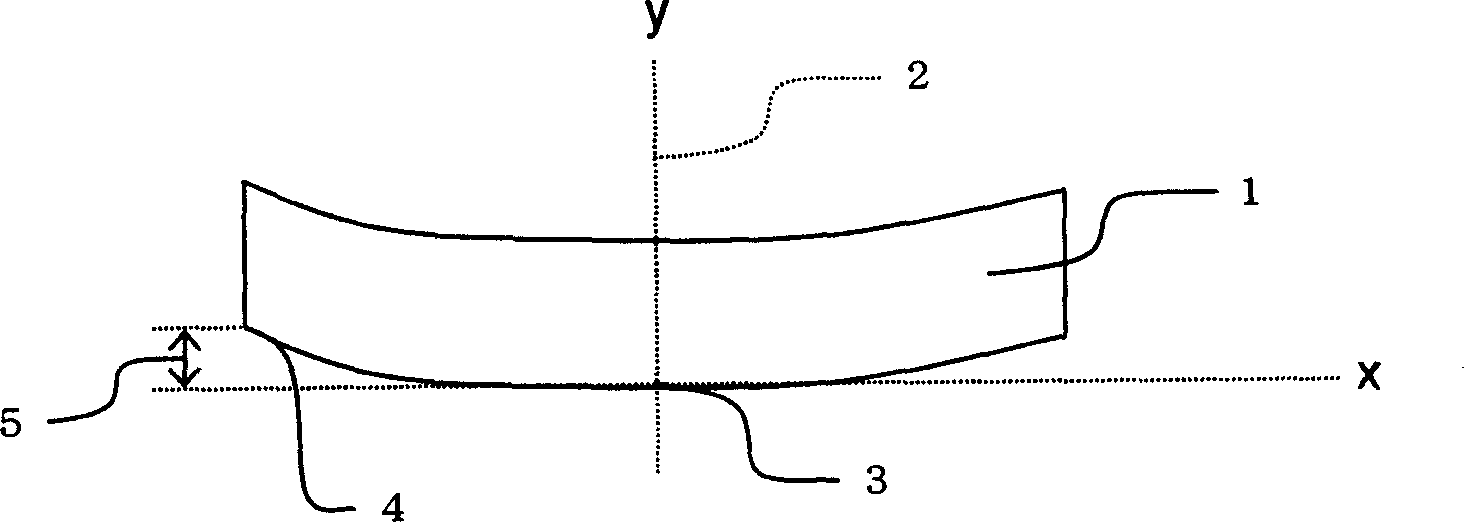

Method for preparing rapidly disintegrating formulation for oral administration and apparatus for preparing and packing the same

InactiveUS8127516B2Disintegrates quicklyEnhanced patient comfortAntibacterial agentsNervous disorderPowder mixtureOral medication

A method and packaging machine for preparing rapidly disintegrating formulations for oral administration are disclosed. The present invention is characterized in that a powdery mixture including a pharmaceutically active ingredient and a sugar or a sugar alcohol powder is filled into a packaging material and, thereafter, the mixture, filled in the packaging material, is heated. The present invention can simply and economically prepare an oral formulation which undergoes rapid disintegration in the oral cavity and provides for high-quality administration to patients.

Owner:HANMI PHARMA

Process of mfg. Mo alloyed targeting materials

ActiveCN1660526AIncrease packing densityReduces the problem of unfavorable shape changesTransportation and packagingVacuum evaporation coatingPowder mixtureAlloy

Disclosed is a method of producing a target material of a Mo alloy, which includes the steps of (a) preparing a green compact by compressing a raw material powder blend consisting of a Mo powder having an average particle size of not more than 20 mum and a transition metal powder having an average particle size of not more than 500 mum; (b) pulverizing the green compact to produce a secondary powder having an average particle size of from not less than an average particle size of the raw material powder blend to not more than 10 mm; (c) filling the secondary powder into a container for pressurizing; and (d) subjecting the secondary powder with the container for pressurizing to sintering under pressure thereby obtaining a sintered body of the target material.

Owner:HITACHI METALS LTD

Process of filling openings in a component

ActiveUS20100059573A1Lower melting temperatureImprove propertiesTurbinesWelding/cutting media/materialsPowder mixtureMicrometer

A process for filling openings, including blind holes, through-holes, and cavities, in high temperature components. The process entails forming a powder mixture by mixing particles of at least a base alloy and a second alloy that contains a sufficient amount of a melting point depressant to have a lower melting temperature than the base alloy. The powder mixture is combined with a binder and compacted to form a compacted preform, which is then heated to remove the binder and form a rigid sintered preform. The sintered preform is produced, or optionally is further shaped, to have a cross-sectional shape and dimensions to achieve a clearance of up to 200 micrometers with the opening, after which the preform is placed in the opening and diffusion bonded within the opening to form a brazement comprising the particles of the base alloy dispersed in a matrix formed by the second alloy.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com