Low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system

A low-temperature furnace and hot air technology, which is used in the preparation of block/powder fuel, lighting and heating equipment, block/powder supply/distribution, etc. Fluctuation and other problems, to meet the requirements of anti-flame and explosion-proof, easy to switch, reduce the effect of oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

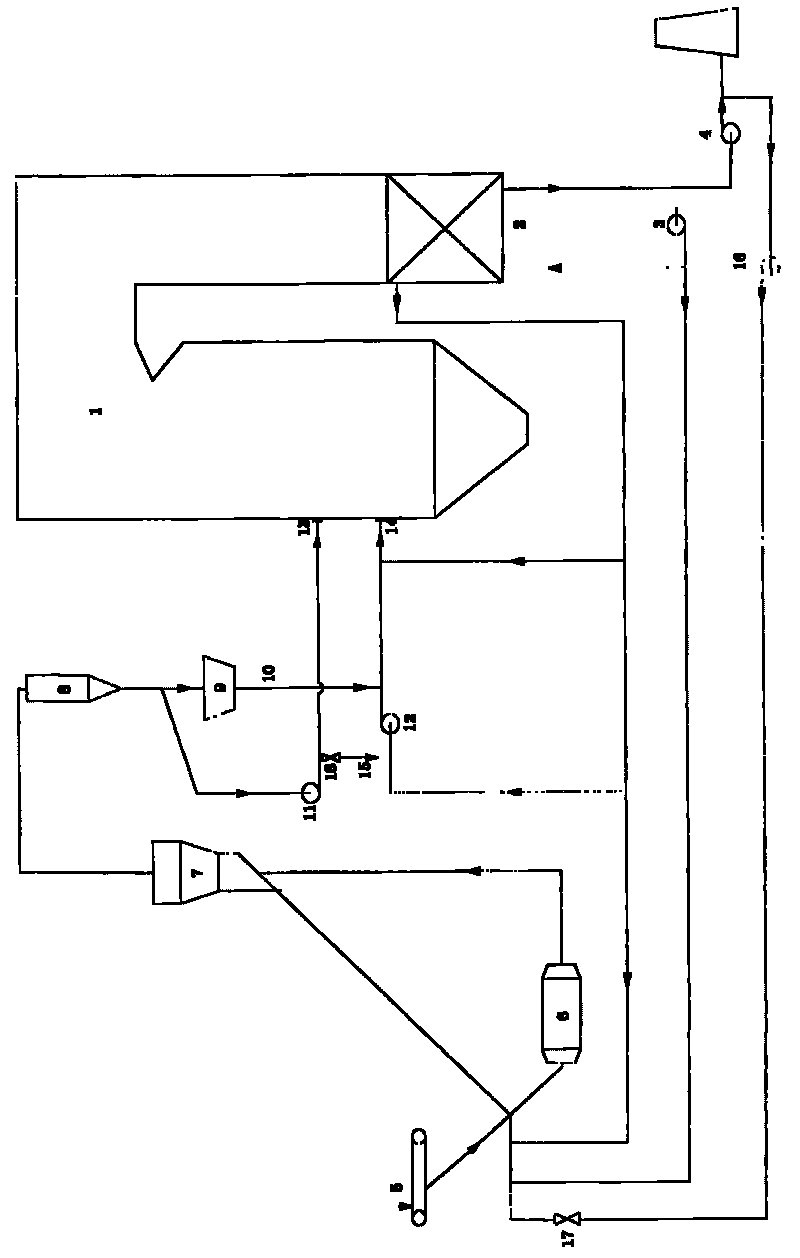

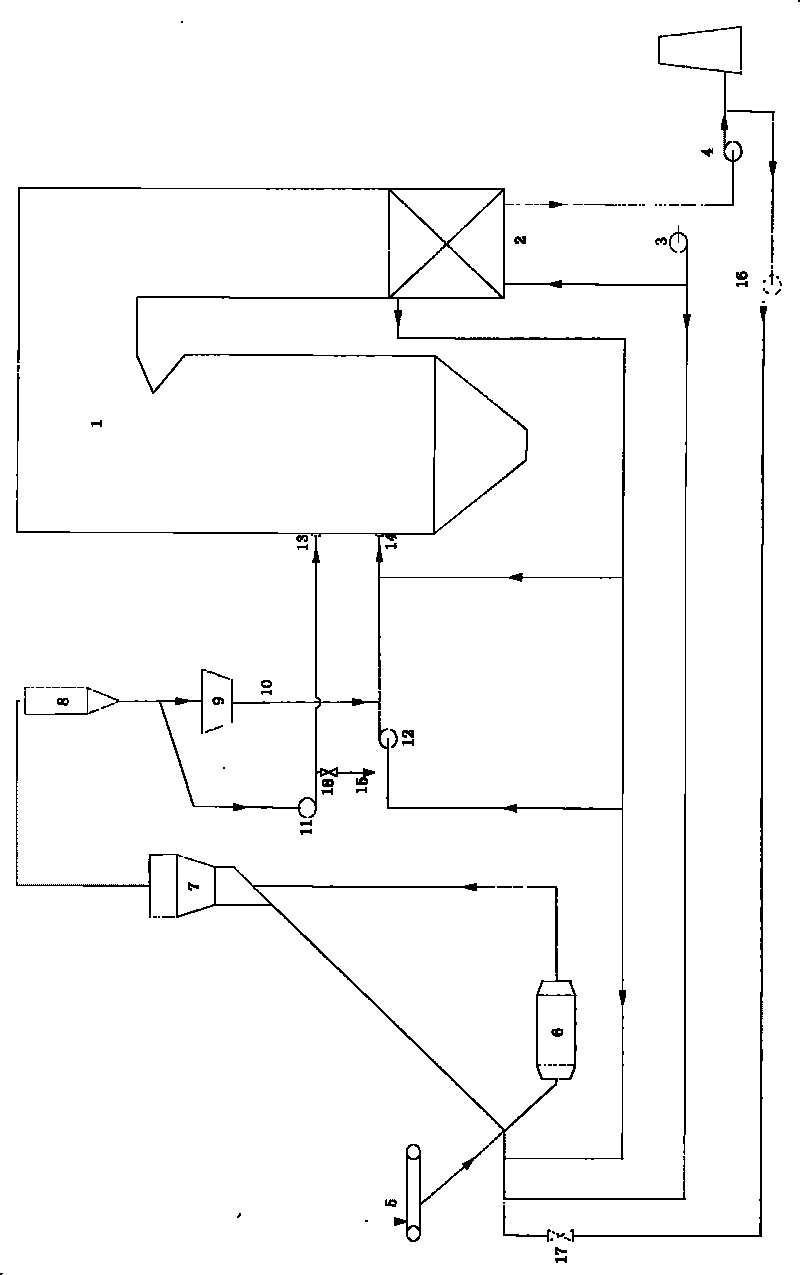

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] see figure 1 , the present invention comprises a coal feeder 5 and a coal mill 6 connected to the coal outlet of the coal feeder 5, and the outlet of the coal mill 6 is sequentially connected with a coarse powder separator 7 and a fine powder separator 8 through a pulverized coal pipeline. and the other outlet of the coarse powder separator 7 is also connected with the inlet of the coal mill 6, the outlet of the fine powder separator 8 is divided into two parts, the air pipeline and the pulverized coal pipeline, and the fine powder separator 8 The pulverized coal pipeline is connected with the boiler burner 14 through the pulverized coal bin 9, the powder feeder 10, and the cold air pipe at the outlet of the blower 3 is divided into two paths, one path is connected with the entrance of the coal mill 6, and the other path passes through the air preheate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com