Patents

Literature

57results about How to "Promote harmlessness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

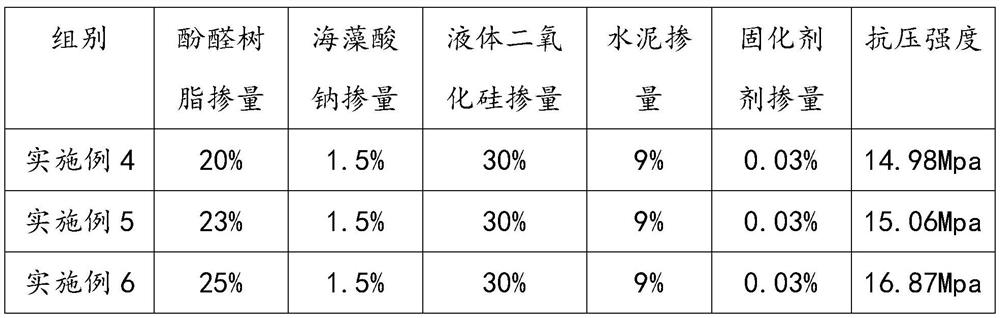

Method and device for reducing emission limits of nitrogen oxides in waste incineration flue gas

InactiveCN102168852APromote harmlessnessImprove utilizationDispersed particle separationIncinerator apparatusFlue gasNitrogen oxide

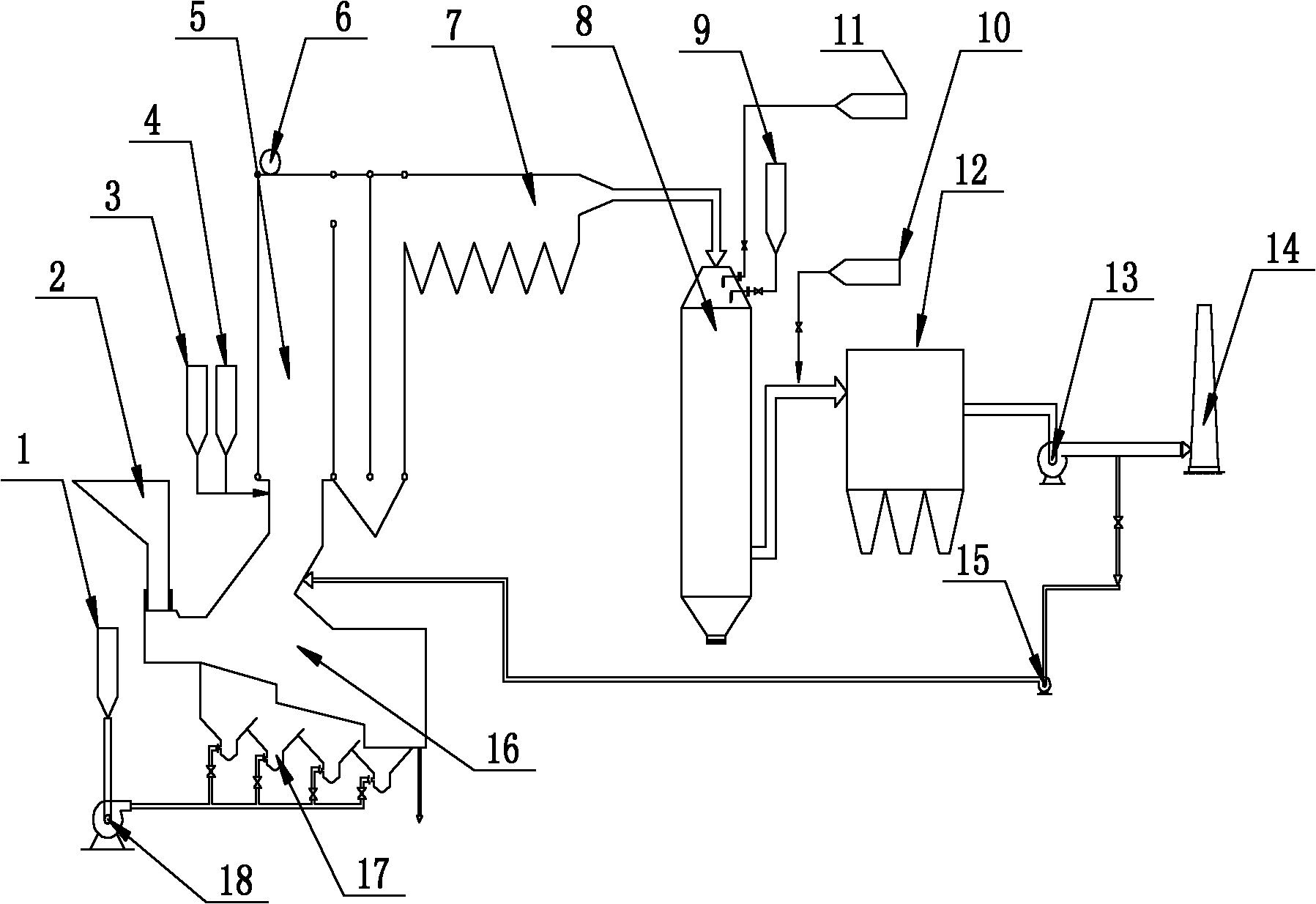

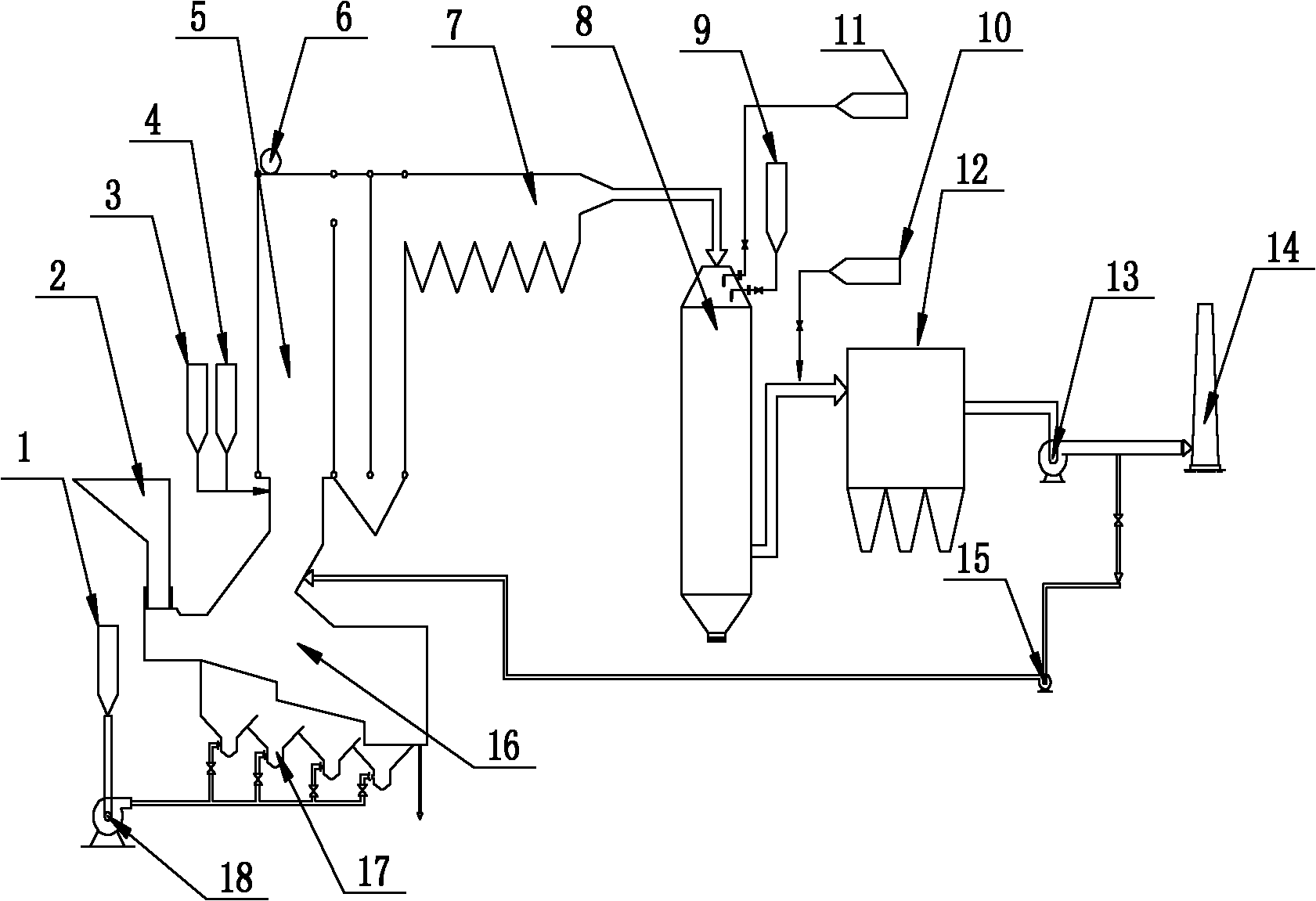

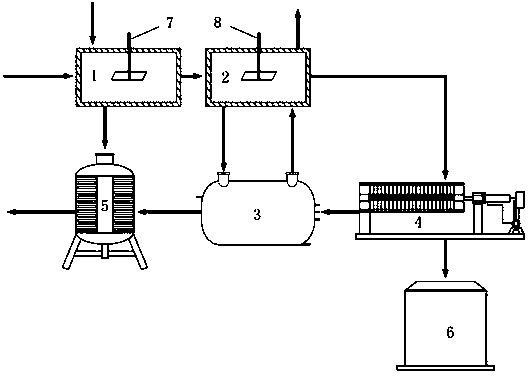

The invention relates to a method and a device for reducing emission limits of nitrogen oxides in waste incineration flue gas. In the method, processes of a waste incineration processing device, an optimizing air supply device, an exhaust-heat boiler device, a selective non-catalytic reduction (SNCR) device, a tail gas processing device and the like are integrated into a whole; by combining clean flue gas serving as secondary air supply and the SNCR device, the situation that the nitrogen oxides in the discharge of tail gas generated after wastes are processed by national waste incineration equipment is not removed effectively in low cost can be changed, and the removal ratio of the nitrogen oxides can be improved; and the removal rate of the nitrogen oxides after the device is optimized is more than 70 percent, so that the concentration of the tail gas discharged finally is lower than 150 mg / Nm<3> specified in the European Union standard 2000. Simultaneously, the optimizing device requires less increment investment and low running cost and is suitable to be applied and popularized in waste incineration equipment at home and abroad, and a denitration device is small in newly increased floor space.

Owner:BMEI

Treatment method of organic solid waste

InactiveCN103274572AImprove dehydration efficiencyIncrease drynessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBuffer tankAerobic digestion

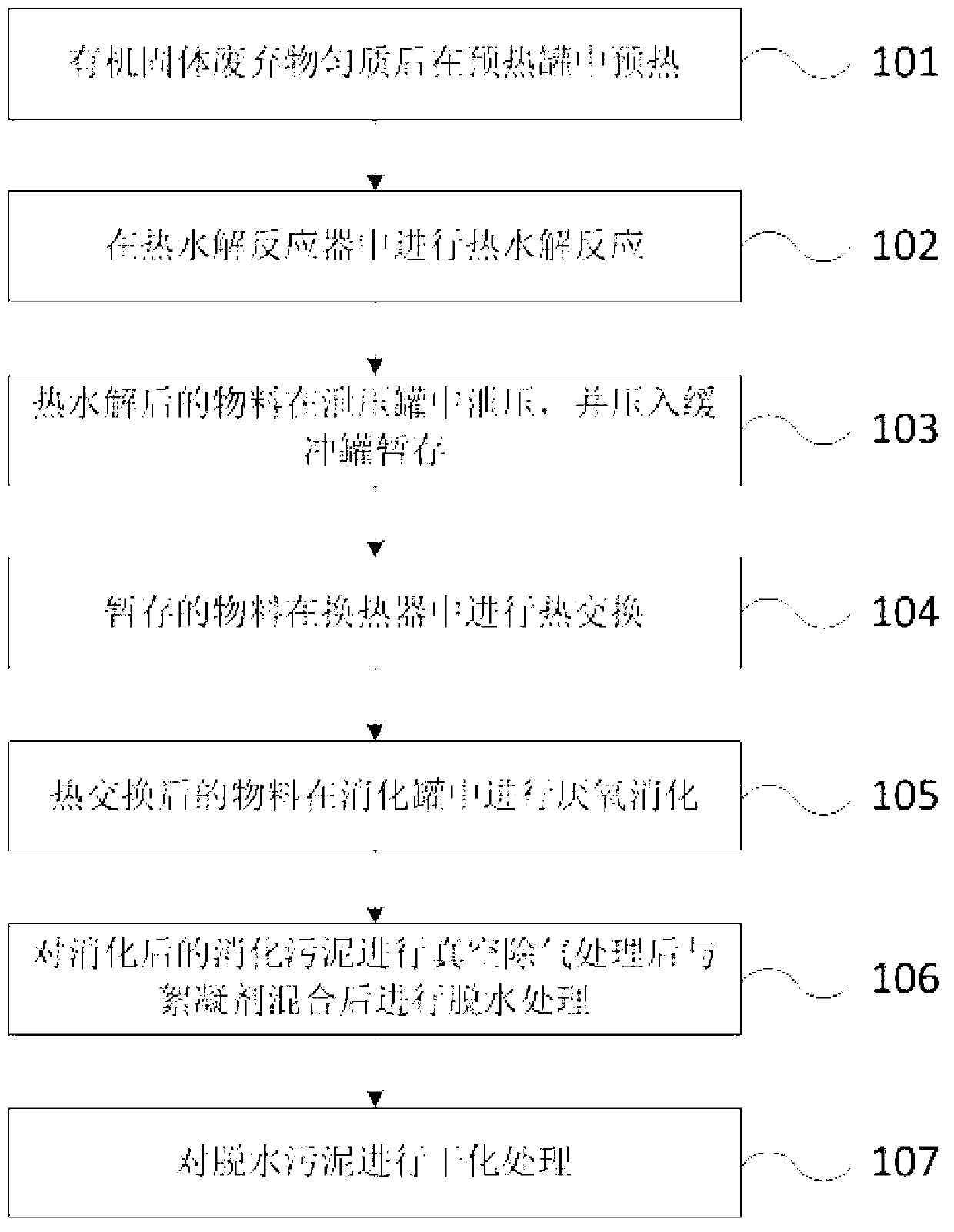

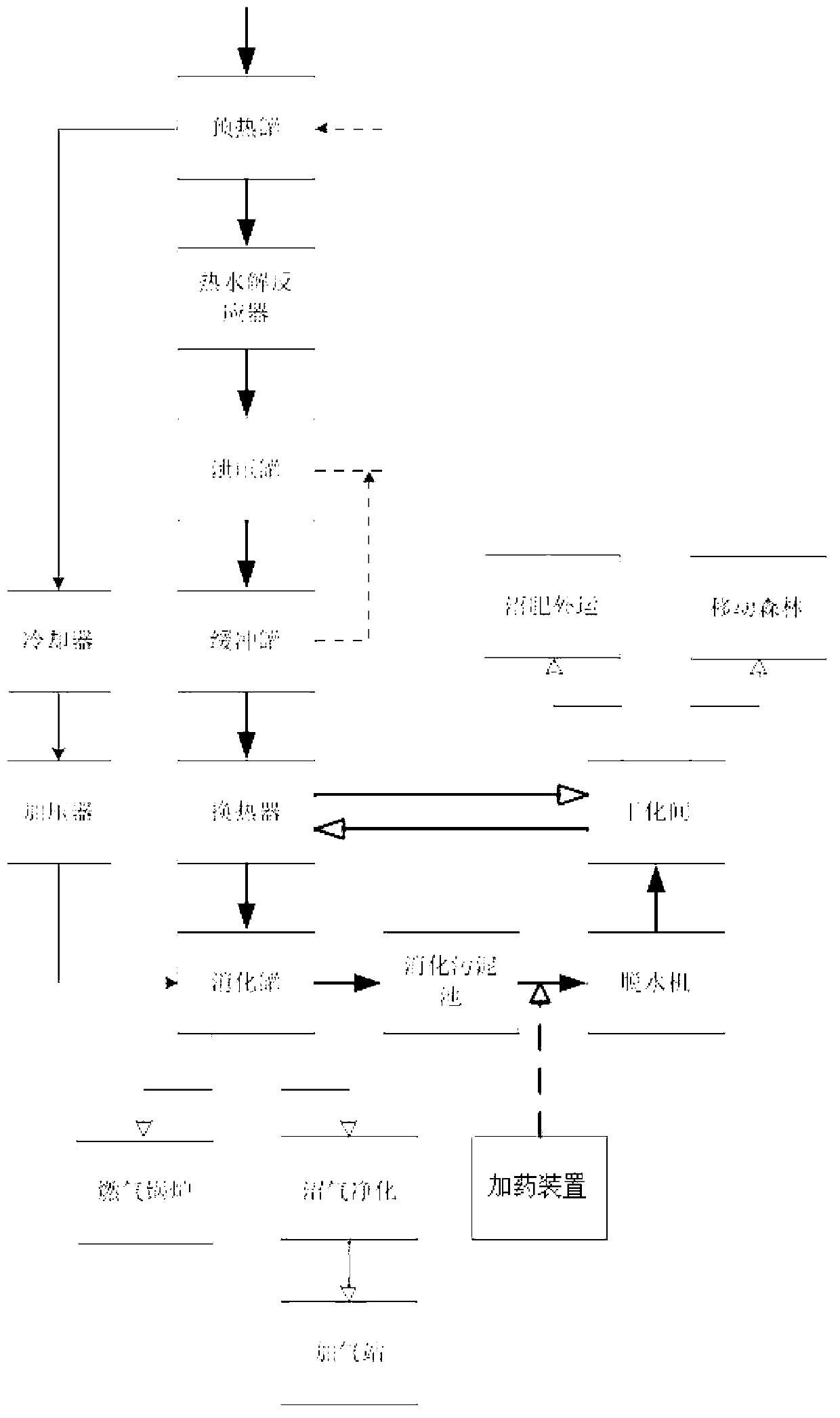

The invention relates to a treatment method of organic solid waste. The treatment method comprises the following steps of: homogenizing the organic solid waste and then preheating, carrying out a thermal hydrolysis reaction on the preheated organic solid waste, then pushing the material into a depressurization tank and a buffer tank to be subjected to primary depressurization and secondary depressurization and then temporary storage, then carrying out heat exchange on the material, carrying out anaerobic digestion on the material subjected to heat exchange, carrying out vacuum degassing treatment on digested sludge in a digested sludge tank, dehydrating the treated digested sludge to form dehydrated sludge, conveying the dehydrated sludge to a drying room to be dried, and producing dried biogas residue. According to the treatment method of the organic solid waste, high temperature hydrolysis and anaerobic digestion technologies are adopted, the problems that resource is wasted when a burning method is adopted and secondary pollution can be easily caused when a burying method is adopted can be avoided, digestive efficiency in follow-up anaerobic digestion is improved, standing time of an anaerobic digestion process is also reduced, and sludge subjected to anaerobic digestion is subjected to vacuum degassing, so that carbon dioxide and ammonium nitrogen in the digested sludge can be effectively removed, and sludge dehydration efficiency is improved.

Owner:HUBEI GUOXIN TIANHUI ENERGY

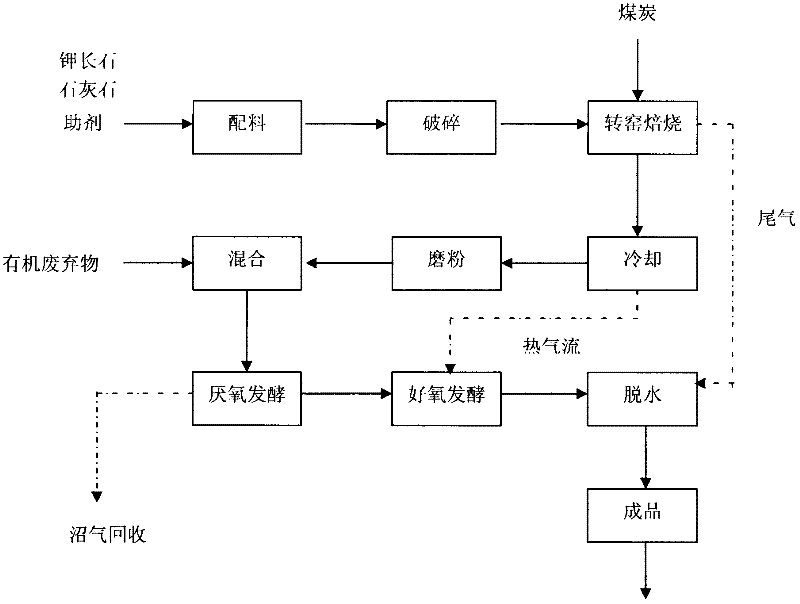

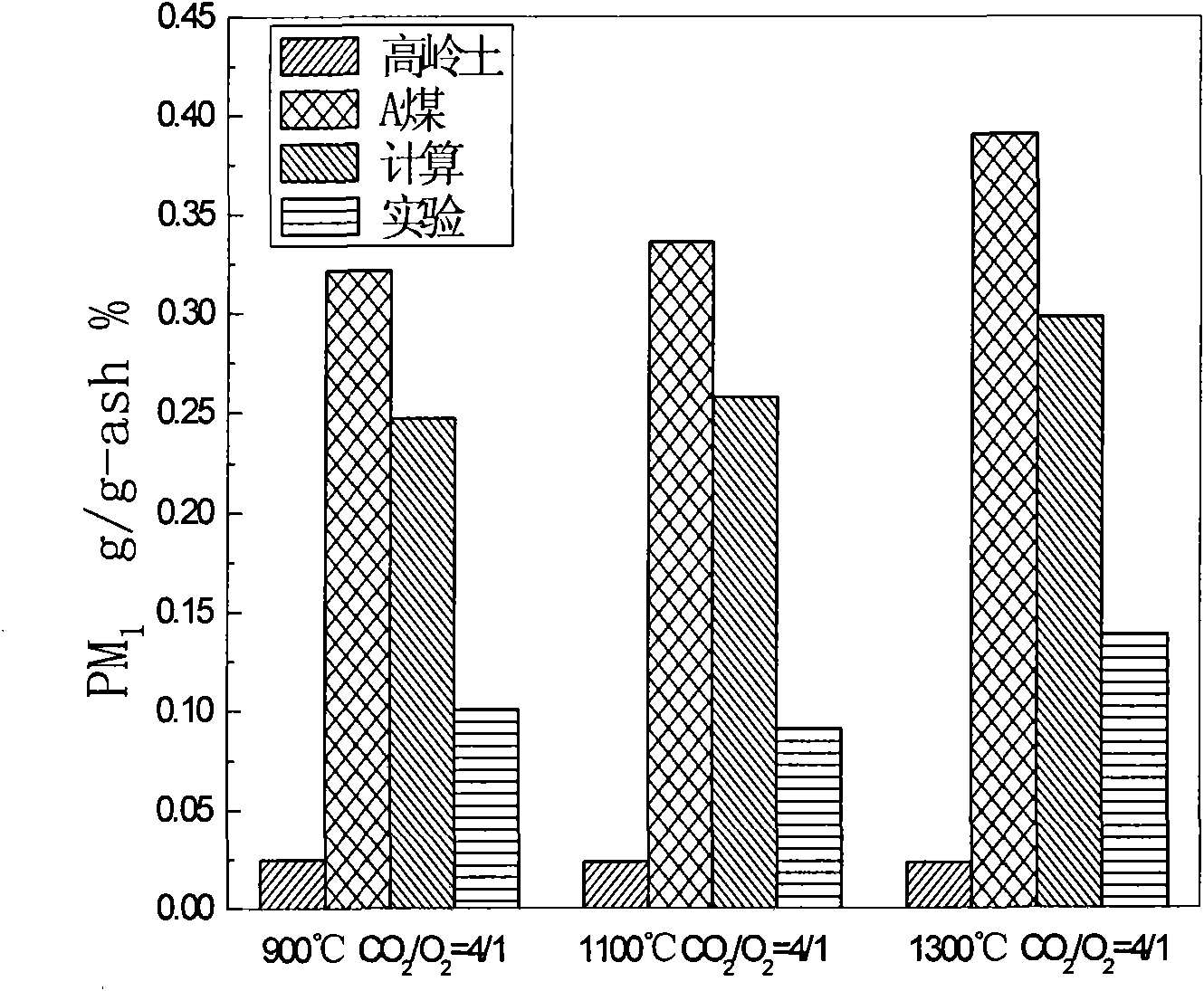

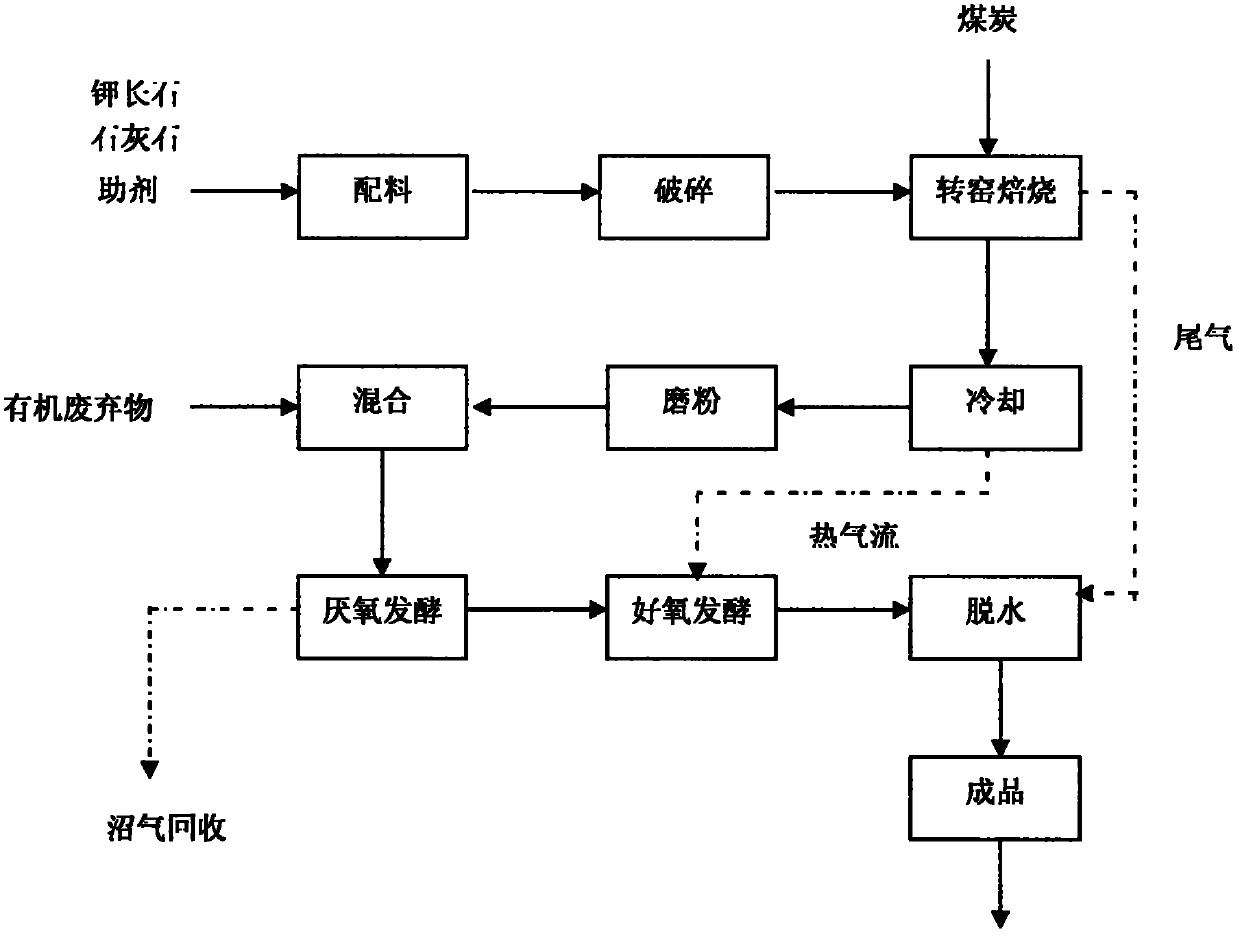

Method for producing long-acting soil conditioning agent by using potassium feldspar and organic waste

ActiveCN102391878ALow costIn line with industrial policyAgriculture tools and machinesOrganic fertilisersPotassiumOxygen

The invention discloses a method for producing a long-acting soil conditioning agent by using potassium feldspar and organic waste. Potassium feldspar, limestone, aid and coal are used as raw materials in the method. The method comprises the following steps of: roasting the crushed raw materials in a rotary kiln by adding the coal, and cooling and milling the roasted raw materials; and mixing the powder and the organic waste such as animal excrement in a farm and the like, performing anaerobic and aerobic continuous fermentation step by step, performing partial dehydration, and thus obtaining a finished product. The produced long-acting soil conditioning agent contains a certain amount of nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, soluble silicon, humic acid and the like, so the soil conditioning agent can effectively improve the soil and provides nutritional components for crops for long time. The soil conditioning agent can be directly applied, and can also be applied with chemical fertilizers. According to the method for producing the long-acting soil conditioning agent by using the potassium feldspar and the organic waste, the production raw materials are mineral in the nature and waste in the farm, the raw materials are extremely rich and cheap, and the production process is energy-saving and environment-friendly.

Owner:SHANGHAI RES INST OF CHEM IND +1

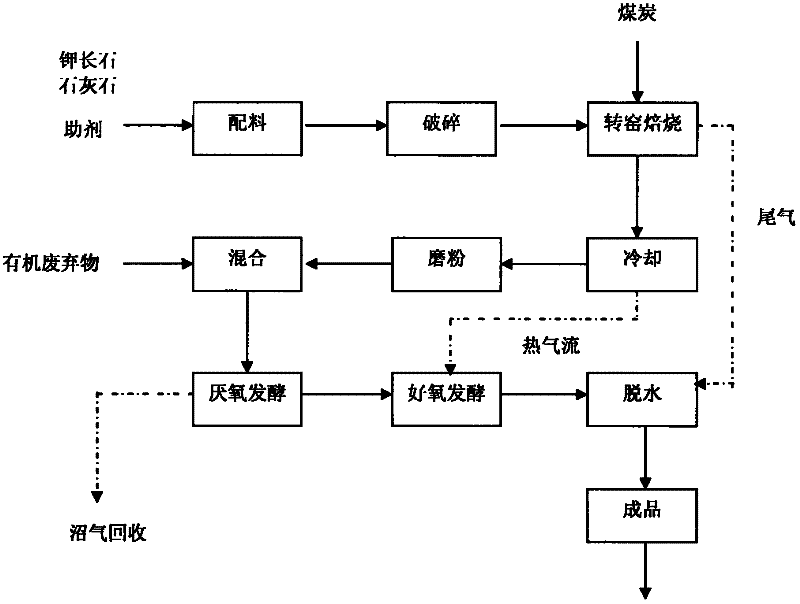

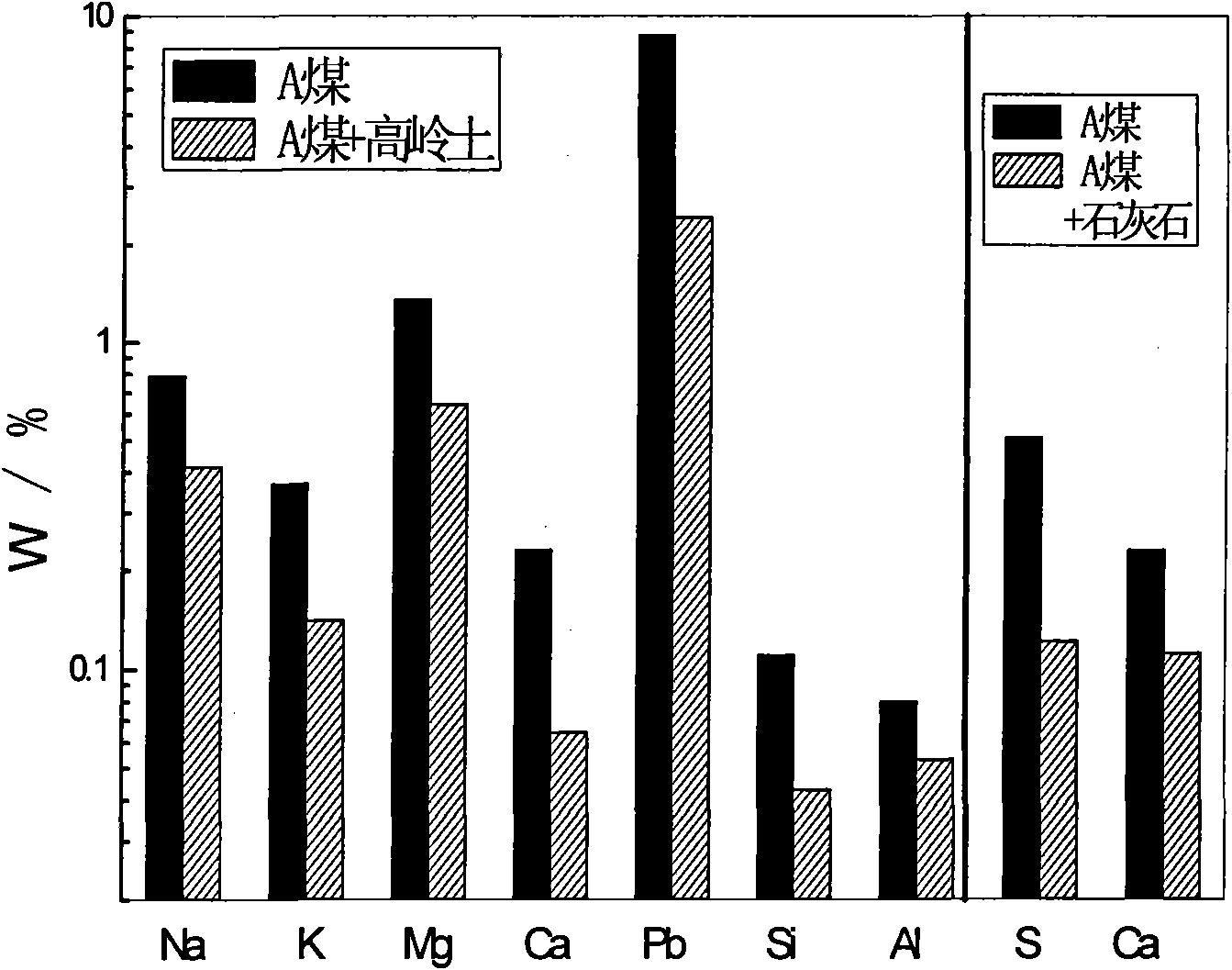

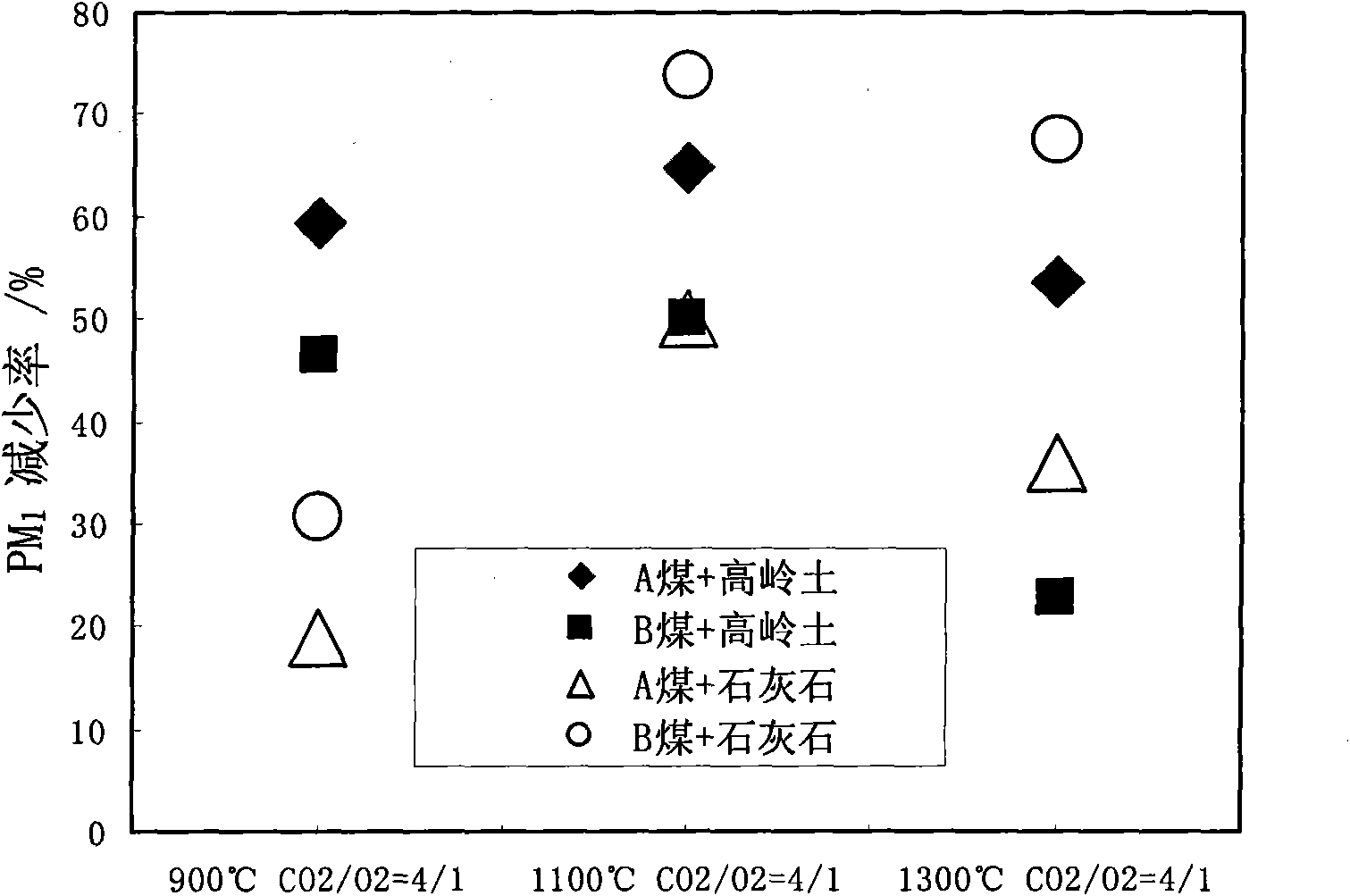

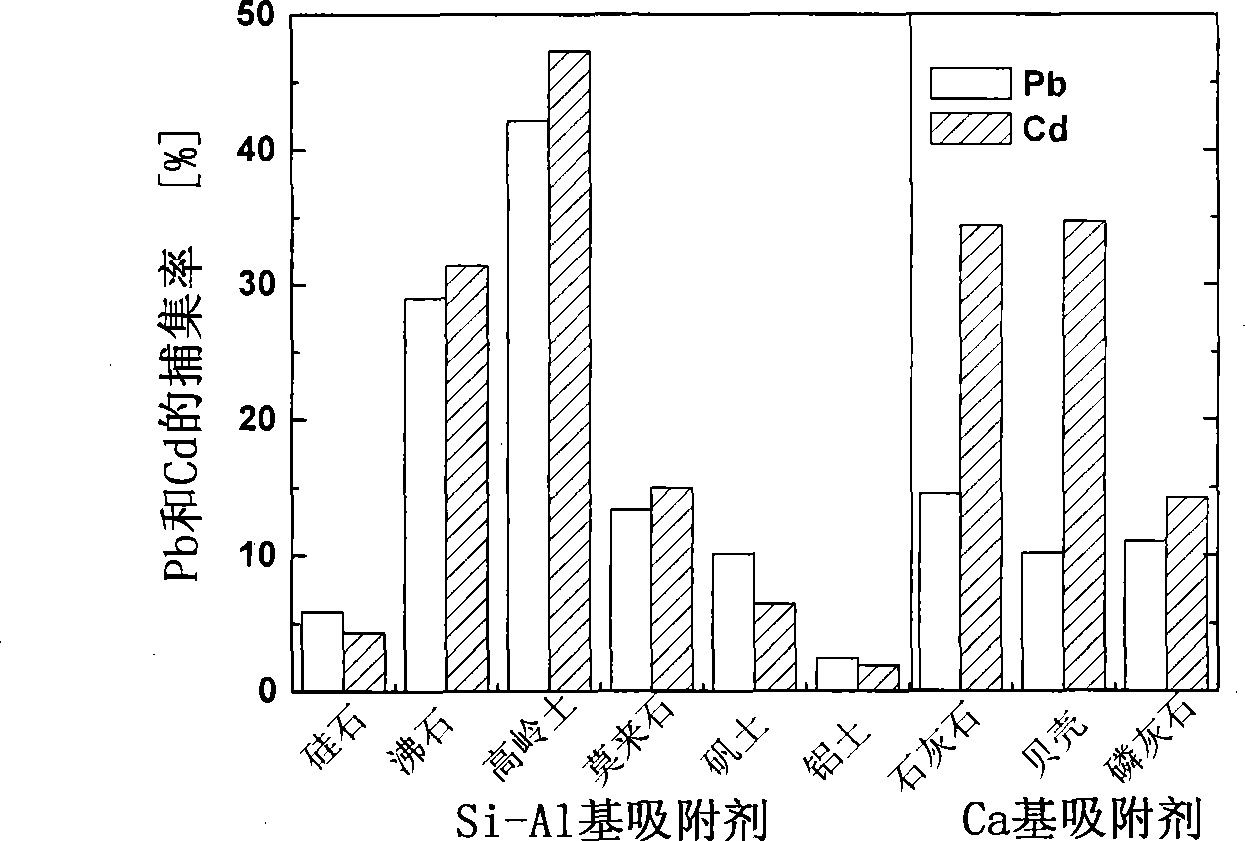

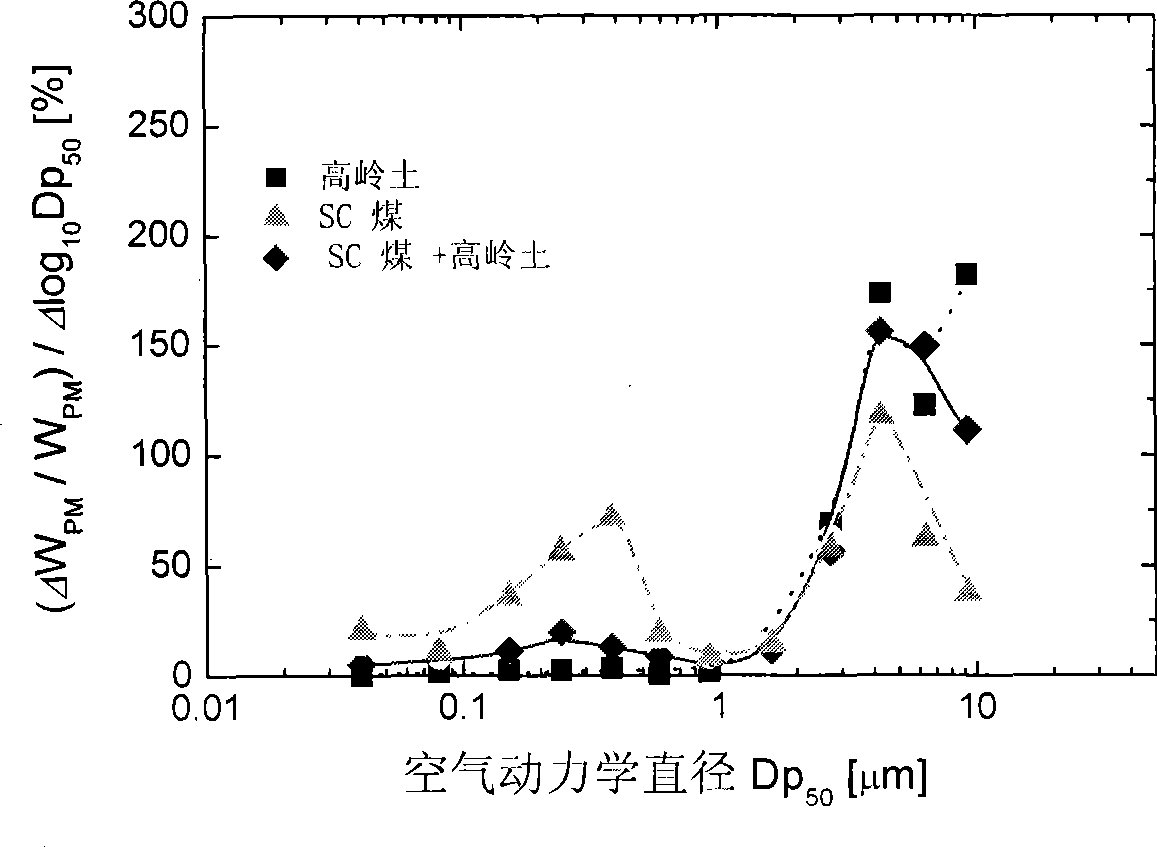

Method for removing contaminations under oxygen-enriched combustion condition

InactiveCN101874963AEasy to capturePromote harmlessnessDispersed particle separationParticulatesChemical reaction

The invention discloses a method for removing contaminations under an oxygen-enriched combustion condition. In an O2 / CO2 combustion mode, adsorbent is sprayed into high-temperature tail flue gas from a coal burning boiler and a garbage incinerator to realize the combined removal of multiple contaminations by chemical reaction and physical adsorption. Metal compounds in the flue gas and volatile S are adsorbed by the adsorbent are converted into solid particulates with an aerodynamic size greater than 1mm which can be easily removed by a dust catcher, thereby greatly reducing the quantity of PM1 formed by metal and S so as to greatly decrease PM1. The most effective adsorbent and the optimum temperature range for removal vary with fuel. When the content of alkali metals (Na and K) in the fuel is greater than 1mg / g or the content of heavy metals (Pb and Cd) is greater than 10mu g / g, Si-Al-based adsorbent, such as kaolin and the like, is used; when the content of sulfur in the fuel is greater than 0.5%, Ca-based adsorbent, such as limestone and the like, is used; and when both the contents of the metals and the sulfur in the fuel are high, mixed adsorbent is used. In the O2 / CO2 combustion mode, the optimum temperature range for the combined removal of multiple contaminations by adsorbent spraying is 1000-1200 DEG C.

Owner:HUAZHONG UNIV OF SCI & TECH

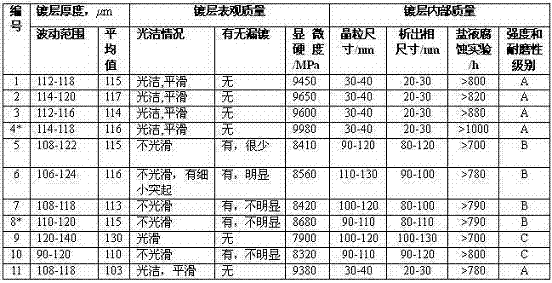

A method for hot-dip aluminum plating of steel structure parts

InactiveCN102268625AImprove corrosion resistanceExcellent immersion performanceHot-dipping/immersion processesMelting tankRare earth

The invention relates to the technical field of metal surface coatings, in particular to a hot dipping method for a steel structure. A hot dipping alloy consists of the following components in percentage by mass: 75 to 85 percent of Al, 3 to 5 percent of Mg, 3 to 5 percent of Si, 0.01 to 0.02 percent of rare earth Y, 0.04 to 0.10 percent of Ni, 0.04 to 0.10 percent of Bi, 0.04 to 0.10 percent of V, and the balance of Zn and inevitable impurities; and in the hot dipping process, a pulsed electric field is applied to a weld pool, and the parameter ranges of the pulsed electric field are that: the pulse width is 80 to 100ms, the acting frequency is 1 to 2Hz and the peak density of pulse current introduced into the weld pool is 0.1 to 10A / cm<2>. By the synergism of the rare earth Y, Ni, Bi and V, the fluidity and wettability of aluminum are improved; the strength and corrosion resistance of a coating are improved by nano Si and Mg2Si phases separated under the action of the pulsed electric field; and the pulsed electric field also has effects of refining grains and improving the compactness of the coating. By the invention, the coating quality is improved, metal consumption is reduced, a process is simple, the conventional process and equipment are mature, the cost is low and the method is worth promoting.

Owner:JIANGSU UNIV

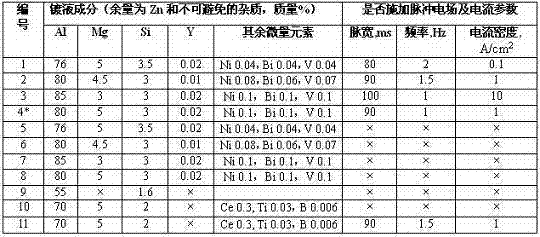

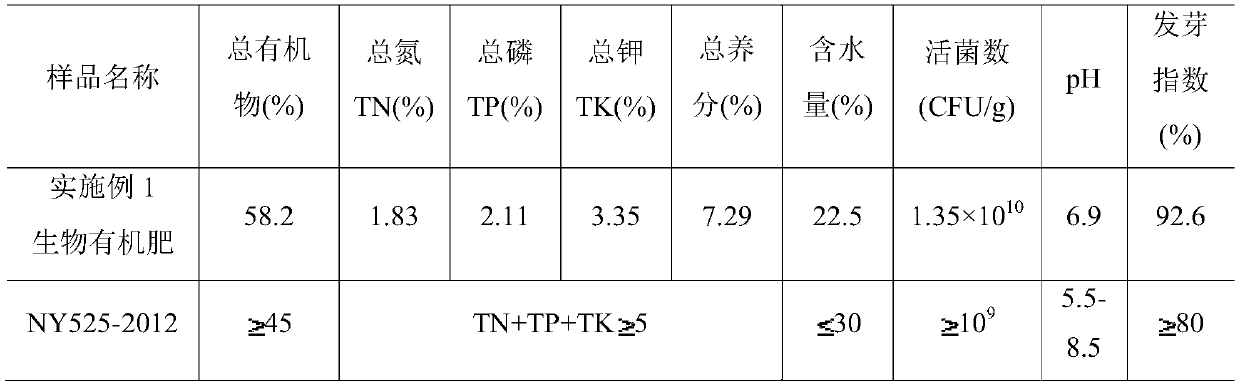

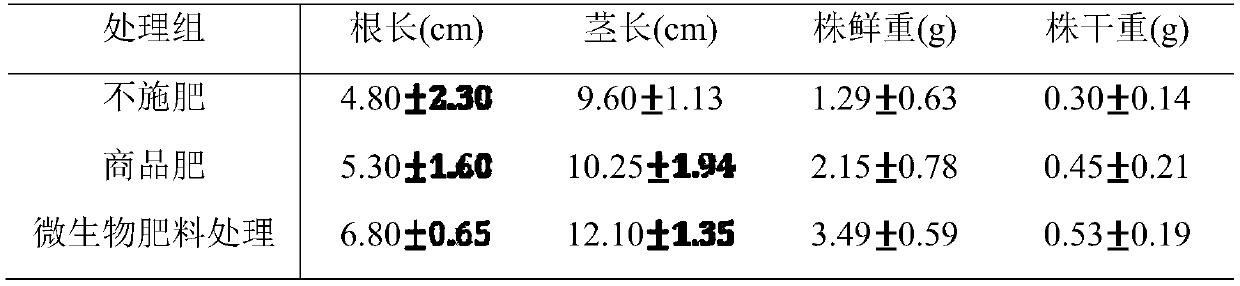

Method for treating organic solid waste and bio-organic fertilizer prepared by using method

InactiveCN110550987AHigh feasibilityIncrease productionBio-organic fraction processingSewage/sludge fertilisersExtreme thermophileEconomic benefits

The invention relates to a method for treating organic solid waste and bio-organic fertilizer prepared by using the method. The method comprises the steps: (1) mixing the wet material of the organic solid waste with crushed auxiliary materials so as to obtain a mixture with a water content of 45-55%; (2) inoculating high-temperature degrading bacteria to the mixture obtained in the step (1), performing ventilation on the mixture so as to ensure a fully aerobic environment of the mixture, performing intermittent turning-mixing treatment, and maintaining the temperature of the mixture at 65-75 DEG C for high-temperature fermentation for 2-6 days so as to obtain an intermediate material; and (3) inoculating extreme thermophiles to the intermediate material obtained in the step (2), performingeven turning, performing ventilation on the intermediate material so as to ensure a fully aerobic environment of the material, maintaining the highest temperature of the intermediate material at 85-90 DEG C continuously for 2-6 days, and performing static fermentation on the material for 18-21 days. Compared with the prior art, the method has the advantages of high feasibility, simple operation,a short production cycle, high output and stable product quality, and a win-win situation of environmental protection and economic benefits is achieved.

Owner:TONGJI UNIV

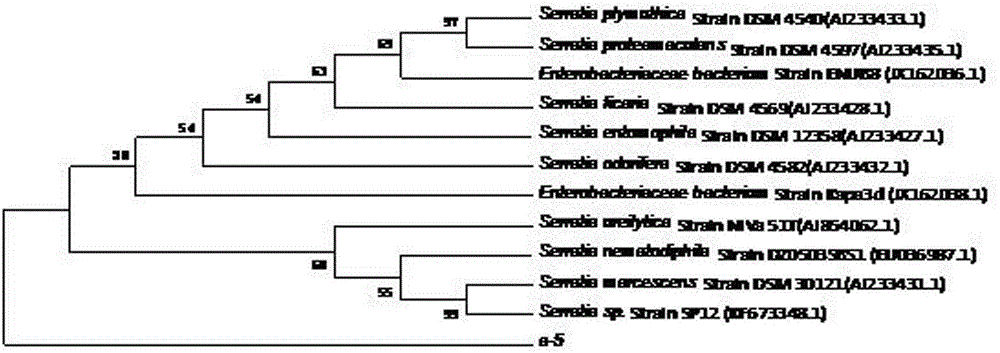

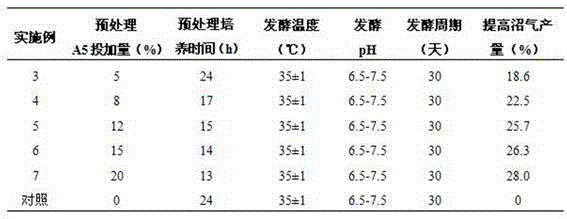

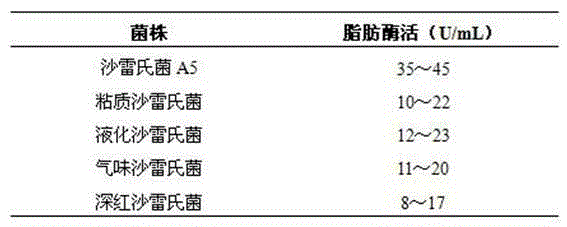

Serratia sp. A5 and uses thereof

ActiveCN104371951ADisinhibition effectImprove hydrolysis efficiencyBacteriaMicroorganism based processesBiotechnologyOil and grease

The present invention relates to Serratia sp. A5 and applications thereof. The Serratia sp. A5 is preserved in the China General Microbiological Culture Collection Center on August 28, 2014, and the preservation number is CGMCC No.9621. According to the present invention, the Serratia sp. A5 is isolated from soil, the suitable growth temperature is 25-35 DEG C, the pH value is 7.0-7.5, and the Serratia sp. A5 has the lipase production ability; and the Serratia sp. A5 can be applied for degrading grease, relieving the inhibition effect of the grease in food waste anaerobic fermentation, increasing the biogas yield by 15-30%, and effectively increasing anaerobic fermentation hydrolysis and biogas production efficiency of other waste containing fat and the like or waste water, and further provides important significance for promotion of harmless, resource and energy utilization of organic waste.

Owner:河北绿茵生化科技有限公司

Method for reducing discharge of fine particulates and metals during combustion process

InactiveCN101445758AEmission reductionEasy to removeFuel additivesChemical reactionHazardous substance

The invention discloses a method for reducing discharge of fine particulates (PM2.5) and metals during the combustion process. An adsorbent with kaolin as the main component is sprayed into the high-temperature (800 to 1,100 DEG C) tail flue gas of a combustion device in a quantity of 1 to 20 g / Nm<3>. The adsorbent is solid powder with the particle diameter being 5 to 73 Mum. Metals such as Na, K, Pb and Cd and PM2.5 in the flue gas are absorbed by the absorbent through chemical reaction and physical adsorption and converted to solid particulates with aerodynamic size being larger than 2.5 Mum at the high temperature, so as to be easily removed by a dust removing device, thereby remarkably reducing the discharge amount of metals such as Na, K, Pb and Cd and PM2.5 to the ambient atmosphere. Gaseous and aerosol-state toxic and harmful substances are converted to solid water-insoluble large particulates, so as to be favorable for entrapment and harmless and resource utilization. The discharge amounts of Na and K, Pb and Cd, and PM2.5 are reduced by 80%, 50% and 50%, respectively.

Owner:HUAZHONG UNIV OF SCI & TECH

Dehydrating combustion treating method for living refuse

InactiveCN1644986AHigh calorific valueImprove burnout rateIncinerator apparatusGrain treatmentsPretreatment methodCombustion

This invention is a dewatering burning treatment method of household garbage. Mechanical dewatering pretreatment method is adopted to replace the heat drying pretreatment method, household garage is broken up at first then efficient deep dewatering process is carried out by high speed centrifuge after removing water by filtering, the garbage dewatered is sent into the furnace to burning, the amount of the calorific power generated is increased by burning garbage through controlling the burning temperature and residence time of flue gas, the amount of generating dioxin is reduced too. The fluw gas generated by burning will be discharged after spray damp dry acid stripping and dsting. This invention can raise the burning temperature of garbage, and reduce the cost for flue gas treatment and environment pollution.

Owner:SHANGHAI JIAO TONG UNIV

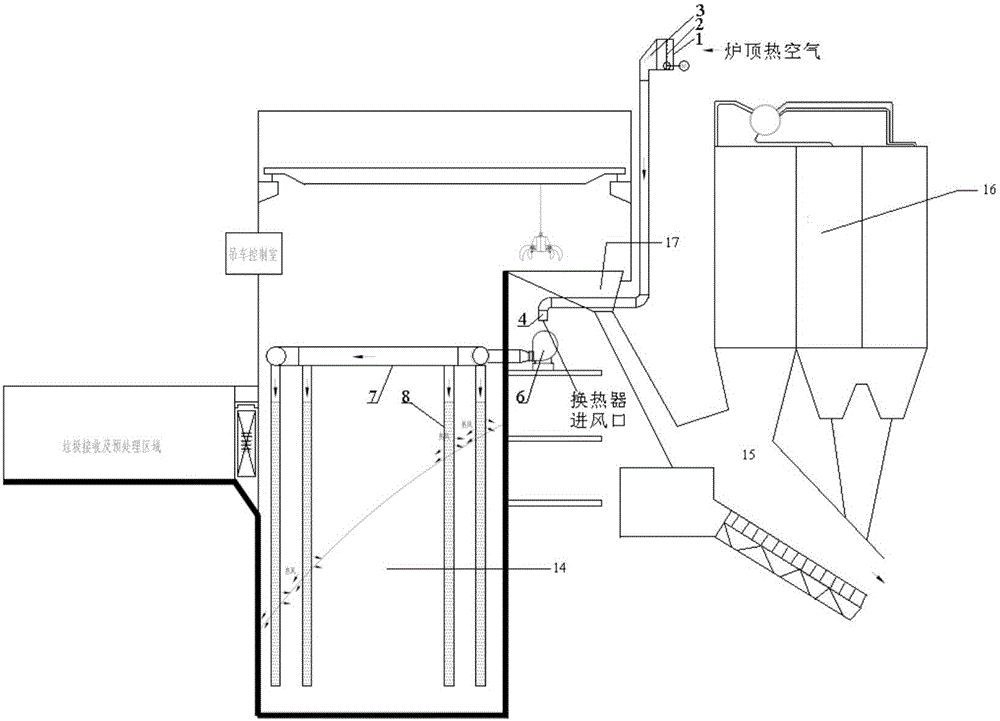

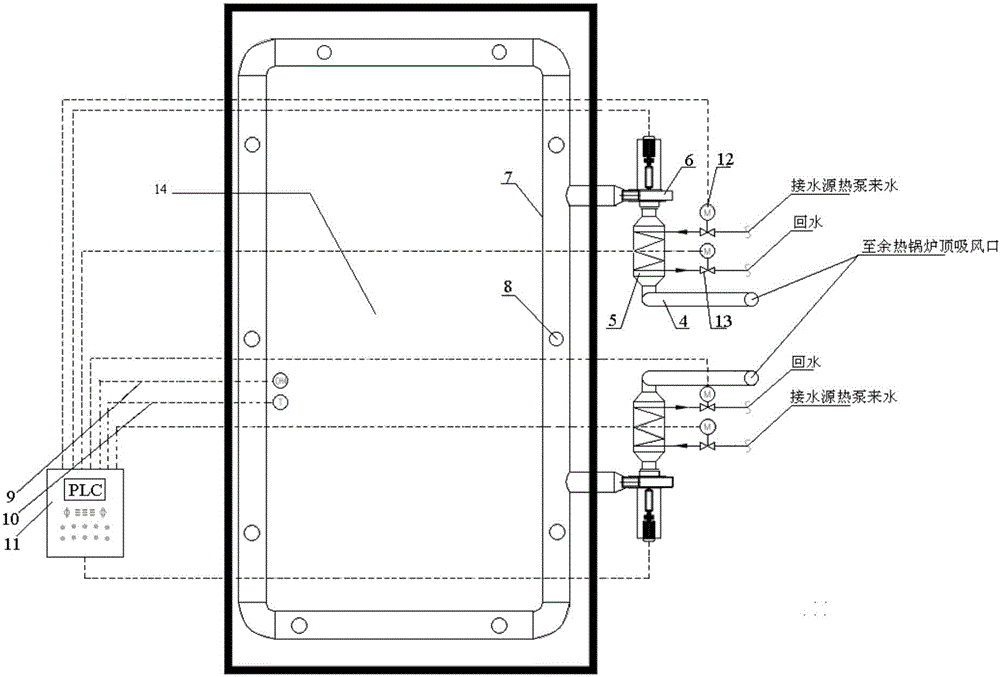

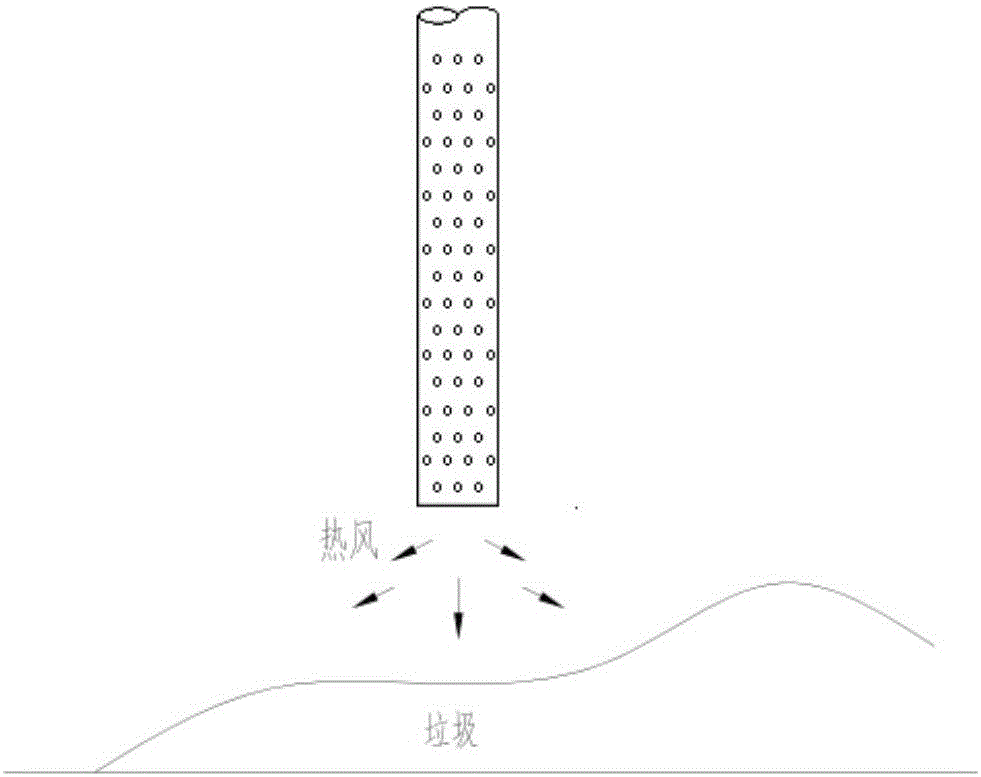

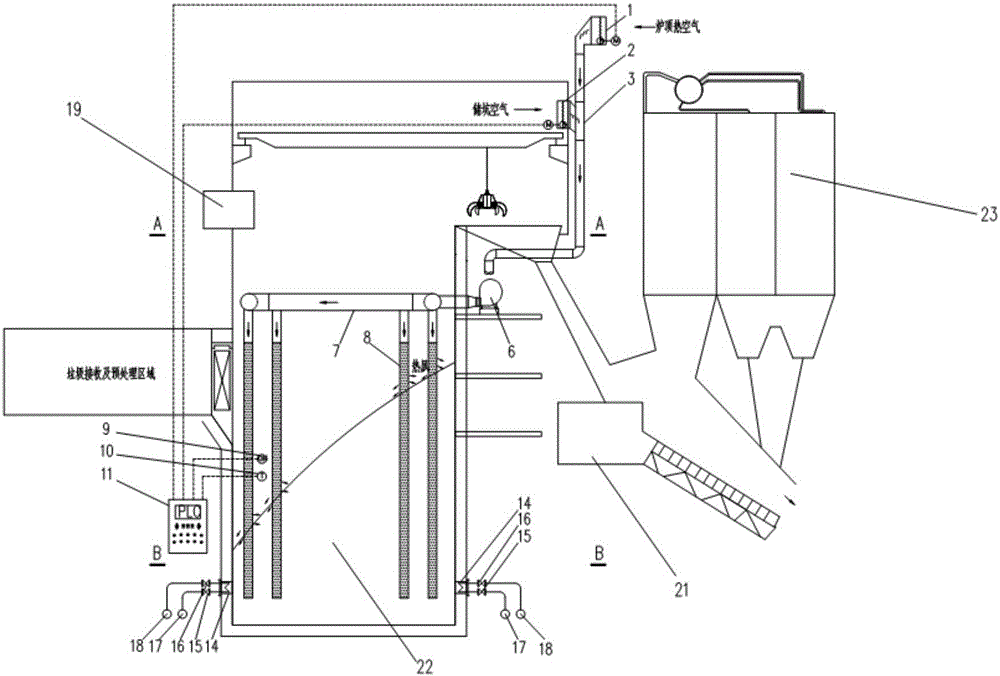

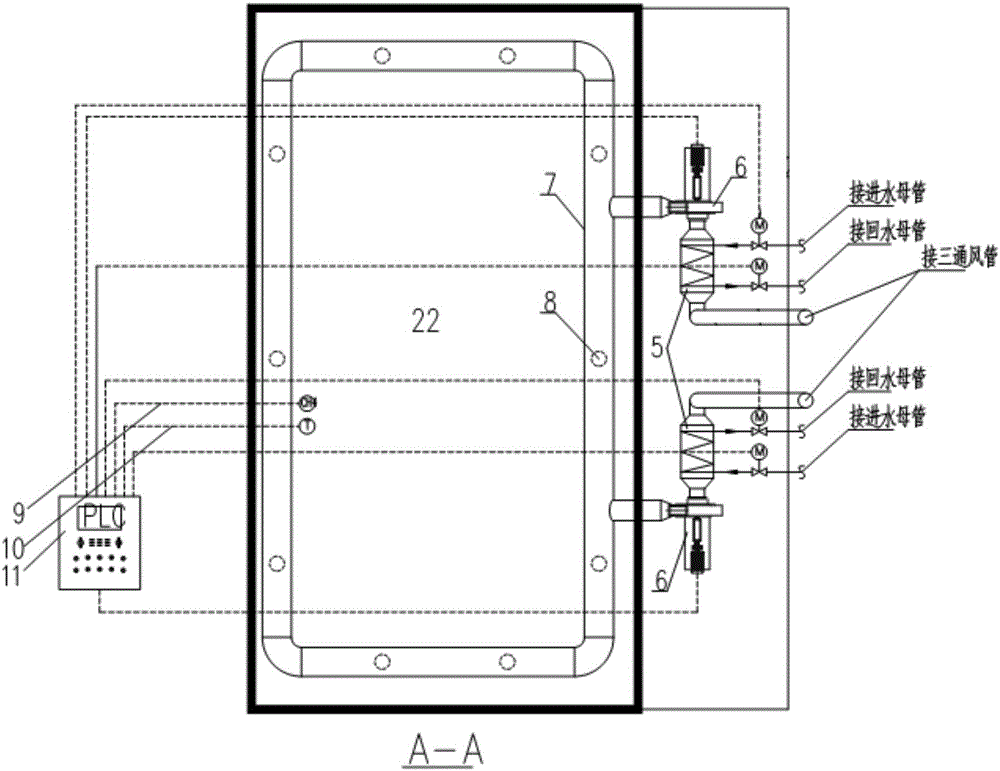

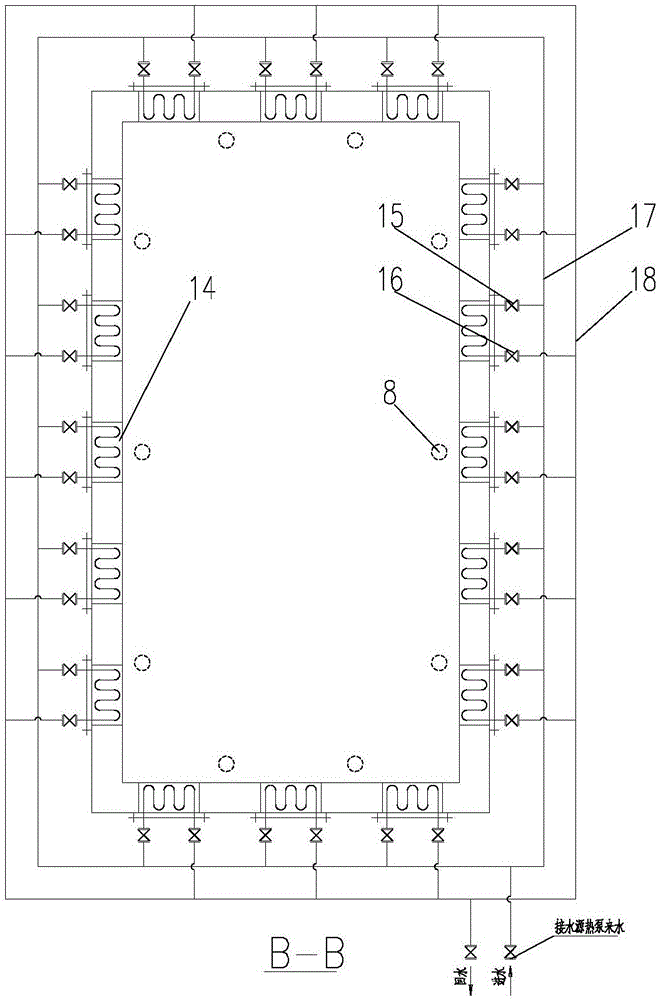

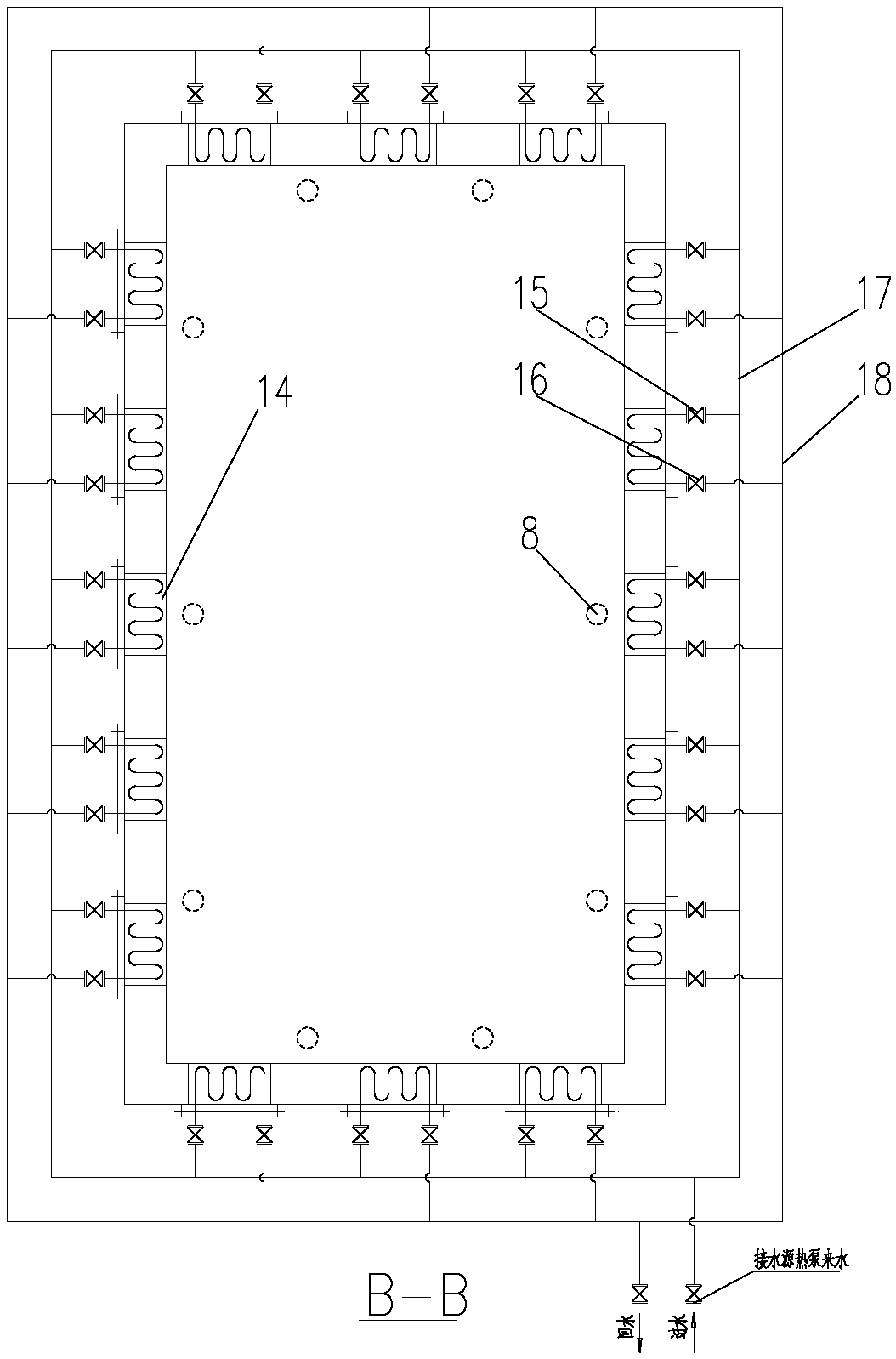

Garbage storage pit heating method

ActiveCN106287730AReduce maintenanceLess investmentIncinerator apparatusWater source heat pumpCombustion

The invention discloses a garbage storage pit heating method. A water source heat pump is used for absorbing heat of industrial circulation water, a water inlet of a heat exchanger is connected with the water source heat pump, the heat exchanger is used for heating hot air on the boiler top of an incineration cross-waste-heat boiler, a draught fan is used for sending air heated by the heat exchanger to a heating device of a garbage storage pit, and garbage in the garbage storage pit is heated. The heating device is provided with a horizontal mother tube communicating with the draught fan and a vertical floral tube communicating with the horizontal mother tube. The horizontal mother tube is arranged along the periphery of the pit wall of the garbage storage pit, and the height of the horizontal mother tube is larger than the maximum garbage stacking height. The vertical floral tube vertically downwards extends to the bottom of the storage pit from the horizontal mother tube, and a plurality of small holes are distributed in the tube wall of the vertical floral tube. The garbage storage pit heating method solves the technical problems that in the northern low-temperature areas or the low-temperature areas in winter, the temperature in a garbage storage pit of a garbage incineration power plant is too low, garbage fermentation is difficult, consequently, the water content of garbage entering the boiler is high, combustion is not easy, combustion of an incinerator is not stable, and efficiency is low.

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

Special nutrition pot for Gobi desert, preparation method and application thereof

ActiveCN107343451AImprove molding rateShorten the timeGrowth substratesCulture mediaHigh oxygenAgriculture

The invention relates to a special nutrition pot for a Gobi desert, a preparation method and an application thereof. The special nutrition pot for the Gobi desert is prepared from the following raw materials in percentages by weight: 55-65% of sludge and agricultural waste fermentation nutrient matrix, 25-30% of bentonite, 5-10% of attapulgite, 3.5-4% of biochar, 0.7-1.2% of a biodegradable flocculant and 0.3-0.5% of a physical light mixture. On one hand, the environmental protection problem of harmless resource utilization of production and life sludge wastes and agricultural wastes is solved; and on the other hand, organic matters in the sludge wastes and agricultural wastes can be effectively utilized, the finally produced special nutrition pot for the Gobi desert has the effects of environmental biodegradablity, high-oxygen humus, heat retention property and low temperature resistance, moisture adsorption, water storage and retention, drought avoidance, root protection, slow release of nutrients, land fertilization and soil improvement, and is suitable form massive industrial seedling of tree seedlings; use of a lot of plastic containers is reduced; the roots are not damaged in transplantation; and the special nutrition pot is especially suitable for popularization in alpine regions, water-deficient areas and serious soil desertification areas.

Owner:王效雷

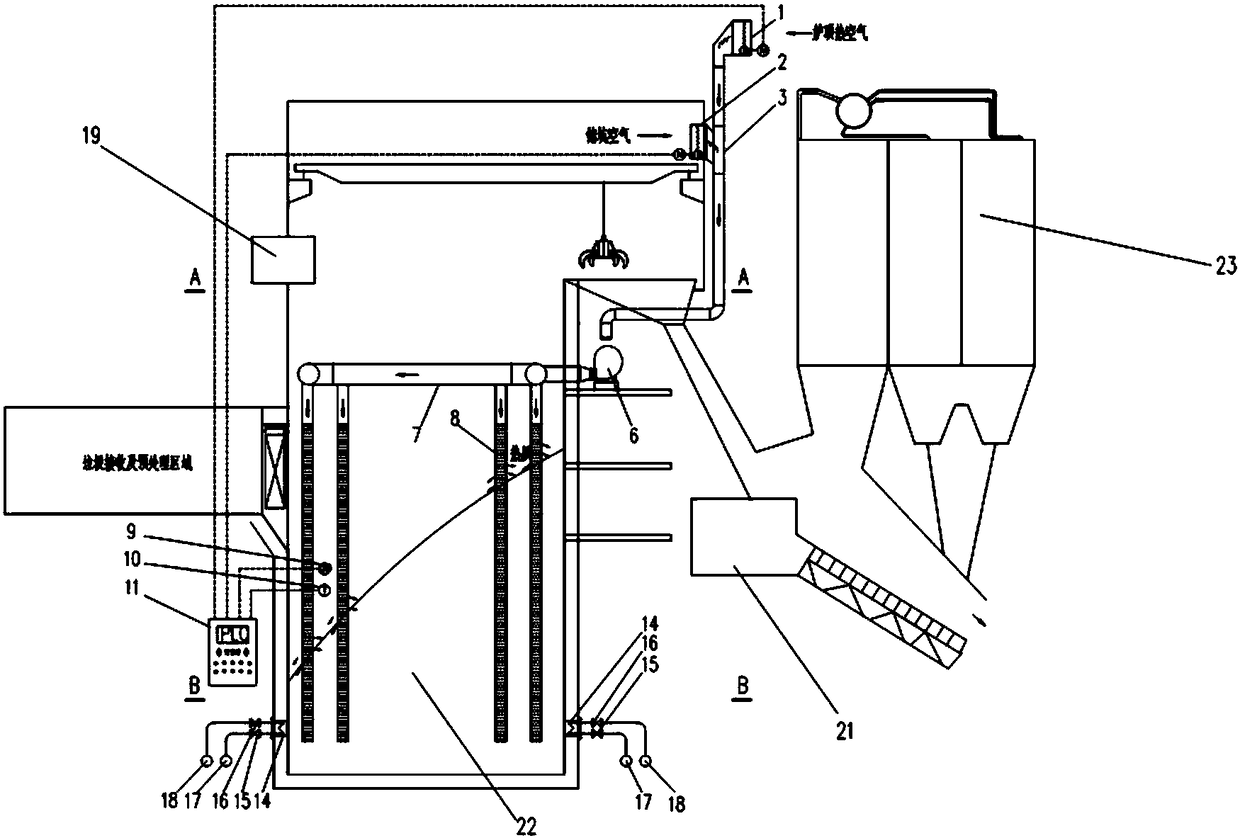

Heating system of garbage storage pit

The invention discloses a heating system of a garbage storage pit. The heating system comprises a primary air inlet system, an upper heating device, a bottom heating device and a storage pit internal heating device, wherein the upper heating device is used for heating air of the primary air inlet system; the primary air inlet system is used for feeding air heated by the heating device into the garbage storage pit; the bottom heating device surrounds the bottom of the garbage storage pit, and is used for heating the bottom of the garbage storage pit; and the storage pit internal heating device is used for heating garbage in the storage pit. According to the heating system, the top and the bottom of a garbage stacking surface are heated at the same time, so that the temperature of the garbage storage pit is effectively increased, fermentation and dehydration of garbage are facilitated, the calorific value of garbage fed into an incinerator is increased, and combustion of the incinerator is more stable; and besides, the temperature in the garbage storage pit is increased through fully utilizing hot water generated from a waste heat utilization system of hot air at the upper part of an incineration bridge and industrial circulating water, so that the primary air inlet temperature is increased, and the heat efficiency of the incinerator is improved.

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

Clean utilization method for municipal sludge

ActiveCN104478184AReduce processing energy consumptionLow costSludge treatment by de-watering/drying/thickeningWaste based fuelThiobacillus sp.Soil organic matter

The invention provides a clean utilization method for municipal sludge. According to the method, the municipal sludge is subjected to high-temperature anaerobic fermentation, then, a thiobacillus thiooxidans enriched bacterial solution is added for culture, and finally, the municipal sludge is dehydrated. By the clean utilization method for the municipal sludge, provided by the invention, biogas can be produced and prepared at an anaerobic digestion stage; after heavy metals are removed through thiobacillus thiooxidans treatment, the sludge can be fully decomposed; meanwhile, for municipal industrial sludge, in the case that the content of the heavy metals is in the range of exceeding the heavy-metal limit value, specified by the national sgricultural standard, by five times, the heavy metal removal effect is good, the removal ratio can reach 90-95%, the treated industrial sludge can fully meet the agricultural requirements of sludge, is made into all types of organic fertilizers, is applied to landscaping, agricultural use and the like and is used for increasing the content of organic matters in soil and improving the structure of the soil; whereas, for municipal domestic sludge, the heavy metal removal effect is more obvious.

Owner:新疆天物生态环保股份有限公司

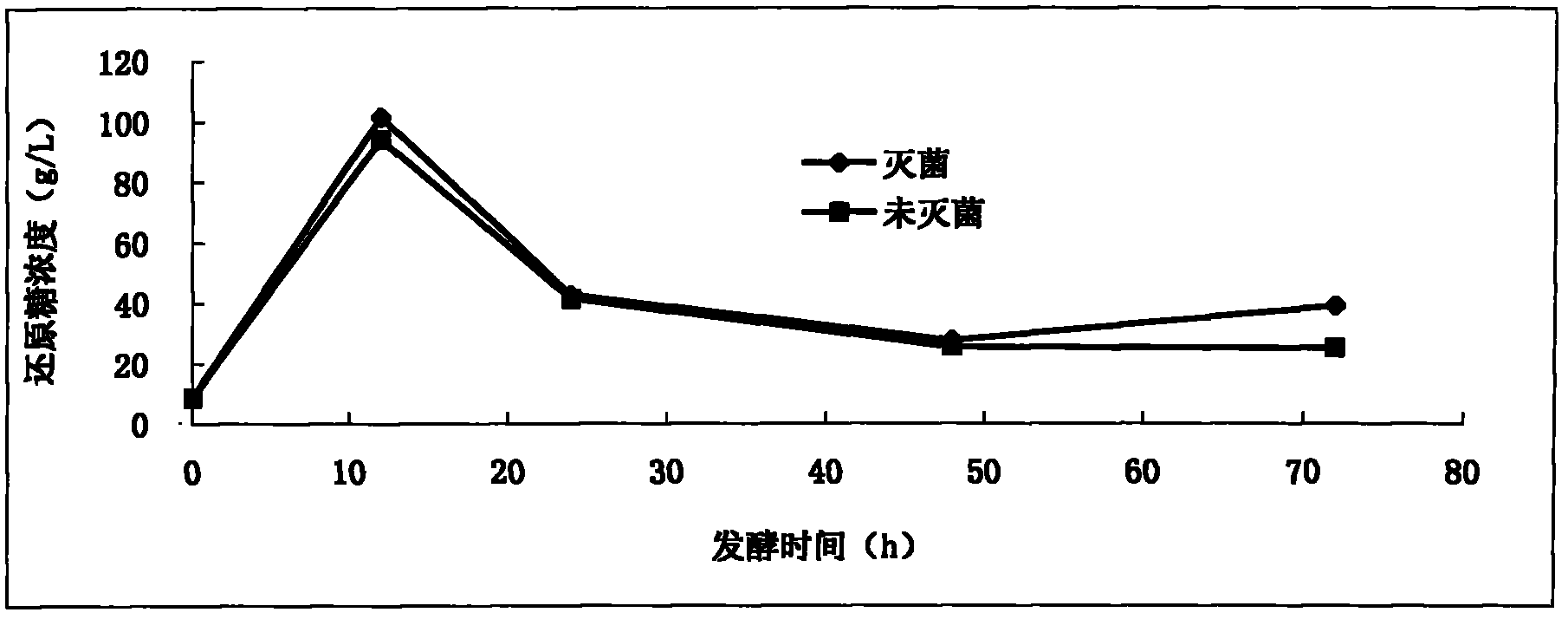

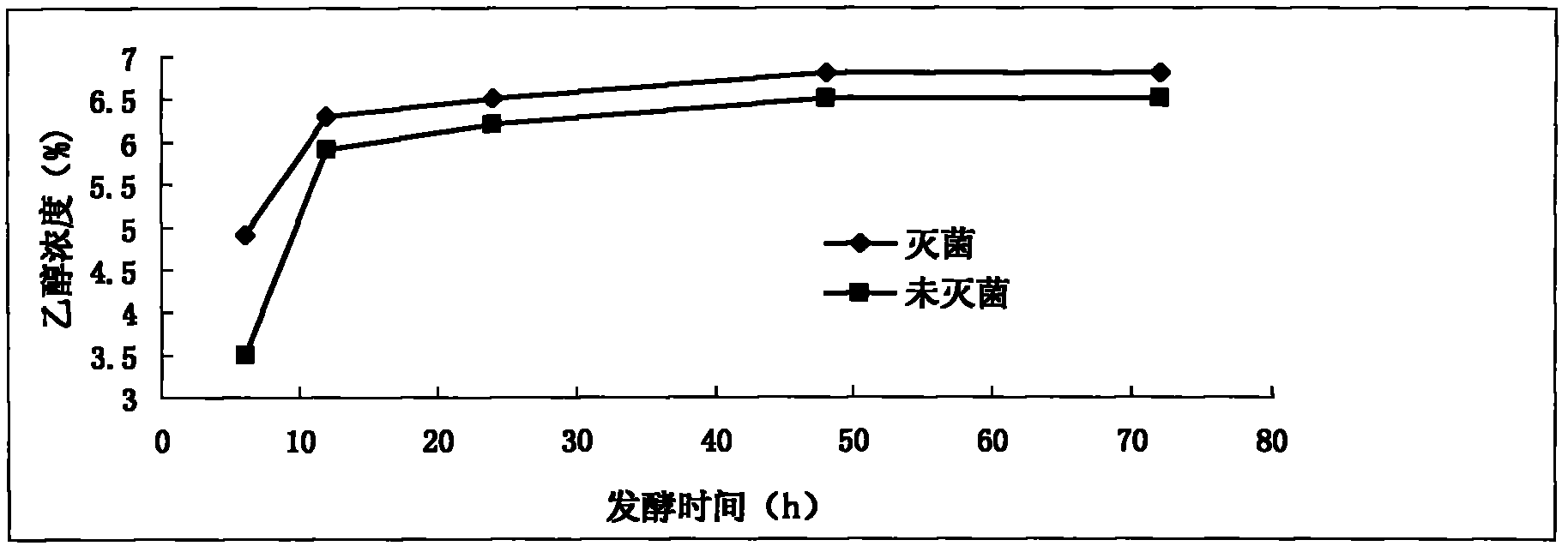

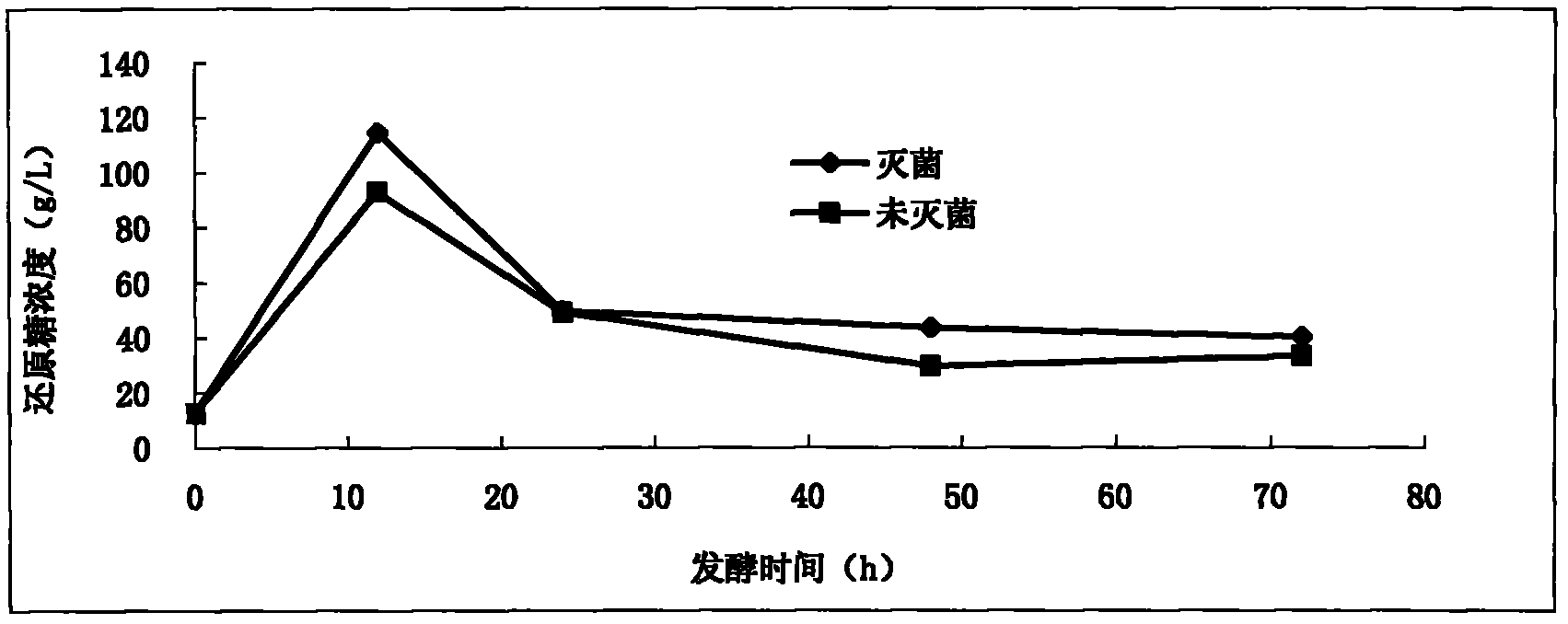

Method for producing fuel ethanol by utilizing papermaking sludge

InactiveCN102010883AEasy to operateSimple processMicroorganism based processesFermentationDecompositionChemistry

The invention provides a method for producing fuel ethanol by utilizing papermaking sludge. In the method, a monosodium glutamate waste liquor is utilized as an energy conditioner for the papermaking sludge, appropriate C / N is obtained, cellulase is added to promote saccharification decomposition of materials, meanwhile a potato nutrient solution is added into the reaction system, and saccharomyces cerevisiae liquor after being cultured is inoculated, thus the saccharification and fermentation of raw material are realized in the same reactor, ethanol can be produced after 5 hours after the fermentation, and no reducing sugar is accumulated. The method provided by the invention is convenient in the whole preparation process, and has the advantages that the process is simple, the energy consumption is reduced, industrial solid waste (papermaking sludge) is utilized to substitute the traditional saccharide and grain raw materials used for producing ethanol, and meanwhile another industrial solid waste (monosodium glutamate waste liquor) is used for optimizer system nutrition structure and is utilized to promote aerogenesis peak and shorten the fermentation period, thus not only improving the processing capacity and processing efficiency of a reactor but also realizing 'free treatment, reducing and recycling' of two solid wastes.

Owner:SOUTH CHINA AGRI UNIV

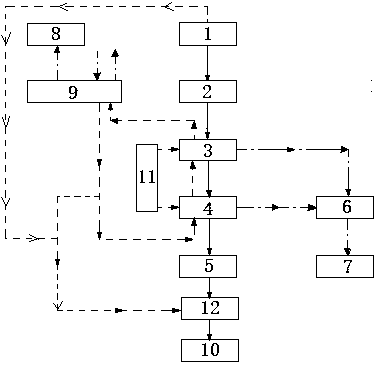

System and method for reclaiming sludge heavy metals

InactiveCN109293203AAchieve recyclingPromote harmlessnessSludge treatmentWater/sewage treatment by irradiationIon exchangeChemistry

The invention discloses a system for reclaiming sludge heavy metals. The system comprises an alkali washing chamber, a backwashing chamber I, a reclaimed water treatment system, a plate-and-frame filter press, an ion exchange system and a drying chamber, wherein the alkali washing chamber is connected with the ion exchange system, upper alkali washing waste liquid containing heavy metals after alkali washing settlement is delivered into the ion exchange system, and waste residues after backwashing and settling in the alkali washing chamber are delivered into the backwashing chamber I; the backwashing chamber I is connected with the reclaimed water treatment system through a circulating pipeline system, and the waste residues after backwashing settlement in the backwashing chamber is delivered into the plate-and-frame filter press; the plate-and-frame filter press is connected with the reclaimed water treatment system through a pipeline, filtrate after filter-press flows into the reclaimed water treatment system, and filter cake is delivered into the drying chamber; and the reclaimed water treatment system is further connected with the ion exchange system, reclaimed water which is treated in the reclaimed water treatment system flows into the ion exchange system, and clean water is obtained after the reclaimed water flows through the reclaimed water treatment system. The invention further discloses a method for reclaiming sludge heavy metals. The system has a simple structure, low cost and high heavy metal reclamation rate.

Owner:GUIZHOU MINZU UNIV

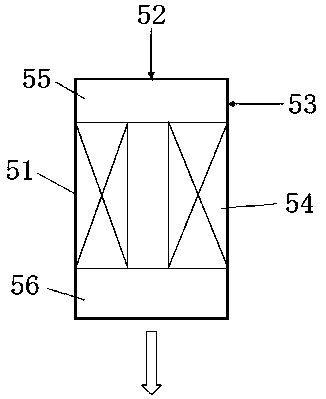

Household waste incineration power generation and sludge drying treatment synergetic method and system

PendingCN108413411APromote harmlessnessPromote reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesLitterWastewater

The invention discloses a household waste incineration power generation and sludge drying treatment synergetic method and system. According to the household waste incineration power generation and sludge drying treatment synergetic method, a low-pressure extracted steam of a steam turbine generator set of a household waste incineration power generation system is used as a heat source for sludge drying treatment, and the dried sludge and household waste are mixed and incinerated for power generation; and odor and waste water in the sludge drying process and smoke and ash generated in the sludgeincineration process are jointly treated through waste water, waste gas and waste residue pollution preventing facilities in the household waste incineration power generation system. By the adoptionof the household waste incineration power generation and sludge drying synergetic treatment method and system, by means of synergy between the household waste incineration power generation and sludgetreatment, the effects of reduction, disinfection, sterilization and odor removal are achieved in the drying process, the harmless requirement of sludge treatment is met, reduction and recycling of the sludge are achieved in a real sense on this premise, and good economic, social and environment benefits are achieved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Method for lowering heavy metal content and water content in sludge

InactiveCN108439736AImprove utilizationReduce heavy metal contentSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesAcetic acidSludge cake

The invention discloses a method for lowering the heavy metal content and the water content in sludge. As for the method provided by the invention, by utilizing modified phosphogypsum and acetic acidto treat the sludge in a combination manner, the heavy metal environment risk and the water content in the sludge are lowered; with addition of the acetic acid and the modified phosphogypsum, the content of heavy metals in a sludge filtrate can be remarkably lowered, the content of heavy metal forms with relatively large risk in a sludge cake can also be obviously reduced, and the heavy metal environment risk is lowered; and meanwhile, as for the sludge subjected to treatment with the acetic acid and the modified phosphogypsum, the dewatering rate is remarkably increased, and the water contentin the sludge after dewatering is lowered to 45 percent or below. The method is simple and feasible in production technology operation and low in production cost, achieves the purpose of treating wastes with wastes by fully utilizing phosphogypsum as a waste resource to perform sludge treatment, improves the dewatering performance of the sludge while improving the heavy metal environment risk ofthe sludge, expands the field of phosphogypsum resource utilization, promotes comprehensive utilization of the phosphogypsum and is wide in application prospect and good in market prospect.

Owner:KUNMING UNIV OF SCI & TECH

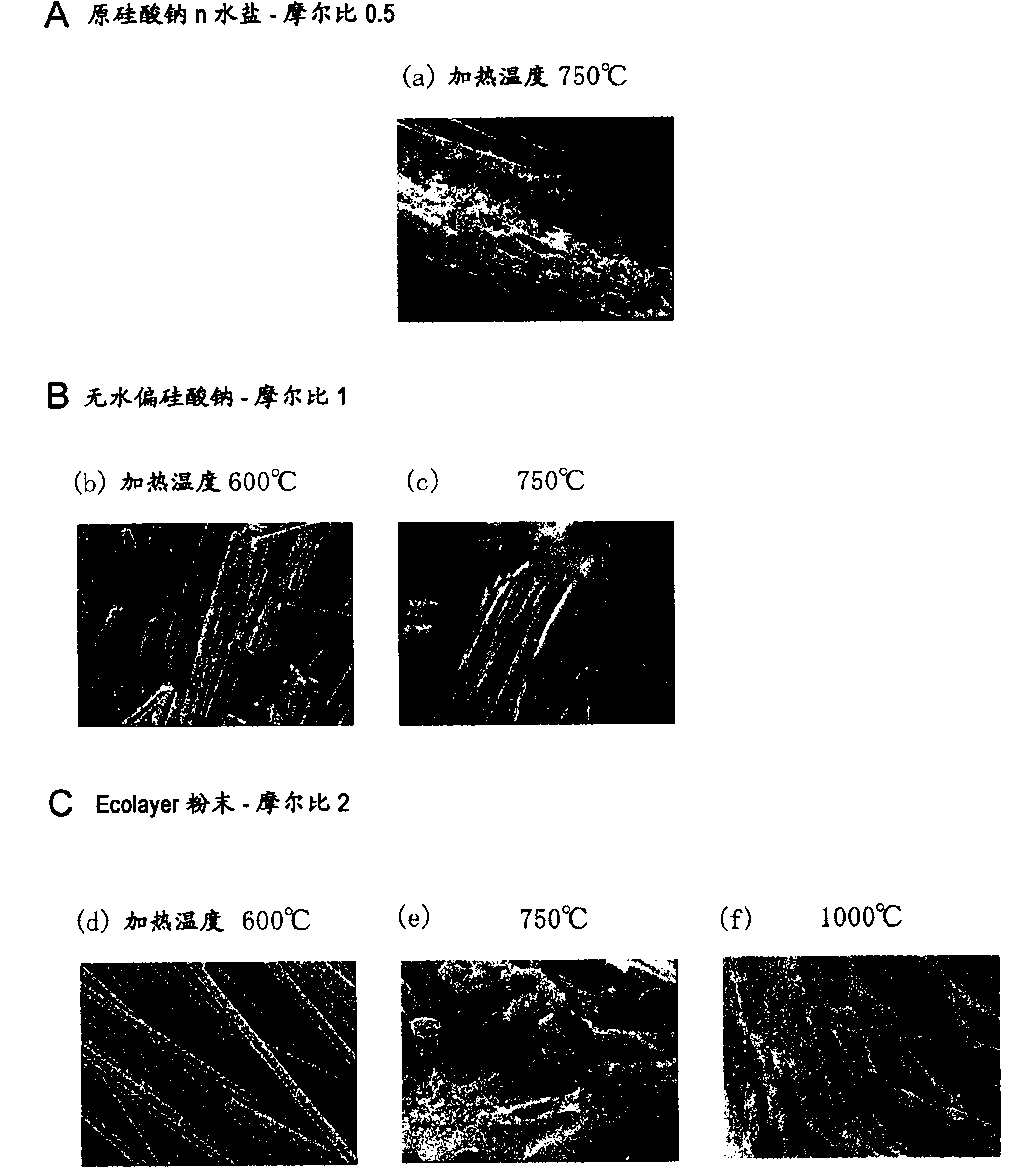

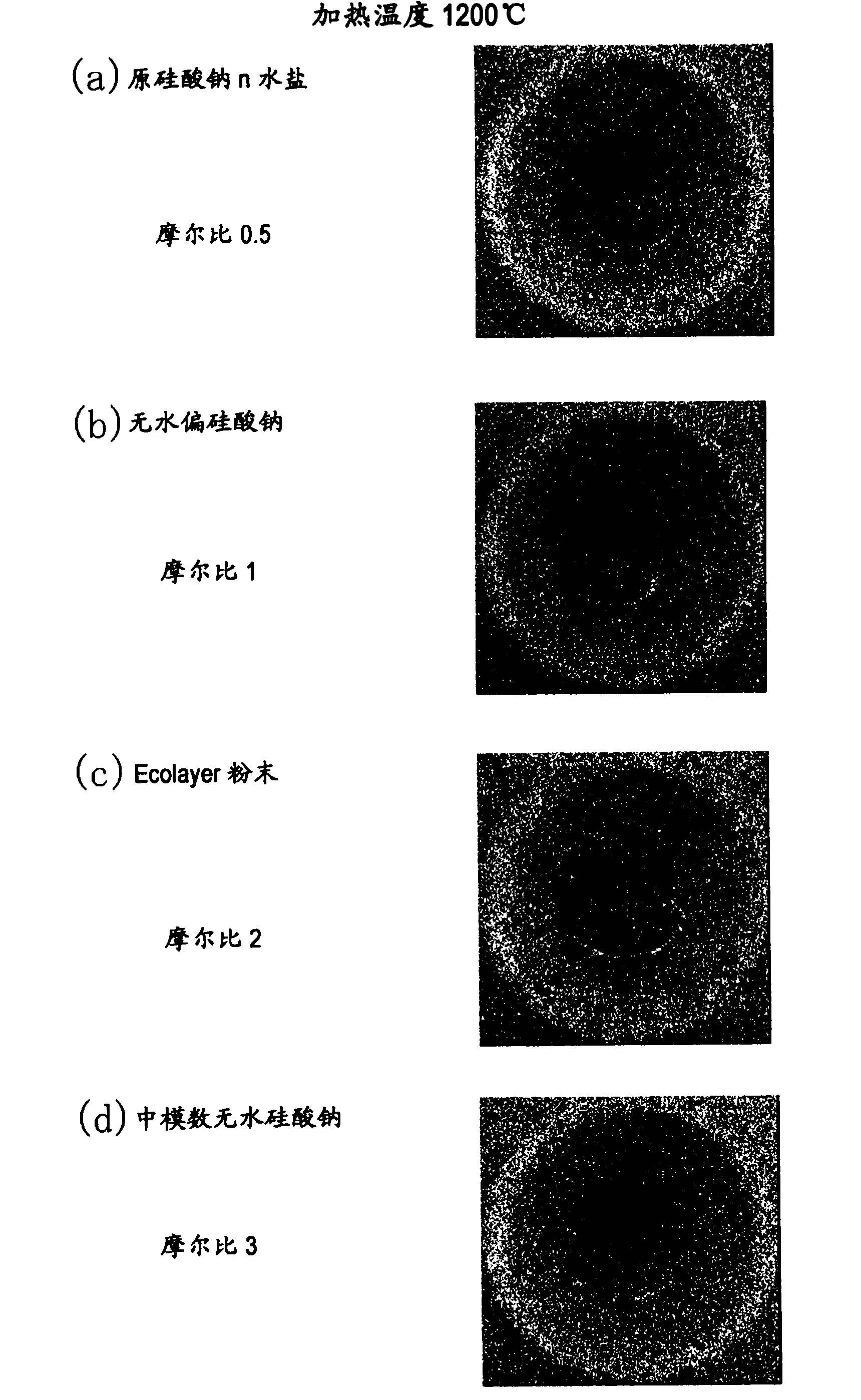

Method of detoxifying asbestos-containing solid waste

InactiveCN102015135AEnergy cost containmentImprove securityOther chemical processesSolid waste disposalEnvironmental engineeringMetal

A method of detoxifying an asbestos-containing waste is provided which includes a heat treatment step reduced in energy cost and is highly safe. In treating an asbestos-containing waste, an alkali silicate as a treating agent therefor is mixed in a solid state with the asbestos-containing waste and the mixture is heated.

Owner:TOKUYAMA SILTECH

Lactobacillus acidipiscis strain and application thereof

ActiveCN111893081AAvoid formingImprove the growing environmentBio-organic fraction processingBacteriaBiotechnologyDecomposition

The invention relates to a lactobacillus acidipiscis strain and application thereof. The preservation number of the Lactobacillus acidipiscis strain is CGMCC No.20471, and the 16s rDNA base sequence of the strain is as shown in SEQ ID NO: 1. The invention also relates to a method for planting and breeding the strain. The method comprises the following specific steps: (1) a fermentation culture medium; (2) a fermentation method (including fermentation parameters and methods); (3) a fermentation liquid planting application method; and (4) a fermentation liquid culture application method. The strain has the beneficial effects that: the strain rapidly propagates in soil, straw, feed or aquaculture water, occupies the advantage of a micro-ecological region meanwhile by continuously inhibiting other microorganisms (including pathogenic bacteria), prevents harmful substances from being formed, improves the growth environment of plants, promotes straw decomposition and harmlessness of decomposition products, improves the gastrointestinal function of animals, and degrades nitrite in aquaculture water.

Owner:浙江森井生物技术股份有限公司

Aluminum electrolysis waste cathode harmless and recycling treatment method and system

InactiveCN108277503APromote harmlessnessImprove resource processing efficiencyBiofuelsSolid fuelsElectrolysisAdhesive

The invention discloses an aluminum electrolysis waste cathode harmless and recycling treatment method and system, and belongs to the technical field of aluminum electrolysis. The aluminum electrolysis waste cathode harmless and recycling treatment method comprises the steps that a waste cathode is processed through high-temperature treatment, so that a first carbon material is obtained; a biomasswaste material is processed through carbonization, so that a second carbon material is obtained; and the first carbon material, the second carbon material and a biomass adhesive are mixed, and afterforming treatment and drying treatment are accomplished, a third carbon material is obtained. The third carbon material can replace or partially replace aggregate materials for production of metallurgy, aluminum anodes and cathodes and electrode pastes such as coke, petroleum coke, calcined anthracite and graphite scraps. The aluminum electrolysis waste cathode harmless and recycling treatment method and system achieve harmless and recycling treatment of the waste cathode. Due to the fact that the waste cathode and biomass energy are matched, the biomass energy is effectively utilized, recycling treatment of the waste cathode can be achieved, non-renewable resources such as coke, petroleum coke, calcined anthracite and graphite scraps are saved, materials generated in the process are effectively utilized, and secondary pollution cannot be caused.

Owner:鲁爽

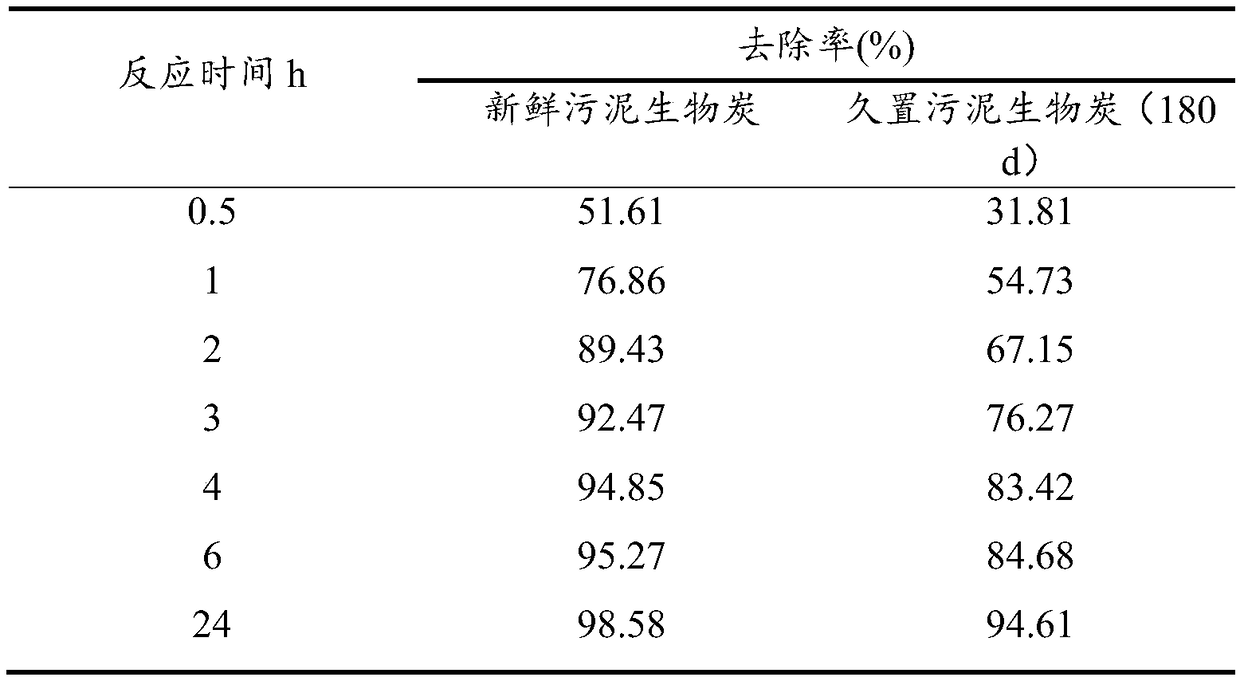

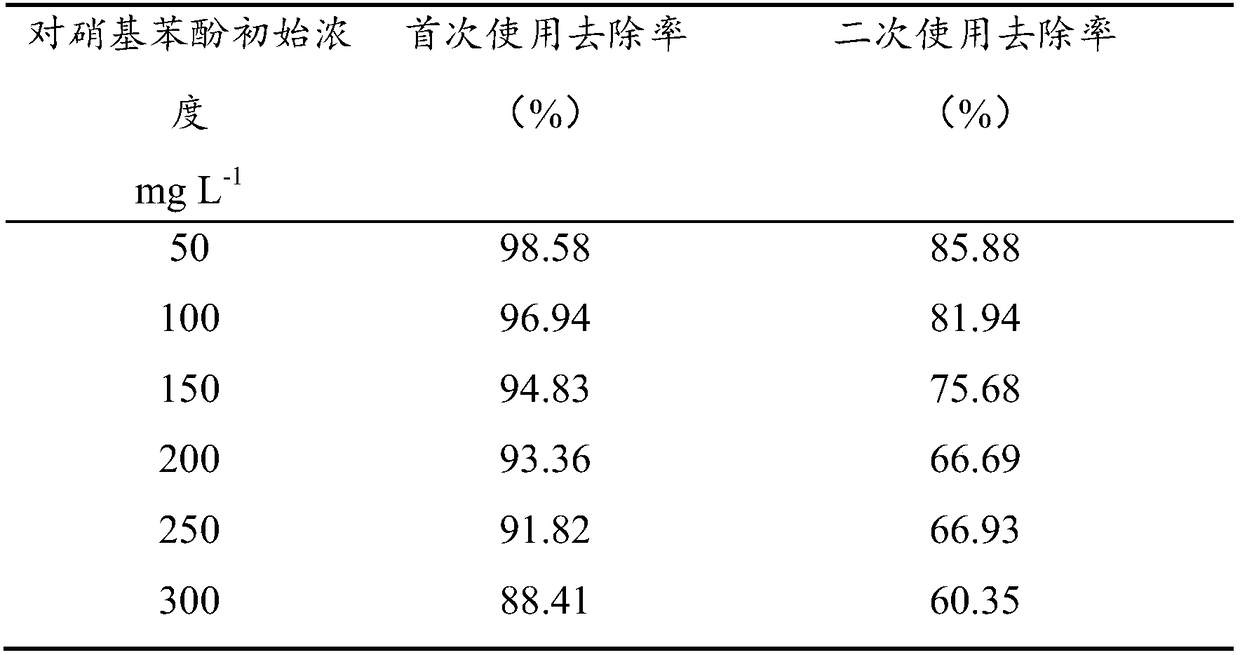

Application of municipal sludge in wastewater treatment

InactiveCN109110861APromote reductionPromote harmlessnessWater contaminantsSpecial form destructive distillationChemistryContact time

The invention discloses application of municipal sludge in wastewater treatment. An application method comprises the following steps: firstly dehydrating municipal sludge, and performing destructive distillation treatment for 2-3 hours at a temperature of 300-400 DEG C to obtain sludge bio-char; enabling the prepared sludge bio-chair to be in contact with wastewater containing p-nitrophenol, and enabling contact time to be greater than 6 hours; adsorbing and degrading p-nitrophenol in wastewater; and regulating the pH value of the wastewater to be smaller than 7.0 when the sludge bio-char is further in contact with wastewater containing p-nitrophenol, and enabling the optimal pH value to be 4.0. The application is beneficial for reduction treatment, harmless treatment and recycling treatment of sludge; the obtained sludge bio-char has relatively good removal effect can be utilized for a second time, and has relatively strong application potential.

Owner:SUN YAT SEN UNIV +1

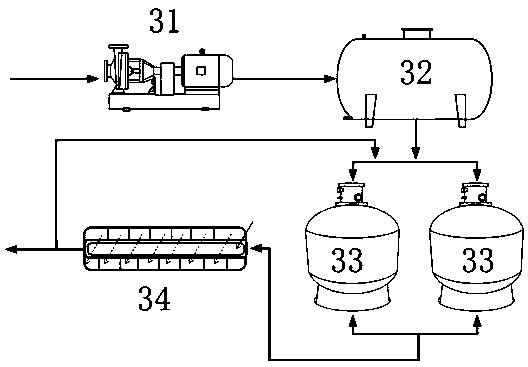

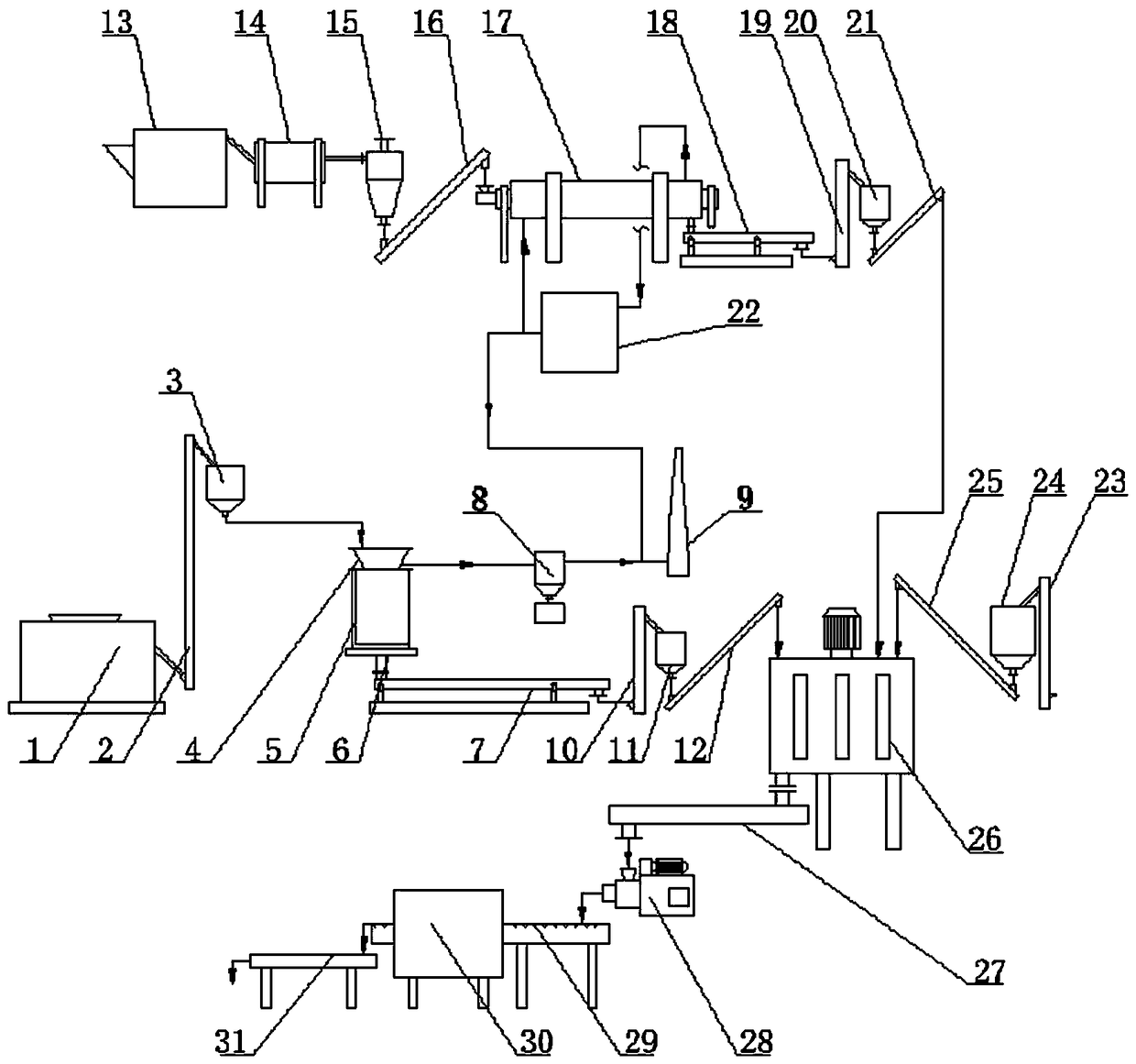

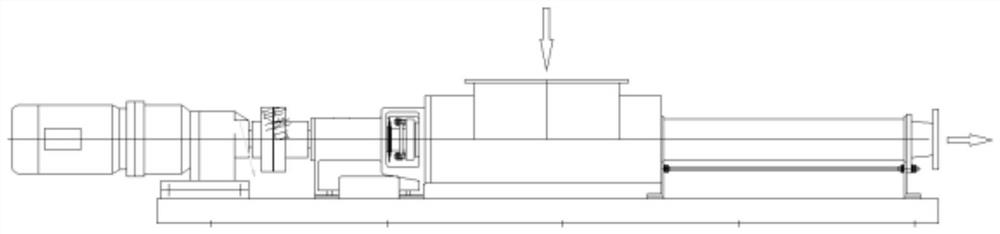

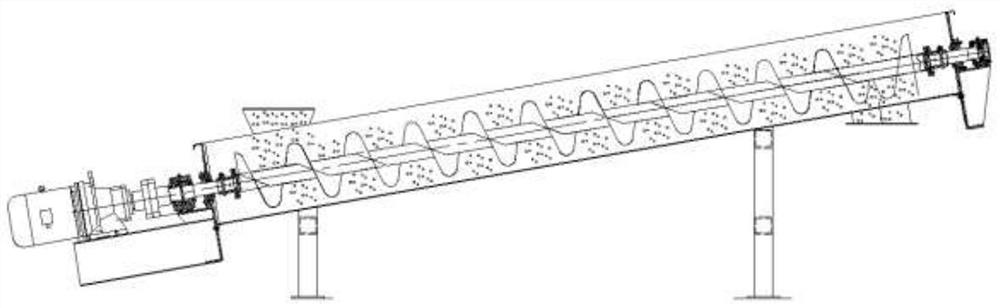

System and process for deep dehydration of sludge by using ultrahigh pressure squeezer

ActiveCN113087346ASolve the problem of deep dehydrationPromote harmlessnessWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningUltra high pressureControl system

The invention discloses a system and process for deep dehydration of sludge by using an ultrahigh pressure squeezer. The system comprises a sludge tank, primary sludge dewatering equipment, a sludge conditioning device, a dry sludge conveying device, an ultrahigh pressure squeezer and a blanking and sludge discharging conveying device which are connected in sequence, and further comprises a quantitative dosing device connected with the sludge conditioning device, wherein a feeding port is formed in one side, namely, a feeding end, of the ultrahigh-pressure squeezer; a full material test sensor and a switch valve are arranged on the other side of the ultrahigh pressure squeezer, namely, a top back flushing opening far away from the feeding end; the full material test sensor is connected with the signal input end of a PLC control system, and the switch valve is connected with the signal output end of the PLC control system; and the sludge conditioning device adopts a double-screw stirrer. The system can solve the problem of deep dehydration of the sludge with the moisture content of about 80%, can reduce the moisture content of the municipal sludge to 50% or below on the premise of low cost, and is convenient for harmless, reduction, stabilization and resourceful treatment of the municipal sludge.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

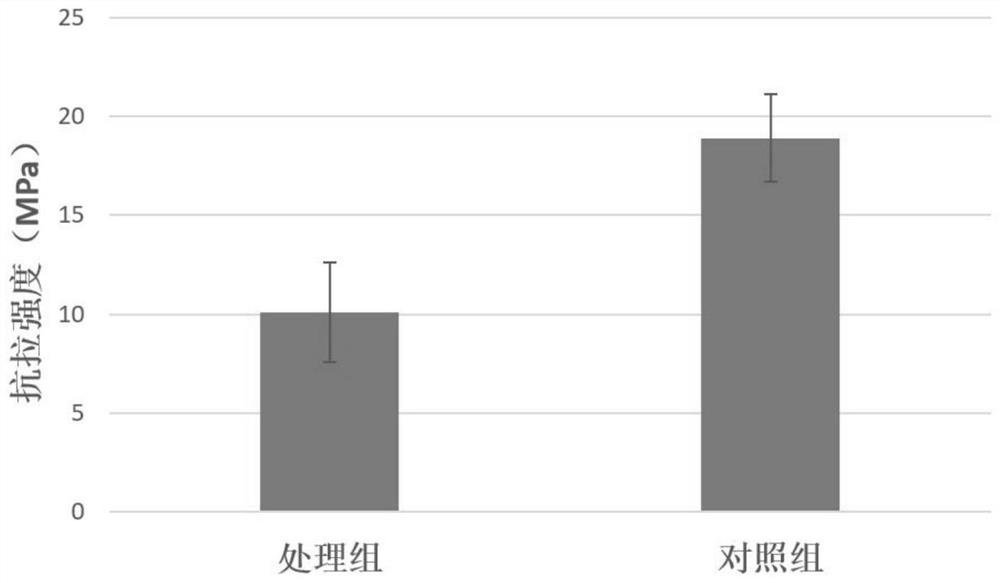

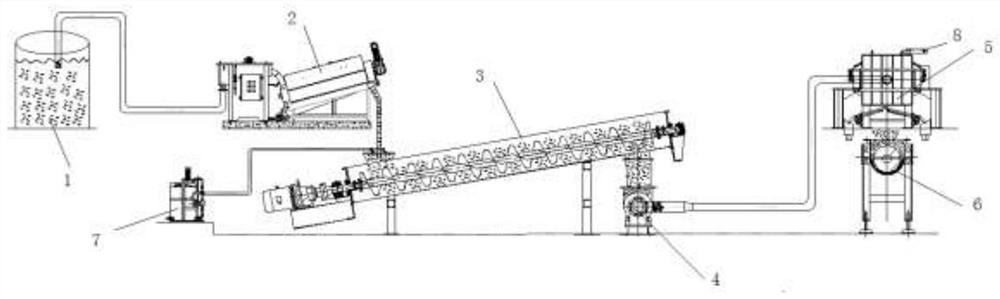

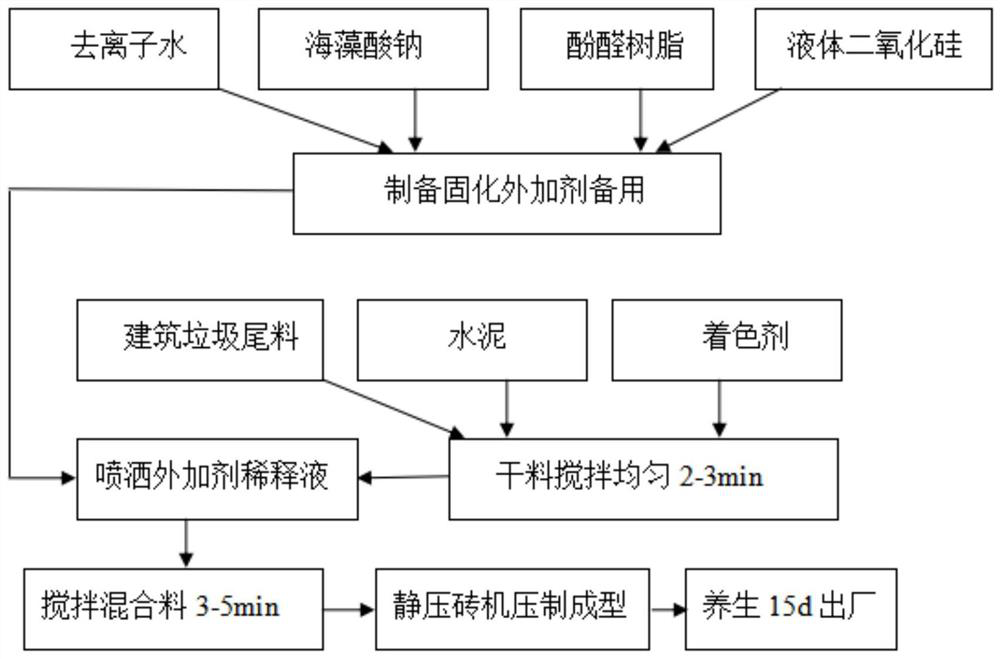

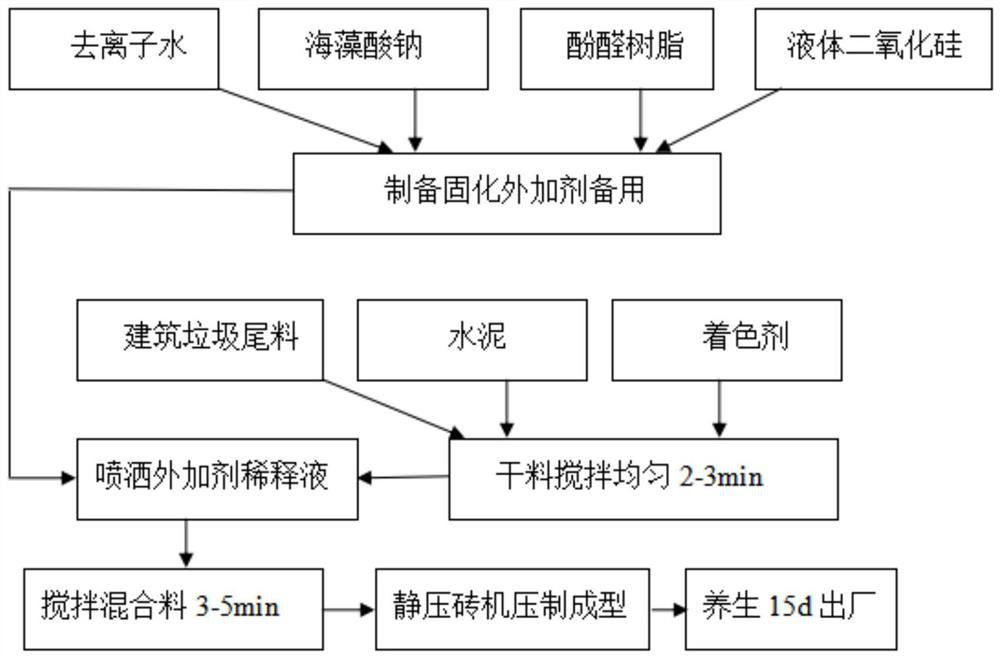

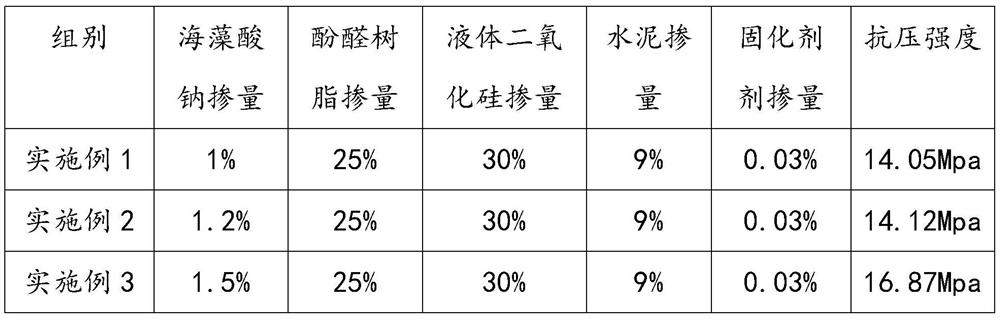

Non-fired antique green brick based on construction waste tailings and its preparation method and application

The invention relates to the field of environmental protection building materials, and specifically discloses a non-burning antique green brick based on construction waste tailings and its preparation method and application. As well as water as raw materials, the unfired antique green bricks prepared by chemical modification have high strength, excellent water resistance and aging resistance, and the high-density hydraulic forming method greatly improves the density of building materials, which can Promote the harmless and efficient utilization of construction waste tailings. The preparation method provided by the invention is simple, and the prepared building materials have the advantages of low production cost, high block strength, good physical waterproof effect, long service life, etc. At the same time, it solves the problem that most of the tailings of construction waste are disposed of through landfill in the prior art, which is easy to cause pollution to the environment, and has a broad market prospect.

Owner:蒋品

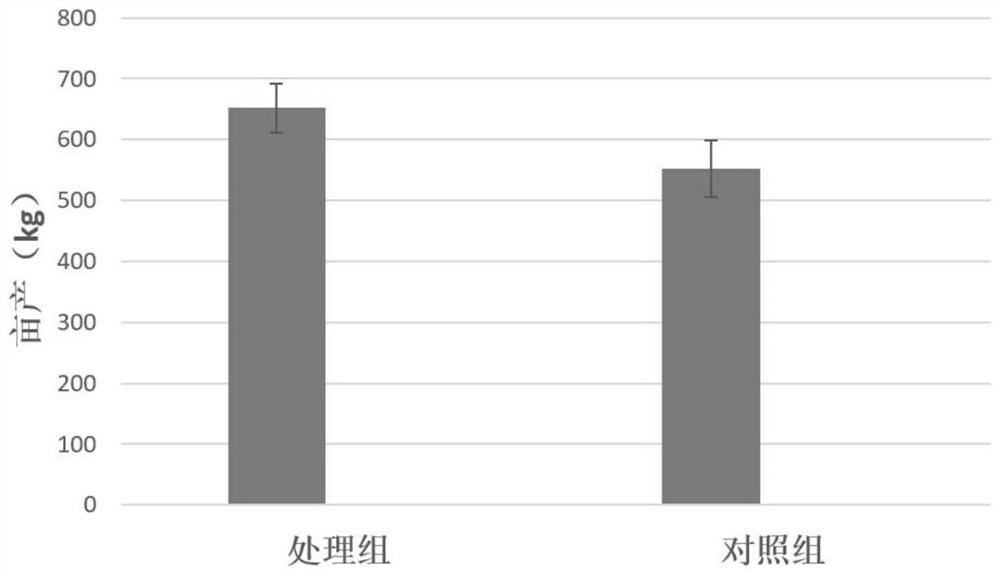

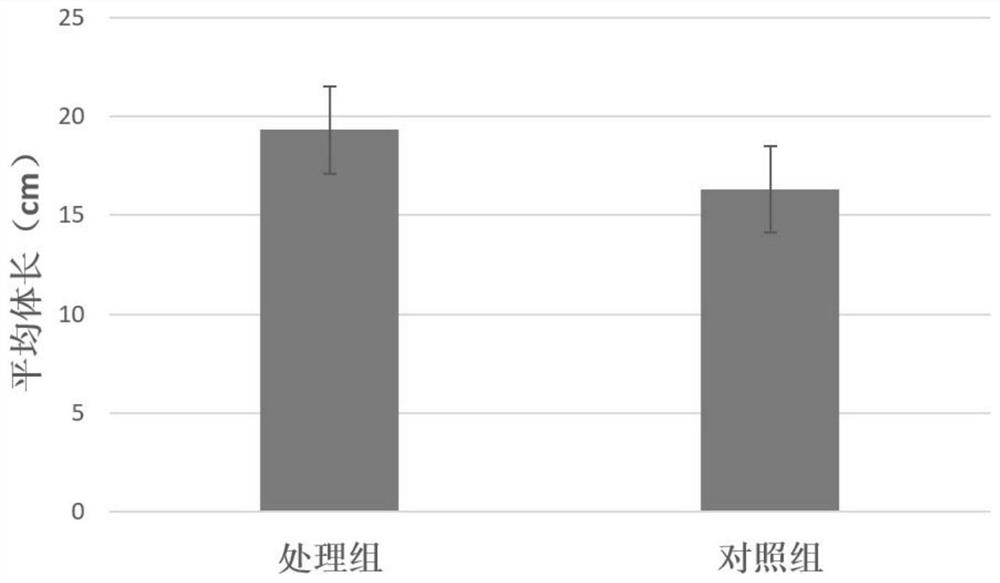

Method for breeding crayfish after rice straw compost fermentation and returning to field

PendingCN113080120AImprove nutritional functionImprove sexual functionClimate change adaptationPisciculture and aquariaBiotechnologyCrayfish

The invention relates to a method for breeding crayfish after rice straw compost fermentation and returning to a field, and belongs to the technical field of crayfish breeding. The method specifically includes the steps of crushing rice straws, adding an organic material leavening agent, performing stacking, and continuously performing composting and fermenting for 60-80 days to obtain compost fermented rice straws; putting the compost fermented rice straws into a crayfish breeding field; planting elodea nuttallii in the crayfish breeding field; and putting young crayfishes into the crayfish breeding field where the elodea nuttallii is planted, and catching the young crayfishes after 50-60 days. According to the method for breeding the crayfish after rice straw compost fermentation and returning to the field, the rice straw is subjected to compost fermentation and then returned to the field for breeding the crayfish, so that the aims of fully utilizing the crop straw and increasing the breeding yield of the crayfish are achieved.

Owner:SUZHOU ACADEMY OF AGRI SCI

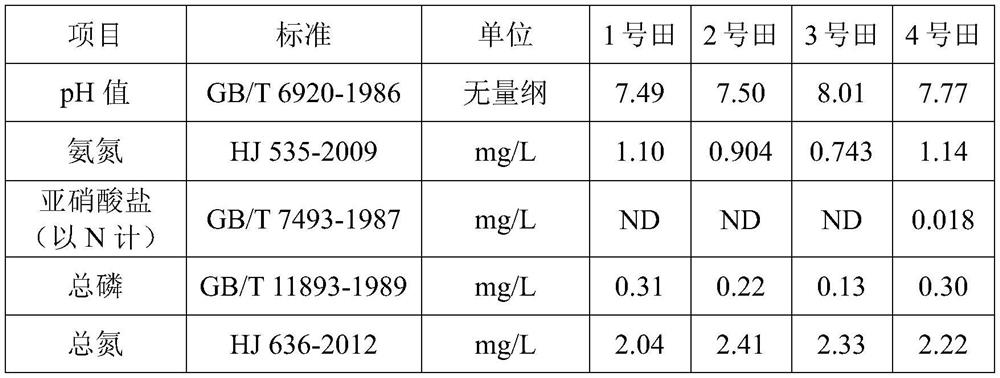

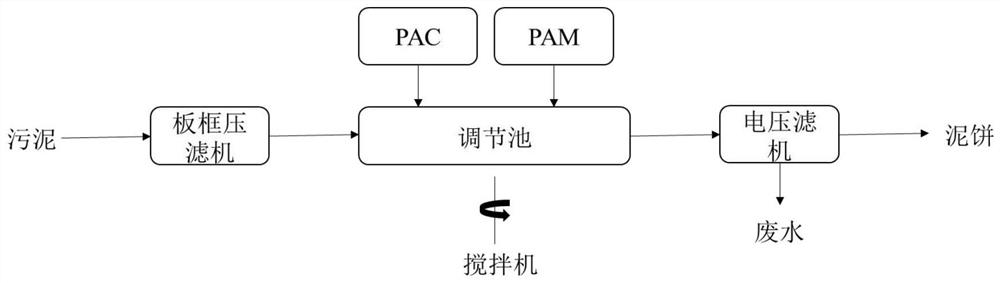

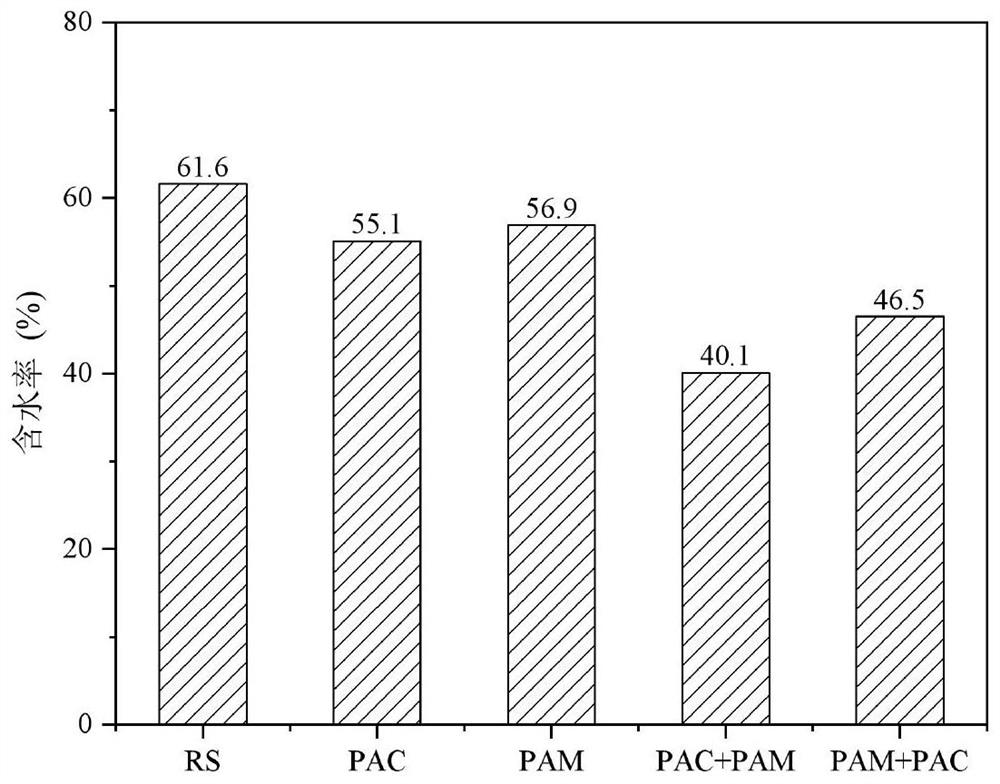

Method for intensifying sludge voltage filtration dehydration by using composite additive

ActiveCN113307463AReduce thicknessDamage structureEnergy based wastewater treatmentElectrochemical sludge treatmentDehydrationSludge dewatering

The invention discloses a method for intensifying sludge voltage filtration dehydration by using a composite additive, and belongs to the technical field of sludge dehydration treatment. The method comprises: adding a coagulant into the pretreated sludge, stirring, then adding a flocculating agent, continuously stirring to obtain a mixture, and dehydrating through a voltage filter. The sludge dehydrated by the method does not generate secondary pollution, is low in water content, can be used as a fertilizer raw material, a fuel raw material or a raw material of a building material, and is energy-saving and environment-friendly.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

Baking-free archaized black brick based on construction waste tailings as well as preparation method and application of black brick

ActiveCN112408905AHigh densityPromote harmlessnessSolid waste managementBrickEnvironmental engineering

The invention relates to the field of environment-friendly building materials, and particularly discloses a baking-free archaized black brick based on construction waste tailings and a preparation method and application of the black brick. The baking-free archaized black brick is prepared from the construction waste tailings, a curing agent, cement, a coloring agent, water and the like as raw materials in a chemical modification mode and is high in strength, high in strength and good in durability. Meanwhile, the black brick has excellent water resistance and anti-ageing property, and a high-density hydraulic forming method is adopted, so that the density of the building material is greatly improved, and harmless and efficient utilization of the construction waste tailings can be promoted.The preparation method provided by the invention is simple, the prepared building material has the advantages of low production cost, high building block strength, good physical waterproof effect, long service life and the like, and the current situation that a large amount of carbon is discharged when most of existing black brick building blocks are manufactured by adopting a sintering method issolved; and meanwhile, the problem that in the prior art, most construction waste tailings are subjected to landfill treatment, and the environment is prone to being polluted is solved, and wide market prospects are achieved.

Owner:蒋品

A garbage storage pit heating system

The invention discloses a heating system of a garbage storage pit. The heating system comprises a primary air inlet system, an upper heating device, a bottom heating device and a storage pit internal heating device, wherein the upper heating device is used for heating air of the primary air inlet system; the primary air inlet system is used for feeding air heated by the heating device into the garbage storage pit; the bottom heating device surrounds the bottom of the garbage storage pit, and is used for heating the bottom of the garbage storage pit; and the storage pit internal heating device is used for heating garbage in the storage pit. According to the heating system, the top and the bottom of a garbage stacking surface are heated at the same time, so that the temperature of the garbage storage pit is effectively increased, fermentation and dehydration of garbage are facilitated, the calorific value of garbage fed into an incinerator is increased, and combustion of the incinerator is more stable; and besides, the temperature in the garbage storage pit is increased through fully utilizing hot water generated from a waste heat utilization system of hot air at the upper part of an incineration bridge and industrial circulating water, so that the primary air inlet temperature is increased, and the heat efficiency of the incinerator is improved.

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

A kind of sludge treatment agent and its application

ActiveCN108947201BRaise the possibilityReduce moisture contentSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeDomestic waste

The invention discloses a sludge treatment agent, which includes a treatment agent A and a treatment agent B. The sludge treatment agent uses potato peels to prepare the treatment agents A and B to treat sludge and reduce the water content of sludge and harmful components in sludge; the addition of sludge treatment agent A can greatly kill bacteria in sludge and reduce the water content of sludge; the addition of treatment agent B can stabilize heavy metals in sludge and weaken the environment of heavy metals toxicity, and can also promote the release of bound water in the sludge, so that the water content of the sludge is significantly reduced; the production process of the present invention is simple and easy to operate, the raw materials are simple and easy to obtain, and the production cost is low, and the sludge treatment agent is prepared by making full use of domestic waste , to achieve the purpose of treating waste with waste; the invention can significantly improve the dehydration performance of sludge, and can greatly reduce the environmental toxicity of sludge, improve the feasibility of subsequent treatment and disposal of sludge, and provide comprehensive utilization of sludge Foundation.

Owner:KUNMING UNIV OF SCI & TECH

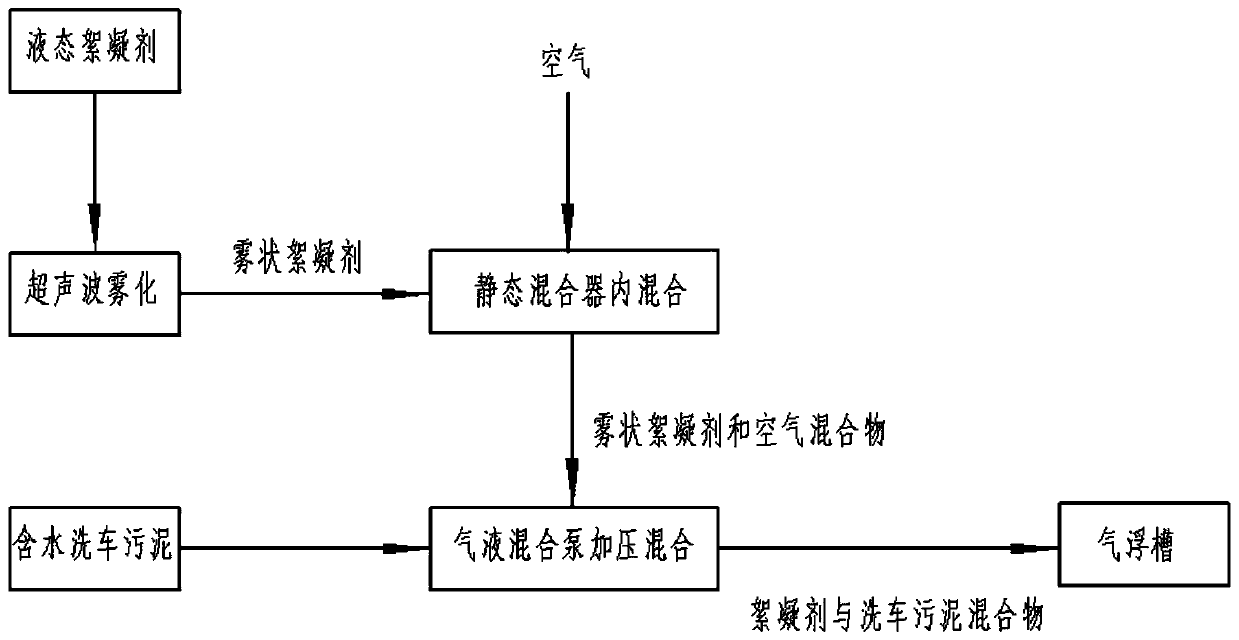

Method for mixing flocculant with motor vehicle cleaning sludge

InactiveCN106316071BIncrease moisture contentPromote reductionSludge treatment by de-watering/drying/thickeningWaste water treatment from vehicle washingFlocculationAtmospheric air

The invention provides a method for mixing a flocculating agent with sludge for cleaning a motor vehicle and especially relates to a method for mixing a flocculating agent with sludge. The method is used for solving the problems of large flocculating agent dosage, high treating cost and poor flocculating dewatering effect and efficiency of the existing flocculation dewatering technical method for mixing a flocculating agent with sludge for cleaning a motor vehicle. The method comprises the following steps: 1) atomizing the flocculating agent; 2) mixing the atomized flocculating agent with air: arranging an atomizing port of an ultrasonic atomizer into a static mixer communicated with the atmosphere, and mixing the atomized flocculating agent with air under normal pressure in proportion, thereby obtaining a mixture of the atomized flocculating agent and air; and 3) adopting an air-liquid mixing pump for pressurizing and mixing the mixture obtained in the step 2) and the water-containing vehicle-cleaning sludge. According to the method, the flocculating agent and sludge for cleaning the vehicle are more uniformly and fully mixed, so that the dosage of the flocculating agent is reduced, the flocculation space is saved, the flocculation time is shortened, the sludge flocculation water effect and efficiency are increased, the treating cost is lowered, and the sludge dewatering efficiency is increased. The method provided by the invention is applied to the field of sludge treatment.

Owner:HEILONGJIANG UNIV

Method for producing long-acting soil conditioning agent by using potassium feldspar and organic waste

ActiveCN102391878BLow costIn line with industrial policyAgriculture tools and machinesOrganic fertilisersPotassiumOxygen

The invention discloses a method for producing a long-acting soil conditioning agent by using potassium feldspar and organic waste. Potassium feldspar, limestone, aid and coal are used as raw materials in the method. The method comprises the following steps of: roasting the crushed raw materials in a rotary kiln by adding the coal, and cooling and milling the roasted raw materials; and mixing the powder and the organic waste such as animal excrement in a farm and the like, performing anaerobic and aerobic continuous fermentation step by step, performing partial dehydration, and thus obtaining a finished product. The produced long-acting soil conditioning agent contains a certain amount of nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, soluble silicon, humic acid and the like, so the soil conditioning agent can effectively improve the soil and provides nutritional components for crops for long time. The soil conditioning agent can be directly applied, and can also be applied with chemical fertilizers. According to the method for producing the long-acting soil conditioning agent by using the potassium feldspar and the organic waste, the production raw materials are mineral in the nature and waste in the farm, the raw materials are extremely rich and cheap, and the production process is energy-saving and environment-friendly.

Owner:SHANGHAI RES INST OF CHEM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com