Method for removing contaminations under oxygen-enriched combustion condition

An oxygen-enriched combustion and pollutant technology, which is applied in separation methods, chemical instruments and methods, dispersed particle separation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

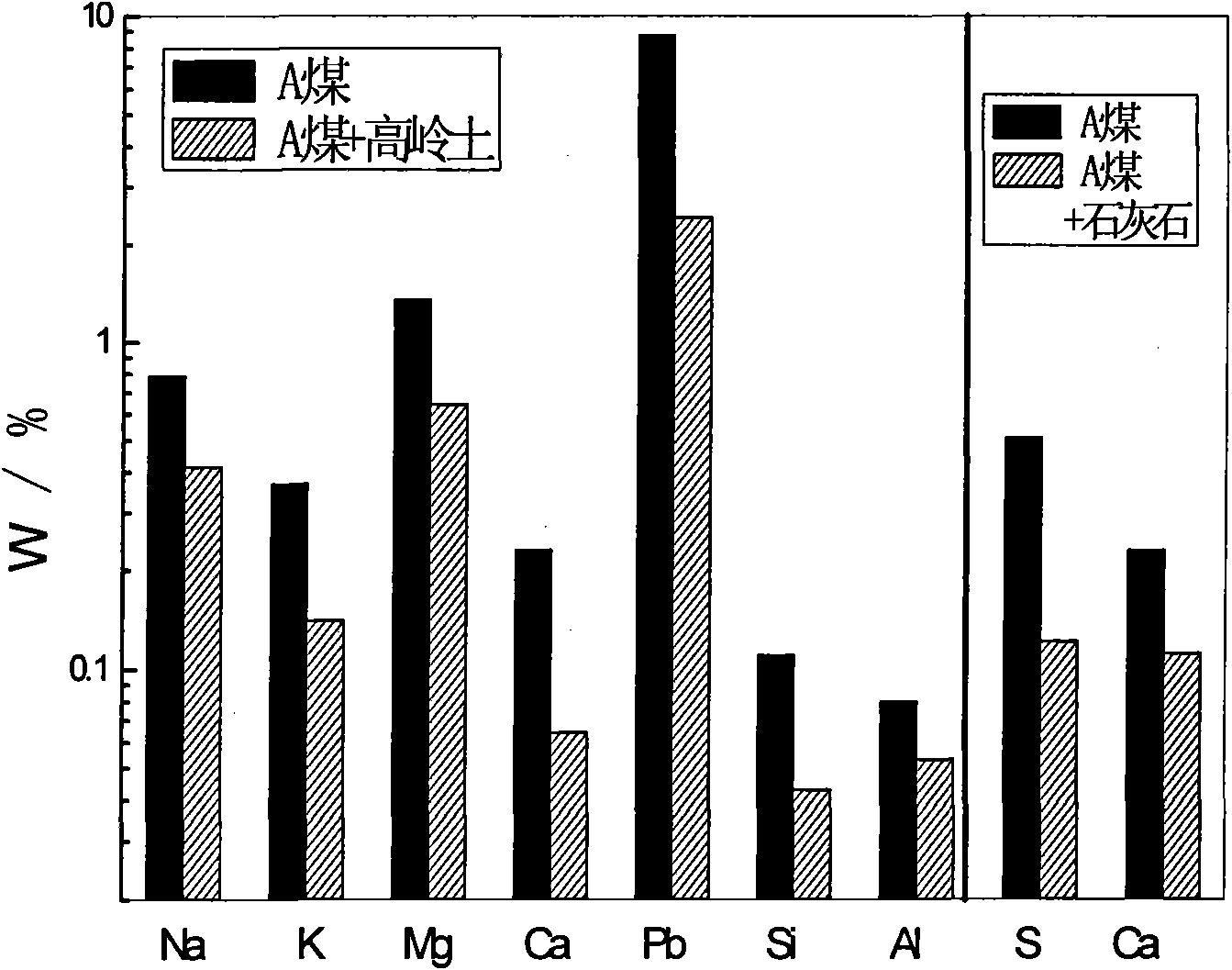

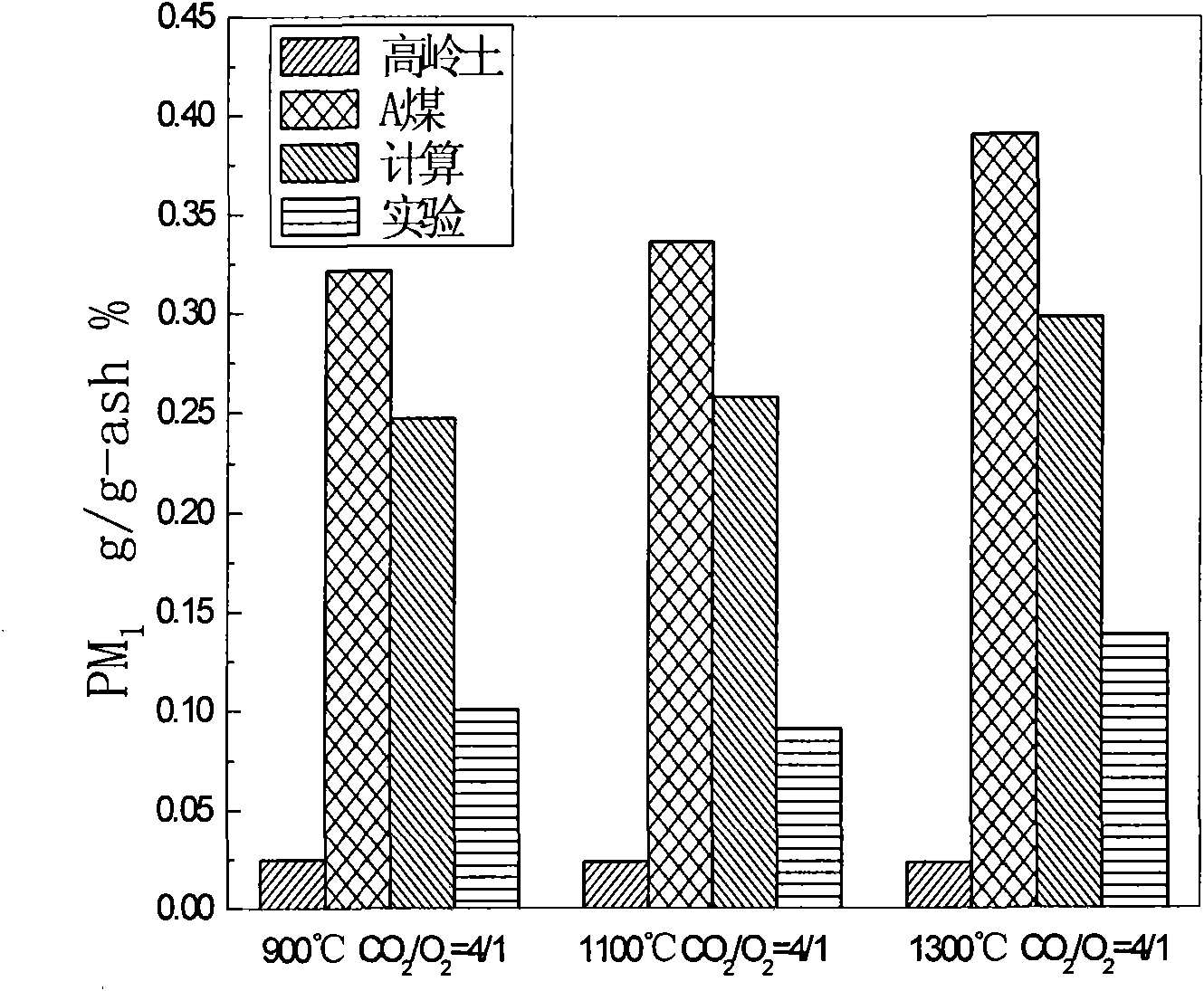

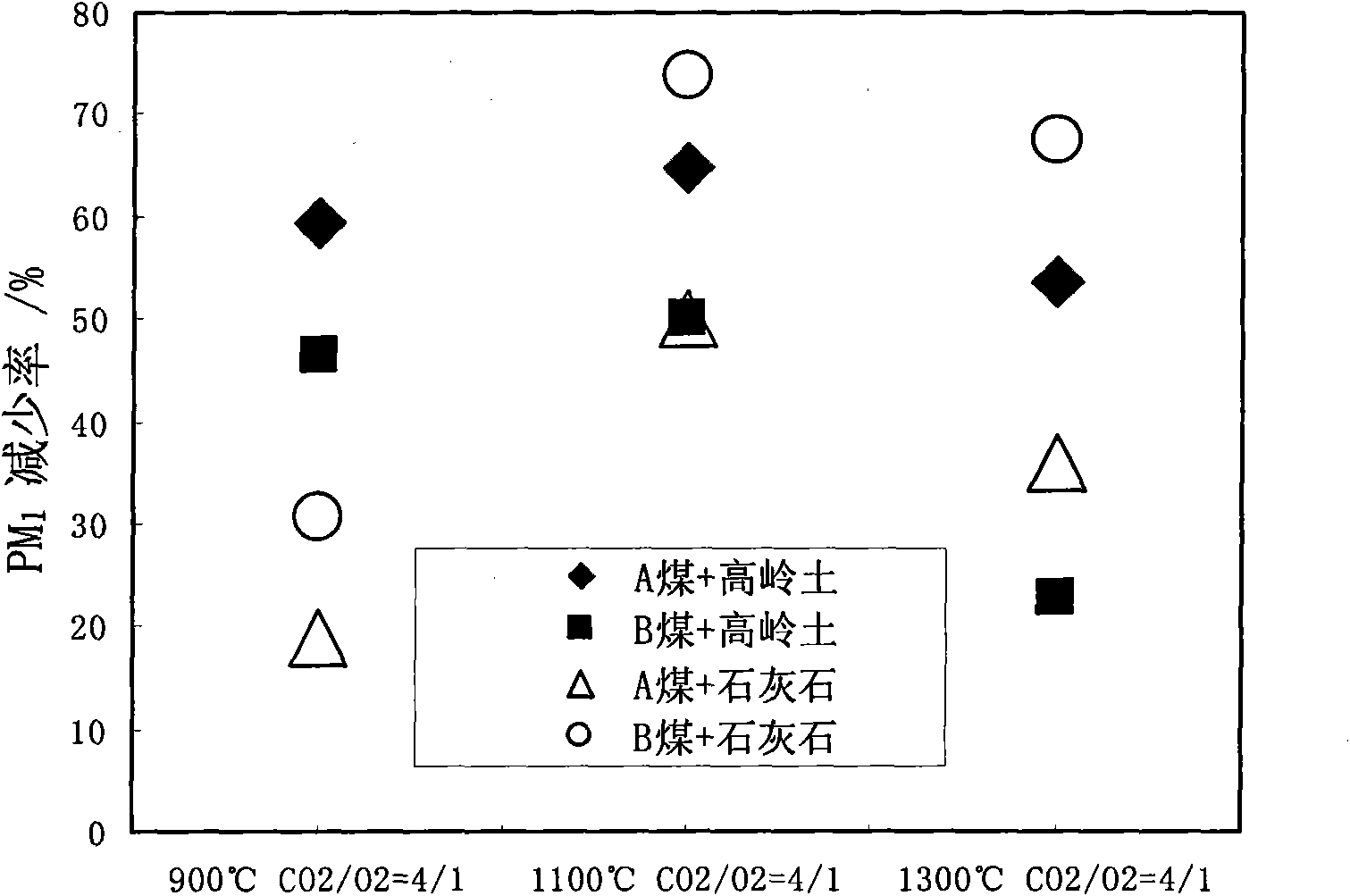

[0014] Through chemical reaction and physical adsorption, the joint removal of various pollutants is realized. Through different fuels and experimental results at 800°C-1300°C, determine the most effective adsorbent for different fuels and the best removal method. temperature segment.

[0015] The present invention will be described in more detail below by means of the following examples, and the following examples are only illustrative, and the present invention is not limited by these examples. This example is carried out in the laboratory, and the specific implementation steps are as follows:

[0016] (1) prepare adsorbent, the particle diameter of adsorbent is less than 150mm, and bake in oven at 45 ℃ for three hours, the selected adsorbent of this example is kaolin and limestone.

[0017] (2) at O 2 / CO 2 Under the combustion mode, two different kinds of lignite are burned in a settling furnace. The experimental combustion temperatures are 900°C, 1100°C, and 1300°C. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com