Patents

Literature

749 results about "Multi pollutant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

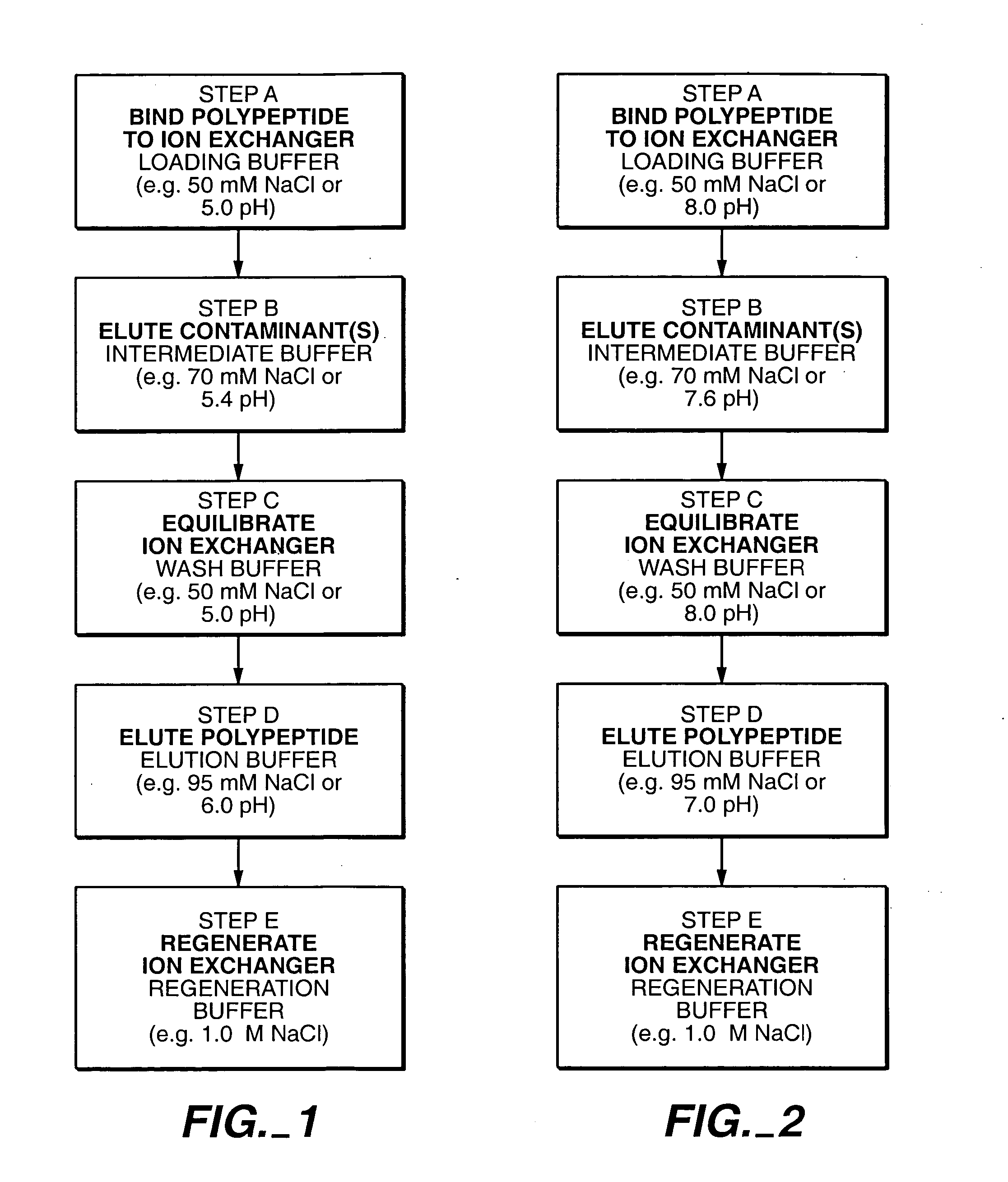

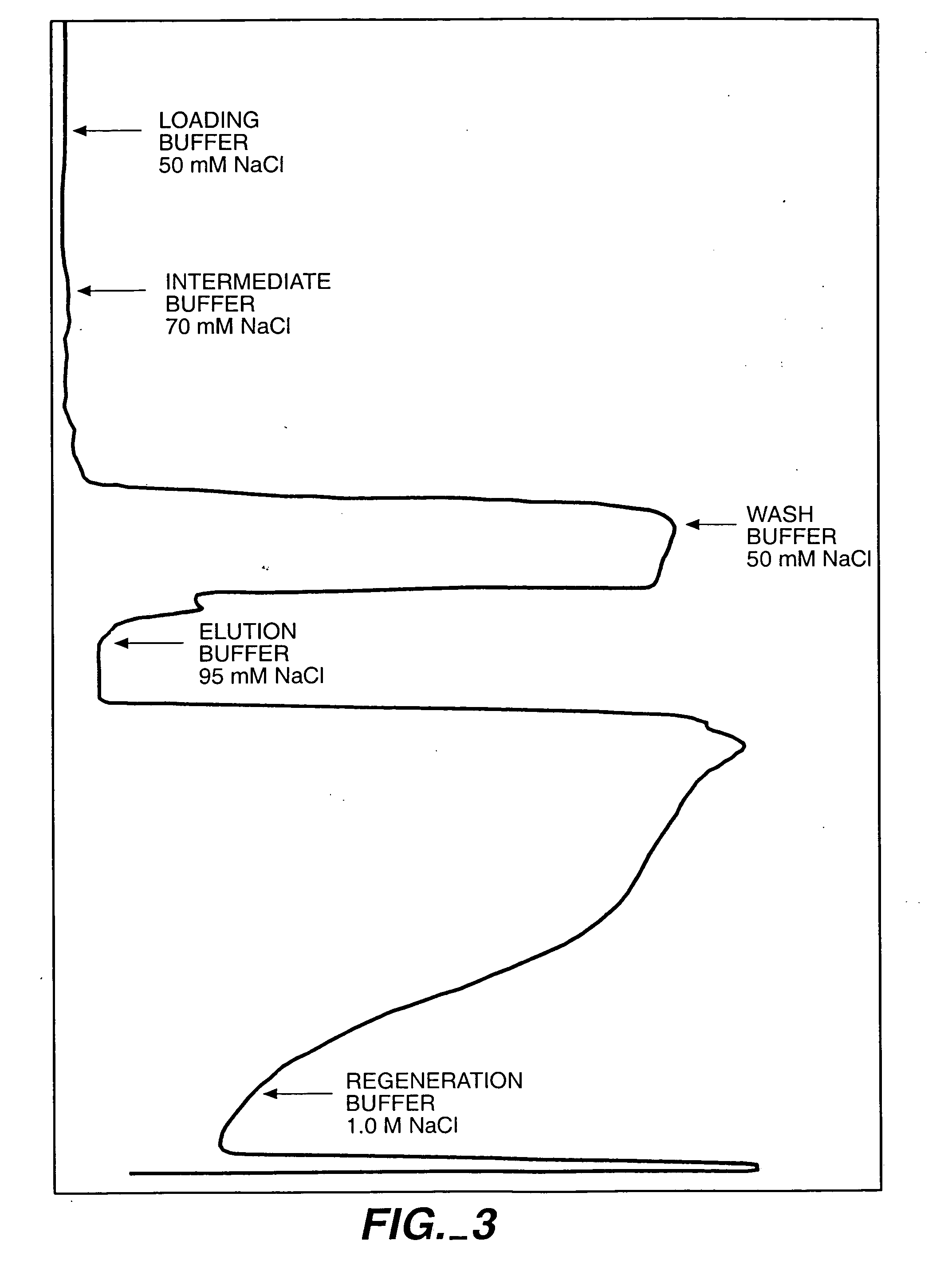

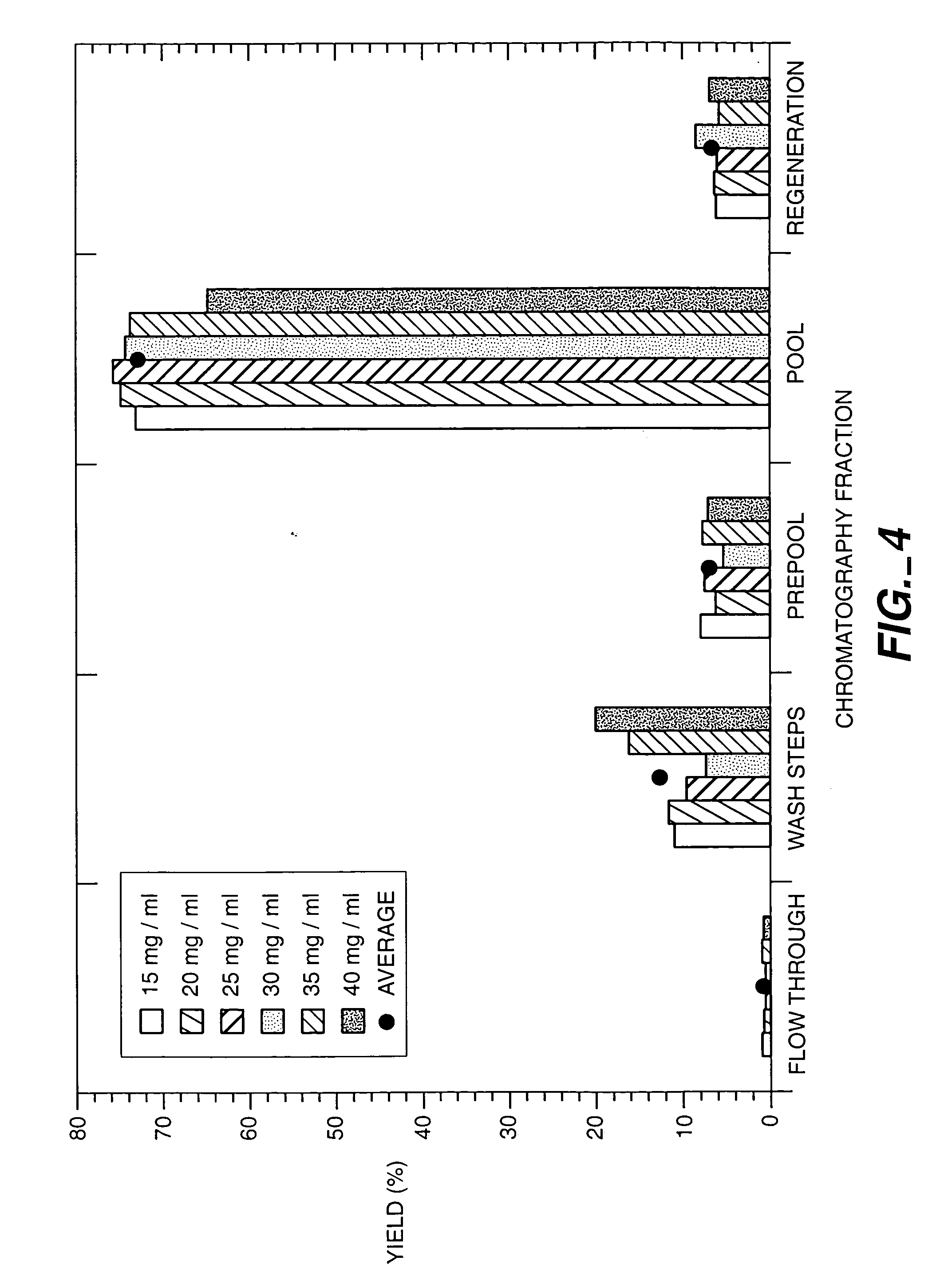

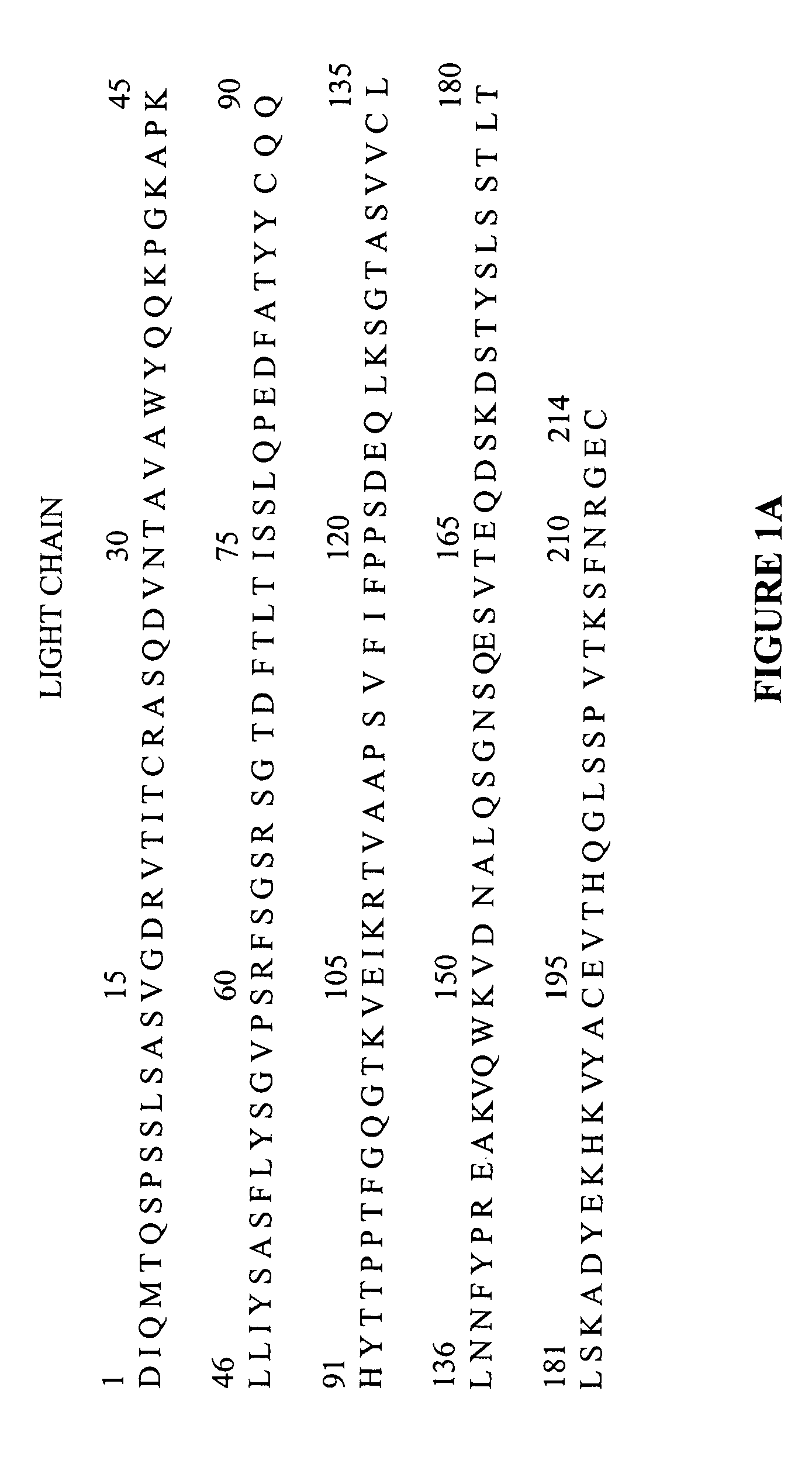

Protein purification

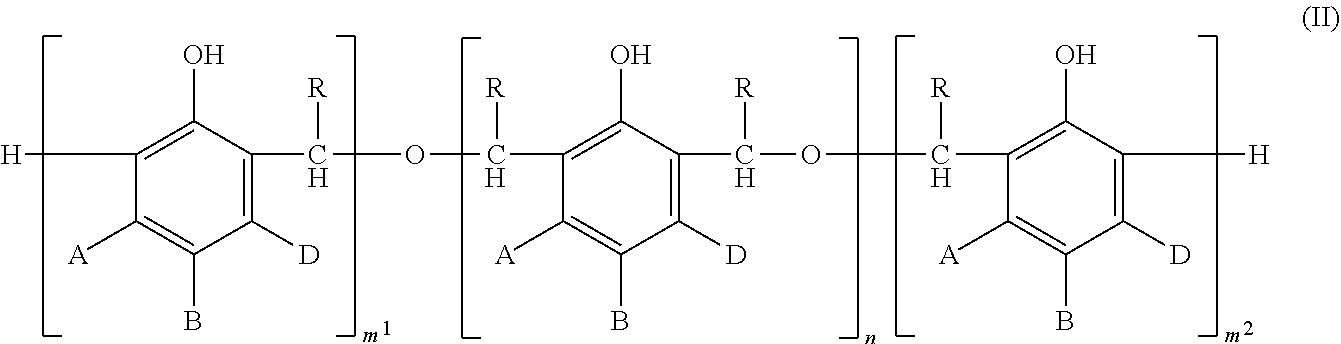

InactiveUS7074404B2High recovery ratePeptide/protein ingredientsSerum immunoglobulinsIon chromatographyMulti pollutant

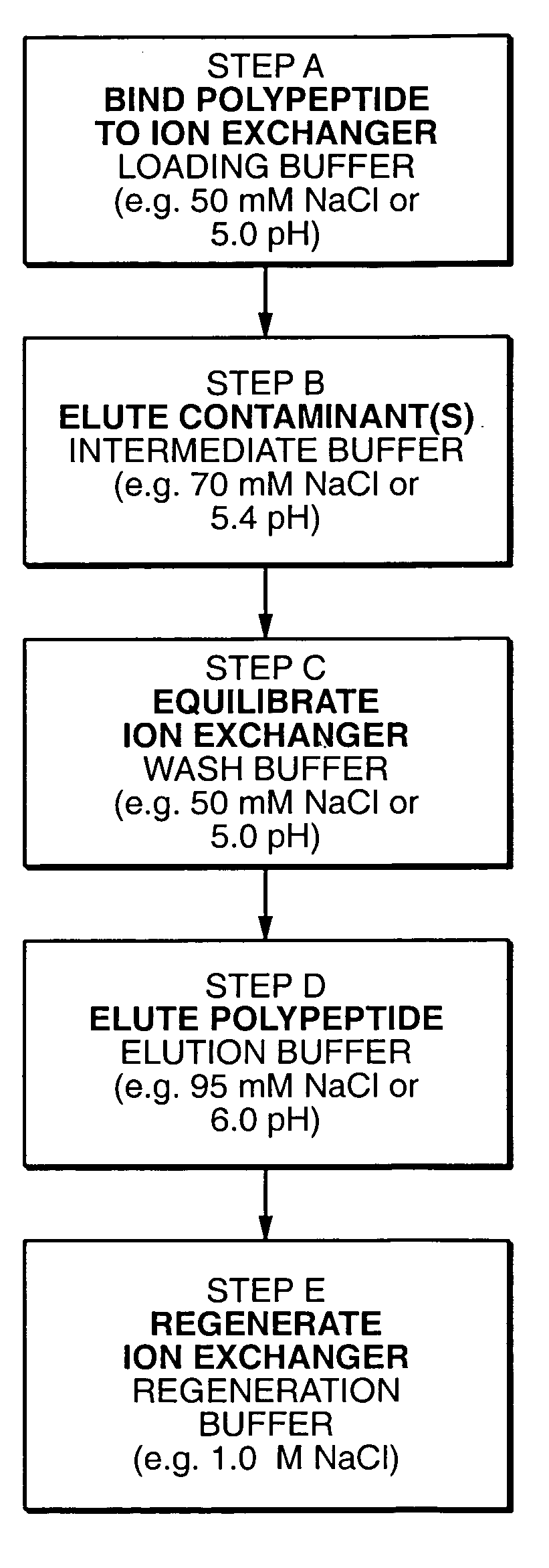

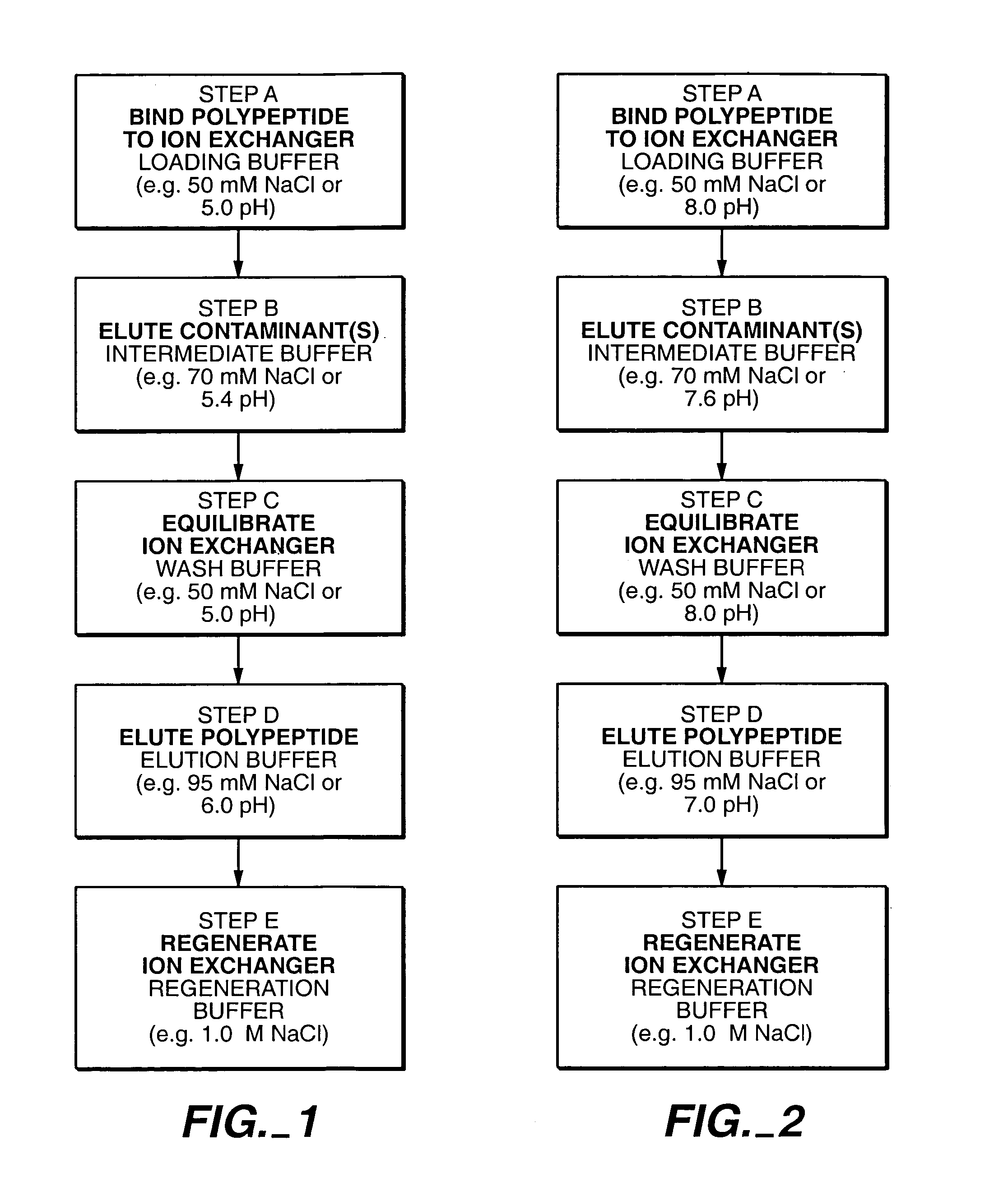

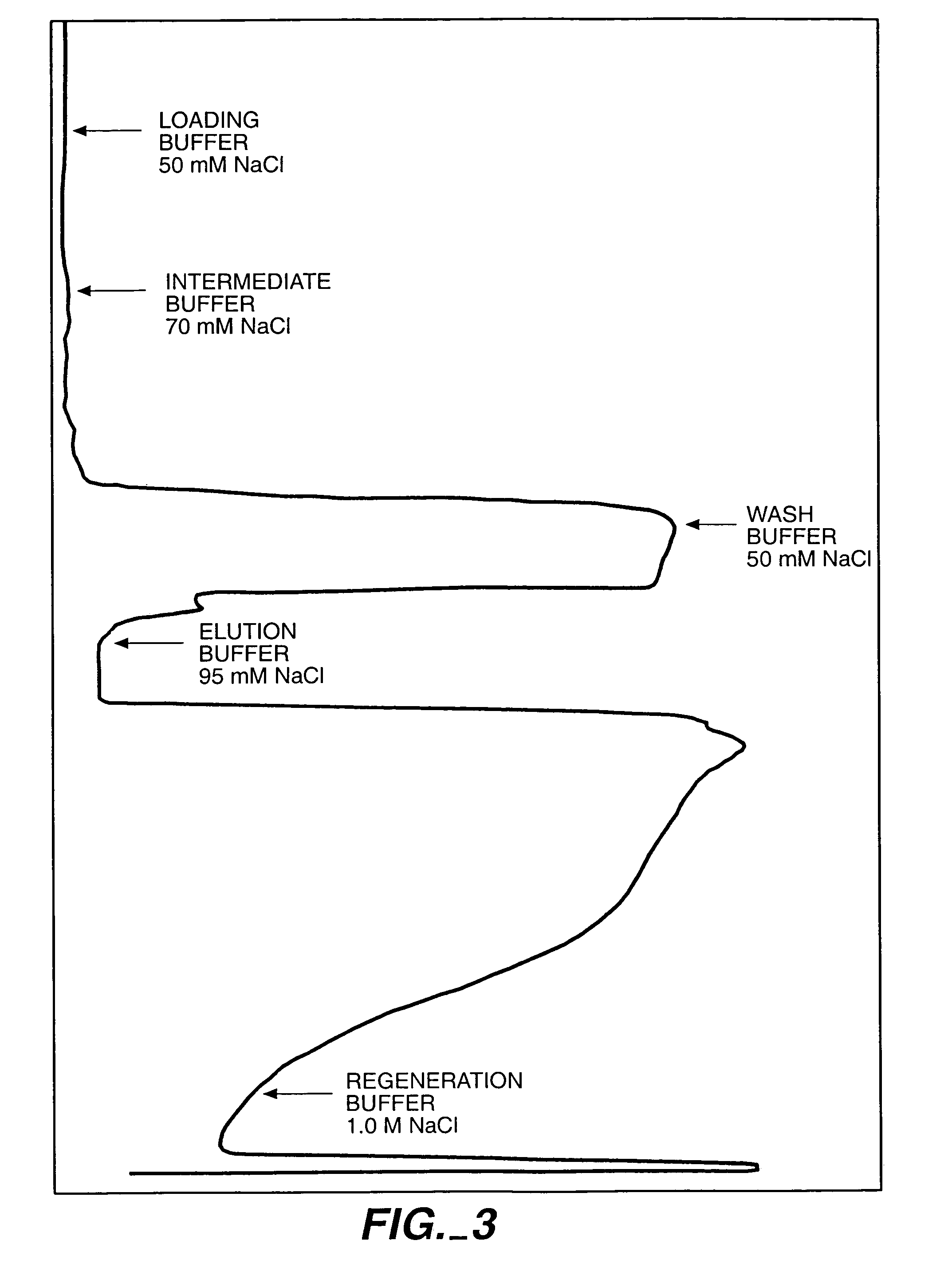

A method for purifying a polypeptide by ion exchange chromatography is described which involves changing the conductivity and / or pH of buffers in order to resolve a polypeptide of interest from one or more contaminants.

Owner:GENENTECH INC

Process for removing a target gas from a mixture of gases by thermal swing adsorption

The separation of a target gas from a mixture of gases using a thermal swing adsorption process wherein a thermal wave is used, primarily in the desorption step. The process of this invention enables one to separately remove multiple contaminants from a treated gaseous stream.

Owner:EXXON RES & ENG CO

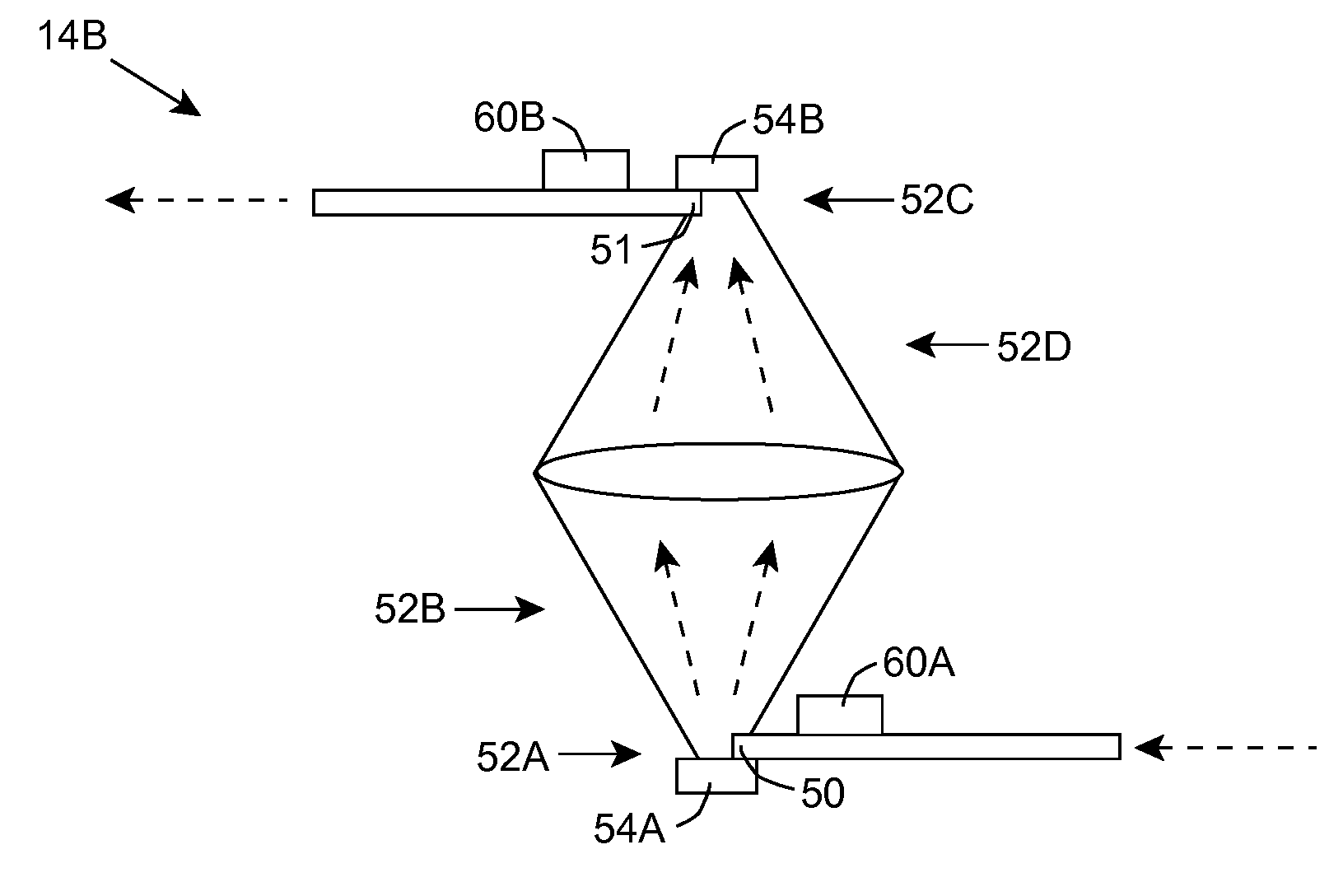

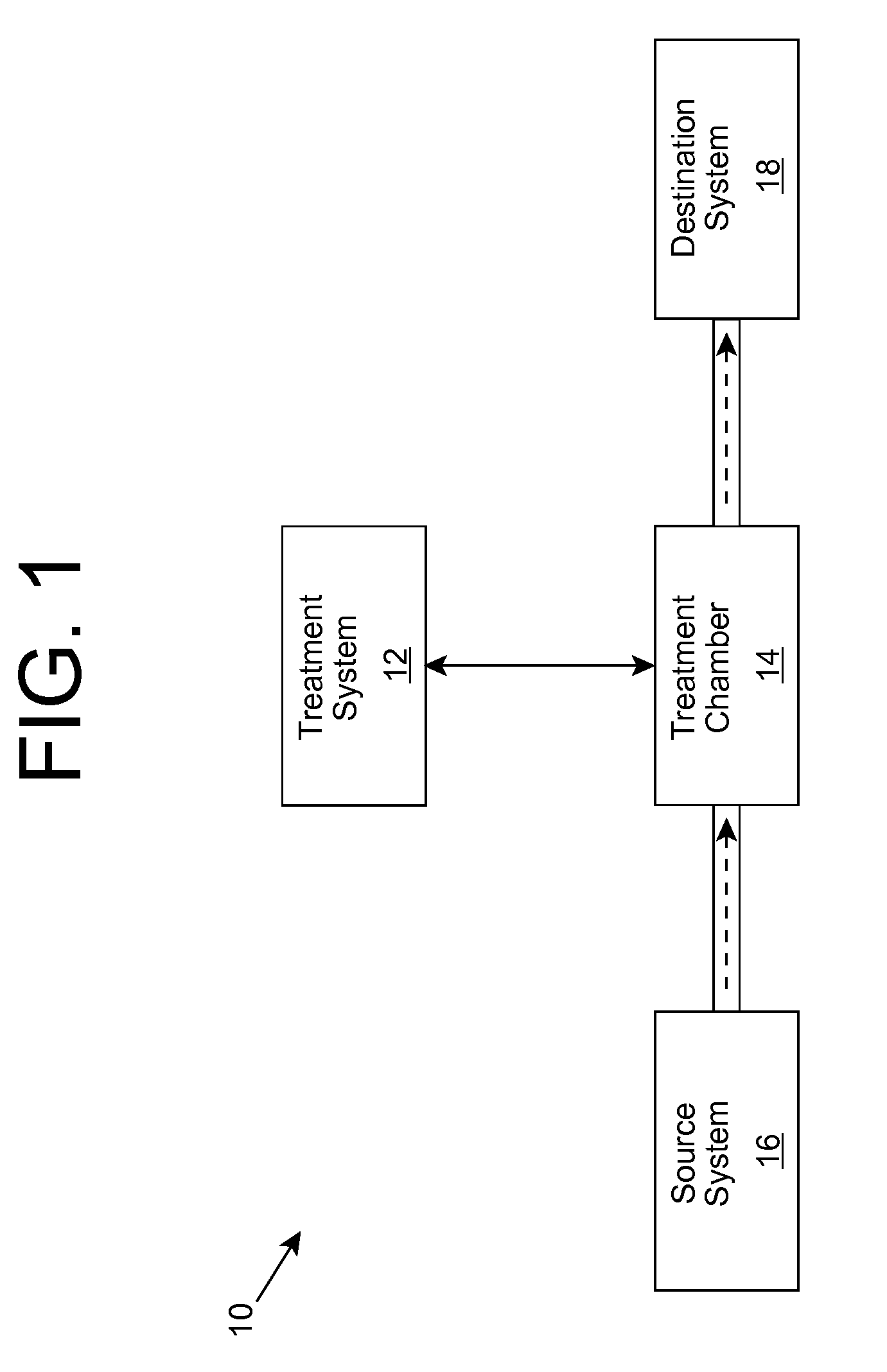

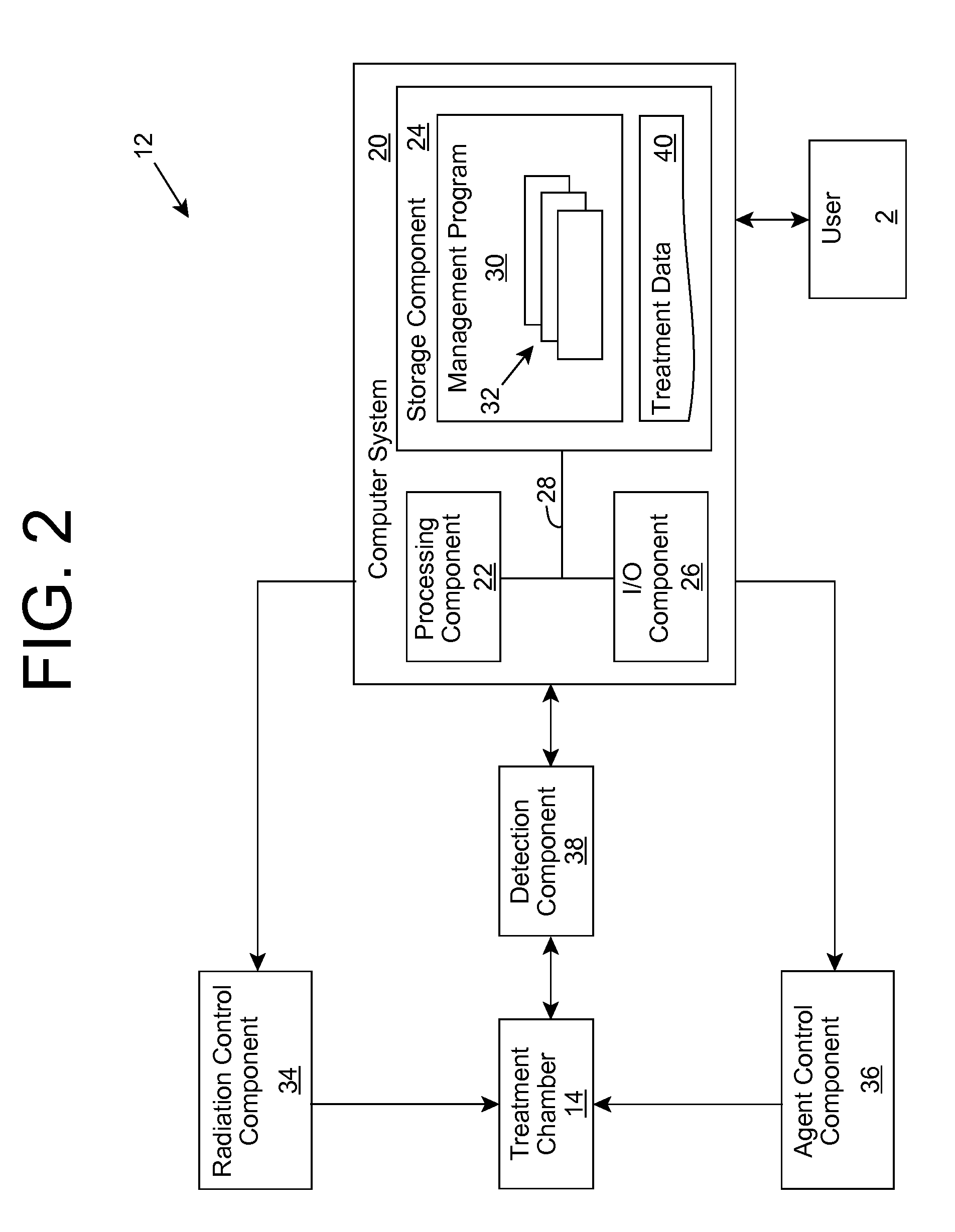

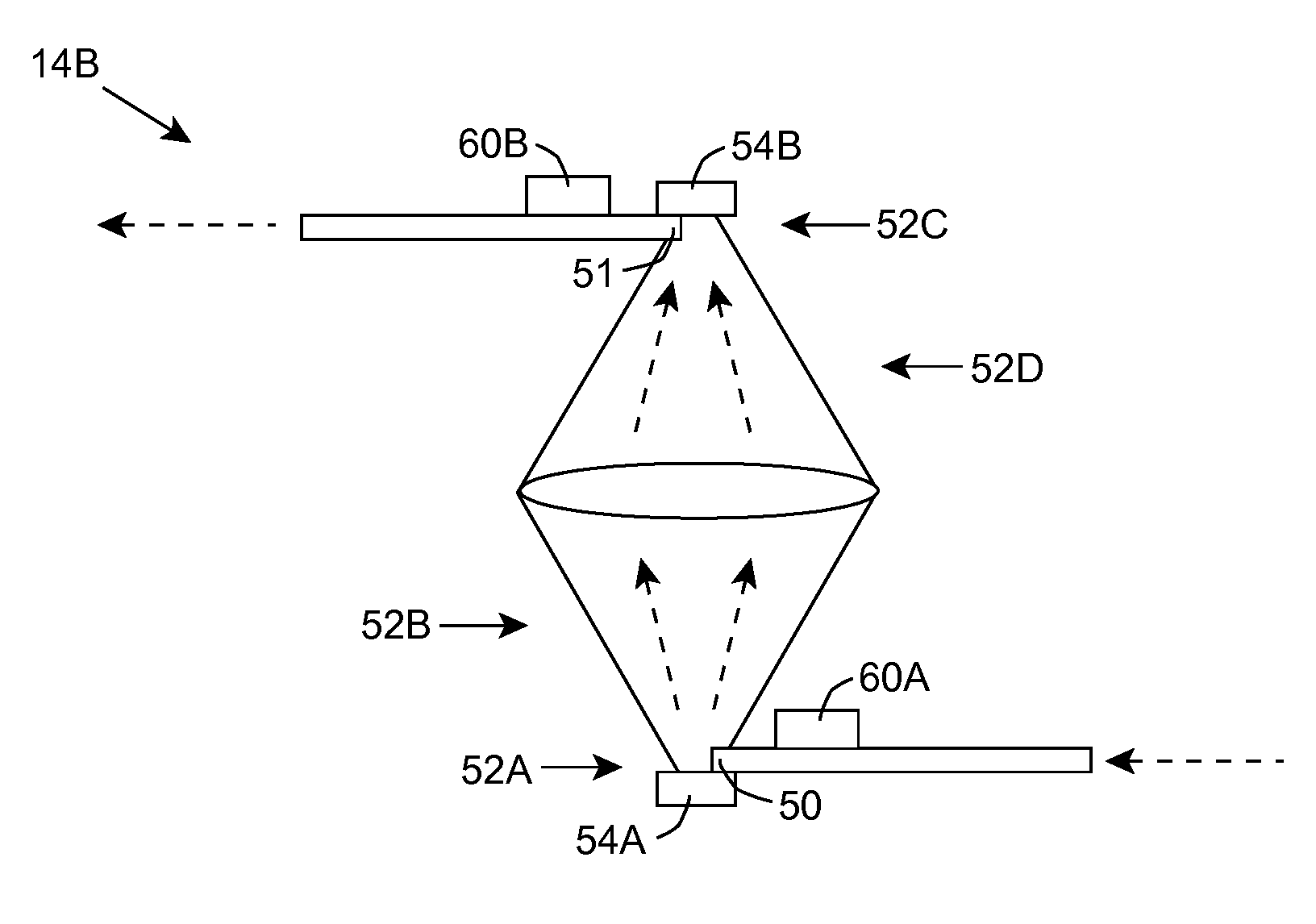

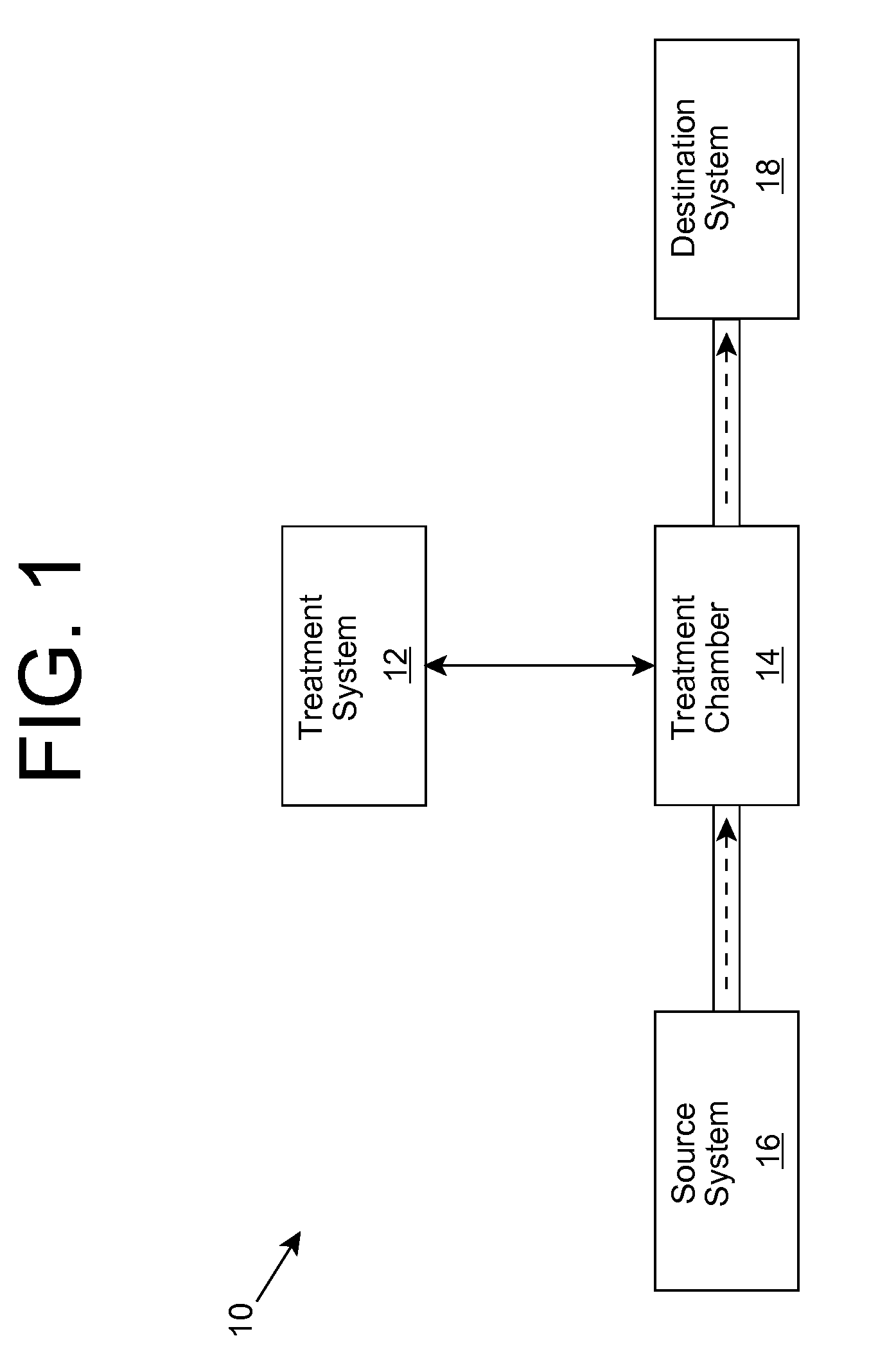

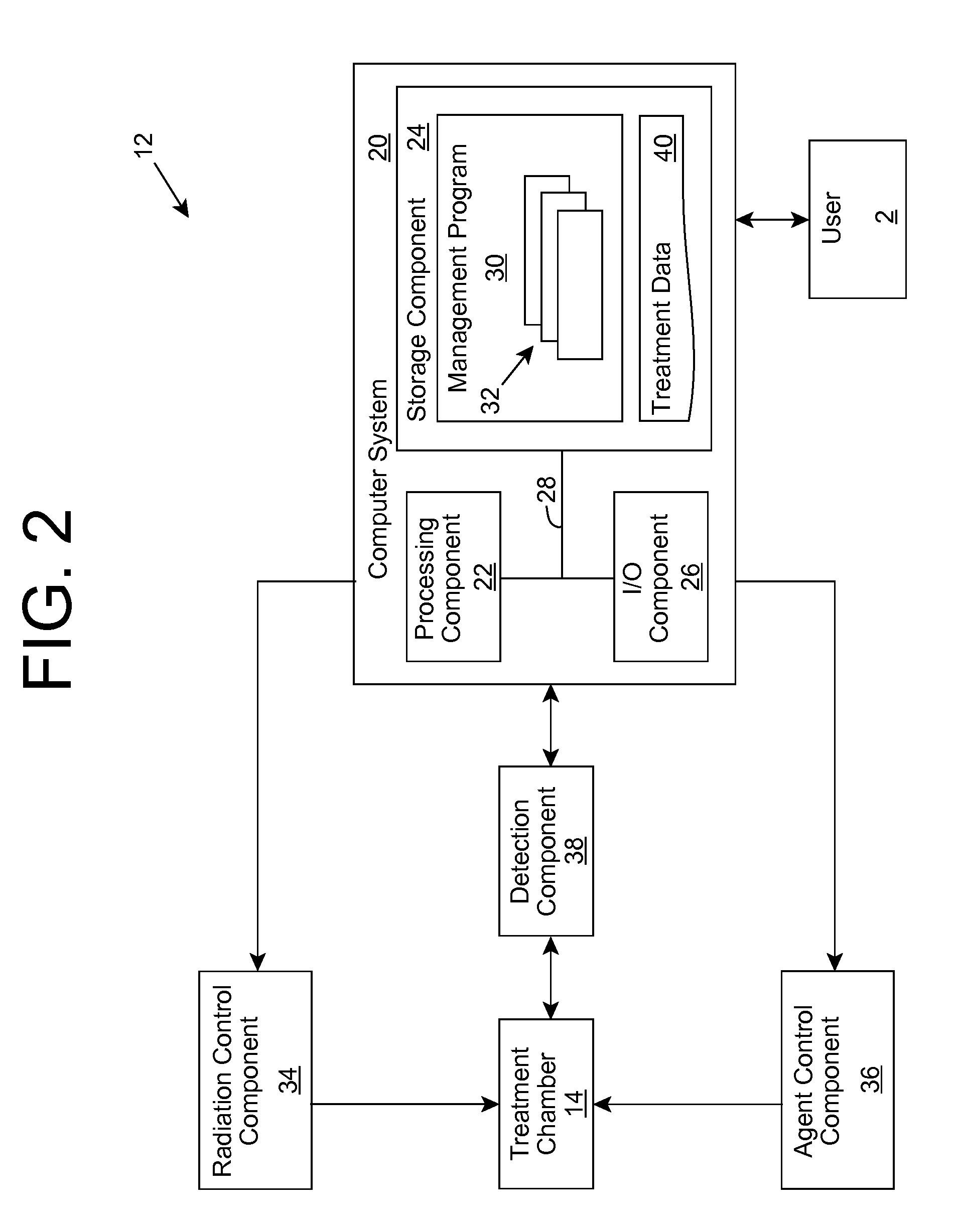

Medium treatment using ultraviolet light

ActiveUS20100296971A1Reduce reflectionPromote absorptionCombination devicesAuxillary pretreatmentMulti pollutantMedicine

A system for treating a medium, such as water, with ultraviolet light is provided. The system can include an ultraviolet treatment chamber that is shaped to reduce reflections of the ultraviolet light within the ultraviolet treatment chamber and / or improve absorption of the ultraviolet light by the medium. Furthermore, the system can add an agent to the medium within the treatment chamber to further treat one or more contaminants that may be present within the medium. Still further, additional treatment, such as filtering the medium with a permeable material can be implemented within the treatment system.

Owner:SENSOR ELECTRONICS TECH

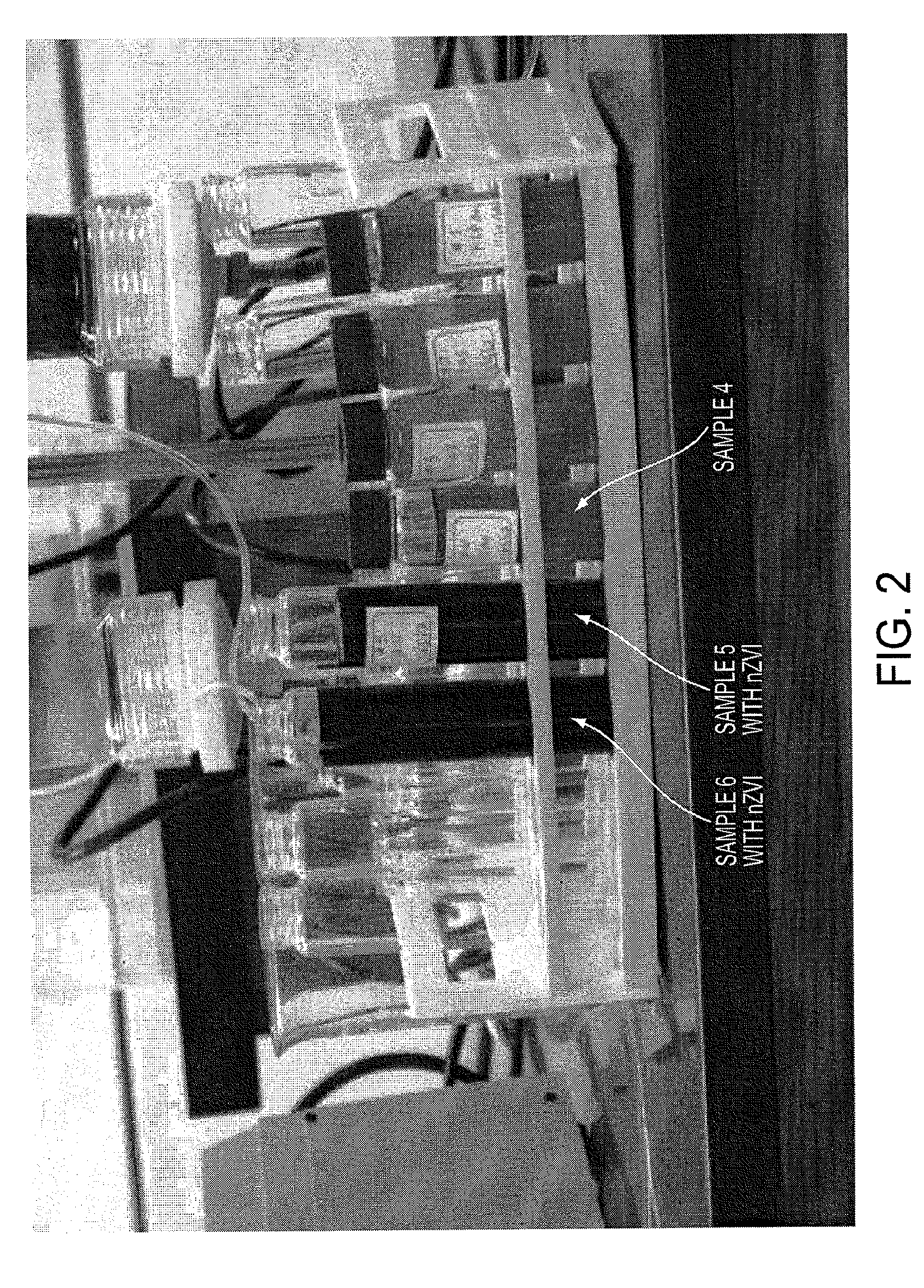

Polymer coated nanoparticle activation of oxidants for remediation and methods of use thereof

InactiveUS7963720B2Extended service lifeNanotechContaminated soil reclamationMulti pollutantNanoparticle

Methods of decreasing the amount of one or more contaminants in contaminated soil comprise introducing polymer-coated nanoparticles into the contaminated soil, optionally with other reagents. The polymer-coated nanoparticles exhibit an enhanced ability to migrate through the soil and provide greater control of the rate of activation of other chemicals, such as oxidants, in the contaminated soil.

Owner:VERUTEK TECH

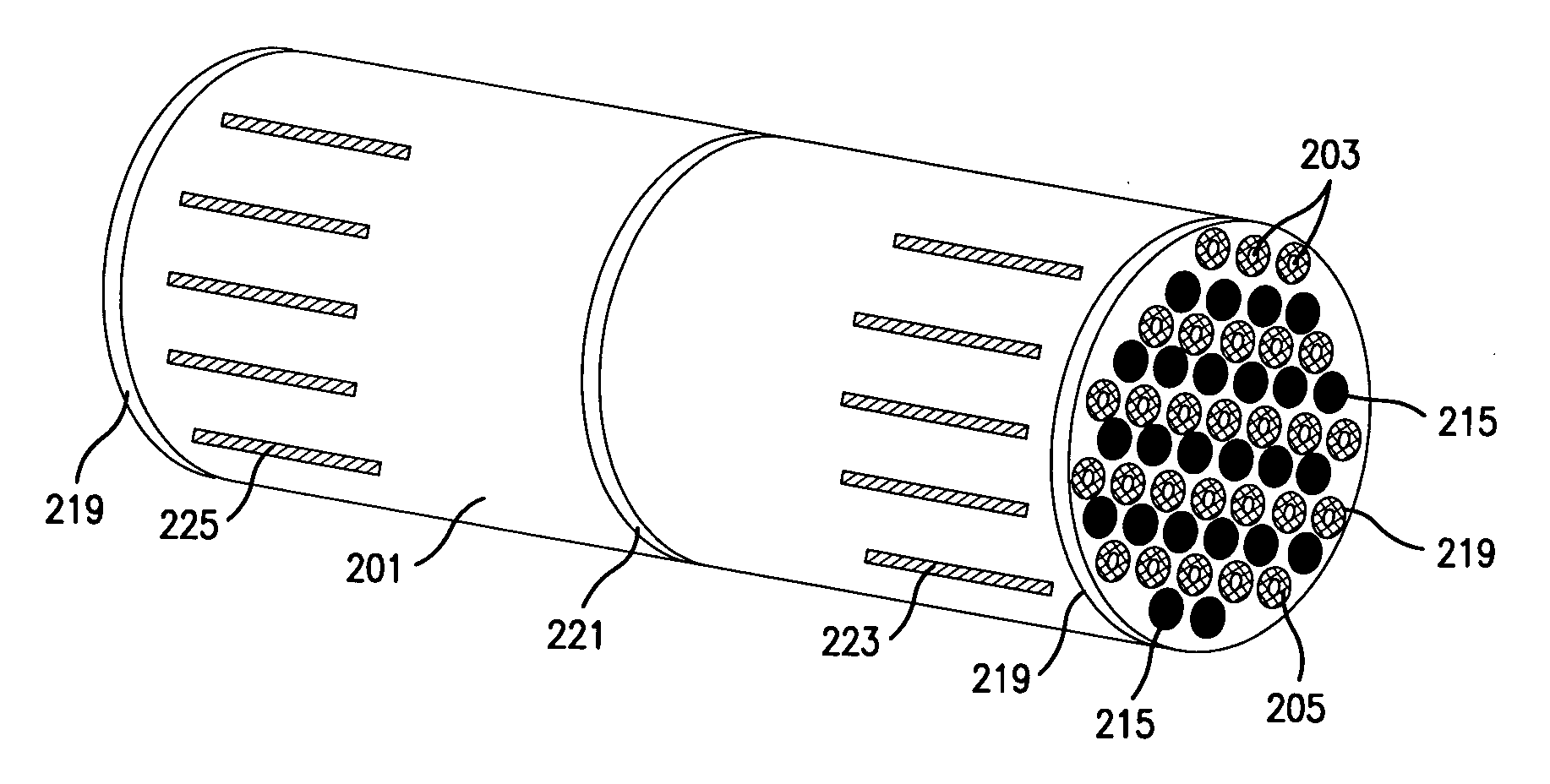

Dual Function Proppants

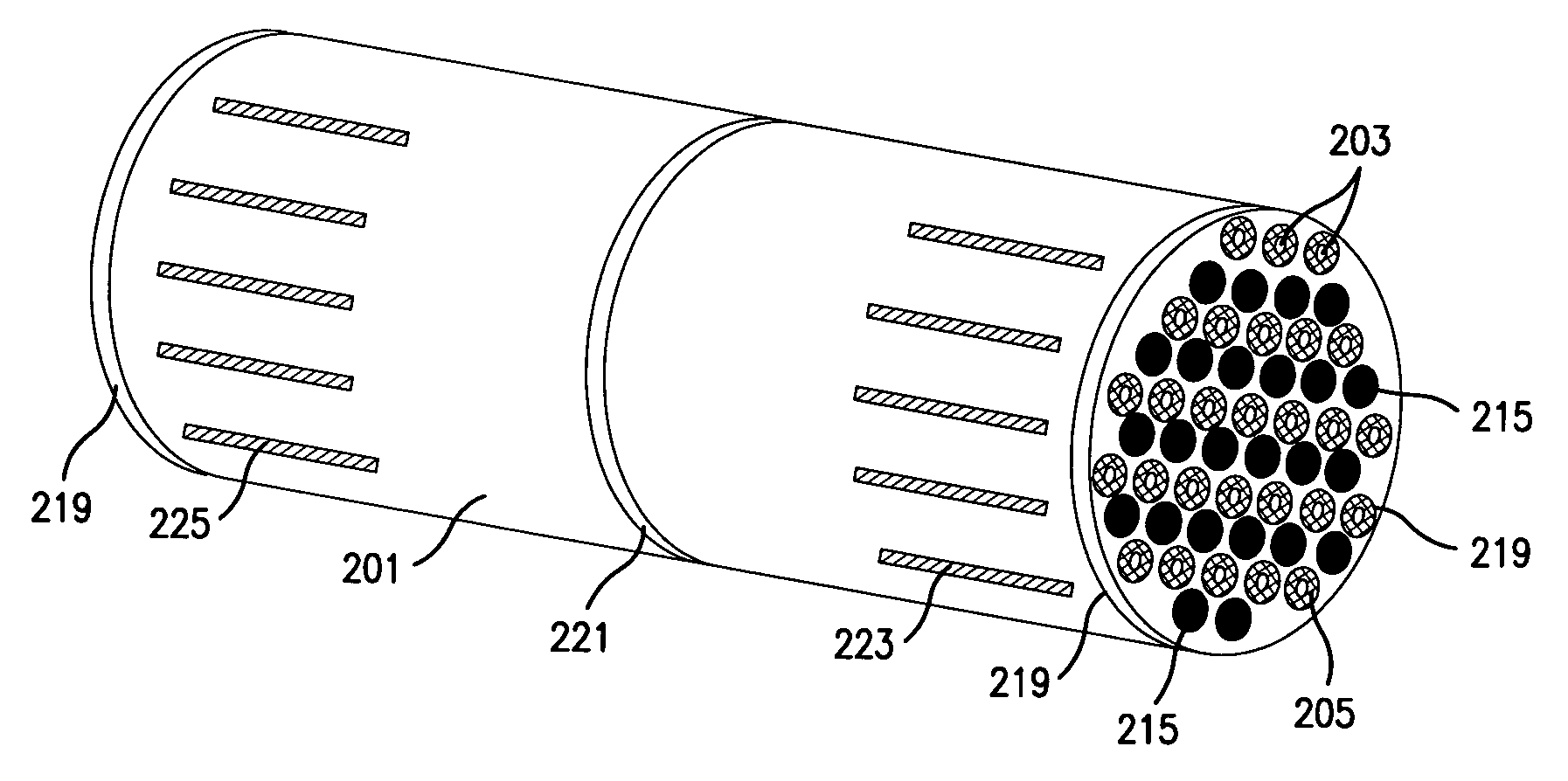

ActiveUS20130056204A1Improve conductivityIncrease valueFluid removalFlushingMulti pollutantIon exchange

Proppants for use in fractured or gravel packed / frac packed oil and gas wells are provided with a contaminant removal component to remove one or more of the contaminants found in subterranean water / hydrocarbon from a production well. The water / hydrocarbon cleaning proppant solids may be used as discrete particles in a proppant formulation, as a coating on proppant solids in pores of a porous proppant solid or as part of the proppant's internal structure. The contaminant removal component removes contaminants, especially dissolved contaminants, in the subterranean water or hydrocarbon before the water / hydrocarbon leaves the well. For those contaminant removal components that can be regenerated, such as ion exchange resins, a measured quantity of an acidic regeneration solution can be injected into the fractured stratum for regeneration and recovered when the well resumes production.

Owner:PREFERRED TECH

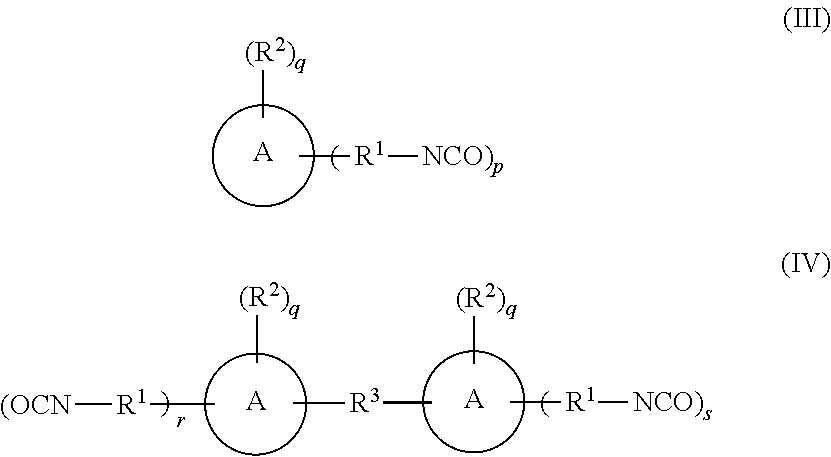

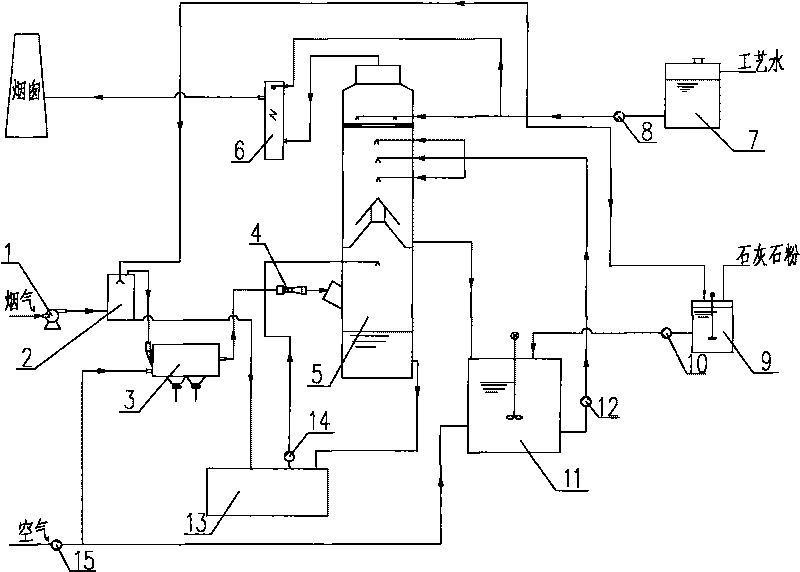

Multi-pollutant removing technique and device of fuel coal smoke

InactiveCN101422691ALow flow resistanceReduce investmentProductsCarbon compoundsHigh concentrationDecarburization

The invention discloses a removal technology of removing coal-fired flue gas pollutants and a device thereof. The technology is as follows: an SCR denitration method is first used for removing NOX in the flue gas; then a dust collector is used for removing dusts and ash particles in the flue gas; then a wet calcium-based desulphurization method is used for removing SO2 in the flue gas; then an MEA decarburization process is used for absorbing the SO2 in the flue gas; simultaneously, a pregnant solution of a generated alkanolamine solution is heated, analyzed and regenerated and the generated barren solution of the alkanolamine solution is continuously and cyclically used; and the analyzed CO2 gas with high concentration is produced to be liquid carbon dioxide of industrial grade with high purity after being cooled, gas-liquid separated, dried, compressed and condensed. The device consists essentially of an SCR denitration reactor, the dust collector, a wet calcium-based desulphurization reactor, an MEA decarburization absorption tower, a regeneration tower, a gas-liquid separator, a dryer, a compressor, a condenser and the like which are connected with each other by pipes. The device has simple and compact overall design, low investment and operation costs, and stable and reliable work and can conduct classified integration processing and highly efficient simultaneous removal on every pollutant in the coal-fired flue gas.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

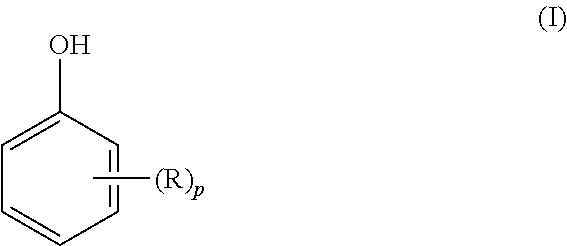

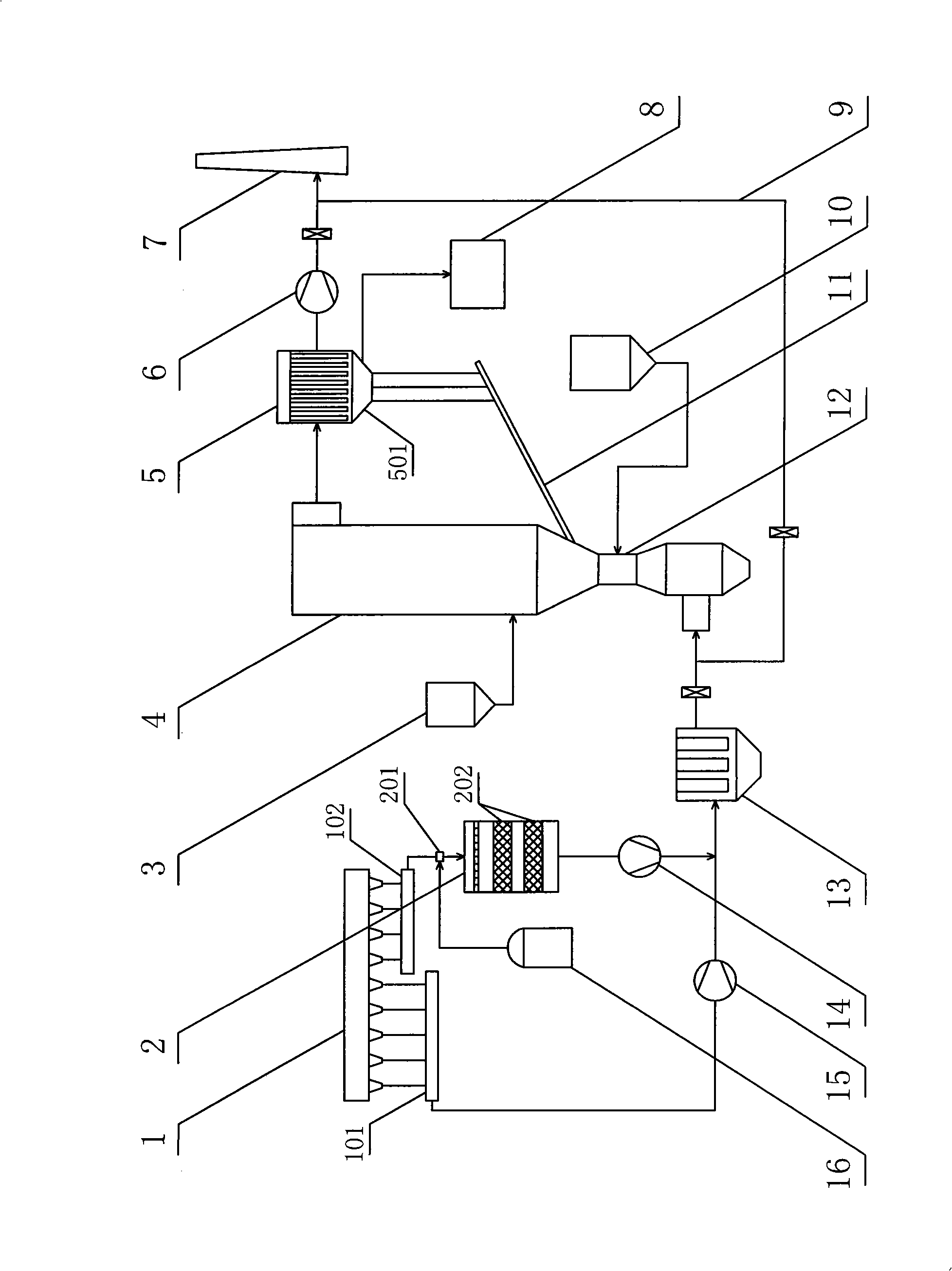

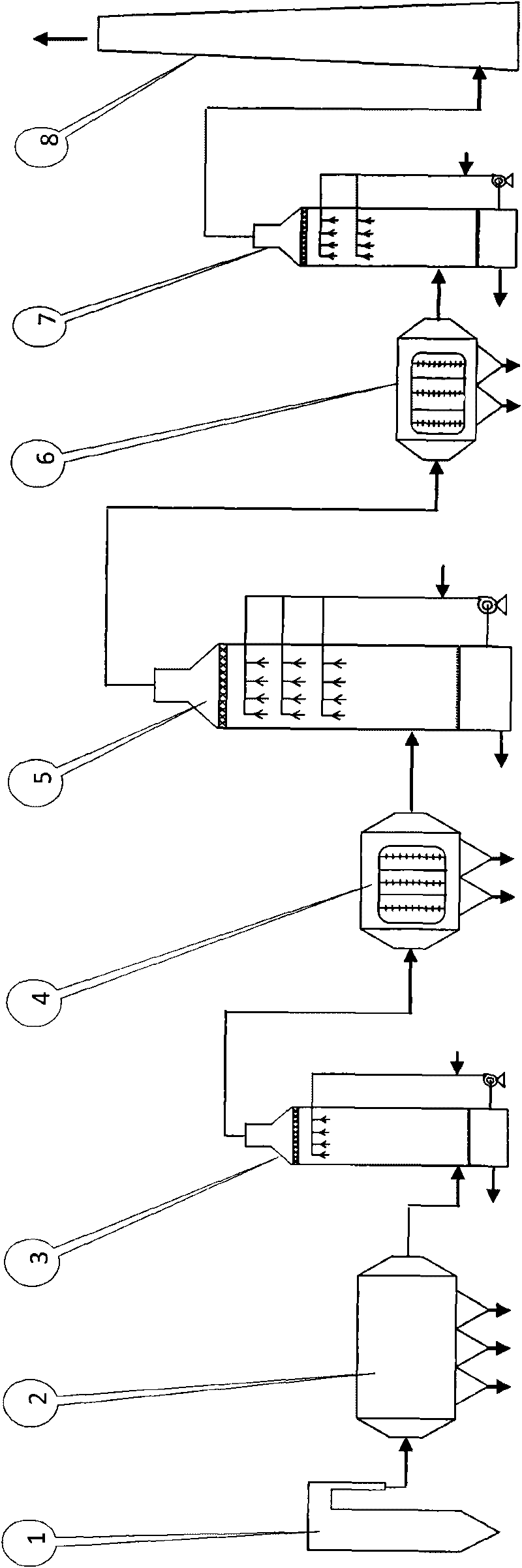

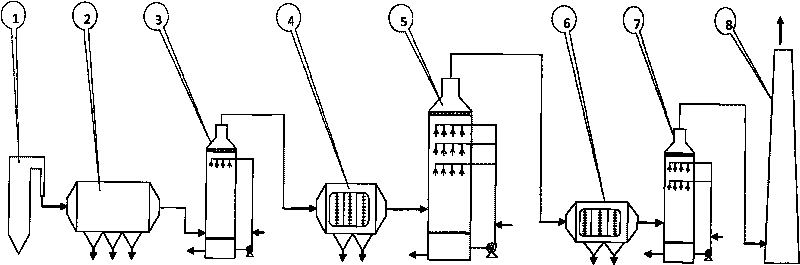

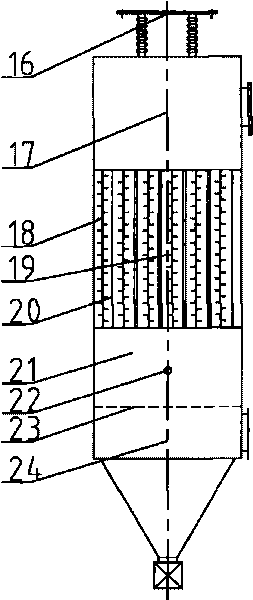

Sintering device flue gas multiple pollutant removing process and system thereof

ActiveCN101254394ALow flow resistanceReduce investmentDispersed particle filtrationElectrostatic separationFluidized bedMulti pollutant

The invention provides a process used for removing multiple contaminants in the off-gas of a sintering machine, as well as the system thereof. The process has the following steps: firstly, the machine tail off-gas undergoes SCR denitrification treatment; then, primary dedusting treatment is carried out to the denitrated machine tail off-gas and un-denitrated machine head off-gas at the same time, so as to remove the dust and ash particles in the off-gas; and then, circulating fluidized bed desulfurization treatment is carried out to the off-gas; finally, secondary dedusting treatment is carried out to the off-gas, so as to remove the resultant particles in the off-gas, the resultant particles are used for recycling, and the purified gas is separated out. The system thereof is mainly composed of a machine head off-gas header and a machine tail off-gas header which are used for collecting the machine head off-gas and the machine tail off-gas of the sintering machine, a SCR denitrification reactor which is used for removing the multiple contaminants in the off-gas, a primary dust remover, a circulating fluidized bed desulfurization reactor and a secondary dust remover. The process can carry out the classification integrated processing as well as the high efficient and synchronous removing to the sulfur dioxide, the nitrogen oxides and the dust in the sintering off-gas. The system has the characteristics of simple and compact whole design, low investment and running cost, and stable and reliable working.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

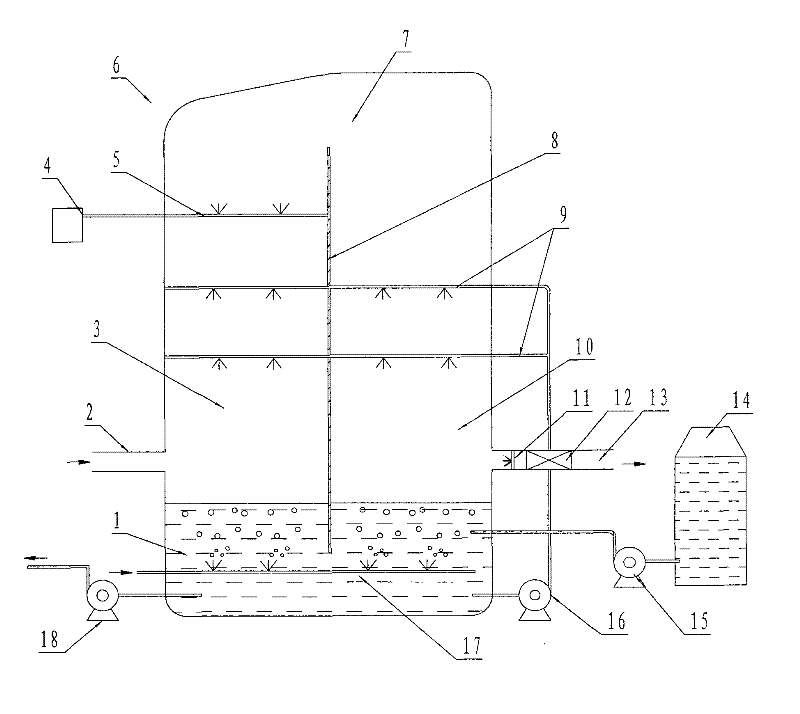

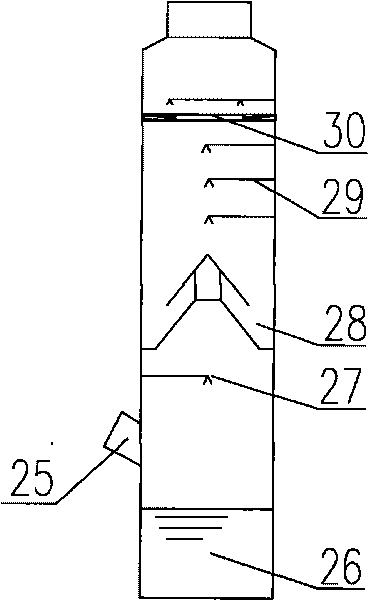

Method for removing various gaseous pollutants from smoke gas

InactiveCN101745305ASolve the problem of separate managementImprove mercury removal performanceDispersed particle separationAir quality improvementMulti pollutantSlurry

The invention provides a method for removing various gaseous pollutants from smoke gas, which is used for solving the problem of limitation of the control and government technology on various pollutants in the smoke gas. The invention utilizes an absorption tower for fully removing SO2, NOX, mercurial vapor and CO2 in the smoke gas, the lower part of the absorption tower is provided an absorptionpulp tank, the middle of the absorption tower is provided with a spraying pipe, the upper part of the absorption tower is provided with an oxidizing agent pipe, the absorption tower is provided with partition boards in the vertical direction, both sides of the partition boards are respectively a desulfurization work section and a denitration and decarburization work section, the upper part of theabsorption tower is a communication oxidization region, the smoke gas enters the desulfurization work section from an inlet of the absorption tower to complete the removal of SO2 and HCL, the smoke gas continuously goes upwards to enter the oxidization region, and NOX is oxidized into water-soluble high oxide in the oxidization region and then enters the denitration and decarburization work section to complete the removal of the NOX, the mercurial vapor and the CO2. The invention breaks through the technical bottlenecks of complicated equipment and high running cost for simultaneously removing various gaseous pollutants from the smoke gas in the prior art. The process method and the device of the invention have the unique novelty.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Medium treatment using ultraviolet light

ActiveUS8980178B2Reduce reflectionPromote absorptionCombination devicesAuxillary pretreatmentMulti pollutantMedicine

A system for treating a medium, such as water, with ultraviolet light is provided. The system can include an ultraviolet treatment chamber that is shaped to reduce reflections of the ultraviolet light within the ultraviolet treatment chamber and / or improve absorption of the ultraviolet light by the medium. Furthermore, the system can add an agent to the medium within the treatment chamber to further treat one or more contaminants that may be present within the medium. Still further, additional treatment, such as filtering the medium with a permeable material can be implemented within the treatment system.

Owner:SENSOR ELECTRONICS TECH

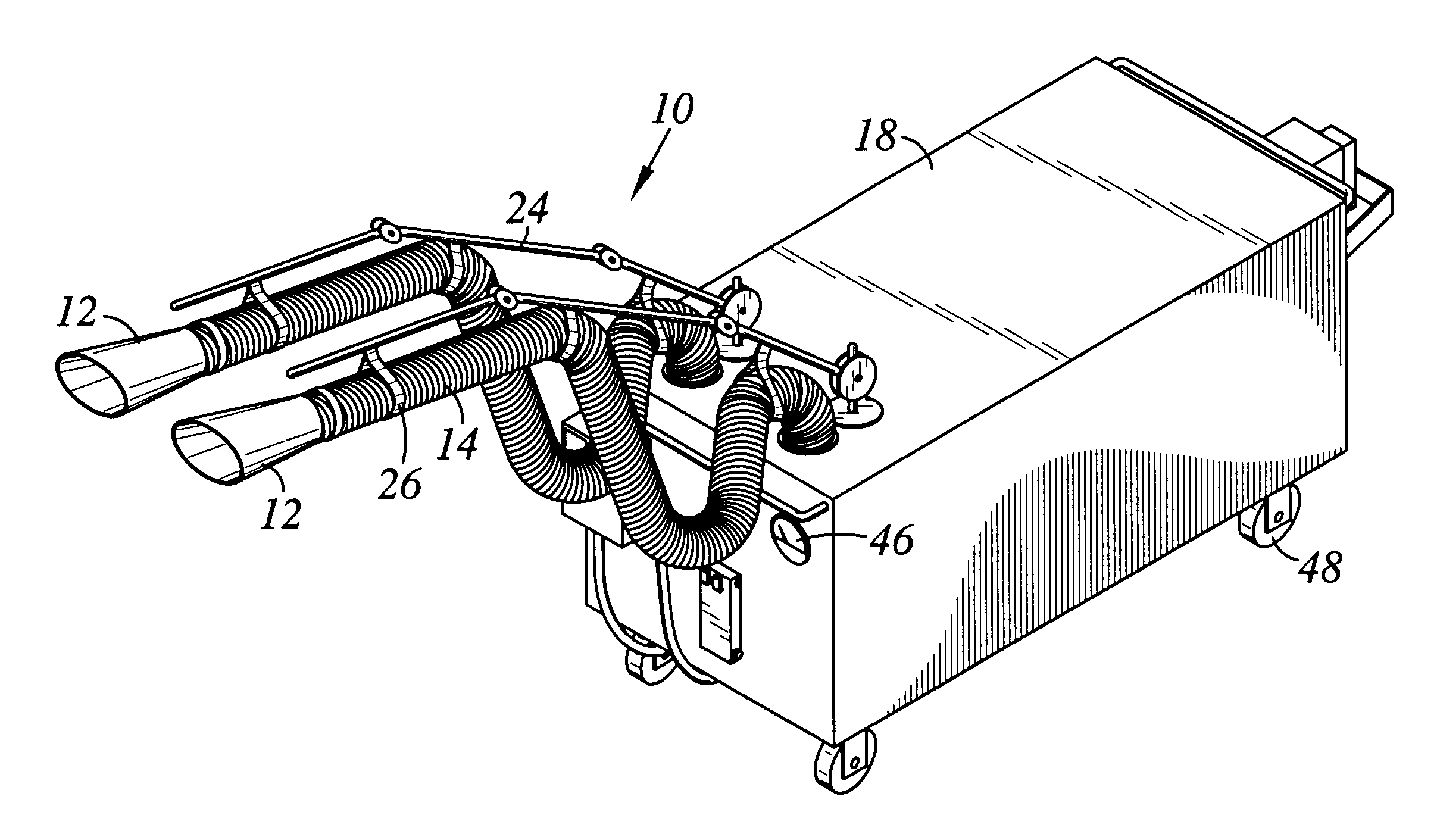

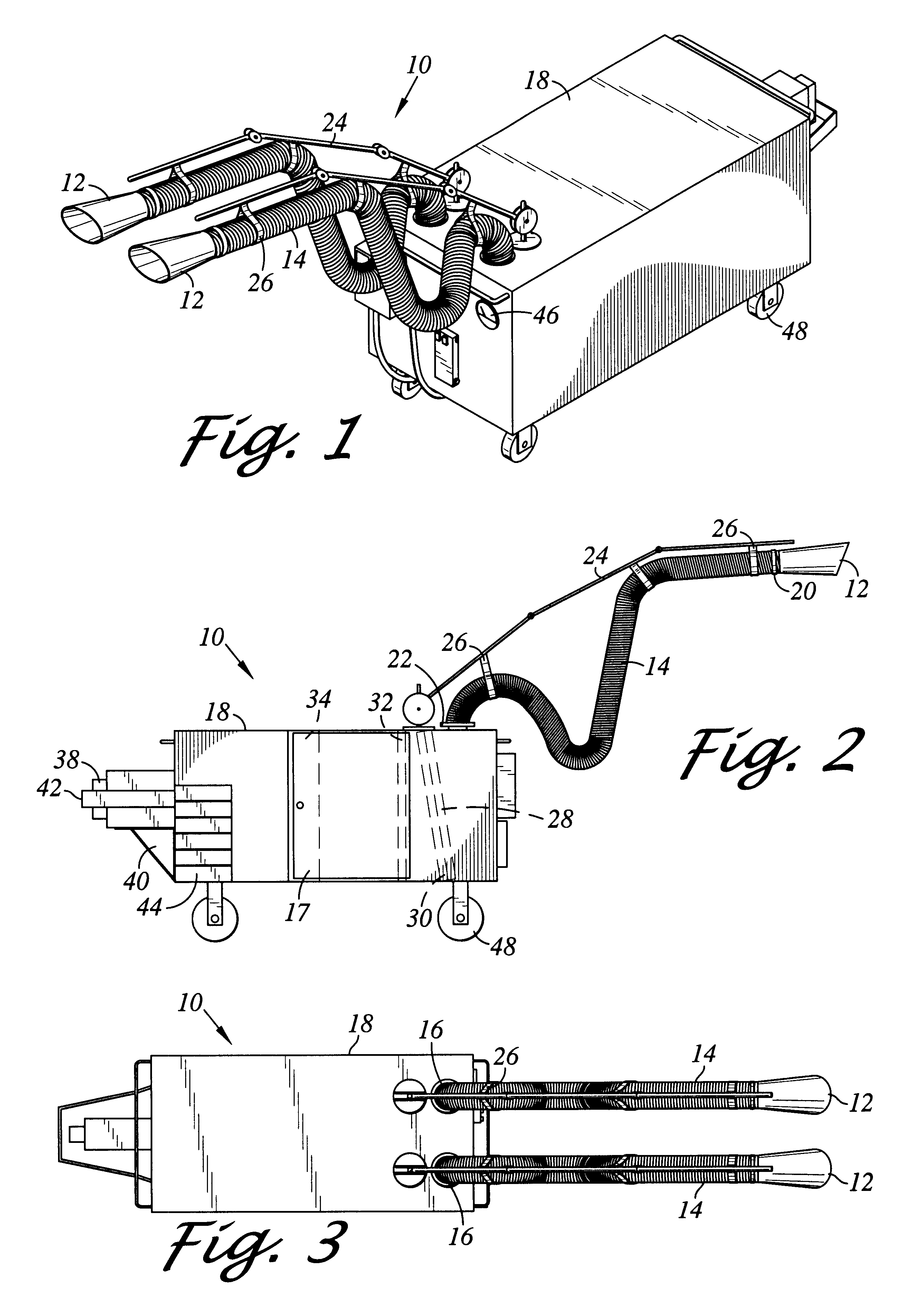

Portable air pollution control apparatus

An air pollution control apparatus usable for capturing airborne pollutants present in a relatively confined environment. The apparatus is a portable airborne-pollutant capturing device movable to a site of pollutant origin and having at least one airborne-pollutant collector member, a vacuum system, and a filter system. The filter system can include one filter or more than one identical or different filters chosen for enhanced filtration capabilities in relation to pollutants present. Preferably, more than one type of filter can be accommodated simultaneously to thereby capture multiple pollutants. Fugitive particulate is captured by positioning the airborne-pollutant collector member proximate the activity causing pollution, and operating the collector member simultaneously with the polluting activity to thereby cause particulate to be captured by the filter system.

Owner:NORTHROP GRUMMAN SYST CORP

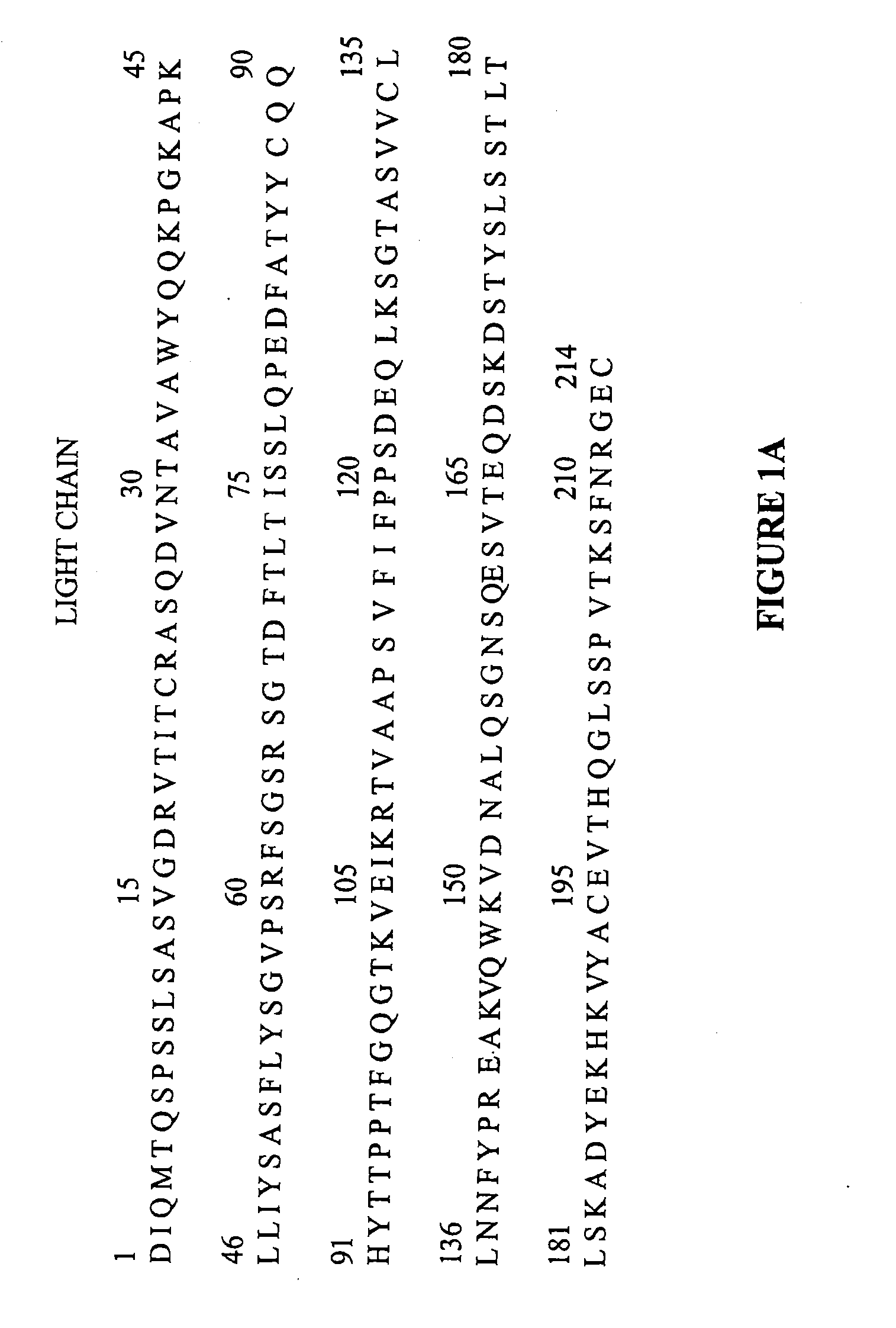

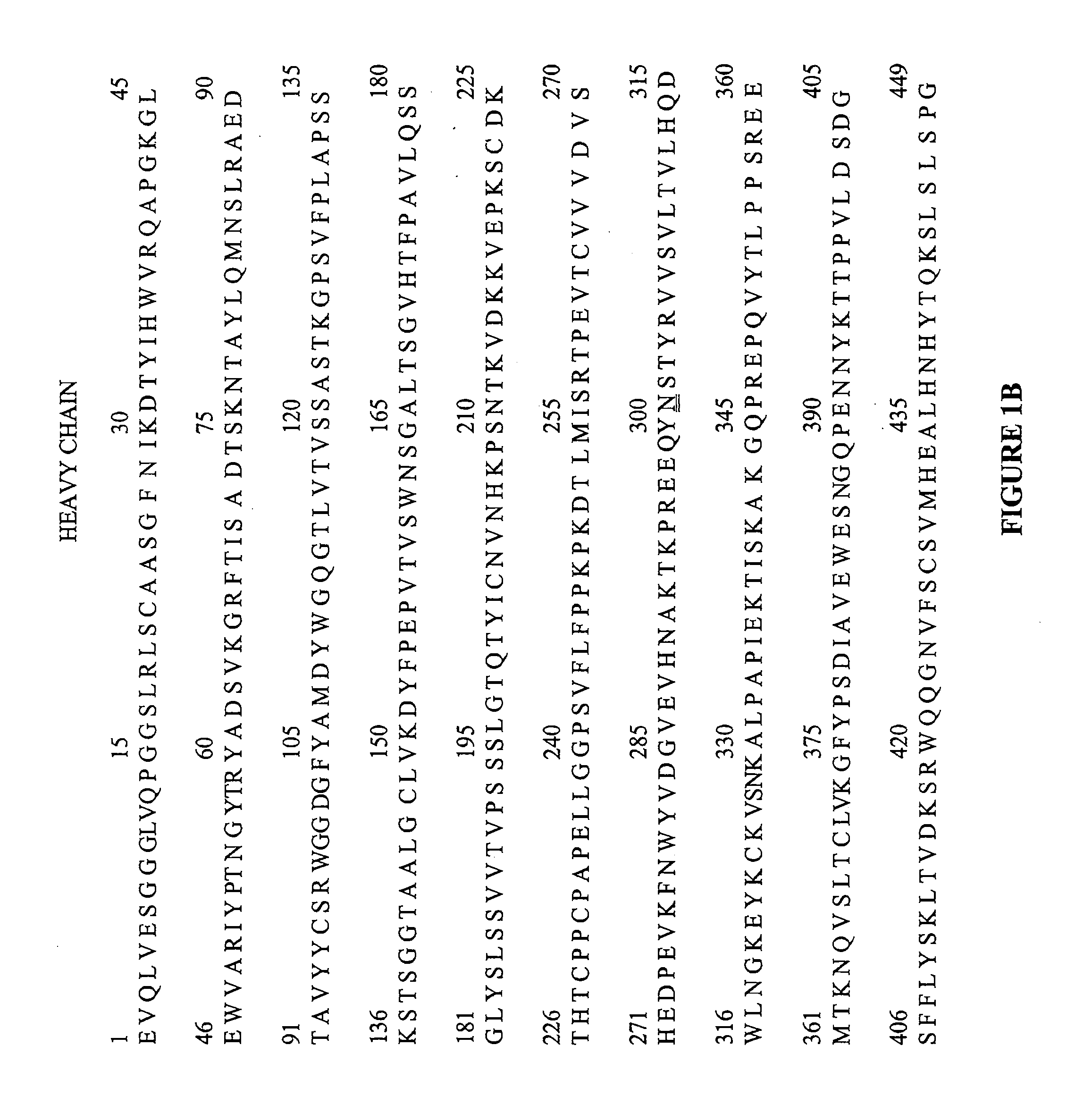

Protein purification

InactiveUS20050063972A1High recovery ratePeptide/protein ingredientsSerum immunoglobulinsMulti pollutantIon exchange

A method for purifying a polypeptide by ion exchange chromatography is described which involves changing the conductivity and / or pH of buffers in order to resolve a polypeptide of interest from one or more contaminants.

Owner:GENENTECH INC

Process for removing a target gas from a mixture of gases by thermal swing adsorption

The separation of a target gas from a mixture of gases using a thermal swing adsorption process wherein a thermal wave is used, primarily in the desorption step. The process of this invention enables one to separately remove multiple contaminants from a treated gaseous stream.

Owner:EXXON RES & ENG CO

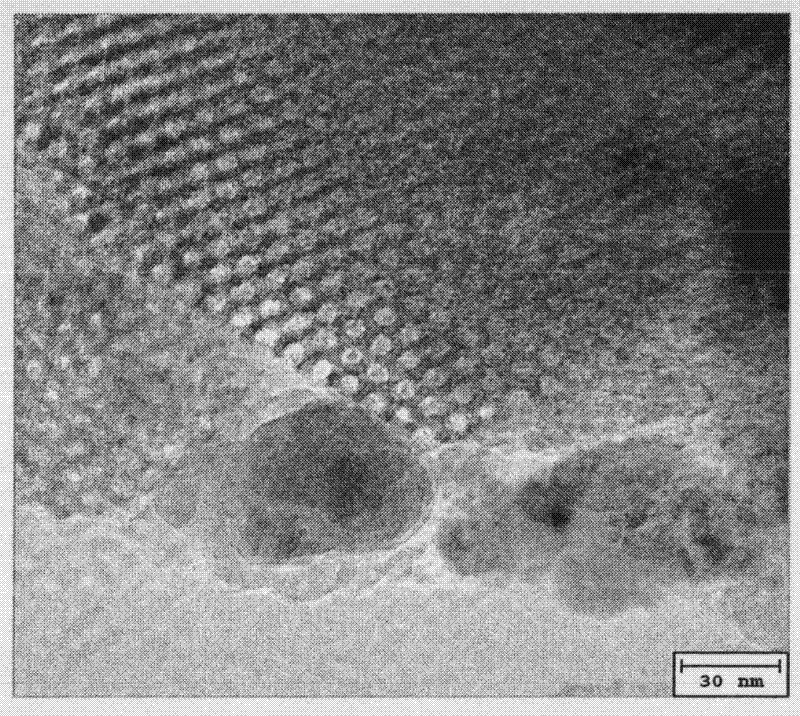

Catalyst with meso pore characteristics and application thereof

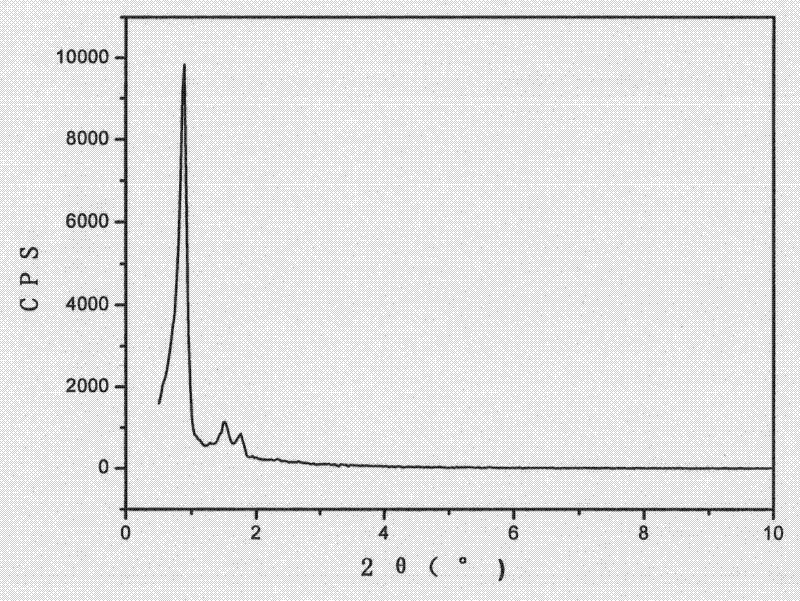

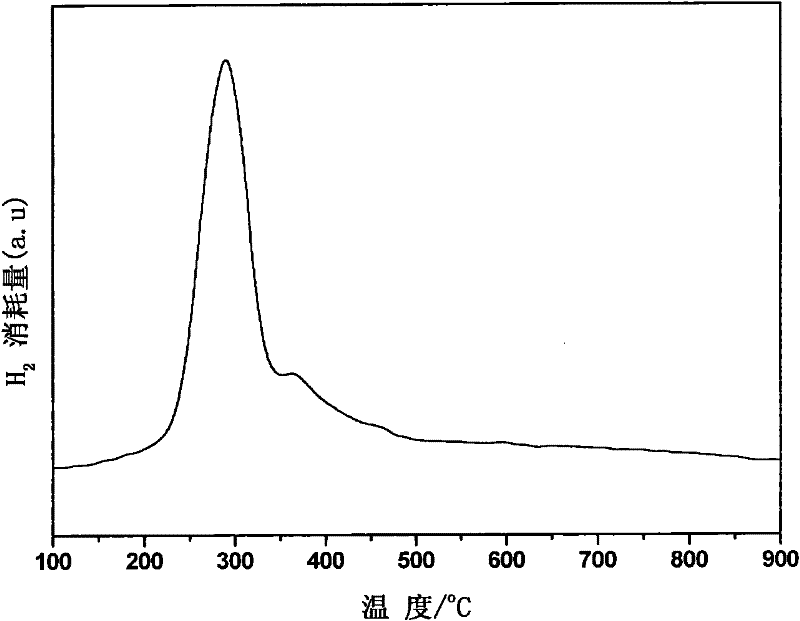

InactiveCN102240570AGood dispersionHigh catalytic activityMolecular sieve catalystsDispersed particle separationAdditive ingredientMulti pollutant

The invention discloses a catalyst with meso pore characteristics and an application thereof. The catalyst with meso pore characteristics is produced by loading ingredients with catalytic activity onto the inner tunnel surface of a meso pore molecular sieve carrier, wherein the meso pore molecular sieve carrier contains one or more elements selected from the group consisting of MCM-41, MCM-48, SBA-15, SBA-16, KIT-5 and KIT-6 with the aperture being from 2nm to 50nm; and the active ingredients contain one or more elements selected from the group consisting of Co, Fe, Ni, Mn, Cr, Ti, Cu, Mg, Nb, Ta, Mo, W, Zn, Zr, Ru, Ag, Au, Ru, Rh, Pt, Re, Al, W, Ga, Ge, Sn, Sb and metal oxide thereof. The catalyst with meso pore characteristics can be applied to the catalytic purification of tail gases containing nitrogen oxide. The catalyst provided by the invention has high catalytic activity and is suitable for a plurality of pollutants; in addition, the active ingredients of the catalyst are fixed so as to avoid loss, volatilization and high-temperature sintering.

Owner:BEIJING UNIV OF CHEM TECH

Filter and sorbent for removal of contaminants from a fluid

InactiveUS7378372B2Lower Level RequirementsForgiving fluctuationWater contaminantsTreatment involving filtrationActivated carbonPesticide residue

Owner:SOLMETEX

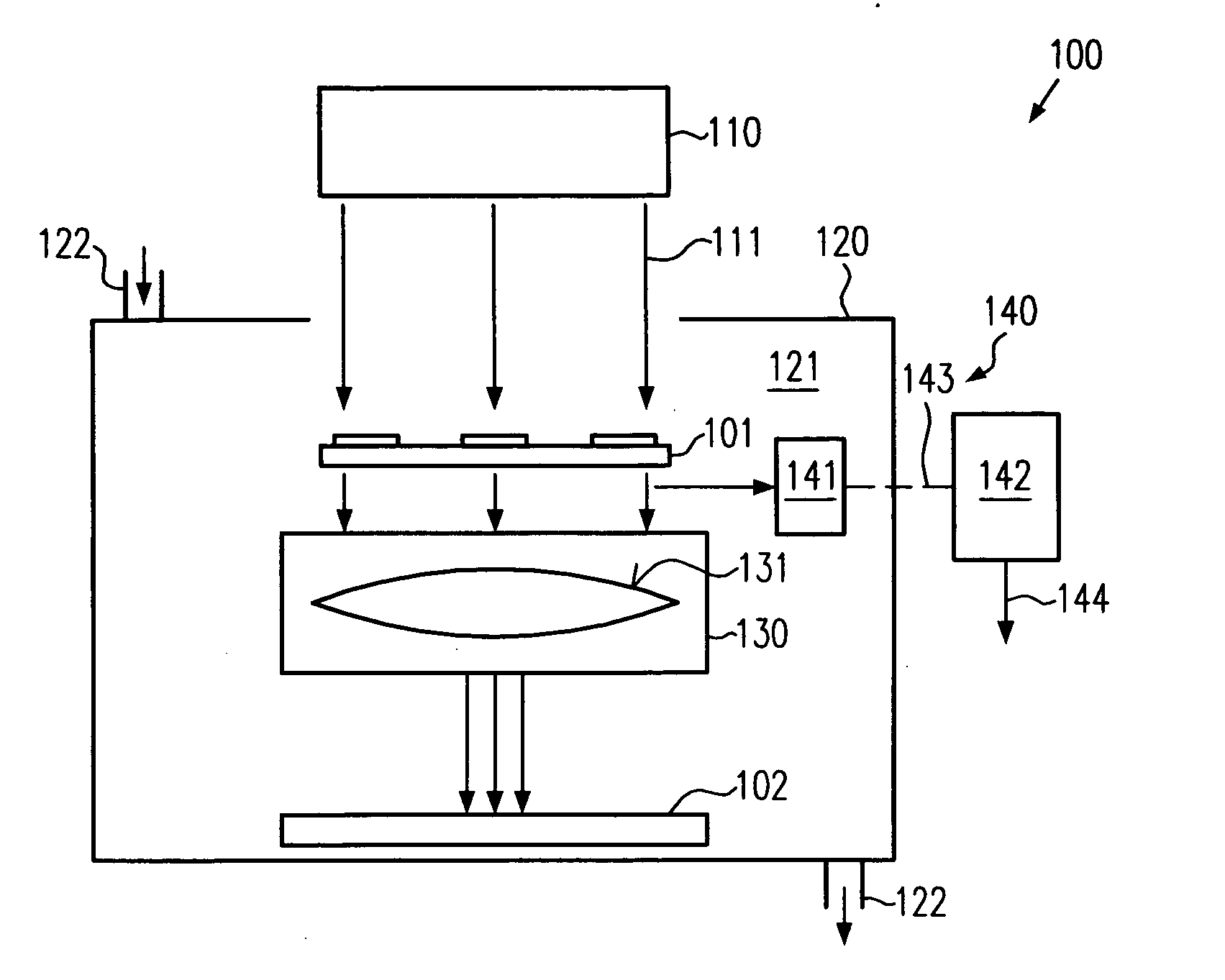

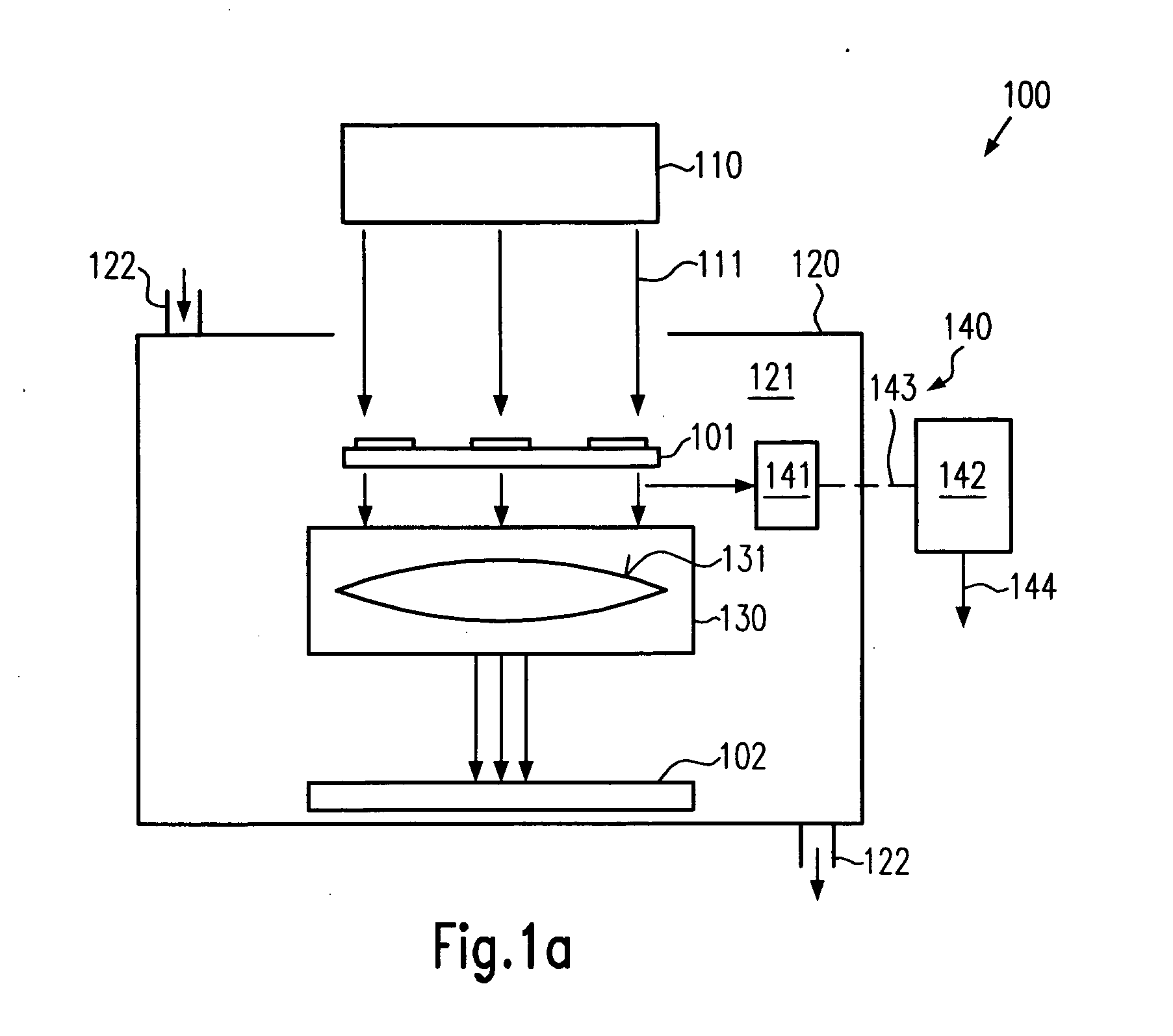

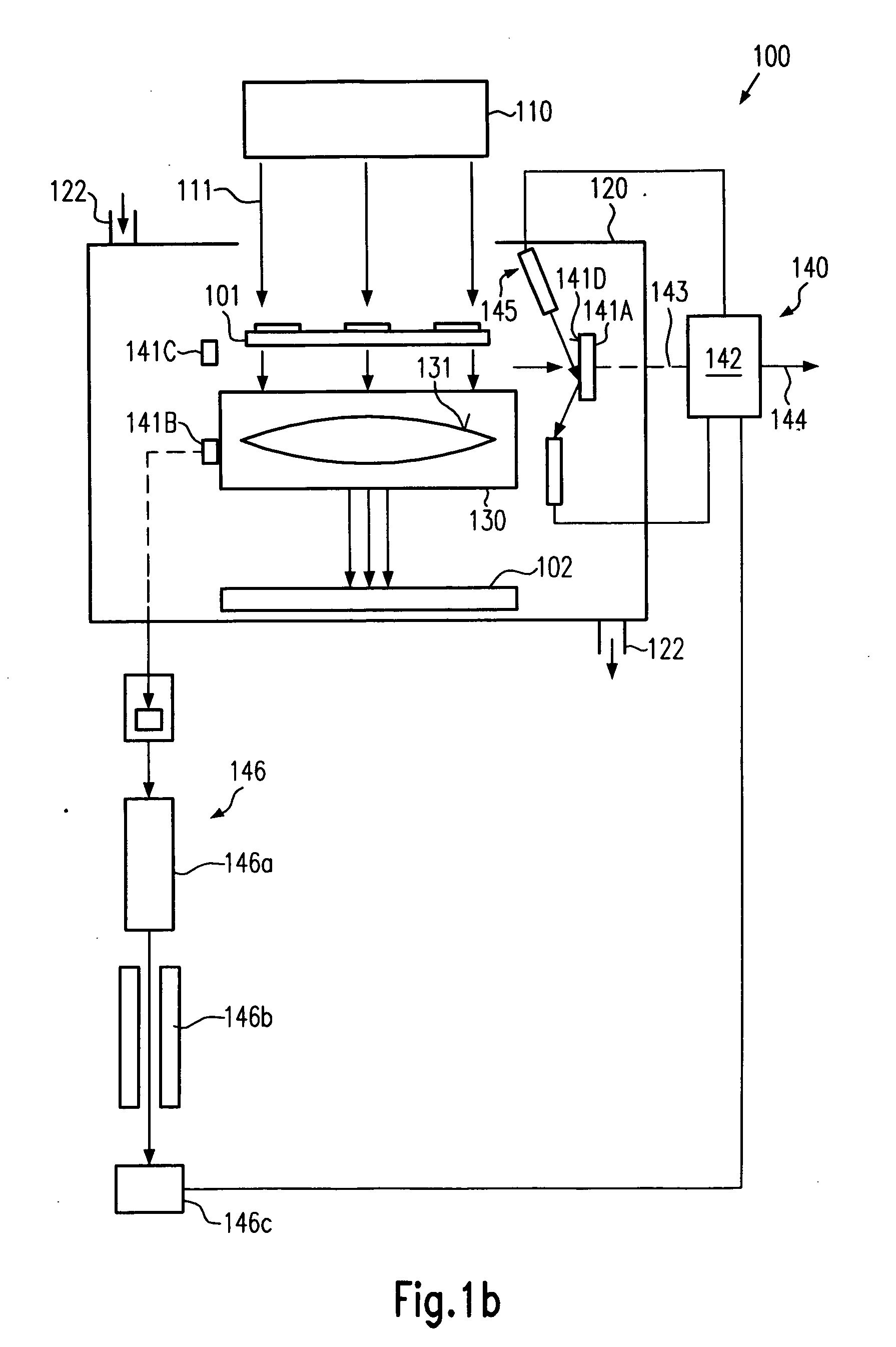

Method and system for contamination detection and monitoring a lithographic exposure tool and operating method for the same under controlled atmospheric conditions

InactiveUS20060066824A1Reduce impactPhotomechanical apparatusMaterial analysis by optical meansInorganic saltsMulti pollutant

By using highly efficient detection techniques, such as chromatography and absorption spectroscopy, one or more contaminants may be identified and the concentration thereof may quantitatively be determined. In this way, the adverse effect on critical components of exposure tools, such as reticles and lenses in the form of, for instance, deposited inorganic salts, may significantly be reduced and the process performance may be enhanced.

Owner:ADVANCED MICRO DEVICES INC +1

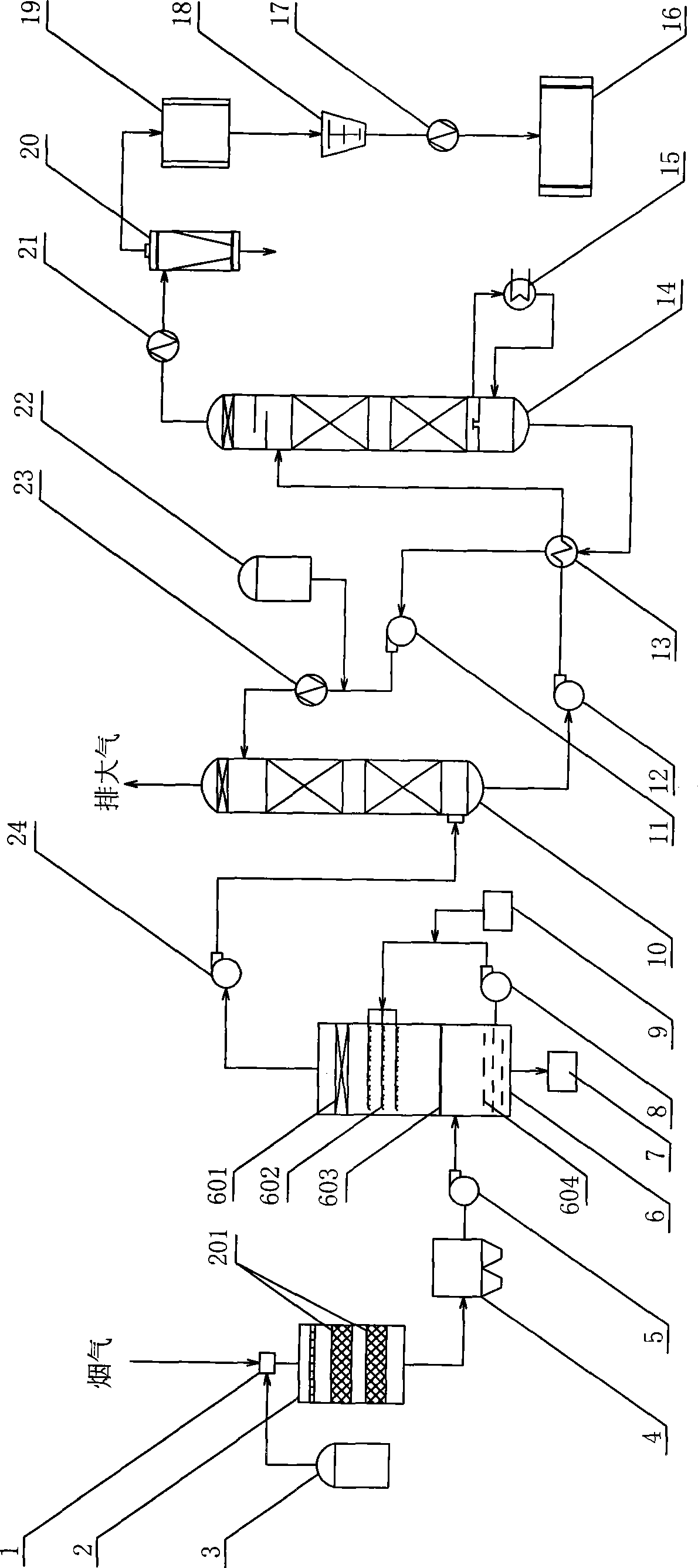

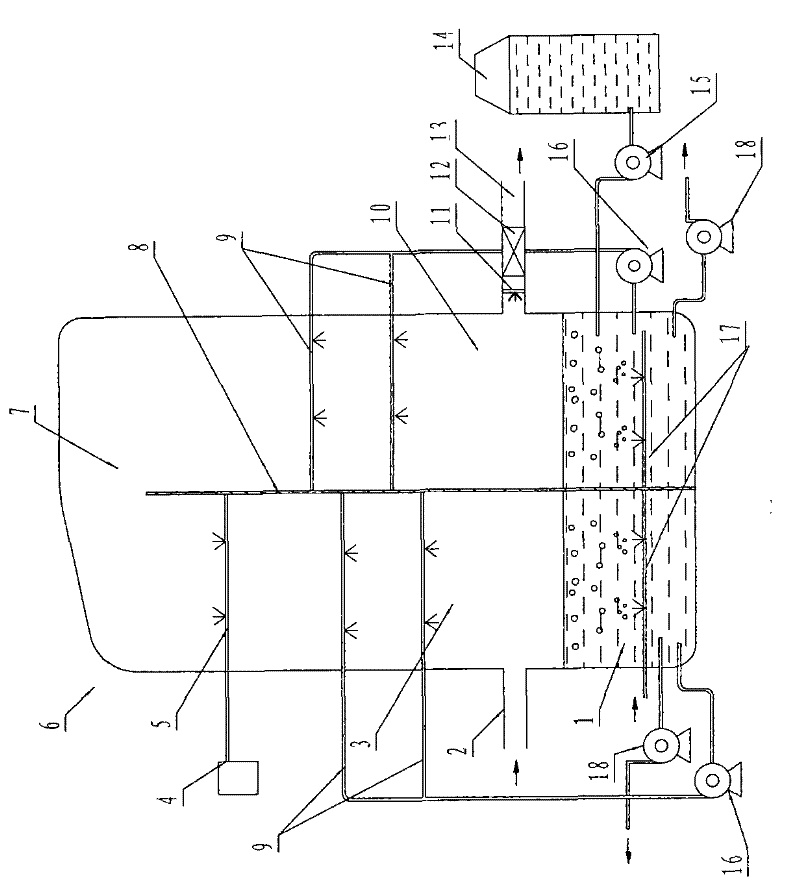

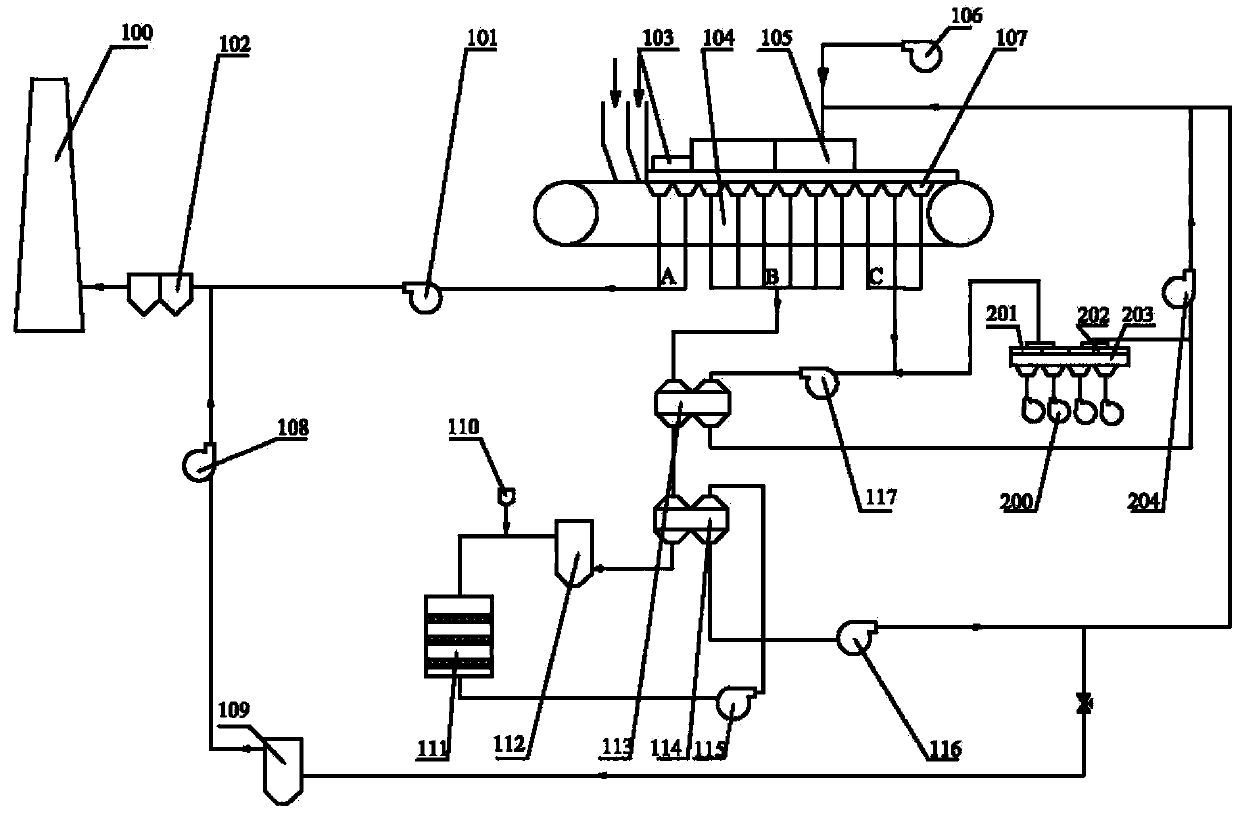

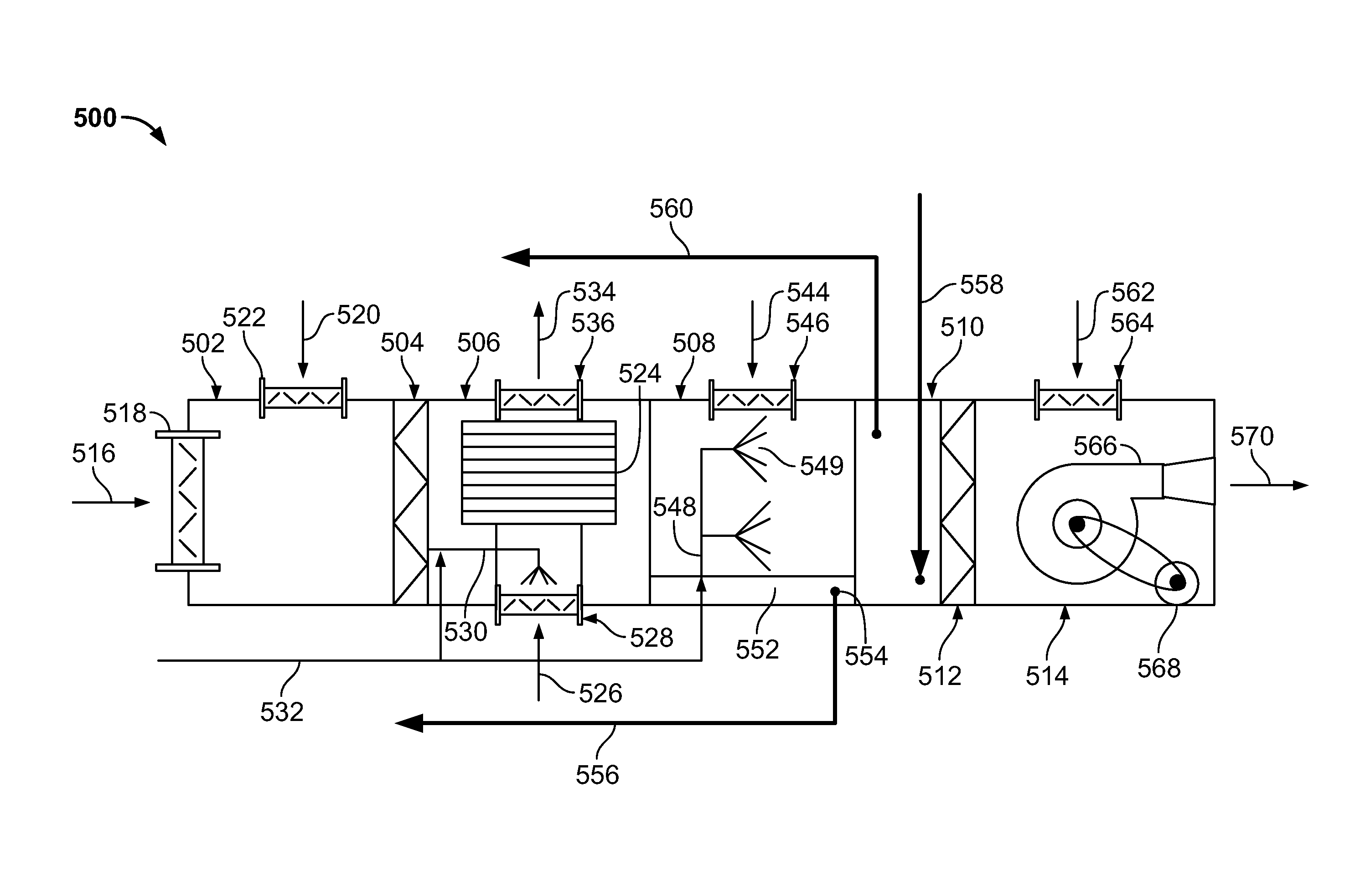

Sintering energy-saving technique and system capable of removing multiple pollutants

InactiveCN104195326ACompact structureOptimize layoutDispersed particle separationAir quality improvementSinter PlantMulti pollutant

The invention discloses a sintering energy-saving technique capable of removing multiple pollutants. Flue gas discharged by a sintering wind box on the lower part of a sintering machine is sequentially divided into section A flue gas positioned at the head of the sintering machine, section B flue gas positioned in the middle of the sintering machine, and section C flue gas positioned at the tail of the sintering machine; the section A flue gas is discharged after being subjected to dust removal treatment; and the section C flue gas is used for preheating the section B flue gas, the preheated section B flue gas is denitrified and divided into two parts, one part is discharged after being subjected to desulfurization treatment, and the other part is sent into the sintering machine together with the section C flue gas to perform circulating sintering. The invention also discloses a sintering energy-saving system capable of removing multiple pollutants. The technique and system can treat dust, oxynitrides, sulfur dioxide, fluorides, heavy metals and many other pollutants in the sintering flue gas, can utilize the excess heat of the flue gas of the main flue of the sintering machine and the flue gas discharged by the cooling machine, and can lower the energy consumption of the sintering plant, thereby implementing energy saving and emission reduction.

Owner:ZHEJIANG UNIV

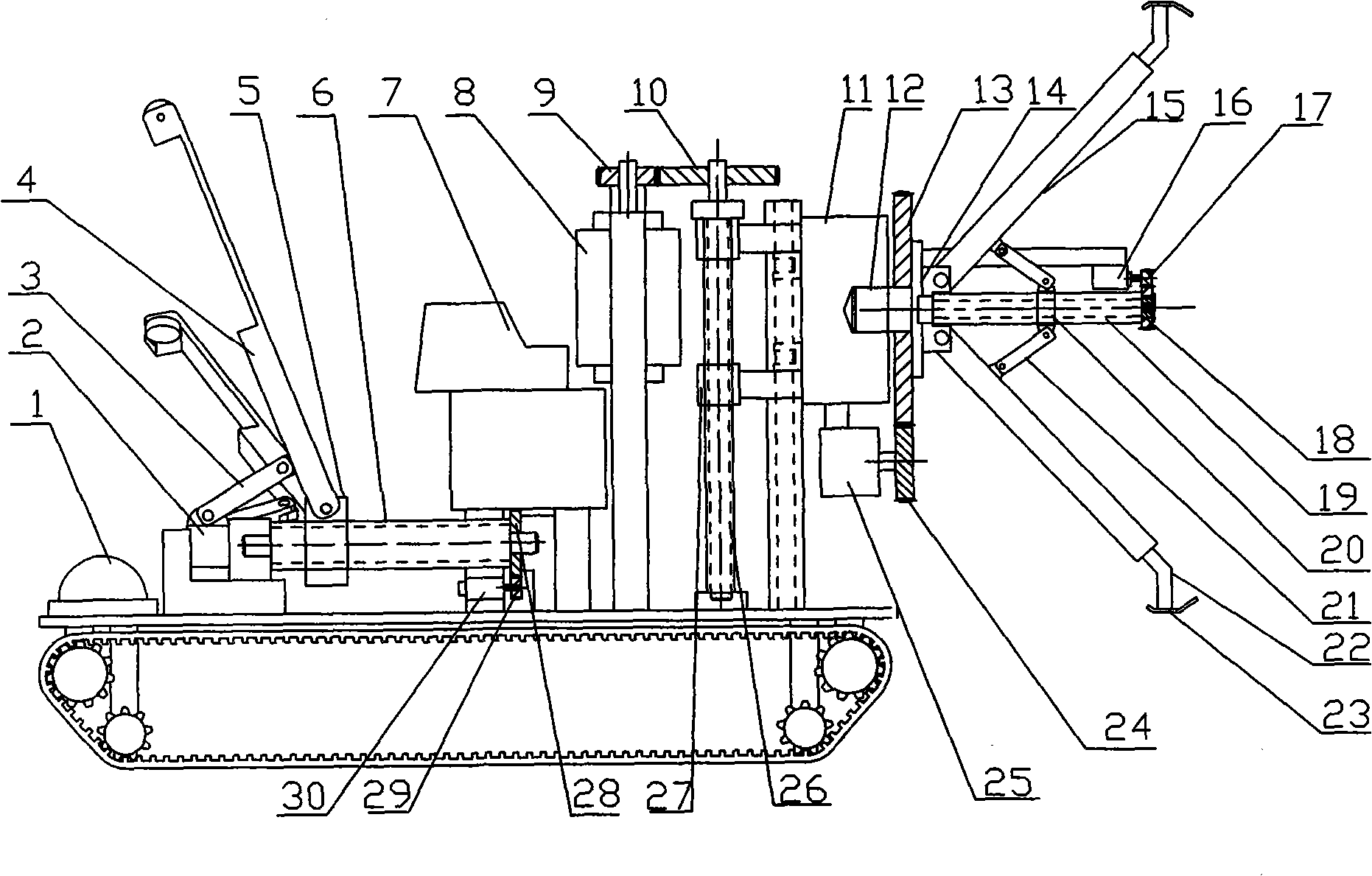

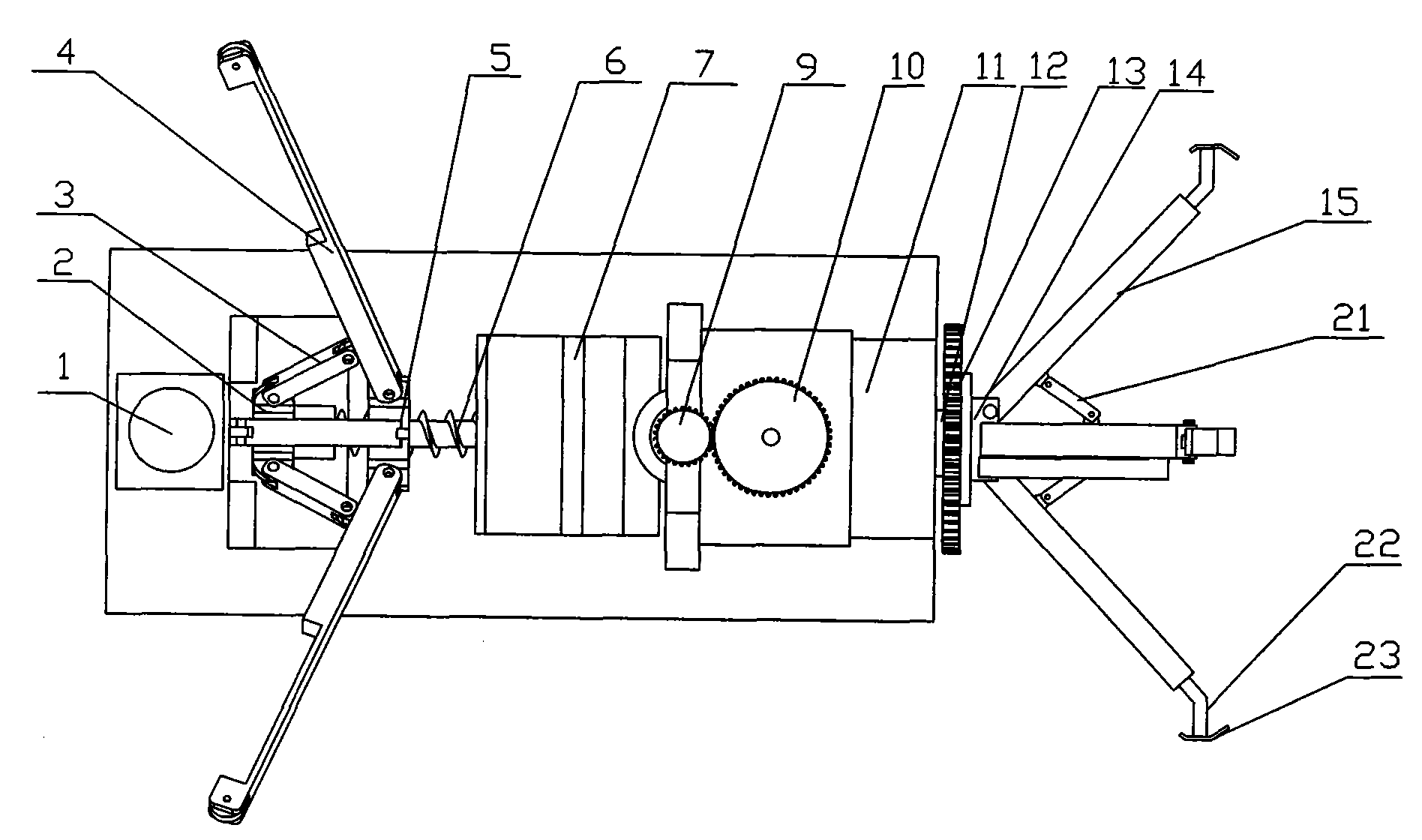

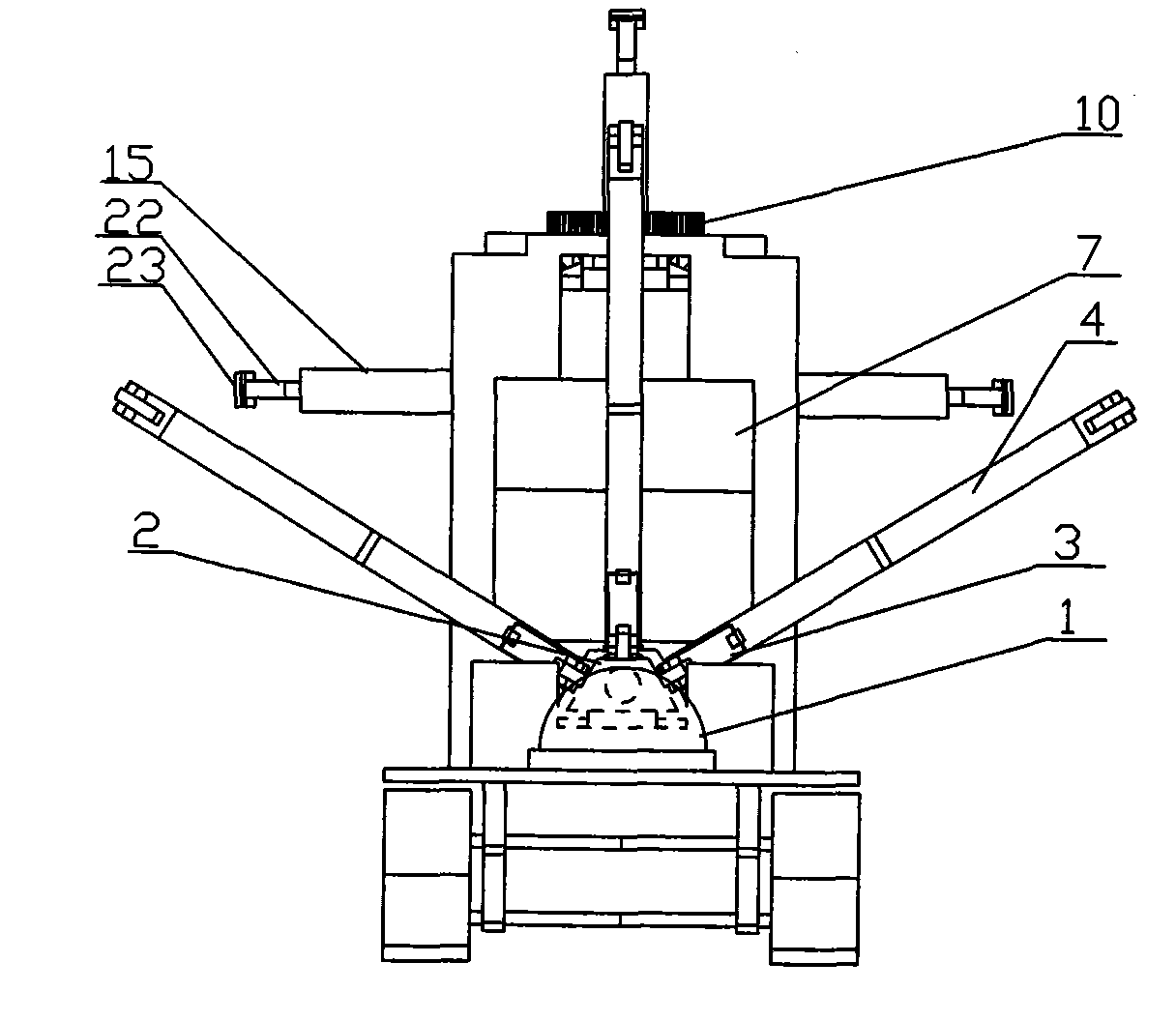

Robot for cleaning and detecting pipes

InactiveCN101537614ACleaning satisfactionComplete efficientlyHollow article cleaningCleaning using toolsControl systemMulti pollutant

The invention relates to a robot for cleaning and detecting pipes. The robot comprises a mechanical system and a control system. The mechanical system is provided with a moving trolley and a cleaning operation device positioned on the trolley; the tail part of the moving trolley is provided with a detection device and a positioning guiding device, the detection device is a camera (1) and the positioning guiding device is a device capable of causing the trolley to advance in parallel; and the cleaning operation device comprises a cleaning arm (15), a cleaning arm lifting mechanism positioned at the front of the moving trolley, a cleaning arm opening-closing mechanism positioned on a second operating platform (14) and a cleaning brush mechanism positioned at the front end of the cleaning arm, the cleaning brush mechanism is provided with four small brushes (23) and a pressure sensor (22), and various small brushes are always in close contact with inner walls of the pipes by synchronous detection and feedback adjustment of the pressure sensor. The robot has the advantages of large effective working area, being capable of cleaning off a plurality of pollutants, no whipping and low cost, and being suitable for cleaning operation of a plurality of round pipes including pipes with changing pipe diameters and being capable of prolonging service life of the pipes.

Owner:WUHAN UNIV OF TECH

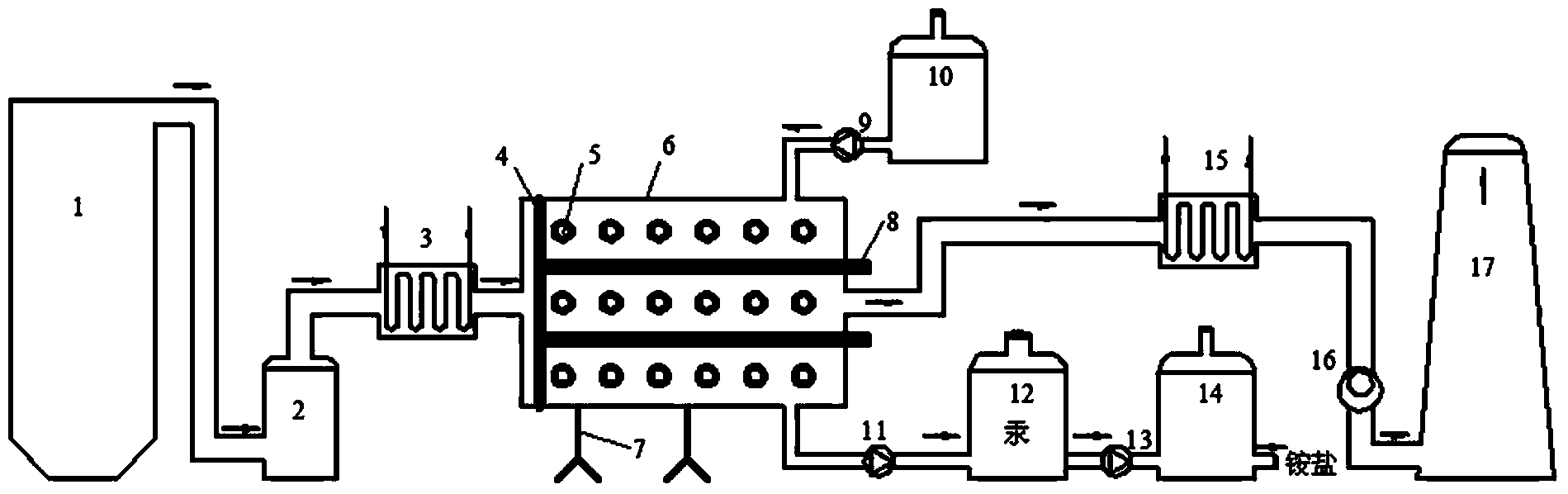

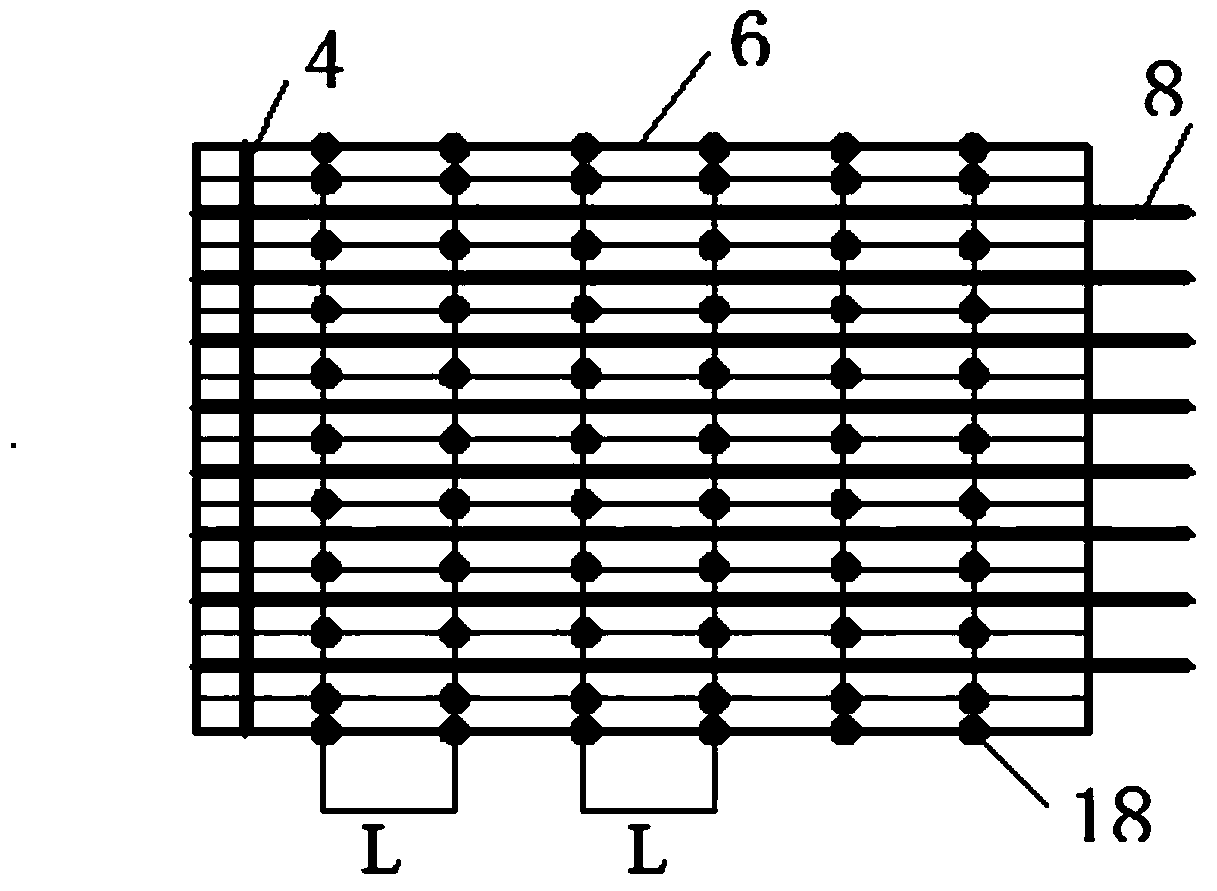

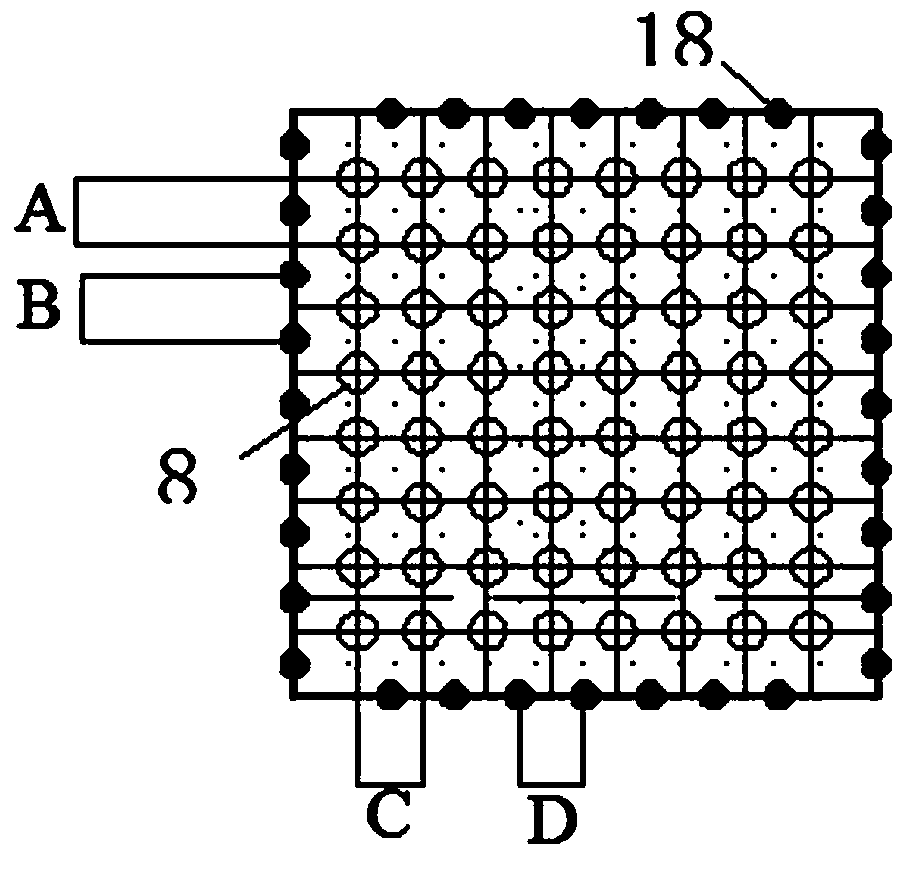

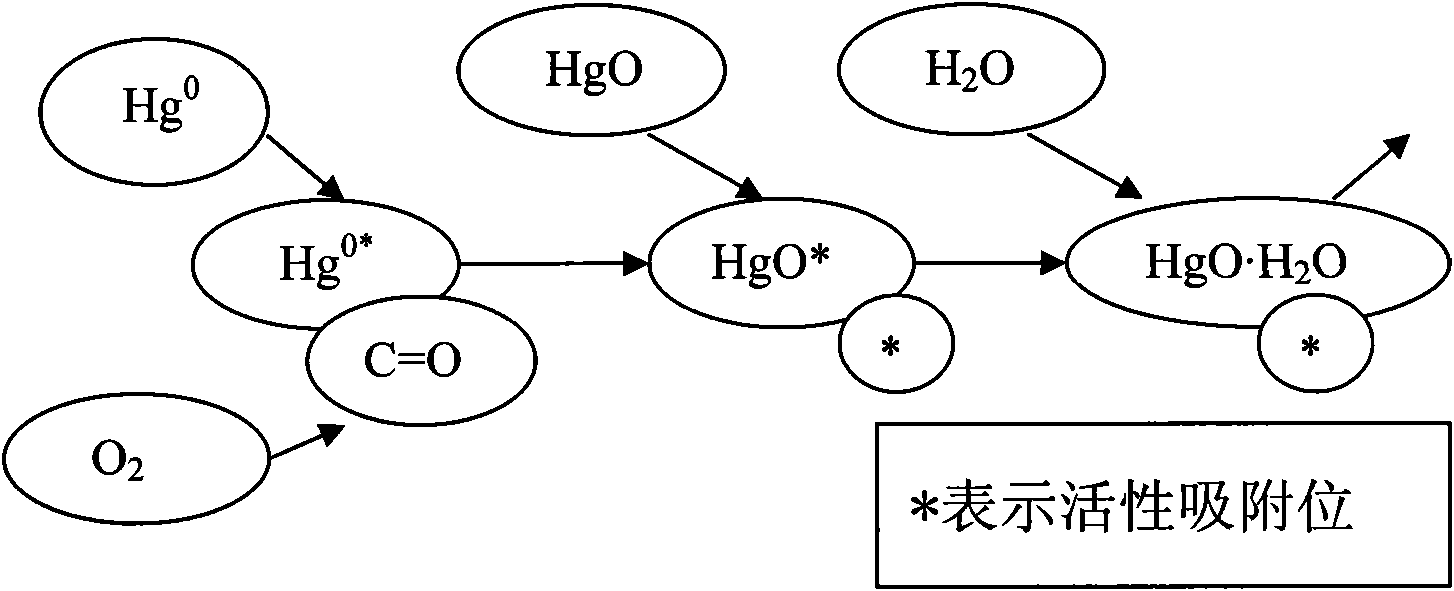

System and method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate

ActiveCN103638796ALow investment costLow running costDispersed particle separationAir quality improvementSulfate radicalsResource utilization

The invention discloses a system and a method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate. The system is mainly provided with a boiler or kiln, a deduster, a flue gas temperature regulator, a photochemistry reactor, a liquid spraying system as well as a byproduct post-processing system. Flue gas discharged from the boiler or kiln enters the photochemistry reactor arranged on a flue channel after being subjected to dedusting and temperature regulation, and an ammonium persulfate solution from the liquid spraying system is sprayed into the photochemistry reactor in a mist form; an UV (ultraviolet) lamp in the photochemistry reactor emits UV light to perform catalytic decomposition on ammonium persulfate, releases sulfate radical free radicals with high oxidizing property (SO4-.), and meanwhile oxidizes and removes SO2, NOx and mercury in the flue gas. Oxidized products are subjected to resource utilization after being processed by the byproduct post-processing system. The method has the prominent advantages that the method can be used for removing multiple pollutants in coal burned flue gas synchronously, has no secondary pollution during removing, and can be used for transforming aging units and the like, and the system is a novel flue gas purifying system with a wide application prospect.

Owner:JIANGSU UNIV

Sorbent for removal of contaminants from fluids

InactiveUS20070080115A1Reduce level of contaminantEconomical and simpleWater contaminantsTreatment involving filtrationActivated carbonPesticide residue

Owner:SOLMETEX

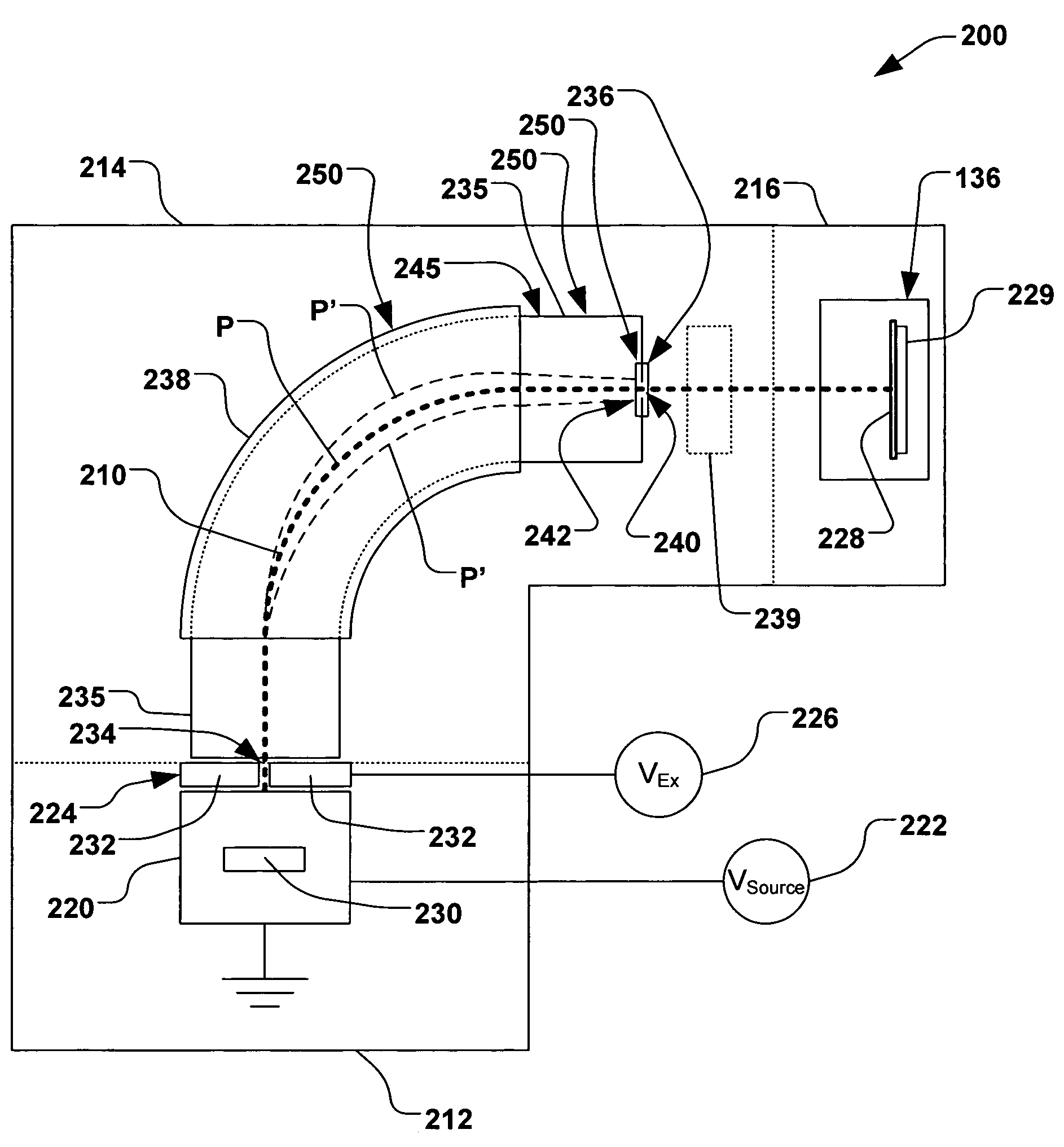

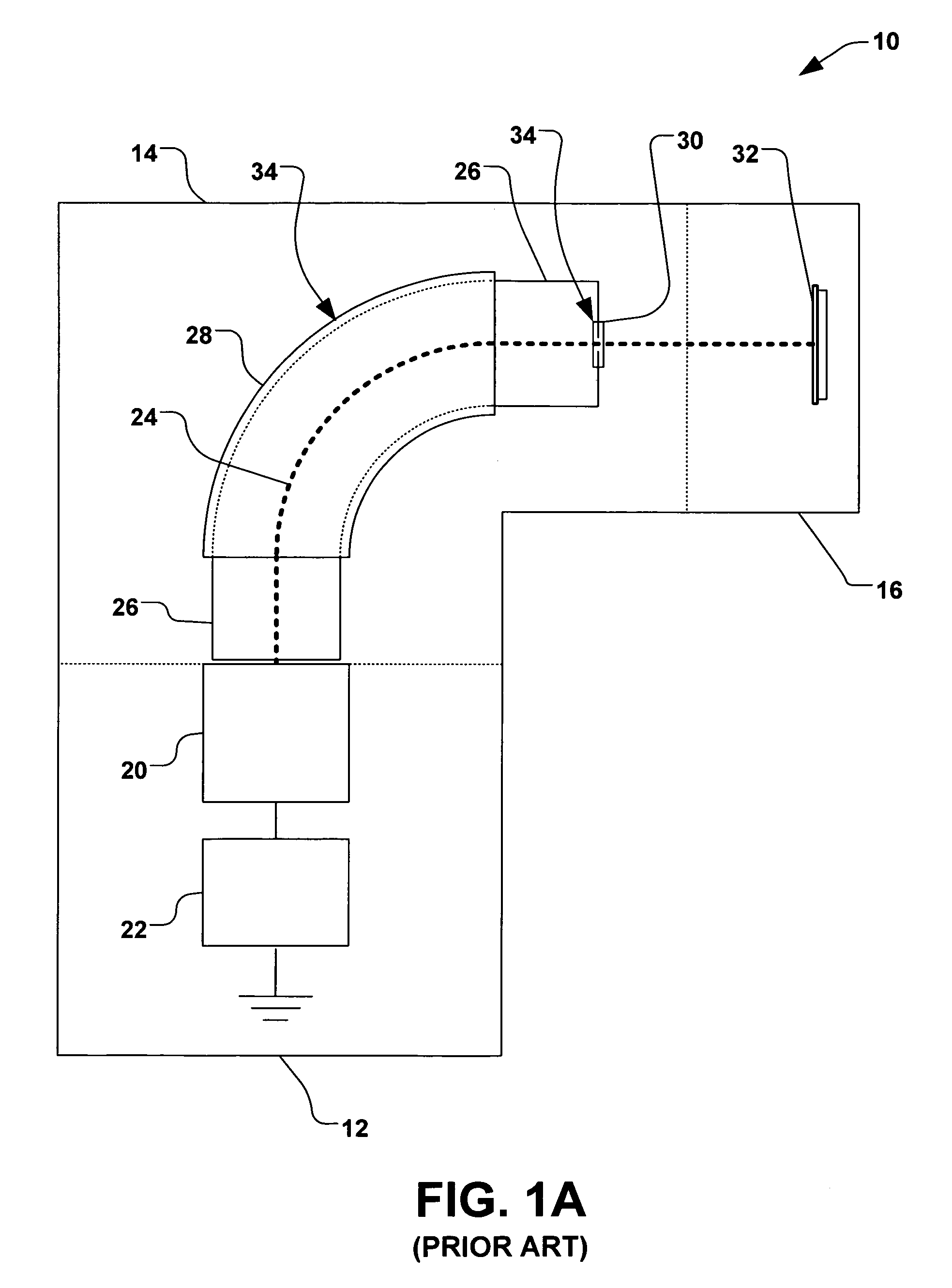

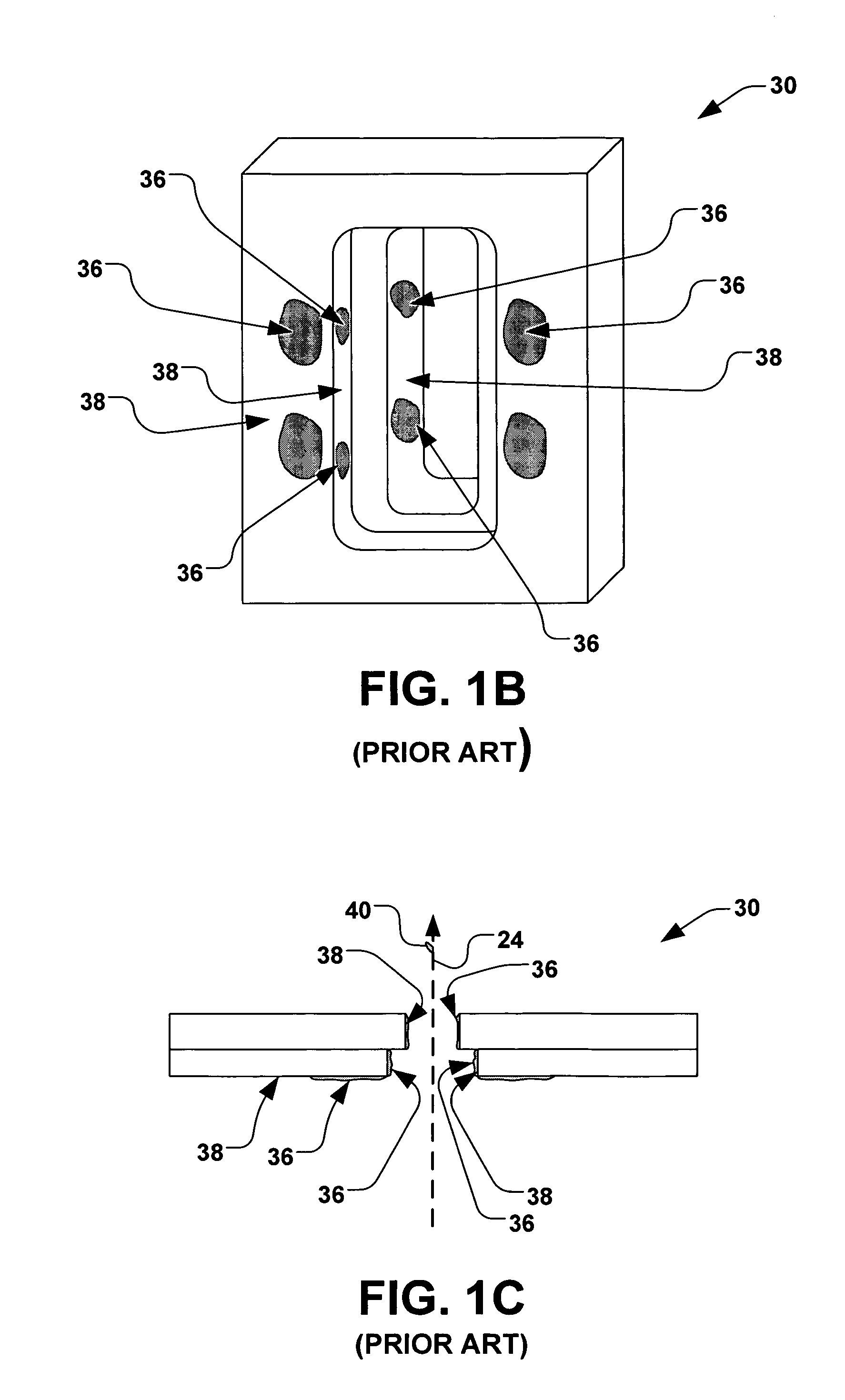

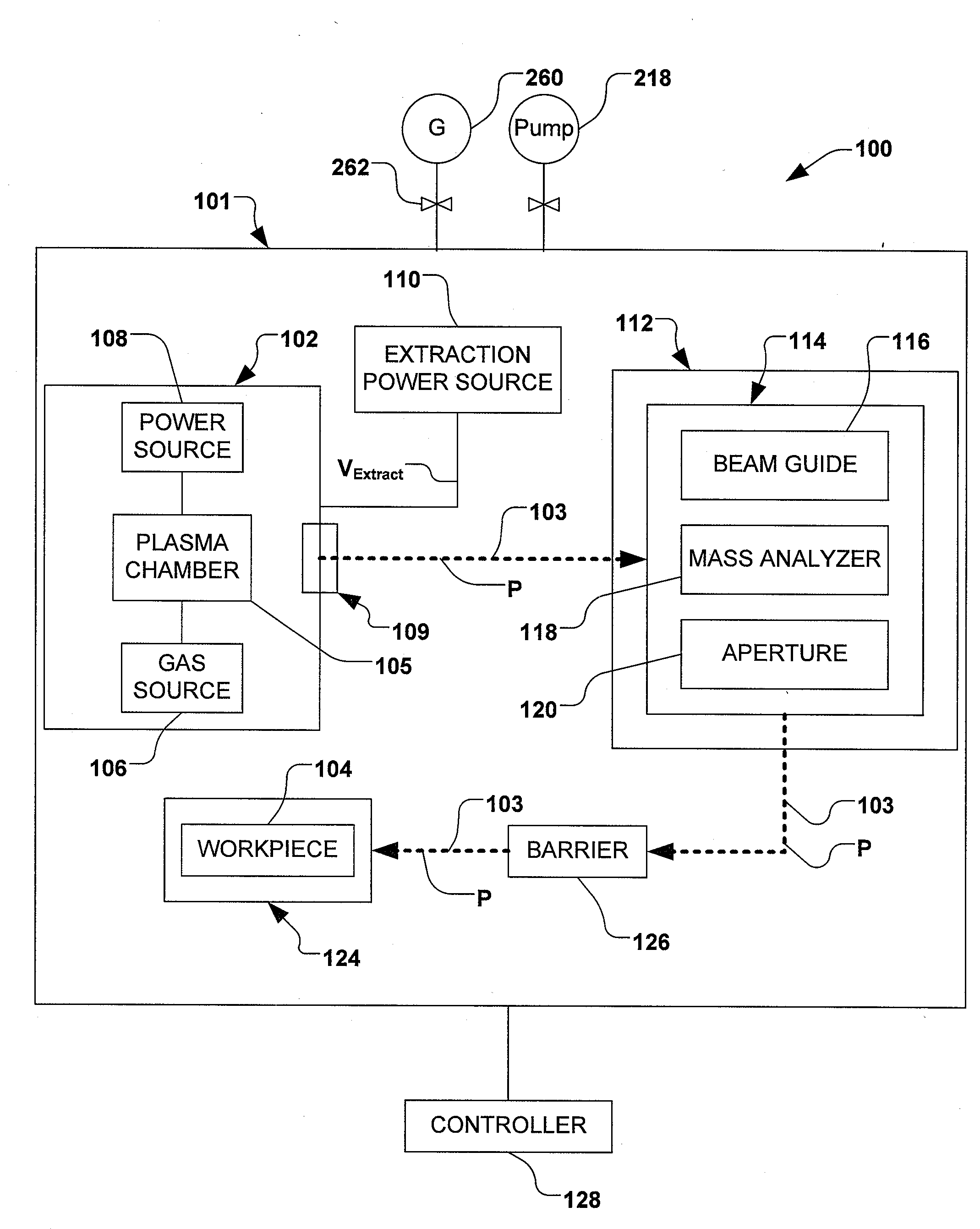

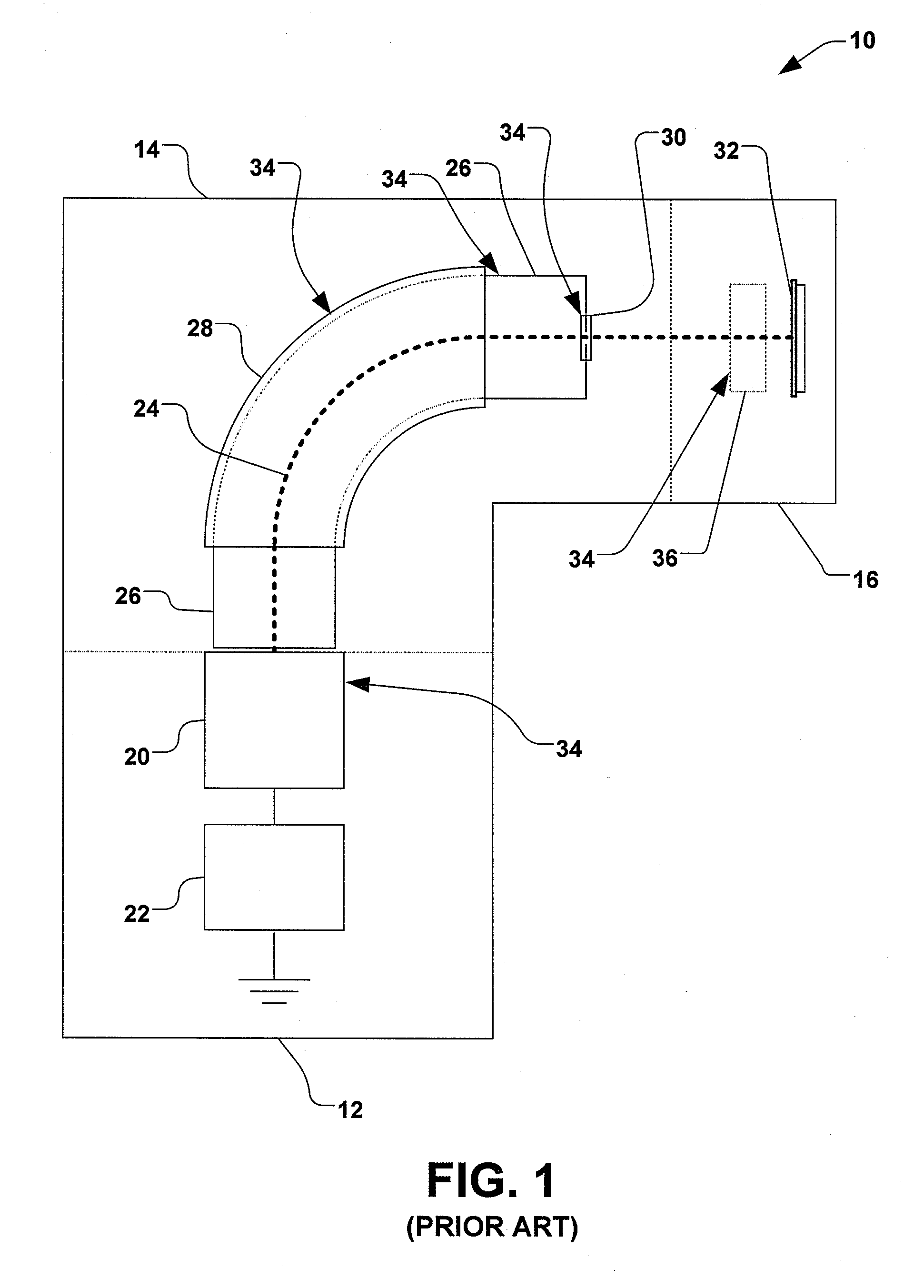

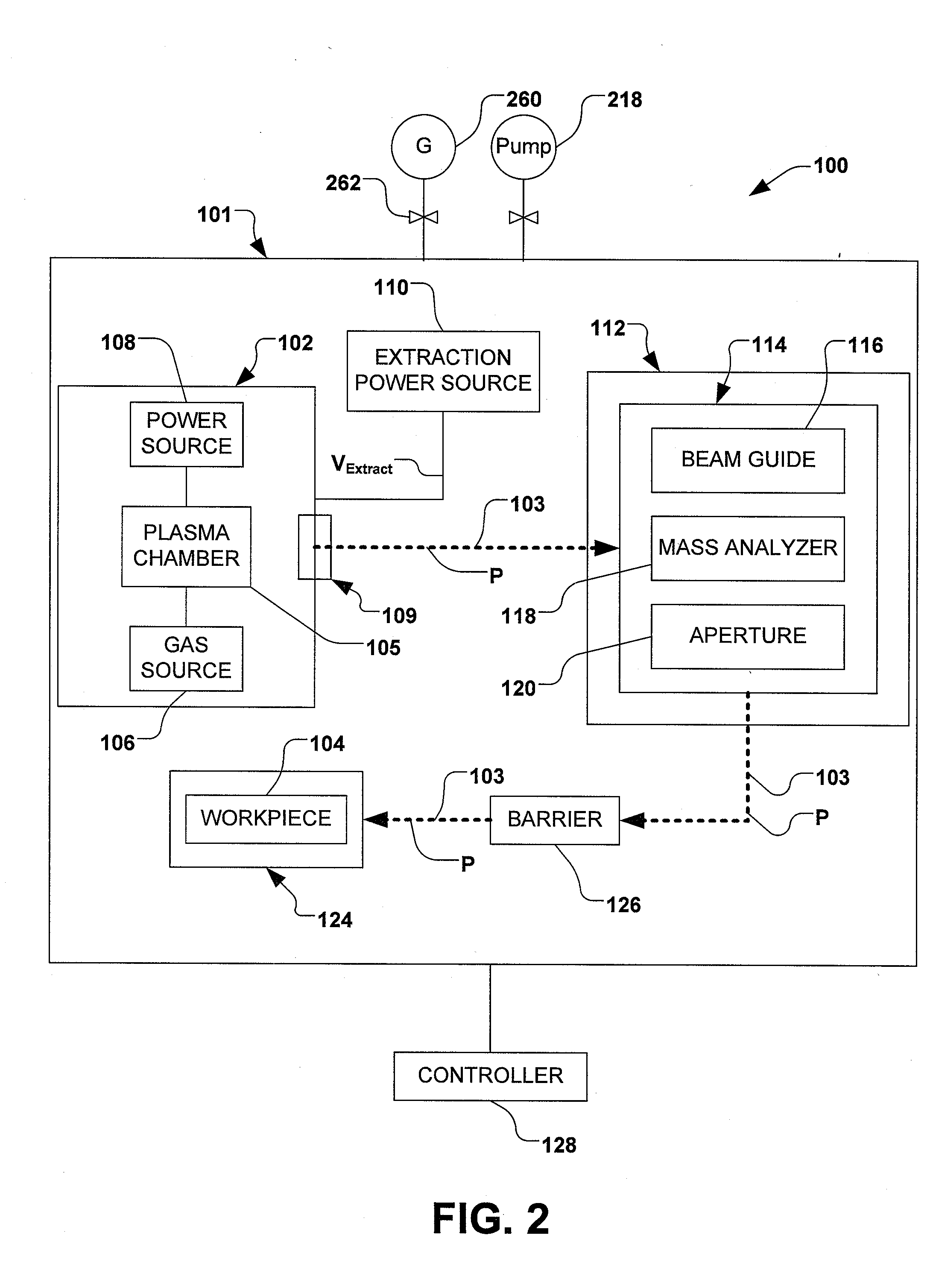

In-situ cleaning of beam defining apertures in an ion implanter

ActiveUS6992311B1Avoid componentsLimiting an amount of cross-contamination within the ion implantation systemElectric discharge tubesMaterial analysis by optical meansMulti pollutantPhysical chemistry

A method for cleaning an ion implantation, comprising providing an ion implantation system, wherein the ion implantation system comprises one or more components having one or more contaminants disposed thereon. A process species is provided to the ion implantation system, wherein the process species is otherwise utilized to implant ions into a workpiece. Ions are formed from the process species, therein defining an ion source. An ion beam is then extracted from the ion source via an application of an extraction voltage to an ion extraction assembly associated with the ion source. The extraction voltage is further modulated, wherein a trajectory of the ion beam is oscillated within a predetermined range. The ion beam is consequently swept across the one or more components, thus substantially removing the one or more contaminants therefrom.

Owner:AXCELIS TECHNOLOGIES

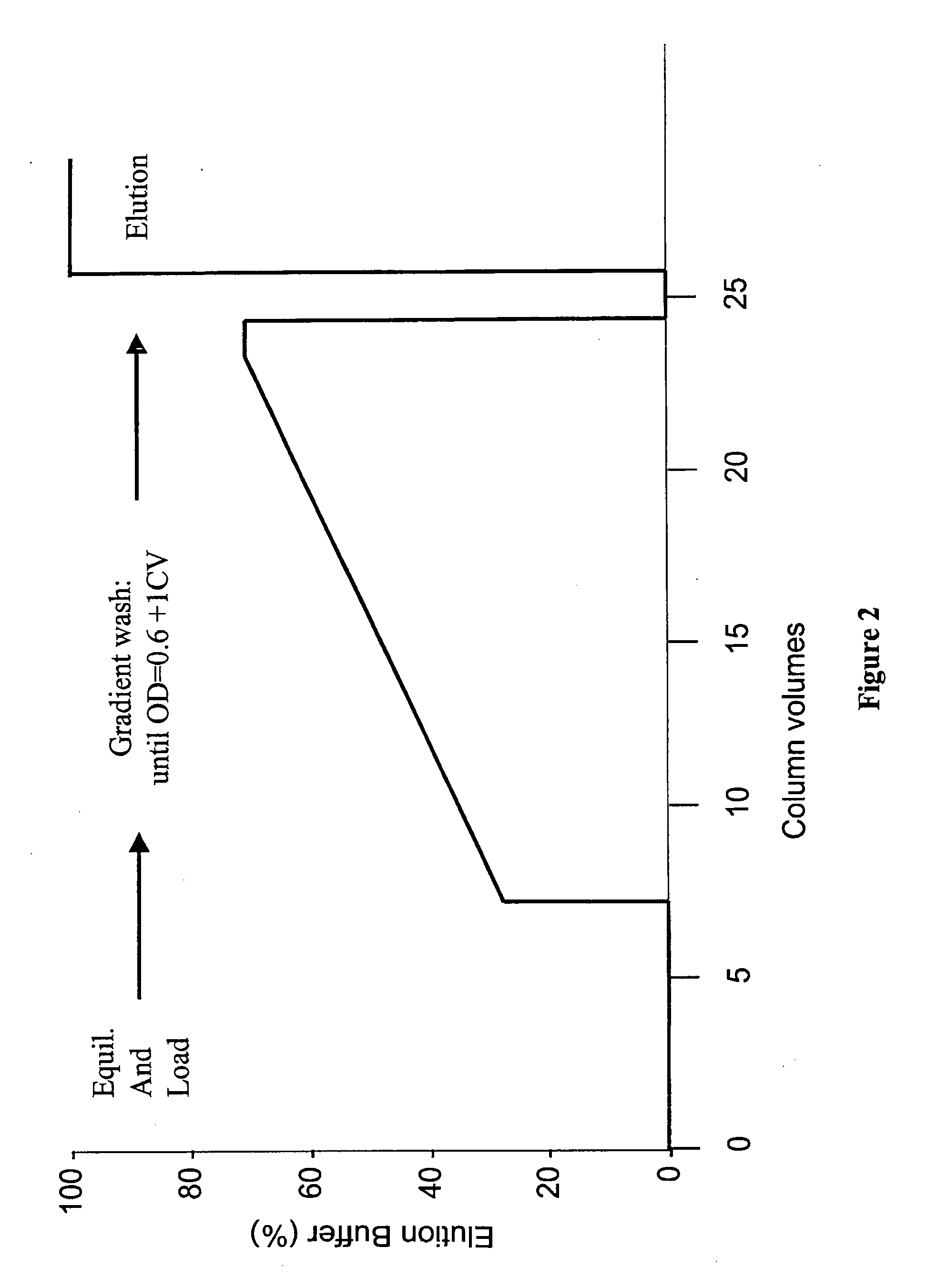

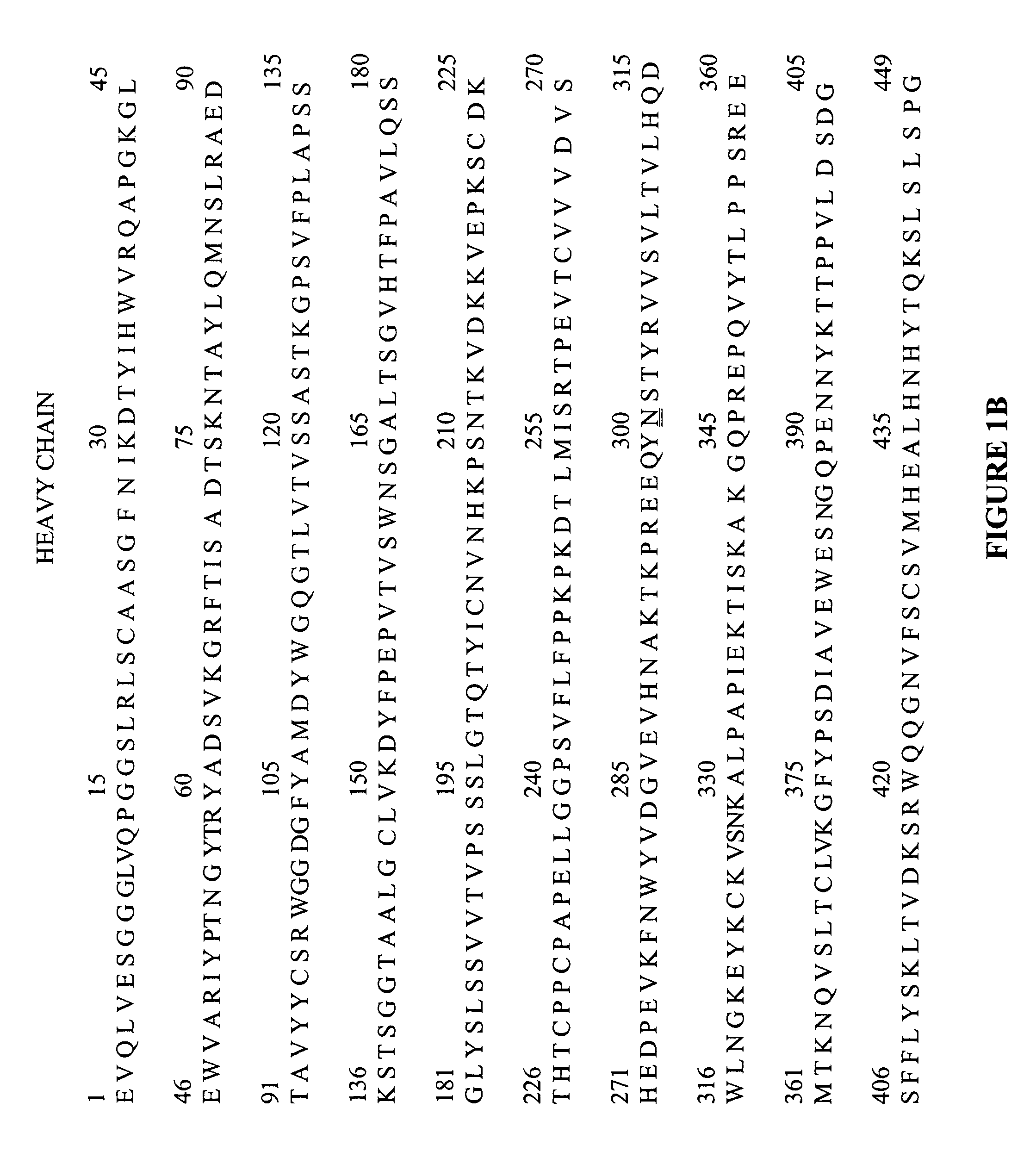

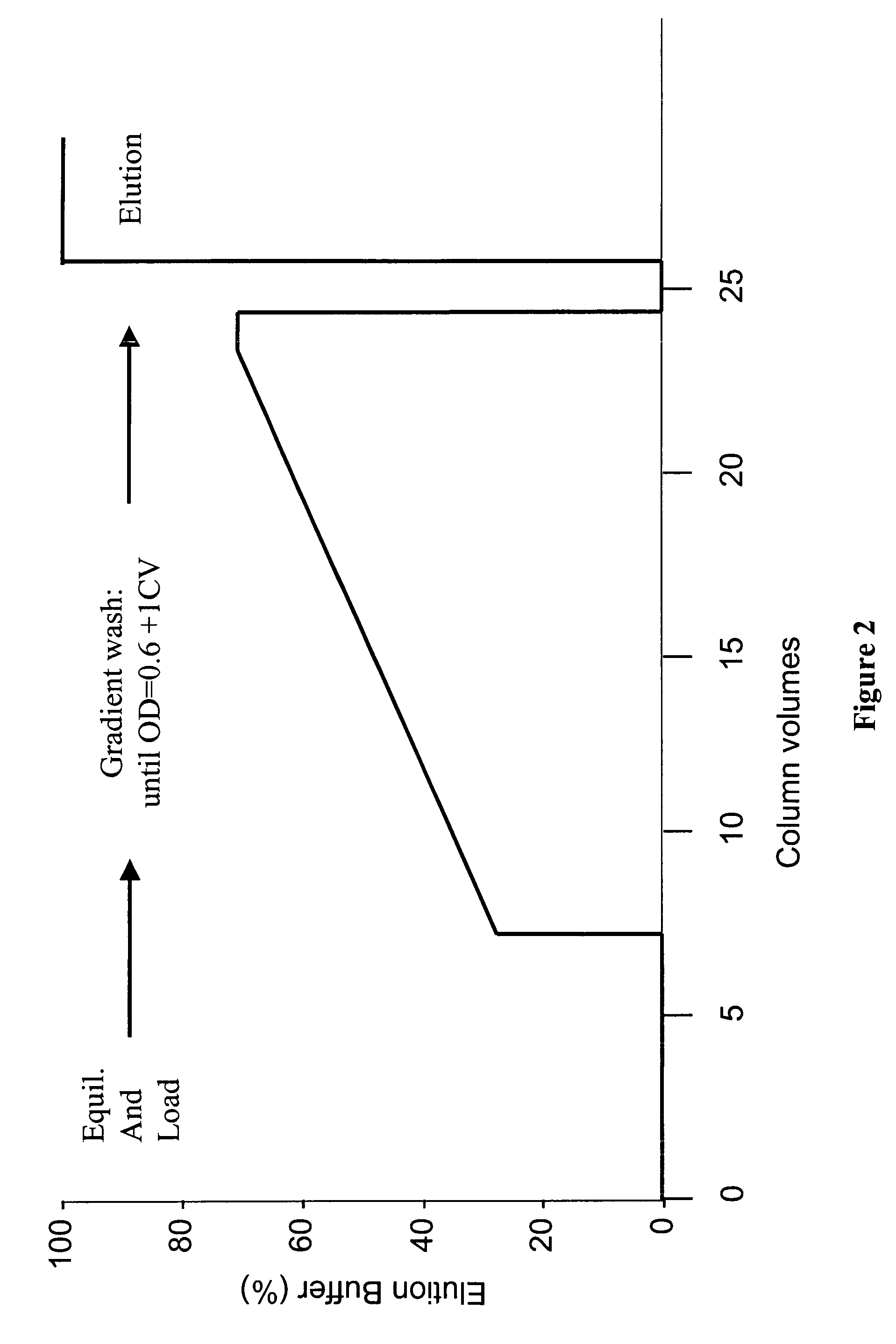

Protein purification

InactiveUS20120065381A1Improve conductivityCation exchanger materialsOrganic anion exchangersIon chromatographyMulti pollutant

A method for purifying a polypeptide by ion exchange chromatography is described in which a gradient wash is used to resolve a polypeptide of interest from one or more contaminants.

Owner:GENENTECH INC

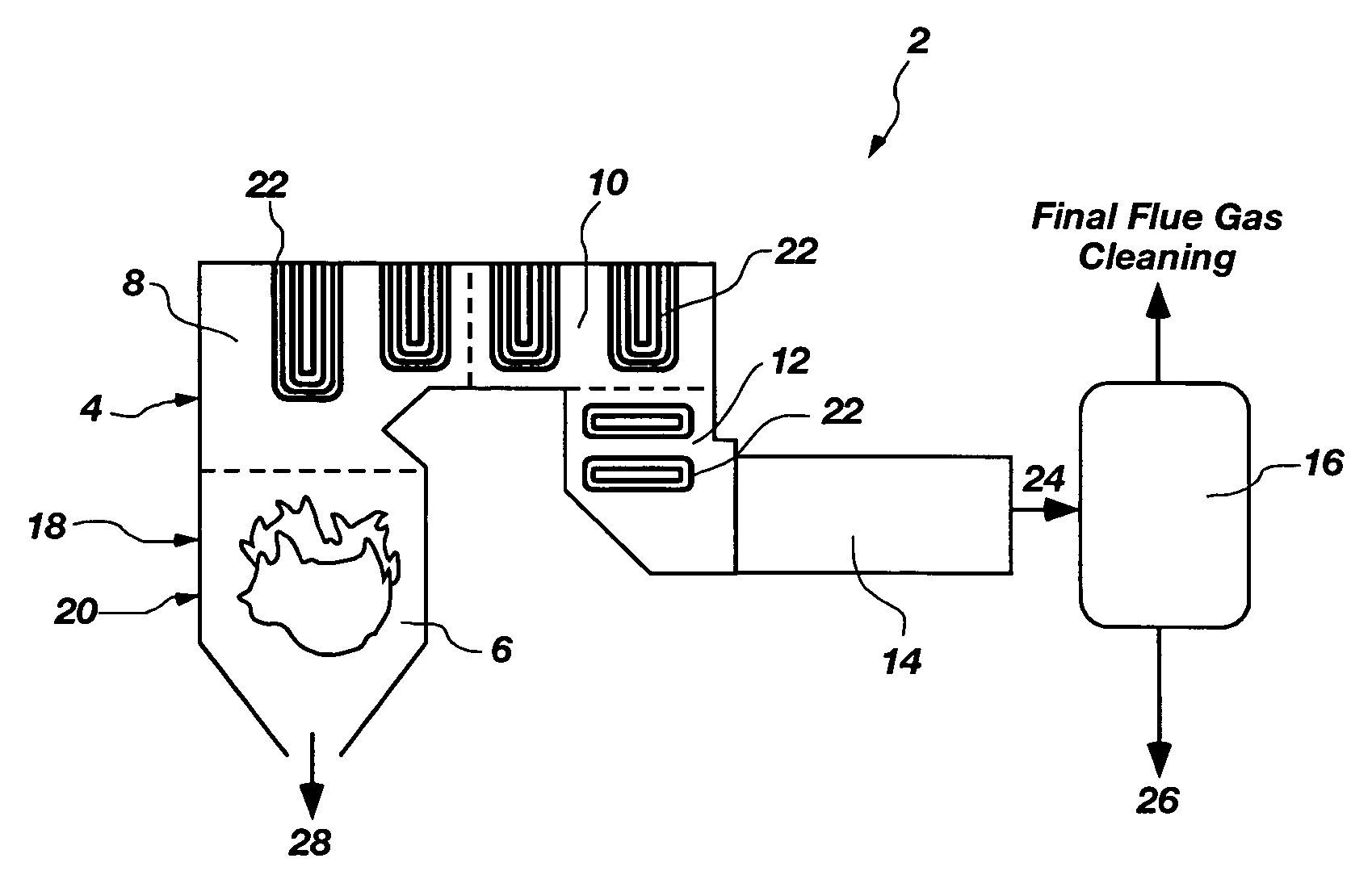

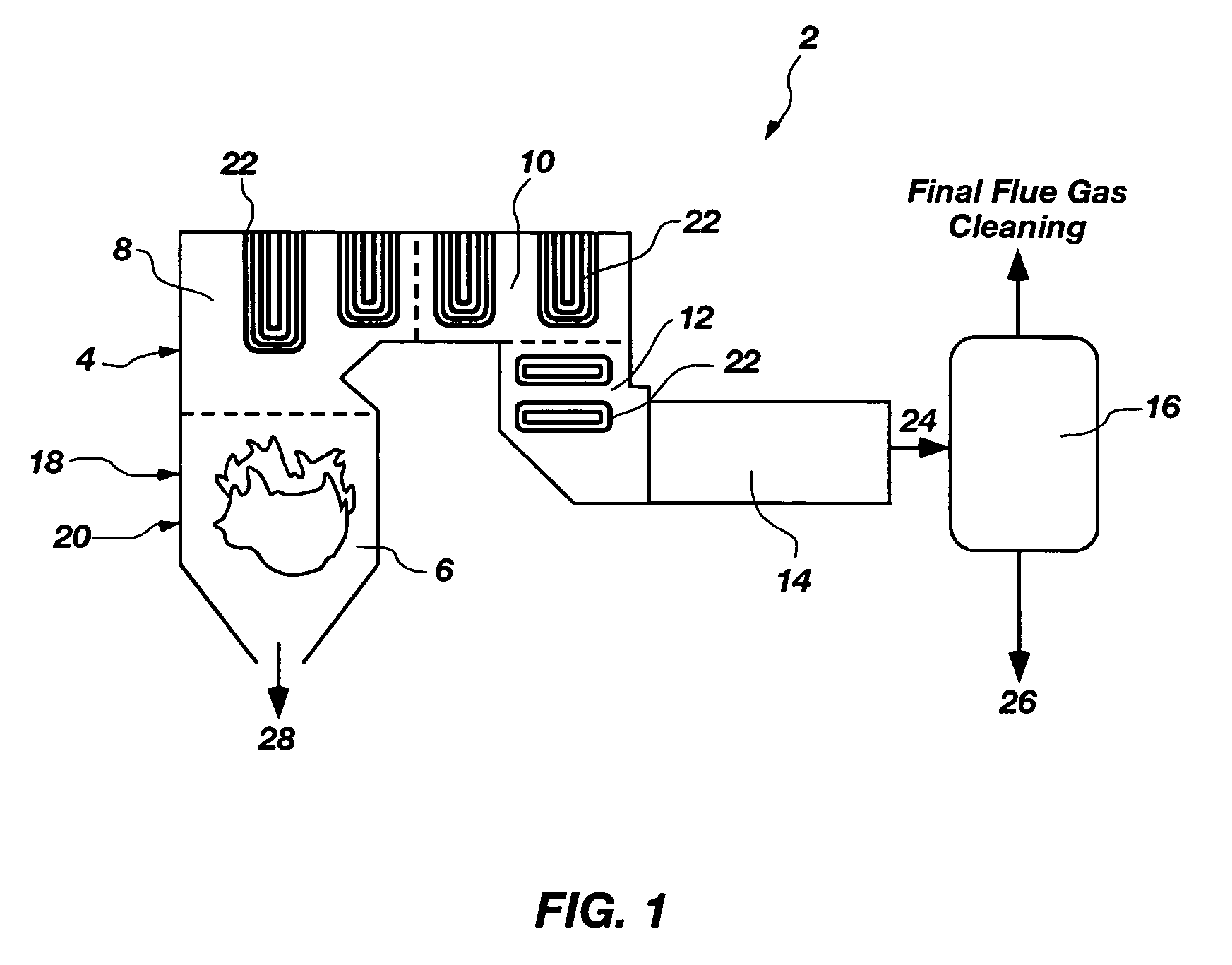

Method for oil shale pollutant sorption/NOx reburning multi-pollutant control

A method of decreasing pollutants produced in a combustion process. The method comprises combusting coal in a combustion chamber to produce at least one pollutant selected from the group consisting of a nitrogen-containing pollutant, sulfuric acid, sulfur trioxide, carbonyl sulfide, carbon disulfide, chlorine, hydroiodic acid, iodine, hydrofluoric acid, fluorine, hydrobromic acid, bromine, phosphoric acid, phosphorous pentaoxide, elemental mercury, and mercuric chloride. Oil shale particles are introduced into the combustion chamber and are combusted to produce sorbent particulates and a reductant. The at least one pollutant is contacted with at least one of the sorbent particulates and the reductant to decrease an amount of the at least one pollutant in the combustion chamber. The reductant may chemically reduce the at least one pollutant to a benign species. The sorbent particulates may adsorb or absorb the at least one pollutant. A combustion chamber that produces decreased pollutants in a combustion process is also disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

Protein purification

ActiveUS8044017B2Improve conductivityPowder deliveryCation exchanger materialsIon chromatographyMulti pollutant

A method for purifying a polypeptide by ion exchange chromatography is described in which a gradient wash is used to resolve a polypeptide of interest from one or more contaminants.

Owner:GENENTECH INC

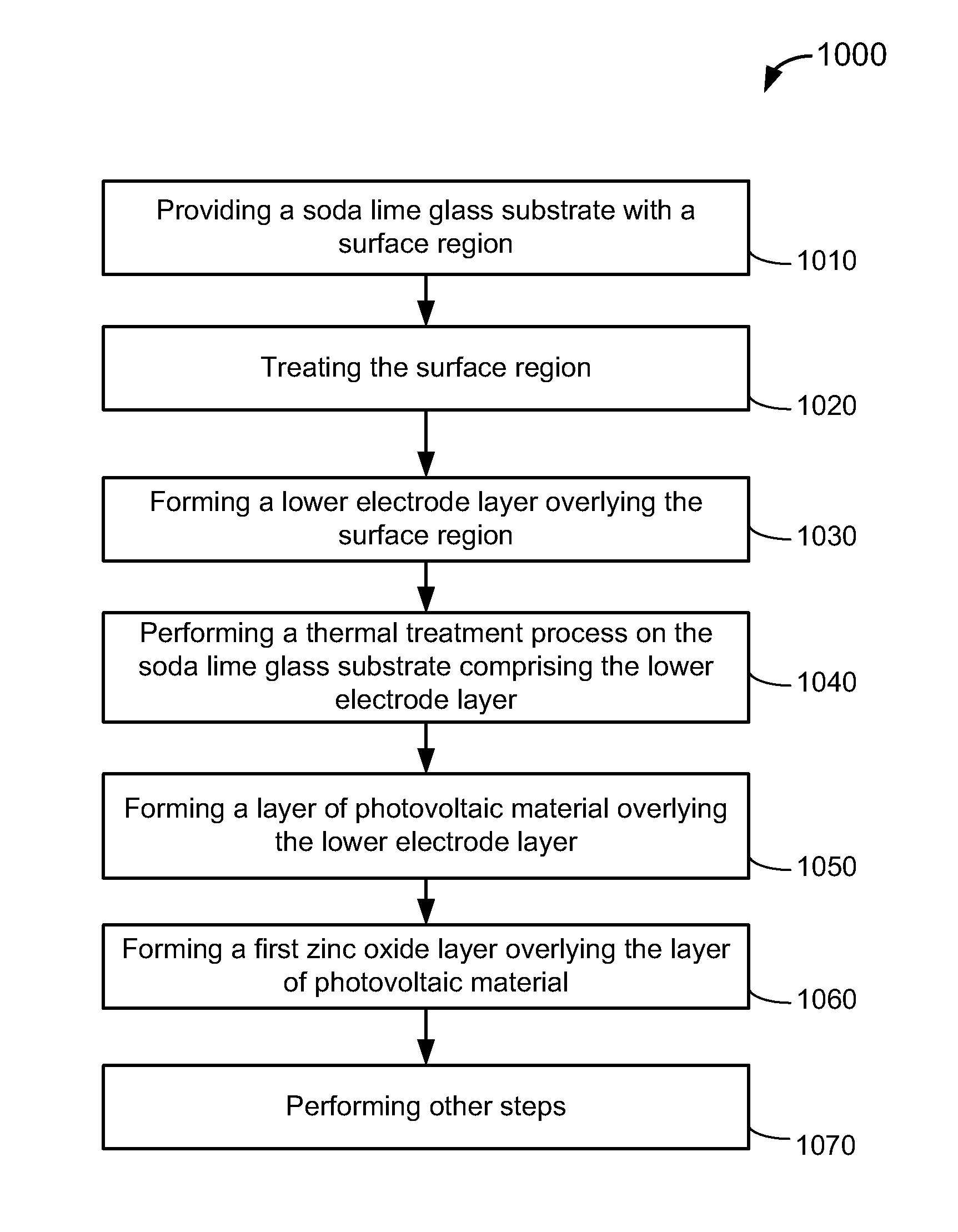

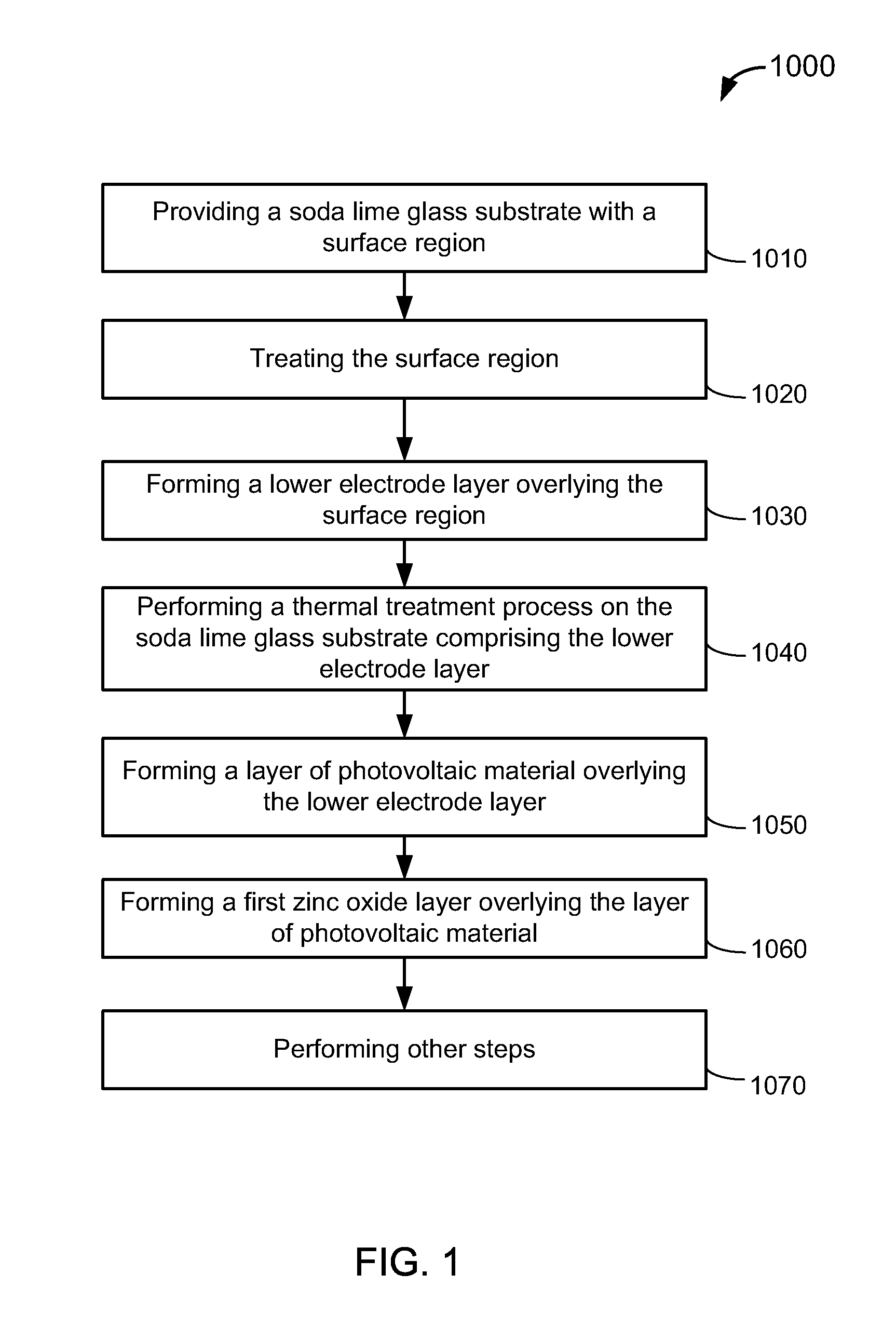

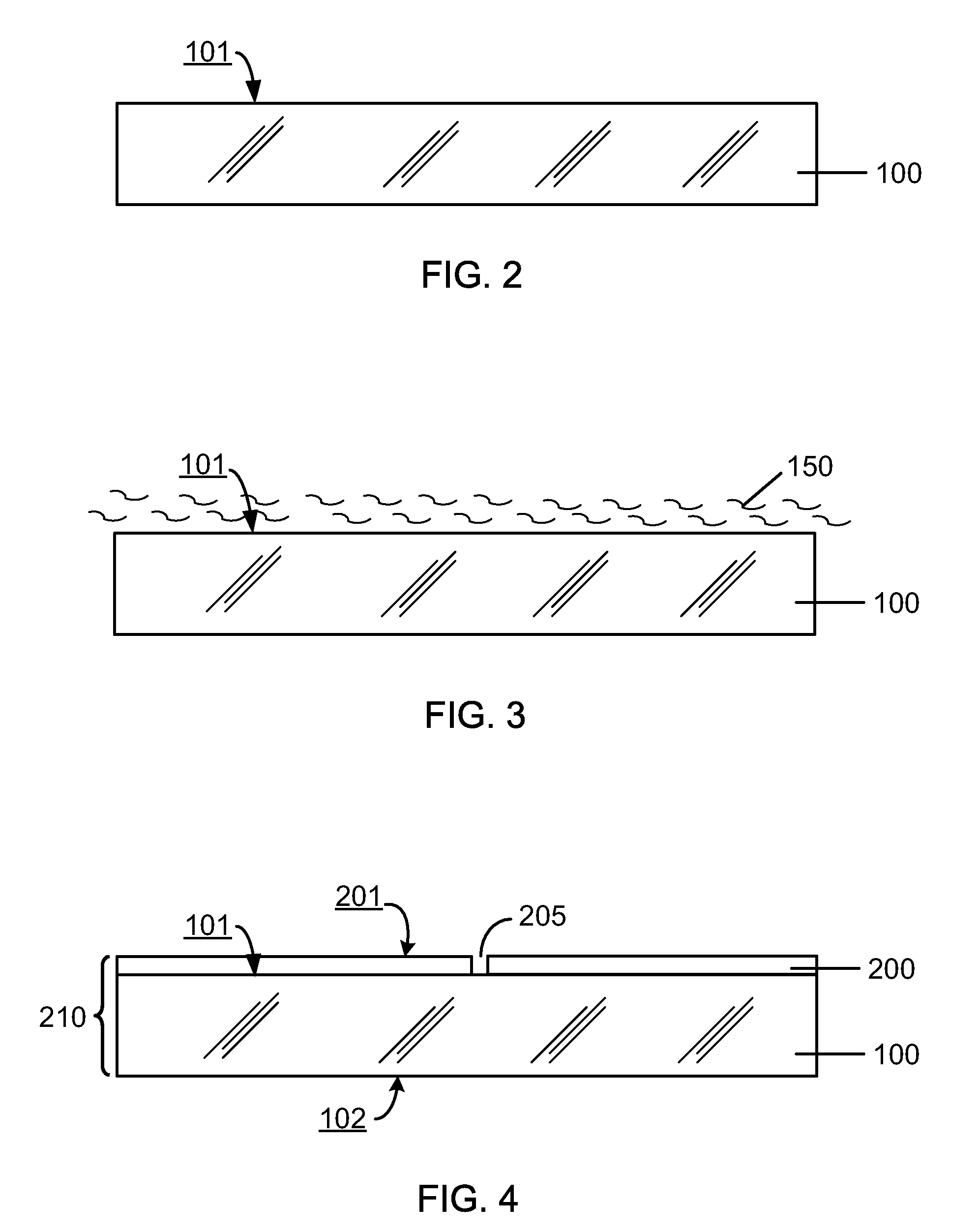

Thermal pre-treatment process for soda lime glass substrate for thin film photovoltaic materials

InactiveUS20110020980A1Easy to implementHigh efficiency photovoltaic absorber layerFinal product manufactureSemiconductor/solid-state device manufacturingMaterials scienceSoda-lime glass

A method for fabricating a thin film solar cell includes providing a soda lime glass substrate comprising a surface region, treating the surface region with one or more cleaning process including an aqueous solution to remove one or more contaminants and / or particulates, and forming a lower electrode layer overlying the surface region. The method also includes performing a thermal treatment process to remove any residual water species to substantially less than a monolayer of water species from the lower electrode layer and soda lime glass substrate. The thermal treatment process changes a temperature of the soda lime glass substrate from a first temperature to a second temperature to pre-heat the soda lime glass substrate. Additionally, the method includes transferring the soda lime glass substrate, which has been preheated, to a deposition chamber and forming a layer of photovoltaic material overlying the lower electrode layer within the deposition chamber.

Owner:CM MFG

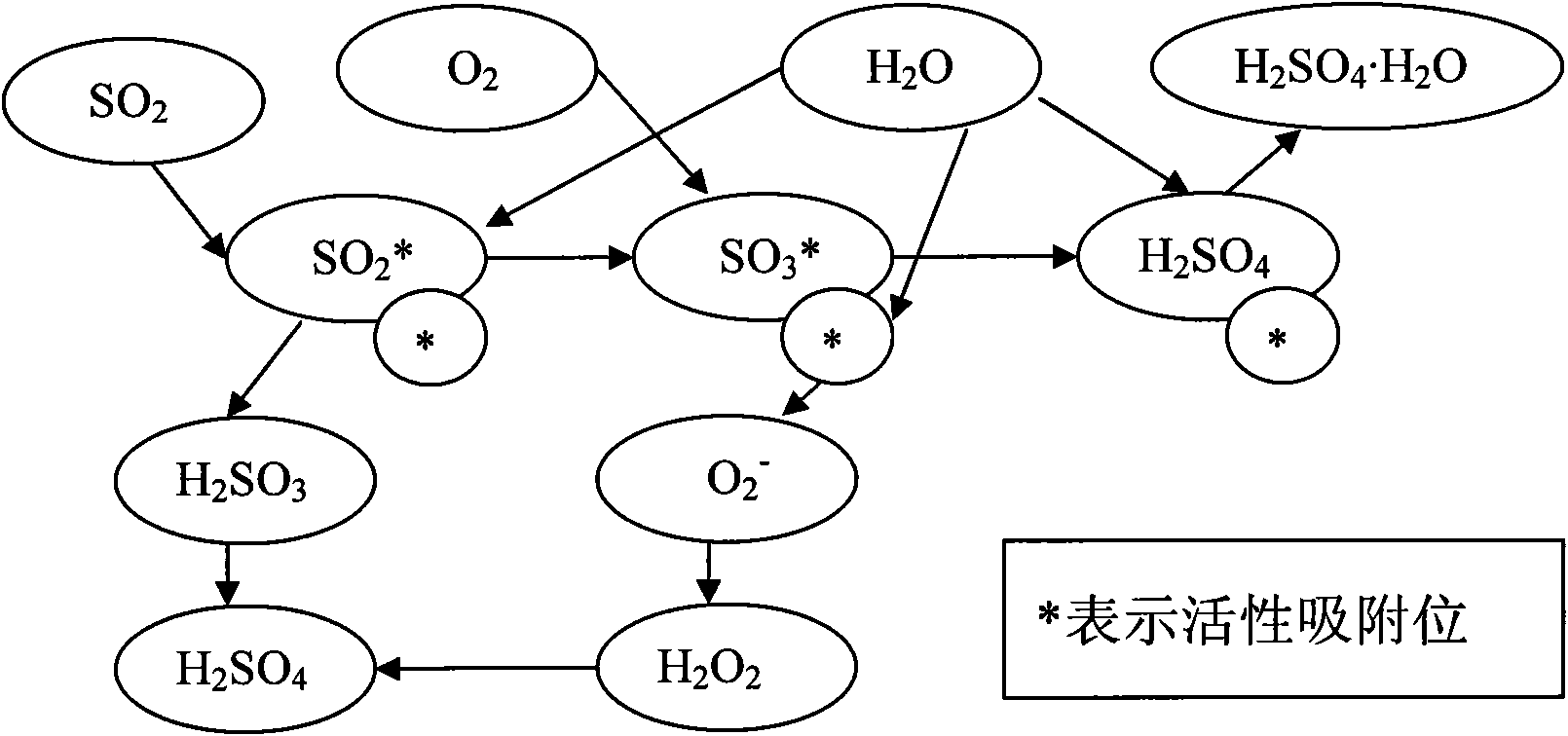

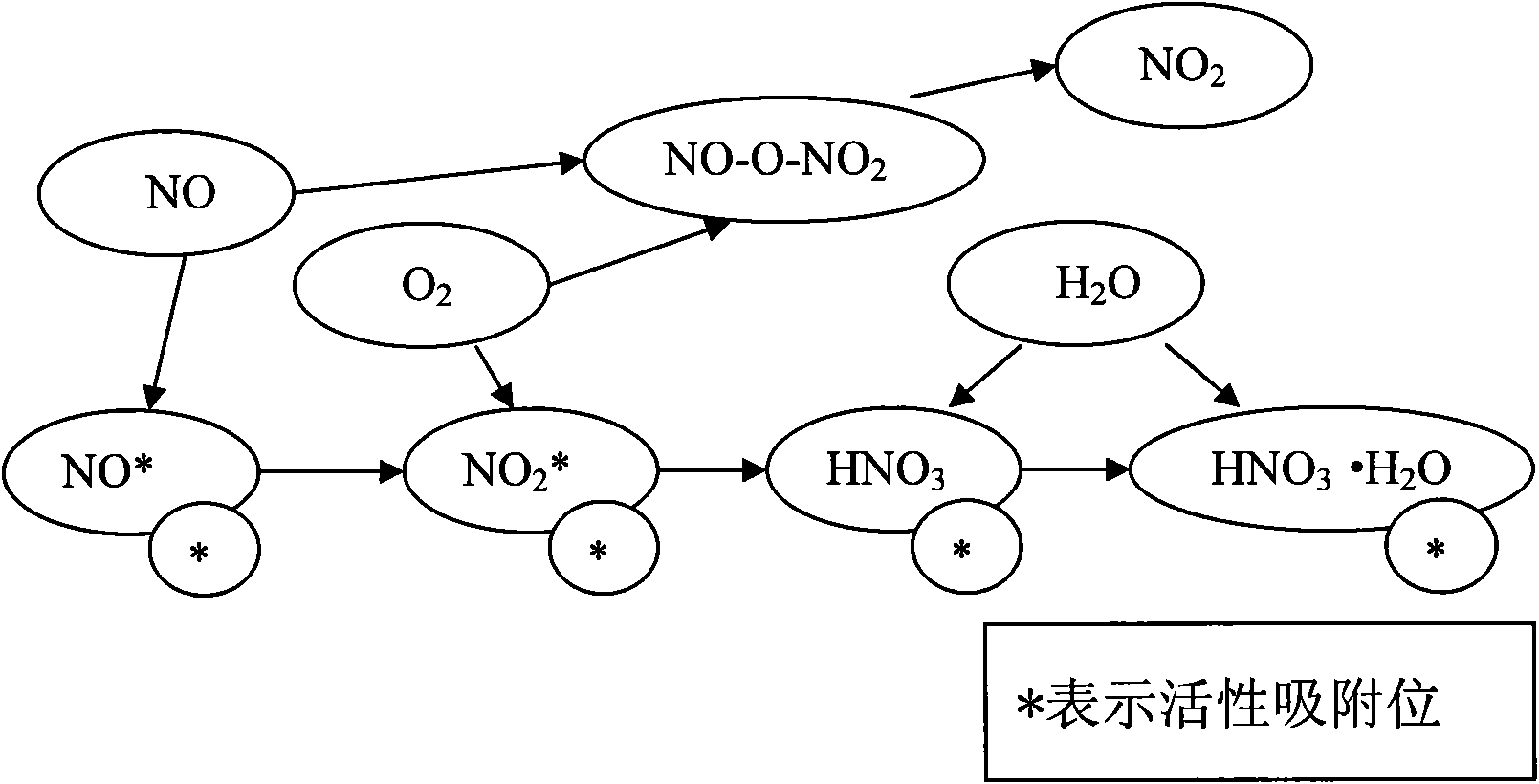

Method for removing various pollutants in fume by combining discharge plasmas and absorption

ActiveCN101716451ACombined removalLow investment costDispersed particle separationAir quality improvementElectricityMulti pollutant

The invention discloses a method for removing various pollutants in fume by combining discharge plasmas and absorption. The method comprises the following steps: electrically dedusting or dedusting fire coal or burning fume by a cloth bag; and sequentially pumping the fume through a pre-washing tower, a primary discharge plasma reactor, a primary absorption tower, a secondary discharge plasma reactor and a secondary absorption tower, wherein the pre-washing tower is used for pre-cleaning the fume, lowering the temperature and condensing the absorption liquid; the primary discharge plasma reactor is used for oxidizing NO, charging thin particulate matter, trapping and removing; the primary absorption tower is used for washing and removing SO2, NOx and charged thin particulate matter; the secondary discharge plasma reactor is used for oxidizing an element Hg, charging acid mist and ammonium mist, trapping and removing; and the secondary absorption tower is used for washing and removing oxidized Hg and other pollutants. By the treatment, the removal rates of the SO2, the NOx, the Hg and the thin particulate matter respectively reach above 95%, 75%, 75% and 80%; and the leakage amountof ammonia is below 5mg / m<3>.

Owner:BEIHANG UNIV

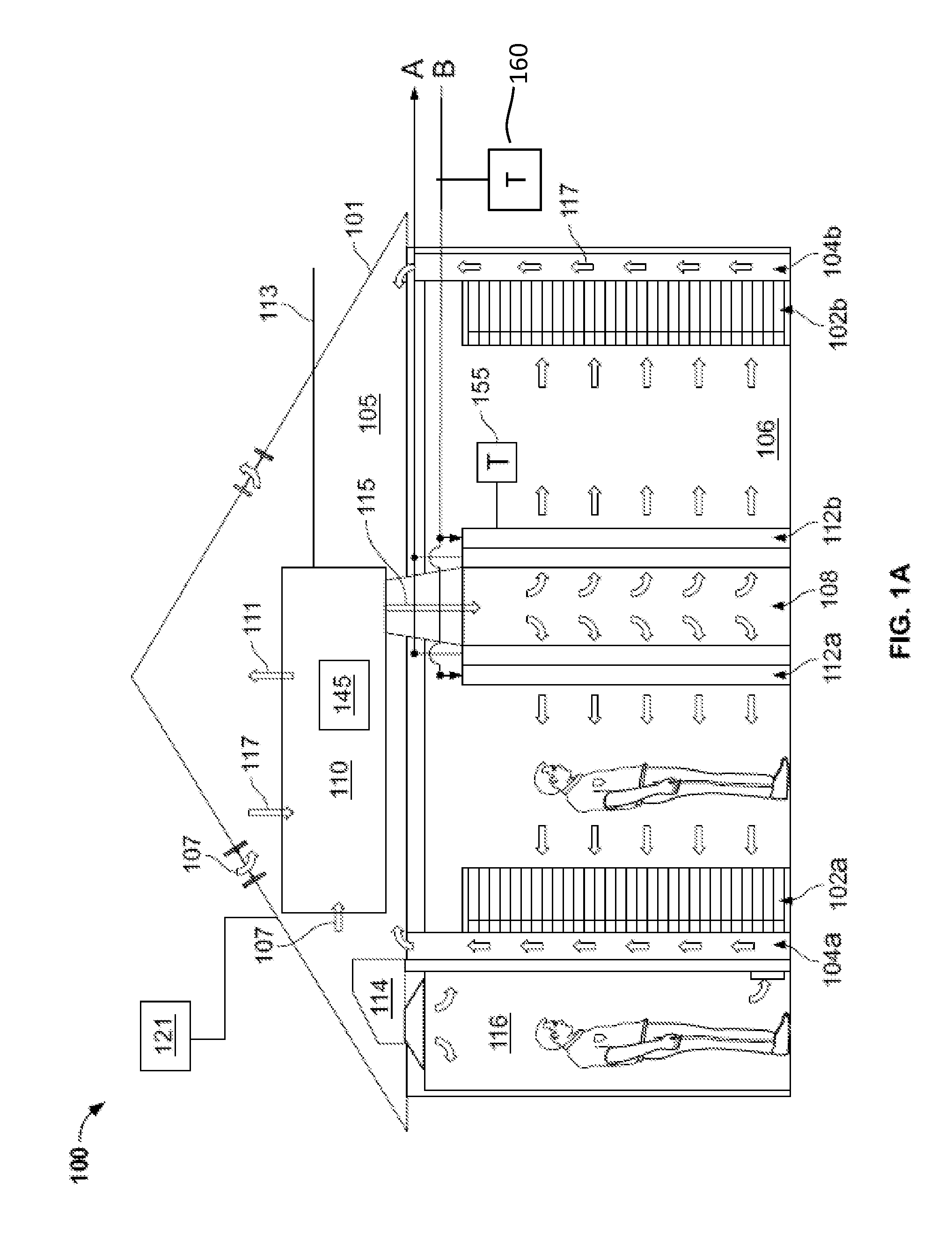

Managing data center airflow

ActiveUS9278303B1Easy to cleanImprove energy efficiencyLighting and heating apparatusUsing liquid separation agentData centerMulti pollutant

Techniques for treating an outside airflow with a direct evaporative economizer include circulating an airflow from an ambient environment into a direct evaporative economizer; circulating a cooling fluid into the direct evaporative economizer at a first rate so that a temperature condition of a supply airflow meets a predetermined range of setpoint temperatures; evaporating at least a portion of the cooling fluid circulated at the first rate into the airflow; determining that a measured air contaminant level of the airflow is greater than a setpoint contaminant level; and based on the determination, circulating the cooling fluid into the direct evaporative economizer at a second rate to precipitate a plurality of contaminants from the airflow into the cooling fluid, the second flow rate of the cooling fluid operable to adjust the temperature condition of the supply airflow outside of the predetermined range of setpoint temperatures of the supply airflow.

Owner:GOOGLE LLC

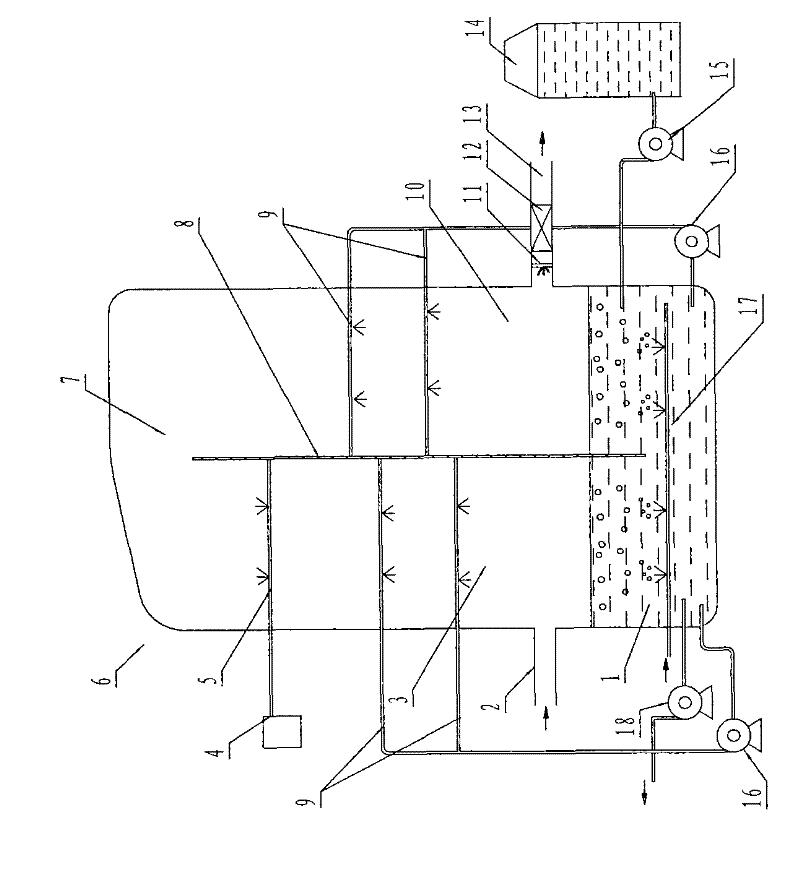

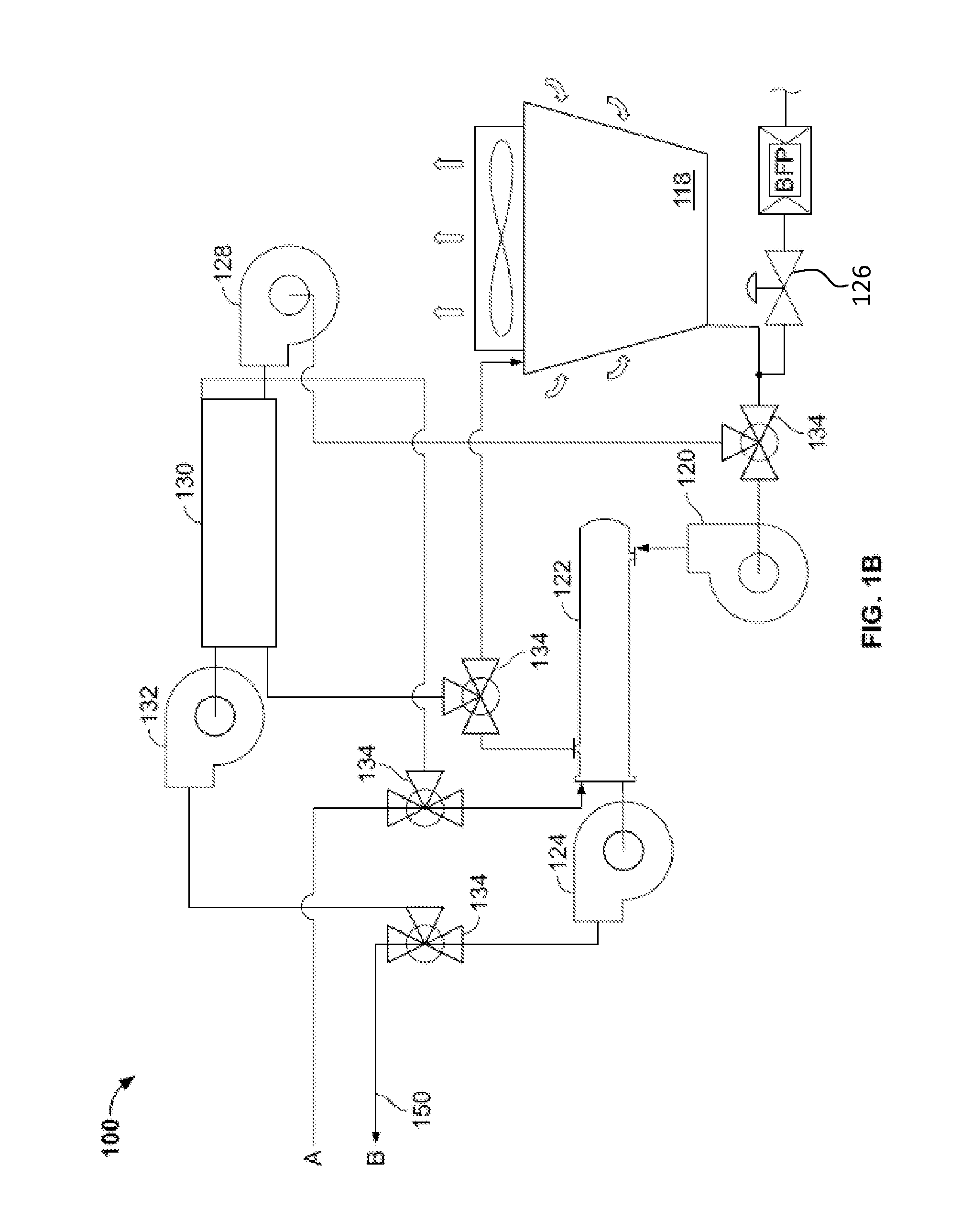

Simultaneous removing device and method of various pollutants by electrocatalytical oxidation combining lime-gypsum method

ActiveCN101716463ALow investment costThe process is simple and reliableUsing liquid separation agentElectricityMulti pollutant

The invention discloses simultaneous removing device and method of various pollutants by an electrocatalytical oxidation combining lime-gypsum method. The device comprises a spraying and cooling device, an electrostatic enhancement reactor, a Venturi device, a double-circulation integrated absorption tower of various pollutants and a wet type electrostatic defroster, wherein after smoke is cooled by the spraying and cooling device, the smoke enters the electrostatic enhancement reactor and is subjected to corona discharge processing in a corona discharge area formed in the electrostatic enhancement reactor; the processed smoke enters the double-circulation integrated absorption tower of various pollutants and is sprayed to remove dust and absorb in the absorption tower; and the purified smoke sequentially enters a corrugated plate defroster and the electrostatic defroster on the upper part of a spraying tower so as to remove aerosol in the smoke. The invention has the advantages that various pollutants can be simultaneously removed, and meanwhile, the pollution of fine granules and the aerosol can be effectively controlled; various pollutants can have higher removal efficiency; and the removal and the absorption of by-products cannot cause secondary pollution to environment.

Owner:ZHEJIANG UNIV

Control of particles on semiconductor wafers when implanting boron hydrides

ActiveUS20090294698A1Reduce particle pollutionElectric discharge tubesCleaning using gasesMulti pollutantIon beam

A method for reducing particle contamination during implantation of ions comprises providing an implantation system for implanting ions into a workpiece via an ion beam, wherein one or more components are under selective vacuum and have one or more contaminants in a first state disposed thereon. A gas is introduced to the implantation system, wherein the gas generally reacts with at least a portion of the one or more contaminants, therein transforming the at least a portion of the one or more contaminants into a second state The at least a portion of the one or more contaminants in the second state remain disposed on the one or more components, and wherein the at least a portion of the second state of the one or more contaminants generally does not produce particle contamination on the one or more workpieces.

Owner:AXCELIS TECHNOLOGIES

Combined removal method for contaminants from coal-fired flue gas and special purification reactor thereof

InactiveCN101564640AEffective controlSignificant technologyDispersed particle separationFiberAtmospheric air

The invention discloses a combined removal method for contaminants from a coal-fired flue gas and a special purification reactor thereof. The method comprises the following steps: (1) the flue gas to which dust removal is conducted at the tail part of a coal-fired boiler is cooled down by a heat exchanger; (2) the cooled flue gas passes through a primary purification reactor and a secondary purification reactor successively; (3) the flue gas discharged by step 2 is heated up by the heat exchanger and then discharged into atmosphere; (4) online monitoring is conducted to the flue gas discharged by step 3; when the emission concentration of the contaminants is higher than the emission standard, step 5 is conducted; otherwise, step 1 to step 3 are conducted circularly; (5) water is sprayed into the primary purification reactor and the secondary purification reactor to repeatedly wash the removal product attached to the surface of activated carbon fiber; and (6) air is heated up and then input into the primary purification reactor and the secondary purification reactor which are washed with water in step 5 so as to dry the activated carbon fiber in the reactors and then step 1 is conducted. The invention has the advantages of high removal rate for a plurality of contaminants, simple technique flow, integrated removal device, recyclable byproducts and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

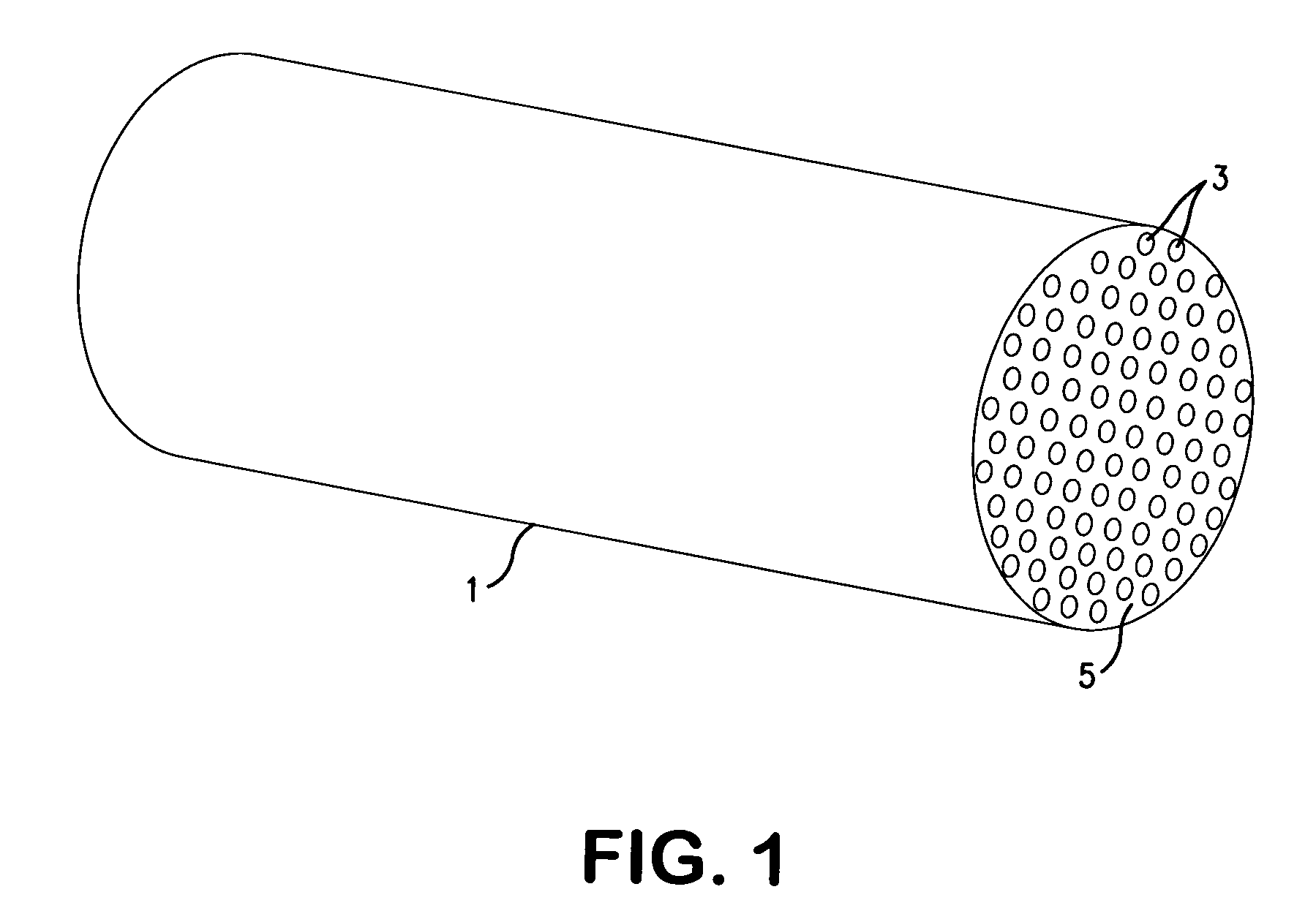

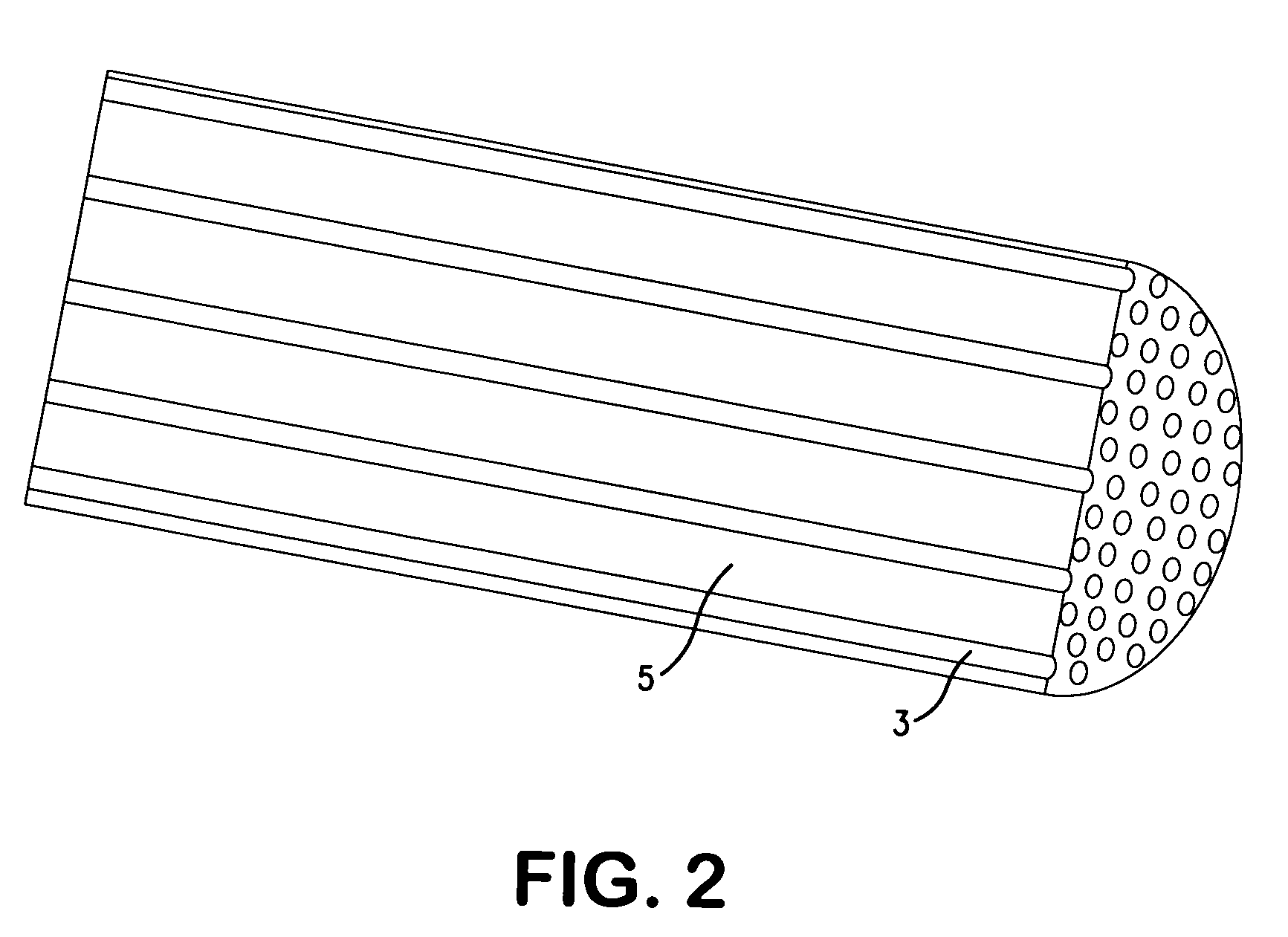

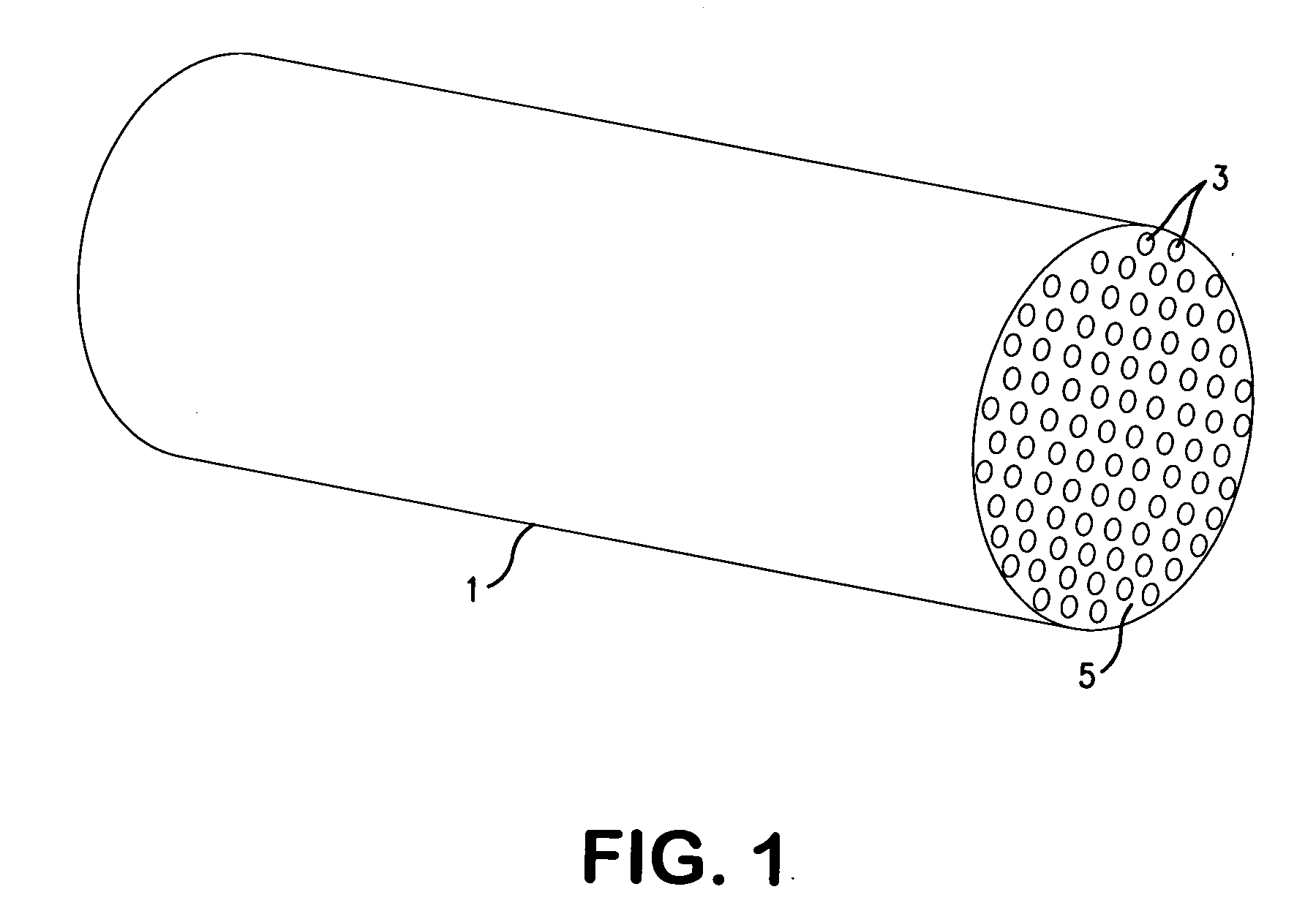

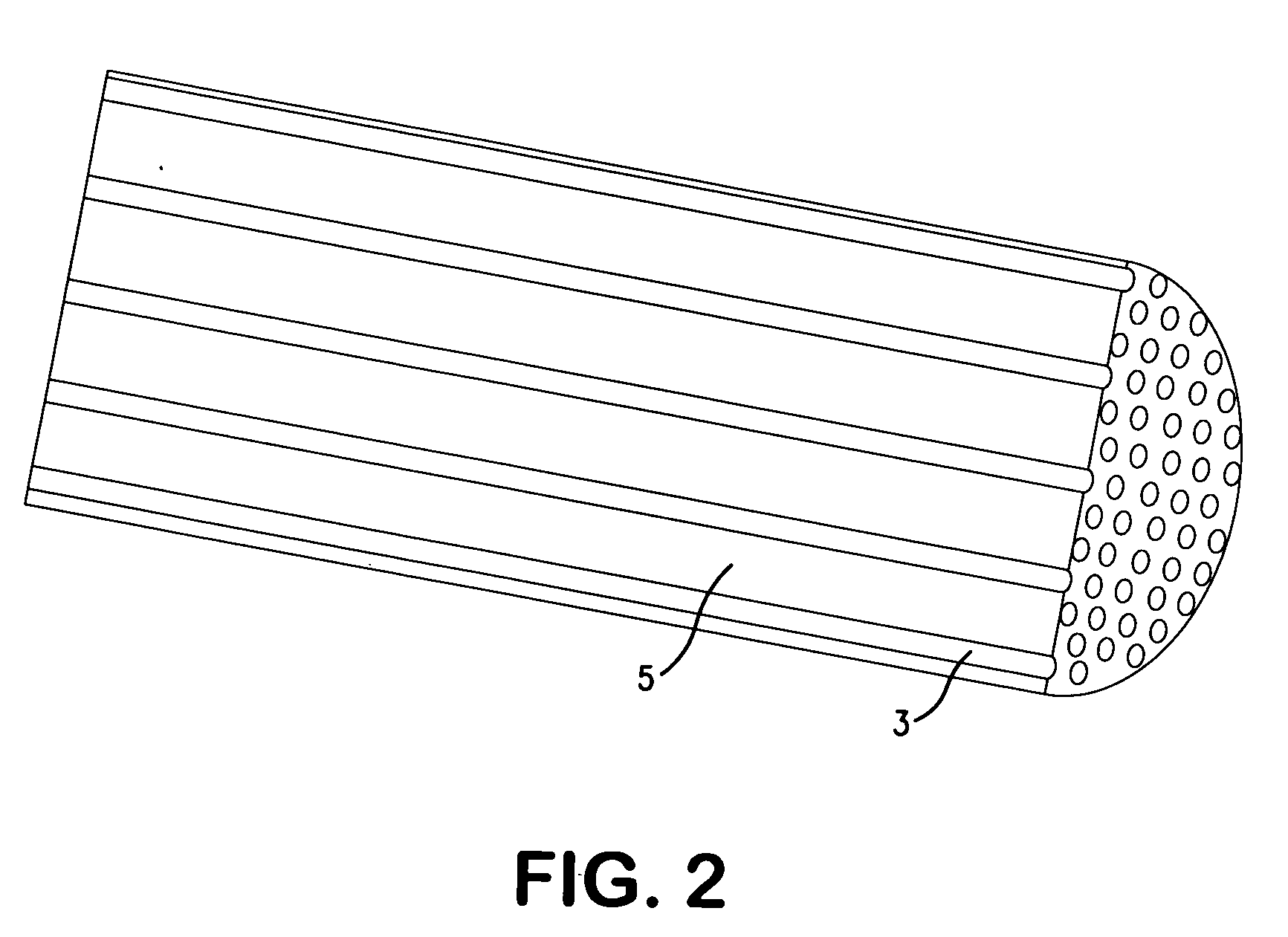

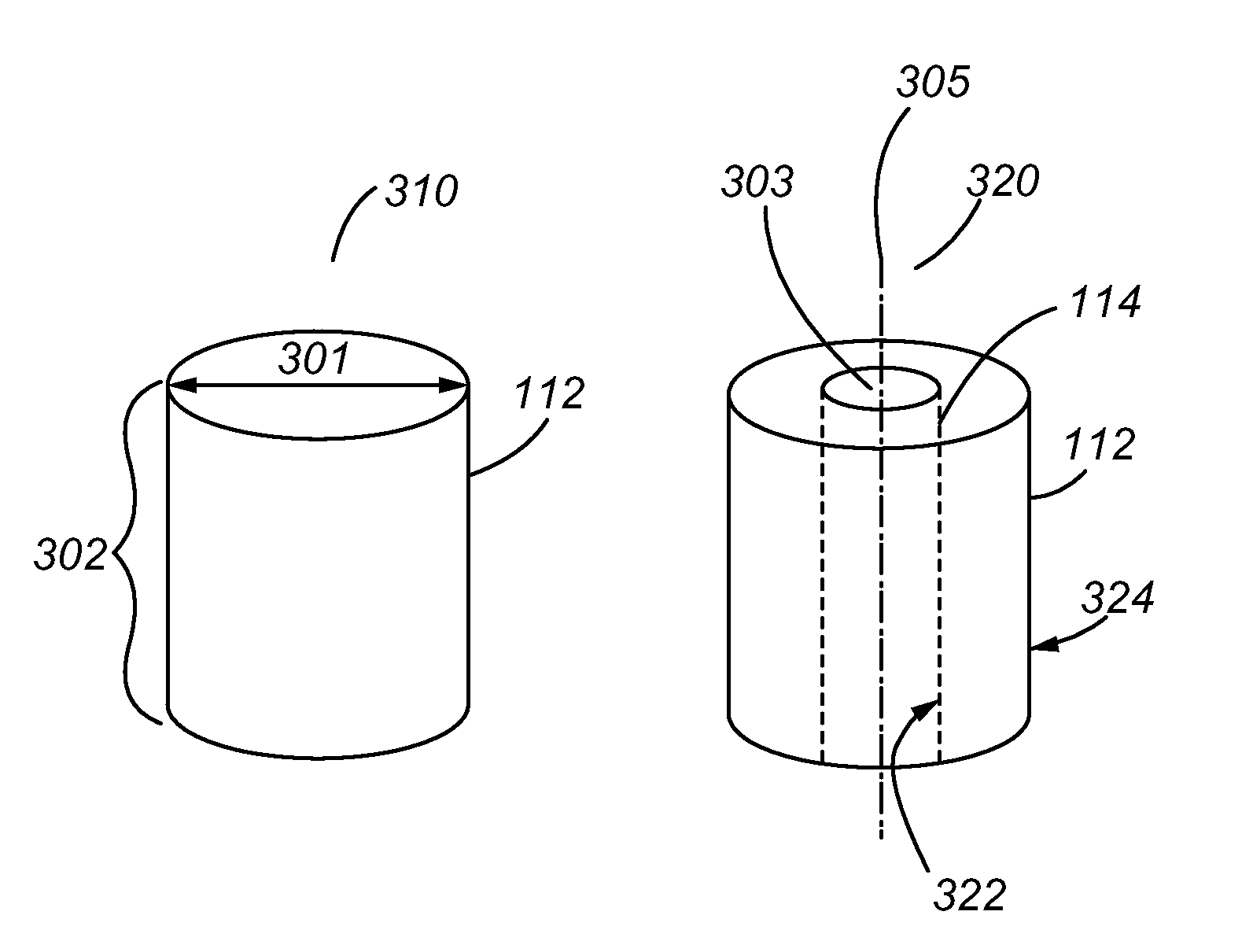

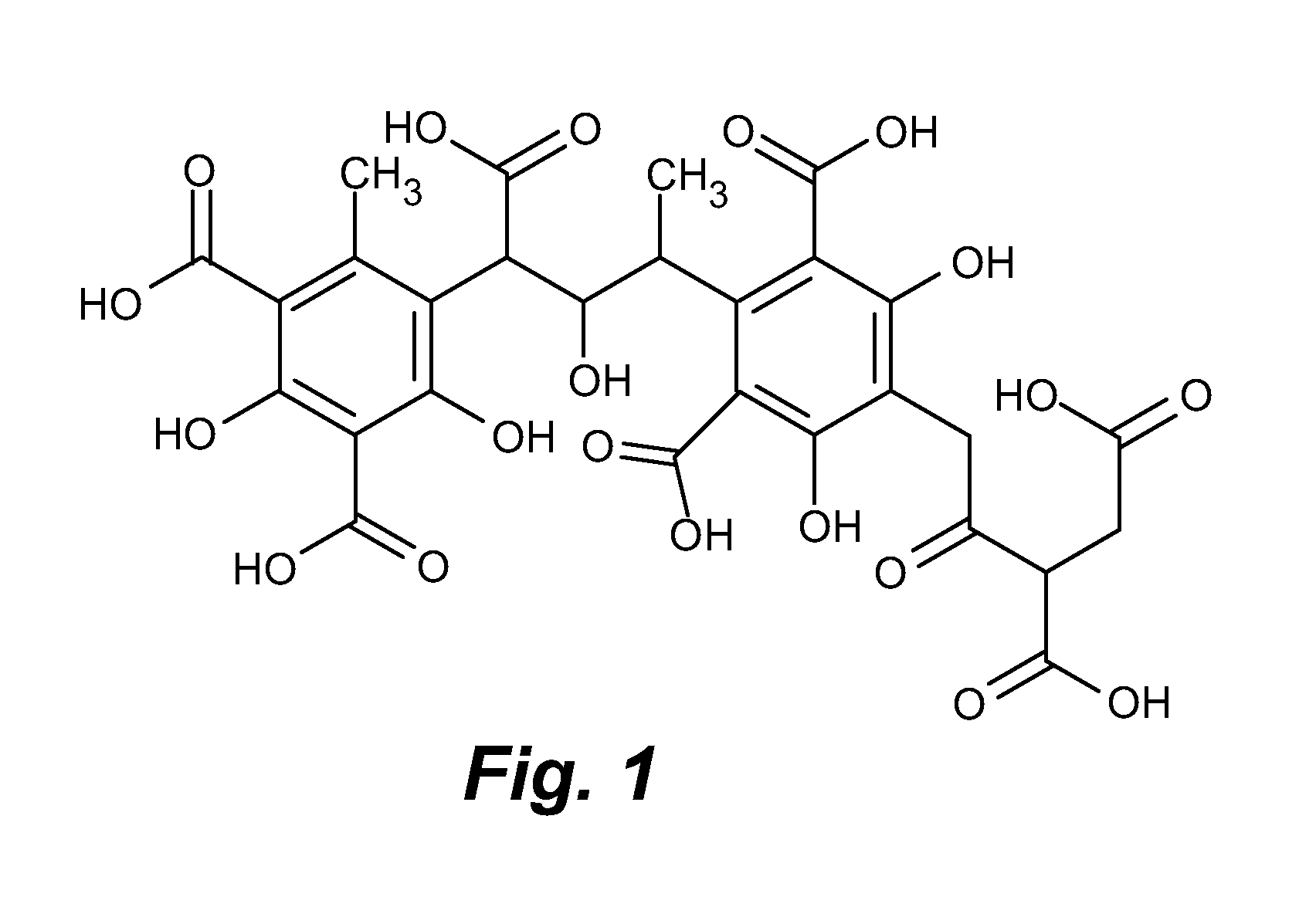

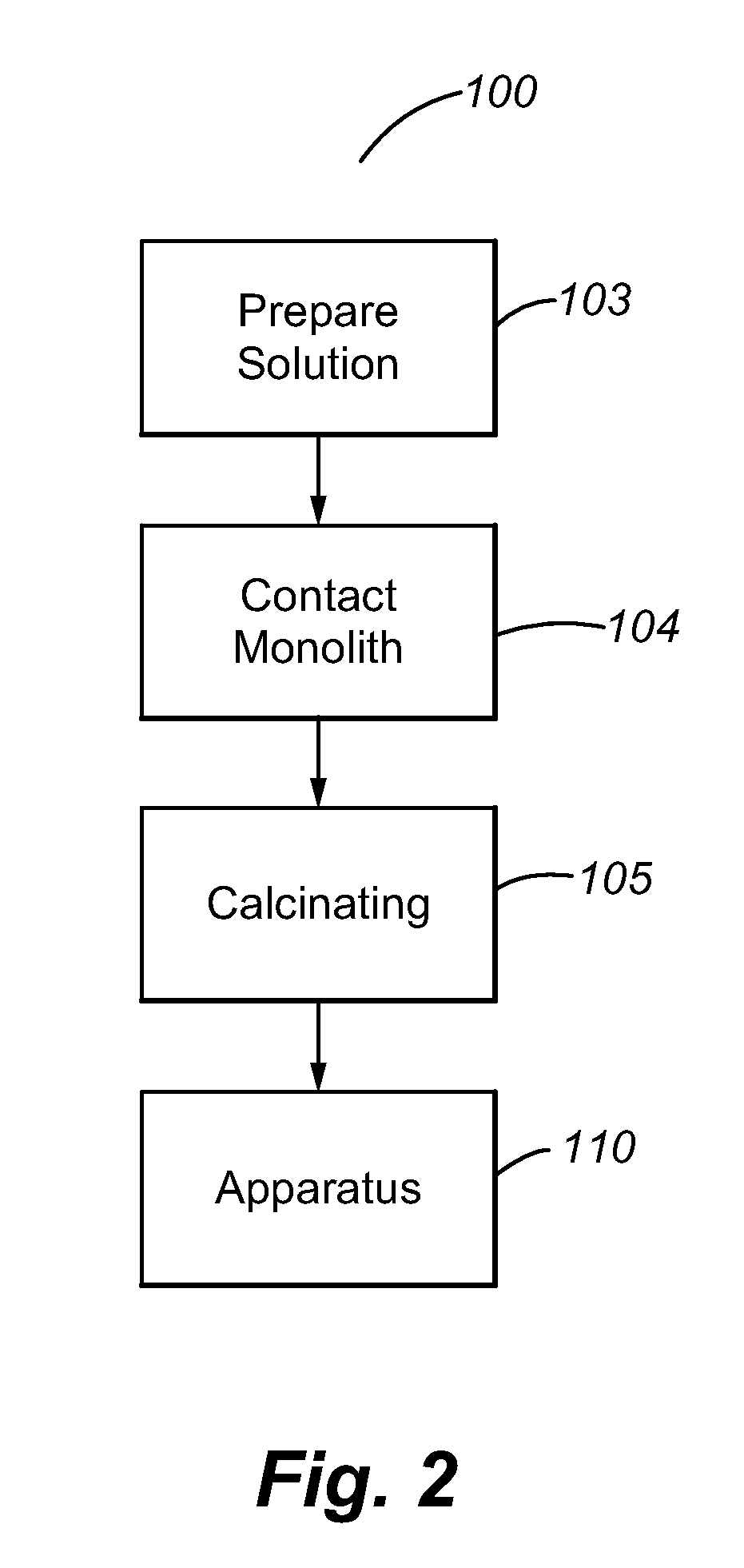

Porous and durable ceramic filter monolith coated with a rare earth for removing contaminants from water

InactiveUS20100230359A1Reduce arsenic levelsReduce pollutantsOther chemical processesSolid sorbent liquid separationMulti pollutantRare earth

The invention is directed generally to a porous and durable ceramic filter monolith coated with one or more rare earth-containing compositions for removing contaminants from a fluid, particularly for removing one or more contaminants from water.

Owner:MOLYCORP MINERALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com