Robot for cleaning and detecting pipes

A technology of robots and pipelines, applied in the field of robots, can solve problems such as inability to complete one-time cleaning, difficulty in achieving satisfactory results, poor stability of robots, etc., and achieve the effects of no tail flicking, low price, and avoiding failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

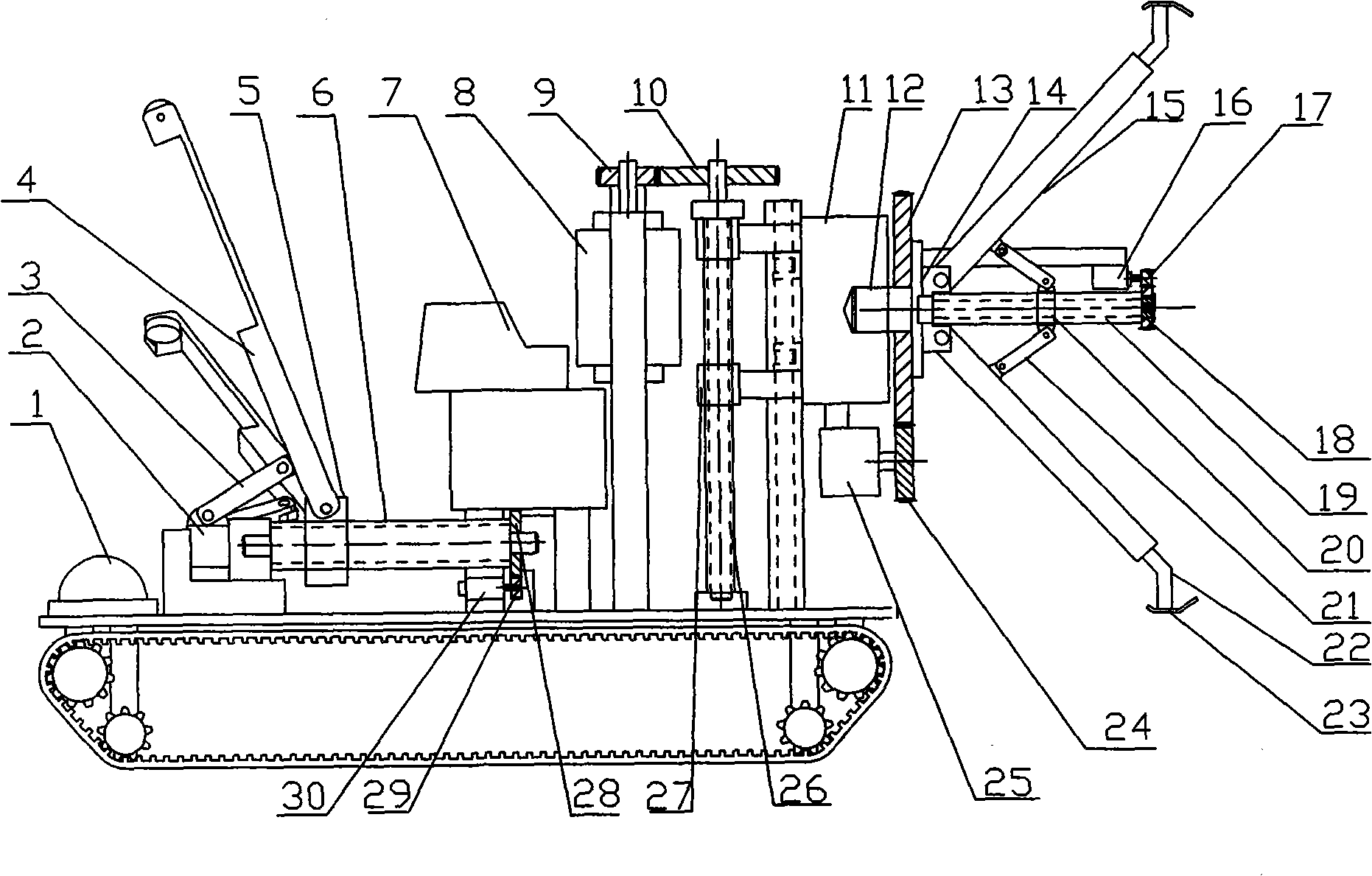

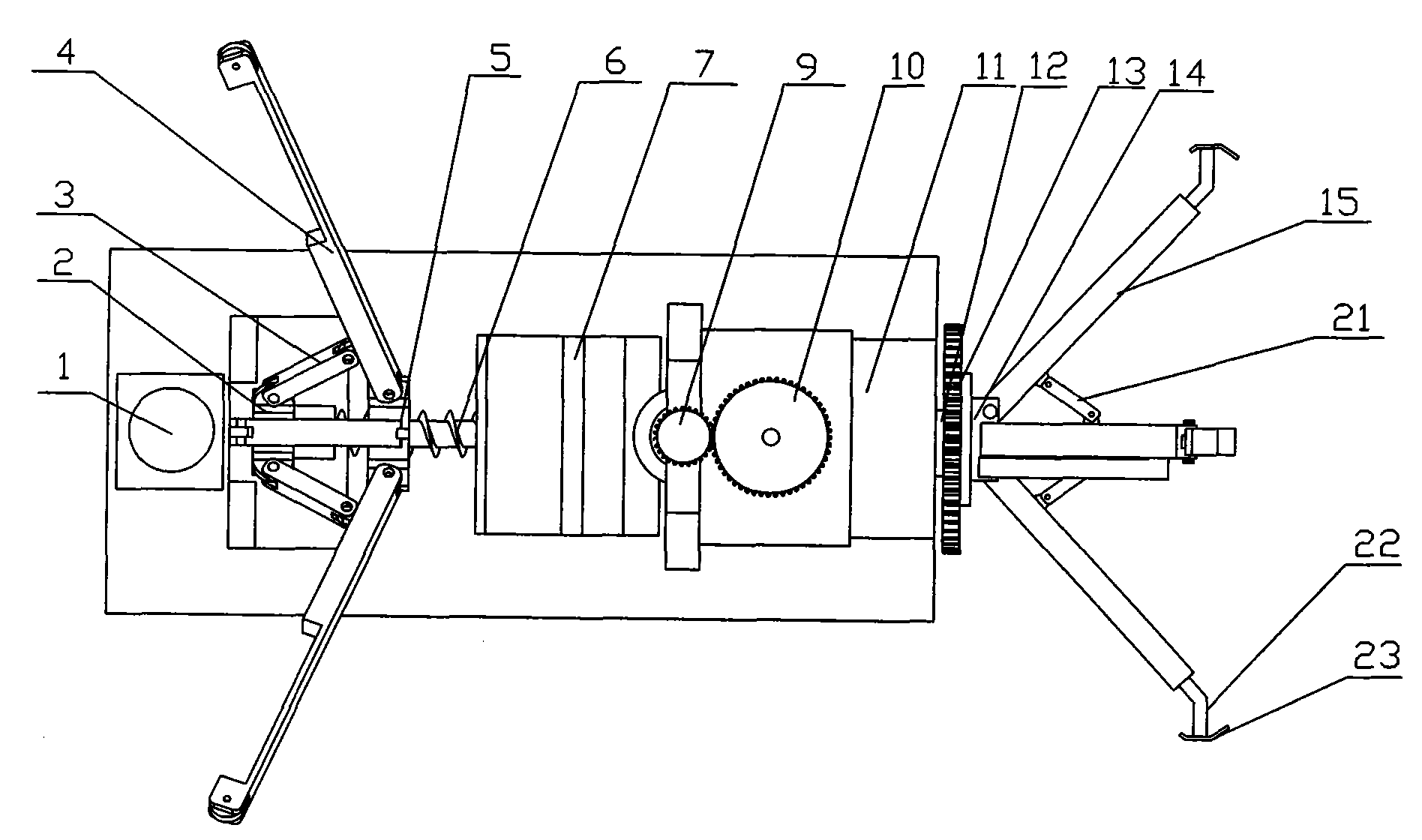

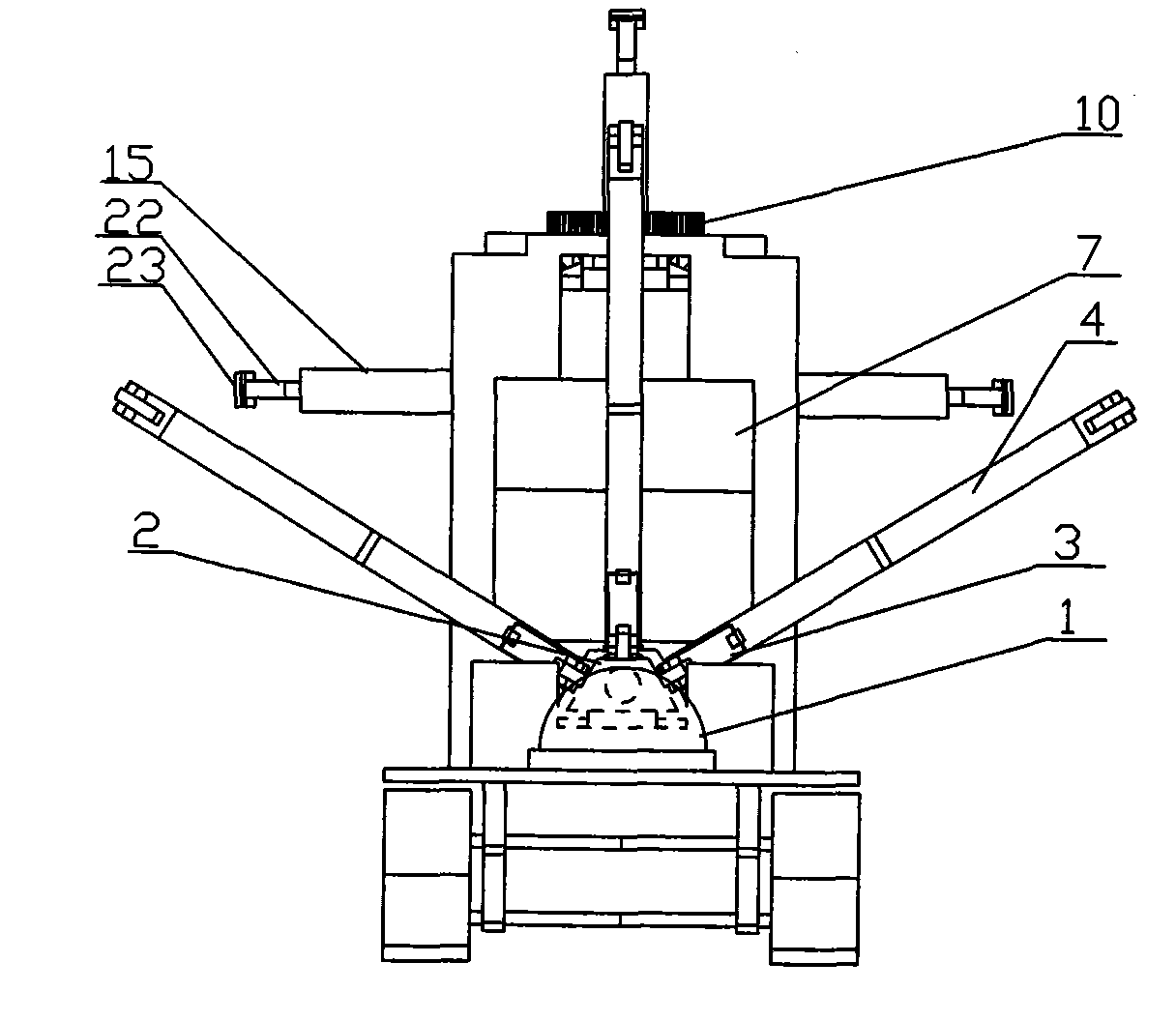

[0020] The present invention is a robot for central air-conditioning pipeline cleaning and detection, such as Figure 1 to Figure 5 As shown: It is mainly composed of two parts: mechanical system and control system, with simple structure, convenient maintenance and low failure rate.

[0021] 1. Mechanical system:

[0022] The mechanical system is composed of a mobile trolley, a cleaning operation device installed on the mobile trolley, a positioning guide device located at the rear of the mobile trolley, and a detection device located at the rear of the mobile trolley.

[0023] The mobile trolley is a crawler trolley, which is a mobile carrier and task carrying platform for performing central air-conditioning cleaning tasks.

[0024] Cleaning operation device: This device is the specific mechanism for the enti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com