Quick sweep device and quick sweep method for sieve mesh of lime milk rotary screen

A technology of cleaning device and sieve, which is applied in the field of cleaning tools, can solve the problems of the sieve cleaning process, unclean cleaning, and labor-intensive, etc., and achieve the effect of simple operation, reduced labor intensity, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Further illustrate the present invention below in conjunction with accompanying drawing. It should be understood that the following description is exemplary and does not constitute any limitation to the present invention.

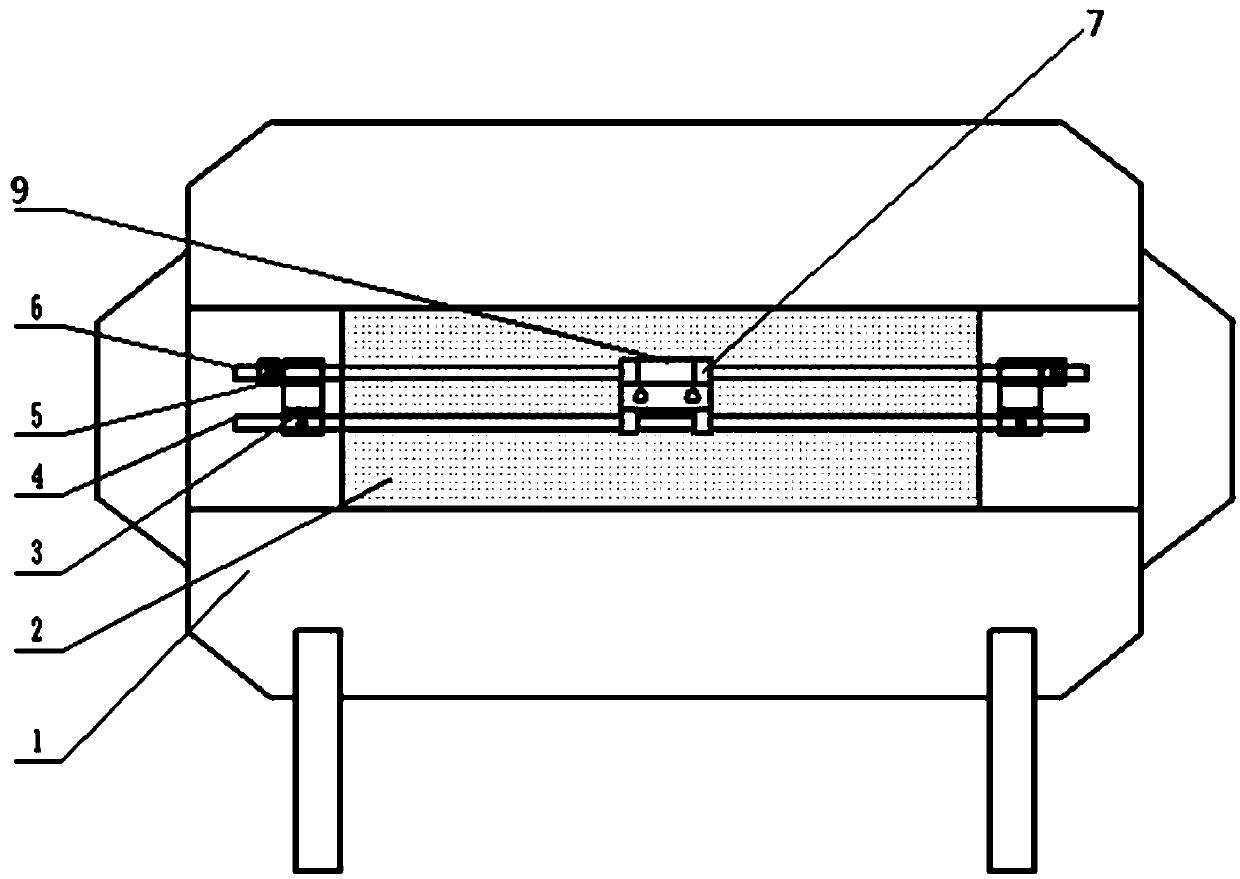

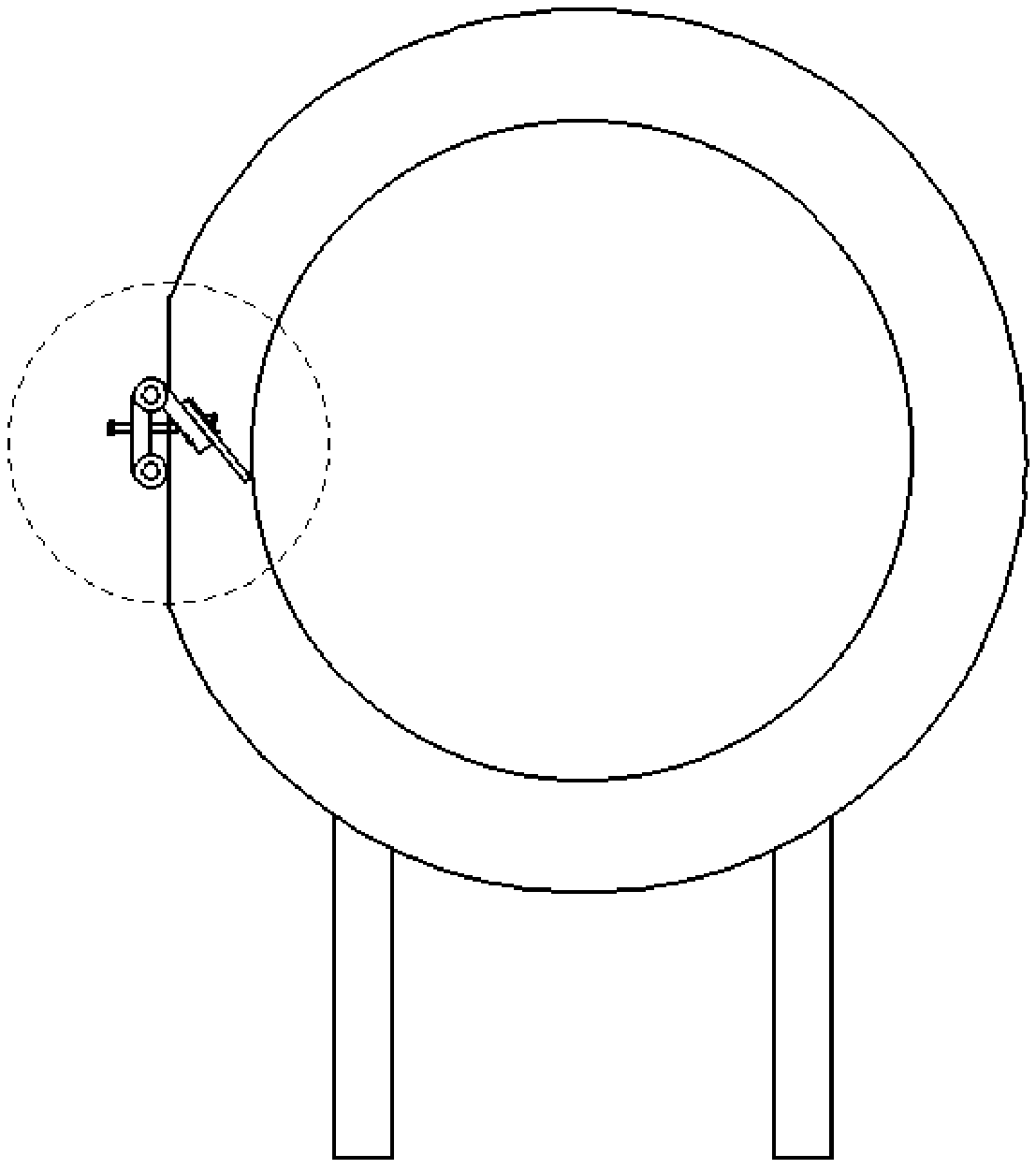

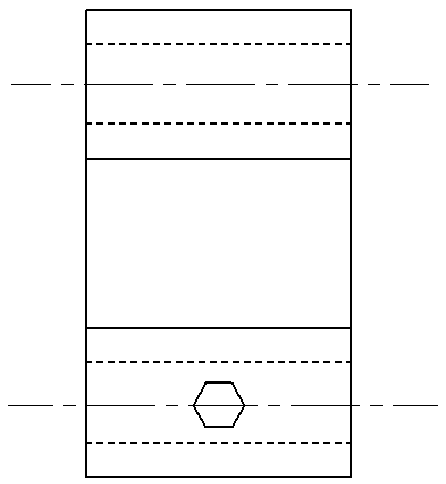

[0039] According to one embodiment of the present invention, propose a kind of gray milk rotary sieve screen cleaning device, as Figure 1-12 As shown, it includes a cleaning support mechanism installed on one lateral side of the gray milk rotary sieve screen, a moving mechanism 7 that can move left and right on the cleaning support mechanism, and a moving mechanism that can move with the moving mechanism and can be used to clean the gray milk rotary sieve screen. Cleaning mechanism 9, the cleaning support mechanism includes lifting lugs 3 fixed on both sides of the gray milk sieve body, threaded rods 6 passing through the round holes 17 at the upper ends of the lifting lugs on both sides and crossed on the lifting lugs on both sides, passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com