Patents

Literature

172results about How to "Significant technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

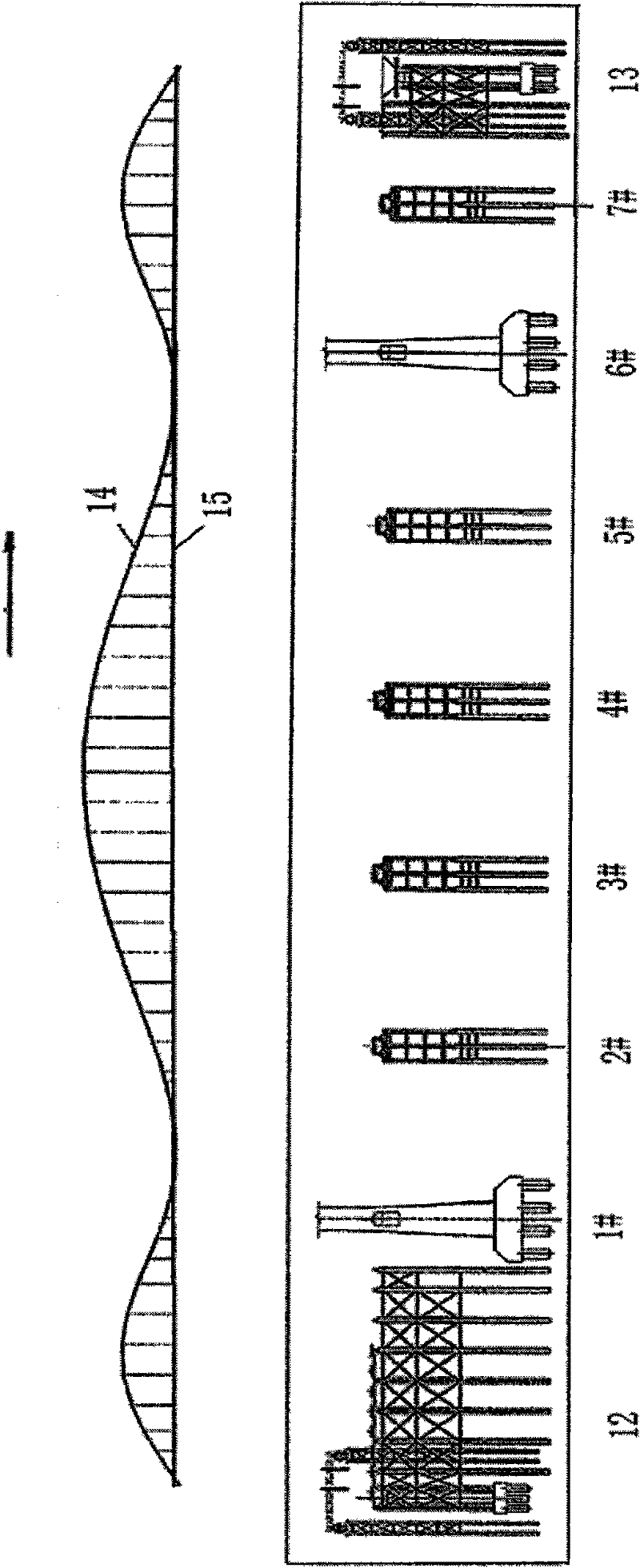

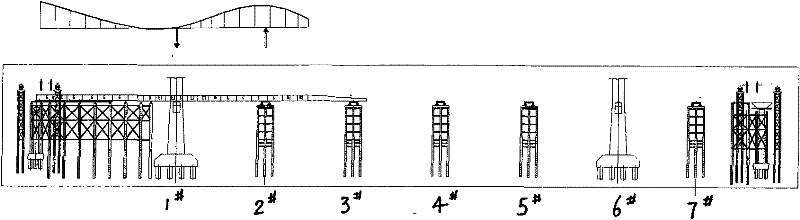

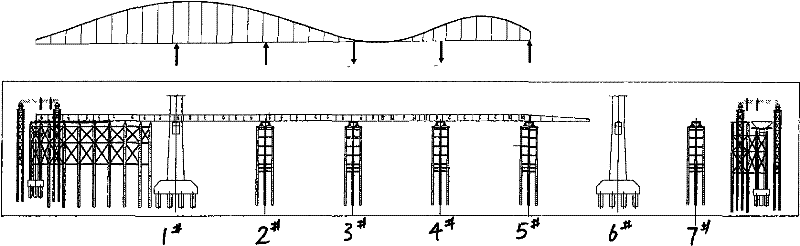

Bridge pushing construction method

ActiveCN102477717ADuration is not affectedSave materialBridge erection/assemblySocial benefitsEngineering

The invention discloses a bridge pushing construction method. In the method, the level of a temporary pier support is adjusted as required to enable a bridge bottom to be in effective close contact with the temporary pier support, thereby actively controlling the counter force of a temporary pier and the internal force of a bridge so as to achieve the same effect with linear or same-radius vertical curve bridge pushing construction. The concrete method is as follows: in the gaps formed by assembling bridge sections, by utilizing a synchronous jack, bulges at convex parts on a curve of the bridge bottom are lifted, and bulges at concave parts are lowered. The pushing construction can be suitable for bridges with change of curvature of vertical curves at bridge bottoms, including bridges with variable heights or bridges provided with multiple sections of composite vertical curves. The bridge pushing construction method disclosed by the invention breaks through and develops the existing bridge construction specification and expands the range of application of pushing construction; and compared with other methods, the bridge pushing construction method can save materials, is fast and safe in construction, and has obvious technical, economic and social benefits.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

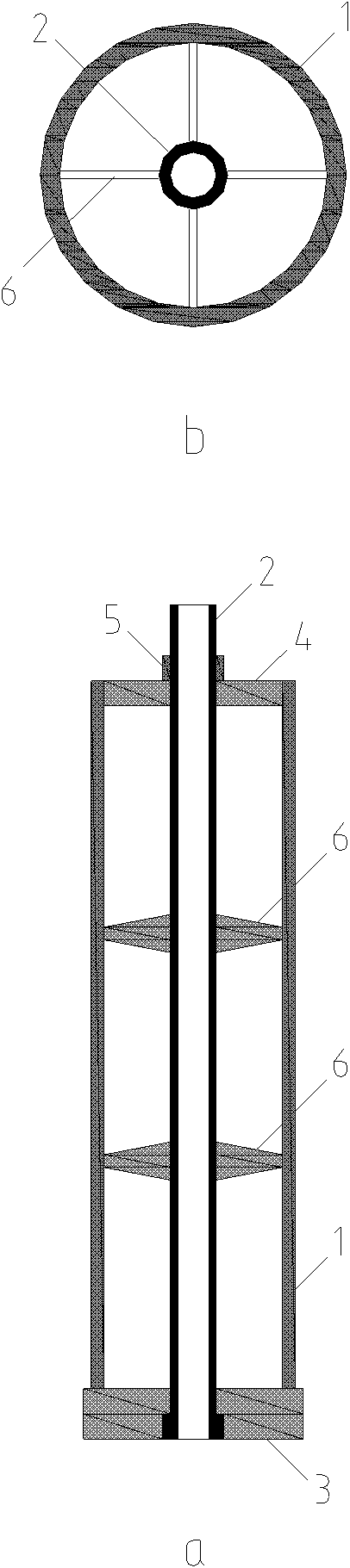

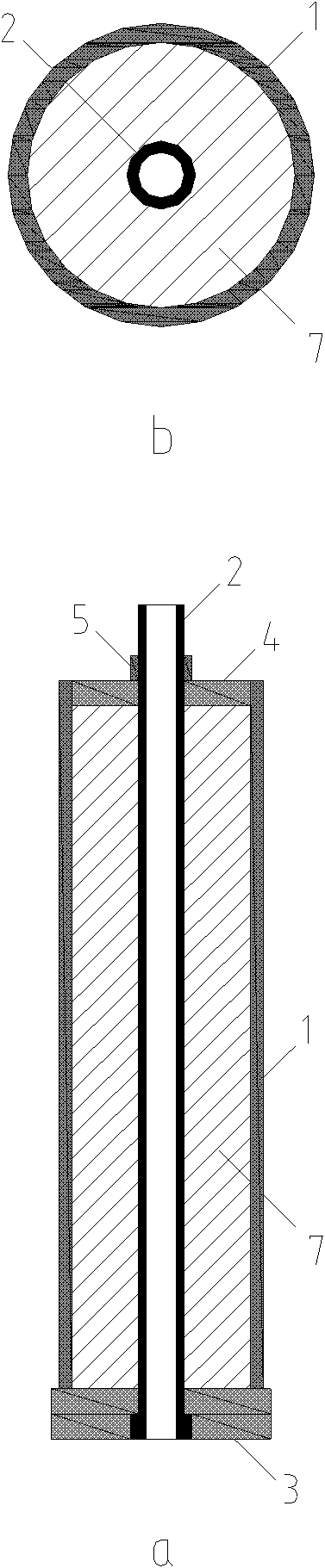

Whole process construction method of driven cast-in-place piles and special device for same

ActiveCN102286970ASimple packagingEasy to controlFoundation testingBulkheads/pilesEconomic benefitsSoil horizon

The invention provides a whole process construction method of driven cast-in-place piles and a special device for the same. The special device comprises pile pipes and base plates, wherein the pile pipes comprise class-A pile pipes, class-B pile pipes and class-C pile pipes. The whole process construction method comprises a pile testing method, a pile manufacturing method, a pile measuring method and a bottom vibration method for inserting reinforcement cages later. The construction method and the device have the following beneficial effects: the problem of higher control difficulty and pile tip cost of the traditional internally driven piles is solved; compared with the long augered press-grouting piles, the driven cast-in-place piles manufactured with the construction method have the pile tip bearing capacity improved by several times; with respect to the aspects of pile testing and pile measuring, the pile tip resistance is obtained not by pressing the whole piles but by pressing the cast-in-place pipes or inner tips with sections being much smaller than the sections of the whole piles, the pressed pile tonnage is greatly reduced and the pile testing and measuring costs and construction periods can be substantially reduced; the ultimate resistance of the tips of the long augered press-grouting piles with diameter being 800mm under the given soil horizon condition is within 400t, but the ultimate resistance of the tips of the piles manufactured by using the construction method exceeds 1300t, which is more than three times that of the tips of the long augered press-grouting piles; and the construction method and the device have good technical and economic benefits.

Owner:毕建东

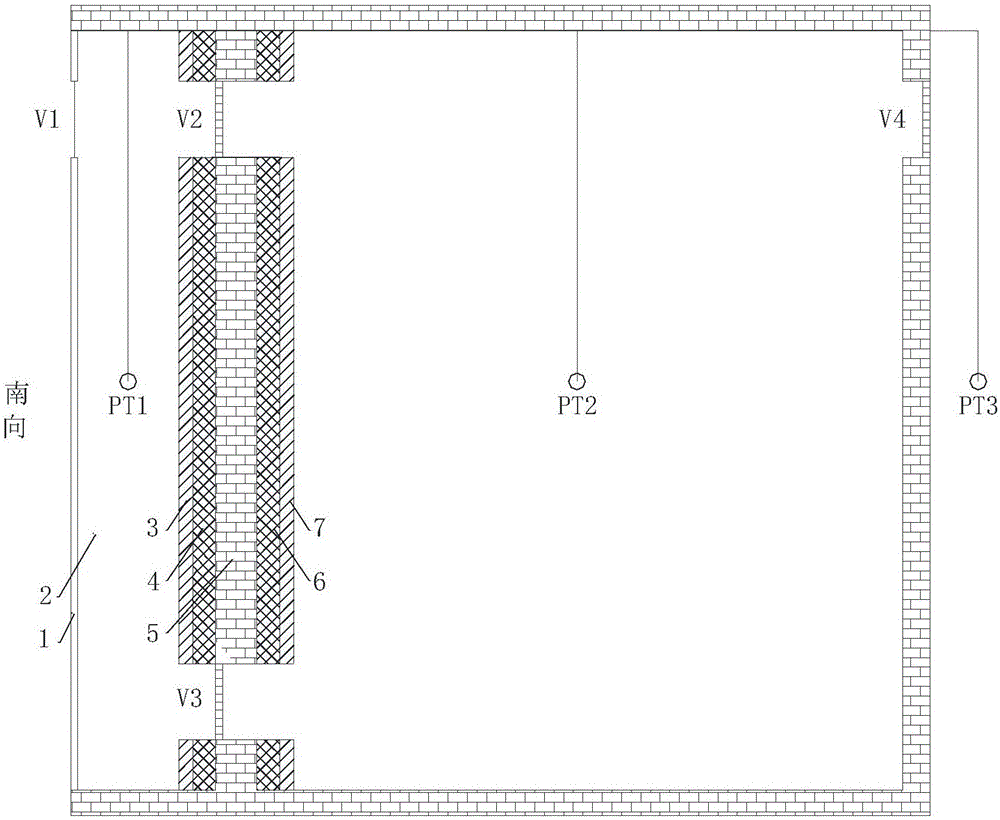

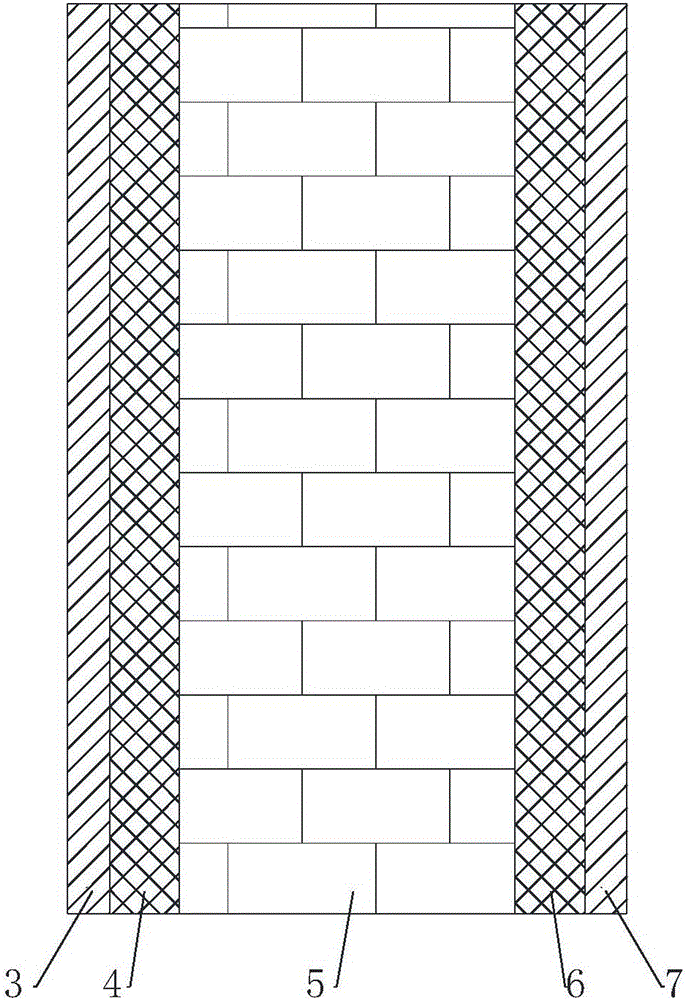

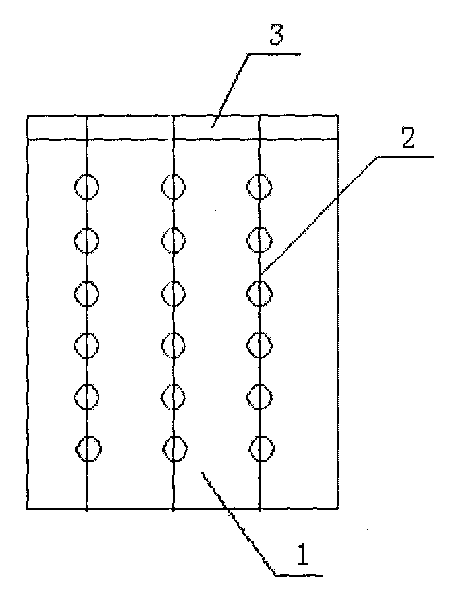

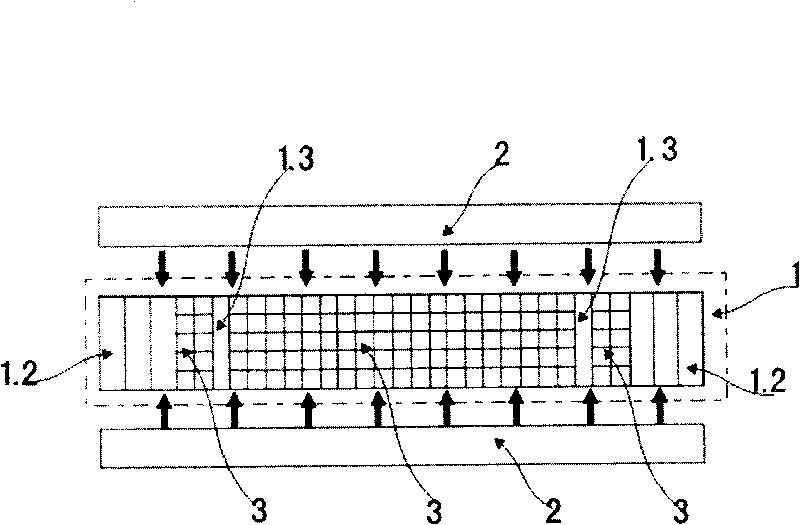

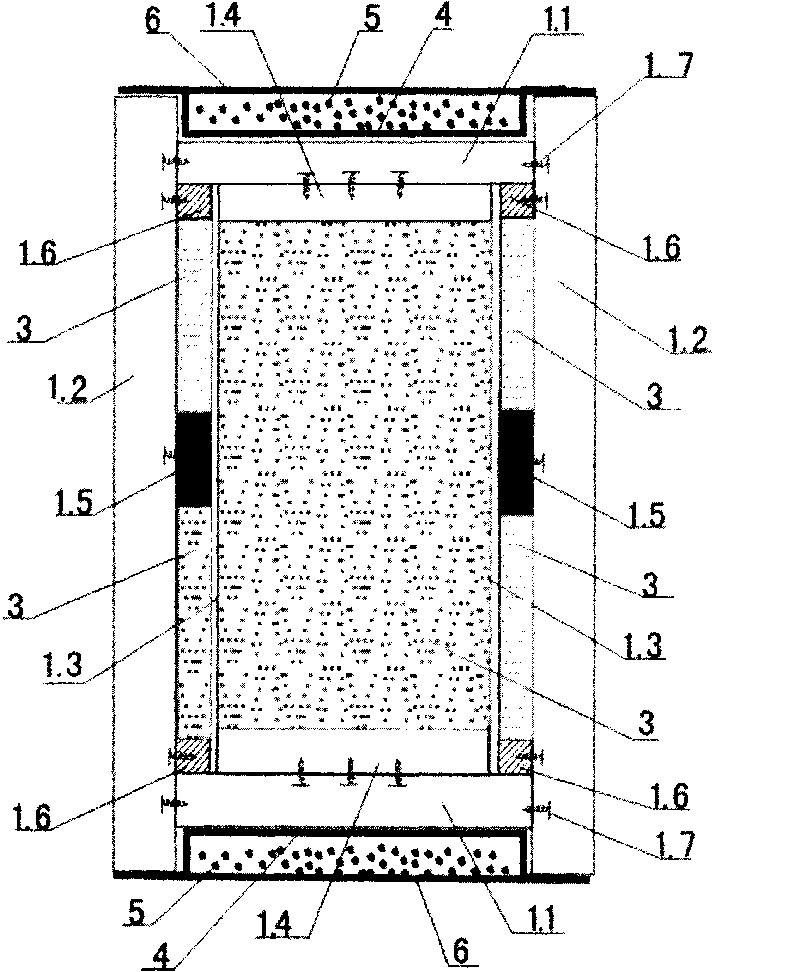

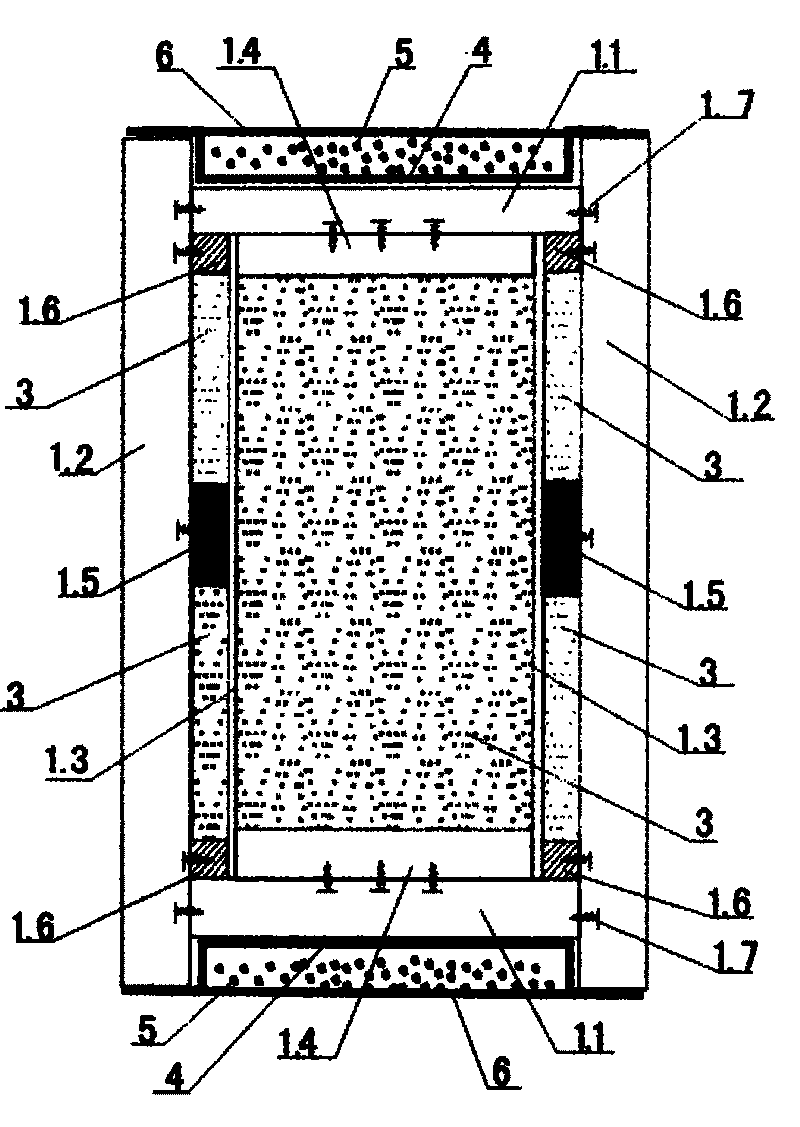

Self-regulating phase change Trombe wall

InactiveCN106836522AEnsure the role of latent heat storageGuaranteed package stabilityWallsTrombe wallParaffin oils

The invention discloses a self-regulating phase change Trombe wall. The self-regulating phase change Trombe wall is composed of a glass layer (1), an air layer (2), a first phase change wall layer (3), a first thermal insulating layer (4), a concrete wall layer (5), a second thermal insulating layer (6) and a second phase change wall layer (7) which are sequentially arranged from outside to inside, wherein the phase change temperature of the first phase change wall layer (3) is 27-29 DEG C; the phase change temperature of the second phase change wall layer (7) is 17-19 DEG C; both the first phase change wall layer (3) and the second phase change wall layer (7) are obtained by melting and blending the raw materials including high-density polyethylene, expanded graphite and paraffin. By improving the key heat storage wall structure, the setting manner of the heat storage wall structure, the setting mode of a ventilation port, the switching conditions of opening and closing states and the like, the self-regulating phase change Trombe wall can effectively solves the problem in the prior art that Trombe walls are insufficient in heat supply in winter days without sun or too hot in summer.

Owner:HUAZHONG UNIV OF SCI & TECH

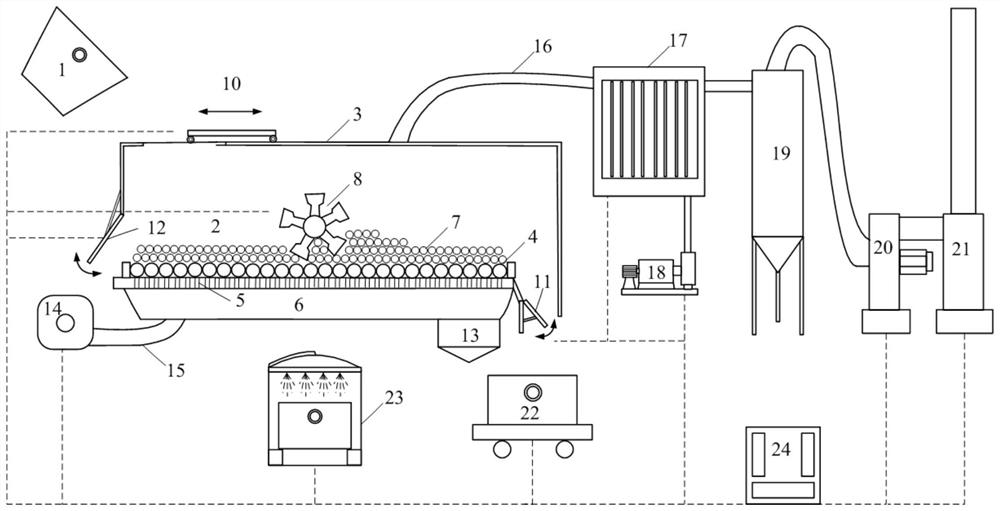

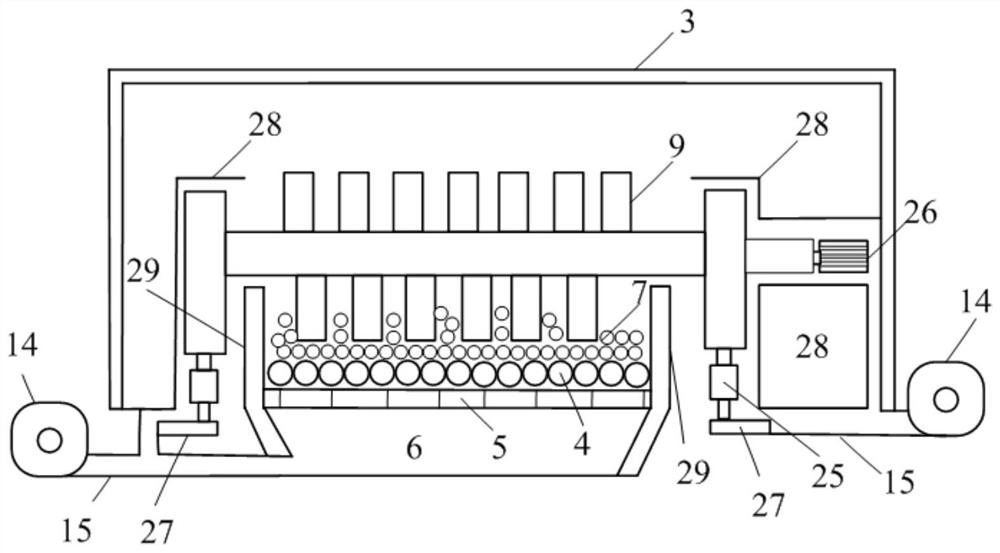

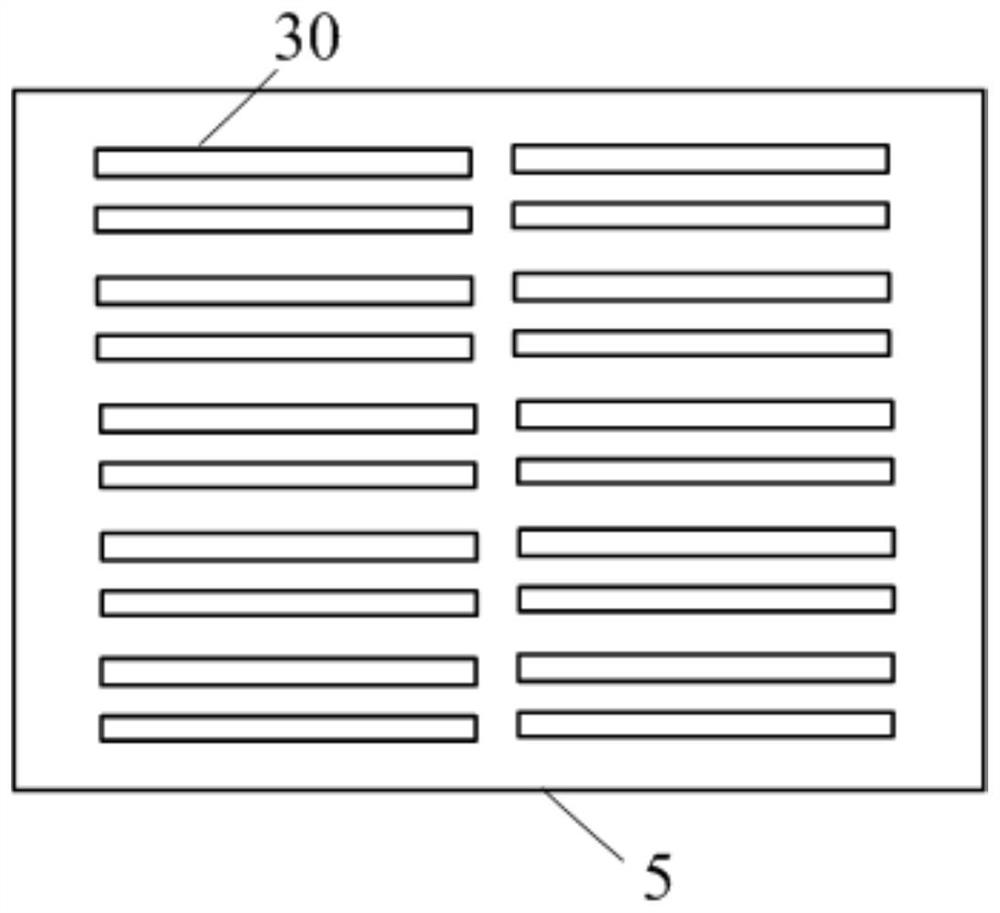

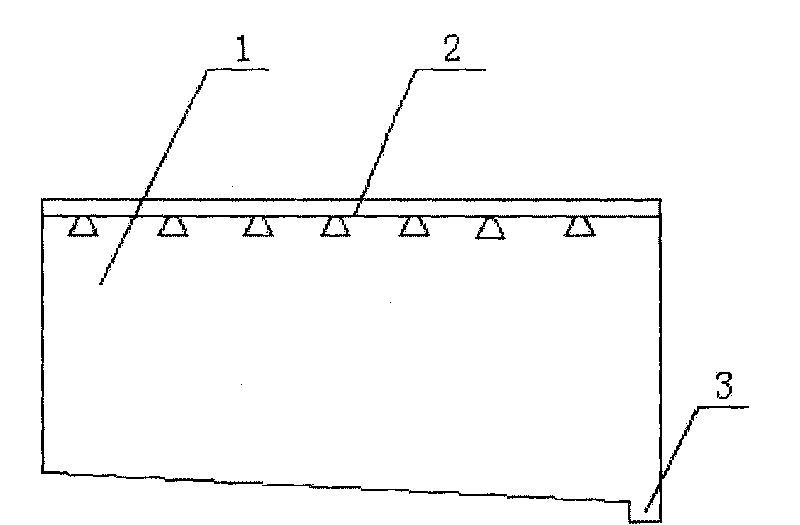

High-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method

PendingCN111850194AImprove pulverization rateImprove processing efficiencyExhaust gas handlingRecycling and recovery technologiesSlagDust control

The invention relates to a high-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method. A crushing bed is adopted as a high-temperature steel slag treatment carrier, a crusher is adopted for efficiently crushing steel slag, meanwhile, cold air is introduced into a bottom blowing air cooling box to solidify and cool the high-temperature steel slag, and meanwhile, the crusher rotates at a certain speed, moves forwards and backwards and rotates to crush the steel slag. A heat exchanger and a generator are adopted for cooling the high-temperature steel slag to generate high-temperature waste heat for recovery and power generation. The crushing capacity is high, the steel slag treatment efficiency is greatly improved, and meanwhile, waste heat recoveryand power generation can be realized by adopting air cooling heat exchange. Efficient crushing and waste heat recovery of the high-temperature steel slag are realized, a steel slag water cooling system device is omitted, a simple dry dust removal mode is adopted to replace a wet flue gas treatment system caused by a previous water cooling process, the advantages of being high in automation degree,small in space occupation, good in leakproofness, low in system investment, capable of achieving ultra-clean emission and the like are achieved, and the comprehensive economic benefits of steel slagtreatment are improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

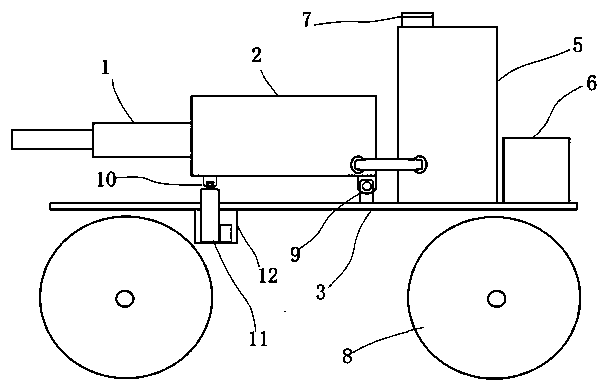

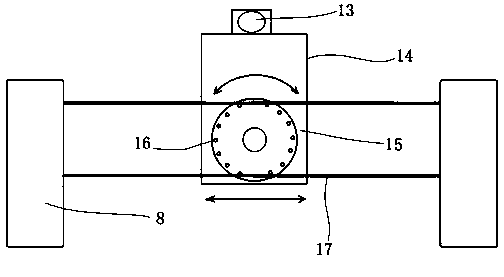

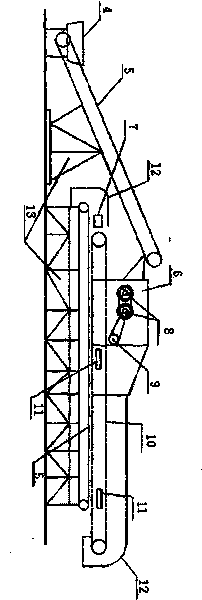

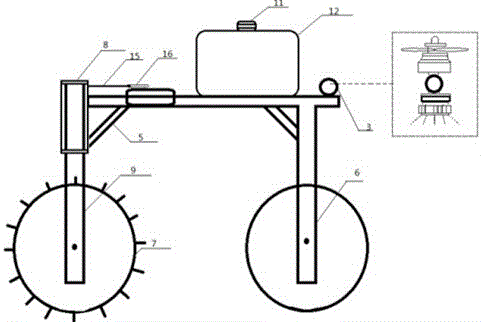

Farmland plant protection robot

ActiveCN104041478AReasonable designWide applicabilityInsect catchers and killersRemote controlControl system

The invention discloses a farmland plant protection robot and belongs to the technical field of agricultural plant protection machines. The farmland plant protection robot is composed of a vehicle body, a steering system, a control system, a driving system and a spraying system and is characterized in that the control system comprises a control cabinet and a remote control, the control cabinet is located at the rear of the vehicle body, the steering system is located at the front end of the vehicle body, the driving system is located in the middle of the vehicle body, and the spaying system is located in the front of the vehicle body. The remote control type plant protection spraying robot is reasonable in design, wide in application range and excellent in technology; first, the vehicle body of the robot is narrow so that the robot can pass through space between rows of crops easily; the plant protection robot can carry a mist sprayer instead of people or an ordinary machine, and thus the plant protection operation is safer, more efficient and wider in application range.

Owner:芜湖多加农业科技有限责任公司

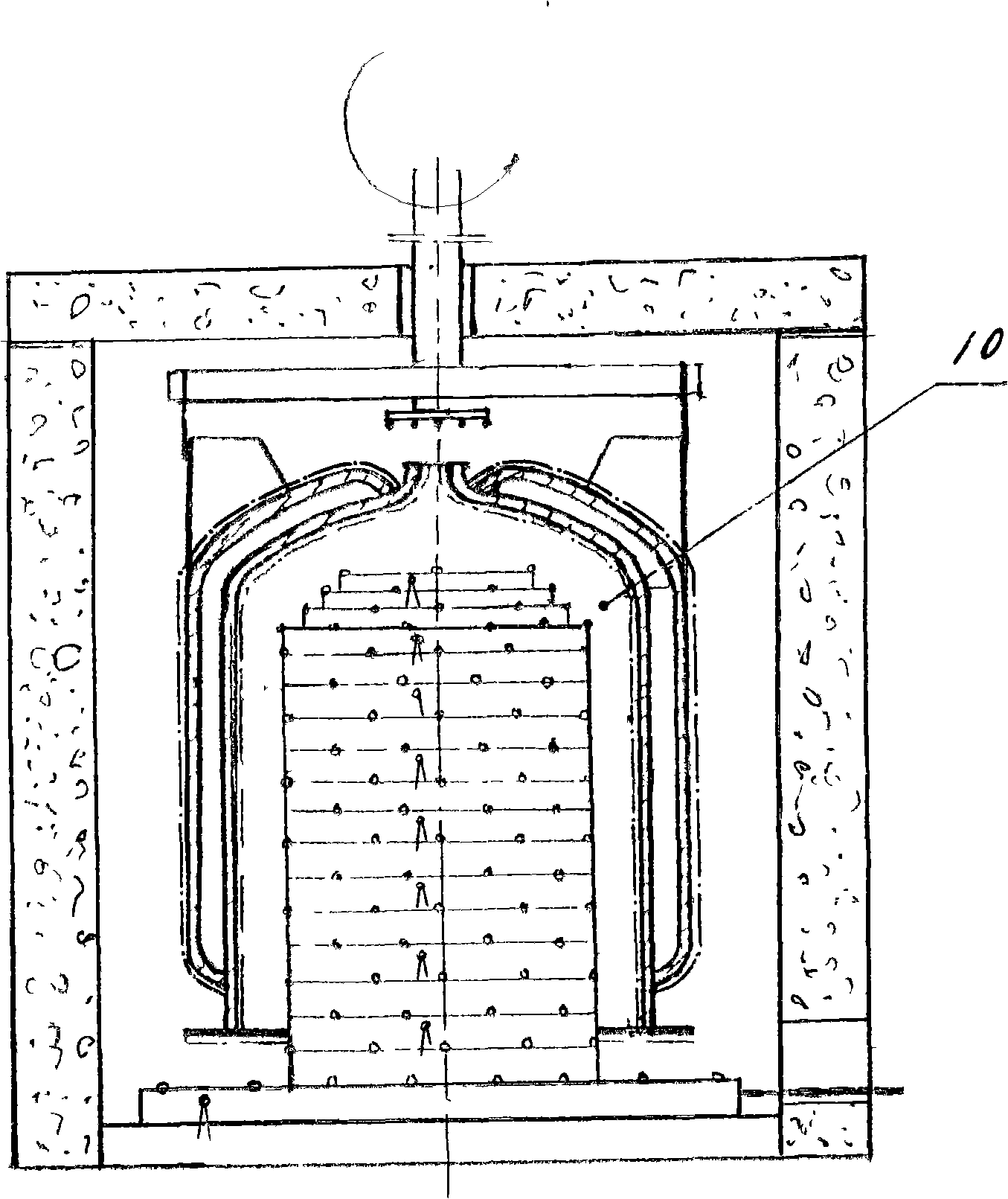

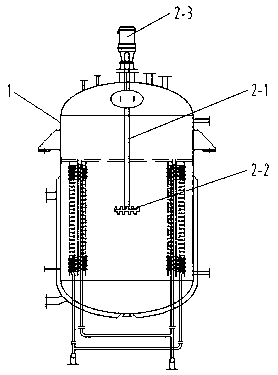

New glass-lined reactor and manufacturing method thereof

InactiveCN102389758AQuality improvementFully combinedChemical/physical/physico-chemical processesTemperature controlManufacturing technology

The invention relates to a new glass-lined reactor and a manufacturing method thereof which are used in the chemical and pharmaceutical industries and belong to the field of pressure vessels. The reactor is characterized in that new inner cylinder bodies and new outer jackets are welded into an integral structure; glass-lined protection glaze layers are coated and fired on the surfaces of butt welds on the inner cylinder bodies and the outer jackets; and the Supervision Regulation on Safety Technology for Pressure Vessel is comprehensively realized. The manufacturing method is characterized in that a precisely controlled inner heated electric furnace formed by intelligent temperature program controllers / regulators / recorders is adopted to implement staged controlled firing and an integral firing process with jackets; and full-automatic glaze slurry spraying equipment and an electrical heating and temperature controlling insulating cylinder are adopted for manufacturing. The reactor and the manufacturing method have the following advantages: the reactor initiates and lays a foundation for that the manufacturing technology standards of the glass-lined reactors in China all realize the Supervision Regulation on Safety Technology for Pressure Vessel and initiates and lays a foundation for datamation and automation of the core technology of controlled enamelling; the integral quality of the reactor is obviously superior to the current national standard; the reactor steps and is developed to innovate and be ahead of the conditions that the international outer heated electric furnace iron billets have no alternative to secondary forming during manufacturing and the core technology of controlled enamelling has the defect of uneven heating; and the integral quality of the reactor is superior to the international leading level, therefore the reactor has global market competitiveness.

Owner:朱文华

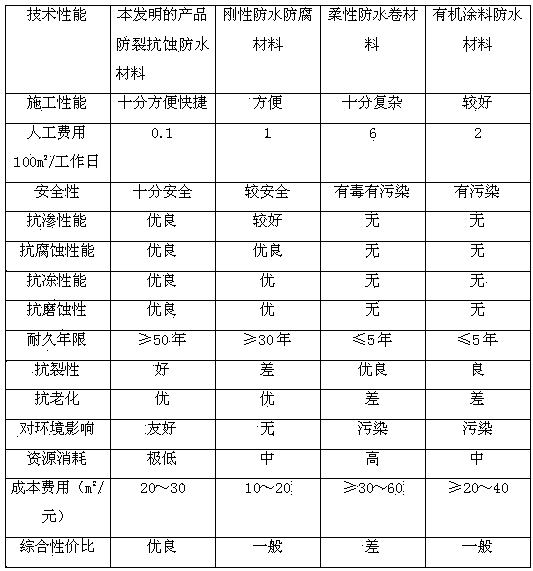

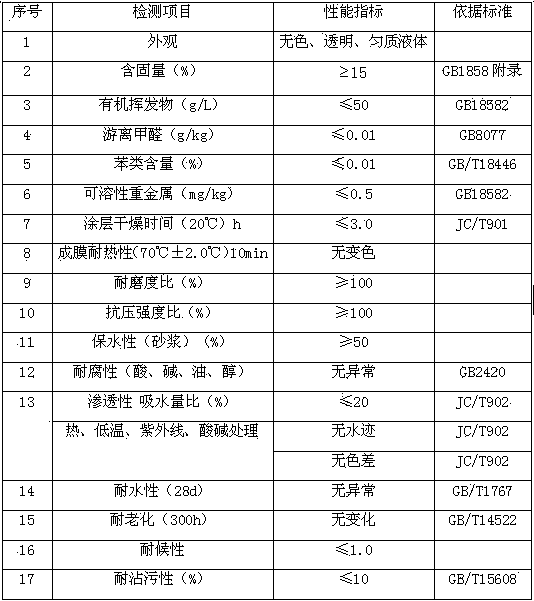

Environment-friendly type anti-cracking corrosion-resistant waterproof material and preparation method thereof

ActiveCN103554850AProvides both internal and external protectionExcellent rigidity, waterproof and anti-corrosion effectOther chemical processesPolyester coatingsCelluloseFiber

The invention discloses an environment-friendly type anti-cracking corrosion-resistant waterproof material and a preparation method thereof, solving the problems that the existing waterproof corrosion-resistant material is single in function, bad performance, high cost and short service life. The waterproof material disclosed by the invention consists of the following components in parts by weight: 5-15 parts of synthesized polyester resin, 3-6 parts of a penetrating agent, 1-3 parts of cellulosic fibers, 0.1-0.3 part of cellulose ether and 75-85 parts of a solvent. The invention further provides a preparation method of the waterproof material. A formula adopted by the invention can effectively achieve effect of internally and externally protecting. The environment-friendly type anti-cracking corrosion-resistant waterproof material disclosed by the invention is mainly used for infiltration type waterproof corrosion-resistant internal and external anti-corrosion engineering, which is infiltration-resistant, waterproof, moisture-proof, mildew-proof, corrosion-resistant, acid and alkali resistant, oil penetration resistant, corrosion-resistant, freezing-thawing resistant, cracking resistant, weather resistant, ageing resistant, and pollution-resistant.

Owner:苏笮斌

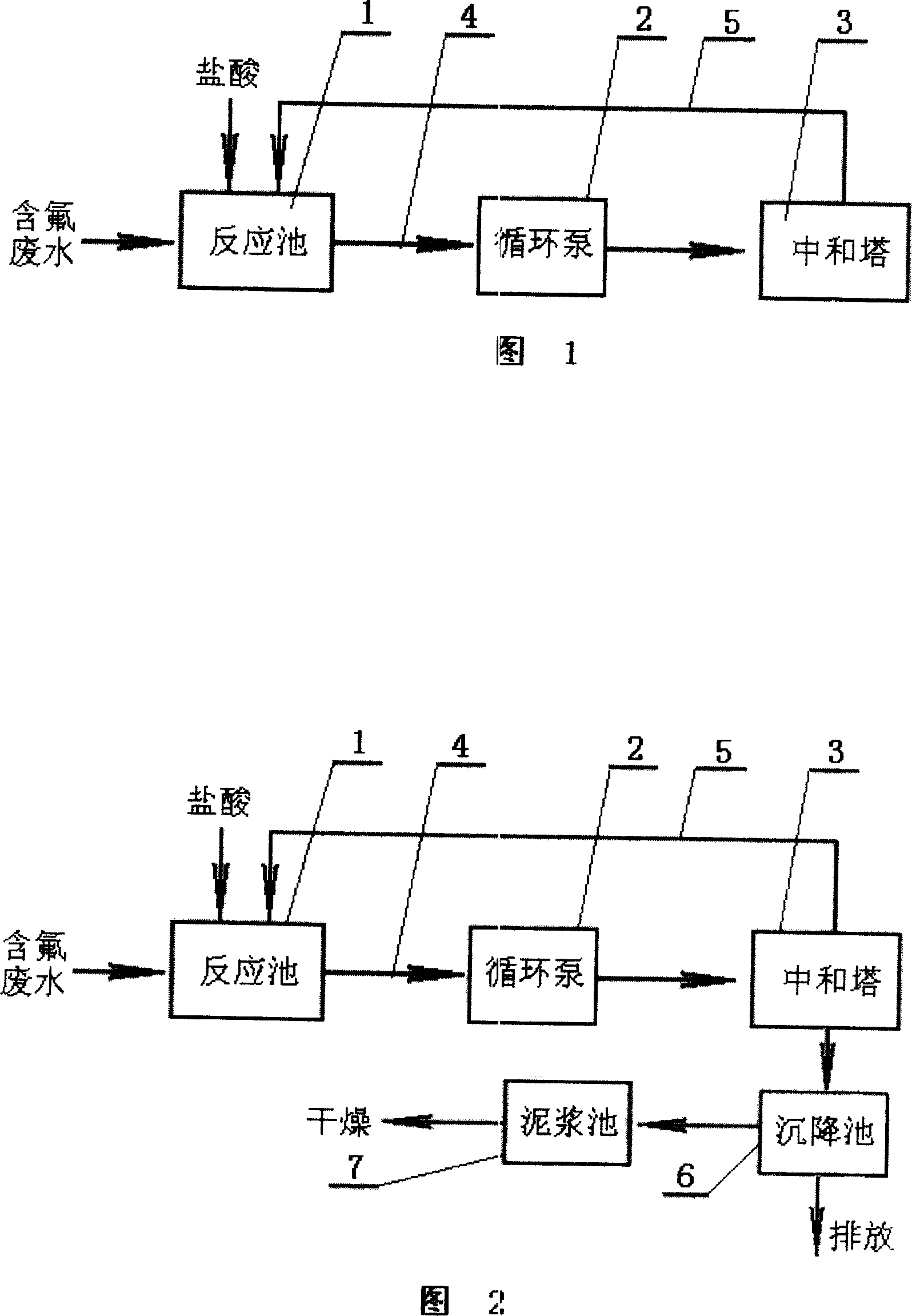

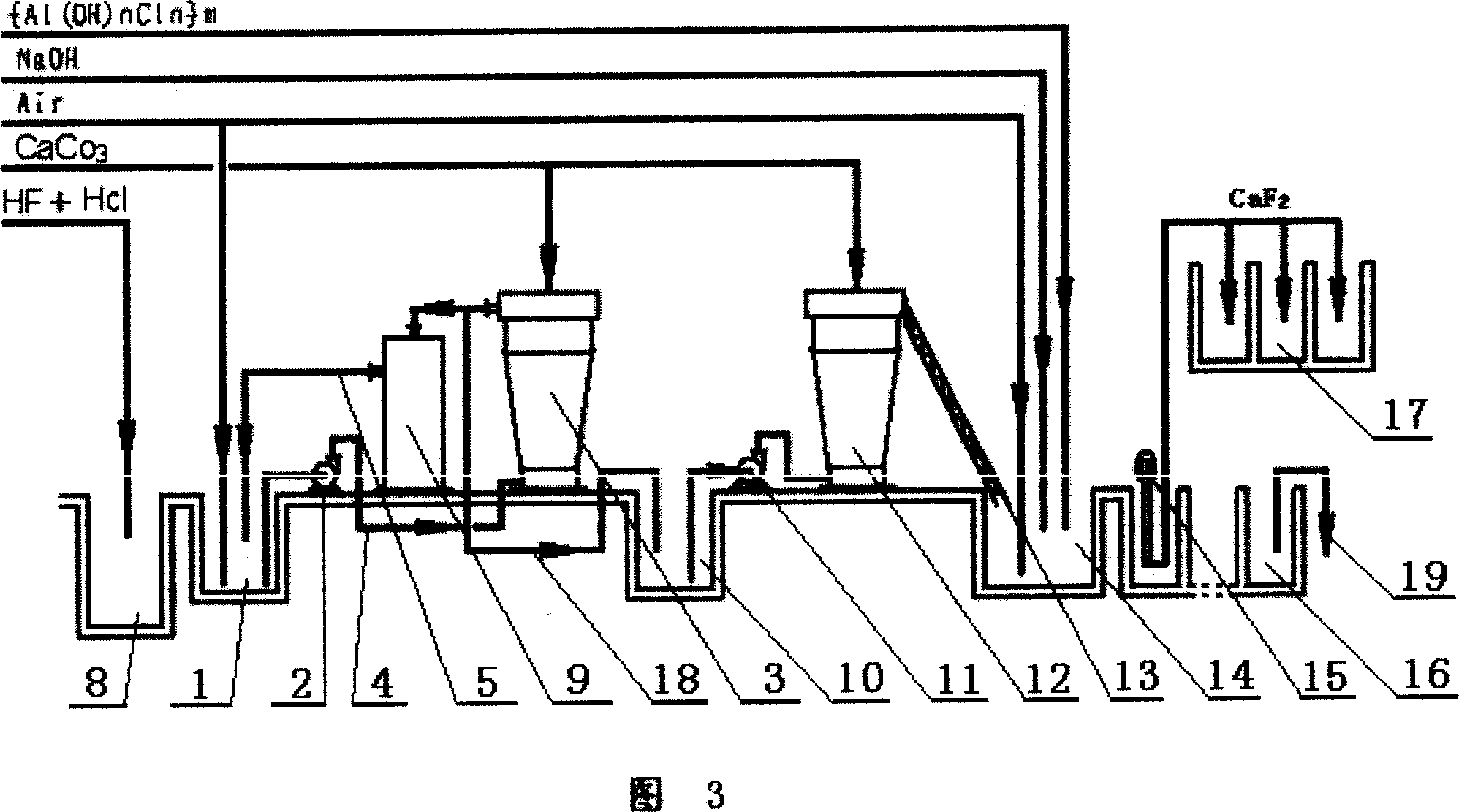

Method and device for treating fluorine-containing waste water using limestone

InactiveCN1962475ALow costReduce auxiliary workloadWater contaminantsMultistage water/sewage treatmentWater useDielectric

The invention discloses a disposing method and device of fluorine waste water through limestone, which comprises the following steps: adopting natural limestone as raw material; proceeding biochemical reaction to produce soluble calcium salt acid as middle dielectric; reacting soluble calcium salt acid and fluorine ion in the fluorine waste water to form indissolvable calcium fluoride and acid middle dielectric; reacting acid middle dielectric and limestone to produce soluble calcium salt; reacting soluble calcium salt acid and fluorine ion in the fluorine waste water to form indissolvable calcium fluoride and acid middle dielectric; circulating; disposing fluorine waste water until reaching standard. The corresponding disposing device contains reacting pond, circulating pump, neutralizing tower, sediment pond and sludge pond.

Owner:谢发达

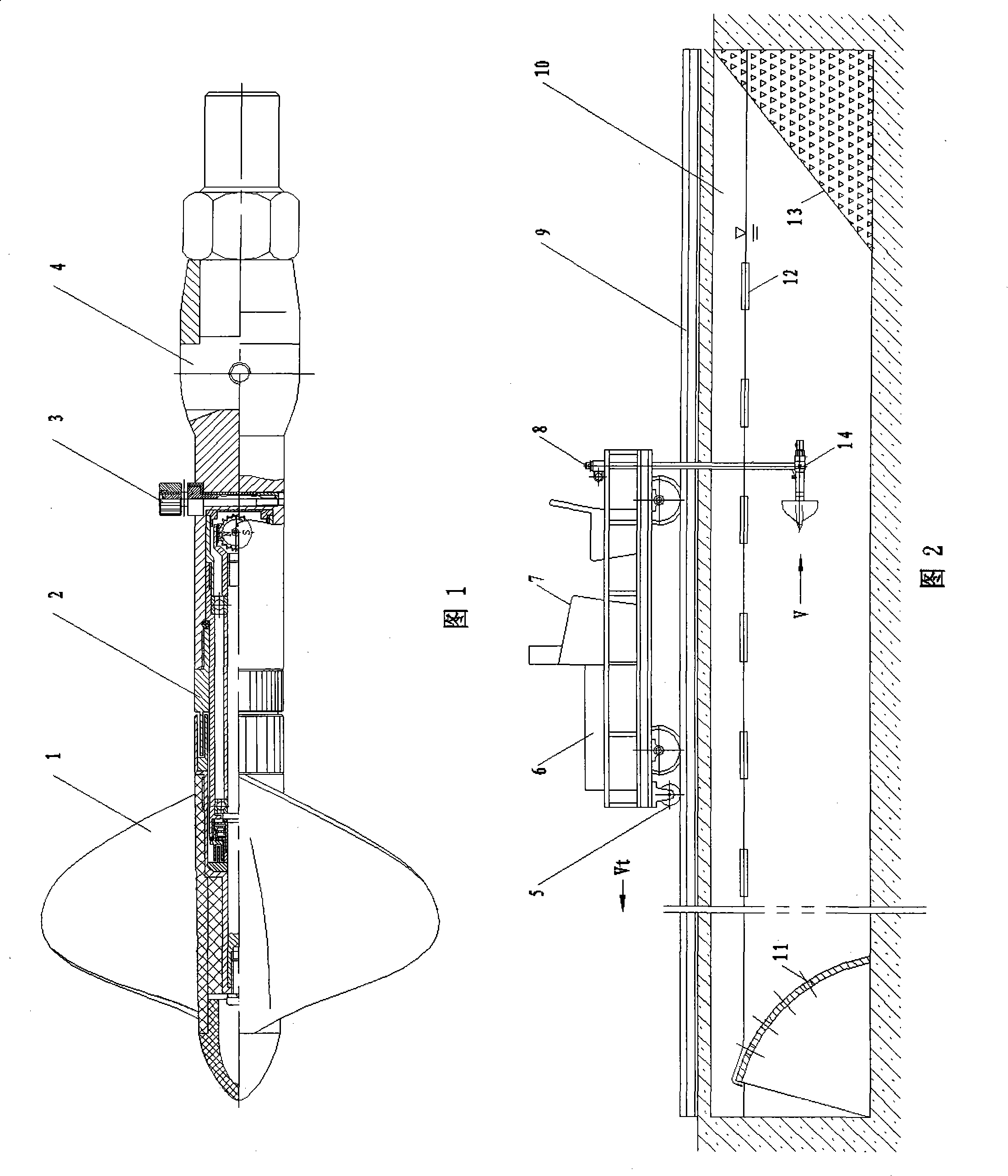

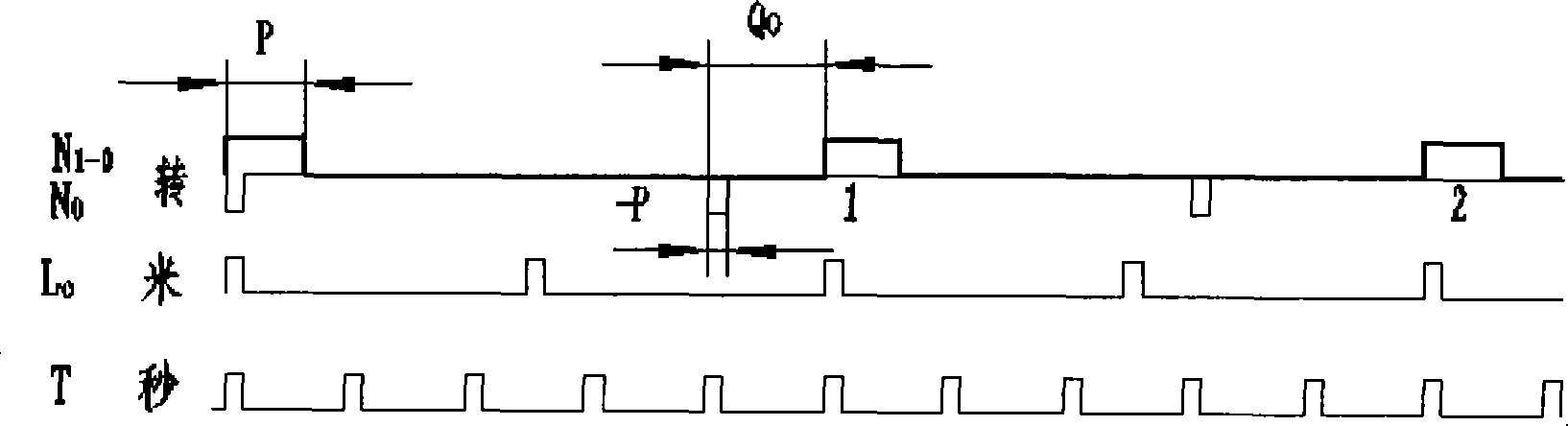

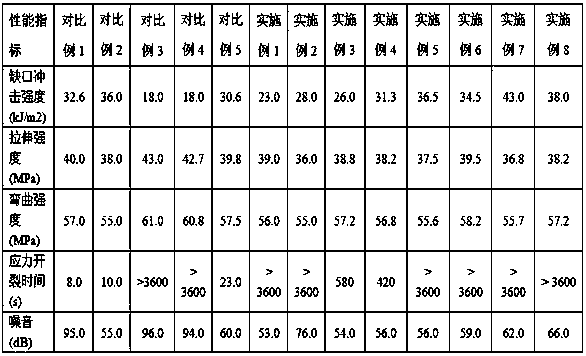

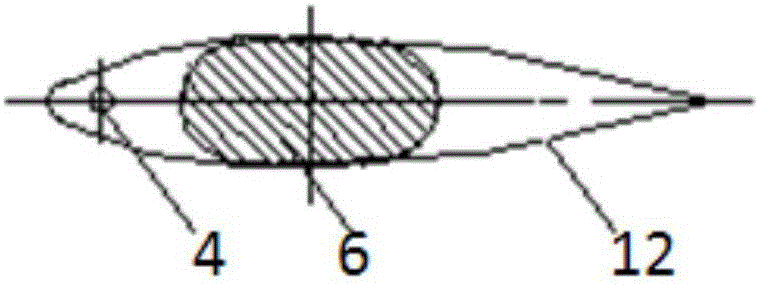

Method for designing rotary oar current meter norm edit value slow speed straight line formula

InactiveCN101251548ASmall and stable frictionReasonable structural designTesting/calibration of speed/acceleration/shock measurement devicesCurrent velocitySocial benefits

The invention relates to a design method for a low speed straight-line formula of a standard revision value of a helical current meter; the invention is characterized in that the steps of the method are as follows: the method is based on a high speed straight-line formula V=Kn+C, and uses a cut line to replace a low speed curve line; the cut line formula is as follows: V1=K1n1+C1; the inflection point formula is as follows: Vk=KnK+C; C1=C+delta C and delta K=delta C / nK are inputted in the low speed straight-line formula, and V1=(K-delta K)n1+(C+deltaC) is obtained; equalizing values which are calculated according to the high and the low straight-line formulas are as follows: delta K=0.0122 and delta C =0.0081, which are inputted in V1=(K-delta K)n1+(C+delta C) to obtain V1=(K-0.0122 )n1+(C+0.0081). The invention does not need to be tested under water while being manufactured; only if the initial rotation speed test meets the standard, the high speed straight-line formula is revised to the low speed straight-line formula by the standard revision value; when the invention is used by a user, directly reading the current velocity can be realized, thereby the method is quite convenient and has good technical, economic and social benefits.

Owner:JIANGSU NANSHUI TECH

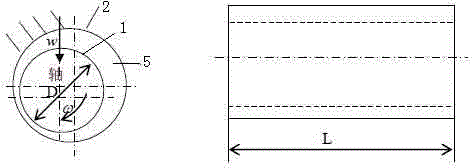

Novel energy-saving radial sliding bearing

ActiveCN104454980AImprove carrying capacityExcellent friction reductionBearing componentsSliding contact bearingsCarrying capacityThin layer

The invention provides a novel energy-saving radial sliding bearing, which is formed by matching a shaft and a bearing sleeve hole or bearing block hole. A bearing sleeve hole wall or bearing block hole wall at an inlet region of a convergent wedge-shaped pore of the bearing is coated by a thin layer material, and the surface-treated bearing sleeve hole wall or bearing block hole wall is paired with the shaft; a gap formed between the bearing sleeve hole wall or bearing block hole wall and the shaft is filled with lubricating oil. The novel energy-saving radial sliding bearing designed by adopting an interface slip technology and adopting a surface coating method has the advantages of great carrying capacity, low coefficient of friction and excellent energy-saving performance. Compared with the traditional interface-slip-free radial sliding bearing, the bearing provided by the invention has the advantages of obviously improved carrying capacity, and obviously improved antifriction and energy-saving performances, thus having an important application value.

Owner:怀宁吉利来精密机械科技有限公司

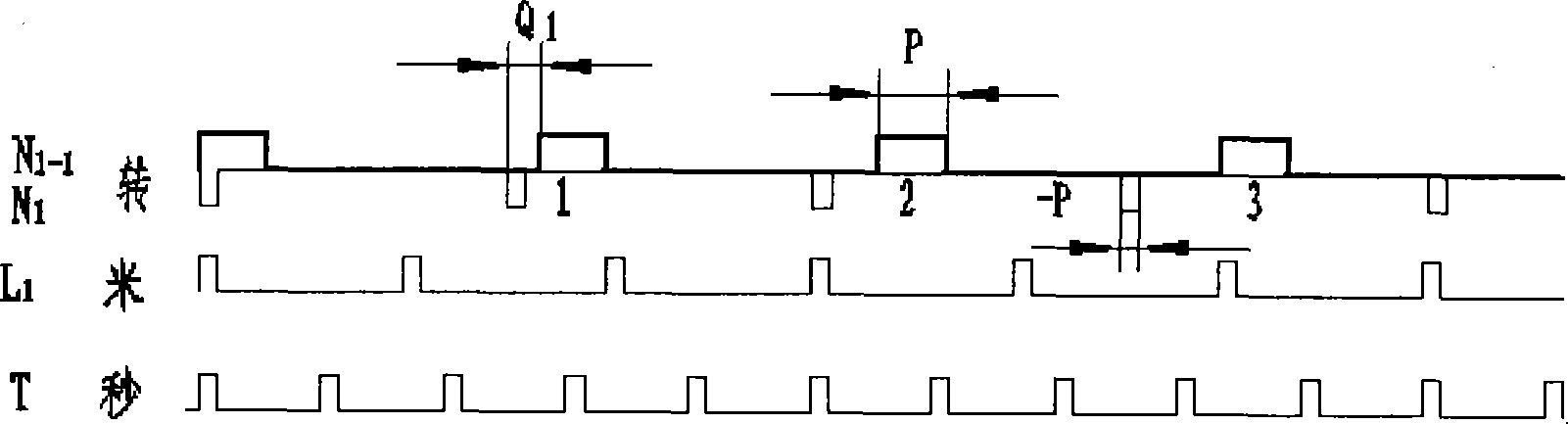

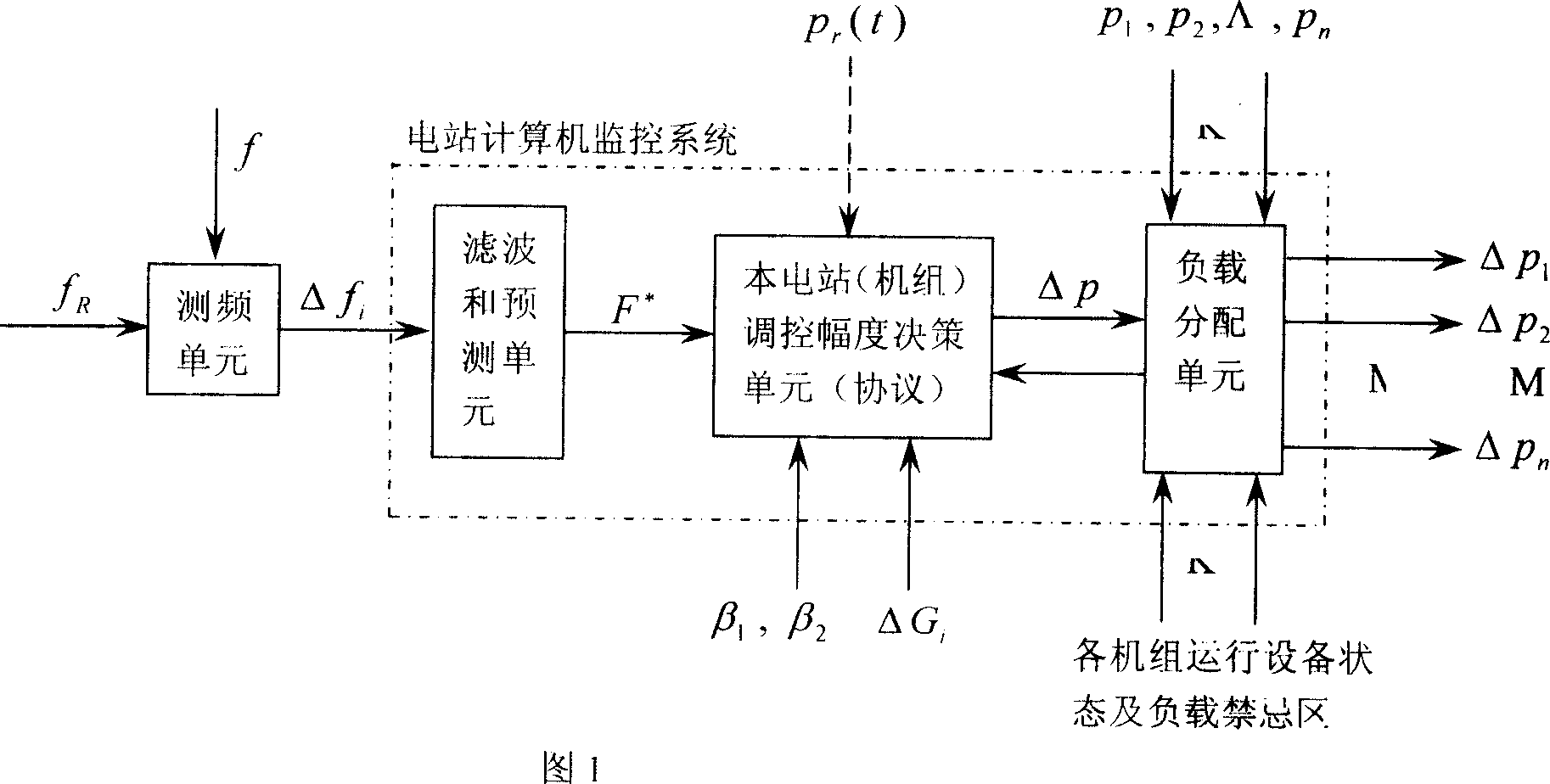

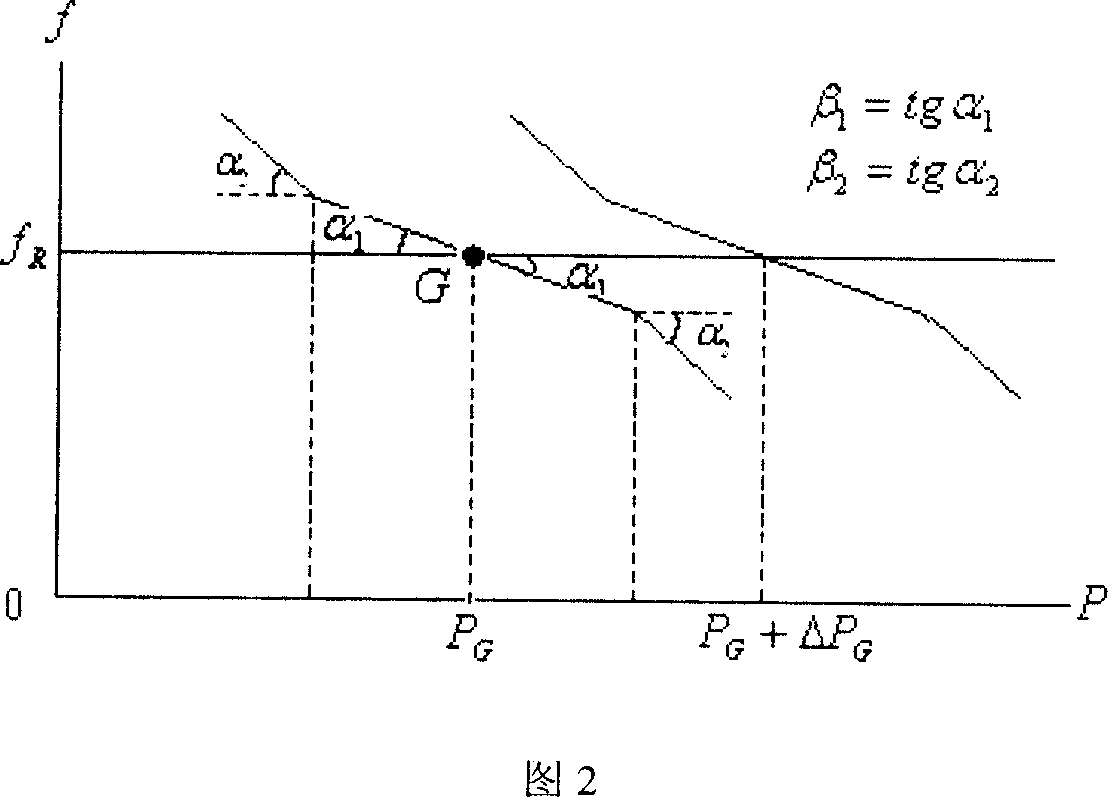

Combined method for regulating power-supply system frequency and active power

InactiveCN101030703ASignificant technologySignificant comprehensive benefitsData processing applicationsSingle network parallel feeding arrangementsElectric power systemResponse Frequency

The invention is concerned with adjustment and control method for frequency and active power to the power system. It is a dynamic correspond method to adjust and control each power plant or unit on the spot under the uniform direct to control station for frequency and active power to whole power system. Install filter to test frequency on power plant or unit, then each power plant unit with different dynamic nature selects suitable control frequency segment according itself characteristic and ability. Thus the quick corresponsive unit answers the higher parts of frequency segment in the frequency change, while the slow corresponsive unit answers the lower parts of frequency segment in the frequency change. It realizes the dynamic correspond, and the control stations give scheduled load propose curve to each power plant or unit. And each power plant or unit can carry the adjustment and control method for frequency and active power on the spot according to the change of system frequency in the scheming range.

Owner:曹保定

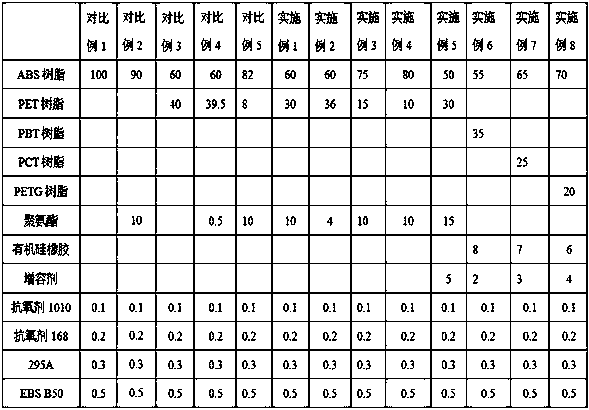

ABS/polyester alloy material as well as preparation method and application thereof

ActiveCN108440892AWith noise reduction effectExcellent resistance to environmental stress crackingElastomerWater leakage

The invention discloses an ABS / polyester alloy material as well as a preparation method and application thereof. The ABS / polyester alloy material comprises the following components by parts: 50-80 parts of styrene-butadiene-acrylonitrile resin, 10-65 parts of polyester resin, and 1.0-15 parts of a high-damping elastomer. According to the method disclosed by the invention, a polyester and high-damping rubber are introduced into an ABS system, so that the prepared ABS / polyester alloy material has excellent environmental stress cracking resistance while having a noise reduction effect, can replace ABS, HIPS or PC / ABS to be used for various plastic parts, can effectively reduce noise made by the parts, can greatly improve environmental stress cracking resistance of the parts, solve the problems of water leakage and cracking caused by the problem, and has significant technical and market value.

Owner:辽宁金发科技有限公司

Ceramic product made of dangerous wastes and solid wastes

InactiveCN106242516AIncrease operating proceduresReduce exposureCeramic materials productionClaywaresManganeseMaterials science

The invention discloses a 'ceramic product made of dangerous wastes and solid wastes', and relates to a ceramic product made of various dangerous wastes, solid wastes and soil polluted by the dangerous wastes by a traditional ceramic production process. The ceramic product comprises an art ceramic product, a chemical ceramic product, a filling ceramic product in a heat exchange or mixing or reaction device, a building ceramic product, a sanitary ceramic product, a daily ceramic product, a ceramic solar panel product and an infrared emitter ceramic product. Total chromium in leach liquor of the ceramic product is less than 1.5mg / L, hexavalent chromium is less than 0.5mg / L, barium is less than 10mg / L, nickel is less than 0.3mg / L, copper is less than 20mg / L, manganese is less than 40mg / L, mercury is less than 0.03mg / L, zinc is less than 40mg / L, lead is less than 0.15mg / L, cadmium is less than 0.1mg / L, beryllium is less than 0.012mg / L, arsenic is less than 0.2mg / L, and selenium is less than 0.7mg / L.

Owner:曹树梁

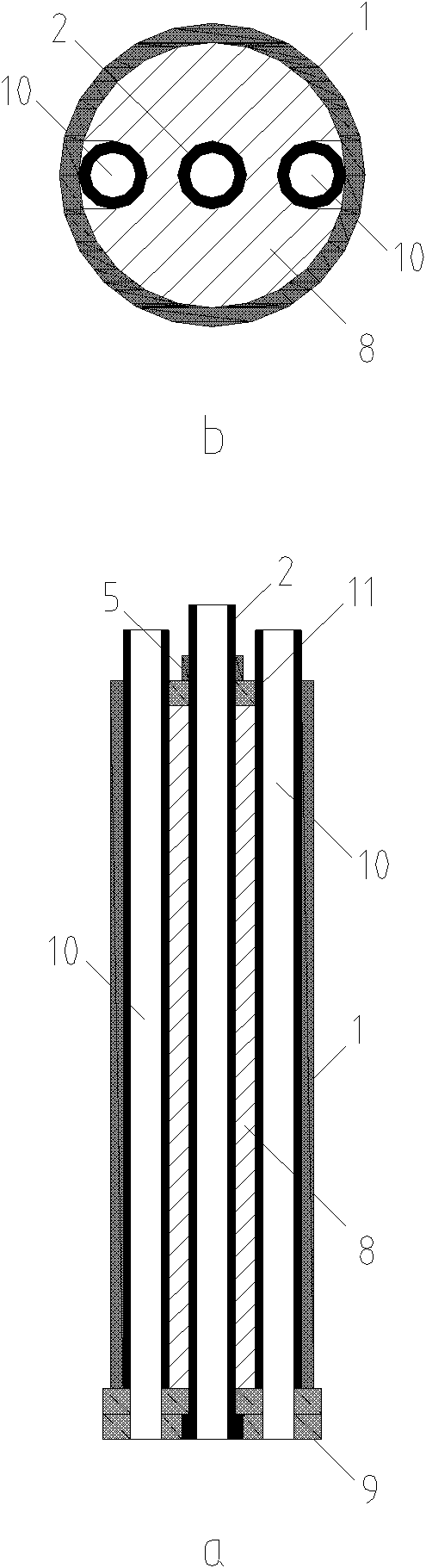

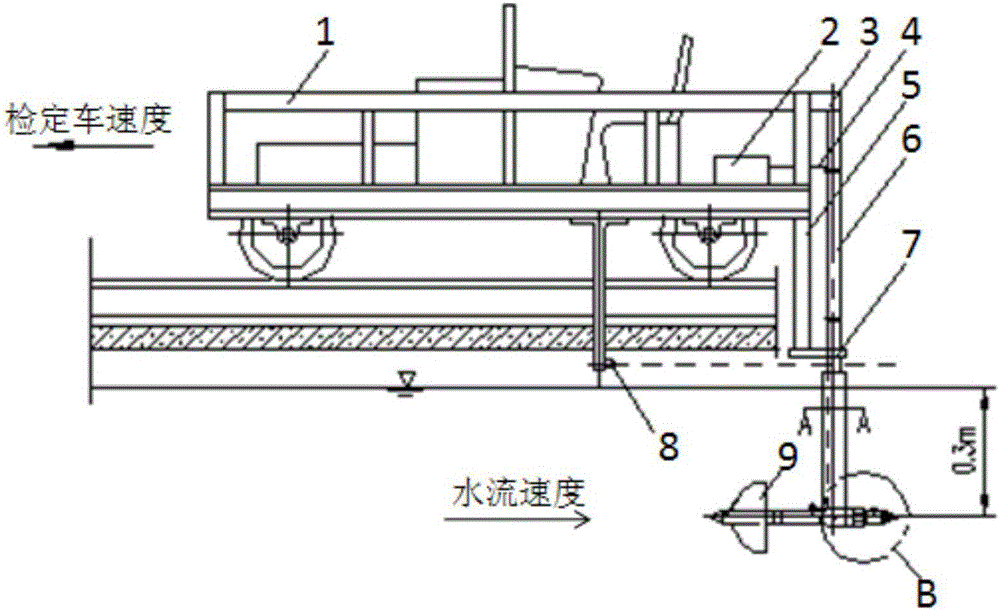

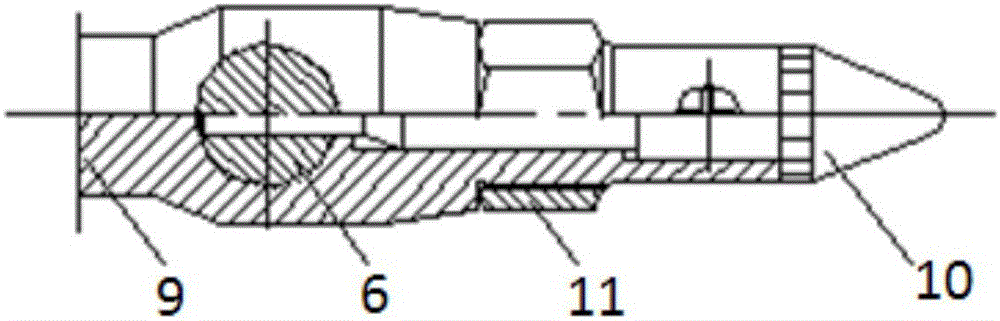

Current meter high-speed linear formula integration detection method and detection device

ActiveCN105954543AImprove test accuracyReliable referenceTesting/calibration of speed/acceleration/shock measurement devicesCurrent meterBall bearing

The invention discloses a current meter high-speed linear formula integration detection method and a detection device. The method comprises the following steps: cleaning a ball bearing; detecting average frictional resistance moment M of the ball bearing; detecting a propeller current meter rotating speed V0 and an instrument rotation bearing internal frictional resistance moment M, and confirming that a standard is reached; fixedly installing three detected current meters at the lower end of a measuring rod and placing them into water of a detection water tank; adjusting an axial directions of the current meters; tranquilizing a water body in the tank; starting a motor, a detection vehicle running from a lowest speed and gradually increasing its speed, and detecting instrument output signals and data; and according to a GB / T21699 detection method of rotor type current meter in linear open channel, by use of a least square method, calculating values of a and b of a detection formula and a middle and high-speed whole-line average mean square deviation sigma. According to the invention, the program and steps of a conventional detection method in the prior art are substantially simplified, the precision of detection results of the current meters can be ensured, at the same time, the production efficiency is improved, the working conditions are improved, the management rules are simplified, manpower and material resources are reduced, and the production operation cost is decreased.

Owner:JIANGSU NANSHUI WATER AFFAIRS TECH CO LTD +1

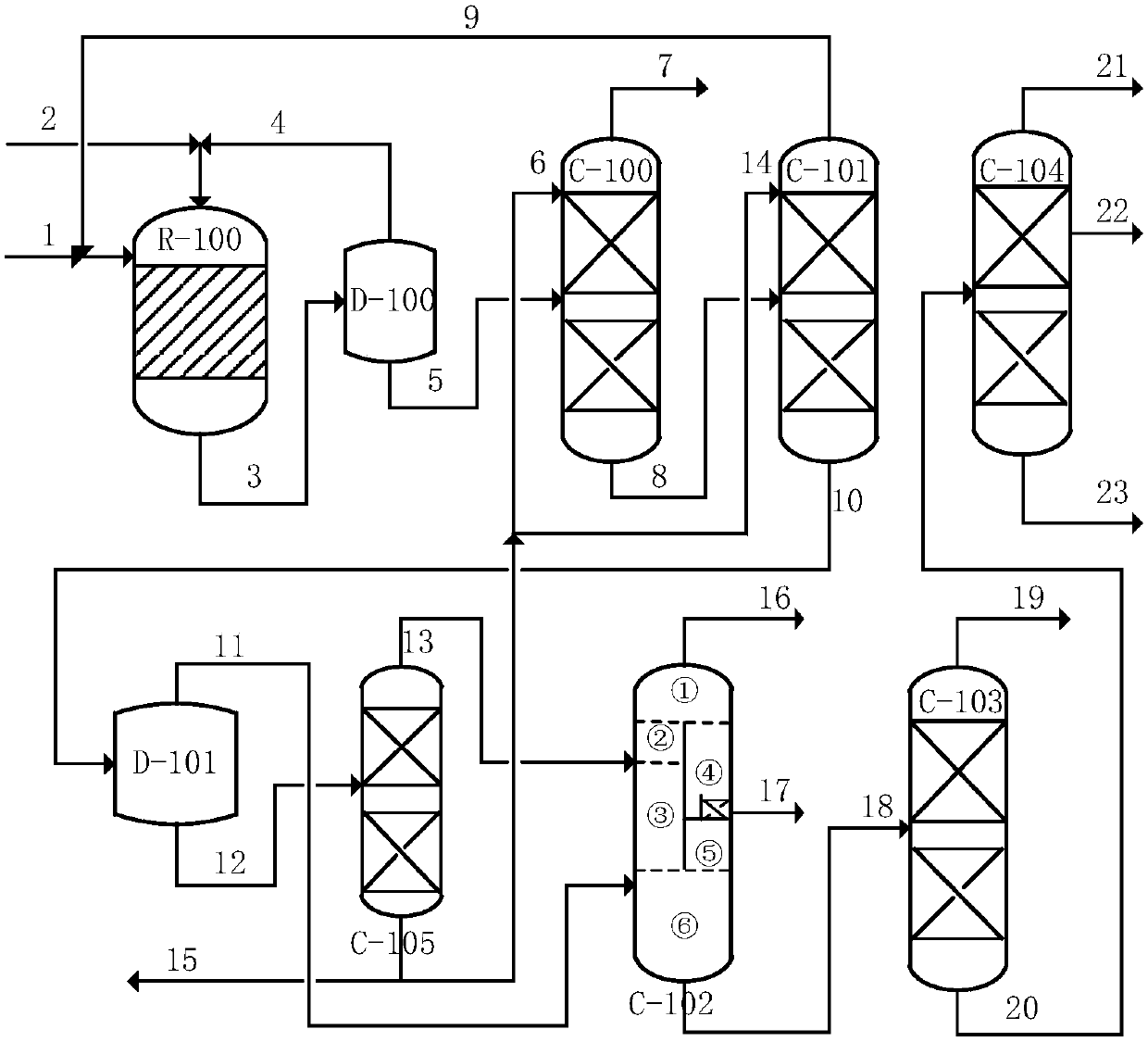

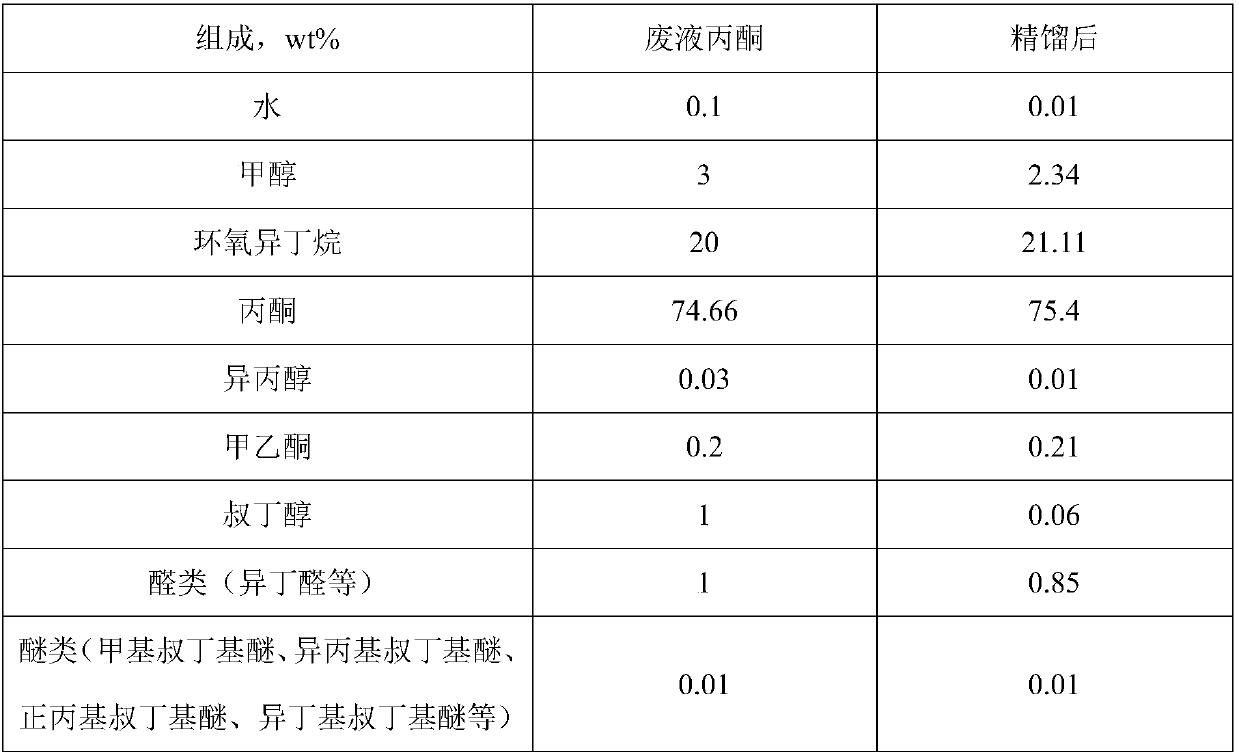

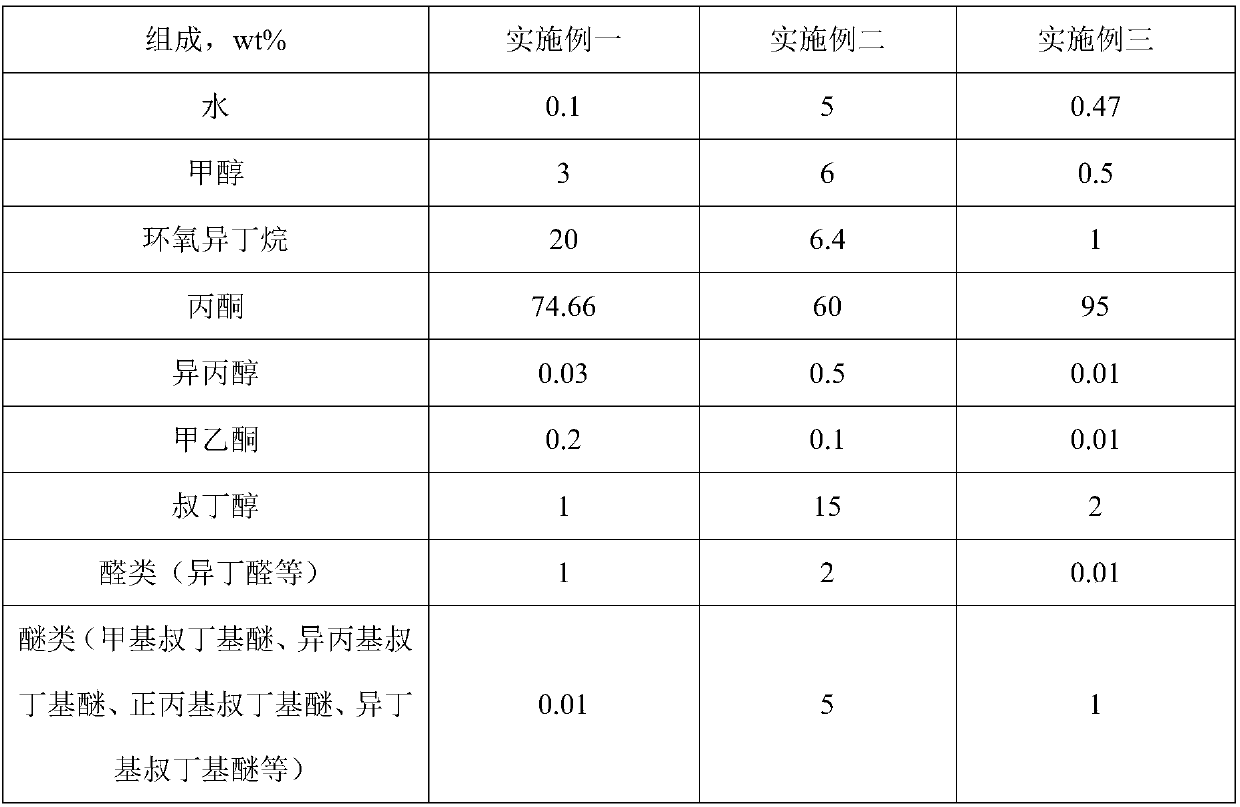

Method for preparing purified MIBK (methyl isobutyl ketone) from industrial byproduct waste acetone liquor

ActiveCN107915612AEfficient use ofResolve separation difficultiesOrganic compound preparationCarbonyl compound separation/purificationAlcoholMethyl isobutyl ketone

The invention discloses a technological process for preparing high-purity MIBK (methyl isobutyl ketone) from industrial byproduct waste acetone liquor. The method comprises the steps as follows: a reaction liquid of MIBK is synthesized from waste acetone liquor, a light component with the boiling point lower than that of acetone is obtained at the top of a light component removal tower, and unreacted acetone is obtained at the top of an acetone recovery tower; an organic matter with the boiling point lower than that of an MIBK / water azeotrope and the MIBK / water azeotrope are obtained at the top of a process water tower; low-boiling-point organic matter such as acetone, methanol and the like coming from raw materials are obtained at the top of a dehydrating tower; an alcohol / water distillate is obtained at the top of an alcohol removal tower and a crude MIBK distillate is obtained from the tower; a light component with the boiling point lower than that of MIBK is obtained at the top ofan MIBK refining tower and an MIBK product with the purity larger than or equal to 99.5% is obtained on the side. The technology is simple, low in energy consumption and low in production cost, the high-purity MIBK product can be obtained from high-impurity waste acetone liquor, and the economic benefits are significant.

Owner:WANHUA CHEM GRP CO LTD

Garbage hazard-free comprehensive treatment equipment

InactiveCN101758063ALarge amount of processingImprove sorting efficiencyGas current separationSolid waste disposalMagnetic separatorEnvironmental resource management

The invention relates to garbage hazard-free comprehensive treatment equipment, comprising a fermentation cabin, a hopper, a belt conveyor, an m type spiral selection type sorting machine, a magnetic separator, a winnowing machine, a vibrating screen, a motor, a chained screening conveyor, a case and a support. The equipment has large daily throughput, high sorting efficiency and multiple recovery types, thus being applicable to various mixed garbage; no secondary pollution is produced, thus completely meeting the requirement of national municipal solid waste 'reduction, reclamation, hazard-free treatment and industrialization', effectively control environmental pollution and protecting ecology environment; equipment is reasonable in configuration, production technology is advanced, technology is mature, social benefit thereof is obvious; and end product has super quality and competitive price, recovery rate is high, and market space is large.

Owner:江苏雪枫环保科技有限公司

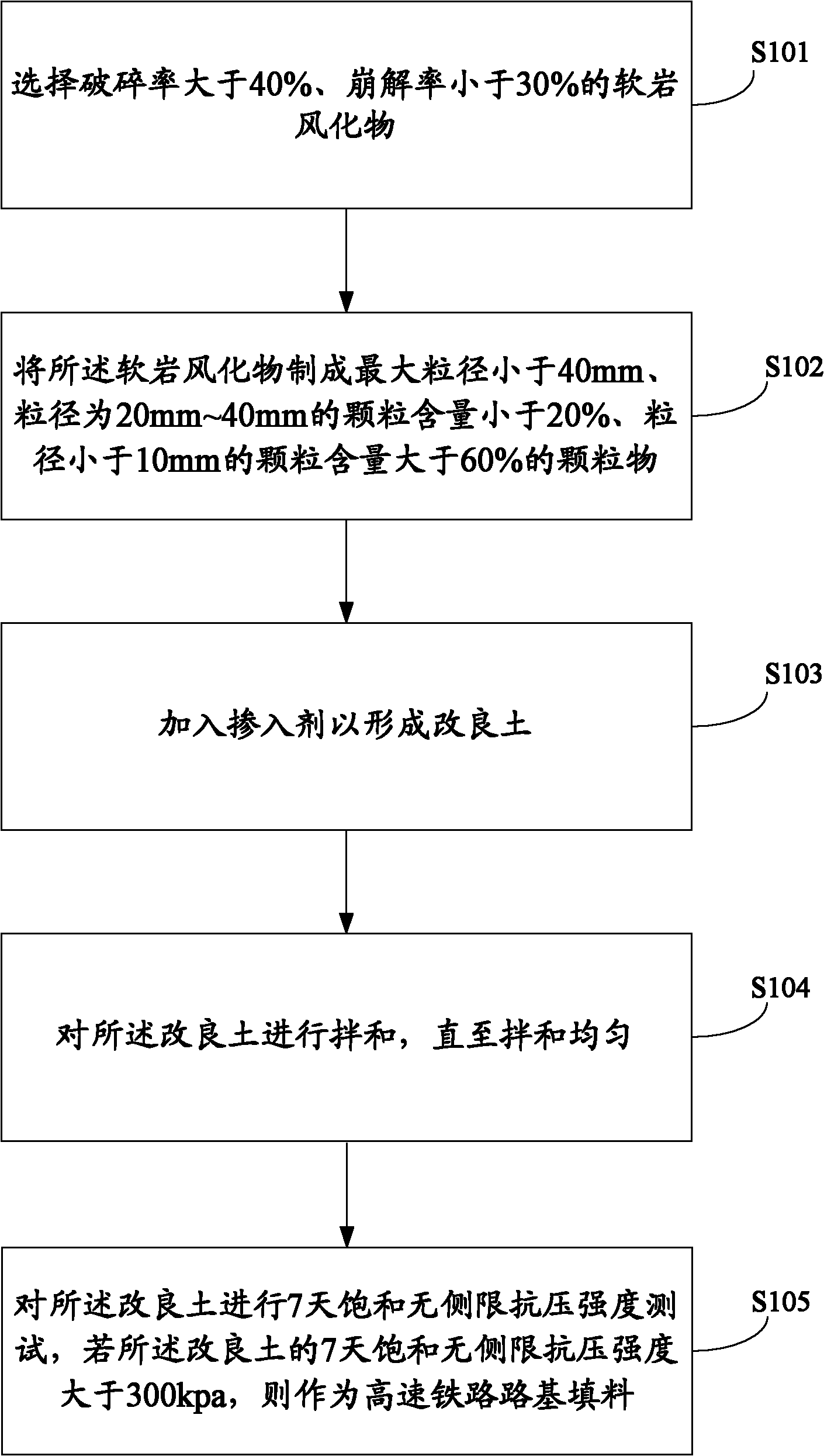

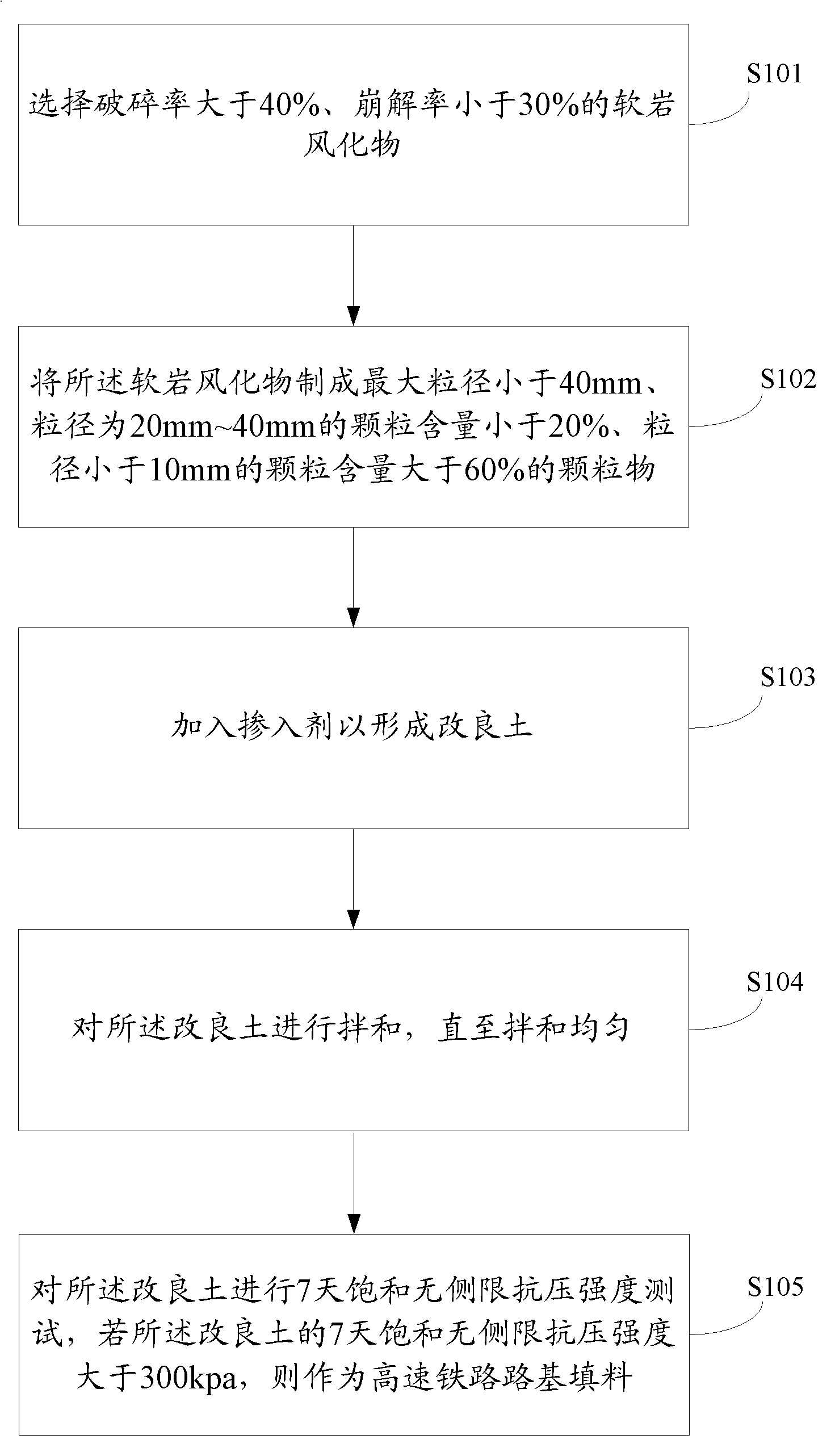

Chemical improving method using soft rock weathered material as high-speed railway subgrade filler

InactiveCN102153303AReduce engineering costsReduce wasteSolid waste managementSocial benefitsWaste material

The invention discloses a chemical improving method using a soft rock weathered material as a high-speed railway subgrade filler, comprising the following steps of: (1) selecting a soft rock weathered material with crushing rate of more than 40% and disintegration rate of less than 30%; (2) making a filler with maximum particle size of less than 40 mm by the soft rock weathered material, wherein the content of particles with particle sizes of 20-40 mm in the filler is less than 20% while the content of the particles with particle sizes of less than 10 mm is more than 60%; (3) adding a doping agent to form improved soil; (4) blending the improved soil until the improved soil is uniformly blended; and (5) carrying out saturated unconfined compressive strength testing on the improved soil for seven days, and if the seven-day saturated unconfined compressive strength of the improved soil is more than 300 kpa, using the improved soil as the high-speed railway subgrade filler. The soft rock weathered material can reach the standard of the high-speed railway subgrade filler after improved by the chemical improving method, and then the engineering cost can be largely reduced, waste materials are reduced, the environment is protected, and finally, good economic, technological, environmental and social benefits are obtained.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

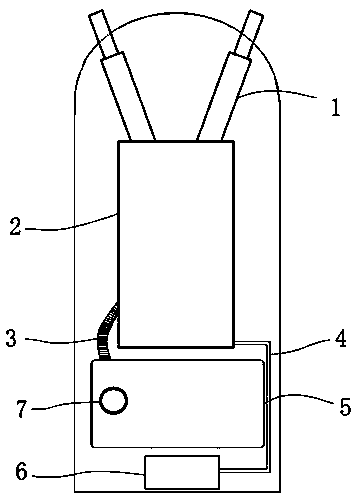

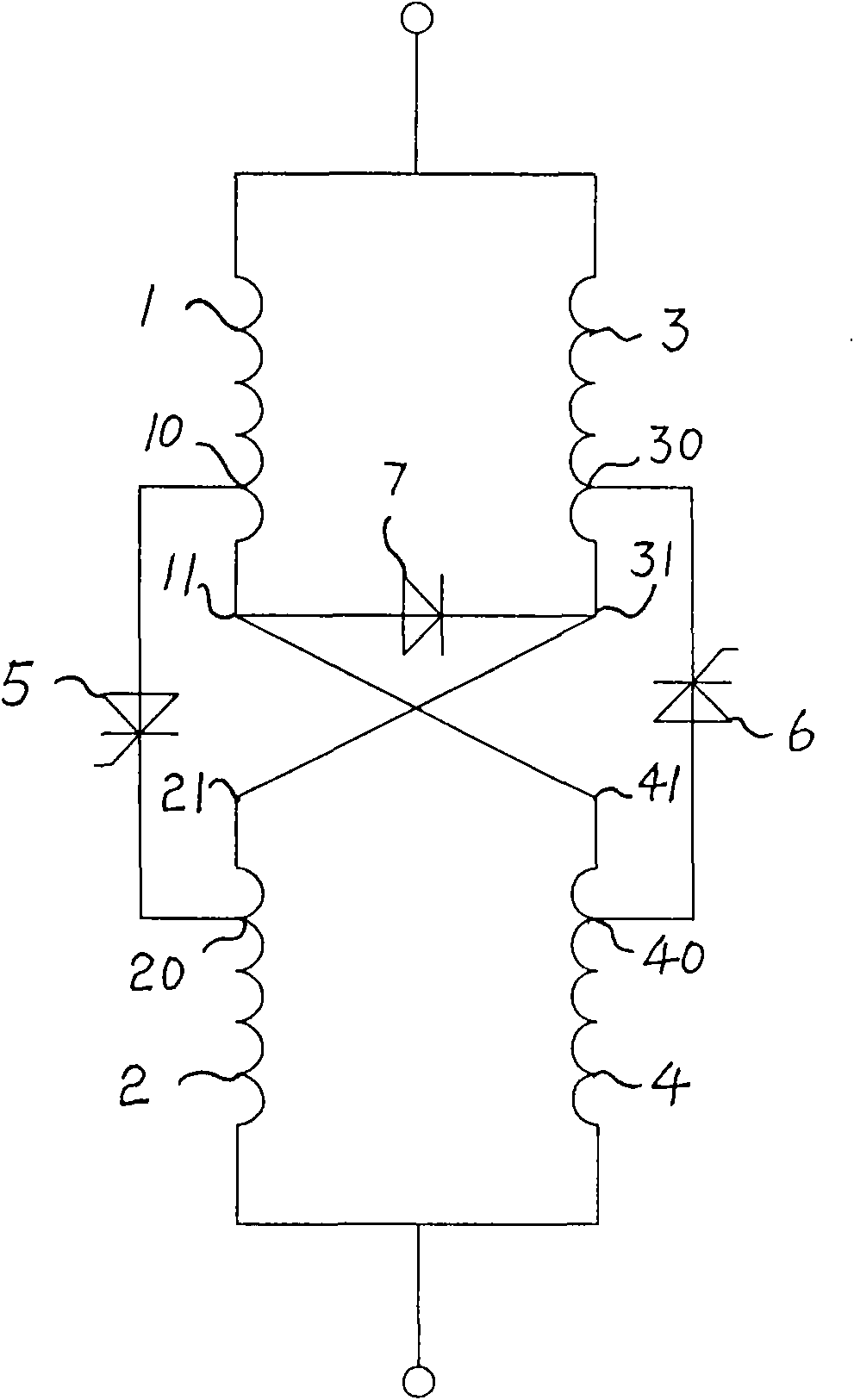

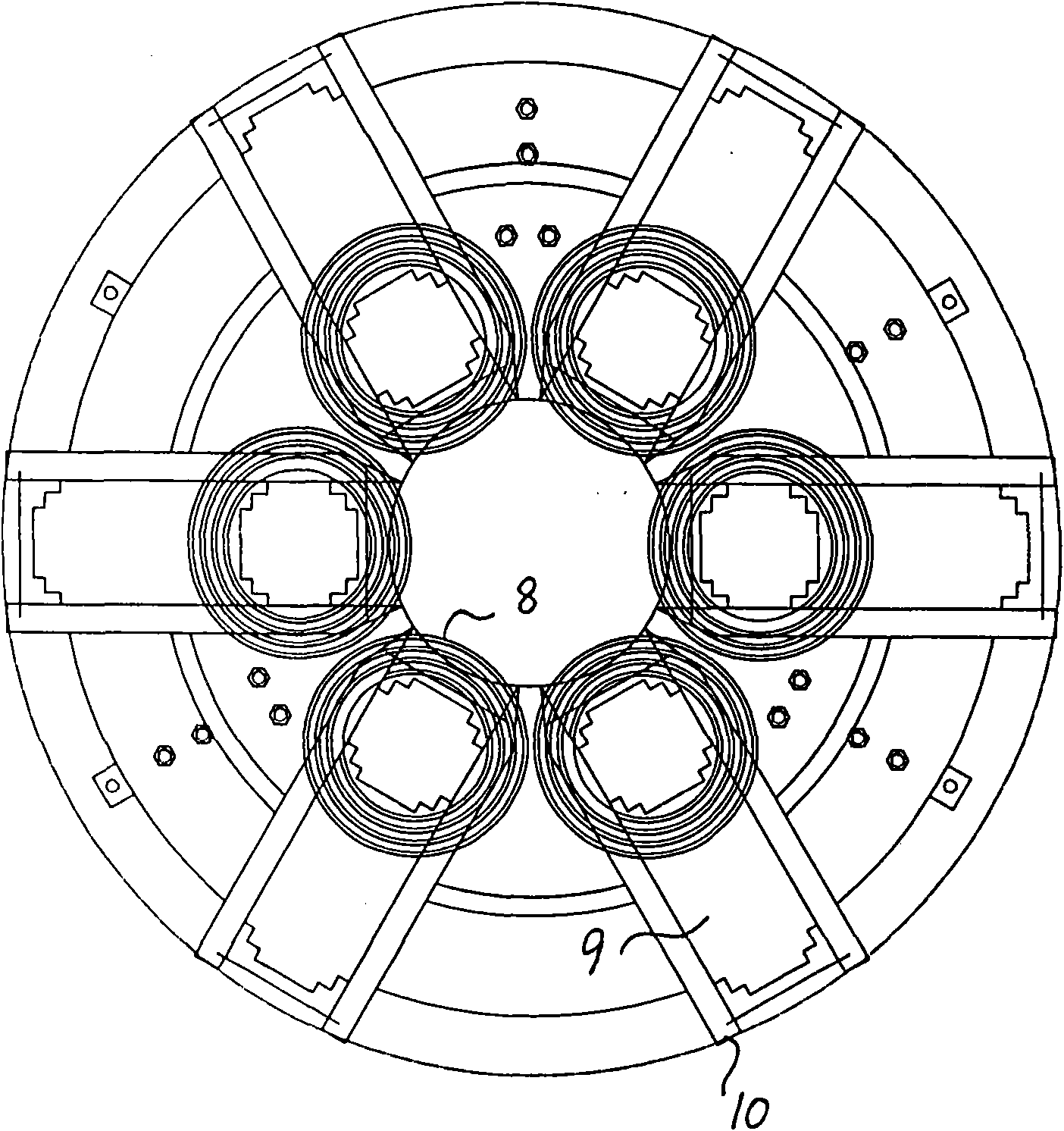

Magnetic valve type controllable reactor

InactiveCN101882499ASignificant technologyImprove economyTransformers/inductances coils/windings/connectionsElectric component structural associationMagnetic valveEngineering

The invention relates to a magnetic valve type controllable reactor which comprises a main iron core, wherein the main iron core comprises two half iron cores; the invention is characterized in that a valve port is arranged at the middle part of each half iron core, the half iron core is divided into an upper segment and a lower segment, a first winding (1), a second winding (2), a third winding (3) and a fourth winding (4) are respectively sleeved on each segment, and the upper end parts of the first winding (1) and the third winding (3) positioned at the upper part are connected in parallel; a first silicon controlled thyristor (5) is connected between a first tap (10) and a second tap (20); a second silicon controlled thyristor (6) is connected between a third tap (30) and a fourth tap (40); and a diode (7) is connected between a first winding end (11) and a second winding end (21). Under different periods, the silicon controlled thyristors are respectively conducted by a power supply to form pulsating direct current, and when the conduction angles of the silicon thyristor are changed, the magnitude of exciting current is changed, thereby changing the saturation degree of the valve port and smoothly regulating the capacity of the reactor.

Owner:宜兴市万盛变压器有限公司

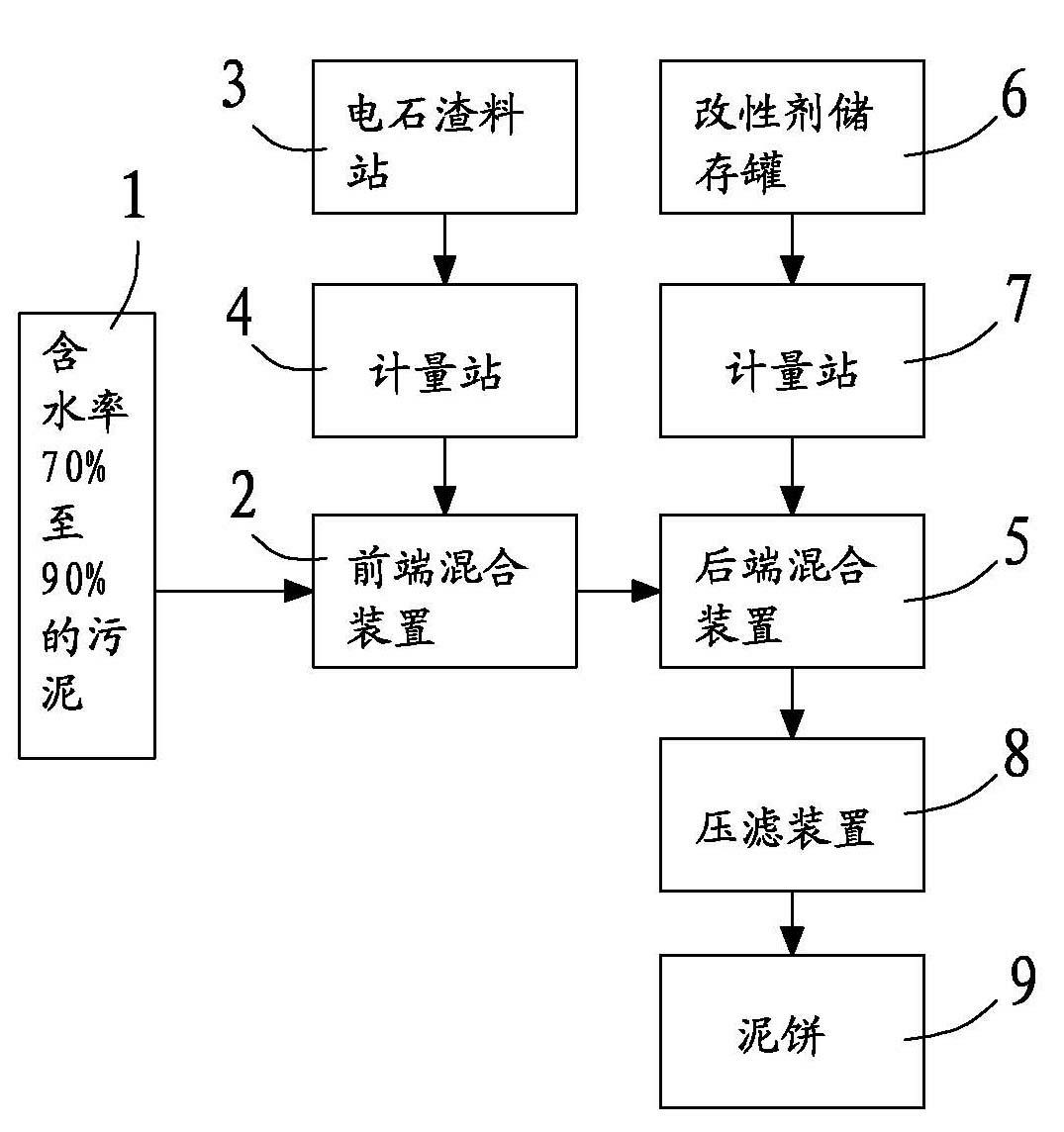

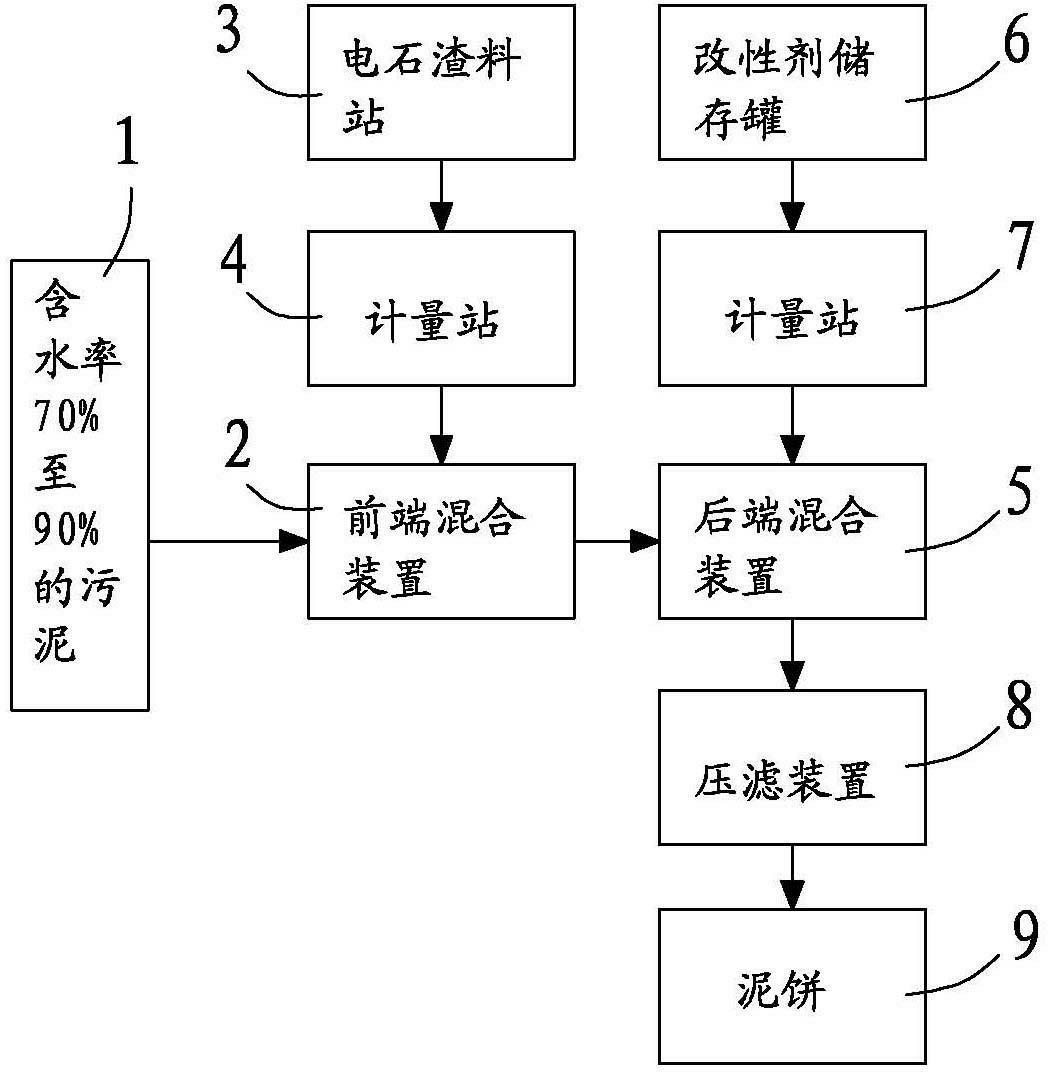

Method for pretreating and strengthening sludge dehydration by using acetylene sludge

ActiveCN102432152AFacilitate final disposalEfficient use ofSludge treatment by de-watering/drying/thickeningFilter pressPre treatment

The invention discloses a method for pretreating and strengthening sludge dehydration by using acetylene sludge. The method comprises adding a modifier and extruded sludge into sludge, wherein acetylene sludge is added before the modifier is added. The method comprises the following steps of: a, doping sludge of which the water content is higher than 70 percent into acetylene sludge, and stirringand mixing uniformly to obtain mixed sludge, wherein the doping amount of the acetylene sludge is 1-50 percent by volume based on the total amount of the sludge; b, continually adding a modifier in an amount which is 0.5-2 percent by volume based on the total amount of the sludge, and stirring to obtain sludge into which the modifier is added; and c, feeding the sludge into which the modifier is added into a plate-and-frame type filter press for extruding to obtain a dehydrated mud cake. In the method, the acetylene sludge is used together with a general modifier, so that the dehydration rateof mechanical filter pressing is increased, the amount and volume of sludge are reduced, and the dehydration energy consumption is lowered greatly simultaneously. In the method, useful components in acetylene sludge are fully utilized, the aims of changing waste into valuable and protecting the environment are fulfilled, and positive technical progress and remarkable economic effect are achieved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Special mortar for aerated concrete using red mud as inorganic mineral thickening agent

The invention discloses special mortar for aerated concrete using red mud as an inorganic mineral thickening agent. The mortar is formed by mixing the following components in percentage by mass: 15-20 percent of cement, 5-10 percent of fly ash, 5-10 percent of red mud, 65-70 percent of phosphorus slag granules, 0.1-0.2 percent of admixture and the balance of water, wherein the water adding amount is based on the consistency controlled at 80-120 millimeters. The characteristic of strong water holding property of the red mud is used in the mortar, and the red mud is used as the inorganic mineral thickening agent, so that the water holding property of the mortar is increased under the condition that other mineral thickening agents are not added, and the workability of the mortar is improved; and meanwhile, the phosphorus slag is used as a fine mortar aggregate, so that the production cost is greatly reduced on the premise that the strength and the other properties meet the requirements of the special mortar for the aerated concrete, the environmental pollution is reduced, and greening of pre-mixed commodity mortar production is realized.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC +1

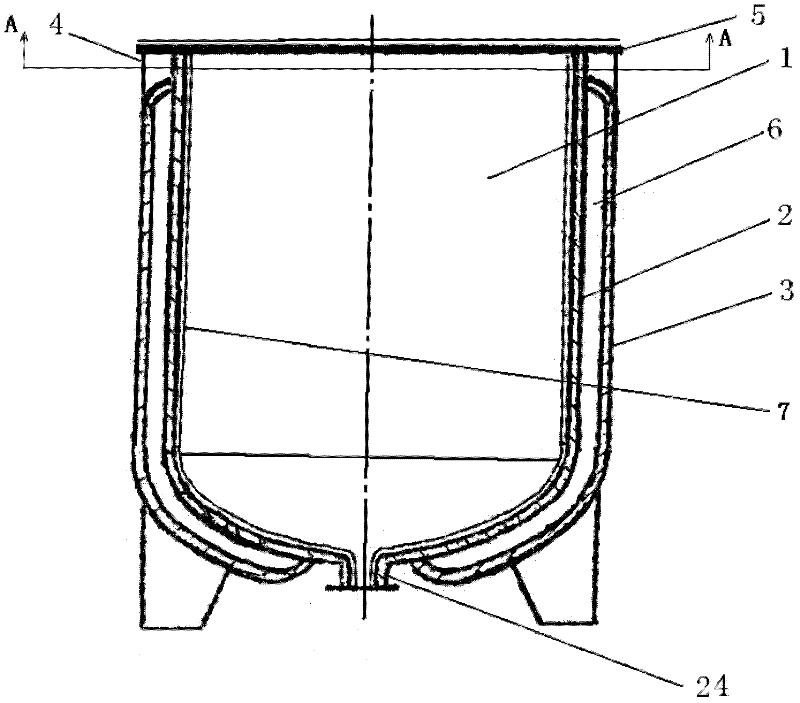

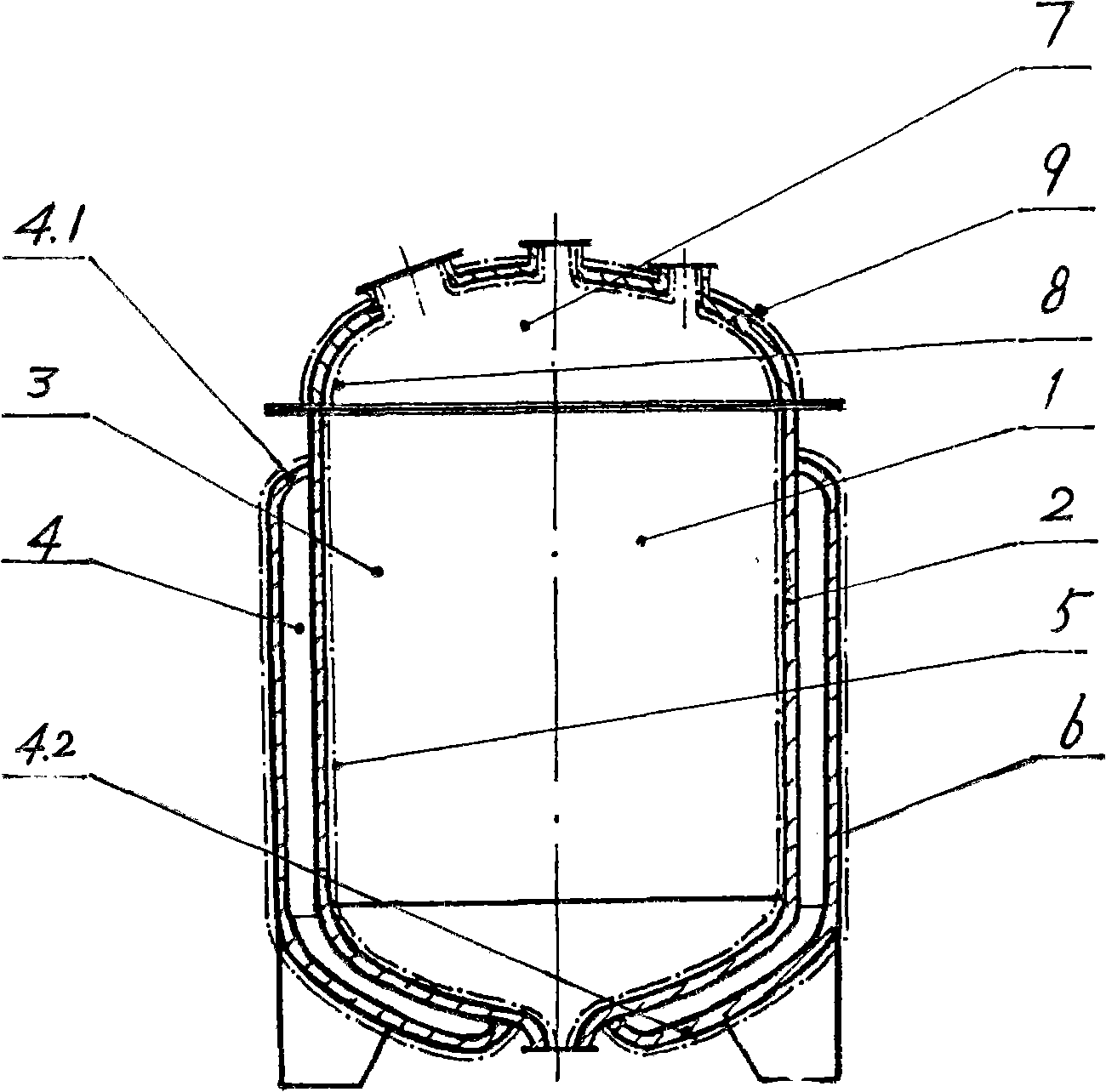

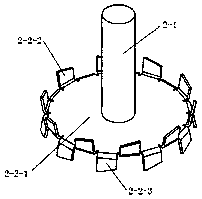

High-capacity K-type composite glass-lined reaction pot and manufacturing method thereof

InactiveCN101514455AImprove manufacturing precisionImprove overall sealing performancePropellerCompound (substance)

The invention provides a high-capacity K-type composite glass-lined reaction pot and a manufacturing method thereof, which belongs to first / second-class pressured-vessel reaction equipment used in the chemical engineering or pharmaceutical industry. The K-type composite glass-lined reaction pot is characterized in that the capacity of the reaction pot is over 10 kilolitres; the inner wall of an inner tube body of a pot body is coated with a glass-lined enamel layer; and the inner wall of a pot cover is lined with organic material. The method has the advantages that the method initiates that the manufacture of iron blank comprehensively meets the standard of pressured vessels; an outer jacket is an integral-structure piece and is welded to the inner tube body so as to form the pot body; the thickness of a steel plate of the outer jacket increases by 2 to 6 millimeters according to the standard of the prior design; the outer wall of the outer jacket is coated with an enamel layer; by applying a multifunctional temperature-control precision inner-heating type electric furnace and implementing a novel enamel firing process of combining the hoisting and autorotation of a glass-lined pot body, the glass-lined pot body of which the surface of a big flange of a pot mouth is nearly free from deformation can be repaired and reused after the glass-lined pot body is damaged; as the inner wall of the pot cover is lined with the organic material and the outer wall of the pot cover is sprayed with KTS enamel, the pot cover is high in manufacture precision, durable and easy to repair; a stirring blade propeller is enlarged; production efficiency is improved; the invention promotes the important development of the prior Chinese Standard to overtake international technical standards; and the method and the pot have extremely remarkable economic benefit and social benefit.

Owner:朱文华

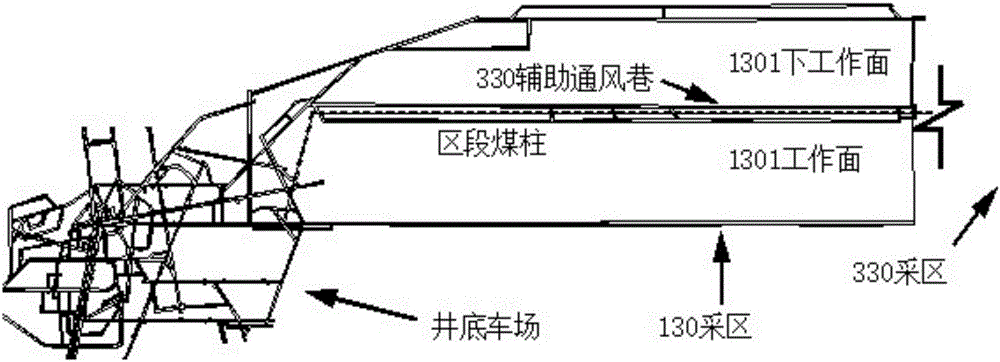

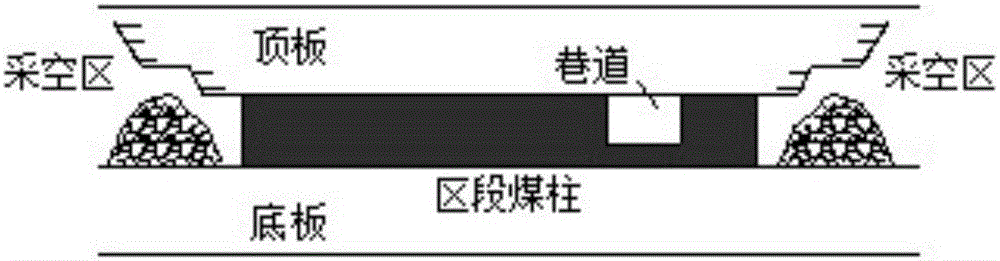

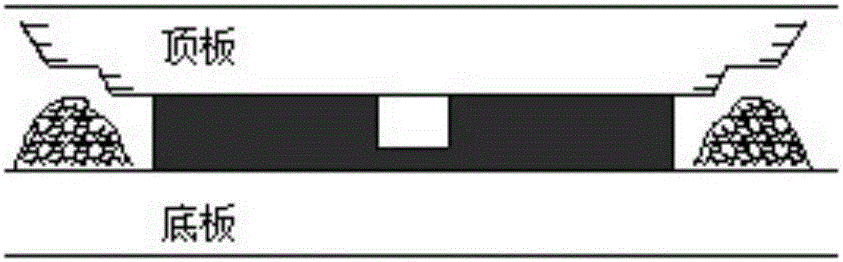

Method for ventilation-assisting roadway arrangement and surrounding rock stability control in later period of coal mining

InactiveCN105134214AEasy to useMeet Ventilation NeedsUnderground chambersUnderground miningAir volumeEconomic benefits

The invention discloses a method for ventilation-assisting roadway arrangement and surrounding rock stabilizing control in the later period of coal mining, belonging to a method for mine ventilating system optimization and roadway arrangement. The method comprises the steps of (1) determining and arranging section coal pillars of roadways for assisting ventilation namely air inlet or air return; (2) analyzing the stability of the section coal pillars; (3) optimizing roadway arrangement schemes in the section coal pillars; (4) determining a technical scheme for reasonable roadway supporting. Aiming at the problems that in the later period of coal mining, a ventilating line is long, ventilation resistance is great, and air loss is great, the method is characterized in that the ventilation-assisting roadways are arranged in the section coal pillars in a left area of a gob, so as to shorten the length of the mine ventilating line length and reduce air loss, and has the advantages of greatly shortening the ventilating line length and reducing air loss by arranging the ventilation roadways in the section coal pillars in the left area of the gob, meanwhile improving a resource extraction rate and increasing the economic benefit of an enterprise by more extracted coal in roadway construction, meeting the need of safe mine production, and achieving obvious technical and economic benefits.

Owner:CHINA UNIV OF MINING & TECH

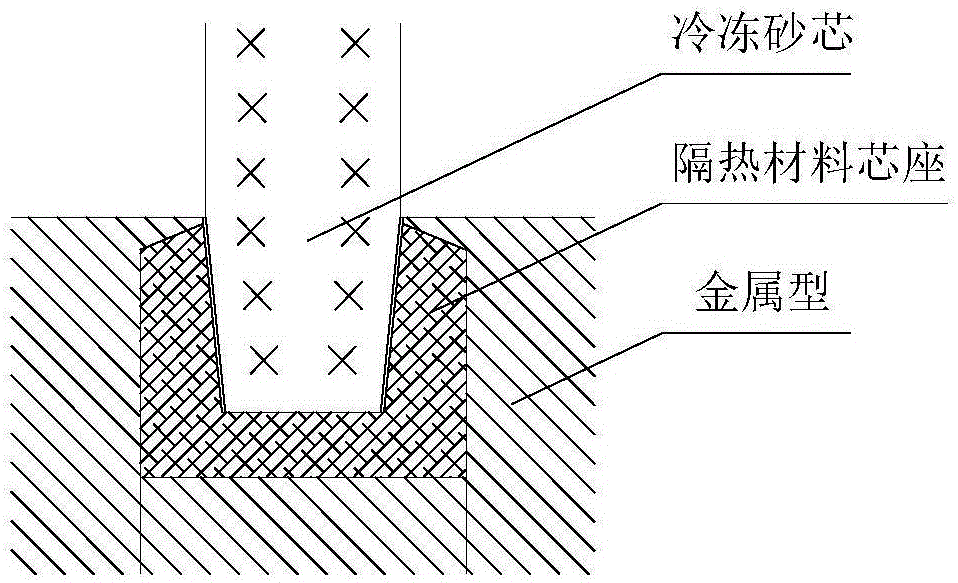

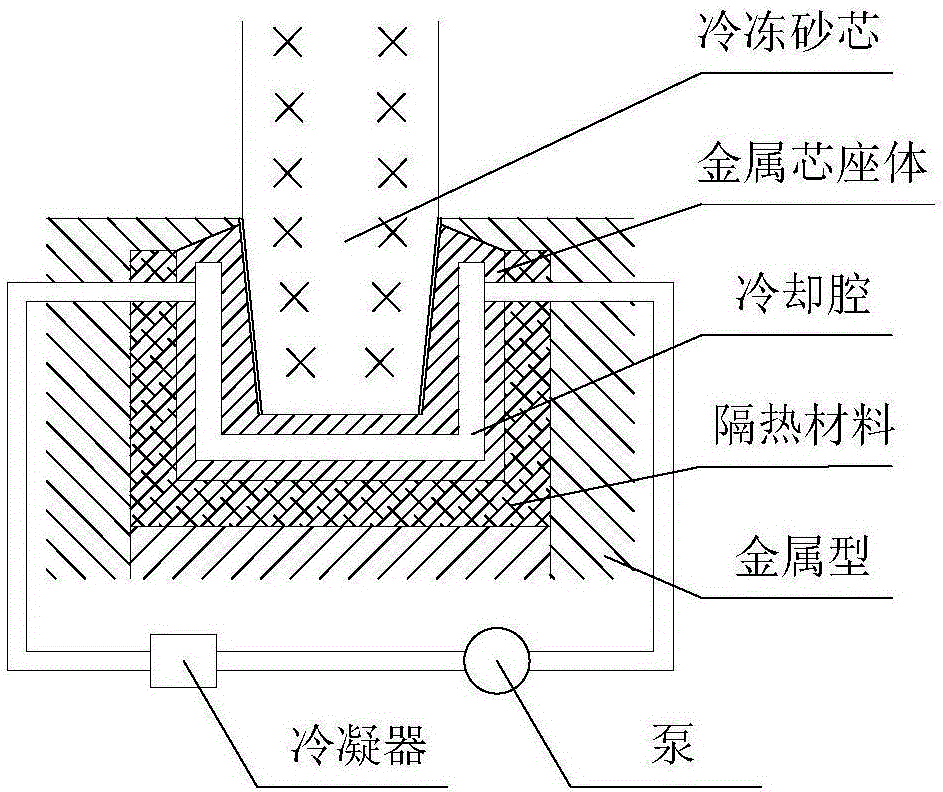

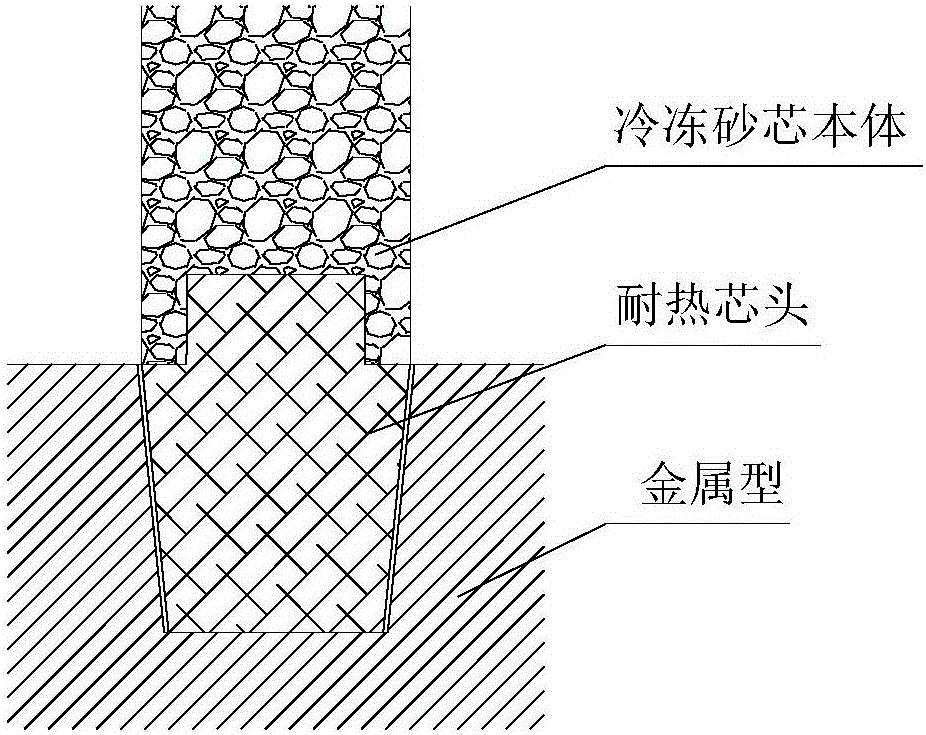

Preparation method of metal mold core for casting

InactiveCN106825425ASolve the problem that it is difficult to withstand the high temperature of the metal moldSignificant technologyFoundry mouldsFoundry coresMetal moldHot Temperature

The invention discloses a preparation method of a metal mold core for casting. Through the method, a freezing sand core is arranged in a metal mold trough a heat isolation core seat to form the metal mold core for casting. The heat isolation core seat is made of heat isolation materials or uses a built-in cooling cavity metal core seat, and has good heat insulation capability; the high temperature of the metal mold can be isolated; the heat transfer can be greatly weakened; the duration of the frozen state of the frozen sand core head and the adjacent positions and the sufficient length maintaining duration can be prolonged, so that the frozen sand core meets the process requirements of the metal mold casting; the application of the green and environment-friendly frozen sand core to the metal mold casting becomes possible.

Owner:CHONGQING UNIV

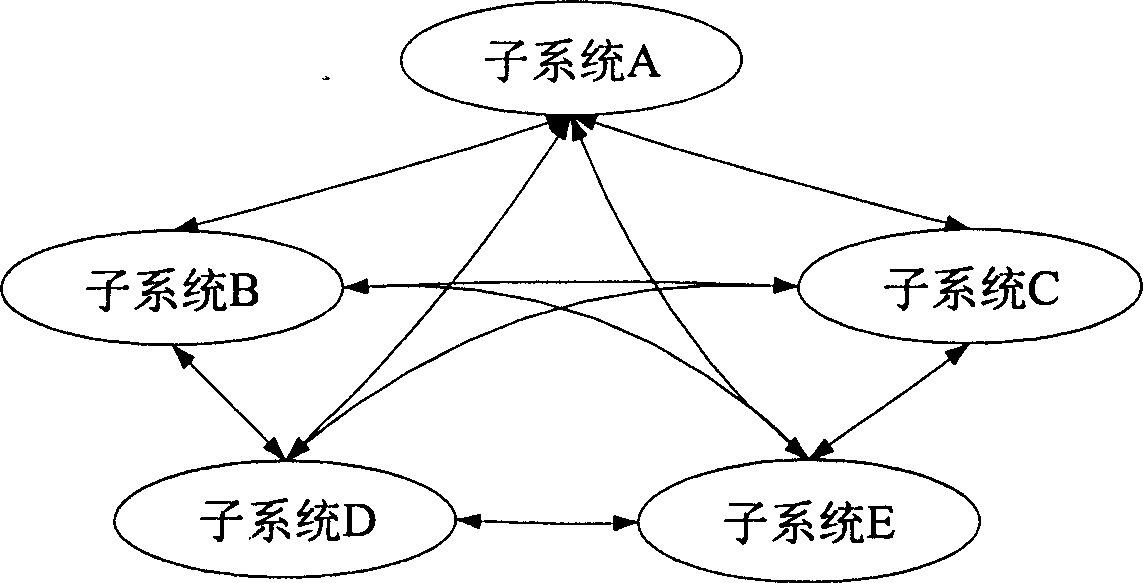

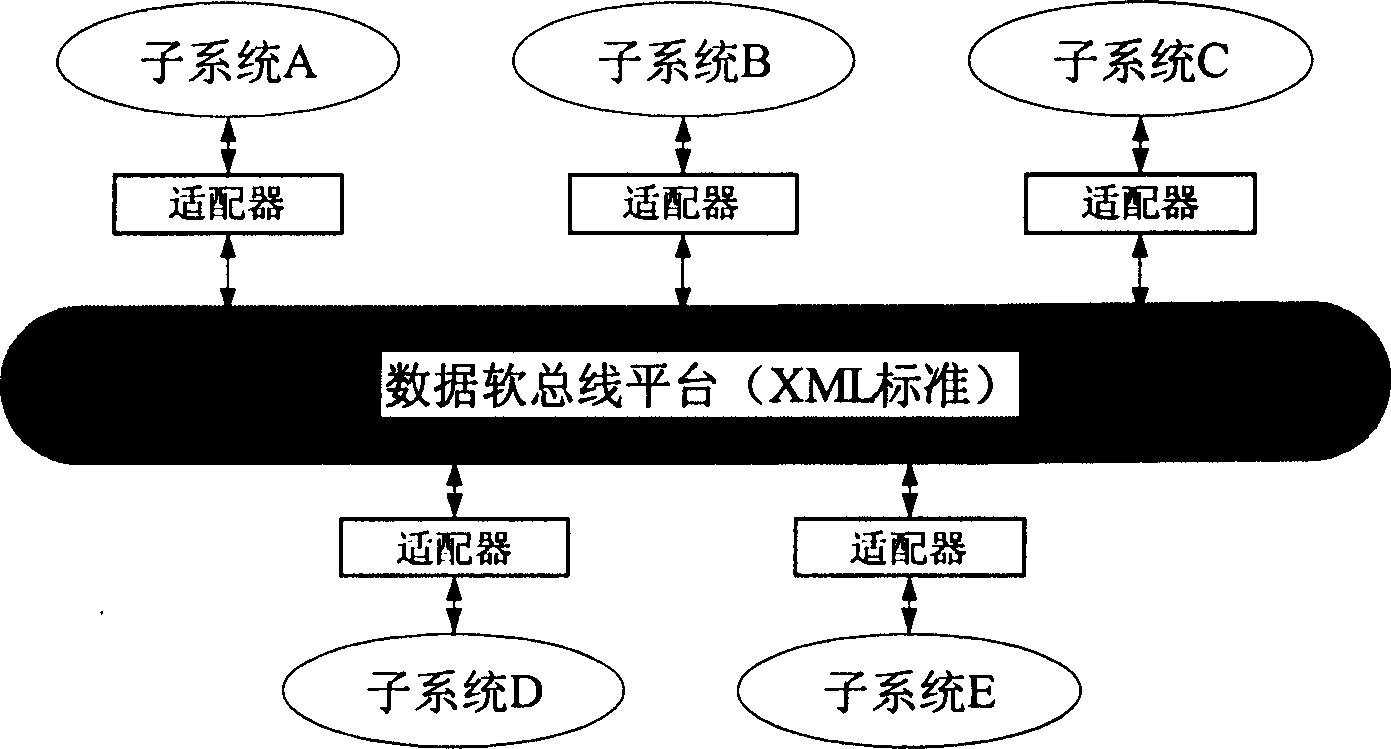

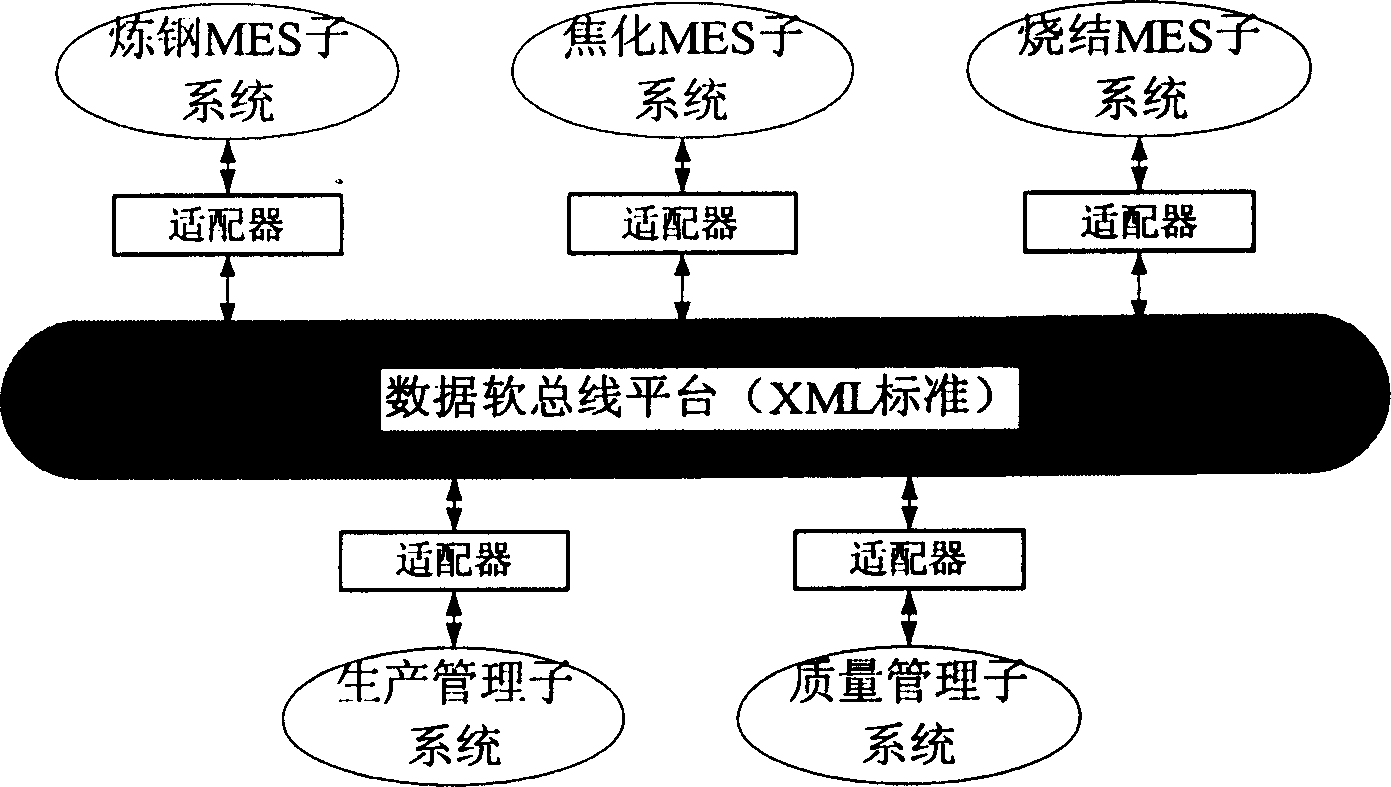

Data transmission method employing data soft bus for application system of metallurgic enterprise

InactiveCN1841415APromote technological progressImprove societySpecial data processing applicationsData transmissionEmbedded system

The related data transmission method for a data flexible bus comprises: when obtaining data, for different condition, the sub system selects different method from active request, passive accepting data as subscription or distribution, and first passive then active request. This invention can improve data processing and transmission efficiency for metallurgical company, reduces development greatly, and shortcuts period.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

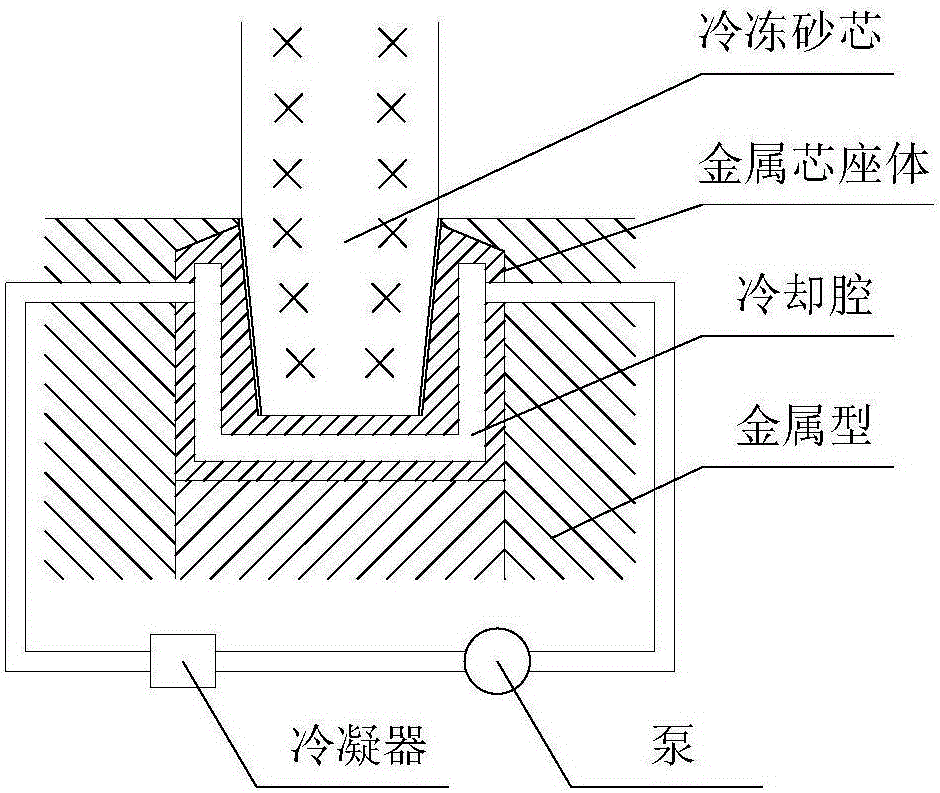

Composite sand core for metal mold casting and preparation method thereof

InactiveCN106799469ASolve the problem that it is difficult to withstand the high temperature of the metal moldSignificant technologyFoundry mouldsFoundry coresMetal moldCasting

The invention discloses a composite sand core for metal mold casting and a preparation method of the composite sand core for the metal mold casting. The preparation method of the composite sand core for the metal mold casting comprises the steps that firstly, a heat-resistant core head is manufactured from ceramic materials or heat-resistant sand blocks; the core head is placed at a corresponding position in a core box; core sand obtained through even mixing of sand, water and an additive is placed in the core box and compacted; and finally, freezing is conducted, and then the composite sand core is obtained. By the adoption of the composite sand core for the metal mold casting and the preparation method of the composite sand core for the metal mold casting, heat transmitted by a high-temperature metal mold to a frozen sand core body can be greatly reduced, the frozen sand core placed in the metal mold can maintain high strength for certain time, so that metal mold casting technological requirements are met, and it is possible that the environment-friendly excellent-performance frozen sand core can be applied to metal mold gravity casting, low-pressure casting and the like.

Owner:CHONGQING UNIV

Ecological aluminium oxide melamine wood door and preparation method thereof

InactiveCN101733807AAdequate gluing propertiesEnough durabilityWood working apparatusPolystyreneEngineering

The invention discloses an ecological aluminium oxide melamine wood door, which is formed by an interlayer door frame and decorating plates which are pressed on the front and rear sides of the interlayer door frame. The ecological aluminium oxide melamine wood door is characterized in that: the decorating plates adopt melamine plates; an anti-wear agent prepared from aluminium oxide is laminated on the sides of the melamine plates; and the front and rear sides of the interlayer door frame are coated with polystyrene foams and then the melamine plates are pressed on the two sides by a hot press or a cold press. The ecological aluminium oxide melamine wood door and the preparation method thereof can not only solve the problem of wasting timber resources and simplify the production process, but also overcome the shortcoming of complicated process of the production method. The product cost is greatly reduced and the production cycle is shortened.

Owner:成都市科创巴赛科技有限公司

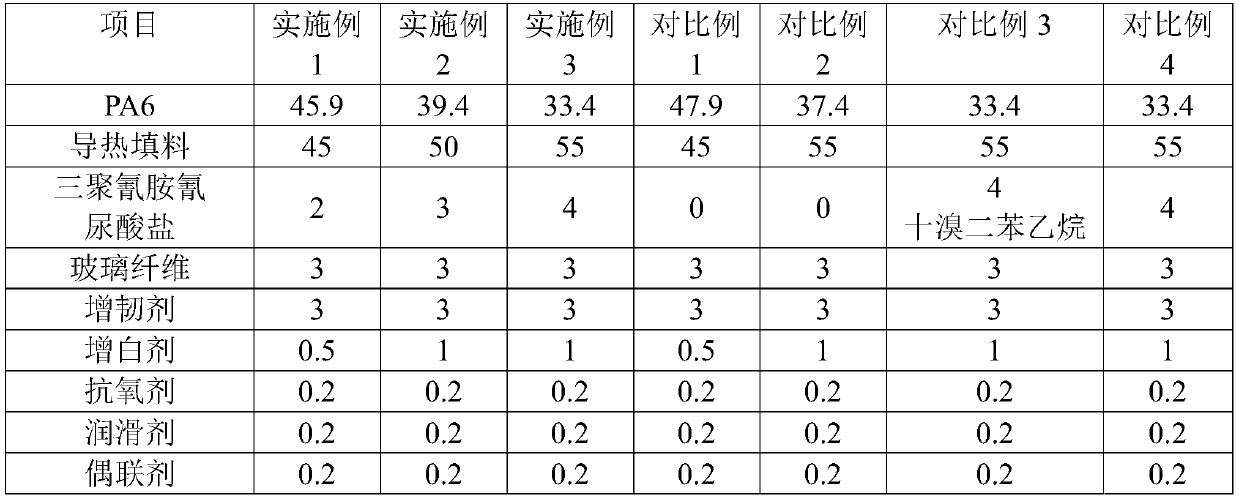

High-flow heat-conducting nylon composite material, preparation method and application thereof

InactiveCN110218442AImprove liquiditySignificant technical and market valueHeat-exchange elementsThermal conductivityThin walled

The invention belongs to the composite material field and discloses a high-flow heat-conducting nylon composite material, a preparation method and an application thereof. The high-flow heat-conductingnylon composite material comprises nylon resin, heat conductive filler, melamine cyanurate and optionally glass fiber, toughening agent, whitening agent, antioxidant, lubricant and coupling agent, The heat conductive filler is hydroxide, and the weight ratio of the heat conductive filler, the melamine cyanurate and the nylon resin is (0.5-2):(0.04-0.13): 1. The nylon composite material provided by the invention has the advantages of high fluidity and high thermal conductivity, and can be well applied in the fields of home appliances, lighting and the like, especially in some thin-wall products, and has remarkable technical and market value.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

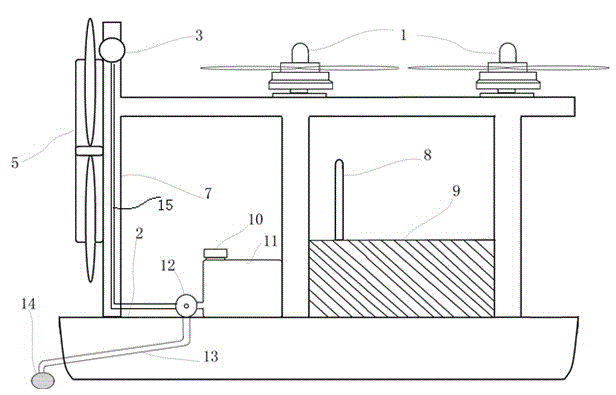

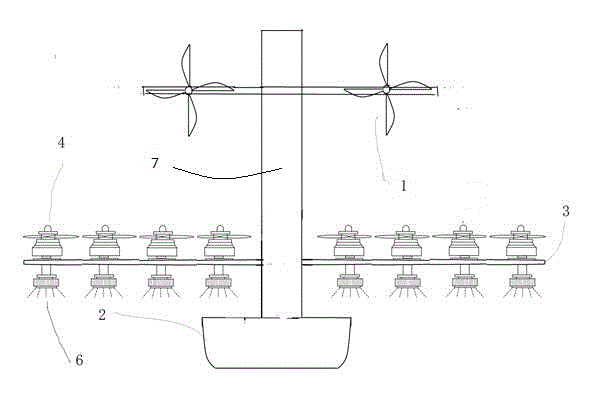

A paddy field plant protection amphibious aircraft

InactiveCN105076098ASmooth goingAvoid getting stuck in a paddy field situationAircraft componentsSeaplanesProduction rateControl system

The invention relates to the technical field of agricultural plant protection and in particular provides a paddy field plant protection amphibious aircraft. The amphibious aircraft comprises an automatic water taking and pesticide mixing system, a spray system, a flying system, a direction control system, a ship body and a support. The water taking and pesticide mixing system is connected with the spray system; the ship body is located under the support; the water taking and pesticide mixing system, the spray system, the flying system and the direction control system are borne by the support. The amphibious aircraft is simple in structure, light, and low in cost, can move conveniently and rapidly when working in paddy fields, solves the problem of difficulty in walking of paddy field plant protection machines, and increases the production efficiency and economic benefit.

Owner:HEFEI DUOJIA AGRI SCI & TECH

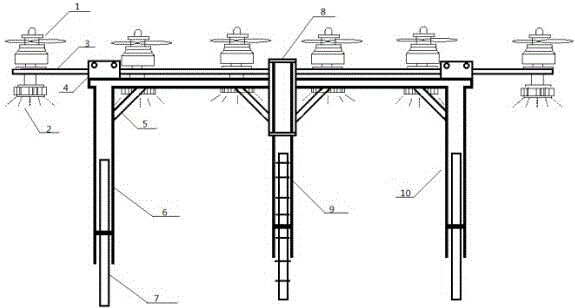

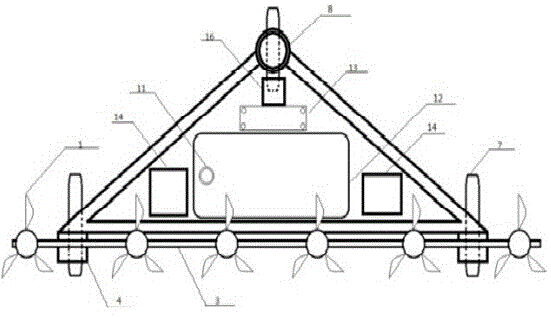

Paddy field plant protection robot

InactiveCN105353756AReduce harmReduce weightPosition/course control in two dimensionsControl systemAgricultural engineering

The invention discloses a paddy field plant protection robot, and relates to the technical field of agriculture plant protection machinery. The paddy field plant protection robot comprises a mist spray module, a control system, a driving device and a machine rack, wherein the machine rack comprises a triangular support, three wheels, a rotating shaft and three support columns; a driving system is connected with the wheels and the control system, and the control system and the mist spray module are arranged on the triangular support. The beneficial effects of the paddy field plant protection robot are that the paddy field plant protection robot is reasonable in design, extensive in applicability, excellent in applied technology, good in trafficability and stable in structure; the paddy field plant protection robot can effectively walk in plants, the cost is saved, agricultural plant output is improved, and benefits are increased.

Owner:HEFEI DUOJIA AGRI SCI & TECH

Method for high-speed mechanical cyclone separation of activated sludge biomass

InactiveCN110615593AHigh extraction rateReasonable designSludge treatmentSpecific water treatment objectivesActivated sludgeCyclone

The invention relates to a method for high-speed mechanical cyclone separation of activated sludge biomass. The biomass comprises extracellular substances and intracellular substances. The method comprises the following steps: high-speed rotating mechanical force directly acts on activated sludge, and meanwhile, hydraulic cyclone is formed; and under the dual action of crushing of high-speed mechanical force and hydrocyclone, activated sludge biomass is separated and eluted. According to the method, a high-speed mechanical cyclone method is adopted, so that a mechanical, hydraulic, temperatureand chemical comprehensive effect is formed under the assistance of hot alkali conditions, extracellular substances in the activated sludge are emphatically separated and eluted, and the separation,elution, hydrolysis and extraction efficiency of the activated sludge biomass is greatly improved.

Owner:张悦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com