New glass-lined reactor and manufacturing method thereof

A manufacturing method and glass-lined technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve problems such as large waste of funds and serious loss of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

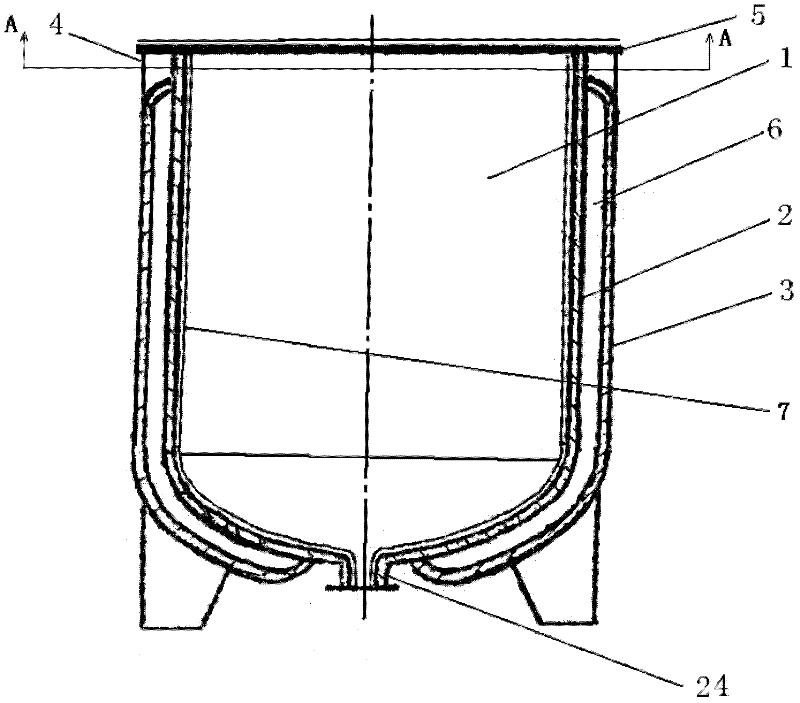

[0062] Such as Figure 1a The new glass-lined reaction tank shown includes a qualified tank body 1, and the tank body 1 includes a qualified new inner cylinder body 2, a qualified new outer jacket 3 and multiple sets of reinforced steel plates 4. The new inner cylinder body 2 and the new outer jacket 3 are welded into an integrated structure, and a cavity 6 is formed between the two; the upper opening of the new inner cylinder body 2 is provided with a large flange 5 for equipment, and the lower opening is provided with a There is a discharge port flange 24, and the inner wall of the new inner cylinder body 2 is coated with a glass-lined glaze layer 7.

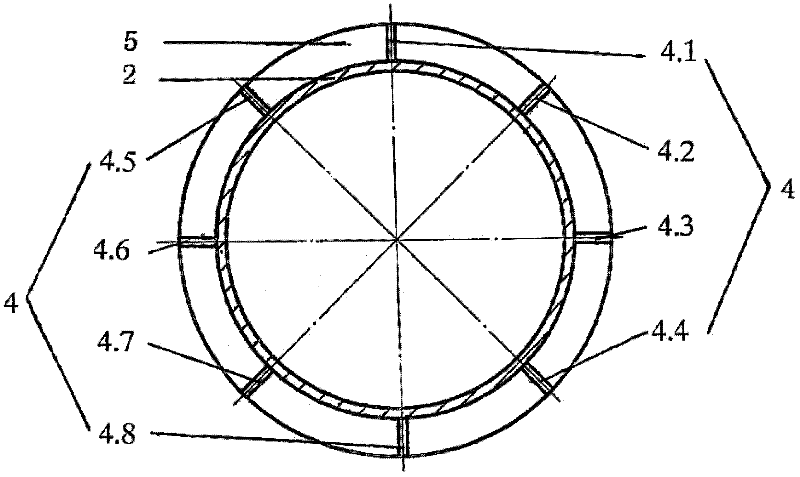

[0063] Such as figure 2 As shown in the new inner cylinder body, the new inner cylinder body 2 includes a straight cylinder body 2.1 and an inner head piece 2.2 connecting the straight cylinder body 2.1, and there are three sets of butt welds on the outer wall of the new inner cylinder body 2, including butt direct welding s...

Embodiment 2

[0094] In the new glass-lined reaction tank of this embodiment and its manufacturing process steps, except that the process conditions in the following steps are different, the others are manufactured according to the steps of Example 1. Wherein, in step 9) and step 10), the firing process of medium-temperature pre-firing, high-temperature sintering, heat preservation, and stage-by-stage controlled firing is adopted during firing. Heat preservation, and then use 450-750°C to heat up and pre-fire and heat-preserve. The time for temperature-raising pre-fire and heat preservation is 2-4 hours in total, and then use 700-920°C for high-temperature firing and heat preservation. The time for high-temperature firing and heat preservation is 1 hour in total. -1.5 hours. The precision-controlled internal heating electric furnace with intelligent temperature program control / regulation / recorder can accurately compile, set and automatically record the firing temperature curves of the whole...

Embodiment 3

[0097] In the new glass-lined reaction tank of this embodiment and its manufacturing process steps, except that the process conditions in the following steps are different, the others are manufactured according to the steps of Example 1. Wherein, in step 9) and step 10), the firing process of medium-temperature pre-firing, high-temperature sintering, heat preservation, and stage-by-stage controlled firing is adopted during firing. Heat preservation, and then use 450-750°C to heat up and pre-fire and heat-preserve. The time for temperature-raising pre-fire and heat preservation is 2-4 hours in total, and then use 700-920°C for high-temperature firing and heat preservation. The time for high-temperature firing and heat preservation is 1 hour in total. -1.5 hours. The precision-controlled internal heating electric furnace with intelligent temperature program control / regulation / recorder can accurately compile, set and automatically record the firing temperature curves of the whole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com