Patents

Literature

35results about How to "Meet design standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

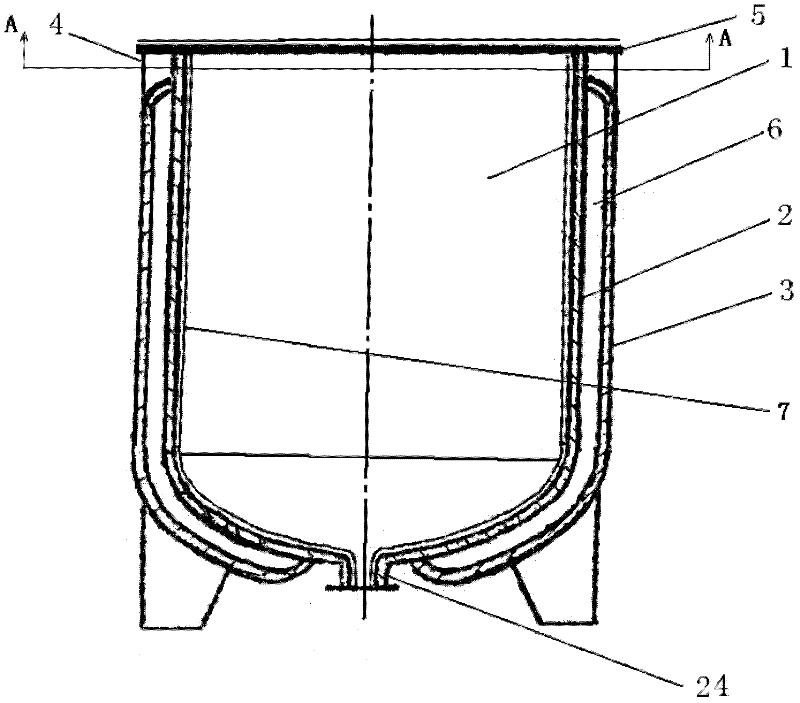

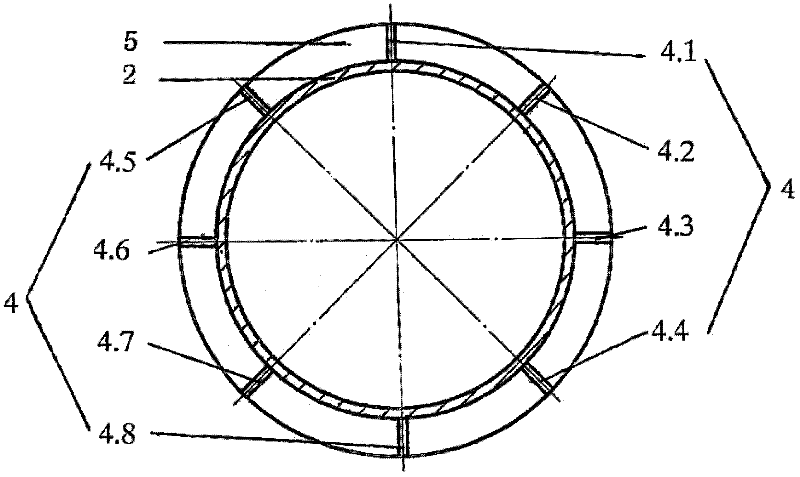

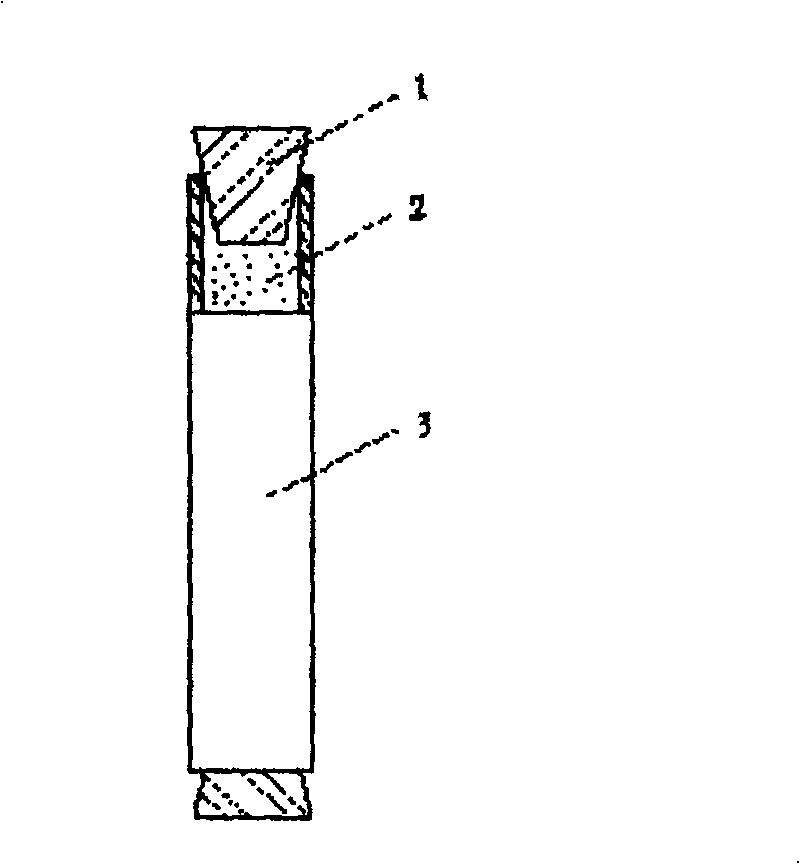

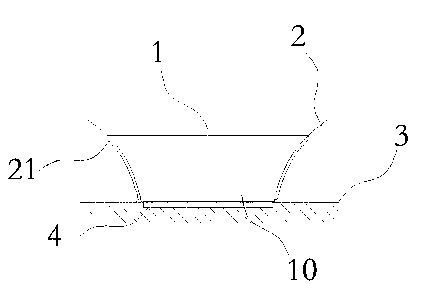

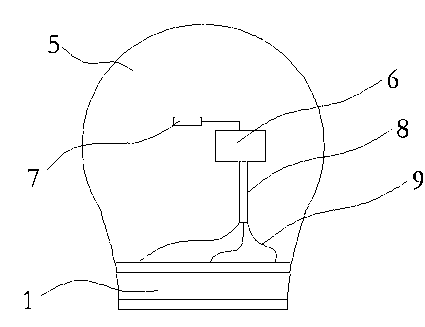

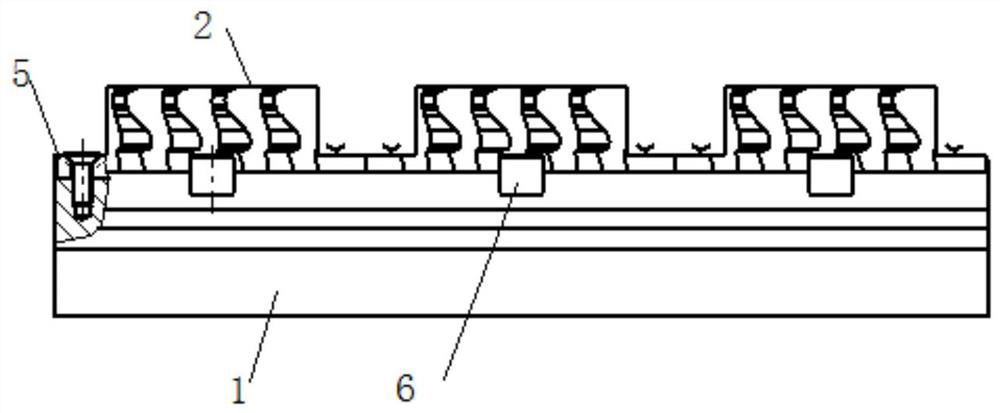

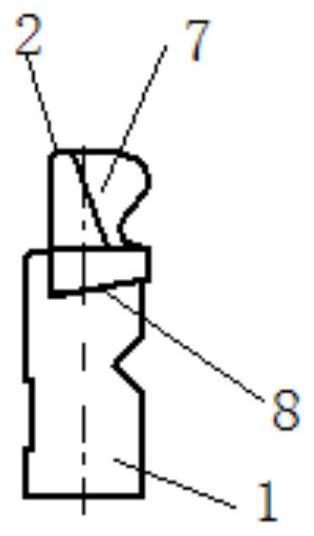

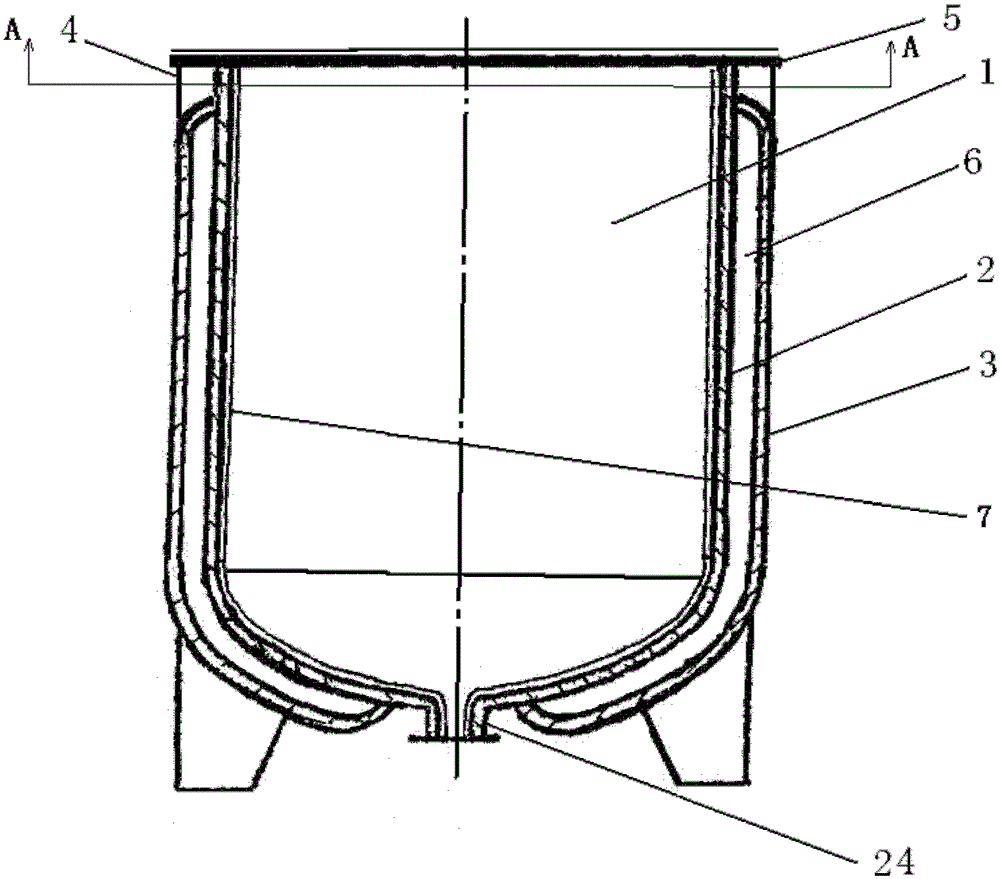

New glass-lined reactor and manufacturing method thereof

InactiveCN102389758AQuality improvementFully combinedChemical/physical/physico-chemical processesTemperature controlManufacturing technology

The invention relates to a new glass-lined reactor and a manufacturing method thereof which are used in the chemical and pharmaceutical industries and belong to the field of pressure vessels. The reactor is characterized in that new inner cylinder bodies and new outer jackets are welded into an integral structure; glass-lined protection glaze layers are coated and fired on the surfaces of butt welds on the inner cylinder bodies and the outer jackets; and the Supervision Regulation on Safety Technology for Pressure Vessel is comprehensively realized. The manufacturing method is characterized in that a precisely controlled inner heated electric furnace formed by intelligent temperature program controllers / regulators / recorders is adopted to implement staged controlled firing and an integral firing process with jackets; and full-automatic glaze slurry spraying equipment and an electrical heating and temperature controlling insulating cylinder are adopted for manufacturing. The reactor and the manufacturing method have the following advantages: the reactor initiates and lays a foundation for that the manufacturing technology standards of the glass-lined reactors in China all realize the Supervision Regulation on Safety Technology for Pressure Vessel and initiates and lays a foundation for datamation and automation of the core technology of controlled enamelling; the integral quality of the reactor is obviously superior to the current national standard; the reactor steps and is developed to innovate and be ahead of the conditions that the international outer heated electric furnace iron billets have no alternative to secondary forming during manufacturing and the core technology of controlled enamelling has the defect of uneven heating; and the integral quality of the reactor is superior to the international leading level, therefore the reactor has global market competitiveness.

Owner:朱文华

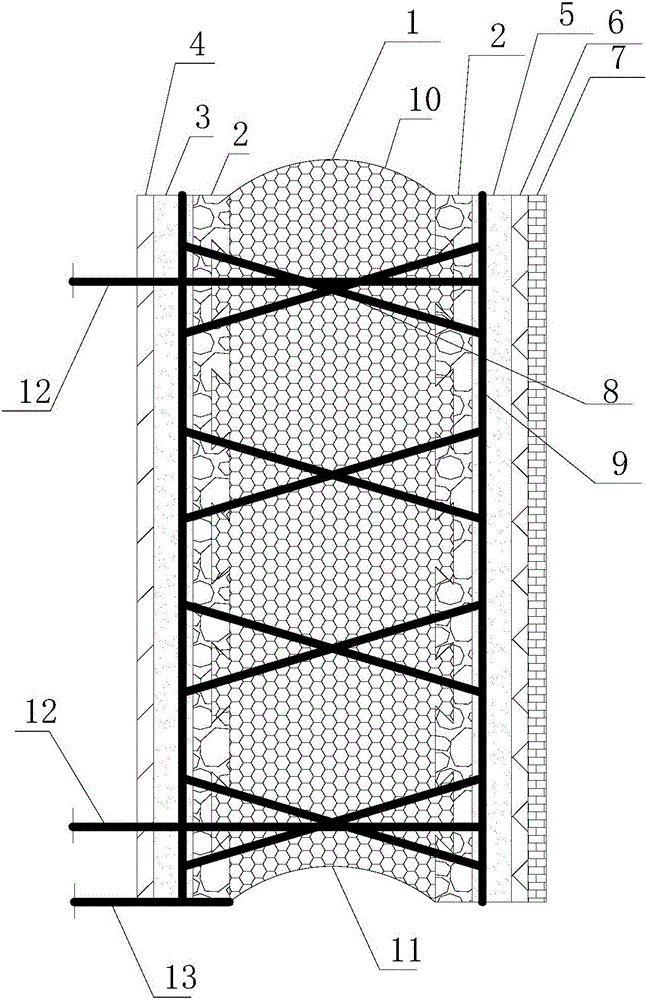

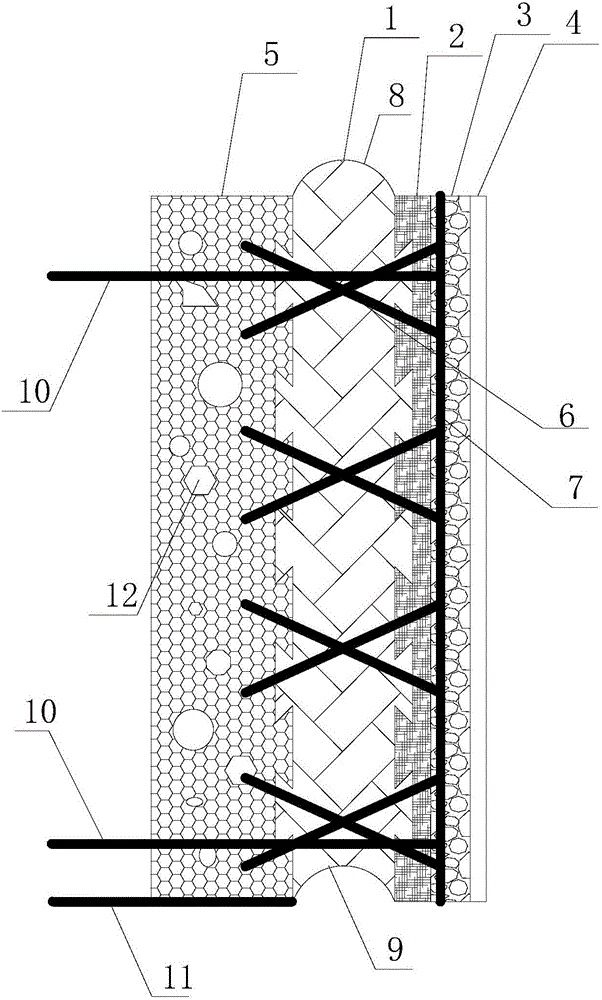

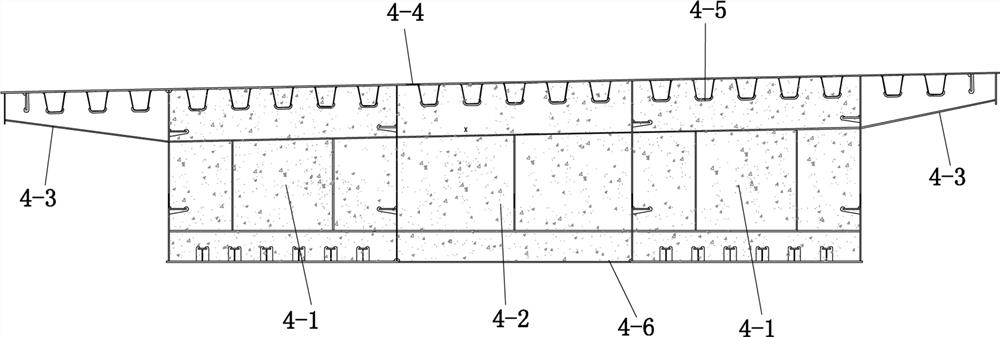

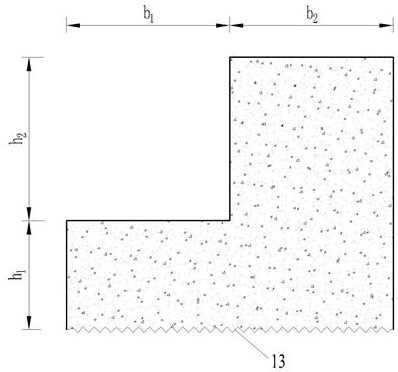

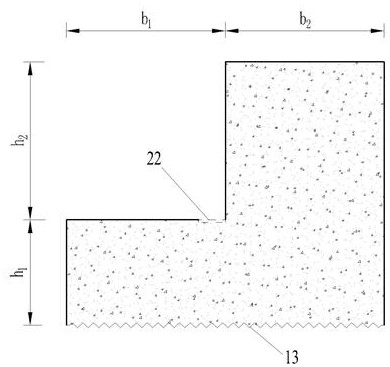

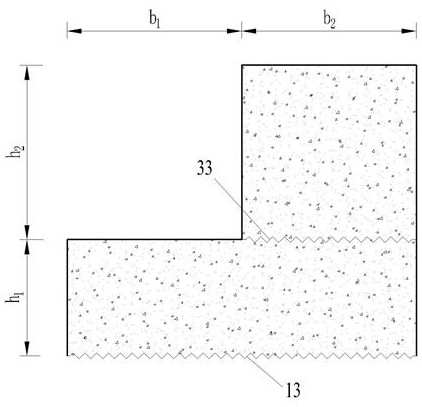

Assembly type energy-saving thermal-insulation composite wall board and making method thereof

ActiveCN106436981ASimple construction workAvoid hot and cold bridgesWallsHeat proofingDesign standardThermal bridge

The invention discloses an assembly type energy-saving thermal-insulation composite wall board. The assembly type energy-saving thermal-insulation composite wall board comprises a middle thermal-insulation layer and a steel wire net frame, an inner wall layer and an outer wall layer are arranged on the two sides of the thermal-insulation layer respectively, the steel wire net frame comprises inclined insertion wires and steel wire net pieces, and the inclined insertion wires penetrate through the thermal-insulation layer and are fixedly connected with the steel wire net pieces arranged in the inner wall layer and the outer wall layer. The composite wall board has the advantages that the structural design is reasonable, mechanical production is completed inside a factory workshop, and no machining operation is needed during on-site construction; 2, the wall board is provided with the thermal-insulation layer and a thermal-insulation mortar layer, the thermal-insulation effect completely meets design standards, external wall thermal insulation is not needed, and the thermal-insulation mortar layer has certain strength and is used for installing a prefabricated door and window frame; assembly arms and an assembly bracket are designed to be matched with pits and protrusions arranged around the thermal-insulation layer, in this way, cold and thermal bridges are avoided, thermal resistance is increased, the thermal-insulation and energy-saving effects are improved, on-site lifting construction operation is simple, and the construction period is effectively shortened.

Owner:山东乾宇建筑节能科技有限公司

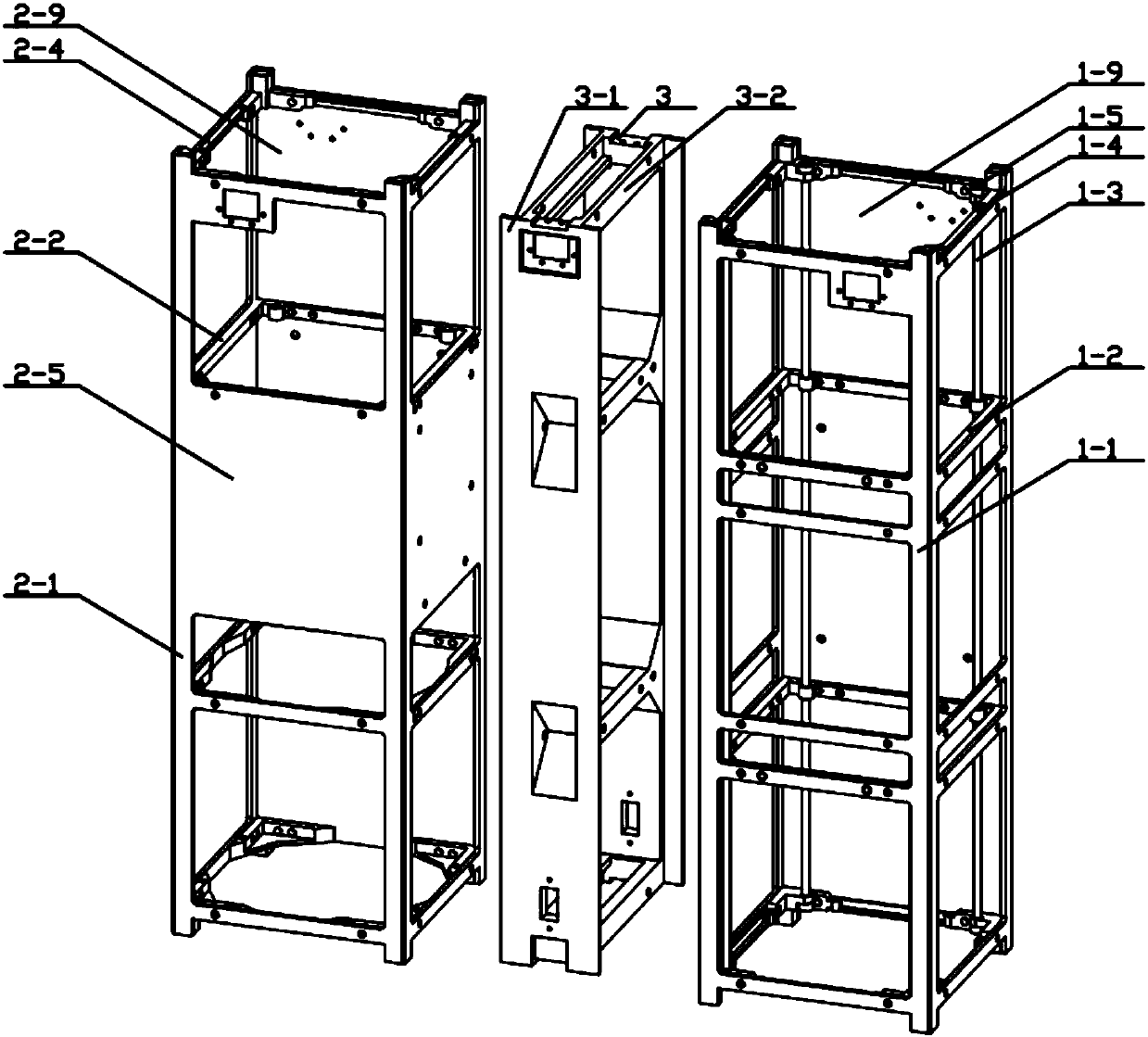

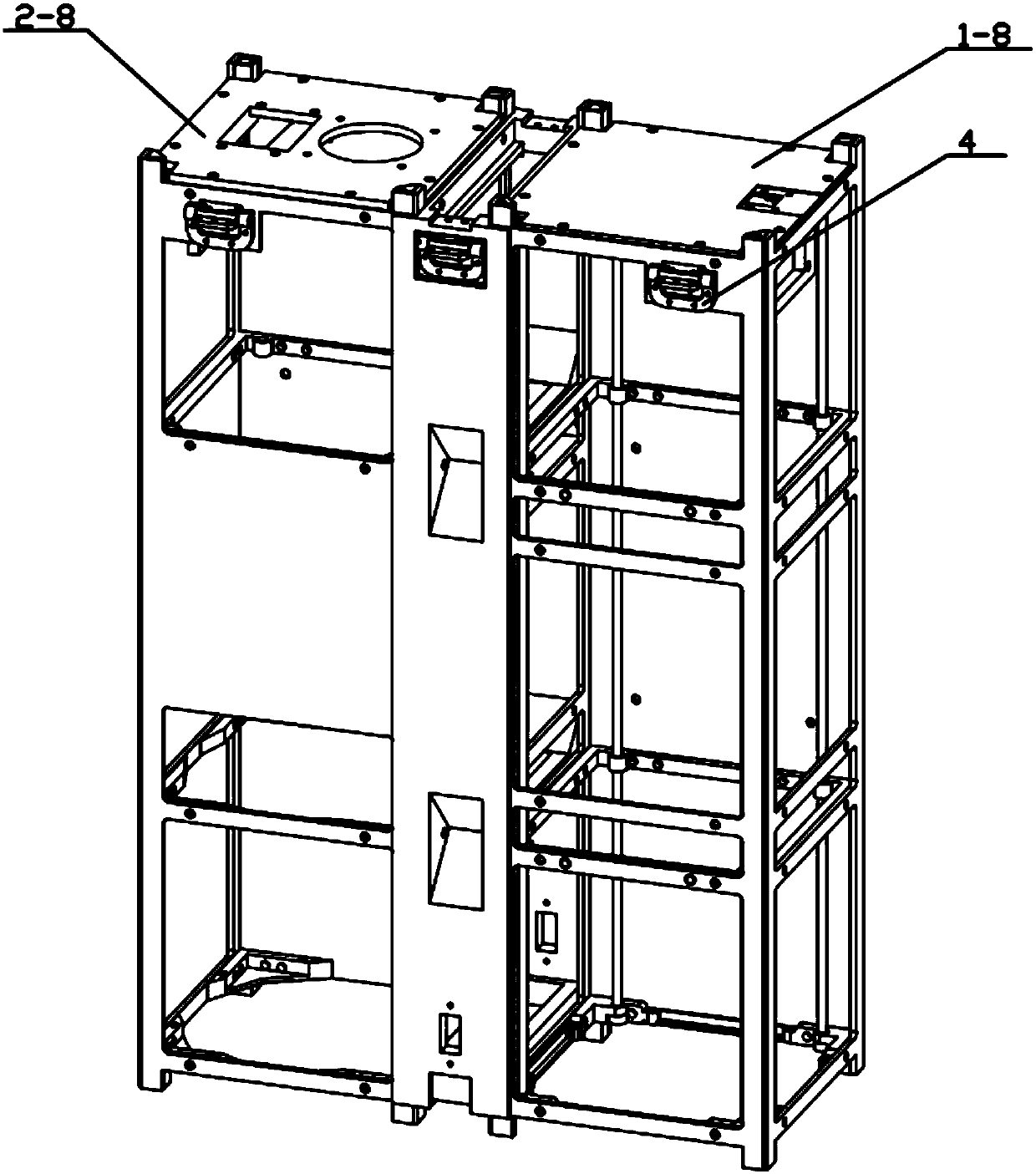

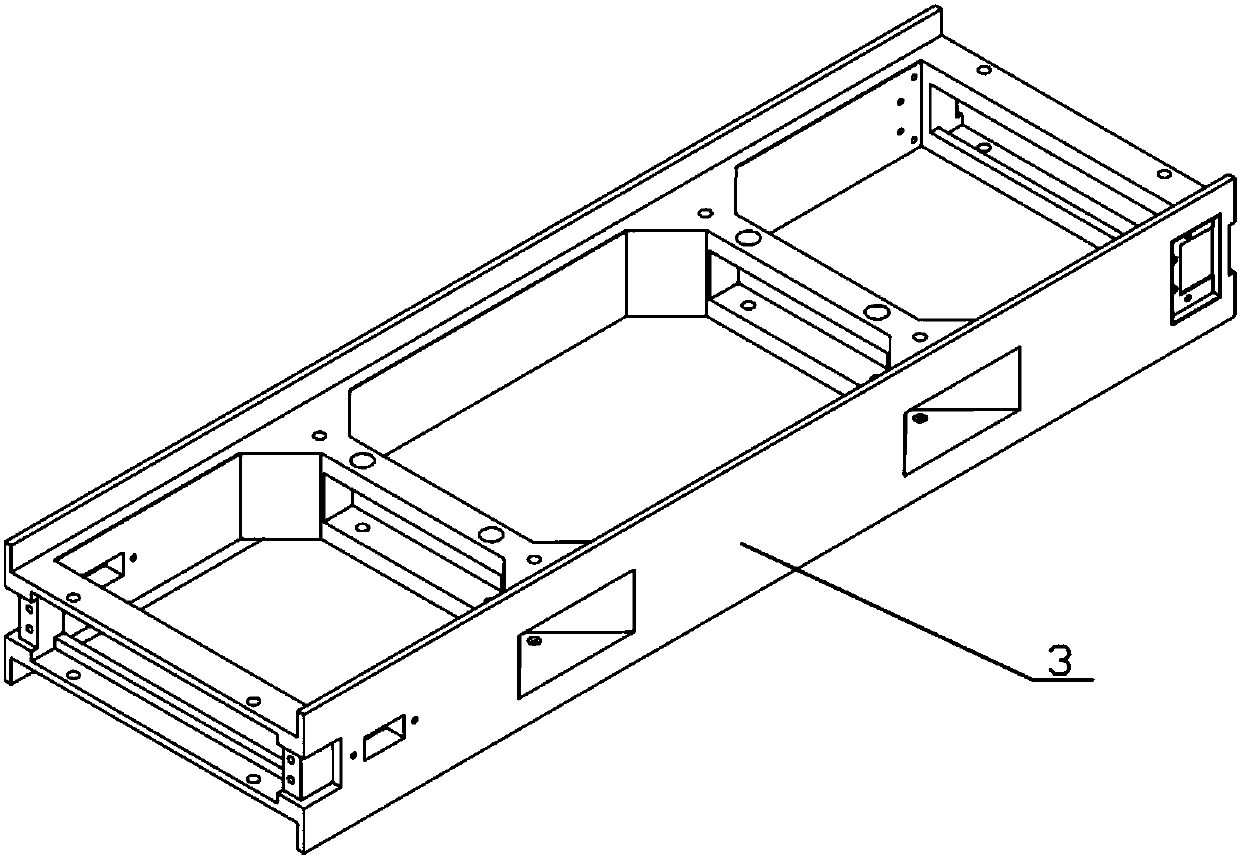

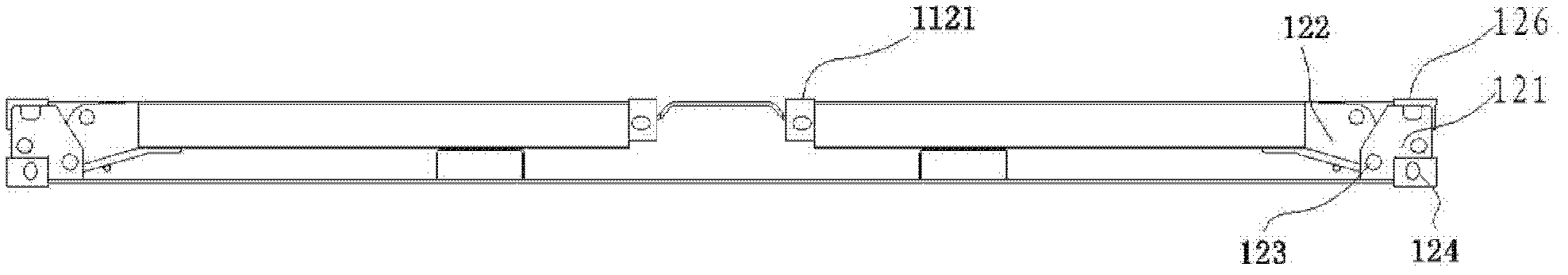

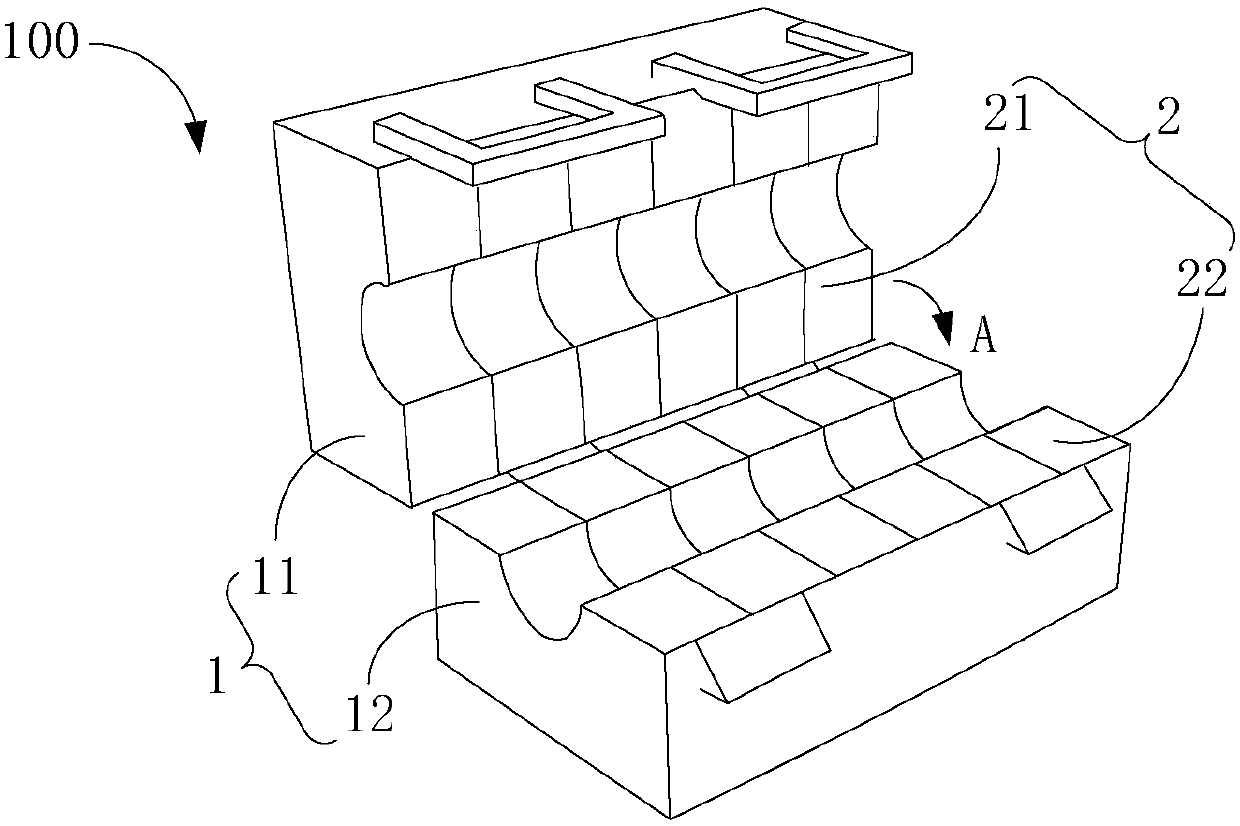

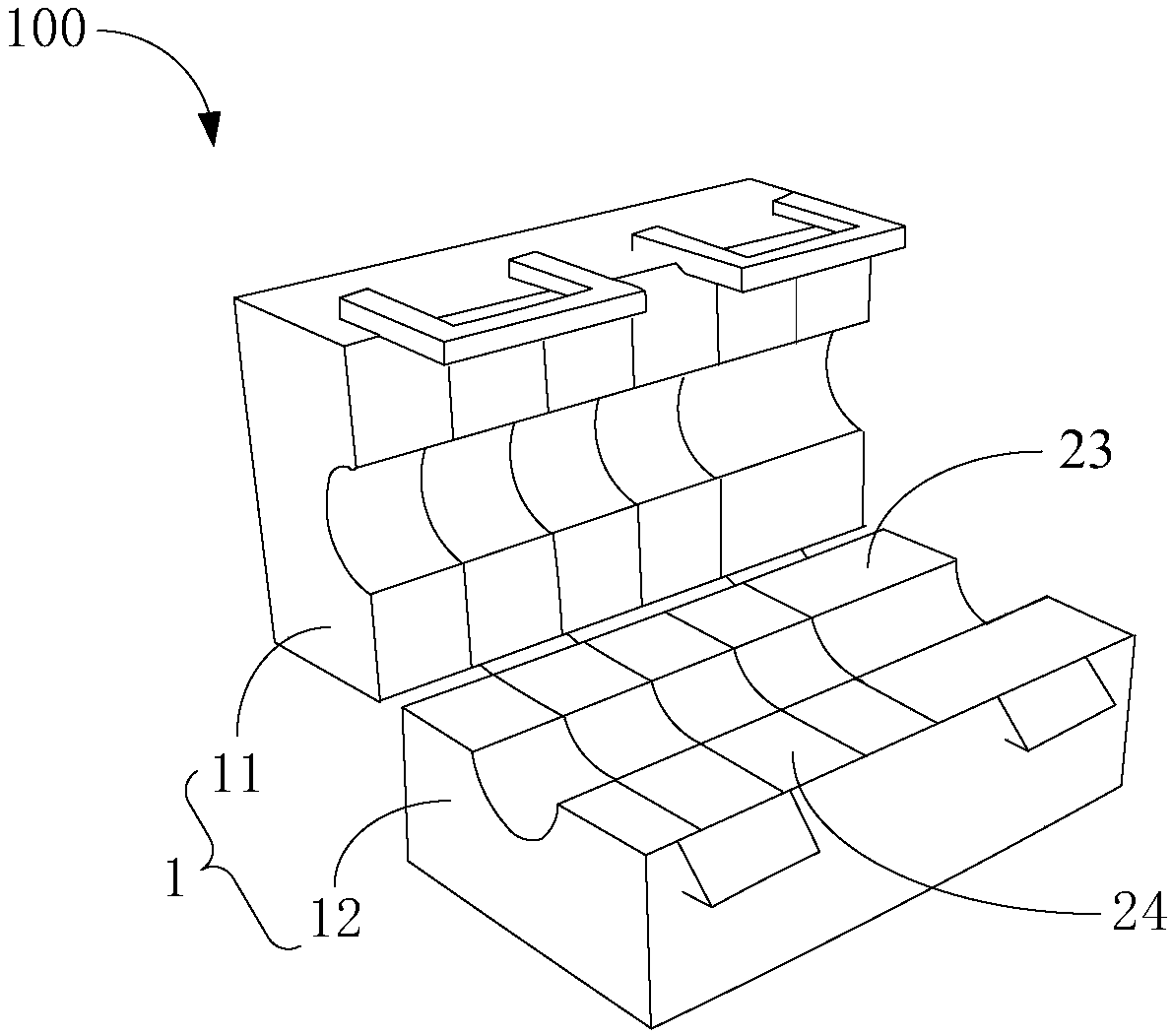

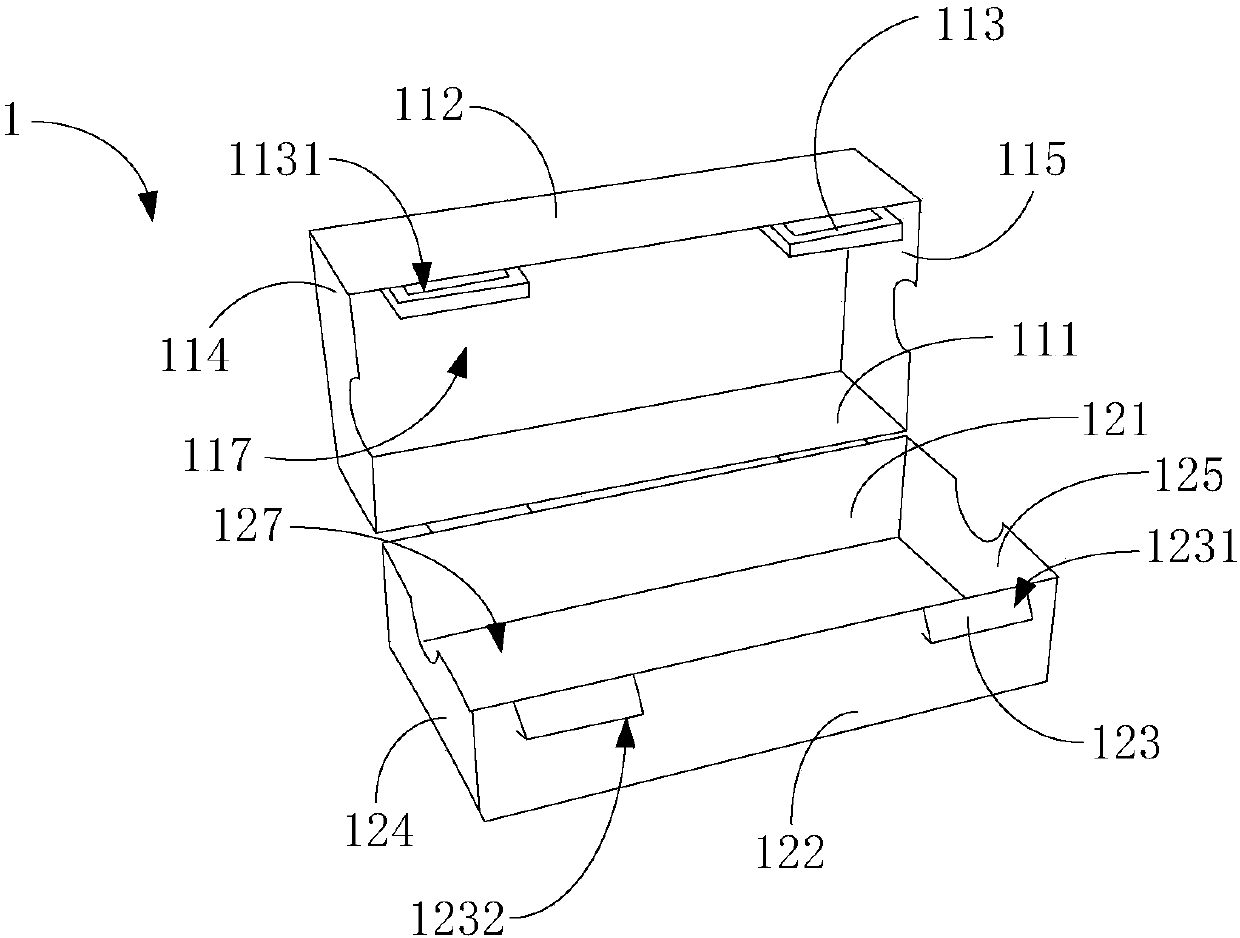

Six-unit cubesat main force bearing structure

PendingCN107902107AGuaranteed parallelismSuccessful launchArtificial satellitesStructural engineeringRocket

The invention discloses a six-unit cubesat main force bearing structure. The six-unit cubesat main force bearing structure is formed by means of the method that two three-unit cubesat main frames cooperate with each other through a connecting frame. The main frames are each of a cuboid frame structure, end covers are arranged at the two ends of each main frame in the direction of the long edge, and middle frameworks are arranged in the middles of the main frames. Four screws are arranged in each main frame and penetrate through the corresponding middle framework to be fixed to the end covers of the two ends of the corresponding main frame, and six hinges are arranged on the connecting frame and the two main frames. The assembly difficulty of a cubesat is lowered, and the integrity of innerlayout is improved. According to the six-unit cubesat main force bearing structure, the main frames are of an integrated structure and connected through the connecting frame making contact with the main frames in a large area so that the parallelism between guiding rails can be ensured, the six-unit cubesat main force bearing structure and a cubesat-rocket separating device are not jammed in launching, and successful launching is ensured.

Owner:NANJING UNIV OF SCI & TECH

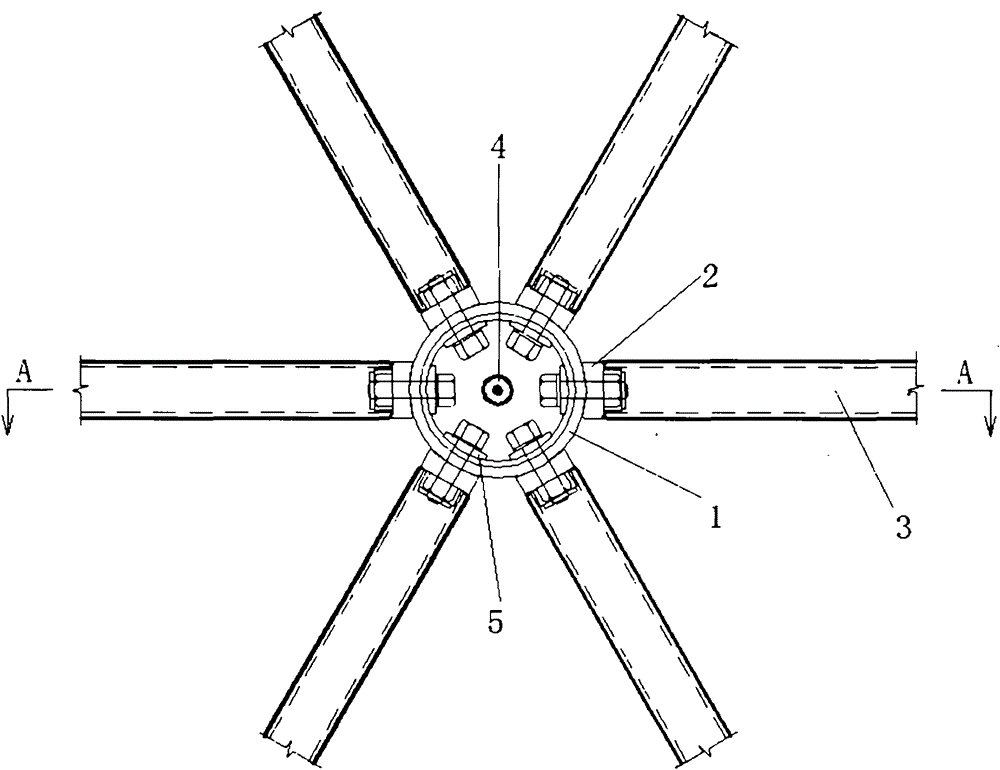

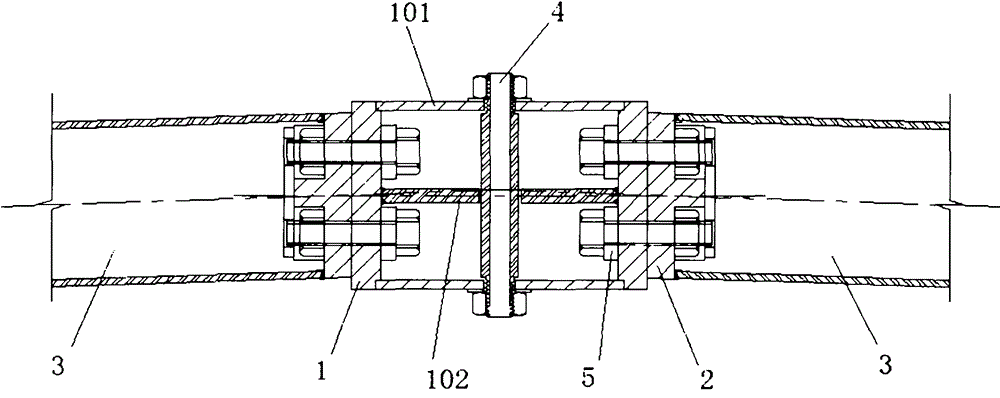

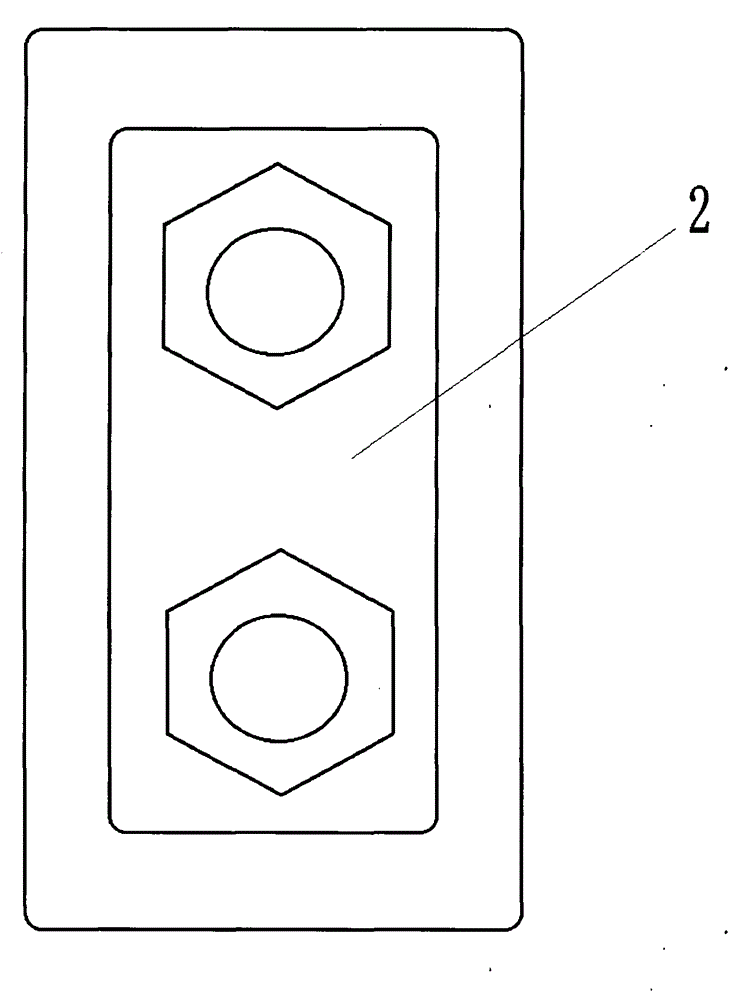

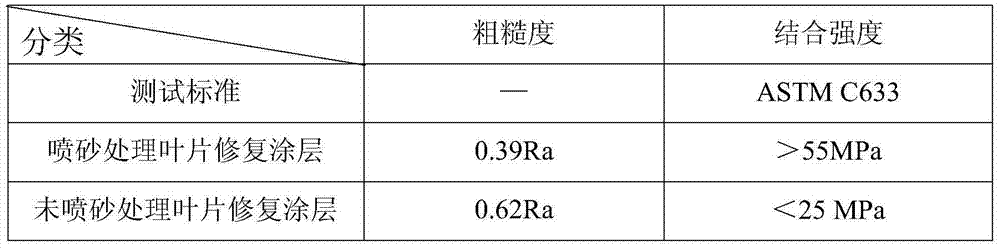

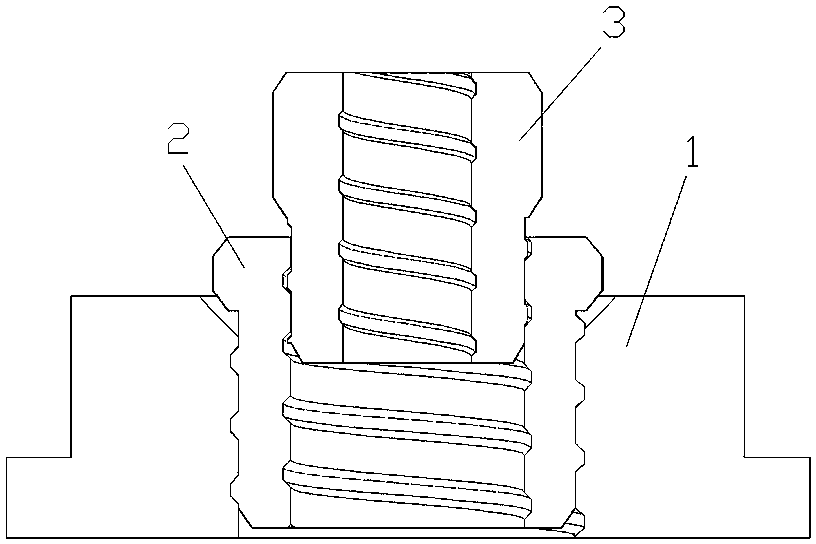

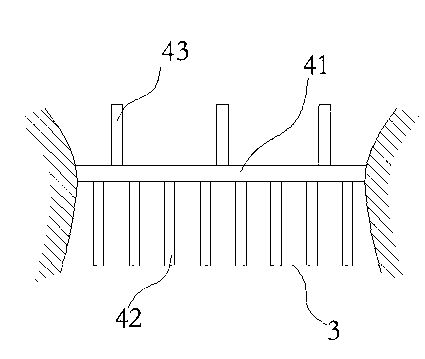

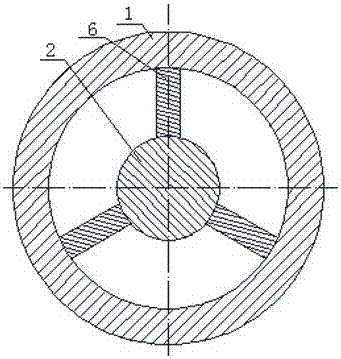

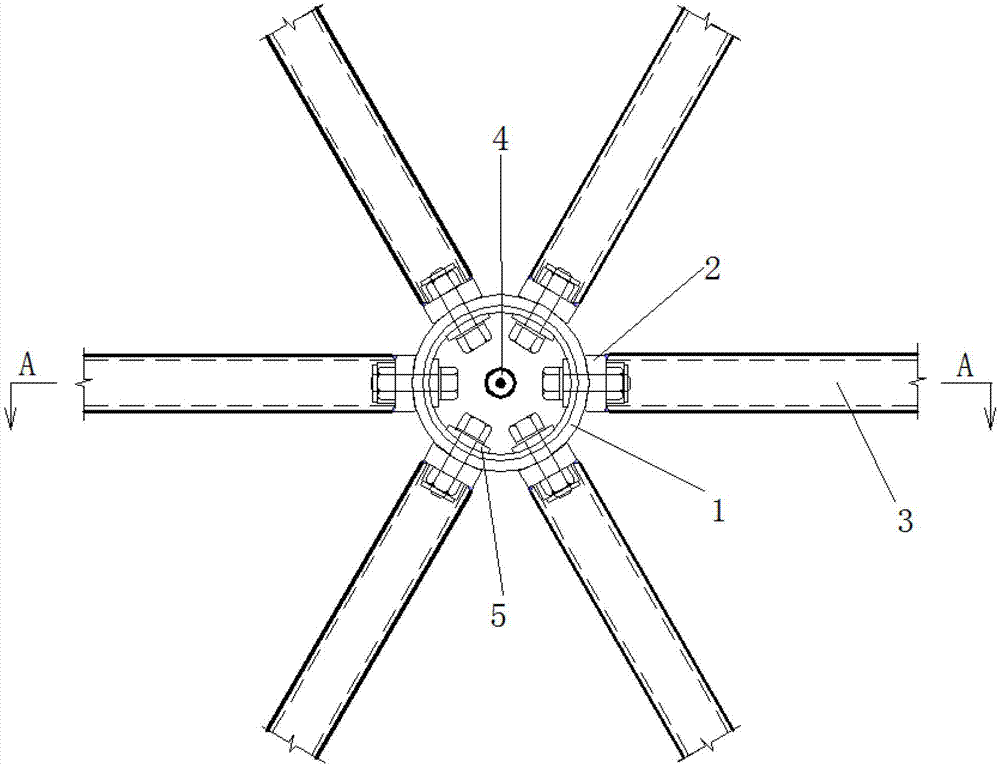

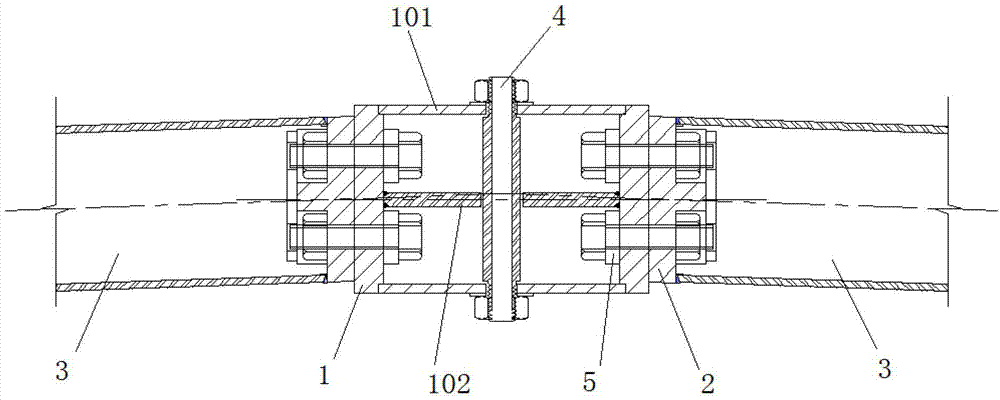

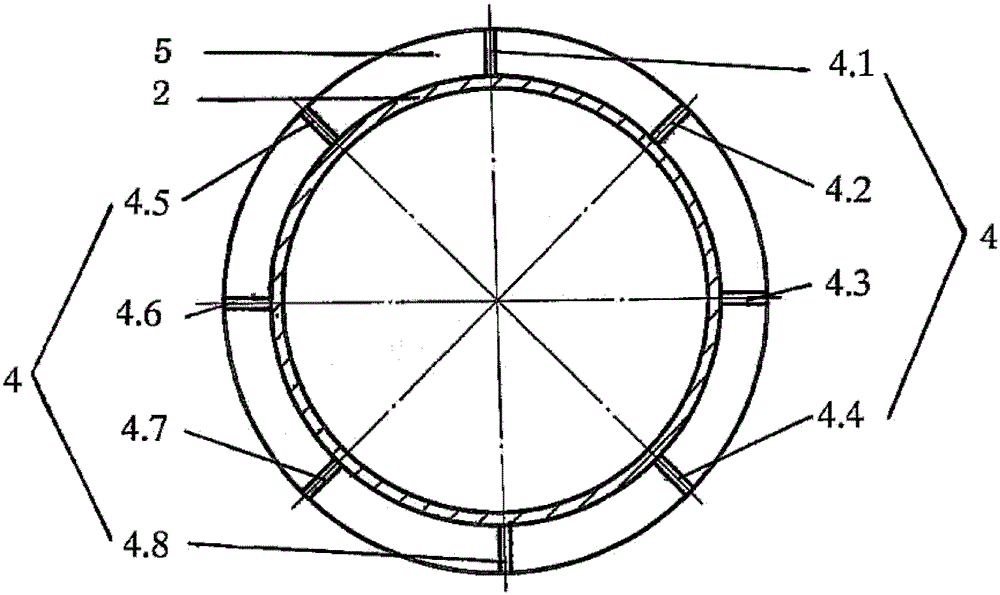

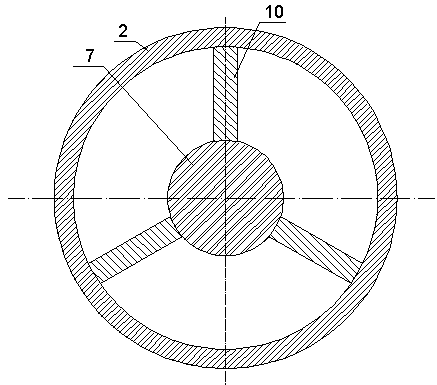

Joint drum structure for connecting steel structural part

InactiveCN104420543AThe structure is complex and beautifulSophisticated node structureBuilding constructionsBolt connectionThin-shell structure

The invention relates to a joint structure, in particular to a joint structure of a single-layer reticulated shell structure, more particularly, is a joint drum structure for connecting a steel structural part, and belongs to the technical field of roof building. A bolt drum joint structure of a rigid single-layer reticulated shell structure is characterized by comprising a bolt drum (1) and six hollow rod pieces (3), wherein the bolt drum (1) is of a hollow cylinder structure; detachable cover plates (101) are arranged on the two end surfaces of the bolt drum; six groups of bolt holes are uniformly distributed in the circumferential direction of the bolt drum (1); the angle of the tangent plane of each hollow rod piece (3) can be adjusted; each hollow rod piece (3) is welded and fixed with a sealing plate (2); a group of bolt holes are formed in each sealing plate (2); the six hollow rod pieces (3) are in bolted connection with the bolt drum (1) through the bolt holes after being welded and fixed with the sealing plates (2).

Owner:上海岑晨钢结构网架有限公司

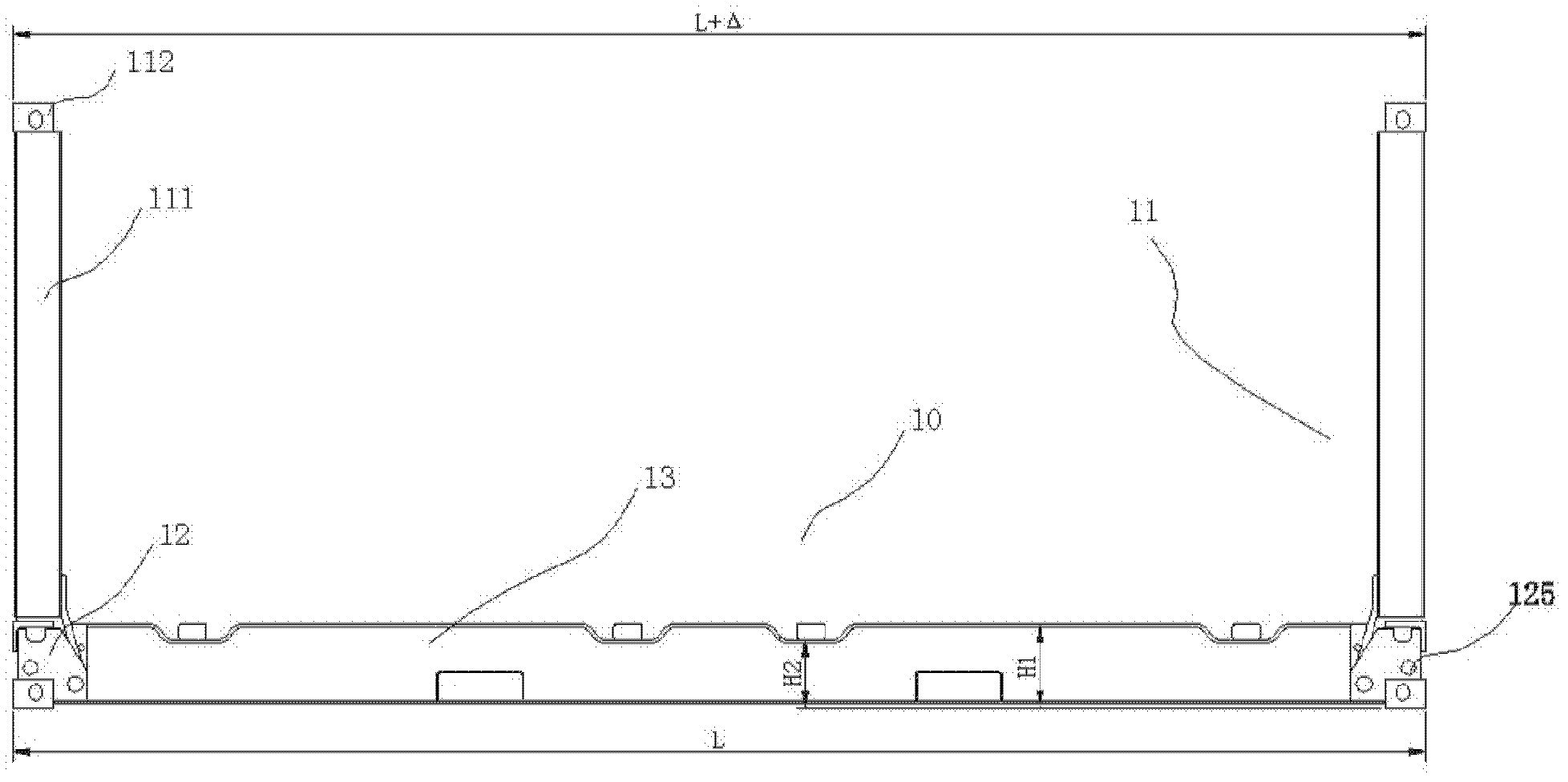

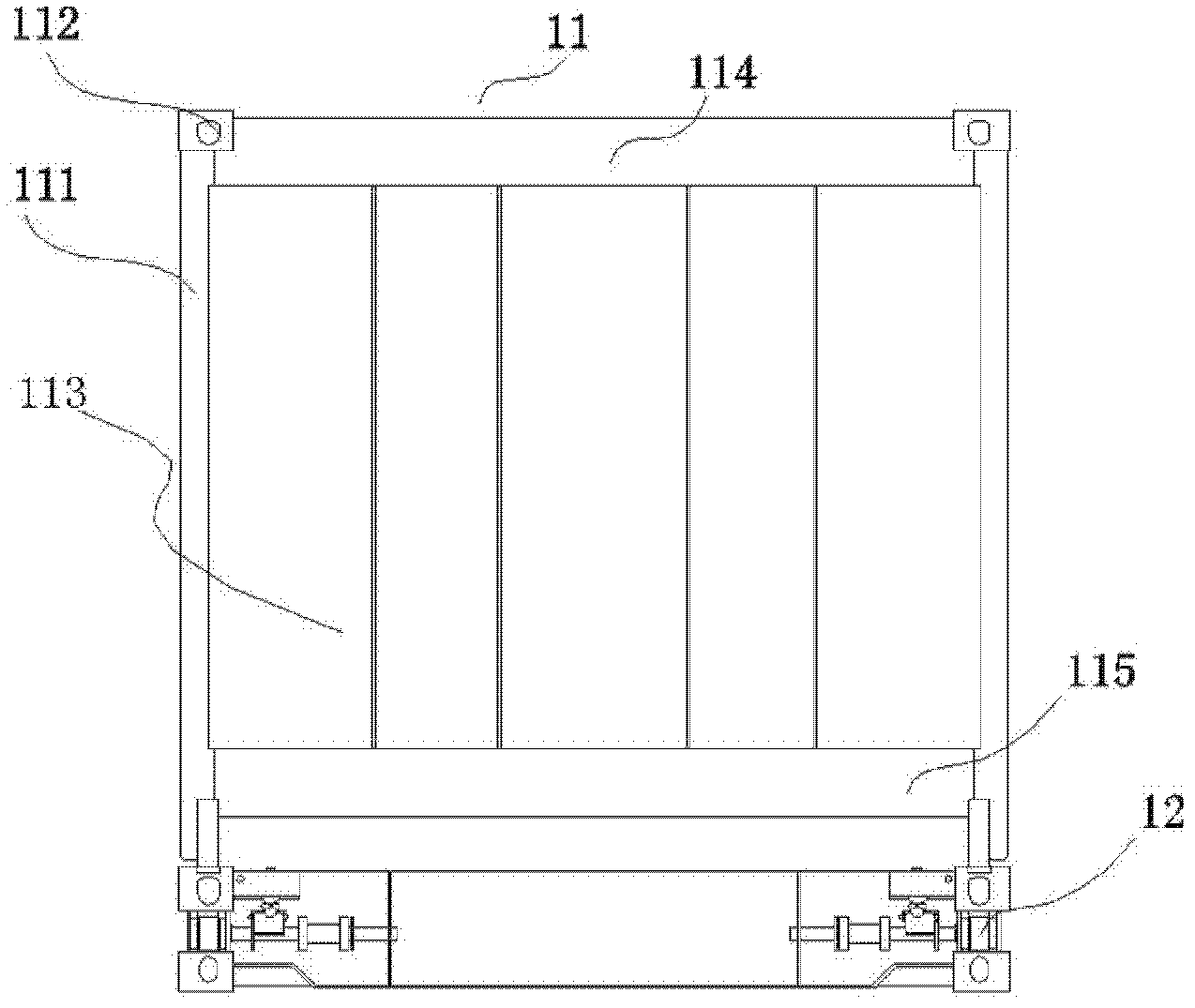

Novel foldable container and assembling method thereof

InactiveCN102556537AMeet design standardsFulfill the standardLarge containersEngineeringManufacturing quality

Owner:上海颖硕金属材料有限公司

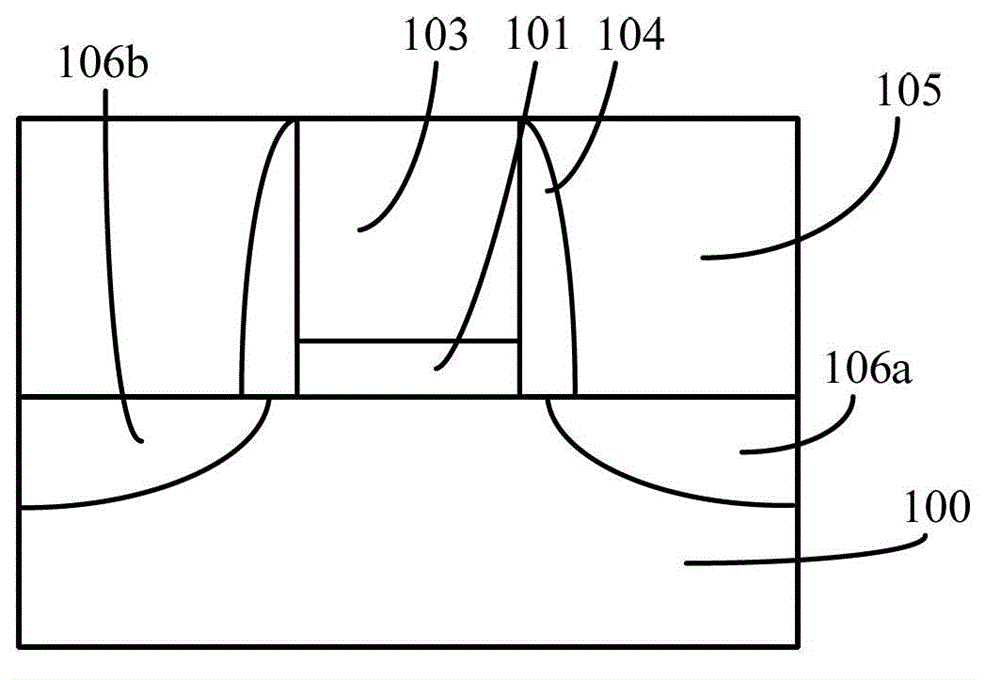

Forming method of semiconductor structure

ActiveCN104022034AReduce etch ratePrecise and easy to control the sizeSemiconductor/solid-state device manufacturingSemiconductor structureProtection layer

A forming method of a semiconductor structure comprises the following steps: providing a semiconductor substrate, a surface of the semiconductor substrate is provided with a stop layer, a surface of the stop layer is provided with a grid electrode film, partial surface of the grid electrode film is provided with a first mask layer, a surface of the first mask layer is provided with a second mask layer, wherein the second mask layer and the stop layer are made of the same material, and the first mask layer and the second mask layer are made of different material; forming a protection layer on a side wall surface of the first mask layer, and the protection, the second mask layer and the stop layer are made of the same material; etching the grid electrode film by using the second mask layer as a mask after the protection layer is formed until the surface of the stop layer is exposed, thereby forming the grid electrode layer; the size of the formed semiconductor structure is easily and accurately controlled, so the formed semiconductor device is stable in performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Assembly type insulating composite wall plate and manufacturing method thereof

InactiveCN106437011ASimple construction workAvoid hot and cold bridgesBuilding componentsSurface layering apparatusDesign standardUltimate tensile strength

The invention discloses an assembly type insulating composite wall plate. The assembly type insulating composite wall plate comprises a middle insulating layer and a steel wire net rack, wherein an interior wall layer and an exterior wall layer are respectively arranged on two sides of the insulating layer; the steel wire net rack comprises steel truss connectors and steel wire meshes; the steel truss connectors penetrate through the insulating layer, extend to the interior wall layer and the exterior wall layer and are fixedly connected with the steel wire meshes arranged in the exterior wall layer; and the interior wall layer is a concrete layer. The assembly type insulating composite wall plate has the advantages that (1) the wall plate is reasonable in structural design, and is mechanically produced in a workshop of a plant, and processing operation is not required in field construction; and (2) the wall plate is provided with the insulating layer and an insulating mortar layer, the insulating effect completely conforms to the design standard, exterior wall insulation is not required, and the insulating mortar layer has certain strength and is used for mounting a prefabricated door window frame.

Owner:李刚

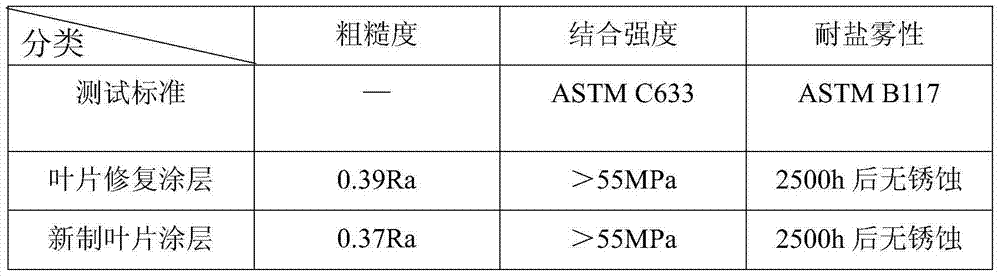

Repairing method of 2Cr12NiMo1W1V blade surface Al coating

InactiveCN103882441AAvoid corrosionAvoid DimensionsMolten spray coatingFurnace typesDesign standardAqueous sodium hydroxide

The invention provides a preparing method of 2Cr12NiMo1W1V blade surface Al coating, comprises the following steps: cleaning and drying the to-be-repaired blade, soaking the blade in a sodium hydroxide aqueous solution at temperature of 70-90 DEG C and concentration of 80-100g / l, reacting for 50-80min, taking out the blade, washing residual bath solution on the blade by using tap water, performing sand blasting on the blade surface by using white emery, checking defect of blade, and preparing new Al coating by using a manual coating mode. The method provided by the invention overcomes the problems that the size of the blade manufactured by using a machining method is out of tolerance and the acid pickling can corrode the substrate; the size of the blade is precisely guaranteed to meet the design standard, the reuse rate of the reworking blade is improved; the cleanliness of the blade surface is guaranteed, and the combining strength of the coating and the blade is improved; the blade repaired by the method is good in use effect, the corrosion resistance, the coating roughness and the combining strength meet the design requirements, the production cost is low, the operation is convenient, and the application prospect is wide.

Owner:DONGFANG TURBINE CO LTD

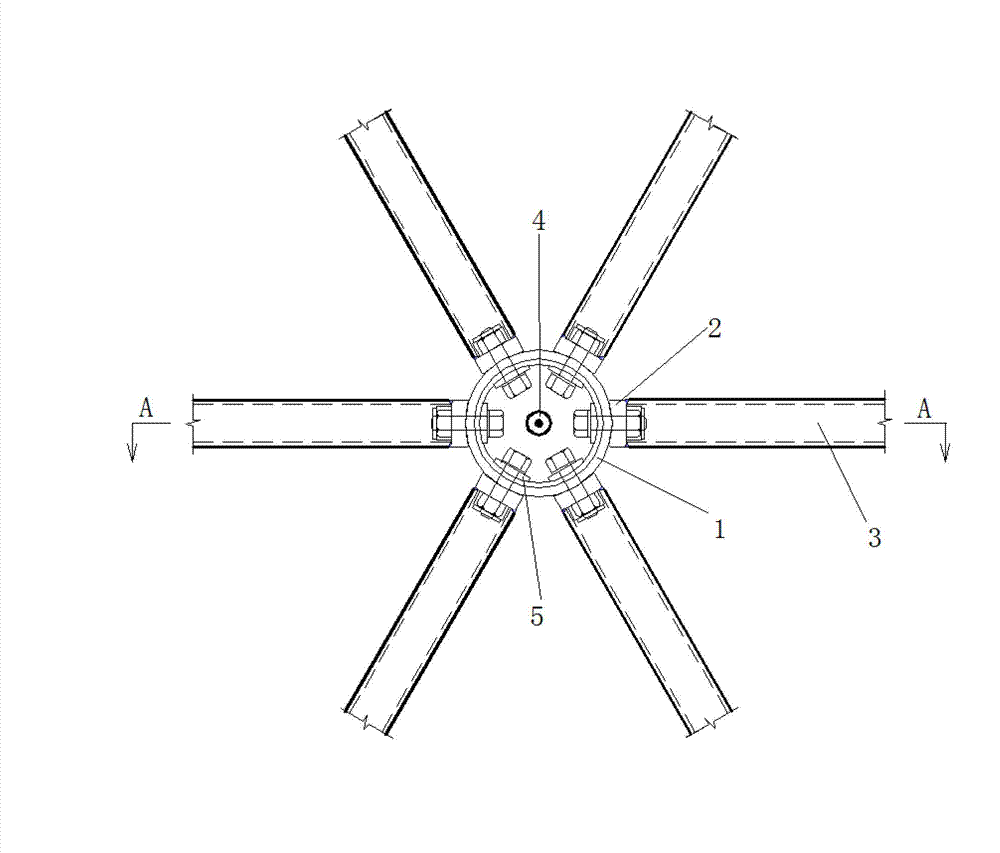

Node structure of rigid single-layered latticed-shell structure

InactiveCN102966186ASimple structureEasy assemblyBuilding constructionsHollow cylinderBolt connection

The invention relates to a latticed-shell structure, in particular to a single-layered latticed-shell structure, more particularly, a node structure of a rigid single-layered latticed-shell structure, and belongs to the technical field of roof buildings. The node structure is characterized by comprising six hollow rod pieces (3) welded and fixed with seal plates (2), and the welding angle is adjustable. The node structure further comprises a bolt drum (1) adopting a hollow cylindrical structure, wherein a detachable cover plate (101) is arranged on at least one end surface of the bolt drum (1); six groups of bolt holes are uniformly distributed in the circumferential direction of the bolt drum (1); the seal plates (2) welded with the hollow rod pieces (3) are in bolted connection with the bolt drum (1) through the bolt holes; and the bolt drum (1) is further provided with an axial bolt (4) through which the cover plate (101) is in bolted connection with the main body of the bolt drum (1).

Owner:上海岑闵新材料科技有限公司

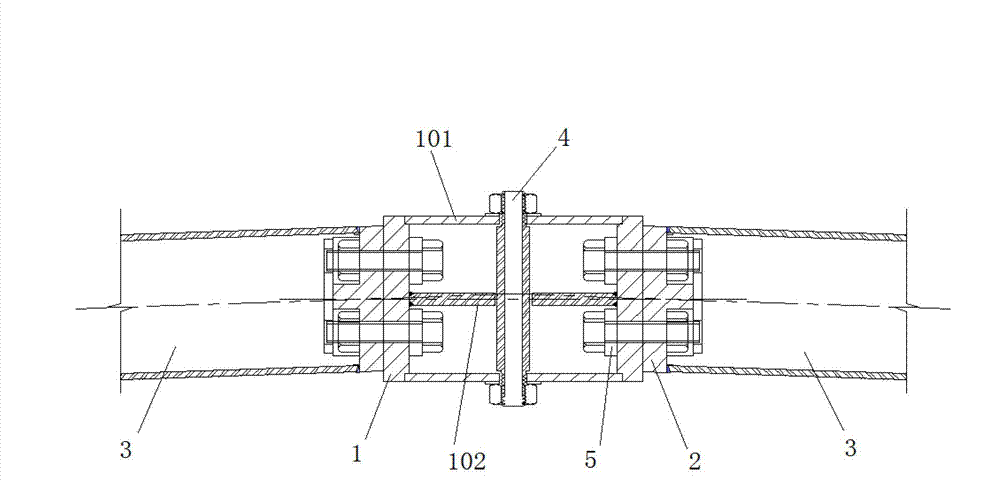

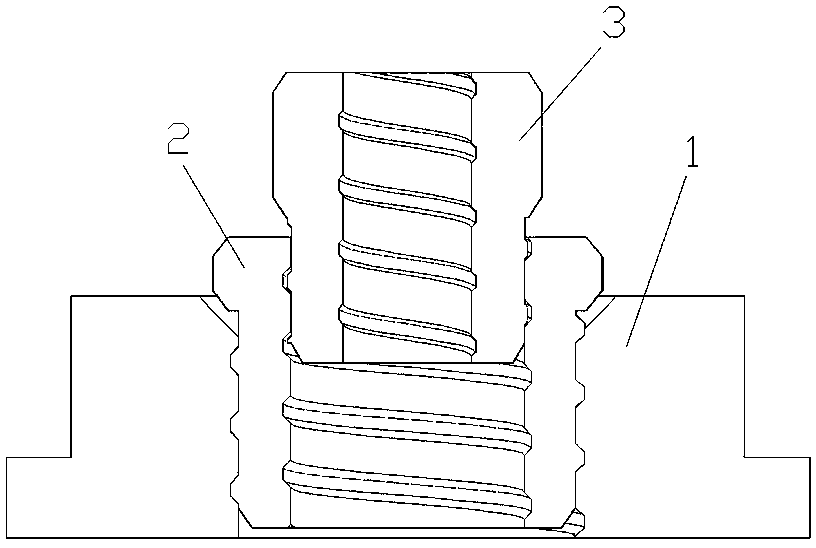

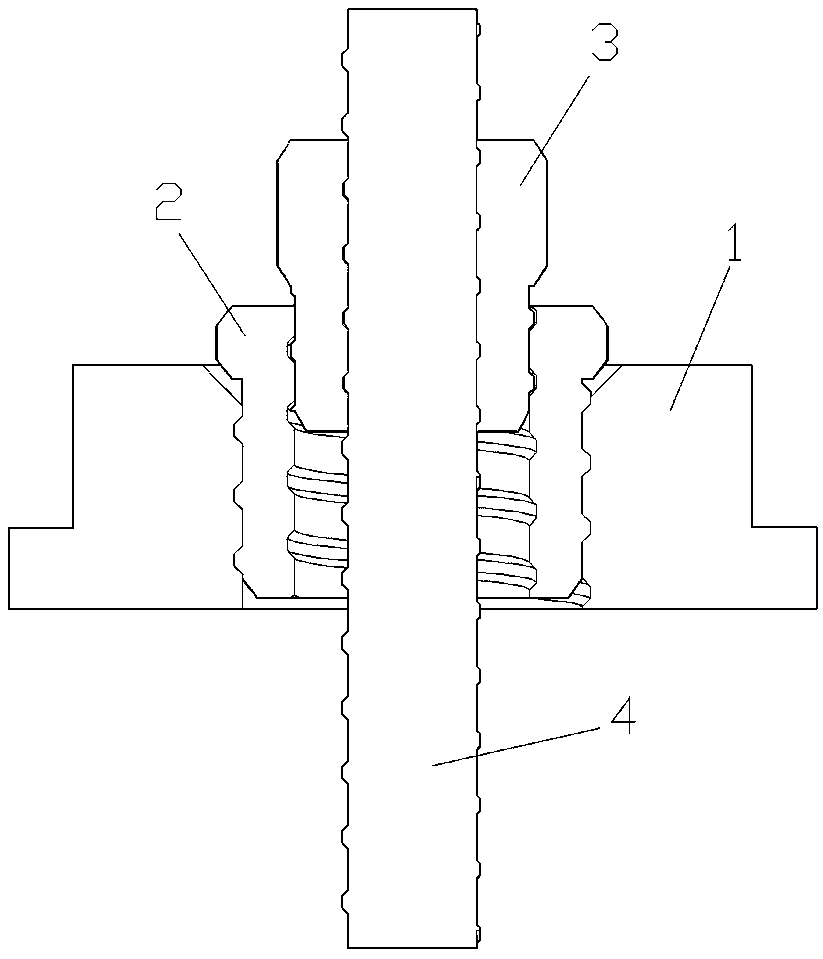

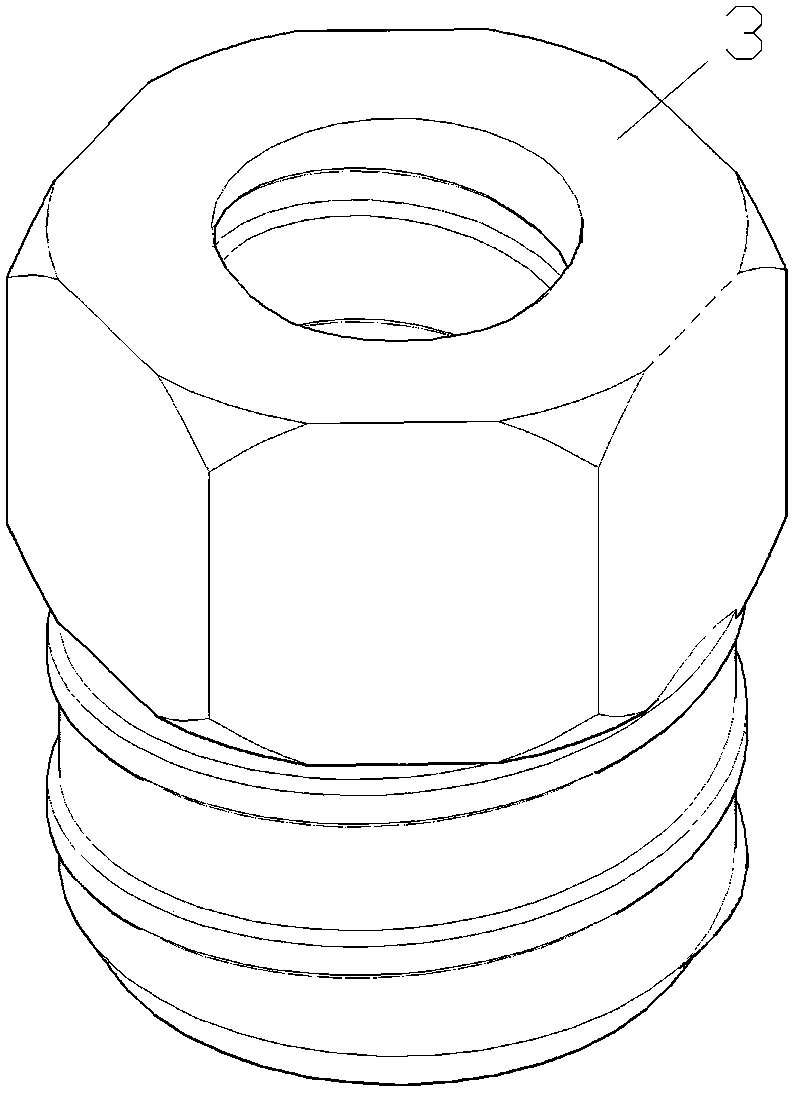

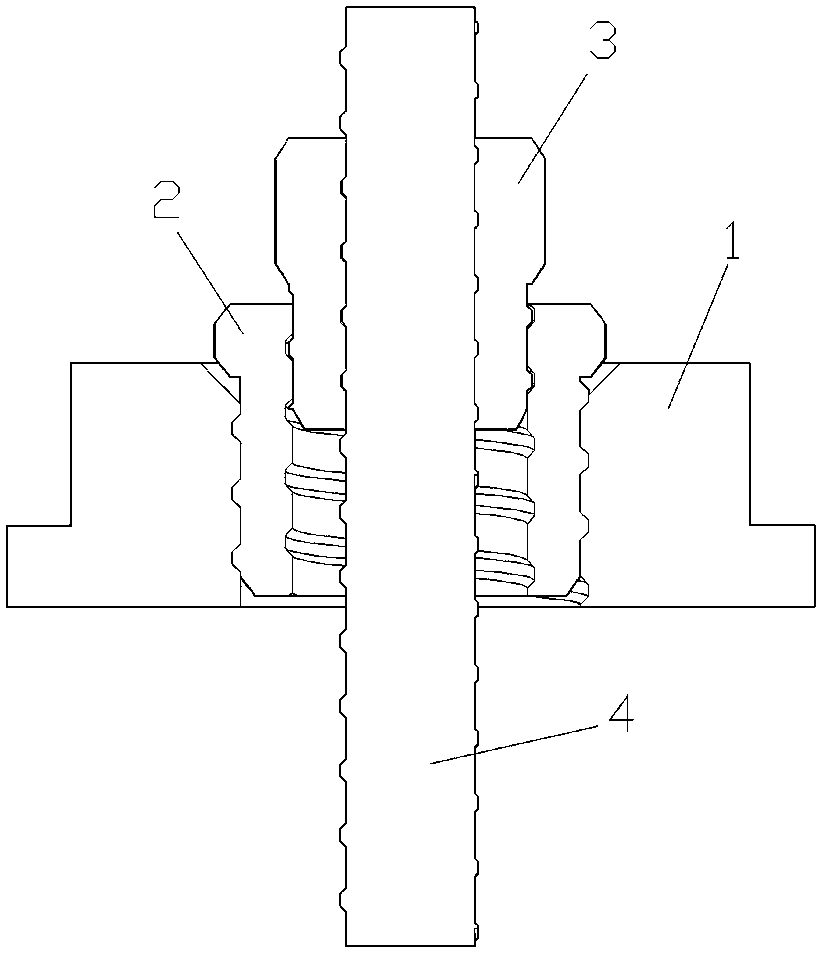

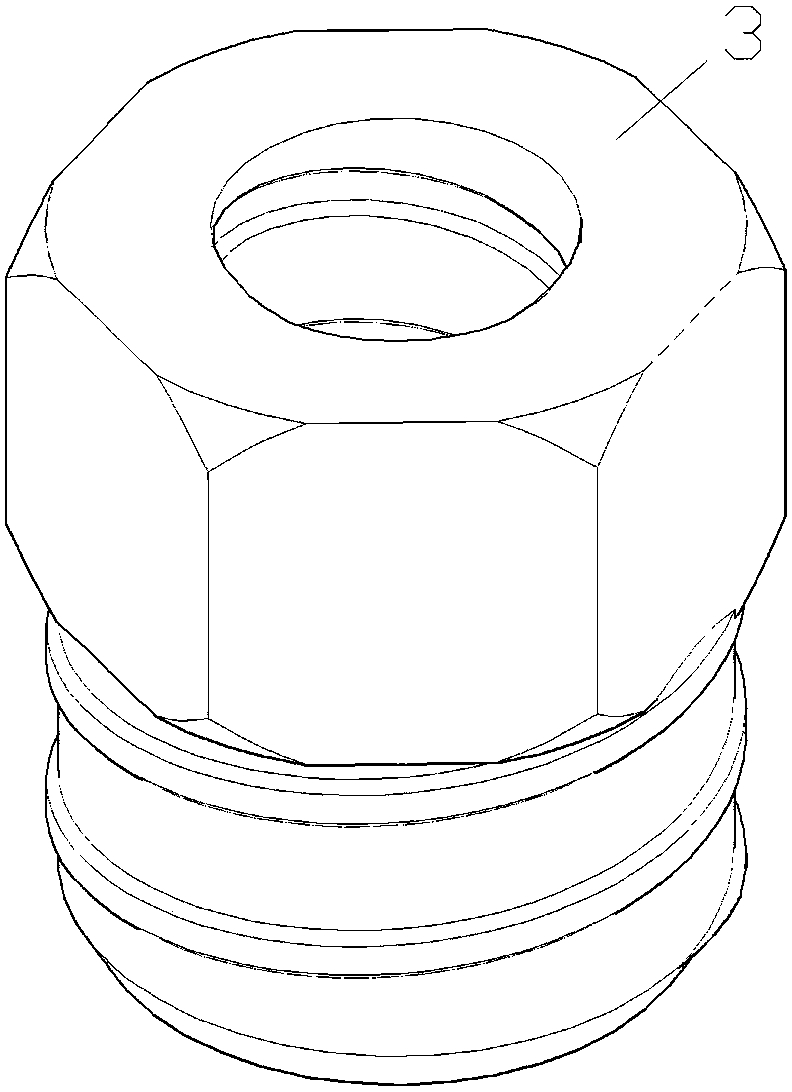

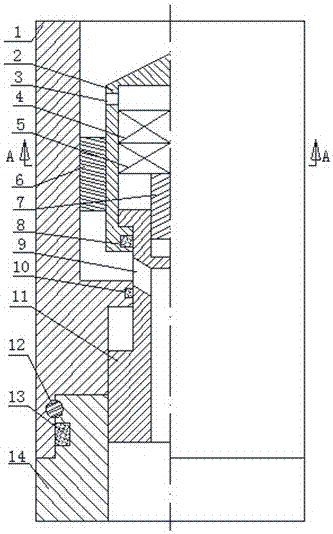

Prestressed Rebar Anchorage Device

ActiveCN108517765BEliminate gapsAvoid stress lossBridge structural detailsBuilding reinforcementsPre stressPre stressing

The invention discloses a pre-stress rebar anchoring device. Pre-stress rebar adopts finish rolling deformed steel bar, and the innovation is characterized in that the device is composed of an anchorbearing plate, a positioning nut and an anchoring nut; the middle of the anchor bearing plate is provided with a first threaded hole, the anchor bearing plate is pre-buried in the top face of a beam body of a box-shaped section bridge, the surface of the lower end of the positioning nut is provided with a first outer thread, the middle of the positioning nut is provided with a second threaded hole, and the positioning nut is in threaded connection with the first threaded hole through the first outer thread; the surface of the lower end of the anchoring nut is provided with a second outer thread, the middle of the anchoring nut is provided with a third threaded hole, and the anchoring nut is in threaded connection with the second threaded hole through the second outer thread; and the anchoring nut is in threaded connection with the finish rolling deformed steel bar through the third threaded hole. The pre-stress rebar anchoring device has the advantages that the structure of the deviceis simple and ingenious, the problem of stress loss during anchoring can be effectively solved, and the safety of the bridge structure is ensured.

Owner:杭州正东预应力锚具有限公司

Red copper tube bending method

The present invention relates to a red copper tube bending process. Said process includes the following steps: selecting dried casting sand whose grain size is 40-80 meshes; selecting wood material and making it into conical wood plug; inserting said wood plug into lower and of said red copper tube and placing said red copper tube vertically; filling said red copper tube with the dried casting sand and inserting another wood plug into upper end of said red copper tube; horizontally placing the red copper tube filled up with dried casting sand on a platform with mould, drawing bending position; placing the bending mould rod and fixing it on the platform; using gas flame to heat bending area, using small winch to draw tube end of red copper tube, using sample rod to check bent tube accuracy, correcting so as to obtain the invented product.

Owner:中国船舶集团渤海造船有限公司

Pre-stress rebar anchoring device

ActiveCN108517765AEliminate gapsAvoid stress lossBridge structural detailsBuilding reinforcementsPre stressPre stressing

The invention discloses a pre-stress rebar anchoring device. Pre-stress rebar adopts finish rolling deformed steel bar, and the innovation is characterized in that the device is composed of an anchorbearing plate, a positioning nut and an anchoring nut; the middle of the anchor bearing plate is provided with a first threaded hole, the anchor bearing plate is pre-buried in the top face of a beam body of a box-shaped section bridge, the surface of the lower end of the positioning nut is provided with a first outer thread, the middle of the positioning nut is provided with a second threaded hole, and the positioning nut is in threaded connection with the first threaded hole through the first outer thread; the surface of the lower end of the anchoring nut is provided with a second outer thread, the middle of the anchoring nut is provided with a third threaded hole, and the anchoring nut is in threaded connection with the second threaded hole through the second outer thread; and the anchoring nut is in threaded connection with the finish rolling deformed steel bar through the third threaded hole. The pre-stress rebar anchoring device has the advantages that the structure of the deviceis simple and ingenious, the problem of stress loss during anchoring can be effectively solved, and the safety of the bridge structure is ensured.

Owner:杭州正东预应力锚具有限公司

Cutting-suction hydraulic-fill/filling damming method for ash storage yards in power industry

The invention relates to a cutting-suction hydraulic-fill / filling damming method for ash storage yards in power industry. The method includes the steps of treating a dam foundation and a dam abutment; laying a seepage pipe system on the dam foundation; installing an underwater ash delivery pipe system, an ash dredger and an overwater ash delivery pipe system according to a dam design drawing; building a plurality of hydraulic fill pond ridges on the dam foundation; making and delivering mud; filling a hydraulic fill pond; separating ash and water; mechanically tamping; and performing multilayer hydraulic filling to the hydraulic fill pond till filling of a dam is complete. The multilayer segmental hydraulic fill pond ridges are built first, a small cutter-suction ash dredger is used with a slurry pump to mix grey water and fly ash in an ash storage yard into slurry which is delivered to the hydraulic fill pond of the dam, an ash dam forms after ash and water separate and solidify, the dam solidifies for three-dimensional drainage, ash-water separation and solidification are fast, water waste is low, dam building speed is high, construction period is short, safety is high, waste is utilized, and service life of the ash storage yard is prolonged. In addition, lift is avoided, pollution is avoided, construction is environment-friendly and the method is highly applicable.

Owner:JIANGSU CHANGTAI CONSTR PROJECT

Semi-automatic torque coupling device

PendingCN107269724AIncrease flow pressureReduce frictional resistanceYielding couplingDirectional drillingHorizontal wellsRemote control

The invention relates to a semi-automatic torque coupling device in the field of a petroleum and gas well drilling device. The device is mainly composed of an upper shell, a protection device, a pressure transfer hole, a pressure sensing device, a stepping motor, a fixed rib plate, a transmission shaft, a seal device, a bypass hole, a spline shaft, a bearing, a lower shell and a spline leading-in body. In the drilling process, torque generated by a ground device is transmitted to a well bottom drill bit along a drill combination, the semi-automatic torque coupling device is mounted in the drill combination according to drill well design, an operator uses opening and closing of a motor in a drilling fluid remote control part so as to control the spline shaft to stretch out of or retract and be locked, torque connection and disconnection are achieved, the semi-automatic torque coupling device can effectively solve the pressure dragging problem commonly existing in the drilling process of complex structure wells of long horizontal segment horizontal wells, large displacement wells and the like, and the device has the important significance in further reducing sliding friction resistance between the drill combination and the well wall, improving the well hole smoothness and improving the drilling efficiency of the complex structure wells.

Owner:中石化石油工程技术服务有限公司 +2

Spherical silo construction method

ActiveCN106639449AIntegrity is not brokenSave materialArched structuresVaulted structuresStress conditionsMembrane bodies

The invention discloses a spherical silo construction method, and relates to the technical field of building construction. The construction method comprises the steps of a step of ring foundation construction, a step of membrane body laying, and a step of painting a polyurethane coating layer in the membrane body. Between the step of ring foundation construction and the step of membrane body laying, the following steps still exist: measuring the positions of preformed holes, and marking the positions on the ground occupied by the ring foundation, after the step of the membrane body laying is completed, the projections of the positions of the preformed holes which are marked on the ground occupied by the ring foundation are projected to the membrane body, and the projection points on the membrane body are marked accordingly. In the step of painting the polyurethane coating layer in the membrane body, the moulds of the preformed holes are placed at the marked points, and painted with the polyurethane layer and / or a concrete layer, after all the painting work is finished, the moulds of the preformed holes are removed, thus the holes are formed above the silo wall or silo cap of the spherical silo in a manner that the integrity of the polyurethane layer and the concrete layer is not undermined. Not only the material is saved, but also the integrity of the polyurethane layer and the concrete layer is not undermined, the overall stress condition is more uniform, the silo produced by the method is more sturdy and durable, and the service life is longer.

Owner:山西天舍建筑工程有限公司

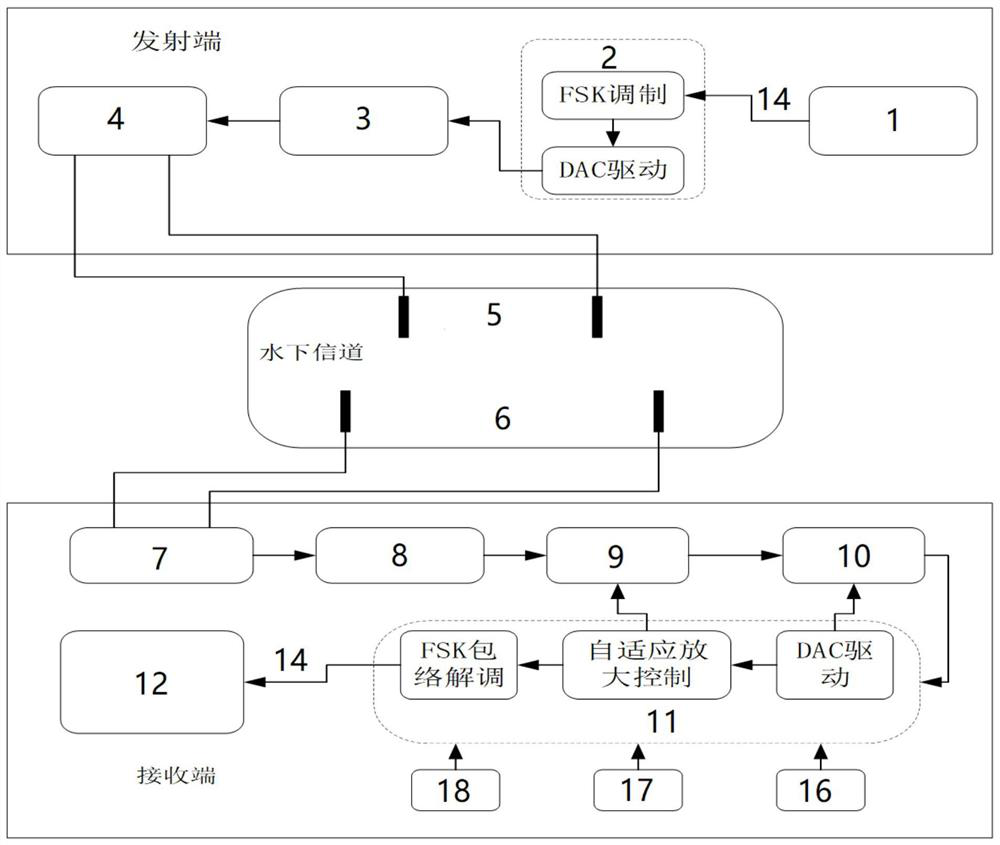

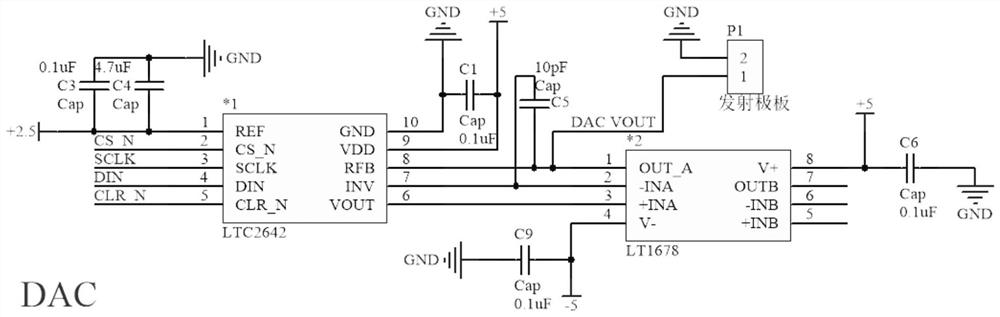

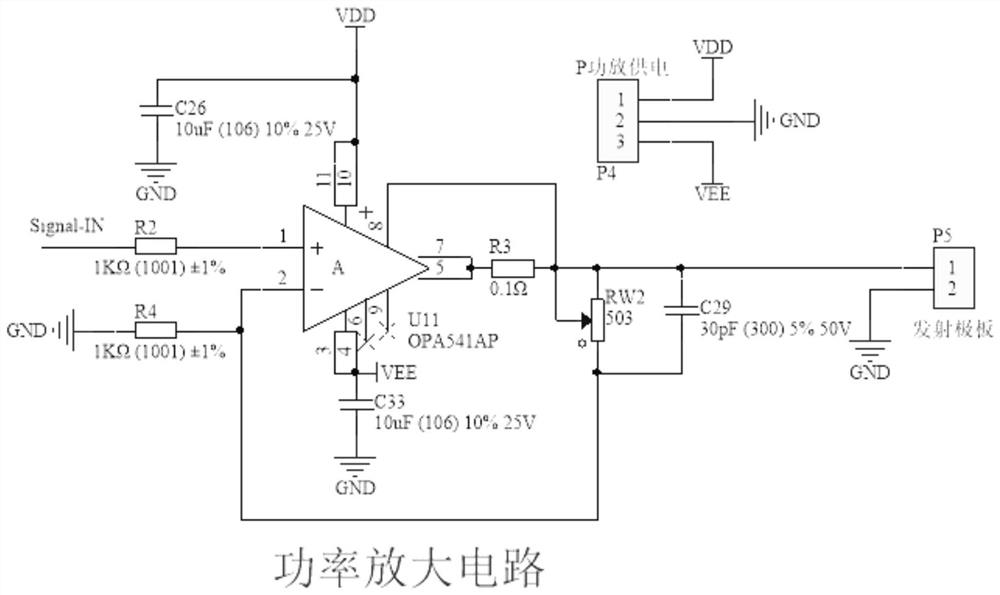

Underwater middle and long distance electric field communication system based on FSK modulation and demodulation

InactiveCN113660044ALarge emission currentControl electric field strengthFrequency-modulated carrier systemsCommunications systemComputer science

The invention discloses an underwater middle and long distance electric field communication system based on FSK modulation and demodulation, which is characterized in that an MCU is arranged at a transmitting end, adopts a 2FSK signal modulation and demodulation mode for communication and can transmit a serial port signal to an FPGA logic controller for signal modulation, and the modulated signal is subjected to digital-to-analog conversion and signal amplification and then is transmitted to an underwater channel through a transmitting electrode; signals emitted by the emitting electrode are received through the receiving electrode, are amplified, filtered and re-amplified in sequence, then are subjected to analog-to-digital conversion processing and then are input into the FPGA logic controller to be demodulated, the demodulated signals are transmitted into the MCU of the receiving end to complete communication, and the emitting end and the receiving end are respectively connected with a power management module. The system is suitable for communication between underwater communication equipment with small volume and low power consumption.

Owner:XI AN JIAOTONG UNIV

Magnetic ring, cable structure and electronic device

InactiveCN107896449AMeet design standardsCasings/cabinets/drawers detailsEMI leakage reductionEngineeringMagnetic loop

The disclosure relates to a magnetic ring, a cable structure, and an electronic device. The magnetic ring includes a volume-adjustable housing and at least one magnetic core adapted to the housing. The housing includes first and second shells rotatably connected at corresponding edge regions. The second shell and the first shell can perform an opening and closing movement based on the connected position to mount the at least one magnetic core when the housing is in an open state. In the disclosure, a volume-adjustable housing is used, so that the magnetic ring most effective for removing noisecan be configured for the cable by changing the specifications of the magnetic core, or the number or material, and the like, so that a cable product configured with the magnetic ring can meet the design criteria.

Owner:HANGZHOU DPTECH TECH

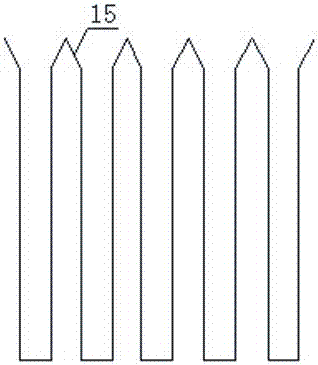

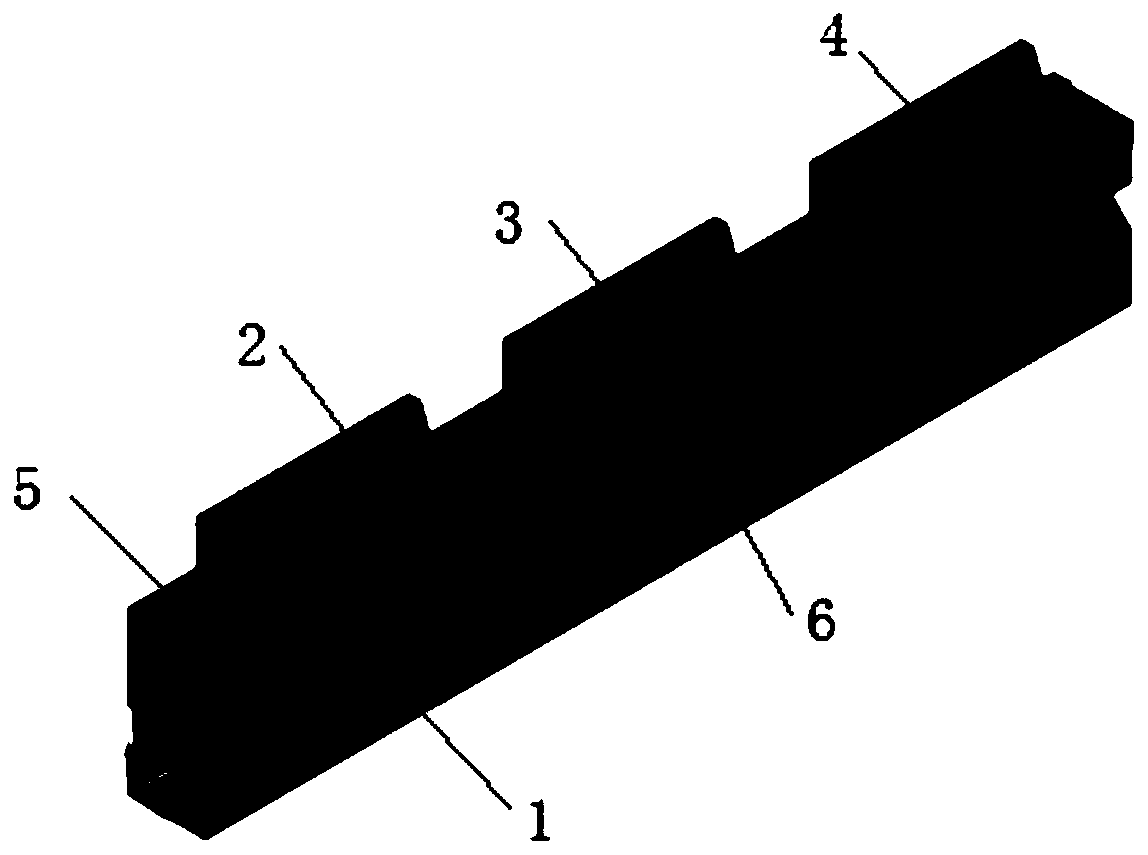

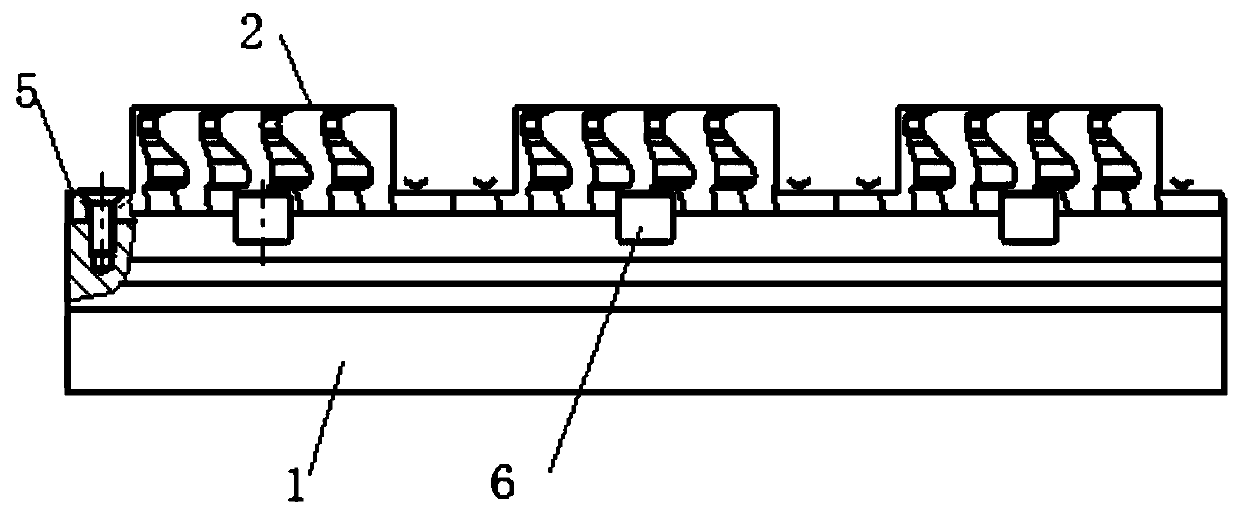

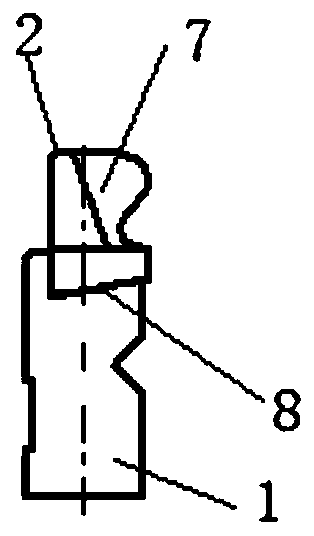

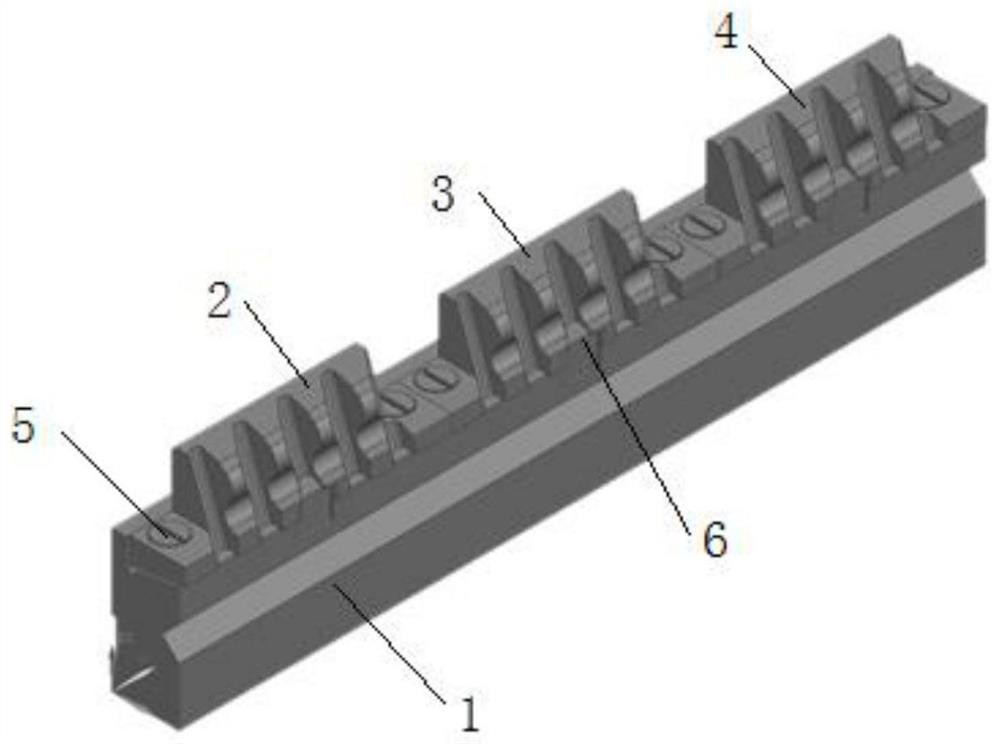

Assembly type broach

ActiveCN110524048AImprove machining accuracyInstalled and disassembledBroaching toolsAlloyMechanical engineering

According to the assembly type broach, a split structure is adopted, the broach body and the blade are machined separately, the machining difficulty of hard alloy is reduced, the machining precision of the broach is improved, and meanwhile the material cost is reduced; secondly, the blade group is mounted on the cutter body through the positioning groove; a positioning key is additionally arrangedbetween the blade group and the cutter body; axial and radial positioning of the blade group and the cutter body is achieved through the positioning groove and the positioning key, mounting and dismounting of the blades and the cutter body are also facilitated, the broach is simple in structure, low in manufacturing cost and convenient to use, and the hard alloy profile finish broach structure has extremely high popularization value in mortise broaching and blade tenon broaching of engine disc parts.

Owner:AECC AVIATION POWER CO LTD

Node structure of a rigid single-layer reticulated shell structure

InactiveCN102966186BSimple structureEasy to assembleBuilding constructionsEngineeringBolt connection

Owner:上海岑闵新材料科技有限公司

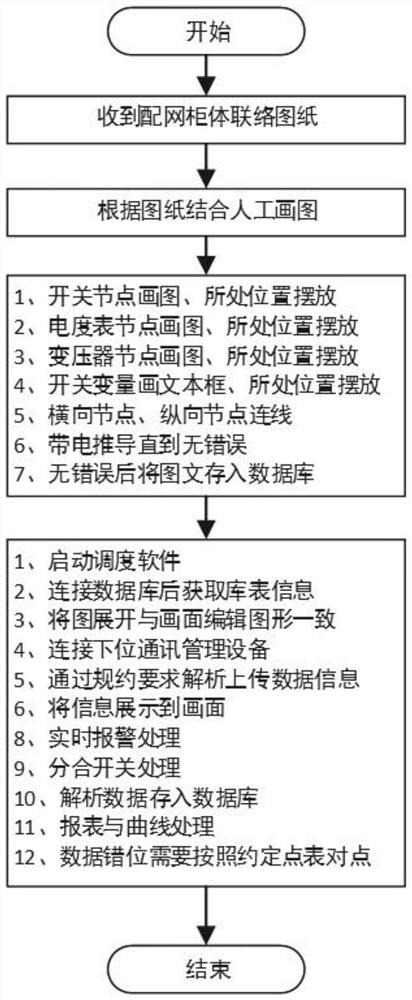

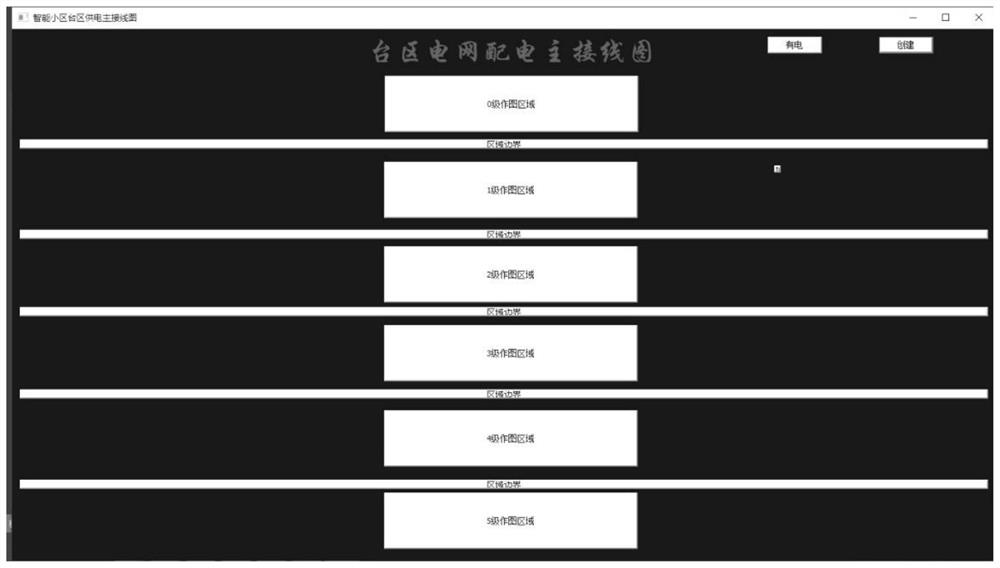

Demonstration method of power distribution network dispatching system

InactiveCN112860966ALow costMeet design standardsResourcesOther databases browsing/visualisationSoftware architectureInformation transfer

The invention discloses a demonstration method of a power distribution network dispatching system, which adopts a communication data character string format to automatically generate a topological structure diagram, and does not need to edit a picture to process a graphical interface in a project implementation process; point alignment in the implementation process is not needed; when a power supply company needs to increase or reduce transformer area users, only hardware switches and matched connecting lines are added, graphs are automatically generated in the information transmission process, the users are increased or reduced, only simple configuration is needed, and point alignment and drawing are not needed; in the implementation process of a plurality of projects, topological structure diagrams are automatically generated, the problem that graphs and real wiring are different does not need to be concerned, and overall implementation is divided into two parts; the first part is to receive the number of all devices in a transformer area and relational data among the devices; the second part is to carry out drawing according to the relation data; and the method is visual and clear, accords with software architecture design standards, and saves cost.

Owner:北京中兆龙芯软件科技有限公司

An assembled broach

ActiveCN110524048BImprove machining accuracyInstalled and disassembledBroaching toolsStructural engineeringCemented carbide

An assembled broach disclosed by the invention adopts a split structure, and the cutter body and the blade are processed separately, which reduces the processing difficulty of cemented carbide, improves the processing accuracy of the broach, and reduces the cost of materials; secondly, the blade The group is installed on the cutter body through the positioning groove, and a positioning key is added between the blade combination cutter body, and the axial and radial positioning of the blade group and the cutter body is realized through the positioning groove and the positioning key, which is also convenient for the installation of the blade and the cutter body Disassembly, the present invention is simple in structure, low in manufacturing cost, and convenient to use. The hard alloy profile broach structure has a very high promotional value in the broaching of the tenon and groove of the engine disk parts and the broaching of the blade tenon.

Owner:AECC AVIATION POWER CO LTD

Production method of high-straightness tubular pile plate DH36

InactiveCN113083893AFulfil requirementsMeet design standardsMetal rolling arrangementsStructural engineeringPipe

The invention discloses a production method of a high-straightness tubular pile plate DH36, and relates to the technical field of steel production. A steel plate comprises the following chemical components in percentage by mass: 0.10 percent to 0.20 percent of C, 1.0 percent to 2.0 percent of Mn, 0.10 percent to 0.30 percent of Si, 0.05 percent to 0.20 percent of Cr, 0.03 percent to 0.05 percent of Nb, no Ca, and the balance of Fe and inevitable impurities. The final rolling pass adopts the flattening pass, the flattening head and the flattening tail adopt a variable roll gap mode, and the roll gap is continuously reduced by 0.3 mm on the basis of plan setting, so that the defect plate types such as warping or buckling of the head and the tail of the steel plate are improved, the unevenness of the flattened steel plate is smaller than or equal to 6 mm / 2 m, the first-pass yield of the plate type of the pipe pile steel plate is increased, and the production cost is reduced.

Owner:NANJING IRON & STEEL CO LTD

A kind of construction method of spherical warehouse

ActiveCN106639449BIntegrity is not brokenSave materialArched structuresVaulted structuresStress conditionsMembrane bodies

The invention discloses a spherical silo construction method, and relates to the technical field of building construction. The construction method comprises the steps of a step of ring foundation construction, a step of membrane body laying, and a step of painting a polyurethane coating layer in the membrane body. Between the step of ring foundation construction and the step of membrane body laying, the following steps still exist: measuring the positions of preformed holes, and marking the positions on the ground occupied by the ring foundation, after the step of the membrane body laying is completed, the projections of the positions of the preformed holes which are marked on the ground occupied by the ring foundation are projected to the membrane body, and the projection points on the membrane body are marked accordingly. In the step of painting the polyurethane coating layer in the membrane body, the moulds of the preformed holes are placed at the marked points, and painted with the polyurethane layer and / or a concrete layer, after all the painting work is finished, the moulds of the preformed holes are removed, thus the holes are formed above the silo wall or silo cap of the spherical silo in a manner that the integrity of the polyurethane layer and the concrete layer is not undermined. Not only the material is saved, but also the integrity of the polyurethane layer and the concrete layer is not undermined, the overall stress condition is more uniform, the silo produced by the method is more sturdy and durable, and the service life is longer.

Owner:山西天舍建筑工程有限公司

Sewage processing control system

ActiveCN106909094AMeet design standardsProgramme controlComputer controlDesign standardControl system

The invention relates to a sewage processing control system which comprises a control room, a control host machine mounted inside the control room, a liquid level sensor, a medicine adding device, and a water quality monitoring instrument. The sewage inlet is provided with the liquid level sensor and the water quality monitoring instrument respectively; the liquid level sensor and the water quality monitoring instrument transmit the acquired data to the host machine where the data are processed. If the sewage liquid level is excessively high, the host machine sends out the instruction of reducing the inlet amount of sewage; and if the sewage water quality is not qualified, the host machine sends out the instruction of initiating the medicine adding device to add medicine. The system of the invention can acquire the water quality data in real time and can master the various indexes for the processing procedures in real time so as to ensure that the water quality of the treated sewage reaches the designed standard.

Owner:浙江众华家纺集团有限公司

A glass-lined reaction tank and its manufacturing method

InactiveCN102389758BFully meltedImprove bindingChemical/physical/physico-chemical processesTemperature controlManufacturing technology

The invention relates to a re-lined and renewed reactor after repair and a manufacturing method thereof which are used in the chemical and pharmaceutical industries and belong to the field of pressure vessels. A damaged glass-lined reactor which originally does not conform to the Supervision Regulation on Safety Technology for Pressure Vessel is repaired to become the re-lined and renewed reactor which comprehensively realizes the Supervision Regulation on Safety Technology for Pressure Vessel and can be repaired and utilized multiple times. The manufacturing method is characterized in that a precisely controlled inner heated electric furnace is adopted to implement staged controlled firing and an integral firing process with jackets; and full-automatic glaze slurry spraying equipment, an equipment large flange reshaping device and an electrical heating and temperature controlling insulating cylinder are adopted for manufacturing. The reactor and the manufacturing method have the following advantages: the reactor initiates and lays a foundation for that the manufacturing technology standards of the glass-lined reactors in China all realize the Supervision Regulation on Safety Technology for Pressure Vessel; the integral quality of the reactor is comprehensively and obviously superior to the current national standard; the reactor steps and is developed to innovate and be ahead of the conditions that the international outer heated electric furnace iron billets have no alternative to secondary forming during manufacturing and the core technology of controlled enamelling has the defect of uneven heating; and the reactor sells well in the international markets with the obvious omnibearing technical, quality and economic advantages and has obvious economic benefits and global market competitiveness.

Owner:朱文华

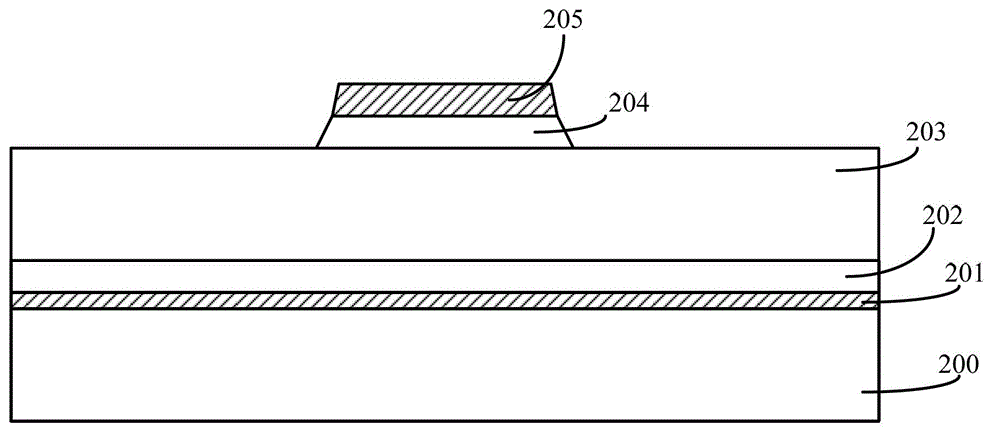

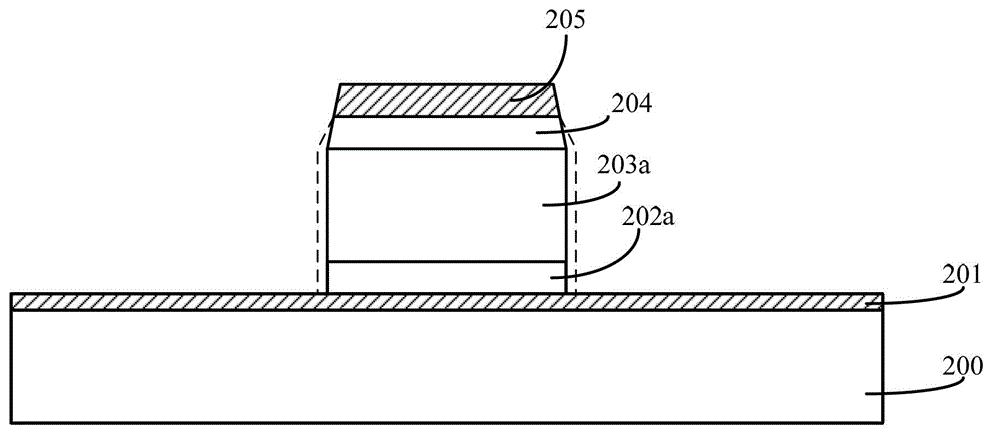

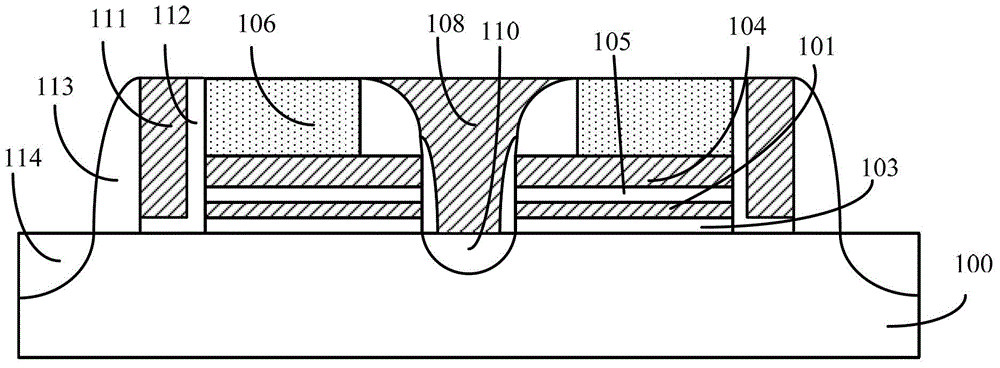

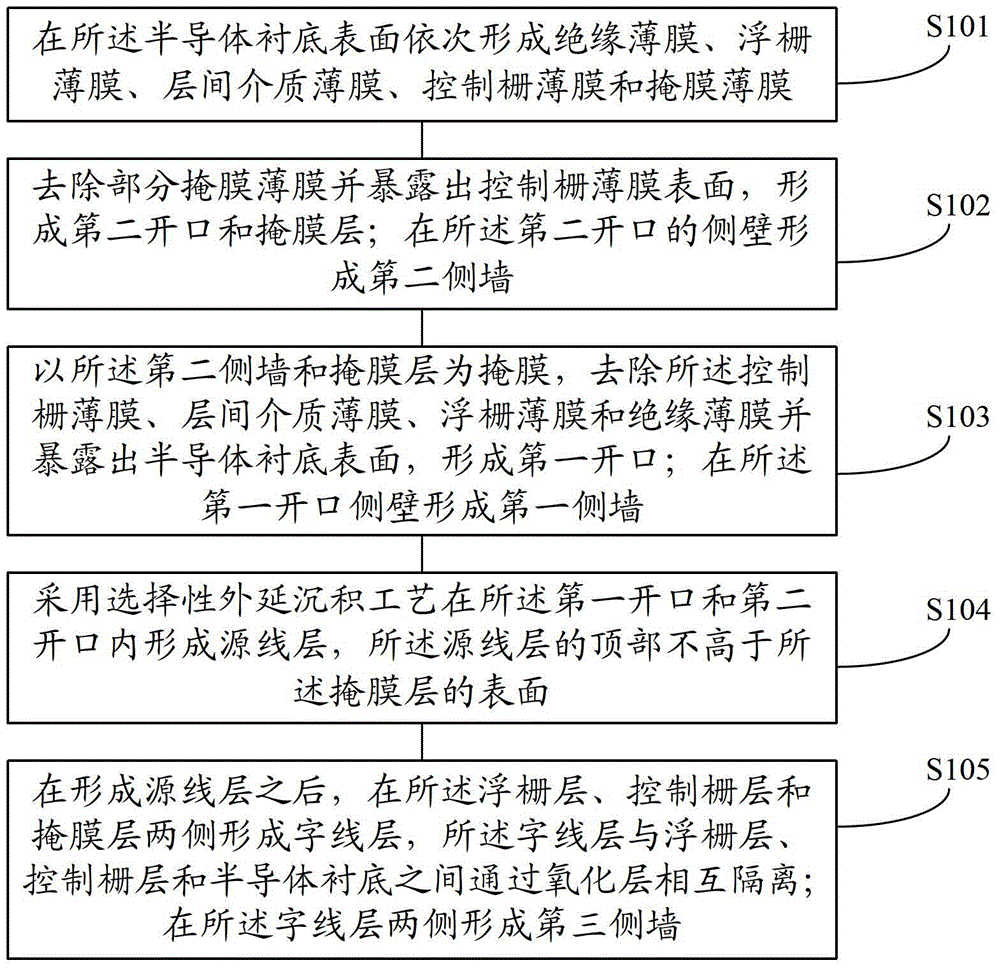

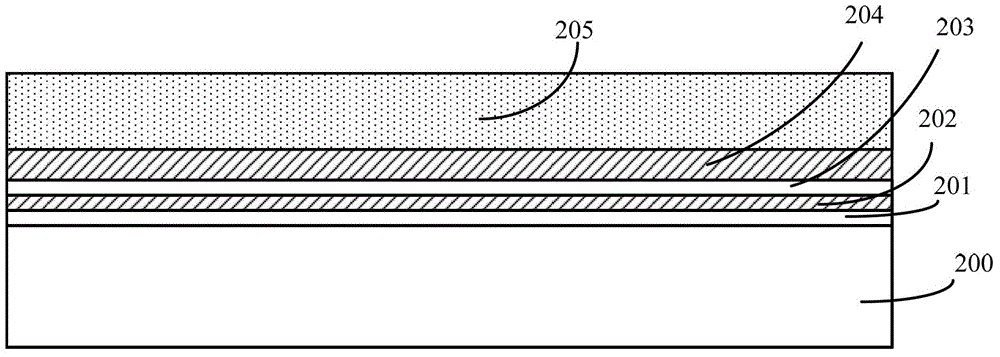

Method for forming memory cell of flash memory

ActiveCN102800679BImprove performanceConsistent sizeSolid-state devicesSemiconductor devicesEngineeringDeposition process

A method for forming a memory cell of a flash memory, including: providing a semiconductor substrate with a floating gate layer on the surface, a first opening in the floating gate layer, the first opening exposing the surface of the semiconductor substrate, and the floating gate layer and The semiconductor substrates are isolated from each other by an insulating layer. There is a control gate layer on the surface of the floating gate layer. The control gate layer and the floating gate layer are isolated from each other by an interlayer dielectric layer. There is a mask layer on the surface of the control gate layer. Inside the mask layer There is a second opening, the second opening is connected with the first opening, and the second opening exposes the surface of the control gate layer; a first side wall is formed on the side wall of the first opening; a second side wall is formed on the side wall of the second opening. , the top of the second side wall is flush with the surface of the mask layer; a selective epitaxial deposition process is used to form a source line layer in the first opening and the second opening, and the top of the source line layer is not higher than the surface of the mask layer. The storage unit of the formed flash memory has stable performance.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

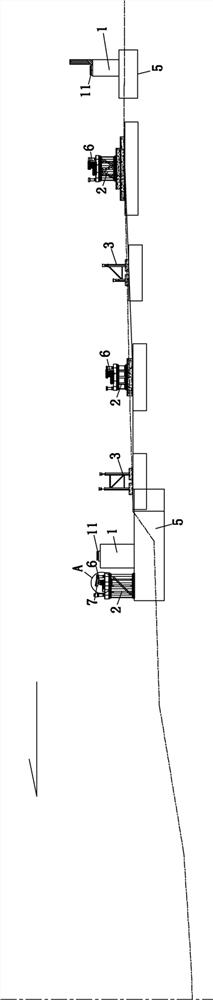

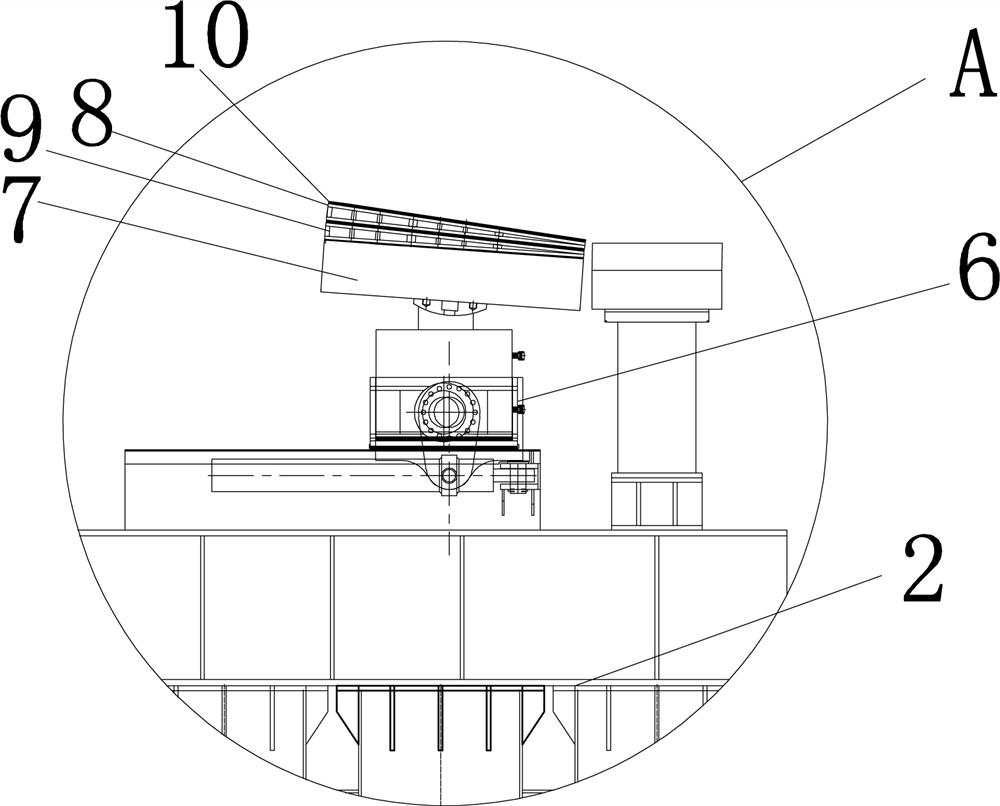

Large-span variable-cross-section steel box girder incremental launching construction method

PendingCN114411571AHigh tensile strengthHigh elastic modulusBridge erection/assemblyStructural reliabilityDesign standard

The invention relates to a large-span variable-cross-section steel box girder incremental launching construction method which is applied to large-span variable-cross-section bridge construction. A supporting support, a pushing support and an assembling support are arranged, the variable-cross-section steel box girder is sequentially arranged on the pushing support and / or the assembling support on the two banks of the water channel after being manufactured, assembling is conducted, the relative position of the steel box girder and the pushing support is adjusted, and pushing is conducted towards the center of the water channel; and after the steel box girder reaches the preset position, posture adjustment, anchoring, closure and welding are conducted, the steel box girder falls on the supporting bracket, and construction is completed. The advantages of high tensile strength, high elastic modulus, high material utilization efficiency, good bearing capacity and no redundant components of the steel box girder are fully utilized, the dead weight is small, and the manufacturing cost is low; the bridge body meets the large-span variable cross-section design requirement and meets the design standard, the structural reliability is high, and water channel navigation is not affected in the construction process; the construction cost is low, the safety coefficient is high, the erection efficiency is high and the construction period is short; the purpose of increasing the height of the bridge arch is achieved, and more complex and changeable navigation requirements are met.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

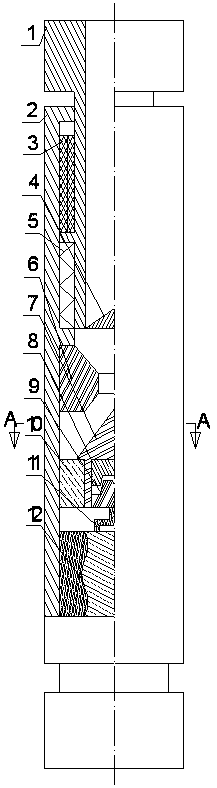

High frequency hydraulic power vibration tool

PendingCN111456622AGood speed-up effectImprove drilling efficiencyBorehole drivesHorizontal wellsEngineering

The invention relates to a high frequency hydraulic power vibration tool. The high frequency hydraulic power vibration tool comprises a center shaft, an outer housing, a spring, a screw motor assembly, a valve seat, a conical valve, an upper cam, a lower cam, a rib plate and a connecting rod mechanism, wherein a mating spline is arranged between the center shaft and the outer housing to form an axial spline for sliding cooperation; the spring is mounted between the center shaft and the outer housing; the valve seat is fixed to the inner wall of the outer housing, and is located at the lower part of the center shaft; the rib plate is mounted between the conical valve and the outer housing, and is fixedly mounted on the outer housing; the conical valve can axially move along the rib plate; the upper cam is fixedly mounted in the conical valve; the lower cam is mounted below the upper cam and is limited axially; the lower cam and the upper cam form a cam transmission cooperation; and thelower cam is in transmission with a rotor of the screw motor assembly through the connecting rod mechanism. The high frequency hydraulic power vibration tool disclosed by the invention can completelymeet domestic drilling technology requirements of wells having complex constructions including straight wells, directional wells, lateral wells and the like, and is a novel tool simple in structure, convenient to operate, low in cost and safe and reliable.

Owner:中石化石油工程技术服务有限公司 +2

A kind of in-situ construction method of stepped concrete

ActiveCN109083404BGuaranteed integrityGuaranteed compactnessTreadsForms/shuttering/falseworksSocial benefitsDesign standard

The invention discloses a step-shaped concrete casting mold assembly and a cast-in-situ construction method, comprising: cleaning the base surface → supporting the side form → pouring the concrete at the lower part of the step → laying a movable die and clamping → pouring the upper part of the step Concrete→Remove the movable die→Tighten the surface of the lower part of the steps→Tighten the surface of the upper part→Conservation→Remove the side formwork and continue the maintenance. Since the present invention adopts the dynamic operation process of "installation later and removal first" of the movable die and the form support method that the 45° contact surface between the movable die and the upper inner mold can be combined and separated, the inner side of the cast-in-place concrete step is completely solved. There is a problem with stencil imprints on the surface. The overall structure of the steps casted by the present invention is complete, without cold joints, and the internal quality meets the design standards; the surface has no template marks, no cracks, no bubbles or spots, pockmarks, etc., and the appearance quality meets the requirements of the specifications, and can be applied to various The cast-in-place stepped concrete project has significant practical significance and good social benefits.

Owner:卜群惠

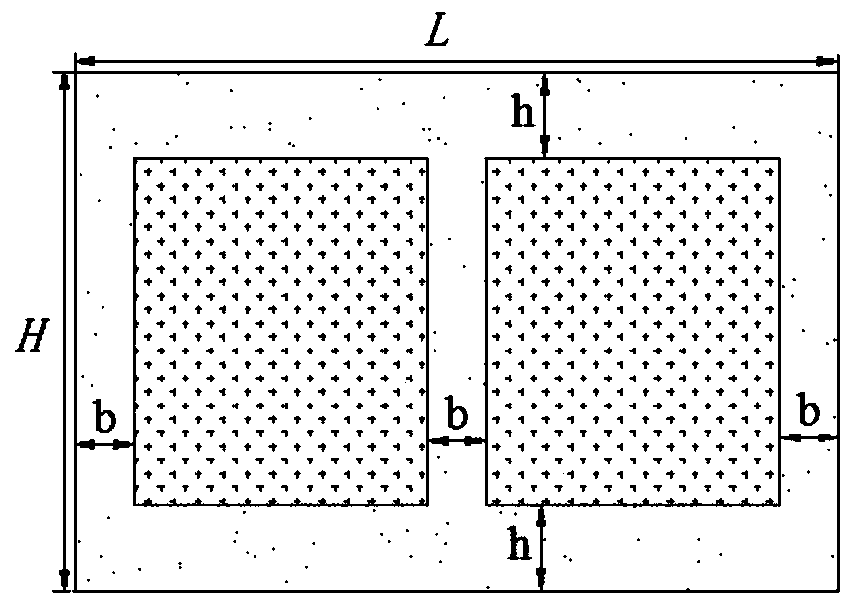

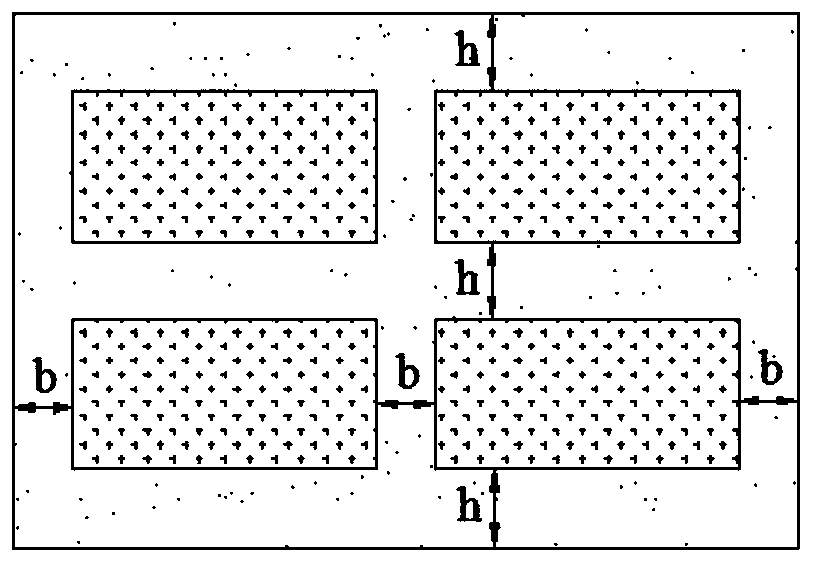

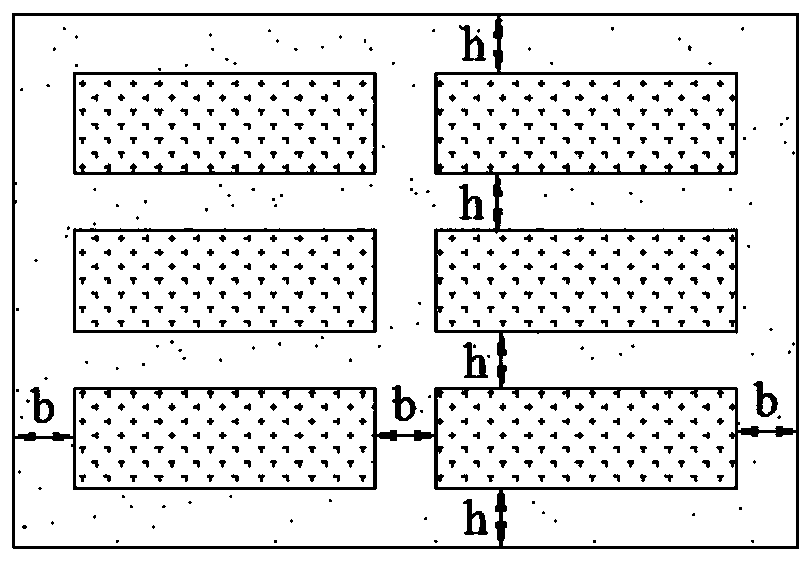

Composite insulation building block hole shape design method and composite insulation building block

InactiveCN110984460ASimplify the design processShorten the construction periodHeat proofingStructural engineeringConcrete composites

The invention discloses a composite insulation building block hole shape design method. The hole shape of a composite insulation building block is designed according to the mutual relation between thehole rate of the composite insulation building block and the length, the width, the number of longitudinal ribs, the number of transverse plates, the thickness of the longitudinal ribs and the thickness of the transverse plates of the composite insulation building block. By means of the design method, the cumbersome design process for reaching the target hole rate can be simplified, the method iseffective in implementation, design cost is saved, the blank that a concrete composite insulation building block hole shape design method is not available in current specifications is filled up, theproduction period of the composite insulation building block is shortened, and the competitiveness is improved.

Owner:上海闰威新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com