Six-unit cubesat main force bearing structure

A six-unit, cubic star technology, applied in the field of the main bearing structure of the six-unit cubic star, can solve the problems of the cubic star cannot be pushed into space, the parallelism cannot be guaranteed, and the work is meaningless, so as to reduce the quality and The effect of space constraints, structural integrity, and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

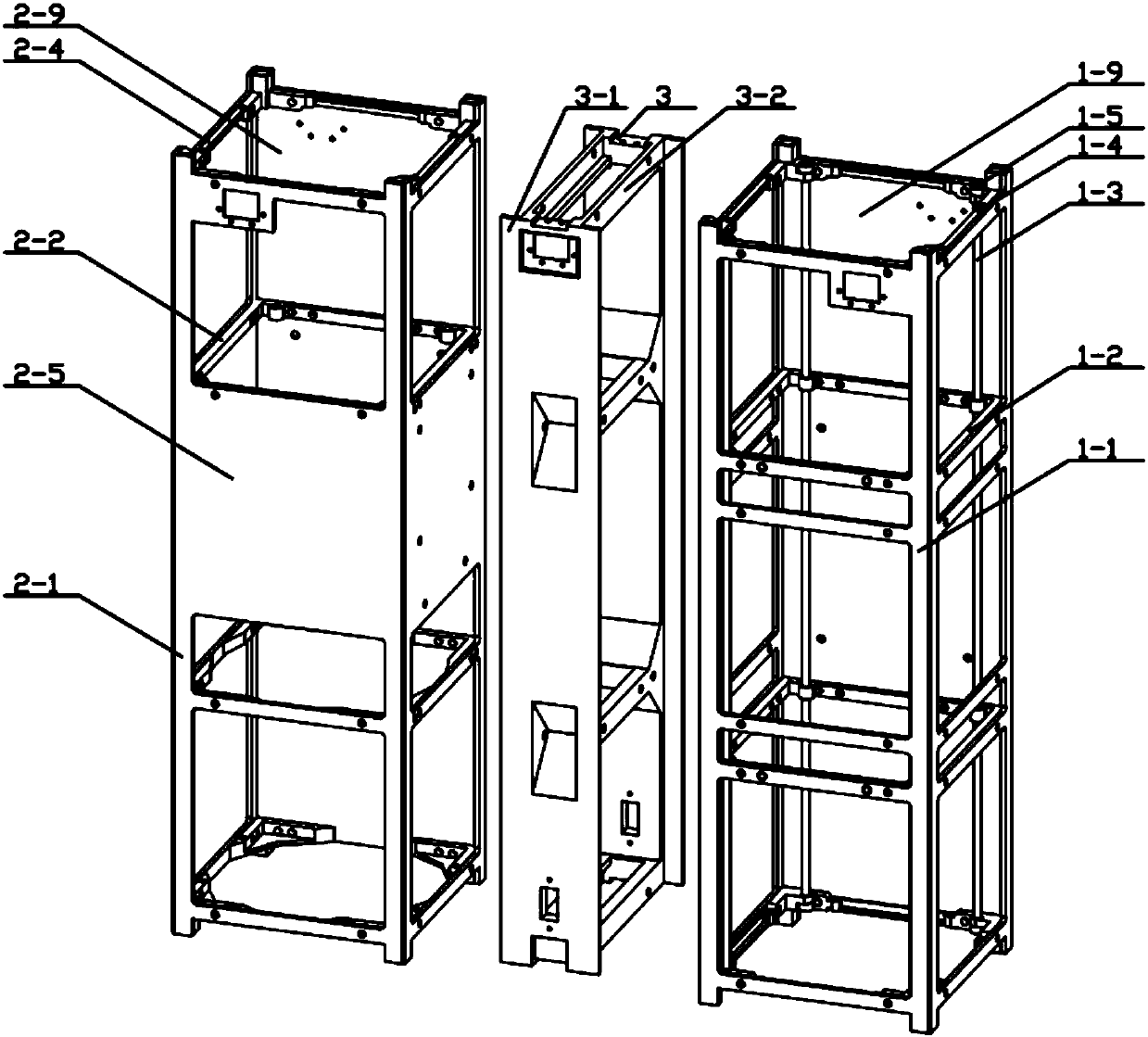

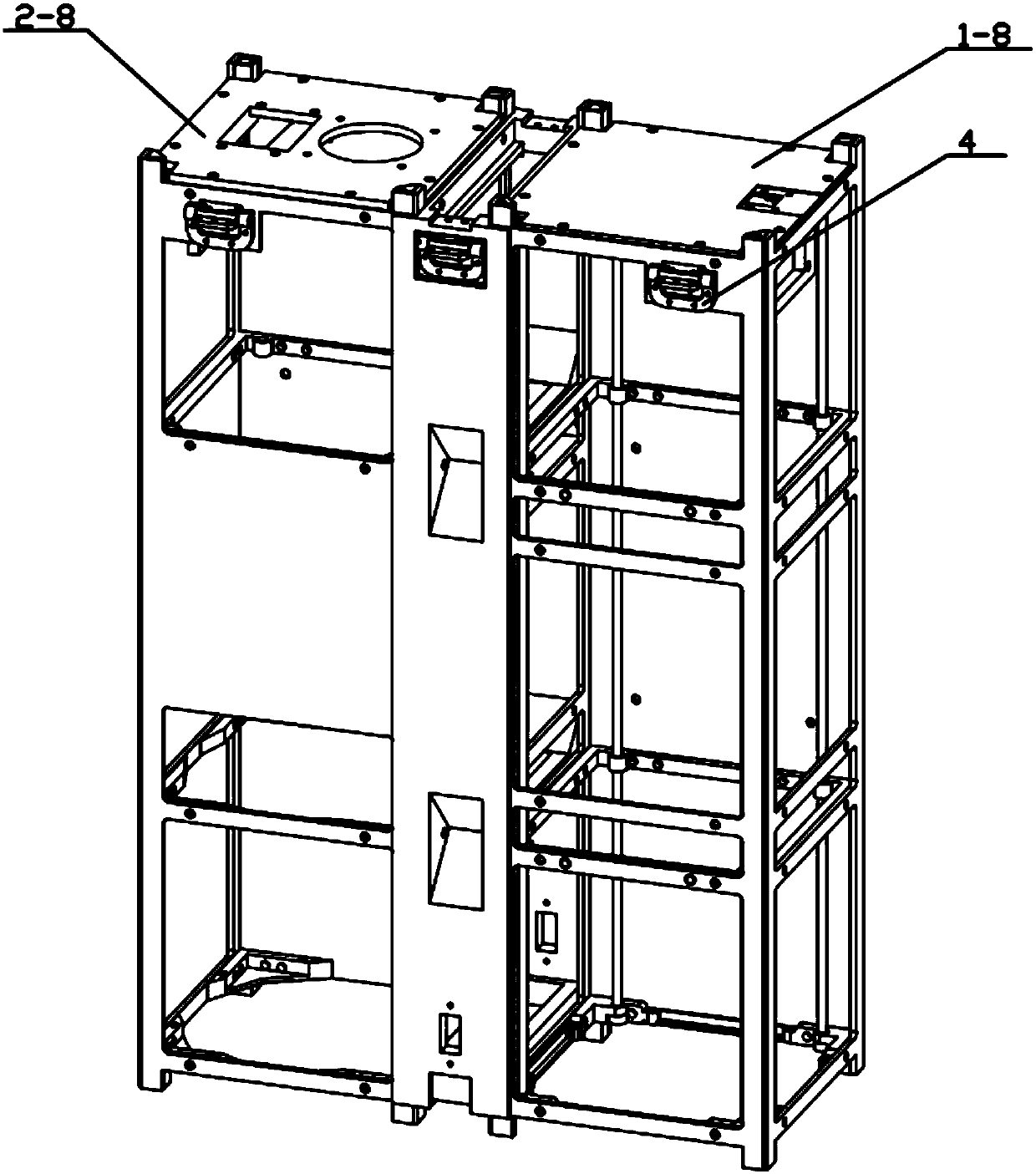

[0042] The present invention is a six-unit cube star main load-bearing structure, comprising a first cube star unit 1, a second cube star unit 2, a connecting frame 3 and six hinges 4, the first cube star unit 1 and the second cube star unit The units 2 are symmetrically fixed on both sides of the connecting frame 3 and are respectively connected by eight screws; the connecting frame 3 , the first cube star unit 1 and the second cube star unit 2 are respectively provided with two hinges 4 .

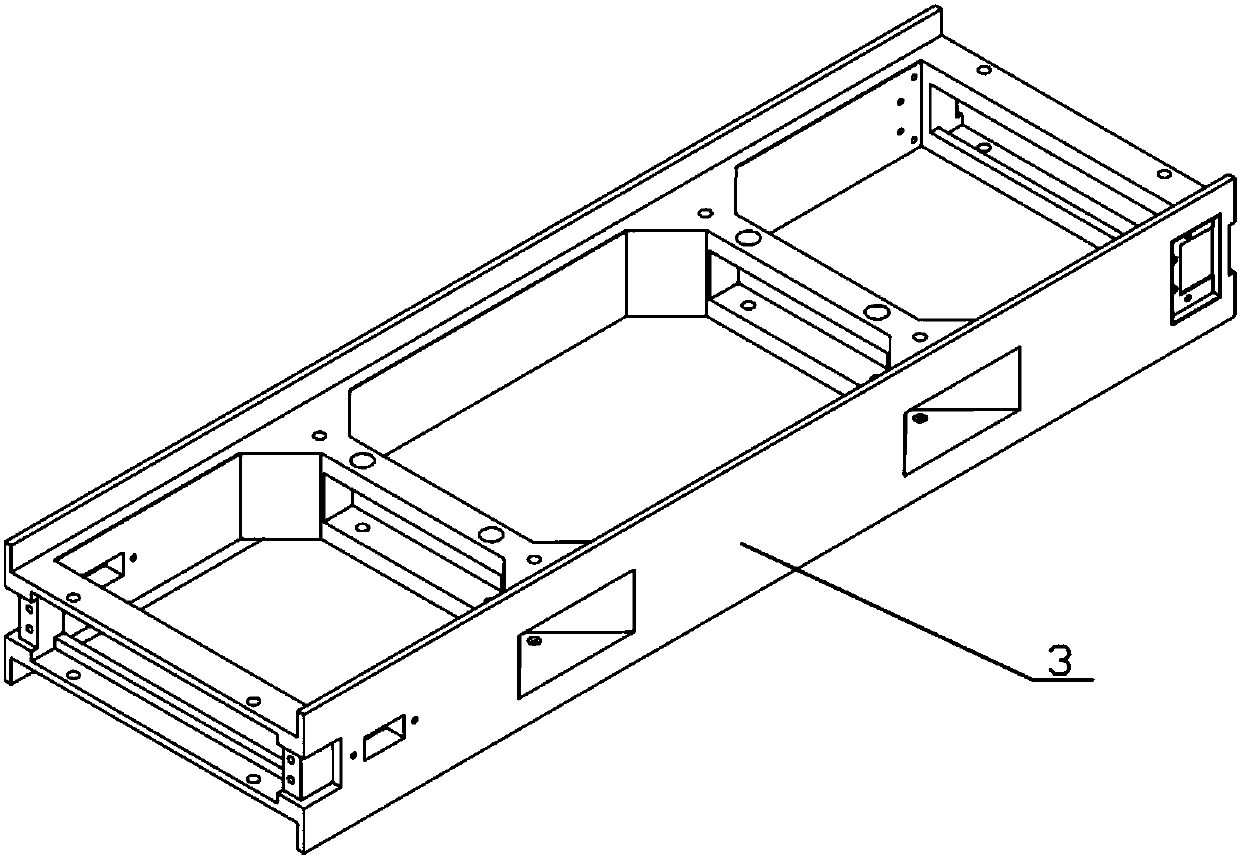

[0043] The connecting frame 3 adopts an escalator structure, including two side plates 3-1 and four connecting plates 3-2 for connecting the two side plates 3-1, the two side plates 3-1 are arranged in parallel, and the two connecting plates 3-2 is located on the top surface and the bottom surface of the side plate 3-1, and the remaining two intervals are arranged between the above two connecting plates 3-2. The two side plates 3-1 are used to fasten the first main frame 1-1 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com