Patents

Literature

61results about How to "Reduce abnormal wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

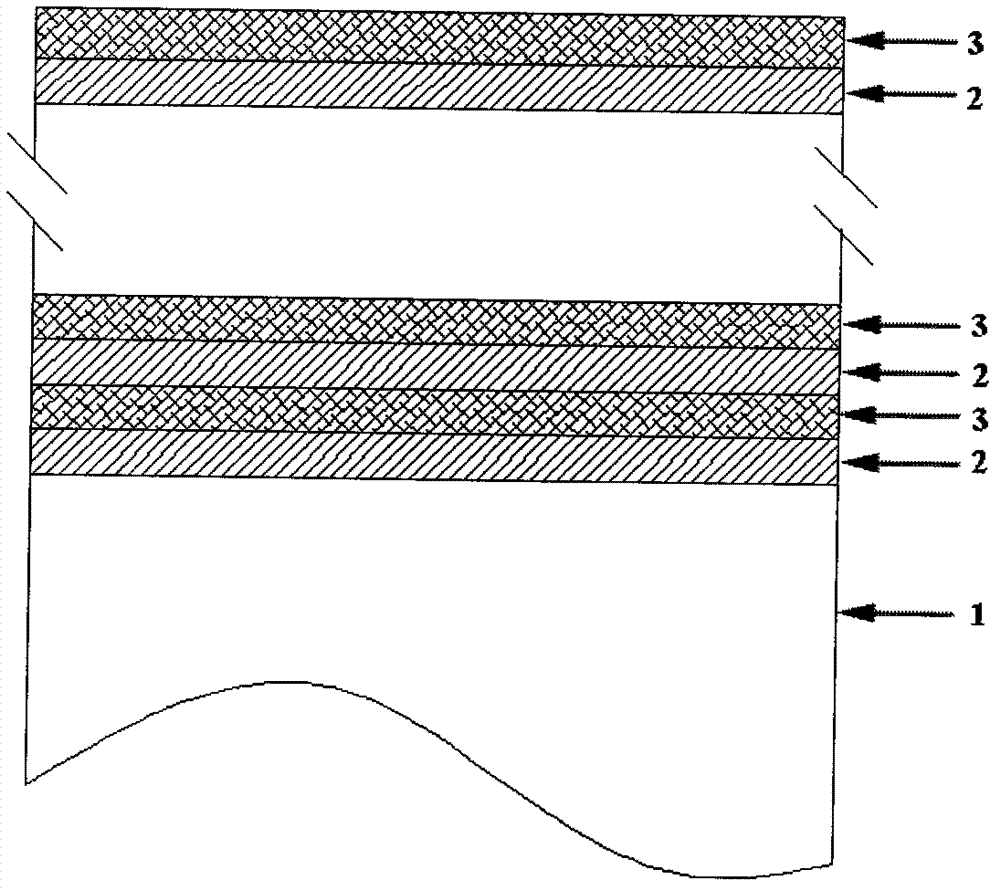

Diamond-like carbon composite molybdenum disulfide nano multilayer film and method for preparing same

ActiveCN102994947AReduce frictionImprove bearing capacityVacuum evaporation coatingSputtering coatingCarbon compositesDiamond-like carbon

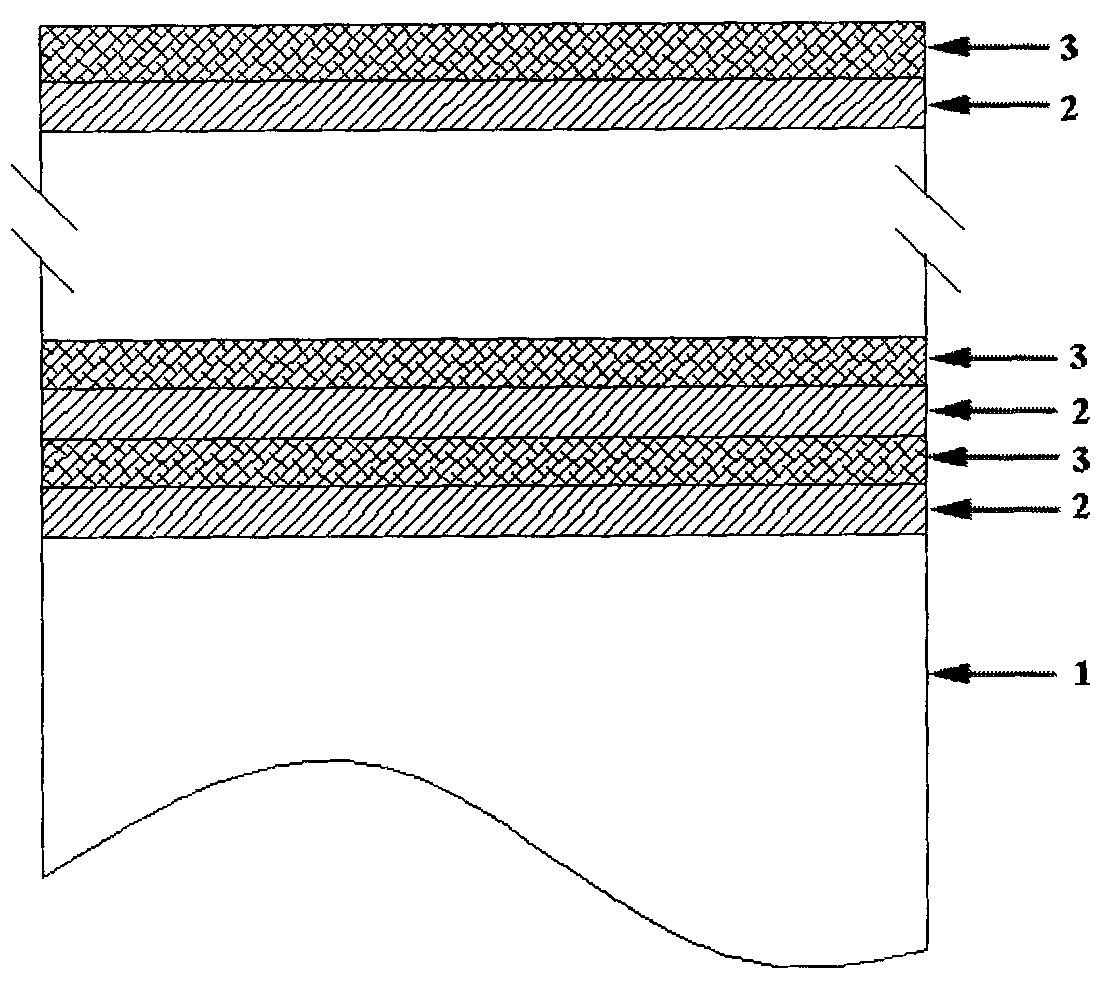

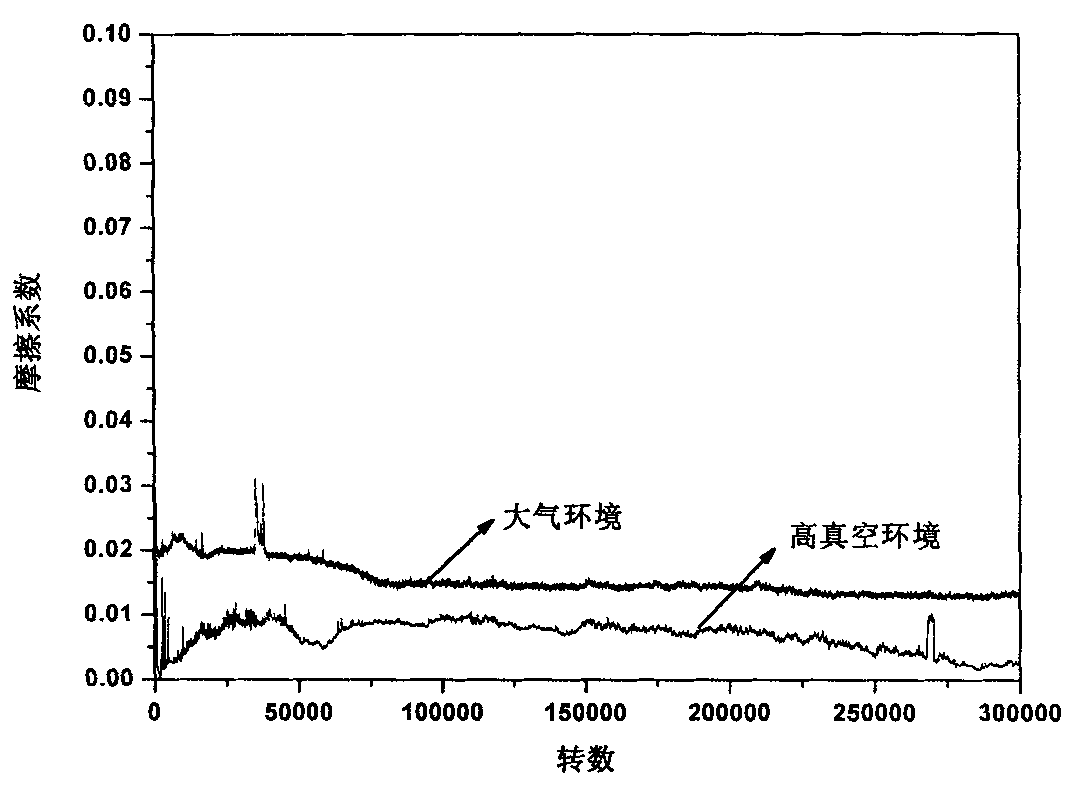

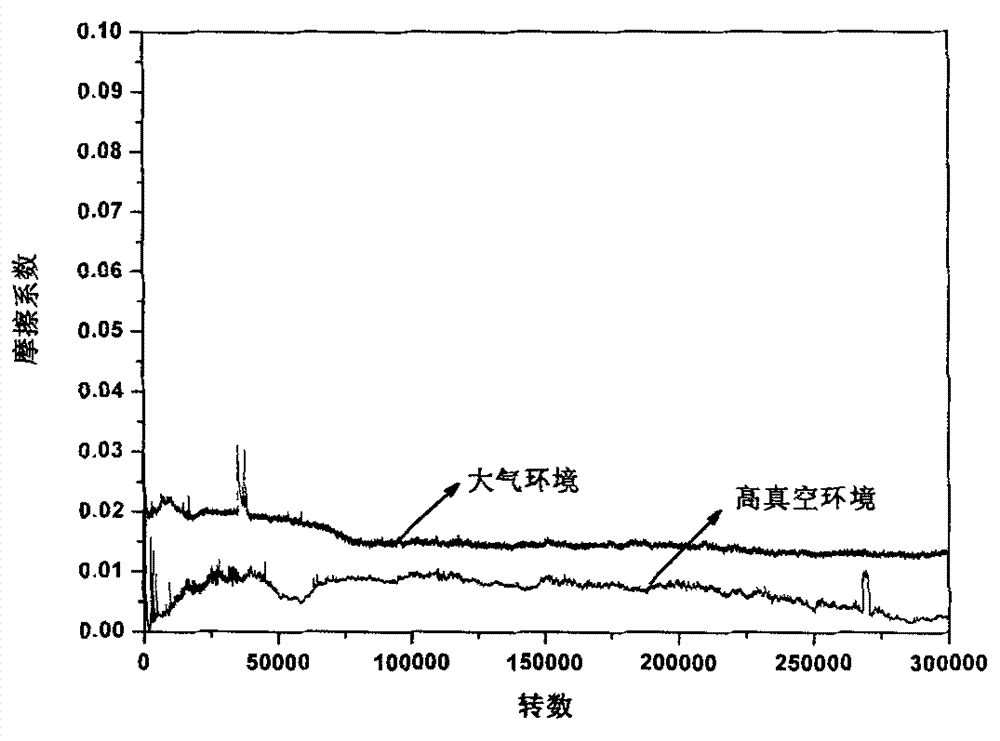

The invention discloses a diamond-like carbon composite molybdenum disulfide nano multilayer film and a method for preparing the same. A double-target magnetron sputtering technology is adopted to alternatively deposit diamond-like carbon layers and molybdenum disulfide layers on a stainless steel base, so that the diamond-like carbon composite molybdenum disulfide nano multilayer film is obtained, wherein the thickness of a single diamond-like carbon layer is between 10 and 100 nanometers, the thickness of a single molybdenum disulfide layer is between 10 and 100 nanometers, and the total thickness of the diamond-like carbon composite molybdenum disulfide nano multilayer film is between 1.5 and 6 micrometers. By the prepared nano multilayer film, the wearing life defect and the problems of friction coefficient environment sensitivity of the molybdenum disulfide layer are improved, moreover, the problems of large brittleness, poor toughness and the like of a hard diamond-like carbon film are solved, so that the wear rate of the nano multilayer film in high vacuum environments is reduced by 1-2 orders of magnitude compared with the wear rate of a conventional molybdenum disulfide or diamond-like carbon film, and the perfect matching of ultralow friction and high hardness and toughness is realized.

Owner:徐州睿创智能科技有限公司

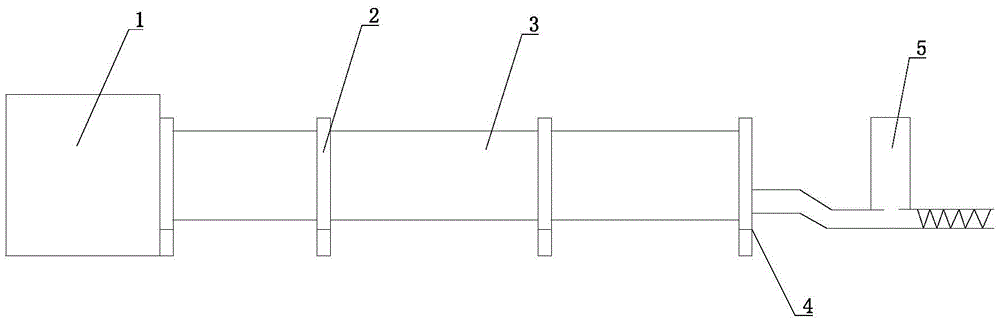

Dual-front axle wheel axle parallel position adjustment method

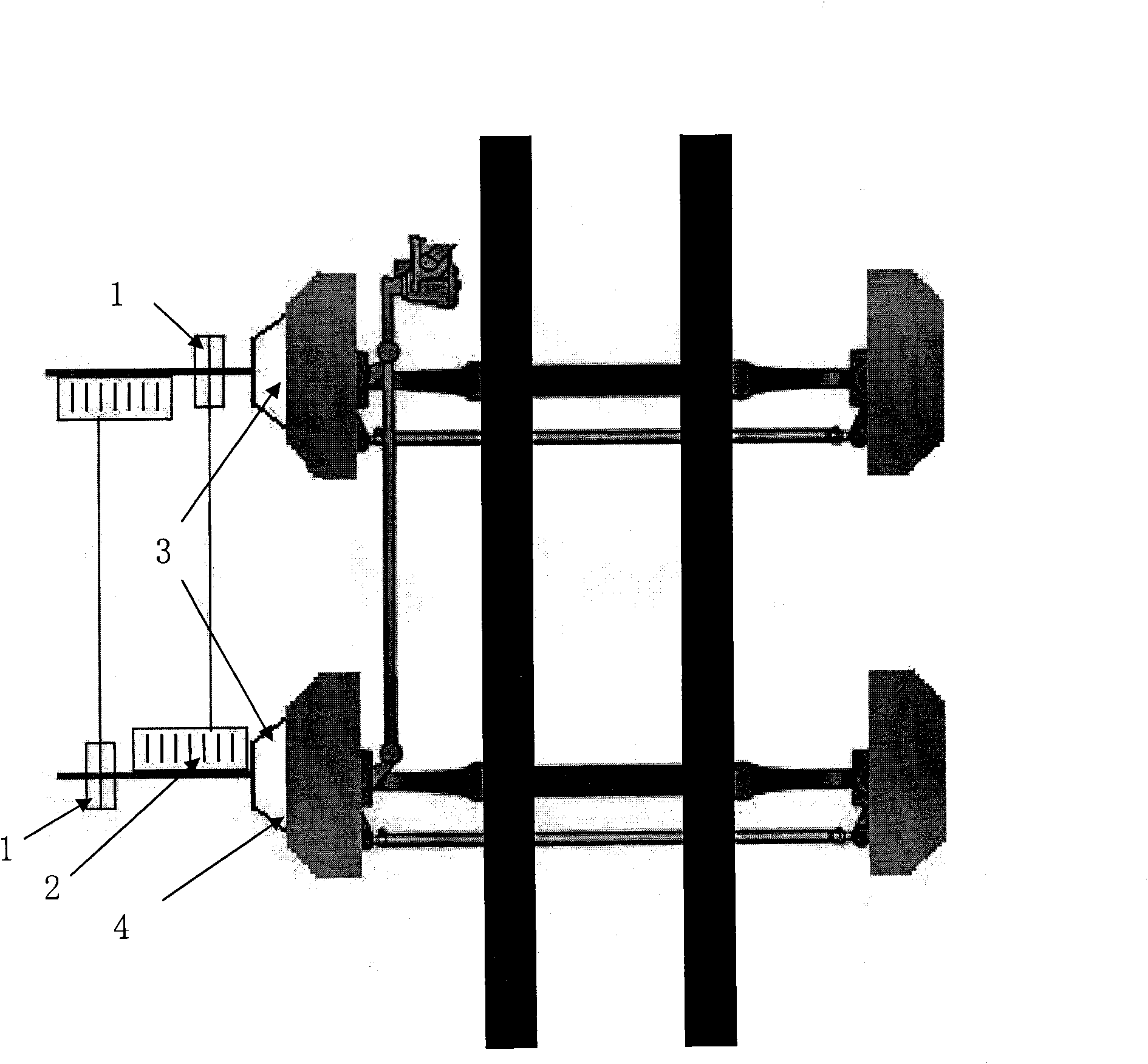

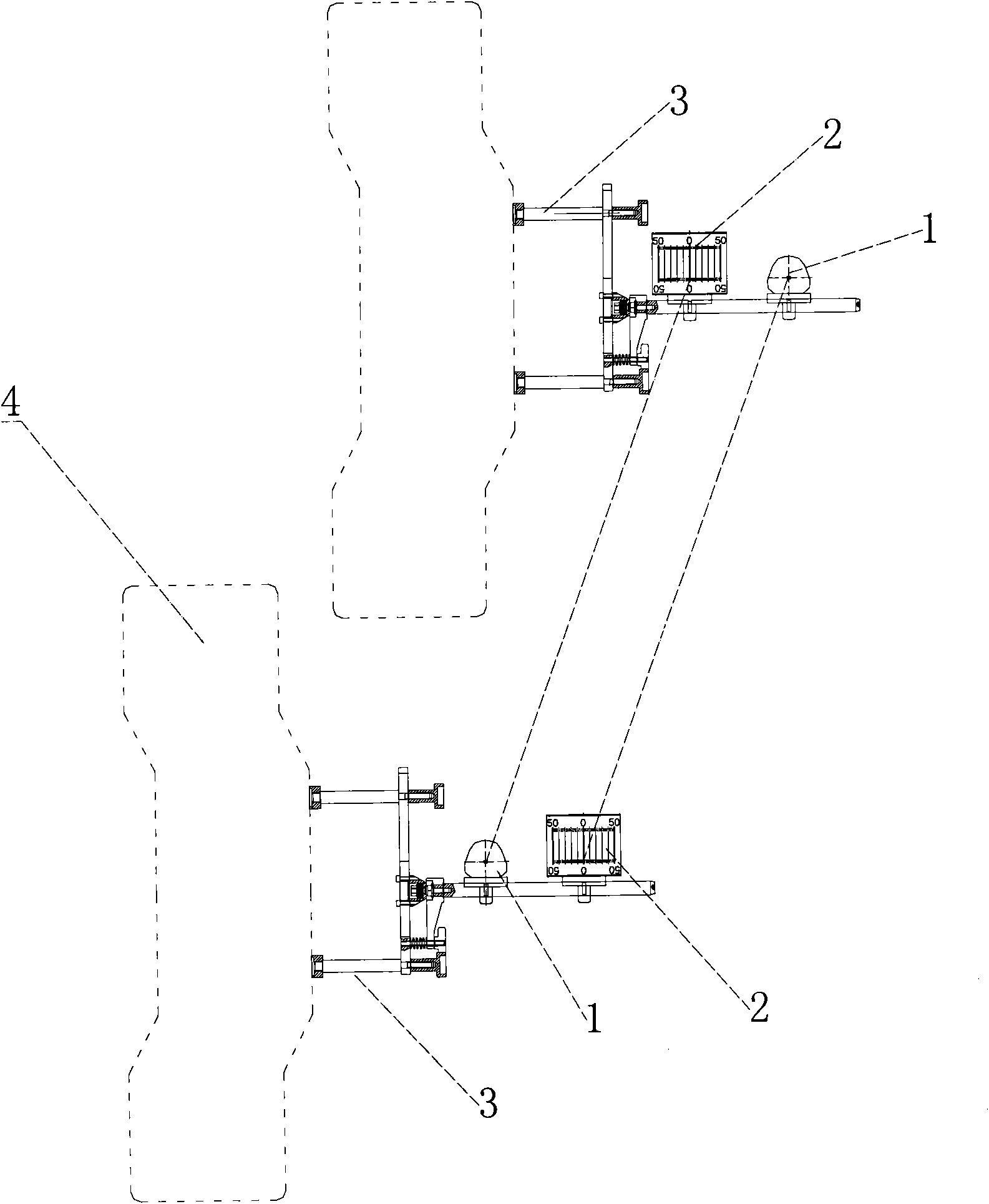

InactiveCN101886910AGuaranteed parallelismReduce abnormal wear and tearUsing optical meansLaser transmitterSteering wheel

The invention provides a dual-front axle wheel axle parallel position adjustment method. The invention comprises the following steps: concentrically clamping on the wheel hub of the dual front axles of a vehicle by a special clamp, fully utilizing the span between the dual front axles, setting operation manners of a laser emitter and a corresponding target respectively, regulating a drag link between two wheel axles, and carrying out precise position on the wheel axles of the vehicle to be positioned by corresponding position manners of laser and the target. After the adjustment, parallelism of the dual-front axle wheel is secured, and all steering wheels upwards roll right ahead when the vehicle runs along a straight line, thereby effectively reducing abnormal wear and fuel consumption of tires, improving driving comfortableness, reducing waste of social resources and strengthening traffic safety.

Owner:深圳市东智科技发展有限公司

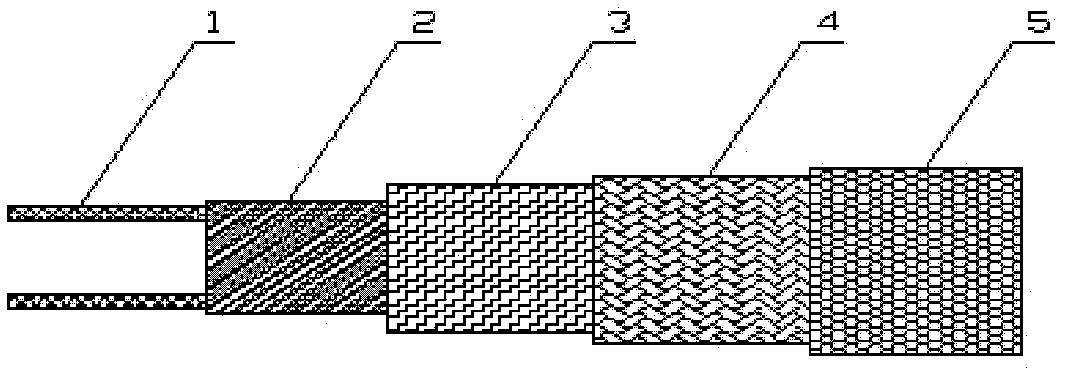

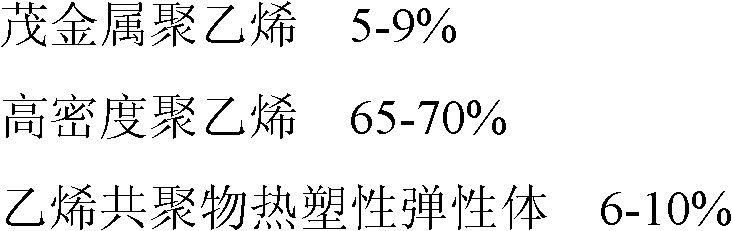

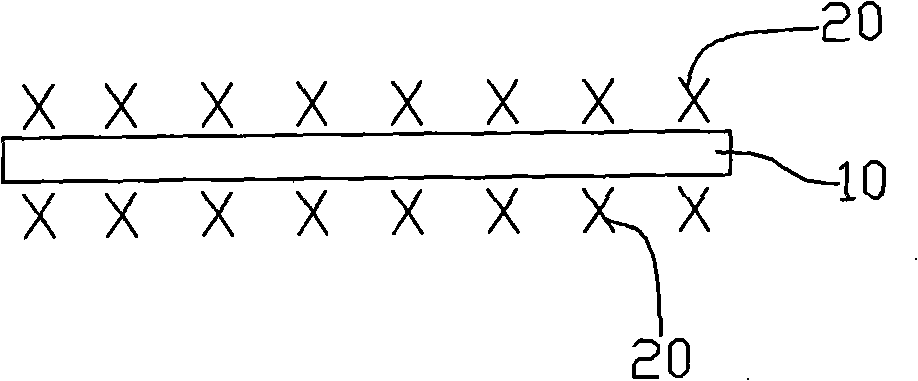

PTC (Positive Temperature Coefficient) high polymer heating material for self-limiting temperature electric tracing band

InactiveCN102604189AImprove PTC StrengthImprove tensile propertiesHeating element shapesPositive temperature coefficient thermistorsFiberCarbon fibers

The invention discloses a PTC (Positive Temperature Coefficient) high polymer heating material for a self-limiting temperature electric tracing band, which is prepared from the following raw materials in percentage by weight: 5 to 9 percent of metallocene polyethylene, 65 to 70 percent of high-density polyethylene, 6 to 10 percent of vinyl copolymer thermoplastic elastomer, 1.5 to 2.5 percent of carbon fibers, 15 to 25 percent of carbon black, 0.25 to 0.35 percent of benzotriazole light stabilizer, 0.10 to 0.20 percent of hindered phenol antioxygen, 0.10 to 0.20 percent of decabromodiphenylethane, 0.10 to 0.20 percent of diisooctyl ortho-phthalate, 0.10 to 0.20 percent of dicumyl peroxide and 0.05 to 0.15 percent of nucleating transparent agent zc-3. According to the invention, the elasticity modulus of the PTC material is improved, the maximum stress and the stress of a breaking point of the PTC material are increased, so that the PTC strength and the stretch resistance performance of the PTC heating material are improved.

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

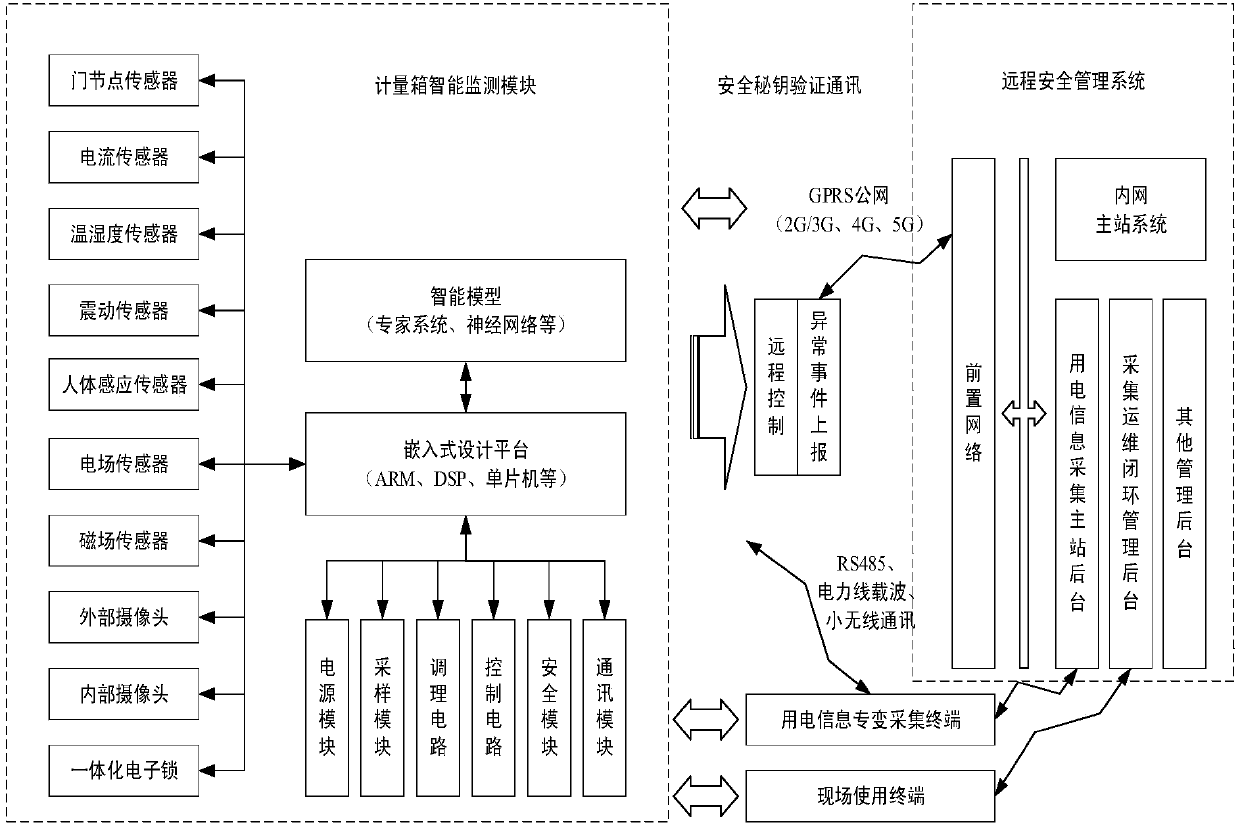

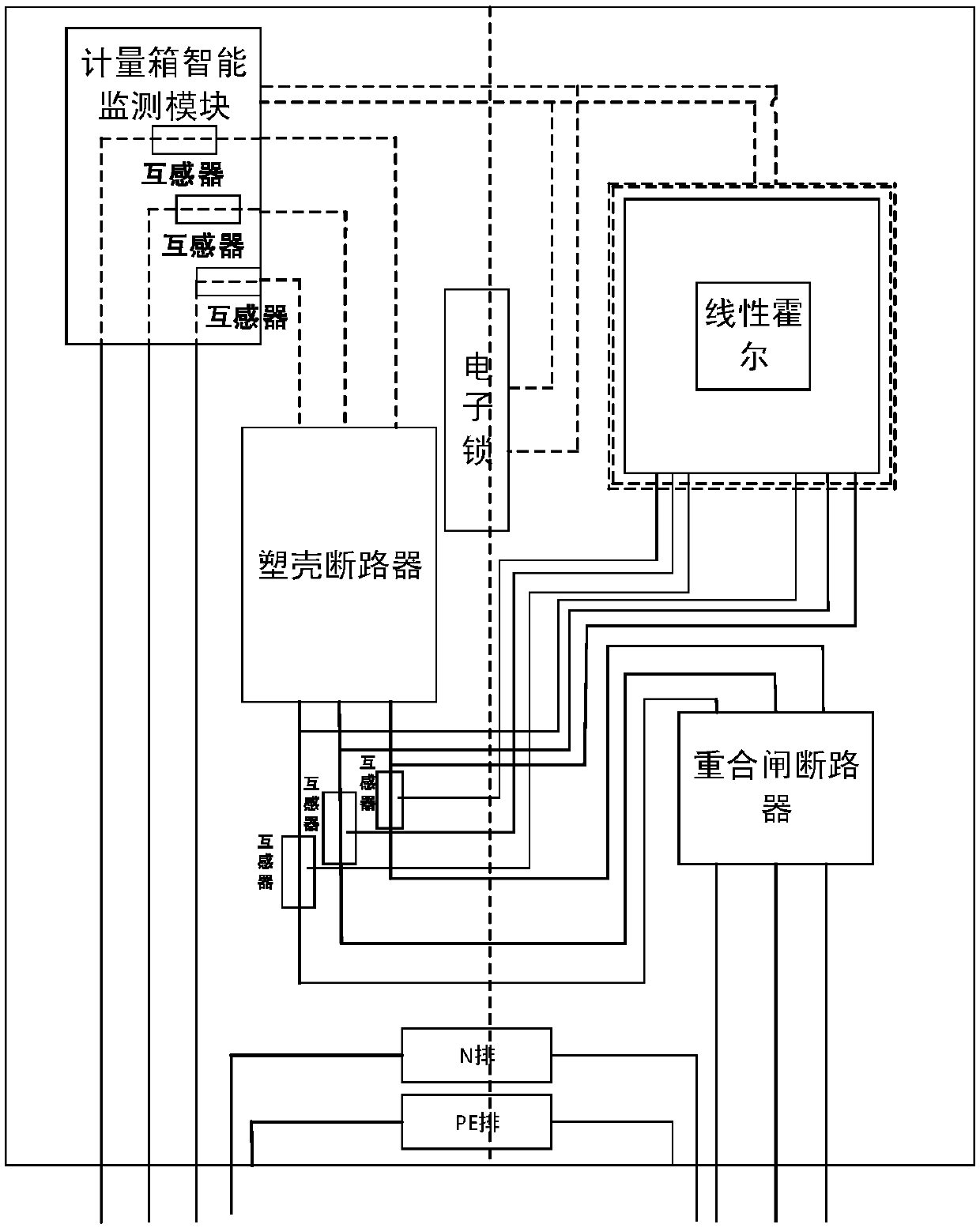

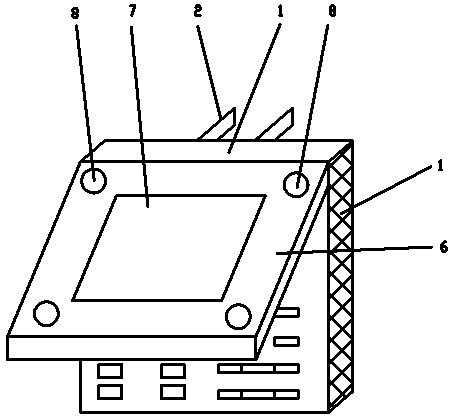

System and method for intelligently protecting metering box

PendingCN108107801AAddress speculationAvoid negotiating and cooperatingProgramme controlComputer controlSafety controlEngineering

The invention discloses a system and a method for intelligently protecting a metering box. The system comprises a metering box intelligent monitoring module and a remote control master station. The metering box intelligent monitoring module is used for monitoring the running state data of a metering box, determining an abnormal event, encrypting the abnormal event and reporting the abnormal eventto the remote control master station. The metering box intelligent monitoring module comprises an electronic lock control unit, a camera acquisition unit, an RFID radio frequency tag reading unit, a DC magnetic field monitoring unit, a high-frequency magnetic field monitoring unit, a temperature and humidity monitoring unit, an incoming line current measuring unit, a security key control unit anda CPU control unit. The remote control master station is used for issuing a control command through the backstage or a mobile terminal to perform safety control on the metering box. Running state dataonline monitoring, remote control and abnormal event reporting in the running link of the metering box are realized in an all-round manner. Intelligent power use is fully supported. The risk of electricity stealing is reduced. The abnormal loss of lines is greatly reduced. The damage to field operation equipment is reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

High temperature-resistant felt and making method thereof

InactiveCN101275364AAvoid the disadvantage of easy separationReduce abnormal wear and tearTextiles and paperEngineeringWear resistance

The invention discloses a high temperature resistant carded felt and manufacturing method thereof, wherein, the high temperature resistant carded felt is composed of a basal layer, and a working layer which is formed by needling and combining multiple layer of base cloth fabric nets, the base cloth fabric net includes base cloth, and the surface of the base cloth is needled with a fabric net. The manufacturing method of the high temperature resistant carded felt includes the following steps: 1 manufacturing base cloth; 2 manufacturing a fabric net; 3 needling the fabric net onto the surface of the base cloth using needling mechanical or felting needle, to form a base cloth fabric net; 4 integrally compounding the base cloth fabric net with a ring shaped nonwoven needling technique, selecting a plurality of layers of base cloth fabric net according to the required thickness of the carded felt to complete the needling and combining molding on the basal layer; 5 using the mechanism and mold to manufacture the base cloth fabric net carded felt formed by needling and combining into the high temperature resistant carded felt. The inventive high temperature resistant carded felt has advantages of good antifriction property, low cost and environment protection.

Owner:黄乐军

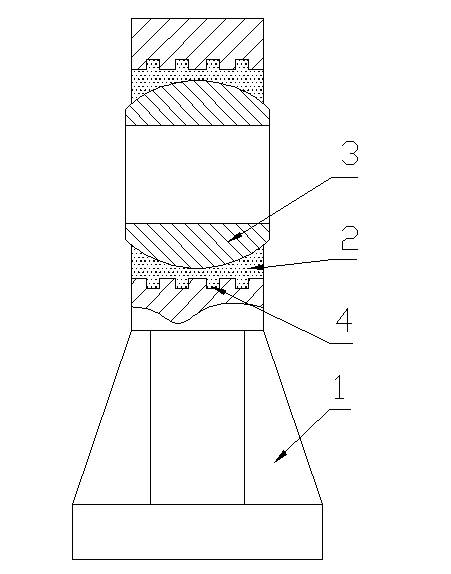

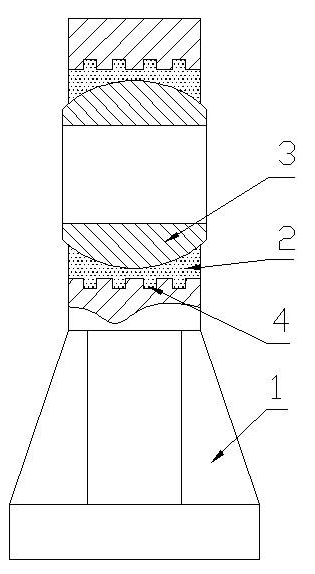

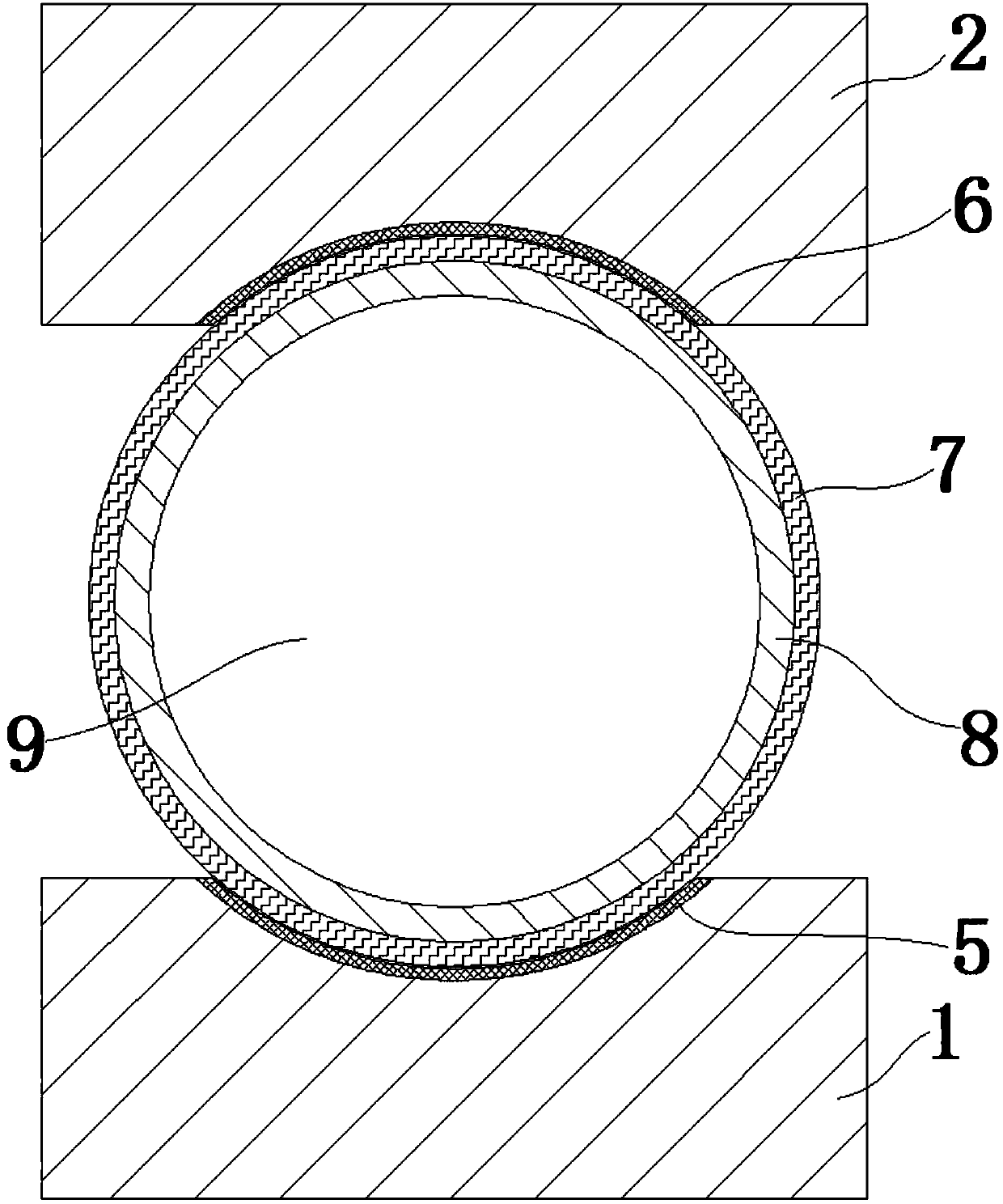

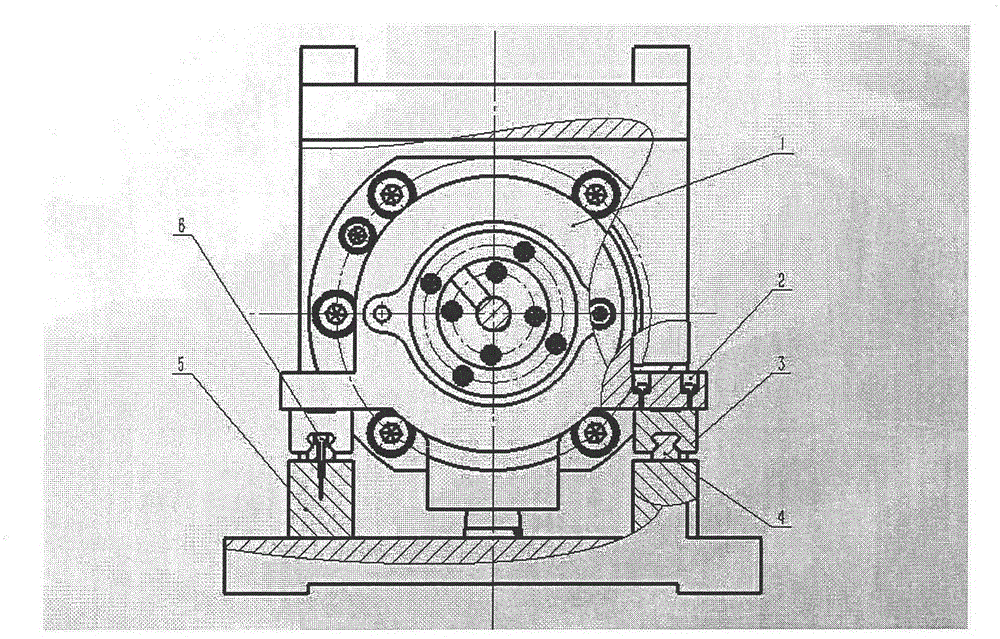

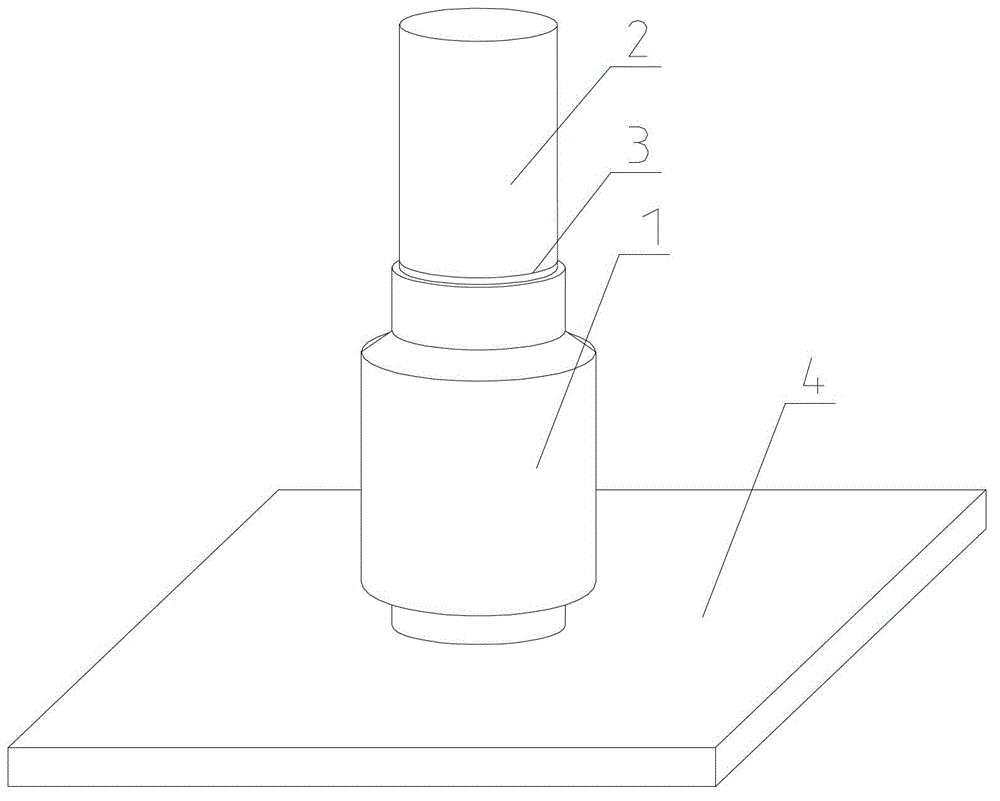

Axle center self-regulation and vibration reduction bearing block

InactiveCN102425607AReduce abnormal wear and tearExtended service lifeBall bearingsBearing unit rigid supportGlass fiberAgricultural engineering

The invention discloses an axle center self-regulation and vibration reduction bearing block and belongs to the technical field of mechanical parts. Annular grooves are formed in an axle hole of a fixed support seat and a bearing block is formed in the central axis of the axle hole; the bearing block has a spherical appearance, and a certain space is kept between the bearing block and the inner circular surface of the fixed support seat; and a gasket is arranged in the space and is formed by the following steps of: mixing 10 to 20 weight parts of teflon powder, 25 to 35 weight parts of glass fiber, and 50 to 60 weight parts of nylon, pelleting, heating, and directly pouring into the space between the axle hole of the fixed support seat and the outer spherical surface of the bearing block. The bearing block can compensate the coaxiality errors and other form and position errors between different bearings, reduce abnormal wearing of the bearing, prolongs the service life of transmission parts, reduce vibration of the transmission parts and overcome the defect that large noises are easy to produce due to vibration.

Owner:江苏华商企业管理咨询服务有限公司

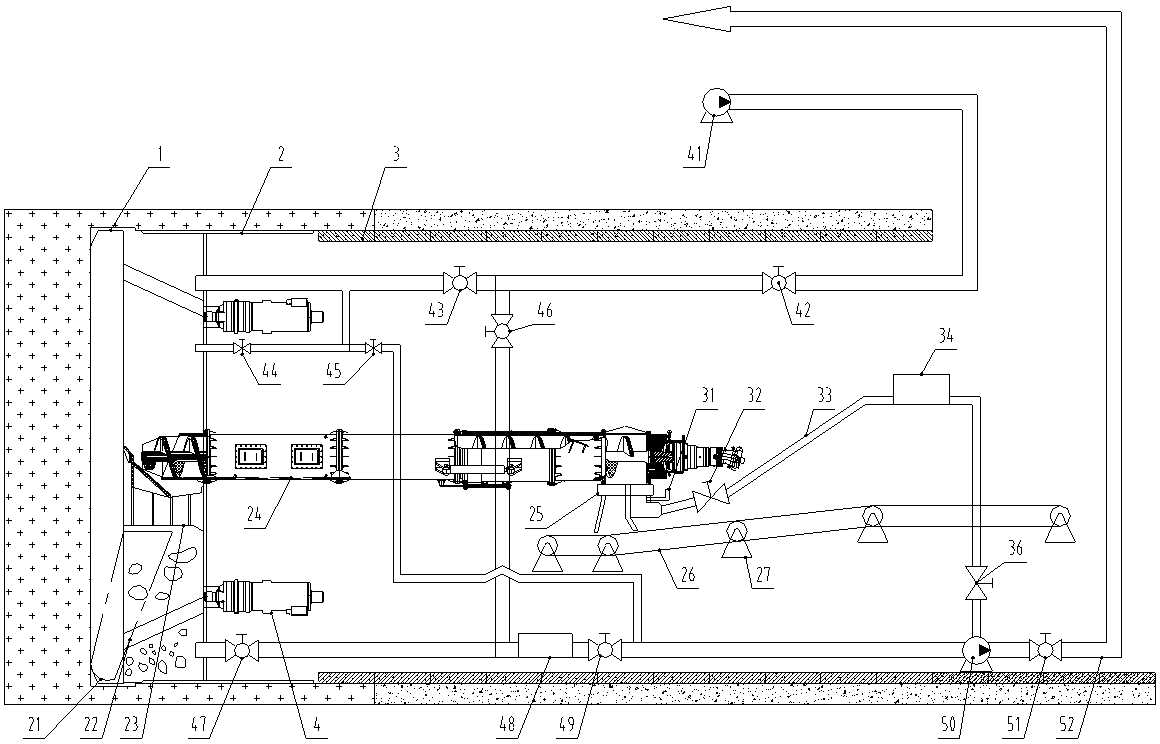

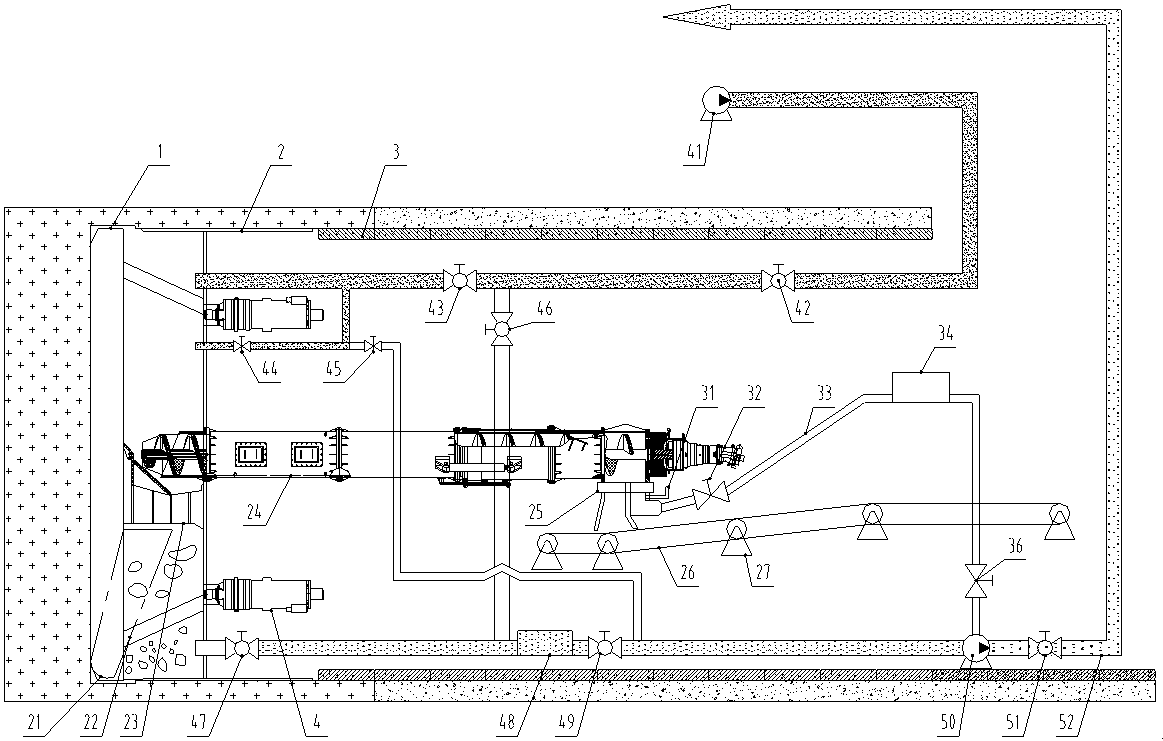

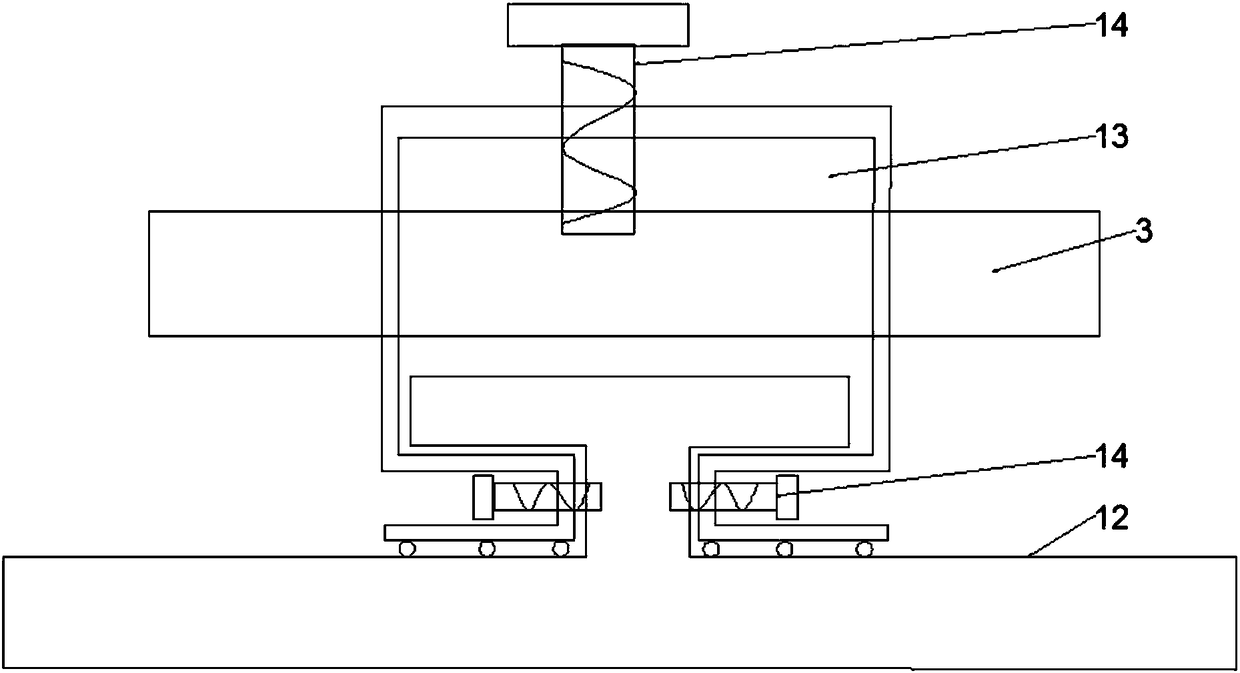

Dual-mode shield tunneling machine muck delivery system

The invention provides a dual-mode shield tunneling machine muck delivery system which comprises a spiral machine muck outlet system. The spiral machine muck outlet system comprises a belt transfer system and a mud-water transfer system, wherein a screw conveyer is connected with a control device, one port of the control device is located at the upper portion of the belt transfer system, and the other port of the control device is connected with the mud-water transfer system. The dual-mode shield tunneling machine muck delivery system has the advantages that the problems of complicated geological tunneling speed, severe device abrasion, long construction period, high construction risk, high input cost and the like of single types of shield tunneling machines are effectively solved; the risk of complicated common shield tunneling modes is reduced; the labor intensity of workers can be reduced; the complicated geology adapting capability of the shield tunneling machine can be improved, the non-normal abrasion degree of the shield tunneling machine can be reduced, and the tunneling speed of the shield tunneling machine can be improved; muck delivery modes can be switched at any time,and the muck delivery efficiency can be improved; the tunneling speed in complicated geological interval is improved, and the construction cost is reduced; the construction safety of the shield tunneling machine in the complicated geological interval is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

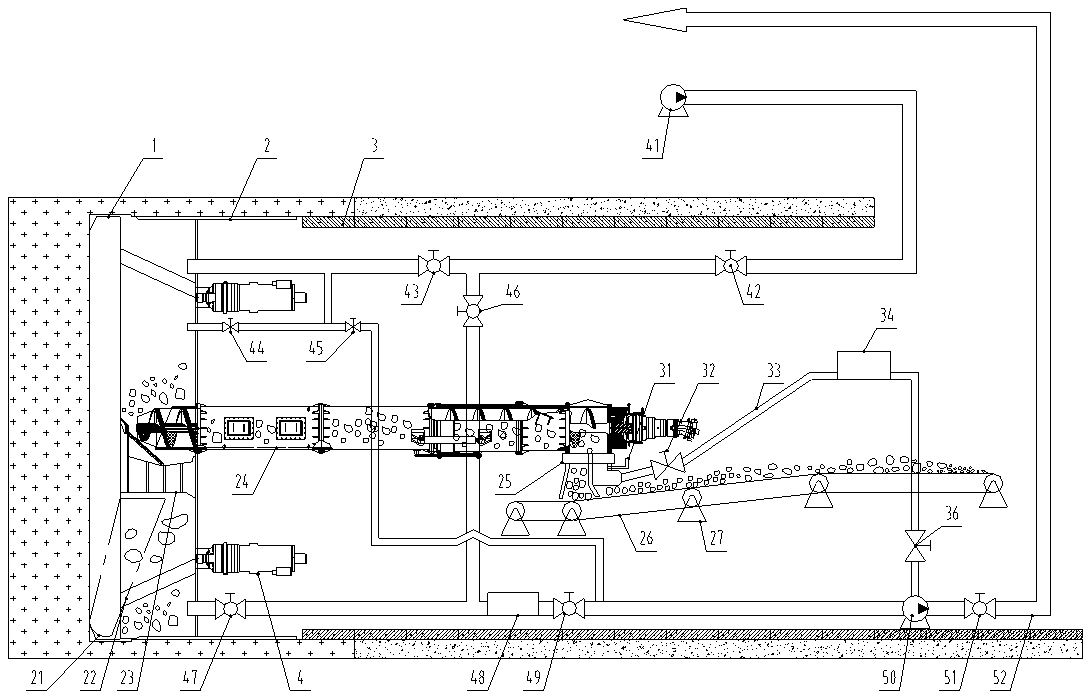

Internal water cooling motor

The invention discloses an internal water-cooling motor, which comprises a left end cover and a right end cover fixed with two axial ends of a cover through bolts. The left end cover and the right end cover are shaped as double-layer plates and a radial section is hollow. The radial external wall of the left end cover is provided with a water inlet hole communicated with the hollow cavity, while the radial external wall of the right end cover is provided with a water outlet hole communicated with the hollow cavity as well. The water inlet hole on the left end cover and the water outlet hole on the right end cover are of inner thread connection structure or flange connection structure. The housing is in a cylindrical interlayer-typed structure, and interval rib pipes are arranged between two concentric circular sections of the housing to constitute internal water ways of the motor. Pairs of through holes are arranged on the left end cover, the right end cover and the relevant surface of the housing. The cooling water way provided by the invention is characterized with simple structure and easy manufacturing process. After cooling water is brought in, the water way can cool the operating system effectively, which is particularly applicable to the motor operating under relatively higher temperature condition.

Owner:JIANGSU YUANDONG ELECTRIC MOTOR MFG

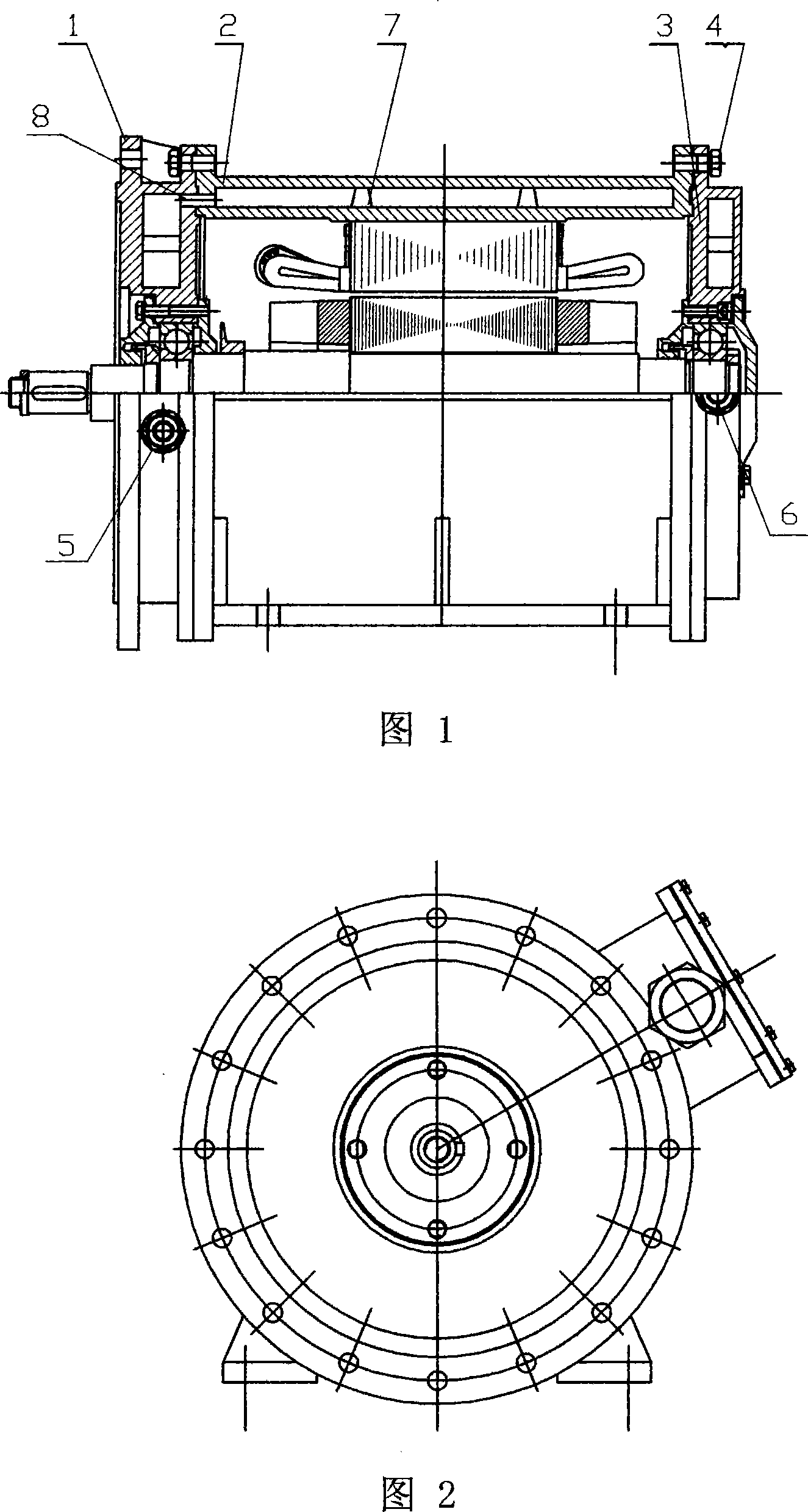

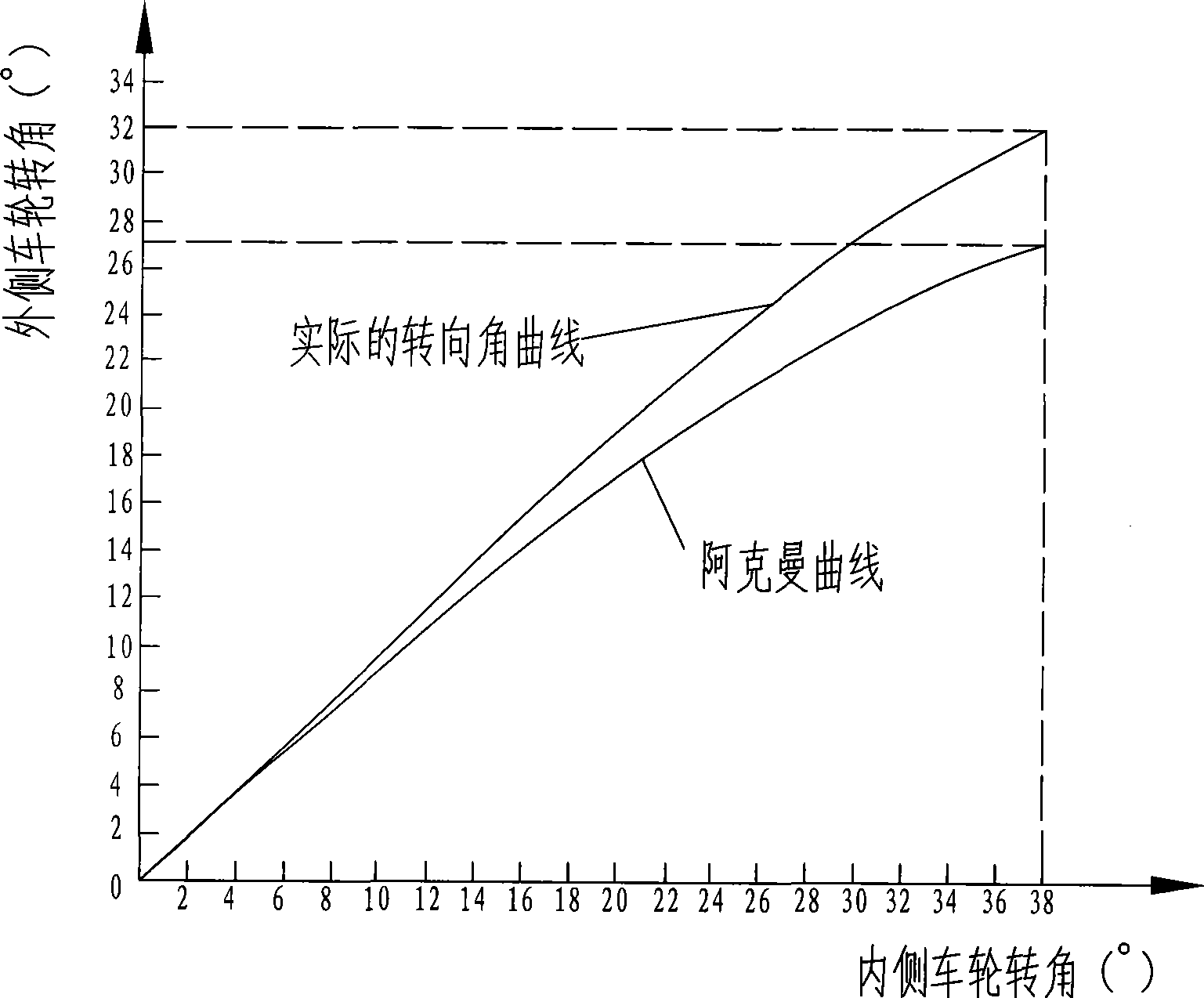

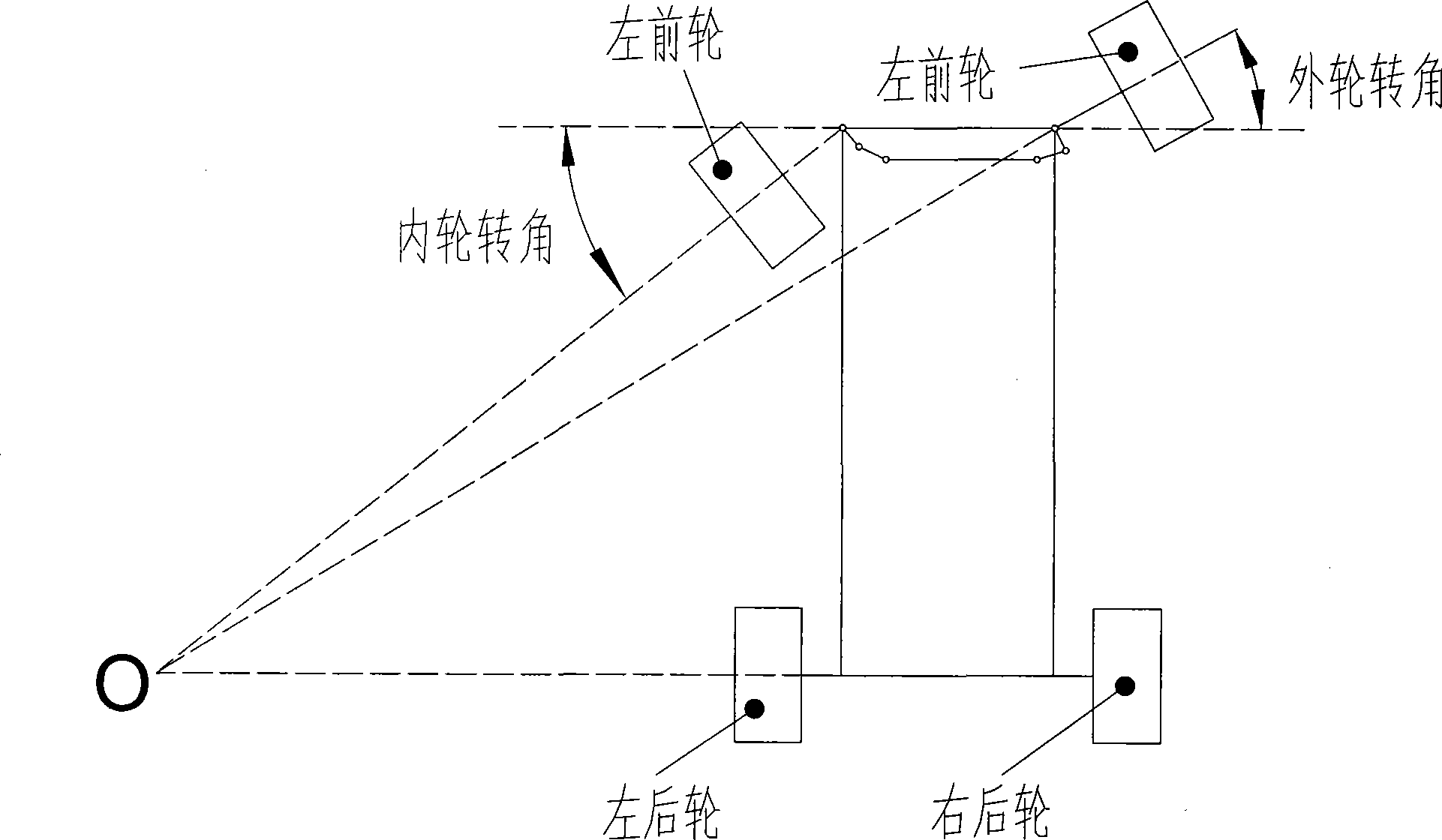

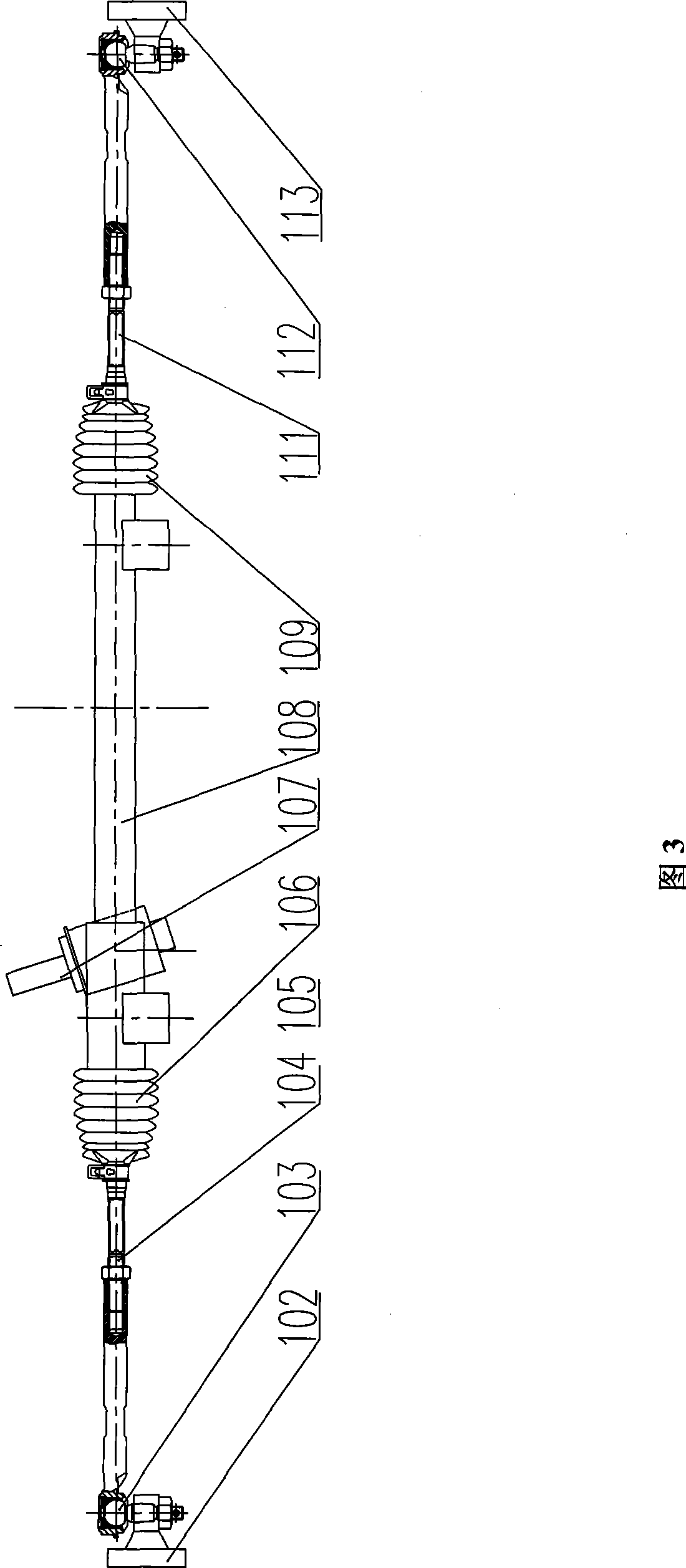

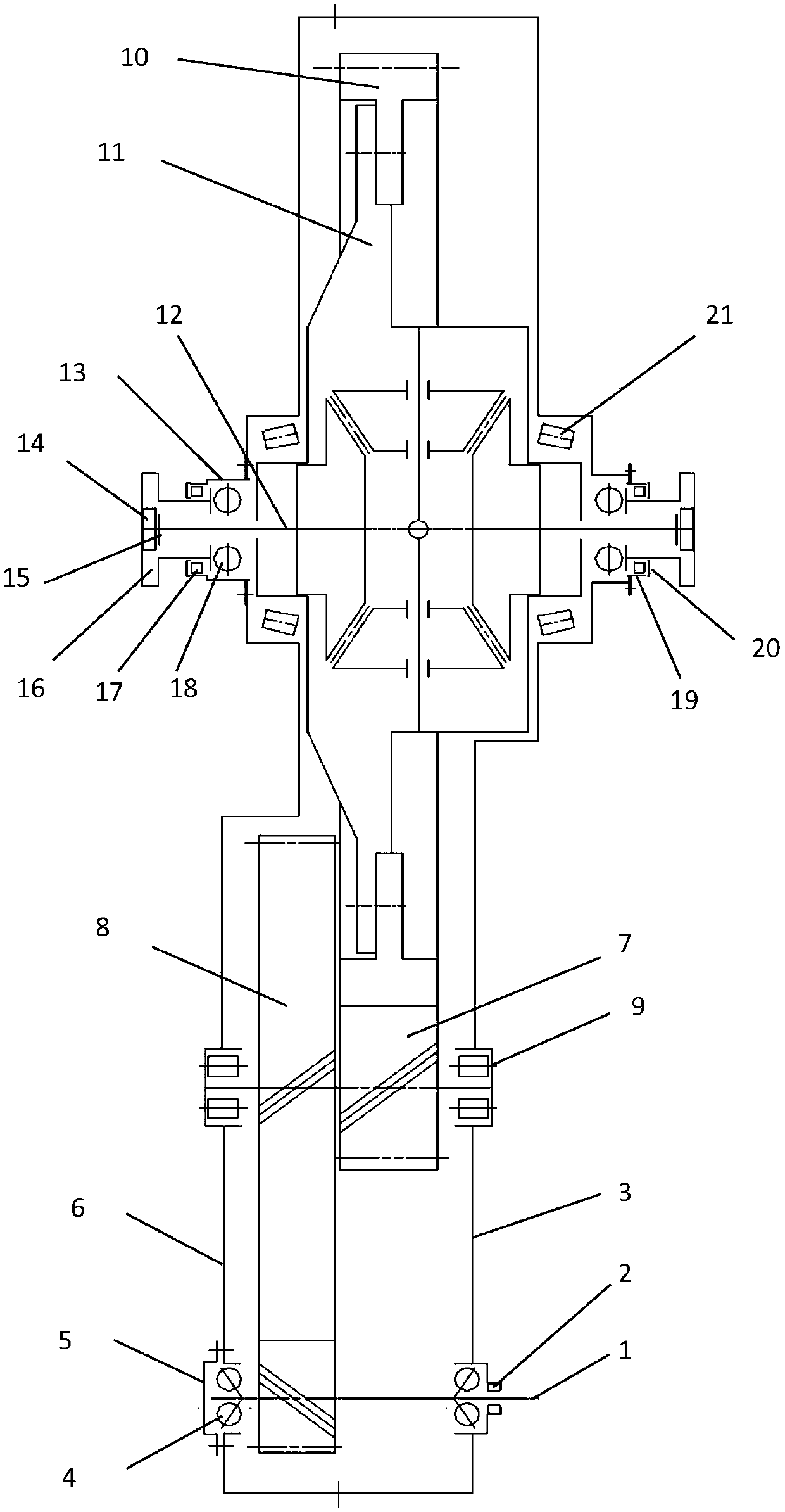

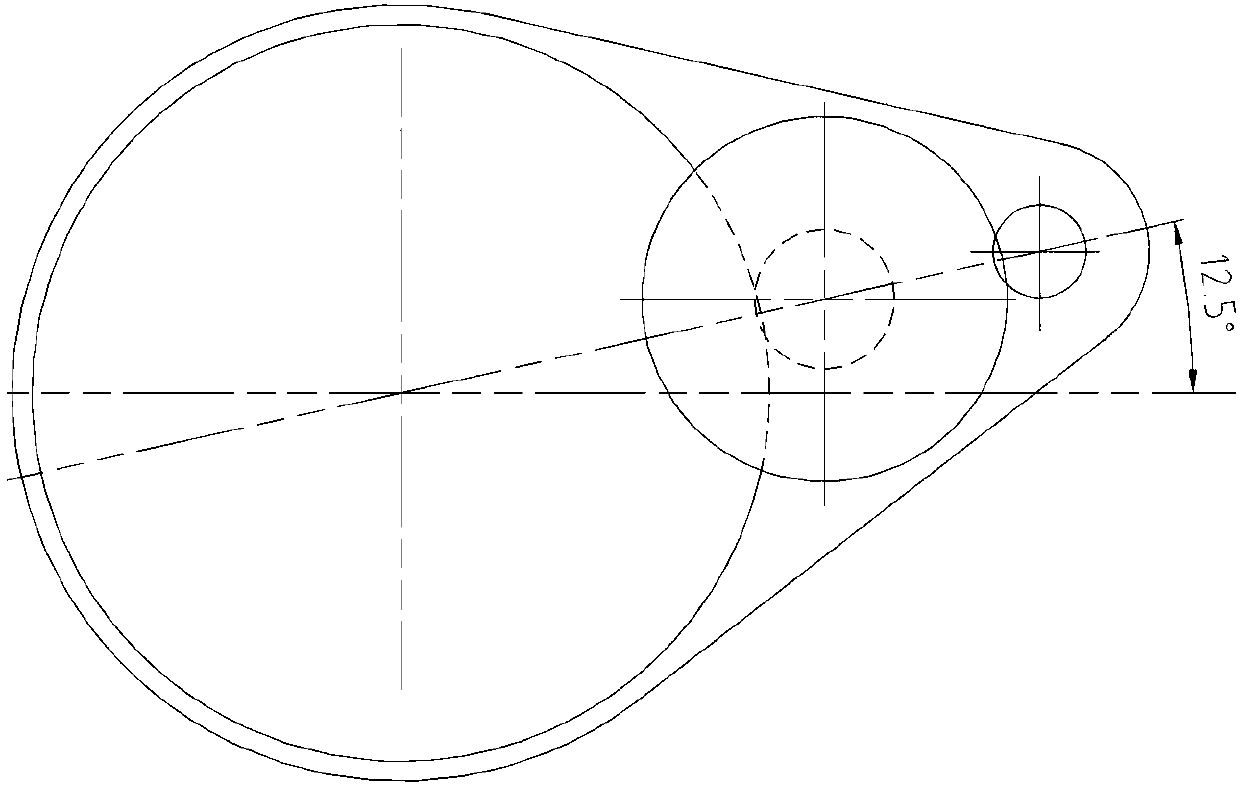

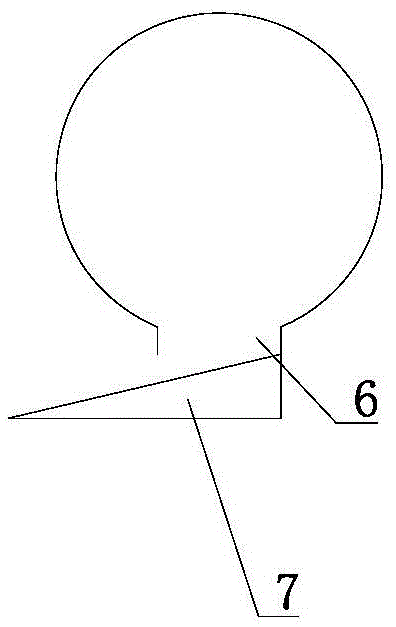

Automobile steering device

InactiveCN101417669ASmall steering sensitivityReduce abnormal wear and tearMechanical steering gearsSteering wheelCam

The invention discloses an automobile steering device which comprises a let steering pull rod, a right steering pull rod, a steering device shell body, a steering input shaft, a pinion, a left handspike, a right handspike and a cam, wherein, the center of the cam is provided with a ring gear whose center is rotatablely connected with the steering device shell body, and the periphery of the ring gear is provided with a left cam slot and a right cam slot. One end of the left handspike is provided with a left pin roll inserted in the left cam slot, and the other end of the handspike is hinged with the left steering pull rod; and one end of the right handspike is provided with a pin roll inserted in the right cam slot, and the other end of the handspike is hinged with the right steering pull rod. The invention makes use of a cam mechanism to cause rotation angles of the left steering wheel and the right steering wheel meet the Ackermann curve in real time, each wheel of the steering device carries out pure rolling movement when an automobile steers, and the abnormal abrasion is reduced when tyres steer, thus enhancing the life of the tyres greatly. The variable transmission ratio is realized, and the operation stability and the security are enhanced.

Owner:SAIC MOTOR

Full electric vehicle central reducer unit with motor side drive

PendingCN107842587ASufficient powerReduce the effect of meshingGearingElectric machinesInterference fitReduction drive

The invention relates to a full electric vehicle central reducer unit with motor side drive, which comprises an input gear shaft with an end part connected with a motor. The input gear shaft is supported on a reducer unit shell through an input bearing; shaft teeth on the input gear shaft are meshed with a middle shaft transmission gear; the middle shaft transmission gear is fixedly arranged on amiddle shaft; two ends of the middle shaft are supported on the reducer unit shell through cylindrical roller bearings; the middle shaft transmission gear is meshed with an output gear; the output gear is of a hollow spoke structure; an inner hole of the output gear is in interference fit to a convex seam allowance of a shell of a differential mechanism assembly; the output gear transmits a torquethrough a way that a plurality of bolts uniformly arranged on a radial plate are connected with the shell of the differential mechanism; half axle gears on two sides of the differential mechanism areconnected with output half axles; and the output half axles are connected with an output flange plate. The full electric vehicle central reducer unit with motor side drive provided by the invention adopts a two-stage fixed shaft for transmission so as to be high in transmission efficiency, and is compact in arrangement, smaller in size, and lower in processing and maintenance cost.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

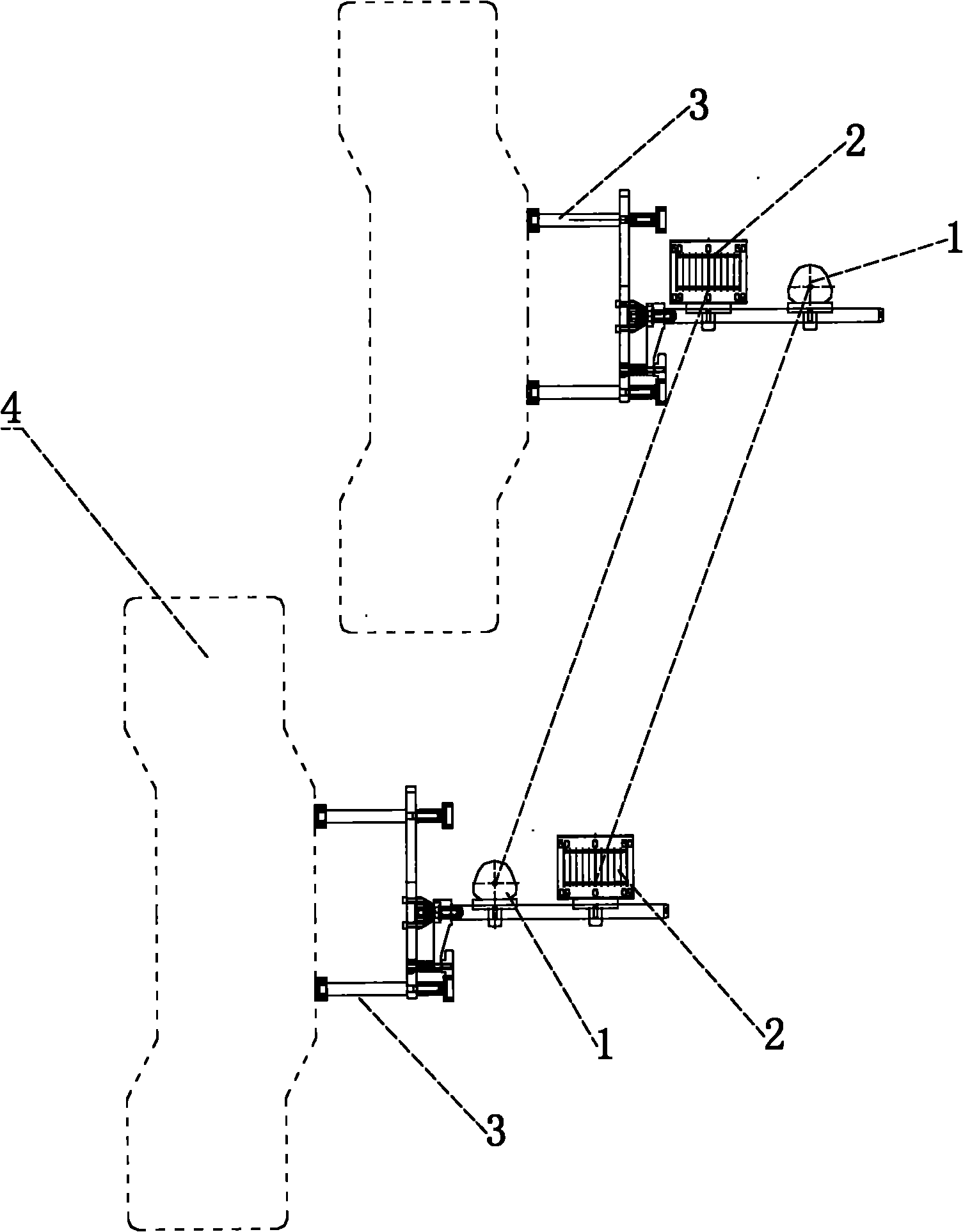

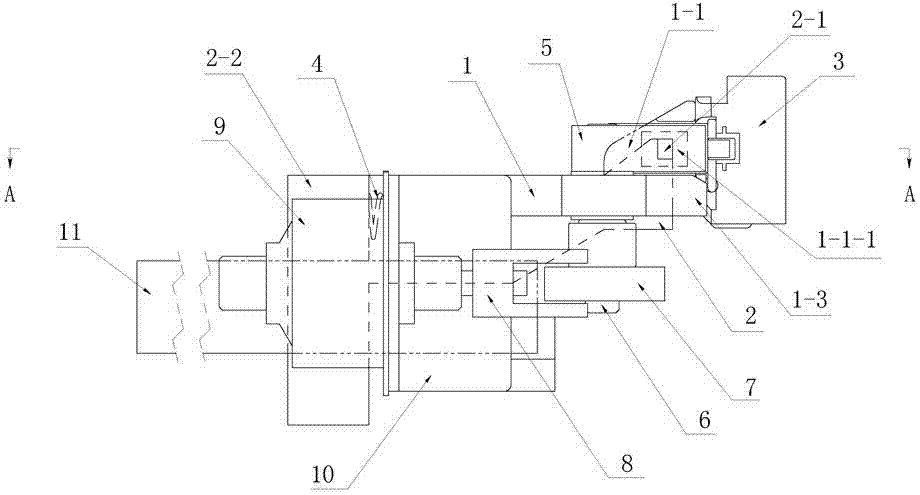

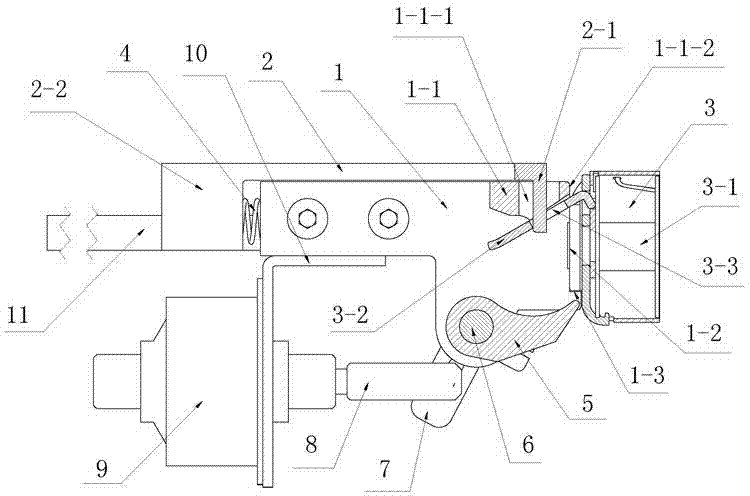

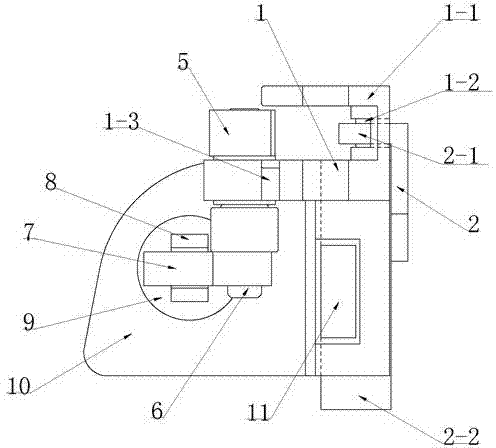

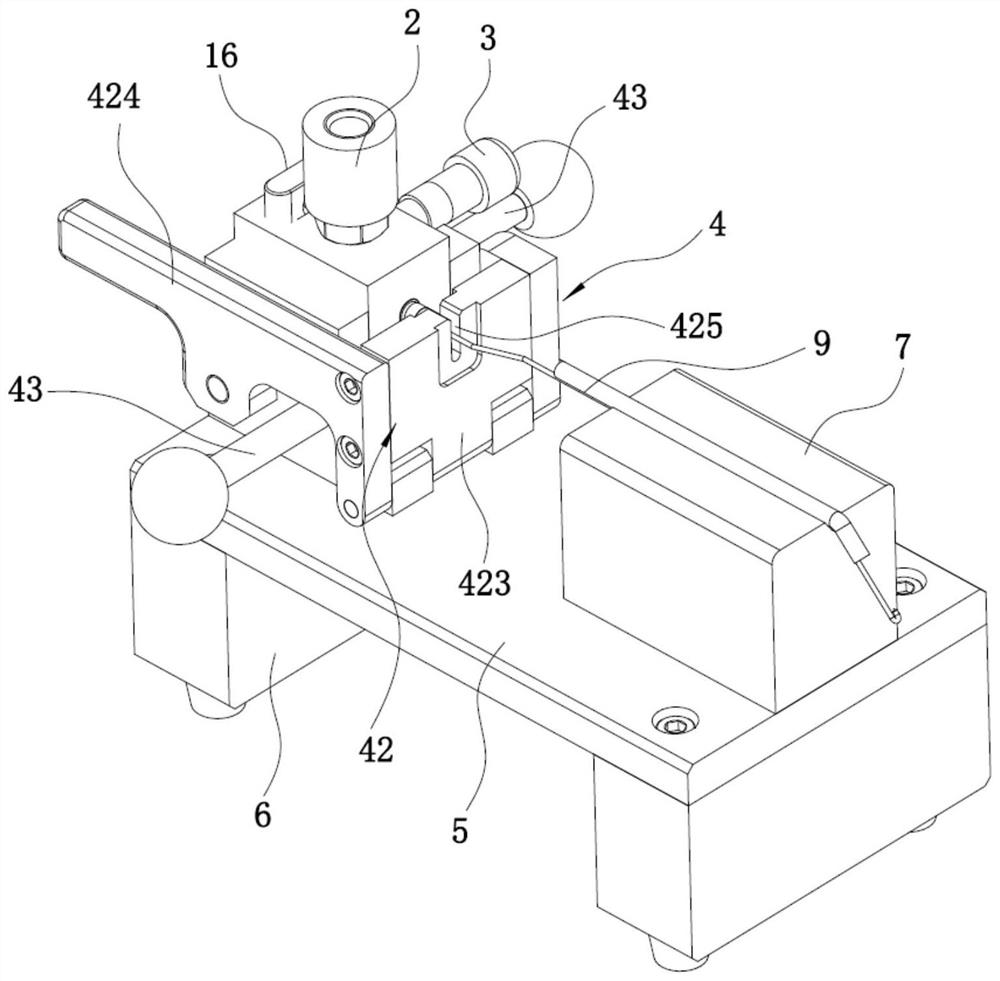

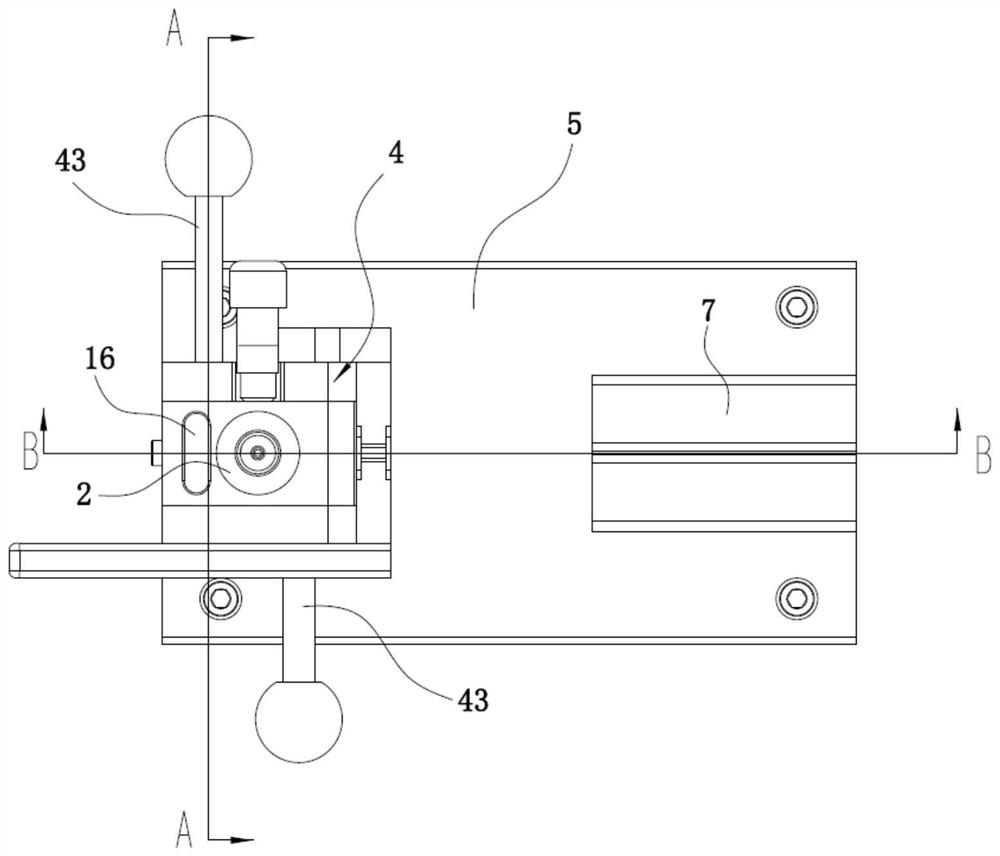

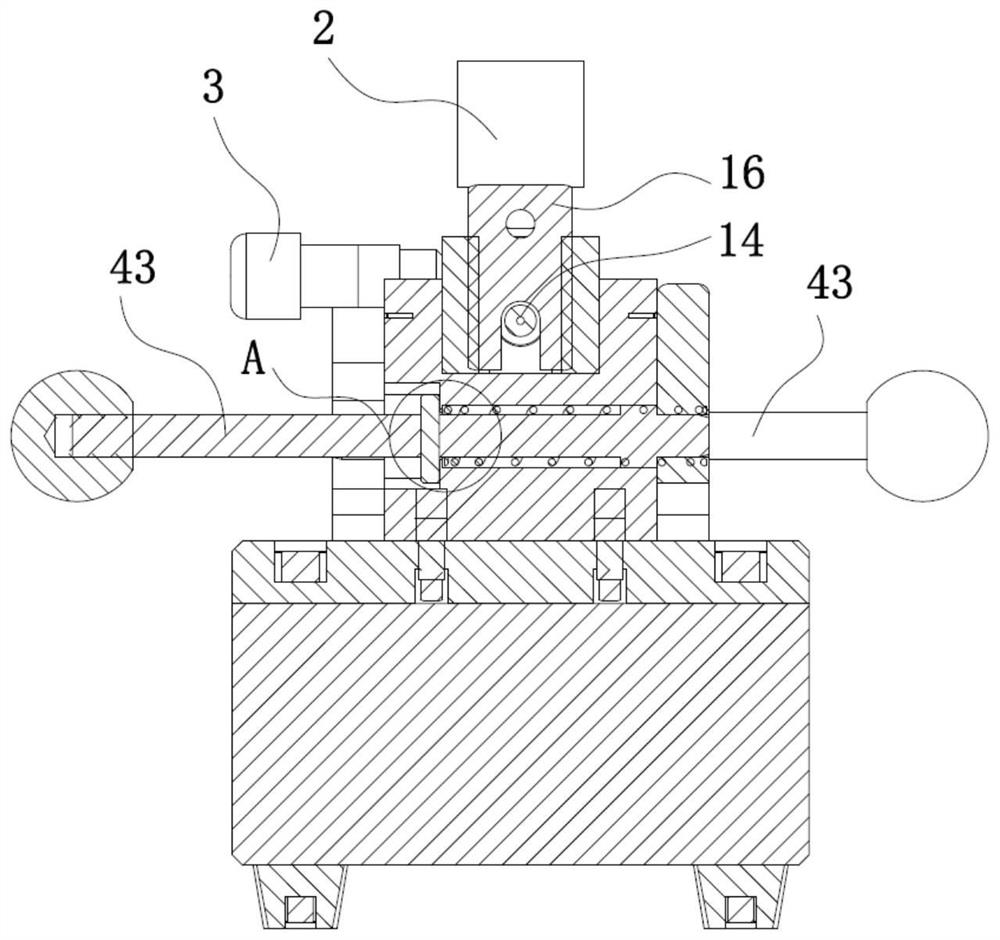

Shuttle core clamping mechanism used in automatic base line replacing device of embroidery machine

ActiveCN103696186AReduce abnormal wear and tearAvoid collisionEmbroidering machines apparatusBobbinElectric machinery

The invention discloses a shuttle core clamping mechanism used in an automatic base line replacing device of an embroidery machine. The shuttle core clamping mechanism consists of a shifting claw rack, a shifting angle limiting rack, a buffer spring, a shifting claw, a shifting claw shaft, a shifting claw push arm, a motor shaft, a thrust motor and a thrust motor rack, wherein the shifting angle limiting rack with a hinge hook at the right end is connected with the shifting claw rack in a sliding manner; the buffer spring is arranged between the shifting claw rack and a mounting base; one end of the shifting claw shaft is fixedly connected with the shifting claw; the other end of the shifting claw shaft penetrates through the shifting claw rack and is fixedly connected with one end of the shifting claw push arm; the outer end of the motor shaft is connected with a guide groove of the shifting claw push arm in a sliding manner; the shifting claw, the hinge hook and a hinge are in contact connection; the shifting angle limiting rack is fixedly connected with a shuttle core access guide plate. By adopting the shuttle core clamping mechanism, a shuttle core can be firmly clamped and is kept be in correct posture when being stored and moved, so that abrasion on components and destructive accidents are effectively reduced.

Owner:FOSHAN QICHUANG TECH DEV

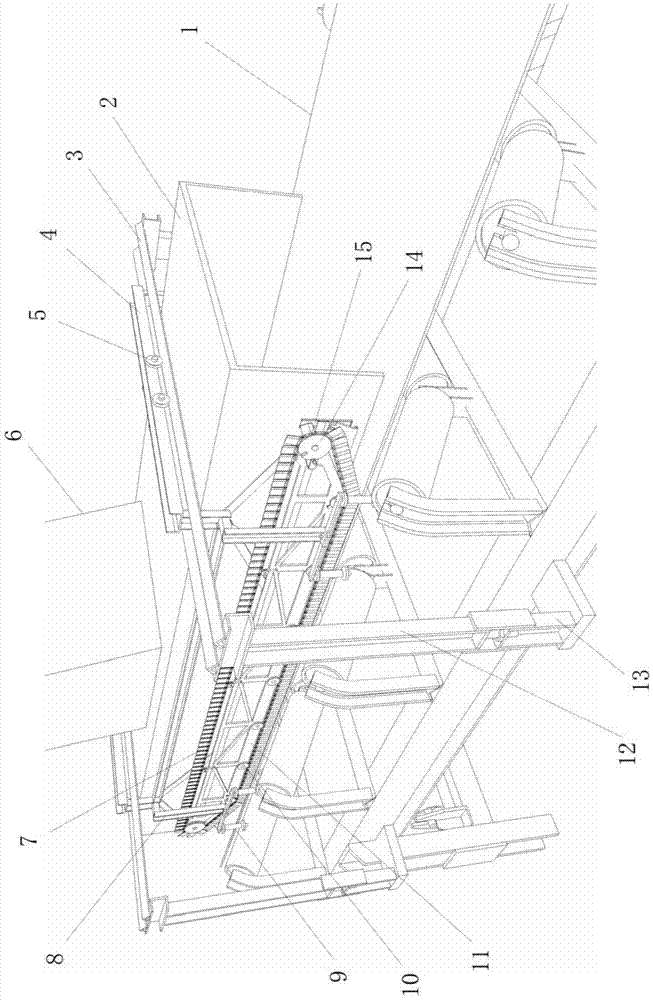

Material guiding device for belt conveyor

InactiveCN104709672AReduce workloadReduce abnormal wear and tearConveyorsConveyor partsEngineeringEnergy consumption

The invention discloses a material guiding device for a belt conveyor. The material guiding device comprises a material guiding groove and a sealing component. The material guiding groove is formed above a conveying belt of the belt conveyor and extends in the longitudinal direction of the conveying belt. The sealing component comprises a mounting rack and a sealing fin which is mounted on the mounting rack and used for sealing the gap between the material guiding groove and the conveying belt, and the sealing fin is in contact with the conveying belt and can be driven by the conveying belt to make longitudinal movement. According to the technical scheme, the coal sealing effect of a material turning-connection point is quite good, and no coal leaks basically; moreover, the workload for replacing the sealing fin of the material guiding device is reduced, and the influence on production operation by replacing the sealing fin is lowered; what's more, abnormal abrasion of the conveying belt is lowered, and the service life of the conveying belt is prolonged; furthermore, the operating resistance of the conveying belt is lowered, and accordingly equipment energy consumption is lowered.

Owner:CHINA SHENHUA ENERGY CO LTD +1

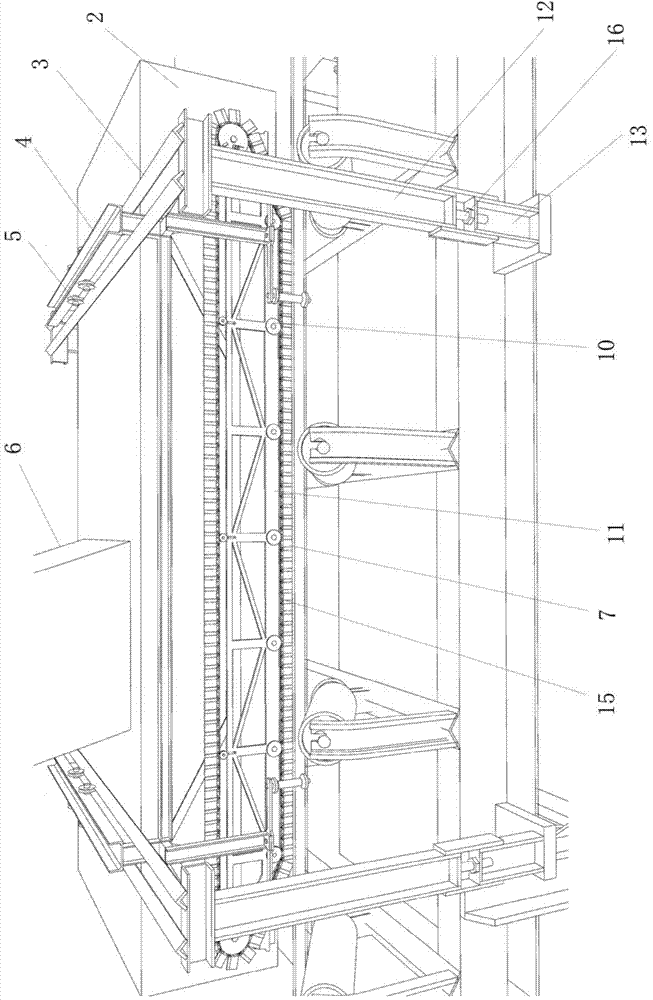

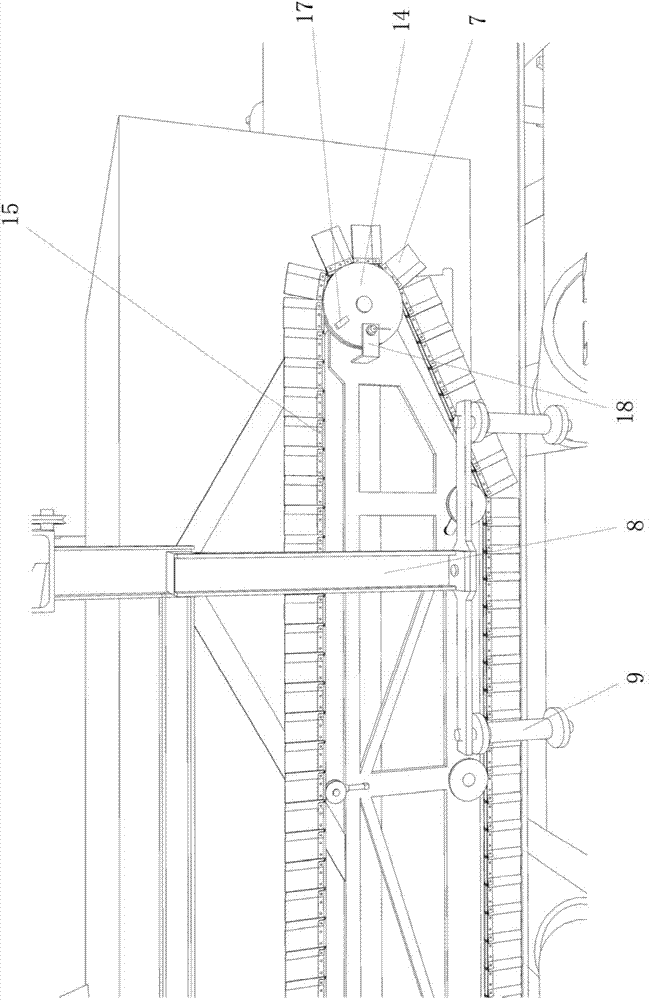

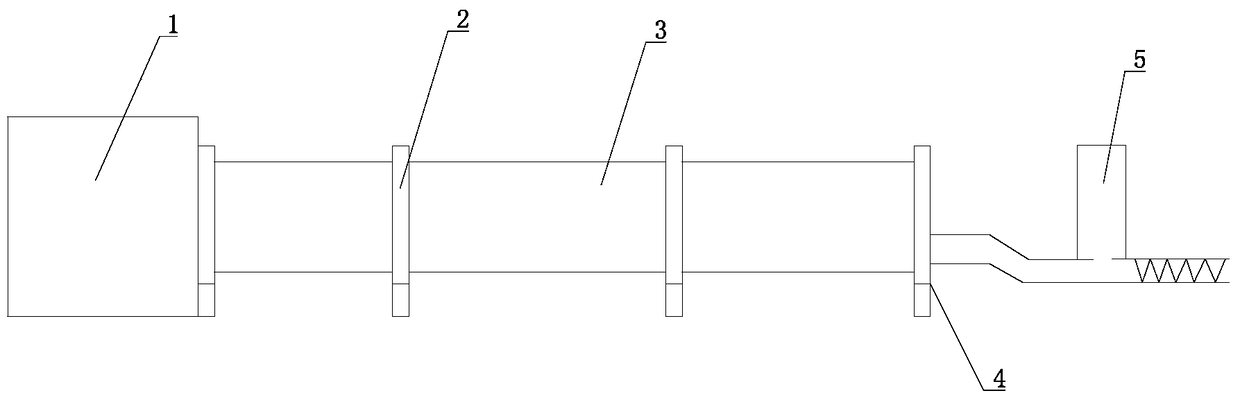

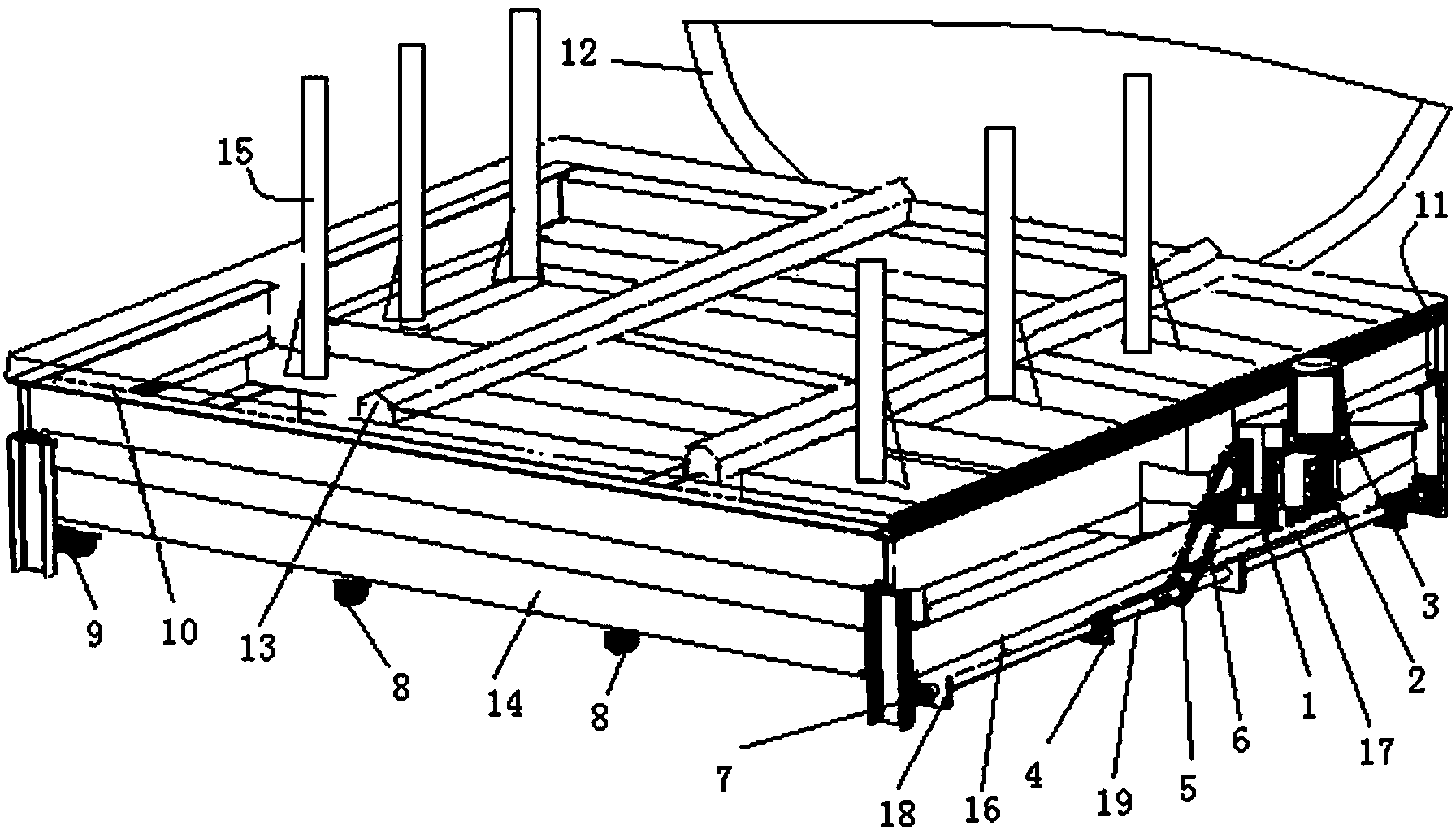

Uninterruptible power supply door operator for refrigerator door test

ActiveCN108562428AExtended service lifeReduced output voltage ripple factorMachine part testingFailure rateRefrigerator car

The invention relates to the technical field of test equipment and discloses an uninterruptible power supply door operator for refrigerator door test. The uninterruptible power supply door operator comprises a fixation connection device for fixing a test refrigerator, a door opening connection device for connecting a refrigerator door, a power device fixedly arranged on the fixation connection device and used for driving the door opening connection device, and an uninterruptible power supply module for providing power supply to the power device. The uninterruptible power supply door operator can prevent the case of power supply abnormity, provides steady and uninterrupted power supply, realizes fast matching of various types of refrigerators and well solves the problem of refrigerator dooropening and closing track matching, is convenient and fast to install, can realize automatic repeated opening and closing of upper and lower doors of the refrigerator, and is high in safety stabilitycoefficient, low in failure rate, not easy to damage the refrigerator, high in automation degree, simple in structure and low in cost.

Owner:合肥羿振电力设备有限公司

Rice milling grinding wheel and preparation method thereof

Owner:EZHOU XINGFANG GRINDING TOOLS

Preparation method of biomass fuel and special device thereof

InactiveCN105623772AReduce abnormal wear and tearRaise the ratioBiofuelsSolid fuelsBiomass fuelsDrying drum

The invention provides a preparation method of biomass fuel and a special device thereof, which solves the technical problems of the traditional biomass fuel preparation method that a drying machine wastes the resource, the production efficiency is low and the environment is polluted. The method comprises the steps: mixing timber and straws; crushing the raw materials into particles; sending the particles into a wood residue drying machine for removing hard impurities, and drying the particles; extruding the dried materials in an extruder to obtain biomass fuel, wherein the wood residue drying machine for removing the hard impurities is provided with a drying chamber, a feeding machine, a drying drum and a draught fan, one end of the drying drum is connected with the drying chamber, and the other end of the drying drum is connected with the drying machine; and the drying drum is provided with the feeding machine, a waste discharging hole is formed in the discharging end, a waste discharging pipe is arranged below the waste discharging hole, and a waste discharging bracket is arranged below the waste discharging pipe. The preparation method can be widely applied to the field of preparation of the biomass fuel.

Owner:WEIHAI BIYUNTIAN ENERGY TECH CO LTD

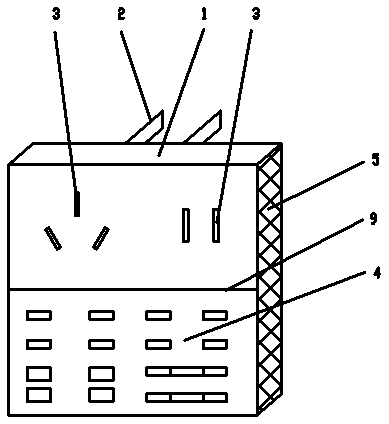

Power equipment on-site real-time monitoring alarm device and control method

InactiveCN108593976APromote intensive useReduce abnormal wear and tearElectrical testingMeasurement instrument housingRemote controlPower equipment

The invention discloses a power equipment on-site real-time monitoring alarm device and control method. The device comprises a monitoring box and a measuring chip which is arranged in the monitoring box and used for measuring power consumption, a power plug connected with a power supply is arranged on a ventral surface of the monitoring box, an electric appliance jack connected with power equipment is formed in the upper portion of the back of the monitoring box, and an input panel for inputting power consumption alarm threshold values is arranged at the back of the monitoring box. A box coveris hinged onto the monitoring box, a visual alarm and a display screen for displaying power consumption information are arranged on the box cover, and an audible alarm is arranged on the side face ofthe monitoring box. The device overcomes the shortcomings of the prior art, abnormal power consumption conditions of various types of power equipment can be subjected to real-time monitoring, audibleand visual alarm and remote control.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD

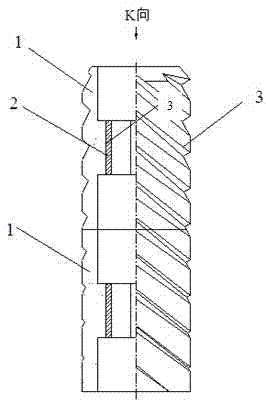

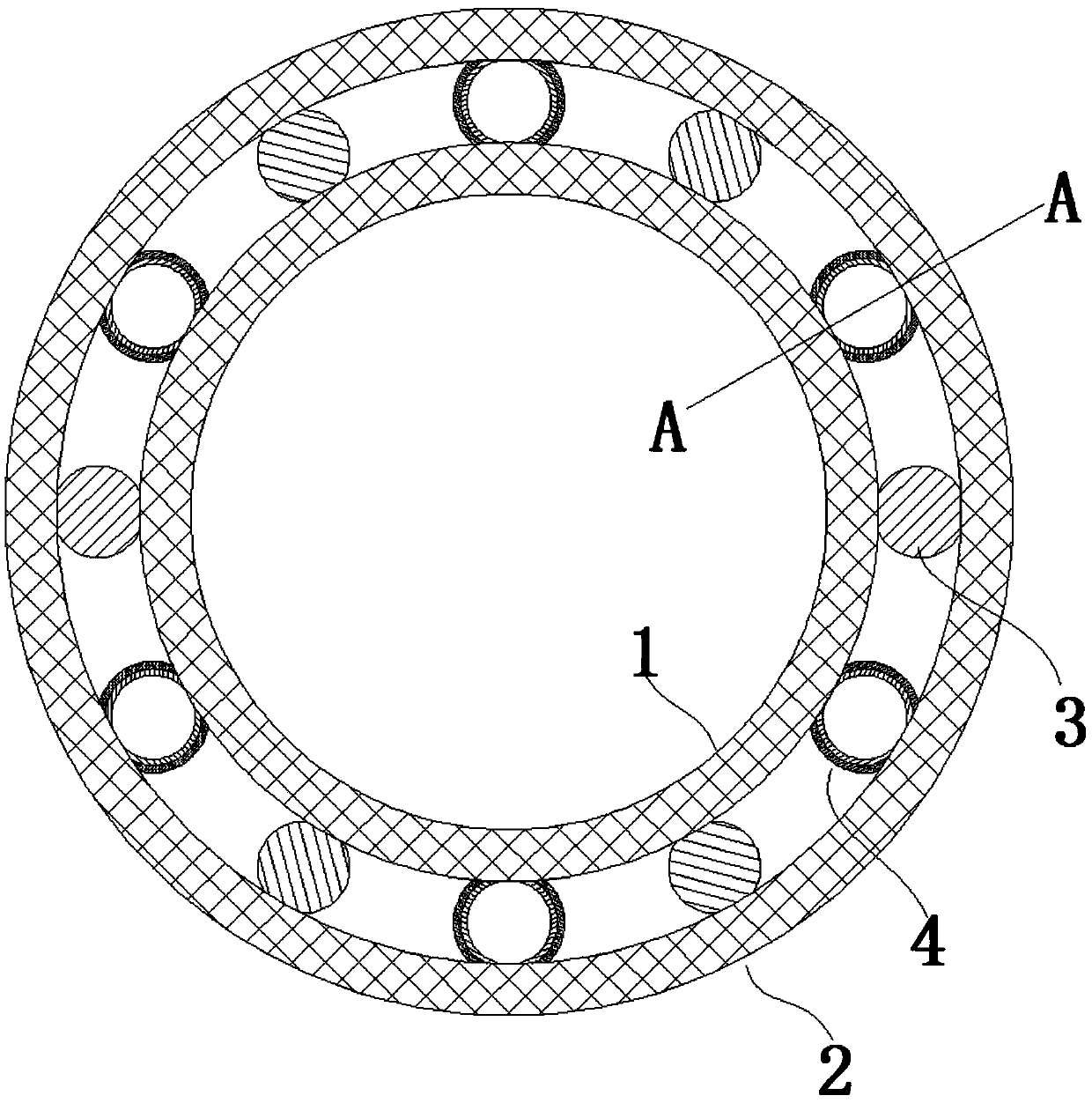

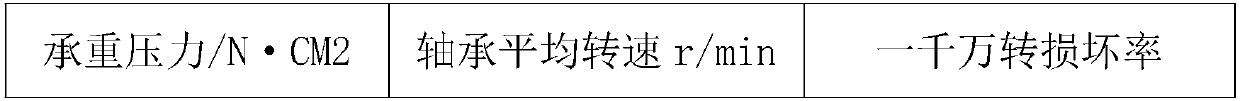

Coordination structure device of high-revolving-speed bearing and balls of high-revolving-speed bearing

InactiveCN107725584AReduce abnormal wear and tearEasy to operateRolling contact bearingsBearing componentsManufacturing technologyEngineering

The invention discloses a coordination structure device of a high-revolving-speed bearing and balls of the high-revolving-speed bearing, and relates to the technical field of bearing machining and manufacturing. According to the coordination structure device of the high-revolving-speed bearing and the balls of the high-revolving-speed bearing, the solid balls and the hollow balls are distributed between a bearing inner ring and a bearing outer ring in a staggered mode at equal intervals; the ball outer diameters of the hollow balls are greater than the ball diameter sizes of the solid balls; the contact layer surface of the bearing inner ring and the solid balls as well as the hollow balls is provided with a first contact layer; and the contact layer surface of the bearing outer ring and the solid balls as well as the hollow balls is provided a second contact layer. According to the coordination structure device of the high-revolving-speed bearing and the balls of the high-revolving-speed bearing, the solid balls and the hollow balls are mounted and arranged between the bearing inner ring and the bearing outer ring in the staggered mode, under the condition that ball supporting force is ensured, even distribution of contact force applied to the bearing inner ring and the bearing outer ring is achieved, abnormal abrasion of the bearing is reduced, and stable operation of the bearing is ensured.

Owner:界首市皖俊轴承有限公司

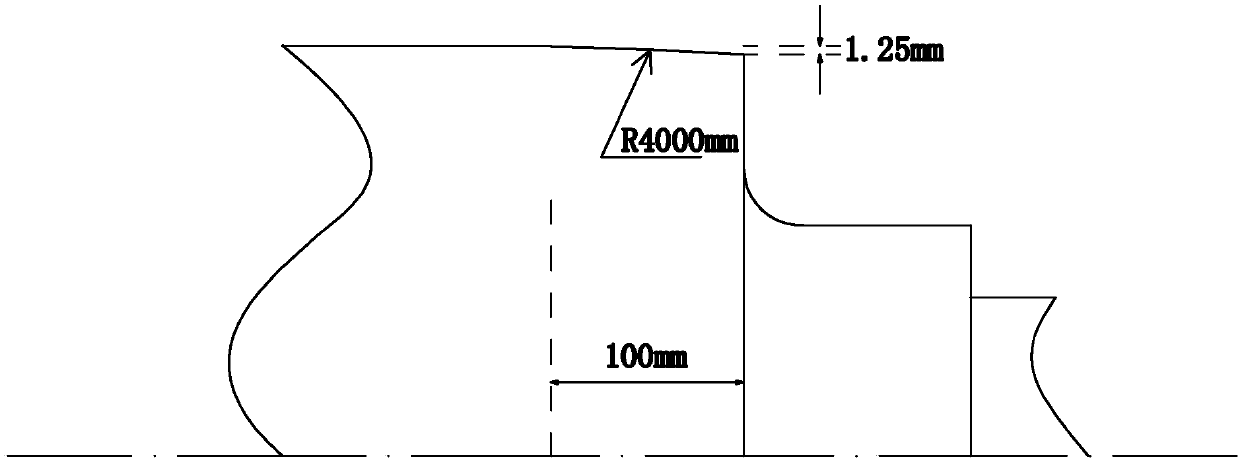

HC six-roller mill middle roller body end chamfer grinding method

ActiveCN109551306AResolve end ring fissuresSolve failure problems such as peelingStress concentrationPulp and paper industry

The invention discloses an HC six-roller mill middle roller body end chamfer grinding method. The method comprises roller body end chamfer structural design and a roller body end chamfer grinding process. In the roller body end chamfer structural design, a roller body end chamfer is designed to be R (3000-5000mm)*(80-120mm), and the unilateral drop is 1-1.5mm; or the roller body end chamfer is designed to be (20-50 degrees)*(30-70mm)+R(800-1200mm)*(30-70mm). In the grinding method, by optimally designing the HC six-roller mill middle roller body end chamfer structure and developing the grinding process matched with the structure, the problem of stress concentration produced by extrusion of a high-hardness working roller on the edge of a low-hardness middle roller can be avoided, therefore,the invalidation problems such as end ring cracking and stripping caused by the fact that the middle roller bears contact fatigue stress in the using process are solved, and abnormal loss of the middle roller is reduced.

Owner:BAOSTEEL ROLL SCI & TECH

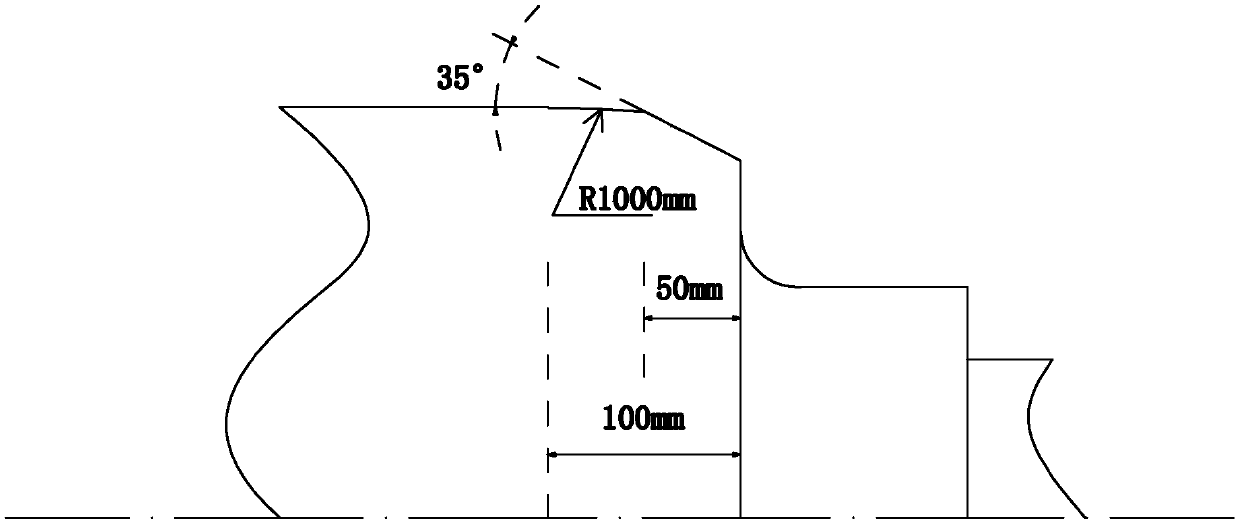

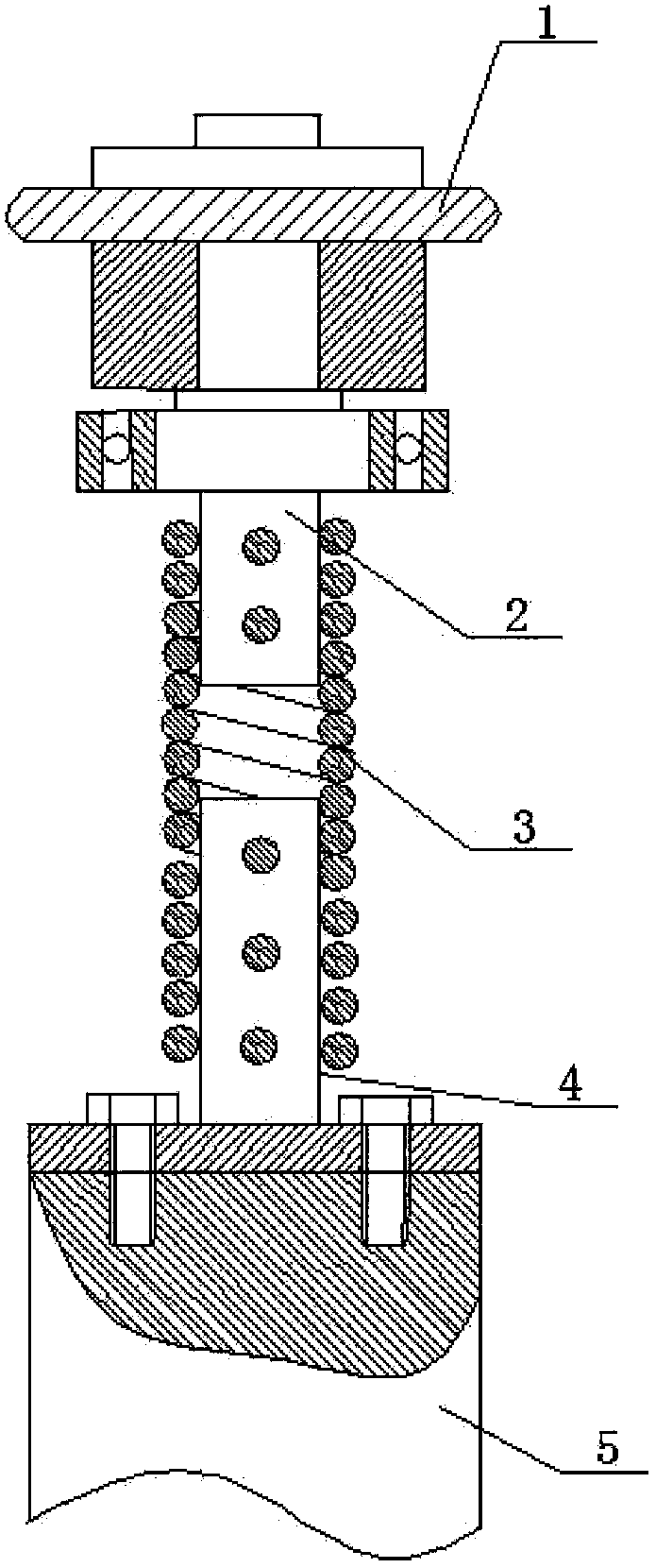

Vibrating-dewatering screen driving mechanism

InactiveCN102974152AImprove sealingReduce abnormal wear and tearEngine sealsMoving filtering element filtersDrive shaftAgricultural engineering

The invention discloses a vibrating-dewatering screen driving mechanism. Two same bearing pedestals are symmetrically and fixedly arranged at an edge opening at the upper part of a screen frame; an eccentric sleeve is fixedly arranged in an inner hole of each bearing pedestal through two bearings; an isolating sleeve is arranged between the two bearings on the outer circle of each eccentric sleeve; a transmission shaft is fixedly arranged in inner holes of the two eccentric sleeves through keys; a bearing pedestal gland is fixedly arranged at the port at each of two ends of each bearing pedestal; a tower-shaped rubber sleeve is fixed at the outer edge opening of each bearing gland through a ring-shaped press plate and a bolt; and a spring pull ring is sleeved on the outer circle of the small head of each tower-shaped rubber sleeve. By the vibrating-dewatering screen driving mechanism, the service life of the bearings and the overall service life of equipment can be prolonged; and furthermore, the vibrating-dewatering screen driving mechanism has the advantages of simple structure, relatively high manufacturing technique, relatively low manufacturing cost and long service life.

Owner:XUZHOU HAILUN AGRI TECH

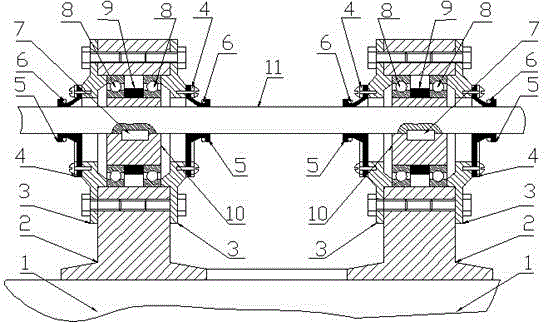

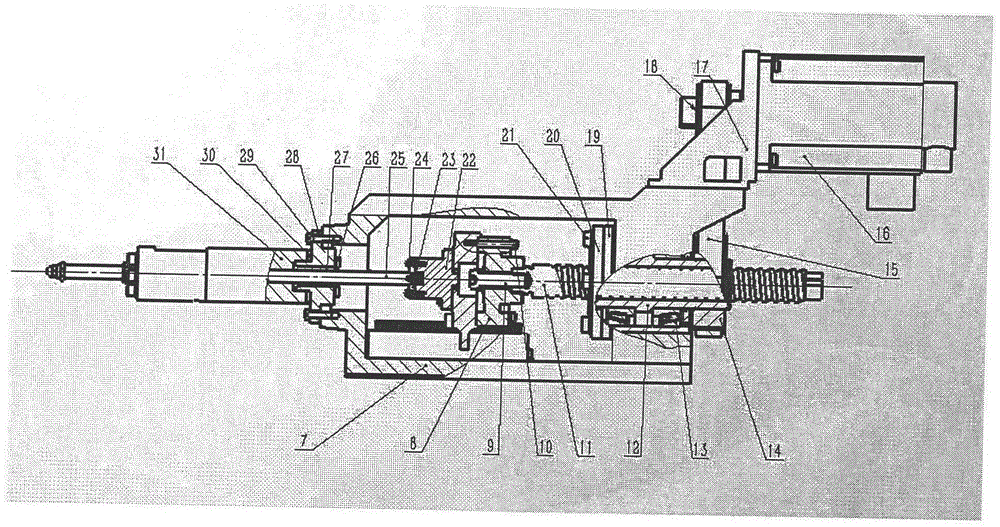

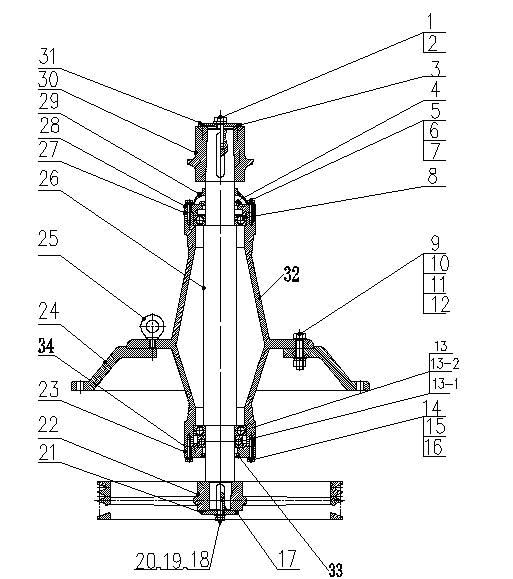

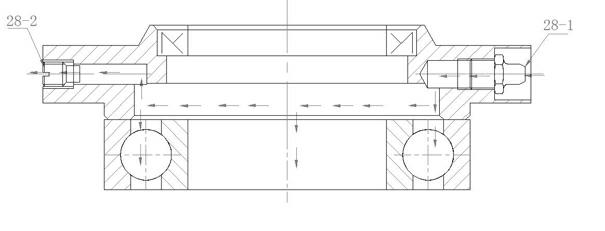

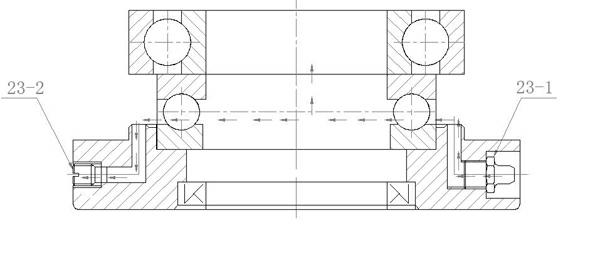

Miniature all-electric injection molding machine injection guide structure

InactiveCN105881812ASolve the accuracy problemSolve the problem of unstable guidance caused by insufficient configurationEngineeringInjection molding machine

The invention discloses a miniature all-electric injection molding machine injection guide structure. The injection guide structure comprises an injection guide plate, sliding block bolts and gaskets, a guide rail sliding block, a guide rail, a guide rail base plate, an injection support, a tension and pressure sensor, an injection screw, a screw nut bearing, a motor belt wheel, an injection synchronous belt, an injection motor, a motor frame, a screw belt wheel, a screw bearing seat, a bearing seat flange, an injection rod base, an injection rod snap joint, an injection rod, a transition guide sleeve, a material pipe flange, a material pipe, an injection advance limiting device and an injection reverse limiting device. The injection guide plate is connected to the guide rail sliding block. The guide rail sliding block fits to the guide rail. The guide rail sliding block slides back and forth on the guide rail along the guide rail. The guide rail is fastened to the guide rail base plate. The guide rail base plate is fixed to the injection support. One end surface of the injection guide plate is connected to the injection rod base. The injection rod base is connected to the injection rod. The injection screw and the tension and pressure sensor are coaxially connected. The end surface and the excircle of the tension and pressure sensor are connected to the injection guide plate.

Owner:BORCH MACHINERY

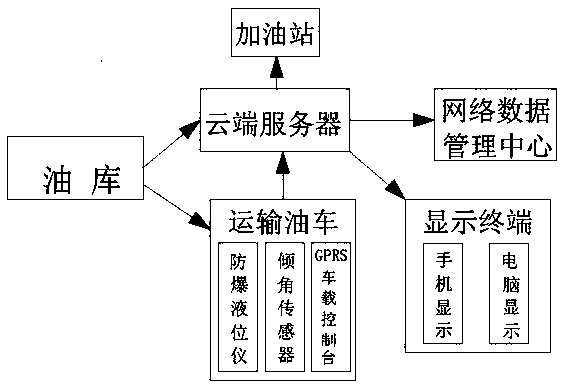

Intelligent control system for oil product transportation

PendingCN110875958AImprove operational efficiencyAvoid human errorMeasurement devicesTransmission systemsPetrol stationOil terminal

The invention relates to an intelligent control system for oil product transportation, and belongs to the technical field of data information control. The intelligent control system for oil product transportation comprises an oil depot, a filling station, an oil transportation vehicle, a cloud server, a display terminal and a network data management center. A GPRS vehicle-mounted console in the oil product transportation intelligent control system collects liquid level, temperature and inclination angle data once at certain time intervals, and transmits the data to a cloud server through GPRS;the control computer can compare the oil distribution quantity of the oil depot with the oil collection quantity of the gas station; a liquid level change curve graph can be generated according to the change of the liquid level instrument in the transportation process; the profit and loss conditions of the bicycle and the single station are automatically compared through big data analysis, auxiliary judgment is provided for managers, and safety risk assessment and early warning prompts are provided for transport vehicles and personnel, so that intelligent management of loss and overflow and safety of an oil product transport link is realized, and the purposes of improving vehicle operation efficiency, reducing abnormal loss and reducing safety risks are achieved.

Owner:PETROCHINA CO LTD +1

Adhesion process for thin PLC wafer and cover plate

InactiveCN110459480AReduce dosageReduce abnormal wear and tearSemiconductor/solid-state device manufacturingAdhesion processGlass cover

The invention provides an adhesion process for a thin PLC wafer and a cover plate. The adhesion process comprises the steps that S1 the wafer is placed on the base of an adhesive jig; S2 UV glue including cyanoacrylate molecules is dispensed in the middle of the wafer through a syringe; S3 a quartz glass cover with a thickness of 1mm gently covers the wafer after step S2; S4 the upper cover of theadhesive jig presses the wafer after step S3, and the upper cover needs to be aligned with a positioning hole in the adhesive jig, and fixing bolts around the adhesive jig are tightened tightly; S5 standing and waiting for 15min are carried out; S6 after 15min, whether the glue under the cover spreads to the edge of the wafer and overflows is observed; S7 the upper cover is removed, and the waferis removed; and S8 the wafer is put into an exposure box and fully exposed for 15min, and the UV glue is cured. According to the invention, defective products can be effectively reduced; the production efficiency is improved; abnormal wear of a blade and the wafer can be reduced; and the amount of production consumables is reduced.

Owner:无锡天创光电科技有限公司

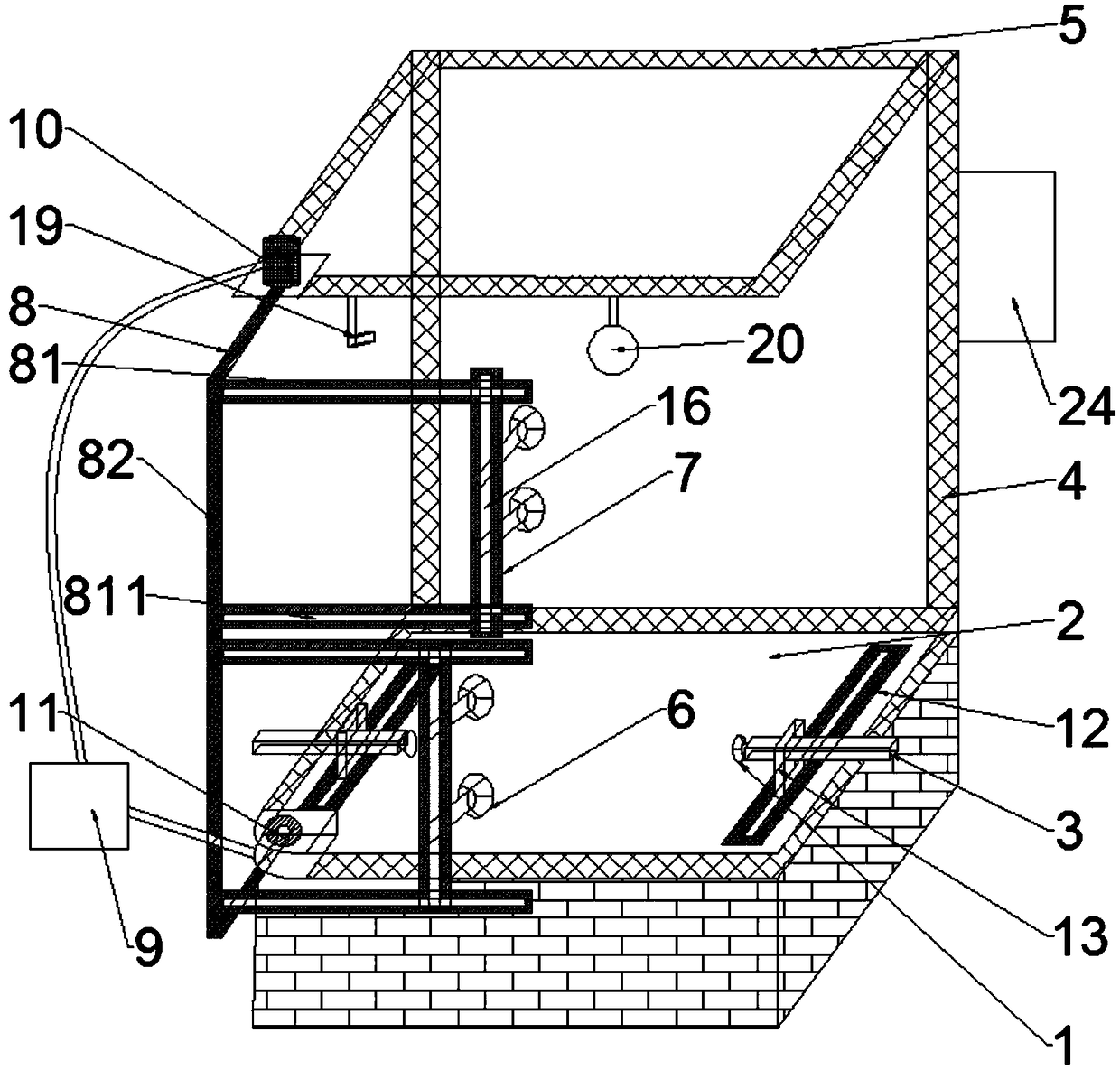

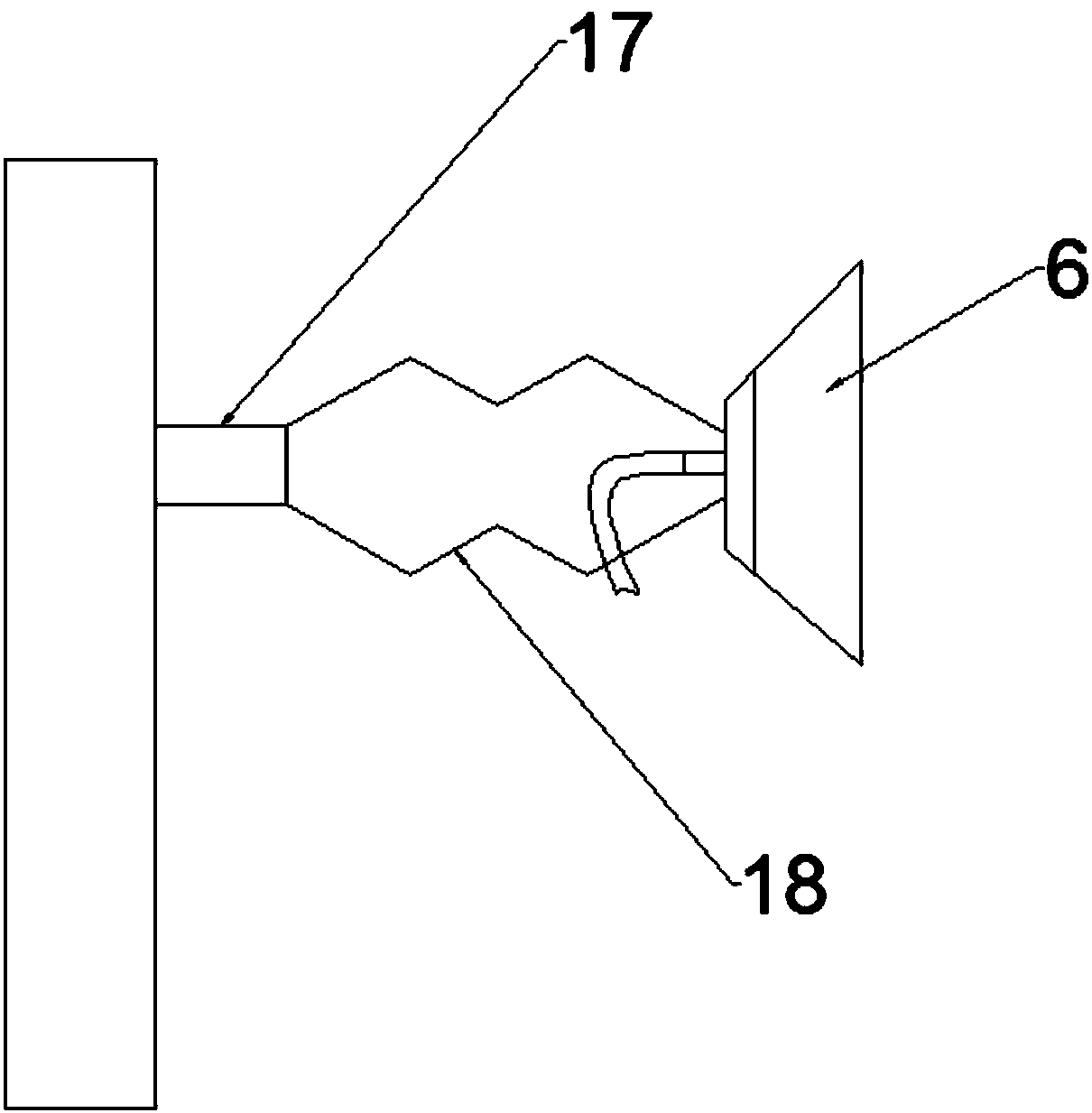

Spray pipe detection device

PendingCN111649922AAvoid overload damageAvoid damageMachine part testingFluid pressure measurementEngineeringSafety valve

The invention relates to the technical field of spray pipe machining, in particular to a spray pipe detection device which comprises: a base, wherein a liquid through hole is formed in the base, the liquid through hole is connected to a pressure detection meter and a safety valve, and the liquid through hole comprises a liquid inlet end and a liquid outlet end; and a spray pipe fixing mechanism which is arranged in the liquid outlet direction of the liquid through hole. The base is provided with the liquid through hole; liquid supply equipment and a tested spray pipe are respectively connectedto two ends of a liquid through hole; pressurized liquid provided by liquid supply equipment flows through the liquid through hole and enters the spray pipe to be sprayed out. In the testing process,the liquid pressure of the liquid through hole is monitored in real time through the pressure detection meter, whether the liquid pressure in the liquid through hole is increased due to blockage of the spray pipe or not is judged, overload protection is achieved through the safety valve when the pressure in the liquid through hole is too large, and liquid supply equipment operation overload damage caused by blockage of the spray pipe or a poor structure is prevented.

Owner:深圳海卓科赛医疗有限公司

Speed reducer used for cooling tower

The invention relates to a speed reducer used for a cooling tower. The speed reducer used for the cooling tower comprises a box body, a base and a transmission main shaft, wherein the base is flange-shaped and is connected with the box body detachably; the top of the base serves as an upper bearing seat; a ball bearing is arranged in the upper bearing seat; the upper bearing seat is fixed by an upper end cover; the bottom of the base serves as a lower bearing seat; a lower bearing is arranged in the lower bearing seat; the lower bearing seat is fixed by a lower end cover; the transmission main shaft is installed and positioned in the box body of the speed reducer through the upper ball bearing and the lower bearing; and the upper end and the lower end of the transmission main shaft penetrate out of the box body, wherein the lower end of the transmission main shaft is connected with a V-belt pulley and the upper end of the transmission main shaft is connected with a fan hub. In the speed reducer used for the cooling tower, the box body, the upper bearing seat and the lower bearing seat are in an integrated casting structure, and the upper bearing seat and the lower bearing seat have very good coaxiality, so that the installation and the self-centering of the upper bearing and the lower bearing are facilitated; therefore, the accuracy of the center position of the main shaft of the speed reducer is ensured; vibration and abnormal abrasion caused by the eccentricity of the main shaft are reduced; and the safe and stable operation of the speed reducer is ensured.

Owner:南京大洋冷却塔股份有限公司

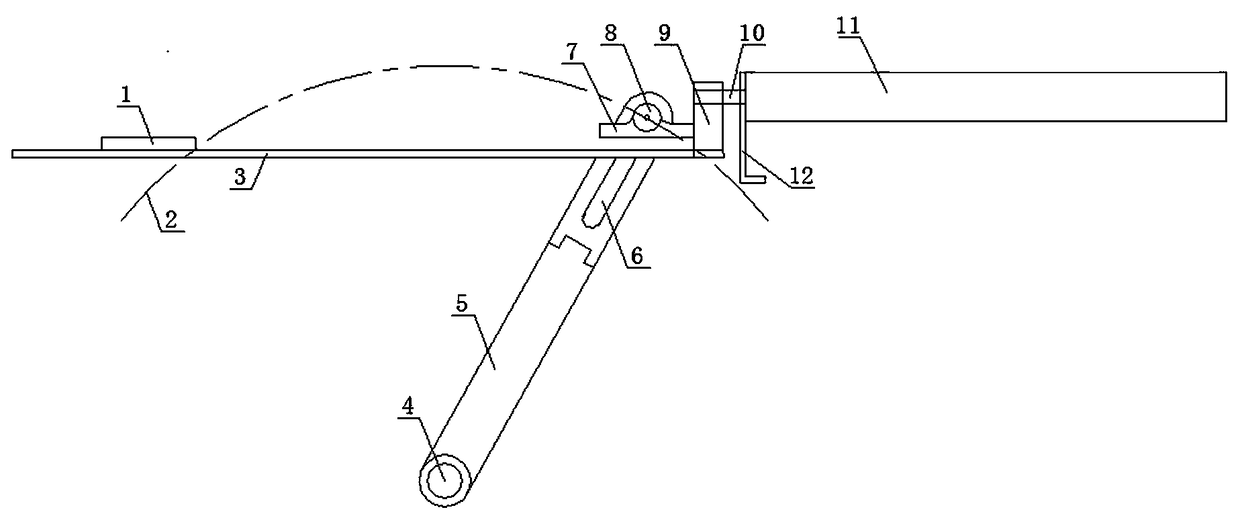

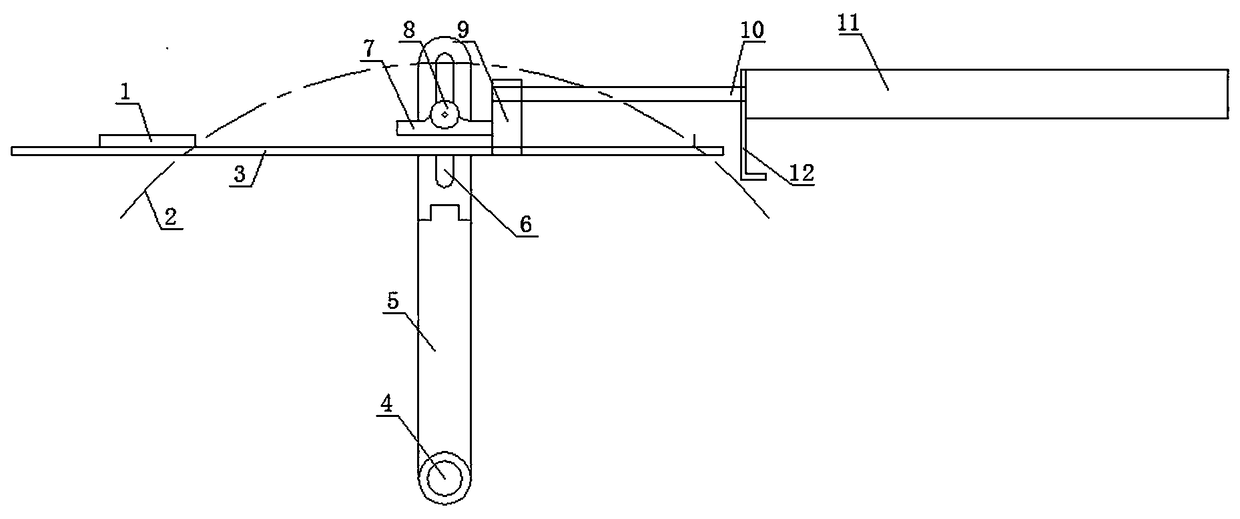

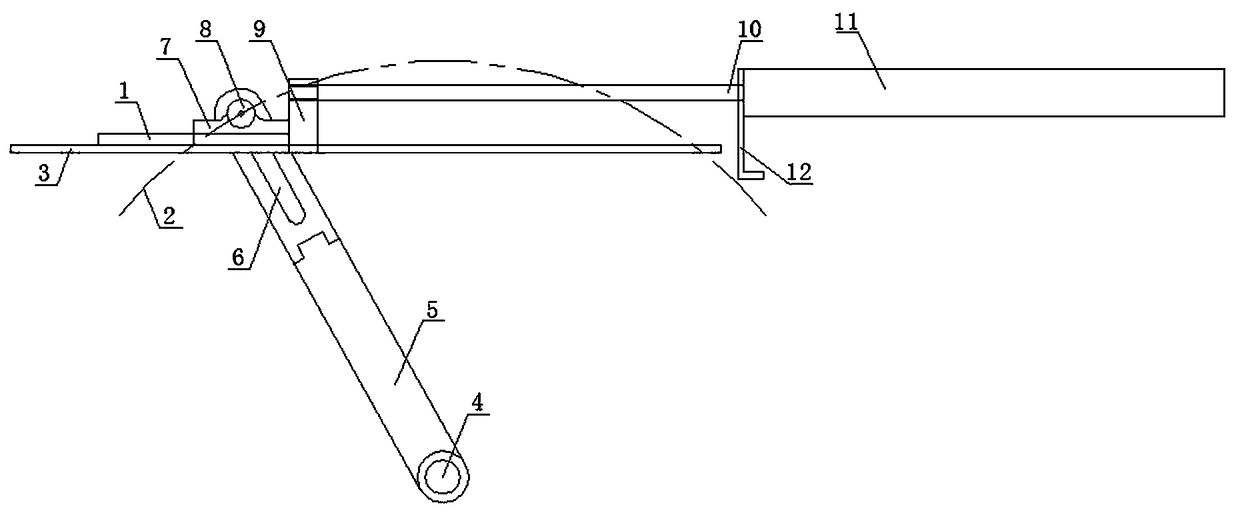

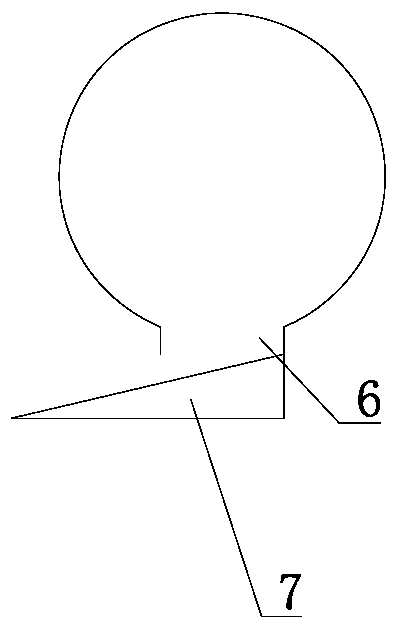

Linear pneumatic drive device for overturning platform

PendingCN108892093AReduce abnormal wear and tearExtend the life cycleGearingLifting devicesRocker armPiston rod

The invention discloses a linear pneumatic drive device for an overturning platform. The linear pneumatic drive device comprises a rocking arm and a horizontal double-sliding-rod linear guide rail, asleeve is arranged at the lower end of the rocking arm and used for connecting with a hinge shaft flat key of the overturning platform, a central axis direction of the sleeve is perpendicular to thatof the rocking arm, a slider mechanism is slidably connected on the double-sliding-rod linear guide rail, a cylinder is fixed with one end of the double-sliding-rod linear guide rail, a piston rod ofthe cylinder is arranged along the sliding direction of the slider mechanism and fixedly connected with the slider mechanism, a cylinder body cannot vertically and frequently swing in the overturningprocess of the overturning platform and the extending and contracting process of the piston rod, abnormal abrasion of a sealing ring of the piston rod is reduced, and the service life of the cylinderis prolonged. Use shows that overall running is more stable, the stroke of the cylinder can be controlled, and positioning is more accurate.

Owner:CHINA TOBACCO HENAN IND

A kind of preparation method of biomass fuel and its special equipment

InactiveCN105623772BReduce abnormal wear and tearRaise the ratioBiofuelsSolid fuelsBiofuelPulp and paper industry

The invention provides a preparation method of biomass fuel and special equipment thereof, which solves the technical problems of wasting resources of dryers, low production efficiency and environmental pollution in the prior preparation method of biomass fuel. Mix wood and straw; crush the above raw materials into granules; send the granules to a wood slag dryer for removing hard impurities and dry them; send the dried materials to an extruder for extrusion to obtain raw Material fuel; the wood residue dryer for removing hard impurities is equipped with a heating chamber, a feeder, a drying cylinder and an exhaust fan, one end of the drying cylinder is connected to the heating chamber, and the other end is connected to the dryer; the drying cylinder There is a feeder on the top, a waste discharge hole is provided at the discharge end, a waste discharge pipe is provided below the waste discharge hole, and a waste discharge rack is provided below the waste discharge pipe. The invention can be widely used in the field of biomass fuel preparation.

Owner:WEIHAI BIYUNTIAN ENERGY TECH CO LTD

Novel transmission mechanism of cutting machine tool

InactiveCN103447871ASimple structureReduce abnormal wear and tearMetal working apparatusDrive shaftSprocket

The invention discloses a novel transmission mechanism of a cutting machine tool. The novel transmission mechanism is characterized in that a transmission sprocket is concentrically mounted on a transmission sprocket shaft, the tail of a transmission crankshaft is concentrically mounted on a rotary transmission shaft, and the transmission sprocket shaft is connected with the rotary transmission shaft by a magnetic steel elastic shaft. The novel transmission mechanism in the structural mode is provided with the rotary transmission shaft, the magnetic steel elastic shaft is additionally arranged on the rotary transmission shaft, two transmission mechanisms are mutually compensatory, and accordingly the integral novel transmission mechanism has the advantages of simple structure, little abnormal abrasion, good service effect and long service life.

Owner:XUZHOU KAILONG MINING SCI & TECH DEV

Diamond-like carbon composite molybdenum disulfide nano multilayer film and method for preparing same

ActiveCN102994947BReduce frictionImprove bearing capacityVacuum evaporation coatingSputtering coatingCarbon compositesDiamond-like carbon

The invention discloses a diamond-like carbon composite molybdenum disulfide nano multilayer film and a method for preparing the same. A double-target magnetron sputtering technology is adopted to alternatively deposit diamond-like carbon layers and molybdenum disulfide layers on a stainless steel base, so that the diamond-like carbon composite molybdenum disulfide nano multilayer film is obtained, wherein the thickness of a single diamond-like carbon layer is between 10 and 100 nanometers, the thickness of a single molybdenum disulfide layer is between 10 and 100 nanometers, and the total thickness of the diamond-like carbon composite molybdenum disulfide nano multilayer film is between 1.5 and 6 micrometers. By the prepared nano multilayer film, the wearing life defect and the problems of friction coefficient environment sensitivity of the molybdenum disulfide layer are improved, moreover, the problems of large brittleness, poor toughness and the like of a hard diamond-like carbon film are solved, so that the wear rate of the nano multilayer film in high vacuum environments is reduced by 1-2 orders of magnitude compared with the wear rate of a conventional molybdenum disulfide or diamond-like carbon film, and the perfect matching of ultralow friction and high hardness and toughness is realized.

Owner:徐州睿创智能科技有限公司

Method for improving cohesive strength of matrix and body of bead string

ActiveCN103231137BExtend your lifeInhibit sheddingMetal sawing tool makingWelding/cutting media/materialsHydrogenShielding gas

Owner:长沙百通新材料科技有限公司

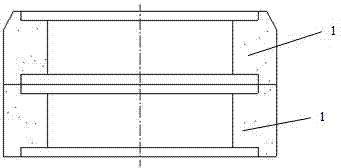

High-temperature and high-pressure kettle transition vehicle for laminated glass

ActiveCN104291009AImprove work efficiencyLess investment in equipmentExternal framesDamagable goods packagingEngineeringHigh pressure

The invention discloses a high-temperature and high-pressure kettle transition vehicle for laminated glass. The high-temperature and high-pressure kettle transition vehicle comprises a vehicle chassis. The four corners of the bottom of the chassis are each provided with a side supporting frame. The side supporting frames are connected with transverse supporting beams and longitudinal supporting beams. Bearing pedestals are arranged at the lower portions of the transverse supporting beams and located on the side supporting frames. Each bearing pedestal is provided with a connection shaft matched with the inner ring of a bearing, the two ends of the connection shafts are matched with inner holes of the bearings, mobile wheels capable of rotating along with the connection shafts are arranged at the two ends, close to the corresponding side supporting frames, of the connection shafts, the mobile wheels are matched with guide rails laid on the horizontal plane, a power transmission structure is arranged on the portion, on one side of each transverse supporting beam, of the chassis, and the power transmission structures drive the connection shafts and the mobile wheels to rotate and drive the transition vehicle to move along the guide rails. A speed reducer is used for driving a gear to operate, a front gear and a rear gear can move on the guide rails front and back, the vehicle can be operated by a single person, time and labor are saved, convenience, safety and high efficiency are achieved, working efficiency is improved greatly, and the high-temperature and high-pressure kettle transition vehicle can be used by multiple high-pressure kettles.

Owner:SHANDONG WENSHENG GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com