Rice milling grinding wheel and preparation method thereof

A grinding wheel and raw material technology, applied in the field of rice milling grinding wheel and its preparation, can solve the problems of short service life, consumption of national resources and high cost, and achieve the effects of reducing abnormal wear, reducing environmental pollution and enhancing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

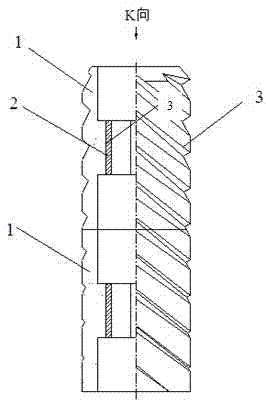

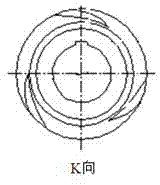

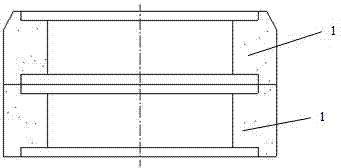

Image

Examples

preparation example Construction

[0036] The specific implementation of the preparation method of the rice milling wheel proposed in the present invention sequentially includes the following steps:

[0037] 1) Weigh the abrasive, new phenol resin, liquid phenol resin, epoxy resin, dibutyl ester and hemihydrate gypsum powder according to the proportion. The proportion of each raw material is as follows:

[0038] 100 parts by weight of abrasive,

[0039] New phenol resin 1~50 parts by weight

[0040] 2-60 parts by weight of liquid phenolic resin,

[0041] 0.5-40 parts by weight of epoxy resin,

[0042] 1-10 parts by weight of dibutyl ester,

[0043] Hemihydrate gypsum powder 0.5 to 80 parts by weight.

[0044] 2) Mix the weighed raw materials to obtain molding materials, specifically:

[0045] Firstly, liquid phenolic resin, epoxy resin and dibutyl ester are mixed to obtain a binder mixture; then the binder mixture is mixed with abrasive; then new phenol resin is added for mixing; finally, hemihydrate gypsum powder is added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com