Patents

Literature

547results about How to "Evenly combined" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

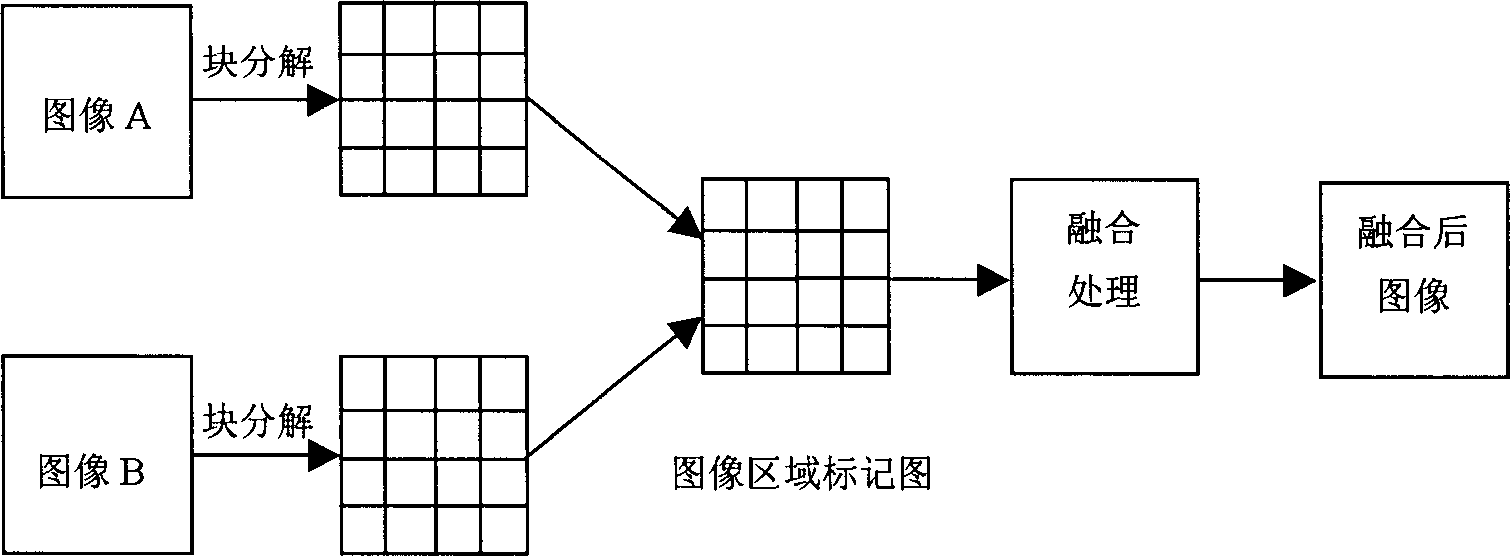

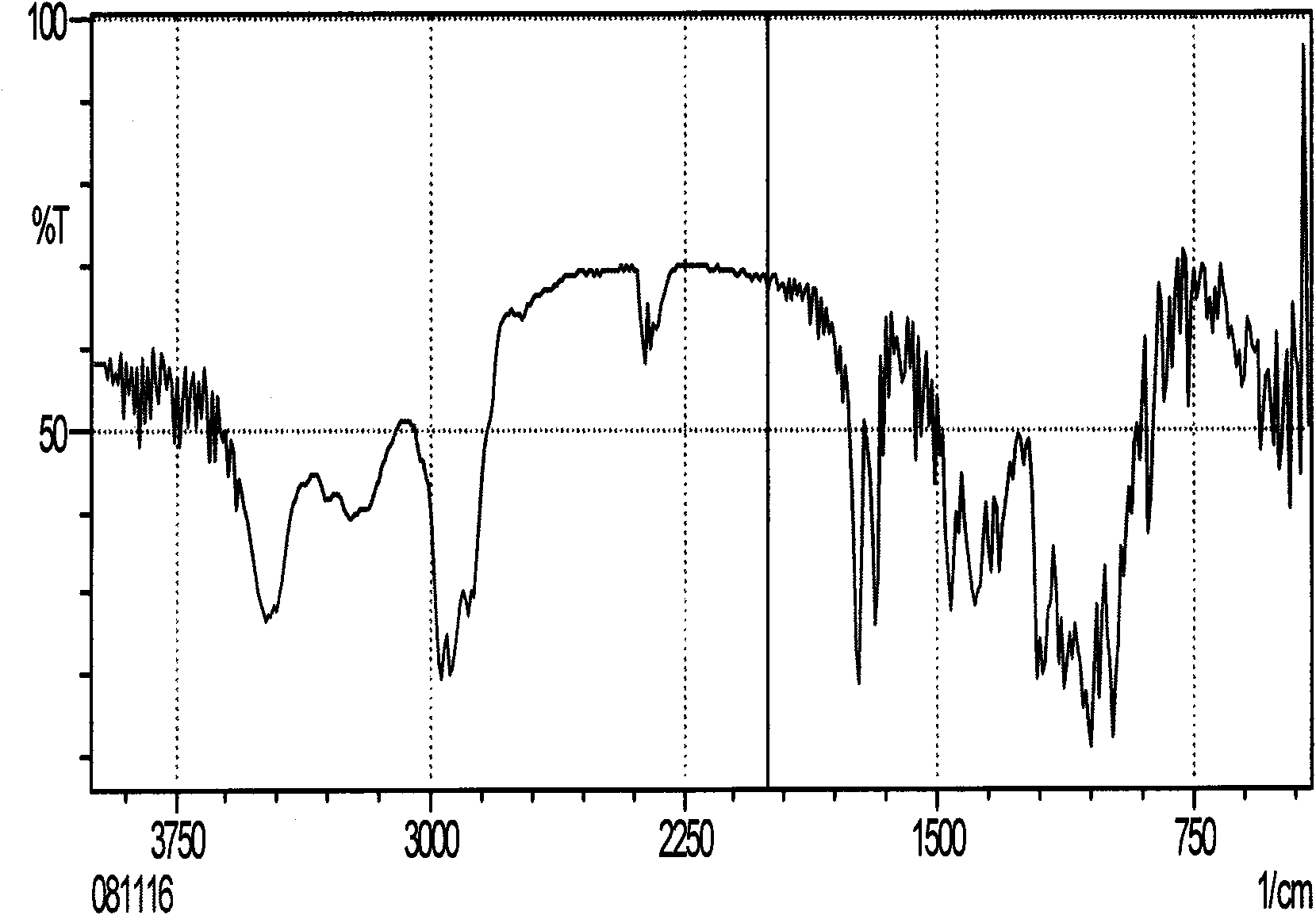

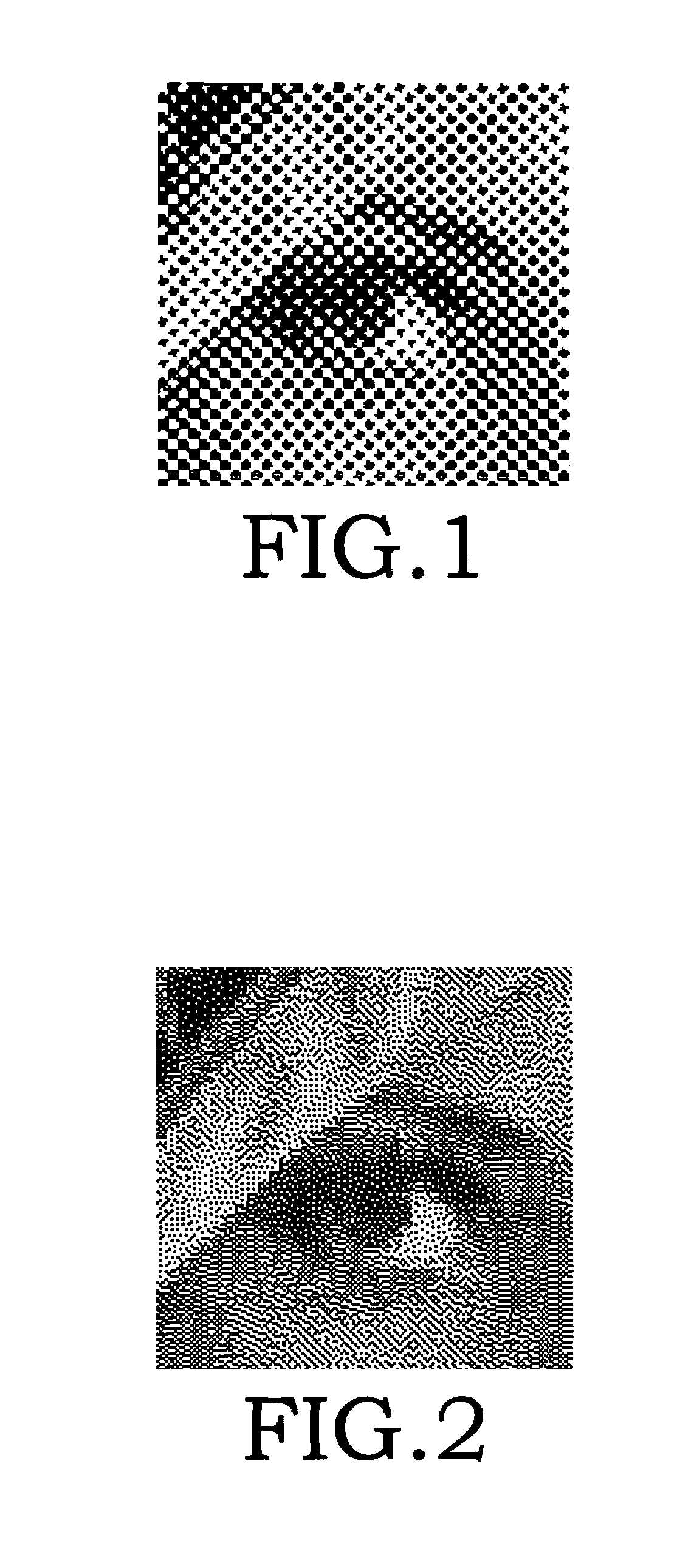

Multiple focussing image fusion method based on block dividing

InactiveCN1402191APreserve edge informationIdeal Fusion ResultsImage analysisImaging qualityImage segmentation

A method based on block division for the fusion of multiple focused images includes dividing the original focused images into blocks with same sizes, finding out the local contrast of each block to reflect the difference between clear focusing area and fuzzy focusing area, dividing an image into clear region and fuzzy region, defining the blocks adjacent to the clear region and fuzzy region as boundary region, expressing said three regions, directly using the clear region as the fused region and using pixel fusion method to fuse the boundary region. Its advantage is high image quality.

Owner:SHANGHAI JIAO TONG UNIV

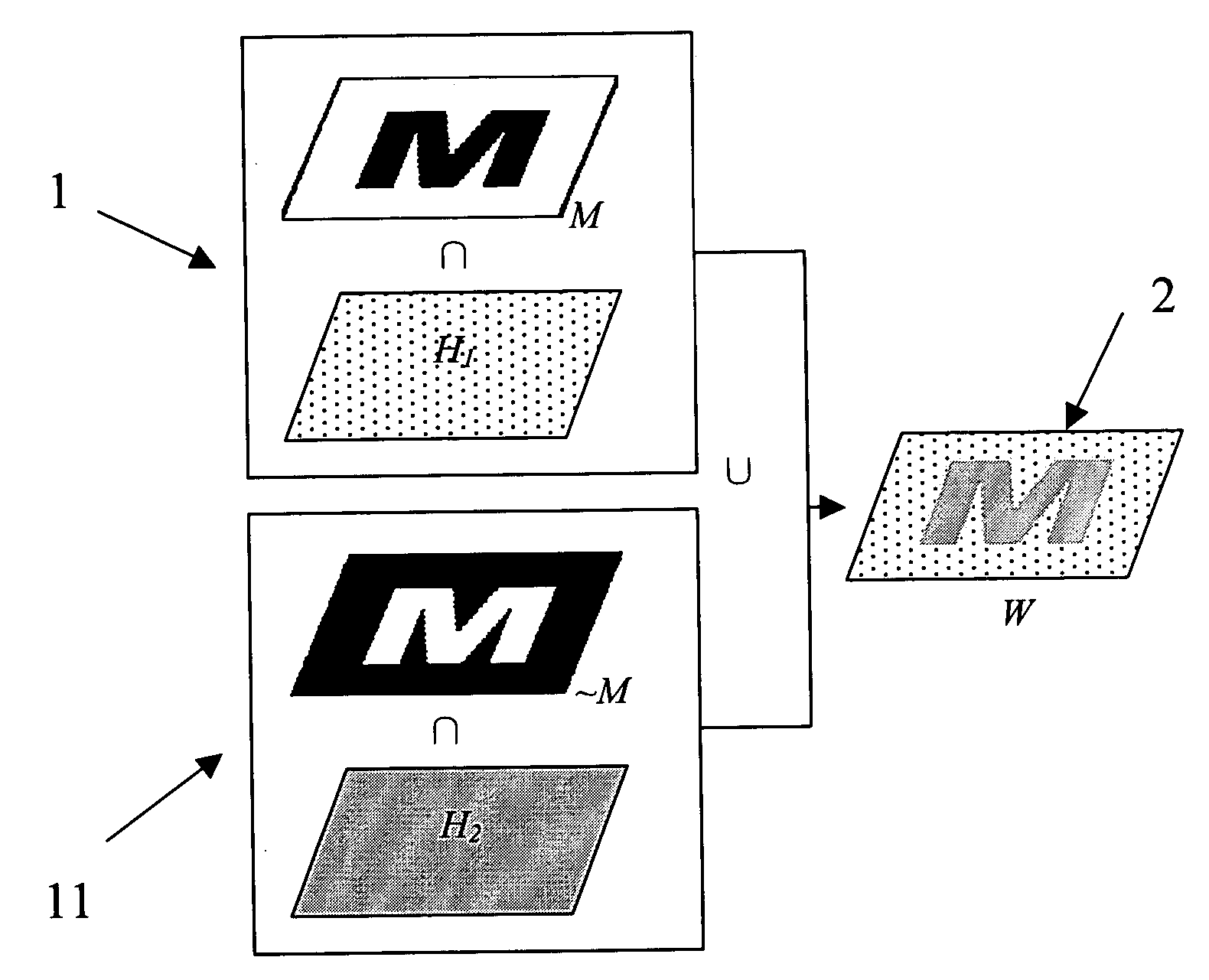

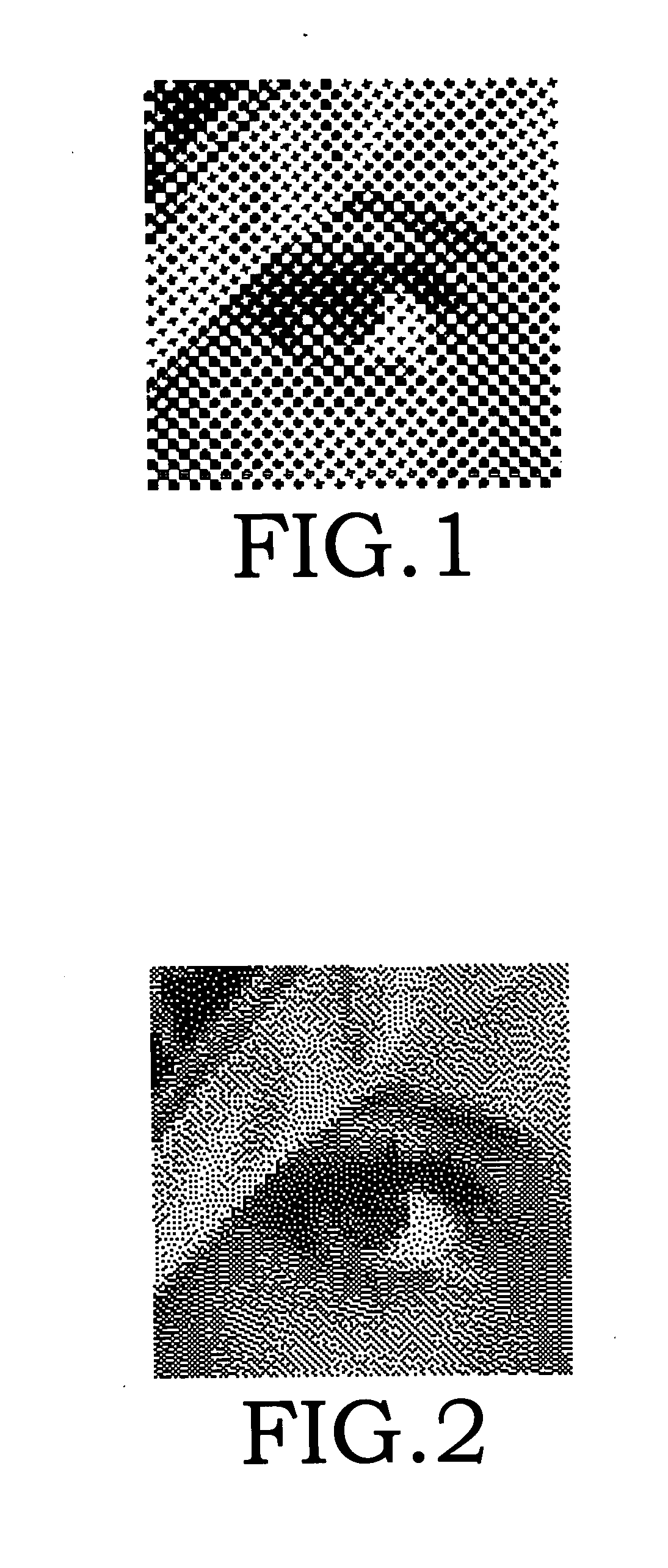

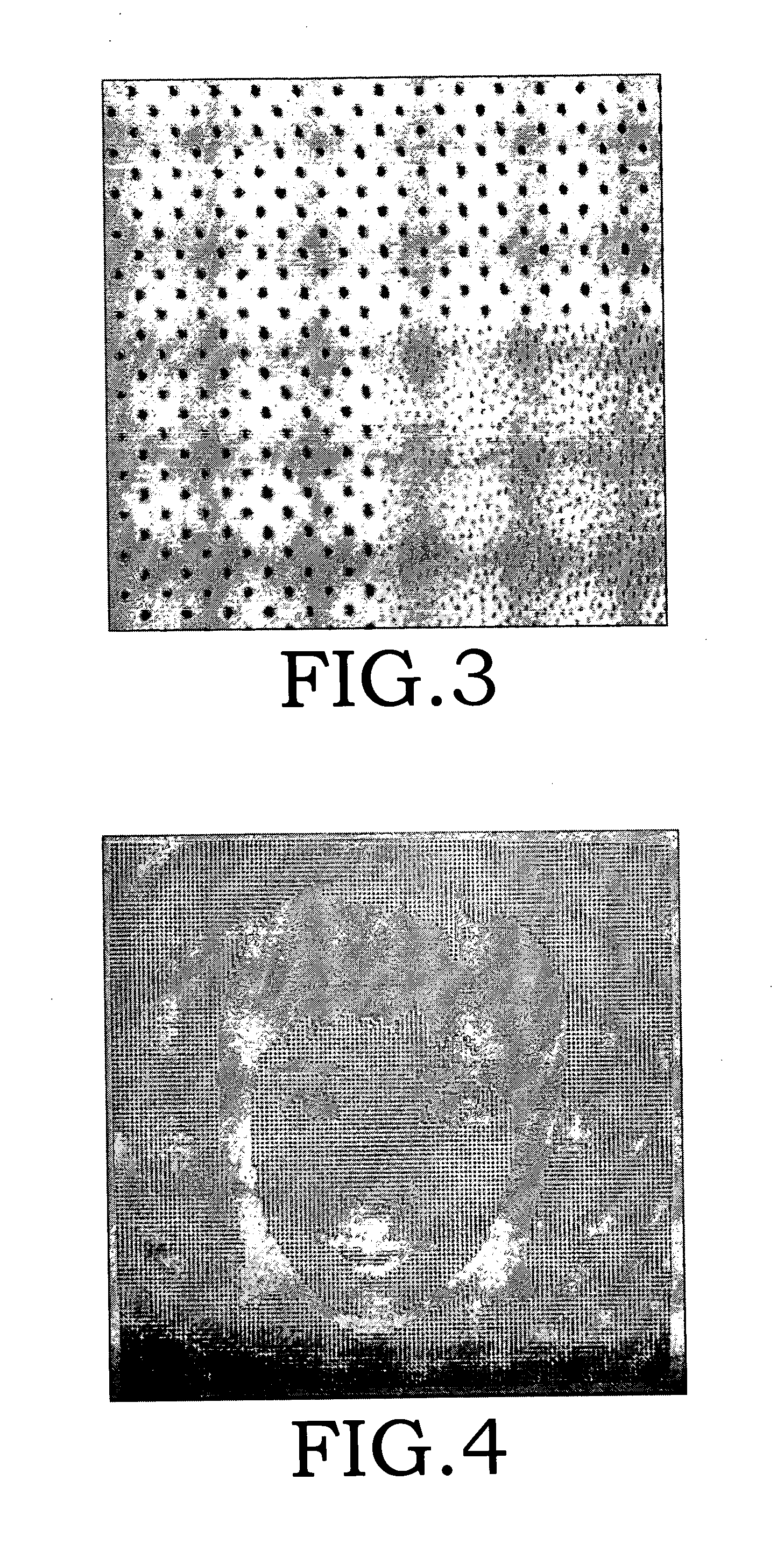

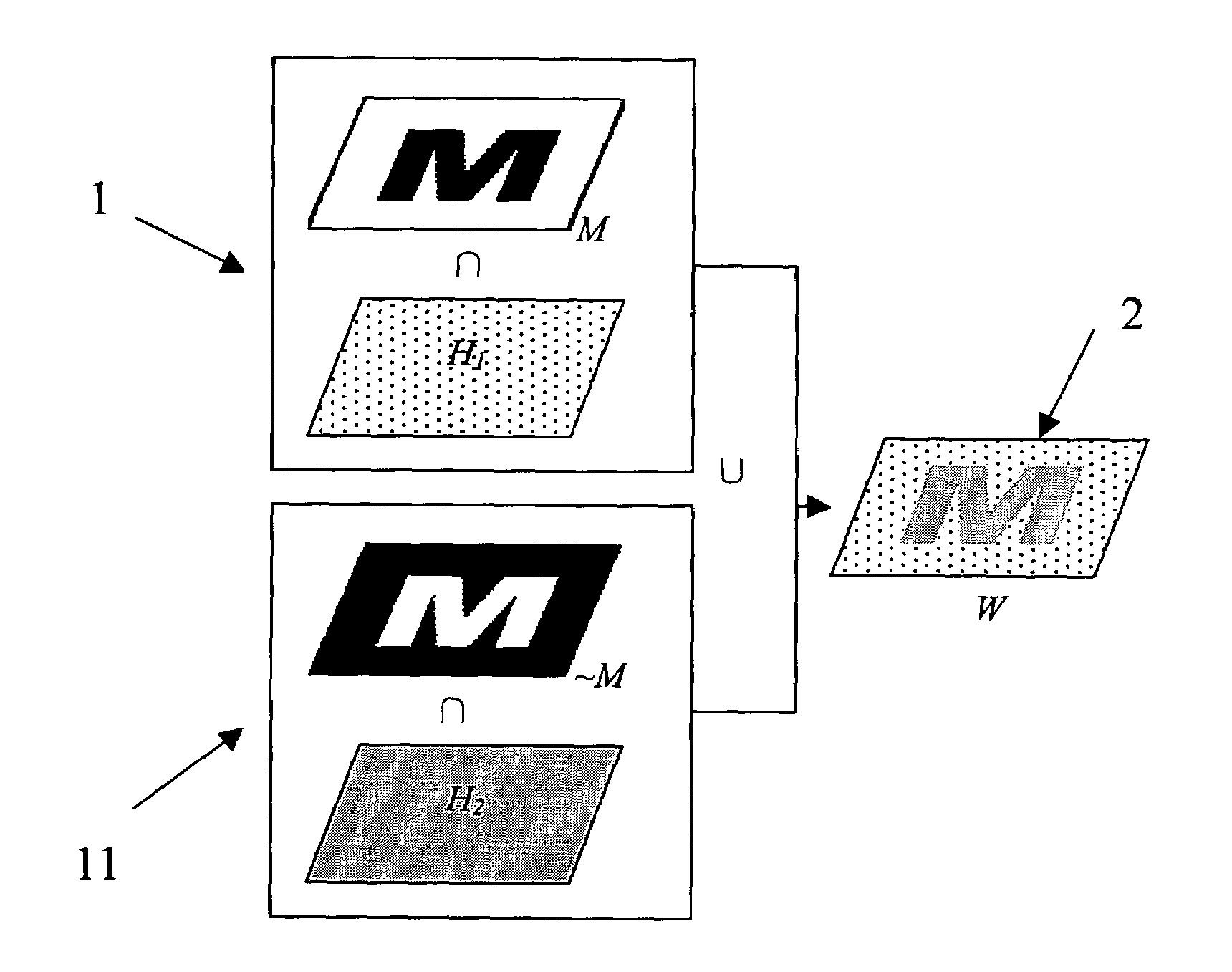

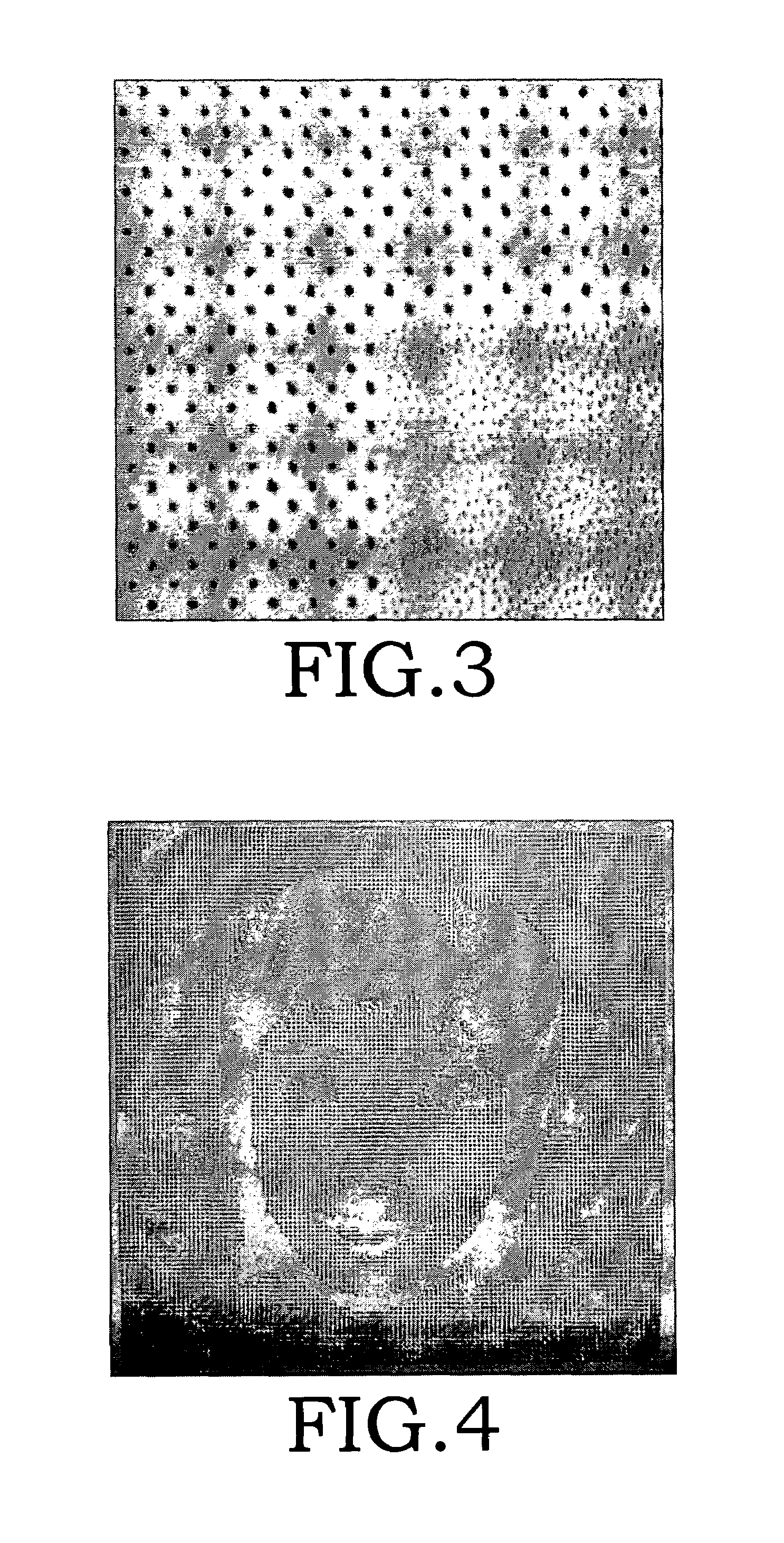

Method of watermark with hybrid halftone dots

ActiveUS20060170974A1Reducing invisibility effectEasy to produceVisual presentationPictoral communicationOptical scannersHue

A method of watermark with hybrid halftone dots that is suitable for a printed shadow image. The watermark patterns that are composed of amplitude modulation (AM) and frequency modulation (FM) halftone dots (their concentration has been calibrated) cannot be perceived beyond a certain distance by the human eye. This is done through outputting the density calibration chart to choose the proper density parameters, which are applied to the manufacture process of the watermark with hybrid halftone dots. The hidden patterns of a watermark need to be pre-processed first, and thereby making the image blocks of AM and FM halftone dots to be combined smoothly. The copy machine, the lenticular lens and the optical scanner can detect the hidden watermark in the printed shadow image. Each secured document possesses a different serial number to achieve the document-version control.

Owner:NATIONAL TAIWAN NORMAL UNIVERSITY

Adsorption method for preparing hydroxyapatite pesticide and slow-release fertilizer compound

InactiveCN101589709AHas biodegradable propertiesQuality improvementBiocideAnimal repellantsBurst effectPhosphate

The invention discloses an adsorption method for preparing hydroxyapatite pesticide and slow-release fertilizer compound, which comprises the following steps: soaking a nano hydroxyapatite carrier in phosphate buffer solution, then adding a starting material into the buffer solution and continuously stirring the mixture to form compound solution, finally centrifuging the compound solution to obtain sediment, and drying the sediment to obtain the compound. By using a porous structure of the nano hydroxyapatite self to embed medicaments into an internal grid of the carrier, the burst effect of the medicaments is avoided, the medicinal effect is long, the medicament residue is greatly reduced, and the medicaments are safer. A product obtained by using the nano hydroxyapatite as a pesticide and fertilizer carrier has the advantages of reliable quality, strong stability, safe use and low cost, greatly improves the medicament loading amount and adsorption amount, is easy for continuous production, and has good application prospect.

Owner:JILIN UNIV

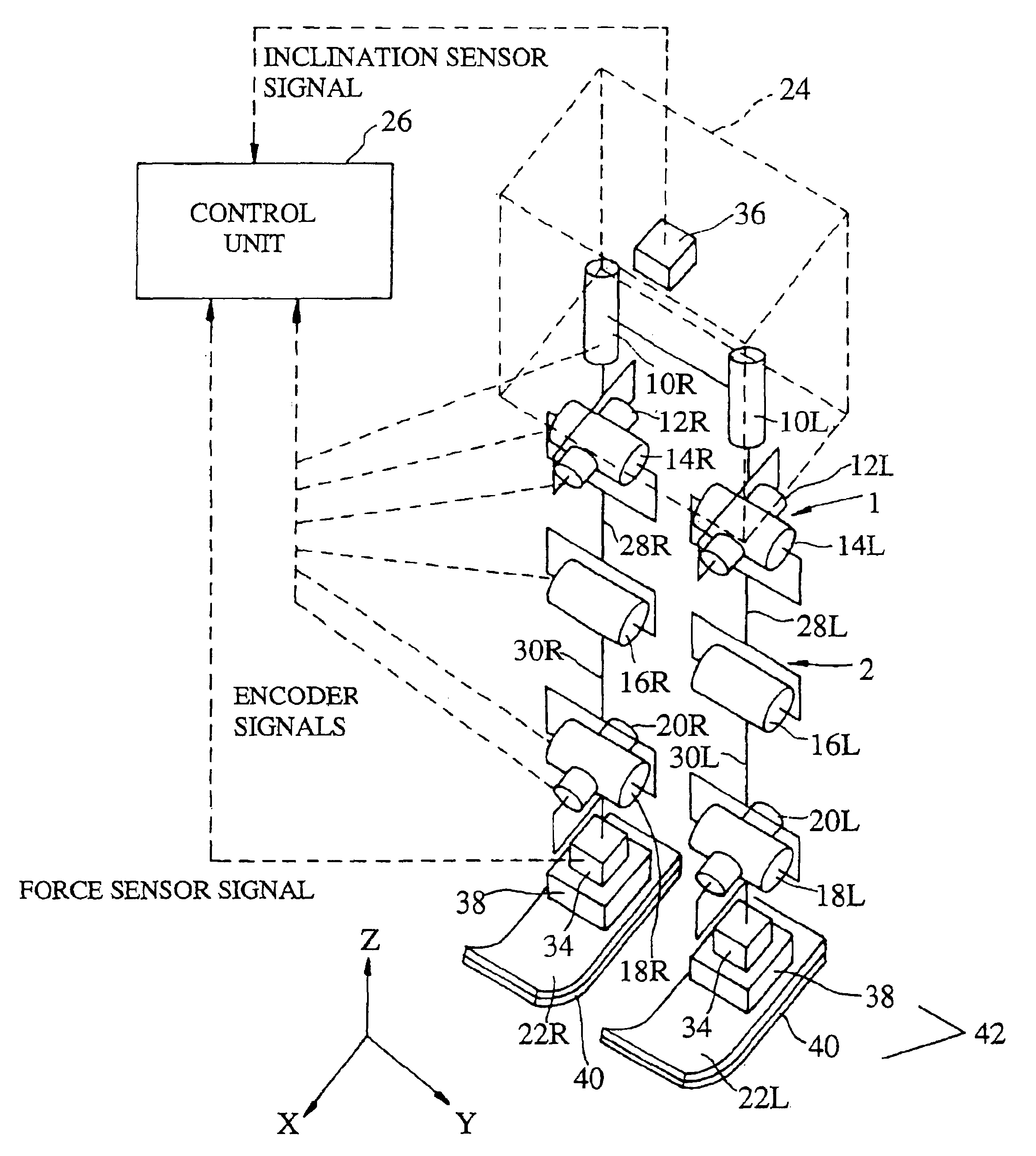

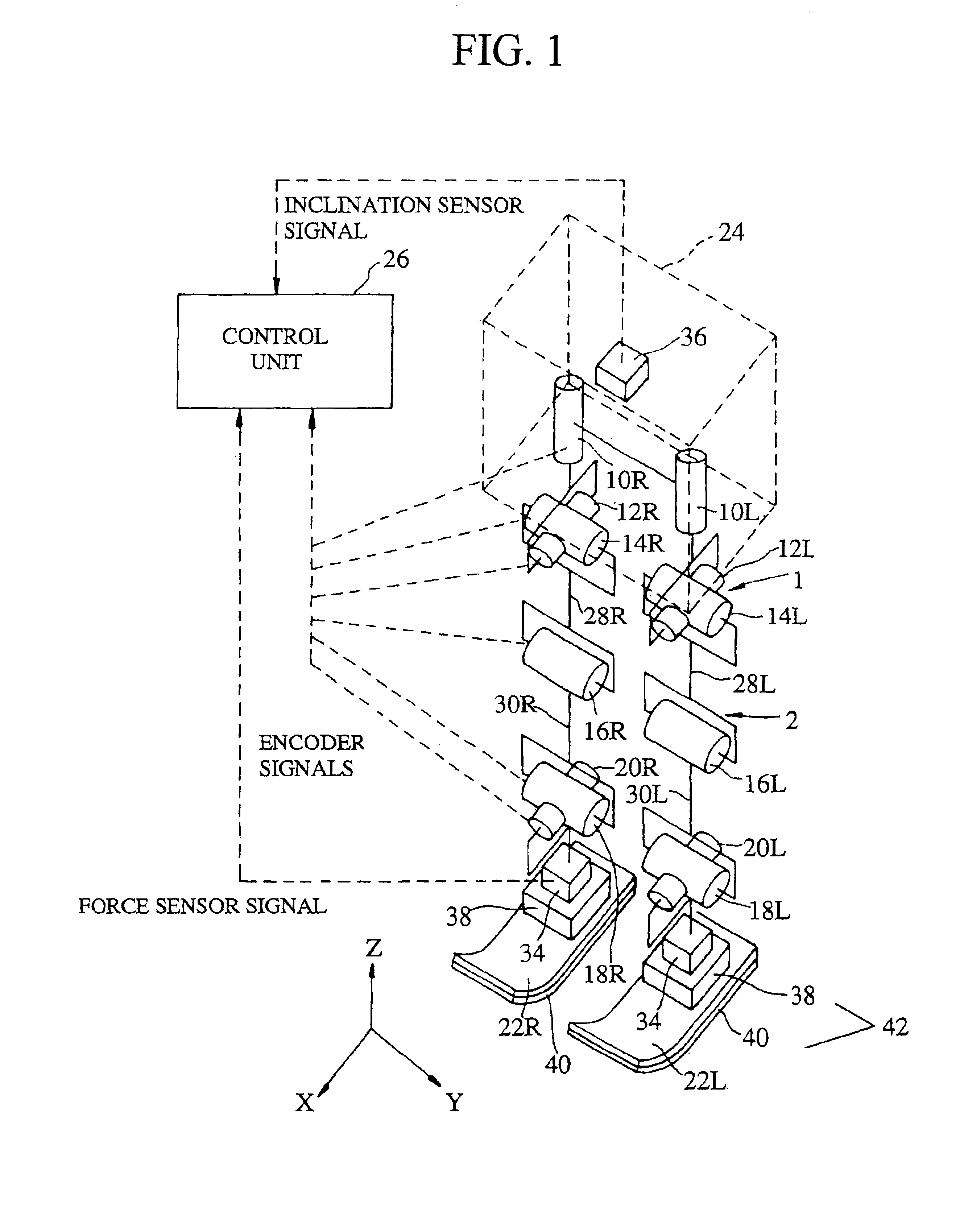

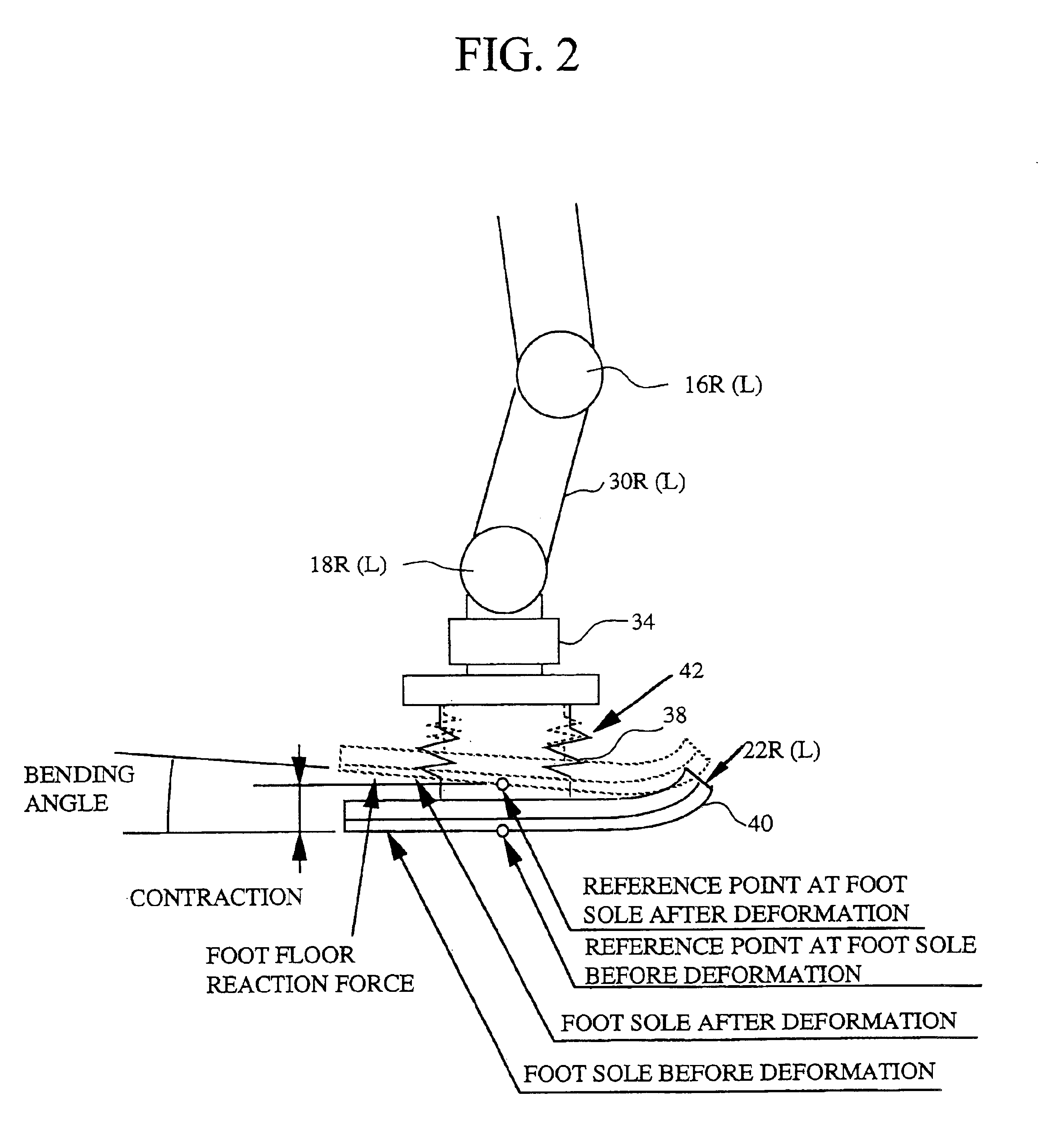

Gait pattern generating device for legged mobile robot

InactiveUS6876903B2Drawback can be obviatedEvenly combinedProgramme-controlled manipulatorComputer controlTurn angleDynamic models

A gait generation system of a legged mobile robot, in particular a biped robot that has the dynamic model expressing the relationship between the motion of the body and leg and the floor reaction force, and provisionally determines the current time gait parameters including at least parameters that determine leg trajectory and the like in response to a demand, supposes the parameters of a periodic gait, corrects the current time gait parameters such that the body trajectory determined from the dynamic model and the parameters of the current time gait, etc., converges to a body trajectory determined from the parameters of the periodic gait, and determines instantaneous values of the current time gait based on the corrected current time gait parameter. With this, the system can generates a gait of any stride, turning angle and walking period, including the floor reaction force acting on the legged mobile robot, that satisfies the dynamic equilibrium condition. Further, the system can generates a gait in such a manner that the displacement and velocity of each robot part are continues at the boundary of the generated gait and that succeeding thereto, can generate a gait that is high in the margin of stability, can predict future behavior of the robot and generate a gait such that no disadvantages such as posture divergence occurs.

Owner:HONDA MOTOR CO LTD

Multi-element nitralloy material and preparation method and application thereof

The invention discloses a multi-element nitralloy material and a preparation method and application thereof and belongs to the technical field of alloy material development. The multi-element nitralloy material comprises 9-48% of V, 13-45% of Si, 0.05-9% of Mn, 3.3-14% of Fe, 15-30.5% of N, 0.01-5.0% of Cr, 0.06-2.0% of Al, 0-7.0% of Ti, 0-6.5% of B, 0-4.5% of Nb, 0-1.8% of C, 0-0.1% of P, and 0-0.1% of S. According to the multi-element nitralloy material and the preparation method and application thereof, the content of nitrogen in the alloy can be effectively controlled to be within a reasonable range according to different combining capacities of various elements and the nitrogen; meanwhile, the content of the nitrogen can be adjusted within a wider range according to requirements of practical purposes, and great convenience is provided for a molten steel microalloying reinforcing technique; safety and environmental friendliness are achieved in the preparation and using process, and no smoke or dust or odor is generated.

Owner:马鞍山中科冶金材料科技有限公司

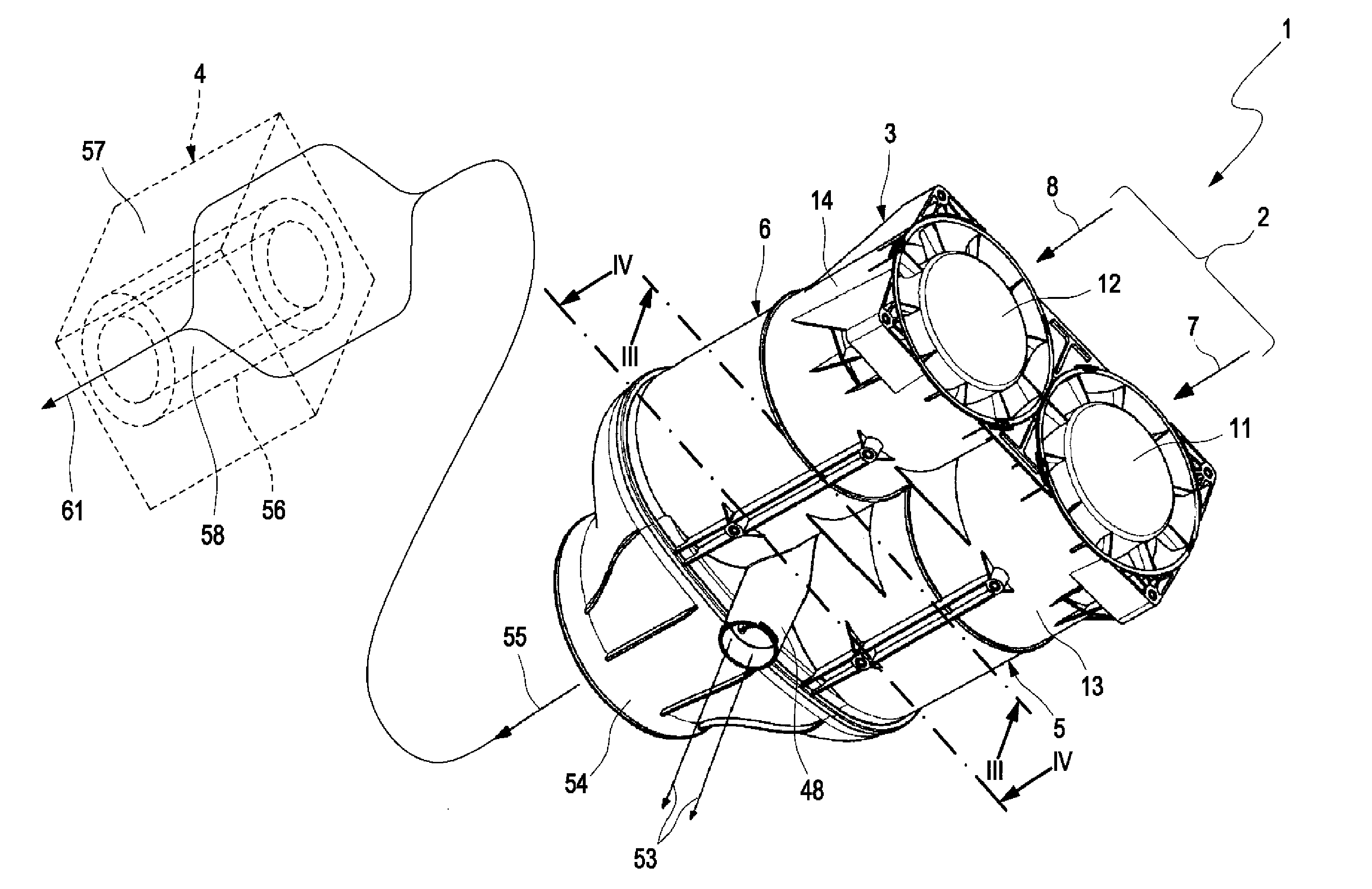

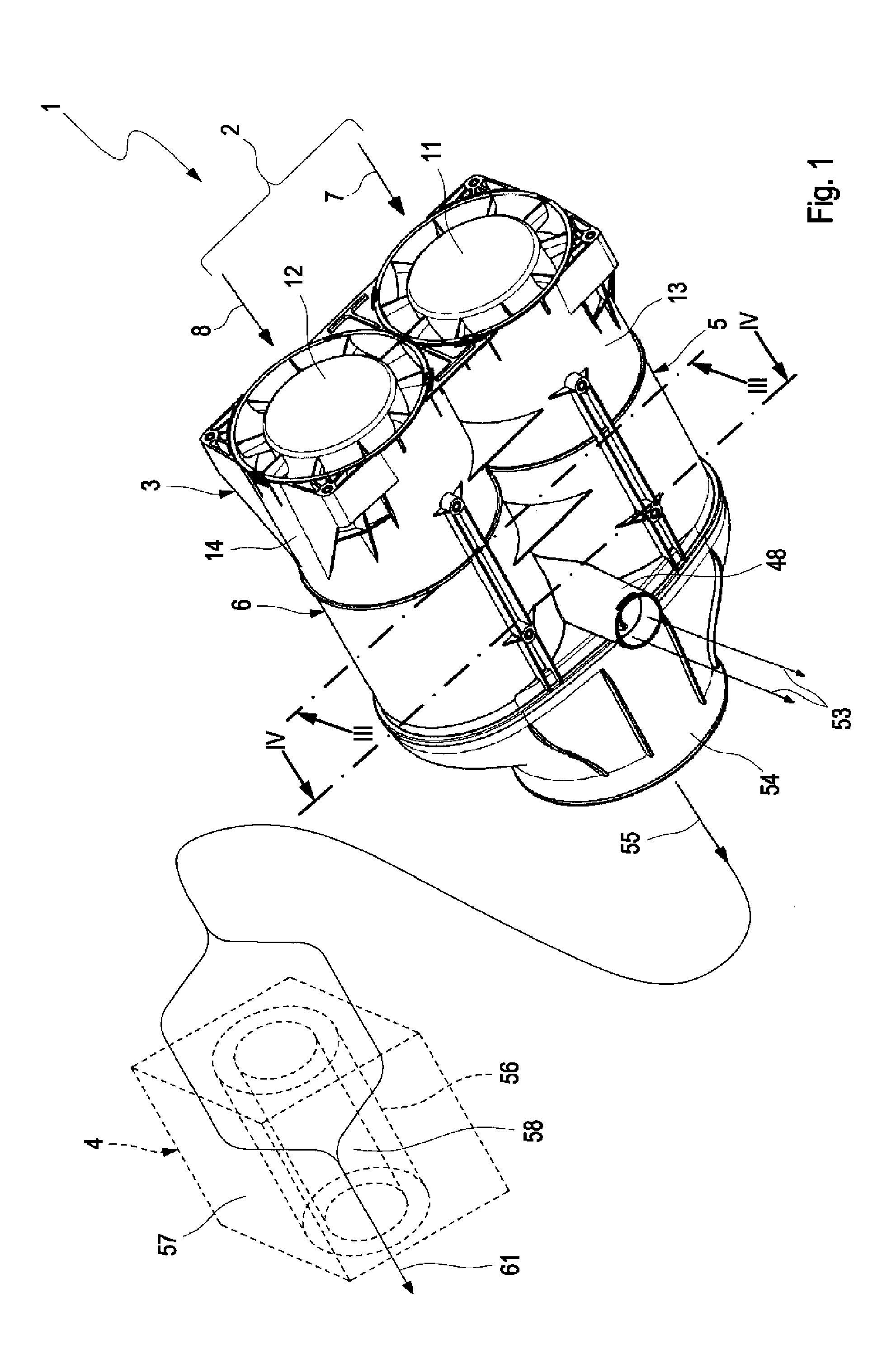

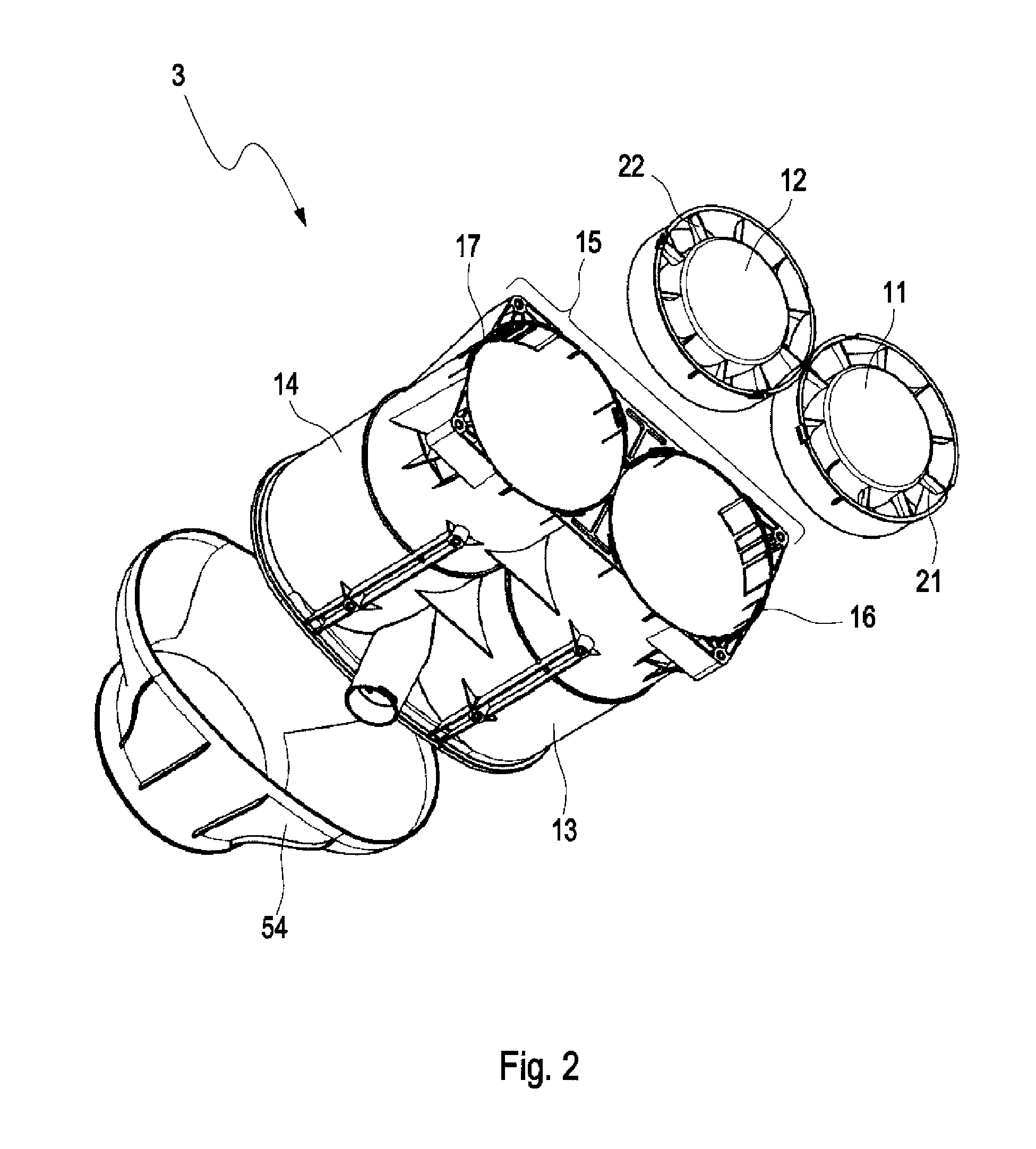

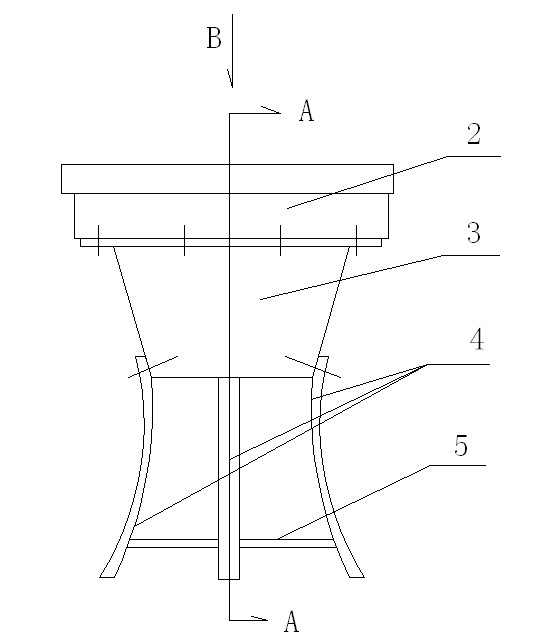

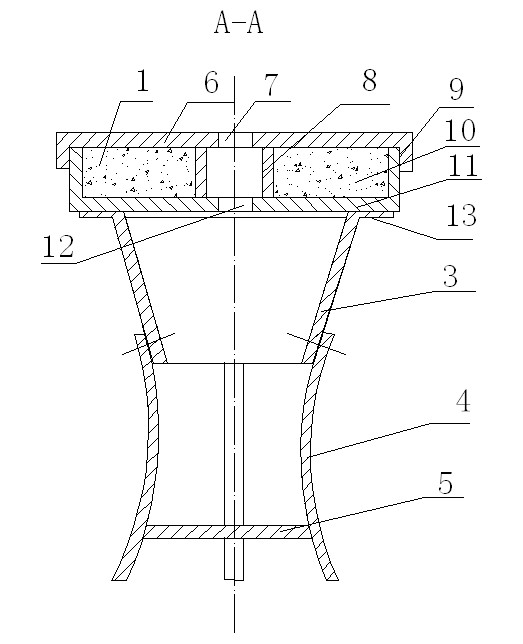

Cyclone Separation Device

ActiveUS20140165513A1Small sizeHigh degree of separationCombination devicesDispersed particle filtrationAirflowInternal combustion engine

A separating device (3) for separating particles from an intake air (2) of an internal combustion engine, comprising two cyclone cells (5, 6) which are designed to cause two raw air streams (7, 8) containing the intake air (2) to rotate oppositely and a discharge device (49) which is designed to guide an exhaust air stream (35, 36) containing the particles tangentially away from a respective cyclone cell (5, 6) and to combine the exhaust air streams (35, 36) to a common exhaust air stream (53).

Owner:MANN HUMMEL GMBH

Alumina coats pulp and preparation method thereof

ActiveCN101491776AHigh bonding strengthHigh hydrothermal stabilityCatalyst carriersDispersed particle separationThin shellsAdhesive

The invention relates to alumina coat slurry and a preparation method thereof, and mainly solves the problems of the prior art of poor stability of a prepared laminar composite carrier and short service life of a prepared thin-shelled noble metal catalyst. The alumina coat slurry comprises the following components: aluminum sol with an average granularity of less than 20 micrometres, active alumina, an organic adhesive, an inorganic adhesive, a surfactant, a pH modifying agent and the balance being water, wherein the average granularity of the slurry is less than 10 micrometres. The preparation method comprises the following steps: dissolving the aluminum sol, the organic adhesive, the surfactant and the pH modifying agent in water; mixing the mixture evenly with stirring at a high speed; then adding the inorganic adhesive and active alumina powder for high-speed dispersion; and regrinding the obtained alumina coat slurry to prepare the alumina coat slurry. Thus, the preparation method better solves the problems by adopting the technical proposal, and can be used in the industrial production of laminar composite carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

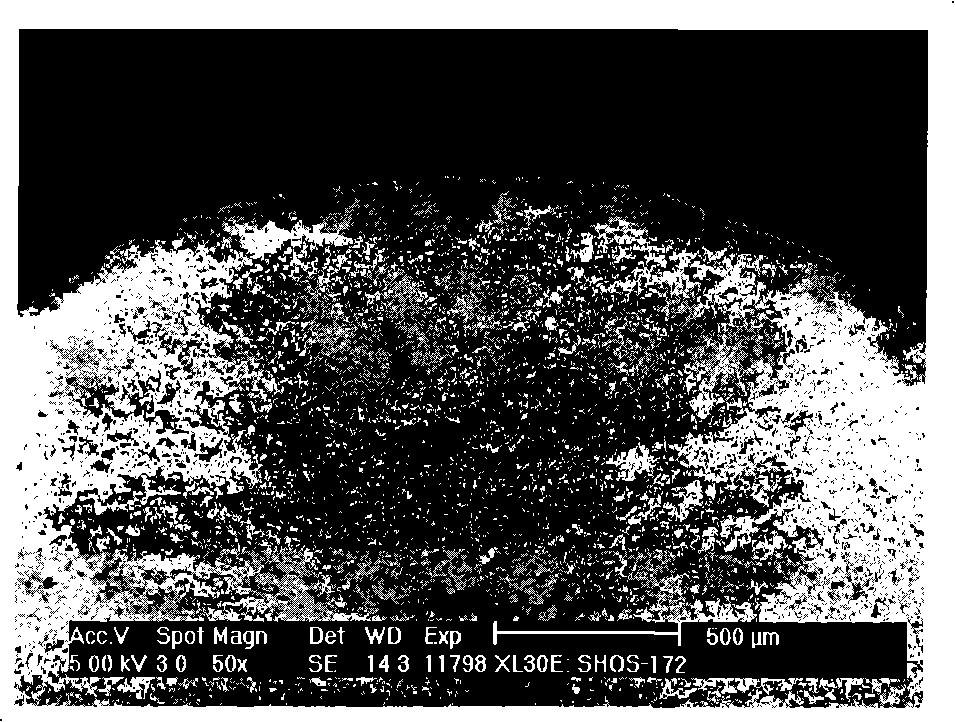

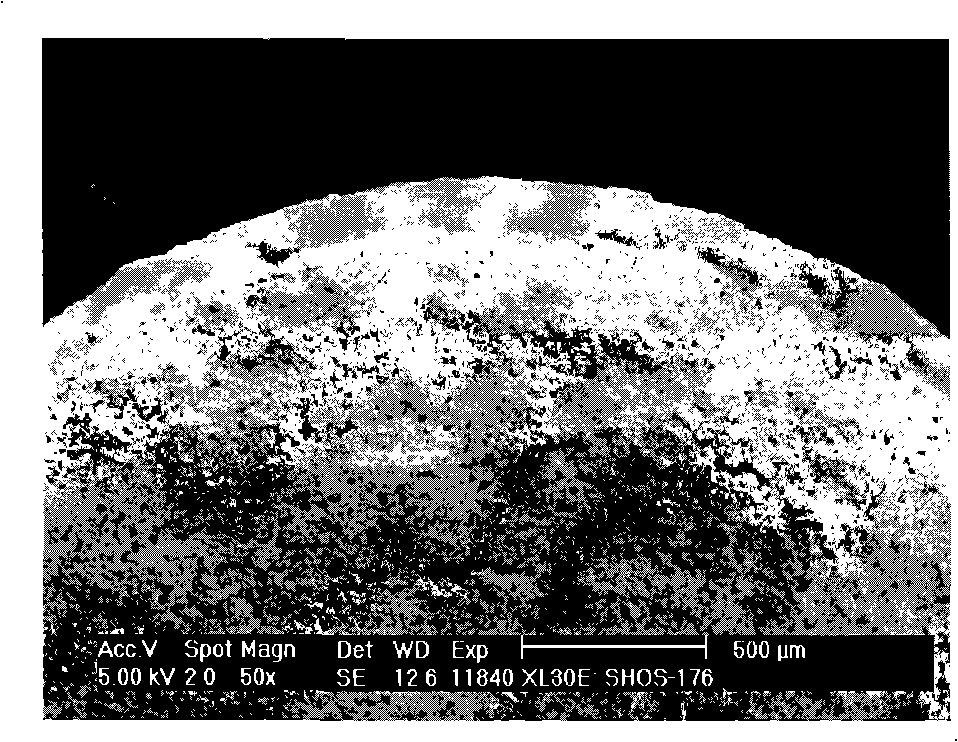

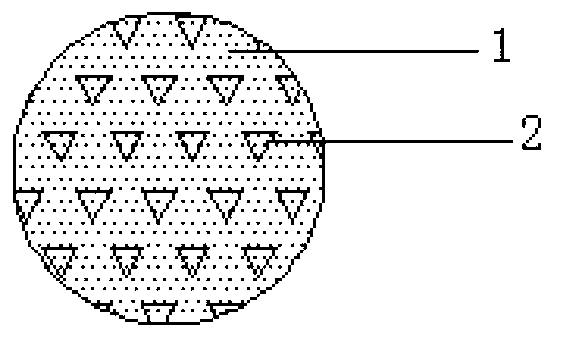

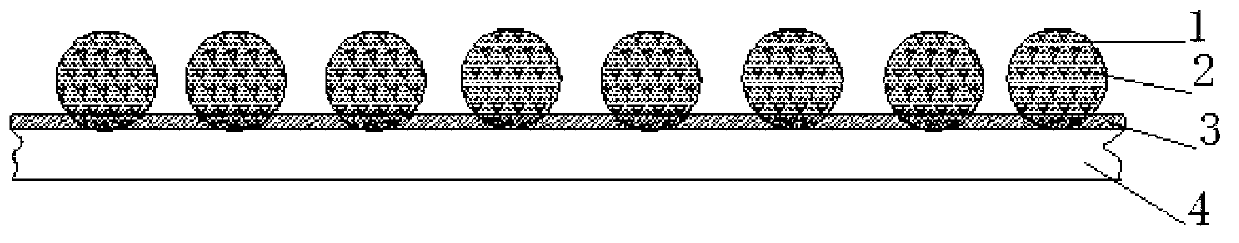

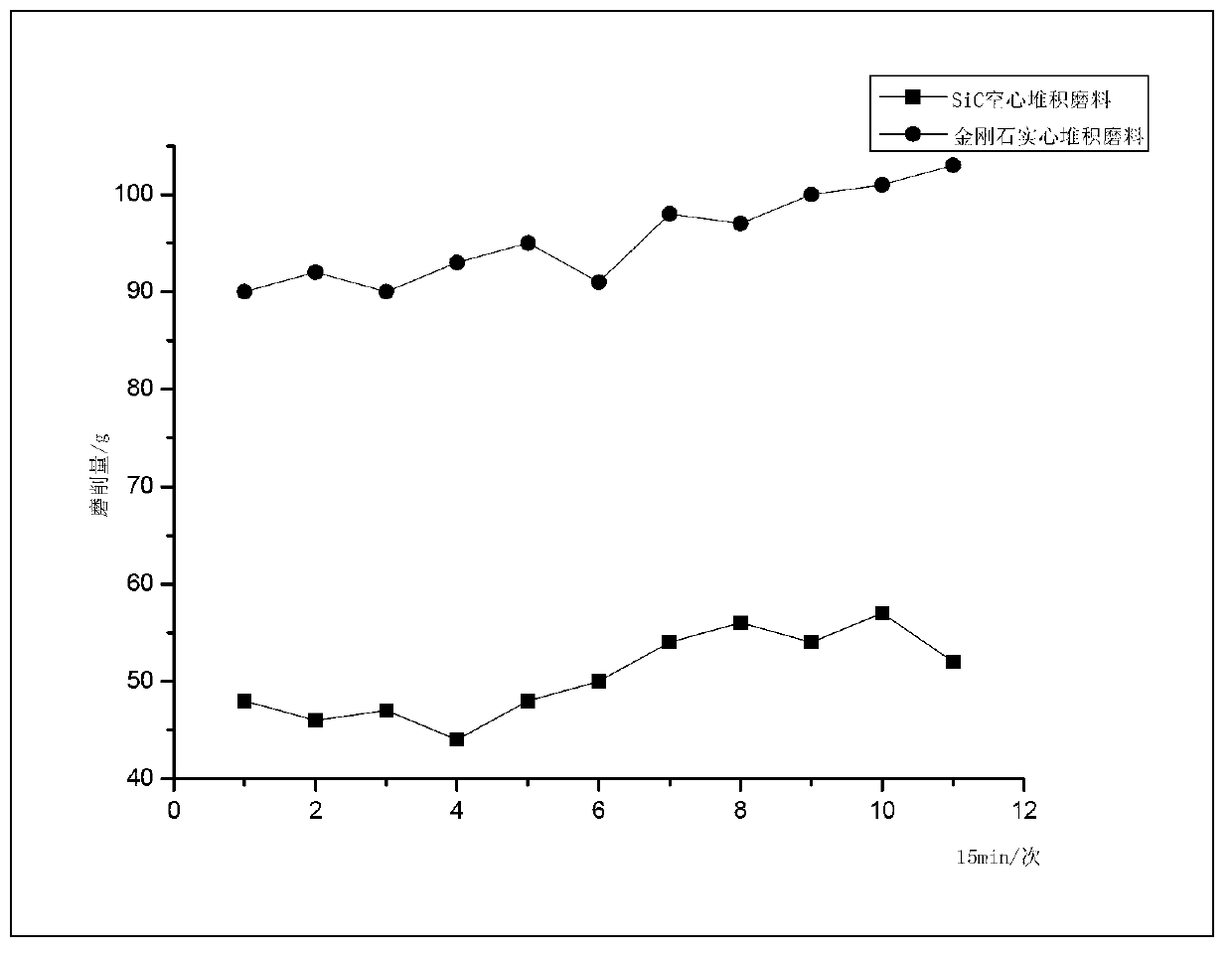

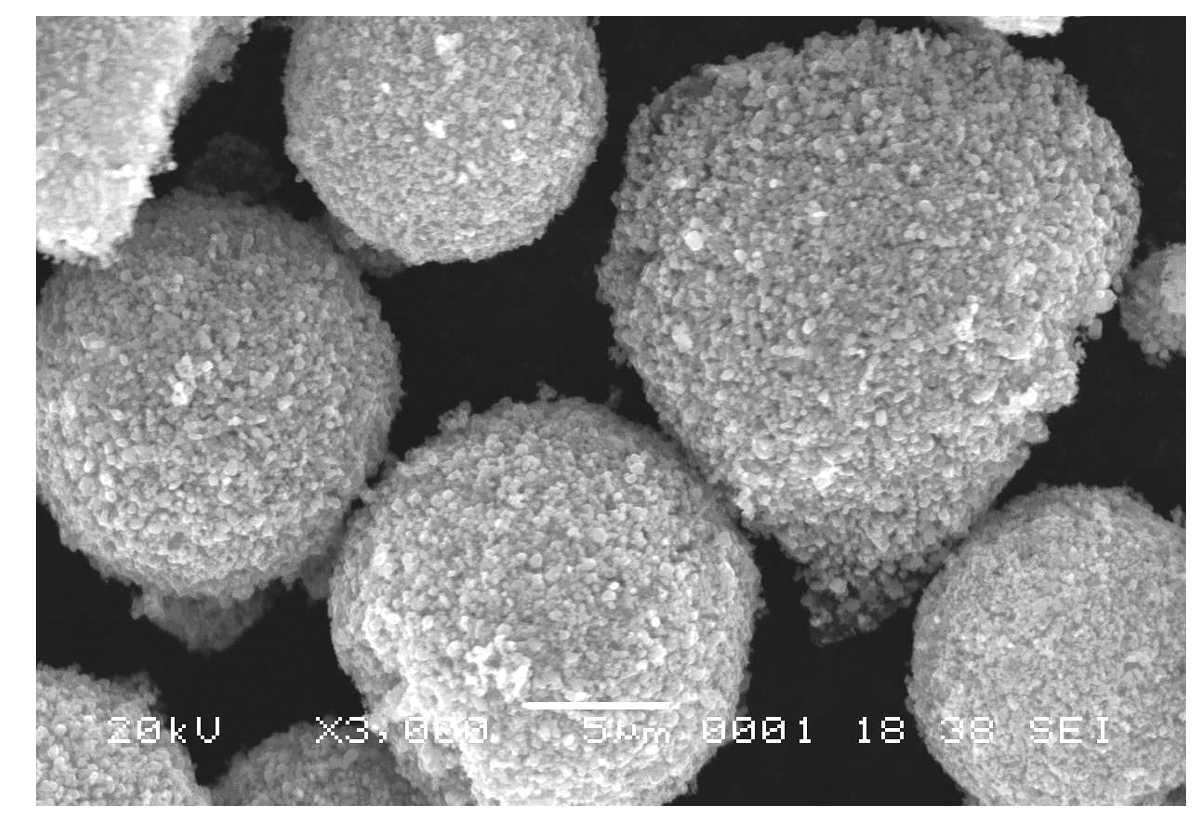

Ultrafine diamond and ceramic binding agent stacked abrasive materials and preparation method thereof

ActiveCN103273434AUniform internal structureBroaden the processing objectGrinding devicesCemented carbideSurface grinding

The invention relates to ultrafine diamond and ceramic binding agent stacked abrasive materials and a preparation method thereof. According to the ultrafine diamond and ceramic binding agent stacked abrasive materials, ultrafine diamond micro powder is added in the colloidal sol of a ceramic binding agent, a sizing agent is dried by spray mist, dry blank spherical stacked abrasive materials are obtained, and the ultrafine diamond and ceramic binding agent stacked abrasive materials can be obtained after calcinations. Stacked abrasive material particles are all spherical and even in particle size and internal organization structure. The ultrafine diamond and ceramic binding agent stacked abrasive materials can be used for preparing resin binder ultraprecise grinding wheels or diamond abrasive belts. A diamond abrasive material tool has high grinding efficiency and long grinding service life, and is mainly used for surface grinding and polishing of parts which are made of engineering ceramics, glass, hard alloy and the like.

Owner:HUNAN UNIV

Polyvinyl alcohol (PVA) film and preparation method, polarizing film and polarizing filter thereof

ActiveCN105440533AReduce precipitationReduce generationPolarising elementsWeight distributionSurface-active agents

The invention provides a polyvinyl alcohol (PVA) film. The PVA film is prepared by the following raw materials of polyvinyl alcohol, a plasticizer and a surface active agent according to the mass ratio of (5-65):(0.1-12):(0.01-2); the molecular weight distribution of PVA is 1.5-3.0. The PVA film has the advantages that after repeated studying and finding, the molecular weight distribution of PVA polymer resin in the PVA film has a significant function on the property of the prepared film; by controlling the molecular weight distribution of the PVA polymer resin within the range of 1.5-3.0, after the PVA film is swelled and dyed, the separating of low-molecule matters is greatly reduced, the original complete structure is maintained, and the breaking is avoided in the subsequent drawing process. The invention also provides a preparation method, a polarizing film and a polarizing filter of the PVA film.

Owner:重庆光谱新材料科技有限公司

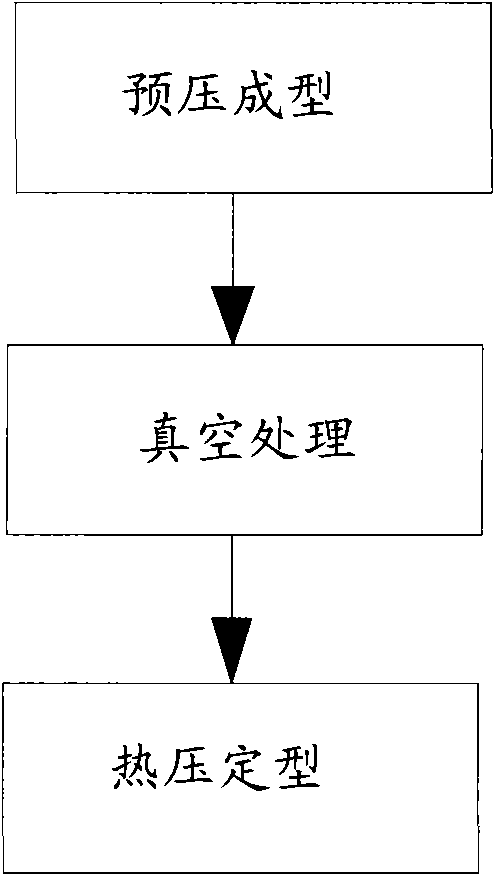

Method for preparing bulletproof formed part

InactiveCN101629794AImprove ballistic performanceImprove liquidityLaminationLamination apparatusFiberAdhesive

The invention discloses a method for preparing a bulletproof formed part, which comprises the steps of: a) overlapping more than two layers of high-performance fiber weftless cloth, imposing the pressure of between 0.1 and 1MPa to ensure that the air among the weftless cloth escapes, then increasing the temperature of the weftless cloth to be between 110 and 120 DEG C, and then imposing the pressure of between 1 and 3MPa for pre-press forming; b) performing heat preservation on the weftless cloth after the pre-press forming for 20 to 120min under the vacuum condition that the temperature is between 120 and 130 DEG C and the pressure is lower than 0.5kpa; and c) imposing the pressure of between 10 and 20MPa on the weftless cloth after the vacuum treatment in a hot pressing mold with a temperature of between 120 and 130 DEG C, performing heat preservation and pressure maintaining for 20 to 60min, and then cooling the weftless cloth to room temperature to obtain the bulletproof formed part. An adhesive in the weftless cloth has good fluidity at high temperature, so the pre-press forming and the subsequent vacuum treatment of the weftless cloth can ensure that the bonding of fiber andthe adhesive is evener, reduce the defects such as pores and the like, and improve the bulletproof performance of the weftless cloth.

Owner:杨珍芬

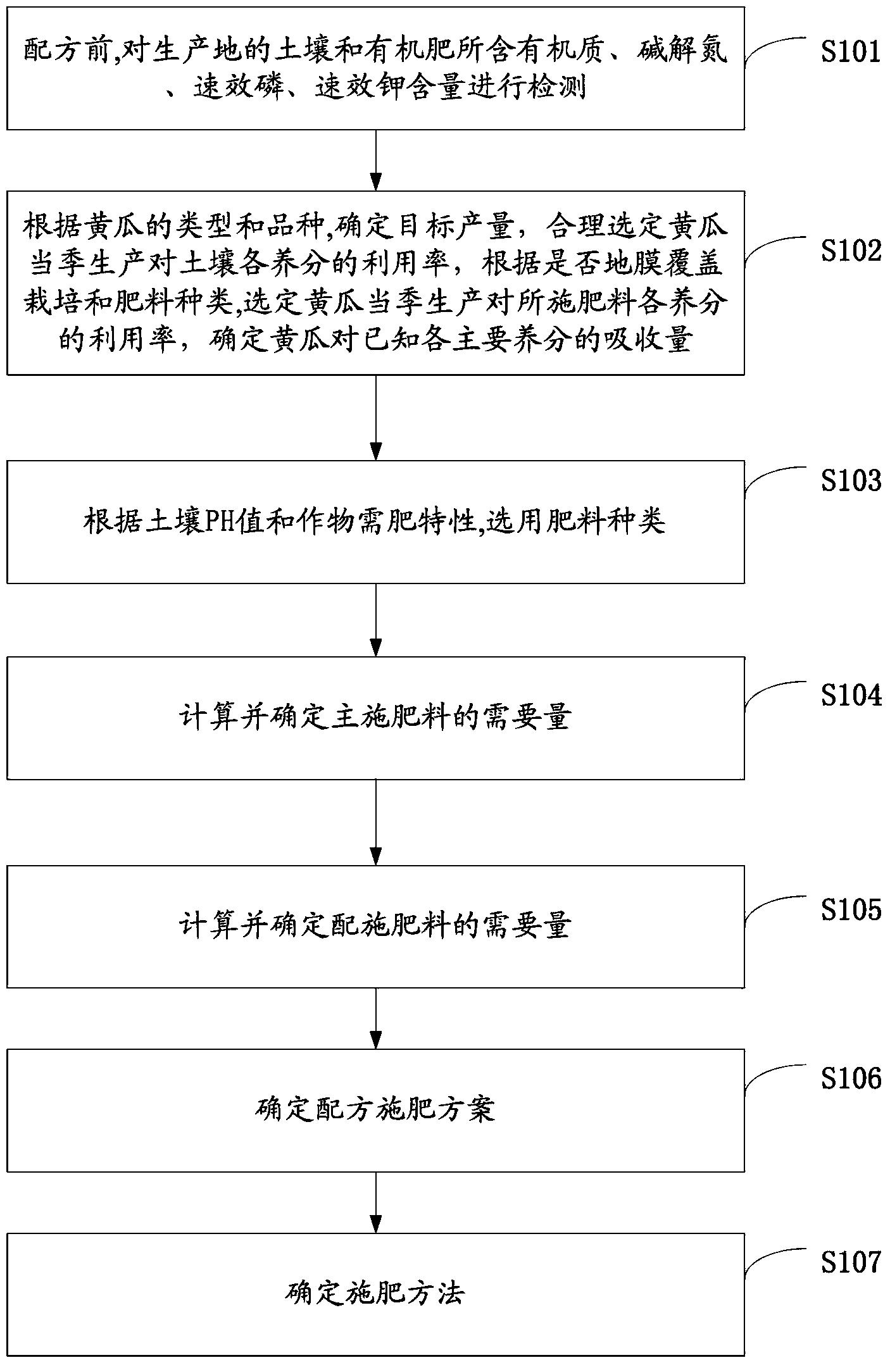

Soil testing and formulated fertilization method for use in environment-friendly cultivation of cucumber

The invention discloses a soil testing and formulated fertilization method for use in environment-friendly cultivation of cucumber. The method comprises the following steps: detecting the soil of a place of origin as well as the contents of organic matters, alkali-hydrolyzable nitrogen, rapidly available phosphorus and rapidly available potassium contained in organic fertilizers; detecting target yield, reasonably selecting the utilization ratio of each nutrient in soil during seasonable production of cucumber, and selecting the utilization ratio of each nutrient in applied fertilizers during seasonable production of cucumber; determining the absorption of each known major nutrient by cucumber; selecting fertilizers according to the pH value of soil and the fertilizer needing characteristics of crops; calculating and determining the needed amounts of a main fertilizer and an auxiliary fertilizer; determining a formulated fertilization scheme; and determining a fertilization method. The calculation of the formulated fertilization amount is more accurate and more reliable than that in the prior art; by considering the types and characteristics of varieties, the target yield is more consistent with practical situations; the nutrient amount of soil is calculated accurately and reliably; the fertilizers are selected under the full consideration of the soil acidity and alkalinity as well as the requirement of cucumber on fertilizer characteristics; by adopting the fertilization method, labor force is reduced, and the production cost is lowered.

Owner:YIYANG RES INST OF VEGETABLE SCI

Bamboo fiber and combed cotton compact siro spinning technology

The invention discloses bamboo fiber and combed cotton compact siro spinning technology, which solves the problem that the fabric made from yarns is susceptible to pilling, has insufficient toughness and strength and the like in the prior art. The technology is characterized in that: by adopting the process of drawing and mixing the bamboo fibers and combed cotton, bamboo fiber and cotton fiber card sliver is produced and is mixed on a drawing frame, and the compact siro spinning yarns are produced by three drawing processes and by a roving frame, spinning frame and an automatic winder. The bamboo fibers and cotton fibers are organically combined, and the processed blended yarns have good moisture absorption, air permeability, drapability and antibiotic property, the fabric is an uncommon natural and cool fabric and is suitable for making high-grade dress, underwear, home textiles, sportswear and socks, and the development of the series of products has a promising market prospect.

Owner:黄冈三泰纺织有限公司

Method of watermark with hybrid halftone dots

ActiveUS7554699B2Improve stealth performanceImprove practicalityVisual presentationPictoral communicationOptical scannersLenticular lens

Owner:NATIONAL TAIWAN NORMAL UNIVERSITY

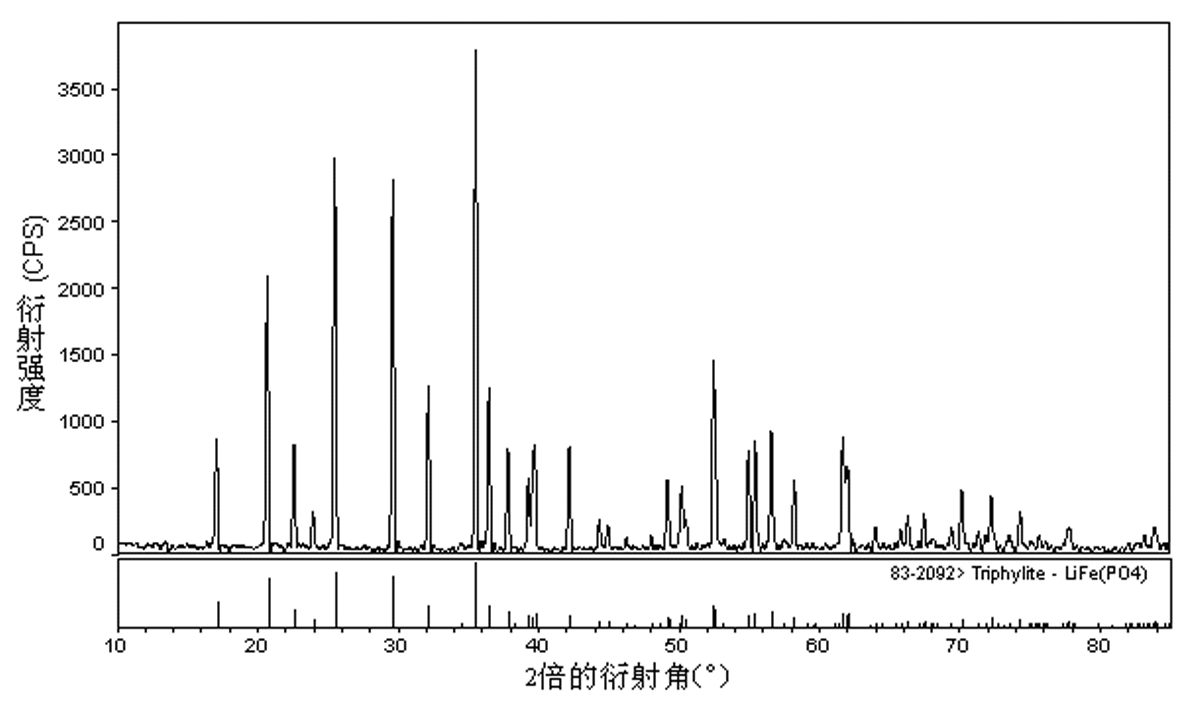

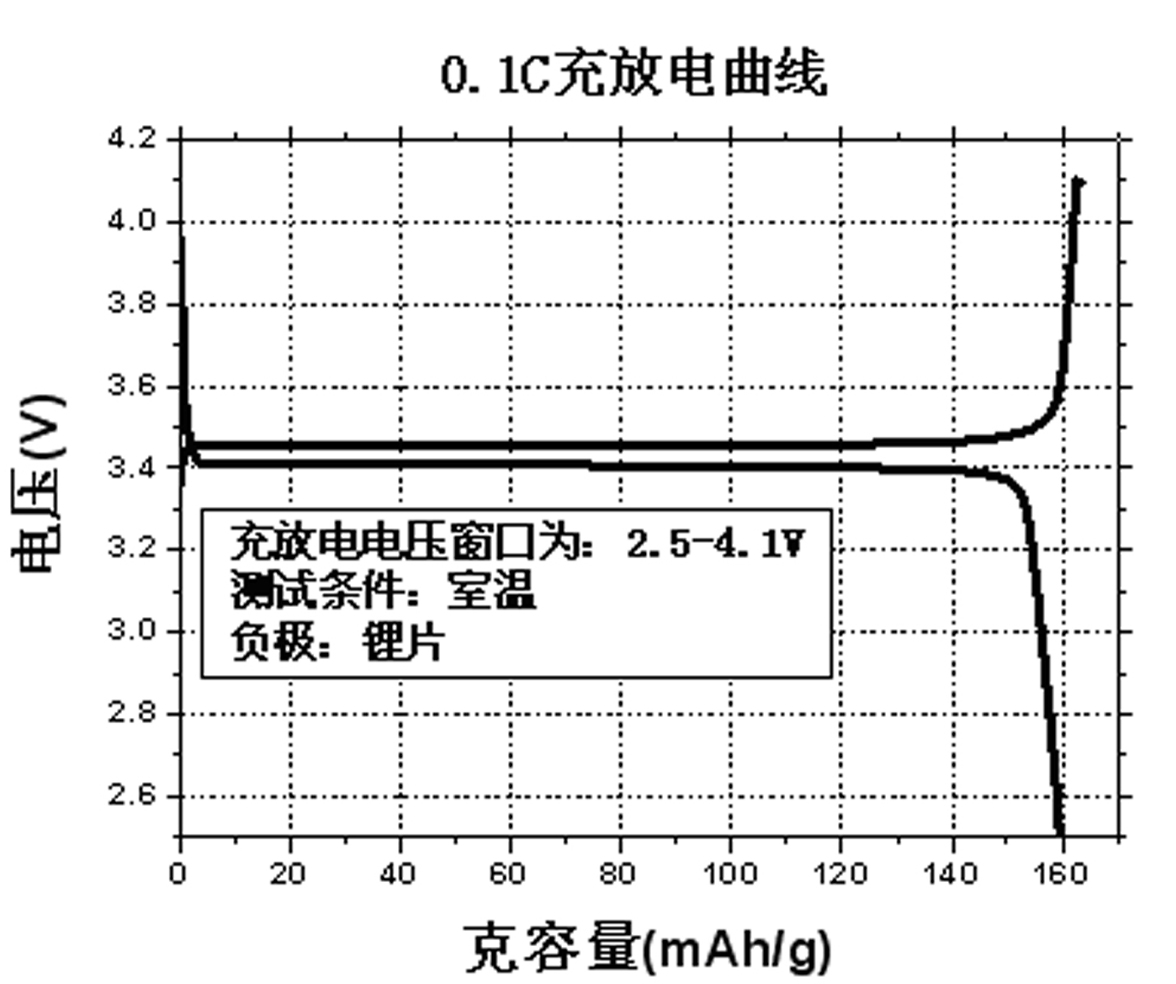

Method for preparing high-density lithium ferric phosphate

ActiveCN102009970AEvenly combinedImprove bindingCell electrodesPhosphorus compoundsPhosphatePotassium

The invention relates to a method for preparing high-density lithium ferric phosphate, which comprises the following steps of: adding a lithium salt, a ferric salt, a phosphorus-containing compound and doping metal-containing elements into a dispersing agent by the conventional method, and performing ball mill twice; performing drying and predecomposition for 3 to 10 hours; crushing, adding at least one of lithium dihydrogen phosphate or potassium dihydrogen phosphate as a bonding agent in an amount which is 1 to 5 percent based on the weight of a predecomposition product, performing ball mill for 1 to 5 hours, and processing according to the prior art to obtain the high-density lithium ferric phosphate. In the method, the ball mill is performed twice in the first step, so that granules are fine; the grain size can be controlled within the range of between 300 and 2,000 nanometers, so that raw materials are mixed uniformly; more importantly, due to the addition of the bonding agent, the bonding among the granules is enhanced, the stacking density of products is improved, and contact conductivity among the granules is reduced; and the prepared products have good crystallization, simple structure and uniform grain fineness distribution and do not contain impure phases, the tap density is between 1.4 and 1.8 g / cm<3>, the specific surface area is between 5 and 11m<2> / g, the compaction density of pole pieces is between 2.4 and 2.8 g / cm<3>, and the specific capacity of first discharging at the room temperature is between 140 and 160 mAh / g.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

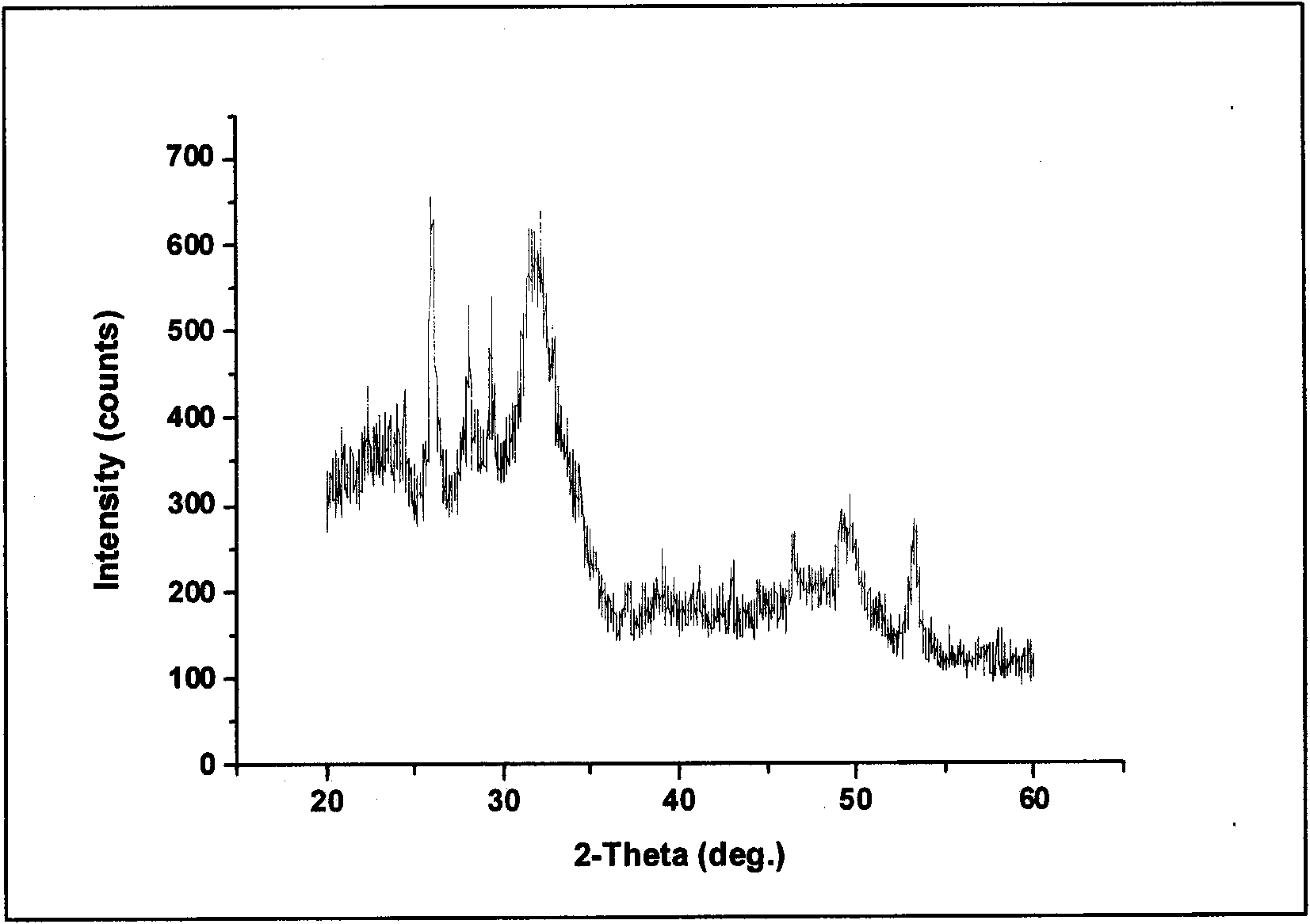

Modified method of natural graphite material for lithium ion battery

InactiveCN101214952AImprove the first charge and discharge efficiencyChange surface chemistryCell electrodesOxidizing acidMaterials science

Disclosed is a modification method for native graphite materials used for lithium ion batteries. The method comprises the following steps that native graphite powders are placed into an autoclave, dense oxidizing acid, oxidizing salt and hydrochloric acid are used for oxidation treatment, wherein the oxidation treatment proceeds at a temperature ranging from 180 to 250 DEC G, the native graphite materials which are washed or not are centrifugalized, then native graphite materials which are centrifugalized are calcined, semi-modified native graphite materials are gained, silanization film forming treatment is completed on the semi-modified native graphite materials, then tetrahydrofuran is used to wash and dry the native graphite materials, thereby obtaining modified native graphite materials. The modified native graphite materials are capable of satisfying the application of the lithium ion batteries, have the advantages of high cost performance, low costs, large specific capacity, perfect circulative property and higher initial charge and discharge efficiency, and simultaneously are adapted to the negative pole application of high-current charge and discharge lithium ion batteries.

Owner:平顶山工学院

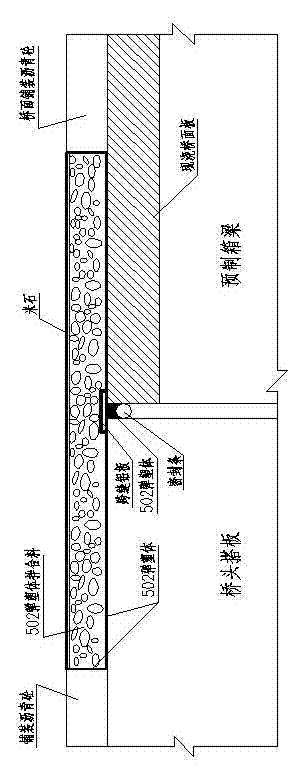

Construction method of bridge seamless type expansion joint

InactiveCN103088752APrevent fallingImprove adhesionBridge structural detailsExtensibilityGranolithic

The invention discloses a construction method of bridge seamless type expansion joint. The construction method of the bridge seamless type expansion joint includes the steps of embedding a sealing strip in the seam portion of the expansion joint, pouring melted 502 elastic-plastic bodies, placing a cross-seam aluminum sheet well, paving various high molecular polymers which fit in with the American society for testing material (ASTM) standard layer by layer, wherein the various high molecular polymers are mixed materials of the 502 elastic-plastic bodies and granite of a corresponding grade, finally using granitic plaster as a surface wearing layer, and the bridge seamless type expansion joint is achieved. The construction method of the bridge seamless type expansion joint has the advantages of satisfying stretch and displacement of an upper portion structure of the bridge, guaranteeing that cars run stably, improving riding comfort, and being strong in elastic restoring force, capable of resisting the high and low temperature, good in plasticity, extensibility, durability, waterproof performance and adhesion performance, long in service life, convenient to install, flexible in installation, rapid in traffic openness and the like. In addition, the construction method of the bridge seamless type expansion joint further has the advantage that the extensible displacement is from 20mm to 50 mm.

Owner:江西省城乡规划设计研究总院

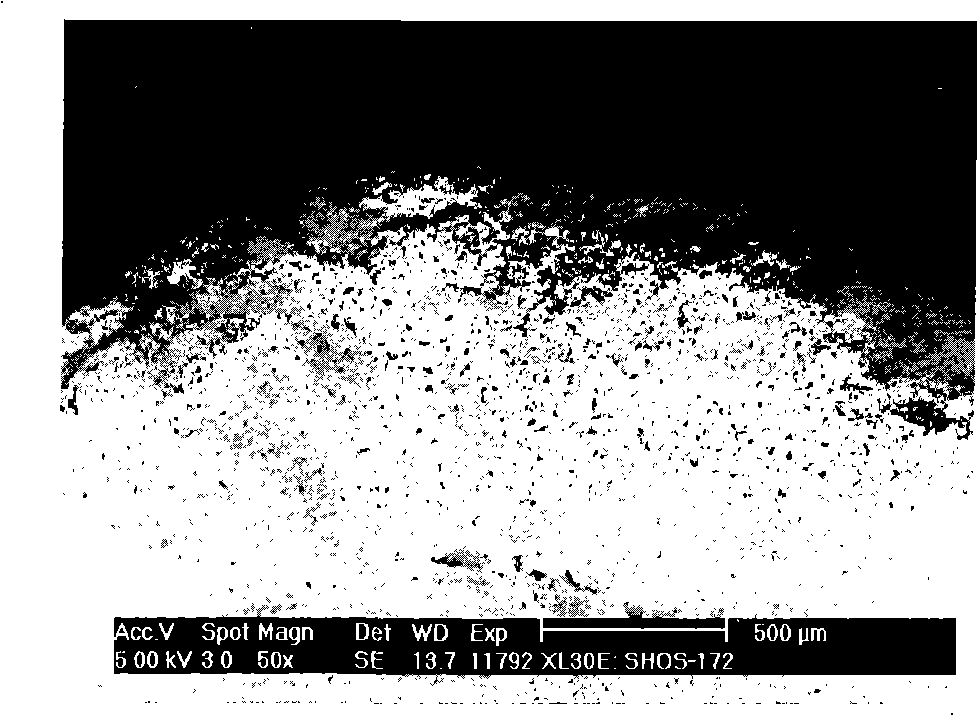

Fiber material surface nanocrystalline processing method

The nano fiber material surface treating process includes compounding solution as coating material precursor, soaking the fiber material to be treated inside the solution for adsorbing the precursor homogeneously, regulating pH value, setting in constant temperature water bath to form 20-100 nm thick film coating the fiber, softening treatment and stoving. The SEM analysis shows that the surface nano layer is homogeneous and has good coating effect, the treated fiber has strength, hand feeling and brightness superior to the un-treated fiber. The treated fiber has far infrared function, antibiotic function, anti-ultraviolet function, etc. depending on the coated matter.

Owner:TAIYUAN UNIV OF TECH +1

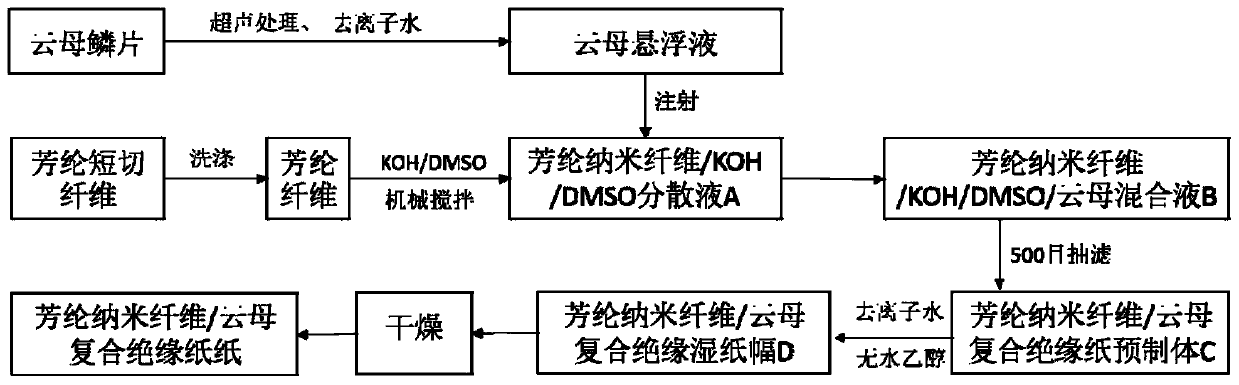

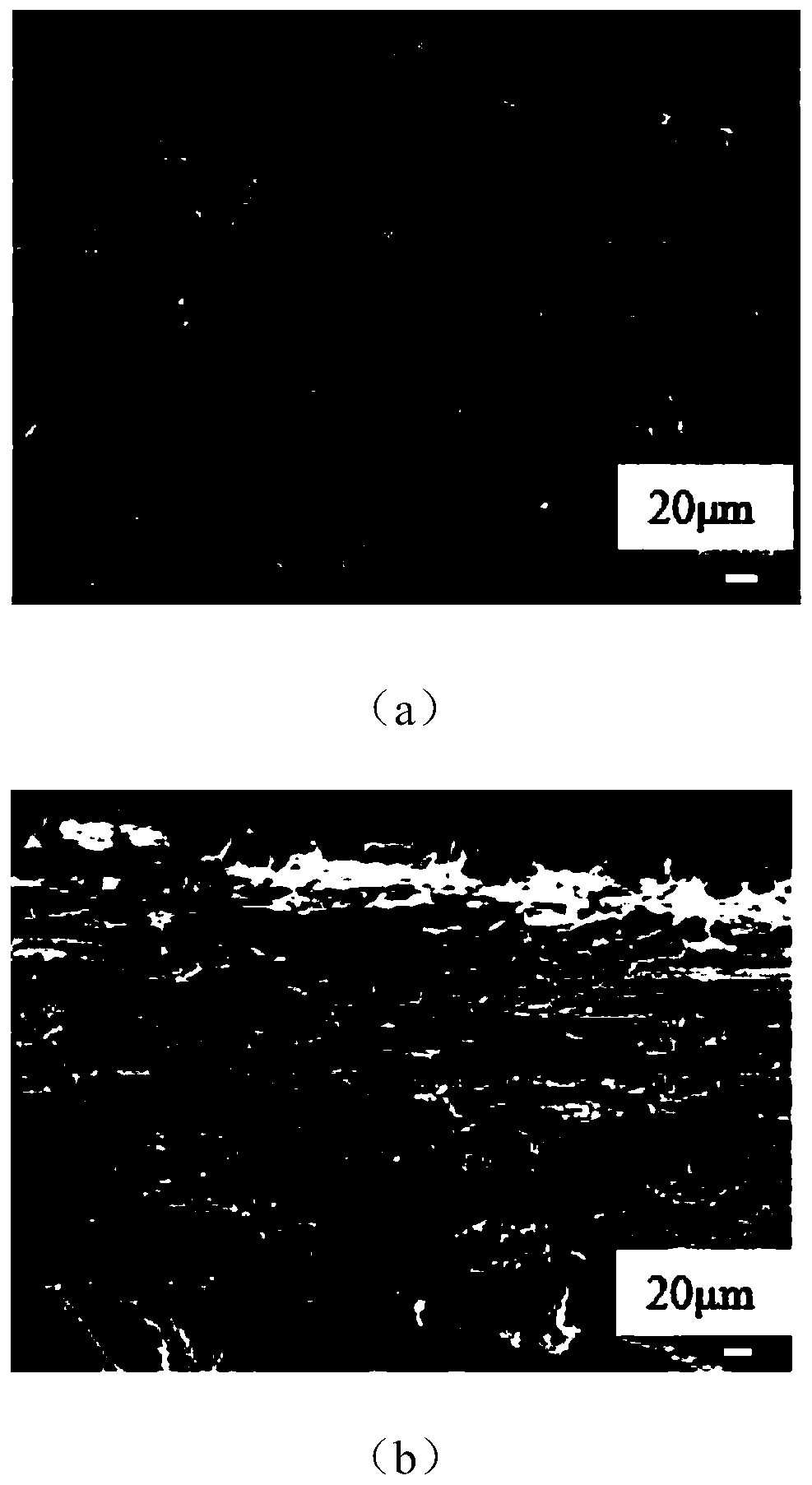

Preparation method of aramid nanofiber/mica composite insulating paper

ActiveCN110106737ALarge specific surface areaMany active sitesPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperMotor insulationPapermaking

The invention discloses a preparation method of aramid nanofiber / mica composite insulating paper. The preparation method of the aramid nanofiber / mica composite insulating paper aims at achieving the self-film-forming coating and interface enhancement effects of aramid nanofibers on mica by turning macro aramid fibers into aramid nanofibers through deprotonation and utilizing an in-situ depositionmethod, achieves that the adaptability of the particle diameter of the mica is wide, and the uniformity, mechanical strength and dielectric strength of the aramid nanofiber / mica composite insulating paper are much higher than the properties of common aramid mica insulating paper, solves the problems of existing aramid mica insulating paper during wet papermaking that (1) the particle diameter of the mica is limited by the properties, (2) the mechanical strength is low, (3) due to voids and pore diameters which are generated by free accumulation and distribution of the mica, the dielectric strength is low, (4) the two faces of paper forming have large difference and low uniformity, is simple in operation, has a significant effect, and provides a novel method for the preparation of a motor insulation material with higher performance.

Owner:SHAANXI UNIV OF SCI & TECH

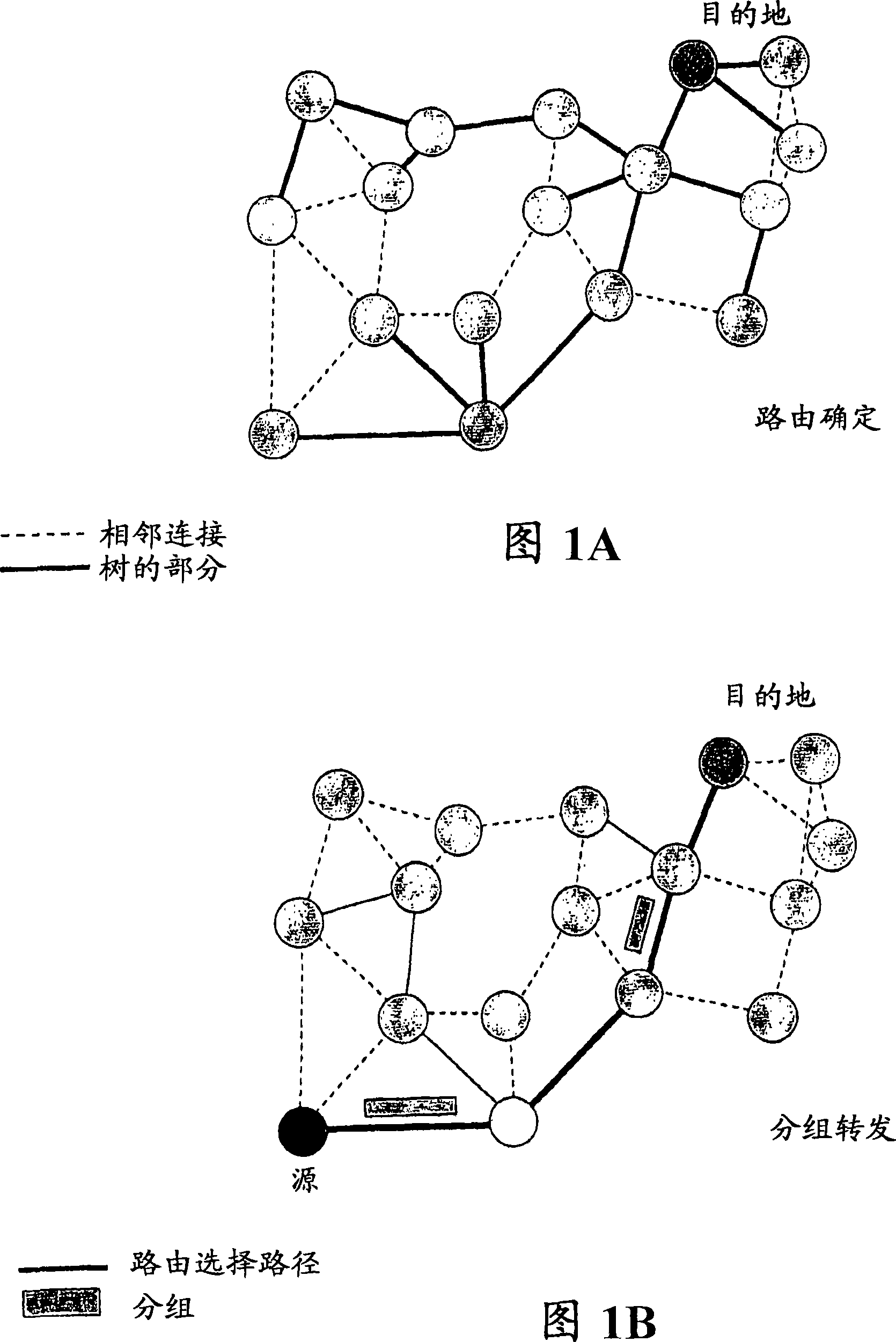

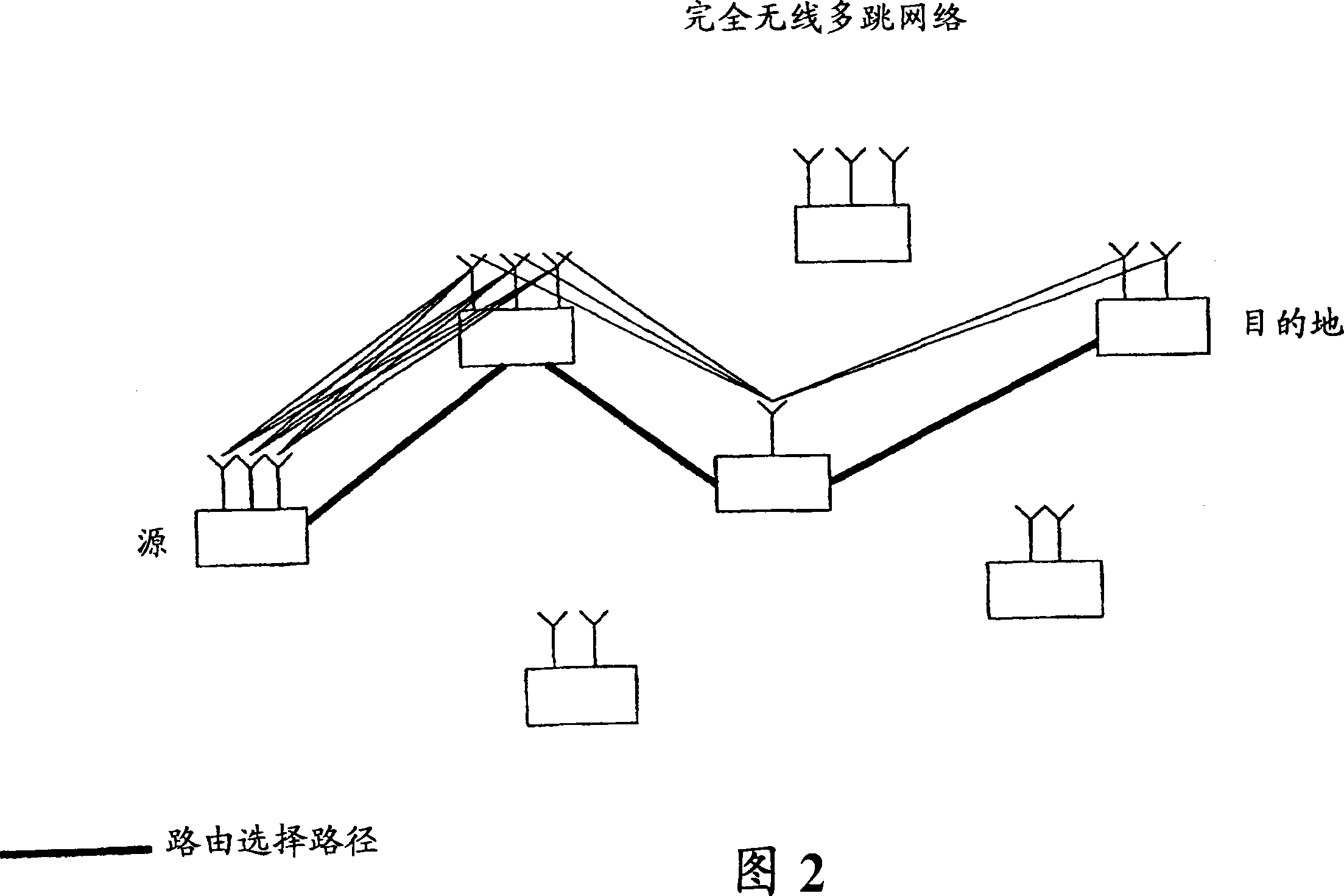

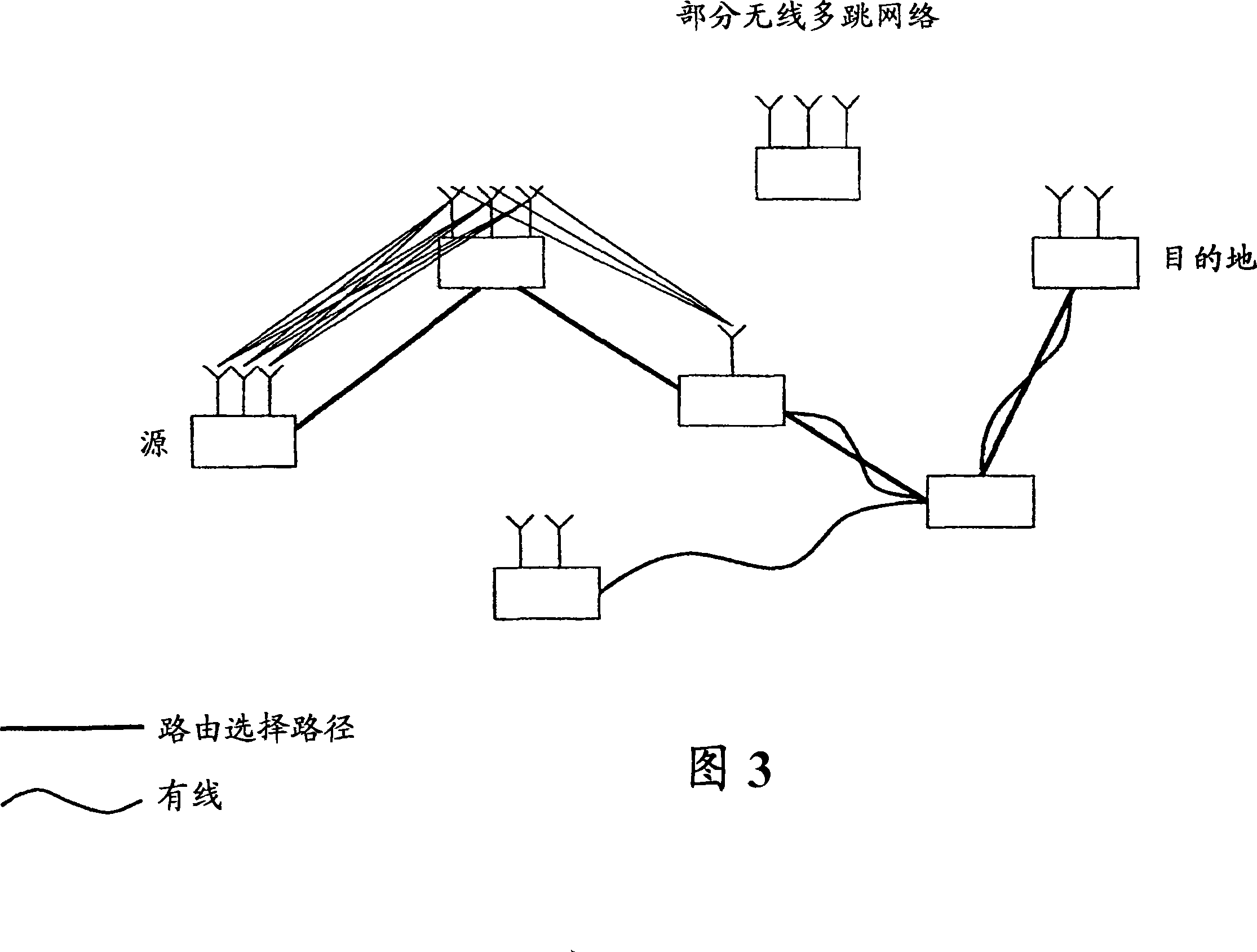

Method and arrangement for advanced routing metrics in multihop networks

InactiveCN101138206AEvenly combinedImprove throughputEnergy efficient ICTNetwork topologiesMatrix estimationPacket forwarding

The inventors have envisioned a multihop network scenario in which nodes are equipped with advanced multi-antenna arrangements, and recognized the advantage of exploring the presence of such advanced antenna arrangements in multihop network nodes for the specific purpose of determining link cost for routing in the network. A basic idea of the invention is therefore to determine link cost (S3) fora wireless link between a pair of nodes in the network based on multi-channel characteristics between the nodes, where at least one of the nodes is configured for operation with multiple antennas to provide for multiple channels. These multi-channel characteristics may for example be determined based on explicit channel matrix estimation (S1) and / or the number of transmit and receive antennas (S2) or other information on the antenna capabilities of the involved nodes. The determined link cost information may subsequently be used together with additional routing cost information for route determination (S4), and packet forwarding (S5).

Owner:TELEFON AB LM ERICSSON (PUBL)

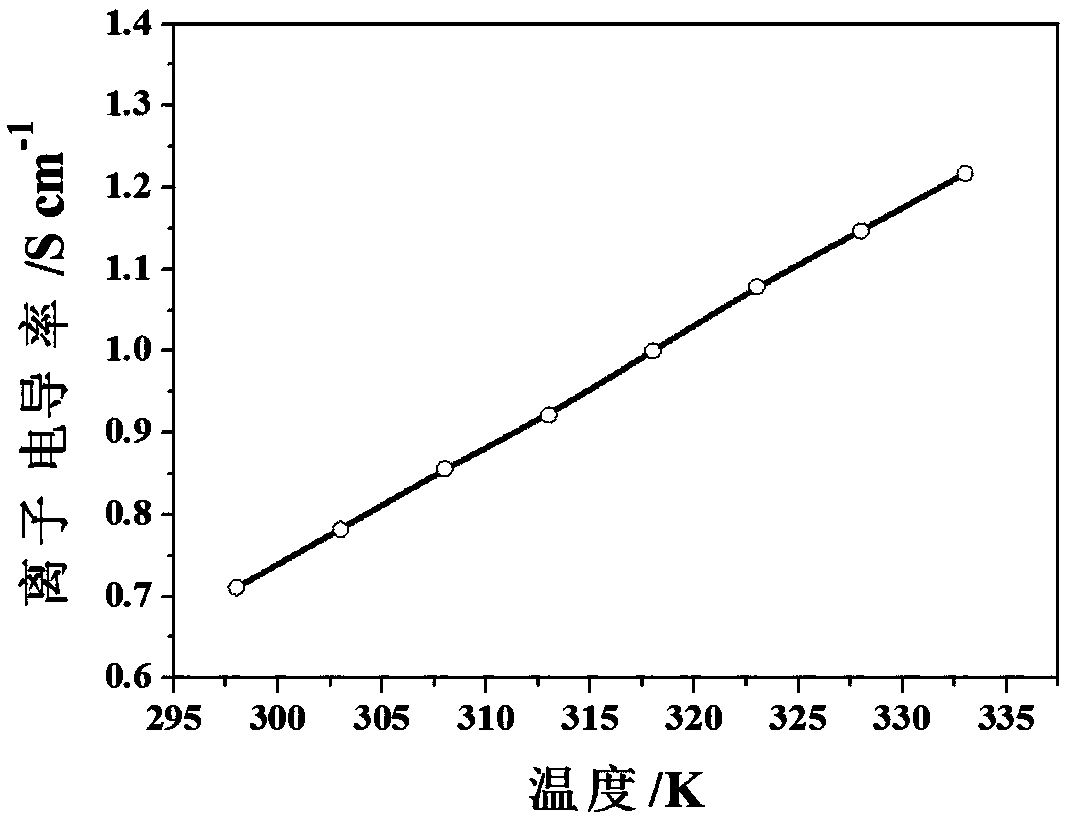

Cellulose nanofibril/metal-organic framework composite lithium ion battery separator and preparation method

ActiveCN108428841AImprove wettabilityWide variety of sourcesMaterial nanotechnologySecondary cellsCelluloseMetal-organic framework

The invention belongs to the crossing field of lithium battery materials, organic coordination materials and biomass and particularly relates to a cellulose nanofibril / metal-organic framework composite lithium ion battery separator and a preparation method. The separator is prepared from components in percentage by weight as follows: 20wt.%-99wt.% of cellulose nanofibril and 0.1wt.%-80wt.% of a metal-organic framework; the diameter of the cellulose nanofibril is 5-100 nm. The provided composite lithium ion battery separator has the characteristics of high mechanical strength, uniform pore sizedistribution and high binding force between the cellulose nanofibril and the metal-organic framework, has higher ionic conductivity and excellent electrochemical interface stability; the preparationmethod is simple and facilitates large-scale production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

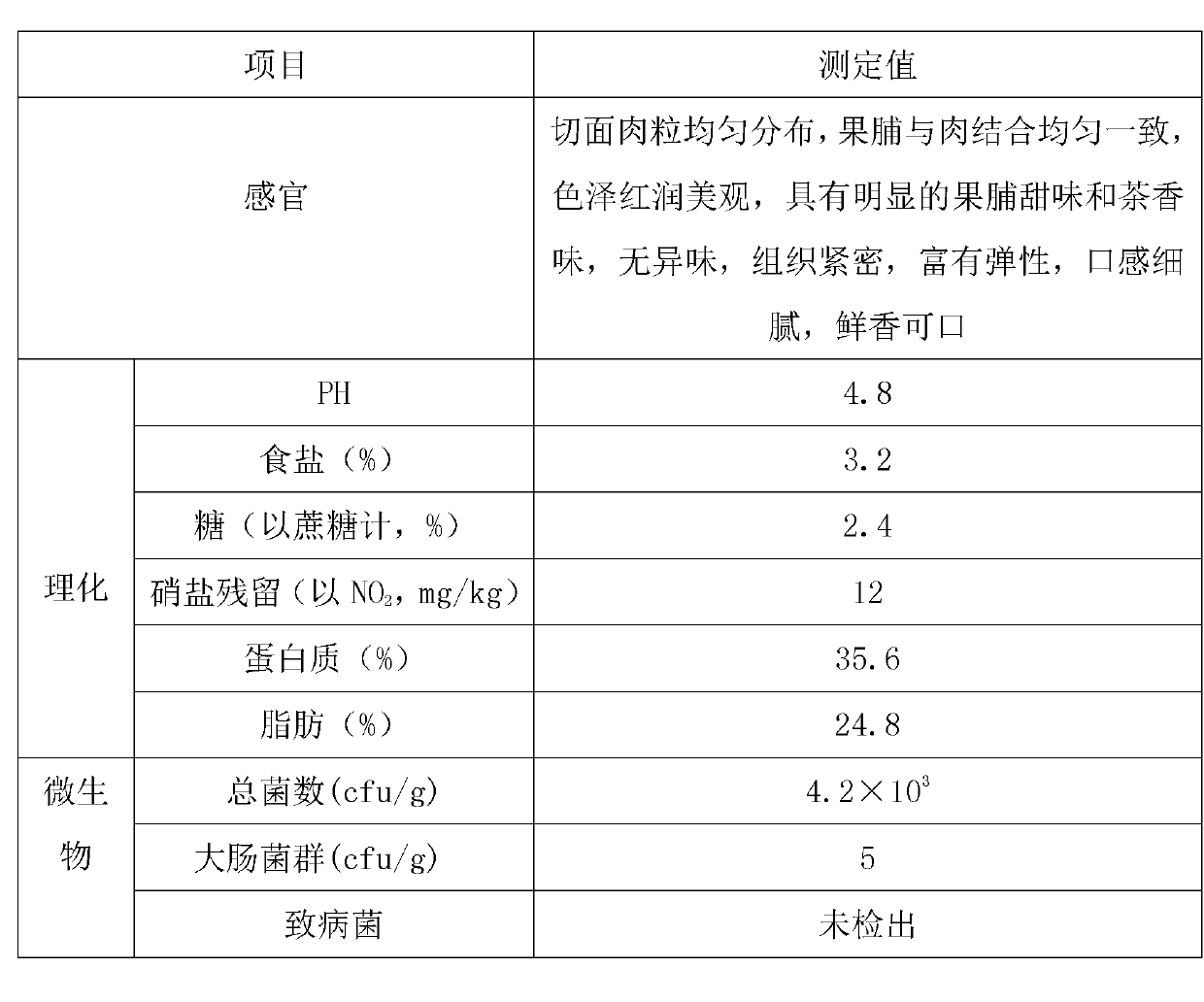

Mini-salami sausage with tea fragrance and preserved fruit flavor and preparation method thereof

InactiveCN103340435AObvious sweetness of preserved fruitObvious tea aromaFood preparationGlucono delta-lactoneVitamin C

The invention discloses a mini-salami sausage with a tea fragrance and a preserved fruit flavor and a preparation method thereof. The mini-salami sausage is prepared by the following raw materials, in parts by weight: 50-60 of beef, 30-40 of pork lean, 15-25 of lardo, 2-3 of a stellaria yunnanensis powder, 2-3 of preserved cherries, 1-2 of kumquat cakes, 1-3 of a hawthorn seed powder, 3-5 of green tea wine, 2-3 of table salt, 1-2 of white sugar, 0.2-0.4 of an edible soy protein, 0.3-0.5 of glucose, 0.01-0.15 of sodium nitrite, 0.01-0.15 of vitamin C, 0.2-0.3 of carrageenan, 0.01-0.02 of glucono-delta-lactone, 0.02-0.03 of sodium tripolyphosphate, and 0.04-0.05 of a fermentation agent. The stellaria yunnanensis powder, the preserved cherries, the kumquat cakes, the hawthorn seed power and the green tea wine selected and used in the mini-salami sausage are rich in nutrition and significant in nourishing function, are added to the sausage, thereby adding unique flavors, having certain nutrition and health care effects, preventing certain diseases, and simultaneously increasing appetite.

Owner:于习和

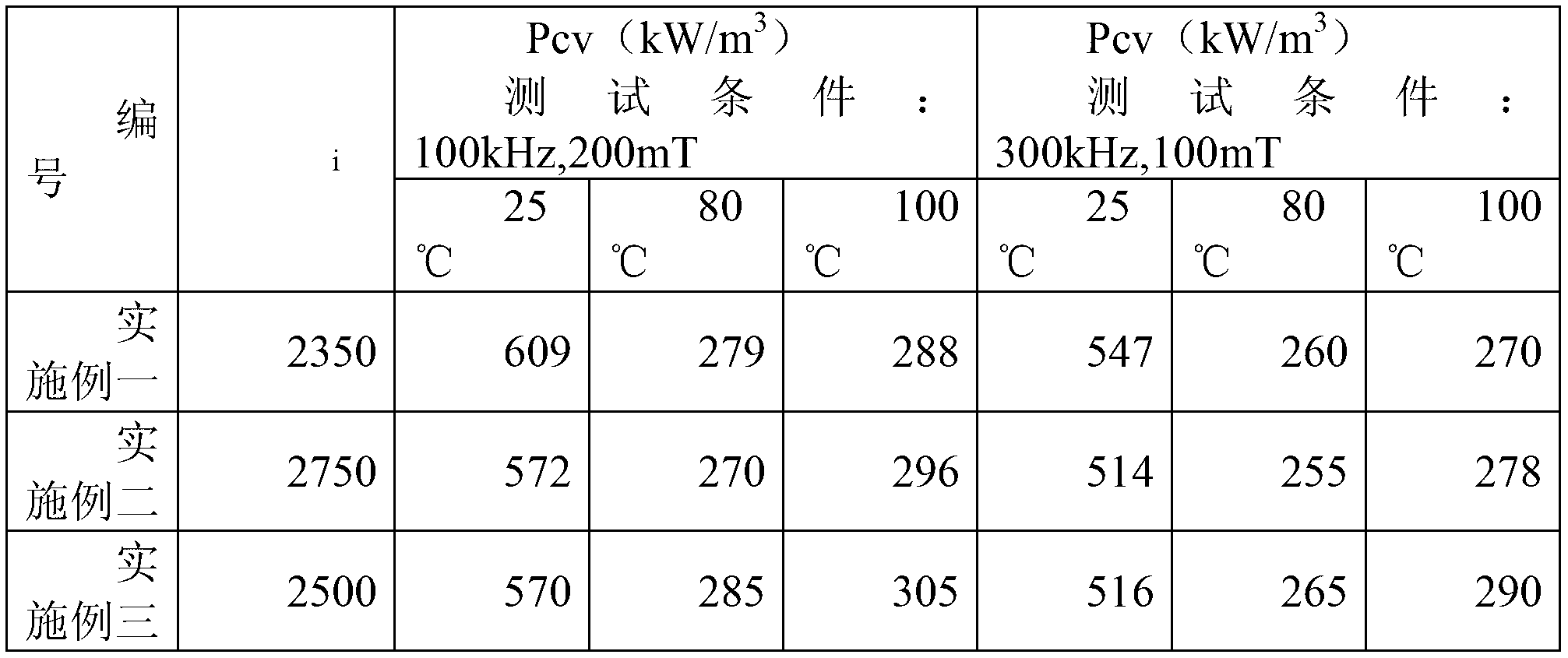

Manganese zinc power ferrite magnetic powder core and preparation method thereof

The invention discloses a manganese zinc power ferrite magnetic powder core and a preparation method thereof. The preparation method comprises the following steps of: (1) preparing raw materials, wherein the raw materials include main materials and auxiliary materials, the main materials include Fe2O3, ZnO, and MnO, or Mn3O4, proportional relation of ingredients in the main raw materials is as follows: 53-55mol% of Fe2o3, 32-34mol% of one or the mixture of the MnO and the Mn3O4, and the balance of ZnO; (2) smelting: placing Fe2O3, ZnO, and MnO, or Mn3O4 into a vacuum furnace in the sequence from bottom to top, covering the furnace cover, and vacuumizing the vacuum furnace to carry out smelting, wherein smelting temperature is 1400-2000 DEG C; (3) preparing powder through atomization; (4) carrying out compression molding; and (5) annealing the molded product in a vacuum annealing furnace at 500-800 DEG C for 1-2 hours. The preparation method disclosed by the invention has lower requirements for the purity and particle size distribution of the raw materials compared with a traditional preparation method, and the cost of the raw materials is reduced.

Owner:HAINING LIANFENG MAGNET IND

Preparation method of loaded cobalt catalyst

ActiveCN106925274AHighlight substantiveEvenly dopedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNanofiberReducing atmosphere

The invention provides a preparation method of a loaded cobalt catalyst, and relates to a cobalt-containing catalyst. The preparation method includes the steps that a spinel-type oxide CoAl2O4 is prepared through a sol-gel method; then, the oxide is loaded on the surface of sepiolite ore nanofiber through an impregnation method, and a CoAl2O4 / sepiolite ore nanofiber composite is obtained; then, the composite is reduced in a reducing atmosphere, and a cobalt / CoAl2O4 / sepiolite ore nanofiber composite, namely, the loaded cobalt catalyst formed by the CoAl2O4 / sepiolite ore nanofiber composite loaded with cobalt is obtained. The defects of an existing loaded cobalt catalyst that the preparation process is complex, the reaction energy consumption is high, and a product is poor in high-temperature stability and prone to agglomeration at a high temperature are overcome.

Owner:HEBEI UNIV OF TECH

Preparation method of carbon-cladding graphite oxide/Sn composite cathode material of lithium ion battery

ActiveCN104766962AAbundant resourcesLow priceCell electrodesSecondary cellsDischarge efficiencyNew energy

The invention belongs to the technical field of new energy, and particularly relates to a preparation method of a carbon-cladding graphite oxide / Sn composite cathode material of a lithium ion battery. The method comprising the following steps of preparing graphite oxide by adopting natural crystalline flake graphite as a raw material and adopting a Hummers method, placing a tin-containing organic compound into the prepared graphite oxide to obtain a graphite oxide / Sn composite, carrying out the organic cladding by adopting a liquid-phase cladding method, carrying out the high-temperature calcining, and obtaining the carbon-cladding graphite oxide / Sn composite sodium ion battery cathode material. The prepared electrode material is large in reversible capacity, small in size variation, good in cycling property and high in primary charging-discharging efficiency.

Owner:LIAONING TECHNICAL UNIVERSITY

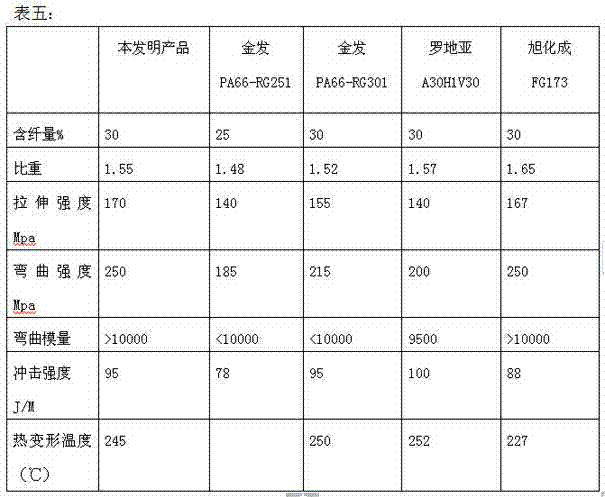

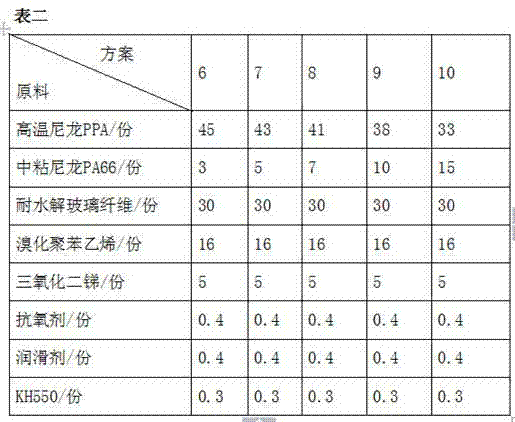

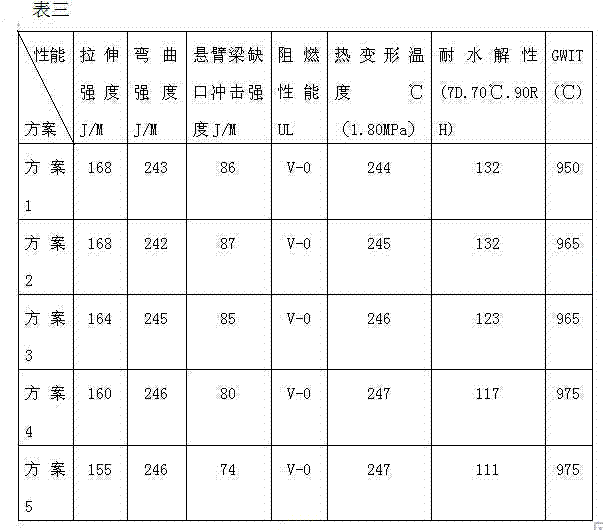

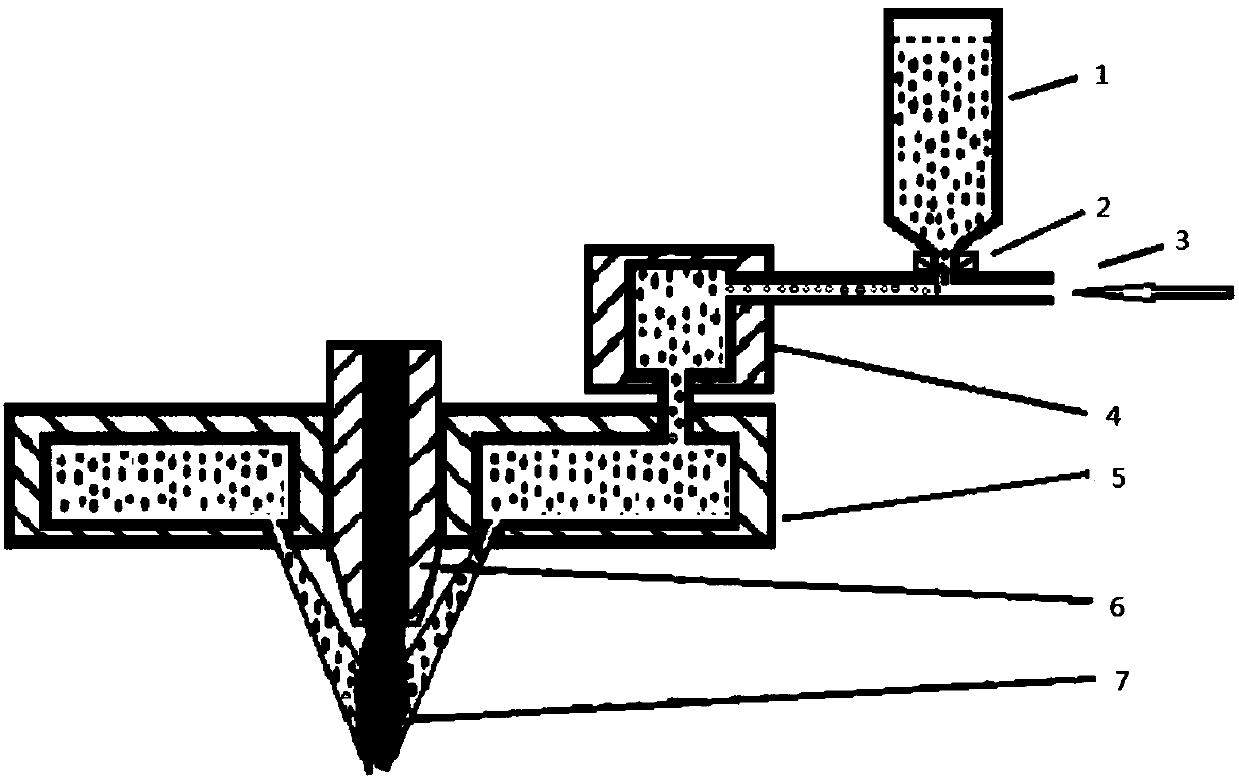

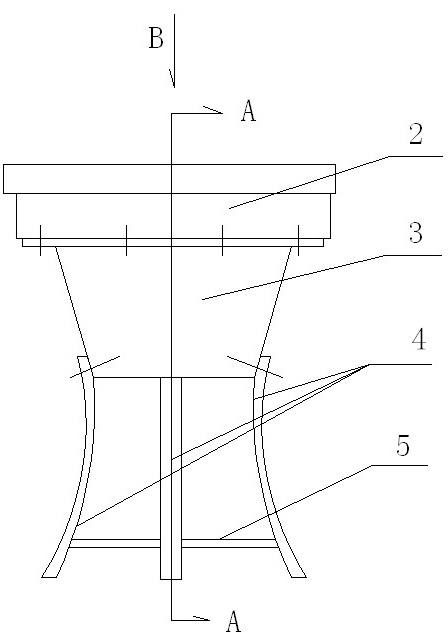

Flame-retardant reinforced high temperature nylon composite material and its preparation method

The invention discloses a flame-retardant reinforced high temperature nylon composite material. The composite material is prepared by blending the following raw materials, by weight, 25-65 parts of PPA, 3-15 parts of PA66, 15-50 parts of glass fiber, 15-22 parts of a bromine family flame retardant, 4-10 parts of a metal oxide flame retardant, 0.4-1 part of an antioxidant, 0.1-1 part of a lubricant and 0.1-1 part of a coupling agent. The invention also discloses a preparation method of the composite material. The method comprises the following steps: uniformly mixing the above raw materials except the glass fiber in a mixer, pouring the obtained mixture into a storage hopper under a feeding speed of 16-20hz, adding the mixture to an extruder, carrying out shearing blending, adding the glass fiber, carrying out melt extrusion, and granulating to obtain the composite material, wherein the extrusion speed is 320-400rpm, and the processing temperature is 280-310DEG C. The composite material has the advantages of high temperature resistance, high strength, good fluidity, good processing performance, good flame retardation property, and hydrolysis resistance.

Owner:DONGGUAN ZHONGYI NEW MATERIAL TECH CO LTD

Preparation method of metal base nanometer composite powder material for added material manufacturing

InactiveCN108015295AEvenly distributedGood dispersionMaterial nanotechnologyTransportation and packagingNanoparticleMetal powder

The invention relates to a preparation method of a metal base nanometer composite powder material for added material manufacturing, and belongs to the technical field of preparation of metal powder. Nanometer reinforcing particles are introduced in the atomization powder preparation process, so that atomization powder preparation and nanometer particle reinforcement are synchronously finished to realize metallurgical bonding of a basal body and nanometer particles. Compared with the prior art, the method can efficiently prepare the nanometer composite powder material with high sphericity and good fluidity, and is more suitable for industrial preparation of the composite powder material for added material manufacturing.

Owner:BEIJING COMPO ADVANCED TECH

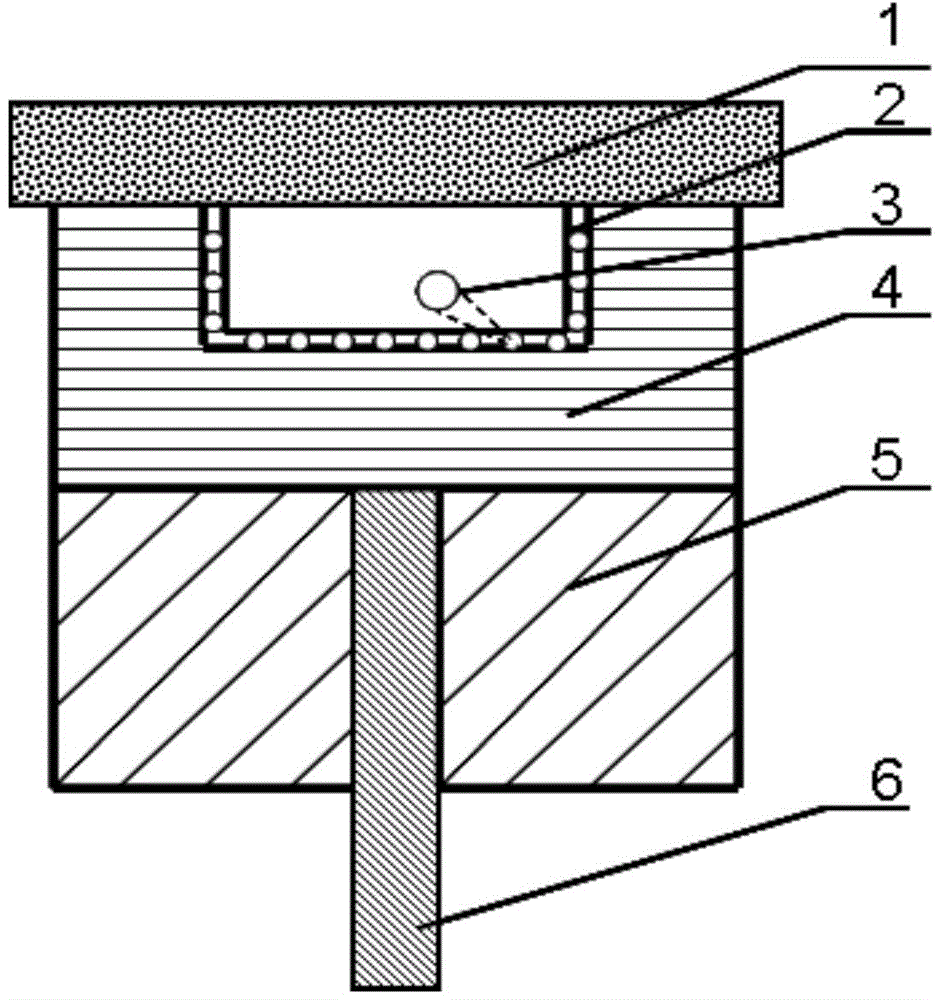

Ladle nozzle casting combined drainage plug

InactiveCN102091776ANovel ideaCompact and reasonable structureMelt-holding vesselsInosculationThin shells

The invention discloses a ladle nozzle casting combined drainage plug, belongs to an accessory device for ladle casting operation, and particularly relates to a ladle brick cup nozzle casting drainage device. The drainage plug is characterized by consisting of a sand storage, an inosculation cylinder, clamping plates and supporting sheets which are connected; the bottom of the sand storage is greater than the diameter of the upper part of a nozzle, a bottom plate is provided with a double-wall annular sand storage chamber in which drainage sand is filled, and a plug cover is tightly covered on the sand storage chamber; the bottom plate is provided with a guide hole corresponding to the center of the plug cover; and the inosculation cylinder is a thin-shell cylinder equivalent to the shape of the inner wall of the nozzle, the upper part of the inosculation cylinder is connected with the bottom plate of the sand storage, the lower part of the inosculation cylinder is provided with the clamping plates in pairs, one end of the supporting sheet is fixed on the clamping plate, and the free end of the supporting sheet is jacked on the opposite clamping plate. The drainage plug has novel conception, compact and reasonable structure; the components are manufactured separately, so the drainage plug is convenient to process, store and transport; the drainage plug saves materials, has light weight, and is easily installed accurately in place; the strength of the drainage plug is remarkably increased, so the drainage plug is stable to install and safe and reliable in use; the nozzle is clean, so the casting success rate is improved; and the drainage plug saves the expense and time for treating drainage faults, and is favorable for smooth operation of steelmaking production.

Owner:马鞍山中冶钢铁冶金高新技术有限公司 +1

High-vacuum optical fiber F-P pressure sensor

ActiveCN105987784AStrong Strength and ConductivityHigh precisionFluid pressure measurement by optical meansPressure sensitiveEngineering

The invention discloses a high-vacuum optical fiber F-P pressure sensor, which comprises a pressure-sensitive diaphragm, an upper insert core, a lower insert core and an optical fiber coated inside the lower insert core. The upper insert core (4) is provided with a groove. A layer of nanoparticles (3) for absorbing residual gases in an F-P cavity is covered onto the bottom surface and the periphery of the groove, and is wrapped by a graphene film (2). The pressure-sensitive diaphragm (1) and the upper insert core (4) are connected to form the F-P cavity. The upper insert core (4) and the lower insert core (5) are connected with each other as a whole. One part of the optical fiber is inserted into the lower insert core, and the other part of the optical fiber is located outside the lower insert core. The optical fiber is connected with a demodulation device as a conductive fiber. The upper insert core and the lower insert core are connected with each other as a whole. The high-vacuum optical fiber F-P pressure sensor is simple in structure, convenient and rapid to manufacture, and low in cost. The high-vacuum optical fiber F-P pressure sensor solves the problem in the prior art that the vacuum degree of residual gases in the F-P cavity cannot be smaller than 1 Kpa.

Owner:CHENGDU KAITIAN ELECTRONICS

Preparation method for hydrophobic modified nano-calcium carbonate filled silicone rubber composite membrane

ActiveCN104084059ALow costImproved mechanical strength and toughnessSemi-permeable membranesSolventPolyvinylidene fluoride

The invention discloses a preparation method for a hydrophobic modified nano-calcium carbonate filled silicone rubber composite membrane. The preparation method comprises the following steps: (1) adding dried nano-calcium carbonate into a modifier, stirring for reaction, repeatedly cleaning by using a solvent, namely n-hexane, removing the excess modifier, drying in vacuum, and grinding to obtain hydrophobic modified nano-calcium carbonate; (2) dissolving dried polyvinylidene fluoride in triethyl phosphate, stirring uniformly, filtering, standing, defoaming, scraping a membrane on polyester non-woven cloth, and naturally airing to obtain a polyvinylidene fluoride base membrane; and (3) dissolving polydimethylsiloxane in n-hexane, stirring uniformly, adding hydrophobic modified nano-calcium carbonate, performing ultrasonic dispersion, adding a crosslinking agent and a catalyst, stirring for reaction, performing centrifugation, defoaming to obtain a casting membrane solution, pouring the casting membrane solution on the polyvinylidene fluoride base membrane and scraping a membrane on the polyvinylidene fluoride base membrane, airing, and drying in the vacuum. According to the composite membrane prepared by the preparation method, the process is simple, the cost is low, and the prior butanol penetration capability is high.

Owner:江苏矽时代材料科技有限公司

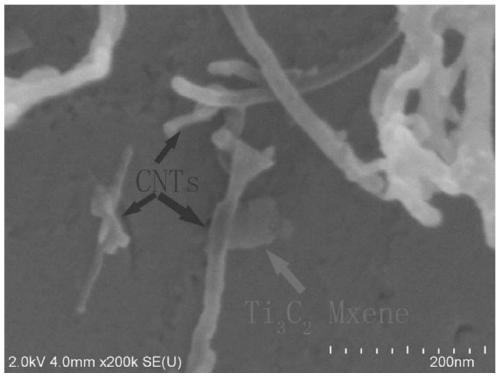

Synergistically enhanced copper matrix composite material and preparing method thereof

The invention relates to a synergistically enhanced copper matrix composite material and a preparing method thereof. The synergistically enhanced copper matrix composite material adopts carbon quantumdots, carbon nanotubes and Ti3C2 Mxene as reinforcing phases. The method comprises the steps that an aqueous dispersion of the carbon quantum dots, the carbon nanotubes and the Ti3C2 Mxene is prepared; the dispersion is added into a copper salt aqueous solution, an alkaline solution is added in to form copper hydroxide, and a reducing agent is added to reduce the copper hydroxide into cuprous oxide; filtering, washing and drying are carried out to obtain composite powder, and the cuprous oxide in the composite powder is reduced into copper; and discharge plasma sintering is carried out on thecopper-based composite powder. The dimensionality synergistic action of the carbon quantum dots, the carbon nanotubes and the Ti3C2 Mxene is used, and the copper-based composite material with the significantly-improved mechanical property is obtained; the copper-based composite powder with uniform dispersion and firm combination is obtained by molecular-scale blending; and discharge plasma sintering is adopted so that the Cu grain growth is effectively suppressed.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com