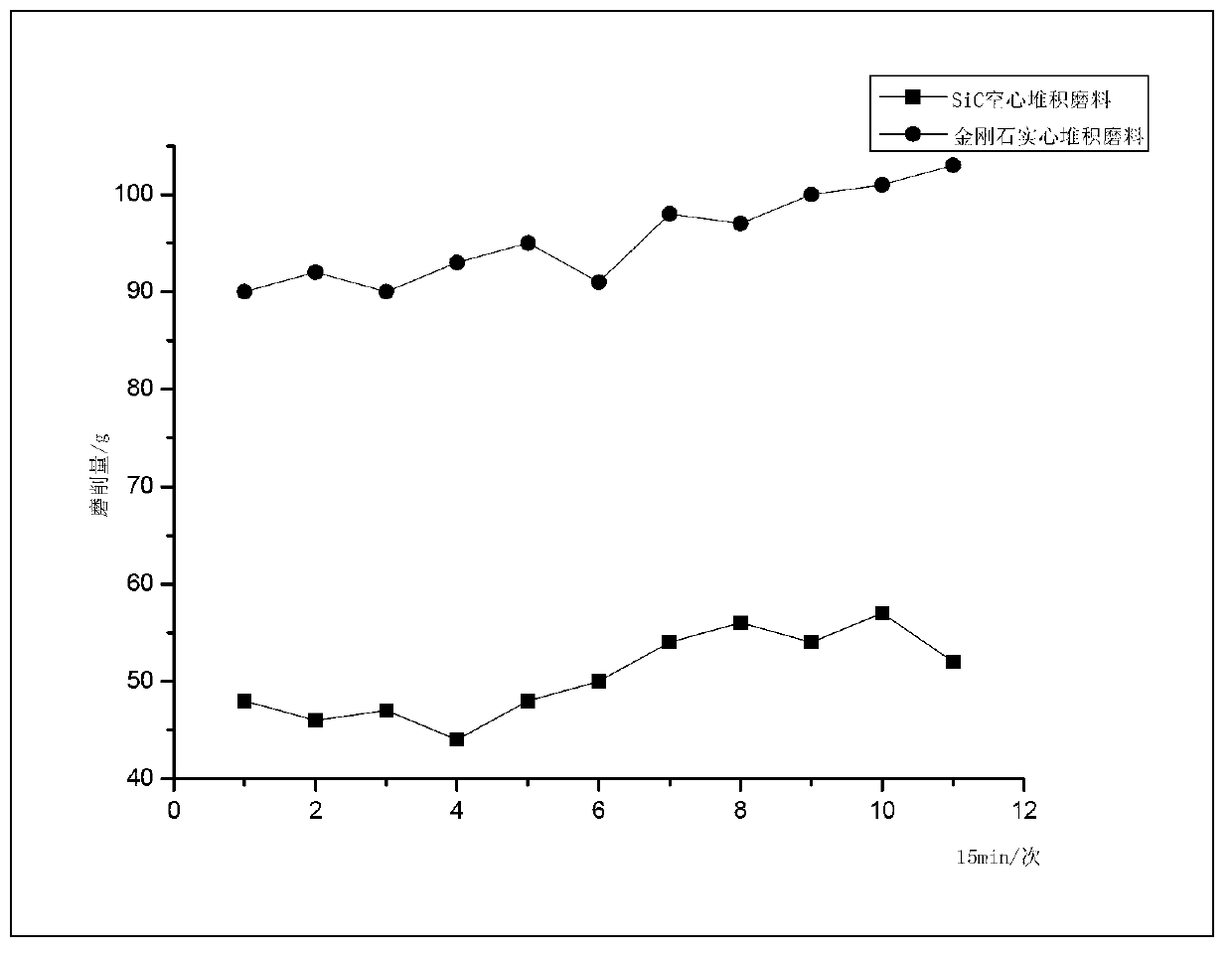

Ultrafine diamond and ceramic binding agent stacked abrasive materials and preparation method thereof

A vitrified bond and stacked abrasive technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding devices, etc., can solve problems such as failure to meet high-performance grinding requirements, poor internal structure uniformity, and poor diamond dispersion. Achieve the effect of uniform internal structure, broaden the processing object, and consistent resection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

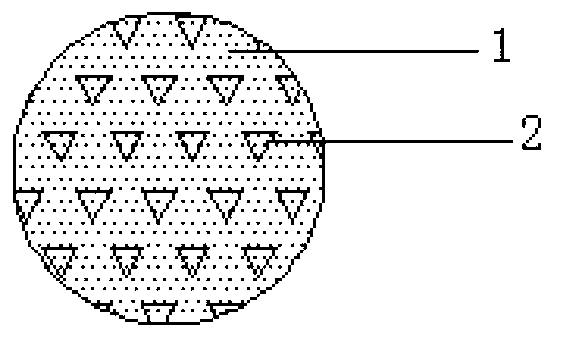

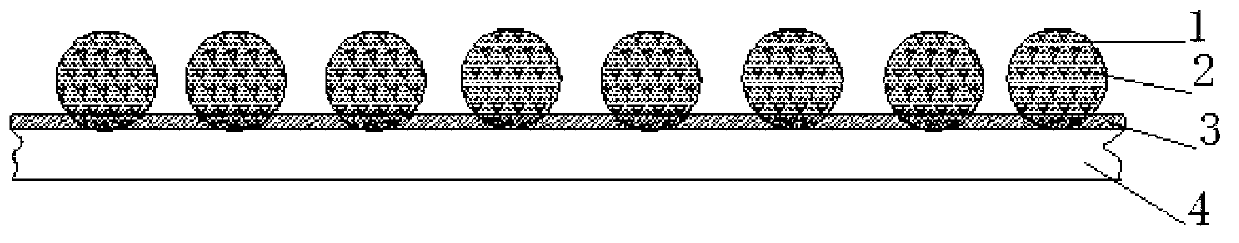

[0023] The present invention prepares ZnO-SiO 2 -Al 2 o 3 -B 2 o 3 -Na 2 O-Li 2 The raw materials used in the O ceramic bond are: SiO 2 Sol, Al 2 o 3 Sol, ZnNO 3 、H 3 BO 3 、NaNO 3 、LiNO 3 , and the content of each component is shown in the table below:

[0024] components

[0025] Take the mass fraction as 10%Al 2 o 3 130 grams of sol solution, the mass fraction is 62% nano-SiO 2 Put 50 grams of sol solution into a glass beaker, add other raw materials, and stir in a constant temperature water bath at 45°C for 30 minutes. At this time, the viscosity of the mixed sol solution is 17mpa.s, and then add 150g of superfine diamond with a particle size of W1.0 Micro powder, stirred for 30 minutes, then the slurry enters the machine through the conduit of the spray dryer, the spray pressure is 0.6MPa, the temperature inside the dryer is 320°C, the diameter of the accumulated abrasive balls sprayed out is 0.3-0.5mm, and then the material is placed in the muffl...

Embodiment 2

[0027] The present invention prepares ZnO-SiO 2 -Al 2 o 3 -B 2 o 3 -Na 2 O-Li 2 The raw materials used in the O ceramic bond are: SiO 2 Sol, Al 2 o 3 Sol, ZnNO 3 、H 3 BO 3 、NaNO 3 、LiNO 3 , and the content of each component is shown in the table below:

[0028] components

[0029] Take the mass fraction as 20%Al 2 o 3 65 grams of sol solution, the mass fraction is 62% nano-SiO 2 Add 50 grams of sol solution into a glass beaker, add other raw materials, and stir for 30 minutes in a constant temperature water bath at 45°C. At this time, the viscosity of the mixed sol solution is 25mpa.s, and then add 150g of ultra- Fine diamond powder, stirred for 30 minutes, and then the slurry enters the machine through the conduit of the spray dryer, the spray pressure is 0.7MPa, the temperature in the dryer is 310°C, and the diameter of the accumulated abrasive balls sprayed out is 0.4-0.6mm, and then the material is placed in the Calcined in a muffle furnace at a ...

Embodiment 3

[0031] The present invention prepares ZnO-SiO 2 -Al 2 o 3 -B 2 o 3 -Na 2 O-Li 2 The raw materials used in the O ceramic bond are: SiO 2 Sol, Al 2 o 3 Sol, ZnNO 3 、H 3 BO 3 、NaNO 3 、LiNO 3 , and the content of each component is shown in the table below:

[0032] components

[0033] Take the mass fraction as 25%Al 2 o 3 Sol liquid 52 grams, mass fraction is the nano-SiO of 62% 2 Add 50 grams of sol solution into a glass beaker, add other raw materials, and stir for 30 minutes in a constant temperature water bath at 45°C. At this time, the viscosity of the mixed sol solution is 30mpa.s, and then add 150g of ultra- Fine diamond powder, stirred for 30 minutes, then the slurry enters the machine through the conduit of the spray dryer, the spray pressure is 0.7MPa, the temperature in the dryer is 300°C, and the diameter of the accumulated abrasive balls sprayed out is 0.4-0.6mm, and then the material is placed in the Calcined in a muffle furnace at a calcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com