Patents

Literature

867results about How to "Uniform appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

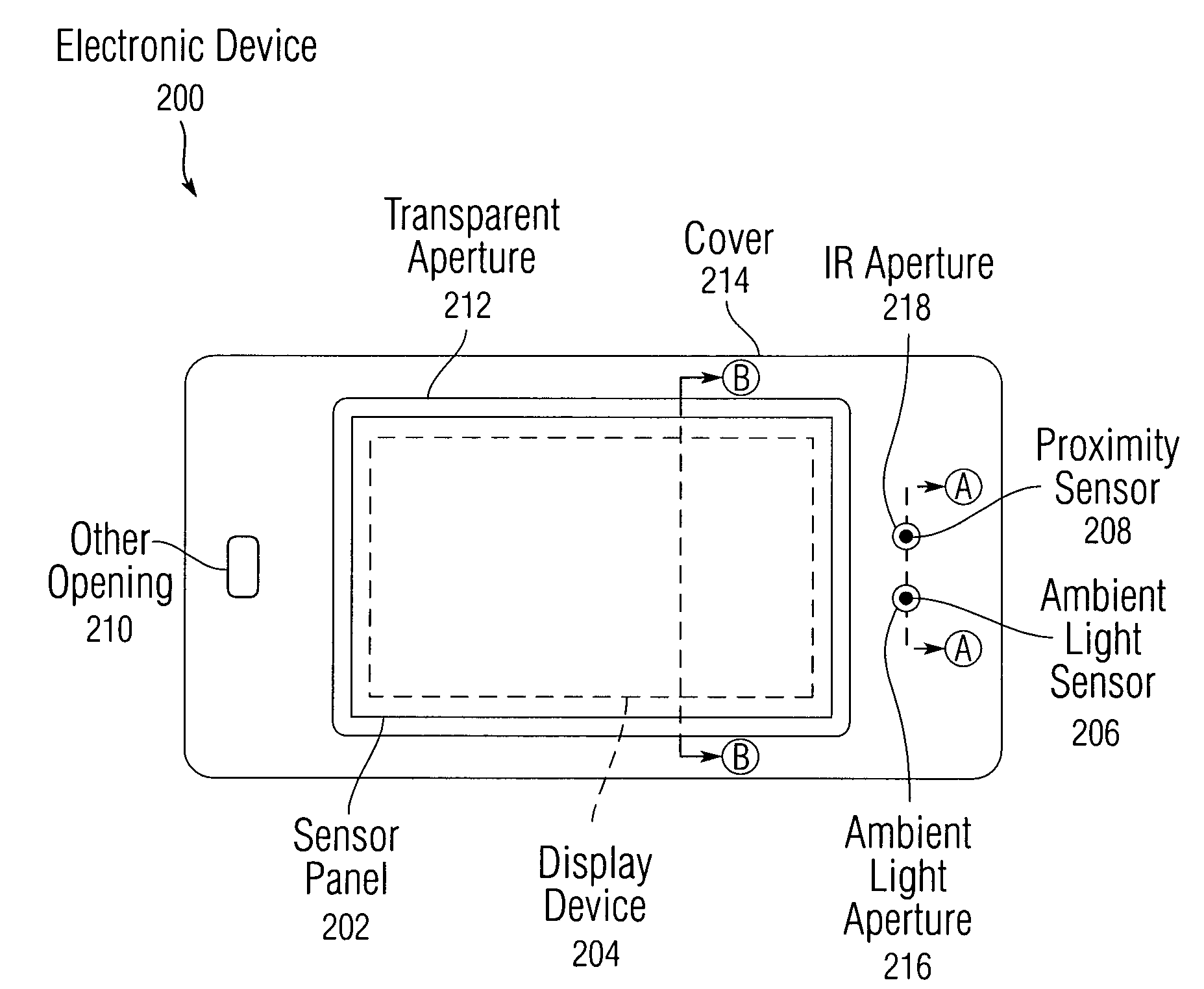

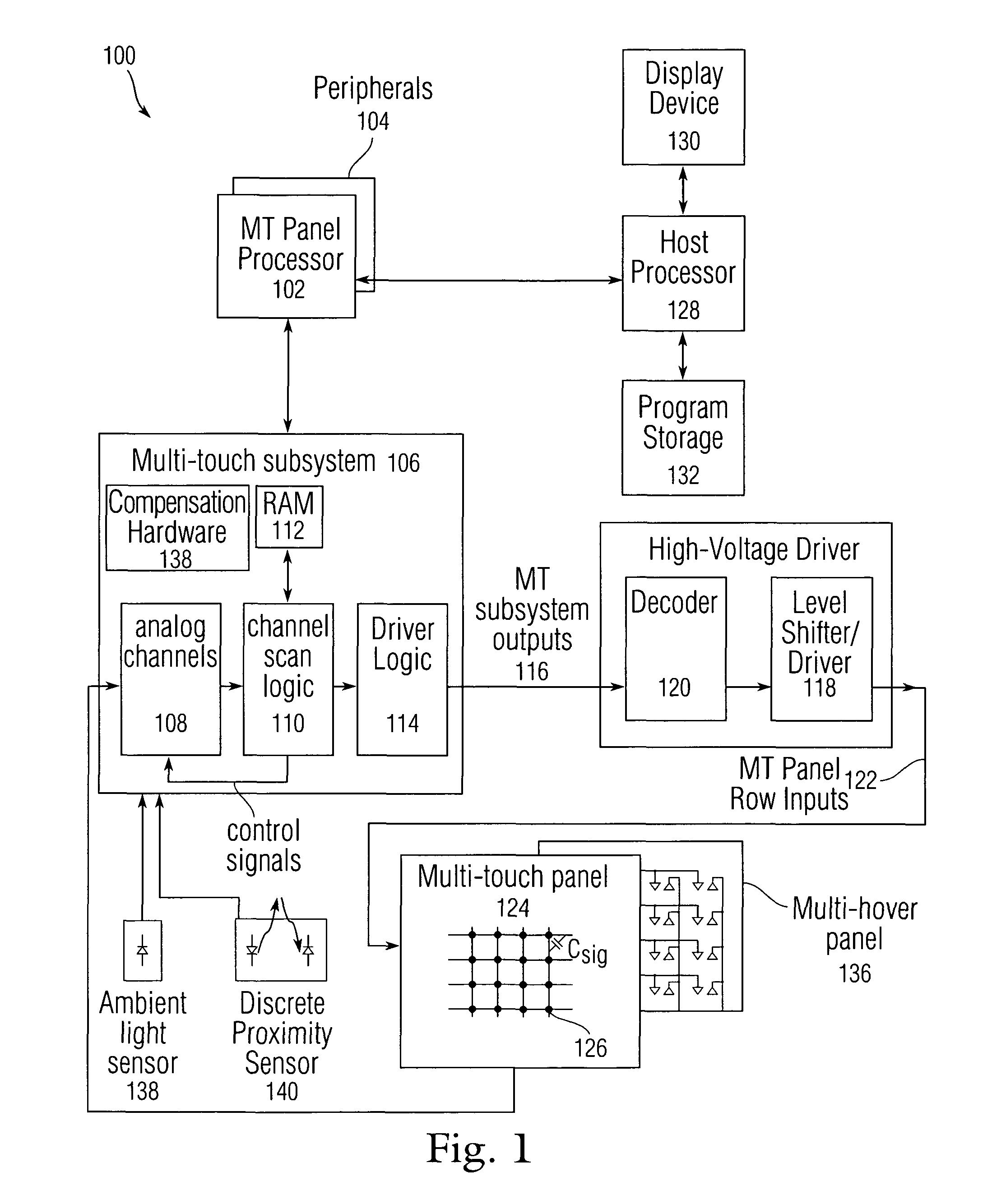

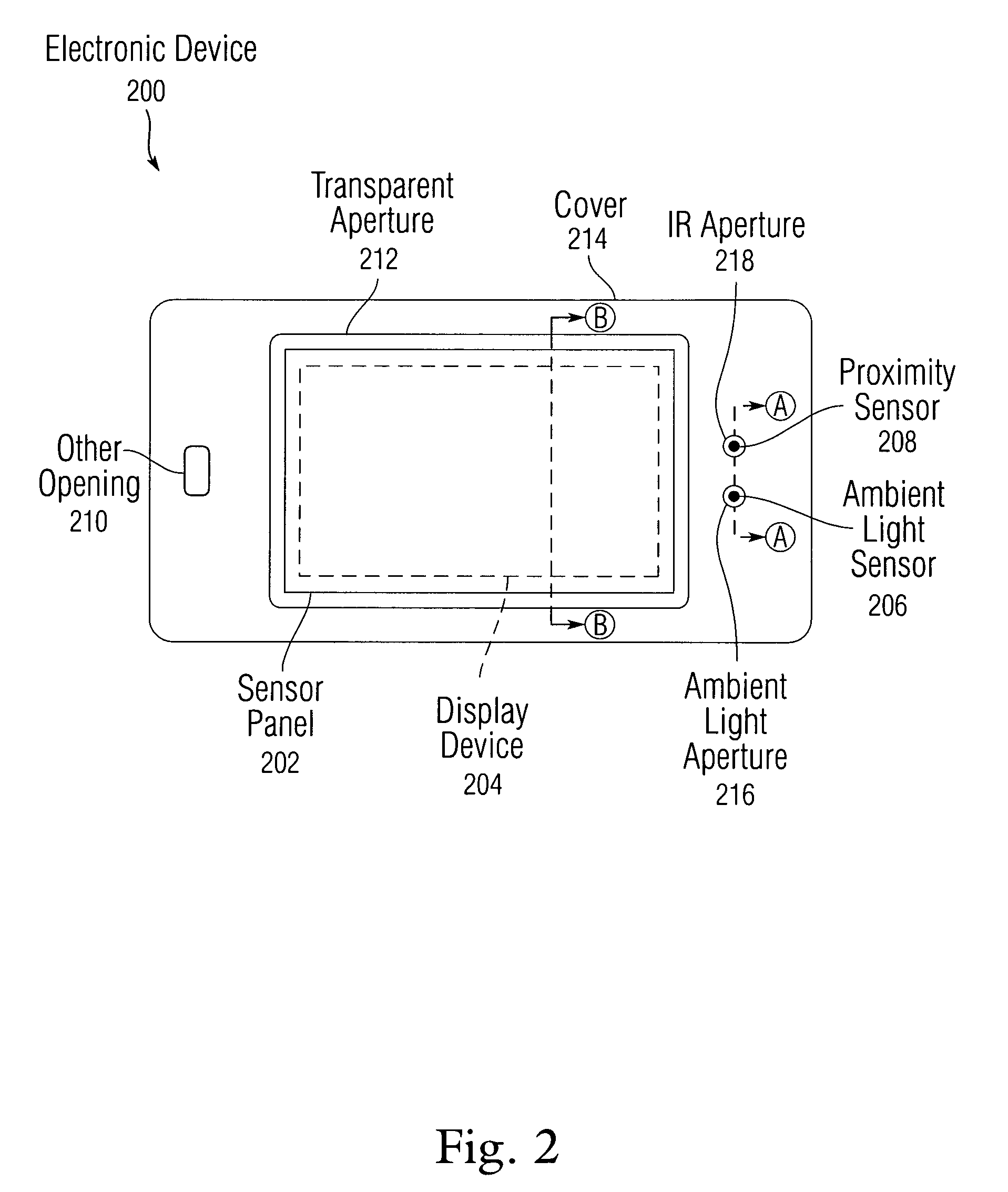

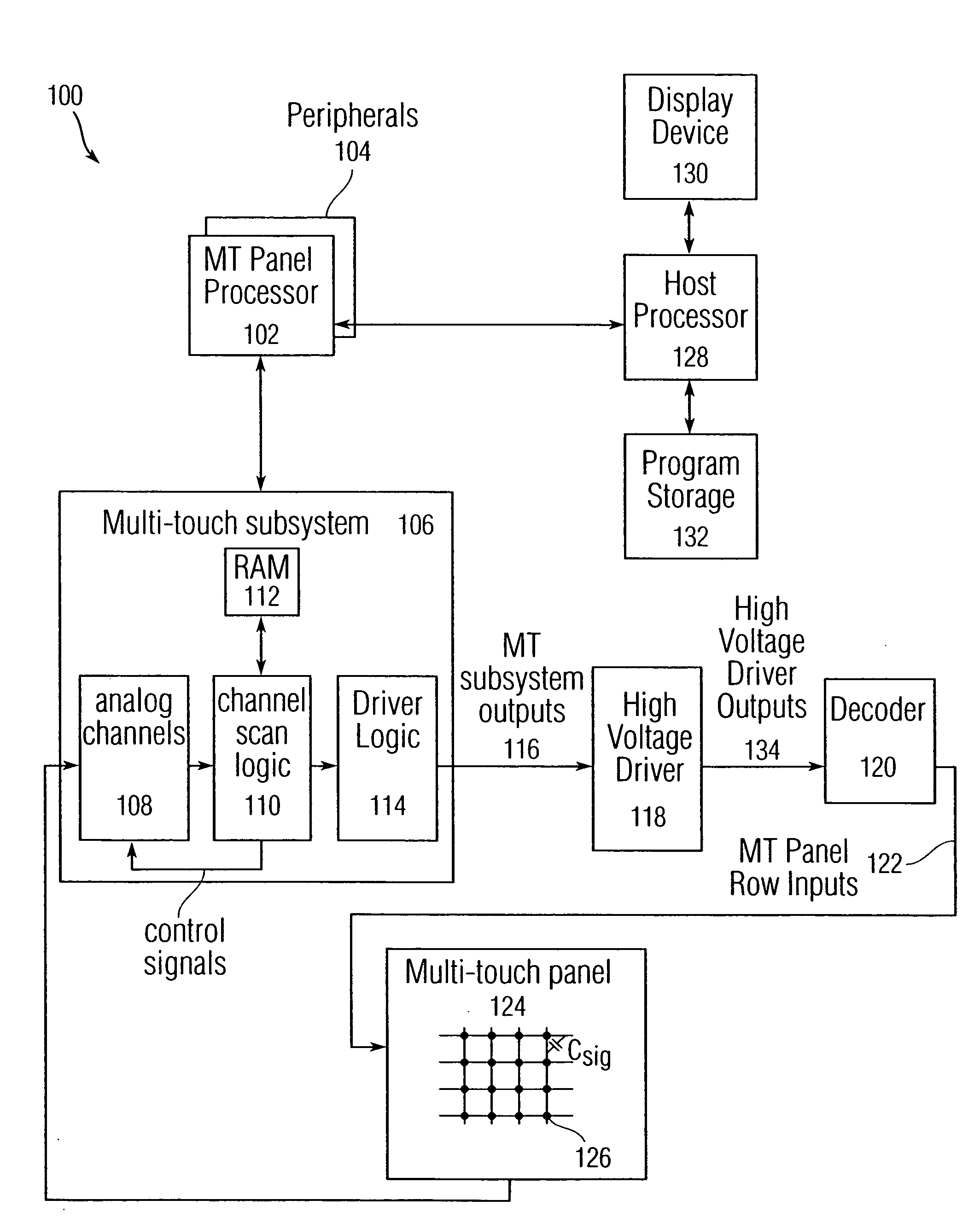

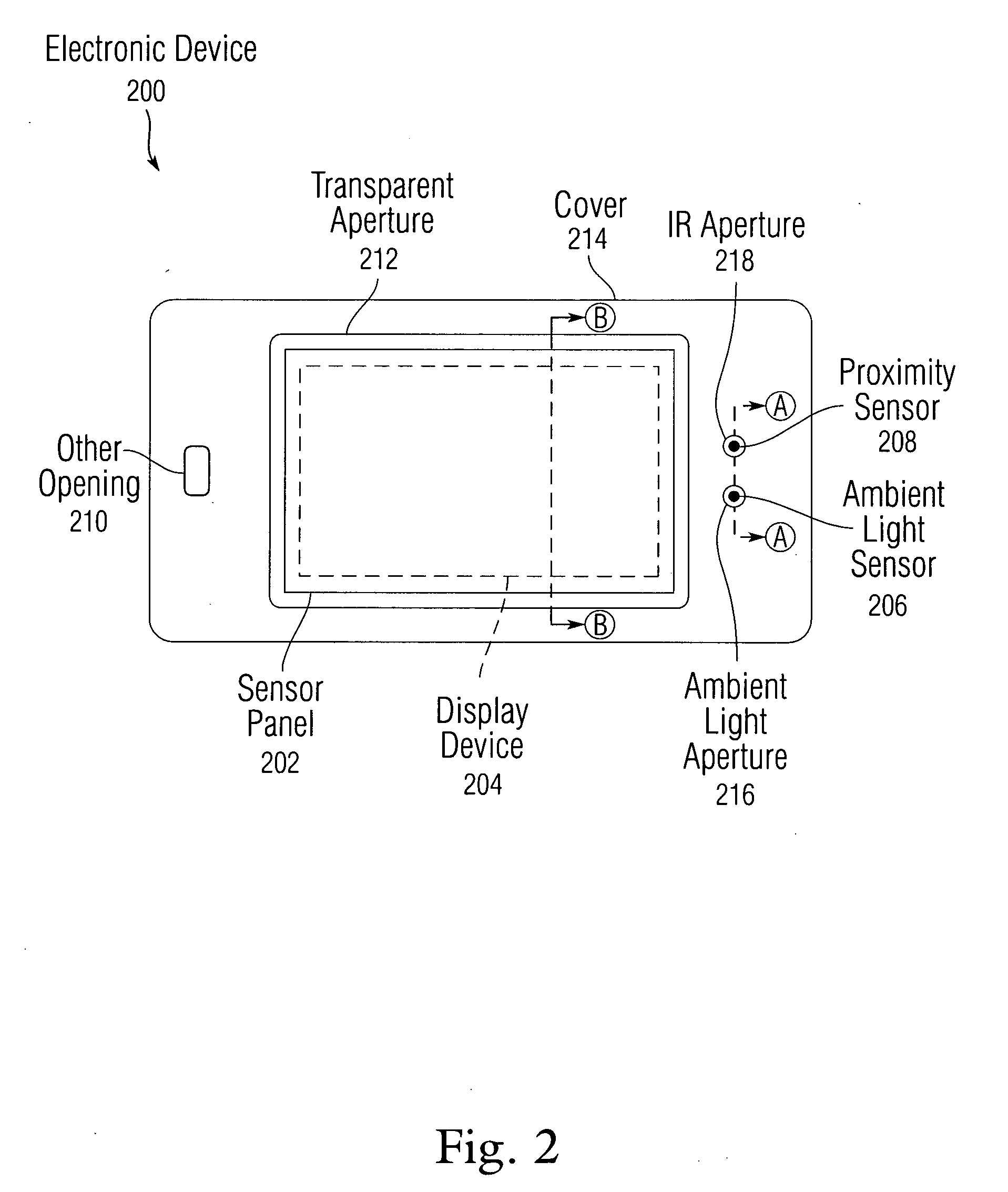

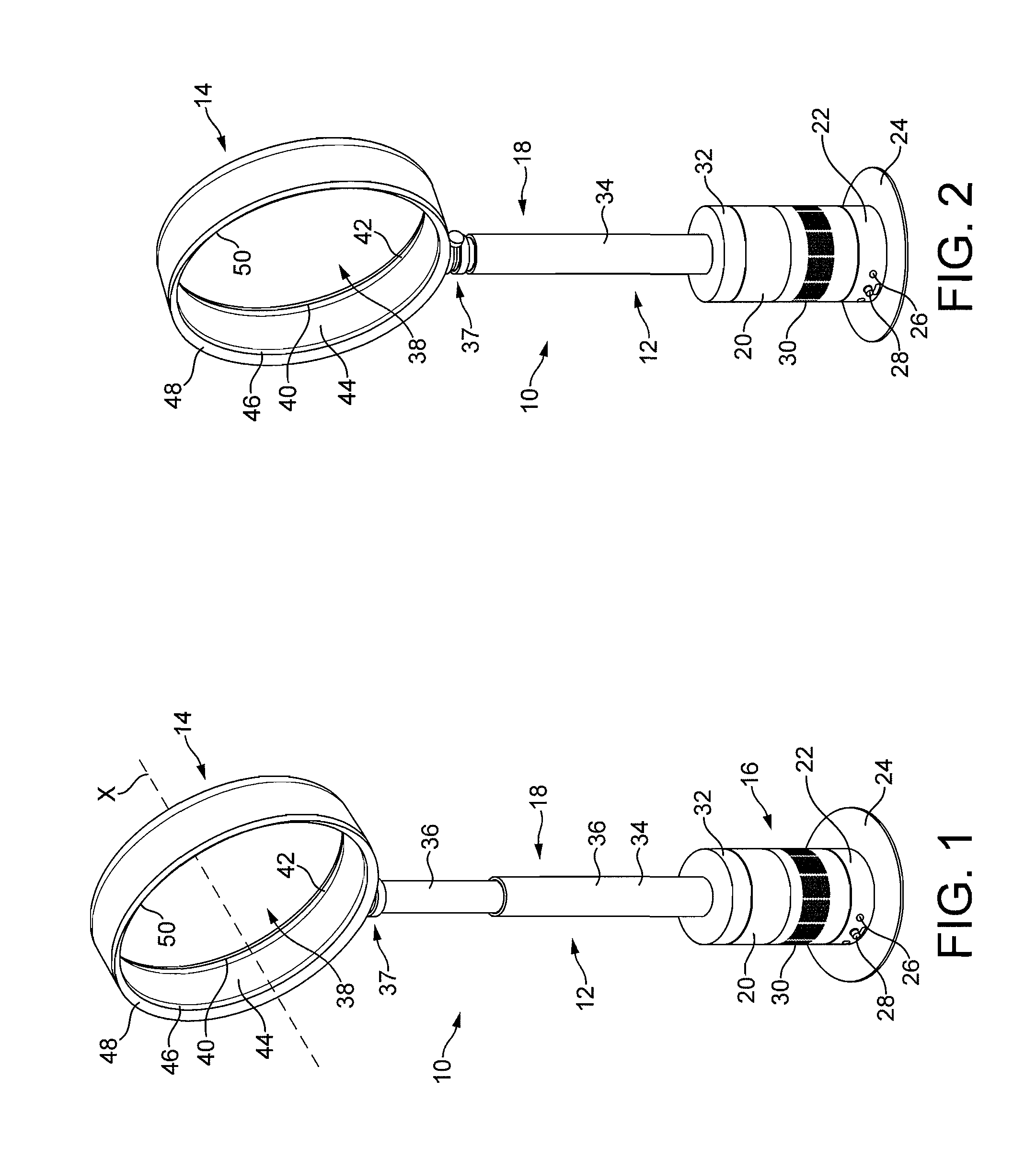

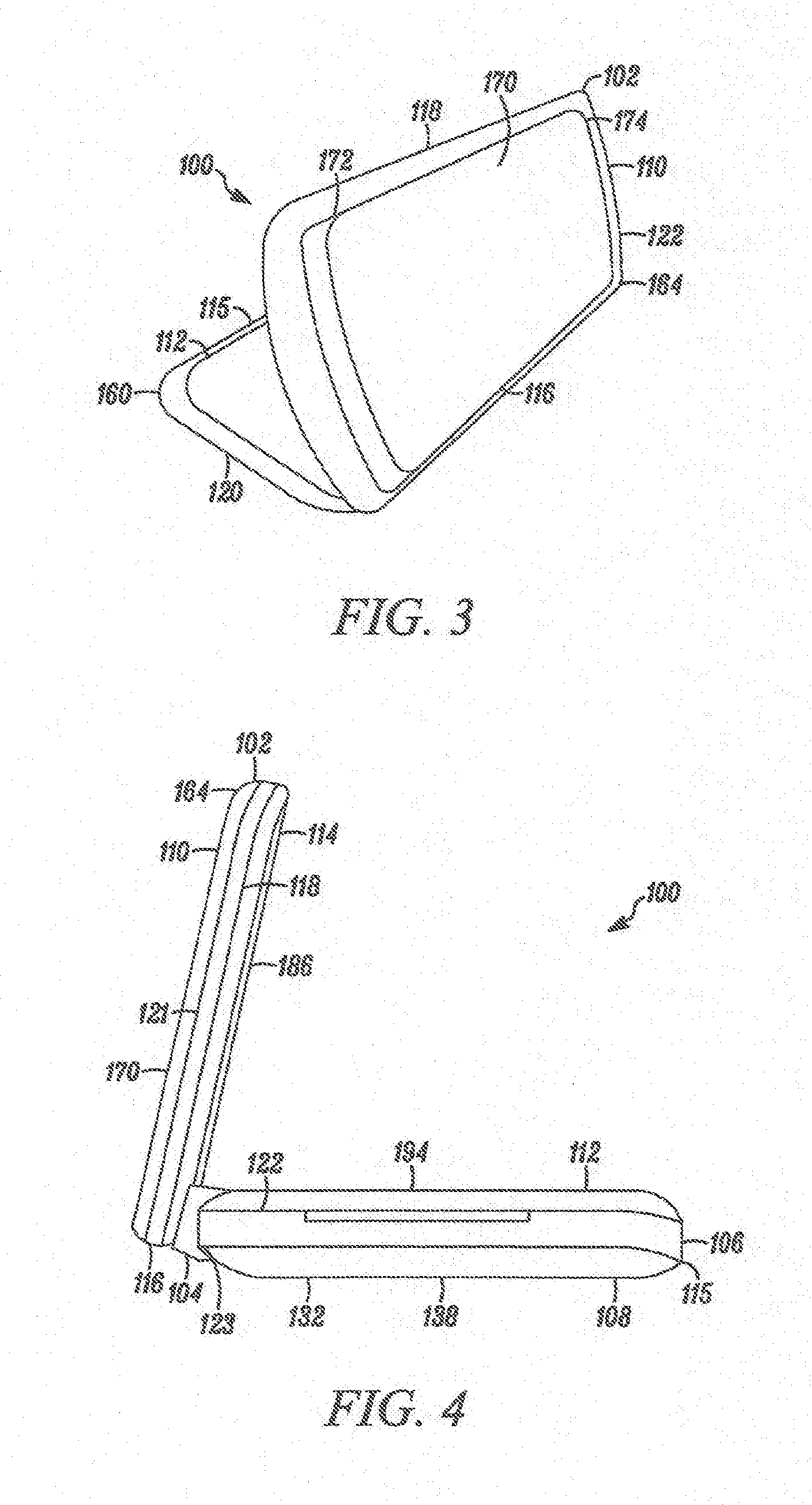

Multi-touch surface stackup arrangement

ActiveUS8031174B2Reduce cover warpageFull surfaceInput/output for user-computer interactionNon-enclosed substationsProximity sensorDisplay device

A multi-layer cover for an electronic device having one or more of a sensor panel, a proximity sensor, an ambient light sensor, and a display device can include an outer hardcoat, a structural layer, an IR transmissive ink layer, a mask layer, and a backside hardcoat. The backside hardcoat can reduce cover warpage, enable full surface lamination of the cover to the sensor panel, prevent bubbles from forming in transparent windows in the cover, enable a wider range of functional inks to be applied in various layering orders to allow certain types of light to pass through while blocking others, and hide the sensors to provide a seamless, uncluttered visual appearance.

Owner:APPLE INC

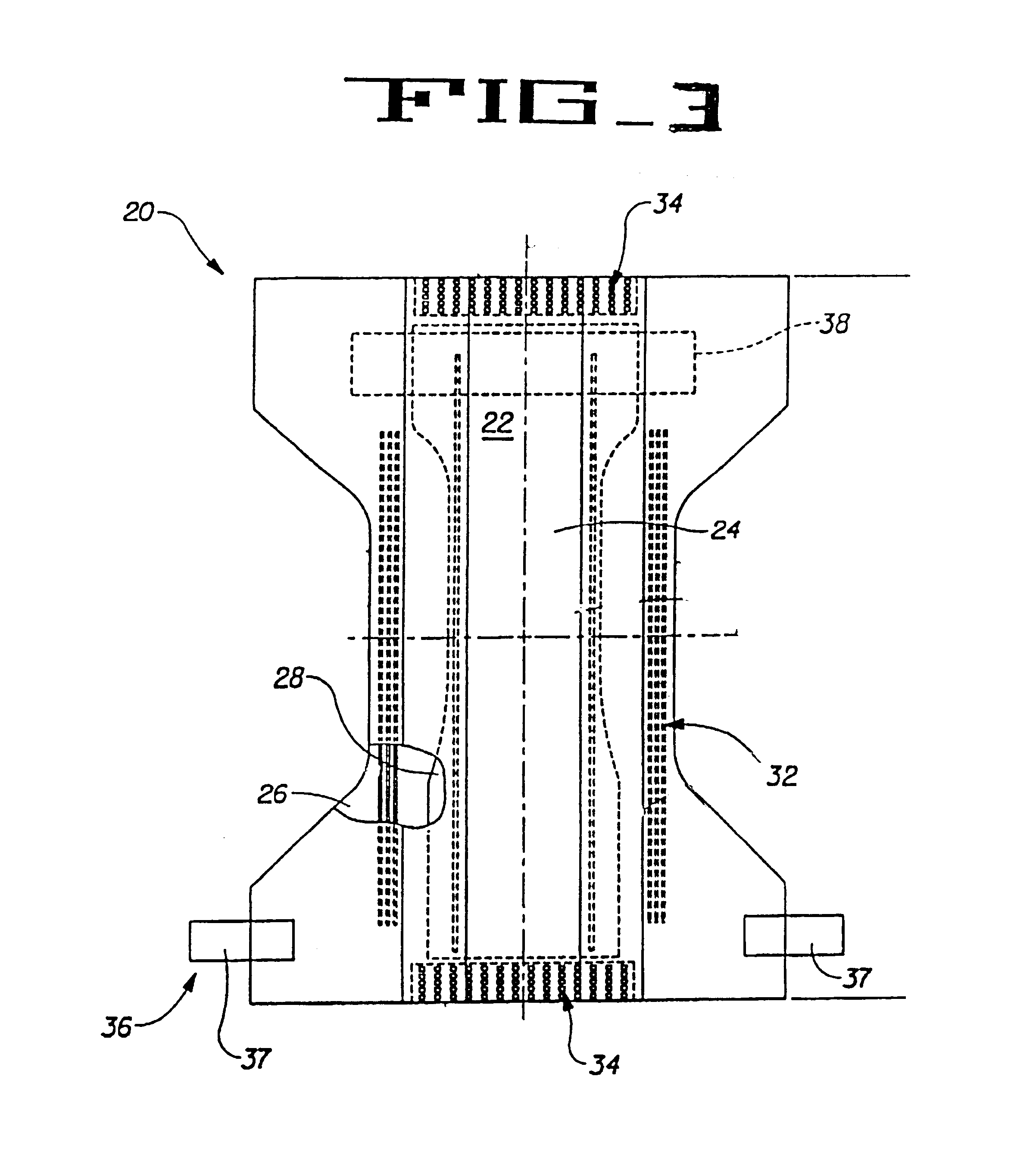

Double-sided touch-sensitive panel with shield and drive combined layer

ActiveUS20080158183A1Space saveUniform appearanceDigital data processing detailsCathode-ray tube indicatorsCapacitive couplingCapacitance

A multi-touch capacitive touch sensor panel can be created using a substrate with column and row traces formed on either side of the substrate. To shield the column (sense) traces from the effects of capacitive coupling from a modulated Vcom layer in an adjacent liquid crystal display (LCD) or any source of capacitive coupling, the row traces can be widened to shield the column traces, and the row traces can be placed closer to the LCD. In particular, the rows can be widened so that there is spacing of about 30 microns between adjacent row traces. In this manner, the row traces can serve the dual functions of driving the touch sensor panel, and also the function of shielding the more sensitive column (sense) traces from the effects of capacitive coupling.

Owner:APPLE INC

Multi-touch surface stackup arrangement

ActiveUS20080158173A1Reduce cover warpageFull surfaceNon-enclosed substationsInput/output for user-computer interactionProximity sensorDisplay device

A multi-layer cover for an electronic device having one or more of a sensor panel, a proximity sensor, an ambient light sensor, and a display device can include an outer hardcoat, a structural layer, an IR transmissive ink layer, a mask layer, and a backside hardcoat. The backside hardcoat can reduce cover warpage, enable full surface lamination of the cover to the sensor panel, prevent bubbles from forming in transparent windows in the cover, enable a wider range of functional inks to be applied in various layering orders to allow certain types of light to pass through while blocking others, and hide the sensors to provide a seamless, uncluttered visual appearance.

Owner:APPLE INC

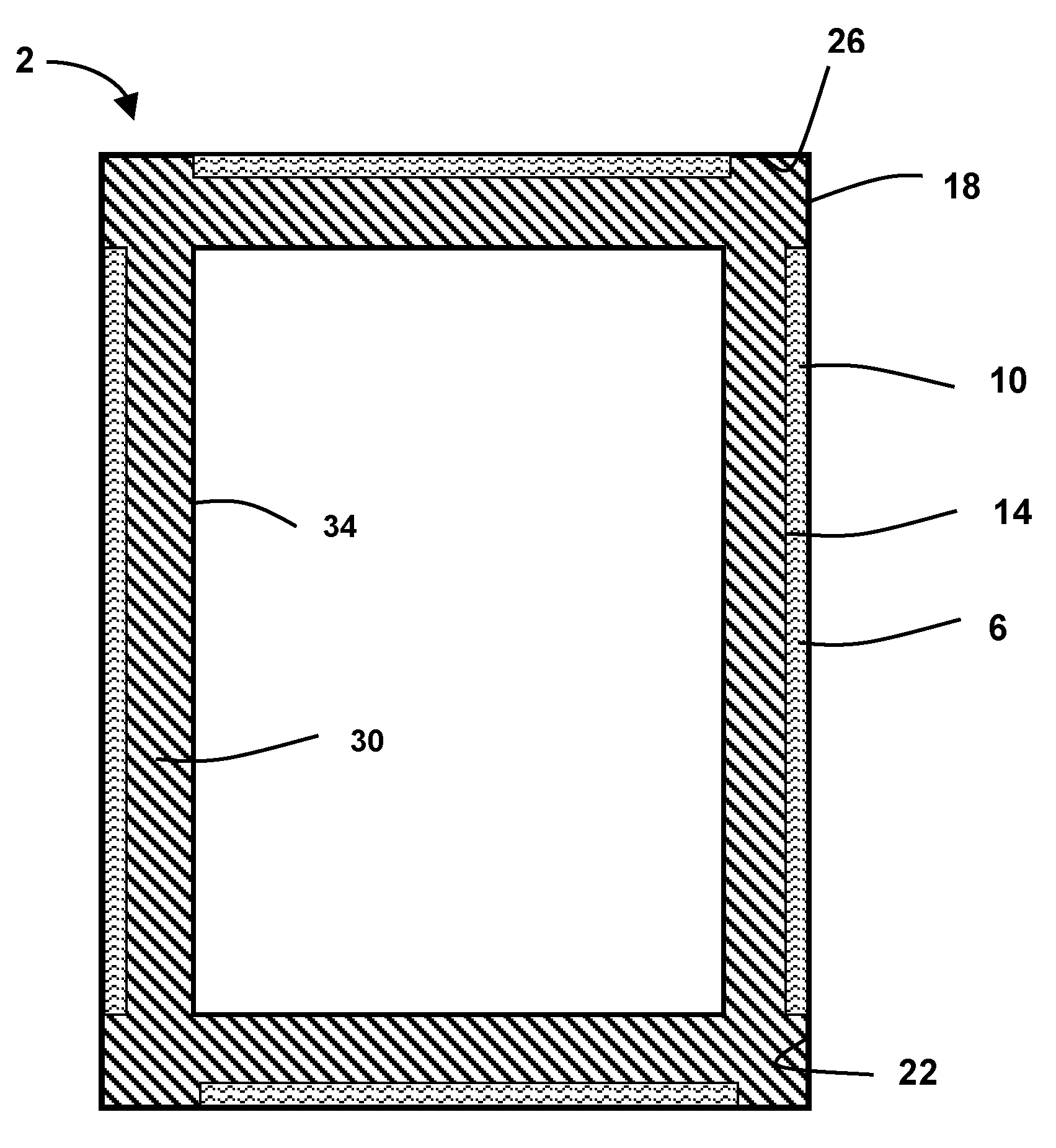

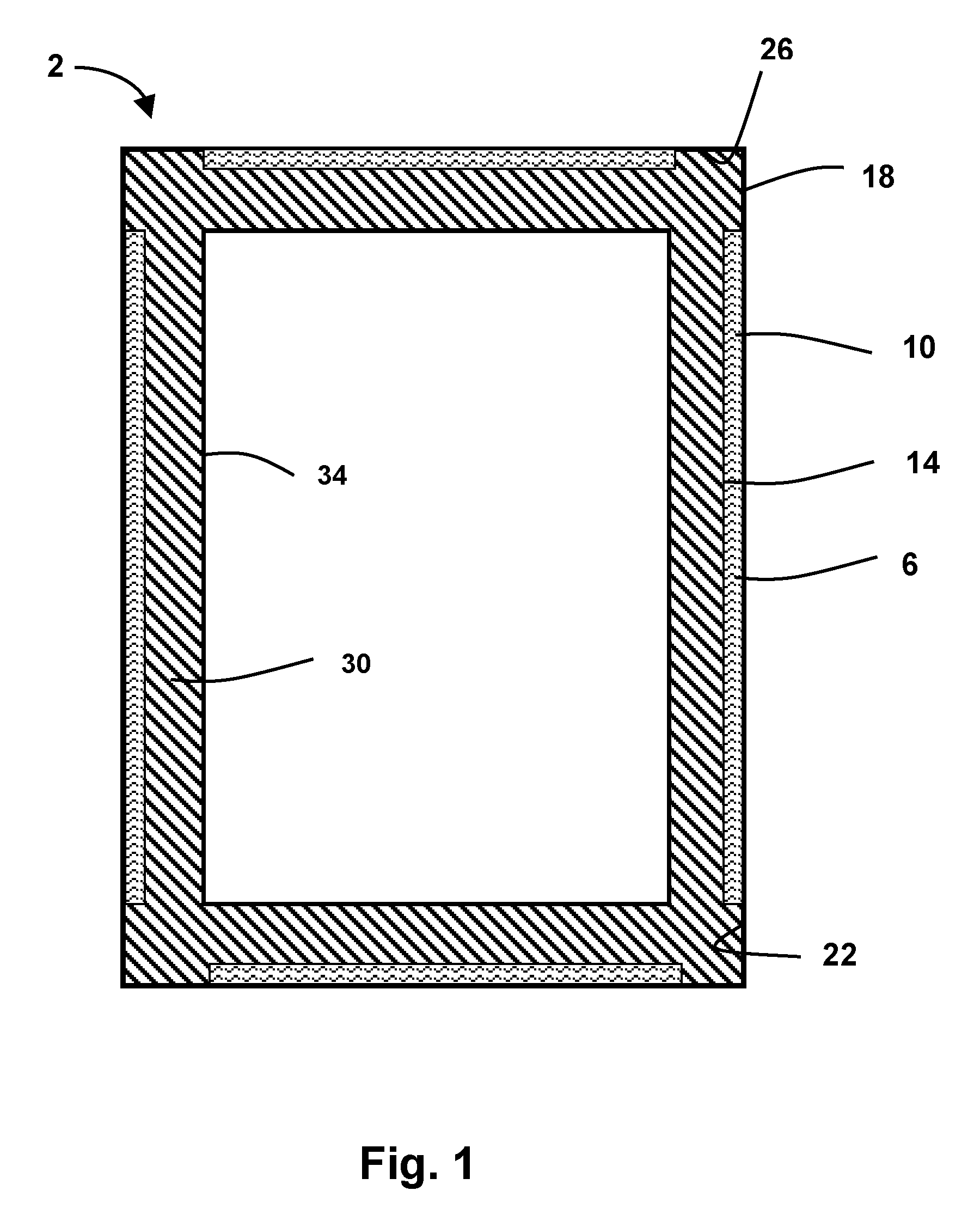

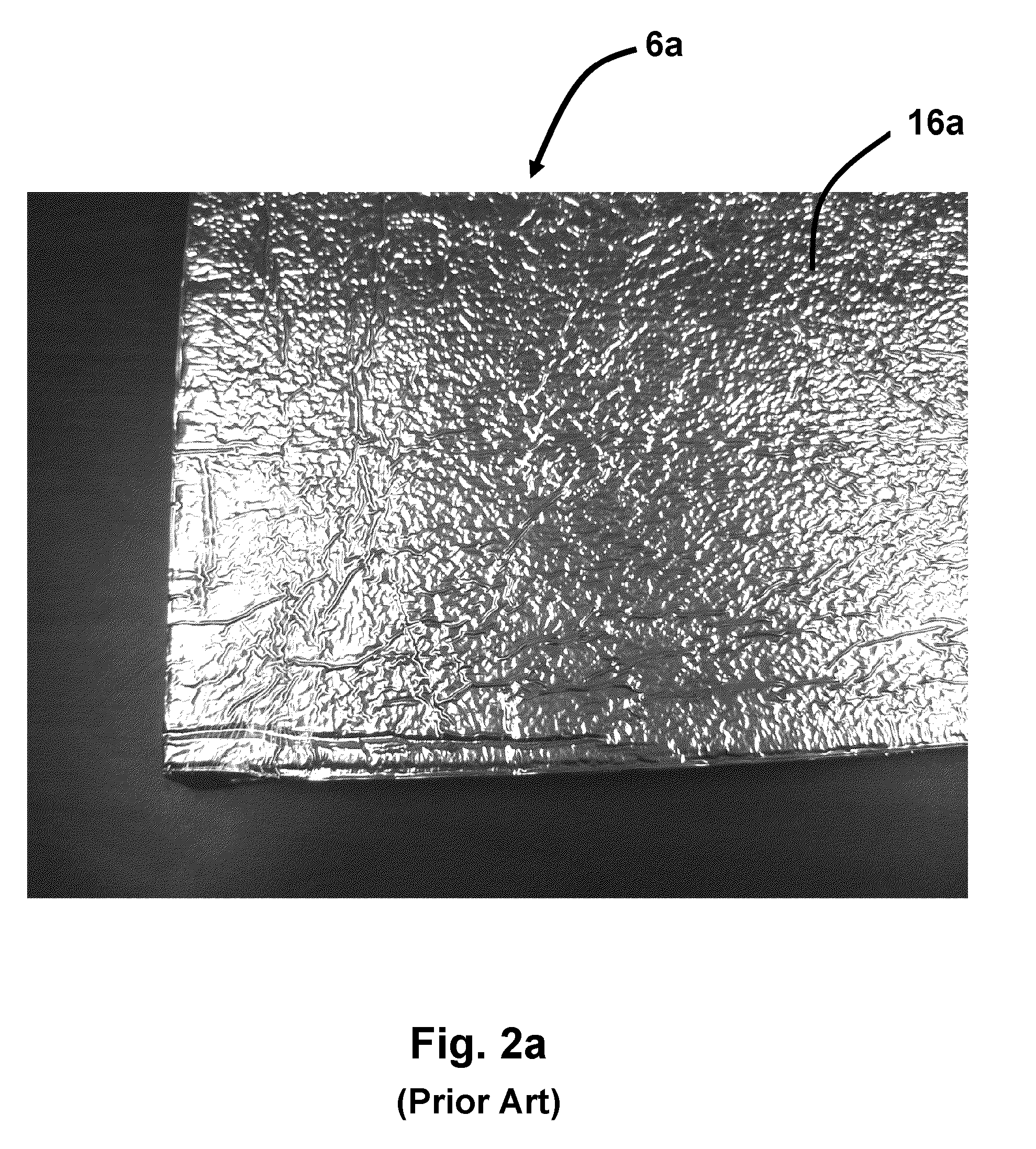

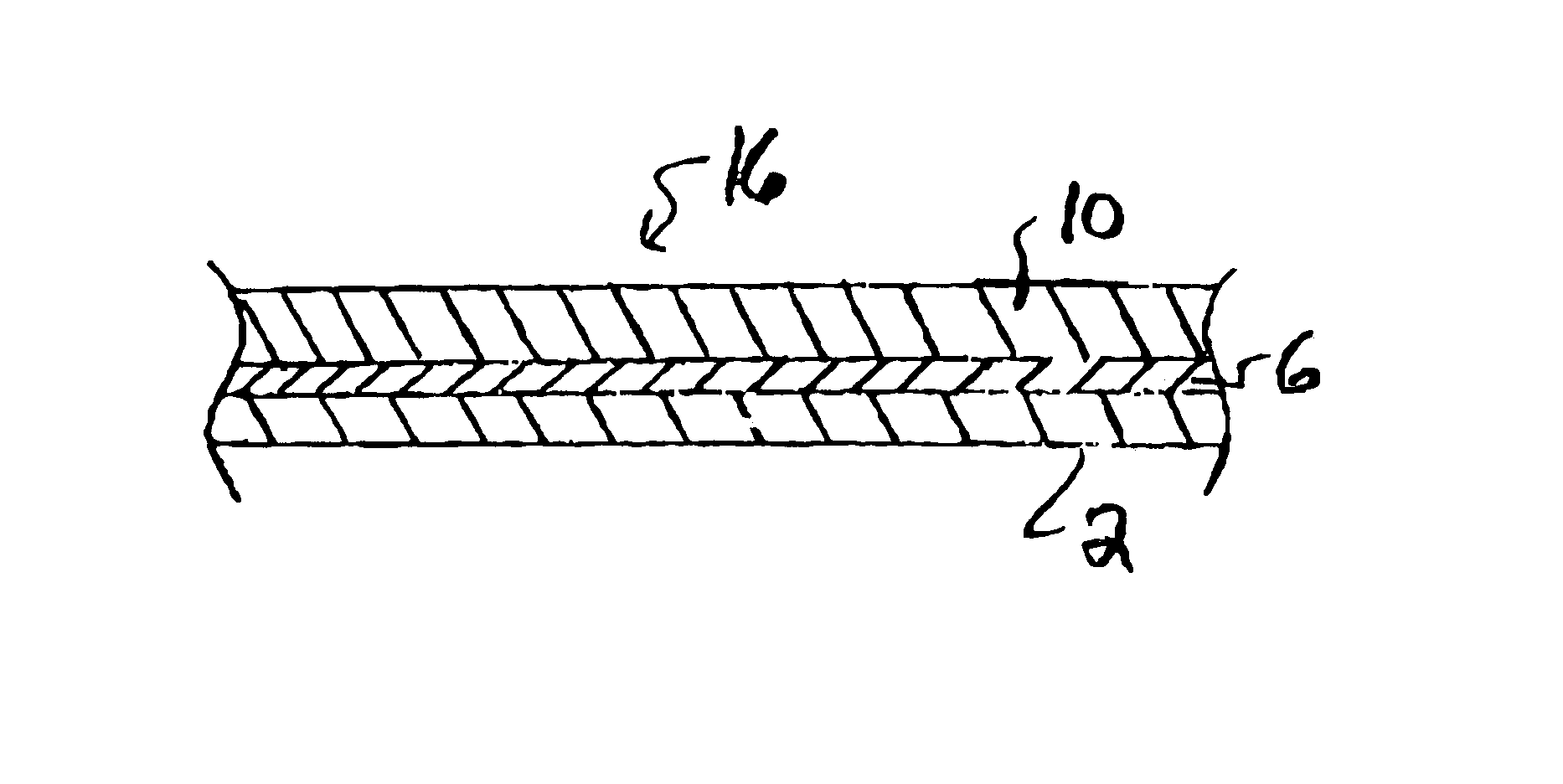

Vacuum insulation panel with smooth surface method for making and applications of same

InactiveUS20090179541A1Reduce roughnessUniform appearanceLighting and heating apparatusHollow inflatable ballsEngineeringRefrigeration

Vacuum insulation panels and methods for making vacuum insulation panels. The panels include first and second spaced-apart sidewalls, where at least one of the sidewalls has a very smooth surface. The panels are particularly useful as insulation in applications where a smooth and aesthetically acceptable surface is required, such as in a refrigeration appliance. A method for making a vacuum insulation panel can include placing an insulative core material and a liner within a barrier envelope defining an enclosure, evacuating the enclosure, and sealing the envelope to form the vacuum insulation panel.

Owner:NANOPORE INC

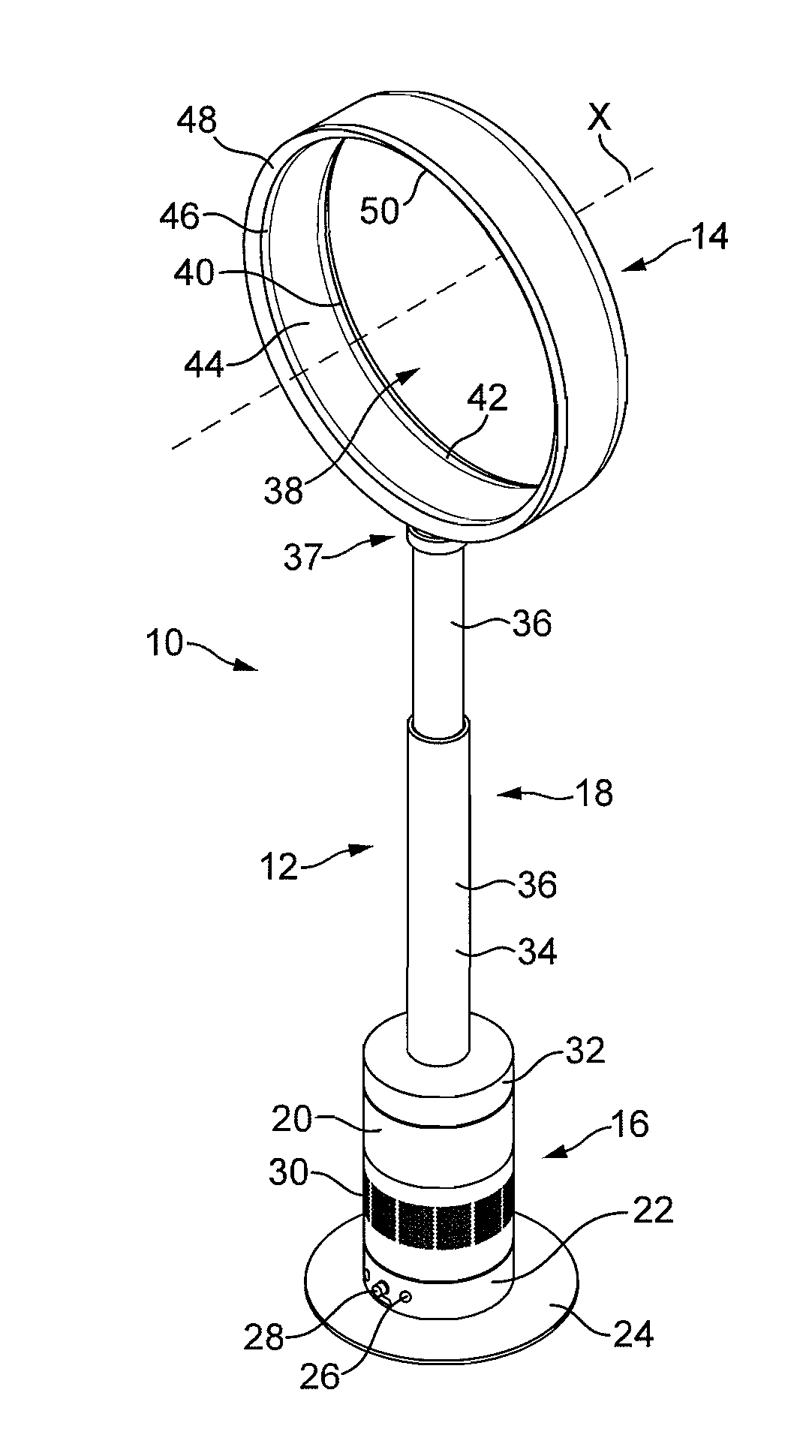

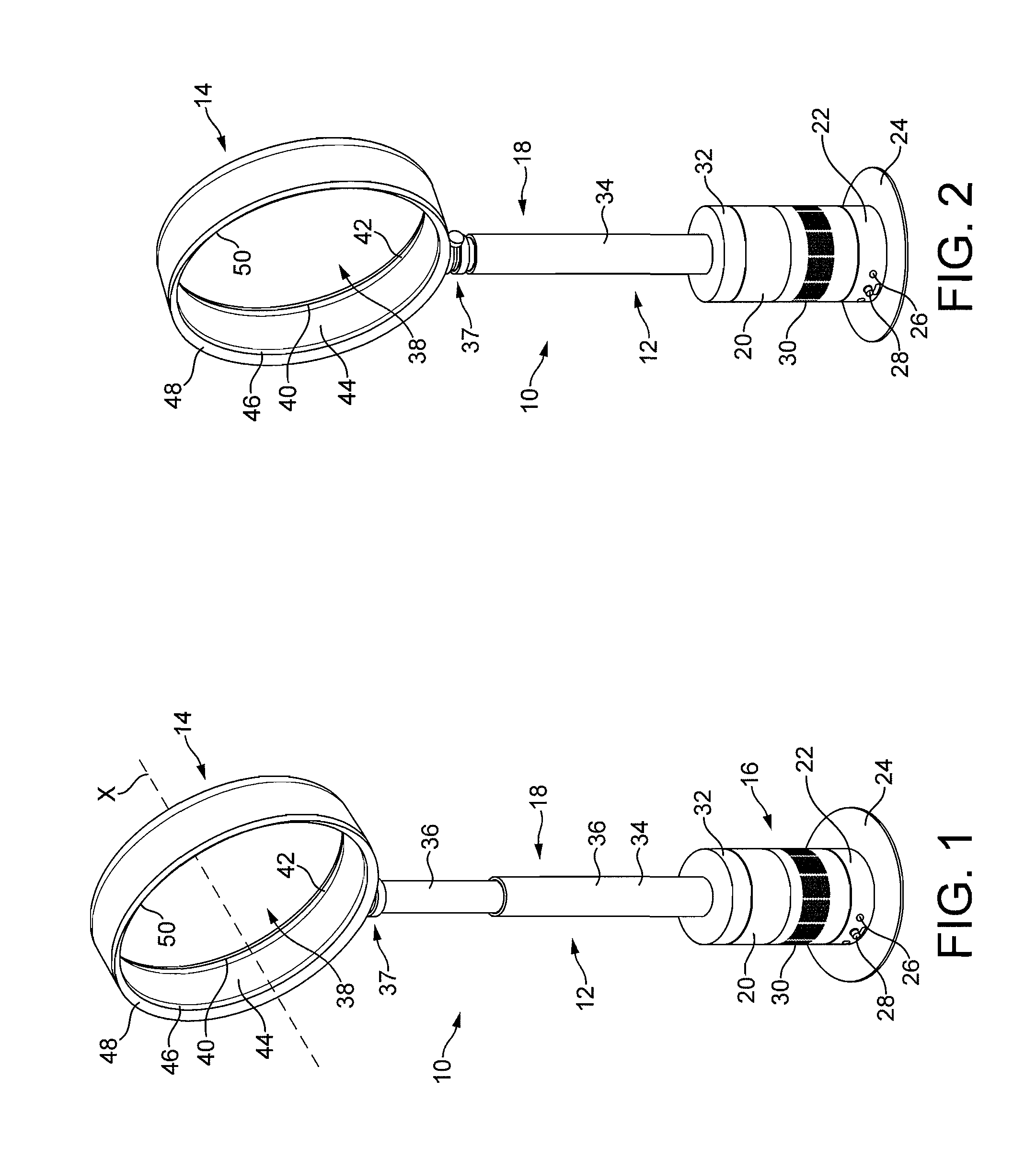

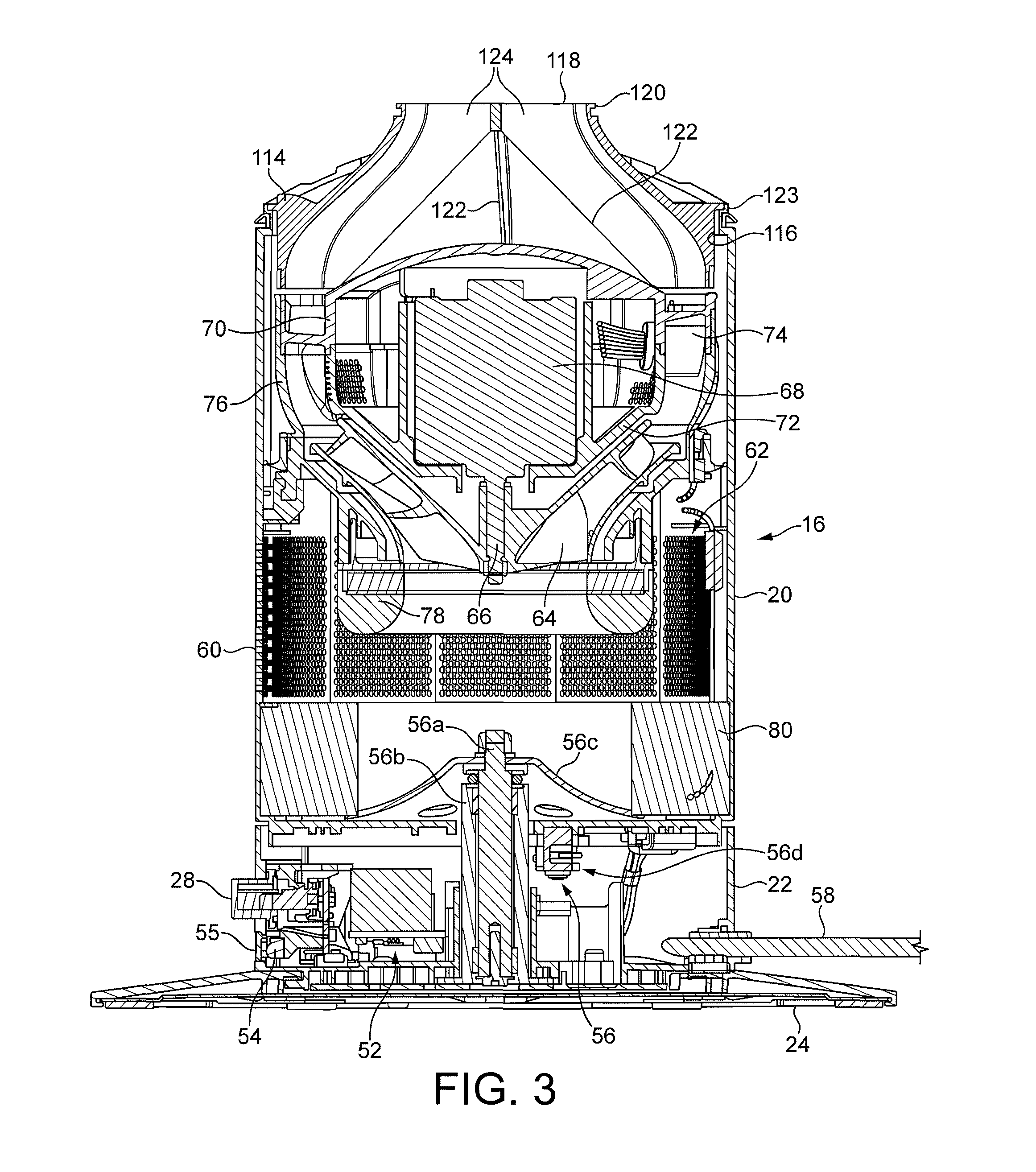

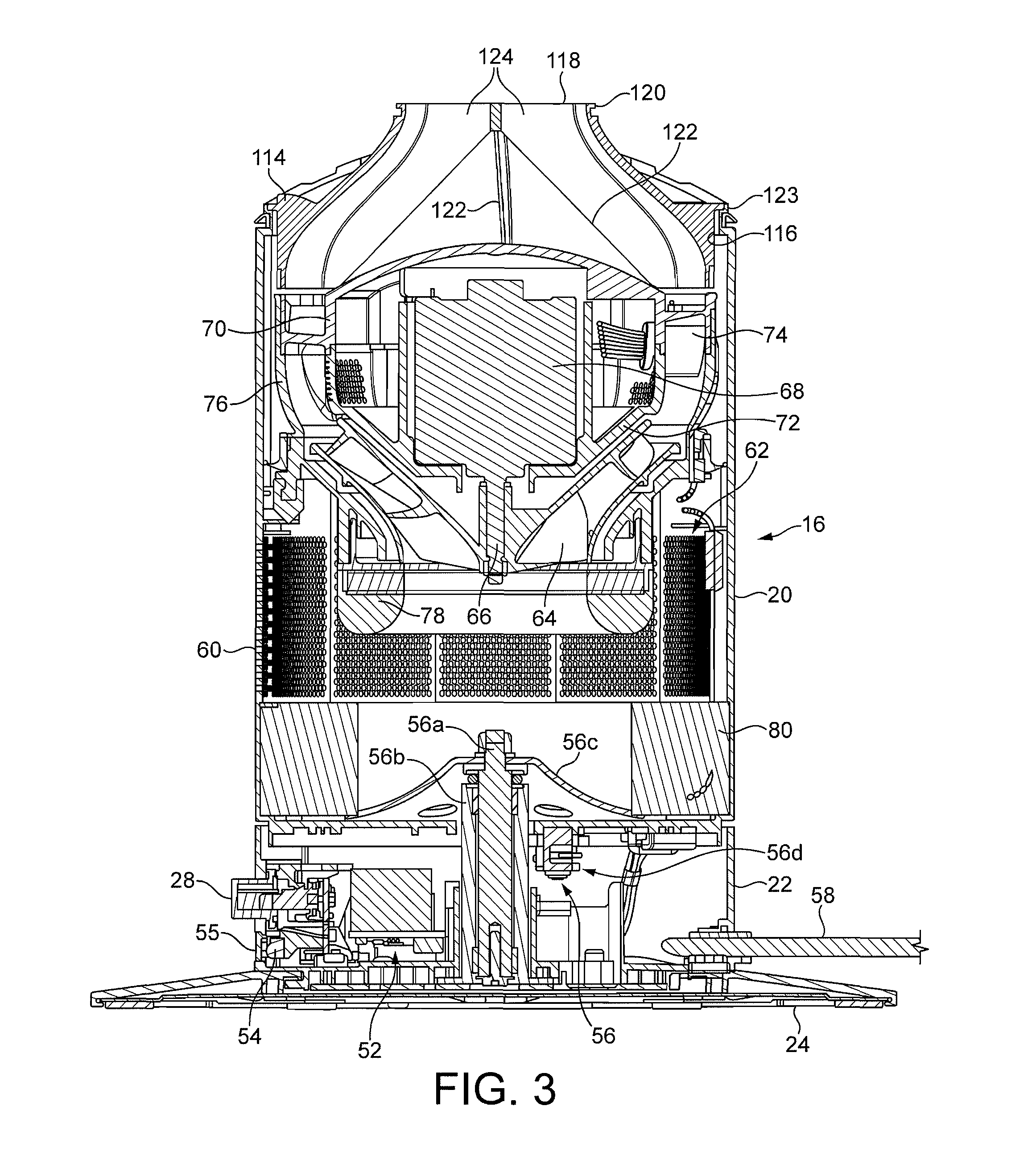

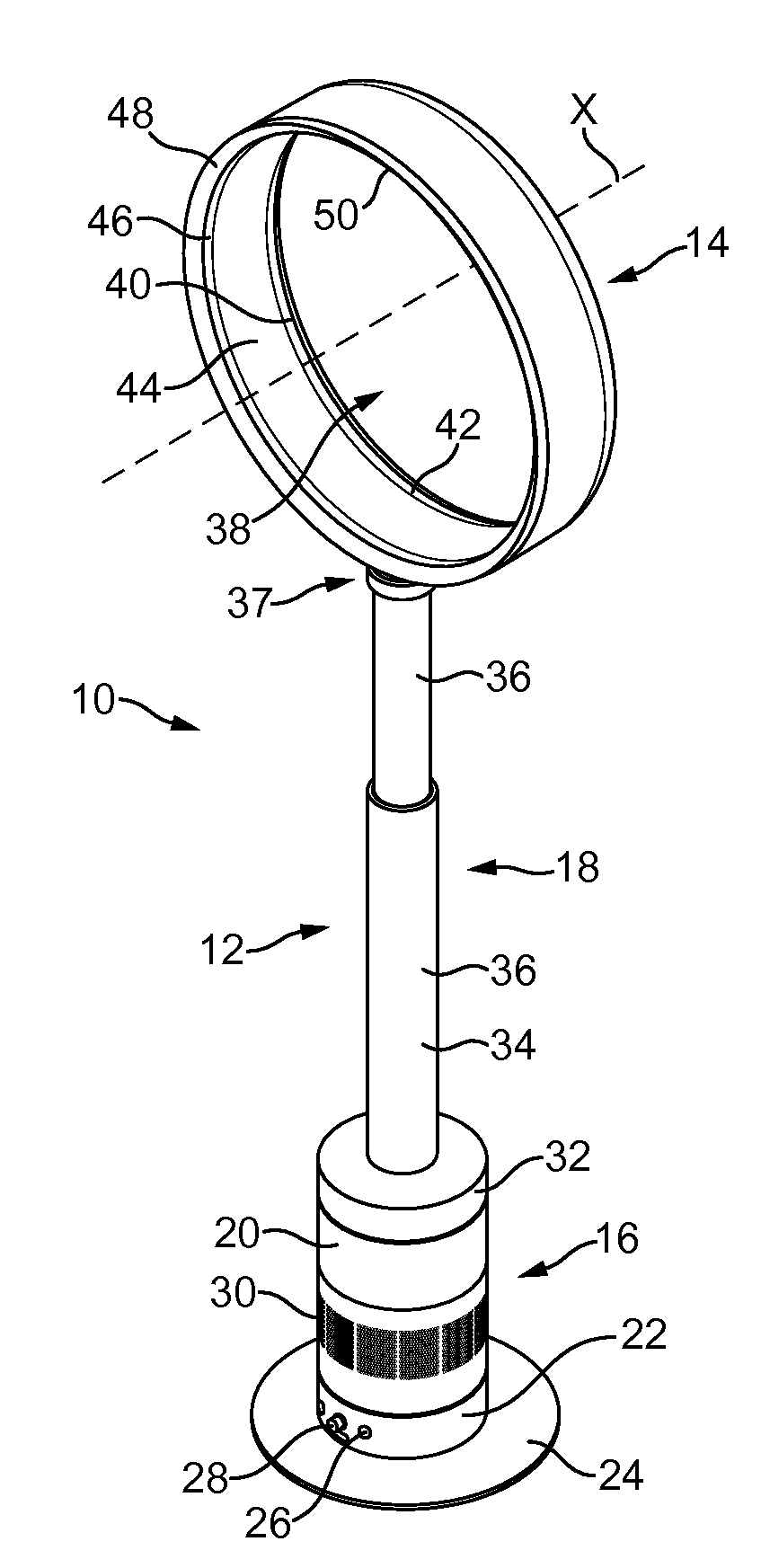

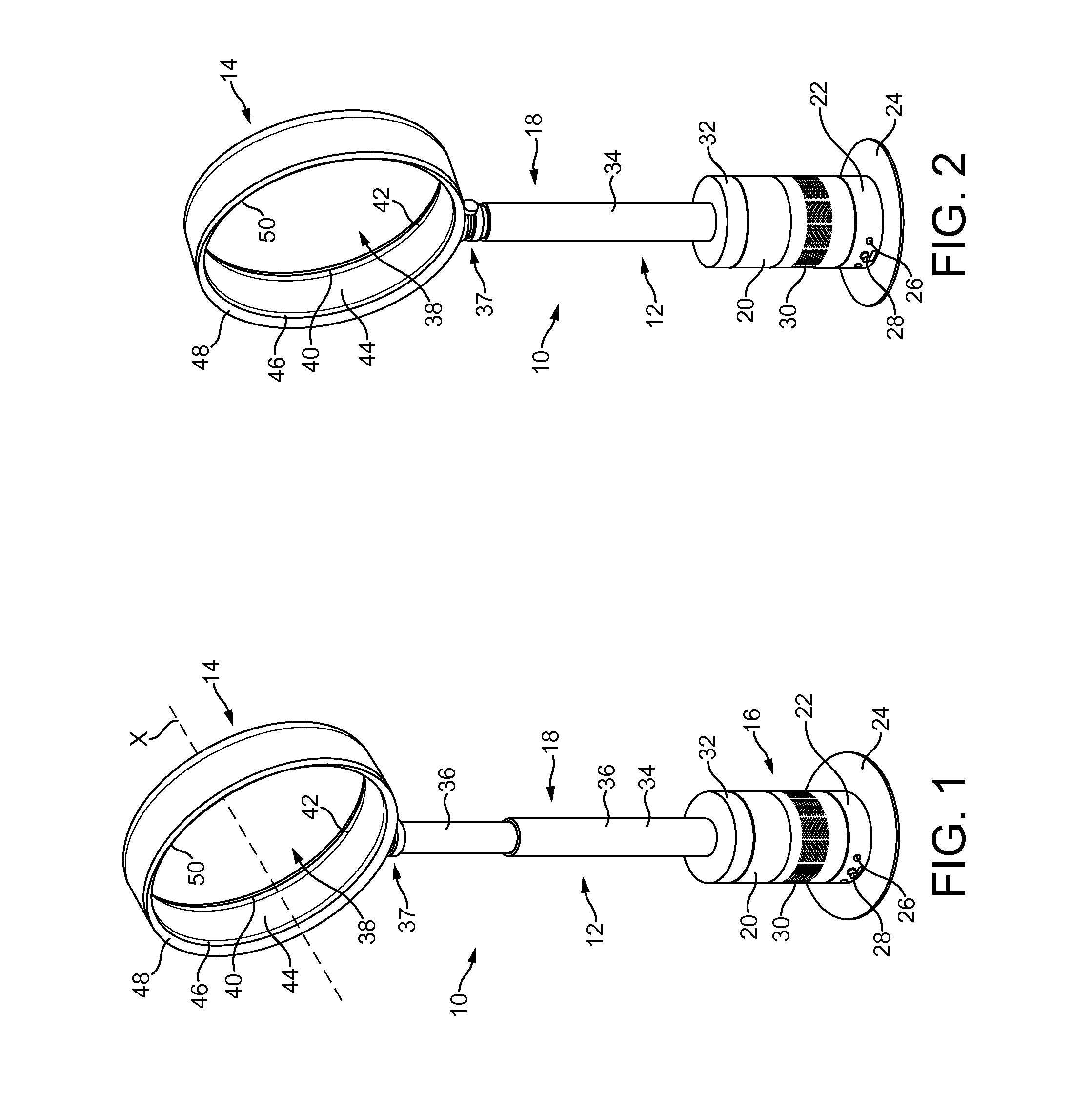

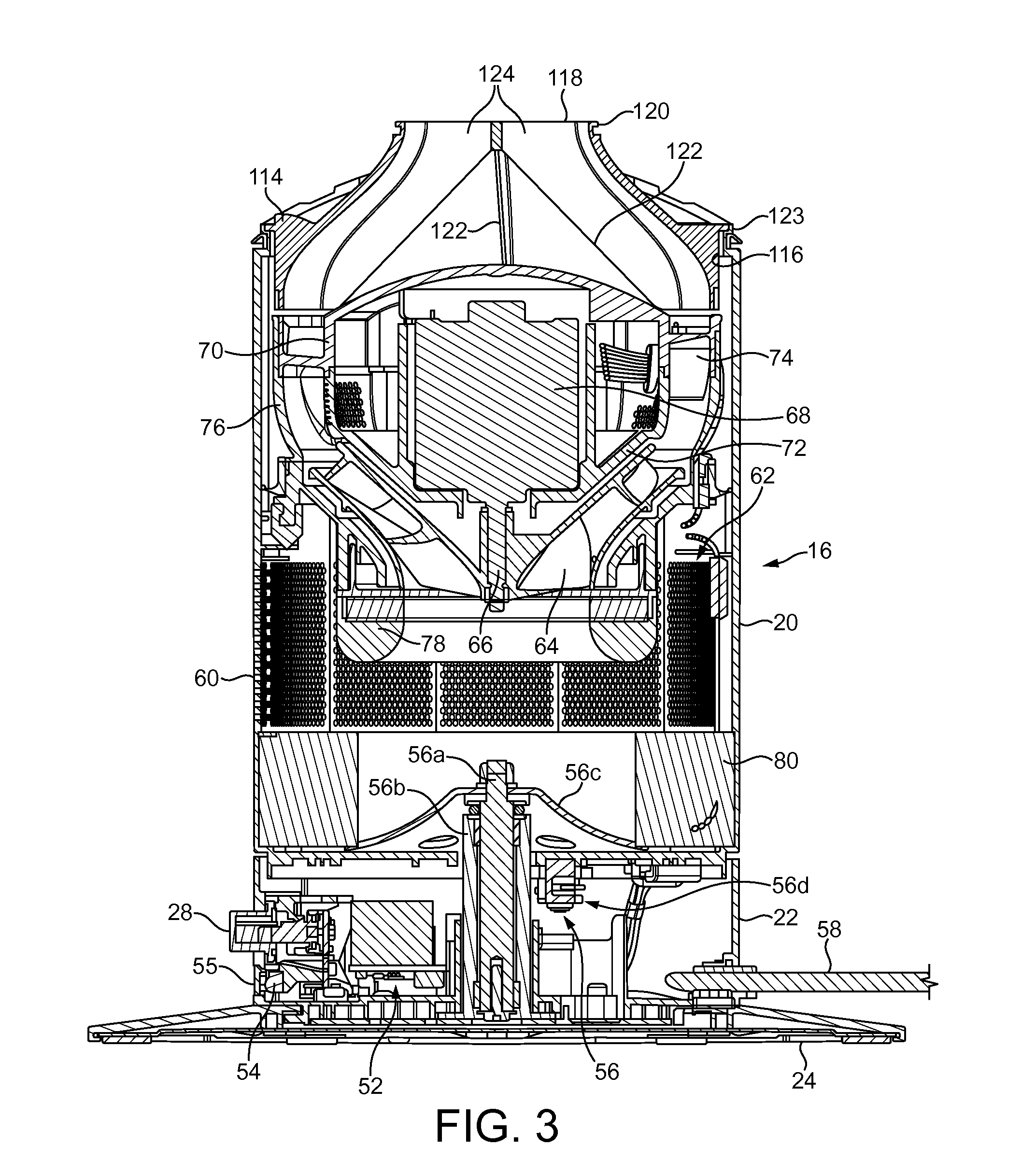

Fan

ActiveUS20110110805A1Emission reductionWide operating speed rangePositive displacement pump componentsJet pumpsImpellerRemote control

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller, a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet, the air outlet comprising an interior passage for receiving the air flow and a mouth for emitting the air flow, the air outlet defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth, a control circuit for controlling the motor, a remote control for transmitting control signals to the control circuit, and at least one magnet for attaching the remote control to the air outlet.

Owner:DYSON TECH LTD

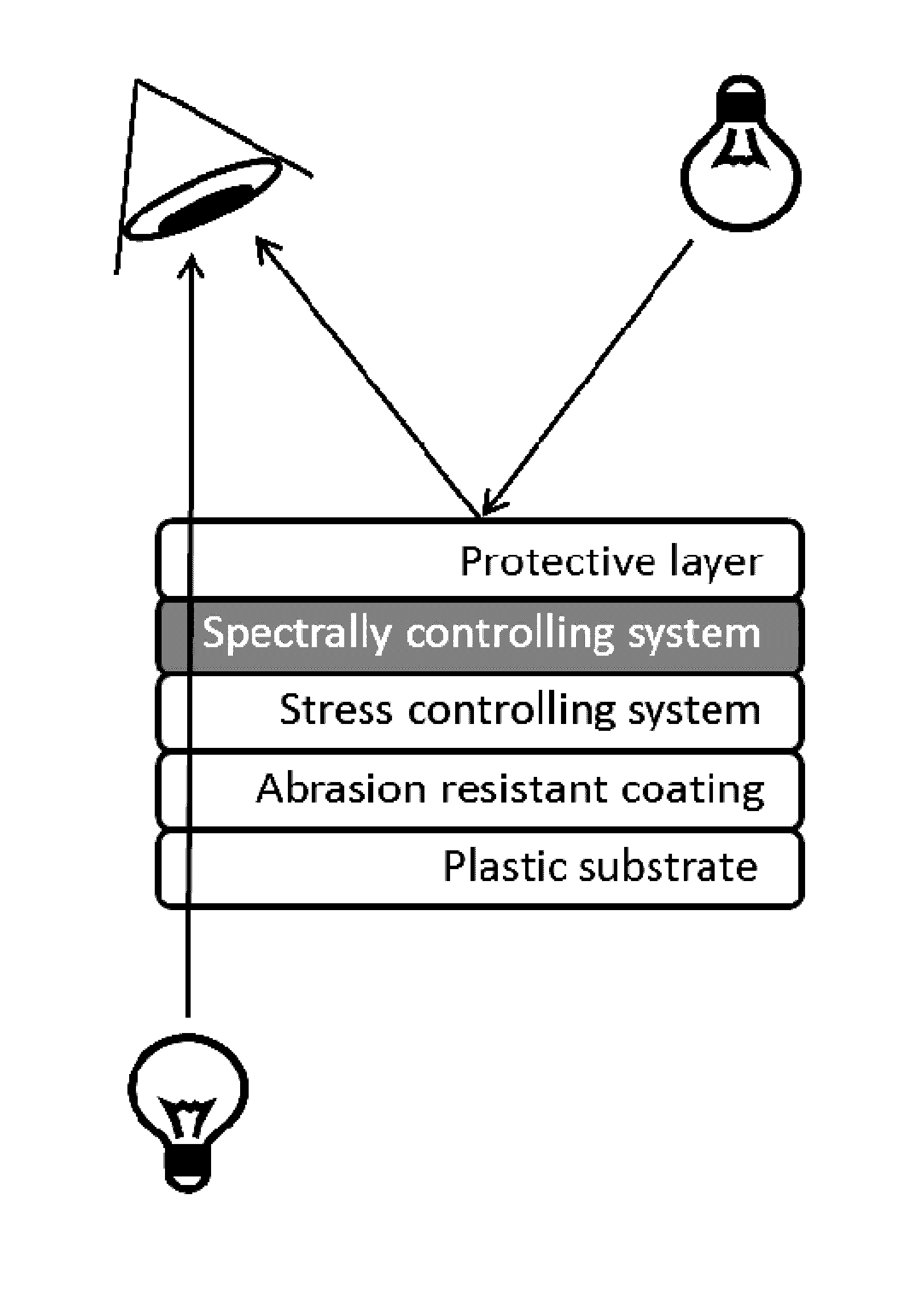

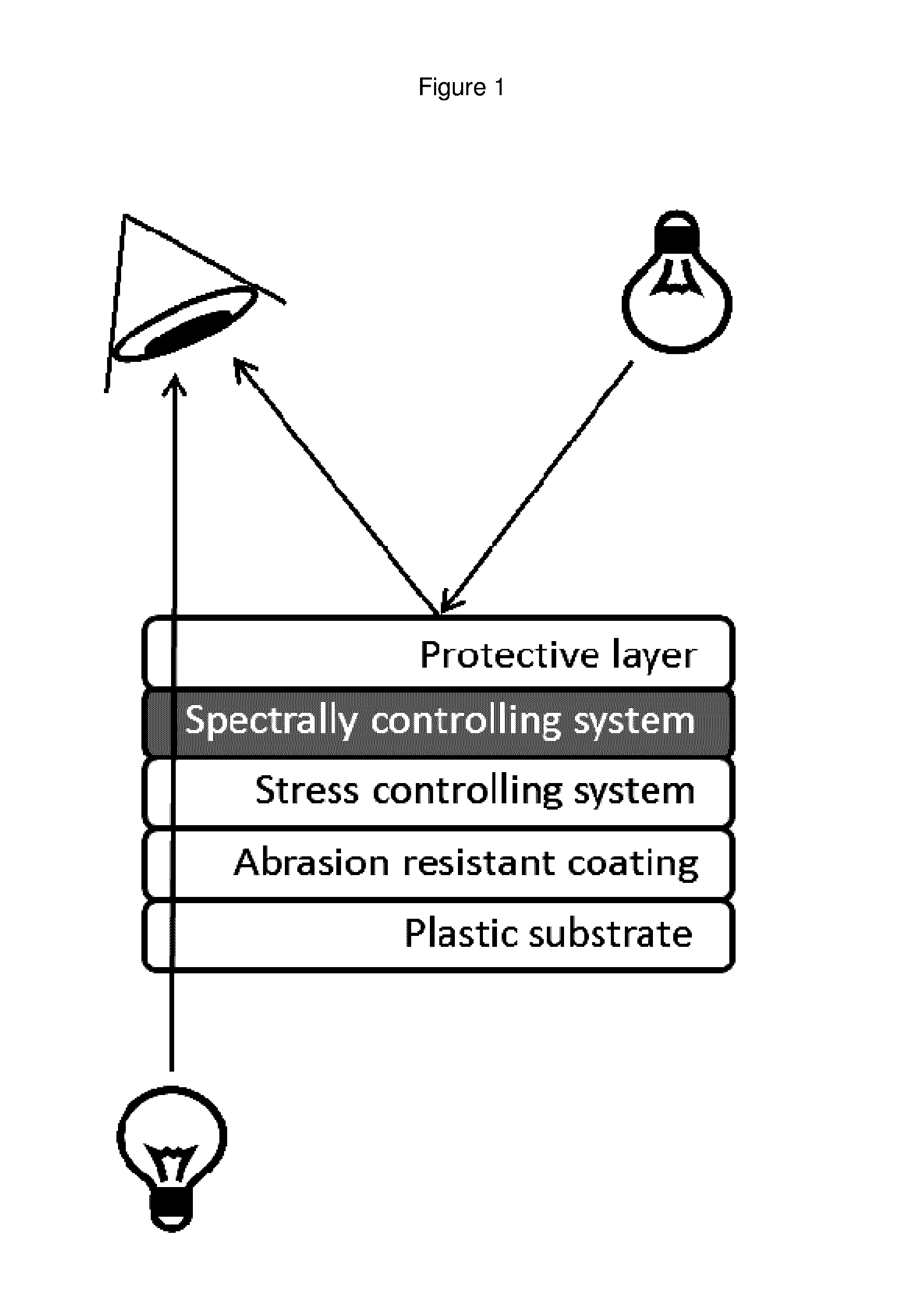

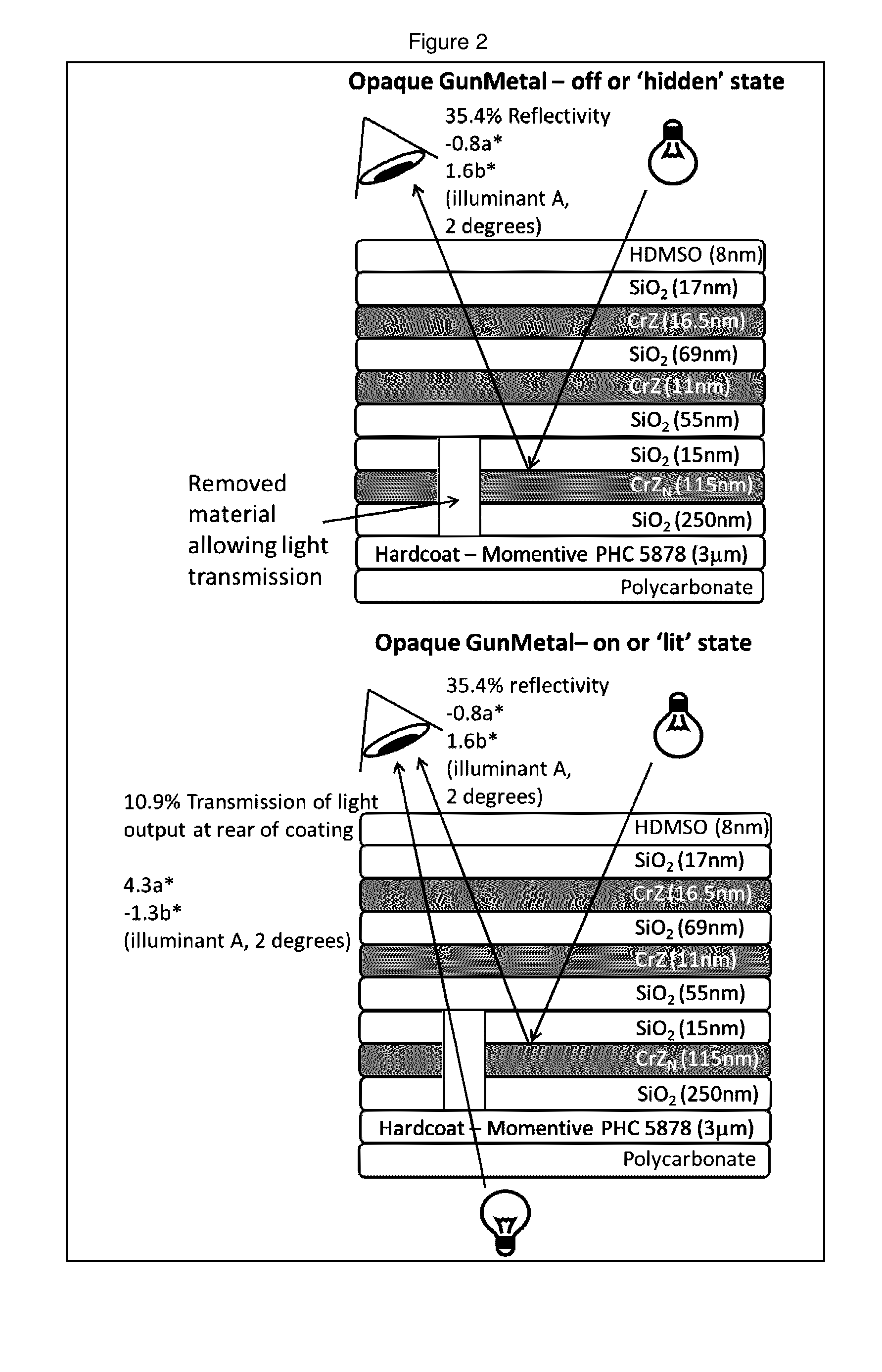

Decorative coatings for plastic substrates

ActiveUS20170015802A1Uniform appearanceVacuum evaporation coatingSputtering coatingEngineeringLight spectrum

The present invention relates to decorative coatings for plastic substrates, the decorative coatings ideally being stable and durable coatings that are spectrally tuneable to permit the selection of a variety of appearances, and ideally providing a decorative metal finish. More particularly the present invention provides for a plastic substrate having a decorative coating including a spectrally controlling system and a stress controlling system. The spectrally controlling system includes alternating absorbing layers and transparent layers, and the stress controlling system controls the overall residual stress of the decorative coating to within a desired range. Further provided are methods for applying to a plastic substrate a decorative coating having a spectrally controlling system and a stress controlling system.

Owner:SMR PATENTS S A R L +1

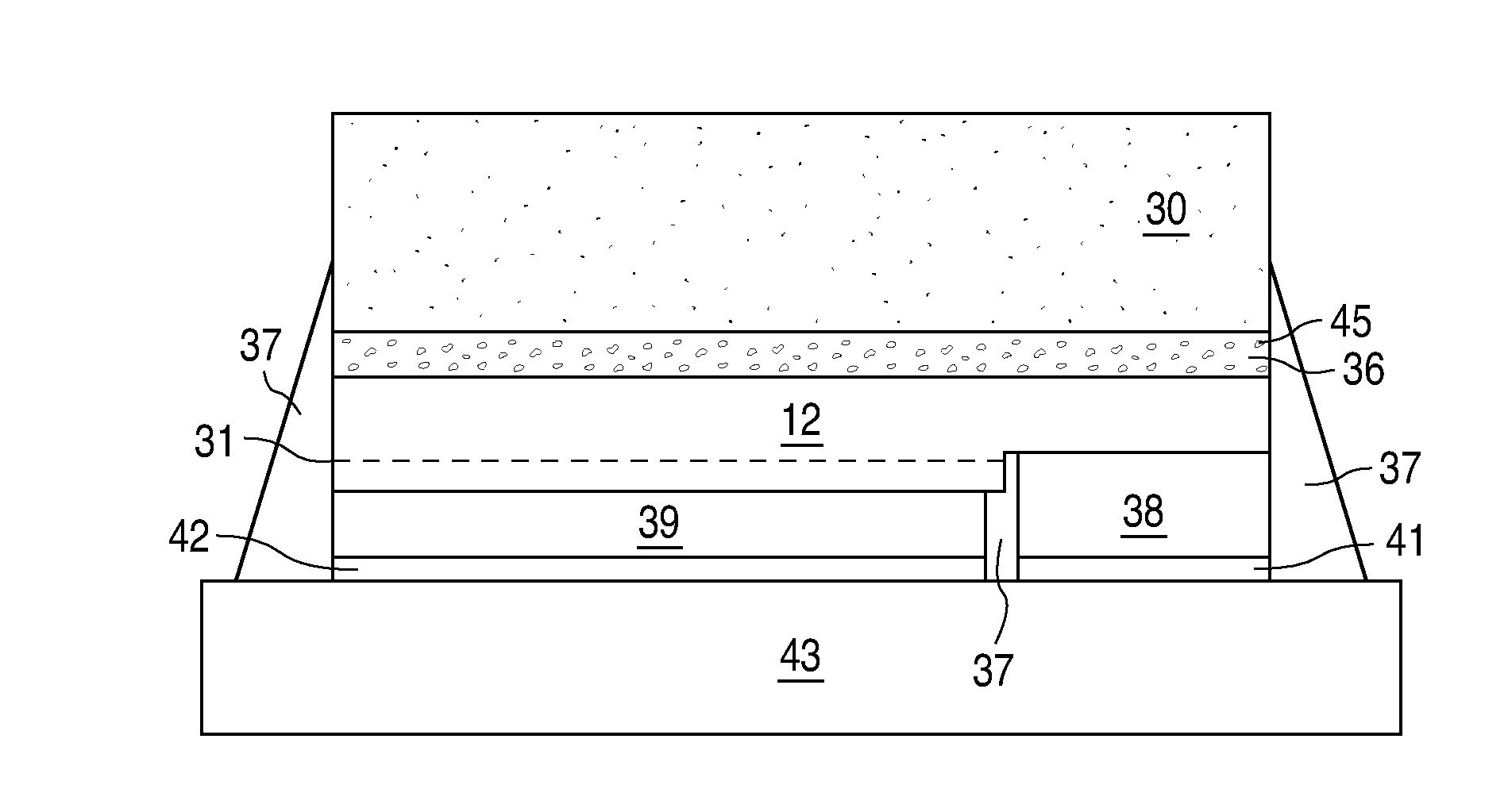

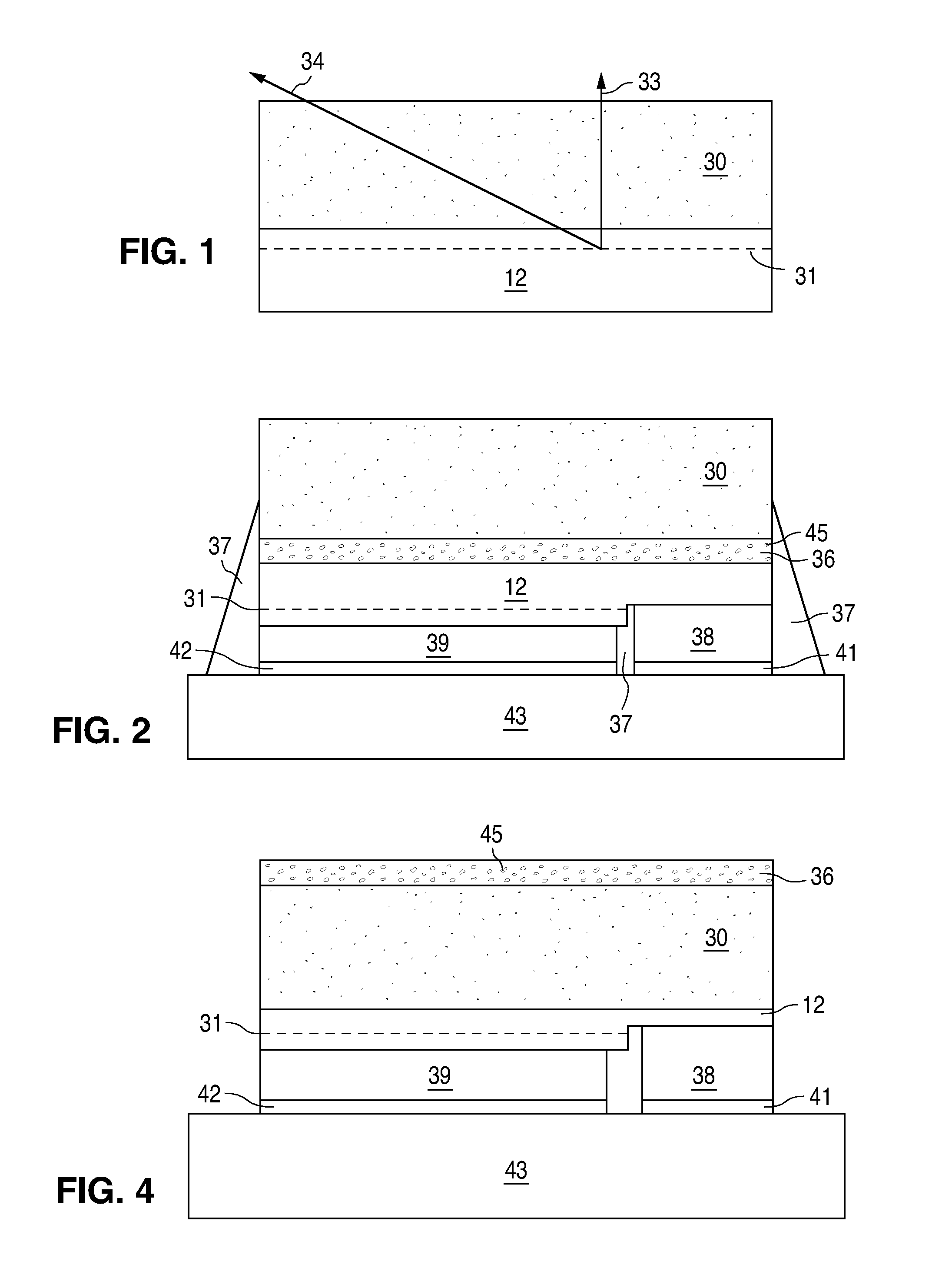

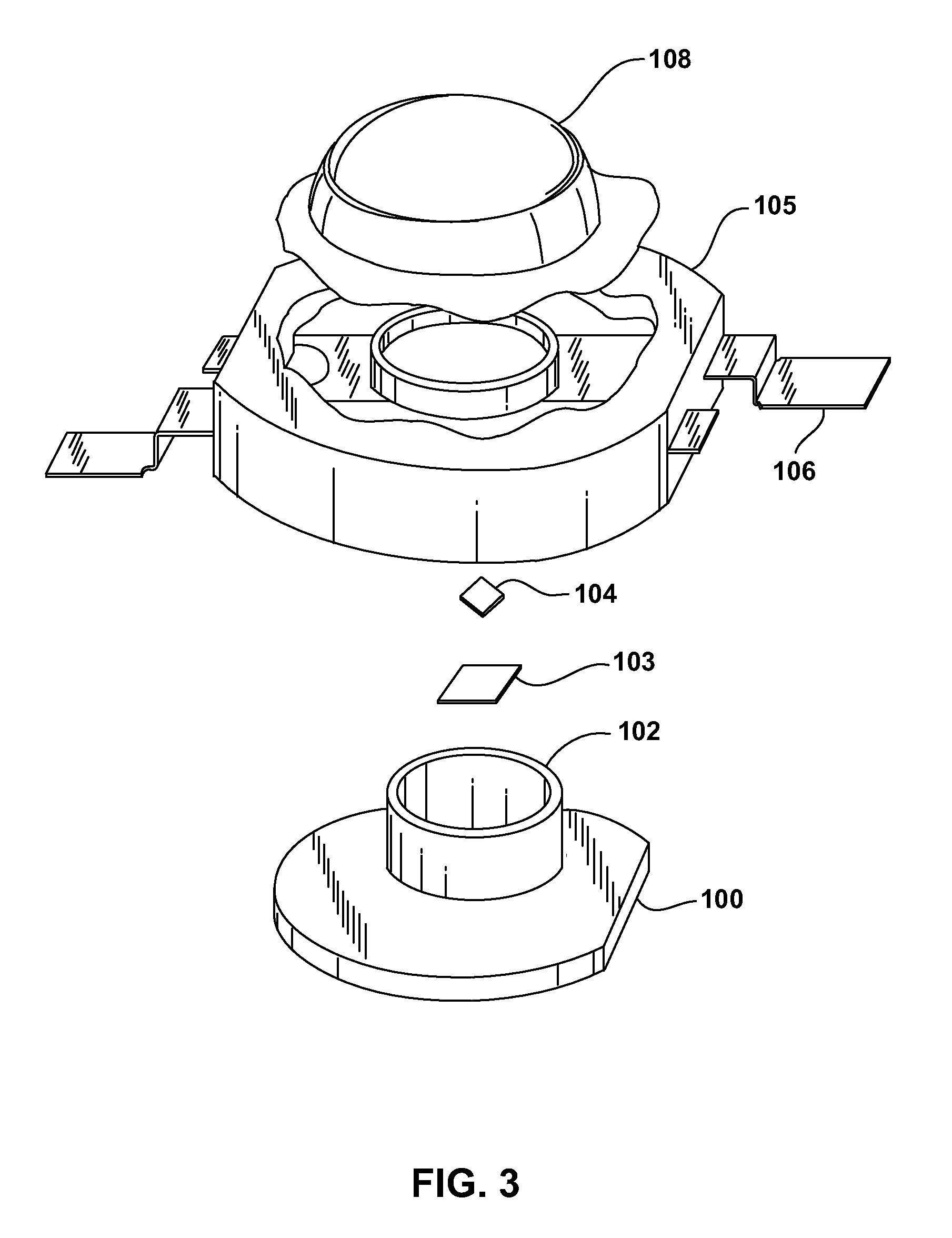

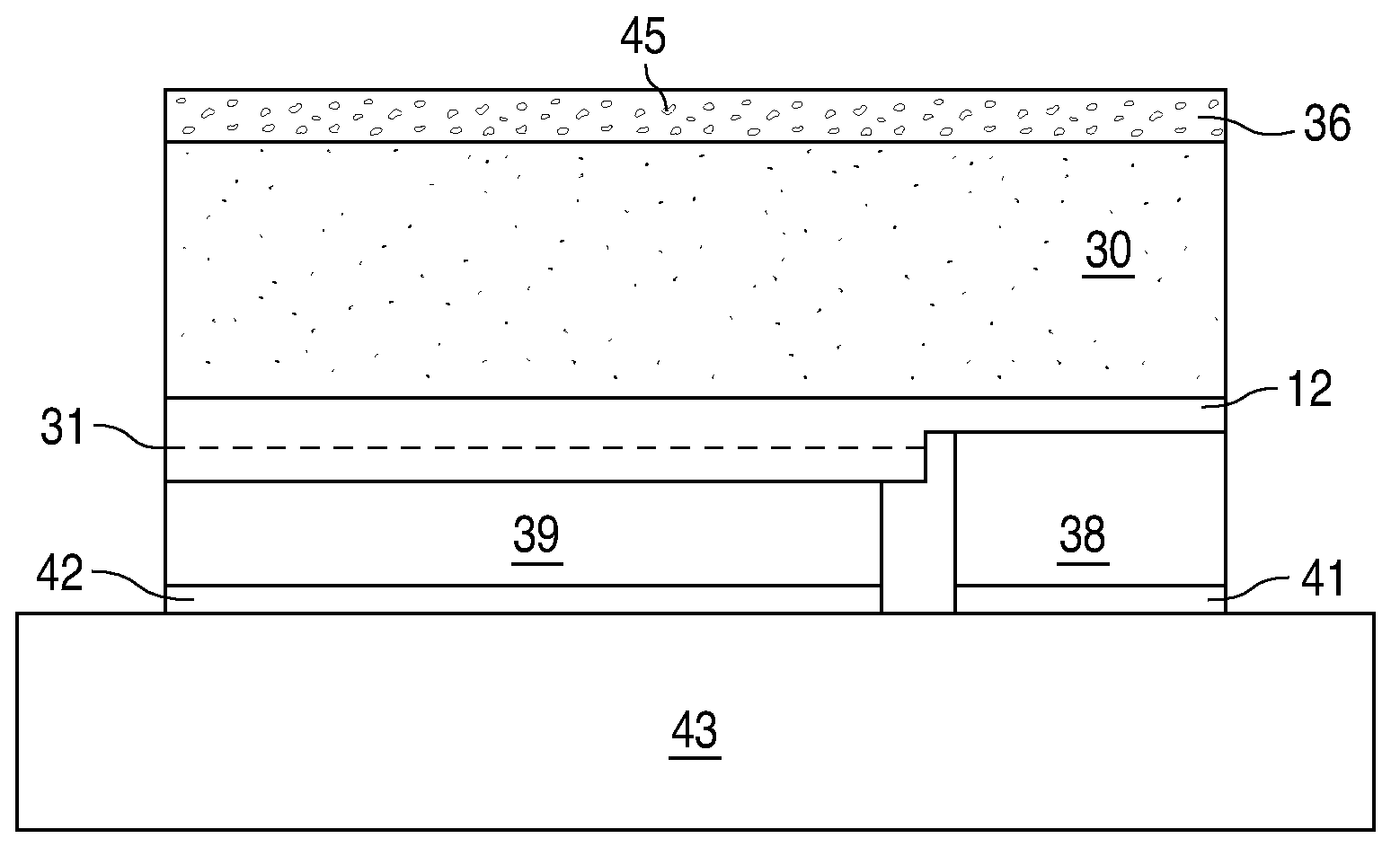

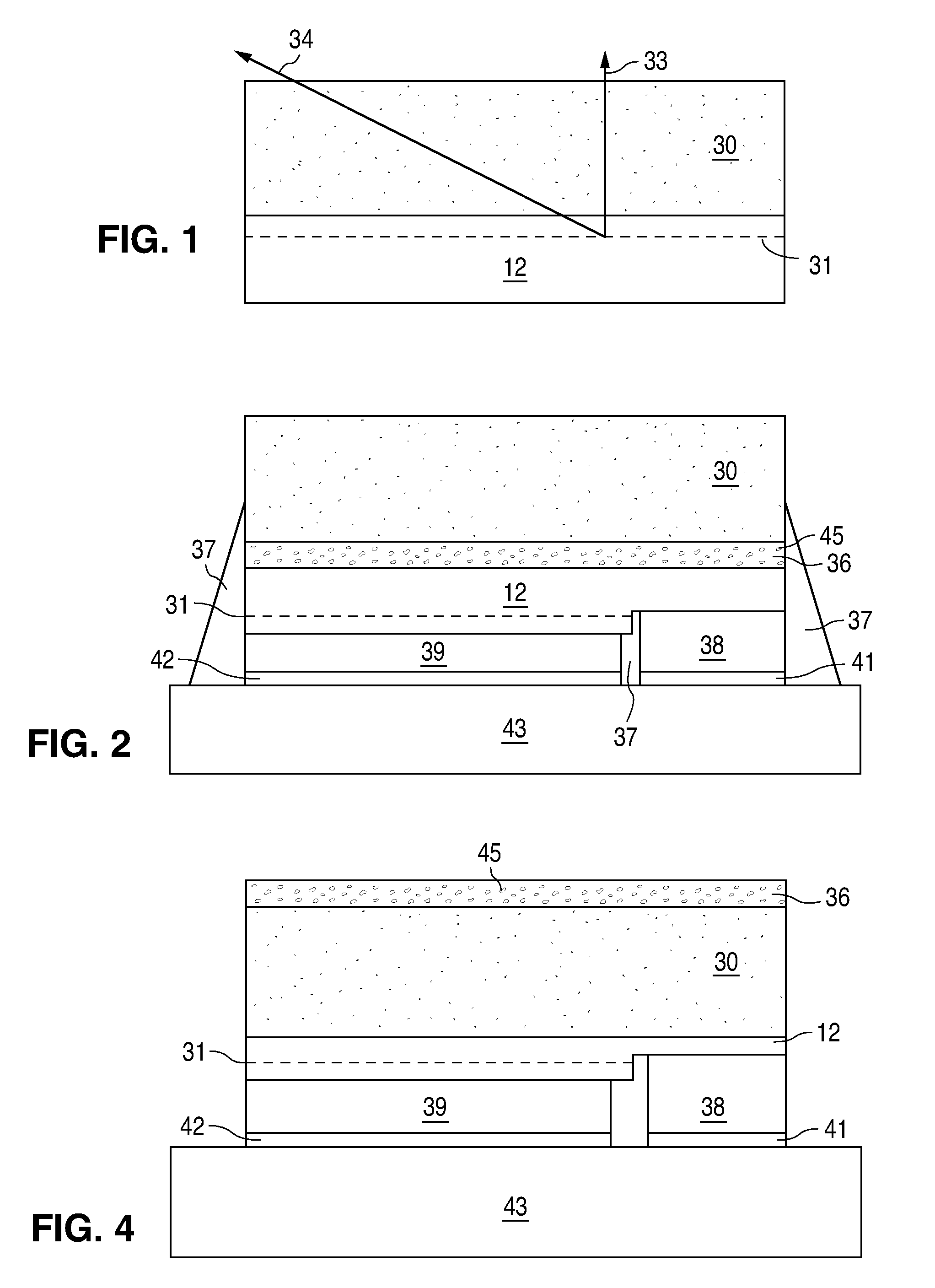

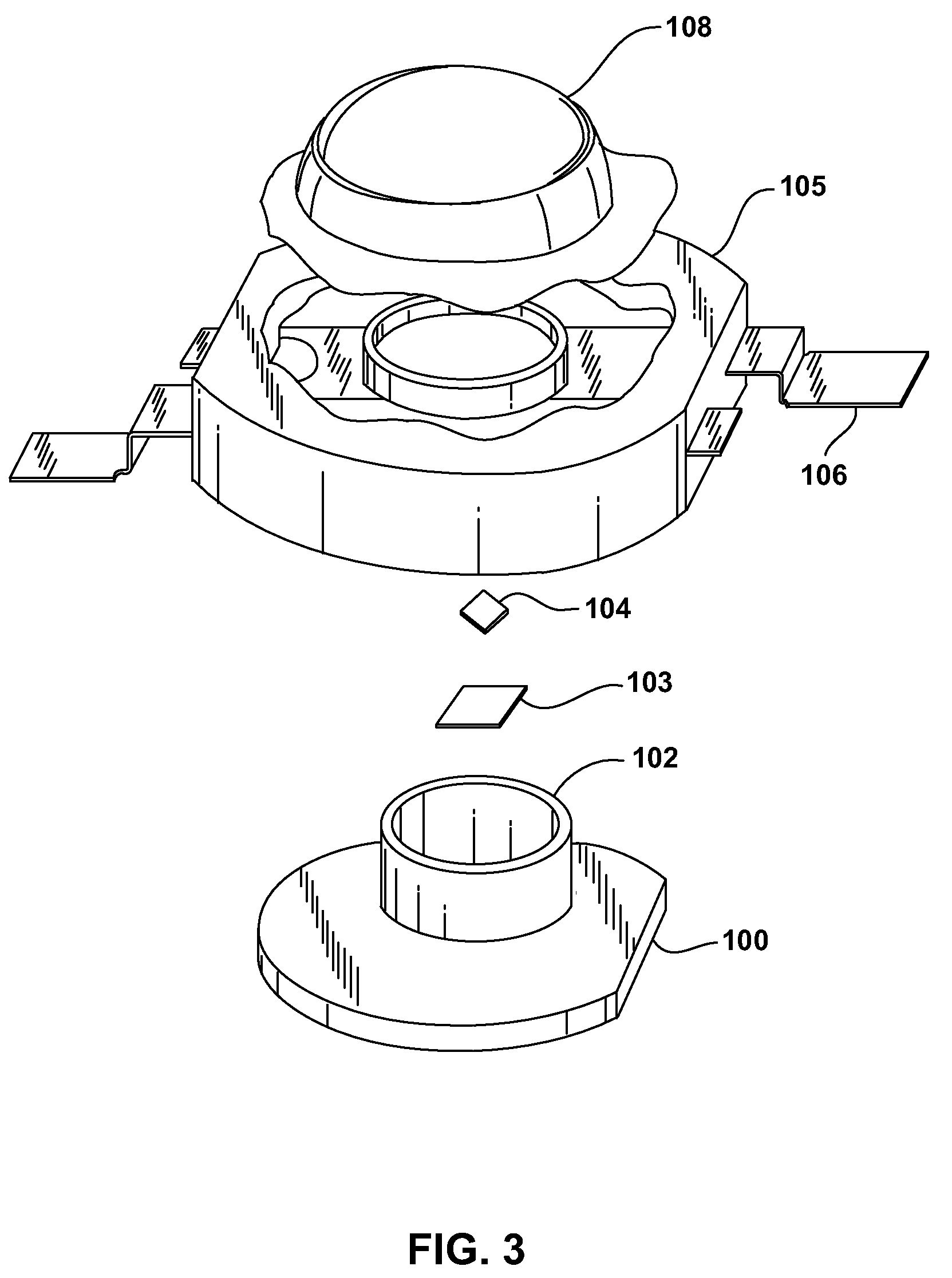

Light Emitting Device Including Luminescent Ceramic and Light-Scattering Material

ActiveUS20080116467A1Improve uniformityImprove color characteristicDischarge tube luminescnet screensElectroluminescent light sourcesScattered lightSemiconductor structure

A ceramic body comprising a wavelength converting material is disposed in the path of light emitted by the light emitting region of a semiconductor structure comprising a light emitting region disposed between an n-type region and a p-type region. A layer of transparent material is also disposed in the path of light emitted by the light emitting region. The transparent material may connect the ceramic body to the semiconductor structure. Particles configured to scatter light emitted by the light emitting region are disposed in the layer of adhesive material. In some embodiments the particles are phosphor; in some embodiments the particles are not a wavelength-converting material.

Owner:LUMILEDS

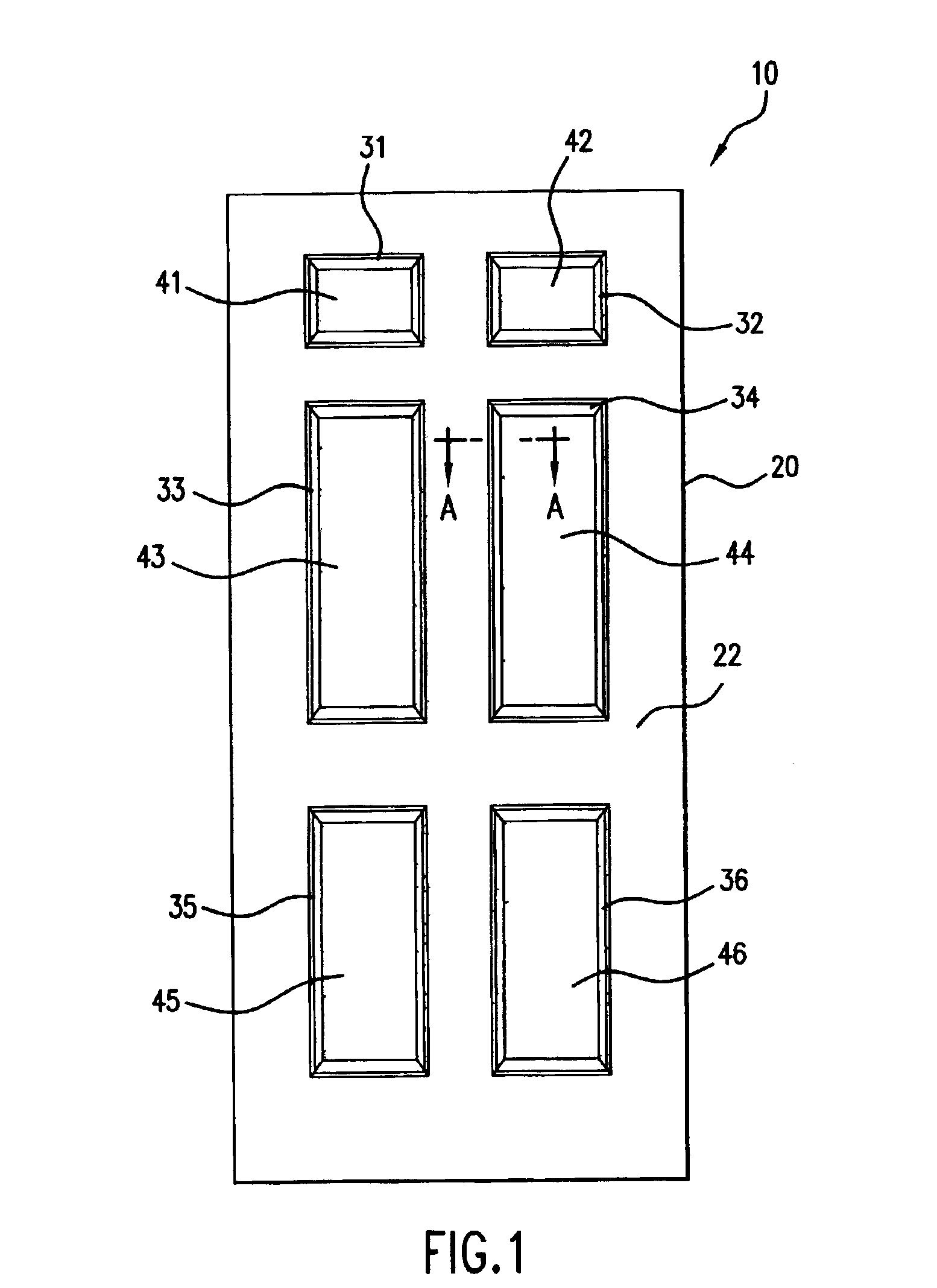

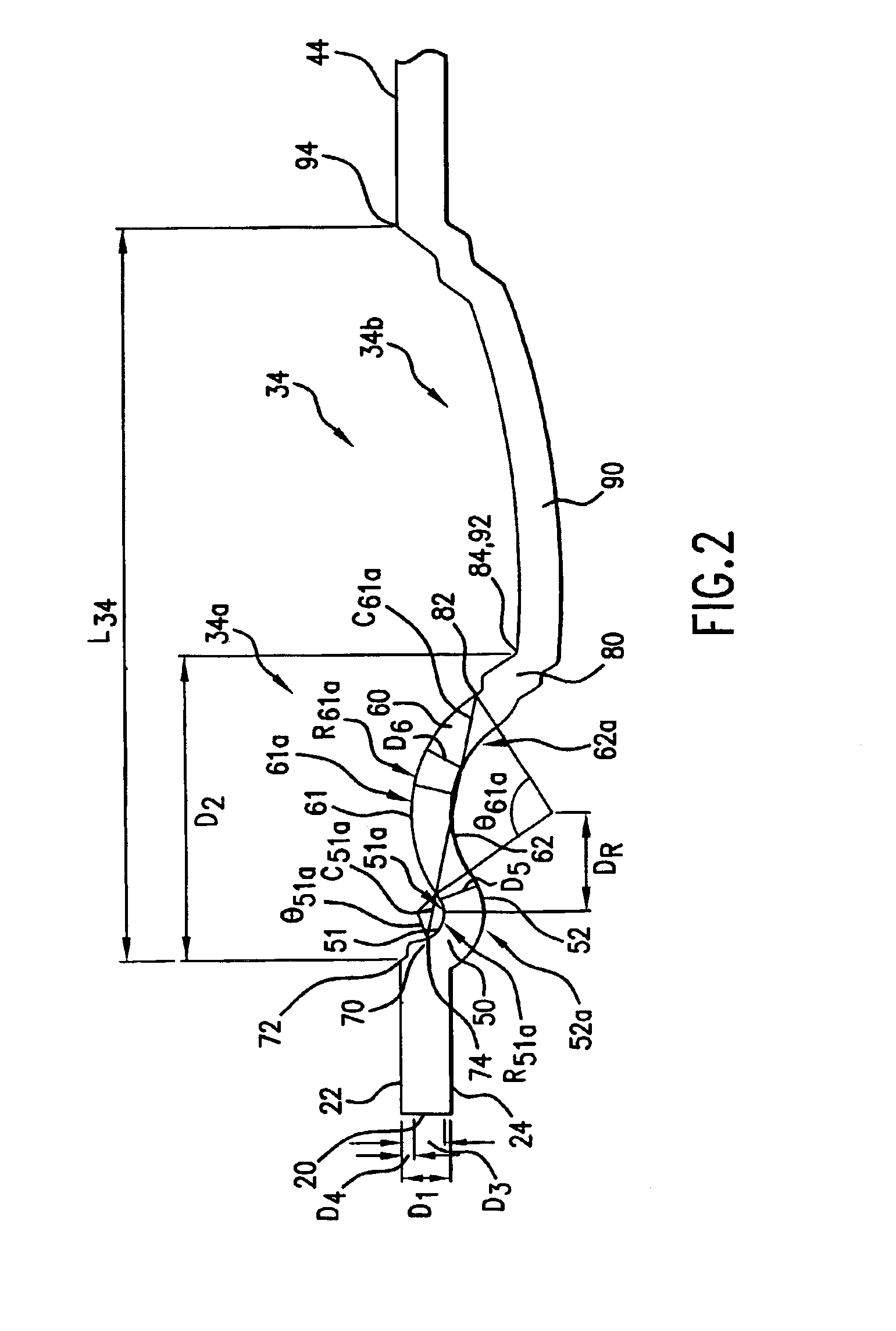

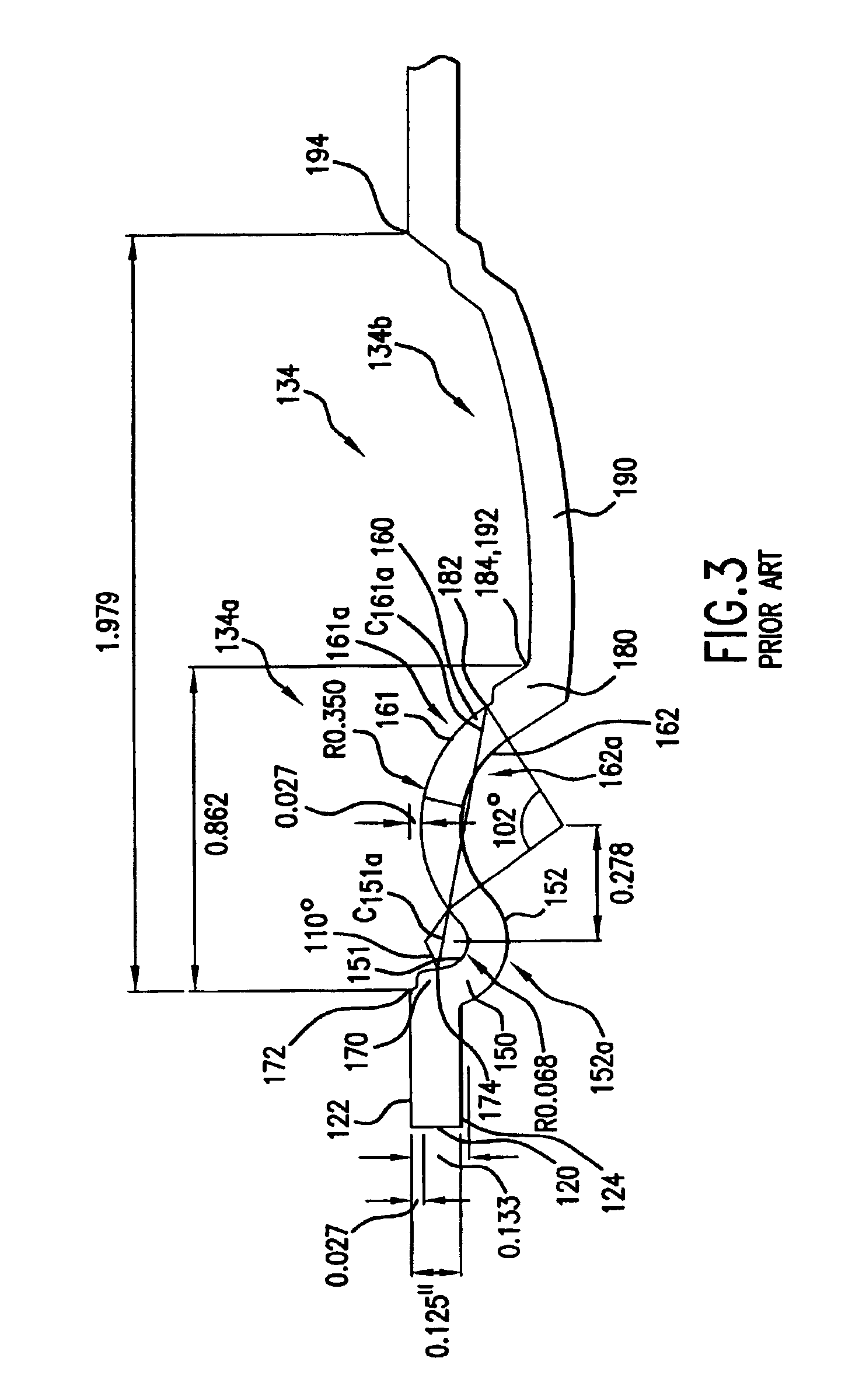

Molded skin with curvature

InactiveUS7022414B2Density is accurateUniform appearanceCeramic shaping apparatusWood layered productsEngineeringSheet material

Molded skins and methods of making molded skins are disclosed. An embodiment of a skin includes a sheet having first and second surfaces, a first arcuate portion integral with the sheet, and a second arcuate portion integral with the sheet and adjacent to the first arcuate portion. The sheet includes a cellulosic material. The first arcuate portion includes a first surface and a second surface, each having an arc. The second arcuate portion includes a first surface and a second surface, each having an arc. An angle forming the arc of the first surface of the first arcuate portion is greater than 110 degrees and an angle forming the arc of the first surface of the second arcuate portion is less than 102 degrees.

Owner:JELD-WEN

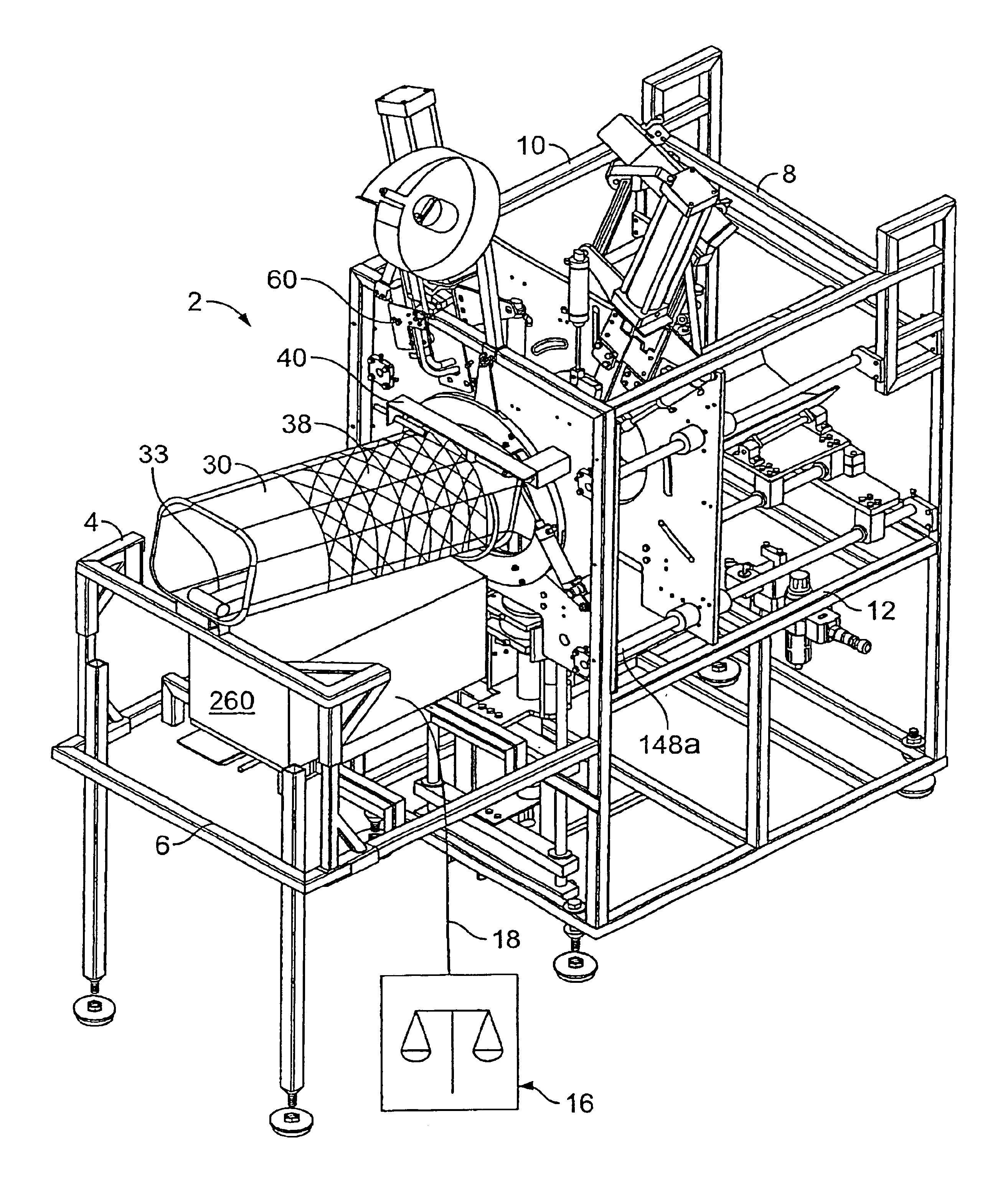

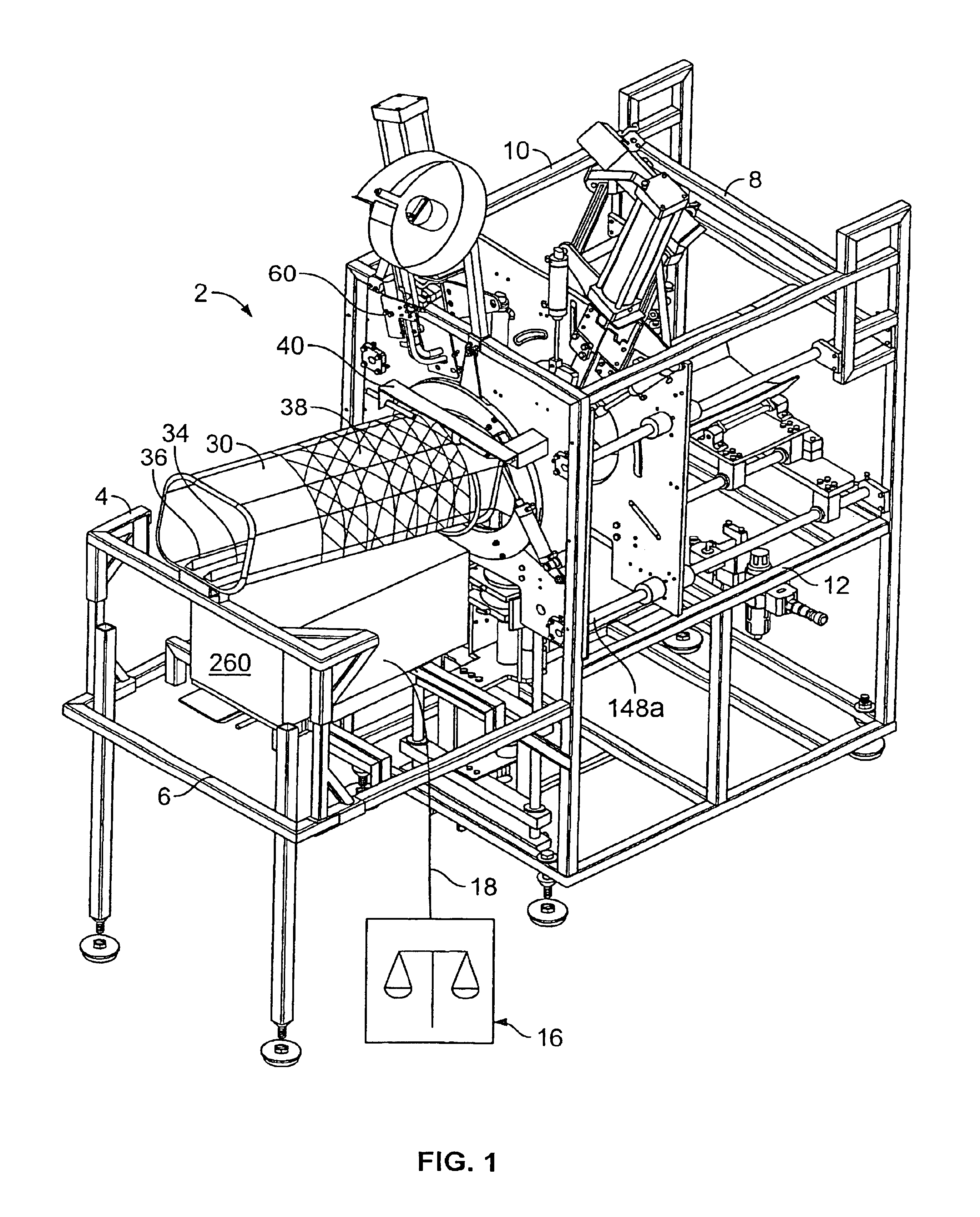

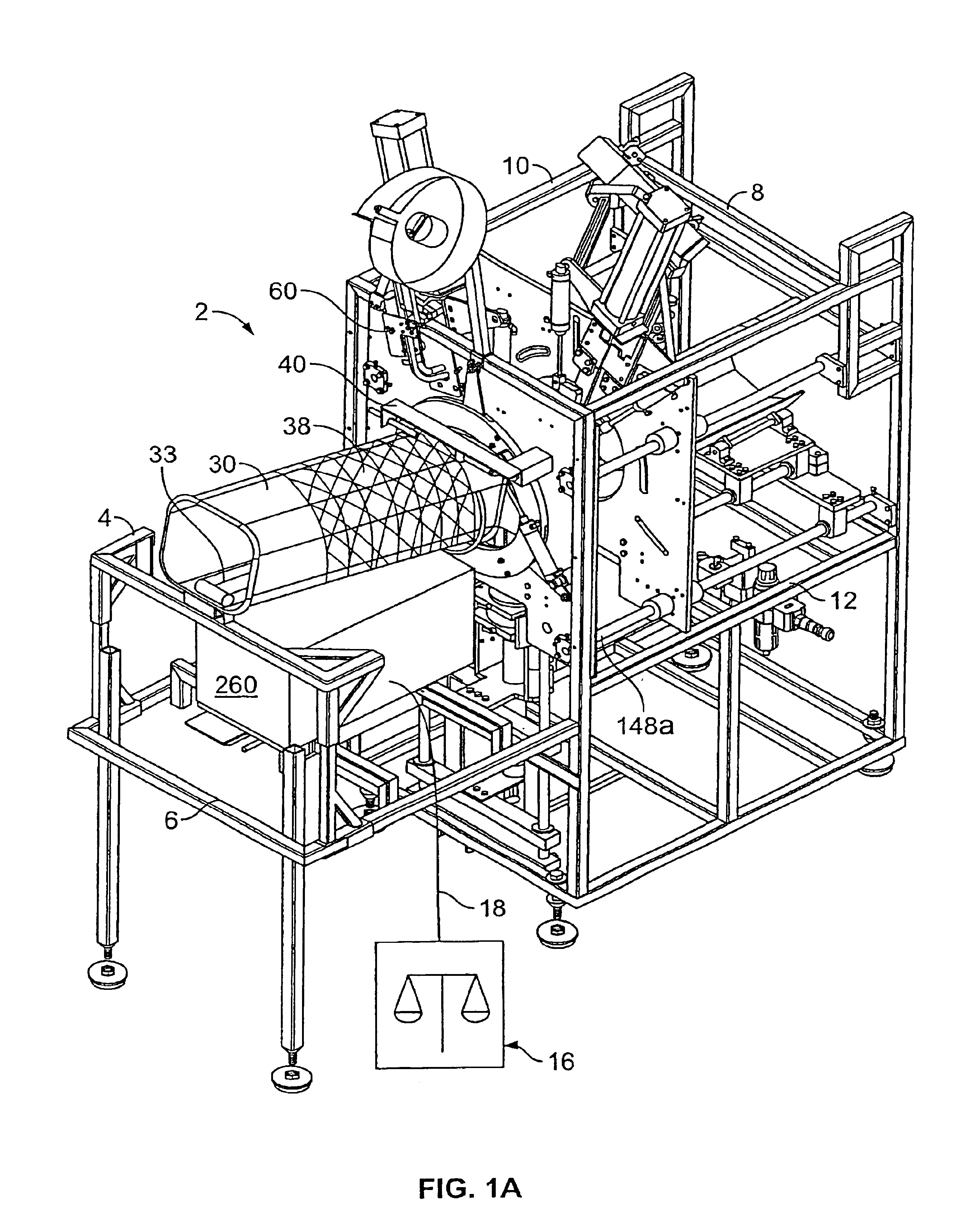

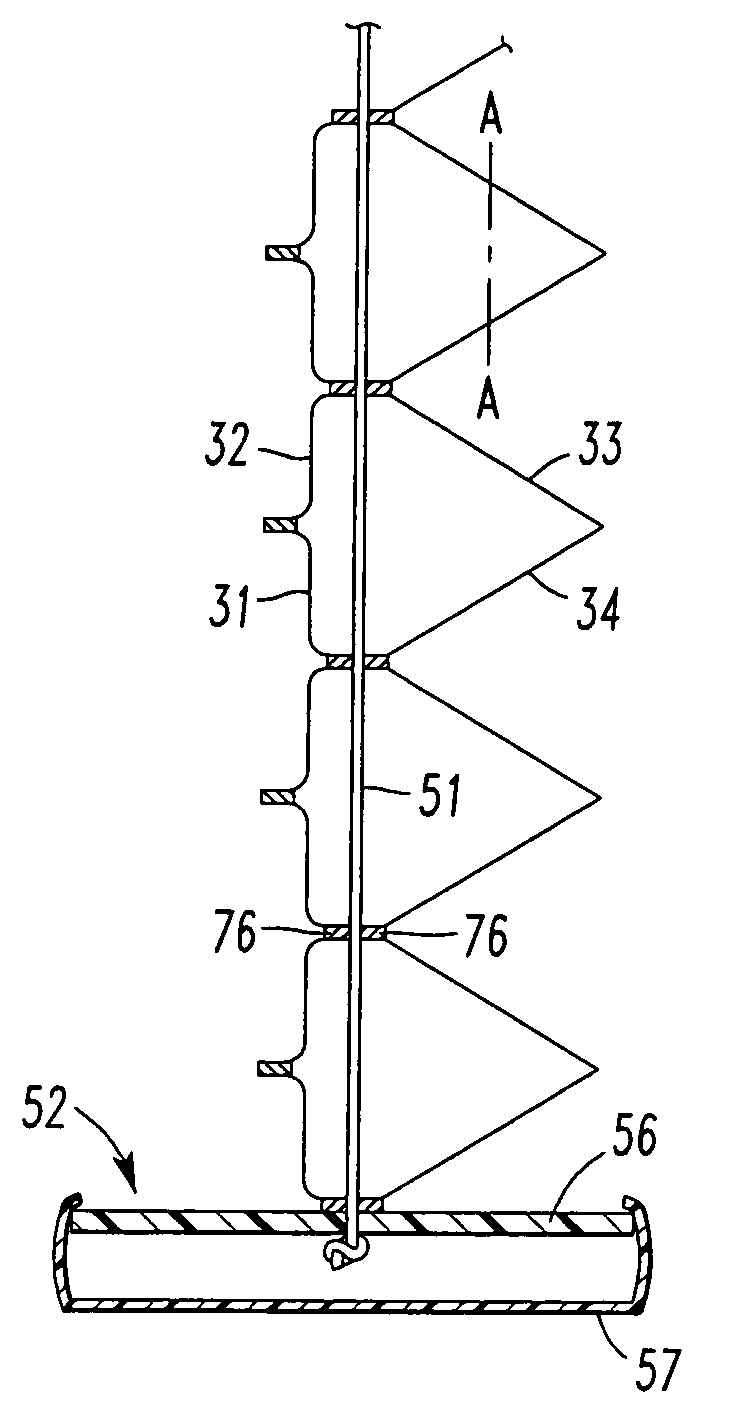

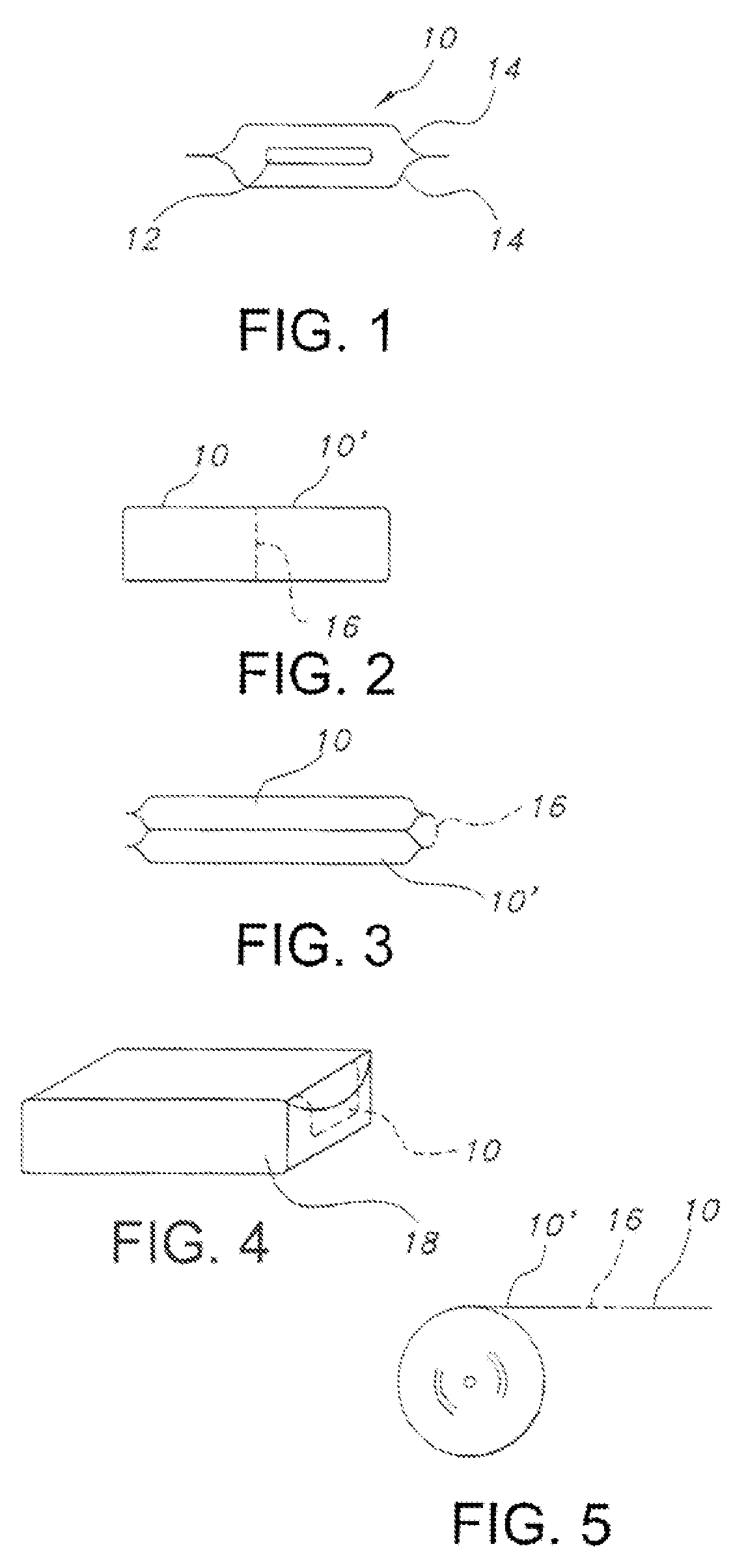

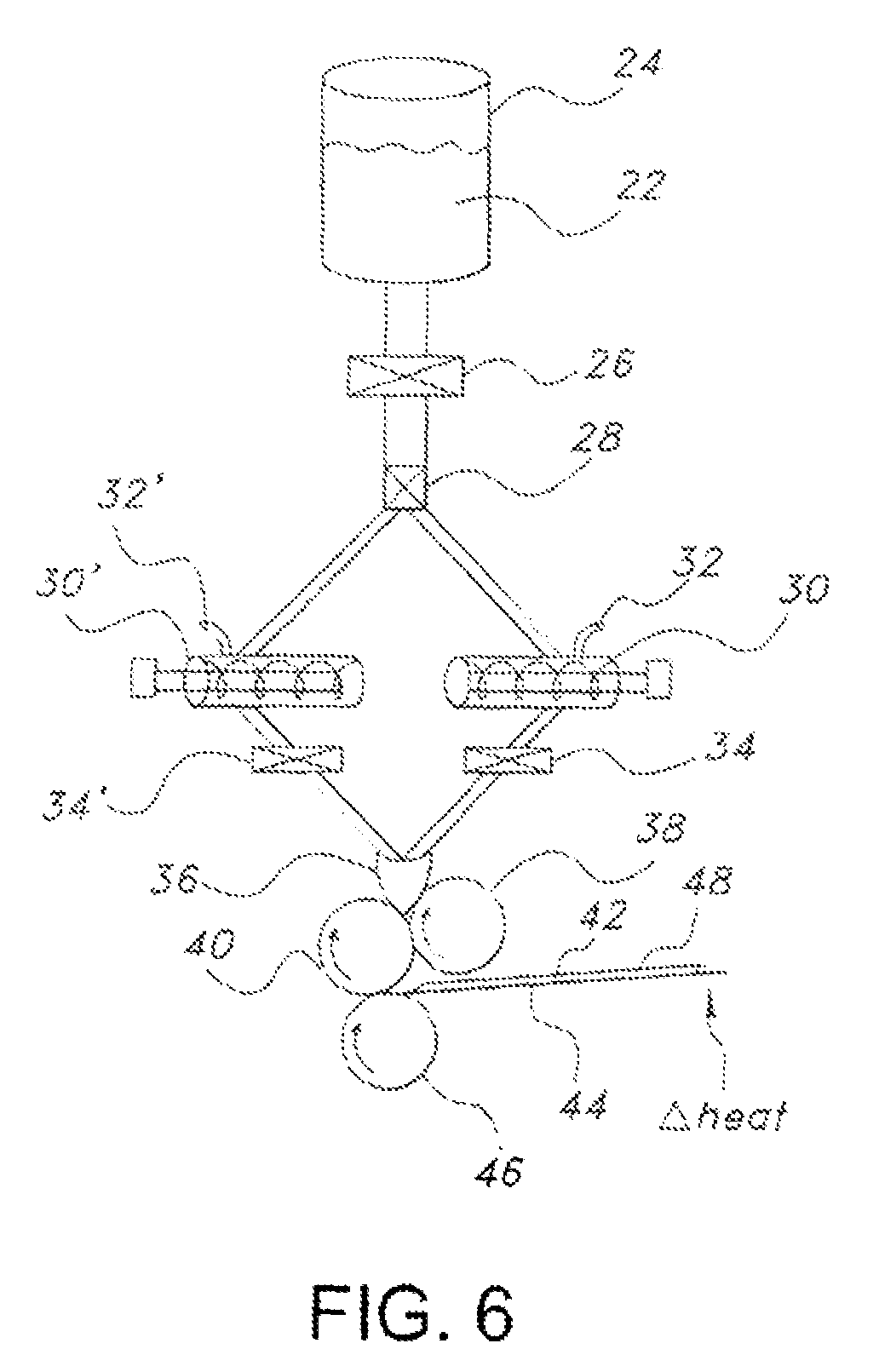

Apparatus for enclosing material in a net

InactiveUS6883297B2Uniform appearanceLighten the taskAffixing tagsSkinless sausage makingEngineeringMechanical engineering

An apparatus and method of enclosing material in a net and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper cuts and closes the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

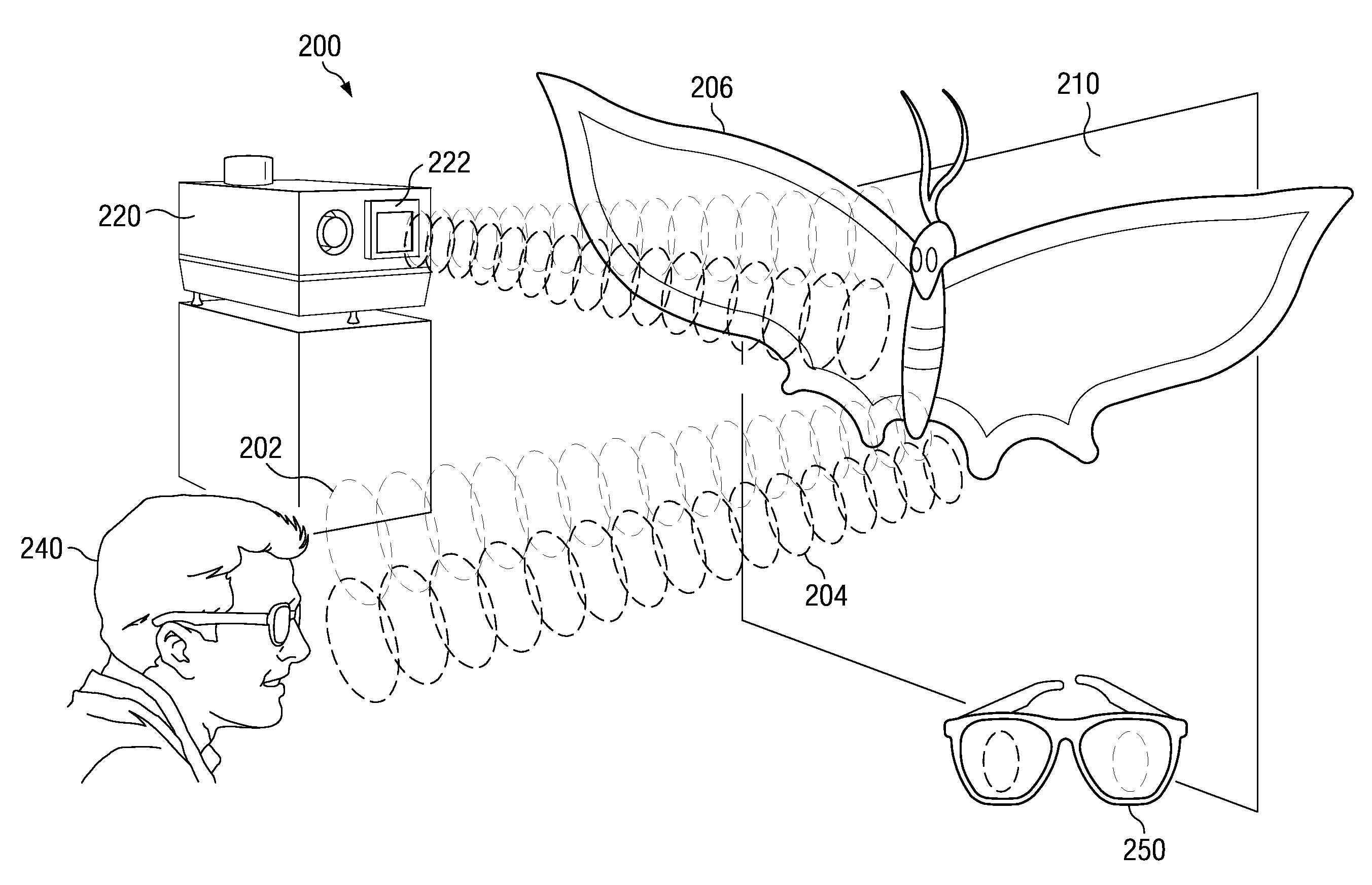

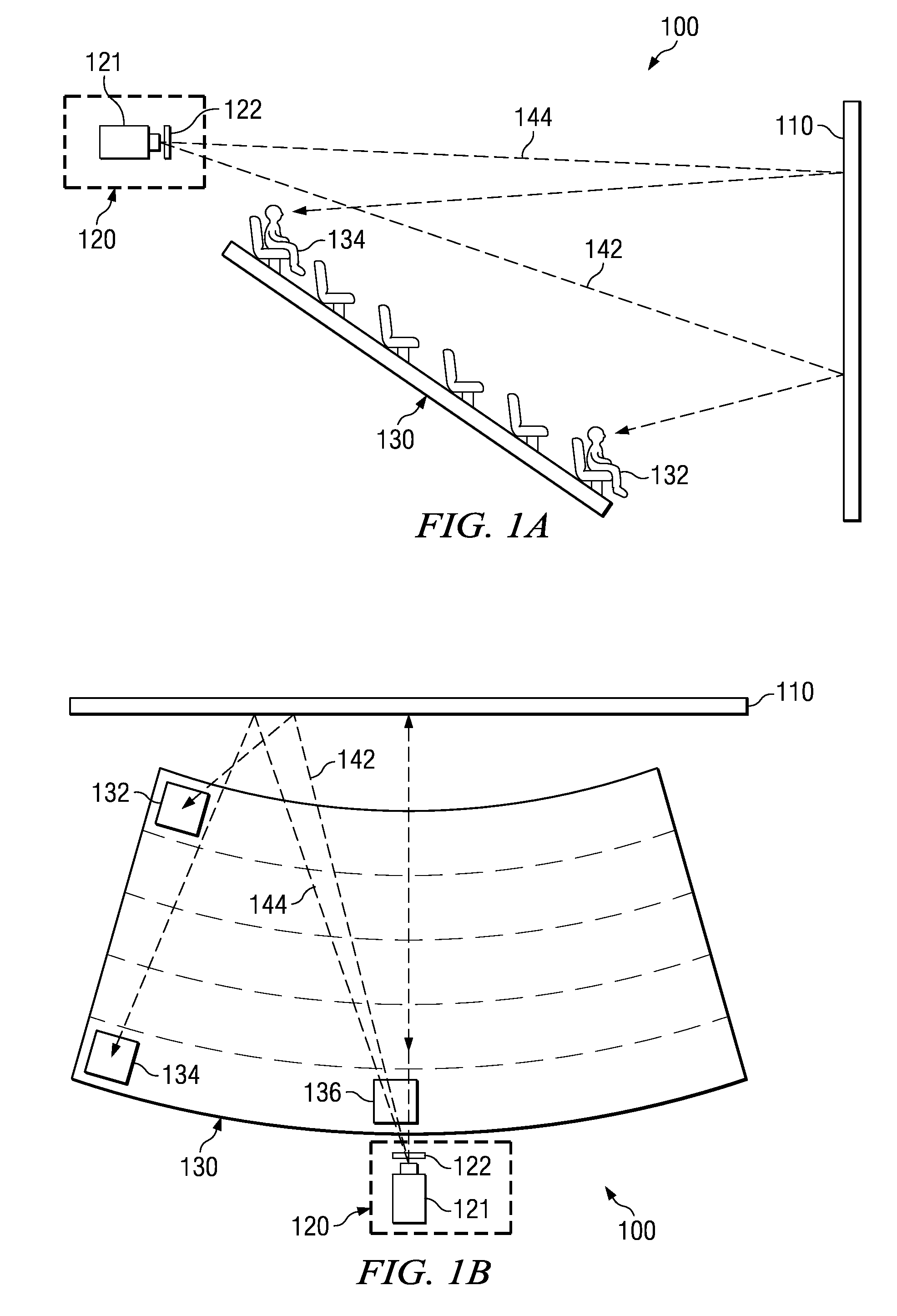

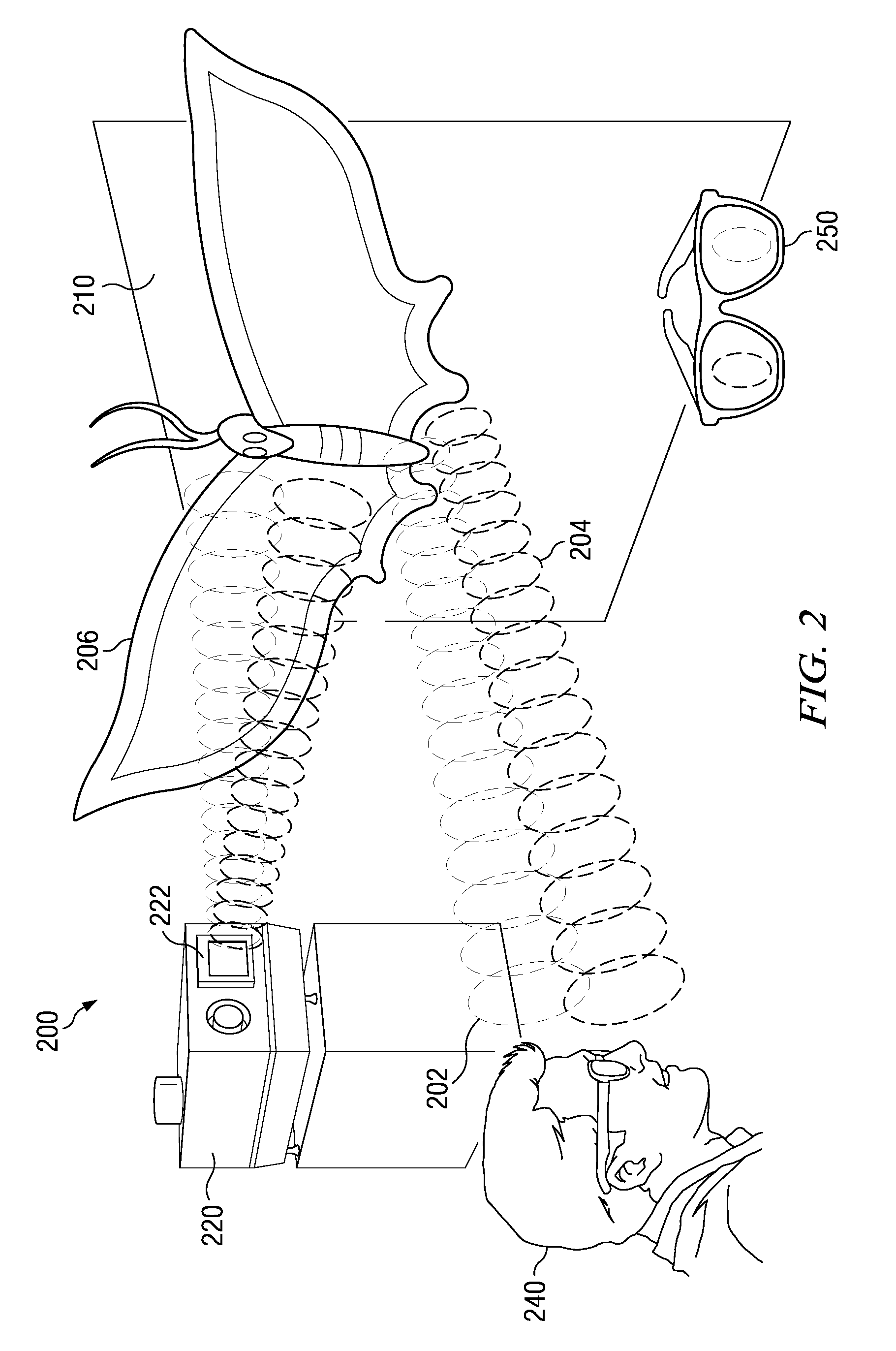

Polarization preserving front projection sceen

ActiveUS20090190210A1Improved light controlEnhanced brightness and uniformity and contrastGearingProjectorsAnaglyph 3DEyewear

Polarization preserving front projection screens and diffusers provide optimum polarization preservation for stereoscopic 3D viewing, as well as improved light control for enhanced brightness, uniformity, and contrast for both 2D and 3D systems. Generally, the disclosed screens direct light from a projector toward viewers within a diffusion locus, while maintaining optimum gain characteristics. More specifically, light incident on a region of the front projection screen from a predetermined projection direction is reflected by an engineered surface to a predetermined diffusion locus after undergoing substantially single reflections. The engineered surface, comprised of generating kernels, is used to optimally diffuse illumination light into a range of viewing angles, within the diffusion locus, with suitable gain profile, while optimally preserving polarization for 3D applications. Such a screen, when combined with matched polarization analyzing eyewear, provides extremely low cross-talk from any observation point.

Owner:REAID INC

Light emitting device including luminescent ceramic and light-scattering material

ActiveUS7521862B2Uniform appearanceGood colorDischarge tube luminescnet screensElectroluminescent light sourcesSemiconductor structureLength wave

A ceramic body comprising a wavelength converting material is disposed in the path of light emitted by the light emitting region of a semiconductor structure comprising a light emitting region disposed between an n-type region and a p-type region. A layer of transparent material is also disposed in the path of light emitted by the light emitting region. The transparent material may connect the ceramic body to the semiconductor structure. Particles configured to scatter light emitted by the light emitting region are disposed in the layer of adhesive material. In some embodiments the particles are phosphor; in some embodiments the particles are not a wavelength-converting material.

Owner:LUMILEDS

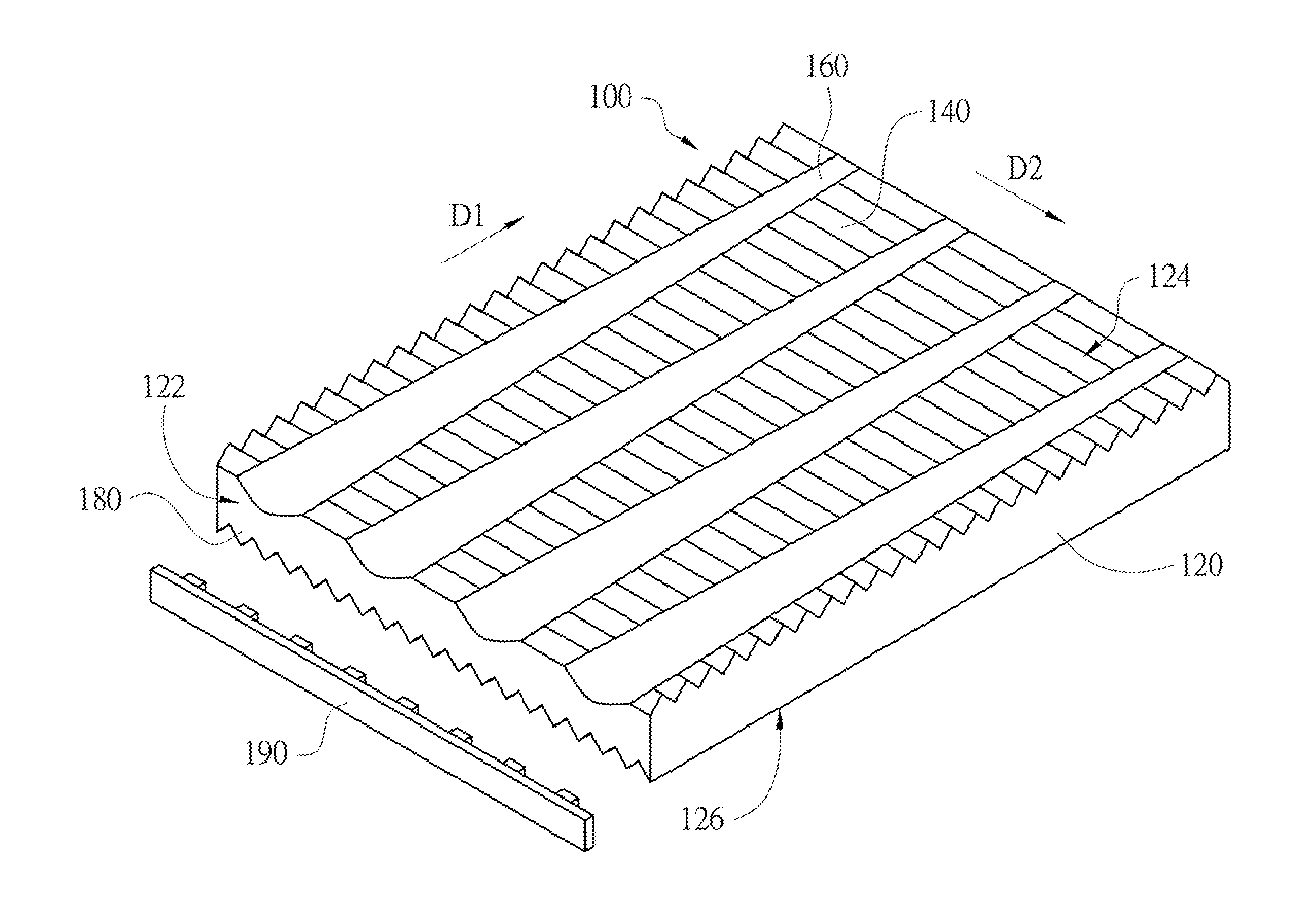

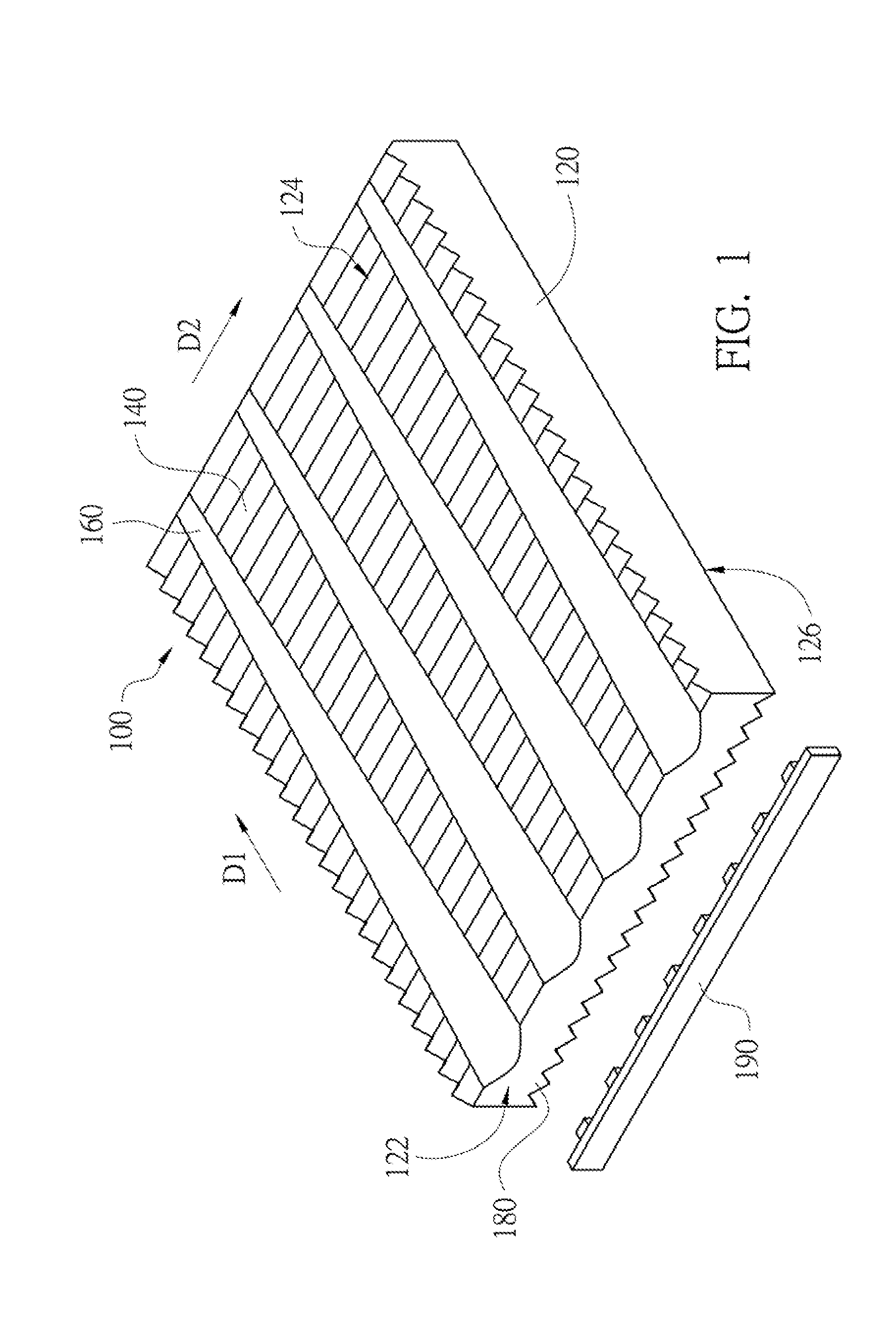

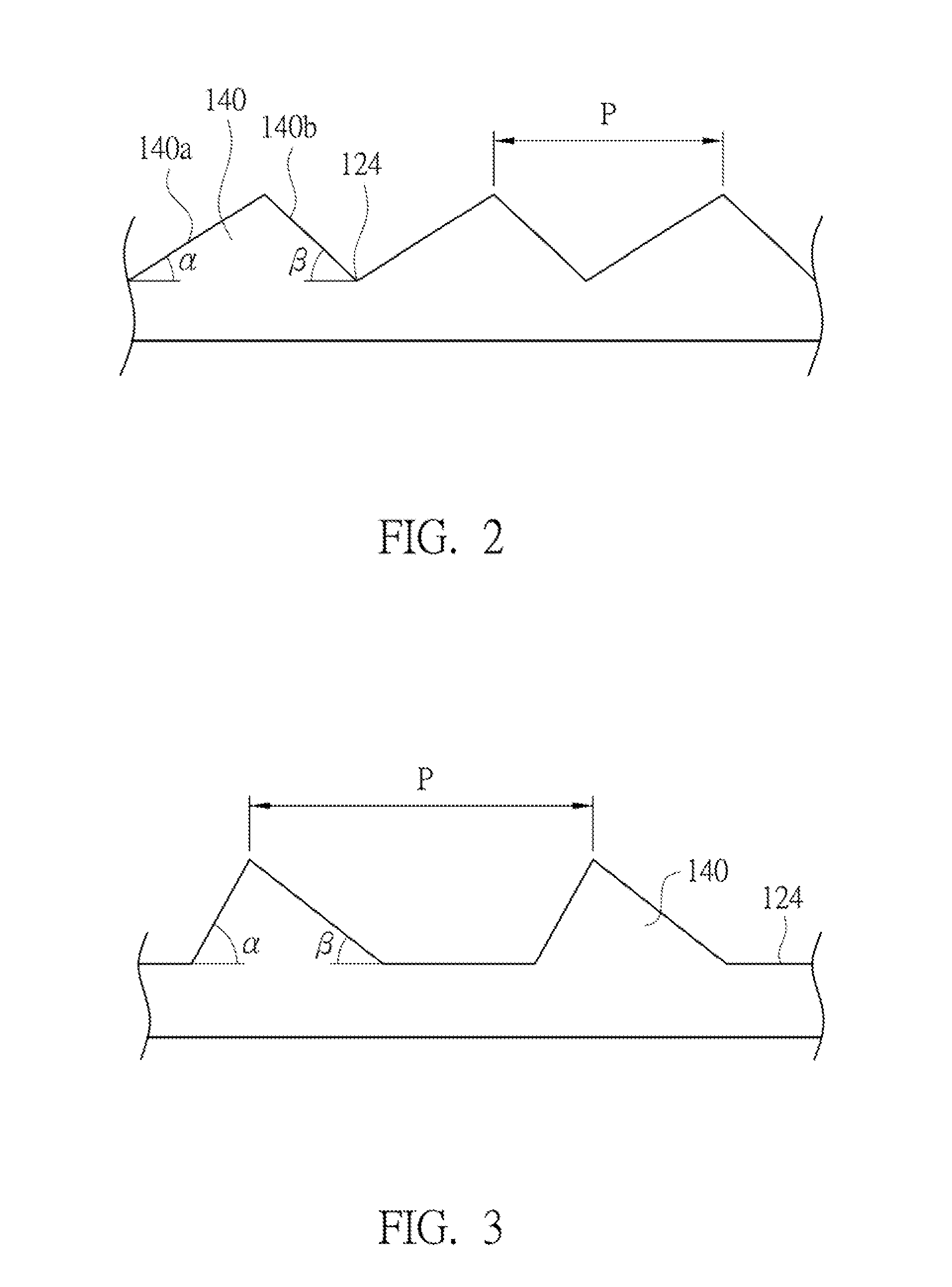

Light guide plate with multi-directional structures

ActiveUS20150055366A1Uniform effectReduce cost burdenMechanical apparatusPlanar/plate-like light guidesLight guideMulti directional

A light guide plate with multi-directional structures includes a main body, a plurality of first microstructures and a plurality of second microstructures. The main body includes a light-incident surface, a light-emitting surface and a reflecting surface. The light-incident surface connects the light-emitting surface and the reflecting surface. The first microstructures are disposed on the light-emitting surface or the reflecting surface and arranged along a first extending direction. The second microstructures are disposed on the light-emitting surface or the reflecting surface and arranged along a second extending direction. The second microstructures and the first microstructures are disposed on the same plane and intersect with each other. Each of the second microstructures is a single stripe pattern, and has a width which becomes gradually smaller from one end of the second microstructure near the light-incident surface to the other end of the second microstructure away from the light-incident surface.

Owner:RADIANT OPTO ELECTRONICS

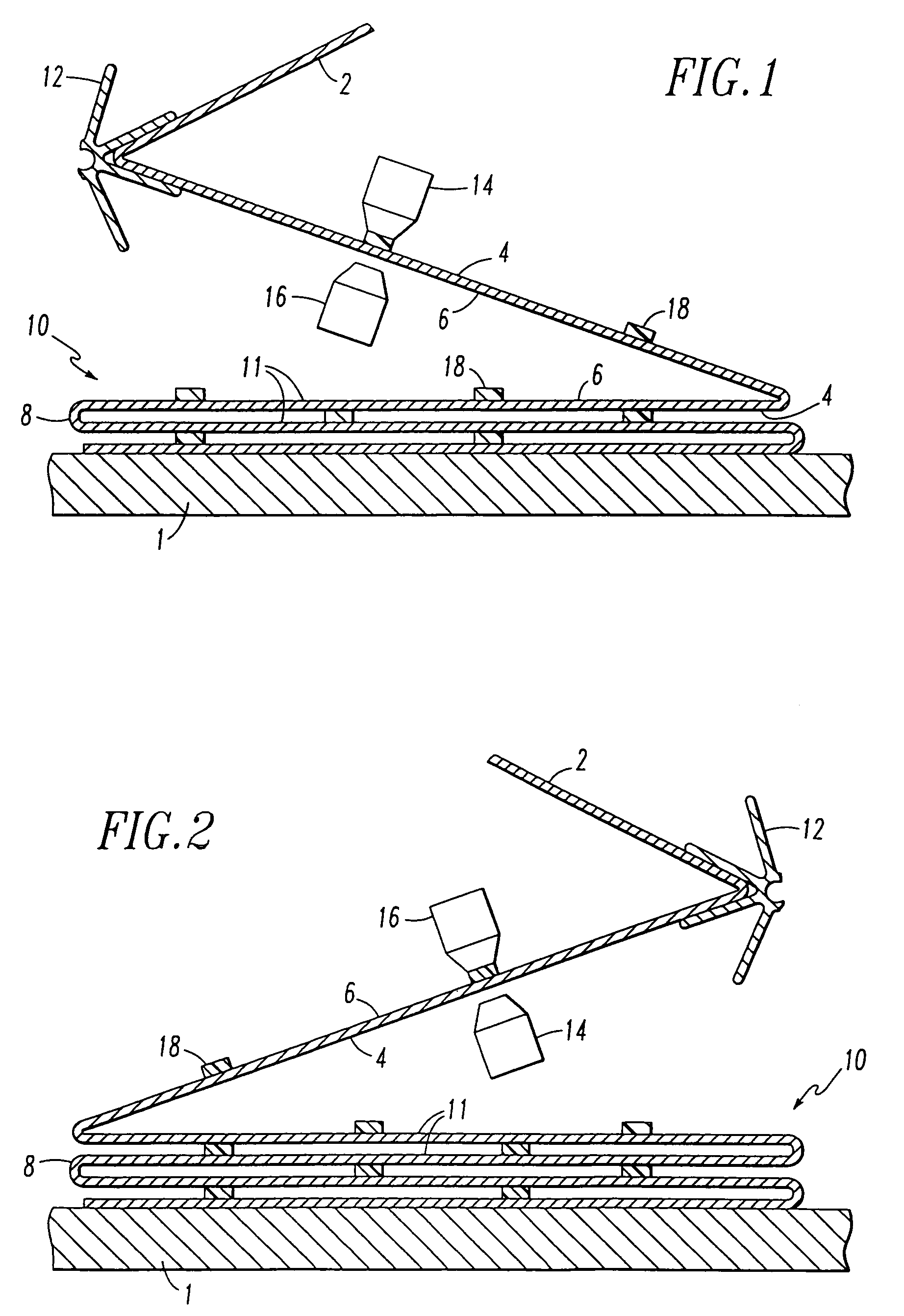

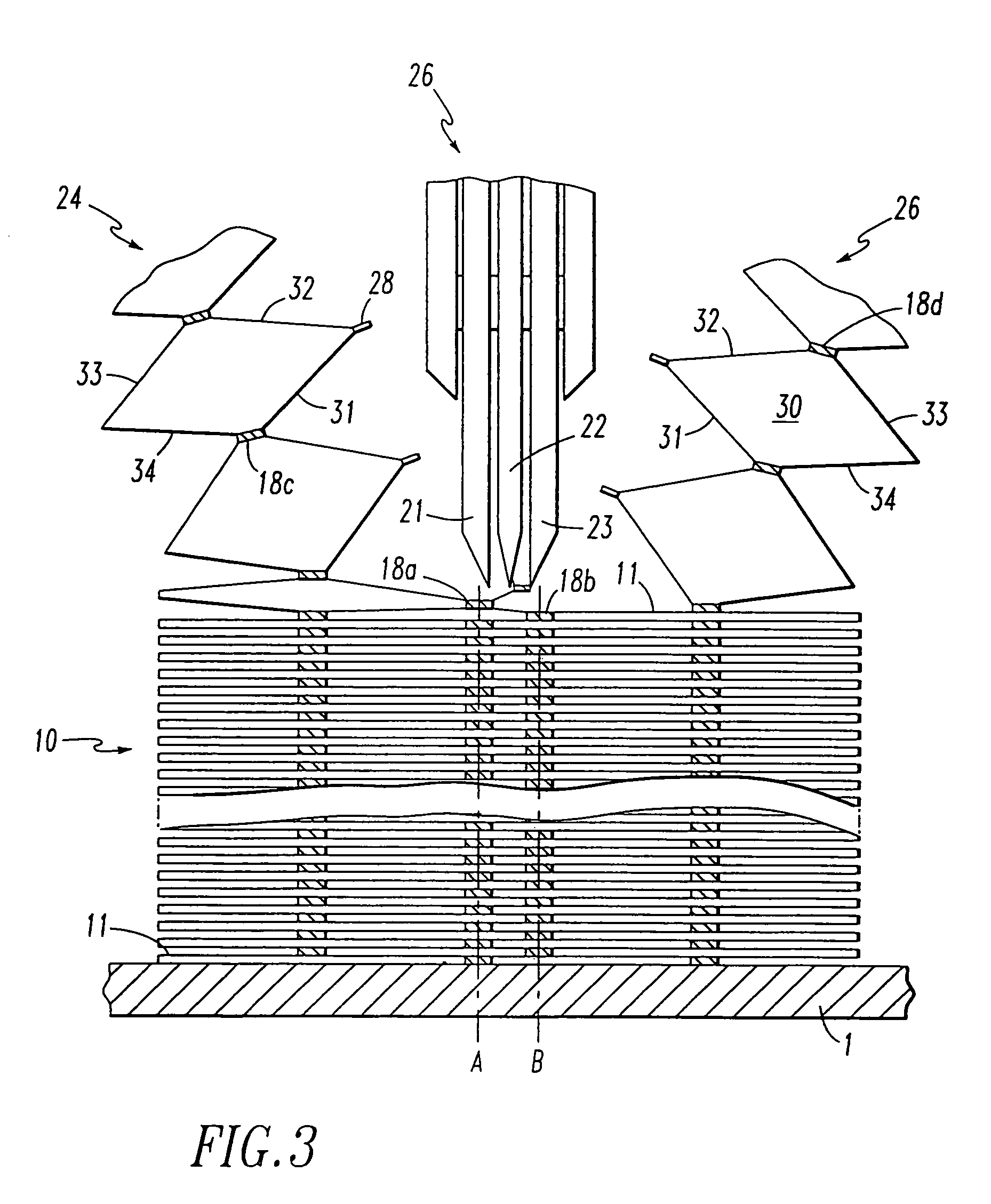

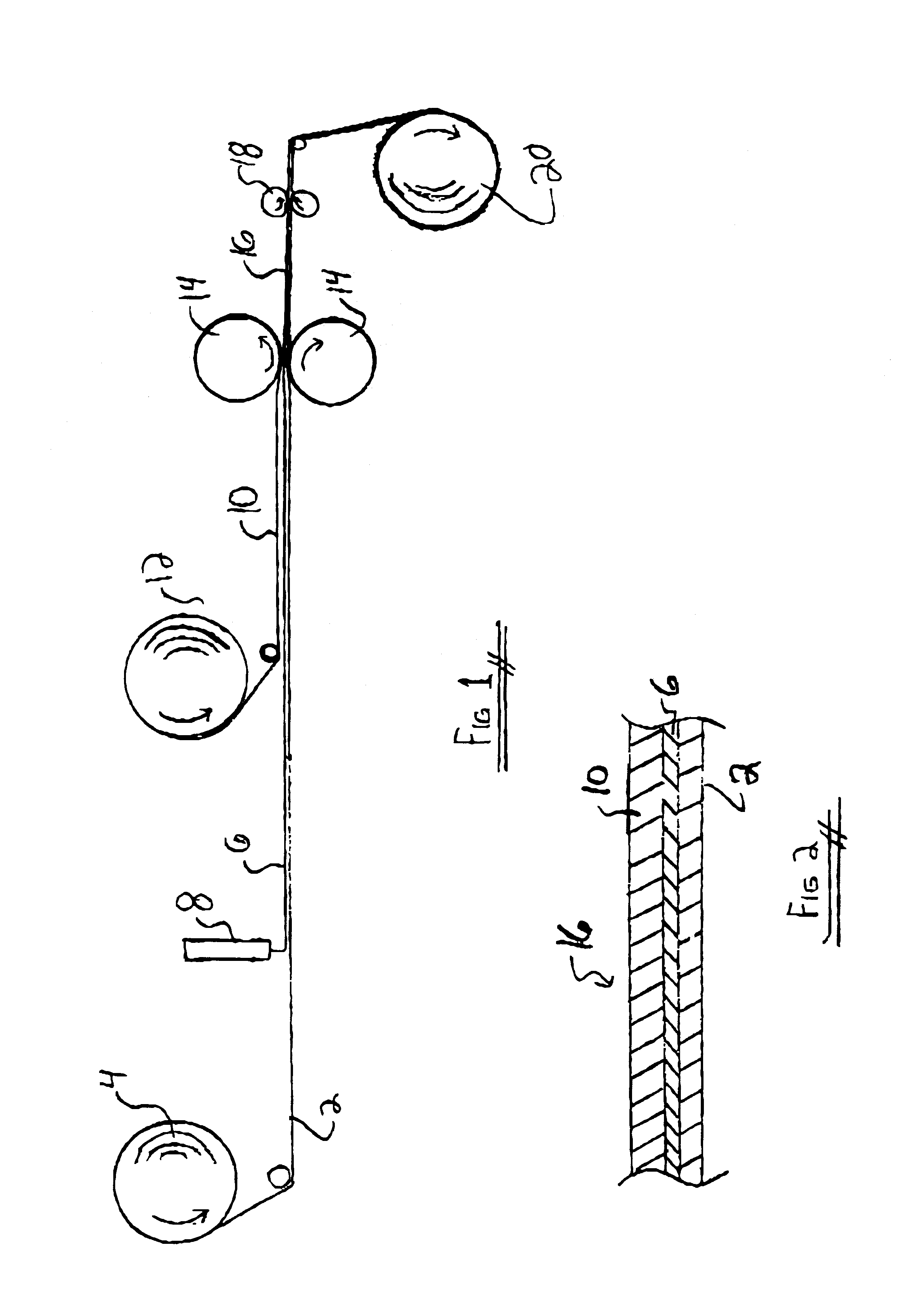

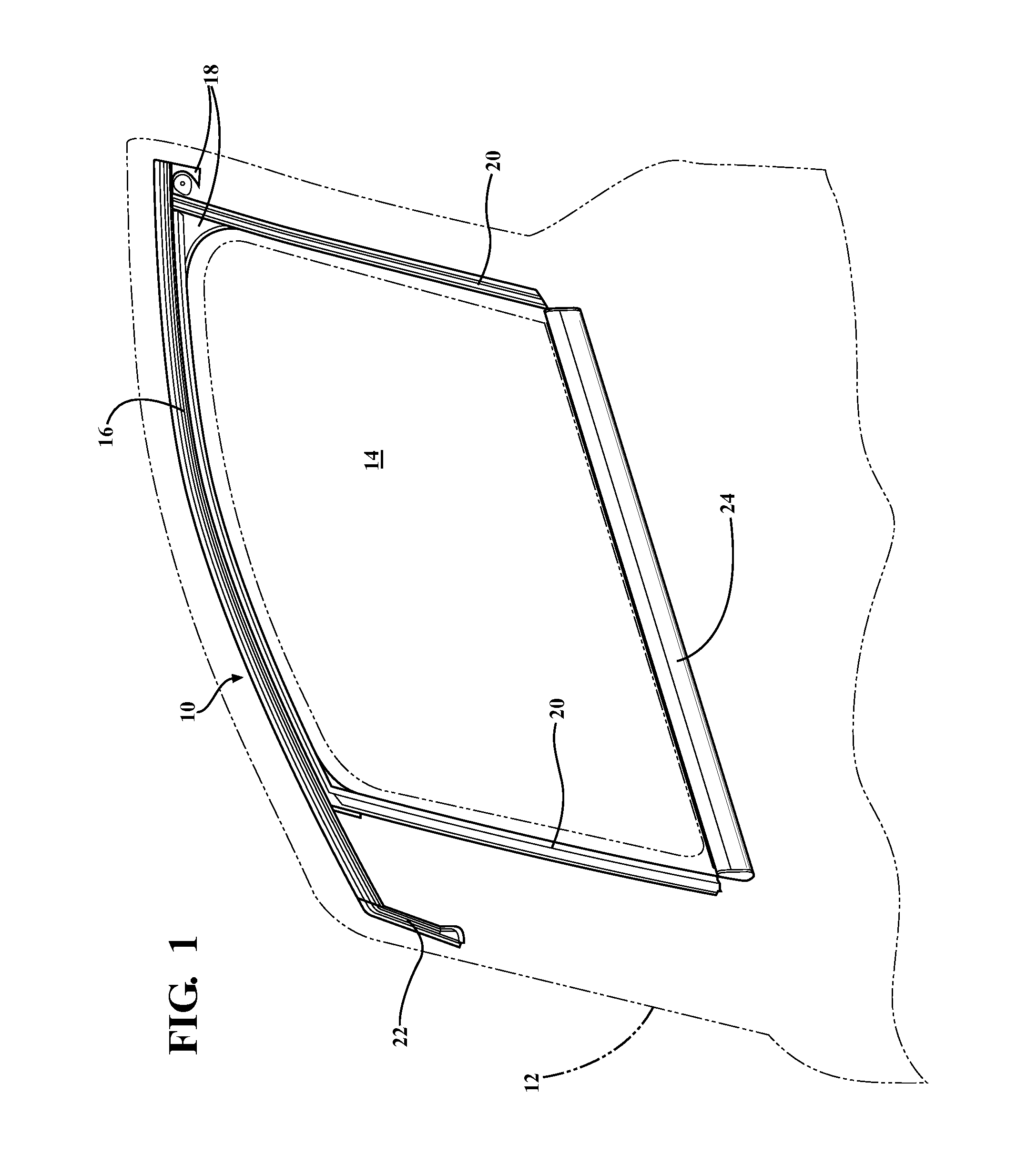

Pleated and cellular materials

InactiveUS7159634B1Easy to operateUniform appearanceExtensible doors/windowsCurtain accessoriesEngineeringMechanical engineering

A tabbed honeycomb structure or pleated panel is made from a stack of collapsed multi-cellular material. The stack is split at bond lines thereby forming the panels of pleated or honeycomb material having a joint tab on one face. The tabbed, honeycomb material is attached between a headrail and a bottomrail to form a window covering.

Owner:JUDKINS REN

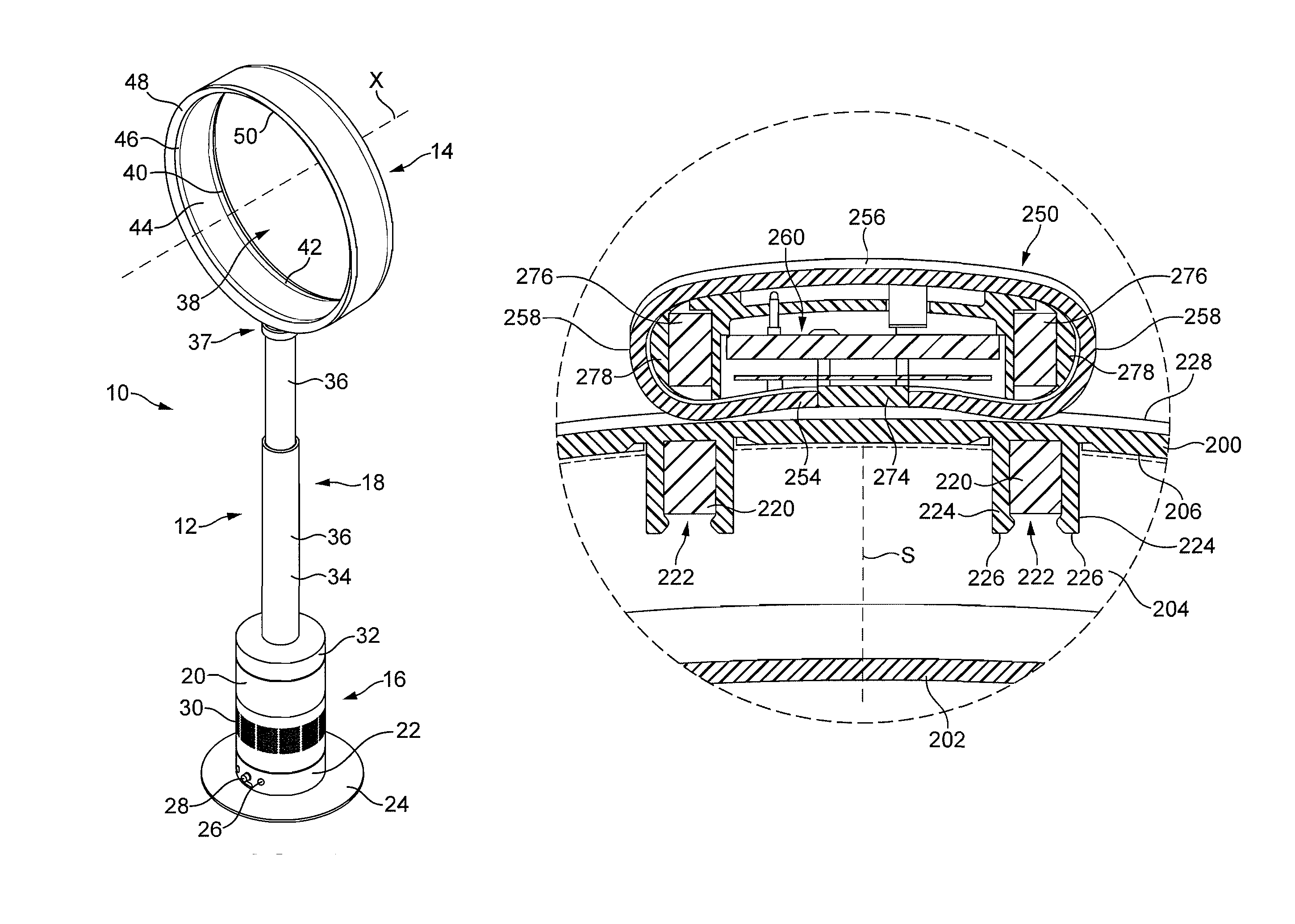

Fan having a magnetically attached remote control

ActiveUS8454322B2Improve accessibilityUniform appearancePositive displacement pump componentsJet pumpsImpellerControl signal

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller, a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet, the air outlet comprising an interior passage for receiving the air flow and a mouth for emitting the air flow, the air outlet defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth, a control circuit for controlling the motor, a remote control for transmitting control signals to the control circuit, and at least one magnet for attaching the remote control to the air outlet.

Owner:DYSON TECH LTD

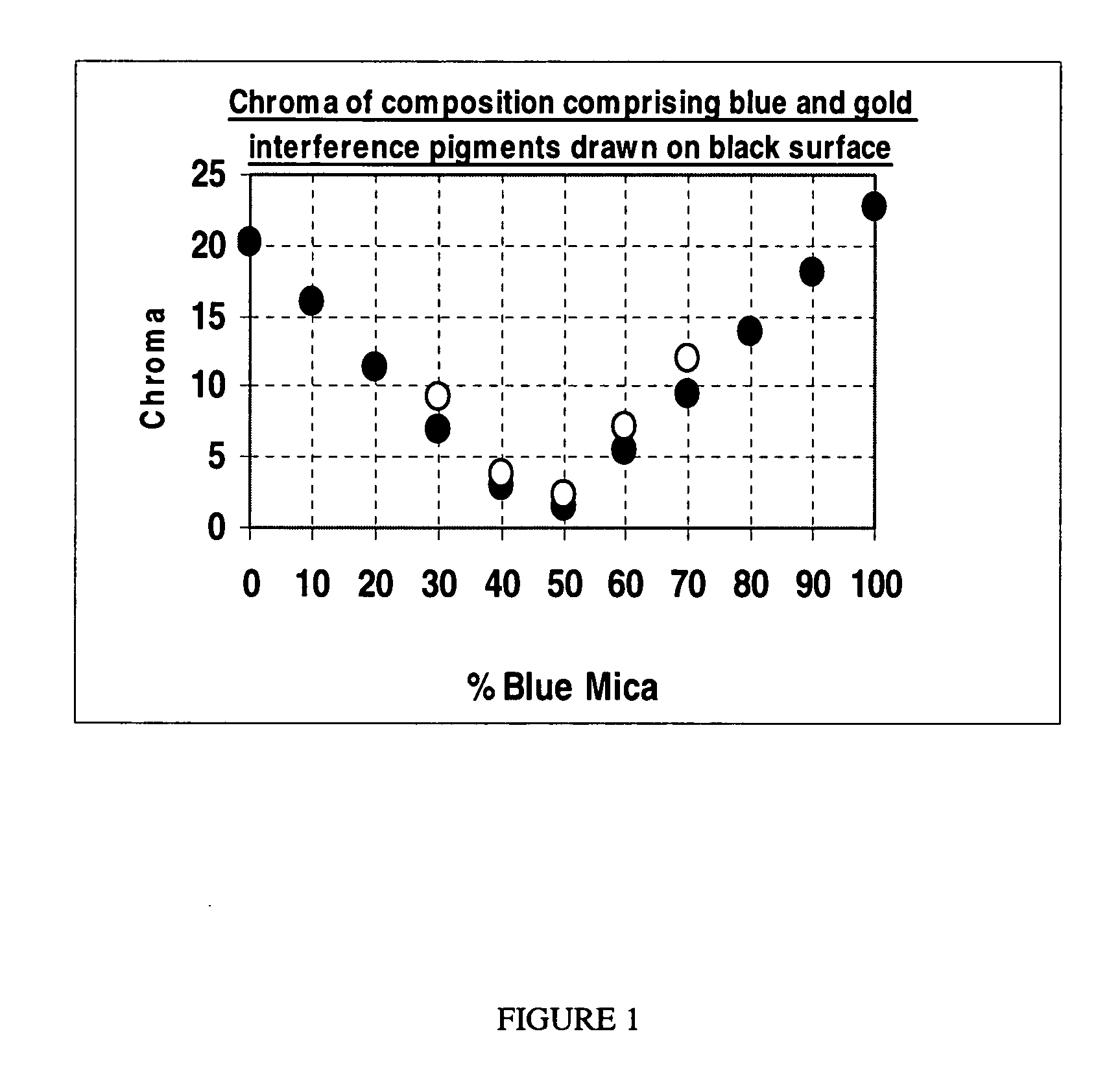

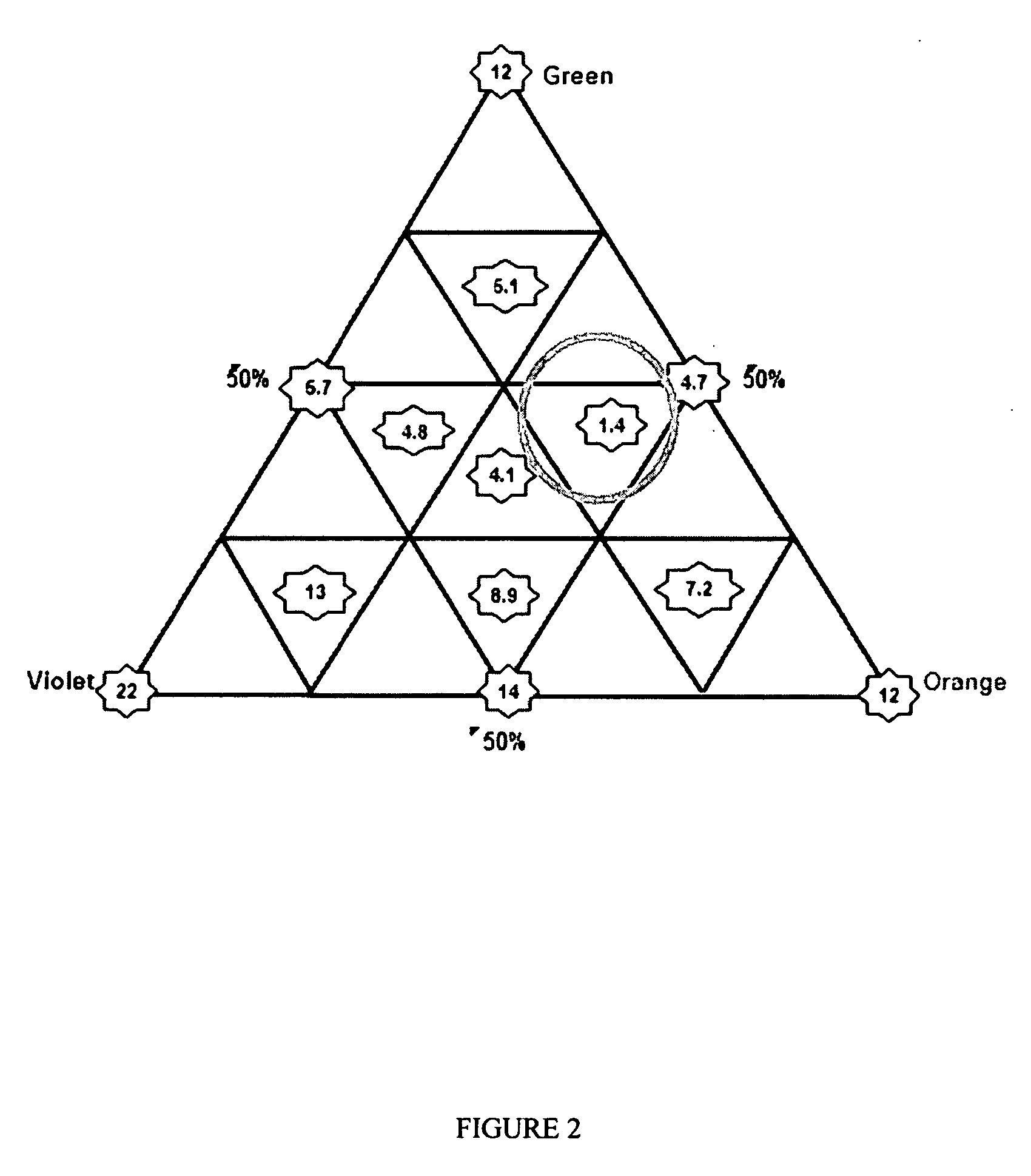

Skin care composition

ActiveUS20070065381A1Good lookingImprove the situationCosmetic preparationsPigmenting treatmentMedicineComplementary colors

Skin care composition comprising a plurality of interference pigments and a dermatologically acceptable carrier. The plurality comprises at least a first interference pigment which reflects a first color, and at least a second interference pigment which reflects a second, complementary color. The total amount of interference pigments is from about 0.1% to about 10%.

Owner:THE PROCTER & GAMBLE COMPANY

Fan

ActiveUS20130280096A1Improve accessibilityUniform appearanceJet pumpsPump controlImpellerControl signal

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller, a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet, the air outlet comprising an interior passage for receiving the air flow and a mouth for emitting the air flow, the air outlet defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth, a control circuit for controlling the motor, a remote control for transmitting control signals to the control circuit, and a plurality of magnets angularly spaced about the air outlet to provide a plurality of angularly spaced docking positions for the remote control on the air outlet.

Owner:DYSON TECH LTD

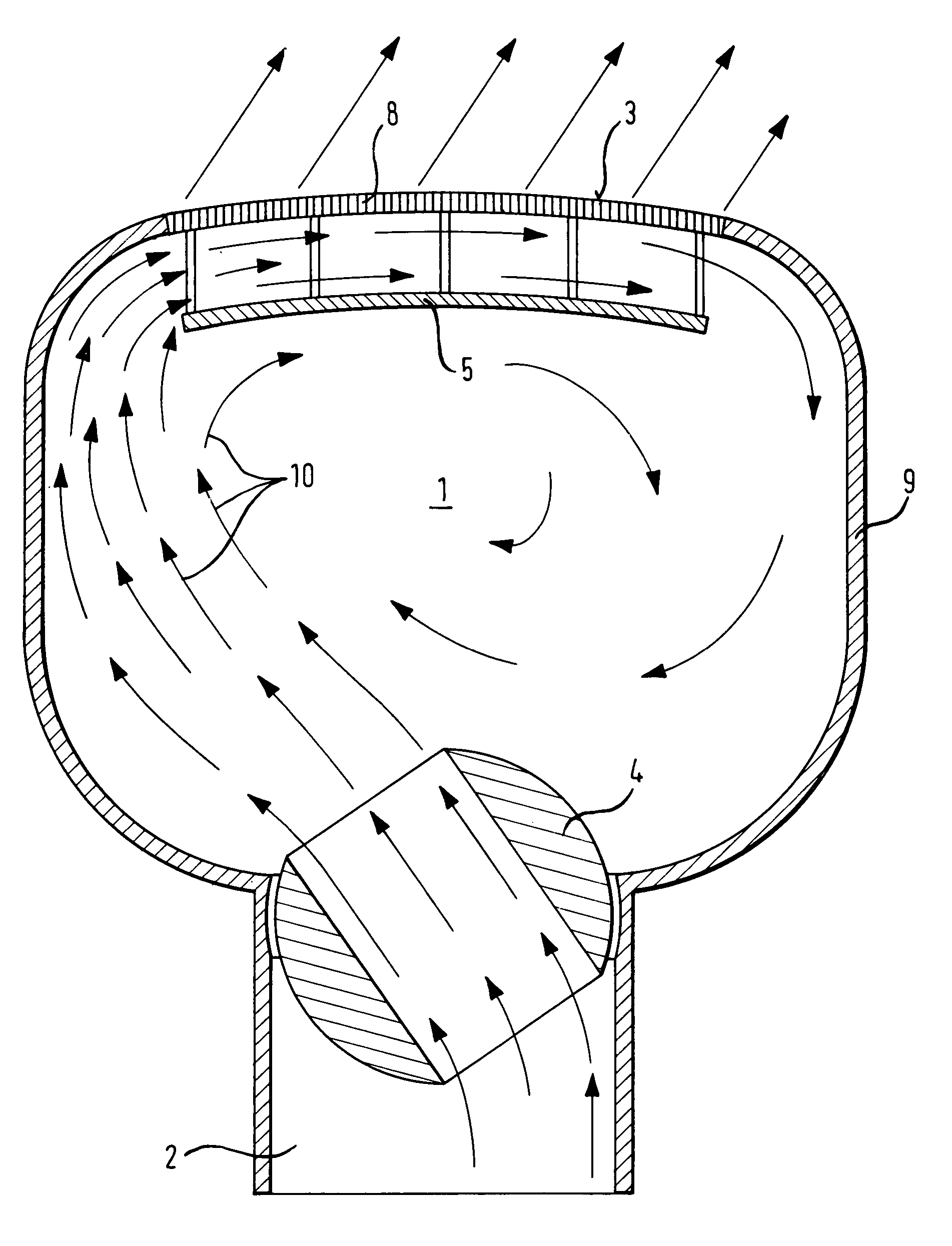

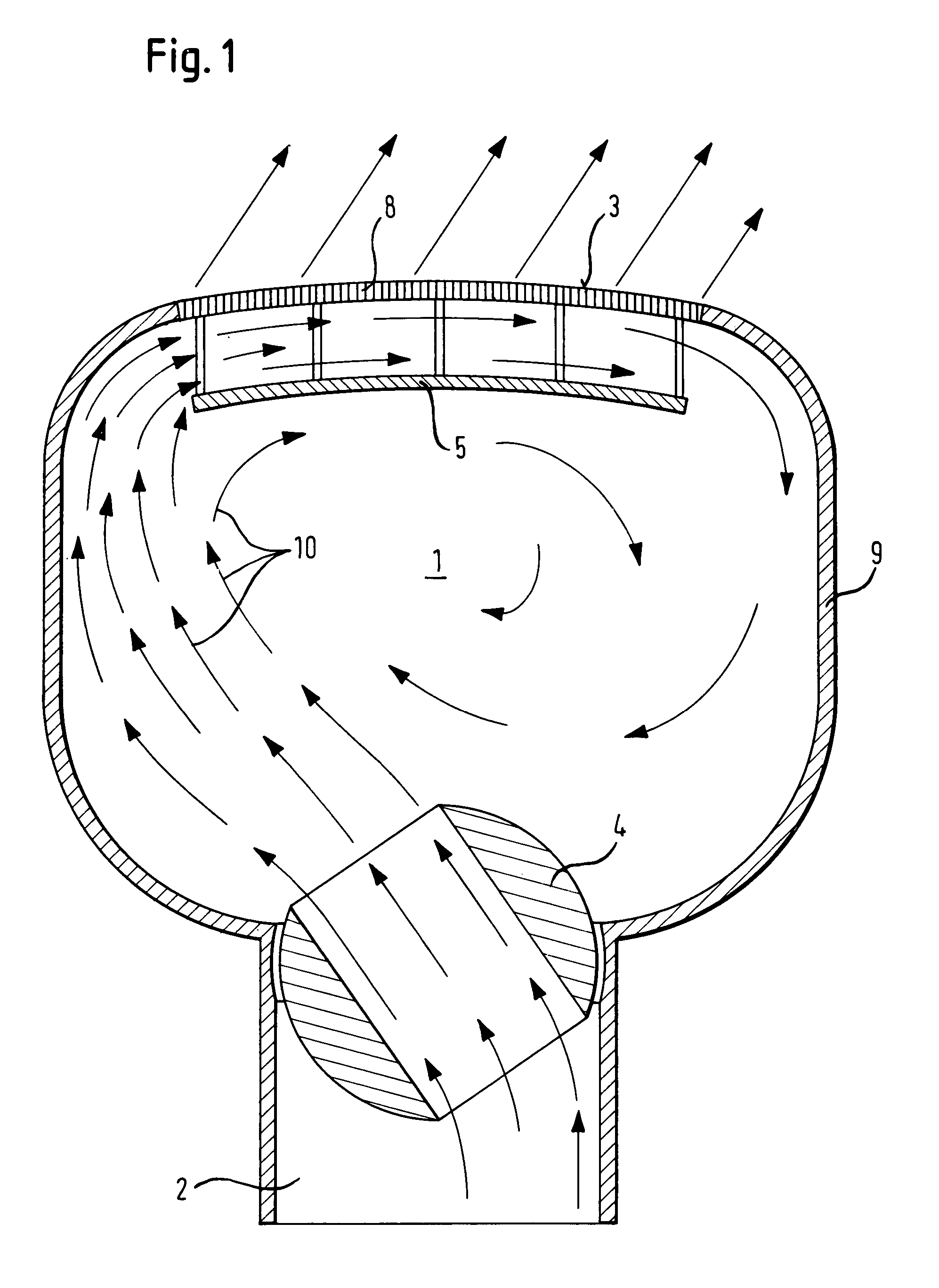

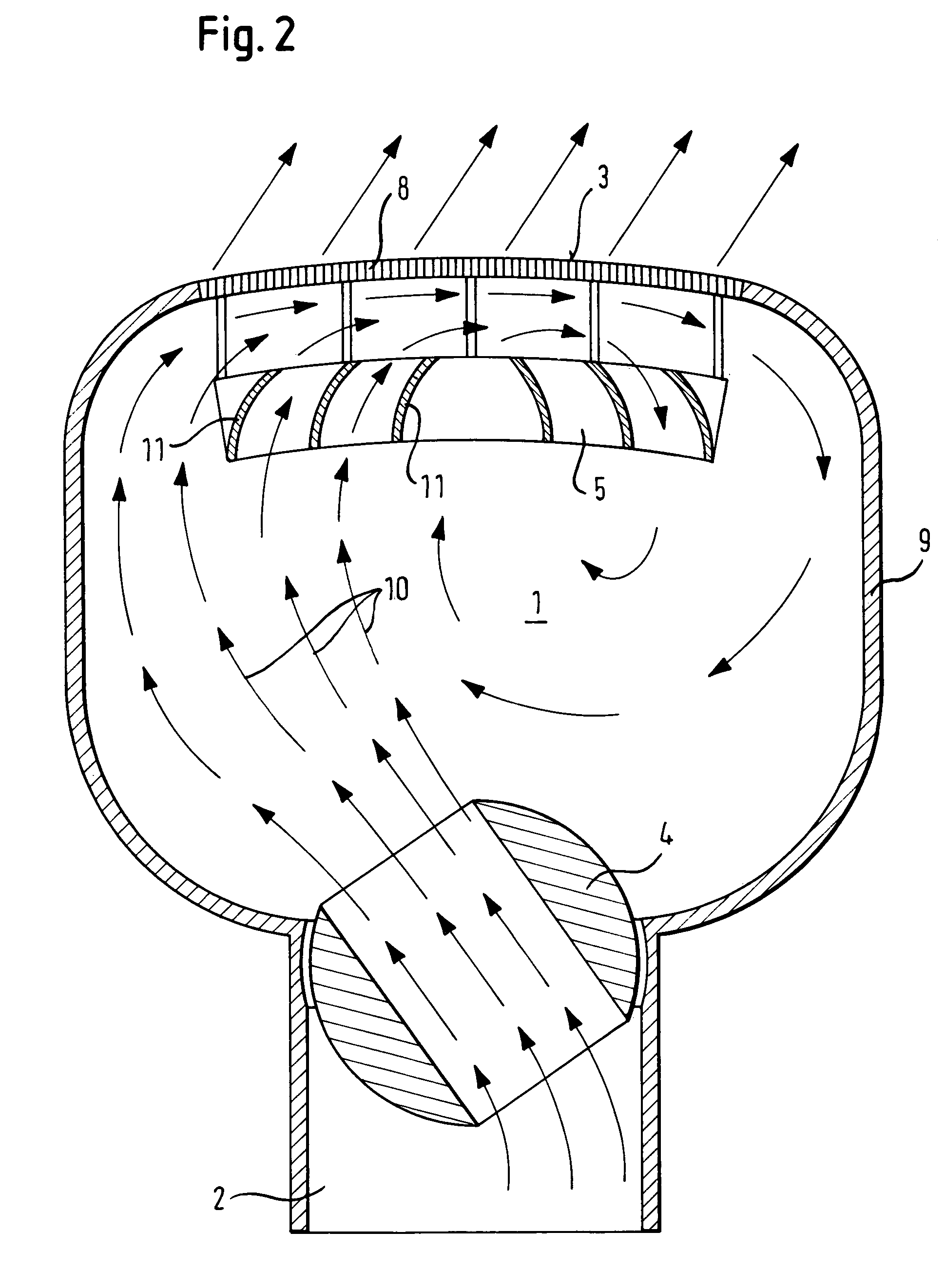

Air vent for a ventilation system

InactiveUS7201650B2Uniform appearanceDeflection of the air flow already caused by the rotation effect can be further intensifiedDucting arrangementsAir-treating devicesAir cycleWaste management

An air vent for a ventilation system in a vehicle is disclosed that has an air circulation chamber (1) defined by a housing (9) that has a generally bulged shape. An inflow duct (2) is connected to this housing and opens into the circulation chamber (1), the housing having a perforated wall area (3). An air stream, in use, enters the circulation chamber (1) through inflow duct (2), circulates through the air circulation chamber and exits through the perforated wall area. The air vent further comprises a movable air deflection member disposed to deflect the air stream transversely to an axial direction of the inflow duct.

Owner:TRW AUTOMOTIVE ELECTRONICS & COMPONENTS GMBH & CO KG

Preparation method for graphene fiber

The invention discloses a preparation method for a graphene fiber and belongs to the field of graphene fiber preparation. The preparation method comprises the following steps: firstly, preparing 2-20 mg.mL<-1> purified graphene oxide solution by using an oxidation stripping graphite method; secondly, injecting the graphene oxide solution in the first step in a pipeline reactor with the inside diameter of 0.1-10 mm and sealing; thirdly, heating the pipeline reactor at the temperature of 100-300 DEG C for 1-6 hours and reducing and assembling the graphene oxide into a water-containing graphene oxide fiber; and fourthly, drying the water-containing graphene fiber obtained in the third step at the temperature of 20-60 DEG C and dehydrating and contracting the water-containing graphene fiber to obtain dry graphene fiber. The preparation method is simple in operation process and low in raw material cost; and the graphene fiber obtained by the method disclosed by the invention has the advantages of uniform structure, excellent mechanical property and easiness in functionalization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

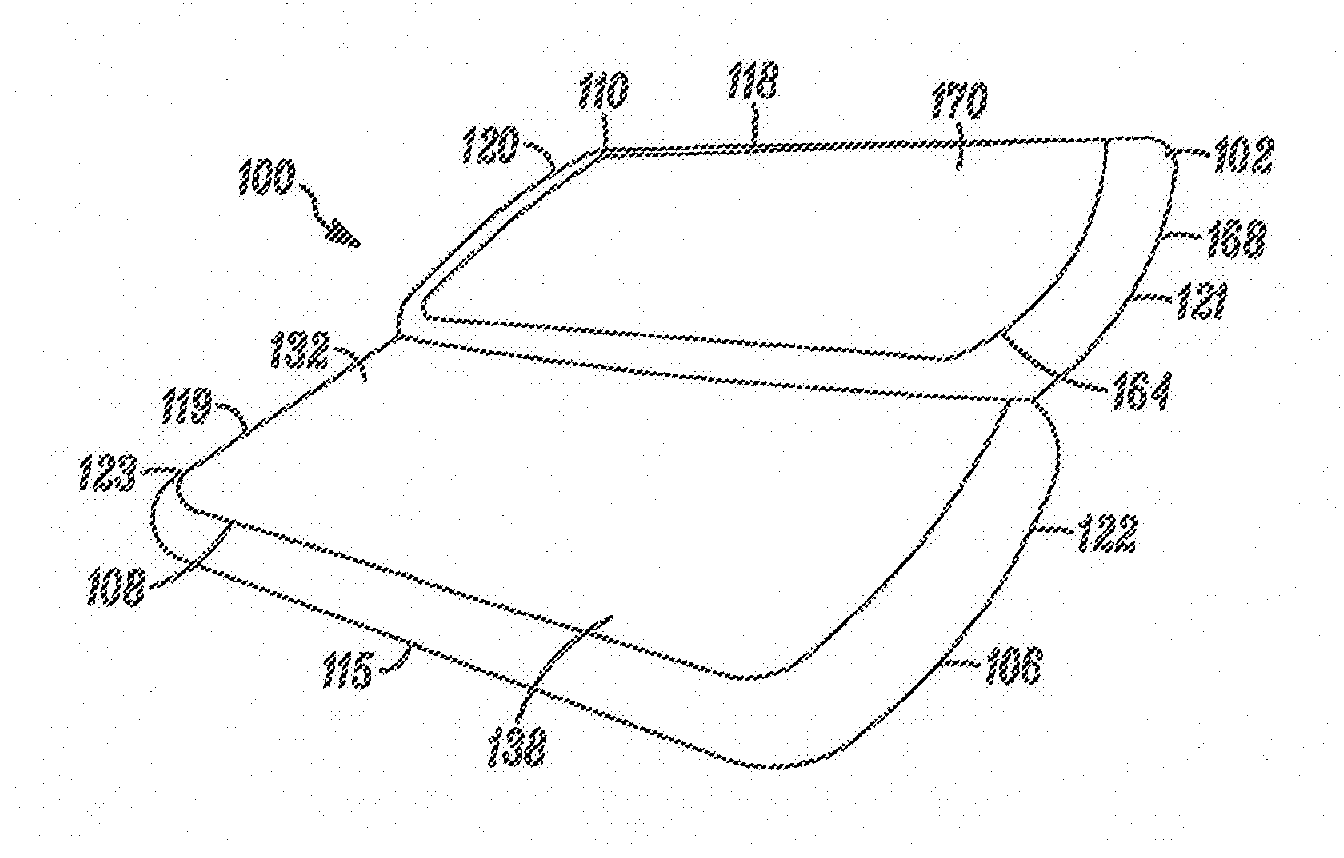

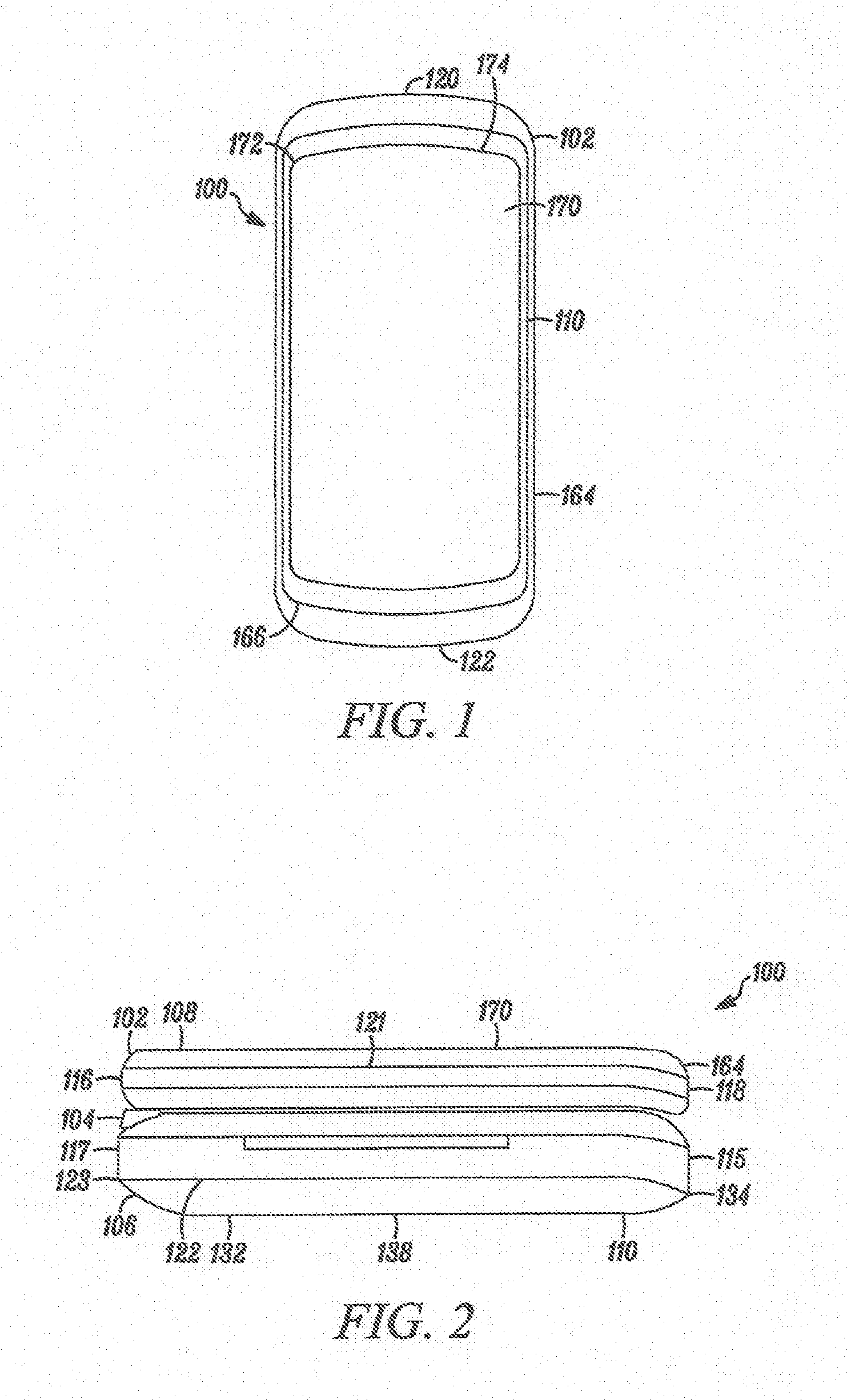

Managed material fabric for composite housing

ActiveUS20130190052A1Improve performanceImpact resistance and strong and durableLayered productsDomestic articlesConductive materialsEngineering

Owner:GOOGLE TECH HLDG LLC

Thermocalendered non-woven elastic laminate

InactiveUS6726983B2High degreeUniform elongationDecorative surface effectsBaby linensPolymer scienceThin membrane

Owner:AVINTIV SPECIALTY MATERIALS INC

Environmental protection type Nano Coating

An envirnomental protection type nano-paint with high resistance to ultraviolet ray, bacteria, mildew, brush, acid, and alkali, photocatalyzing function and amphophobic performance is prepared from filming material, nano material chosen from TiO2, SiO2 and zinc oxide, additive and water.

Owner:张海波

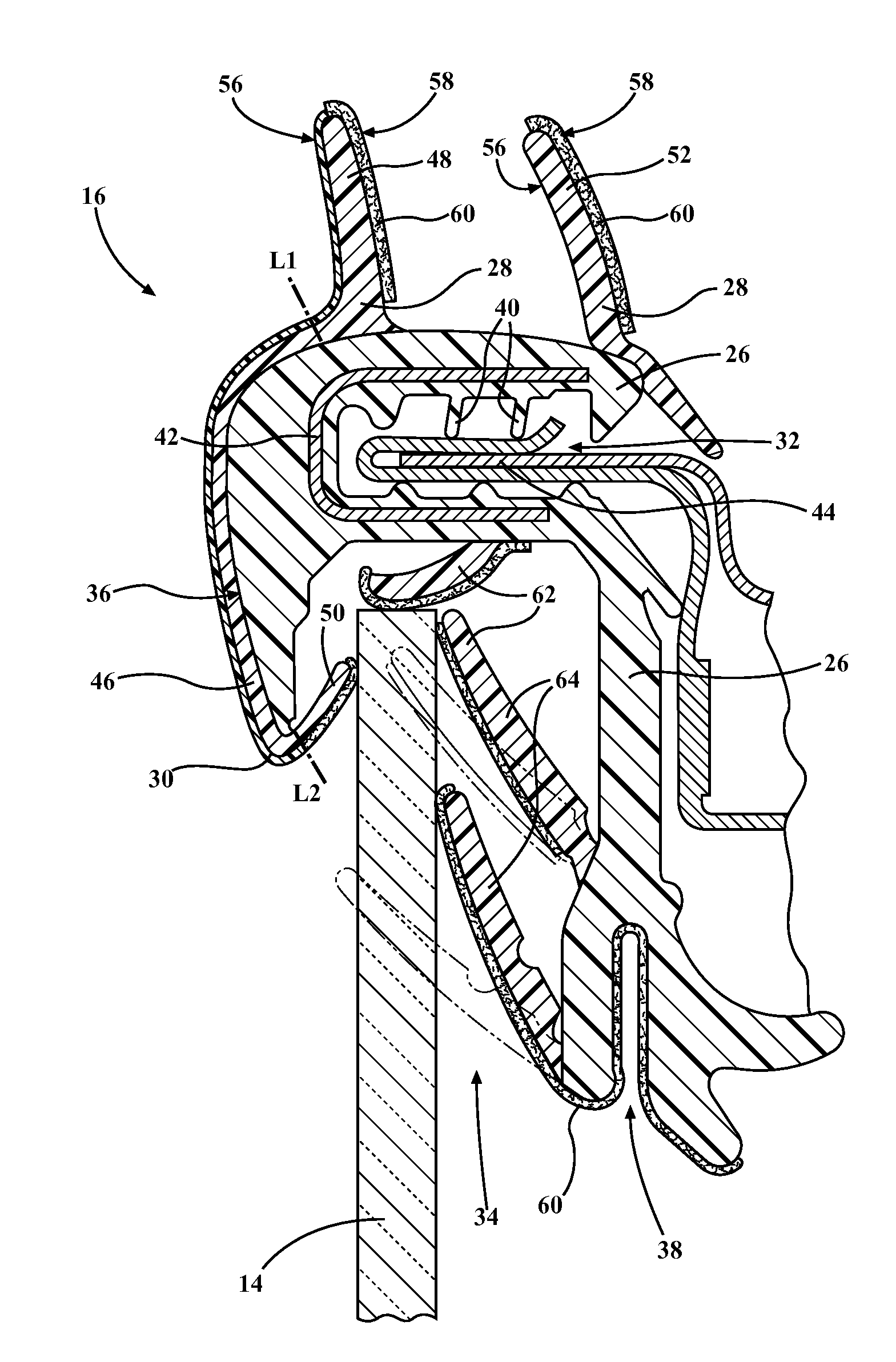

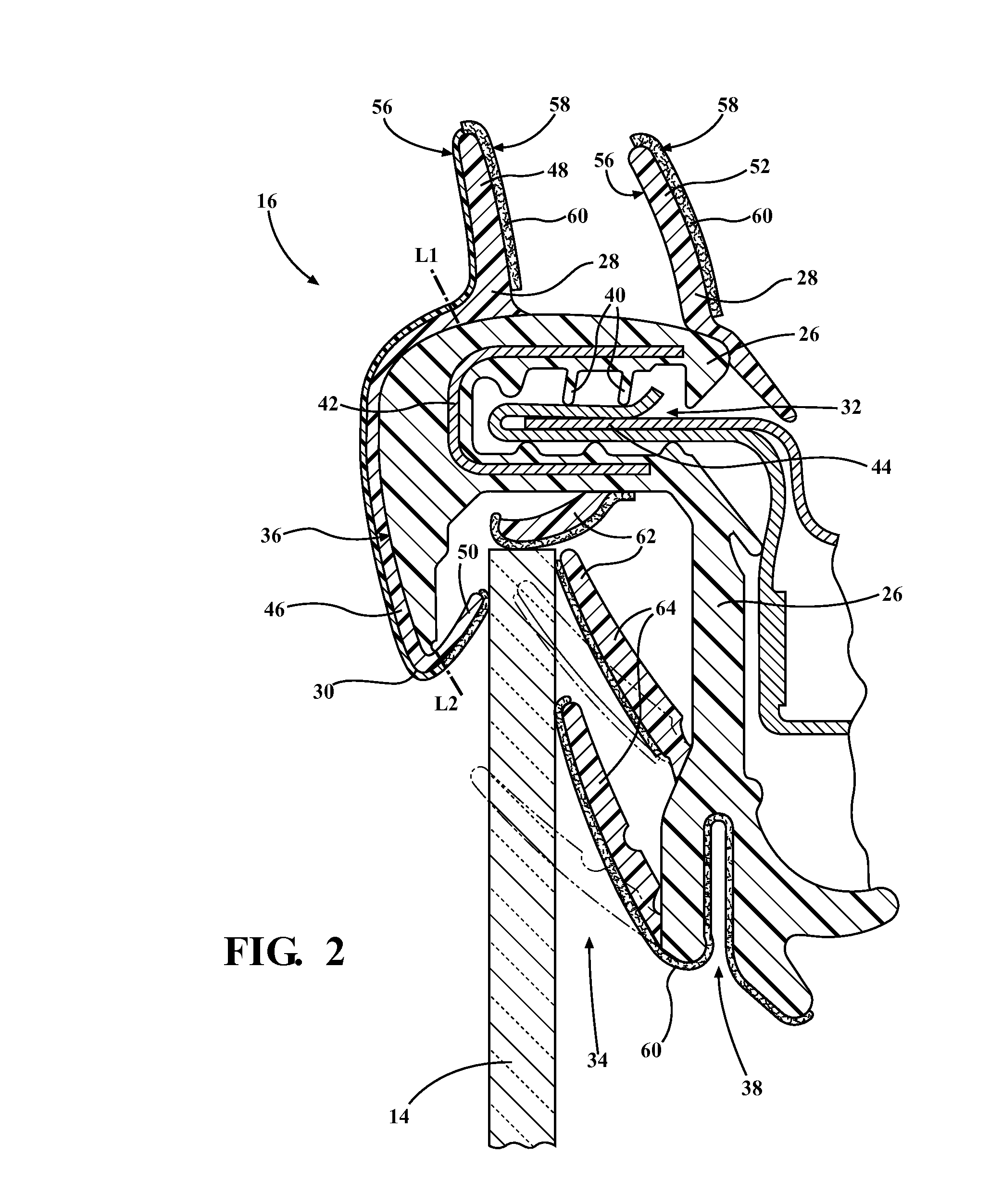

Sealing member

ActiveUS20130305612A1Good weather resistanceUniform appearanceVehicle sealing arrangementsSealing arrangementsEngineeringElectrical and Electronics engineering

A sealing member for a vehicle opening includes a first co-extrusion layer formed from a first elastomeric composition, a second co-extrusion layer formed from a second elastomeric composition, and a third co-extrusion layer formed from a thermoplastic vulcanizate composition. The first co-extrusion layer defines a mounting channel, a window channel, and a front face spaced from the mounting channel and the window channel. The second co-extrusion layer has a portion disposed on the front face of the first co-extrusion layer and a sealing lip disposed on the first co-extrusion layer abutting the portion and extending away from the first co-extrusion layer towards a distal end. The third co-extrusion layer is disposed on the portion and the sealing lip of the second co-extrusion layer for covering segments of the second co-extrusion layer that are visible from an exterior of the vehicle.

Owner:HENNIGES AUTOMOTIVE SEALING SYST NORTH AMERICA

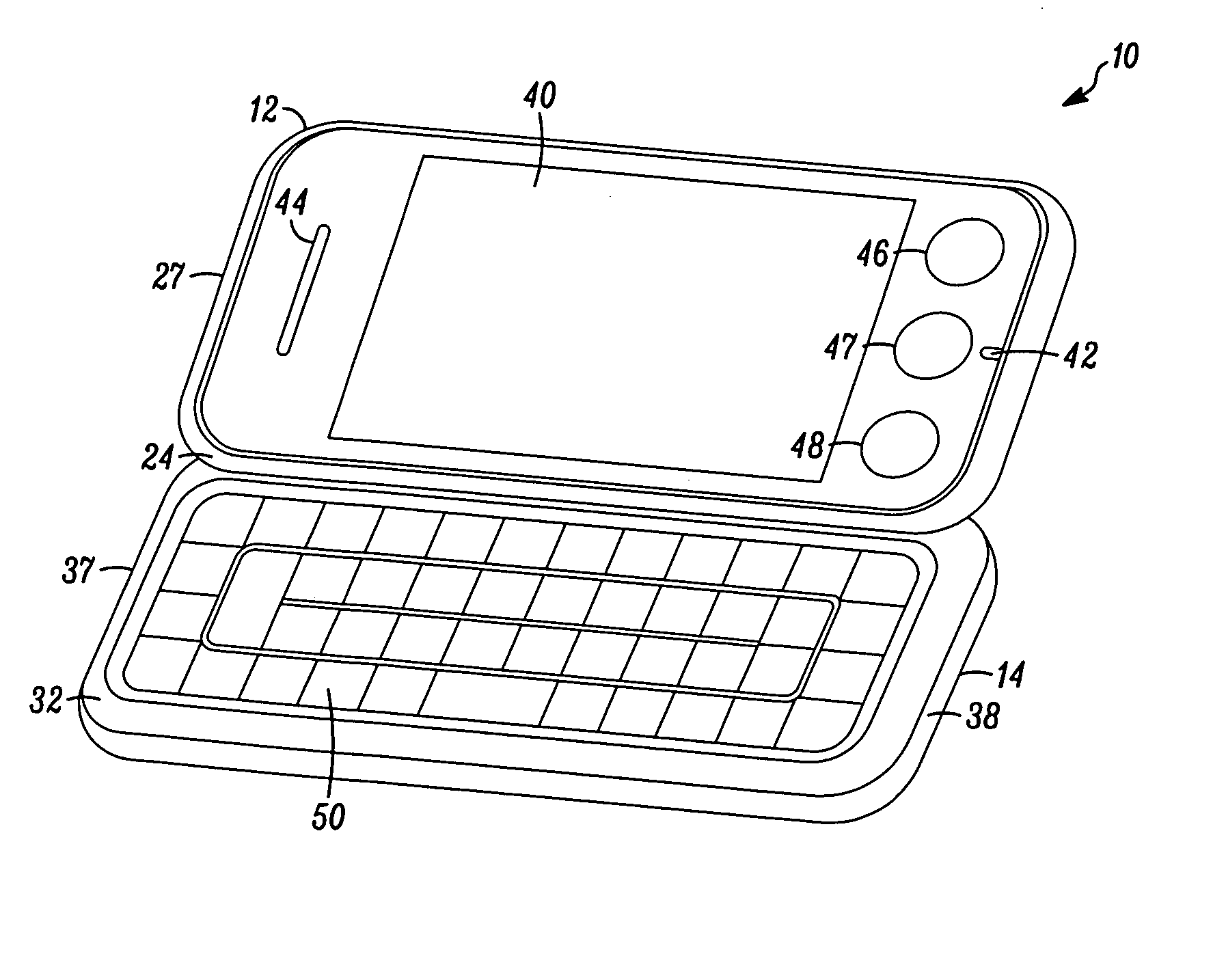

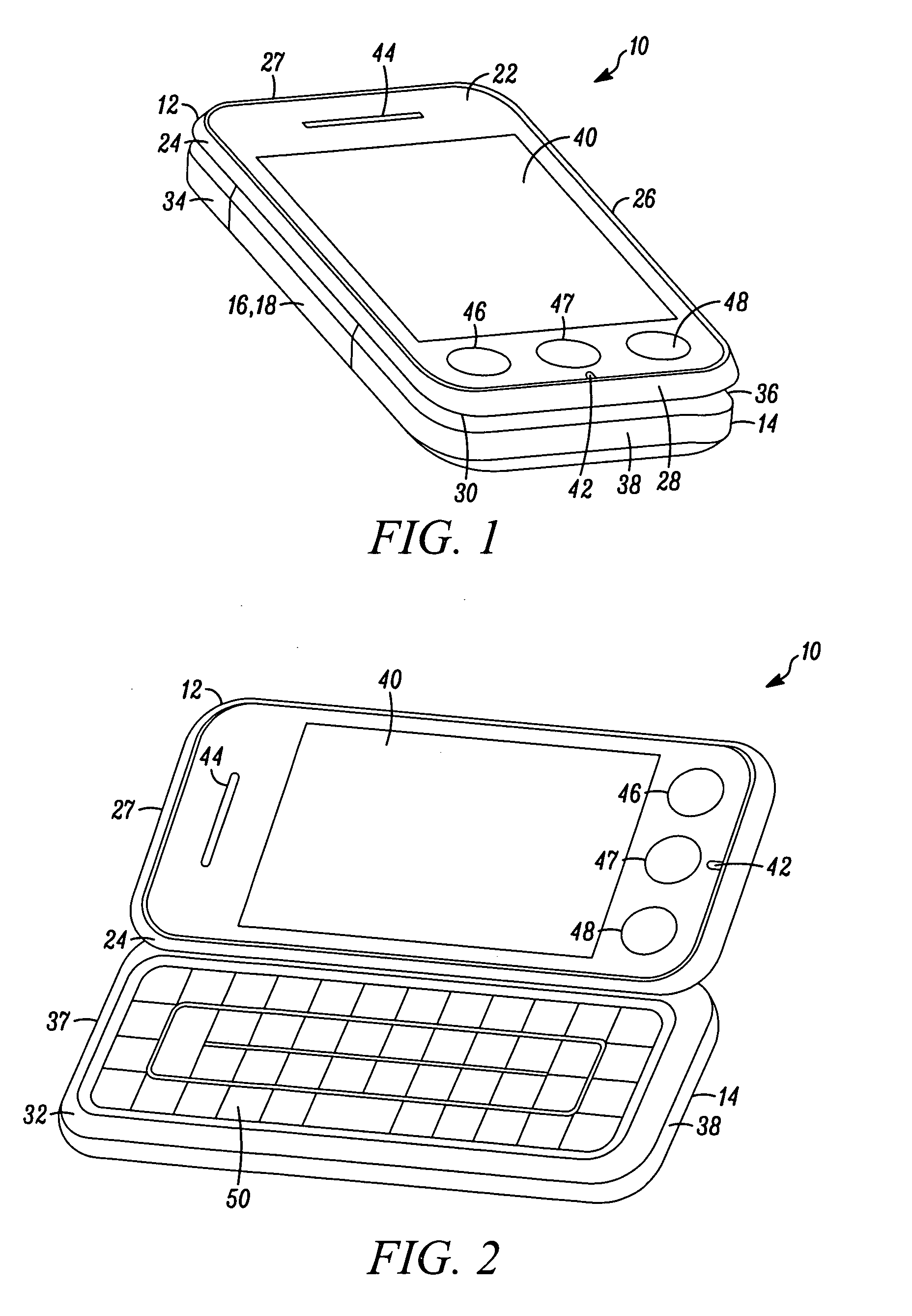

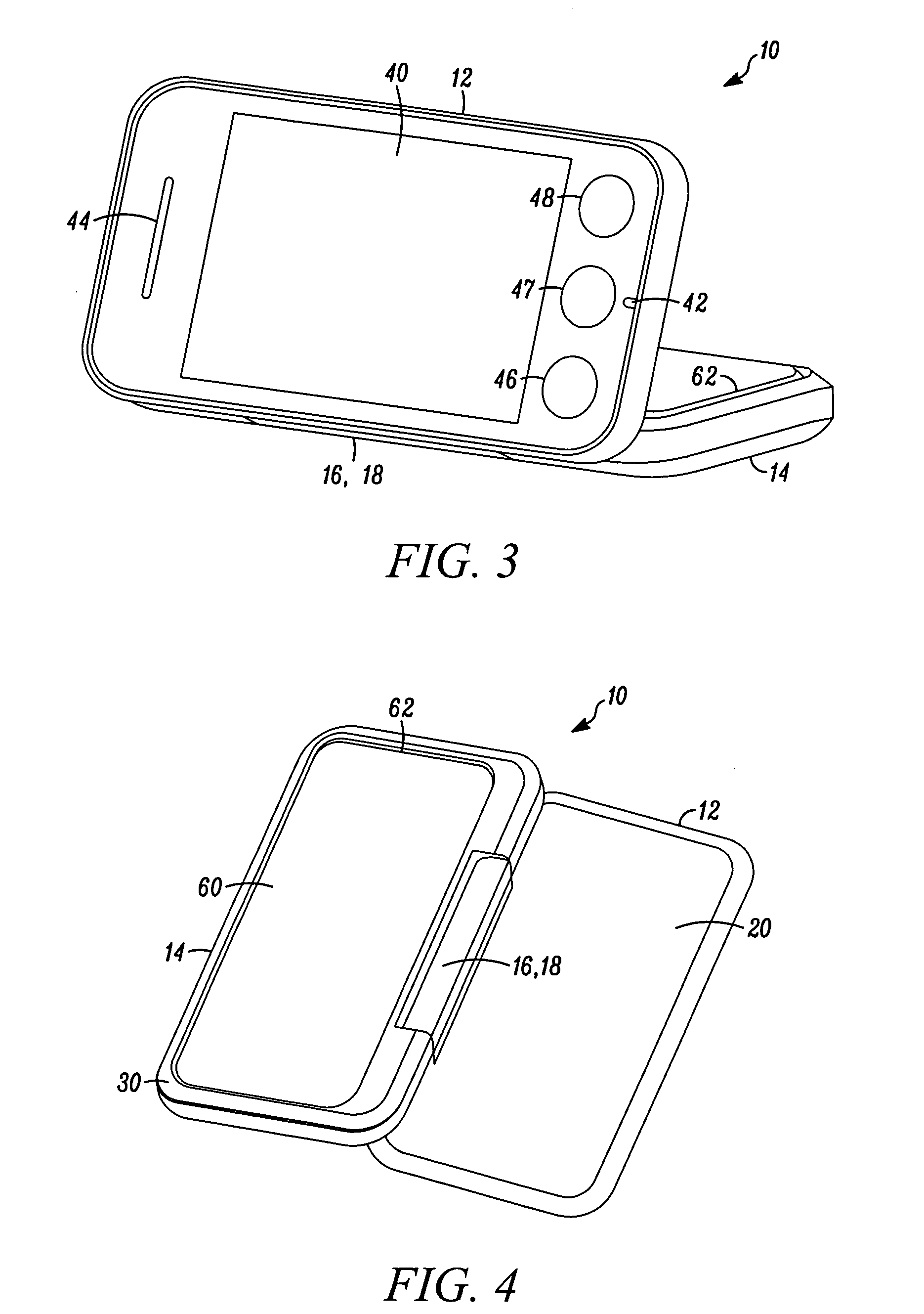

Electronic device having a clamshell configuration

InactiveUS20100113100A1Uniform appearanceMinimize appearanceDigital data processing detailsSubstation equipmentDisplay deviceEngineering

An electronic device comprising a first housing and a second wherein, the first and second housings have outward surfaces. One of the outward surfaces includes an electronic display and the other of the outward surfaces includes a keyboard or other input device. A hinge couples the two housing elements together. In a collapsed orientation the outward surfaces of the housing elements are exposed and face away from each other. In a fully deployed orientation, the display and the keyboard are in a side by side orientation. In a partially deployed orientation, the housing containing the display surface is angled away from the housing containing the keypad and the housing containing the keypad acts as a base to hold the angled display open for viewing purposes.

Owner:GOOGLE TECH HLDG LLC

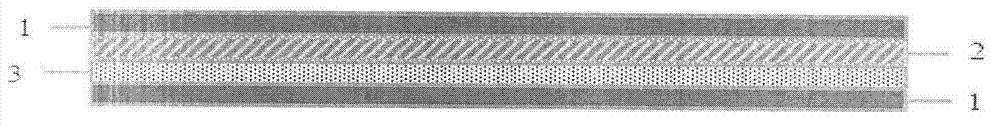

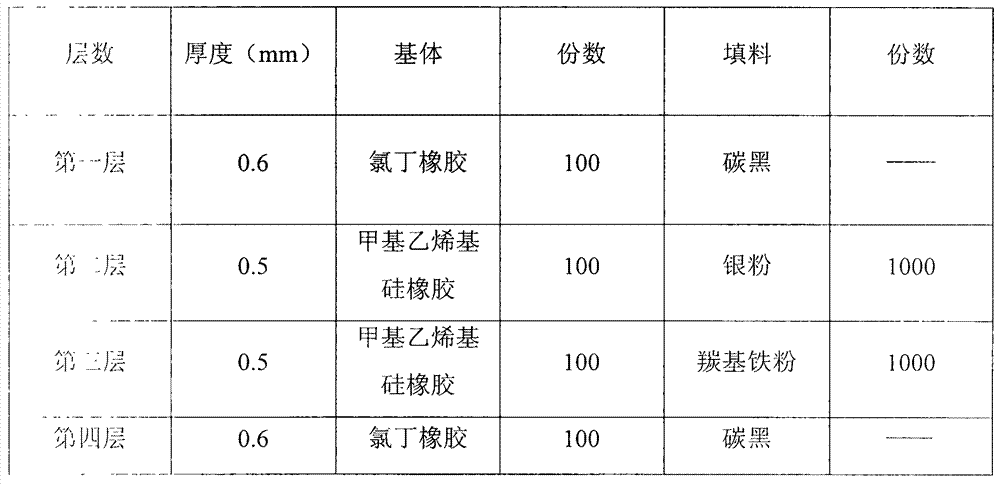

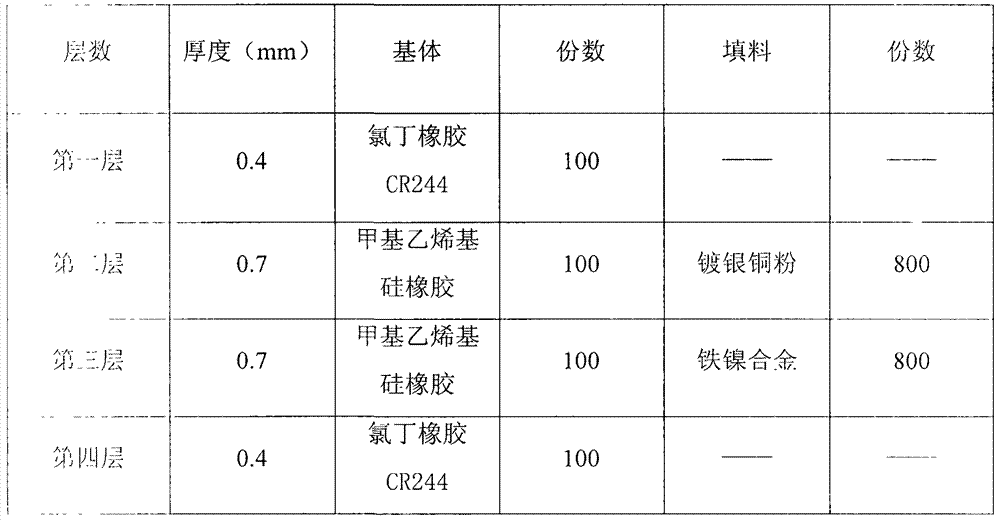

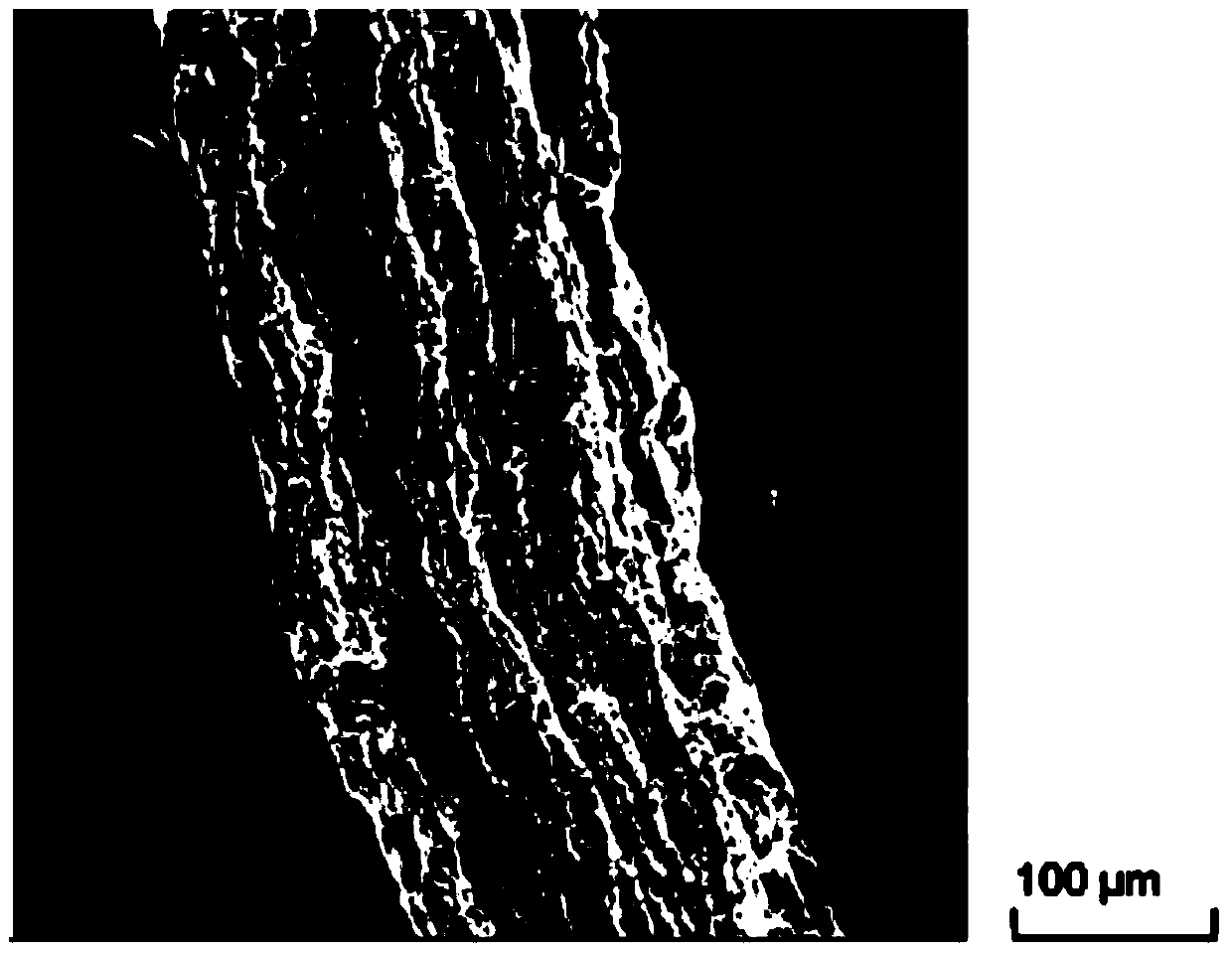

Electromagnetic shielding composite rubber material and preparation method thereof

ActiveCN104494241AAchieve electrical continuityImprove shielding effectLaminationLamination apparatusRubber materialBroadband

The invention provides an electromagnetic shielding composite rubber material, which is of a laminated structure, and comprises a shielding layer and a protective layer which are arranged from inside to outside, wherein the shielding layer comprises a conductive silicone rubber layer and a magnetic conductive silicone rubber layer, and the protective layer is a rubber layer. The shielding layer of the electromagnetic shielding composite rubber material comprises the conductive silicone rubber layer and the magnetic conductive silicone rubber layer, has an electromagnetic shielding performance in a broadband, wide shielding range and high shielding effectiveness, and can be widely used for electromagnetic shielding of electric power, electronics and other industries, and the protective layer selects rubber, and has excellent air tightness, and excellent watertight and mechanical properties, so that the overall strength of the composite material can be improved, the air is isolated, and the oxidation of the conductive filler is slowed, and thus the service life of the shielding material is prolonged, the service performances of the shielding material can be improved, and the shielding effectiveness of the material keeps stable as the service time increases.

Owner:STATE GRID CORP OF CHINA +2

Steel mill continuous annealing galvanized sheet chromium-free compound passivator and preparation method thereof

InactiveCN103834938AImprove corrosion resistanceExcellent coating adhesion performanceAnti-corrosive paintsMetallic material coating processesChromium freeEnvironmental resistance

The invention discloses a steel mill continuous annealing galvanized sheet chromium-free compound passivator which comprises the following raw materials in percentage by weight: 5-20 percent by weight of a main film-forming agent, 0.1-5 percent by weight of a coupling agent, 0.1-0.5 percent by weight of inorganic complex film-forming agent, 0.1-4 percent by weight of silicate, 0.1-0.4 percent of an emulsifying agent, 0.1-0.2 percent of a dispersing agent, 0.1-0.4 percent of a corrosion inhibitor, 0.1-0.3 percent of a protective colloid, 0.1-1 percent of a nanometer sealing agent, 0.1-0.4 percent of phosphate and the balance of water. The steel mill continuous annealing galvanized sheet chromium-free compound passivator disclosed by the invention is uniform in appearance, stabilizes a liquid, has an expiration date of above 90 days, is nontoxic and environment-friendly, and accords with the ROHS (Restriction Of Hazardous Substances) requirement. The steel mill continuous annealing galvanized sheet chromium-free compound passivator is simple in preparation process; a passivated film is uniform in appearance and has certain glossness. A galvanized sheet passivated by using the passivator has the advantages that the corrosion resistance is remarkably improved, the neutral salt mist SST (Sea Surface Temperature) resistant time reaches above 72 hours, the white rust area is less than 5 percent, the blackening resistance delta E is less than 5, the yellowing resistance delta E is less than 3, the alkaline resistance delta E is less than 3, the interlamination resistance R is less than 3 omega / cm, and the conductivity is less than 1 m Omega.

Owner:NORTHEASTERN UNIV

Nanocrystalline iridium series oxide coating electrode preparation method

The invention discloses a making method of nanocrystalline iridium-series oxide coating electrode in the electrochemical appliance technical domain, which comprises the following steps: predisposing base; proceeding mechanic disposal; deoiling through alkaline and acid; allocating the coating liquid; coating. The solution of IrO2-Ta2O5-MO2 coating is composed of 30-95% H2IrCl6 solution and TaCl5 solution with the molar rate of Ir and Ta at 7: 6 and 5-70% third element M chloride with Sn, Mn, Ti, Nb, Pb and Si, wherein the even size of IrO2 grain is 8-15nm, which stabilizes the electrode.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of graphene fibers

ActiveCN103966699ALow reaction temperatureEasy to operateArtificial filament chemical after-treatmentEthylenediamineFiber

The invention discloses a preparation method of graphene fibers. The preparation method comprises the following steps: (1), a mixture of a graphene oxide solution and a water-soluble reducing agent is added into a tubular reactor, wherein the water-soluble reducing agent is one or more of ascorbic acid, sodium ascorbate, sodium citrate, HI, HBr, NaHSO3, Na2S, ethylenediamine, p-phenylenediamine and hydroquinone; (2), the tubular reactor in the step (1) is heated, and graphene oxide is reduced and assembled to aqueous graphene gel fibers, and the heating temperature is 60-95 DEG C; and (3), the aqueous graphene gel fibers obtained in the step (2) is dried to obtain the graphene fibers. The preparation method is simple to operate, mild in conditions and low in raw material cost; and the graphene fibers obtained with the preparation method are uniform in structure, excellent in mechanical property and easiness in functionalization.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Antimicrobial adhesive latexes and methods of making thereof

InactiveUS6342212B1Uniform appearanceEasy to produceBiocideNon-macromolecular adhesive additivesIonIon exchange

Broadly defined adhesive latex formula s exhibiting antimicrobial properties. Such formulations comprise certain antimicrobial compounds, such as, preferably, metal-containing ion-exchange and / or zeolite compounds, are provided. The inventive latex formulations must also exhibit substantially uniform characteristics (such a similar viscosity and / or appearance throughout) in order to provide a functionally and aestheticially pleasing formulation for utilization within any number of applications. In order to provide such an inventive latex formulation, it has been found that compounding of all the base ingredients (polymer, antimicrobial agent, fillers) must be undertaken prior to the final thickening step, which ultimately produces the desired latex. The specific method of producing such formulations is also encompassed within this invention.

Owner:MILLIKEN & CO

Edible water-soluble film containing a foam reducing flavoring agent

ActiveUS7972618B2Uniform appearanceEasy to solvePharmaceutical delivery mechanismPharmaceutical non-active ingredientsWater solubleDefoaming Agents

An edible water-soluble film is provided. The film includes at least one water-soluble polymer, and a foam reducing flavoring agent, wherein the film is free of added anti-foaming or defoaming agents.

Owner:AQUESTIVE THERAPEUTICS INC

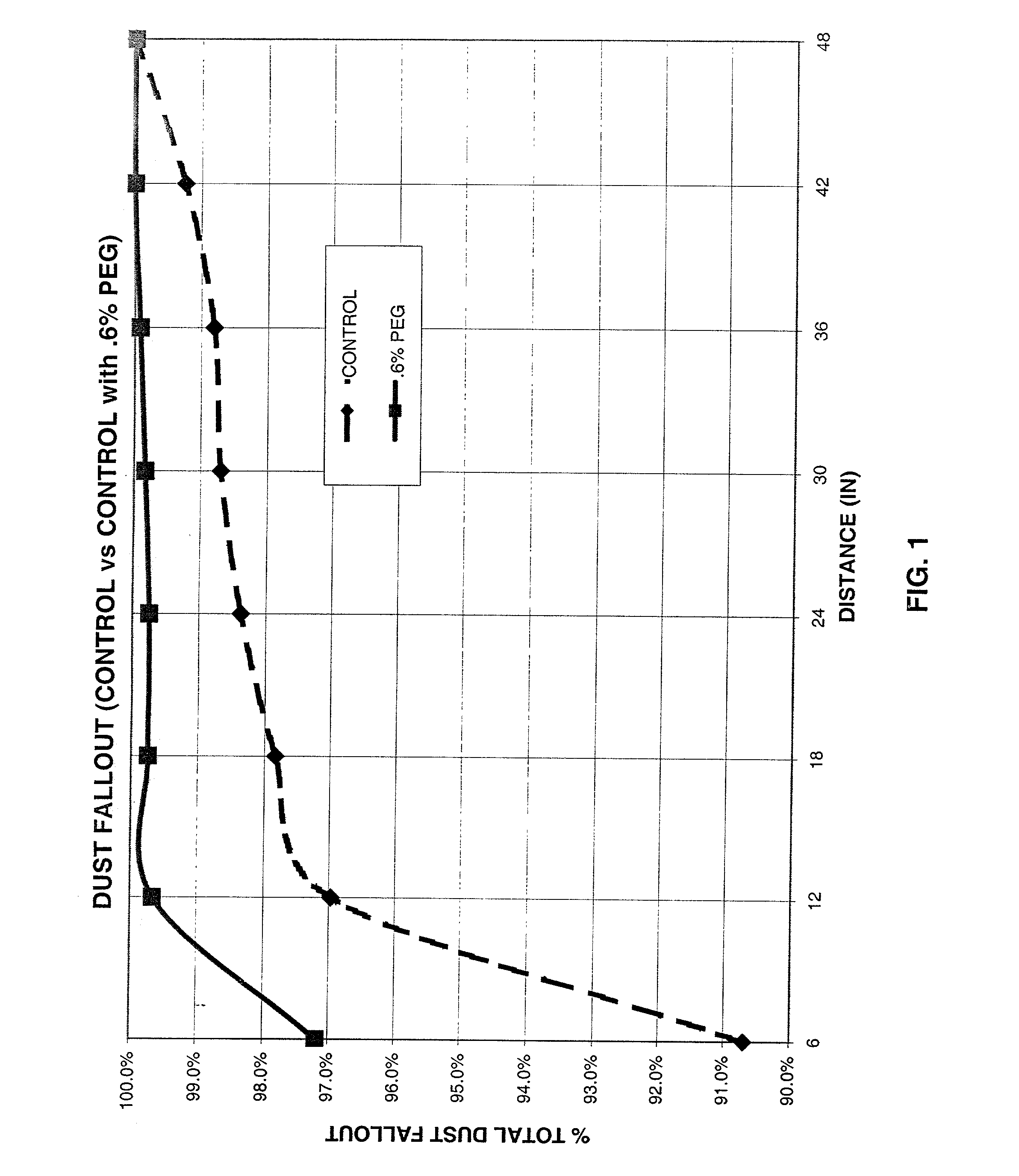

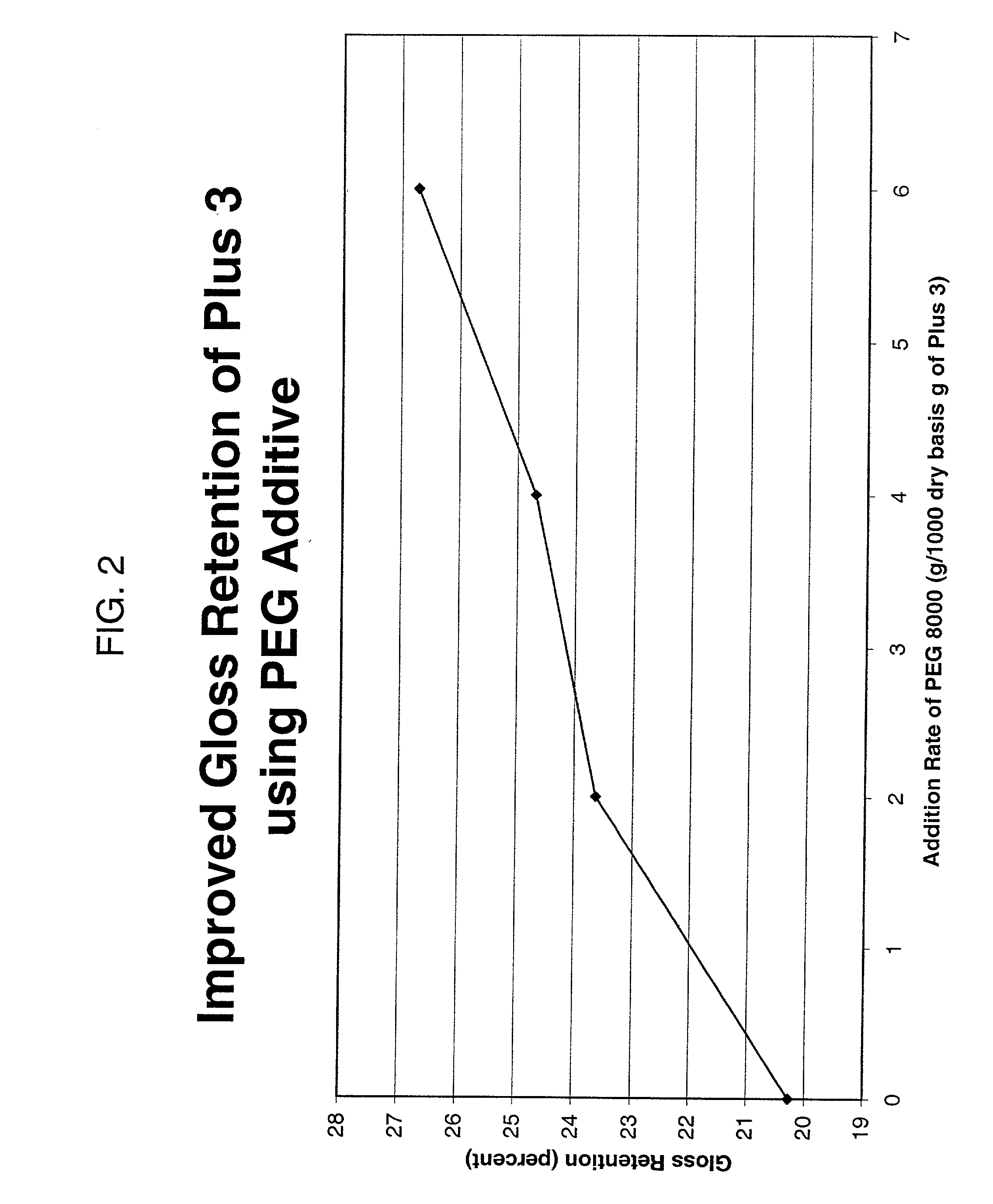

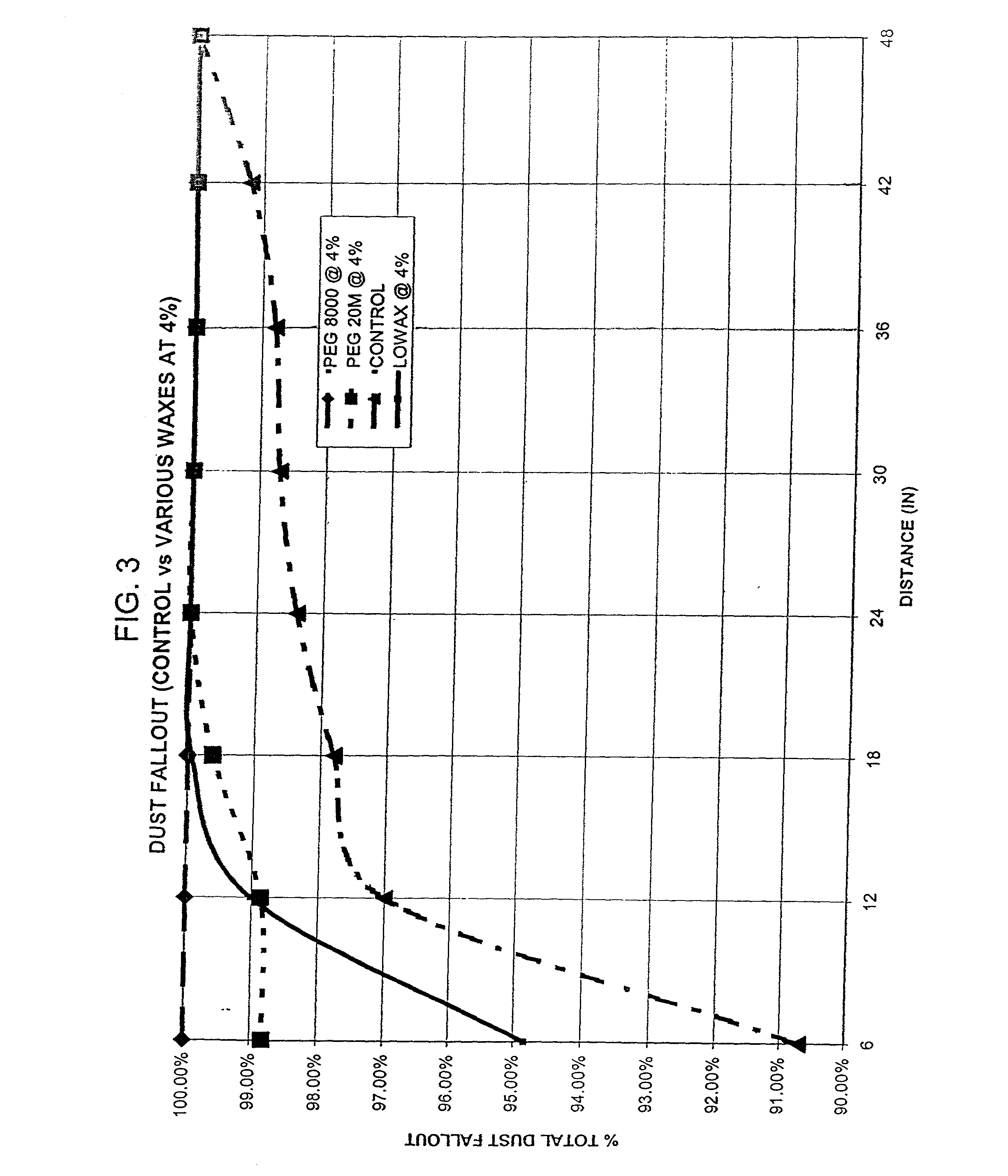

Joint compound providing low dusting and good gloss retention

InactiveUS20020129744A1Minimizes and localizes dustGood gloss retentionCoatingsPigment pastesWaxJoint compound

The present invention provides a low dusting joint compound comprising a filler, a binder, a thickener and one or more synthetic polymeric waxes that are at least slightly soluble in water and are solid at room temperature. Preferably the wax includes a high molecular weight polyethylene glycol or methoxy polyethylene glycol having an average melting point of from about 80.degree. F. (27.degree. F.) to about 150.degree. F. (80.degree. C.). These additives impart low dusting properties without a sticky or oily feel. High molecular weight synthetic waxes also act as an internal binder to hold the joint compound together and improves paint gloss retention. The invention results in a joint compound with improved properties for drywall finishing.

Owner:UNITED STATES GYPSUM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com