Patents

Literature

32results about How to "Minimizes warp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

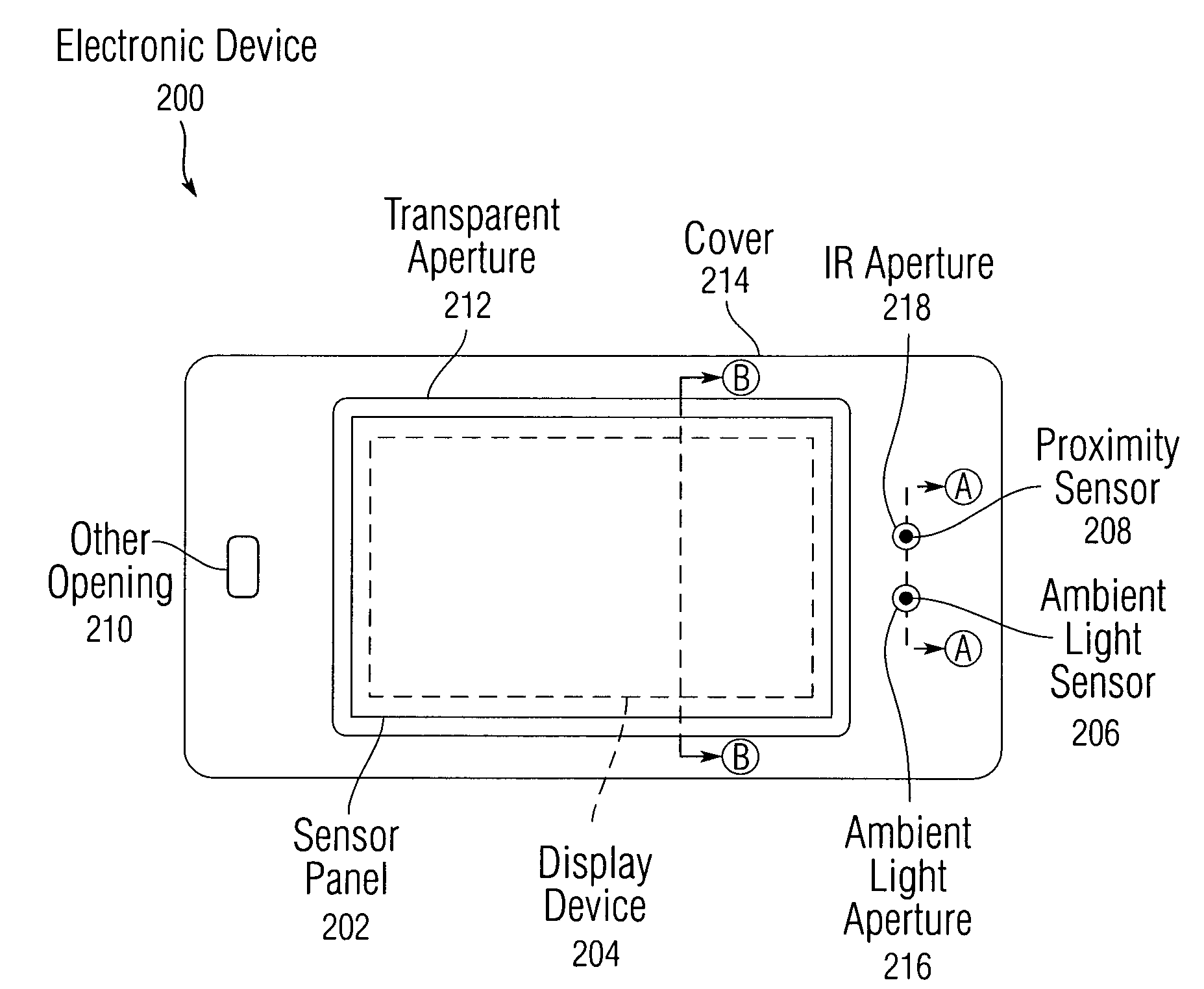

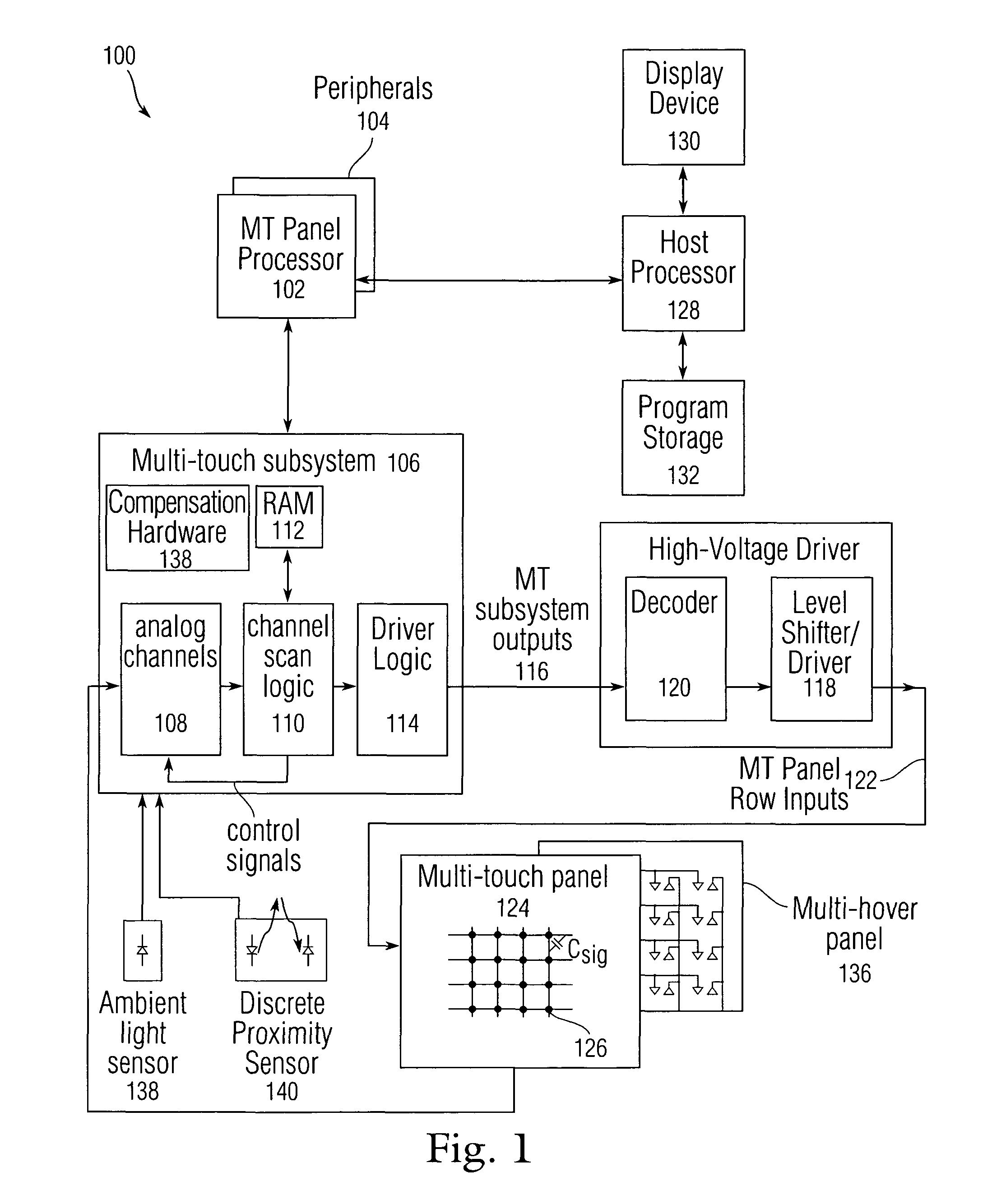

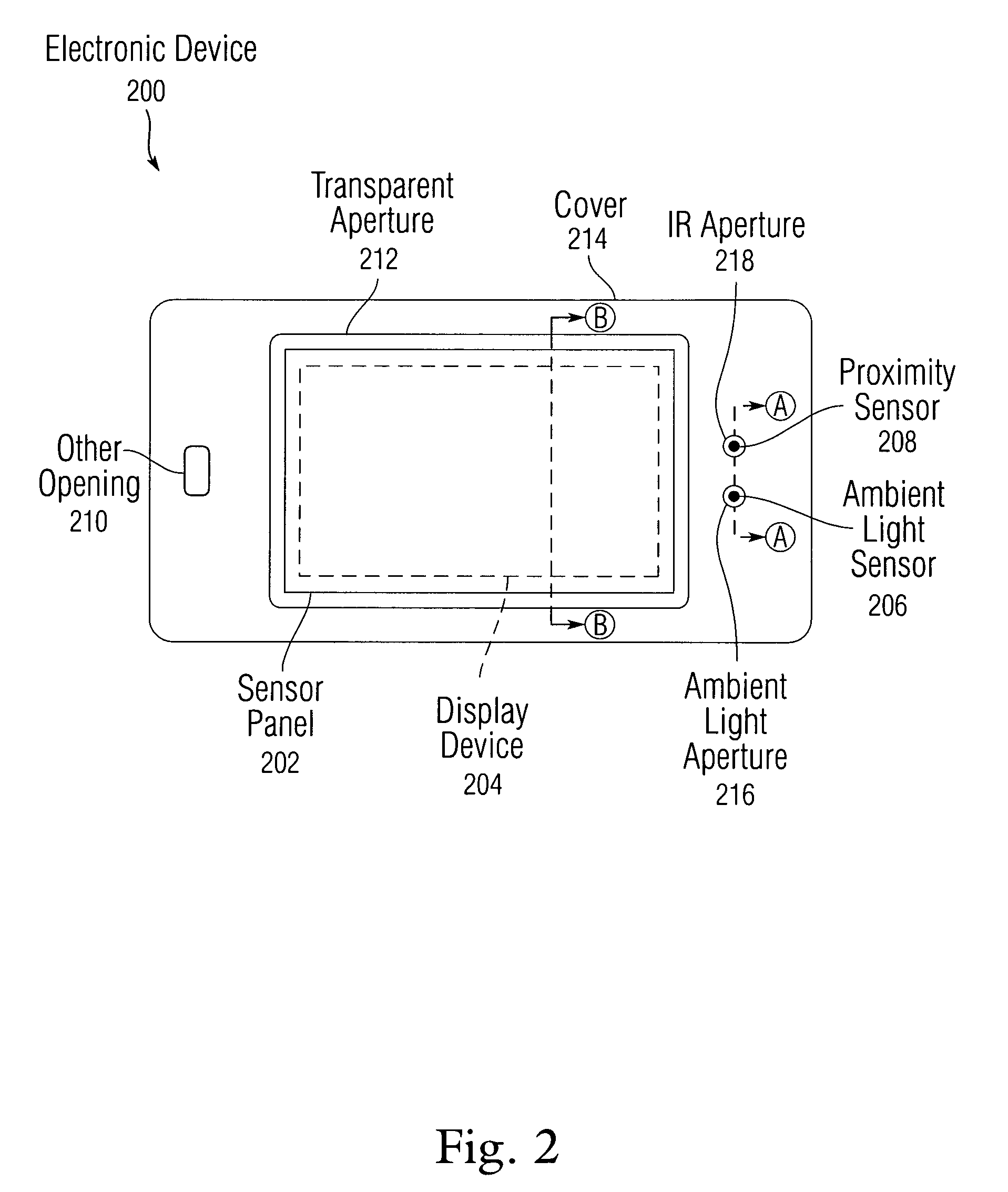

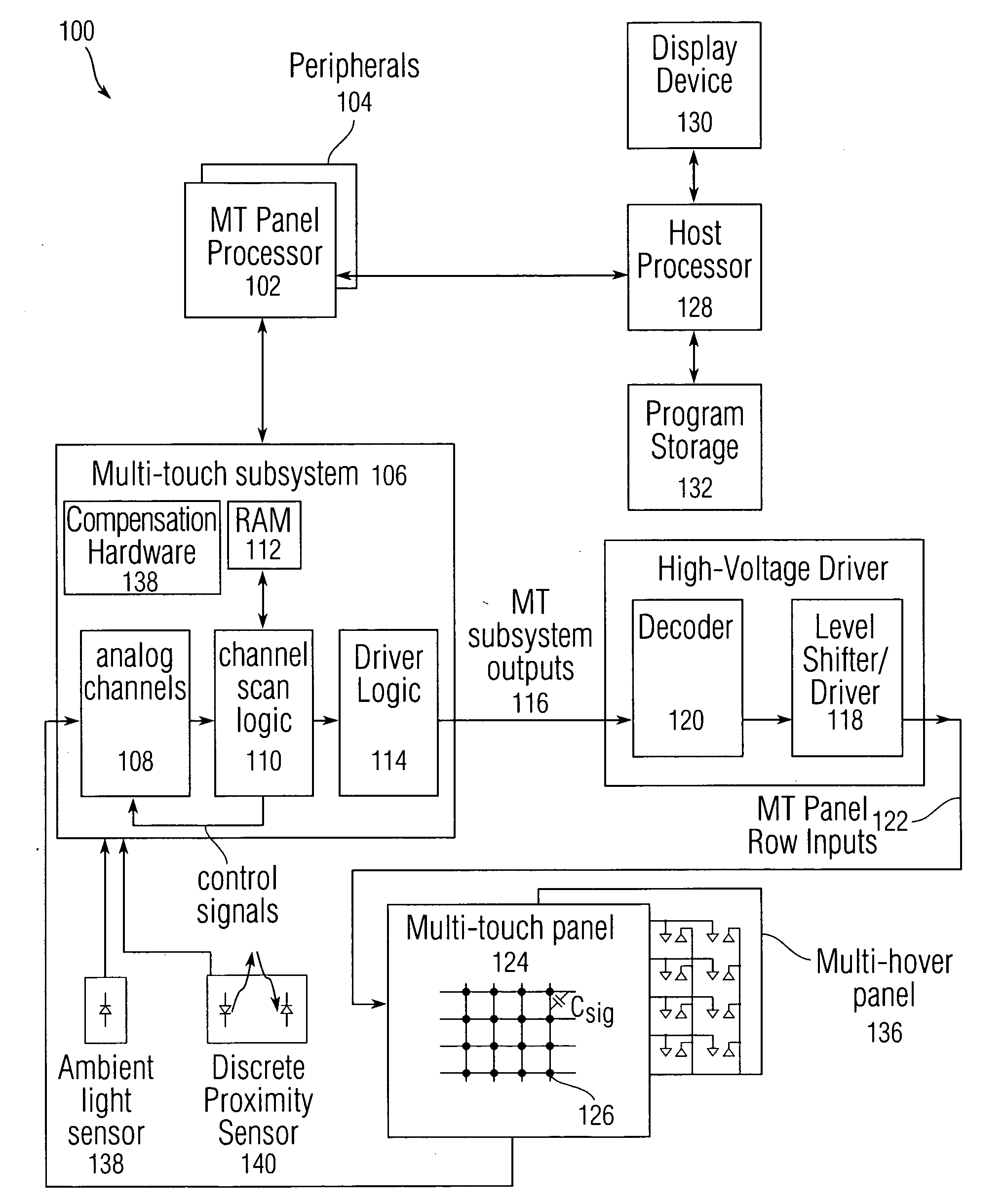

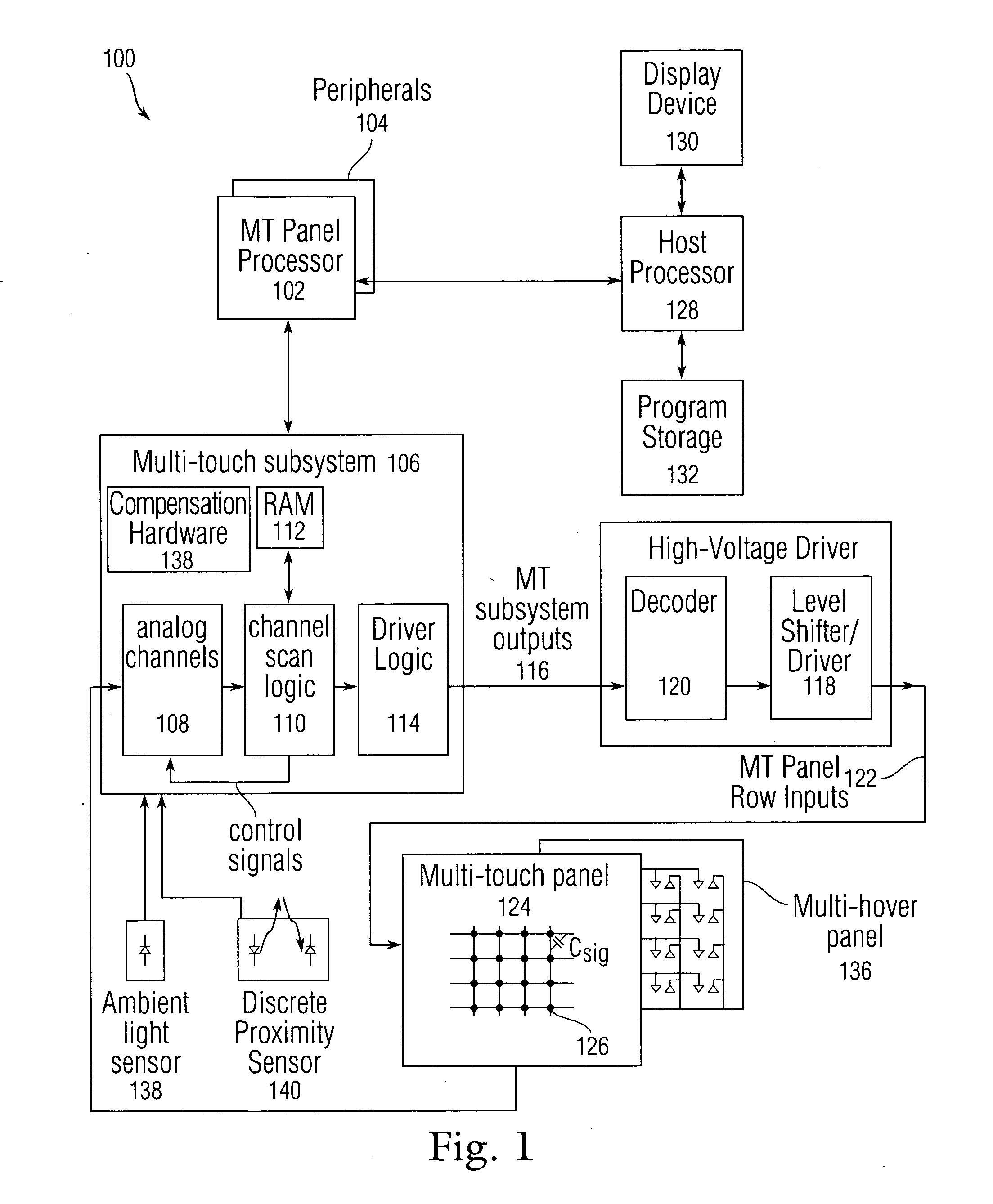

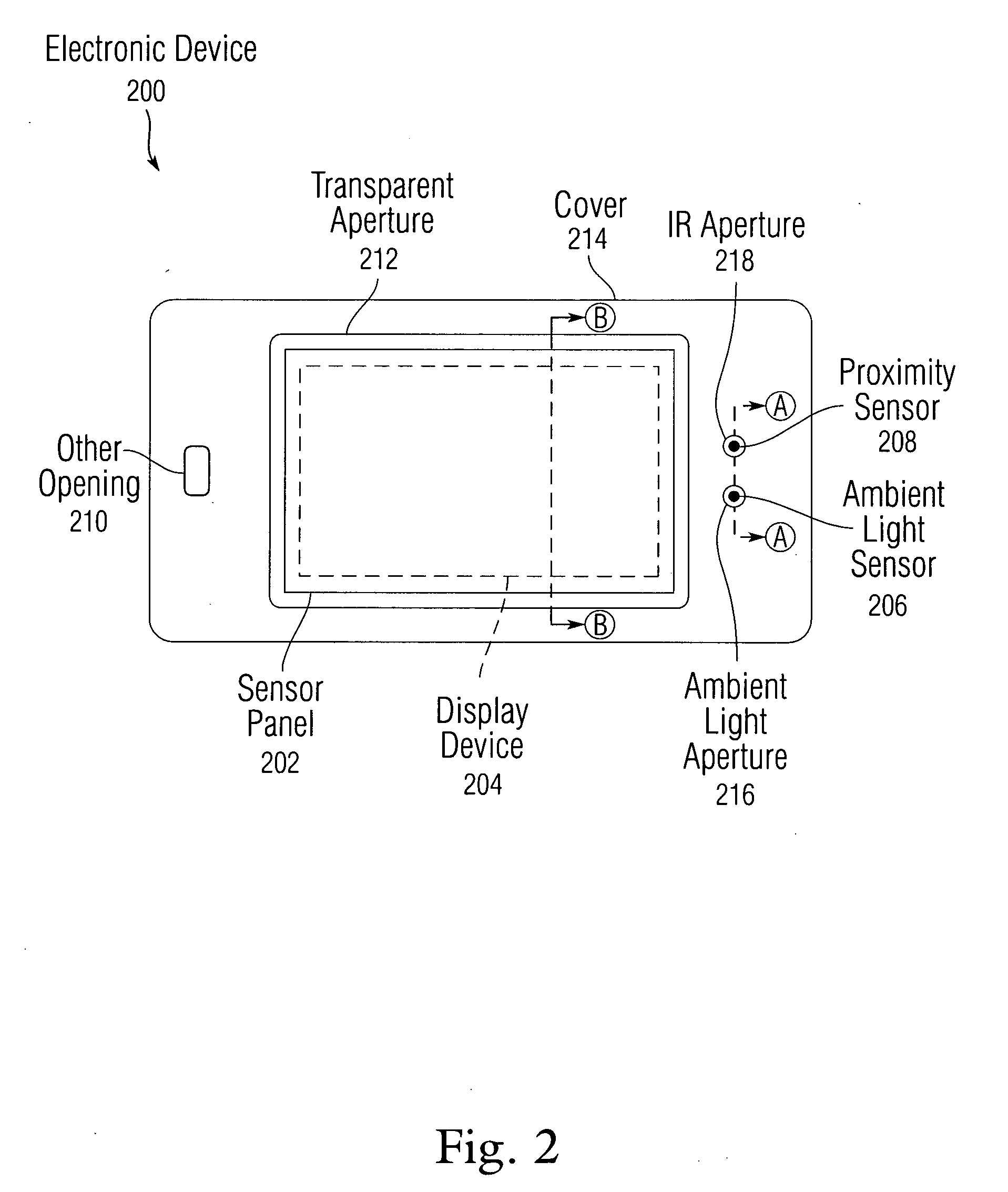

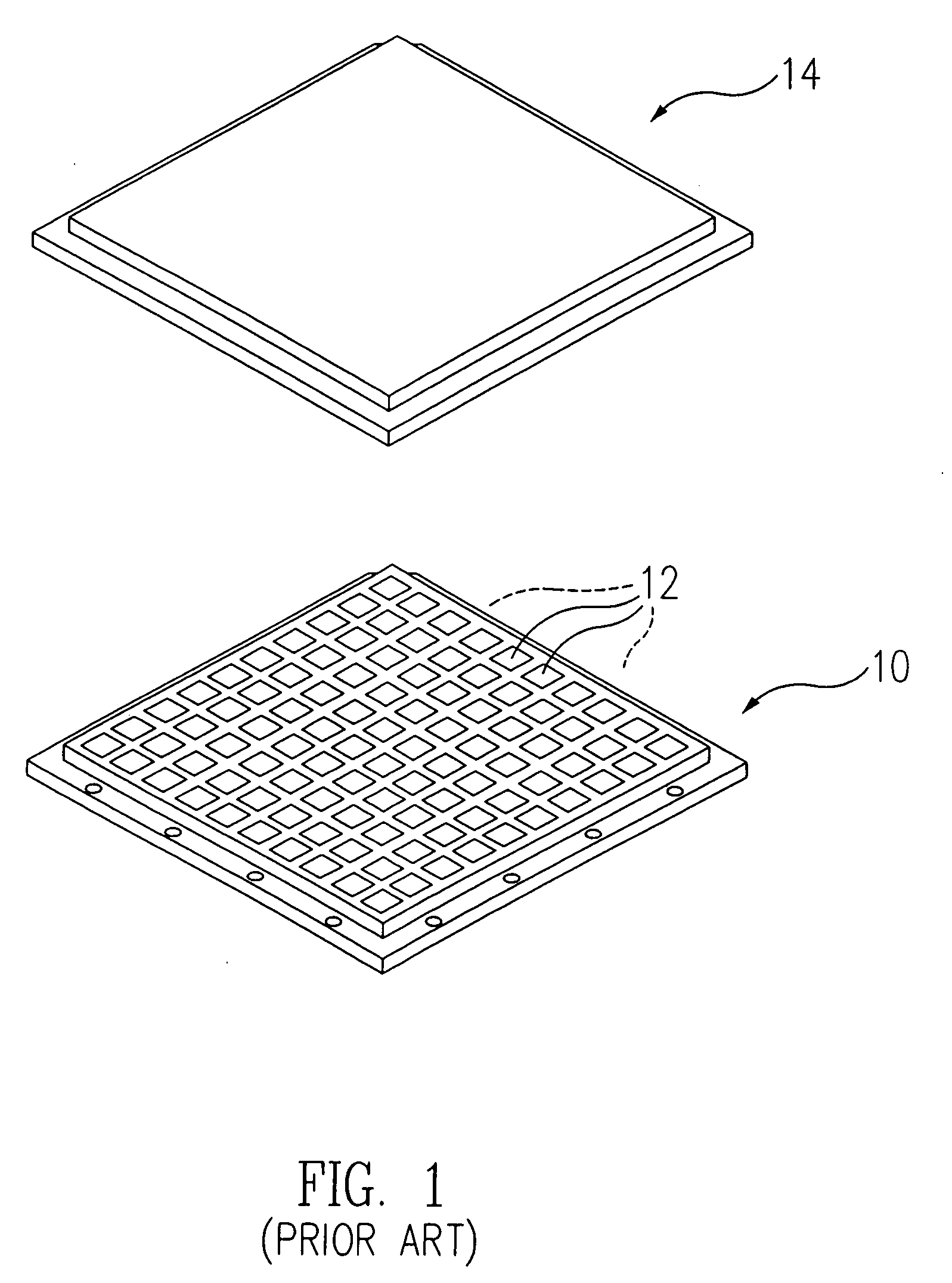

Multi-touch surface stackup arrangement

ActiveUS8031174B2Reduce cover warpageFull surfaceInput/output for user-computer interactionNon-enclosed substationsProximity sensorDisplay device

A multi-layer cover for an electronic device having one or more of a sensor panel, a proximity sensor, an ambient light sensor, and a display device can include an outer hardcoat, a structural layer, an IR transmissive ink layer, a mask layer, and a backside hardcoat. The backside hardcoat can reduce cover warpage, enable full surface lamination of the cover to the sensor panel, prevent bubbles from forming in transparent windows in the cover, enable a wider range of functional inks to be applied in various layering orders to allow certain types of light to pass through while blocking others, and hide the sensors to provide a seamless, uncluttered visual appearance.

Owner:APPLE INC

Multi-touch surface stackup arrangement

ActiveUS20080158173A1Reduce cover warpageFull surfaceNon-enclosed substationsInput/output for user-computer interactionProximity sensorDisplay device

A multi-layer cover for an electronic device having one or more of a sensor panel, a proximity sensor, an ambient light sensor, and a display device can include an outer hardcoat, a structural layer, an IR transmissive ink layer, a mask layer, and a backside hardcoat. The backside hardcoat can reduce cover warpage, enable full surface lamination of the cover to the sensor panel, prevent bubbles from forming in transparent windows in the cover, enable a wider range of functional inks to be applied in various layering orders to allow certain types of light to pass through while blocking others, and hide the sensors to provide a seamless, uncluttered visual appearance.

Owner:APPLE INC

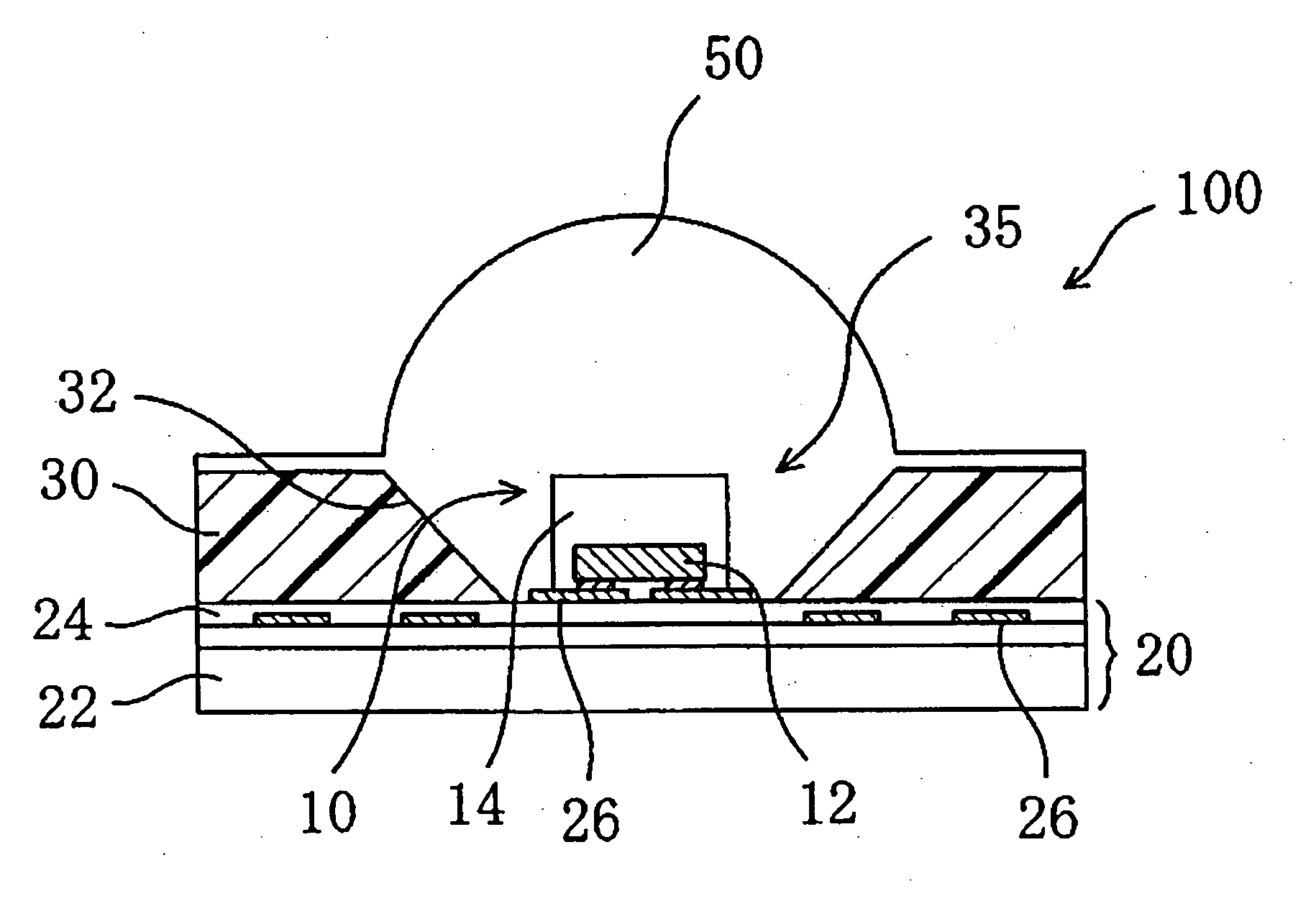

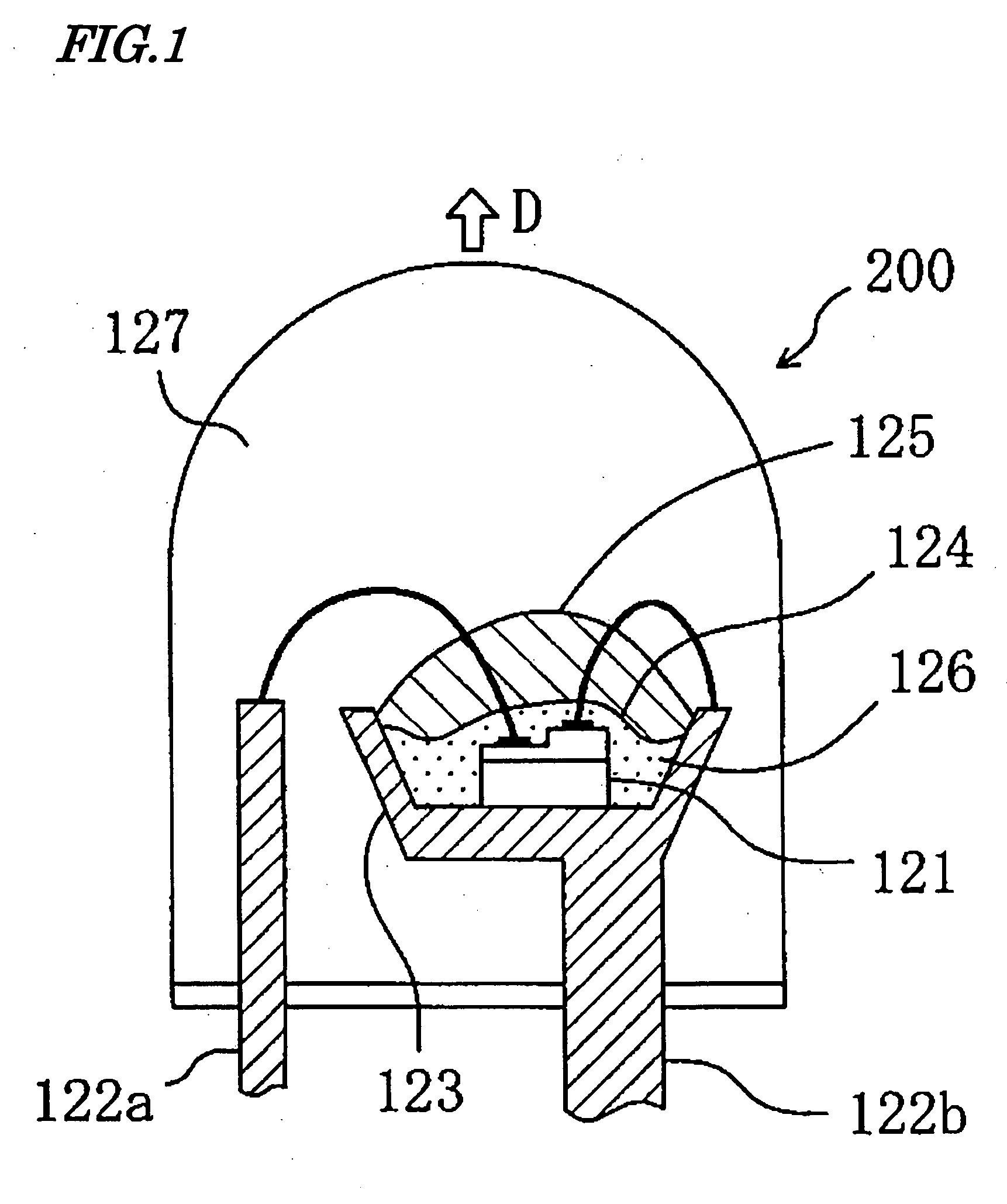

LED lamp

InactiveUS20060186425A1Increased bending stiffnessImprove rigidityPlanar light sourcesPoint-like light sourceEngineeringLED lamp

An LED lamp 100 according to the present invention includes: a substrate 20 with an upper surface; a plurality of LED chips 10, which are arranged on the upper surface of the substrate 20; and a reflector 30, which has reflective surfaces that reflect emissions of the respective LED chips 10 at least partially. The reflector 30 includes a resin and a framework that is made of a material having a higher flexural rigidity than the resin.

Owner:PANASONIC CORP

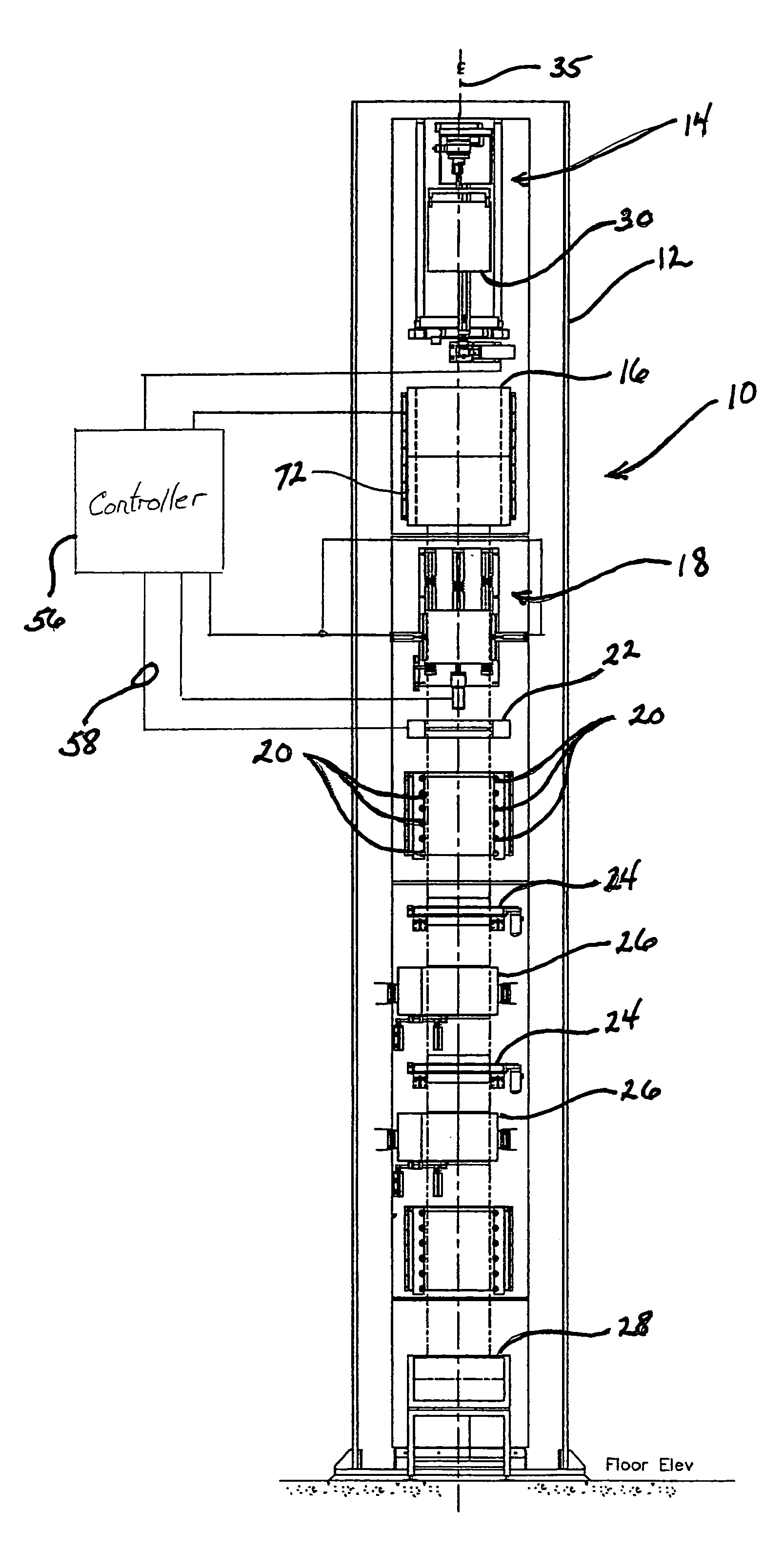

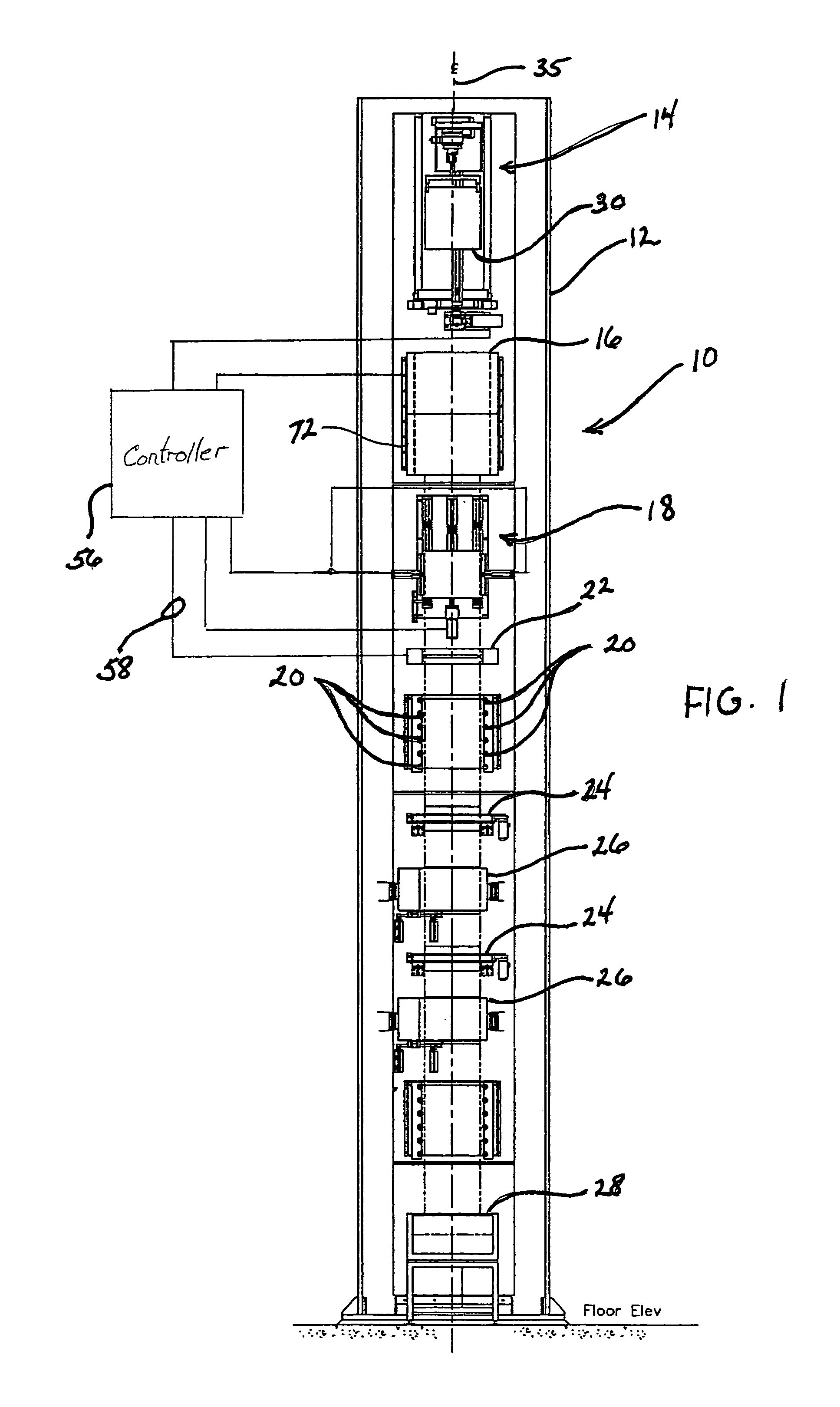

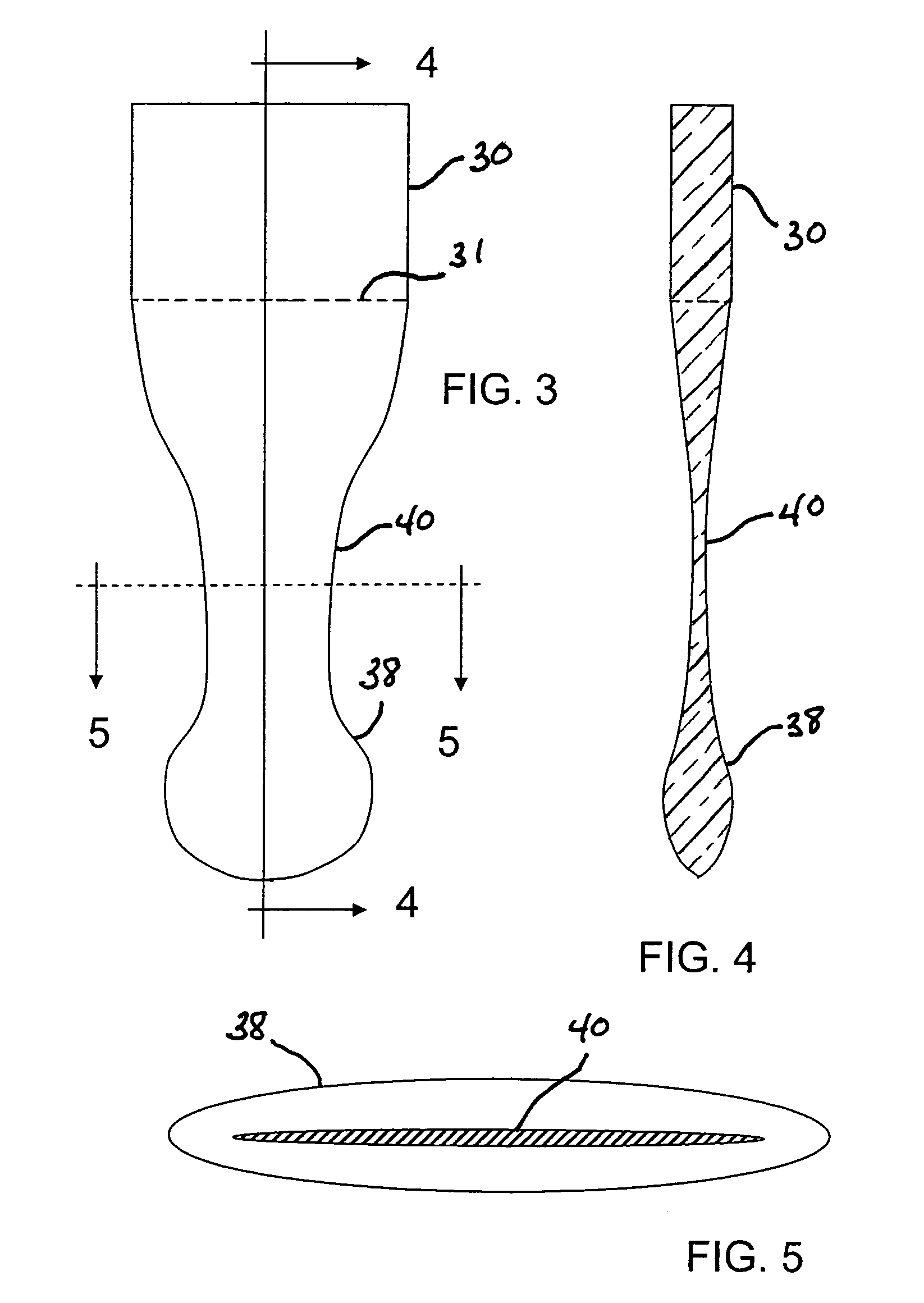

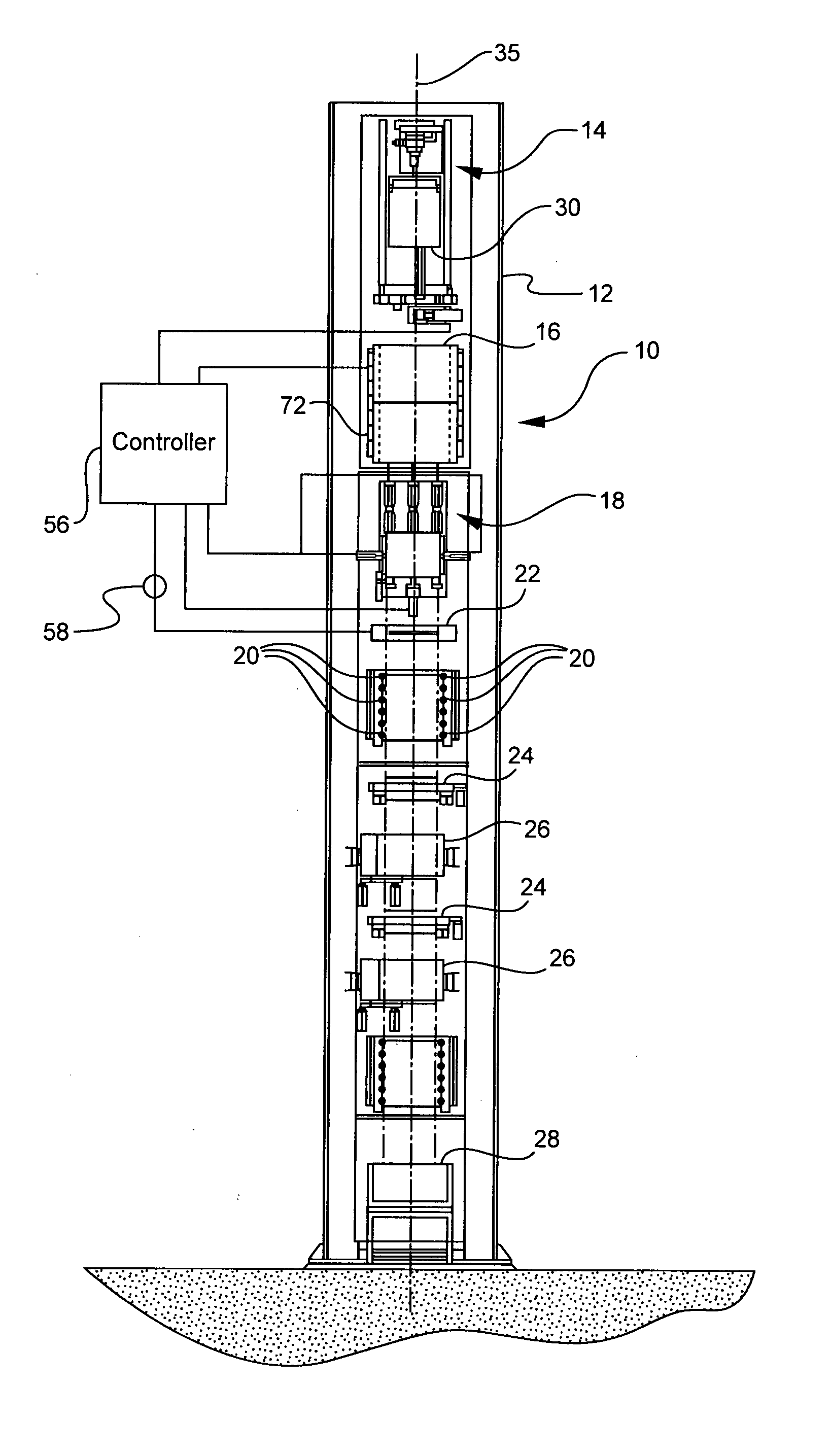

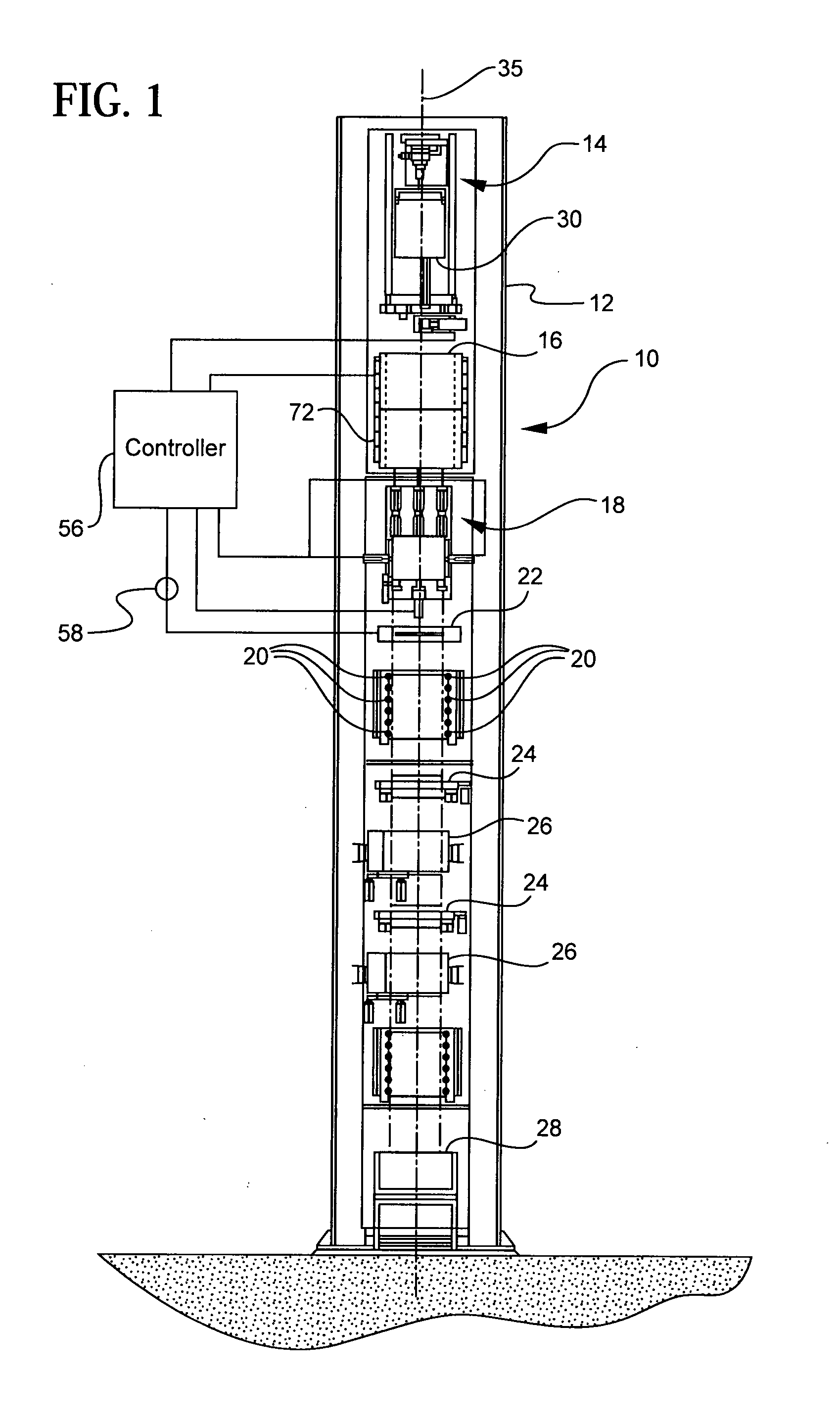

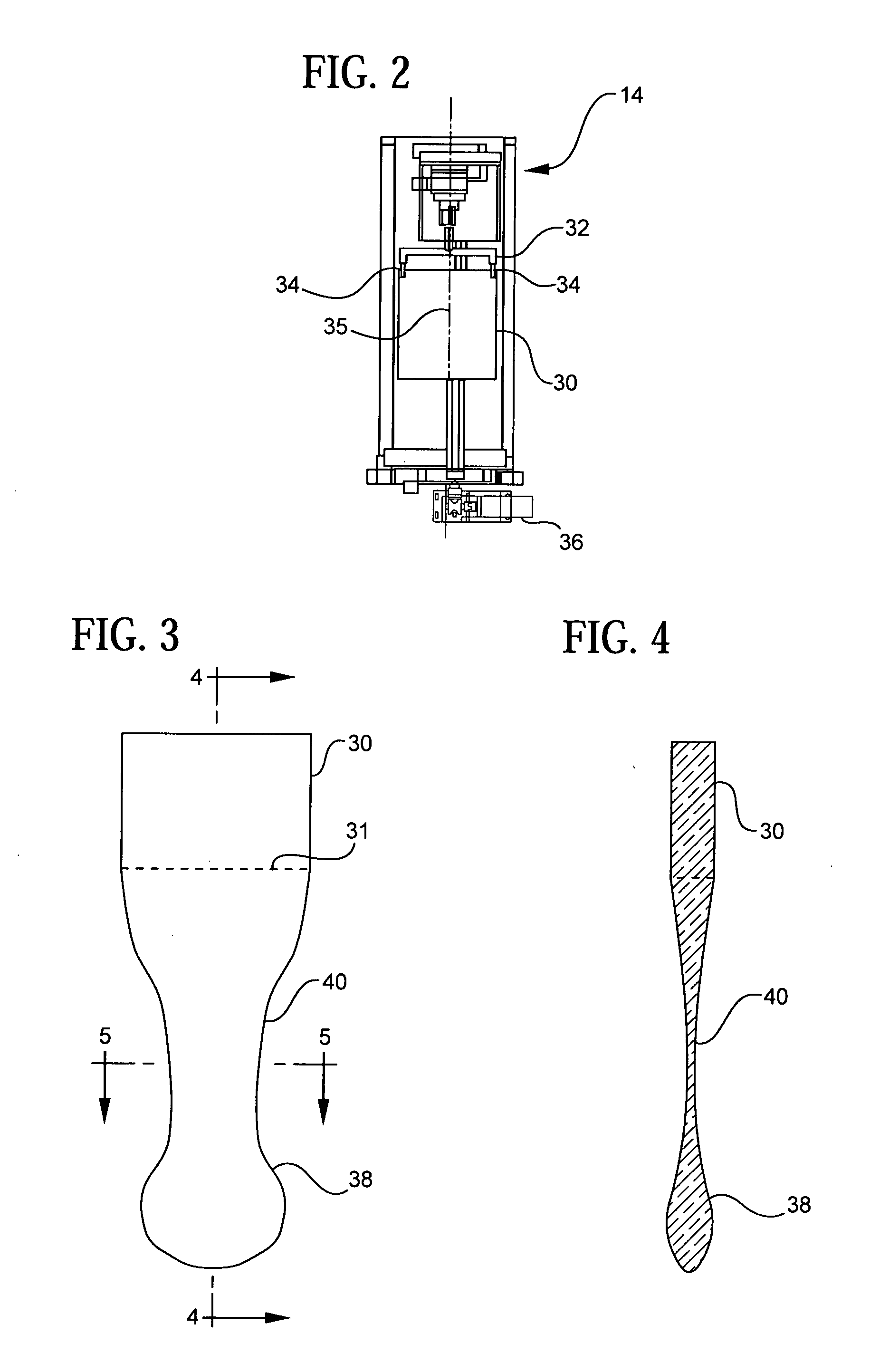

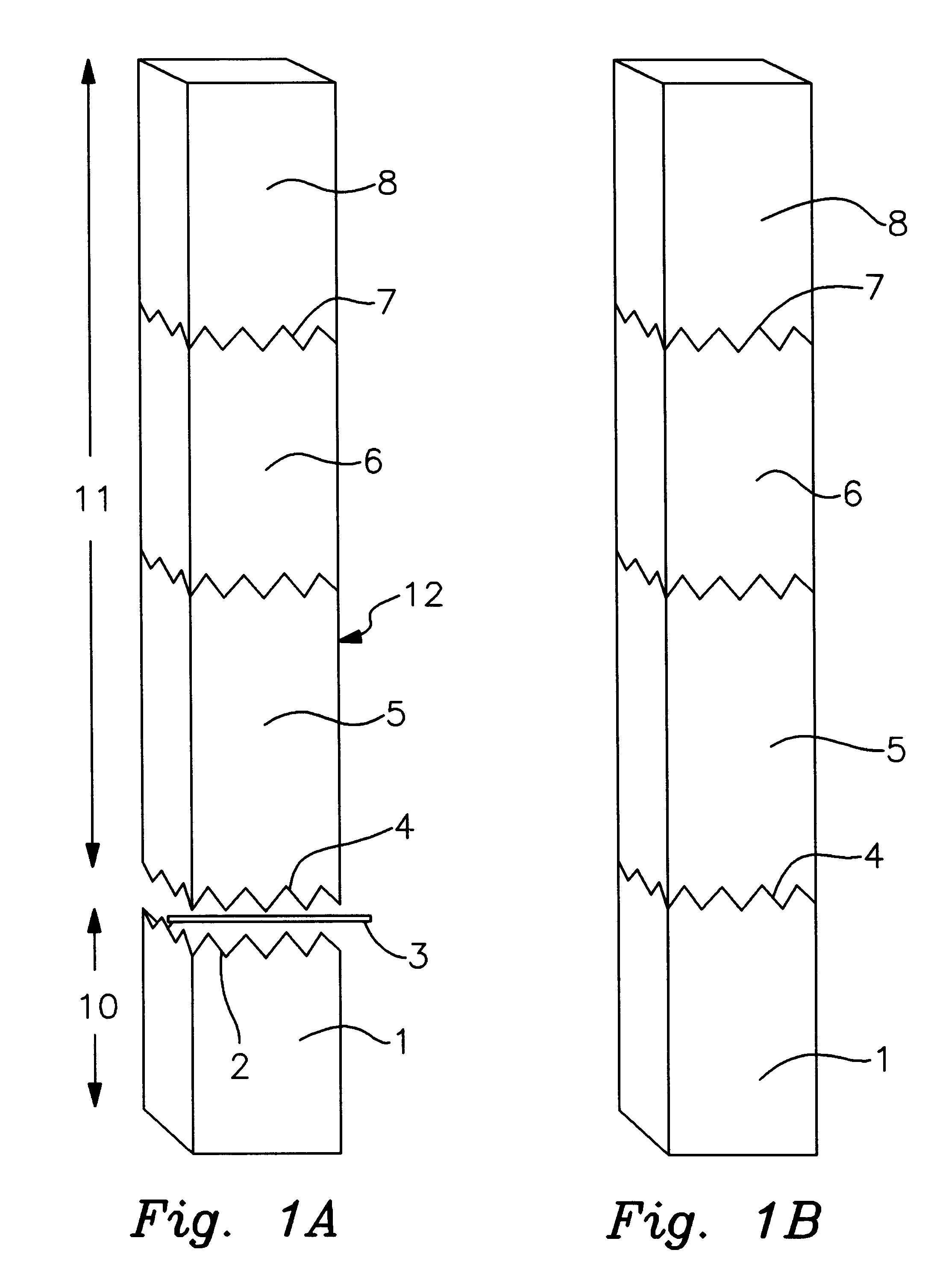

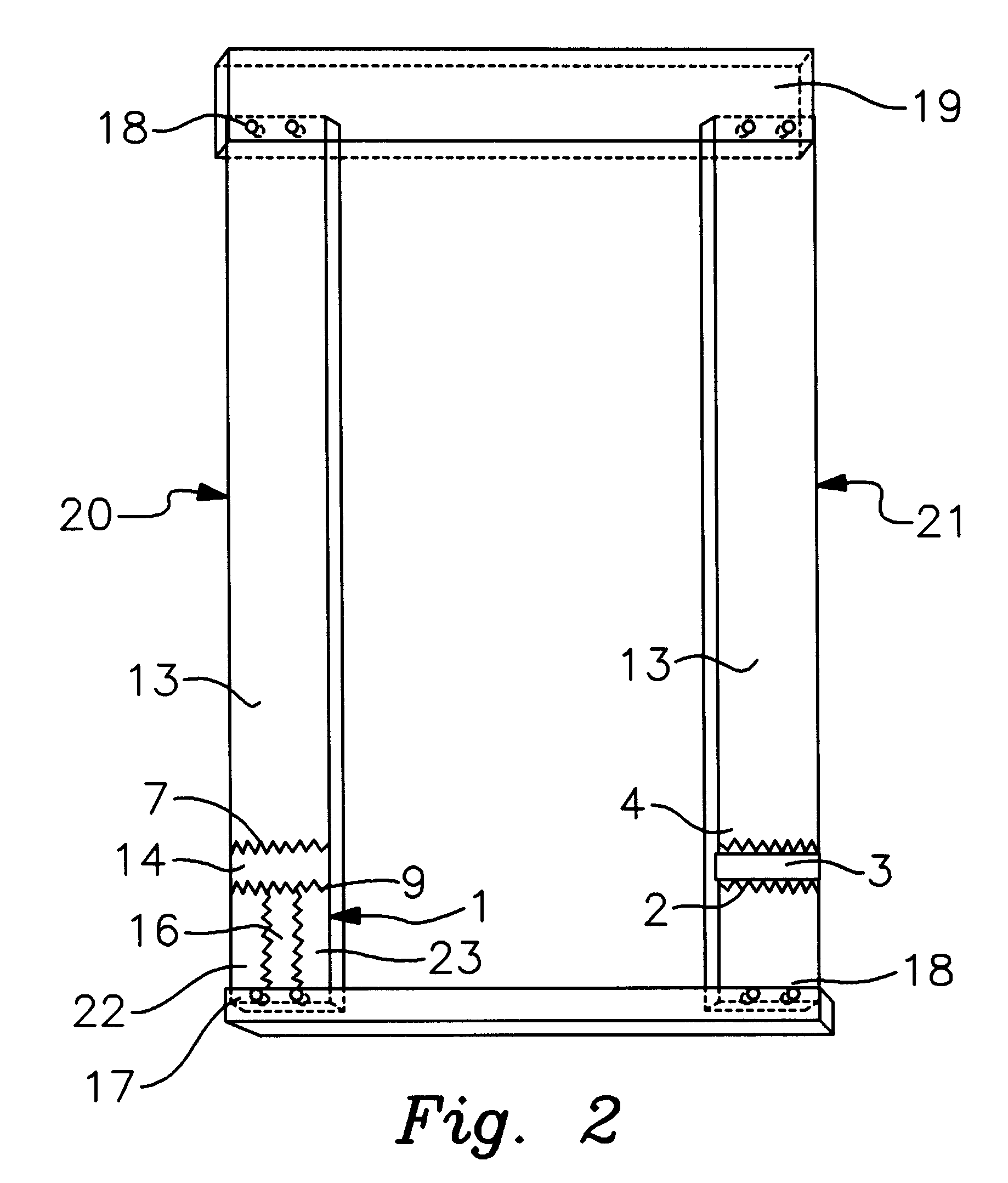

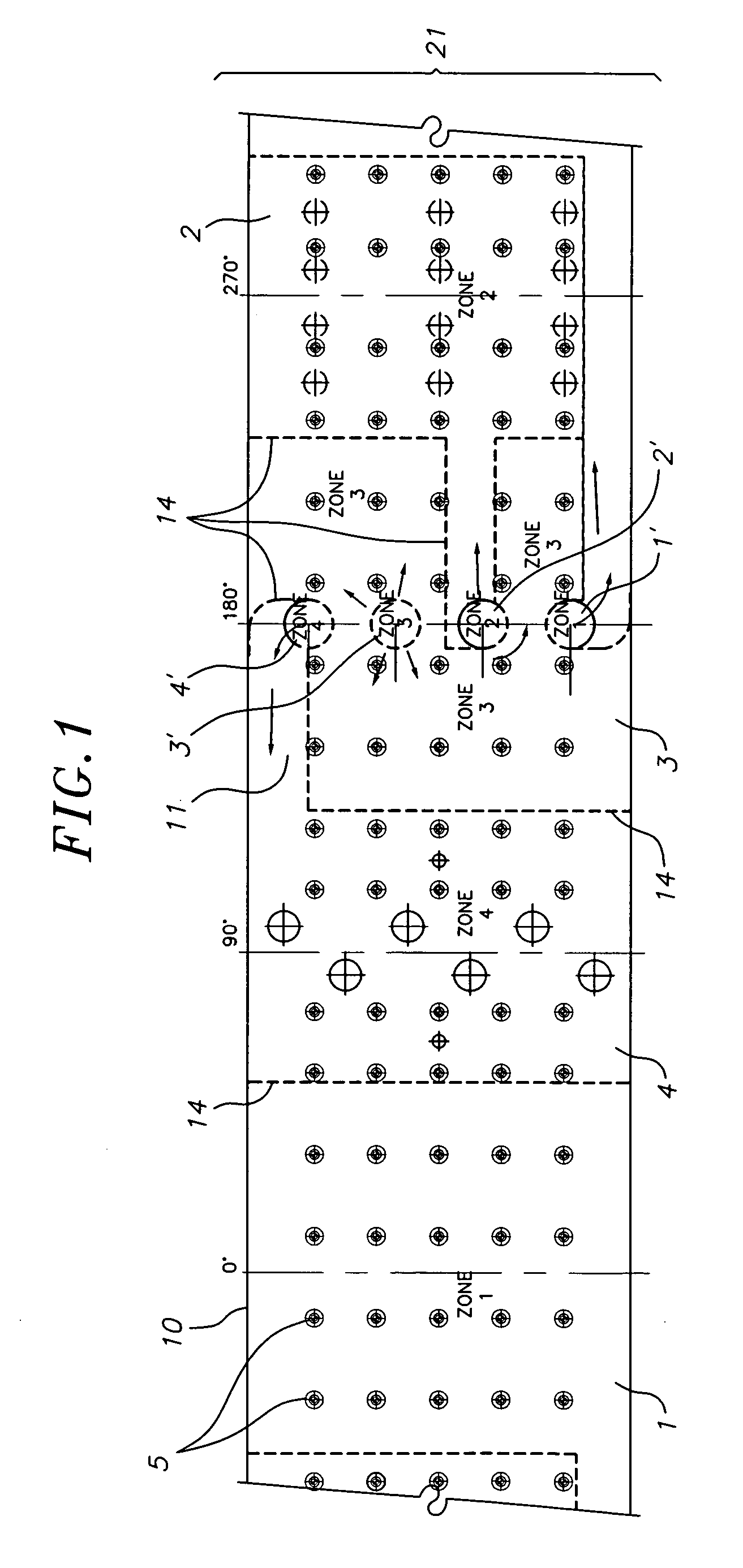

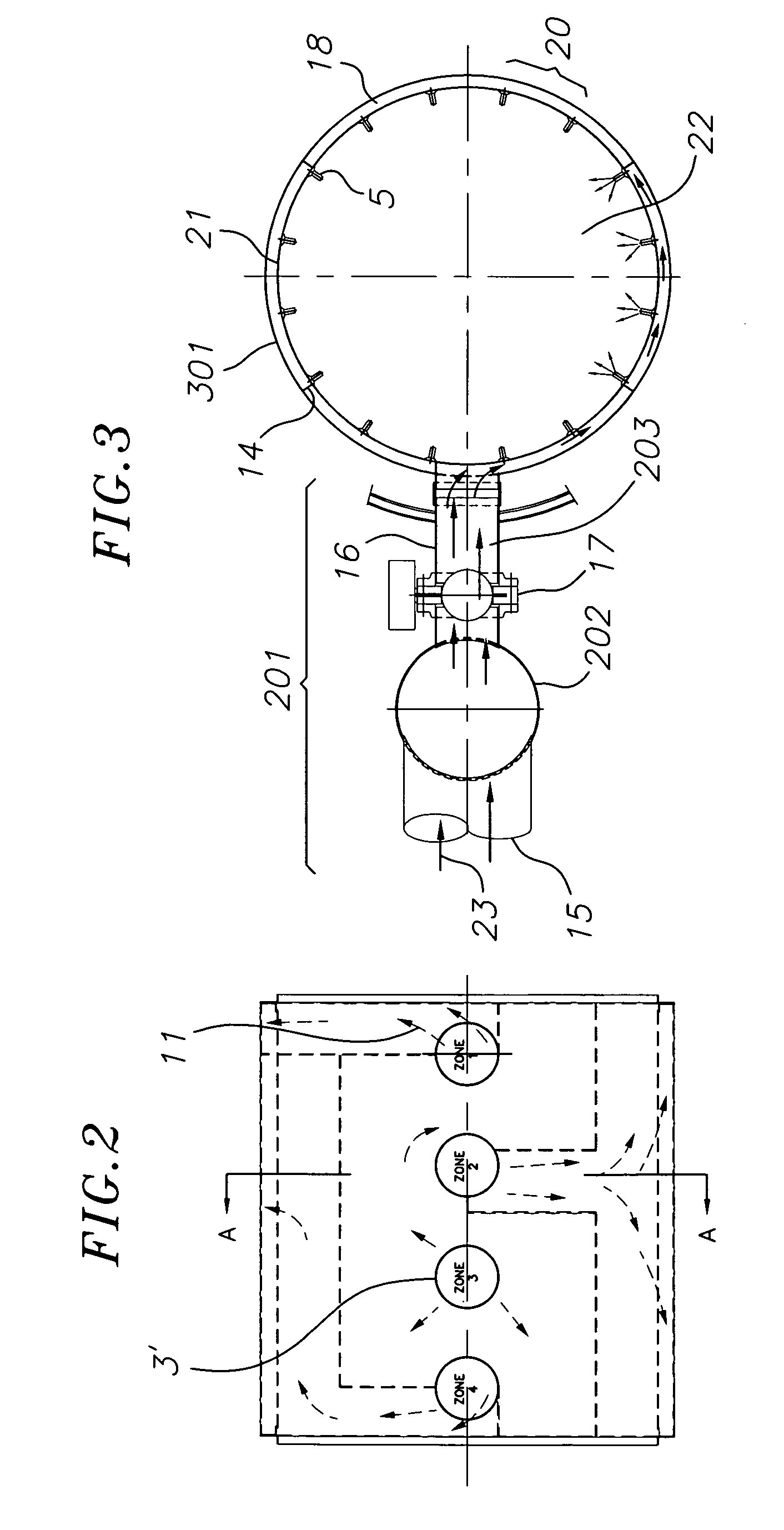

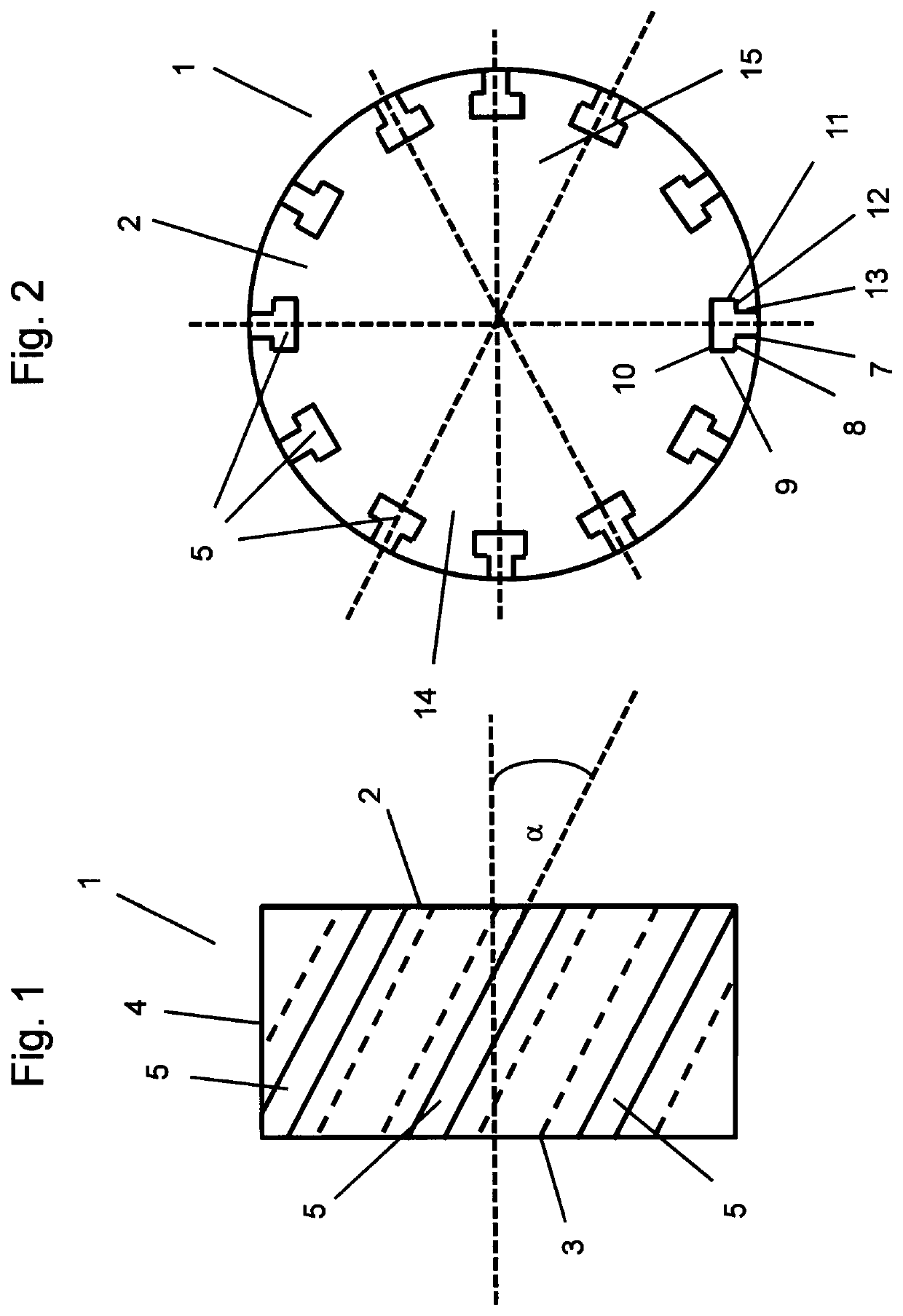

Process and device for manufacturing glass sheet

InactiveUS7231786B2Minimizes warpGlass furnace apparatusGlass drawing apparatusFlat glassGlass sheet

The present invention relates to a process for manufacturing flat sheets of a glass-based material and to an apparatus therefor. The process comprises providing a glass preform, heating the glass preform in a furnace, forming a gob and a pre-sheet, removing the gob and drawing the glass pre-sheet into a flat glass sheet. Also provided is an apparatus for drawing a glass preform into a glass sheet, the apparatus comprising a draw furnace, stretching arms for stretching and drawing the pre-sheet into a glass sheet, and opposing edge rollers for applying a downward force on the glass sheet. The draw furnace may include a plurality of individual heating elements, the temperature of each heating element capable of being separately controlled. The apparatus may further include an annealing furnace for annealing the glass sheet.

Owner:CORNING INC

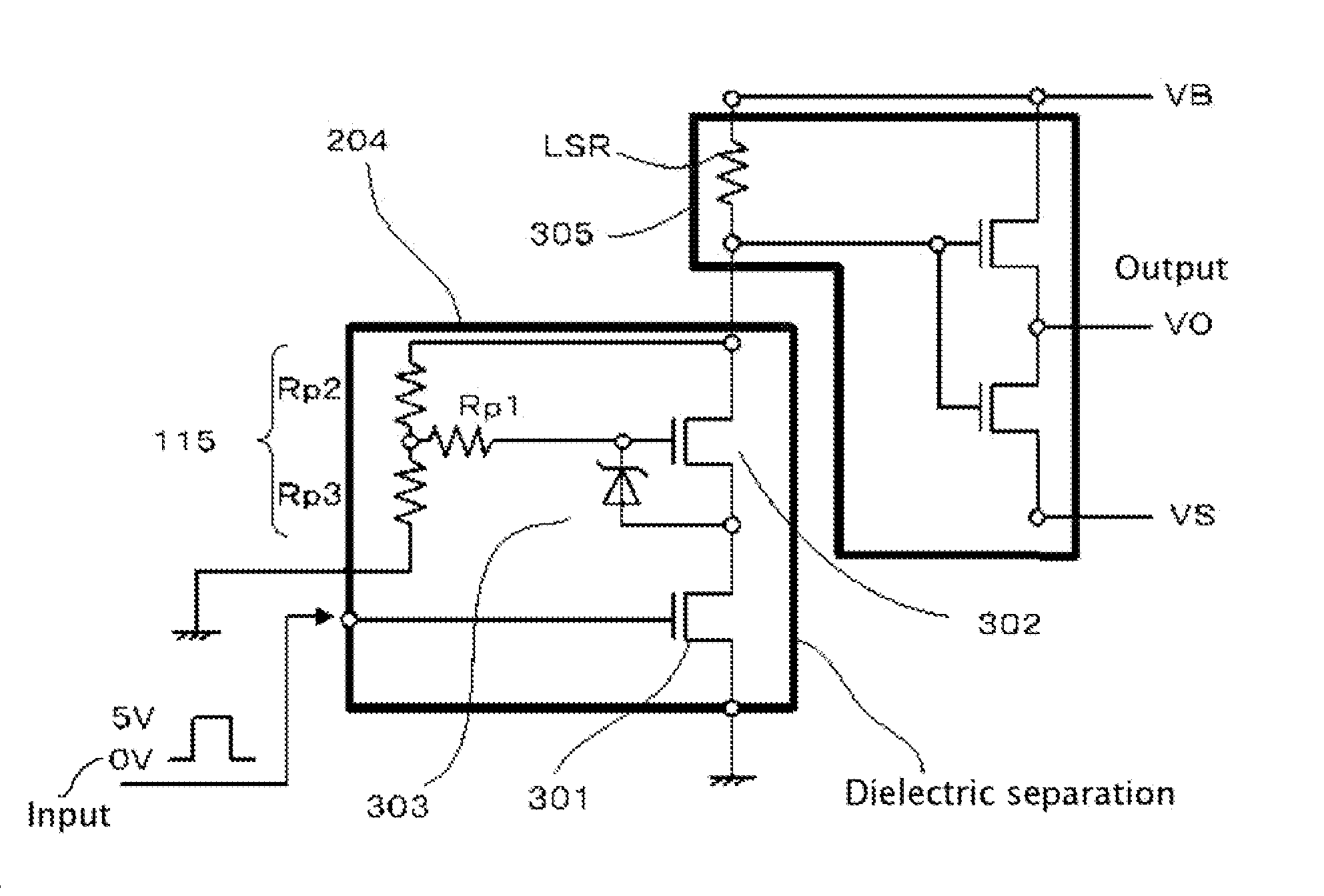

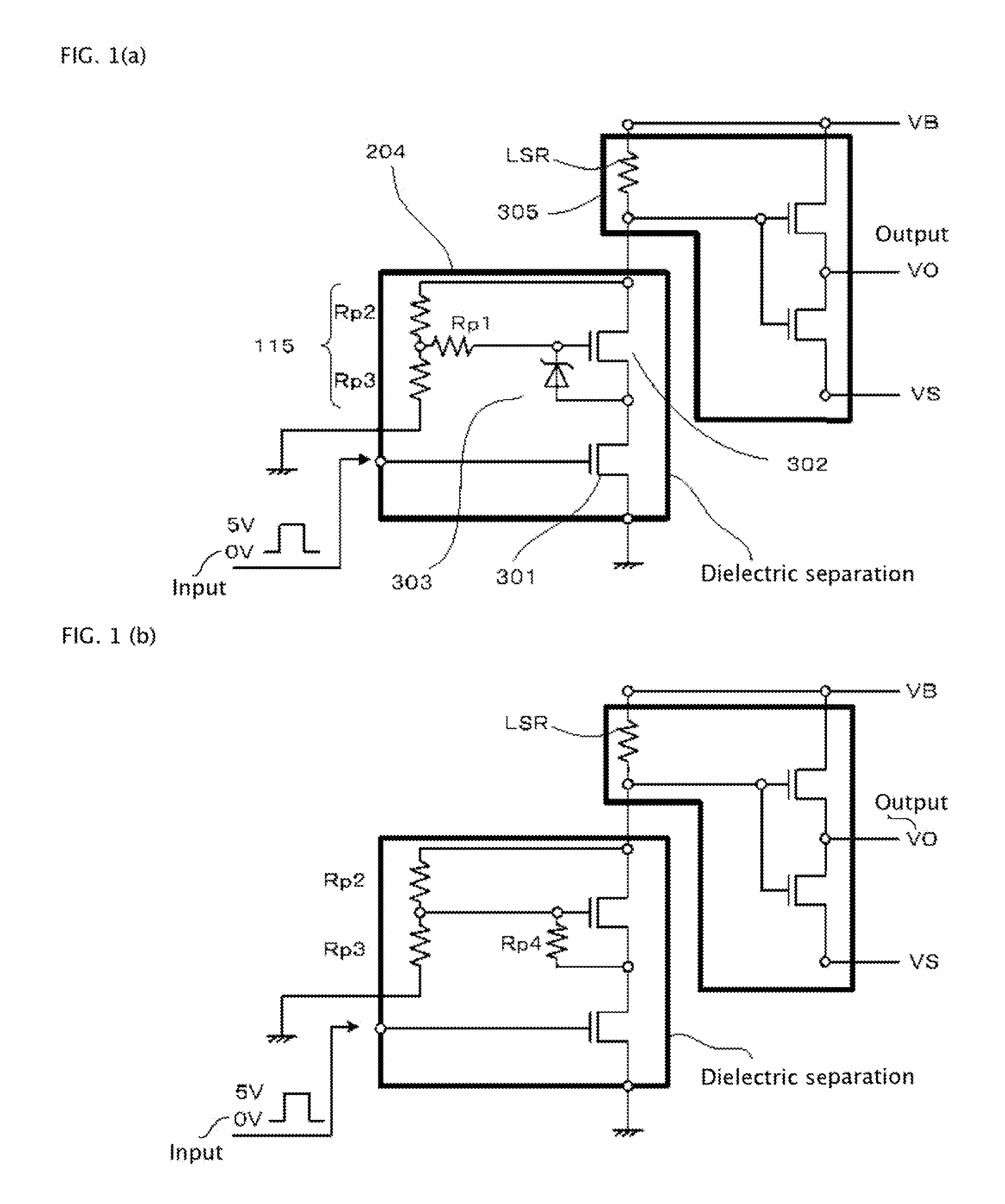

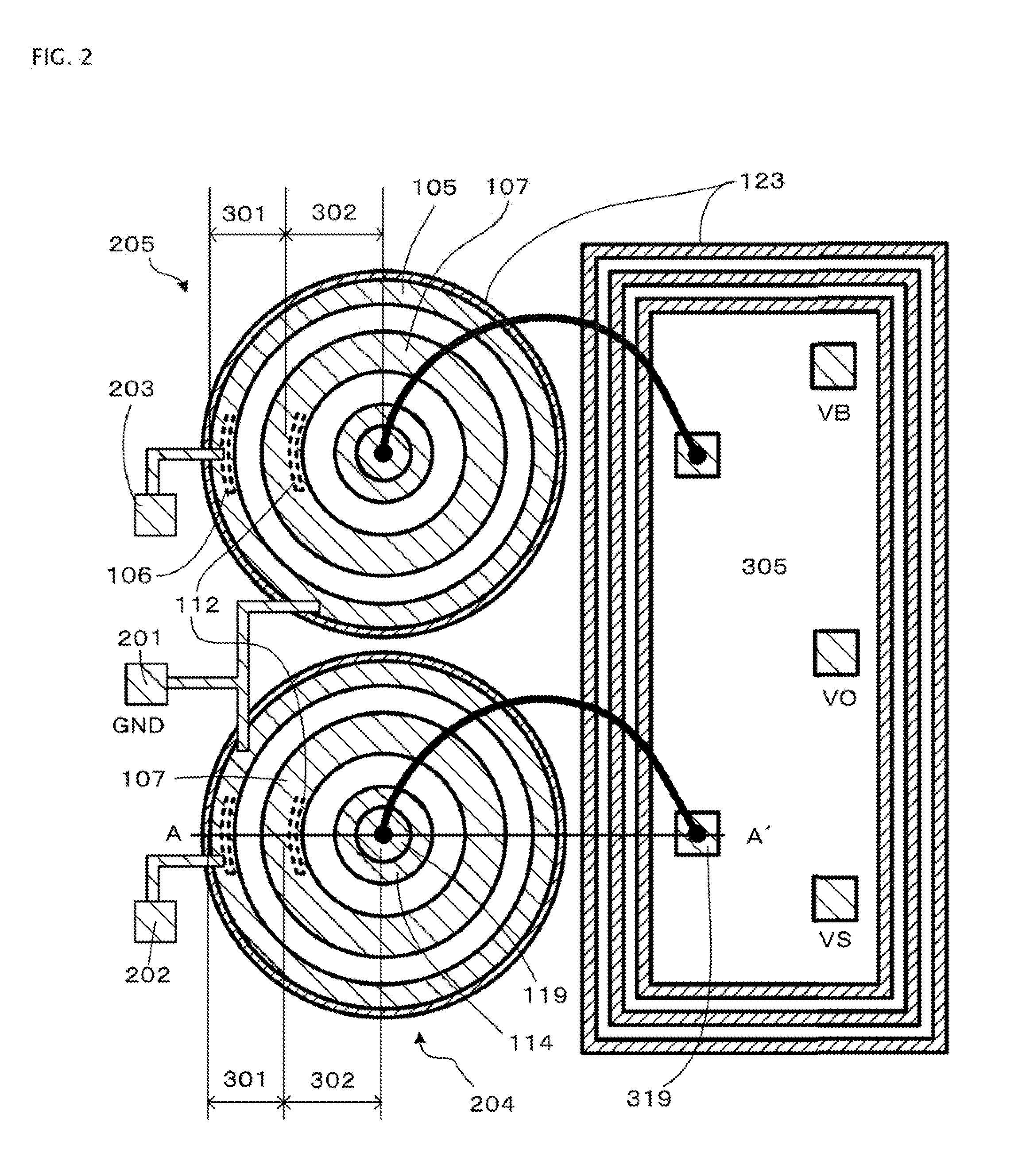

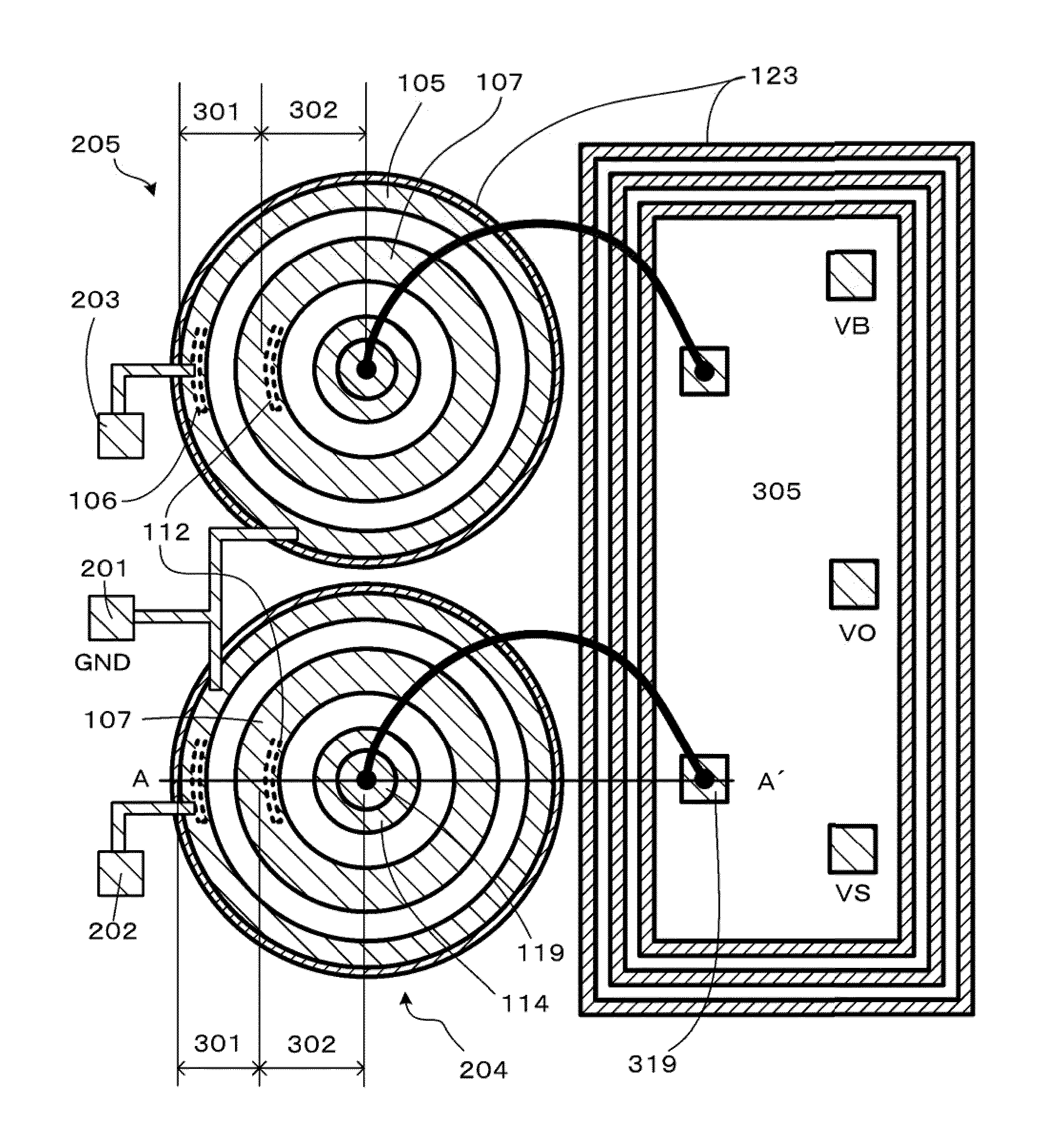

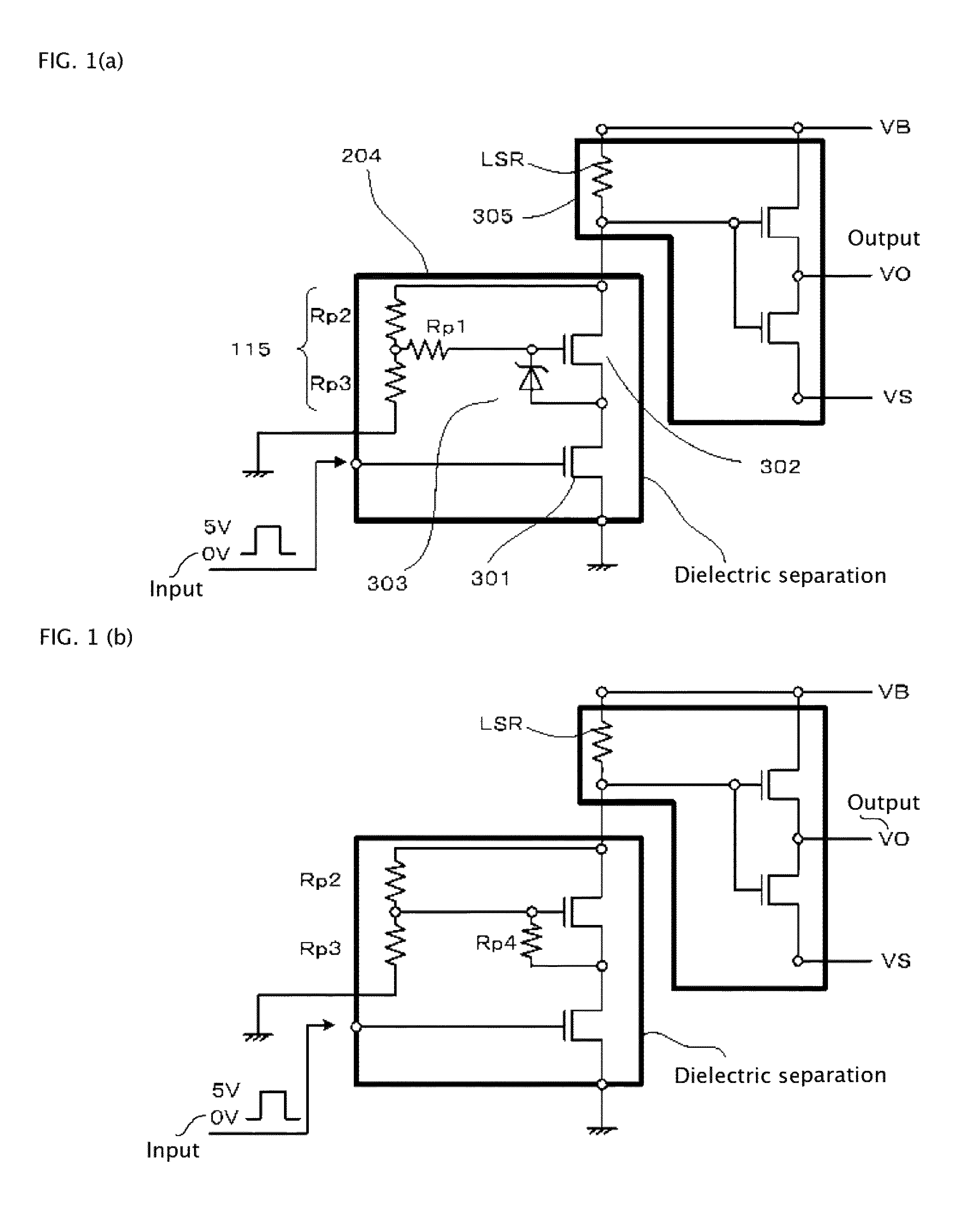

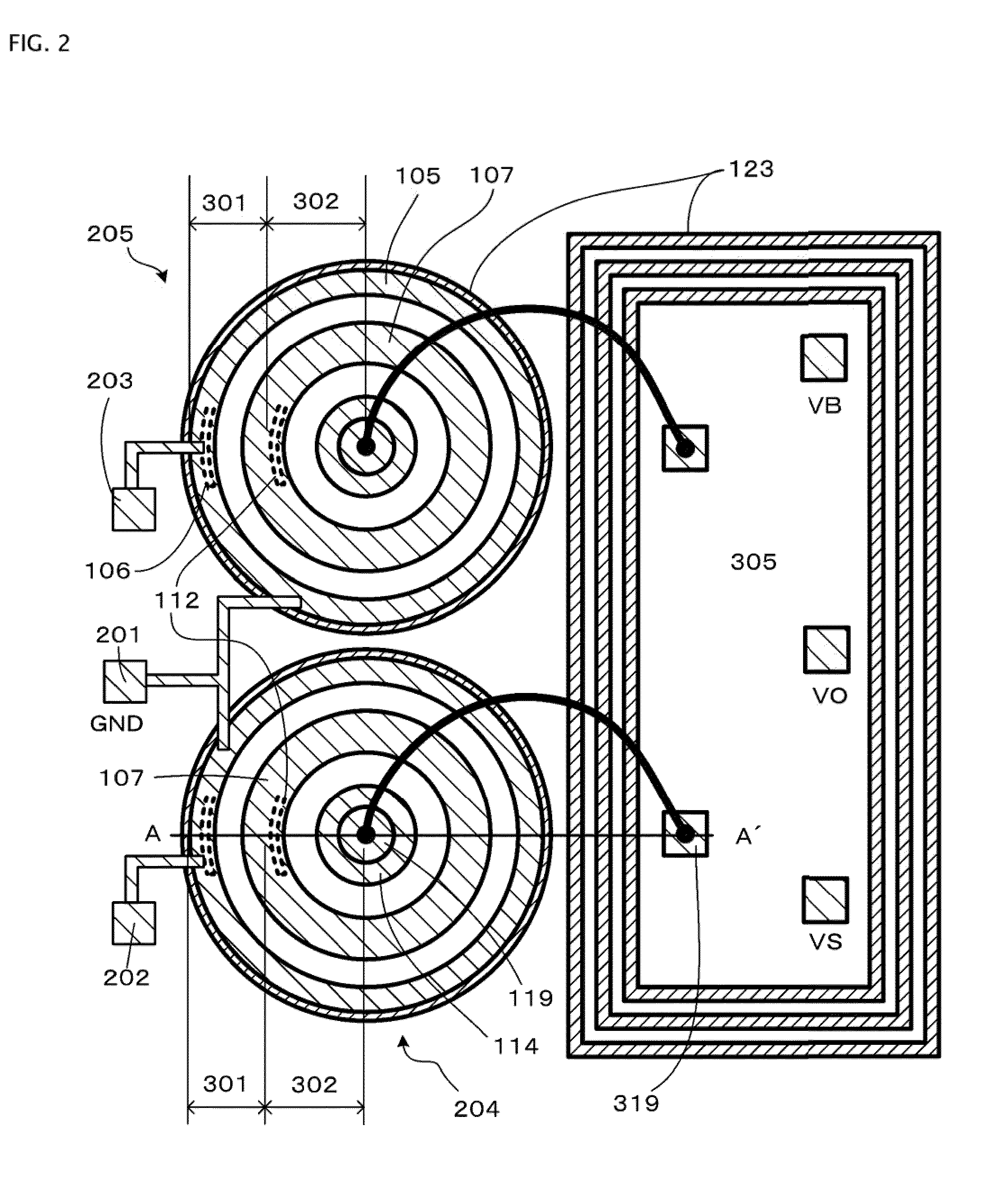

High-voltage semiconductor device

ActiveUS20100314710A1Minimize manufacturing processLow costTransistorSolid-state devicesHigh potentialIntegrated circuit

Aspects of the present invention provide a high-voltage semiconductor device and a high voltage integrated circuit device while minimizing or eliminating the need for the addition of back surface steps. Aspects of the invention provide a high-voltage semiconductor device that achieves, low voltage driving and quick response by way of stable high voltage wiring and a low ON voltage. In some aspects of the invention, a high-voltage semiconductor device can include a semiconductor layer is formed on a support substrate interposing an embedded oxide film therebetween. A high potential side second stage transistor and a low potential side first stage transistor surrounding the second stage transistor are formed on the surface region of the semiconductor layer. The source electrode of the second stage transistor is connected to the drain electrode of the first stage transistor. A drain electrode of the second stage transistor is connected to a drain pad.

Owner:FUJI ELECTRIC CO LTD

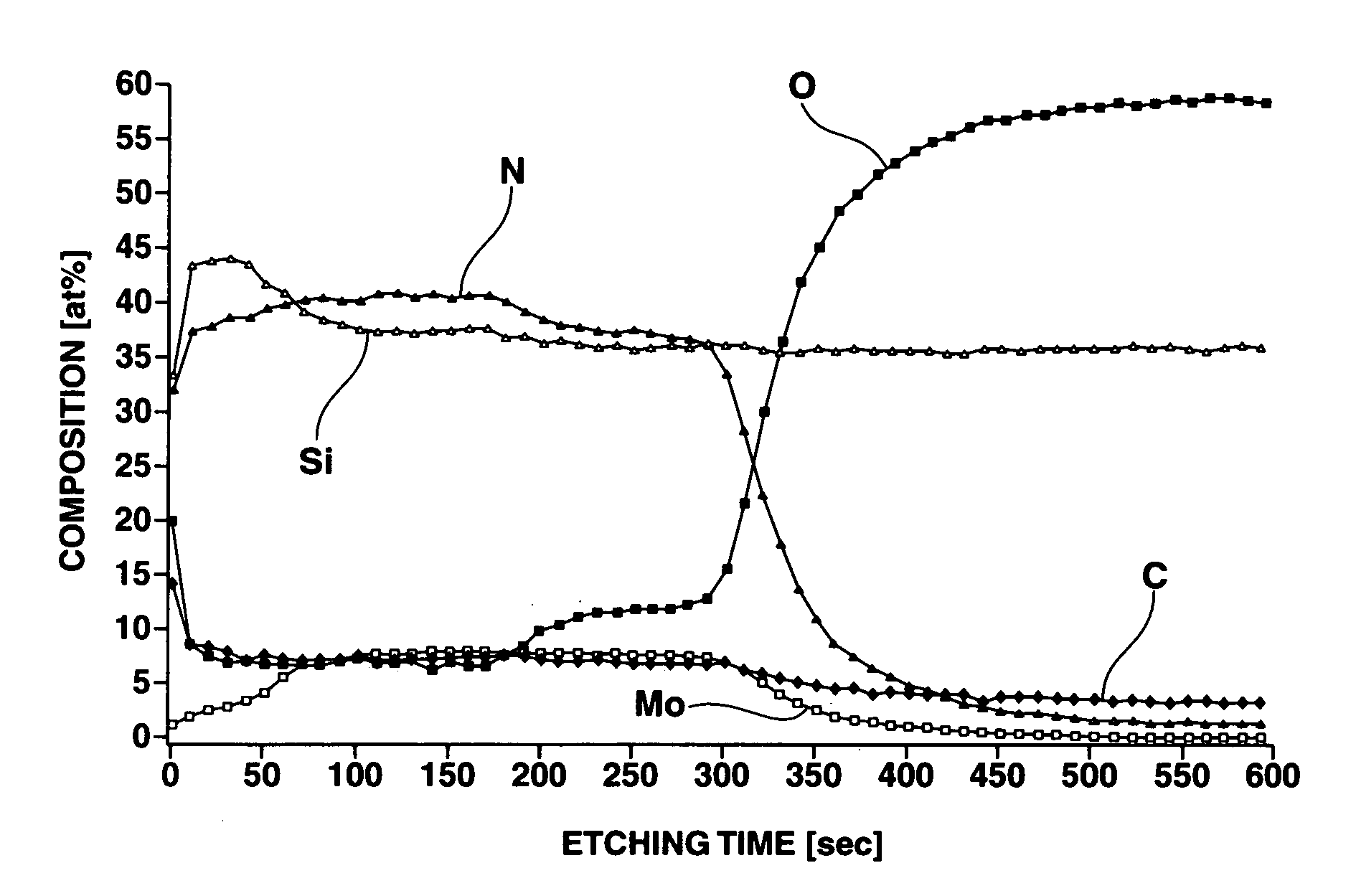

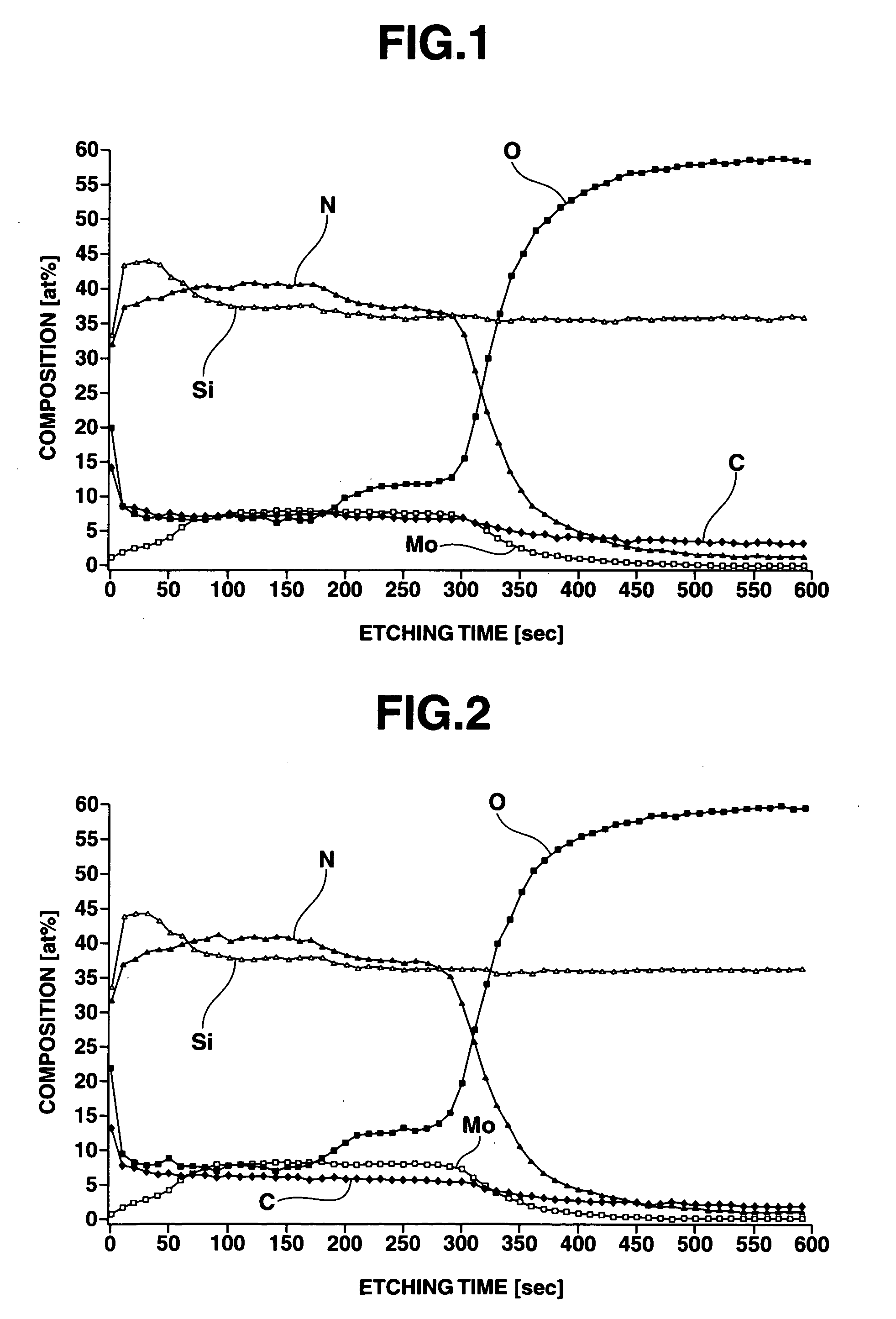

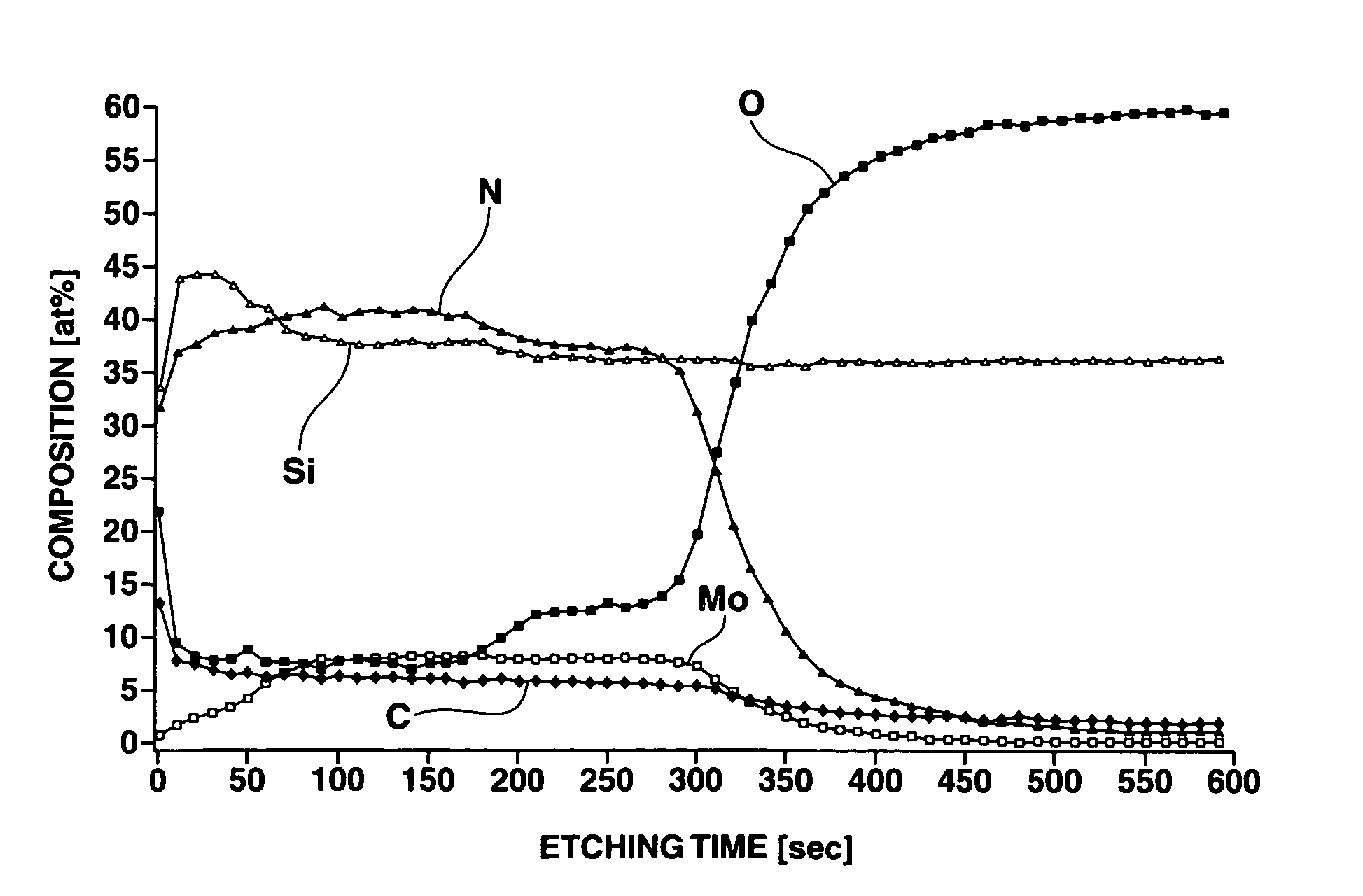

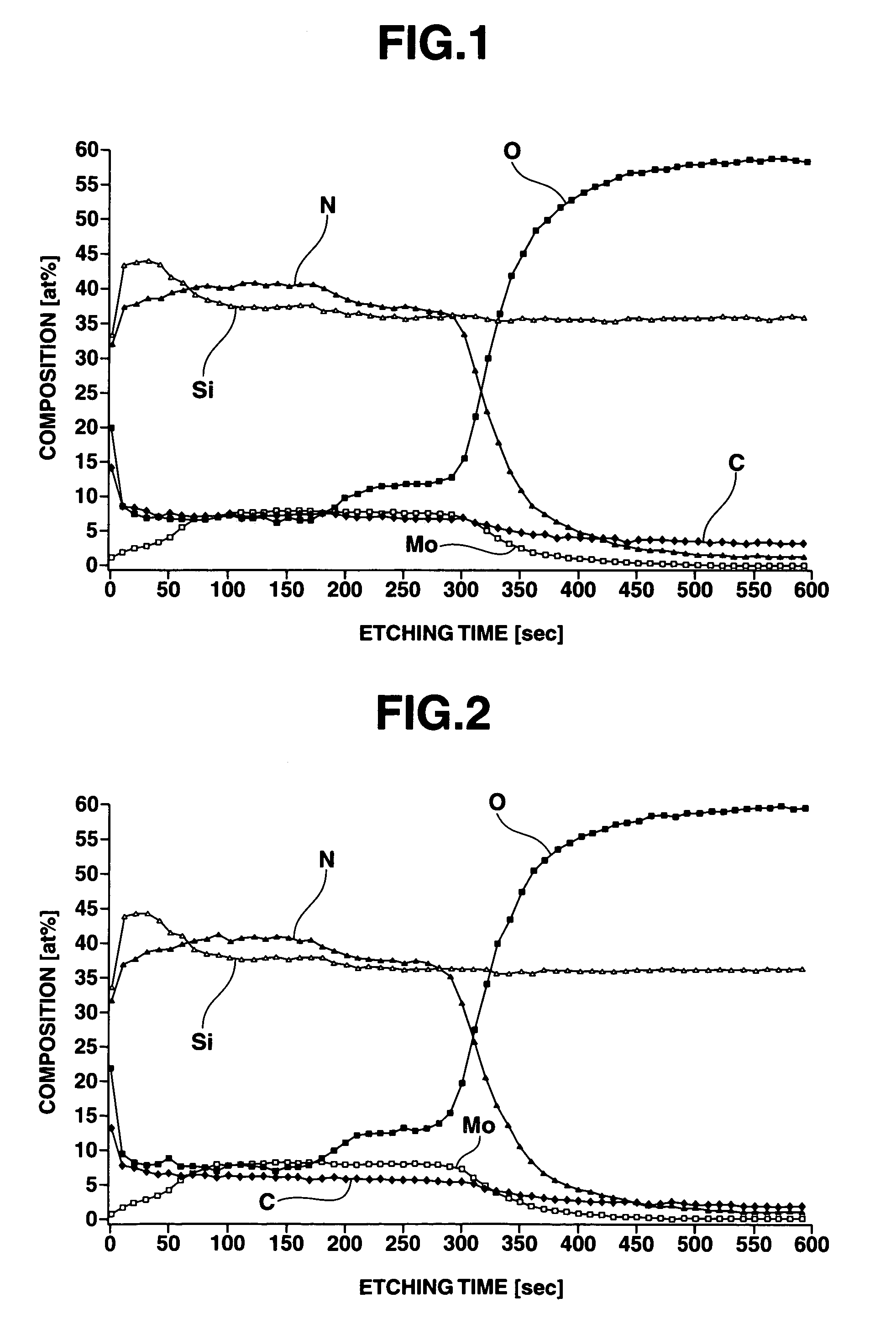

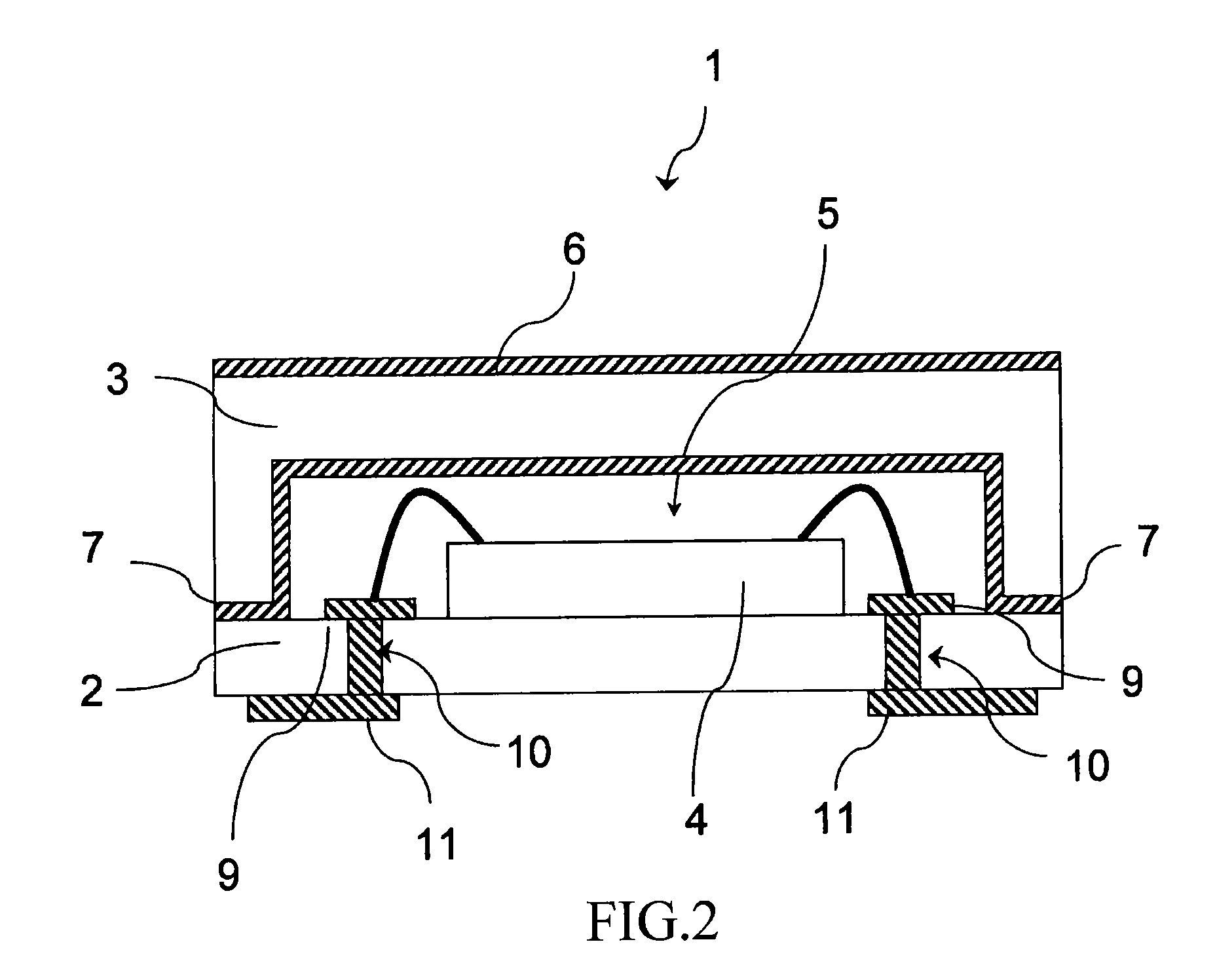

Preparation of photomask blank and photomask

ActiveUS20050260505A1Improve chemical resistanceSuppress changesCellsVacuum evaporation coatingFlash-lampResist

A photomask blank is prepared by forming a light-absorbing film on a transparent substrate, and irradiating the light-absorbing film with light from a flash lamp at an energy density of 3 to 40 J / cm2. A photomask is prepared by forming a resist pattern on the photomask blank by photolithography, etching away those portions of the light-absorbing film which are not covered with the resist pattern, and removing the resist.

Owner:SHIN ETSU CHEM IND CO LTD

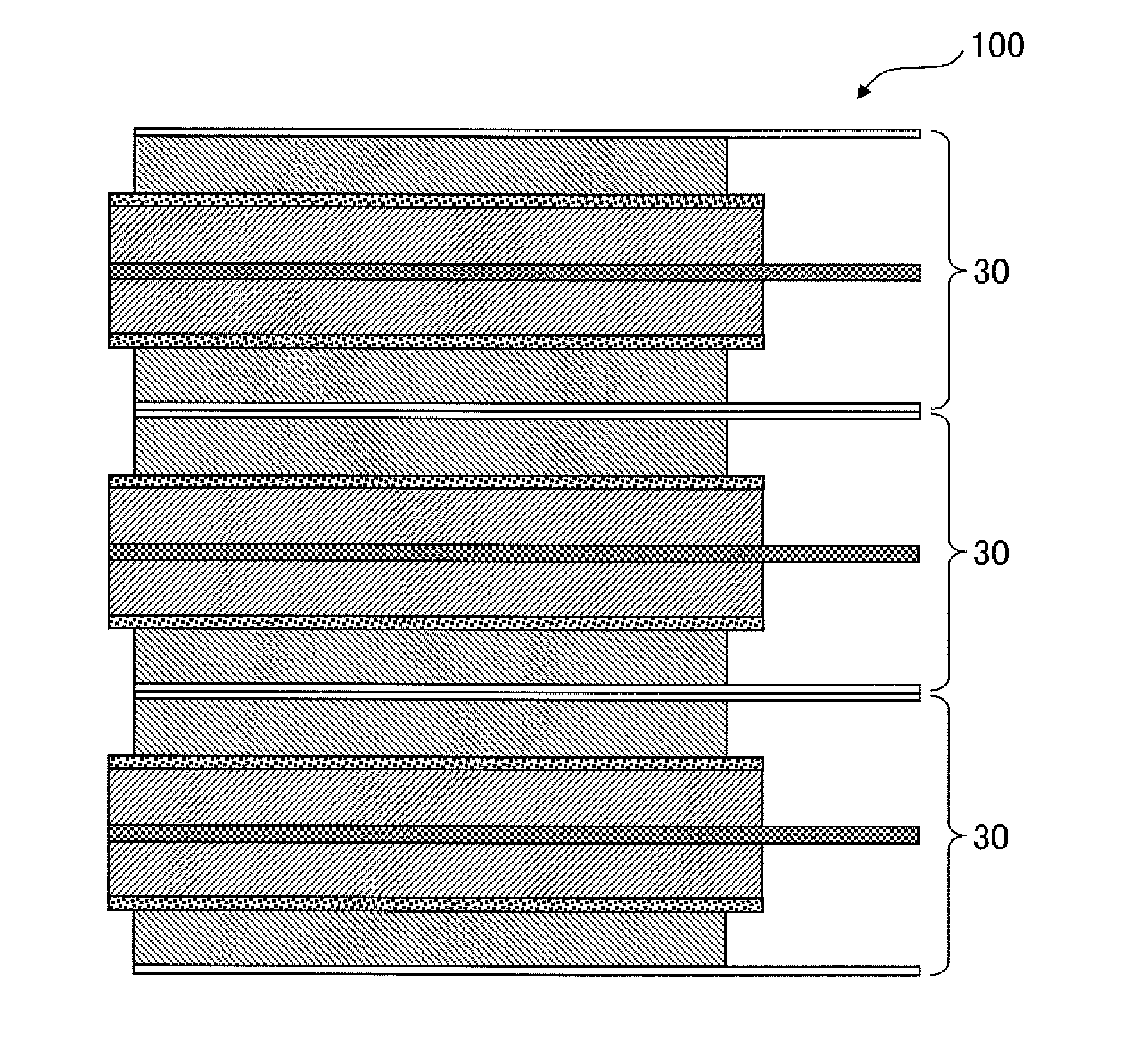

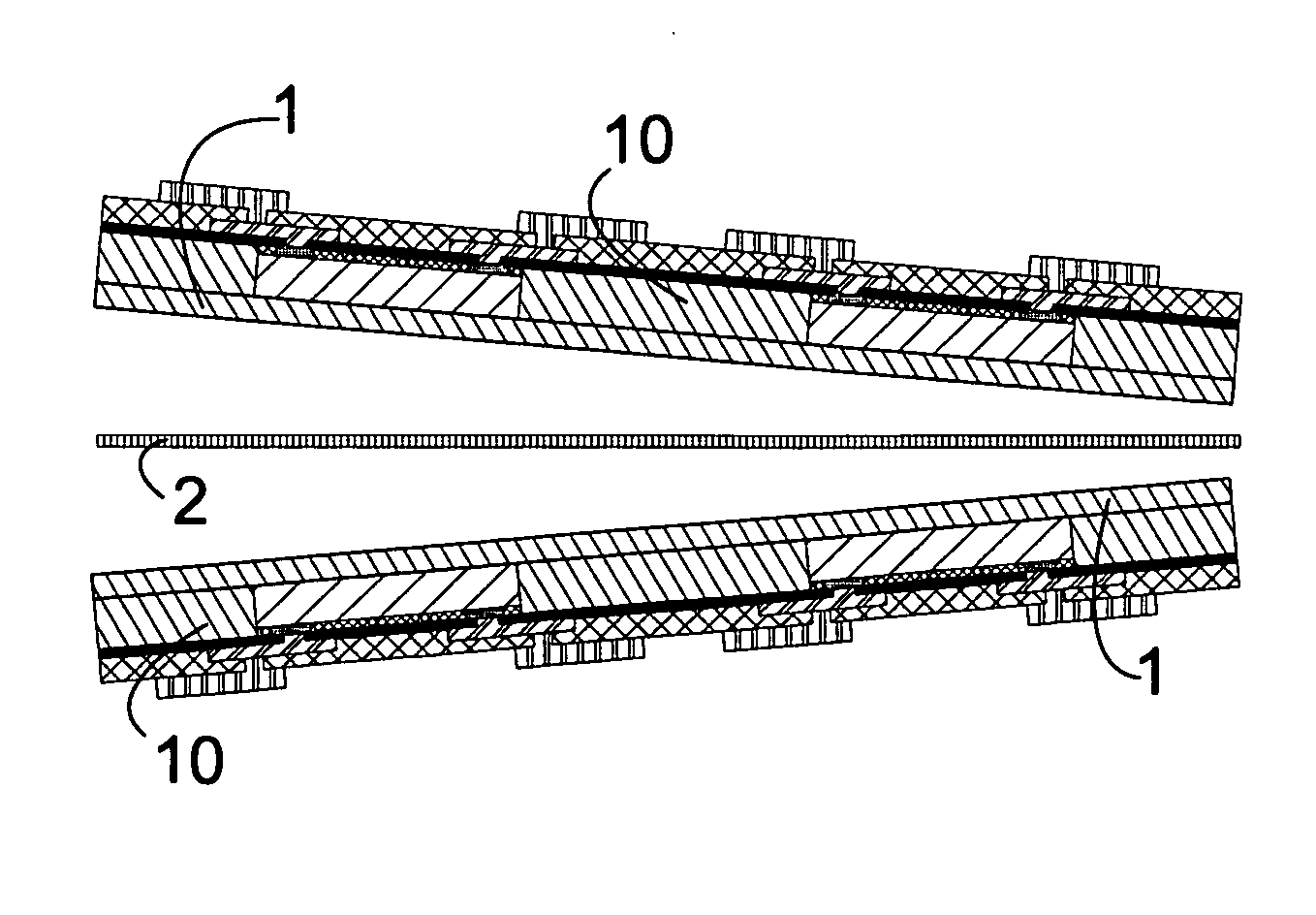

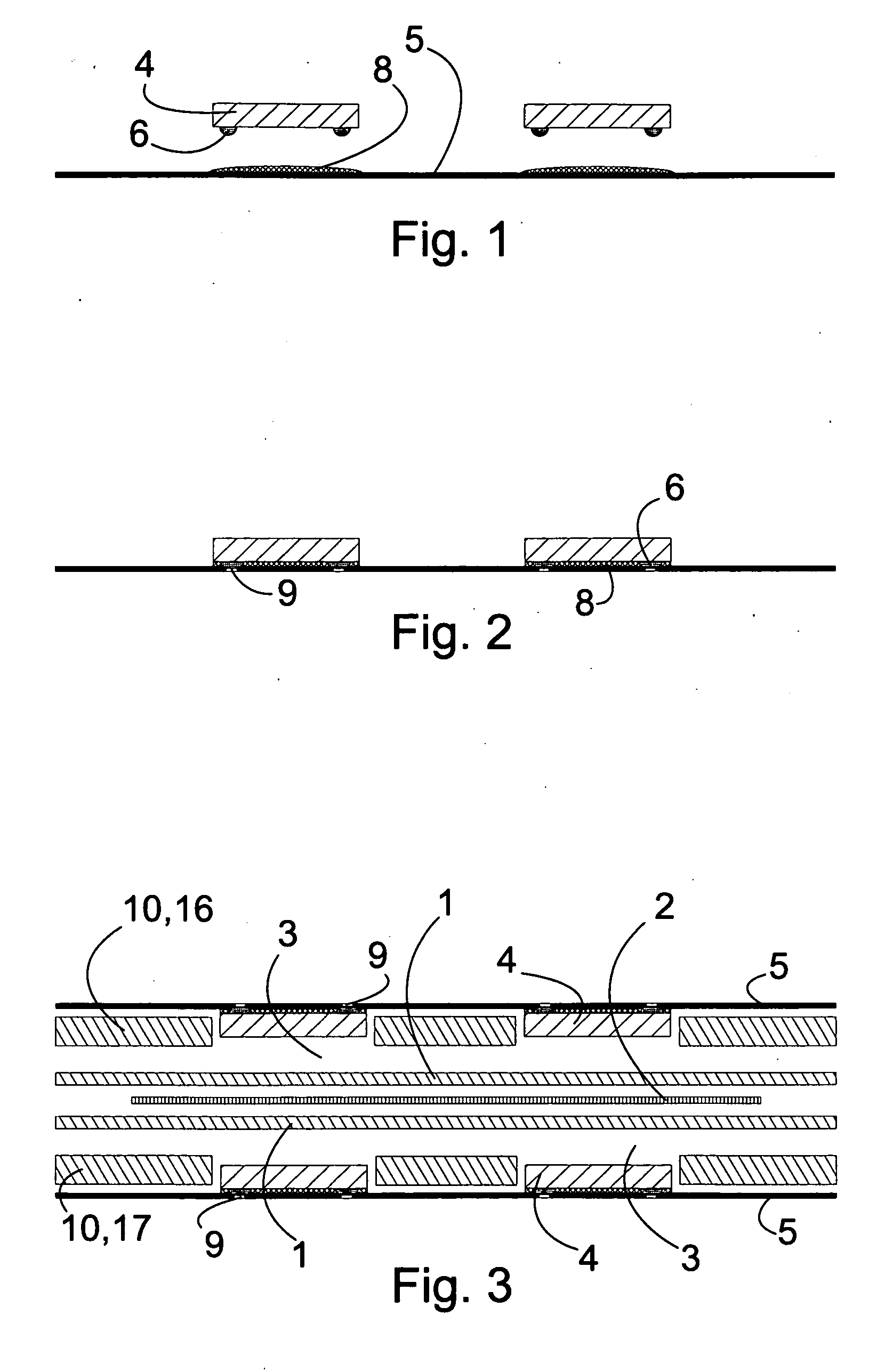

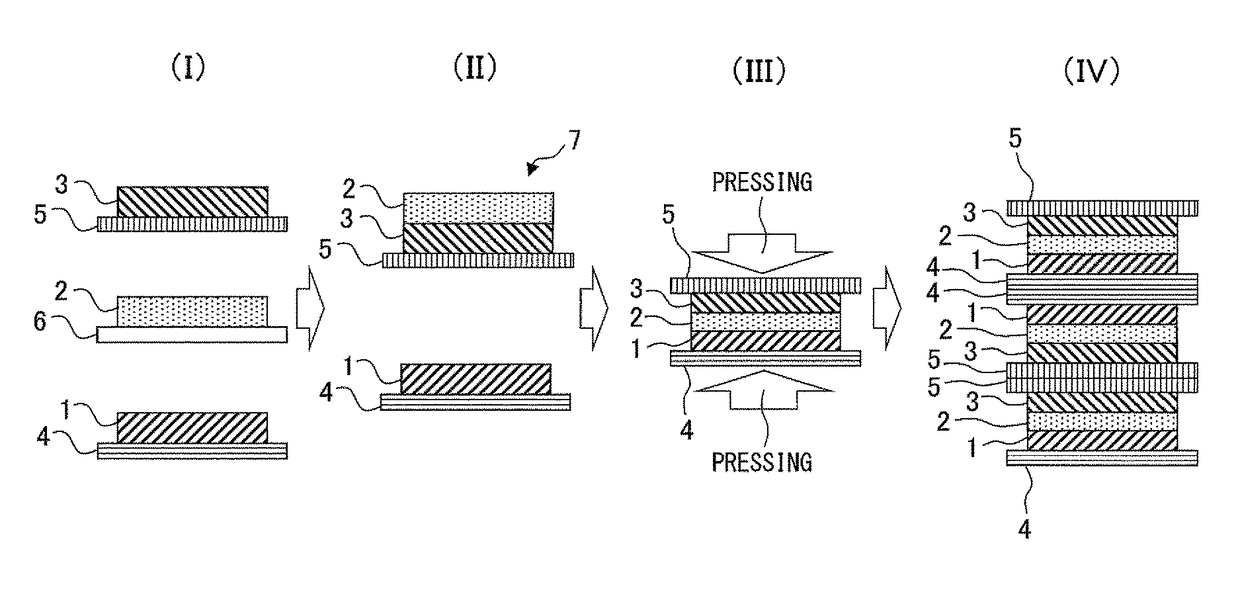

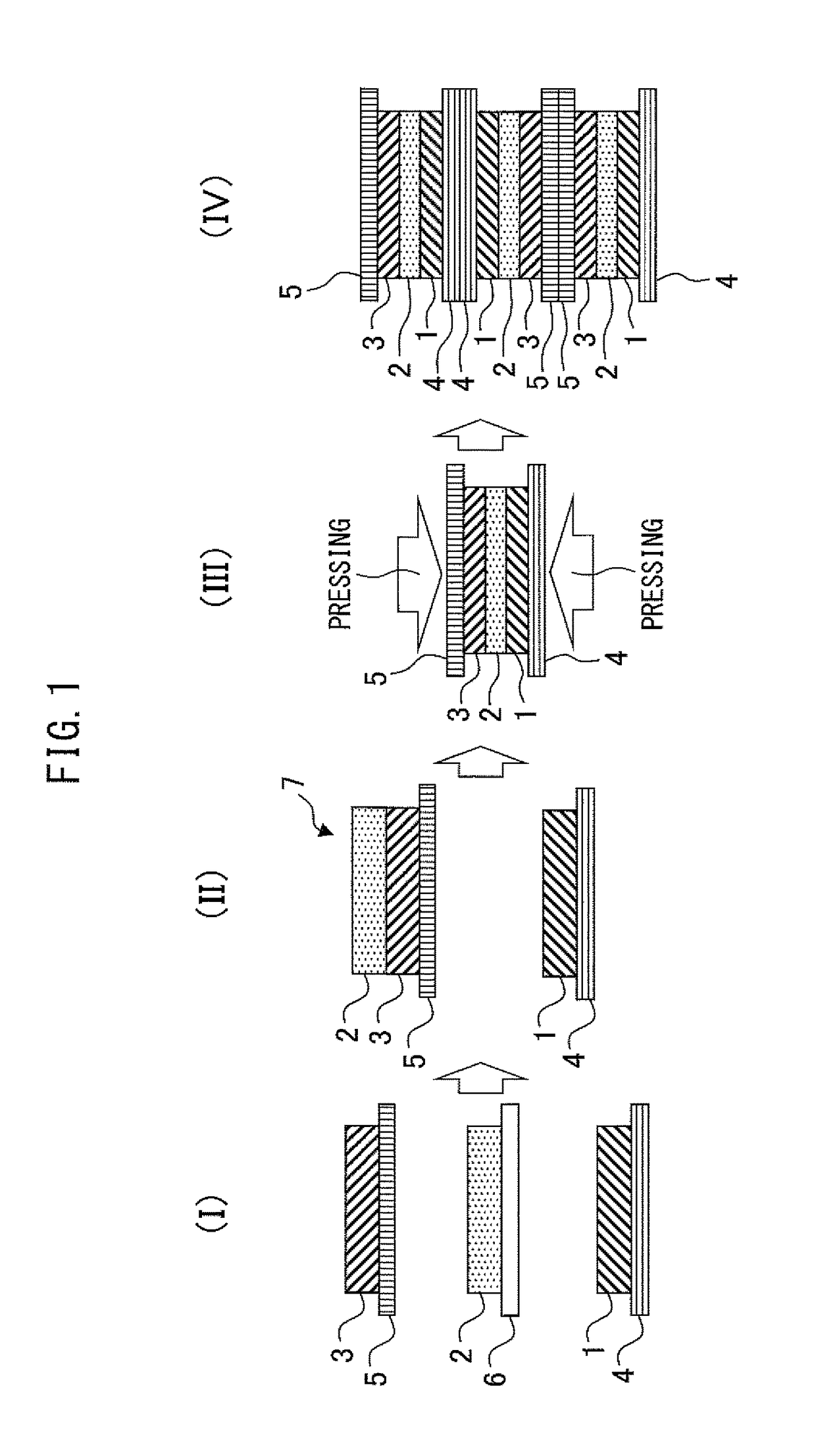

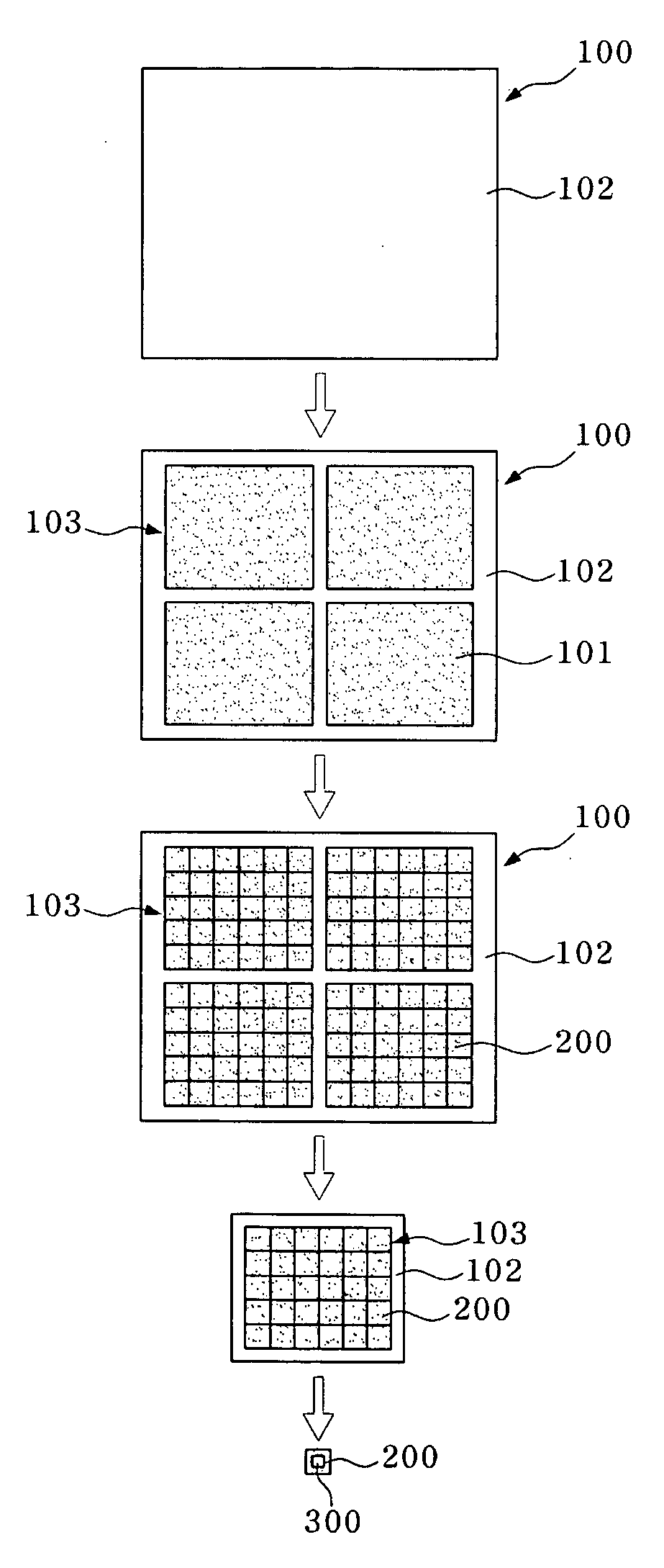

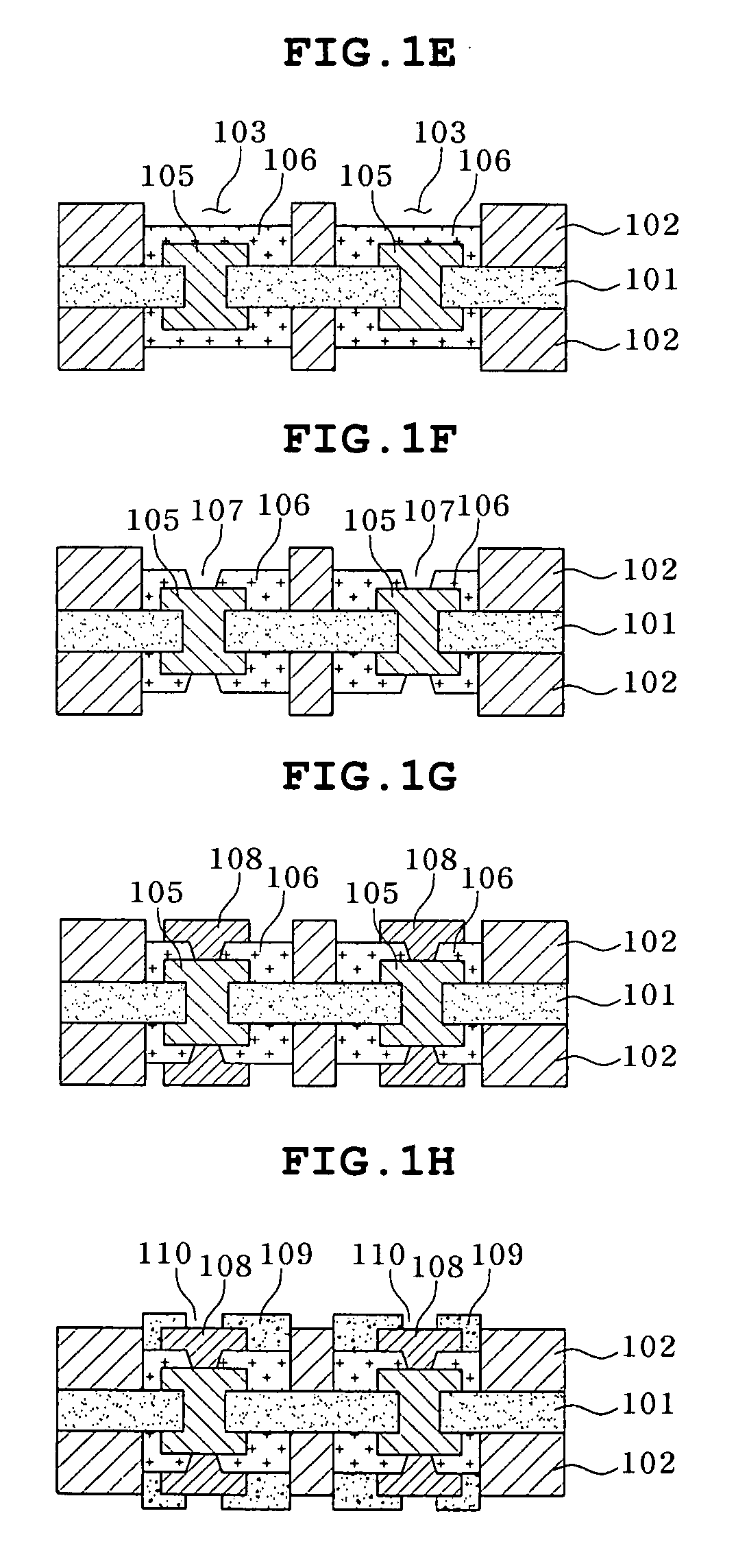

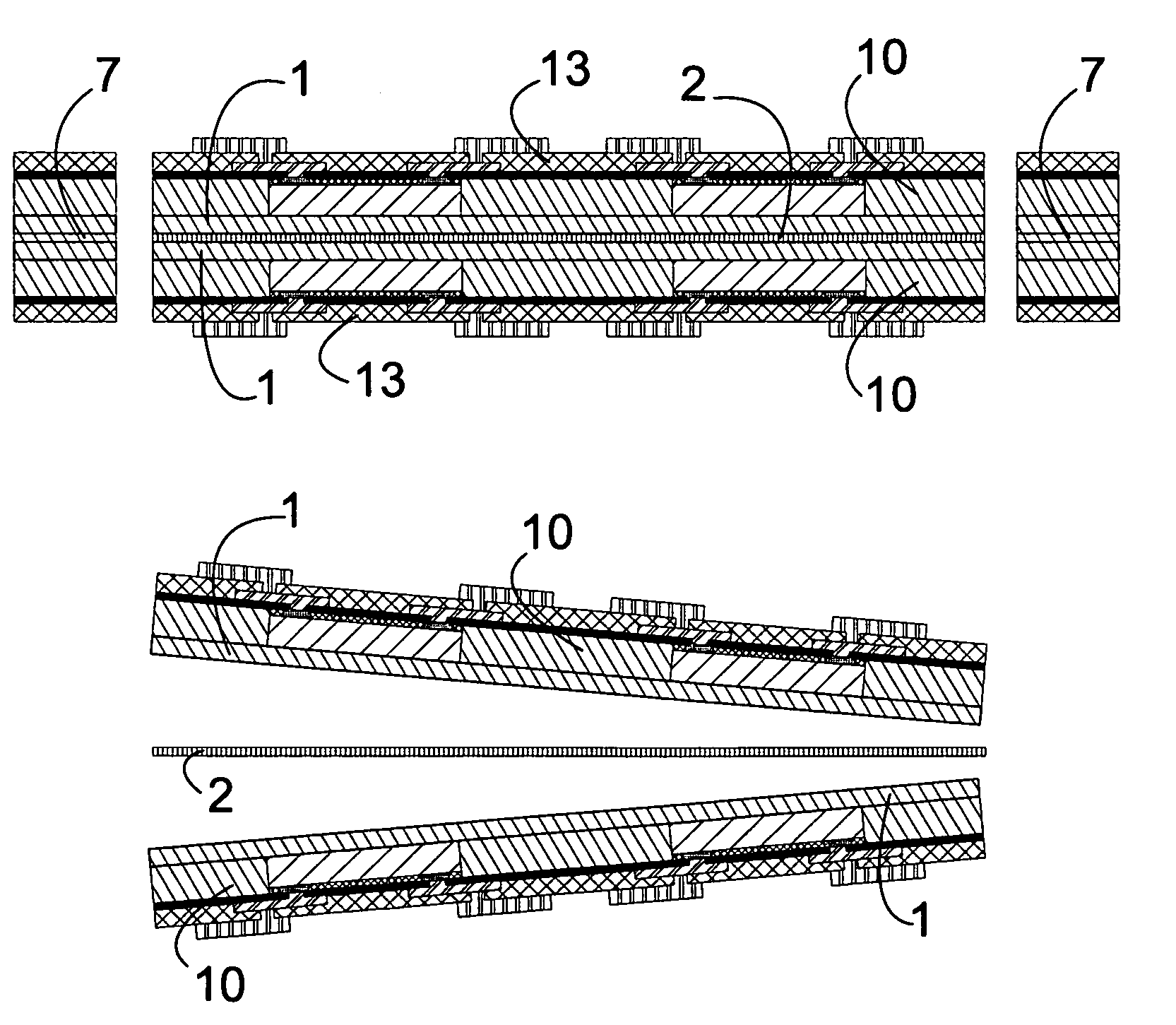

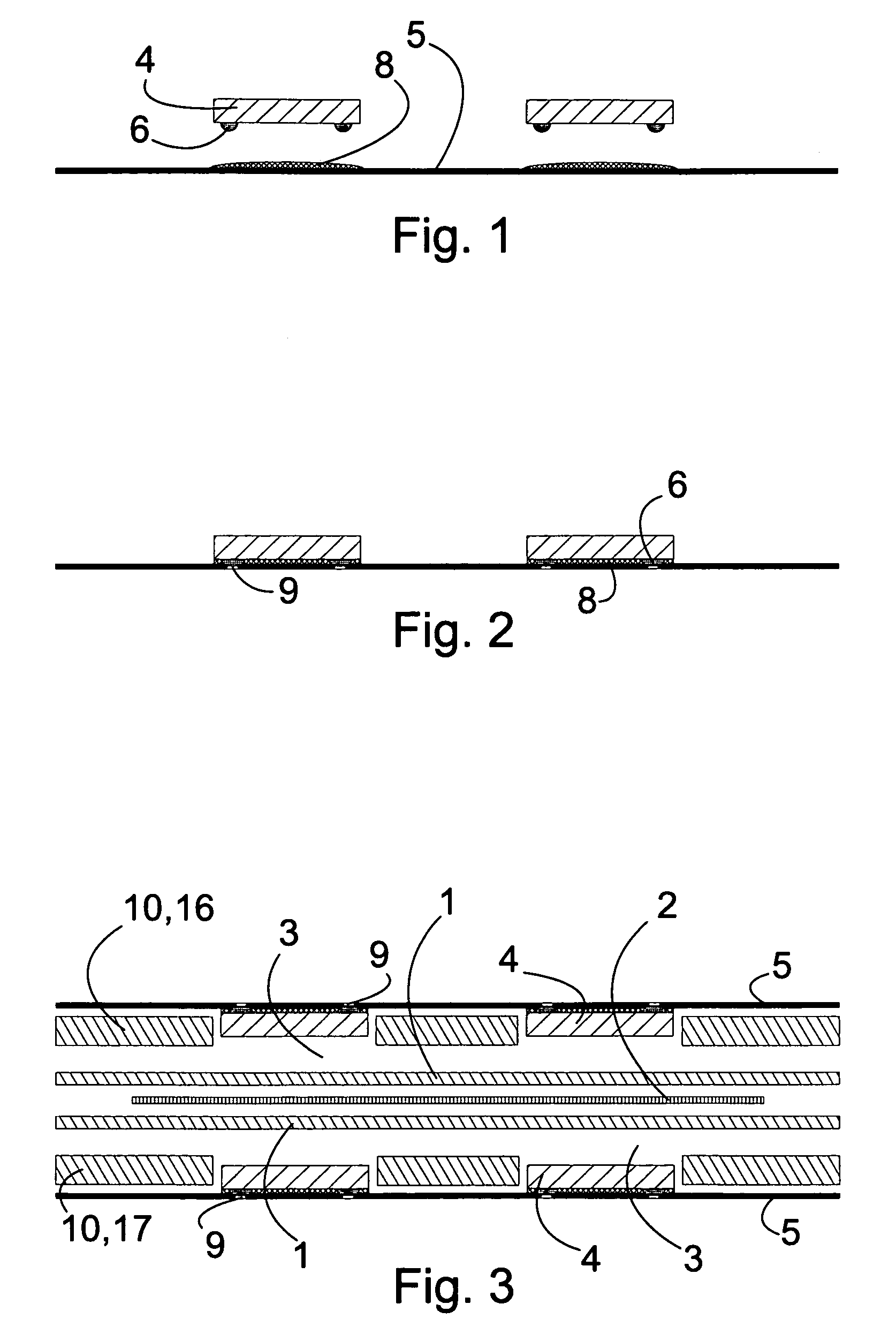

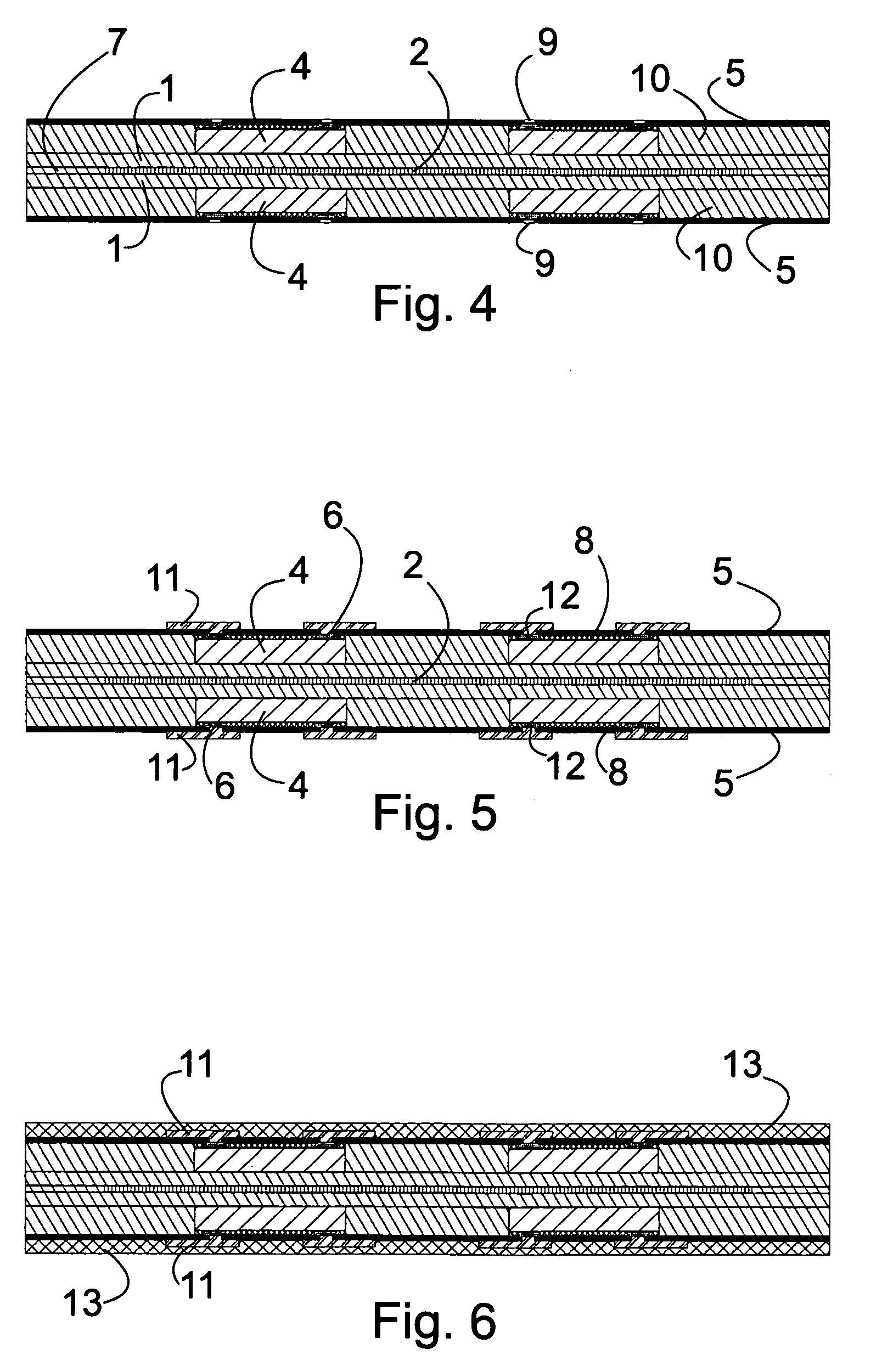

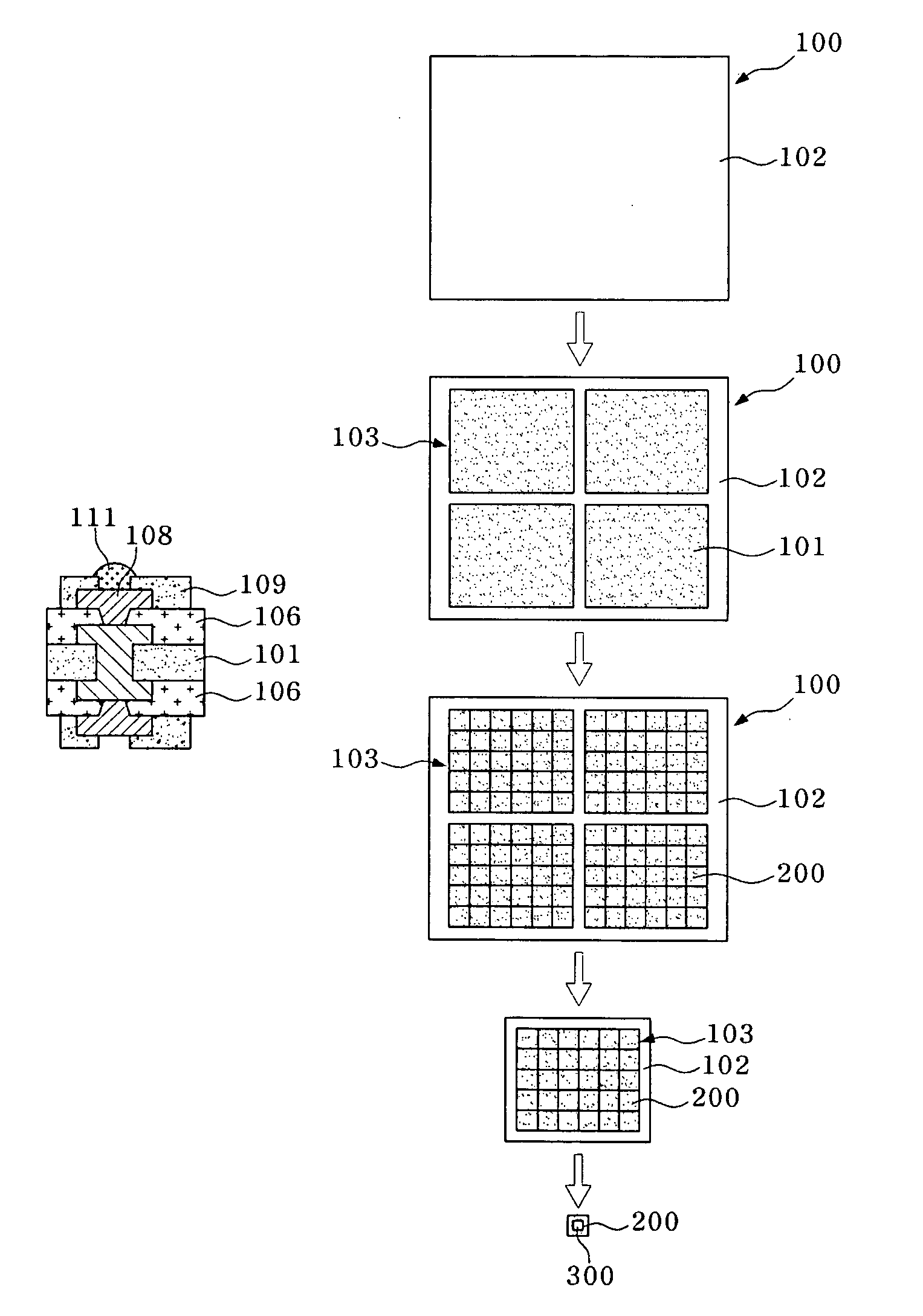

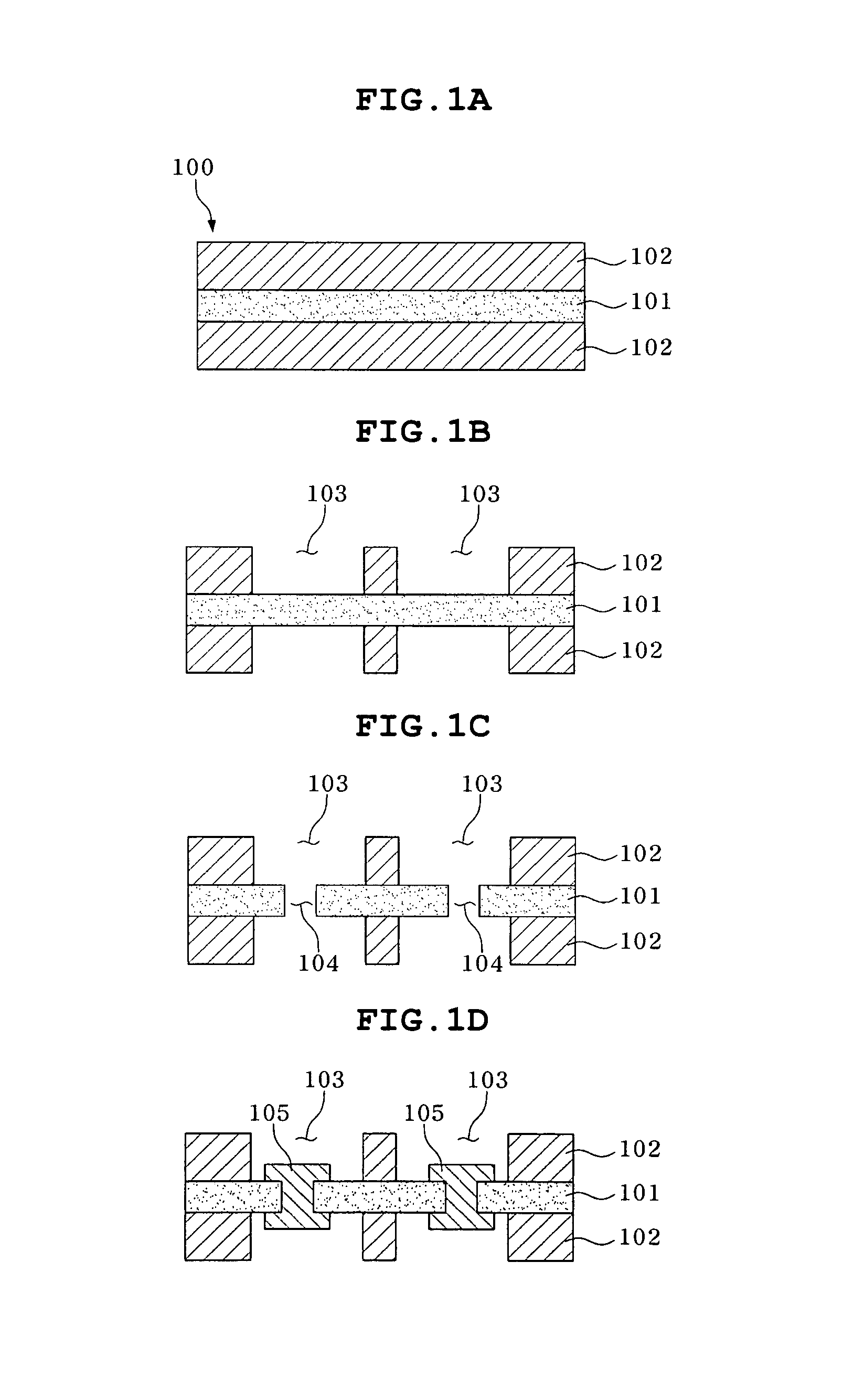

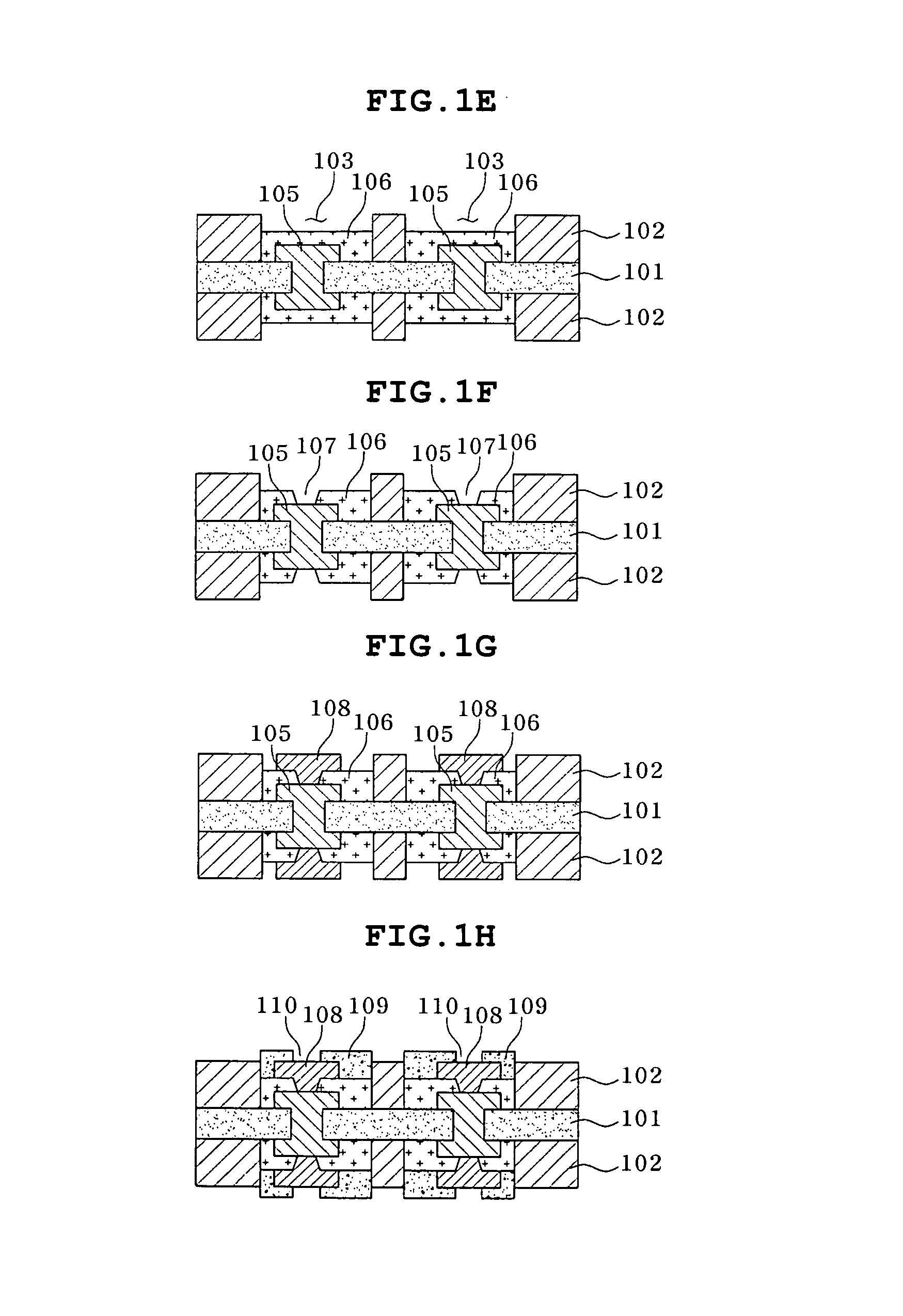

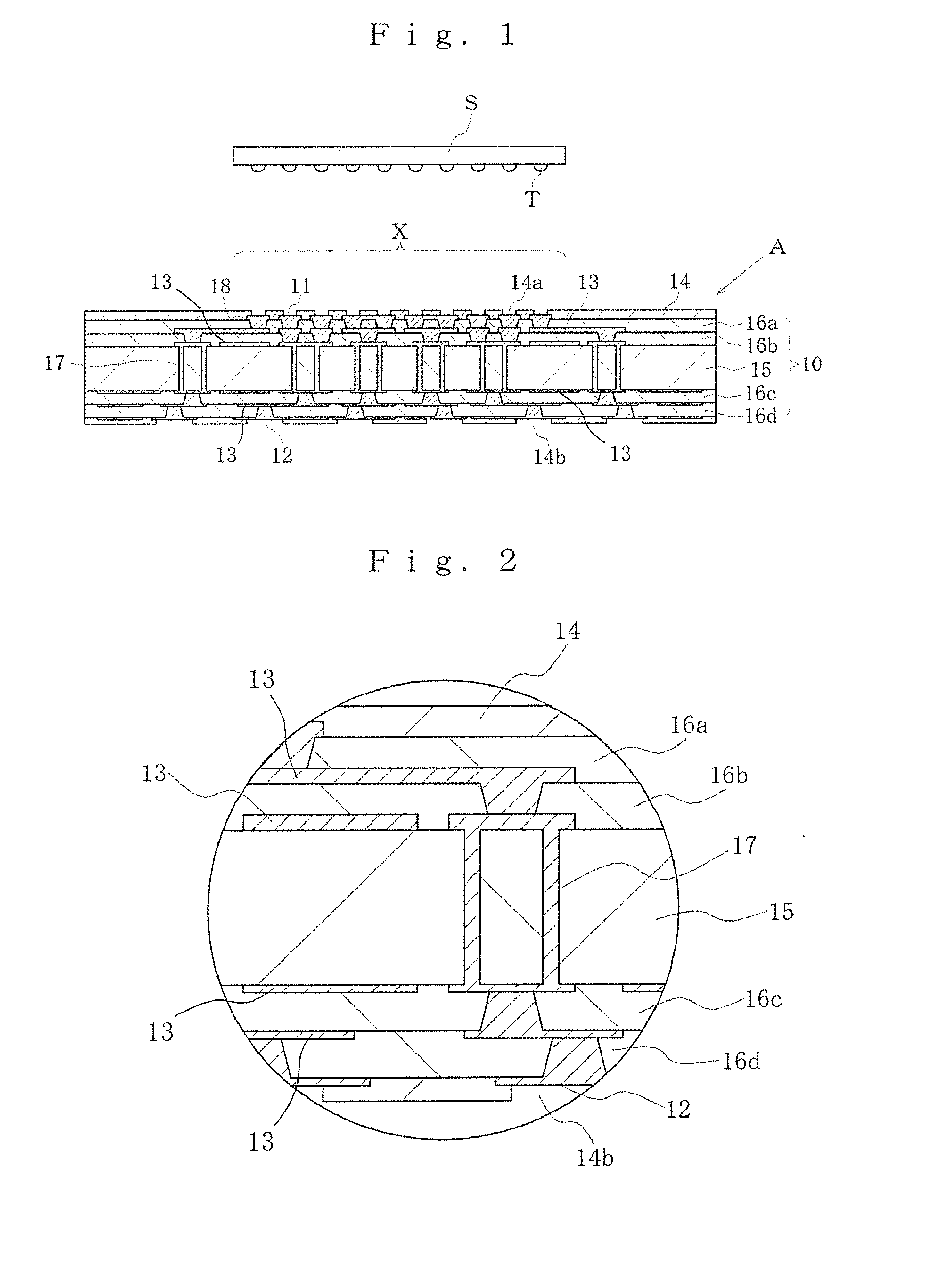

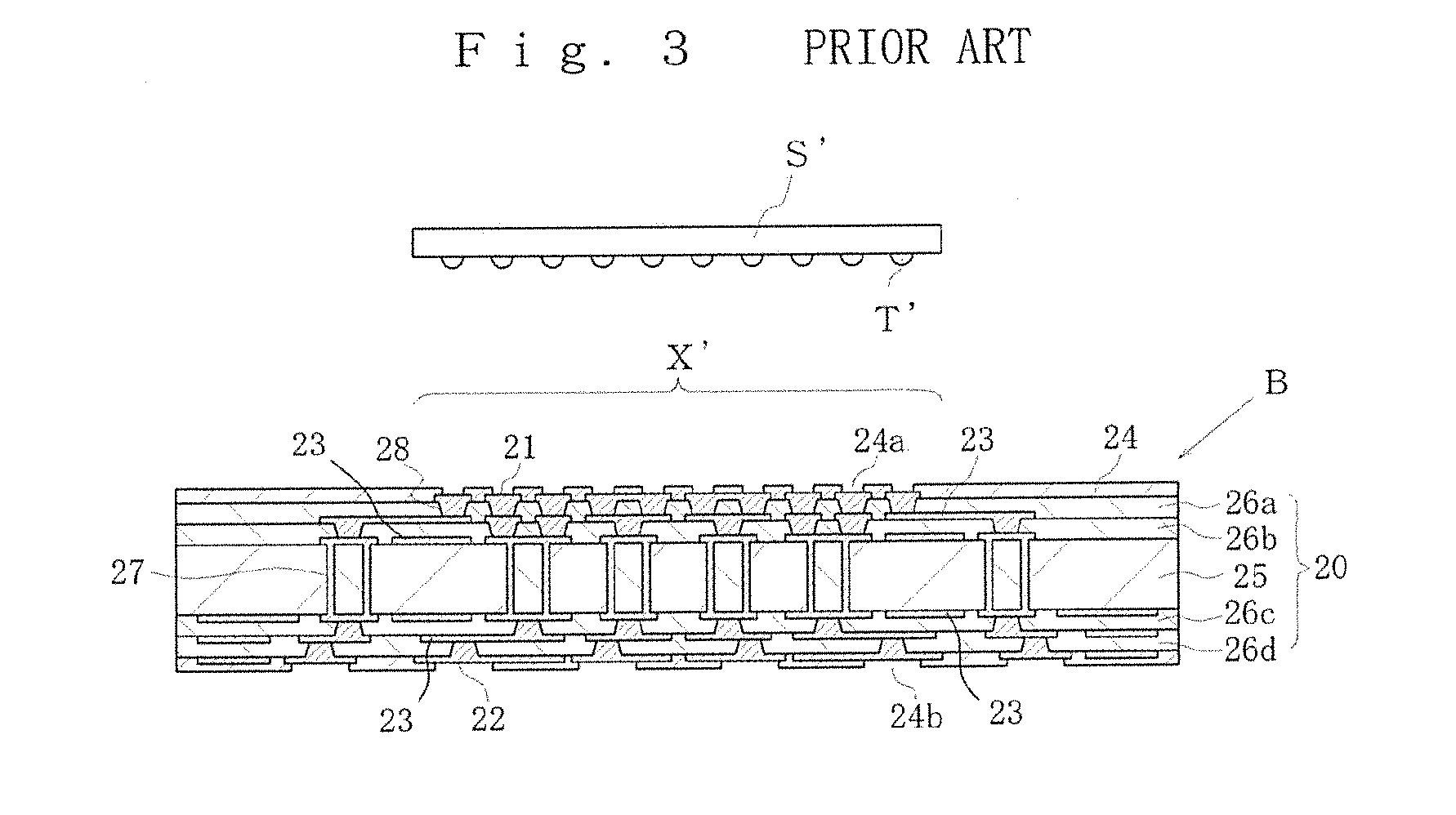

Method for producing all-solid-state battery, and all-solid-state battery

ActiveUS20150188195A1Reduce warpageFew stepsFinal product manufactureElectrode carriers/collectorsAll solid stateEngineering

An objective of the invention is to provide a method for producing an all-solid-state battery with fewer steps for minimizing warping than in the prior art, and an all-solid-state battery with lower warping. This is achieved by a method comprising the steps of: (A) disposing a first electrode active material layer on both sides of a first collector to form a first electrode layer, (B) disposing a solid electrolyte layer on each of the first electrode active material layers, (C) disposing a second electrode active material layer and a second collector on the solid electrolyte layers, in such a manner that the second electrode active material layers contact with the solid electrolyte layers, (D) pressing a stack formed in steps (A) to (C), to form a battery unit, (E) repeating steps (A) to (D) to form a plurality of battery units, and (F) stacking the plurality of battery units.

Owner:TOYOTA JIDOSHA KK

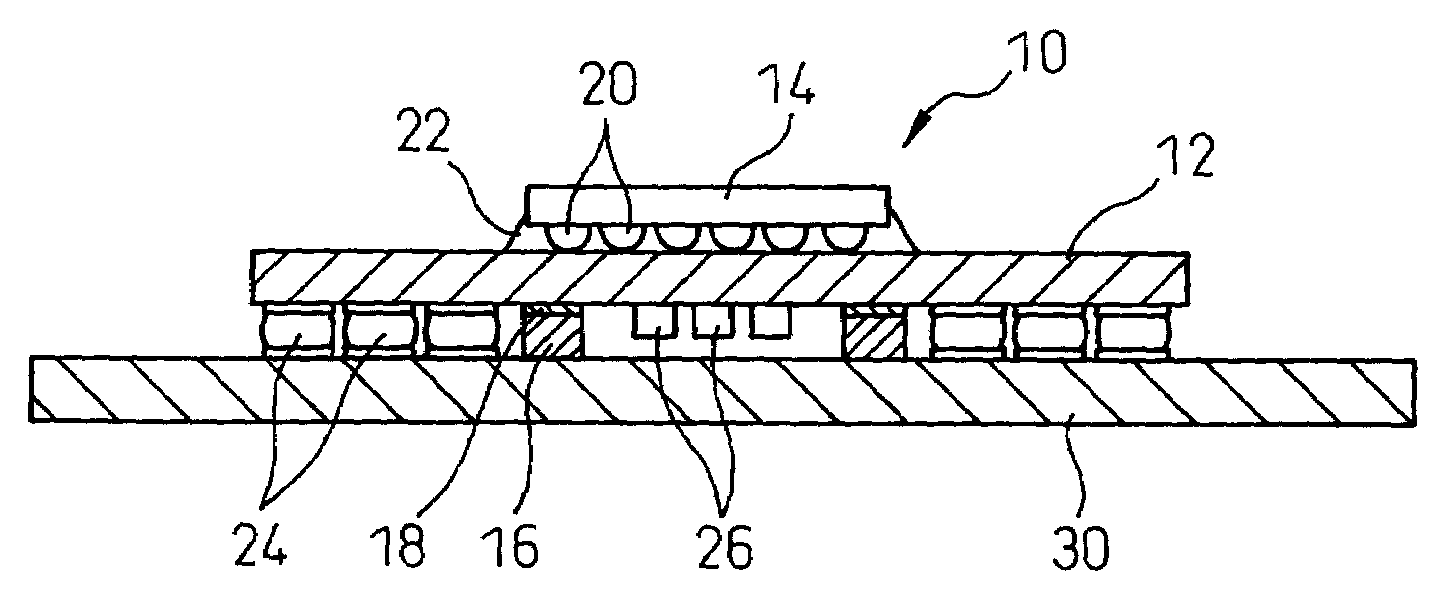

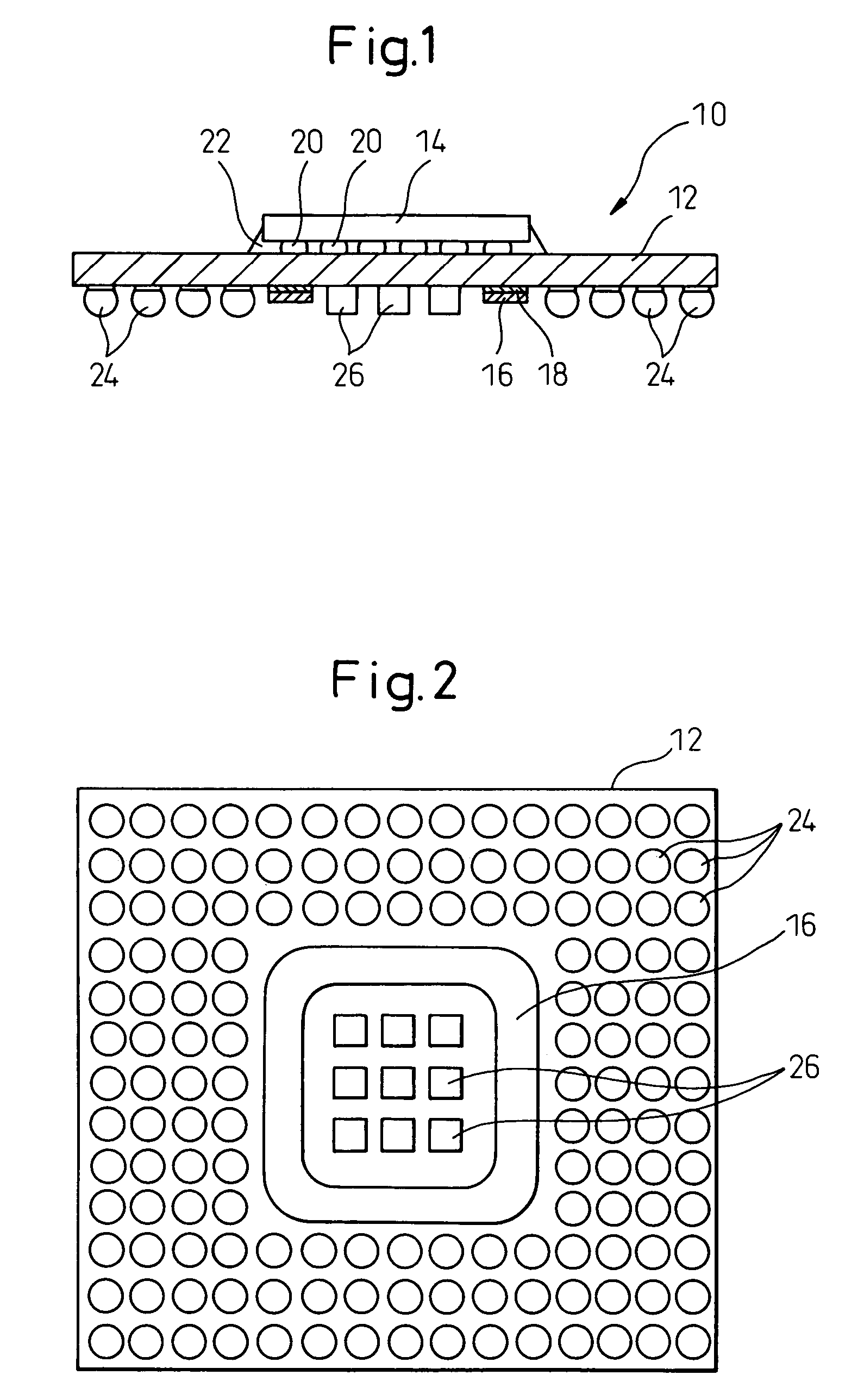

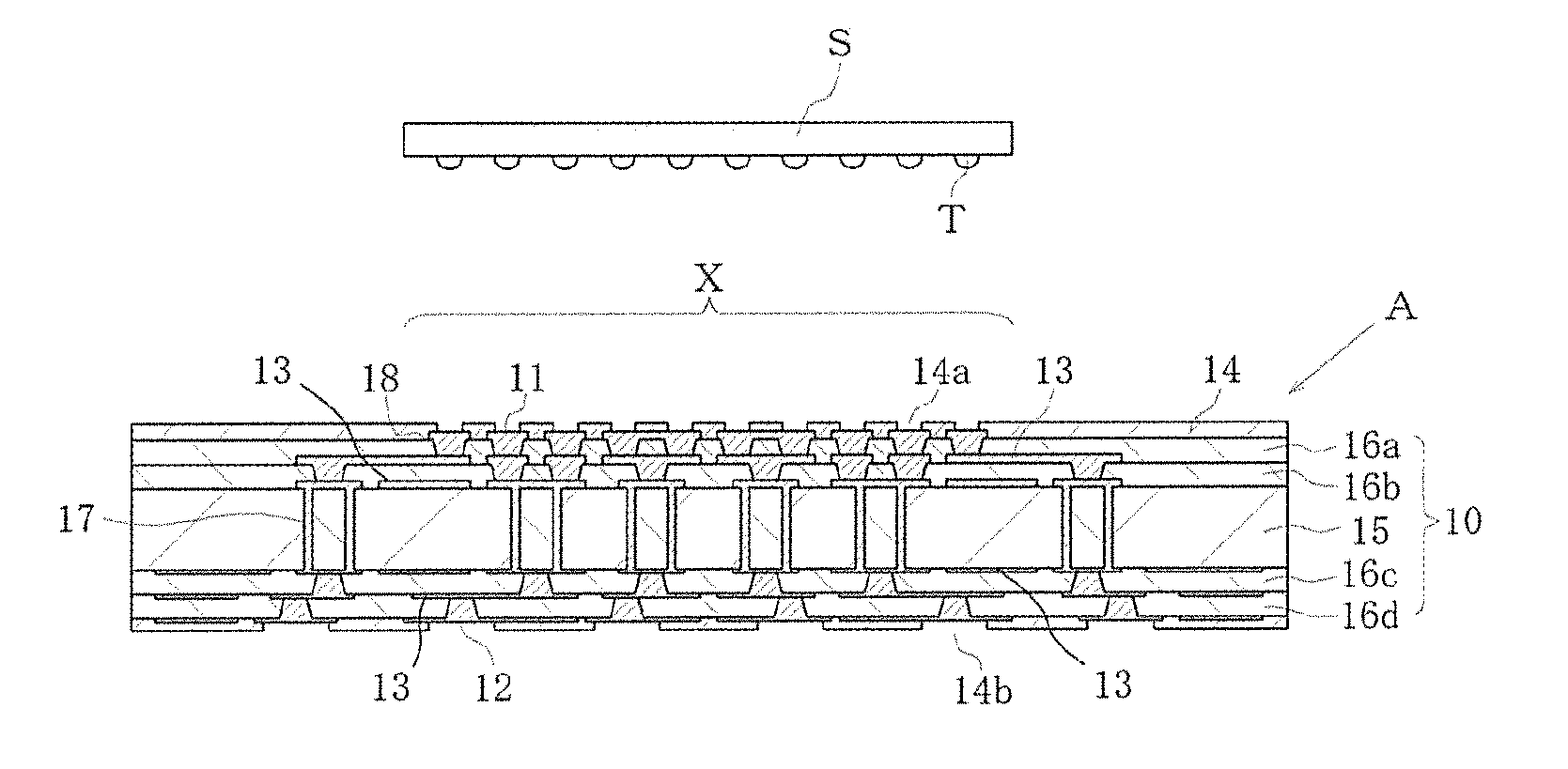

Wiring board and method for manufacturing the same

ActiveUS20090260866A1Structure miniaturizationSimplify the manufacturing processPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

Owner:IMBERATEK LLC

Process and device for manufacturing glass sheet

The present invention relates to a process for manufacturing flat sheets of a glass-based material and to an apparatus therefor. The process comprises providing a glass preform, heating the glass preform in a furnace, forming a gob and a pre-sheet, removing the gob and drawing the glass pre-sheet into a flat glass sheet. Also provided is an apparatus for drawing a glass preform into a glass sheet, the apparatus comprising a draw furnace, stretching arms for stretching and drawing the pre-sheet into a glass sheet, and opposing edge rollers for applying a downward force on the glass sheet. The draw furnace may include a plurality of individual heating elements, the temperature of each heating element capable of being separately controlled. The apparatus may further include an annealing furnace for annealing the glass sheet.

Owner:CORNING INC

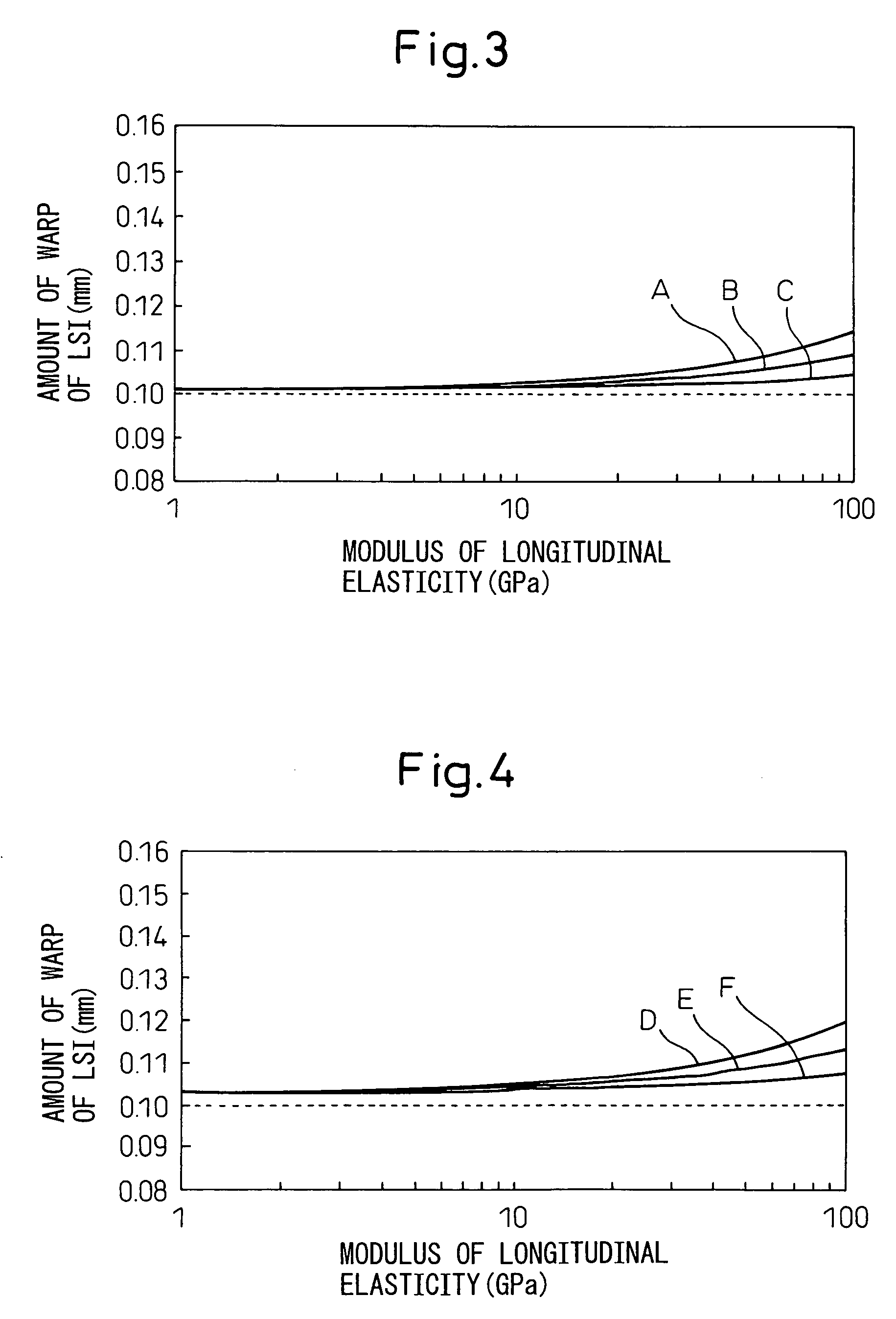

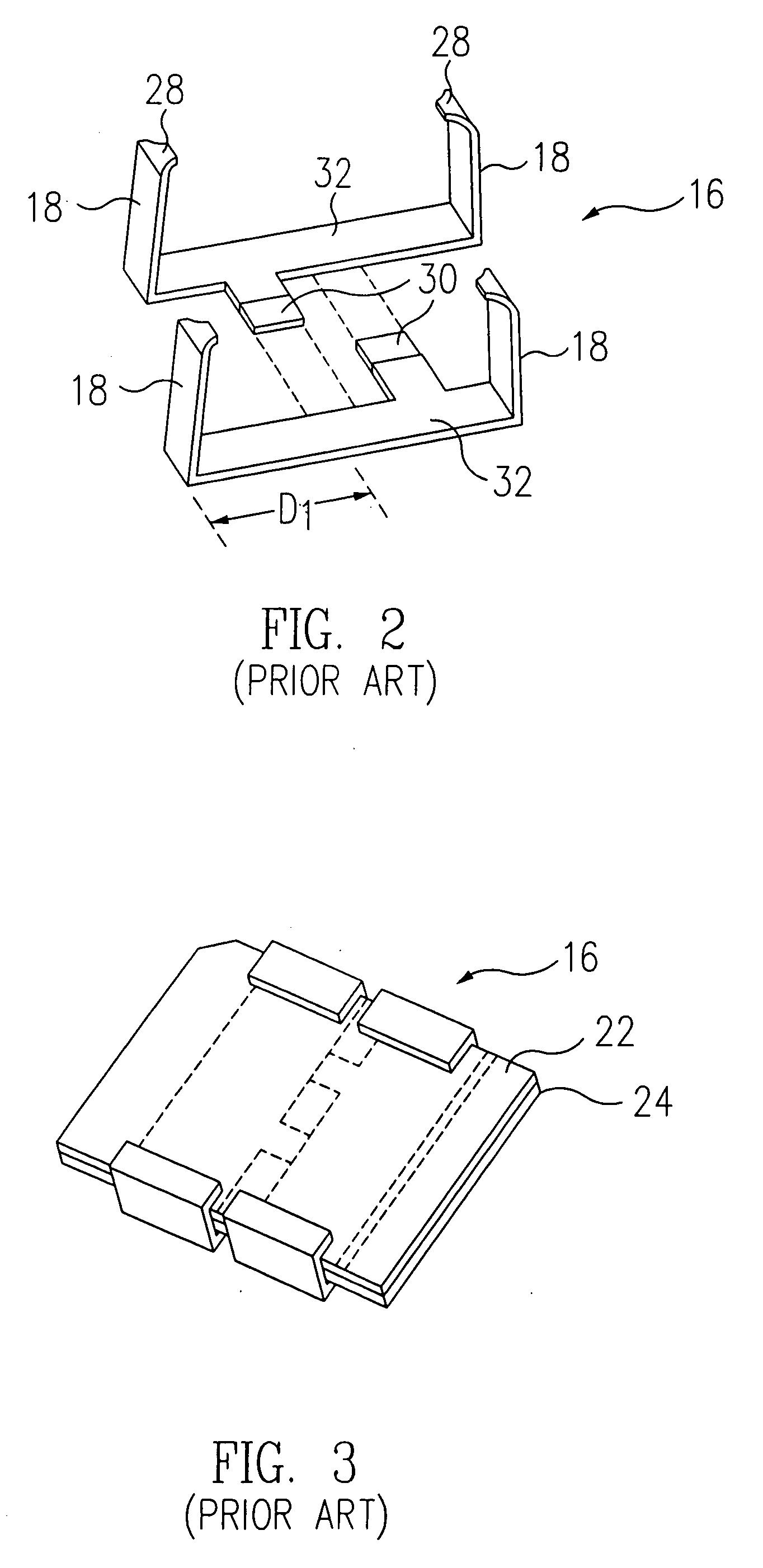

Semiconductor device having stiffener

ActiveUS7053493B2Reduce warpageMinimizes warpFinal product manufactureSemiconductor/solid-state device detailsAdhesiveEngineering

Owner:FUJITSU LTD

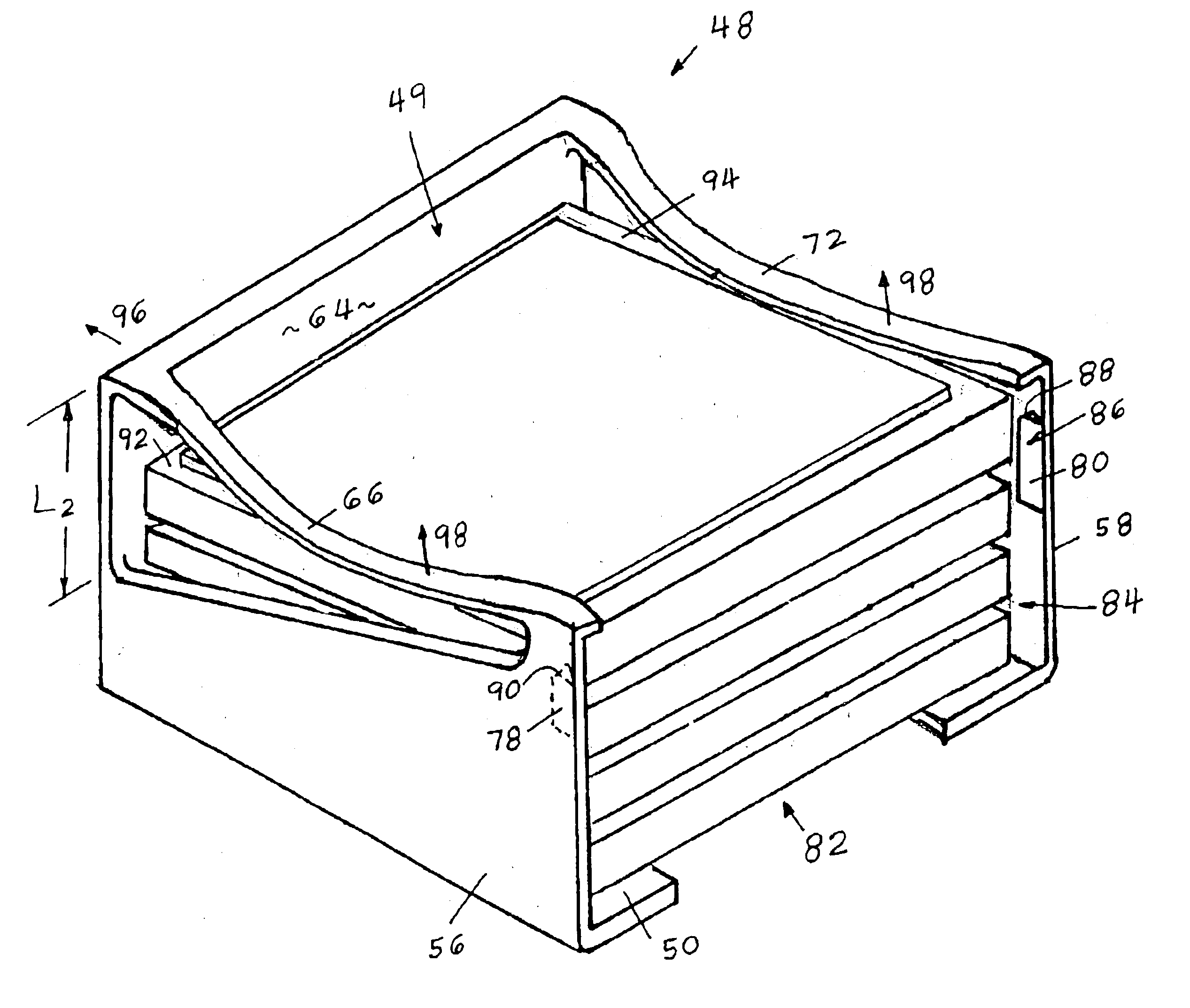

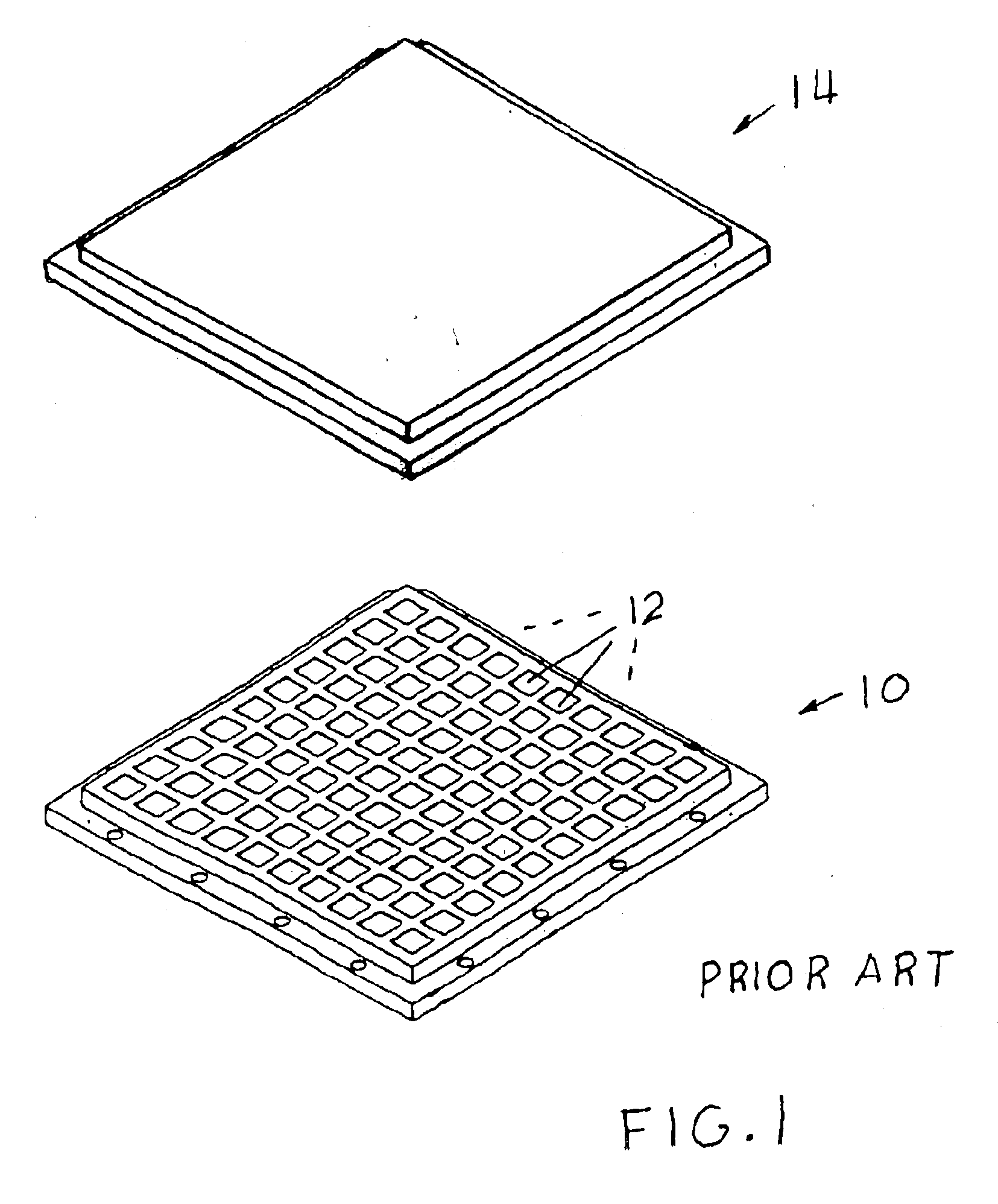

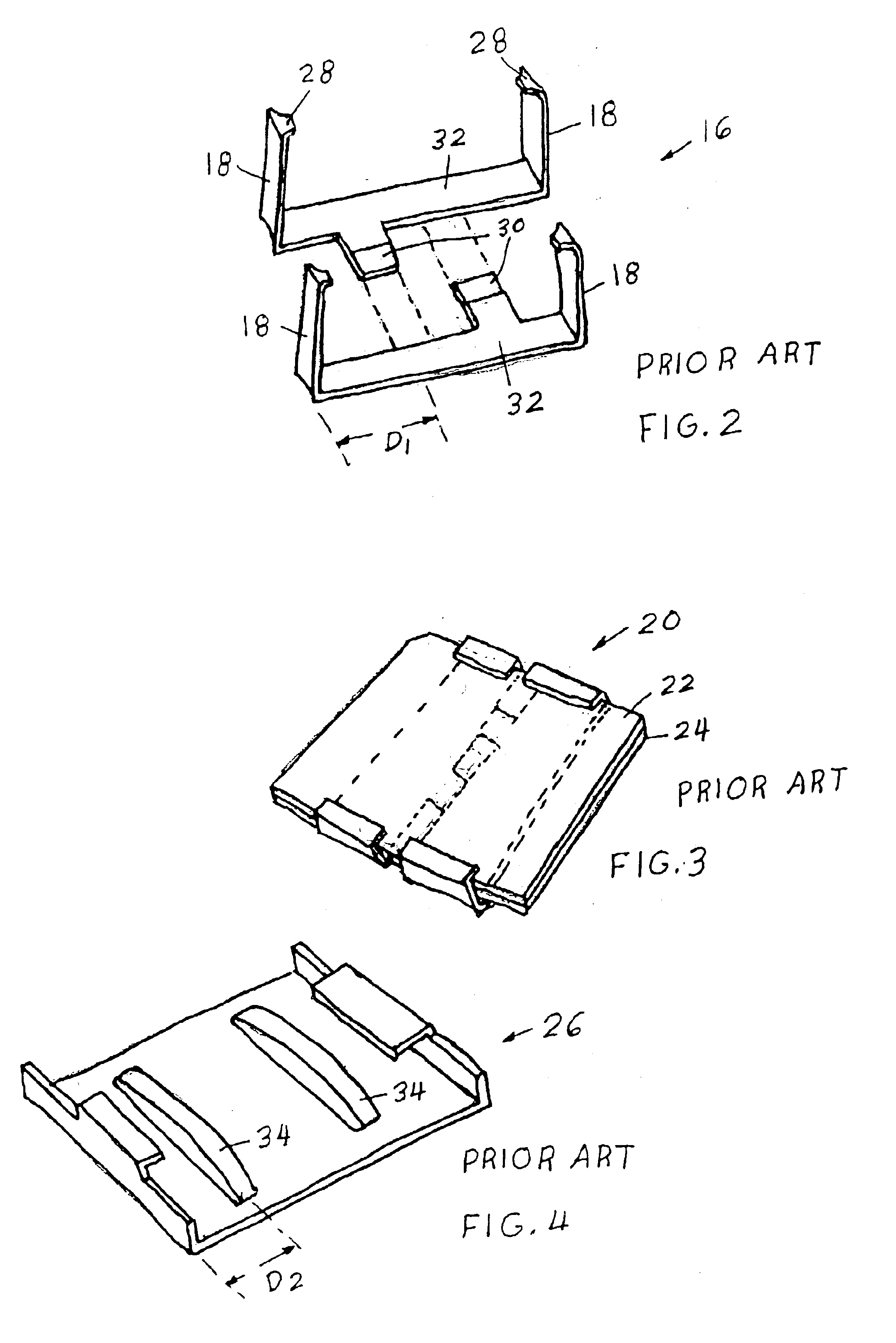

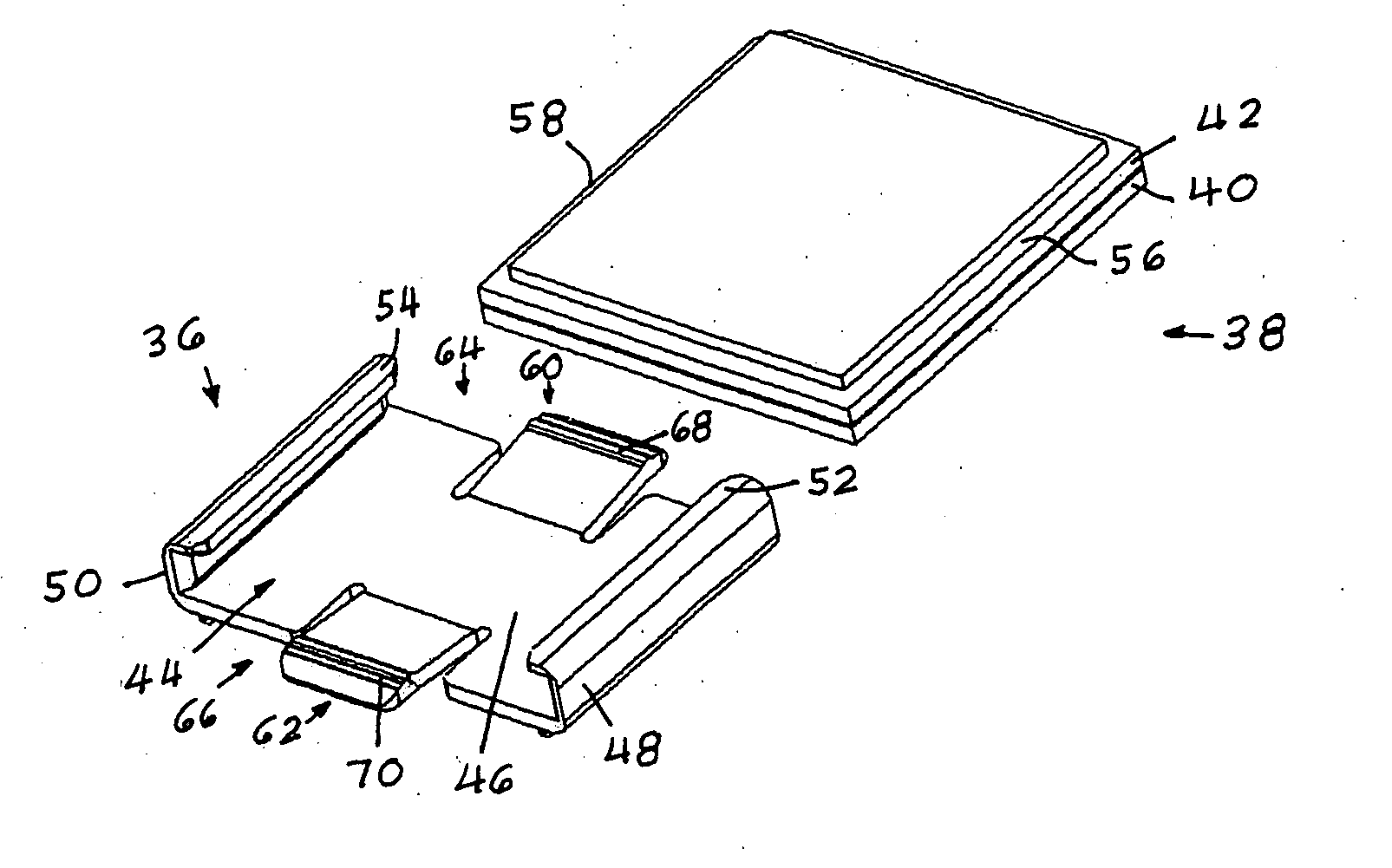

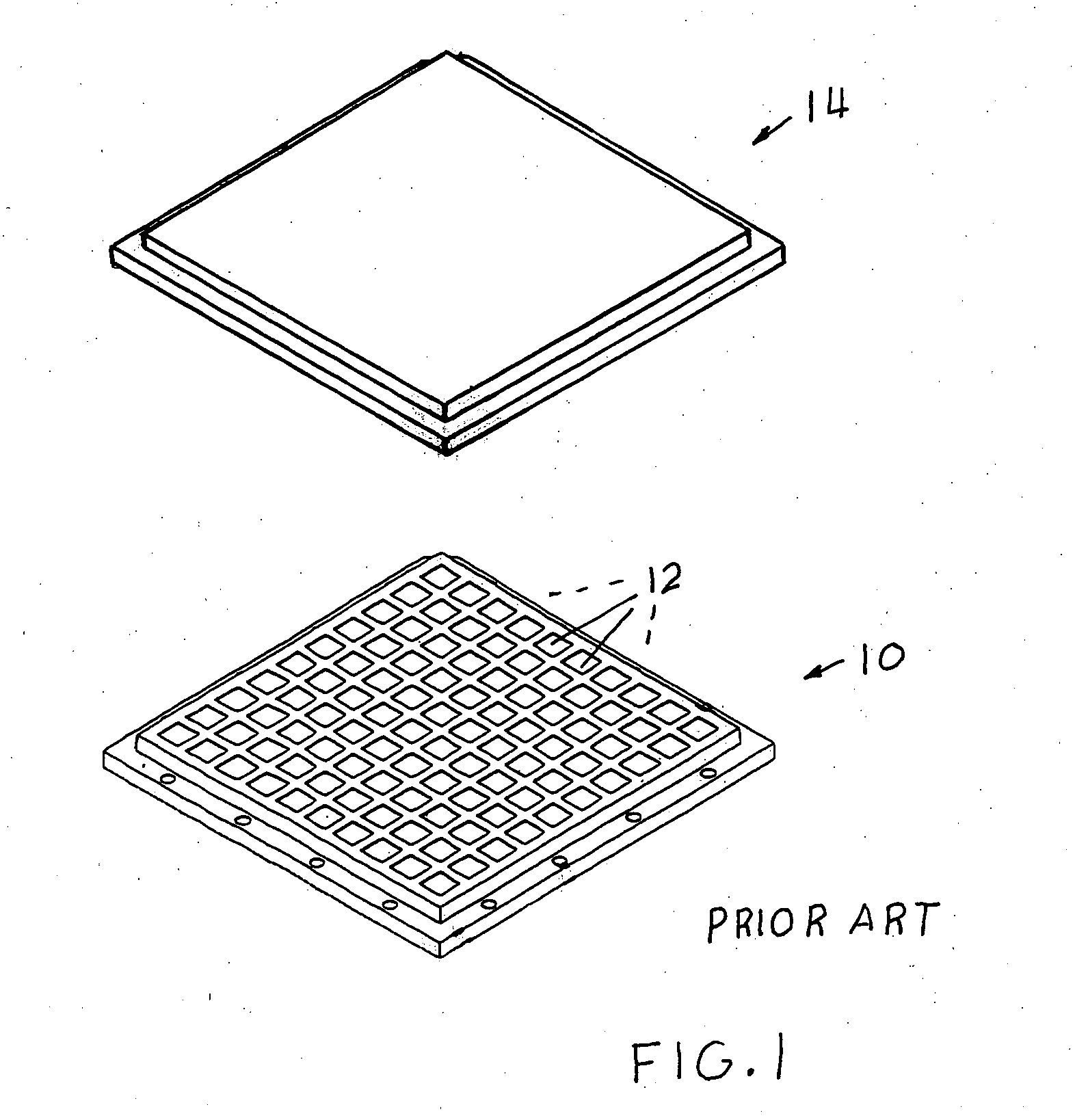

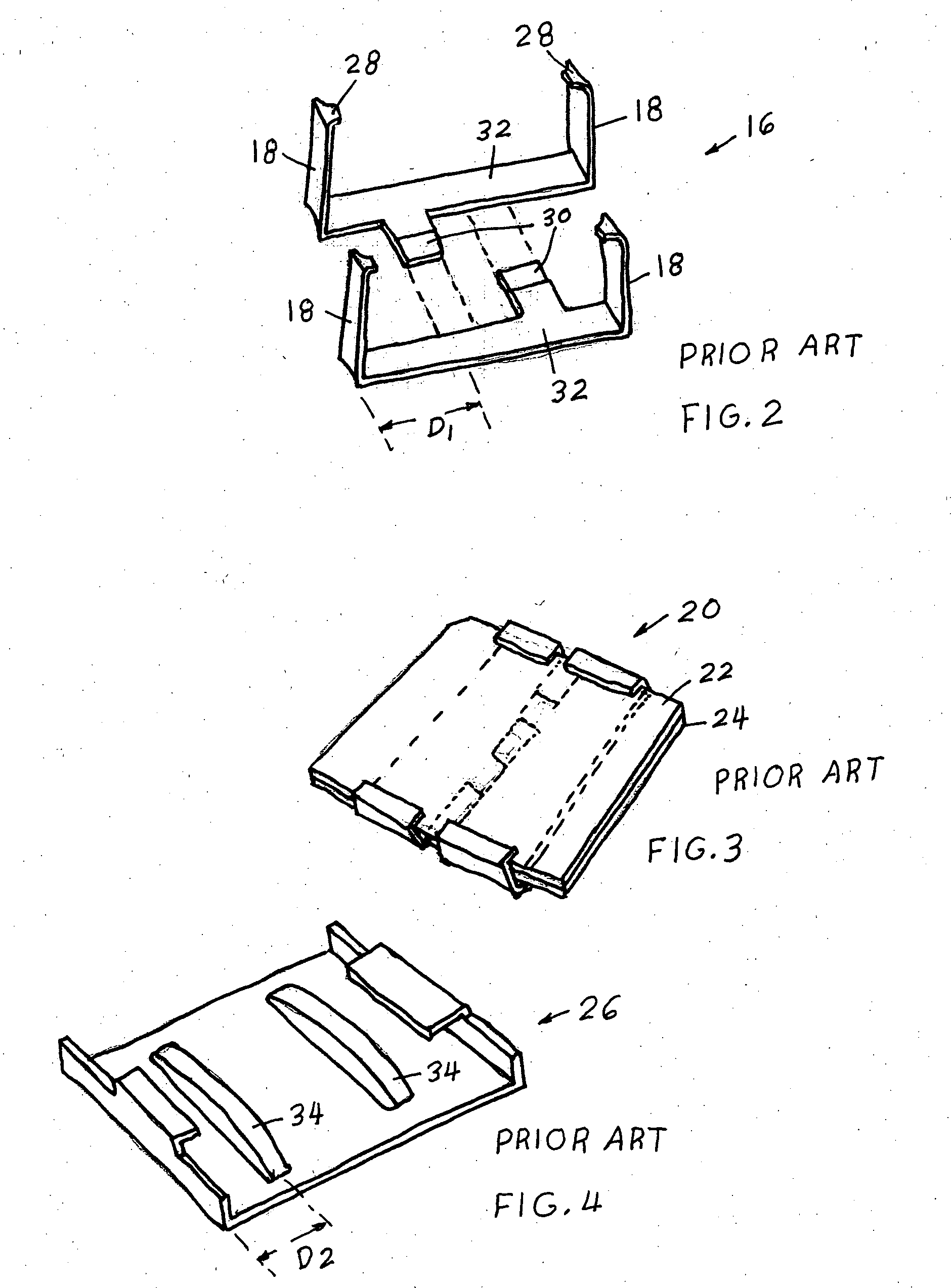

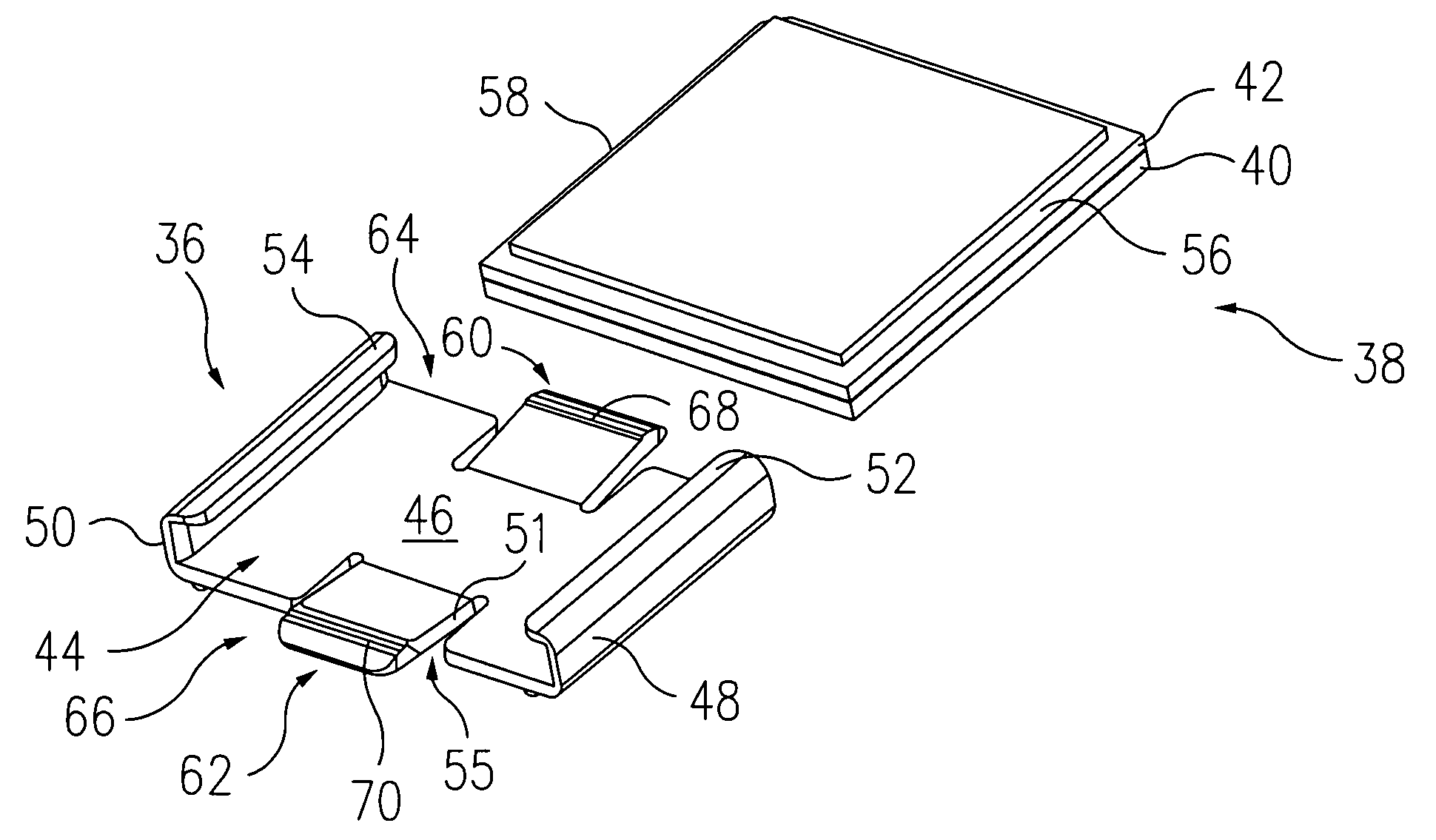

Open frame tray clip

InactiveUS6877194B2Minimizes warpEasy to cutSnap fastenersRecord information storageEngineeringMechanical engineering

A clip is provided for holding a stack of trays and a tray cover. The clip has a base having a width providing clearance for a width of a tray and a cut-away relief area for finger access. First and second opposing resilient side walls and a resilient back wall extend upward from the base, forming a structure with an open front and top. First and second resilient, elongated and downwardly curved members are included, each having a proximal end attached to an upper front of a corresponding side wall, and a distal end attached to the back wall. The resilient members are positioned so as to apply pressure to first and second opposing perimeter portions of a tray placed in the clip.

Owner:PEAK PLASTIC & METAL PRODS INT

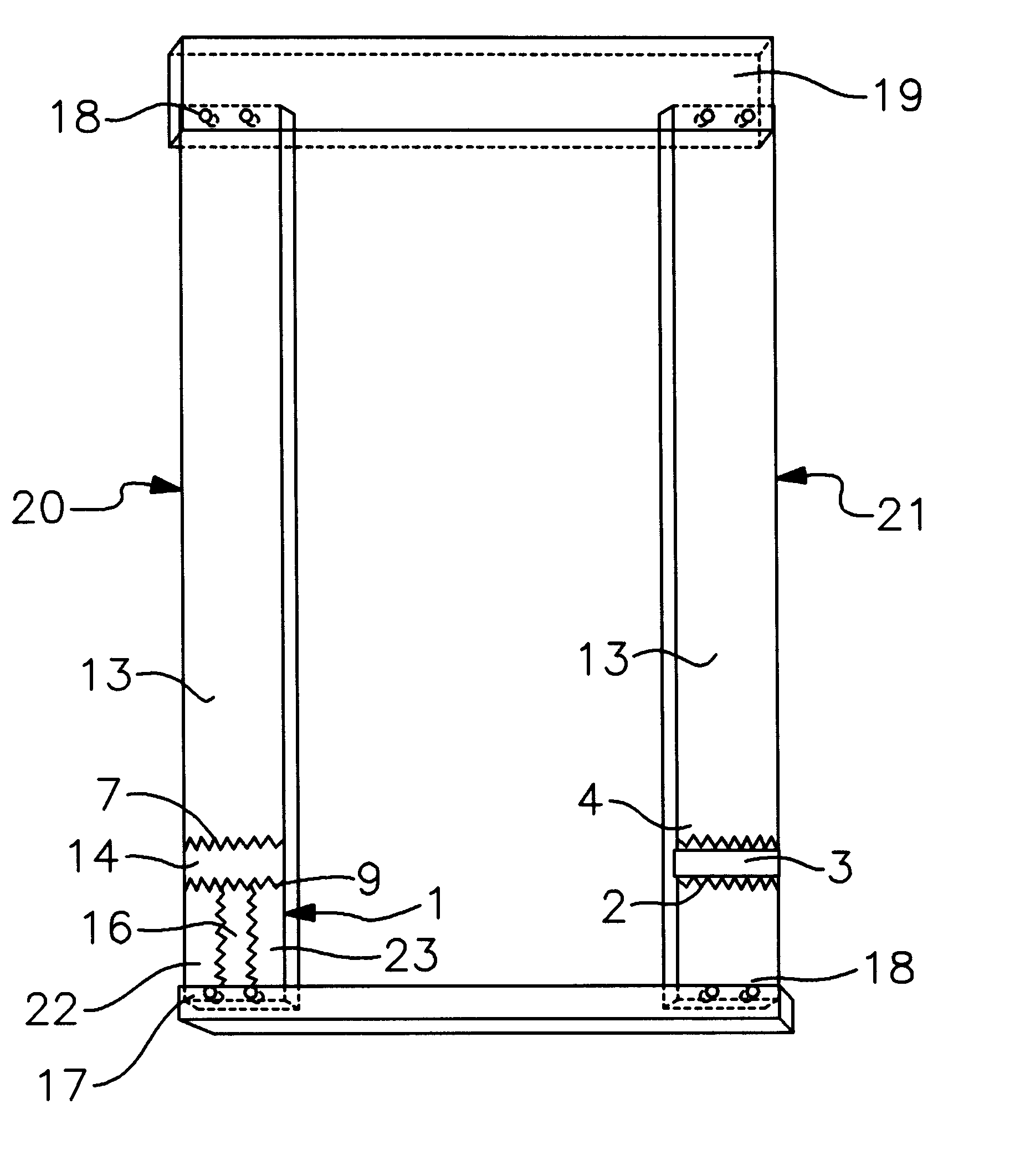

Frame with environment resistant members

A frame for improved moisture, decay and insect resistance includes frame members each possessing a short treated lumber member joined to a longer untreated lumber member so that the length of the overall board achieves a desired length with an acceptable amount of distortion. The untreated member may be treated but the treatment is not so invasive as to impart a high degree of warping. The treated member may have more or less treatment depending on the amount of distortion which is acceptable. Top and bottom boards connect the frame members to form a door frame.

Owner:BARNETT PAUL

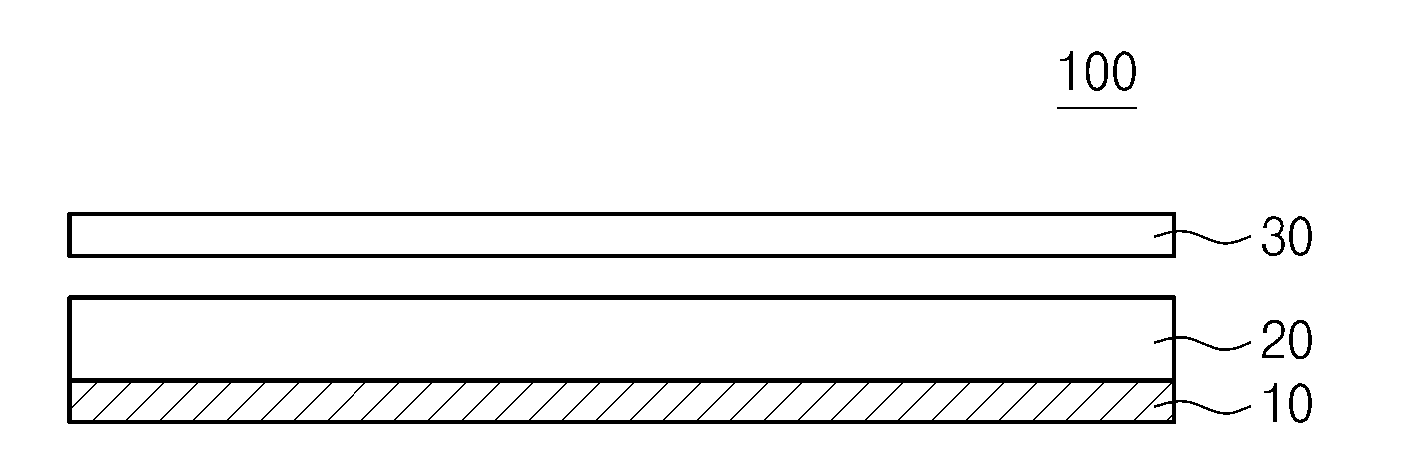

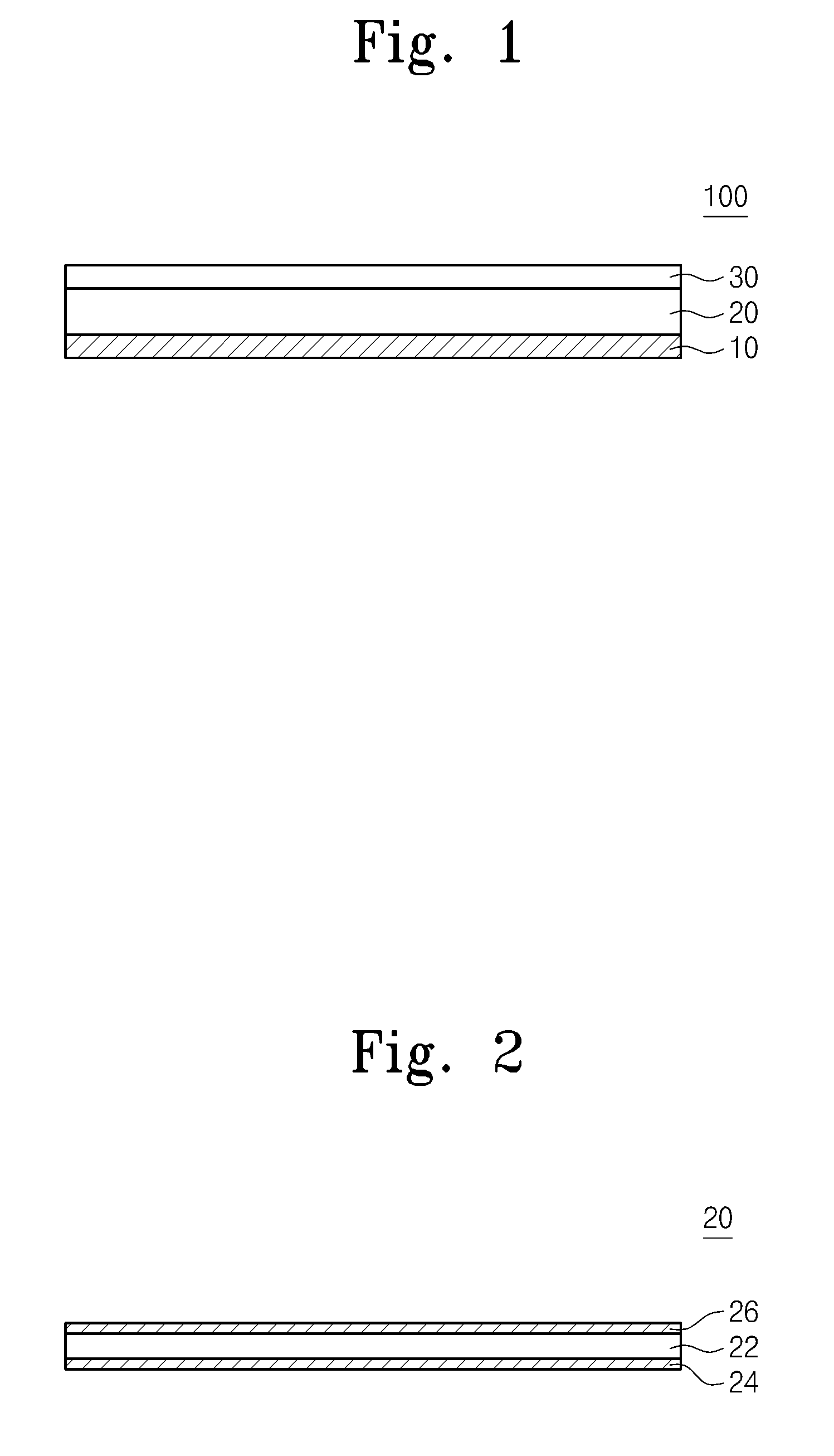

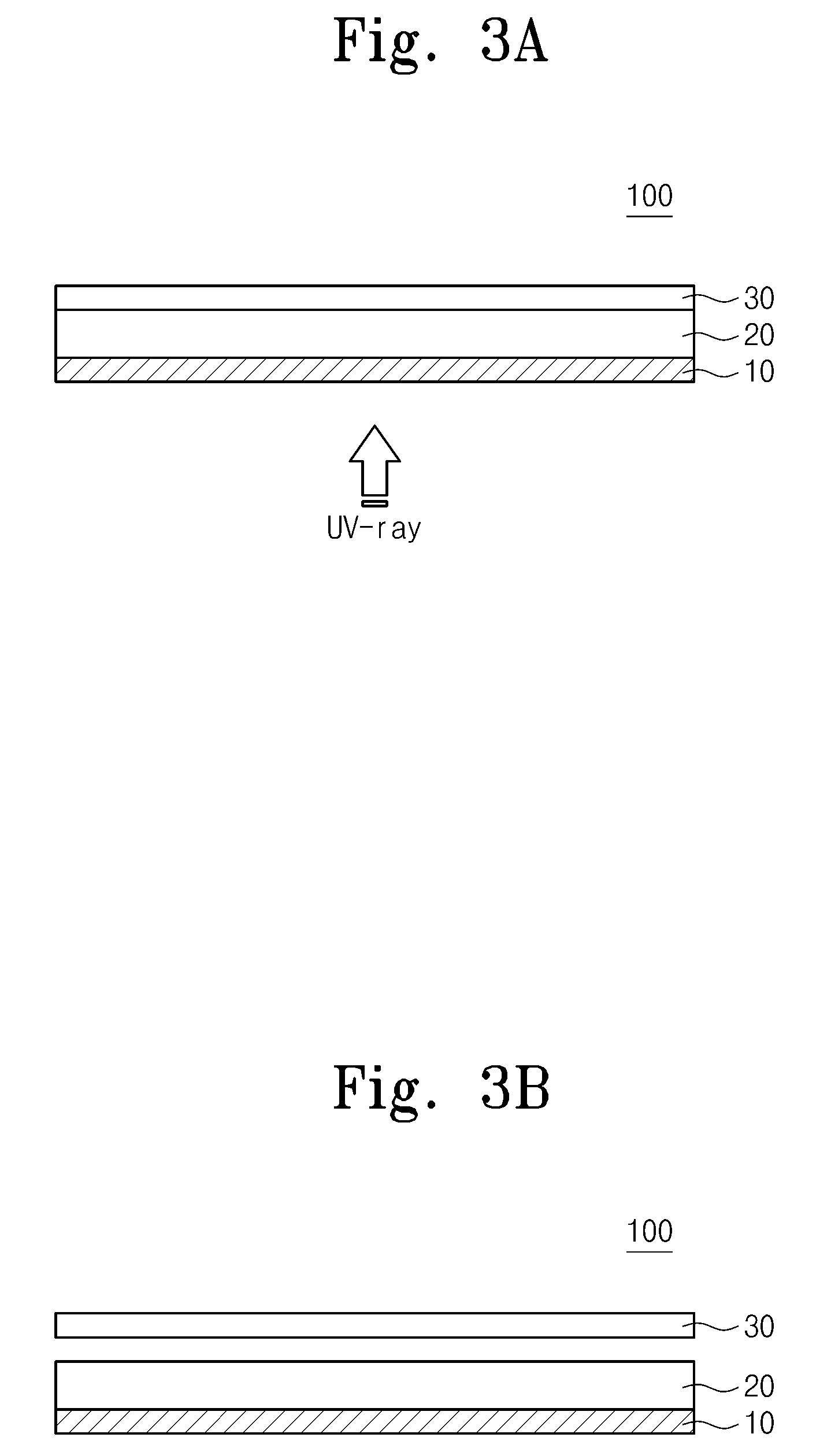

Adhesive film and method of fabricating flexible display using the same

InactiveUS20090038749A1Easy to separateAvoid warpingLamination ancillary operationsFilm/foil adhesivesEngineeringFlexible display

Provided is an adhesive film used for manufacturing a flexible display. The adhesive film includes a support body, a first adhesive layer, and a second adhesive layer. The support body has a first surface and a second surface. A flexible substrate is attached on the first surface. A support substrate is attached on the second surface. The second surface is opposite to the first surface. The first adhesive layer is provided on the first surface of the support body, and the second adhesive layer is provided on the second surface of the support body. The first adhesive layer and the second adhesive layer have the same adhesive strength.

Owner:ELECTRONICS & TELECOMM RES INST

Preparation of photomask blank and photomask

Owner:SHIN ETSU CHEM IND CO LTD

Method for producing all-solid-state battery, and all-solid-state battery

ActiveUS9634358B2Reduce warpageFew stepsCell electrodesSecondary cells testingState of artAll solid state

An objective of the invention is to provide a method for producing an all-solid-state battery with fewer steps for minimizing warping than in the prior art, and an all-solid-state battery with lower warping. This is achieved by a method comprising the steps of: (A) disposing a first electrode active material layer on both sides of a first collector to form a first electrode layer, (B) disposing a solid electrolyte layer on each of the first electrode active material layers, (C) disposing a second electrode active material layer and a second collector on the solid electrolyte layers, in such a manner that the second electrode active material layers contact with the solid electrolyte layers, (D) pressing a stack formed in steps (A) to (C), to form a battery unit, (E) repeating steps (A) to (D) to form a plurality of battery units, and (F) stacking the plurality of battery units.

Owner:TOYOTA JIDOSHA KK

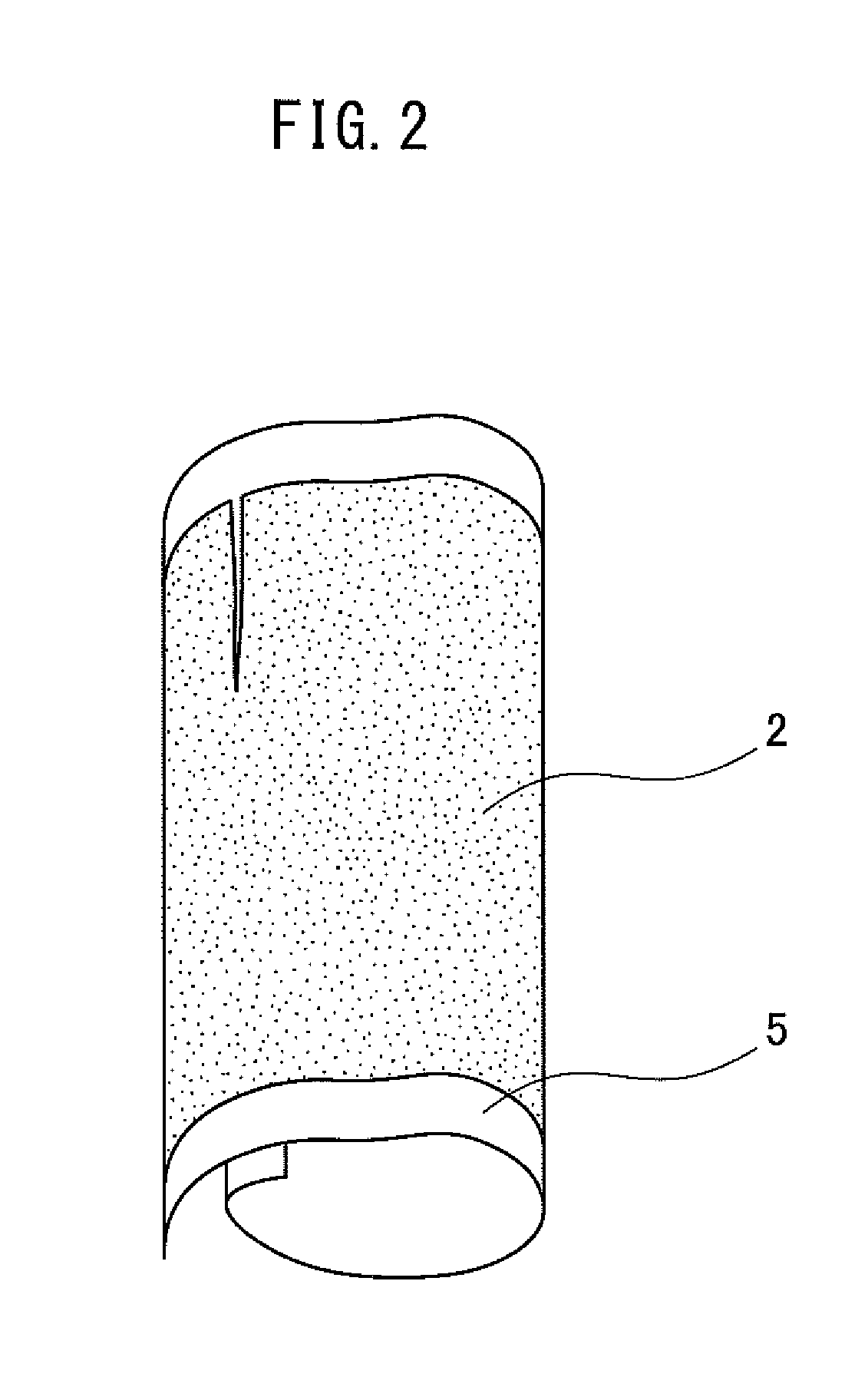

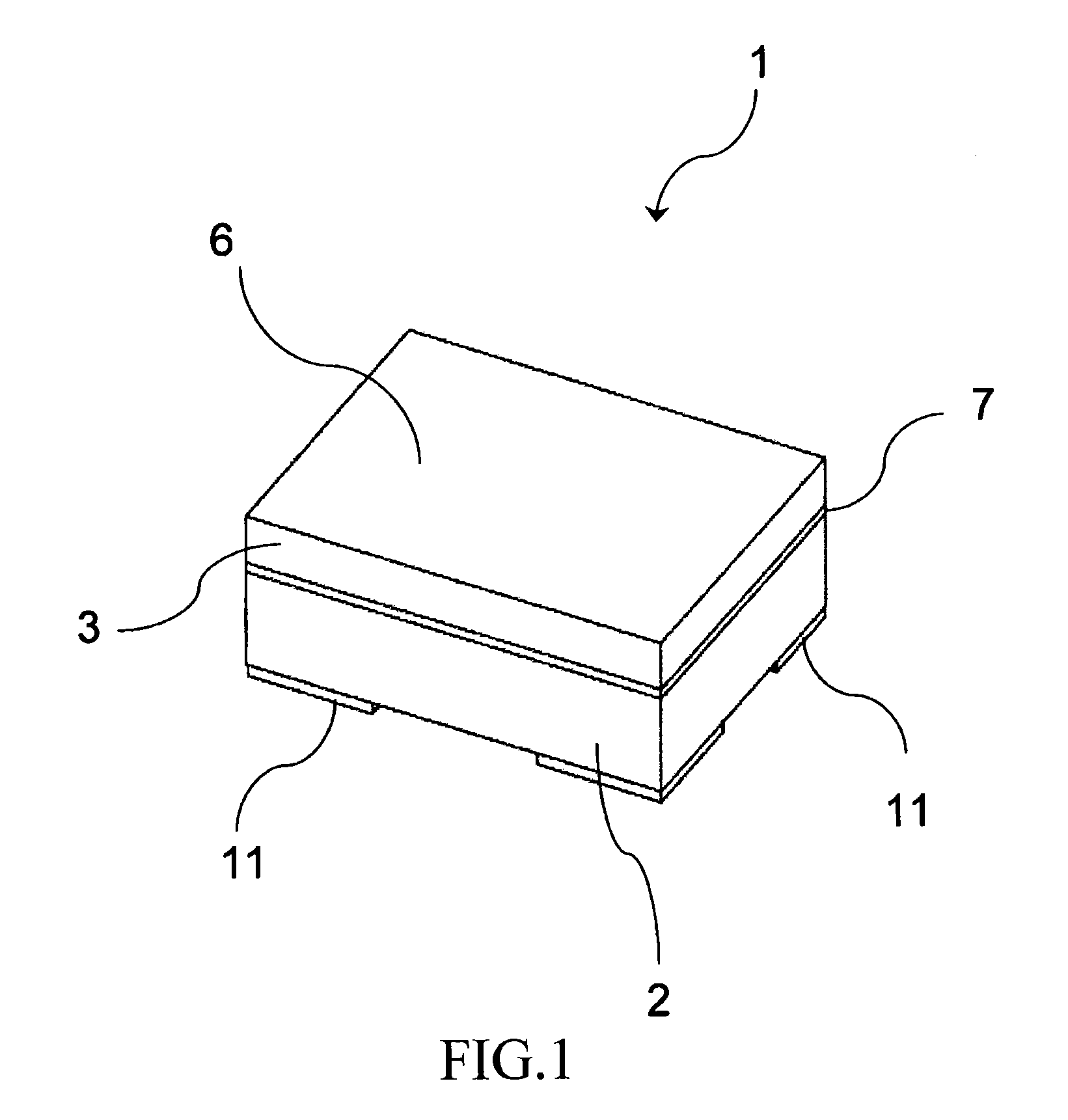

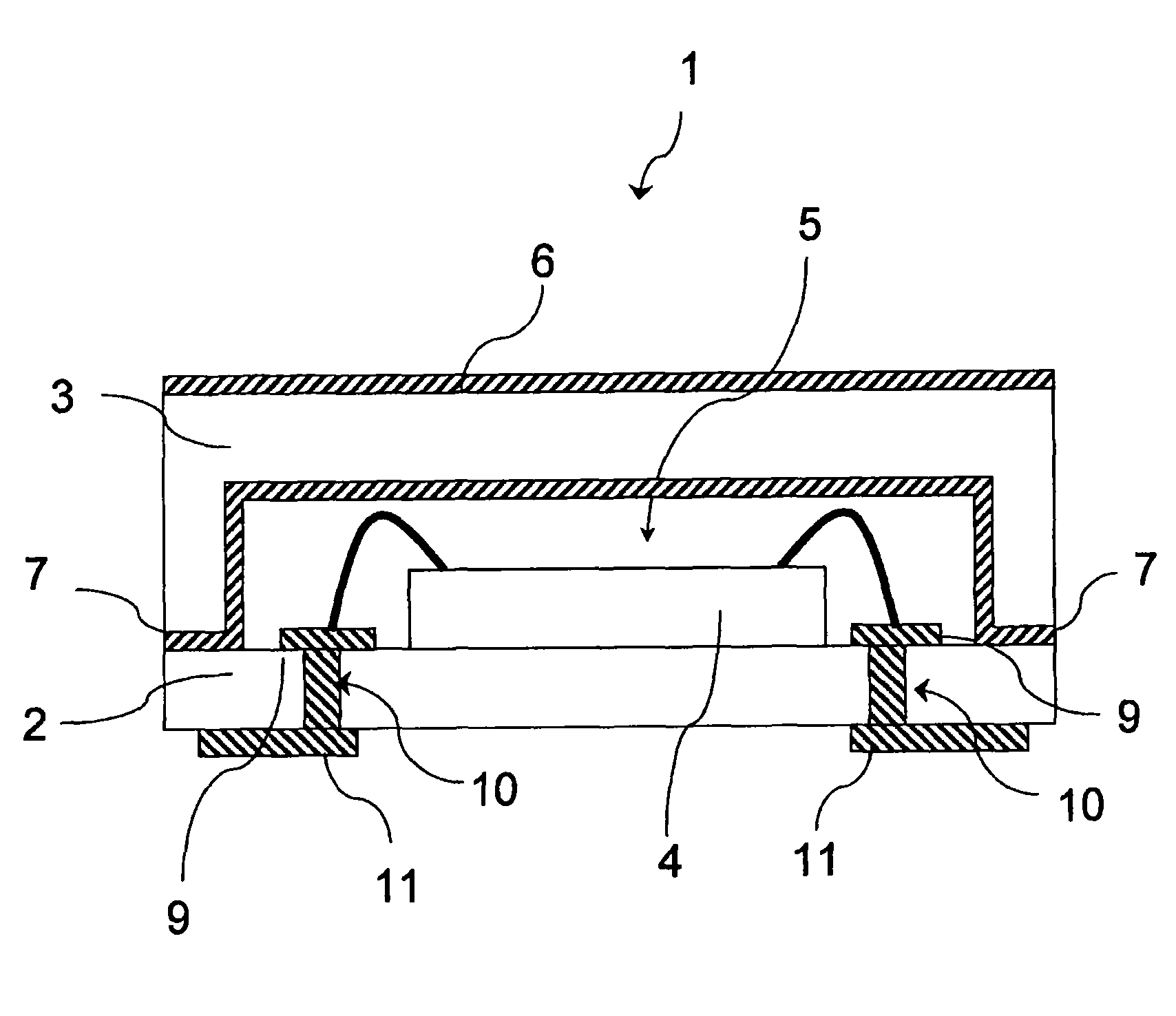

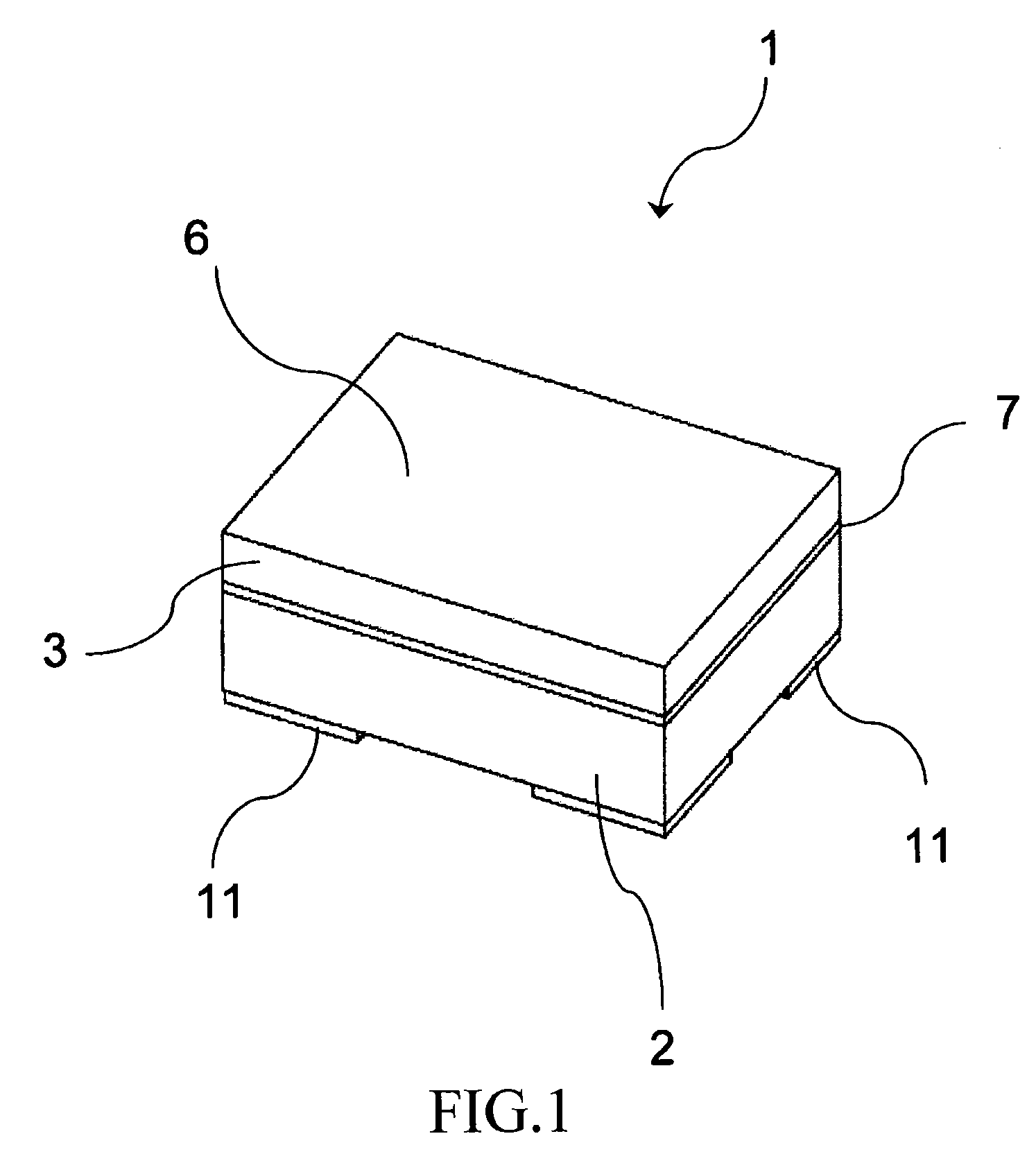

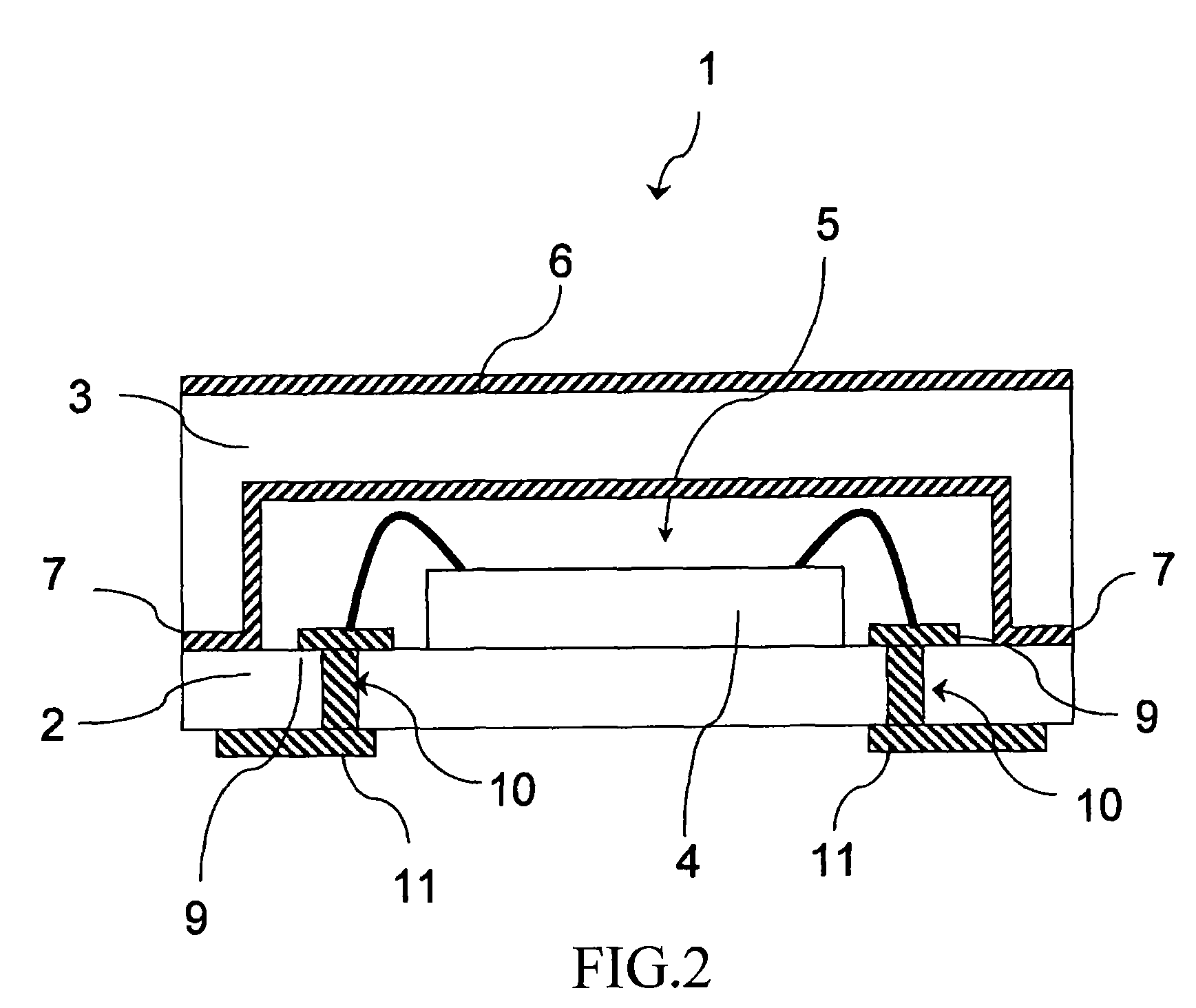

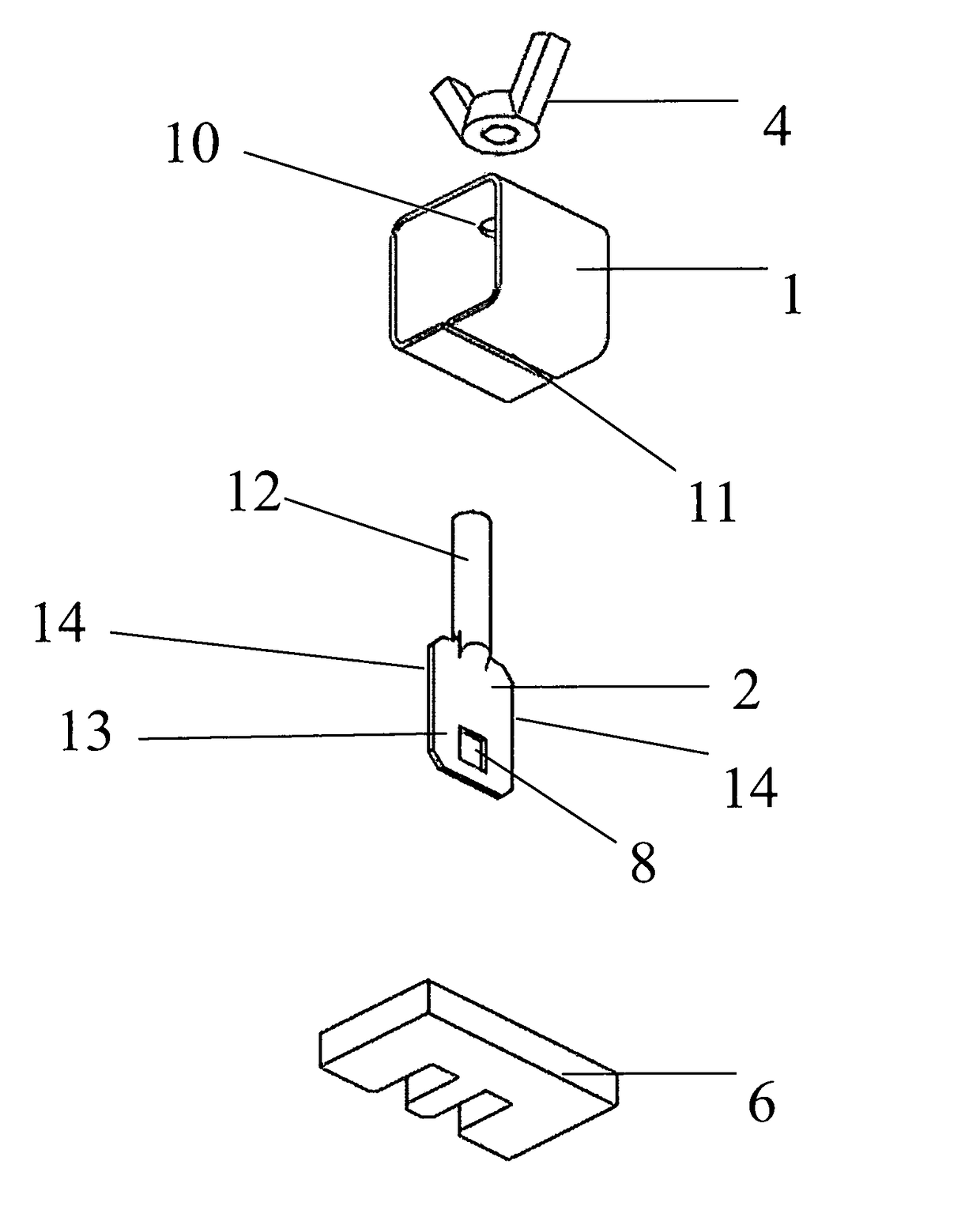

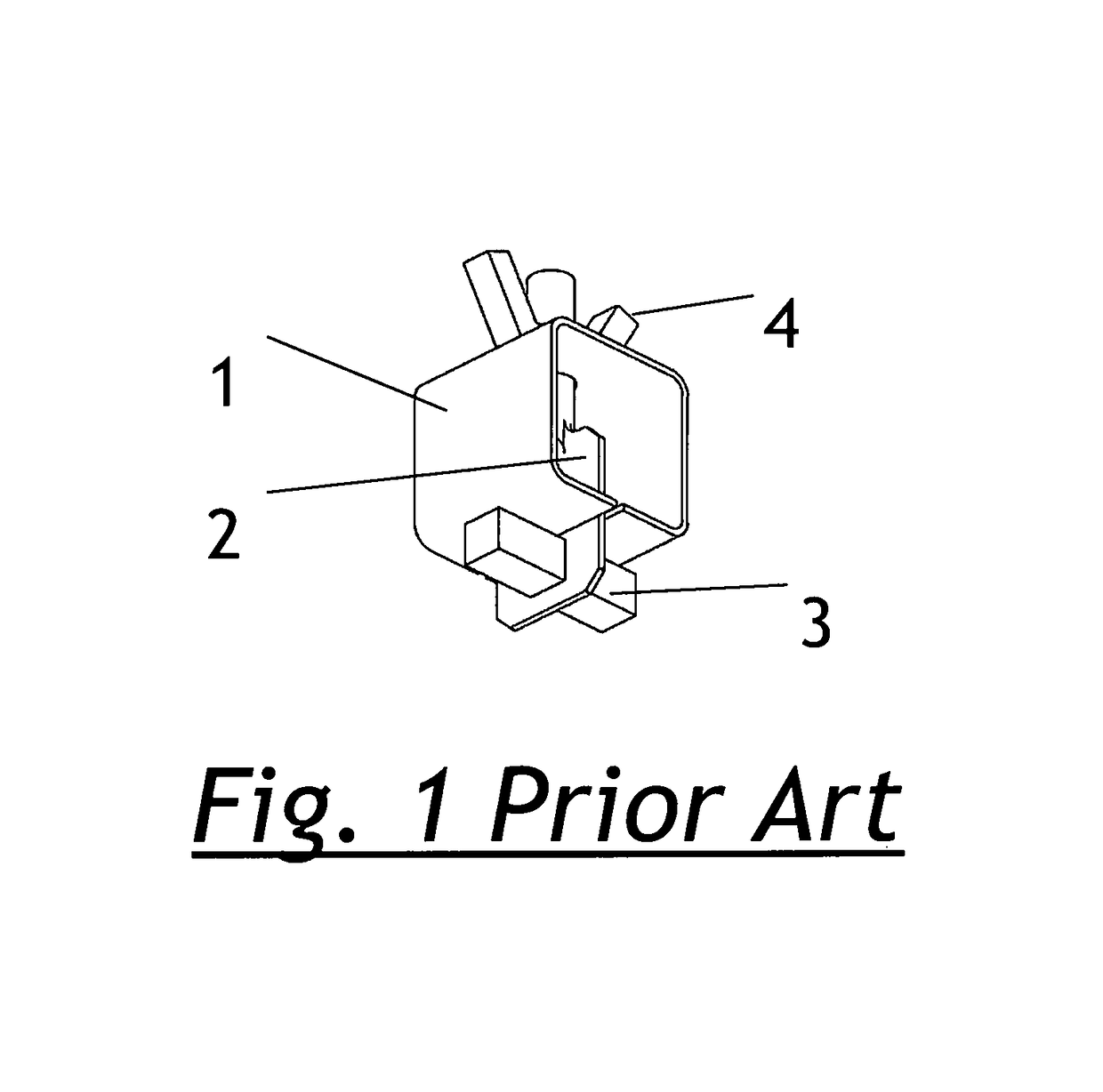

Manufacturing method of electronic device package, electronic device package, and oscillator

ActiveUS20110233694A1Avoid warpingMinimizes warpTransducer detailsImpedence networksMetallurgyOscillistor

A manufacturing method of an electronic device package includes: forming concave portions that later form the cavities in one surface of a cover substrate; forming a first metal film on the cover substrate on a surface opposite to the surface in which the concave portions are formed; forming a second metal film on the cover substrate on the surface in which the concave portions are formed; bonding a base substrate and the cover substrate together via the second metal film. It thus becomes possible to provide an electronic device package in which the base substrate and the cover substrate are boned together via the metal film in a stable manner by minimizing warping of the substrate even when the substrate is made thinner.

Owner:SEIKO INSTR INC

Method of manufacturing printed circuit board

InactiveUS20080184558A1RigidityMinimizes warpPrinted circuit assemblingElectrically conductive connectionsPrinted circuit boardProduct Part

This invention relates to a method of manufacturing a printed circuit board, in which a dummy metal frame enclosing the outer periphery of a product part is formed, thus simultaneously assuring the rigidity of the printed circuit board and minimizing the warping thereof thanks to the dummy metal frame left in place on a finished product, thereby realizing a structure compatible with conventional flip chip mounting lines.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

High-voltage semiconductor device

Owner:FUJI ELECTRIC CO LTD

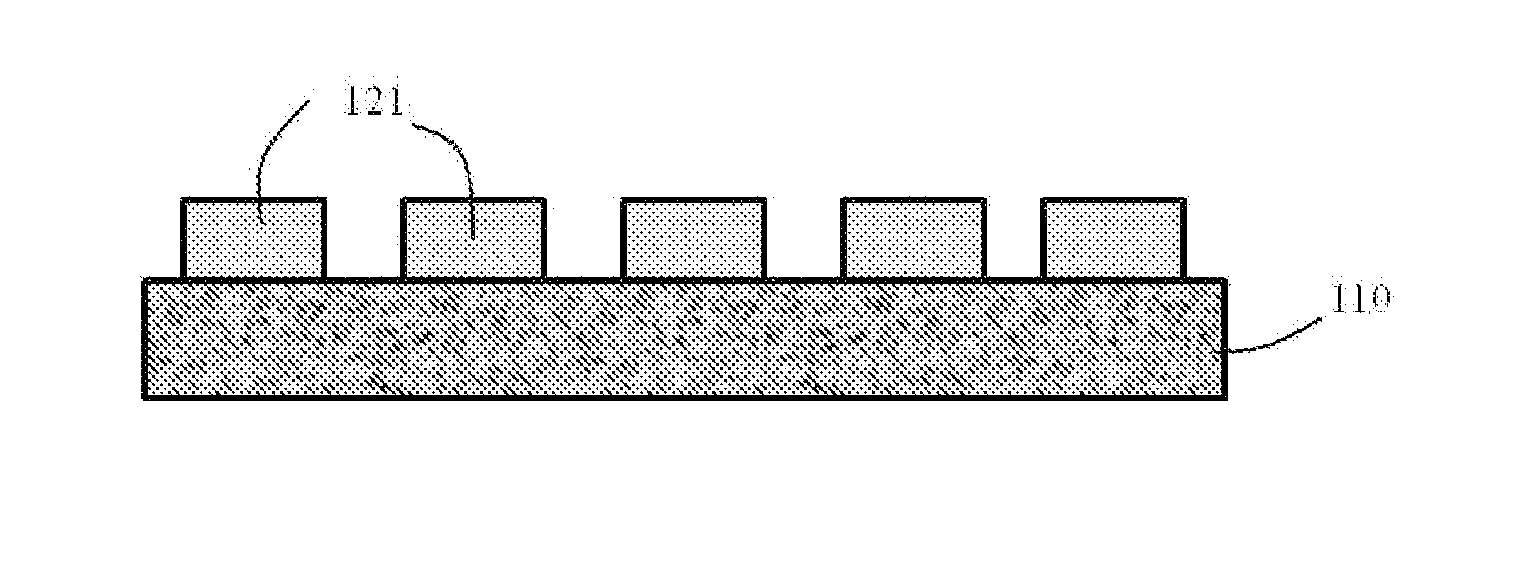

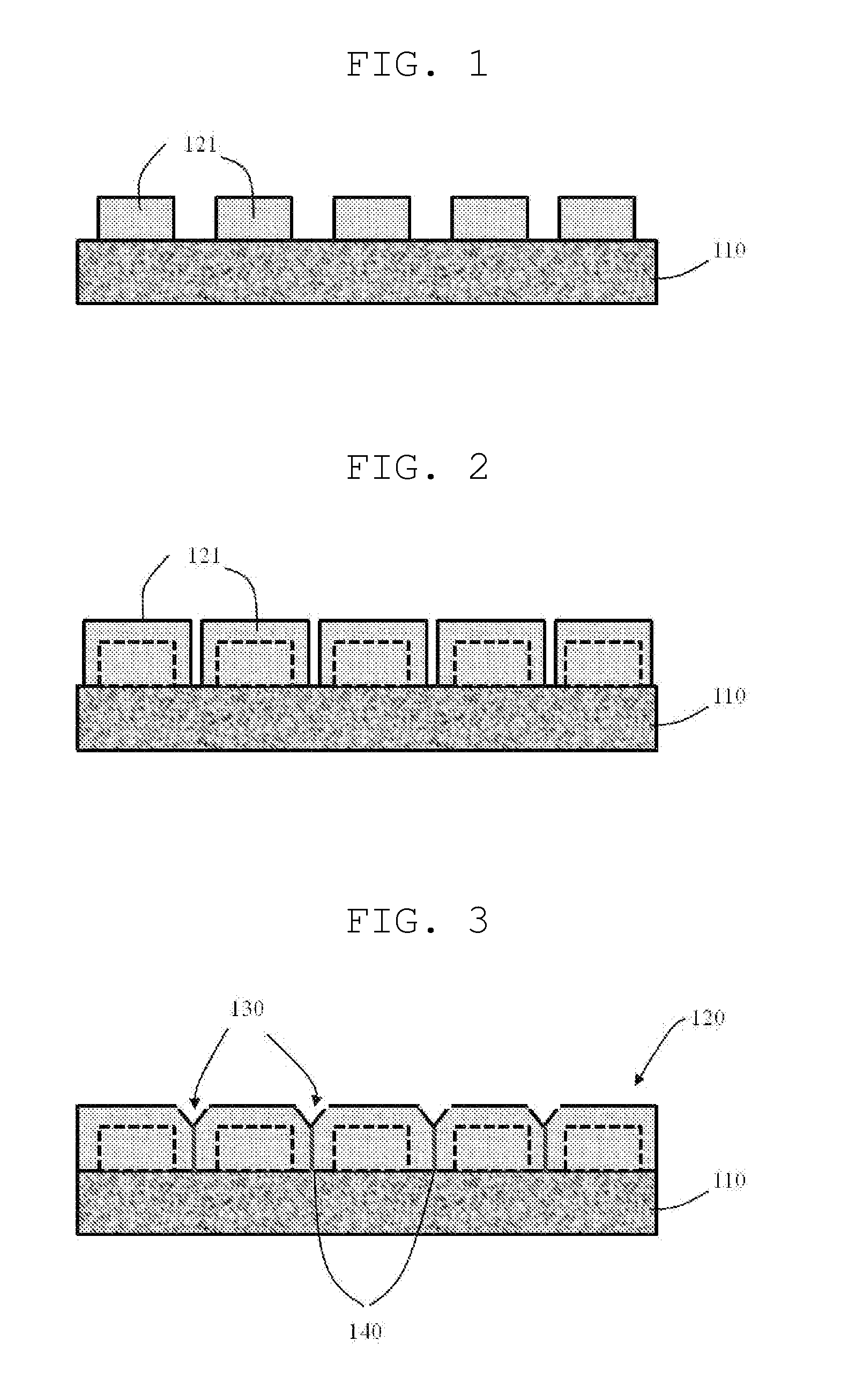

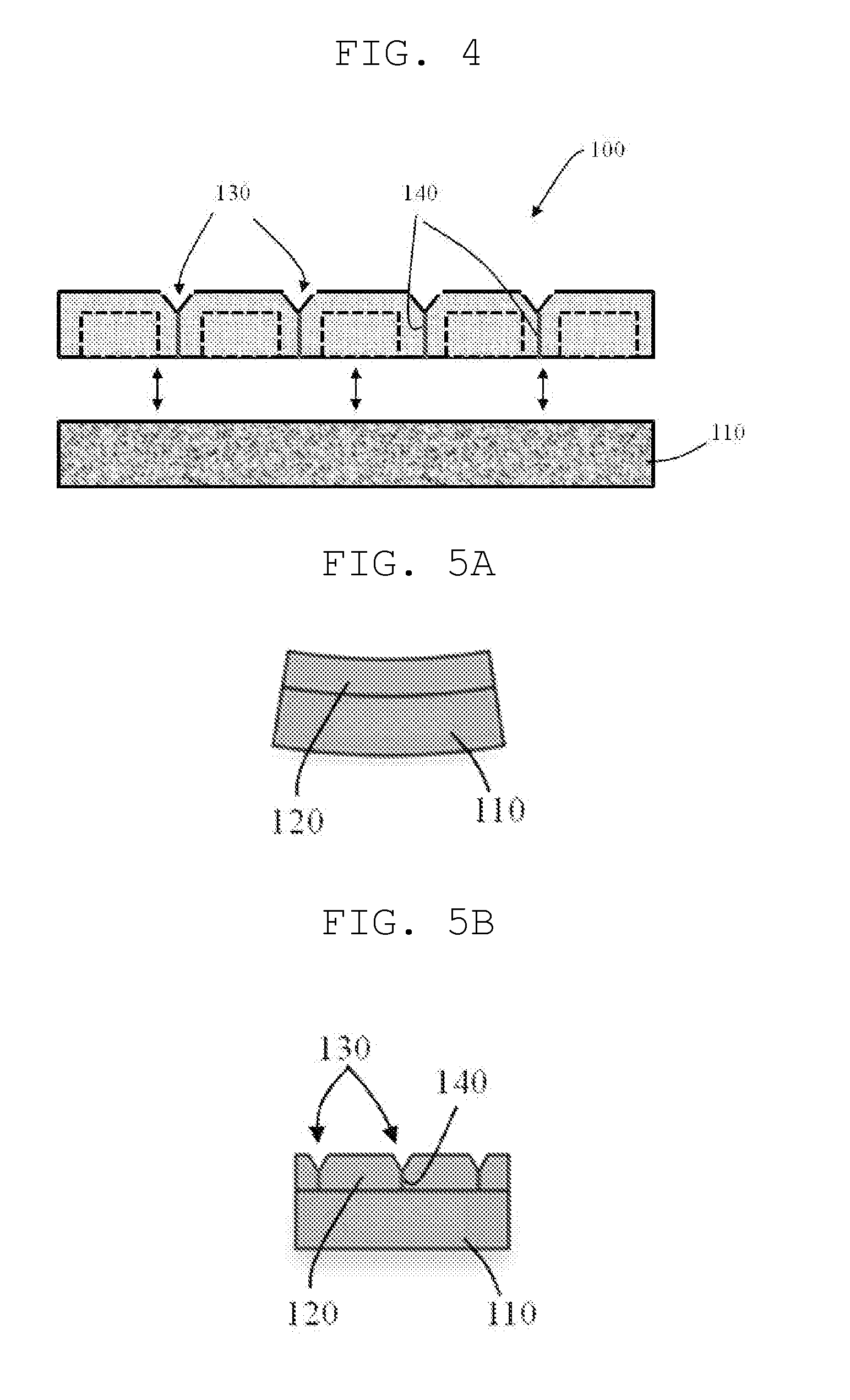

Method Of Manufacturing Gallium Nitride Substrate And Gallium Nitride Substrate Manufactured By The Same

InactiveUS20140001484A1Warping of the GaN substrate can be minimizedAvoid crackingPolycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitride

A method of manufacturing a gallium nitride (GaN) substrate and a GaN substrate manufactured by the same. The method includes the steps of growing a GaN film on a base substrate and separating the base substrate from the GaN film. The step of growing the GaN film includes forming pits in the GaN film, the pits inducing an inversion domain boundary to be formed inside the GaN film. The GaN substrate can have a predetermined thickness with which it can be handled during layer transfer (LT) processing, and the warping of the GaN substrate can be minimized, thereby preventing cracks due to warping.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

Method of manufacturing a wiring board

ActiveUS8286341B2Structure miniaturizationSimplify the manufacturing processPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

Owner:IMBERATEK LLC

Bare die tray clip

InactiveUS20050011056A1Minimizes warpEasy to cutSnap fastenersSemiconductor/solid-state device manufacturingSpring forceEngineering

A clip is provided for holding a stack of at least one tray and tray cover. Stack compressive, forces applied by the clip are substantially limited to tray and cover perimeter rail portions. The clip has a channel base with left and right side retaining walls attached for restricting movement of a stack in left and right directions. Left and right rods protrusions above the base extend inward towards the walls of the channel from the left and right side walls respectively for captivating the stack in an upward direction. Spring protrusions extend upward from the base on input and output ends of the channel, and are configured for applying an upward spring force on opposing bottom edge areas of the stack.

Owner:PEAK PLASTIC & METAL PRODS INT

Manufacturing method of electronic device package, electronic device package, and oscillator

ActiveUS8530986B2Minimizes warpWarping of the cover substrate can be suppressedTransducer detailsImpedence networksMetallurgyOscillistor

A manufacturing method of an electronic device package includes: forming concave portions that later form the cavities in one surface of a cover substrate; forming a first metal film on the cover substrate on a surface opposite to the surface in which the concave portions are formed; forming a second metal film on the cover substrate on the surface in which the concave portions are formed; bonding a base substrate and the cover substrate together via the second metal film. It thus becomes possible to provide an electronic device package in which the base substrate and the cover substrate are boned together via the metal film in a stable manner by minimizing warping of the substrate even when the substrate is made thinner.

Owner:SEIKO INSTR INC

Method of manufacturing printed circuit board

InactiveUS7600315B2RigidityMinimizes warpPrinted circuit assemblingElectrically conductive connectionsPrinted circuit boardProduct Part

This invention relates to a method of manufacturing a printed circuit board, in which a dummy metal frame enclosing the outer periphery of a product part is formed, thus simultaneously assuring the rigidity of the printed circuit board and minimizing the warping thereof thanks to the dummy metal frame left in place on a finished product, thereby realizing a structure compatible with conventional flip chip mounting lines.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Wiring board

InactiveUS20160219690A1Thermal expansion and contraction behavior difference be reduceMinimizes warpPrinted circuit aspectsPrinted circuits stress/warp reductionEngineeringElectrical conductor

A wiring board of the present invention includes a core substrate, insulating layers laminated on upper and lower surfaces of the core substrate, and a conductor layer deposited on the upper and lower surfaces of the core substrate and a surface of each of the insulating layers, in such a manner as to make a difference in area occupation ratio between the upper and lower surfaces of the core substrate. A thickness of a conductor that has a large area occupation ratio is smaller than a thickness of a conductor that has a small area occupation ratio between the conductor layers deposited on the upper and lower surfaces of the core substrate, and between the conductor layers deposited on the surface of each of the insulating layers laminated at an identical level on upper and lower surface sides with the core substrate as a center.

Owner:KYOCERA CORP

Apparatus for securing sheet metal panels for butt-welding with integral copper backing plate

InactiveUS9862062B1Minimize and totally eliminate blowoutReduce warpageWelding/cutting auxillary devicesAuxillary welding devicesButt weldingCopper

A welding clamp uses opposing metal pieces to clamp two pieces of sheet metal together with a defined gap between panels for the purpose of welding, in this case, butt welding. The clamp has an integral copper backing plate to provide weld backing support and thermal dissipation to the metal for improved butt weld results. The integral copper backing plate adds stiffness to the adjoined panels while providing a solid non-weldable backing support to the panels being joined, reducing or eliminating weld blow-through.

Owner:PALMER EDWARD G

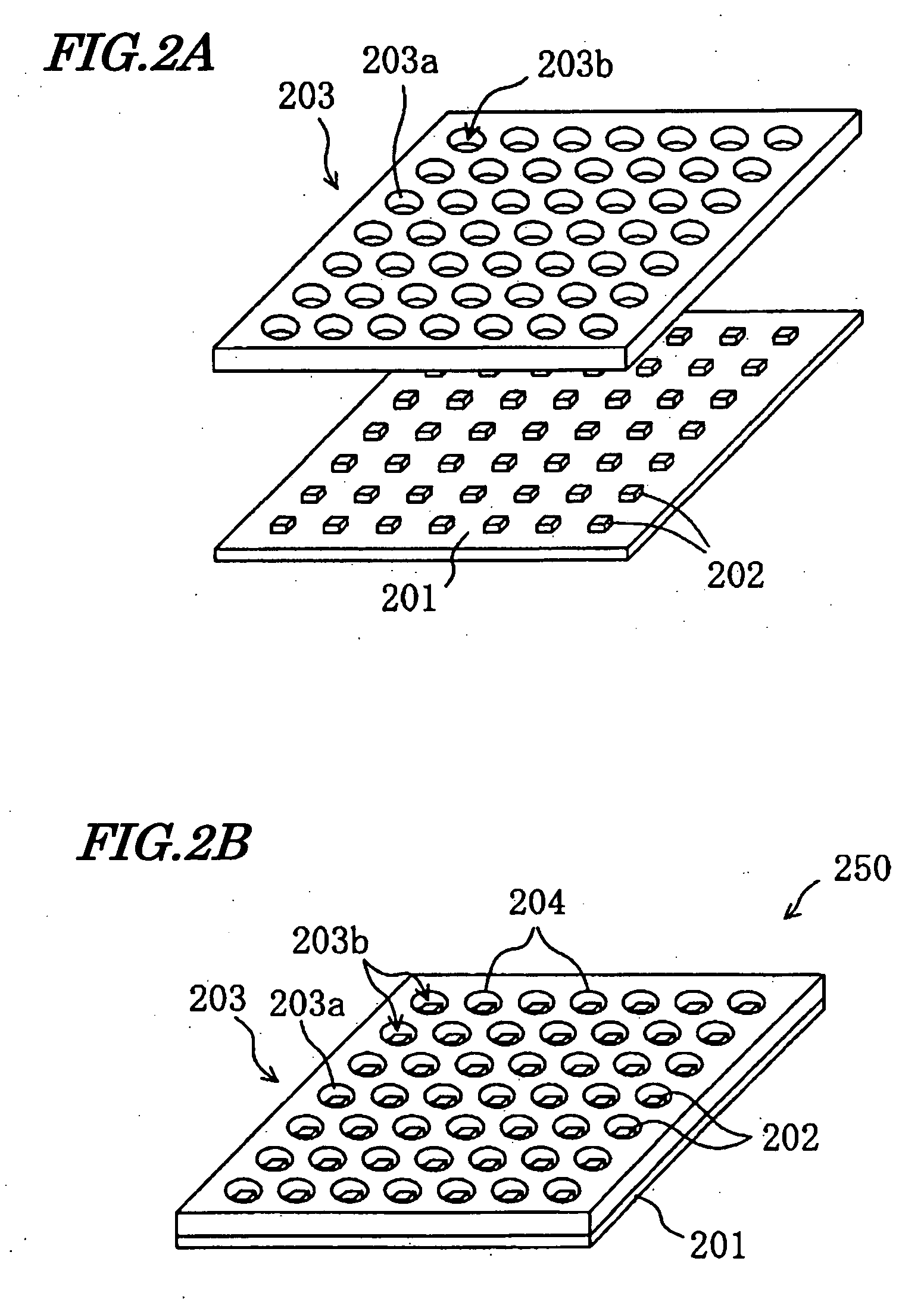

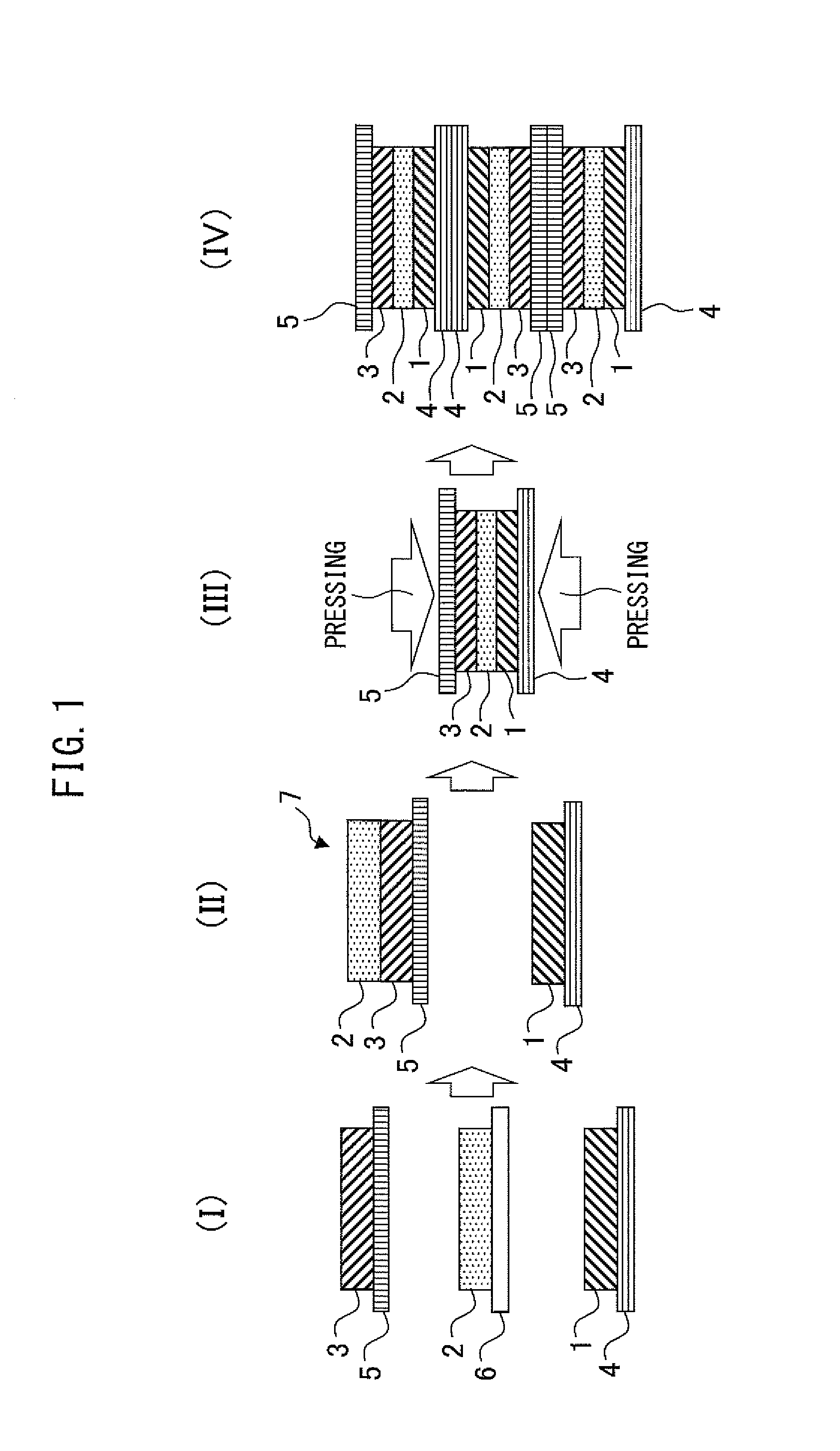

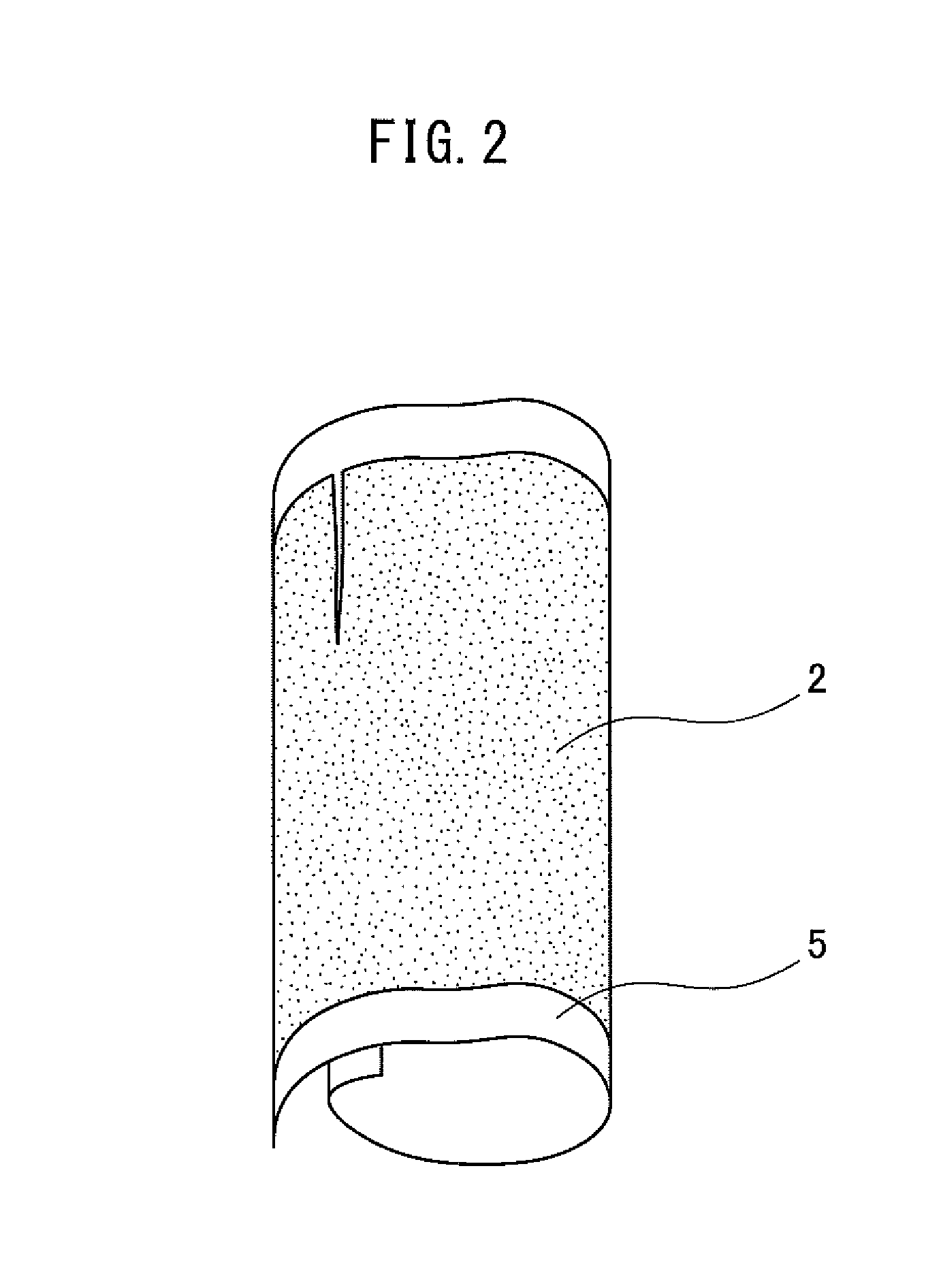

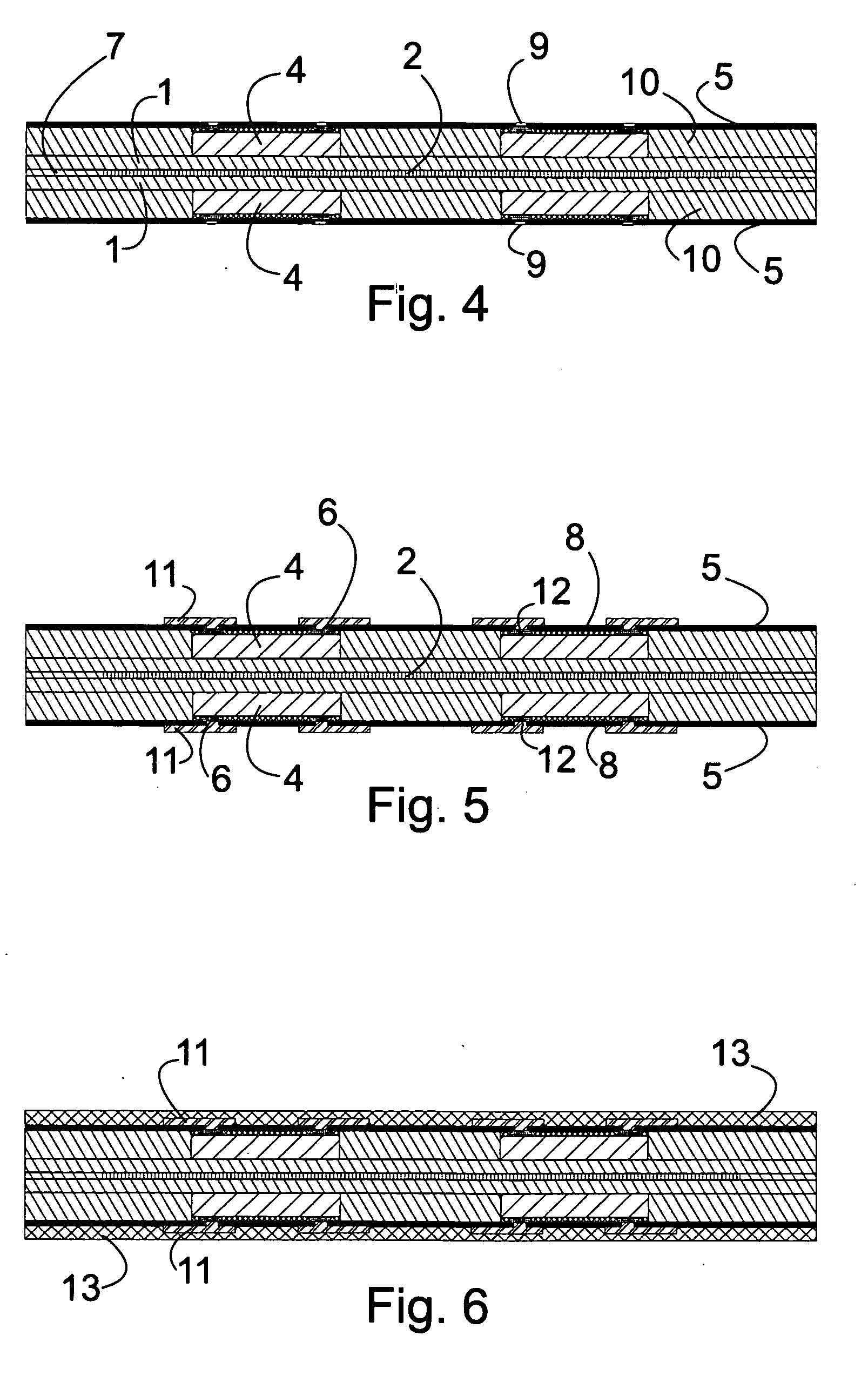

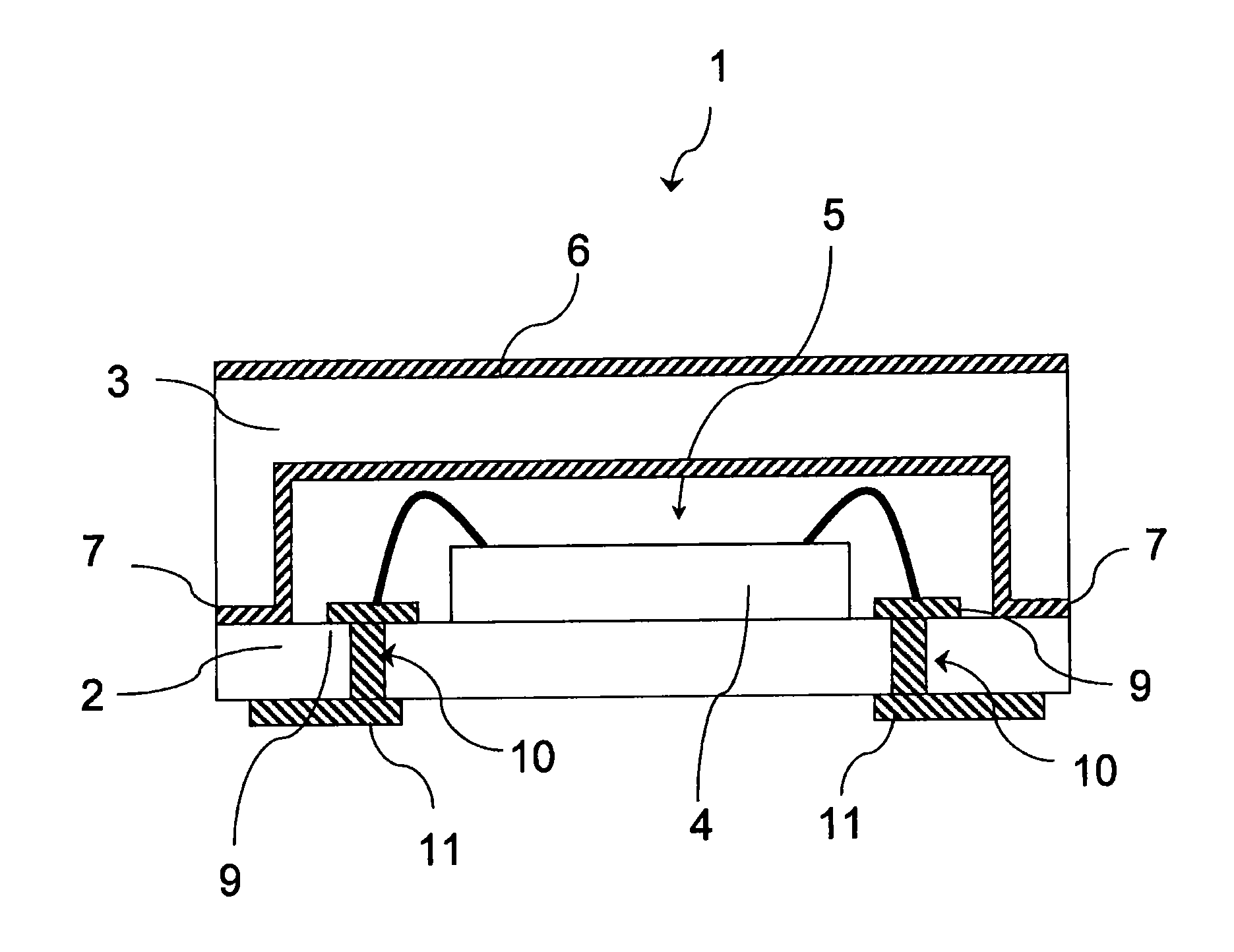

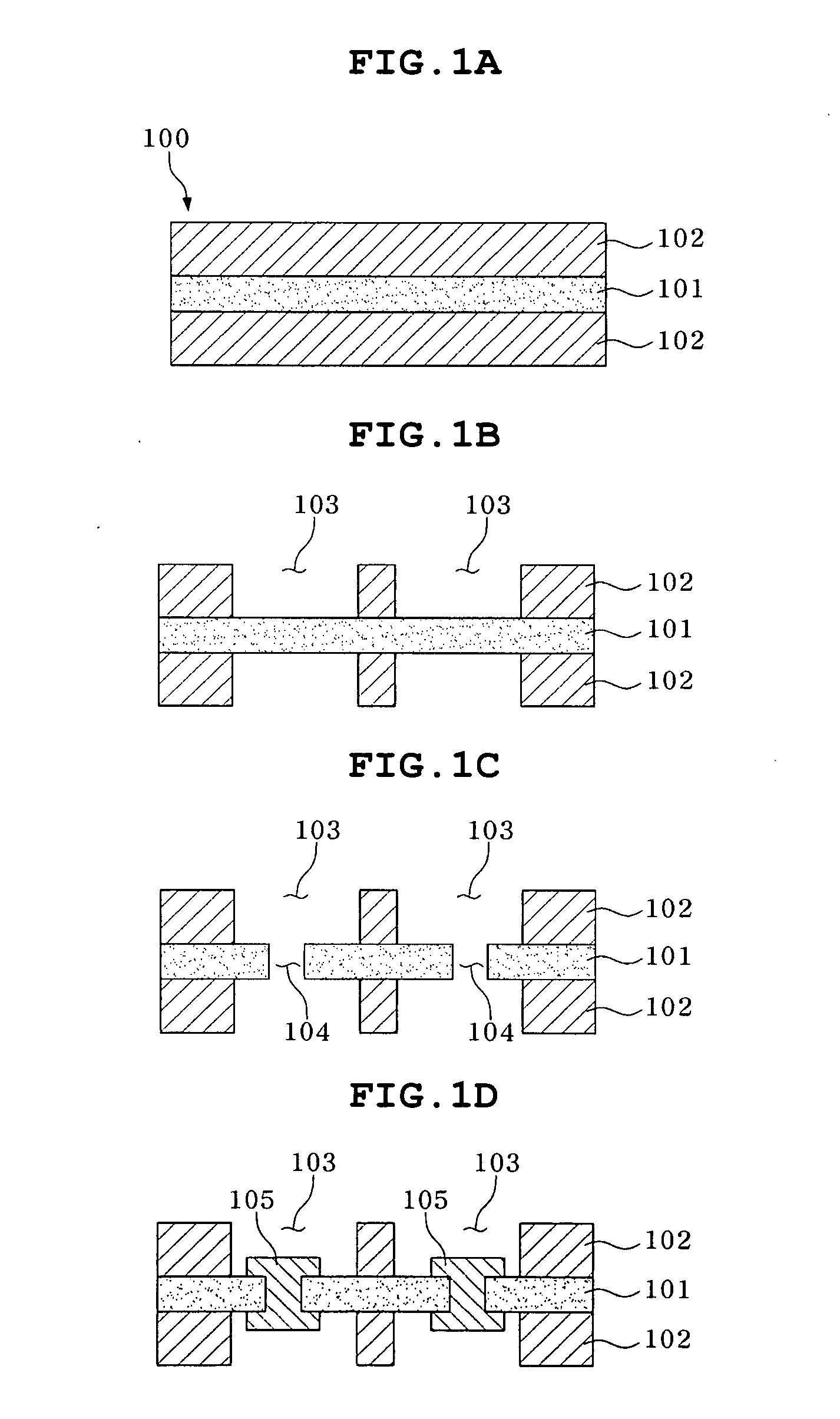

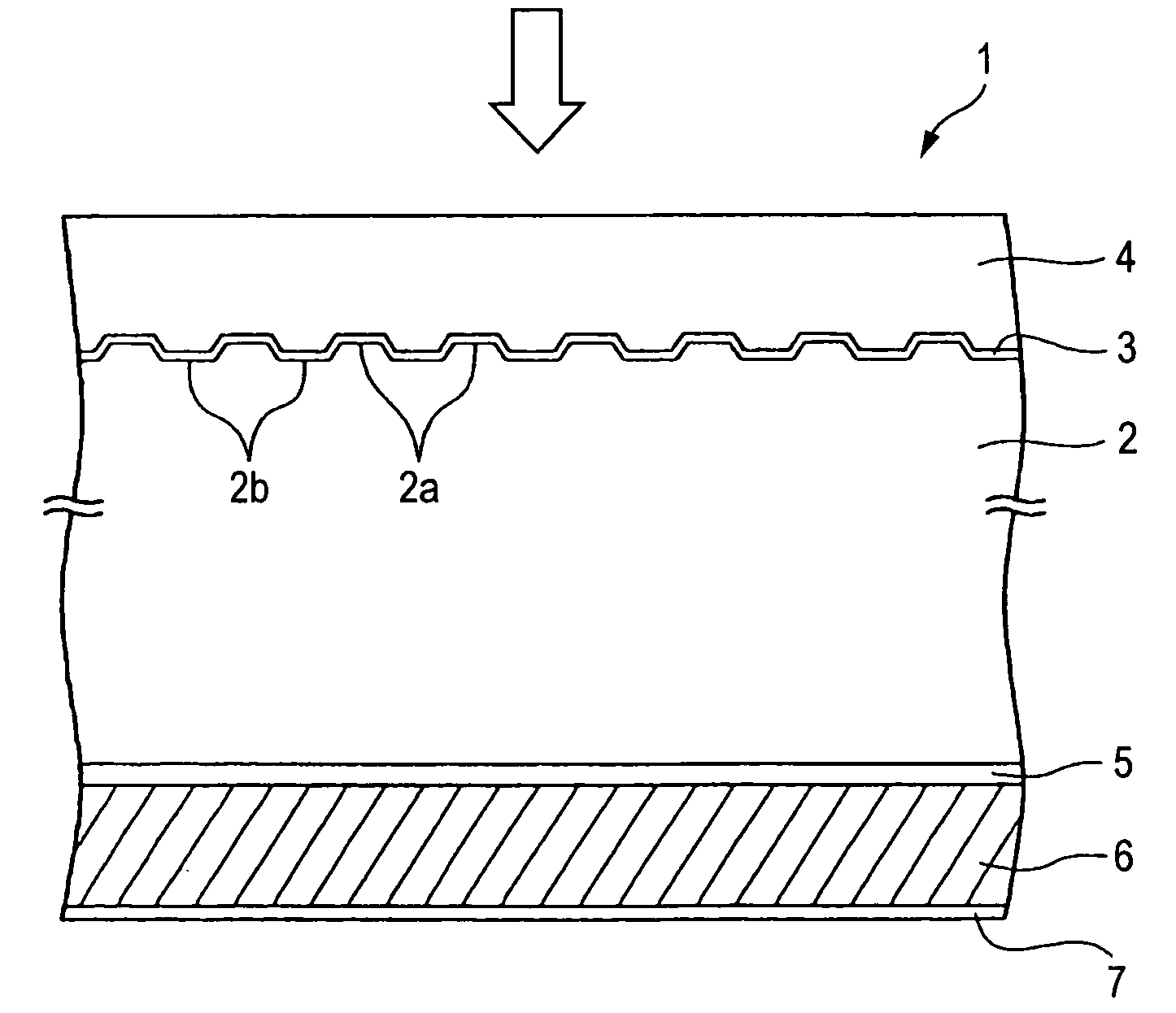

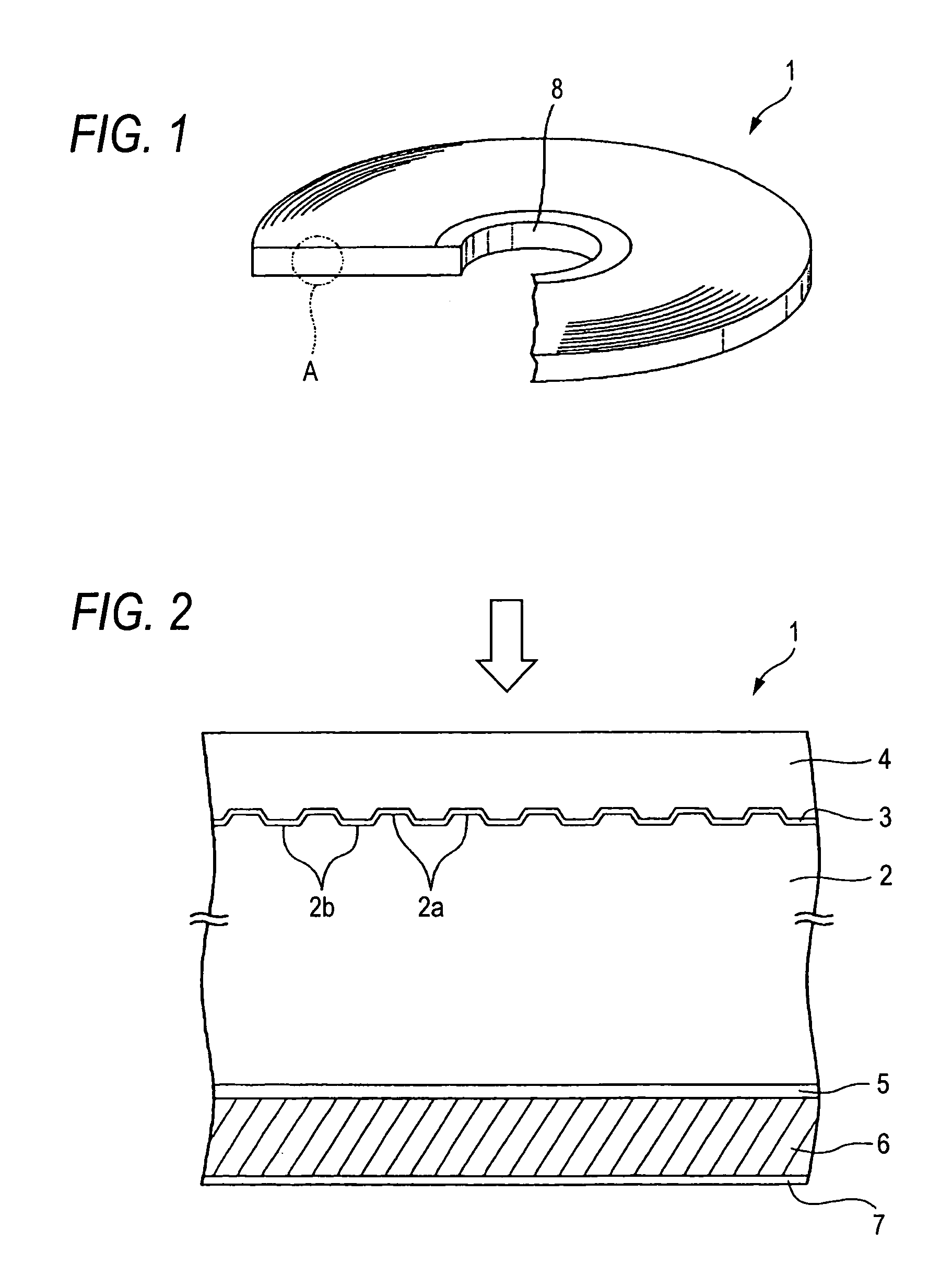

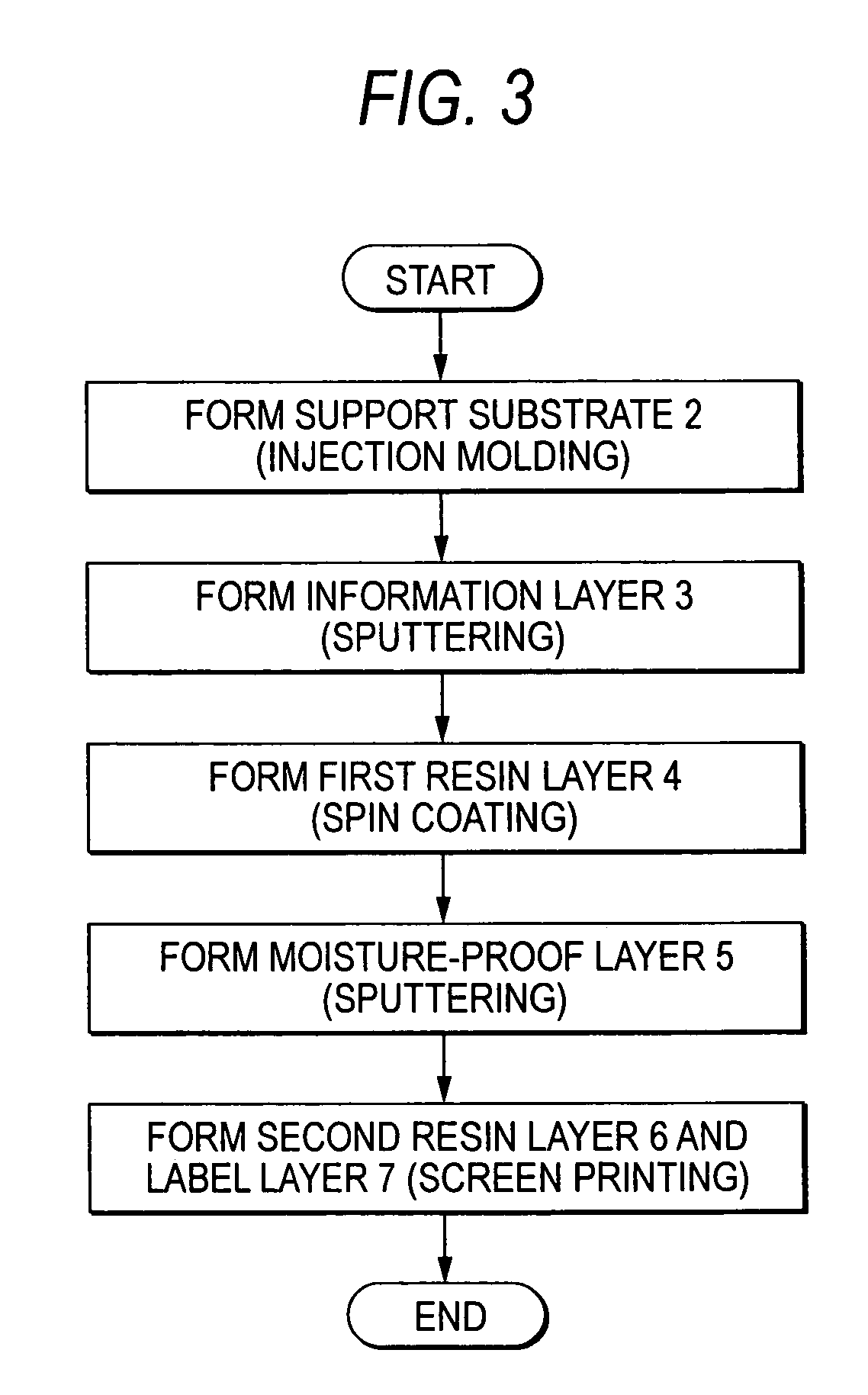

Optical recording medium

InactiveUS7695791B2Good surface shapeLow costLayered productsPhotomechanical apparatusScreen printingInformation layer

An optical recording medium 1 includes a support substrate 2, an information layer 3 formed on one of the surfaces of the support substrate 2, a first resin layer 4 formed on the information layer 3 and having a thickness of 30 to 200 μm, a moisture-proof layer 5 formed on the other surface of the support substrate 2, a second resin layer 6 formed on the moisture-proof layer 5 and having a thickness of 30 to 200 μm, and a label layer 7 formed on the second resin layer 6, and has such a structure that a laser beam is irradiated through the first resin layer 4. The second resin layer 6 contains 0.5 to 2.8 mass part of a silicon antifoaming agent with respect to 100 mass part of an ultraviolet curing resin, and is formed by a screen printing method.

Owner:TDK CORPARATION

Bare die tray clip

InactiveUS20060248692A1Minimizes warpEasy to cutSnap fastenersSemiconductor/solid-state device manufacturingSpring forceEngineering

A clip is provided for holding a stack of at least one tray and tray cover. Stack compressive forces applied by the clip are substantially limited to tray and cover edge portions. The clip has a channel base with left and right side walls attached for restricting movement of a stack in left and right directions. Protrusions above the base extend inward towards the walls of the channel for captivating the stack in an upward direction. Spring protrusions extend upward from the base on input and output ends of the channel, and are configured for applying an upward spring force on opposing bottom edge areas of the stack.

Owner:PEAK PLASTIC & METAL PRODS INT

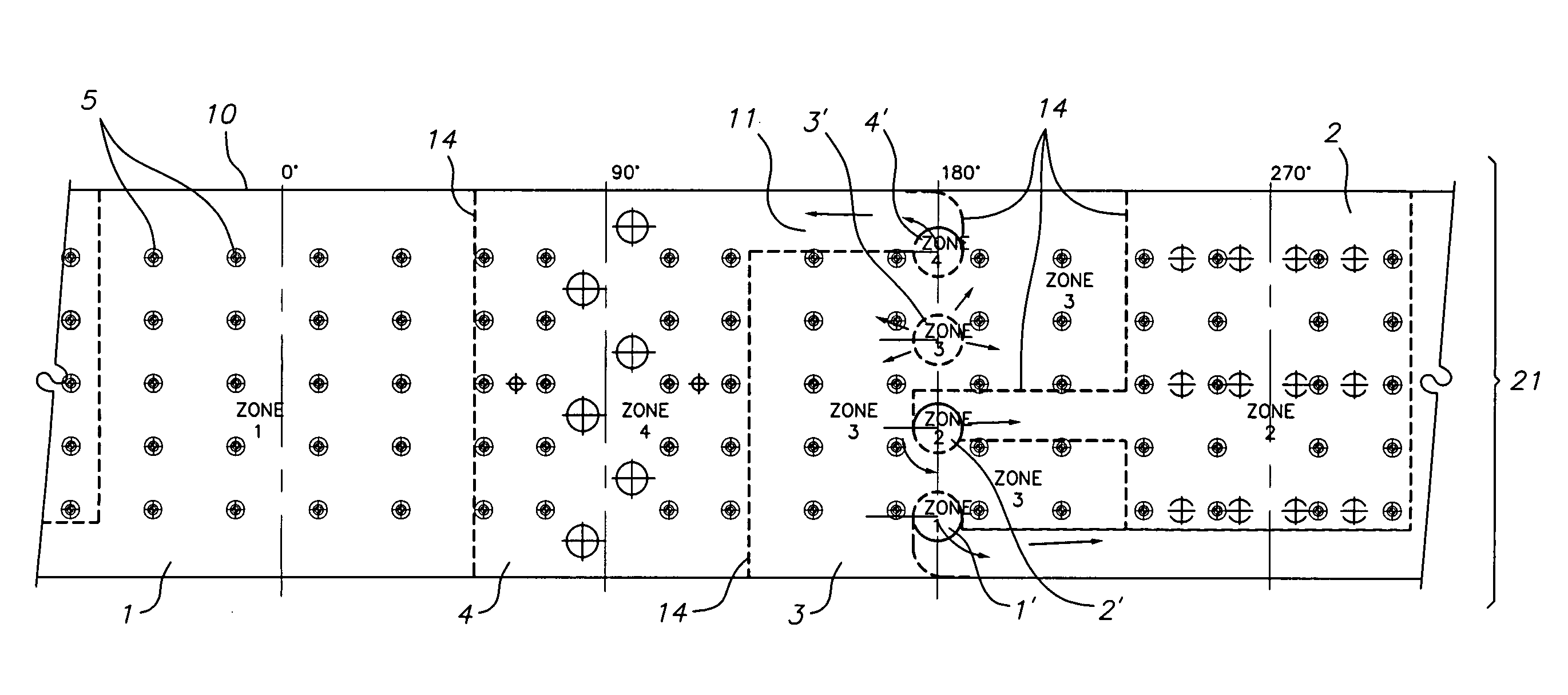

Method and apparatus for directional and controlled cooling in vacuum furnaces

A vacuum furnace with a gas manifold branching into a plurality of secondary gas manifolds, the secondary gas manifolds each including a valve that is contained in each secondary gas manifold; a hot gas plenum including an inner and an outer shell with the outer shell attached at one side to the secondary gas manifold; a series of gas restrictor walls between the inner and outer shells of the hot gas manifold that serves the purpose of dividing the plenum into a plurality of non-circumferential sectors so that the load in the plenum may be cooled from the top, bottom, left, or right side or any combination thereof.

Owner:G T ENTERPRISES

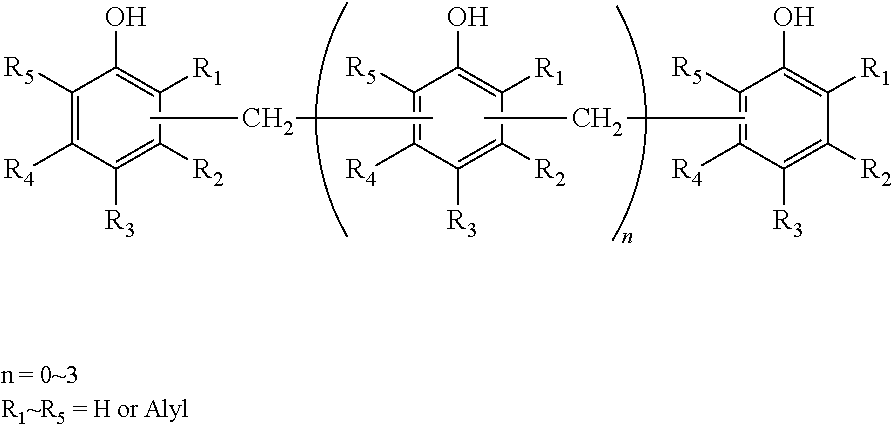

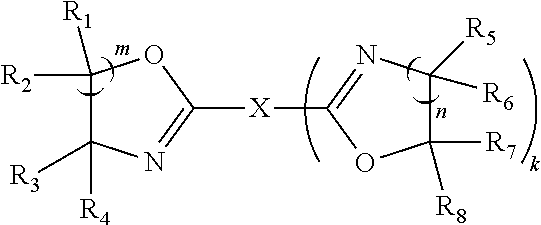

Methods to control wafer warpage upon compression molding thereof and articles useful therefor

ActiveUS20160079187A1Reduced tendency to warpReducing wafer warpageSemiconductor/solid-state device detailsSolid-state devicesCompression moldingEngineering

Provided herein are multilayer structures having a reduced propensity to warp upon curing of certain components thereof. In one aspect, there are provided multilayer assemblies comprising a plurality of the above-described multilayer structures. In another aspect, there are provided methods for reducing wafer warpage upon cure of molding compositions applied thereto. In yet another aspect, there are provided methods for preparing wafers having substantially no warpage upon cure thereof.

Owner:HENKEL IP & HOLDING GMBH

Method for producing a plate of a turbomachine

PendingUS20220032384A1Suitable for processingHigh dimensional accuracyMachining electrodesBlade accessoriesRotational axisEngineering

The present invention relates to a method for manufacturing a plate of a turbomachine having a plurality of receiving grooves, which are formed on the cylindrical peripheral surface of the plate in order to receive blade roots of blades of the turbomachine. The receiving grooves extend in a straight line from one face of the plate to the other face of the plate, such that a straight line delimits the receiving groove from each point on the cross section of the receiving groove on one of the faces to the corresponding point on the cross section on the other face. A circular plate is provided and a plurality of receiving grooves are introduced into the plate simultaneously on opposing regions relative to a central axis of rotation of the plate.

Owner:MTU AERO ENGINES GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com