High-voltage semiconductor device

a semiconductor device and high-voltage technology, applied in semiconductor devices, diodes, electrical devices, etc., can solve the problems of increasing severe electric field on the surface of high-voltage semiconductor devices, and thick dielectric layer tox, so as to reduce the cost of soi substrates. , the effect of reducing the warping of wafers in the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

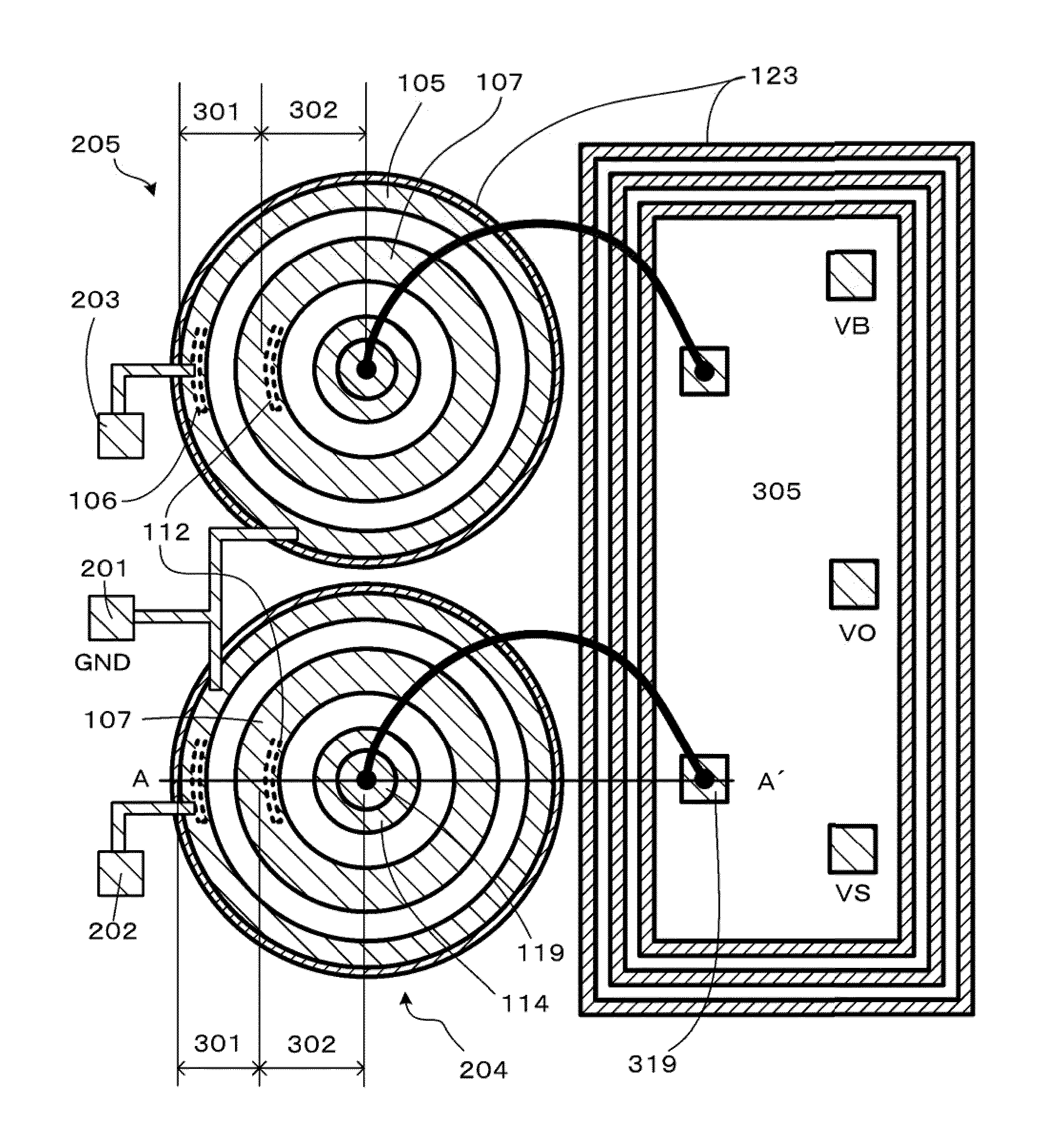

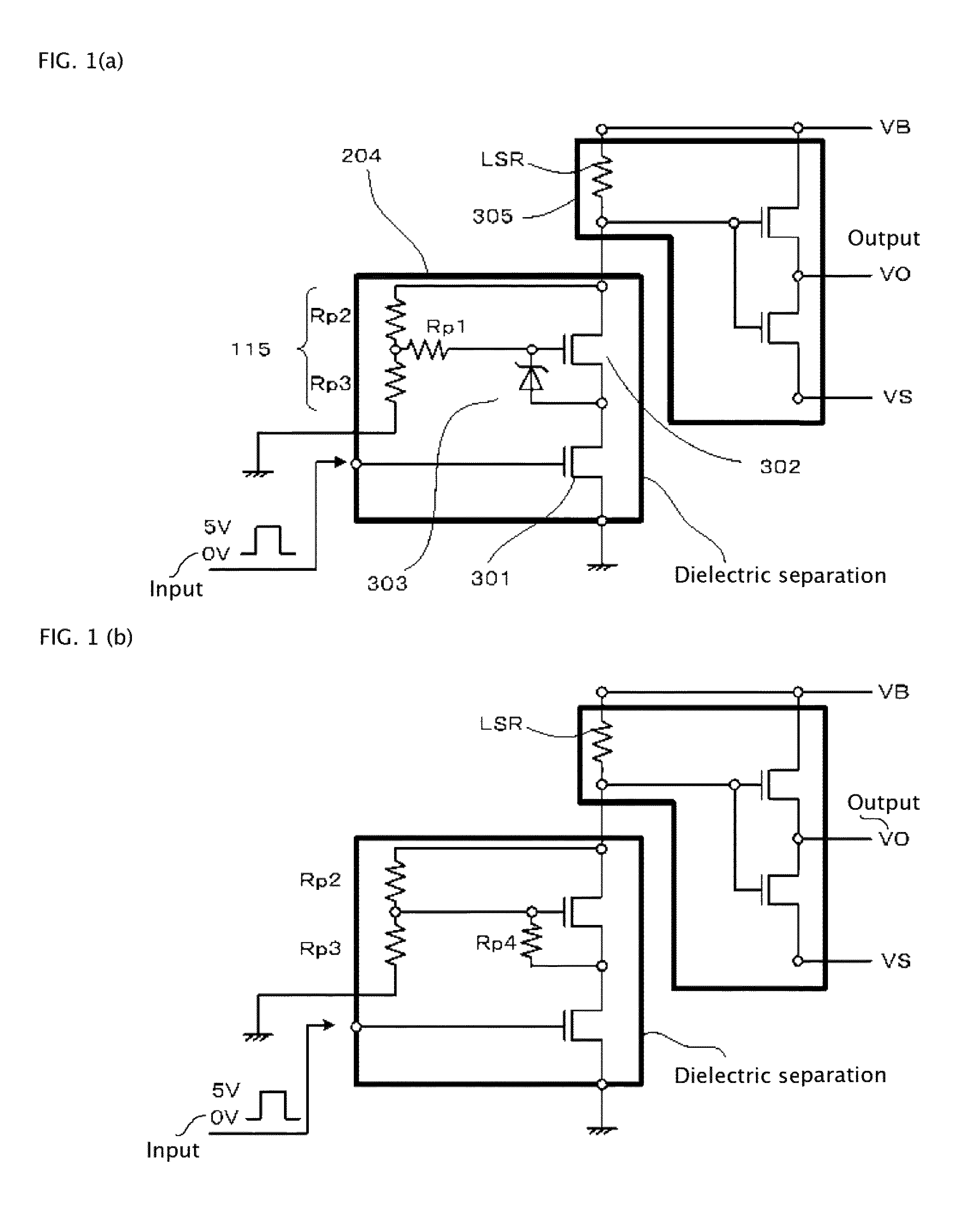

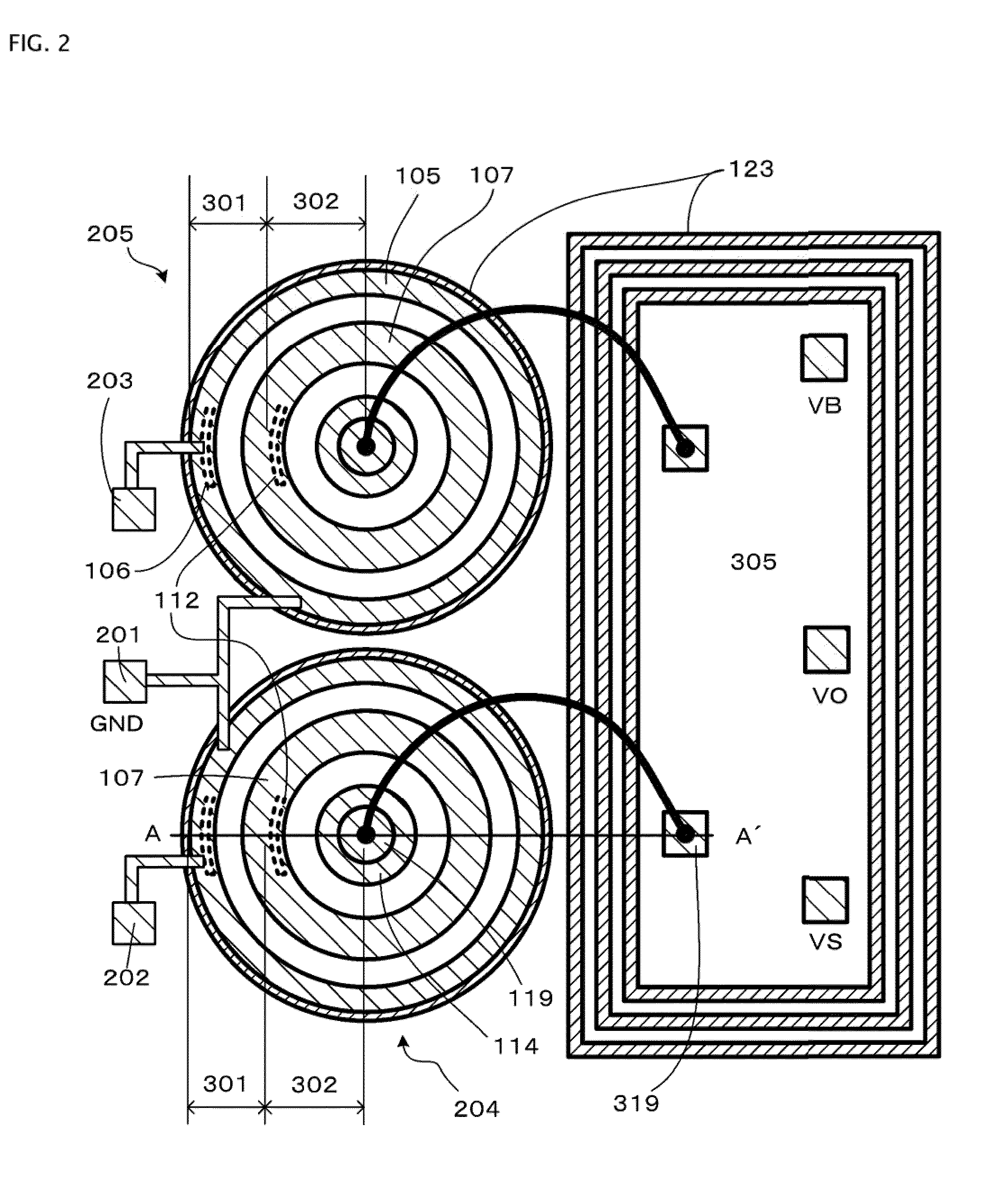

[0070]FIGS. 1(a) and 1(b) show an equivalent circuit diagram of an HVIC including a high-voltage semiconductor device according to the present invention. The constructions of FIGS. 1(a) and 1(b) are different in that a Zener diode 303 is used between a gate and a source of the second stage transistor 302 in the construction of FIG. 1(a) whereas a resistance element Rp4 is employed at that place in the construction of FIG. 1(b). FIG. 2 is a schematic plan view of the high-voltage semiconductor device 204 shown in FIGS. 1(a) and 1(b), another high-voltage semiconductor device 205 (not shown in FIGS. 1(a) and 1(b)), and a floating reference gate drive circuit region 305.

[0071]FIGS. 1(a) and 1(b) show block circuit diagrams in simplified representation for a level sifter input to the HVIC, a level shift resistance LSR, and a high side driving circuit in the floating reference gate drive circuit region 305. A set signal is inputted to the first stage transistor 301 of the high-voltage se...

second embodiment

[0089]FIG. 10 is a sectional view of an essential part of another embodiment example of a high-voltage semiconductor device of the invention.

[0090]This second embodiment differs from the first embodiment in that an NMOSFET 304 is added between the first stage transistor 301 and the second stage transistor 302 to construct a three stage construction with three NMOSFETs connected in series.

[0091]The NMOSFET 304 is formed, similar to the second stage transistor 302, in a ring shaped planar configuration of a p type well diffusion layer 1111 reaching the embedded dielectric layer 200. The p type well diffusion layer 1111 isolates the NMOSFET 304 from the first stage transistor 301. In the surface region of the p type well diffusion layer 1111, a source n+ layer 1091 and a well pick up p+ layer 1101 are formed. A source electrode 1074 connected to the source n+ layer 1091 and the well pick up p+ layer 1101 is connected to the drain electrode 1072 of the first stage transistor 301. A drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com