Patents

Literature

78results about How to "Good surface shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display Device

ActiveUS20150362776A1Reduce qualityIncrease of surface irregularityPrinted circuit aspectsSolid-state devicesInput/outputEngineering

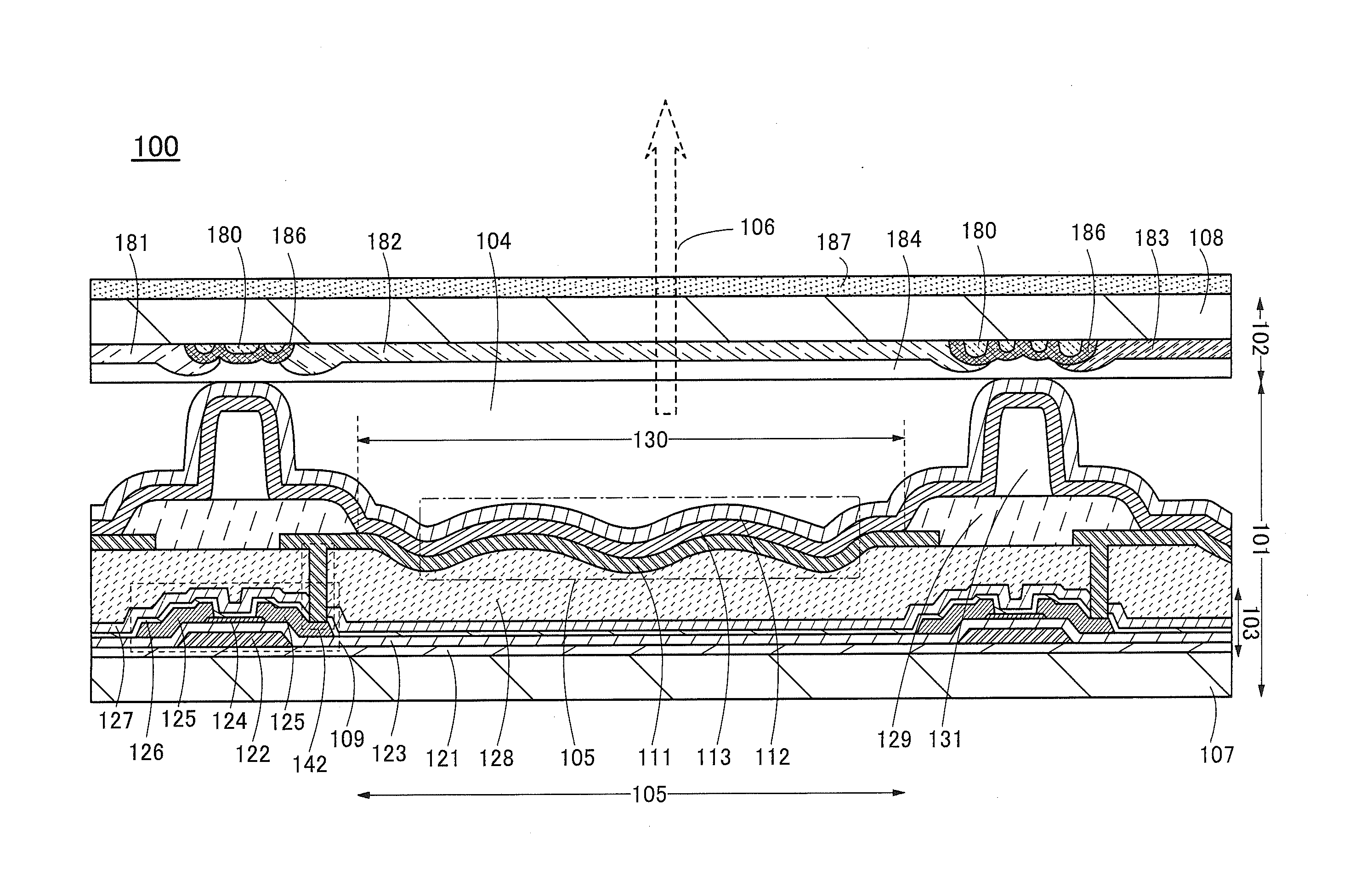

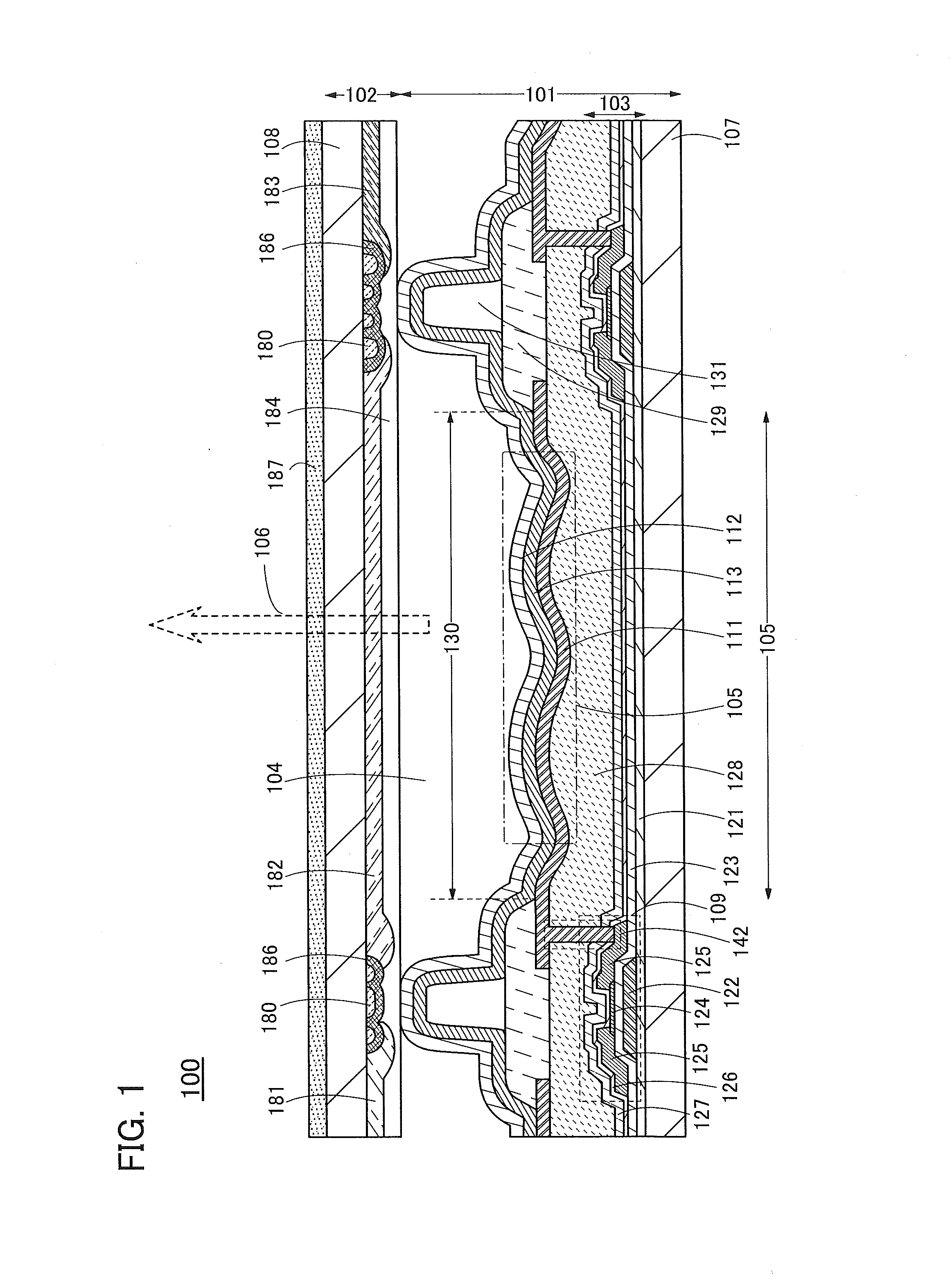

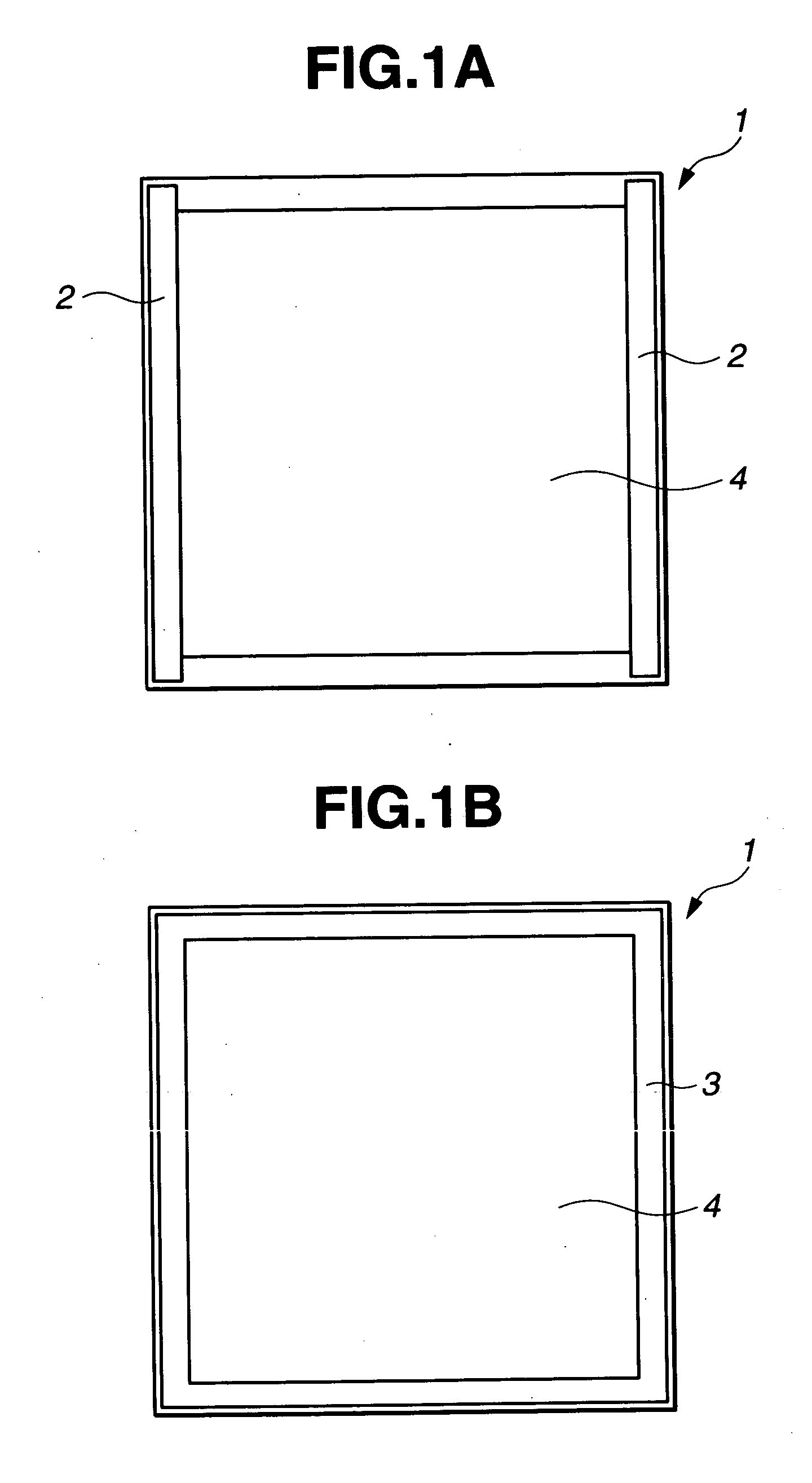

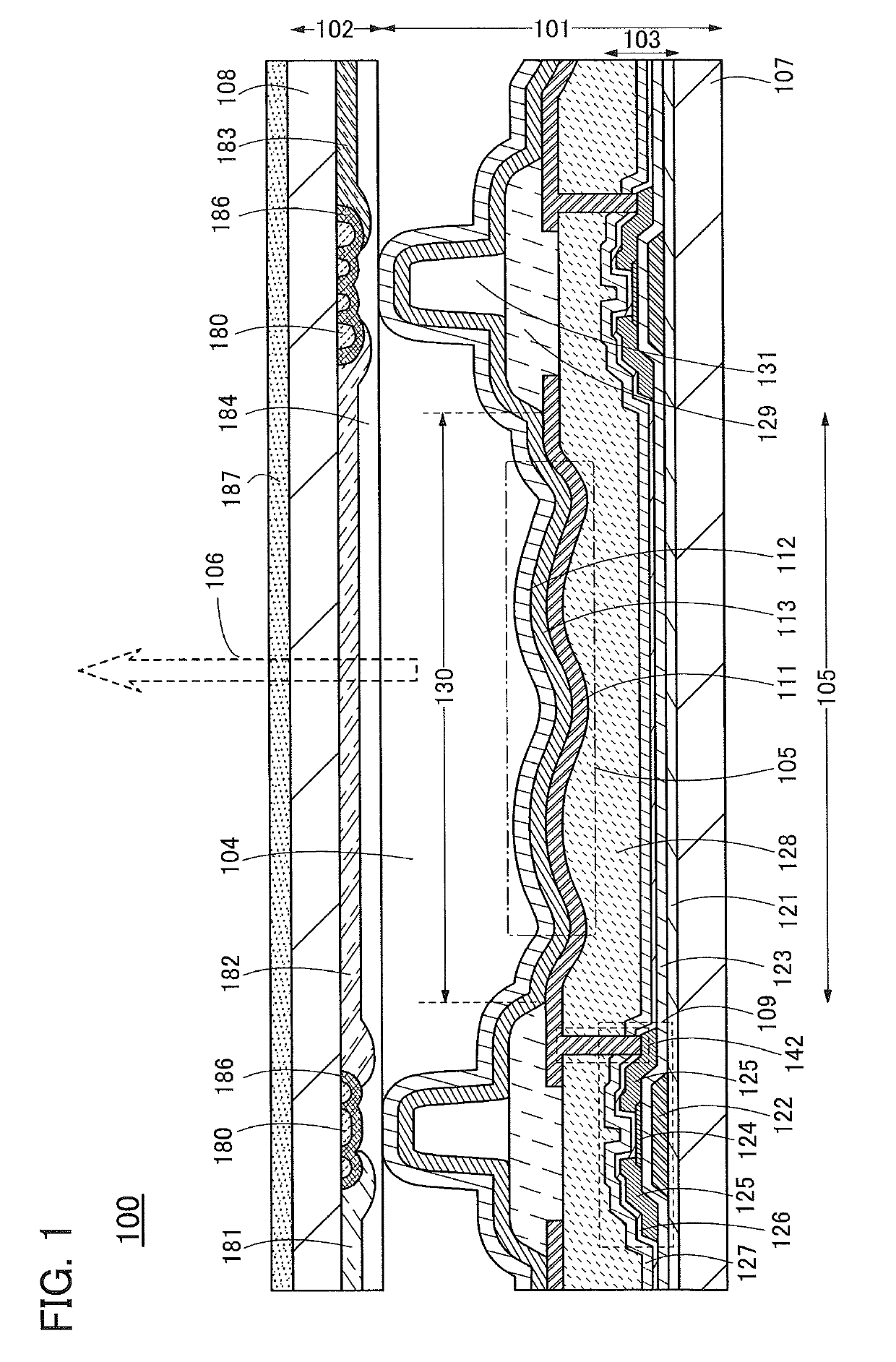

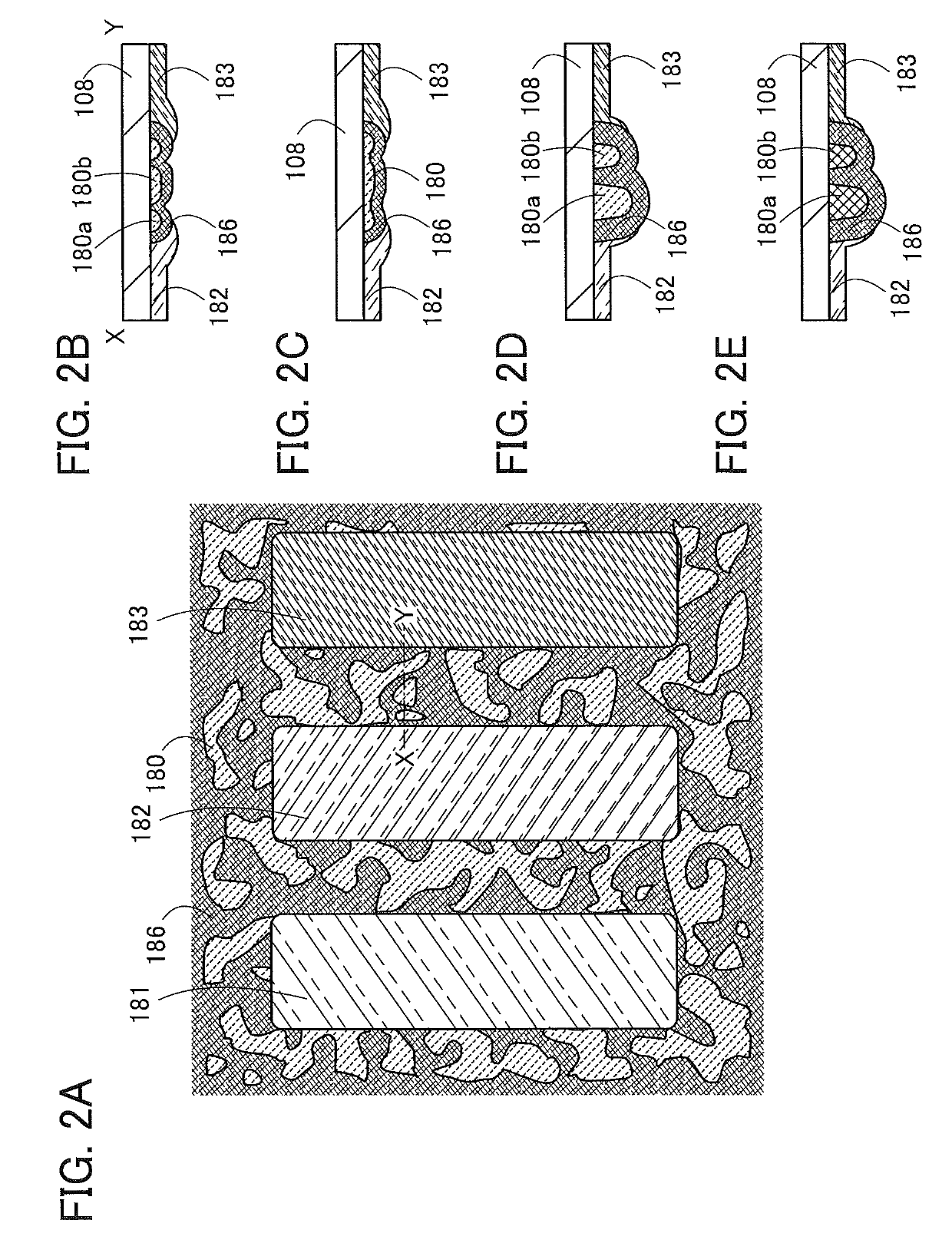

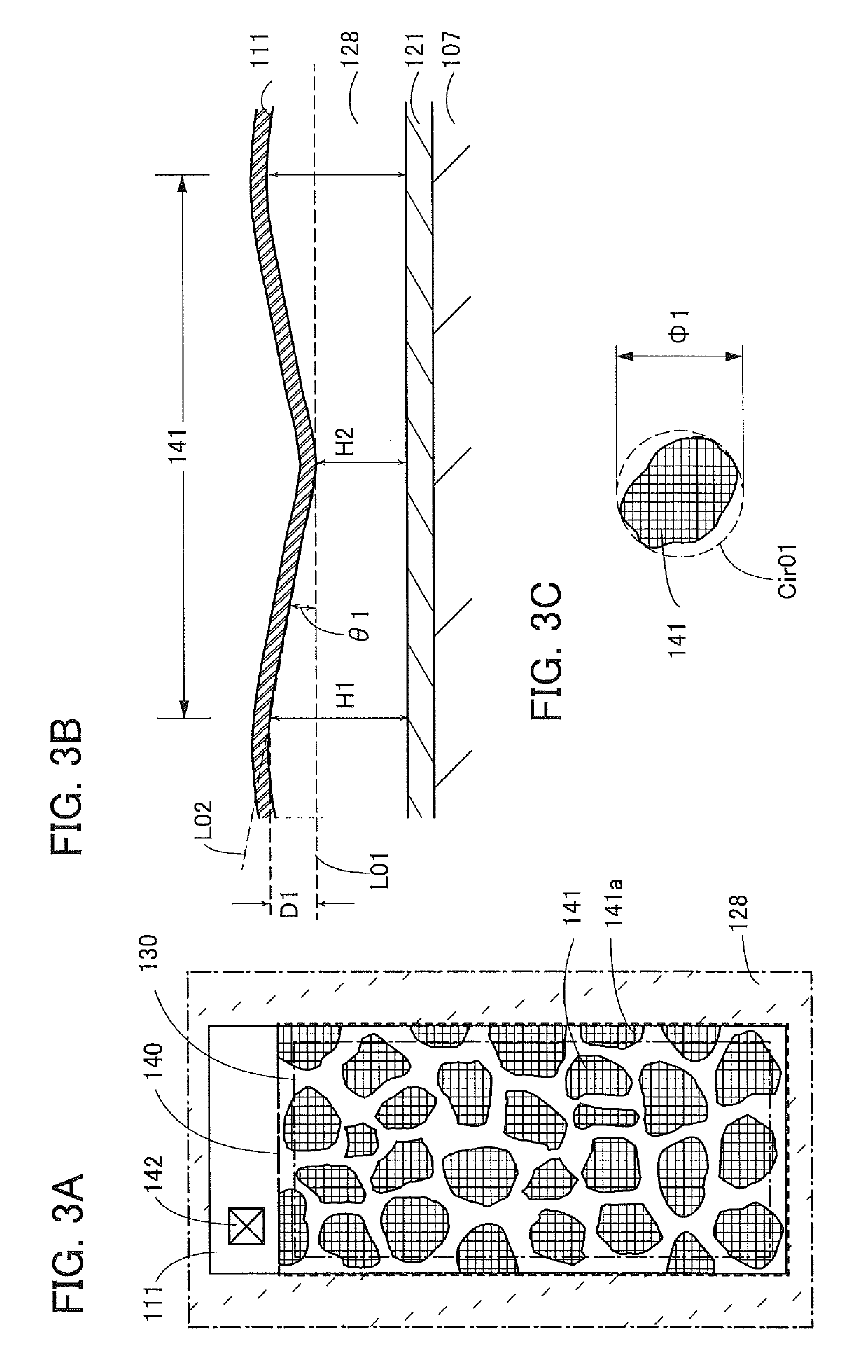

Provided is a display device or an input / output device in which reflection of outside light is reduced. The display device includes a first substrate and a second substrate. The first substrate includes a first surface. A transistor is over the first surface. The second substrate includes a second surface. A first structure having a projection, a second structure having a projection, a black matrix covering the first structure and the second structure, and a color filter are over the second surface. The first surface faces the second surface. The black matrix has a plurality of projections reflecting the projection of the first structure and the projection of the second structure. A planar shape of the first structure is different from a planar shape of the second structure.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing lignin urea-formaldehyde pesticide microcapsule

InactiveCN102349509AHigh reactivityImprove physical and chemical propertiesBiocideAnimal repellantsOil emulsionActive agent

The invention discloses a method for preparing a lignin urea-formaldehyde pesticide microcapsule. According to the invention, the method comprises the following steps: taking modified lignin, formaldehyde and urea as a monomer, forming a water-soluble performed polymer under base catalysis, diluting and forming continuous phase, forming dispersed phase by pesticide, an organic solvent and a surfactant, mixing and stirring the continuous phase and the dispersed phase to form an oil-in-water emulsion, performing in situ condensation polymerization under the acidic condition, heating and solidifying, pumping filtration and washing, drying to obtain the solid microcapsule particles. The modified lignin is obtained by formaldehyde hydroxymethyl modification of the industrial grade wheat straw soda lignin. According to the invention, the waste wheat straw soda lignin in paper industry is taken as the main wall material, so that the production cost of the microcapsule can be effectively reduced and the resource utilization of waste biomass can be realized. The preparation method of the invention has the advantages of simple process, rapidity and controllable microcapsule particle size, and is capable of realizing the industrial production, increasing the pesticide utilization rate, prolonging the persistent period, minimizing the environmental pollution in the process of agriculturalproduction, reducing the agriculture production cost and the like, and has good market prospect.

Owner:SOUTH CHINA AGRI UNIV

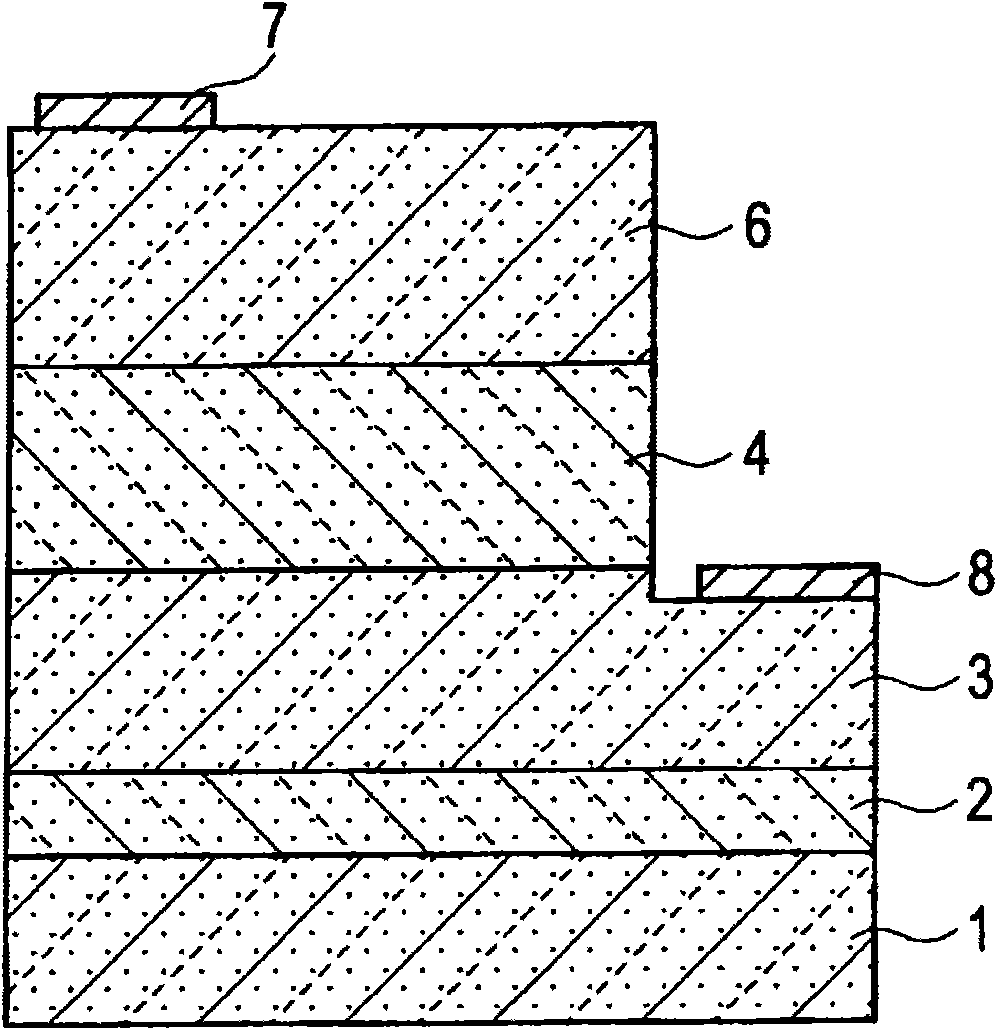

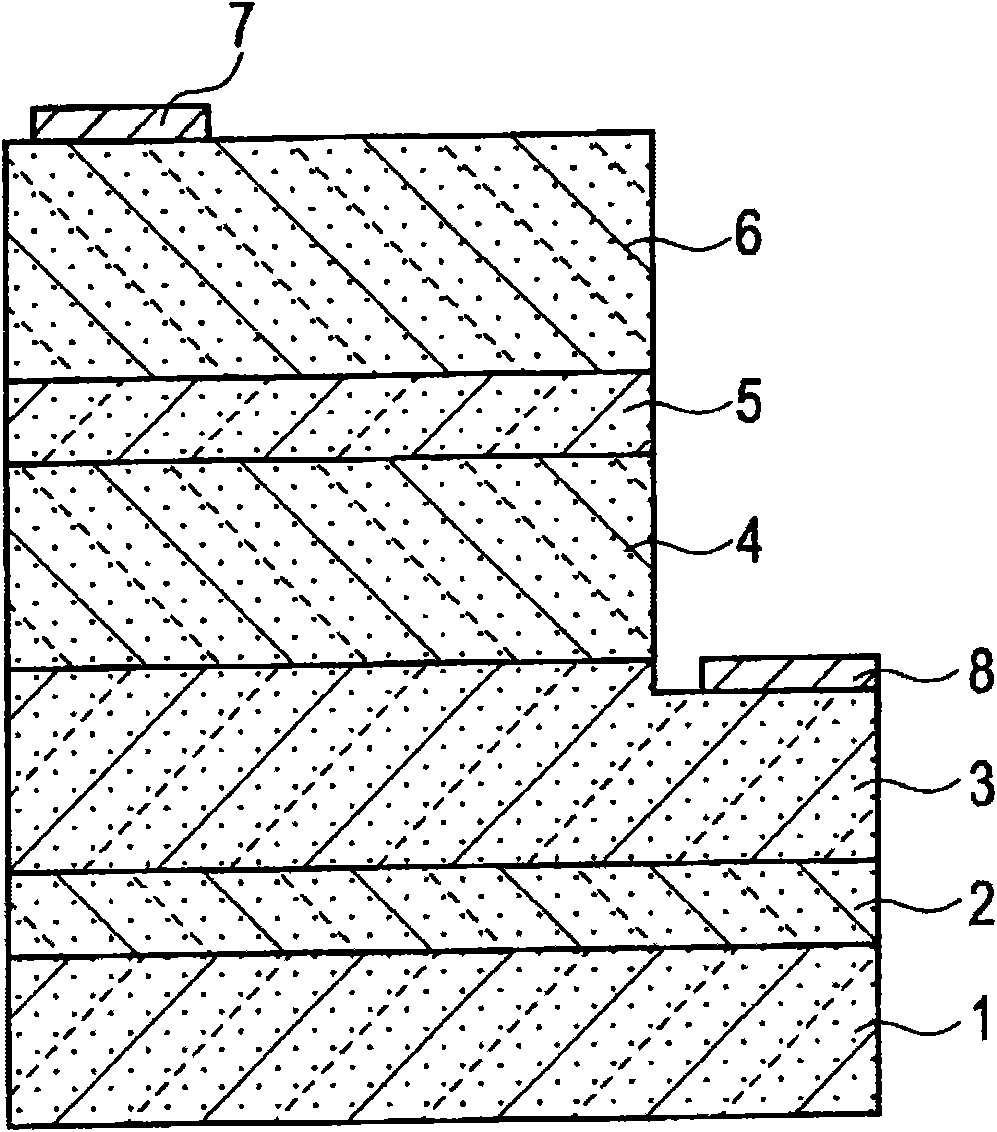

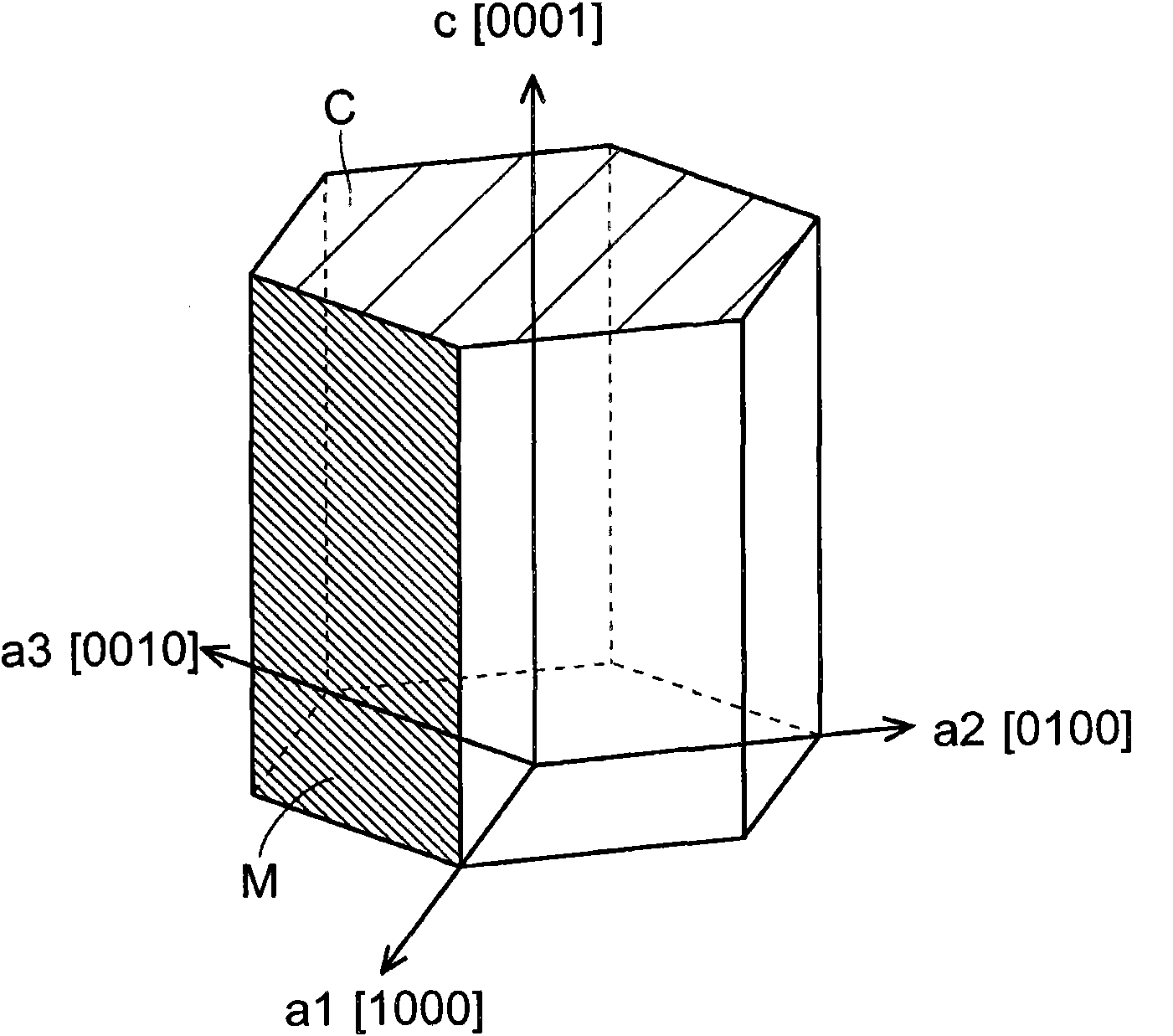

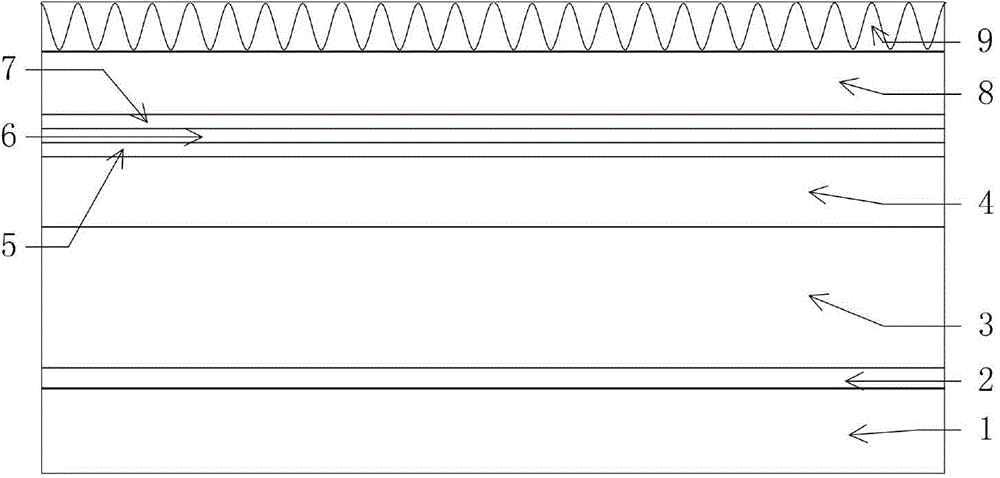

Nitride semiconductor light emitting element and method for manufacturing nitride semiconductor

InactiveCN101689586AGood lattice matchingImprove crystal qualityNanoopticsSemiconductor devicesActive layerNitride semiconductors

Provided is a nitride semiconductor light emitting element having improved optical output with improved qualities, such as crystal qualities, of a nitride semiconductor laminated on an AlN buffer layer. An AlN buffer layer (2) is formed on a sapphire substrate (1), and on the buffer layer, nitride semiconductors of an n-type AlGaN layer (3), an InGaN / GaN active layer (4) and a p-type GaN layer (5)are laminated in sequence. On the surface of the n-type AlGaN layer (3), an n-electrode (7) is formed, and on the p-type GaN layer (5), a p-electrode (6) is formed. The n-type AlGaN layer (3) operates as a clad layer for confining light and carriers. The AlN buffer layer (2) is manufactured by alternately supplying an Al material and an N material at a growing temperature of 900 DEG C or higher.

Owner:ROHM CO LTD

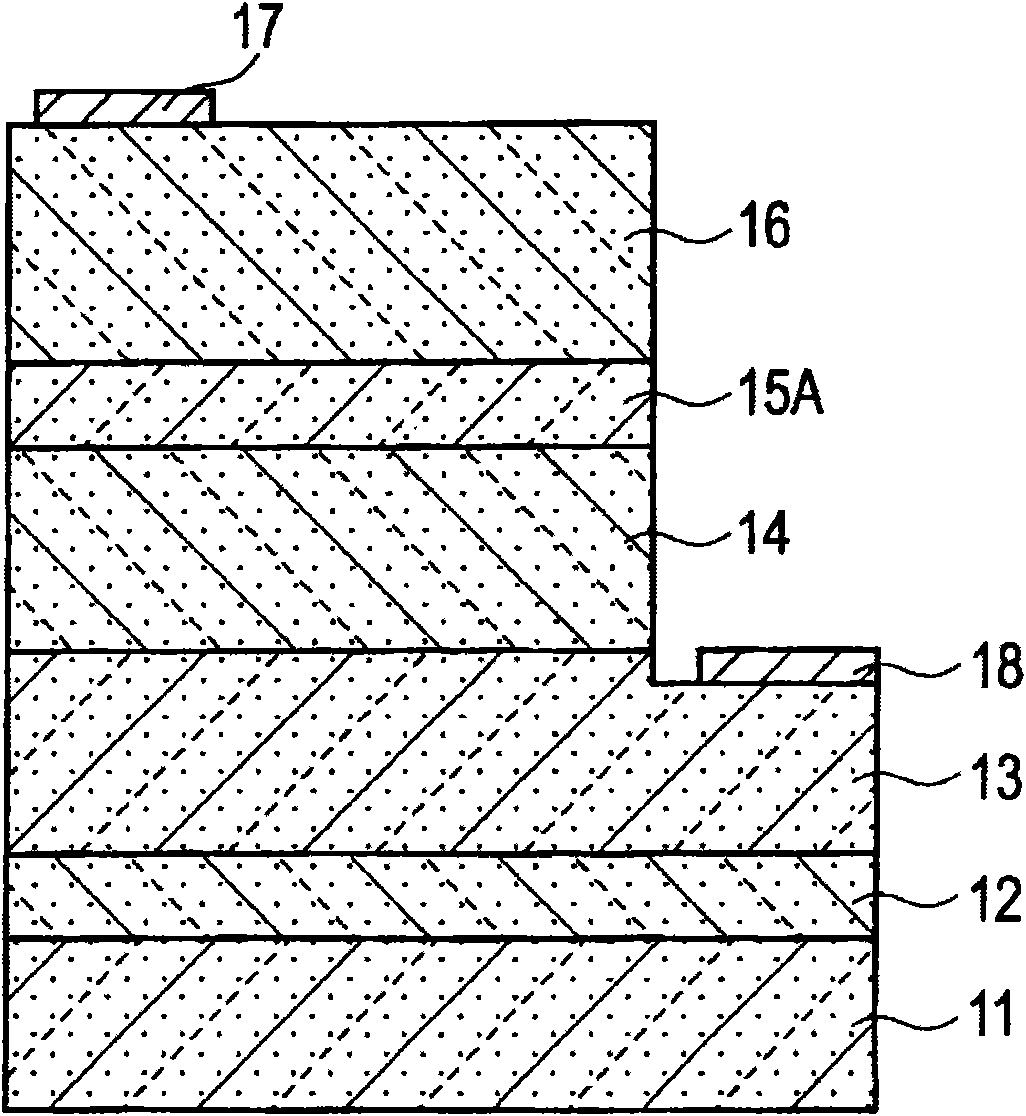

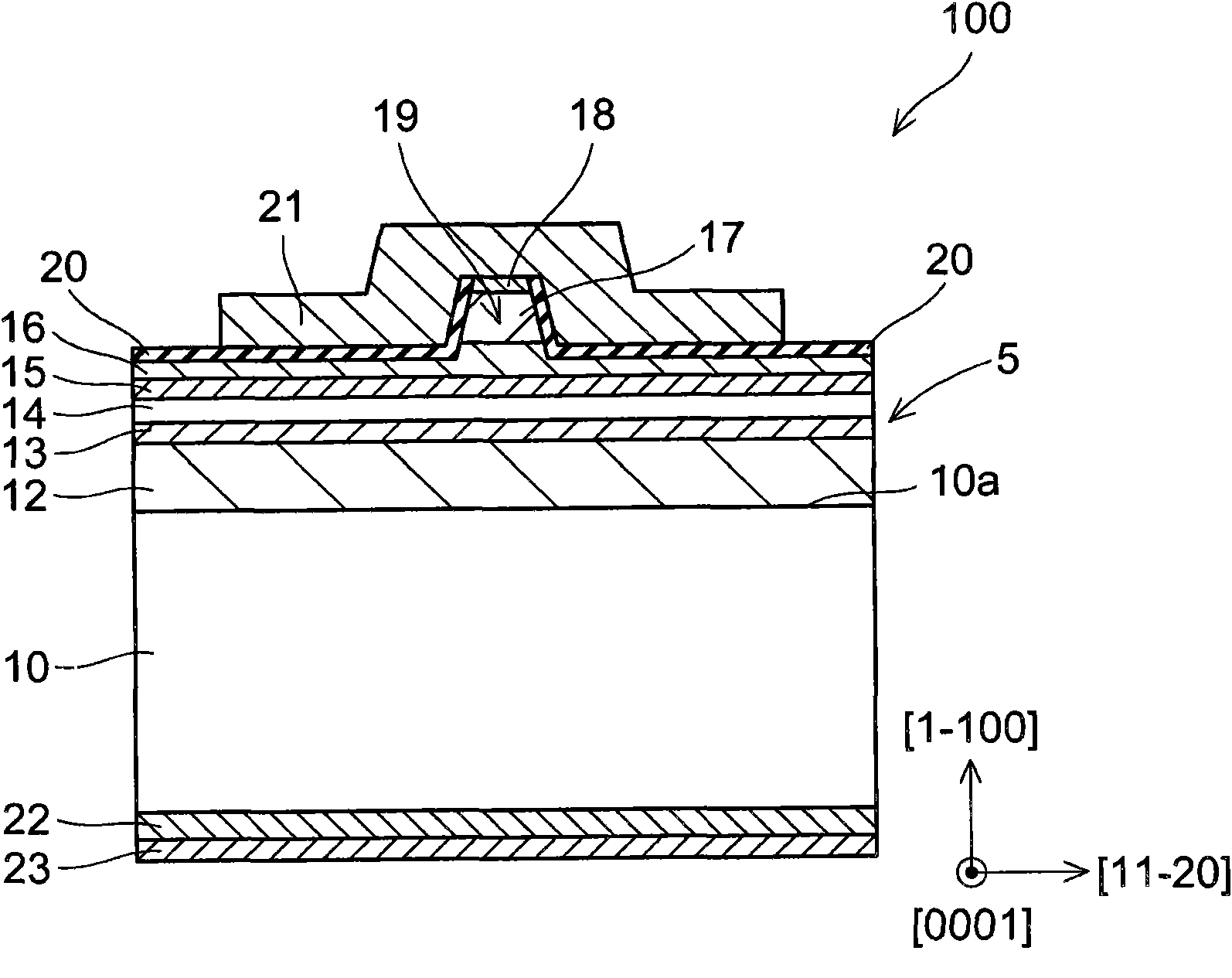

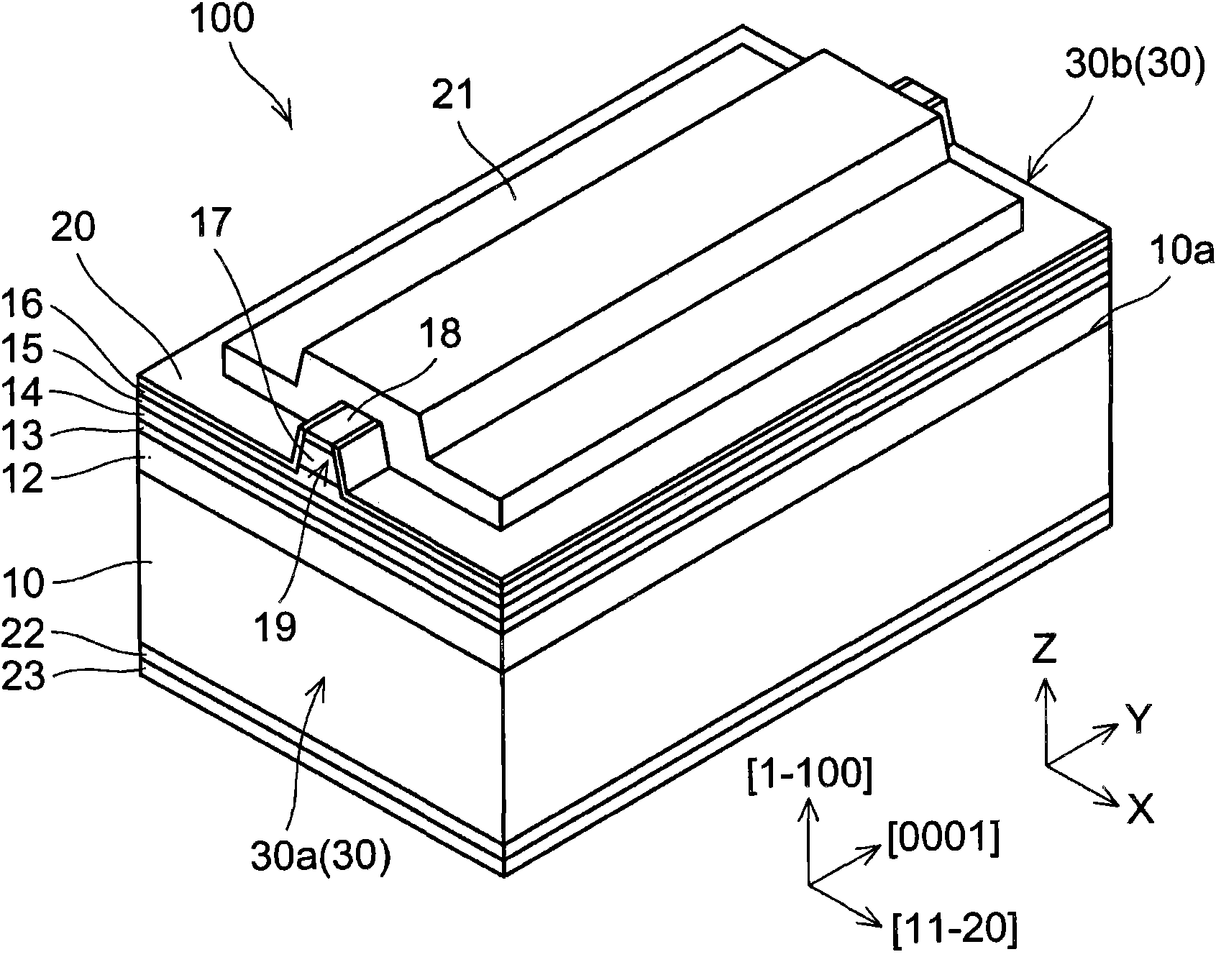

Nitride semiconductor chip, method of fabrication thereof, and semiconductor device

InactiveCN101944480AReduce the driving voltageImprove yieldLaser detailsSemiconductor/solid-state device manufacturingSemiconductor chipNitride semiconductors

A nitride semiconductor chip is provided that offers enhanced luminous efficacy and an increased yield as a result of an improved EL emission pattern and improved surface morphology (flatness). This nitride semiconductor laser chip (nitride semiconductor chip) includes a GaN substrate having a principal growth plane and individual nitride semiconductor layers formed on the principal growth plane of the GaN substrate. The principal growth plane is a plane having an off angle in the a-axis direction relative to the m plane, and the individual nitride semiconductor layers include a lower clad layer of AlGaN. This lower clad layer is formed in contact with the principal growth plane of the GaN substrate.

Owner:SHARP KK

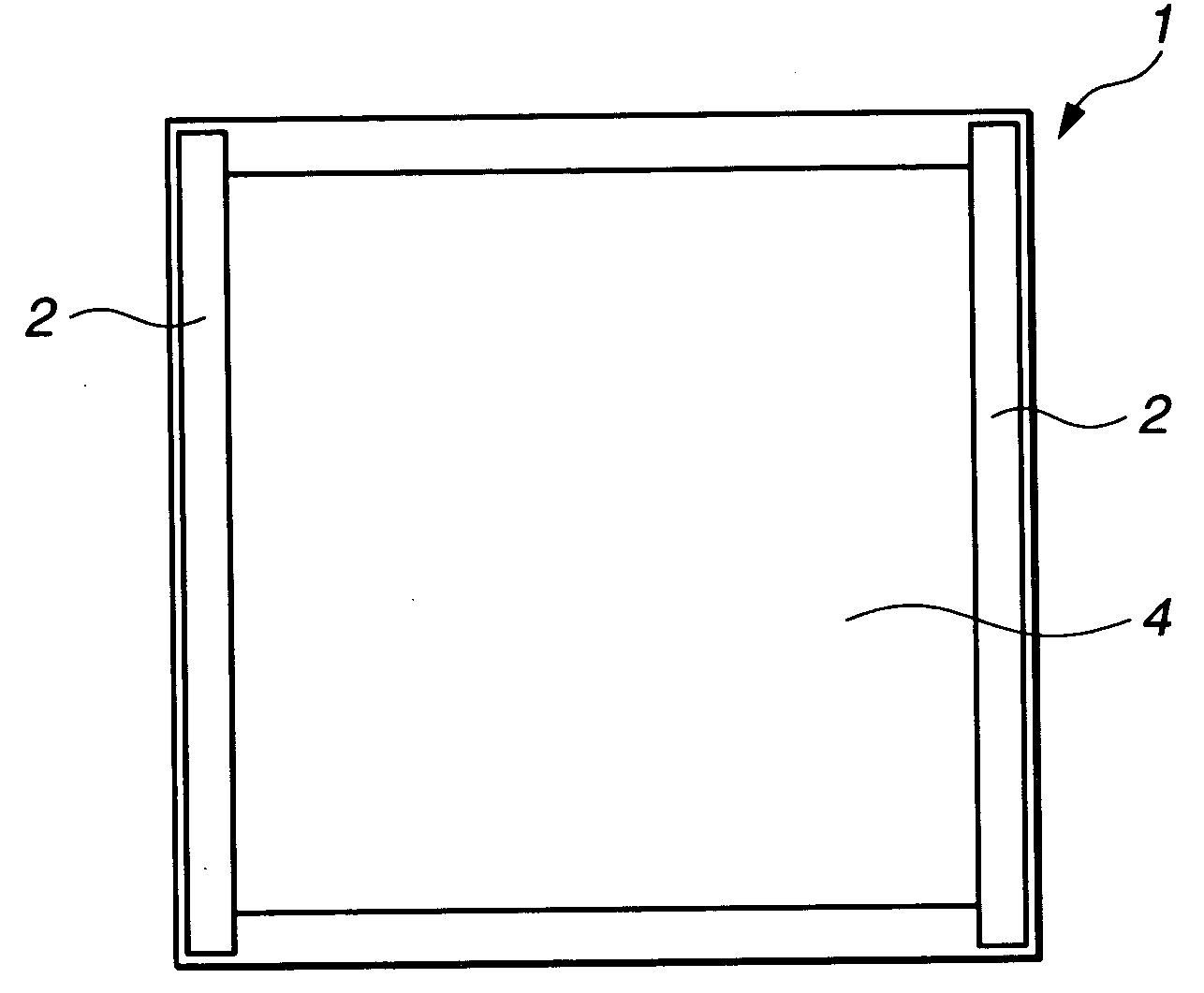

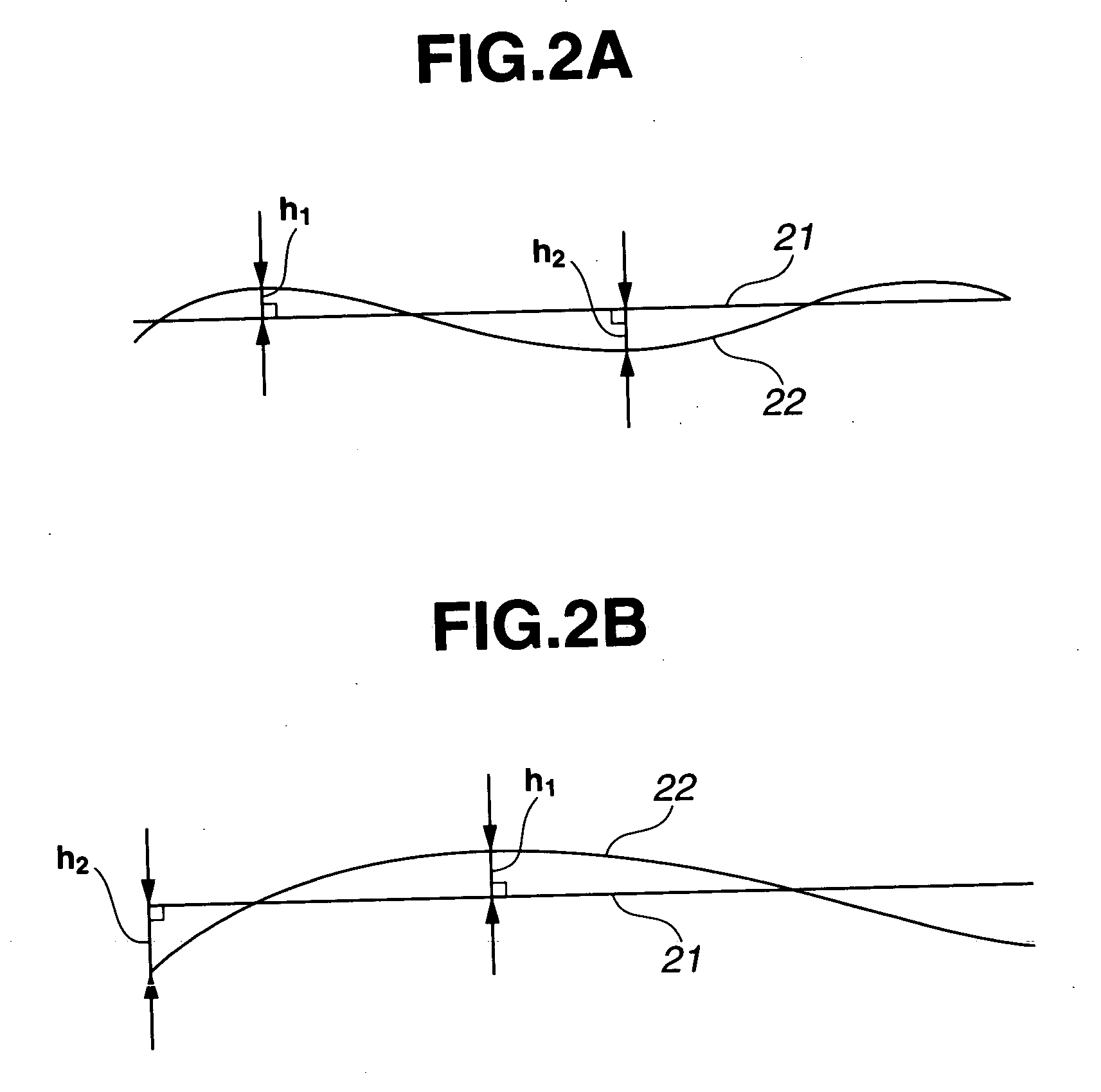

Method of selecting photomask blank substrates

ActiveUS20050019676A1Reduced minimum feature sizeImprove accuracySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentMeasurement pointBand shape

Provided that a pair of strip-like regions extend from 2 mm to 10 mm inside each of a pair of opposing sides along an outer periphery of a top surface of a substrate on which a mask pattern is to be formed, with a 2 mm edge portion excluded at each end in a lengthwise direction thereof, the height from a least squares plane for the strip-like regions on the substrate top surface to the strip-like regions is measured at intervals of 0.05-0.35 mm in horizontal and vertical directions, and a substrate in which the difference between the maximum and minimum values for the height among all the measurement points is μoτμoρετηαν 0.5 μm is selected.

Owner:SHIN ETSU CHEM IND CO LTD +2

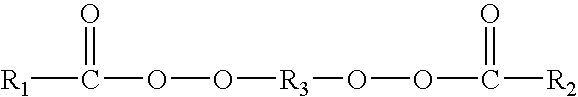

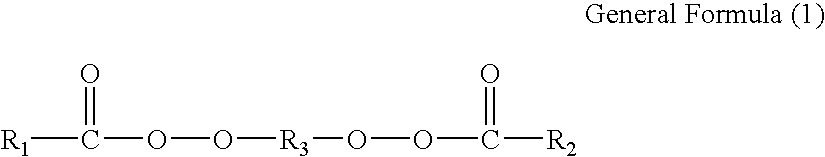

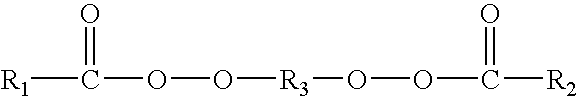

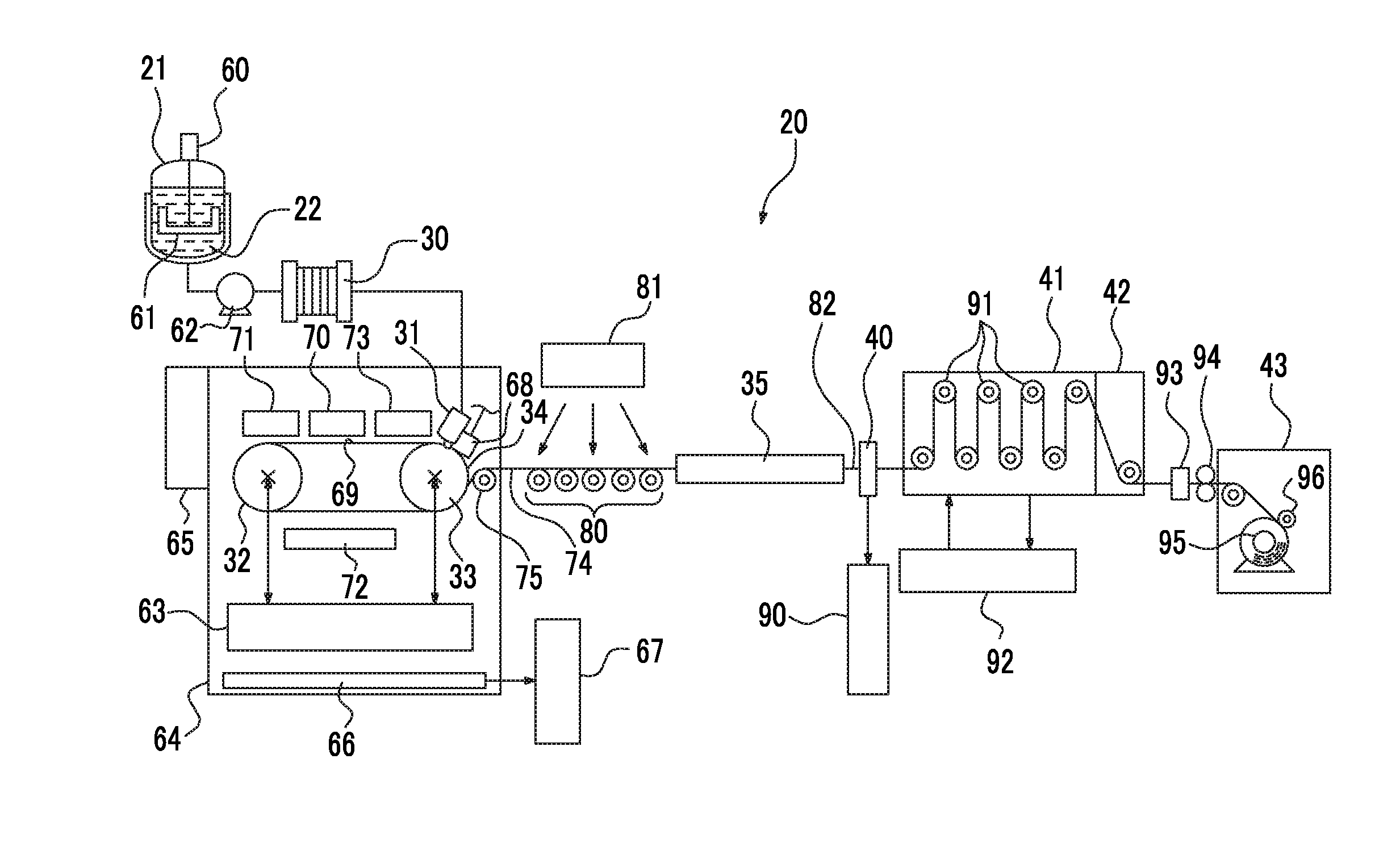

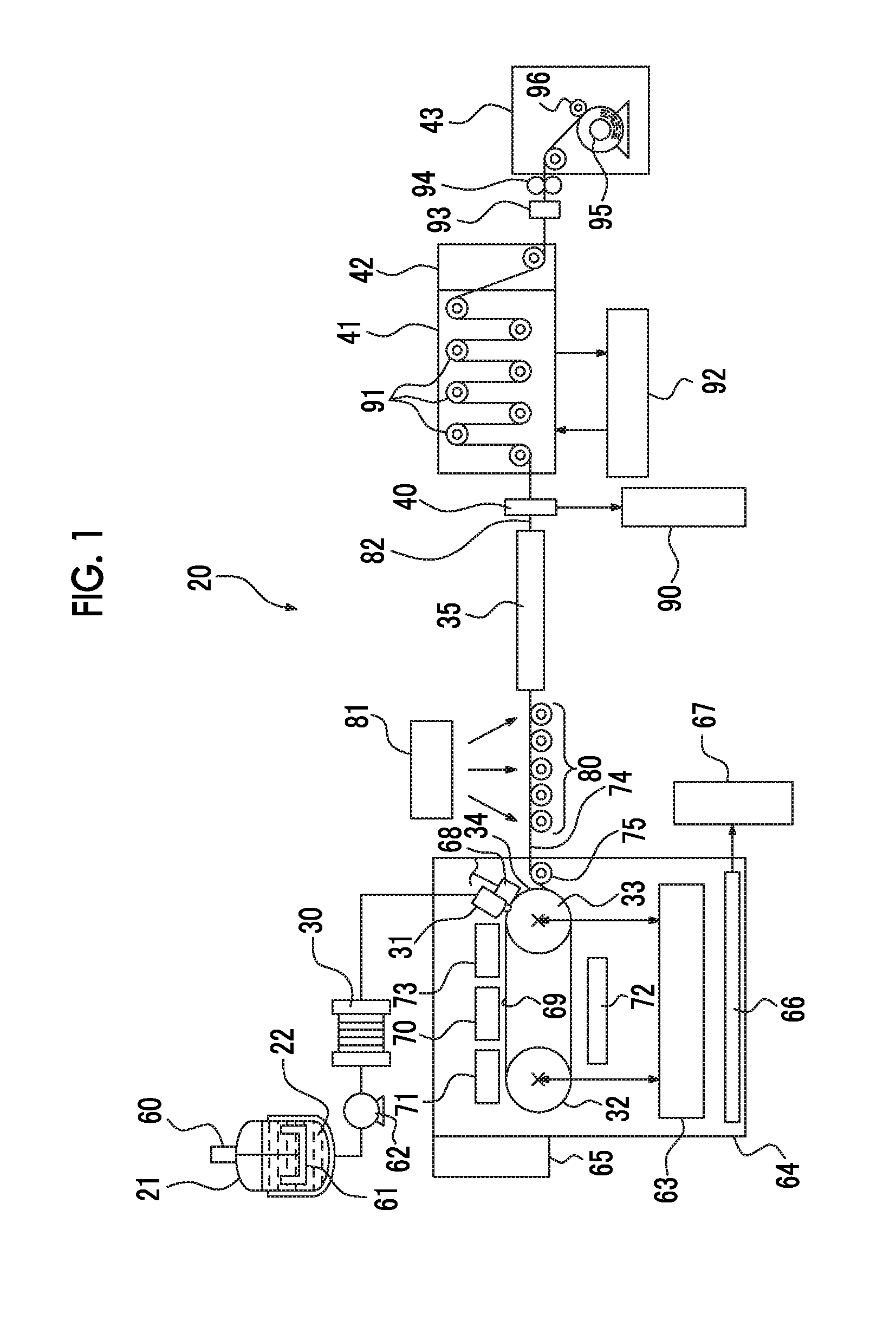

Method for producing polymerized toner, polymerized toner, method for producing binder resin for toner and binder resin for toner

ActiveUS8178275B2Eliminate the effects ofIncrease profitDevelopersMicroballoon preparationMonomer compositionPolymer science

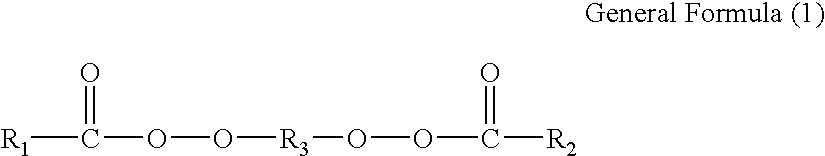

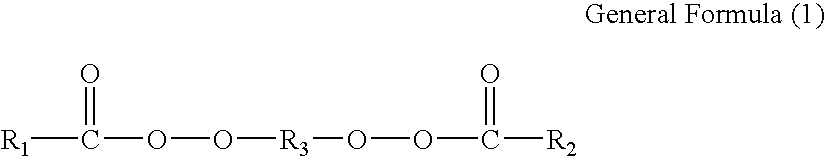

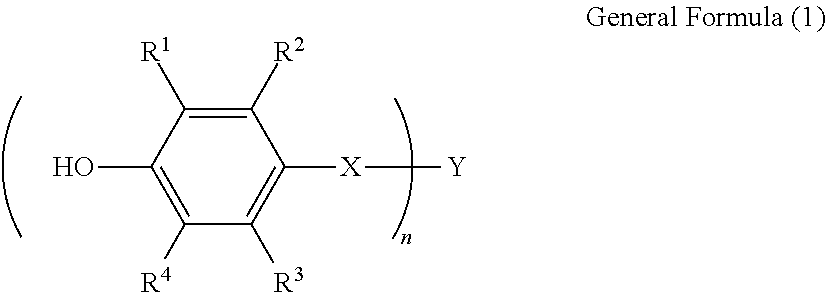

The present invention provides a method for producing a toner that can suppress the production of the decomposition products derived from a polymerization initiator, and can suppress the remaining presence, in the toner particles, of the unreacted polymerizable monomer and decomposition product residues. On the basis of this method, the present invention provides a toner that is excellent in triboelectric charging stability and can yield stable images over a long term. The present invention provides a method for producing a polymerized toner including a step of producing a polymerized toner particle by dispersing in an aqueous medium a polymerizable monomer composition including at least a polymerizable monomer and a colorant and by polymerizing the polymerizable monomer by using a polymerization initiator in the aqueous medium, the method being characterized in that the polymerization initiator has a structure represented by the following General Formula:(wherein R1 and R2 each independently represent an optionally branched or substituted aliphatic hydrocarbon group having 1 to 6 carbon atoms, and R3 represents an optionally branched aliphatic hydrocarbon group having 3 to 12 carbon atoms).

Owner:CANON KK

MEMS device and method of manufacturing the same

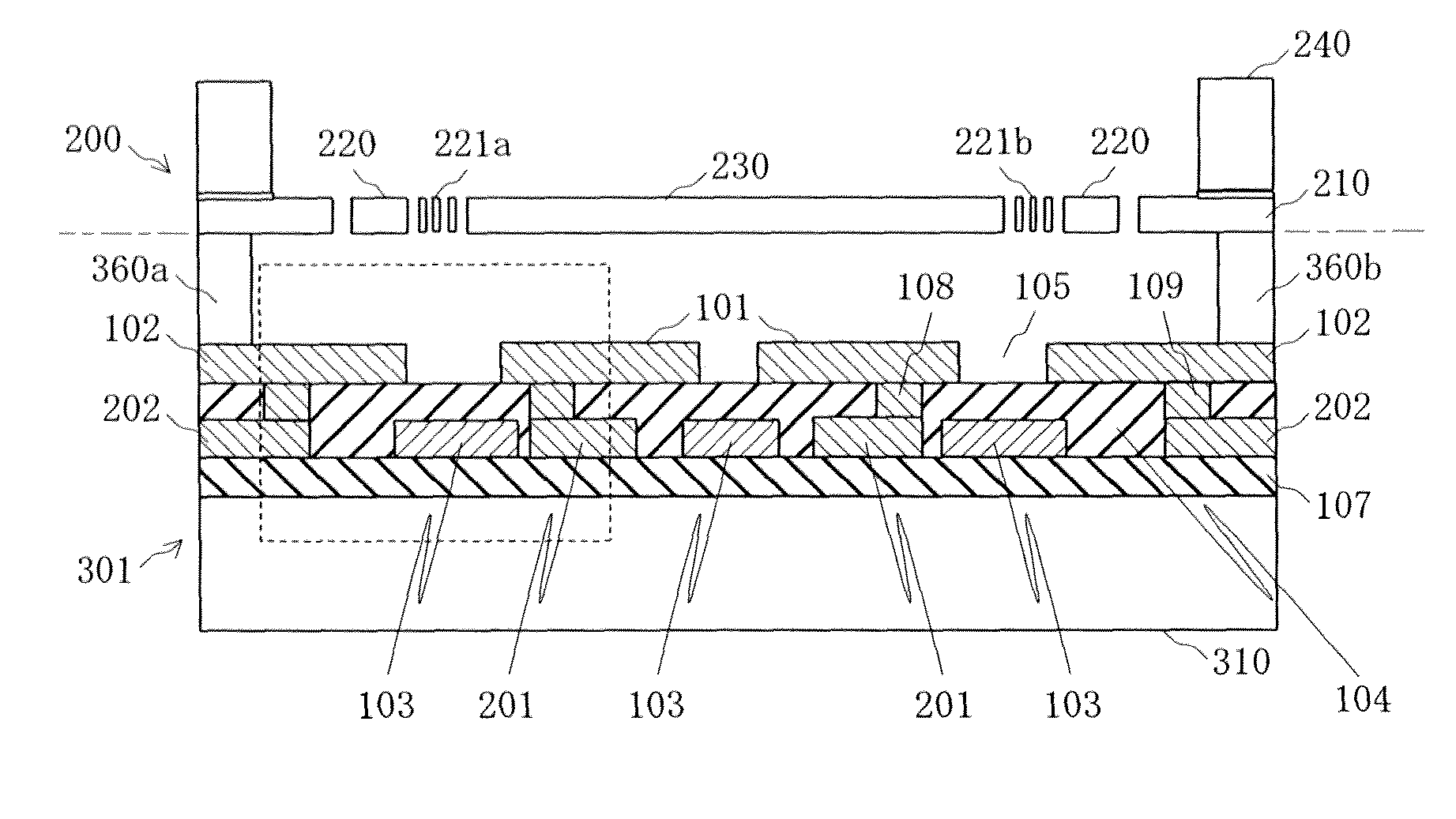

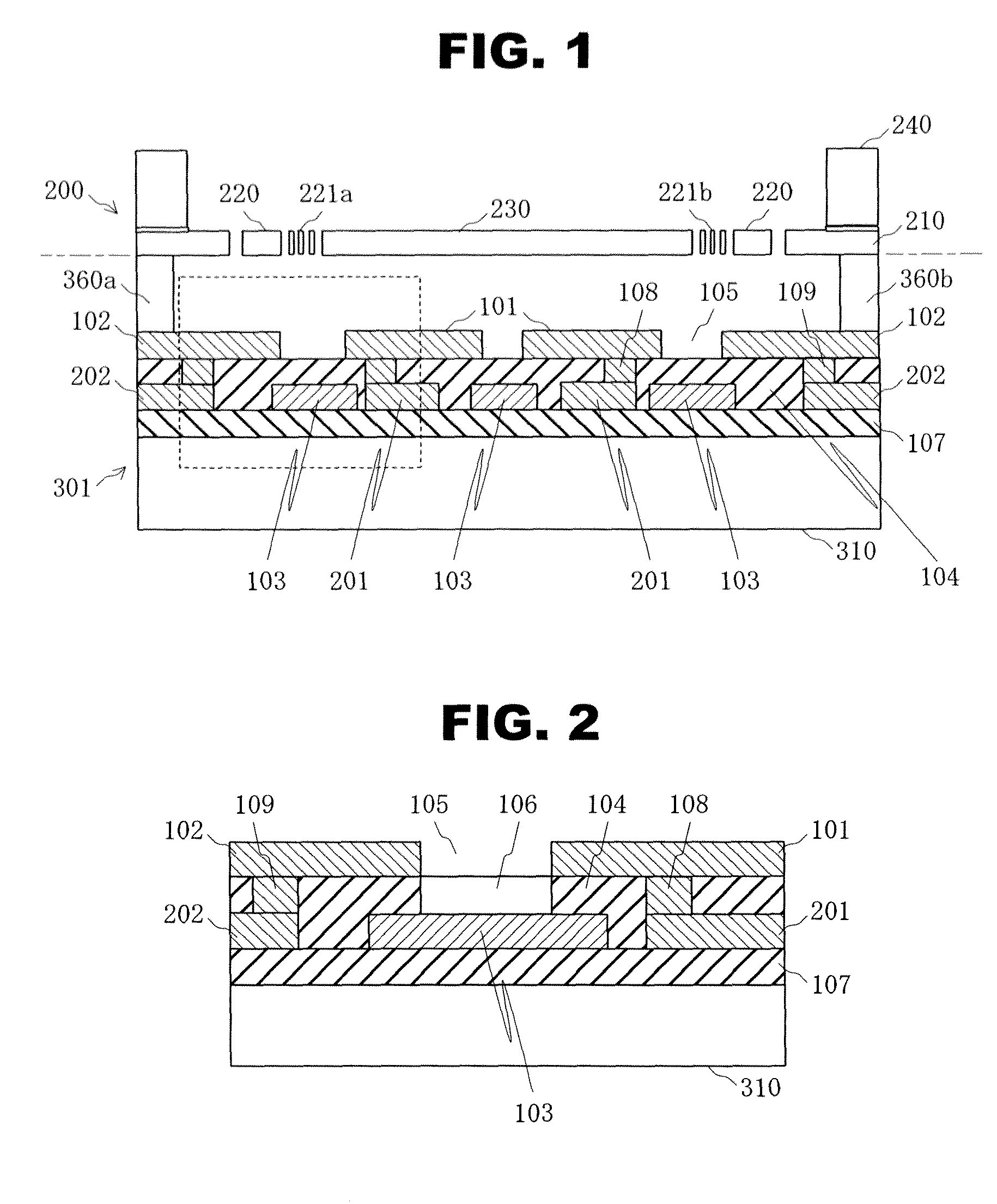

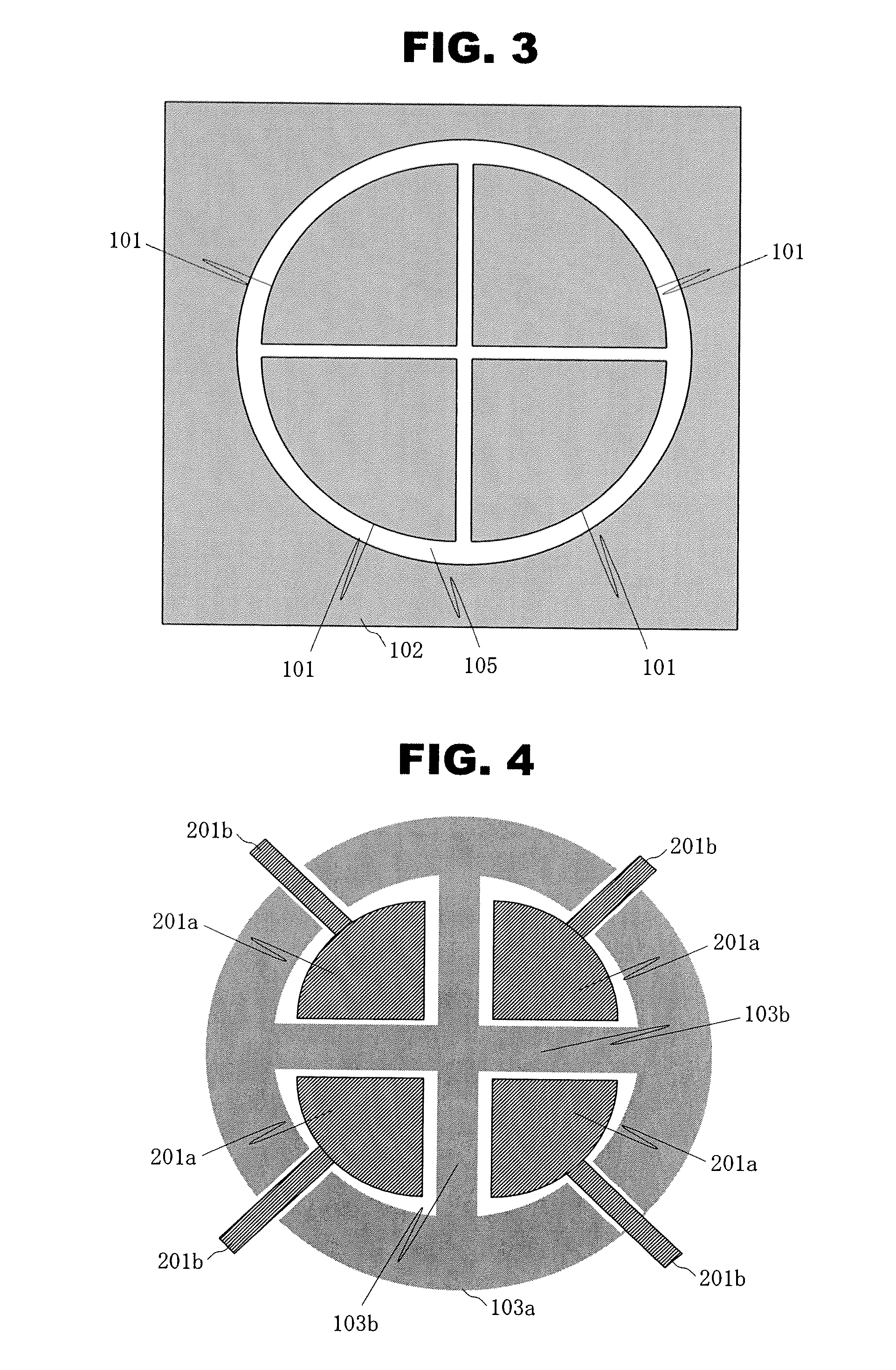

ActiveUS20110013256A1Reduce and prevent charge accumulationDrift suppressionDecorative surface effectsOptical articlesEngineeringSemiconductor

A MEMS device includes a mirror substrate (200), an electrode substrate (301) arranged so as to face the mirror substrate (200), a mirror (230) serving as a movable member rotatably supported in an opening portion of the mirror substrate (200) via support members, a driving electrode (101) arranged on an insulating film (104) on a surface of the electrode substrate (301) facing the mirror substrate (200) so as to face the mirror (230) across a gap and drive the mirror (230), and a lower electrode (103) made of a metal or a semiconductor and formed under the insulating film (104) exposed to the gap so as to be in contact with the insulating film (104).

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

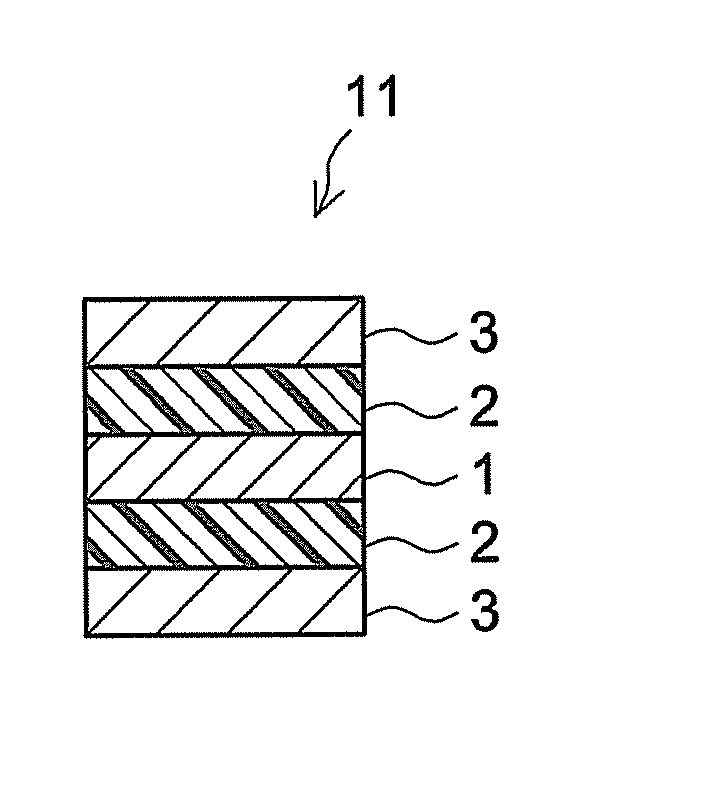

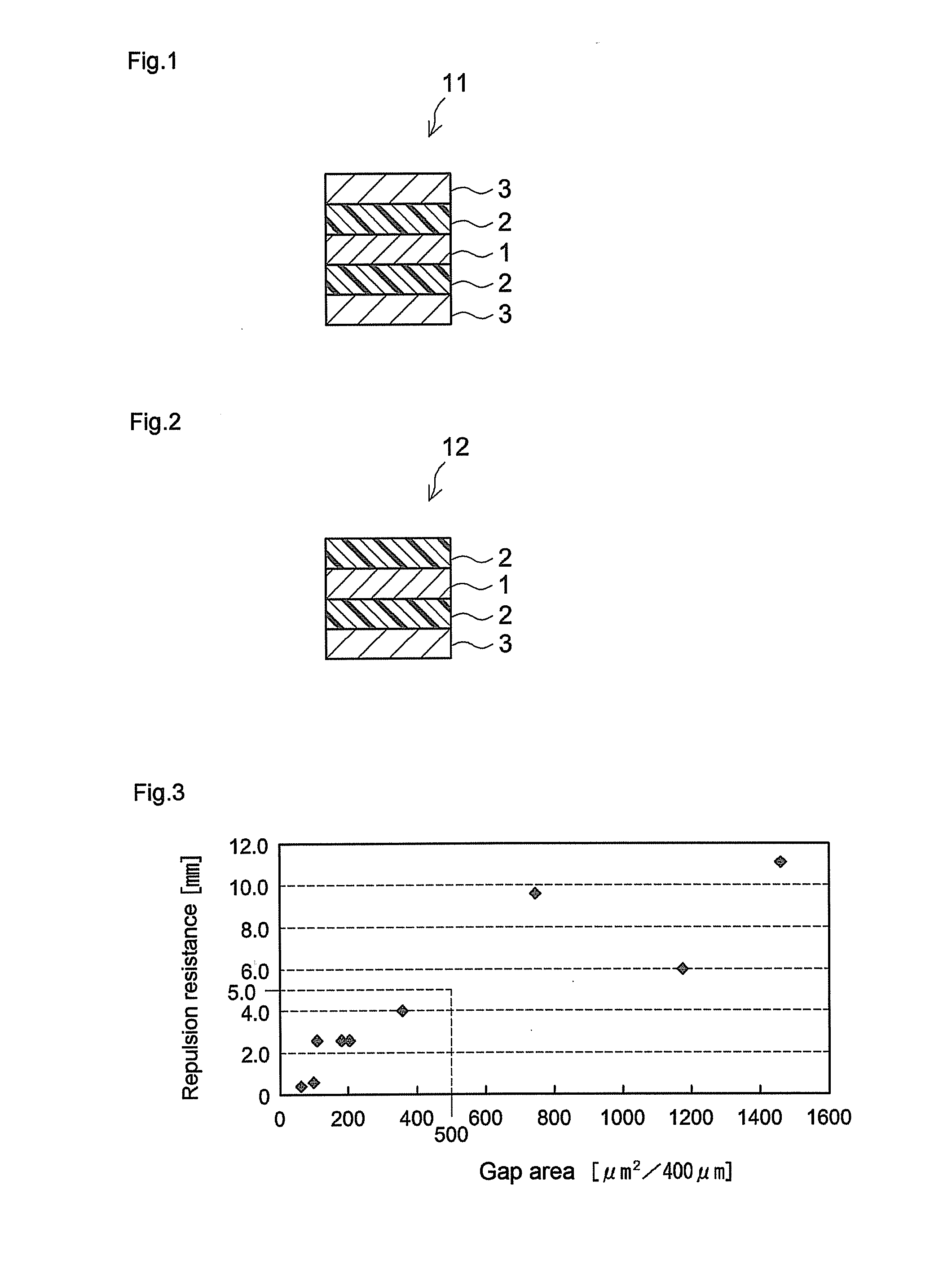

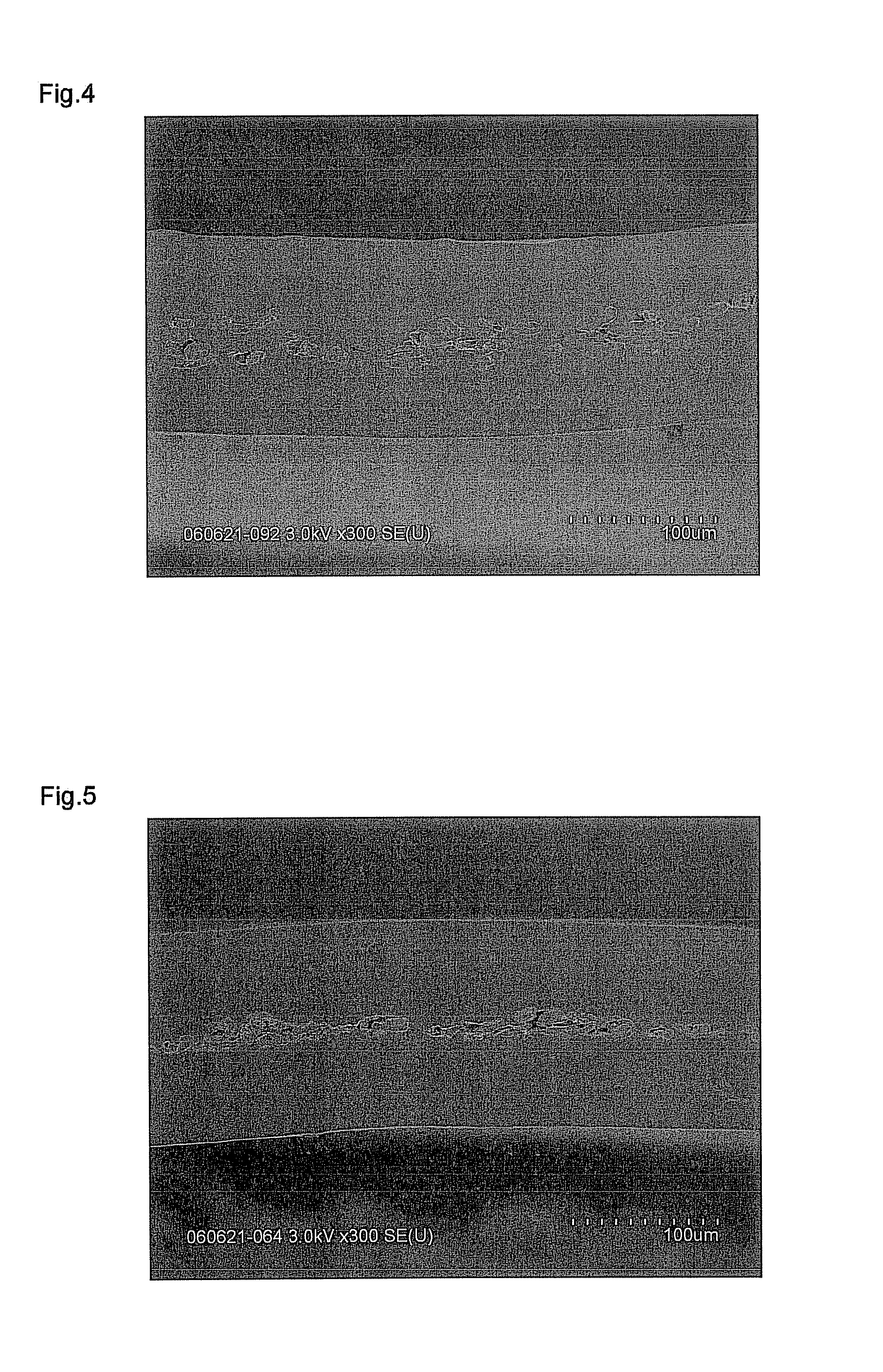

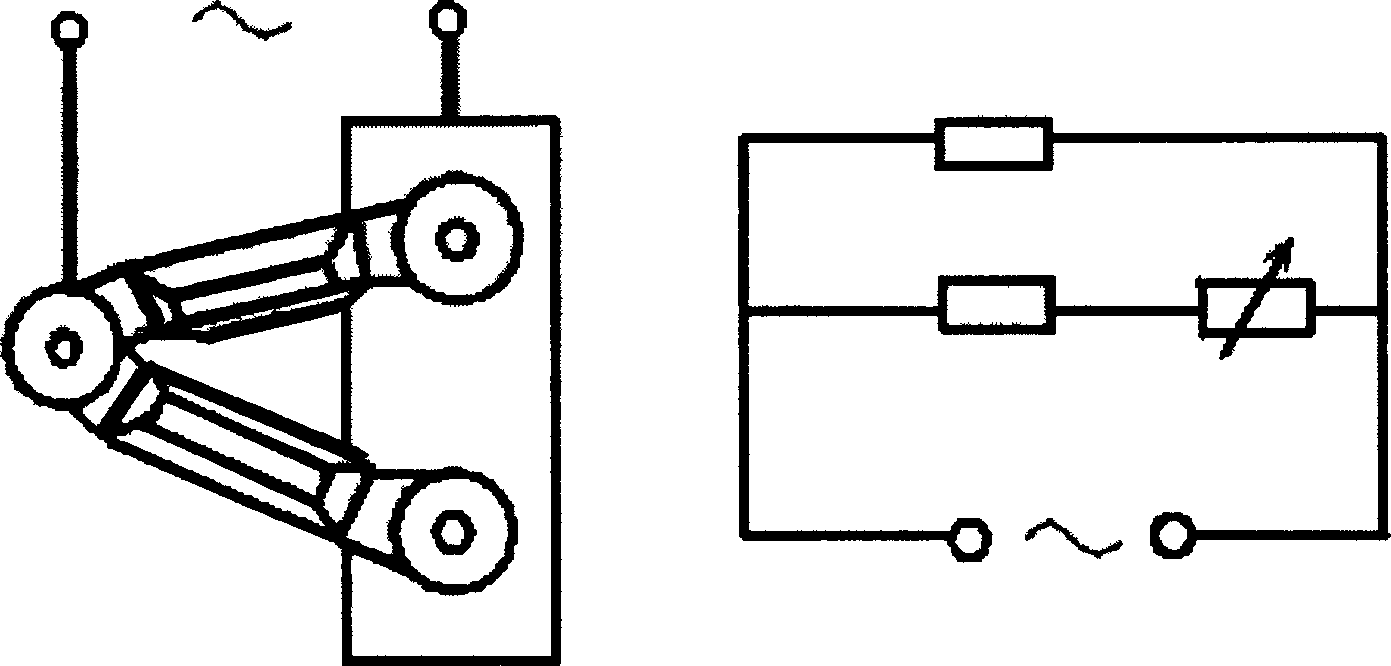

Method for producing double-sided pressure-sensitive adhesive sheet

InactiveUS20080138617A1Improve adaptabilityEfficient productionSpecial surfacesCoatingsNonwoven fabricAqueous dispersion

A method is provided for producing a double-sided pressure-sensitive adhesive (PSA) sheet of a nonwoven fabric substrate, whereby the inherent performance of the PSA is more fully exploited using an aqueous dispersion-type PSA composition. This method comprises preparing an aqueous dispersion-type PSA composition and a nonwoven fabric substrate serving as a support. The method also comprises forming PSA layers which impregnate the substrate and which are obtained by drying the composition. These PSA layers impregnate the substrate so that the area of gaps observed in a vertical cross-section perpendicular to the machine direction of the substrate is about 500 μm2 / 400 μm or less.

Owner:NITTO DENKO CORP

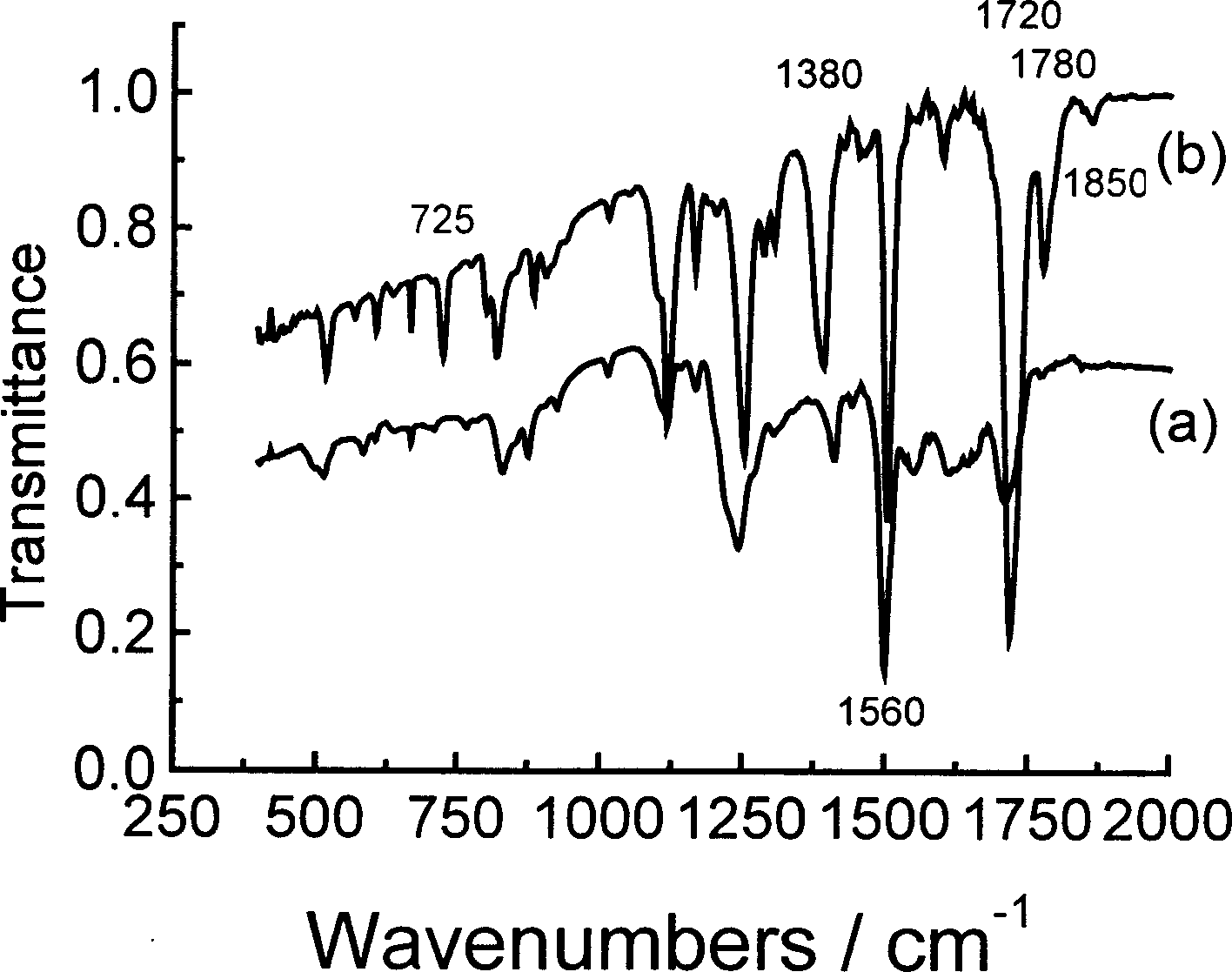

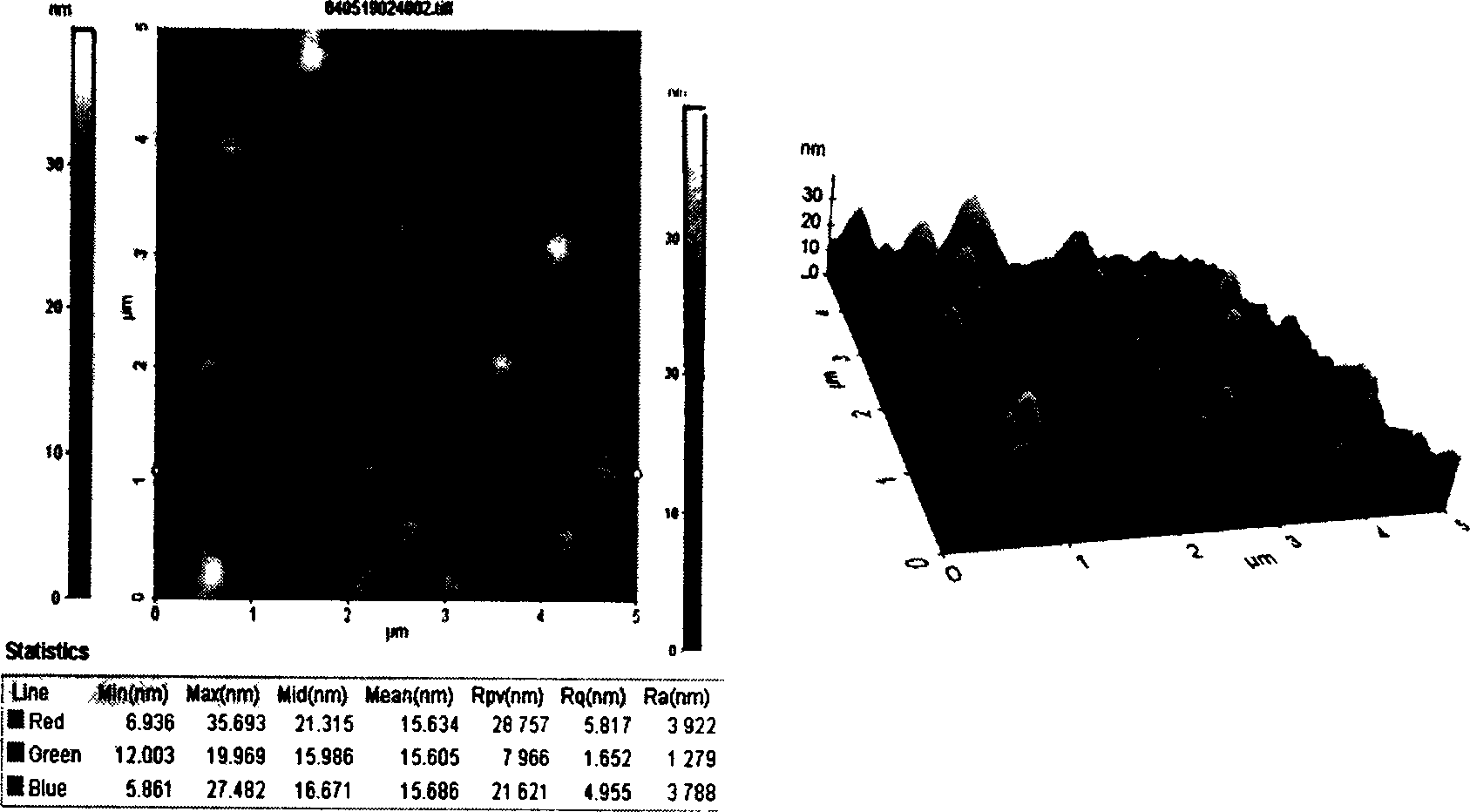

Preparation process for physics vapour phase deposition of ultrathin self-suporting polyimide filter film

InactiveCN1598041AReduce pollution sourcesReduce defectsVacuum evaporation coatingSputtering coatingGas phaseOptoelectronics

The invention provides a method of preparation ultrathin self-supporting polyimide light sieving film. Using completely PVD method, successively depositing doffing pellicle twain anhydride and diamine on the polishing glass substrate in the high vacuum environment, and then processing heat treatment in proper surrounding temperature., make sure twain anhydride and diamine form polymeric amic acid, and more ring-imidization. Sticking the orbicular copper frame on the surface of polyimide thin film, followed by removing the film in the deionized water, finally form the ultrathin self-supporting polyimide light filter film. The thin film could be applied as the light filter component of shortwave optics.

Owner:TONGJI UNIV

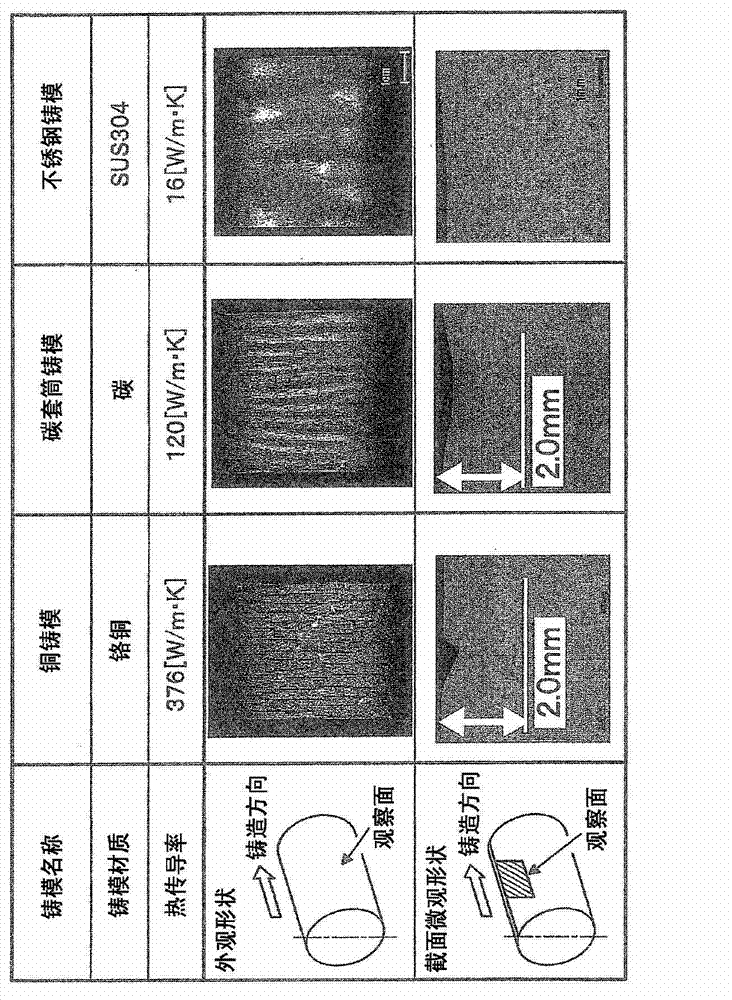

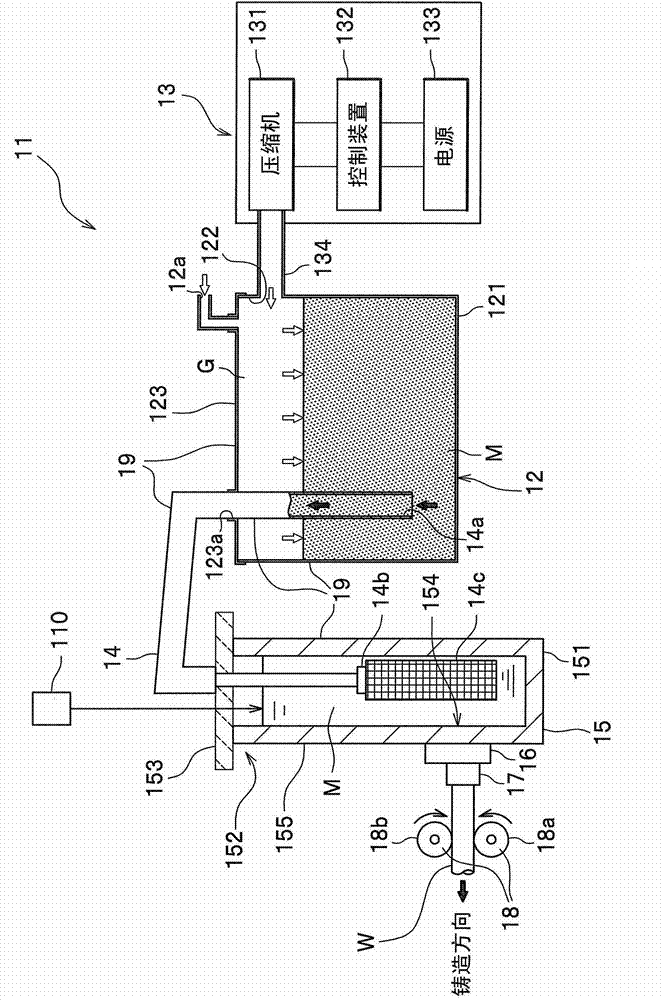

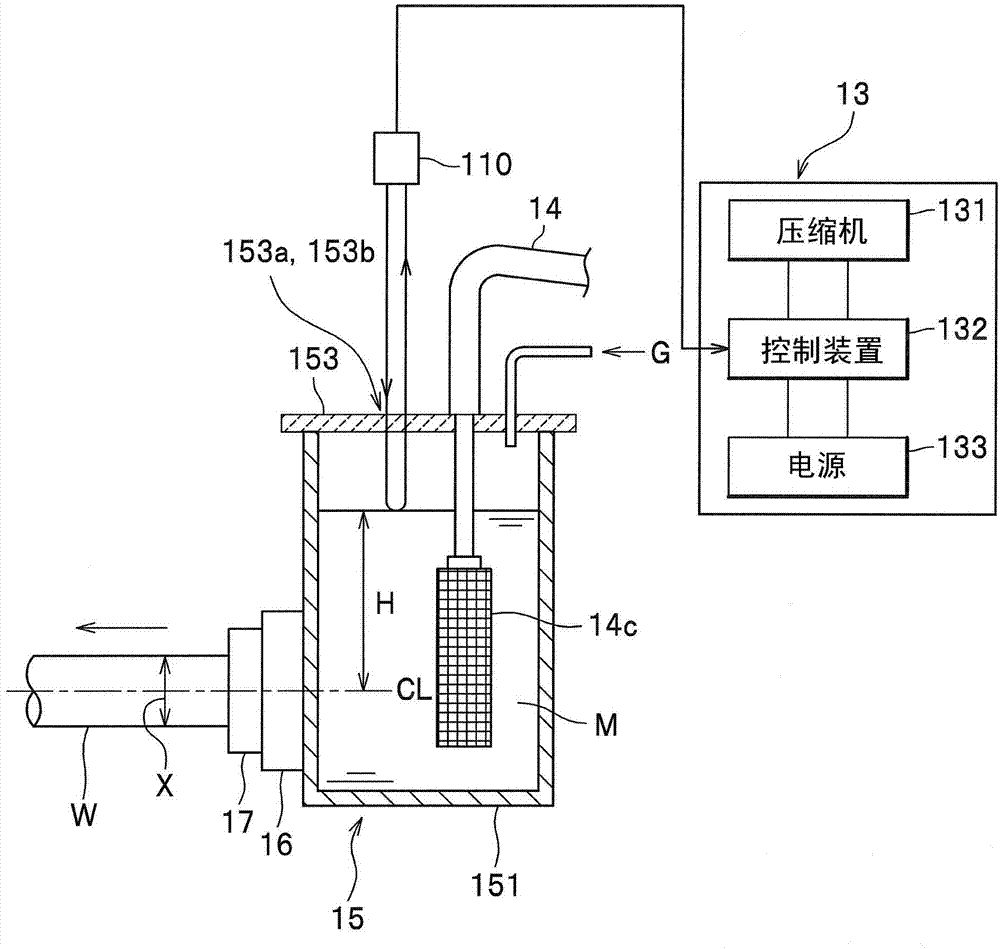

A continuous casting device and a continuous casting method for continuously casting castings formed by magnesium or magnesium alloys

InactiveCN103286286AImprove casting qualityEasy to cleanCasting parameters measurement/indication devicesMolten metalMagnesium alloy

The invention provides a continuous casting device and a continuous casting method, which are capable of stably conducting continuous casting of magnesium alloys. The continuous casting device comprises a holding furnace used for holding molten metal of magnesium or magnesium alloys; a leaking groove used for internally storing up the molten metal supplied from the holding furnace and supplying the stored molten metal continuously to a casting mould used for continuous casting; a molten metal supplying pipe arranged between the holding furnace and the leaking groove and used for supplying the molten metal to the leaking groove; a heating device used for heating the leaking groove; the casting mould used for continuous casting, which is connected with the leaking groove; and a drawing device used for drawing the castings delivered from the casting mould used for continuous casting by a conveying roller.

Owner:KOBE STEEL LTD

Polytetrafluoroethylene-based ion exchange membrane for vanadium batteries, and its making method

InactiveCN104332642AHigh mechanical strengthGood surface shapeFinal product manufactureCell electrodesIon-exchange membranesChemistry

The invention relates to a making method of an ion exchange membrane composite membrane for all-vanadium redox flow batteries. The method comprises the following steps: immersing a high-molecular polymer polytetrafluoroethylene (PTFE) porous membrane in anhydrous ethanol to remove organic matters on the surface of the porous membrane; casting a perfluorosulfonate resin (Nafion) and nano-SiO2 mixed solution on the PEFE; and heating the obtained composite membrane in a common drying box in order to remove the above organic solvent, transferring to the vacuum drying box after the surface has no obvious flow, and drying to prepare the PEFE / Nafion / SiO2 composite membrane. The composite proton exchange membrane made in the invention has the characteristics of easy regulation of the thickness, low cost, simple operation, high proton conductivity, high vanadium resistance, and great reduction of the cost of diaphragms for the all-vanadium redox flow batteries.

Owner:HARBIN INST OF TECH AT WEIHAI

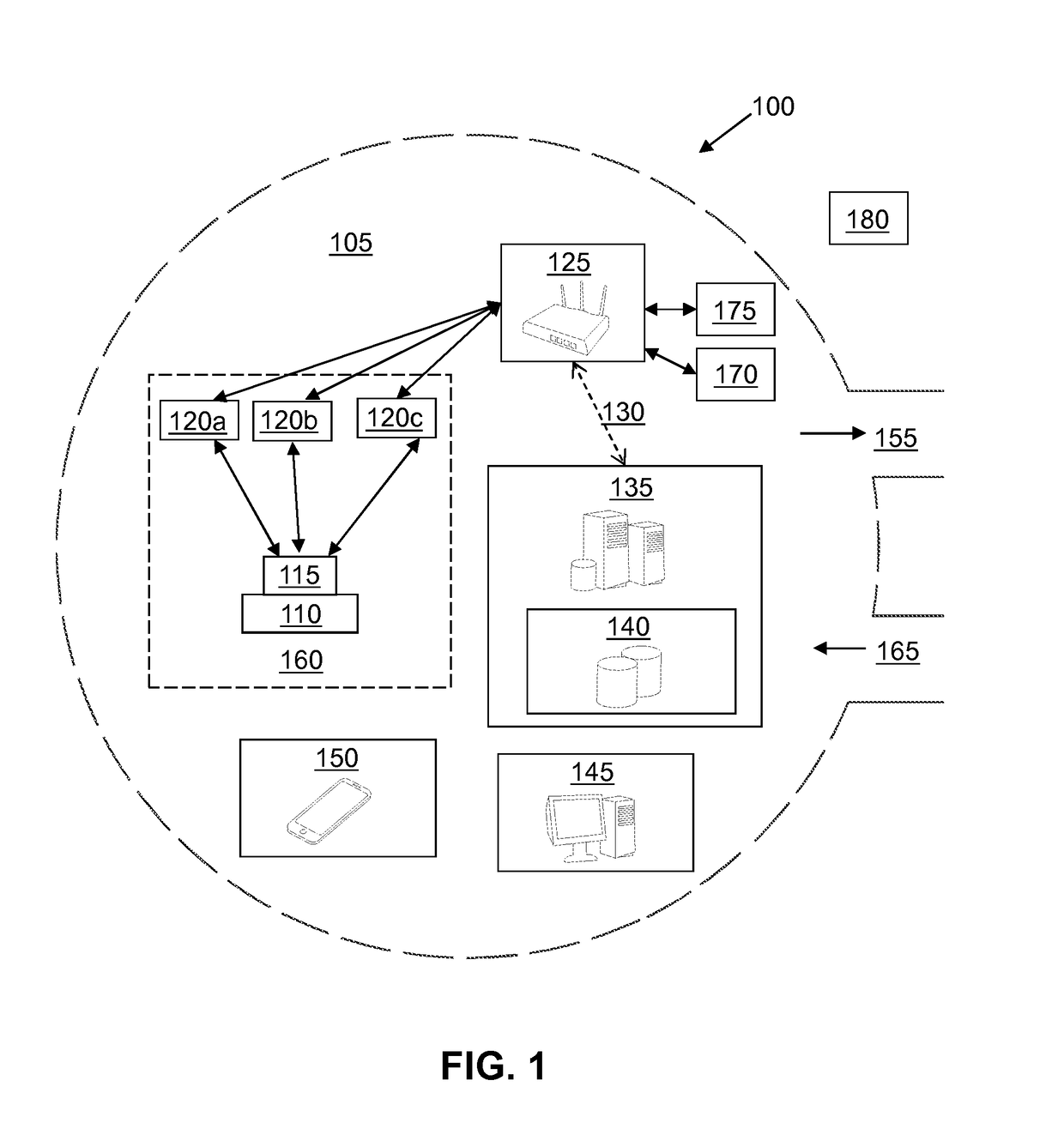

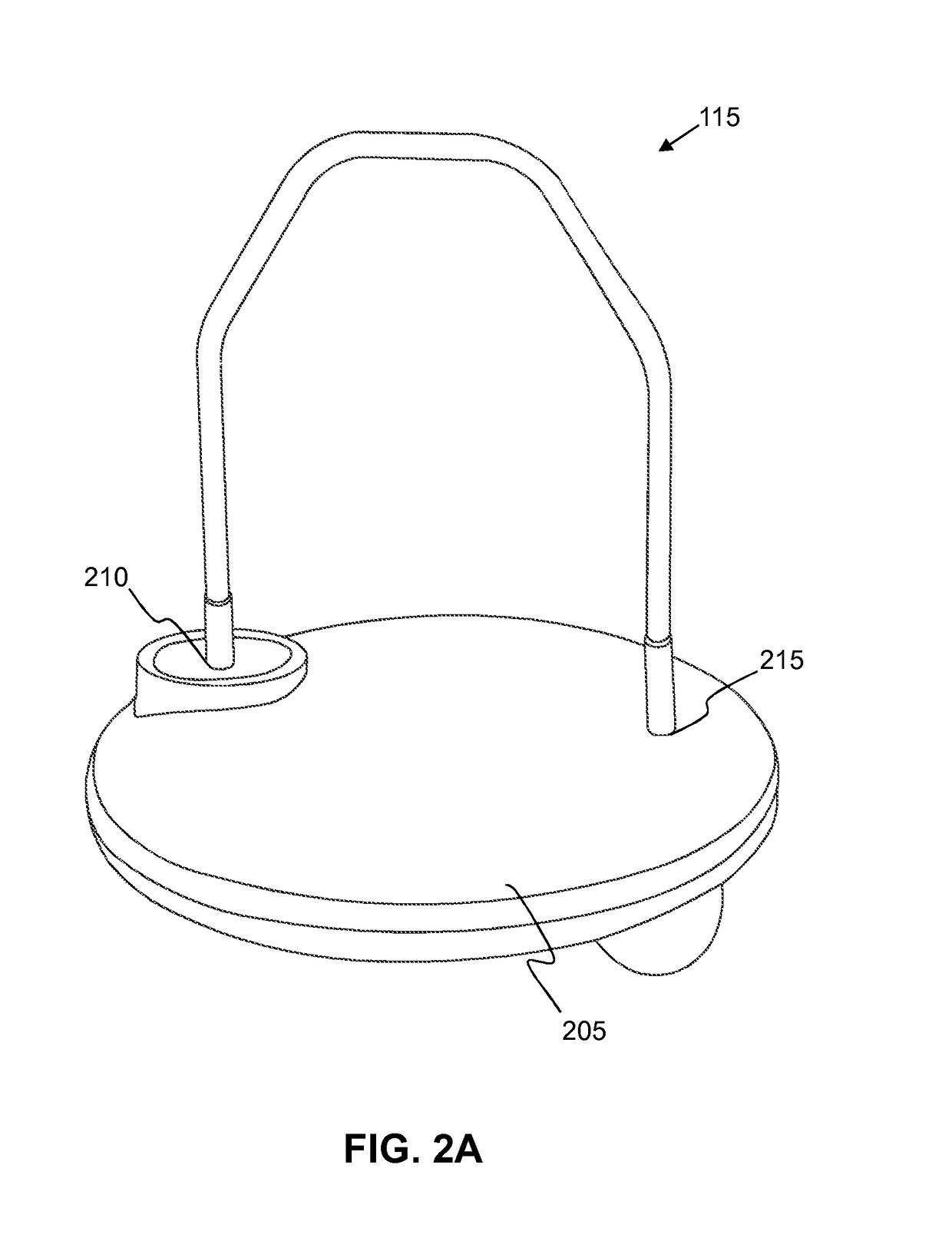

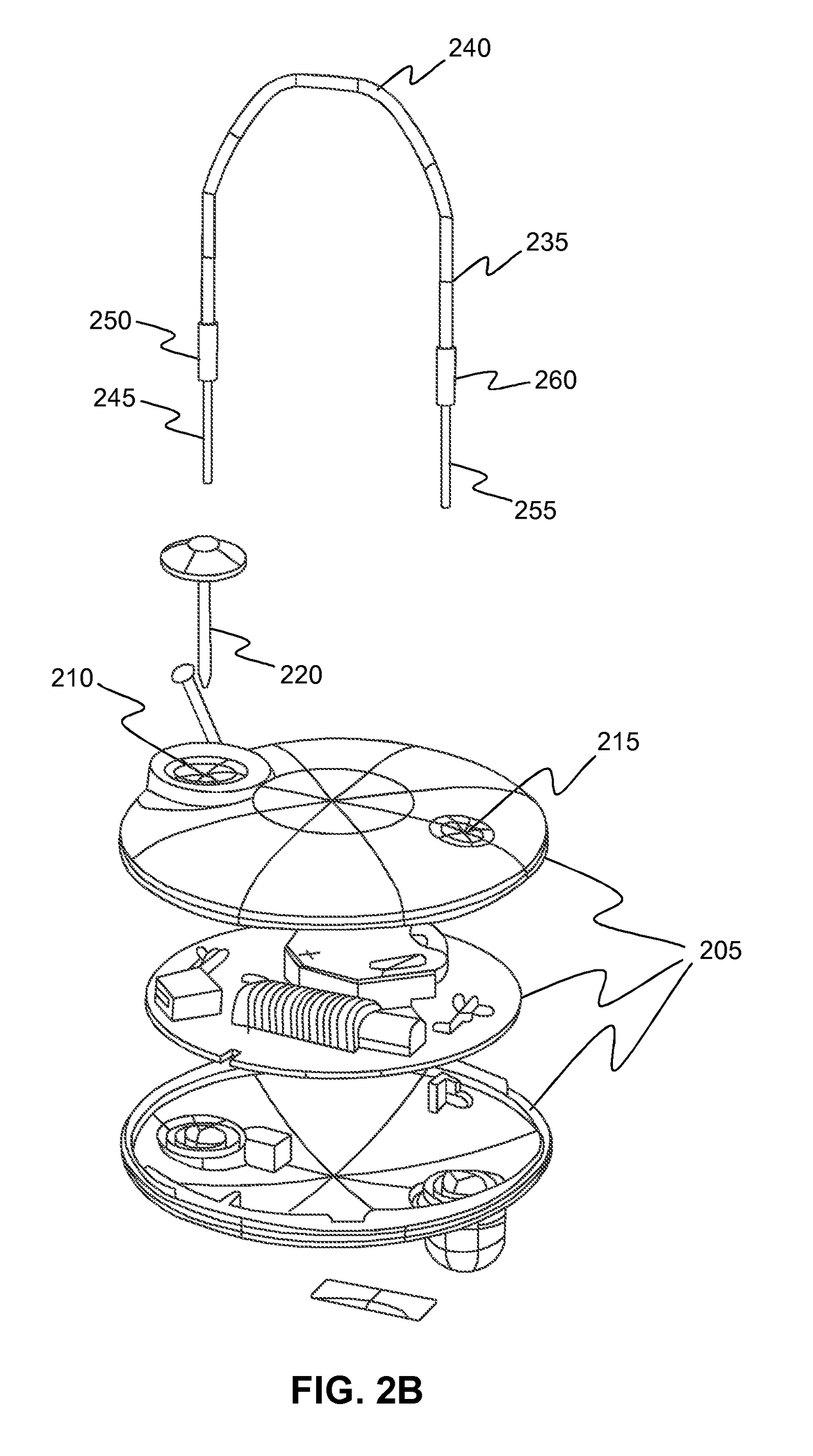

Electronic article surveillance tag

ActiveUS20190027009A1Good adhesionReduce thicknessBurglar alarm electric actuationLocking mechanismEngineering

The present invention relates to an electronic article surveillance tag that comprises a body provided with a battery compartment for holding a battery. The body comprises a first opening through which an end of a first pin can be inserted inside the body and releasably locked therein by a first locking mechanism. The electronic article surveillance tag further comprises a slidable cover for closing the battery compartment. The slidable cover comprises a second opening that is aligned with the first opening when the slidable cover is in a closed position. The present invention also relates to an alarm system for a facility (105).

Owner:NOCCELA

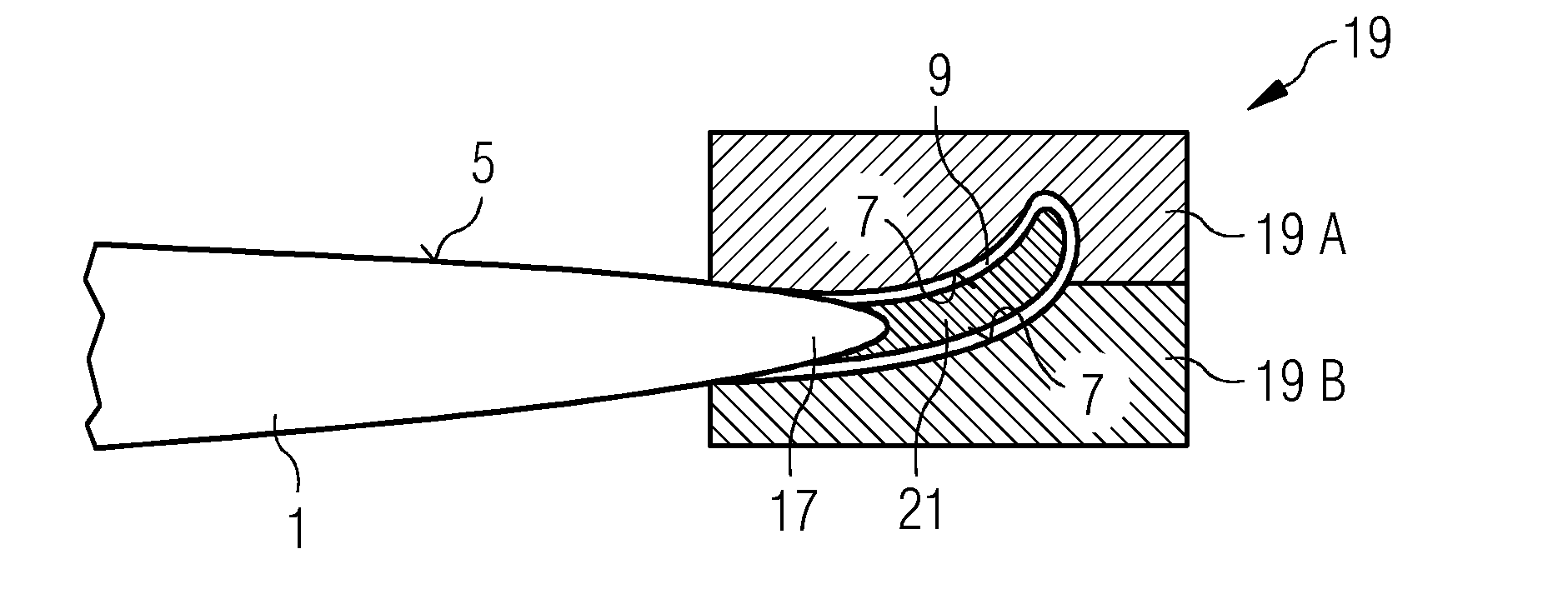

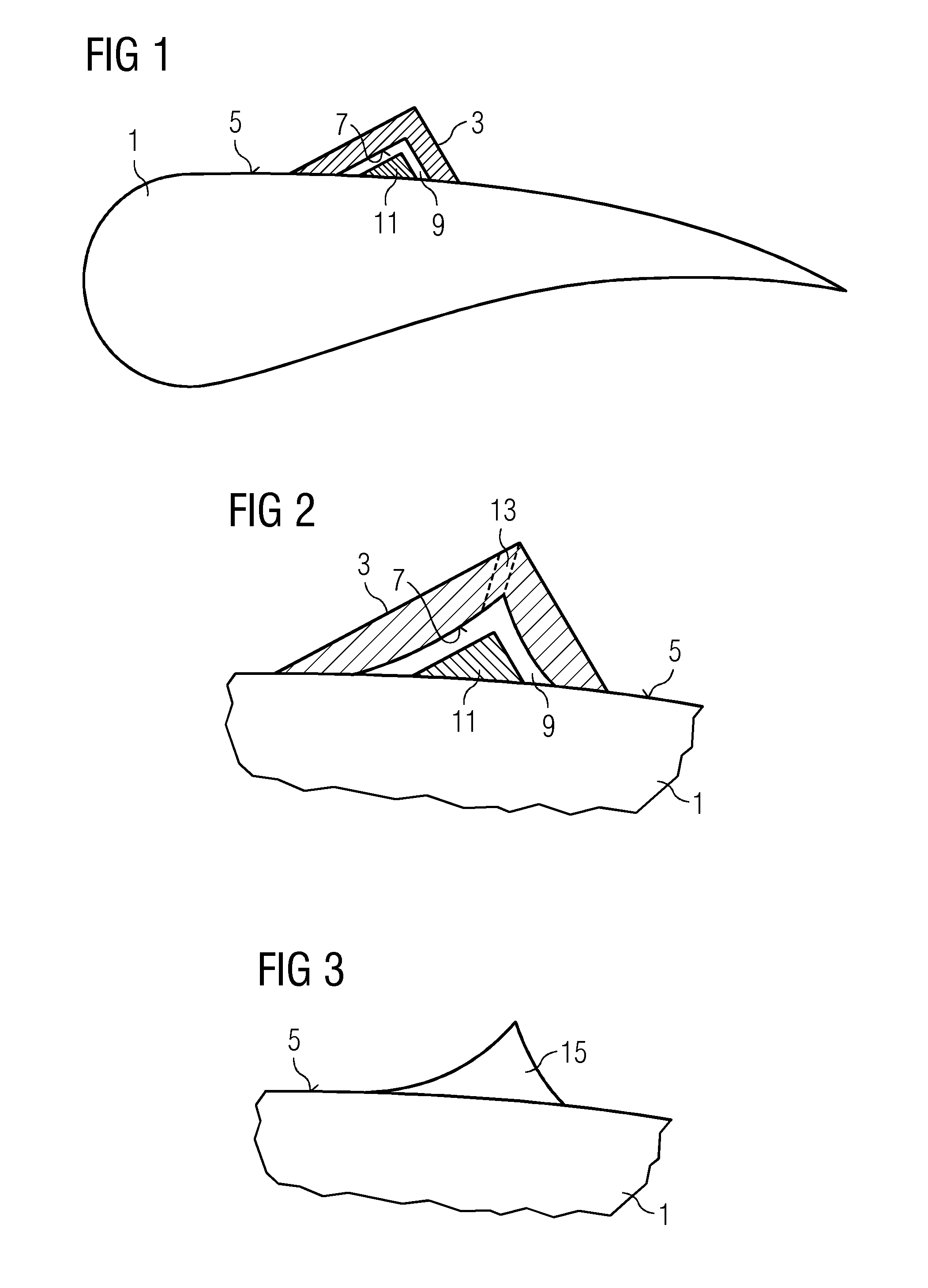

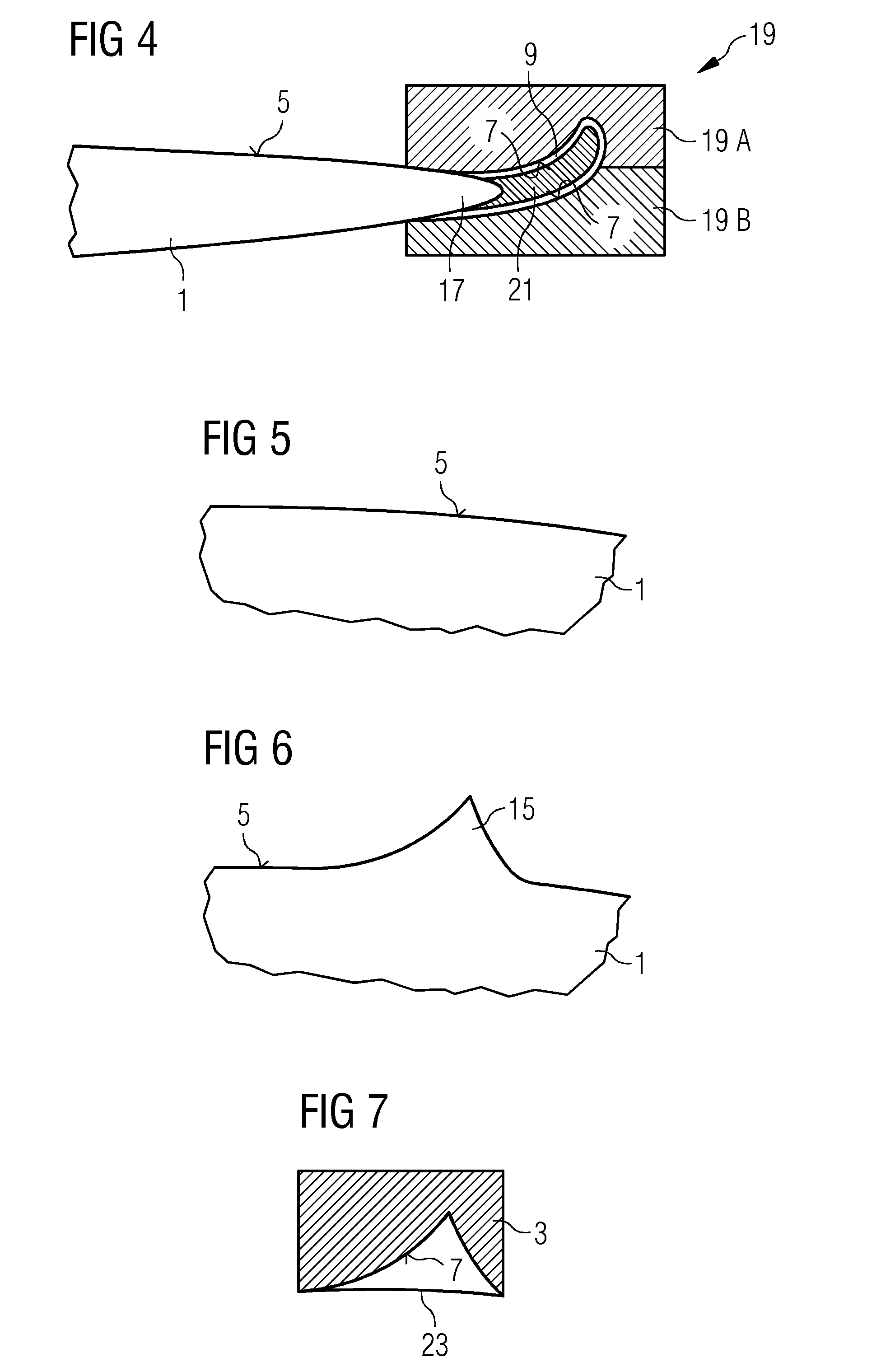

Method of modifying the surface shape of a wind turbine rotor blade and tool for use in this method

InactiveUS20120313291A1Simple mountingGood surface shapeEngine manufactureTailstocks/centresEngineeringSurface shape

A method of modifying the surface shape of a wind turbine rotor blade is provided in which a shape modifying element is cast on a surface of the wind turbine rotor blade. A mould includes an inner mould surface, the shape of which is defined according to a result of subtracting an unmodified surface shape of the wind turbine rotor blade from a desired modified surface shape.

Owner:SIEMENS AG

Method for producing polymerized toner, polymerized toner, method for producing binder resin for toner and binder resin for toner

ActiveUS20100119965A1Stable imageEliminate the effects ofDevelopersMicroballoon preparationChemistryDecomposition

The present invention provides a method for producing a toner that can suppress the production of the decomposition products derived from a polymerization initiator, and can suppress the remaining presence, in the toner particles, of the unreacted polymerizable monomer and decomposition product residues. On the basis of this method, the present invention provides a toner that is excellent in triboelectric charging stability and can yield stable images over a long term. The present invention provides a method for producing a polymerized toner including a step of producing a polymerized toner particle by dispersing in an aqueous medium a polymerizable monomer composition including at least a polymerizable monomer and a colorant and by polymerizing the polymerizable monomer by using a polymerization initiator in the aqueous medium, the method being characterized in that the polymerization initiator has a structure represented by the following General Formula:(wherein R1 and R2 each independently represent an optionally branched or substituted aliphatic hydrocarbon group having 1 to 6 carbon atoms, and R3 represents an optionally branched aliphatic hydrocarbon group having 3 to 12 carbon atoms).

Owner:CANON KK

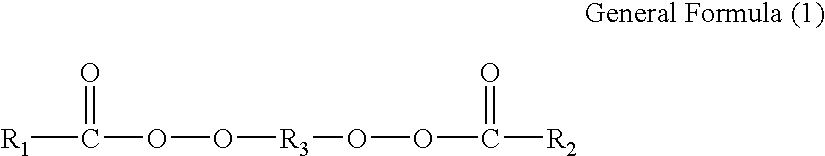

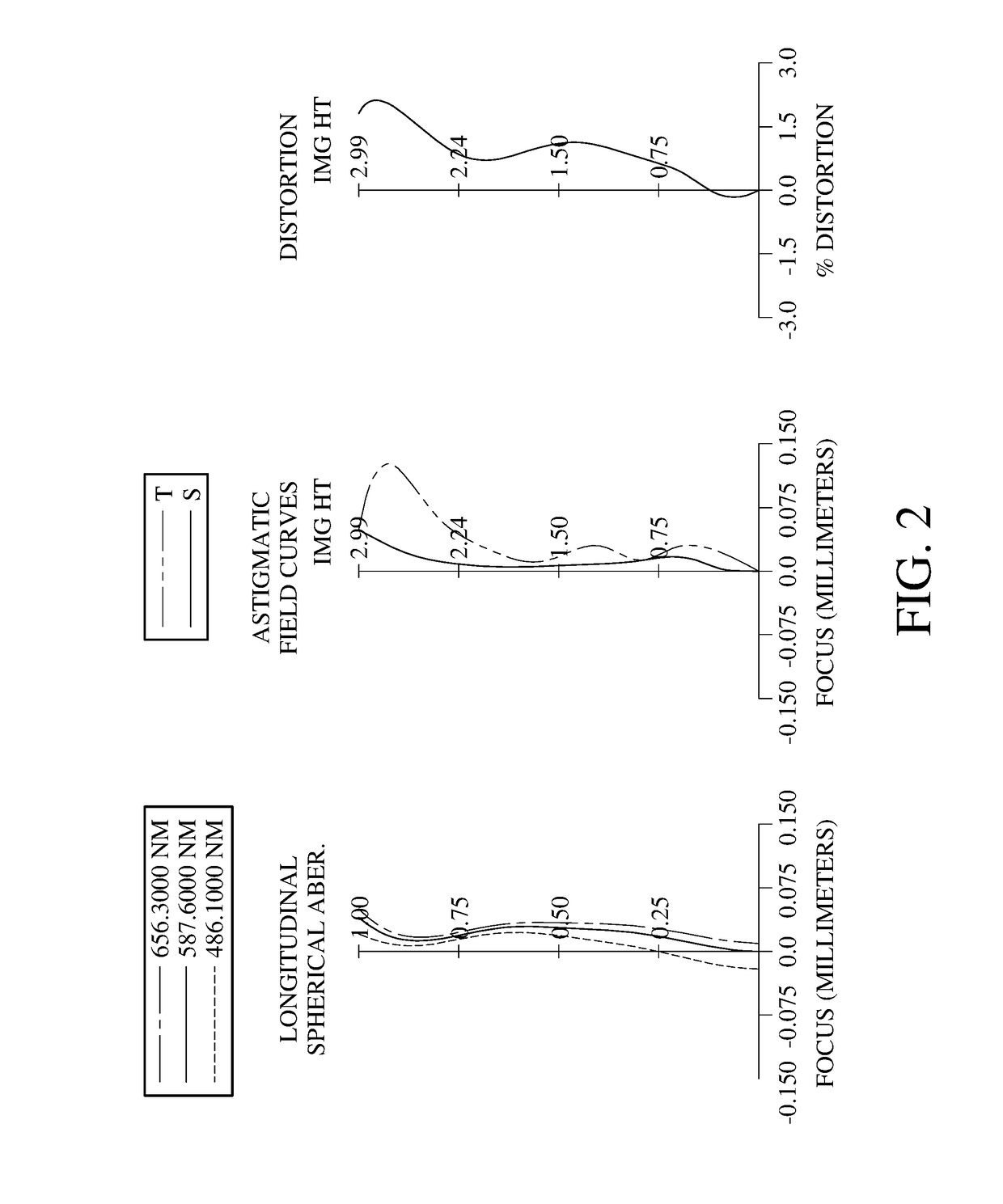

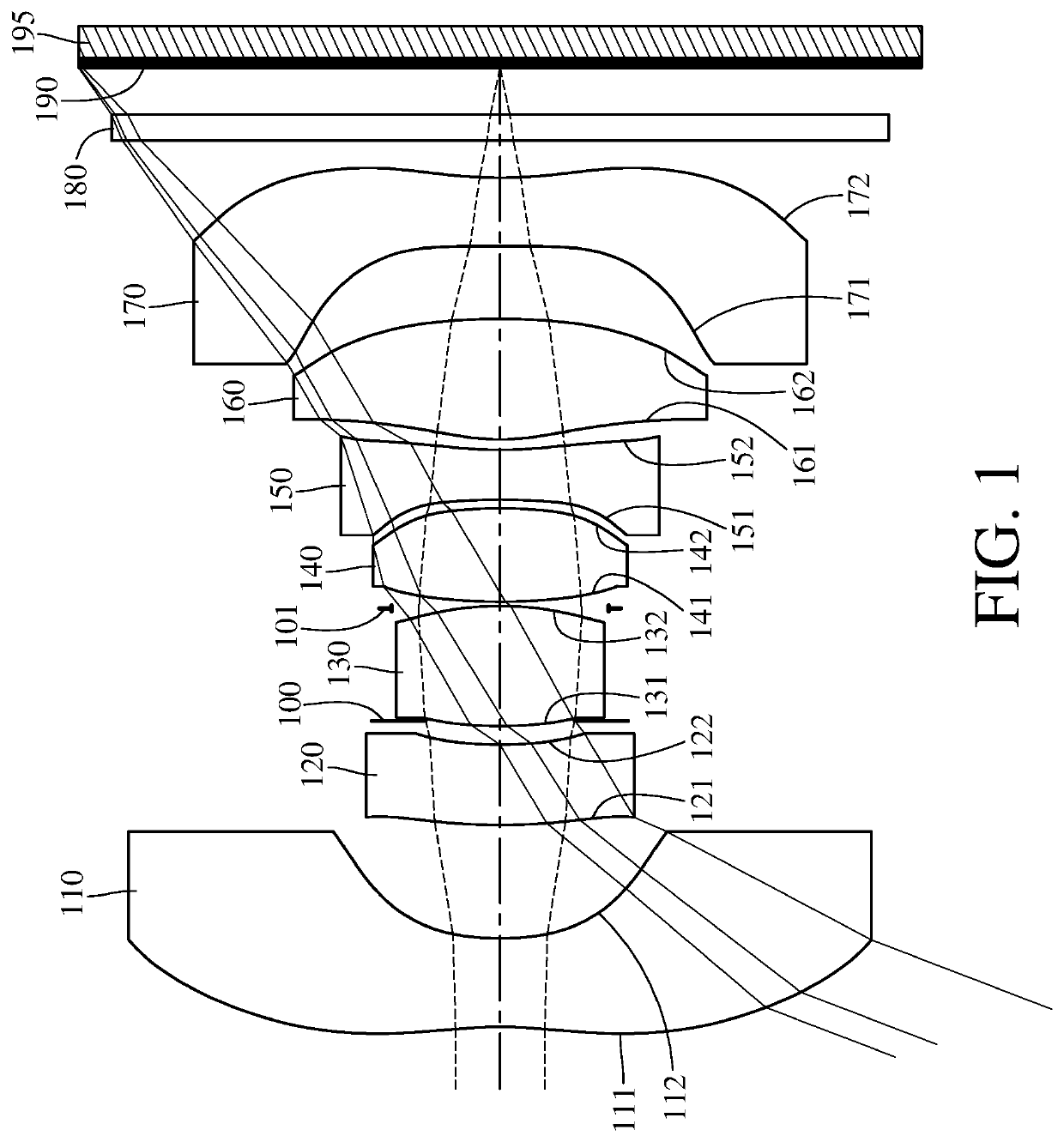

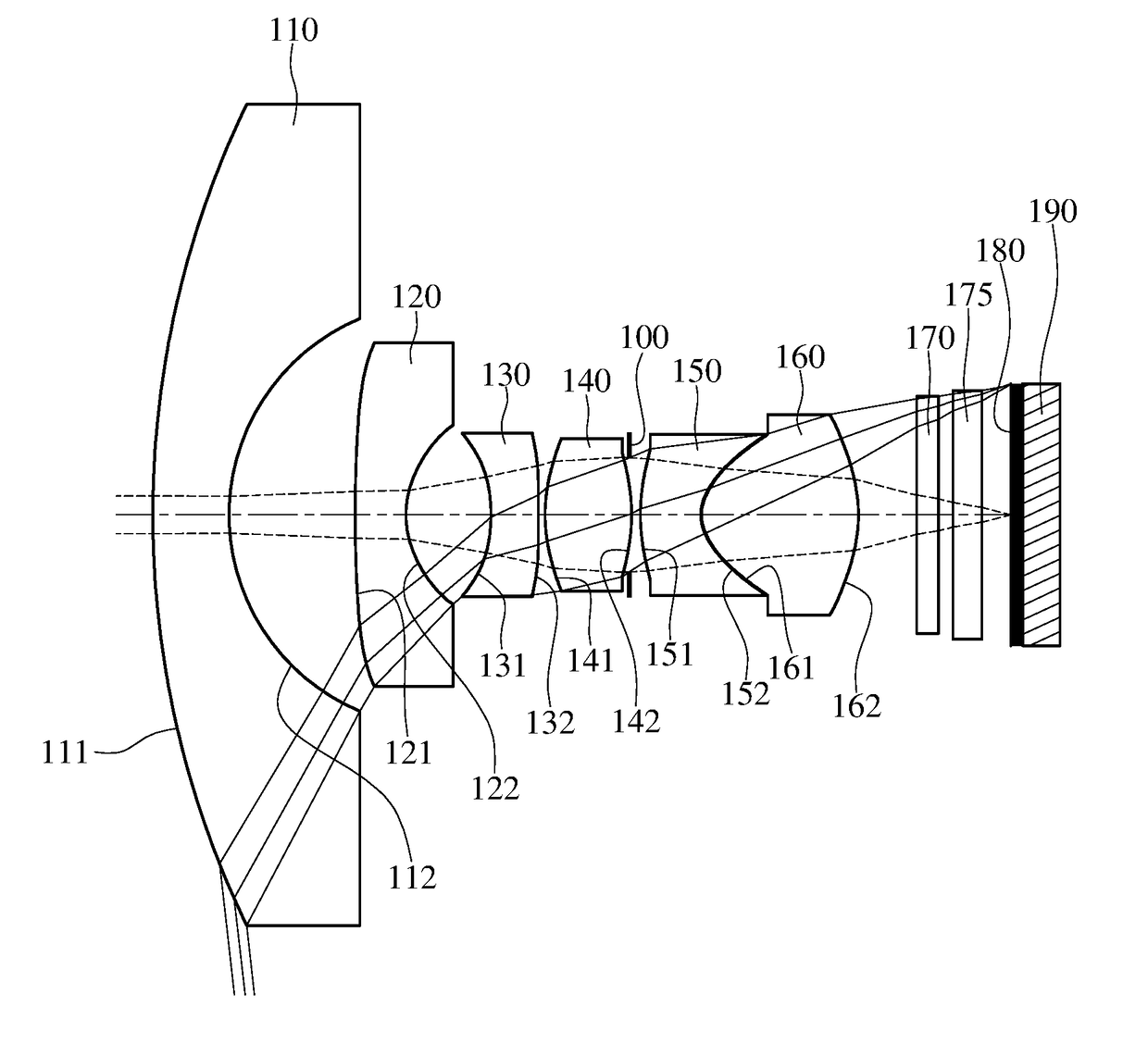

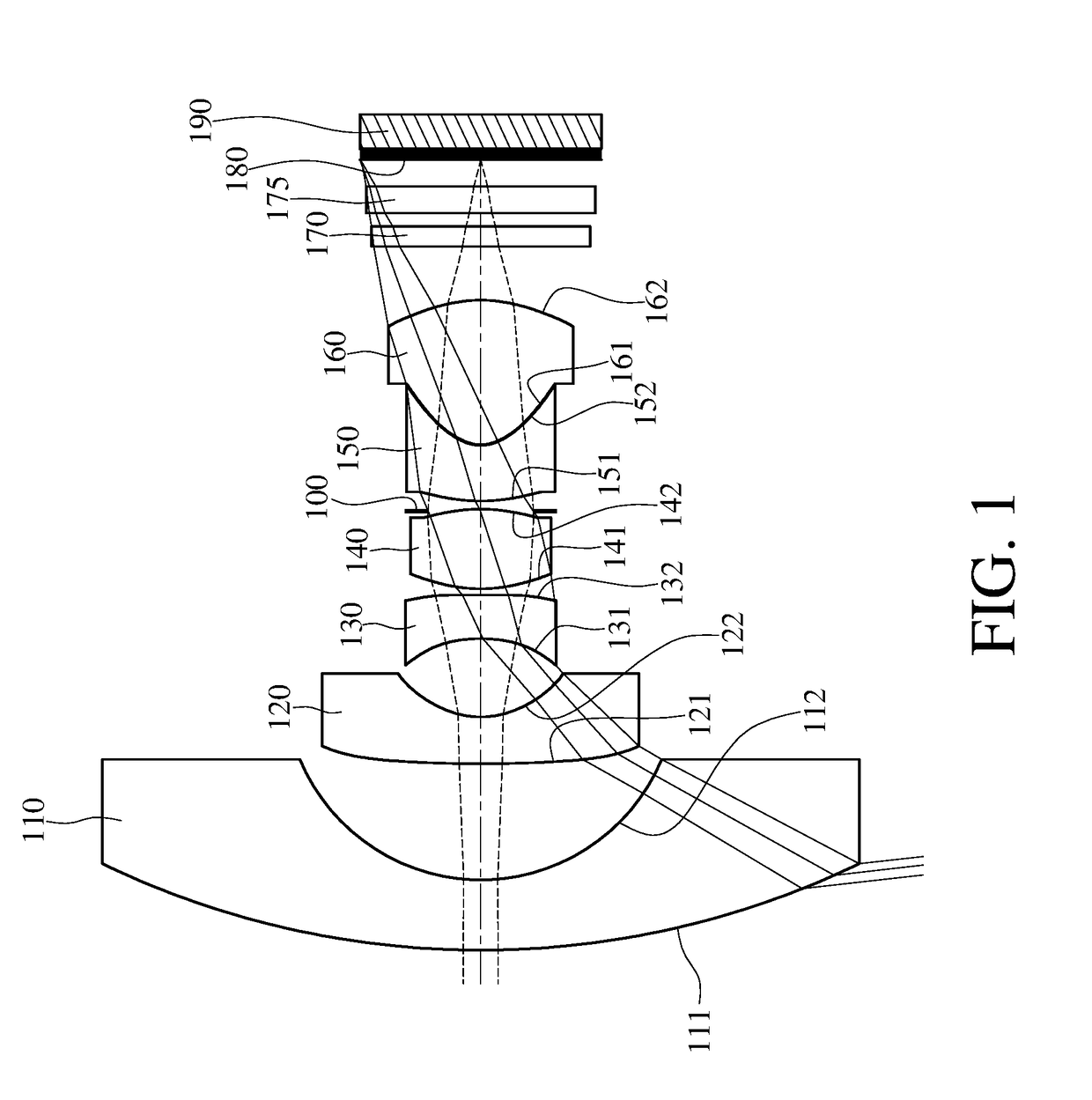

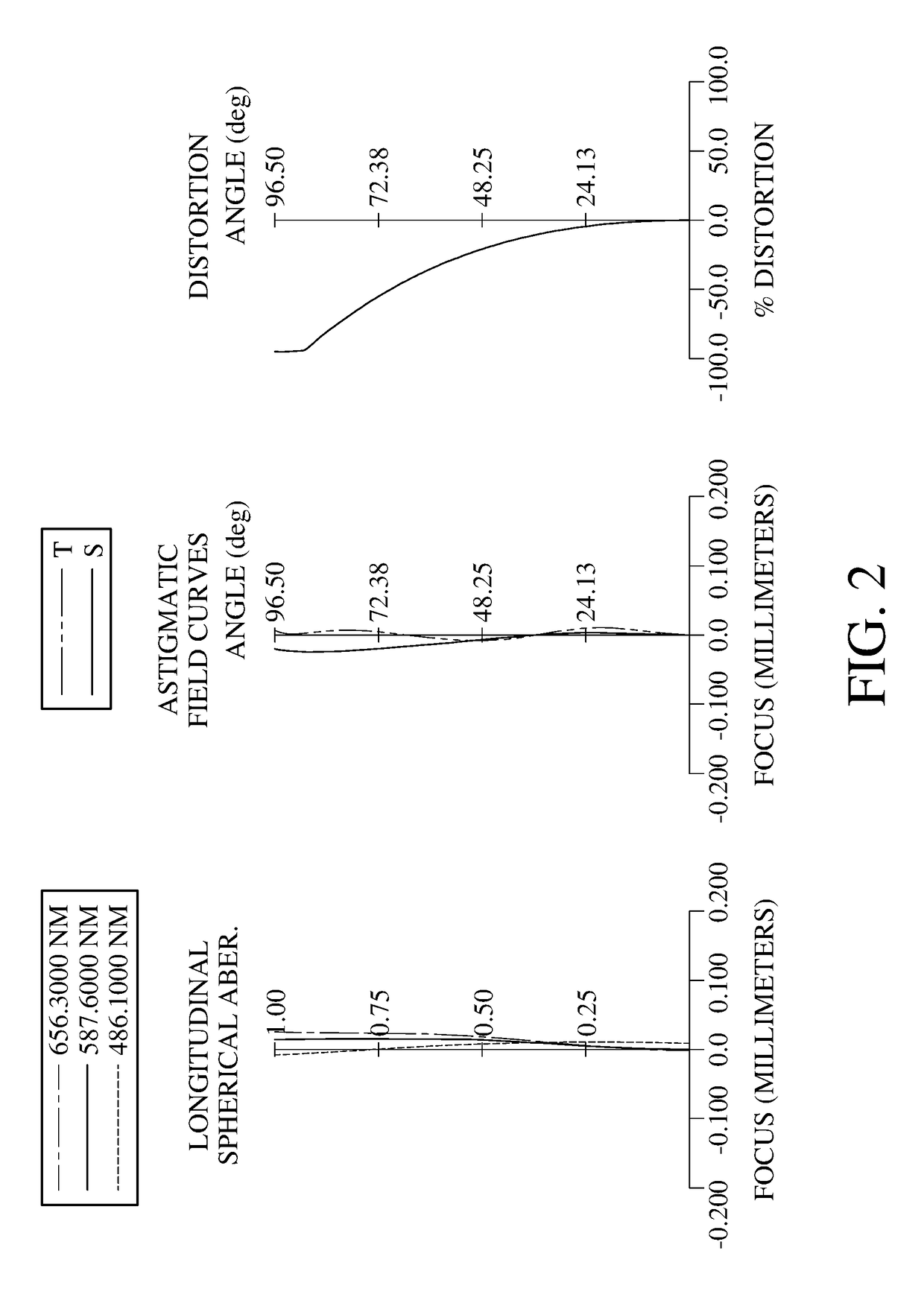

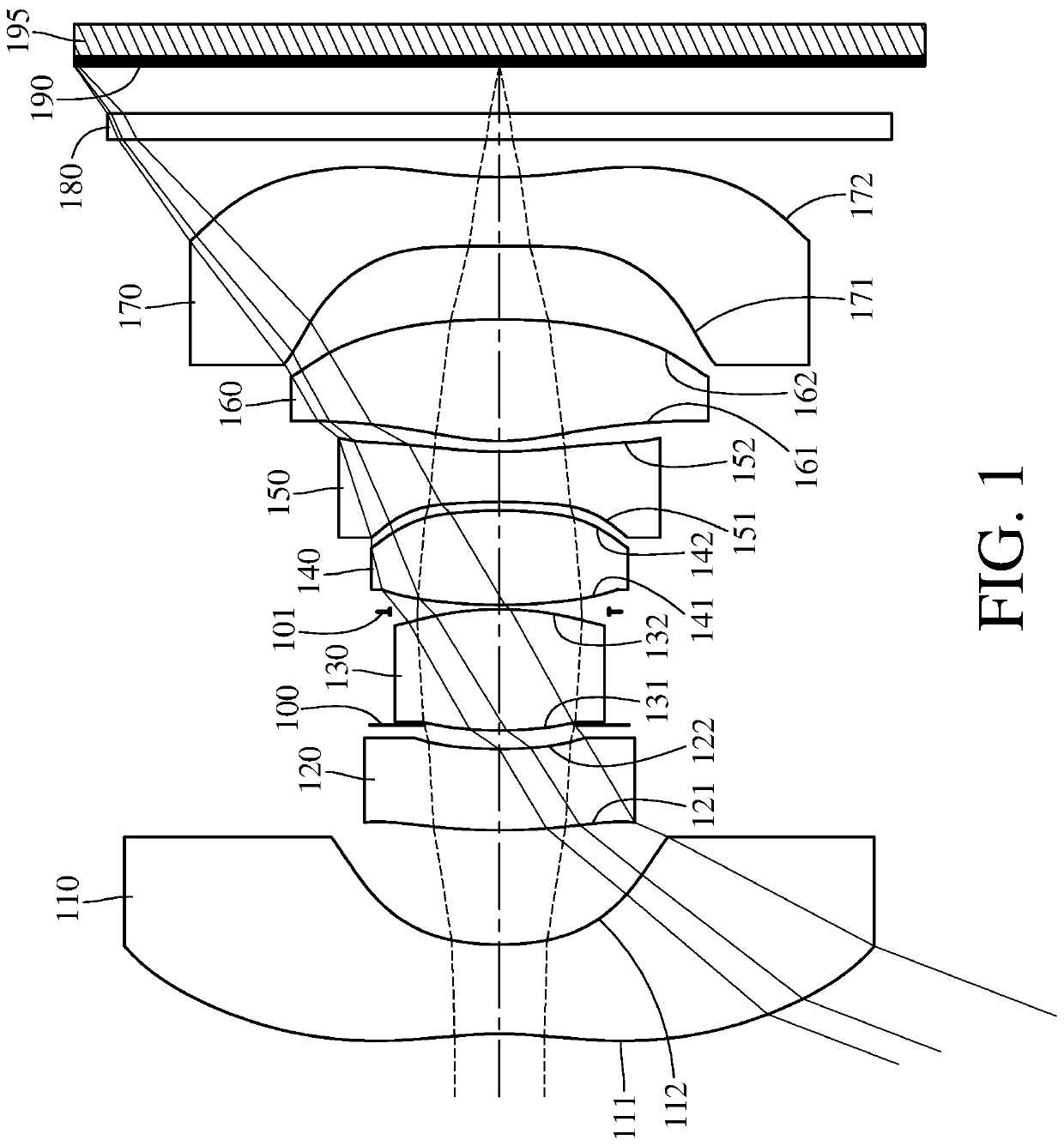

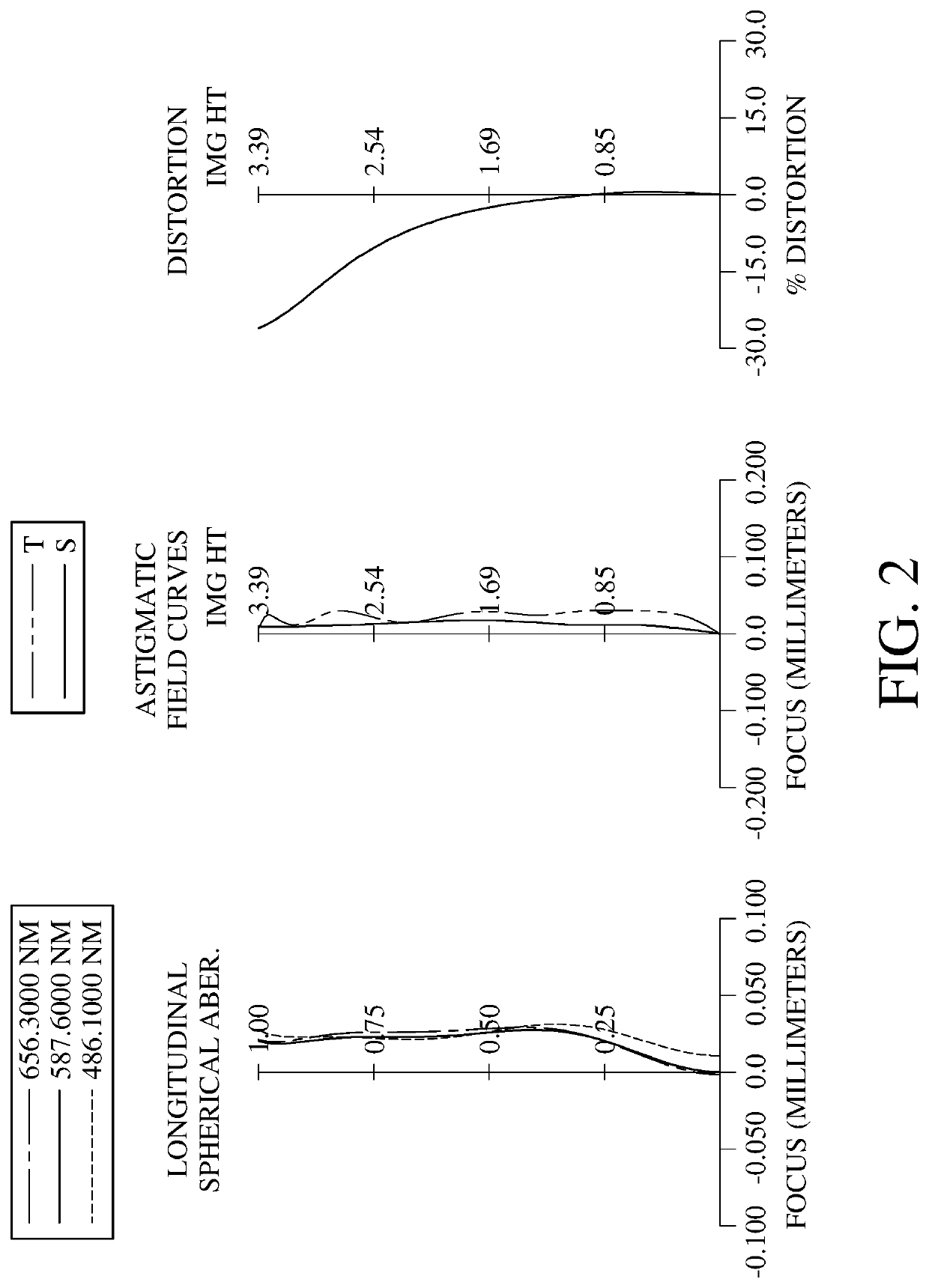

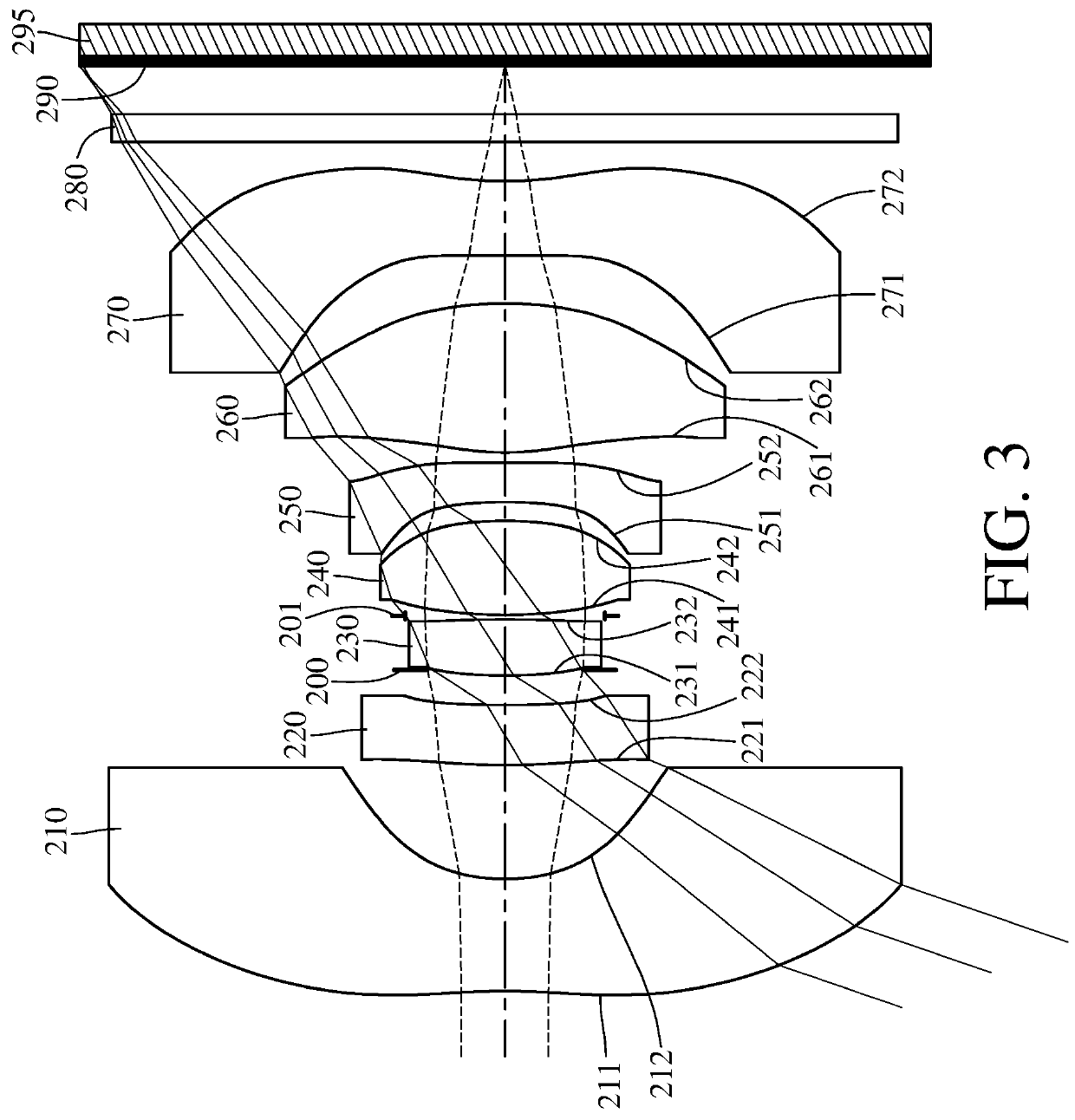

Optical photographing lens assembly, image capturing unit and electronic device

ActiveUS20180239114A1Improve yieldReduce impactTelevision system detailsColor television detailsPhysics

An optical photographing lens assembly includes five lens elements, in order from an object side to an image side: a first lens element, a second lens element, a third lens element, a fourth lens element and a fifth lens element. The first lens element with positive refractive power has a convex object-side surface in a paraxial region thereof. The second lens element with negative refractive power has a convex object-side surface and a concave image-side surface in a paraxial region thereof. The fourth lens element with positive refractive power has a convex image-side surface in a paraxial region thereof. The fifth lens element with negative refractive power has a concave image-side surface in a paraxial region thereof, wherein the image-side surface of the fifth lens element has at least one convex critical point in an off-axial region thereof, and two surfaces of the fifth lens element are both aspheric.

Owner:LARGAN PRECISION

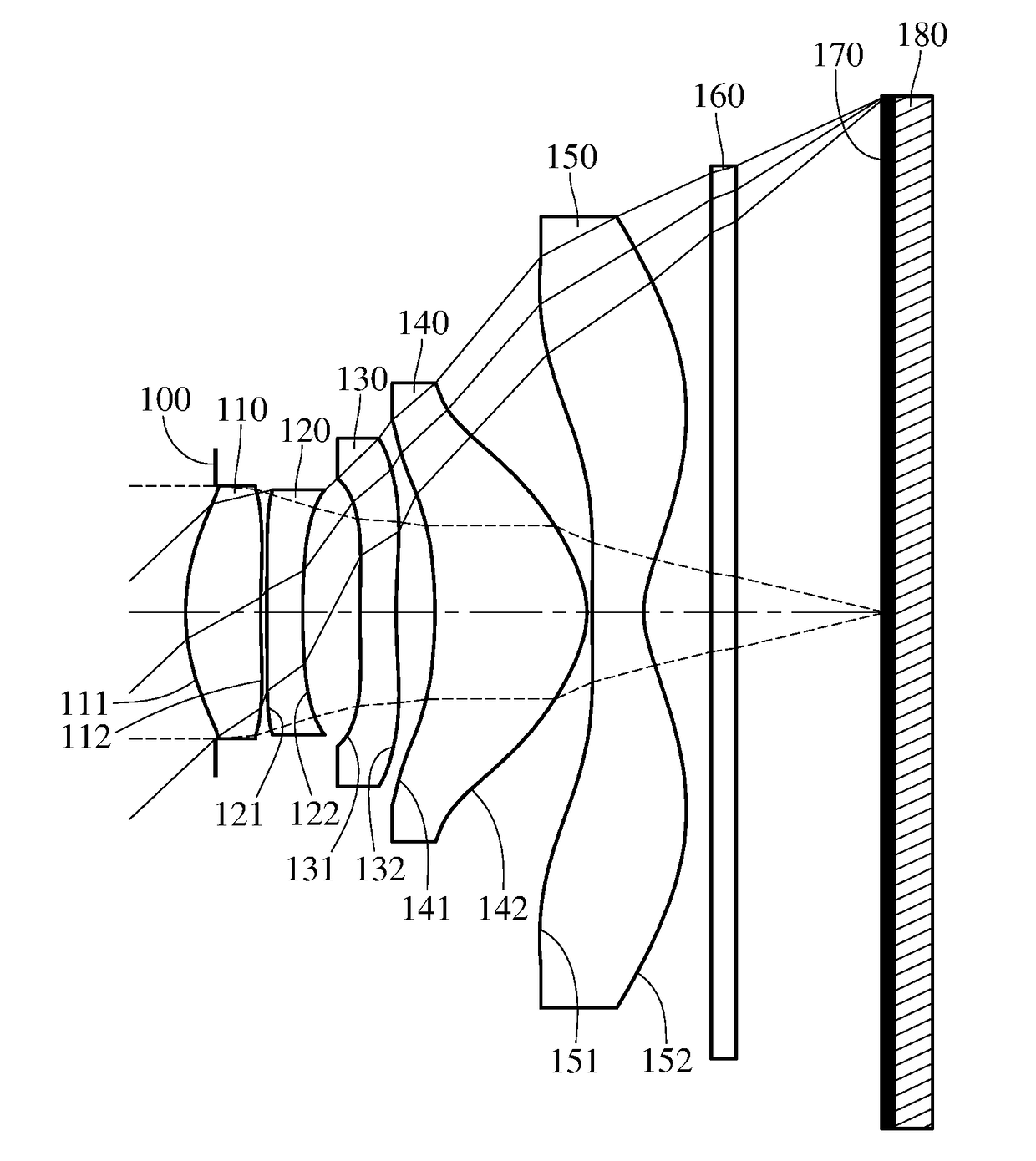

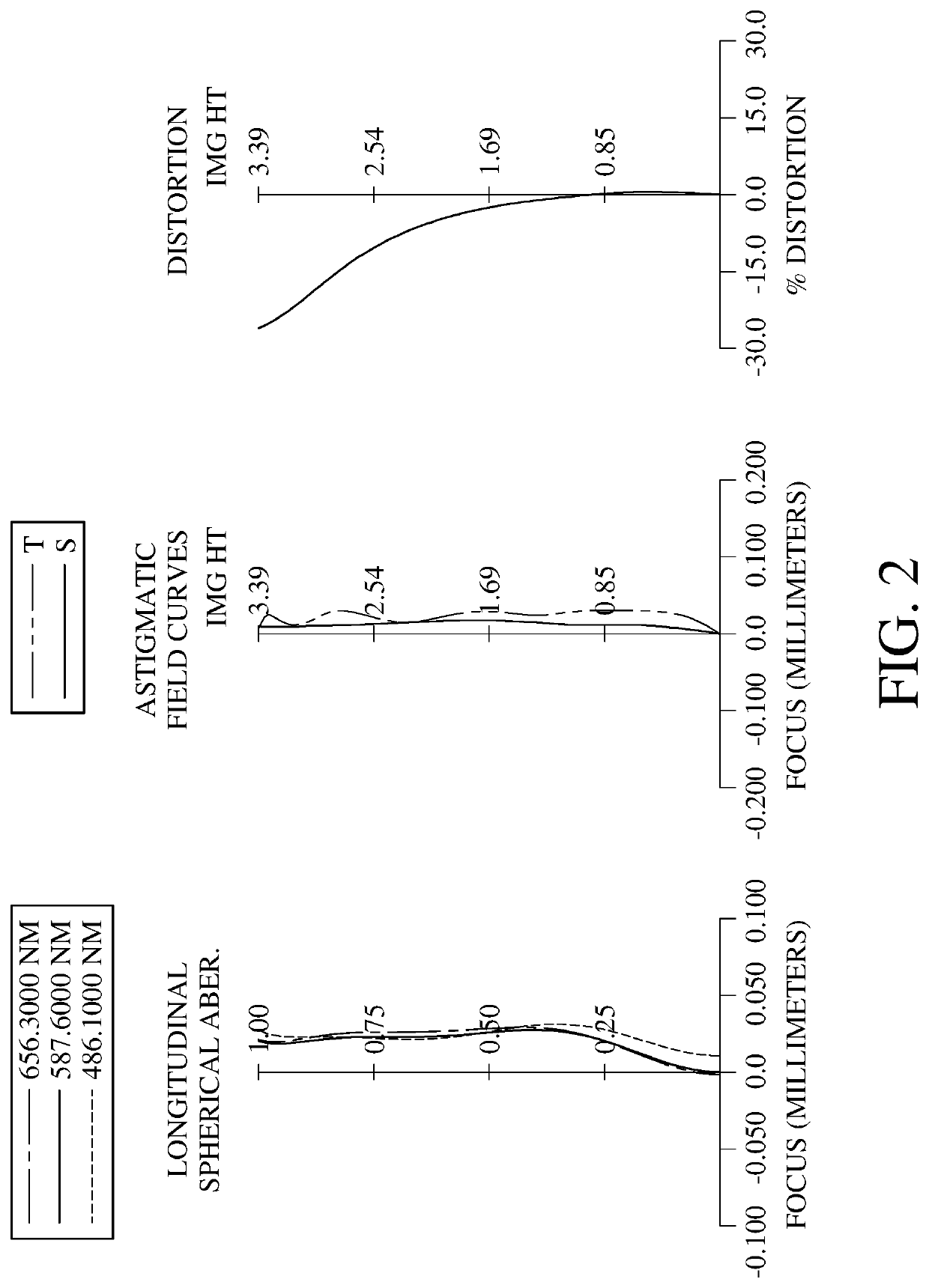

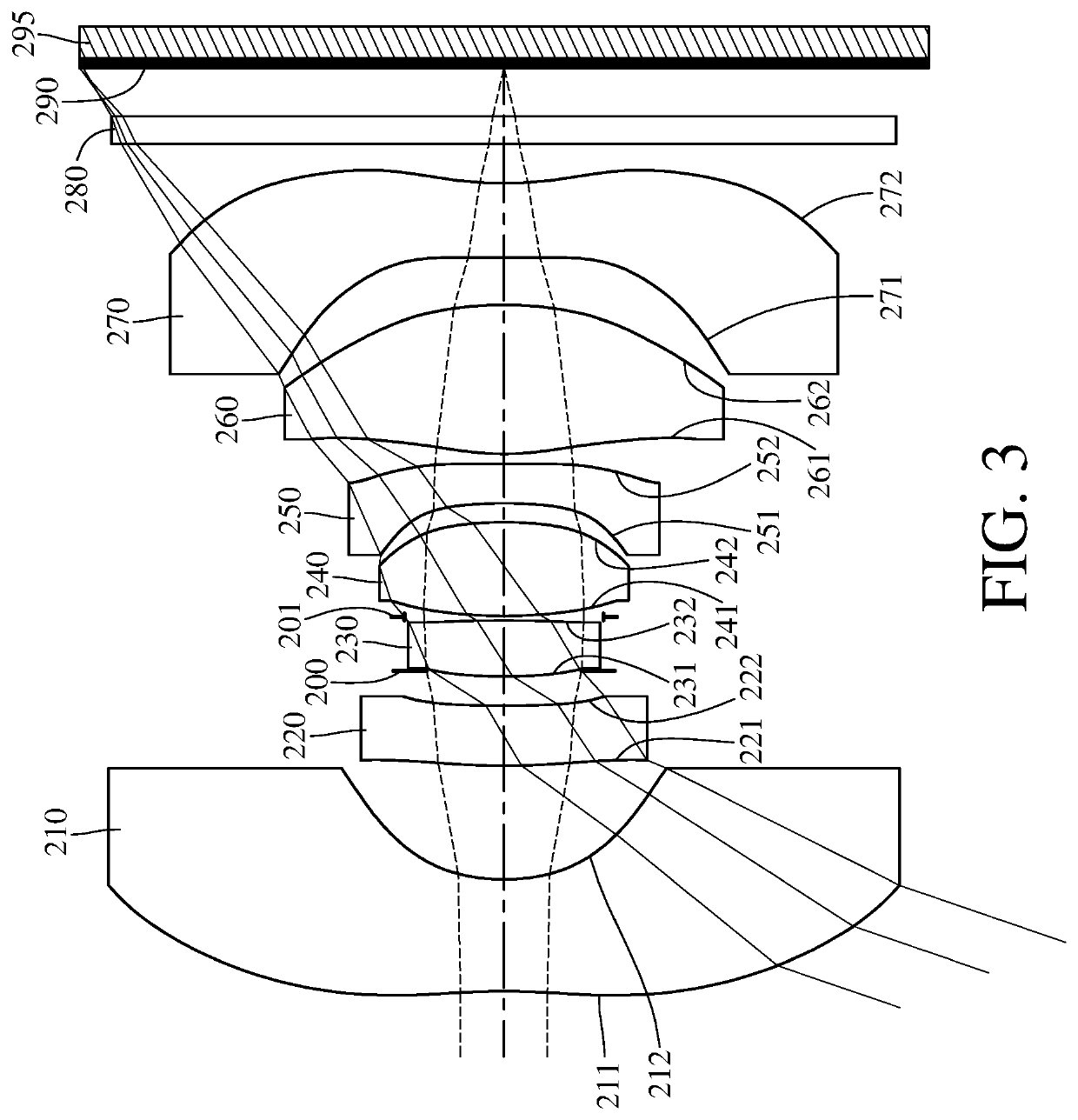

Photographing optical lens assembly, image capturing unit and electronic device

ActiveUS20210199933A1Increase illuminationShorten the trackOptical elementsOphthalmologyOptical axis

A photographing optical lens assembly includes seven lens elements, which are, in order from an object side to an image side along an optical path: a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element and a seventh lens element. The first lens element has negative refractive power. The third lens element with positive refractive power has an image-side surface being convex in a paraxial region thereof. The fifth lens element has an object-side surface being concave in a paraxial region thereof. The sixth lens element has an object-side surface being convex in a paraxial region thereof. The seventh lens element has an image-side surface being concave in a paraxial region thereof and having at least one convex critical point in an off-axis region thereof.

Owner:LARGAN PRECISION

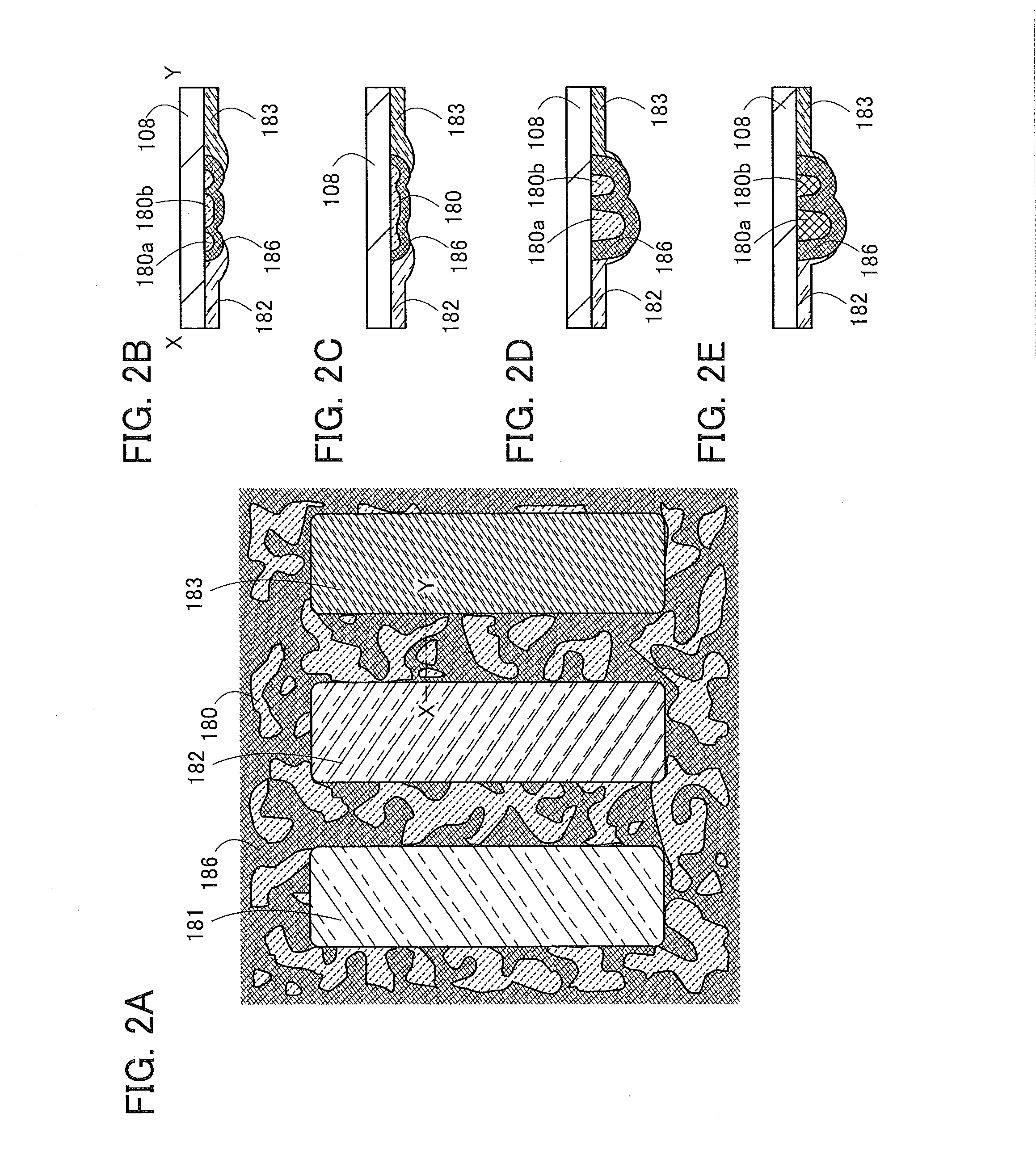

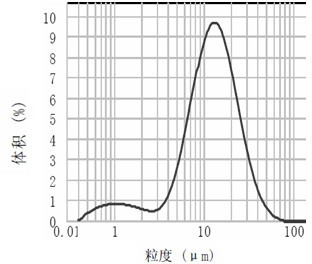

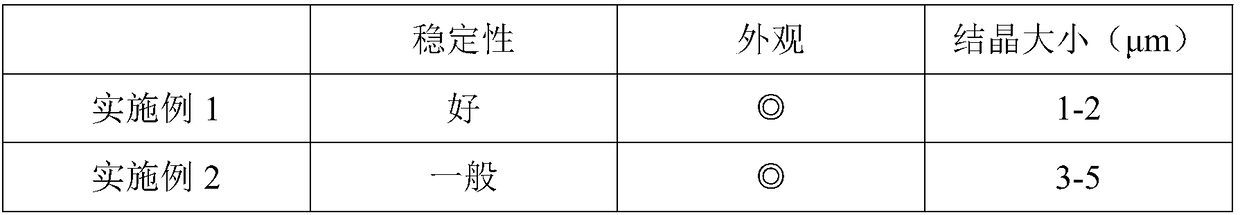

Surface adjusting agent containing manganese phosphate

The invention provides a surface adjusting agent containing manganese phosphate. The surface adjusting agent containing the manganese phosphate comprises the following components of, by weight, 0.4-5parts of the manganese phosphate, 80-100 parts of a solvent, 2-10 parts of a dispersing agent, 0.5-3 parts of a neutralizer and 0.5-2 parts of a thickening agent; and the average particle size of themanganese phosphate in the surface adjusting agent containing the manganese phosphate is 2 microns or below, D90 is 1.5 microns or below, and the PH value is 3-9. According to the surface adjusting agent containing the manganese phosphate, the stability is excellent, brushing is not needed after chemical conversion treatment of the iron and steel wear-resistant manganese phosphate, and the excellent treatability is realized.

Owner:SHANGHAI YAOYAN CHEM CO LTD

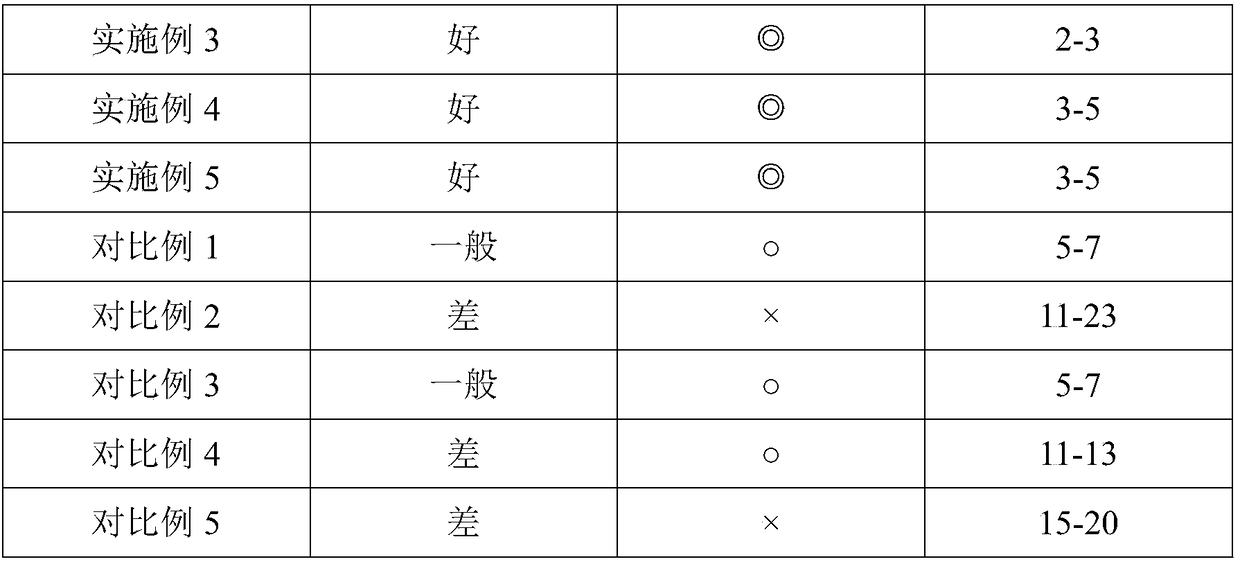

Backside deep trench-isolated backside-illuminated image sensor manufacturing method

InactiveCN105810696AWithout regard to damageGood choiceSemiconductor/solid-state device manufacturingRadiation controlled devicesEngineeringDielectric layer

The present invention provides a backside deep trench-isolated backside-illuminated image sensor manufacturing method. The manufacturing method comprises the steps of providing a first wafer; forming a dielectric layer on the first surface of the first wafer and etching the dielectric layer to expose the first surface of the first wafer to form a plurality of isolation regions; selectively extending the first wafer to cover the isolation regions; forming an image sensor device, thinning or removing one part of the second surface of the first wafer to form a deep trench isolation structure. According to the technical scheme of the invention, the deep trench isolation region of the dielectric layer is formed before the formation of the image sensor device. The isolation regions are good in surface shape and have fewer defects. Meanwhile, through selectively extending the first wafer to cover the isolation regions, the isolation regions are protected. Since the silicon grows after the formation of the isolation regions, no stress is conducted into the region of the silicon device during the high-temperature process.

Owner:GALAXYCORE SHANGHAI

Imaging optical lens assembly, image capturing unit and electronic device

An imaging optical lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element has negative refractive power. The second lens element has negative refractive power. The third lens element has negative refractive power. The imaging optical lens assembly has a total of six lens elements.

Owner:LARGAN PRECISION

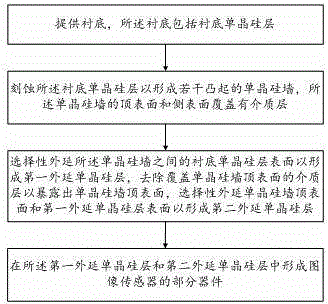

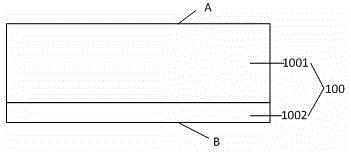

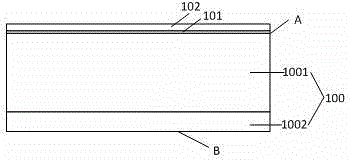

Manufacturing method of image sensor using deep trench isolation

InactiveCN104952896AQuality assuranceSimple interfaceSemiconductor/solid-state device manufacturingRadiation controlled devicesOptoelectronicsDielectric layer

The invention provides a manufacturing method of image sensor using deep trench isolation. The manufacturing method includes: providing a substrate which comprises a substrate monocrystalline layer; etching the substrate monocrystalline layer to form a plurality of monocrystalline walls raised, the top and lateral surfaces of each which are covered with a dielectric layer; subjecting the surface of the substrate monocrystalline layer between the monocrystalline walls to selective epitaxy so as to form a first epitaxial monocrystalline layer, removing the part, covering the top surfaces of the monocrystalline walls, of the dielectric layer so as to expose the top surfaces of the monocrystalline walls, and subjecting the top surfaces of the monocrystalline walls and the surface of the first epitaxial monocrystalline layer to selective epitaxy so as to form a second epitaxial monocrystalline layer; forming part of components of the image sensor in the first and second epitaxial monocrystalline layers. The manufacturing method has the advantages that the defects of the isolation structure of the epitaxial monocrystalline layers are effectively decreased, functional damage to the components of the image sensor is avoided, and quality of the components of the image sensor is improved.

Owner:GALAXYCORE SHANGHAI

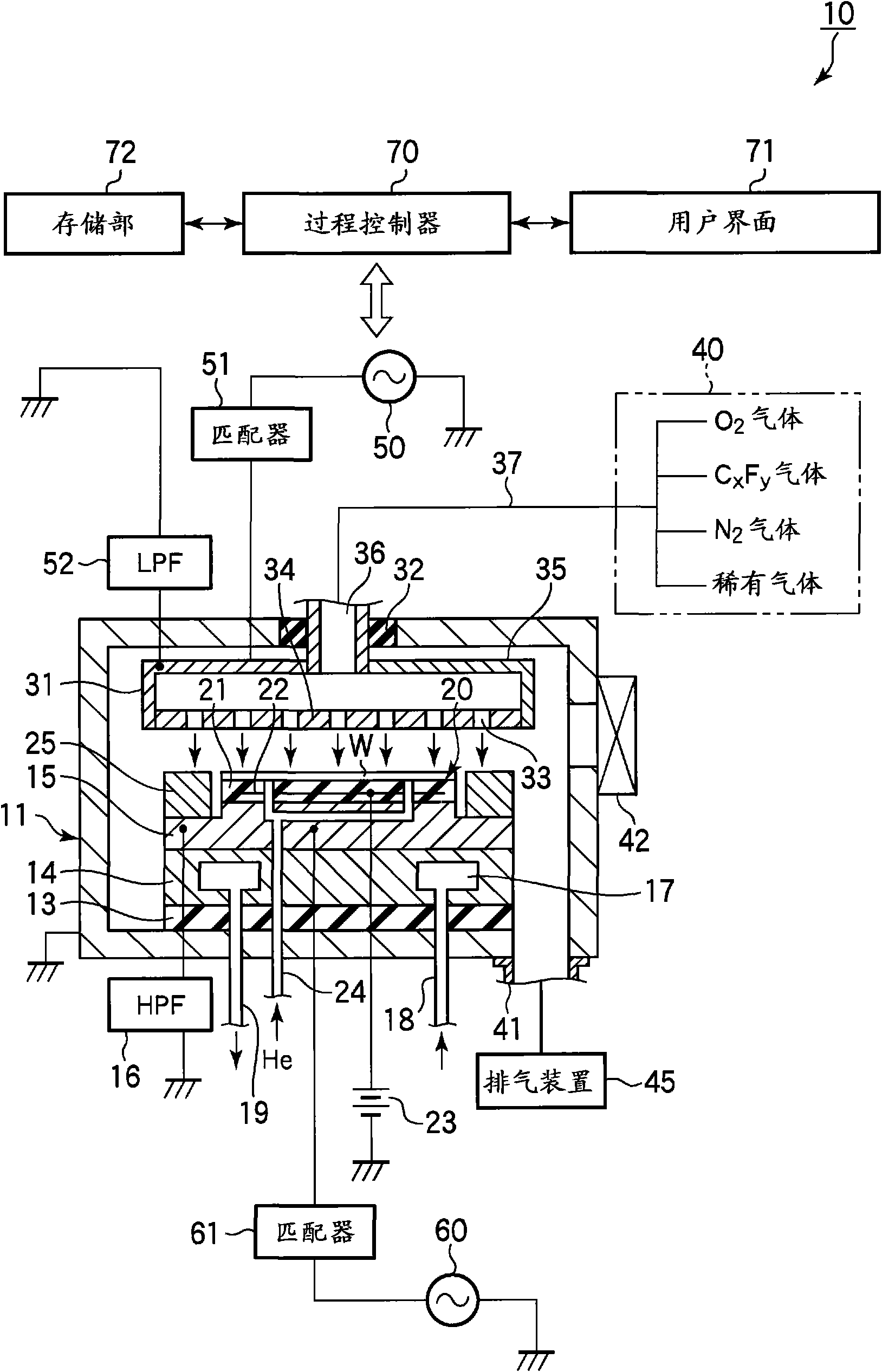

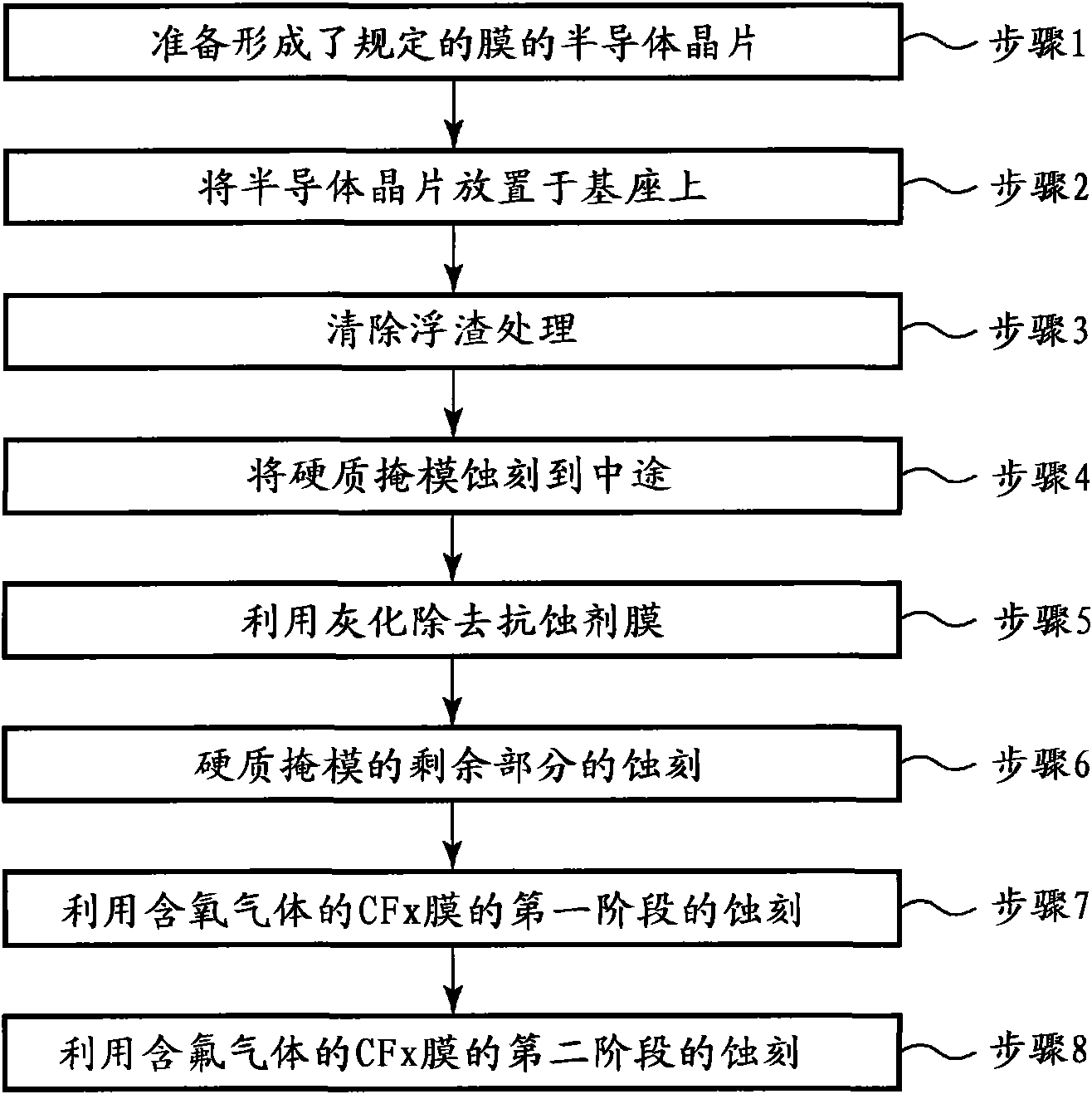

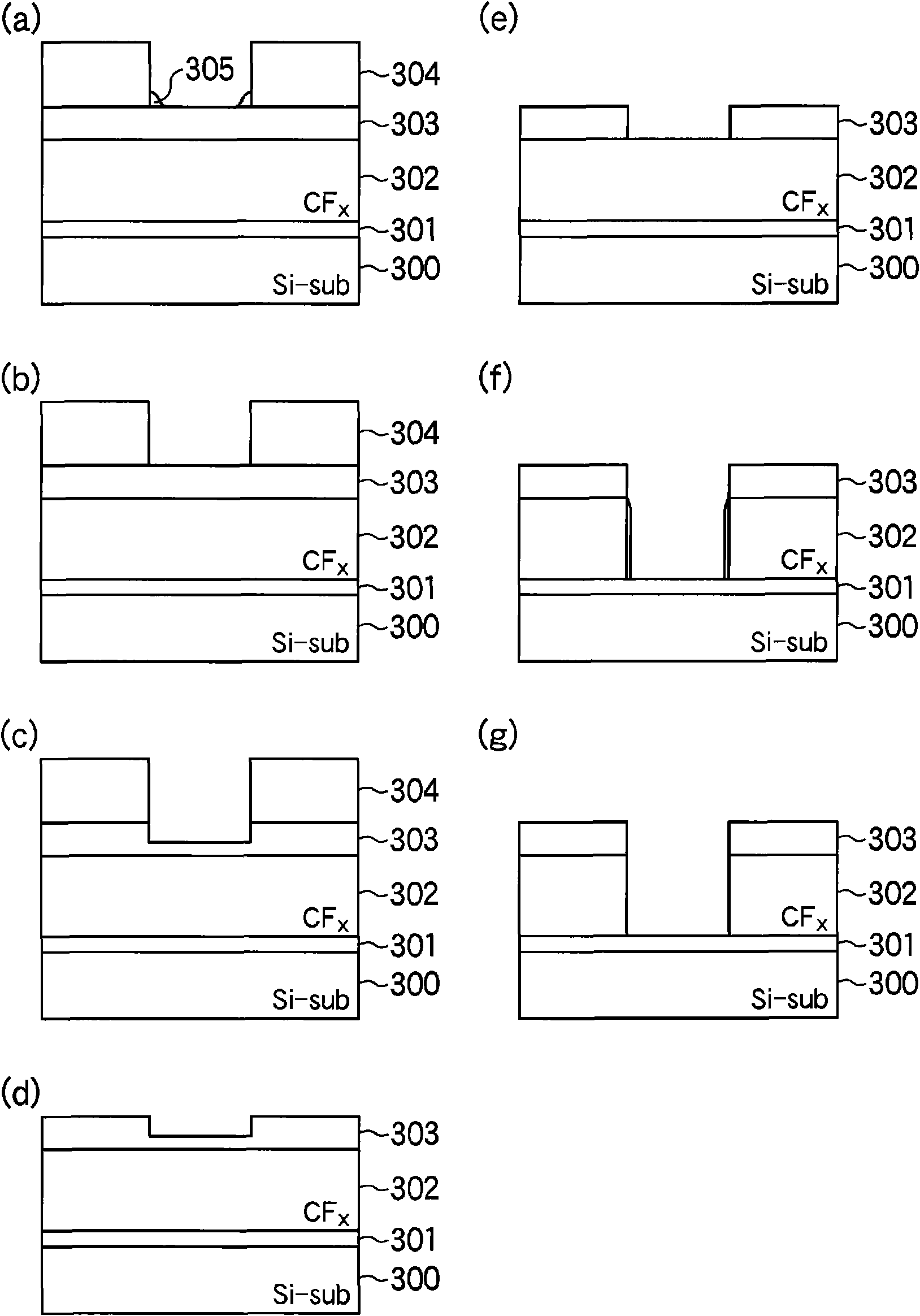

Etching method and recording medium

InactiveCN101606234AEasy to shapeGood surface shapeElectric discharge tubesSemiconductor/solid-state device detailsCarbon filmOxygen

Owner:TOKYO ELECTRON LTD

Surface processing method for wafers

InactiveCN106736881ARapid thinningGood surface shapeSemiconductor/solid-state device manufacturingLapping machinesSurface roughnessOptoelectronics

The invention relates to a surface processing method for wafers. The surface processing method comprises the following steps that a wafer is ground to obtain a ground wafer; the whole surface of the ground wafer is subjected to plasma etching to obtain an etched wafer; and the etched wafer is polished. According to the above surface processing method for the wafers, plasma etching is adopted after grinding and then polishing is performed, so that the wafer can be thinned rapidly; and besides, the surface state of the processed wafer is good, so that the whole processing process is short in time and high in efficiency, and the production efficiency of element production is favorably improved. Furthermore, stress accumulated in the grinding process and a surface damage layer of the wafer can be effectively and uniformly removed through plasma etching. Besides, difference between the surface roughness of the ground wafer and the surface roughness of the plasma etched wafer as well as between the surface roughness of the plasma etched wafer and the surface roughness of the polished wafer is small, so that a problem that difference between surface roughness of traditional fine grinding and surface roughness of polishing is large is avoided.

Owner:苏州爱彼光电材料有限公司

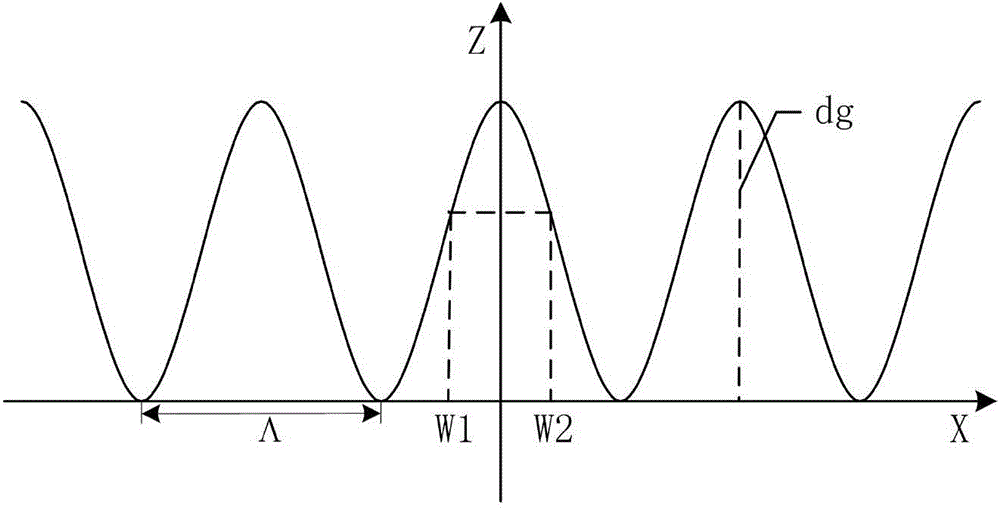

High-power 808nm DFB LD built-in grating preparation method

InactiveCN105406354AGood surface shapeGood wavelength driftLaser optical resonator constructionEtchingGrating

The invention aims to prepare a distributed feedback Bragg grating suitable for a high-power 808nm semiconductor laser by using holographic lithography and wet etching process, and relates to the technical field of semiconductor device manufacture. The invention is characterized by comprising the steps of carrying out one-time epitaxial growth on a GaAs substrate by using metal organic chemical vapor deposition (MOCVD) technology; exposing the prepared epitaxial wafer by using a holographic exposure system with an exposure source being a 325nmHe-Cd laser; carrying out developing and hardening; and finally, etching an InGaP grating layer by using an etching solution with a volume ratio of HCl:C2H6O2=3:2 and obtaining a grating. The beneficial effects of the invention are that a second-order grating with better morphology is prepared on the InGaP grating layer and the duty cycle, groove depth and other parameters enables the laser to have narrow linewidth and small wavelength shift. Meanwhile, the process can be used for high-power compound semiconductor laser of other wavelength and has a wide range of application.

Owner:CHANGCHUN UNIV OF SCI & TECH

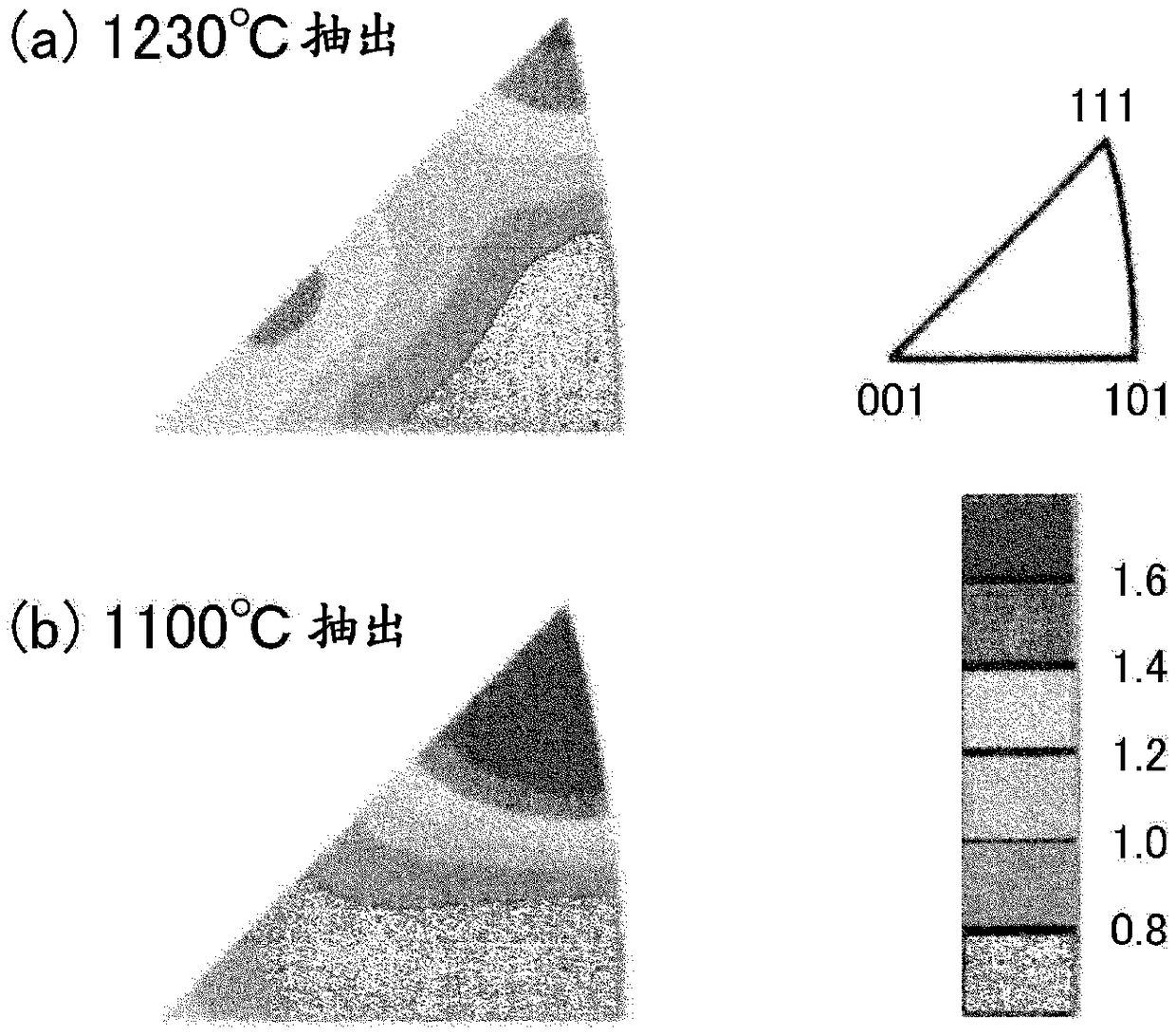

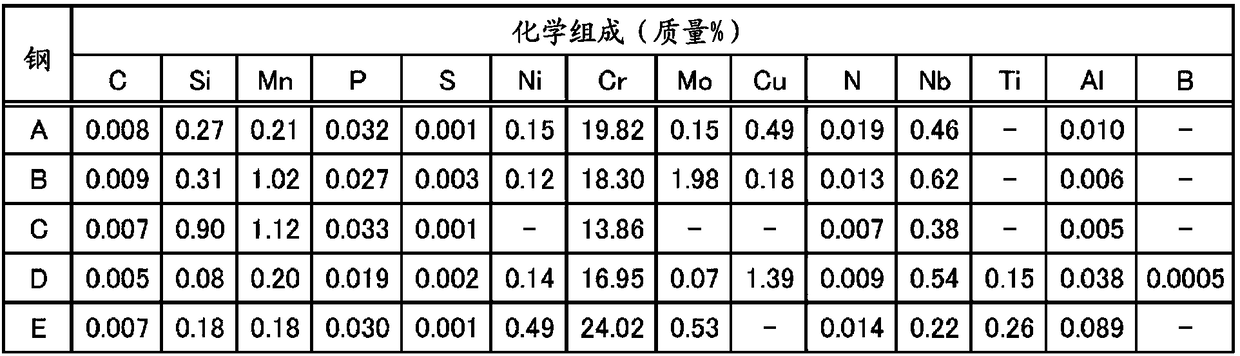

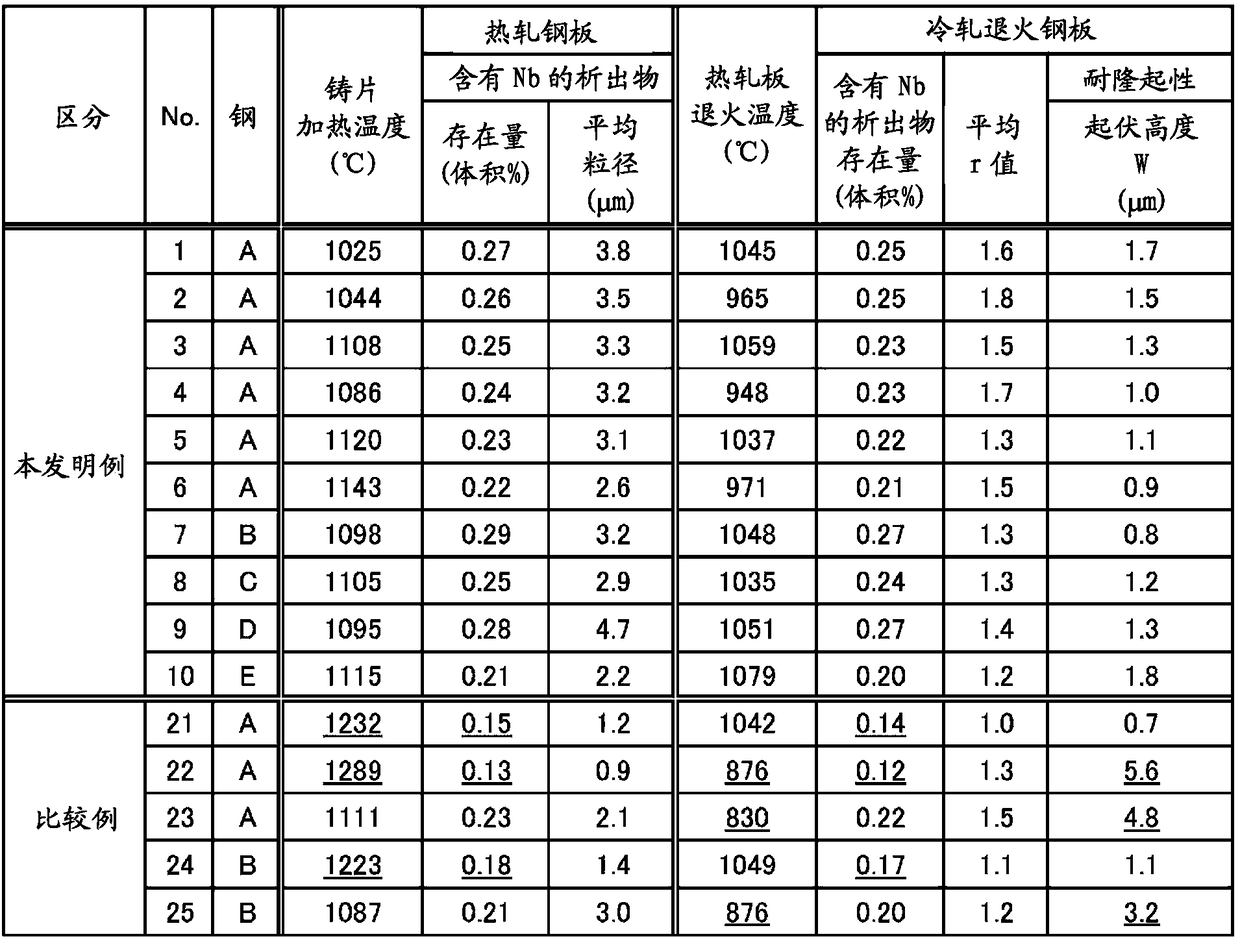

Nb-containing ferritic stainless steel sheet and manufacturing method therefor

PendingCN109072378AHigh pressabilityGood surface shapeFurnace typesHeat treatment furnacesChemical compositionMetallurgy

The invention simultaneously improves the r value and ridging resistance of an Nb-containing ferritic stainless steel sheet. A ferritic stainless steel raw material sheet for annealing and cold rolling is obtained, the sheet having a chemical composition made, in mass%, of C: 0.004-0.030%, Si: 1.50% or less, Mn: 1.50% or less, P: 0.040% or less, S: 0.010% or less, Cr: 12.0-25.0%, Mo: 0-3.0%, Cu: 0-2.0%, Ni: 0-2.0%, N: 0.005-0.025%, Nb: 0.20-0.80%, Al: 0.10% or less, B: 0-0.0030%, Ti: 00.30% or less, the balance being Fe and unavoidable impurities and the amount of remaining Nb-containing deposits being at least 0.20 mass%. After performing a 900-1100 DEG C annealing on said raw material steel sheet, cold rolling and finish annealing are performed.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Photographing optical lens assembly, image capturing unit and electronic device

A photographing optical lens assembly includes seven lens elements, which are, in order from an object side to an image side along an optical path: a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element and a seventh lens element. The first lens element has negative refractive power. The third lens element with positive refractive power has an image-side surface being convex in a paraxial region thereof. The fifth lens element has an object-side surface being concave in a paraxial region thereof. The sixth lens element has an object-side surface being convex in a paraxial region thereof. The seventh lens element has an image-side surface being concave in a paraxial region thereof and having at least one convex critical point in an off-axis region thereof.

Owner:LARGAN PRECISION

Dope composition, polarizing plate protective film, polarizing plate protective film manufacturing method, polarizing plate, and liquid crystal display device

ActiveUS20160297939A1Excellent manufacturing aptitudeLow haze valuePolarising elementsOptical articlesTectorial membraneMeth-

A dope composition containing an acrylic resin having a weight average molecular weight of greater than or equal to 250,000; and an additive having a weight average molecular weight of less than 50,000, in which the acrylic resin includes a methyl methacrylate unit (a), and a mass fraction of an alkyl (meth)acrylate unit (b) other than methyl methacrylate is less than 5 mass %, has excellent manufacturing aptitude from the viewpoint of having a high drying speed and large breaking elongation at a time point of forming an un-stretched film, and enabling a crack at the time of being stretched to be suppressed, has a low haze value and an excellent surface shape at the time of preparing a polarizing plate protective film, and has excellent heat resistance; a polarizing plate protective film; a polarizing plate protective film manufacturing method; a polarizing plate; and a liquid crystal display device.

Owner:FUJIFILM CORP

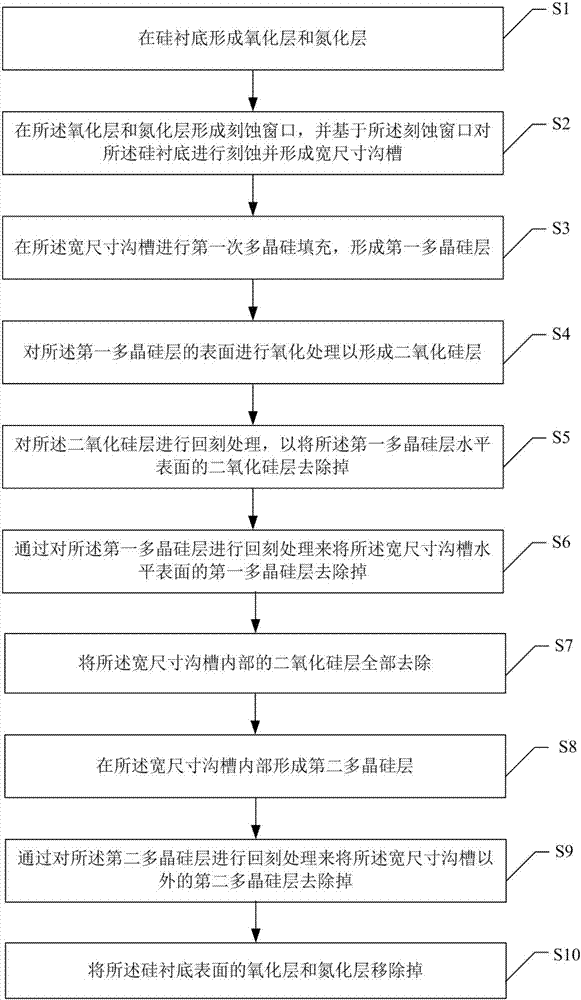

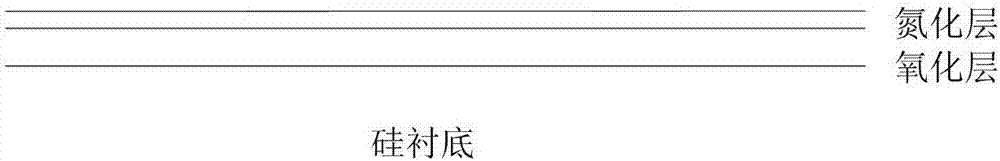

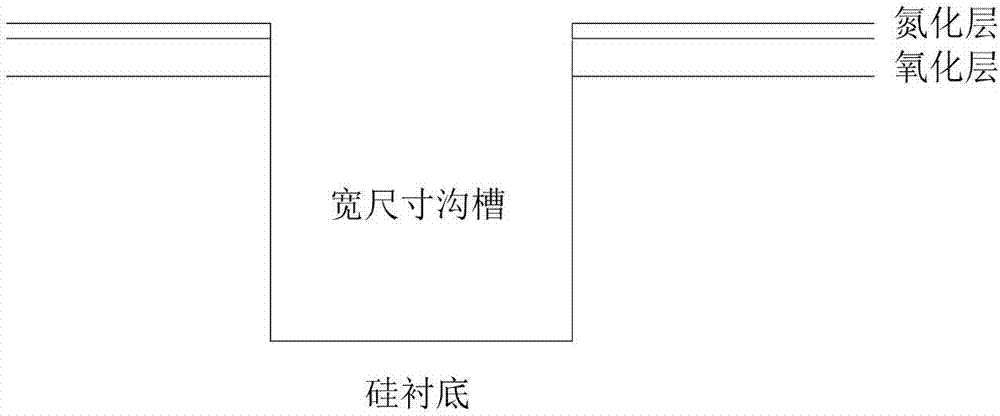

Poly-silicon filling method suitable for wide-size groove

InactiveCN107248494ASolve poor filling effectGood surface shapeSemiconductor/solid-state device manufacturingPhysicsPolycrystalline silicon

The invention provides a poly-silicon filling method suitable for a wide-size groove. The poly-silicon filling method suitable for the wide-size groove comprises the steps of performing first poly-silicon filling on the wide-size groove to form a first poly-silicon layer; oxidizing a surface of the first poly-silicon layer to form a silicon dioxide layer; respectively etching the silicon dioxide layer and the first poly-silicon layer; removing the silicon dioxide layer in the wide-size groove, wherein the effective width of the wide-size groove becomes narrow by the first poly-silicon layer filled in the wide-size groove; performing second poly-silicon filling on the wide-size groove to form a second poly-silicon layer; and etching the second poly-silicon layer to remove the second poly-silicon layer outside the wide-size groove.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

Green sheet, manufacturing method thereof and slurry composition for forming green sheet

The invention provides a raw film, the manufacturing method thereof and the slurry combination for generating the raw film. The raw file is good in binding property, plasticity, property for stripping off from the slices or film used in manufacturing and surface property with no concavo convex, no crack and no wrinkles. The raw film is prepared by coating the slurry combination containing component solvent, binding agent and power onto the slices or films and stripping off after it is dry. In which, the component solvent contains the low boiling point solvent with boiling point below 100 degrees centigrade and high boiling point solvent with boiling point above 100 degrees centigrade.

Owner:NITTETABU MINING CORP

Display device

InactiveUS10342124B2Quality improvementInhibition reflexSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

Provided is a display device or an input / output device in which reflection of outside light is reduced. The display device includes a first substrate and a second substrate. The first substrate includes a first surface. A transistor is over the first surface. The second substrate includes a second surface. A first structure having a projection, a second structure having a projection, a black matrix covering the first structure and the second structure, and a color filter are over the second surface. The first surface faces the second surface. The black matrix has a plurality of projections reflecting the projection of the first structure and the projection of the second structure. A planar shape of the first structure is different from a planar shape of the second structure.

Owner:SEMICON ENERGY LAB CO LTD

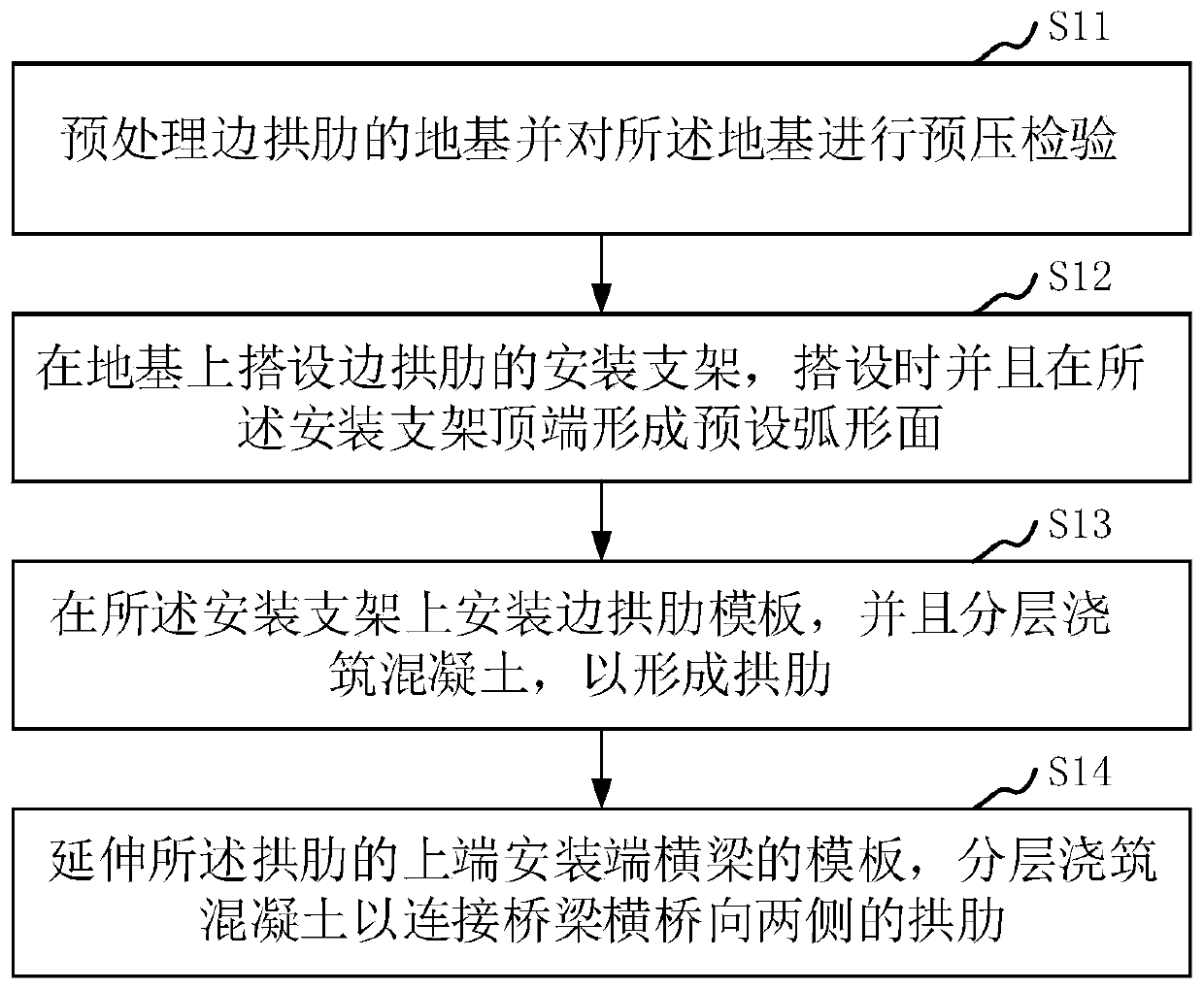

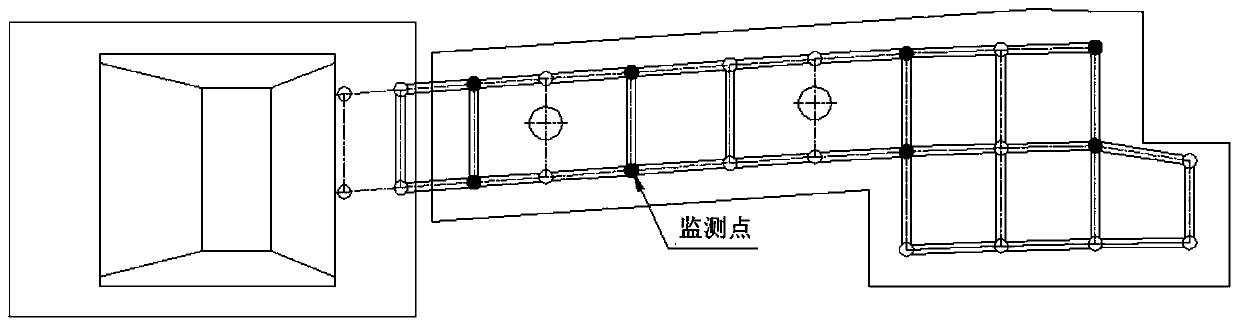

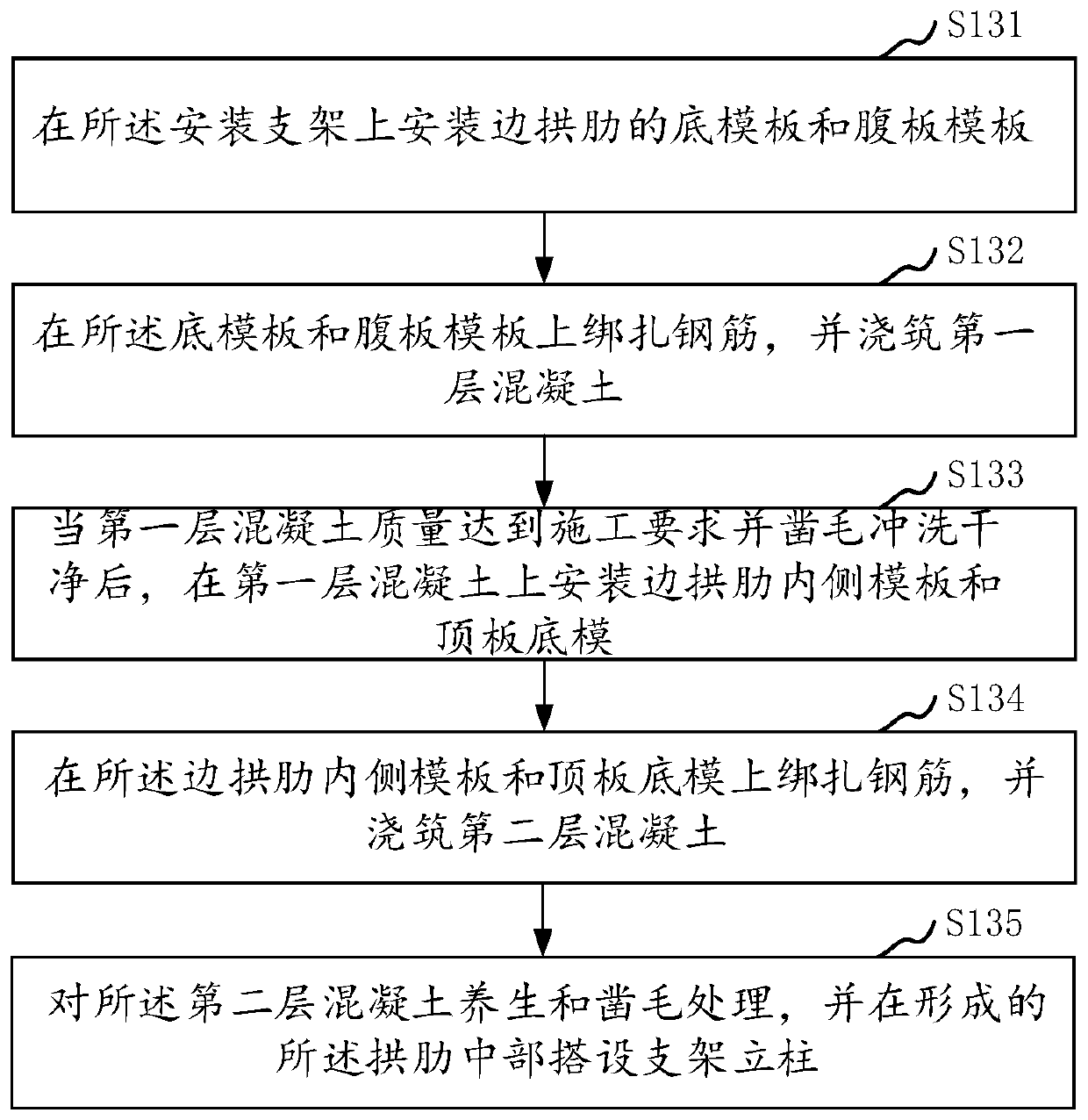

Side arch rib construction method and side arch rib

InactiveCN110777635AImprove stabilityImprove bearing capacityBridge erection/assemblyIn situ soil foundationArchitectural engineeringStructural engineering

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com