Preparation process for physics vapour phase deposition of ultrathin self-suporting polyimide filter film

A technology of physical vapor deposition and polyimide, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of narrow application range, low stability, high cost, etc., and achieve excellent mechanical properties, Thickness of the film is easy to reduce the effect of pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

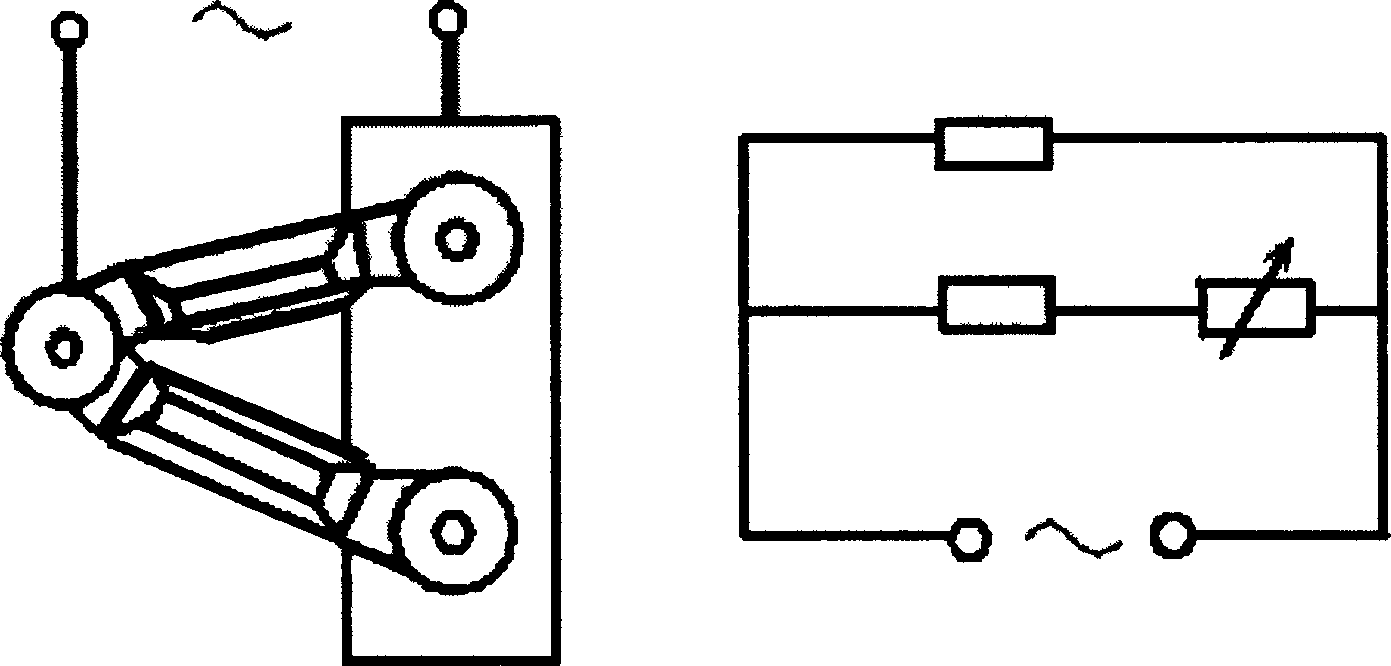

[0039] figure 1 is a schematic diagram of a double-boat single-source evaporation design circuit, in which the relative size of the resistance in the two evaporation boat circuits is obtained by properly designing the shape and size of the evaporation boats.

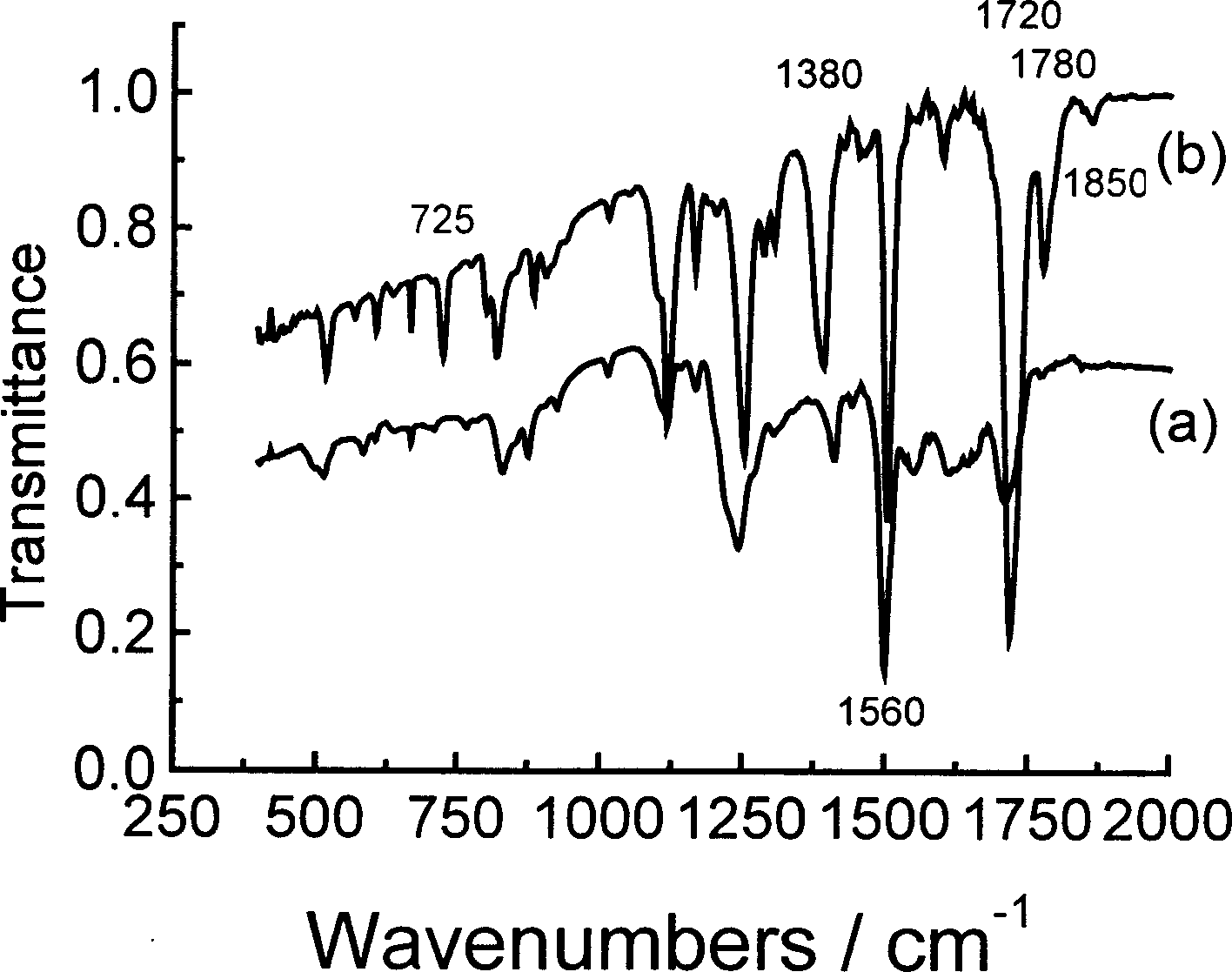

[0040] figure 2 (a) and (b) are the infrared transmission spectra of the polyimide film after pretreatment and heat treatment, respectively, wherein the abscissa is the wave number, and the ordinate is the transmittance. At wavenumber 1560cm -1 The absorption peak at corresponds to the stretching vibration of C==O in the amide bond, which is the characteristic absorption of polyamic acid. figure 2 (b) at a wavenumber of 725cm -1 、1380cm -1 、1720cm -1 、1780cm -1 The absorption peaks at other places correspond to the C==O bending vibration, C-N stretching vibration and C==O bending vibration in the imide bond r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com