Intermittent-type multifunctional stirring station

A multi-functional mixing station technology, which is applied in municipal engineering equipment and municipal transportation, can solve problems such as difficulty in obtaining commercial asphalt or commercial cement concrete, wasting land, power distribution engineering personnel, and affecting production efficiency, so as to save power distribution , Reduce equipment installation and transportation, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

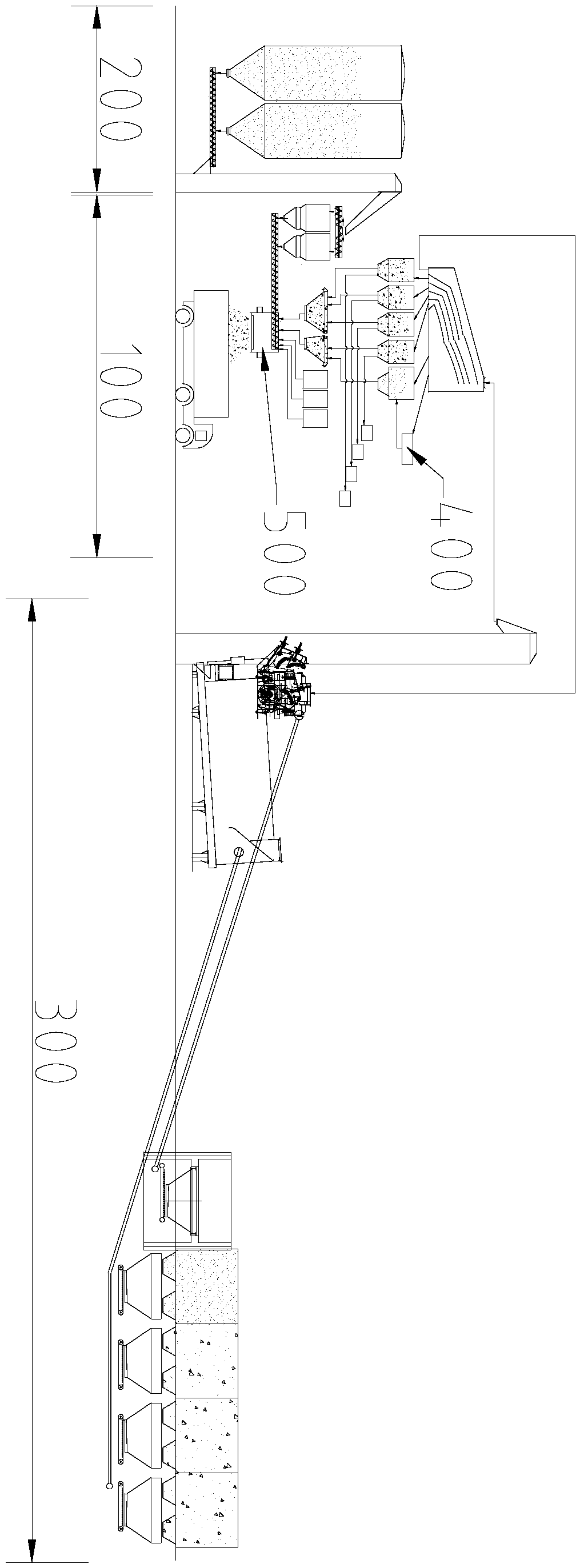

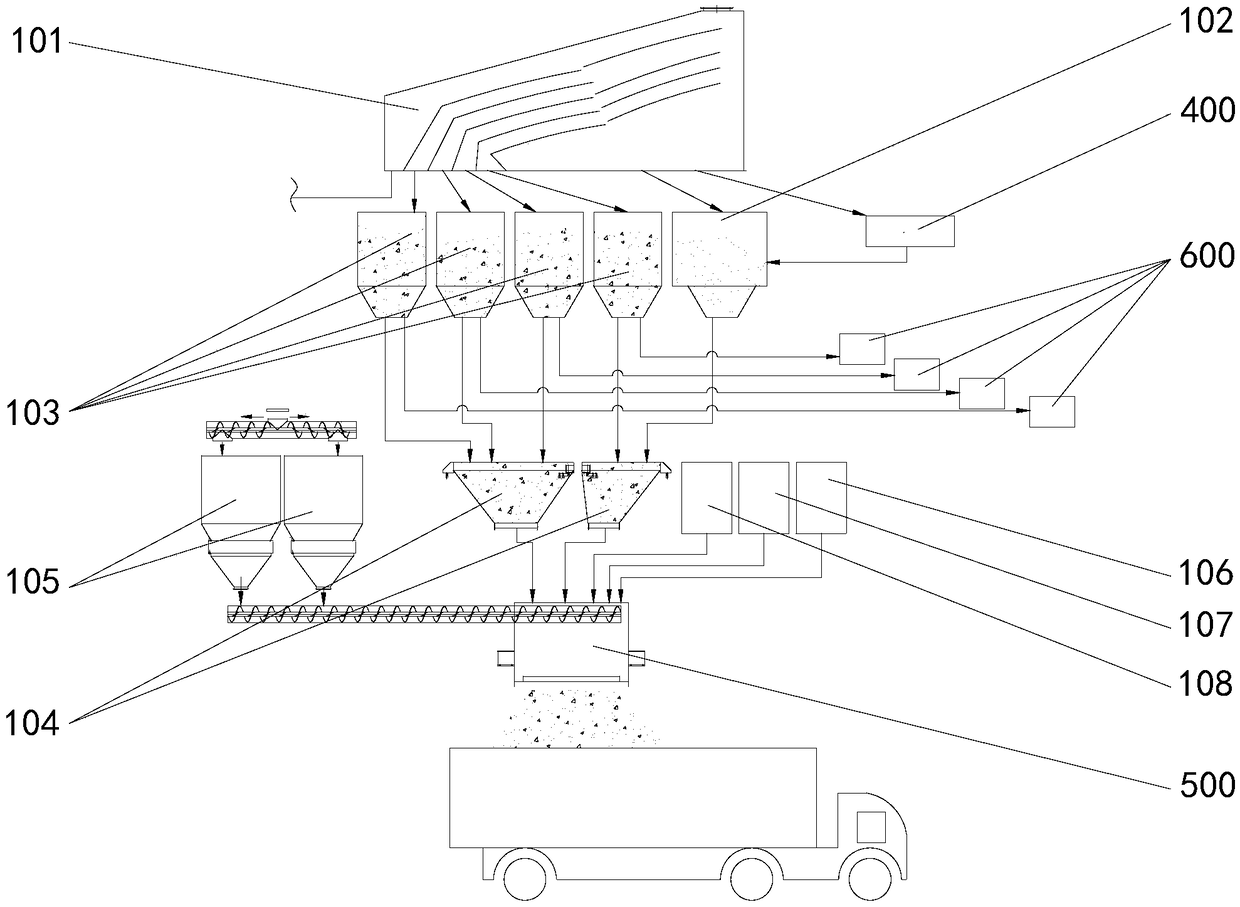

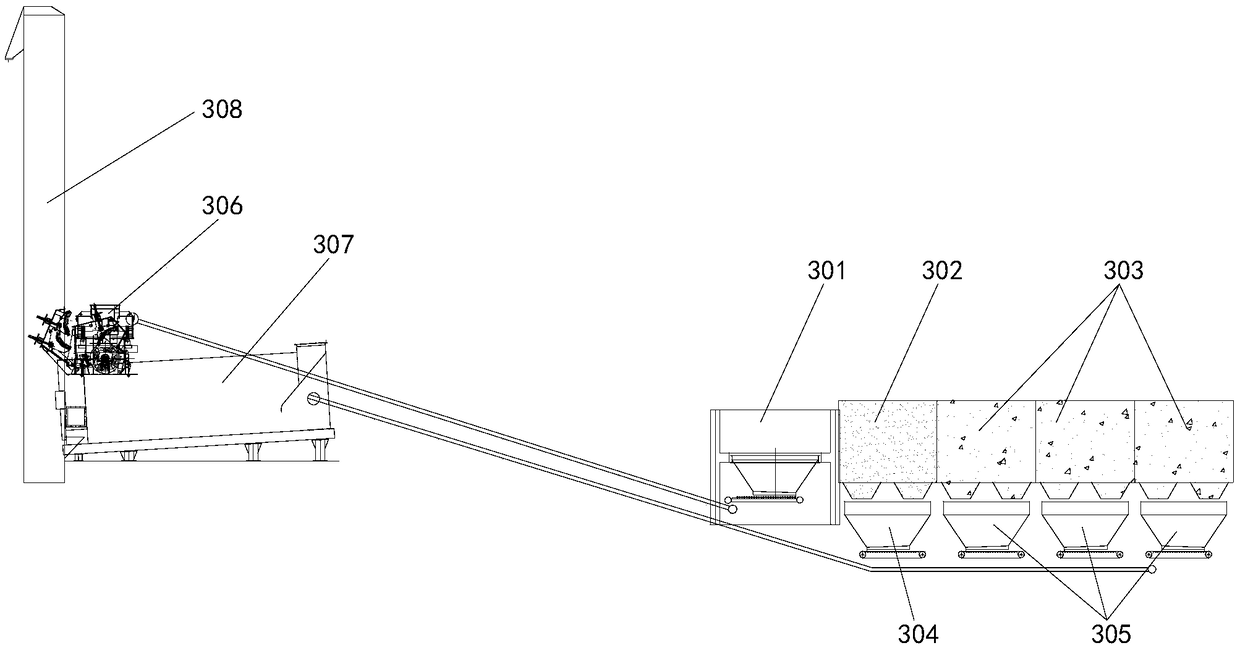

[0055] Such as Figure 1-3 As shown, this embodiment provides an intermittent multifunctional mixing station, including a mixing system 100, a powder feeding device 200 and an aggregate feeding device 300 with a drying function; the mixing system 100 includes a vibrating screen 101 , sand powder separation device 400, sand buffer bin 102, gravel buffer bin 103, aggregate metering hopper 104, powder metering hopper 105, asphalt metering hopper 106, water metering hopper 107, admixture metering hopper 108 and mixing host 500, The sand outlet of the vibrating screen 101 is connected to the sand buffer bin 102 through the sand powder separation device 400, and the stone outlet of the vibrating screen 101 is connected to the gravel buffer bin 103; the sand buffer bin 102 and the gravel buffer bin 103 pass through the aggregate weighing hopper 104 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com