Patents

Literature

207results about How to "Reduce pollution sources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

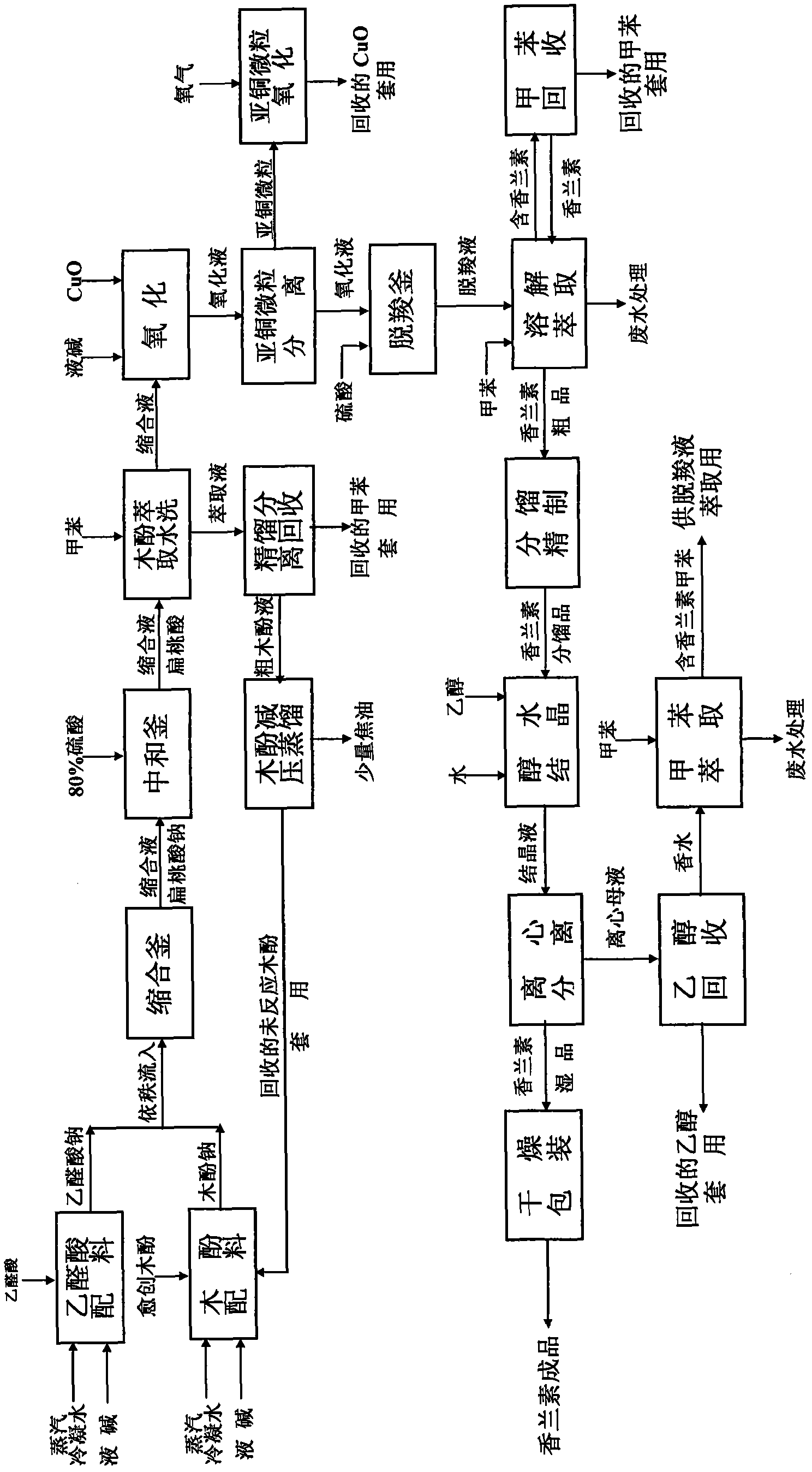

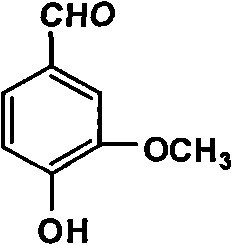

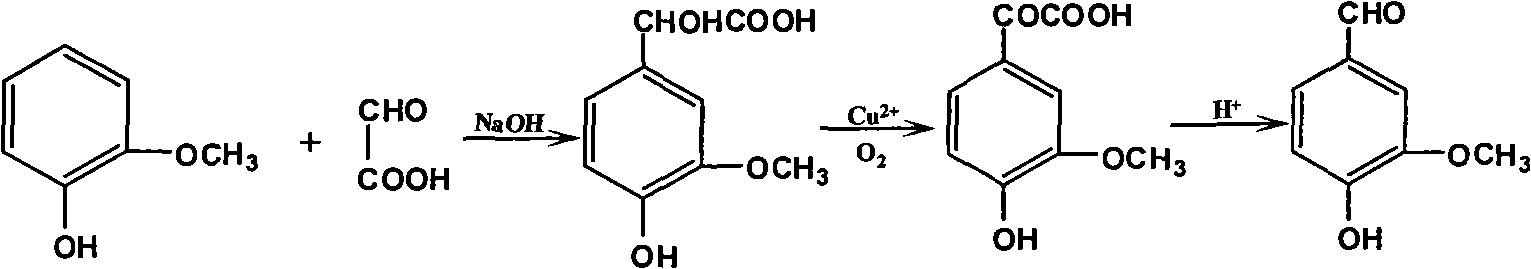

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310AReduce organic contentReduce pollution sourcesOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsFractionation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

Method for treating aquaculture wastewater

InactiveCN101885554AReduce nitrogen and phosphorus contentSolve the problem of not being able to remove dissolved pollutants in water bodiesMultistage water/sewage treatmentBiological water/sewage treatmentAquatic animalSelf purification

The invention discloses a method for treating aquaculture wastewater. The method comprises the following steps of: performing modular processing on wastewater by using microalgae and beneficial bacteria; and throwing snails, filter-feeding fishes and other aquatic animals into a water body to realize self-purification of an aquaculture water environment after the modular processing. Dominant and beneficial microalgae such as diatom, green algae and the like capable of absorbing nitrogen and phosphor in the aquaculture water body are screened out, inoculated, rapidly cultured and put into the aquaculture water body; the water color is regulated and the alga concentration is controlled by the methods of rational fertilization and rotifer inoculation; the beneficial bacteria are bacillus and photosynthetic bacteria capable of degrading organic matters and ammonia nitrogen in the water body; the beneficial bacteria and feed are proportionally mixed before the feed is put into the water body; after the feed is put into the water body, an underwater biomembrane taking the feed as a matrix is formed; the nitrogen, the phosphor and other harmful pollutants in the aquaculture water body can be effectively removed by jointly using the microalgae and the beneficial bacteria; simultaneously, the utilization efficiency of the feed can be improved by mixing the beneficial bacteria and the feed; and the water body is processed by using the microalgae and the beneficial bacteria, and then the snails and the filter-feeding fishes are put into the water body to prevent excessive multiplication of phycomycete, so that the self-purification of the aquaculture water environment can be realized.

Owner:上海楚水水产科技有限公司

Method and device for making iron by smelting reduction

ActiveCN101649366ALess investmentReduce pre-restore timeCalcium carbideManufacturing convertersElectric arc furnaceSlag

The invention relates to a method and a device for making iron by smelting reduction. The method for making iron by smelting reduction comprises the following steps: putting raw material forming matters into a smelting ironmaking device; heating and reducing the raw material forming matters into metallic iron; after the reduced metalation rate of various oxides of iron reaches 40-95 percent in rawmaterials, heating and melting products of a reducing furnace; and producing direct reduction molten steel or molten iron produced by the similar blast furnace. The raw materials comprise a breath shell or a half-breath shell or an opening shell or the combination of the raw materials, a coating shells of the breath shell, the half-breath shell and the opening shell is prepared by adding an adhesive in calcium oxide or calcium carbonate or calcium carbide or the combination of the materials. The device for making iron by smelting reduction comprises an arc furnace, a buried arc furnace, a converter, an induction furnace, and the like. After reduction products are heated and melted, and oxygen or inert gas is blown into the arc furnace in order to remove slag. Due to the adoption of a shell coating technology, the method and the device effectively prevent from oxidizing reduced matters in the process, avoid bonding formed matters for contact and are combined with blowing gas and are good for making slag. Slag iron has good separation effect, and the produced iron and steel products have good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

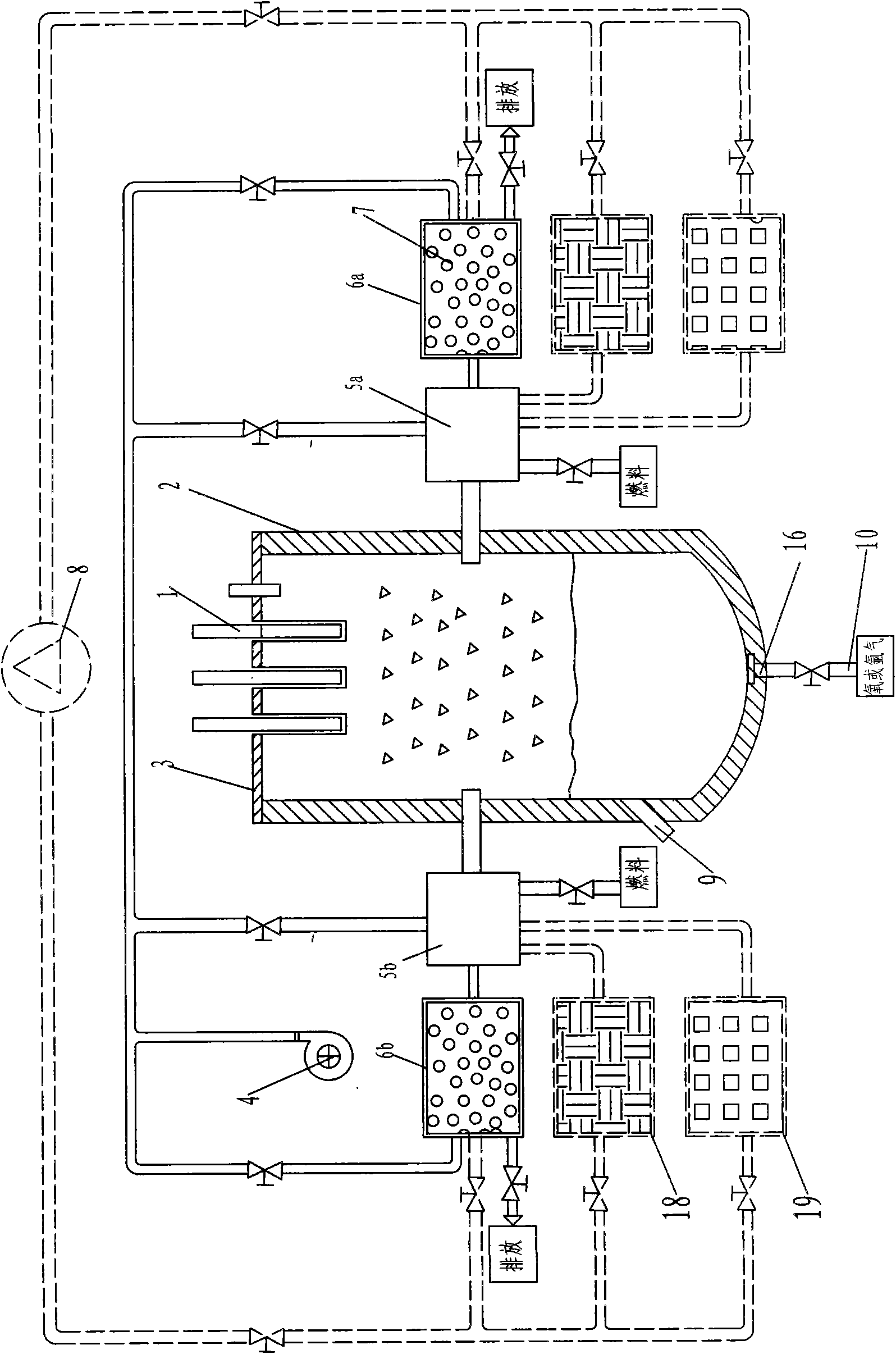

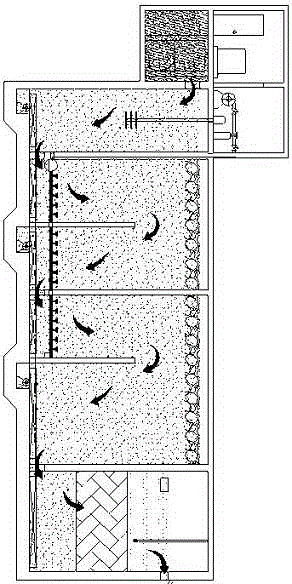

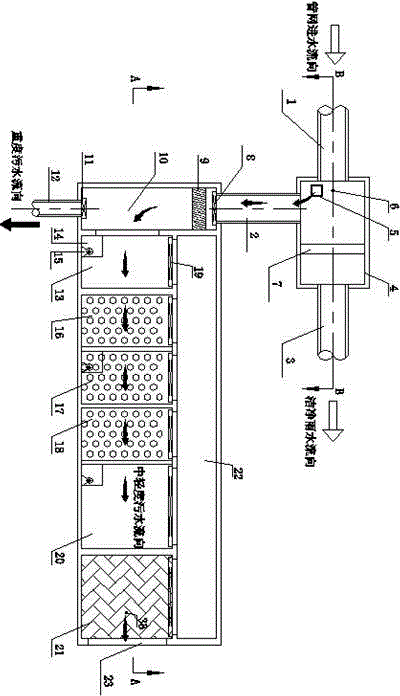

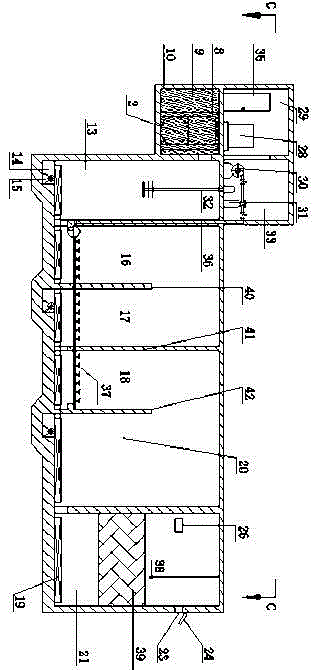

Buried efficient treater of initial rainwater

ActiveCN104817209ASmall footprintImprove processing efficiencyFatty/oily/floating substances removal devicesMultistage water/sewage treatmentRemote monitoring and controlSmall footprint

The invention discloses a buried efficient treater of initial rainwater. The buried efficient treater integrates coagulating sedimentation, air flotation, quick filtration and intelligent detection and features small floor area, high treatment efficiency and high load resistance; treatment level of the initial rainwater can be automatically adjusted according to water conditions, the initial rainwater is quickly subjected to coagulating sedimentation, air flotation, water reoxygenation, filtration and the like, energy is saved, ideal cleaning effect is achieved, remote supervision is available, mangers are allowed to monitor the flow of a drainage network and the water conditions anytime and anywhere and monitor the treatment state of rain sewage in the treater, remote intelligent control is available, management of a rain sewage network is greatly facilitated, and the ability of people to control the rain sewage is improved.

Owner:ANHUI QINGHUAN WATER ENG SCI & TECH

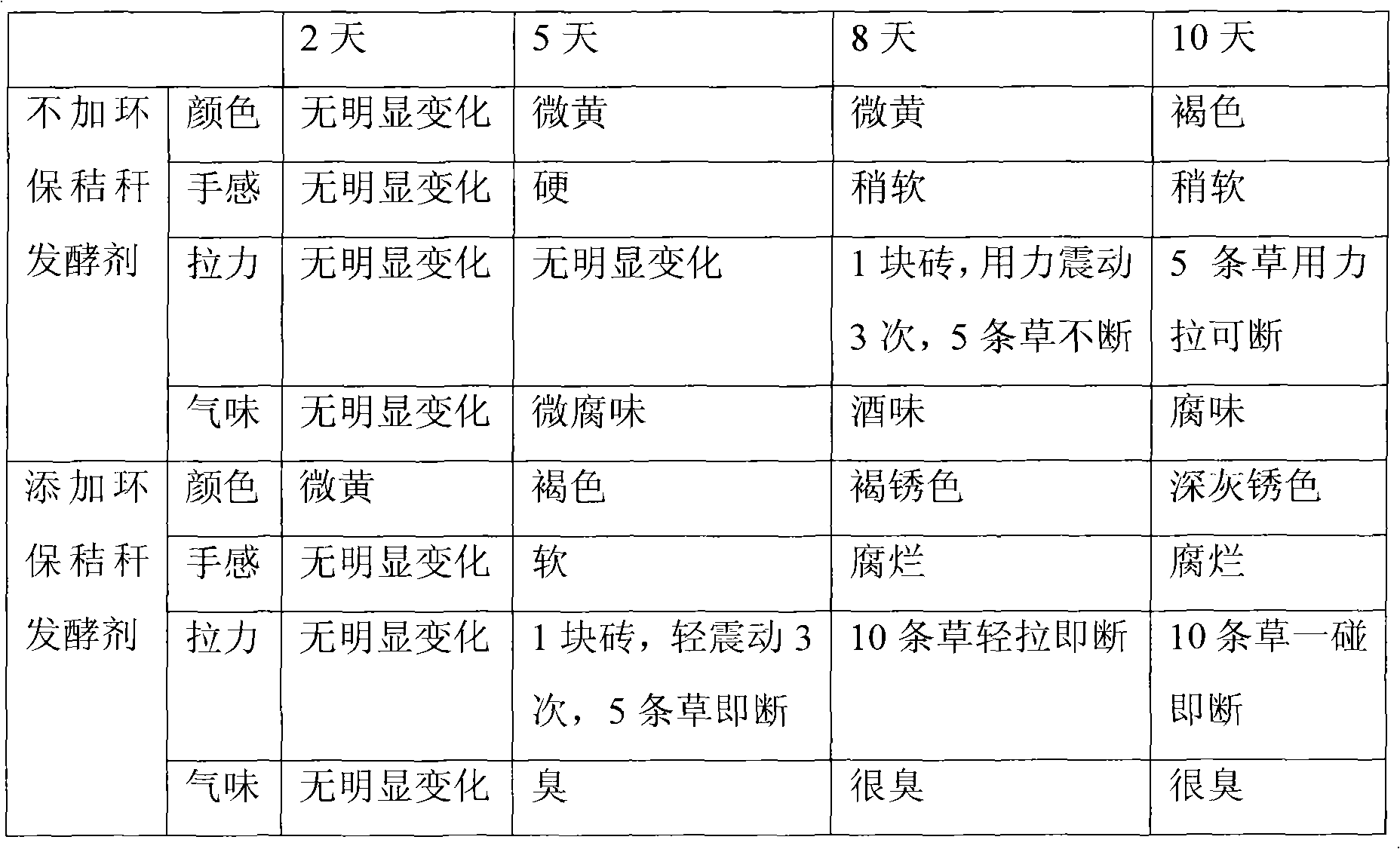

Environment-friendly straw fermenting agent

InactiveCN102517217APromote growth and developmentHigh in nutrientsFungiBacteriaCelluloseStreptomyces hygroscopicus

The invention relates to an environment-friendly straw fermenting agent. The environment-friendly straw fermenting agent is prepared from the following seven raw materials in percentage by weight: 25 percent of bacillus subtilis, 15 percent of trichoderma viride, 18 percent of saccharomyces cerevisiae, 12 percent of aspergillus niger, 10 percent of streptomyces hygroscopicus, 10 percent of trichoderma koningii and 10 percent of arthrobacter. The environment-friendly straw fermenting agent can accelerate the decomposition speed of cellulose and can completely decompose crop straws within aboutten days to return to the field, so that the straws are corroded, blackened and composted. The environment-friendly straw fermenting agent can accelerate release of nutrient elements in the straws, provides more nutrients for growth of the crops at the later stage, maintains and improves soil fertility, improves soil organic matter, improves physicochemical property of the soil, increases the yield of the crops by about 10 percent, and can be widely applied to returning straws of the crops such as rice, wheat, corn and the like to the field.

Owner:宋保德

Disease-suppression antibacterial beautiful sealant and preparation technology thereof

InactiveCN105969046AReduce pollutionReduce pollution sourcesAntifouling/underwater paintsPaints with biocidesDiseaseEpoxy

The present invention provides a disease-suppressing and antibacterial beautifying agent and a preparation process thereof, wherein the disease-suppressing and antibacterial beautifying agent includes components A and B; component A includes: 50-90 parts of epoxy resin, benzyl alcohol 1-5 parts, 0.2-1.2 parts of defoaming agent, 1-9 parts of fumed silica, 0.3-1.2 parts of thixotropic agent, 0.2-0.8 parts of silver antibacterial agent, 0.5-1.2 parts of ultraviolet absorber, and 1 part of water repellent ‑6 parts, 3‑40 parts of toner, 1‑20 parts of flexibility additive; component B includes: 10‑20 parts of polyetheramine, 9‑35 parts of alicyclic amine, 25‑45 parts of epoxy resin, benzyl alcohol 20-40 parts, 0.5-2 parts of defoamer, 0.5-4 parts of fumed silica, 1-5 parts of thixotropic agent, 0.2-0.9 parts of silver antibacterial agent. The invention can fill the gaps to bring aesthetics, and at the same time, suppress live viruses and bacteria existing in the gaps, and reduce indoor microbial pollution sources.

Owner:苏州久居环保科技有限公司

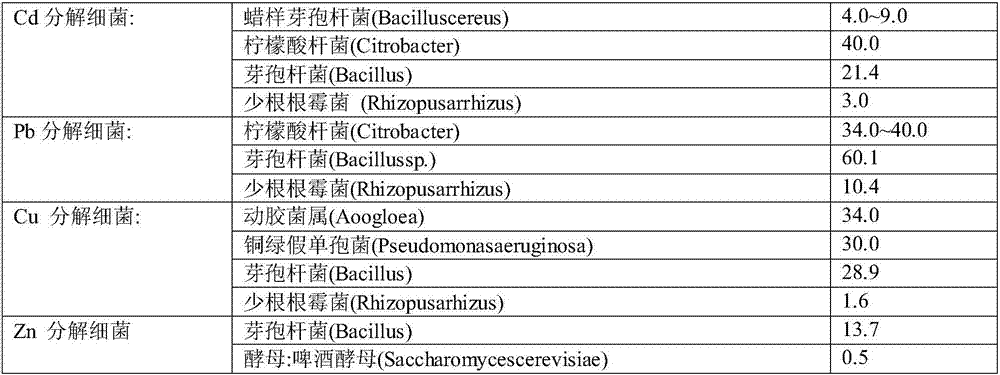

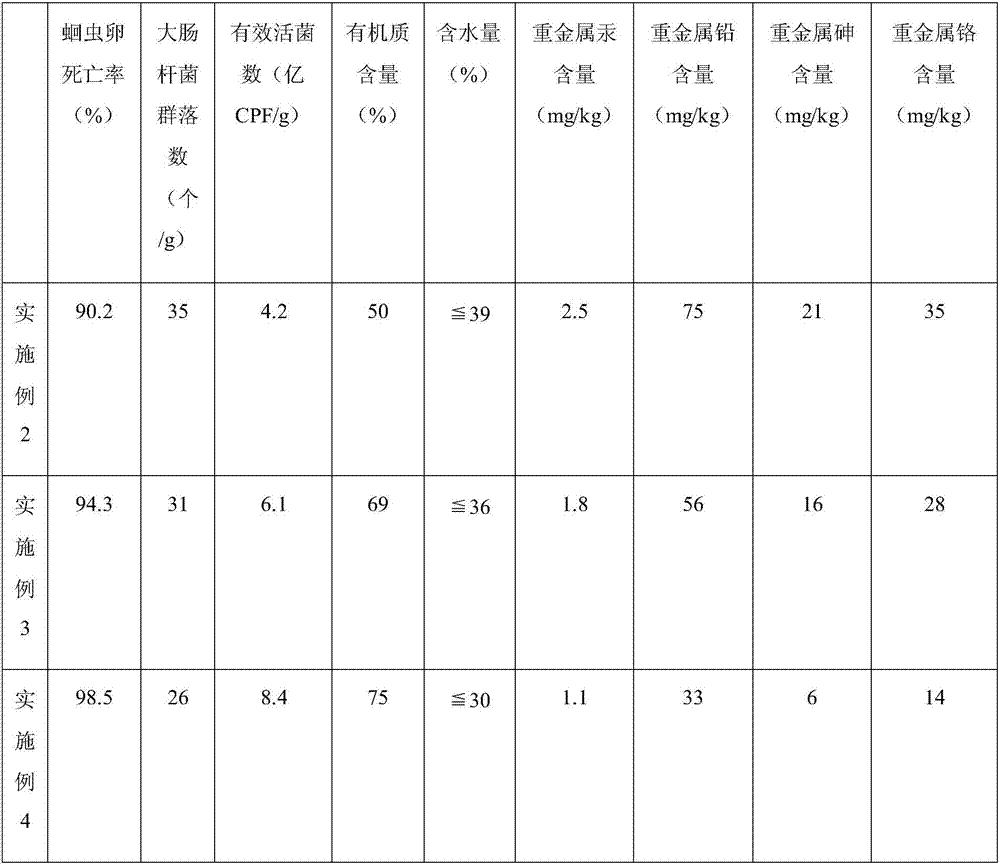

Heavy metal sludge soil restorer, preparation method and application thereof in sludge elimination

ActiveCN106905980AResolve disposal issuesCan regulate fertilitySludge treatment by de-watering/drying/thickeningContaminated soil reclamationSludgeSoil remediation

The invention provides a heavy metal sludge soil restorer, a preparation method and an application thereof in sludge elimination. The adopted technical scheme comprises: municipal sludge is subjected to pretreatment, thermophiles are used for decomposing organic substances, and a heavy metal is added to treat microorganisms. After the sludge restorer is used in a test, the effective removal rate of various pollutants in soil reaches 95% or above, in line with national standards. At the same time, sulfate can be used to repair heavy metal land in situ, and is also a very good organic fertilizer, and is beneficial to reduction in the use of chemical reagents and chemical fertilizers in agricultural production, thereby eliminating pollution sources and secondary pollution from the source.

Owner:北京绿安创华环保科技有限公司

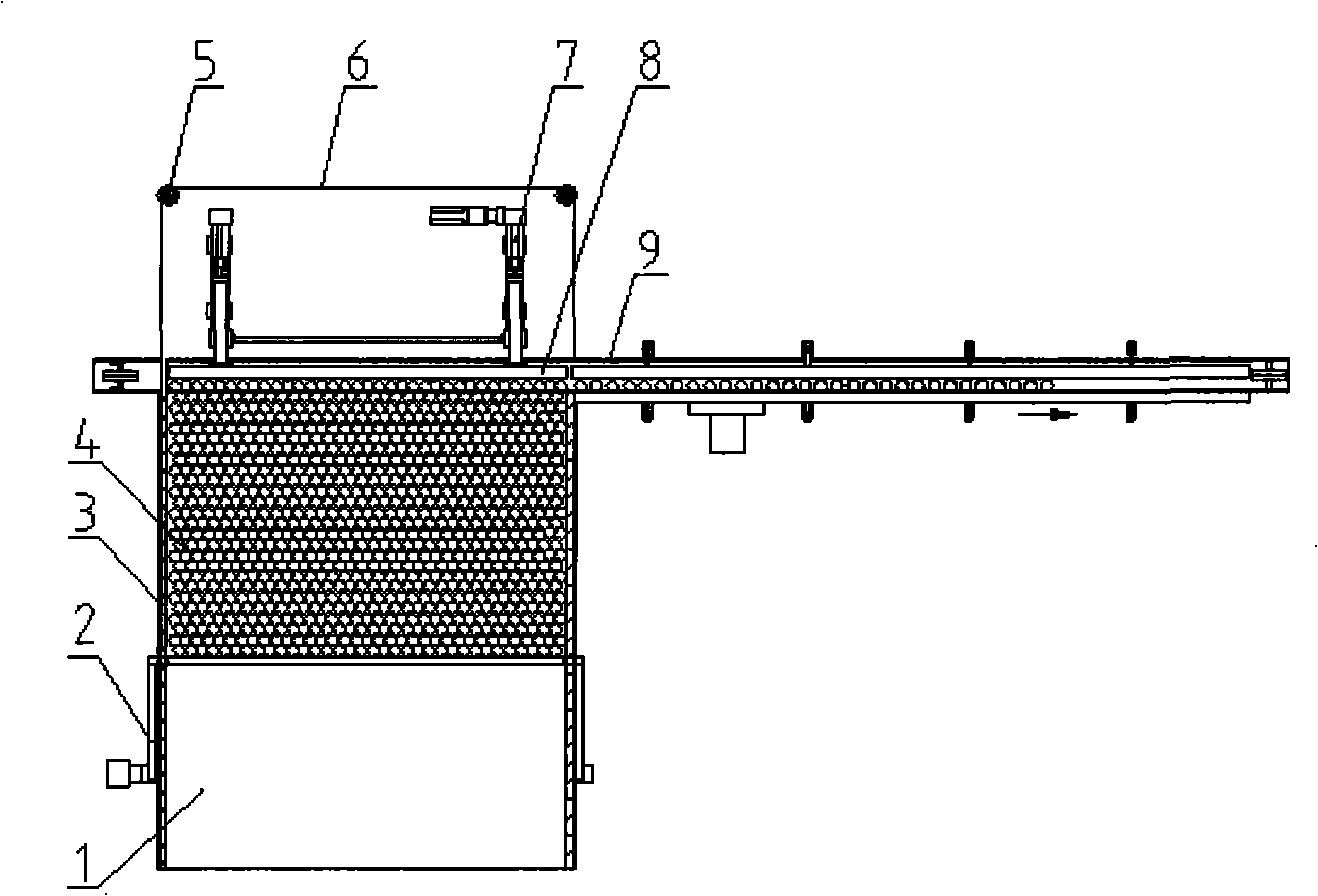

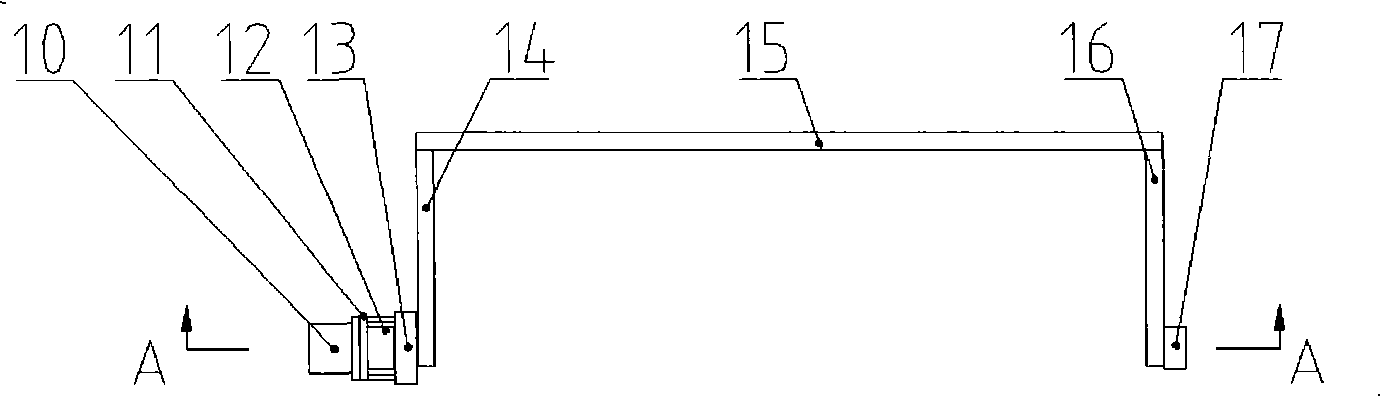

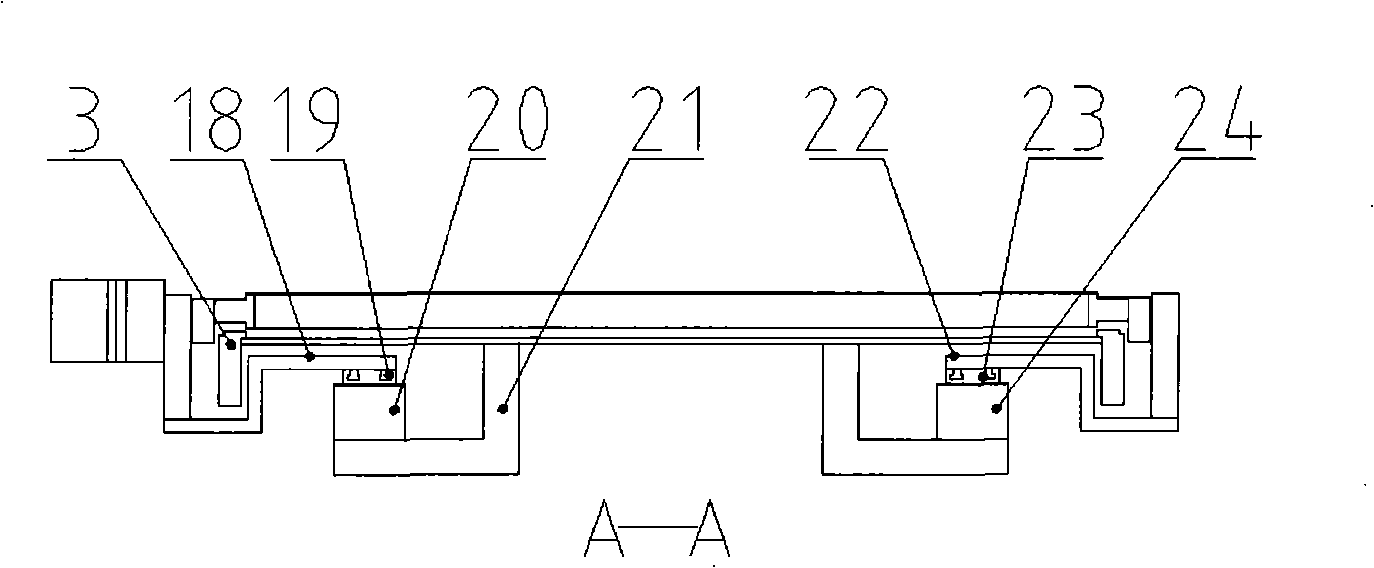

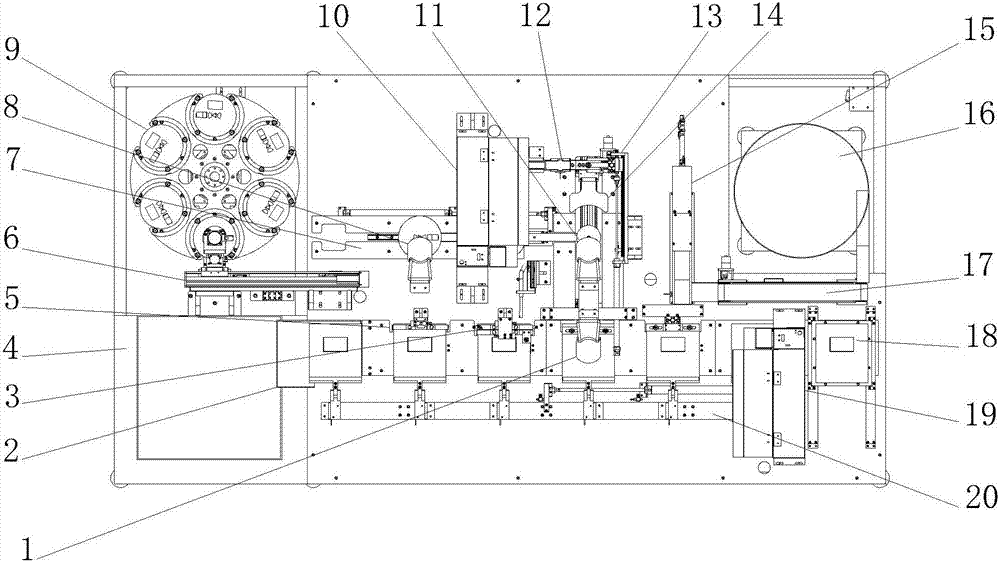

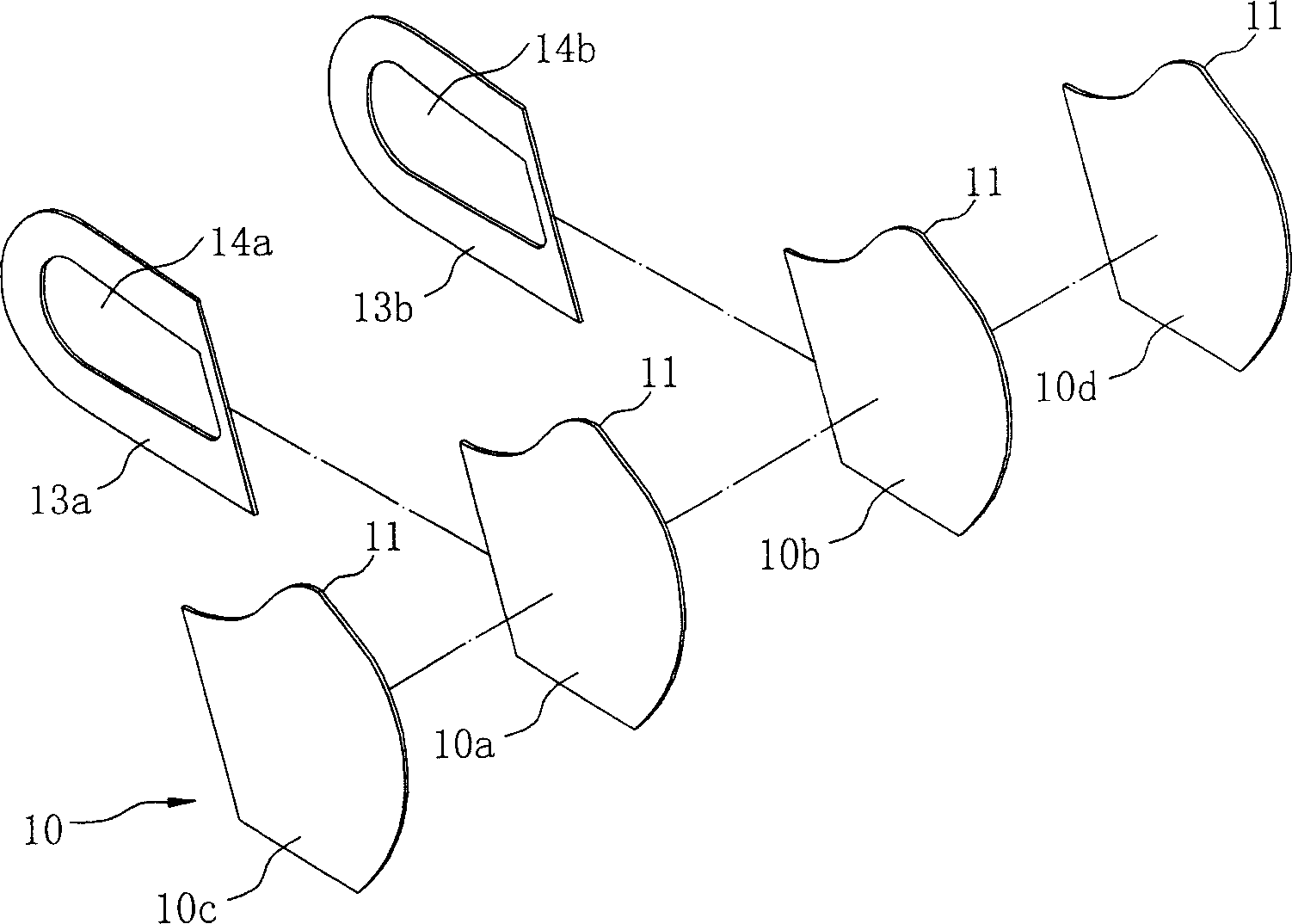

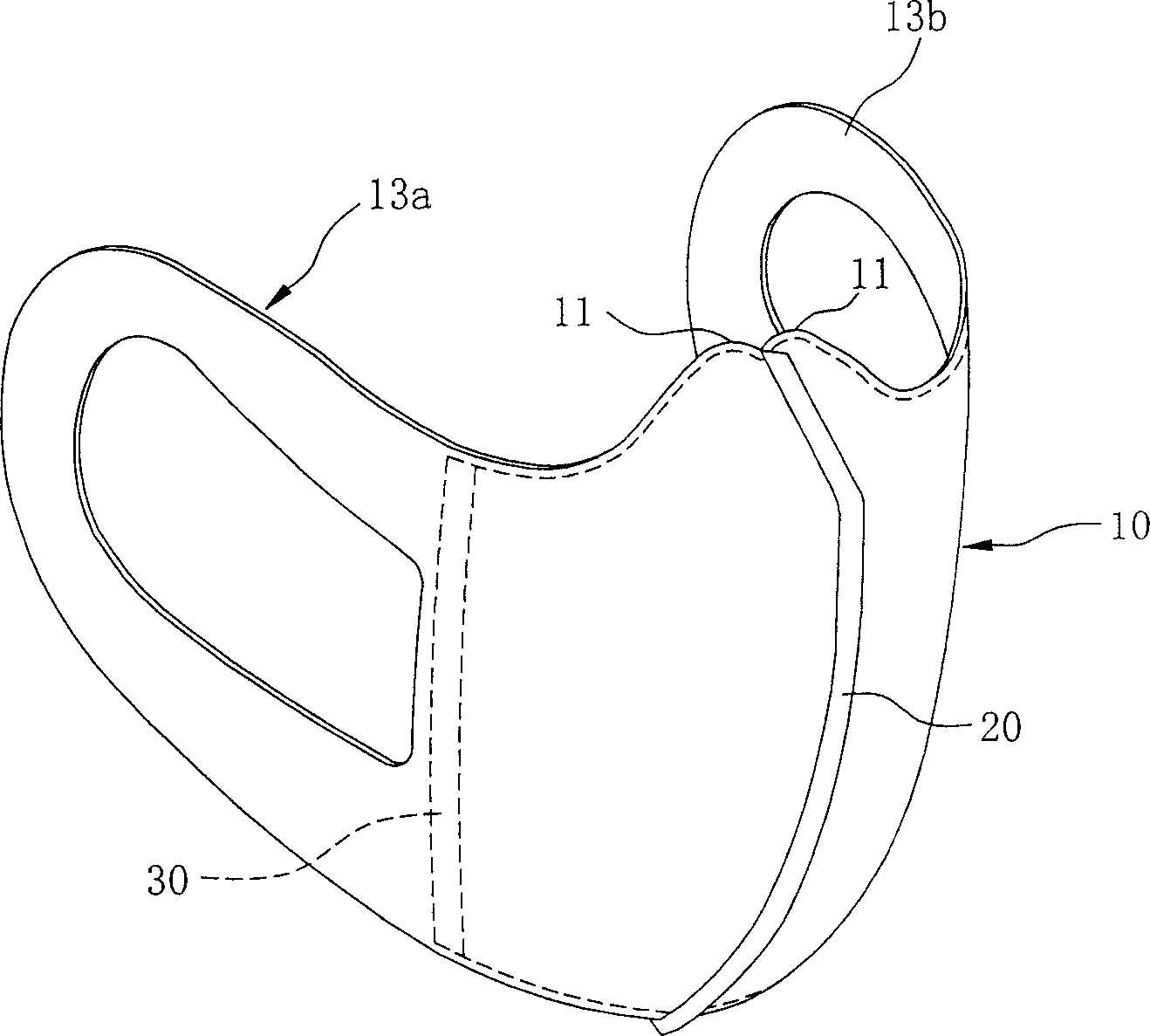

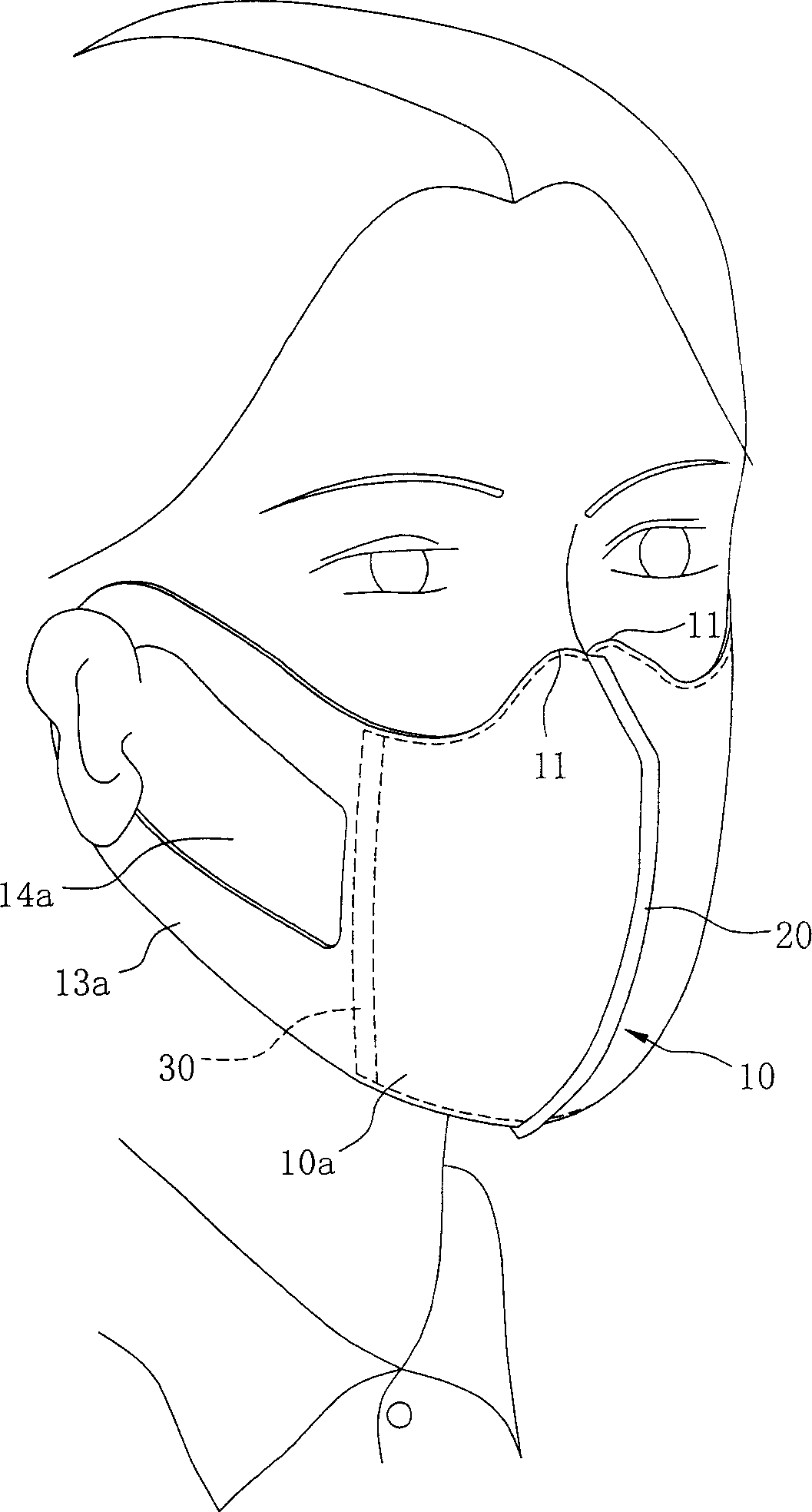

Silin bottle automatic drawing mechanism used for freeze-drying machine

ActiveCN101403563ARealize automatic dischargeRealize unmannedDrying solid materials without heatFreeze-dryingEngineering

The invention relates to a vial automatic discharging device used for a freeze dryer. The device is characterized by consisting of a material containing desk, a discharging system subassembly, guide tracks, a bracket, a decorative board, a thruster system subassembly, a handspike subassembly and a transmitter system subassembly, wherein, the material containing desk, the decorative board and the thruster subassembly are arranged on the bracket which can be slightly adjusted, the transmitter system subassembly is connected with the end of the material containing desk, the thruster system subassembly is arranged on the decorative board which is arranged at the side end of the transmitter system subassembly, the handspike subassembly is connected with a slider in the thruster system subassembly, and the discharging system subassembly is arranged on the guide tracks which are arranged at two sides of the material containing desk. The device has the advantages of providing the possibility of unmanned operation in a clean room, and and reducing pollution sources, thus providing higher guarantee for the sterility of products and effectively improving the labor productivity.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

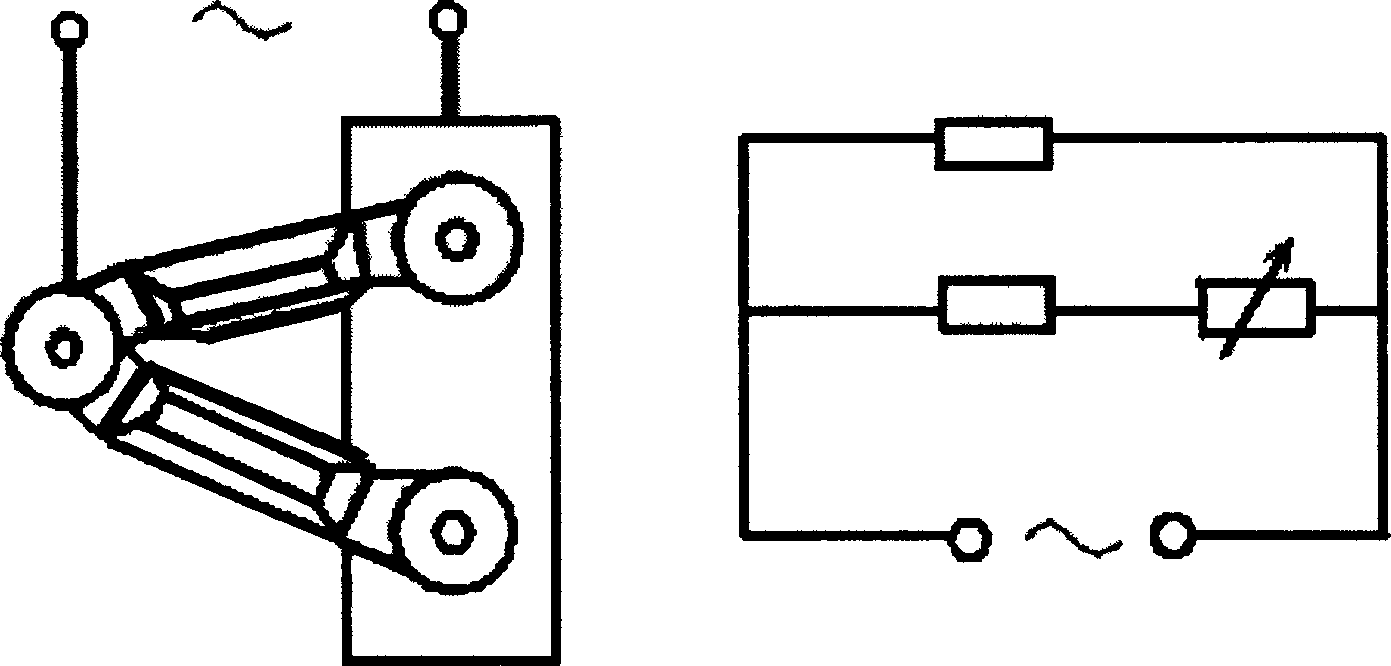

Physical and chemical combination repair technology of the lead acid accumulator

InactiveCN101017920AImprove repair rateChange natureBatteries circuit arrangementsWaste accumulators reclaimingAdditive ingredientEngineering

The exploited renovating technology for irreversible sulfuration of lead-acid accumulator applies nano synthesis technology and leading theory, and comprises steps as following: detecting cell state, determining ingredient and proportion for recovery liquid, knocking the lead sulfate crystal by a match-cell renovation device, opening ion channel to full discharge and activate original active material.

Owner:邢纪国

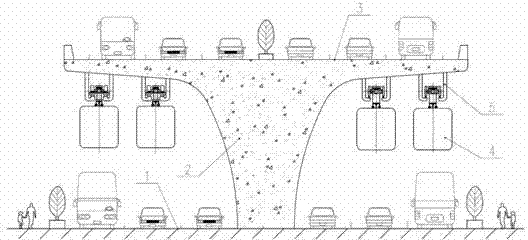

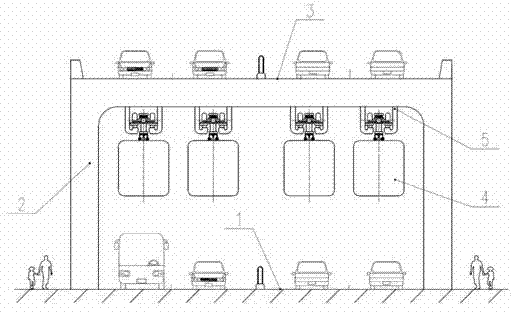

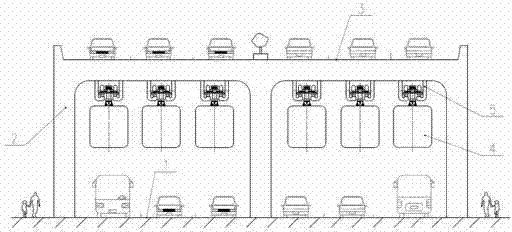

Elevated urban traffic system

InactiveCN103693045AImprove transportation capacityImprove traffic space utilizationElevated railway with suspended vehicleTraffic capacityEngineering

The invention provides an elevated urban traffic system. The elevated urban traffic system comprises the ground road; the elevated bridge floor is straddled above the ground road through a supporting bridge pier; the upper surface of the elevated bridge floor is provided with the bridge road; a hanging rail is paid on the lower surface of the elevated bridge floor; the hanging rail is provided with hanging vehicles in a matched mode. According to the elevated urban traffic system, the space utilization rate of the urban traffic is improved and the traffic mode of two layers of roads and one layer of light rail is formed in the same space and accordingly the traffic capacity is improved furthest.

Owner:CRRC SHANDONG CO LTD

Method for degumming ambary by low-temperature plasma and biological enzyme

The invention discloses a method for degumming ambary by low-temperature plasma and a biological enzyme. The method comprises the following steps: firstly, pretreating crude ambary by the low-temperature plasma, i.e., breaking the glucoside bonds in an ambary fiber material by virtue of a large quantity of active particles in the plasma to generate macromolecule free radicals, unsaturated chains and cross-linking layers, thereby enabling the structure of a colloid complex to become loose and parts of colloid molecules to be decomposed into small molecules to reduce the adhesive performance of fiber surface colloid, thus providing good conditions for biological enzyme degumming; secondly, degumming the ambary by high-efficiency biological enzyme, wherein the colloid such as pectin and hemicelluloses can be completely decomposed by means of treating the crude ambary by virtue of the synergistic effect of different-component enzyme systems, so that the aim that the cellulose is not damaged even if the colloid is degraded can be achieved. The method has the characteristics of high degumming efficiency, good degummed ambary product quality and no chemicals, and is energy-saving and environmental friendly.

Owner:QINGDAO SAMCDC COMMON HEALTH DETECTION CO LTD

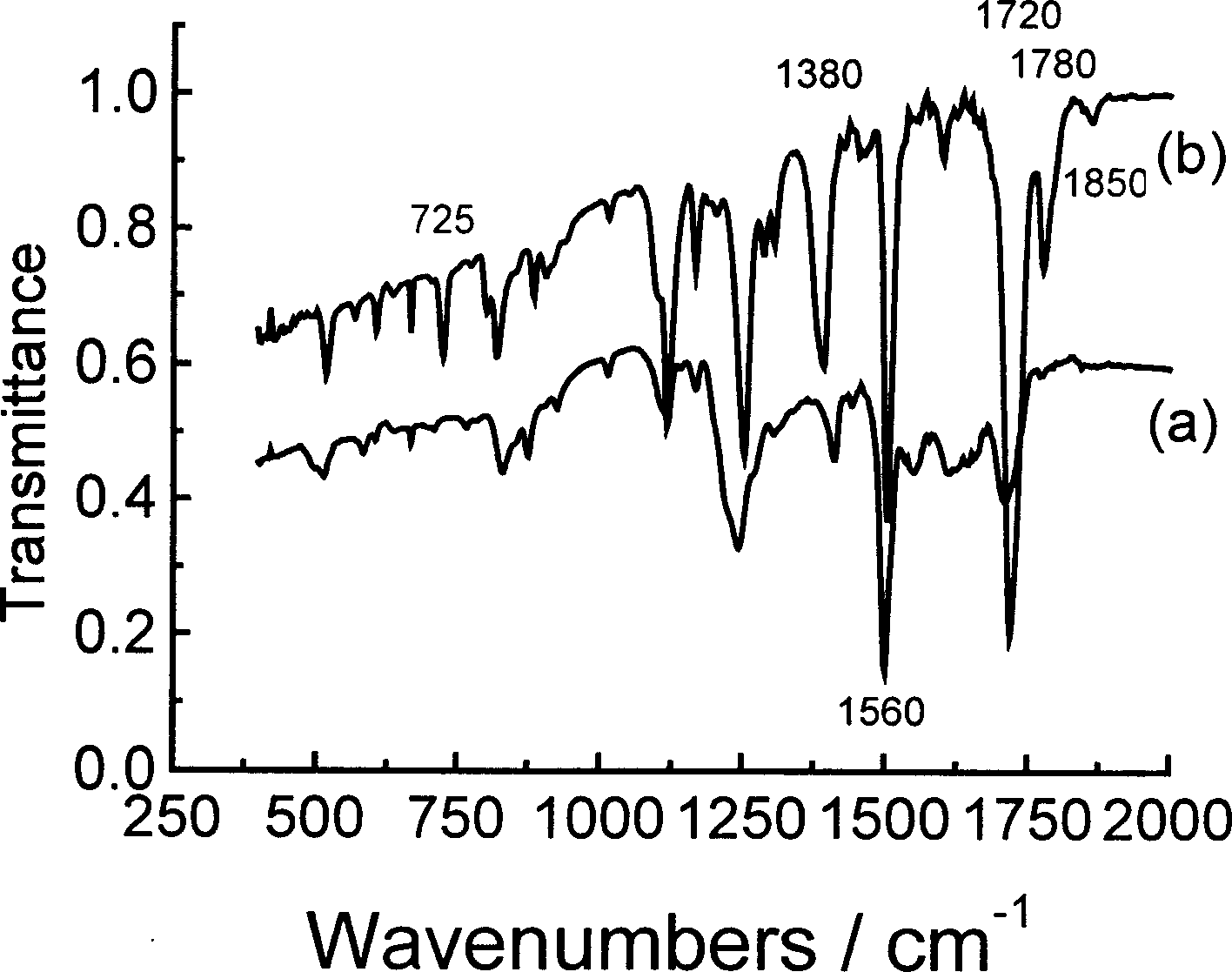

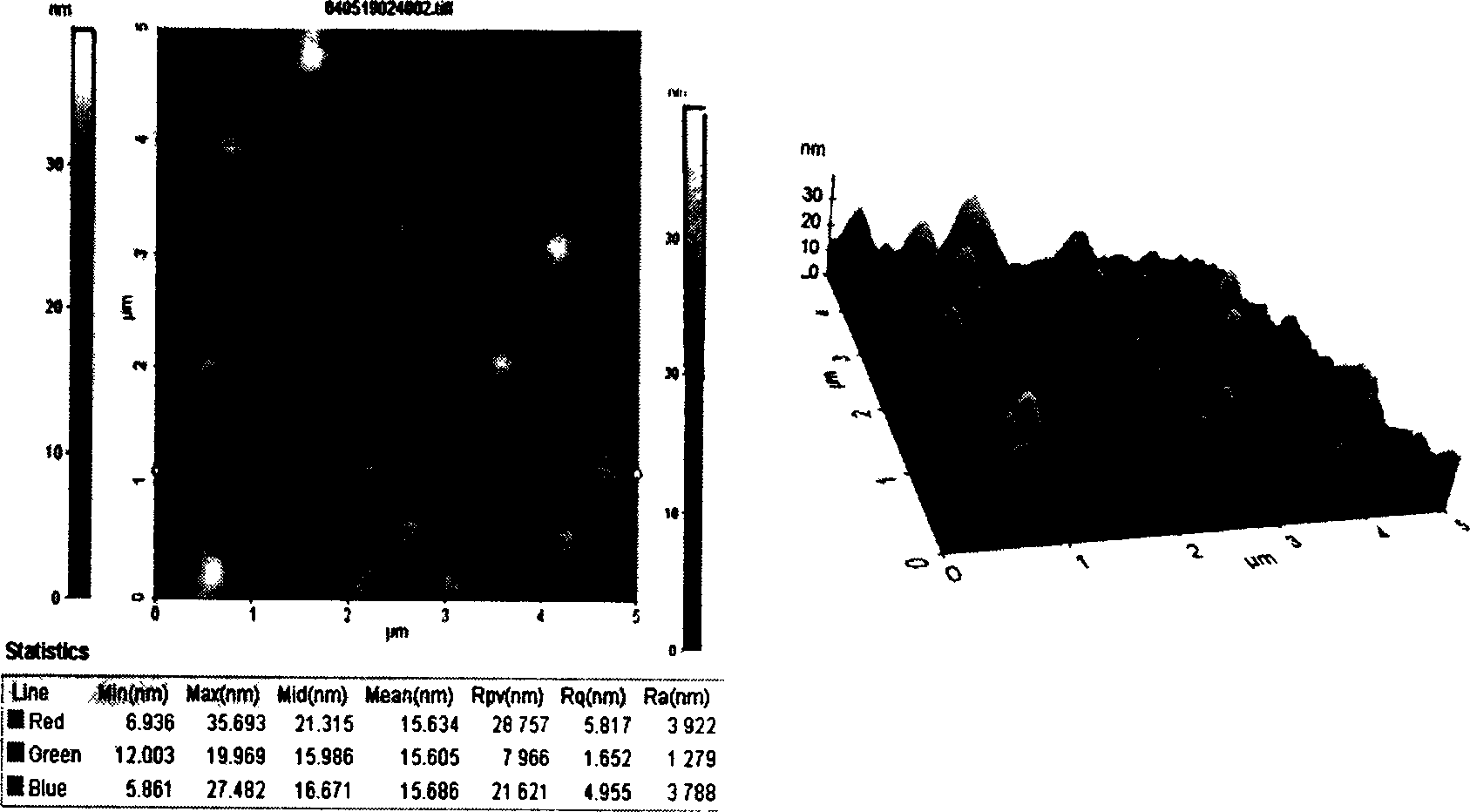

Preparation process for physics vapour phase deposition of ultrathin self-suporting polyimide filter film

InactiveCN1598041AReduce pollution sourcesReduce defectsVacuum evaporation coatingSputtering coatingGas phaseOptoelectronics

The invention provides a method of preparation ultrathin self-supporting polyimide light sieving film. Using completely PVD method, successively depositing doffing pellicle twain anhydride and diamine on the polishing glass substrate in the high vacuum environment, and then processing heat treatment in proper surrounding temperature., make sure twain anhydride and diamine form polymeric amic acid, and more ring-imidization. Sticking the orbicular copper frame on the surface of polyimide thin film, followed by removing the film in the deionized water, finally form the ultrathin self-supporting polyimide light filter film. The thin film could be applied as the light filter component of shortwave optics.

Owner:TONGJI UNIV

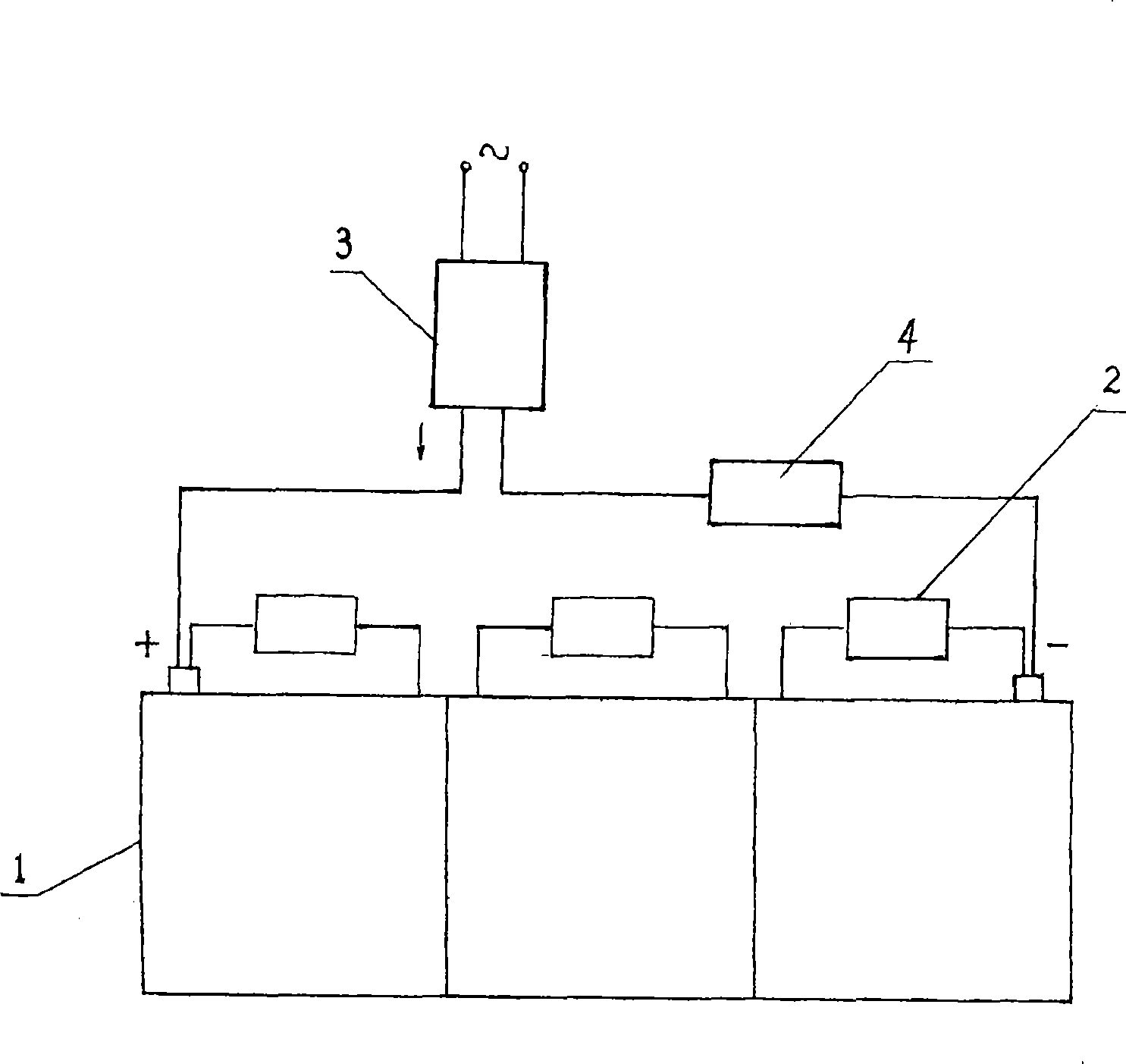

Lead acid accumulator renovation system and method thereof

InactiveCN101431170ASmall self-dischargeReduce pollutionCharge equalisation circuitLead-acid accumulatorsSocial benefitsElectrical battery

The invention relates to a lead-acid battery repair system which is designed against the difficult problem of irreversible vulcanization of a lead-acid battery and formed by combining a battery balancer and a devulcanized charger; and a developed repair agent is used for repair. Or a repair instrument is matched with the repair agent for direct repair. The repair technology can repair and use a waste vulcanized battery. The invention realizes the purpose of rapid elimination of the vulcanization by the self-repair and the principle of combing the physics and the chemistry to eliminate the vulcanization. The invention can prolong the service life of various lead-acid batteries to more than two times, lengthen the driving distance of various vehicles and repair various waste lead-acid batteries. The technology has simple operation, low cost, easy promotion, wide range of application and remarkable economic and social benefits.

Owner:邢纪国

Method for preparing culture medium of beech mushrooms and needle mushrooms by utilizing waste material of agaric culture medium

ActiveCN102633563AReduce pollutionAchieve recyclingHorticultureFertilizer mixturesBiotechnologyAgaric

The invention provides a method for preparing a culture medium of beech mushrooms and needle mushrooms by utilizing a waste material of an agaric culture medium. The method comprises the following steps: (1) collecting and materializing treatment for the waste material of the agaric culture medium: selecting a qualified fungus bag for debagging, crushing under tiny wet state, adding a modifier while crushing to adjust a pH value to be 6.0-7.0, and standing in sunlight for exposing 2-8 days or drying for 6-12 hours at 65-75 DEG C until the water content is 10%-13% for later use, and (2) nutrient balancing preparing for the culture medium: taking 65-75% of processed agaric waste materials, 10-25% of bran or rice bran, 2% of bean flour, 5-10% of corn flour, 0.5% of white sugar, 1-2% of calcium superphosphate or potassium phosphate, 1-2% of gypsum and 0.5-1% of magnesium sulfate, and then adding water until the water content is 55%-65%, and uniformly stirring after an absorbing nutritional solution of 0.3-2.5% nutritional type biopolymer is saturated. According to the method, the cost is low, the yield is high, the waste is efficiently reused and the environmental pollution is reduced.

Owner:黑龙江省诚美盛世知识产权运营有限公司

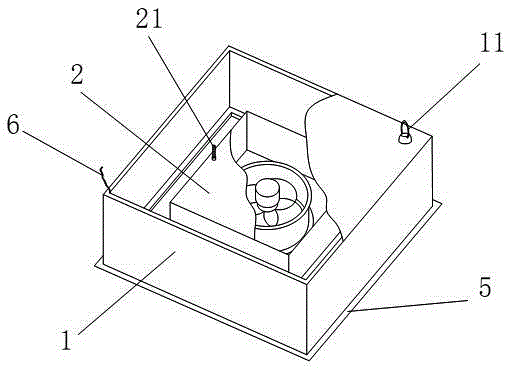

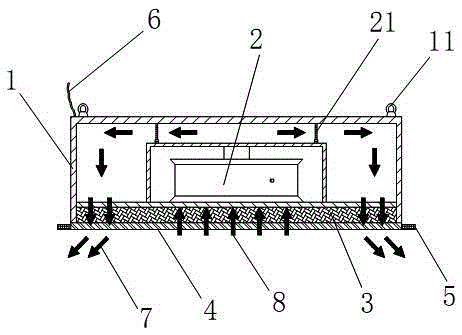

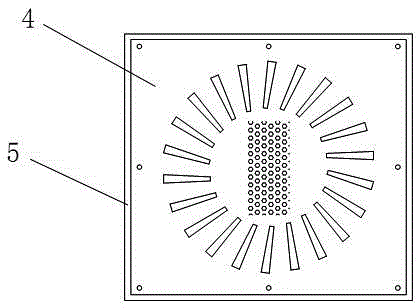

Modularization clean room unit device

ActiveCN105276720AOverall small sizeImprove sealingMechanical apparatusLighting and heating apparatusUnit deviceEngineering

The invention discloses a modularization clean room unit device, and relates to the technical field of clean room equipment. The unit device comprises an outer box, a filter draught fan, a filter and a flow scattering plate. The outer box is a cover with the upper closed end and the lower open end. The flow scattering plate is arranged at the opening in the lower end of the outer box. The filter and the filter draught fan are sequentially arranged above the flow scattering plate. The flow scattering plate comprises an air supply port and an air returning port. An air inlet of the filter draught fan is aligned with the air returning port of the flow scattering plate. A channel is formed by an air outlet of the filter draught fan and the air supply port of the flow scattering plate. The device is provided with the filter draught fan, and air supplying and air returning are integrated. The modularization clean room unit device is compact in size, good in sealing performance, easy and convenient to install, reliable and stable in running, capable of saving energy, free of dust generation and dust accumulation, capable of effectively reducing the pollution source of a clean room and wide in application range.

Owner:中国电子系统工程第四建设有限公司

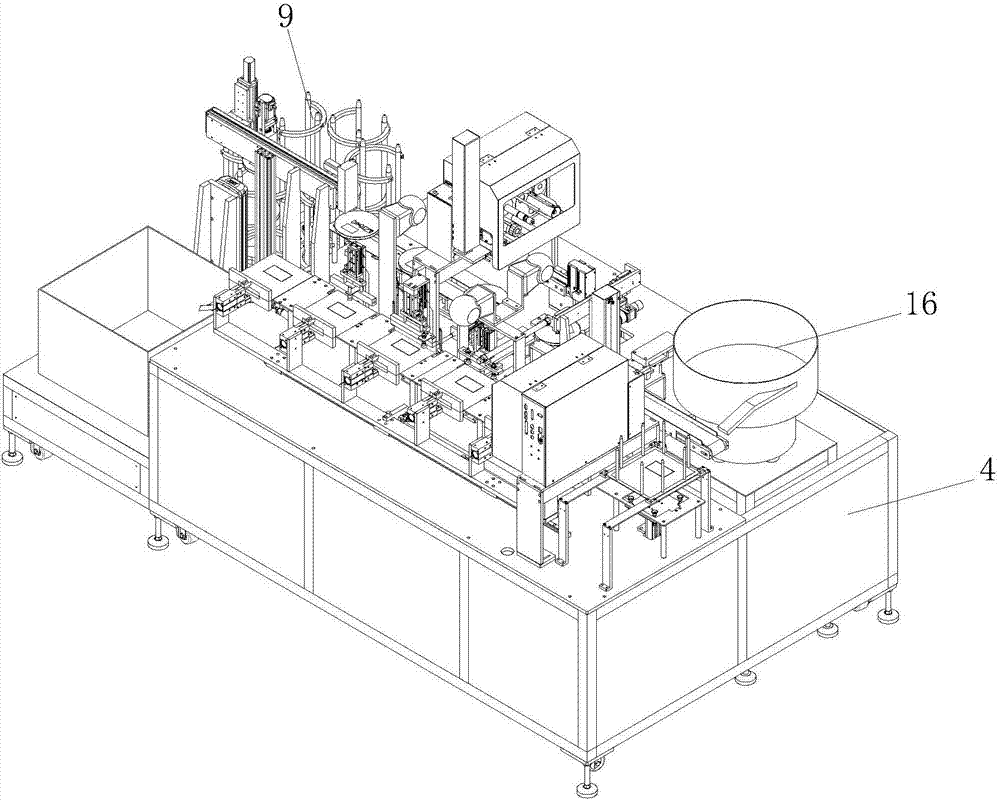

Intelligent packaging machine

PendingCN107985669AReduce volumeEasy to adjustPackaging by pressurising/gasifyingWrapper twisting/gatheringHuman–machine interfaceMan machine

The invention discloses an intelligent packaging machine. The intelligent packaging machine comprises a worktable, an electronic warehouse is fixedly arranged on one side of the top of the worktable,a vacuum sealing mechanism is arranged on one side of a cooling embossing mechanism, and a lower heating block is arranged at the bottom of a first glue bag. According to the intelligent packaging machine, an electronic material disc transplanting mechanism jacks up and puts down a disc through rising and falling actions of a lifting air cylinder, after the lifting air cylinder rises, the electronic material disc is jacked up, the electronic material disc transplanting air cylinder moves the electronic material disc, the material disc can reach the next station, the lifting air cylinder descends, the electronic material disc is put down and returns to the original position, and overloading is achieved; according to customer product characteristics, a function unit assembly is achieved, one-step operation from raw materials to products is achieved, use of manpower and material resources is reduced, unit cooperation is optimized, the automation degree is high, workshop space occupying issmall, the pollution source is small, power consumption is little, the cost is low, maintaining is easy, and unit matching can be finished through man-machine interface communication operation by oneperson.

Owner:广东金昇智能数控有限公司

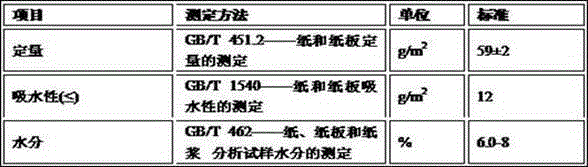

Fruit cultivating bag paper and preparation method thereof

ActiveCN105379594AGuaranteed waterproof performanceGood shading effectCoatingsPlant protective coveringsPaper sheetCarbon black

The invention relates to the field of fruit cultivating bag paper, in particular to fruit cultivating bag paper and a preparation method thereof. Raw paper is correspondingly smeared with an outer coating prepared from iron oxide yellow, iron oxide red, a color fixing agent, a waterproof agent and a water-resistance agent and an inner coating prepared from calcium carbonate, carbon black pigment, a color fixing agent and a waterproof agent, and the fruit cultivating bag paper is obtained through coiling. The fruit cultivating bag paper has good waterproof performance and high shading performance, coating distribution is uniform, and the performance of the fruit cultivating bag paper is excellent. In the production process of the fruit cultivating bag paper, pollution sources are effectively reduced, coating smearing is conducted through a coating method, the shading performance is uniform, and the shading degree is high; meanwhile, the technology is simple, operation is easy, the production cycle is short, and the production efficiency is high.

Owner:NINE DRAGONS PULP PAPER LESHAN CO LTD

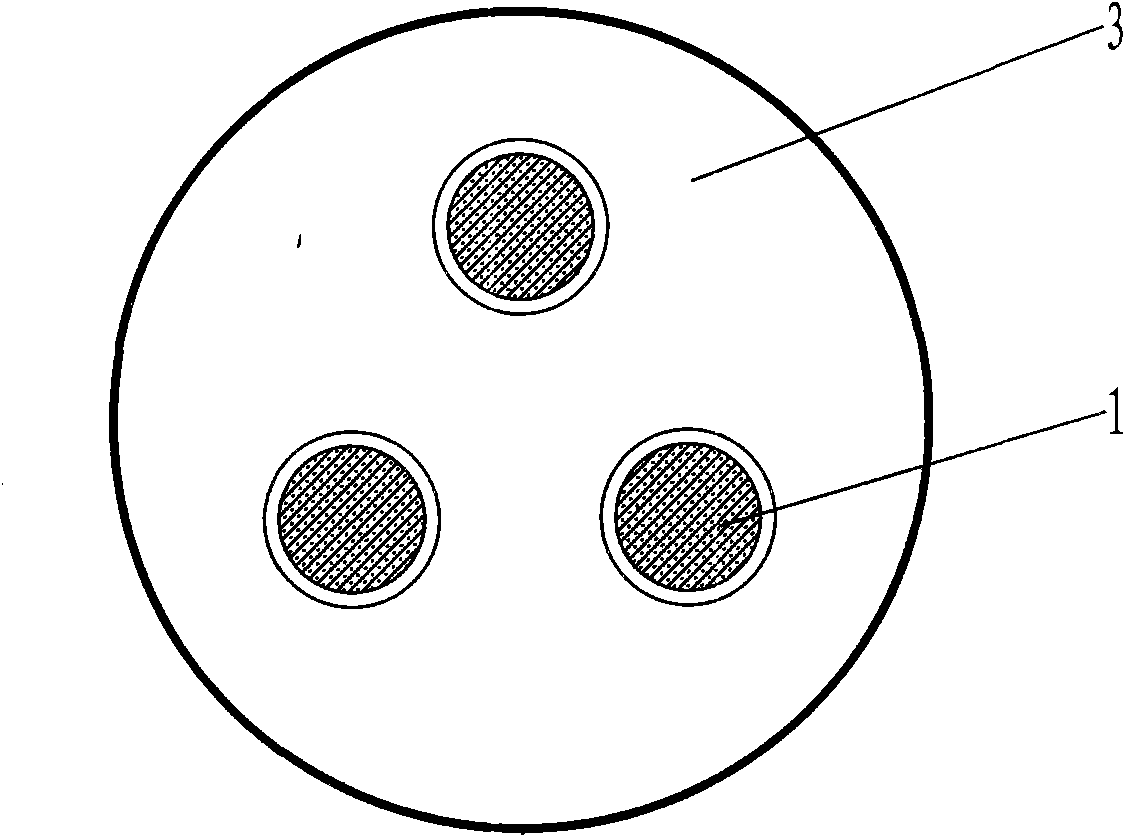

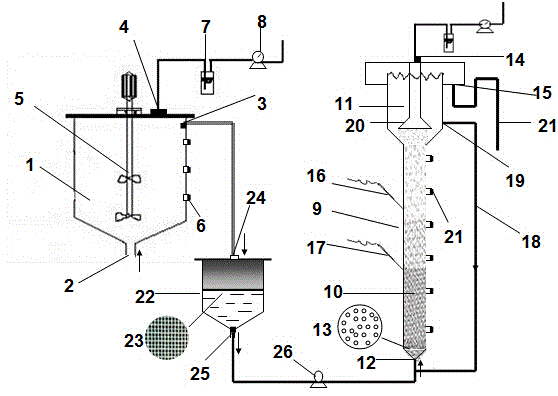

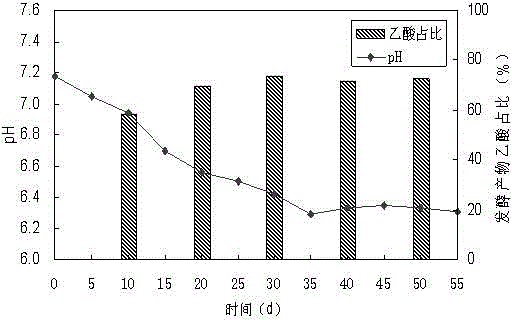

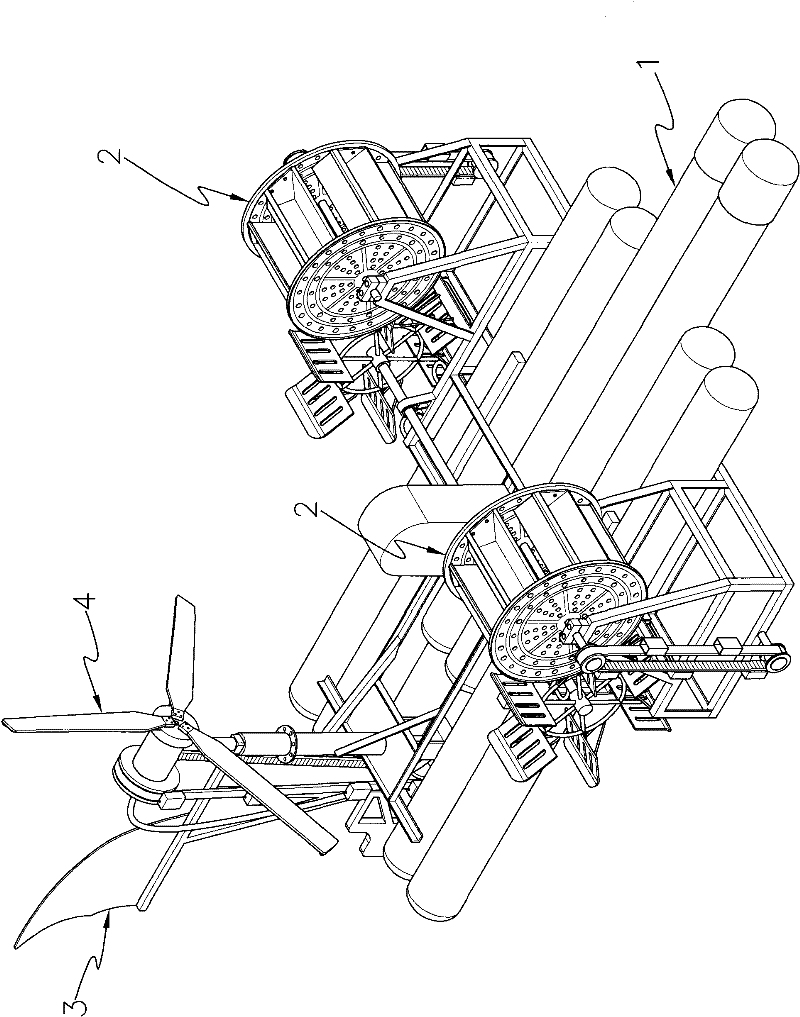

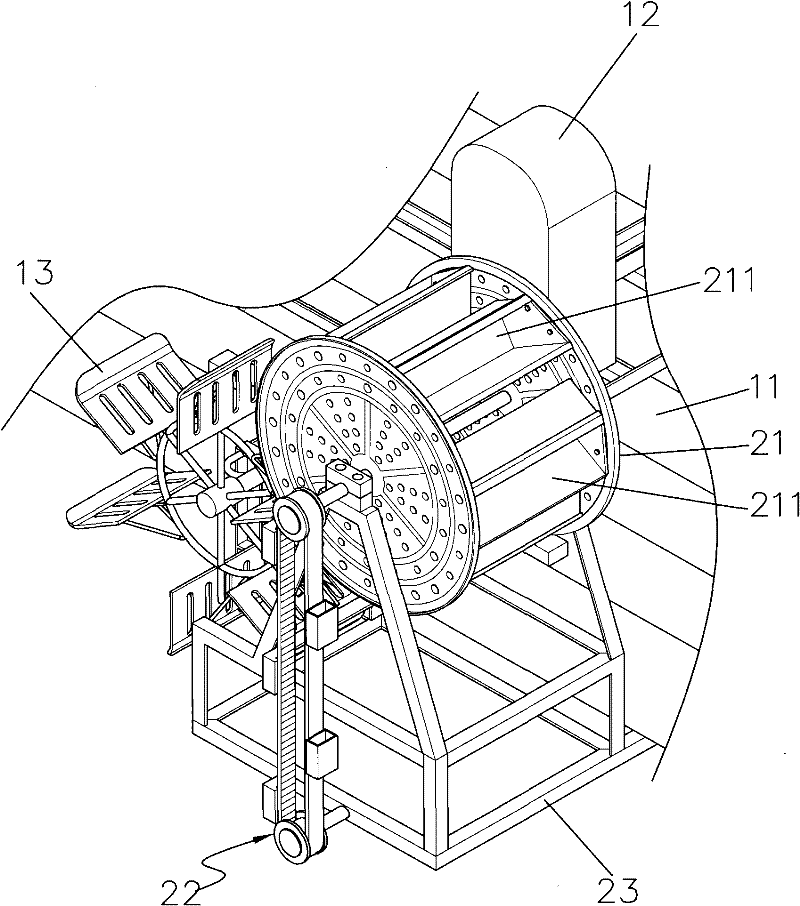

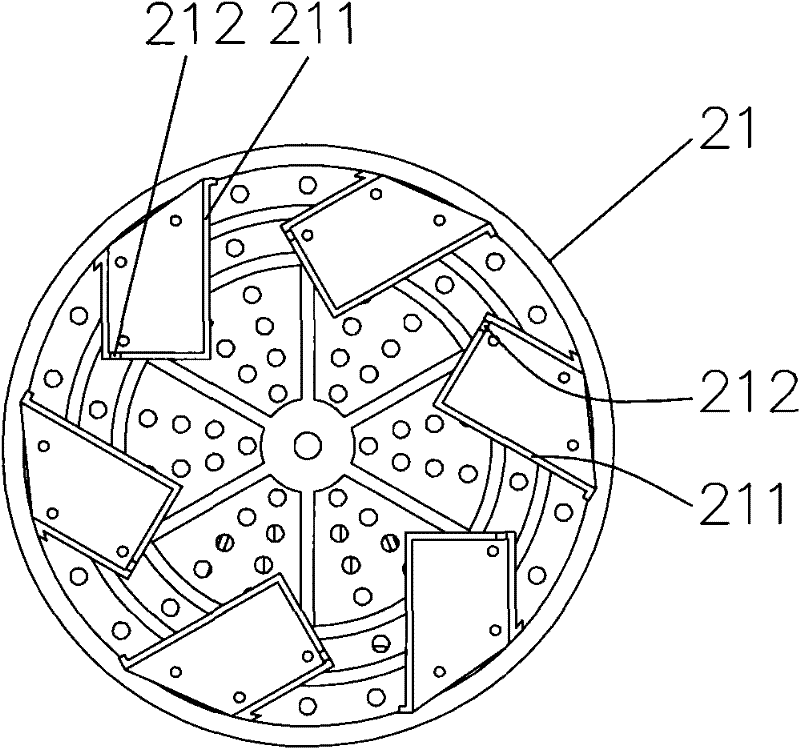

Agricultural organic waste anaerobic fermentation recovery biogas reaction apparatus and recovery method thereof

InactiveCN104130942ARelieve blockageRelieve blocked technical bottlenecksBioreactor/fermenter combinationsBiological substance pretreatmentsRecovery methodGeneration rate

The invention relates to an agricultural organic waste anaerobic fermentation recovery biogas reaction apparatus and a recovery method thereof. The apparatus comprises an acidogenic fermentation phase reactor and a methanogenic phase reactor, a filtering device exists between the acidogenic fermentation phase reactor and the methanogenic phase reactor, wherein the acidogenic fermentation phase reactor adopts a continuous stirred tank reactor, the methanogenic phase reactor adopts an anaerobic expanded granular sludge bed reactor with the ratio of height to diameter of 9:1-10:1, a filtering material made of a nylon filter screen or a polyethylene filter screen is arranged in the filtering device, the aperture size of the filter screen is 0.5-3mm, and a total volume ratio of the acidogenic fermentation phase reactor to the filtering device to the methanogenic phase reactor is 2.5-3.5:1:1. The apparatus and the method can improve the degradation efficiency of agricultural organic wastes in an anaerobic fermentation system, alleviate the bottlenecks of the obstruction technology of equipment and pipelines, reduce the fluctuation interference of northern low temperature environment to the whole anaerobic fermentation system, and improve the running stability and the biogas generation rate of the system.

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION +1

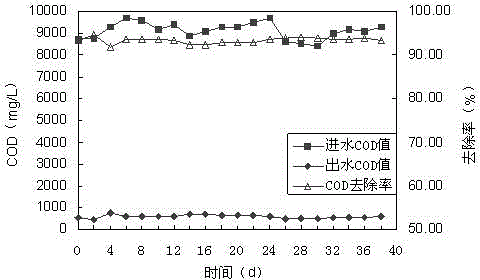

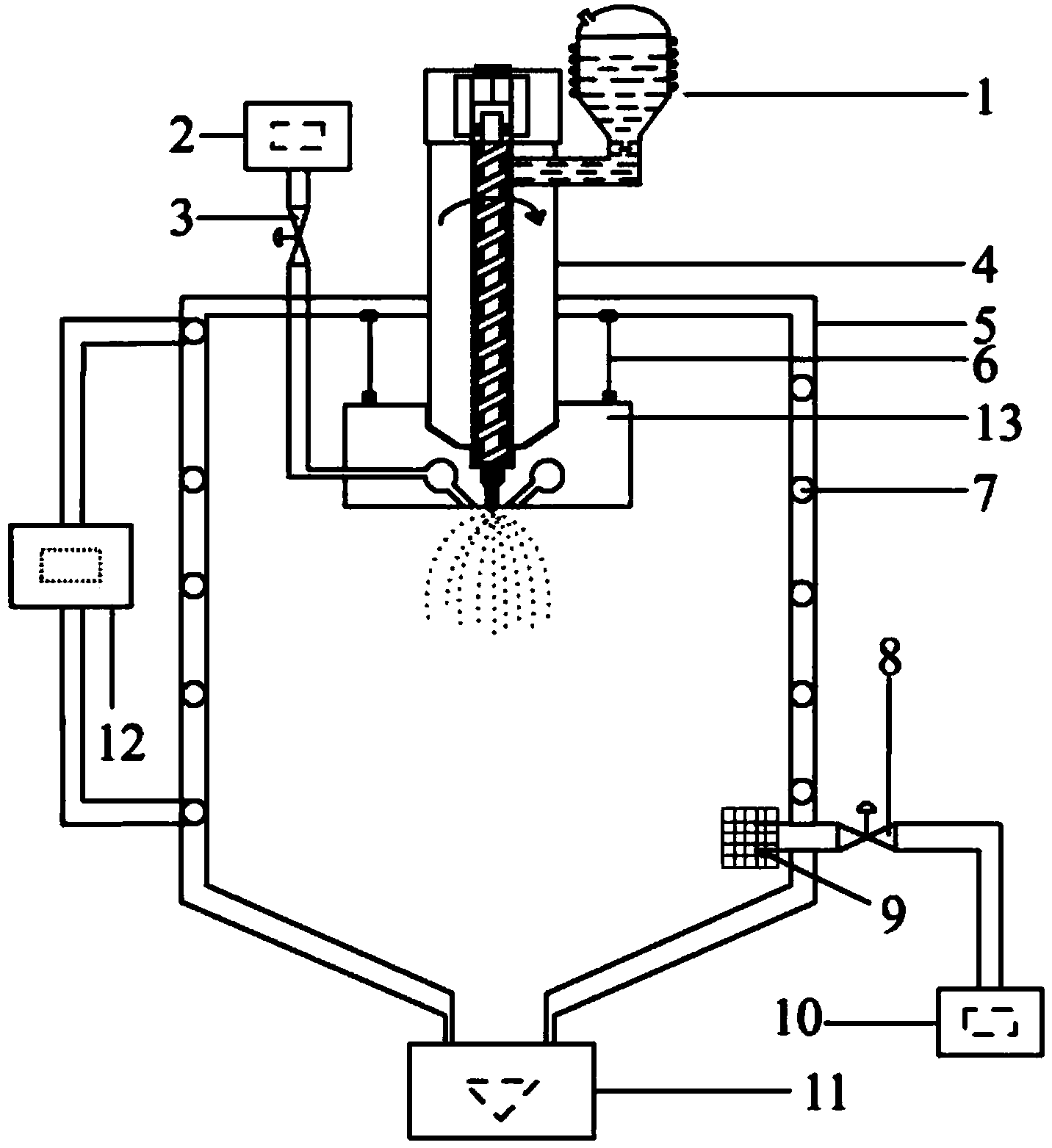

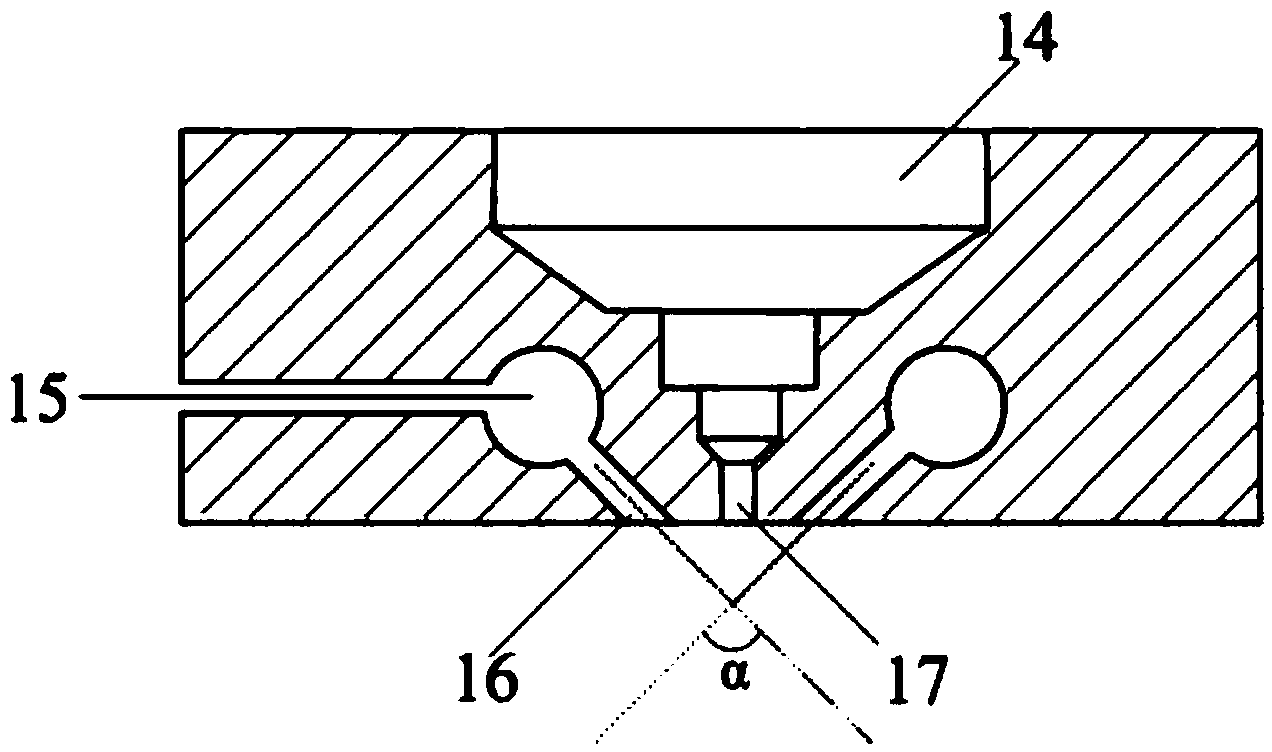

Gas atomization method and device for preparing mesocarbon microbeads

ActiveCN103663440AHigh yieldGood sphericityCarbon compoundsCell electrodesTemperature controlControl system

The invention discloses a gas atomization method and device for preparing mesocarbon microbeads. A technological process comprises preparation of mesophase pitch, extruding and drawing, gas atomization, cooling, powder collection and screening, oxidization and carbonization, graphitization and the like. The device comprises an electric mesophase pitch smelting furnace, a screw extruding and conveying machine, an atomization chamber and a gas atomization head, wherein one end of the screw extruding and conveying machine is connected with the electric mesophase pitch smelting furnace, and the other end extends into the atomization chamber and is connected with the gas atomization head; the gas atomization head is fixed at the top of the atomization chamber through an atomization head fixing device; a gas channel of the gas atomization head is connected with an atmospheric pressure control system; a powder collector is arranged at the bottom of the atomization chamber; and a temperature control pipeline is arranged on the inner wall of the atomization chamber and connected with a temperature control system.

Owner:SHAANXI COAL & CHEM TECH INST

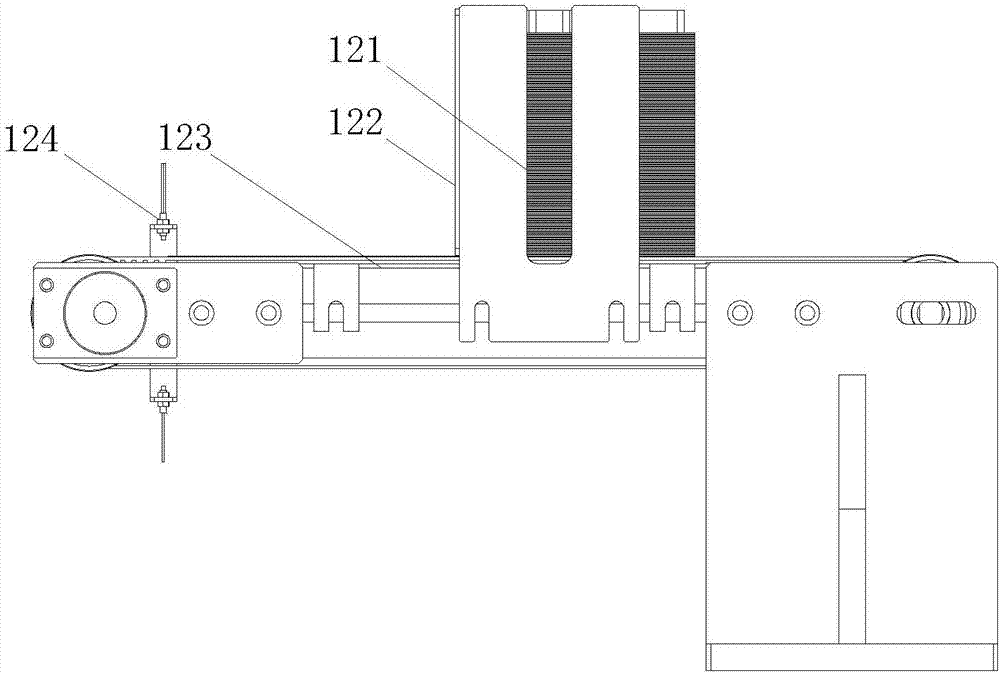

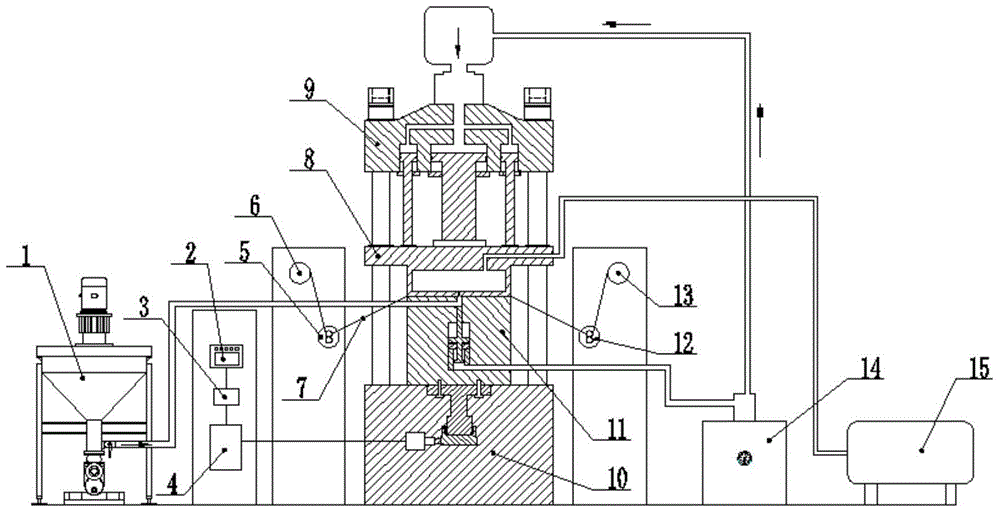

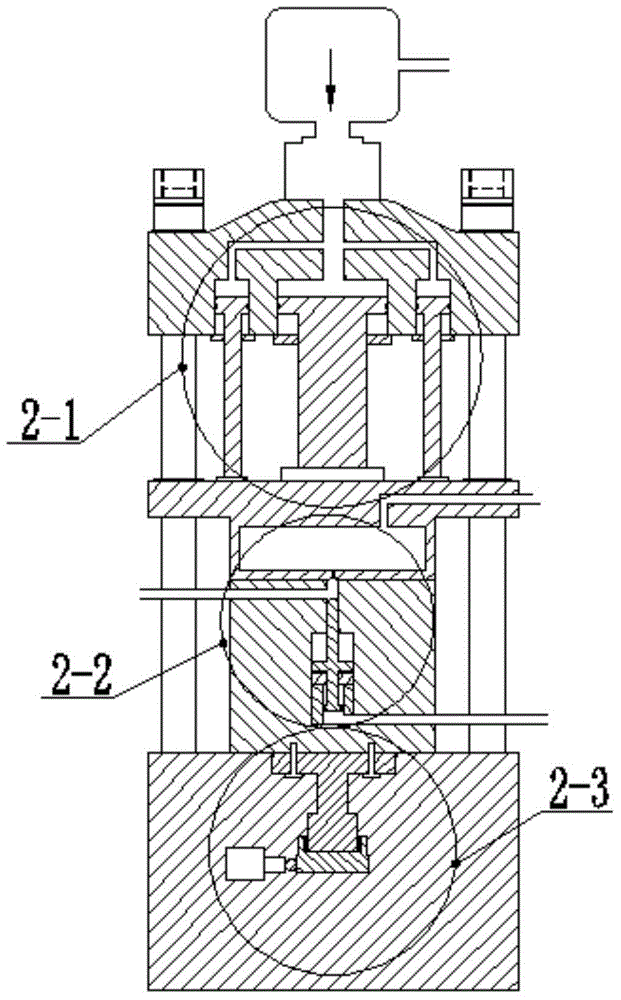

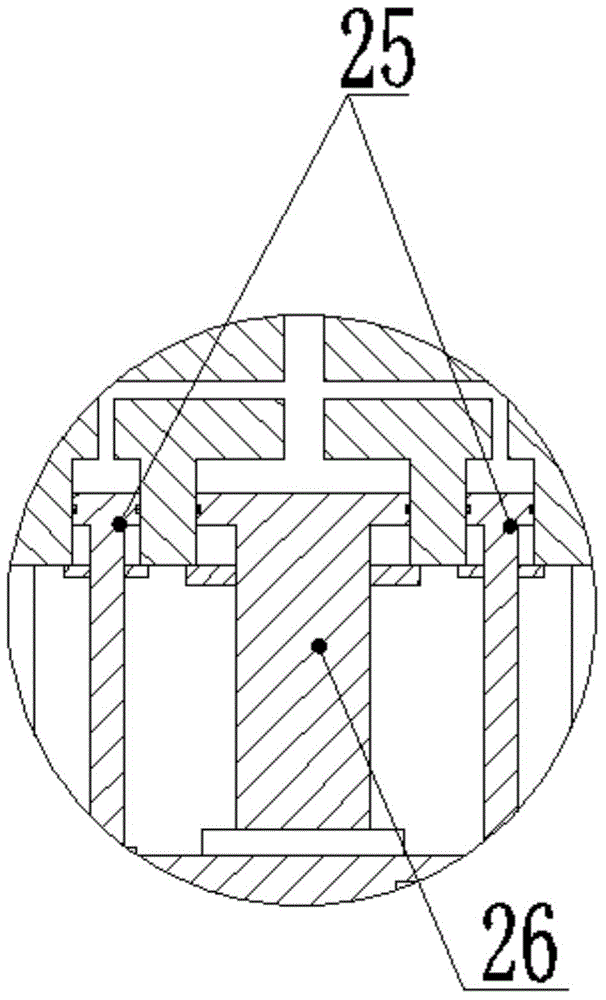

Downward-pushing magnetic material wet forming hydraulic machine and use method thereof

The invention discloses a downward-pushing magnetic material wet molding hydraulic machine and a use method thereof and belongs to the magnetic material wet forming field. The downward-pushing magnetic material wet molding hydraulic machine comprises a downward-pushing pressing structure. The downward-pushing magnetic material wet molding hydraulic machine further comprises a mechanical limiting structure, a packing structure, a blank fetching system, a double-oil cylinder balance system and a mould surface cleaning system; the downward-pushing pressing structure comprises an upper mould seat, a pushing rod, a large-bore oil cylinder, a fixing mould frame and a lower mould hydraulic cylinder, wherein the upper mould seat is driven by the large-bore oil cylinder, the pushing rod is located in the fixing mould frame, and the fixing mould frame is connected with the lower mould hydraulic cylinder, the large-bore oil cylinder and the lower mould hydraulic cylinder are both communicated with a hydraulic station; the mechanical limiting structure includes a horizontal mechanical limiting structure and a longitudinal mechanical limiting structure; the horizontal mechanical limiting structure comprises the pushing rod and the fixing mould frame; a fixing mould cavity is arranged in the fixing mould frame; the pushing rod is located in the fixing mould cavity in the fixing mould frame; and the longitudinal mechanical limiting structure includes a servo motor A and a transmission mechanism. With the downward-pushing magnetic material wet molding hydraulic machine and the use method thereof adopted, product formation error is small, and the pollution source of slurry to hydraulic oil can be eliminated.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Ultrahigh-characteristic-value three-phase flue gas foam for oil-gas field and preparation method thereof

ActiveCN109517592AReduce moisture contentReduce water consumptionDrilling compositionGas phaseHigh pressure

The invention discloses ultrahigh-characteristic-value three-phase flue gas foam for an oil-gas field and a preparation method thereof. The three-phase flue gas foam is composed of a gas phase, a liquid phase and a solid phase, wherein the gas phase is flue gas produced by a coal-fired power plant; the liquid phase is a water solution of a surfactant, a pH (Potential of Hydrogen) value regulator and inorganic salt; the solid phase is a compound of fly ash and nano silicon dioxide; and the characteristic value of the foam is 90 to 99 percent. According to the ultrahigh-characteristic-value three-phase flue gas foam disclosed by the invention, a used solid-phase foam stabilizer is a compound system of fly ash particles and nano silicon dioxide particles; the cost is relatively low and a stable solid-phase particle adsorption layer can be formed on a foam liquid membrane; and unstable characteristics including liquid membrane cracking of the foam, gas dispersion, foam coalescence and thelike are greatly weakened and the stability of the foam is effectively improved. The ultrahigh-characteristic-value three-phase flue gas foam system disclosed by the invention can be adaptive to hightemperature of 230 DEG C and the stability is enhanced along the rising of pressure; and the ultrahigh-characteristic-value three-phase flue gas foam has good temperature resistance and pressure resistance and can be applicable to development operation of high-temperature and high-pressure oil and gas reservoirs.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

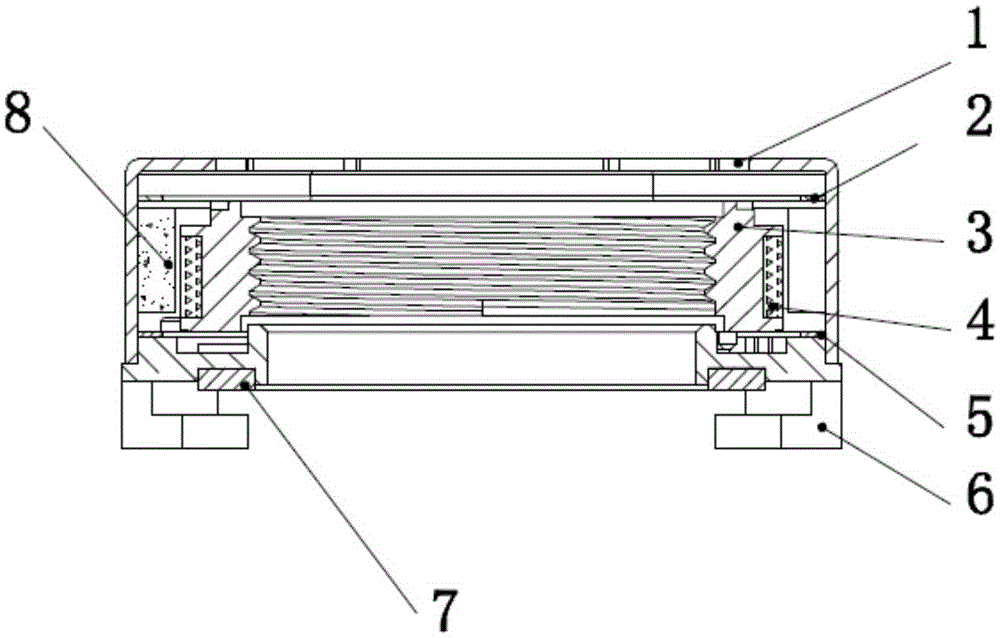

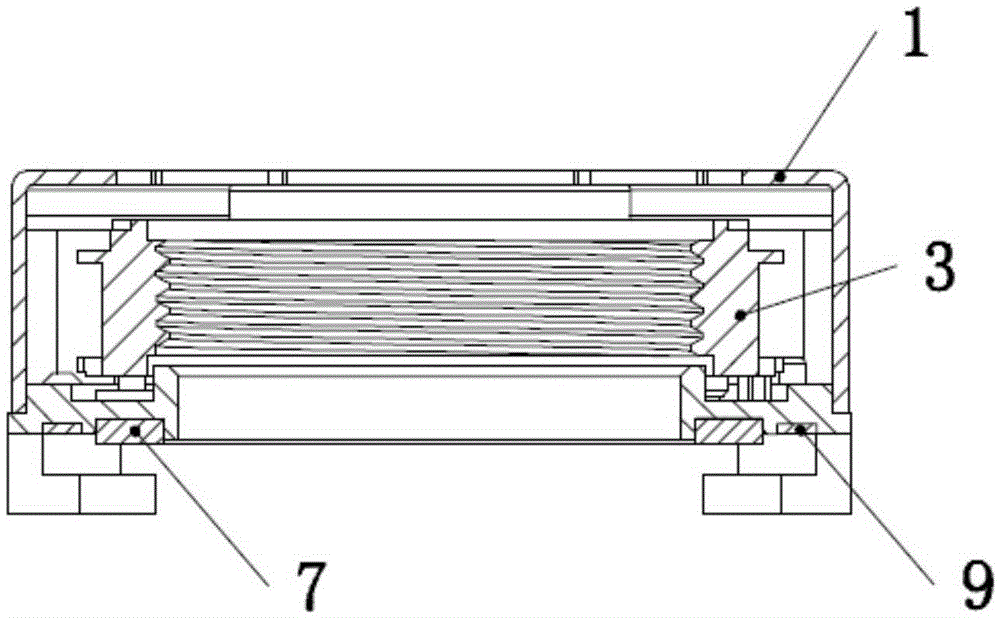

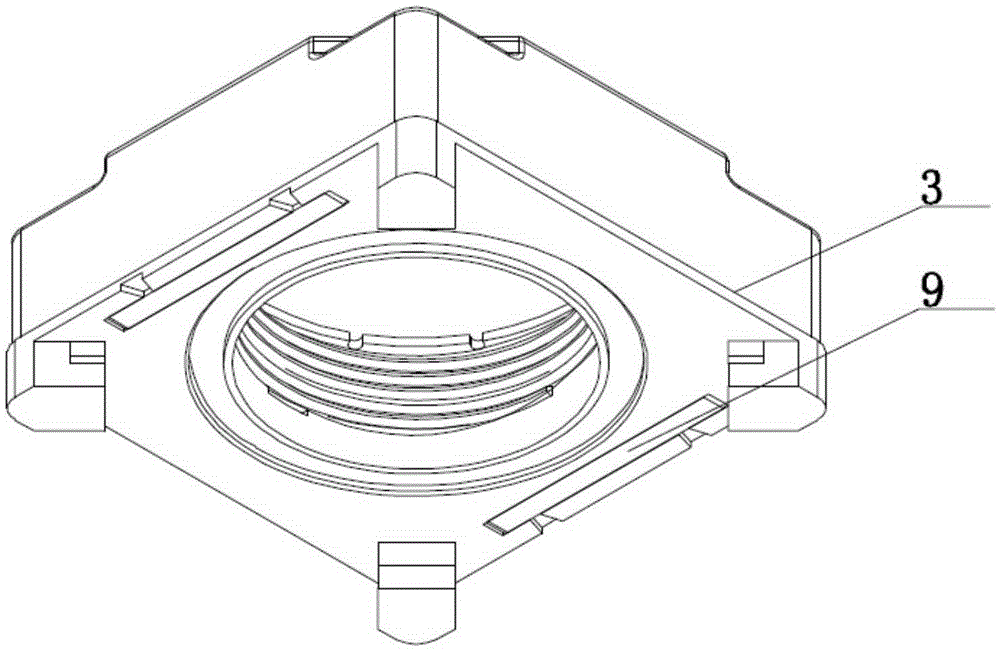

Ultra-thin VCM motor mounted in buckle type way

InactiveCN105356714ALow costSimple production processSupports/enclosures/casingsEngineeringContact type

The invention discloses an ultra-thin VCM motor mounted in a buckle type way. The ultra-thin VCM motor comprises a base; a power-on terminal is arranged on the surface of the upper end of the base; a lower spring piece is arranged at the upper end of the base; a dustproof ring is arranged between the lower spring piece and the base; contact type elastic piece electrodes are symmetrically arranged on the outer side of the dustproof ring; a carrier is arranged on the upper side of the lower spring piece; four corners at the upper end of the carrier have stepped structures; coils are arranged on the surface of the outer side of the carrier; magnets are correspondingly arranged on the outer sides of the coils; an upper spring piece is arranged on the upper side of the magnet; and a shell is arranged on the upper side of the upper spring piece. According to the ultra-thin VCM motor mounted in the buckle type way, the production technology is simplified, the cost is reduced, and the reduction of powder that is most concerned in the module is facilitated; by matching with the motor structure, a chip module can be directly implanted with a mobile phone main board in a patch manner; the use of FPC and sockets on the module is directly reduced; and due to the simplified technology and the reduction of manpower cost, the total cost of the module can be reduced by 20-30%.

Owner:SANKYO PRECISION HUIZHOU

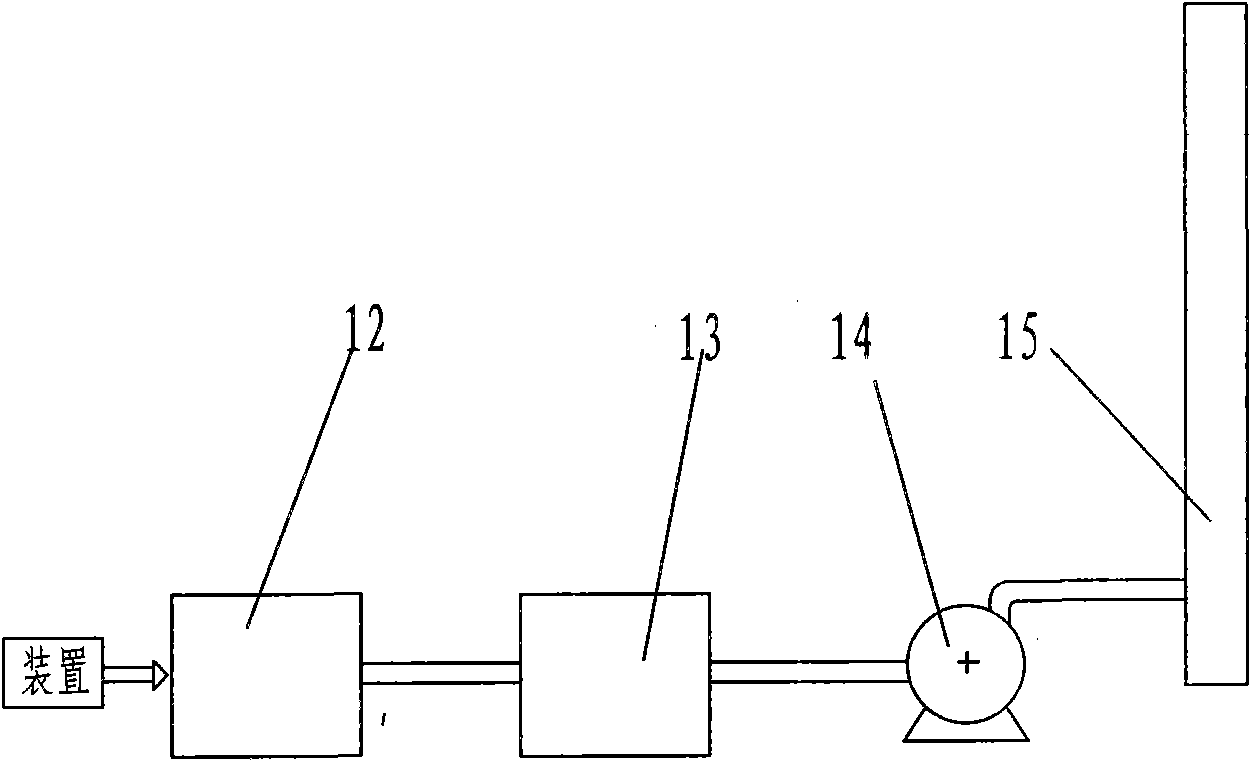

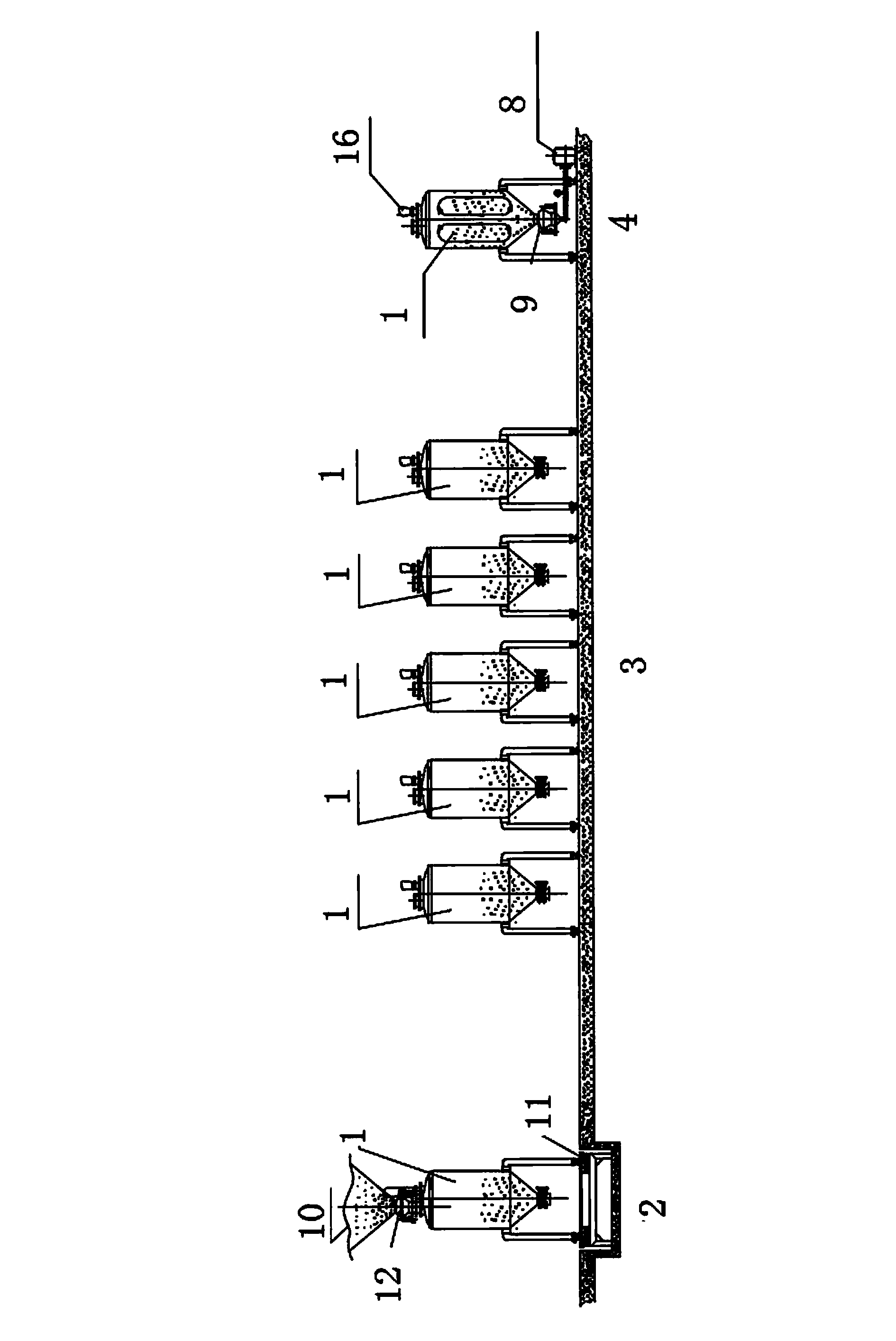

Temporary storage and mixing system used for material, and application method thereof

InactiveCN103386274AReduce cleaning and disinfection workReduce pollution sourcesTransportation and packagingMixer accessoriesHybrid systemEngineering

The invention relates to a temporary storage and mixing system used for materials, and an application method thereof. The system is characterized in that: the material temporary storage and mixing system is provided with a feeding station and a mixing station which are respectively provided with a feeding device and a mixing device matching a material temporary storage container. When in use, functions such as feeding, storing, and mixing can be completed in a same material temporary storage container. During mixing, the system is directly connected with a high-pressure air machine through an air injection structure on the bottom of the material temporary storage container; clean high-pressure air is injected into the material temporary storage container; the material is lifted and turned under the driving of air, such that a purpose of uniform mixing is achieved. Also, secondary pollution during material temporary storage and mixing is reduced. The operation of the entire mixing process is convenient and less error-prone.

Owner:上海博正名荣包装机有限公司

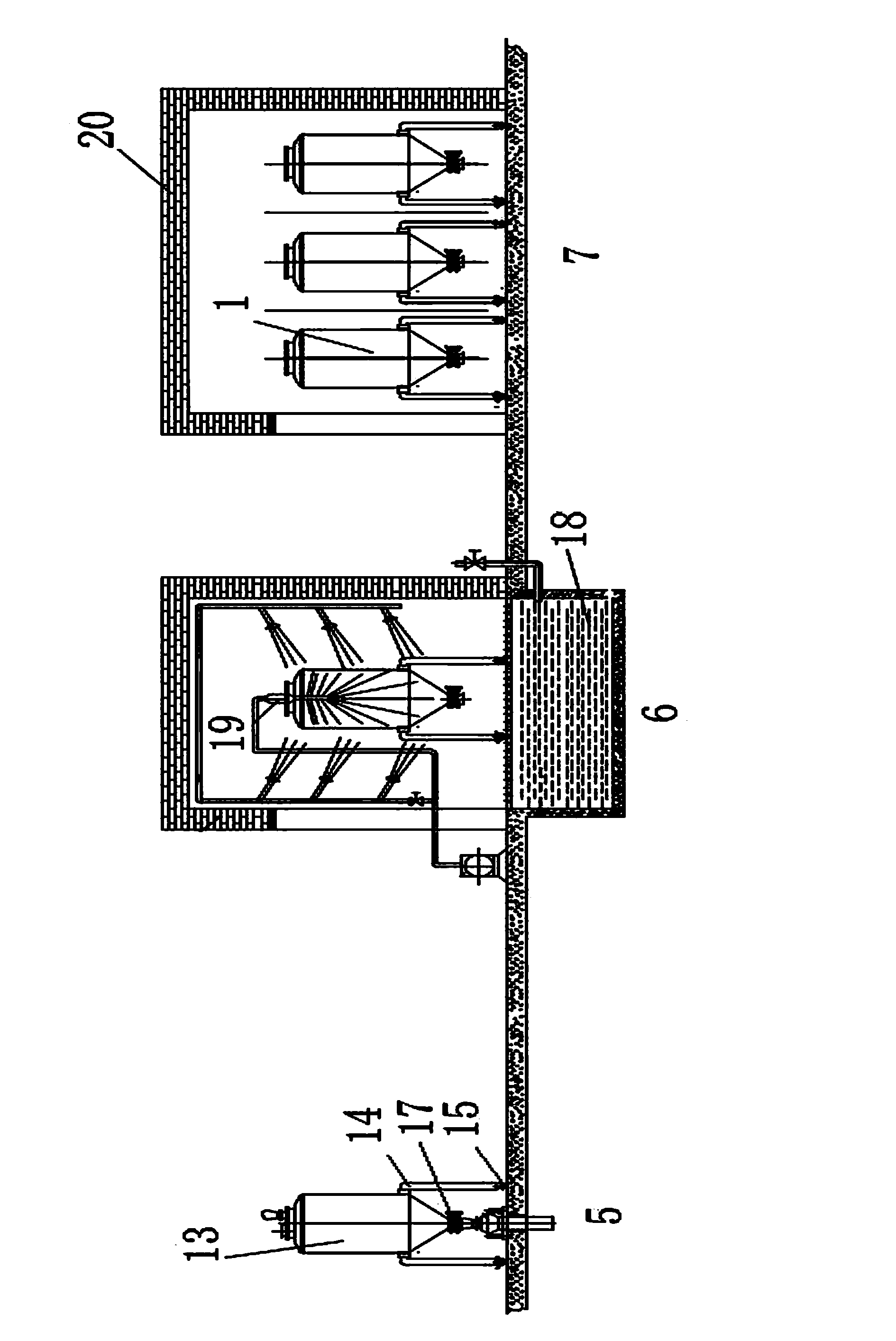

Multistage equipment for increasing dissolved oxygen in water

InactiveCN102234156AReduce running timeIncrease dissolved oxygenWater aerationPisciculture and aquariaElectricityWater wheel

The invention relates to multistage equipment for increasing dissolved oxygen in water. The equipment comprises an electric water wheel, an agglomerated water refining device, a wind oxygen increasing device and a steering device, wherein the agglomerated water refining device receives agglomerated water generated when the electric water wheel beats the water surface and refines the agglomerated water through a rotating mechanism to increase the contact area of water drops and air and bring more oxygen to the water; the agglomerated water refining device and the wind oxygen increasing device are combined with a water drawing mechanism respectively; the water drawing mechanisms directly draw the water to the sky and slowly drip the water to increase the content of the oxygen in the water and save electricity; the steering device is used for adjusting the direction of a floating platform of the electric water wheel to make the direction of the floating platform of the electric water wheel consistent with the wind direction; therefore, the aim of effectively increasing the dissolved oxygen in the water and saving the electricity is fulfilled.

Owner:温昀哲

Industrial smoke exhaust gas recovery purifier and application method thereof

InactiveCN102430305AIncrease the reaction areaImprove reaction speedHuman health protectionCombination devicesExhaust gasSorbent

The invention discloses an industrial smoke exhaust gas recovery purifier and an application method thereof. A scheme is characterized in that: tilting grid plates are arranged in a dedusting chamber; each grid plate is provided with a grid hole; separation plates divide a purification chamber into relatively independent compartments; a main shaft penetrating through the purification chamber is fixed with rotary blades and bearings in an interval mode; one rotary blade is arranged in one compartment; and one bearing is fixed corresponding to one separation plate. By utilizing mechanical and chemical reaction principles in the invention, the reaction area and the reaction speed are increased, so the industrial smoke exhaust gas is gradually adsorbed and purified in the compartments of the dedusting chamber and the purification chamber, and the recovery rate can reach above 95%. The smoke exhaust gas is adsorbed before being discharged to airspace, so the air pollution source is greatlyreduced. An absorbent used in the invention has the advantages of low cost and high adsorption efficiency, so the purifier of the invention, which has an important meaning to the industrial smoke exhaust gas pollution reduction and the air environment purification, is an ideal industrial smoke exhaust gas adsorption purifier.

Owner:万怡震

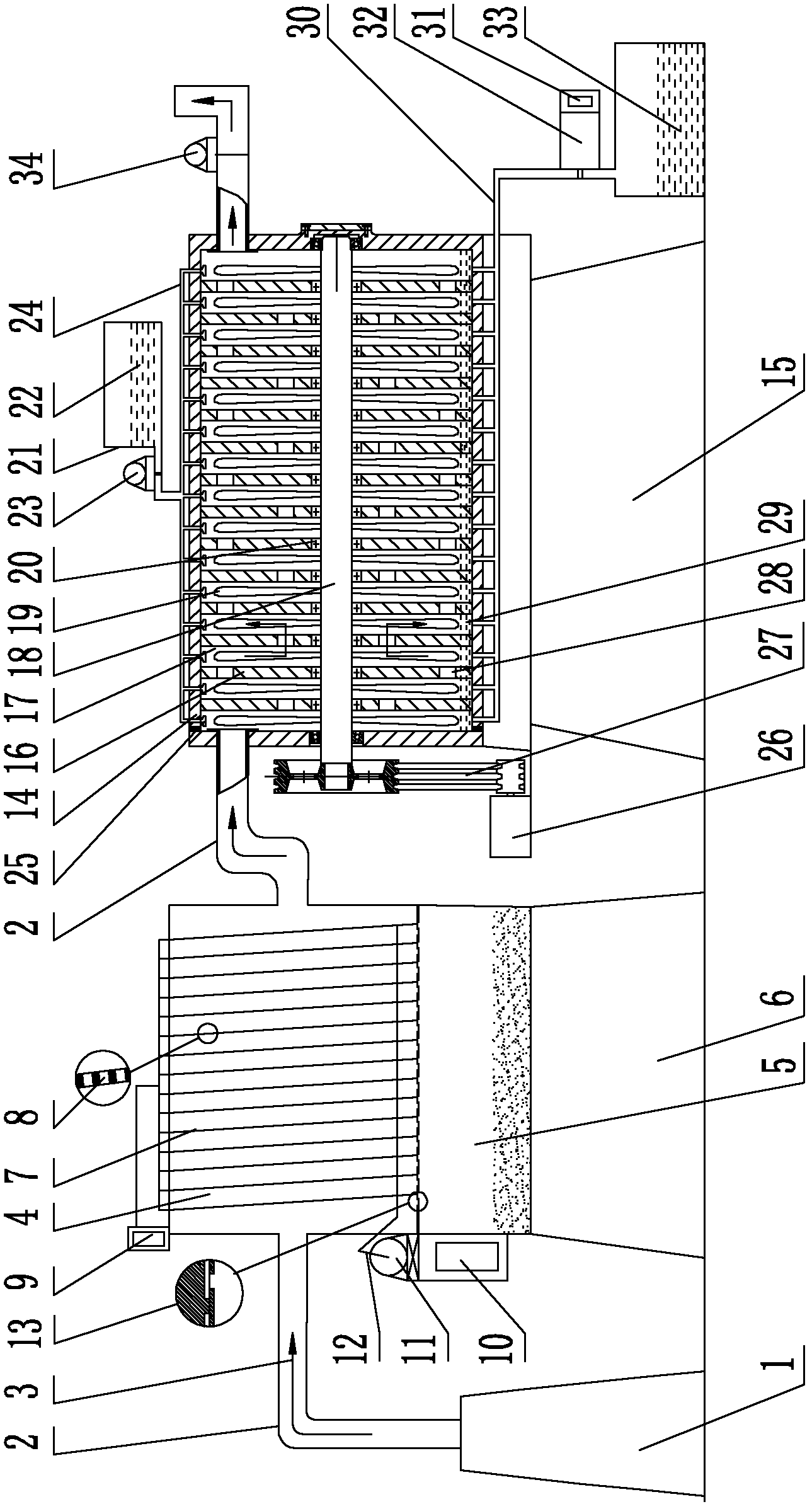

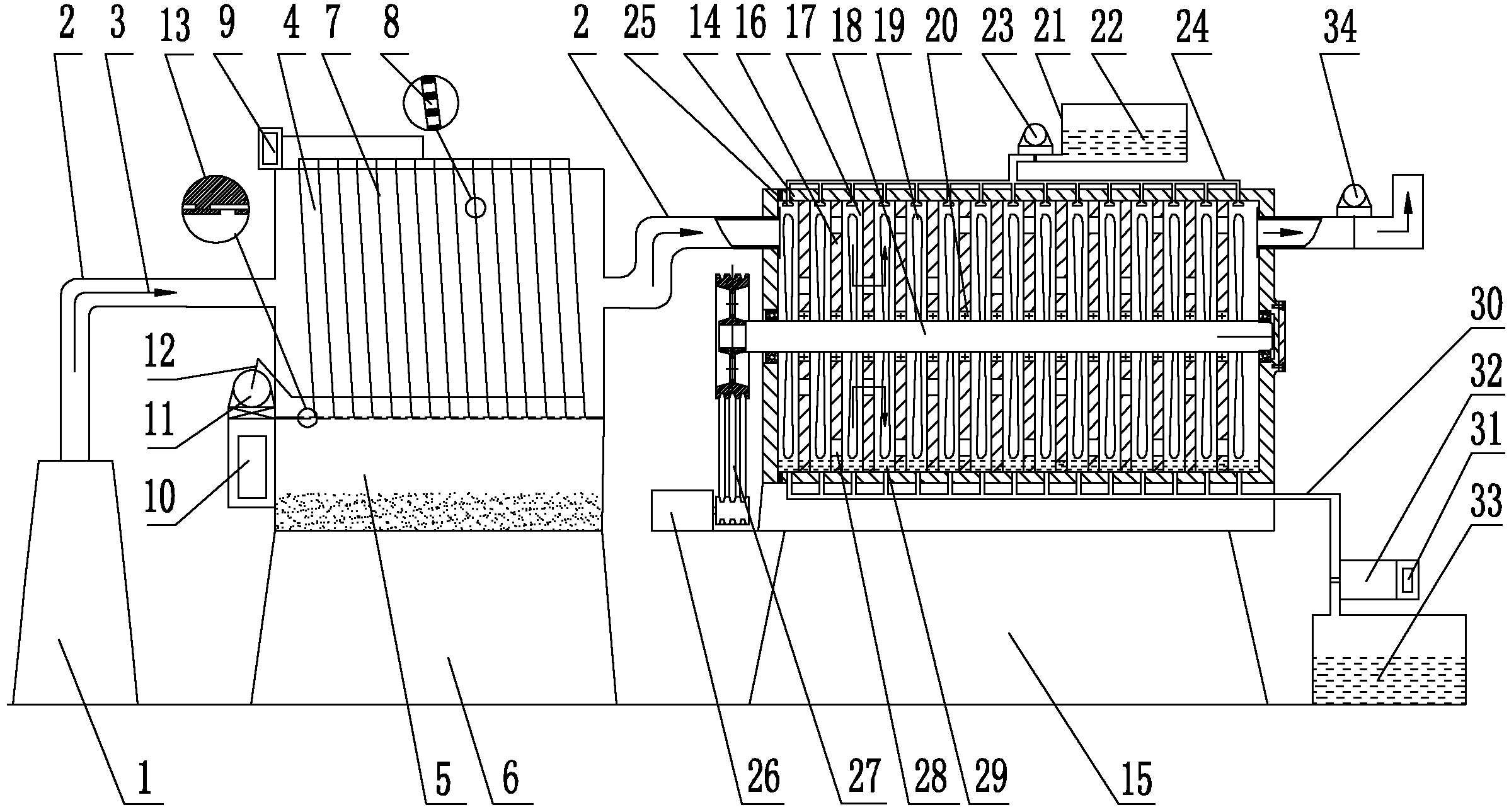

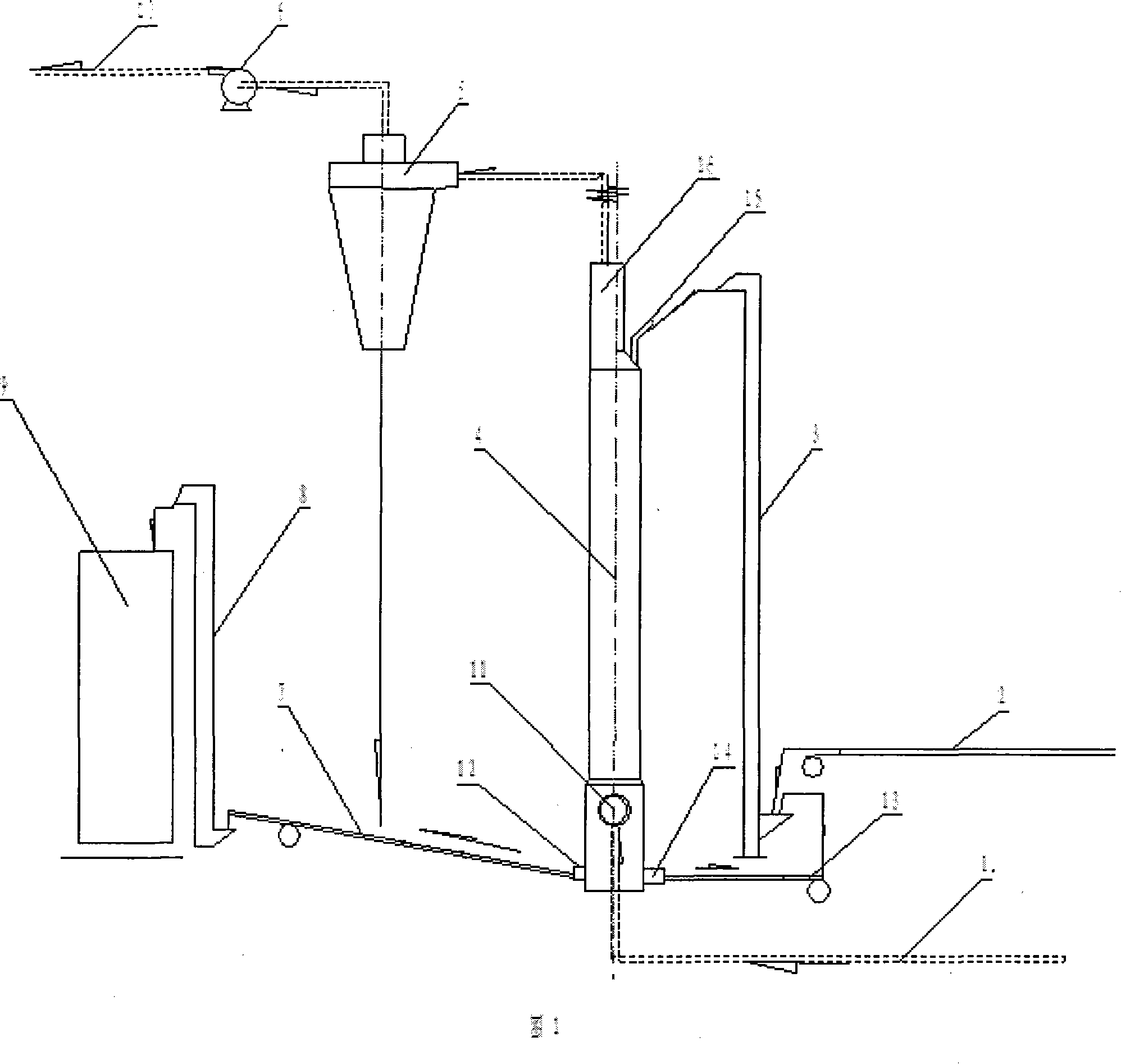

Drying system using rotary kiln waste gas residual heat

InactiveCN101105364AEmission reductionSimple processDrying gas arrangementsHeating arrangementSlagDust emission

The invention relates to a drying system utilizing residual heat in exhaust gas from kiln tail of a rotary kiln. The drying system comprises a vertical air-drying heat exchanger and auxiliary equipments including an exhaust gas inlet pipe, an exhaust gas outlet pipe, a feeding lifter, a feeding belt conveyer, a cyclone separator, a centrifugal blower, a discharge belt conveyer, a warehousing lifter, a dry slag warehouse, an air inlet port for vertical air-drying heat exchanger, a dry slag outlet port, a recycled material belt conveyer, a recycled material outlet port, a material inlet pipe for vertical air-drying heat exchanger, and an air outlet port for vertical air-drying heat exchanger. The system can effectively utilize the residual heat in the exhaust gas from the kiln tail of a rotary kiln to dry the raw material slag. The circulating load of the materials to be dried is 2-3 times of the yield of finished product. The inventive system has simple processes, simple structure of equipments, high heat exchange efficiency and high economic performance. The water content in the dried slag is not more than 1 percent. The inventive system overcomes the shortcomings of the existing slag drying using rotary type drying machine including high coal consumption and power consumption and environmental pollution due to large amount of dust emission. The invention reduces greenhouse gas emission and environmental pollution sources, improves economic benefit of enterprise, and brings distinct social benefit in the energy-saving and emission reduction project.

Owner:郑用琦

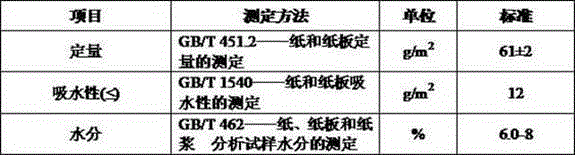

Method for producing artistic paperboard by taking commercial wood pulp as raw material

ActiveCN105332316AModerately absorbentMeet the requirements of printing performanceCoatings with pigmentsWater-repelling agents additionPaperboardPapermaking

The invention discloses a method for producing an artistic paperboard by taking a commercial wood pulp as a raw material. The method comprises preparing a mixed wood pulp, then preparing a paper pulp, successively adding an internal sizing agent, heavy calcium carbonate and polyacrylamide into the paper pulp, and finally performing calendaring and reeling for obtaining finished paper, so as to obtain raw paper of the artistic paperboard; and preparing a coating, smearing the raw paper with the coating, performing calendaring by a supercalender, and performing rewinding by a rewinder, so as to obtain the artistic paperboard finished product. The beneficial effects comprise that 1, after the raw paper produced from high-quality commercial wood pulp is subjected to coating and calendaring, the surface is fine, printing ink absorption property is moderate, and printing performance is good; 2, the production technological flow does not employ self-made pulp and whitening agents, pollution source is less, and environmental influence is extremely small; and 3, produced sewage is extremely less, and cleaning production and neutral environment-friendly papermaking are realized.

Owner:临朐玉龙造纸有限公司

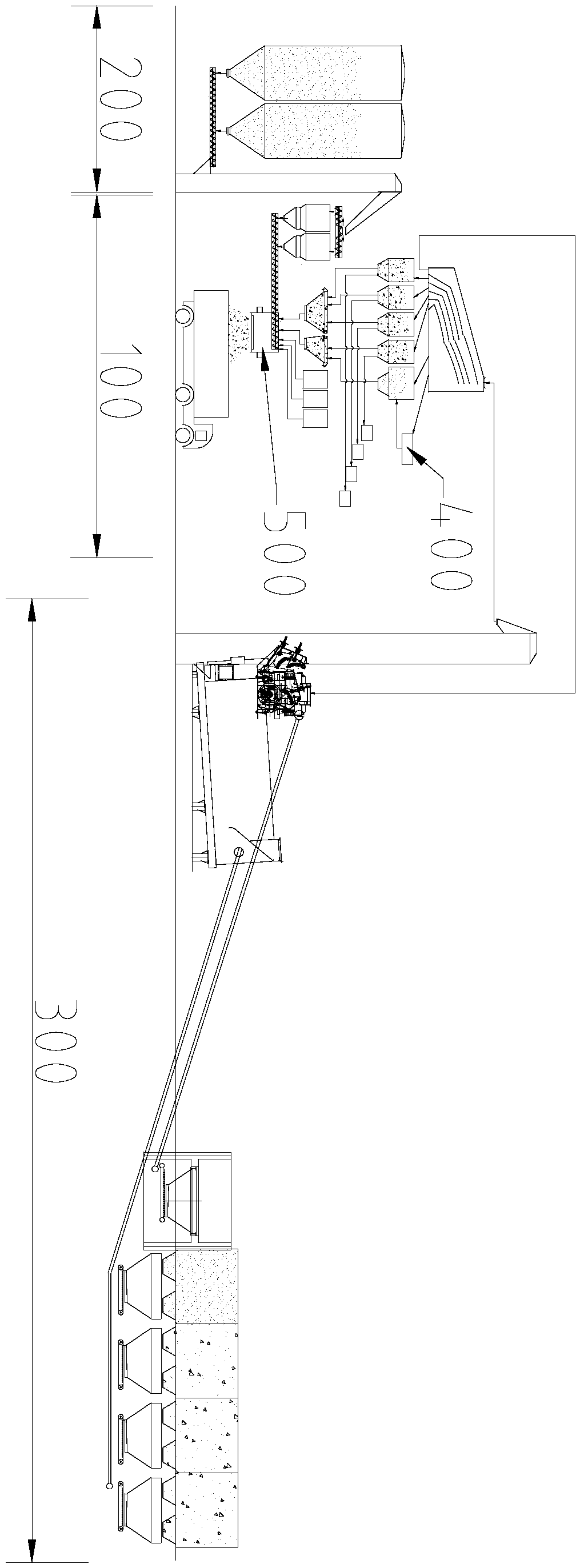

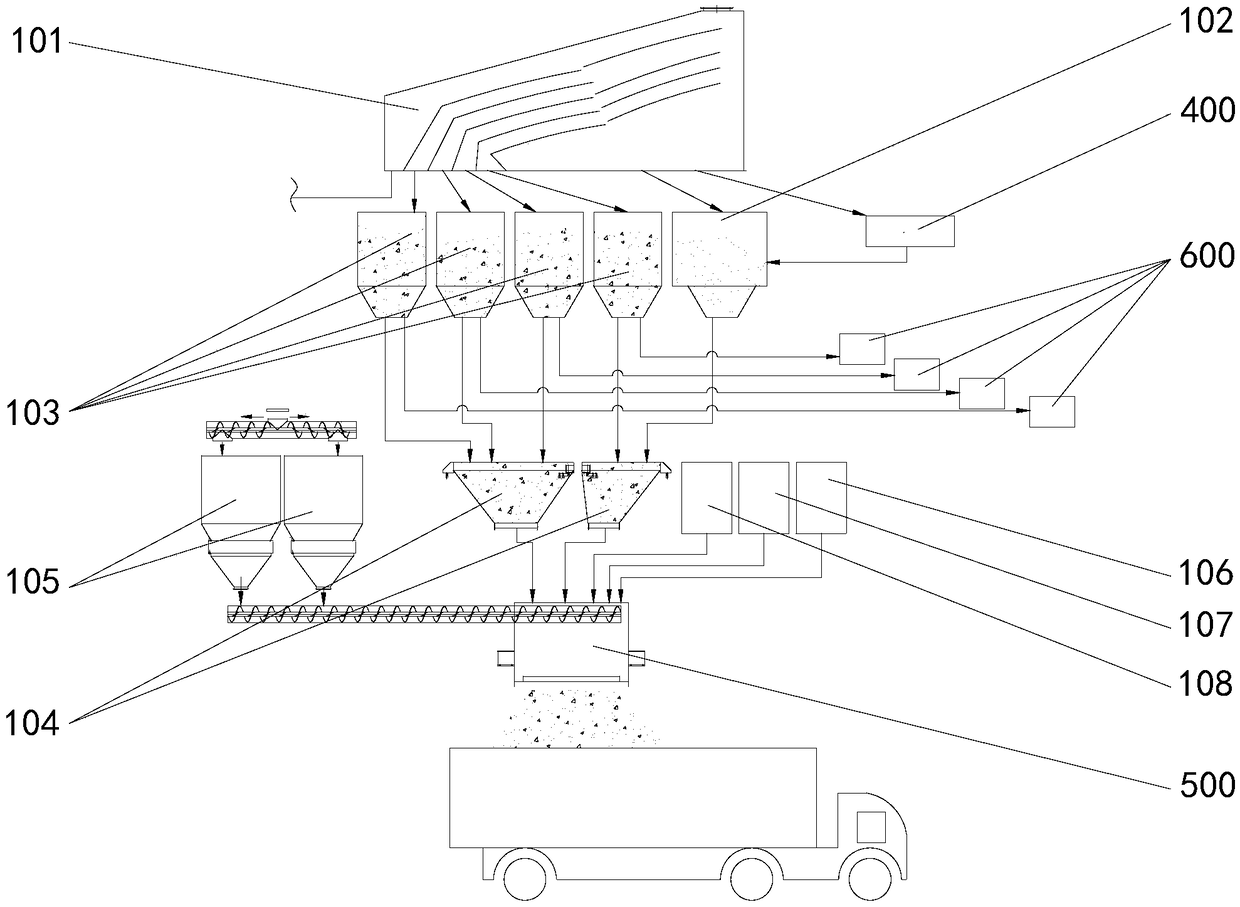

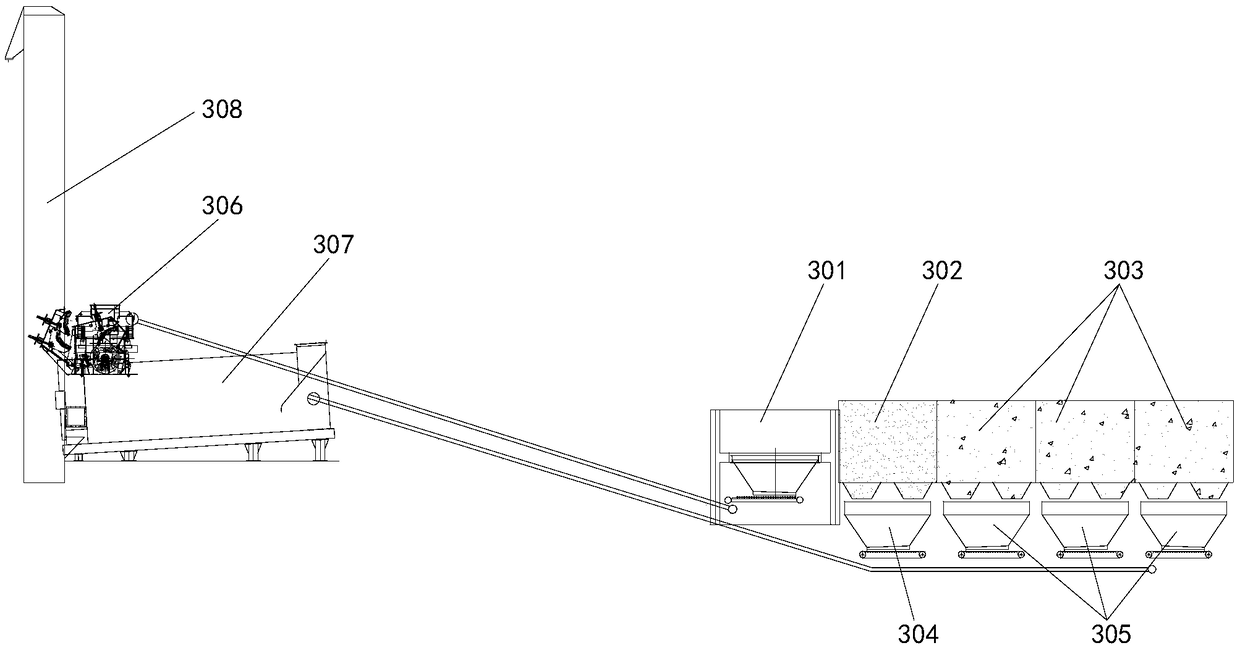

Intermittent-type multifunctional stirring station

PendingCN108708251AExtended service lifeImprove product qualityRoads maintainenceHybrid systemAsphalt

The invention discloses an intermittent-type multifunctional stirring station and belongs to the technical field of municipal engineering equipment. The intermittent-type multifunctional stirring station comprises a stirring and mixing system, a powder feeding device and an aggregate feeding device with a drying function. The stirring and mixing system comprises a vibrating screen, a sand-powder separating device, a sand temporary-storage bin, stone temporary-storage bins, aggregate measuring hoppers, powder measuring hoppers, an asphalt measuring hopper, a water measuring hopper, an admixturemeasuring hopper and a blending main machine. A stirring shaft of the blending main machine is provided with a shaft end water-cooling device. The powder feeding device is connected with the powder measuring hoppers. The aggregate feeding device is connected with the vibrating screen. The intermittent-type multifunctional stirring station integrates multiple functions, and compared with combination of existing equipment, the occupied land is saved by 50% or above, the distribution power is saved by 50% or above, and the equipment input is reduced by 40% or above; equipment mounting and transporting are reduced, and the construction cost of ancillary facilities is reduced by 50% or above; and meanwhile, environmental pollution sources can further be reduced, and the input of environment-friendly facilities is reduced by 50% or above under the situation of meeting the same environment-friendly requirement.

Owner:成都广维重工科技有限公司

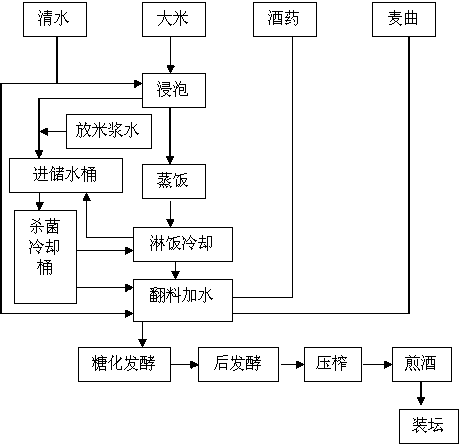

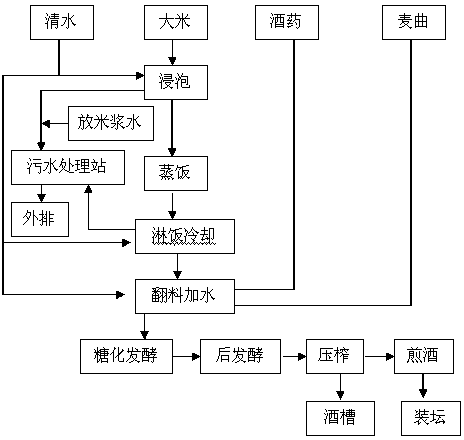

New process for recycling rice milk

InactiveCN103865730AReduce labor intensityReduce pollution sourcesAlcoholic beverage preparationWater useWater storage

The invention relates to a new process for recycling rice milk. The process comprises the steps of (1) discharging rice milk obtained by socking rice into a water storage bucket, and introducing the rice milk into a sterilizing and cooling bucket to perform sterilization and cooling for later use; (2) steaming rice by using the soaked rice, sprinkling cooked rice and cooling by using the rice milk for later use in the step (1), collecting water used for sprinkling the cooked rice and cooling into the water storage bucket, sterilizing, cooling and recycling; (3) after sprinkling the cooked rice and cooling, performing turning-over and mixing, adding clean water and the water in the sterilizing and cooling bucket, and adding Chinese yeast and wheat koji required for making wine; (4) enabling the brewing raw materials subjected to turning-over and water adding to be subjected to saccharification fermentation, post-fermentation, squeezing and wine sterilizing so as to prepare a wine product. According to the new process disclosed by the invention, the flow of the conventional brewing production process is changed, the labor intensity of workers is reduced, the production environment is changed, the largest pollution source in yellow rice wine production is reduced, water resources are saved, the utilization rate of production resources is increased, and the discharge amount of brewing wastewater is reduced.

Owner:绍兴白塔酿酒有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com