Temporary storage and mixing system used for material, and application method thereof

A mixing system and material technology, applied in the field of temporary storage and mixing systems of food materials, can solve the problems of difficult management, easy pollution, high error rate, etc., and achieve the effects of good airtightness, reduced pollution sources, and low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

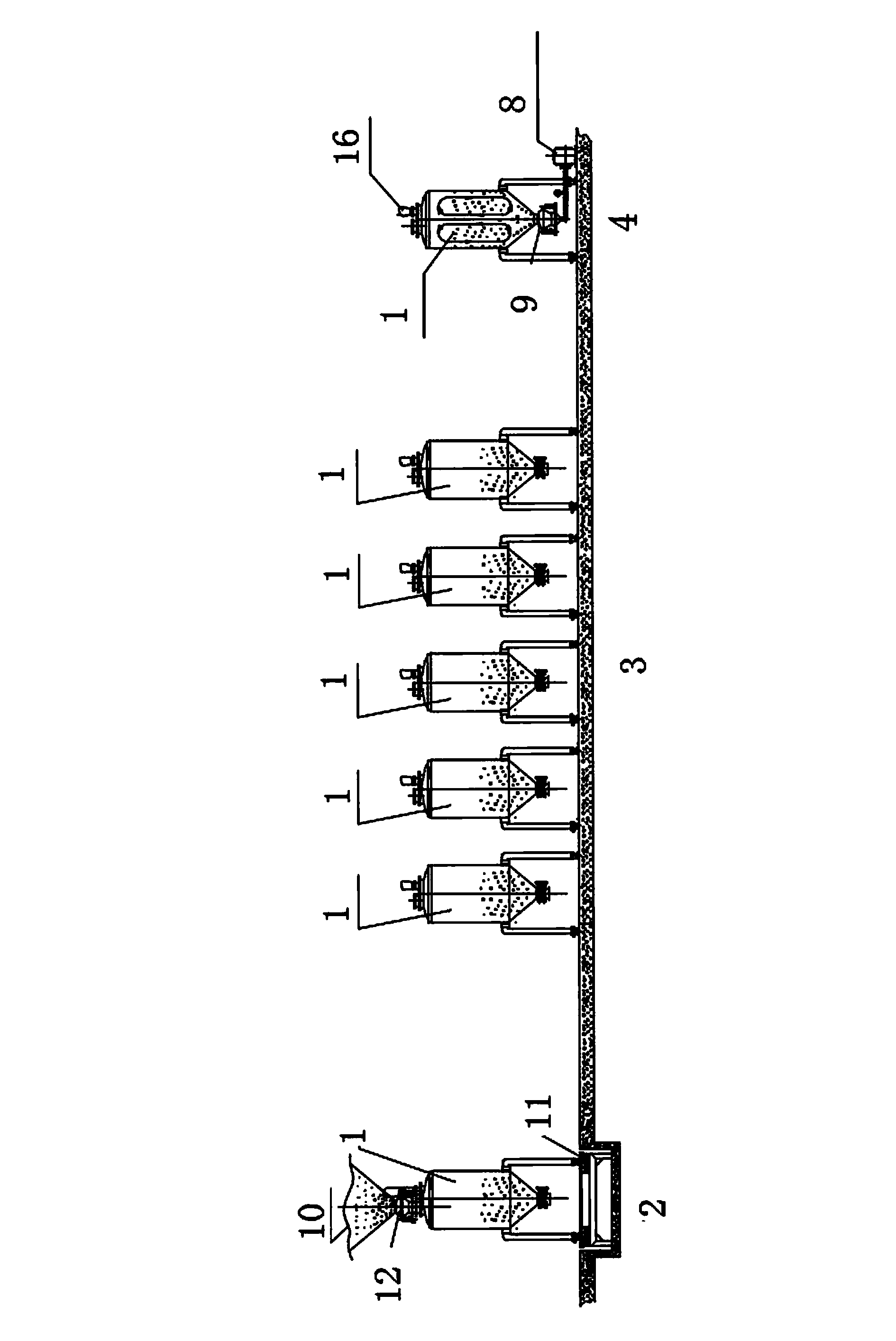

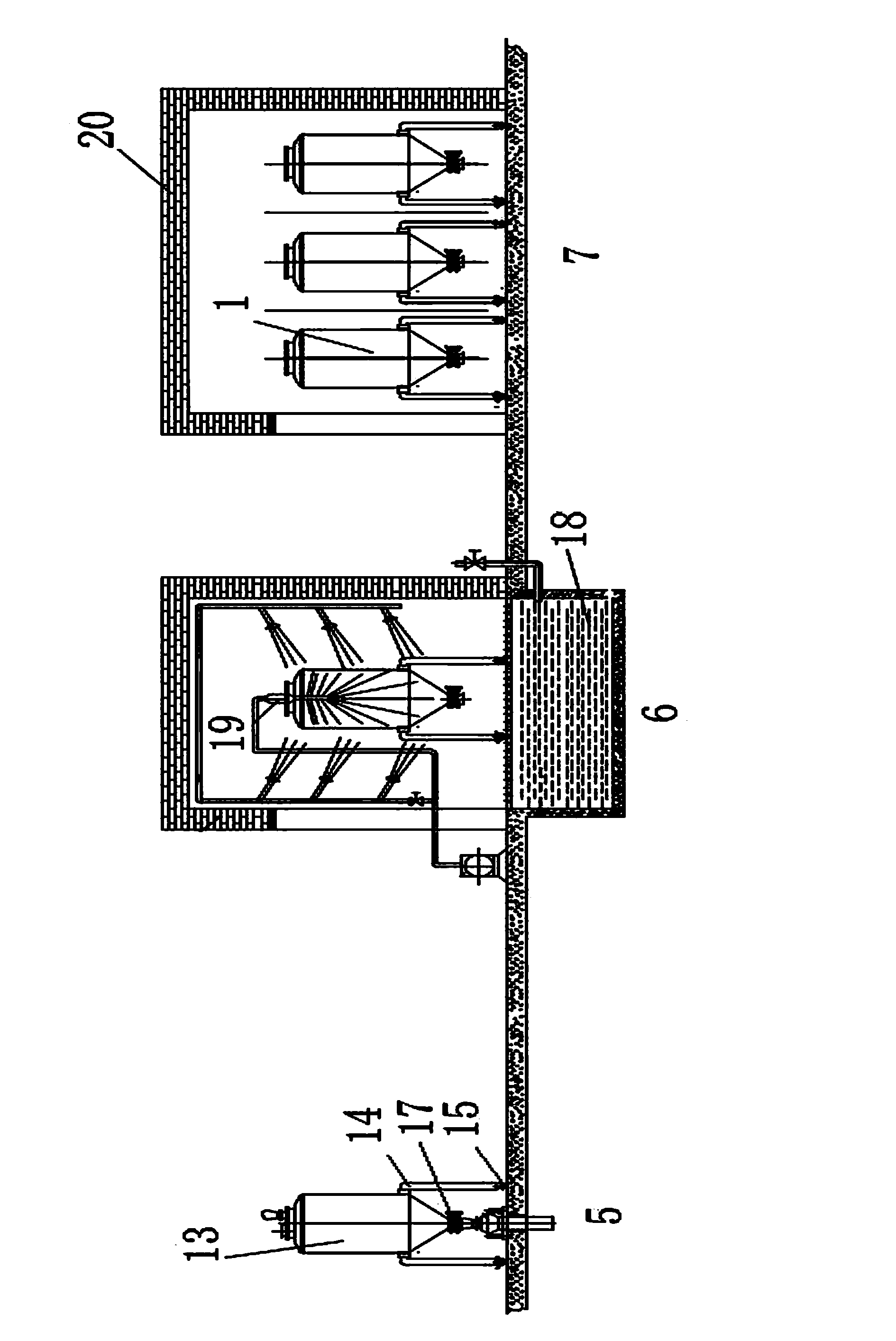

[0023] The material temporary storage container is equipped with at least one powder bin body, which is made of stainless steel. The volume of the powder bin body is 1 cubic meter. The lower part is conical, and the lower end has a discharge port and a gas injection structure, and a butterfly valve is provided on the discharge port. Wheels are arranged at the bottom of the powder bin body, which can move among various stations of the present invention, such as feeding, mixing, discharging, and cleaning. When the material temporary storage container moves to the feeding station, the material can be directly fed into the powder bin body through the feeding hopper. A weighing device is installed under the working position platform of the feeding station, which has weight for the powder bin body moved above it. The weighing function can set the weight of the material added to the powder bin according to the processing requirements. When the material temporary storage container mo...

Embodiment 2

[0025] At the feeding station, materials are injected into the material temporary storage container, but the feeding is stopped after the weight of the material reaches the set amount. After the feeding is stopped, the material temporary storage container that will not be mixed for the time being can be moved to the storage station for storage. The material temporary storage container for mixing processing is moved to the mixing station. According to the formula requirements, ingredients can be put in here. If there is no ingredient, directly connect the high-pressure air compressor to the material temporary storage container, and inject clean, The dry and cold air makes the materials empty and flip in the material temporary storage container until they are uniformly mixed; then the material temporary storage container is moved to the discharge station, and the butterfly valve at the discharge port is opened, so that the mixed material can be directly mixed. Supply packaging ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com