Drying system using rotary kiln waste gas residual heat

A drying system and rotary kiln technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of multiple main and auxiliary equipment, environmental pollution sources, complex process systems, etc., to reduce emissions and environmental pollution sources, improve The effect of economic benefit, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

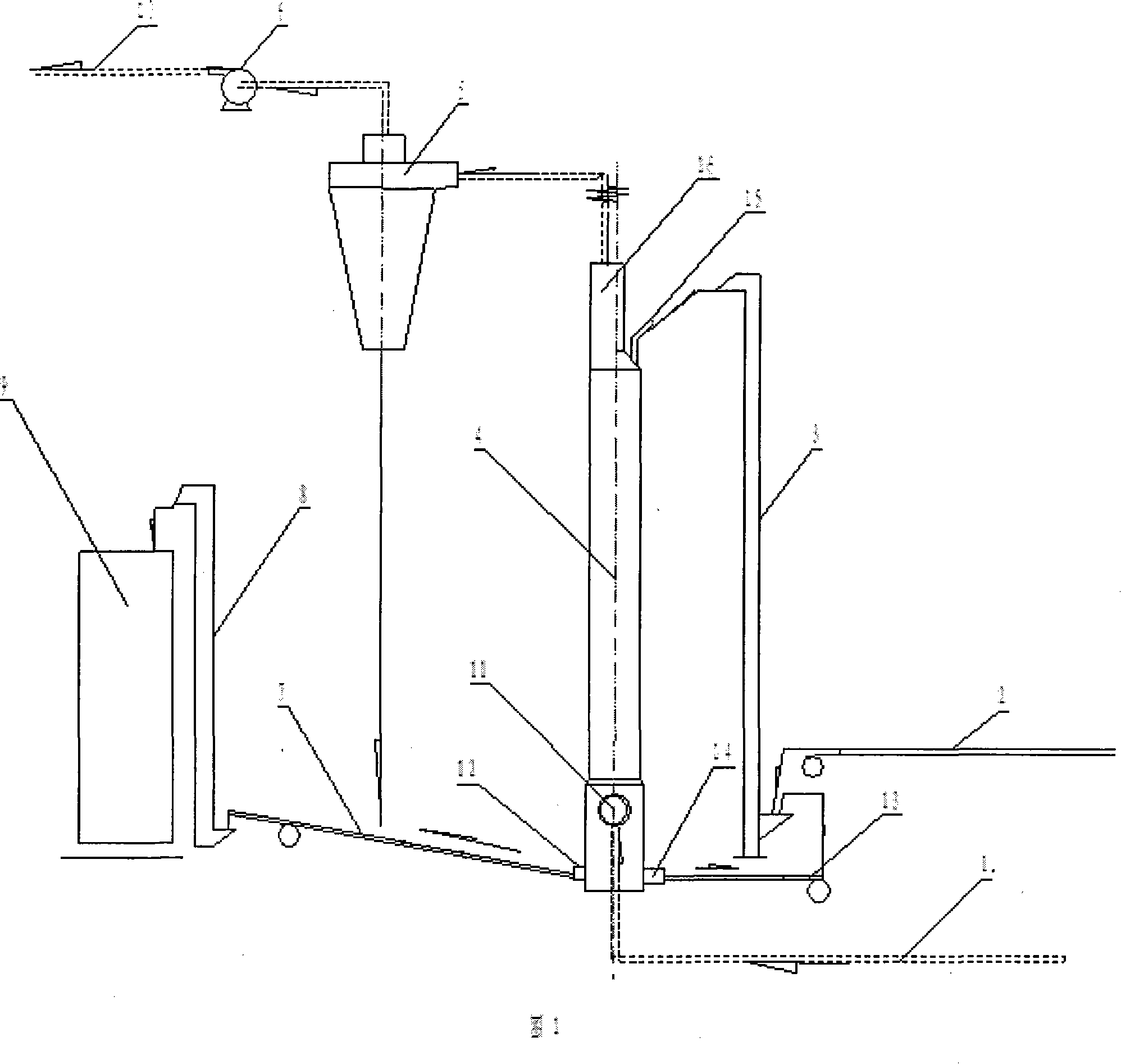

[0016] As shown in Figure 1, in the embodiment of the present invention, the waste gas inlet pipe 1 is drawn from the high-temperature fan outlet pipe at the end of the rotary kiln (or the outlet pipe of the humidifying tower) (the other part is used intermittently by the raw meal mill) The exhaust gas with a temperature of 150-250°C enters the vertical air-drying heat exchanger 4 through the air inlet 11 of the vertical air-drying heat exchanger. Due to the negative pressure of the centrifugal fan 6, it starts to flow upwards. Due to the effect of the internal components of the vertical air-drying heat exchanger 4, the exhaust gas exchanges heat directly and indirectly with the slag that falls downwards. The heat of the waste gas will gradually decrease during the rising process, and the temperature will gradually drop. The waste gas enters the cyclone separator 5 from the air outlet 16 of the vertical air-drying heat exchanger. Under the action of the cyclone separator 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com