Patents

Literature

3230results about How to "Improve heat exchange efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

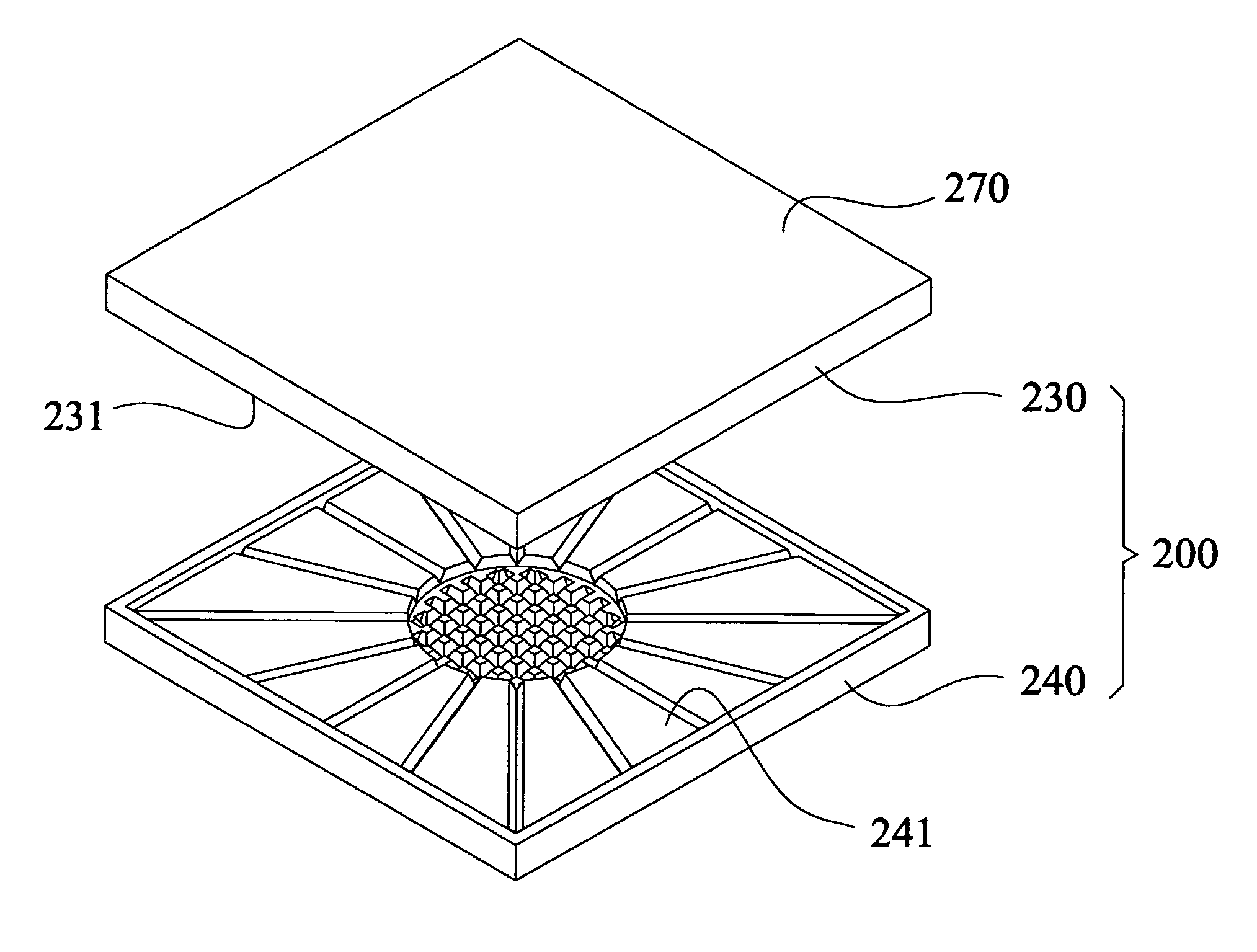

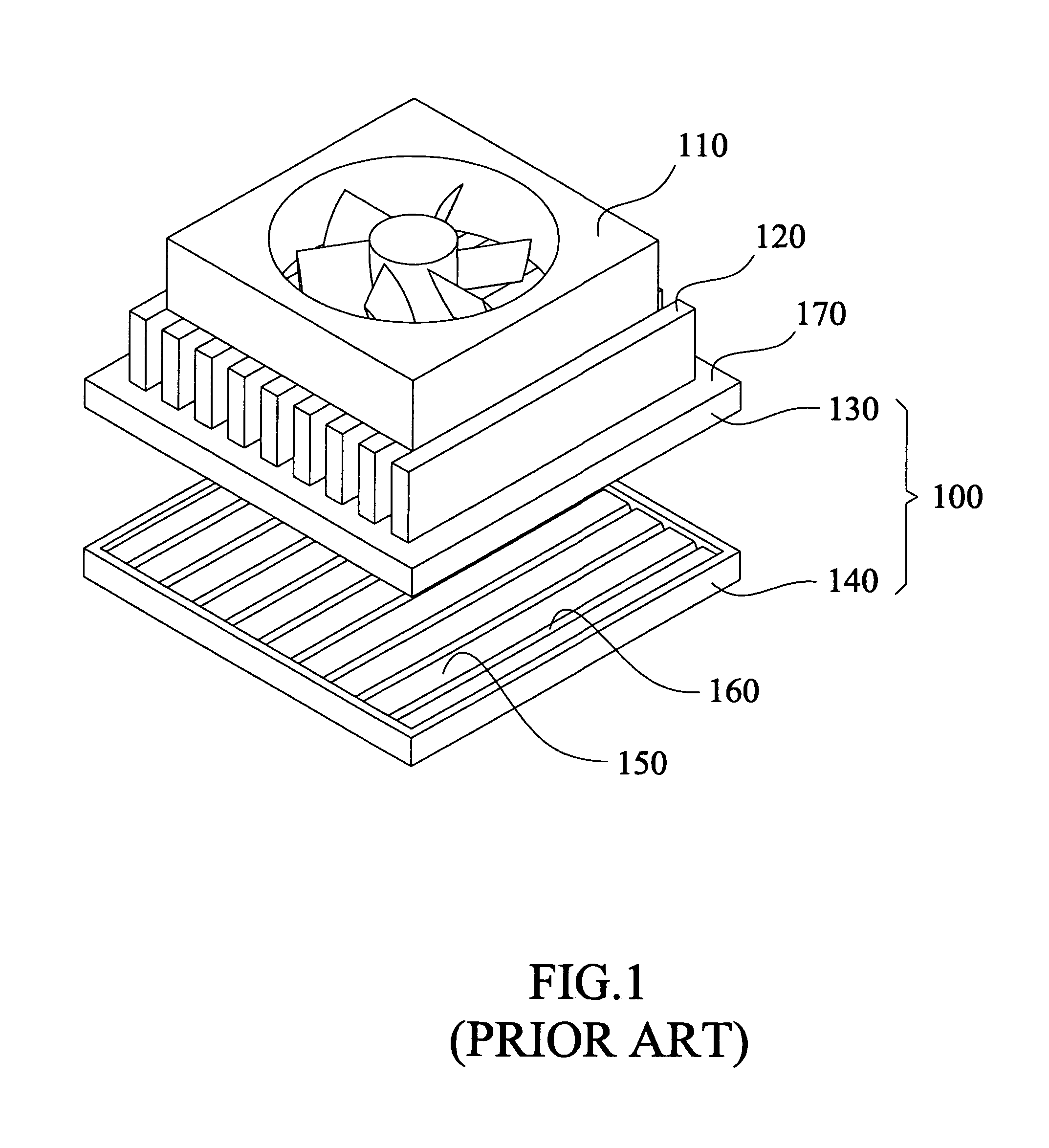

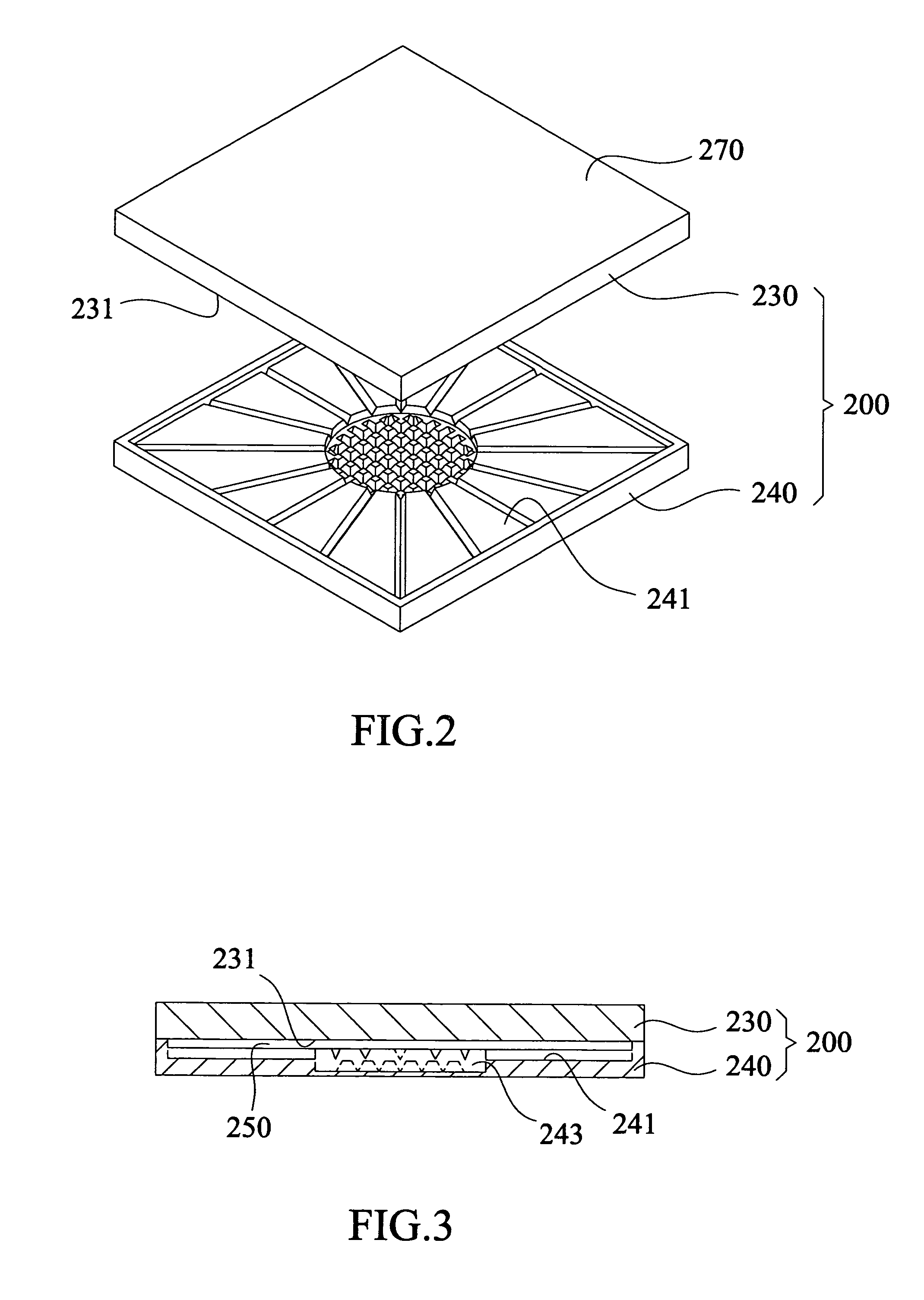

Heat-dissipating device

InactiveUS6957692B1Promoting heat exchange efficiencyAbsorb heat of the heat-generating source more easilySemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringCapillary Tubing

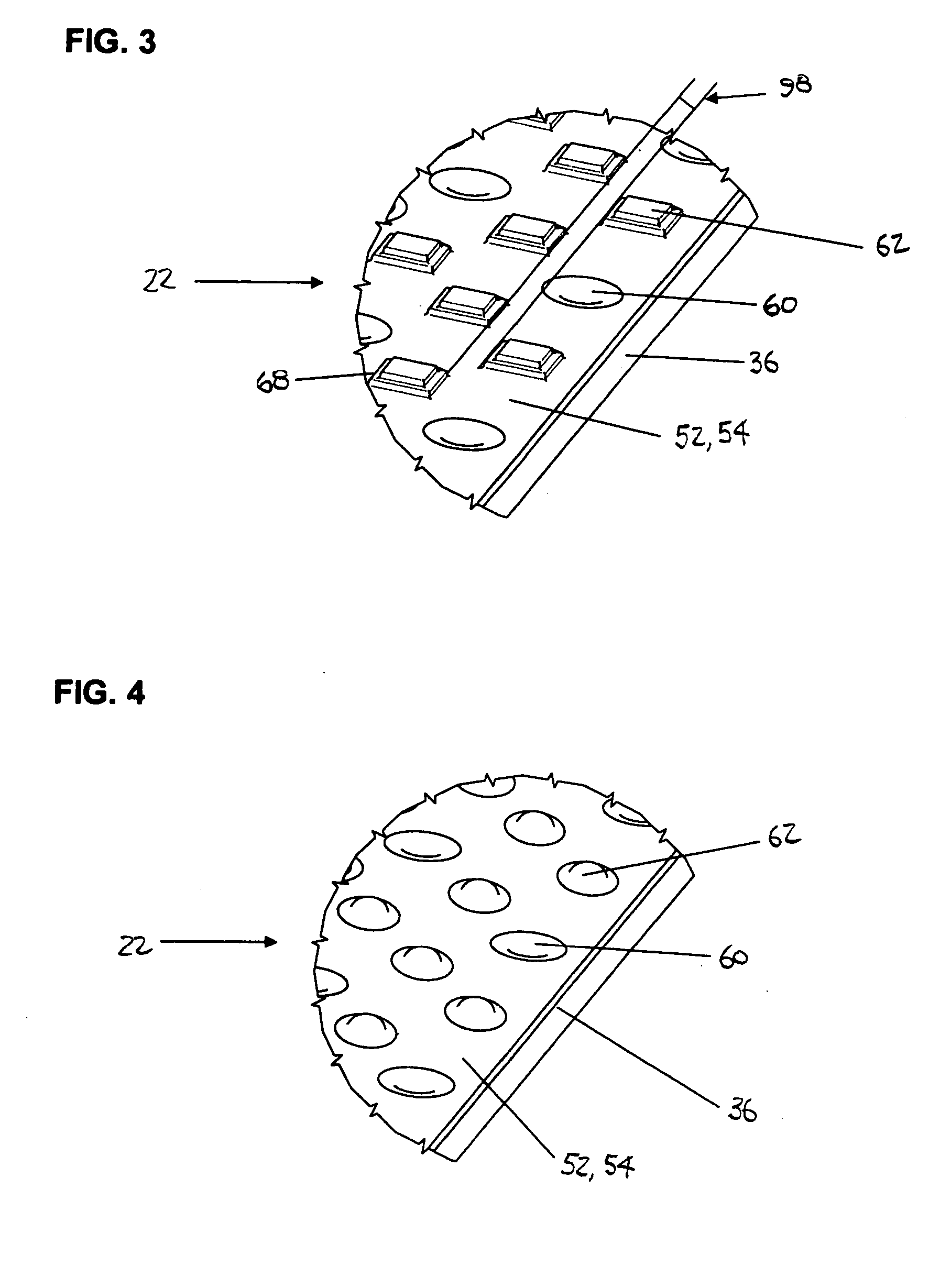

The present invention relates to aheat-dissipating device, which comprises an upper part and a lower part. The upper part further includes an inner joining face and an outer face opposite the inner joining face and the lower part further includes a concave surface which is engaged with the inner joining face of the upper part to form an air-tight chamber with a suitable quantity of circulating liquid being filled therein. The concave surface of the lower part further includes a plurality of capillary trenches and at least one basin, wherein each capillary trench connects the basin and further grid-like trenches are formed inside the basin in order to enhance vaporizing efficiency of the circulating liquid.

Owner:INVENTEC CORP

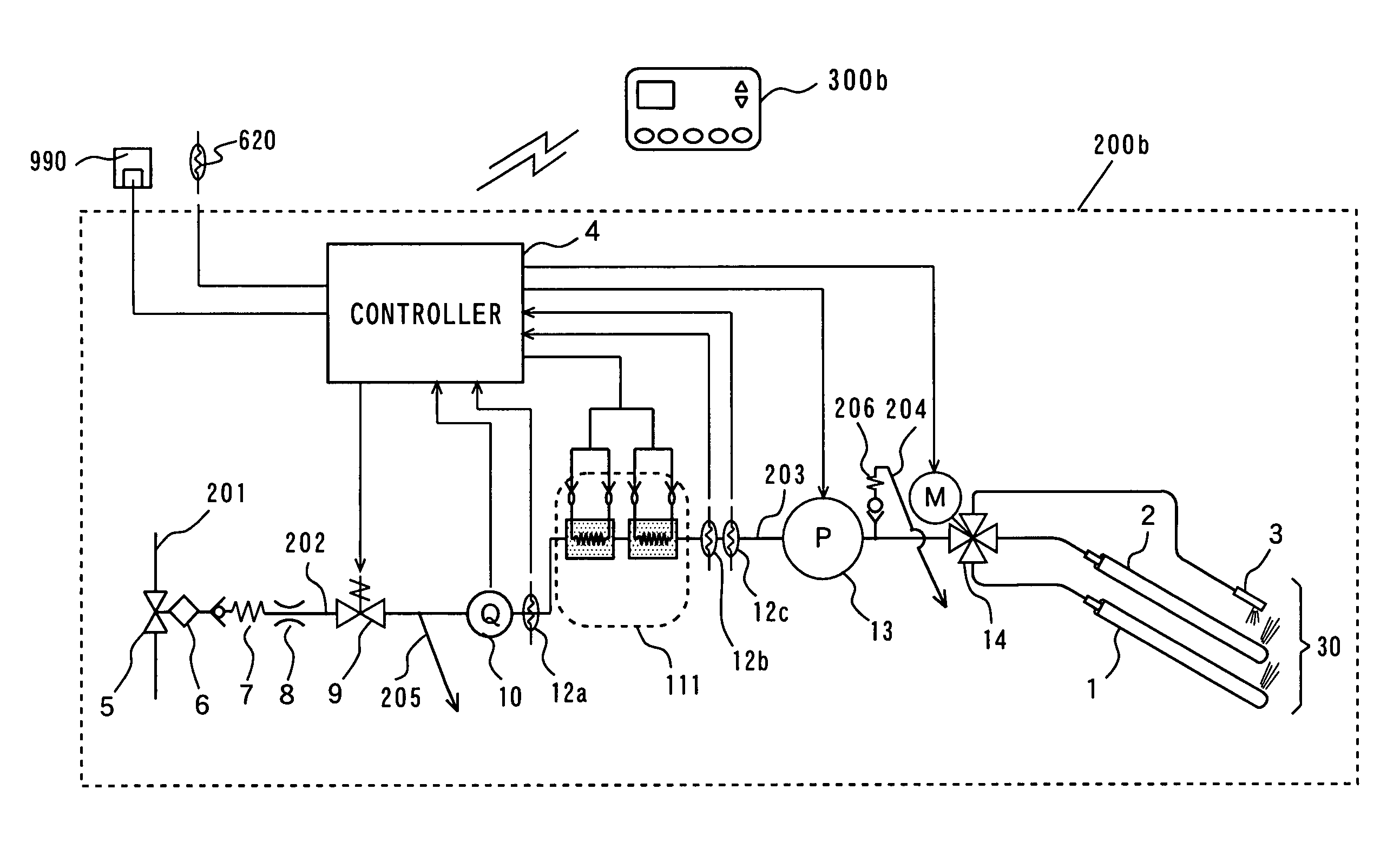

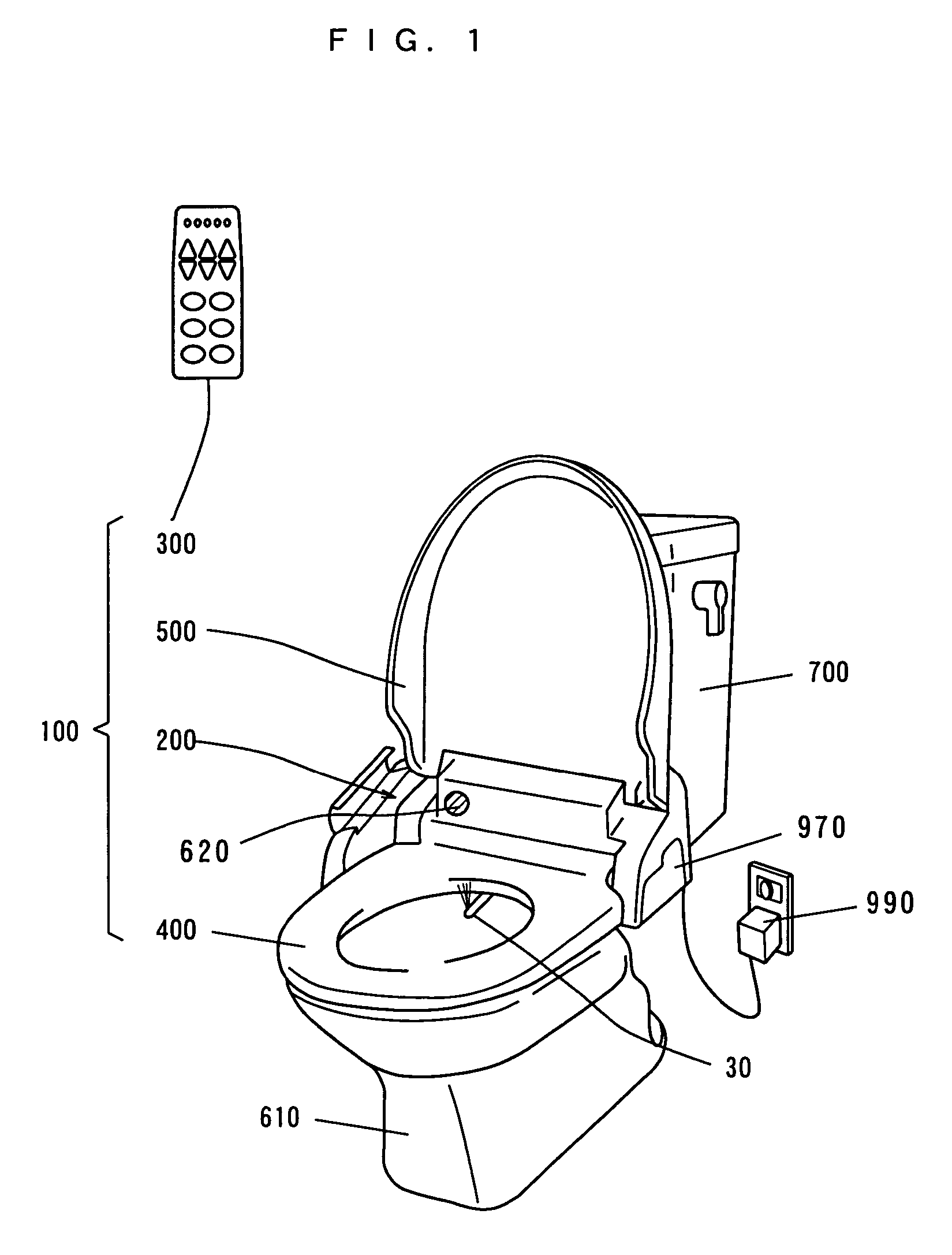

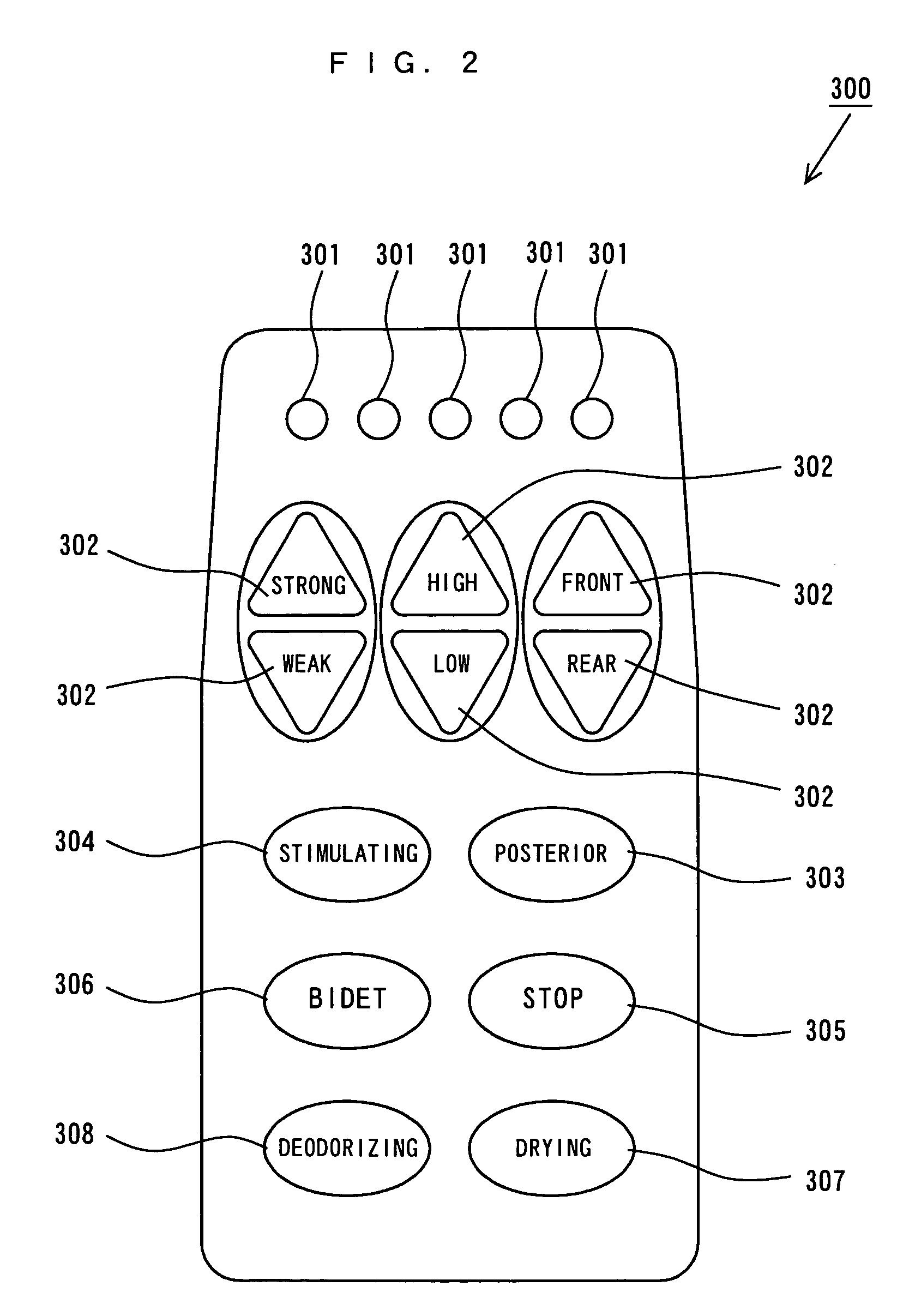

Fluid heating device and cleaning device using the same

InactiveUS7372002B2Small sizeImprove heat exchange efficiencyOther washing machinesLavatory sanitoryEngineeringMechanical engineering

A washing water inlet for receiving washing water is provided on an upper surface at one end of a case main body in a fluid heating device, and a washing water outlet for feeding heated washing water to a pump is provided on an upper surface at the other end of the case main body. A linear sheathed heater is arranged so as to penetrate the case main body. A spring is spirally wound around an outer peripheral surface of the sheathed heater. An outer peripheral surface of the sheathed heater, the spring, and an inner peripheral surface of the case main body form a flow path. The flow path is formed in a spiral shape with the length of the case main body used as its axis.

Owner:PANASONIC CORP

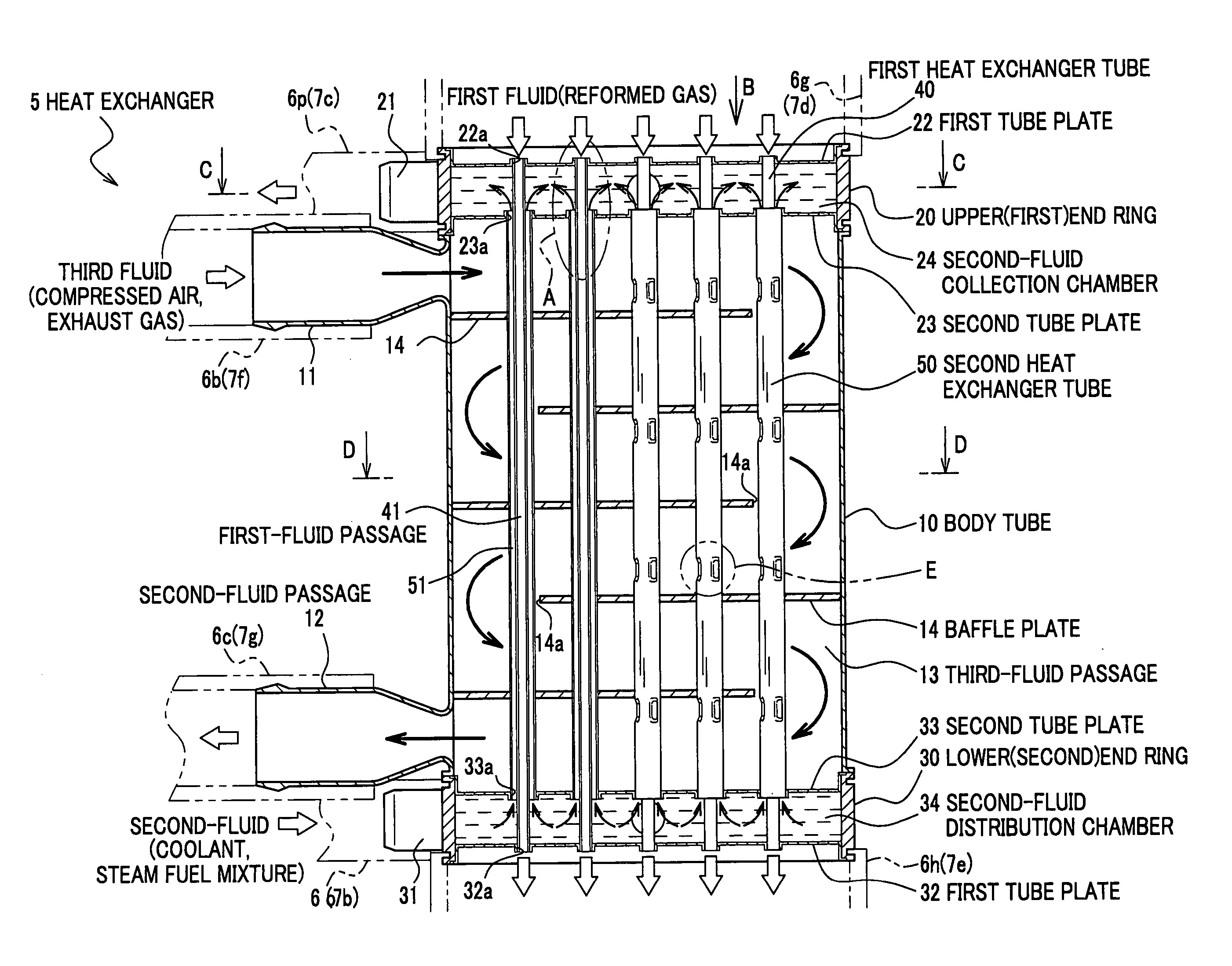

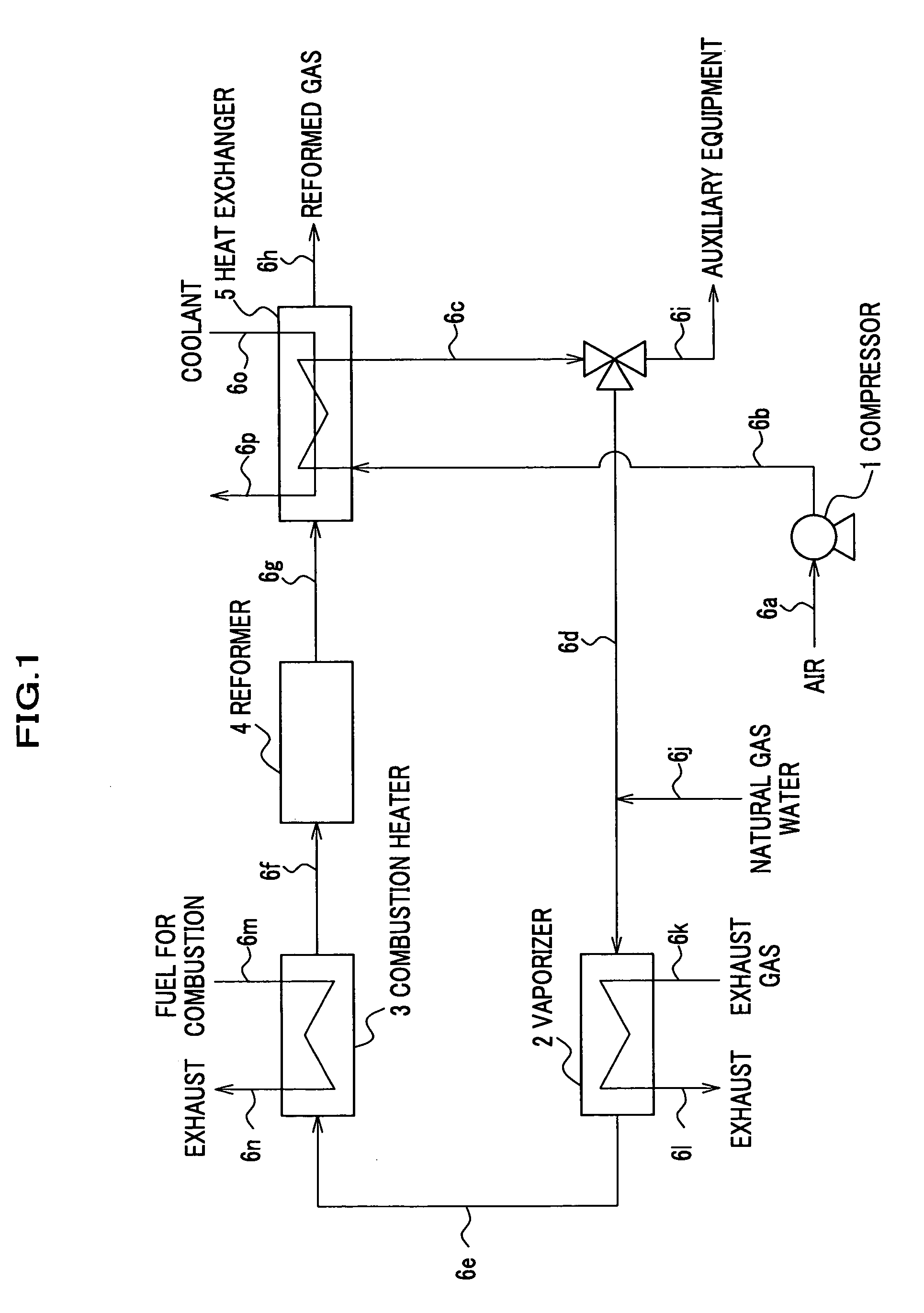

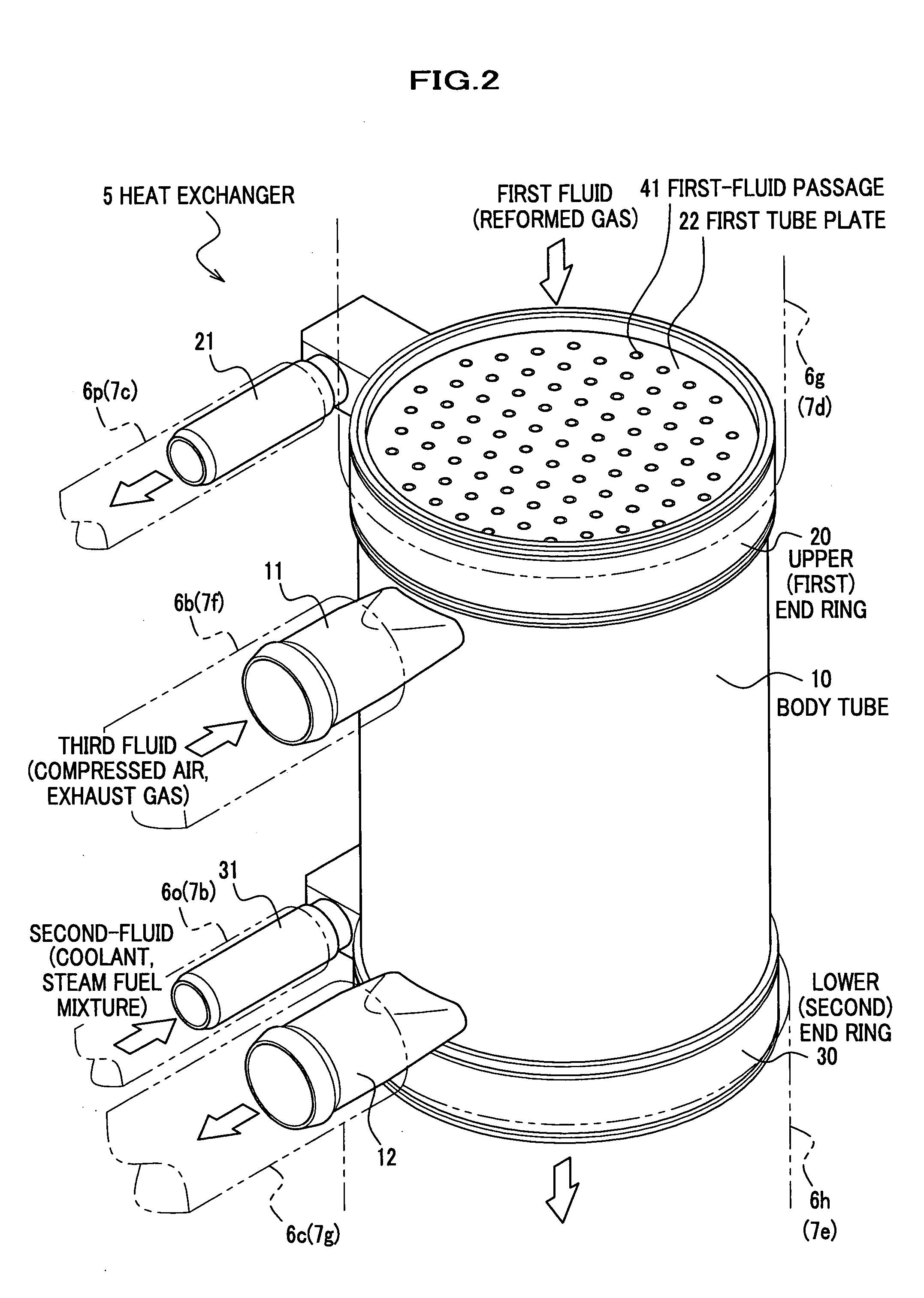

Heat exchanger

InactiveUS20050236145A1Improve heat exchange efficiencyLarge heat capacitySpacing meansHydrogenEngineeringHeat exchanger

End rings are coupled with upper and lower ends of a cylindrical body tube. A plurality of first heat exchanger tubes are fitted and held in holes provided in a pair of first tube plates. A plurality of second heat exchanger tubes are fitted and held in holes provided in a pair of second tube plates. The inside of each first heat exchanger tubes forms a first-fluid passage for carrying a reformed gas. The space defined between an outer wall of each first heat exchanger tube and an inner wall of the corresponding second heat exchanger tube forms a second-fluid passage for carrying a coolant. The space defined among an inner wall of the body tube and outer walls of the second heat exchanger tubes form a third-fluid passage for carrying compressed air.

Owner:HONDA MOTOR CO LTD

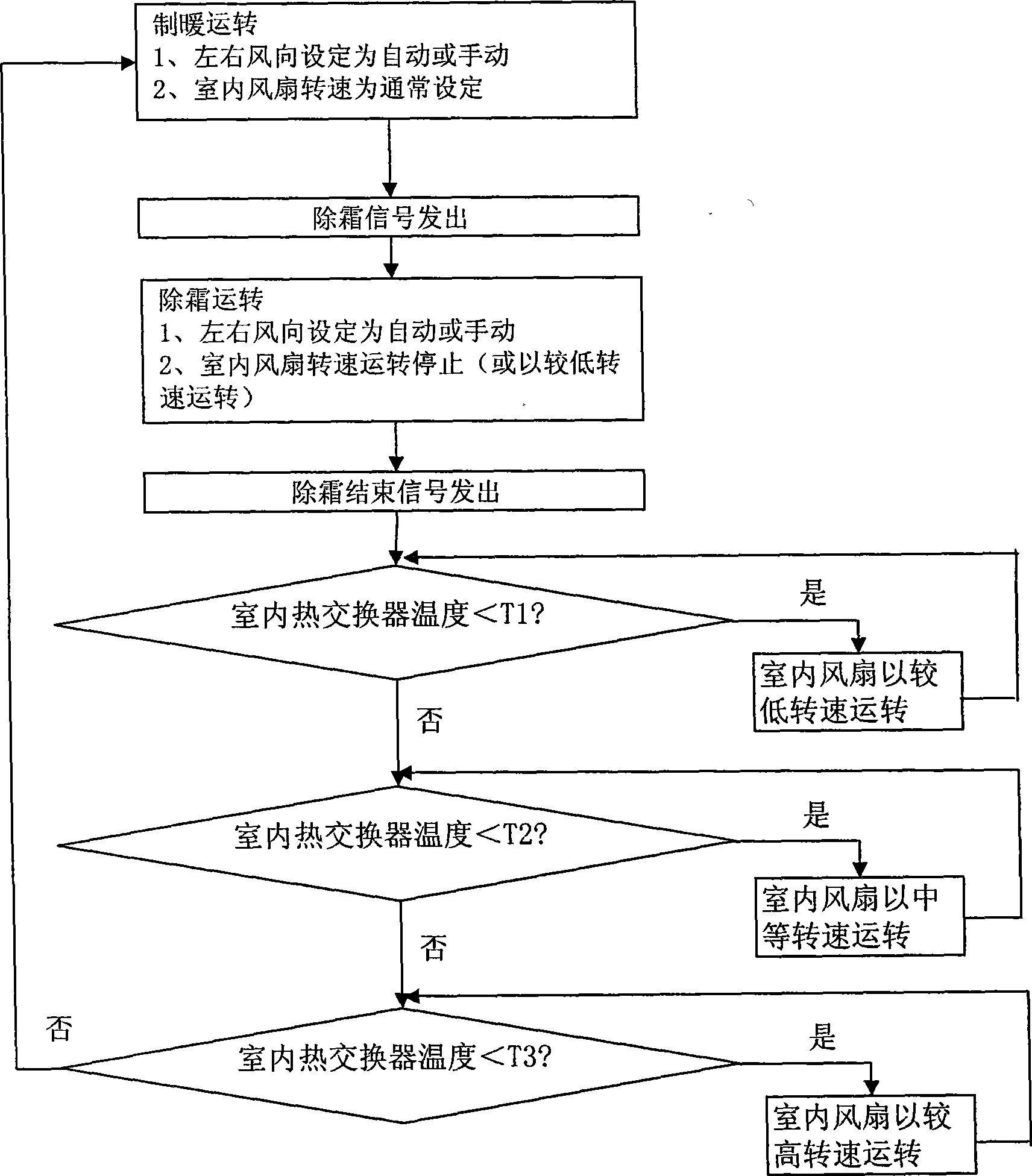

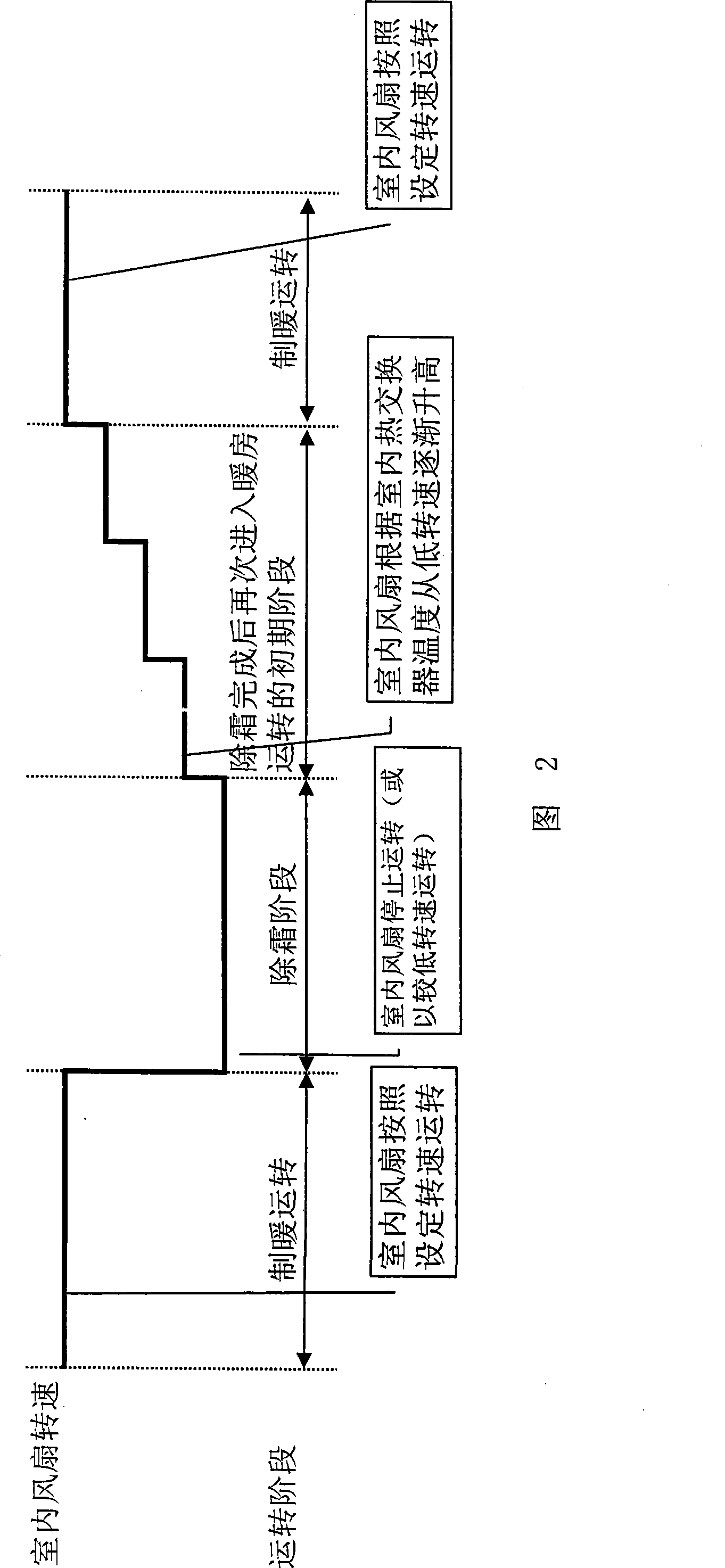

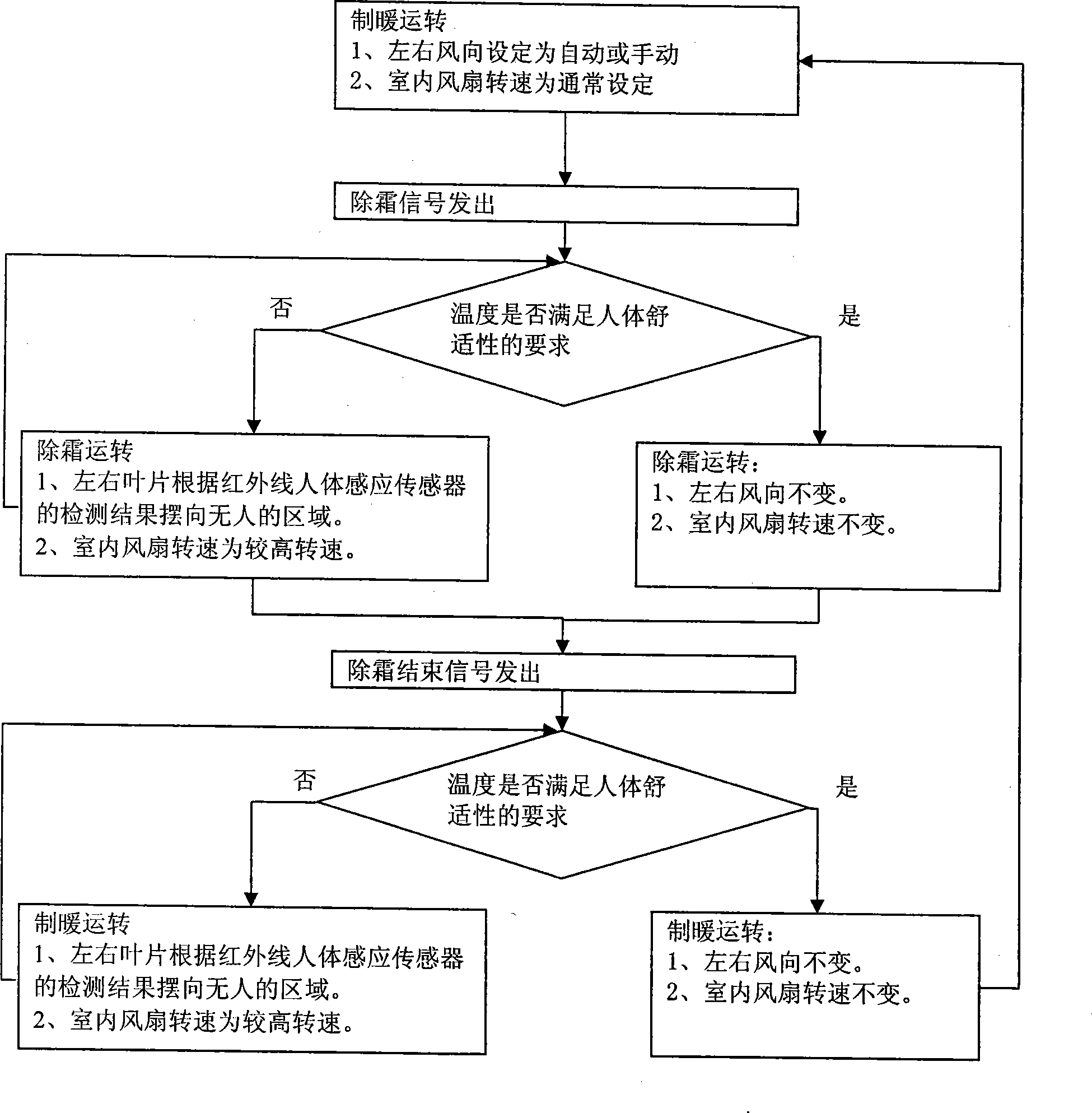

Air conditioner control method

ActiveCN101392940AAvoid blowingImprove heat exchange efficiencyMechanical apparatusSpace heating and ventilation safety systemsRoom temperatureEngineering

The invention discloses a method for controlling an air conditioner. The method is carried out during the defrosting operation and / or in the early stage of the reentering heating operation after finishing defrosting; according to the judgment of the room temperature, the directions of a left blade and a right blade are controlled by utilizing a result detected through a human induction sensor in order that the swinging directions of the left blade and the right blade point to a peopleless region judged by a detection result. During the defrosting, an indoor fan can operate at high rotational speed, improve heat-exchange efficiency in the indoor side and shorten defrosting time; and in the early stage of reentering the heating operation after finishing defrosting, the indoor fan can operate at high rotational speed and improve the heating effect, avoid cold wind from directly blowing on people and improve comfortableness.

Owner:PANASONIC HOME APPLIANCES AIR CONDITIONING GUANGZHOU CO LTD

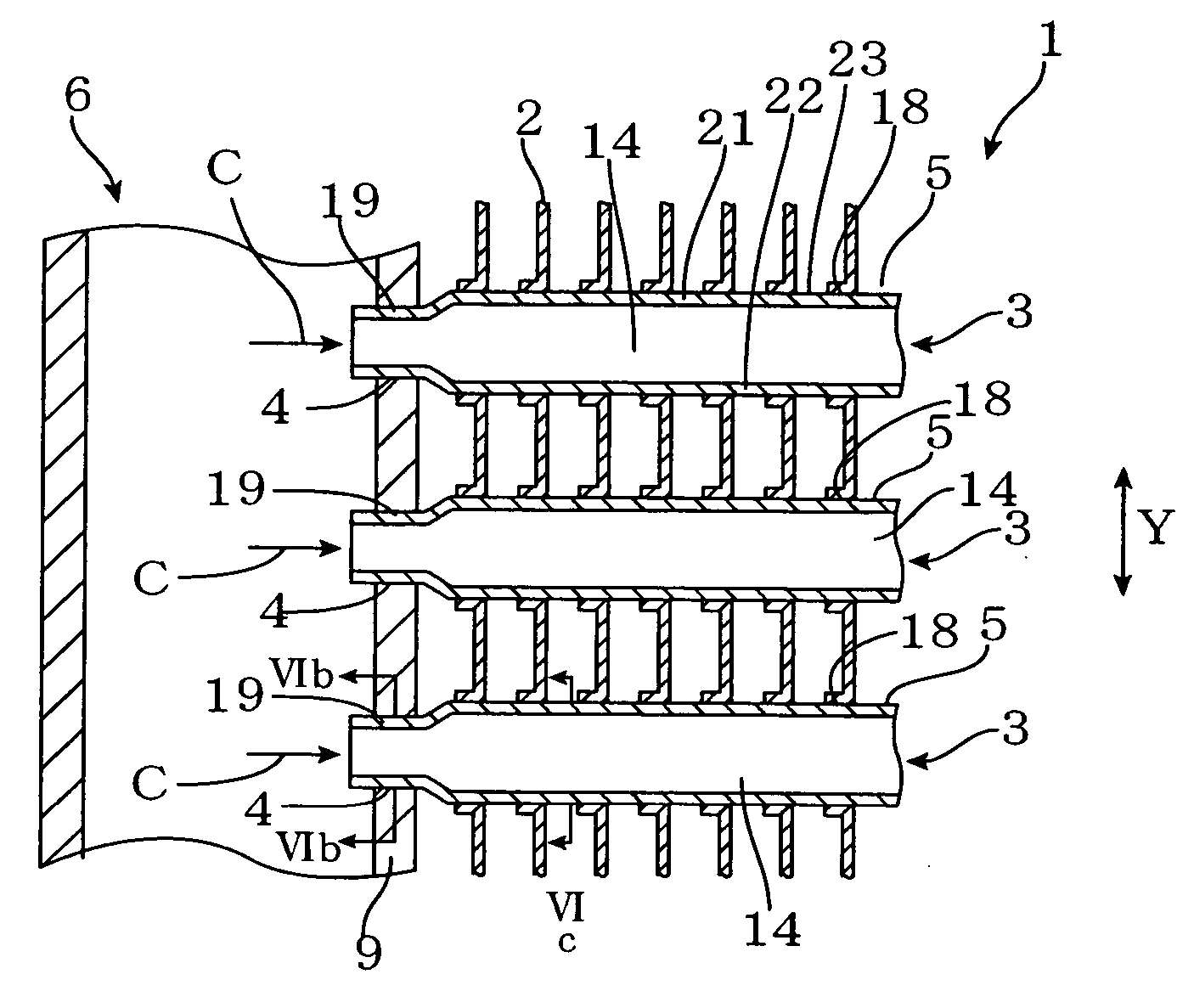

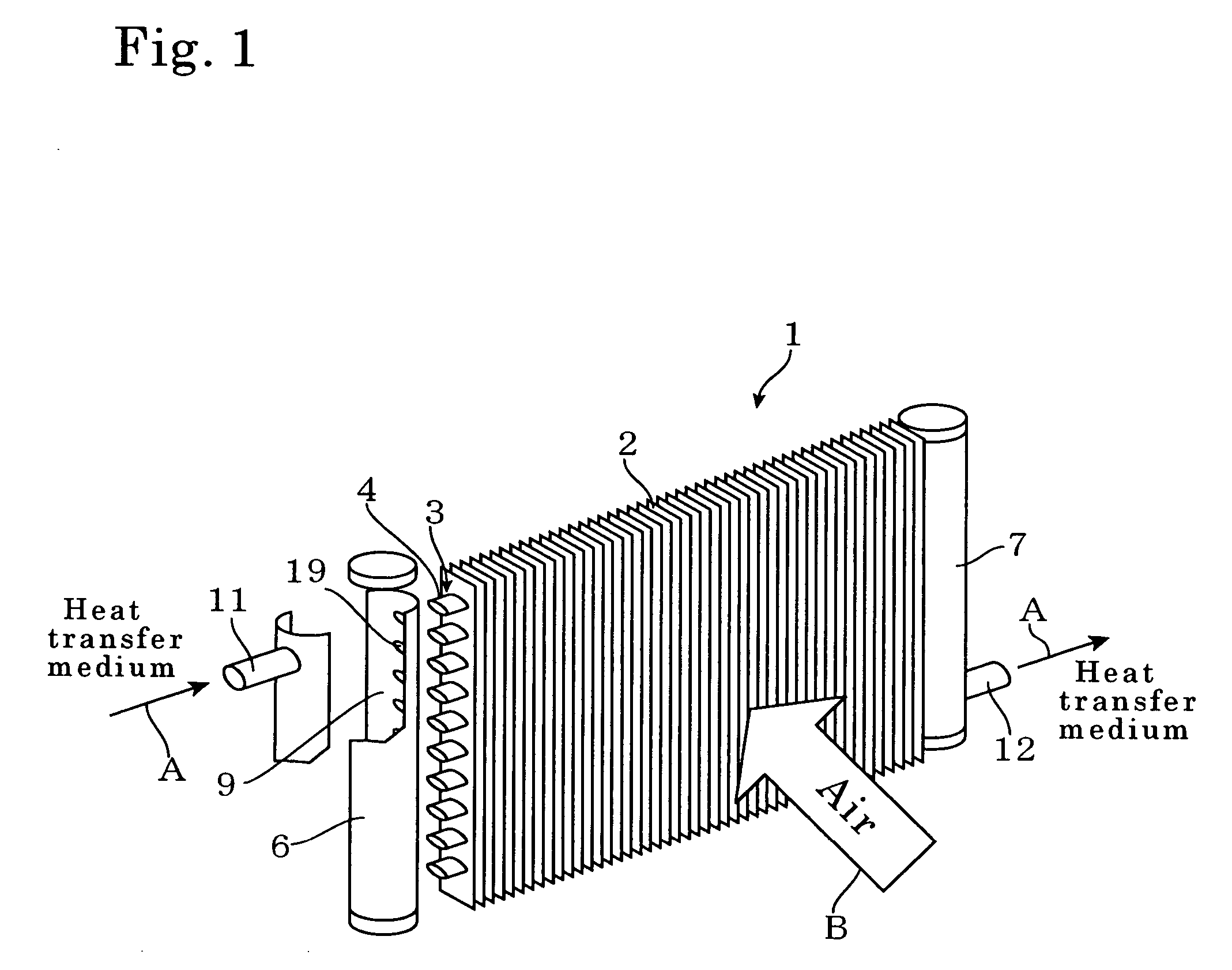

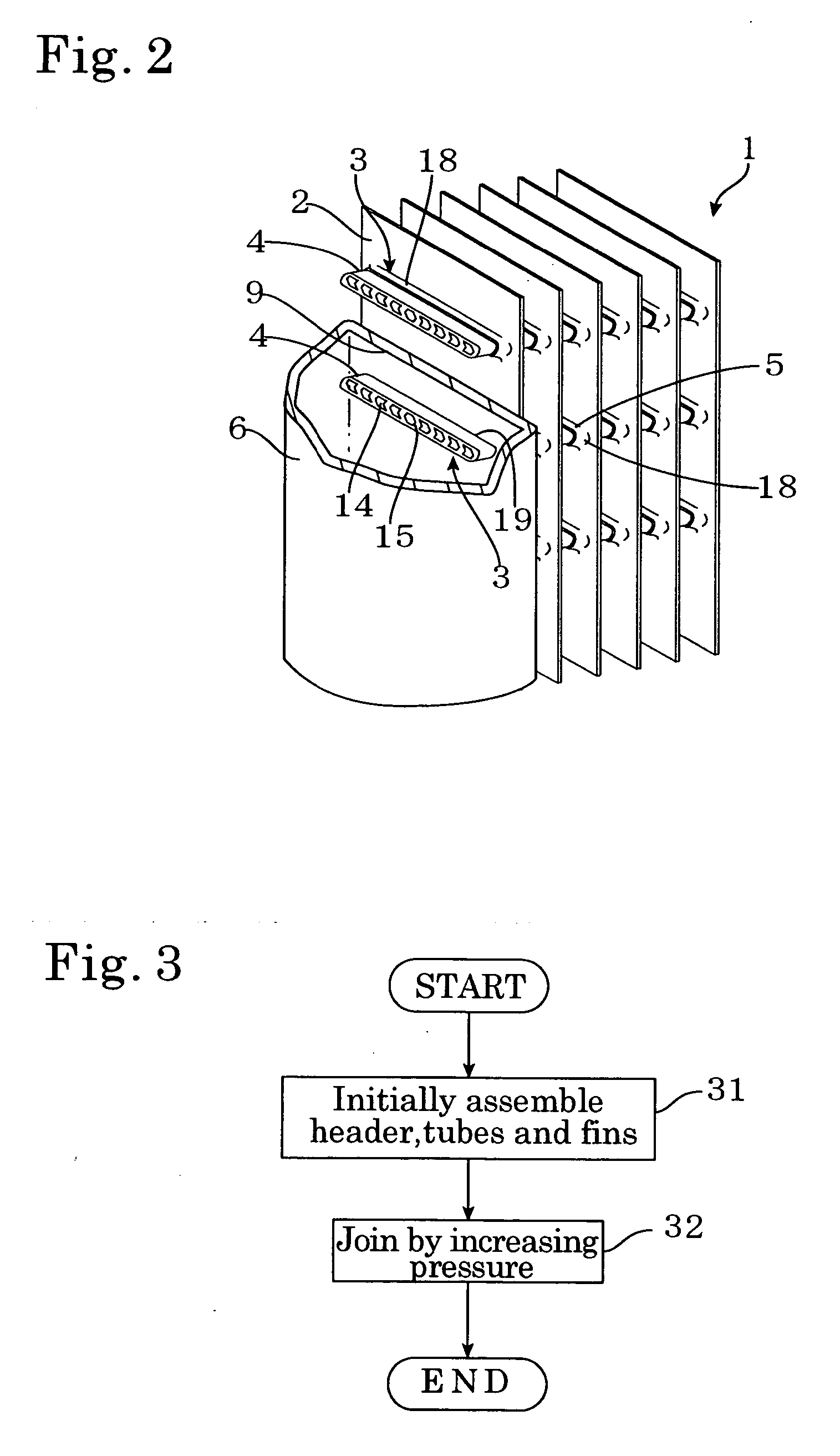

Heat exchanger and method of manufacturing the same

InactiveUS20050061494A1Increase internal pressureAdd partsStationary conduit assembliesHeat exchanger casingsInternal pressureEngineering

There is provided a method of manufacturing a heat exchanger, including a first step of mounting an end part of flat tube to a header, assembling the flat tube and fins, and sealing a part where the header and the end part is attached, and a second step of increasing an internal pressure of the flat tube to expand other part of flat tubes aside from the end parts with respect to the end part of the tube in order to make the fins and the other part of the flat tube in contact each other. According to this method of manufacturing, in the second step, the other part of the flat tube that passes through the fins is expanded, so that it is possible to mechanically join the flat tube and the fins, and a plate fin-type heat exchanger with high strength and heat exchange efficiency can be easily provided.

Owner:DENSO AIRCOOL CORP

Heat exchange module of a sorptive type and a method for the manufacture thereof

ActiveUS7704305B2Increased durabilityImprove heat exchange efficiencyBoiler absorbersDomestic cooling apparatusMolecular sieveActivated carbon

As conventional heat exchange modules, adsorptive agents of an inorganic type such as silica gel, zeolite, active alumina, active carbon and molecular sieve have been used. While these adsorptive agents have characteristics of high moisture absorptive ability and easy handling, they have problems of durability, regenerating temperature and generation of bacteria or fungi. An object of the present invention is to solve these problems which are noted in the inorganic adsorptive agents and to provide a heat exchanger module of a energy conservation type having a high heat exchange efficiency and a method for the manufacture thereof. The present invention is a heat exchange module of a sorptive type, characterized in that, a moisture absorptive layer in which a sorptive agent of an organic polymer type comprising organic polymer having hydrophilic polar group and cross-linking structure in a molecule is an essential component, saturated moisture absorbing rates at 20° C. and 65% RH and 90% RH are not less than 20% by weight and not less than 40% by weight, respectively and the difference in the saturated moisture absorbing rates under such a condition is not less than 20% by weight is formed on a metal surface having excellent heat conductivity.

Owner:POWERWAVE TECH SWEDEN AB +1

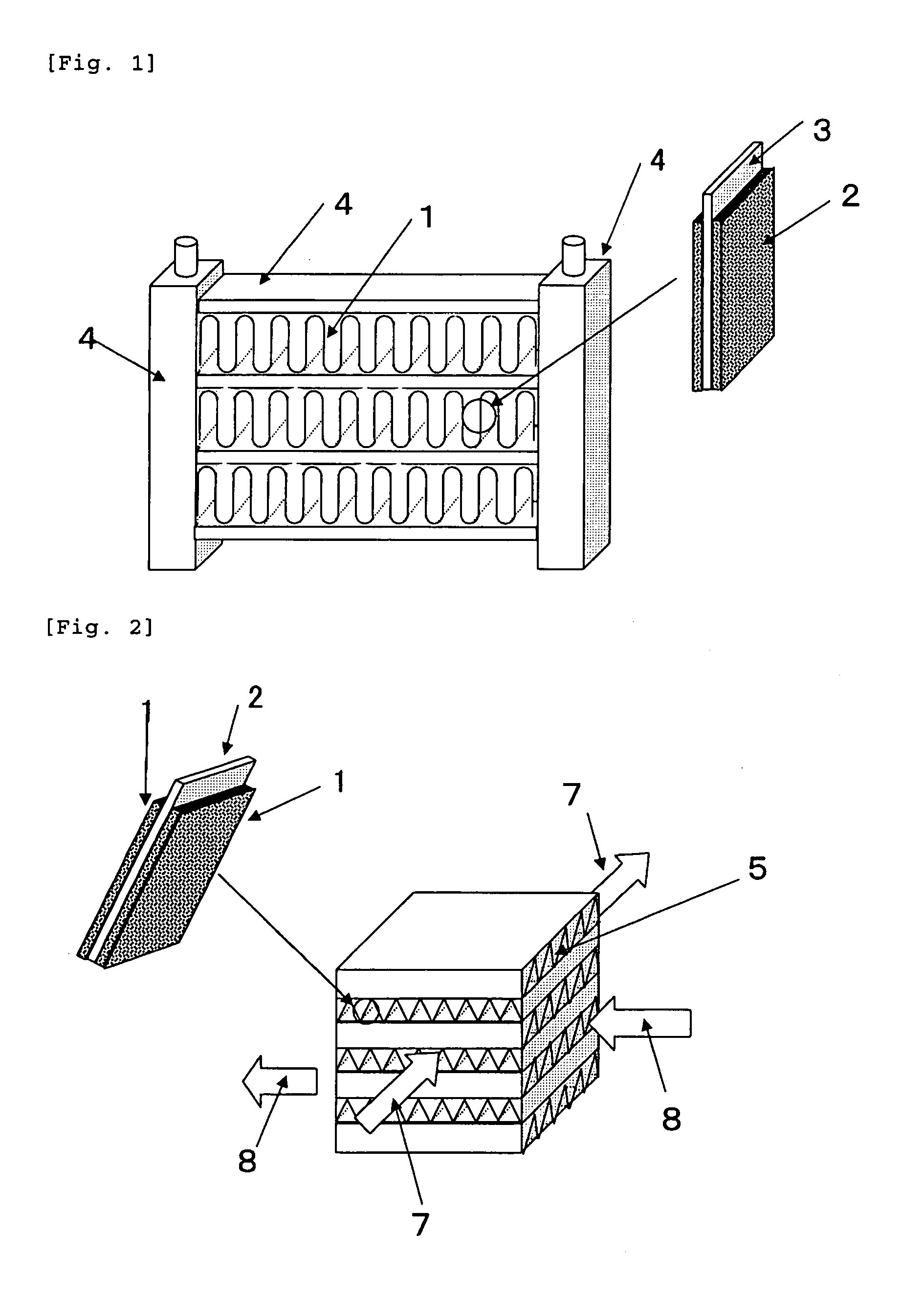

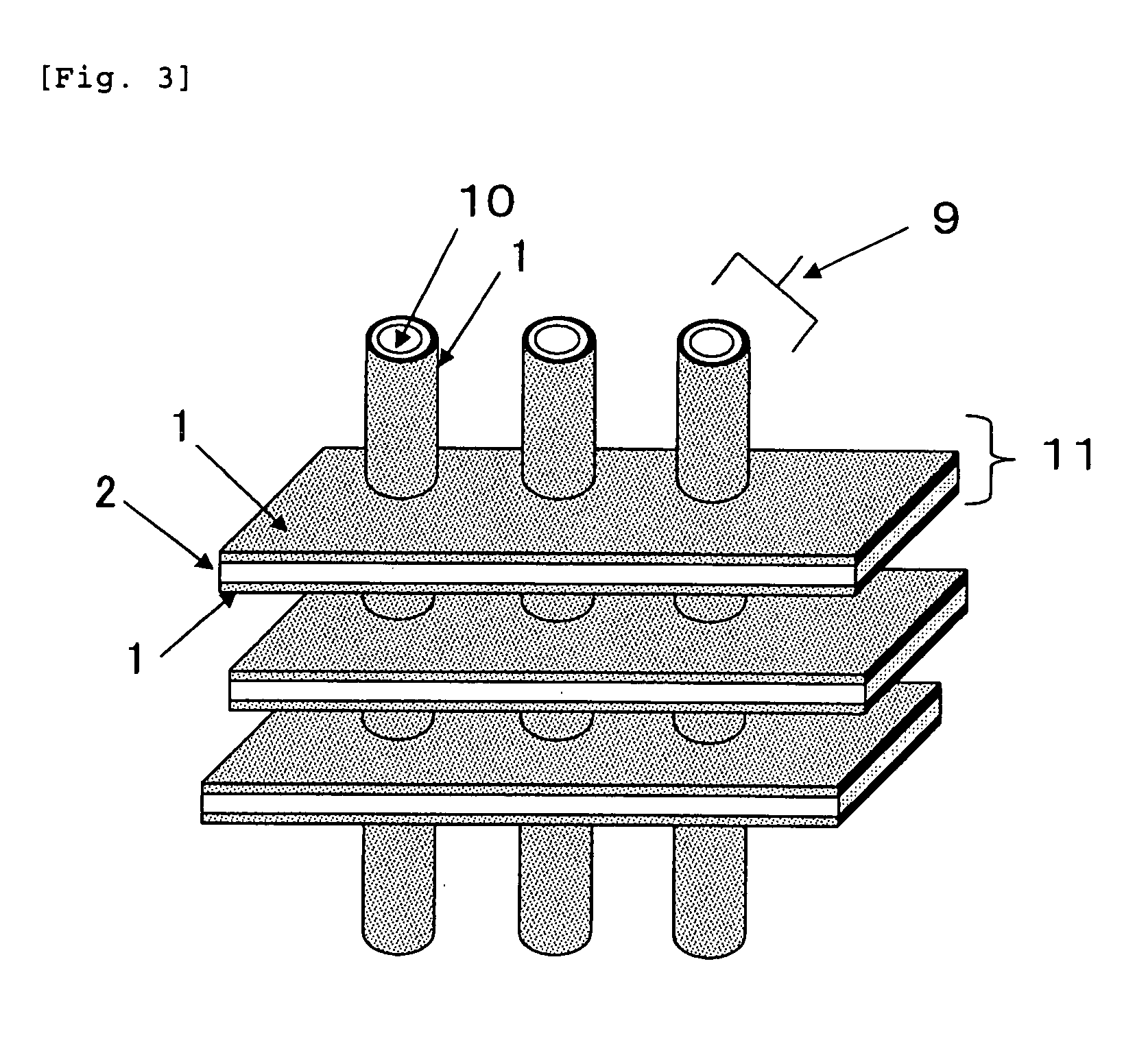

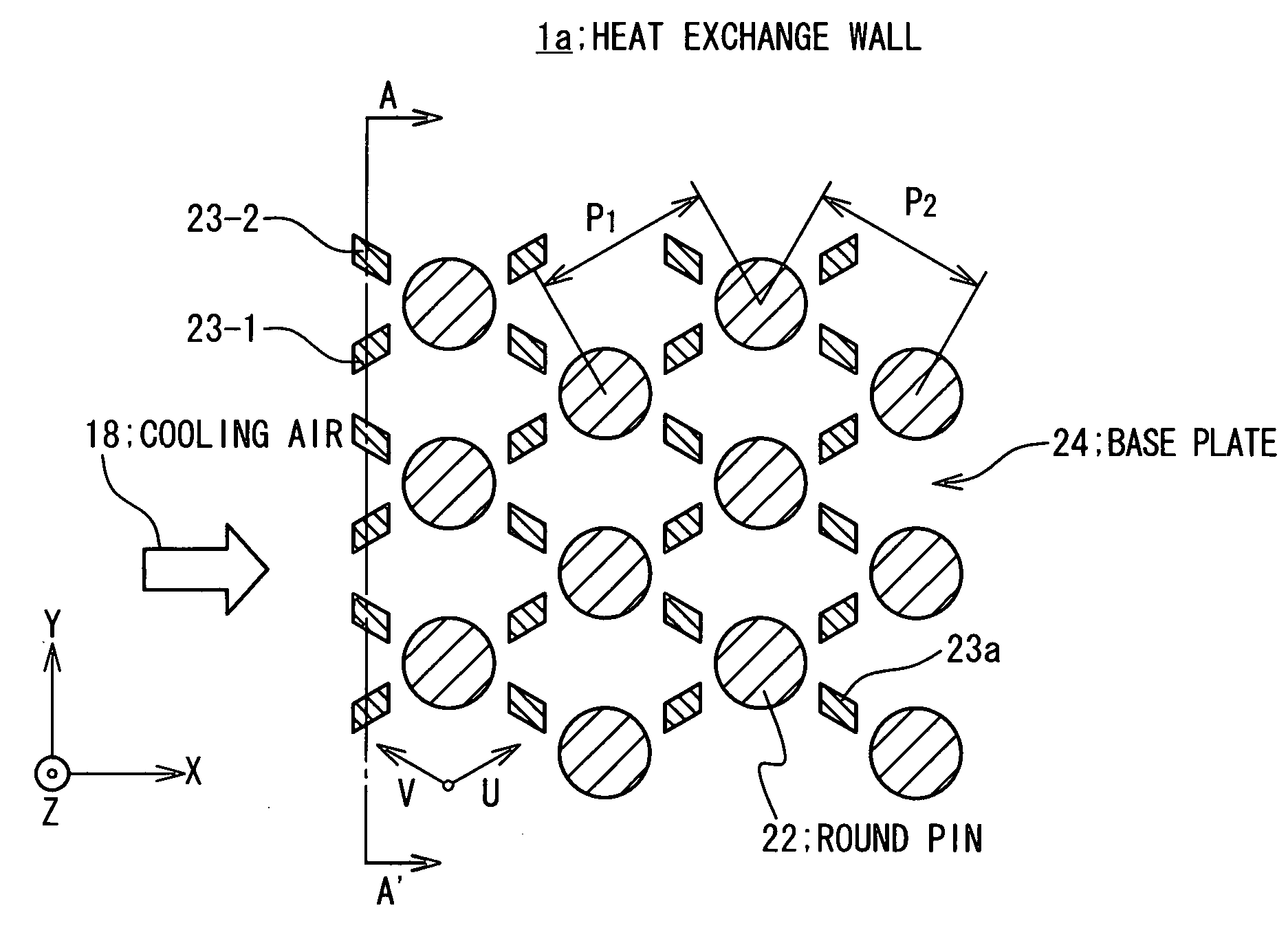

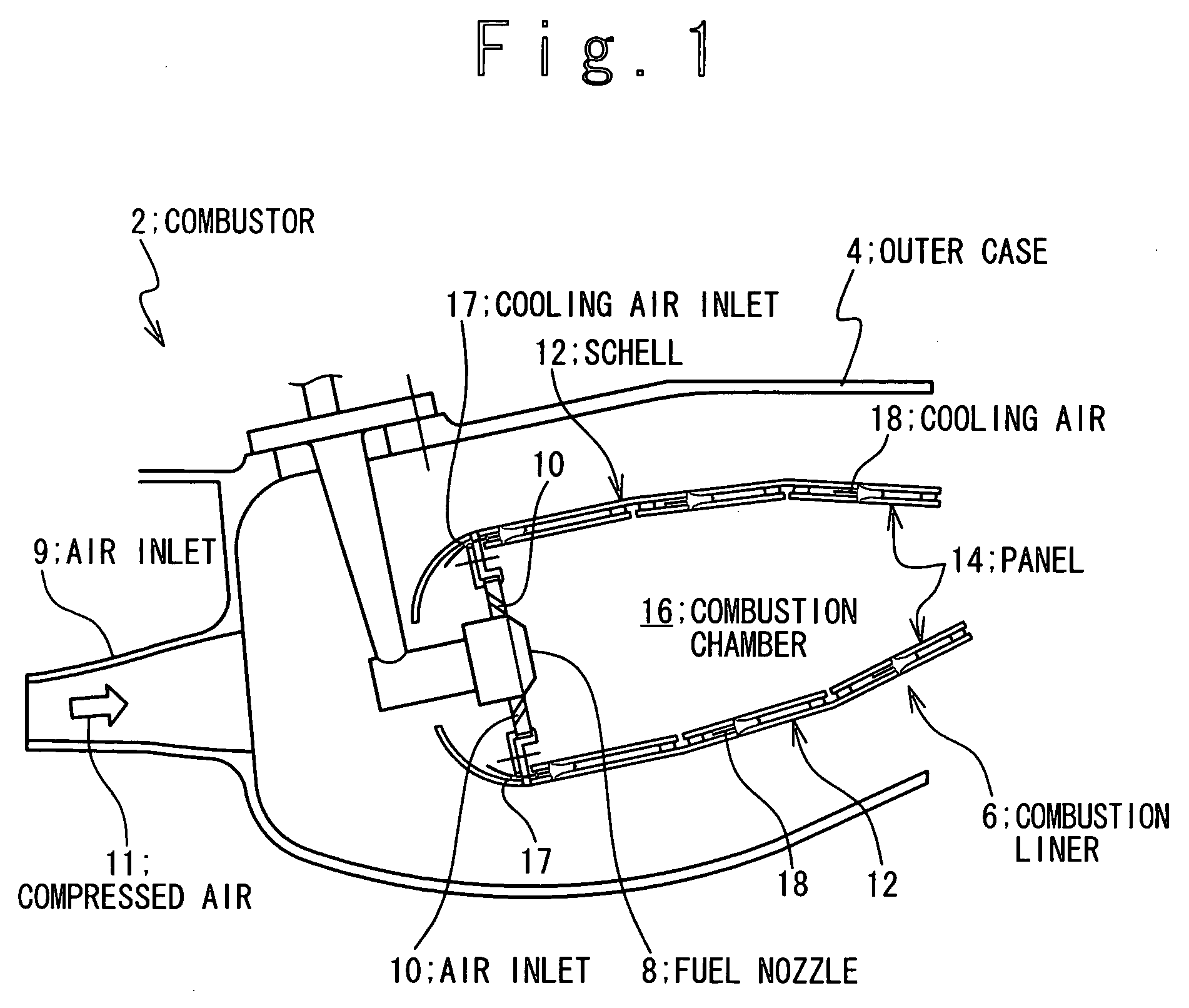

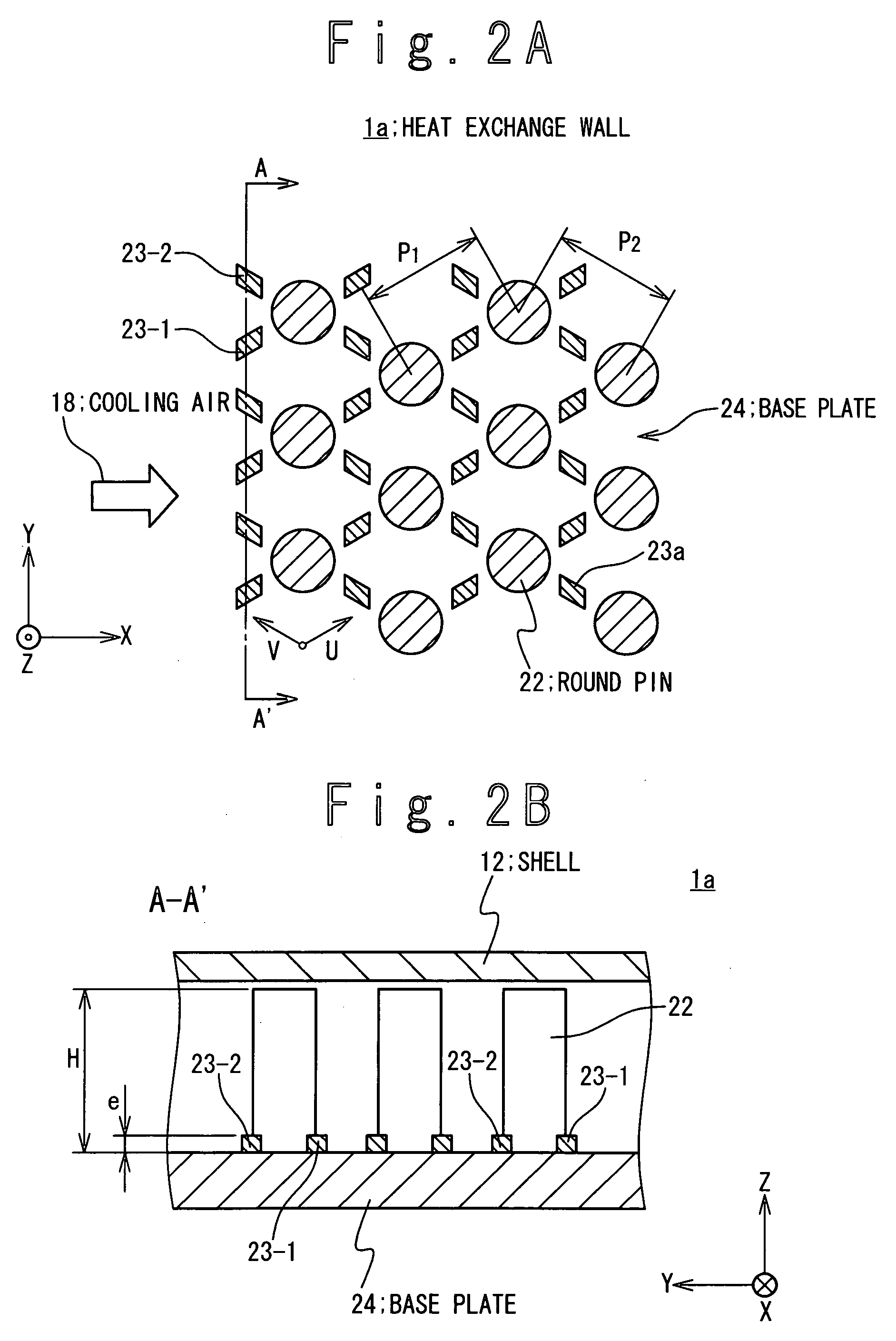

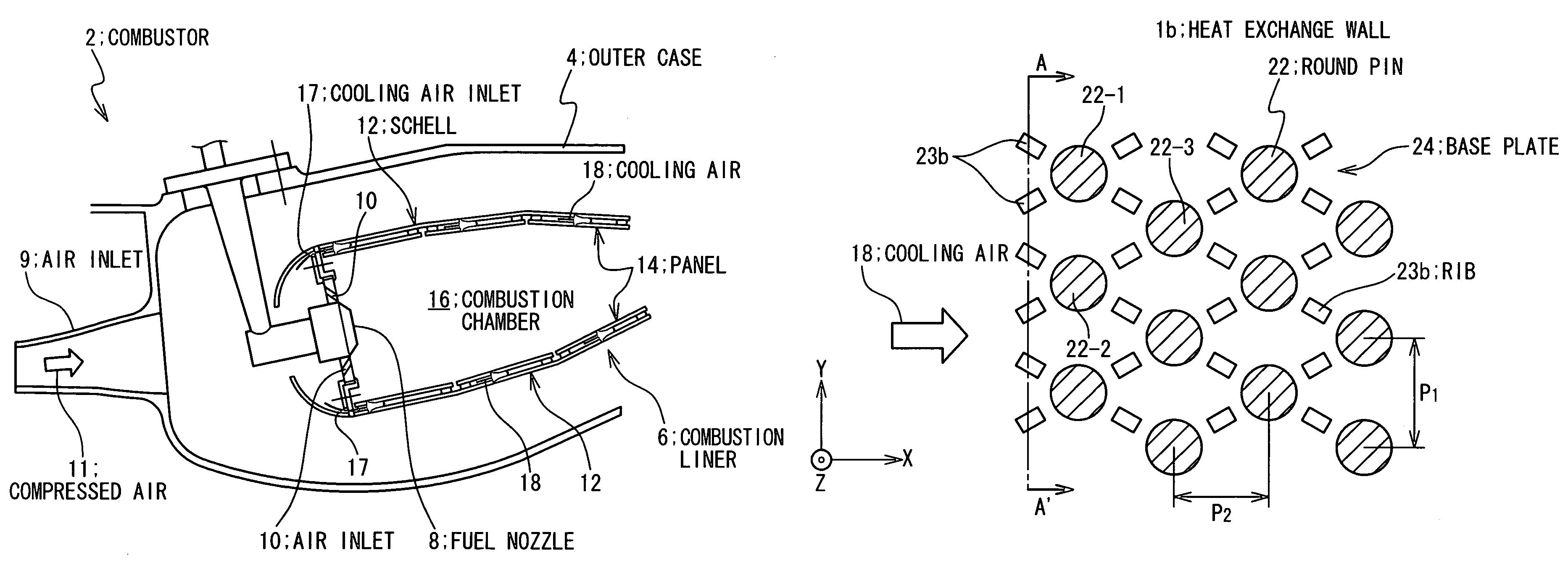

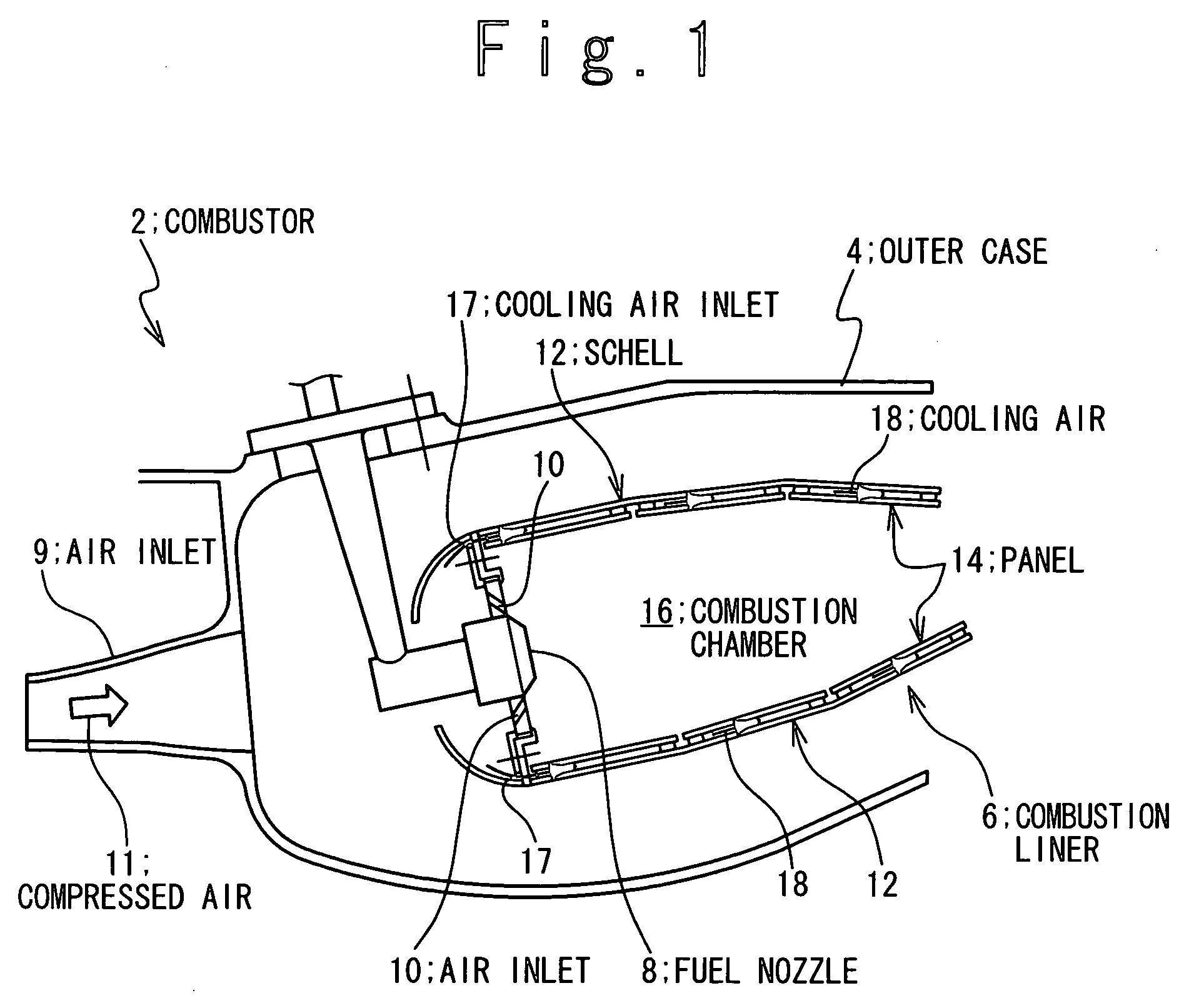

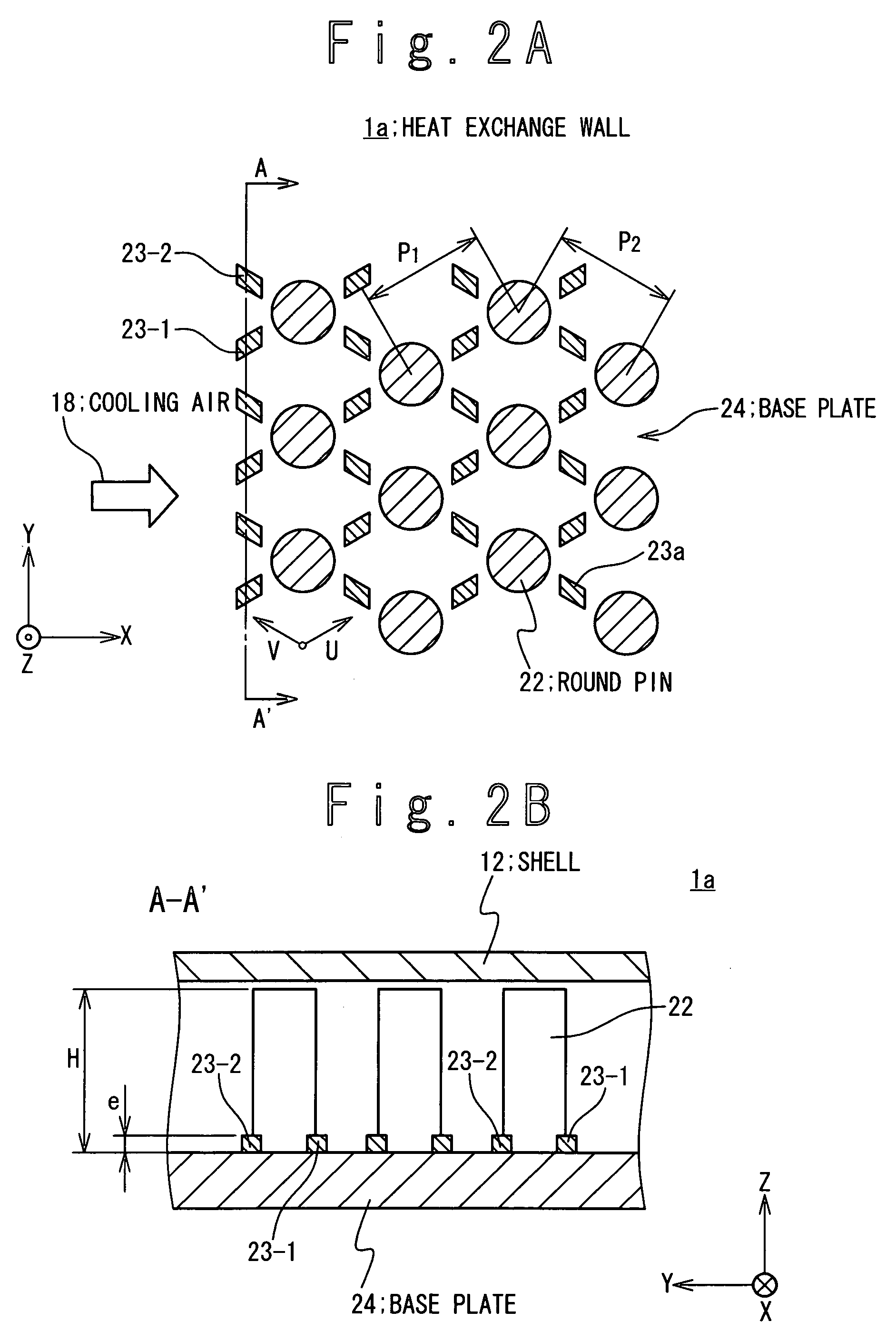

Heat exchanging wall, gas turbine using the same, and flying body with gas turbine engine

ActiveUS20050047932A1High heat exchange efficiencyImprove heat exchange efficiencyContinuous combustion chamberPositive displacement pump componentsGas turbinesEngineering

Owner:MITSUBICHI HEAVY IND AERO ENGINES LTD +1

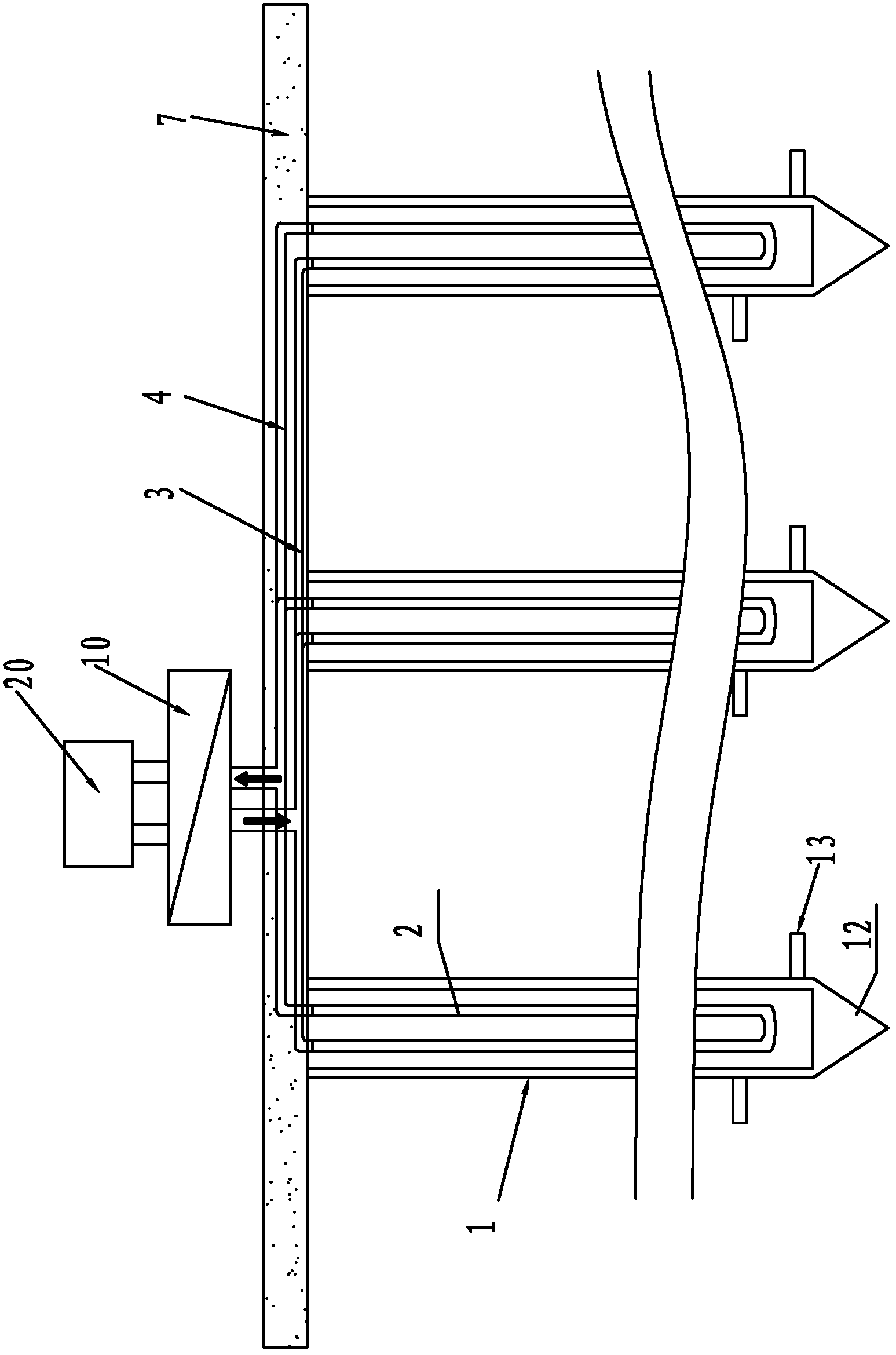

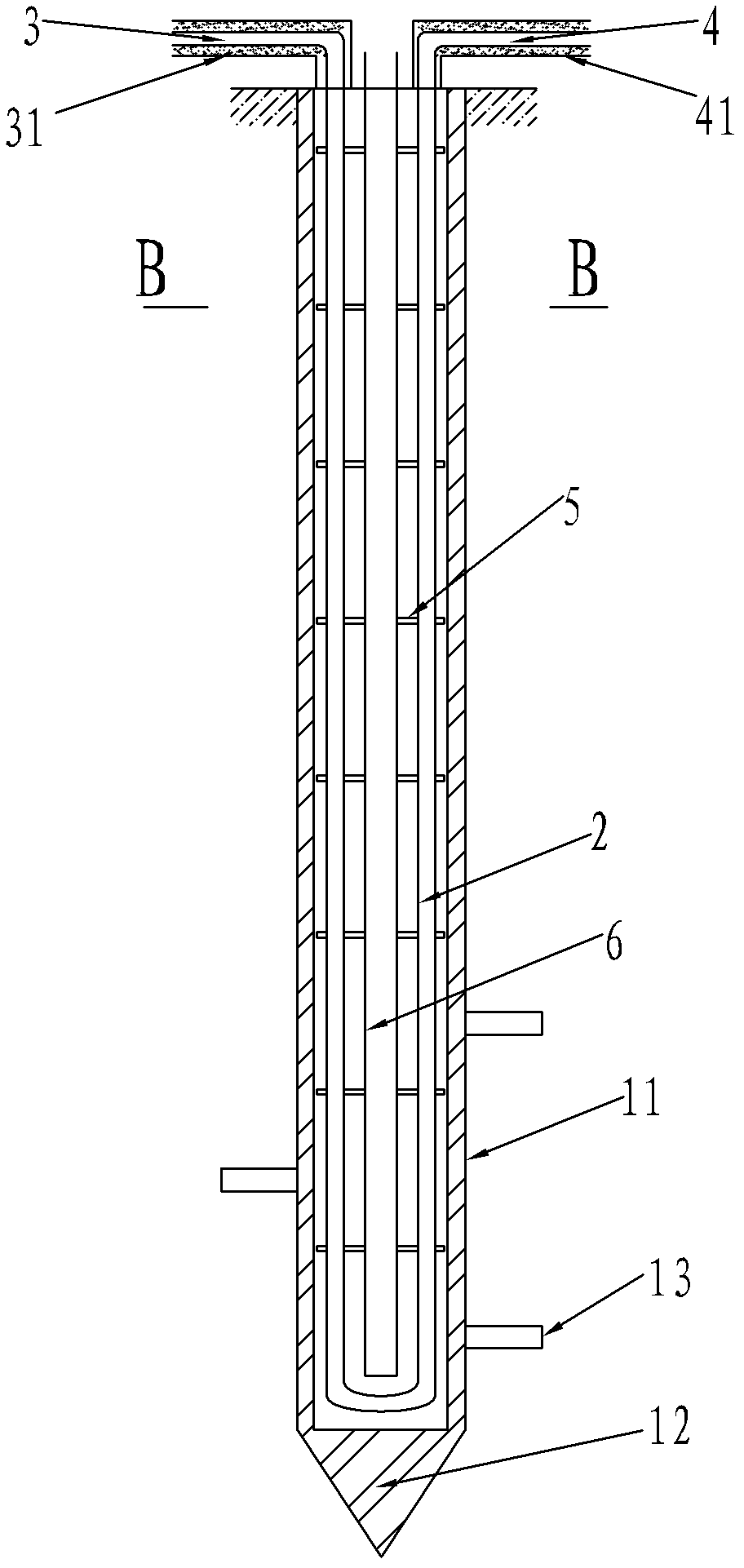

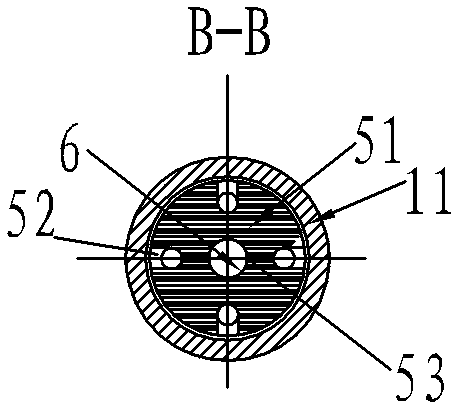

Precession-type backfill grouting ground source thermal energy conversion precast pile device and method for embedding precast pile device into stratum

InactiveCN102587365AConvenient closed loop conversionImprove bearing capacityHeat pumpsBulkheads/pilesThermal energyGeothermal heat pump

The invention discloses a precession-type backfill grouting ground source thermal energy conversion precast pile device, which comprises a plurality of precession-type backfill grouting prefabricated screw piles respectively embedded into pile holes, wherein a vertical heat exchanger is embedded in each screw pile; the inlet end and the outlet end of each vertical heat exchanger respectively extend out of an opening at the upper end of the screw pile to be respectively connected with a horizontal liquid-feeding collecting pipe and a horizontal liquid outlet collecting pipe in a bearing platform or a cushion layer; centring brackets are arranged at an interval of 1-3 m along the length direction of each vertical heat exchanger; each precession-type backfill grouting prefabricated screw pile comprises a hollow pile core, wherein the bottom of the pile core is provided with a cone-shaped pile head; a screw blade is arranged on the position far away1-3m from the lower part of the outer wall of the pile core; and a post grouting reinforcing layer is poured between the middle upper part of the outer wall of the pile core and a pile hole wall. The precession-type backfill grouting ground source thermal energy conversion precast pile device comprises a plurality of precession-type backfill grouting prefabricated screw piles, and the vertical heat exchanger is embedded in each screw pile; the pile foundation construction and the ground source heat pump construction are integrated so as to avoid a drilling and pipe-laying program of a ground source heat pump system on the ground, greatly lower the front-end investment cost and save the land use area; and the post grouting reinforcing layer is poured between the middle upper part of the outer wall of the pile core and the pile hole wall so as to enlarge a heat conduction area, improve the heat conduction performance and simultaneously improve the pile body bearing capacity.

Owner:CHINA JINGYE ENG +2

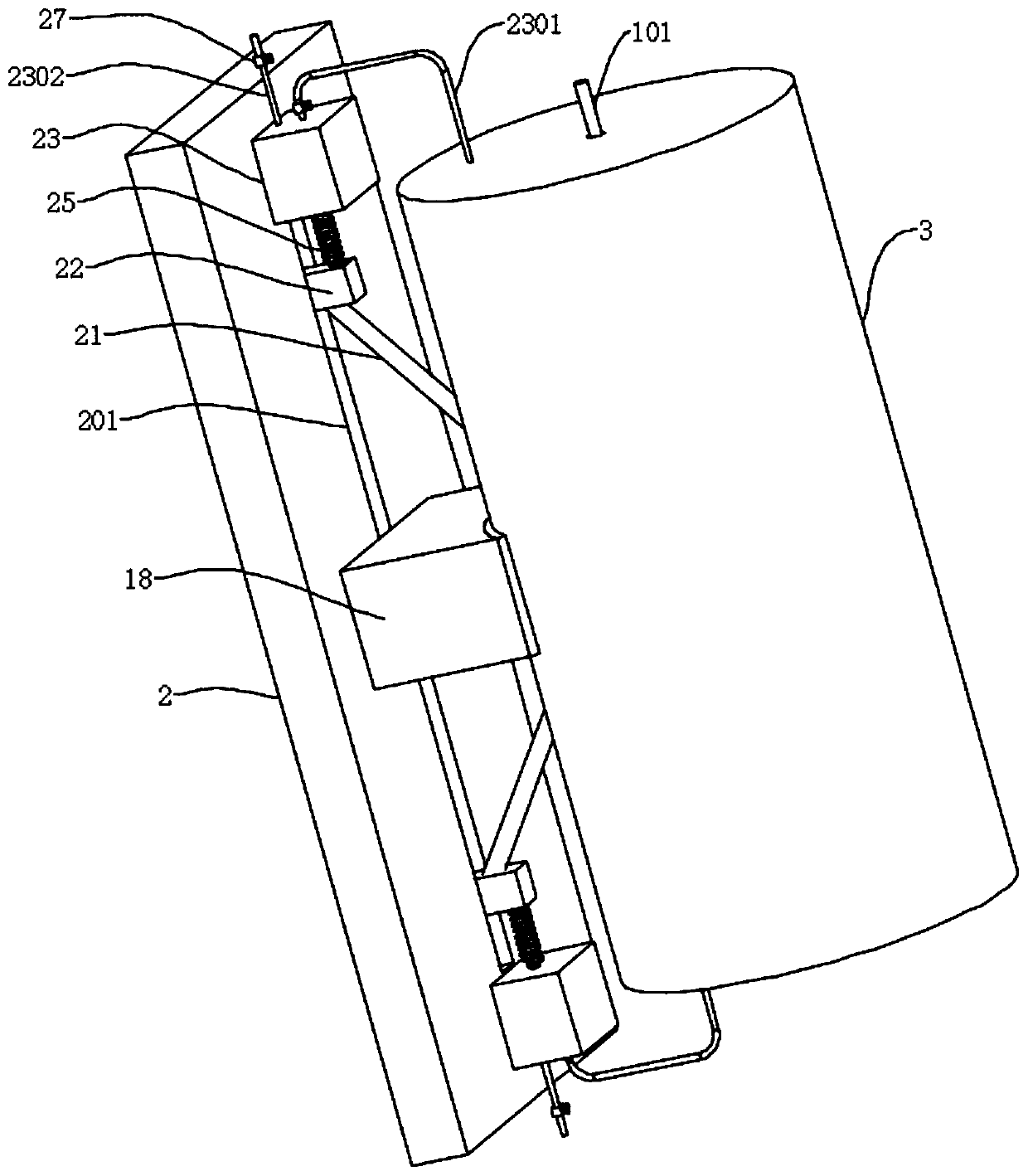

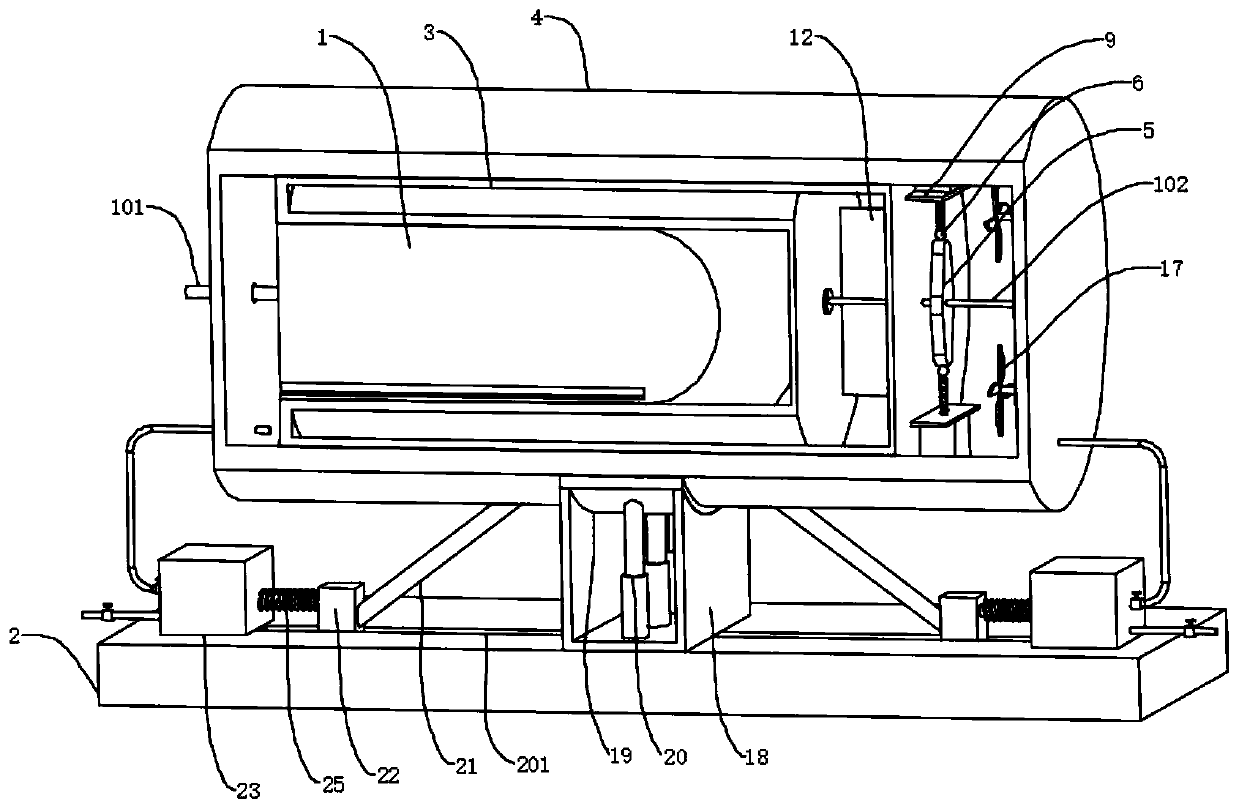

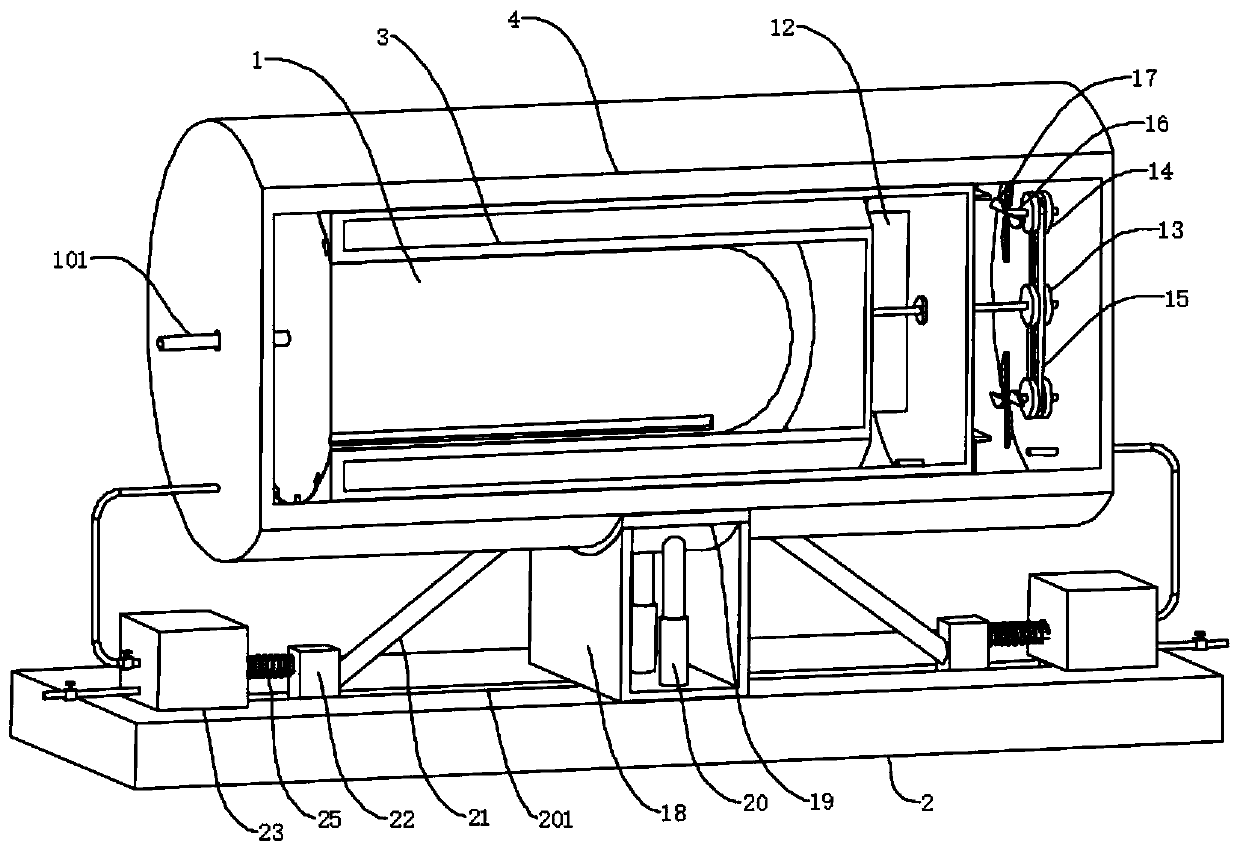

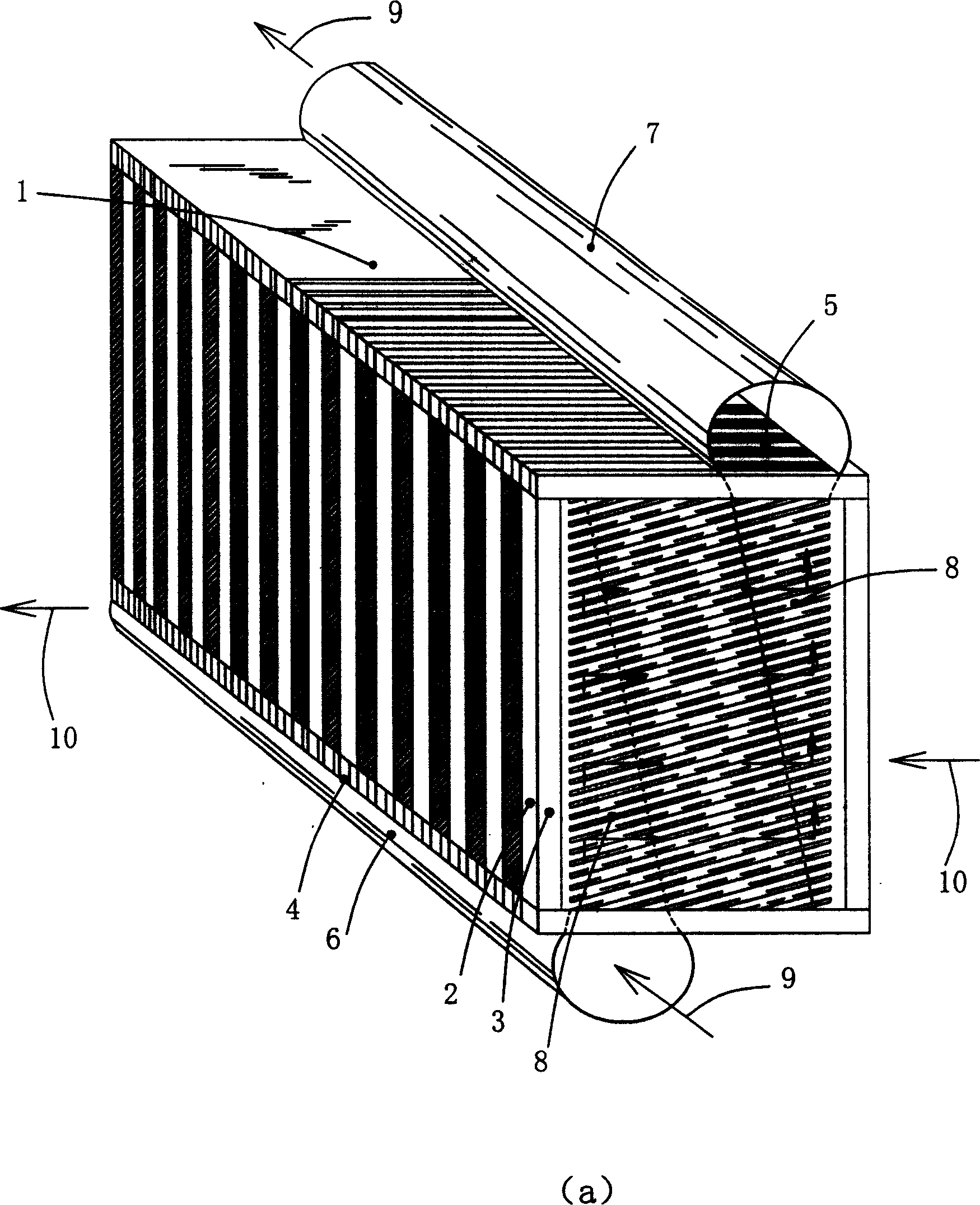

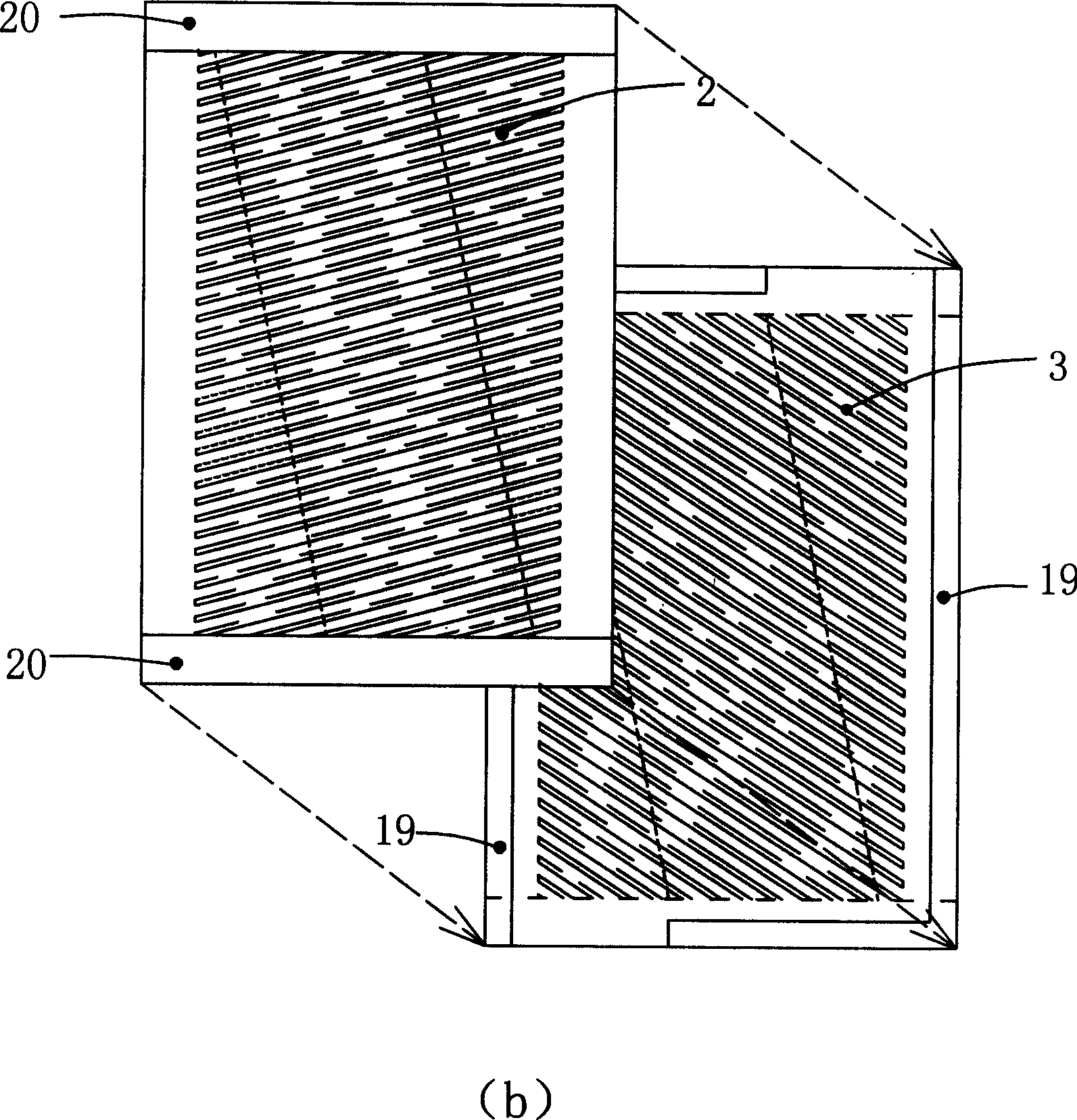

Heating Apparatus

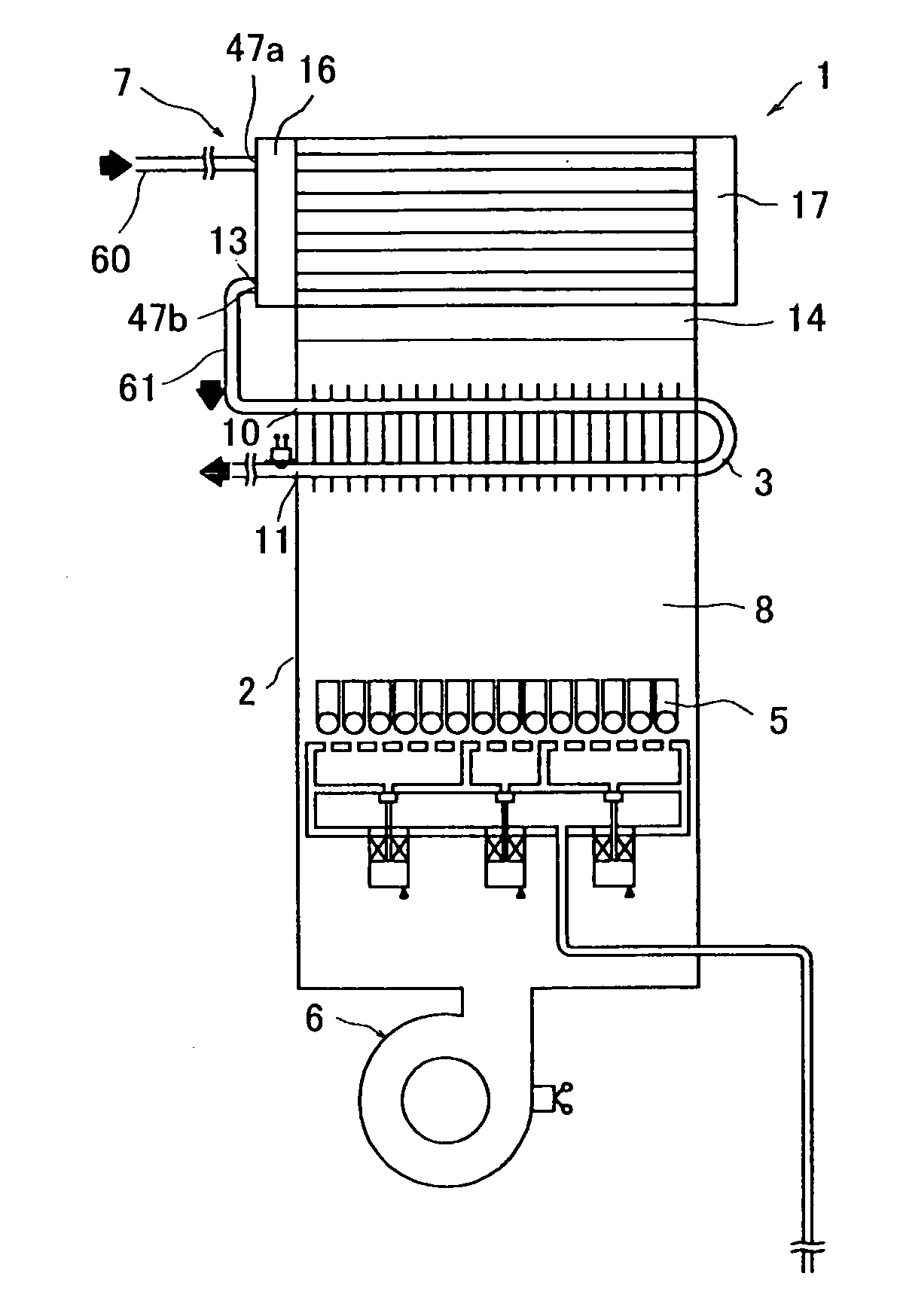

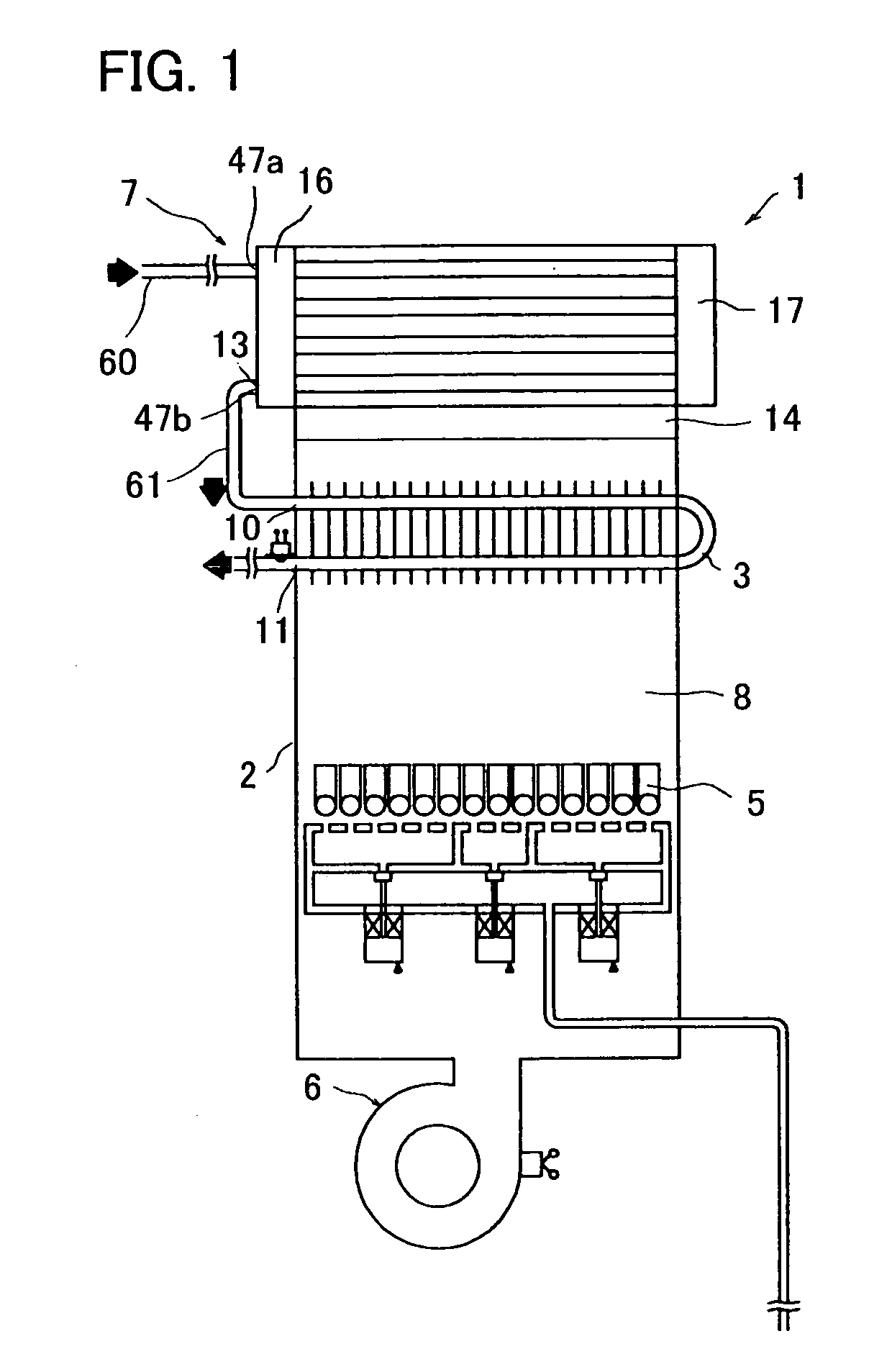

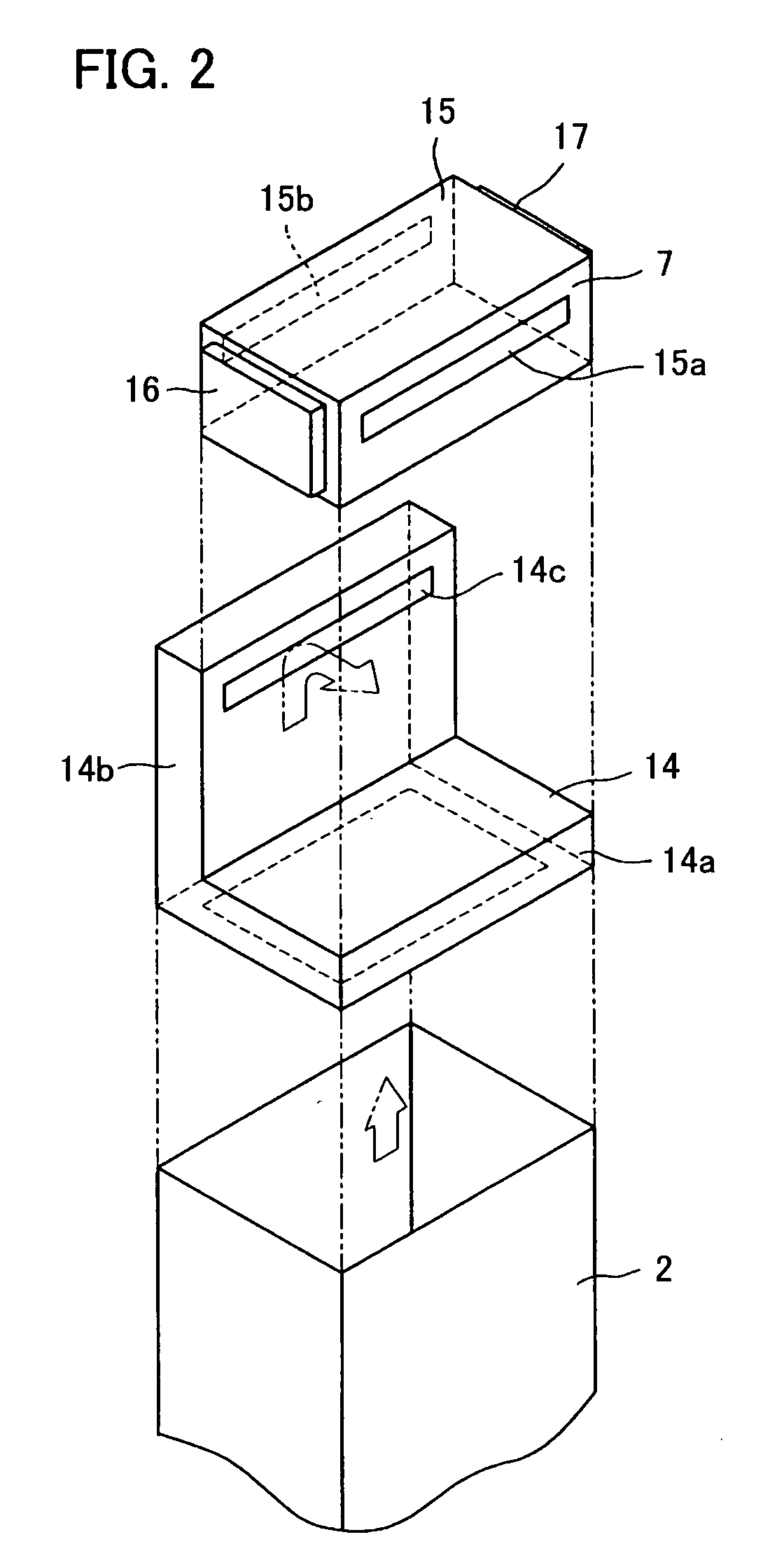

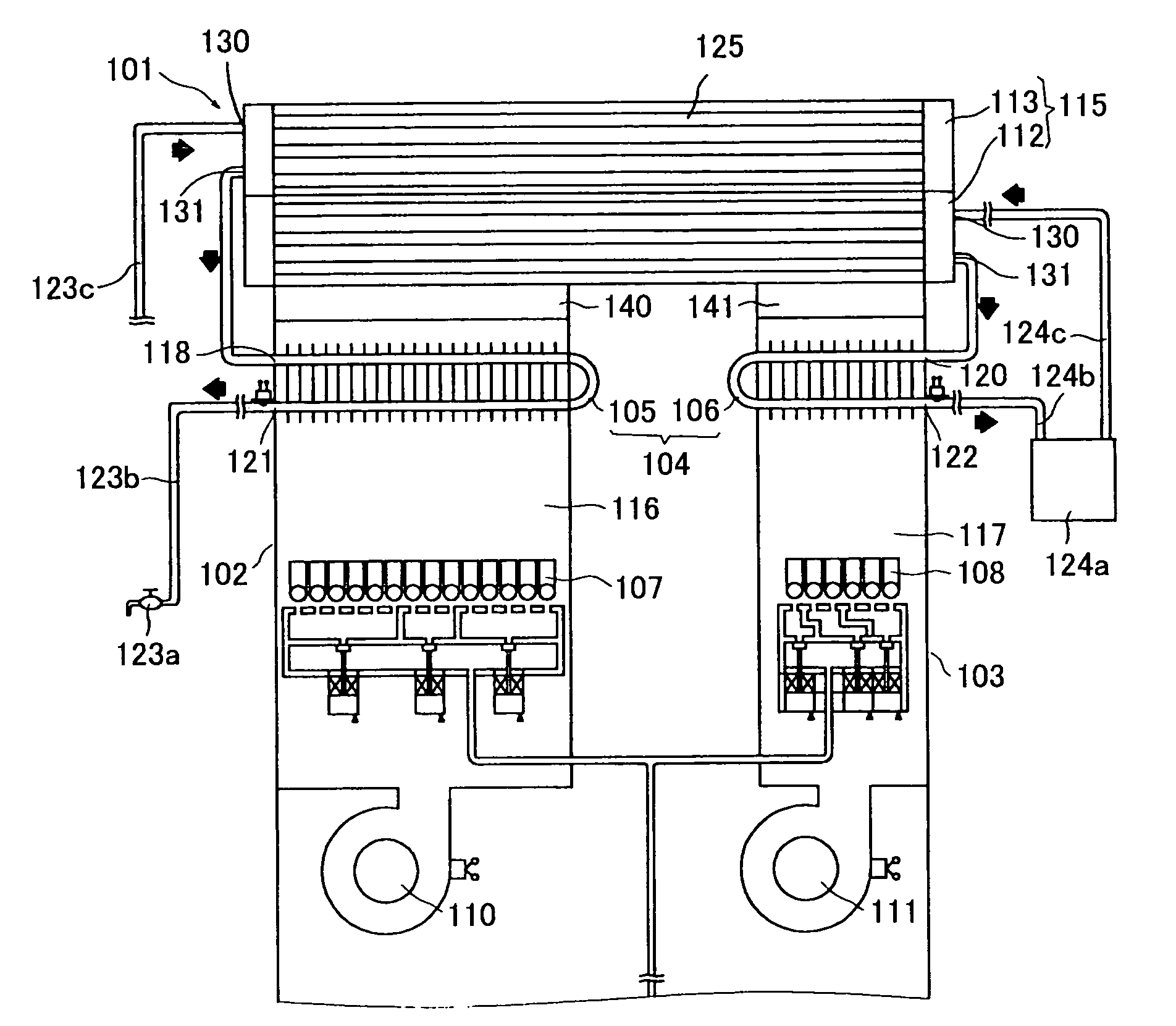

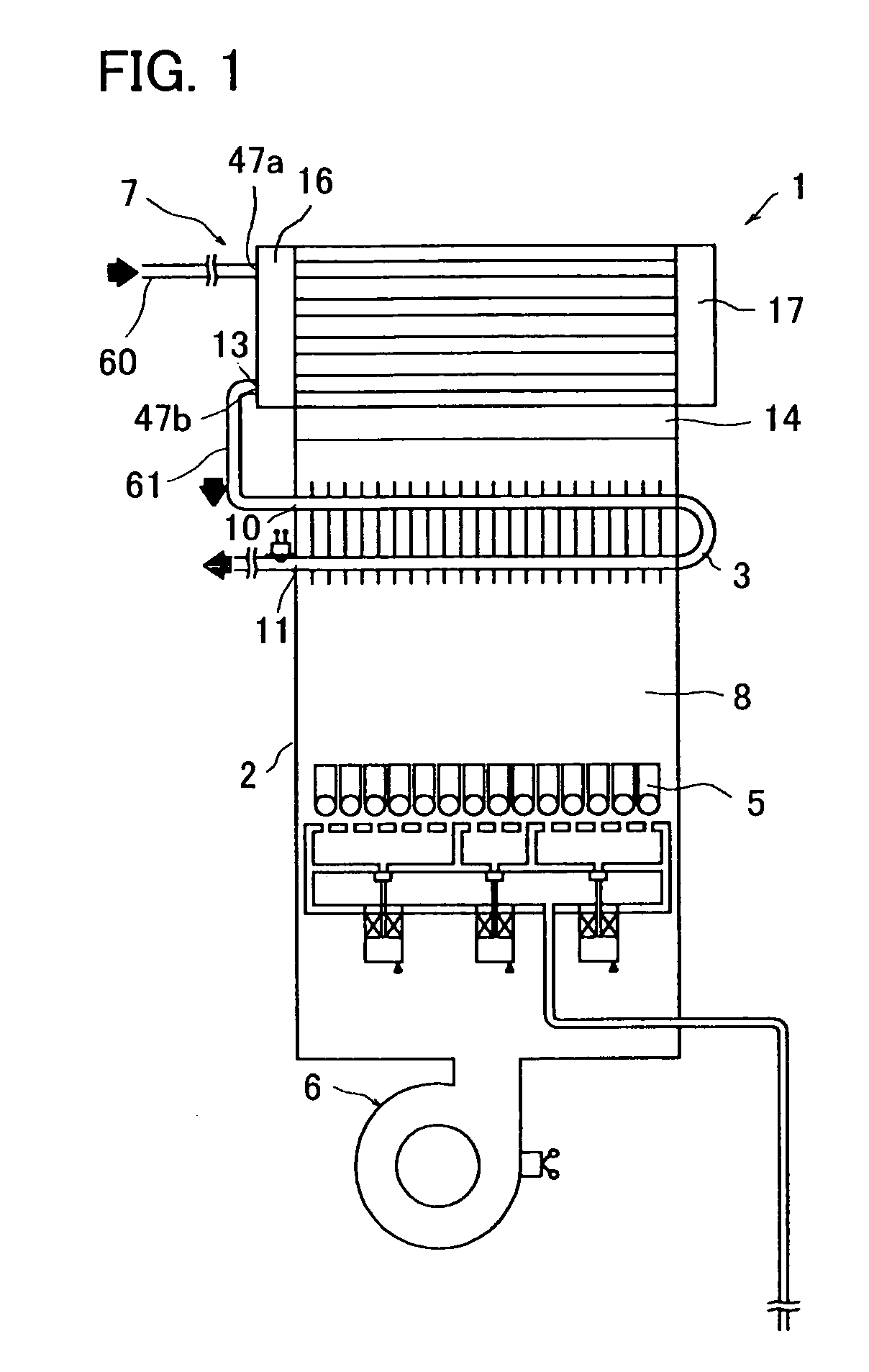

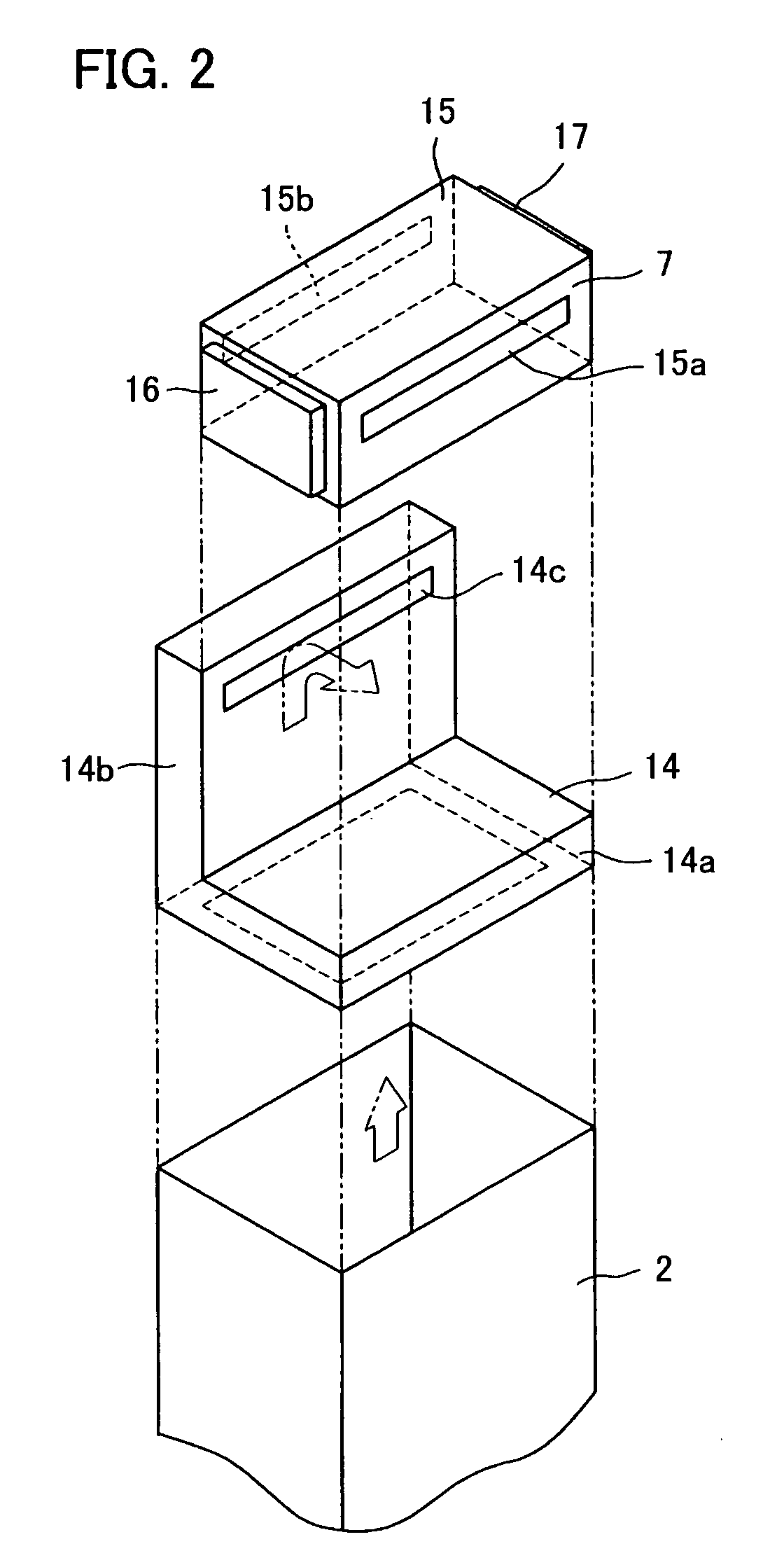

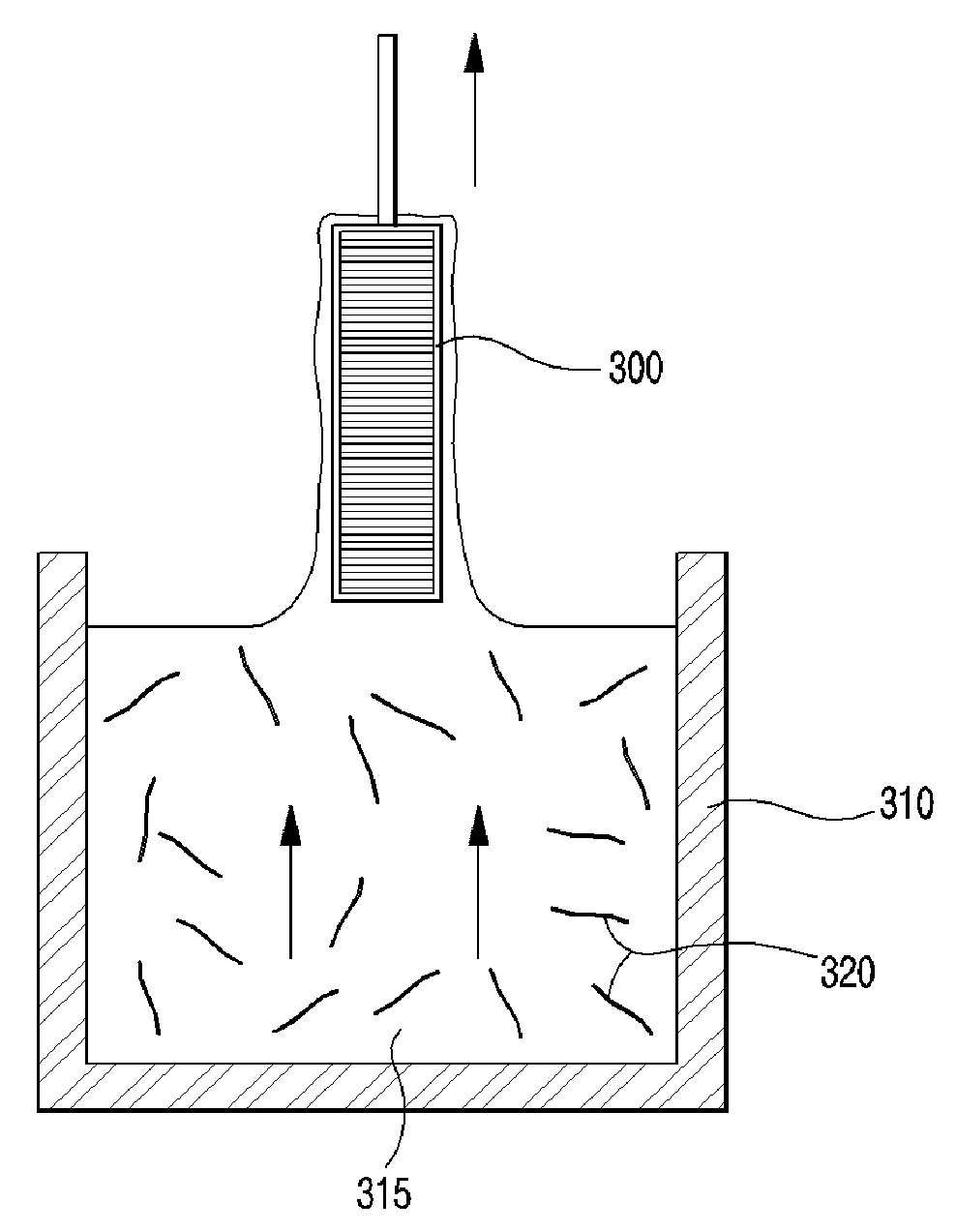

InactiveUS20080061160A1High heat exchange efficiencyImprove heat exchange efficiencyEnergy efficient heating/coolingAir heatersProcess engineeringCombustion

A heating apparatus 1 includes a shell 2, a primary heat exchanger (sensible heat exchanger)3, a burner (combustion means) 5, and a fan 6. A secondary heat exchanger (latent heat exchanger) 7 has a plurality of heat receiving tubes 18 arranged in parallel between a pair of headers 16 and 17, the heat receiving tubes 18 being fixed to tube plates 20. The heat receiving tubes 18 are bare tubes without fins and are arranged across flow of combustion gas. The number of the tubes 18 arranged vertically is less than the number of the tubes 18 arranged horizontally.

Owner:NORITZ CORP

Heating apparatus

InactiveUS7647897B2Improve heat exchange efficiencyEnergy efficient heating/coolingAir heatersCombustionProcess engineering

A heating apparatus 1 includes a shell 2, a primary heat exchanger (sensible heat exchanger) 3, a burner (combustion means) 5, and a fan 6. A secondary heat exchanger (latent heat exchanger) 7 has a plurality of heat receiving tubes 18 arranged in parallel between a pair of headers 16 and 17, the heat receiving tubes 18 being fixed to tube plates 20. The heat receiving tubes 18 are bare tubes without fins and are arranged across flow of combustion gas. The number of the tubes 18 arranged vertically is less than the number of the tubes 18 arranged horizontally.

Owner:NORITZ CORP

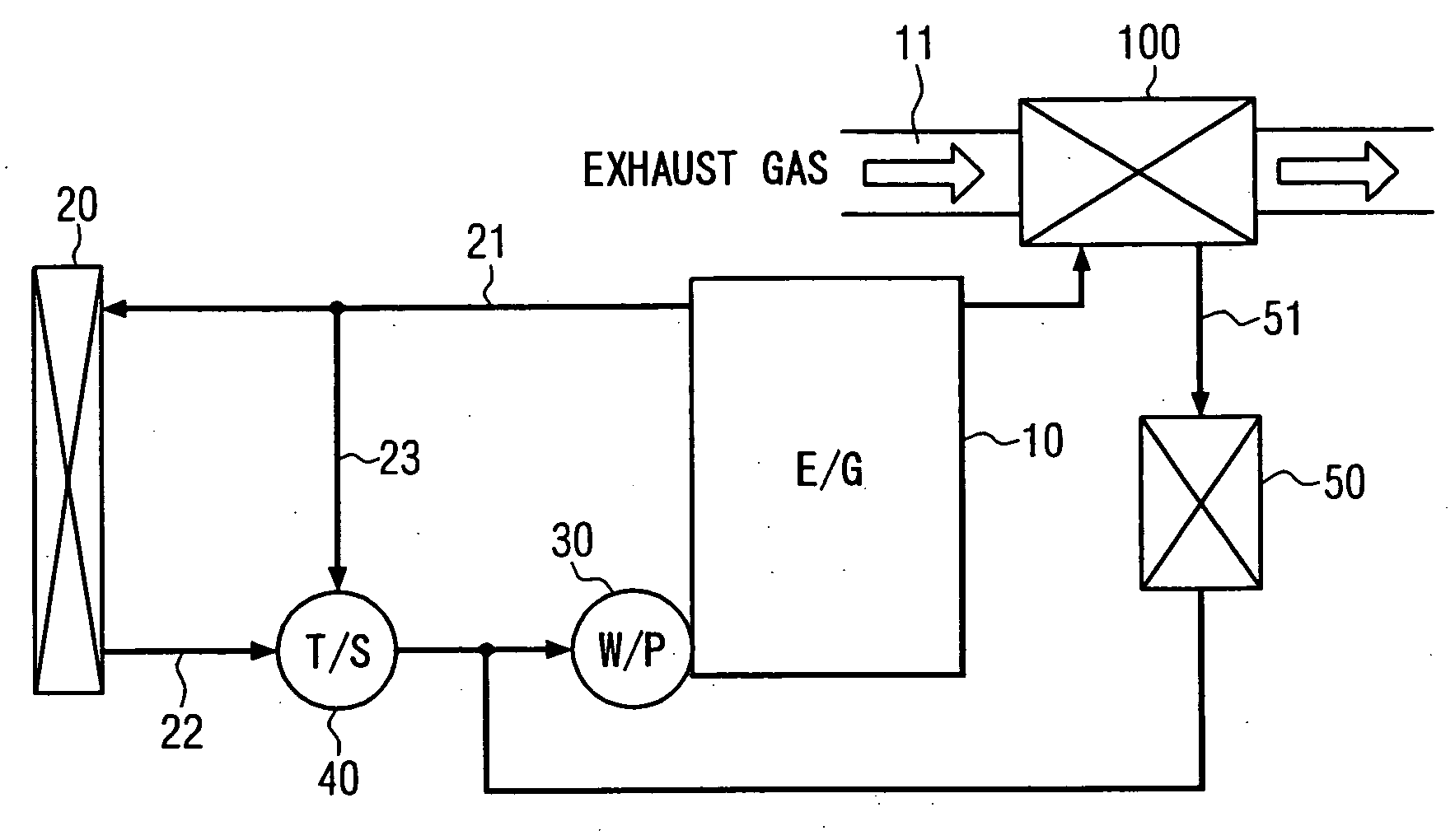

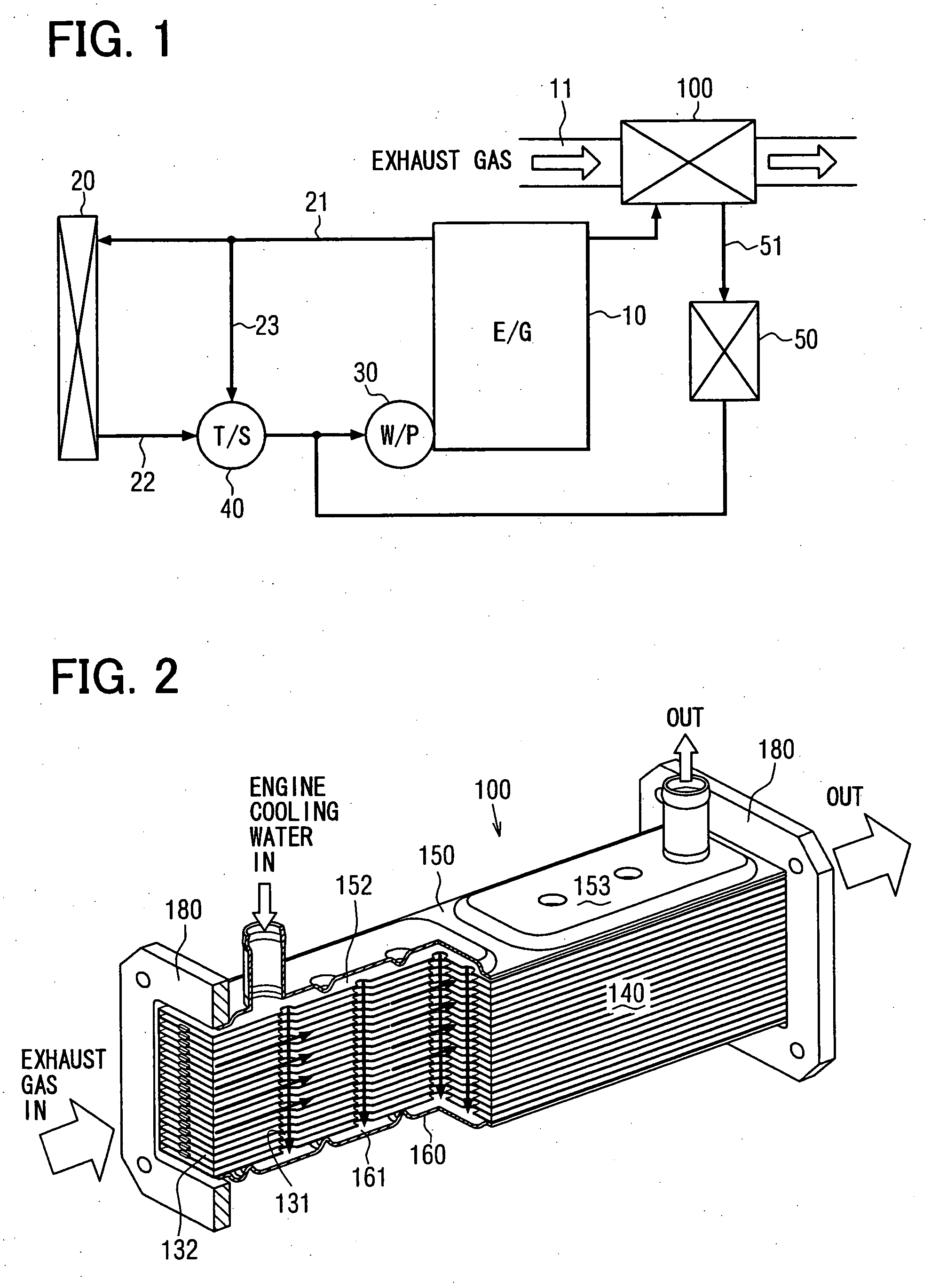

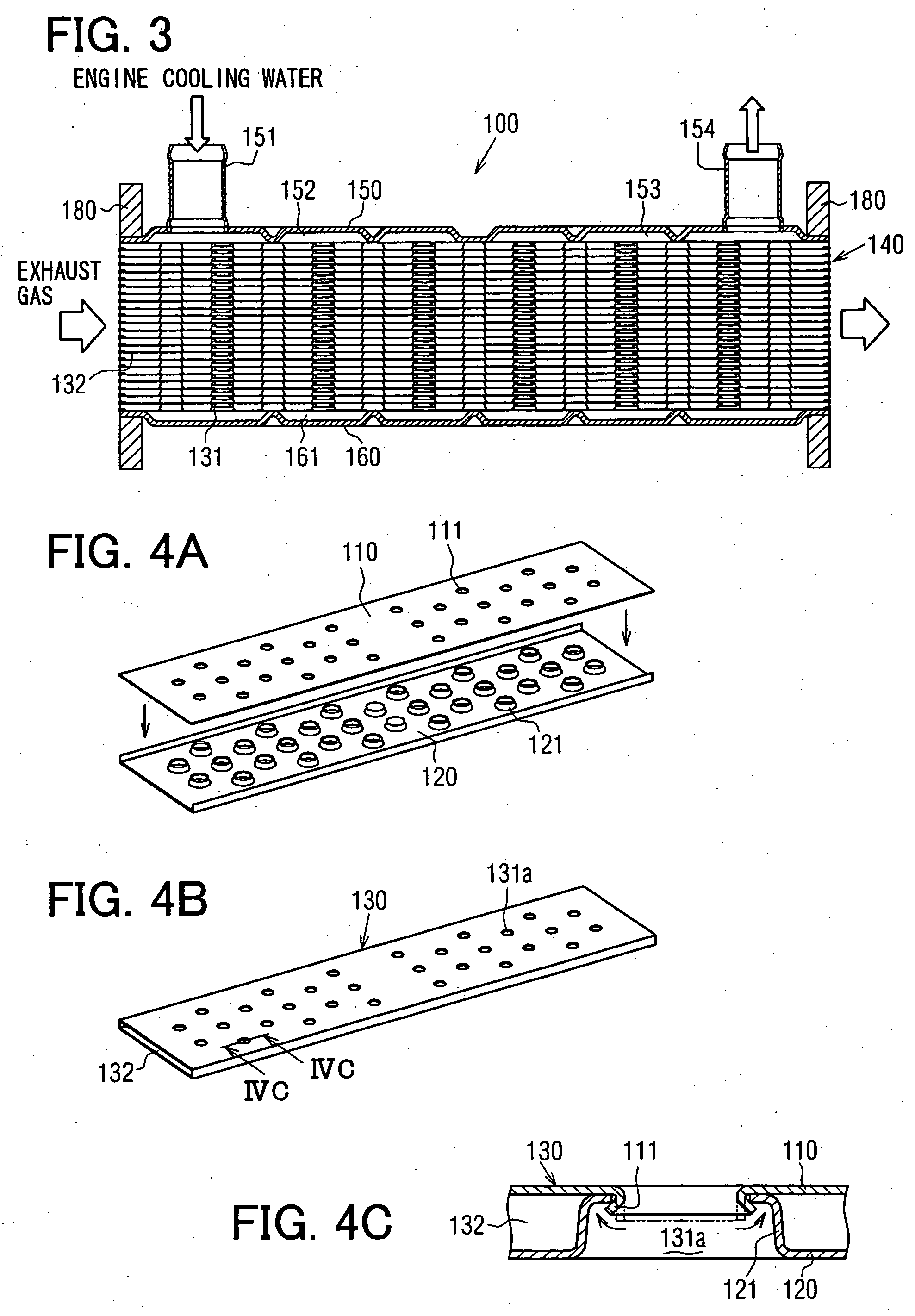

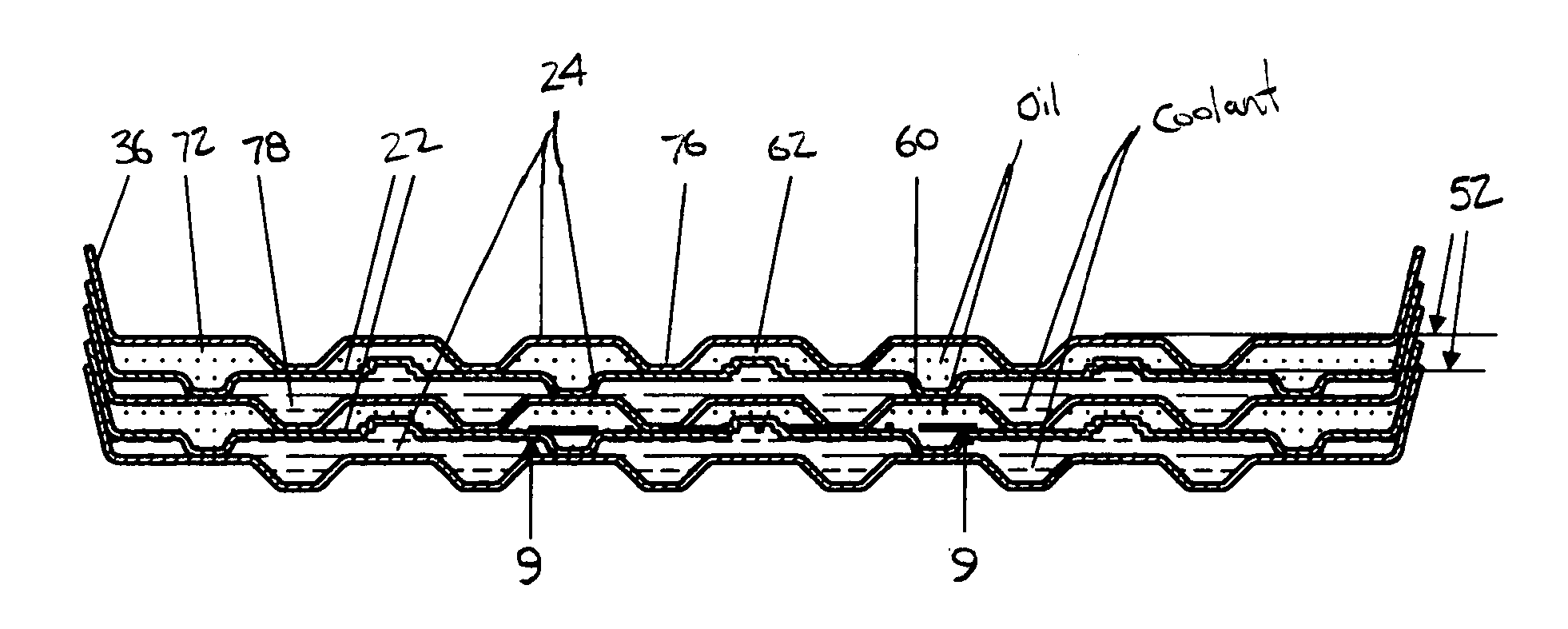

Exhaust gas heat exchanger

InactiveUS20060207245A1Easy to optimizeReduce manufacturing costNon-fuel substance addition to fuelInternal combustion piston enginesCoolant flowEngineering

A heat exchange core has a plurality of flat tubes laminated in a thickness direction, each flat tube defining an exhaust gas passage in which the exhaust gas flows. A plurality of coolant flow pass holes are formed in each of the flat tubes, wherein each of the coolant flow pass holes penetrates the flat tube in the thickness direction. The coolant flow pass holes of each flat tube are connected with the coolant flow pass holes of the other flat tubes, in order to respectively form a plurality of coolant flow passages through which liquid coolant flows, and the coolant flow pass holes of each coolant flow passages are communicated with each other in the laminated direction, so that the coolant flow passages are formed to be perpendicular to the exhaust gas passages.

Owner:DENSO CORP

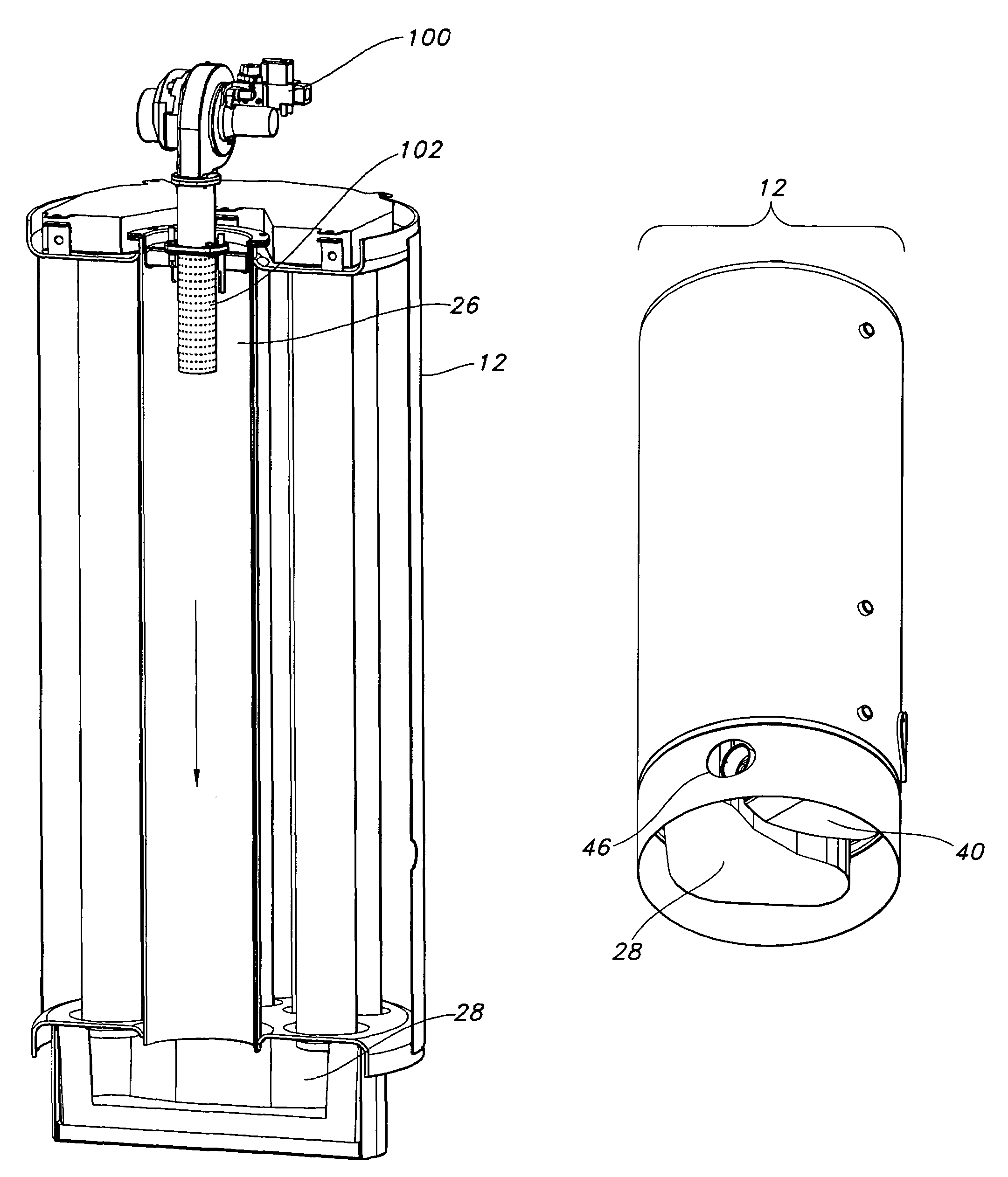

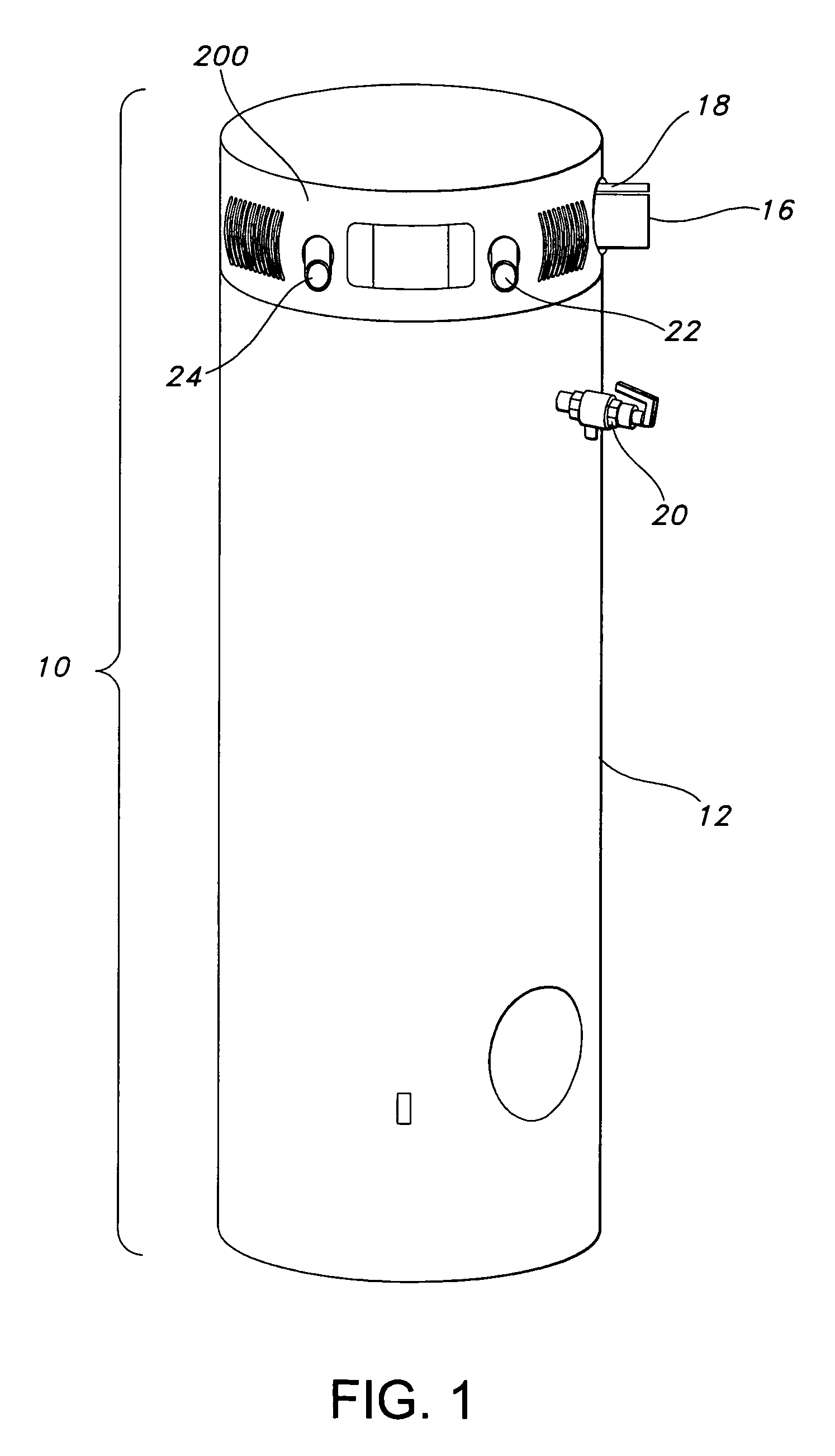

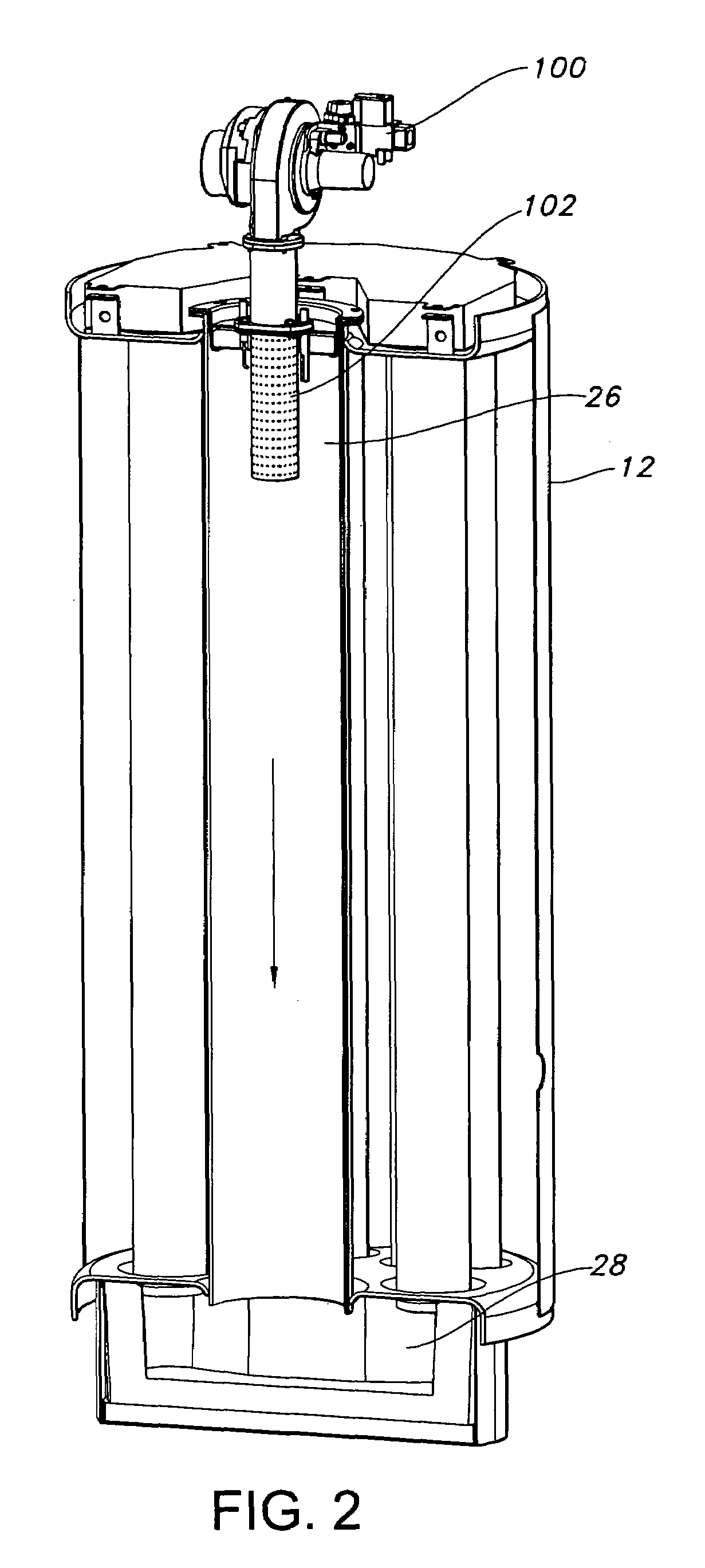

High efficiency water heater

InactiveUS7559293B2Improve heat transfer efficiencyReduce corrosionFurnace-tube steam boilersWater heatersEngineeringFlue

A flue system is provided for a water heater having improved heat exchange efficiency. The flue system includes an upstream heat exchange portion having at least one substantially vertical flue tube. The flue system also includes a downstream heat exchange portion having at least one substantially vertical flue tube. The upstream heat exchange portion provides a first pass for heat exchange with water in a water heater. The downstream heat exchange portion provides a second pass for heat exchange with water in the water heater.

Owner:BRADFORD WHITE

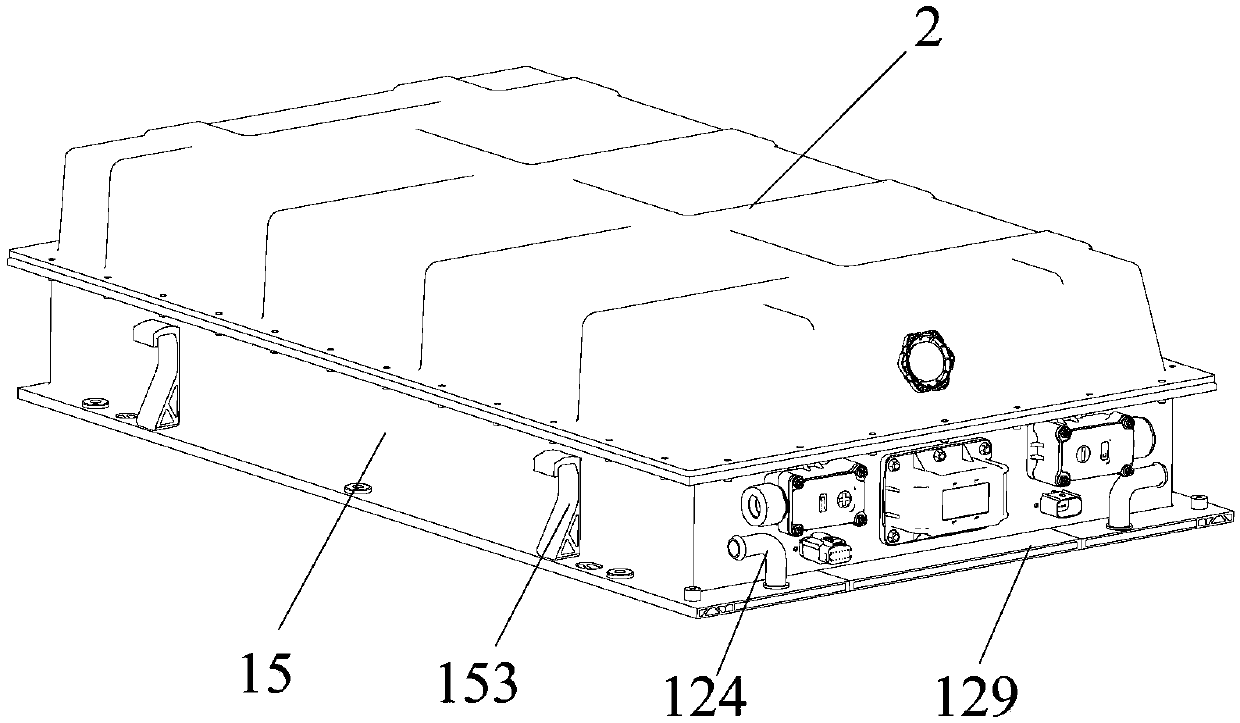

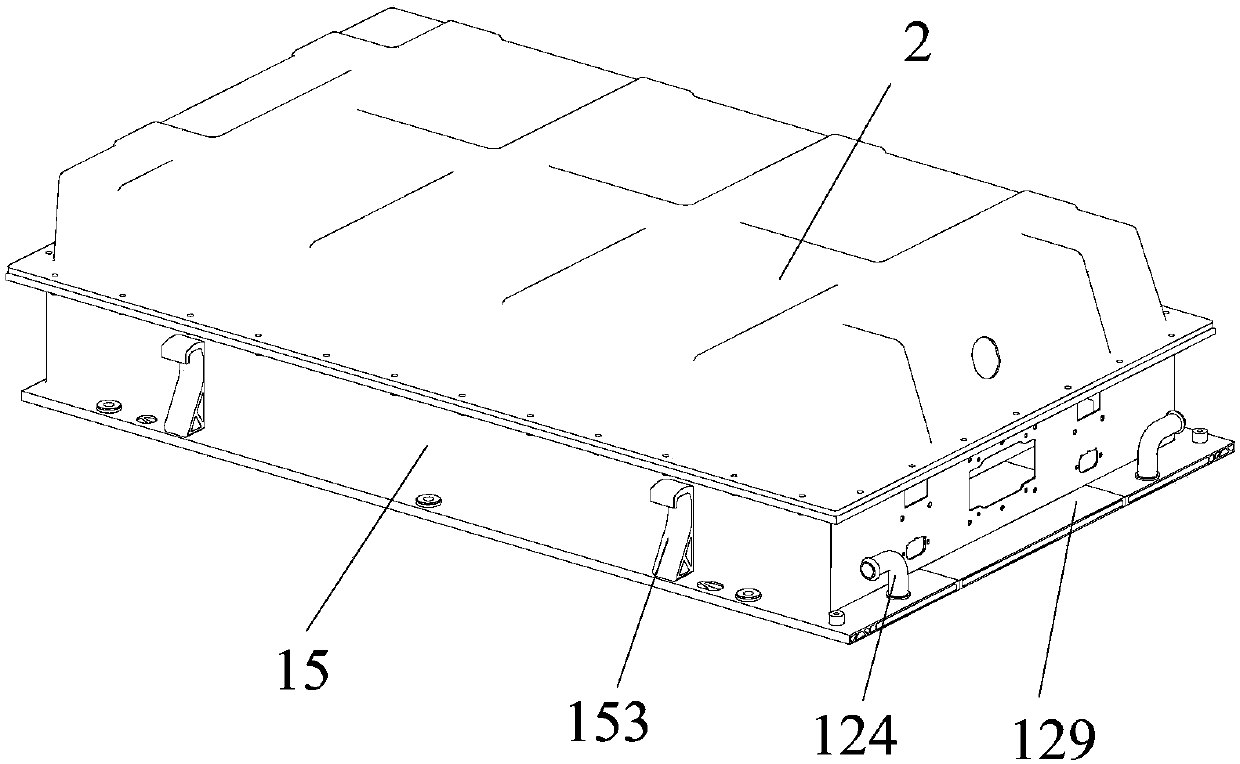

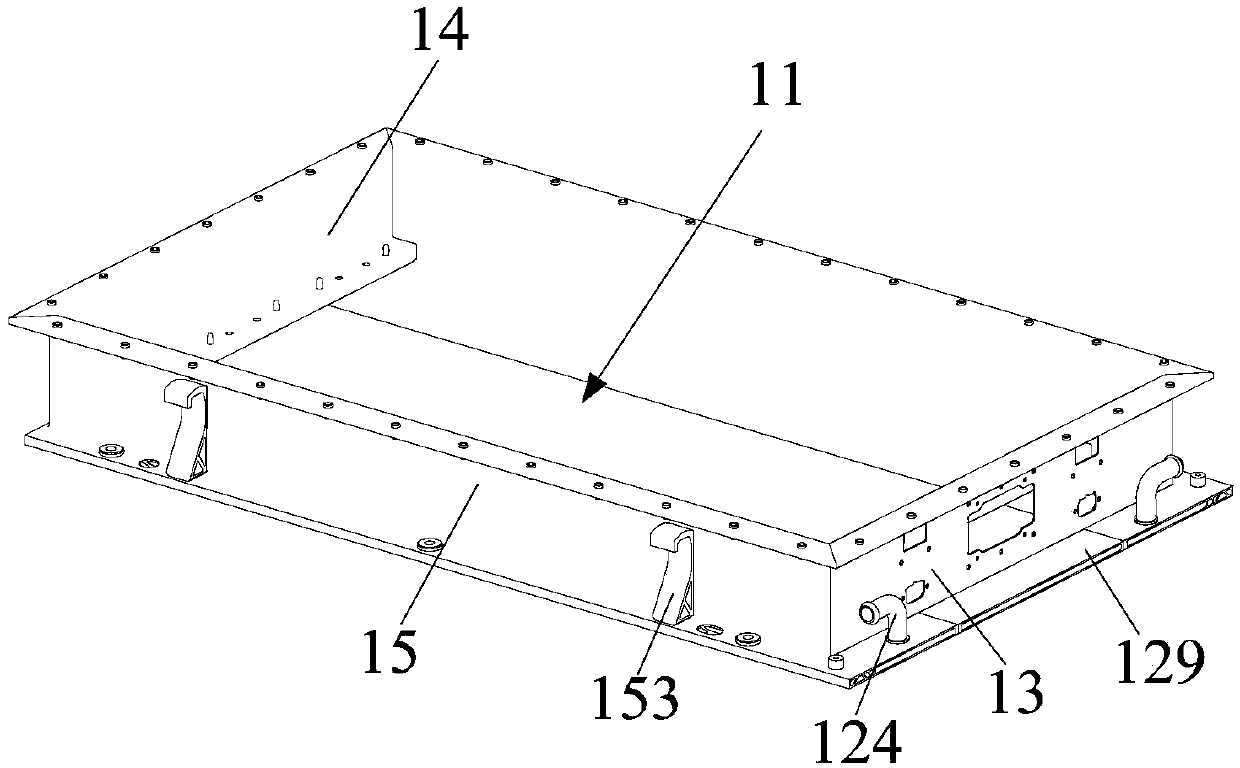

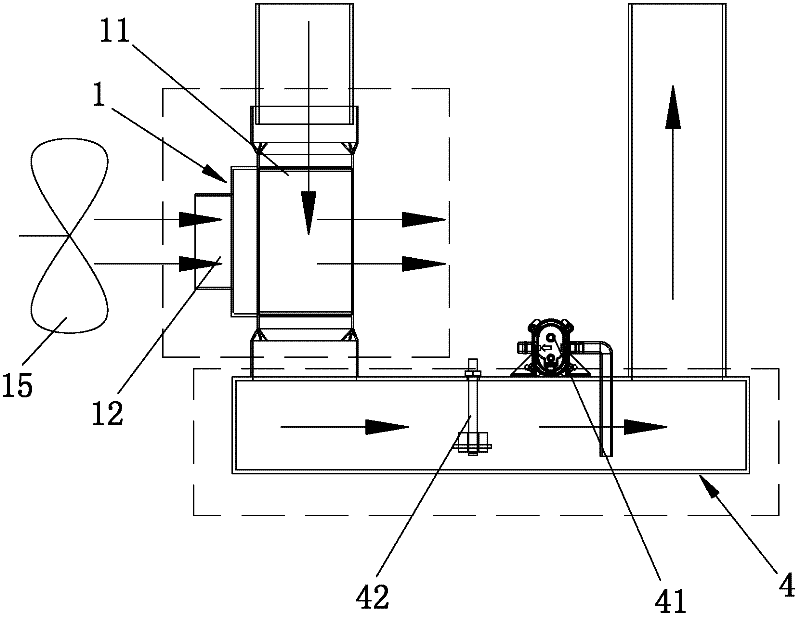

Integrated water-cooled power battery box

PendingCN108039434AMeet the intensityFulfil requirementsBattery isolationSecondary cellsPower batteryMechanical property

The invention relates to the technical field of electric cars, in particular to an integrated water-cooled power battery box. The integrated water-cooled power battery box provided by the invention comprises a box cover, a box body and a temperature regulating power system, wherein the box body is made of an aluminum alloy material and is manufactured by an extrusion moulding technology; a circulating flow passage is formed in the wall of the box body; a circulating loop for a temperature regulating medium to flow circularly is arranged inside the wall of the box body; and the temperature regulating power system can drive the temperature regulating medium to circularly flow in the circulating loop. In such a way, a water cooling board and a battery box are designed in an integrated manner,a hollow aluminum alloy section is adopted to achieve lightweight design, mechanical properties such as strength and rigidity are met, the integrated water-cooled power battery box is simpler in structure, better in technical performance and smaller in occupied space, and the comprehensive cost can be reduced; the heat-dissipating, cooling and temperature-raising and heating functions can be achieved by using one set of temperature regulating power system, the integrated water-cooled power battery box is simpler in structure, more convenient and fast to use and smaller in occupied space, themanufacturing cost and the using cost can be reduced, and the heat-dissipating efficiency and the heating efficiency can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

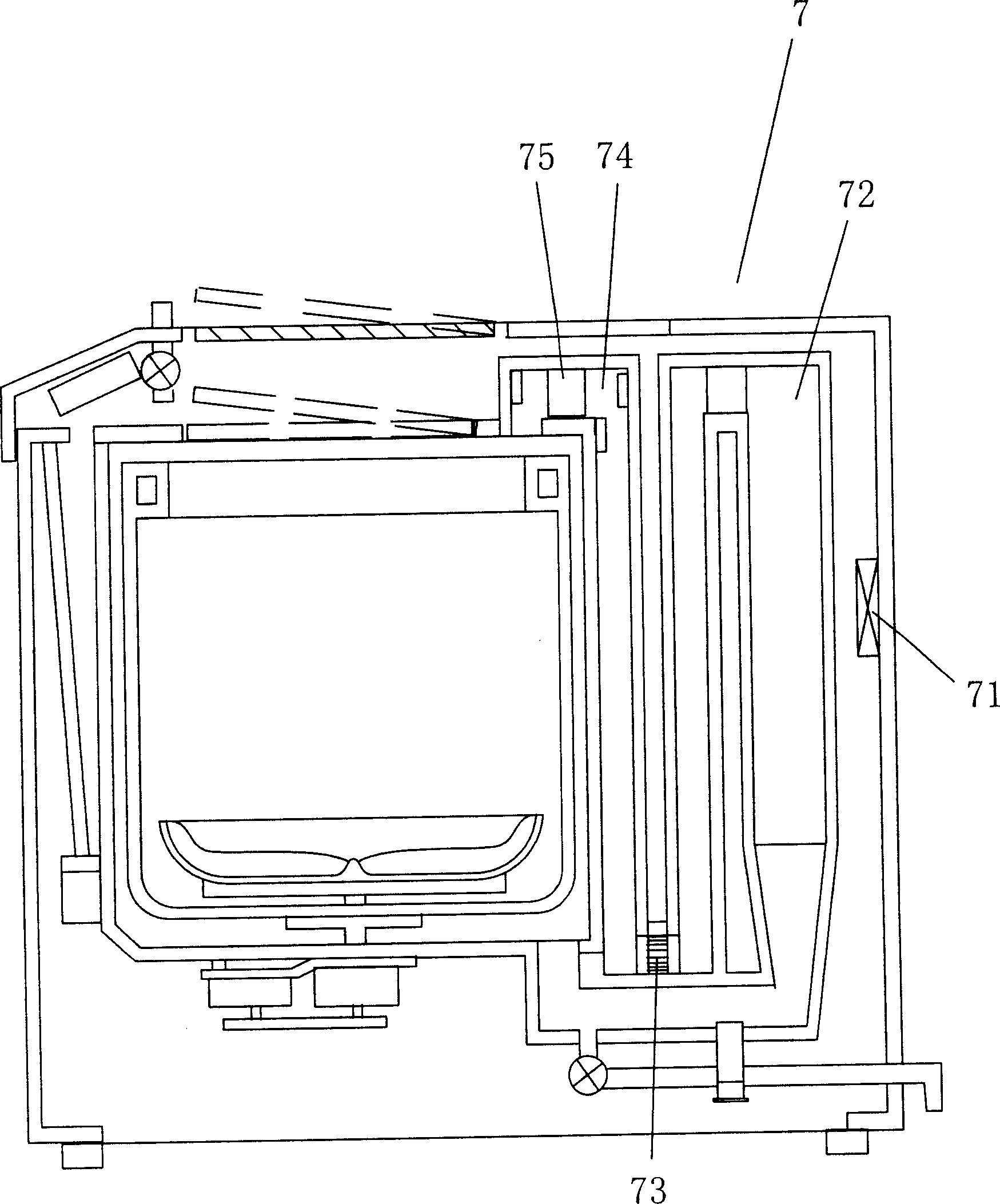

Clothes drying temperature detection control method and clothes drier

ActiveCN102517861AImprove heat exchange efficiencyEasy to transportTextiles and paperLaundry driersElectric energyProcess engineering

The invention discloses a clothes drying temperature detection control method and a clothes drier. In the process of drying, a control system is used for detecting a change delta T of temperature of outgoing air in front and in rear of a condenser after drying, and determines whether the change of temperature difference of outgoing air before or after passing the condenser reaches a corresponding set value delta Tt_g or not; g is the weight of clothes to be dried; if the delta T is larger than or equal to the delta Tt_g or lasts for a set time T within a certain set value range, the clothes are dried and a heating device stops operating; after the heating device stops operating, a drying program proceeds and does not ends until the detected temperature of incoming air is lower than the set temperature; and in the process of drying, heat of humid hot air after being subjected to heat exchange with clothes and before being subjected to cooling and dehumidification is subjected to heat exchange with air which is subjected to condensation and dehumidification, and the preheated air subjected to condensation and dehumidification is heated again and led into the clothes to dry the clothes. Using the waste heat saves electric energy and time, temperature detection and determination are accurate, and drying efficiency is improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

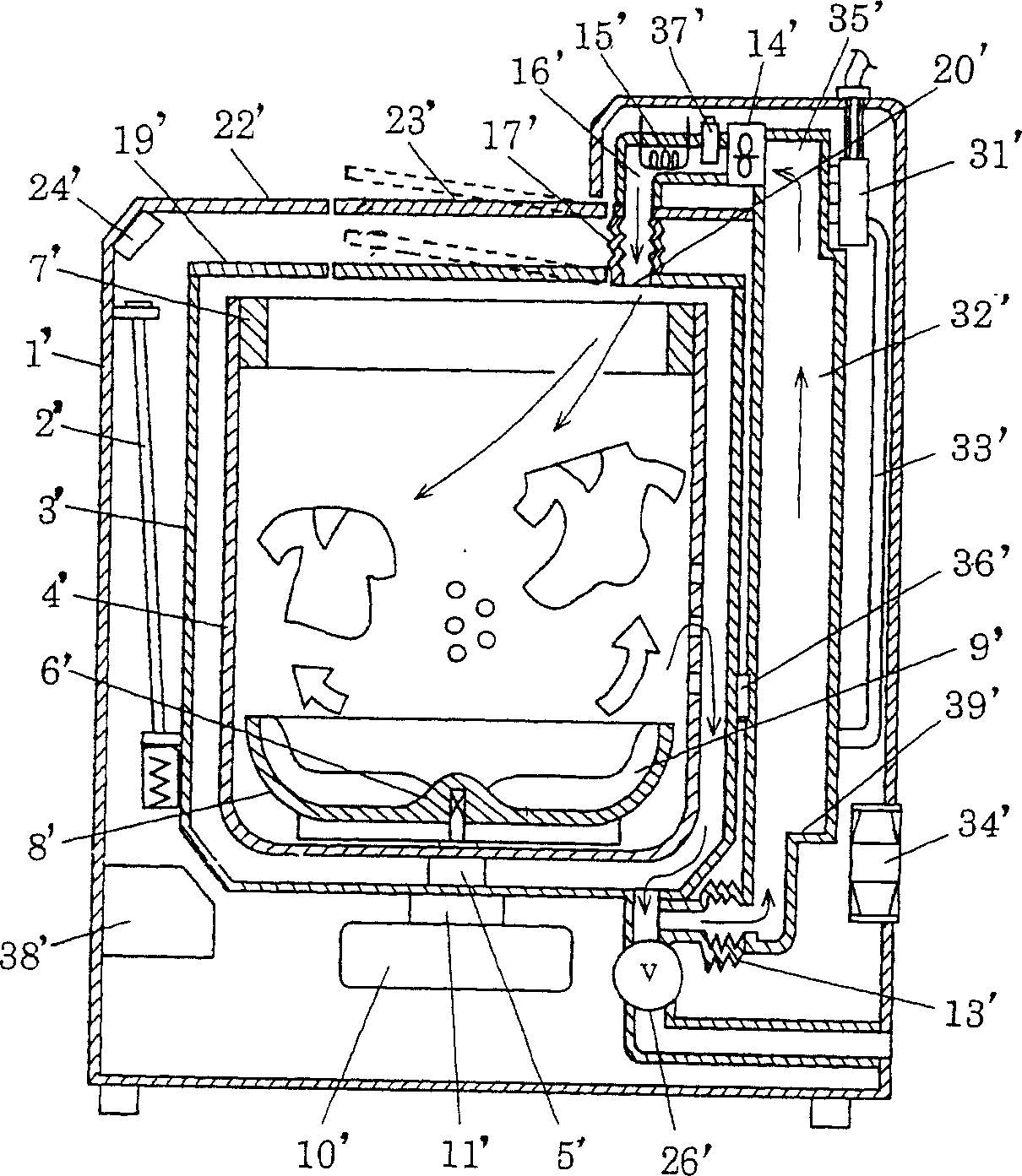

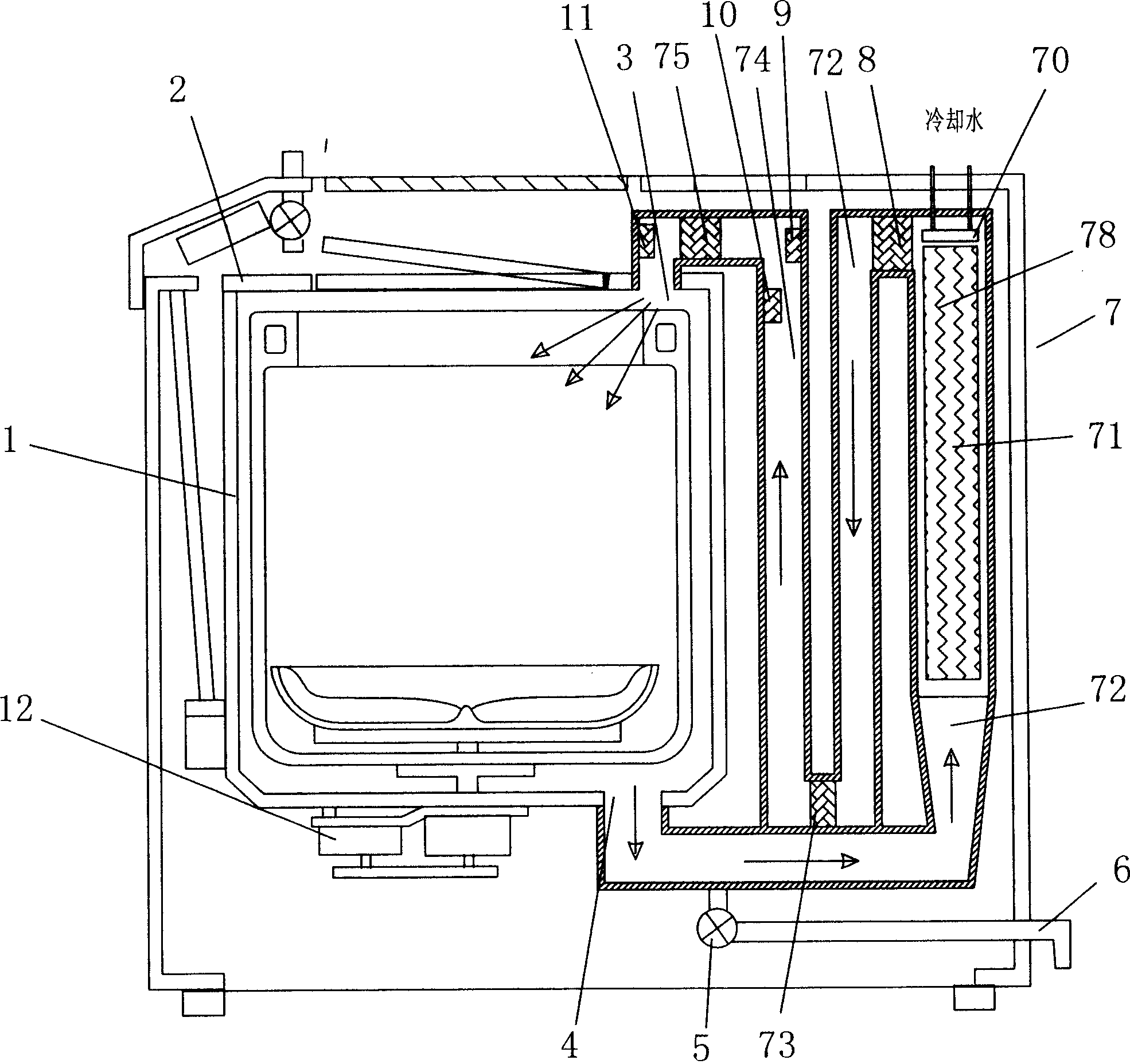

Washing machine with high efficiency drying function and drying method thereof

InactiveCN1834333AReduce the temperatureIncrease contact areaWashing machine with receptaclesTextiles and paperControl systemEngineering

A washer with drying function in high efficiency consists of washing-dewatering-water draining system, drying system and control system. It is featured as setting a condensing air channel set with a condensing unit having a condensed water spraying element in drying system, setting said condensing air channel and air sending mechanism as well as dried air channel and heater on internal wall of washer shell. Its drying method is also disclosed.

Owner:HAIER GRP CORP +1

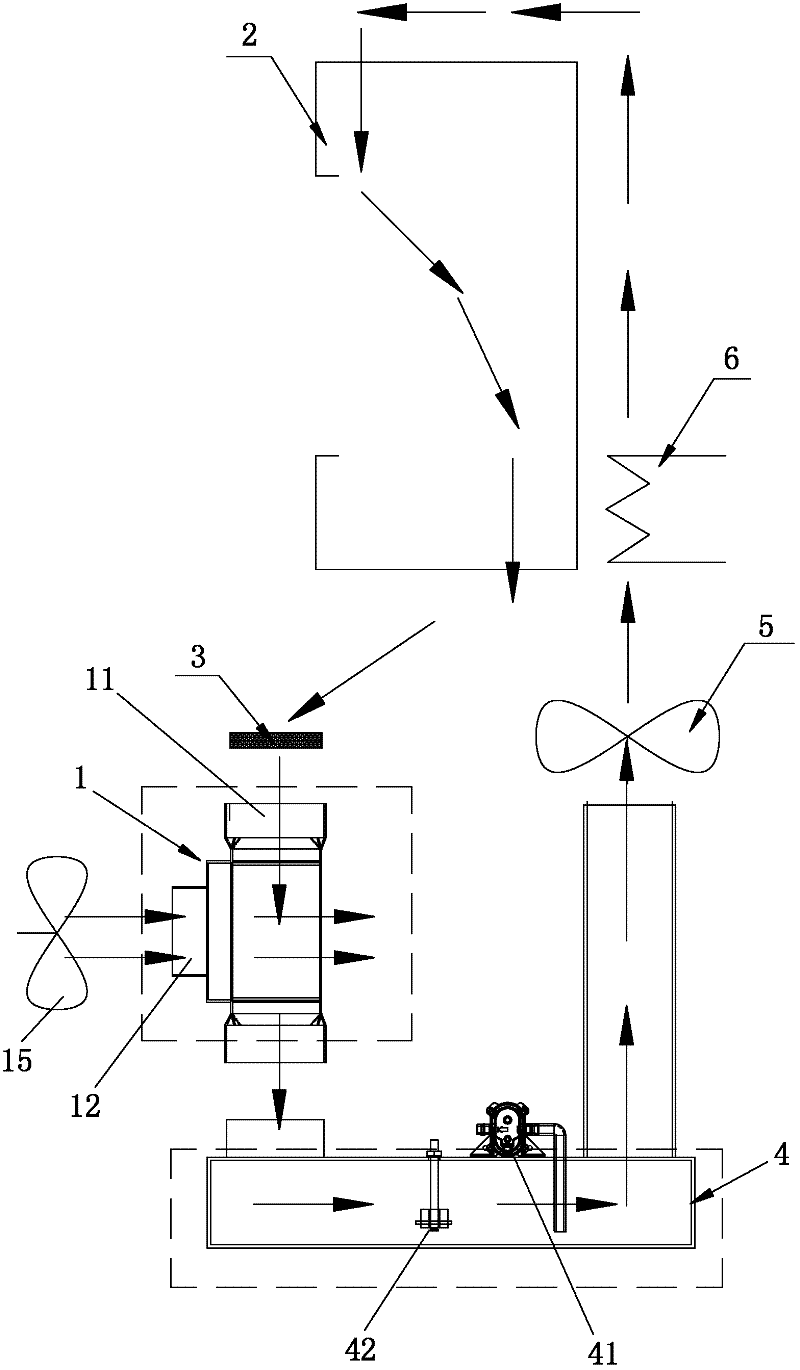

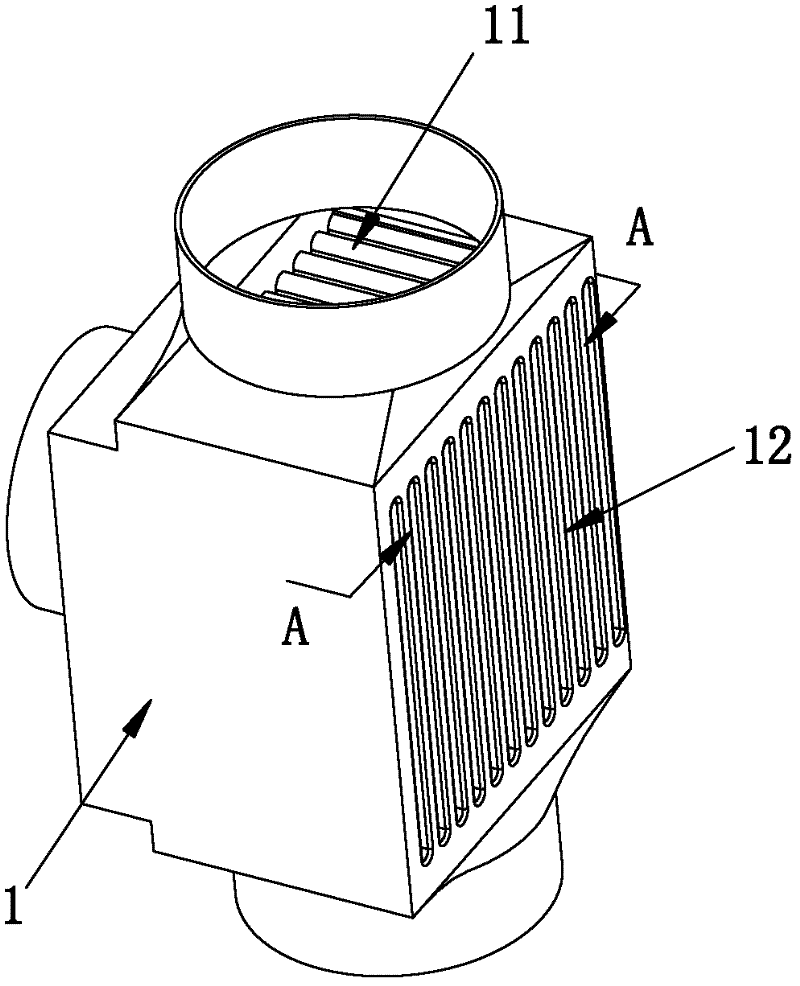

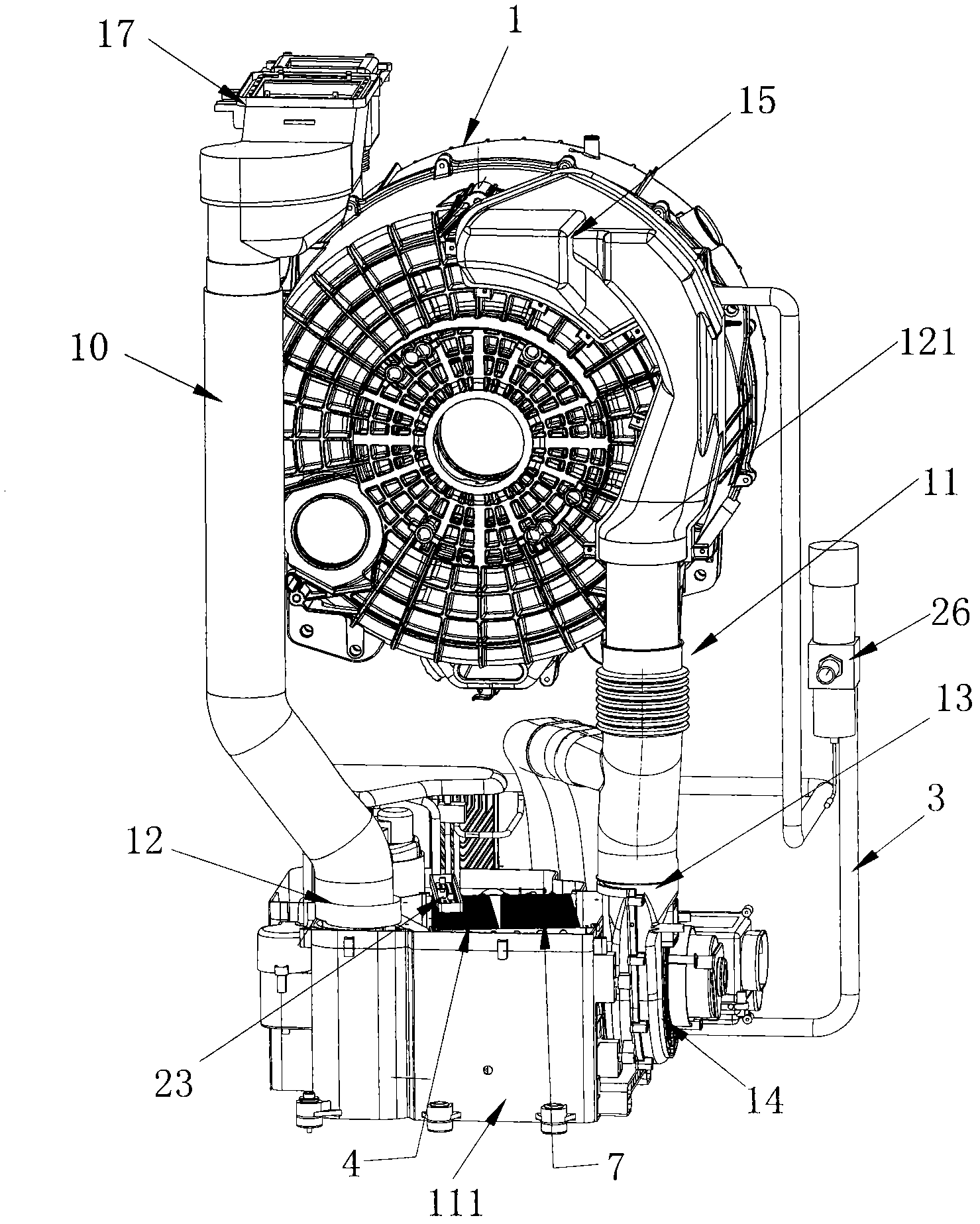

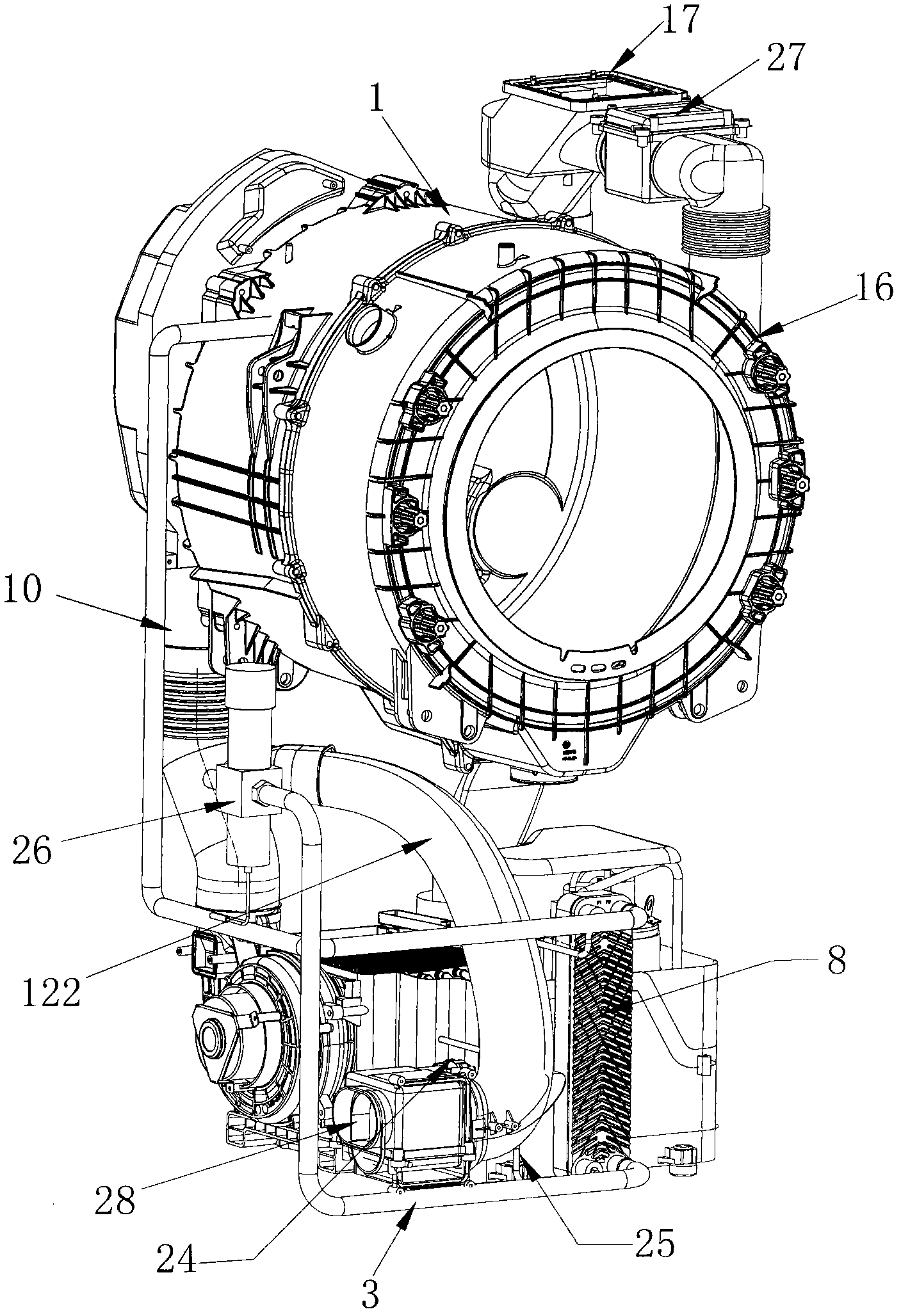

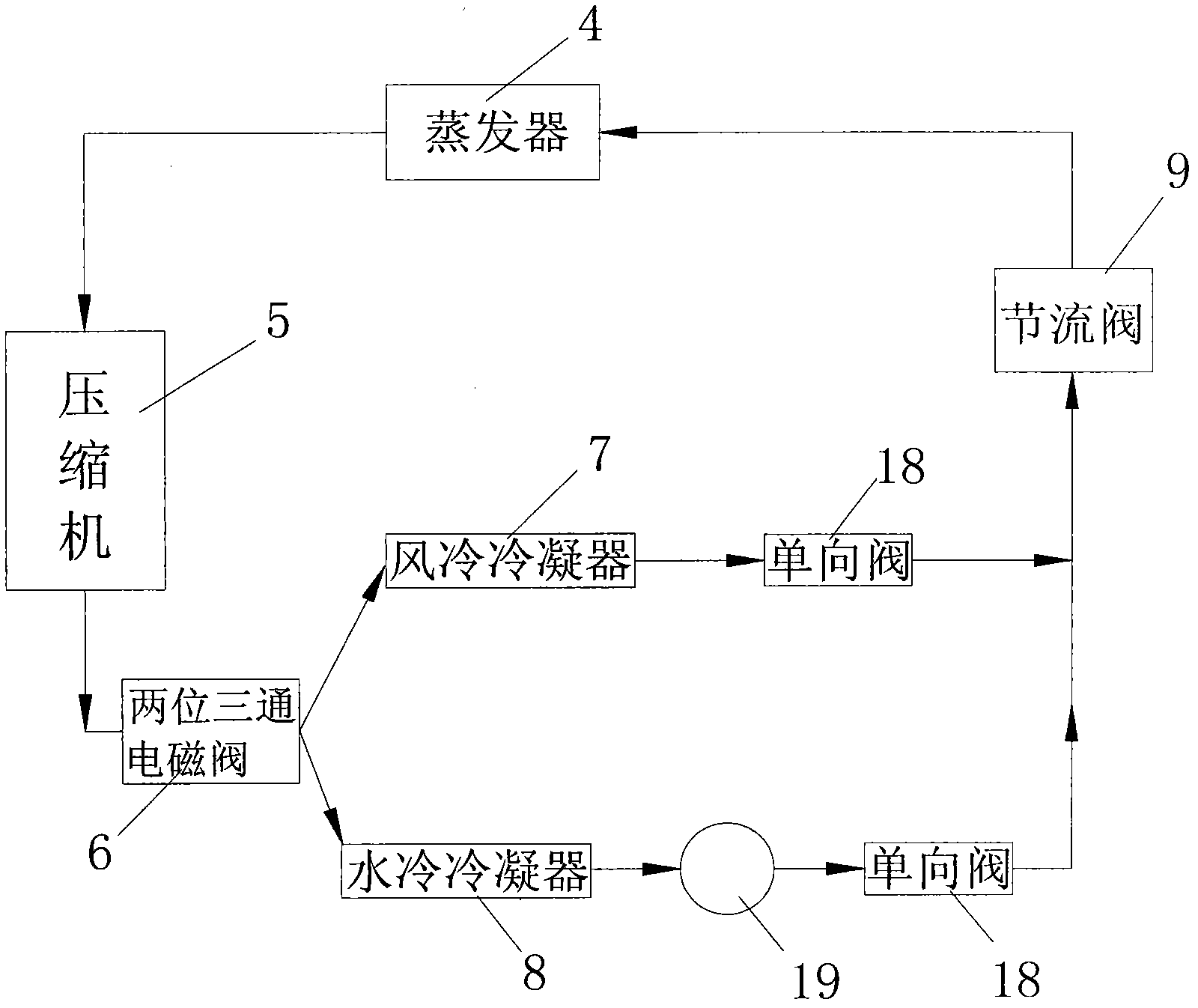

Washing and drying integrated machine for washing clothes by adopting water heated by heat pump

ActiveCN102251368AImprove condensation efficiencyEnergy savingOther washing machinesWashing machine with receptaclesFlueRefrigerant

The invention discloses a washing and drying integrated machine for washing clothes by adopting water heated by a heat pump. The washing and drying integrated machine comprises an outer barrel, an inner barrel, a heat pump system and a water inlet pipeline; the inner barrel is arranged in the outer barrel; the outer barrel and the inner barrel are coaxially arranged; the heat pump system comprises an evaporator, a compressor, a two-position three-way electromagnetic valve, a condenser bank and a throttling valve, wherein the condenser bank is formed by connecting an air-cooled condenser and a water-cooled condenser in parallel; the evaporator, the compressor, the two-position three-way electromagnetic valve, the condenser bank, the throttling valve and the evaporator are connected in series to form a circulating system; the water inlet pipeline, the heat pump system and the outer barrel form a water heating system; the outer barrel is connected with the heat pump system through two sections of air flues to form a drying and circulating air path for drying the clothes; and the two-position three-way electromagnetic valve is used for switching and controlling a refrigerant through the air-cooled condenser or the water-cooled condenser to realize the cloth drying or water heating function of the washing and drying integrated machine. Besides the functions of drying the clothes and heating the water, cooling and dehumidifying functions, heating and dehumidifying functions and the like can be provided by arranging a switching mechanism and an external air inlet / outlet in the air path.

Owner:HAIER GRP CORP +1

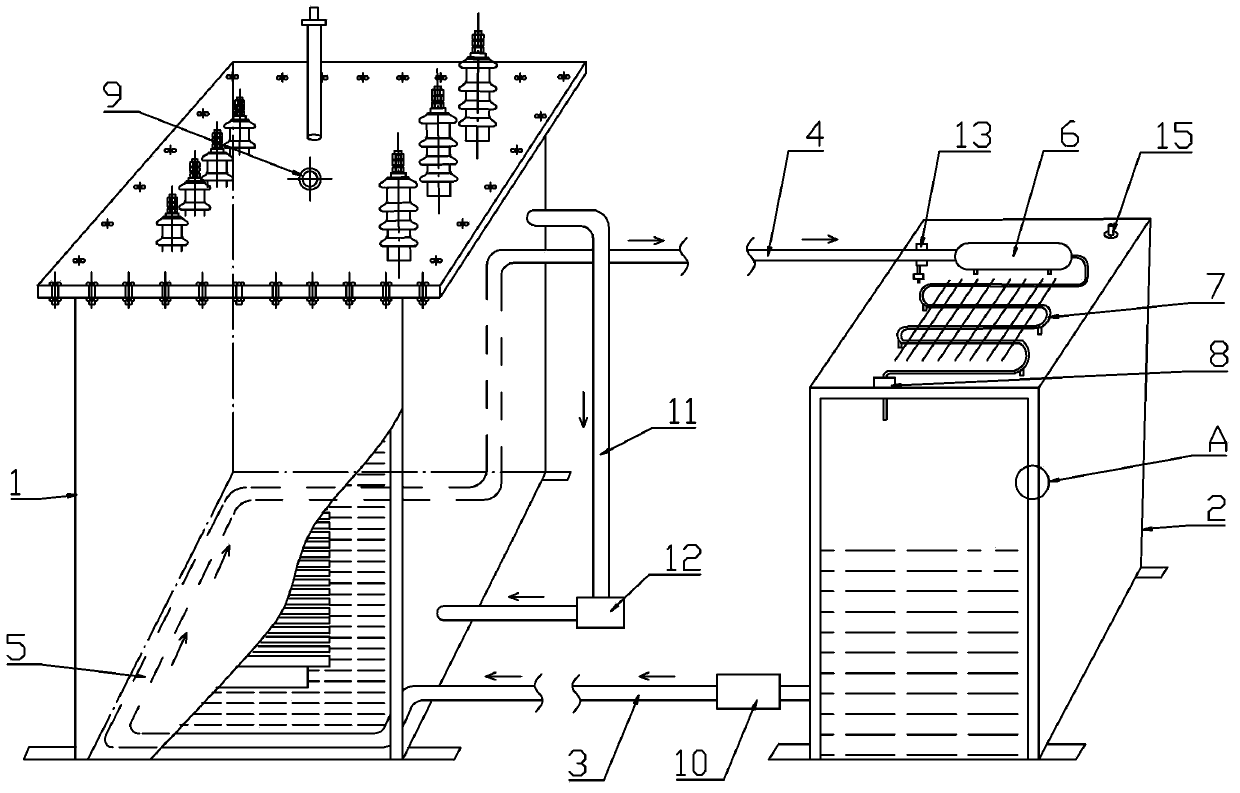

Liquid nitrogen strong cooling transformer and refrigerating method thereof

InactiveCN103390485AImprove heat exchange efficiencyAchieve the purpose of coolingTransformers/inductances coolingTemperature control using electric meansElectricityLiquid state

The invention relates to a liquid nitrogen strong cooling transformer and a refrigerating method thereof. The transformer comprises a transformer oil tank and a liquid nitrogen tank; the liquid nitrogen tank is connected with a liquid nitrogen outlet pipe; the transformer oil tank is connected with a gas nitrogen outlet pipe; an evaporating pipe is coiled in the transformer oil tank; one end of the evaporating pipe is communicated with the liquid nitrogen outlet pipe and the other end of the evaporating pipe is communicated with the gas nitrogen outlet pipe; the gas nitrogen outlet pipe is sequentially provided with a liquid nitrogen compressor, a condenser and a throttling valve; the tail end of the gas nitrogen outlet pipe extends into the liquid nitrogen tank; a temperature sensor is arranged in the transformer oil tank; and the liquid nitrogen outlet pipe is provided with a heat preservation electromagnetic valve electrically connected with the temperature sensor. The liquid nitrogen strong cooling transformer and the refrigerating method thereof have the beneficial effects that 1, heat exchange is carried out between liquid nitrogen and transformer oil, heat exchange efficiency is high and gas nitrogen is retransformed into liquid nitrogen by the liquid nitrogen compressor and the condenser and is recycled; and 2, the transformer oil in upper and lower cavities of the transformer oil tank is repeatedly circulated by a transformer oil circulating pipe and a circulating oil pump so as to enable the oil temperature to be balanced.

Owner:王文中

Motor cooling and vibration reducing mechanism

InactiveCN110535282AAvoid damageIncrease heat exchange rateCooling/ventillation arrangementSupports/enclosures/casingsEngineeringWater jacket

The invention discloses a motor cooling and vibration reducing mechanism, and belongs to the technical field of motors. The motor cooling and vibration reducing mechanism comprises a motor main body,a heat dissipation shell and a base, wherein the motor main body is fixedly connected to the interior of the heat dissipation shell through a heat dissipation water jacket, a refrigerant sucking and discharging assembly is fixedly connected to the side wall of a supporting plate, one end, away from a second driving shaft, of a reciprocating mechanism is connected to the refrigerant sucking and discharging assembly, one end, away from the motor main body, of the second driving shaft is connected to a heat dissipation assembly, a push rod is movably connected to the side wall, close to the base,of the heat dissipation shell, and an air diffusion assembly is connected to one end, away from the push rod, of a sliding block. According to the invention, the cooling liquid in the heat dissipation water jacket is sucked out and then pressed back through the refrigerant sucking and discharging assembly to increase the liquid flowing speed so as to improve the heat dissipation efficiency; and under the actions of the buffer assembly and the second spring of the push rod, the motor can be subjected to vibration reducing while the hot gas in the heat dissipation shell can be discharged to dissipate the heat of the motor so as to improve the heat dissipation efficiency and the vibration reducing efficiency.

Owner:山东博发智能科技有限公司

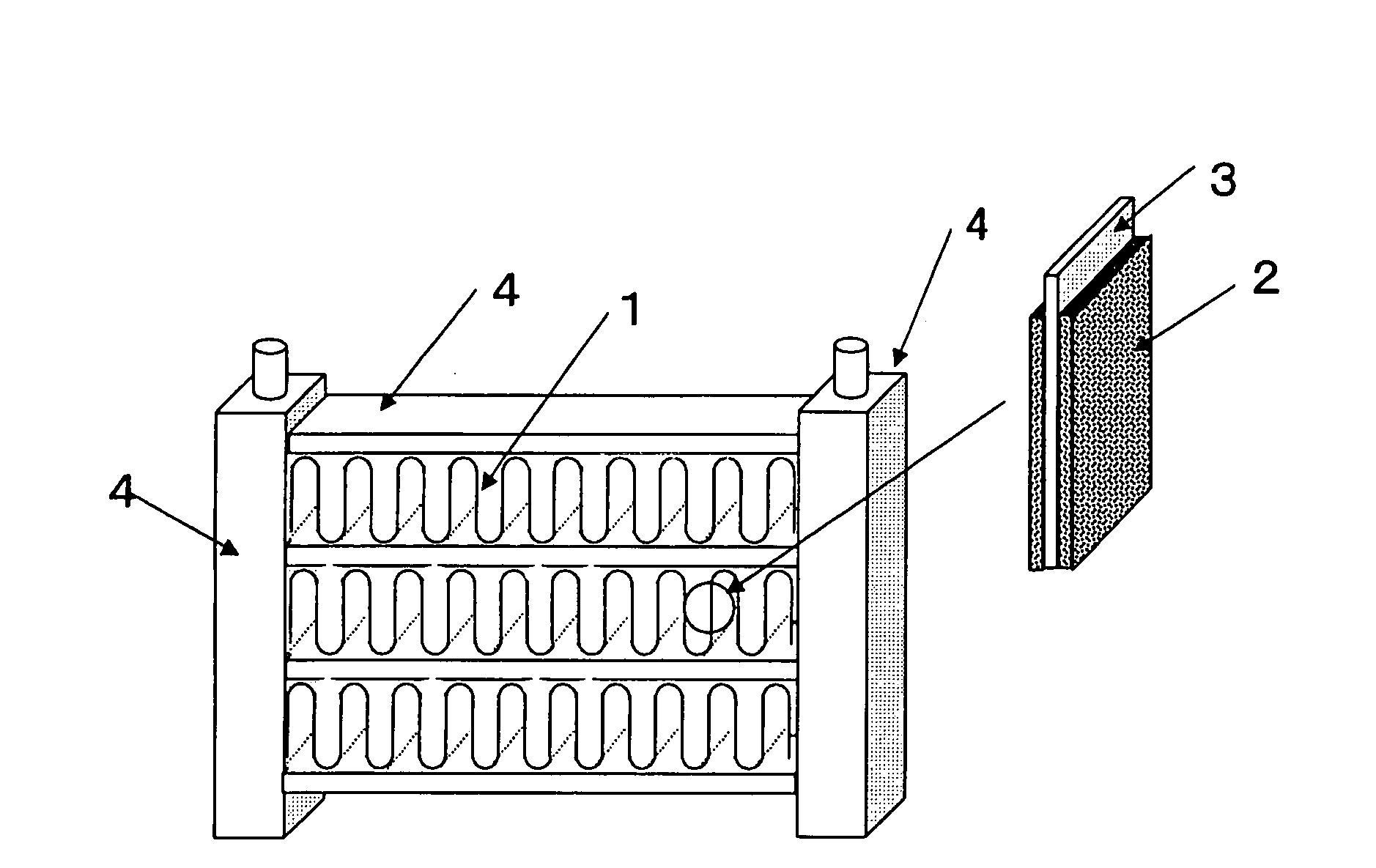

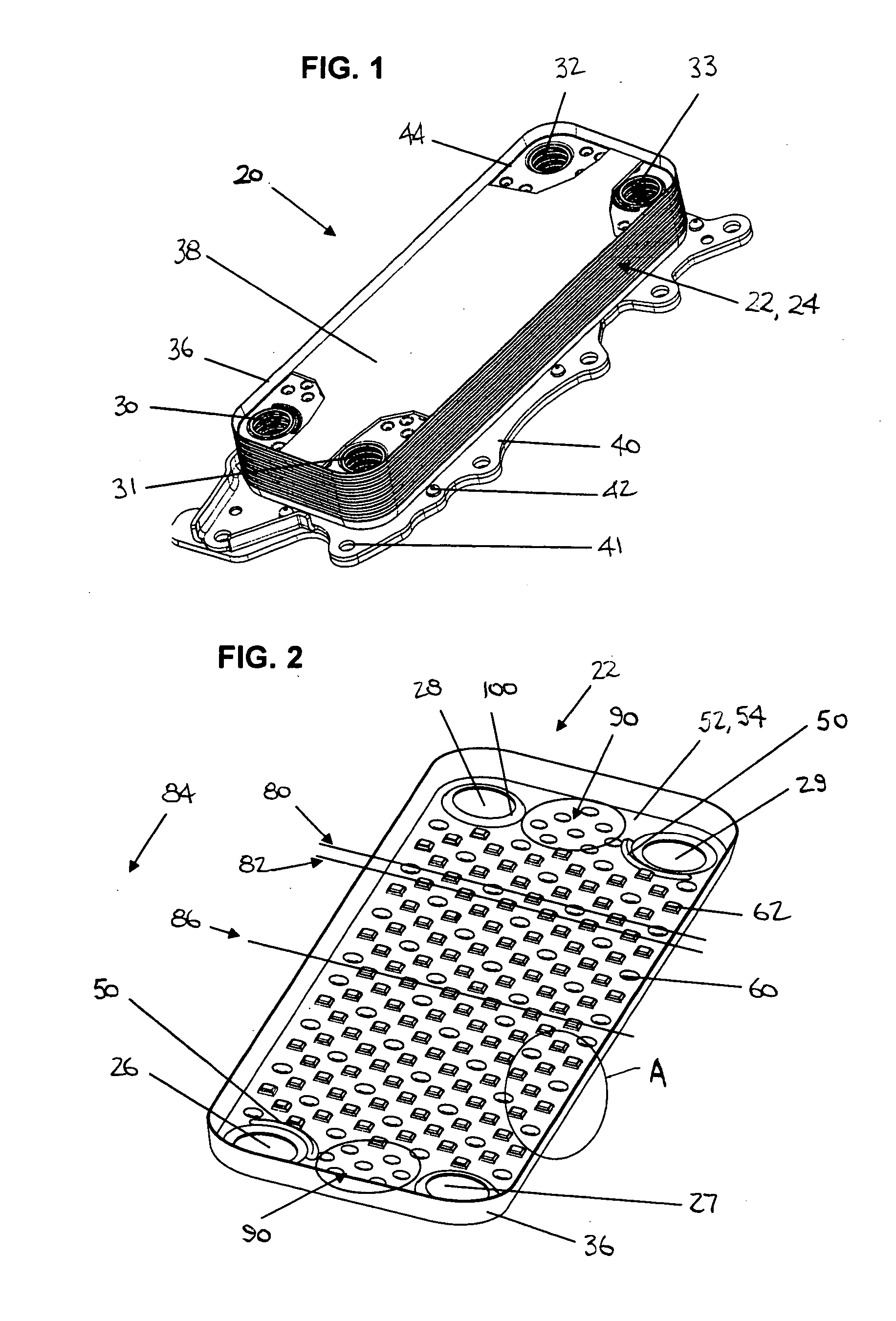

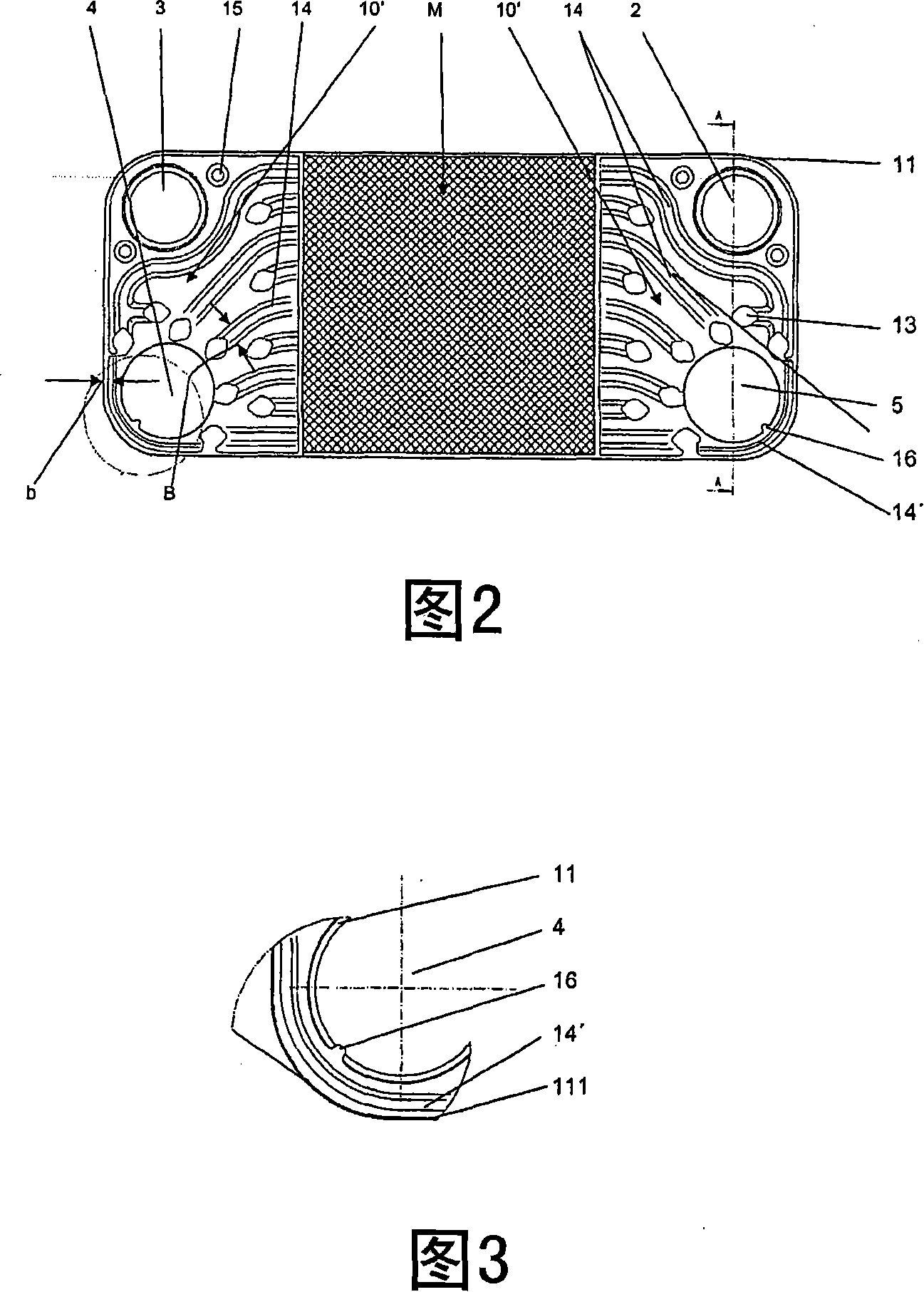

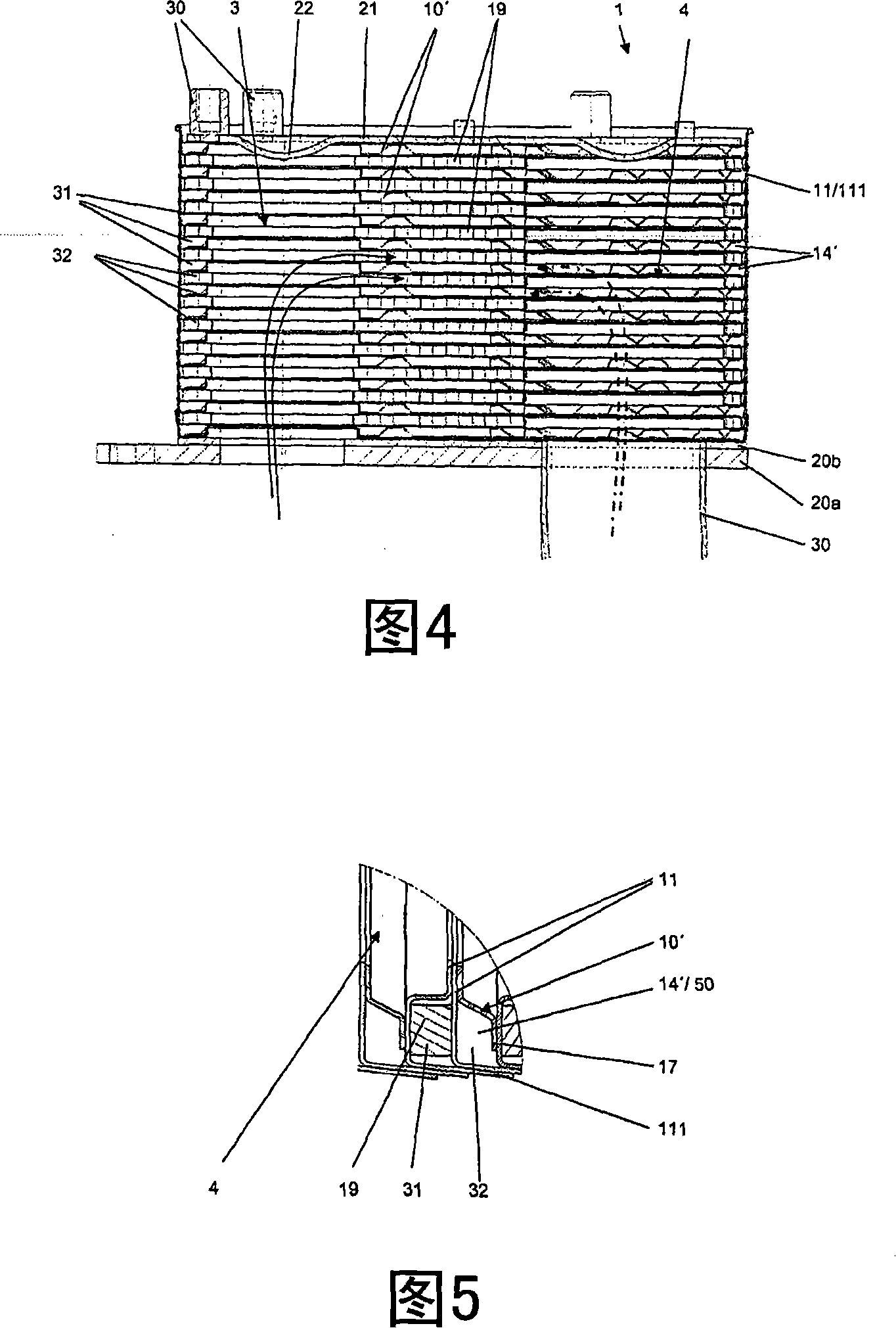

Heat exchanger with plate projections

InactiveUS20070006998A1Improve heat exchange efficiencyLaminated elementsStationary plate conduit assembliesPlate heat exchangerMechanical engineering

A plate heat exchanger including first and second sets of heat exchanger plates. The second set plates are alternately stacked with the first set plates to form flow channels therebetween. The first set plates have first projections protruding in one direction from the plane of the plates and second projections protruding in the opposite direction from the plane of the plate. The second set plates have third projections protruding in the one direction from the plane of the second set plates. The first projections are connected to adjacent second set plates and the second projections protrude into the space between at least two of the third projections. The second projections may be spaced from and not connected to the second set plates, with the height of the third projections from the second set plates being greater than the height of the first and second projections from opposite sides of the first set plates.

Owner:MODINE MFG CO

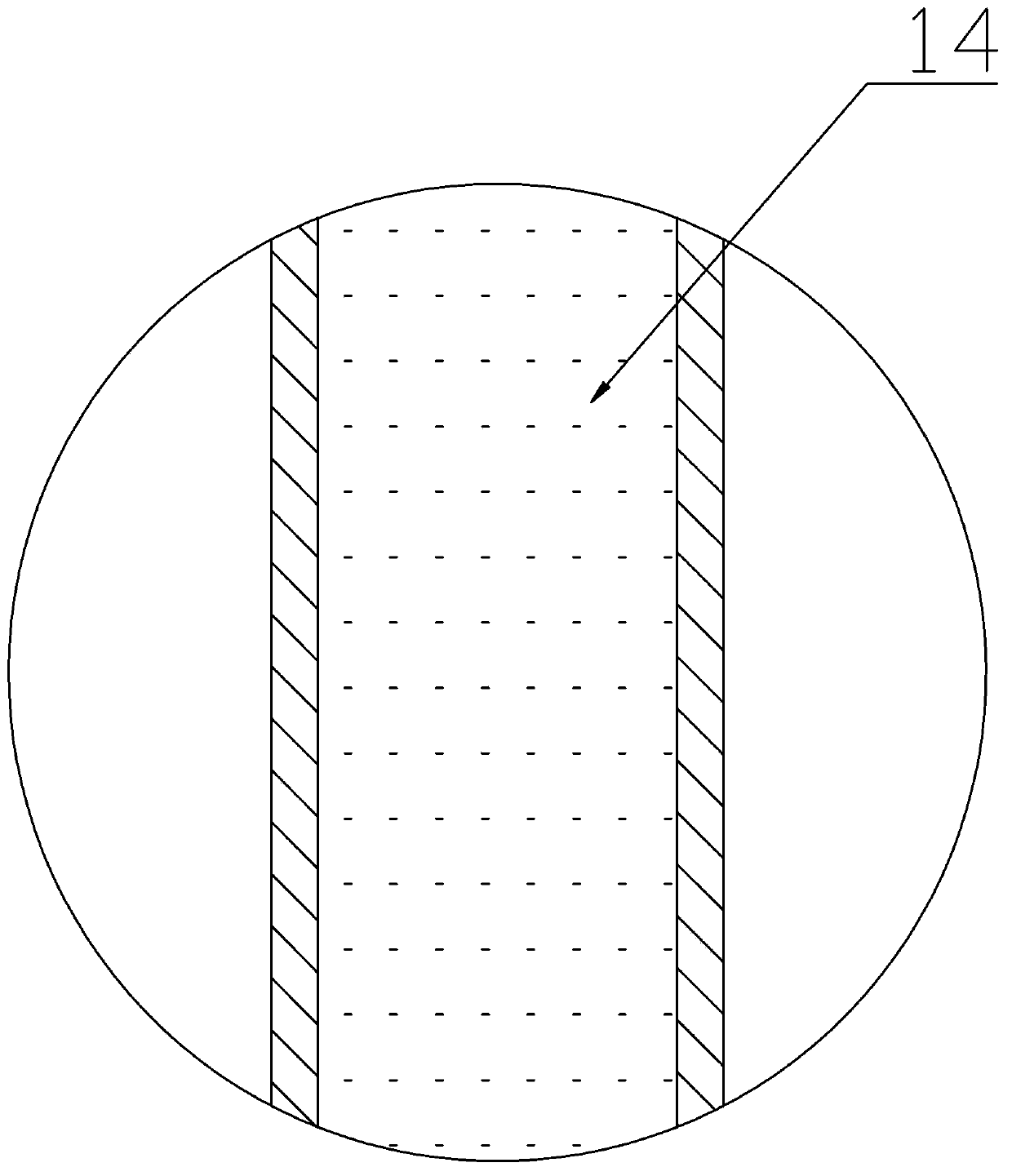

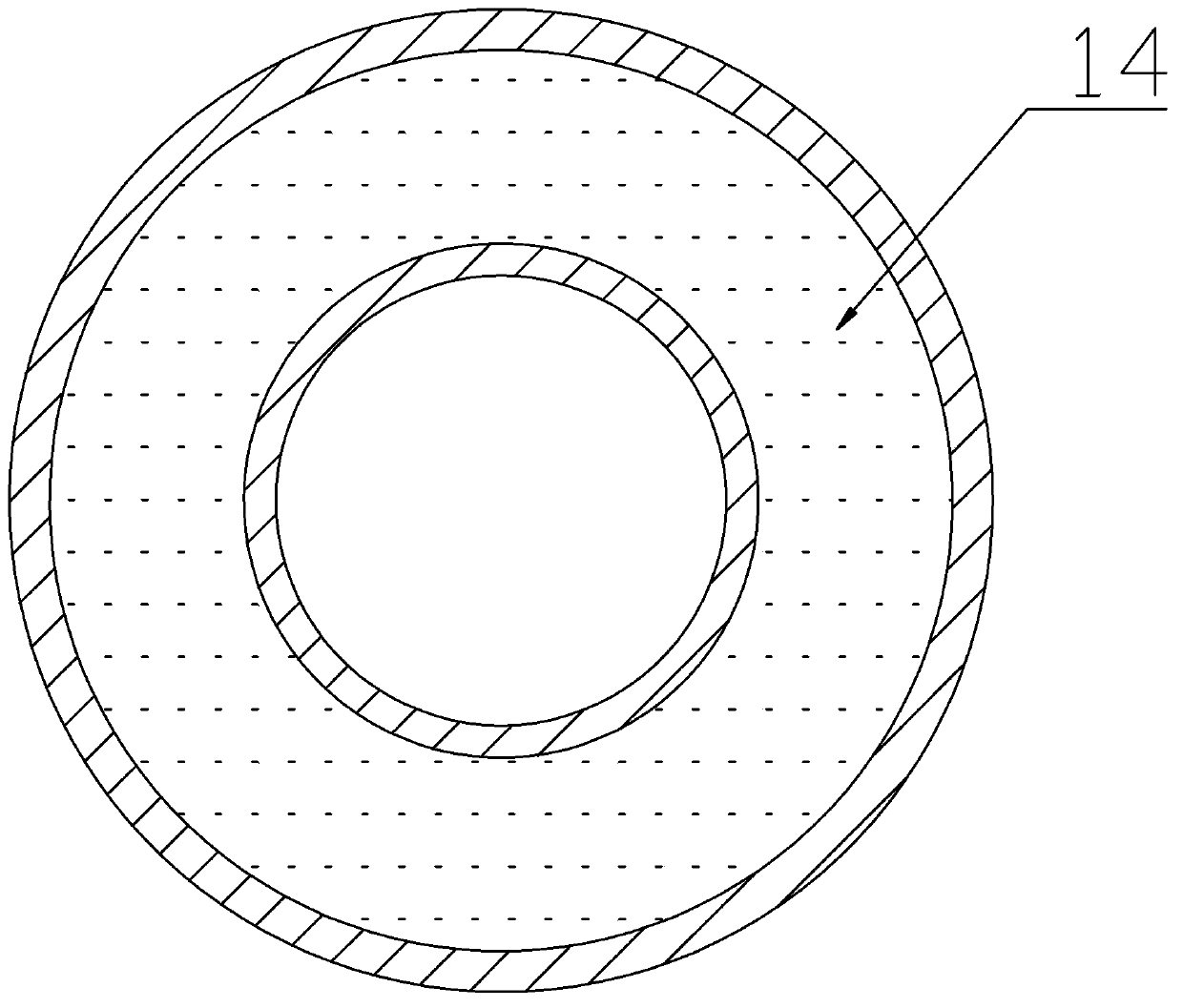

High-strength silicon carbide ceramic pipe and manufacturing method thereof

The invention discloses a high-strength silicon carbide ceramic pipe and manufacturing method thereof, and belongs to the technical field of engineering ceramic materials. Silicon carbide ceramic powders with different granularities are used as the main raw materials, graphite powder and carbon black are used as binders, and resin is used as a binder. The materials are uniformly mixed by a spray granulation process; an organic plasticizer of cellulose and a lubrication agent are added into the mixture; and vacuum pugging, decaying and extrusion molding are conducted to obtain a pipe base substrate; and the base substrate is subjected to drying solidification, high temperature sintering reaction, sandblast and heat treatment to obtain the high strength silicon carbide ceramic pipe. The pipe biscuit manufactured by the process has high strength and length of more than 4000mm; after sintering, the pipe has strength of 300MPa or more, and has the advantages of moderate density, high thermal conductivity, high fracture toughness, good thermal shock resistance and low cost, and can be widely applied to chemical and metallurgy fields, such as acid and alkaline corrosion and high temperature erosion.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

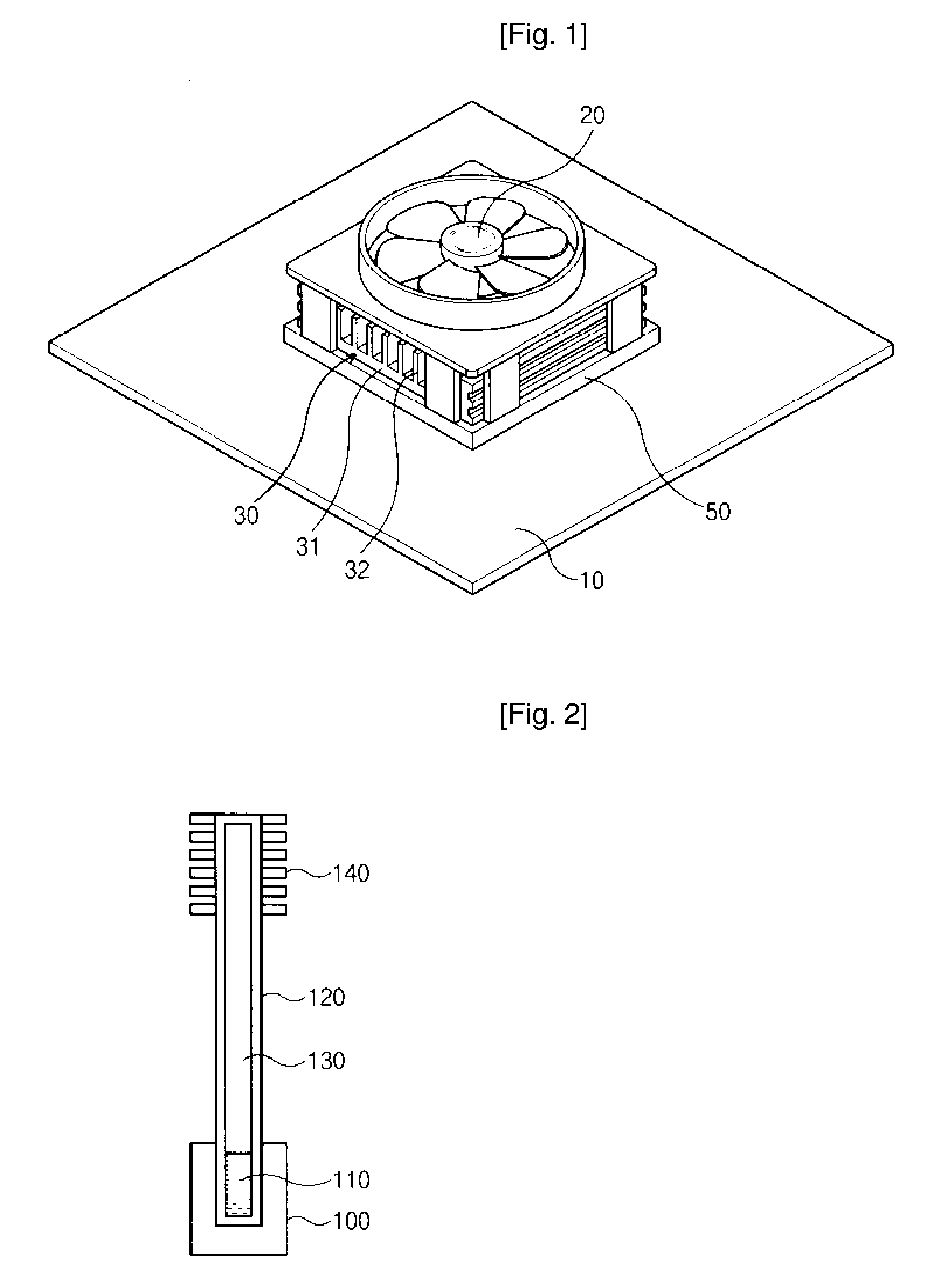

Cooling device coated with carbon nanotube and of manufacturing the same

InactiveUS20090059535A1Maximize heat exchange efficiencyEfficient heat generationMaterial nanotechnologyPretreated surfacesCarbon nanotubeOptoelectronics

Provided are a cooling device coated with carbon nanotubes and method of manufacturing the same. Carbon nanotubes are dispersively coated on a surface of the cooling device that radiates generated by a predetermined apparatus or component through thermal exchange. Thus, a carbon nanotube structure is formed so that the cooling device can improve in a thermal radiation characteristic and become small-sized. As a result, electronic devices can be downscaled and heat generated by a highly integrated electronic circuit chip can be effectively radiated, thus increasing lifetime and performance of an operating circuit.

Owner:KIM YONG HYUP +7

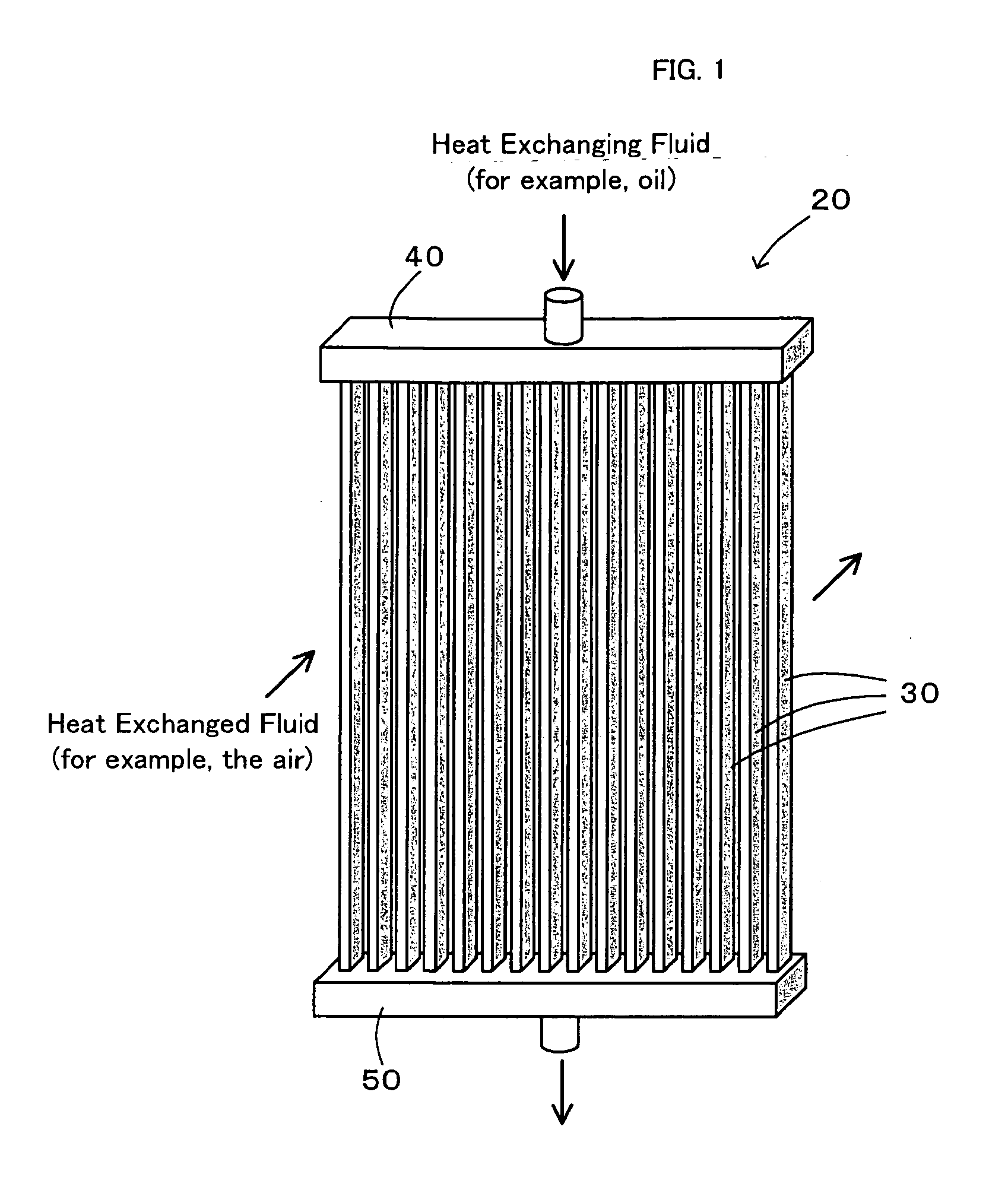

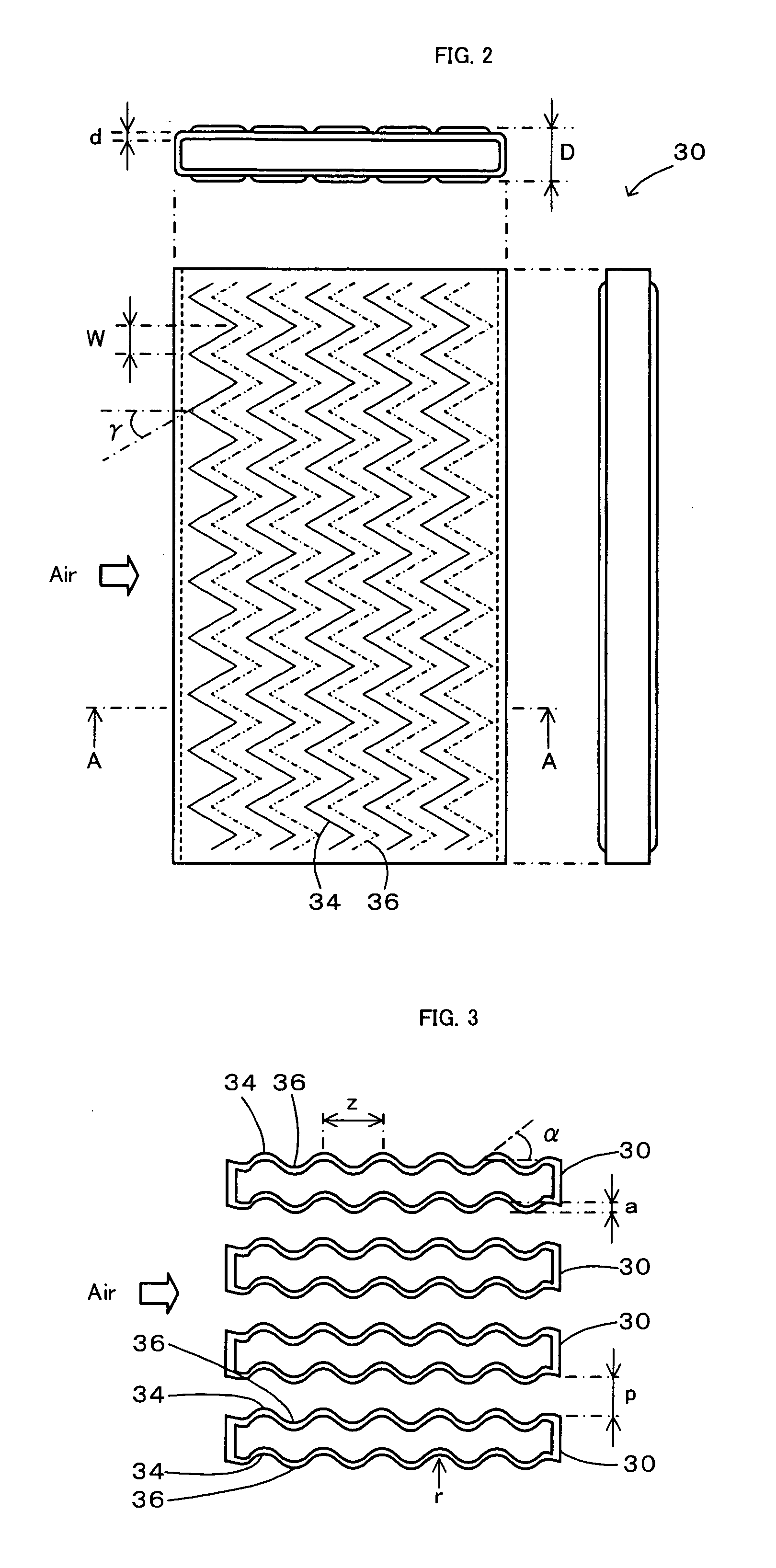

Heat exchanger

ActiveUS20100089560A1Improve heat exchange efficiencyImprove efficiencyStationary conduit assembliesHeat transfer modificationEngineeringHeat exchanger

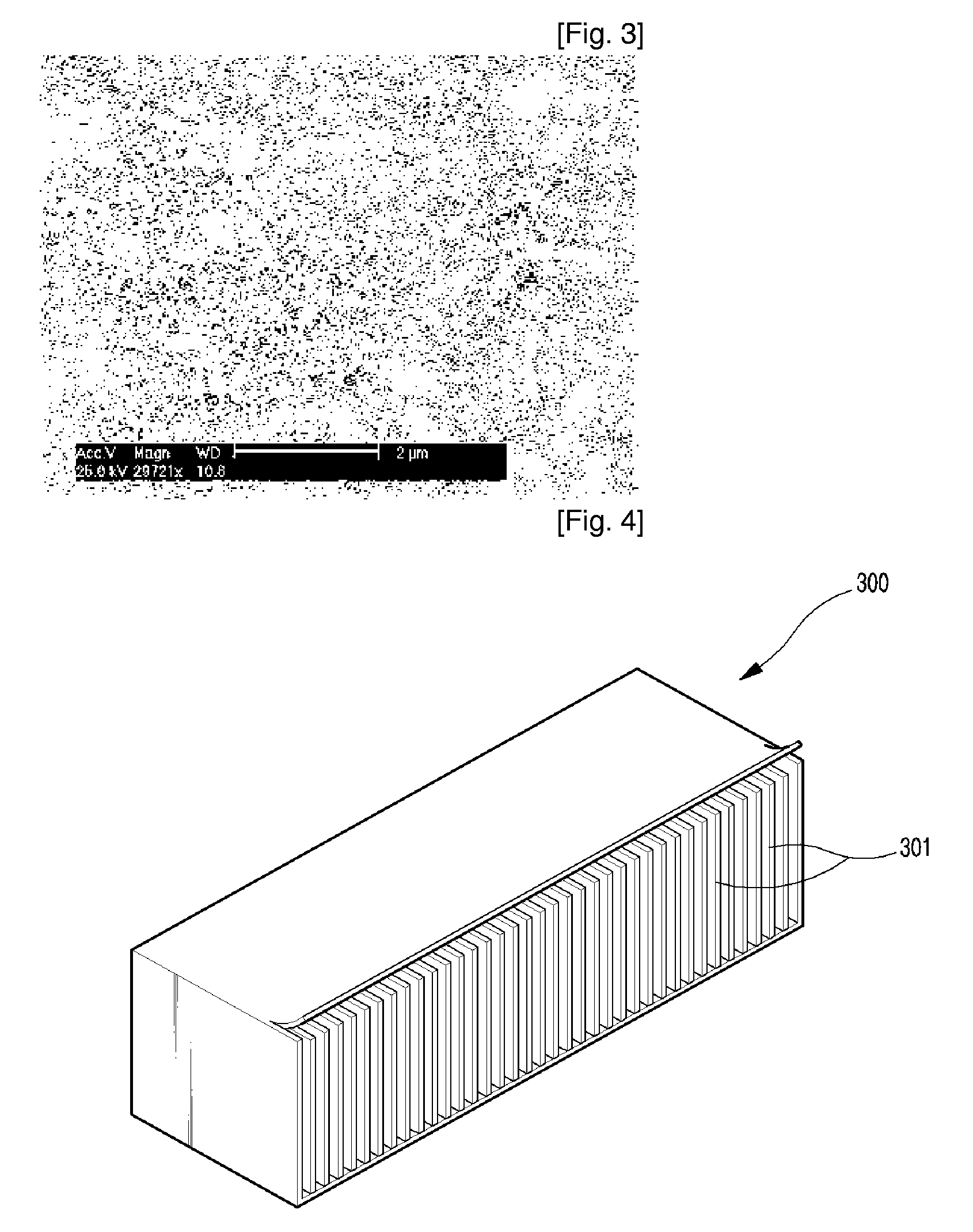

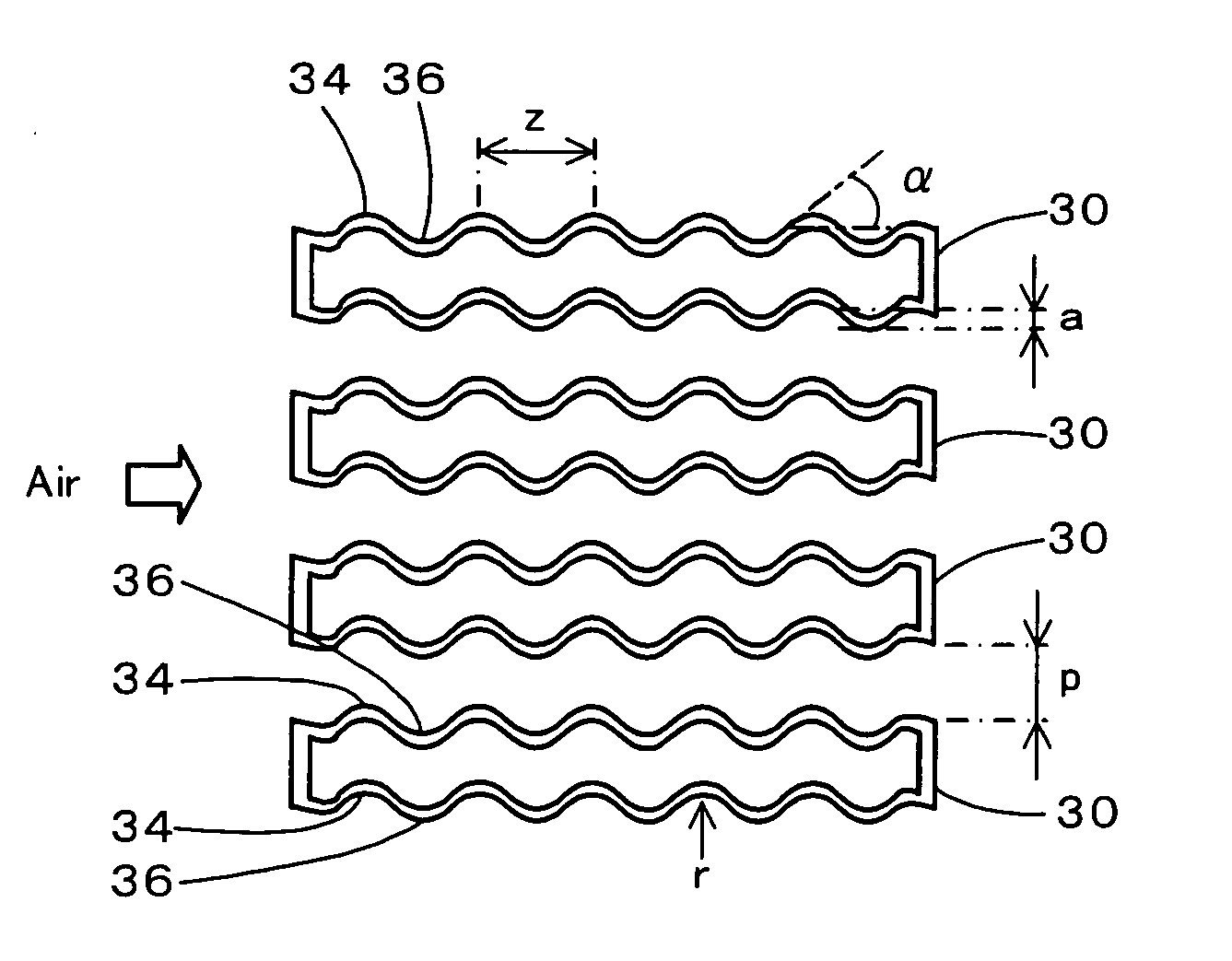

A heat exchanger assembled from multiple heat exchanging tubes. Each of the multiple heat exchanging tubes is formed as a flattened tube of 0.5 mm in thickness by press work or bending work of a stainless steel plate member having a thickness of 0.1 mm. Each of the multiple heat exchanging tubes is structured to have multiple lines of sequential wave crests and multiple lines of sequential wave troughs formed on each of flattened faces of the heat exchanging tube. The multiple lines of the sequential wave crests and the multiple lines of the sequential wave troughs are arranged to have a preset angle γ relative to a main stream of an air flow. The lines of the sequential wave crests and the lines of the sequential wave troughs are symmetrically folded back about folding lines arranged at a preset interval W along the main stream of the air flow.

Owner:THE UNIV OF TOKYO +1

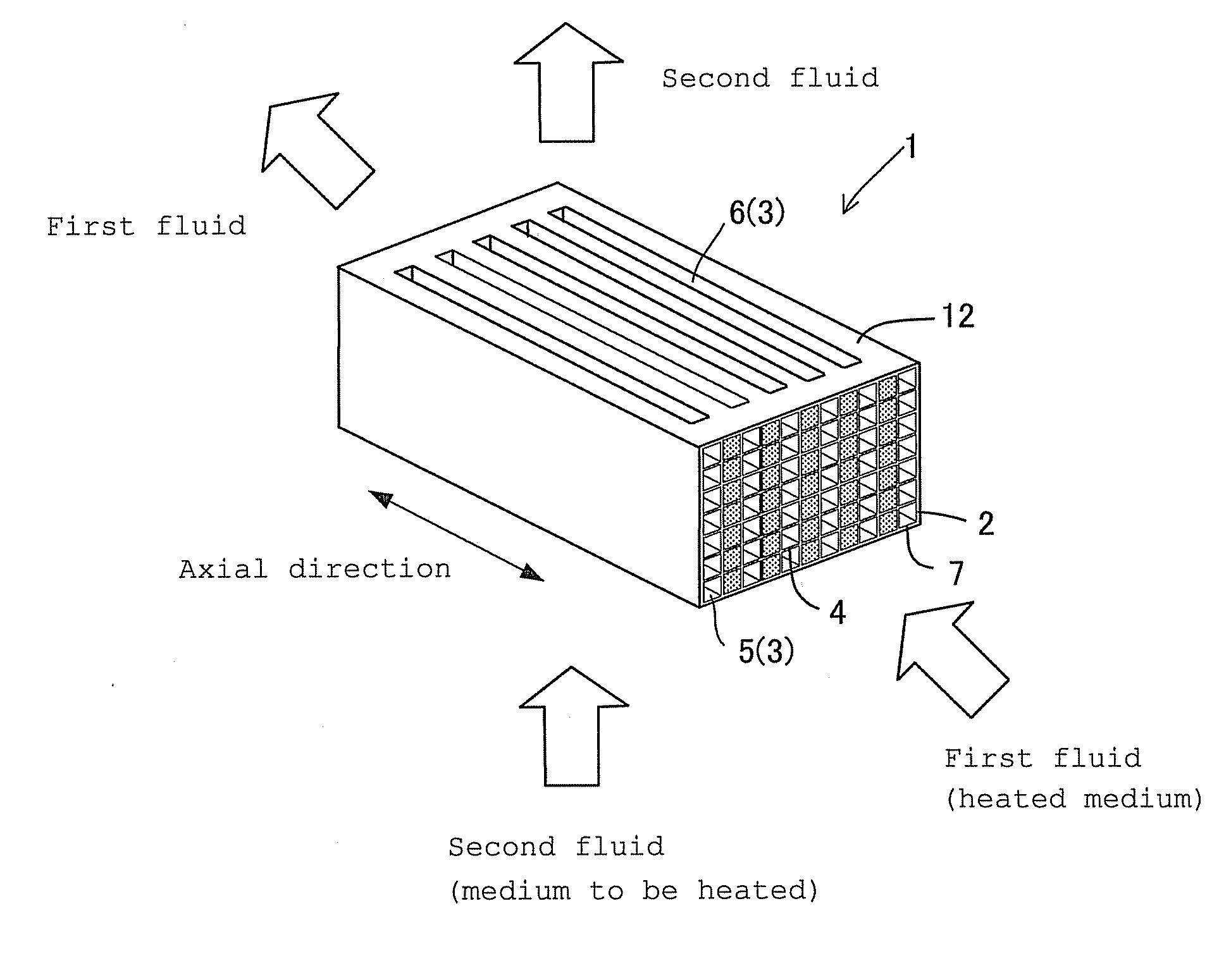

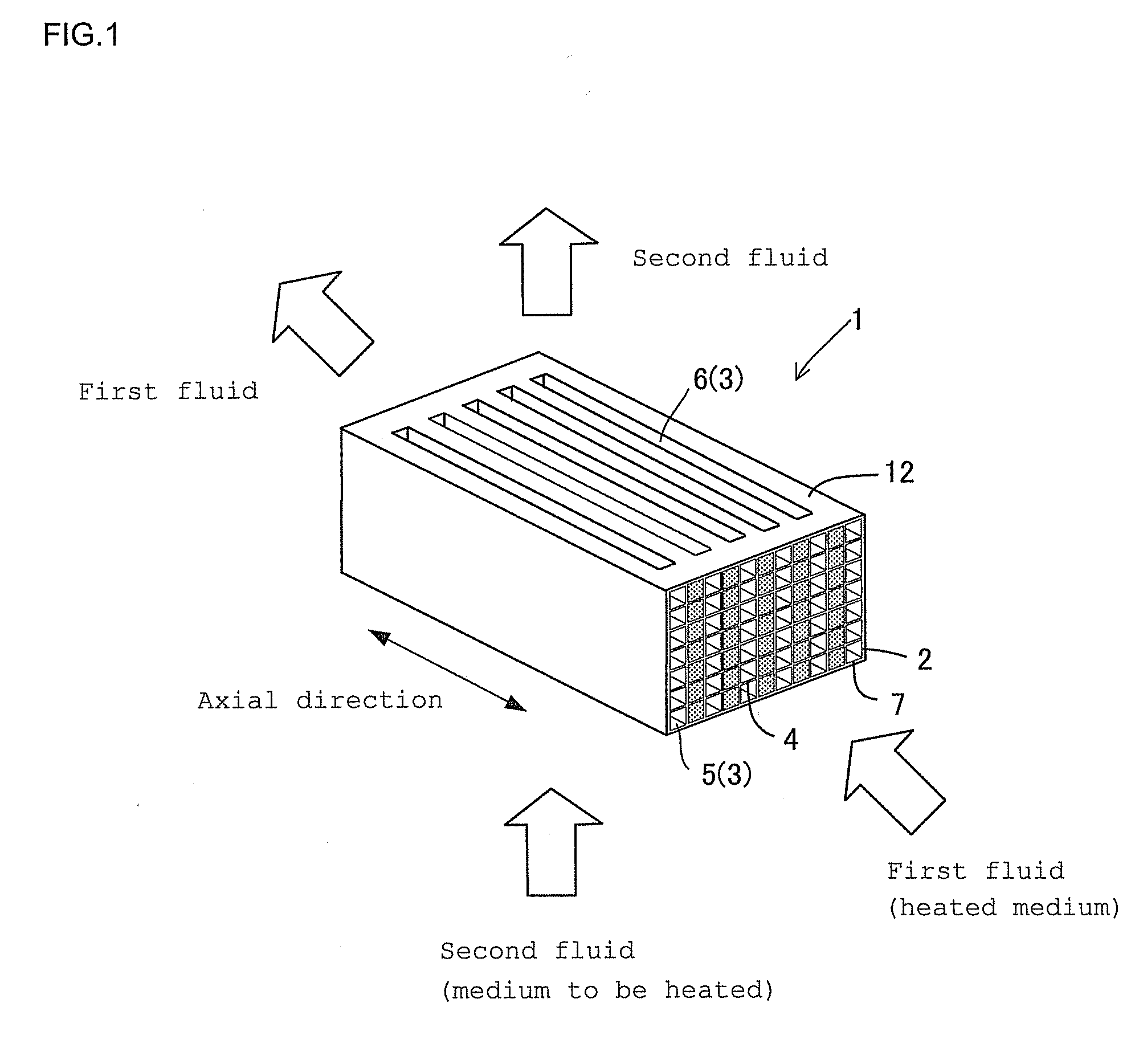

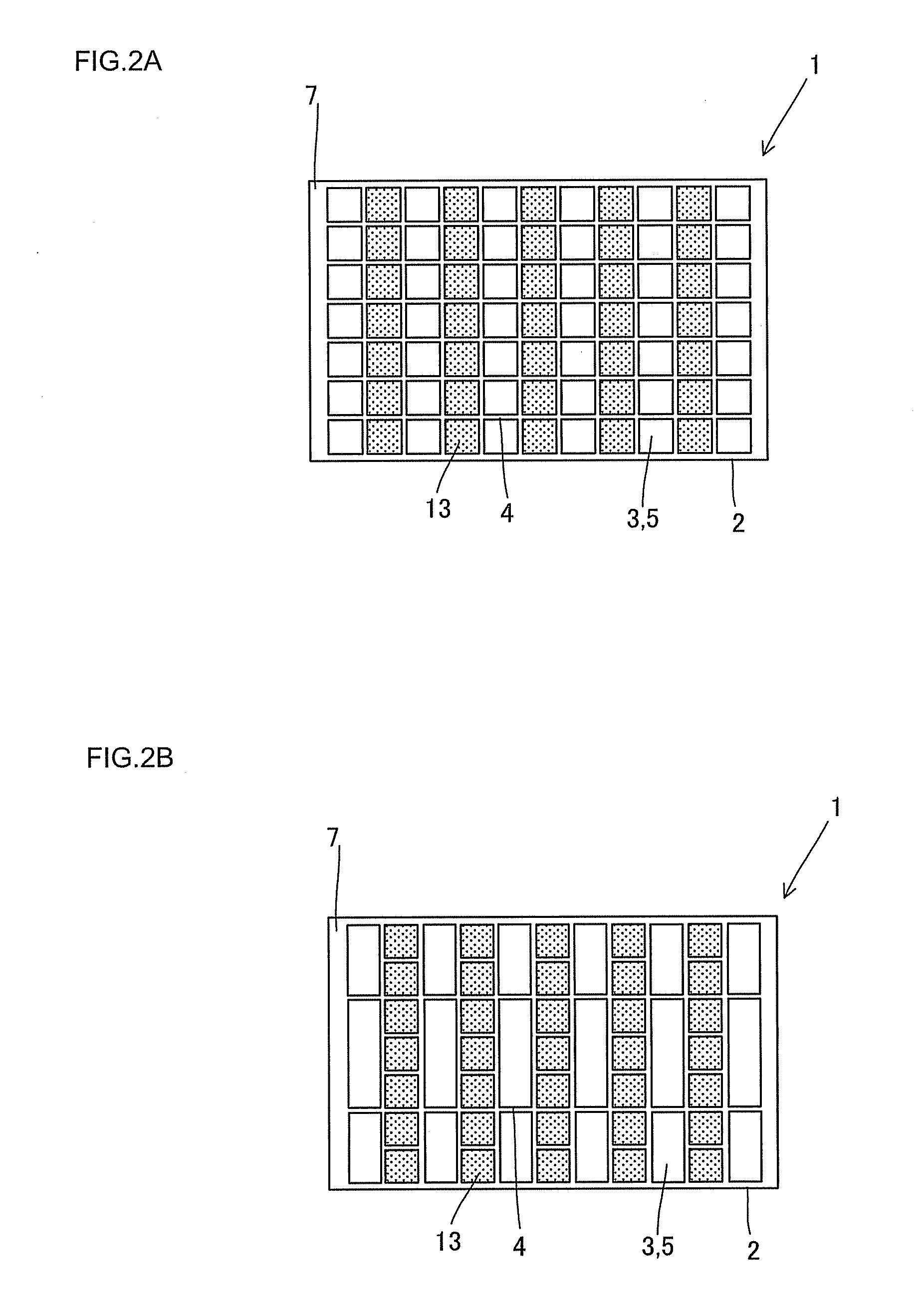

Ceramics heat exchanger and production method thereof

InactiveUS20100270011A1Improve heat exchange efficiencyHighly miniaturizedRecuperative heat exchangersMetal-working apparatusVolumetric Mass DensityEngineering

In a heat exchange element 1, first fluid circulation portions 5 having a honeycomb structure having a plurality of cells separated by ceramic partition walls 4, extending through in an axial direction from one end face 2 to the other end face 2, and allowing a heated medium as a first fluid to flow therethrough and second fluid circulation portions 6 being separated by ceramic partition walls 4, extending in the direction perpendicular to the axial direction, allowing a second fluid to flow therethrough, transferring heat to a medium to be heated as the second fluid are alternately formed as a unit. The cells 3 on the first fluid circulation portion 5 side are smaller than the cells 3 on the second fluid circulation portion 6 side, and the partition walls have a density of 0.5 to 5 g / cm3 and a thermal conductivity of 10 to 300 W / mK.

Owner:NGK INSULATORS LTD

Heat exchanging wall, gas turbine using the same, and flying body with gas turbine engine

ActiveUS7694522B2Improve heat exchange efficiencyContinuous combustion chamberEfficient propulsion technologiesEngineeringGas turbines

Owner:MITSUBICHI HEAVY IND AERO ENGINES LTD +1

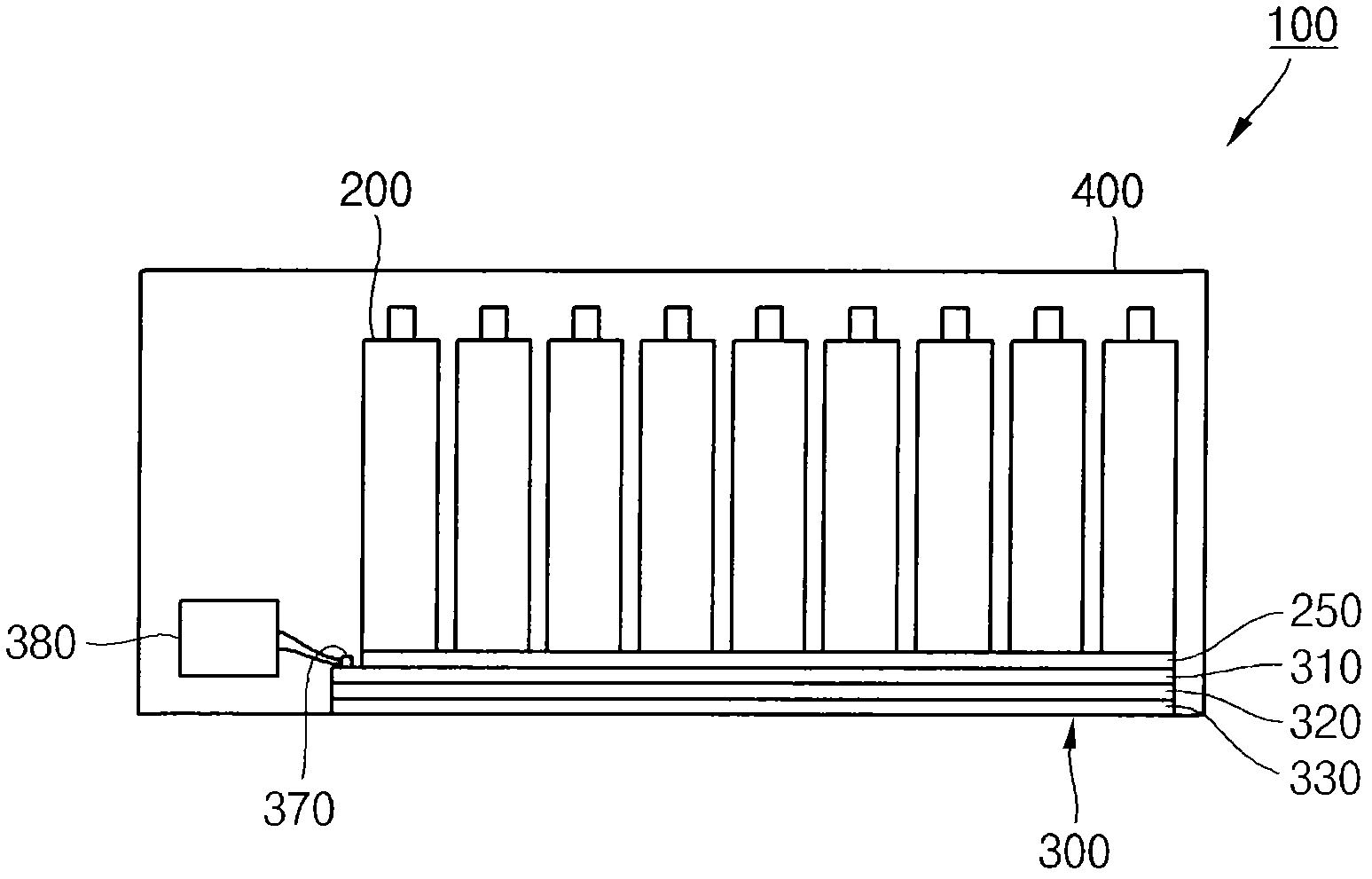

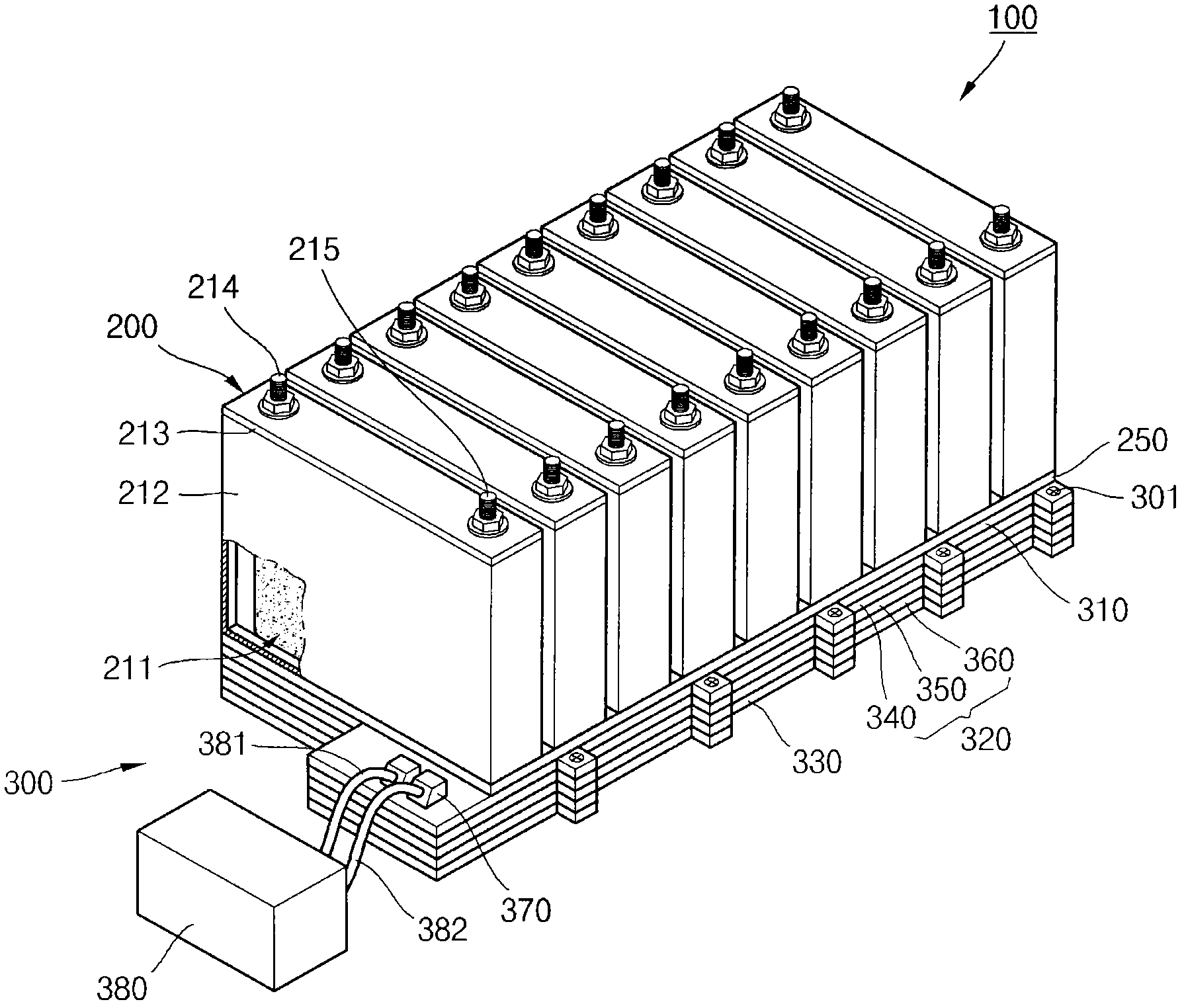

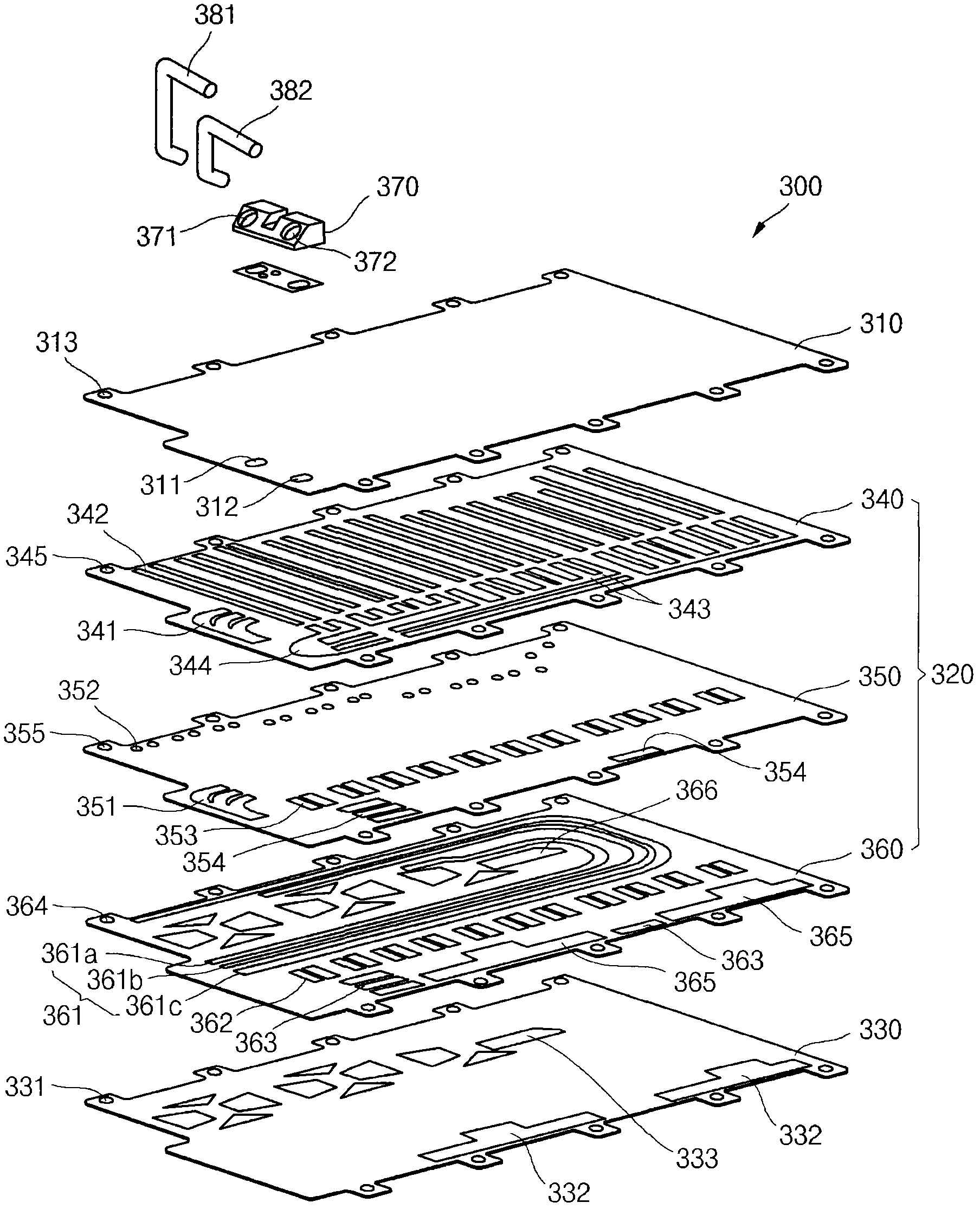

Battery

ActiveCN102270776AReduce performanceImprove heat exchange efficiencyCell temperature controlCell component detailsCoolant flowBattery cell

Owner:SAMSUNG SDI CO LTD +1

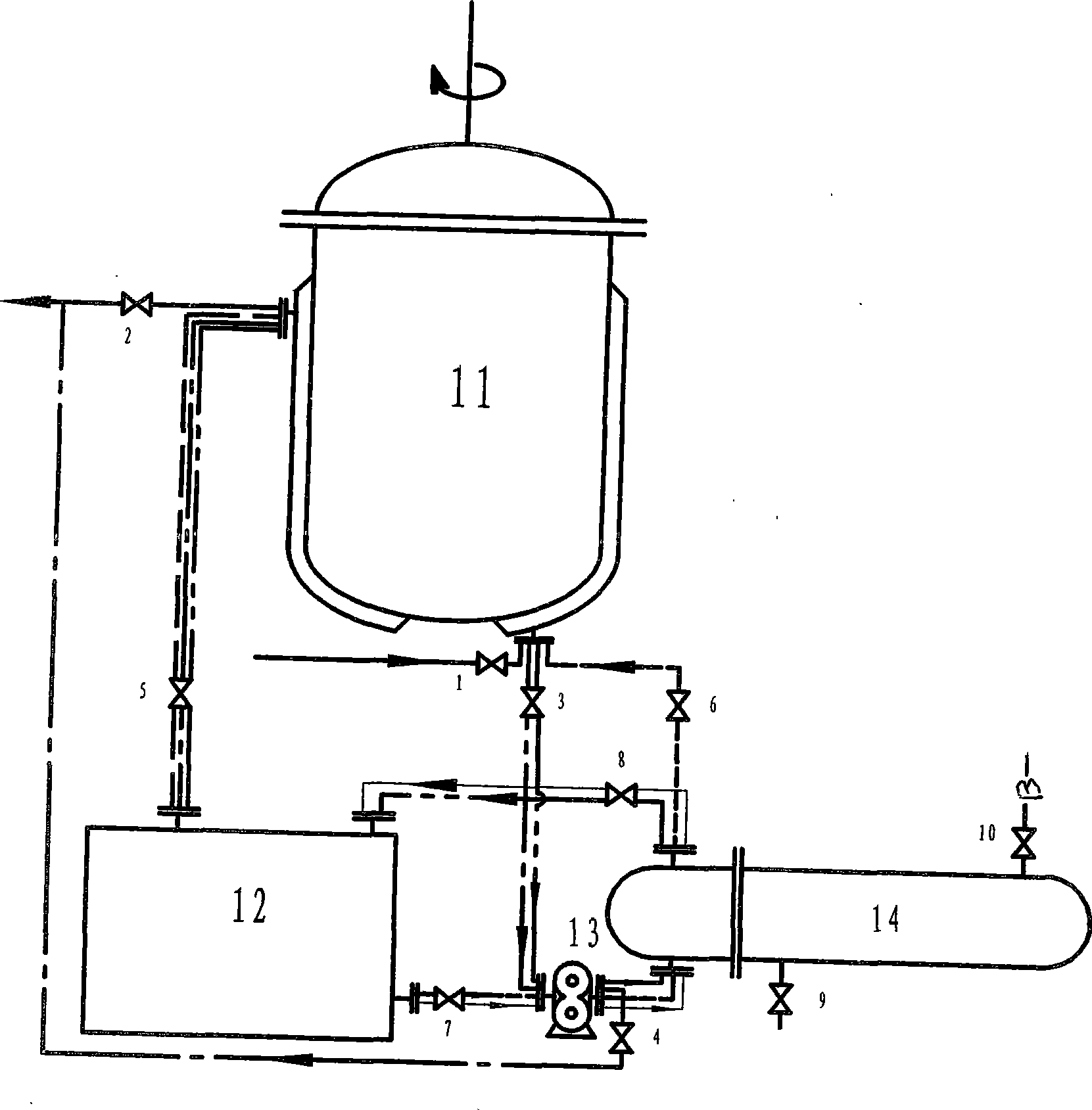

Technique for heating and cooling material in reactor by heat carrier through jacket

InactiveCN101480599AEasy to useCompact structureIndirect heat exchangersChemical/physical/physico-chemical processesSaline waterHeat carrier

The invention relates to a process for heating and cooling materials in a reaction kettle through a jacket by using a heat carrier. The process completes five working procedures by six loops. The loops are as flollows: a heat conduction oil heating loop: heat oil flows out from an oil outlet of a boiler and comes in and out of the jacket of the reaction kettle through a pipeline and a valve for circularly heating; a heating and cooling shift loop: the heat oil is sent back to the boiler by an oil pump through a pipeline; a cold conduction heat oil cooling loop and an ice salt water cooling loop: cold oil enters the jacket of the reaction kettle from an outlet of a cool oil tank by the pump through a pipeline and a cooler and returns to the cool oil tank through a pipeline provided with a balance valve; ice salt water returns to a cooling device from a refrigerating device through a cooler shell side and a pipeline, and cold conduction heat oil is circularly cooled in the cooler; a cool heating shift loop: cold oil comes out of the jacket of the reaction kettle, passes through the pipeline and returns to the cold oil tank from an inlet by the pump through the cooler; a cold oil pre-cooling loop: cold oil comes out of the outlet of the oil tank and returns to the cold oil tank by the pump through the pipeline and the shell side of the cooler introducing ice salt water. The invention has the advantages that the loop structure is compact, the process is stable, the heat exchange efficiency is high, and the high temperature and the low temperature are 300 DEG C and 15 DEG C below zero respectively.

Owner:天元航材(营口)科技股份有限公司

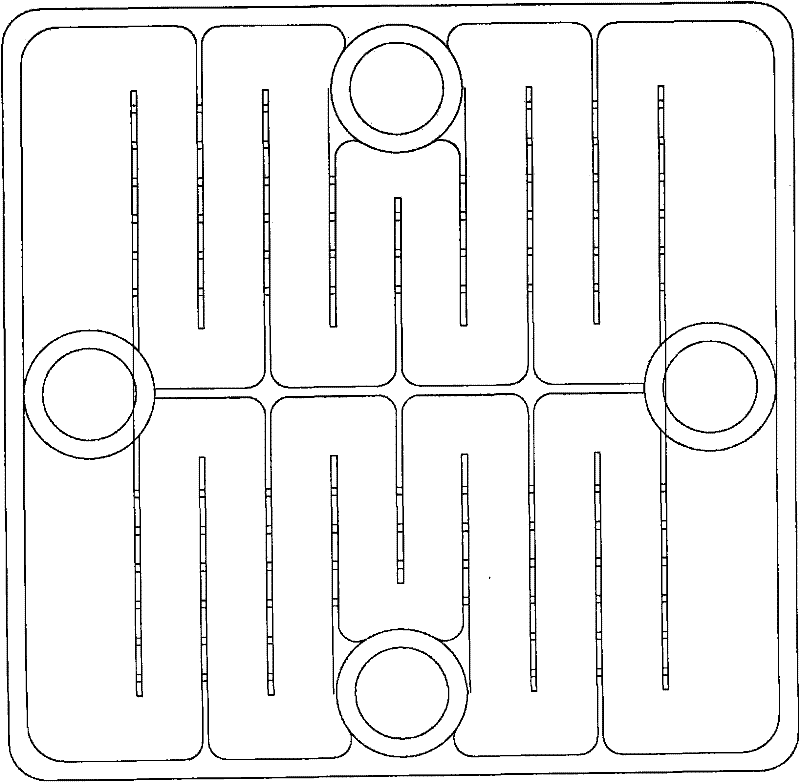

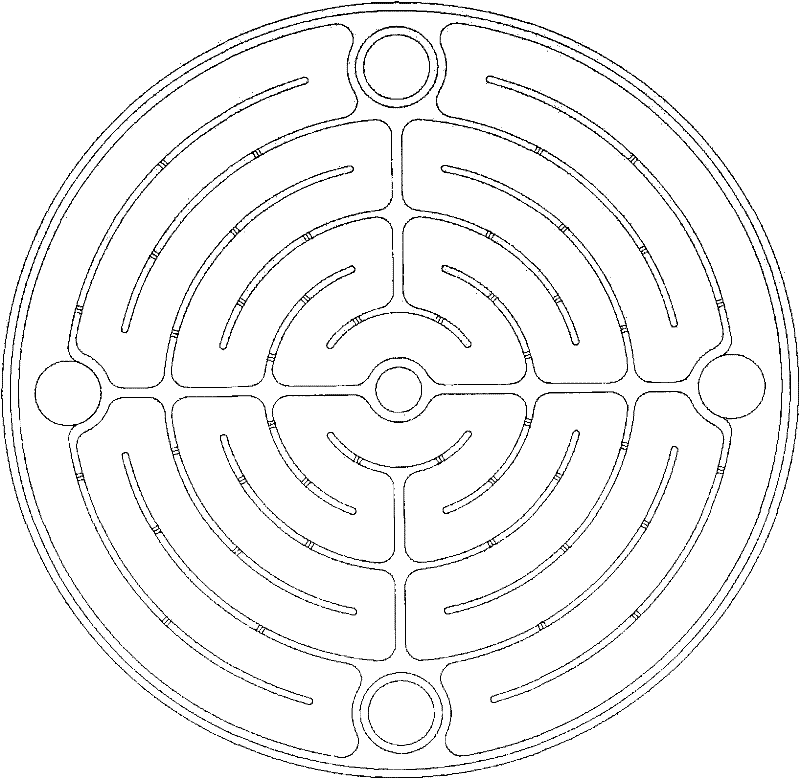

Silicon carbide ceramic heat-exchanging board and manufacturing method thereof

InactiveCN102538546AReduce manufacturing costImprove heat exchange efficiencyLaminated elementsCentrosymmetryCeramic

The invention provides a silicon carbide ceramic heat-exchanging board. The heat-exchanging board is of a centrosymmetry structure in design shape, and the centrosymmetry structure can be quadrate or round; the heat-exchanging board is provided with a heat-exchanging channel of a dual loop structure; and the silicon carbide content of silicon carbide ceramic is not lower than 95wt% in terms of the total weight of the silicon carbide ceramic. The invention further provides a preparation method and application of the heat-exchanging board. The silicon carbide ceramic heat-exchanging board disclosed by the invention can be used for greatly increasing the heat-exchanging efficiency and prolonging the service of a heat exchanger.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

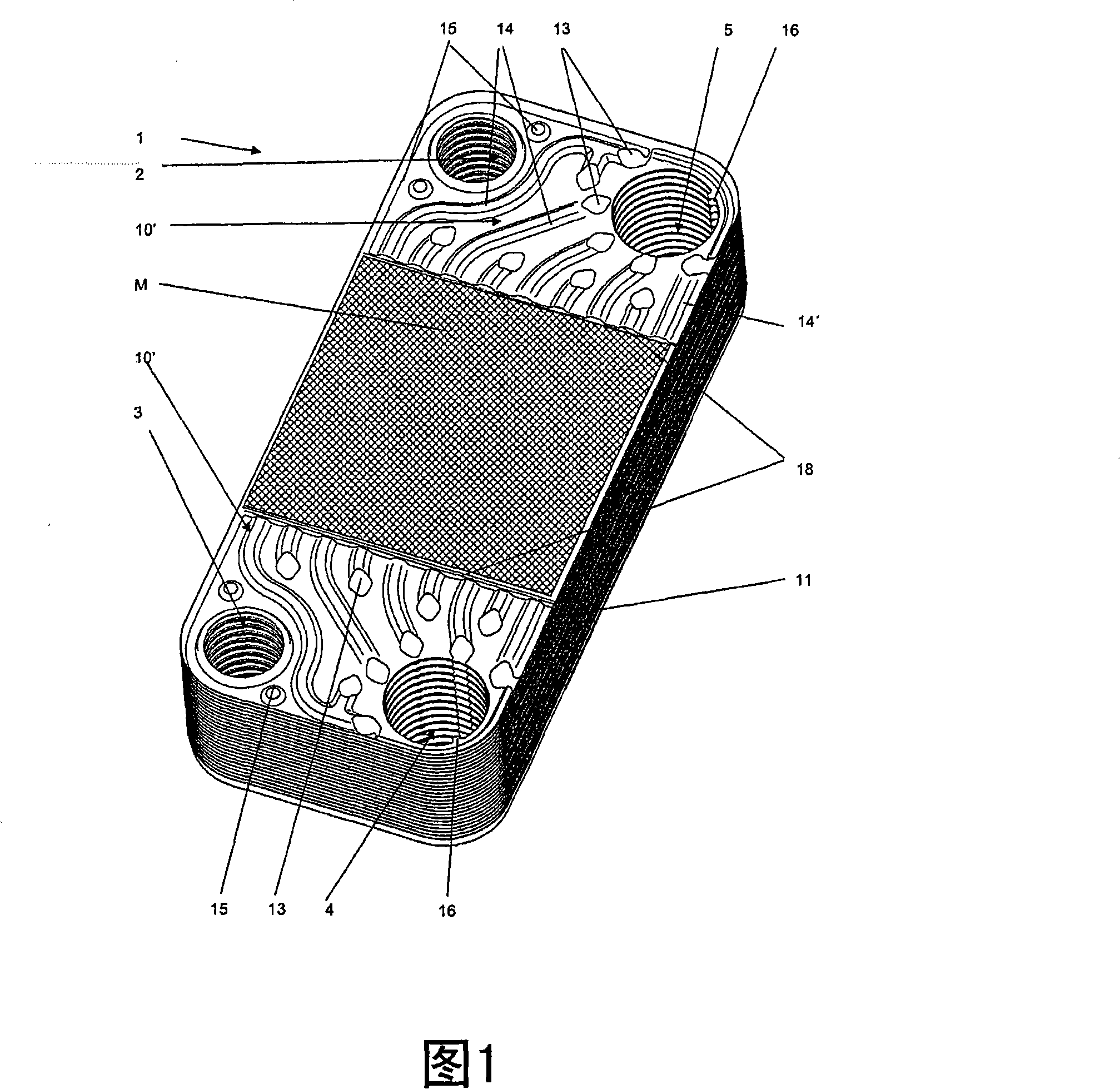

Plate heat exchanger

ActiveCN101162132AOptimization lossOptimize heat exchange efficiencyHeat exchanger casingsHeat transfer modificationPlate heat exchangerMetal sheet

The invention relates to a flat heat exchanger comprising a plurality of trough-shaped heat exchanger plates stacked on top of each other, the heat exchanger plates having edges abutting against each other. The plates may have flow conduits for the cooling fluid and for another fluid between the heat exchanger plates. The flow ducts are assembled with inserts in the form of turbulator plates. The heat exchanger has at least four inlet and outlet openings in the corners of the heat exchanger plates forming two vertical ducts for the cooling fluid and two for the other fluid in the stack. a vertical conduit. An insert in a flow conduit for a cooling fluid consists of one or more components. The flow duct for the cooling fluid is equipped with a plate-like insert with a width guiding the duct in the region near the opening. The insert is formed as a turbulence generator in the central area between the plate-like parts. The openings are arranged in the corners in such a way that only a narrow strip is left occupied by the guiding duct whose width is significantly smaller than that of the other guiding ducts.

Owner:MODINE MFG CO

Heat regenerator of original surface for gas turbine

InactiveCN1560437AExtended service lifeImprove heat transfer efficiencyTurbine/propulsion engine coolingGas turbine plantsInlet channelMicro gas turbine

The invention relates to a regenerator for a micro gas turbine, concretely is a original surface heat exchanger for increasing the heat efficiency of the gas turbine, it can increase the compactness and the service life of regenerator. The gas inlet and outlet channels are arranged on the right lower horn and the left upper horn, the high pressure air flows into the regenerator through the air inlet channel, flows out from the air outlet channel, the left and right frames of the heat exchanging board are welded and formed a air in / out aperture, the fuel gas can flow into the regenerator through the aperture, flows out form aperture on another side, the centre is heat exchanging corrugation plates, the flatten area at two sides of the plates is used to place flow guiding plate, the heat exchanging board has a side frame for welding and sealing. The flow speed at two sides has a little difference, the heat exchanging effect is the best, and it can upgrade the heat exchanging efficiency.

Owner:XI AN JIAOTONG UNIV

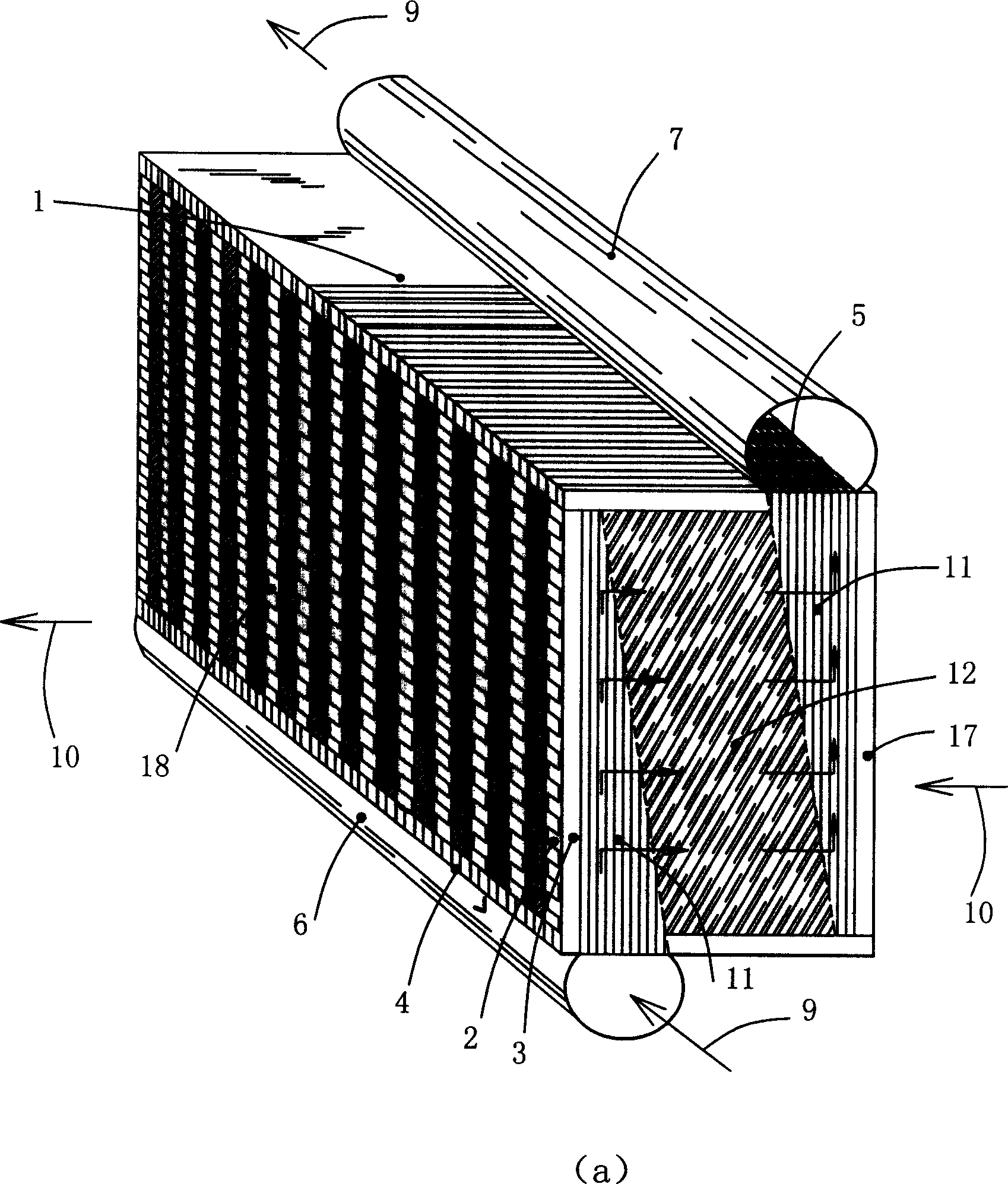

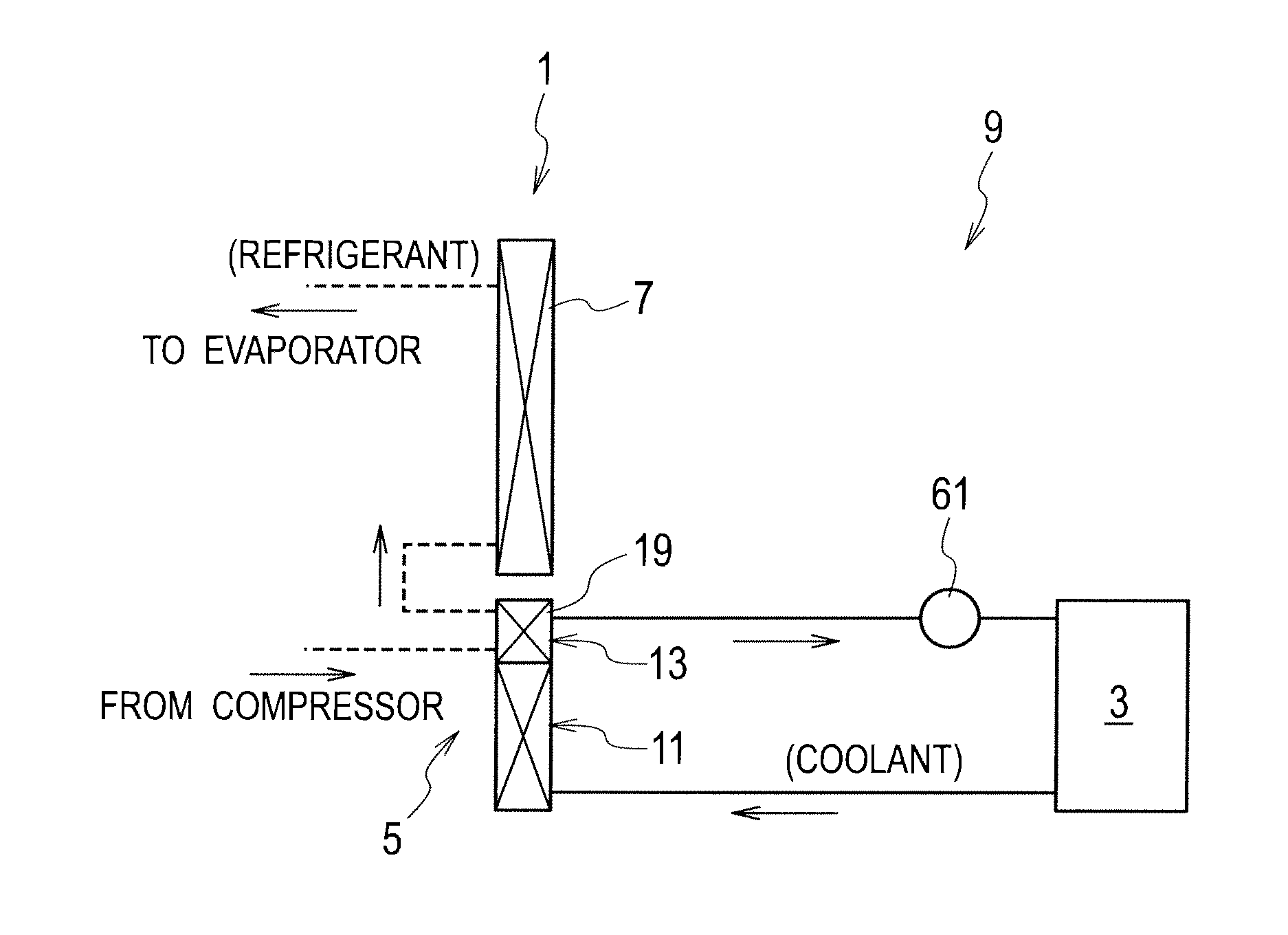

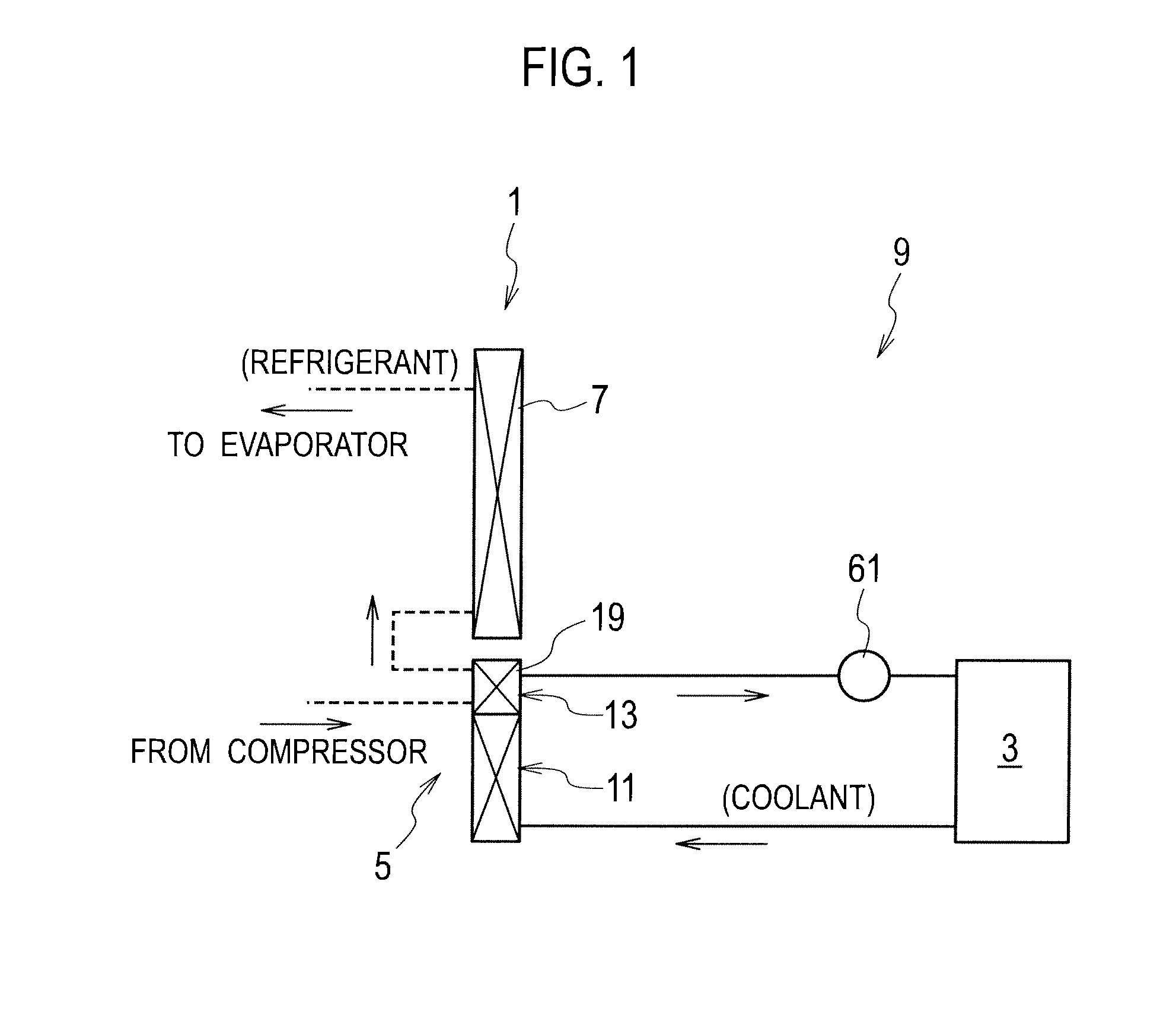

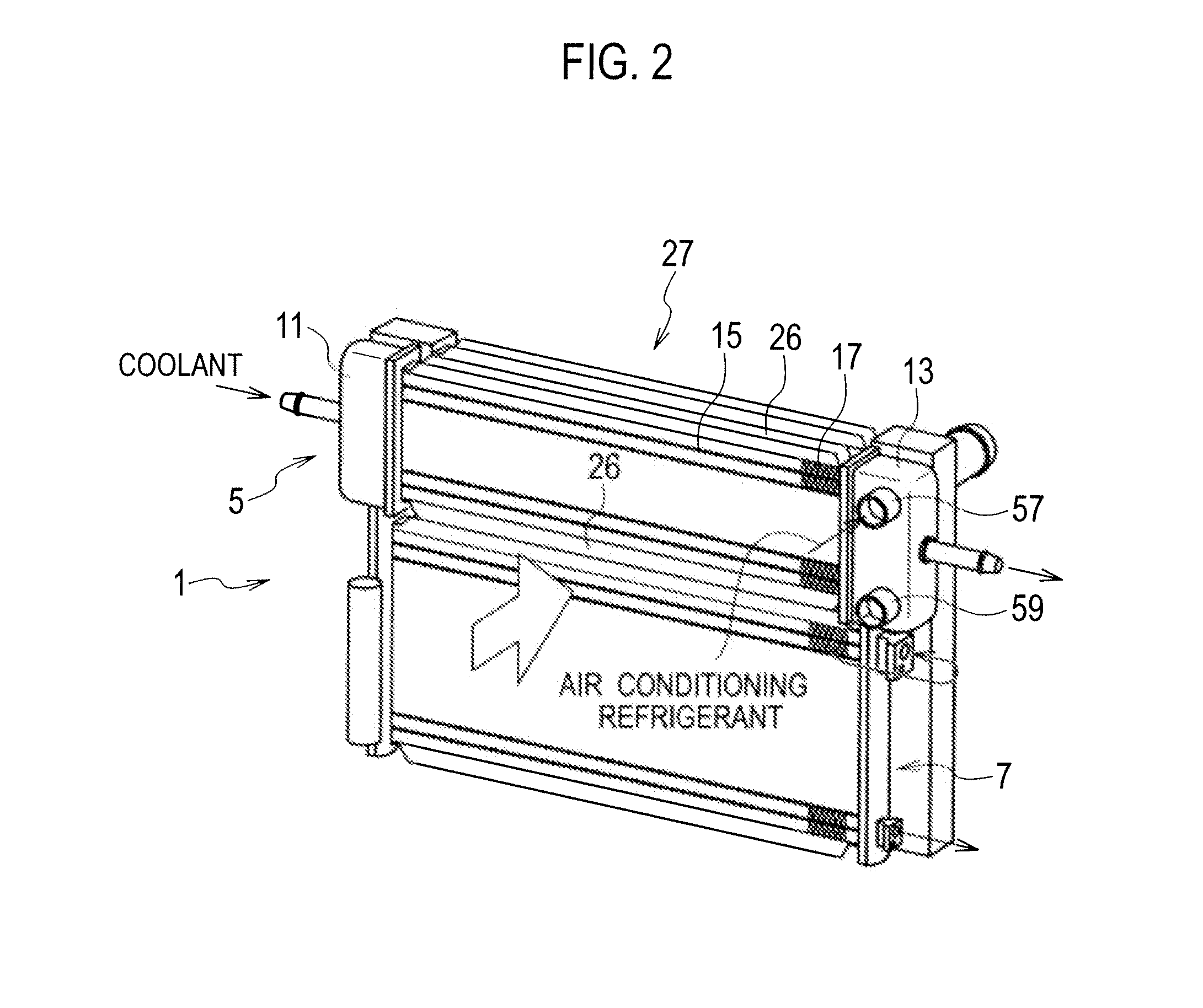

Combined heat exchanger

InactiveUS20110232868A1Improve heat exchange efficiencyGood effectStationary conduit assembliesHeat exchanger casingsCoolant flowEngineering

A combined heat-exchanger includes a first air-cooled heat-exchanger for cooling coolant for a heat generator other than an internal combustion engine in an automobile and a second air-cooled heat-exchanger for cooling refrigerant for air-conditioning. The first air-cooled heat-exchanger includes an upstream tank into which the coolant flows, a downstream tank form which the refrigerant flows out, flow channel members that communicate the upstream tank with the downstream tank, heat release fins that are alternately stacked with the flow channel members, and a water-cooled heat-exchanger for cooling the refrigerant. The water-cooled heat-exchanger is disposed within the downstream tank, and includes an inlet port to which the refrigerant flows at its upper portion and an outlet port from which the refrigerant flows out at its lower portion. According to the heat-exchanger, staying of oil mixed in the refrigerant can be prevented, heat exchange efficiency can improve and downsizing can be achieved.

Owner:CALSONIC KANSEI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com