Clothes drying temperature detection control method and clothes drier

A technology for detection and control of clothes dryers, applied in the field of clothes dryers, can solve problems such as affecting environmental comfort, and achieve the effects of improving drying efficiency, reducing drying time, and making accurate judgments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

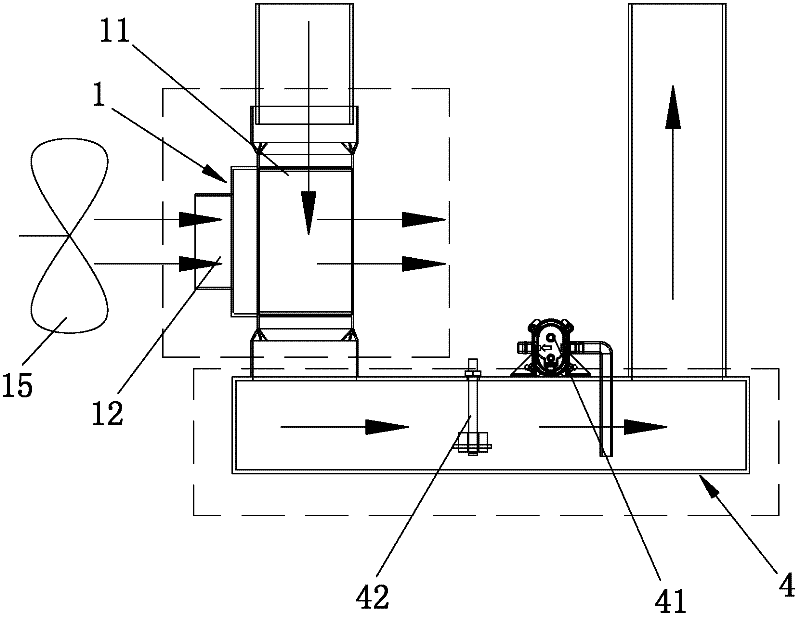

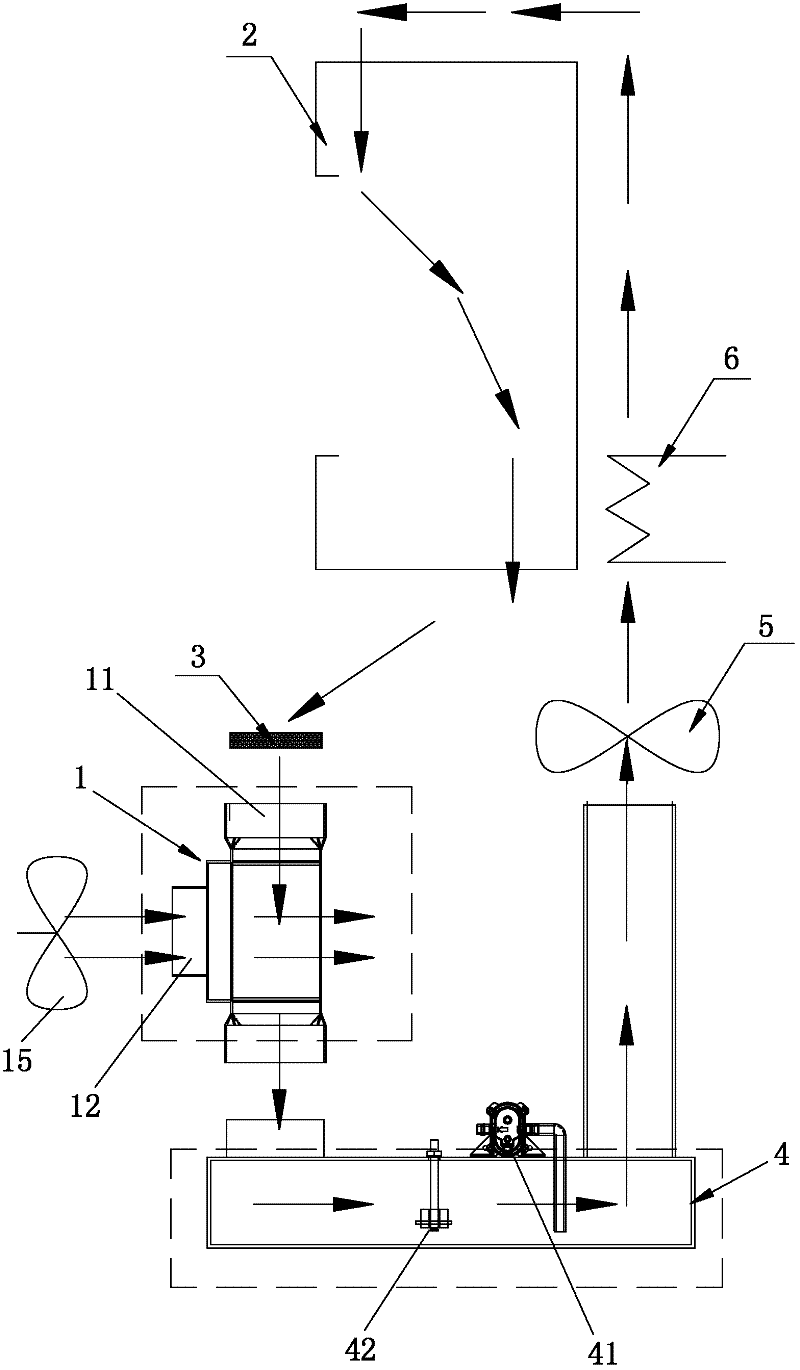

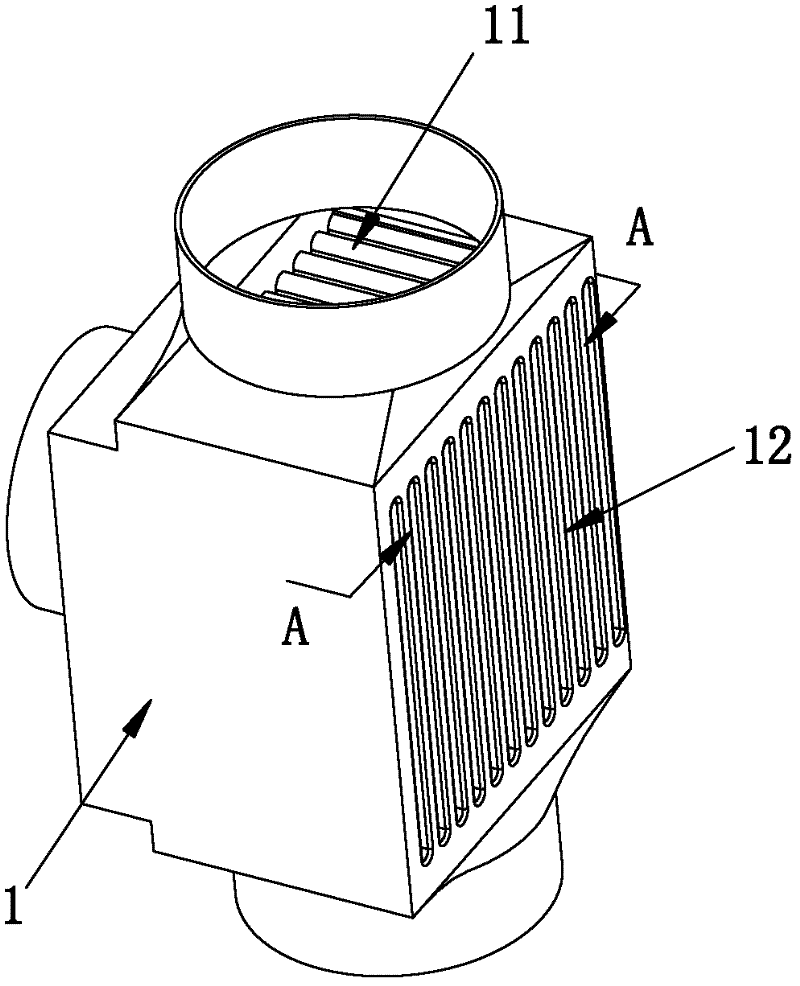

[0052] Such as figure 1 with figure 2 As shown, the clothes dryer according to the present invention includes a clothes bucket 2, an air outlet, a filter 3, a condenser 1, a water collection box 4, a drying fan 5, a heating device 6 and an air inlet. The tuyere is communicated with the condenser 1, the condenser 1 is communicated with the water collecting box 4, the water collecting box 4 is communicated with the air inlet, the filter 3 is arranged between the air outlet and the condenser 1, and the drying fan 5 and the heating device 6 are arranged successively. Between the water collection box 4 and the air inlet (the air outlet and the air inlet are not shown in the figure). The water collecting box 4 communicates with the outside through the drain pump 41 , and the water collecting box 4 is provided with a water level sensor switch 42 for controlling the opening of the drain pump 41 .

[0053] Wherein clothes bucket 2, air outlet, filter 3, drying fan 5, heating device ...

Embodiment 2

[0060] Such as Figure 5 to Figure 7 As shown, the present invention adds a waste heat recovery device 7 on the basis of Embodiment 1. The waste heat recovery device 7 is set between the filter 3 and the condenser 1, and is also set between the water collection box 4 and the drying fan 5 In the meantime, the waste heat recovery device 7 is provided with two sets of air flow paths, which are hot and humid air path 71 and waste heat recovery air path 72 respectively. The two sets of air flow paths form a heat exchange structure, and the hot and humid air path 71 communicates with the filter 3 and the device 1, the waste heat recovery air path 72 is connected to the water collection box 4 and the drying fan 5, and the hot and humid air comes out from the air outlet of the clothes tub 2 and then passes through the hot and humid air air path 71 of the waste heat recovery device 7, the condenser 1, and the water collecting box 4, and then through the waste heat recovery air path 72 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com