Heat regenerator of original surface for gas turbine

A gas turbine and regenerator technology, which is applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve the problem of reduced heat exchange effect, large difference in flow velocity, undetermined ratio of air and gas flow passages on both sides, etc. problems, to achieve the effect of improving service life, high heat exchange efficiency, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Accompanying drawing is the specific embodiment of the present invention.

[0031] Below in conjunction with accompanying drawing, the specific content of the present invention is described in further detail:

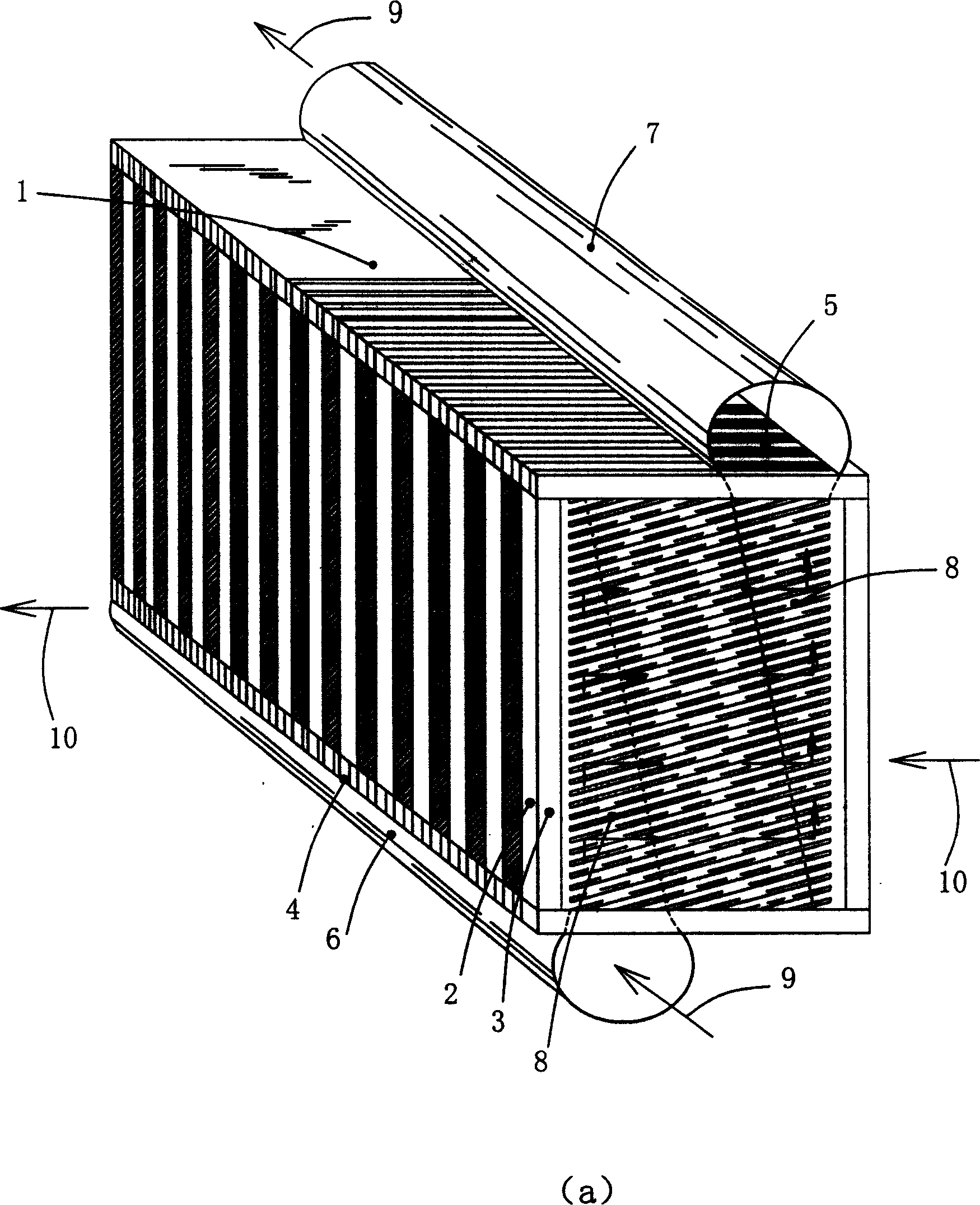

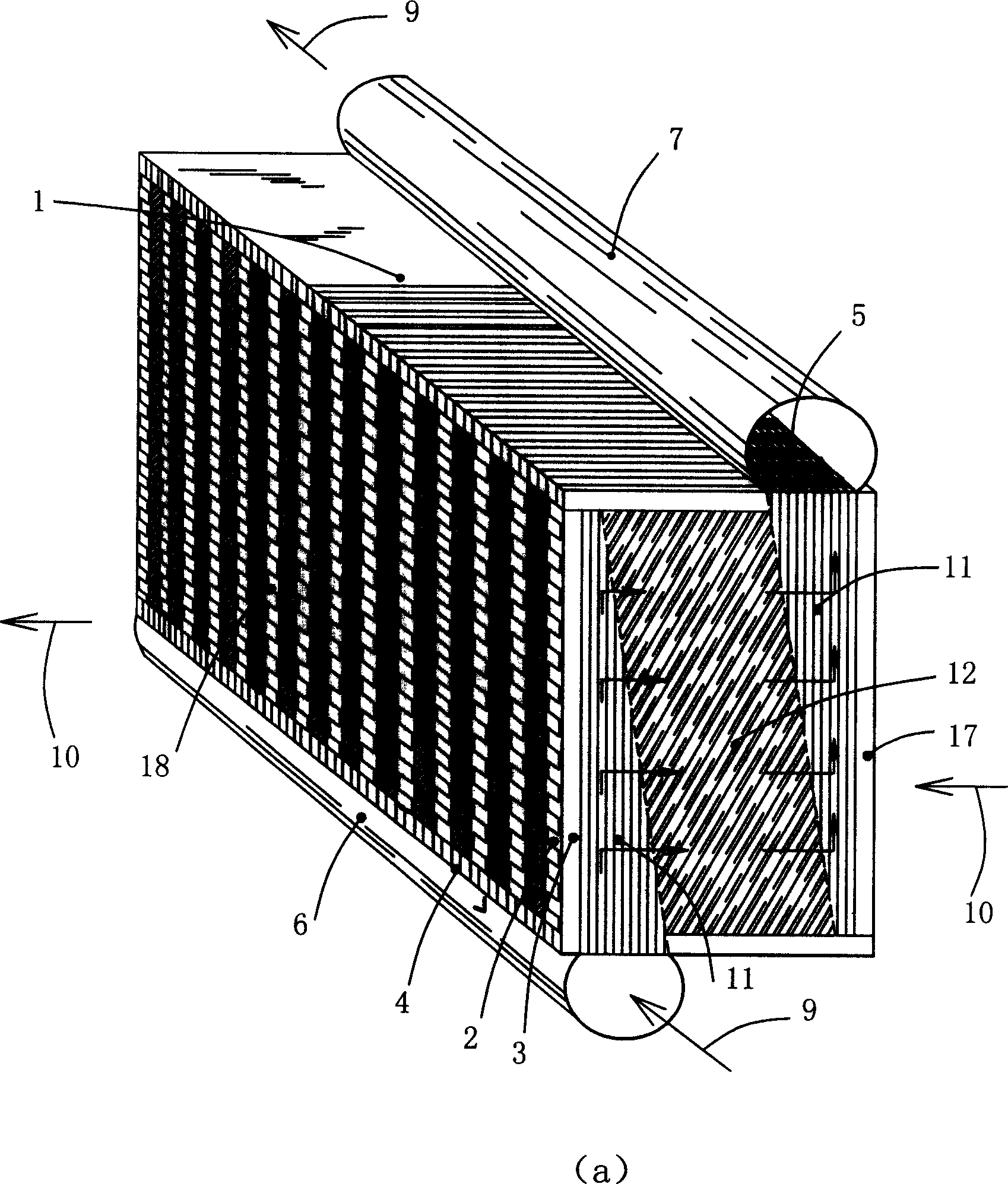

[0032] refer to figure 2 As shown in (a), the original surface regenerator is composed of the main body 1 welded with the air inlet and outlet circular channels 6, 7, the main body 1 is formed by welding together a plurality of heat exchange plates 2, 3, and the heat exchange plates are formed when welding Air inlet and outlet 4, 5, air inlet and outlet circular channels 6, 7 are respectively parallel to air inlet 4 and air outlet 5, and are respectively welded on two opposite corners of the regenerator, and the air flows along the direction shown in 9 Enter the port 4, enter the heat exchange corrugated area 12 through the deflector 11, and then lead out of the main body 1 along the other side of the deflector 11, and flow out of the regenerator along the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com