Patents

Literature

1922 results about "Oil cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil cooling is the use of engine oil as a coolant, typically to remove surplus heat from an internal combustion engine. The hot engine transfers heat to the oil which then usually passes through a heat-exchanger, typically a type of radiator known as an oil cooler. The cooled oil flows back into the hot object to cool it continuously.

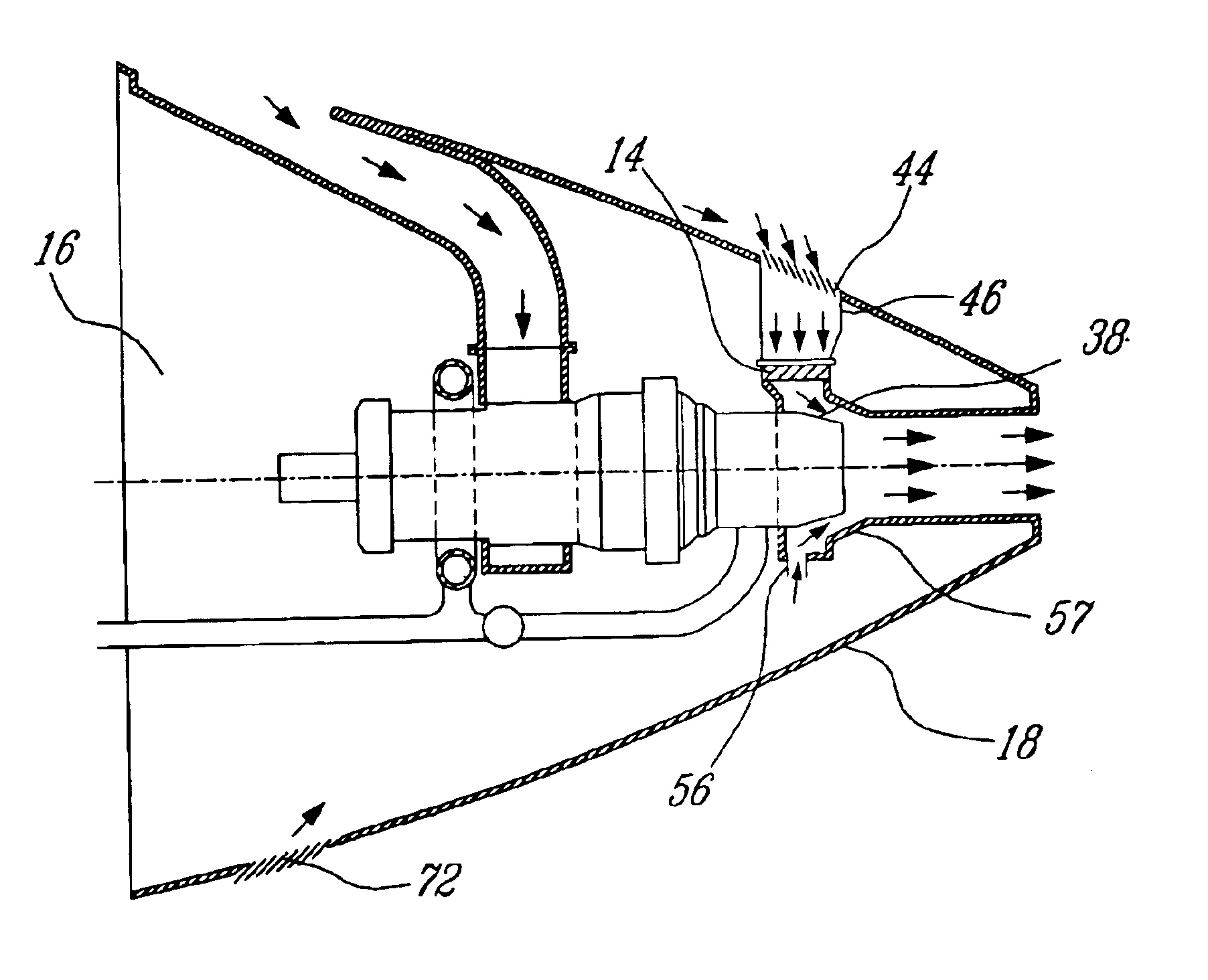

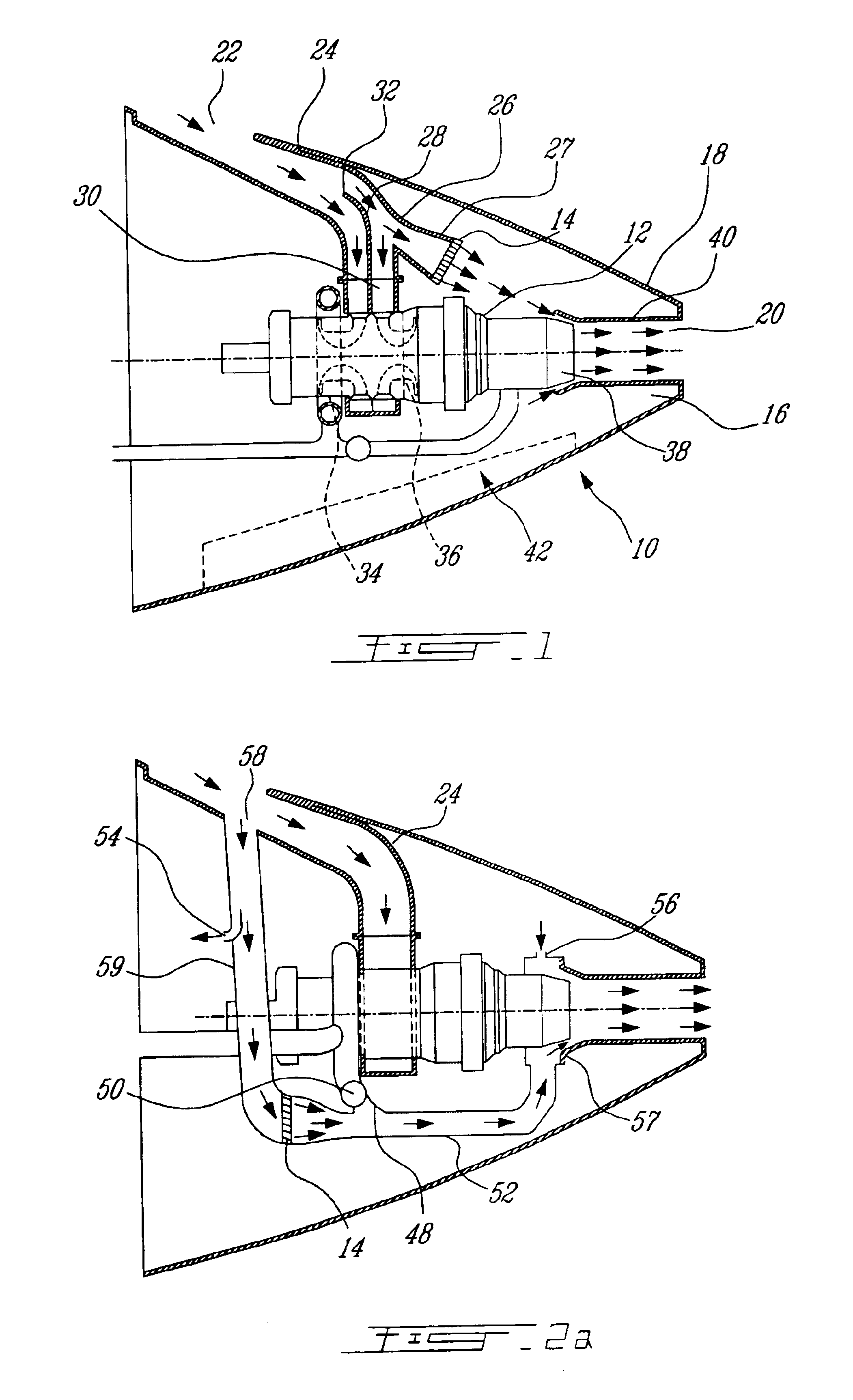

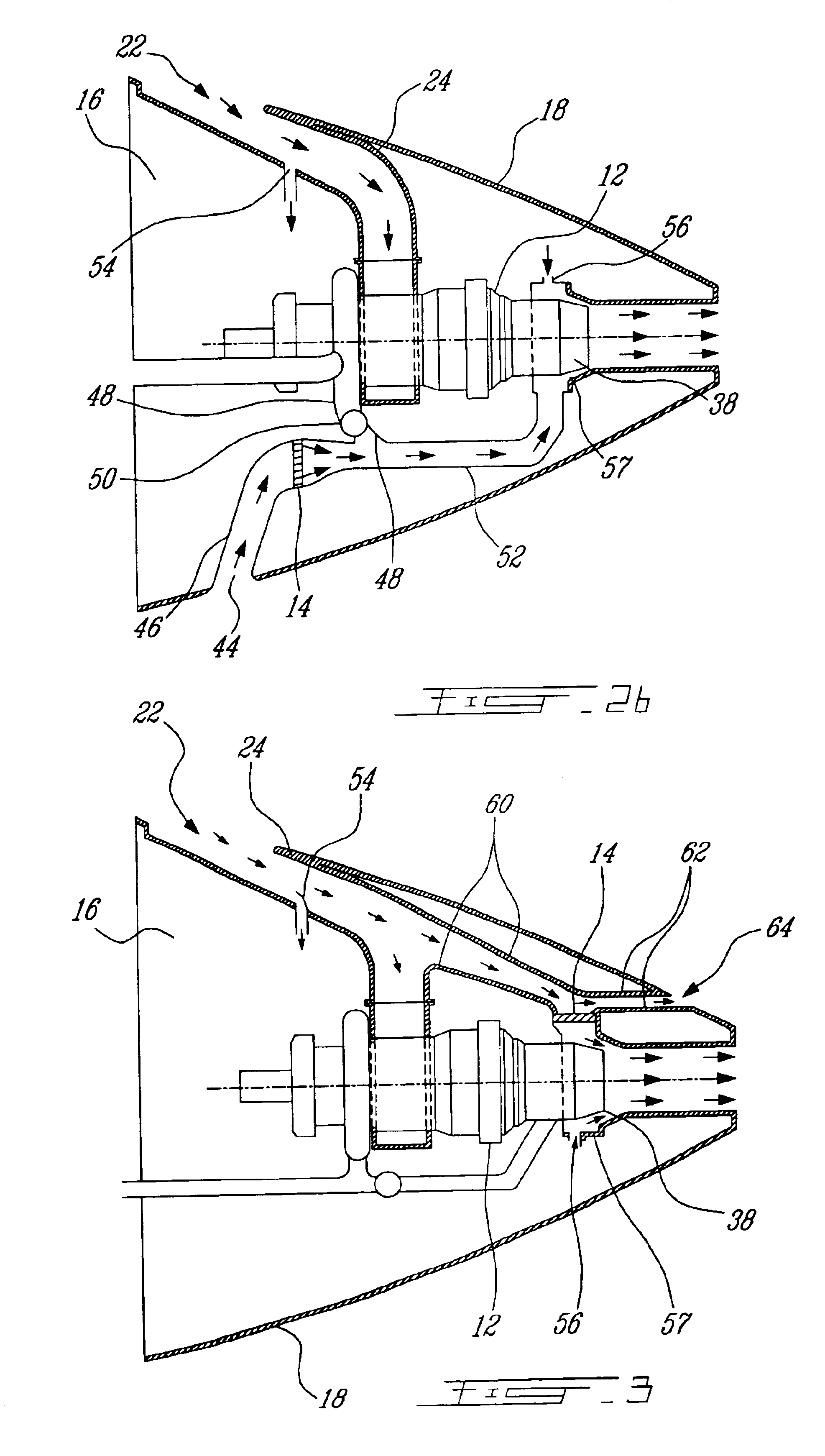

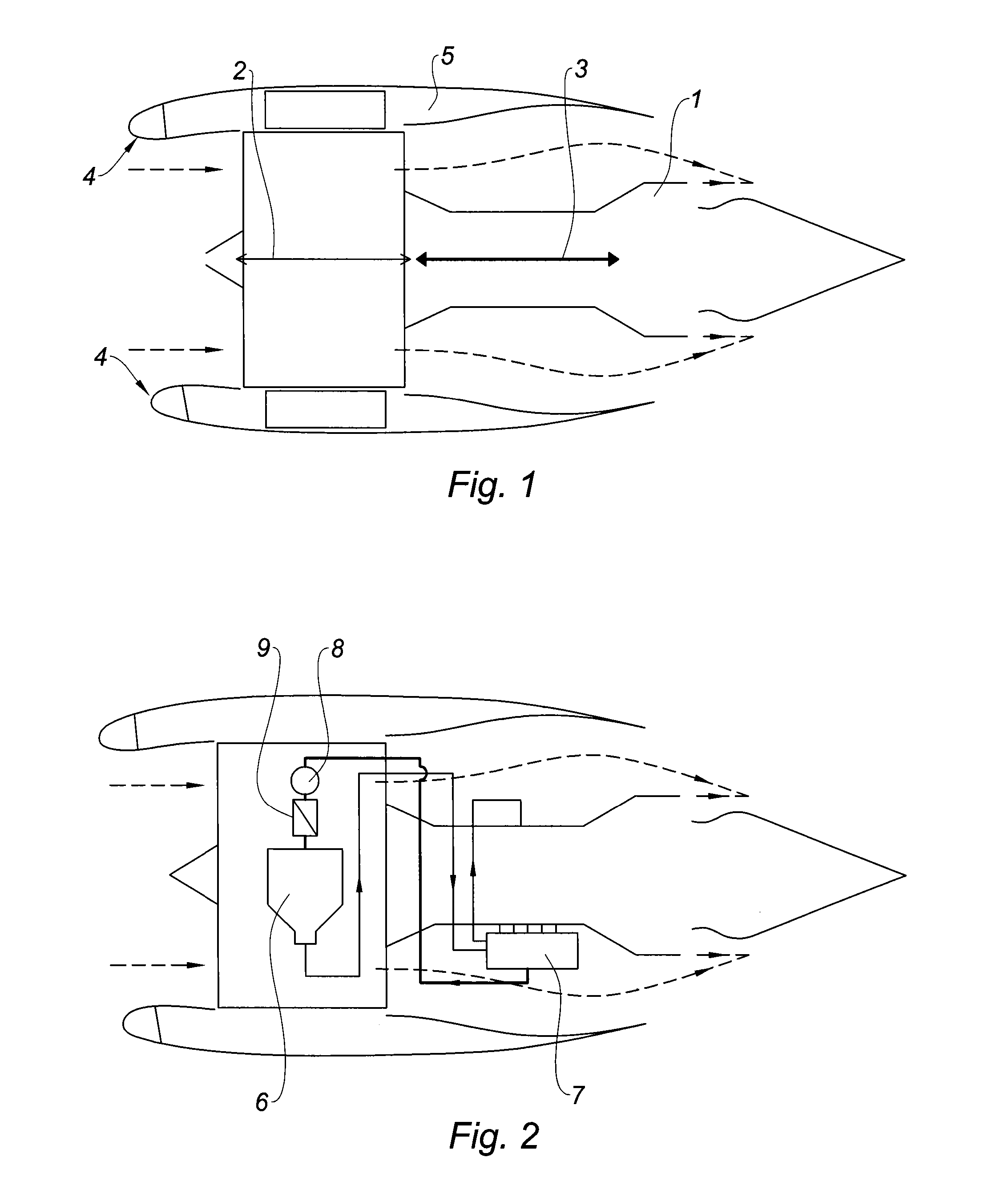

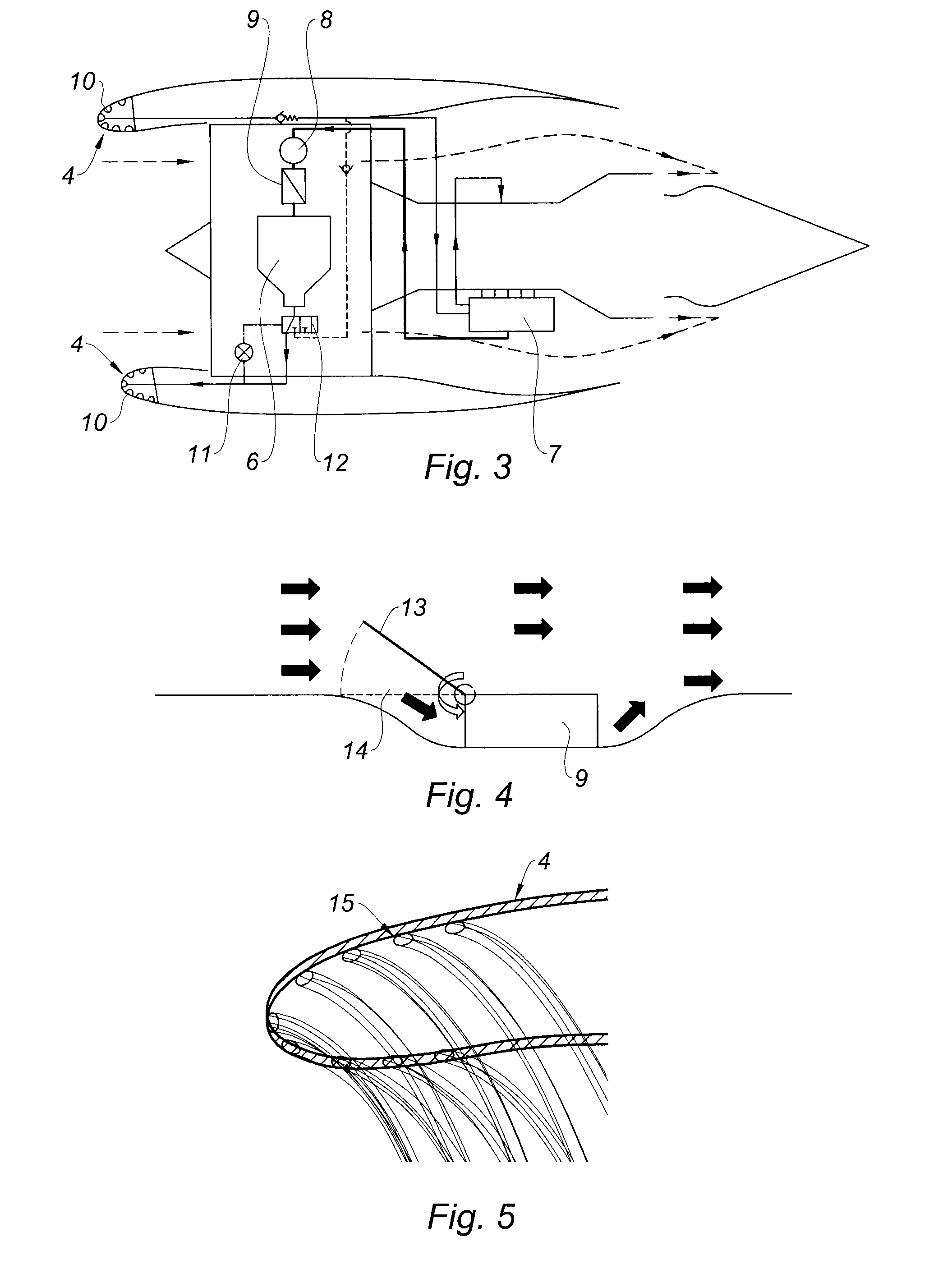

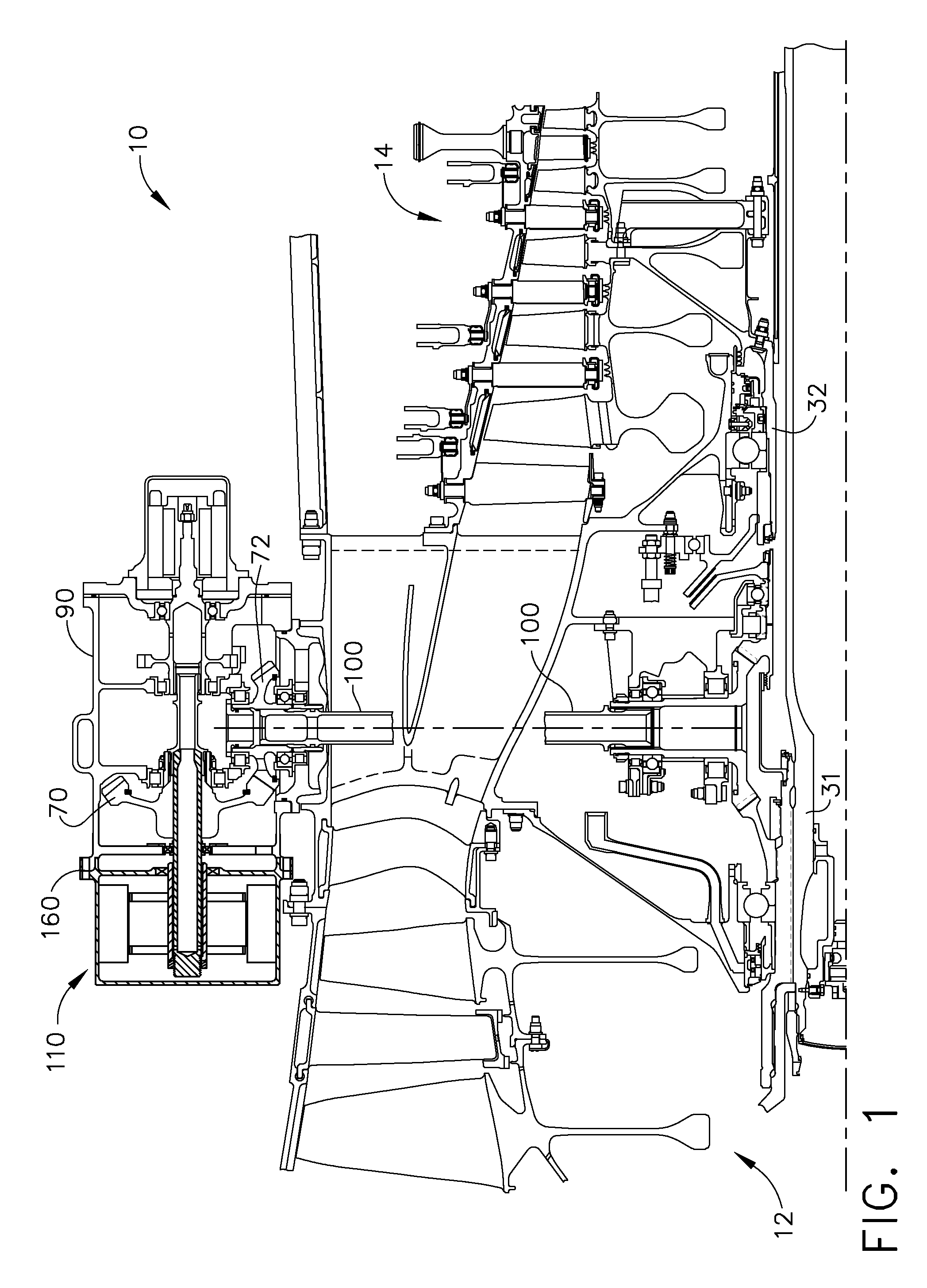

Passive cooling system for auxiliary power unit installation

InactiveUS6942181B2Improve cooling effectEnhanced cooling airflowPower plant cooling arrangmentsAir-treating devicesAuxiliary power unitOil cooling

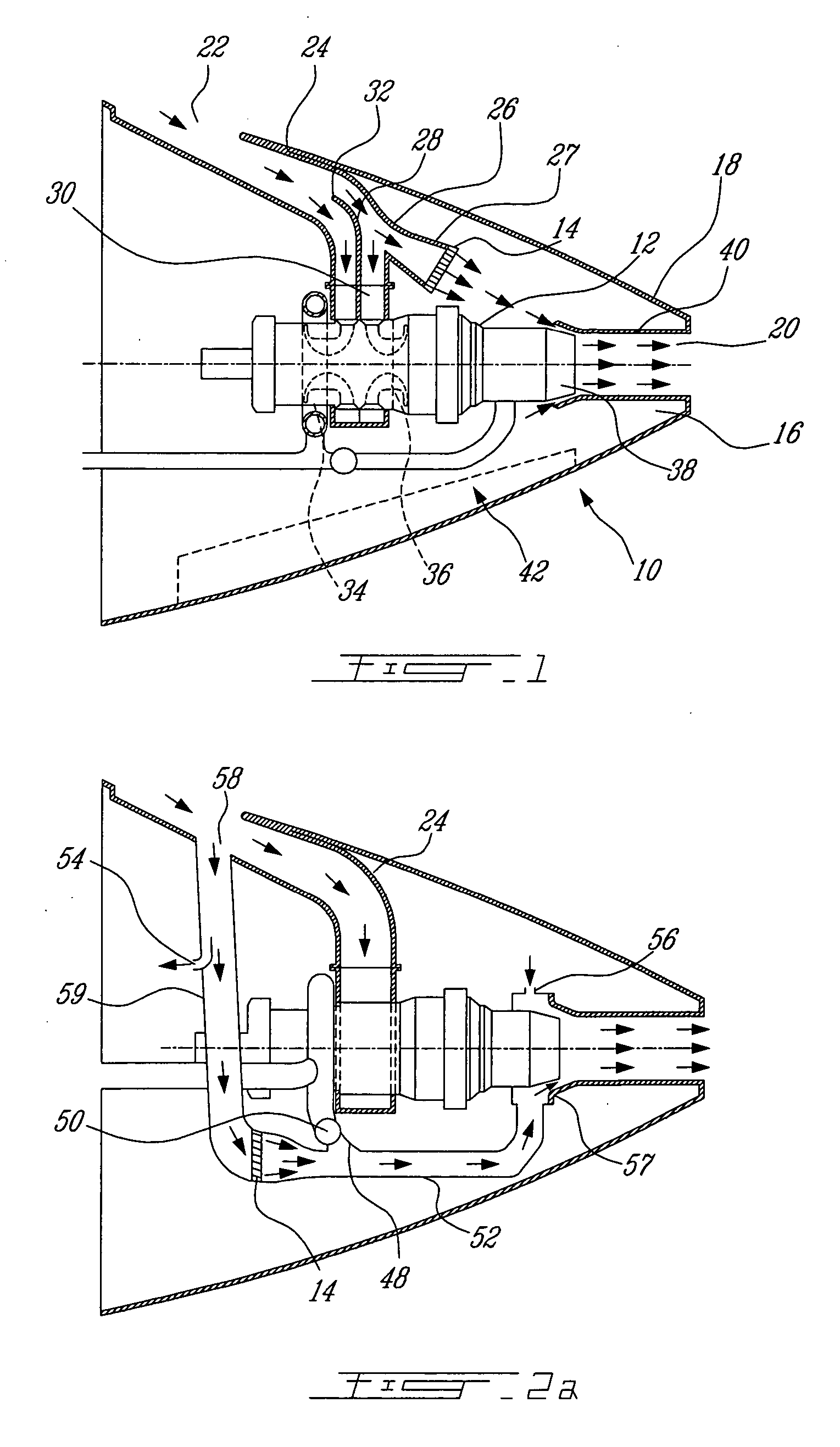

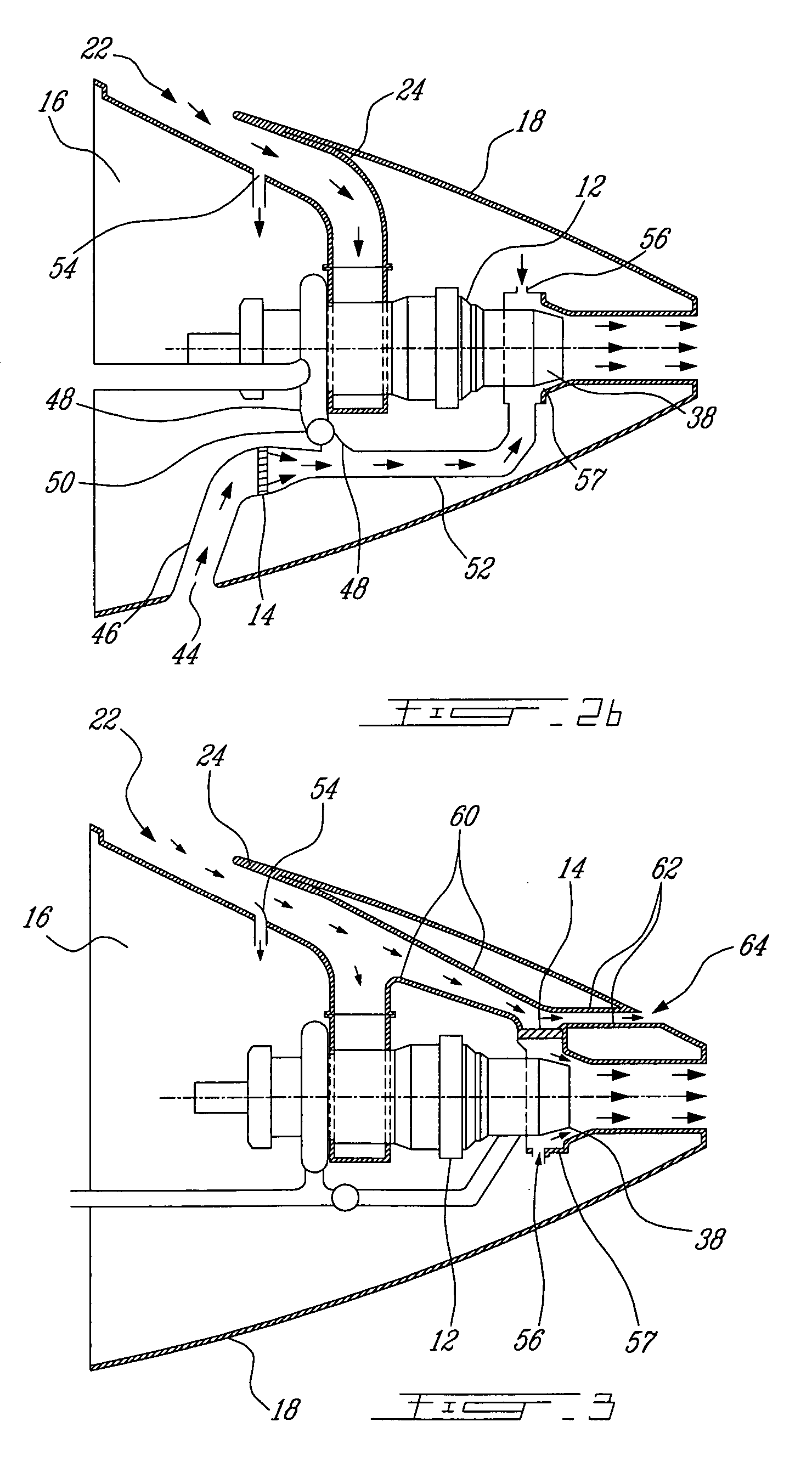

A passive cooling system for an auxiliary power unit (APU) installation on an aircraft is provided. The system is for an auxiliary power unit having at least a compressor portion of a gas turbine engine and an oil cooler contained separately within a nacelle. The system includes the auxiliary power unit housed within the nacelle of the aircraft, an engine exhaust opening defined in the aft portion of the nacelle and communicating with the gas turbine engine, at least a first air inlet duct communicating with a second opening defined in said nacelle and with said compressor portion and the oil cooler is located within a second duct communicating with an opening other than the engine exhaust opening of said nacelle and with the engine exhaust opening. Exterior cooling air and engine exhaust ejected through said engine exhaust opening entrain cooling air through said second duct to said oil cooler, and thus provide engine oil cooling. An exhaust eductor is also provided.

Owner:PRATT & WHITNEY CANADA CORP

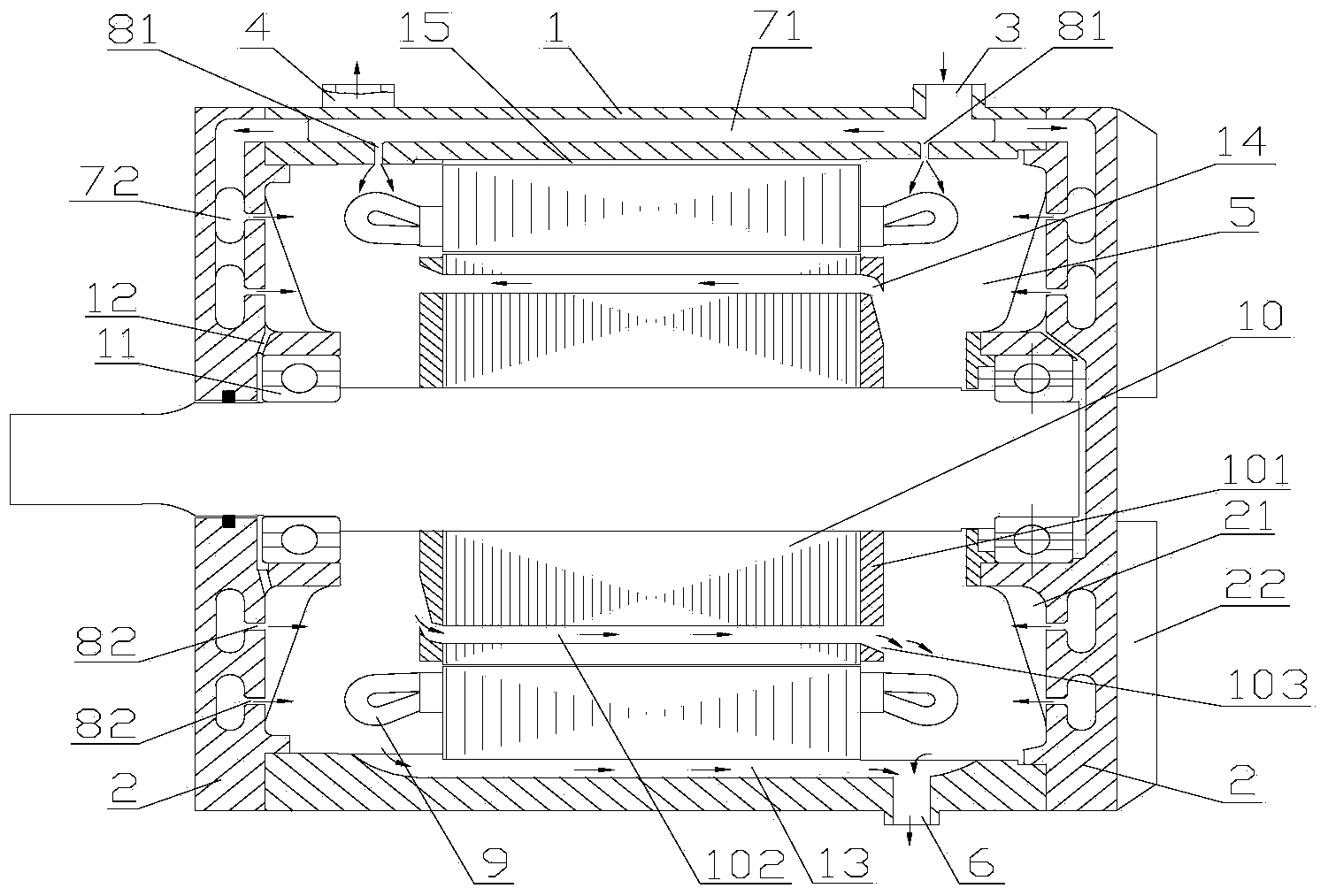

Permanent magnet synchronous traction motor and oil cooling device thereof

ActiveCN103532307AAchieve coolingImprove cooling effectCooling/ventillation arrangementSupports/enclosures/casingsWork performanceOil cooling

The invention discloses an oil cooling device used for a permanent magnet synchronous traction motor. The oil cooling device comprises a cooling channel formed in a shell and an end cover; the cooling channel is communicated with an external oil supplying pipeline by an oil inlet and is communicated with an external oil returning pipeline by a first oil outlet; an oil spraying port is formed in the shell and / or the end cover and is communicated with the cooling channel and an inner cavity of the permanent magnet synchronous traction motor; a second oil outlet is formed in the shell; the inner cavity is communicated with the external oil returning pipeline by the second oil outlet to guide cooling oil in the inner cavity. In such a mode, the oil cooling device can realize the direct cooling of the shell and the end cover, and meanwhile, the inner structure of the shell can be directly and effectively cooled by the cooling oil entering the inner cavity from the oil spraying port, so the cooling efficiency of the oil cooling device is improved, and the work performance of the oil cooling device is improved. The invention also discloses a permanent magnet synchronous traction motor comprising the oil cooling device.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST +1

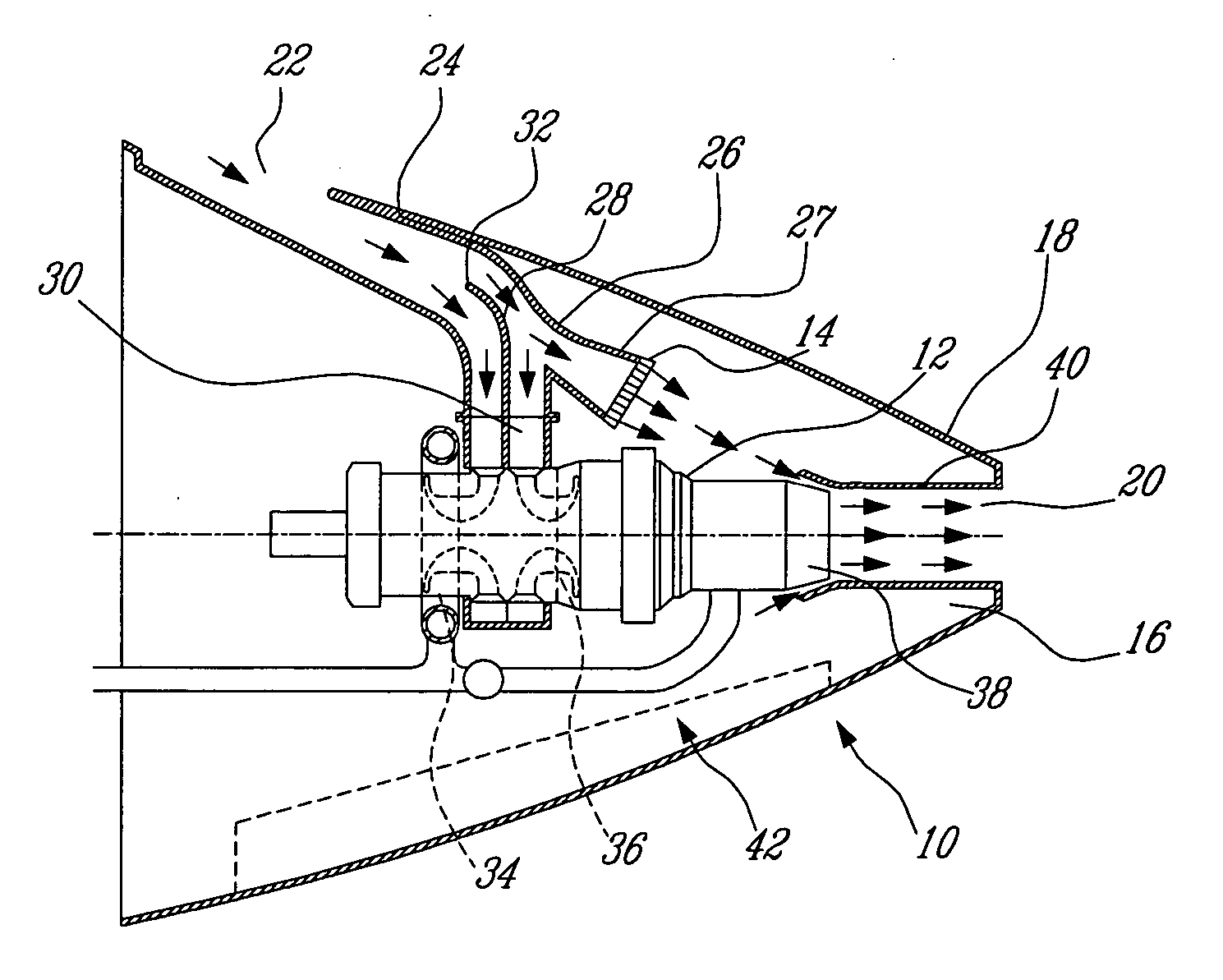

Regulated oil cooling system for a turbine engine with deicing of the nacelle

InactiveUS20140205446A1Many timesDischarging heatPump componentsGas turbine plantsNacelleCooling capacity

The invention relates to an oil cooling system of a turbine engine installed in an aircraft comprising a circuit suitable for circulating the oil between the engine and at least one external heat exchanger placing the oil in thermal communication with a part of the lip of the nacelle, wherein it also comprises at least one air / oil heat exchanger placing the oil in thermal communication with the air circulating in the cold zone of the turbine engine, equipped with a device suitable for varying its oil cooling capacity, and with a control means for said cooling capacity variation device.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

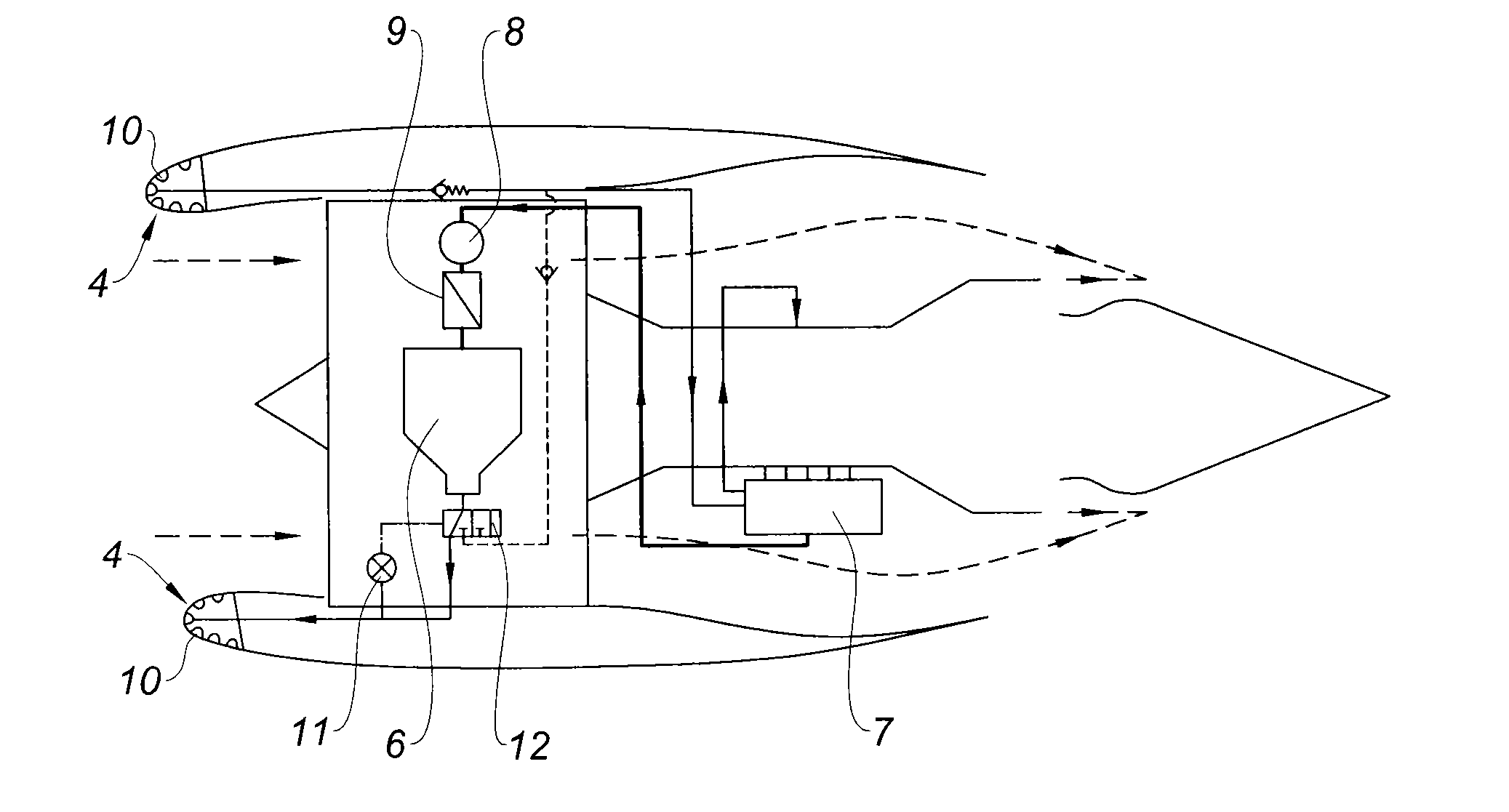

Passive cooling system for auxiliary power unit installation

InactiveUS20070063098A1Improve cooling effectEnhanced cooling airflowPower plant cooling arrangmentsPower installationsNacelleAir entrainment

A passive cooling system for an auxiliary power unit (APU) installation on an aircraft is provided. The system is for an auxiliary power unit having at least a compressor portion of a gas turbine engine and an oil cooler contained separately within a nacelle. The system includes the auxiliary power unit housed within the nacelle of the aircraft, an engine exhaust opening defined in the aft portion of the nacelle and communicating with the gas turbine engine, at least a first air inlet duct communicating with a second opening defined in said nacelle and with said compressor portion and the oil cooler is located within a second duct communicating with an opening other than the engine exhaust opening of said nacelle and with the engine exhaust opening. Exterior cooling air and engine exhaust ejected through said engine exhaust opening entrain cooling air through said second duct to said oil cooler, and thus provide engine oil cooling. An exhaust eductor is also provided.

Owner:PRATT & WHITNEY CANADA CORP

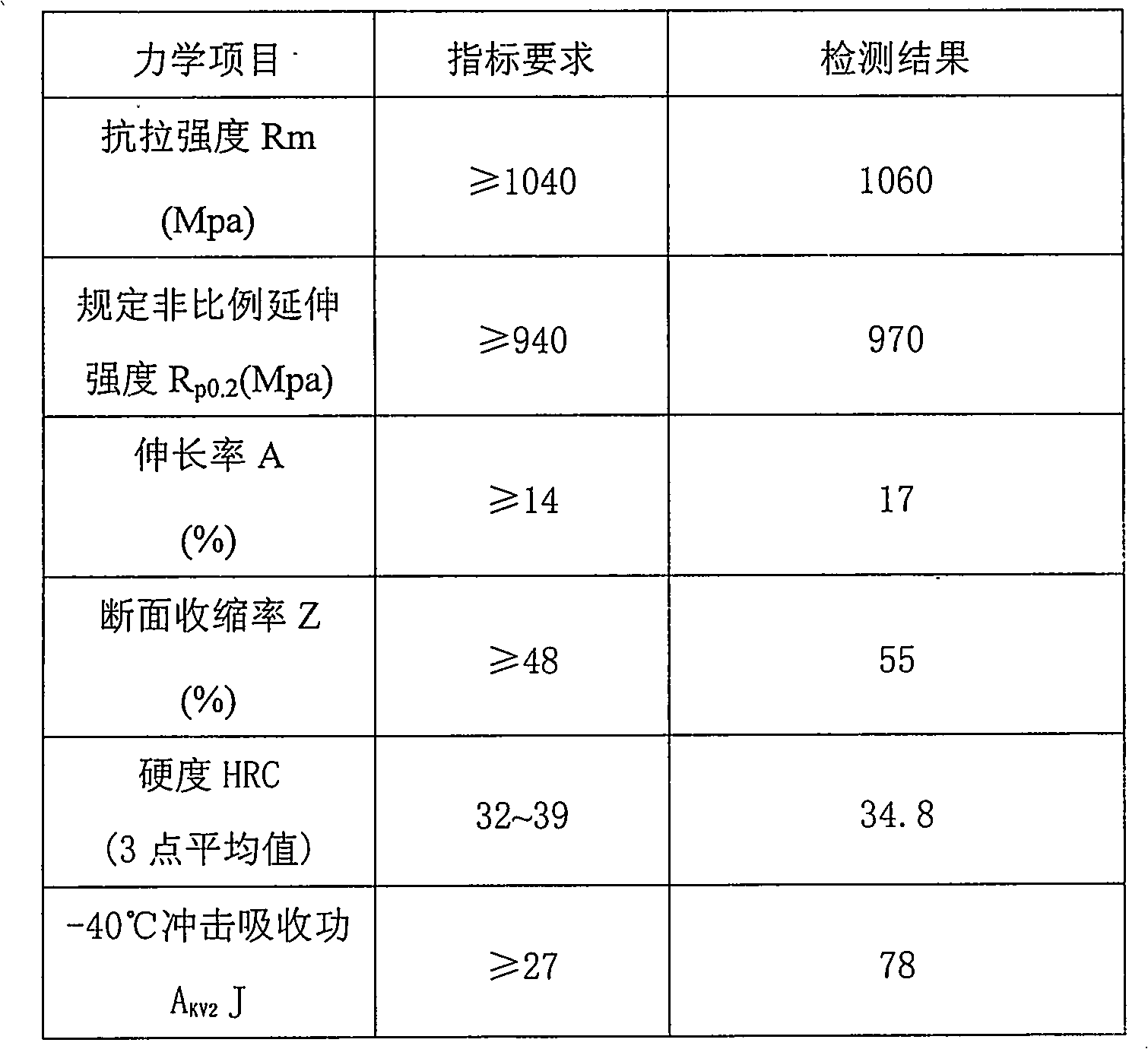

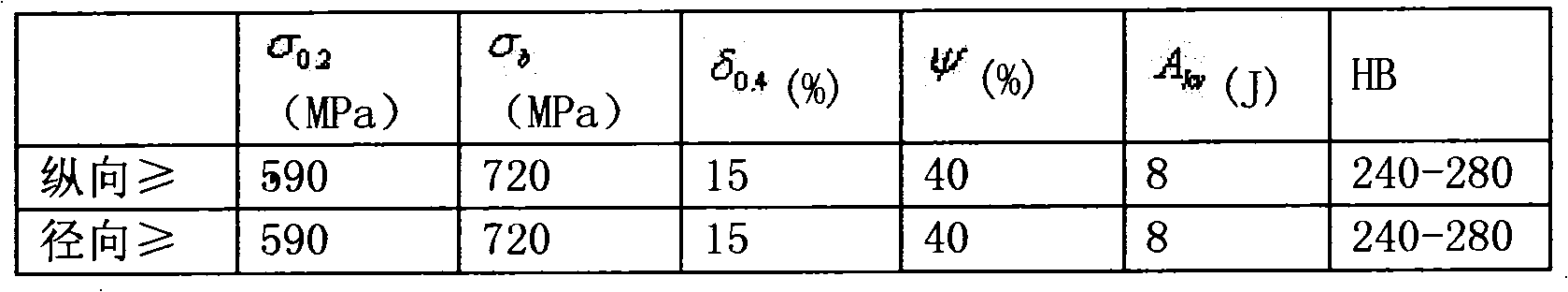

Low-temperature high-strength, high-toughness steel and preparing method therefor

InactiveCN101024870AHigh strengthGuaranteed toughnessHeat treatment process controlLift systemThermal treatment

The invention relates to a low-temperature, high-intensity, high-toughness steel and the making method thereof, applicable to the environment down to -60 deg.C, adopting low-carbon Cr-Ni-Si-Mn-Mo-V alloy, and its chemical composition includes in mass percent (mass%): C: 0.16-0.24,Si:1.0-1.4, Mn:1.10-1.50,Cr:0.80-1.20,Ni:1.00- 1.40,Mo:0.20-0.40,V:0.05-0.20,S=<0.035,P=<0.035,Cu =<0.050, and the rest Fe. And its making method comprises: (1) smelting; (2) forging: heating at 1280-1320deg.C, where initial forging temperature: 1100-1250deg.C, final forging temperature >=850deg.C; annealing after forging, where heating temperature: 700+-30deg.C, and tapping temperature =<300deg.C; (3) thermal treatment: normalizing: air cooling at 930-950deg.C; tempering: air cooling at 790-720deg.C; quenching: oil cooling at 900-930deg.C; and tempering: air cooling at 200-260deg.C; (4) supersonic crack detection and magnetic particle crack detection. And it is especially applied to the materials for flying rings, hocks, pin shafts, etc, in the lifting systems of mechanical facilities.

Owner:RG PETRO MACHINERY GROUP

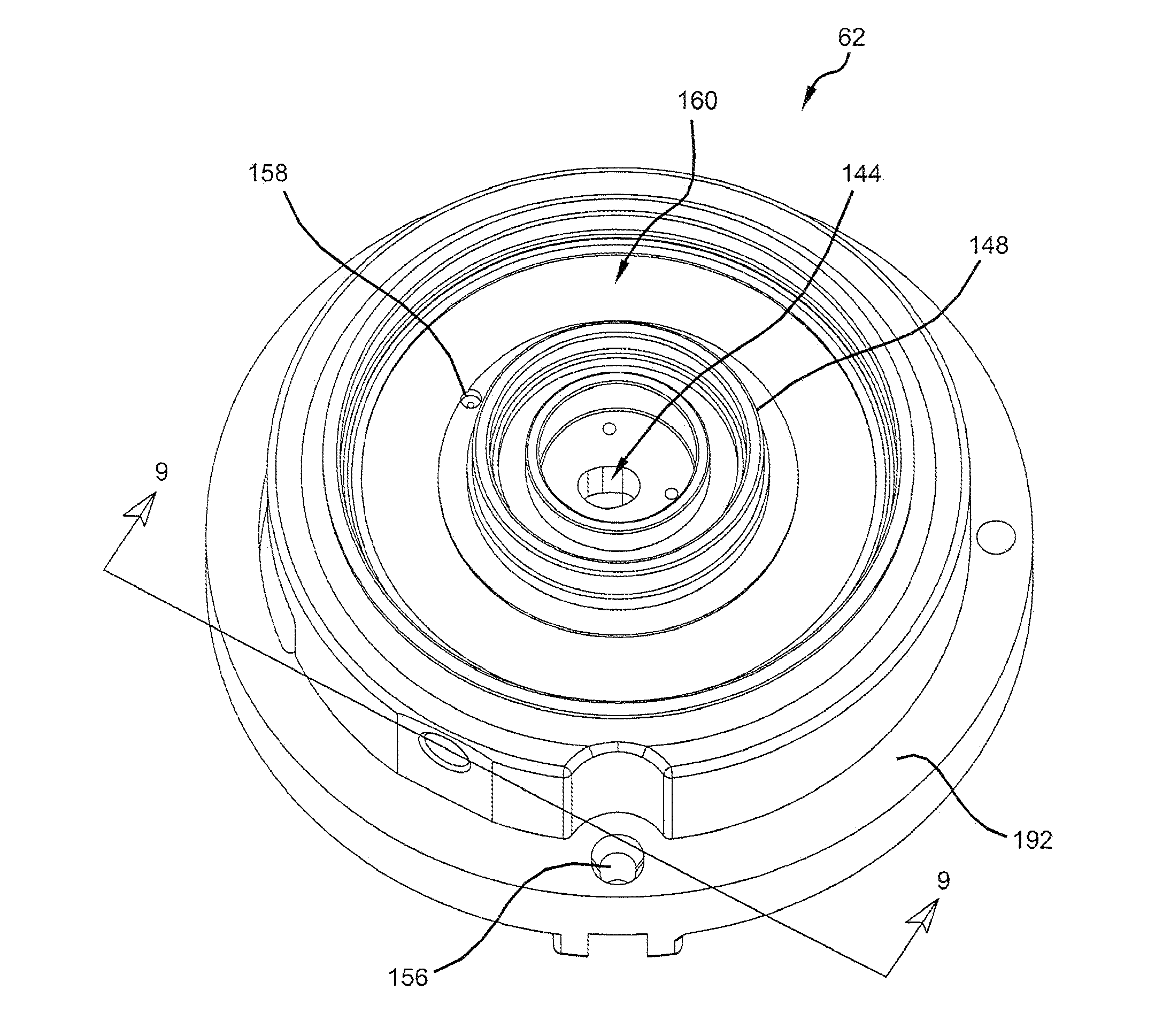

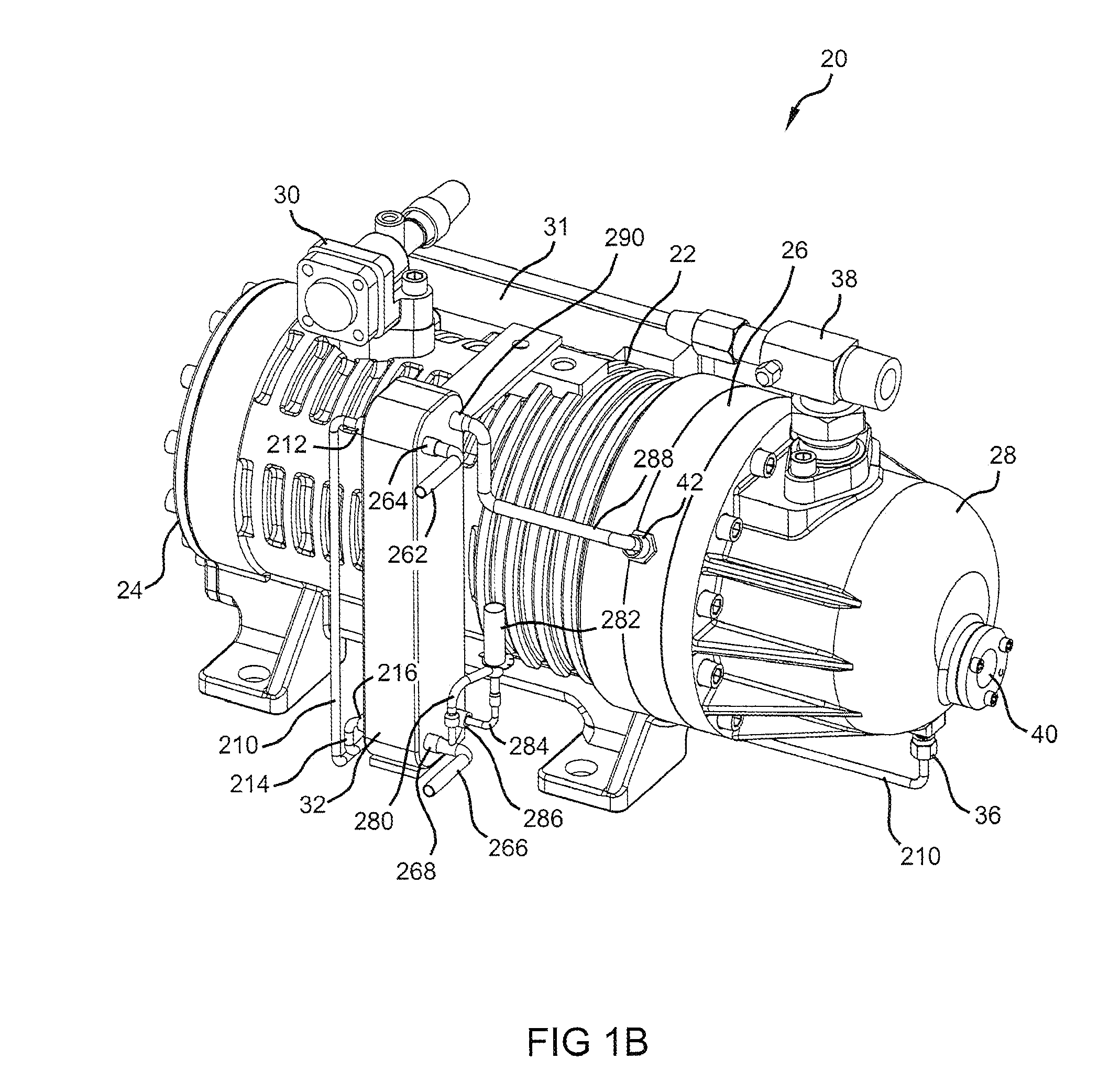

Compressor and oil-cooling system

ActiveUS20100307173A1Reduce suction superheatImproving compressor volumetric efficiencyCompressorRotary/oscillating piston combinations for elastic fluidsWorking fluidEngineering

An external heat exchanger is used to transfer heat from a compressor lubricant to an expanded working fluid, thereby cooling the lubricant. The heat exchanger may also be used to sub-cool condensed working fluid with the same flow of expanded working fluid. A horizontal scroll-type compressor includes an intermediate lubricant sump between a main bearing support and a scroll member. A counterweight on the crankshaft can travel through the lubricant in the intermediate sump to splash the lubricant around. A horizontal scroll-type compressor can include multiple machined surfaces that are utilized to precisely center and align components of the compressor.

Owner:COPELAND LP

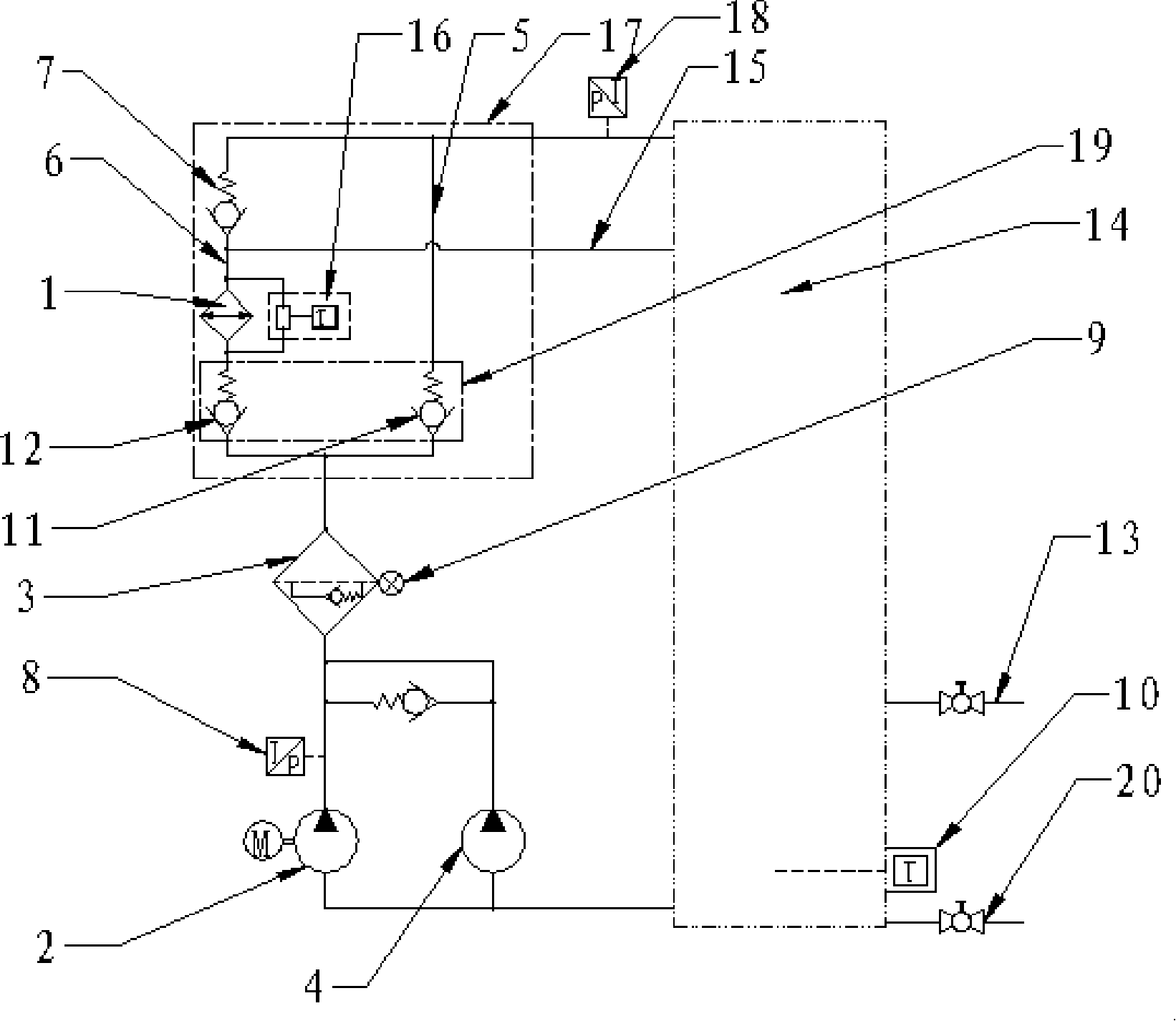

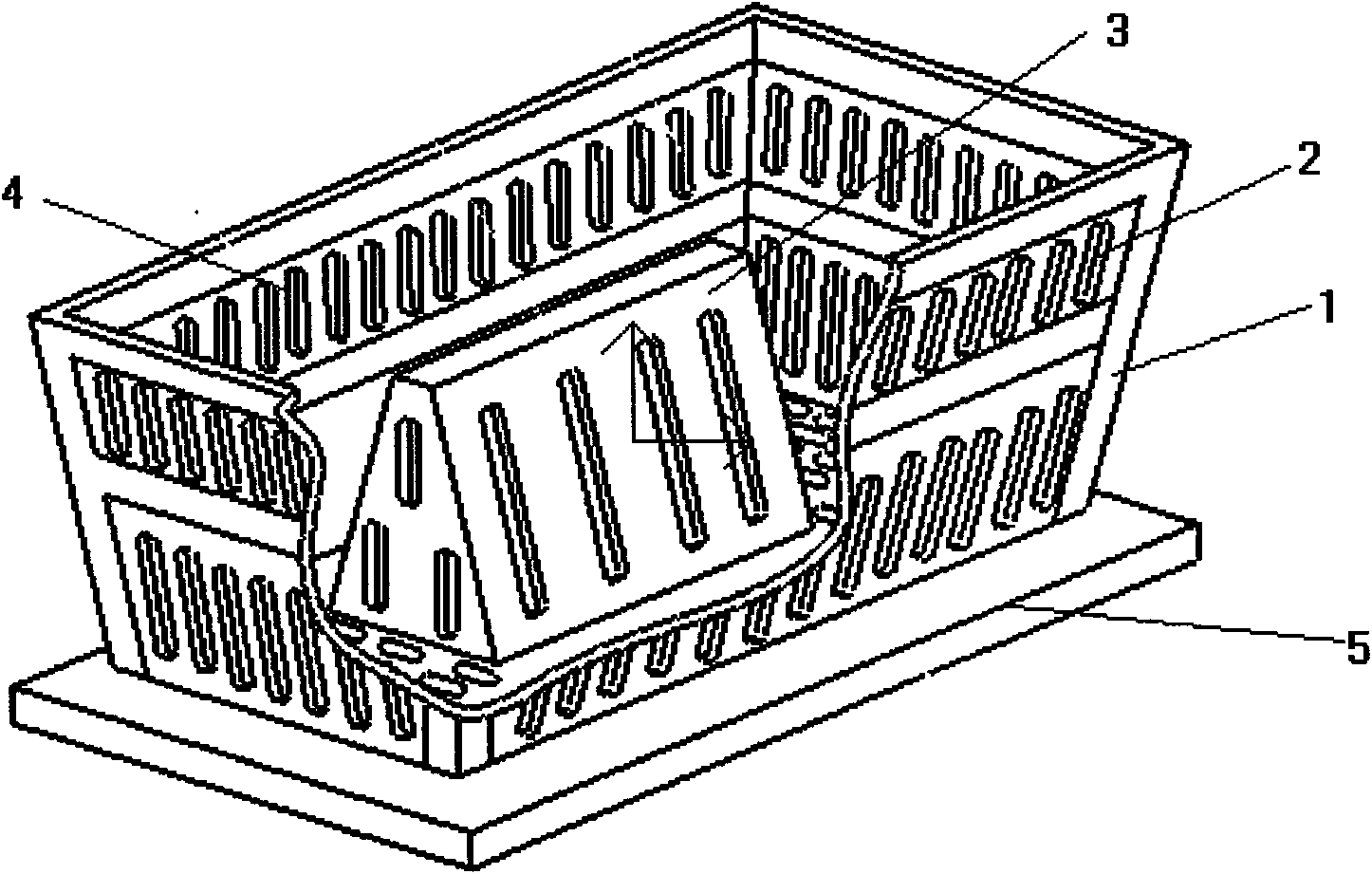

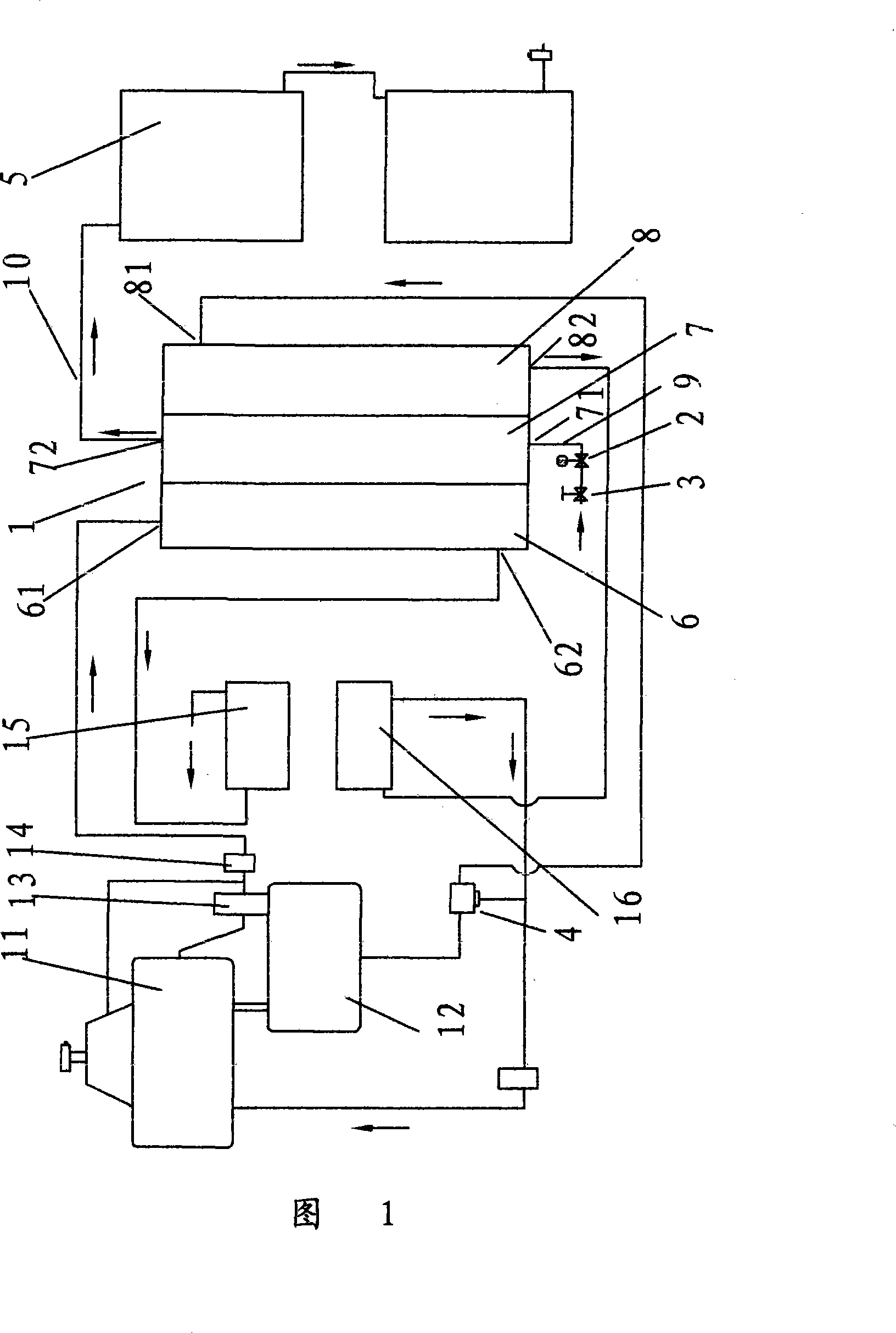

Low temperature wind-driven generator speed increasing engine oil lubrication system

ActiveCN101196176AExtended service lifeImprove protectionGear lubrication/coolingMachines/enginesWind drivenFiltration

The invention discloses a low temperature type wind power generator accelerator oil lubricating system being able to start up under the condition of low temperature. The lubricant in the system enters an electric pump and a mechanical pump after being heated by a heater; the outlets for the electric pump and the mechanical pump are both connected to an oil filtration device; the oil filtration device is communicated with the accelerator via a pipeline system configured with an oil cooling device; the pipeline system comprises a normative open passage and a startup passage connected in parallel; the oil cooling device is positioned on the normative open passage. The normative open passage and the startup passage can switch automatically via a startup one-way valve and a normative open one-way valve; an ultra low pressure one-way valve on the normative open passage is able to provide accident protection for a high-speed axle of the accelerator; a pressure sensor can control the motor of the electric pump via a control circuit, so that the electric pump can supply oil to the system on demand. Therefore, the invention, which enhances the reliability and service life of equipment, can be best applied for the wind power generator system in harsh cold region.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

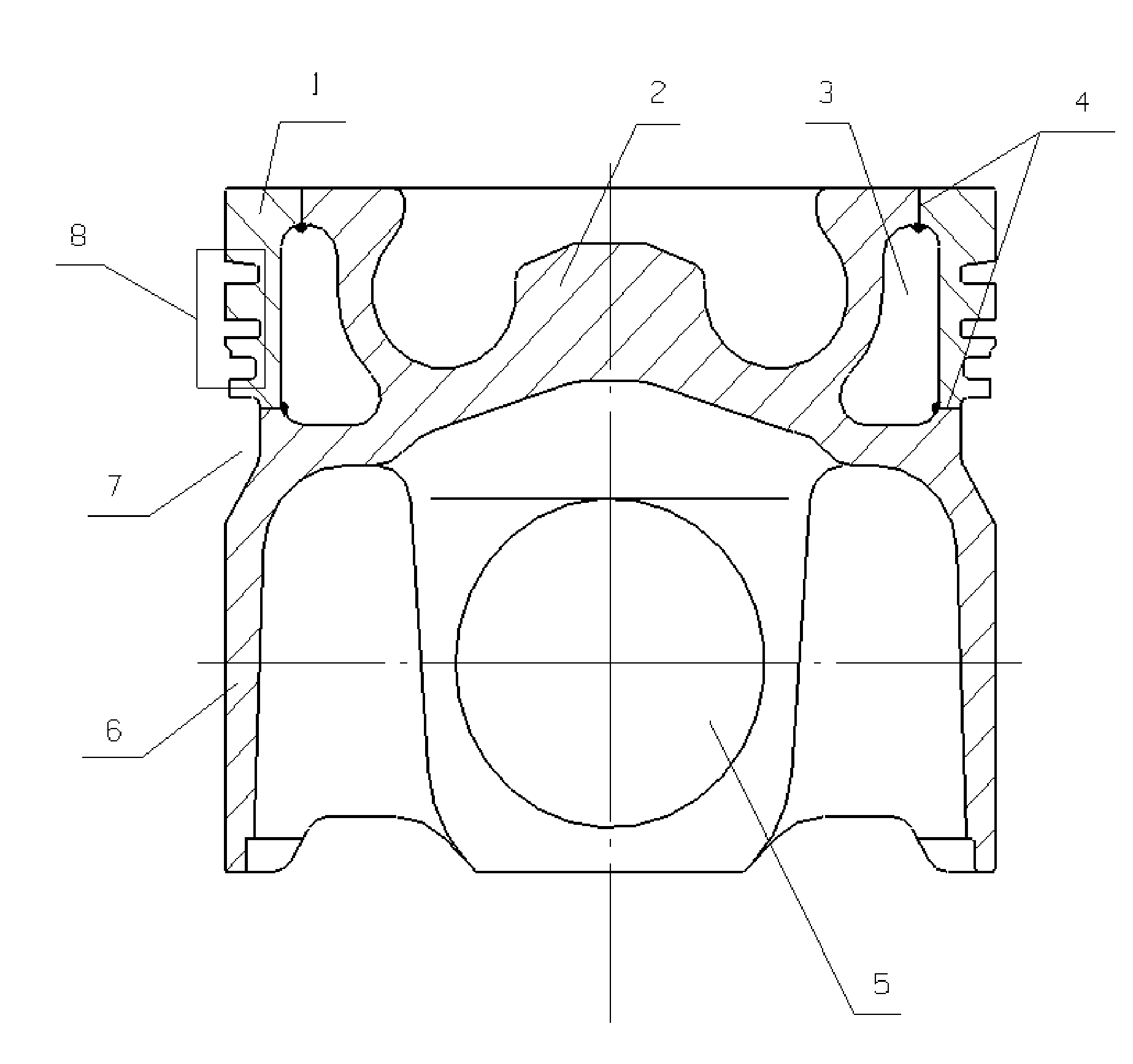

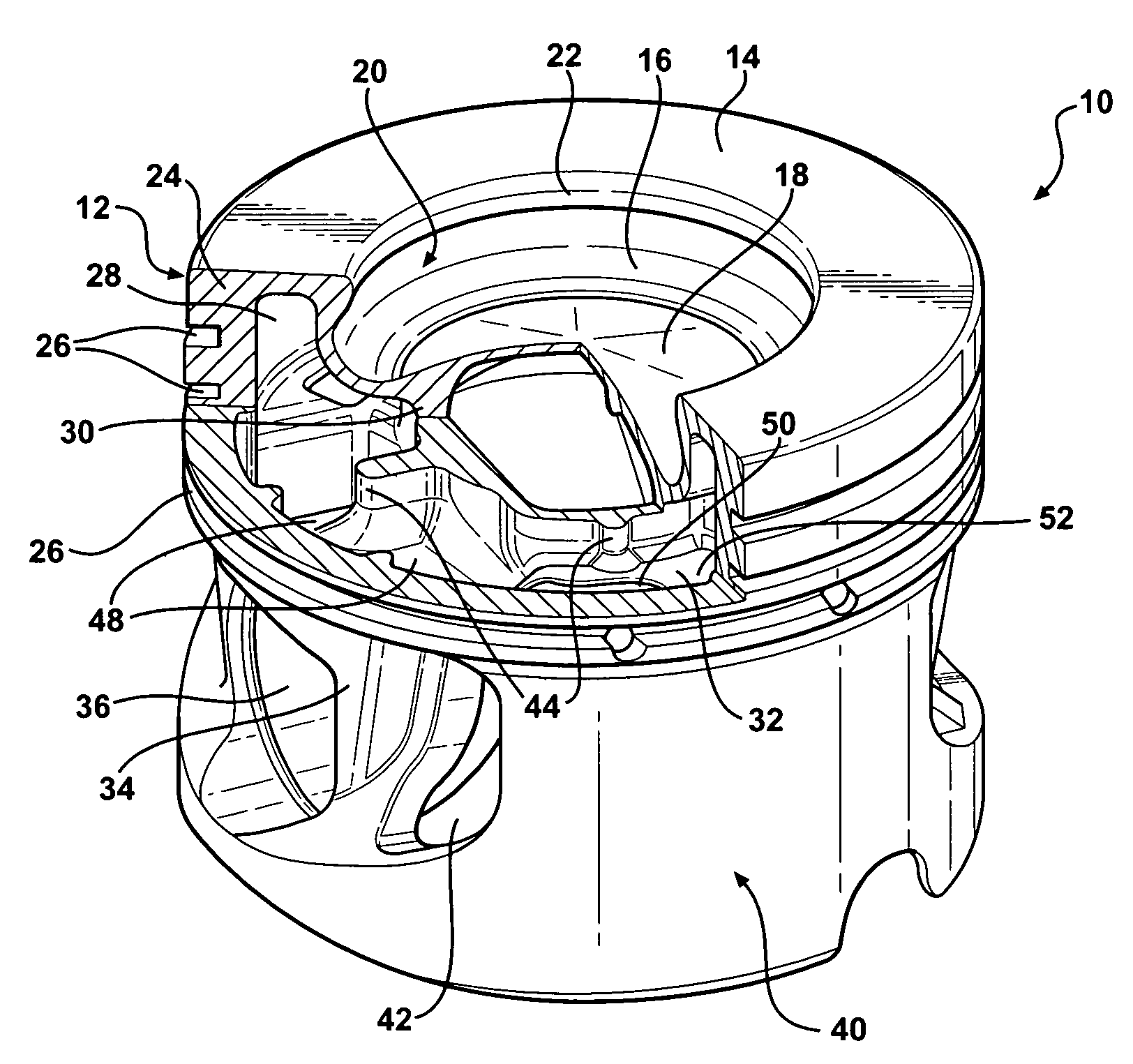

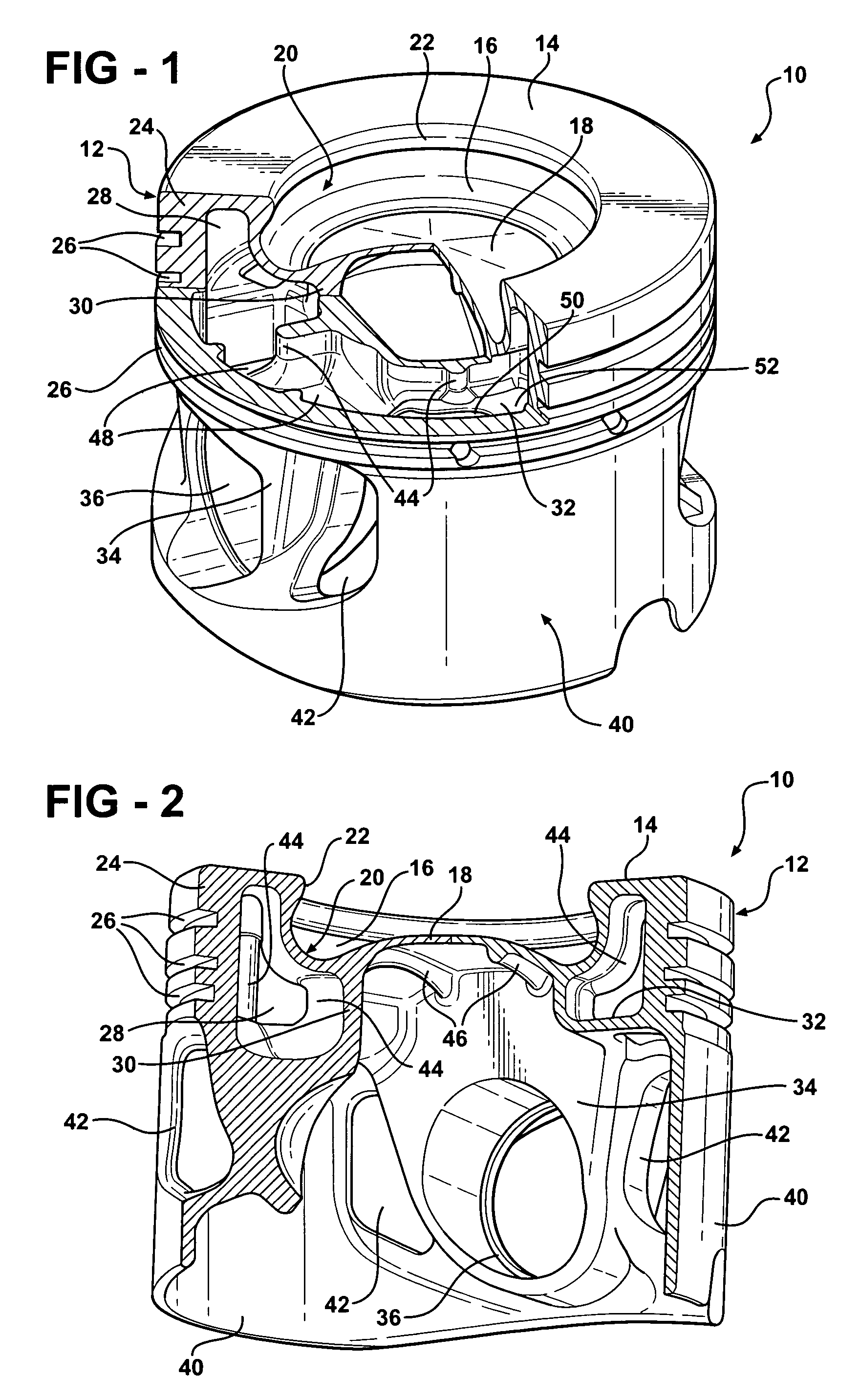

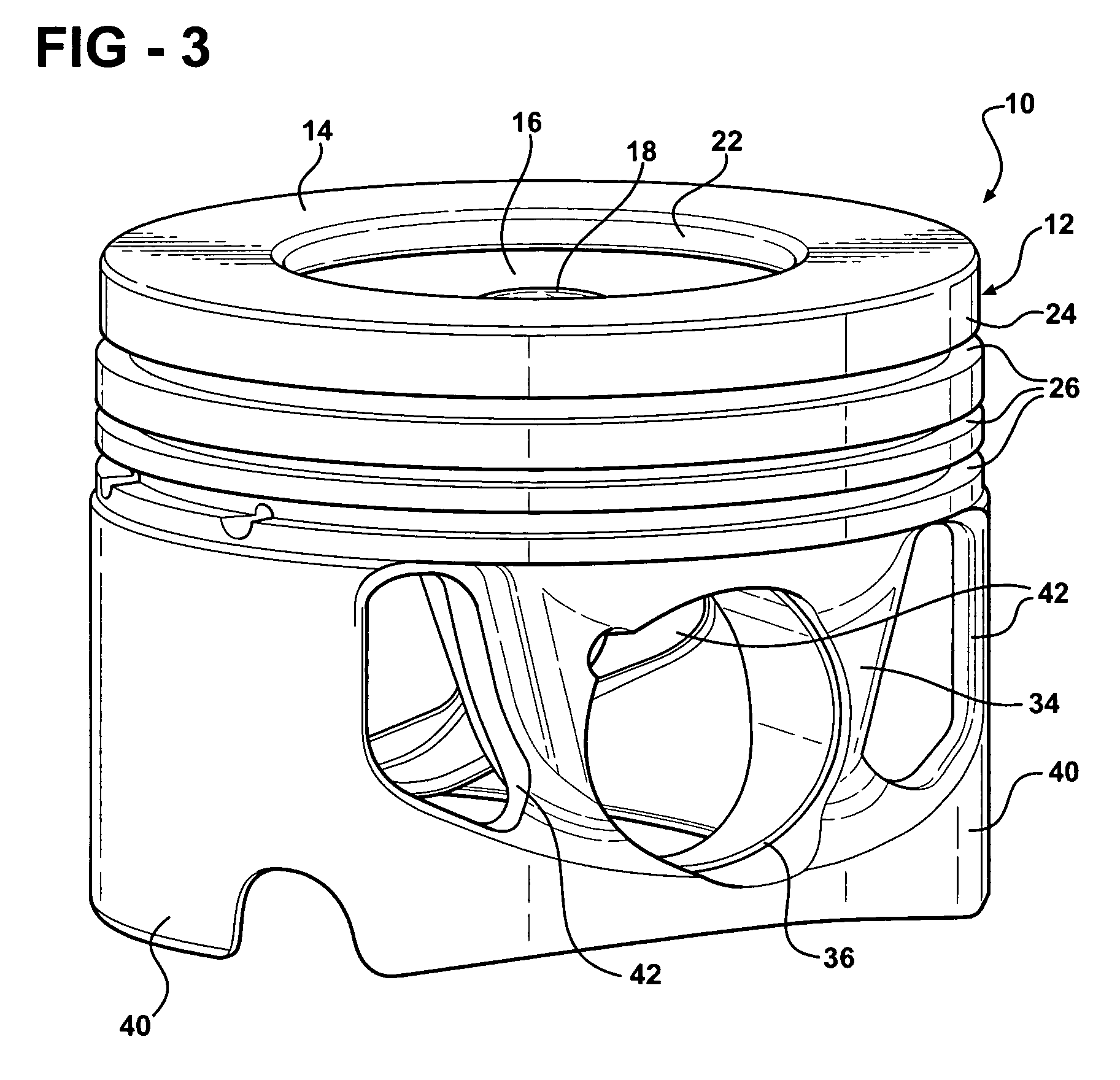

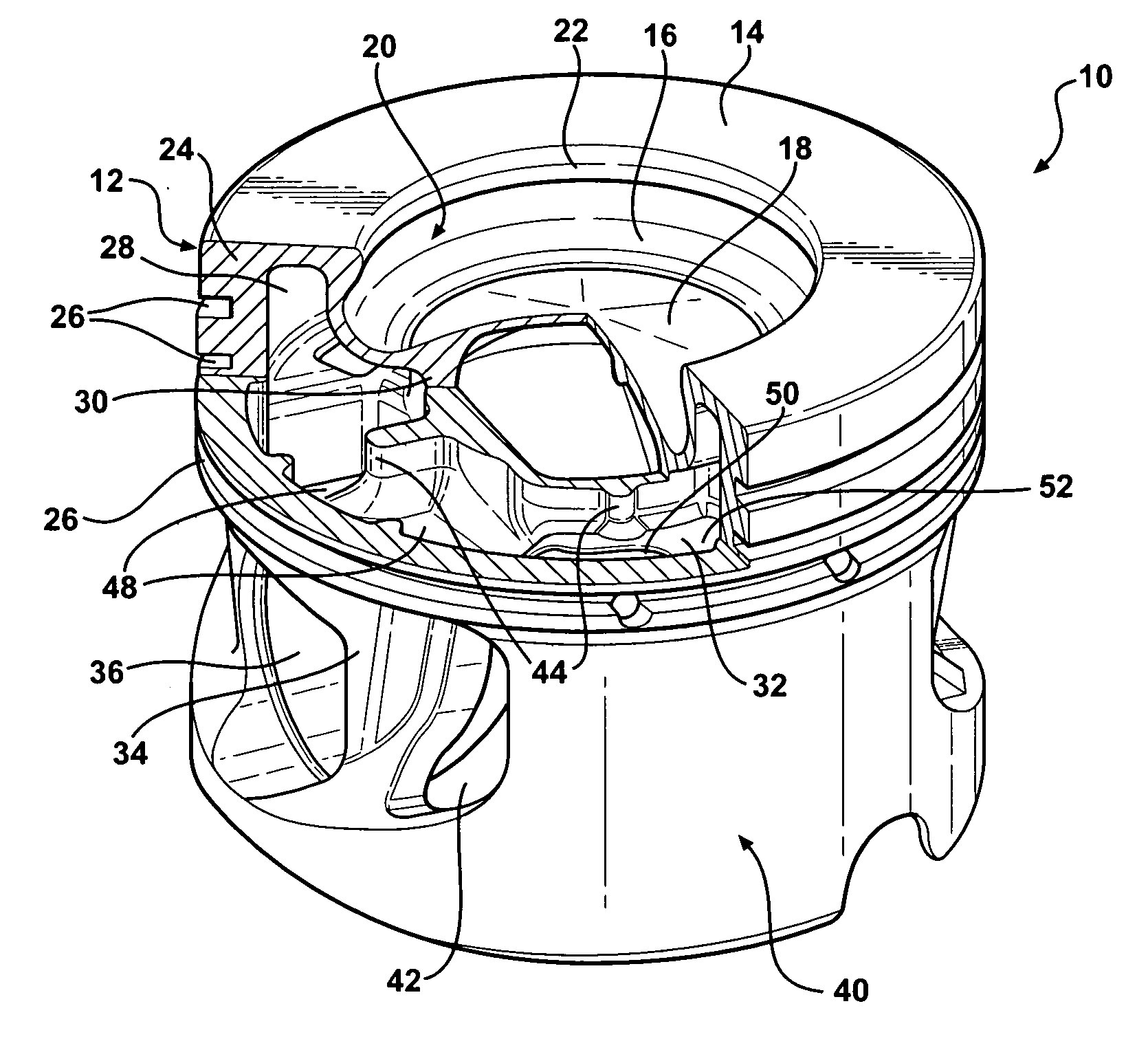

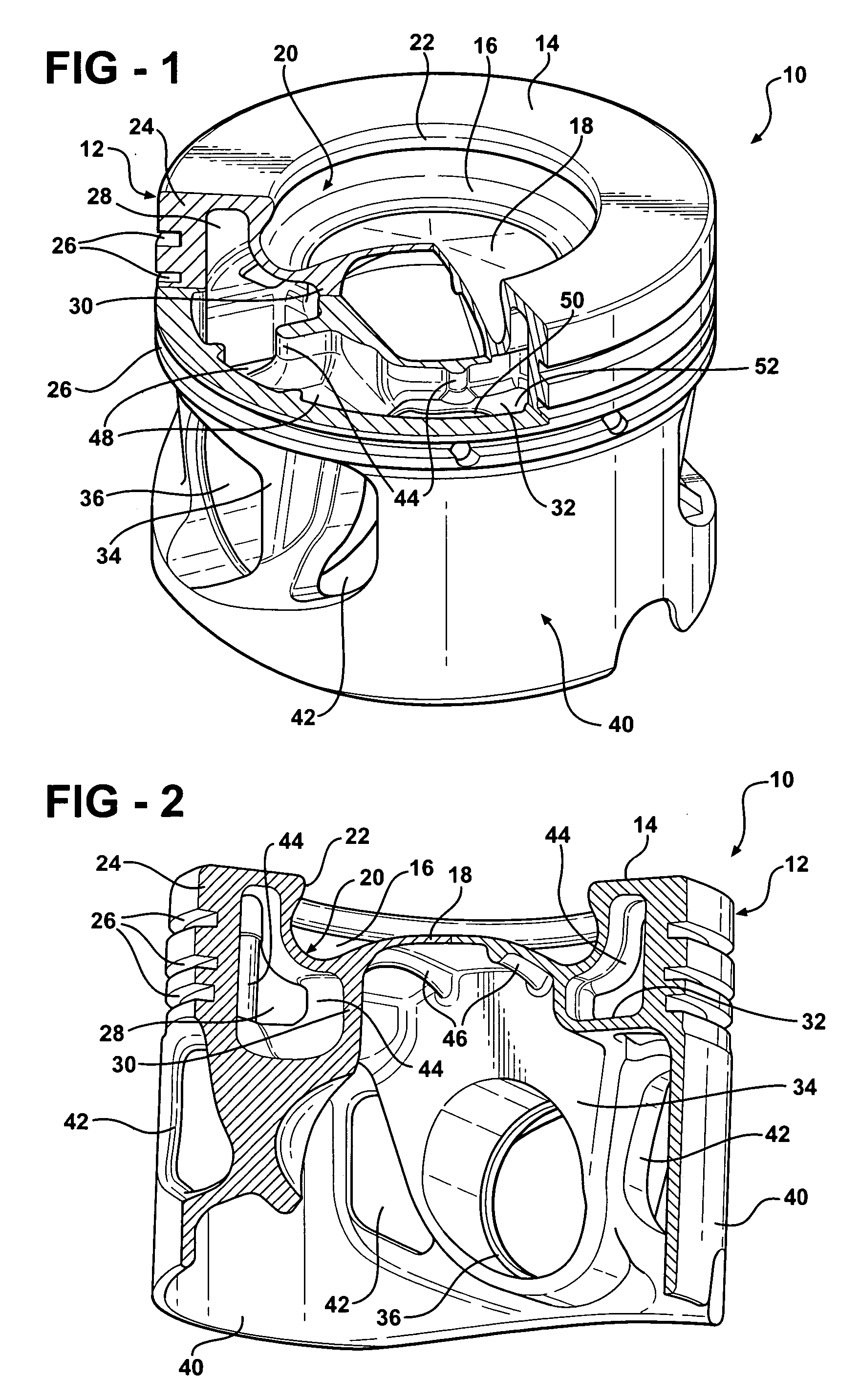

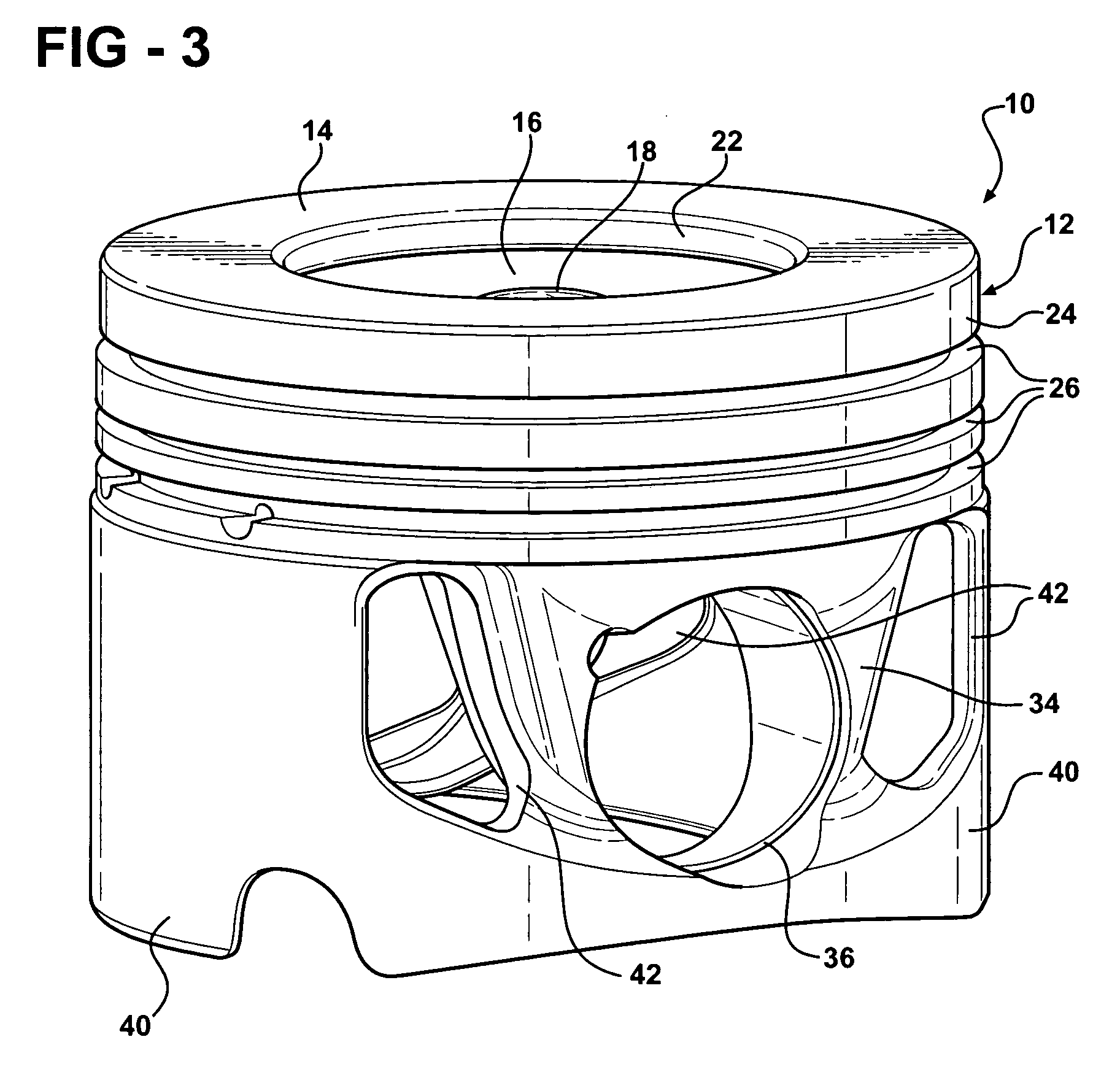

Single-piece forged-steel piston with inner oil cooling chamber and a method for manufacturing thereof

InactiveUS20090020007A1Simple structureEasy to makeValve arrangementsPlungersPiston ringCooling chamber

A laser-welded single-piece forged-steel piston with an enclosed inner oil cooling chamber having the advantages of simple structure and easy manufacturing process, and capable of satisfying the requirement of engines for high power, high rigidity, and low discharge development, and its manufacturing process. The laser-welded single-piece forged-steel piston of the invention comprises a piston body member and a piston ring member, wherein the piston body member is welded together with the piston ring member through laser welding procedure, an enclosed inner oil cooling chamber is formed between the piston body member and the piston ring member, and is connected with the piston inner cavity by means of at least two oil inlet / outlet holes, and a pin hole is opened at the lower portion of the piston body member.

Owner:LIN FENGHUA +3

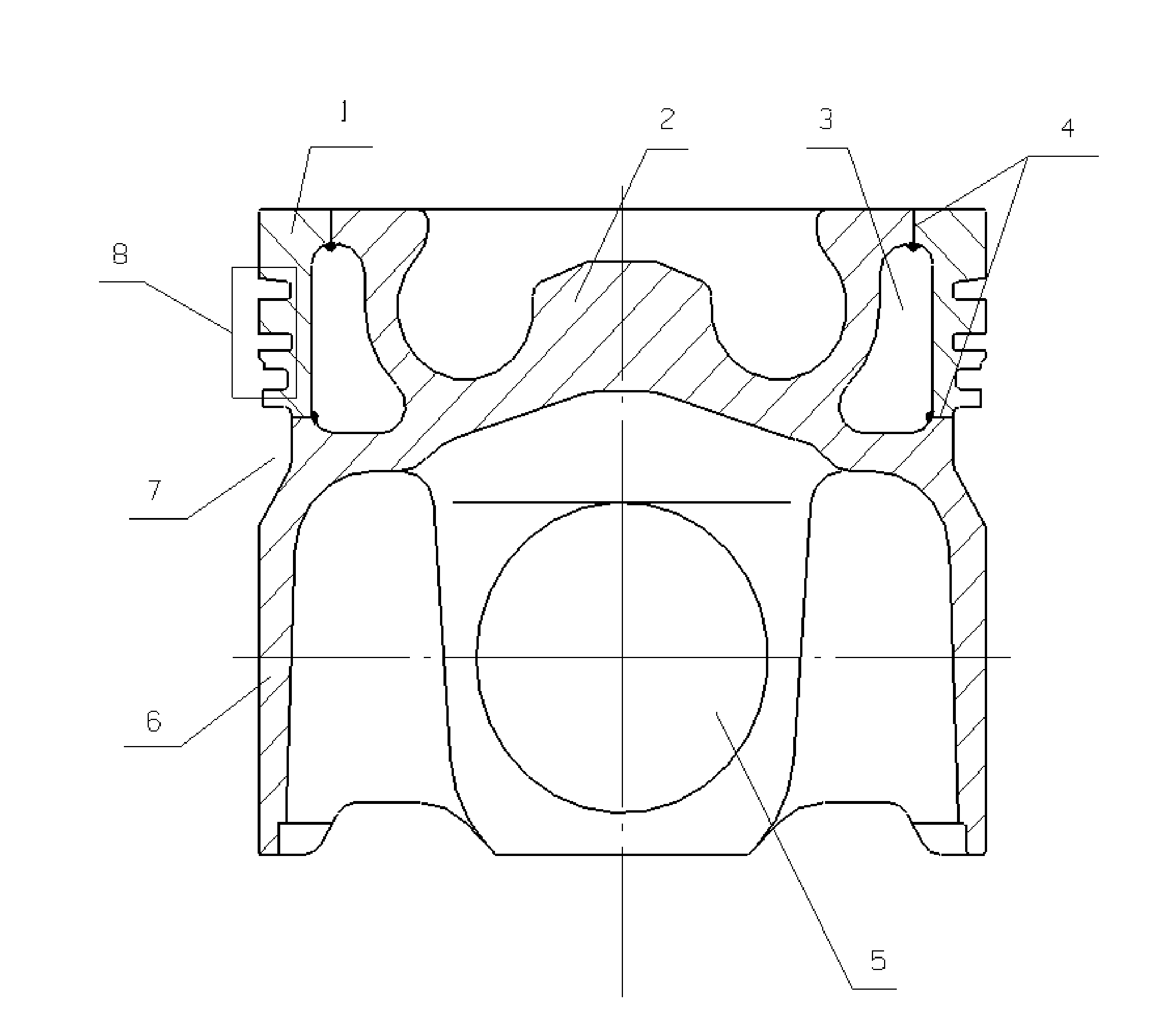

One piece cast steel monobloc piston

A piston for diesel engine applications has a piston body cast entirely of one piece of steel and includes a piston head with a combustion bowl, a ring belt and an oil cooling gallery. A pair of pin bosses and a piston skirt are cast as one piece with the piston head out of the same steel material.

Owner:FEDERAL MOGUL WORLD WIDE LLC

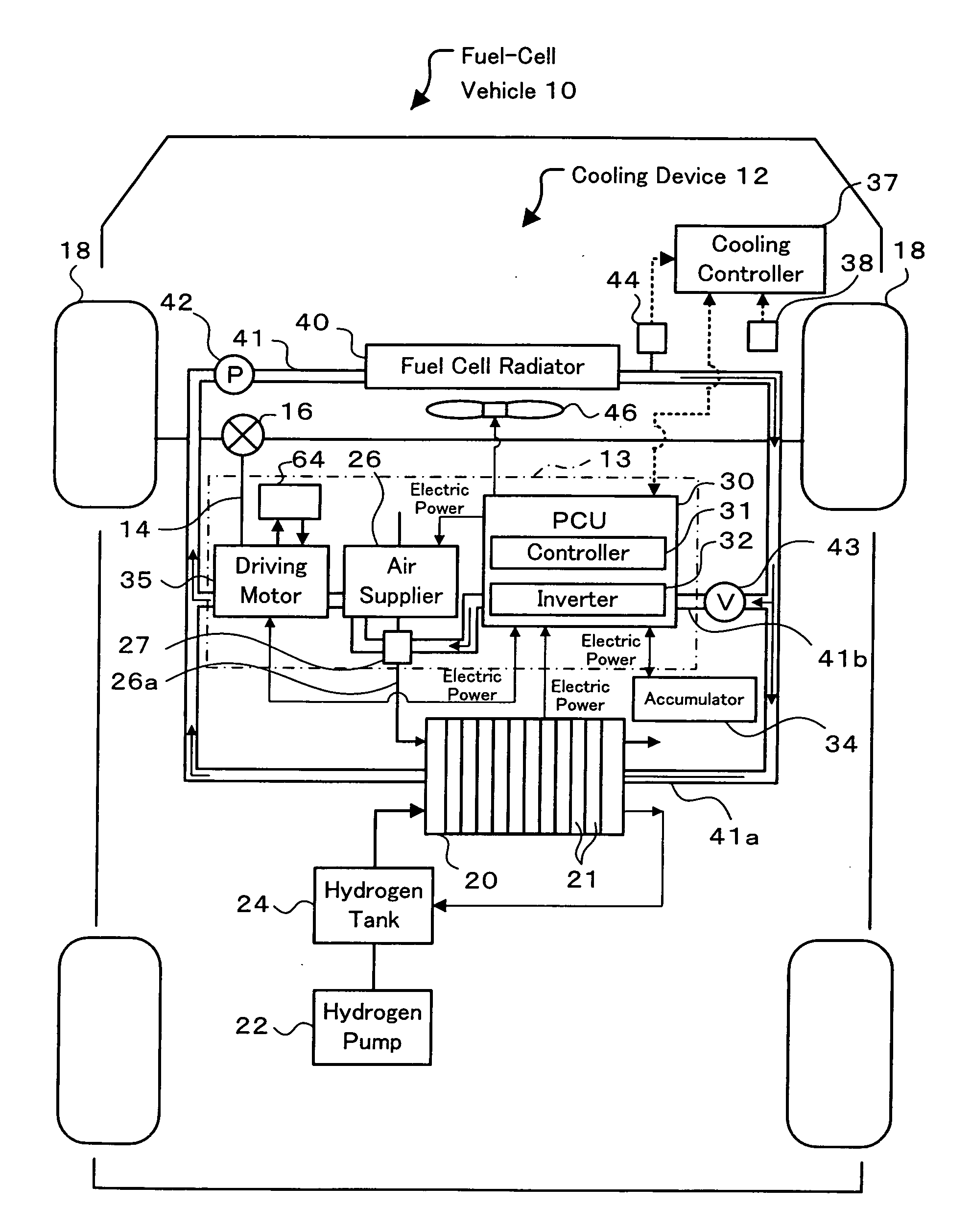

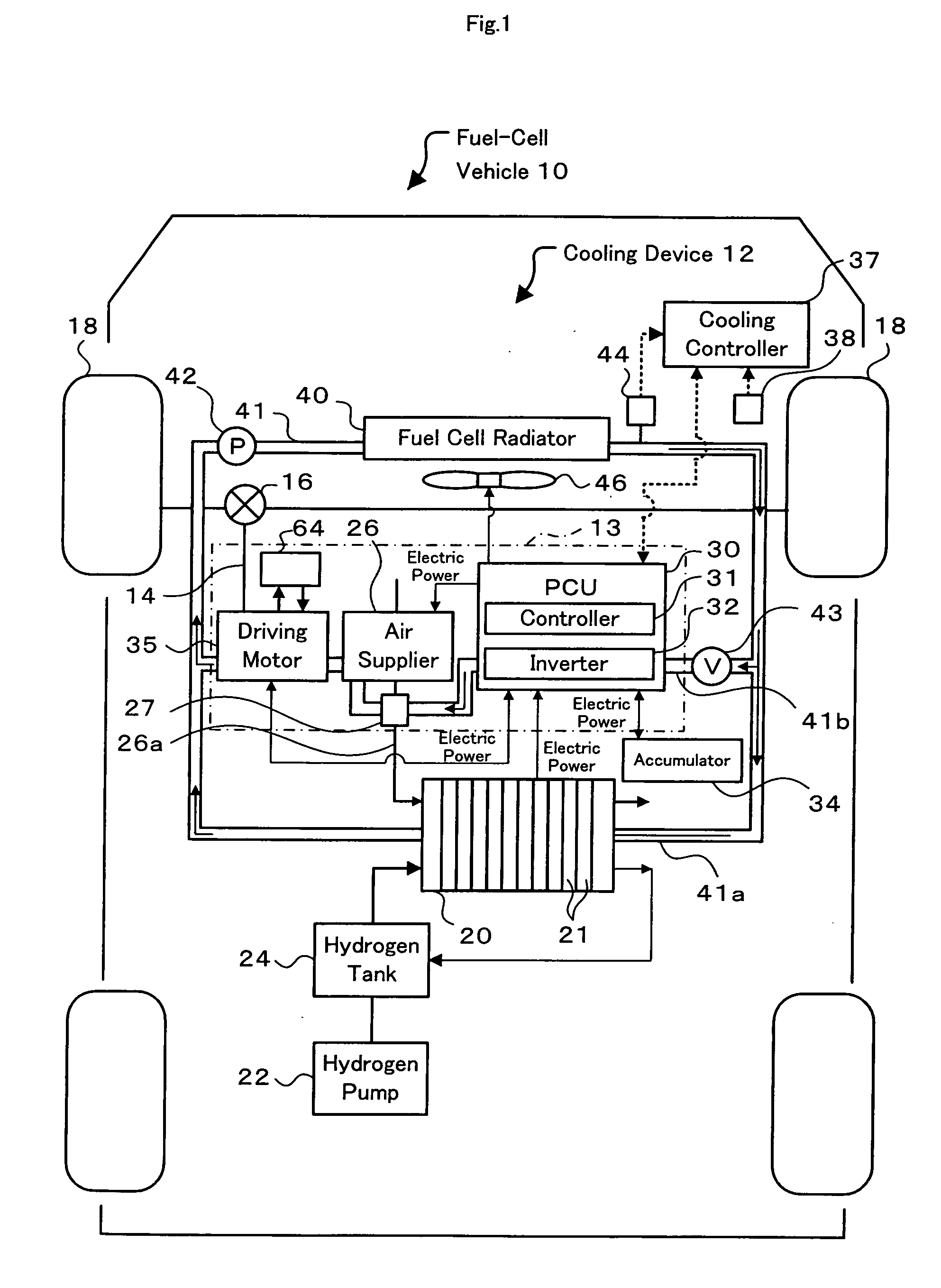

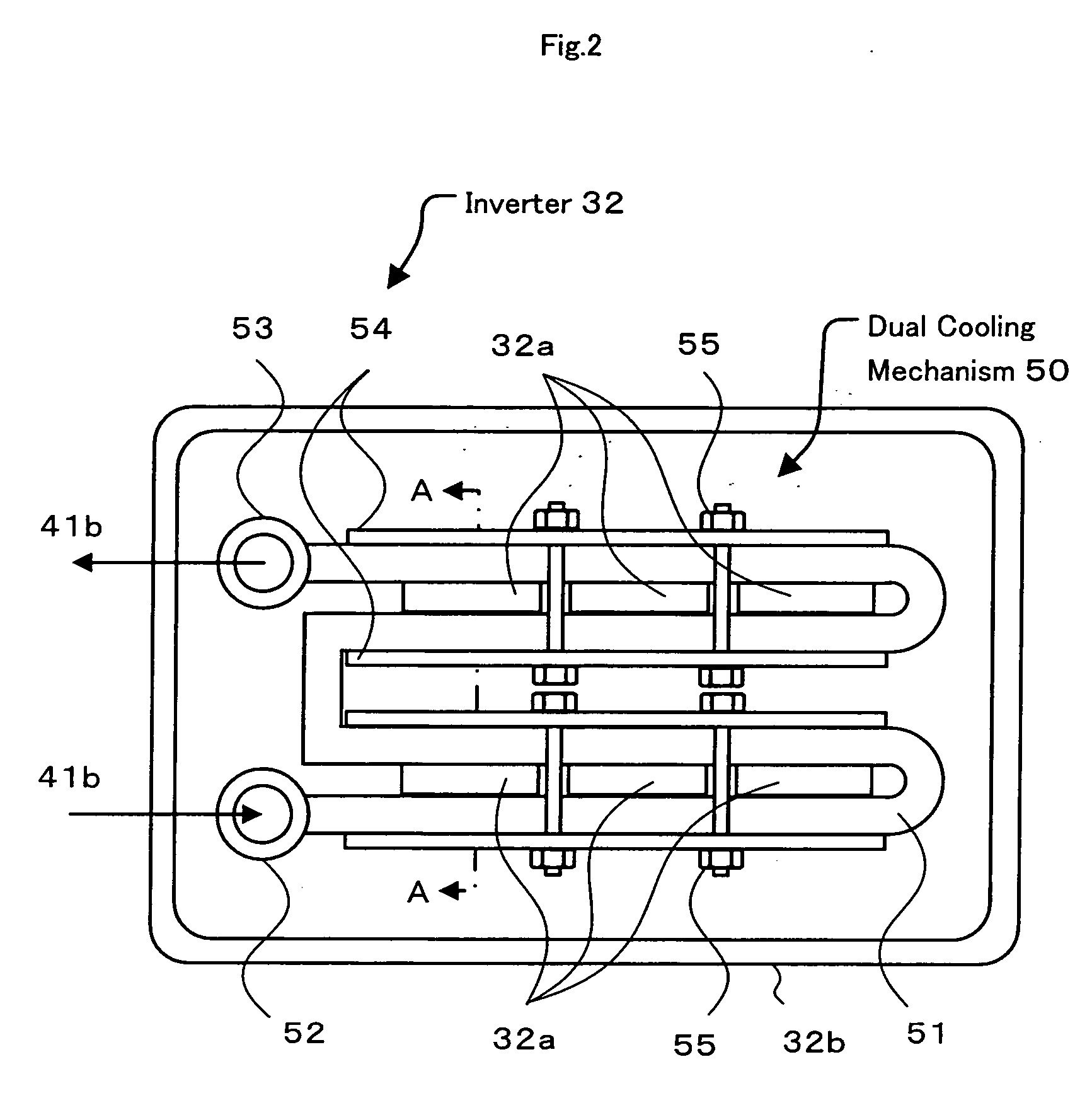

Cooling device for fuel cells and motor vehicle equipped with such cooling device

InactiveUS20070248861A1Simple structureIncrease the number ofElectric propulsion mountingFuel cell auxillariesWater useFuel cells

A cooling water flow path 41 connected with a radiator 40 includes a fuel cell flow path 41a that makes circulation of cooling water from the radiator 40 via a fuel cell stack 20 to the radiator 40, and an exothermic equipment flow path 41b that is placed in parallel to the fuel cell flow path 41a and makes circulation of cooling water from the radiator 40 via exothermic equipment 13 (including an inverter 32 of a power control unit (PCU) 30, an air supplier 26, a heat exchanger 27, and a driving motor 35) to the radiator 40. The multiple pieces of exothermic equipment 13 are arranged in series along the exothermic equipment flow path 41b in the flow direction of cooling water in an ascending order of heat discharge quantity. The inverter 32, the heat exchanger 27, and the driving motor 35 are respectively equipped with a dual cooling mechanism, an air cooling mechanism, and an oil cooling mechanism. The arrangement of the invention ensures stable operations of the respective pieces of exothermic equipment 13 even when the cooling water used for cooling down the exothermic equipment 13 has a higher temperature.

Owner:TOYOTA JIDOSHA KK

One piece cast steel monobloc piston

A piston for diesel engine applications has a piston body cast entirely of one piece of steel and includes a piston head with a combustion bowl, a ring belt and an oil cooling gallery. A pair of pin bosses and a piston skirt are cast as one piece with the piston head out of the same steel material.

Owner:FEDERAL MOGUL WORLD WIDE LLC

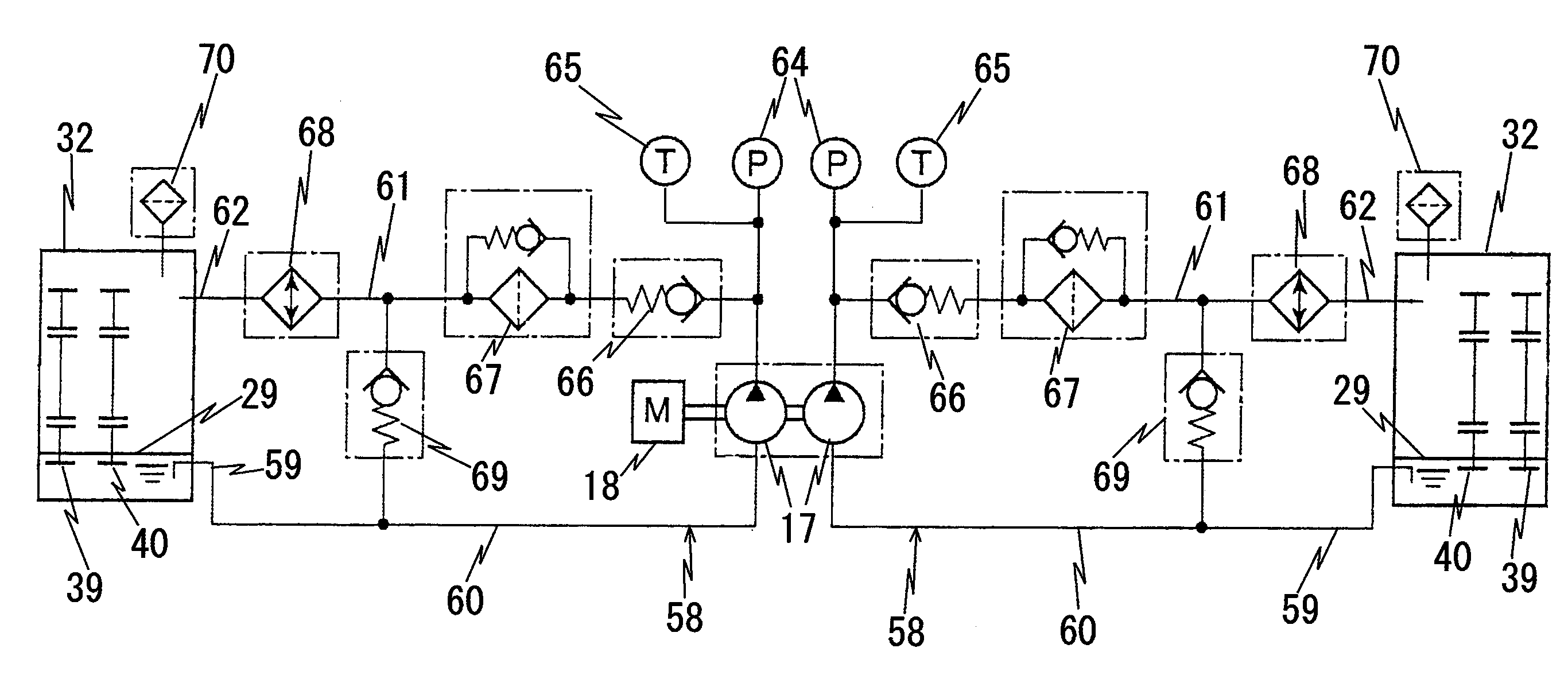

Lubricating oil cooling device for traveling speed reduction gear

ActiveUS20100187043A1Small motorReduce the temperatureGearboxesAnalogue computers for trafficTemperature controlLow speed

The present invention provides a traveling speed reduction gear lubricating oil cooling device that enables optimal temperature control for lubricating oil delivered via a lubricating oil pump that can be started up with a relatively small motor without running the risk of damage to an oil cooler in a cold work environment even when a temperature sensor that detects the temperature of the lubricating oil is installed outside a wheel mounting sleeve. During a startup operation, provided that the detected temperature at a traveling motor is higher than the reference temperature, the lubricating oil pump is driven at a speed in a lower speed range relative to the normal operation speed range. In addition, during the startup operation, the rotation speed of the drive motor for the lubricating oil pump is increased in correspondence to a rise in the temperature detected by a lubricating oil temperature detection sensor.

Owner:NIHON KENKI CO LTD

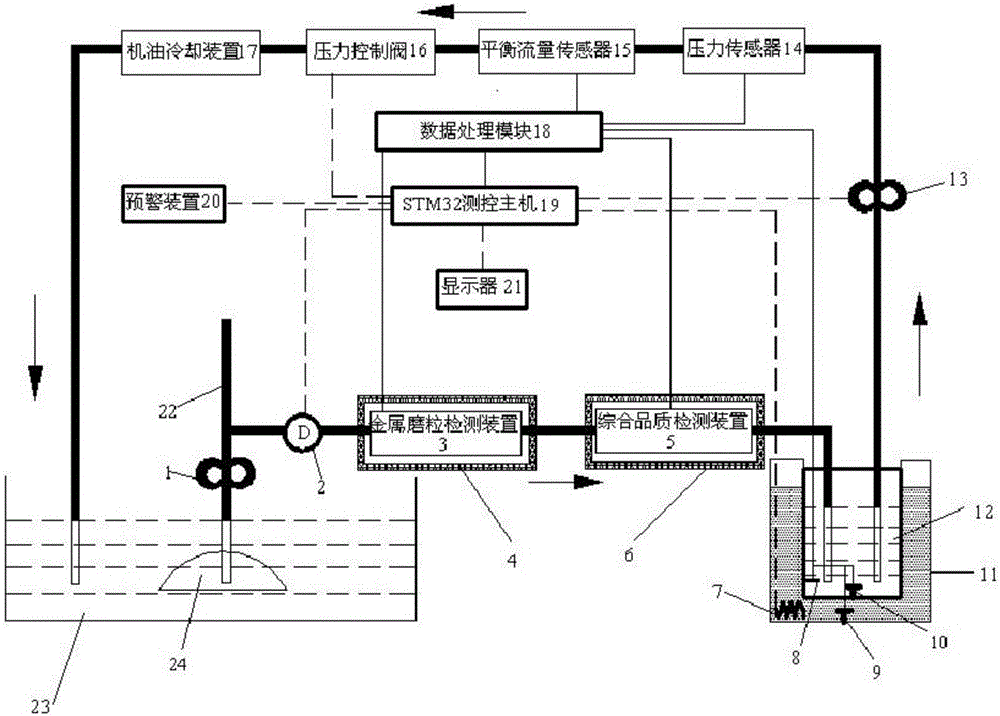

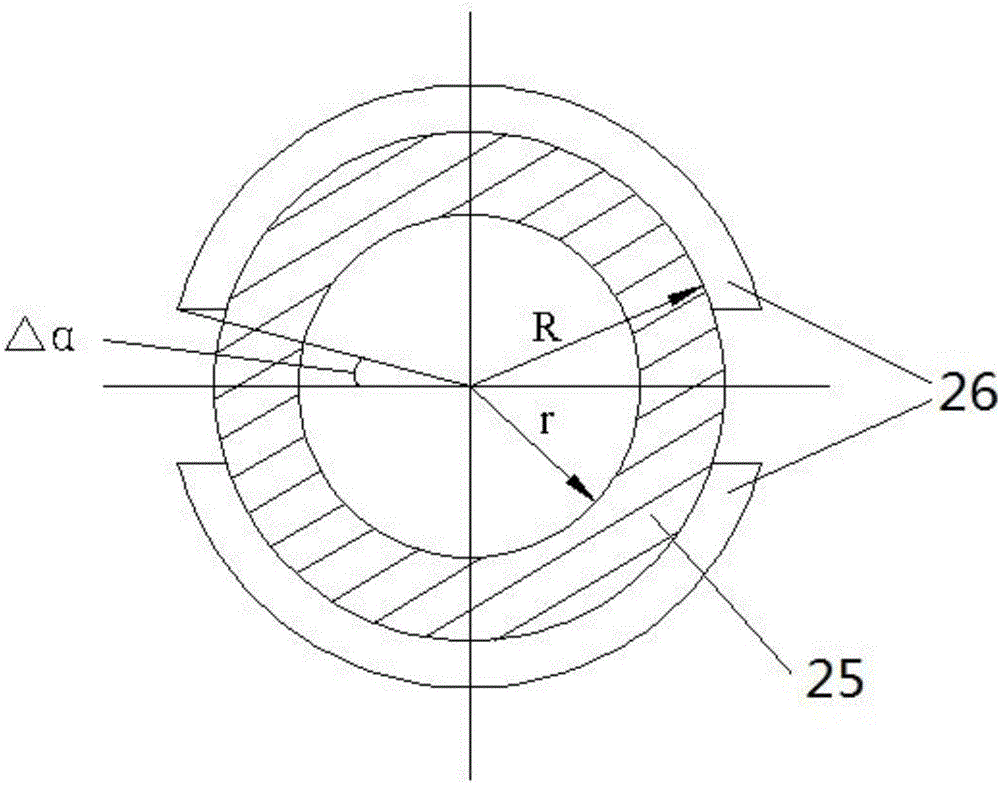

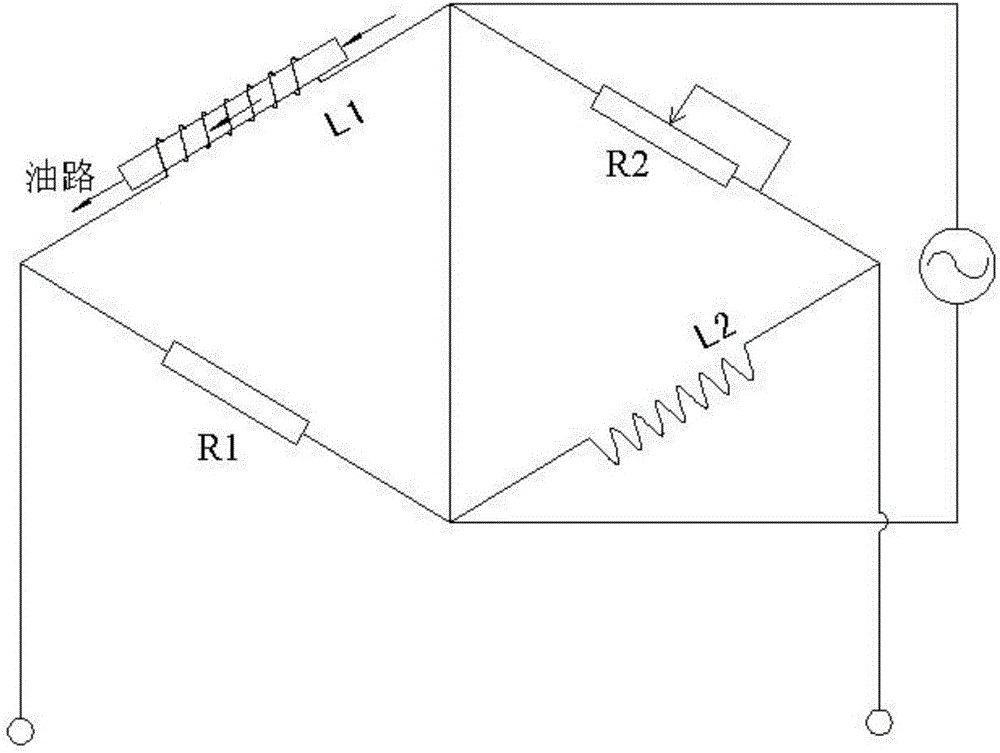

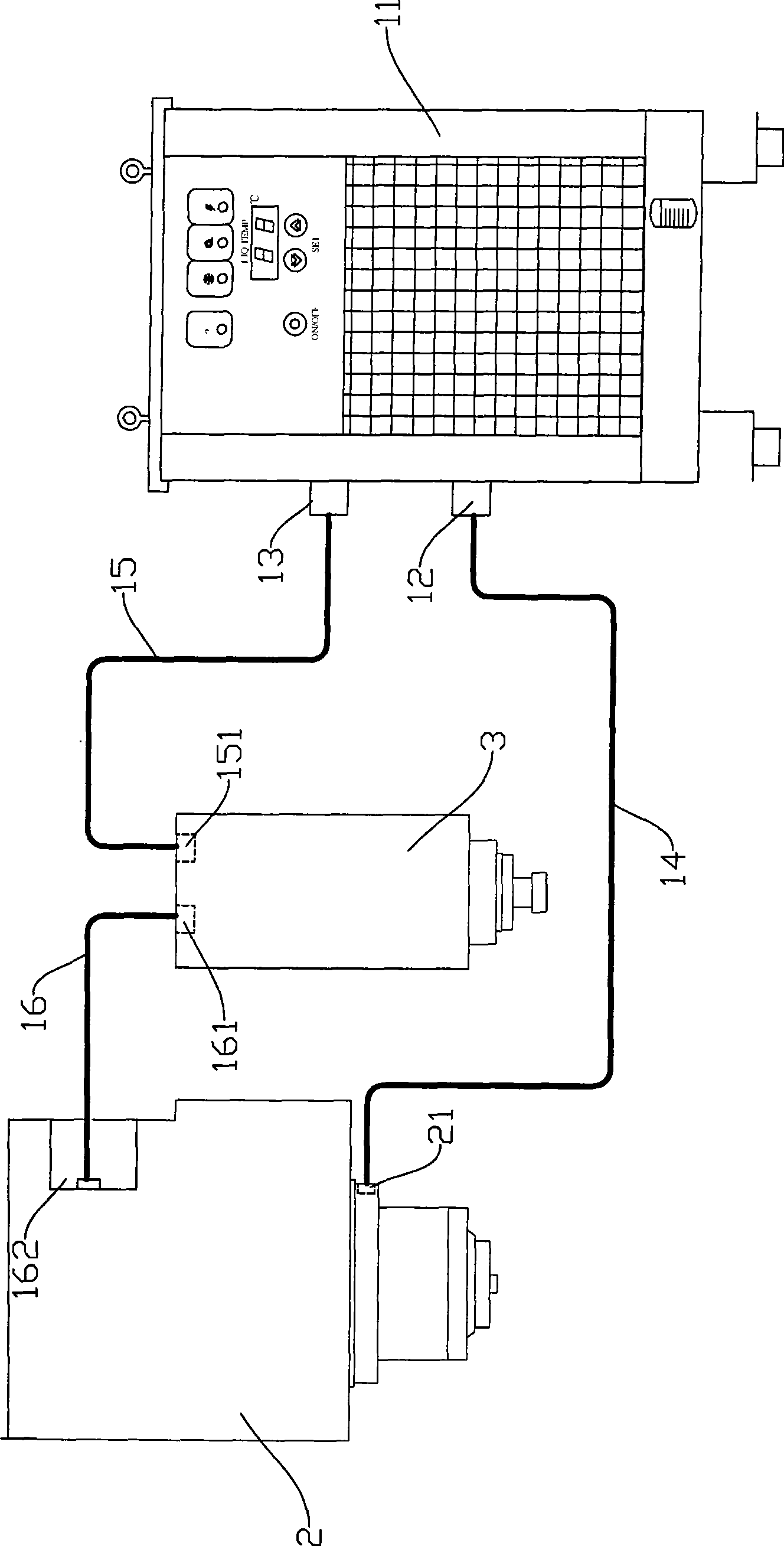

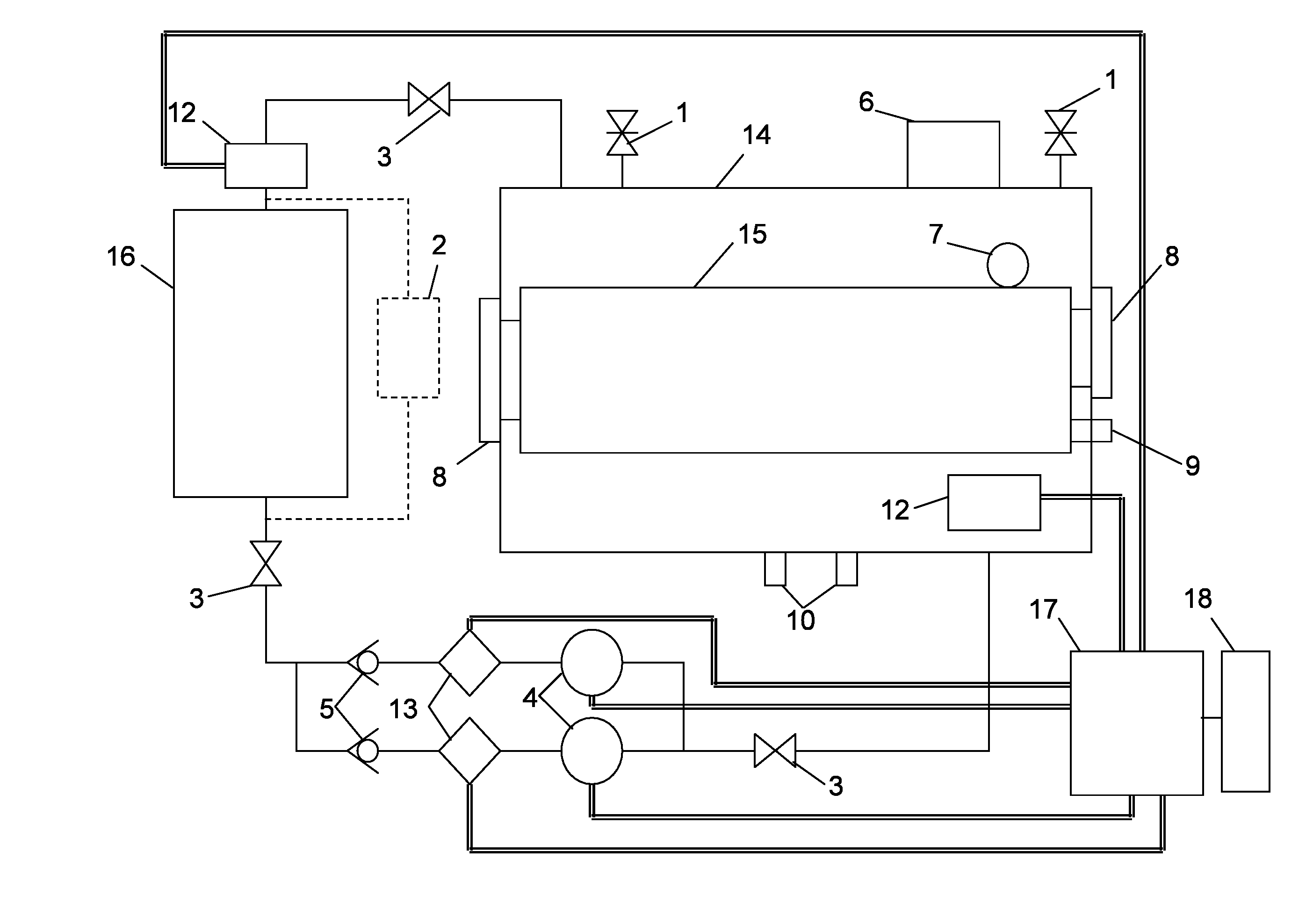

On-line engine oil quality monitoring system and method adopting multi-sensor information fusion

ActiveCN105065085AShield interferenceImprove detection accuracyLubrication indication devicesWater contentLubrication

The invention discloses an on-line engine oil quality monitoring system and method adopting multi-sensor information fusion. The engine oil quality monitoring system comprises a test oil circuit control valve, a metal abrasive grain detection device, a comprehensive quality detection device, a viscosity detection device, an engine oil cooling device, a data processing module, an STM32 measurement and control main unit, a man-machine interaction module and the like, wherein the viscosity detection device consists of an engine oil sampling device, a thermostatic oil-bath box, a heater, a constant-flow pump, a liquid level sensor, an oil-bath temperature sensor, a sampling temperature sensor, a pressure sensor, a balanced flow sensor and a pressure control valve. The on-line engine oil quality monitoring system is mounted at the downstream of a lubrication circuit oil pump of an automobile engine, can monitor the viscosity of engine oil, the content of metal abrasive grains and changes of such comprehensive qualities of engine oil as the pH value and the moisture content on line, adopts the multi-sensor information fusion technology to comprehensively analyze the oil state, displays information of the oil state through a display and sends an early-warning signal if necessary.

Owner:JILIN UNIV

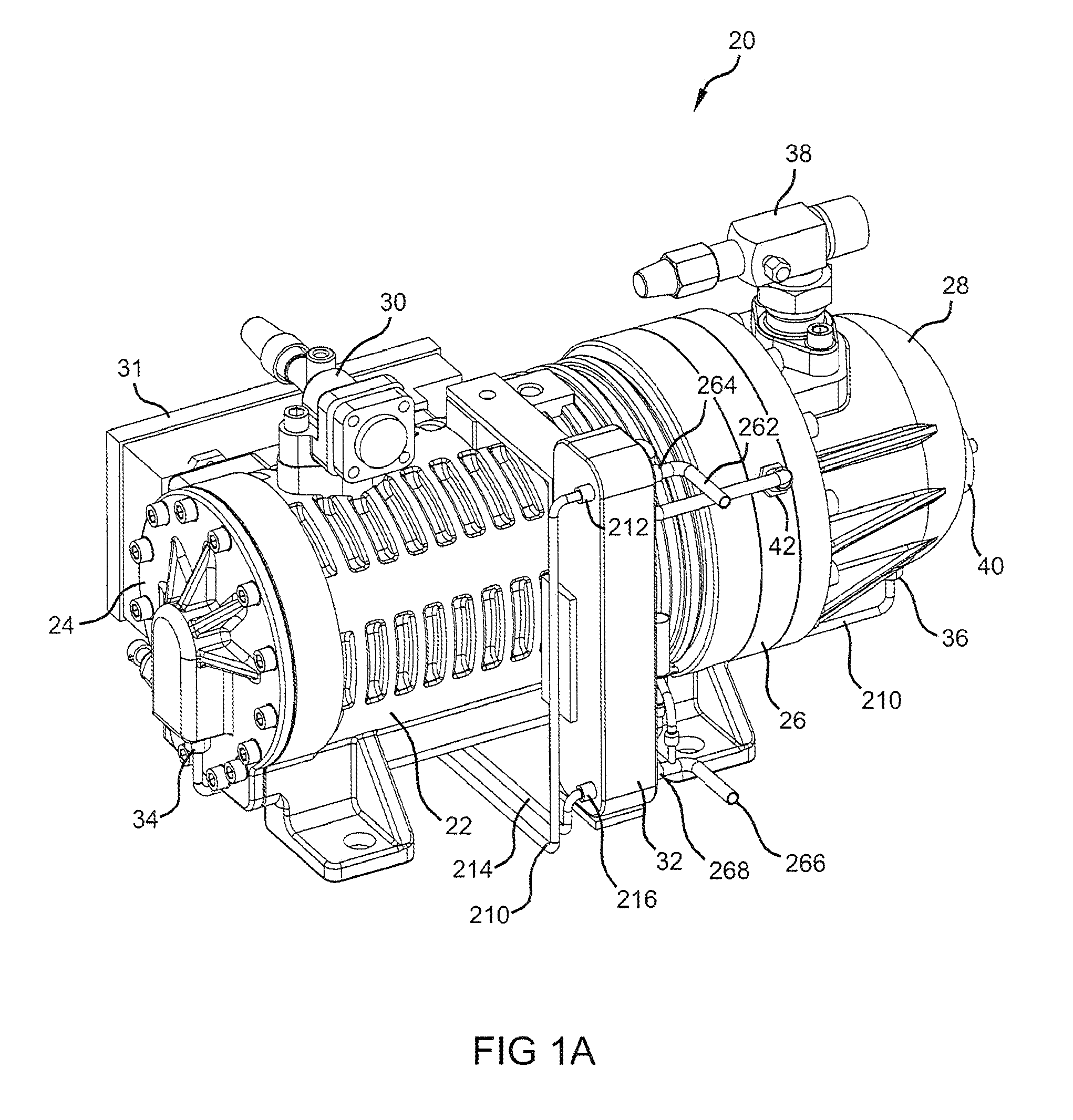

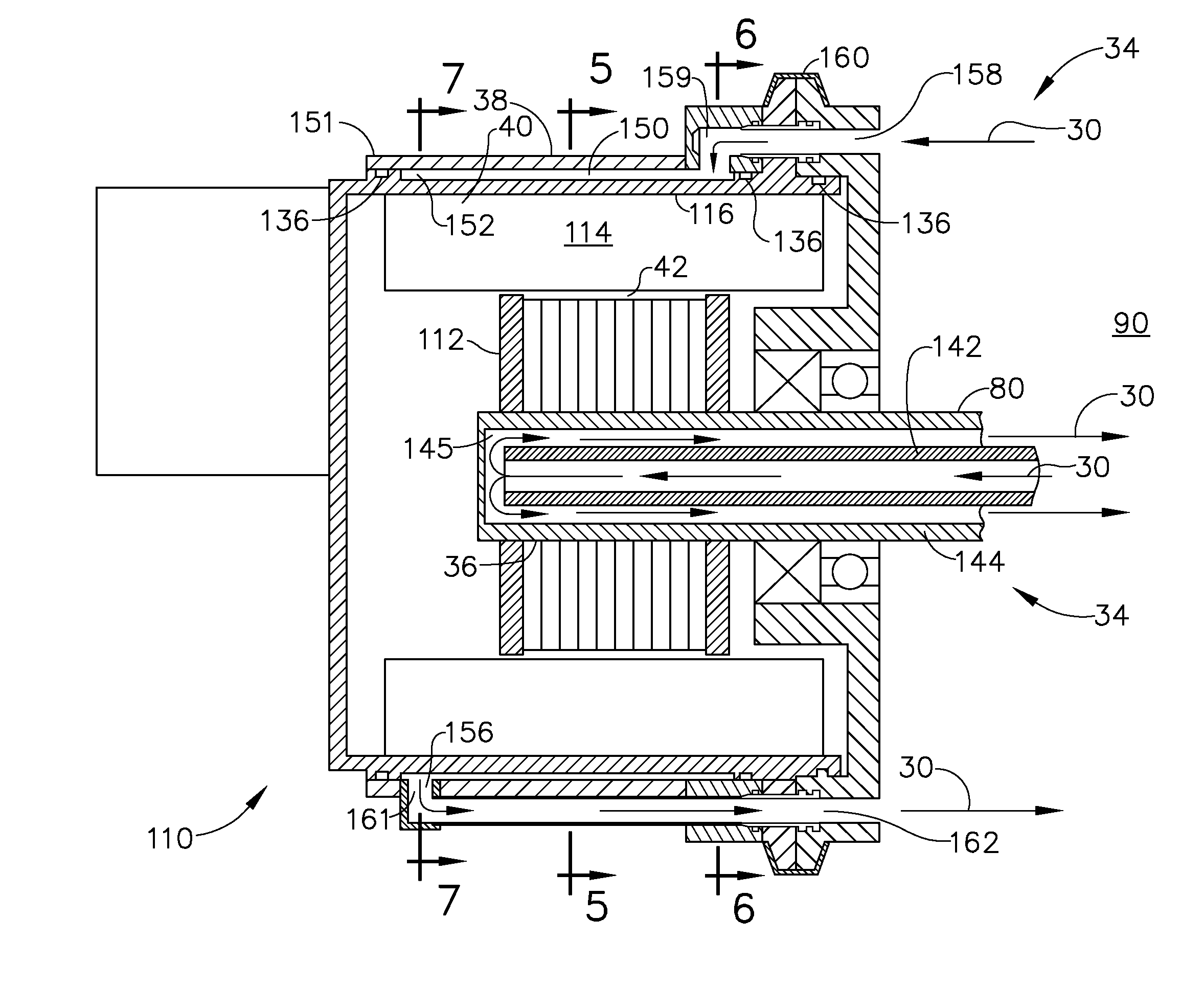

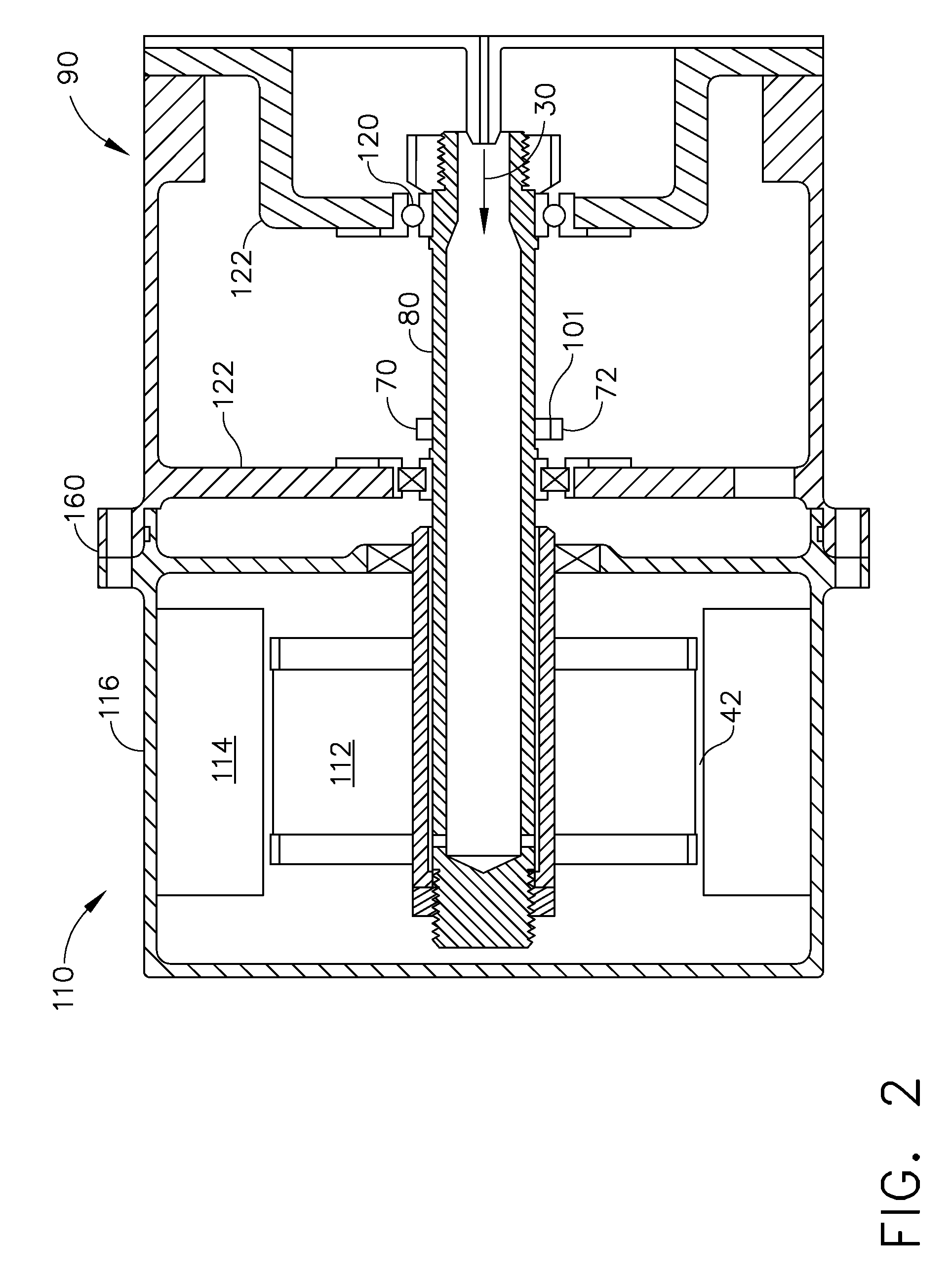

Integrated brushless starter/generator system

ActiveUS8450888B2Magnetic circuit rotating partsMagnetic circuit stationary partsEngineeringOil cooling

A brushless starter / generator includes a rotor rotatably mounted within a stator mounted within a housing and an oil cooling system using cooling oil from an engine accessory gearbox for cooling the rotor and the stator. The rotor is fixedly mounted on a rotor shaft having a rotor heat exchanger disposed therein. A stator heat exchanger for cooling the stator includes an oil jacket around the housing. The stator heat exchanger includes a grooved tube around the housing and axially extending axial passages connected to annular inlet and outlet manifolds in the grooved tube. The rotor shaft is operably connected to a power take-off shaft within the gearbox and rotatably supported by a shaft bearing in a gearbox casing of the accessory gearbox. The oil cooling system is a dry cavity oil cooling system which prevents cooling oil from entering an air gap between the rotor and the stator.

Owner:GENERAL ELECTRIC CO

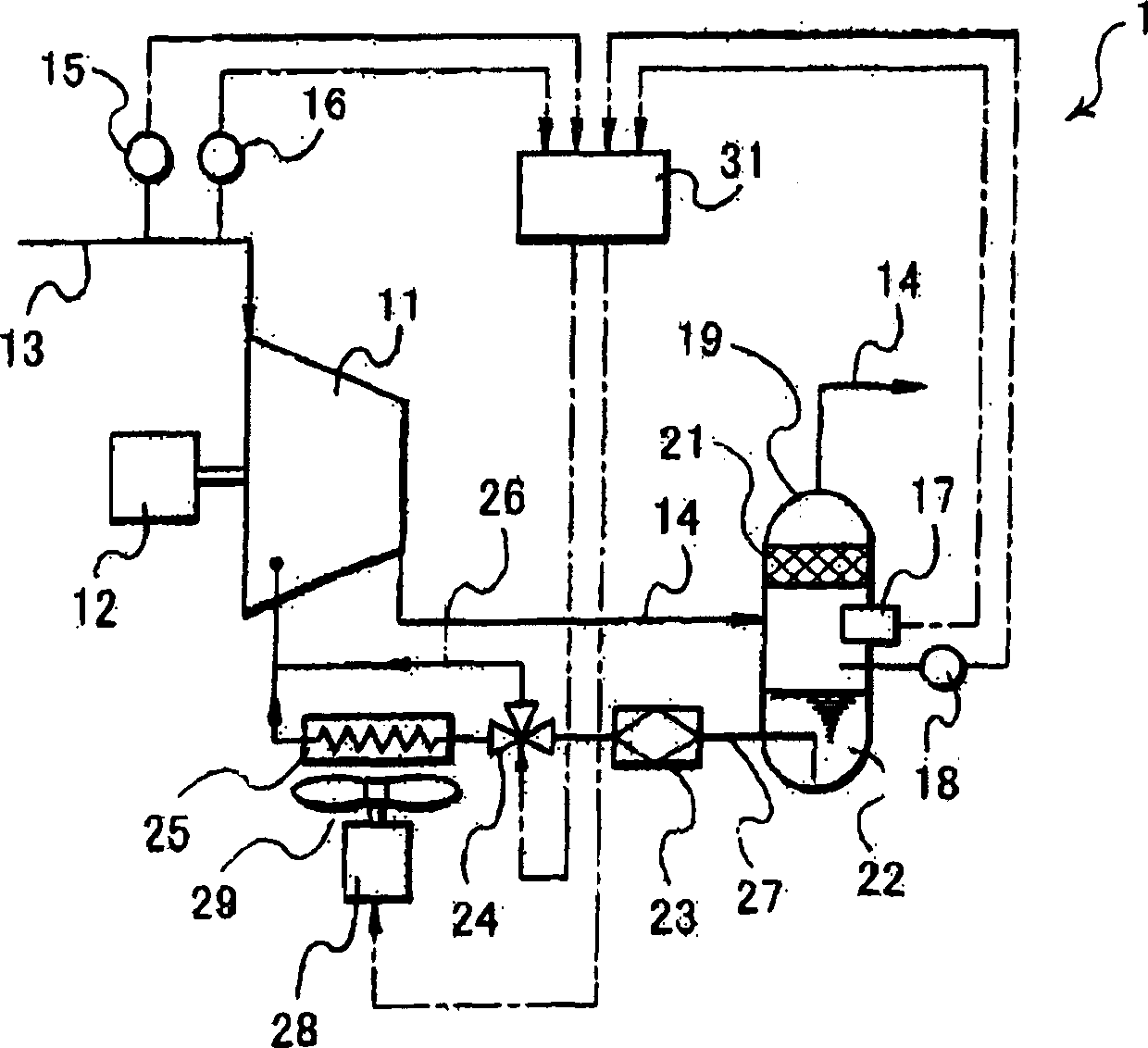

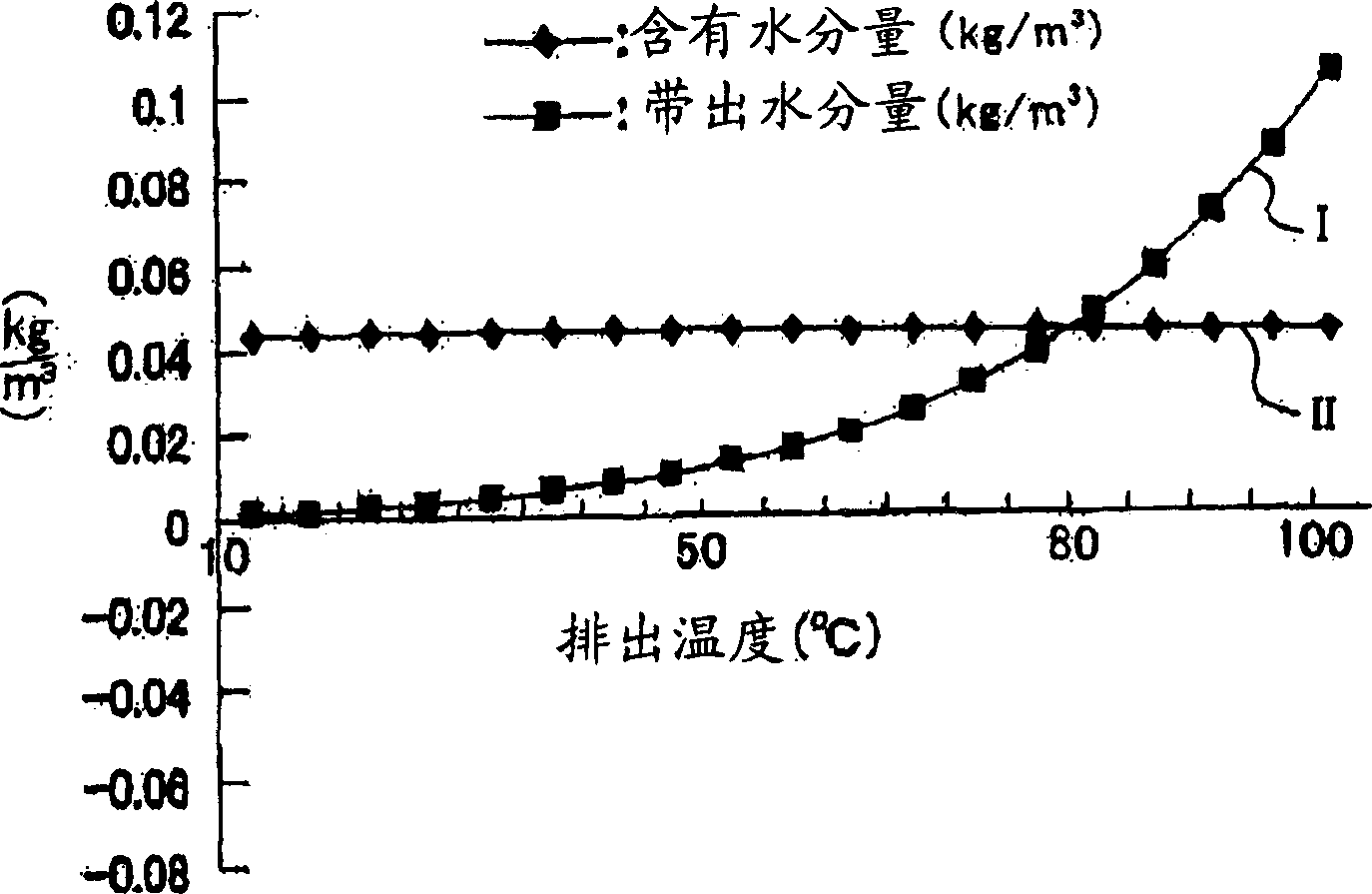

Oil cooling compressor

ActiveCN1862019AAvoid jitterPositive displacement pump componentsMulti-stage pumpsTemperature controlMoisture condensation

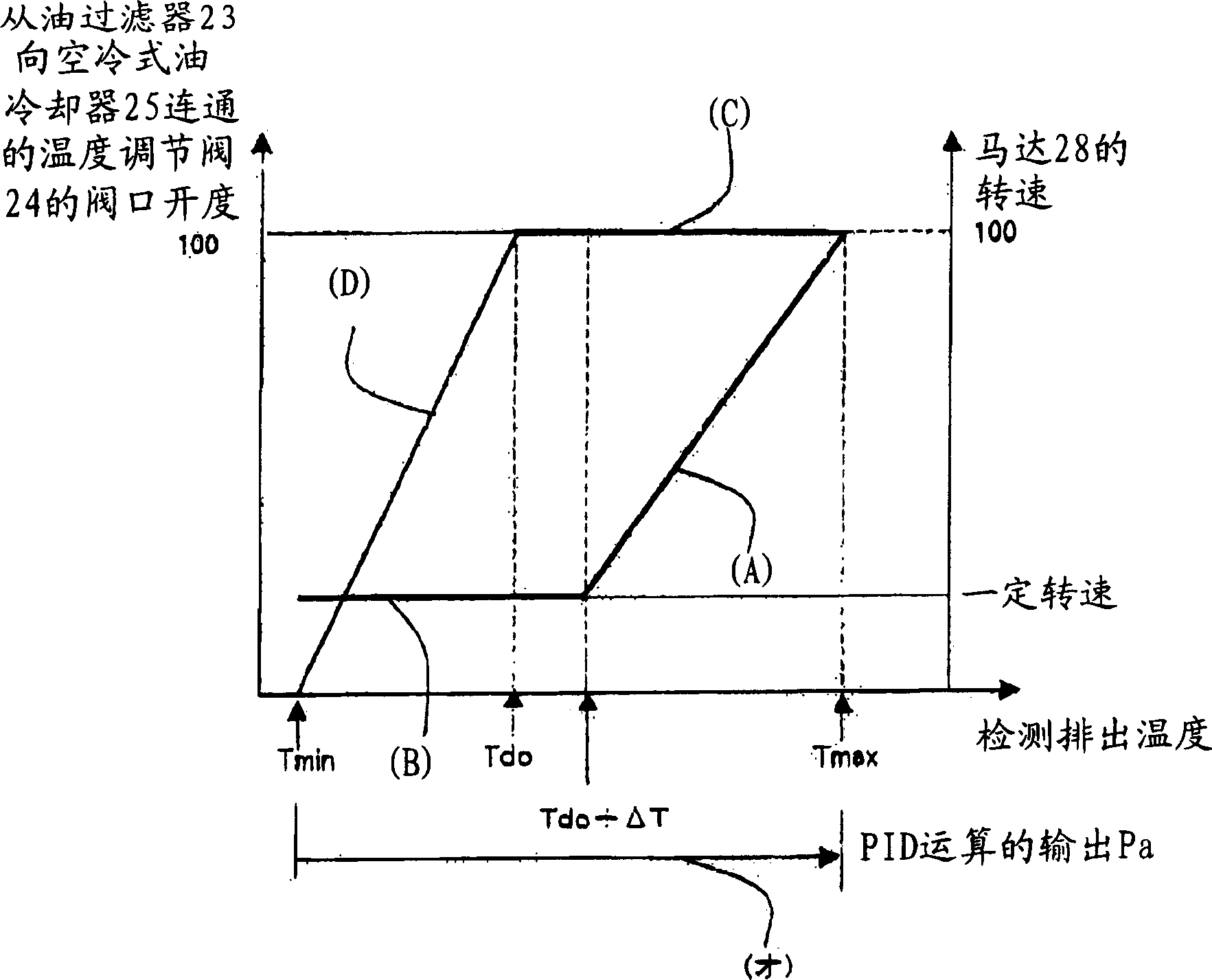

The oil-cooled compressor is equipped with an oil flow path, a discharge temperature detector and a control device. The oil flow path starts from the oil storage part of the oil separator and recovers to the temperature regulating valve with a two-way variable diversion function, and passes through the cooling After the air-cooled oil cooler supplied by the fan, or after passing through the bypass flow path instead of the air-cooled oil cooler, it leads to the above-mentioned gas compression space, and the oil separation and recovery device compresses the gas supplied to the main body of the compressor The oil behind the space is separated and recovered from the discharge gas; the discharge temperature detector detects the discharge temperature of the gas; the control device controls the cooling fan motor and the temperature regulating valve based on the discharge temperature detected by the discharge temperature detector to Adjust the speed of the motor and the split ratio of the temperature regulating valve. The oil-cooled compressor can prevent condensation and precipitation of moisture in the discharge gas, and can save energy.

Owner:코벨코컴프레서가부시키가이샤

High-silicon high-manganese type high-thermal stability hot work die steel and thermal treatment process thereof

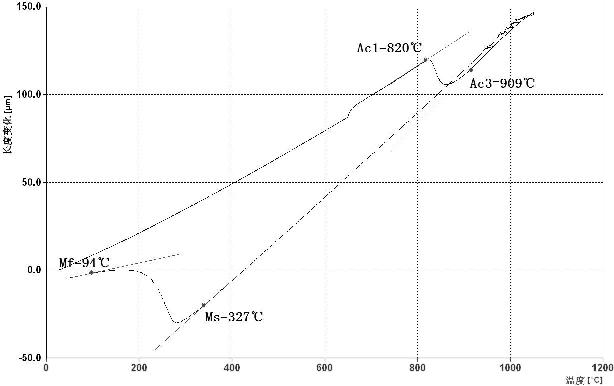

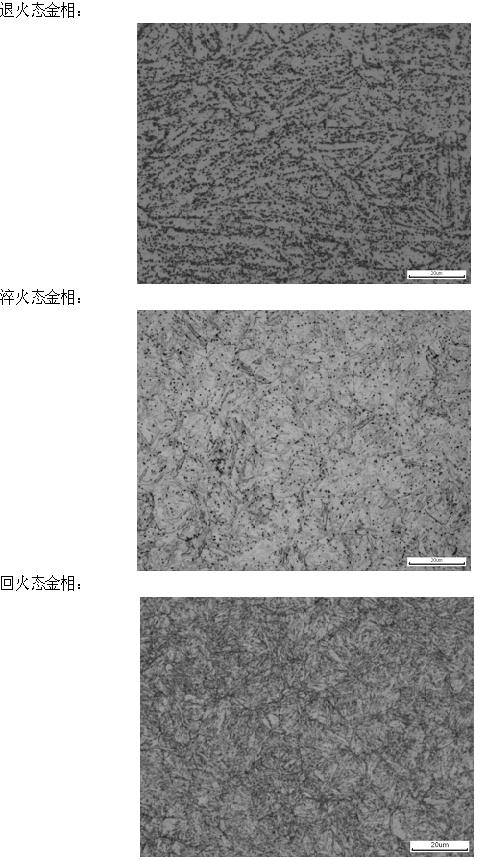

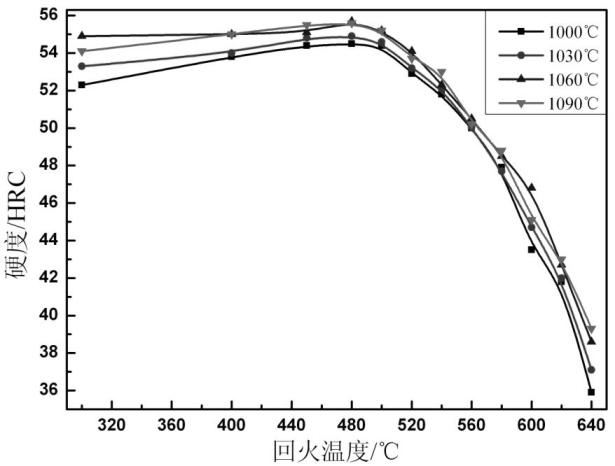

The invention relates to high-silicon high-manganese type high-thermal stability hot work die steel and a thermal treatment process thereof, and belongs to the technical field of alloy steel manufacturing process. The hot work die steel is characterized in that the ratio of high silicon to high manganese in chemical components is kept to be 1 to 1 and main alloy elements by mass percent comprise 0.25-0.45% of C, 0.8-2.0% of Si, 0.8-2.0% of Mn, 3.5-4.5% of Cr, 0.6-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and Fe for the rest. A preparation process for the hot work die steel comprises the steps as follows: firstly, preparing materials, smelting and casting; secondly, carrying out electroslag remelting; carrying out high temperature homogenization thermal treatment, and carrying out multi-direction forging hot working; thirdly, carrying out superfine thermal treatment and isothermal annealing treatment; and lastly, carrying out quenching and tempering thermal treatment, namely heating to be 980-1100 DEG C for austenitizing, carrying out oil cooling or mist cooling, and tempering for two to three times at a temperature of 540-600 DEG C. The hot work die steel has the advantages of high thermal stability, high flexibility and good thermal fatigue performance.

Owner:SHANGHAI UNIV

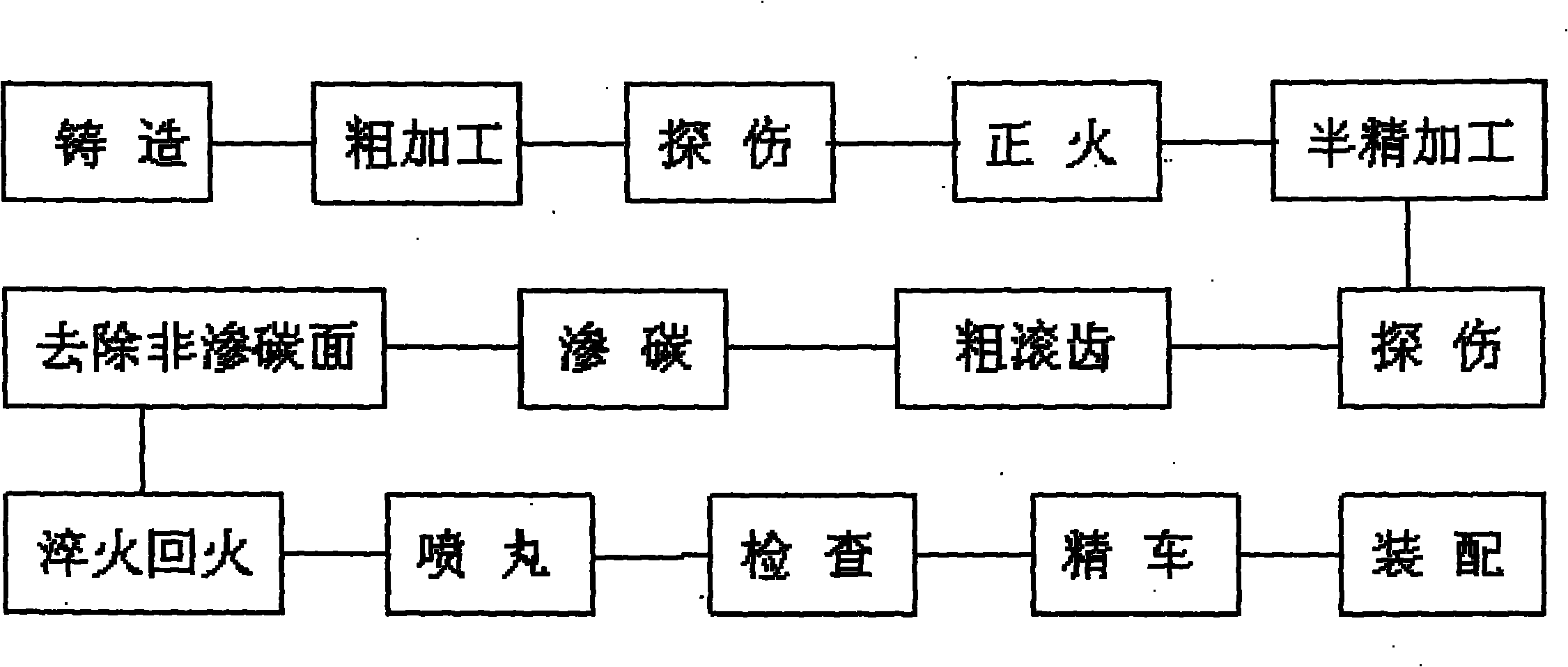

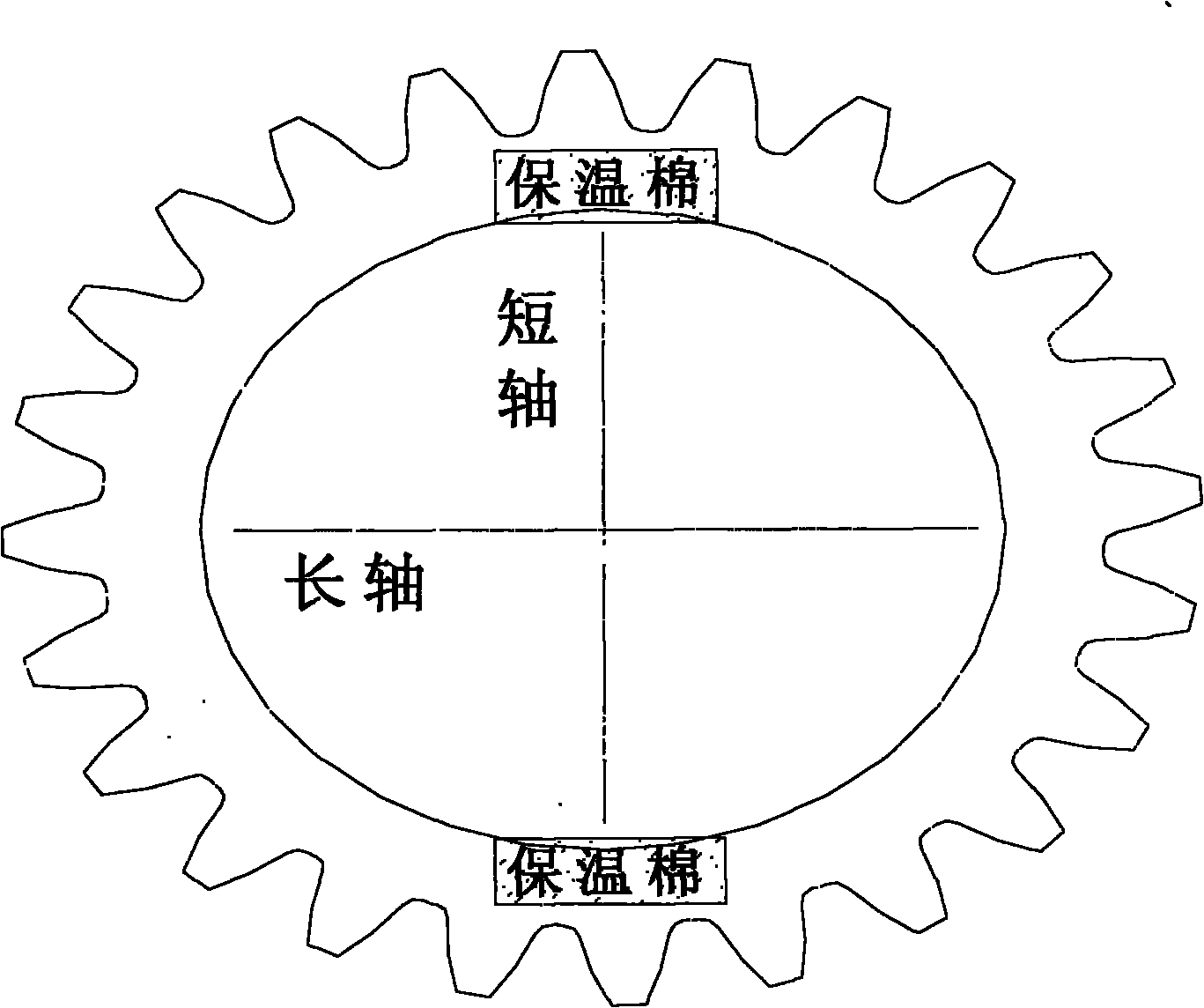

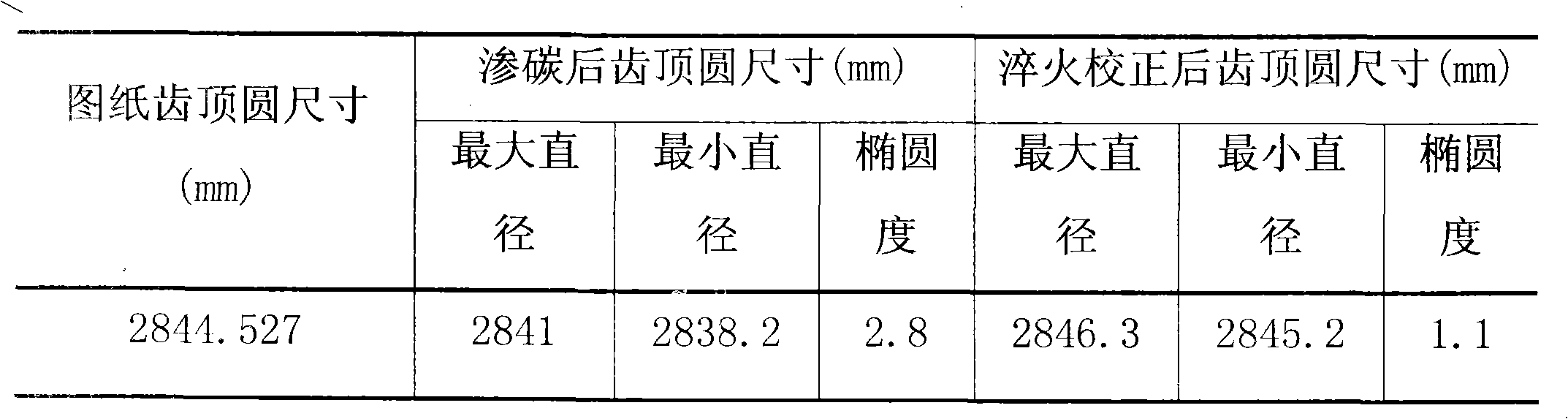

Reversible deformation correcting method for elliptical gear ring subjected to deformation after carburization

InactiveCN101838730AControl expansionLow costFurnace typesHeat treatment furnacesOil coolingMinor axis

The invention provides a reversible deformation correcting method for an elliptical gear ring subjected to deformation after carburization, which comprises the following steps of: measuring the addendum circle diameters of a gear ring which is subjected to ellipse deformation after carburization every 30 degrees, wherein the difference between the measured addendum circle diameters is the major axis and the minor axis of the gear ring which is subjected to ellipse deformation; binding a layer of heat insulation cotton at both sides of the inner end surface of the gear ring in the minor axis-distributed area with iron wires at a moderate tightening degree; and exposing other gear rings and external gear parts. In the quenching process, the elliptical gear ring is heated to 810 DEG C at a heating rate of 60 DEG C / h and is kept for 4 hours. Because the minor axis-distributed area is covered with the heat insulation cotton, the heating rate of the minor axis-distributed area covered with the heat insulation cotton is smaller than that of the major axis-distributed area uncovered with the heat insulation cotton, and the cooling speed of the minor axis-distributed area of the gear ring is smaller than that of the major axis-distributed area in the quenching oil cooling process, thereby correspondingly reducing the difference between the distributed areas with different addendum circle diameters of the gear ring and consequently realizing the reversible deformation correction of the elliptical gear ring.

Owner:CITIC HEAVY INDUSTRIES CO LTD

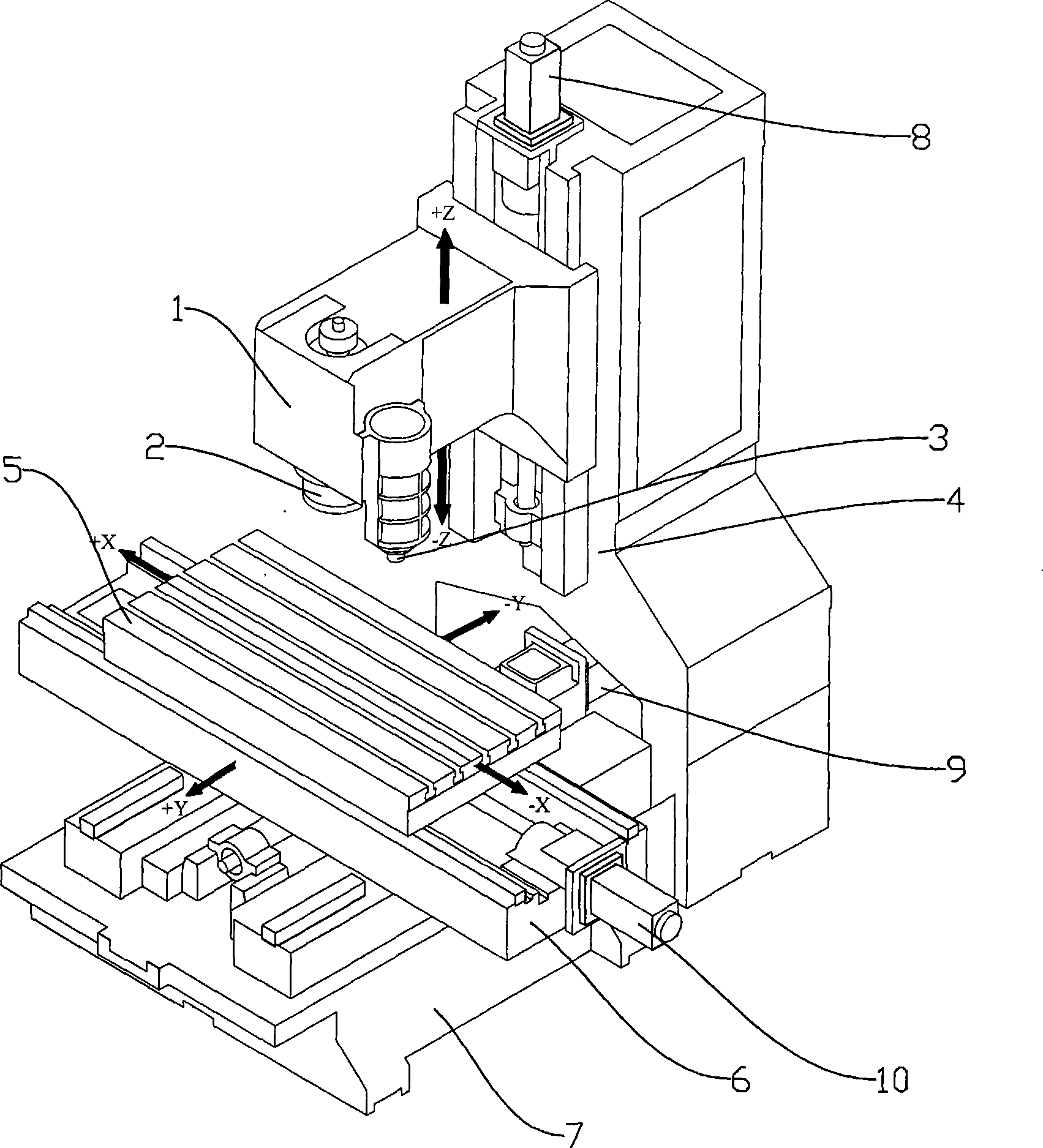

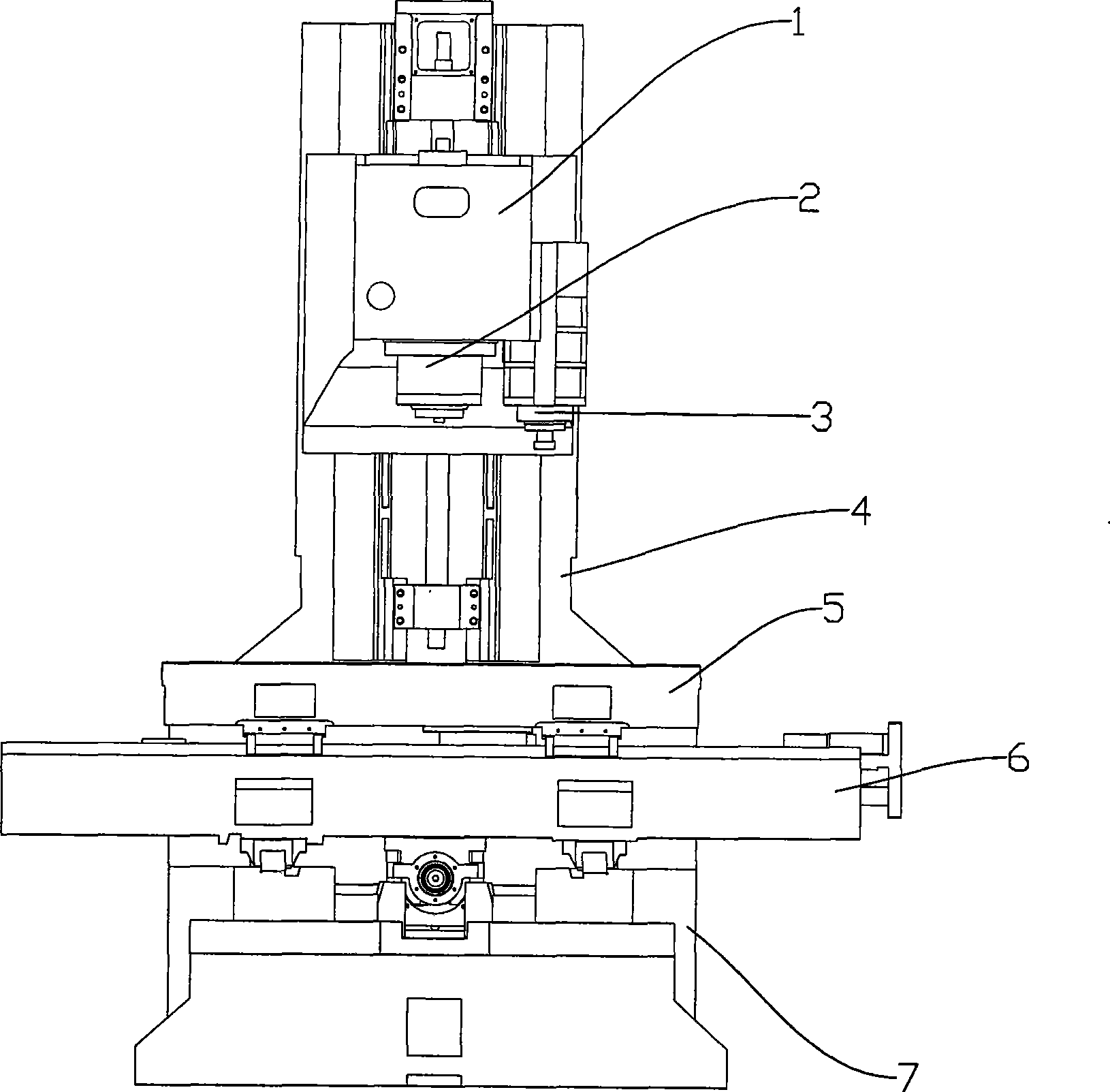

Double-main shaft double-speed compound numerical control milling machine

InactiveCN101502890ACompact and reasonable structureImprove processing efficiencyMilling machinesElectric machineryOil cooling

The invention provides a double-spindle and double-speed composite NC milling machine and pertains to the field of mechanical processing technology. The invention consists of a main power spindle, a high-speed motorized spindle, a spindle box for arranging the main power spindle and the high-speed motorized spindle, an upright column, a workbench, a bed saddle, a bed body, a servo motor, a servo drive and a NC system. The invention is characterized in that the main power spindle and the high-speed motorized spindle are arranged in the spindle box; the spindle box is supported on the guide rail of the column and can slide along a guide rail; an X-shaft motor is arranged on the bed saddle so that the workbench can move horizontally and a Y-shaft motor is arranged on the bed body so that the bed saddle can move back and forth; a Z-shaft motor is arranged on the column to drive the spindle box to move in a straight-line way; the NC system consists of a controller, a system input I / O unit, a system output I / O unit, a servo amplifying unit and a system bus for connecting these parts; a cooling system is a series-wound oil cooling circuit. The invention increases the processing efficiency and also reduces the cost.

Owner:周勇

Medium chromium multielement alloy cast ball and cast segment oil quenching heat treatment technique

The invention discloses a medium chromium multielement alloy cast ball and cast segment oil quenching heat treatment technique, wherein the contained components are as follow: 1.7-3.1 of C, 0.3-1.0 ofSi, 0.3-1.0 of Mn, 5-10 of Cr, less than or equal to 0.09 of S, less than or equal to 0.08 of P, and trace of Mo, Ni, Nb, Cu, Y, B, V and Ti; cast medium chromium multielement alloy cast ball and cast segment are heated to 930-1050 DEG C, the temperature is kept for 1.5-3h followed by oil cooling treatment, when the surface temperature of medium chromium multielement alloy cast ball and cast segment are decreased to 100-250 DEG C, the product is moved off the oil tank to halt oil quenching, and the product is poured into an iron bucket, when the iron bucket is full the product is put into a tempering furnace for tempering treatment. The invention solves the problem of poor use quality as cast condition of the medium chromium multielement alloy cast ball and cast segment, in addition, theproduct has no crack, the hardness, toughness and antifatigue impact service life is improved, consumption is reduced, and the ball fragmentation rate is low, thus saving quantities of chromium alloyresource for the nation and reducing operation cost for the user.

Owner:宁国市南洋机械有限公司

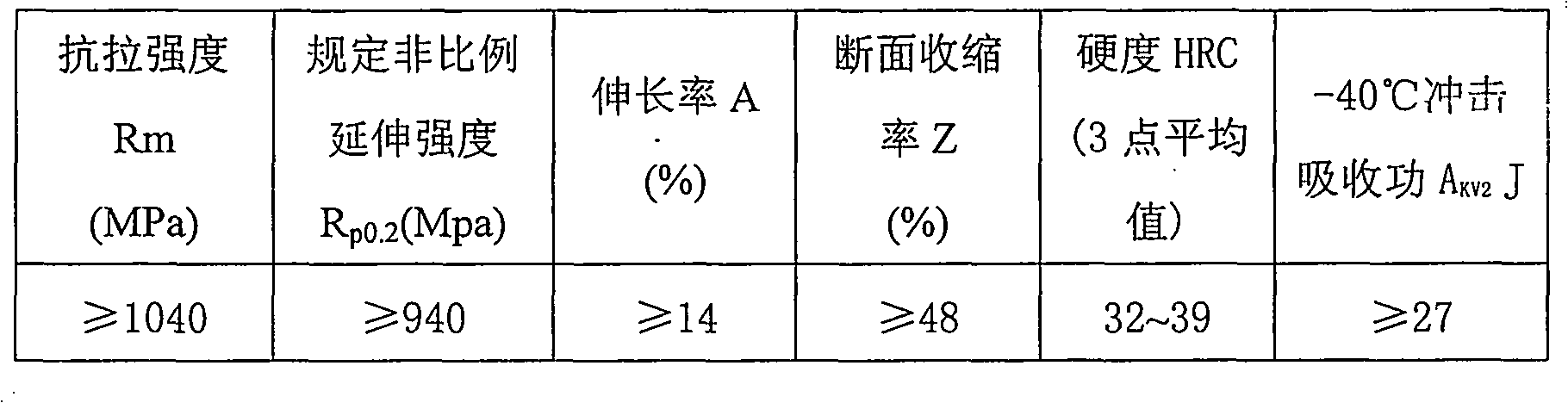

Heat treatment technology of high-strength bolt

ActiveCN102851479AImprove hardenabilityHigh strengthFurnace typesHeat treatment process controlHigh intensityTower

The invention relates to a heat treatment technology, specifically to a heat treatment technology of a high-strength bolt, and belongs to the technical field of heat treatment processing. The high-strength bolt is suitable for joint of anchor bolts, tower tubes, machine heads and wind wheels on wind power generation equipment. According to the technology, after quenching heating insulation, a two-liquid quenching mode of water quenching and oil cooling is adopted, a heating workpiece is taken out from a quenching furnace and putted into water to be cooled for 10-15 s such that the temperature of the workpiece is reduced below 400 DEG C, and then the workpiece is putted into oil for continuous cooling. The heat treatment technology by water quenching and oil cooling has effects of refining crystal grains, effectively raising hardenability of large-sized bolts and minimizing and preventing quenching deformation and cracking tendency of large-sized bolts. The connecting bolt prepared by the technology has high strength and simultaneously has high plasticity and low-temperature impact toughness.

Owner:徐州瑞达装备制造有限公司 +1

Method for producing hot water by air compressor waste heat and water heating machine adopting the method

InactiveCN101245773AStable temperatureThe oil is stable and constantPositive displacement pump componentsPositive-displacement liquid enginesTemperature controlEngineering

The invention relates to a method used for preparing hot water by the waste heat of an air compressor, comprising the following steps: (1) the front of an oil wind cooler of the air compressor is provided with a heat exchanger and a temperature control valve; the heat exchanger comprises an air path part, a water path part and an oil path part; an oil cooling circuit is formed between the air compressor, the oil gas barrel of the air compressor, the temperature control valve, the oil path part of the heat exchanger and the oil wind cooler of the air compressor; (2) the air path part of the heat exchanger is connected with the pressure retaining valve of the air compressor; the air outlet of the air path part is connected with the wind cooler of the air compressor; the compressed air is exhausted after passing through the oil gas barrel, the oil / gas separator of the air compressor, the pressure retaining valve, the air path part of the heat exchanger and the wind cooler; (3) the water inlet of the heat exchanger is connected with a cold water pipe which is provided with a tap water adjusting valve and an electromagnetic valve; the water outlet of the heat exchanger is connected with a heat water pipe; the end of the heat water pipe is connected with a temperature preservation hot water tank; the method used for preparing hot water by the wasted heat of an air compressor also discloses a hot water machine which adopts the method.

Owner:GUANGDONG HIWAVE TECH

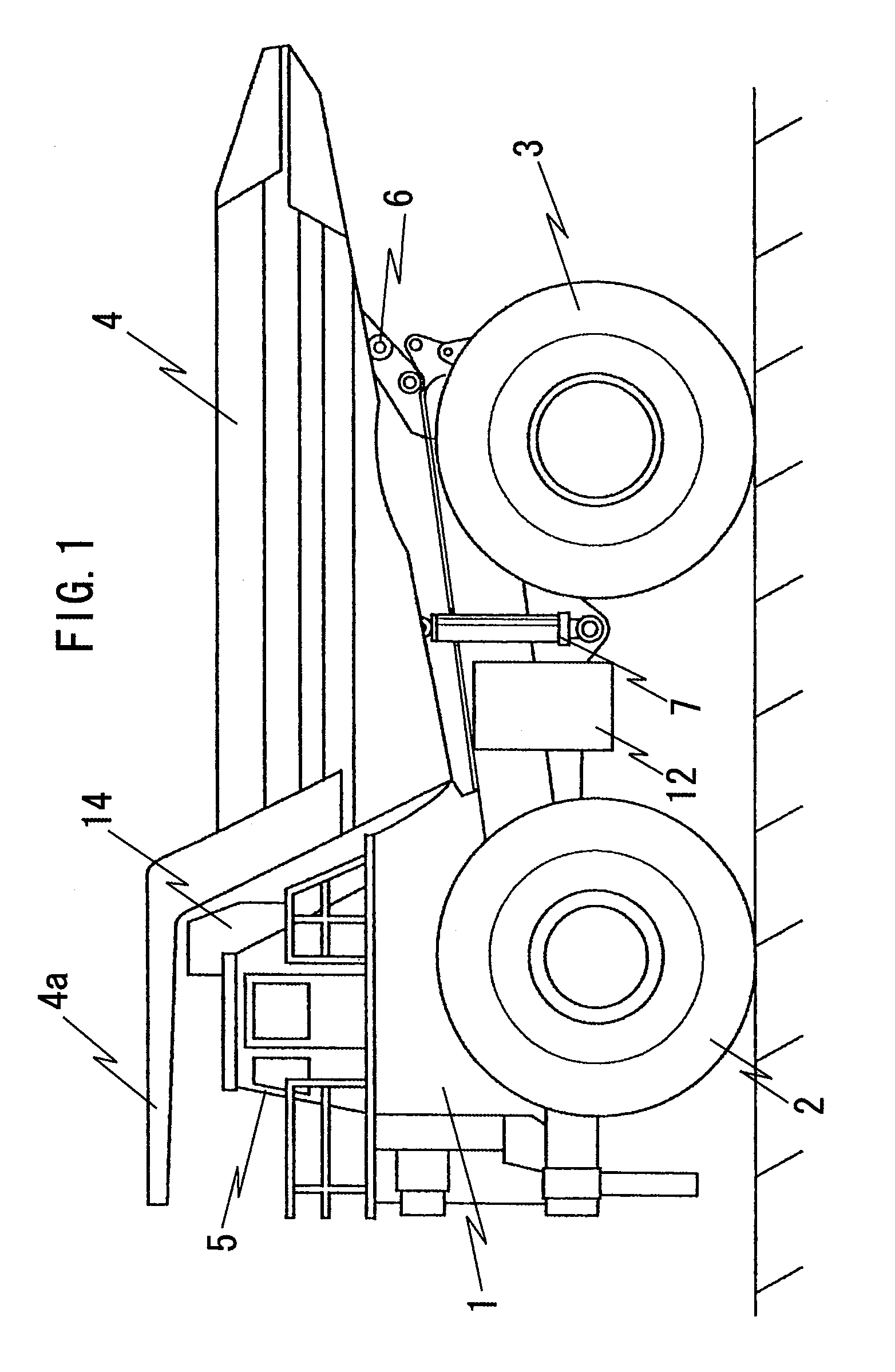

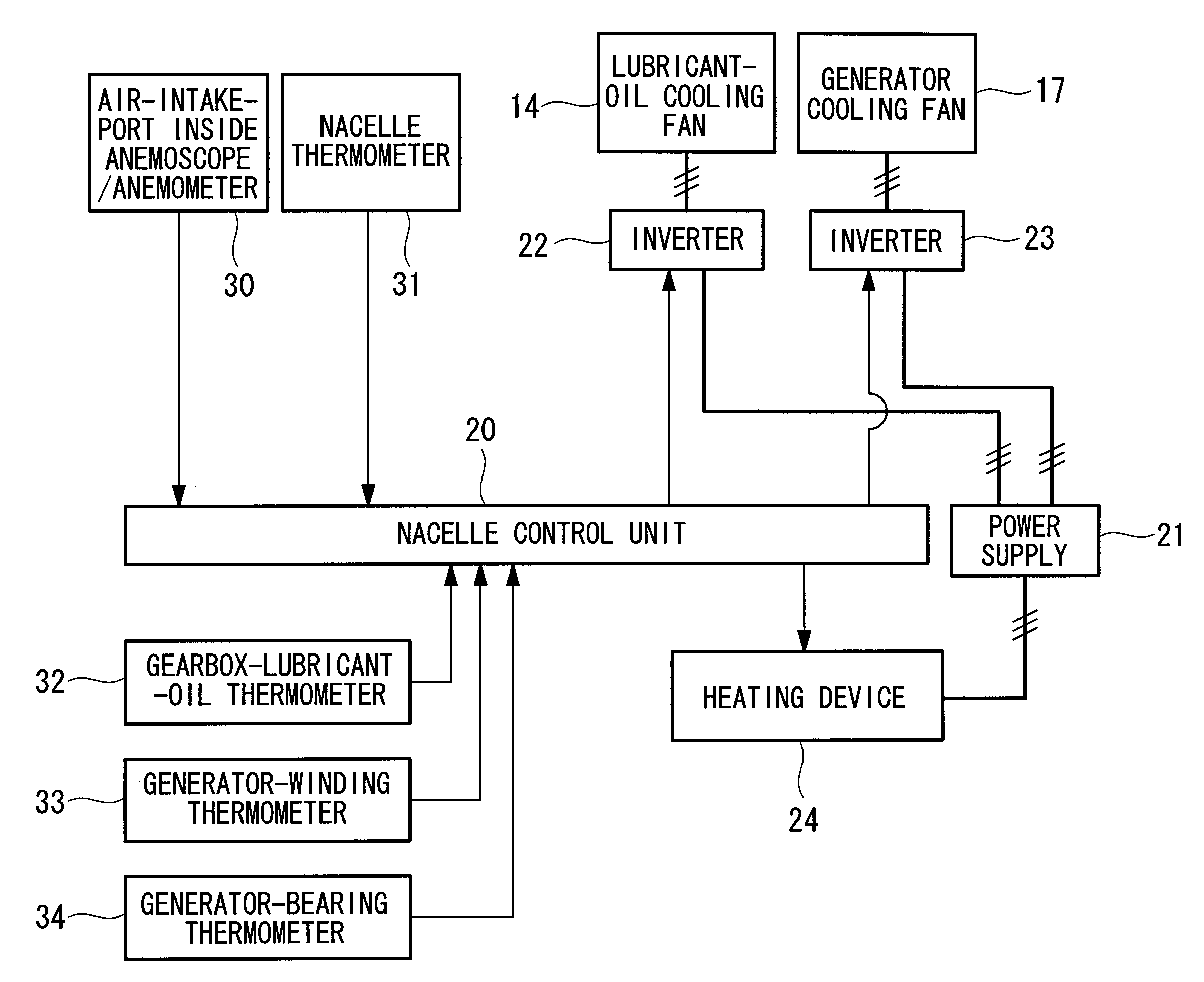

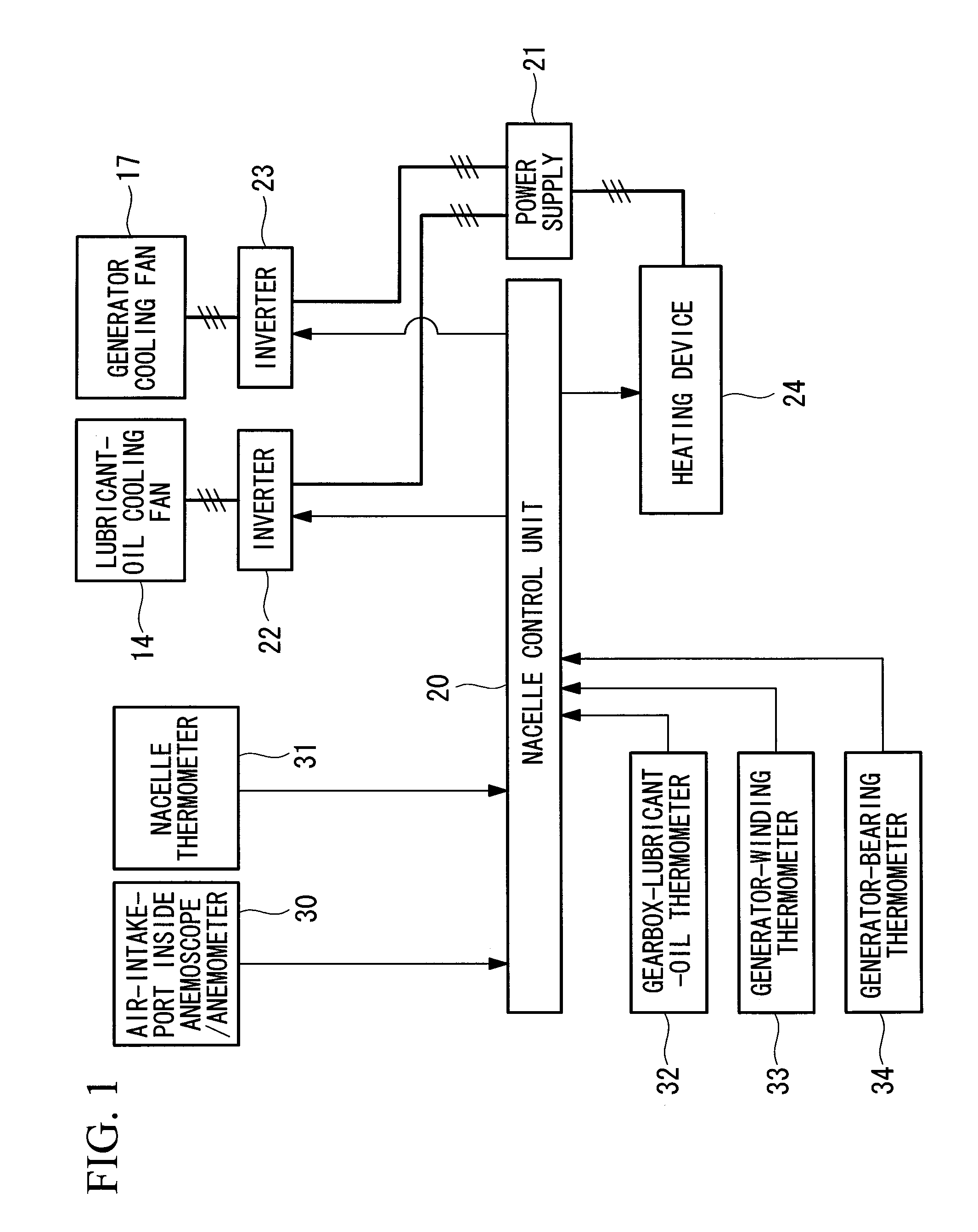

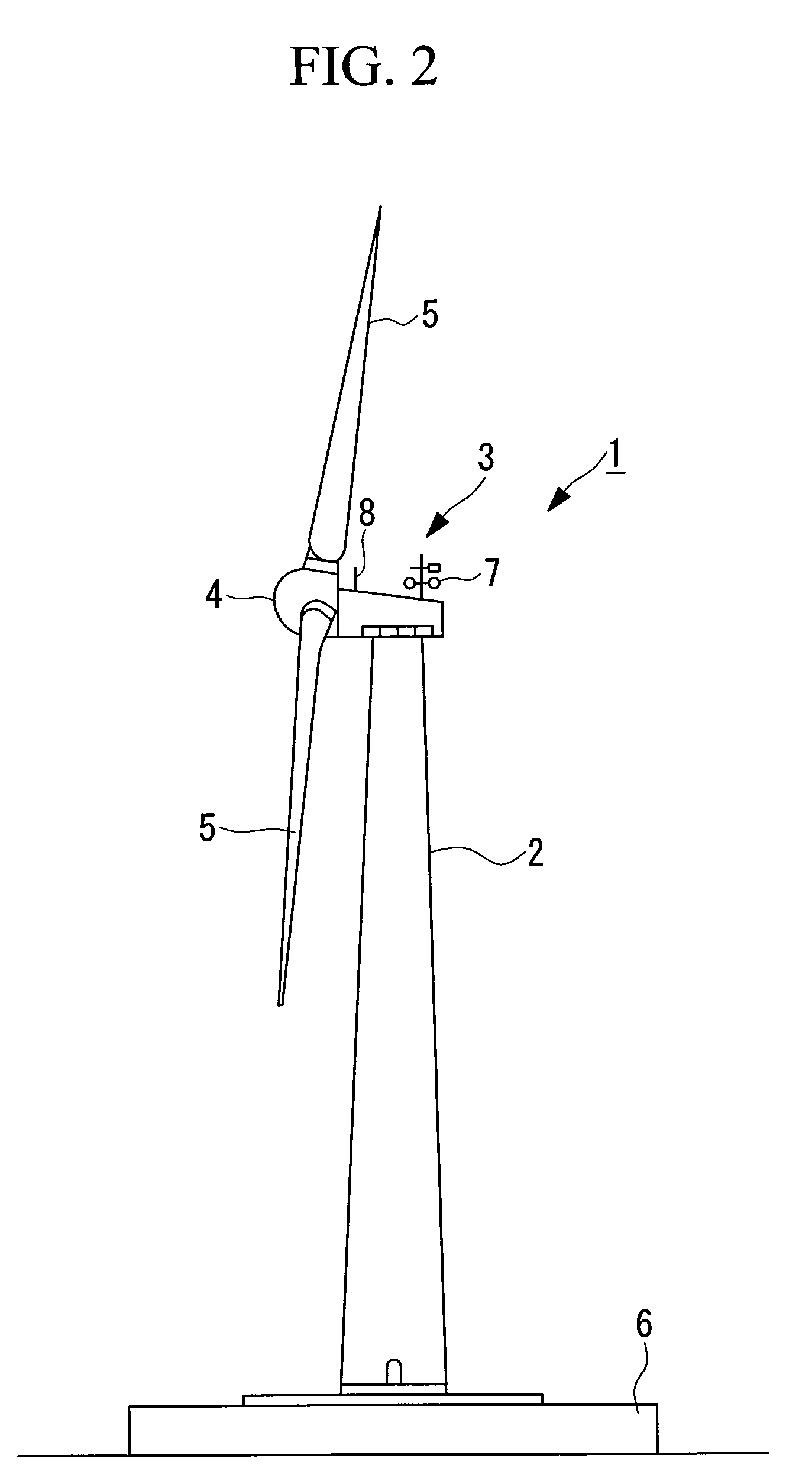

Wind turbine generator

A wind turbine generator is provided in which the efficiency of heating the interior of a nacelle can be improved at a low outside air temperature in a cold region. The wind turbine generator includes a nacelle that accommodates a driving and generating mechanism connected to a rotor head fitted with turbine blades, wherein the nacelle is equipped with a lubricant-oil cooling fan and a generator cooling fan that ventilate the interior of the nacelle to prevent an increase in the temperature of the interior and a heating device that raises the temperature of the interior of the nacelle at a low outside air temperature, wherein the cooling fans can be operated with the rotating directions and the rotational speeds thereof being controlled, and during the operation of the heating device, the rotating directions and the rotational speeds of the cooling fans are controlled so as to make the wind velocity at the ventilation ports thereof about zero.

Owner:MITSUBISHI HEAVY IND LTD

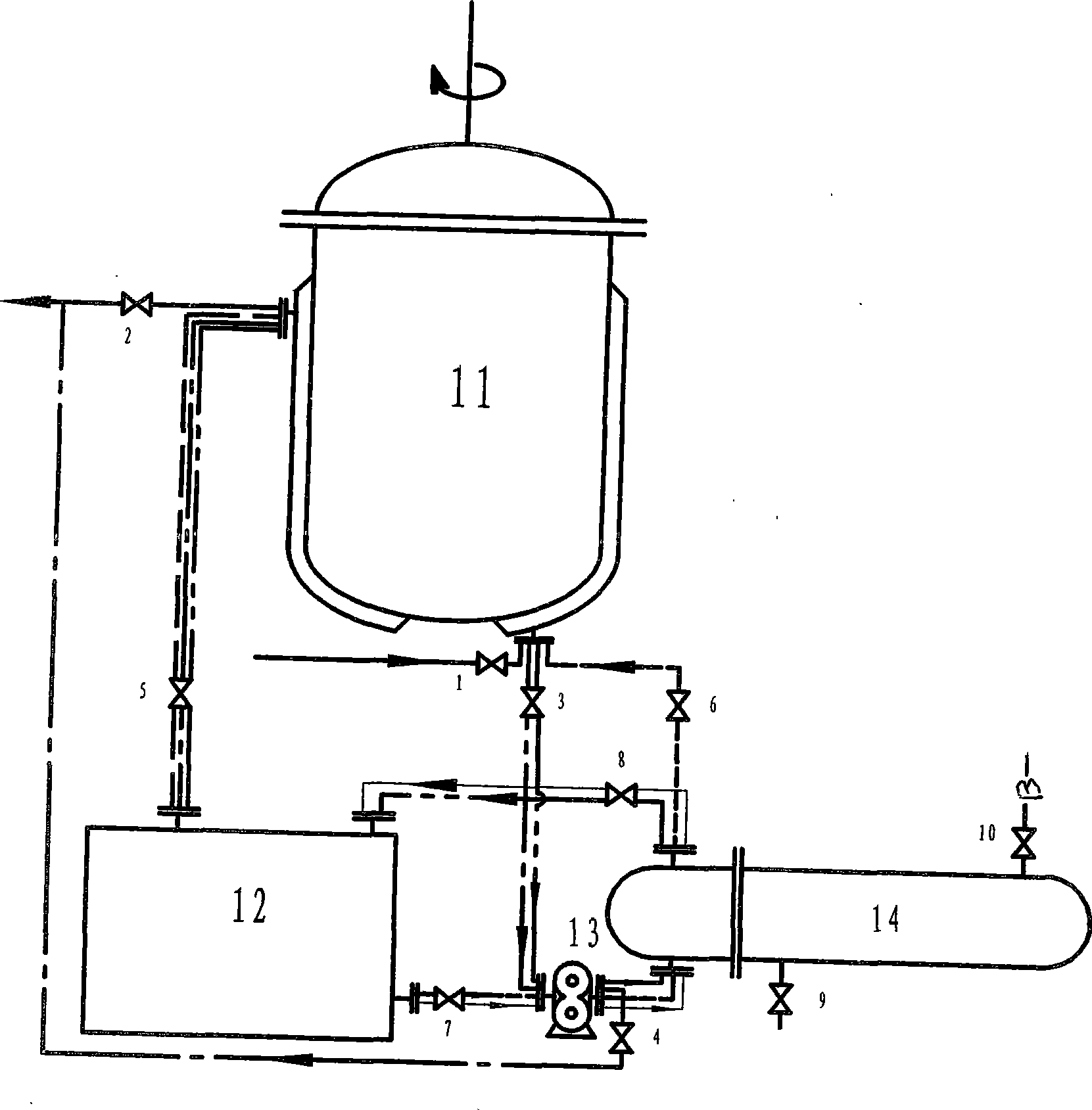

Technique for heating and cooling material in reactor by heat carrier through jacket

InactiveCN101480599AEasy to useCompact structureIndirect heat exchangersChemical/physical/physico-chemical processesSaline waterHeat carrier

The invention relates to a process for heating and cooling materials in a reaction kettle through a jacket by using a heat carrier. The process completes five working procedures by six loops. The loops are as flollows: a heat conduction oil heating loop: heat oil flows out from an oil outlet of a boiler and comes in and out of the jacket of the reaction kettle through a pipeline and a valve for circularly heating; a heating and cooling shift loop: the heat oil is sent back to the boiler by an oil pump through a pipeline; a cold conduction heat oil cooling loop and an ice salt water cooling loop: cold oil enters the jacket of the reaction kettle from an outlet of a cool oil tank by the pump through a pipeline and a cooler and returns to the cool oil tank through a pipeline provided with a balance valve; ice salt water returns to a cooling device from a refrigerating device through a cooler shell side and a pipeline, and cold conduction heat oil is circularly cooled in the cooler; a cool heating shift loop: cold oil comes out of the jacket of the reaction kettle, passes through the pipeline and returns to the cold oil tank from an inlet by the pump through the cooler; a cold oil pre-cooling loop: cold oil comes out of the outlet of the oil tank and returns to the cold oil tank by the pump through the pipeline and the shell side of the cooler introducing ice salt water. The invention has the advantages that the loop structure is compact, the process is stable, the heat exchange efficiency is high, and the high temperature and the low temperature are 300 DEG C and 15 DEG C below zero respectively.

Owner:天元航材(营口)科技股份有限公司

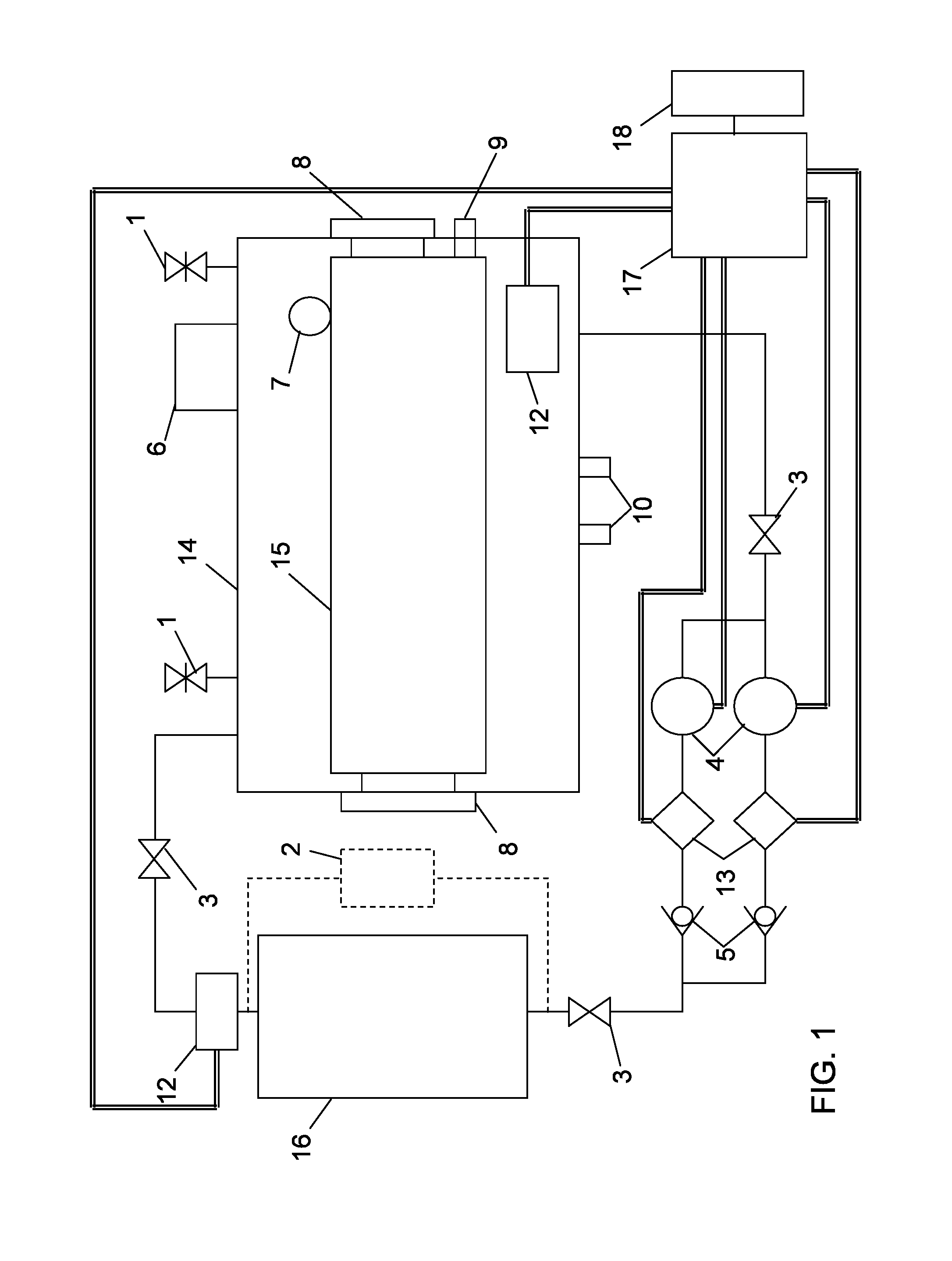

Cooling system of power assembly

InactiveCN105134357AAchieve reasonable controlImprove cooling effectLiquid coolingCoolant flow controlWater flowThermostat

The invention relates to a cooling system of a power assembly. The cooling system comprises an engine, a first cooling water pump, a radiator, a second cooling water pump, a first thermostat, a second thermostat, an engine oil cooler, a gearbox oil cooler, a warm air blower and a connecting pipeline. By means of the cooling system of the power assembly, it is guaranteed that an engine is warmed up rapidly during cold engine starting, the whole vehicle major cycle and the unnecessary minor cycle at the low temperature can be closed through the first thermostat and the second thermostat, and more water flow circulates between an engine cylinder and a cylinder cover through an engine minor cycle pipeline; and heat exchange is reduced, and the engine warming-up speed is increased. When the temperature of the water of the engine is low, the minor cycle of a gearbox oil cooling system is reduced at the low temperature through the second thermostat so that it can be guaranteed that the gearbox oil does not exchange heat with the cooling water of the engine at the low temperature; and the oil temperature of a gearbox is increased more rapidly, and then a better lubrication effect is achieved.

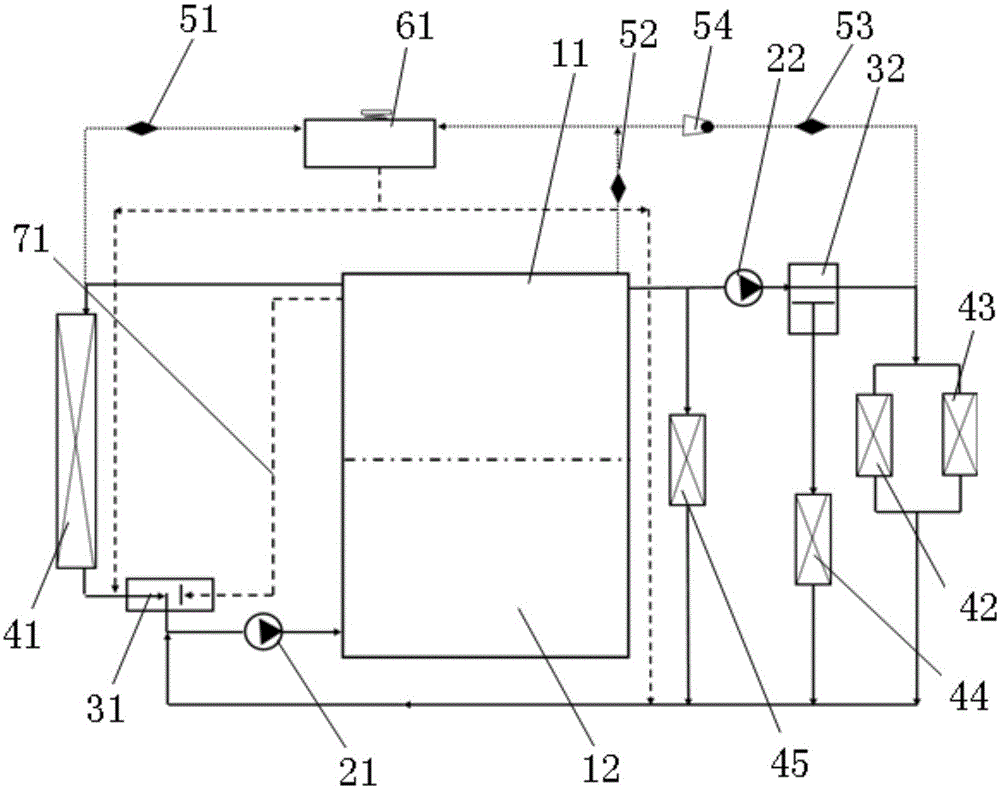

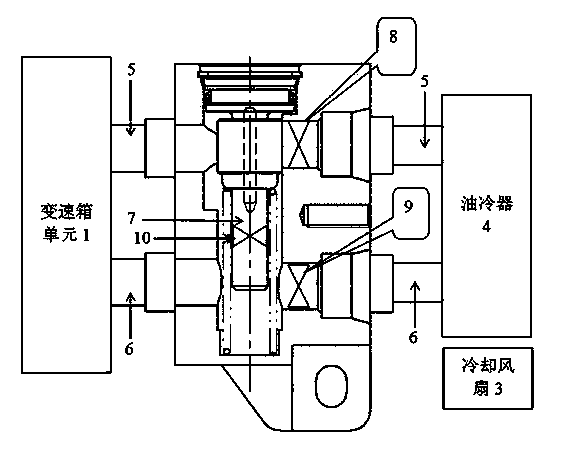

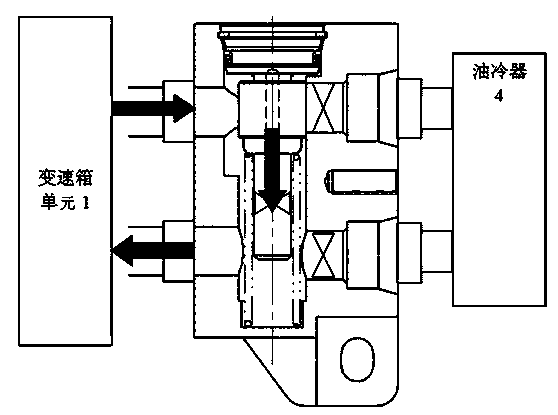

Hybrid power automobile gearbox unit cooling system and cooling method

ActiveCN104279306AImprove cooling effectGuaranteed uptimeGear lubrication/coolingTransmission elementsTemperature controlFriction loss

The invention provides a hybrid power automobile gearbox unit cooling system and cooling method. An oil incoming pipe, an oil discharging pipe and a returning pipe communicating the oil incoming pipe and the oil discharging pipe are arranged in an oil cooling temperature control valve unit, the oil temperature sensing information of a gearbox unit is combined, and valves of oil pipes are controlled to open and close dynamically; on the idling condition, oil from the gearbox unit flows back to the gearbox from the oil cooling temperature control valve unit directly, time for the oil flowing back the gearbox is shortened, oil pressure can be established rapidly, and the gearbox and a coupled mechanism thereof operate at the proper temperature rapidly; when an engine operates in high speed and the gearbox is under high load, oil friction heat is increased sharply, oil of the gearbox flows to an oil cooler completely through the oil cooling temperature control valve, waste heat is radiated through the oil cooler, and the coil flows back to the gearbox unit, so that the accurate control of the oil temperature of the gearbox is implemented, friction loss, oil consumption and discharging are reduced, service life of the gearbox unit is prolonged, and shift quality is guaranteed.

Owner:奇瑞控股集团有限公司

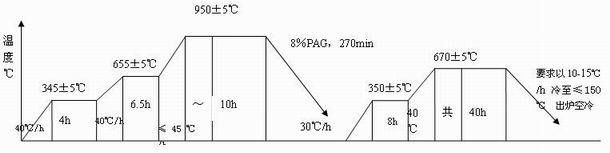

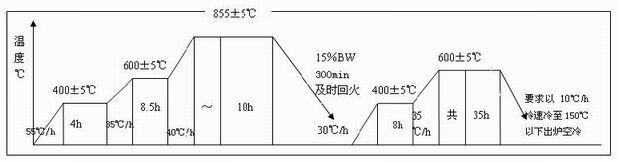

Environment-friendly heat treatment process for large shaft forgings

InactiveCN102115809AUniformly hardenedReduce cleaning costsFurnace typesHeat treatment process controlWater solubleLaser cooling

The invention discloses an environment-friendly heat treatment process for large shaft forgings. According to the heat treatment process, the traditional oil and tap water are substituted by a commercial water soluble quenching medium PAG (poly alkylene glycol) or BW, the concentration of the quenching medium PAG or BW is adjusted, and the process parameters such as the heating speed, holding time, quenching temperature, quenching time, tempering temperature, cooling speed and the like are strictly controlled, thereby solving the problems of deformation and even defects liable to occur by water cooling of large shaft parts and lower rigidity, environmental pollution and the like liable to occur by oil cooling of large shaft parts, and simultaneously solving the problems of heavy weight, great change of sectional dimension, uneven performance after heat treatment and the like of large shaft parts.

Owner:HENAN UNIV OF SCI & TECH

Oil cooling system, particularly for transformers feeding traction electric motors, transformer with said system and method for determining the cooling fluid flow in a cooling system

ActiveUS20090231075A1Easy to assembleEasy to useTransformers/inductances coolingTransformers/inductances casingsNuclear engineeringTransformer

An oil cooling system, which may be employed for transformers feeding traction electric motors and for oil in a high viscosity condition, includes a first heat exchanger between a heat generating source to cooling oil that is connected by delivery and return ducts to a second heat exchanger cooling the oil by transmitting the heat absorbed at the first heat exchanger to an environment having a lower temperature than the cooling oil. The oil cooling system also includes devices flowing the cooling oil from the first to the second heat exchanger and vice versa, and devices monitoring oil flow in the circuit, for example by indicating operating conditions of the cooling system and / or by performing safety operations when the heat generating source becomes overheated.

Owner:ALSTOM TRANSPORT TECH SAS

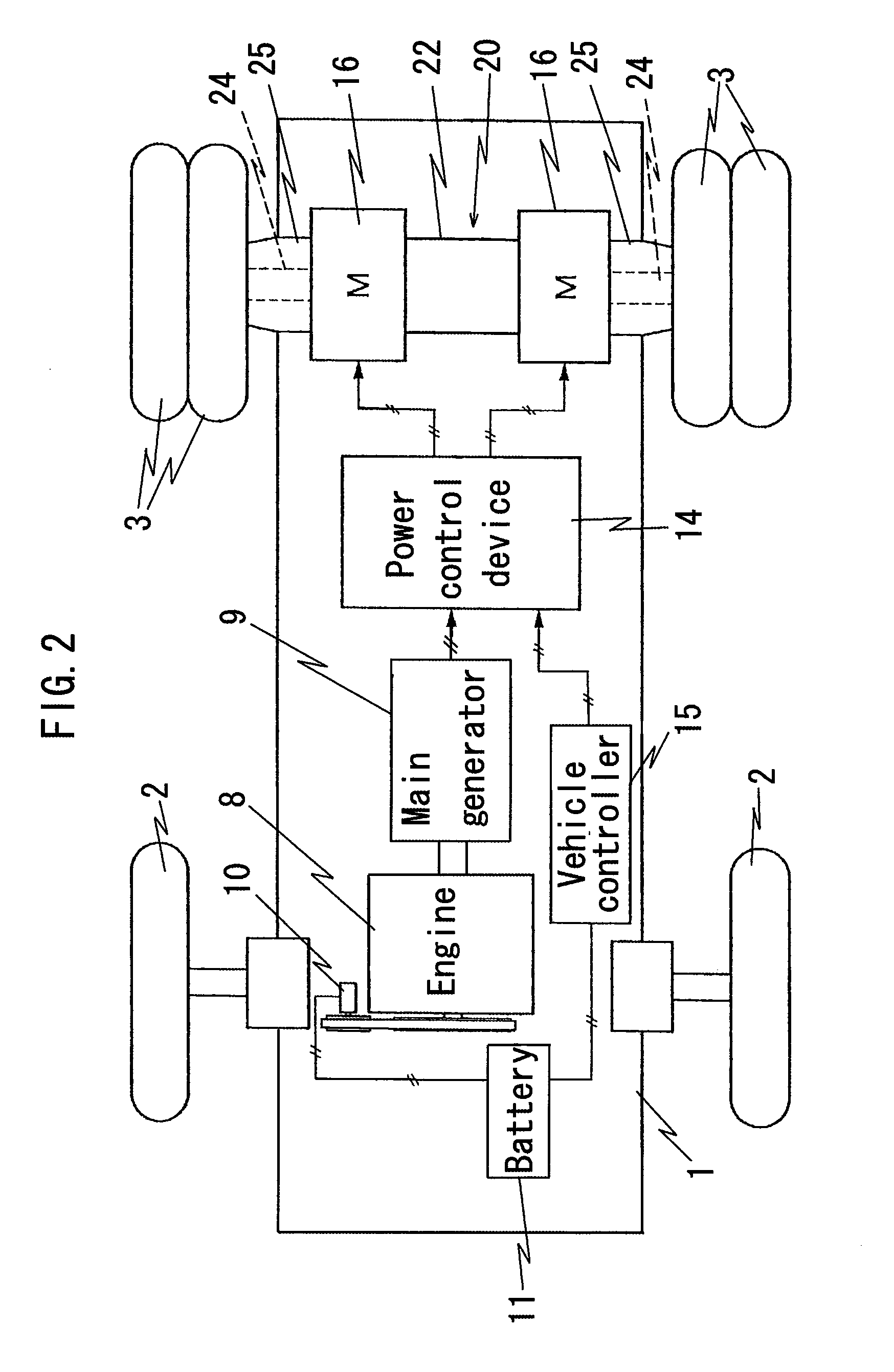

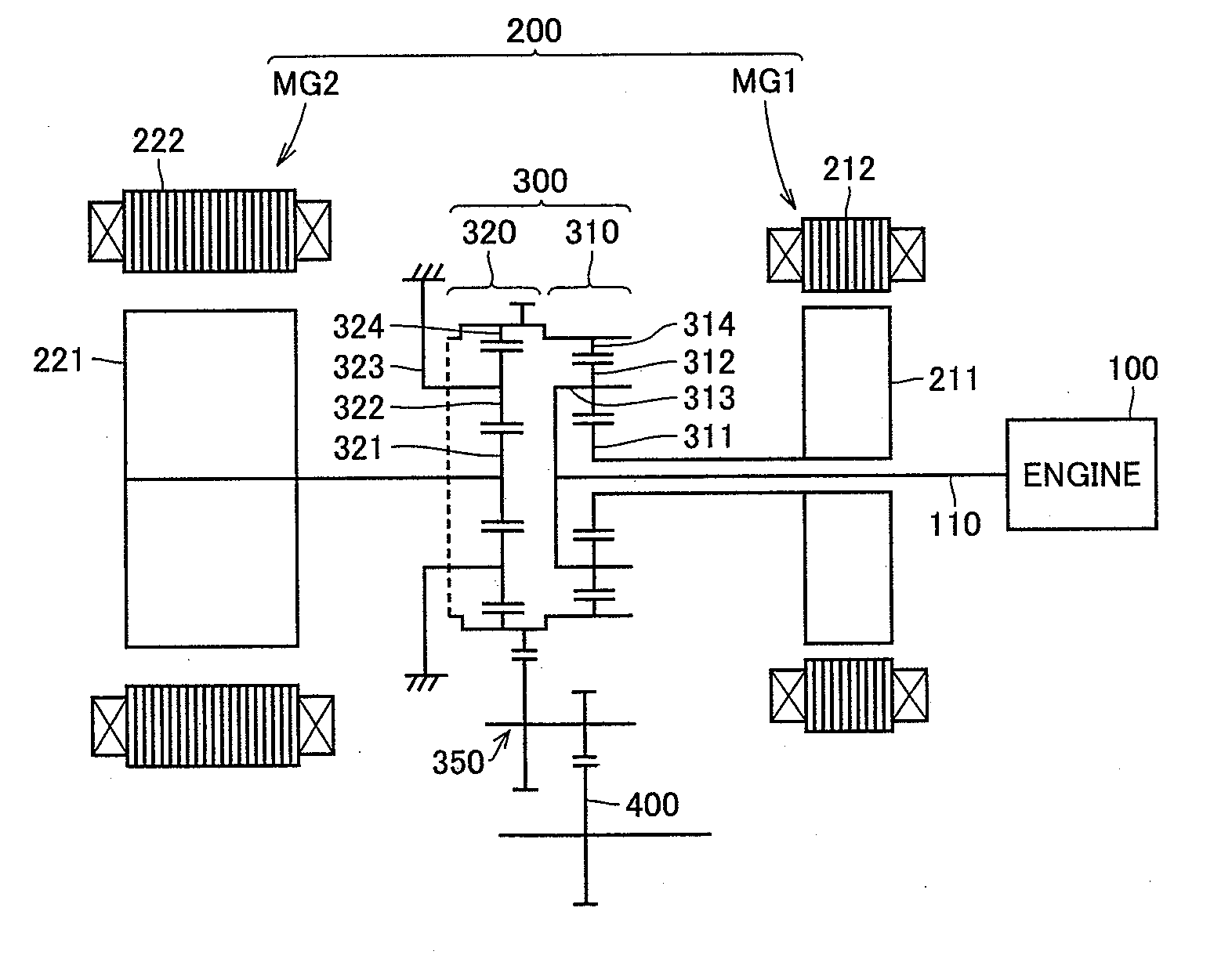

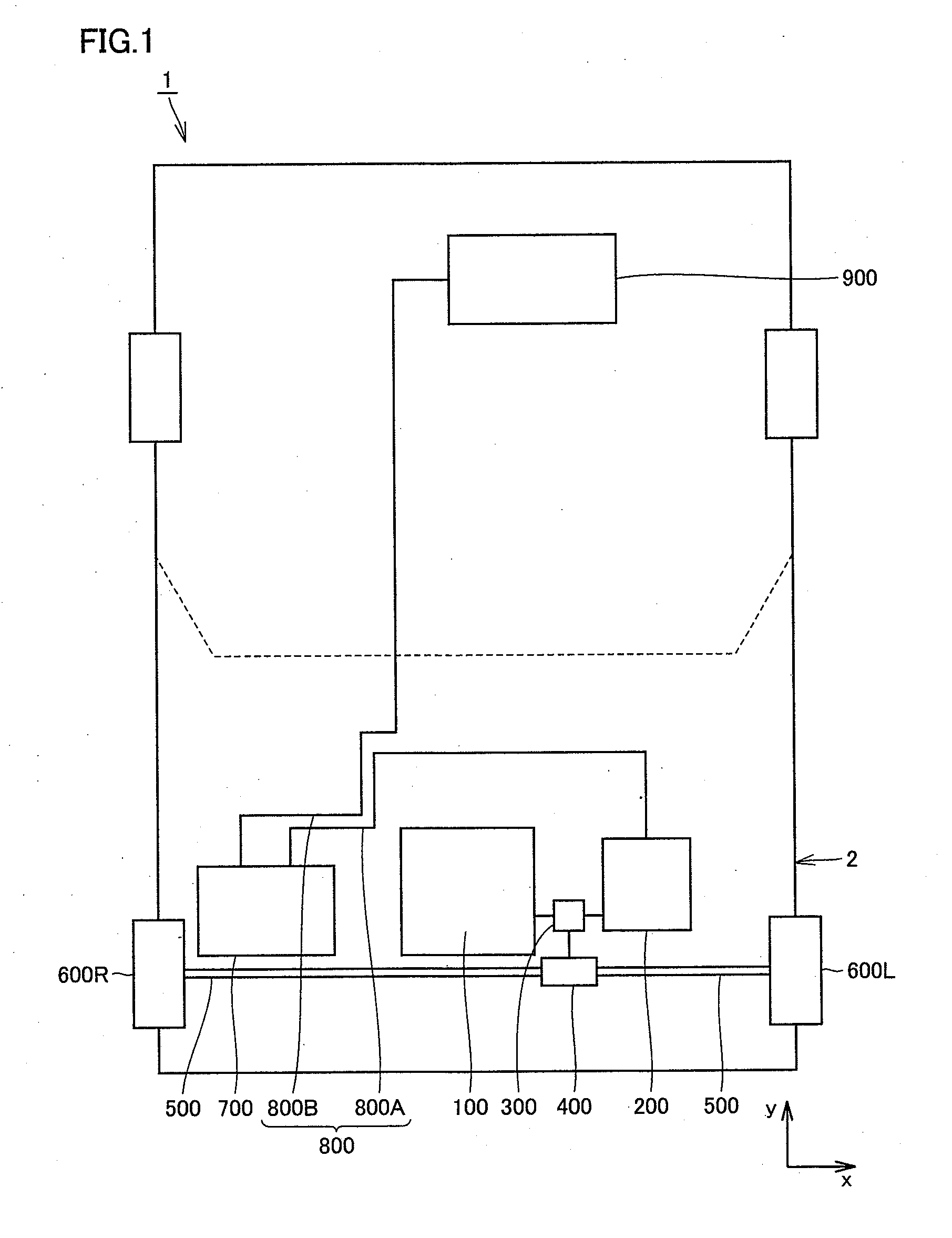

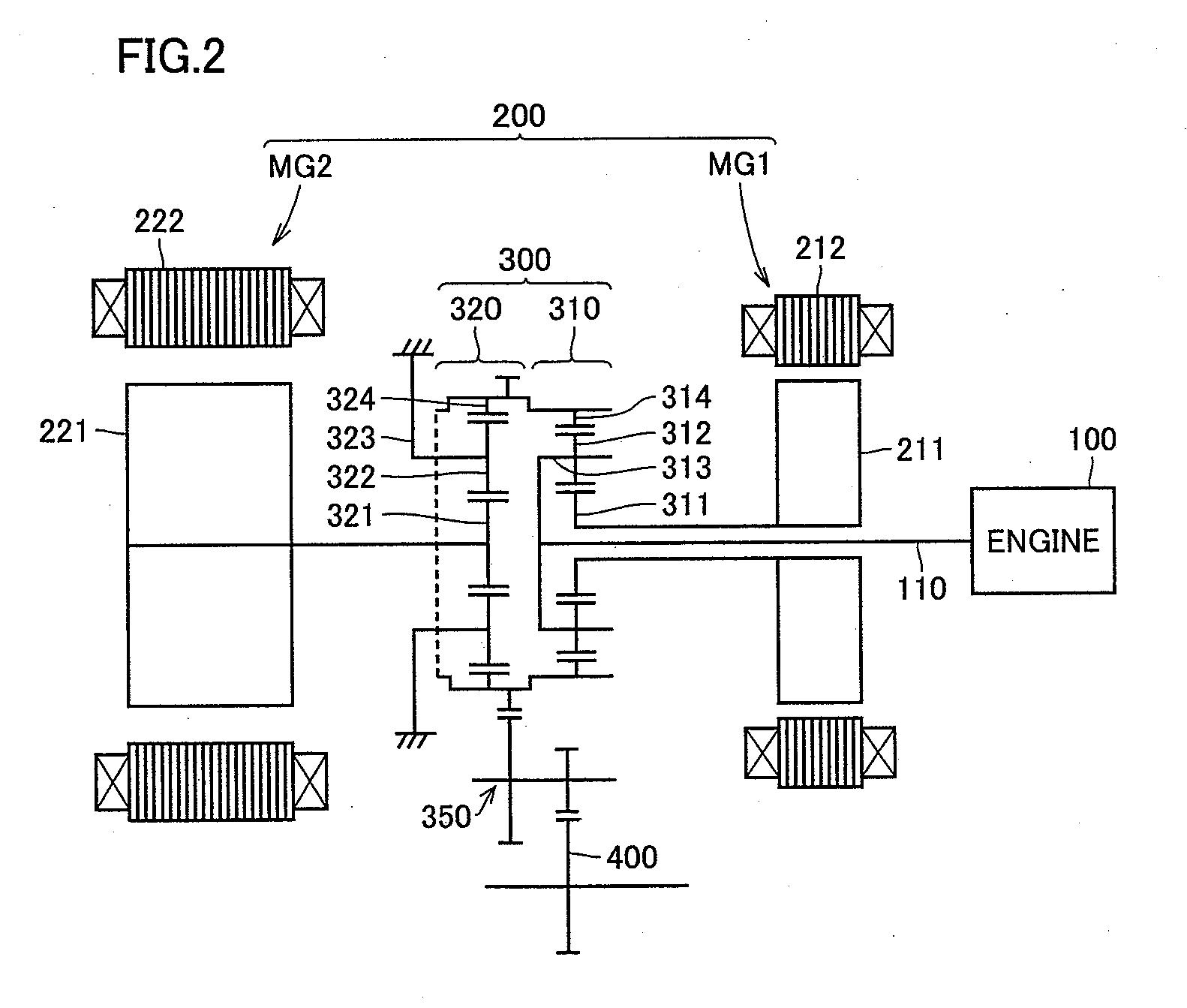

Vehicle drive system

ActiveUS20100084206A1Improve installabilityReduce impactHybrid vehiclesElectric propulsion mountingElectrical batteryOil cooling

A vehicle drive system includes a battery, motor generators driving the vehicle using electric power from the battery or driven by the vehicle, a PCU integrated with the motor generators, having inverters and controlling the motor generator, cooling water cooling inverters, and oil cooling motor generators. The PCU includes a smoothing capacitor and a filter capacitor provided electrically closer to the battery than the smoothing capacitor. Here, the smoothing capacitor is cooled by the cooing water, while the filter capacitor is cooled by the oil.

Owner:TOYOTA JIDOSHA KK +1

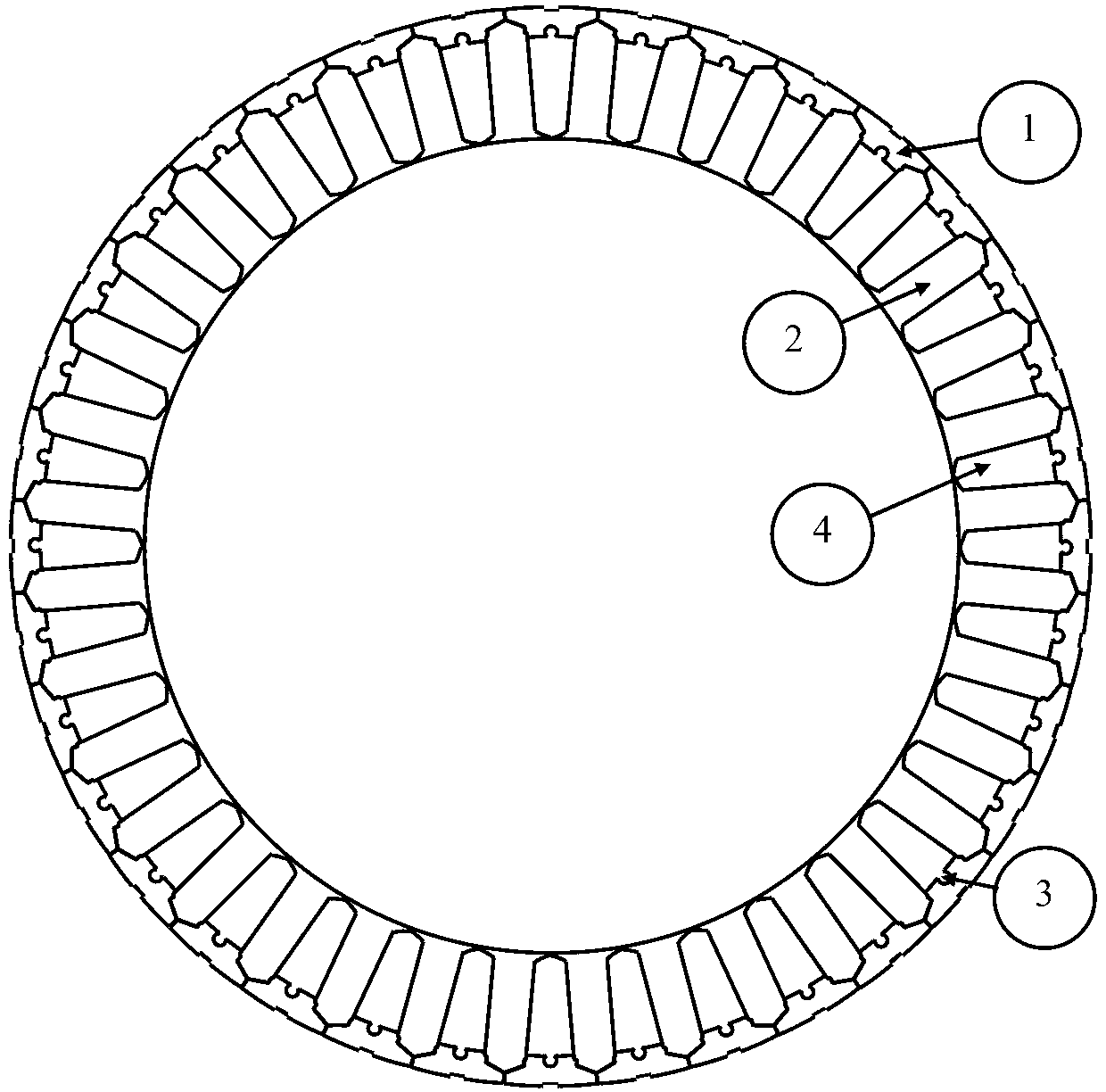

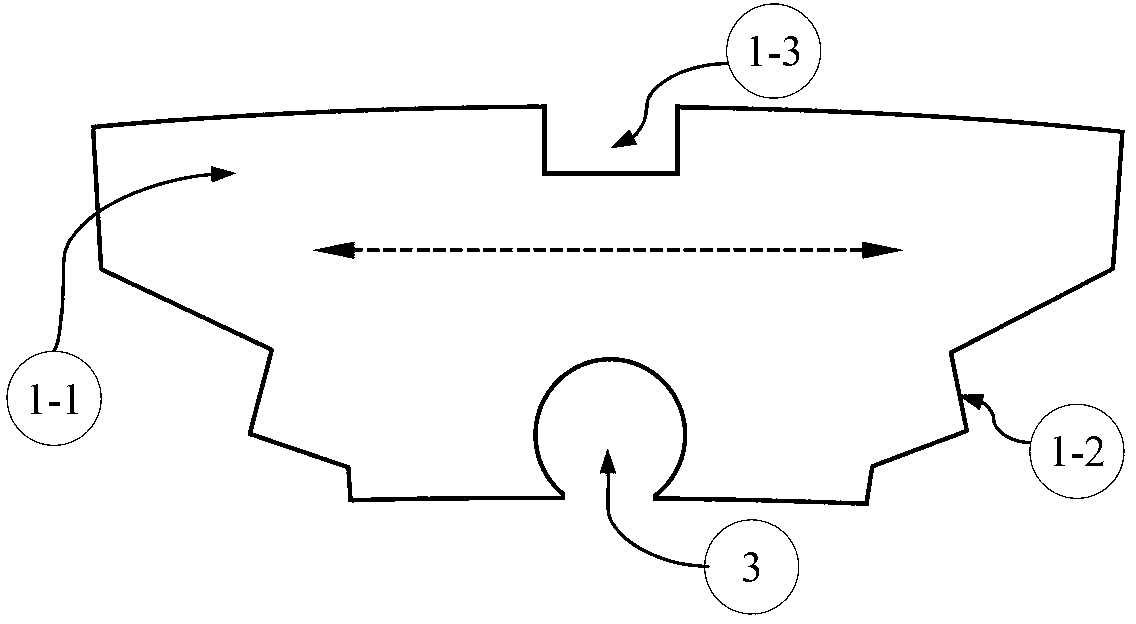

Structure of motor stator core and cooling method for motor stator based on structure of motor stator core

ActiveCN103280903ALow ferromagnetic lossImprove efficiencyWindings insulation shape/form/constructionMagnetic circuit stationary partsWater coolingOil cooling

The invention relates to a structure of a motor stator core and a cooling method for a motor stator based on the structure of the motor stator core. The structure is characterized in that the stator core is formed by splicing and combining stator yoke units and stator tooth units, wherein the quantities of the stator yoke units and the stator tooth units are the same, and are equal to the slot number Z1 of a stator; the stator yoke units and the stator tooth units are formed by laminating oriented silicon steel sheets; a stator yoke unit is connected between every two adjacent tooth units; the tooth units and the stator yoke units are in joggle joint; the silicon steel sheets of the stator yoke units are oriented circumferentially; and the silicon steel sheets of the stator tooth units are oriented radially. The cooling method is selected from one of air cooling, water cooling and oil cooling. The structure has the advantage that the motor has the characteristics of low ferromagnetic loss, high efficiency, low torque pulsation, low slot effect, low running noise, low wind resistance, high slot fullness rate of a stator winding, high utilization ratio of a silicon steel sheet material, suitability of the stator for automatic mass production and the like.

Owner:曹宇轩

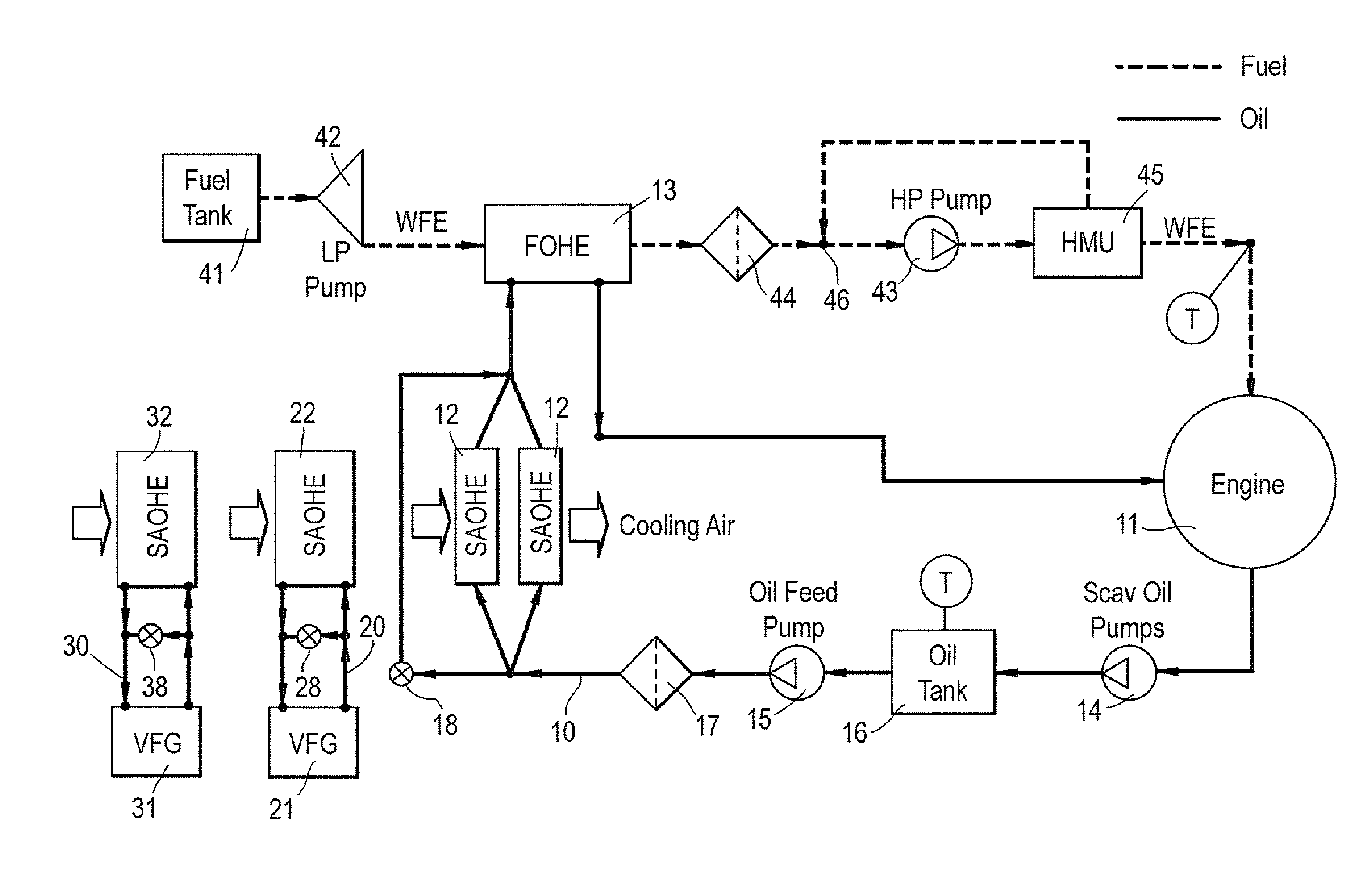

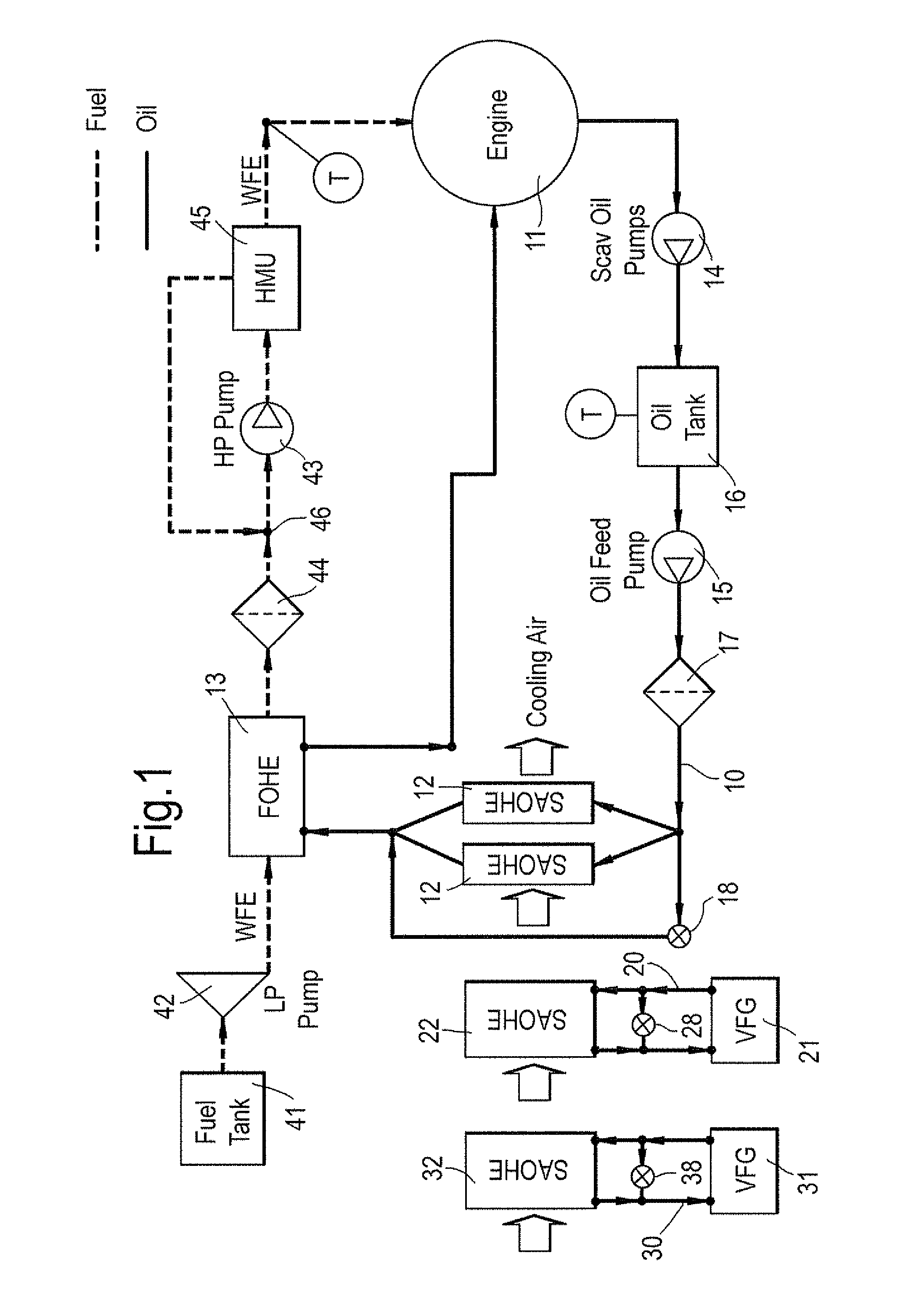

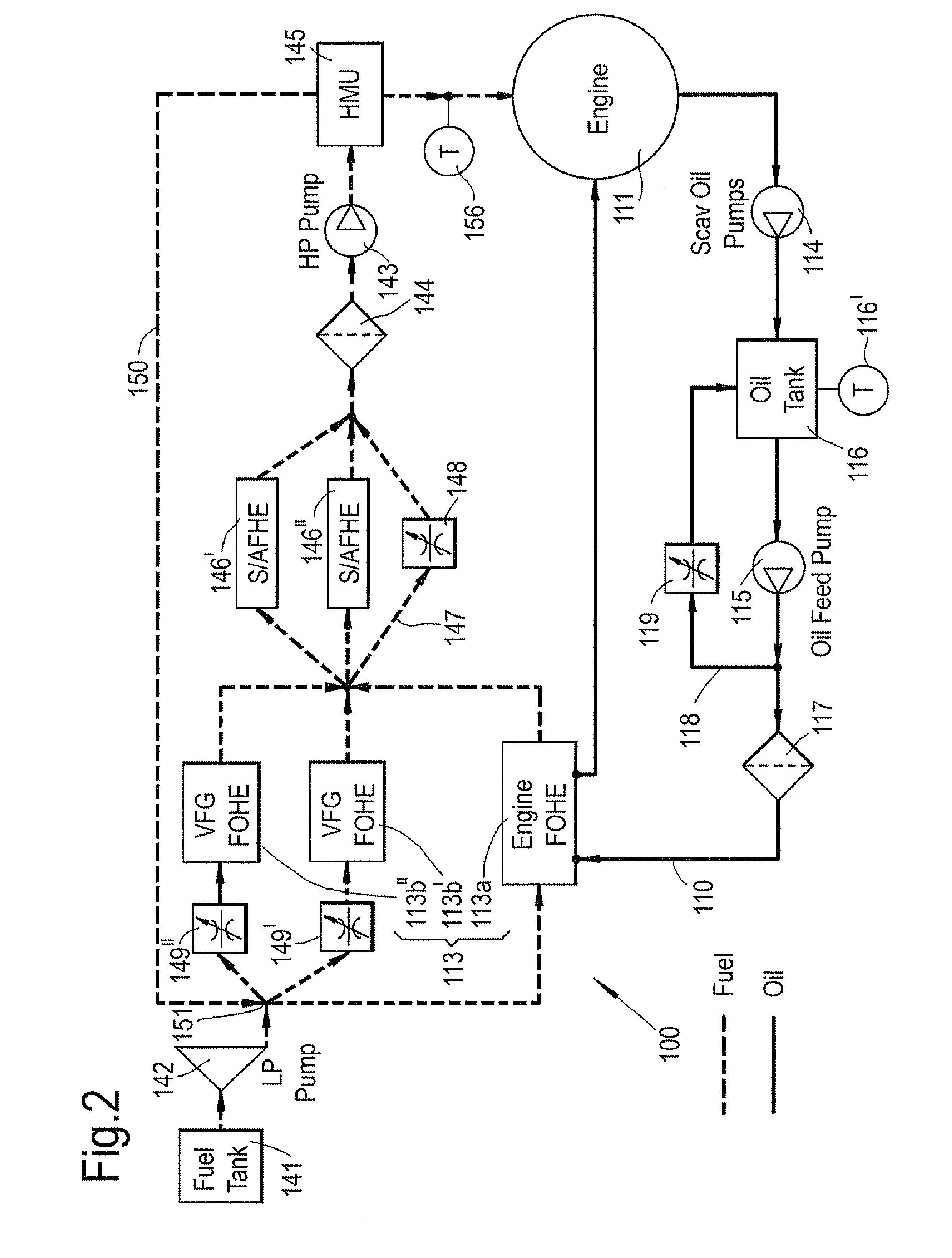

Oil cooling system

A system for cooling one or more circulating flows of oil, the system including: one or more fuel-oil heat exchangers, the fuel-oil heat exchangers using fuel for an engine to cool at least one of one or more circulating flows of oil; and a fuel return line in flow communication with a point downstream of the fuel-oil heat exchangers and a point upstream of the fuel-oil heat exchangers, wherein the fuel return line is arranged so that at least a portion of the fuel exiting the fuel-oil heat exchangers may be diverted to the point upstream of the fuel-oil heat exchangers. Furthermore, a system for cooling a circulating flow of oil may include one or more fuel-oil heat exchangers and one or more air-fuel heat exchangers, the fuel-oil heat exchangers using fuel to cool the circulating flow of oil and the air-fuel heat exchangers using air to cool the fuel.

Owner:ROLLS ROYCE PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com