Method for producing hot water by air compressor waste heat and water heating machine adopting the method

A technology of air compressor and waste heat system, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve problems such as troublesome operation, uncontrollable, and low energy saving, and achieve convenient operation, The effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

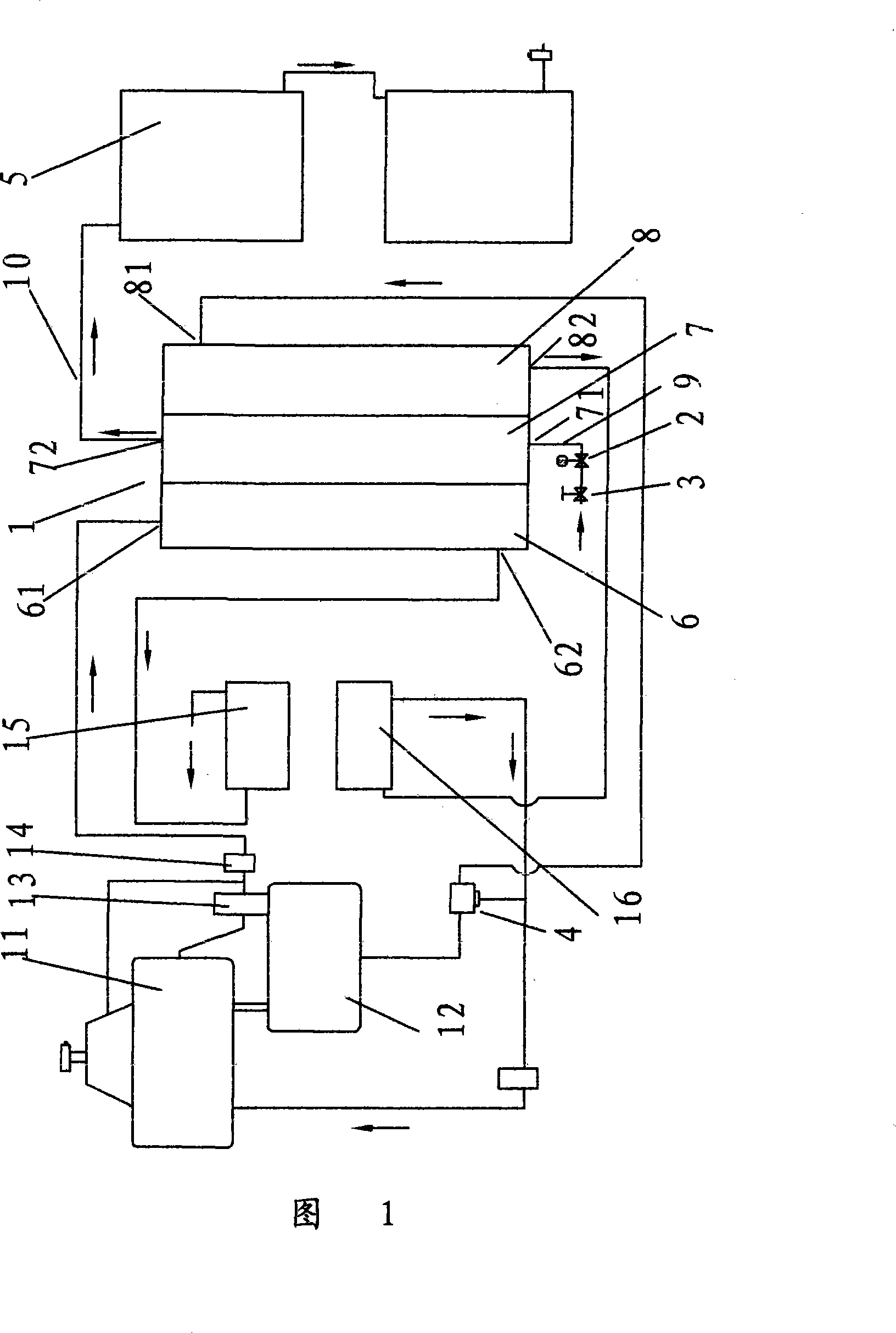

[0025] Embodiment: referring to Fig. 1, a kind of method for heating hot water with the waste heat of air compressor provided by the present invention, it comprises the following steps:

[0026](1) A heat exchanger 1 and a temperature control valve 4 are arranged in front of the oil-air cooler 16 of the air compressor 11. The heat exchanger 1 includes an air passage 6, a water passage 7 and an oil passage 8. An oil cooling circuit is formed between the machine 11, the oil and gas barrel 12 of the air compressor 11, the temperature control valve 4, the oil circuit part 8 of the heat exchanger 1, and the oil air cooler 16 of the air compressor 11;

[0027] (2) Connect the air passage part 6 of the heat exchanger 1 to the pressure maintaining valve 14 of the air compressor 11, and the air outlet 62 of the air passage part 6 is connected to the air cooler 15 of the air compressor 11, and the compressed air passes through the oil and gas The barrel 12, the oil-gas separator 13 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com