Calcination predictive control system and method for rotary cement kiln

A cement rotary kiln, predictive control technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve the problems of variable time lag, inability to adapt to strong coupling, and system nonlinearity, etc., to achieve Simple operation, good control effect, strong adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

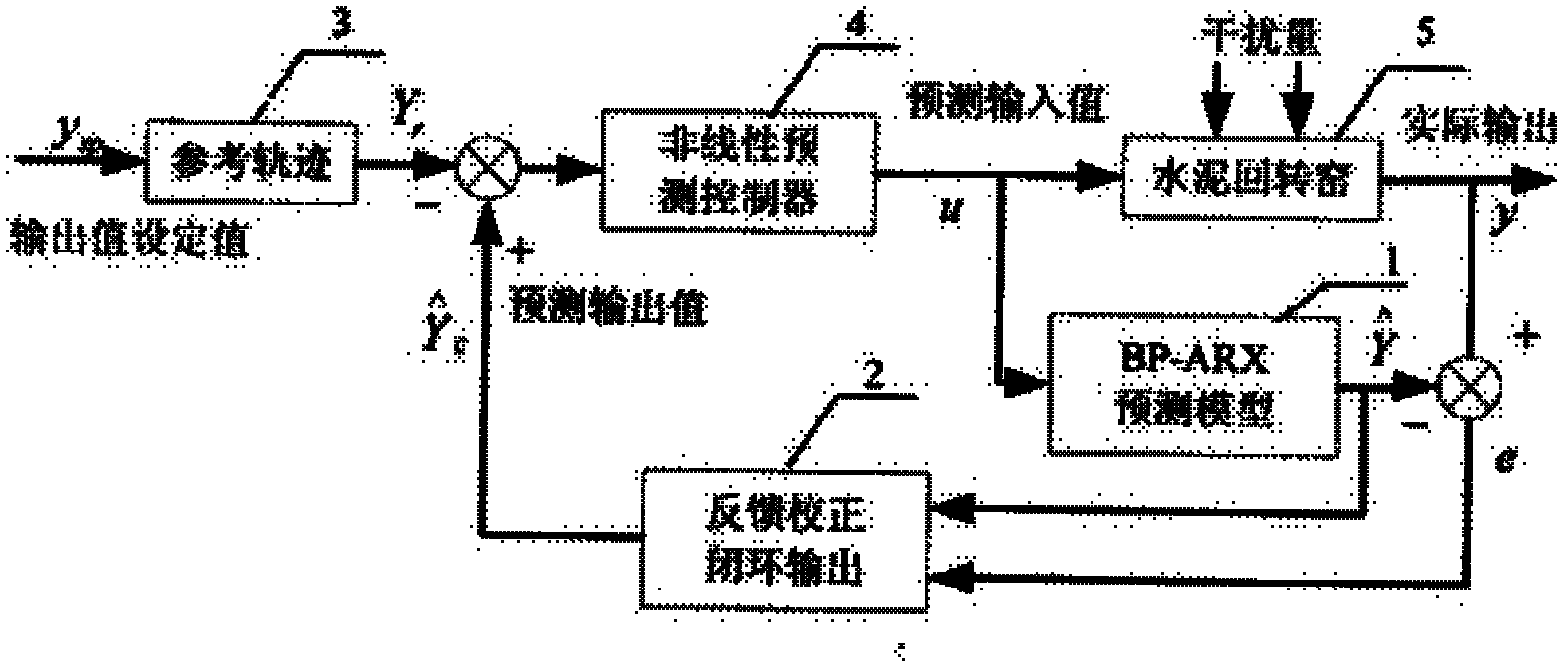

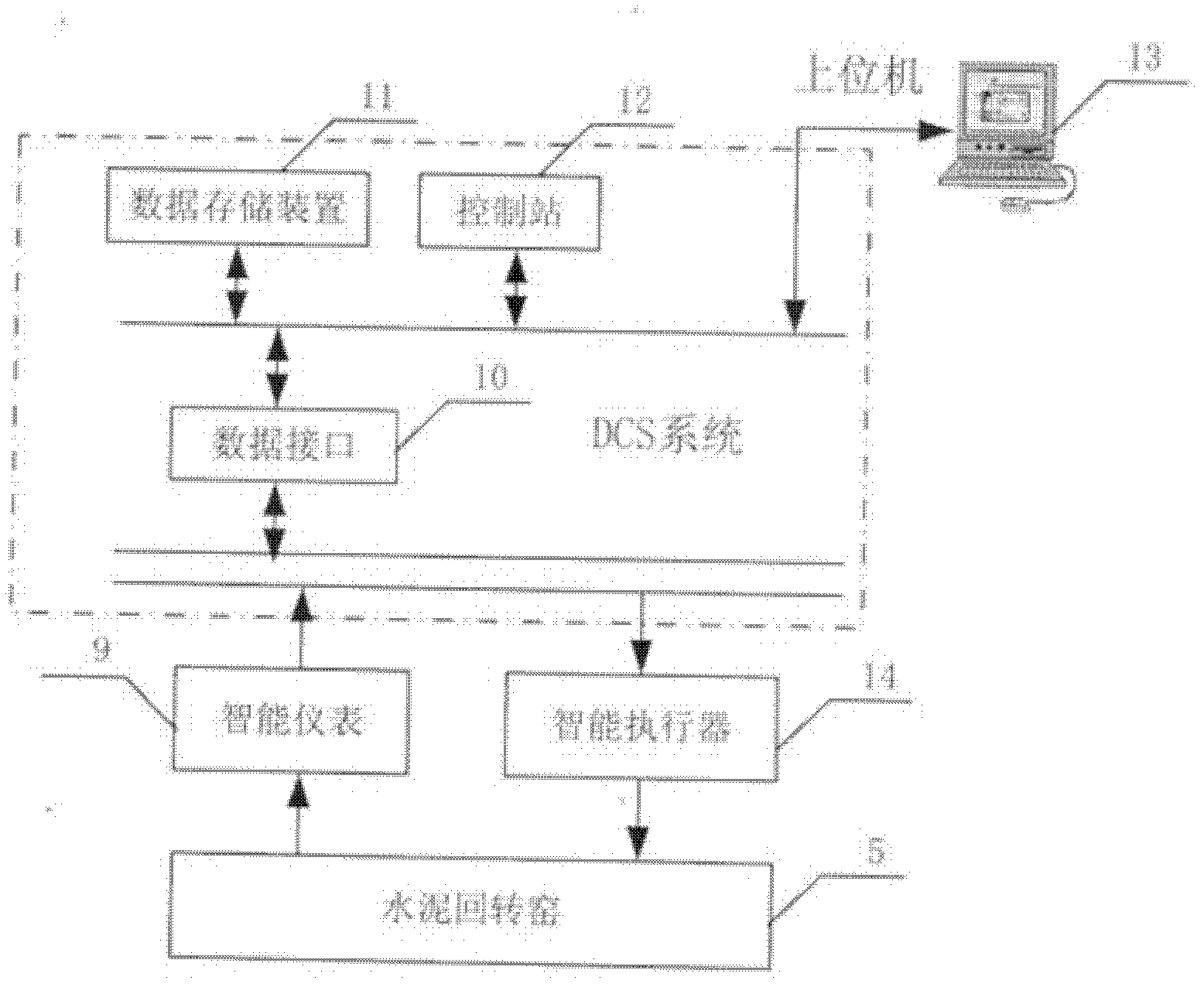

[0034] like figure 1 Flowchart of the predictive control method shown and image 3 The block diagram of the control system shown:

[0035] 1. Establish a forecasting model based on the BP-ARX model

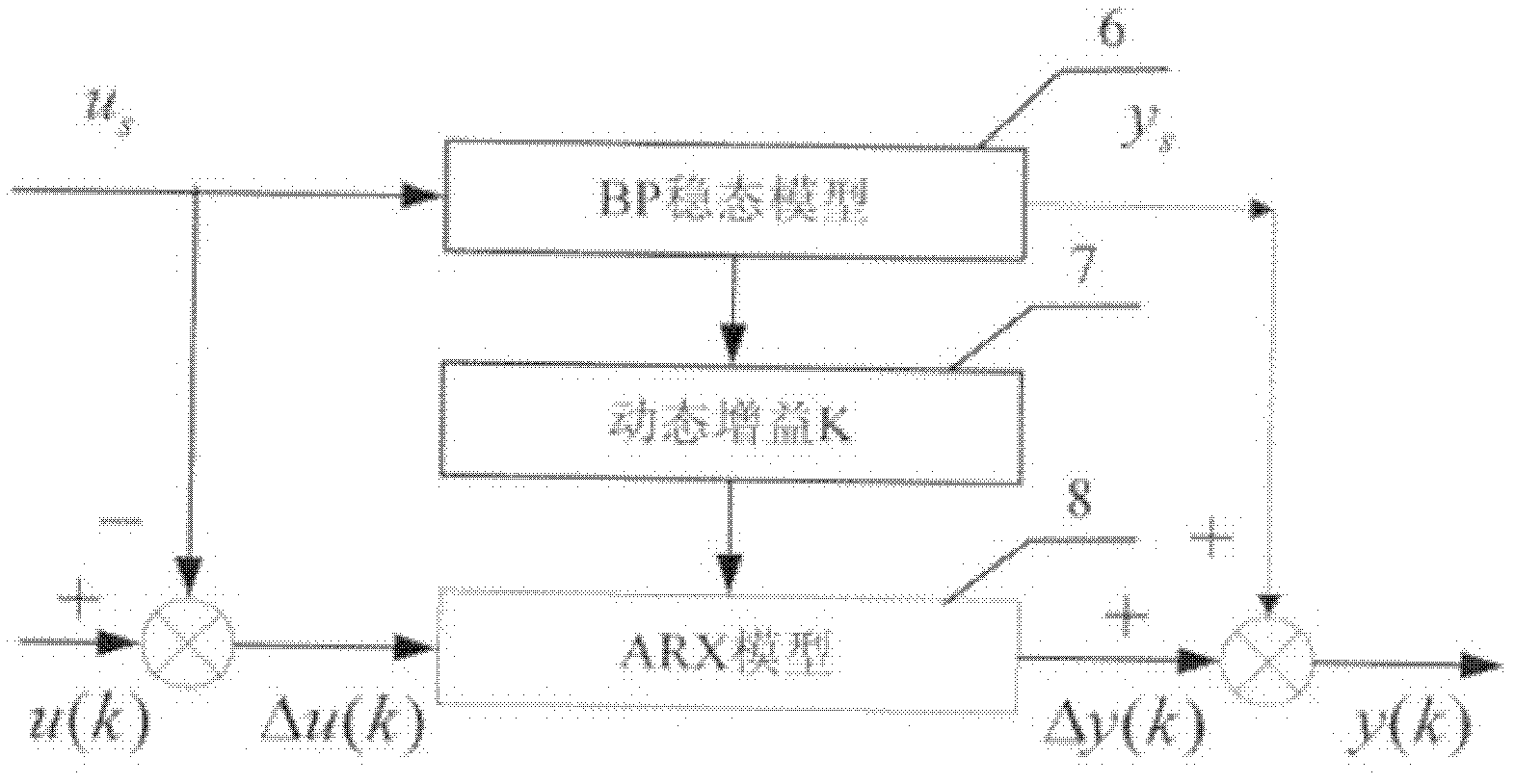

[0036] The BP-ARX forecasting model is a combination model composed of the nonlinear BP steady-state model and the linear ARX dynamic model in parallel. The detailed model structure relationship is as follows: figure 2 shown. The establishment of the BP-ARX model is generally divided into two steps: training data acquisition and model identification.

[0037] (1). Training data acquisition

[0038]In this embodiment, the NO in the rotary kiln calcination process x Content, O 2 The four variables of content, coal injection amount and high temperature fan baffle opening are passed through image 3 The data storage device (11) of the DCS system collects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com