Heat treatment technology of high-strength bolt

A high-strength bolt and process technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as rapid cooling, deformation and cracking, prevent quenching deformation and cracking tendency, refine grains, Effects of high plasticity and low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The material specification is M36, and the material composition is shown in Table 2; the heat treatment process is shown in Table 3; the mechanical properties of bolts are shown in Table 4:

[0013] Table 2 Material chemical composition analysis (wt.%)

[0014] the element

C

Si

mn

S

P

Cr

Mo

content

0.41

0.248

0.79

0.004

0.010

0.95

0.15

[0015] Table 3 heat treatment process

[0016] Normalizing process

860℃~880℃ for 60 minutes, air cooling

Quenching process

820℃~830℃ for 50 minutes, water quenching and oil cooling

tempering process

575℃~585℃ for 60 minutes, water cooling

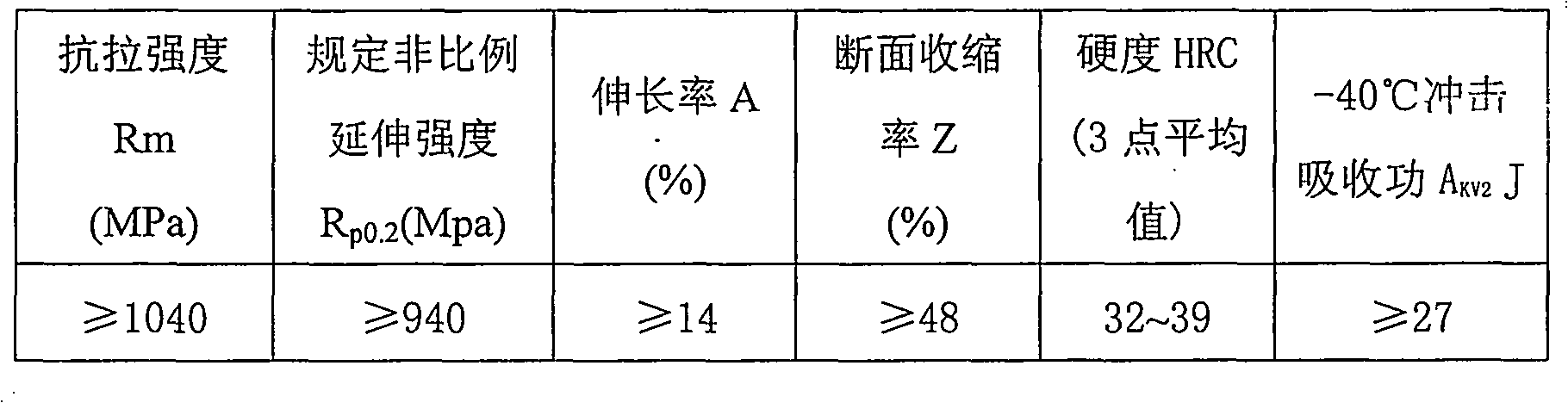

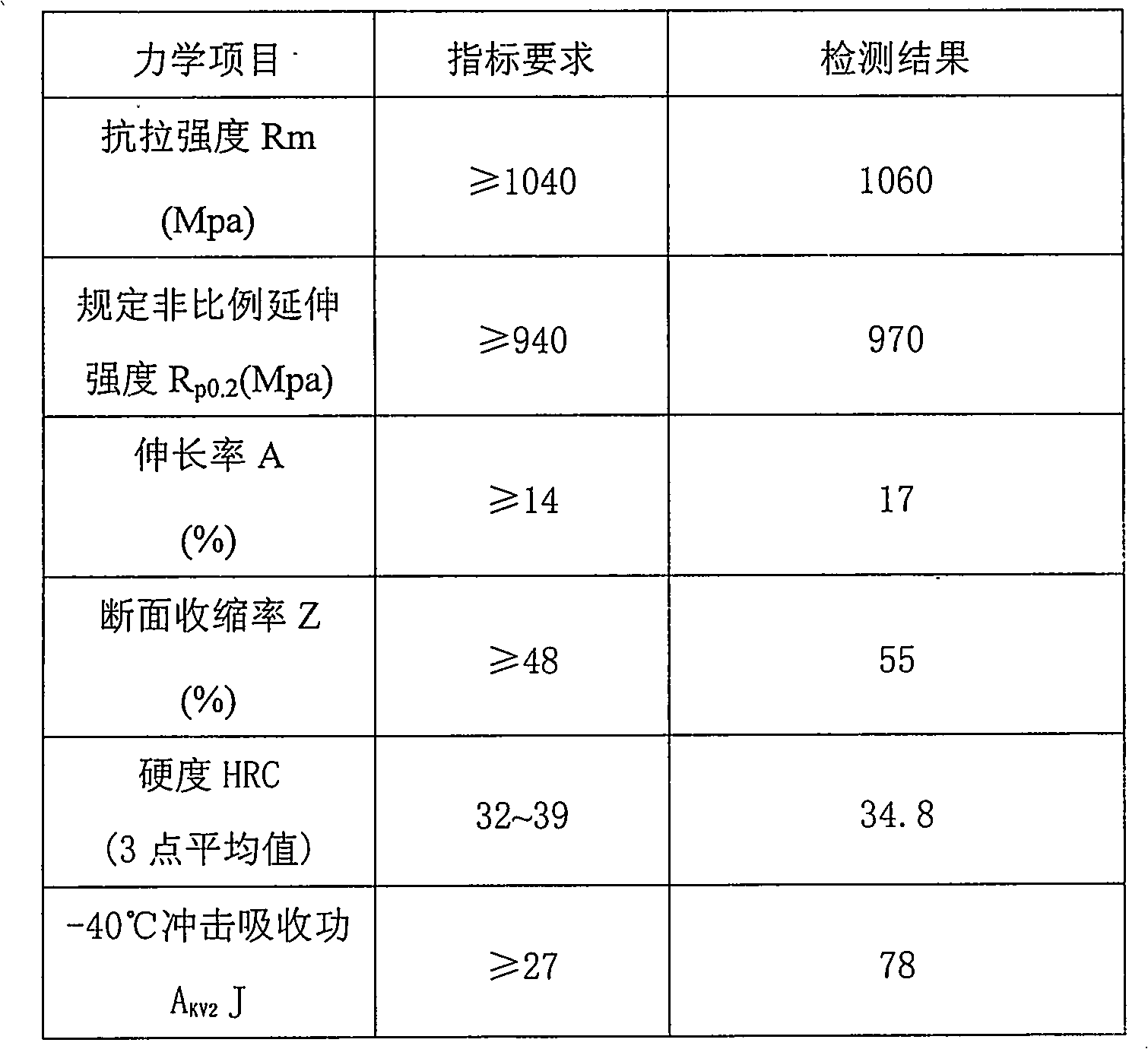

[0017] Table 4 Mechanical properties of bolt samples

[0018]

[0019] The strength grade of the high-strength bolt of the present invention is above grade 10.9, and the mechanical properties meet the requirements in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com