Patents

Literature

1608results about How to "Reduce cleaning costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel cleaning agent

InactiveCN101135056AImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

Water-based cleaner

ActiveCN101538512ACause wasteAvoid cleaning costsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSodium metasilicate

A water-based cleaner is prepared by surfactant primary washing part, alkaline auxiliary washing part, solvent part, preservative and water; wherein the surfactant primary washing part is compounded by anion and nonionic surfactant; the alkaline auxiliary agent part selects trolamine, sodium metasilicate pentahydrate which has dispersive action on dirt and EDTA disodium which has chelation on metallic ions, and excludes phosphate accessory aid which pollutes water quality. The solvent part selectes alcohol, glycol ether or natural orange oil extract D-limonene which have good safety performance, strong solvency and little environmental pollution. The preservative selects food grade preservative propylparaben which is safe and nontoxic. The invention adopts concentrate formula, the preparation method is simple, users can dilute the product according to object to be washed and the degree of dirt, and operate with reasonable using concentration, thus avoiding the waste of washing cost due to excessive concentration and the waste of energy. The inventive water-based cleaner reduces package cost and transportation cost, and has no adverse effect on the environment.

Owner:SHANGHAI JIUSHENG IND

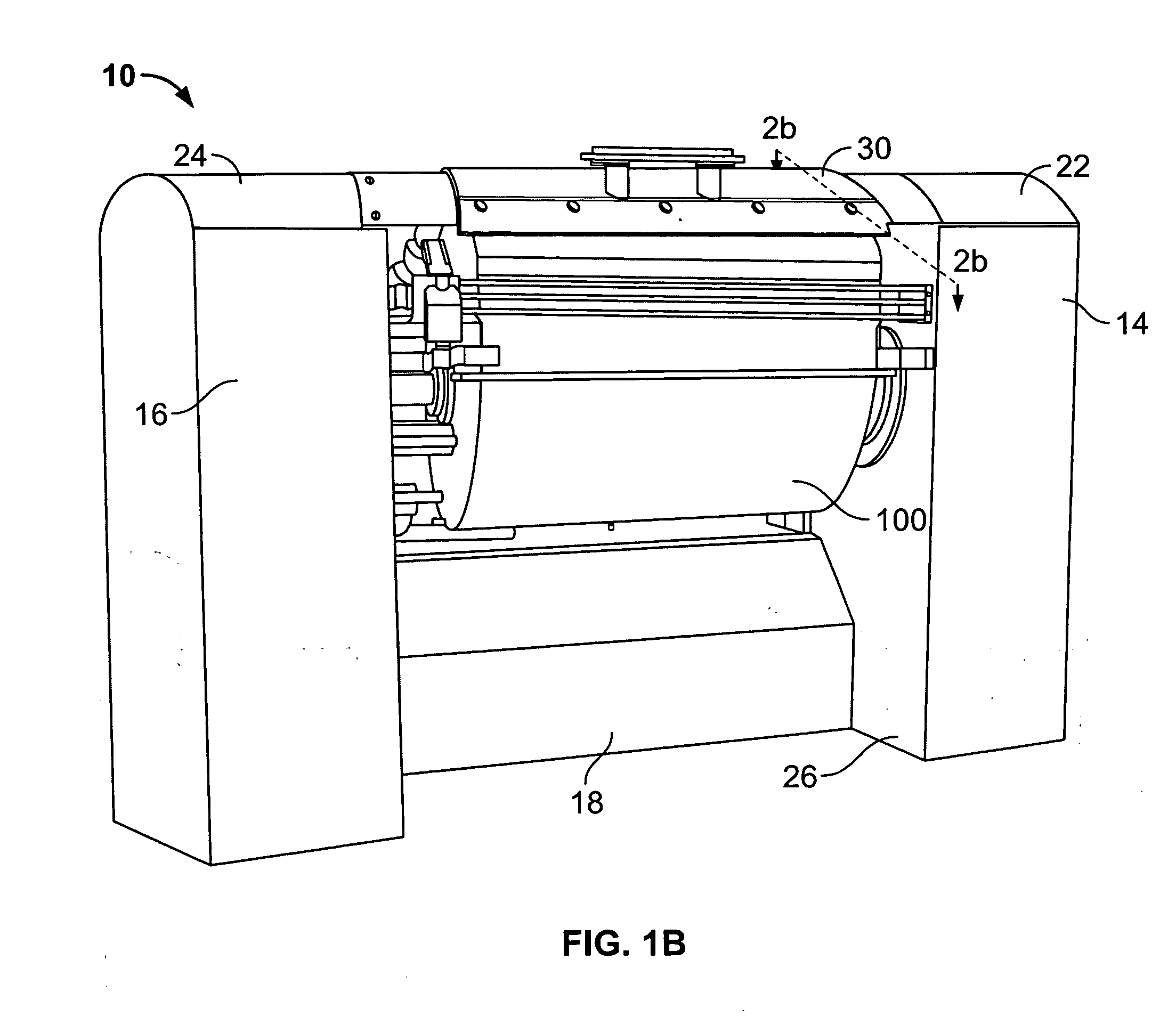

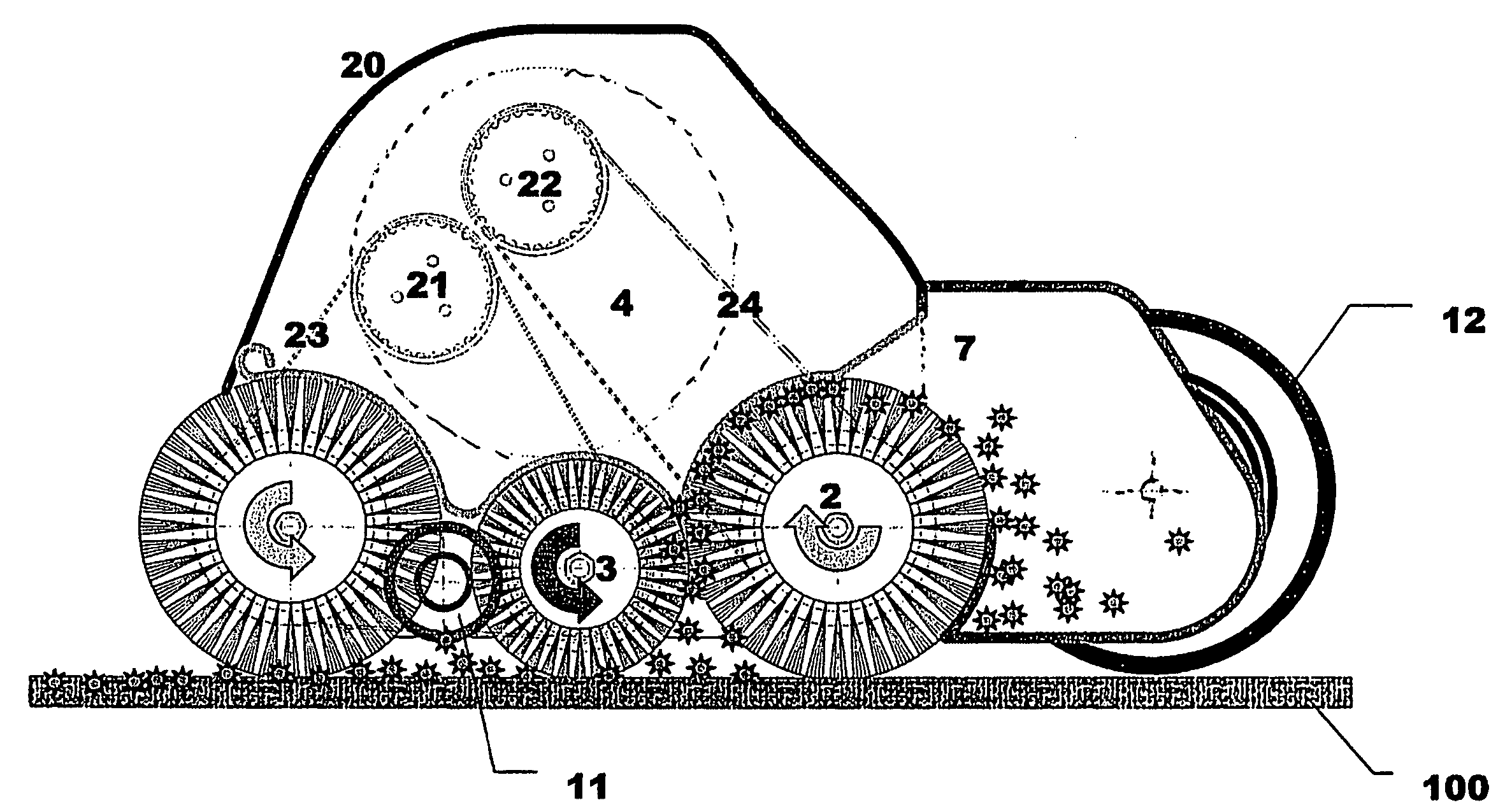

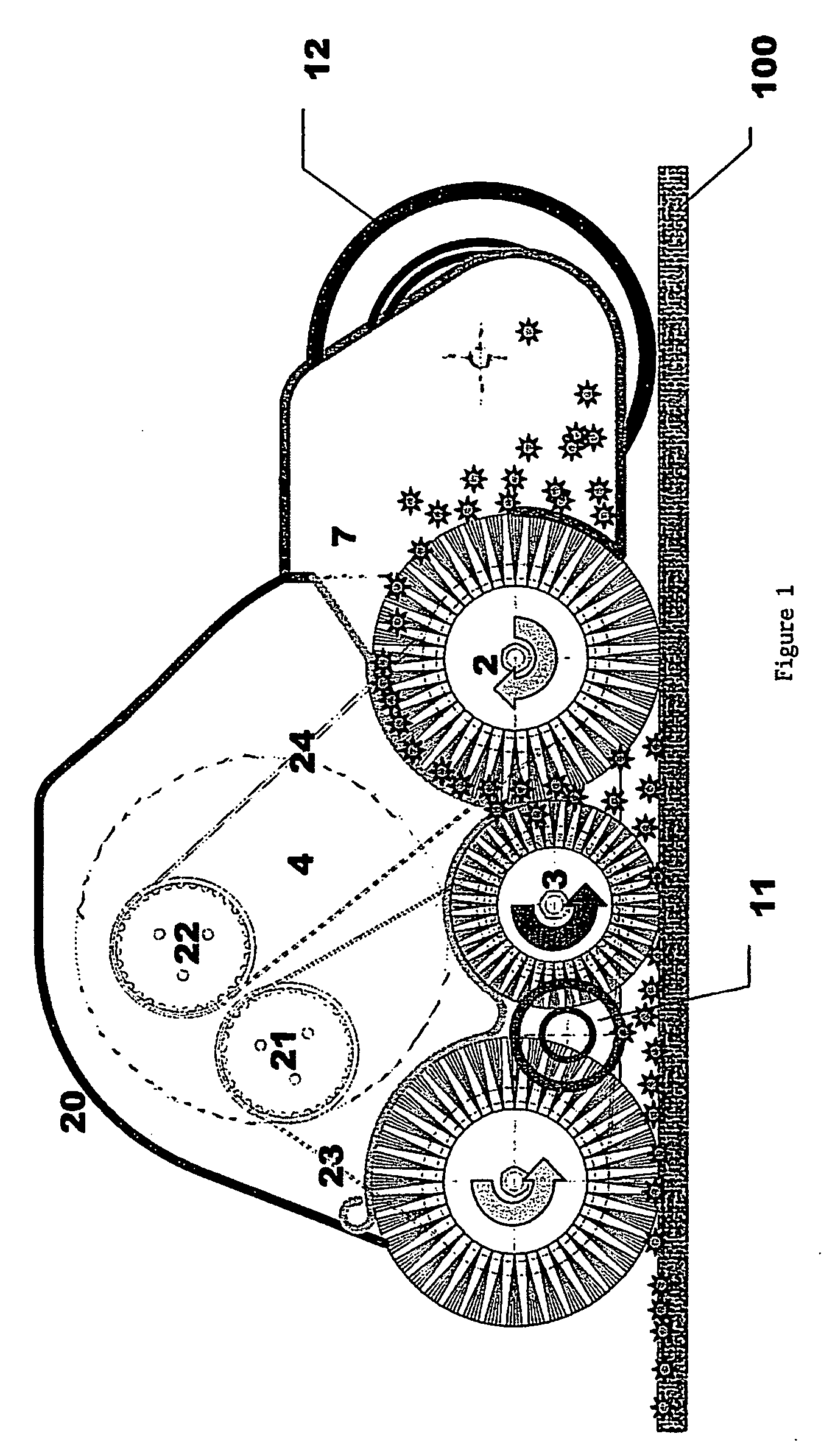

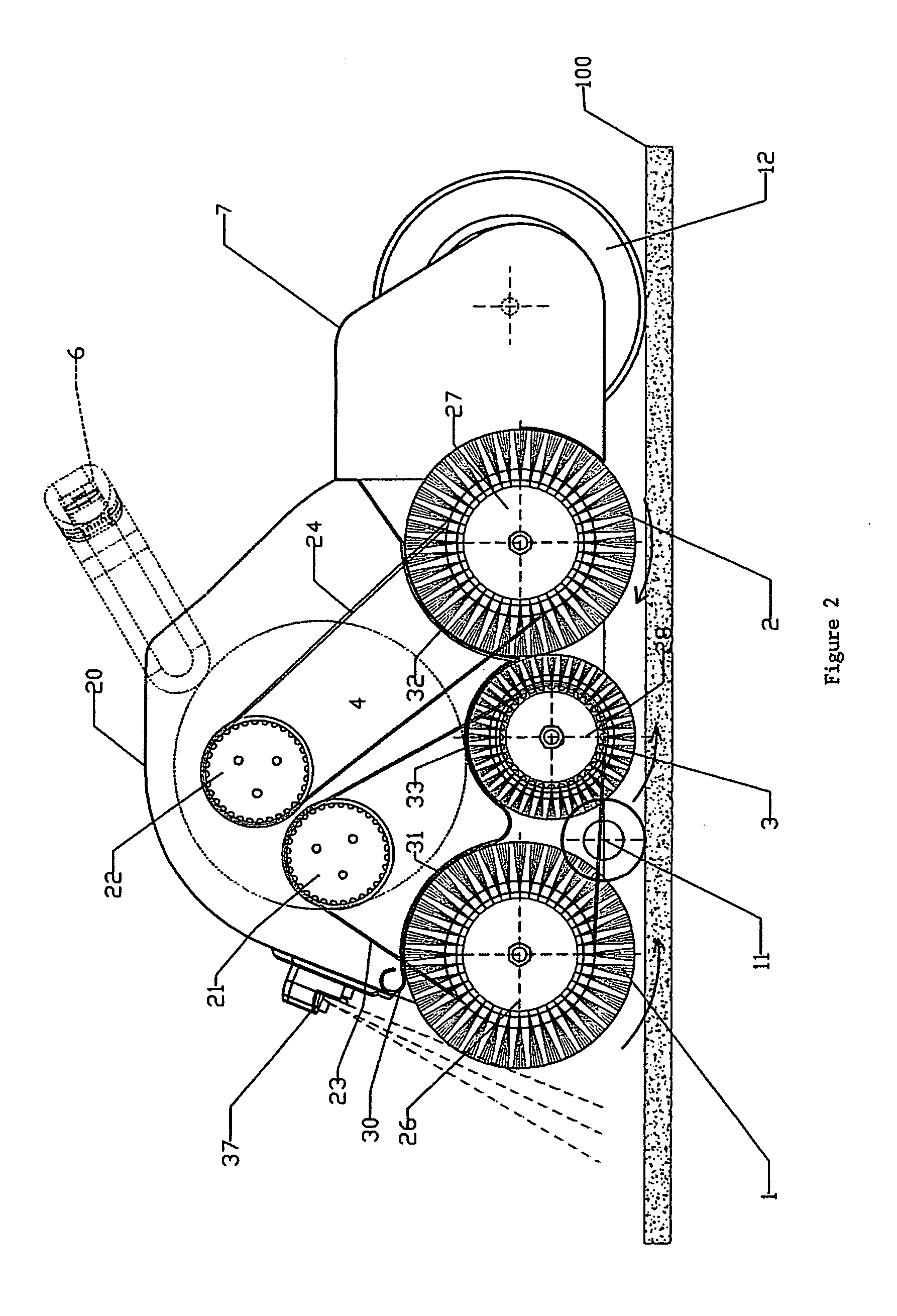

Transport cleaning device

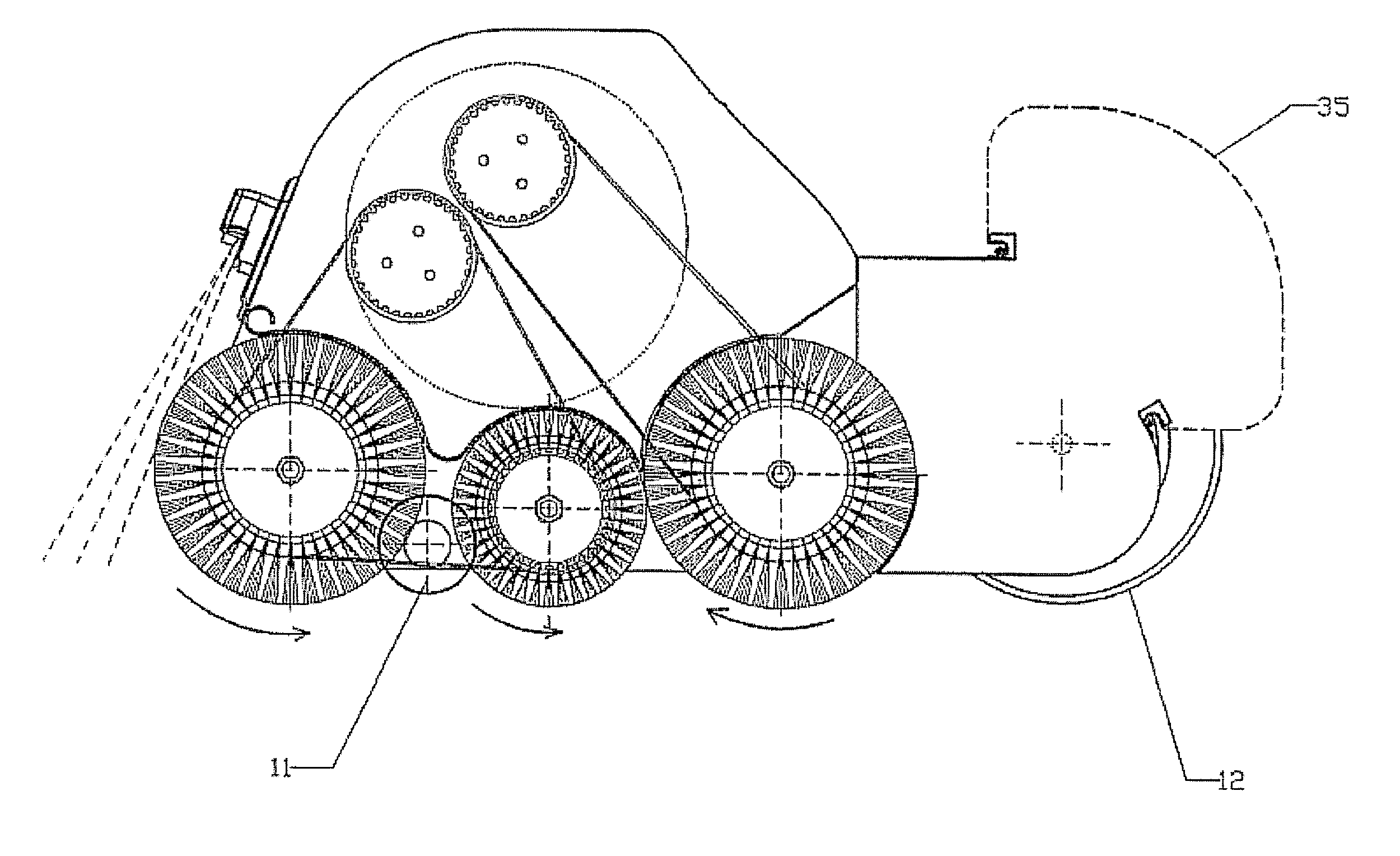

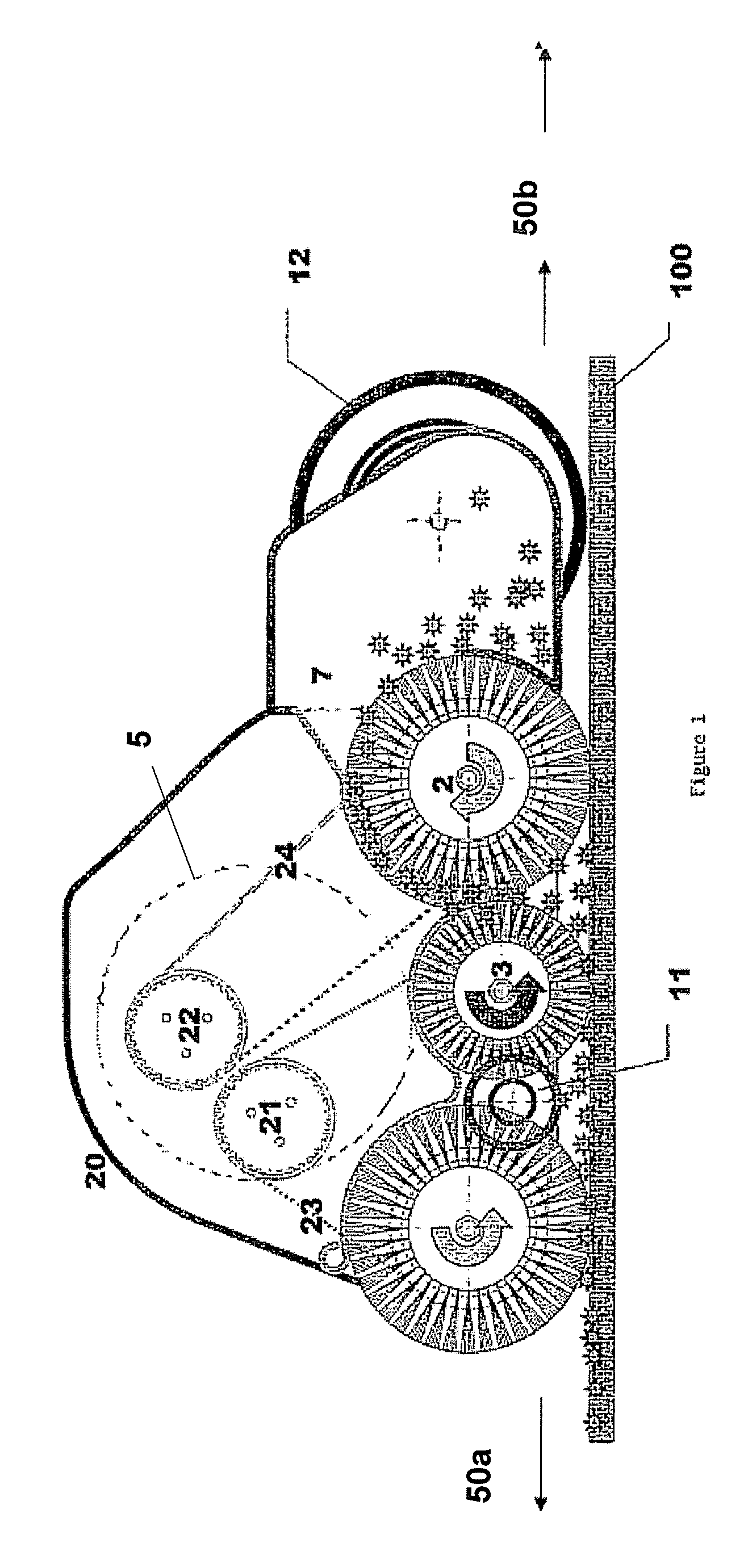

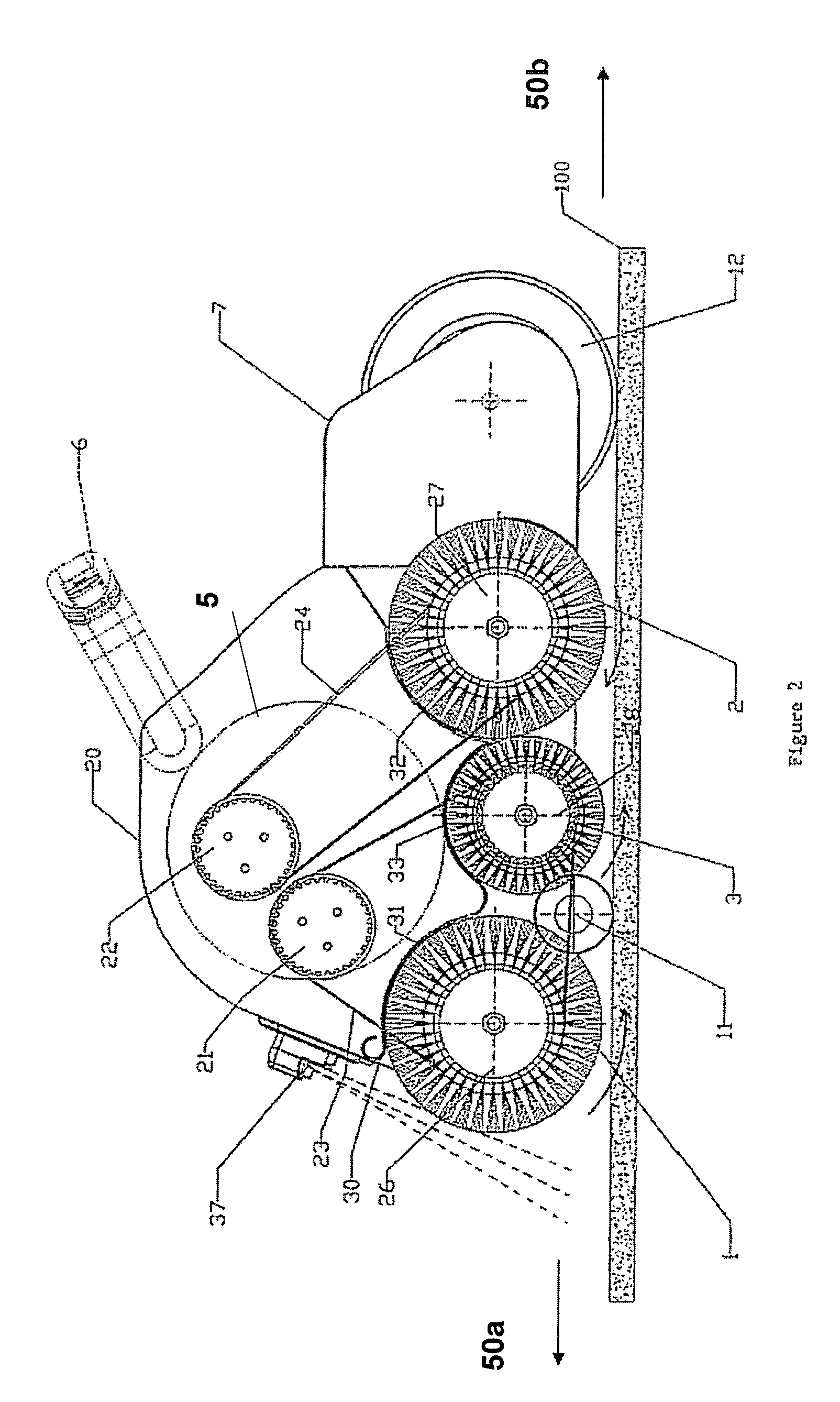

InactiveUS20060191097A1Improve rendering capabilitiesImprove efficiencyCarpet cleanersFloor cleanersEngineeringWaste management

A device for removing waste from a surface includes a housing, first and second agitators rotateably attached to the housing, each having an arcuate surface area and rotation in opposite direction. A third agitator is located between the first and second agitators, the third agitator having an arcuate surface area and a counterclockwise rotation. The first agitator transports waste to the second agitator which in conjunction with the third agitator projects debris into a waste container. A method of using the device to remove debris from a surface is also described.

Owner:R E WHITTAKER

Glass cleaning agent composite for electronic industry

InactiveCN1482223AEasy to cleanRaw materials are easy to getInorganic non-surface-active detergent compositionsSodium bicarbonateSodium metasilicate

The electronic industrial glass cleaning agent composition belongs to the field of electronic industrial cleaning technology. The cleaning agent consists of sodium metasilicate, sodium hydroxide, sodium carbonate, sodium bicarbonate, Pluronic polyol, CMC, fluoric surfactant, complexing agent, defoaming agent and deionized water. It is used to clean substrate glass and coated conducting glass. During the cleaning, the cleaning agent in 1-5 % is compounded with deionized water in 95-99 % to compound the cleaning liquid for showering or ultrasonic cleaning to eliminate pollutant on glass fastcompletely. It is used to replace strong acid and strong alkali cleaning agent and has no damage to glass surface and no corrosion to ITO film. The cleaning agent has no bad smell, no toxicity and no corrosion, and is safe, reliable, environment friendly and low in cost.

Owner:SHANDONG UNIV

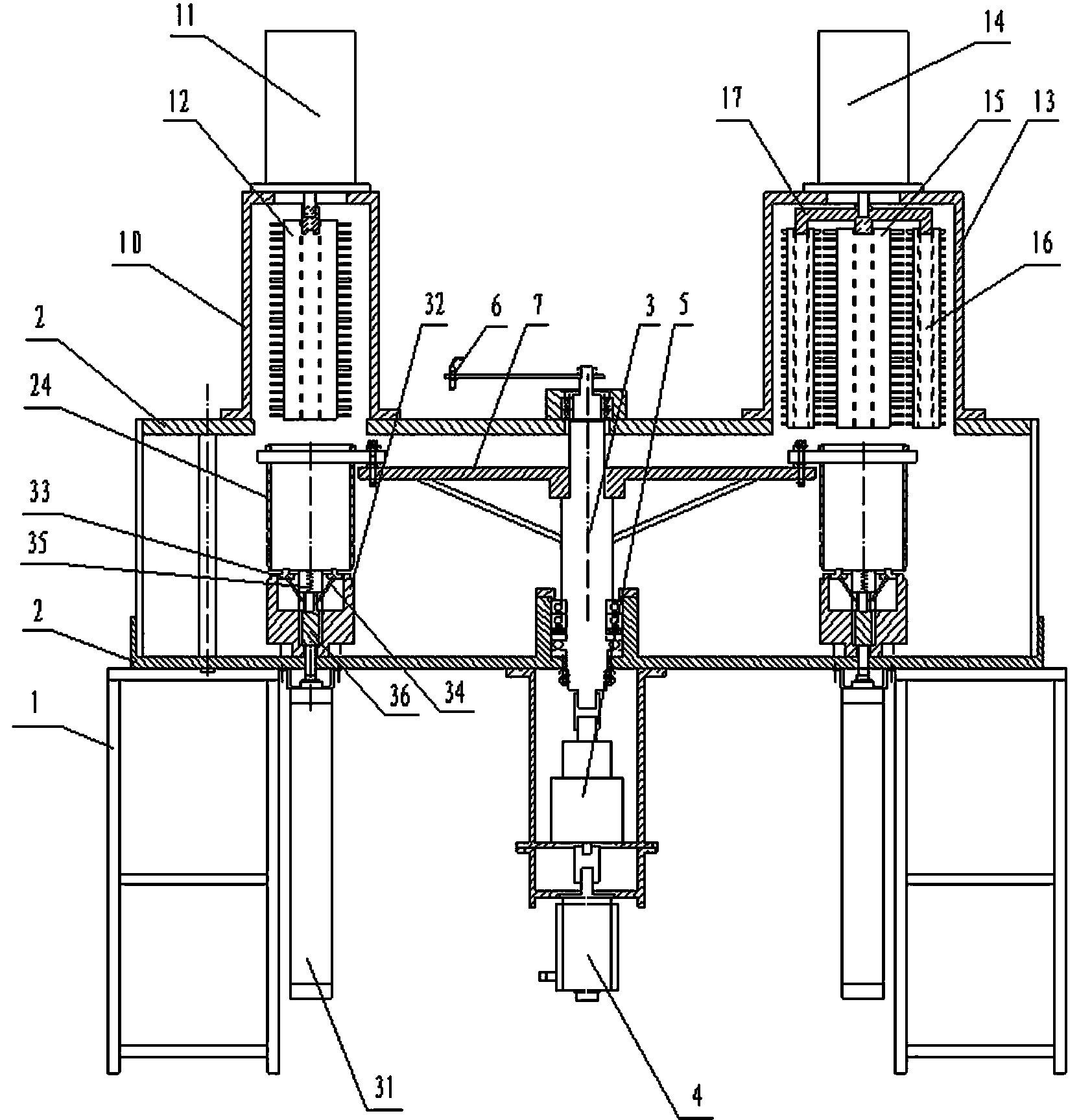

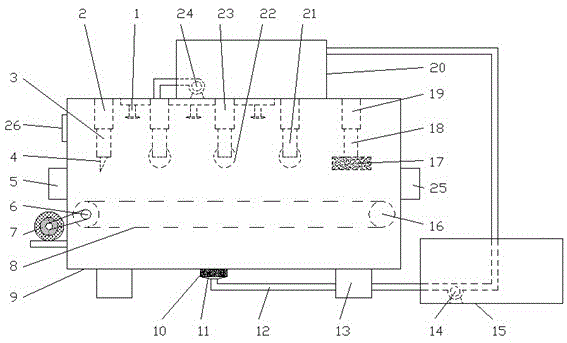

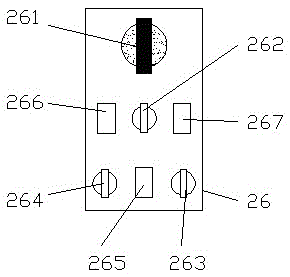

Multistation full-automatic cylinder sleeve cleaning machine

InactiveCN103464430AEasy to prevent rustReasonable structural designHollow article cleaningCold airEngineering

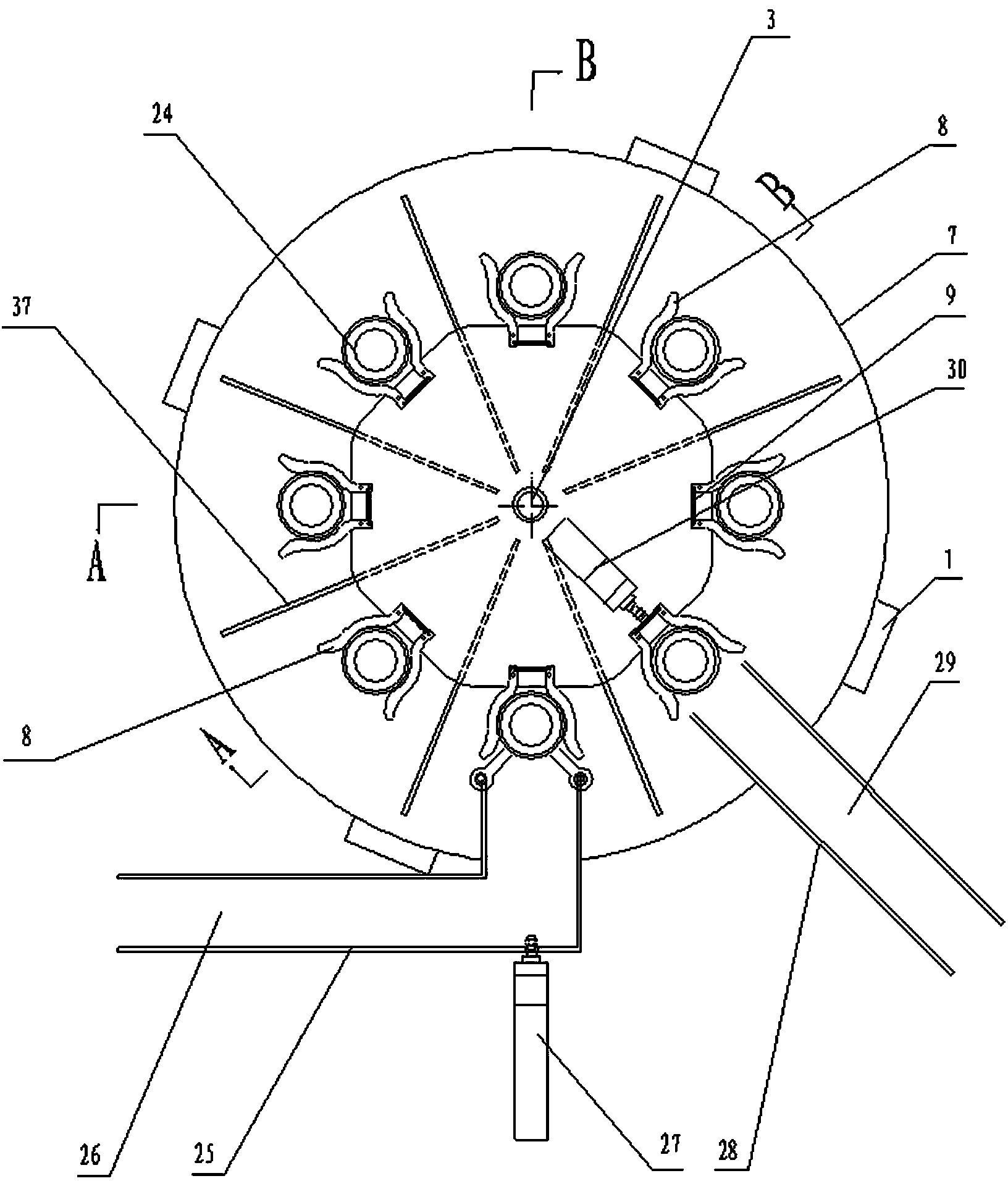

The invention discloses a multistation full-automatic cylinder sleeve cleaning machine. The cleaning machine comprises a supporting seat, a lathe bed and a time relay. The lathe bed is a box body, and a cylindrical cavity is formed inside the lathe bed. A working spindle which axially penetrates through the lathe bed is arranged at the center of the lathe bed. A servo motor is installed below the lathe bed. The lower end of the working spindle is fixedly connected with a motor shaft of the servo motor. A round rotating disc is fixedly arranged on the working spindle in the cavity of the lathe bed. A plurality of workpiece clamps are evenly distributed along the outer side of the circumference of the rotating disc at intervals. A workpiece loading device, an inner wall cleaning device, an inner and outer wall cleaning device, an oil cleaning device, a secondary cleaning device, a cold air drying device, a hot air drying device and a workpiece unloading device are circularly, sequentially and evenly distributed on the upper portions of box bodies at the upper end of the lathe bed at intervals. According to the technical scheme, the multistation full-automatic cylinder sleeve cleaning machine is reasonable in structural design, small in occupied area, high in automation degree, good in cleaning effect and low in cleaning cost.

Owner:ANHUI WHITE RABBIT POWER

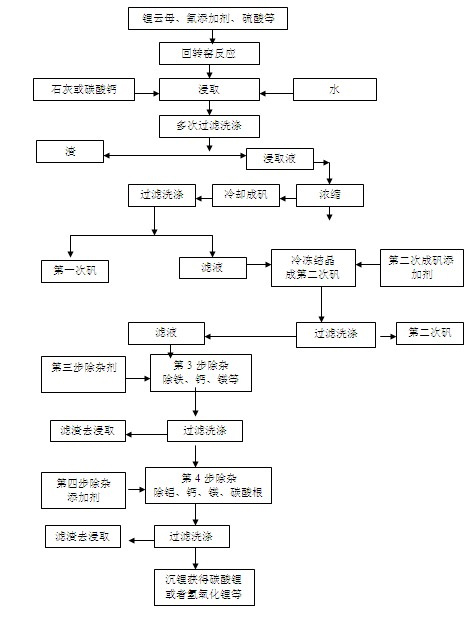

Process for removing impurities from lepidolite leaching solution

The invention relates to a process for removing impurities from a lepidolite leaching solution. The process is completed by carrying out impurity removal on alumina twice and adjusting pH values for twice. Lithium salt precipitation products are obtained by adding additives to a lithium sulfate solution after impurity removal, and corresponding refined lithium salts can be prepared as required. The process has the advantages that the cost of impurity removal is low, by-products with high added values can be obtained, the extraction rate of lithium is high, various useful components of lepidolite ores can also be fully utilized when lithium salts are produced, and the recycling of resources is realized.

Owner:江西海汇龙洲锂业有限公司

Cleaning agent for molybdenum aluminum molybdenum coated glass

ActiveCN102586035AEfficient removalImprove decontamination abilityNon-ionic surface-active compoundsDetergent compounding agentsActive agentCleansing Agents

The invention discloses a cleaning agent for molybdenum aluminum molybdenum coated glass, which comprises the following components by weight: 3-8% of anionic surfactants, 10-30% of nonionic surfactants, 0.2-3% of corrosion inhibitors, 10-30.25% of cosolvents, 5-15% of organic solvent, 0.2-0.5% of chelants and 37.35-64.1% of deionized water. The cleaning agent for the molybdenum aluminum molybdenum coated glass is strong in dirt-removing capacity, wide in environmental suitability, good in stability, low in foam, easy to rinse, good in wettability, free of damage to glass surface, elements such as phosphorus and silicium, peculiar smell, toxicity, corrosivity and pollution to environment, safe, reliable, incombustible, low in cost, convenient to transport and store and low in cleaning cost. In addition, the cleaning agent for the molybdenum aluminum molybdenum coated glass does not explode.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

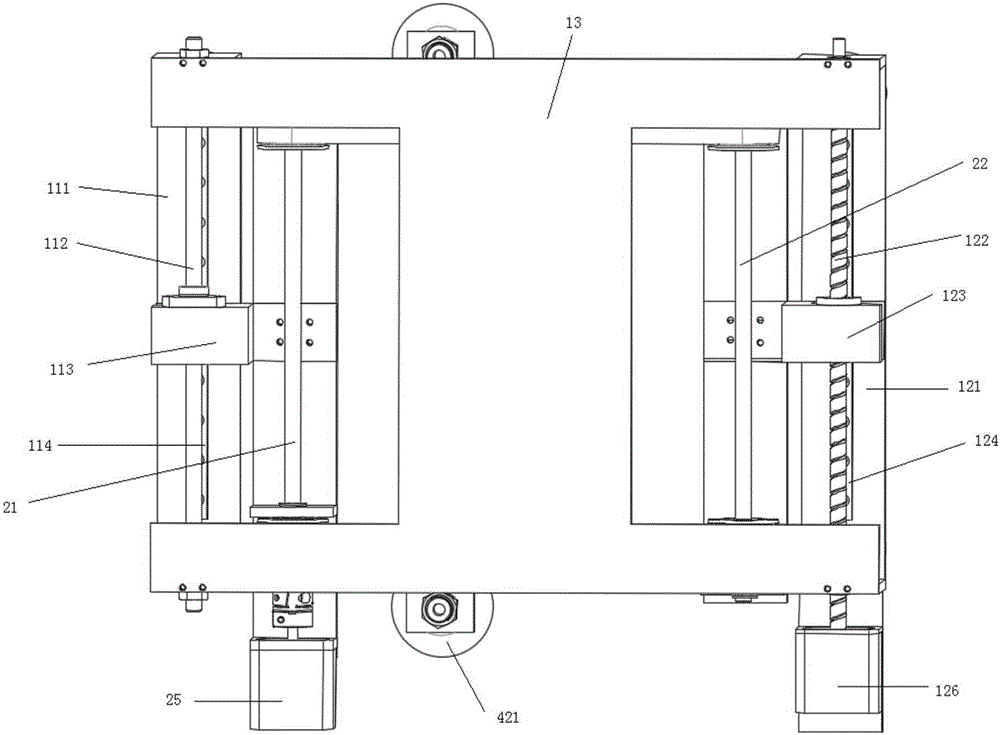

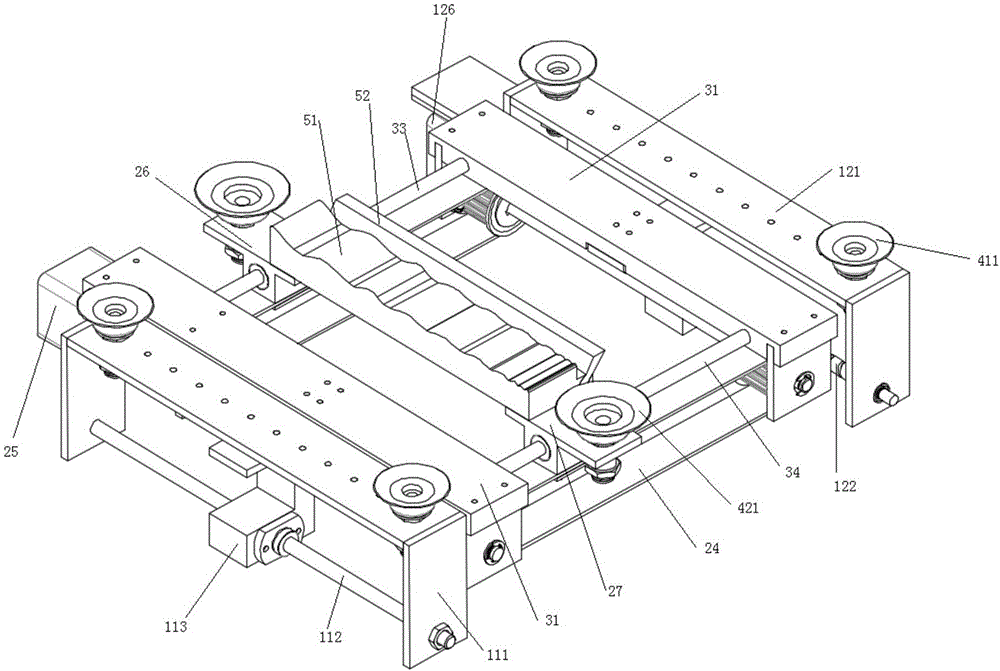

Automatic glass cleaning robot

ActiveCN106419722AReduce cleaning costsAchieve freedom of movementCarpet cleanersFloor cleanersAgricultural engineeringRobot

The invention relates to the field of robot invention, and particularly to an automatic glass cleaning robot which comprises an engine base, a first translation mechanism, a second translation mechanism, an adsorption mechanism and a cleaning mechanism, wherein the first translation mechanism and the second translation mechanism are respectively installed on the engine base; the cleaning mechanism is installed on the second translation mechanism; the adsorption mechanism is installed on the first translation mechanism and the second translation mechanism respectively; the first translation mechanism matches the adsorption mechanism to realize the movement of the robot towards a first direction; the second translation mechanism matches the adsorption mechanism to realize the movement of the robot towards a second direction; the second translation mechanism matches the adsorption mechanism and the cleaning mechanism to realize the glass cleaning function of the automatic glass cleaning robot; and the first direction and the second direction are vertical to each other. The automatic glass cleaning robot provided by the invention can realize the free movement of the robot along two vertical directions, the operation is easy and saves both time and labor, the cleaning effect is good, the structure is simple, and the manufacturing cost is low.

Owner:唐山新禾智能科技有限公司

Phosphate-free environment-friendly cleaning agent

InactiveCN101597547AReduce cleaning costsRelieve pressureInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsGluconic acidCleansing Agents

The invention discloses a phosphate-free environment-friendly cleaning agent which has non-toxic, innocuous, noncombustible, non-explosive, non-volatile, nonflammable, inodorous and phosphate-free. The cleaning agent mainly comprises the following raw material formulations in portion by weight: group A: 3 portions of sodium citrate, 2 portions of sodium gluconate, 4 portions of sodium hydroxide, 3 portions of sodium silicate, and 1 portion of sodium carbonate; group B: 3 portions of fatty alcohol-polyoxyethylene ether-AEO9, 4 portions of octylphenol-polyethoxylate OP-10, and 3 portions of triethanolamine; and group C, 60 to 80 portions of purified water.

Owner:陈安友

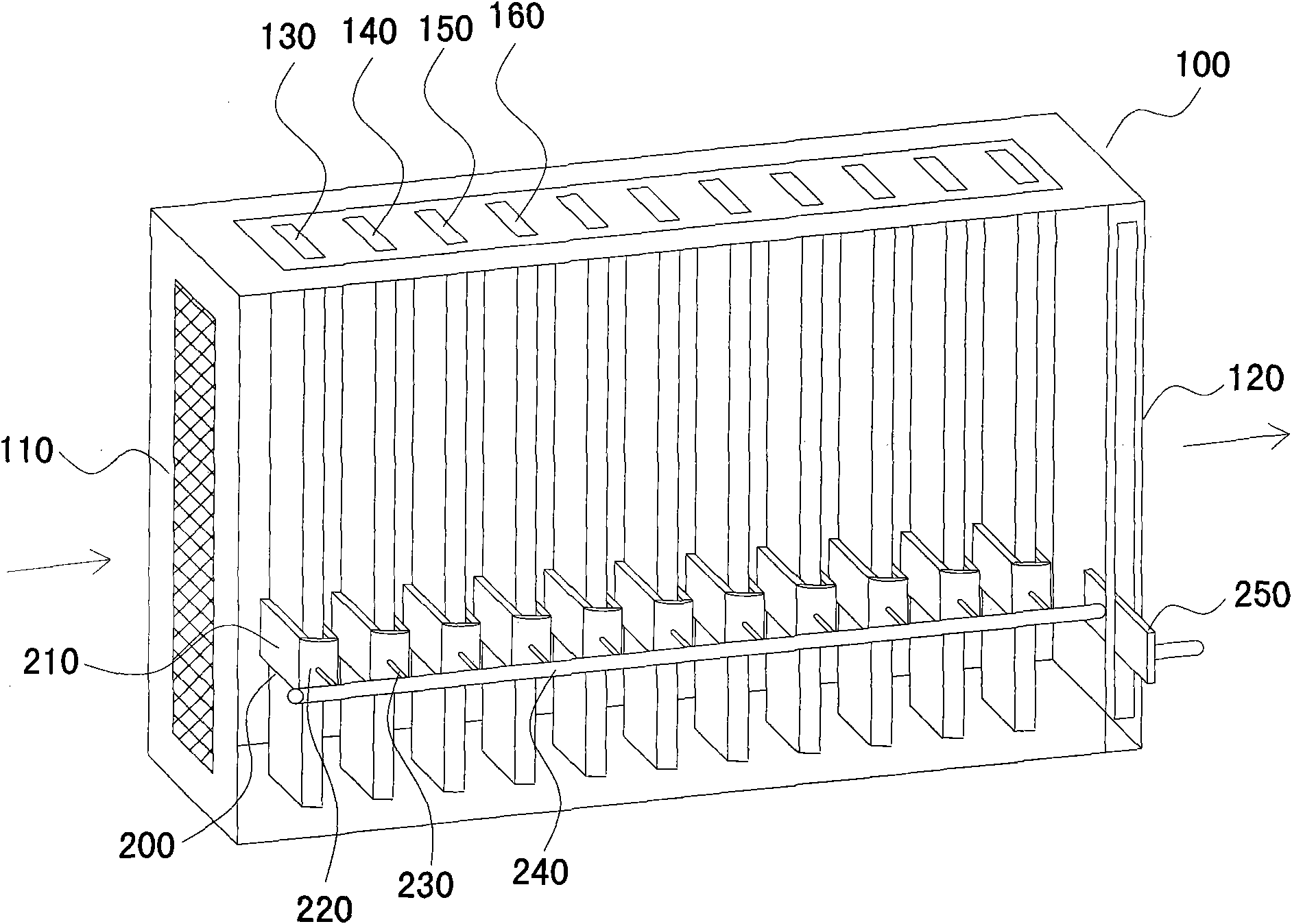

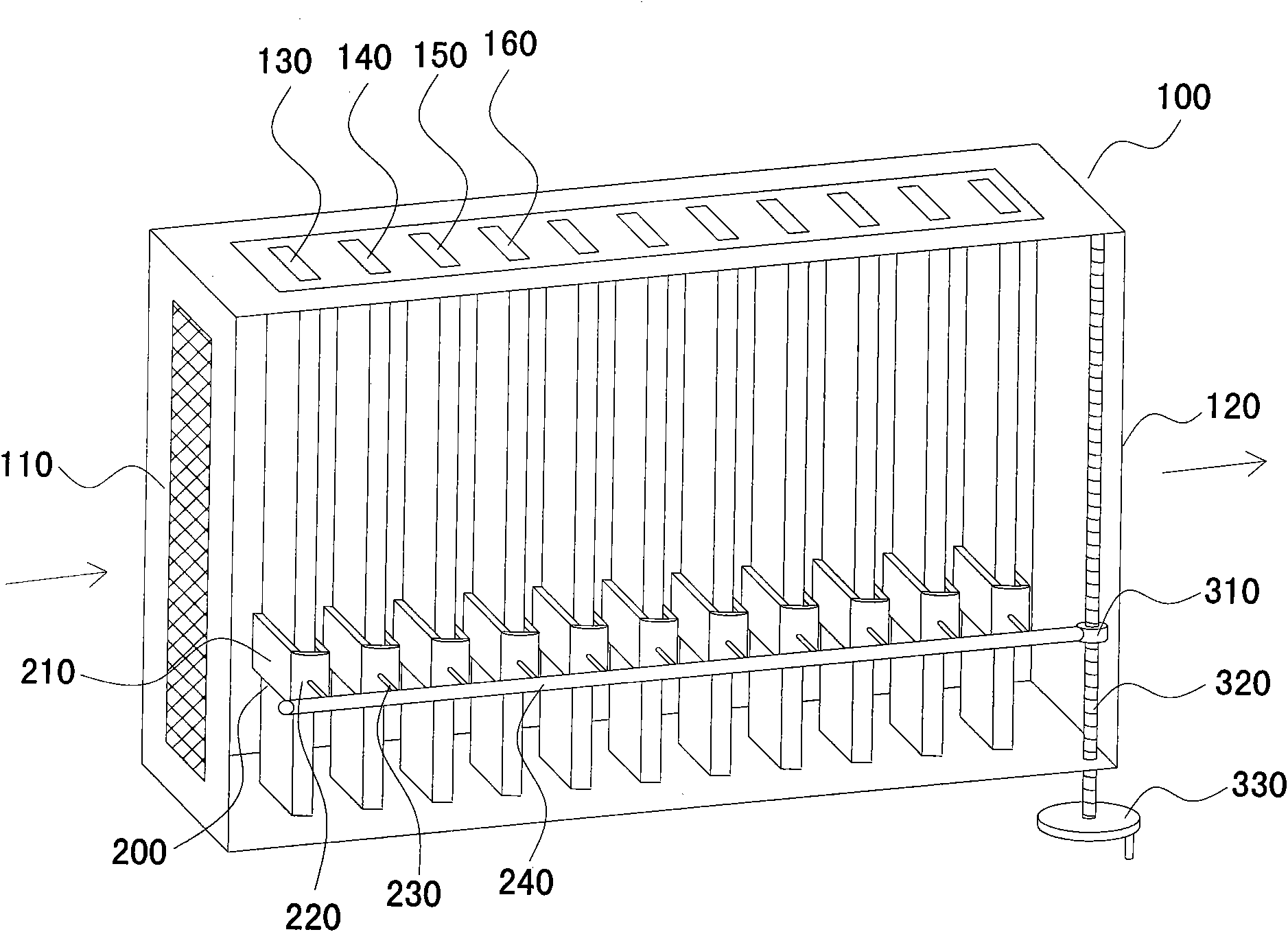

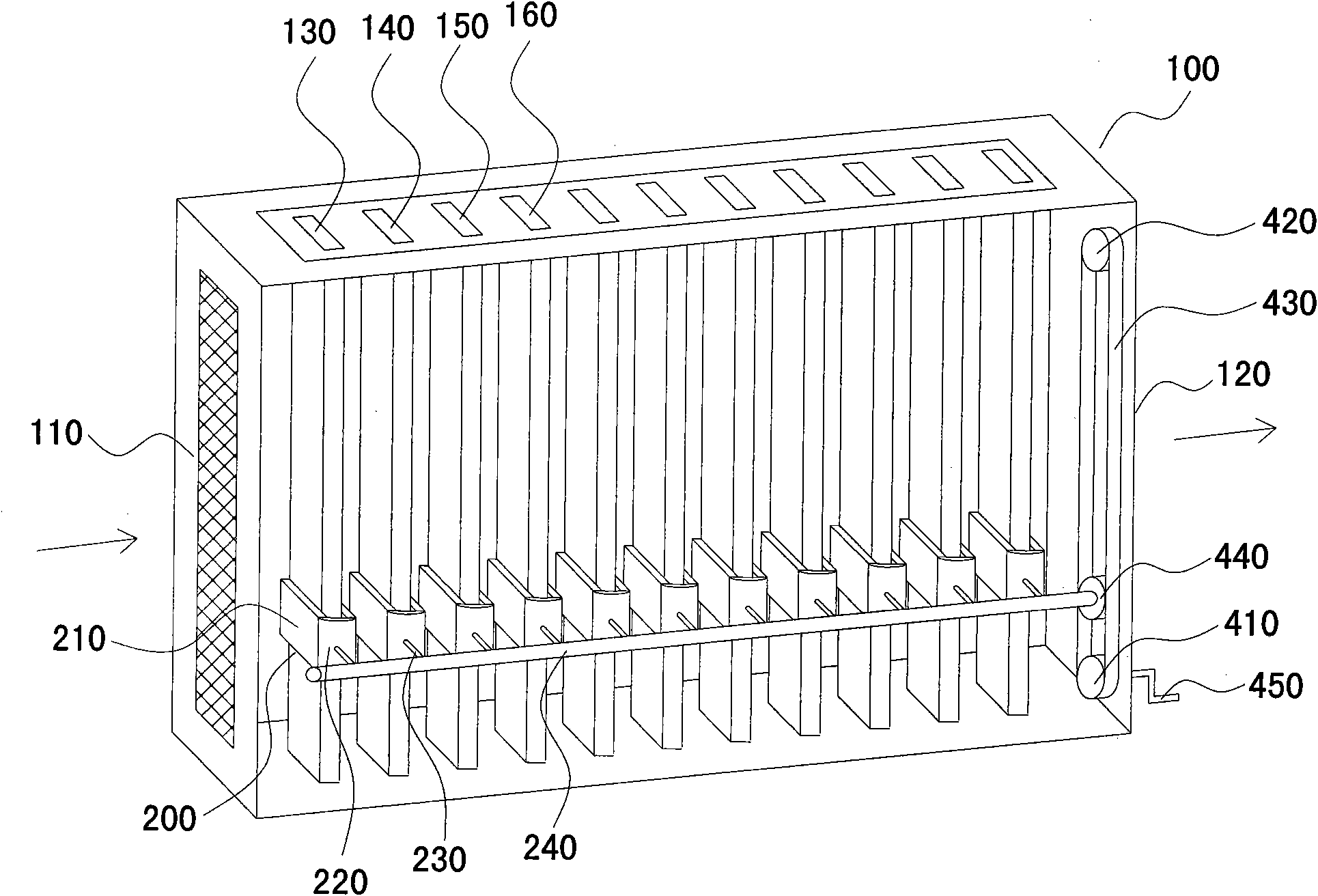

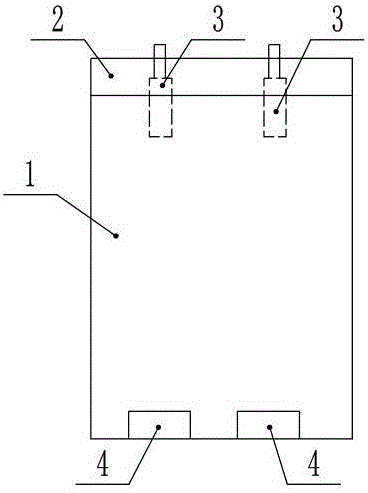

Purifier with cleaning function

InactiveCN101559406AEasy to replaceReduce cleaning costsCleaning using toolsElectrostatic separation detailsElectricityHigh voltage

The invention discloses a purifier with cleaning function. The purifier comprises a box body with an air inlet and an air outlet. The box body therein is provided with a filtering unit, a collision absorbing unit, a high voltage charge and ozone generating unit, and an electrostatic absorbing unit. Cleaning brushes capable of moving up and down are arranged on the units. All cleaning brushes are driven by a driving device such that the cleaning brushes rotate synchronously, so as to clean the oil stains on the filtering unit, the collision absorbing unit, the high voltage charge and ozone generating unit, and the electrostatic absorbing unit. The invention can clean the filtering unit, the collision absorbing unit, the high voltage charge and ozone generating unit, and the electrostatic absorbing unit in a ventilation system with a relatively simple mechanism and relatively low cleaning cost. The cleaning brushes can be conveniently replaced after the cleaning brushes are adhered with dusts and oil strains or blunt. The invention is suitable for cleaning the filtering unit, the collision absorbing unit, the high voltage charge and ozone generating unit, and the electrostatic absorbing unit in all ventilation systems.

Owner:上海汉宝净化专业技术有限公司

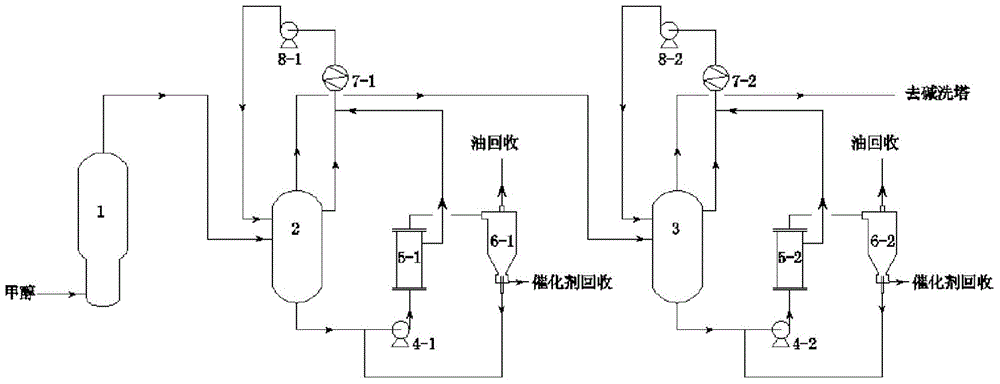

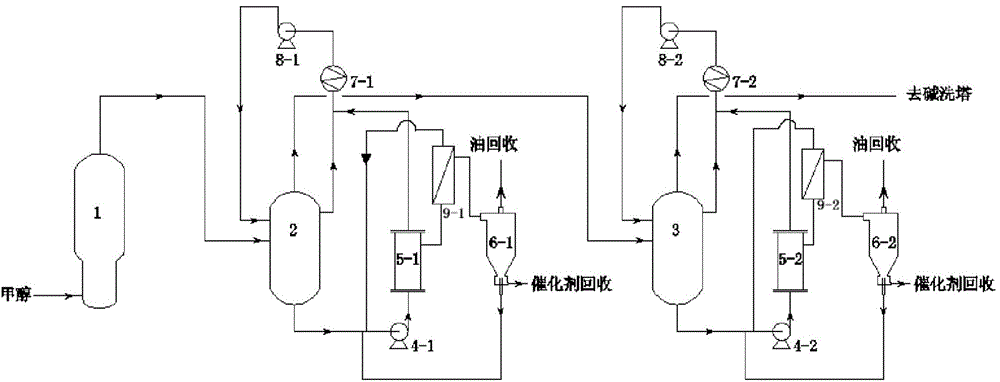

Solid and oil removal method and device for chilled water and washed water in MTO (methanol to olefin) process

ActiveCN103951098AEliminate enrichmentReduce the probability of forming large particlesHydrocarbon from oxygen organic compoundsMultistage water/sewage treatmentUF - UltrafiltrationChemistry

The invention relates to a solid and oil removal method and device for MTO (methanol to olefin) / MTP (methanol to propylene) chilled water and washed water. The method disclosed by the invention mainly comprises the following steps of carrying out ultrafiltration membrane separation on MTO / MTP chilled water, feeding an ultrafiltration membrane concentrated solution into a three-phase cyclone-separator separation system, and recovering a catalyst and oil; cooling ultrafiltration membrane permeated liquid, and feeding the obtained liquid back to a chilled water system to cyclically reuse; carrying out ultrafiltration membrane separation on MTO / MTP washed water, feeding an ultrafiltration membrane concentrated solution into the three-phase cyclone-separator separation system, and recovering a catalyst and oil; and cooling ultrafiltration membrane permeated liquid and feeding the obtained liquid back to a washed water system to cyclically reuse. The invention also provides a solid and oil removal device for MTO / MTP chilled water and washed water.

Owner:JIANGSU JIUWU HITECH

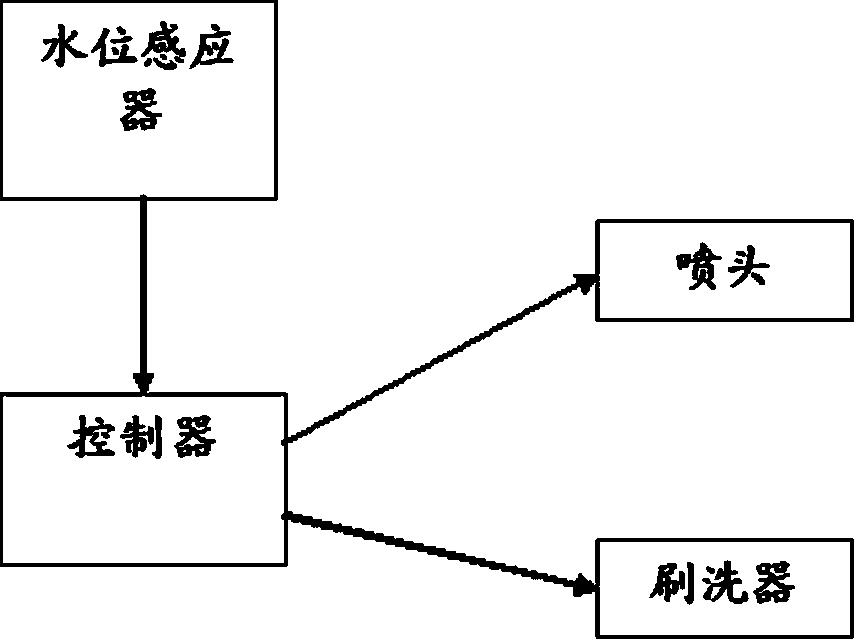

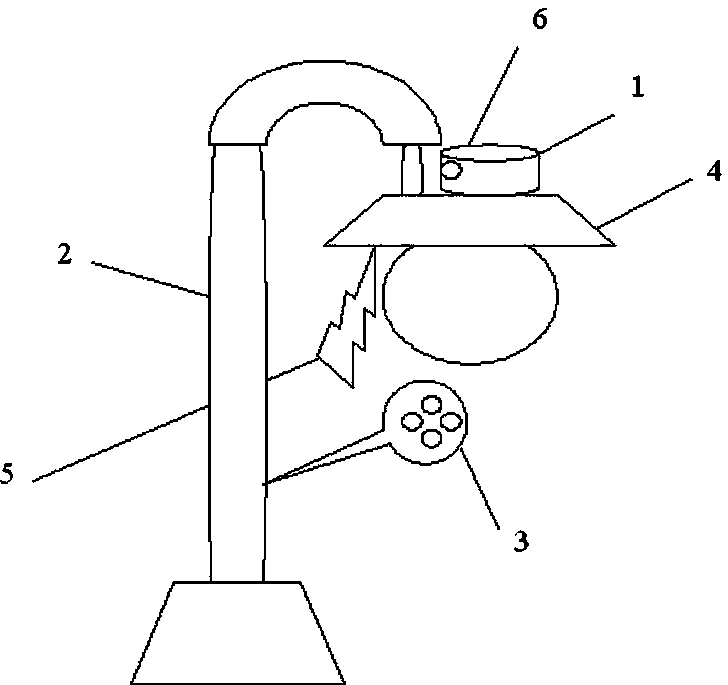

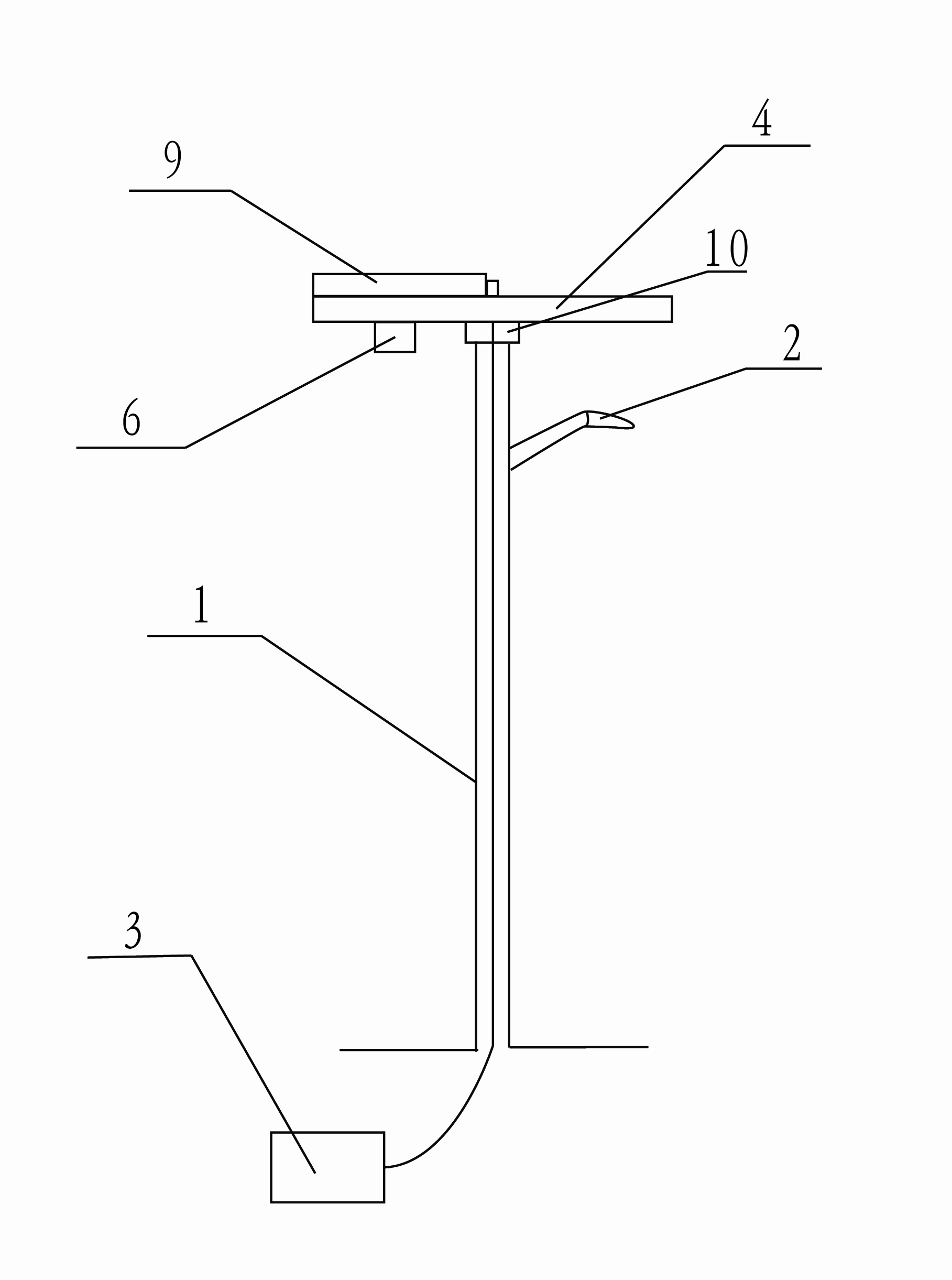

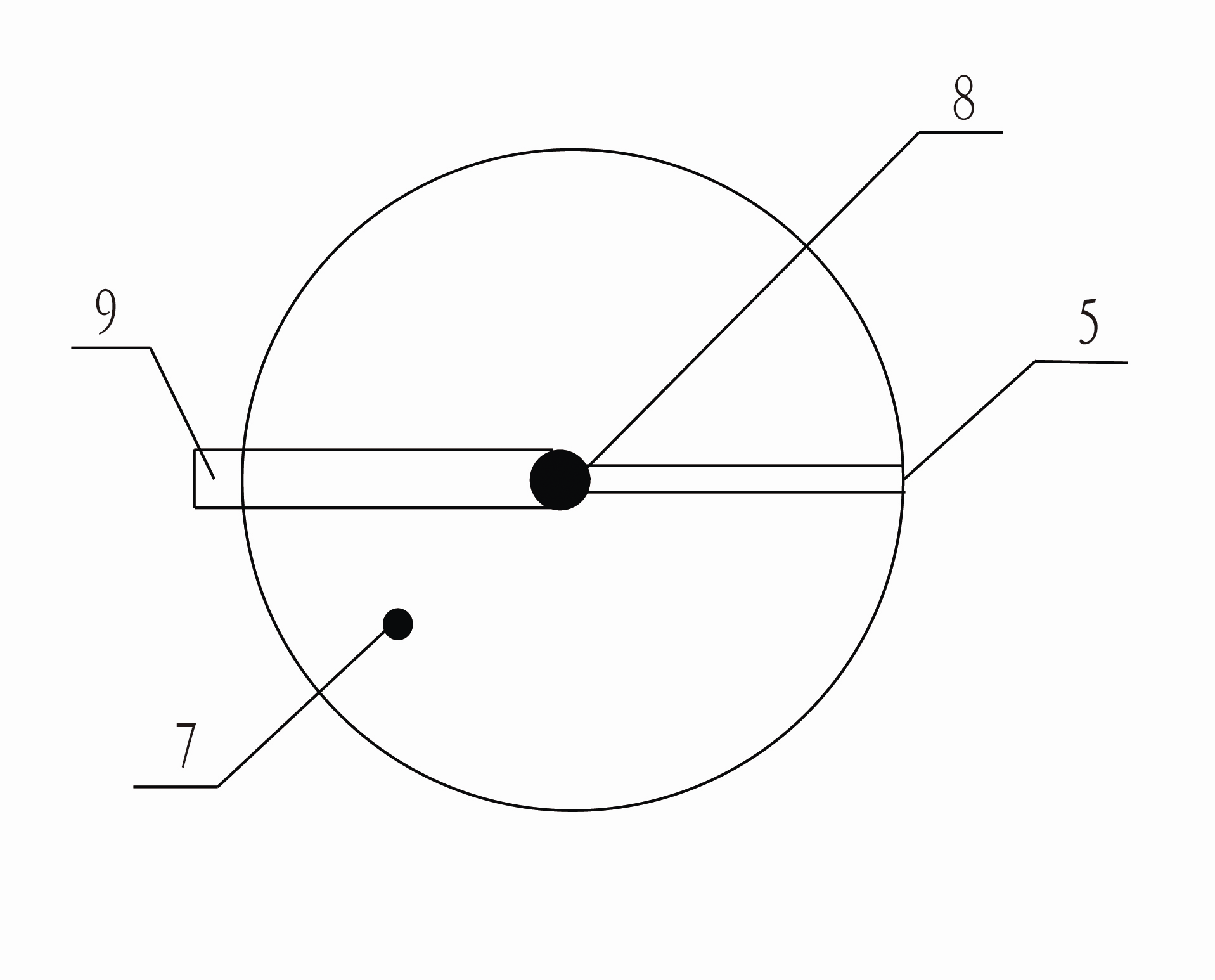

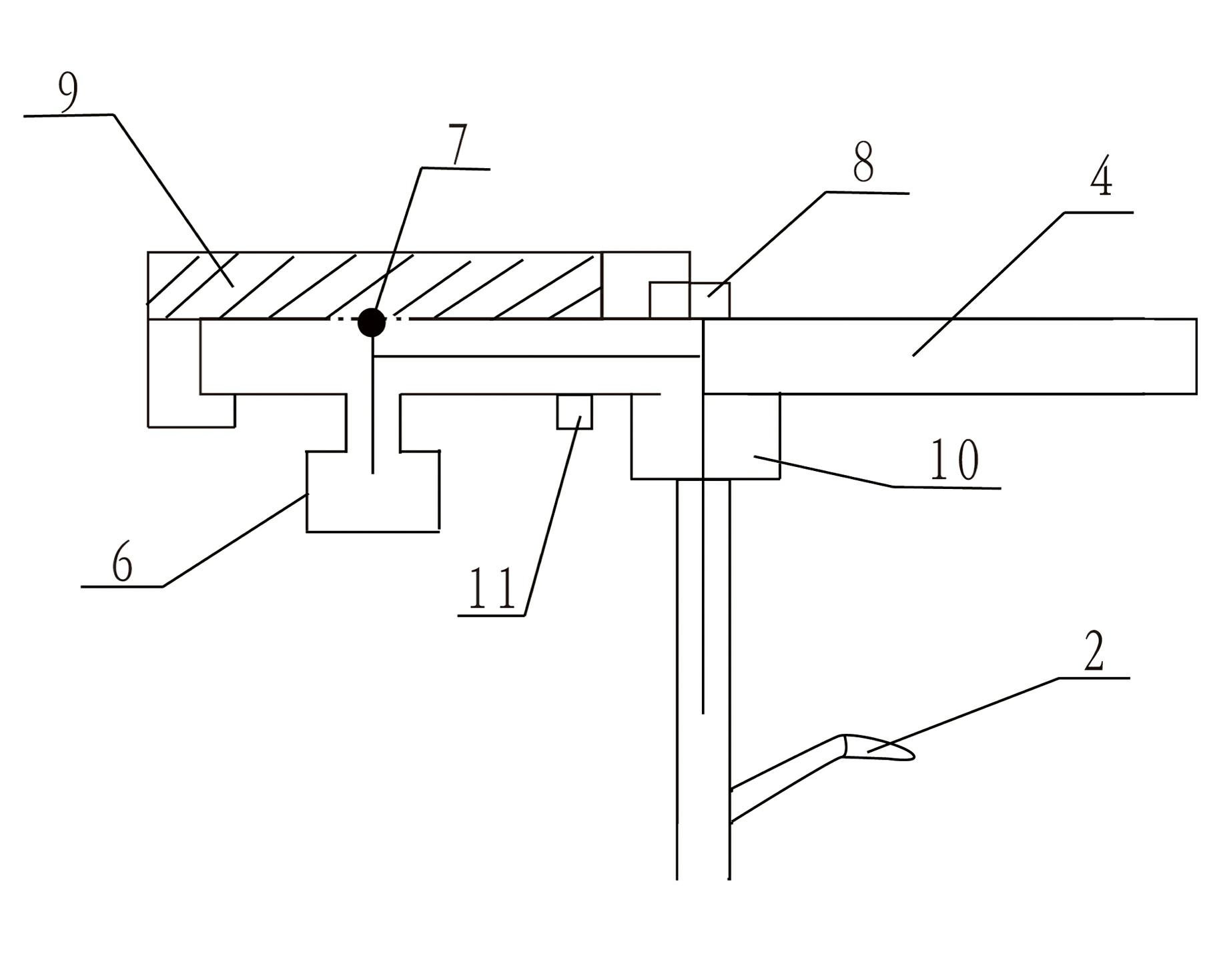

Street lamp self cleaning device

InactiveCN104214624ARealize regular cleaning and maintenanceGuaranteed lighting effectsLighting elementsOutdoor lightingWater pipeWaste management

The invention discloses a street lamp self cleaning device, and belongs to the technical field of a cleaning and energy saving device. The street lamp self cleaning device comprises a water collector, a controller and a spray head, wherein the water collector and the controller are positioned on the top of a street lamp, the spray head is arranged on a lamp pole of the street lamp and is positioned at the lower side of the street lamp, the lower part of a luminous cover of the street lamp is provided with a brushing and washing device, the water collector is connected with the spray head through a water pipe, a water level sensor is arranged in the water collector, the water level sensor is connected with the controller, and the spray head and the brushing and washing device are respectively connected with the controller. The street lamp self cleaning device has the advantages that rainwater in rainy days is collected for automatically cleaning a lampshade of the street lamp, the cost is low, water resources are not wasted, in addition, artificial participation is not needed, the regular cleaning of the street lamp is realized, and the effect of the street lamp is ensured.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

Roller with ink-repellent coating

InactiveUS20010051567A1Reduce solutionReduce contentShaft and bearingsMetal-working apparatusPolyolefinFluorocarbon

A roller comprising a roller core and a roller covering being composed of an elastomer or elastic plastic material is characterized in that the elastomer or elastic plastic material of the roller covering cadditionally comprises fluorinated polyolefin. Preferably, from 0.2 to 25% by weight of a fluorocarbon plastic, in particular of polytetrafluoroethylene powder or fiber, is incorporated into the roller coating material to improve the ink-repellent properties of the roller covering. In one embodiment, the fluorinated polyolefin is employed in the form of a fibrous material, e.g. a web or the like, provided with the coating material and wrapped around the roller to form a surface layer.

Owner:PAUL SAUER & WALZENFAB

Synchronous spraying device for large machine

InactiveCN105772293ARealize simultaneous sprayingEnsure consistencySpraying apparatusArthrobotrysMechanical engineering

The invention provides a synchronous spraying device for a large machine. The synchronous spraying device comprises a plurality of movable bases (1), wherein a six-axis joint robot is installed on each movable base (1), and a spray gun is installed at the tail end of each six-axis joint robot; a steel plate (2) is arranged at the front end of each movable base (1), a piston cylinder (3) is further horizontally arranged at the front end of each movable base (1), the outer end of a piston rod of each piston cylinder (3) is level with the outer side of the corresponding steel plate (2) while retracting, and an electrically-controlled magnetic attraction device (4) is arranged at the rear end of each movable base (1); and the movable bases (1) attract the electrically-controlled magnetic attraction devices (4) through the steel plates (2) and are sequentially connected in series to form an integrated movable platform. According to the synchronous spraying device provided by the invention, the integrated movable platform formed by sequentially connecting the plurality of movable bases (1) in series is provided, and synchronous spraying of all the six-axis joint robots can be realized; and moreover, the problem of interference is avoided, and the consistency of the spraying quality of parts of the large machine can be ensured.

Owner:李富平

Chemical mechanical polishing solution for large-sized silicon wafers and preparation method thereof

ActiveCN101870852AImprove consistencyReduce hardnessPolishing compositions with abrasivesCompound (substance)Cleansing Agents

The invention relates to a chemical mechanical polishing solution for large-sized silicon wafers and a preparation method thereof, and the chemical mechanical polishing solution is mainly applied to the ultraprecision machining of large-sized semiconductor silicon substrate slices, and can obtain a nanometer-level ultrasmooth surface. The polishing solution consists of the following components inpercentage by weight: 5 to 50 percent of silicon dioxide abrasive, 1 to 10 percent of pH value regulator, 0.01 to 5 percent of surfactant, 0.01 to 0.05 percent of cleaning auxiliary, 0.01 to 2 percent of chelator and the balance of deionized water; and the silicon dioxide is added in the state of silicasol. Under proper polishing technological conditions, the polishing solution prepared with the components according to the contents can obtain a high-quality polished surface and meet the requirement of the semiconductor industry on the surface quality and removal rate of silicon substrate slices, and moreover, the invention has the advantages of low cost, easy cleaning, low corrosiveness and the like, and has a good application prospect.

Owner:BEIJING GRISH HITECH

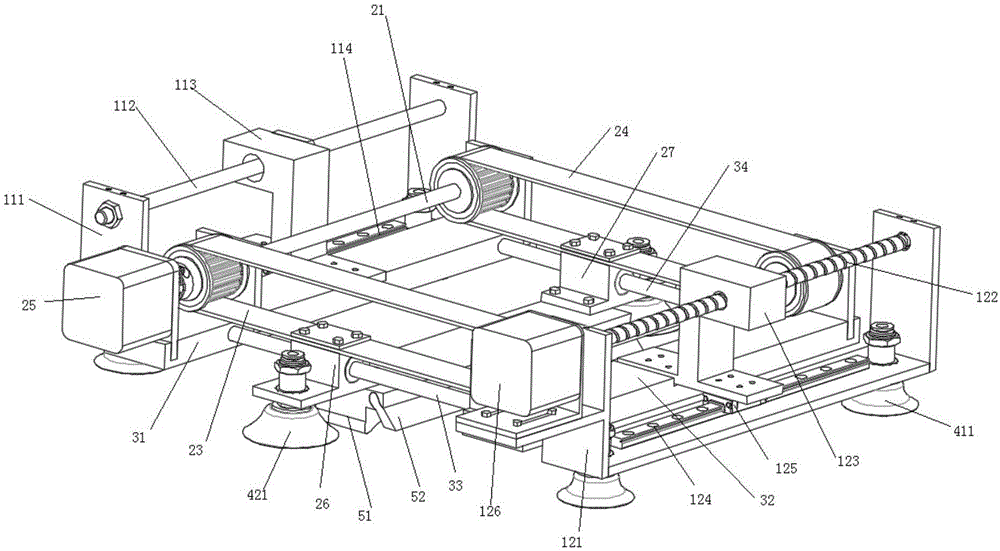

Plate cleaning machine

InactiveCN105618405AImprove cleaning efficiencyKeep clean and tidyCleaning using toolsCleaning using liquidsDrive wheelEngineering

The invention discloses a plate cleaning machine which comprises a housing and spray heads, wherein a driven wheel is arranged at the lower right end of an inner cavity of the housing, and is in transmission connection with a driving wheel through a conveying belt; the driving wheel is in transmission connection with a motor through a belt; the motor is arranged at the lower end of the left side of the outer surface of the housing; a first driving hydraulic rod is arranged at the left end of the top of the inner cavity of the housing; a first driven hydraulic rod is arranged at the bottom of the outer surface of the first driving hydraulic rod, and is connected with an inner cavity of the first driving hydraulic rod in a sleeving manner; a scraping plate is arranged at the bottom of the outer surface of the first driven hydraulic rod; second driving hydraulic rods are arranged at the right end of the outer surface of the first driving hydraulic rod; and second driven hydraulic rods are arranged at the bottoms of the outer surfaces of the second driving hydraulic rods, and are connected with inner cavities of the second driving hydraulic rods in a sleeving manner. The plate cleaning machine is provided with three hairbrush rolls, and can effectively clear away blots on the surface of a plate, and the cleaning efficiency of the plate is improved.

Owner:陈建荣

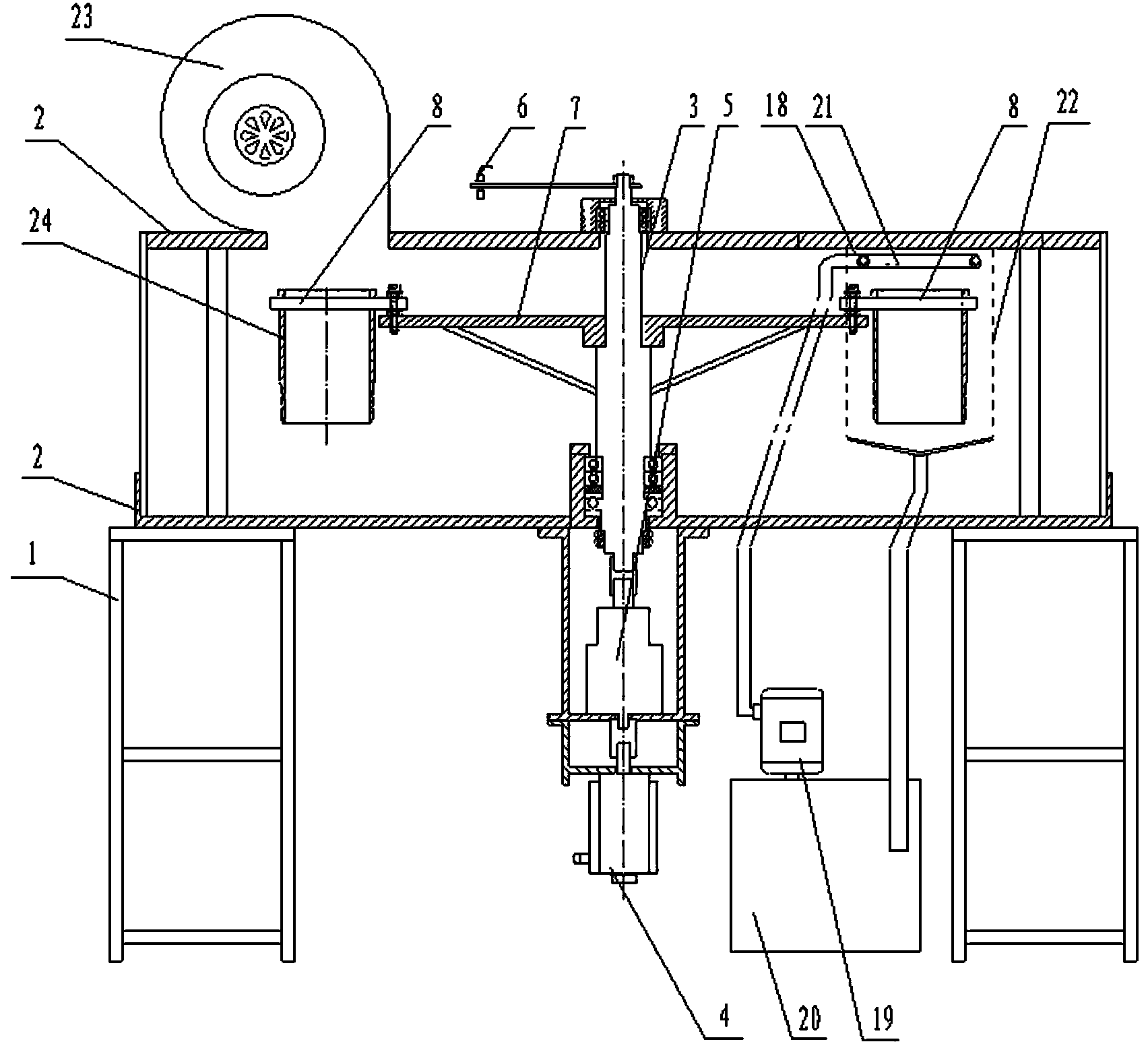

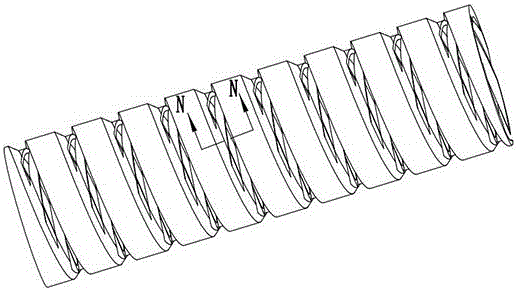

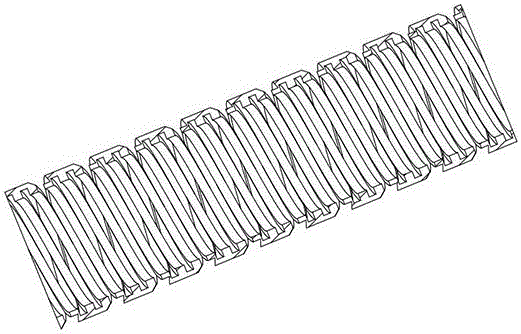

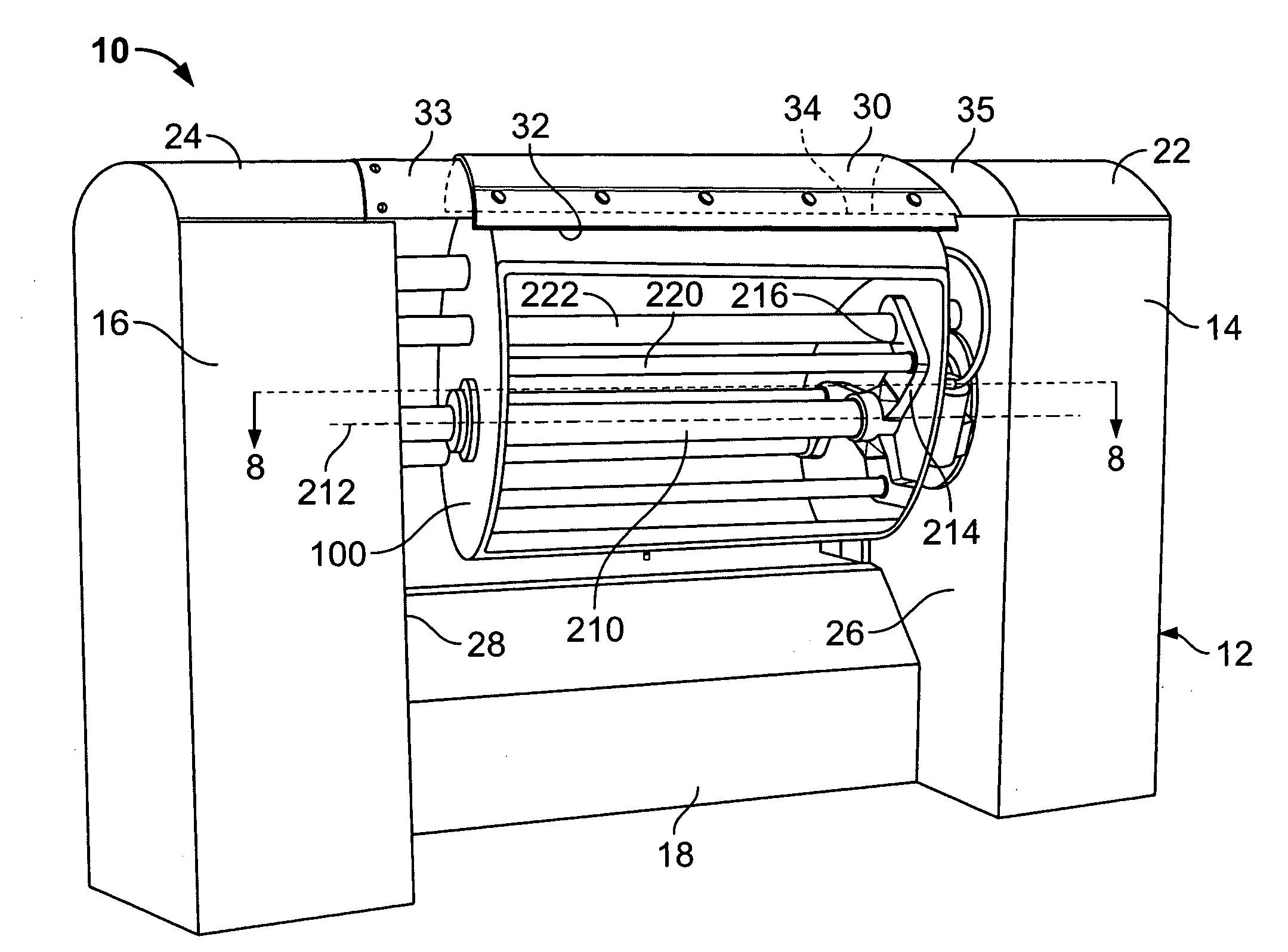

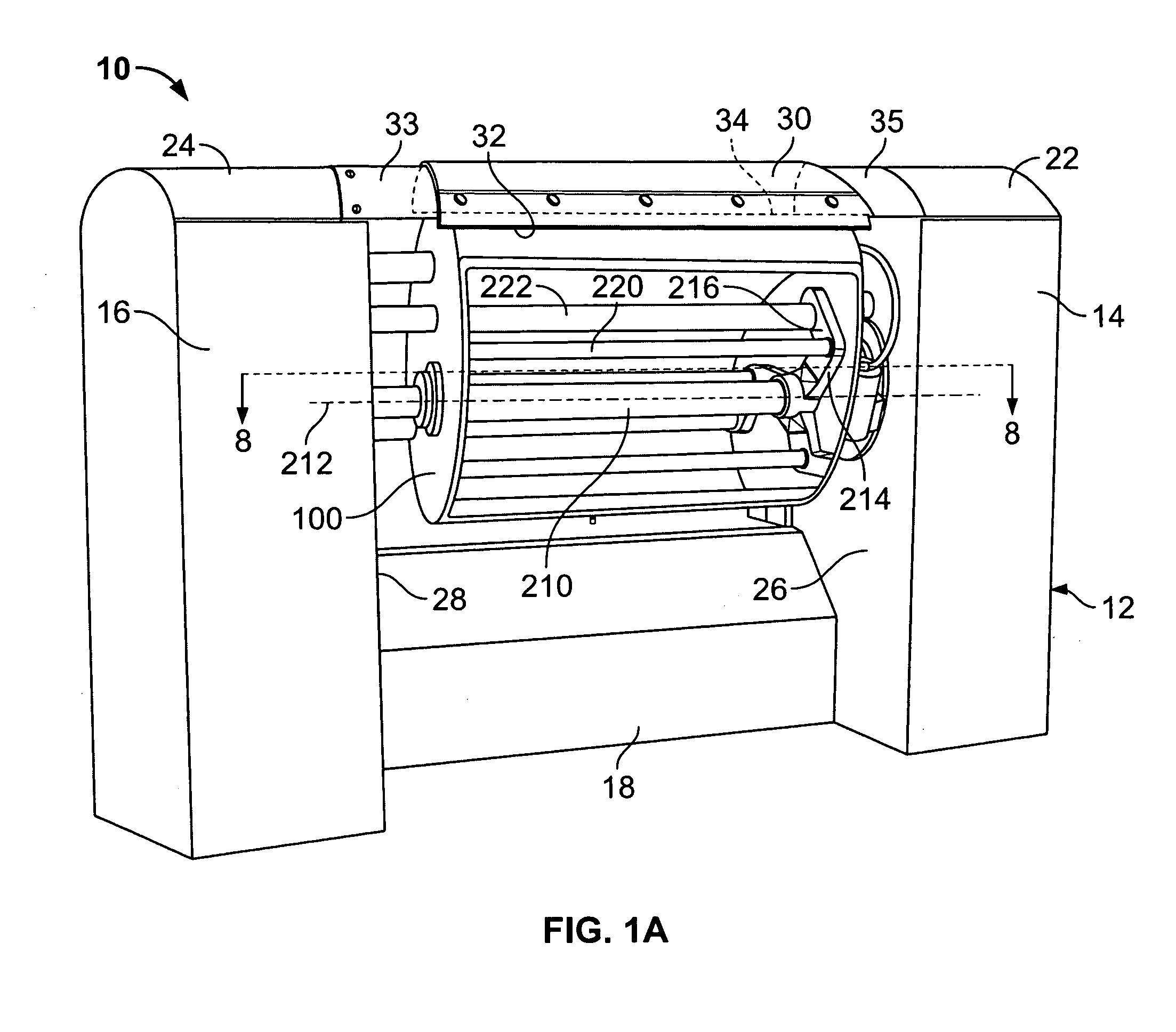

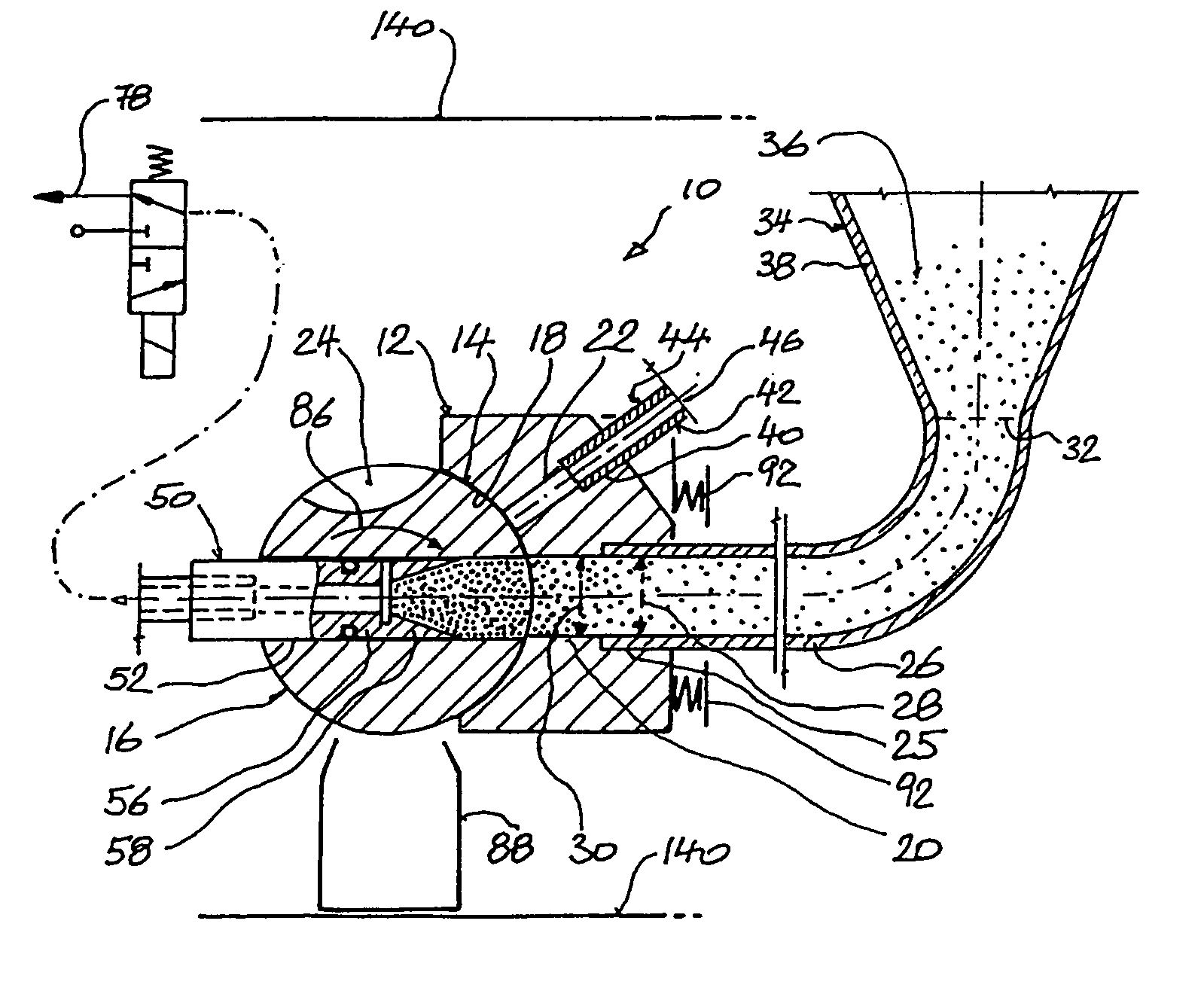

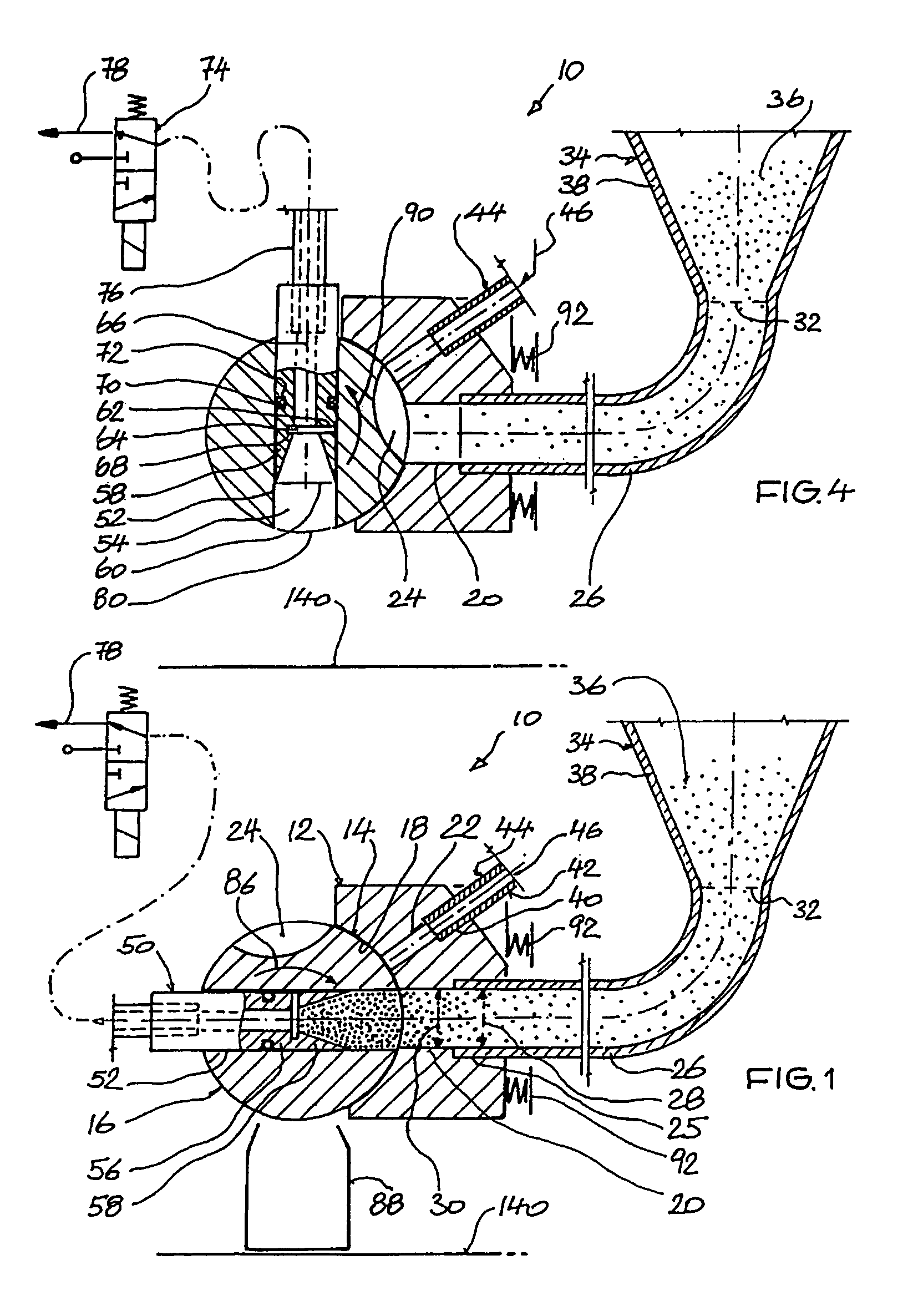

Method and apparatus for mixing dough

InactiveUS20080151682A1Improved efficiency and effectivenessCooling effectRotary stirring mixersTransportation and packagingAir cycleEngineering

The invention provides an apparatus and method for improved mixing of yeast-raised and yeast-raised type dough. The device and method keep the dough cool by an improved structure and method for circulating coolant around a jacketed bowl, and by circulating cooled air through the spinning agitator roller bars. Better aeration of the dough and faster mixing time are achieved along with full water and flour absorption, and reduced operating temperatures by controlling placing of the agitator driveshaft in a carefully defined region. Finally, the invention provides a wiper for wiping the lip of the bowl to keep it clean of dough and to insure a proper seal along the bowl lip when a resilient, expandable bowl seal is used, and it provides a pneumatic seal for securely sealing the mix ingredients in the bowl during mixing.

Owner:CMC AMERICA CORP

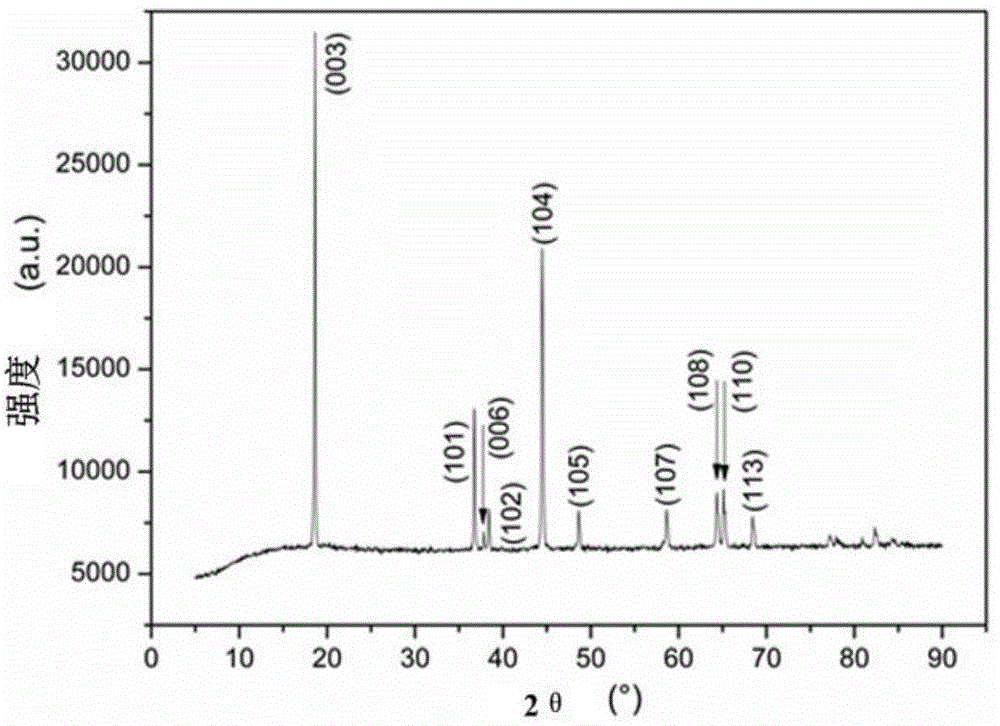

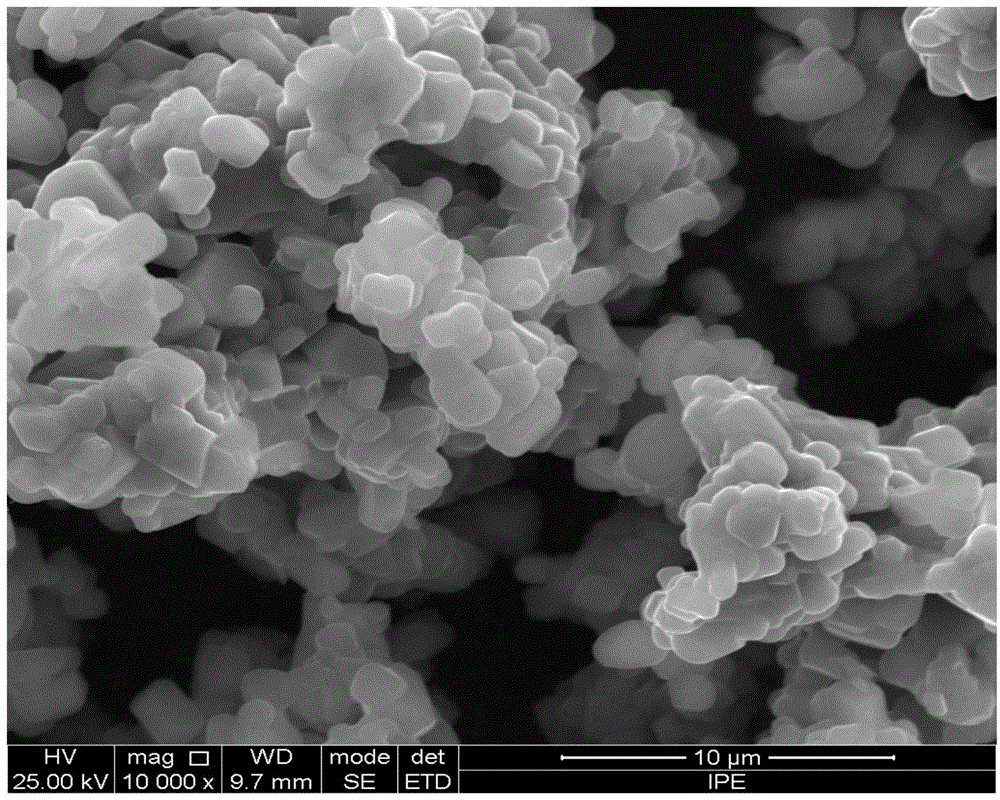

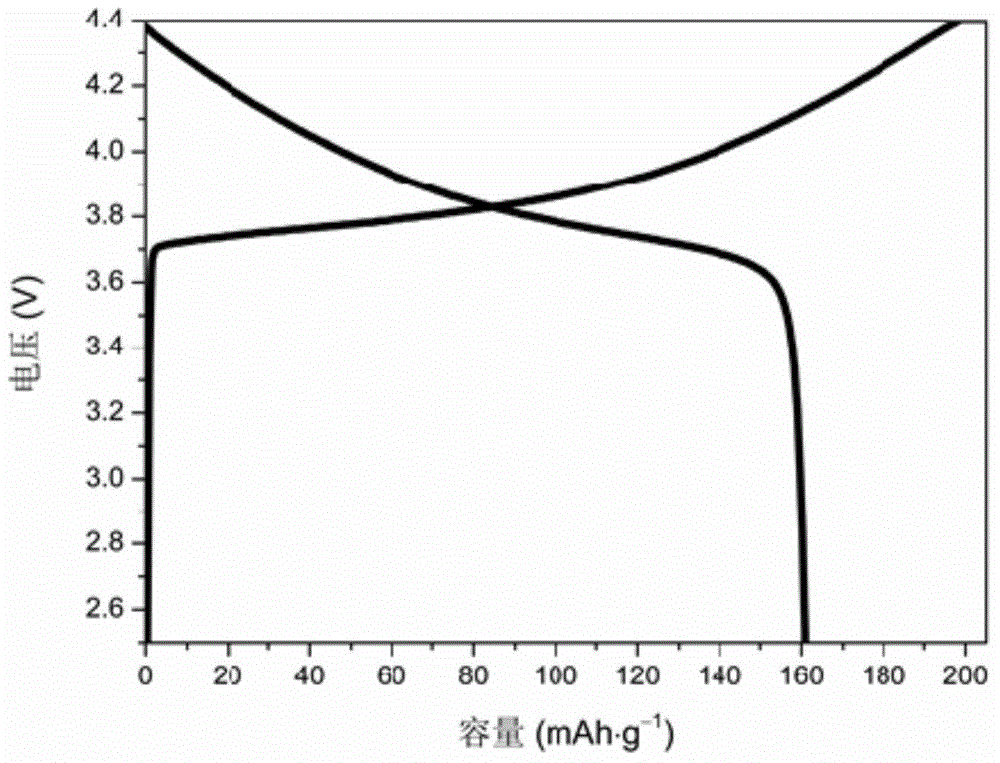

Metal doping LiMn(1-x-y)NixCoyO2 compounded by lithium ion battery positive electrode waste, as well as preparation method and application of metal doping LiMn(1-x-y)NixCoyO2

ActiveCN104953199AImprove electrochemical performanceShort processCell electrodesWaste accumulators reclaimingElement compositionLithium-ion battery

The invention provides metal doping LiMn(1-x-y)NixCoyO2 compounded by lithium ion battery positive electrode waste, as well as a preparation method and an application of the metal doping LiMn(1-x-y)NixCoyO2. The method comprises the steps: removing a binder and a conductive agent from the lithium ion battery positive electrode waste so as to obtain a positive electrode active material; determining the element composition of the positive electrode active material; adjusting the content / contents of one or more of Ni, Co, Mn and M in the positive electrode active material, so as to enable a molar ratio to accord with the molar ratio of Ni to Co to Mn to M in the molecular formula LiNixMnyCo(1-x-y-z)MzO2 so as to obtain positive electrode active material precursor powder; and adding a lithium source, and performing high-temperature solid-phase reaction so as to obtain metal doping LiMn(1-x-y)NixCoyO2. The method is wide in application range, easy to operate, low in cost and capable of avoiding secondary pollution, and achieving the short-range cleaning circulation of the positive electrode active material in a waste lithium ion battery. The prepared metal doping LiMn(1-x-y)NixCoyO2 is excellent in electrochemical performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for cleaning solar streetlight photovoltaic panel

ActiveCN102588860ARealize self-cleaningReduce or save maintenance costsWith built-in powerEnergy efficient lightingControl signalWater flow

The invention provides a method for cleaning a solar streetlight photovoltaic panel. When a photovoltaic panel (4) is cleaned each day, control signals are outputted to the photovoltaic panel (4) and a water sprayer (8) by a self-cleaning controller (11); the photovoltaic panel (4) is rotated with a circle center thereof as an axis under the drive of wind power; the water sprayer (8) is driven to spray water at 360 degrees from the circle center of the photovoltaic panel (4) to the circumference of the photovoltaic panel (4) by a streetlight device power system (10); during the rotation, an upper surface of the photovoltaic panel (4) is contacted with a brusher (9); the brusher (9) is used for brushing dust with the help of water, and then the brushed dust is discharged along the water from a sewer (5); and the photovoltaic panel (4) is rotated circularly so as to finish cleaning.

Owner:BEIJING UNION UNIVERSITY

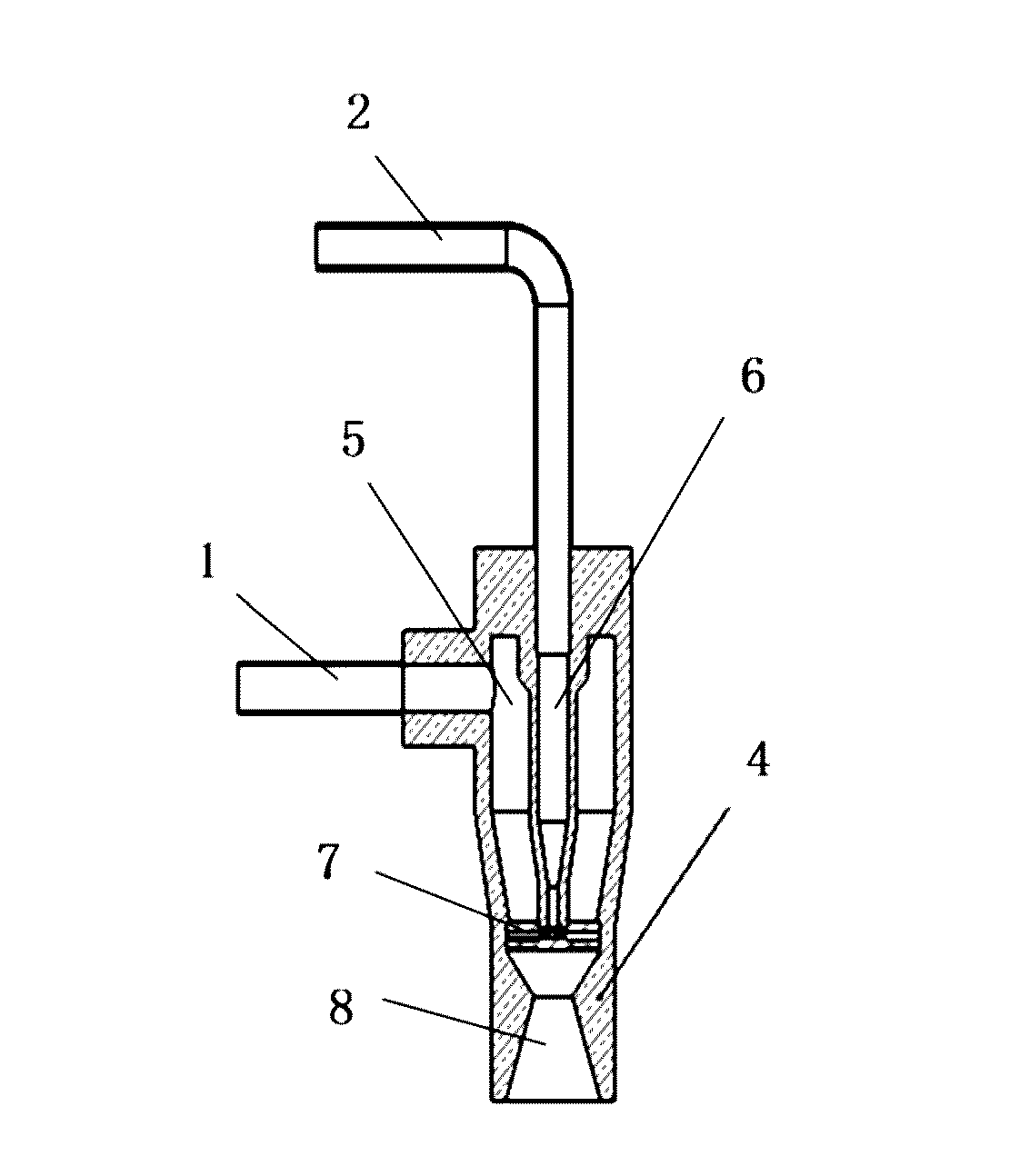

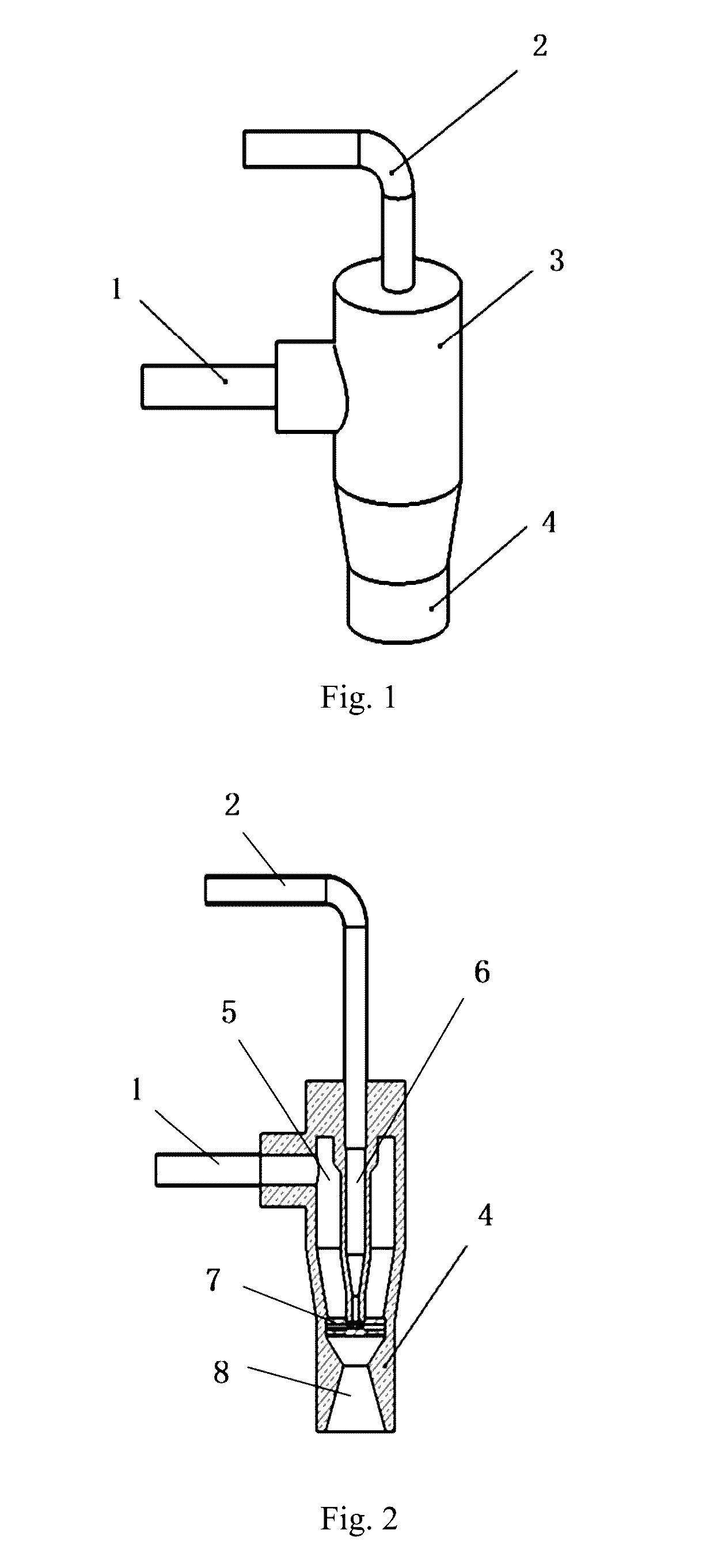

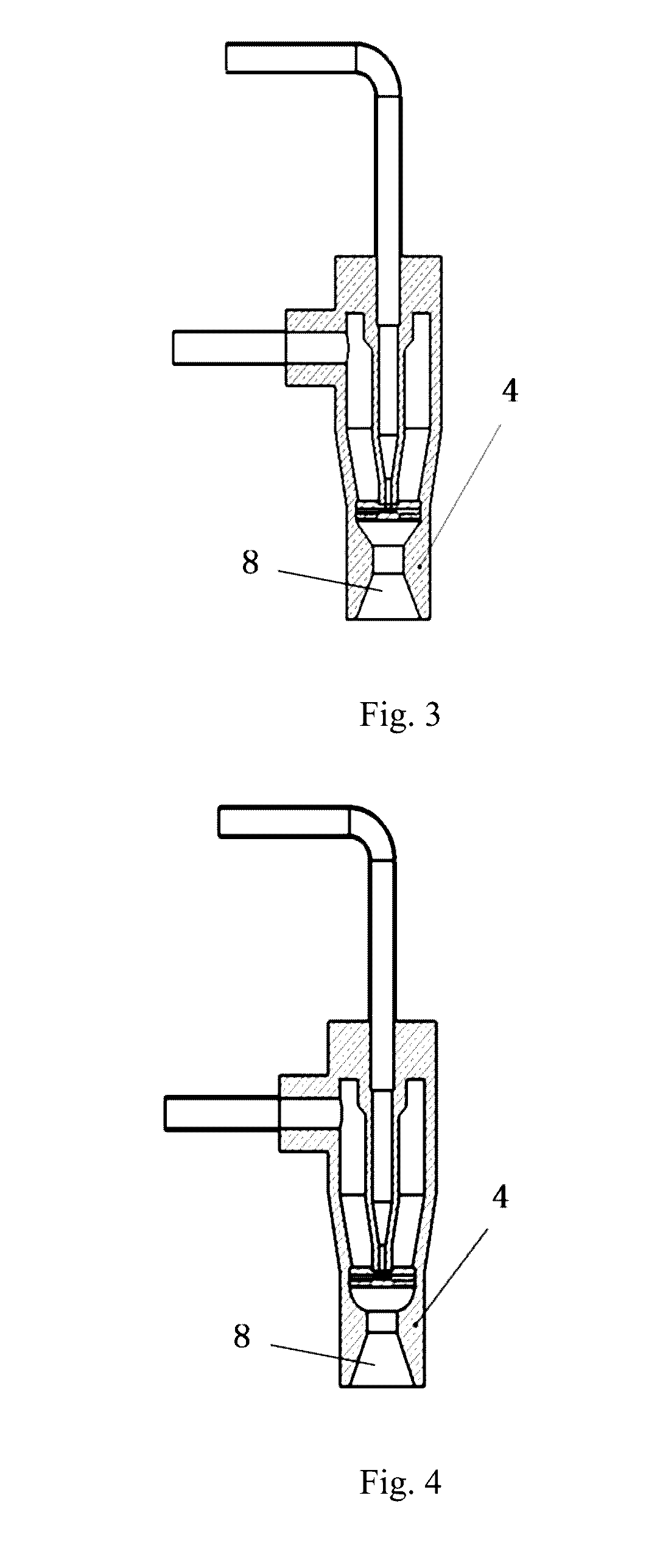

Cleaning device for atomizing and spraying liquid in two-phase flow

ActiveUS20170170035A1Even air distributionIncrease in sizeMovable spraying apparatusSemiconductor/solid-state device manufacturingSpray nozzleAcoustic wave

A cleaning device for atomizing and spraying liquid in two-phase flow comprising a nozzle provided with multiple liquid bypass pipelines each having liquid guiding outlets inclined at a predetermined angle and an exhaust mesh plate having vertical gas guiding outlets, which makes the high speed liquid flow and high speed gas flow sprayed out therefrom collide against each other sufficiently to form ultra-micro atomized particles with uniform and adjustable size. The ultra-micro atomized particles are sprayed out downwardly to the wafer surface under the acceleration and vertical orientation effects of an atomized particle guiding outlet to perform a reciprocating cleaning for the wafer. Other components such as an ultrasonic or megasonic generation unit, a gas shielding unit, a self-cleaning unit or a rotating unit can also be provided to perform the multifunction of the nozzle.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

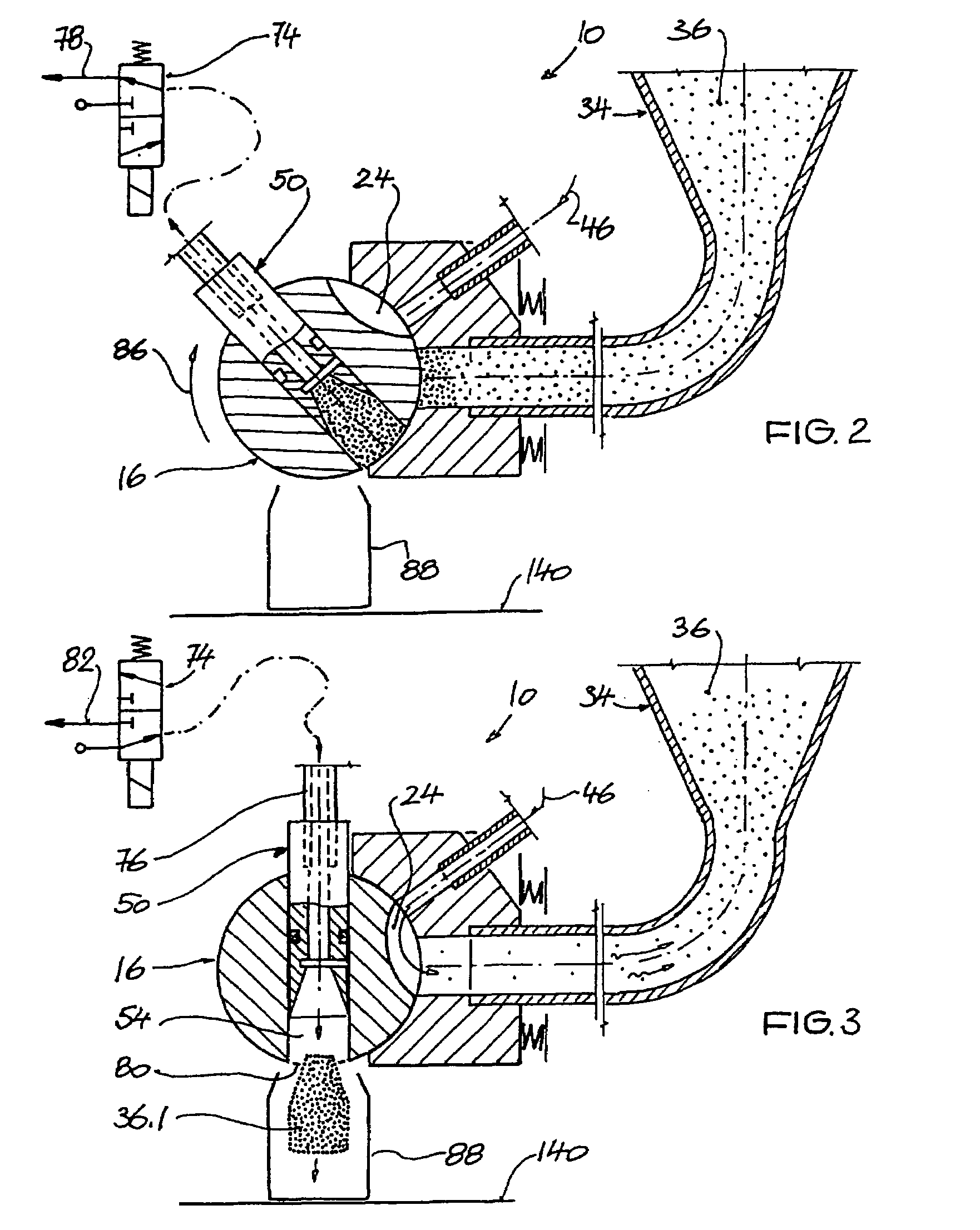

Method of dispensing pulverulent contents and apparatus for implementing this method

ActiveUS7284679B2Straightforward toReduce cleaning costsOpening closed containersBottle/container closureLine tubingConcave surface

An apparatus for dispensing respectively predetermined quantities of pulverulent contents has a rotatably drivable metering roller containing at least one metering chamber and a material store which stores the pulverulent contents. The metering roller contains at least one lateral line, which is not line-connected to the metering chamber and of which the at least two line ends terminate on the surface of the metering roller. A gas line is guided into the housing and passes out of the housing again in a concave surface region. Gas is introduced into the material store via the lateral line, in dependence on the respective rotary position of the metering roller, through said gas line. Depending upon the rotary positions of the metering roller, the gas line, which fluidizes the contents present in the material store, is closed or opened by the metering roller.

Owner:HARRO HOFLIGER VERPACKUNGSMASCHEN

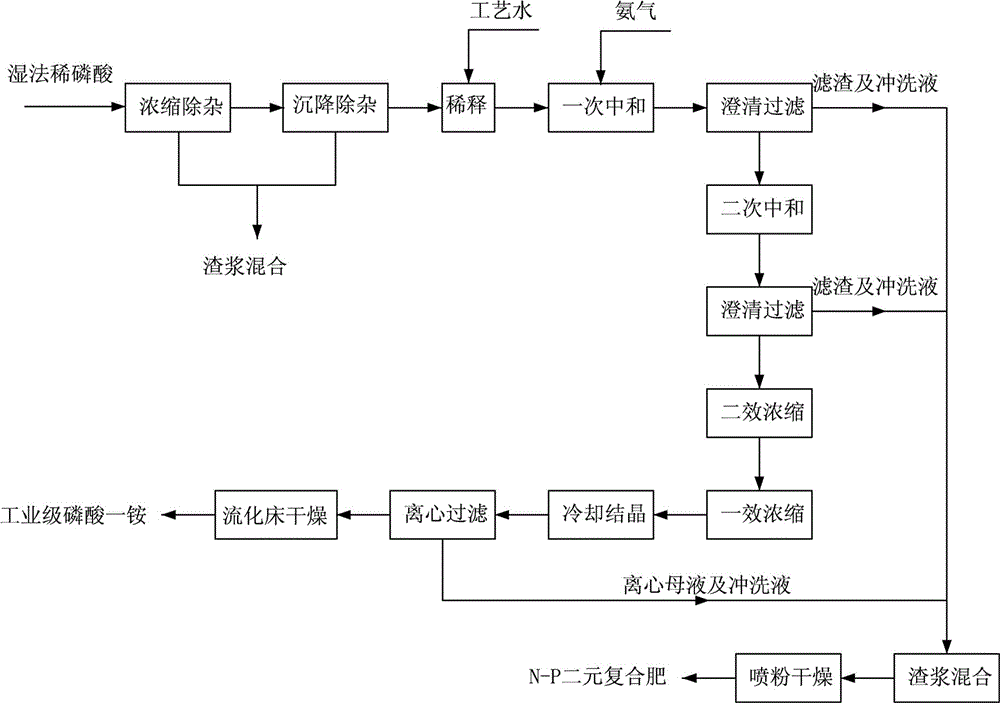

Method for producing monoammonium phosphate and coproducing N-P binary compound fertilizer by using wet-process phosphoric acid

ActiveCN102863267AReduce cleaning costsSimple processEnergy inputFertilizer mixturesLow gradedGaseous ammonia

The invention discloses a method for producing monoammonium phosphate and coproducing an N-P binary compound fertilizer by using wet-process phosphoric acid. According to the method, wet-process phosphoric acid prepared from low-grade phosphate ores is used as a raw material. The method comprises the following steps: concentrating and setting the wet-process phosphoric acid to remove impurities; diluting with process water; neutralizing with ammonia twice; filtering twice; concentrating; cooling for crystallization; centrifugally separating; drying to obtain the industrial grade monoammonium phosphate finished product; and mixing acid sludge, the centrifugalized mother liquor, residue and the flushing fluid in a slurry mixing tank, performing spray drying to obtain the N-P binary compound fertilizer. According to the method, wet-process phosphoric acid and gaseous ammonia are directly used as raw materials and the existing related devices in the phosphoric acid industry and resources such as waste heat steam and self power can be utilized, thus the yield of industrial grade monoammonium phosphate can be increased, the output of the byproduct N-P binary compound fertilizer can be reduced, the production cost of industrial grade monoammonium phosphate can be greatly reduced, the industry scale can be enlarged, the adaptability of the equipment can be enhanced, the market demands can be met, the stepped comprehensive utilization of the phosphorus resource can be realized and the economic benefit is higher.

Owner:HUBEI SANNING CHEM

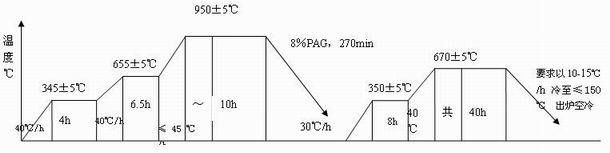

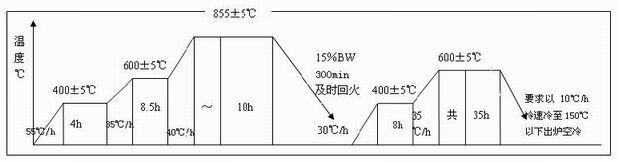

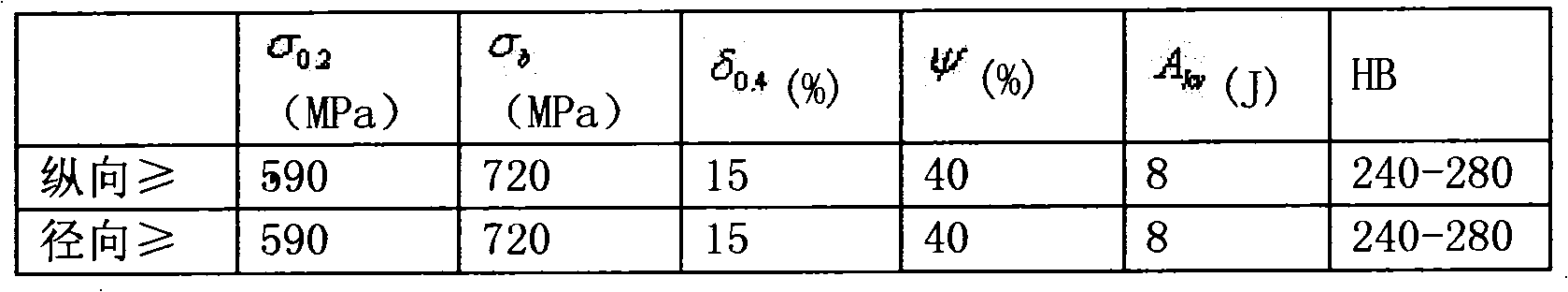

Environment-friendly heat treatment process for large shaft forgings

InactiveCN102115809AUniformly hardenedReduce cleaning costsFurnace typesHeat treatment process controlWater solubleLaser cooling

The invention discloses an environment-friendly heat treatment process for large shaft forgings. According to the heat treatment process, the traditional oil and tap water are substituted by a commercial water soluble quenching medium PAG (poly alkylene glycol) or BW, the concentration of the quenching medium PAG or BW is adjusted, and the process parameters such as the heating speed, holding time, quenching temperature, quenching time, tempering temperature, cooling speed and the like are strictly controlled, thereby solving the problems of deformation and even defects liable to occur by water cooling of large shaft parts and lower rigidity, environmental pollution and the like liable to occur by oil cooling of large shaft parts, and simultaneously solving the problems of heavy weight, great change of sectional dimension, uneven performance after heat treatment and the like of large shaft parts.

Owner:HENAN UNIV OF SCI & TECH

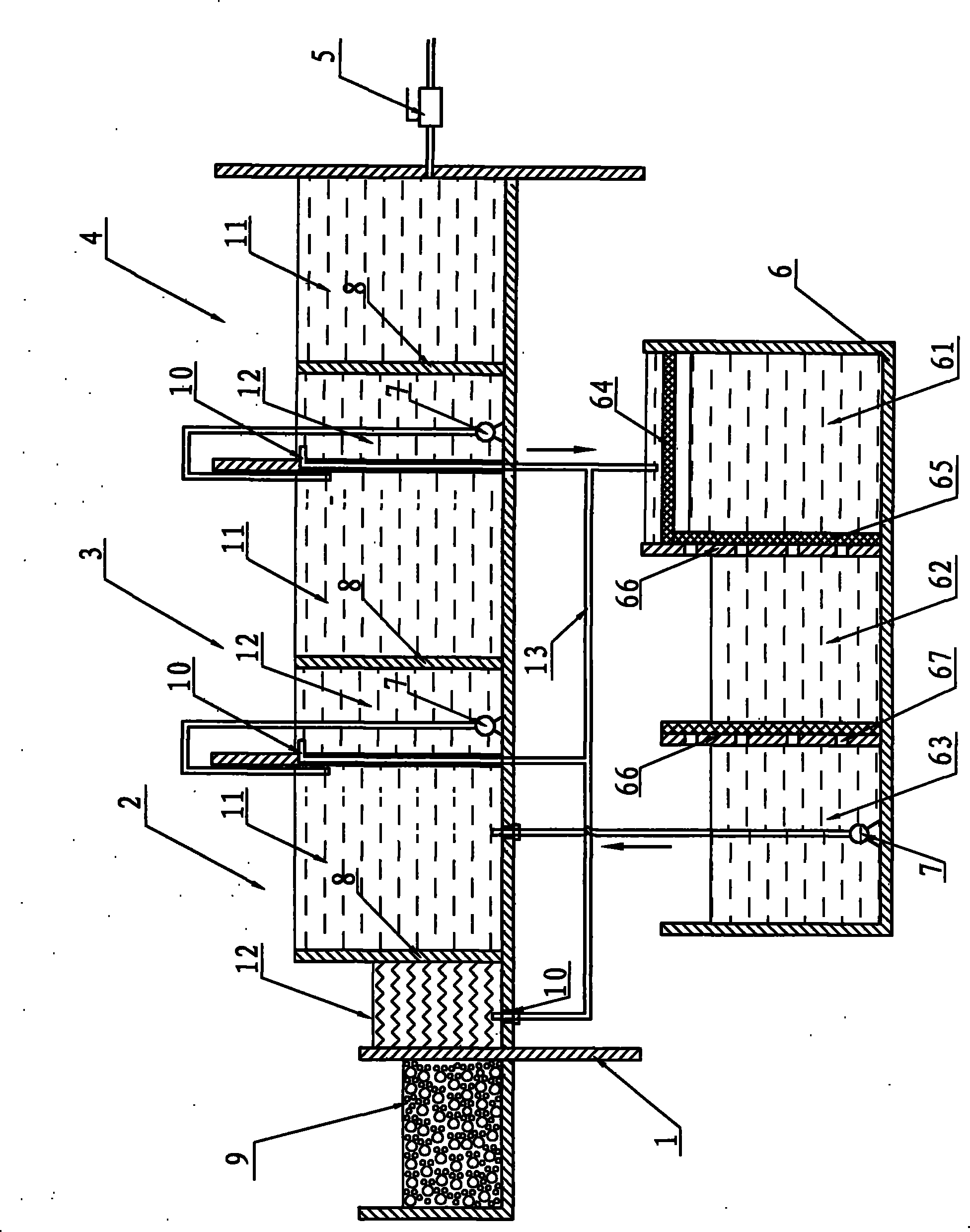

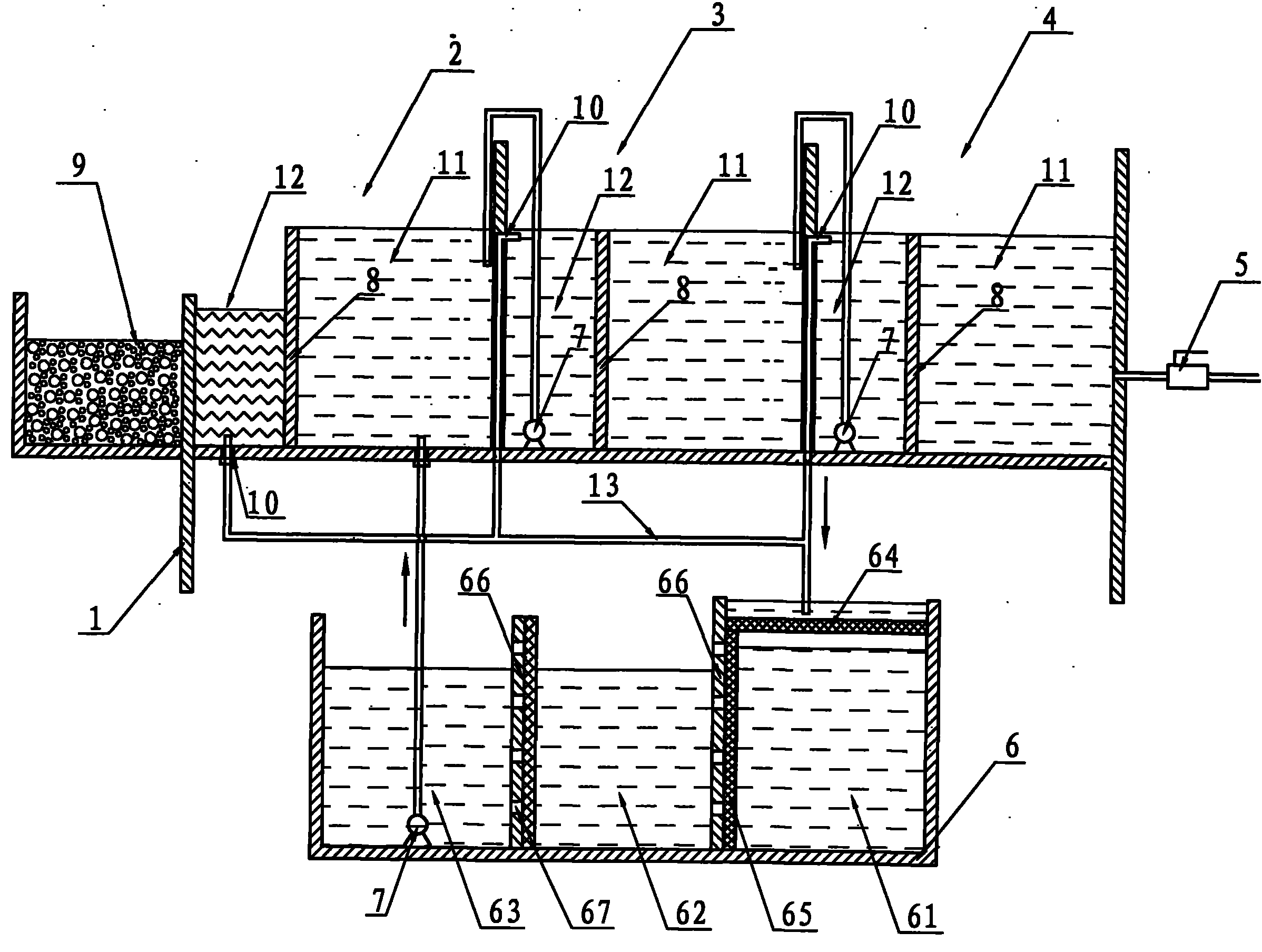

Multilevel circulating cleaning equipment for solar cell silicon wafers

The invention relates to multilevel circulating cleaning equipment for solar cell silicon wafers, which comprises a first rinse tank, a transition rinse tank, a final rinse tank, a water inlet valve, a filter treating pond, a circulating pump, partition embankments and a sewage sump. The partition embankment is arranged in each rinse tank; each rinse tank is divided into a cleaning room and a sewage overflowing room; cleanout fluid overflowed from a rear-way rinse tank is pumped by the circulating pump and is used as cleanout fluid of a front-way rinse tank; sewage overflowed from the outside of the upper surface of each rinse tank flows into the filter treating pond through a flexible pipe for secondary treatment; and the treated cleanout fluid is conveyed to the first rinse tank through the circulating pump and is used as cleanout fluid of the first rinse tank. The actual use of an applicant proves that by the adoption of the multilevel circulating cleaning equipment for the solar cell silicon wafers, the water consumption of cleaning the silicon wafers per ton is only 3 tons, and compared with the conventional cleaning machine, the multilevel circulating cleaning equipment saves water by over 5 tons; and thus the multilevel circulating cleaning equipment has obvious water-saving effect and avoids water resource waste caused by independent water service of the rinse tanks.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

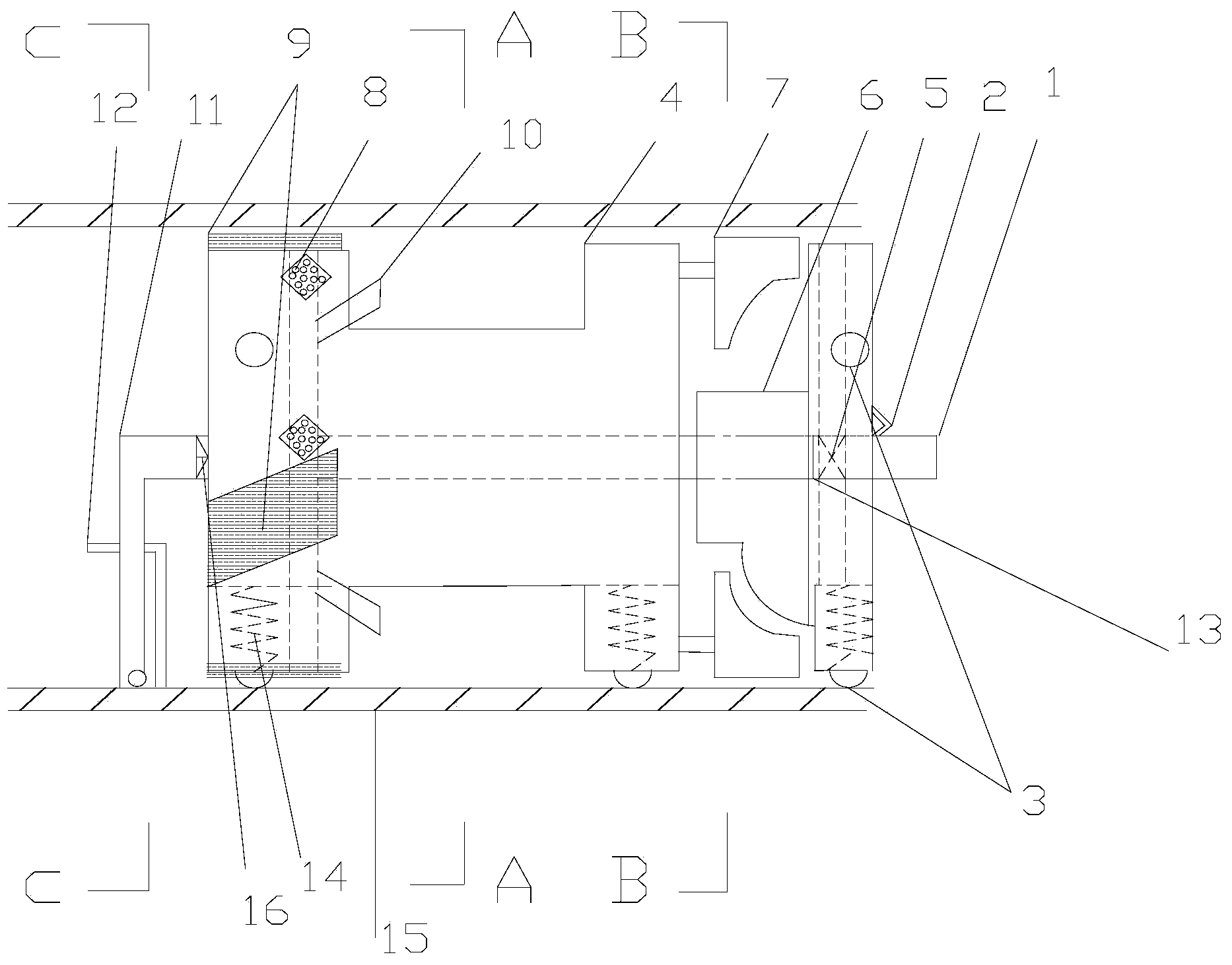

Self-rotating pipeline cleaning device

The invention discloses a self-rotating pipeline cleaning device which comprise a water feeding mechanism, a sweeping mechanism and a pre-sweeping mechanism. The water feeding mechanism is used for spraying water on the inner wall of a pipeline. The pre-sweeping mechanism is used for sweeping bricks, stones, ash blocks and other large-size sundries. The sweeping mechanism successfully sweeps dust and other small-size sundries. Under the effect of counter-acting force of water spray, a cylinder can rotate autonomously for washing through a brush. Compared with the prior art, the self-rotating pipeline cleaning device improves work efficiency, reduces cleaning cost, has strong applicability, is applicable to cleaning of pipes of various models by changing its size, meets use requirements of customers, and can be popularized and used in industries conveniently.

Owner:TIANJIN HUASHUI WATER CONSTR +1

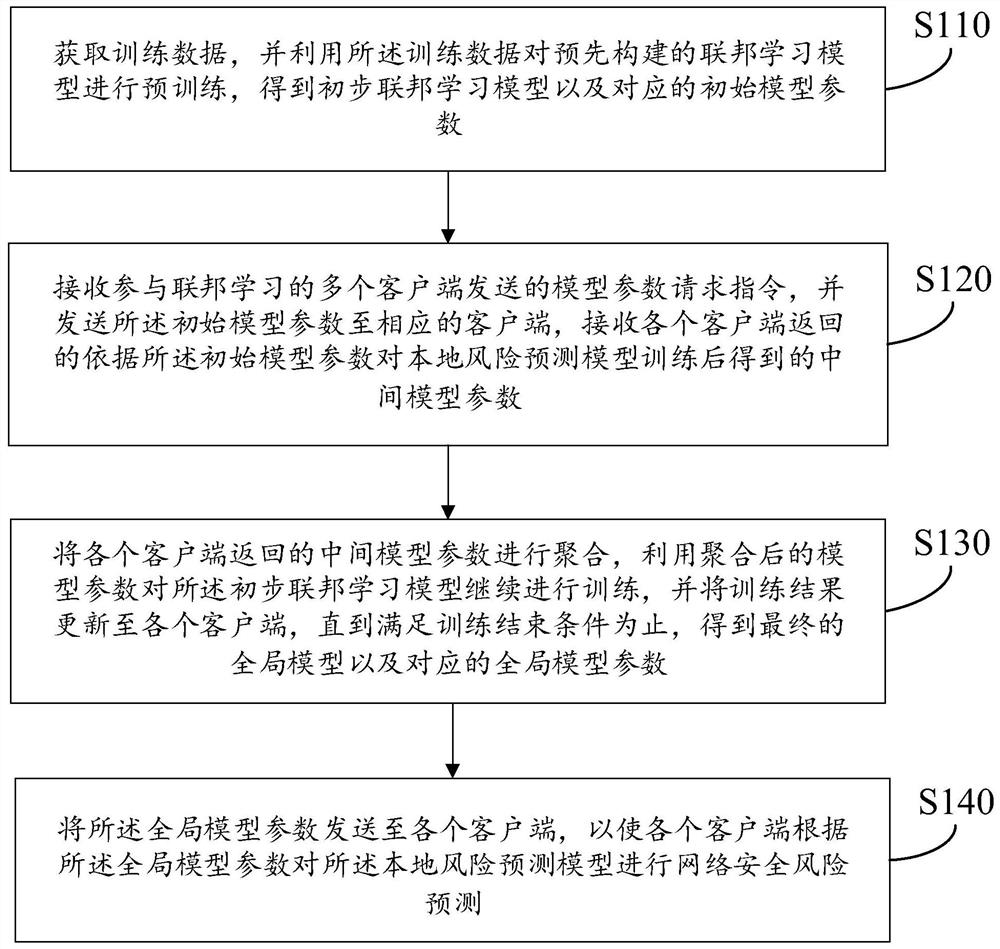

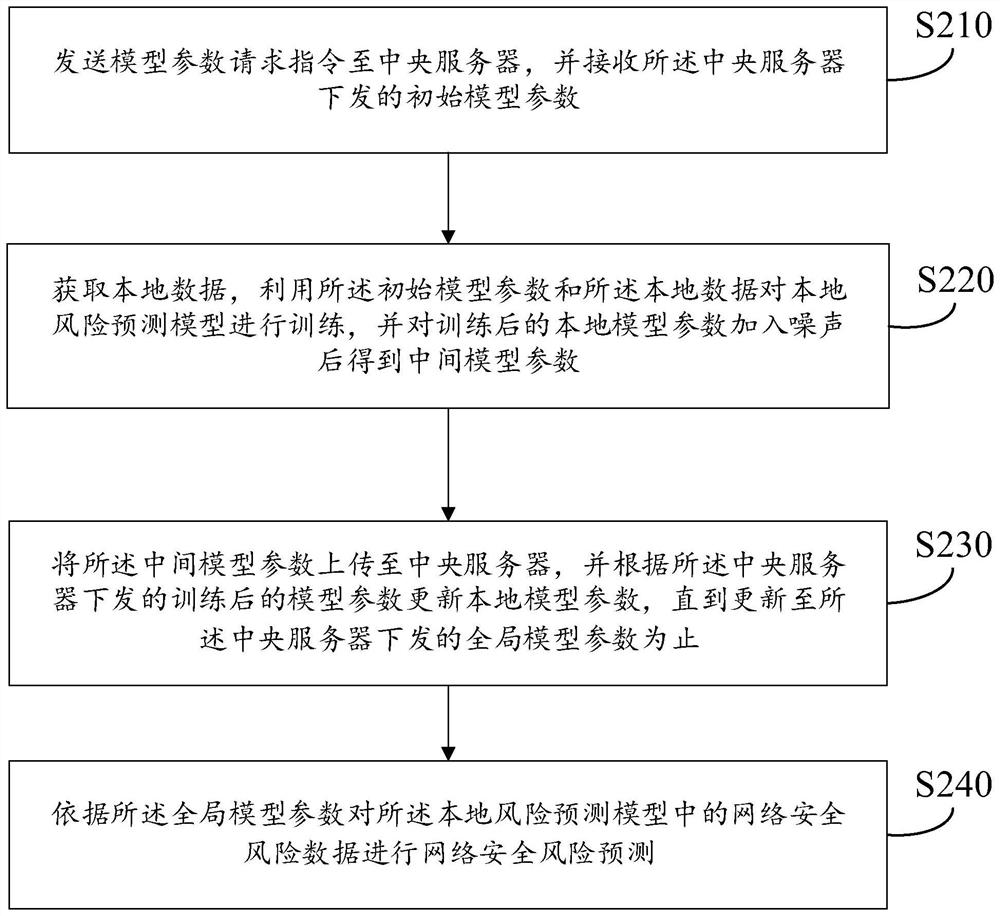

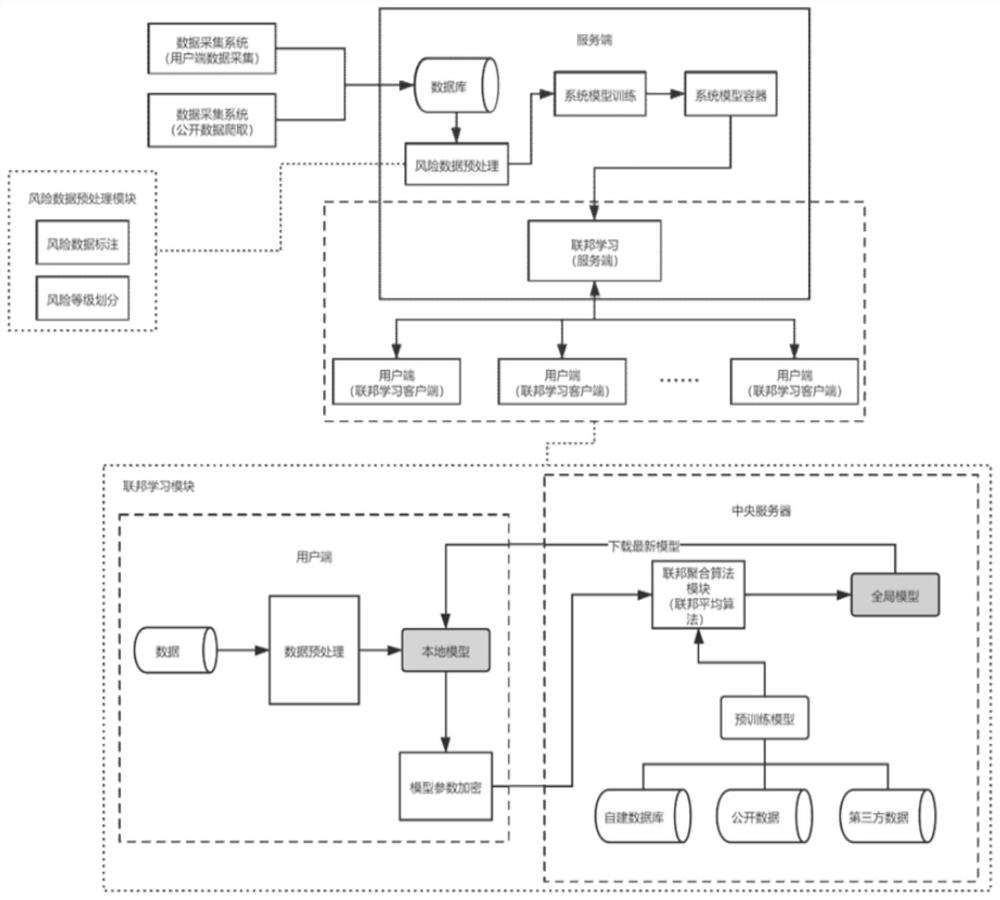

Network safety risk prediction method and device, storage medium and computer equipment

PendingCN112906903AReduce cleaning costsImprove the accuracy of security risk predictionForecastingResourcesEngineeringModel parameters

According to the network safety risk prediction method and device, the storage medium and the computer equipment provided by the invention, firstly, the initial model parameters obtained after pre-training are updated to the plurality of clients participating in federated learning, and the local risk prediction model is trained by using the updated model parameters; then, each client sends the intermediate model parameters obtained after training to the central server so as to continue to train the preliminary federated learning model; according to the global model obtained by training the model parameters, related safety data does not need to be directly obtained from an enterprise and a user side, so that the cost of cleaning and labeling the obtained data is avoided; besides, the trained global model parameters are deployed at the user client, and the safety risk prediction is carried out according to the network environment where the enterprise user is located, the local safety configuration and other related parameters, so that the accuracy of the enterprise safety risk prediction can be further improved.

Owner:北京源堡科技有限公司

Transport cleaning device

InactiveUS20060195991A1Reduce cleaning costsEasy to removeCarpet cleanersFloor cleanersWaste management

A device for removing waste from a surface includes a housing, first and second agitators rotateably attached to the housing, each having an arcuate surface area and rotation in opposite direction. A third agitator is located between the first and second agitators, the third agitator having an arcuate surface area and a counterclockwise rotation. The first agitator transports waste to the second agitator which in conjunction with the third agitator projects debris into a waste container. A method of using the device to remove debris from a surface is also described.

Owner:R E WHITTAKER

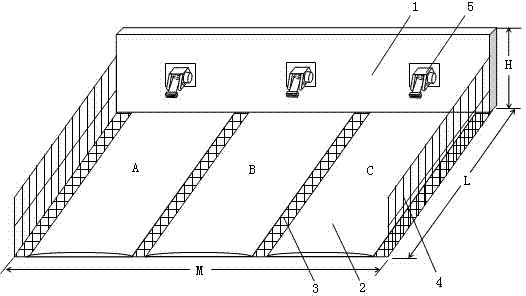

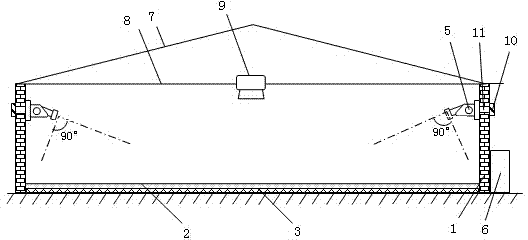

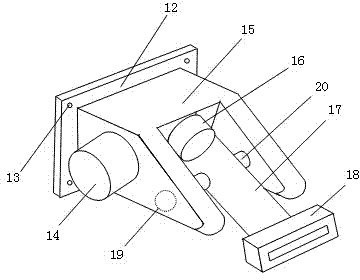

Intelligent pigsty cleaning device and method

ActiveCN104255536AFlush fully without dead endsHigh degree of automationAnimal housingSpray nozzleEnvironmental engineering

The invention discloses an intelligent pigsty cleaning device and method. The ground of a pigsty is equally divided into a plurality of identical regions in the left-and-right width direction, a wall on the front side of each region and a wall on the rear side of each region are each provided with an automatic rotary water spray device, and each automatic rotary water spray device is connected with an electric regulating valve through a hard water pipe penetrating through the corresponding wall. An embedded controller controls all cameras to monitor the pollution situations of all the regions of the ground regularly in real time, the polluted regions in need of cleaning can be judged out, the electric regulating valves corresponding to the polluted regions are regulated to be in one third opening, rectangular spray nozzles are controlled to spray water at low speed from bottom to top in a rotary mode, and pigs are evacuated to be made to enter the rest of the regions. The embedded controller processes collected images, processing results are matched with preset pigsty ground pollution level thresholds, and the flushing time is determined according to the pollution level; the ground of the pigsty can be flushed comprehensively in a non-dead-corner mode, manual intervention is not needed in the whole process, and therefore the automation degree of pigsty breeding is increased.

Owner:江阴智产汇知识产权运营有限公司

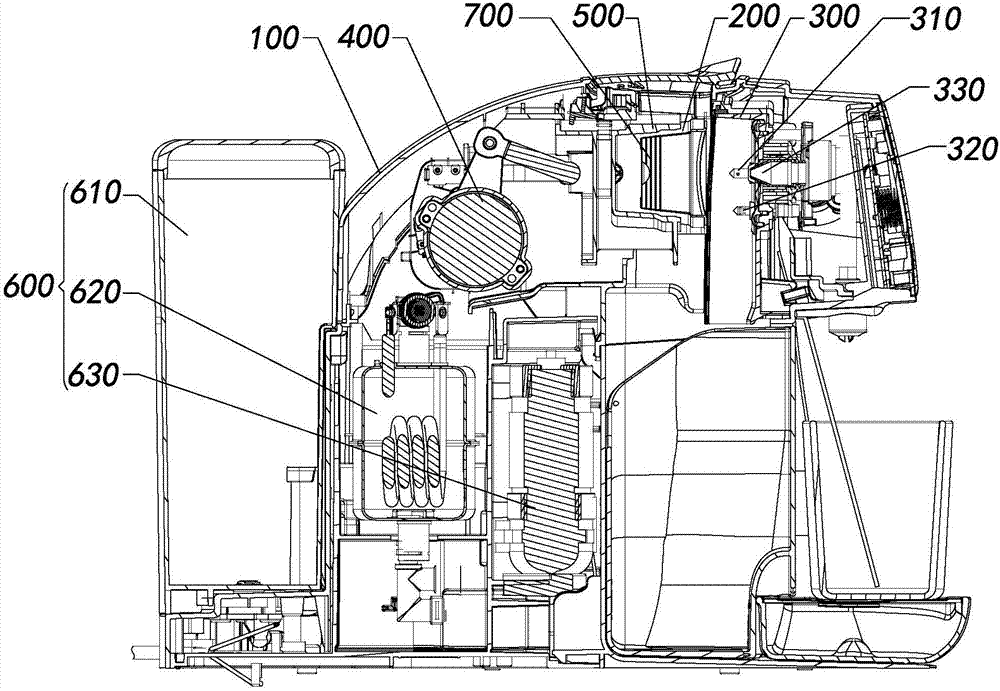

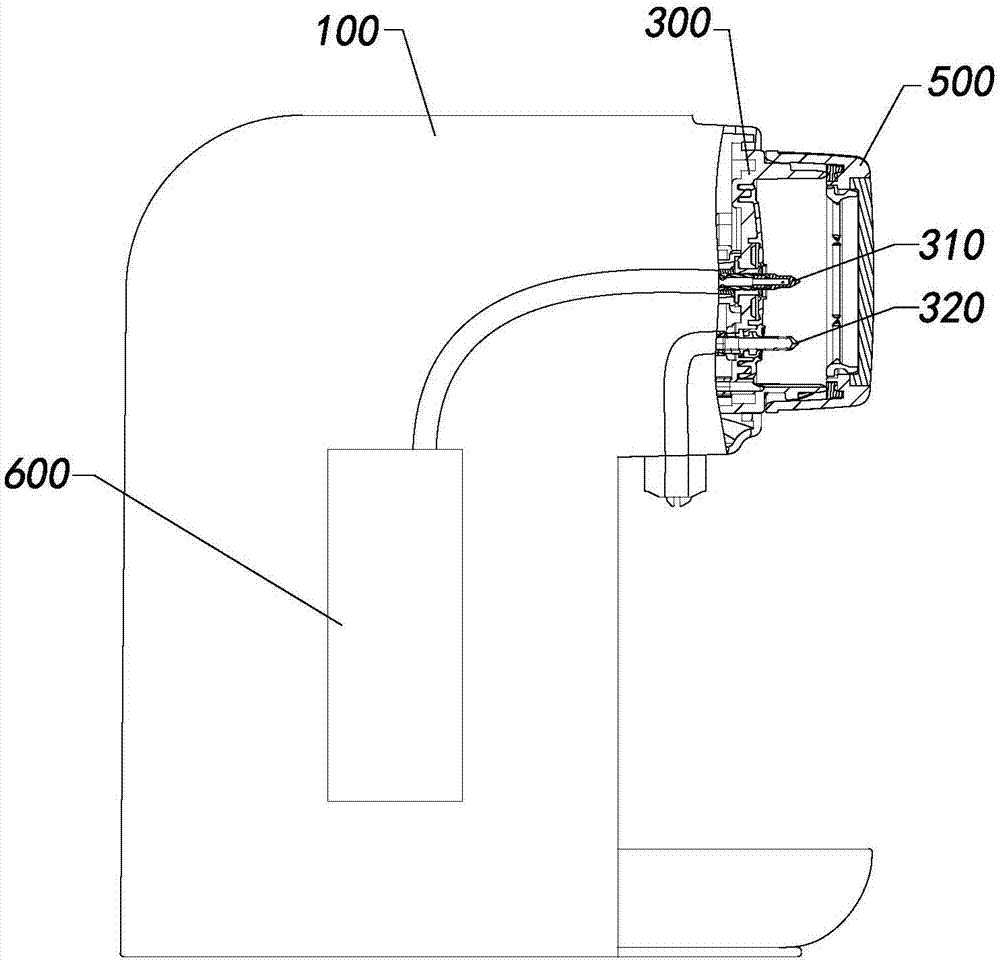

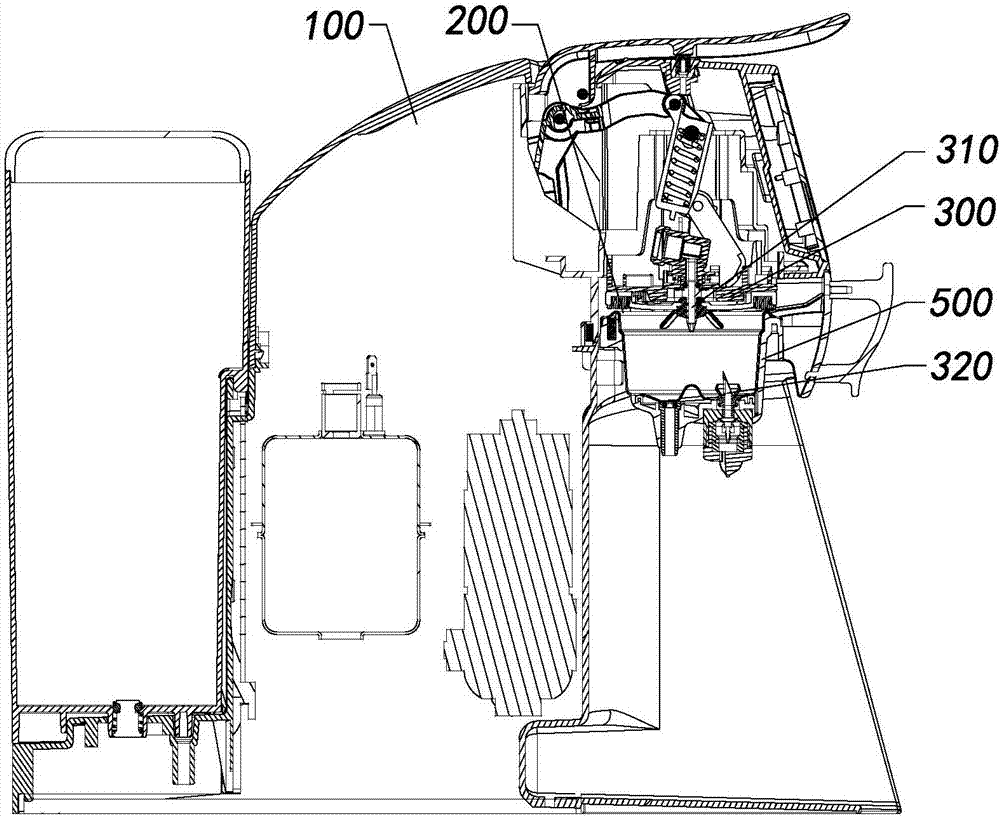

Method for cleaning capsule beverage dispenser

The invention discloses a method for cleaning a capsule beverage dispenser, and belongs to the technical field of beverage preparation. The problems that wasting of water is caused in the cleaning process of an existing capsule beverage dispenser and the cleaning effect is poor are solved. The capsule beverage dispenser comprises a machine base with a brewing cavity, a liquid feeding mechanism, an input module and a control module. The control module controls the capsule beverage dispenser to be cleaned according to signals of the input module. The cleaning method includes a first cleaning stage and a second cleaning stage capable of being selected to be executed. The first cleaning stage at least includes a first washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a first power P1 for cleaning. The second cleaning stage at least includes a second washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a second power P2 for cleaning. The rated power of the liquid feeding mechanism is PE1, and P1<P2<=PE1. The method disclosed by the embodiment of the invention is used for cleaning the capsule beverage dispenser. The capsule beverage dispenser can be a capsule coffee maker, a capsule soybean milk machine and the like.

Owner:杭州易杯食品科技有限公司

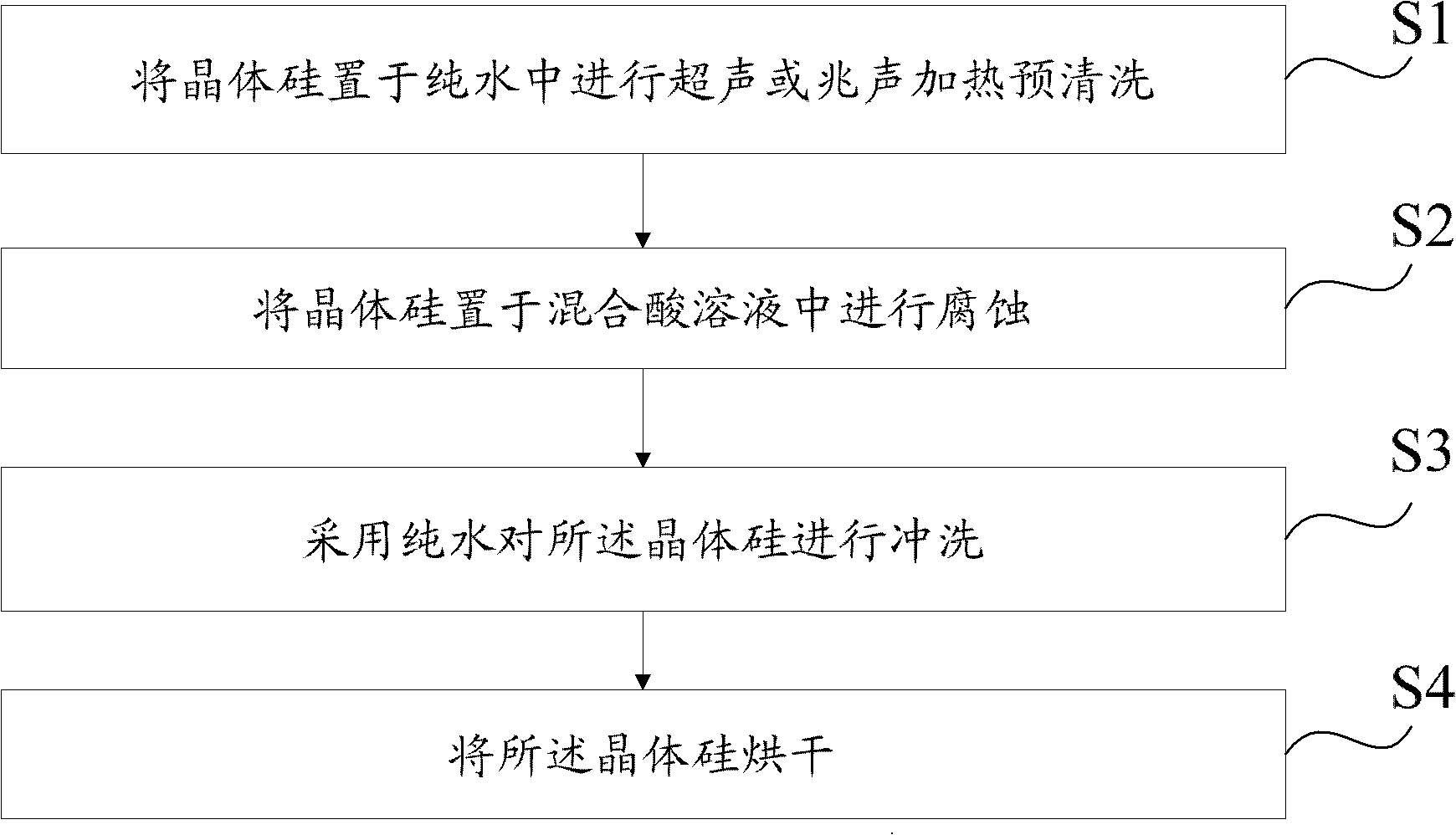

Method for cleaning crystalline silicon

InactiveCN102832101AReduce corrosion lossReduce concentrationFinal product manufactureSemiconductor/solid-state device manufacturingLiquid wasteChemical solution

The embodiment of the invention discloses a method for cleaning crystalline silicon, which comprises the following steps: placing crystalline silicon in pure water to carry out ultrasonic or mega-sound heating pre-cleaning; placing the crystalline silicon in a mixed acid solution to carry out corrosion; cleaning the crystalline silicon by the pure water; and drying the crystalline silicon. The crystalline silicon cleaning method adopts a combination manner of physic cleaning and chemical cleaning to clean the crystalline silicon, can effectively remove the impurities and particles on the surface of crystalline silicon (especially reclaimed materials) and can reduce the amount of the chemical solution, the damage of the chemical solution to the human body, equipment and environment, the corrosion loss of the chemical solution to the crystalline silicon and the follow-up treatment of the waste solution, thereby reducing the cleaning cost.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com