Synchronous spraying device for large machine

A spraying device and large-scale machinery technology, applied in the direction of the spraying device, etc., can solve the problems of asynchronous spraying device action, difficult to ensure the consistency of spraying quality, etc., to avoid clogging of the spray gun, increase the number of times, and ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0024] A synchronous spraying device for large-scale machinery, comprising a plurality of mobile bases 1, each of which is equipped with a six-axis joint robot, and a spray gun is installed at the end of the six-axis joint robot;

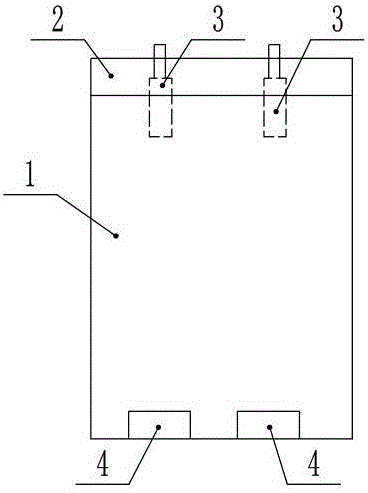

[0025] Such as figure 1 The front end of the mobile base 1 has a steel plate 2, and the front end of the mobile base 1 is also horizontally provided with a piston cylinder 3. When the piston rod of the piston cylinder 3 is retracted, the outer end of the piston rod is flush with the outer side of the steel plate 2. The outer end of the piston rod of the piston cylinder 3 is made of plastic material; the rear end of the mobile base 1 has an electronically controlled magnetic suction device 4;

[0026] The mobile base 1 attracts each other through the steel plate 2 and the electronically controlled magnetic attraction device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com