Technological method for spraying pearlescent paint on bumper

A process method and bumper technology, which is applied to the surface coating liquid device, coating, special surface, etc., can solve the problems of high labor cost, poor stability, and inability to guarantee the consistency of spraying quality, so as to reduce the number of spraying times , Spraying quality controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0024] Without loss of generality, this embodiment takes the bumper shown in the figure as the description object, and explains its partition and the process method of spraying pearlescent paint on it. It should be understood that the specific structural form of the bumper does not affect the protection of the application The process method constitutes a substantial limitation.

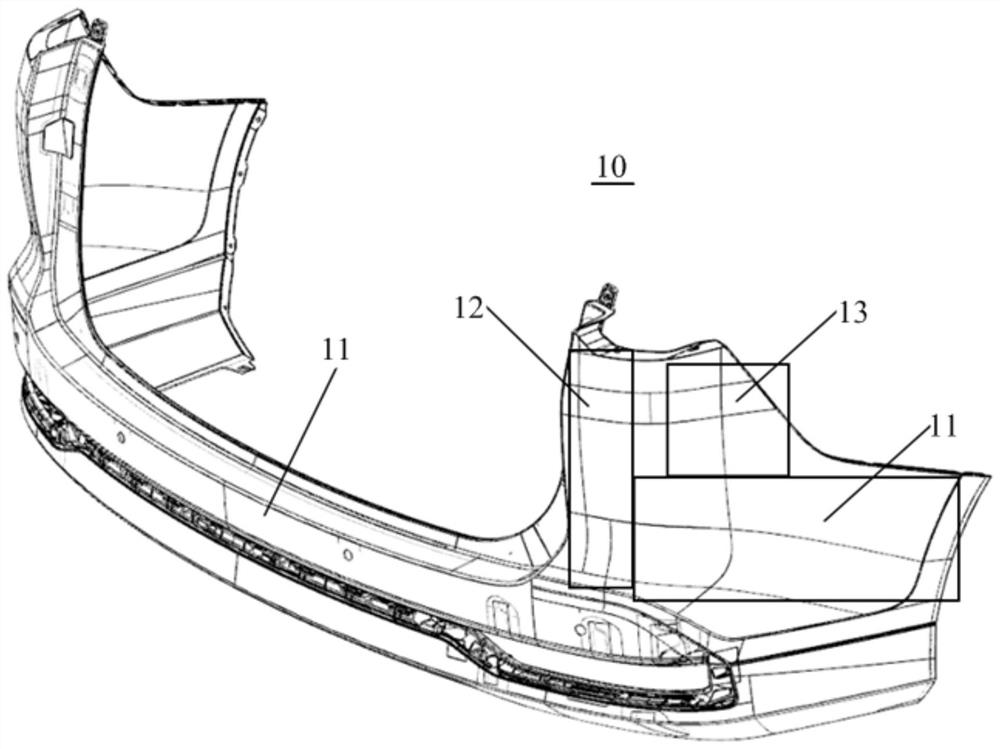

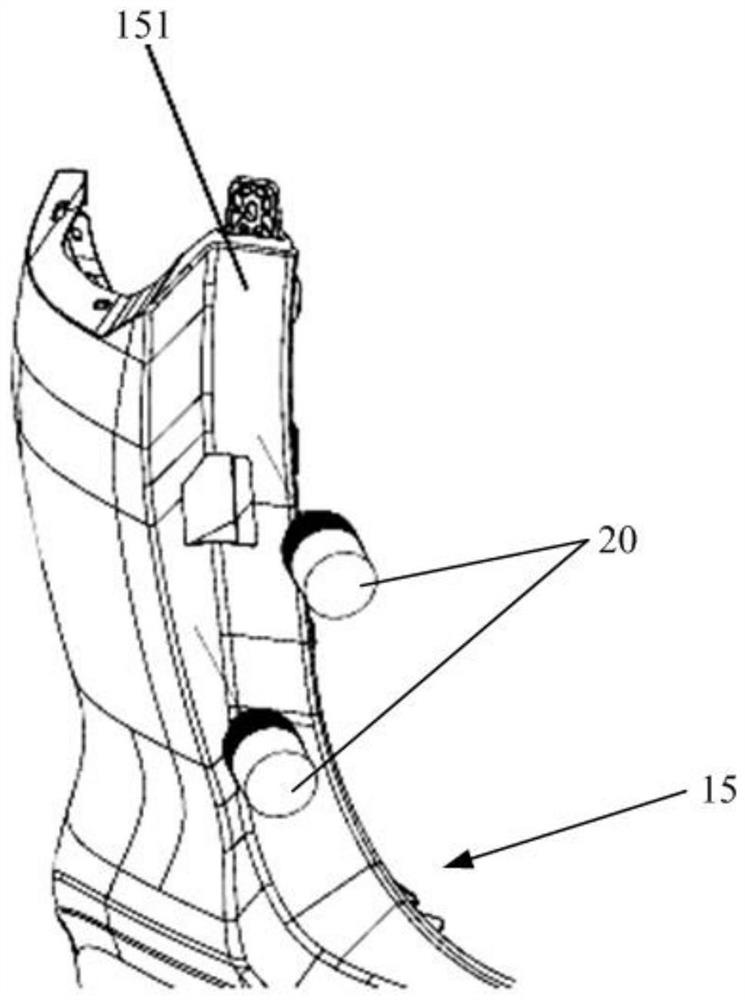

[0025] Please refer to figure 1 and figure 2 , figure 1 is a schematic structural diagram of a bumper in a specific embodiment;

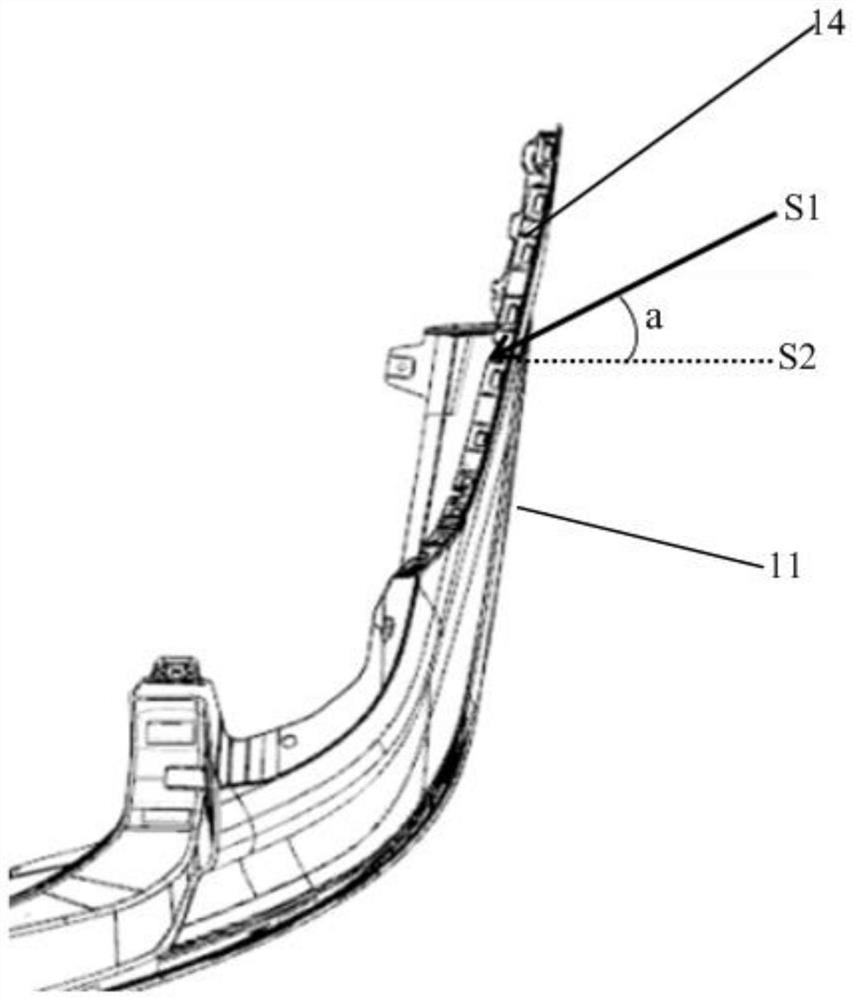

[0026] figure 2 It is a schematic diagram of the spraying angle when spraying the overlapping position of the bumper A surface area and the flanging surface in the specific embodiment.

[0027] In order to optimize the process fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com