A kind of sole release agent spraying equipment

A technology of spraying equipment and release agent, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of easy mixing of release agents, time-consuming and labor-intensive, etc., and achieve the effect of ensuring accurate interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

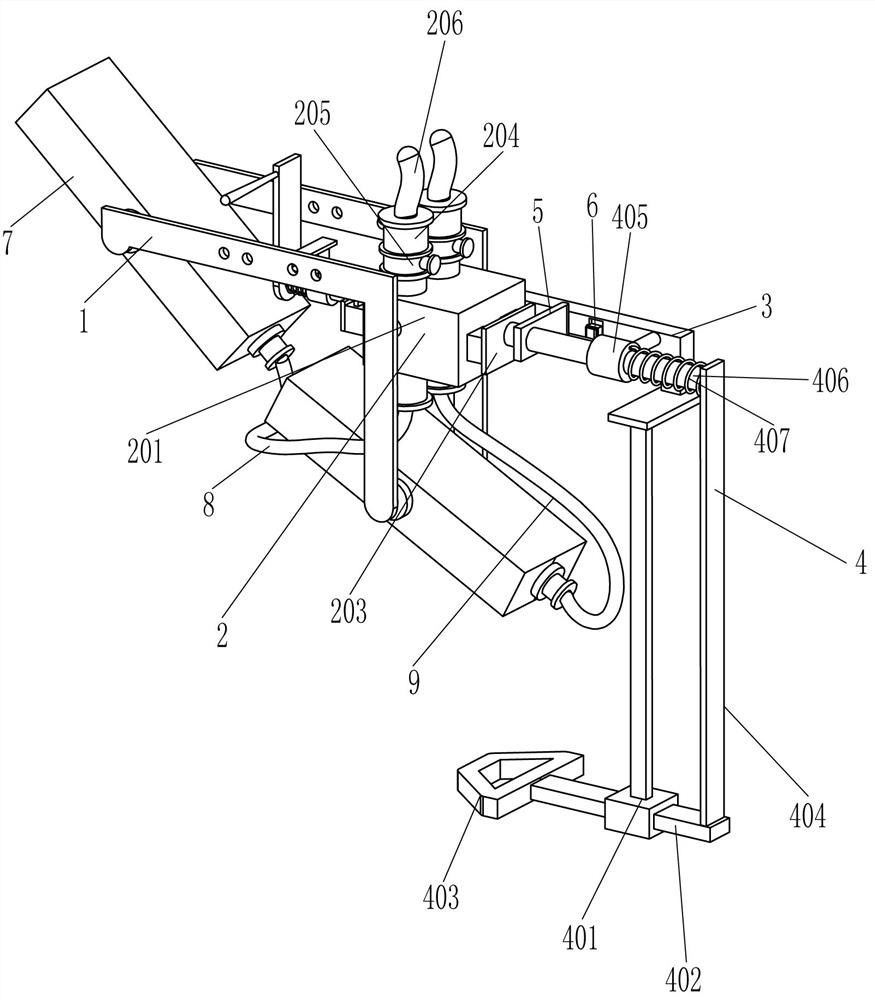

[0038] A kind of sole release agent spraying equipment, such as Figure 1-3 As shown, it includes an L-shaped mounting frame 1, a shut-off device 2, a mounting plate 3, a pulling device 4, a push plate 5, a control switch 6, a liquid sprayer 7, a first hose 8 and a second hose 9, and the shut-off device The front and rear sides of 2 are equipped with L-shaped mounting brackets 1, and the left and lower ends of the L-shaped mounting brackets 1 on both sides are connected to the liquid sprayer 7, and the right side of the left liquid sprayer 7 is connected to the bottom of the shut-off device 2 A first hose 8 is connected between them, a second hose 9 is connected between the right part of the right sprayer 7 and the bottom of the shut-off device 2, and a mounting plate 3 is provided on the right side of the rear L-shaped mounting frame 1, The middle part of the front side of the mounting plate 3 is provided with a control switch 6, and the right side of the shut-off device 2 is...

Embodiment 2

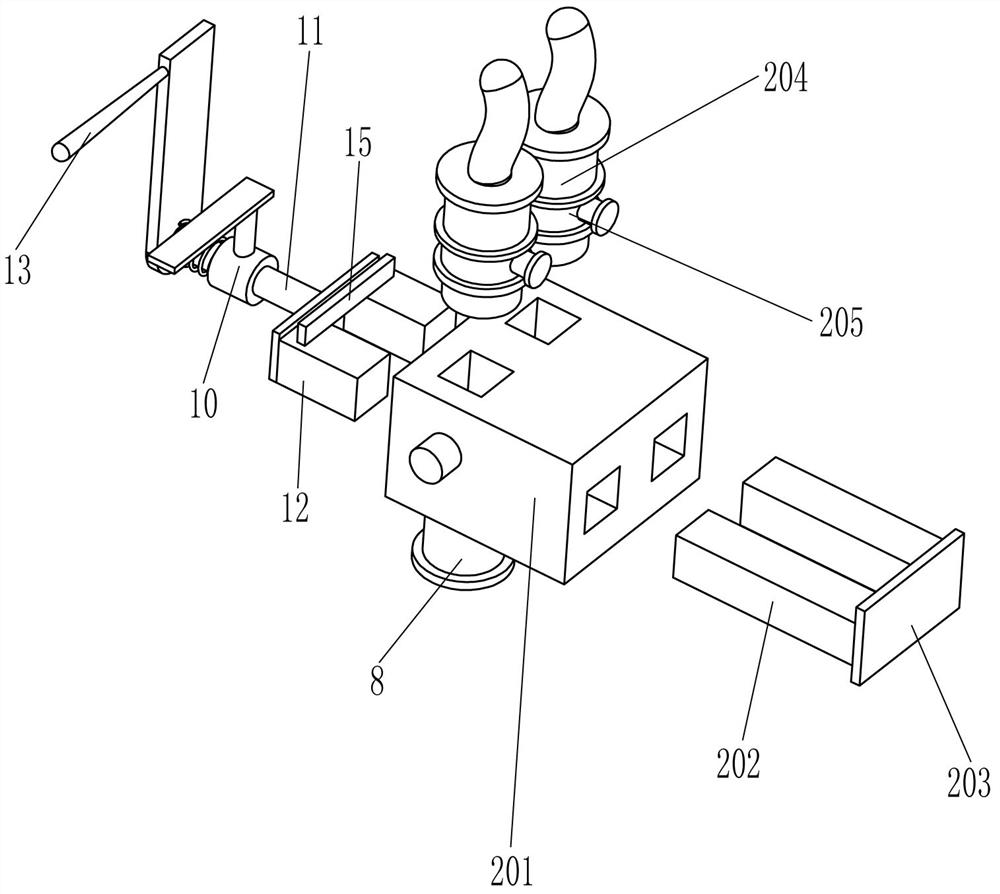

[0041] On the basis of Example 1, such as Figure 1-3 As shown, the intercepting device 2 includes a porous block 201, a retaining bar 202, a connecting plate 203, a liquid inlet pipe 204, a timing solenoid valve 205 and an infusion hose 206, and a porous block 201 is installed between the corners of the L-shaped mounting frame 1 on both sides. , the right wall and the top of the porous block 201 are provided with two connected square holes, the two square holes on the right side of the porous block 201 are slidingly provided with a retaining bar 202, the right end of the retaining bar 202 is provided with a connecting plate 203, the porous block Liquid inlet pipes 204 are arranged in the two square holes on the top of the 201, and a timing solenoid valve 205 is installed in the middle of the liquid inlet pipes 204, and an infusion hose 206 is provided at the upper ends of the two liquid inlet pipes 204.

[0042] When the pulling part of the pulling device 4 moves to the right...

Embodiment 3

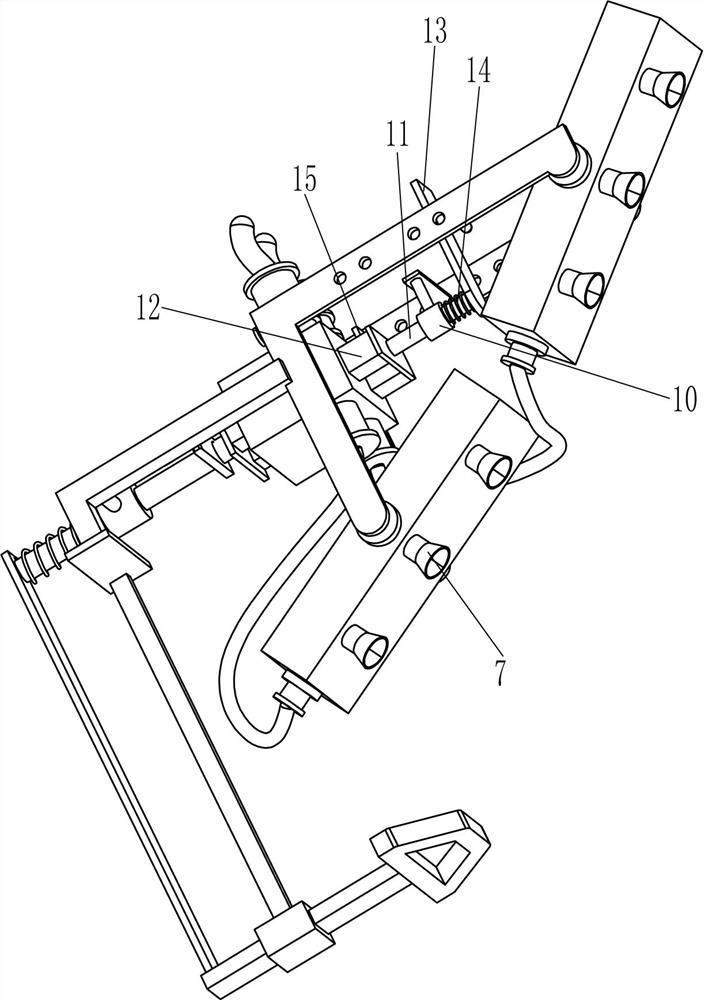

[0046] On the basis of Example 2, such as Figure 1-3 As shown, it also includes a third guide frame 10, a guide rod 11, an interceptor frame 12, a pull handle 13 and a second compression spring 14, and the two square holes on the left side of the porous block 201 are slidingly provided with an interceptor frame 12. A third guide frame 10 is installed on the rear side of the middle part of the side L-shaped mounting frame 1, and a guide rod 11 is slidably provided in the third guide frame 10. The left end of the rod 11 is provided with a pull handle 13, and a second compression spring 14 is connected between the right part of the pull handle 13 and the left part of the third guide frame 10, and the second compression spring 14 is wound on the guide rod 11.

[0047] When the mold needs to be cleaned, manually hold the pull handle 13 and push the guide rod 11 to the right, and the interceptor frame 12 then enters the multi-empty block to intercept the release agent to prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com