Patents

Literature

10279 results about "Rubber ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

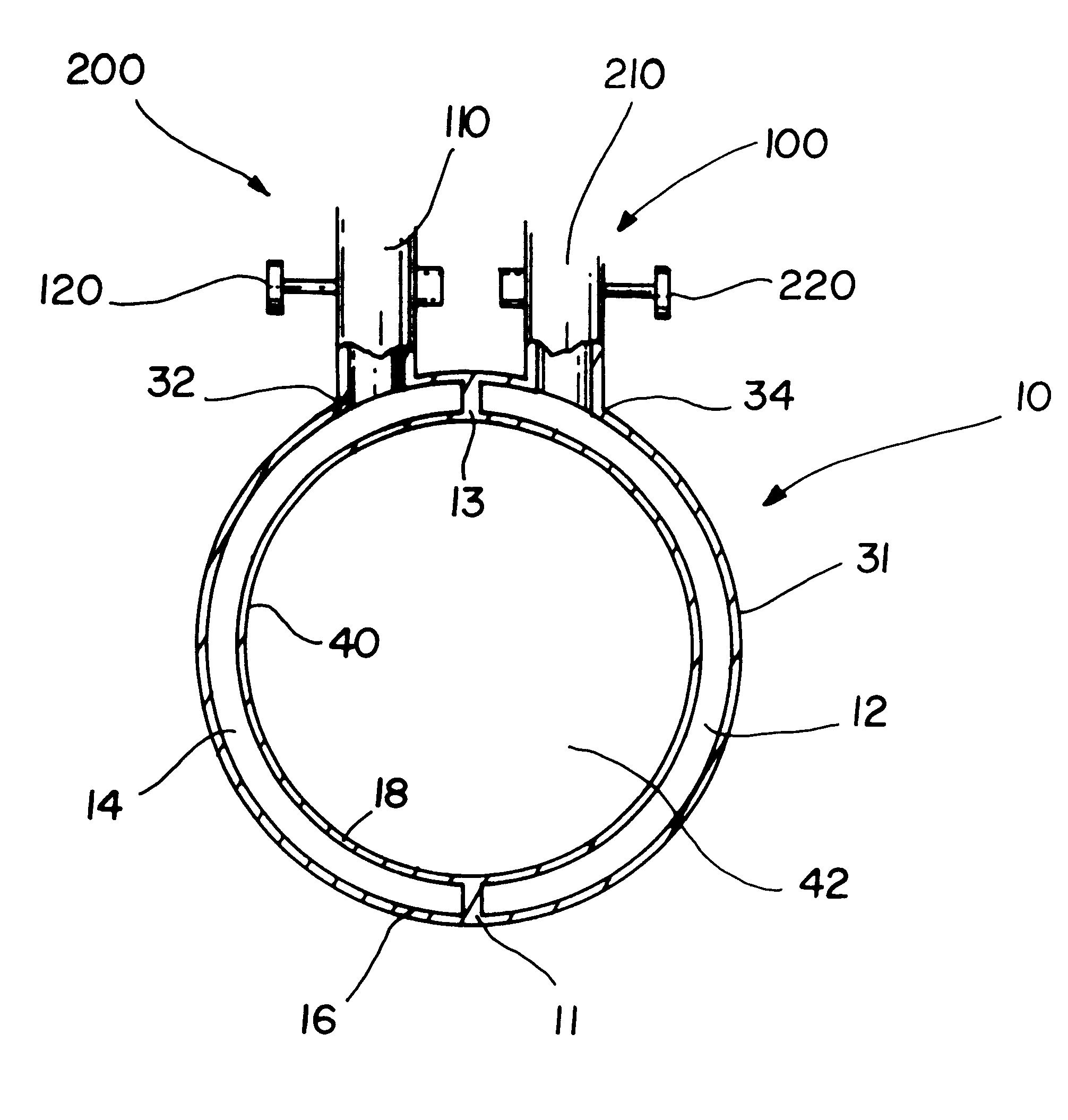

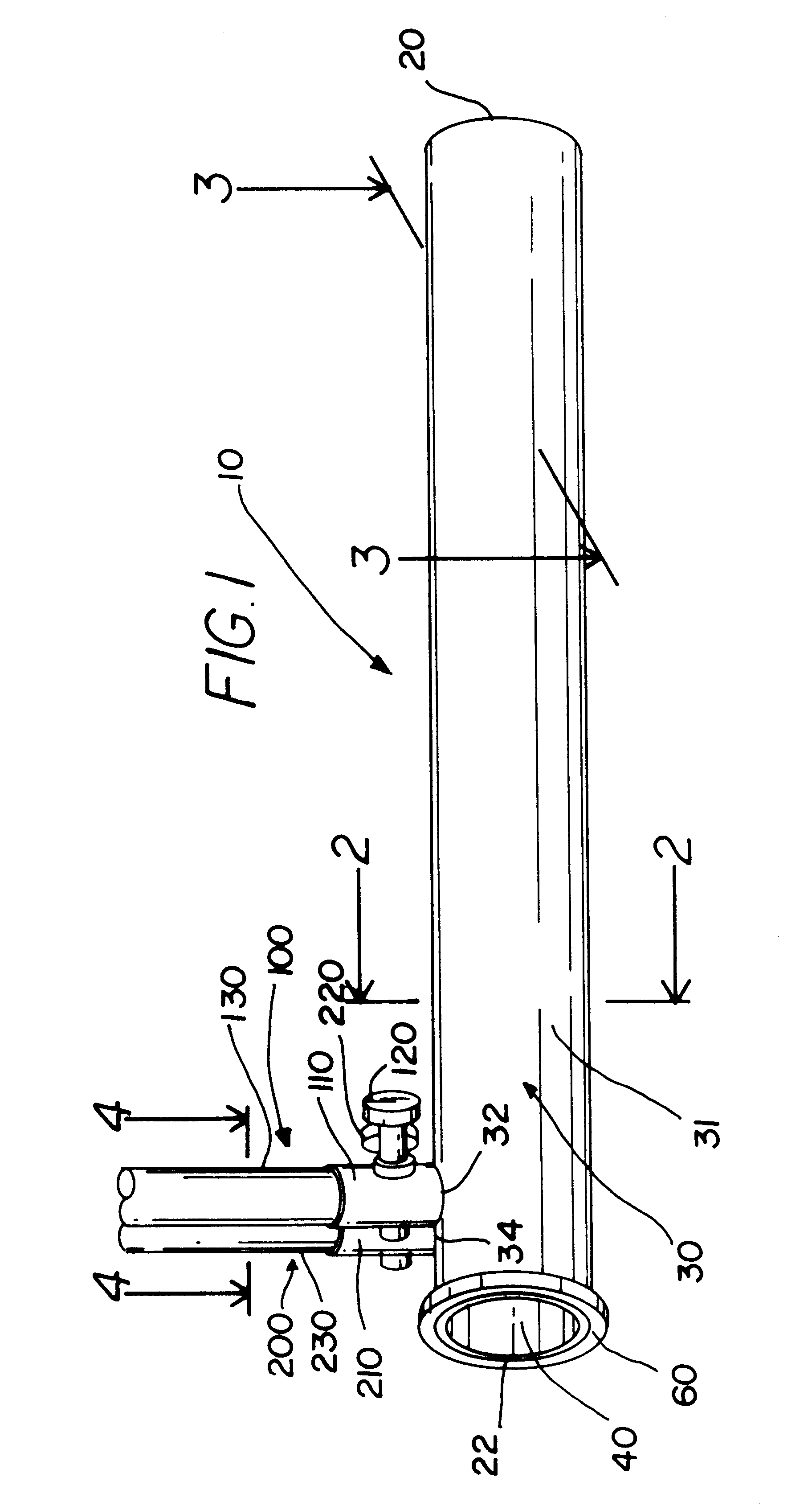

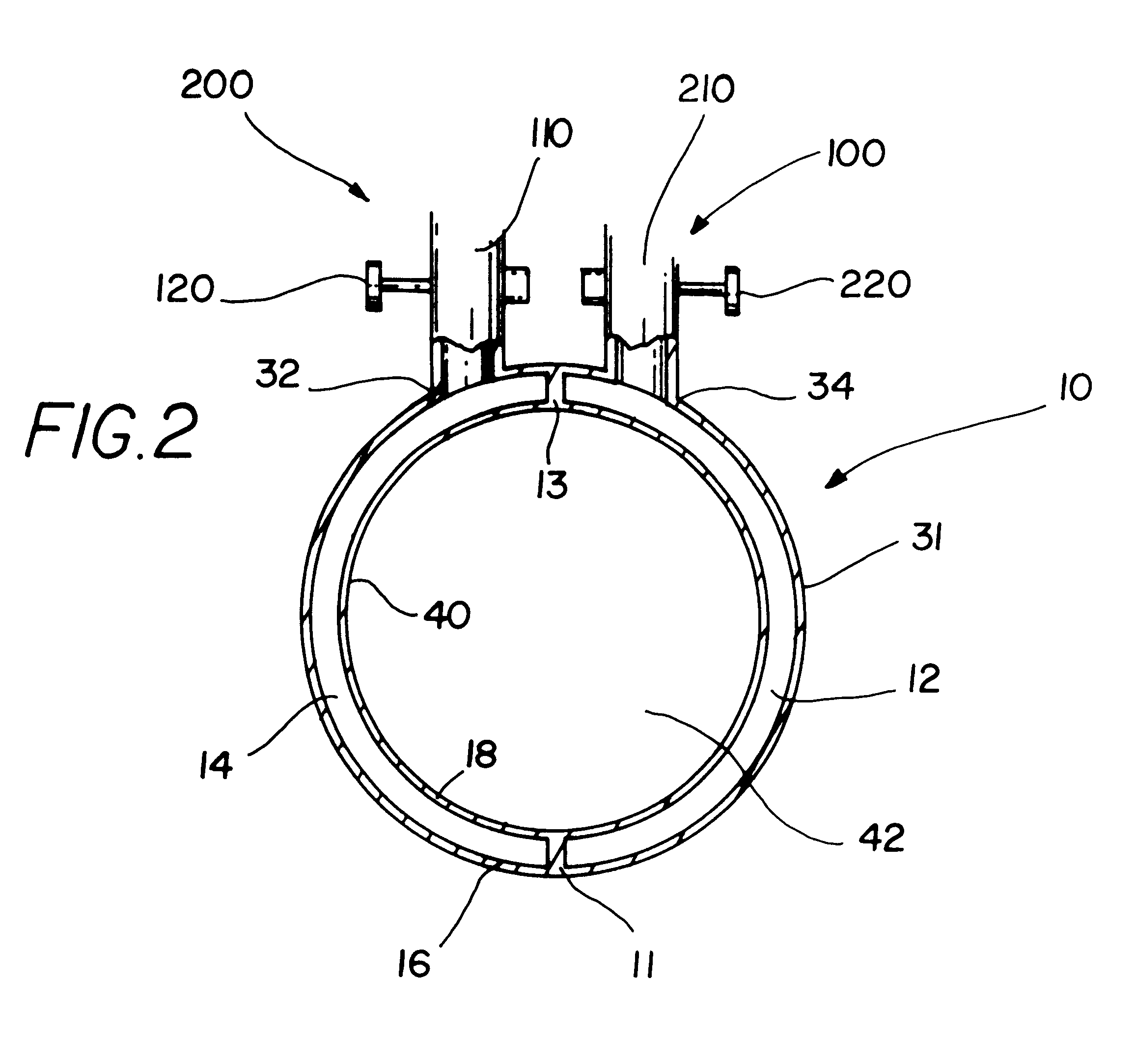

Automated laparoscopic lens cleaner

An apparatus and method for cleaning the objective lens of a laparoscope, endoscope, or coeloscope during surgery and also removing the solution and debris during and after the cleaning. The result is obtained by using a rigid hollow split sheath for the scope. The split sheath has two separate channels. One channel is for irrigation and the cleaning fluid flows through this channel to be directed onto the lens. The other channel is for suction to remove the solution and debris during and after the cleaning. Control buttons located at the operator's end activate the irrigation and suction functions. The control buttons for irrigation and suction are fabricated into an existing valve type device which can regulate either of these functions. In addition, two ports, one for irrigation and one for suction emerge from the operator's end to connect to the appropriate tubing for irrigation and suction. A rubber ring device screws down at the operator's end allowing the surgeon to secure the sheath to the scope and prevent any leakage of the standard carbon dioxide gas used to distend the abdomen for operative laparoscopy in the patient.

Owner:KATO DANIEL T

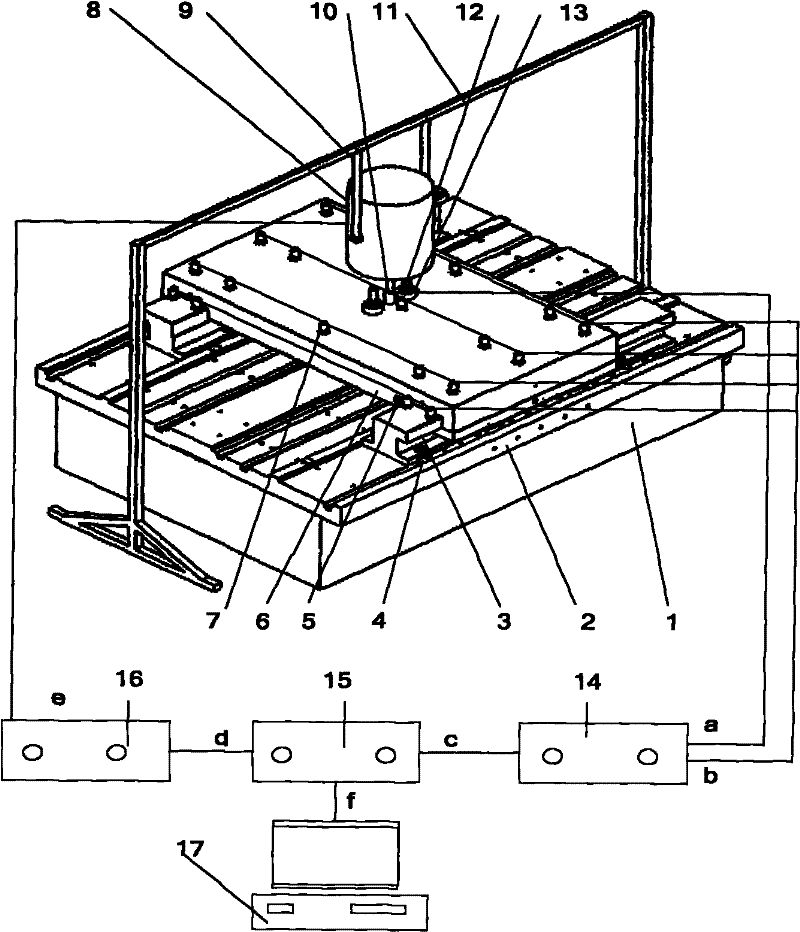

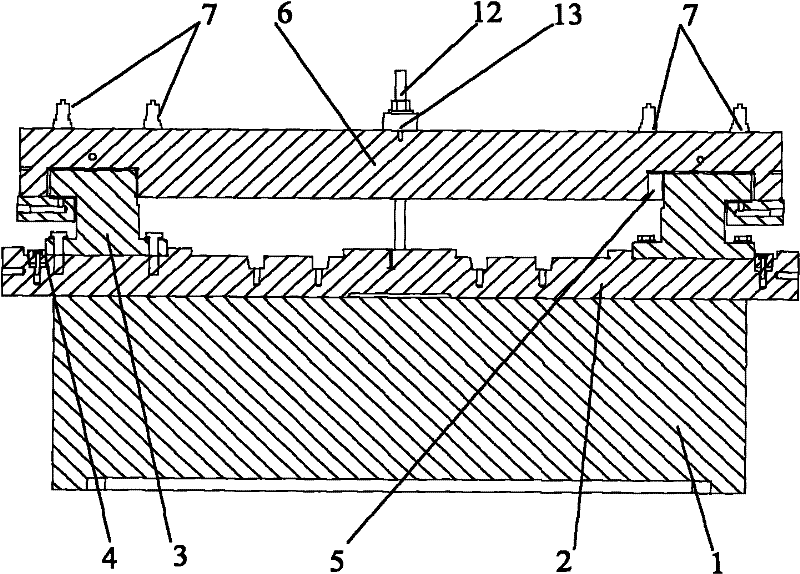

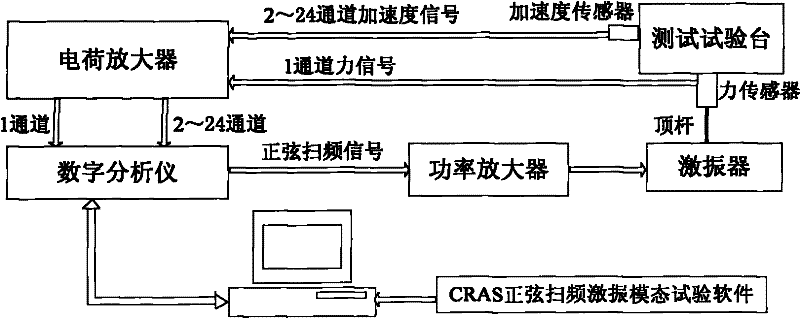

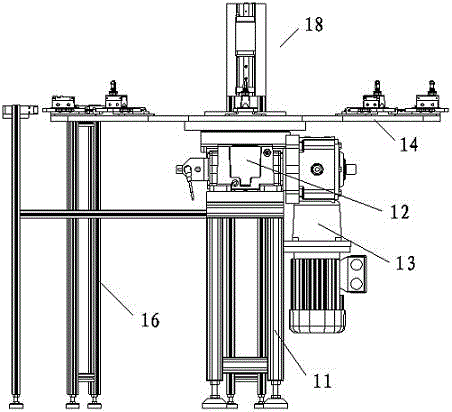

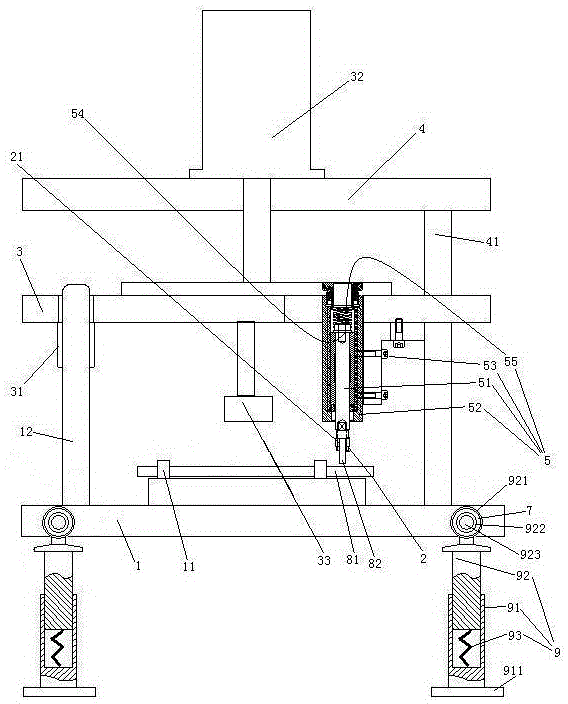

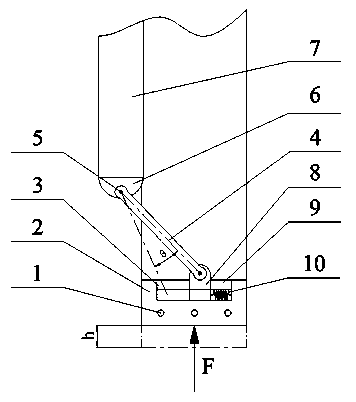

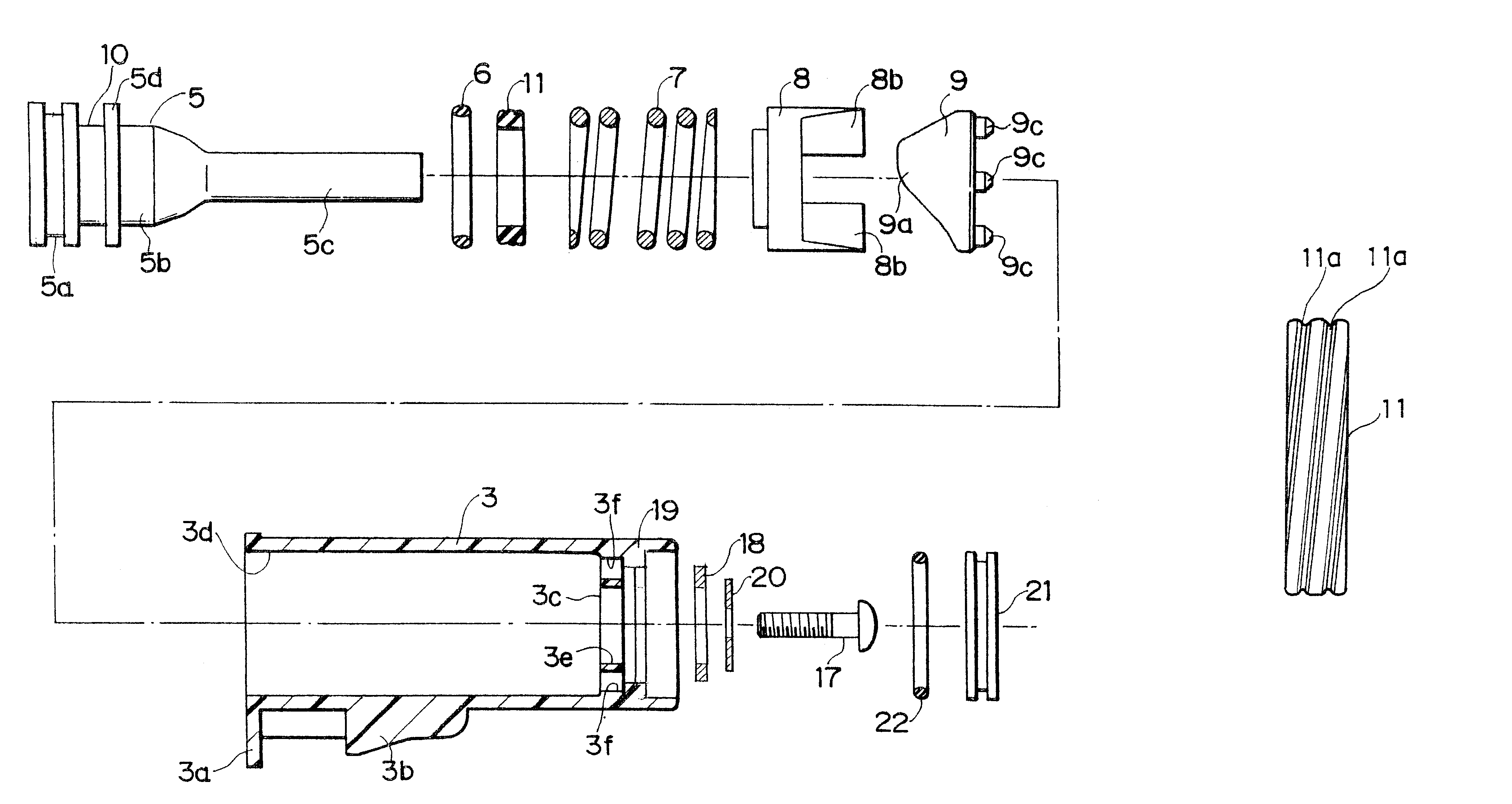

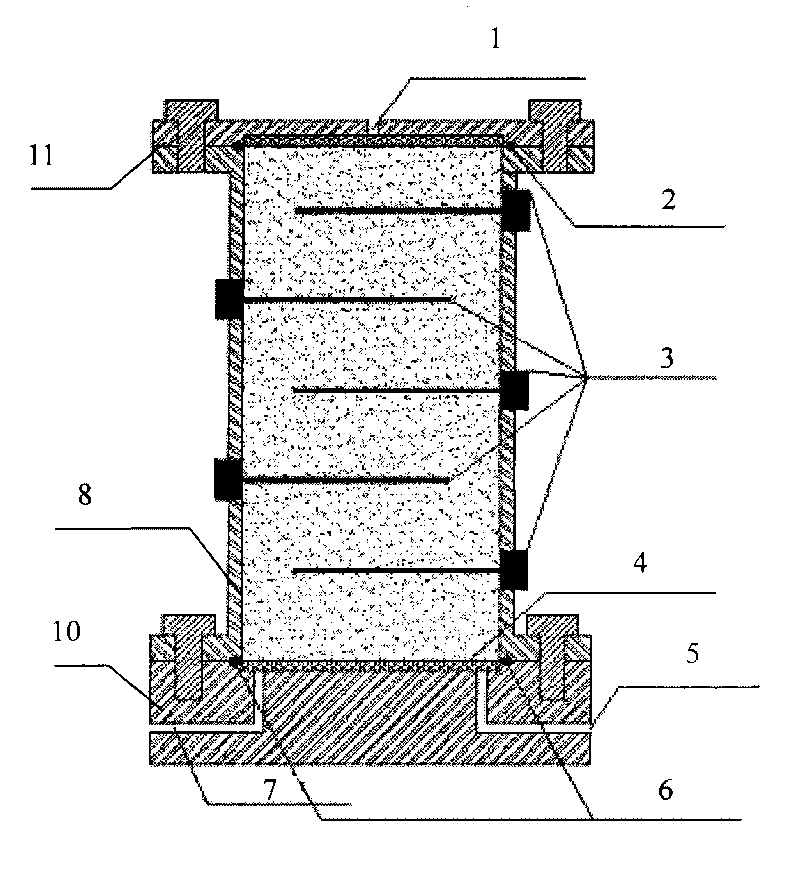

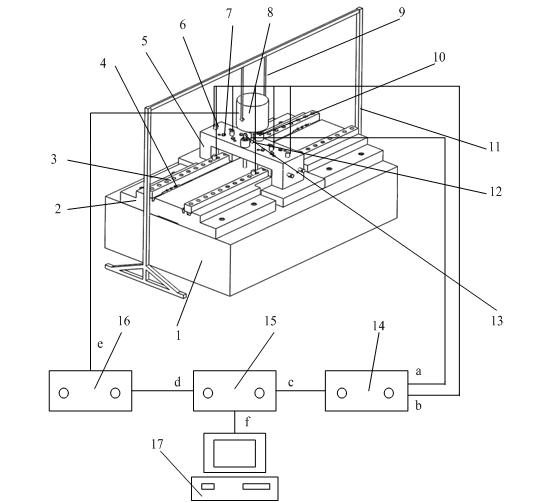

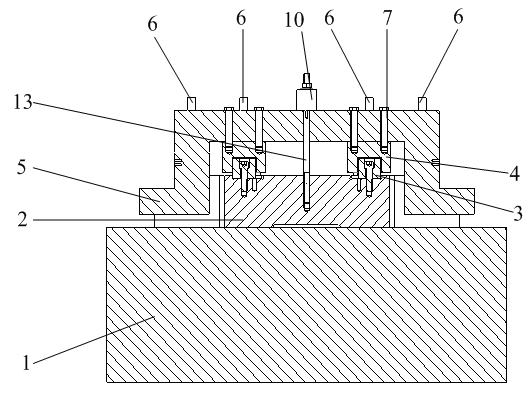

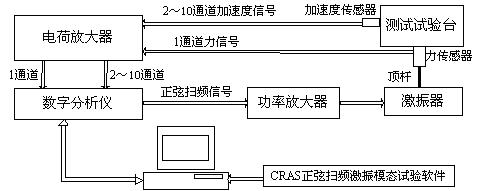

Dynamic characteristic parameter test device and method of sliding guide rail junction surface

InactiveCN102183363AAccurate acquisitionImprove accuracyMachine part testingVibration testingData acquisitionEngineering

The invention relates to a dynamic characteristic parameter test device of a sliding guide rail junction surface, which can be simplified into a single degree of freedom system. The device comprises a base, an installation platform, a fixed guide rail, a wedge-shaped block, an inlaid strip, a sliding block, a plurality of piezoelectric type acceleration sensors, a vibration exciter, an elastic rope, an impedance head, a stand, a normal force applying bolt, a rubber ring, a charge amplifier, a data acquisition unit, a power amplifier and an electronic computer. Compared with the prior art, thedynamic characteristic parameter test device has the advantages that: the structure is compact, the test principle is distinct, dynamic characteristic parameters of the junction surface under different load states can be measured by adjusting the pretightening force of a normal force applying bolt, the vibration exciting force direction passes through the gravity of the sliding block during measurement so that vibration signals of the sliding block and the base can be measured simultaneously, the influence of the vibration signals of the base is eliminated when a frequency response function of a system is calculated, and the characteristics of high efficiency, high stability and high precision are achieved.

Owner:NANJING UNIV OF SCI & TECH

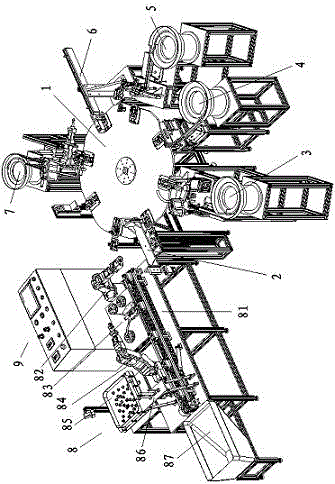

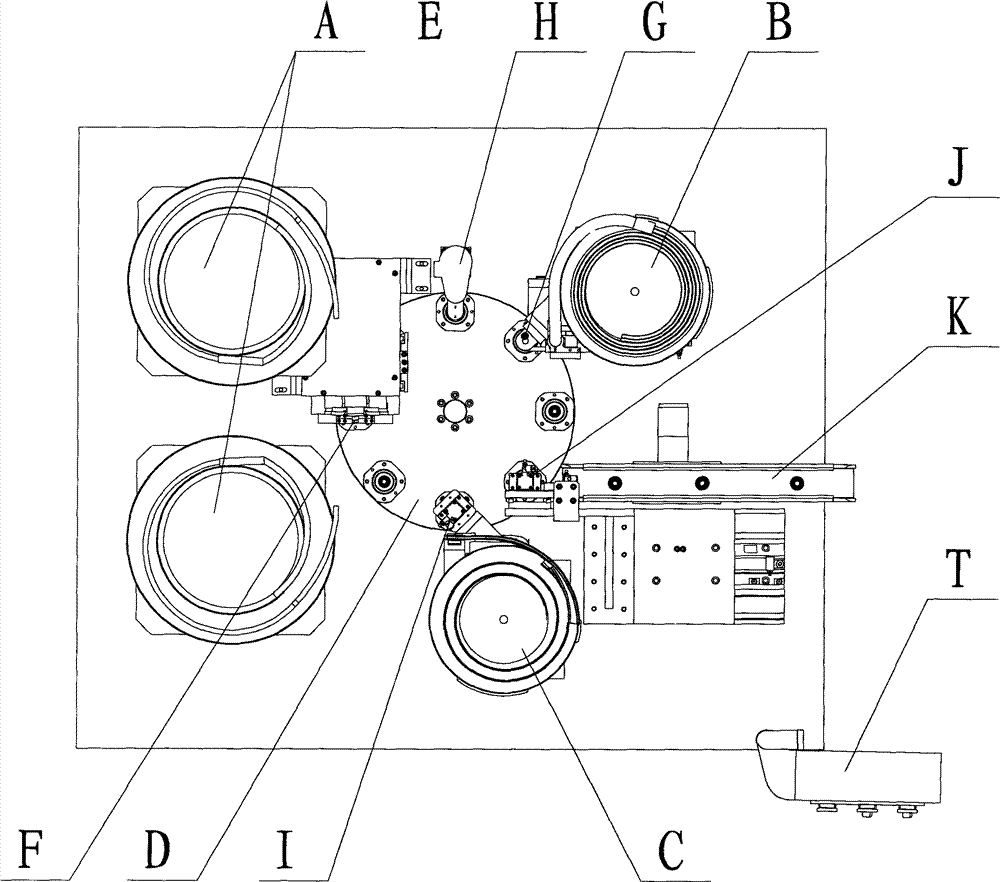

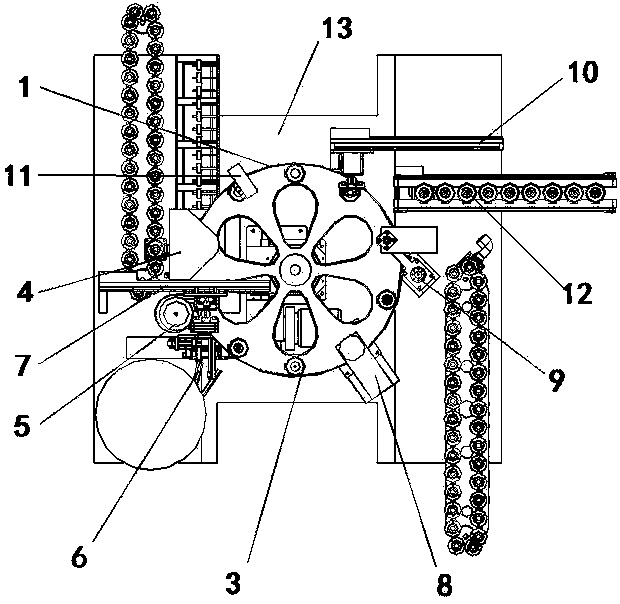

Stroke switch assembly machine

InactiveCN105990053ANeatly assembledLabor savingElectric switchesMetal working apparatusRubber ringAssembly line

The invention discloses a stroke switch assembly machine, which comprises an eight-working position turntable mechanism, a bottom charging manipulator, a waterproof rubber ring charging mechanism, a clasp charging mechanism, a rubber ring protective cover charging mechanism, a contact charging mechanism, a rivet charging mechanism, a labeling assembly line and a main electric control cabinet, wherein the bottom charging manipulator, the waterproof rubber ring charging mechanism, the clasp charging mechanism, the rubber ring protective cover charging mechanism, the contact charging mechanism and the rivet charging mechanism are annularly located around the eight-working position turntable mechanism; the labeling assembly line is arranged at the left rear side of the eight-working position turntable mechanism; and the rear side of the eight-working position turntable mechanism is provided with the main electric control cabinet. Through the above mode, the manual labor can be replaced, assembly of the stroke switches can be completed automatically, high efficiently and tidily, the labor is saved and the production cost is reduced.

Owner:乐清市华田电力科技有限公司

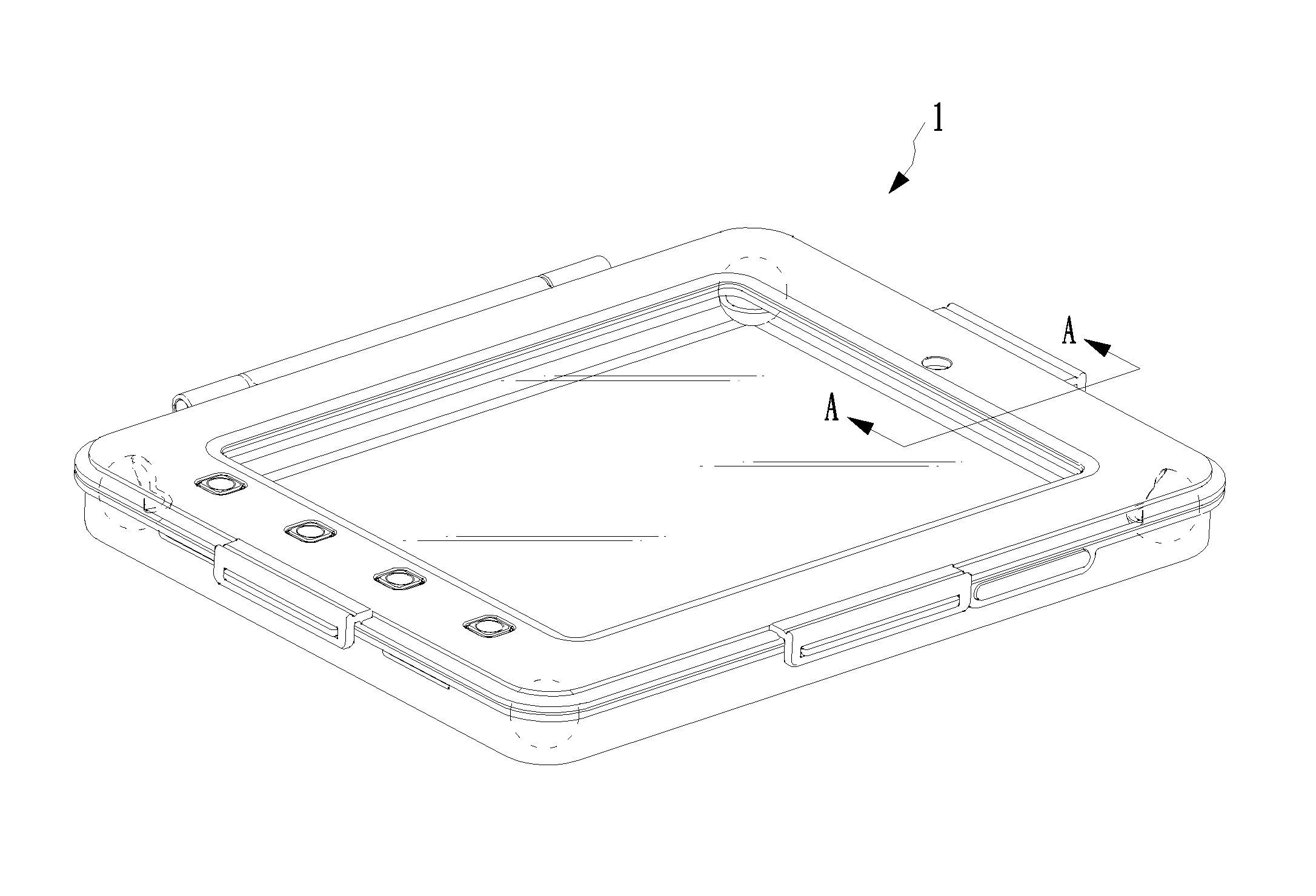

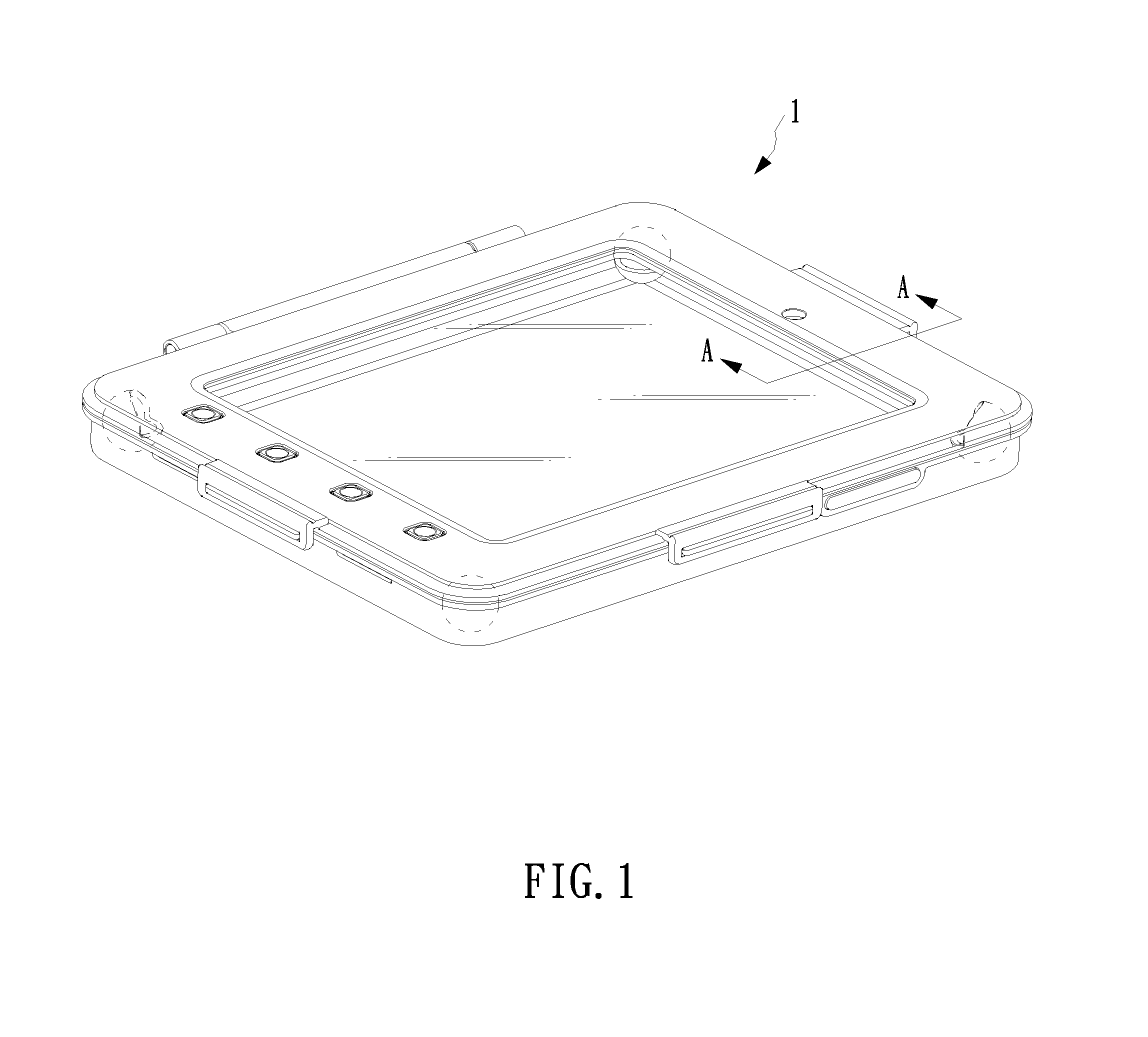

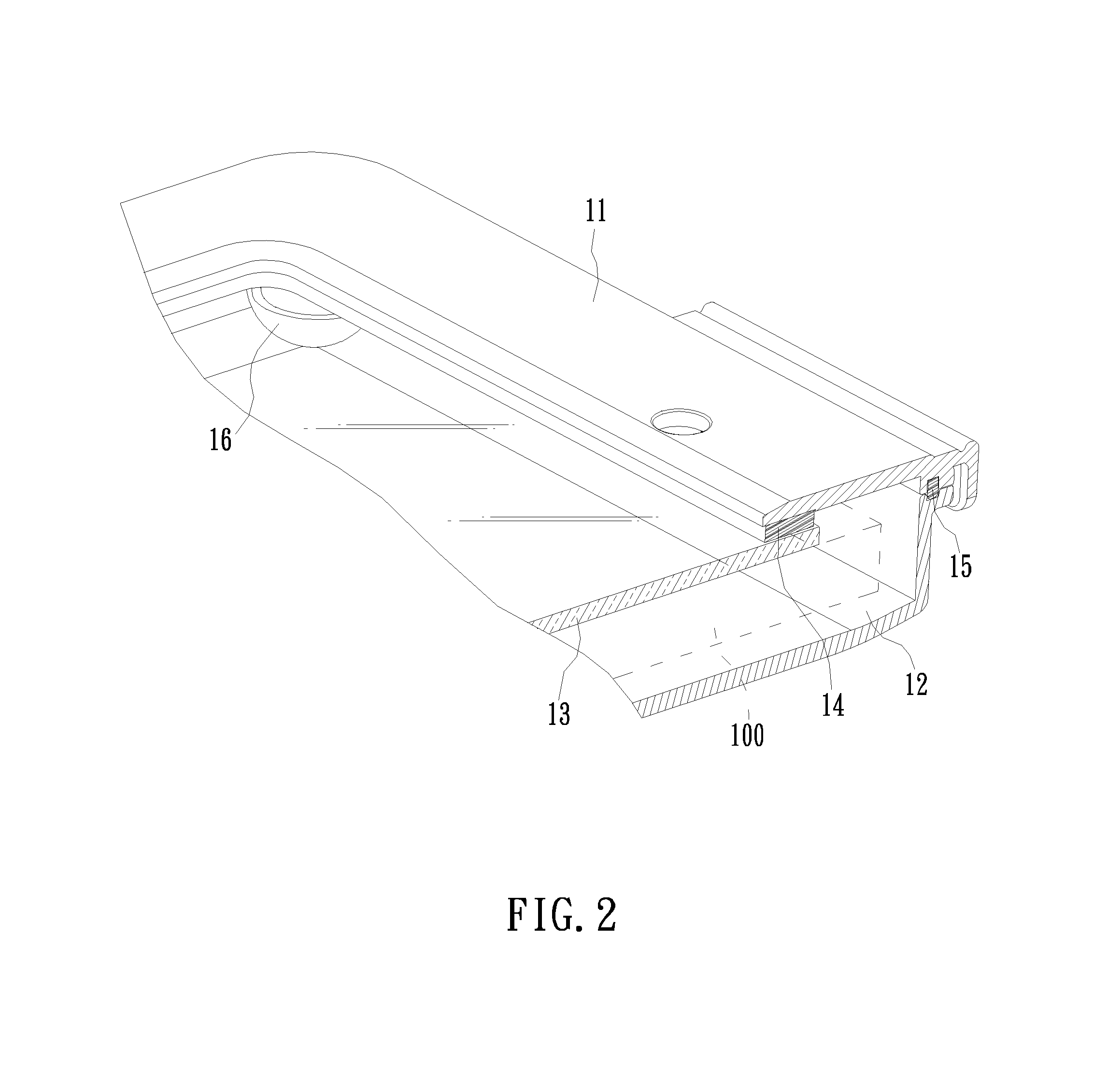

Waterproof and shockproof cover for a PAD computer

A waterproof and shockproof cover for a PAD computer is disclosed. The cover comprises an upper housing, a base housing, a glass, a first rubber ring, a second rubber ring and four shockproof elements. The base housing is corresponding to the upper housing, wherein the upper housing comprises a first connection and the base housing comprises a second connection corresponding to the first connection for fastening with each other. The upper housing comprises a viewing window hole and a first groove formed around the rim of the viewing hole, and the first rubber ring is disposed within the first groove. The glass covers the viewing window hole and the first rubber ring. The four shockproof elements disposed respectively at four corners of a rectangular accommodation space of the base housing for bearing the PAD computer.

Owner:FIRST INTERNATIONAL COMPUTER

Welding device for side sealing plate barb of switch cabinet

InactiveCN105057865AImprove connection strengthImprove quality consistencyResistance electrode holdersWelding/cutting auxillary devicesRubber ringElectricity

The invention relates to the technical field of manufacturing of low-voltage drawer-type switch cabinets and discloses a welding device for a side sealing plate barb of a switch cabinet. The welding device comprises an electric welding machine, a spot welding gun, supporting pillars, a lower base, an electric conduction block, a suspending plate and an upper seat. The electric welding machine is provided with two electrodes, and the spot welding gun is connected with one of the electrodes. Clamps are arranged on the lower seat, and the suspending plate is connected with the upper seat through an air cylinder. The electric conduction block is connected to the suspending plate. The electric conduction block is electrically connected with the other electrode. The spot welding gun is connected to the suspending plate and is provided with a barb fixing structure. The supporting pillars comprise damper springs, upper sections and lower sections, wherein the upper sections and the lower sections are sleeved together. The upper ends of the upper sections are provided with connecting rings, inner rings are arranged in the connecting rings in a penetrating mode, the inner rings and the connecting rings are connected together through rubber rings, and connecting pins connected to the lower seat are arranged in the inner rings in a penetrating mode. The welding device has the advantages that a welded part does not need to be fixed manually, and the vibration isolation effect is good; the problems that much effort is cost in welding and the welding quality is poor due to welding by manually fixing the welded part are solved.

Owner:张进

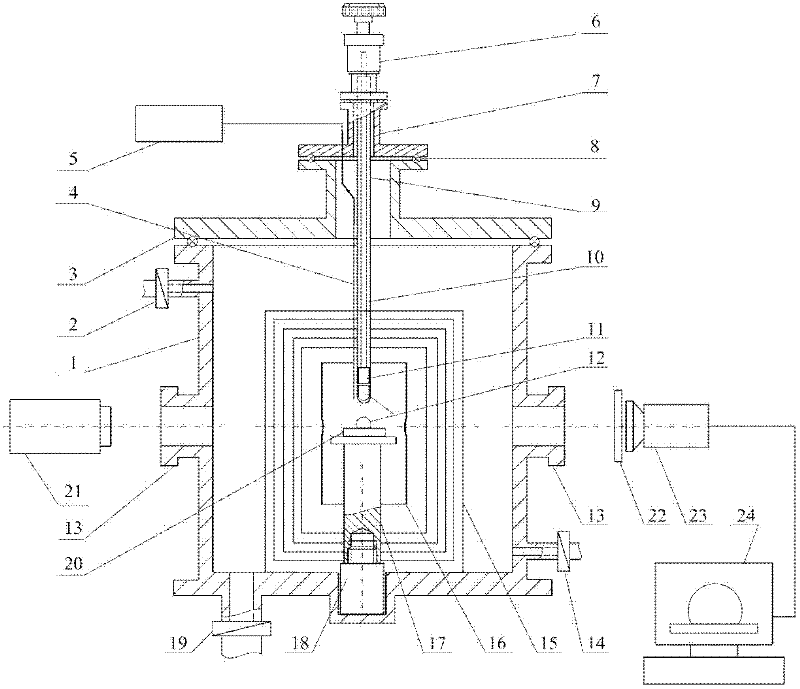

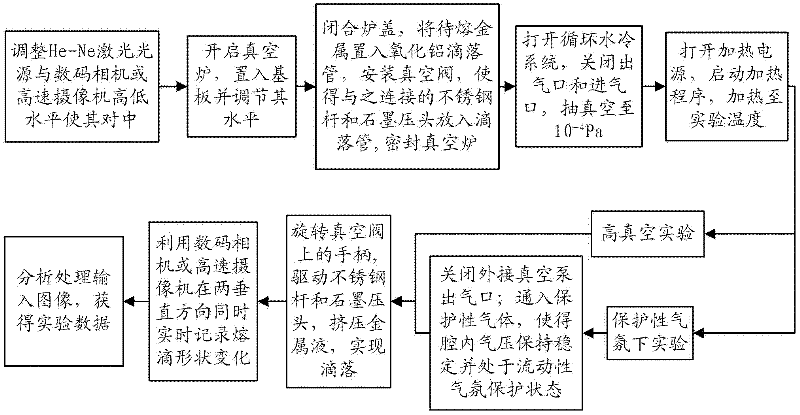

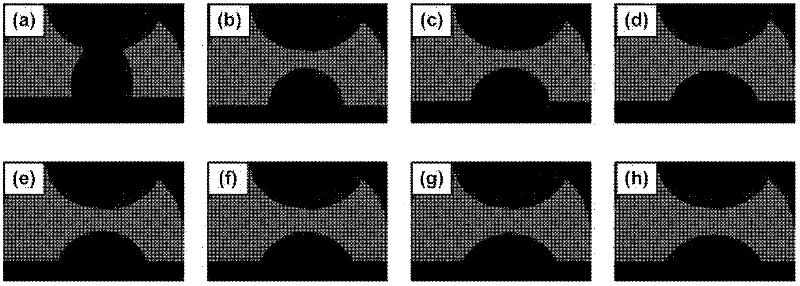

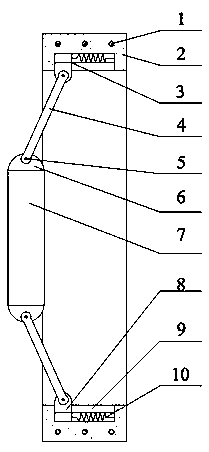

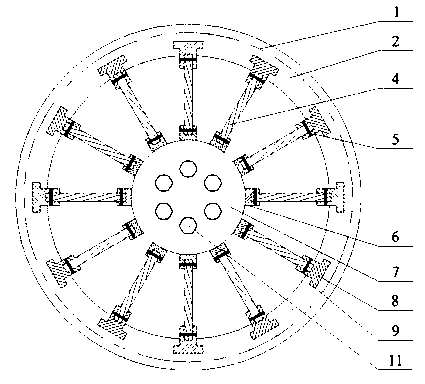

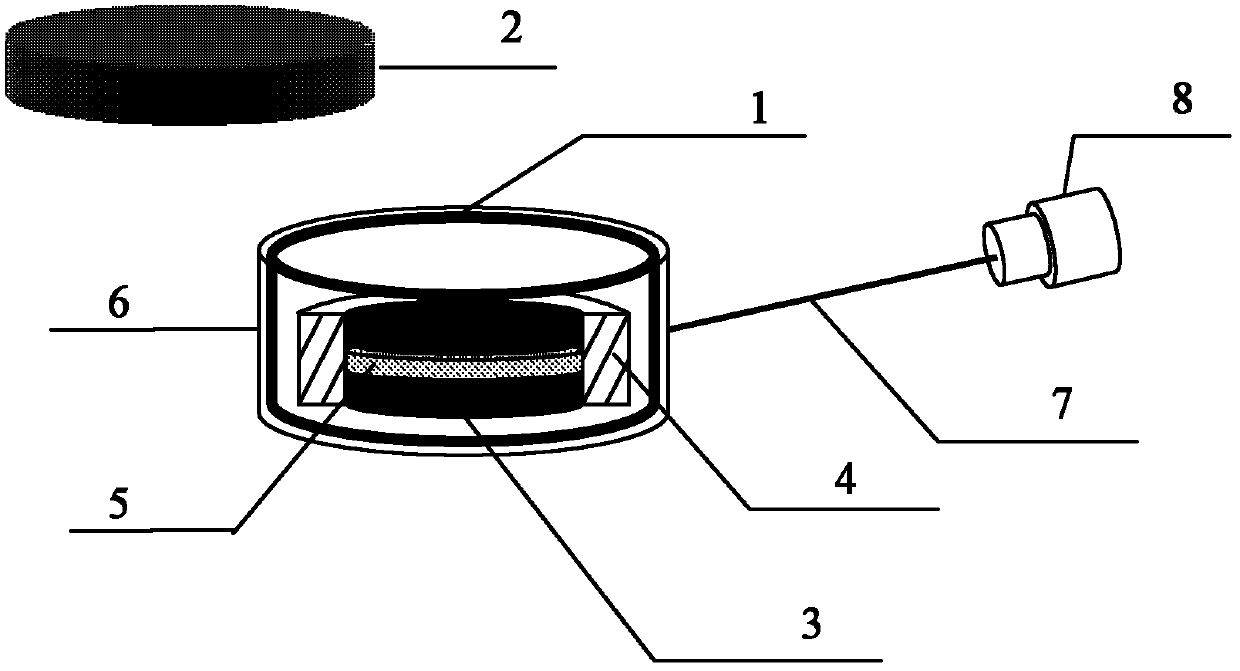

Apparatus and method for determining high temperature wettability

InactiveCN102353620ARealize separate heatingPrevent oxidationSurface/boundary effectFurnace typesRubber ringEngineering

Owner:JILIN UNIV

Side-turning resistant elastic wheel

ActiveCN103287201AReduce hysteresisSimple structureHigh resiliency wheelsRubber ringTransverse force

The invention discloses a side-turning resistant elastic wheel and belongs to a wheel structure. The wheel comprises a wheel hub (7), a wheel rubber ring and spoke rods (4), wherein grooves (6) are distributed on the outer side of the wheel hub (7), T-shaped sliding grooves (9) are distributed on the inner side of the wheel rubber ring, a T-shaped sliding block (8) is installed at one end, close to the wheel hub (7), inside each T-shaped sliding groove (9), a reset spring (10) is installed between one end, away from the wheel hub (7), of each T-shaped sliding grove (9) and each T-shaped sliding block (8), one end of each spoke rod (4) is transversely hinged to each groove (6), the other end of each spoke rod (4) is transversely hinged to each T-shaped sliding block (8), and a connecting rod can rotate in a plane perpendicular to a wheel plane about a hinge point and can not rotate in a tangent direction of the wheel. The side-turning resistant elastic wheel is simple in structure, low in cost, few in phenomenon of slow moving of the wheel when driving and braking are conducted and capable of delaying a side-turning tendency when a vehicle makes a turn and transverse force or transverse acceleration is imposed on the wheel, and has a certain side-turning resistant effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

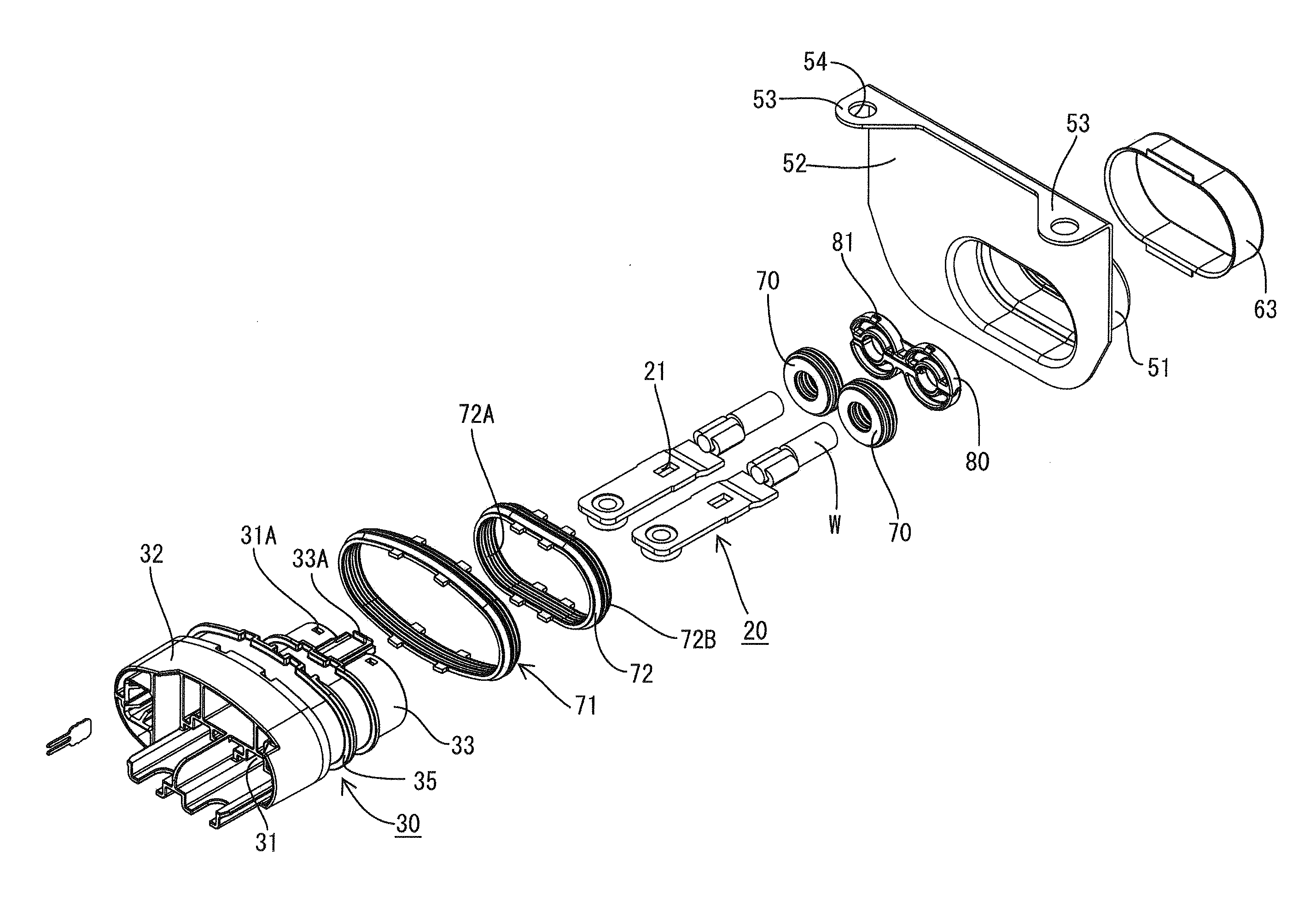

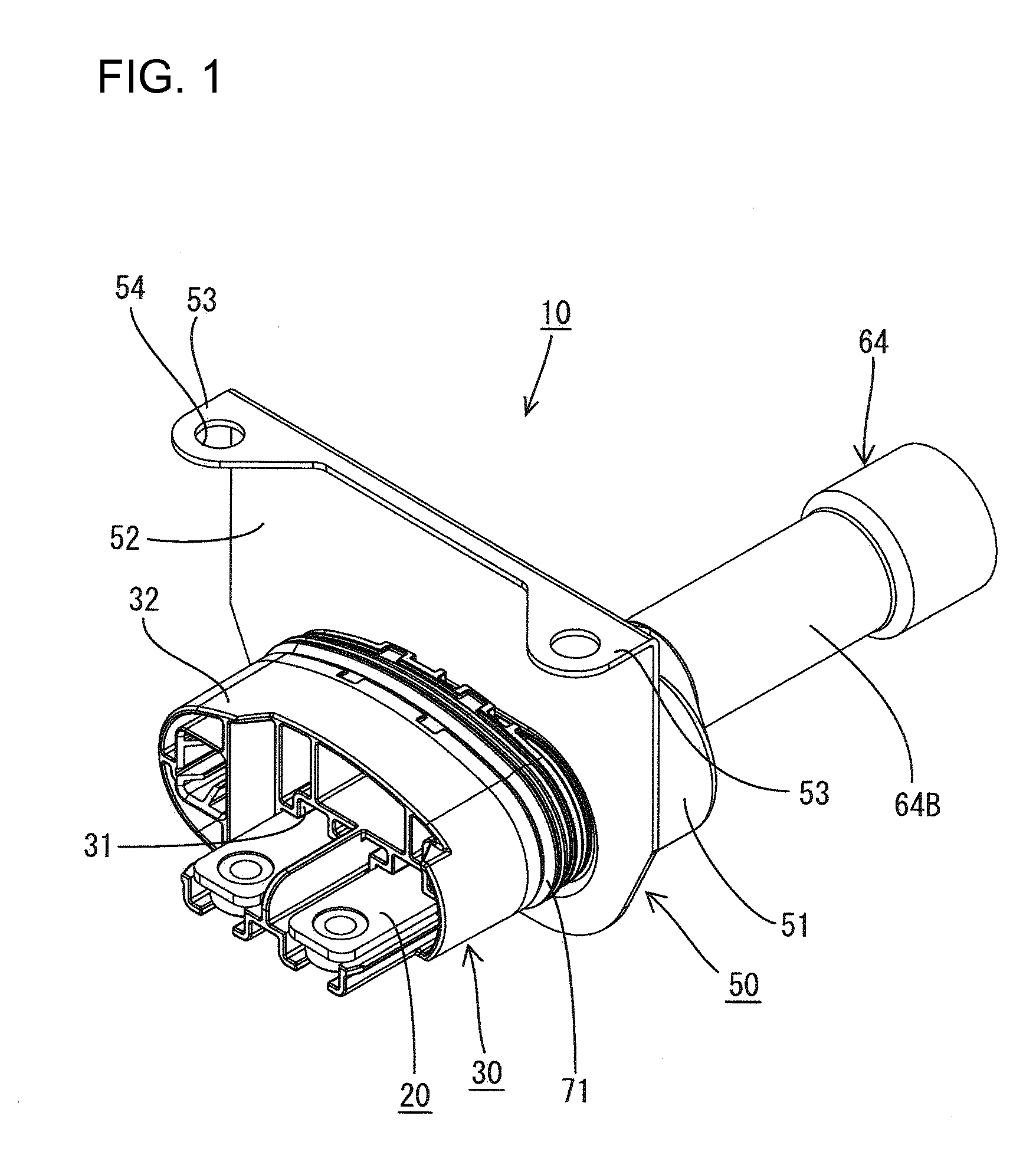

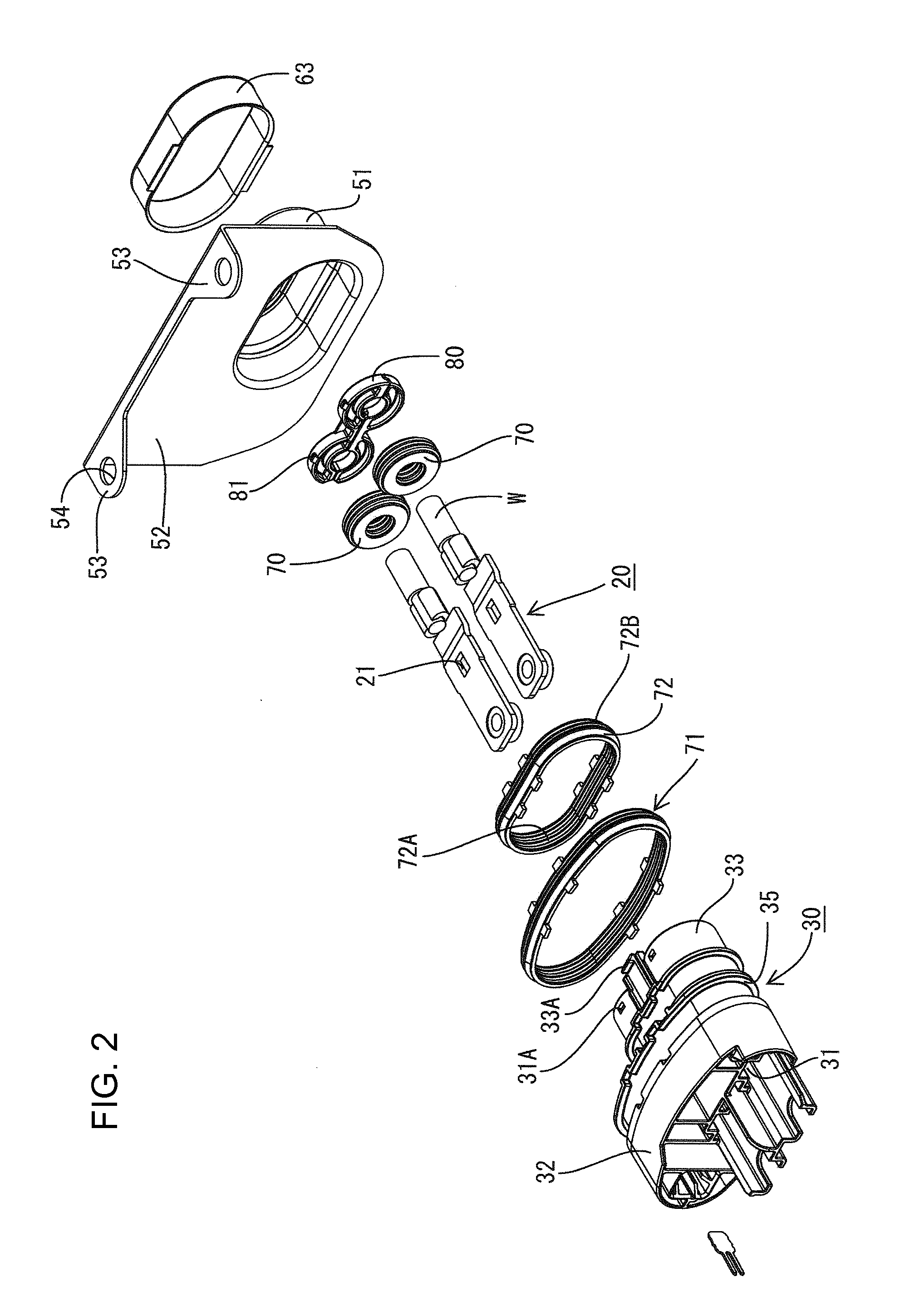

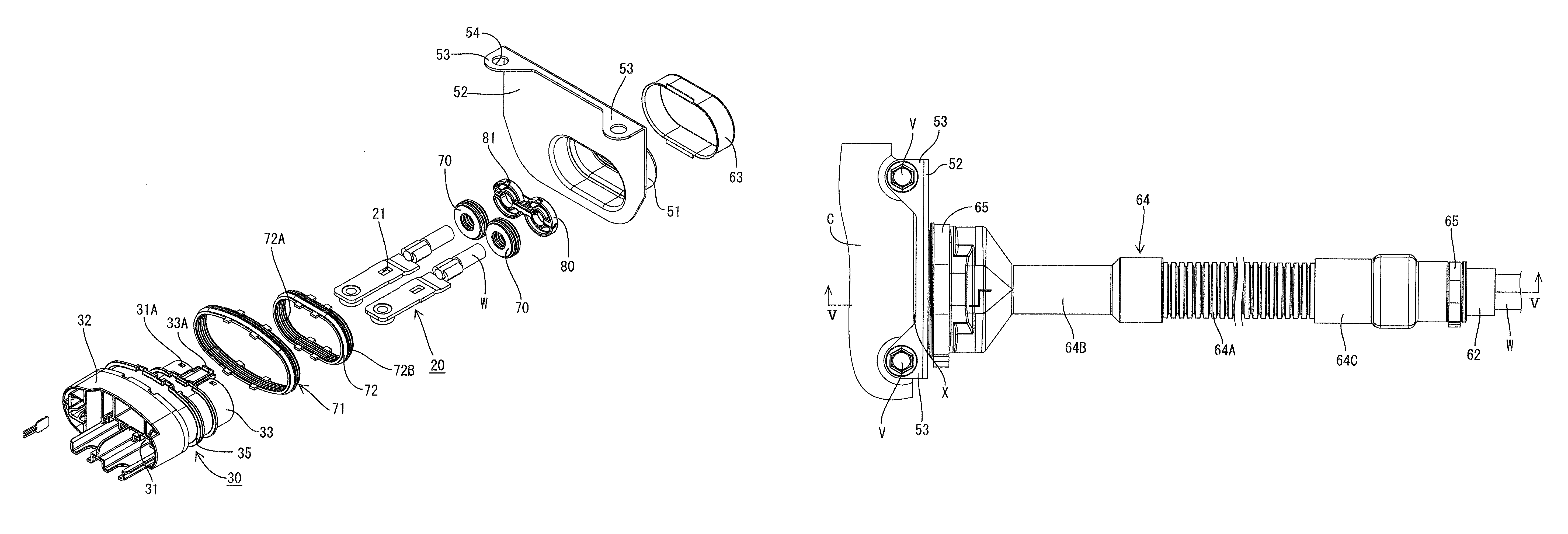

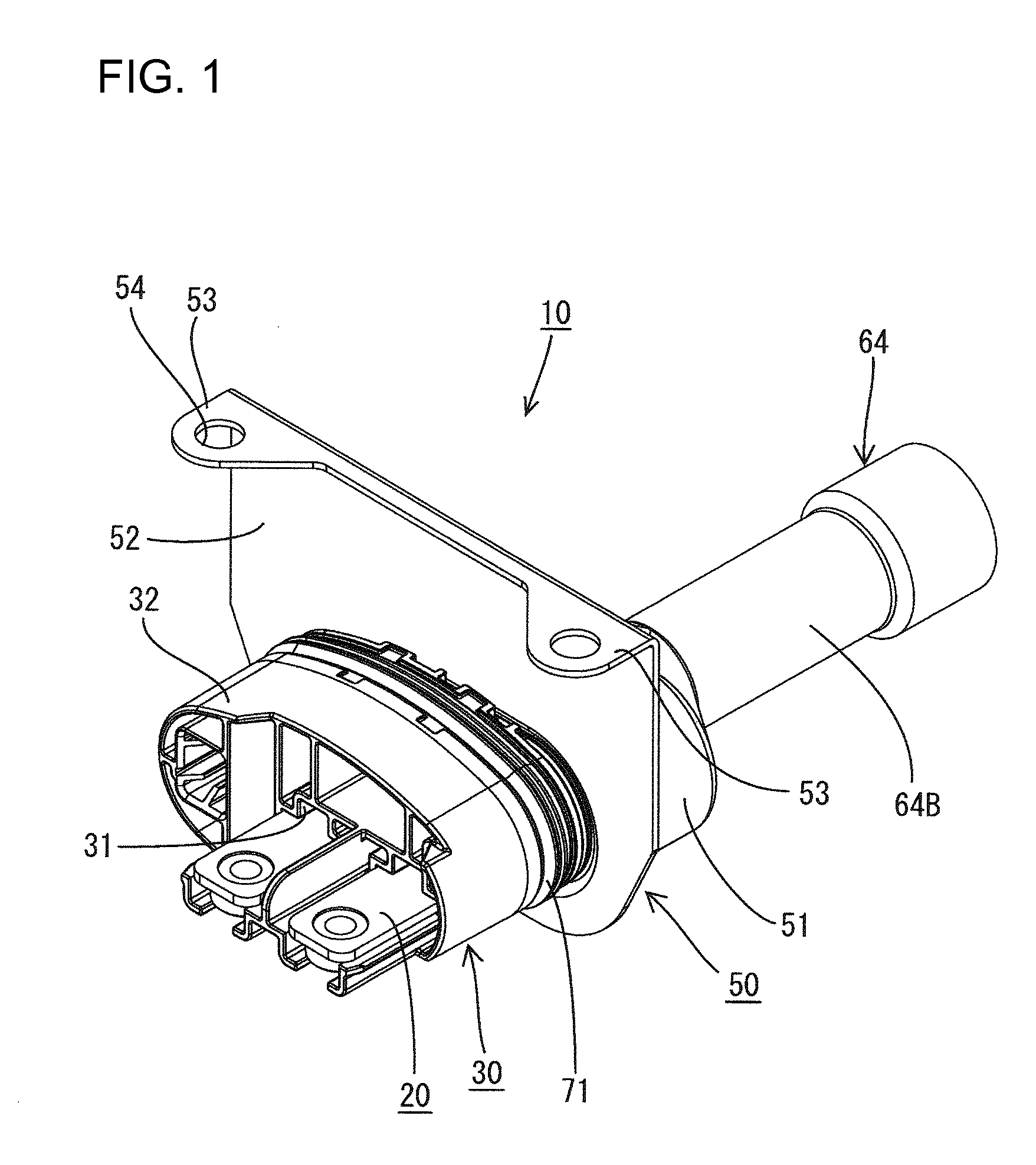

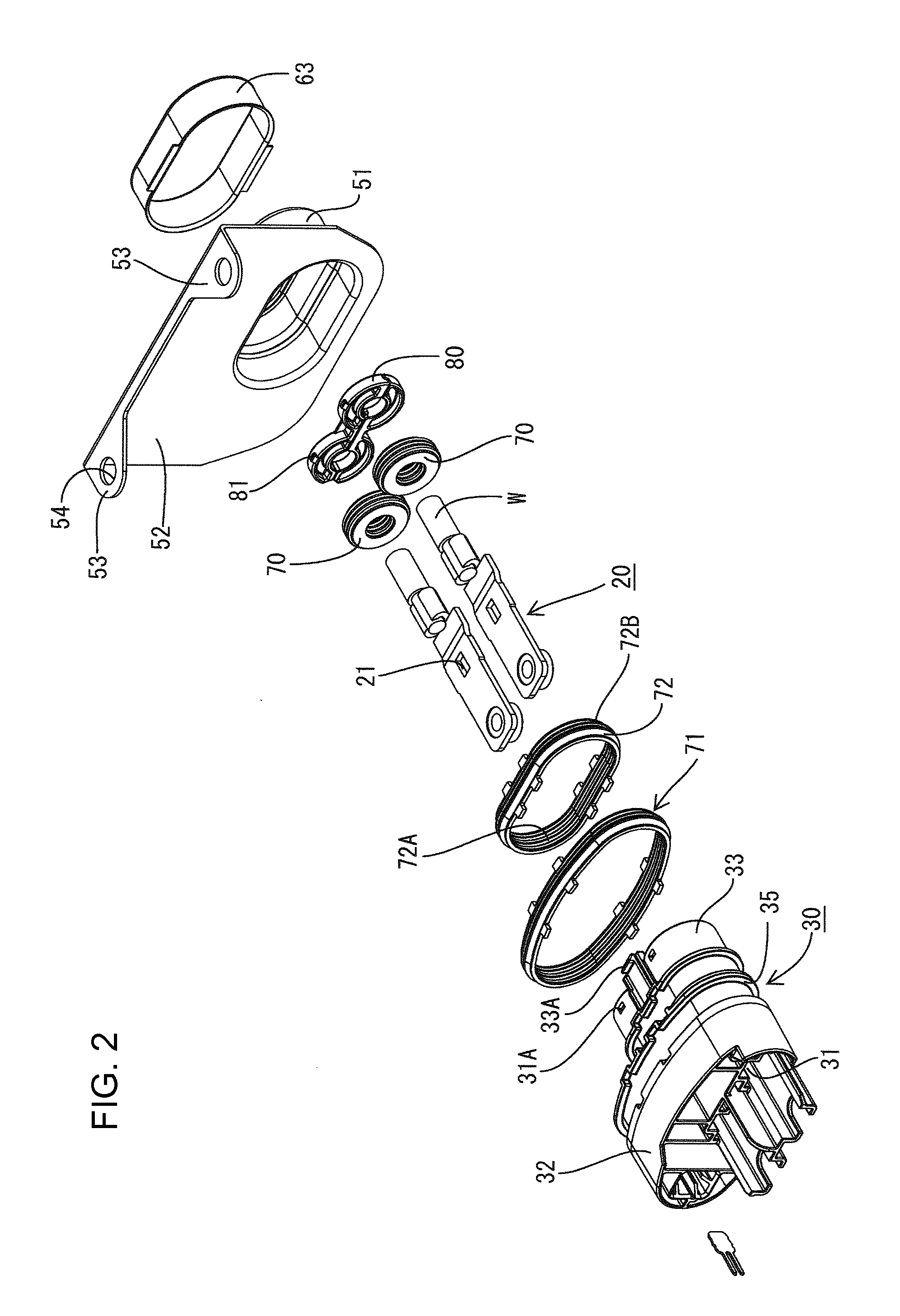

Shield connector

InactiveUS20120270444A1High strengthEasy to transformElectrically conductive connectionsCoupling device detailsRubber ringElectrical conductor

A shield connector (10) is mounted in a metal case (C) that contains a device to be mounted in a vehicle. The shield connector (10) has a housing (30) in which terminal fittings (20) connected to ends of wires (W) are accommodated and from which the wires (W) are pulled out. Rubber plugs (70) are provided for sealing between the inner peripheries of cavities (31) in the housing (30) and the outer peripheries of the wires (W). A shield shell (50) covers the housing (30) and is connected electrically to the case (C) and also to a shield conductor (60) through which the wires (W) are inserted. A second rubber ring is provided between the housing (30) and the shield shell (50).

Owner:SUMITOMO WIRING SYST LTD

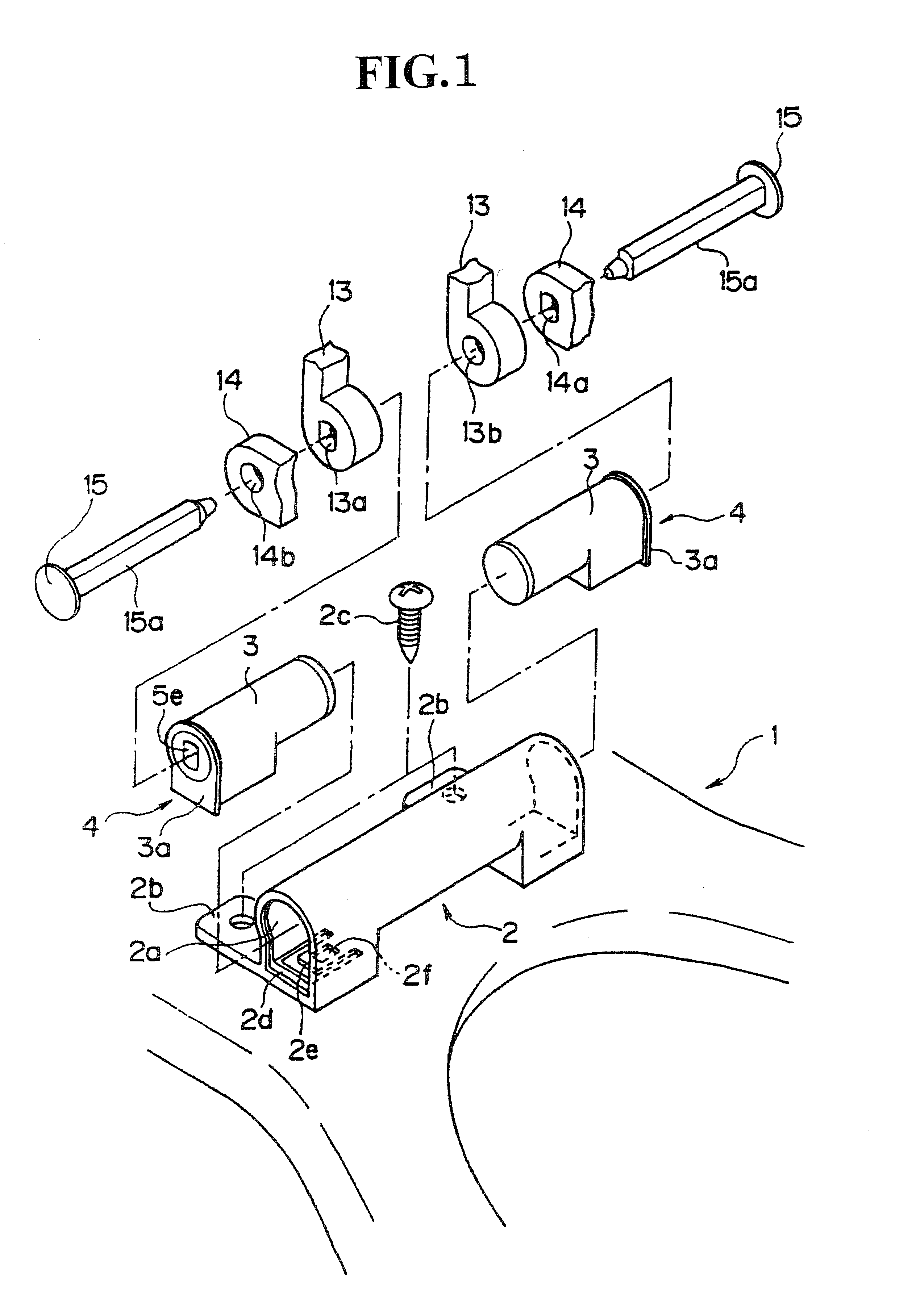

Operative hinge for opening/closing body

An operative hinge for use with an opening / closing body is provided which comprises a hinge case to be installed to a toilet bowl body for operating the opening / closing body; a shaft provided rotatably within the hinge case to support the opening / closing body; a stationary cam fixed within the hinge case and having formed therein a central through-hole through which the rotating shaft is axially penetrated; a cam provided within the hinge case and having formed therein a central through-hole through which the rotating shaft is axially penetrated to be slidable on, and rotatable with, the rotating shaft; and a resilient means for urging the rotatable sliding cam toward the stationary can, the hinge further comprising, to further positively control the rotation or the rotating means, a damping means consisting of a rubber ring fitted on the rotating shaft and interposed between the outer surface of the rotating shaft and the inner wall of the hinge case; and a viscous oil applied between the outer surface of the rubber ring and inner wall of the hinge case; the rubber ring having spiral recesses formed on the outer surface thereof.

Owner:KATOH ELECTRIC MACHINERY

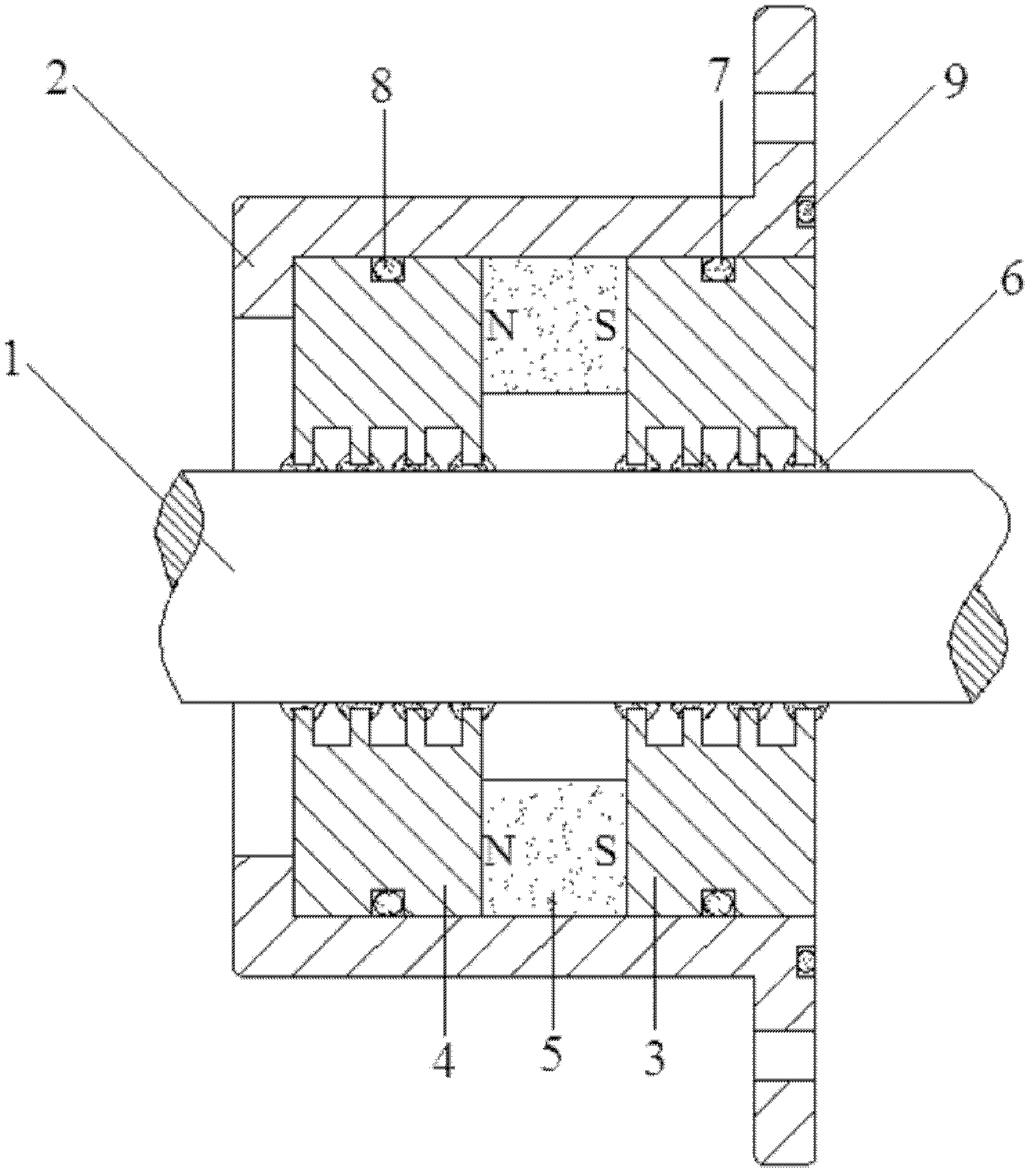

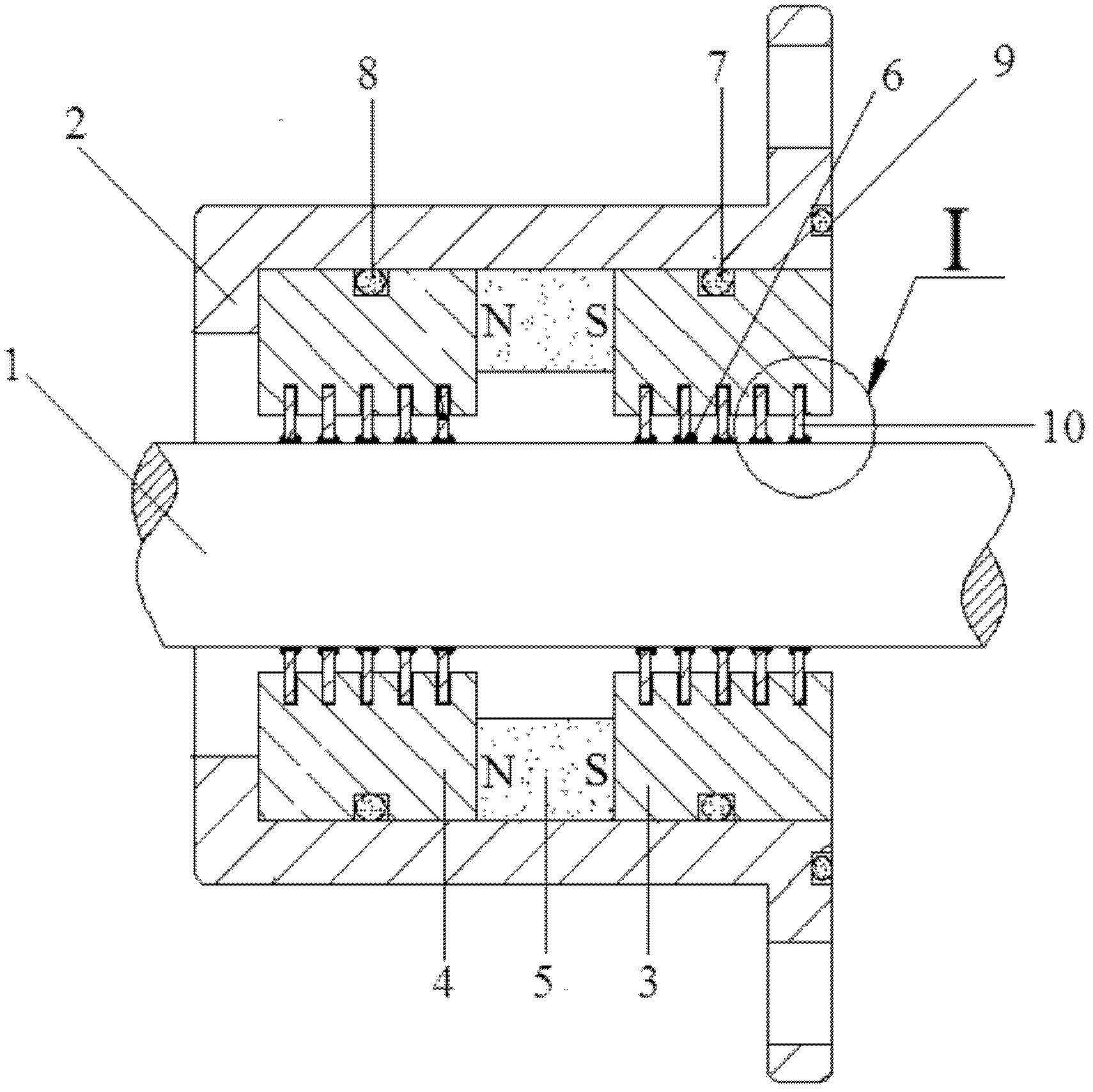

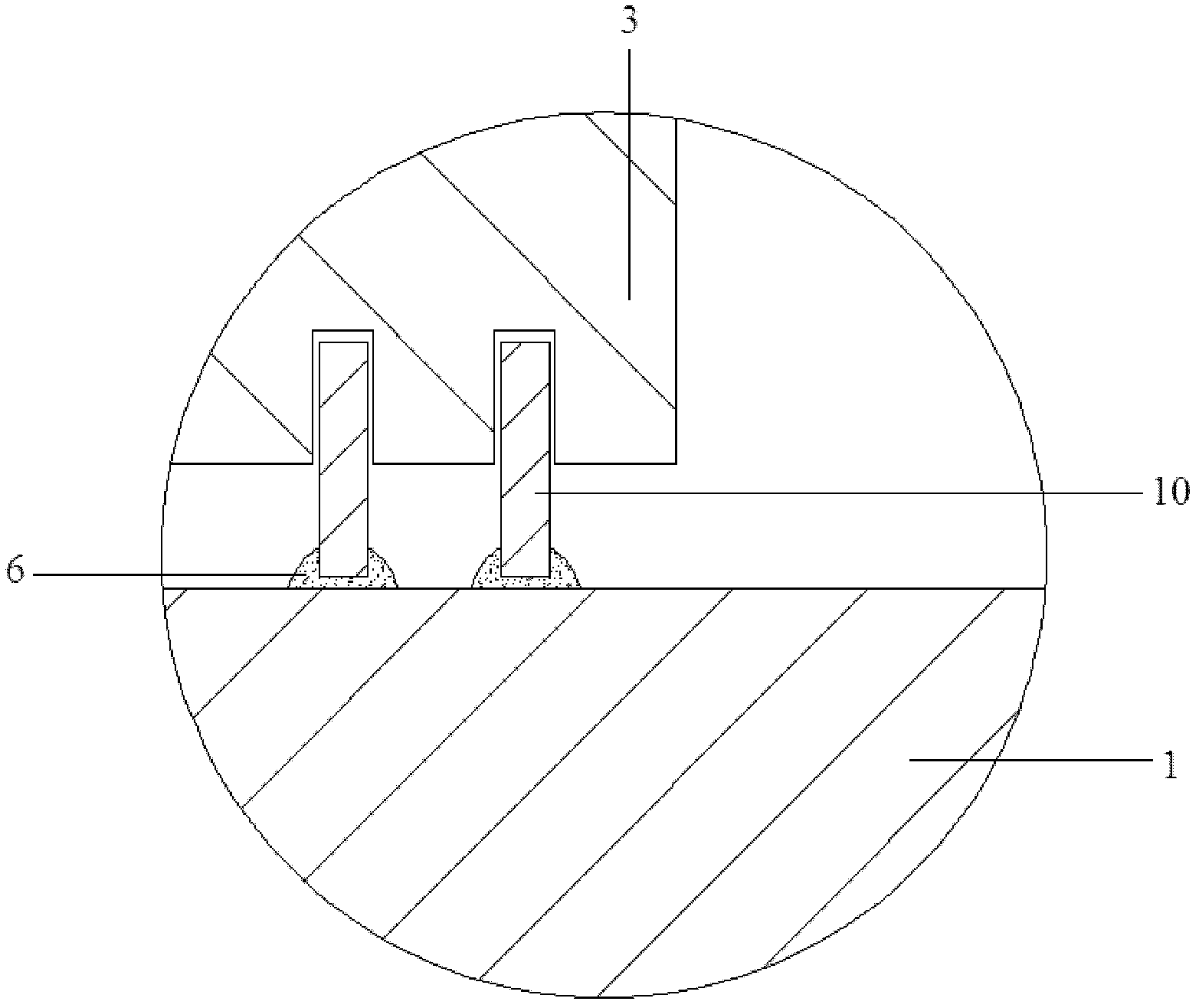

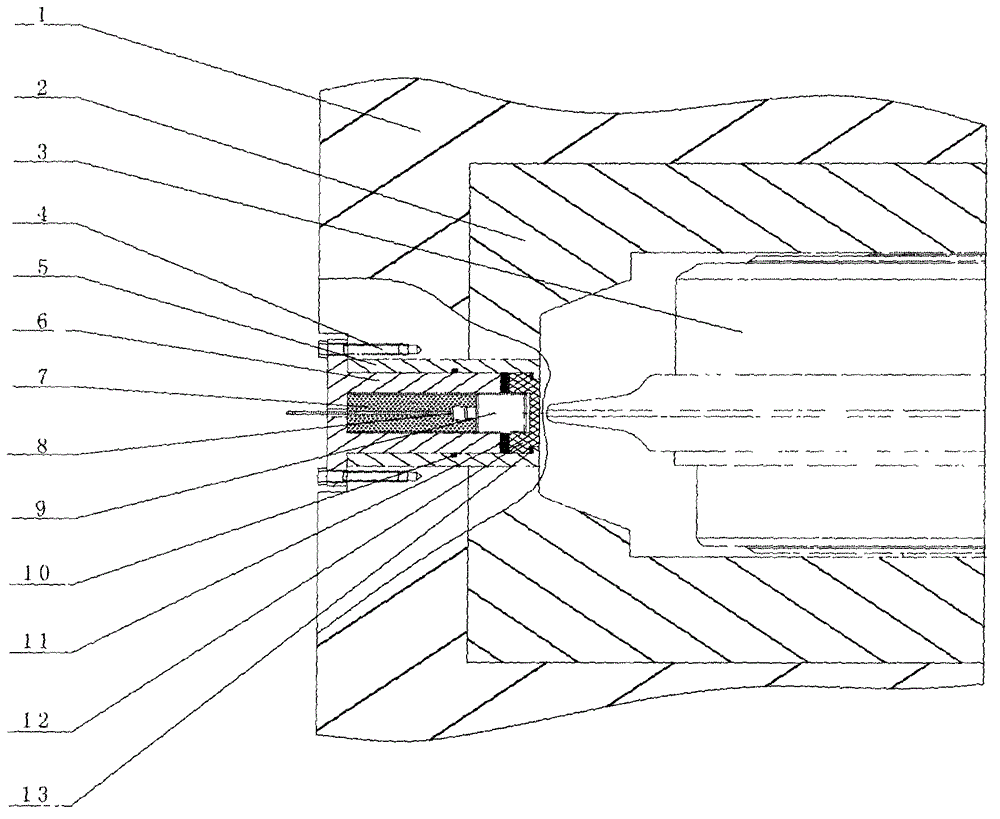

Shaft sealing device with magnetic fluids

InactiveCN102537367AReduced seal pressureAutomatically adjust the coaxialityEngine sealsRubber ringMagnetic poles

The invention relates to a shaft sealing device with magnetic fluids, which is characterized in that based on an existing shaft sealing device with magnetic fluids mainly comprising a rotating shaft, a non-magnetic metal shell, magnetic poles, a permanent magnet, the magnetic fluids and a rubber ring, sealing pole teeth made of soft magnetic materials are additionally arranged in sealing pole tooth grooves of the magnetic poles, a sealing pole tooth ring is sleeved on the rotating shaft, the inner diameter of the sealing pole tooth ring is 0.1-0.6mm larger than the diameter of the rotating shaft, the outer diameter of the sealing pole tooth ring is 0.1-0.3mm smaller than the inner diameter of each tooth groove, the thickness of the sealing pole tooth ring is 0.1-0.3mm smaller than the width of each tooth groove, the magnetic fluids are distributed in an annular sealing gap between the rotating shaft and the sealing pole tooth ring, and each magnetic pole comprises two half annular magnetic poles. The positions of the sealing pole teeth of the device can be changed radially along the rotating shaft to adjust coaxiality of the rotating shaft and the sealing pole teeth, uneven distribution of the annular sealing gap in the circumferential direction of the rotating shaft is decreased, reduction of the pressure bearing capacity of the device and abrasion of the rotating shaft and the sealing pole teeth are avoided, and the requirements of sealing components on machining and mounting precision are lowered.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

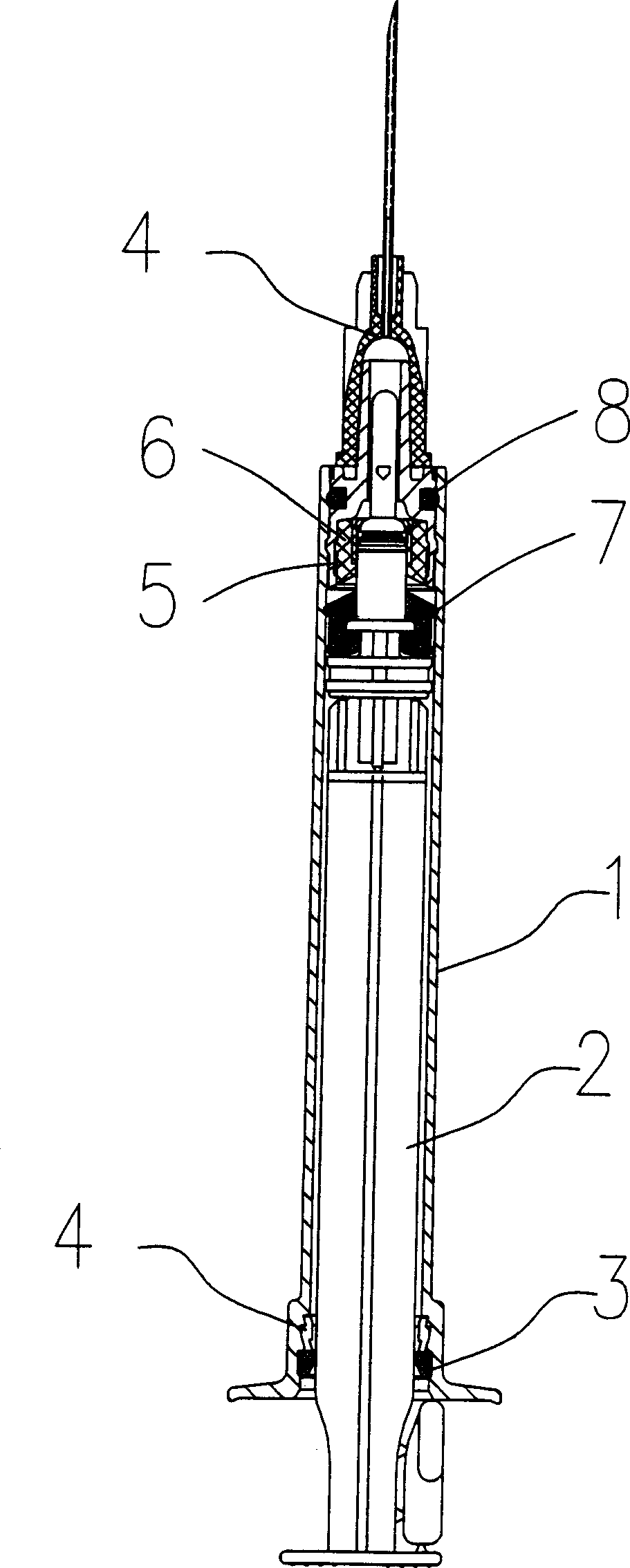

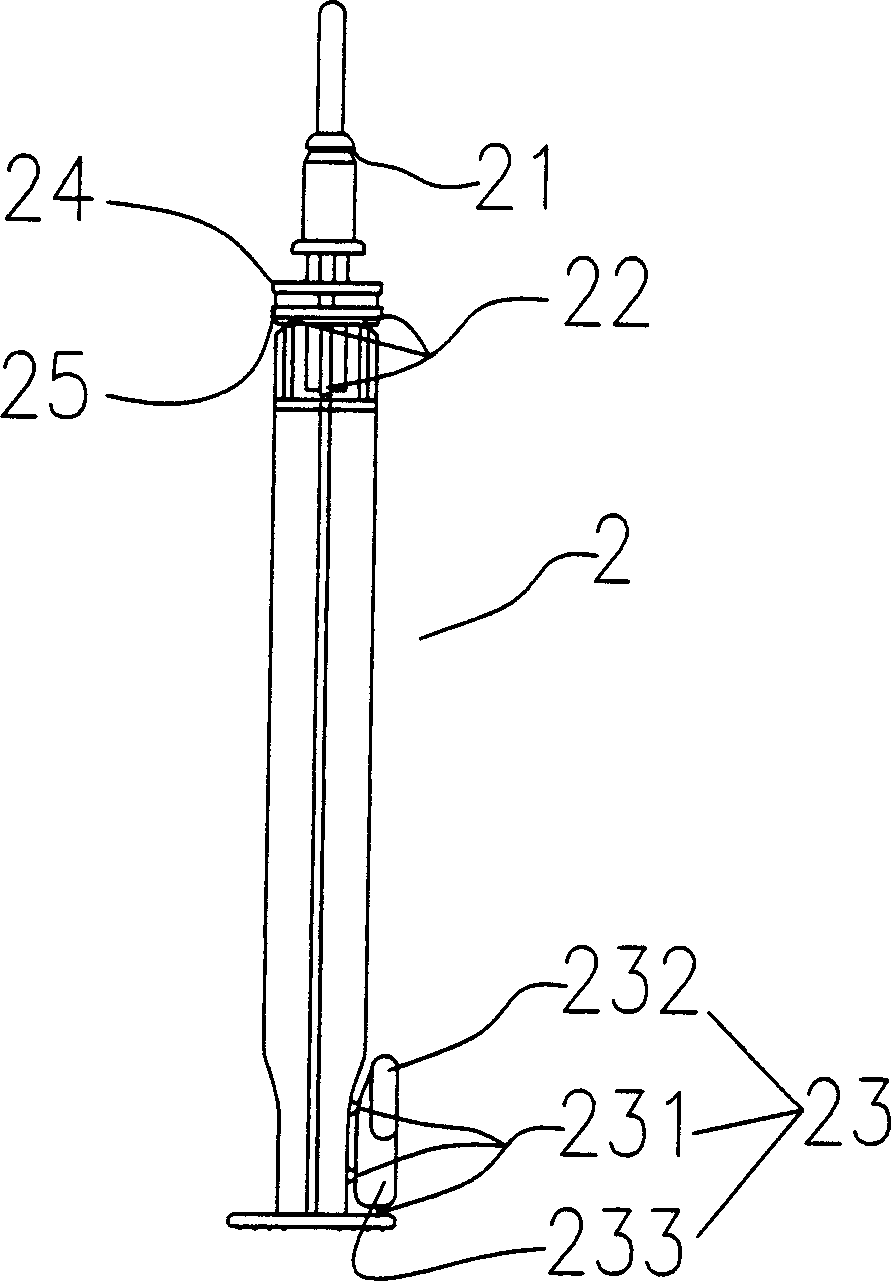

Safe self-destruction syringe for medical purpose

InactiveCN1803212APlay a limiting rolePrevent premature self-destructInfusion syringesIntravenous devicesRubber ringFlute

The invention discloses a safe self-destroying medical injector, which comprises the following parts: hollow cylinder, snap coil, needle seat and core bar, wherein the plug is assembled in the core bar head; a coil of flute is set in the head of cylinder; the boss is set on the top of core bar with upper round boss and lower round boss under the boss; the easy-breakpoint is set under the lower round boss; the needle seat is composed of separable conical seat and support seat with an 'O' rubber ring between the excircle of conical seat bulk and cylinder; two through-grooves of central symmetry are set under the conical seat, which sets two bosses of central symmetry between two through-grooves; the boss snaps the flute on the cylinder; the flute is set on the inner hole bottom of conical seat.

Owner:SHANGHAI SOL MILLENNIUM MEDICAL PRODUCTS CO LTD

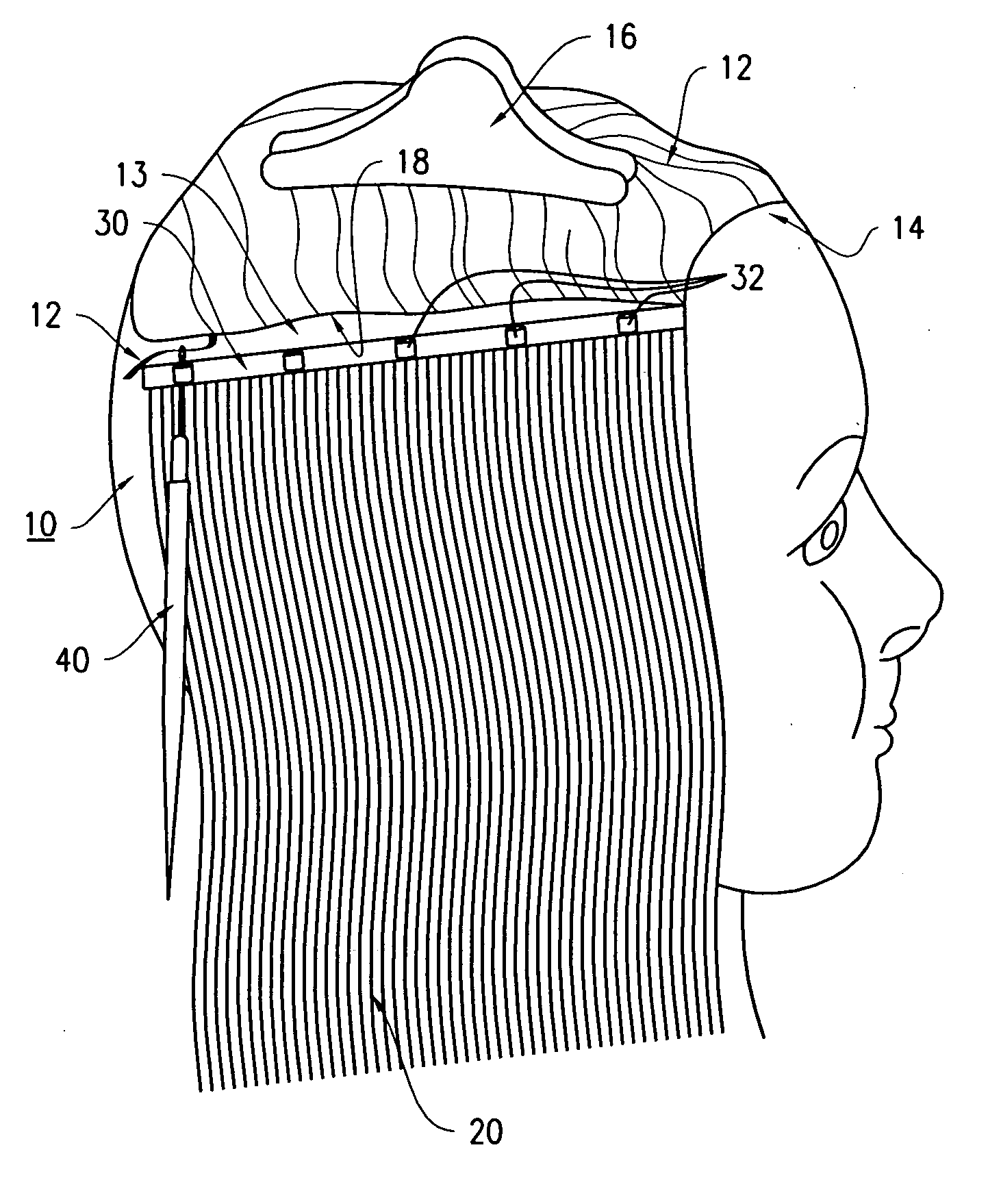

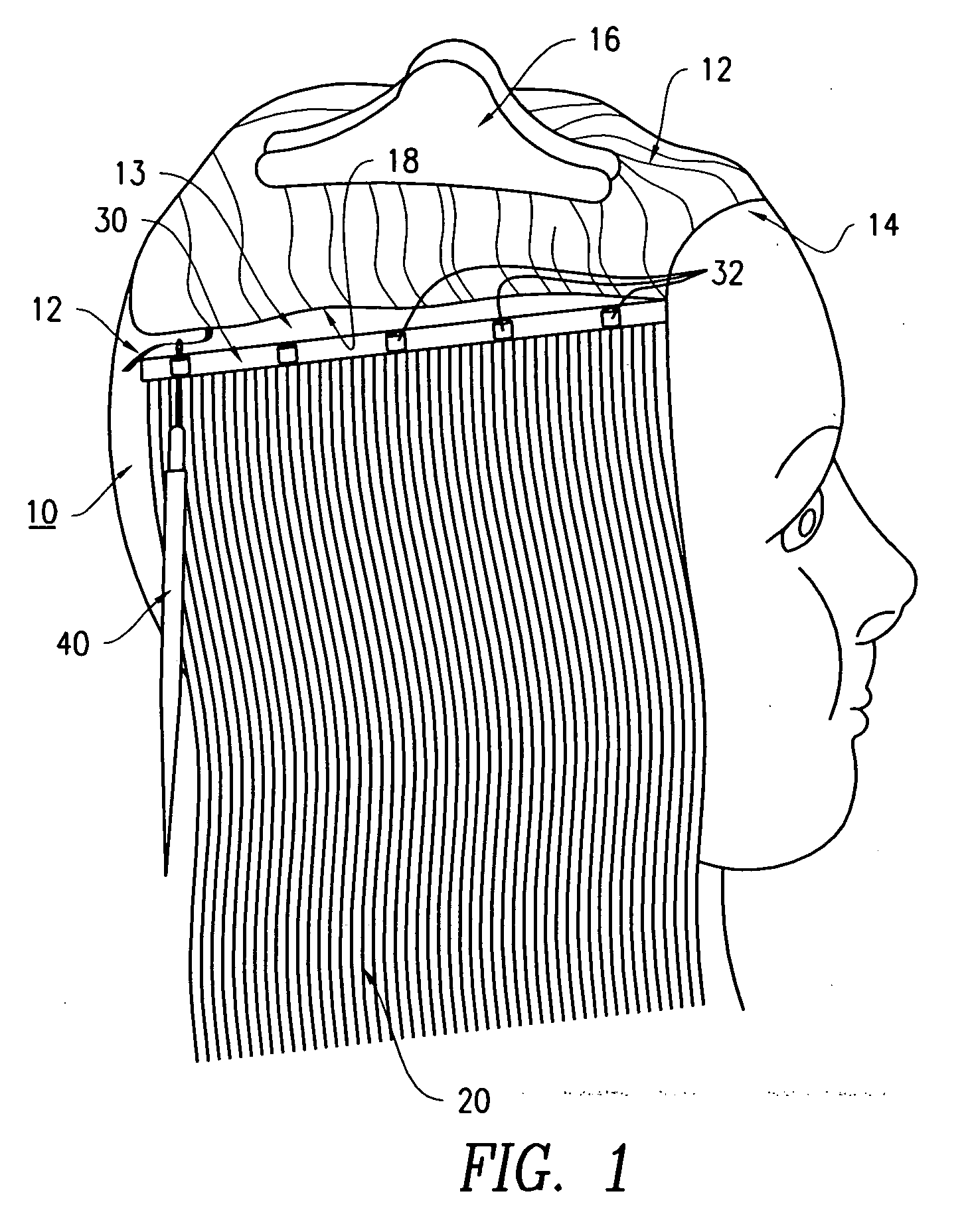

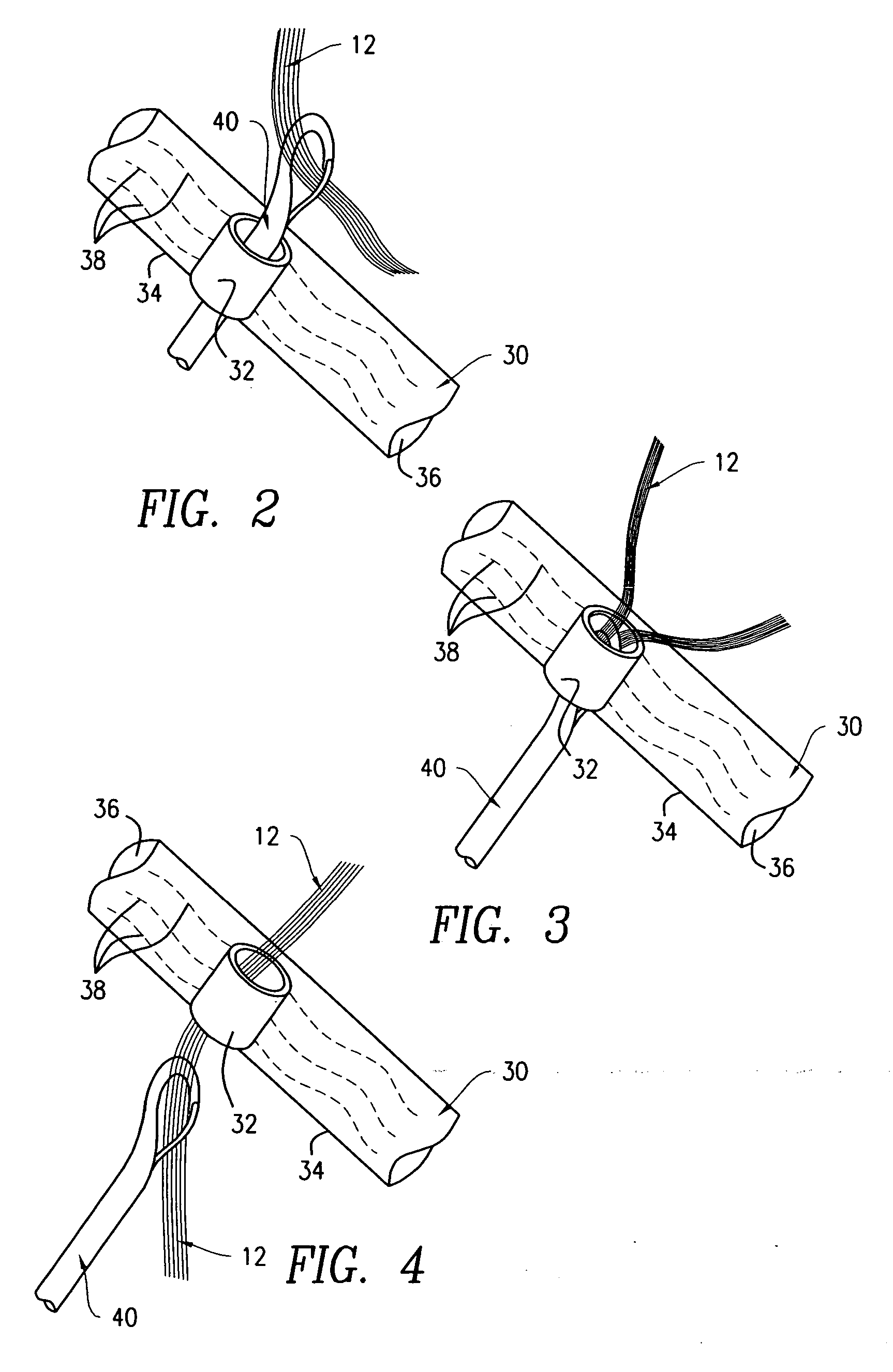

Hairpiece with attachment rings and heating kit for attaching hairpiece

A hairpiece assembly for adding body and / or length to the user's real hair. The hairpiece assembly includes a plurality of natural or synthetic strands of hair arranged in parallel and forming a first edge; and an elongated strip attached to the first edge to hold the plurality of strands together. The hairpiece assembly further includes a plurality of spaced-apart rubber rings attached to the elongated strip to form a hairpiece assembly; and each of the rubber rings having an opening for receiving therethrough the user's real hair for attaching the hairpiece assembly to the user's real hair, using a crimping and heating tool to flatten the rubber rings and the user's real hair to join them so that the flat rubber rings grip and hold the user's real hair.

Owner:KIM KEVIN

Floating bulwark with flexible structure

ActiveCN103215919AEnsure safe operationGuaranteed to workBreakwatersQuaysRubber ringMarine engineering

The invention discloses a floating bulwark with a flexible structure. The floating bulwark with the flexible structure comprises multiple water surface wave absorbing structural units, an underwater wave absorbing structure and an anchoring system. Each water surface wave absorbing structural unit comprises at least two cylinder-shaped floating cylinders. Every two adjacent cylinder-shaped floating cylinders are connected through a connection column in a rigid mode. The underwater wave absorbing structure comprises a wave-proof net and wave-proof balls. The wave-proof net is arranged below the cylinder-shaped floating cylinders. All the water surface wave absorbing structural units are elastically connected through connecting devices. With the cylinder-shaped floating cylinder connection structures and especially the double-connection-cylinder structures, materials can be effectively saved or the width of the bulwark can be effectively increased. By absorbing wave energy on the water surface and below the water surface, facilities can work normally. The connection devices can connect all the modules into a whole to fight against waves and collision among all the modules can be avoided. A concave steel plate can facilitate replacement of an aged rubber ring. The anchoring system can ensure safety working of the floating bulwark under the action of the waves, and meanwhile, the floating bulwark can work normally in water zones where piling is not convenient.

Owner:JIANGSU UNIV OF SCI & TECH +1

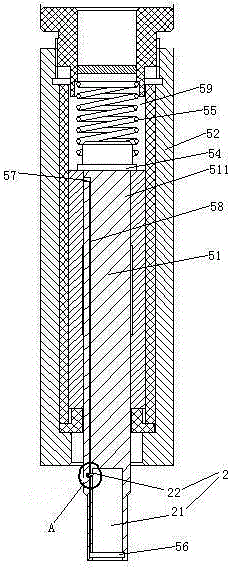

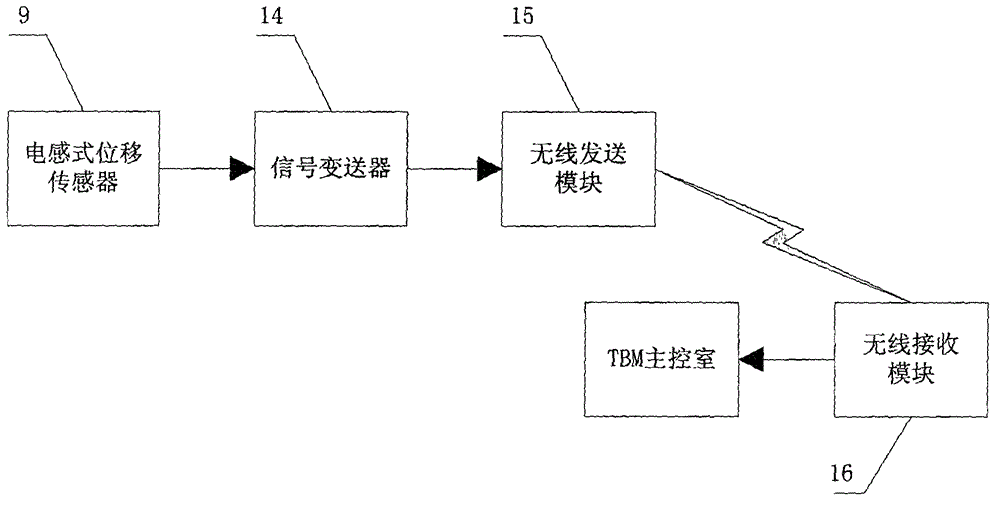

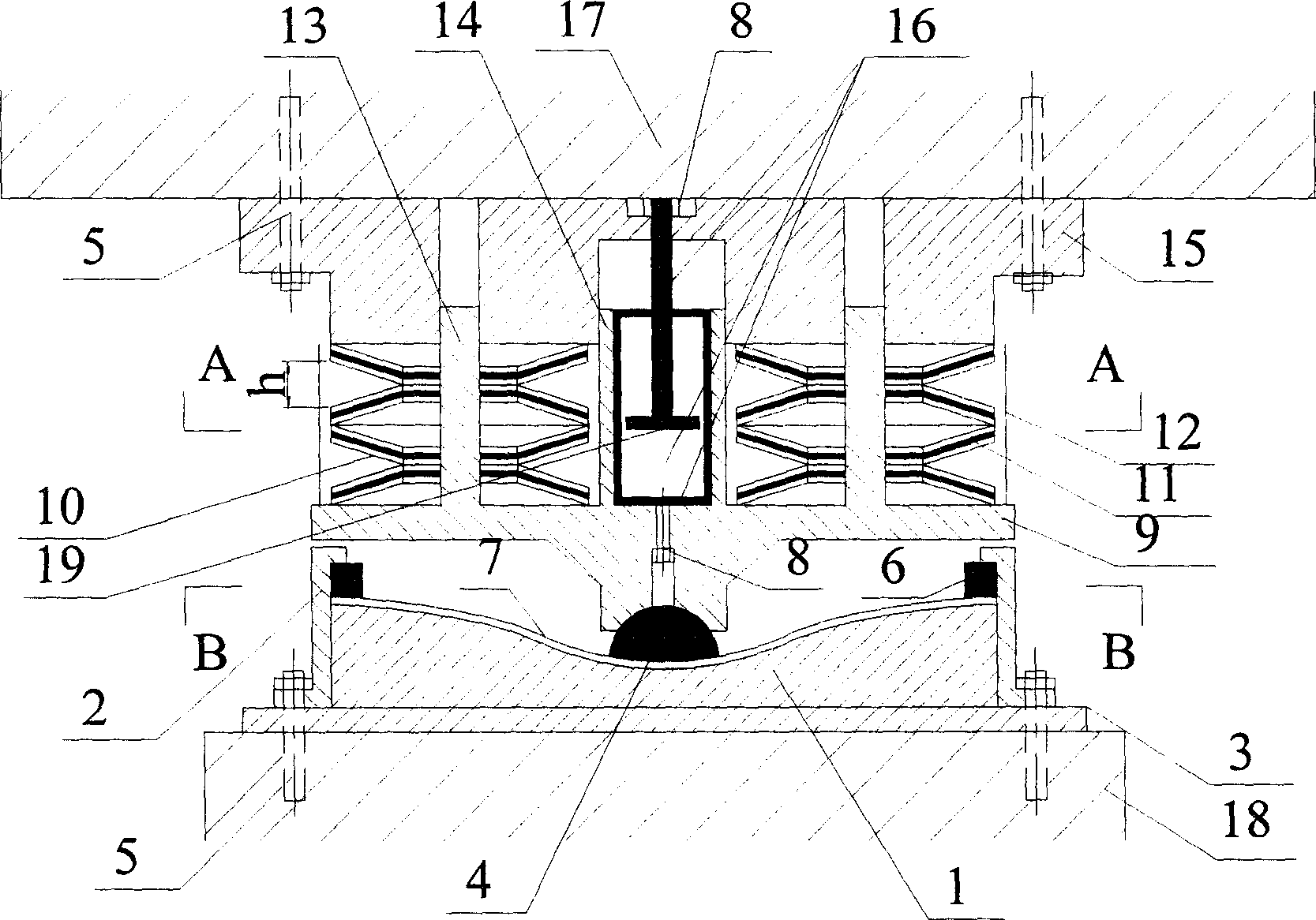

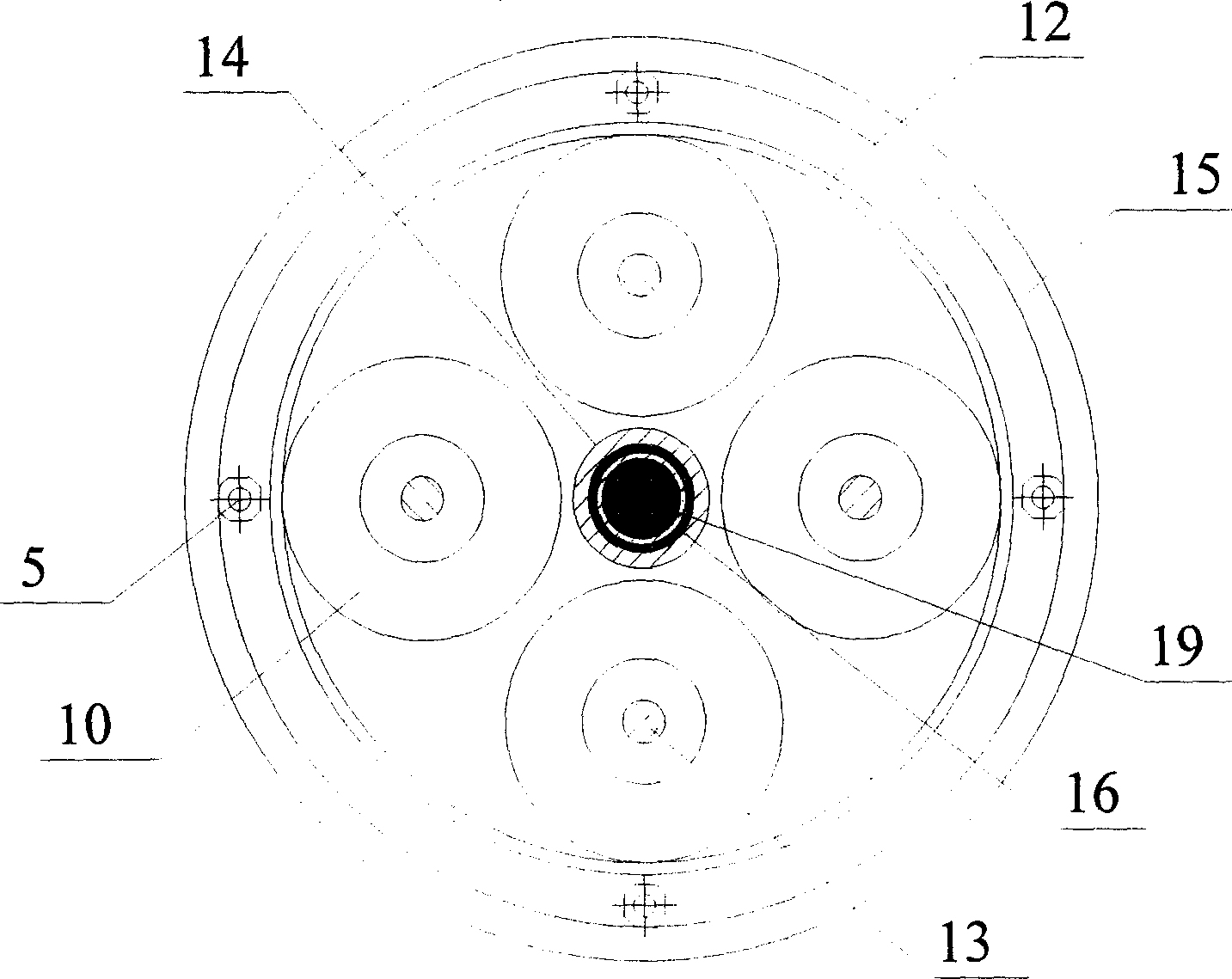

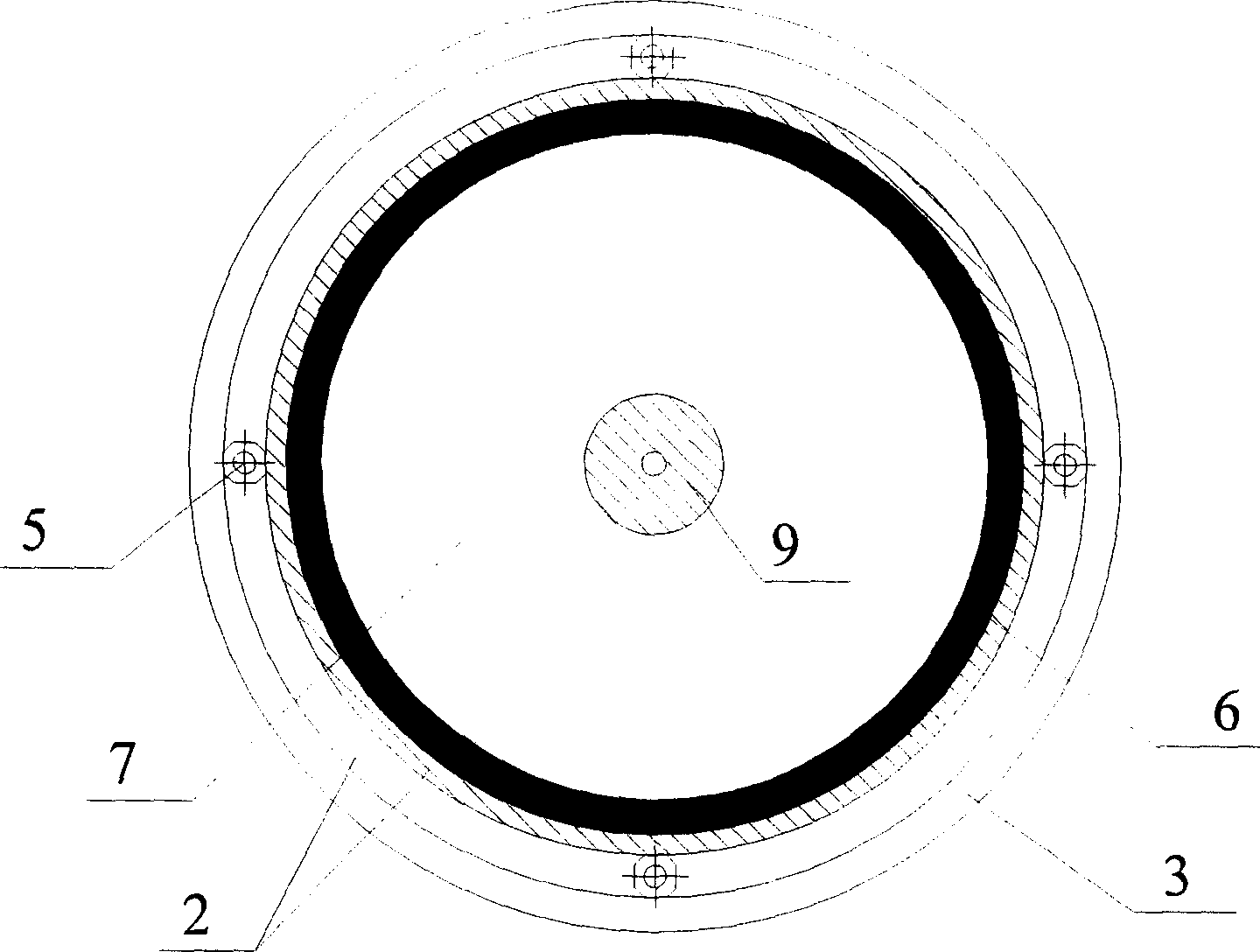

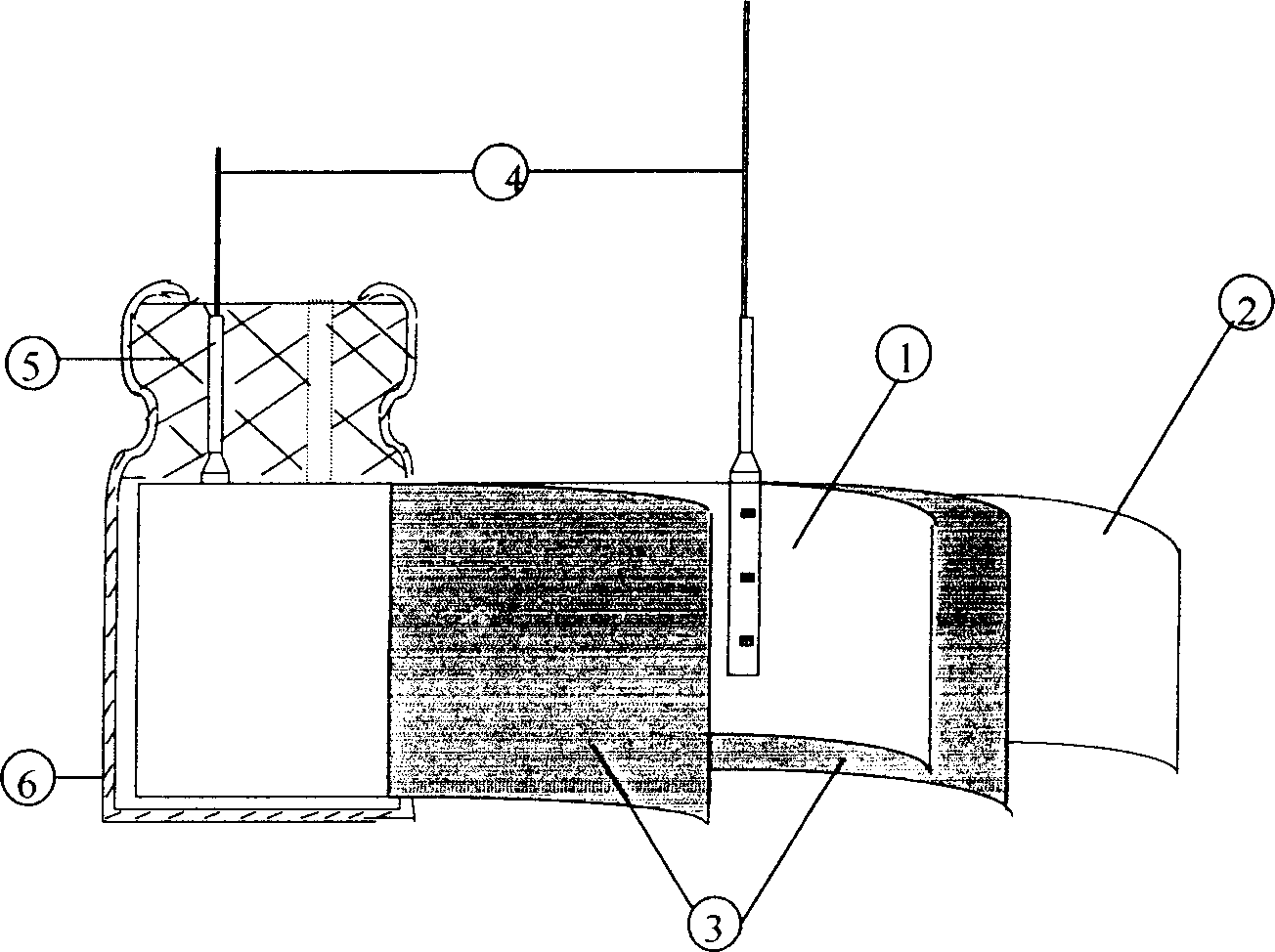

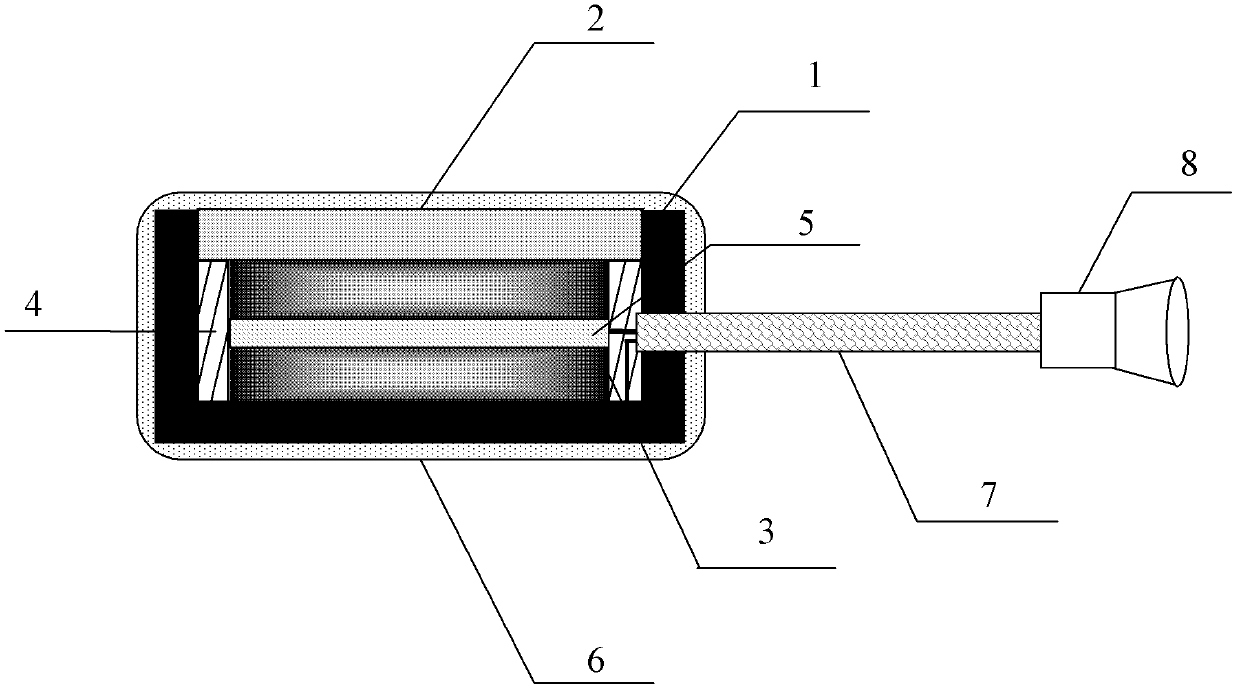

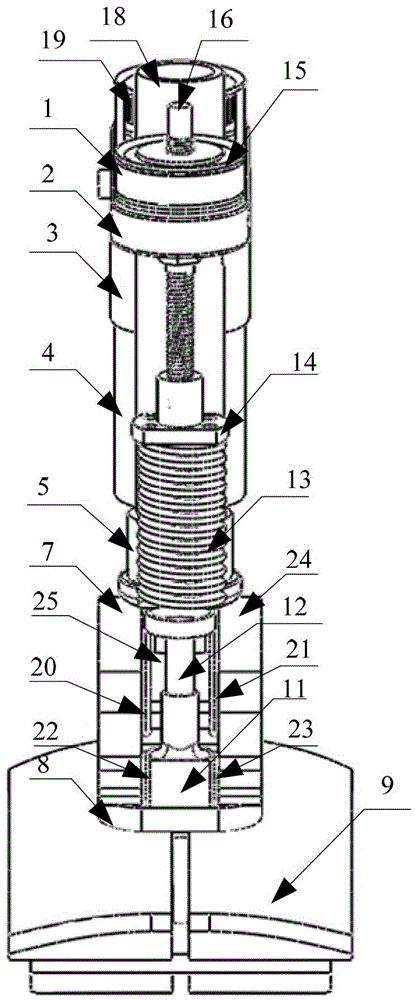

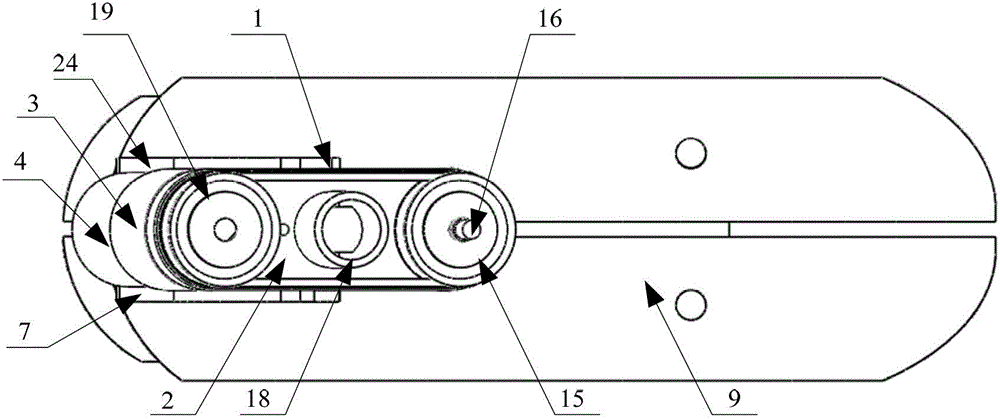

Real-time tunnel boring machine (TBM) hob abrasion monitoring device

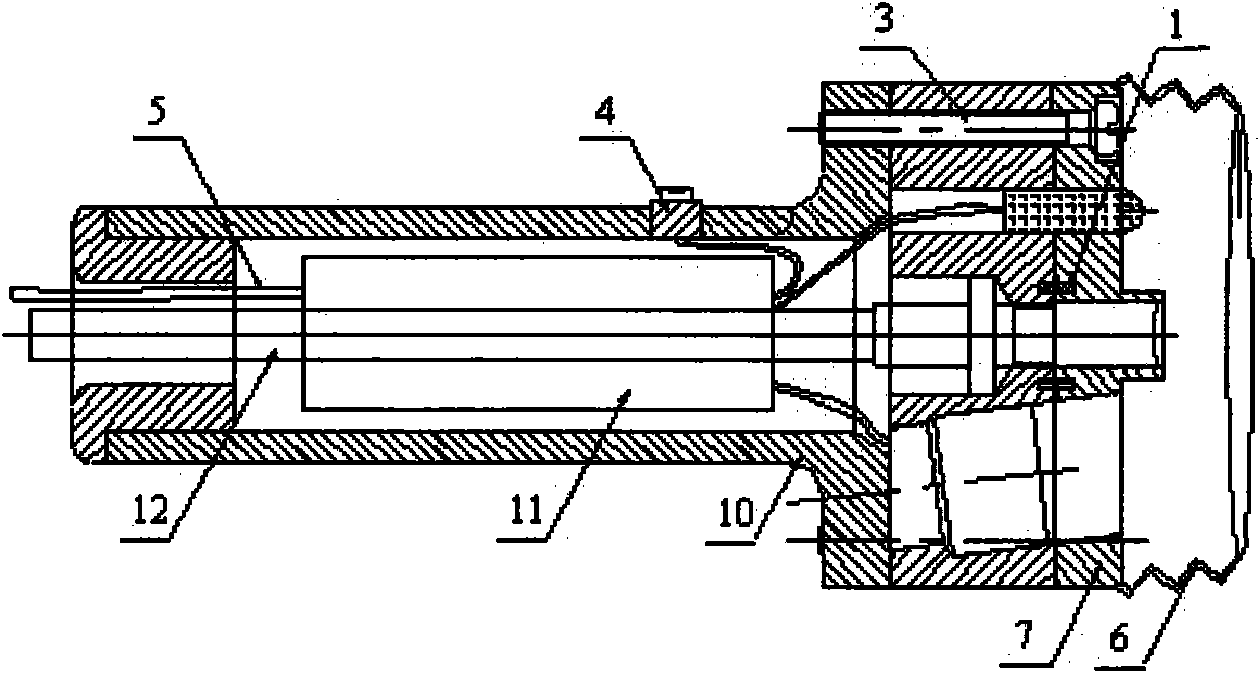

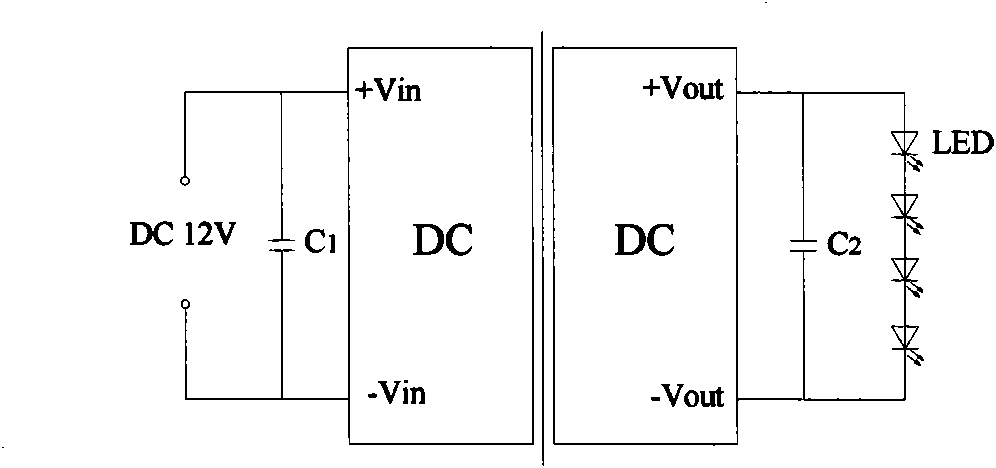

ActiveCN103148771AReal-time monitoring of wear statusKeep abreast of the operation status in timeUsing electrical meansRubber ringTransformer

The invention discloses a real-time tunnel boring machine (TBM) hob abrasion monitoring device based on an inductive displacement transducer. The device is characterized in that the inductive displacement transducer is installed in a transducer base, a lead pin is connected onto the inductive displacement transducer, and the internal gap of the transducer base is filled by an AB glue. A zirconia protection sleeve and the transducer base are installed in a transducer positioning sleeve, and a waterproof rubber ring is assembled in a groove of the transducer positioning sleeve. A small waterproof rubber ring is sealed between the zirconia protection sleeve and the transducer positioning sleeve, and a large waterproof rubber ring is sealed between the zirconia protection sleeve and the transducer base. The transducer positioning sleeve is installed into round holes in the middle of the side surfaces of a cutter head reinforcing plate and a tool apron, and the transducer base and the cutter head reinforcing plate are fixed into a whole through bolts. Hob abrasion signals which are detected by the inductive displacement transducer are processed by a signal transformer and then transmitted in a wireless manner. The device can be suitable for severe working environments of a hob and monitors the hob abrasion in real time.

Owner:CENT SOUTH UNIV

Curvature variable self-reset and protection three-dimensional shock damping and insulation energy dissipating support

InactiveCN1702248AExtend the vertical natural vibration periodReduce excessive displacementShock proofingRubber ringVibration control

This invention relates to a variable curvature self-reset protecting three-dimensional shock mount, which belongs to the shock insulation control and vibration control fields. The structure of the mount is: coating the frictional layer on the variable curvature chassis and its surface, the lower connection board and the limiting composition board; setting high elastic rubber ring between the chassis and the limiting composition board; setting the slide block in the center of the chassis and applying middle-connection board on it, wherein the convex axial and center arbor is arranged on the middle-connection board, the convex axial is covered the disk spring superposition, and between the superposition is arranged damping material, outside the superposition is covered with steel ring; between the center arbor is arranged damper, the convex axial and center arbor plunge the upper-connection board and have gap distance to the board. The invention can guard and repress horizontal and vertical earthquake wave at the same time, and eliminate the disadvantage of torsion and P-delta effect to the supperstructure, in addition to limiting protection.

Owner:BEIJING UNIV OF TECH

Handheld near-infrared probe for nondestructive internal quality testing of fruit and detection method

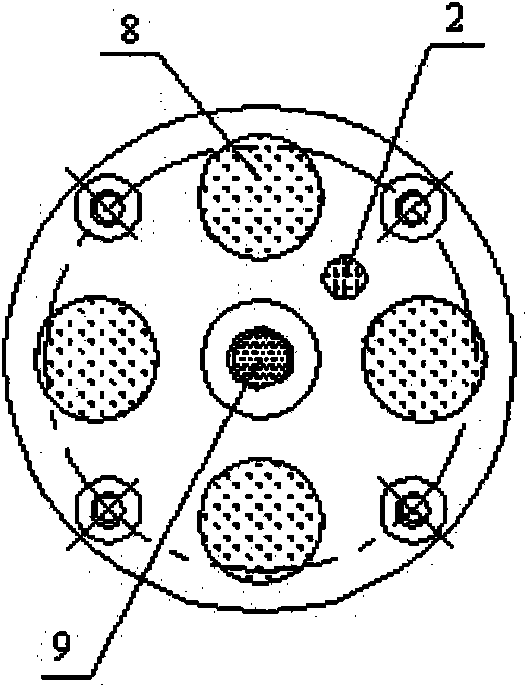

InactiveCN101799401AEasy to collectImprove final detection efficiencyPoint-like light sourceScattering properties measurementsHand heldWavelength

The invention relates to a handheld near-infrared probe for nondestructive internal quality testing of fruit and a detection method. The optical fiber probe consists of four LED light sources with different waverlengths, a detection optical fiber, an automatic sampling control system, a light source stabilizing circuit, a digital temperature and humidity sensor, a circular lug boss, a darkening ring, a soft rubber ring, a switch, a circuit box and a shell. The probe has the characteristics of high stability, simple structure, low cost and spectra collecting controllability, and can be widely used for on-line monitoring and on-site sampling of fruit. A voice system and a wireless transmission system can be used for realizing the humanization and easy operation of equipment and effectively expand application space.

Owner:EAST CHINA JIAOTONG UNIVERSITY

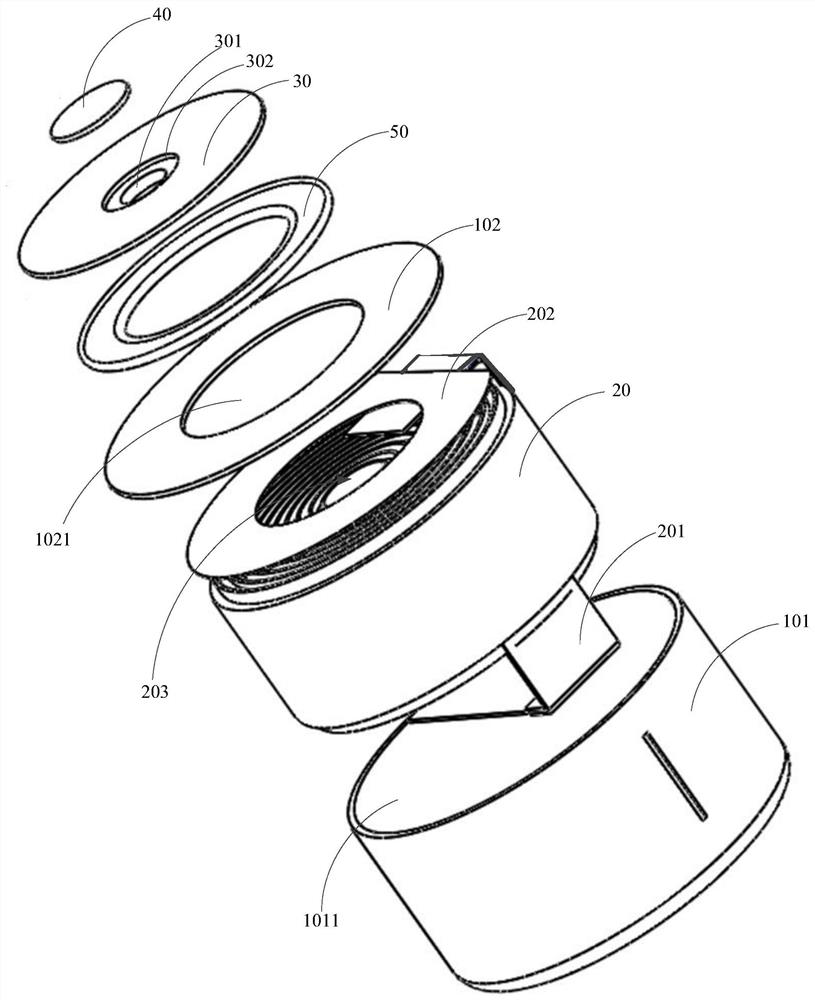

Button cell and manufacturing method thereof and electronic equipment

The invention provides a button cell and a manufacturing method thereof and electronic equipment, and relates to the technical field of batteries. The technical problems that a button cell is poor insealing effect, high in assembly difficulty and low in production efficiency are solved. The button cell is covered on the through hole of the top cover through a conductive piece; the top cover and the conductive piece are connected together in an insulating and sealing manner througha sealing rubber ring; the battery cell is placed in the accommodating cavity of the bottom shell; the first tab on the battery cell is welded with the inner bottom wall of the bottom shell; then the top cover with the conductive piece is connected with the bottom shell in a sealed mode, the second tab on the battery cell is electrically connected with the conductive piece, finally, electrolyte is injected into the containing cavity from the electrolyte injection port in the conductive piece, after electrolyte injection is completed, the electrolyte injection port is covered with the sealing part in a sealed mode, and the sealing part is connected with the electrolyte injection port in a sealed mode. Thebutton cell provided by the invention is used for improving the sealing performance.

Owner:ZHUHAI COSMX BATTERY CO LTD

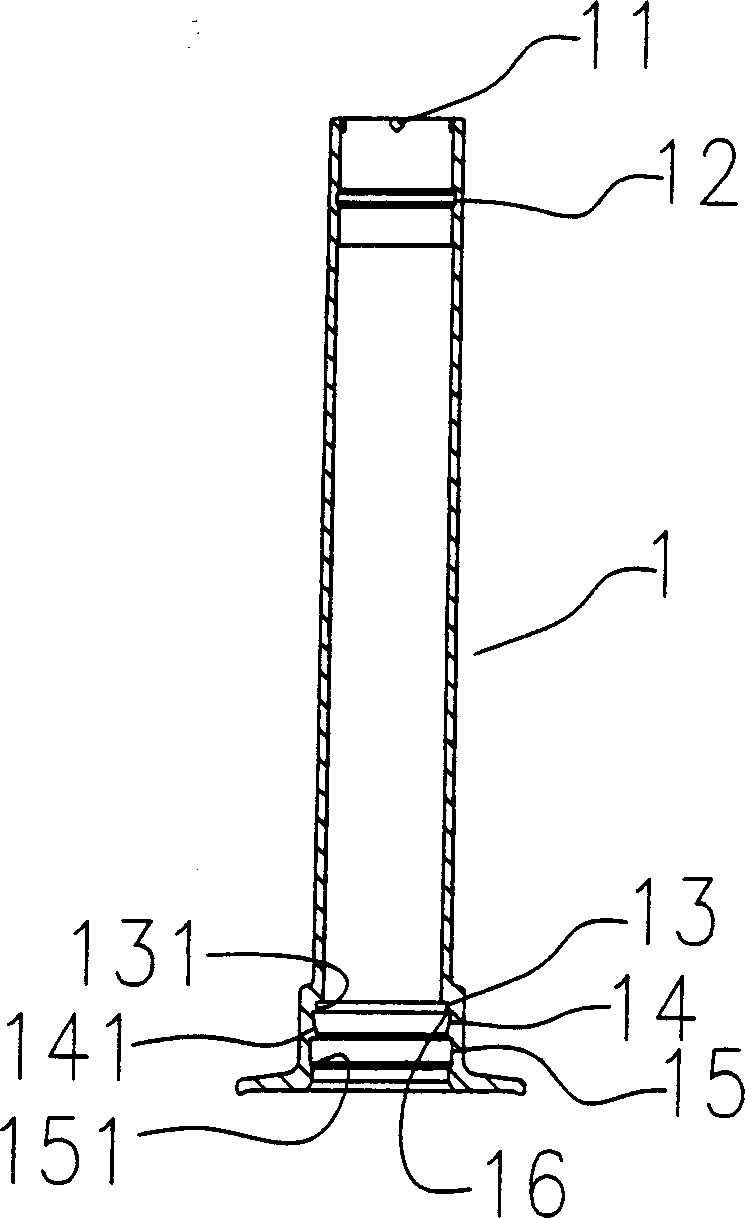

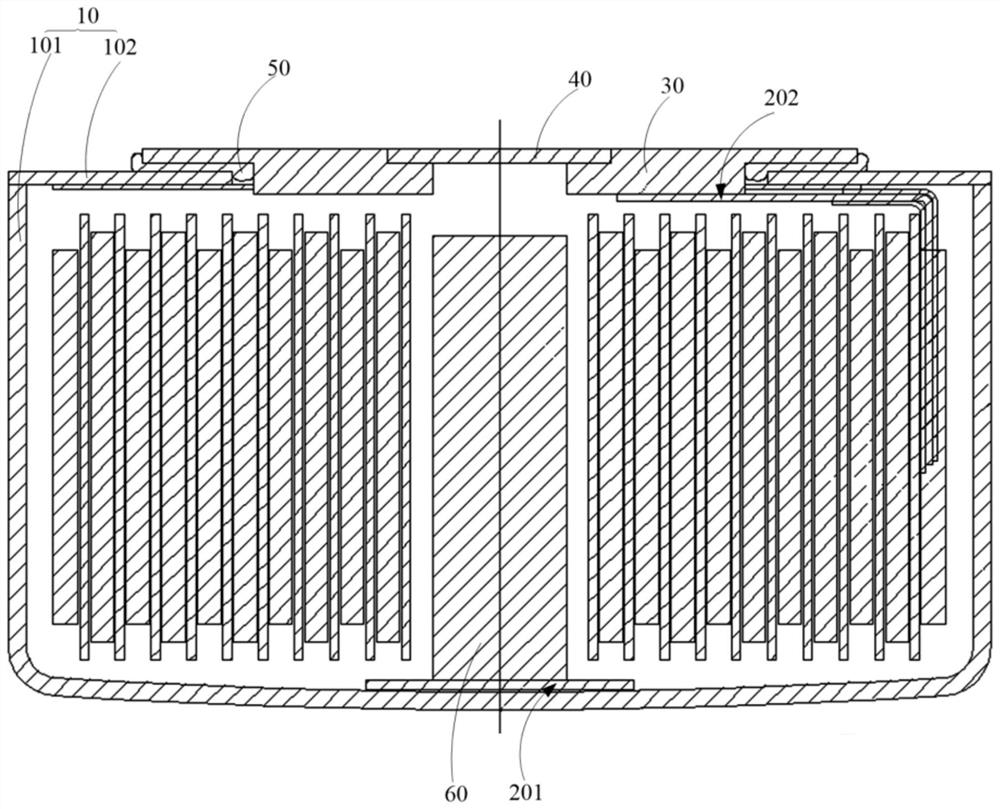

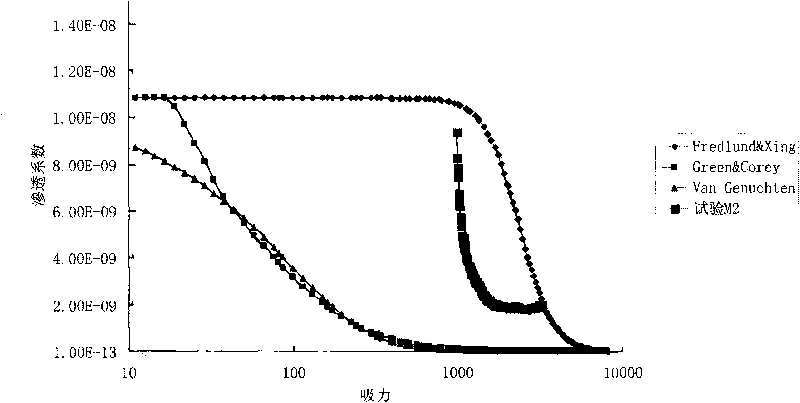

Time domain reflection unsaturated permeameter and method for measuring unsaturated permeability coefficient

InactiveCN101738360APreparing sample for investigationPermeability/surface area analysisRubber ringTime domain

The invention relates to a time domain reflection unsaturated permeameter. The center of a barrel cap (11) is provided with an air outlet (1); the joint of the barrel cap (11) and a barrel wall (8) is sealed by a first rubber ring (2), and the joint of a base (10) and the barrel wall (8) is sealed by a second rubber ring (6); and 5 buried waveguides (3) are arranged at equal intervals in the barrel wall (8), a soil sample in the barrel wall (8) is isolated from the base (10) by porous stones (4), and the positions on the base, corresponding to the porous stones, are respectively provided with a water inlet (7) and a water outlet (5). The invention also provides a method for measuring the unsaturated permeability coefficient of a soil body. The method uses a time domain reflection probe to measure the water content of the soil body in the fixed positions and solves the unsaturated permeability coefficient of the measured medium by making use of the beforehand-measured soil-water characteristic curve of the measured soil body and finally using the instant section method. The invention can be used for measuring the unsaturated permeability coefficient of different soil samples (undisturbed or remolded) and improves the accuracy.

Owner:TONGJI UNIV

Transparent-aerogel vacuum glass and manufacturing method thereof

ActiveCN102839893ALow thermal conductivityHigh strengthClimate change adaptationWindows/door improvementRubber ringDesiccant

The invention provides transparent-aerogel vacuum glass and a manufacturing method of the vacuum glass. The transparent-aerogel vacuum glass comprises glass panes, desiccating agent aluminum bars and a sealing rubber ring. The desiccating agent aluminum bars are arranged inside the periphery between the two glass panes, the sealing rubber ring is used to seal the outside of each of the desiccating agent aluminum bars, a hollow interlayer is formed between the two glass panes, and then the hollow interlayer is vacuumized. The transparent-aerogel vacuum glass is characterized in that transparent aerogel is placed inside the hollow interlayer. The transparent-aerogel vacuum glass has the advantages that since thermal conductivity coefficient of the aerogel is quite low, by matching of the aerogel and special properties of a piece of vacuum glass, the requirement of energy conservation can be met; and since the aerogel is high in strength, and external pressure bearing capacity is large, whole strength of the transparent-aerogel vacuum glass is greatly enhanced, and the transparent-aerogel vacuum glass is not prone to break.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

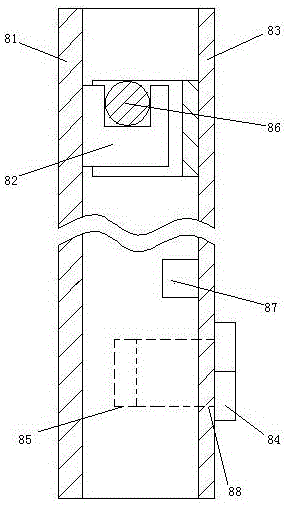

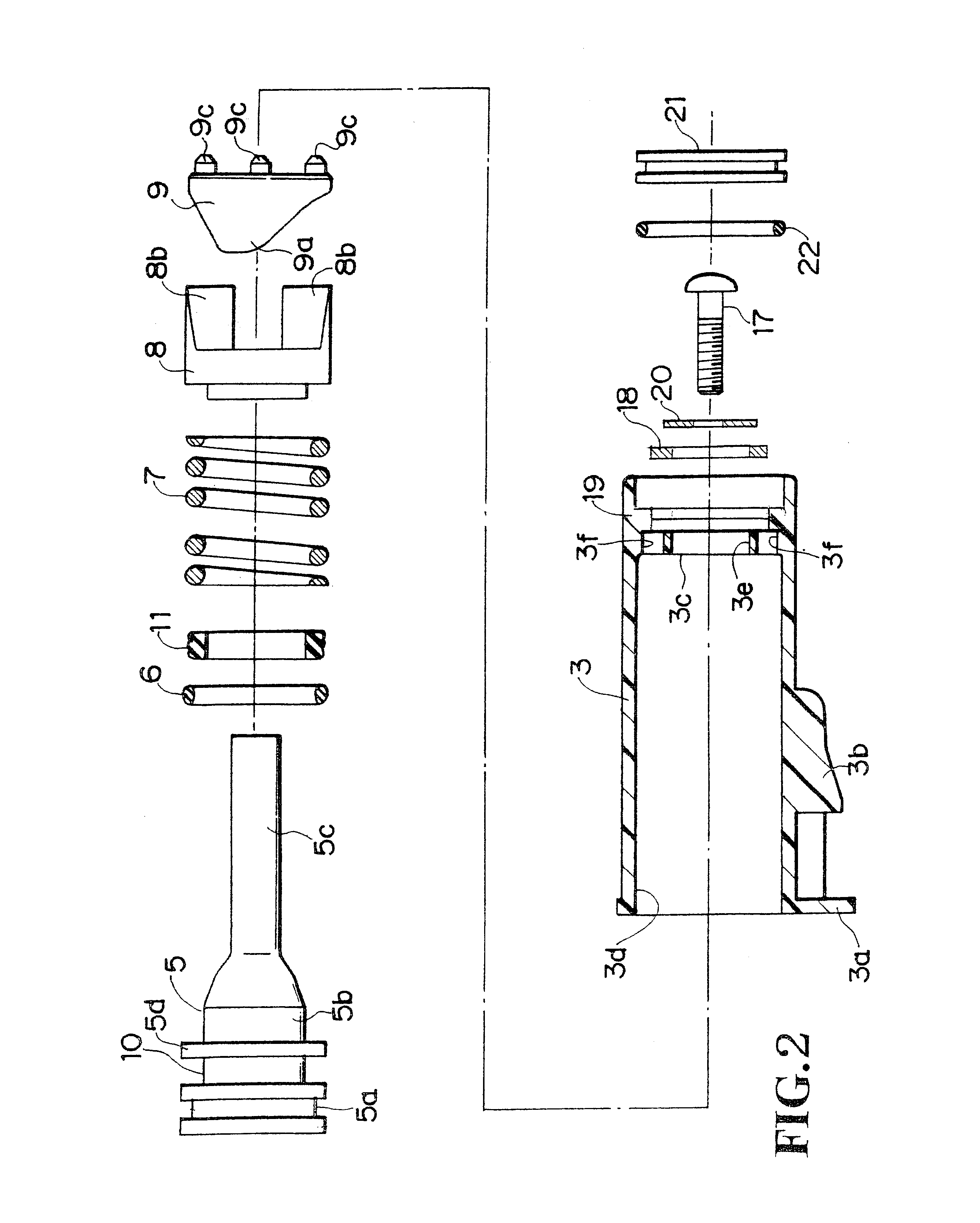

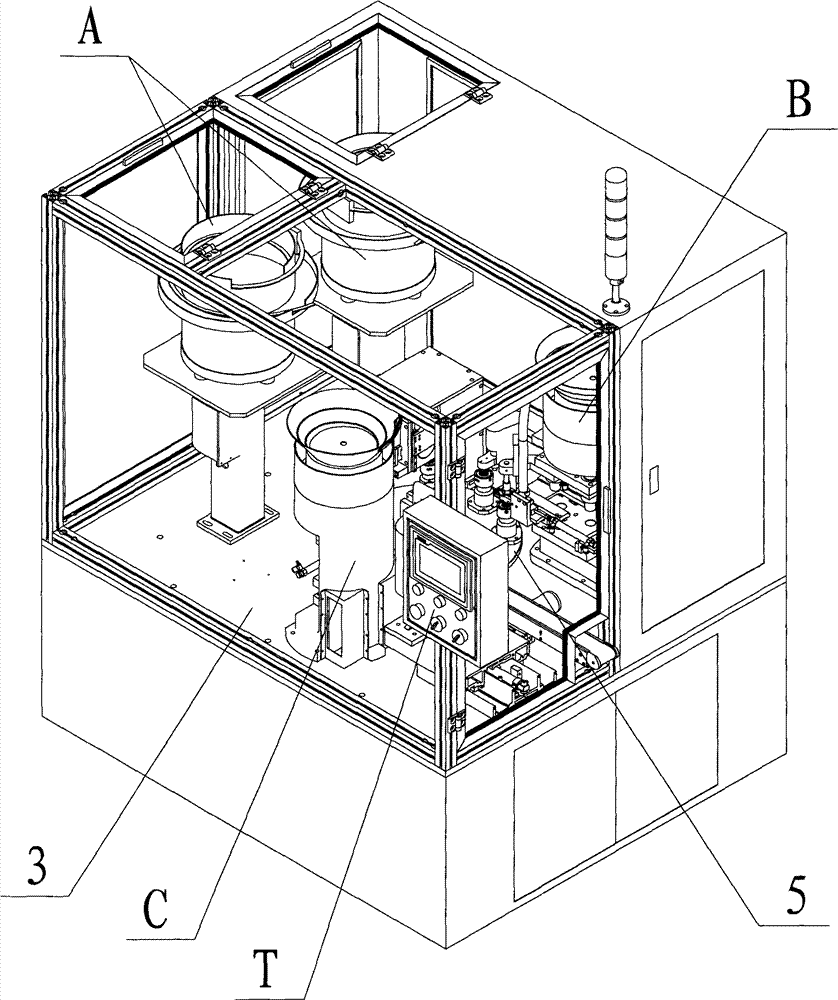

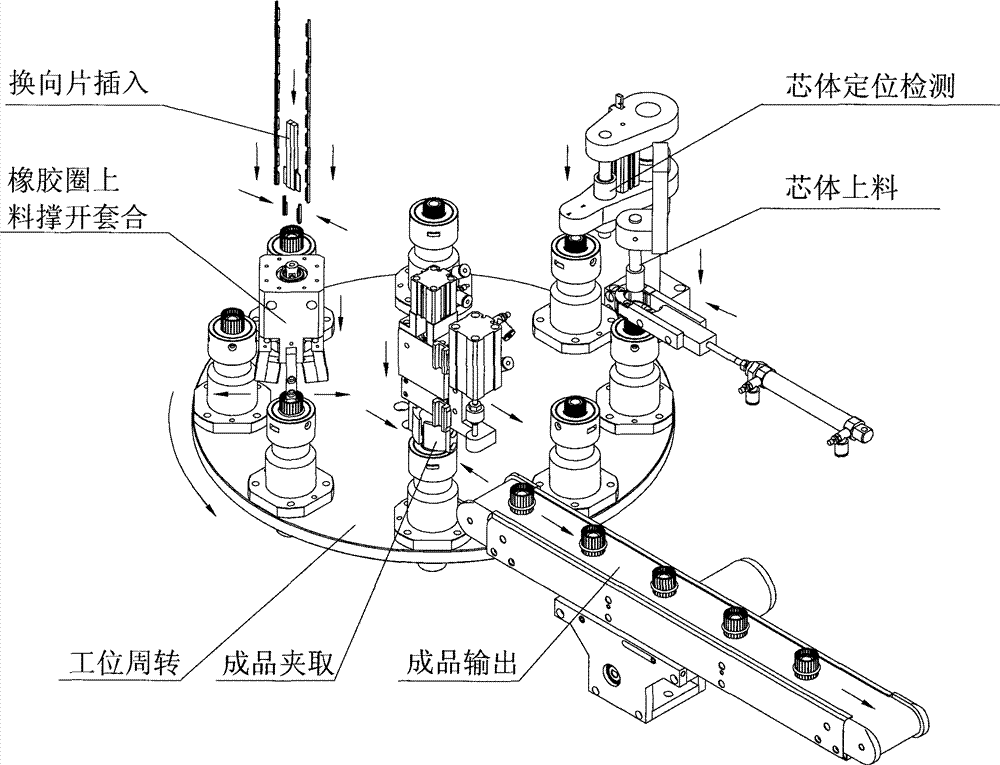

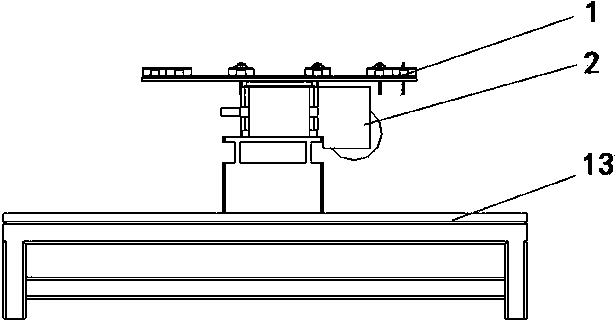

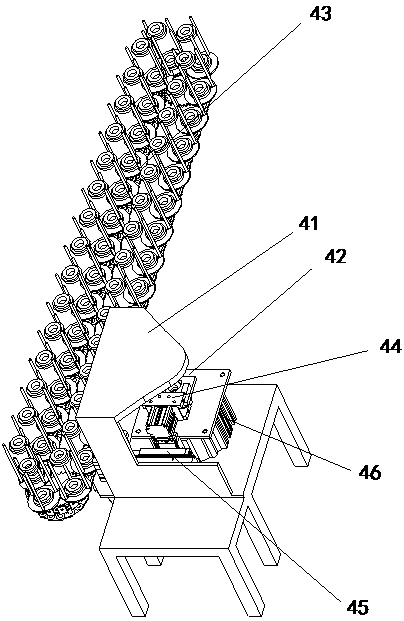

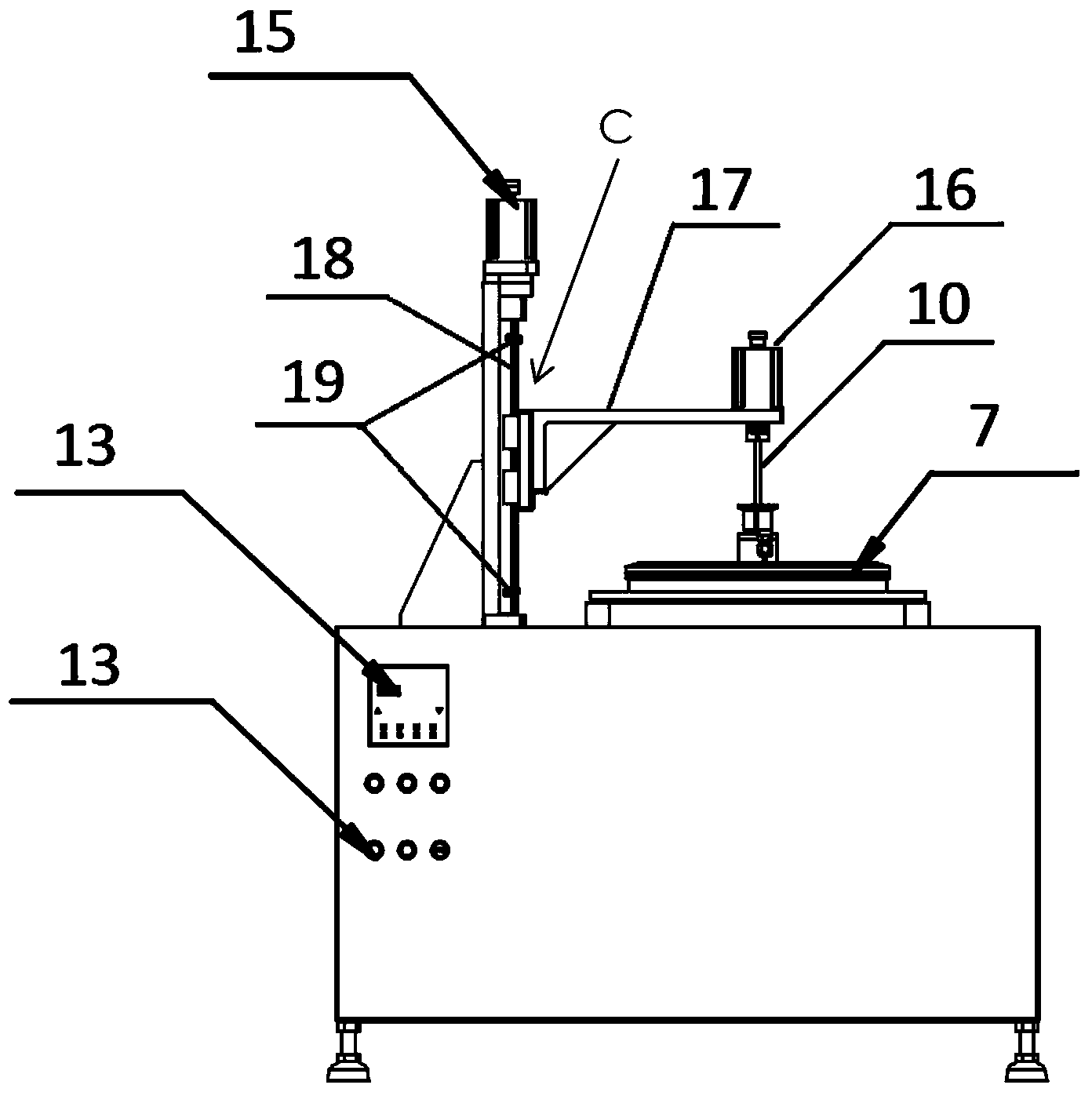

Commutator segment automatic assembly technology and full-automatic commutator segment assembly machine

The invention discloses a commutator segment automatic assembly technology. Through the rotation of a dividing plate, in a core feeding position, a core feeding machine conveys the cores into the dividing plate through a core feeding device to carry out location. In a detection position, a detection device carries out detection on the location conditions of the cores. In a sheet inserting position, a sheetbody feeding machine inserts commutator segments into the cores through a sheeting inserting device. In a rubber ring feeding position, a rubber feeding machine props the rubber rings and sleeves the rubber rings on the outer circles of the cores with the inserted commutator segments through a rubber ring sleeving device. In a blanking position, a finished product clamping device clamps finished products and outputs the finished products. The commutator segment automatic assembly technology achieves complete automation of a whole assemble process of assembling scattered commutator segments into cylinders, and has the advantages of reducing amount of labor used, improving efficiency, guaranteeing quality and reducing cost. Meanwhile, the invention provides a full-automatic commutator segment assembly machine for applying the commutator segment automatic assembly technology.

Owner:WENZHOU K Q B W AUTOMATIC EQUIP

Shield connector having a shield shell connected to a metallic case and a shield conductor

InactiveUS8562377B2High strengthEasy to transformElectrically conductive connectionsCoupling device detailsRubber ringElectrical conductor

A shield connector (10) is mounted in a metal case (C) that contains a device to be mounted in a vehicle. The shield connector (10) has a housing (30) in which terminal fittings (20) connected to ends of wires (W) are accommodated and from which the wires (W) are pulled out. Rubber plugs (70) are provided for sealing between the inner peripheries of cavities (31) in the housing (30) and the outer peripheries of the wires (W). A shield shell (50) covers the housing (30) and is connected electrically to the case (C) and also to a shield conductor (60) through which the wires (W) are inserted. A second rubber ring is provided between the housing (30) and the shield shell (50).

Owner:SUMITOMO WIRING SYST LTD

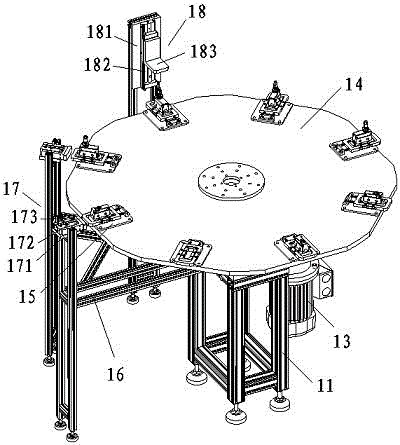

Automatic assembly production line for plastic package motor

ActiveCN103956862AReduce volumeSave human effortManufacturing dynamo-electric machinesRubber ringProduction line

The invention particularly relates to an automatic assembly production line suitable for a plastic package motor. The automatic assembly production line mainly comprises a wave coil feeding mechanism and a motor transplanting mechanism and is characterized by further comprising a rotating table and a divider for driving the rotating table to rotate intermittently, the rotating table is erected on the divider and provided with a plurality of stations for placing stators, a lower cover press-fitting mechanism, a bearing press-fitting mechanism, a rotor transplanting mechanism, an upper cover press-fitting mechanism and a rubber ring press-fitting mechanism are sequentially arranged around the rotating table, the lower cover press-fitting mechanism is used for press-fitting of lower covers and the stators, the bearing press-fitting mechanism is used for press-fitting of rotors and bearings, and the rotor transplanting mechanism is used for transferring the rotors and the bearings after press-fitting to the rotating table and inserting the rotors and the bearings into the stators. The wave coil feeding mechanism is located between the lower cover press-fitting mechanism and the bearing press-fitting mechanism, and the motor transplanting mechanism is located on the next process station of the rubber ring press-fitting mechanism. The size of equipment is reduced, occupied area is saved, and the divider and all the press-fitting mechanisms are matched tightly, so that the production period is shortened to seven seconds, labor is reduced, and production efficiency is improved.

Owner:广州金和精密机电设备有限公司

Aluminium electrolytic capacitor and electrolyte

InactiveCN1707710ANon-flammableImprove reliabilityCapacitor electrolytes/absorbentsCapacitor housing/encapsulationElectrolysisSolvent

The aluminum electrolytic capacitor consists of anode aluminum foil, electrolyte paper, cathode aluminum foil, and is produced through winding the electrolyte paper into roll core, soaking the roll core inside electrolyte solution, setting the roll core inside aluminum casing and sealing. The present invention features the electrolyte solution comprising main electrolyte 10-30 wt%, solvent 65-89.95 wt%, and additive 0.05-5 wt%; the main electrolyte of ammonium salt compound and with water content of 15-95 %; the organic solvent of alcohol or ether; and the additive of waterproof compound. The electrolyte paper is made of Manila hemp and soaked with the electrolyte solution. The mouth of the aluminum casing is sealed with rubber ring of rubber mixture. The aluminum electrolytic capacitor has electrolyte solution well adsorbed onto the anode aluminum foil and the cathode aluminum foil, no corrosion to leads, high sealing performance and other advantages.

Owner:WUXI WANYU ELECTRONICS

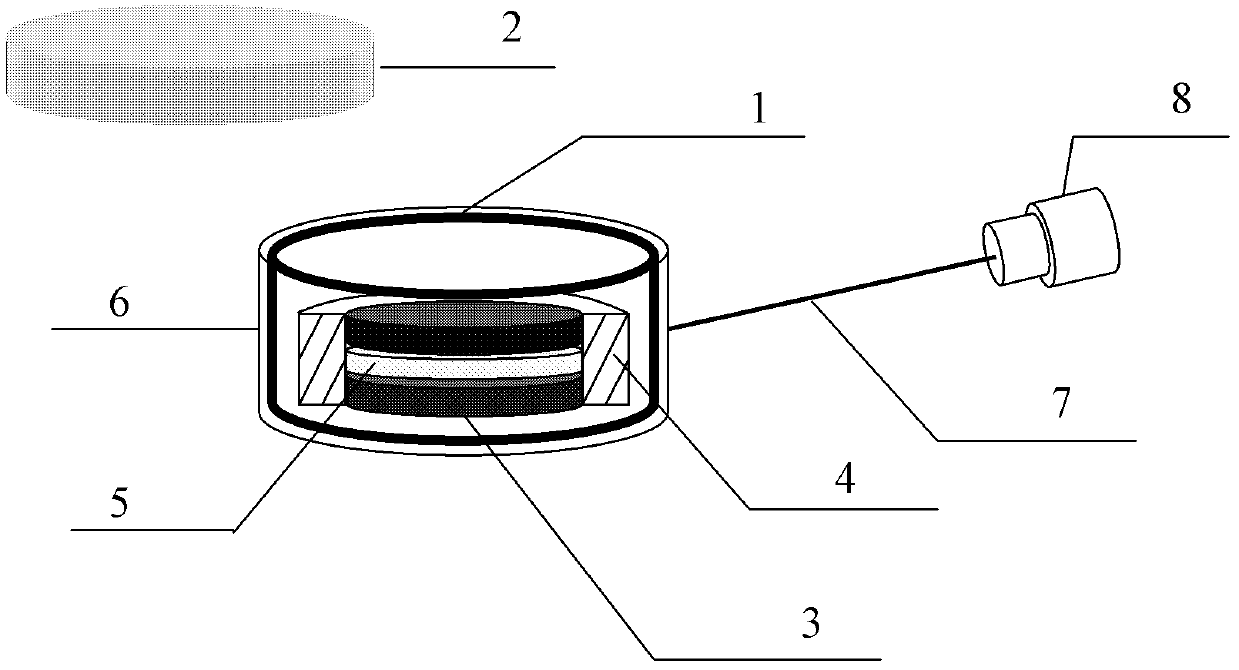

Electromagnetic interference preventing embedded type multifunctional piezoelectric intelligent aggregate of concrete structure

InactiveCN102384803APlay a protective effectHigh measurement accuracyMagnetic/electric field screeningForce measurement using piezo-electric devicesEpoxyShielding gas

The invention discloses electromagnetic interference preventing embedded type multifunctional piezoelectric intelligent aggregate of a concrete structure, which comprises a metal shielding base, a metal shielding cover, d33 mode piezoelectric ceramic chips, an insulating rubber ring, a conducting strip, an epoxy resin insulating layer, a shielding lead and a shielding joint, wherein positive electrodes of the two piezoelectric ceramic chips are arranged face to face; the conducting strip is placed between the positive electrodes of the two piezoelectric ceramic chips; the conducting strip is welded with the positive electrode of the shielding lead to form a whole; a peripheral shielding line of the shielding lead is welded with the metal shielding base to form a whole; the side surfaces of the piezoelectric ceramic chips are banded by utilizing the insulating rubber ring; the metal shielding base is connected with the metal shielding cover to form a whole through a screw thread, and certain precompression is applied to the upper surface and the lower surface of the whole; after the connecting parts of the metal shielding base and the metal shielding cover are welded, an epoxy resin insulating waterproof layer is coated on a metal shell; and after the metal shell is air-dried after 24 hours, the piezoelectric intelligent aggregate is formed. Certain coarse sand can be pasted tothe metal shell when the epoxy resin is coated on the outer part of the metal shell, so as to guarantee good compatibility between a sensor and concrete. The piezoelectric intelligent aggregate has the advantages of remarkable shielding effect, interference exemption of a concrete internal stress field, overall process monitoring of concrete internal dynamic damage evolution, explicit force bearing path, simple structure and low construction cost.

Owner:DALIAN UNIV OF TECH

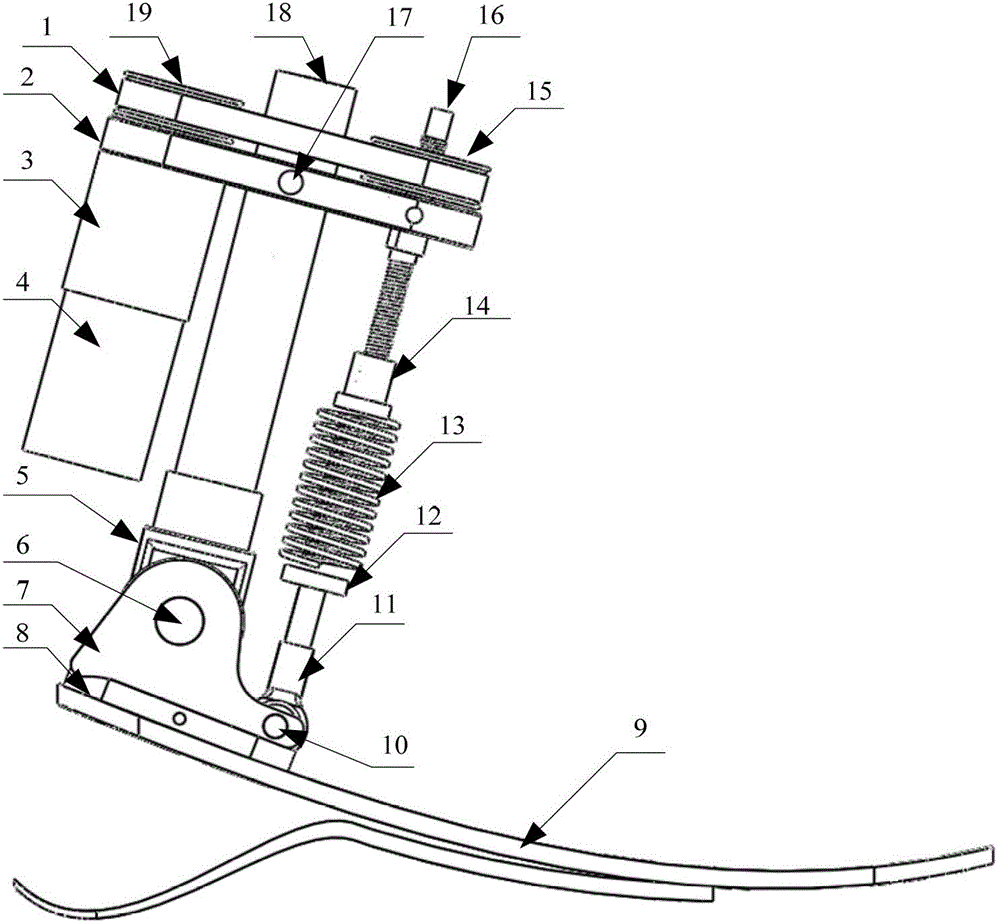

Active-passive type ankle joint prosthesis and movement mode thereof

The invention discloses an active-passive type two-degrees-of freedom ankle joint prosthesis, comprising a carbon fiber energy storage sole, a motor, a speed reducer, a motor fixing supporting seat, a belt pulley transmission device, a carbon fiber pipe, a ball screw, an energy storage springs, joint bearings, energy storage rubber rings and joint supporting seats, wherein the carbon fiber energy storage sole is connected with the carbon fiber pipe through the joint supporting seats; the motor fixing supporting seat is connected with the carbon fiber pipe through an active pin; the motor is fixedly arranged on one end of the motor fixing supporting seat; the ball screw is fixedly arranged on the other end of the motor fixing supporting seat; two ends of the motor fixing supporting seat are connected by the belt pulley transmission device; the energy storage springs areis connected with a ball screw nut; and the energy storage rubber rings are connected with the joint bearings and the joint supporting seats through a shaft. The ankle joint prosthesis provided by the invention not only can completely provide required energy for human gait, but also can adapt to various landforms; in addition, the ankle joint prosthesis can completely imitate movement angles of a human ankle joint on a sagittal plane or a coronal plane; and therefore, the normal walking requirement of an amputation patient can be satisfied better.

Owner:SHANGHAI JIAO TONG UNIV

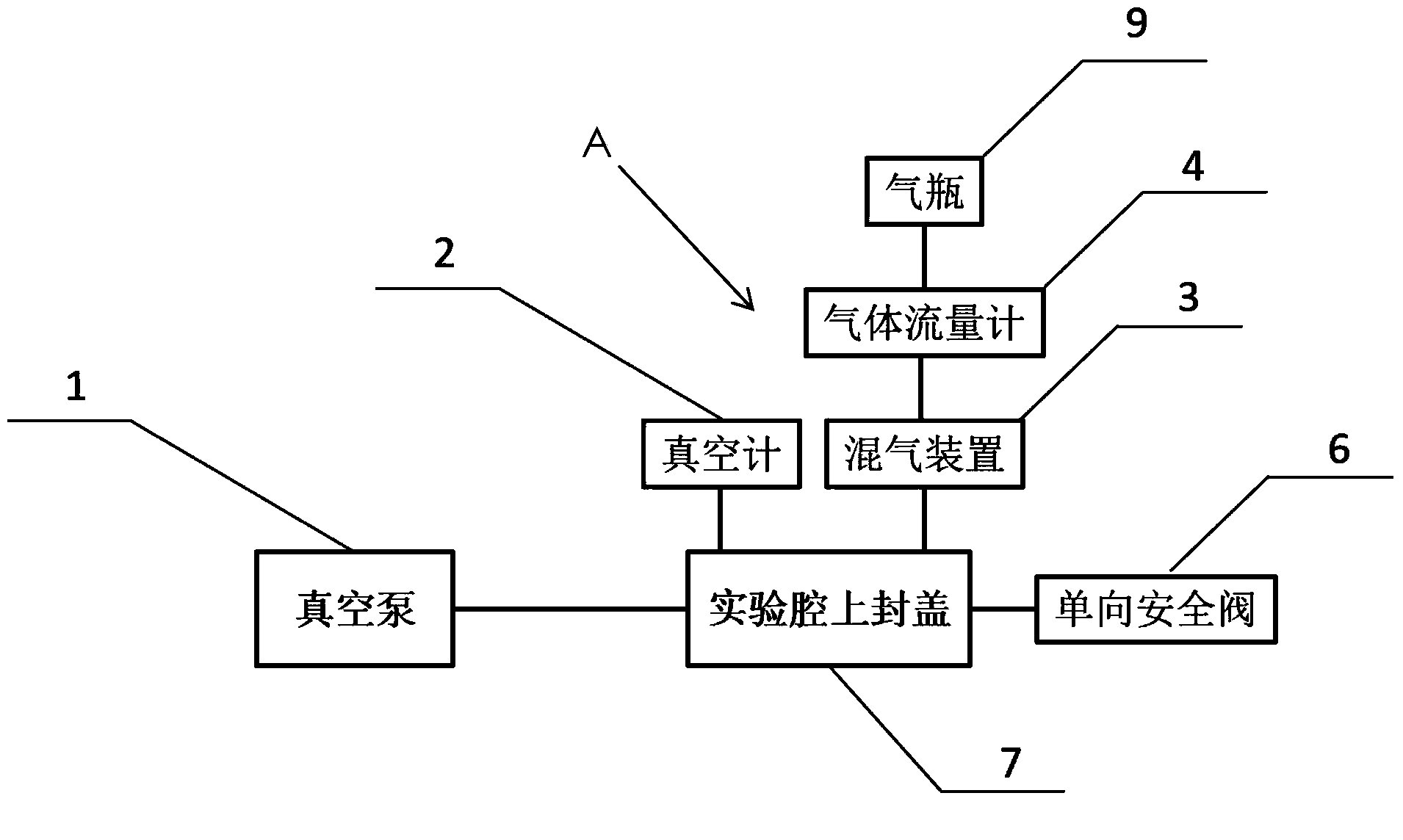

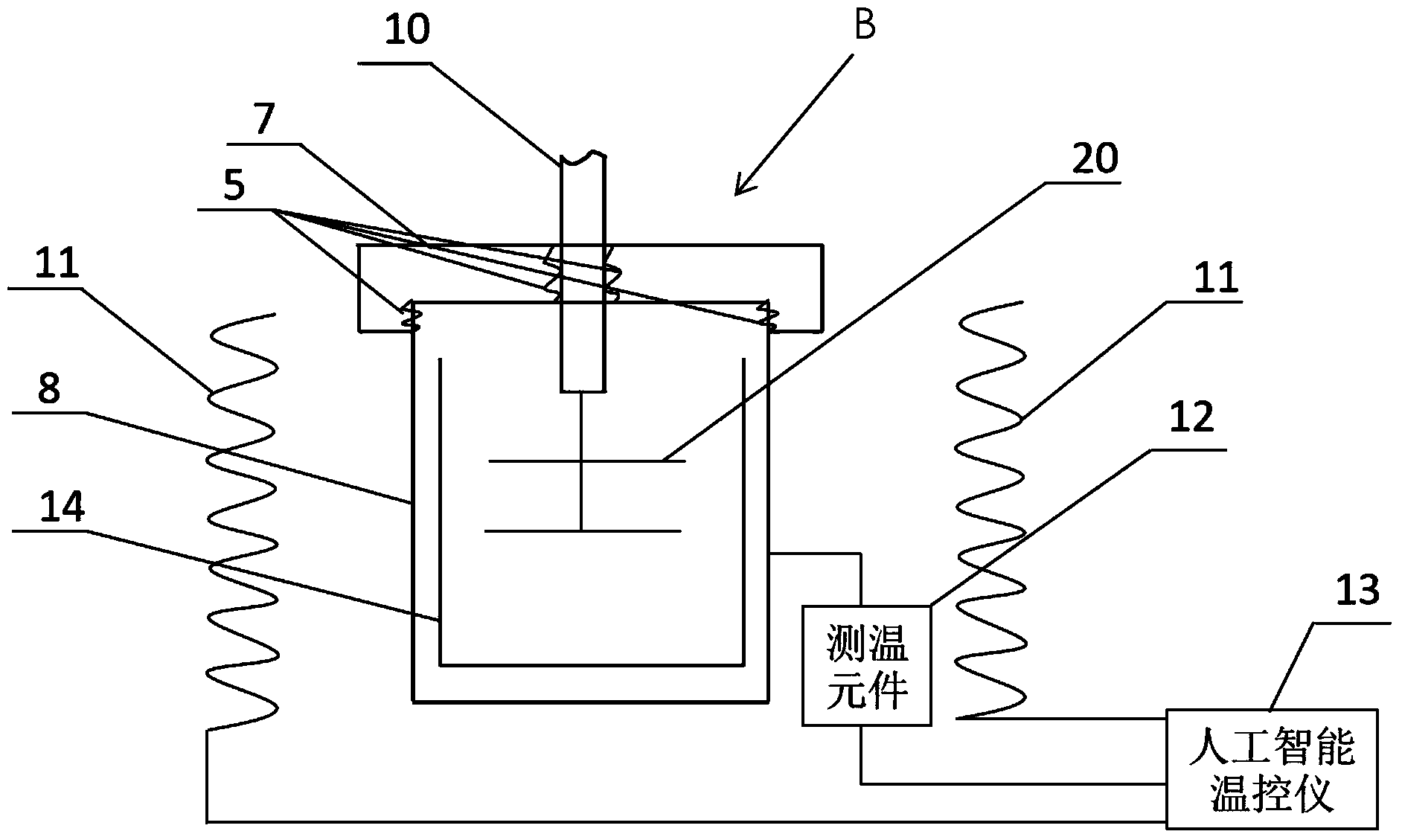

Rotary dynamic metal corrosion testing device and using method thereof

ActiveCN103454210AGuaranteed tightnessAchieving Relative Motion Rate ChangesWeather/light/corrosion resistanceEngineeringLiquid metal

The invention relates to the field of high-temperature corrosion of liquid metal and particularly relates to a rotary dynamic metal corrosion testing device and a using method thereof. The device is provided with a gas path and sealing system, a temperature control and reactor system and a lifting and rotating system, wherein the gas path and sealing system mainly comprises a vacuum pump, a resistance type vacuum gauge, a gas mixing device and a gas flow controller; the temperature control and reactor system mainly comprises heating elements, a temperature measuring element, an artificial intelligent temperature controller, a heat resistant steel experiment cavity, an experiment cavity upper sealing cover and glass lining; the lifting and rotating system mainly comprises a stepping motor, a sliding slipway, a ball screw, limiting stoppers, a rotary rod and a sample holder. According to the device, the experiment environment atmosphere is controllable through the extrusion sealing mode of metal and a high-temperature rubber ring, the experiment temperature is accurate and controllable through intelligent temperature control, the relative movement of a sample and a corrosive medium (liquid metal) is realized through the mode that rotary motor drives an agitator arm to rotate, and high-temperature dynamic corrosion experiment is realized under the simple dynamic equipment composing condition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

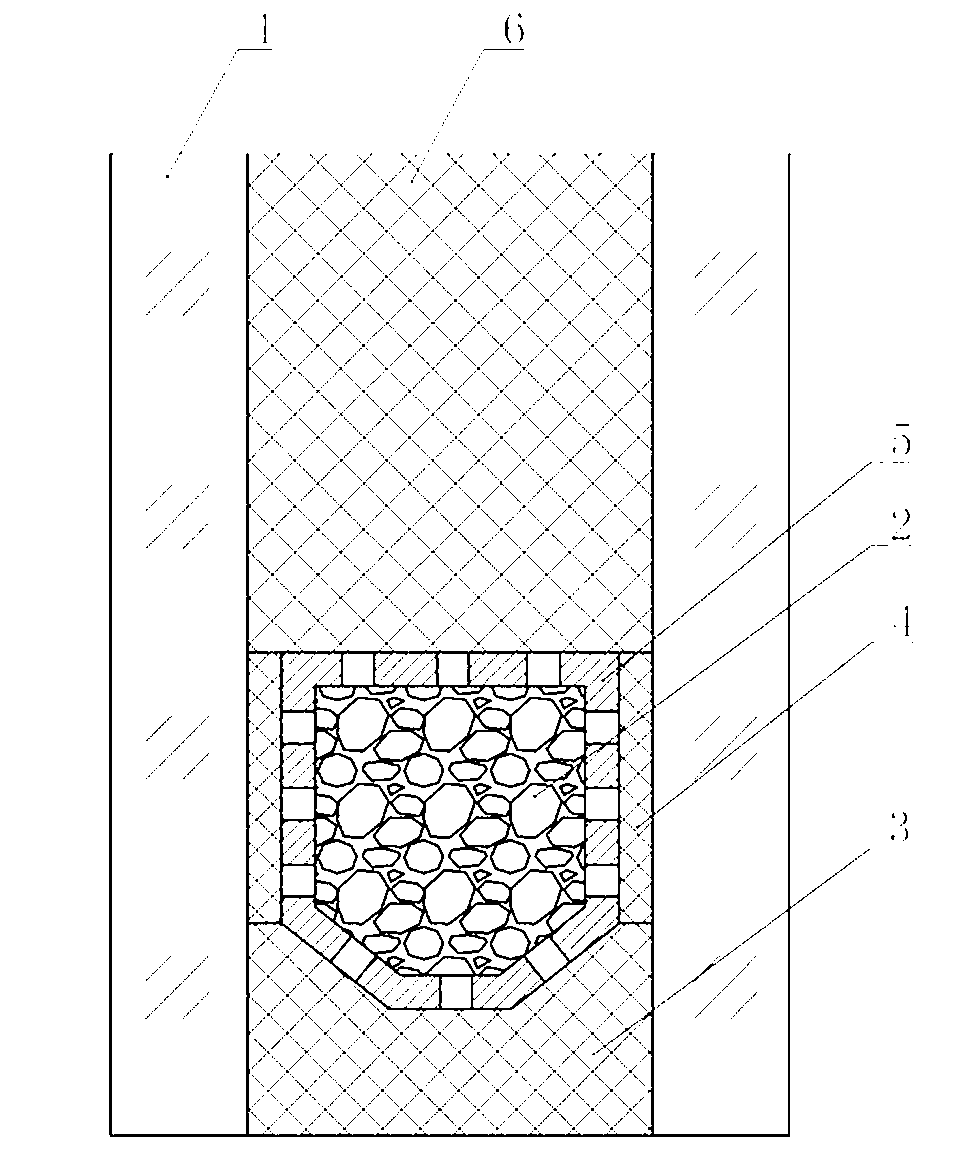

Model test device of shield tunnel uplifting mechanism

ActiveCN104677664AAccurate responseAccurately respond to on-site construction conditionsStructural/machines measurementRubber ringEngineering

The invention provides a model test device of shield tunnel uplifting mechanism. The model test device comprises a main soil box for accommodating test soil, a tunnel model segment, a latex film for sealing and connecting the tunnel model segment, a displacement meter for measuring the tunnel uplifting amount, a displacement meter bracket for fixing the displacement meter, weights inside a tunnel for simulating excavated soil, a latex film fixing plate for fixing the latex film and a rubber ring for hooping the latex film. The model test device is an indoor model test device capable of simulating the tunnel uplift when the tunnel soil is evacuated, can obtain uplifting rules of the tunnel in the case of different soils, different soil coverage depths and different excavation lengths, so that the model test results achieve the purpose of effectively and accurately reflecting the site construction conditions.

Owner:SHANGHAI JIAO TONG UNIV

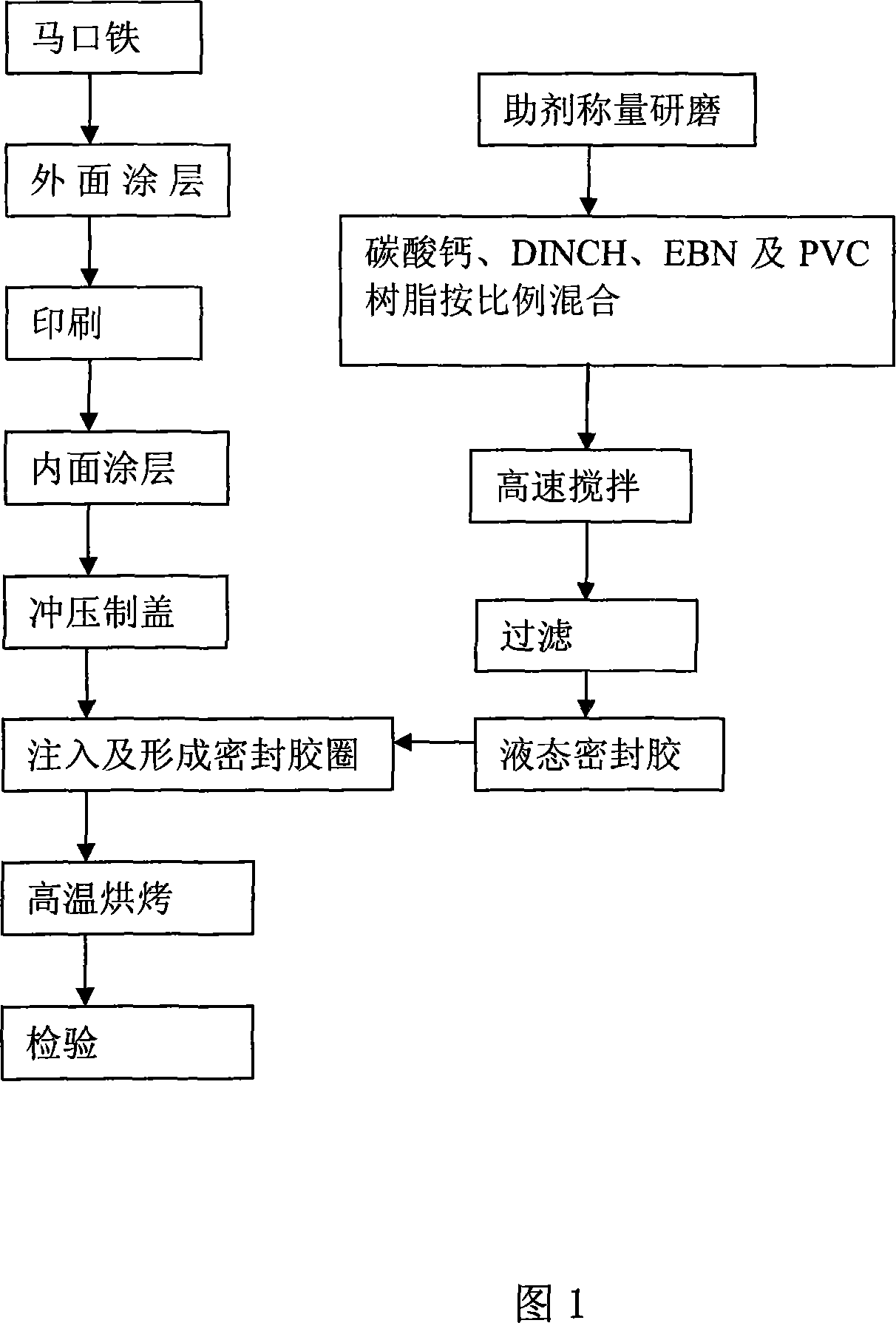

Seal rubber ring of paw-type rotating cover

The invention relates to a sealing washer of claw spin-cap. Its manufacturing method show as follow: the raw materials are PVC paste resin and its reshaping accessory ingredient. The described reshaping accessory ingredient includes stabilizer ESBO and calcium stearate, paraffin lubricant, titanium dioxide pigment. It grinds the reshaping accessory ingredient to slurry, and then puts the slurry into a high-speed mixer, and then it adds PVC paste resin as main raw material and calcium carbonate as filling material, then it mixes the mixture with high-speed for 15 to 25 minutes and achieves liquid sealant through filtering. It injects the liquid sealant into the medial side of the cap and forms a thin layered liquid sealant with the high-speed rotating of the cap, and the cape is baked at 180 deg.C +- 10 deg.C for 60 to 90 seconds. Its character is that it adds the secondary raw material PVC resin, DINCH plasticizer and LGFLEX EBN plasticizer before mixing.

Owner:WUXI HUAPENG BOTTLE CAP

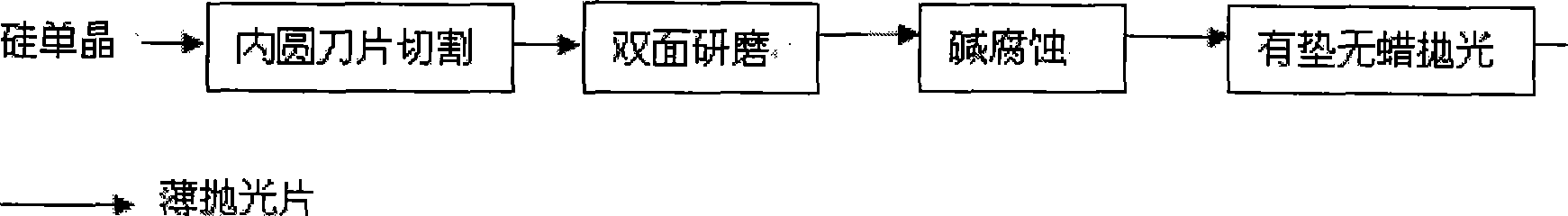

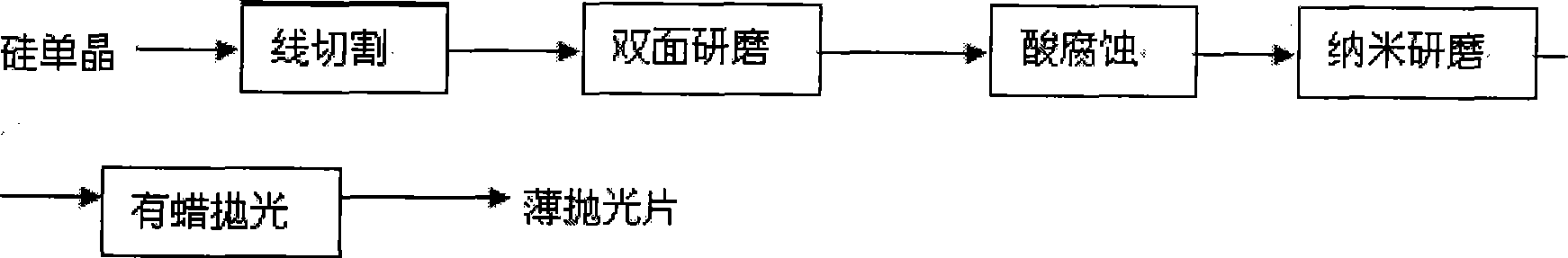

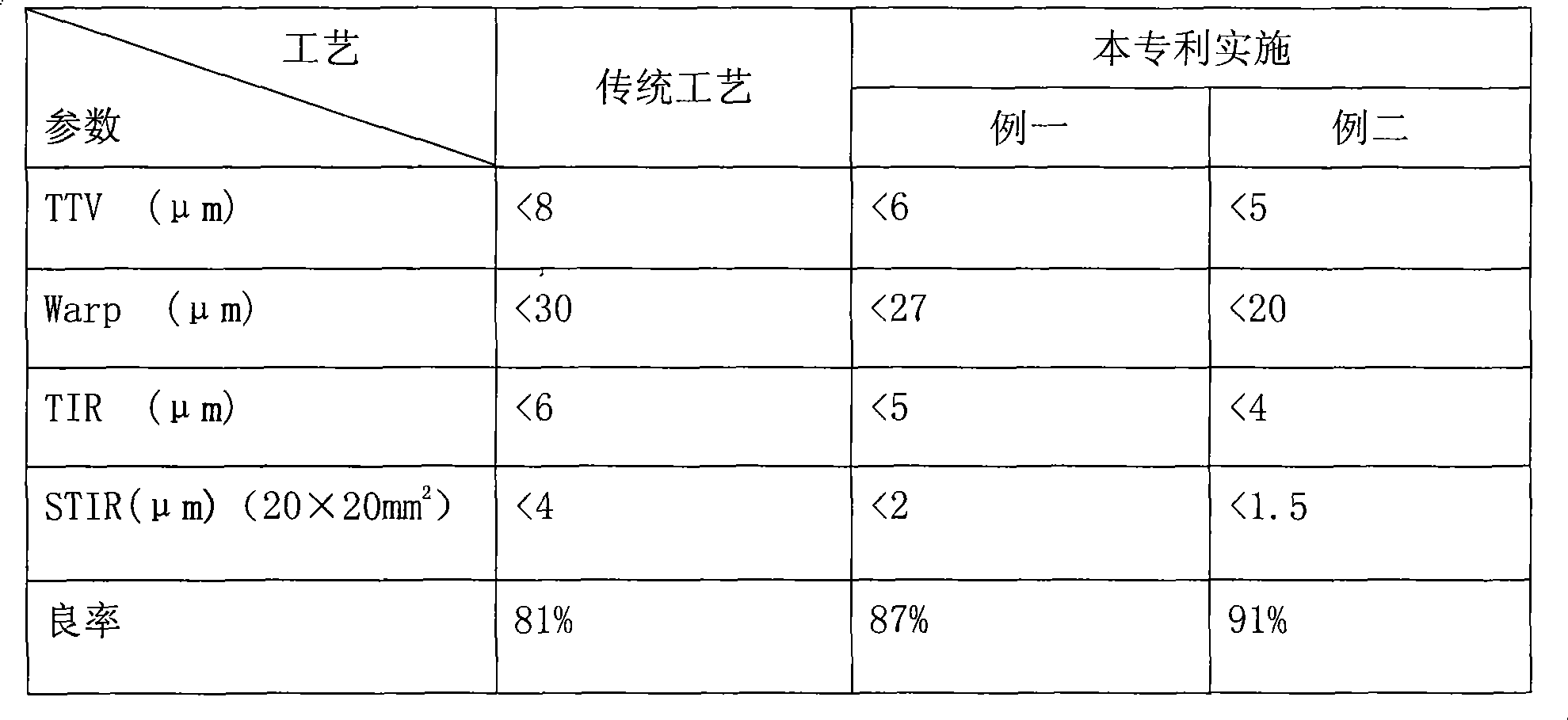

Processing method of thin silicon monocrystal polished section

ActiveCN101431021AImprove productivityImprove qualitySemiconductor/solid-state device manufacturingRubber ringWax

The invention relates to a method for producing thin monocrystalline silicon polished wafer. The method comprises the following steps: Step 1, monocrystalline silicon is sliced up by adopting wire cutting; Step 2, a slotting double-face grinder which adopts a stainless steel planetary sheet with an internal circle inlaid with a soft rubber ring is adopted to carry out double-surface grinding on the sliced monocrystalline silicon; Step 3, a technique of acid corrosion thinning is adopted, wherein, the removal amount resulted from acid corrosion is 10 micrometers to 60 micrometers; Step 4, a nanometer grinding technique is adopted, wherein, the removal amount resulted from nanometer grinding is 1 micrometer to 25 micrometers; and Step 5, a wax polishing technique is adopted, wherein, the removal amount resulted from wax polishing is 5 micrometers to 30 micrometers. By adopting a new technical route and a new technical procedure for producing new thin monocrystalline silicon polished wafer, the invention effectively improves TTV level, WARP level, TIR level, STIR level and other levels as well as the finished product rate of the thin monocrystalline silicon polished wafer.

Owner:JINGHUA ELECTRONICS MATERIAL

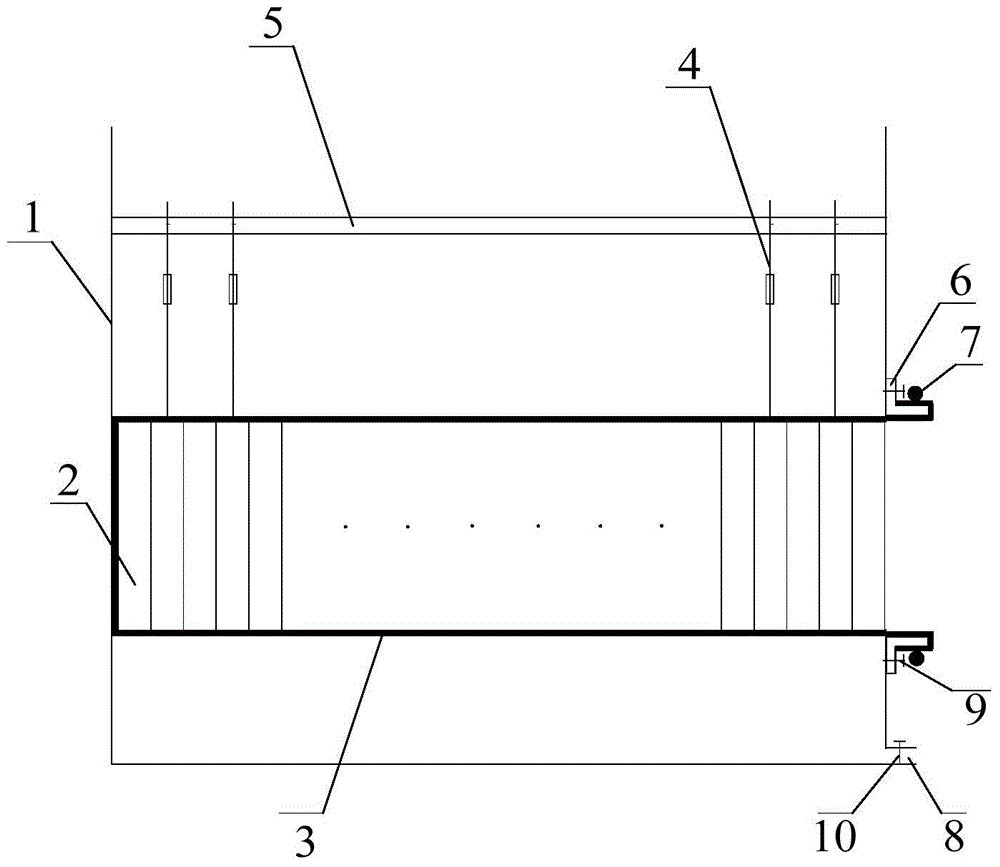

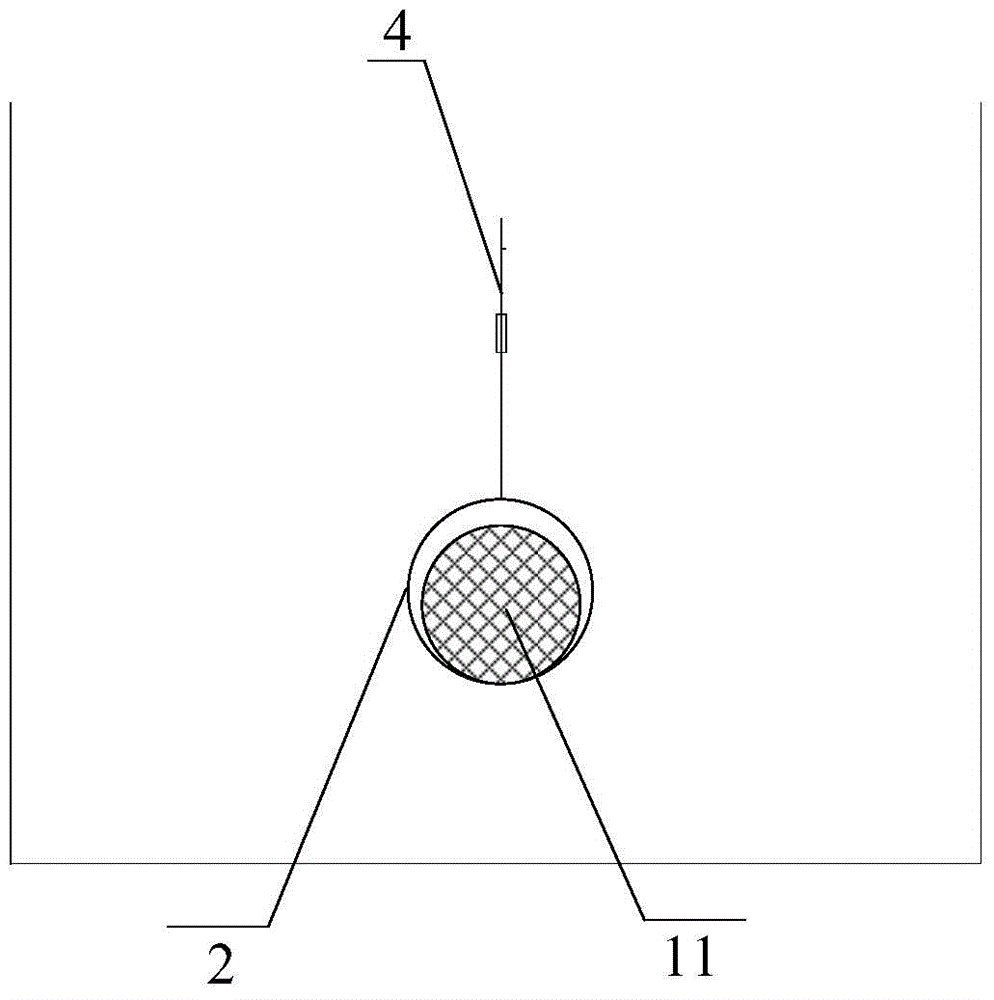

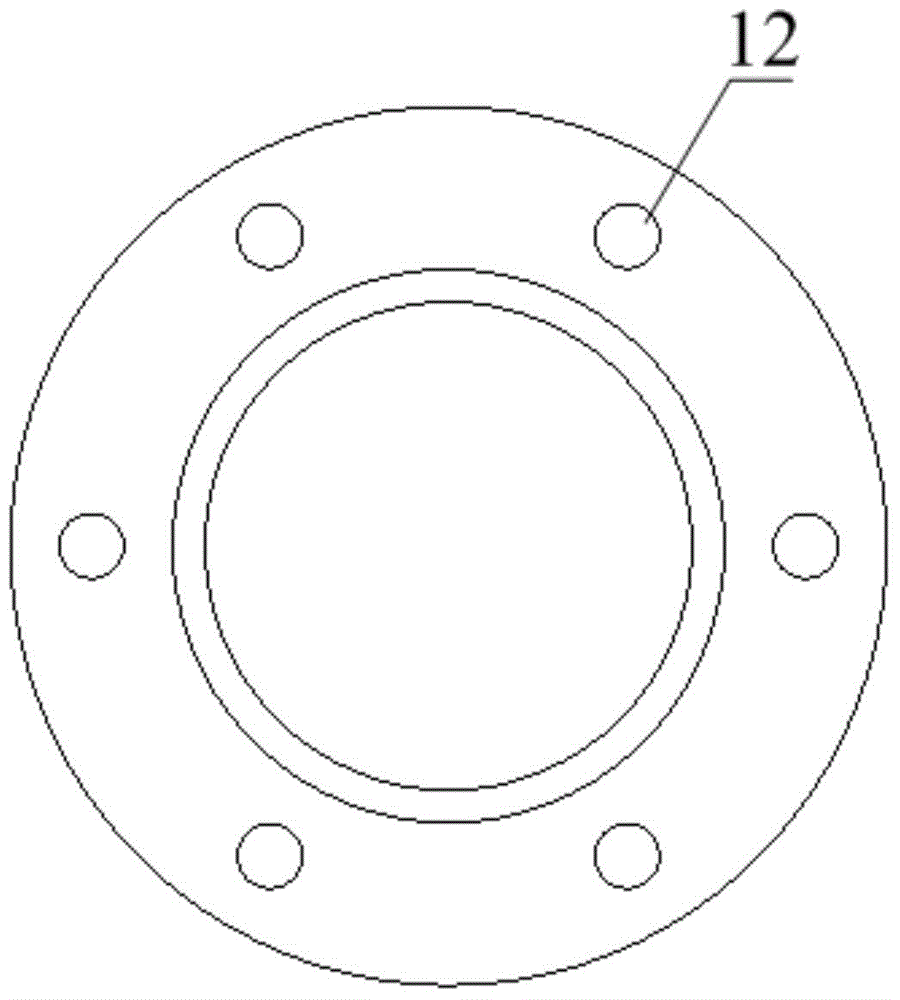

Joint surface dynamic characteristic parameter testing device of rolling guide rail and testing method thereof

InactiveCN102095574AAccurate acquisitionReduce complexityMachine part testingGravity centerVibration exciter

The invention relates to a joint surface dynamic characteristic parameter testing device of a rolling guide rail, which can be simplified to a single-degree-of-freedom system. The joint surface dynamic characteristic parameter testing device comprises a base, a mounting bottom plate, a rolling guide rail, a rolling guide rail slider, a bridge plate, a plurality of piezoelectric acceleration sensors, an exciter, an elastic rope, a rubber ring, a frame, an impedance head, a normal pressing bolt, a charge amplifier, a data collector, a power amplifier and a computer. Compared with the prior art,the joint surface dynamic characteristic parameter testing device has the significant advantages of compact structure and clear testing principle, and can simultaneously measure the joint surface dynamic characteristic parameters in the normal and lateral directions of the rolling guide rail. In addition, the device can measure the joint surface dynamic characteristic parameters under different load states by adjusting the pre-tightening force of the normal pressing bolt; the exciting force direction passes through the gravity center of the bridge plate during the measurement; the vibration signals of the bridge plate and the base can be measured at the same time; and the influences of basic vibration signals can be eliminated during the measurement of the system frequency response function. Therefore, the joint surface dynamic characteristic parameter testing device has the advantages of high efficiency, high stability and high accuracy.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com