Seal rubber ring of paw-type rotating cover

A sealing rubber ring and unscrew cap technology, applied in sealing, closing, packaging, etc., can solve problems such as odor, large volatilization, easy migration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

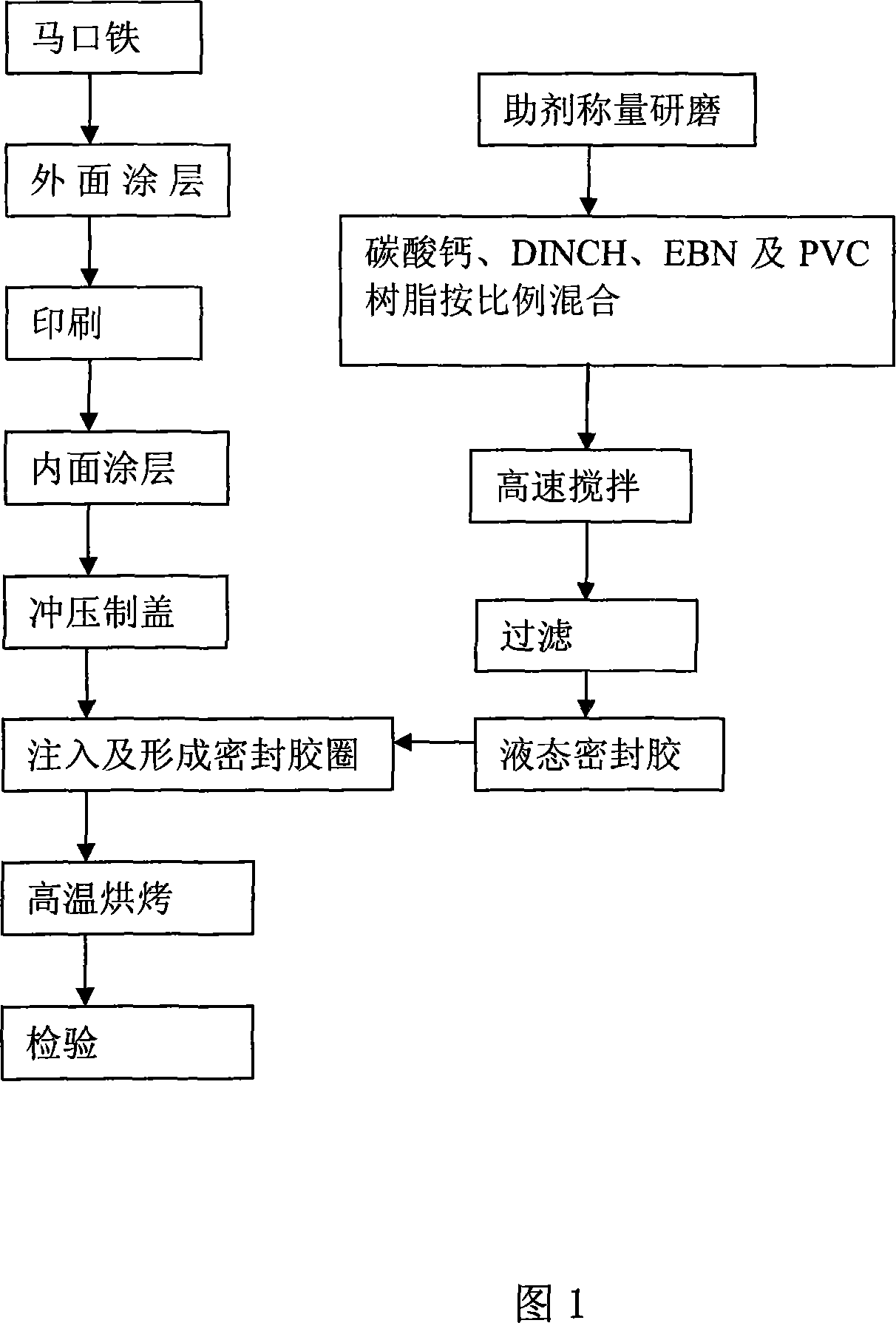

[0032] The present invention will be further described below through examples and FIG. 1 .

[0033] Weigh the parts by weight of each component as shown in Table 2 below, put the weight parts of epoxidized soybean oil, calcium stearate, paraffin, and titanium dioxide into a conventional ball mill to grind into a slurry; grind the slurry Put the material into the high-speed mixer, as shown in Table 2, for embodiment 2 to embodiment 8, add the weight of polyvinyl chloride paste resin, calcium carbonate, polyvinyl chloride blending resin and DINCH plasticizer in the high-speed mixer simultaneously part, also add the weight part of LGFLEX EBN plasticizer in addition for embodiment 5,6,7,8, do not add polyvinyl chloride blending resin for embodiment 1, other added composition and embodiment 5,6,7, 8 are the same, but the weight parts of the added ingredients are different from those of Examples 5, 6, 7, and 8; the ingredients added to the high-speed mixer in each of the above examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com