Patents

Literature

46results about How to "Simple and low-cost process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

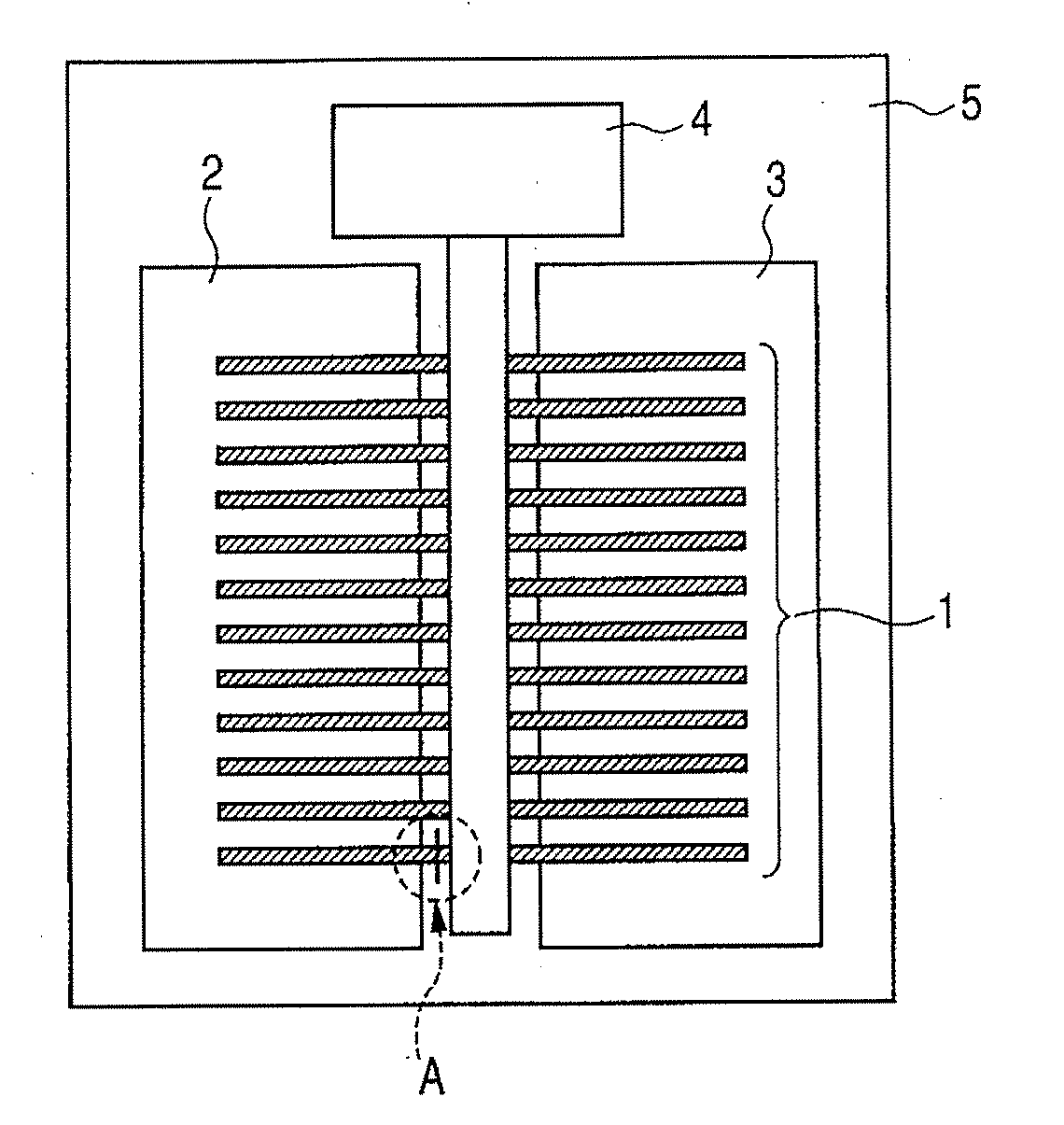

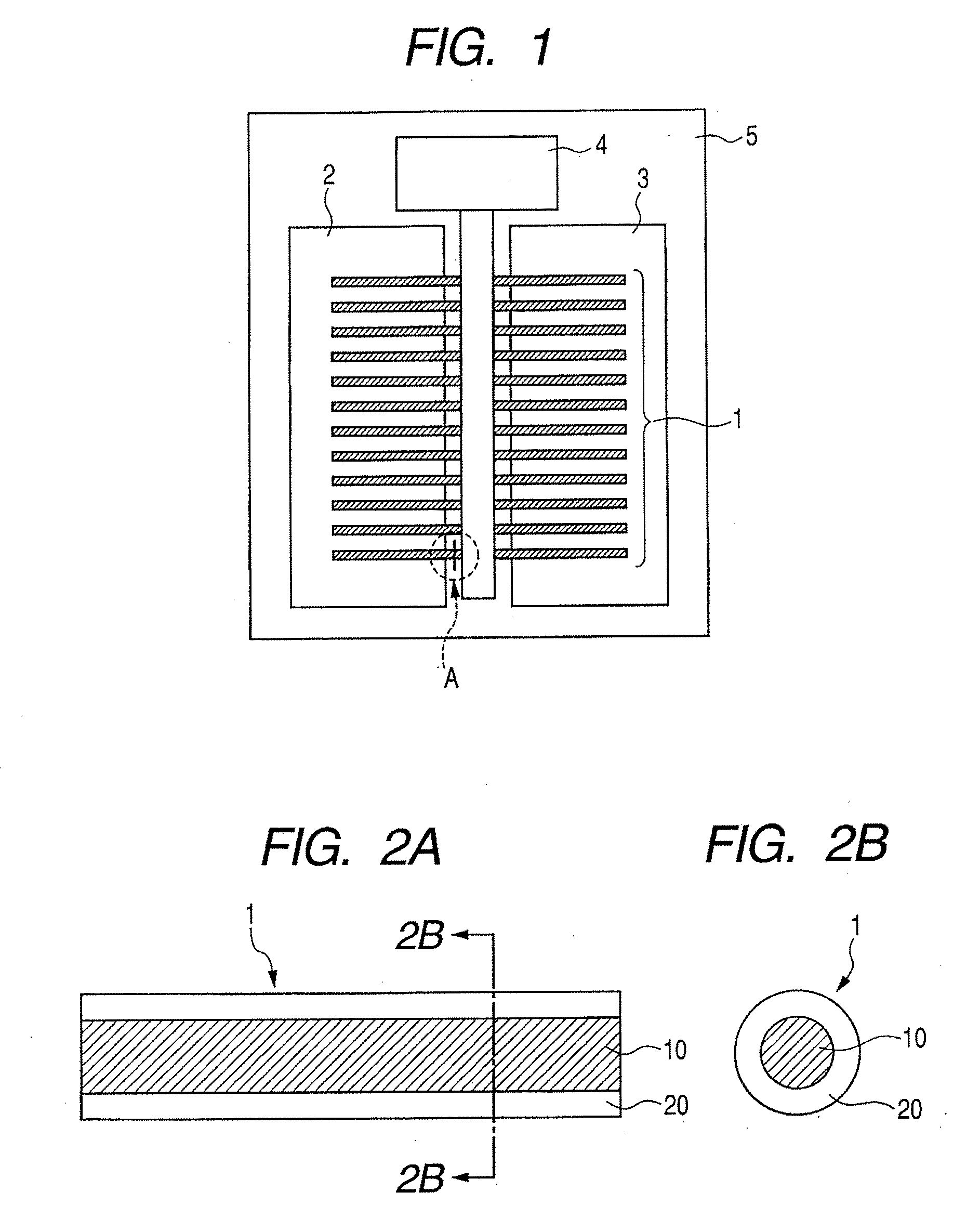

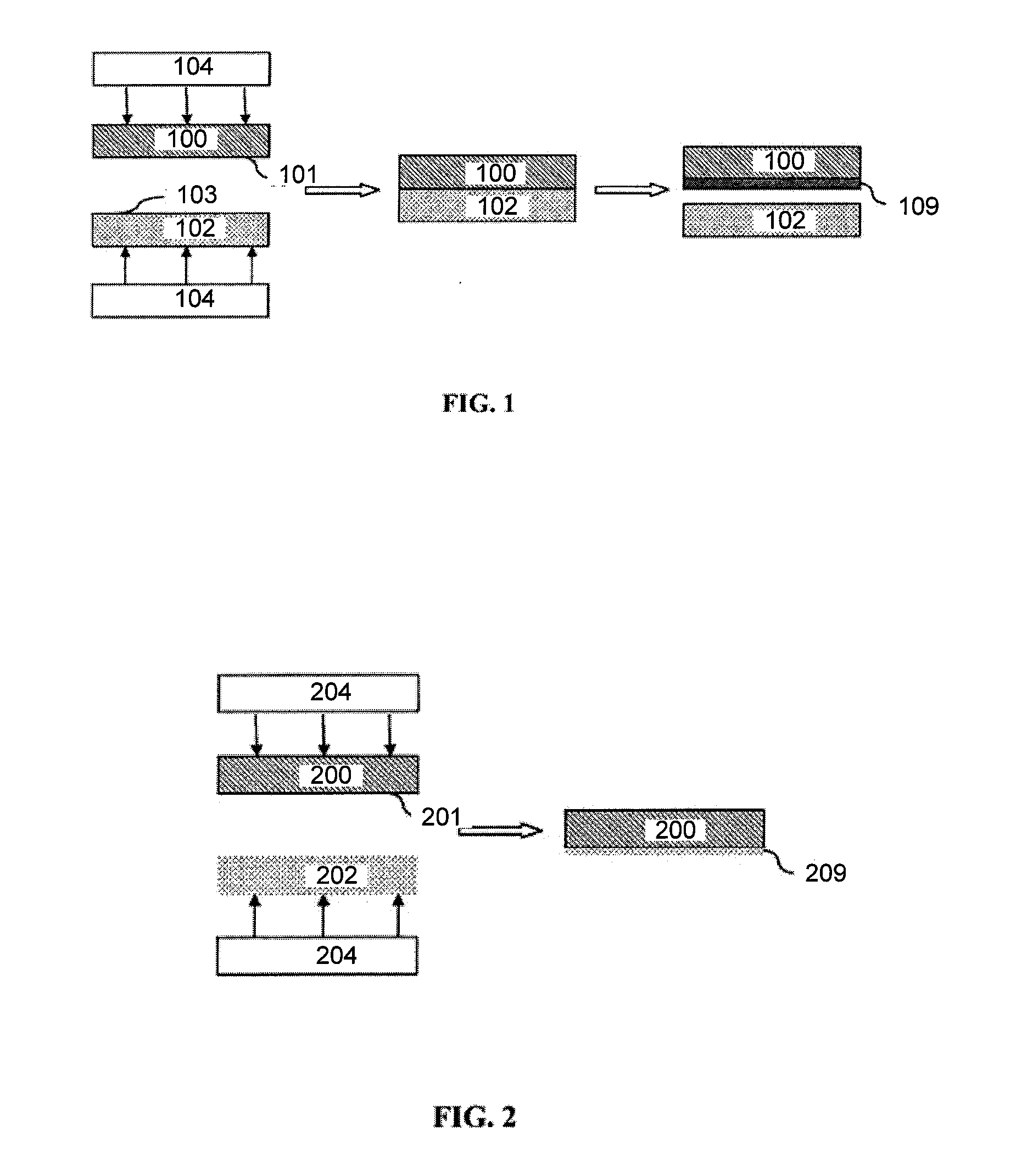

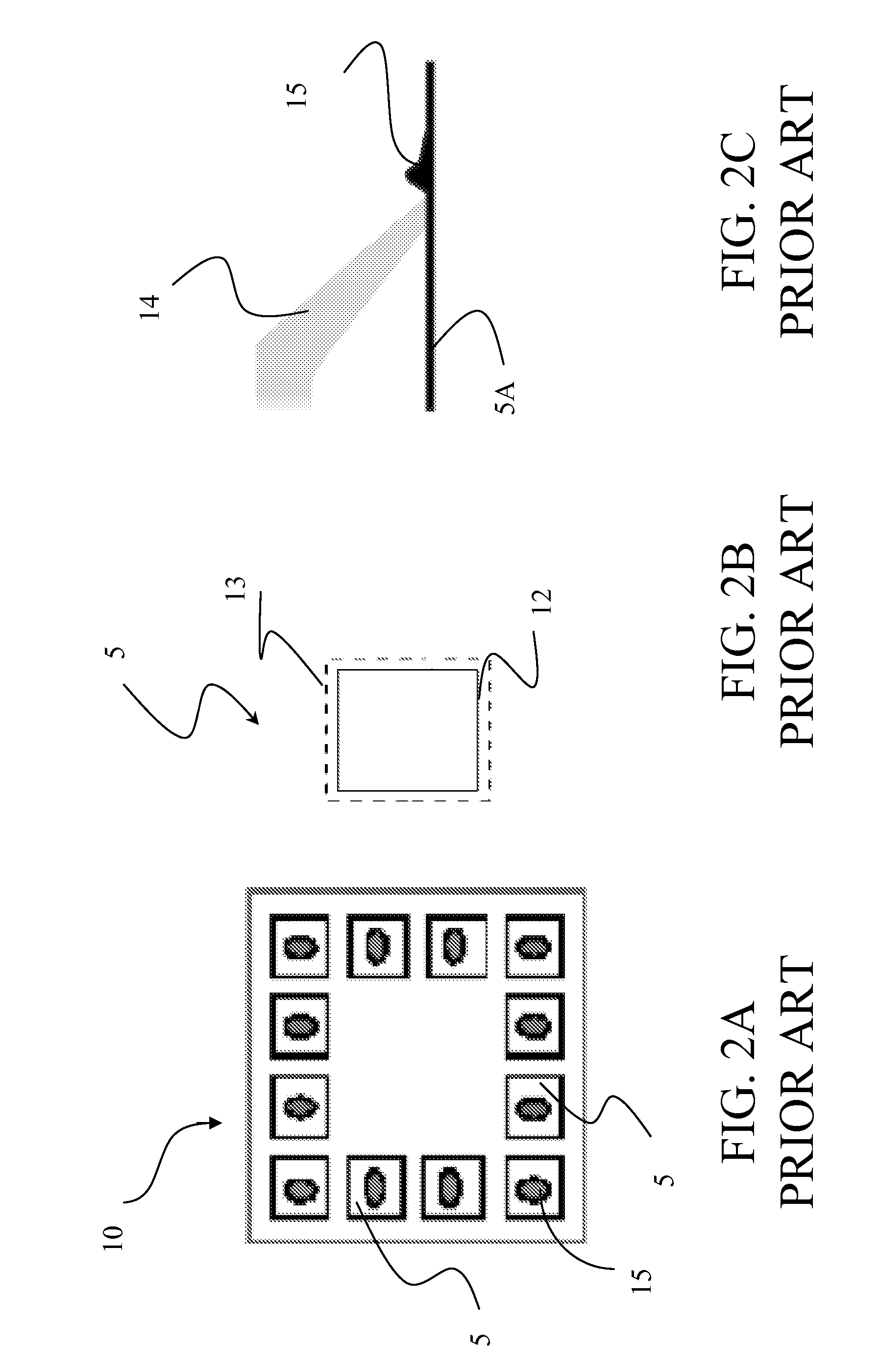

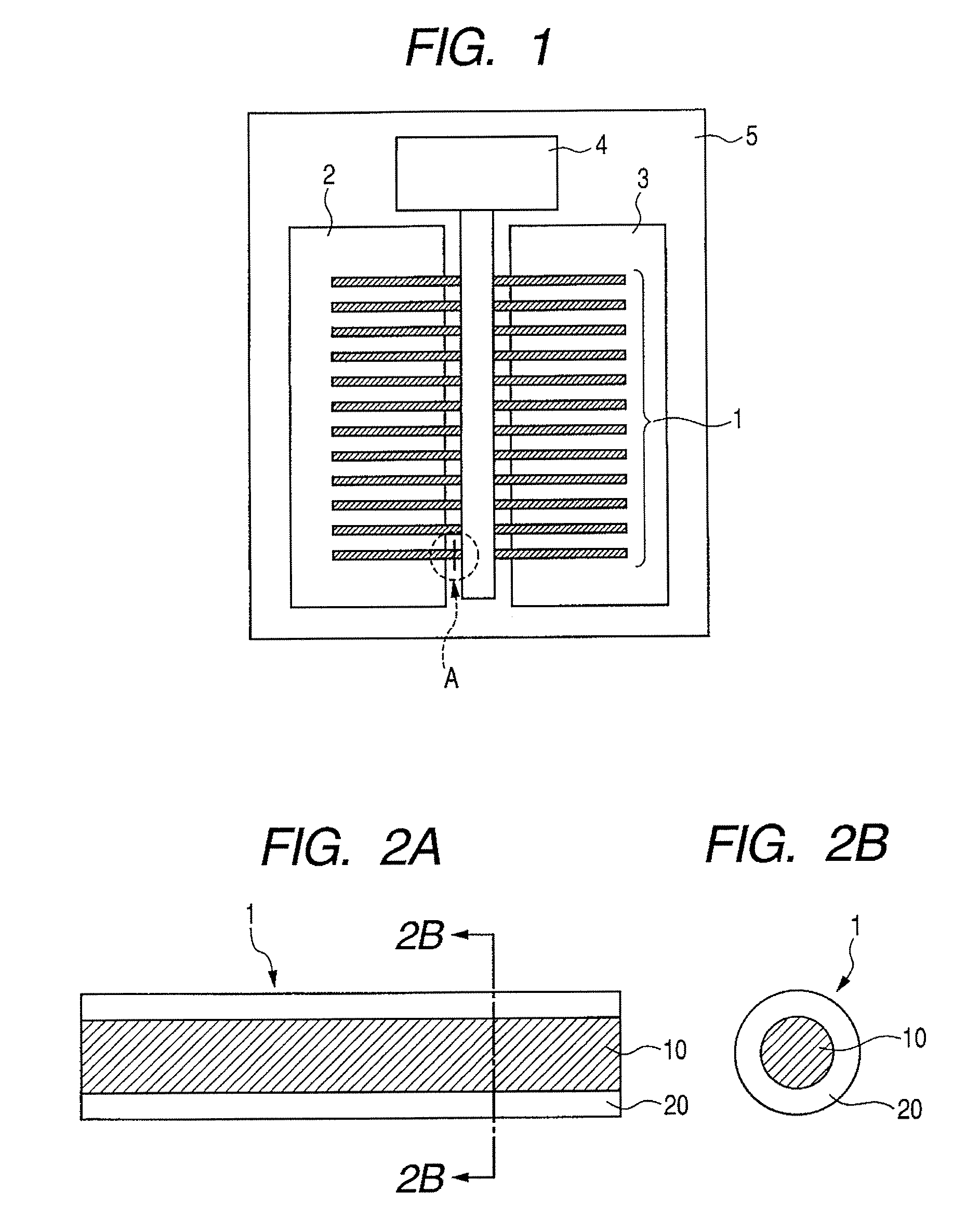

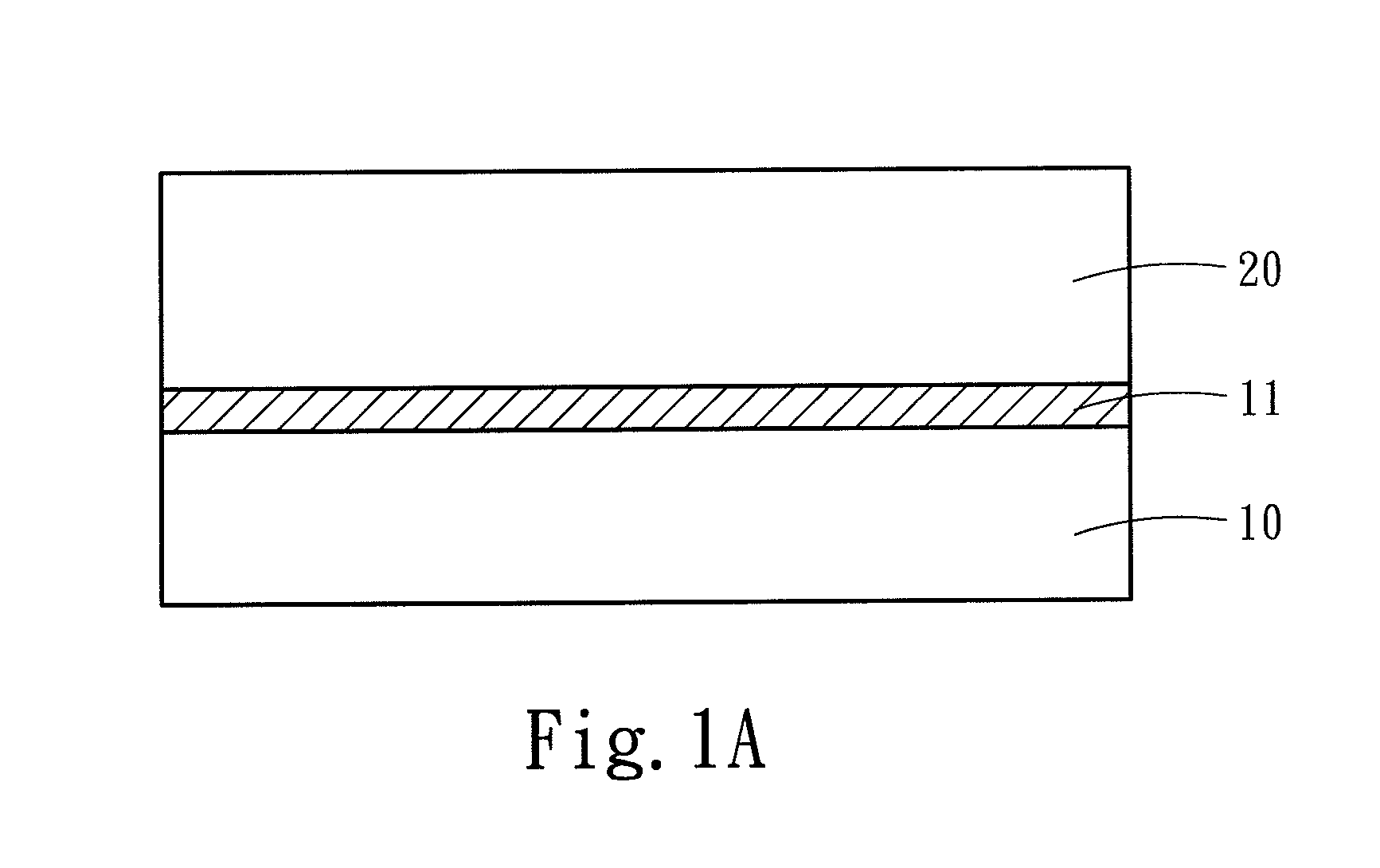

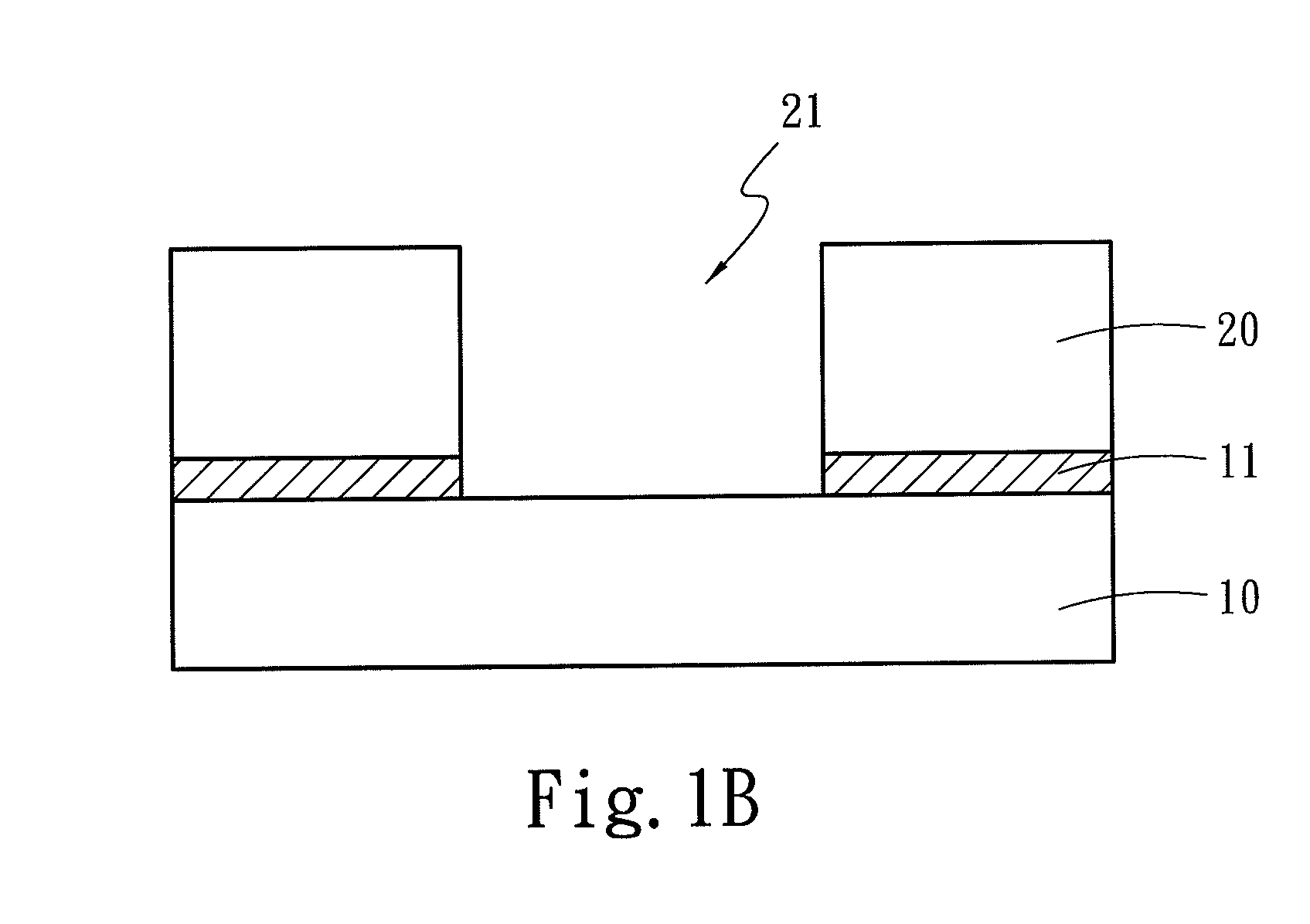

Electric device having nanowires, manufacturing method thereof, and electric device assembly

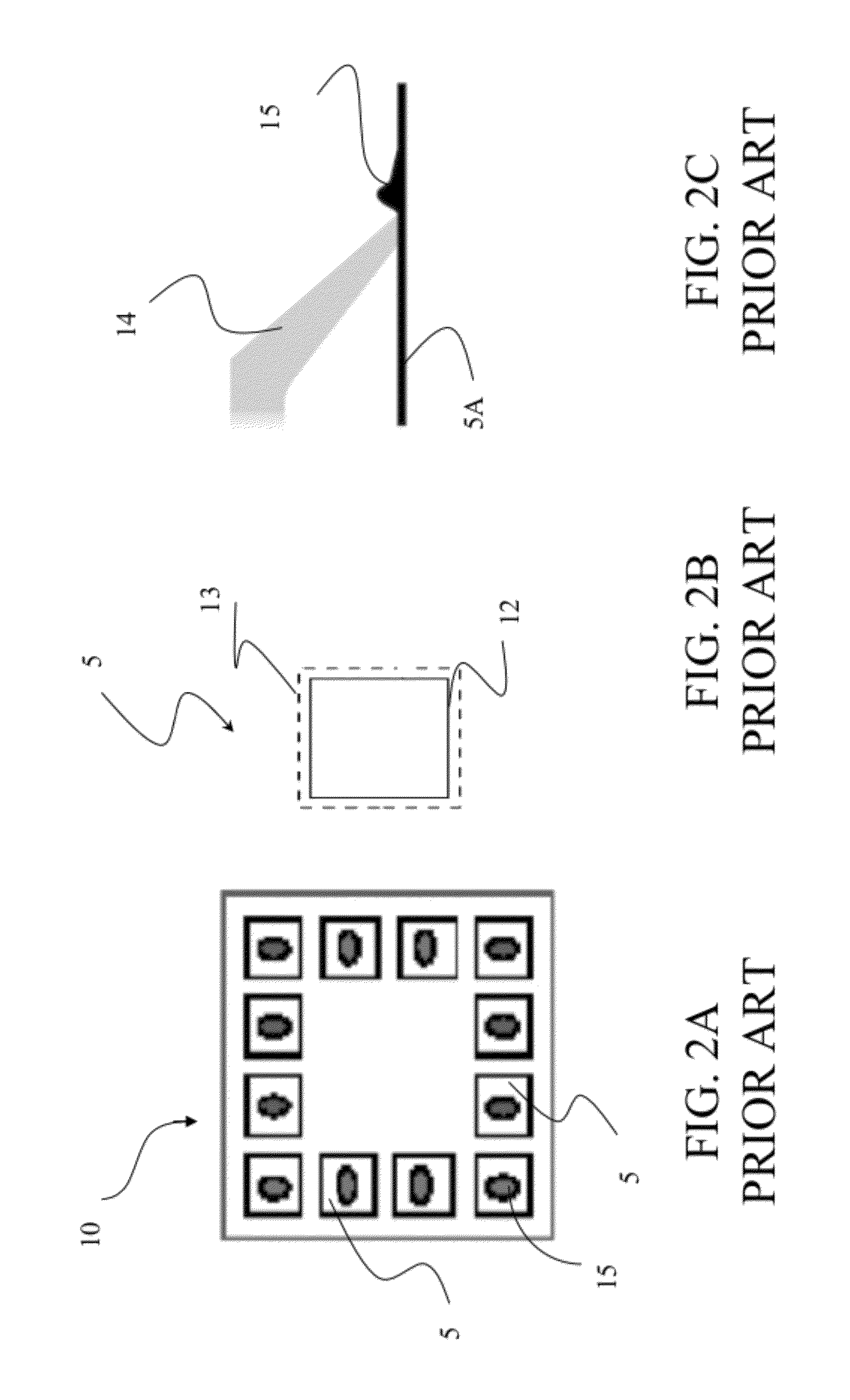

InactiveUS20070126037A1Simple and low-cost processImprove performanceNanoinformaticsSolid-state devicesElectricityNanowire

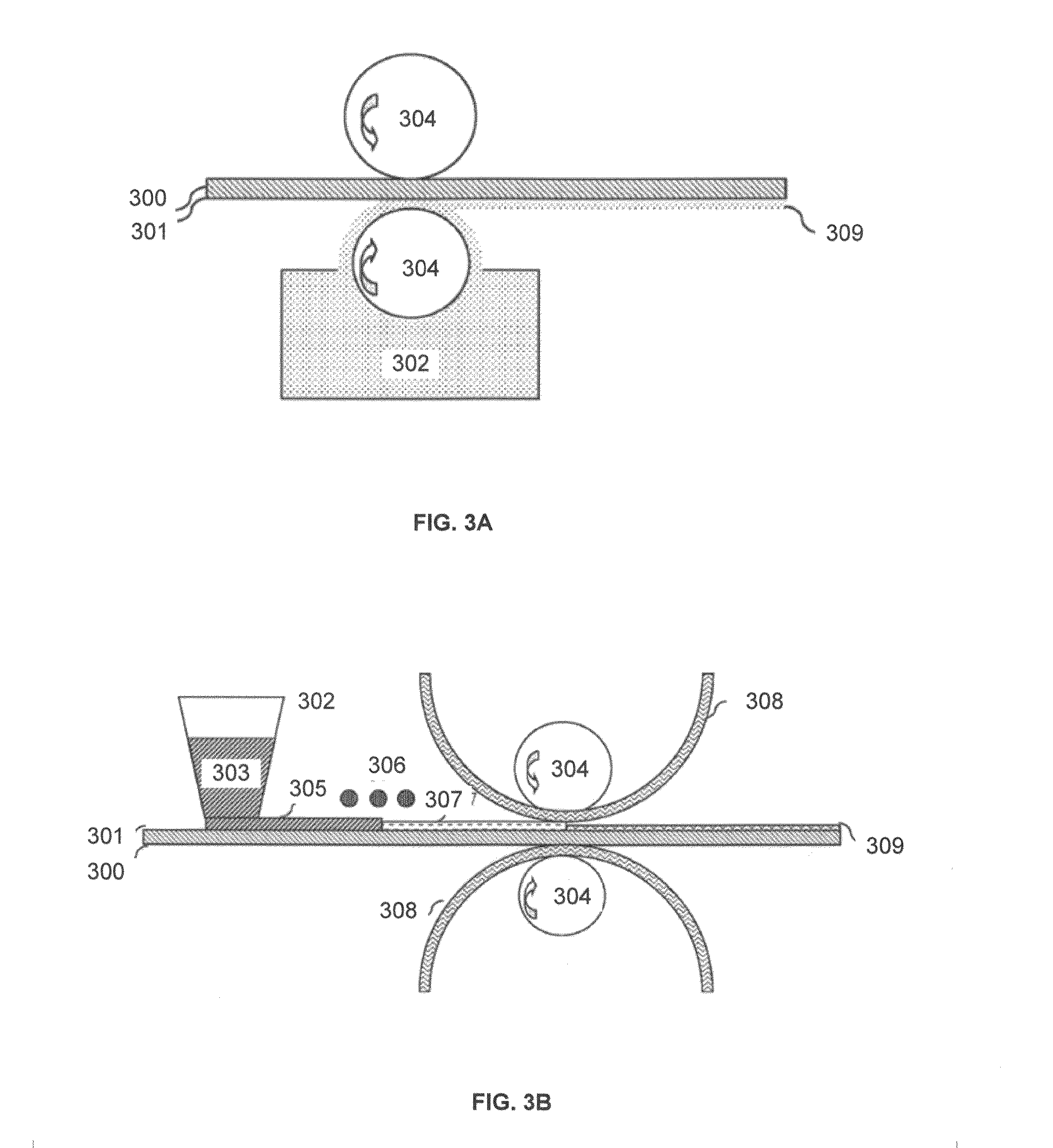

An electric device having a plurality of nanowires, in which at least one of the nanowires is cut or changed in its electric characteristics so as to have a desired characteristic value of the electric device.

Owner:CANON KK

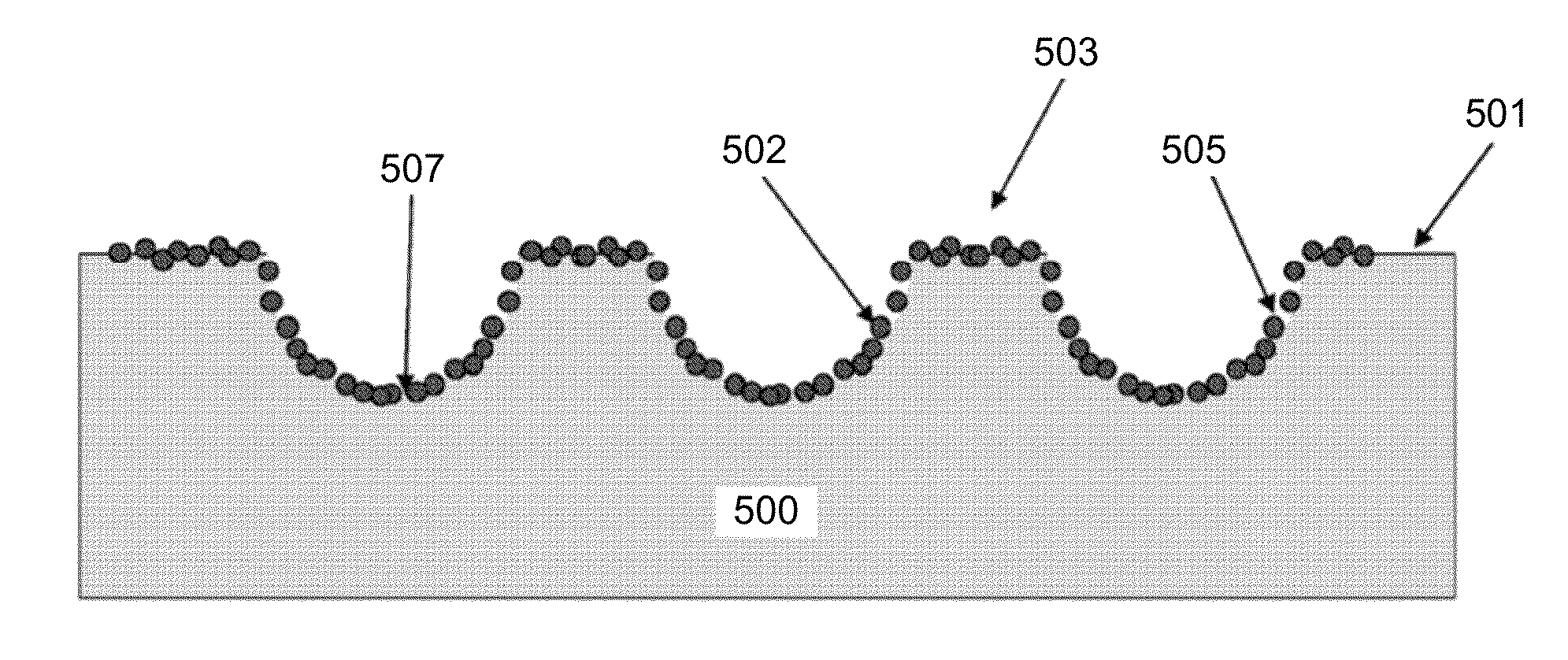

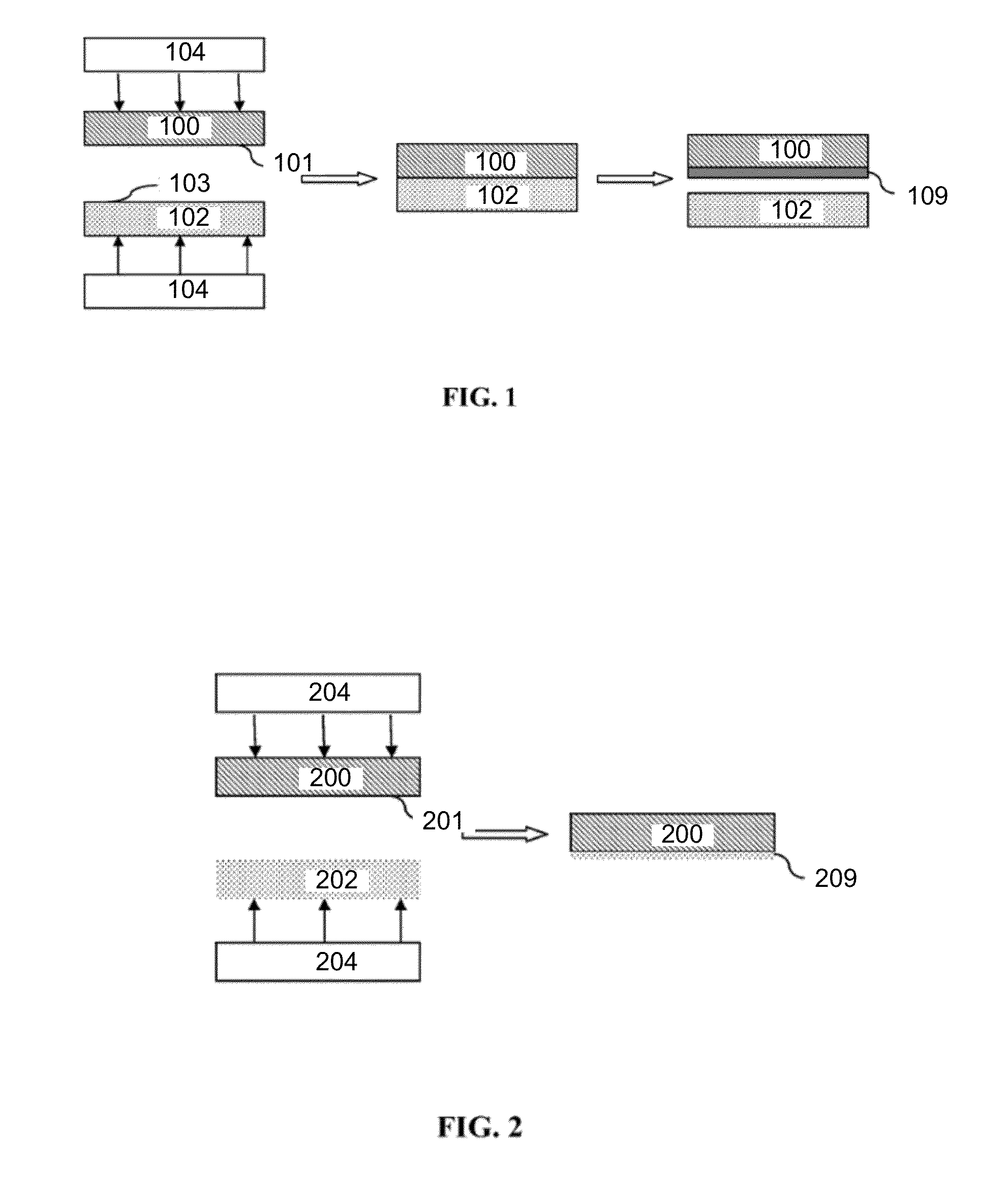

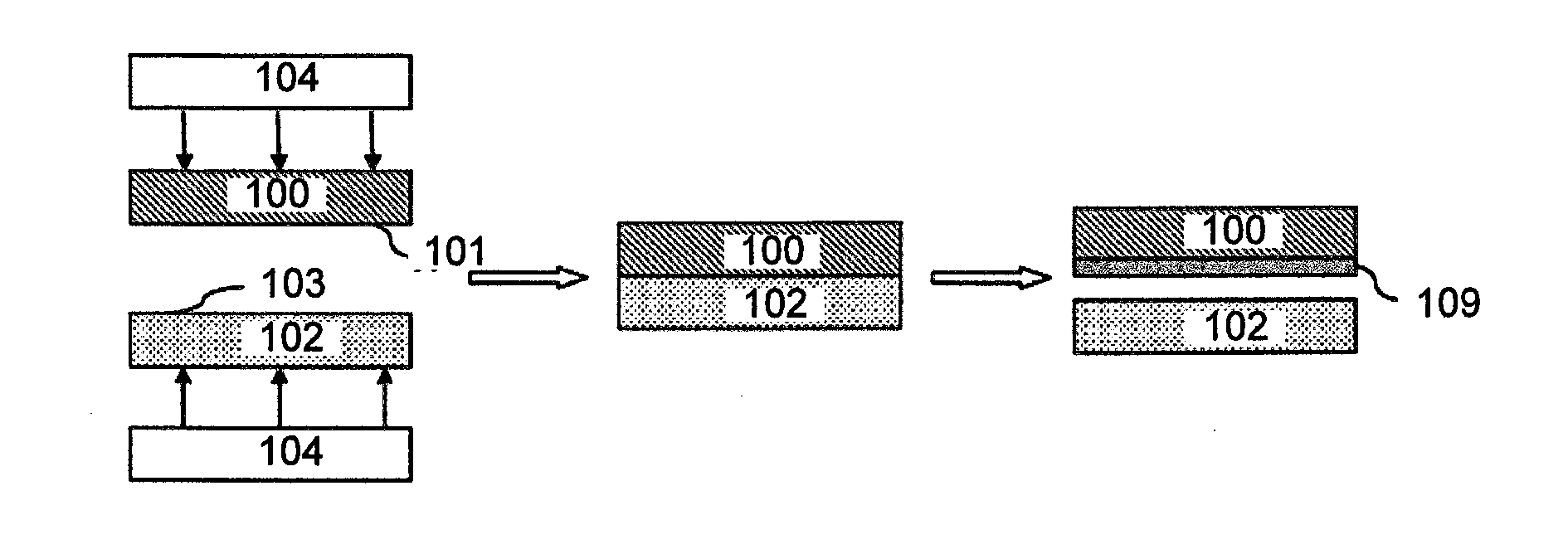

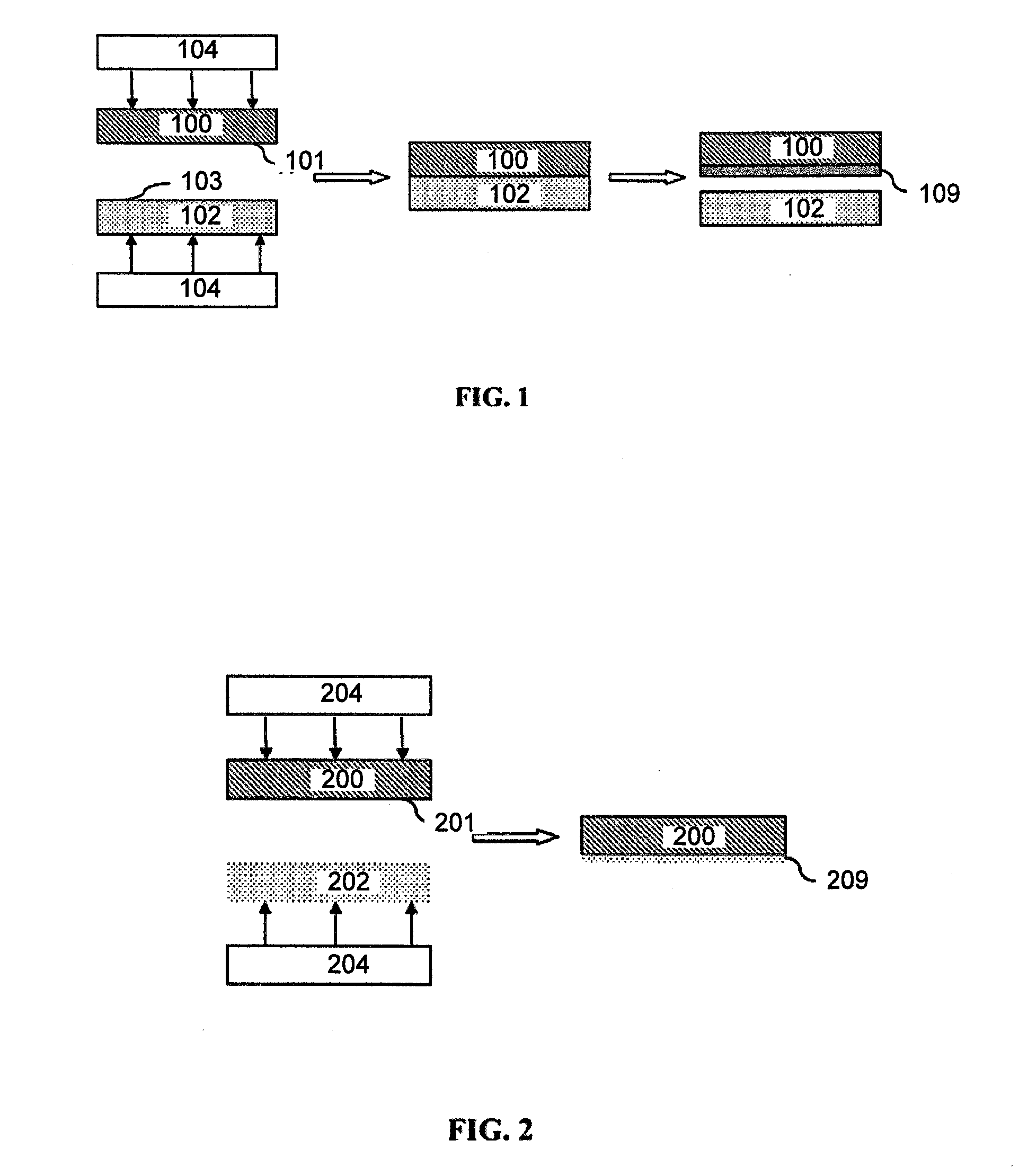

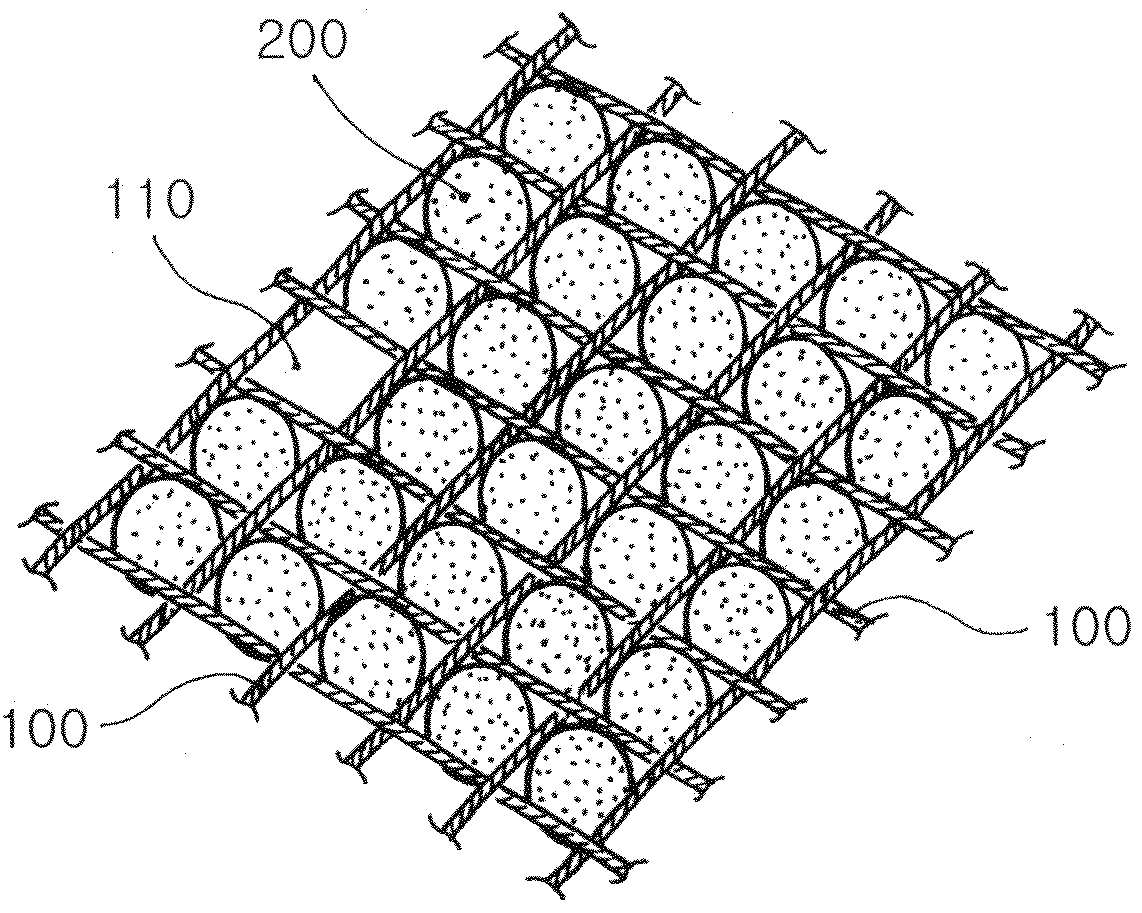

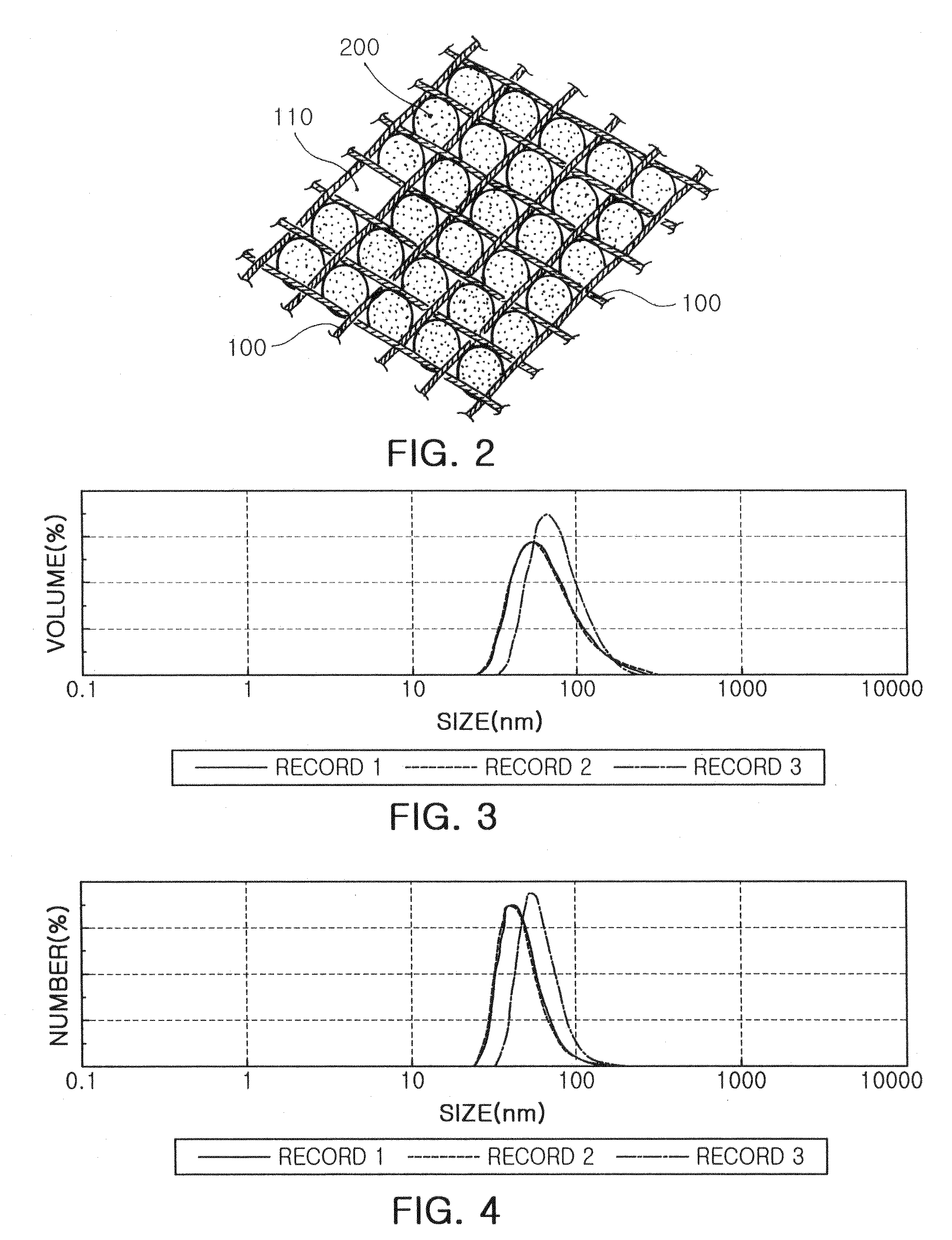

Polymer having superhydrophobic surface

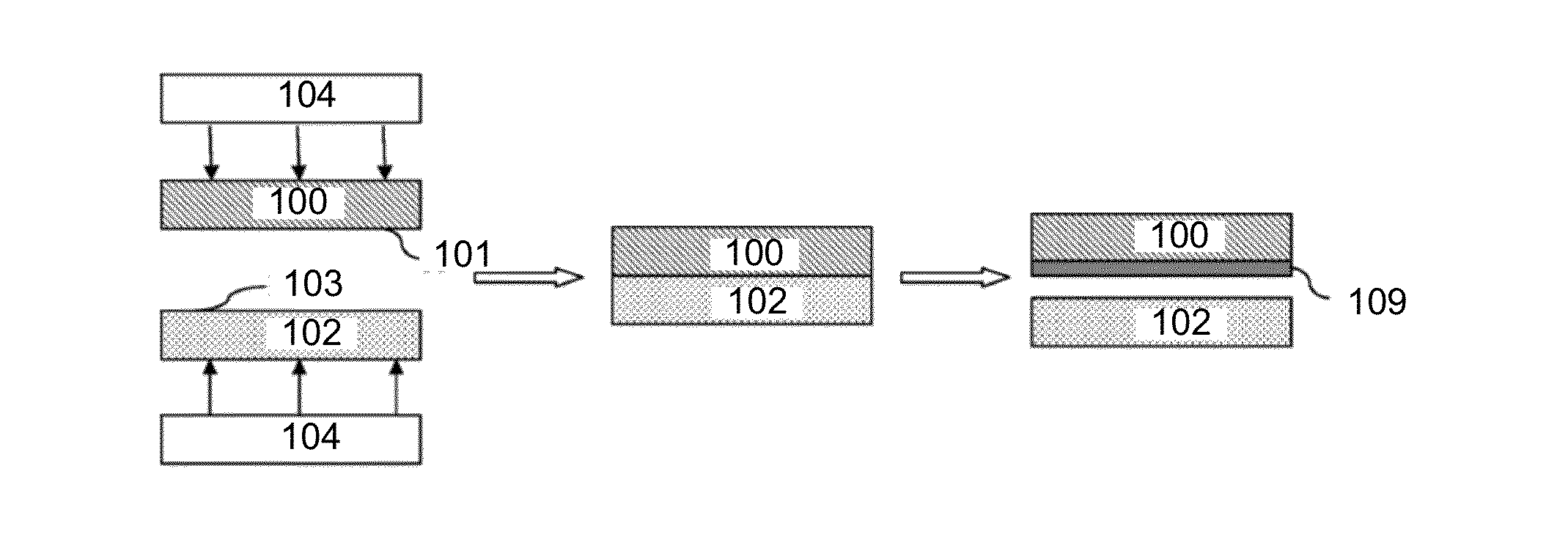

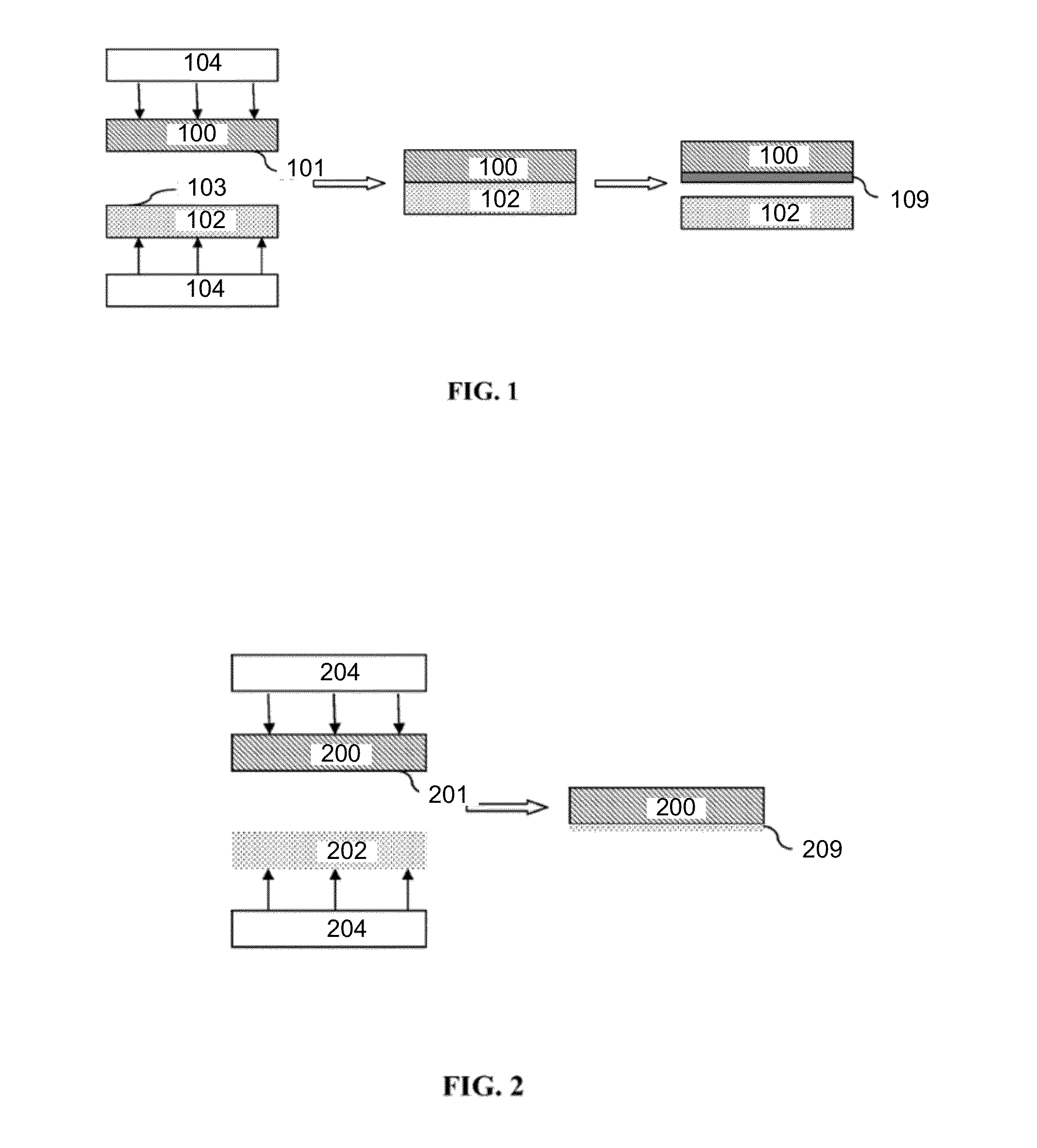

ActiveUS20130251948A1Simple and low-cost processMaintain good propertiesMaterial nanotechnologySpecial ornamental structuresPolymer scienceNanoparticle

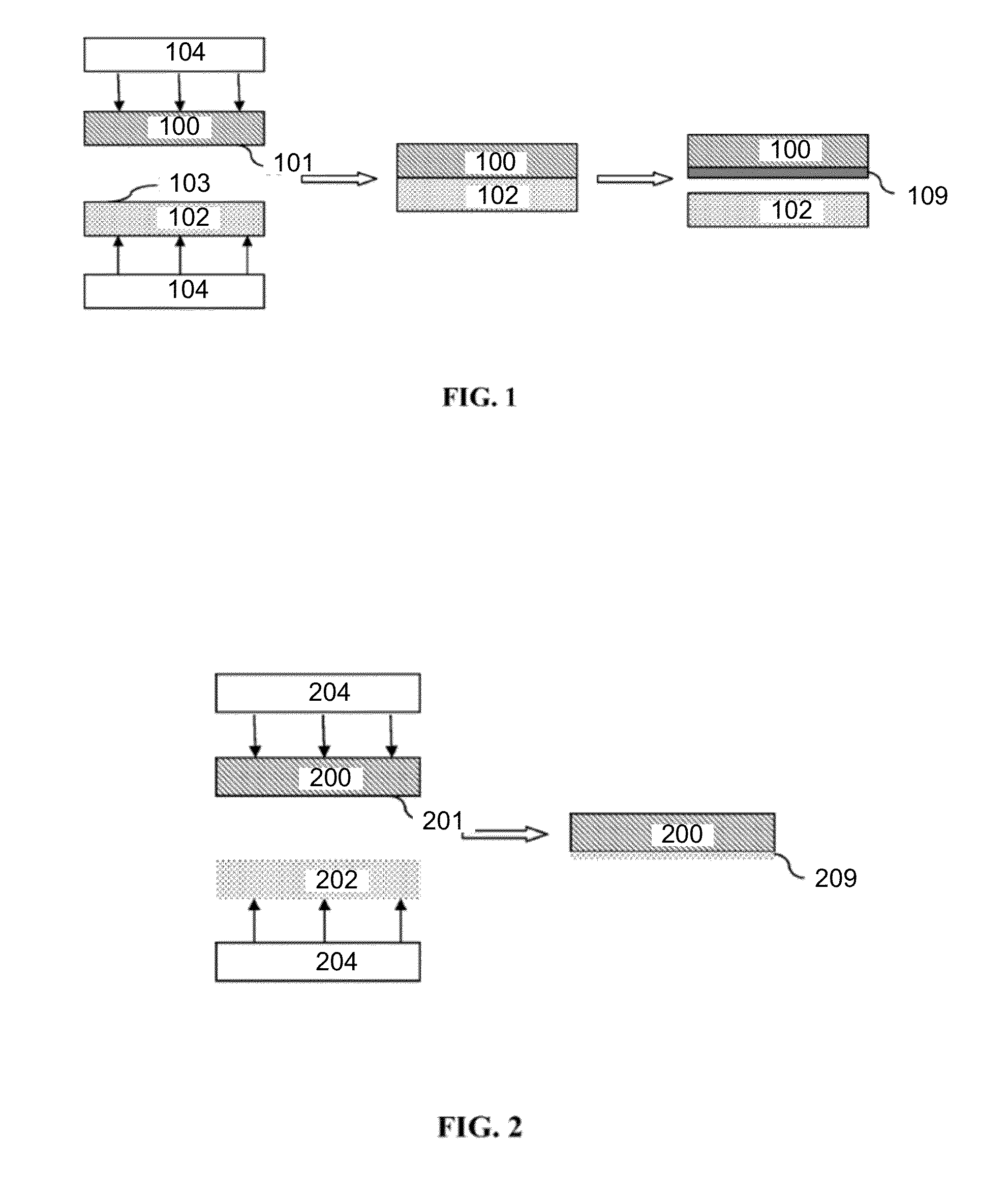

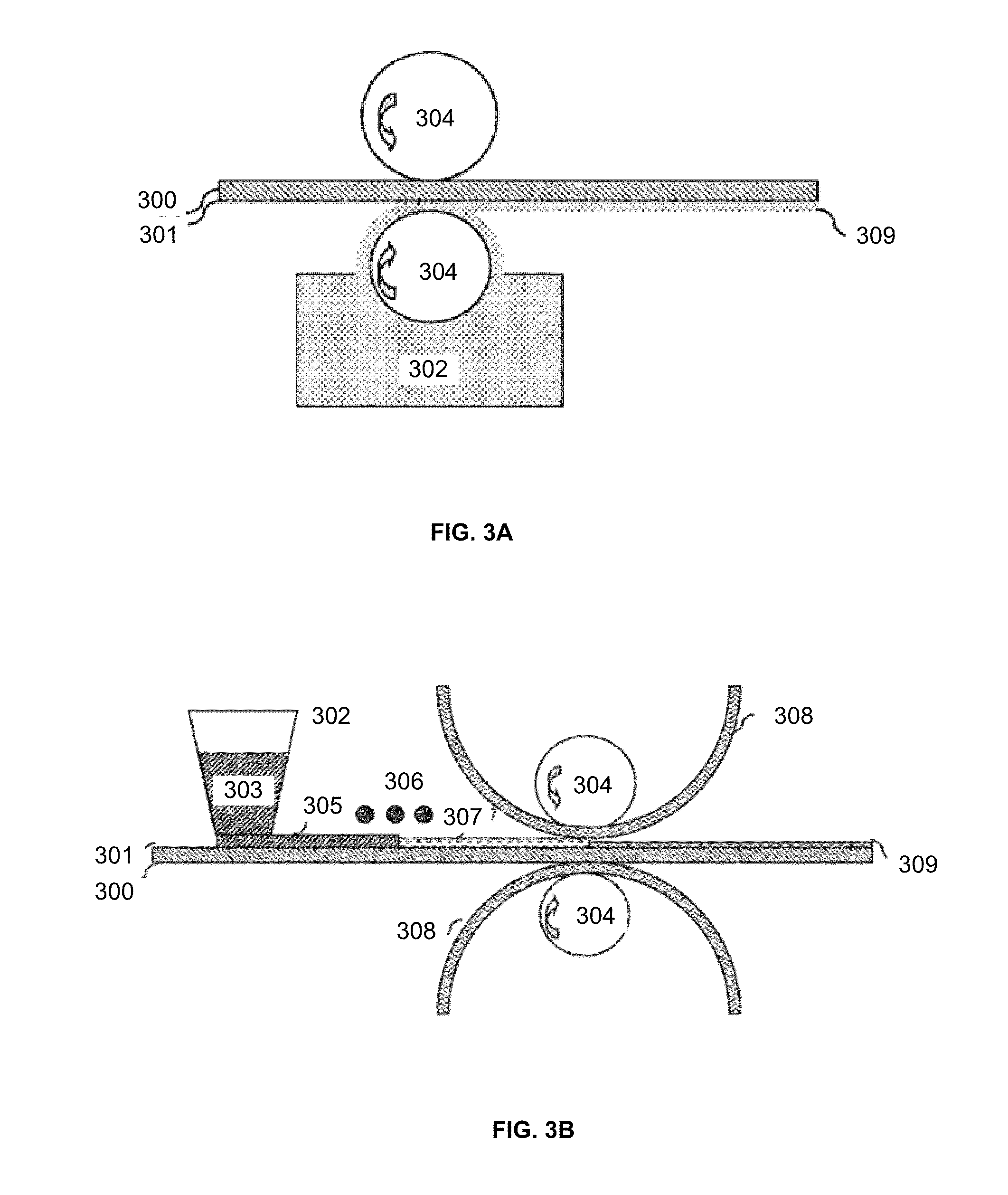

The disclosure relates to a superhydrophobic surface. Methods of fabrication are disclosed including laminating a polymer sheet having a surface to a template having a textured surface or a layer of a nanomaterial (e.g., nanoparticles or nanofibers) to convert the surface of the polymer sheet to a hydrophobic surface having a water contact angle of at least about 150°.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

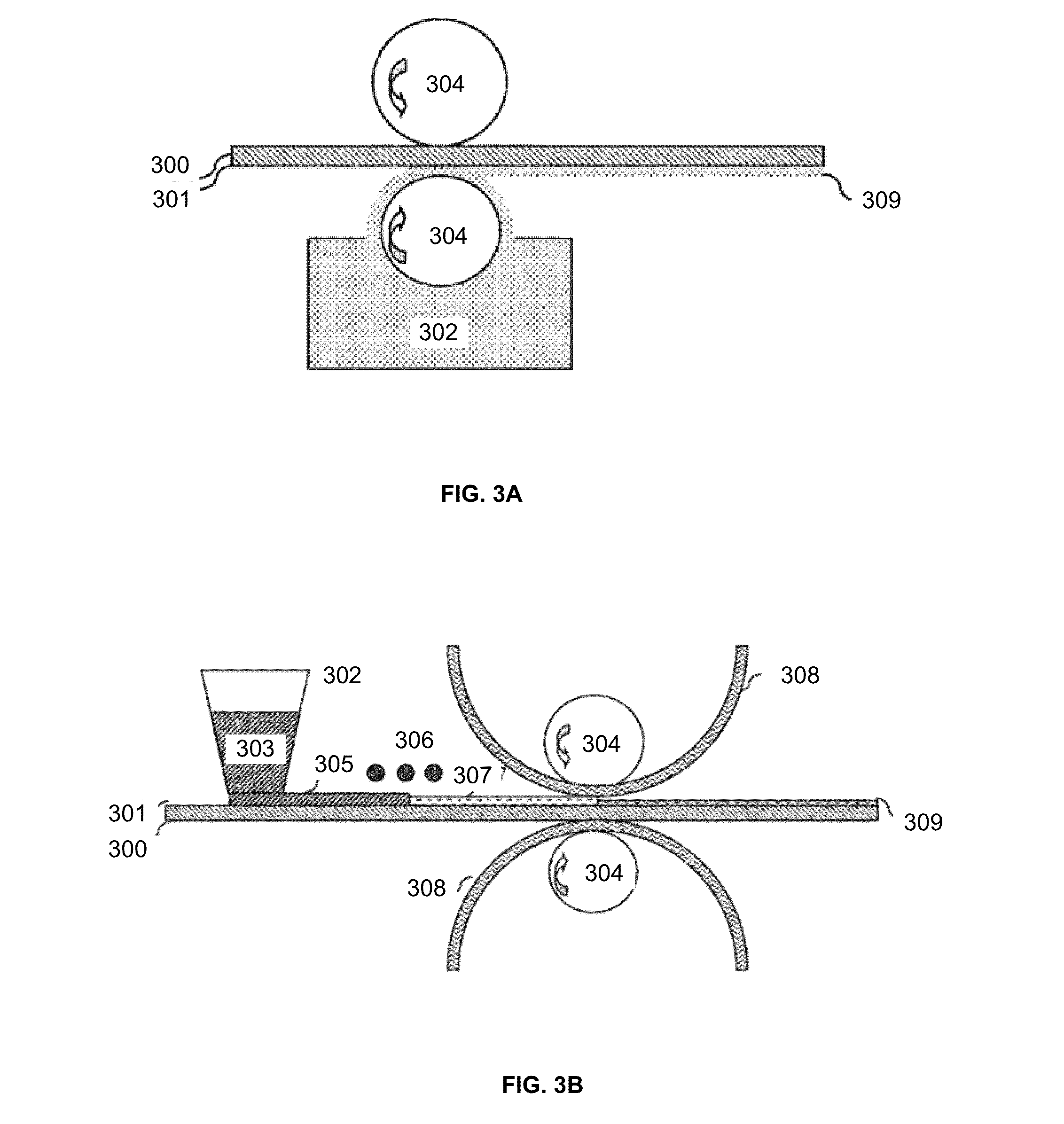

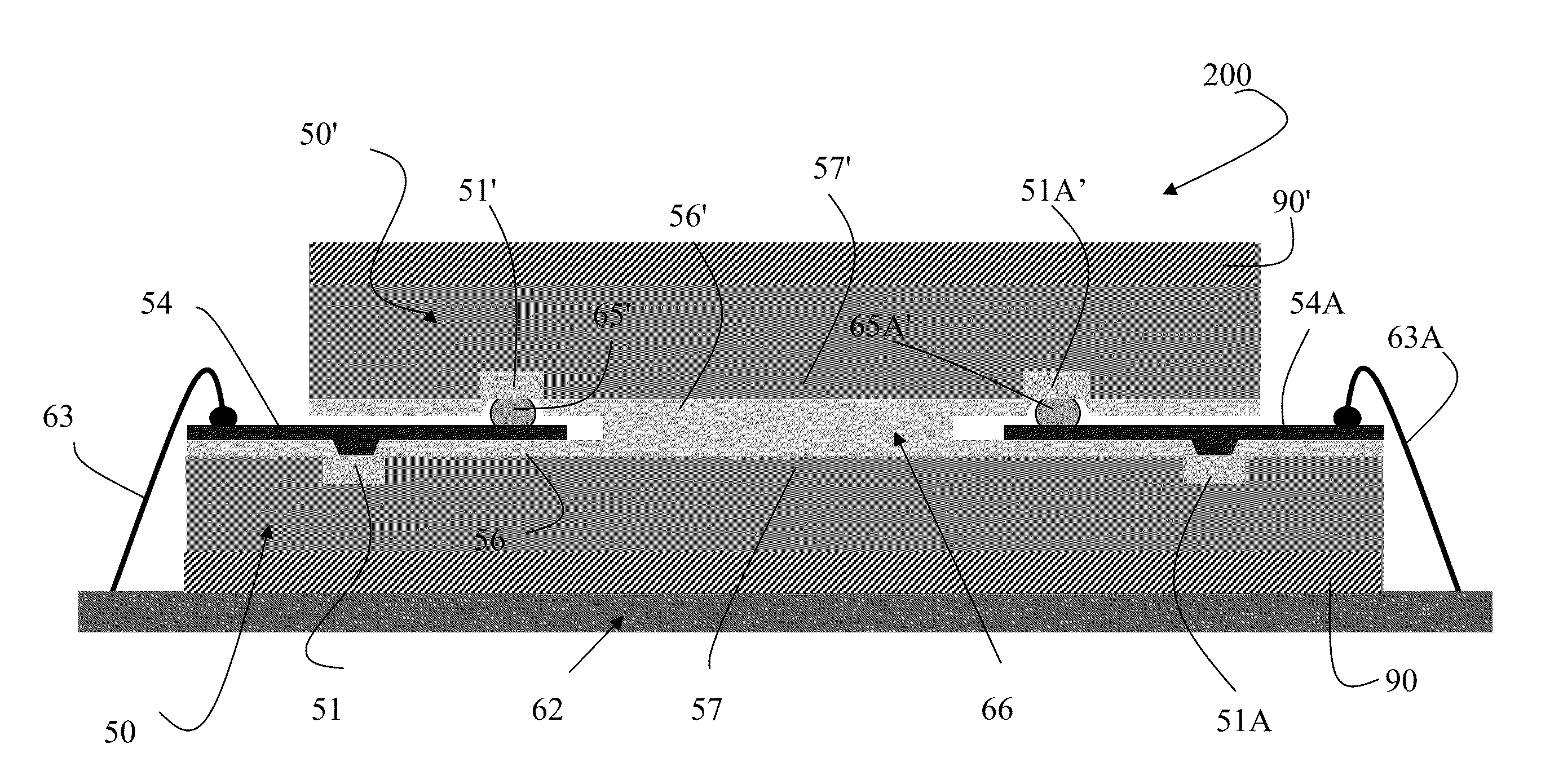

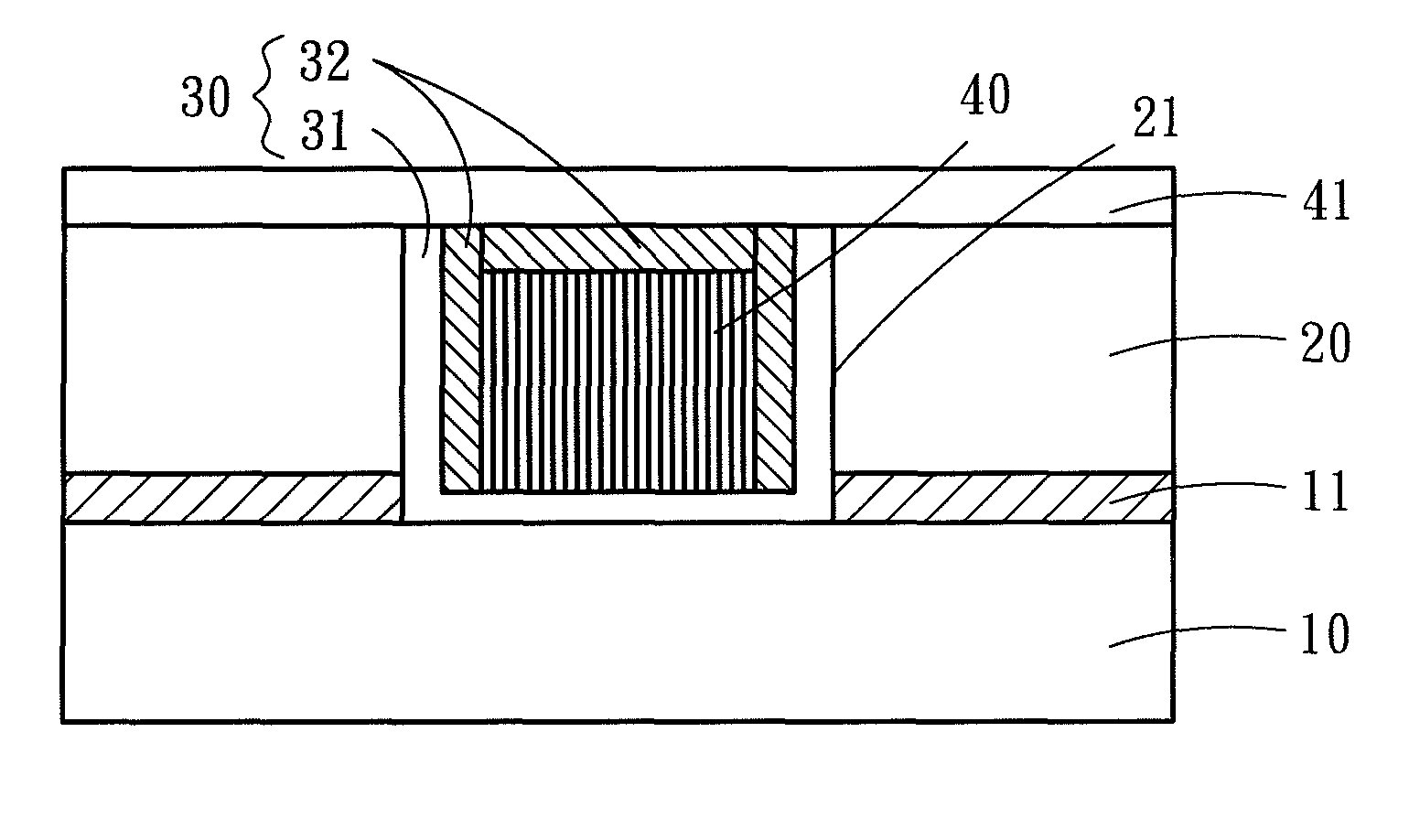

Electronic devices with extended metallization layer on a passivation layer

ActiveUS8362620B2Reduce harmSimple and low-cost processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectricityElectrical testing

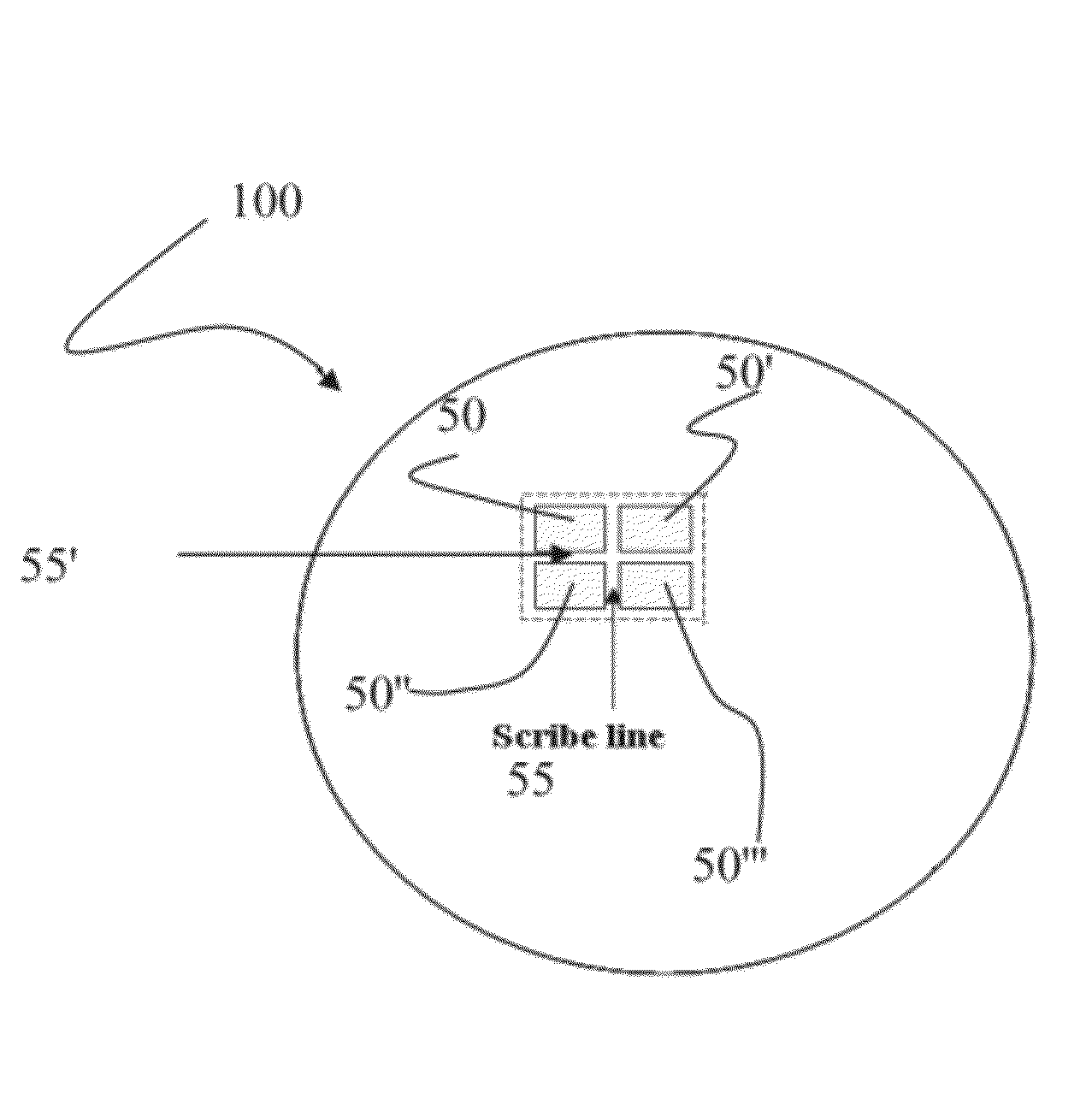

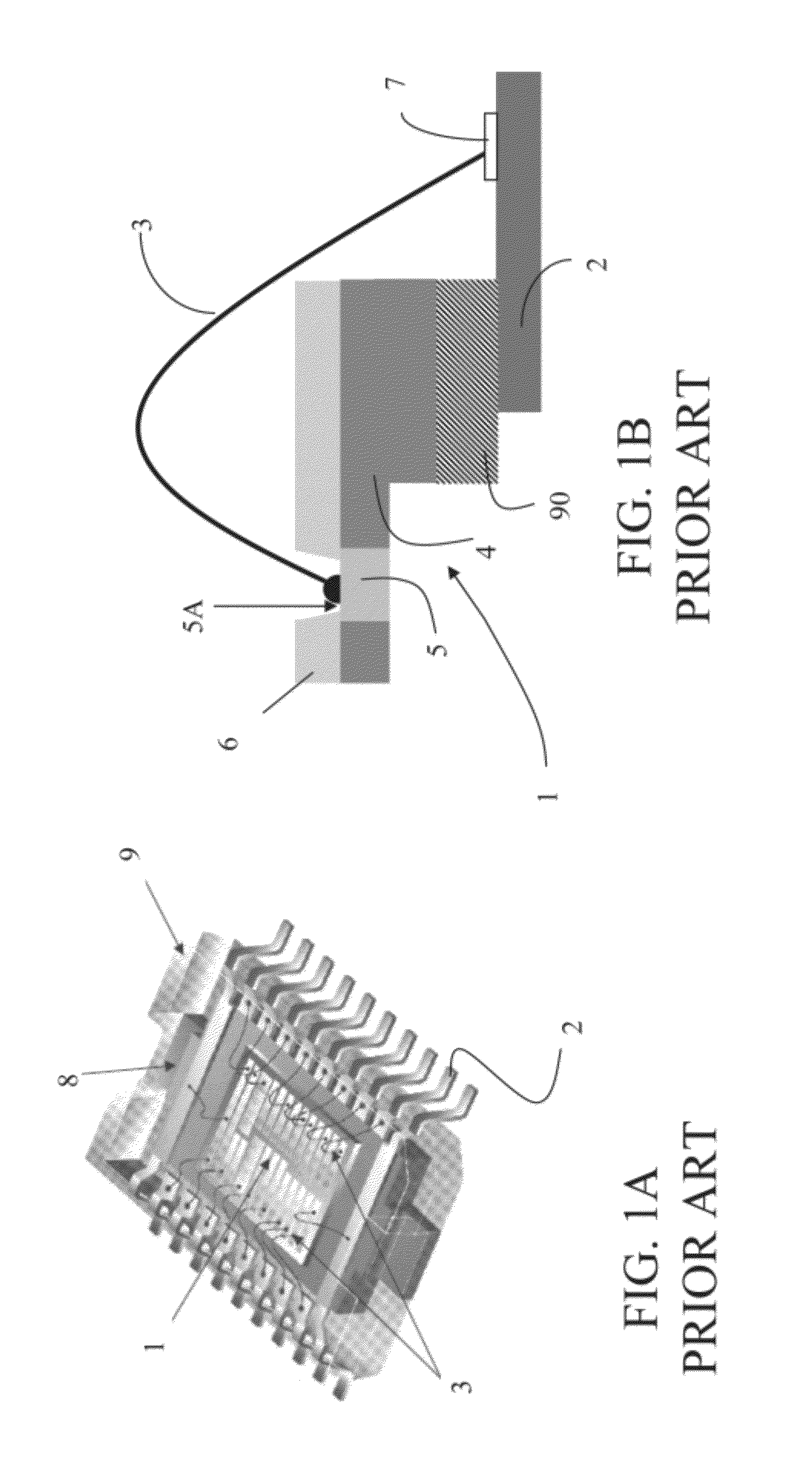

A method performs electrical testing and assembly of an electronic device on a wafer and comprising a pad made in an oxide layer covered by a passivation layer. The method includes connecting the electronic device to a testing apparatus; providing said electronic device with a metallization layer extending on the passivation layer from the pad to a non-active area of said wafer. The method comprises-performing the electrical testing on wafer of the electronic device by placing a probe of on a portion of the extended metallization layer; performing the cut of said wafer, reducing the extension of the metallization layer to the edge of the electronic device; embedding the device inside a package, forming on the metallization layer an electrical connection configured to connect the metallization layer to a circuit in said package.

Owner:STMICROELECTRONICS SRL

Polymer having optically transparent superhydrophobic surface

InactiveUS20140106127A1Maintain good propertiesIncrease resistanceTraffic signalsGlass/slag layered productsNanoparticleMaterials science

The disclosure relates to an optically transparent superhydrophobic surface. Methods of fabrication are disclosed including laminating an optically transparent polymer sheet with hydrophobic nanoparticles such that the nanoparticles are partially embedded and partially exposed. The resulting assembly remains optically transparent.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

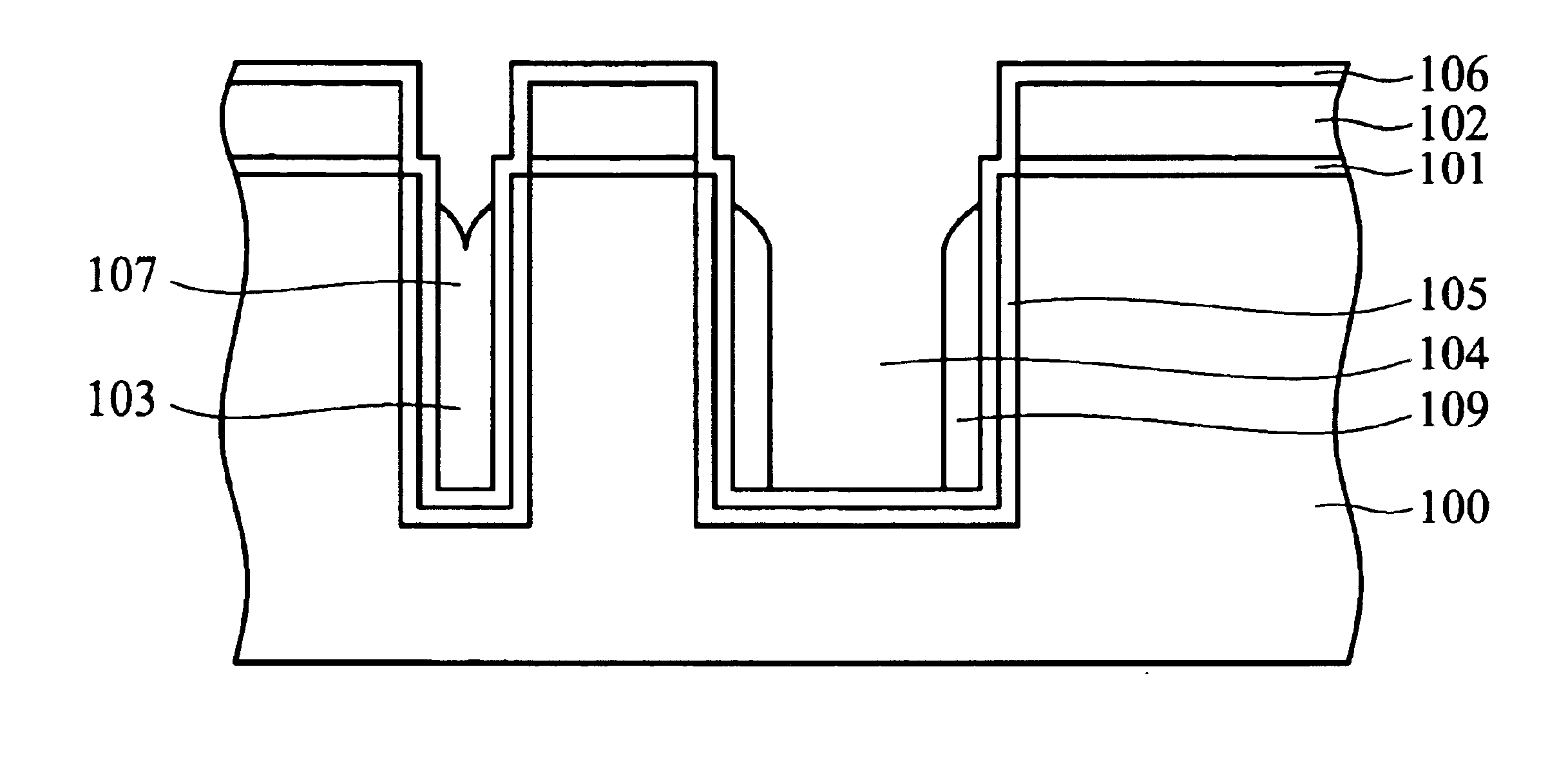

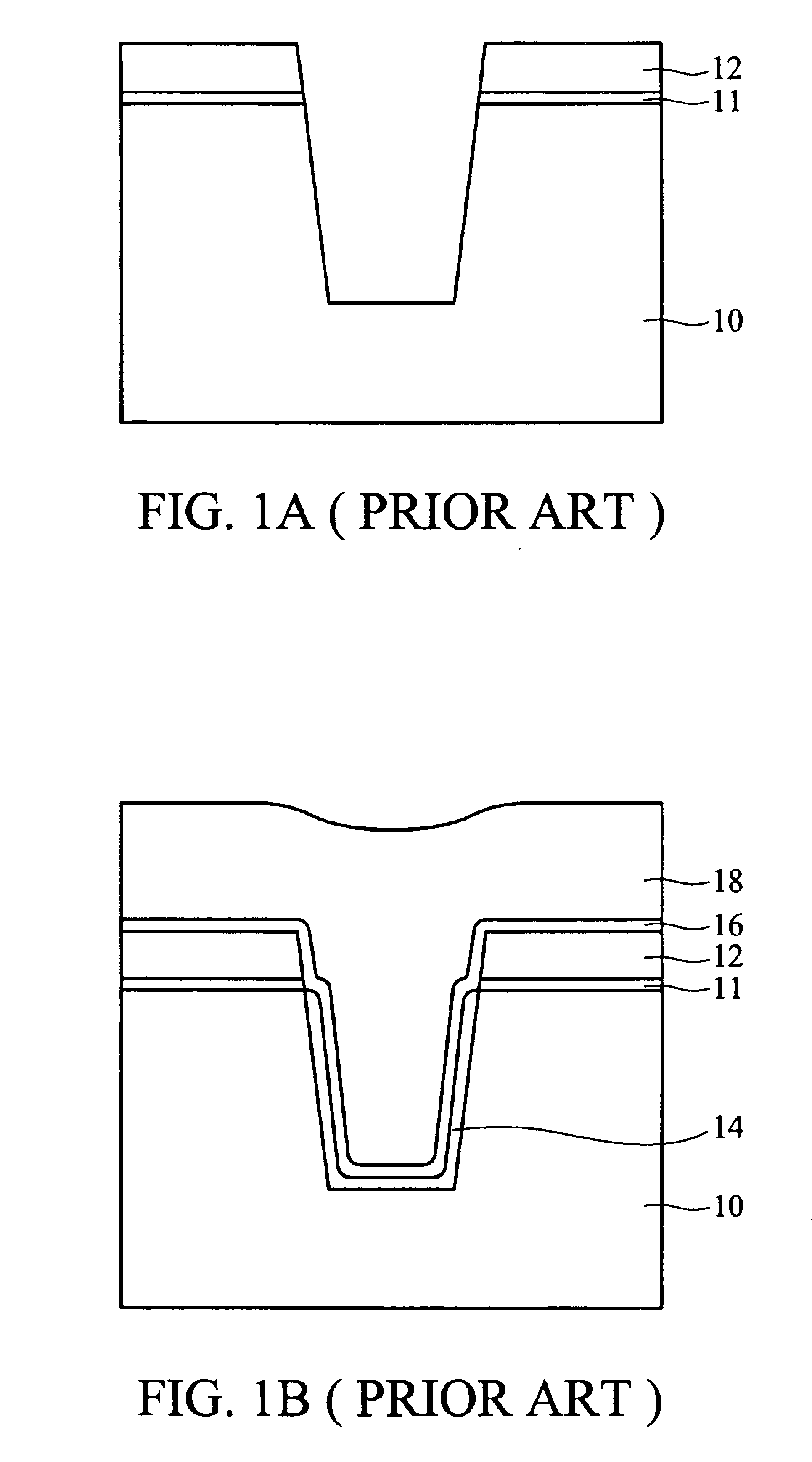

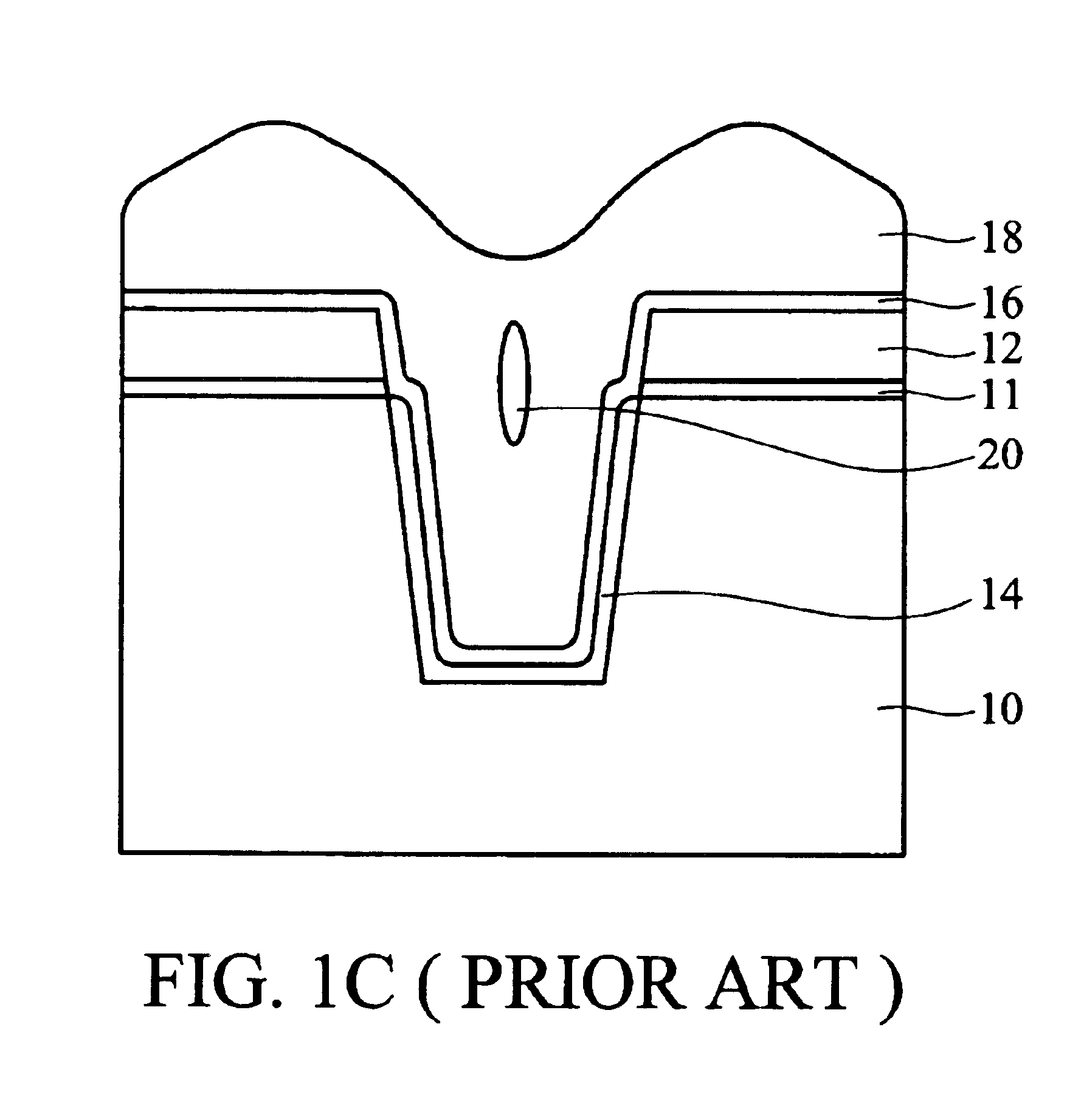

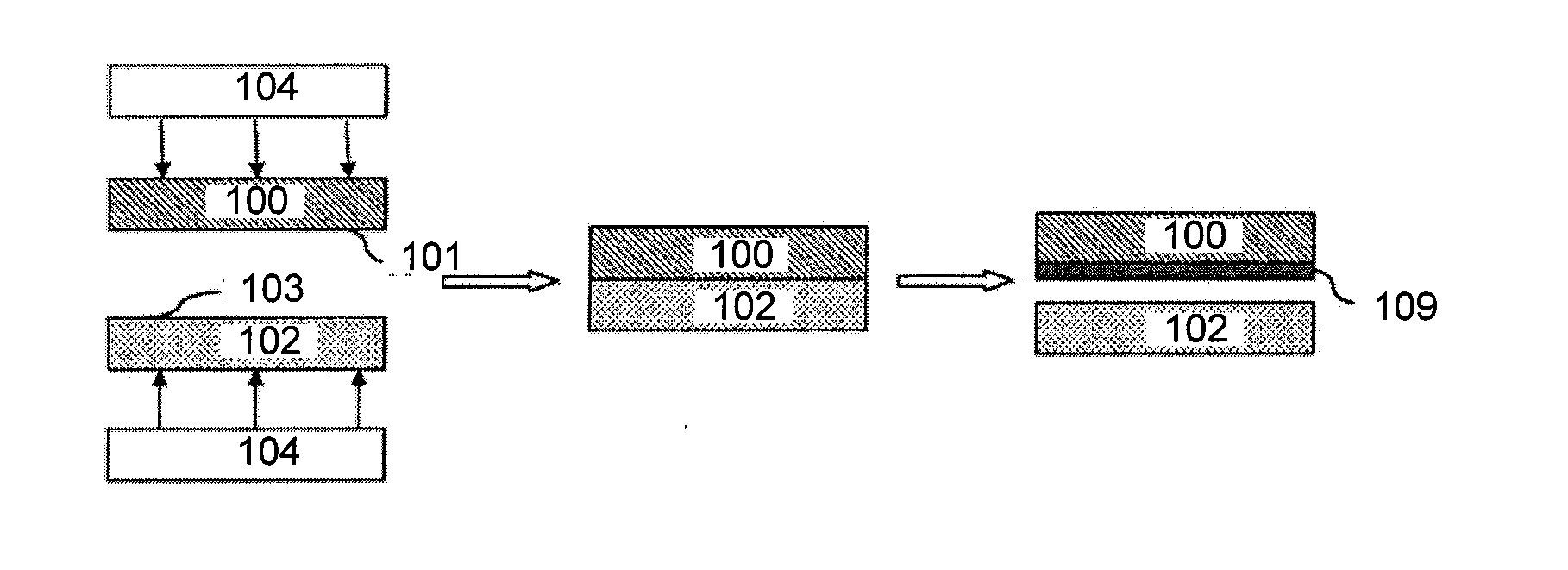

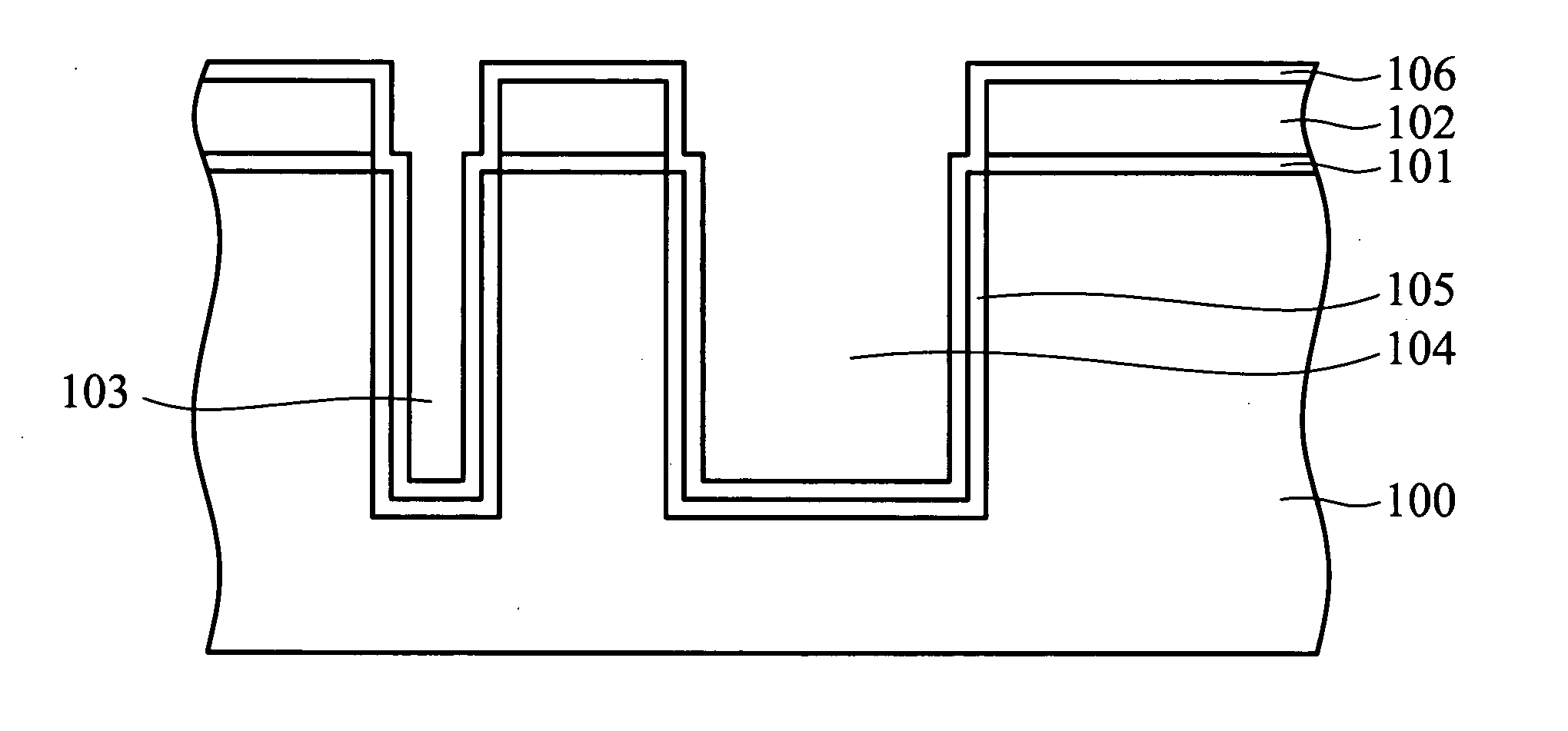

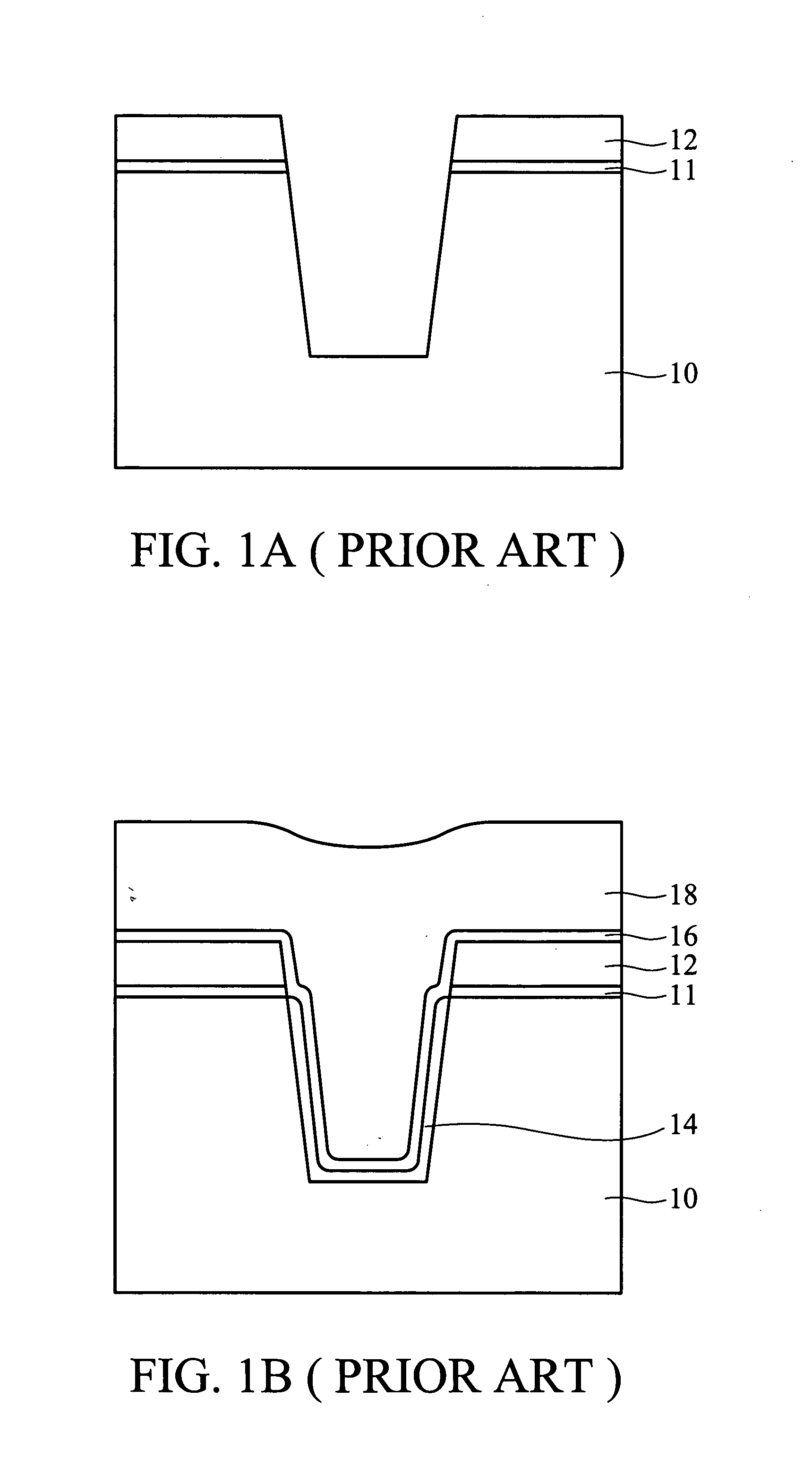

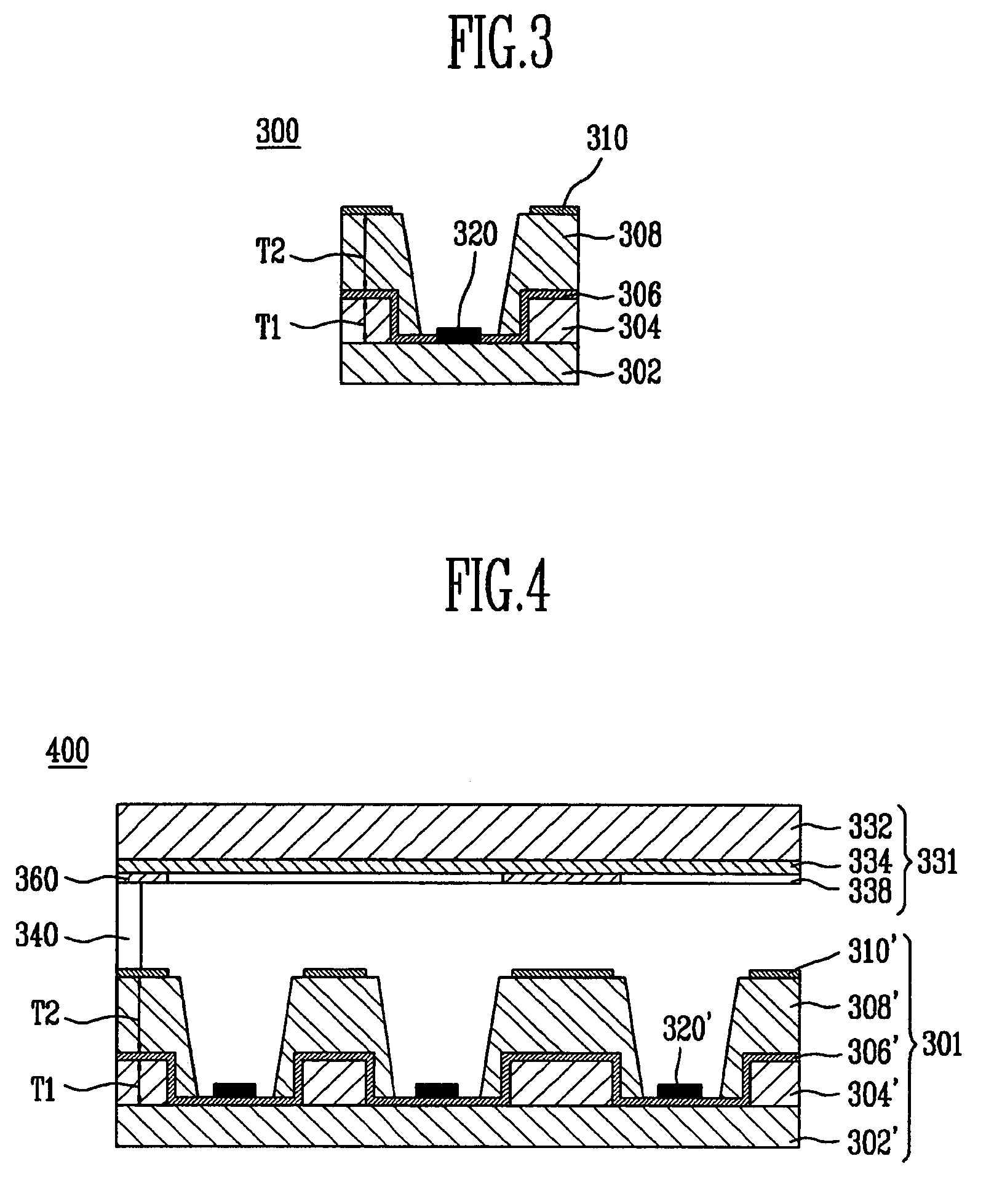

Method for fabricating trench isolations with high aspect ratio

InactiveUS6946359B2Excellent gap fillingQuicker procedureSemiconductor/solid-state device manufacturingCable/conductor manufactureHigh densityCompound (substance)

A method of fabricating a trench isolation with high aspect ratio. The method comprises the steps of: providing a substrate with a trench; depositing a first isolation layer filling the trench by low pressure chemical vapor deposition; etching the first isolation layer so that its surface is lowered to the opening of the trench; depositing a second isolation layer to fill the trench without voids by high density plasma chemical vapor deposition and achieving global planarization by chemical-mechanical polishing then providing a rapidly annealing procedure. Accordingly, the present invention achieves void-free trench isolation with high aspect ratio.

Owner:NAN YA TECH

Preparation method of igy for preventing and cure mouth disease and the toothpaste base on the igy

InactiveUS20060198849A1Prolong lifeHigh activityCosmetic preparationsEgg immunoglobulinsToothpasteMouth disorder

The present invention relates to a preparation method of IgY for preventing and cure mouth disease, and a safe toothpaste containing the IgY.

Owner:JASON MEDICAL GROUPFAR EASTLTD

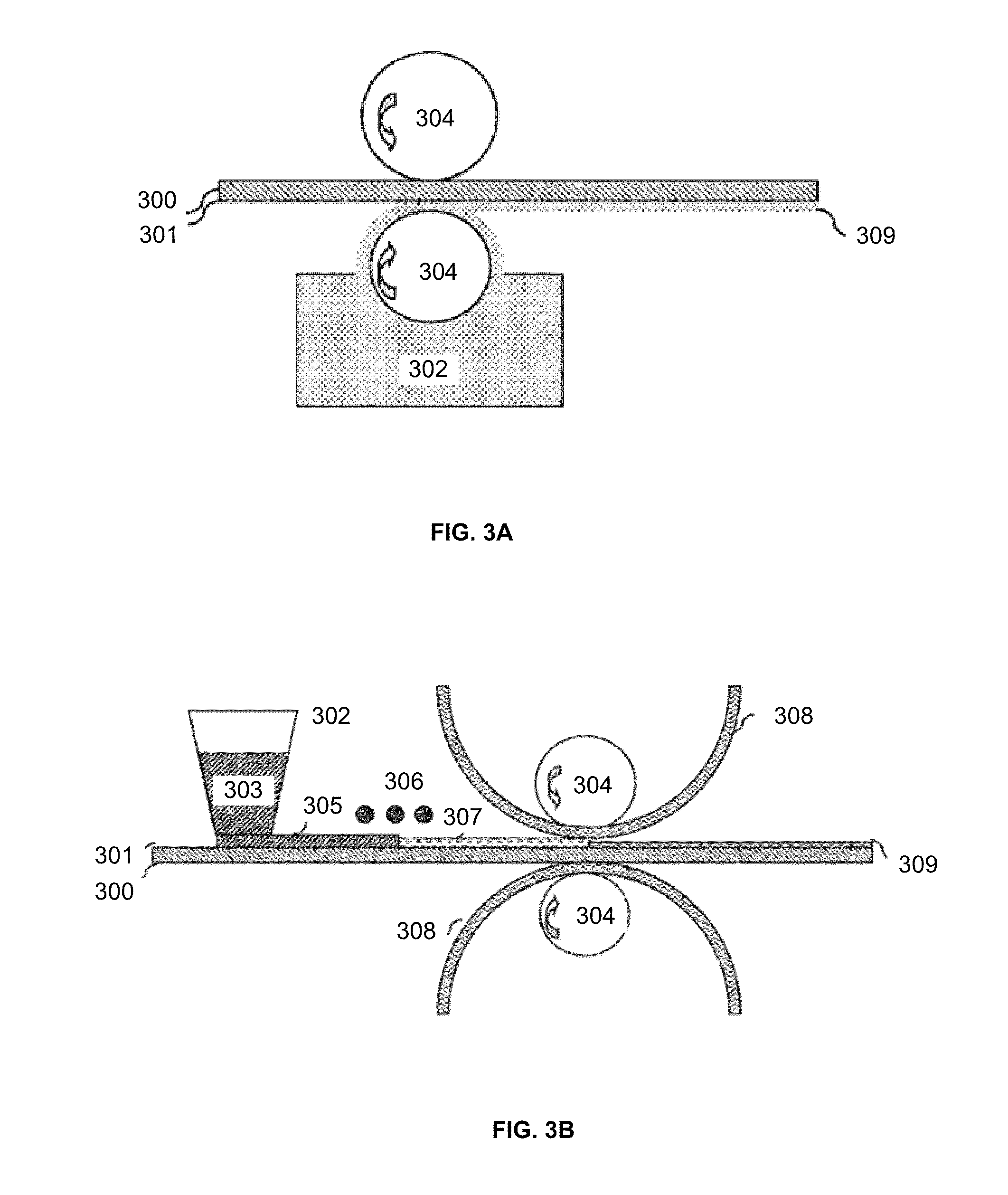

Flexible fabric having superhydrophobic surface

ActiveUS20160160436A1Simple and low-cost processMaintain good propertiesMaterial nanotechnologyFouling preventionNanoparticleShell molding

The disclosure relates to a superhydrophobic surface. Methods of fabrication are disclosed including laminating an optically transparent polymer sheet with hydrophobic nanoparticles such that the nanoparticles are partially embedded and partially exposed. The resulting assembly remains optically transparent. Additional methods include the lamination of nanoparticles to flexible fabrics and the production of molded articles using nanoparticle-treated molds.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

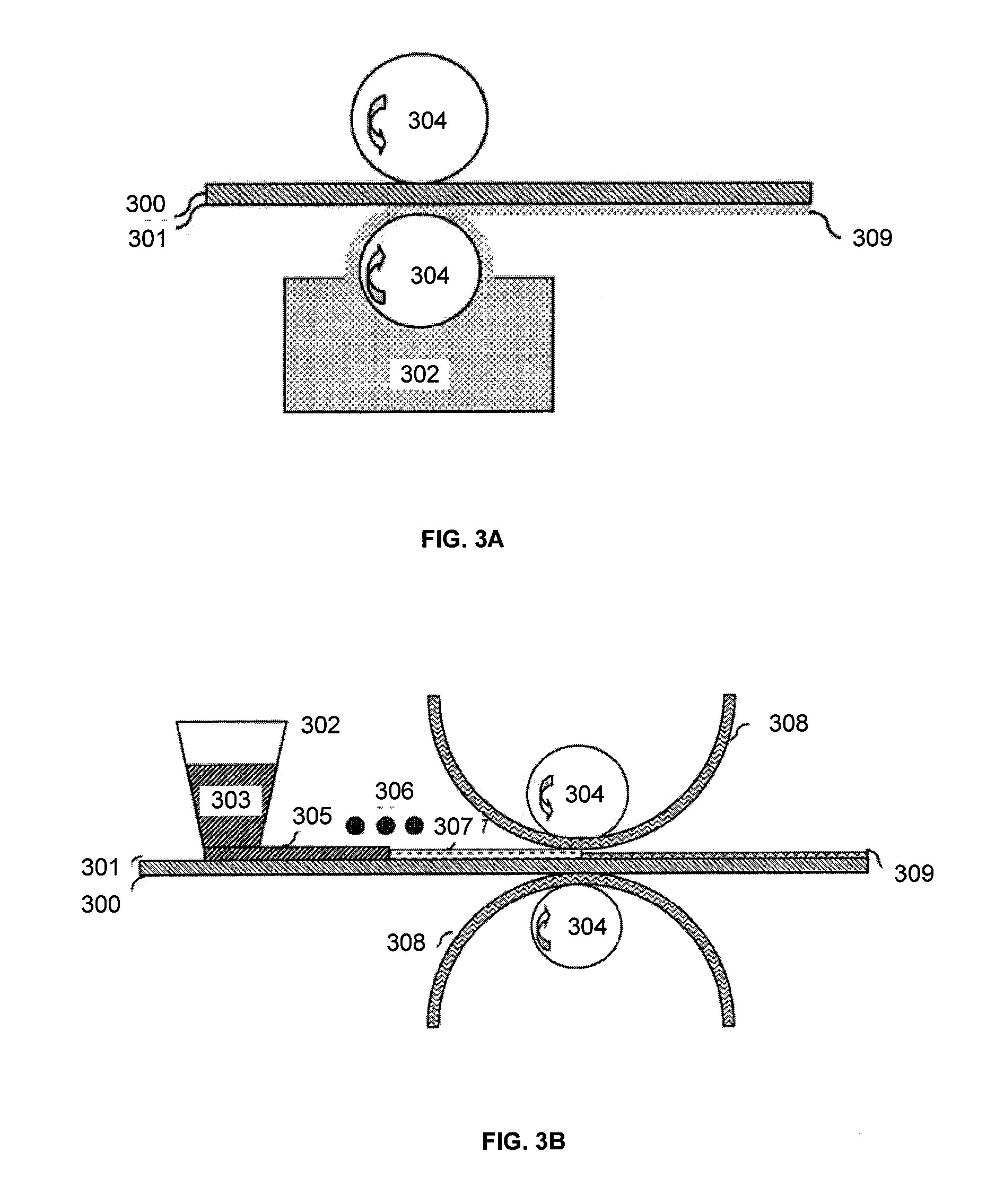

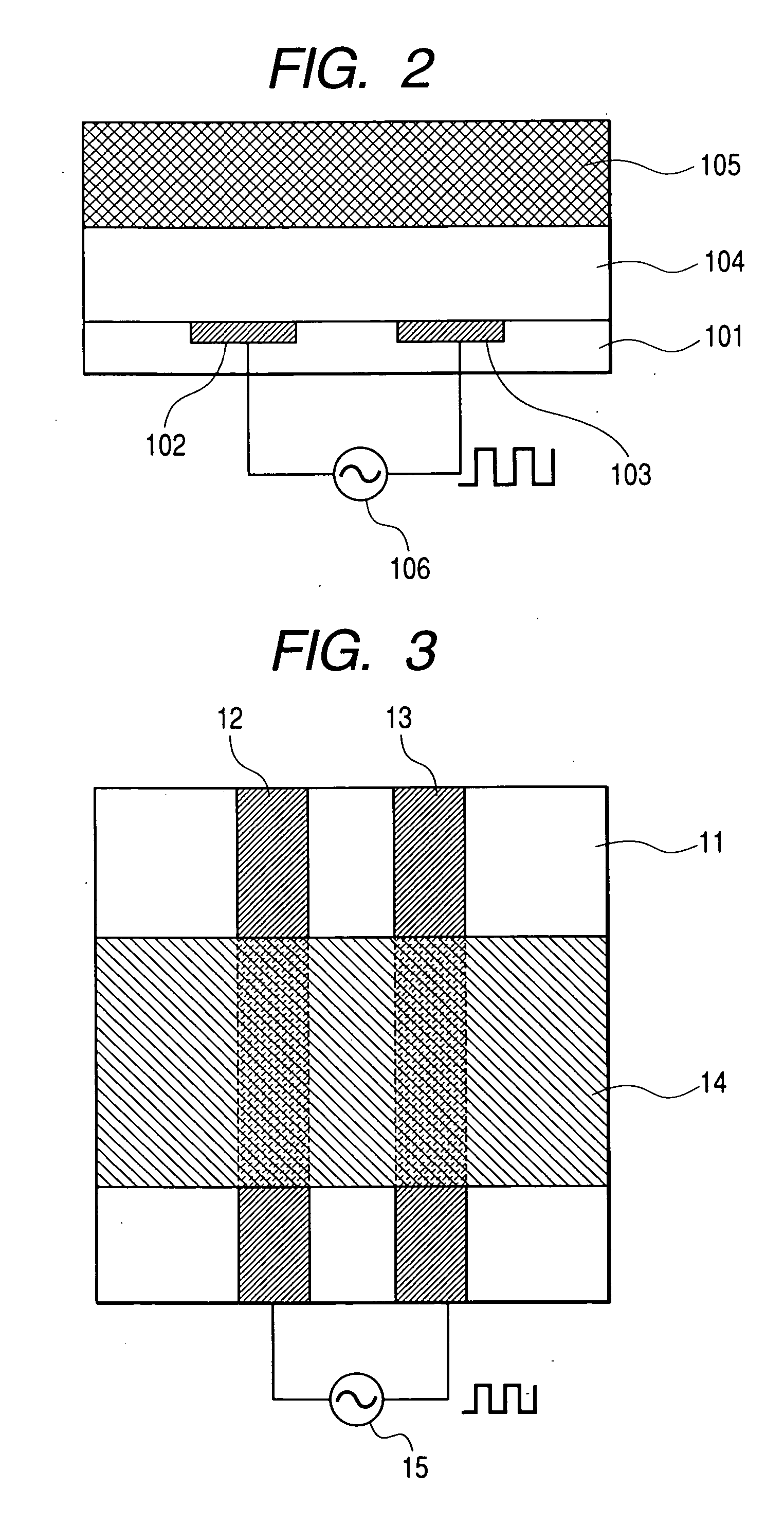

Display and displaying method

InactiveUS20060018001A1Bright can be producedImprove light utilization efficiencyNon-linear opticsDisplay deviceEngineering

An electrochromic device with high transmittance is for use as a display device. The electrochromic device includes at least a first and a second electrode formed on an insulative substrate and a conductive layer formed in contact with the insulative substrate, the first electrode, and the second electrode. Since an electrode layer functions in one layer, the transmittance through the device is enhanced, and the device can be fabricated in a simple process, allowing a reduction in the device fabrication costs.

Owner:HITACHI LTD

Method for fabricating trench isolations with high aspect ratio

ActiveUS20050016948A1Excellent gap fillingRapid thermal annealing procedureSemiconductor/solid-state device manufacturingCable/conductor manufactureAspect ratioHigh density

A method of fabricating a trench isolation with high aspect ratio. The method comprises the steps of: providing a substrate with a trench; depositing a first isolation layer filling the trench by low pressure chemical vapor deposition; etching the first isolation layer so that its surface is lowered to the opening of the trench; depositing a second isolation layer to fill the trench without voids by high density plasma chemical vapor deposition and achieving global planarization by chemical-mechanical polishing then providing a rapidly annealing procedure. Accordingly, the present invention achieves void-free trench isolation with high aspect ratio.

Owner:NAN YA TECH

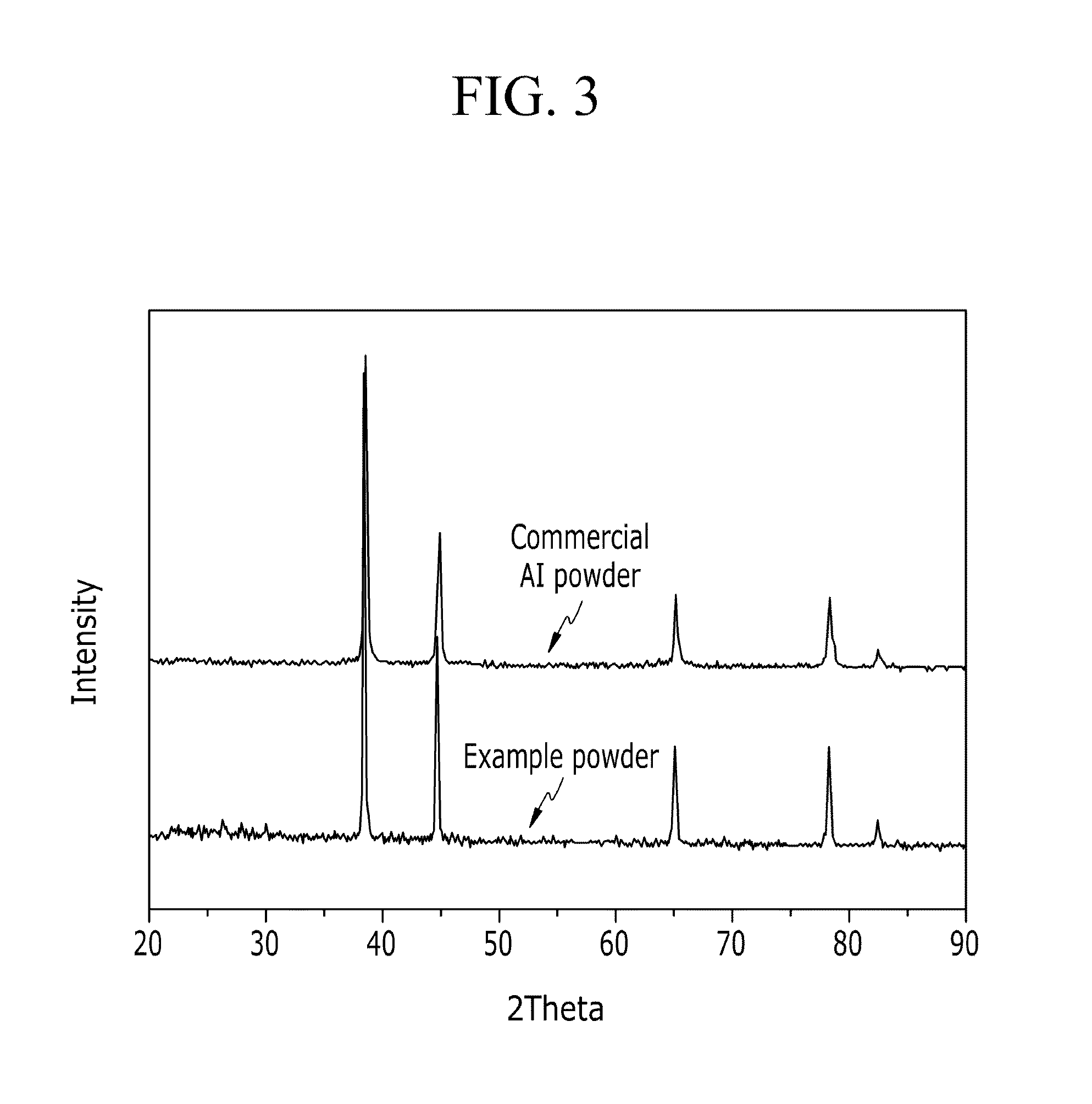

Metal precursor powder, method of manufactuirng conductive metal layer or pattern, and device including the same

ActiveUS20140360762A1Avoid reactionChemical stabilityConductive materialInksHydrogenGibbs free energy

A metal precursor powder, a method of manufacturing a conductive metal layer or pattern, and an electronic device including the same, are provided, and in the metal precursor powder, the Gibbs free energy change of hydrogen removal at a temperature range of −25° C. to 25° C. is −100 kJ / mol to 300 kJ / mol.

Owner:ALINK CO LTD

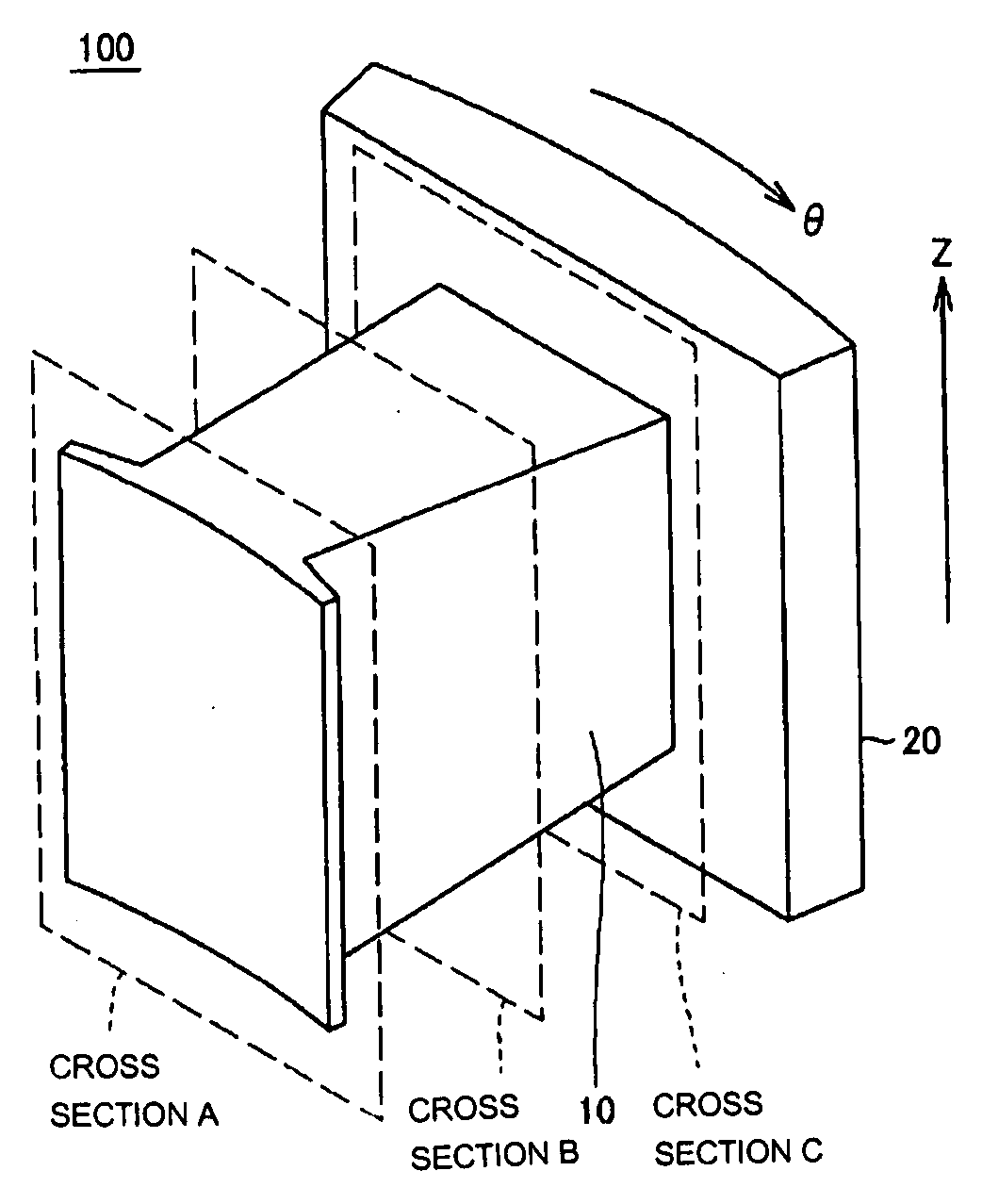

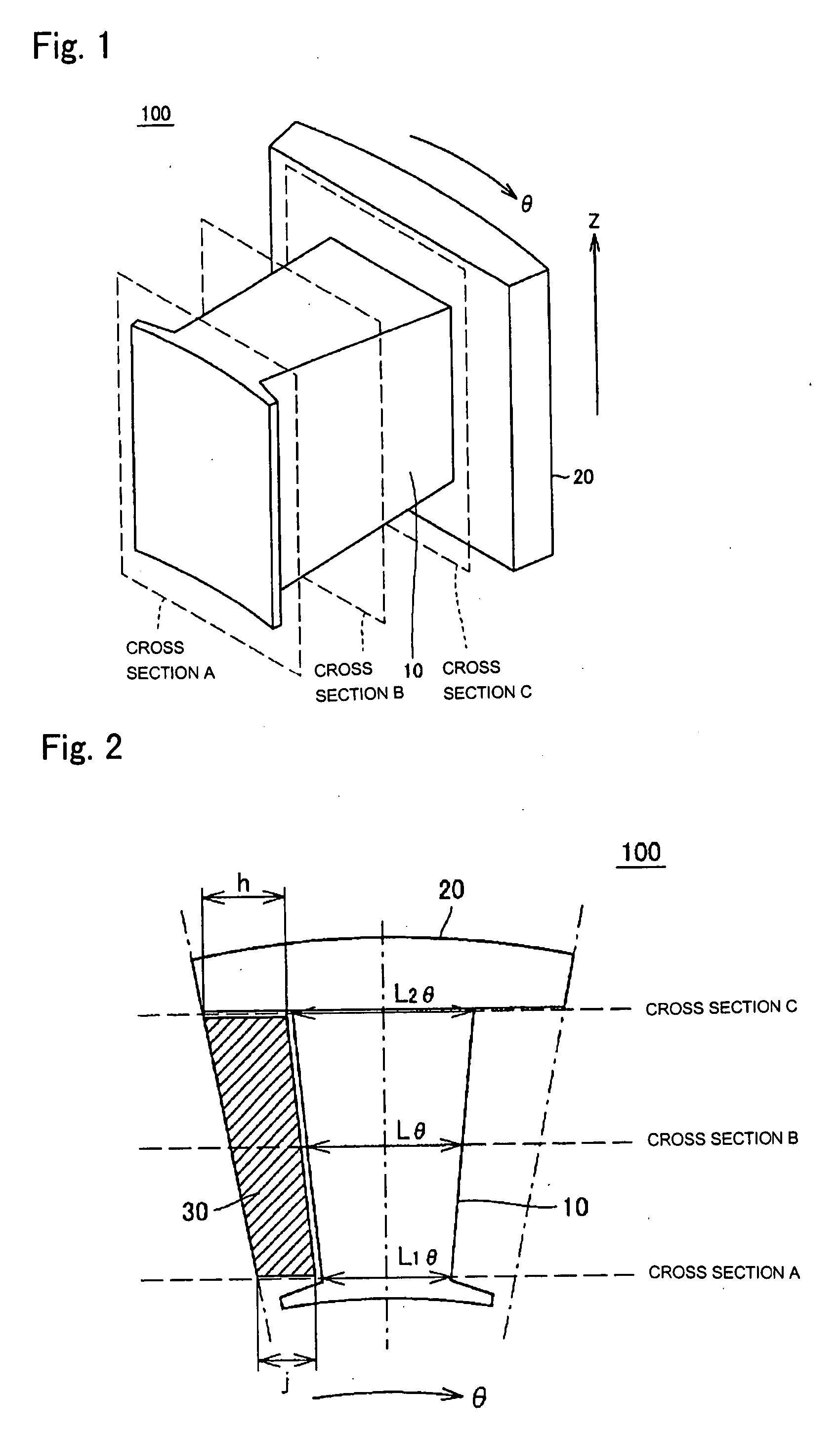

Motor Generator and Automobile Carrying the Same

ActiveUS20080001494A1Improve installabilityBroad range of output performanceWindingsElectric propulsion mountingHeight differenceDynamo

In a stator core composed of a powder compacted magnetic body, a yoke part comprises a protrusion protruding from an axial end face of a tooth. The tooth has an axial length gradually decreases towards an outside along the radial direction of the stator core, and a circumferential length which gradually increases towards an outside along the radial direction of the stator core. In one of the cross sections of stator core perpendicular to a radial direction, the height difference between axial end faces of the yoke part and the tooth is substantially equal to an axial length of a coil end part. Further, a cross-sectional area of the tooth perpendicular to the radial direction is substantially maintained constant along the radial direction, and the cross-sectional area is secured at a junction between the tooth and the yoke part, while half of the cross-sectional area is secured in a circumferential cross section of the yoke part.

Owner:KAISHA TOYOTA MOTORS KABUSHIKI

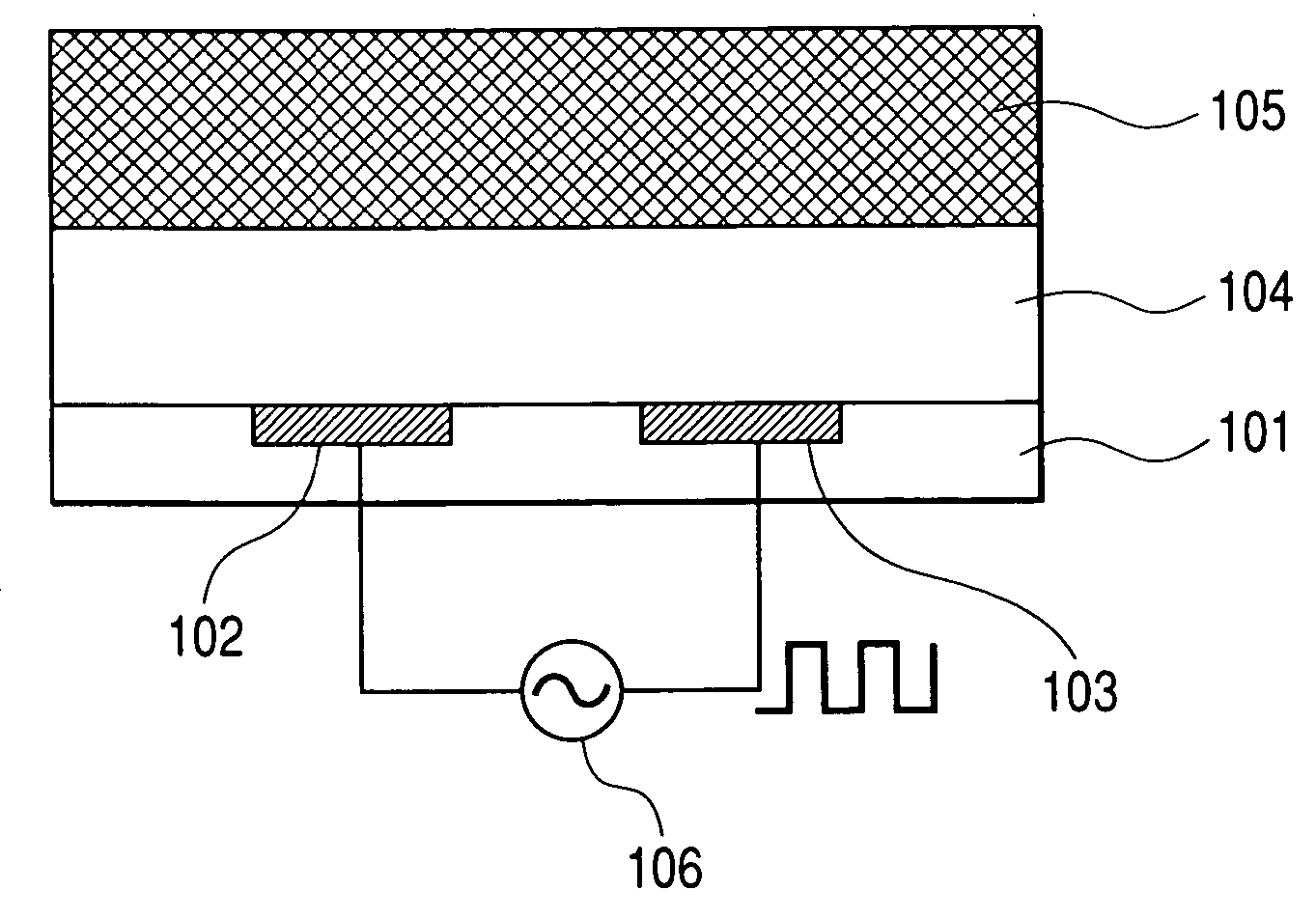

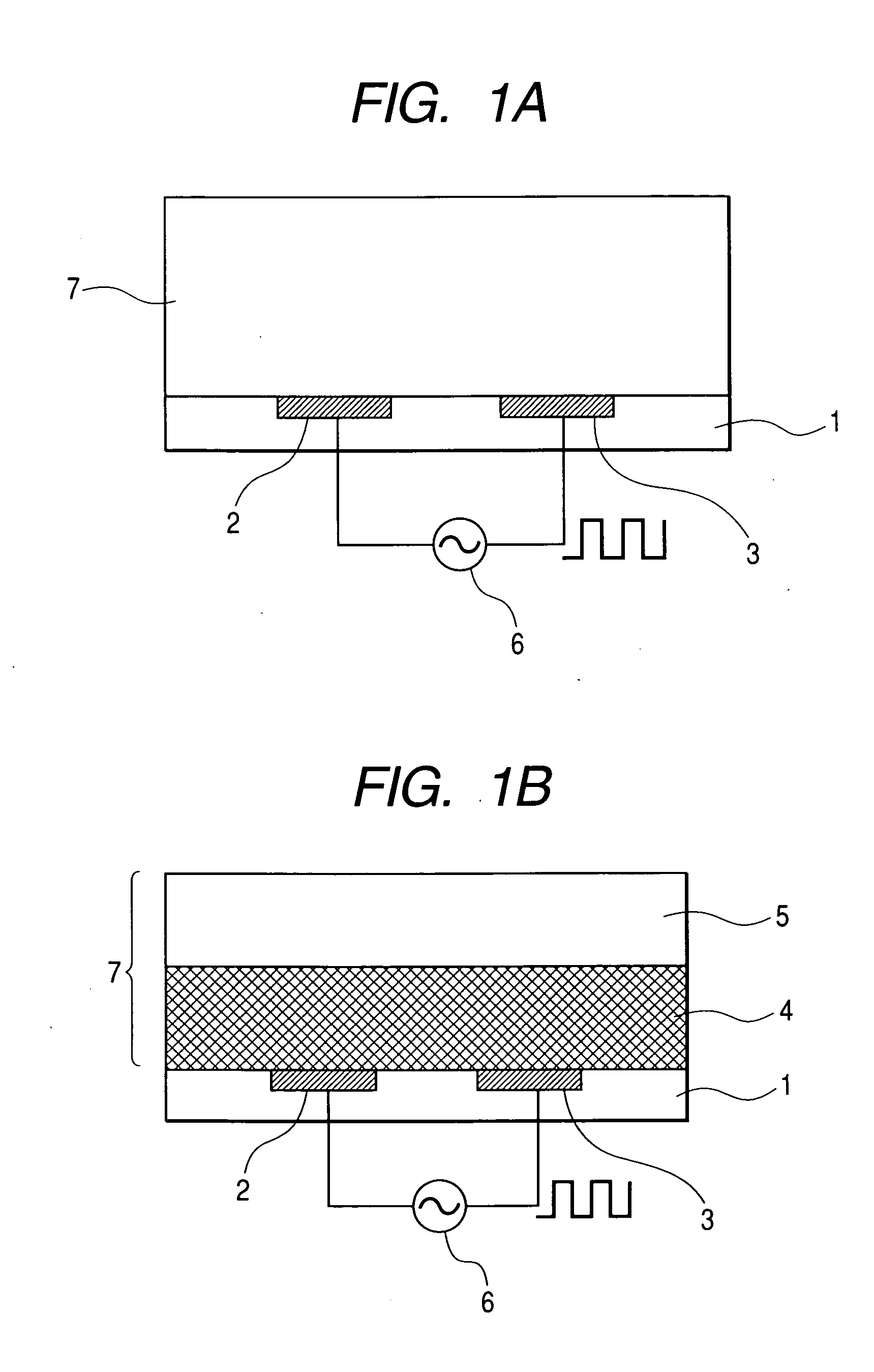

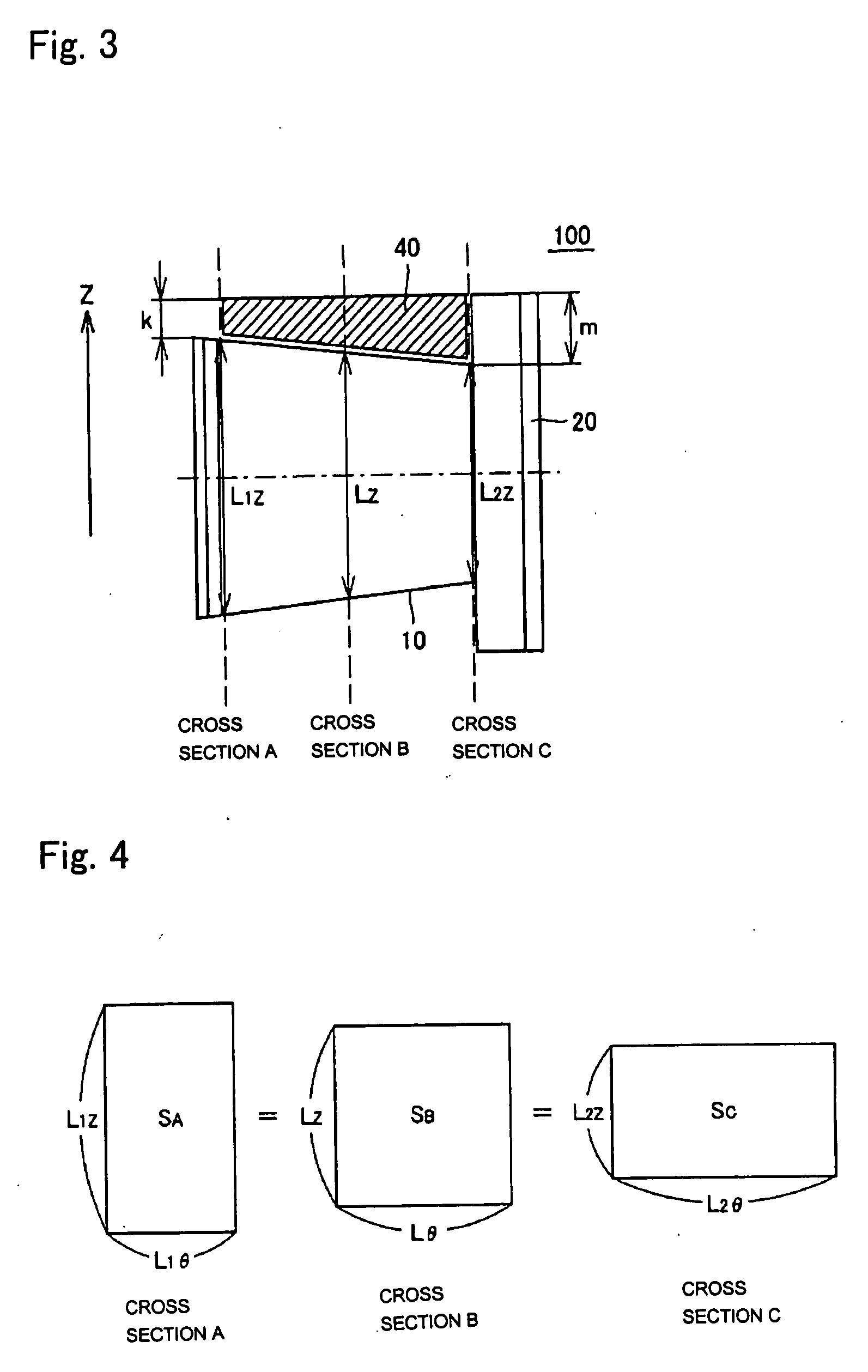

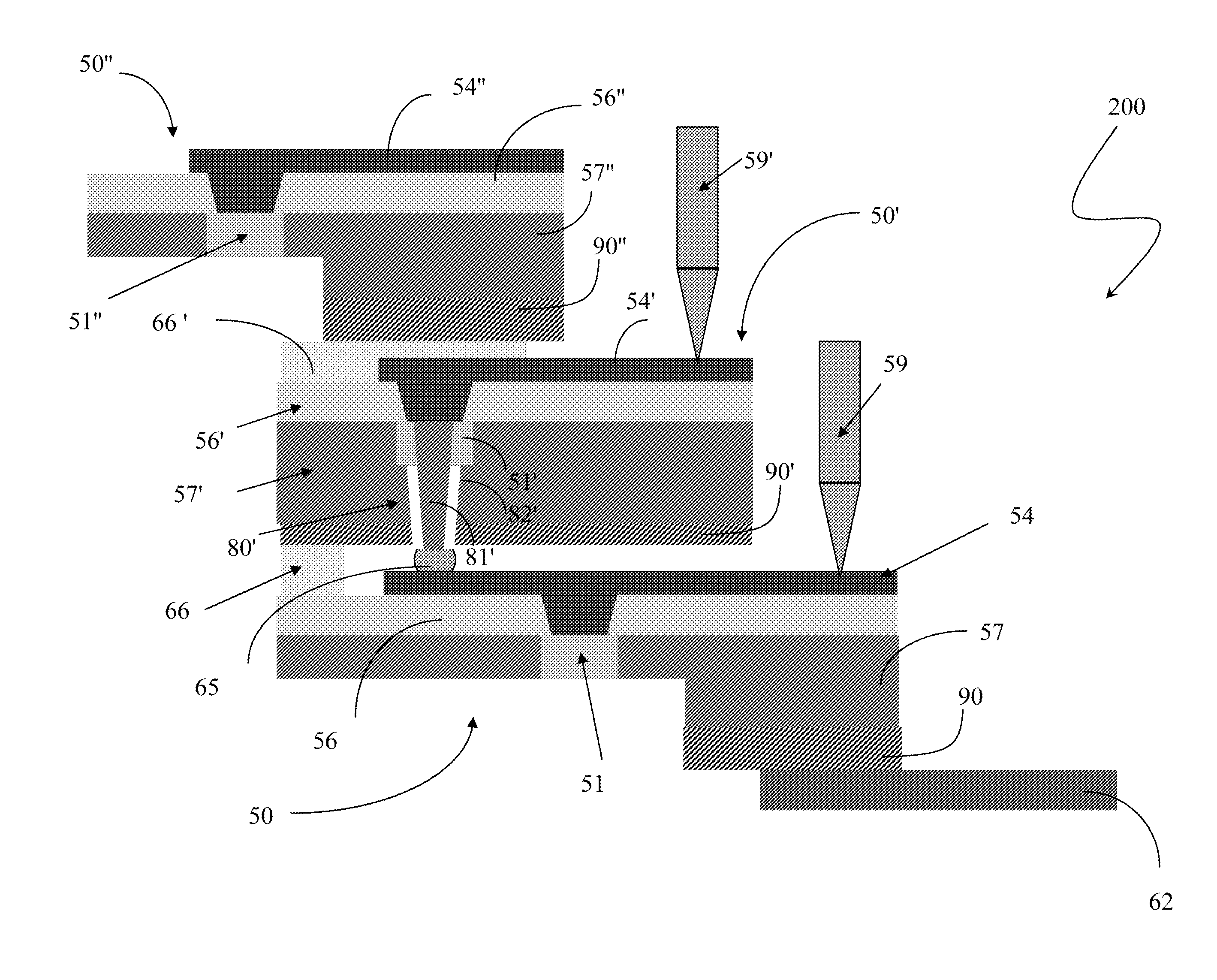

Method to perform electrical testing and assembly of electronic devices

ActiveUS20110049728A1Low extensionReduce harmSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectricityElectrical connection

A method performs electrical testing and assembly of an electronic device on a wafer and comprising a pad made in an oxide layer covered by a passivation layer. The method includes connecting the electronic device to a testing apparatus; providing said electronic device with a metallization layer extending on the passivation layer from the pad to a non-active area of said wafer. The method comprises-performing the electrical testing on wafer of the electronic device by placing a probe of on a portion of the extended metallization layer; performing the cut of said wafer, reducing the extension of the metallization layer to the edge of the electronic device; embedding the device inside a package, forming on the metallization layer an electrical connection configured to connect the metallization layer to a circuit in said package.

Owner:STMICROELECTRONICS SRL

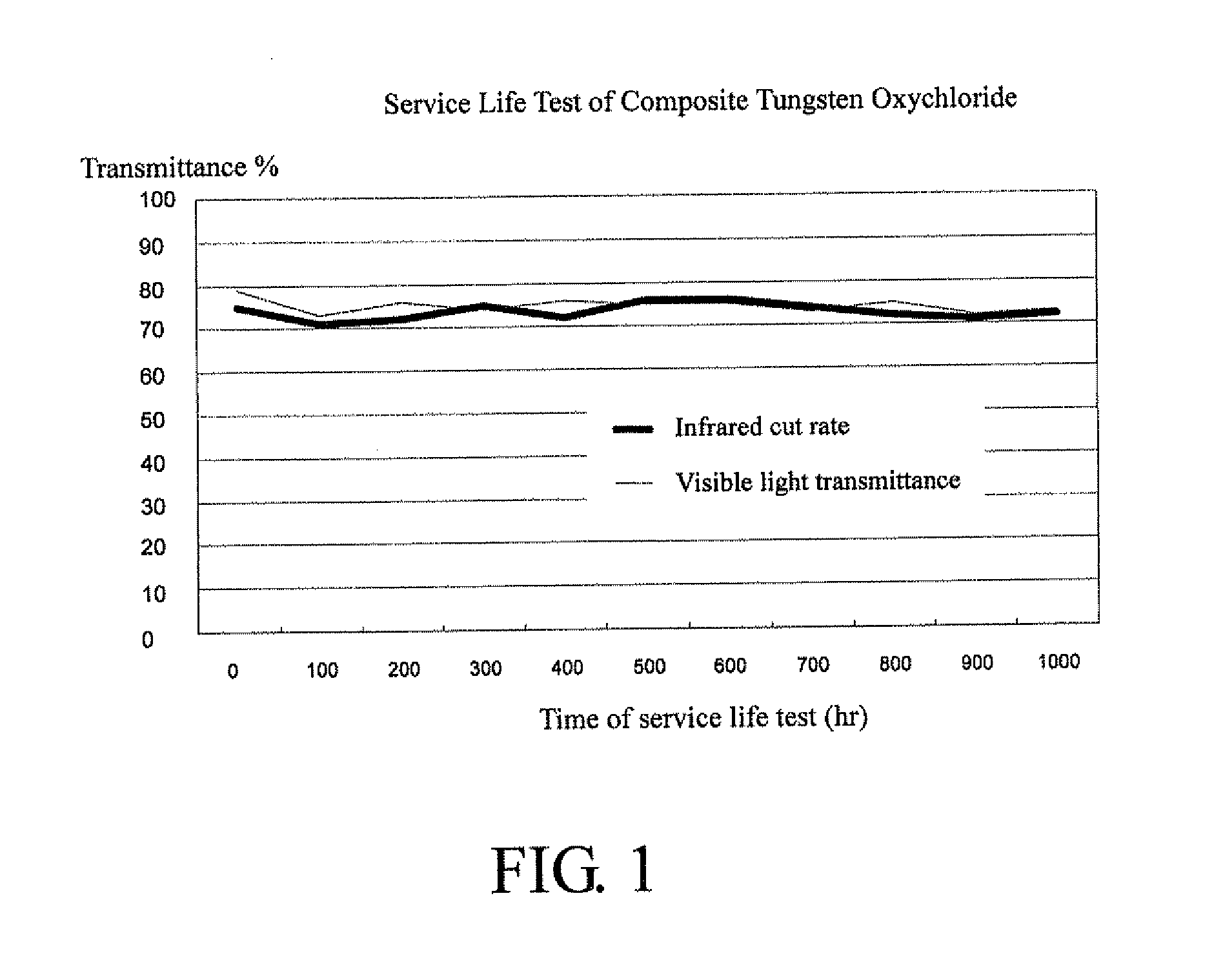

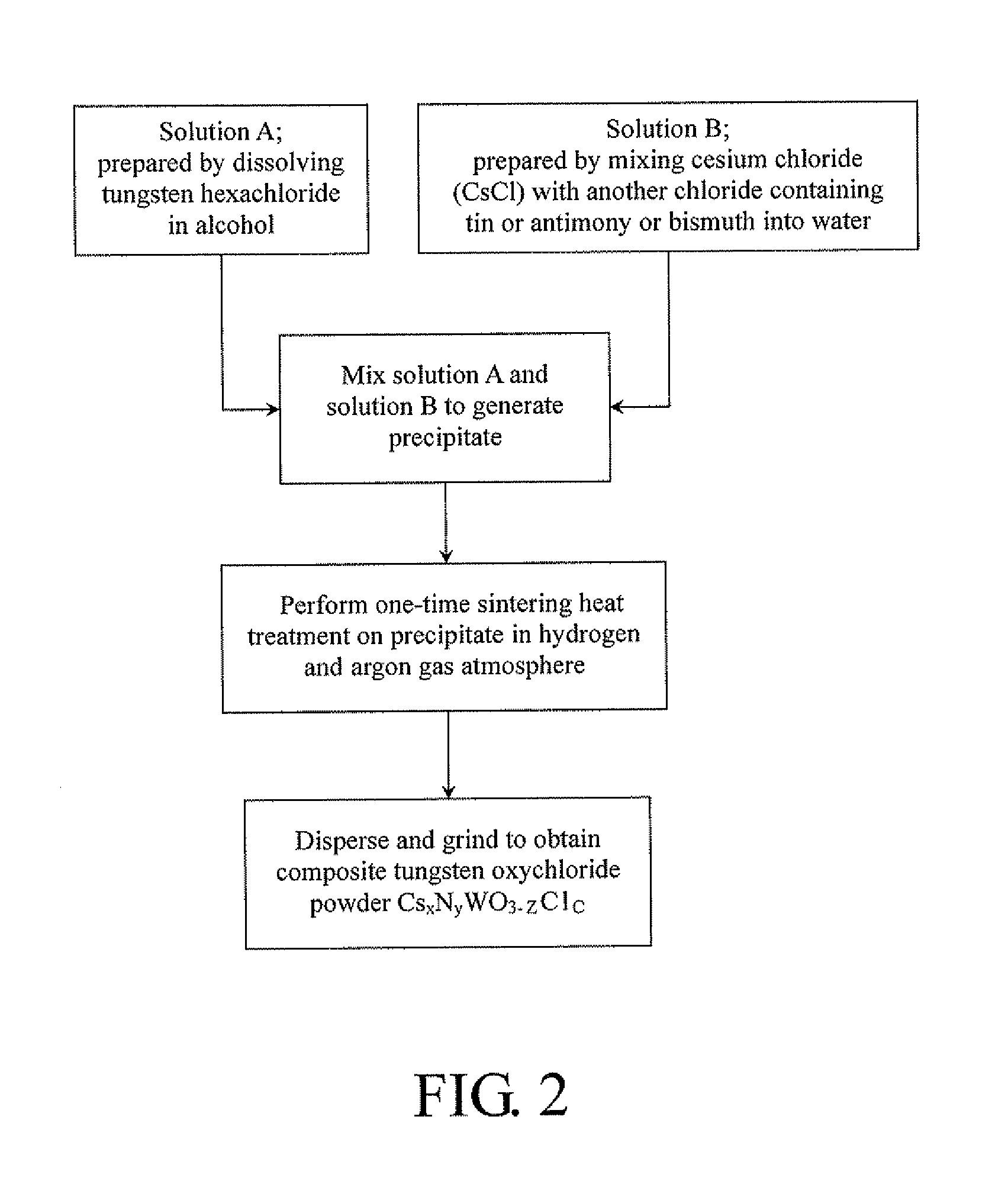

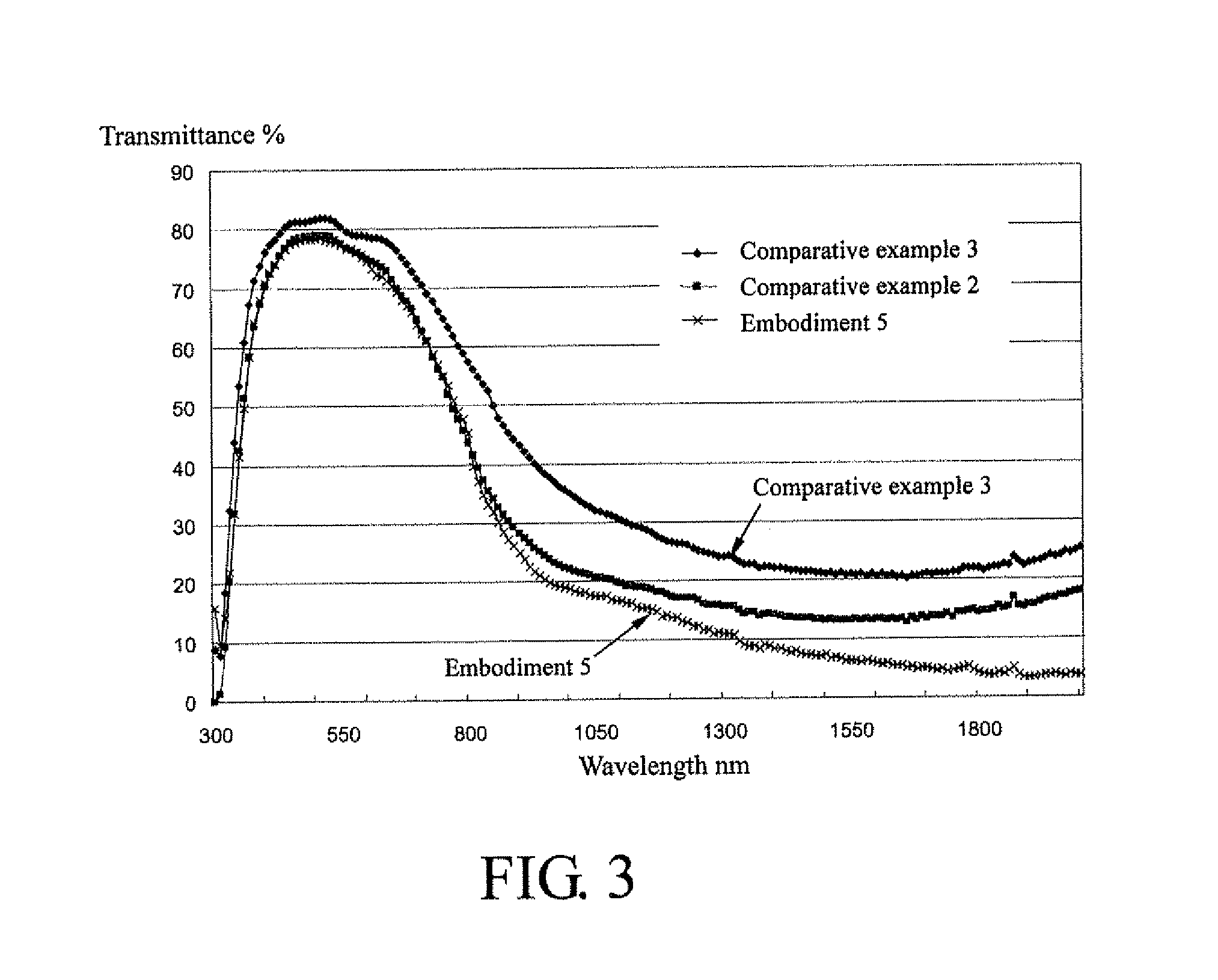

Transparent heat-shielding material excellent in infrared-blocking properties and transparent heat-shielding film made of the same

ActiveUS20130200292A1Simple processLow production costTungsten oxides/hydroxidesClimate change adaptationComposite substrateOxygen

A transparent heat-shielding material having a chemical formula CsXNYWO3-ZClC, characterized by being co-doped with elements of different groups in the periodic table, wherein Cs is cesium; N is tin (Sn) or antimony (Sb) or bismuth (Bi); W is tungsten; O is oxygen; and X, Y, Z, and C are positive numbers satisfying the following conditions:X≦1.0, Y≦1.0, Y / X≦1.0, Z≦0.6, and C≦0.1;the transparent heat-shielding material is used to make a highly transparent and highly effective heat-shielding film which can be adhered to glass panels of buildings and automobiles to block infrared radiation in the wavelength range of 800-2000 nm, thereby insulating heat and saving energy; and the film is also applicable as a composite substrate for electronic components.

Owner:NANYA PLASTICS CORP

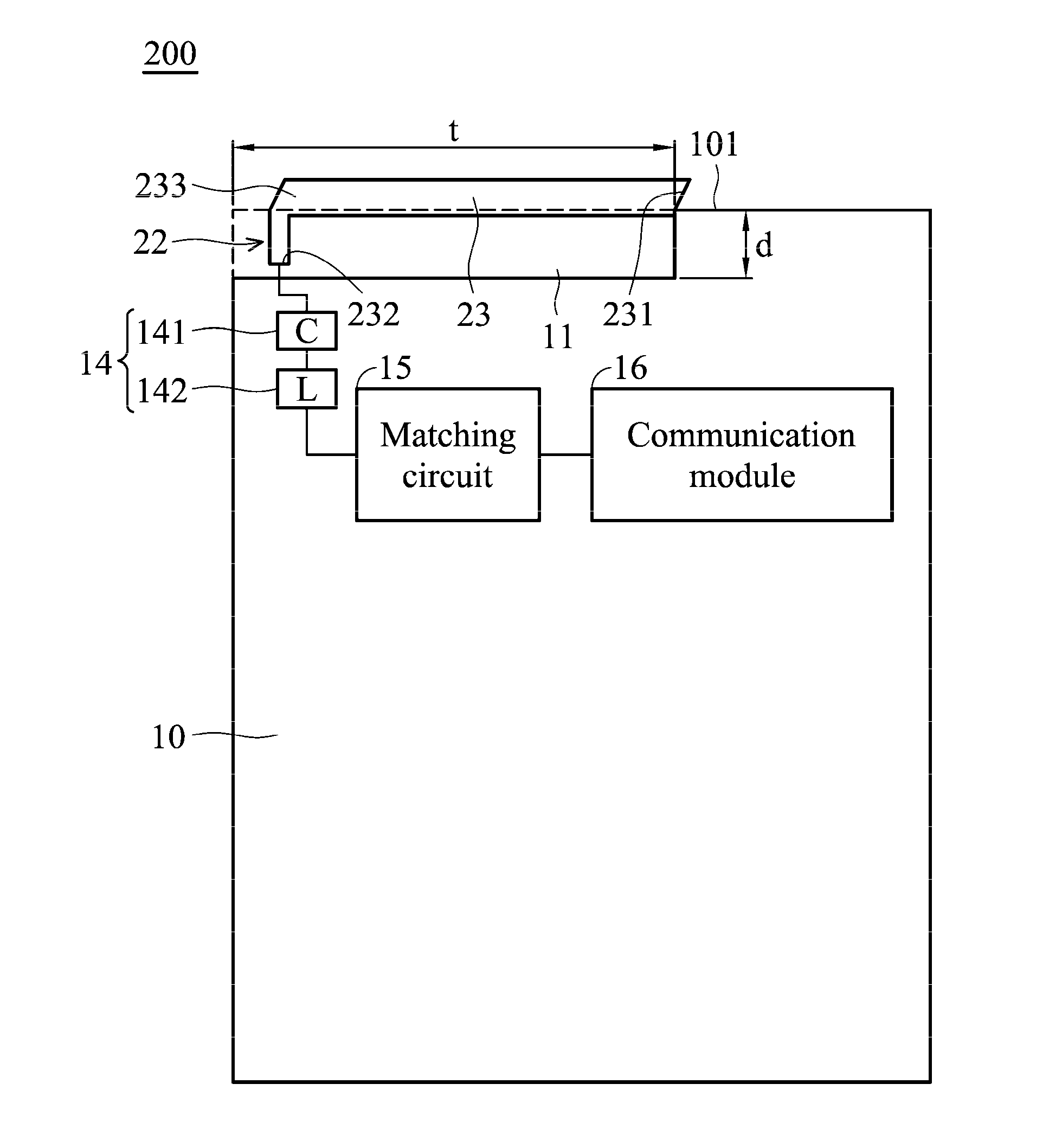

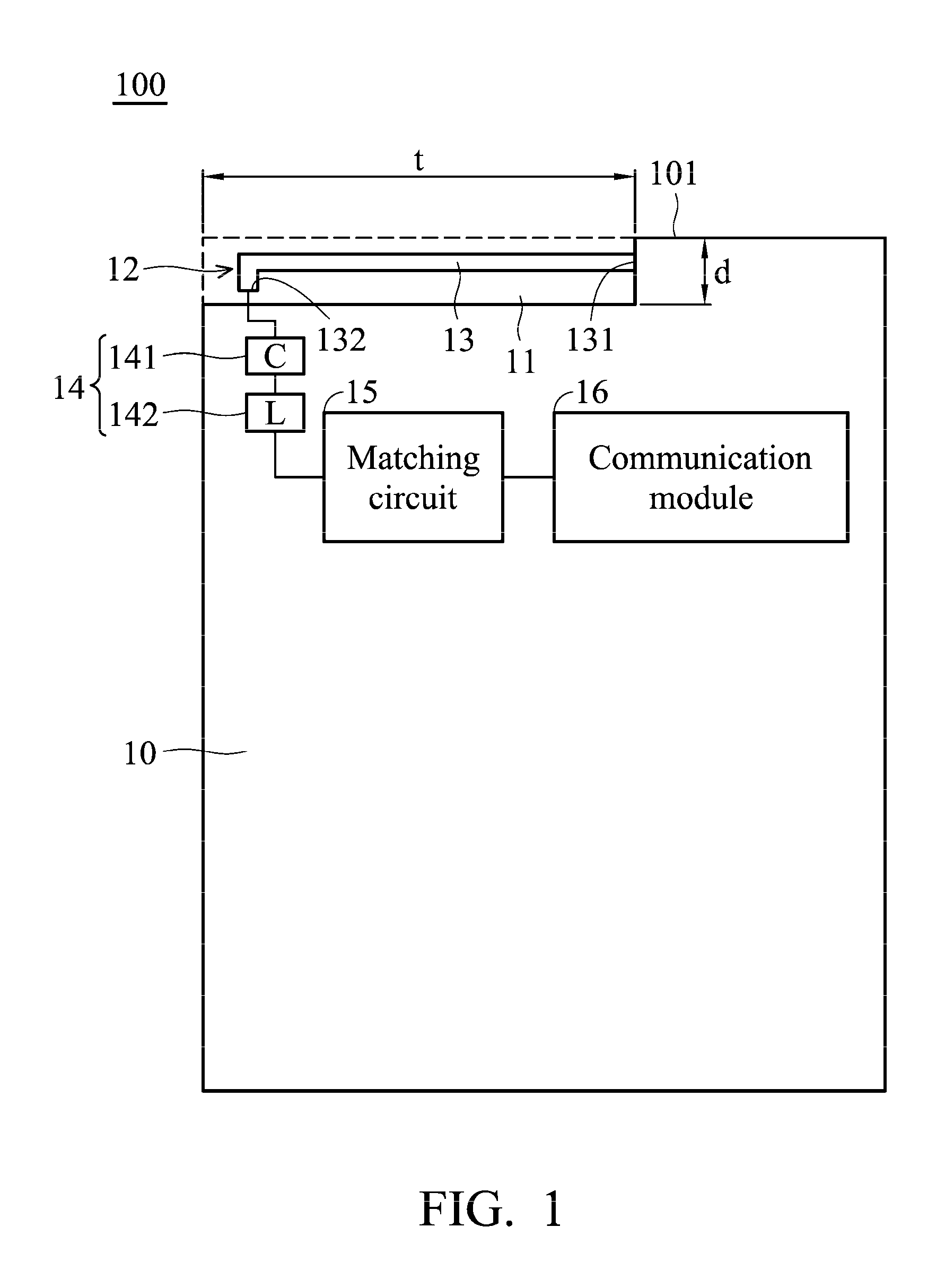

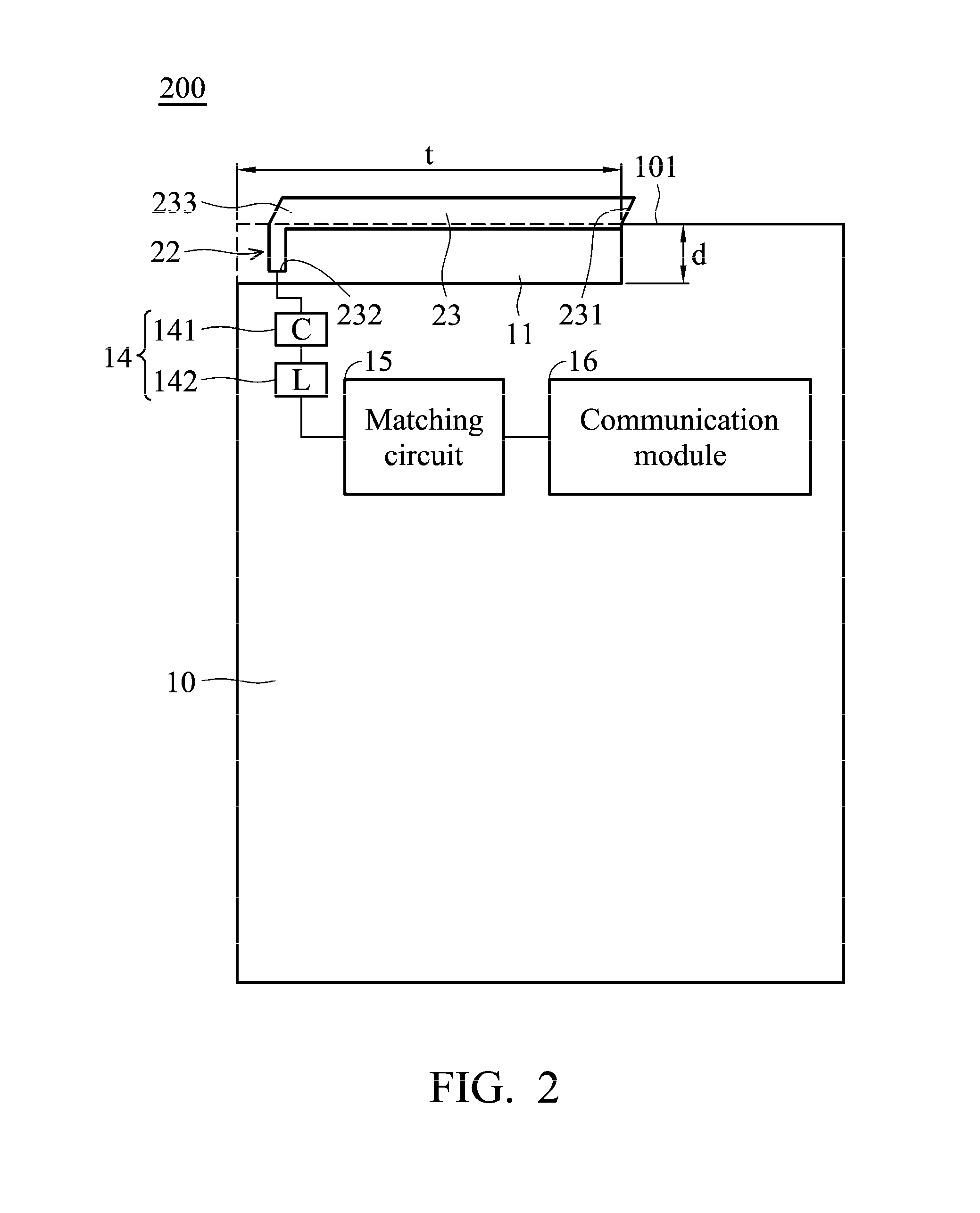

Communication device and antenna structure therein

ActiveUS20120188135A1Simple and low-cost processSmall overall lengthSimultaneous aerial operationsRadiating elements structural formsInductorCapacitance

A communication device including an antenna structure is provided, wherein the antenna structure includes a ground element, an antenna element, and a circuit element group. The ground element has a notch at one of its edges, and a long edge of the notch is at least two times longer than a short edge of the notch. The antenna element includes a metal portion disposed in the notch. Two ends of the metal portion are extended away from each other and are positioned substantially at or around two opposite edges of the notch. One end of the metal portion is coupled to the ground element, and the other end of the metal portion is a feeding terminal of the antenna element. The circuit element group includes at least a capacitive element and an inductive element.

Owner:ACER INC

Electric device having nanowires, manufacturing method thereof, and electric device assembly

InactiveUS7696022B2Simple and low-cost processImprove performanceNanoinformaticsSolid-state devicesNanowireElectron

An electric device having a plurality of nanowires, in which at least one of the nanowires is cut or changed in its electric characteristics so as to have a desired characteristic value of the electric device.

Owner:CANON KK

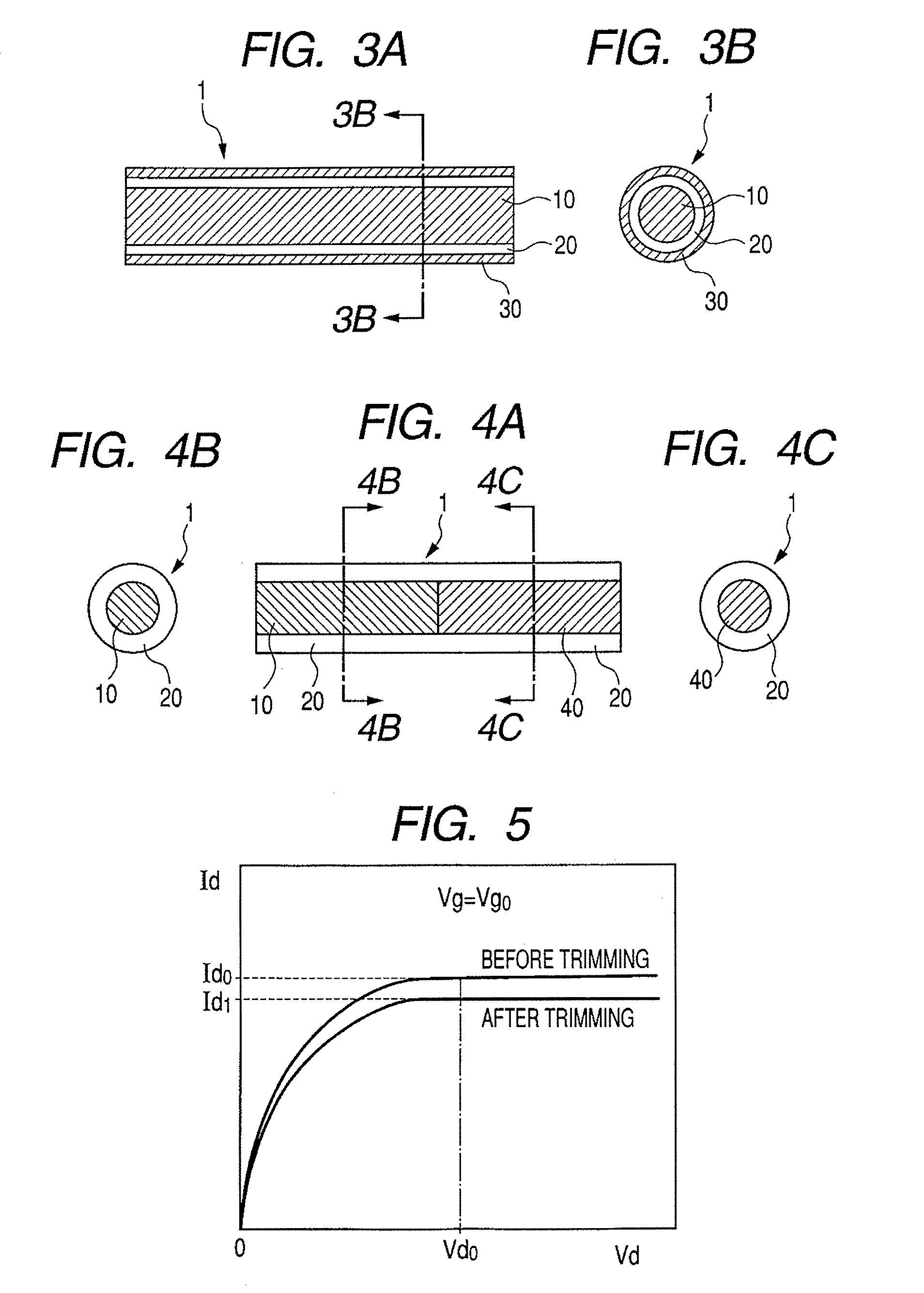

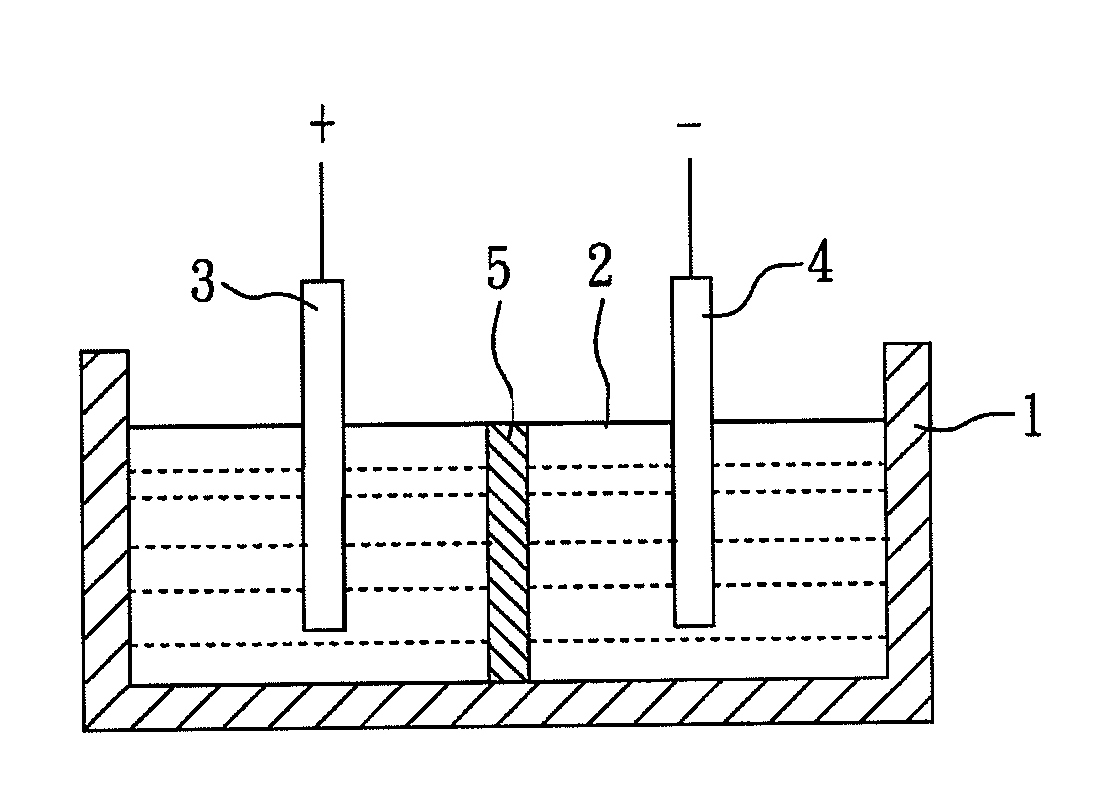

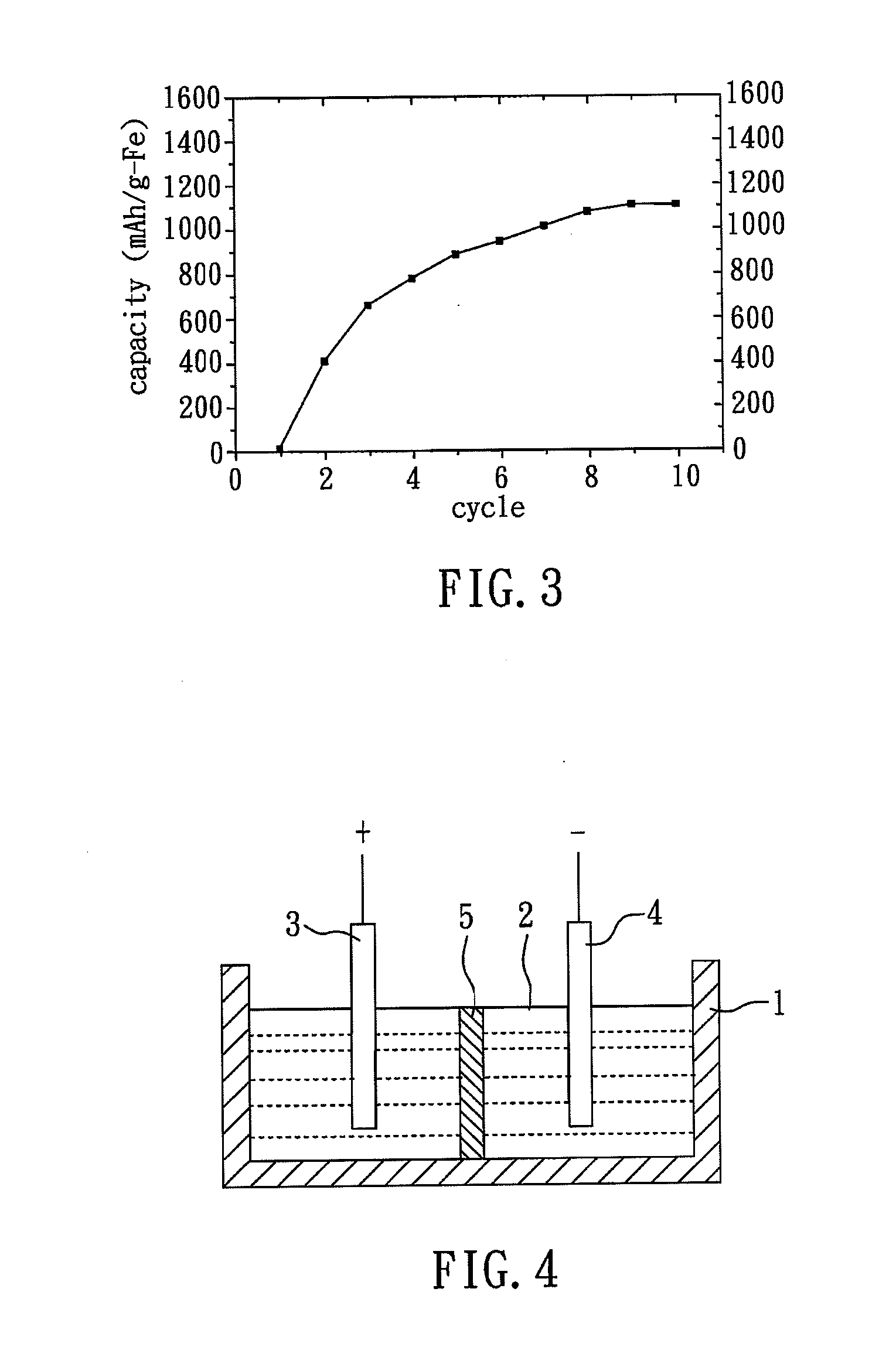

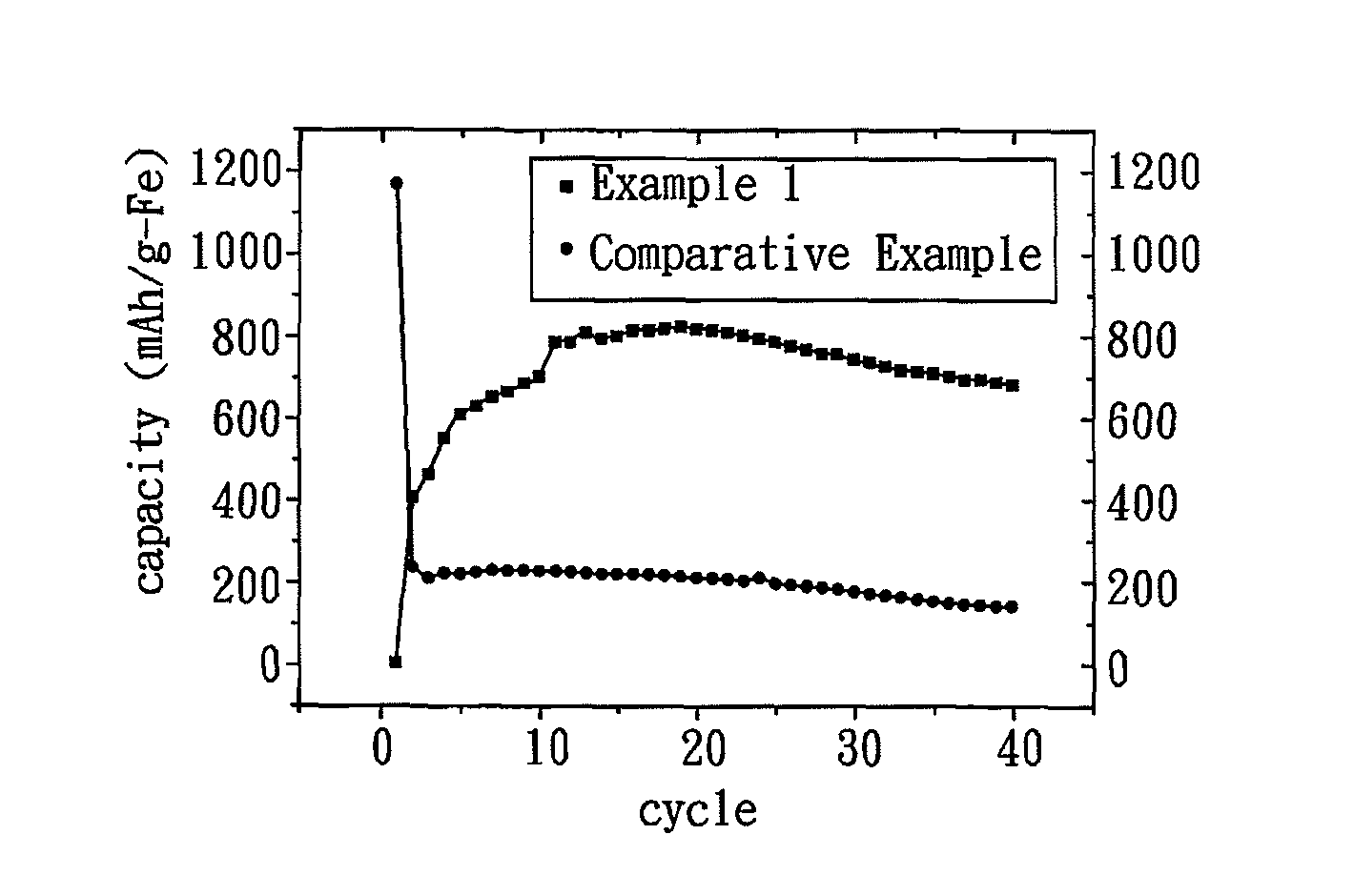

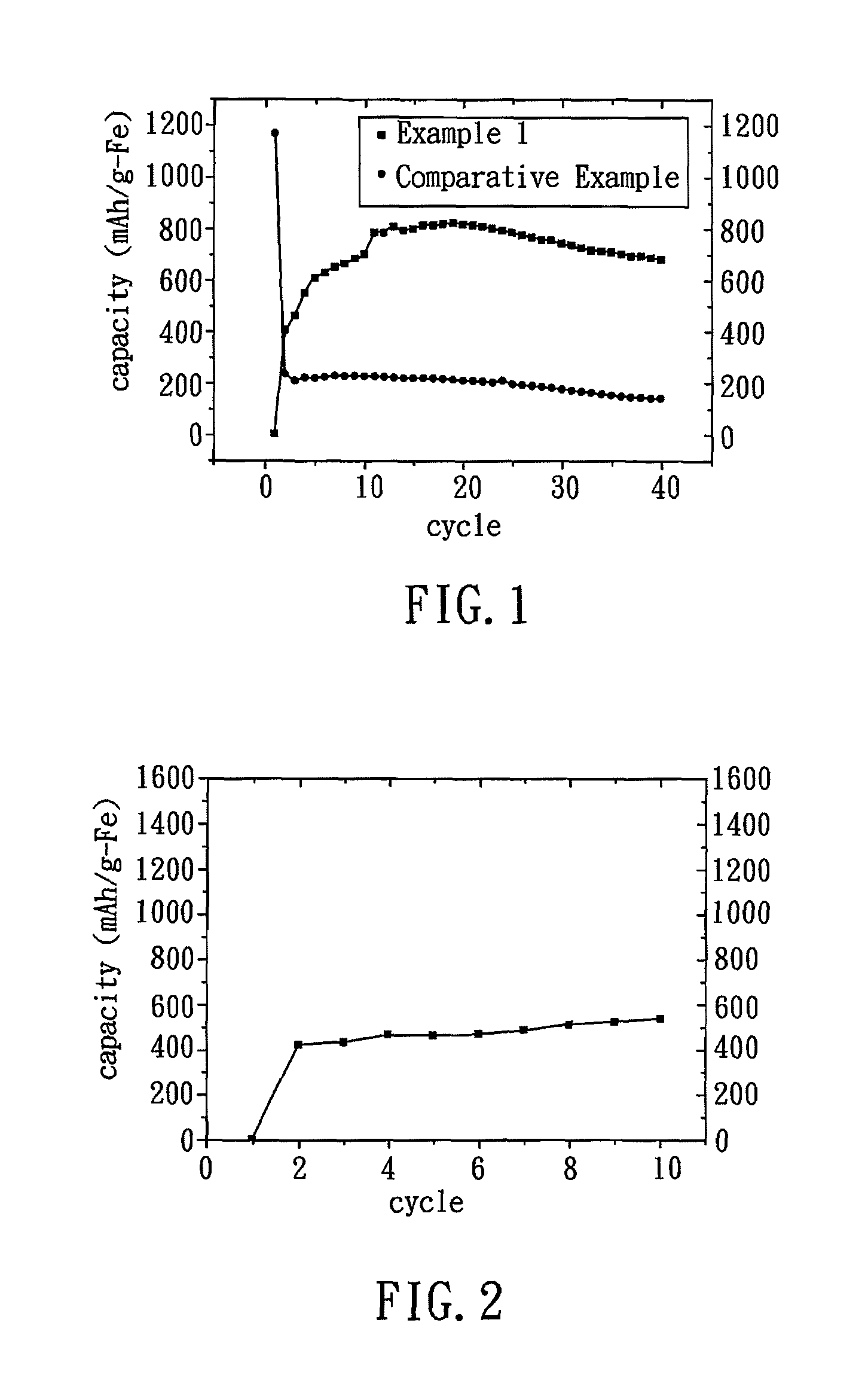

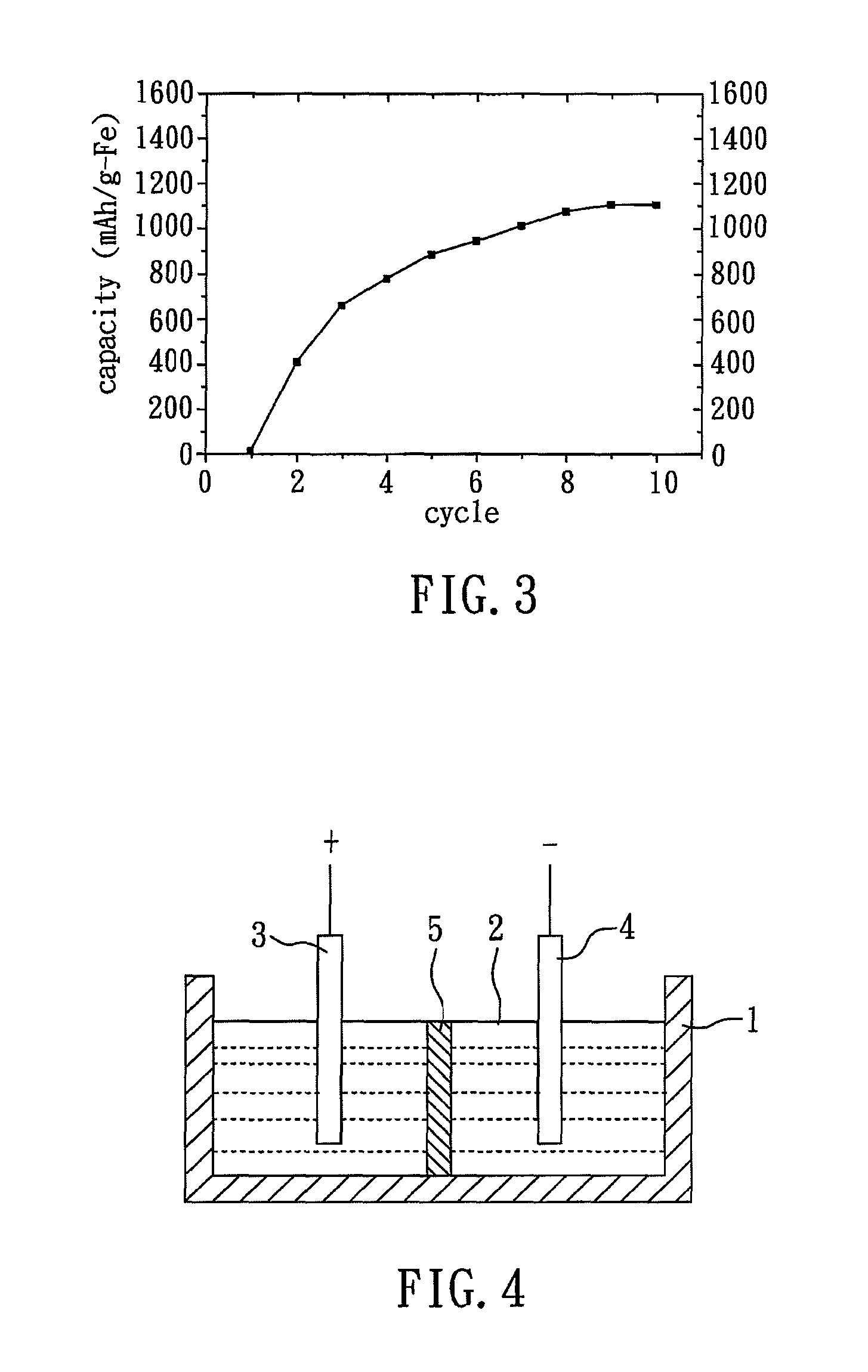

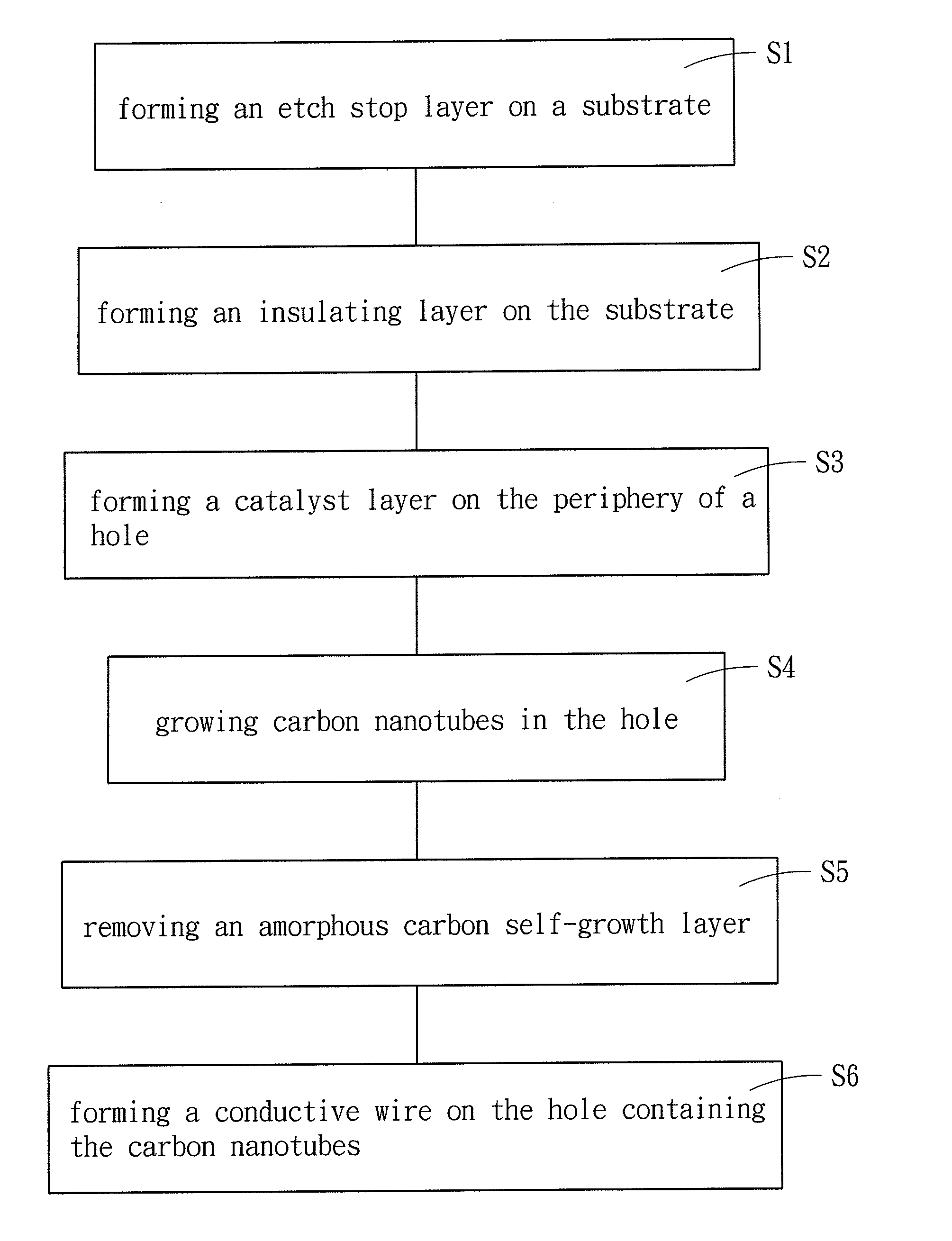

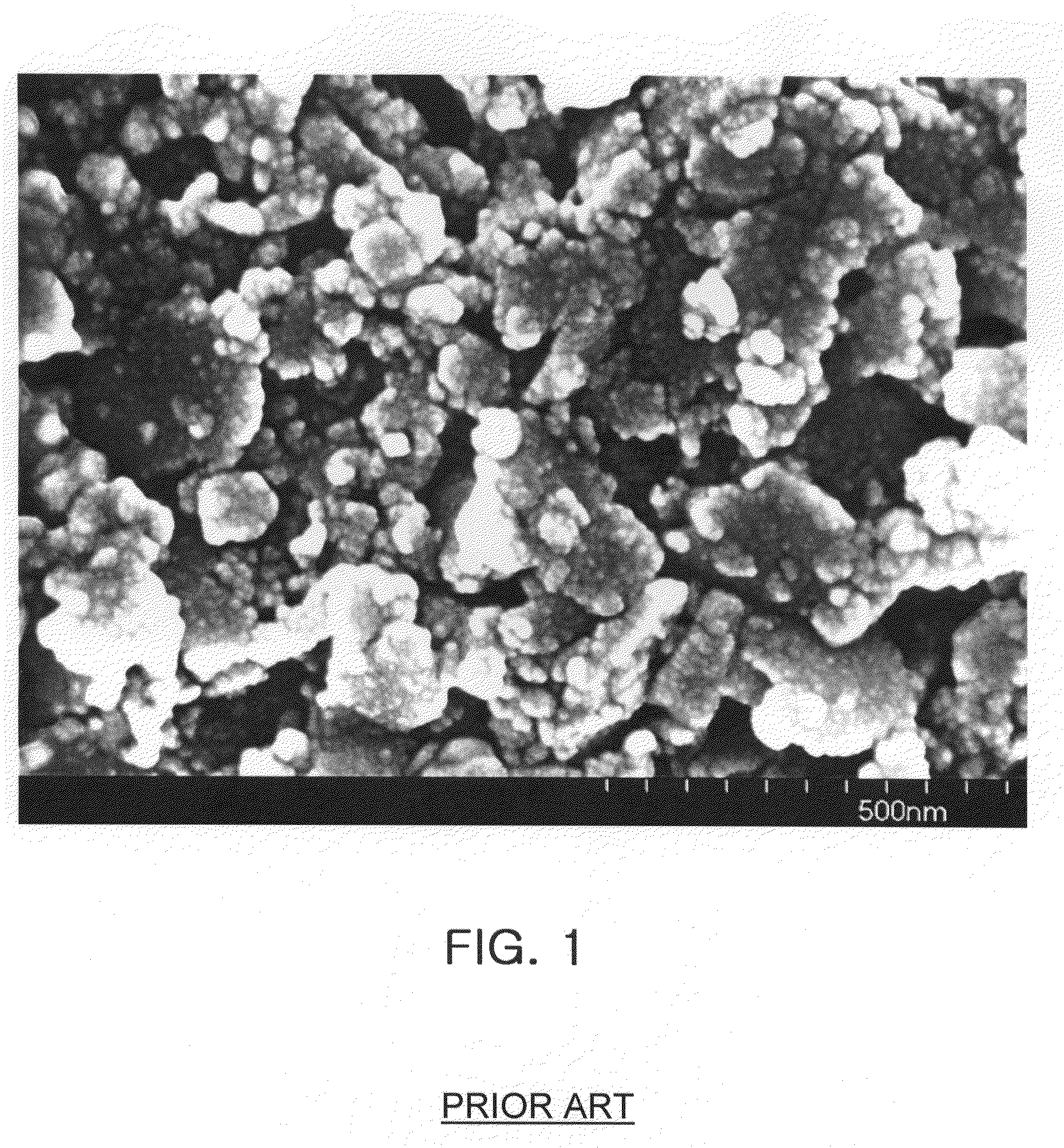

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS20110236747A1Large capacityLarge scaleSilver accumulatorsNon-metal conductorsIndiumNickel salt

The present invention relates to a composite material for a negative electrode, including: a plurality of iron oxide particles; and a conductivity improver, which is selected form the group consisting of copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, copper salt, cobalt salt, nickel salt, tin salt, antimony salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, copper hydroxide, cobalt hydroxide, nickel hydroxide, stannic hydroxide, antimony hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and the combination thereof. In the case of applying the composite material for a negative electrode according to the present invention in an electrochemical device, the improved charge / discharge characteristics and high capacity can be achieved. In addition, the present invention further provides a method for fabricating the above-mentioned composite material for a negative electrode and an electrochemical device using the same.

Owner:NATIONAL TSING HUA UNIVERSITY

Polymer having superhydrophobic surface

ActiveUS9040145B2Maintain good propertiesIncrease resistanceMaterial nanotechnologySpecial ornamental structuresPolymer scienceNanoparticle

The disclosure relates to a superhydrophobic surface. Methods of fabrication are disclosed including laminating a polymer sheet having a surface to a template having a textured surface or a layer of a nanomaterial (e.g., nanoparticles or nanofibers) to convert the surface of the polymer sheet to a hydrophobic surface having a water contact angle of at least about 150°.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

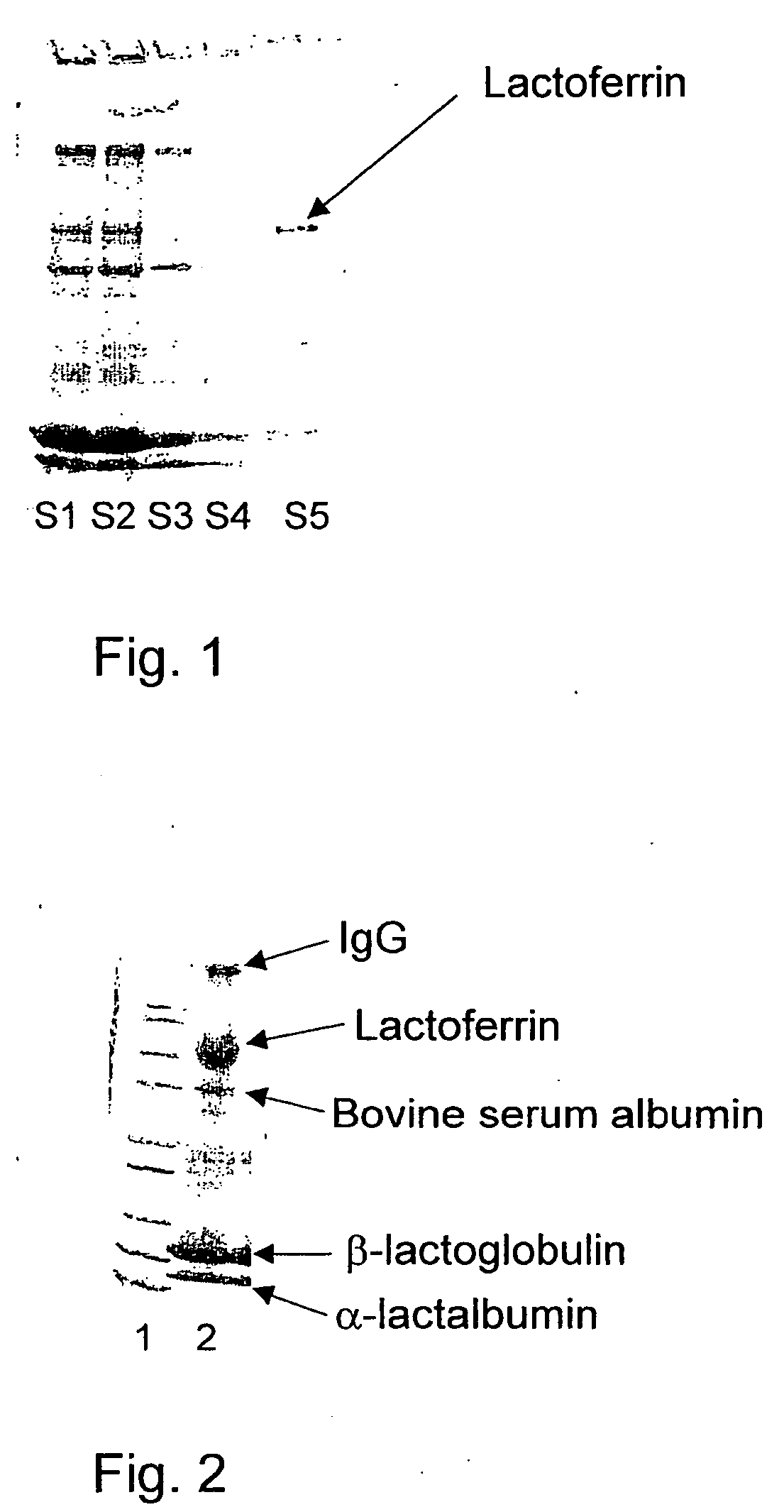

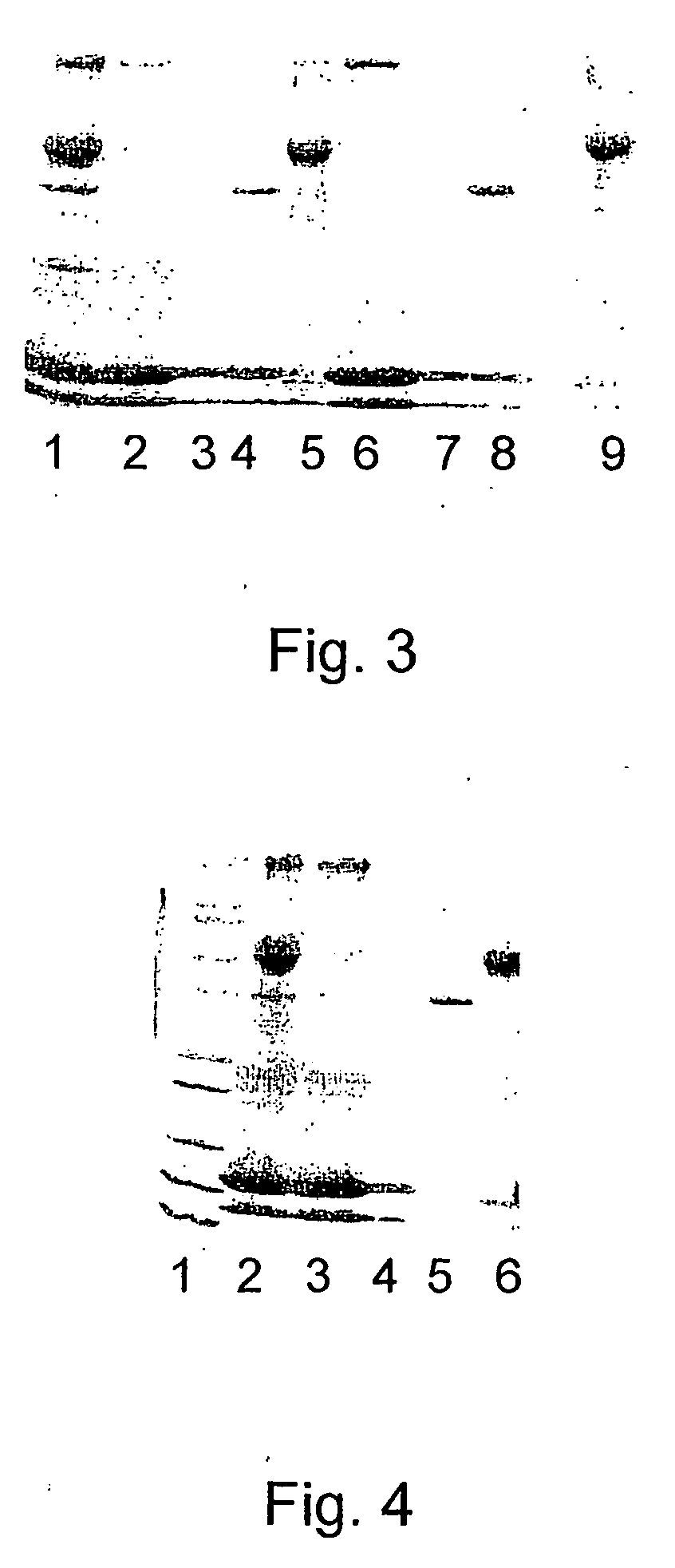

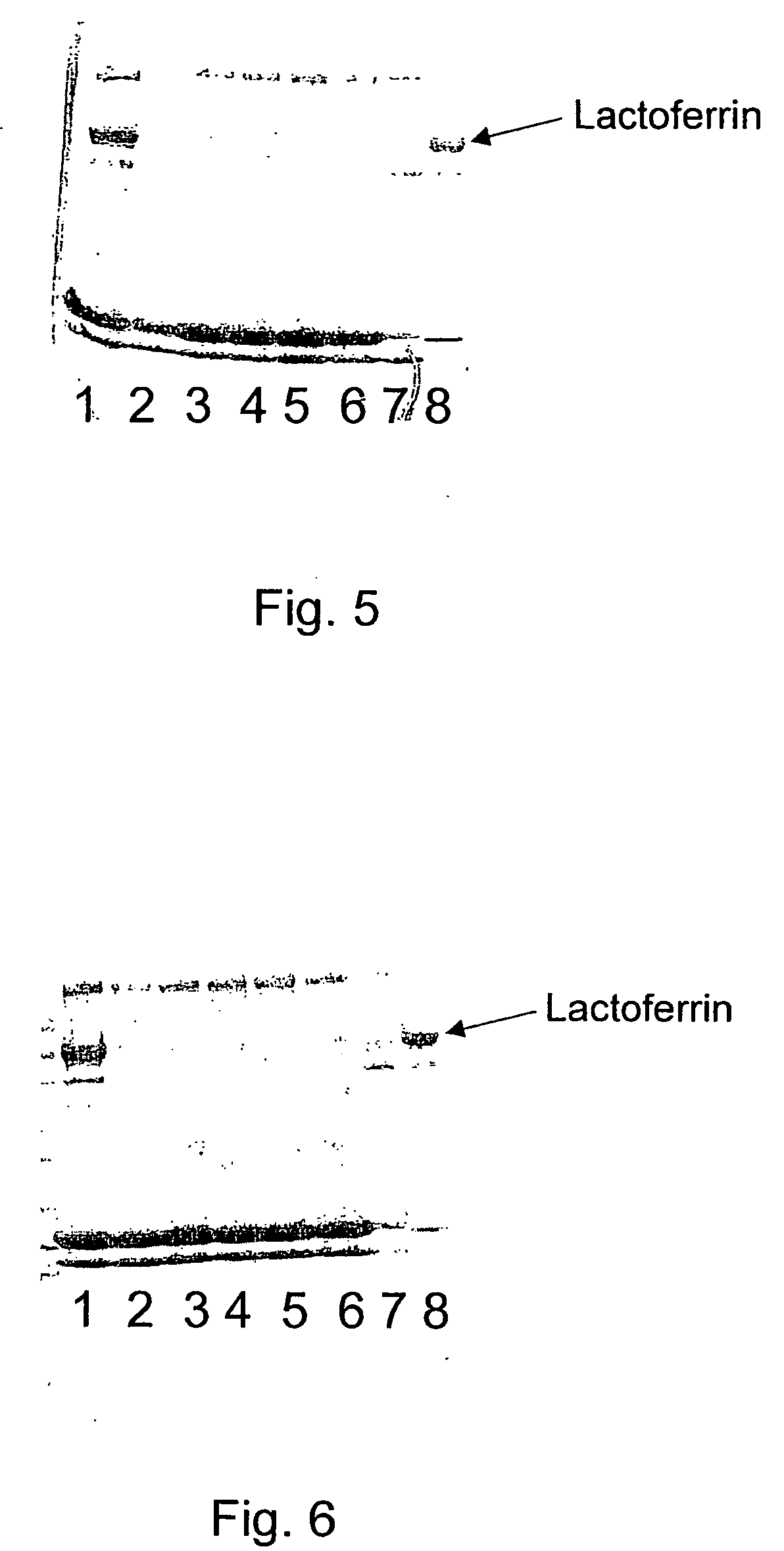

Process of isolating lactoferrin

ActiveUS20050220953A1Simple and low cost processEasy to useMilk preparationFood preservationCulture mediumsLactoferrin

A process for isolating lactoferrin from milk or a casein-containing component or product containing lactoferrin, comprising subjecting a precipitate of casein obtained from the milk of the casein-containing component or product, with which precipitate at least part of the milk lactoferrin is associated, to a treatment with an extraction medium whereby at least part of the lactoferrin associated with the precipitate of casein is released to the medium. When lactoferrin has been released, the medium may be subjected to different types of purification operation steps. The purification operations are selected in accordance with the purity requirements of the intended specific application. Furthermore, lactoferrin and / or a composition comprising lactoferrin according to the above-mentioned process is provided.

Owner:UPFRONT CHROMATOGRAPHY

Polymer having superhydrophobic surface

InactiveUS20150224539A1Maintain good propertiesIncrease resistanceMaterial nanotechnologyFouling preventionPolymer scienceNanoparticle

The disclosure relates to a superhydrophobic surface. Methods of fabrication are disclosed including laminating a polymer sheet having a surface to a template having a textured surface or a layer of a nanomaterial (e.g., nanoparticles or nanofibers) to convert the surface of the polymer sheet to a hydrophobic surface having a water contact angle of at least about 150°.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

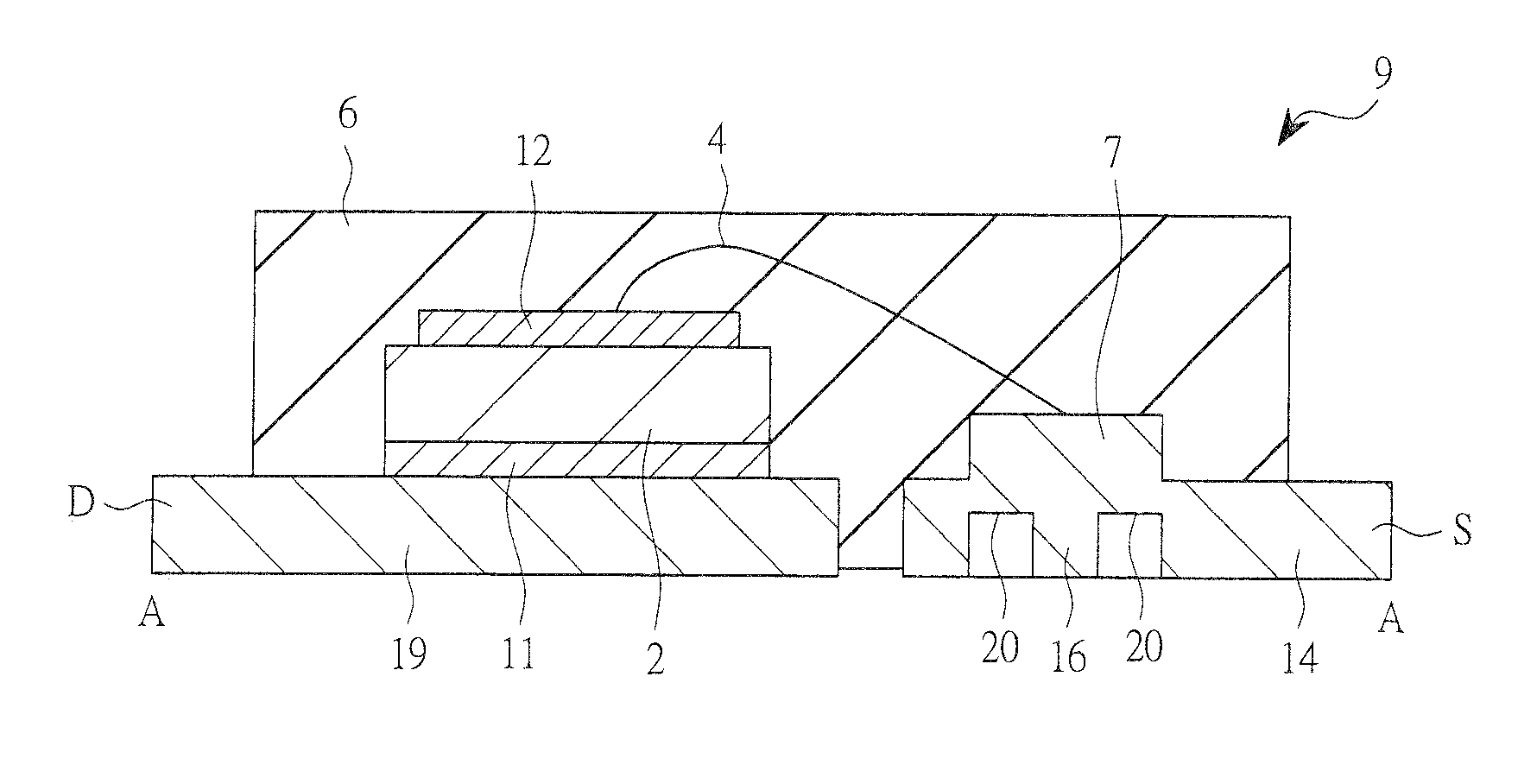

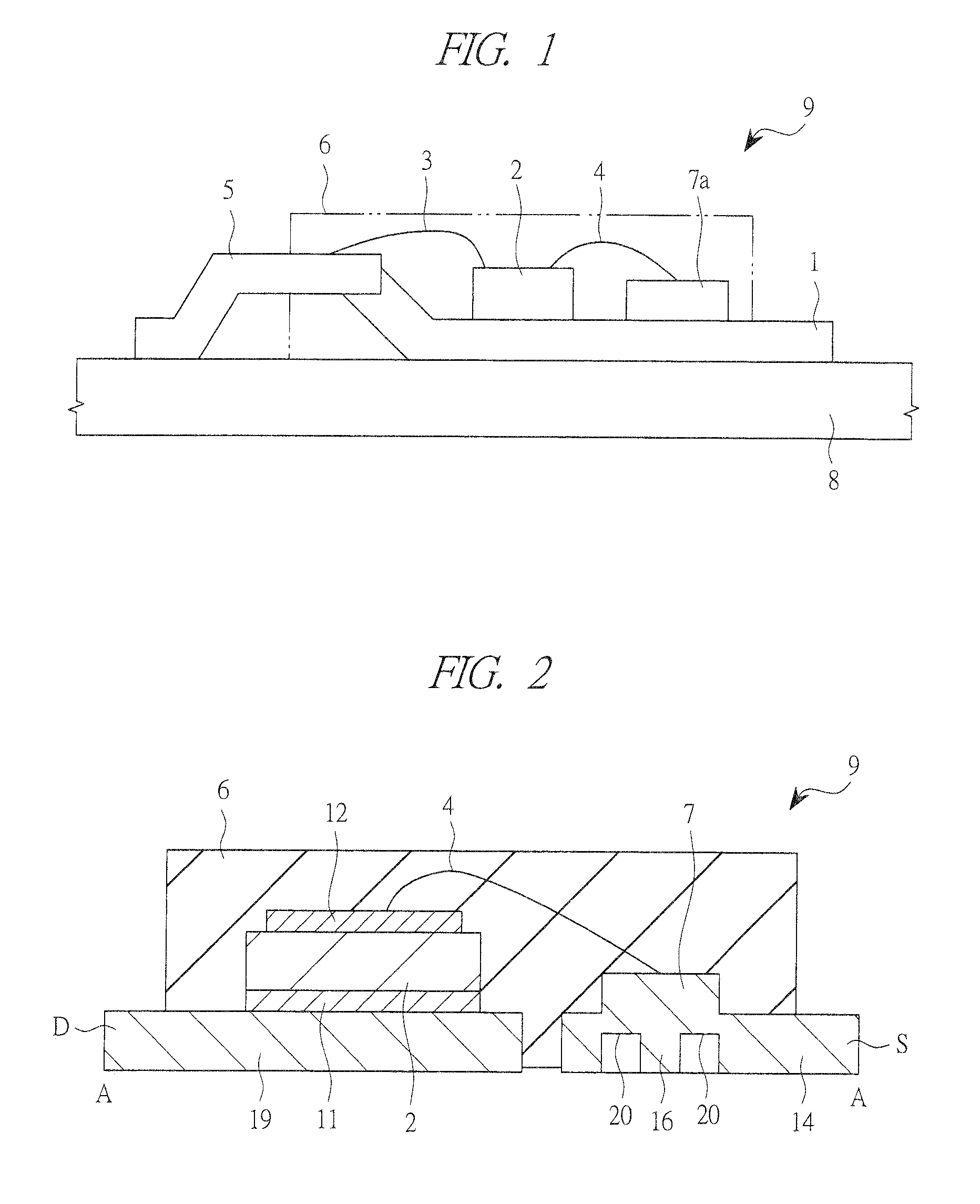

Semiconductor device

InactiveUS20100181628A1Improve reliabilitySimple processTransistorSemiconductor/solid-state device detailsEngineeringUltimate tensile strength

Prevention of disconnection of a bonding wire resulting from adhesive interface delamination between a resin and a leadframe, and improvement of joint strength of the resin and the leadframe are achieved in a device manufactured by a low-cost and simple processing. A boss is provided on a source lead by a stamping processing, and a support pillar is provided in a concave portion on a rear side of the source lead in order to prevent ultrasonic damping upon joining the bonding wire onto the boss, so that an insufficiency of the joint strength between the bonding wire and the source lead is prevented. Also, a continuous bump is provided on the boss so as to surround a joint portion between the source lead and the bonding wire, so that disconnection of the bonding wire resulting from delamination between the resin and the source lead is prevented.

Owner:RENESAS ELECTRONICS CORP

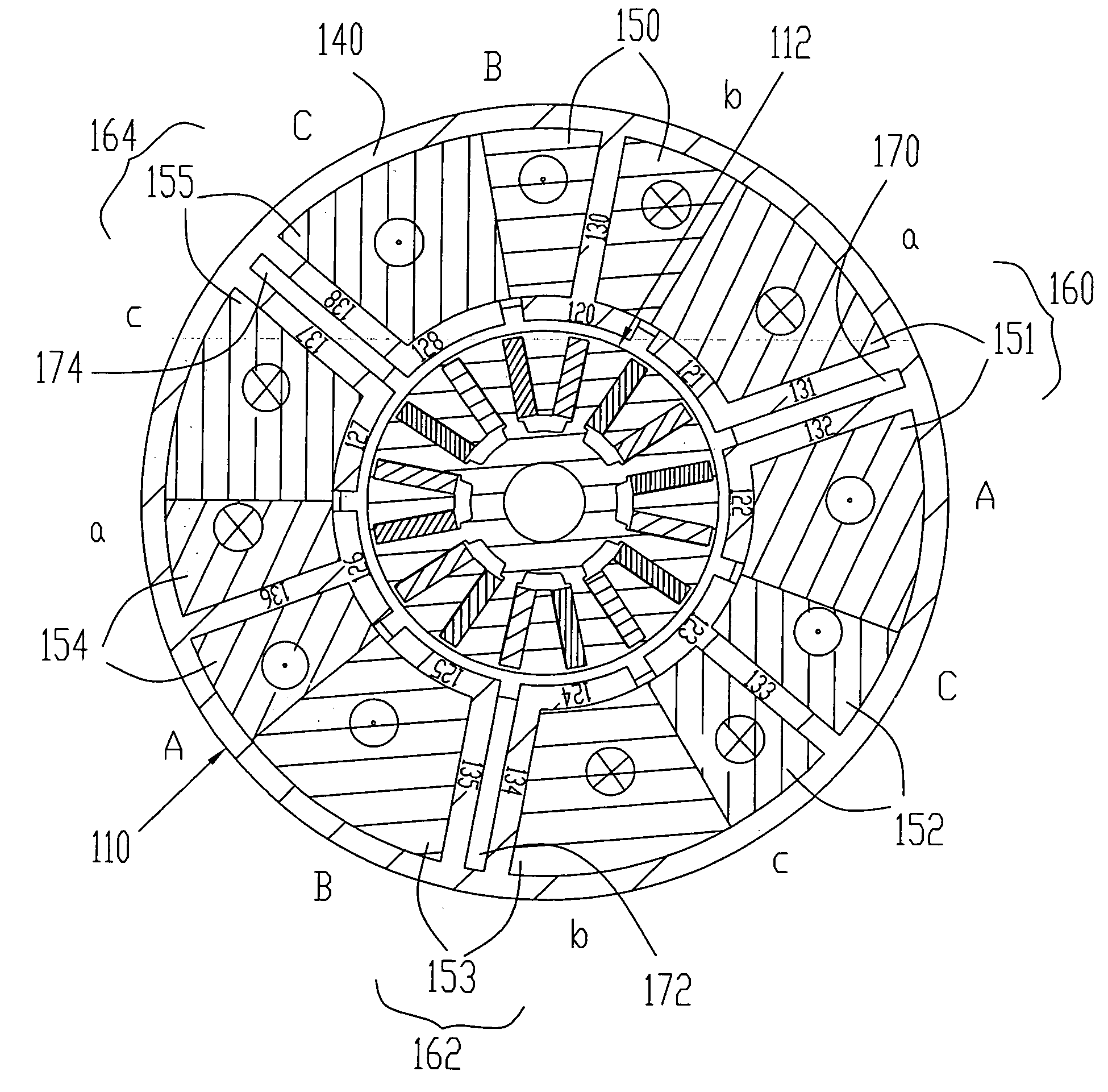

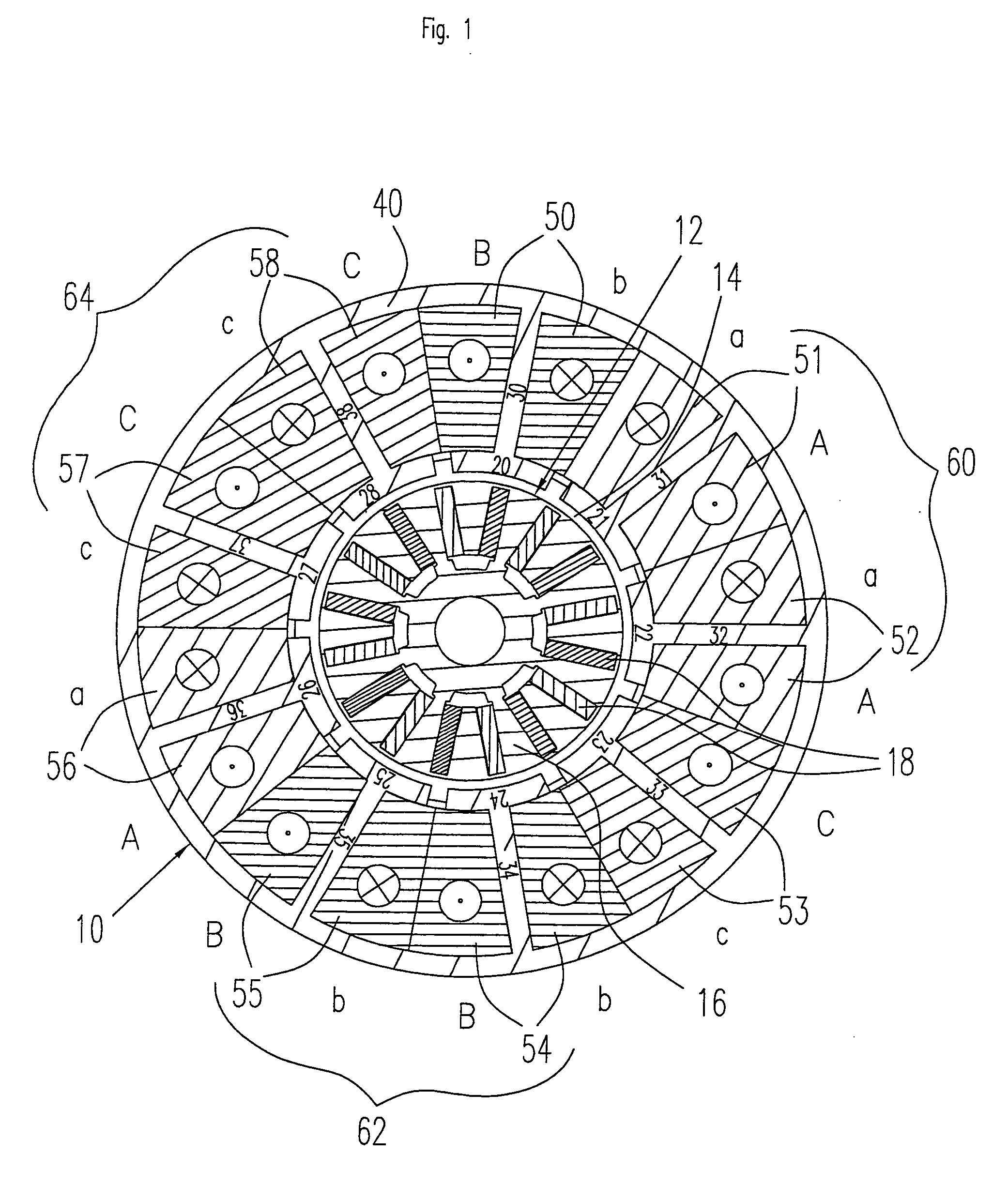

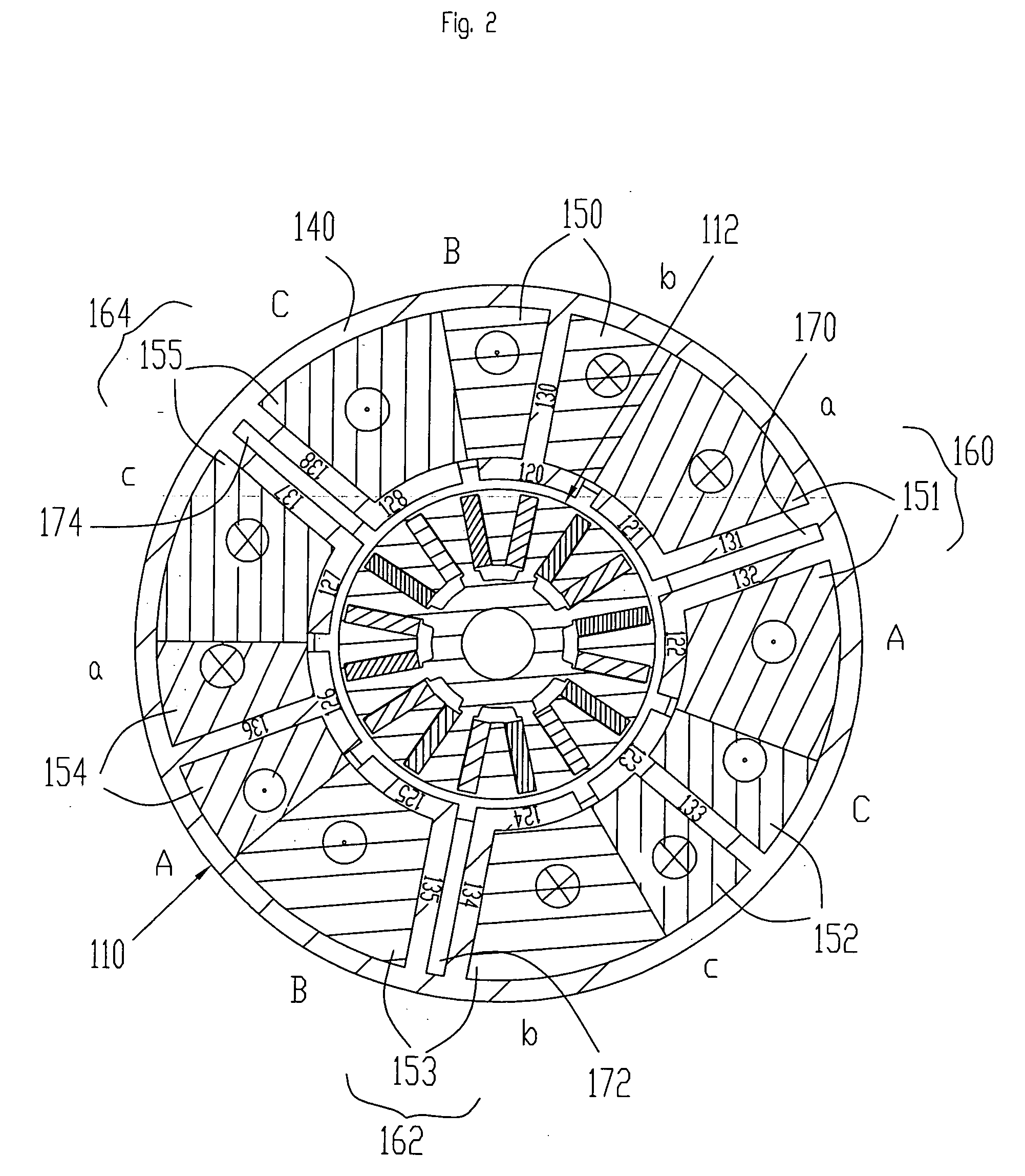

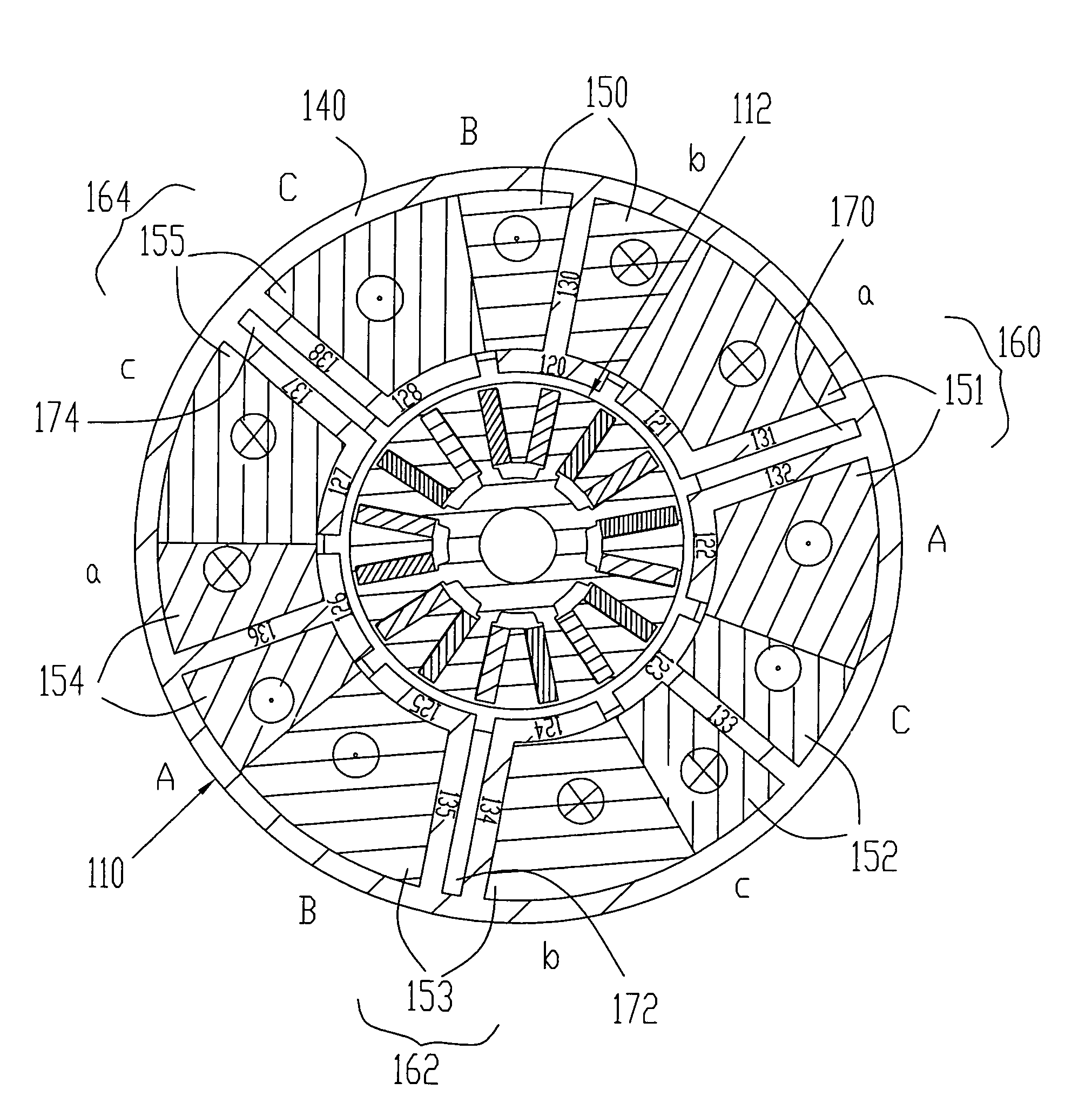

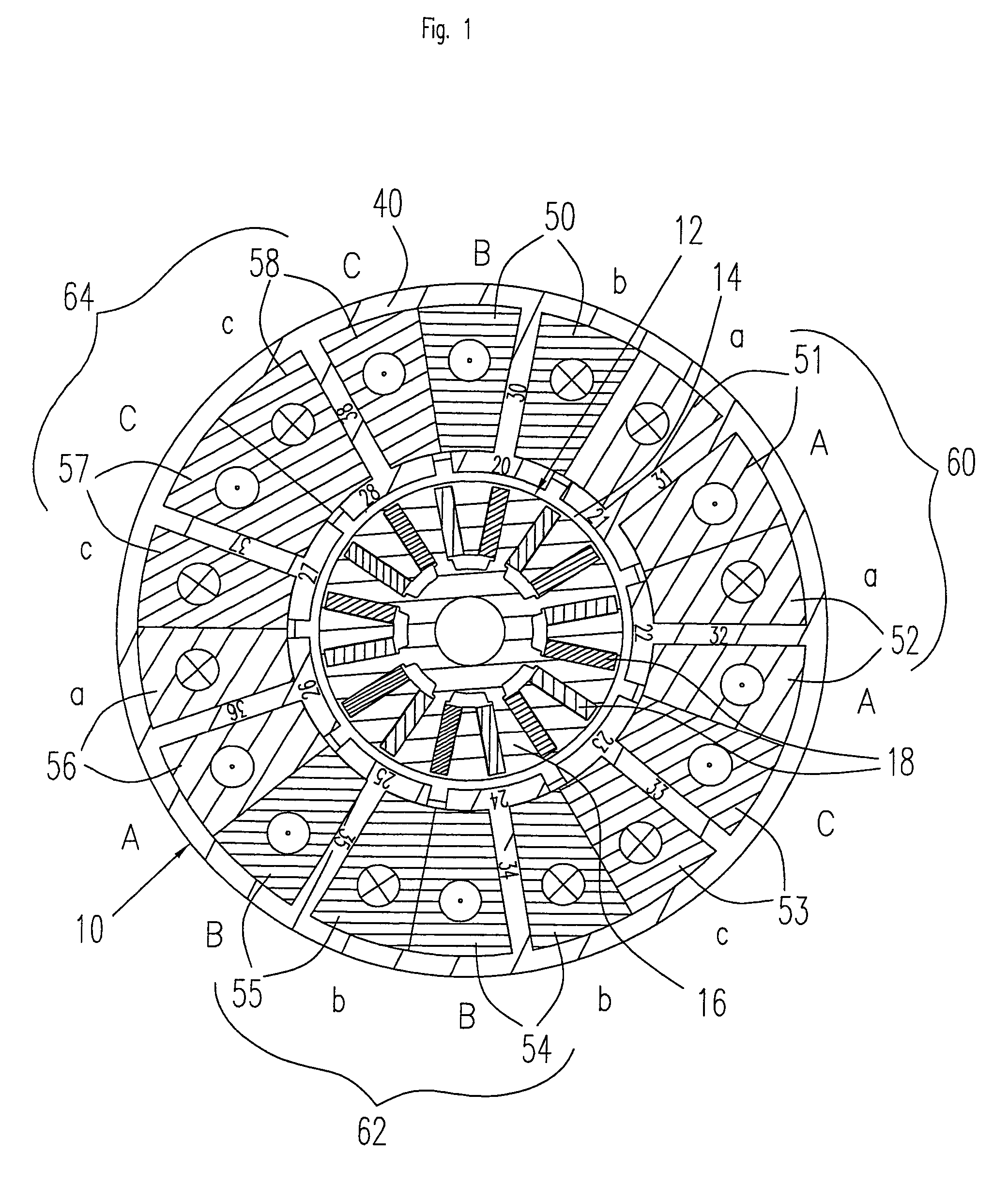

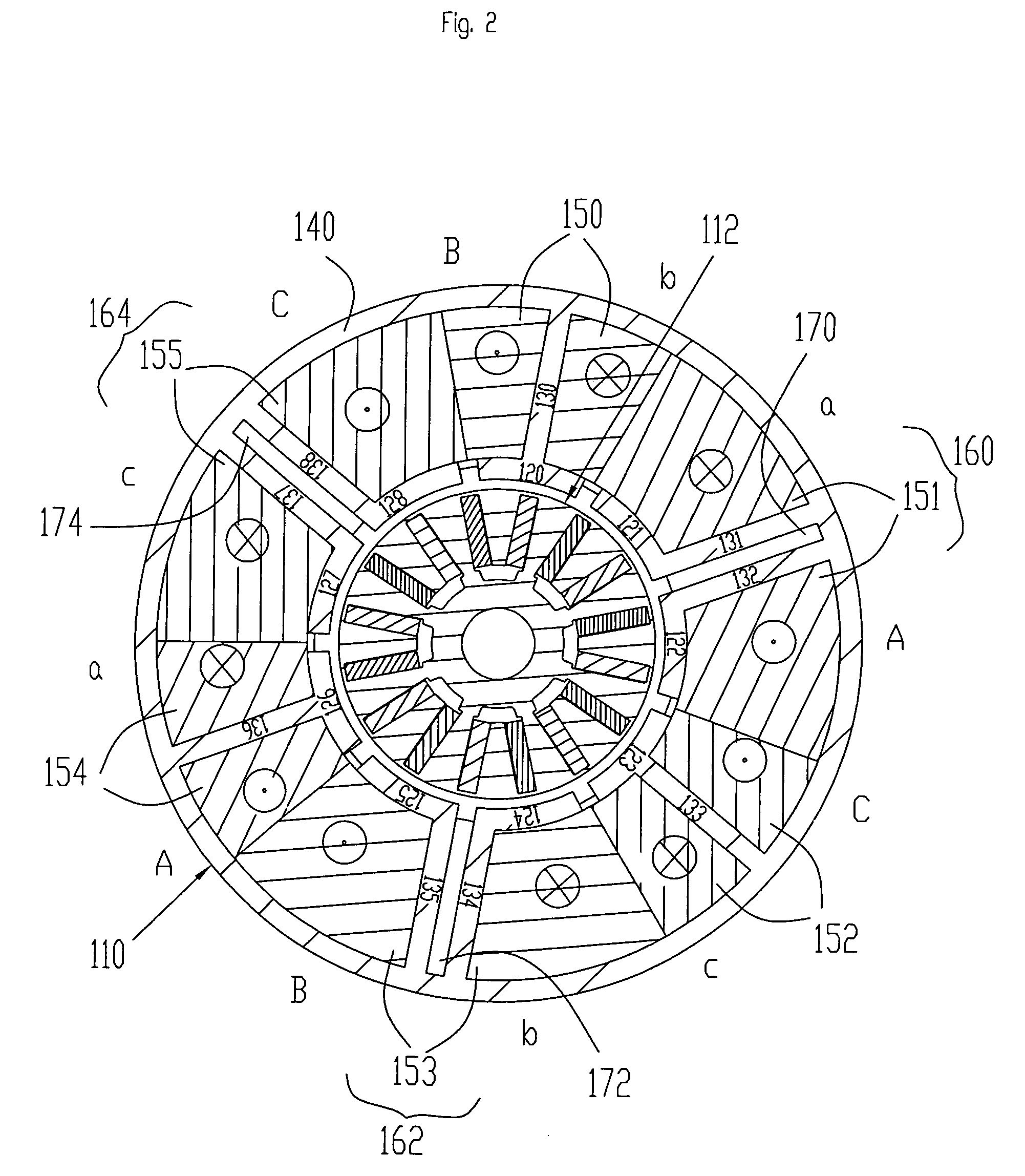

Brushless direct current motor

InactiveUS20050280326A1Same operating performancePosition unchangedSynchronous generatorsWindingsDirect currentStator poles

A direct current motor having a stator that has a plurality of radially arranged stator pole bridges to each of which one phase is allocated, at least one stator pole group being formed by at least two adjoining stator poles which are associated with the same phase, no winding sections being provided between the stator poles of the at least one stator pole group and the respective stator pole bridges of this stator pole group being disposed with a smaller spacing between each other than two adjoining stator pole bridges that are associated with different phases.

Owner:MINEBEA CO LTD

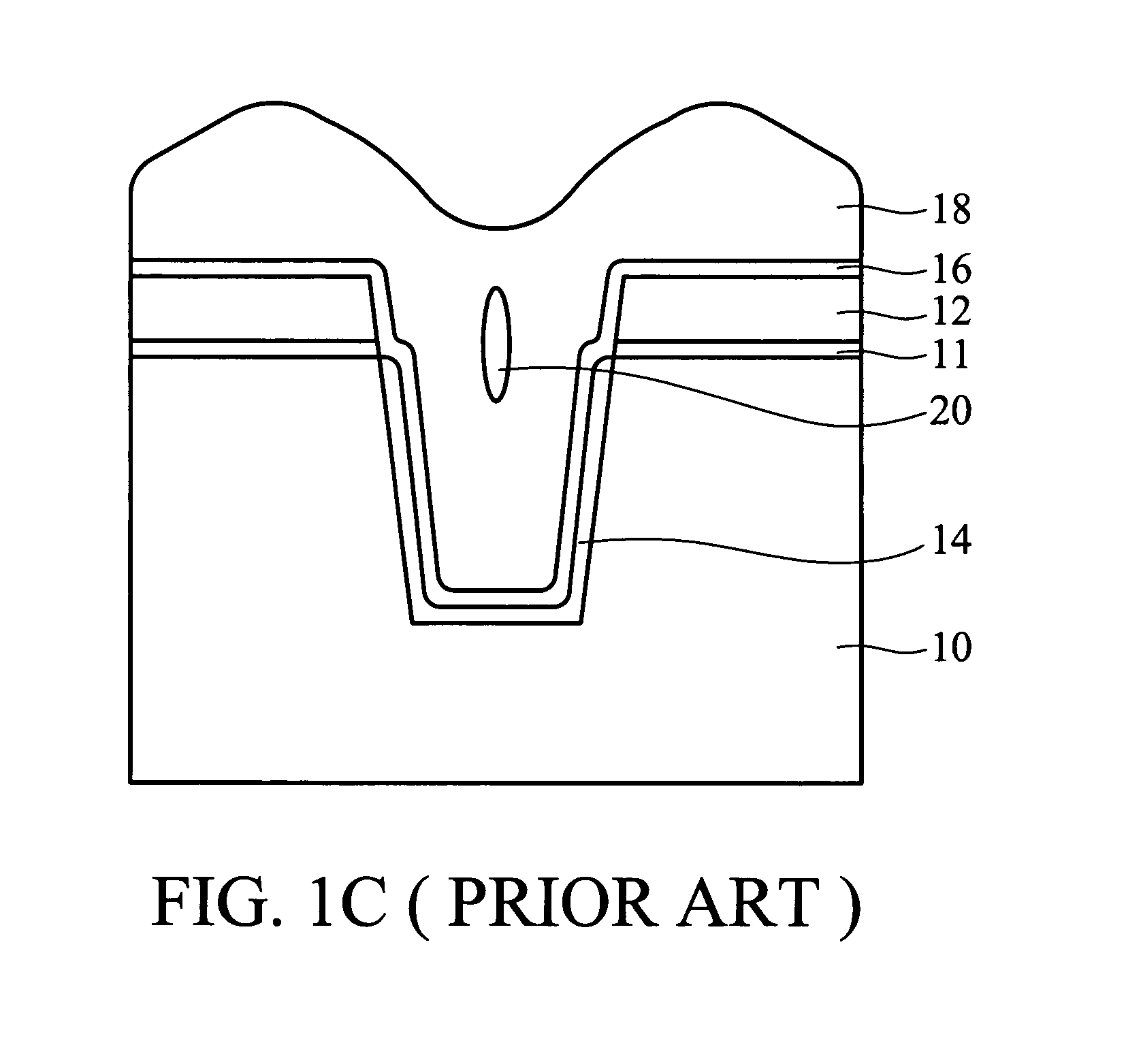

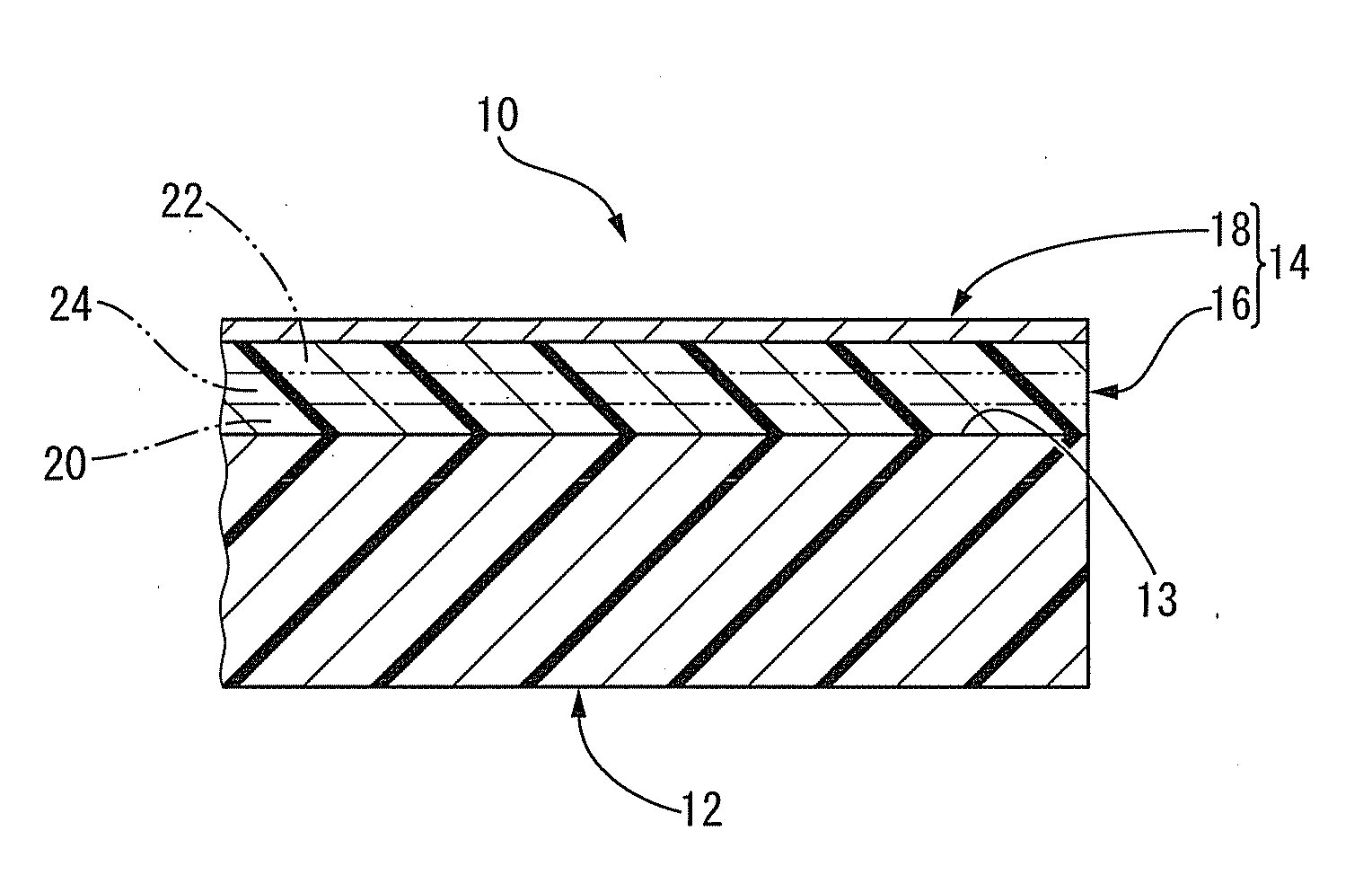

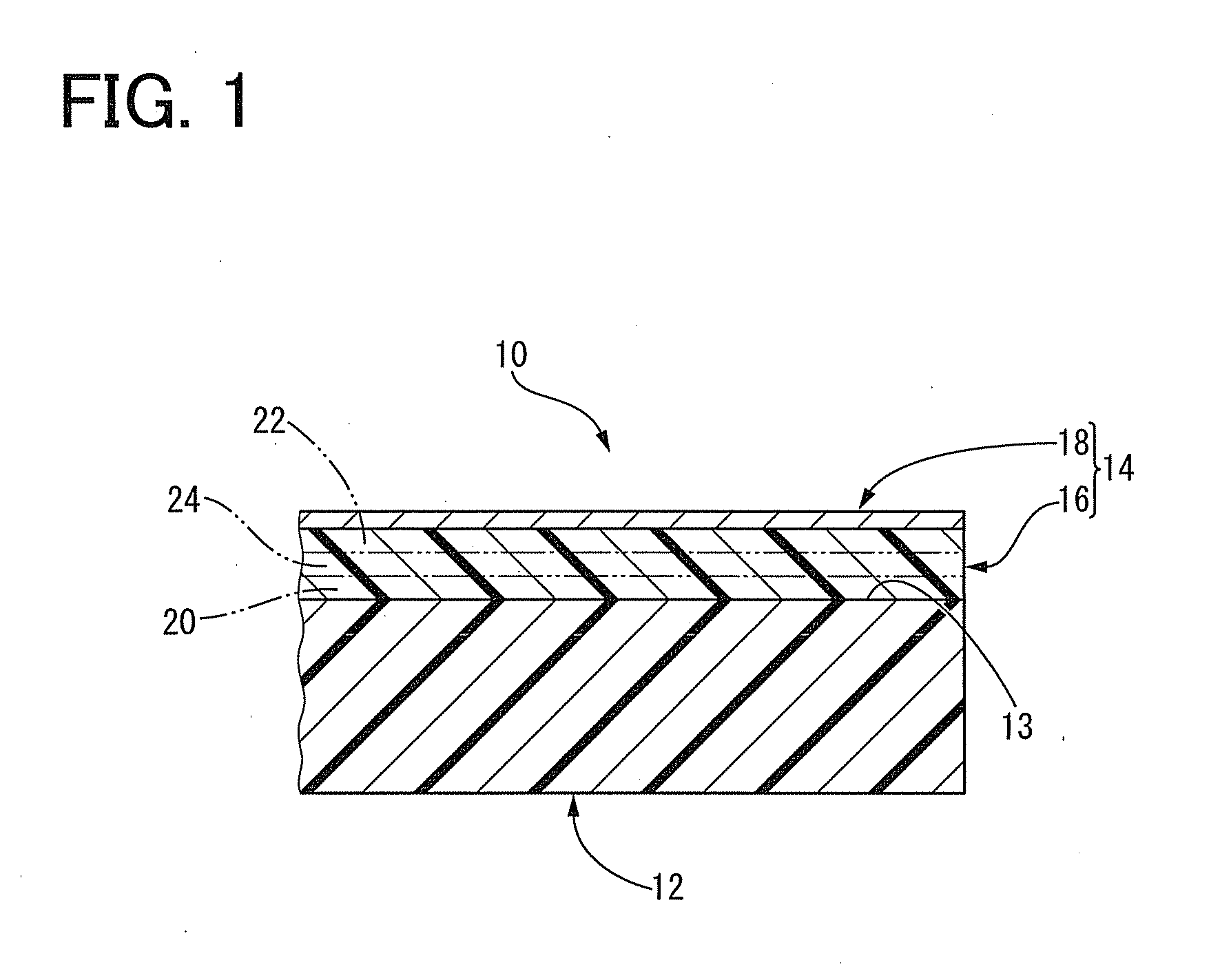

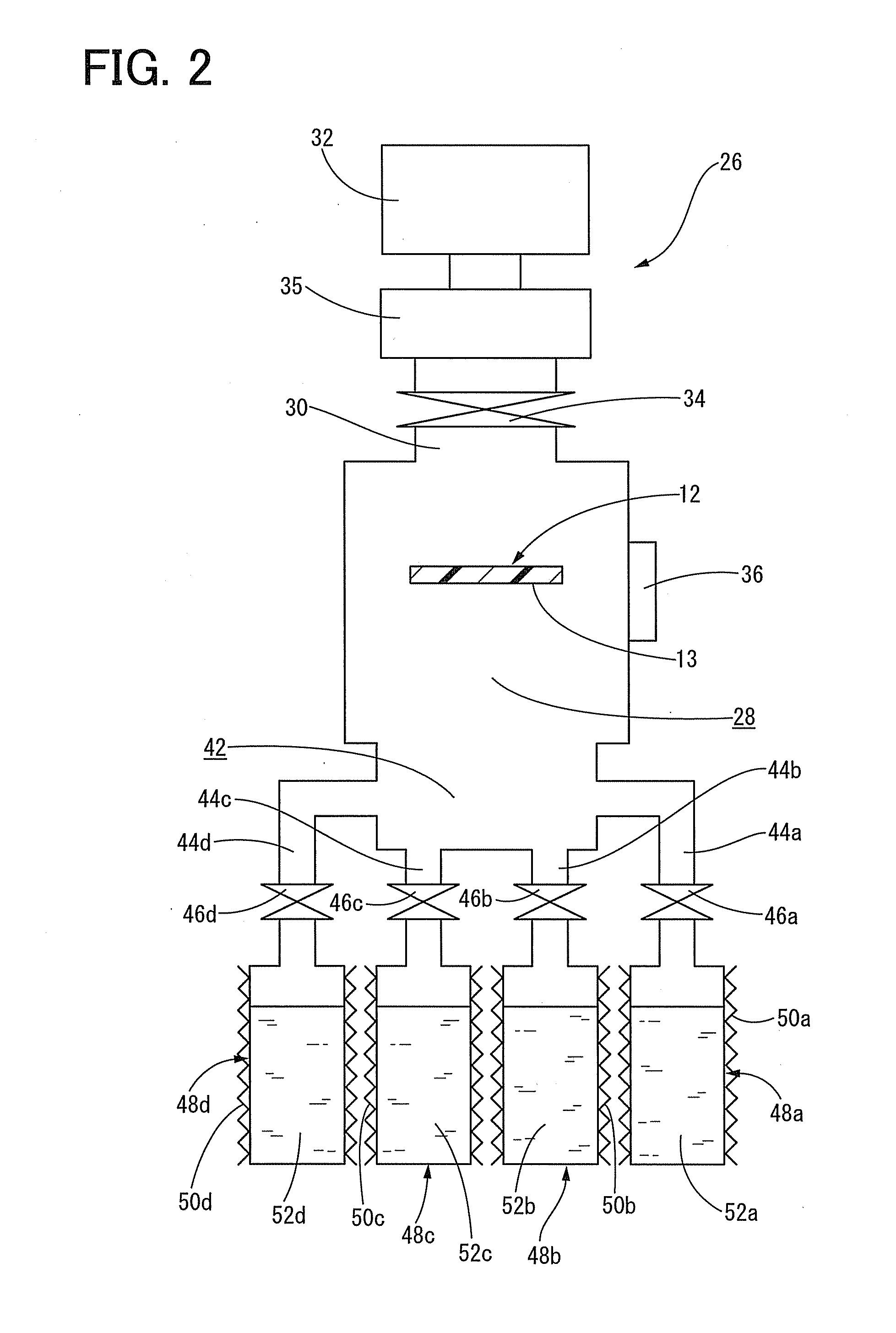

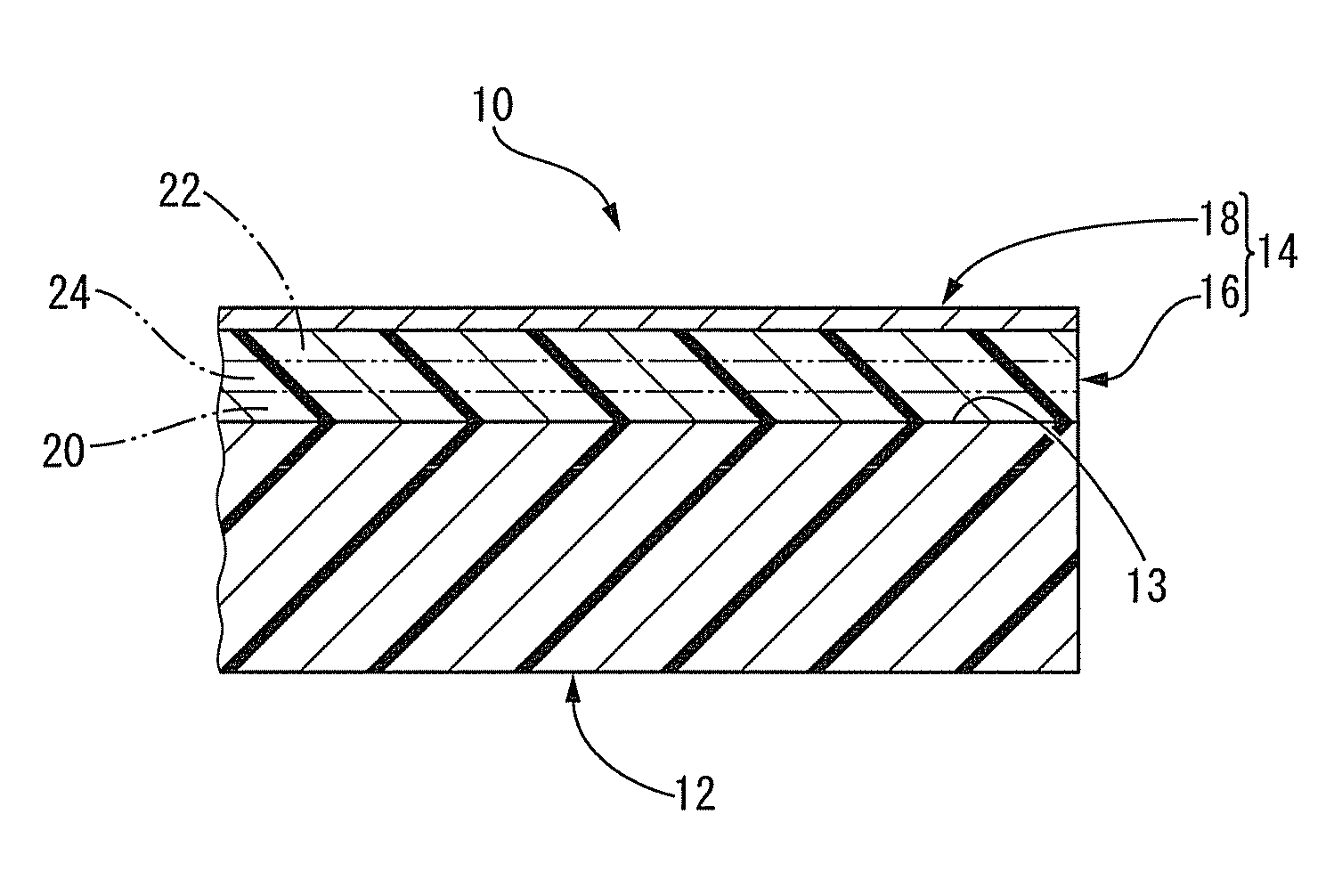

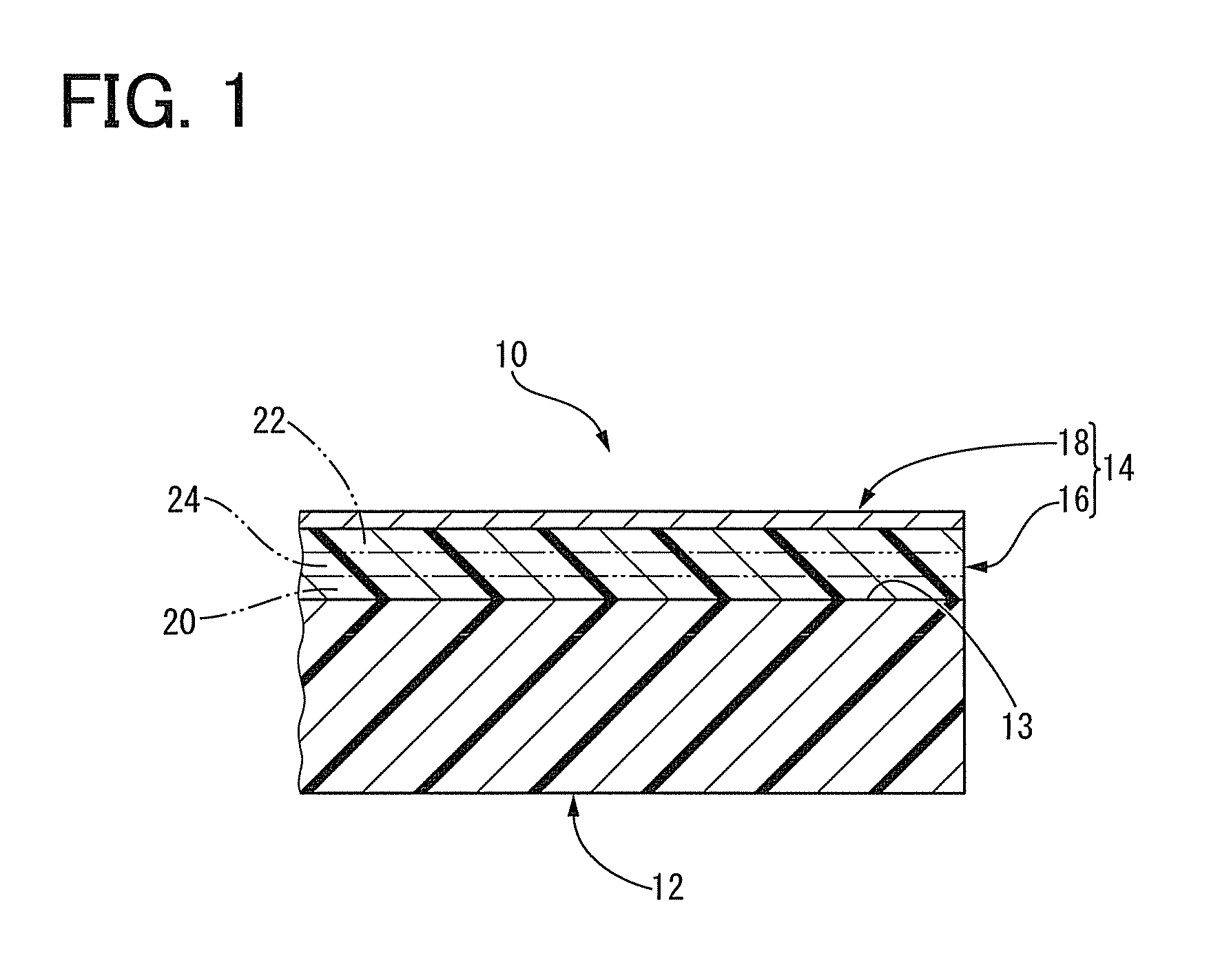

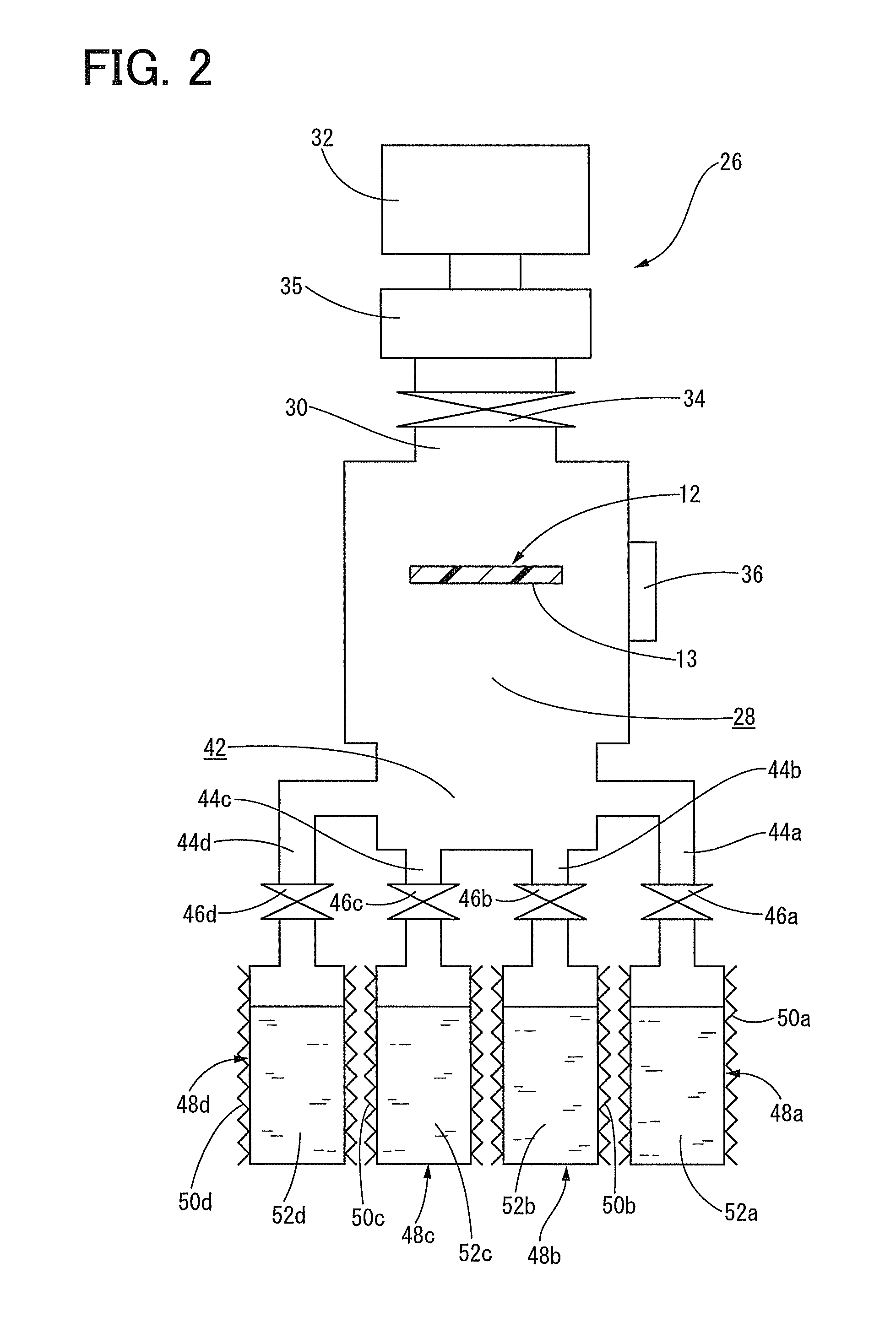

Organic glass for automobile and process for producing the same

ActiveUS20110129664A1Good weather resistanceSimple and low cost processSynthetic resin layered productsVacuum evaporation coatingWear resistanceMaterials science

An organic glass for automobile is provided which has excellent weatherability, wear-resistance and abrasion-resistance, and which can be mass-produced by a simple and inexpensive process. The organic glass comprises a transparent resin base plate 12 and a hard coat layer 14 formed on at least one surface of the resin base plate. The hard coat layer includes an organic thin film 16 formed by vacuum deposition polymerization.

Owner:KOJIMA PRESS IND CO LTD

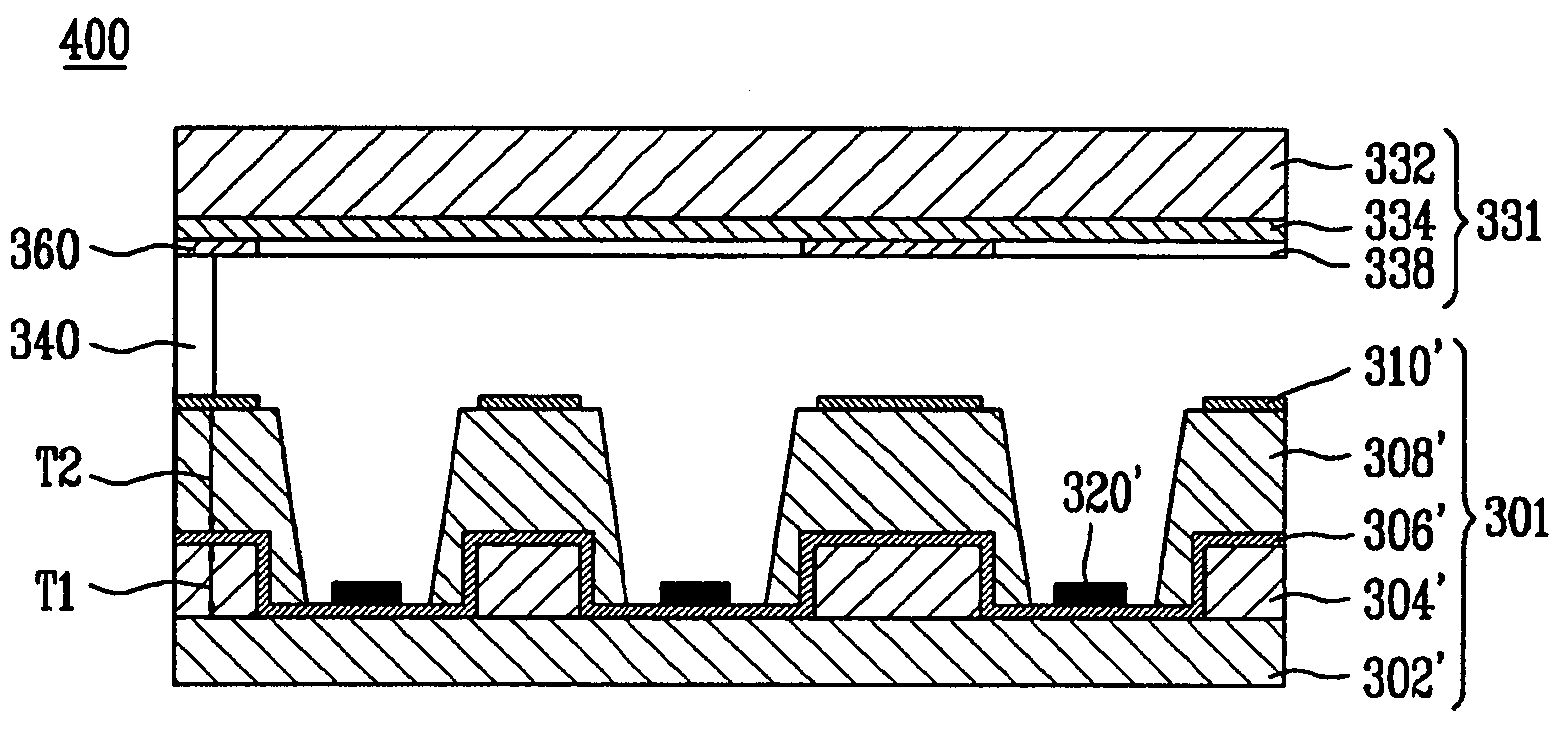

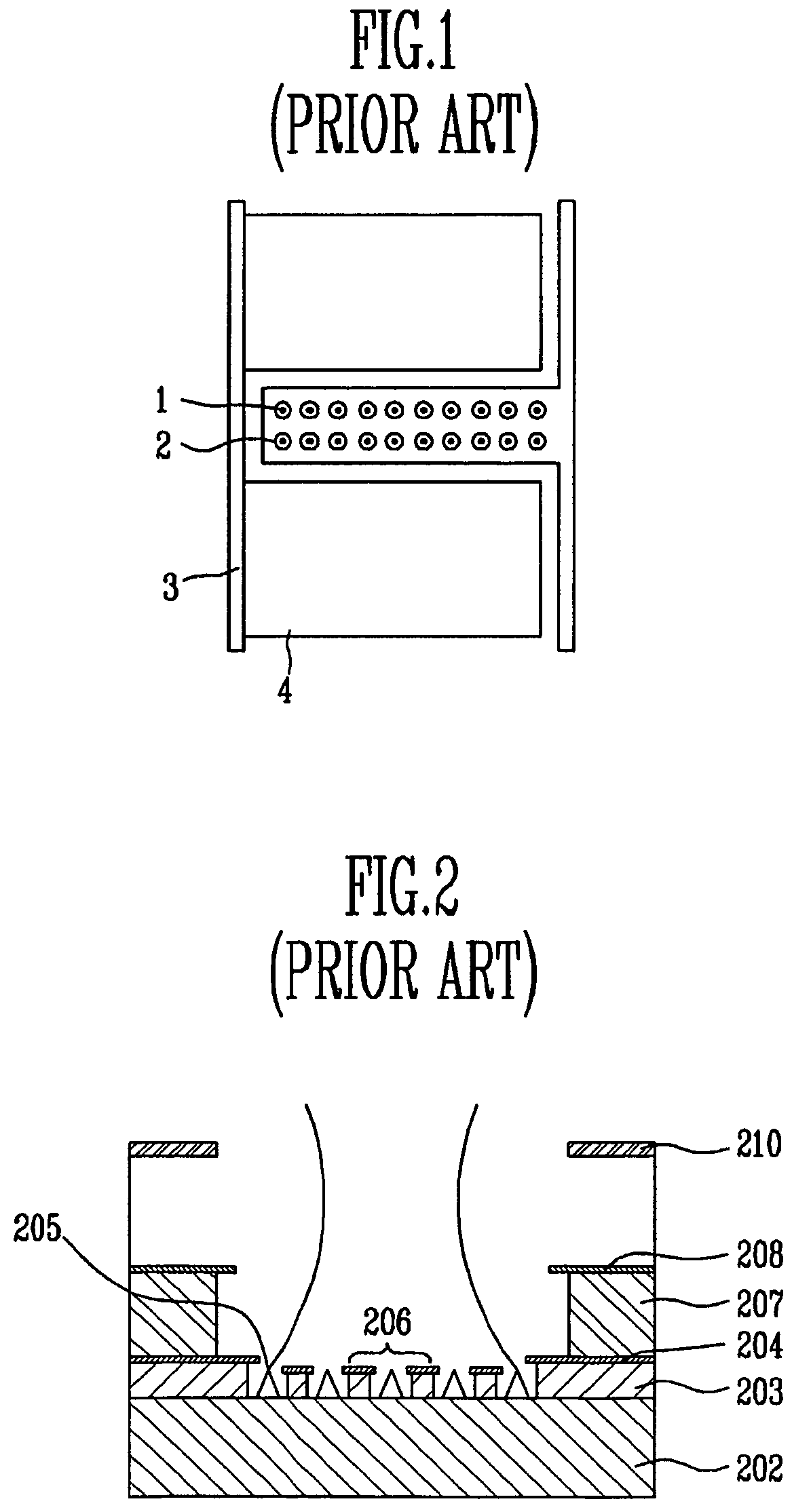

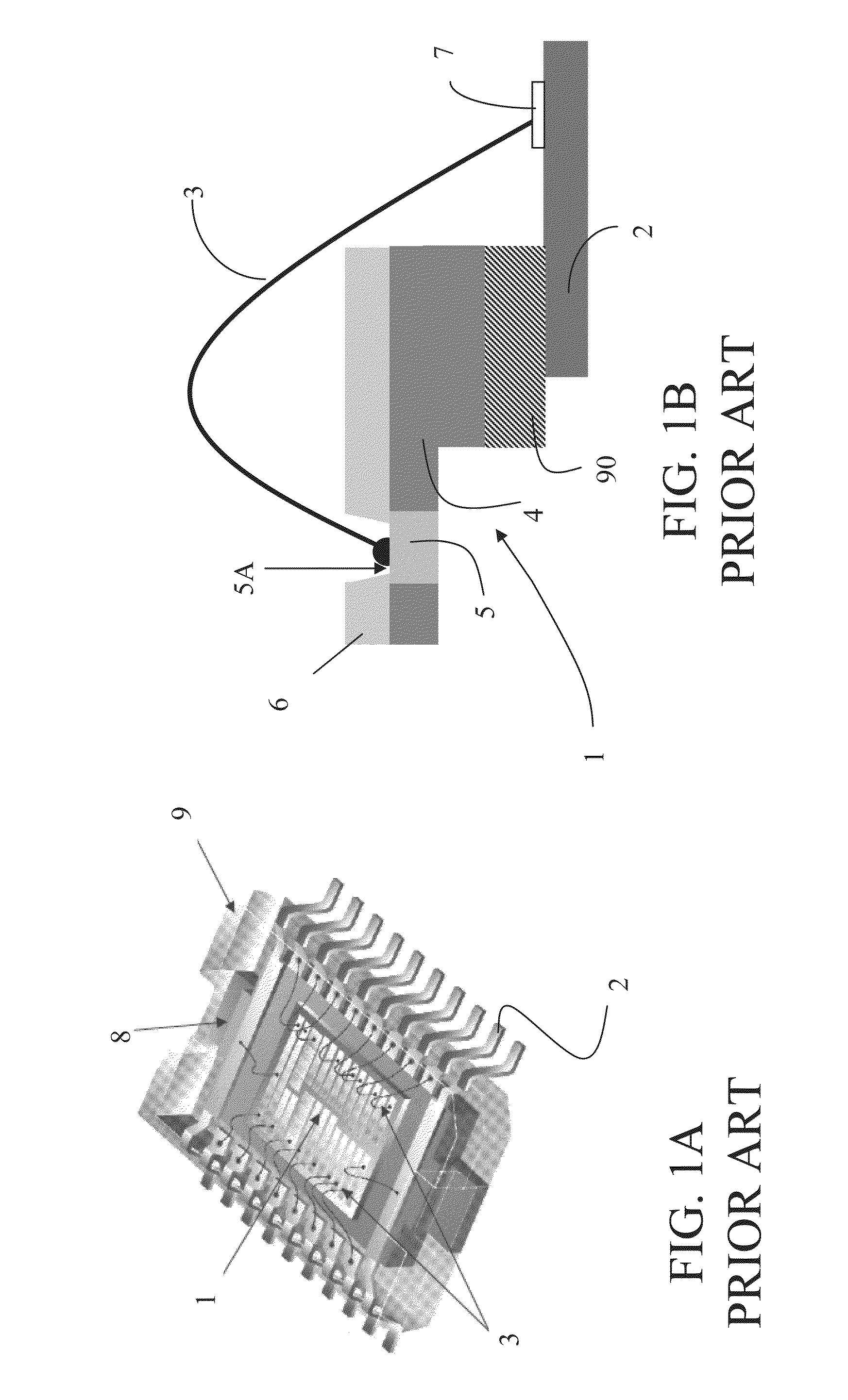

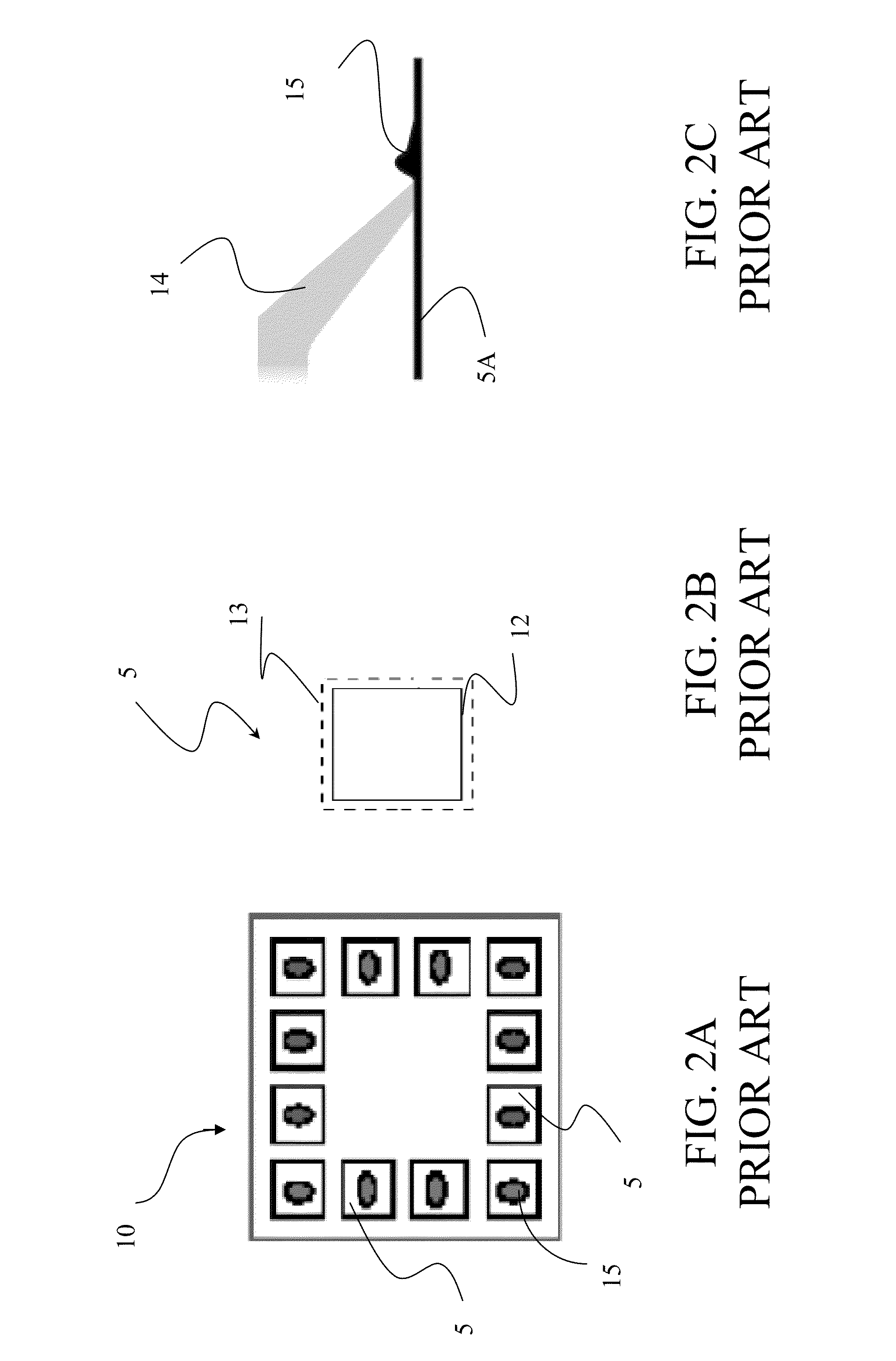

Electron emission device and electron emission display having beam-focusing structure using insulating layer

InactiveUS7138760B2FocusSimplify the manufacturing processPaper-money handling devicesDischarge tube luminescnet screensLight beamDisplay device

An electron emission device and / or display using the same includes a beam-focusing structure. The beam-focusing structure has a first insulating layer formed on a plate. The first insulating layer has a thickness, and is formed with a first hole. A first electrode is formed on the first insulating layer and extending into the first hole. An emission portion is formed in the first hole and connected to the first electrode. A second insulating layer is formed on the first electrode and is also formed with a second hole through which the emission portion is at least partially exposed. A second electrode is formed on the second insulating layer. In the electron emission device and / or the display, an electric field between the first electrode and the second electrode causes the emission portion to emit an electron beam and focuses the electron beam from the emission portion.

Owner:SAMSUNG SDI CO LTD

Brushless direct current motor

InactiveUS7132773B2Winding space availableImprove motor efficiencySynchronous generatorsWindingsConductor CoilDirect current

A direct current motor having a stator that has a plurality of radially arranged stator pole bridges to each of which one phase is allocated, at least one stator pole group being formed by at least two adjoining stator poles which are associated with the same phase, no winding sections being provided between the stator poles of the at least one stator pole group and the respective stator pole bridges of this stator pole group being disposed with a smaller spacing between each other than two adjoining stator pole bridges that are associated with different phases.

Owner:MINEBEA CO LTD

Method to perform electrical testing and assembly of electronic devices

ActiveUS20130109111A1Reduce harmSimple and low-cost processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical testingElectrical connection

Owner:STMICROELECTRONICS SRL

Organic glass for automobile and process for producing the same

ActiveUS8580378B2Good weather resistanceSimple and low cost processSynthetic resin layered productsVacuum evaporation coatingWear resistanceVacuum deposition

An organic glass for automobile is provided which has excellent weatherability, wear-resistance and abrasion-resistance, and which can be mass-produced by a simple and inexpensive process. The organic glass comprises a transparent resin base plate 12 and a hard coat layer 14 formed on at least one surface of the resin base plate. The hard coat layer includes an organic thin film 16 formed by vacuum deposition polymerization.

Owner:KOJIMA PRESS IND CO LTD

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS8486563B2Large capacityLarge scaleSilver accumulatorsNon-metal conductorsGold(III) hydroxideIndium

Owner:NATIONAL TSING HUA UNIVERSITY

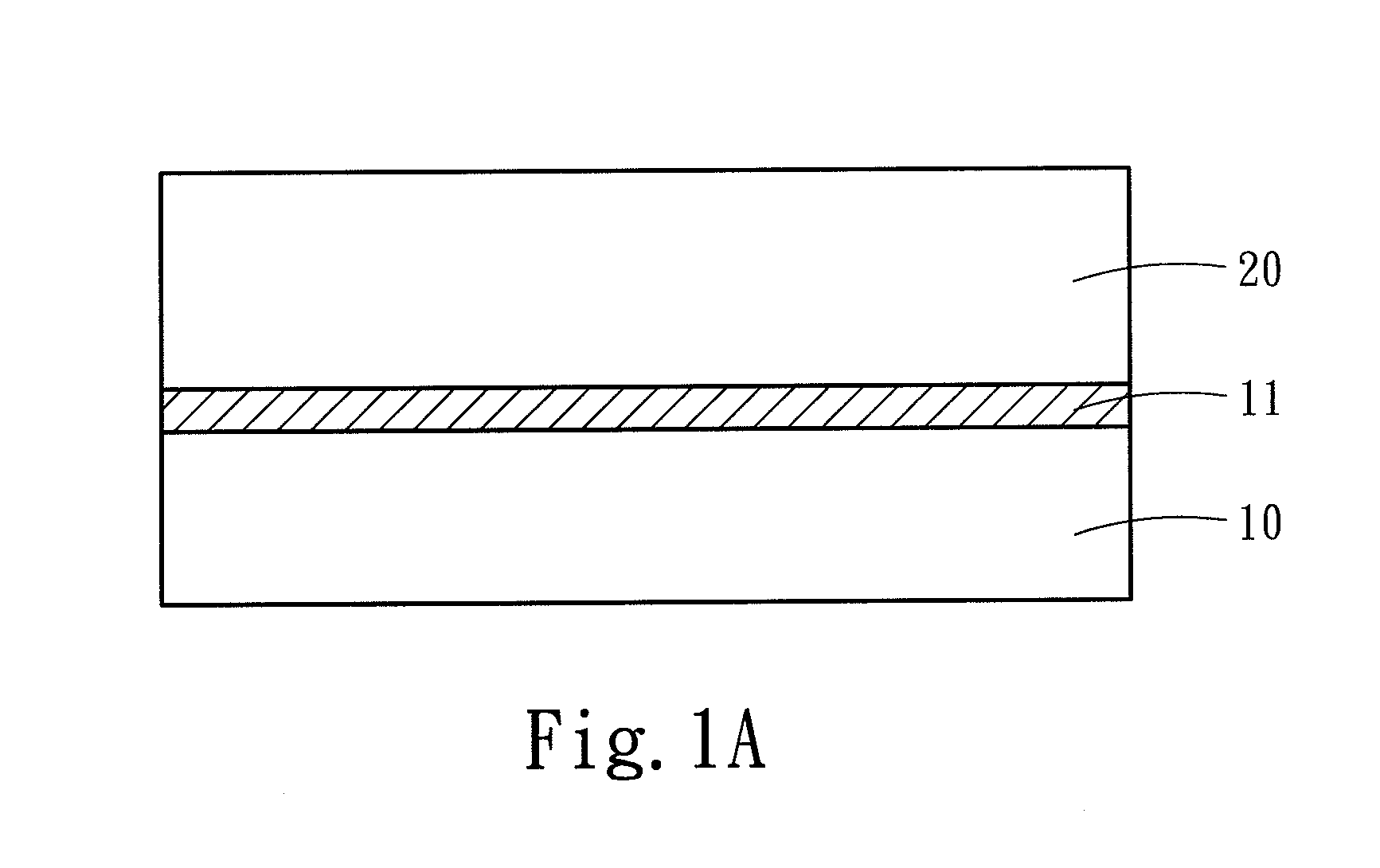

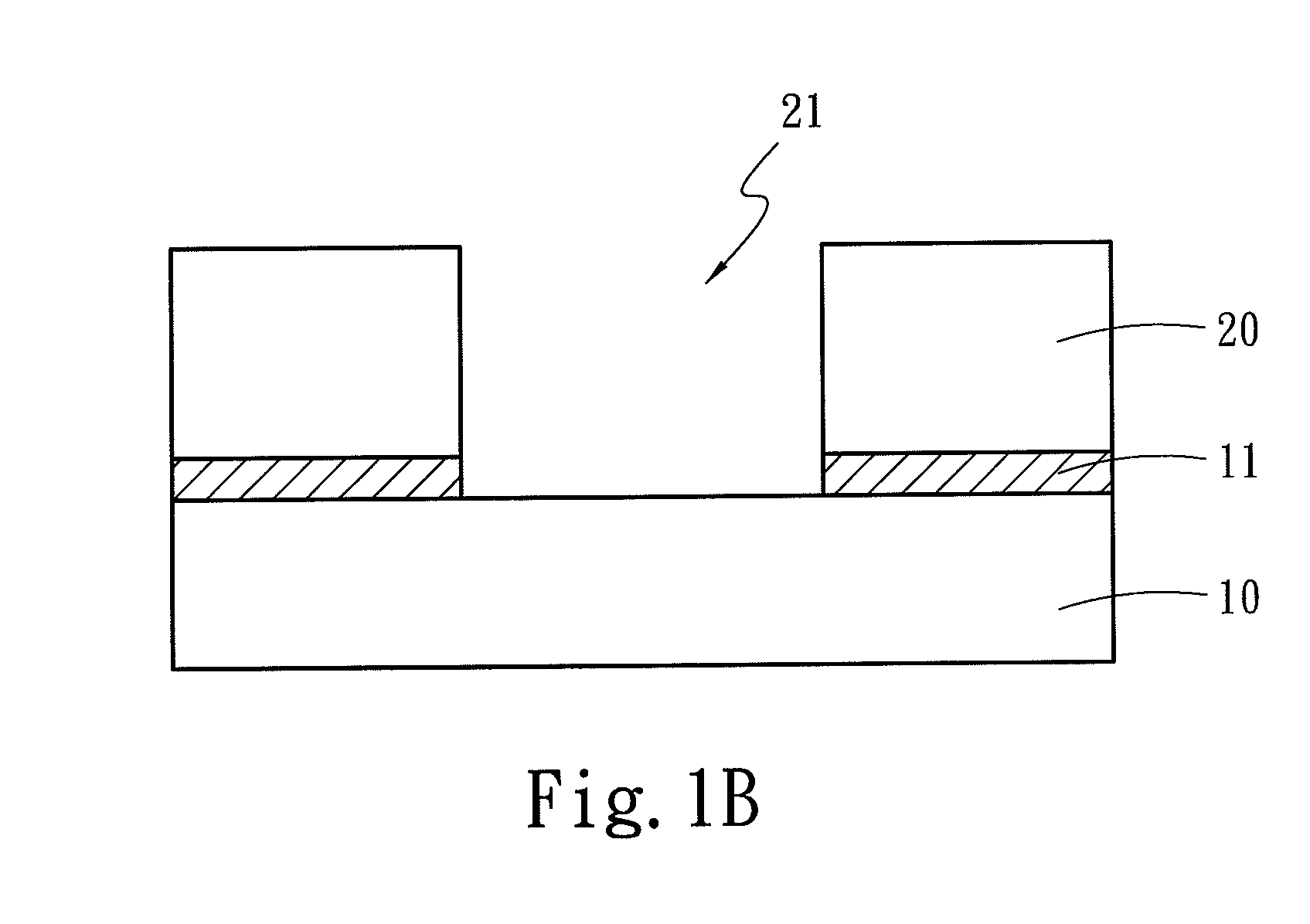

Method for fabricating interconnections with carbon nanotubes

InactiveUS20120135598A1Improve scalabilitySimple and low-cost fabrication processSemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeInterconnection

A method for fabricating interconnections with carbon nanotubes of the present invention comprises the following steps: forming a dual-layer that contains a catalytic layer and an upper covering layer on the periphery of a hole connecting with a substrate; and growing carbon nanotubes on the catalytic layer with the upper covering layer covering the carbon nanotubes. The present invention grows the carbon nanotubes between the catalytic layer and the upper covering layer. The upper covering layer protects the catalytic layer from being oxidized and thus enhances the growth of the carbon nanotubes. The carbon nanotubes are respectively connected with the lower substrate and an upper conductive wire via the catalytic layer and the upper covering layer, which results in a lower contact resistance. Moreover, the upper covering layer also functions as a metal-diffusion barrier layer to prevent metal from spreading to other materials via diffusion or other approaches.

Owner:NATIONAL TSING HUA UNIVERSITY

Method of manufacturing magnesium oxide nanoparticles and method of manufacturing magnesium oxide nanosol

InactiveUS20090148609A1High yieldSimple and low-cost processMaterial nanotechnologyNanostructure manufactureNanoparticleMagnesium salt

Disclosed are a method of manufacturing magnesium oxide nanoparticles and a method of manufacturing a magnesium oxide nanosol, which can prepare magnesium oxide particles having a size of tens of nanometers with high yield by using a simple, low-cost process. The methods of manufacturing magnesium oxide nanoparticles and manufacturing magnesium oxide nanosol include preparing a magnesium salt solution by dissolving a magnesium salt in a solvent; impregnating an organic polymer comprising a nanosized pore with the magnesium salt solution; and heating the organic polymer impregnated with the magnesium salt solution until the organic polymer is fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for fabricating interconnections with carbon nanotubes

InactiveUS8461037B2Simple manufacturing processProtection interfaceSemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeInterconnection

A method for fabricating interconnections with carbon nanotubes of the present invention comprises the following steps: forming a dual-layer that contains a catalytic layer and an upper covering layer on the periphery of a hole connecting with a substrate; and growing carbon nanotubes on the catalytic layer with the upper covering layer covering the carbon nanotubes. The present invention grows the carbon nanotubes between the catalytic layer and the upper covering layer. The upper covering layer protects the catalytic layer from being oxidized and thus enhances the growth of the carbon nanotubes. The carbon nanotubes are respectively connected with the lower substrate and an upper conductive wire via the catalytic layer and the upper covering layer, which results in a lower contact resistance. Moreover, the upper covering layer also functions as a metal-diffusion barrier layer to prevent metal from spreading to other materials via diffusion or other approaches.

Owner:NATIONAL TSING HUA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com