Motor Generator and Automobile Carrying the Same

a motor generator and stator technology, applied in the direction of electric propulsion mounting, magnetic circuit characterised by magnetic materials, shape/form/construction, etc., can solve the problems of difficult to reduce the total axis length including the winding, the possibility of reducing the body size is limited, and the motor generator is difficult to mount the stator. , to achieve the effect of a wide range of output performance, simple and low-cost molding process, and superior mountability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Referring to drawings, preferred embodiments of the present invention will be described in detail bellow. It should be noted that identical reference characters in the drawings represent identical or equivalent components.

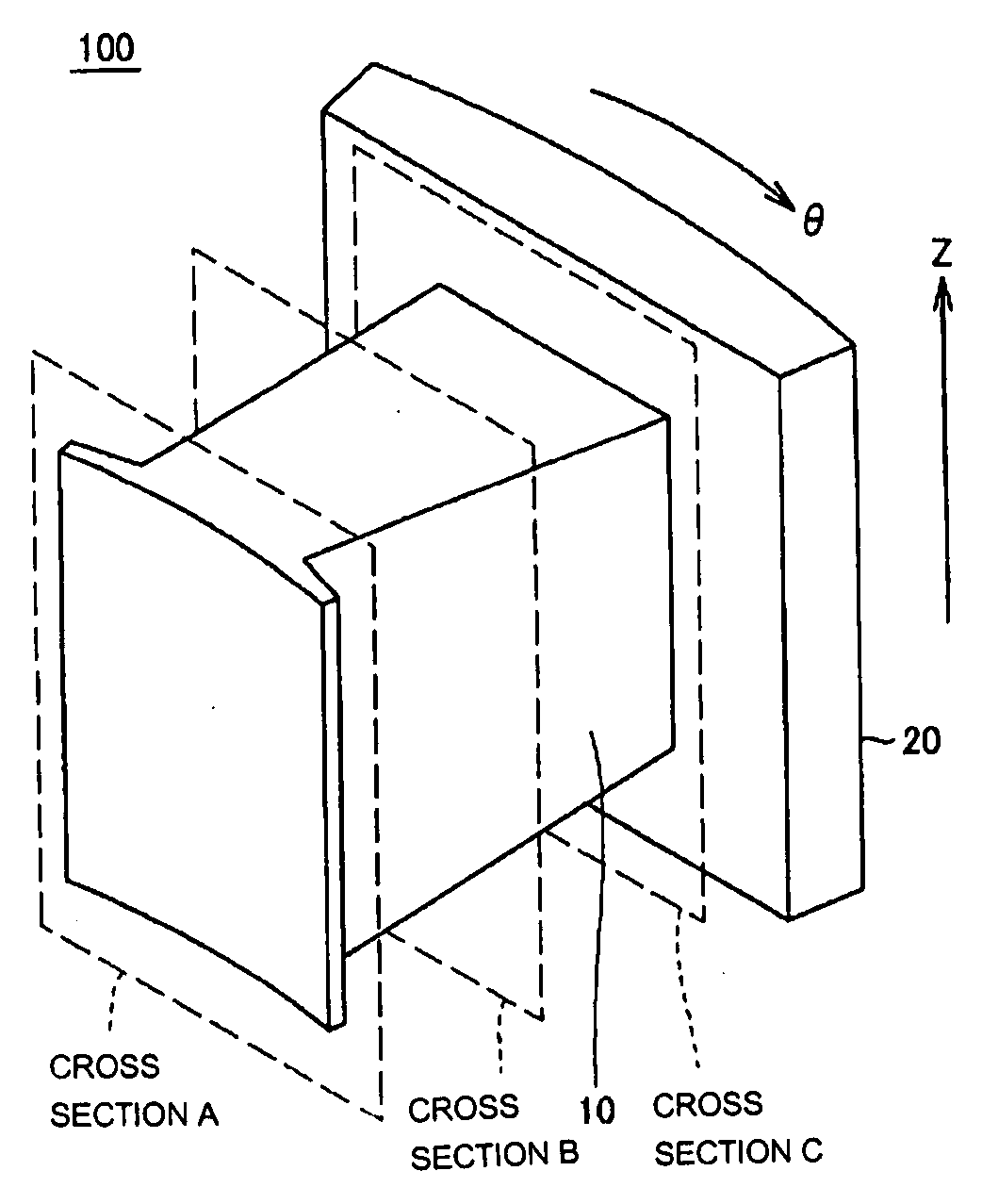

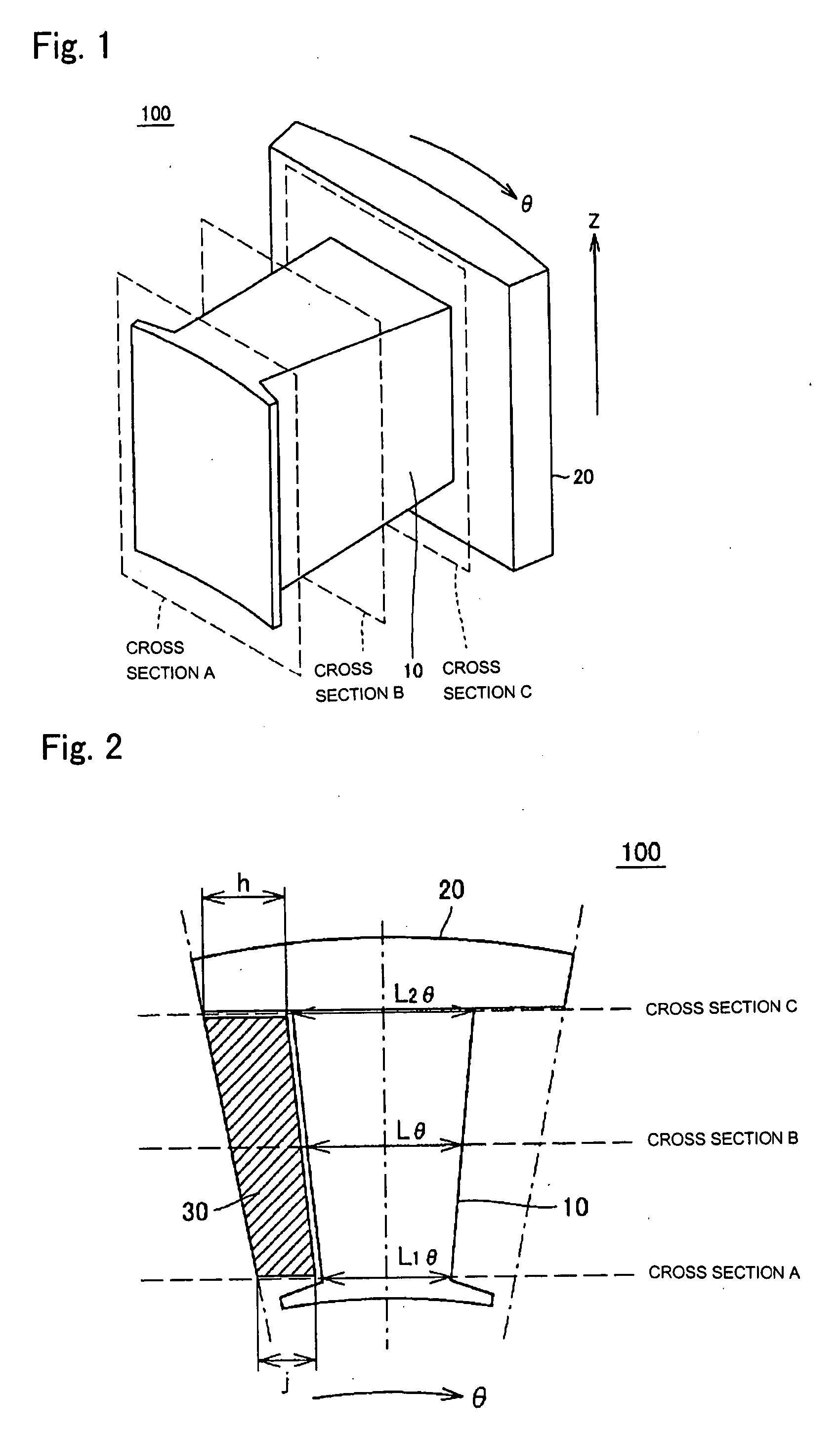

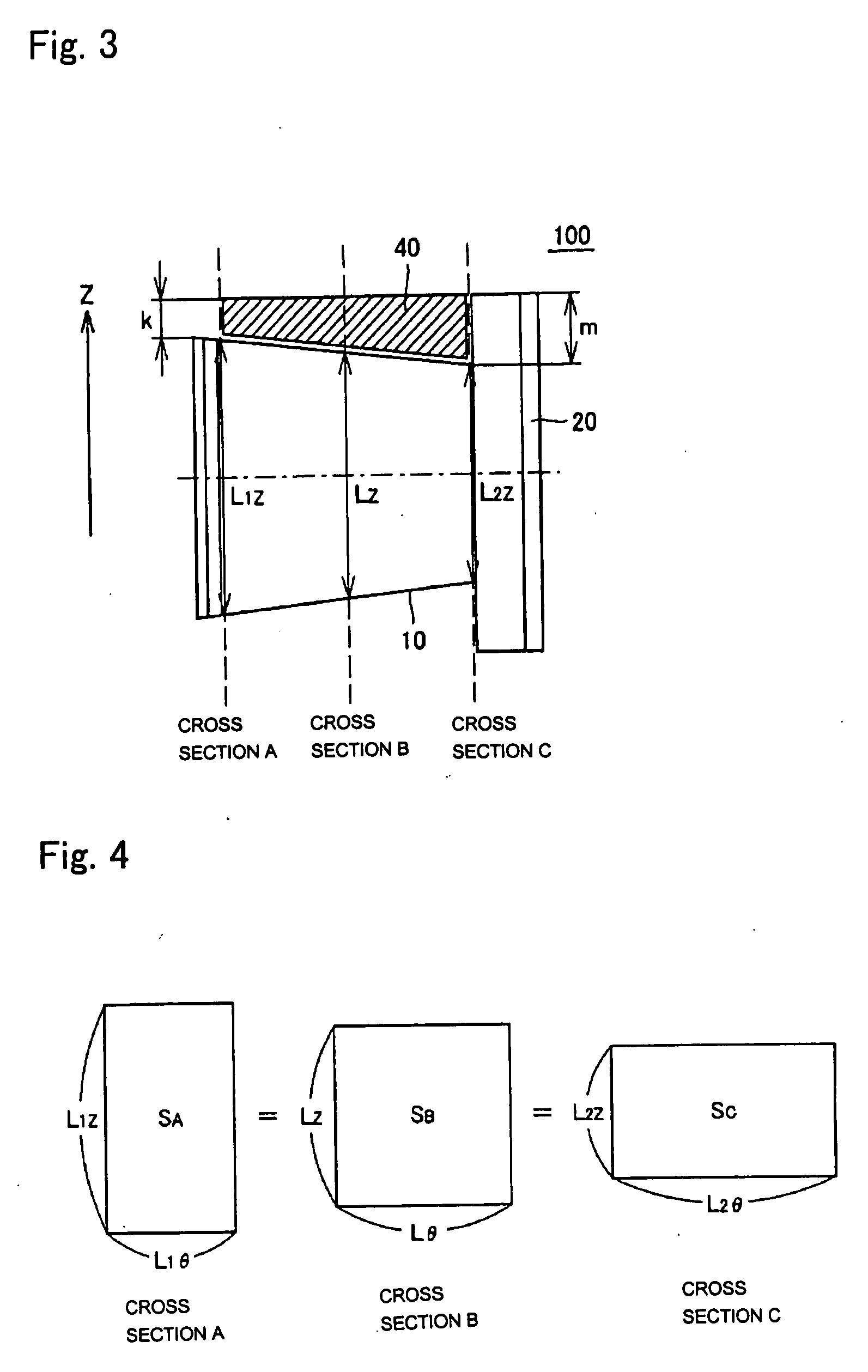

[0050]FIG. 1 is a perspective view showing one pole of a stator core in a stator of a motor generator according to an embodiment of this invention. Although it is not illustrated, the stator core is, on the whole, formed in a hollow cylindrical shape in which a number, which is equal to the number of poles of a motor generator, of poles of the stator core 100 in FIG. 1 are annularly arranged. Further, the stator core includes an annular yoke part, a teeth part having a predetermined number of teeth arranged in an annular form on an inner circumference side of the yoke part so as to direct to a radial inside, and a predetermined number of slots formed between adjacent teeth and extending along the axial direction. The numbers of the teeth and the slots match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com