Patents

Literature

303results about "Salient poles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

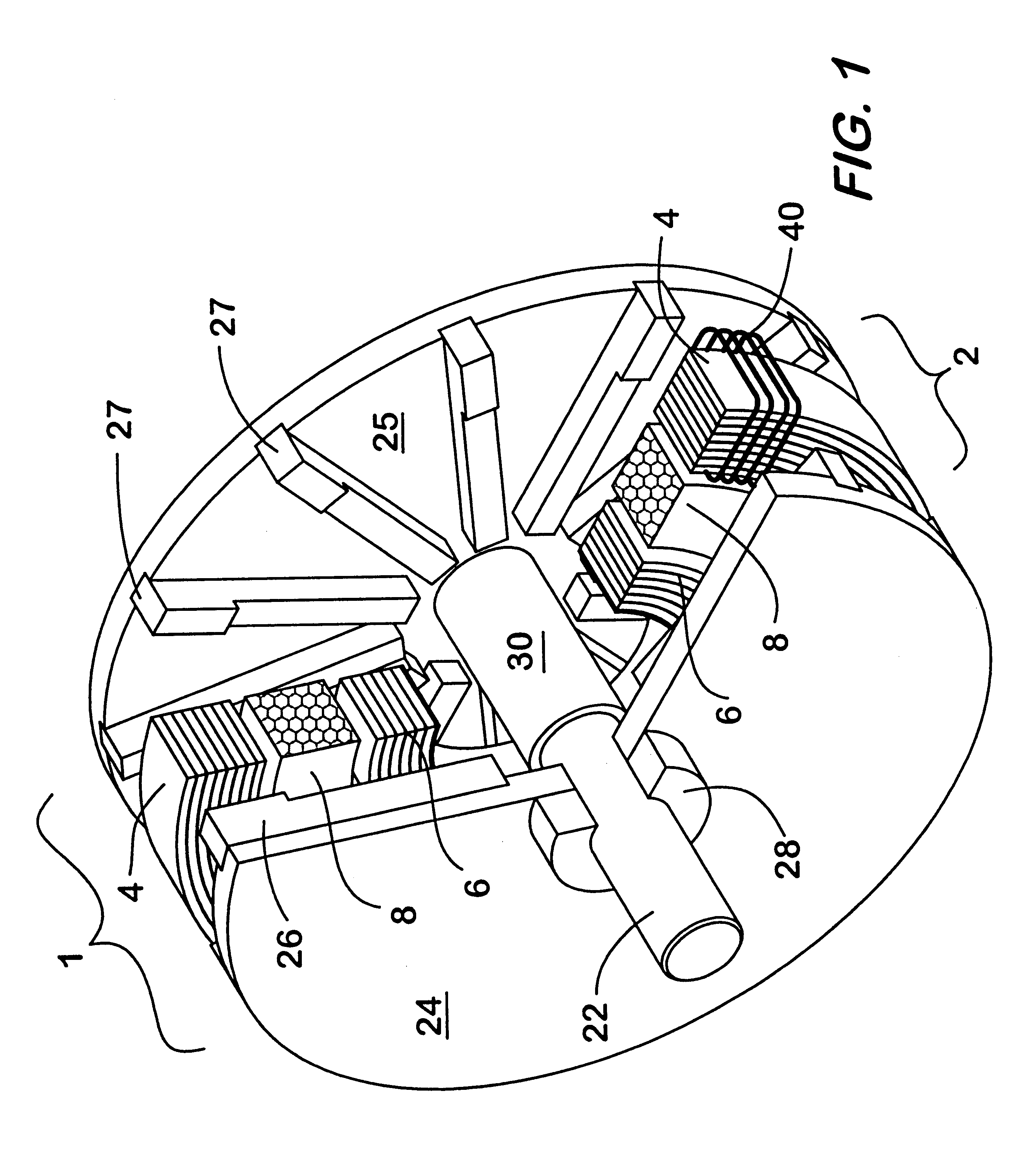

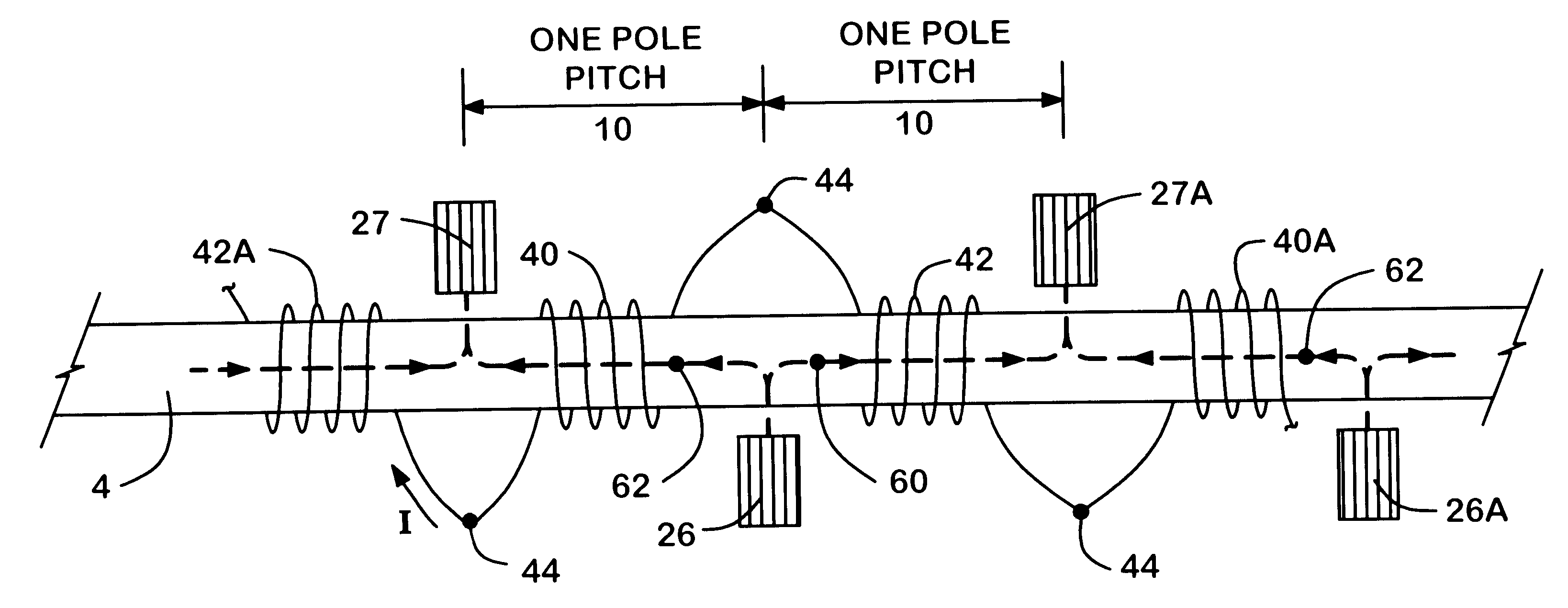

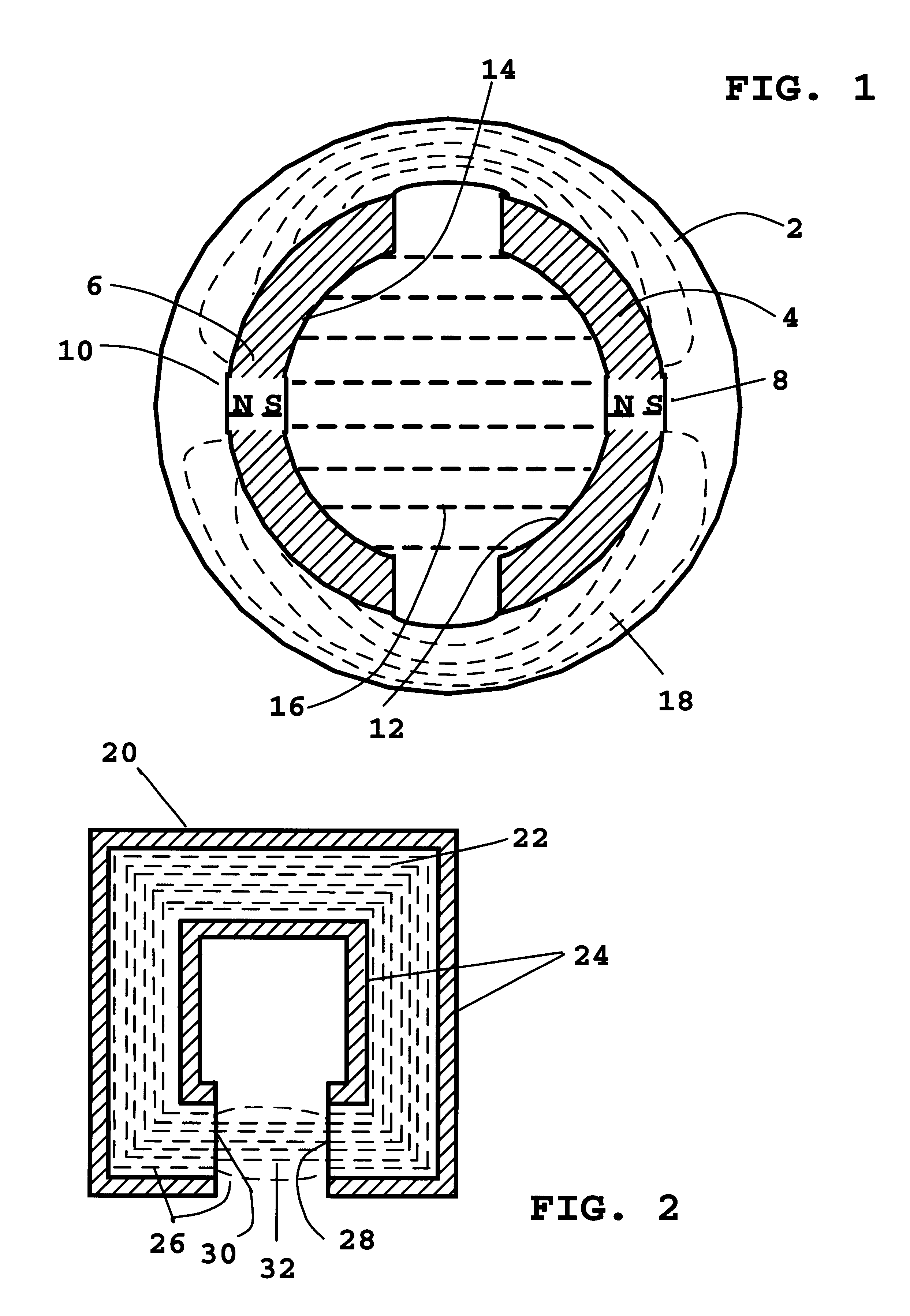

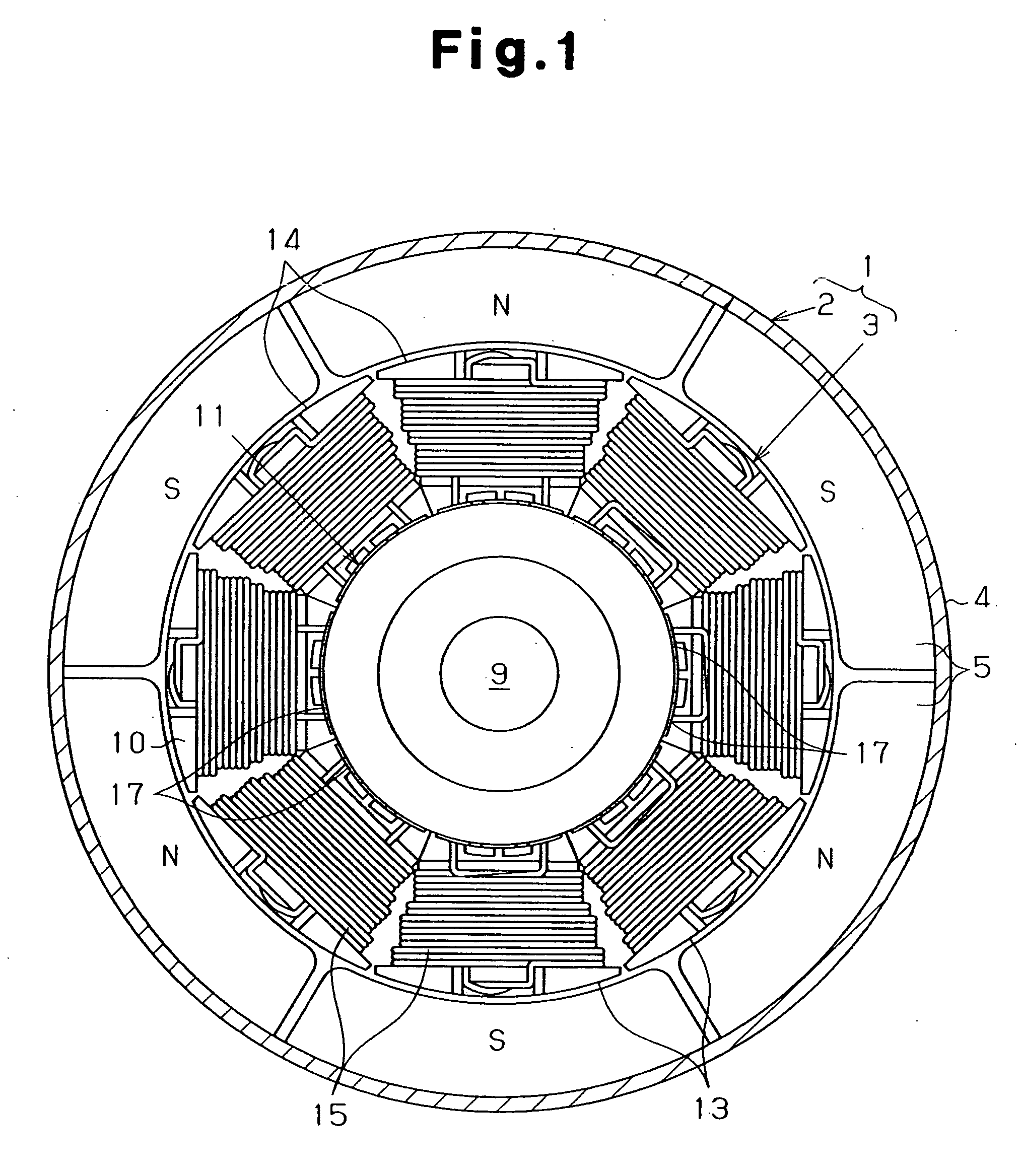

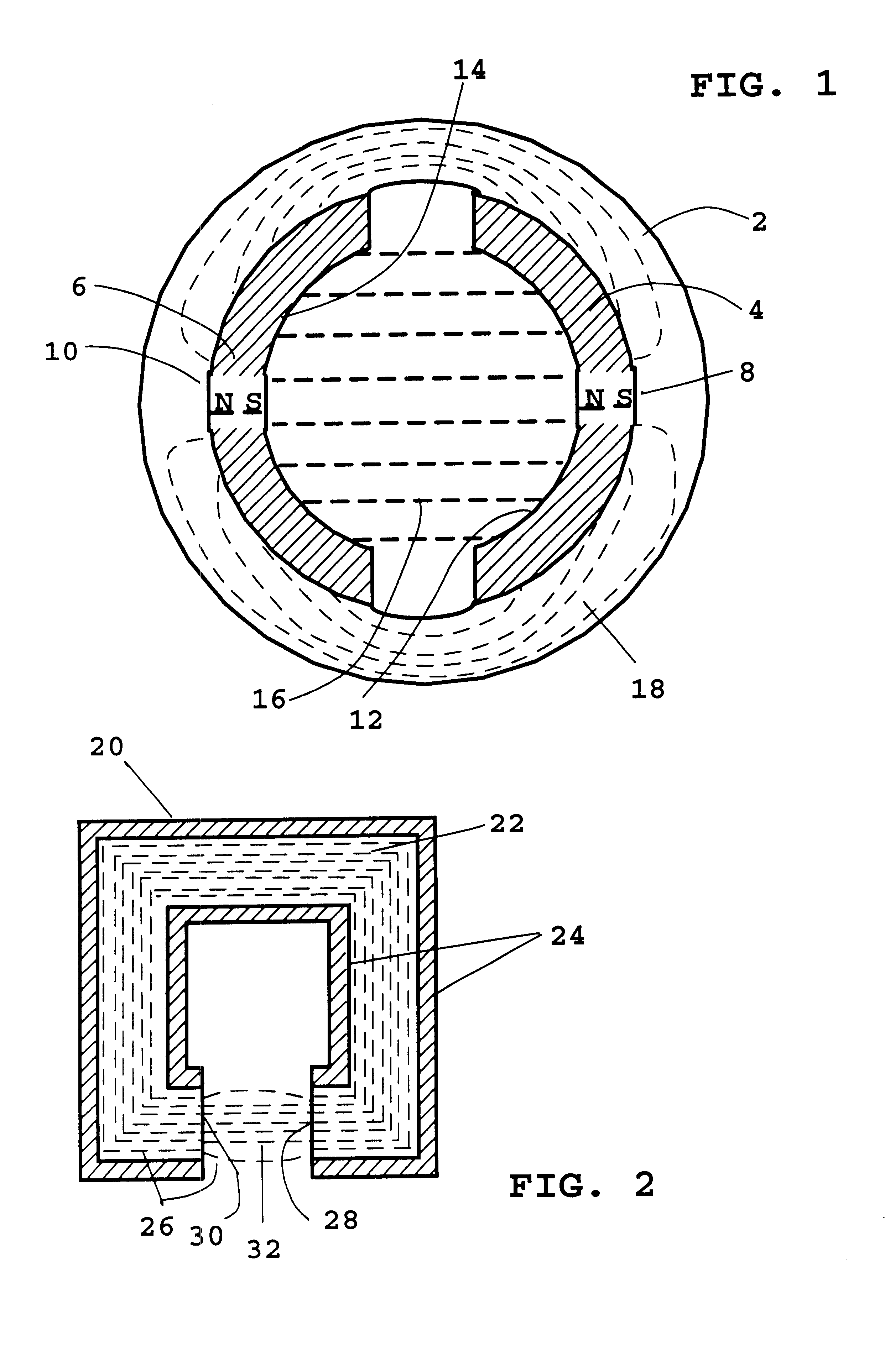

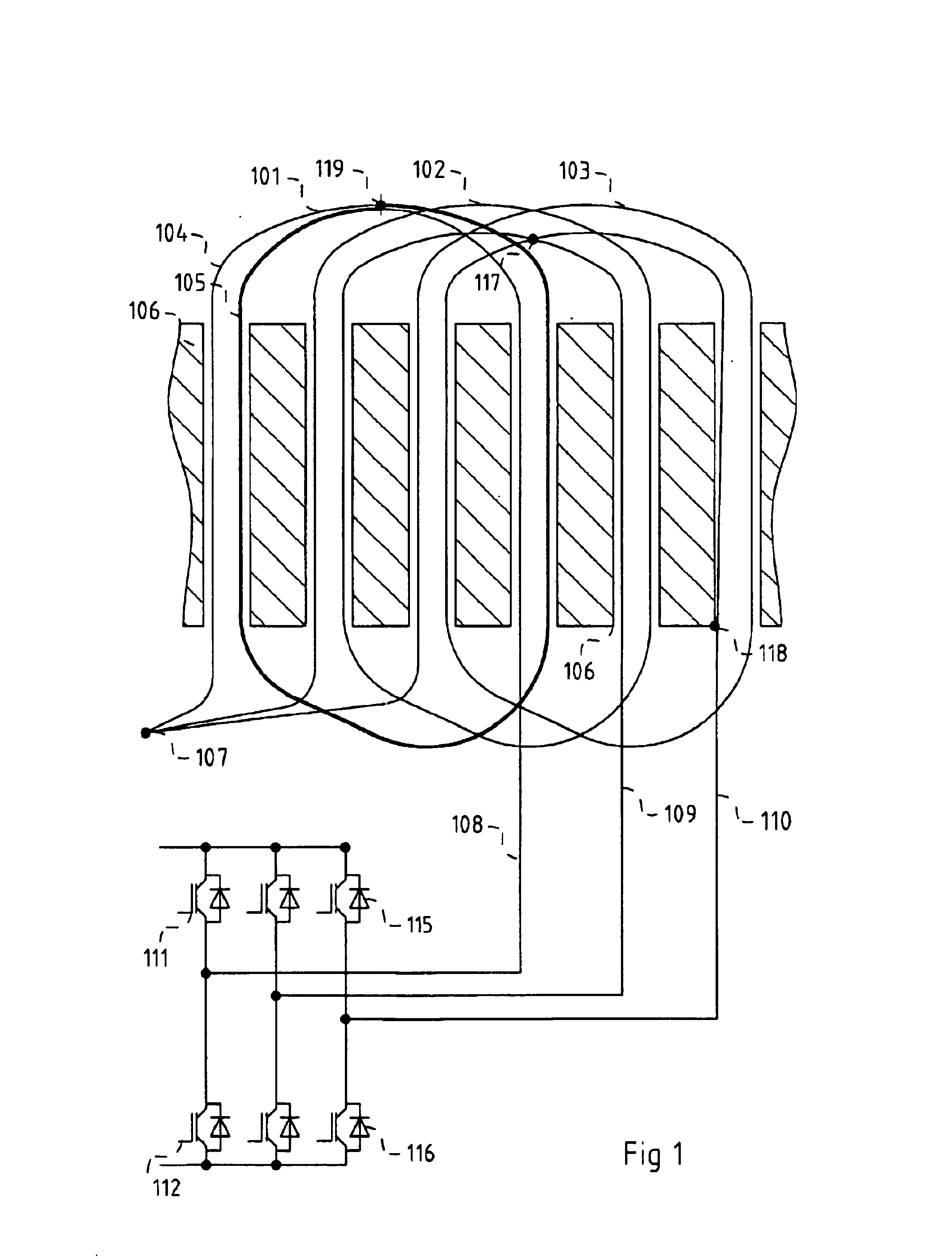

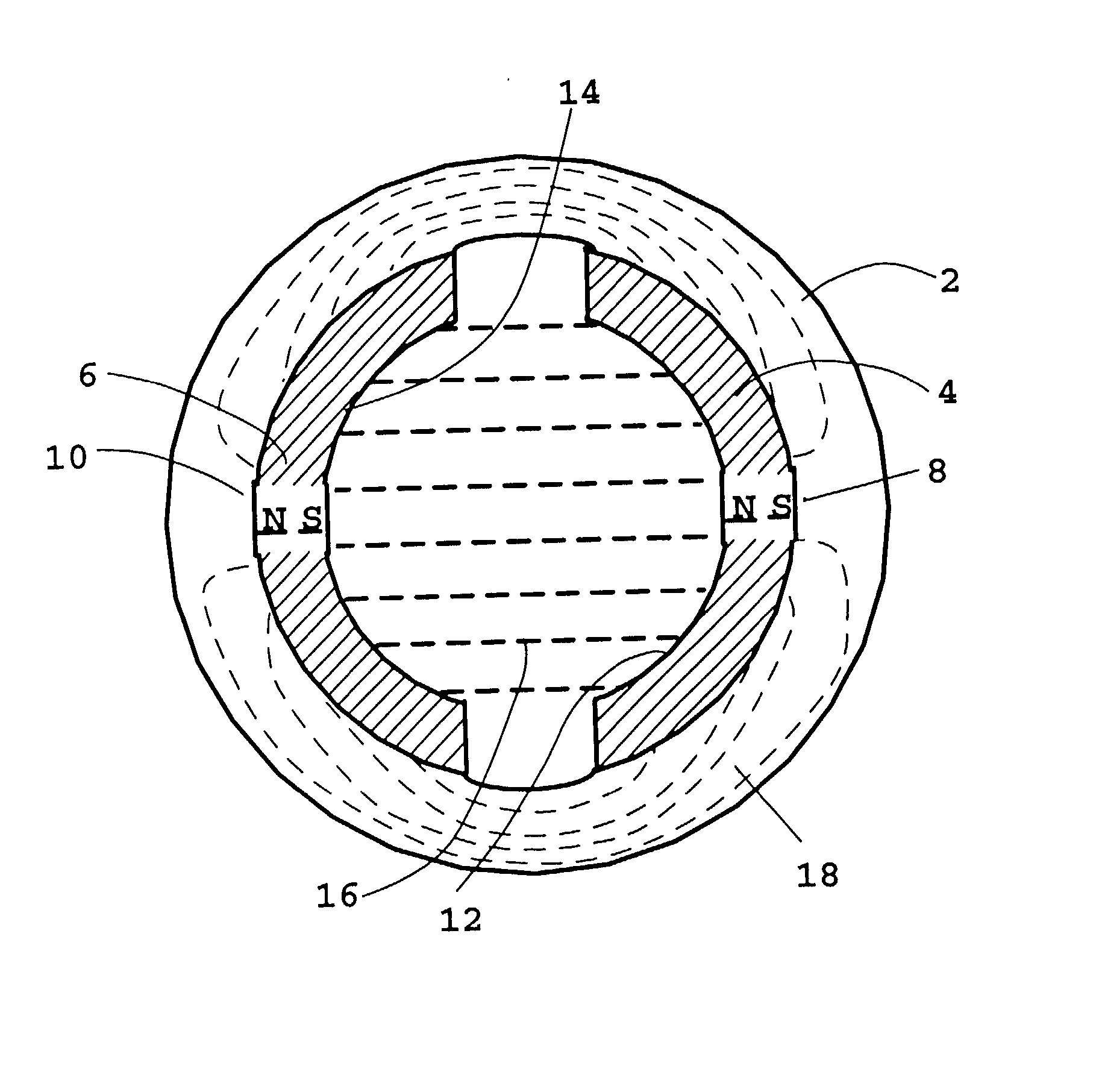

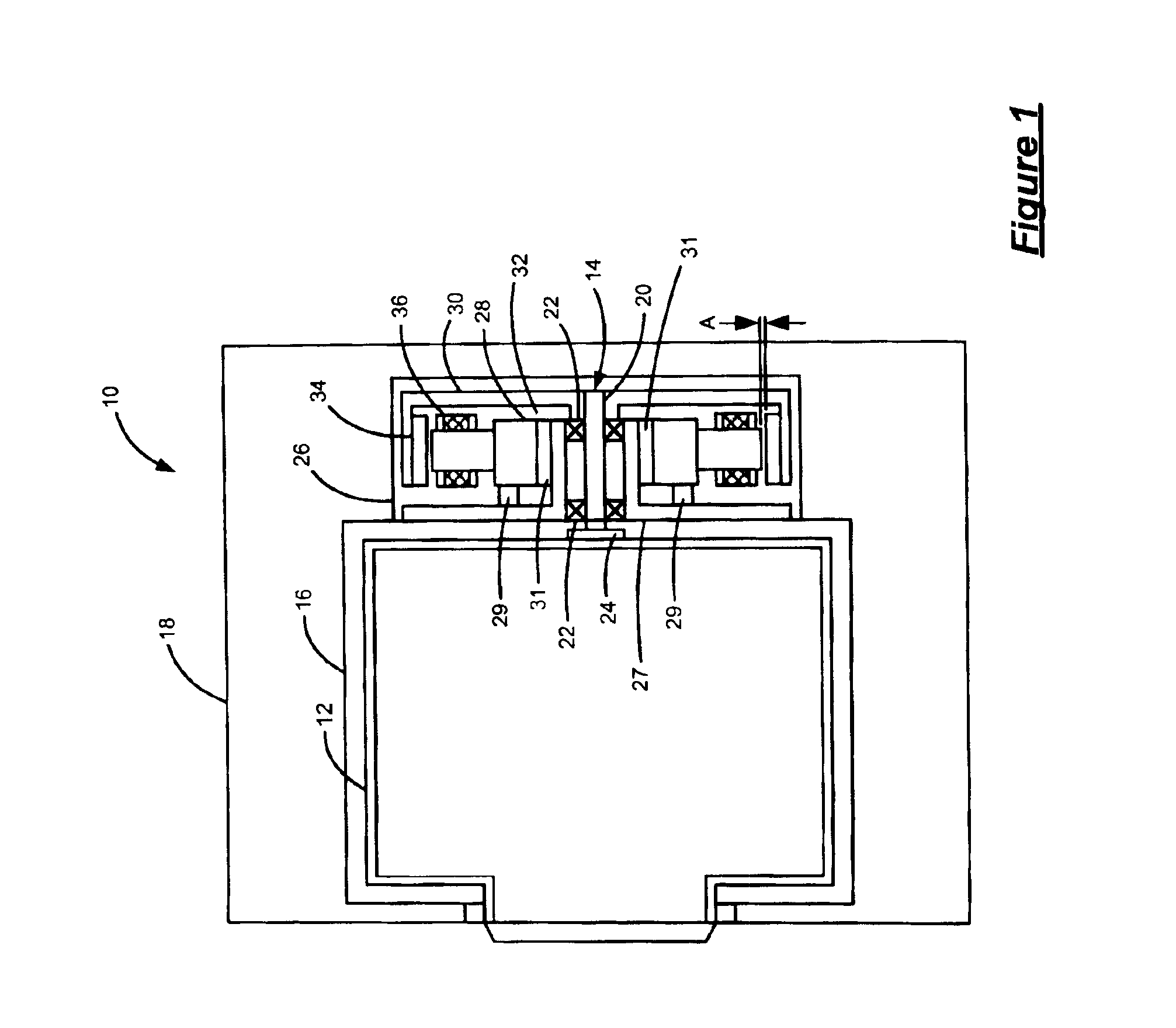

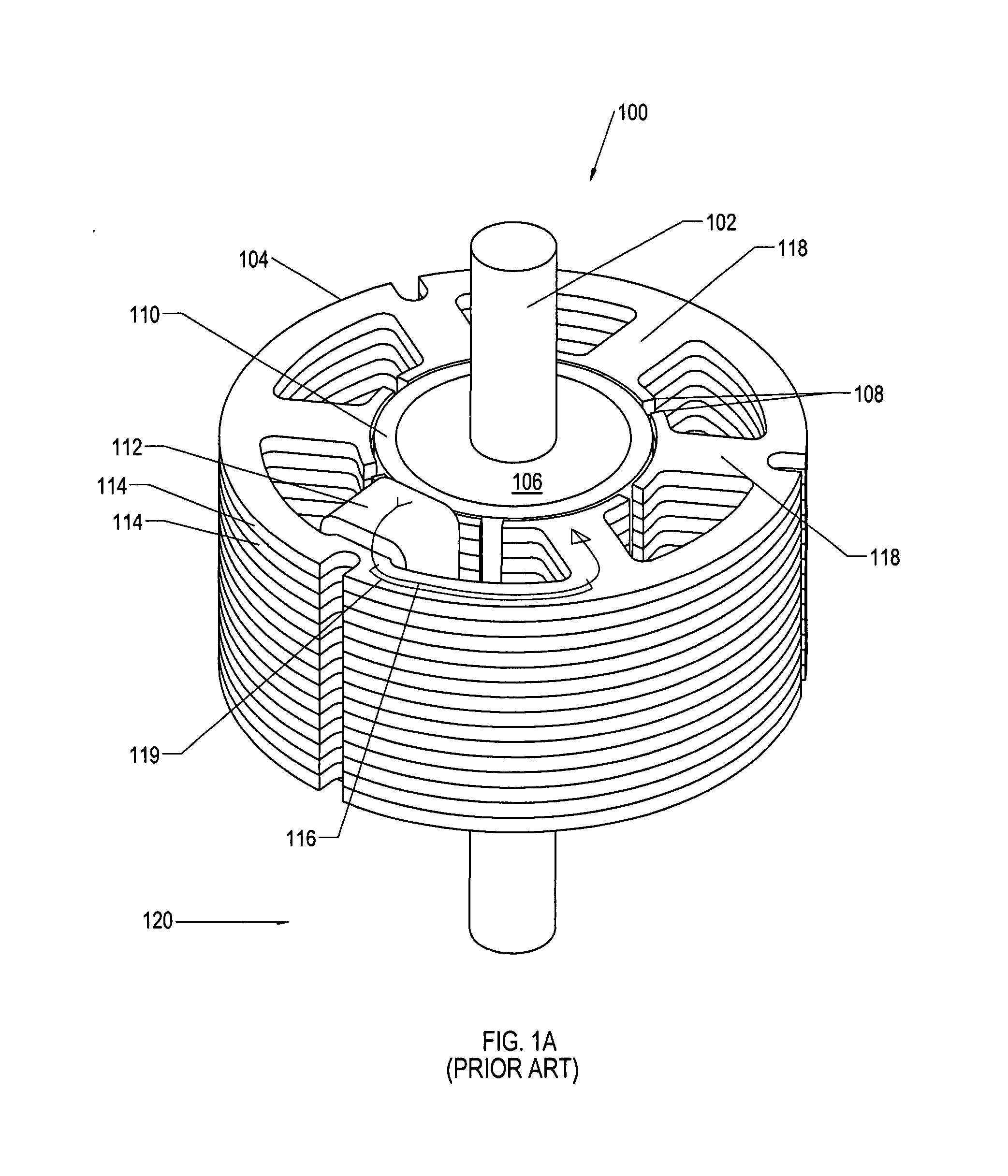

Low inductance electrical machine

A low inductance electrical machine that may be used as an alternator or motor with low armature inductance is disclosed. Arrangements of complementary armature windings are presented in which the fluxes induced by currents in the armature windings effectively cancel leading to low magnetic energy storage within the machine. This leads to low net flux levels, low core losses, low inductance and reduced tendency toward magnetic saturation. The inclusion of additional gaps in the magnetic circuit allows for independent adjustment of air gap geometry and armature inductance. Separately excited field arrangements are disclosed that allow rotor motion to effect brush-less alternator or brush-less motor operation. An exemplary geometry includes a stator including two annular rings and a concentric field coil together with a rotor structure separated from the stator by four air gaps.

Owner:RAVEN TECH

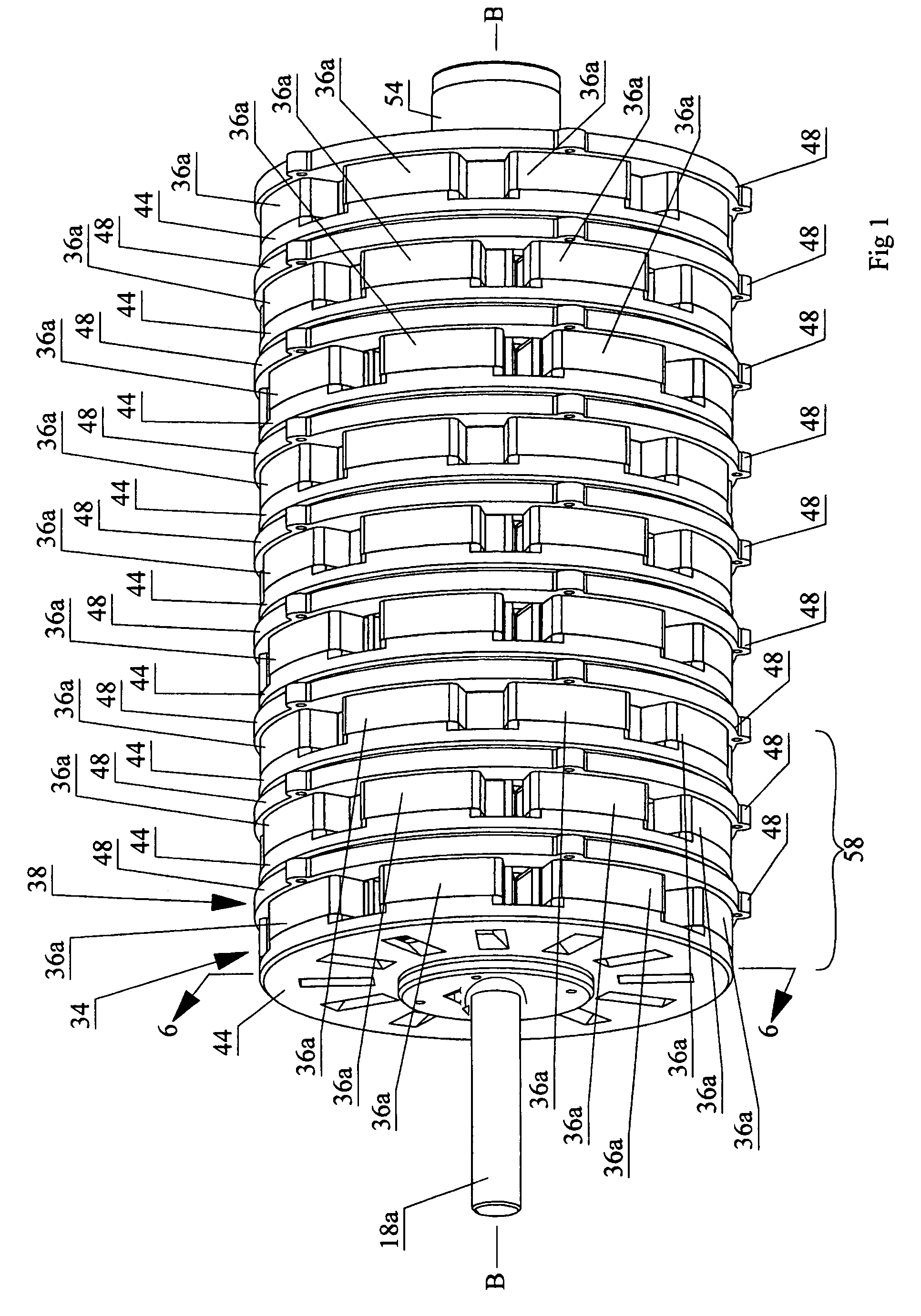

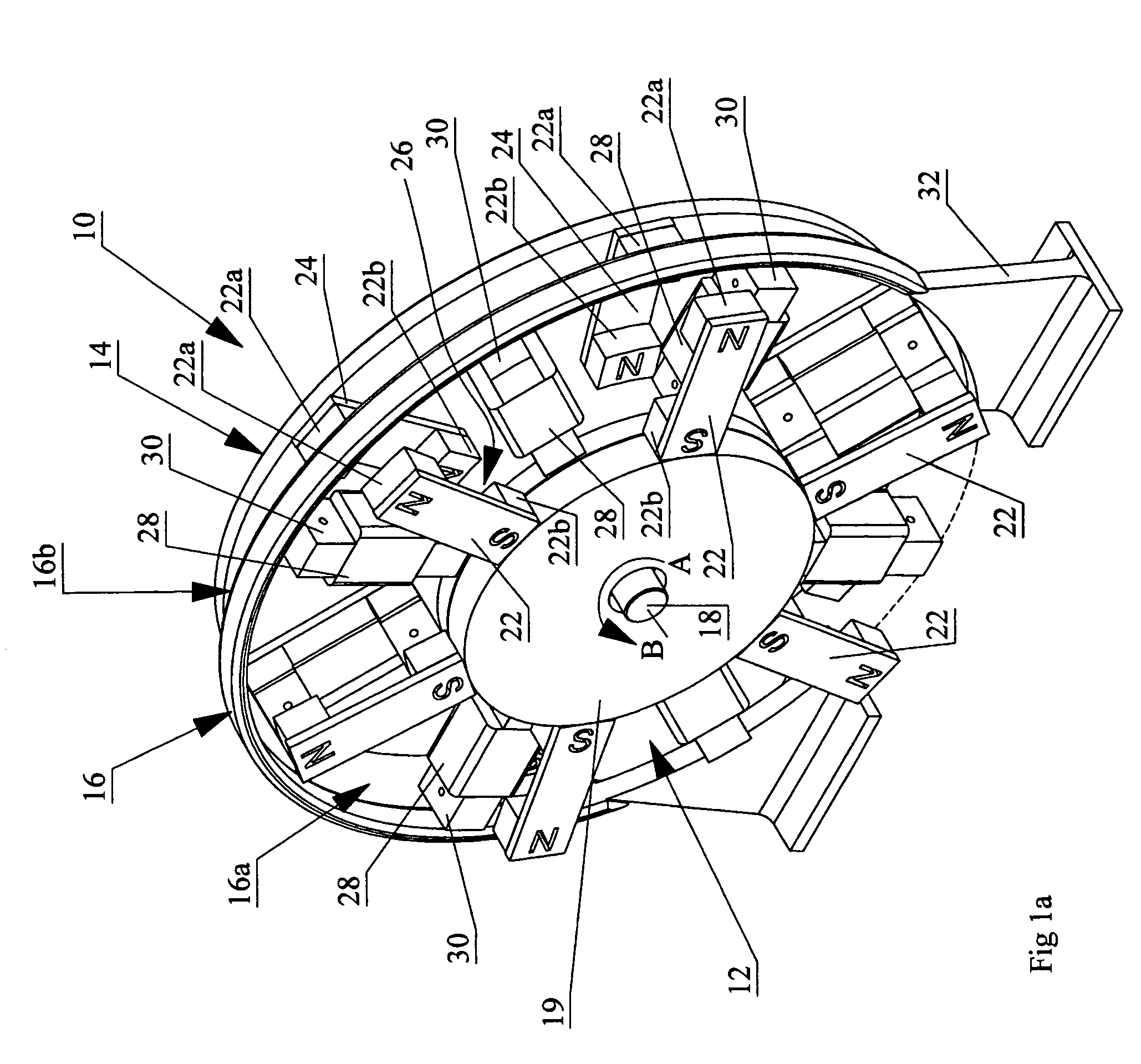

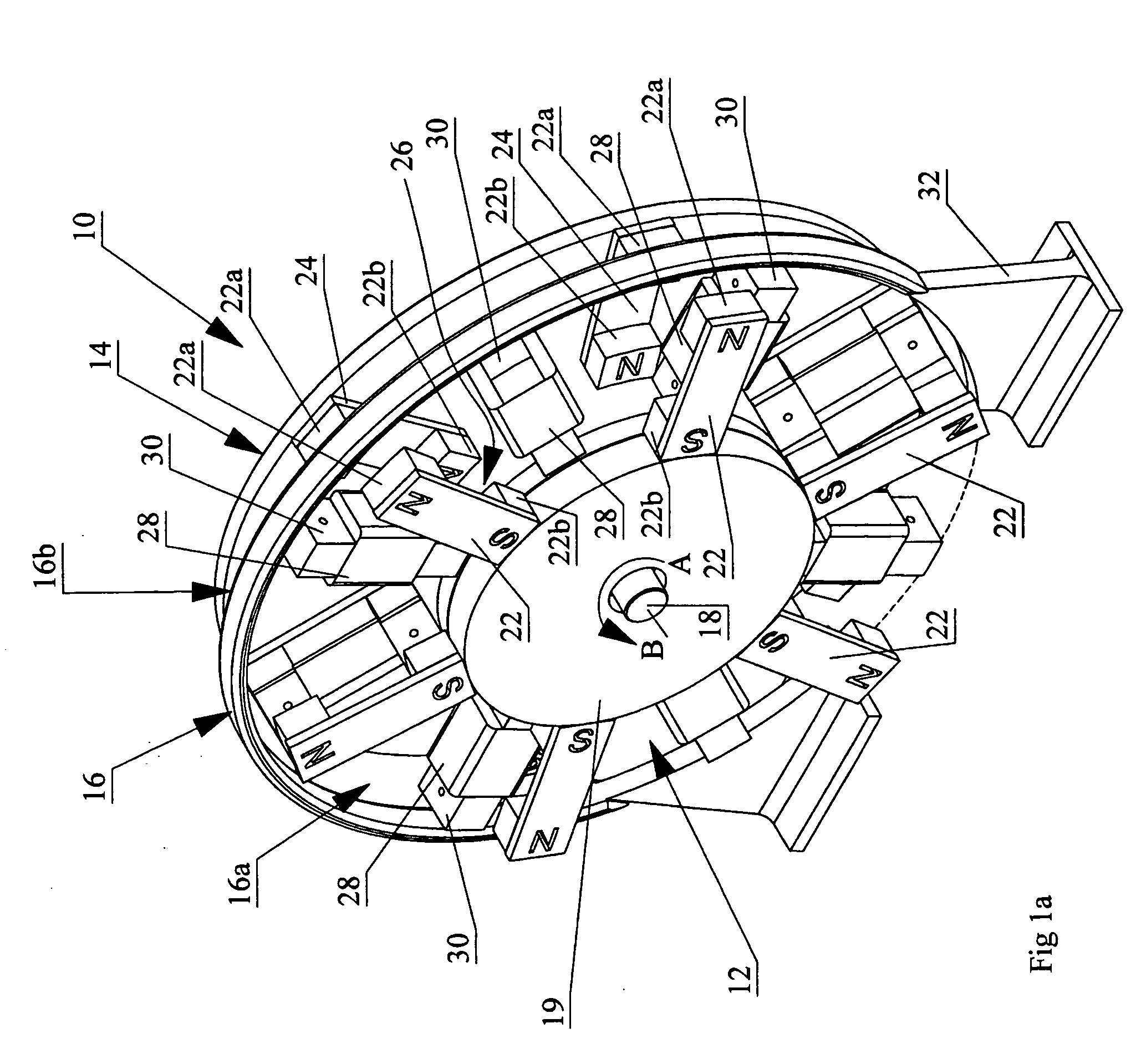

Polyphasic multi-coil generator

ActiveUS7081696B2Reduce resistanceSynchronous generatorsMagnetic circuit rotating partsDrive shaftAngular orientation

Owner:DPM TECH INC +1

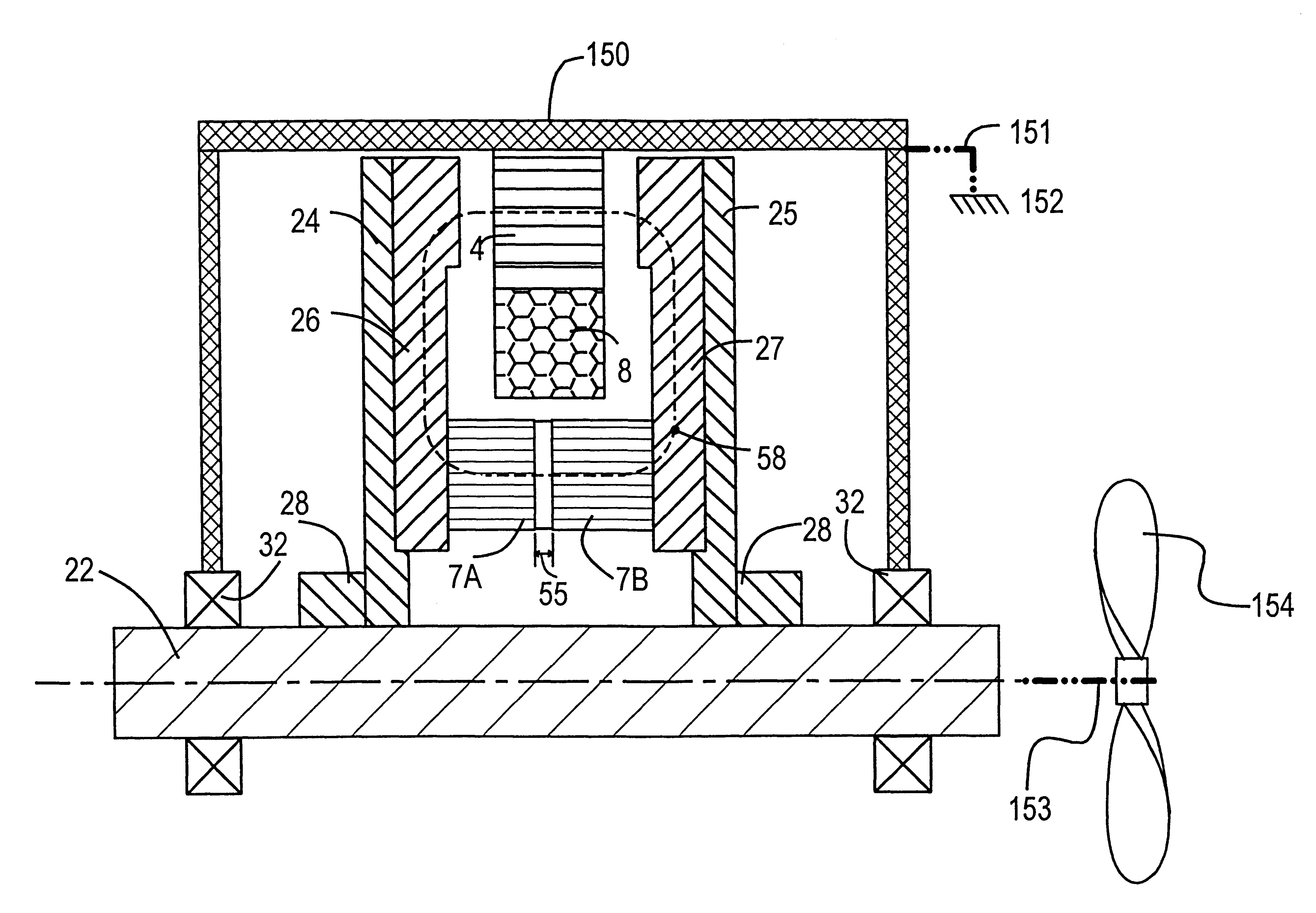

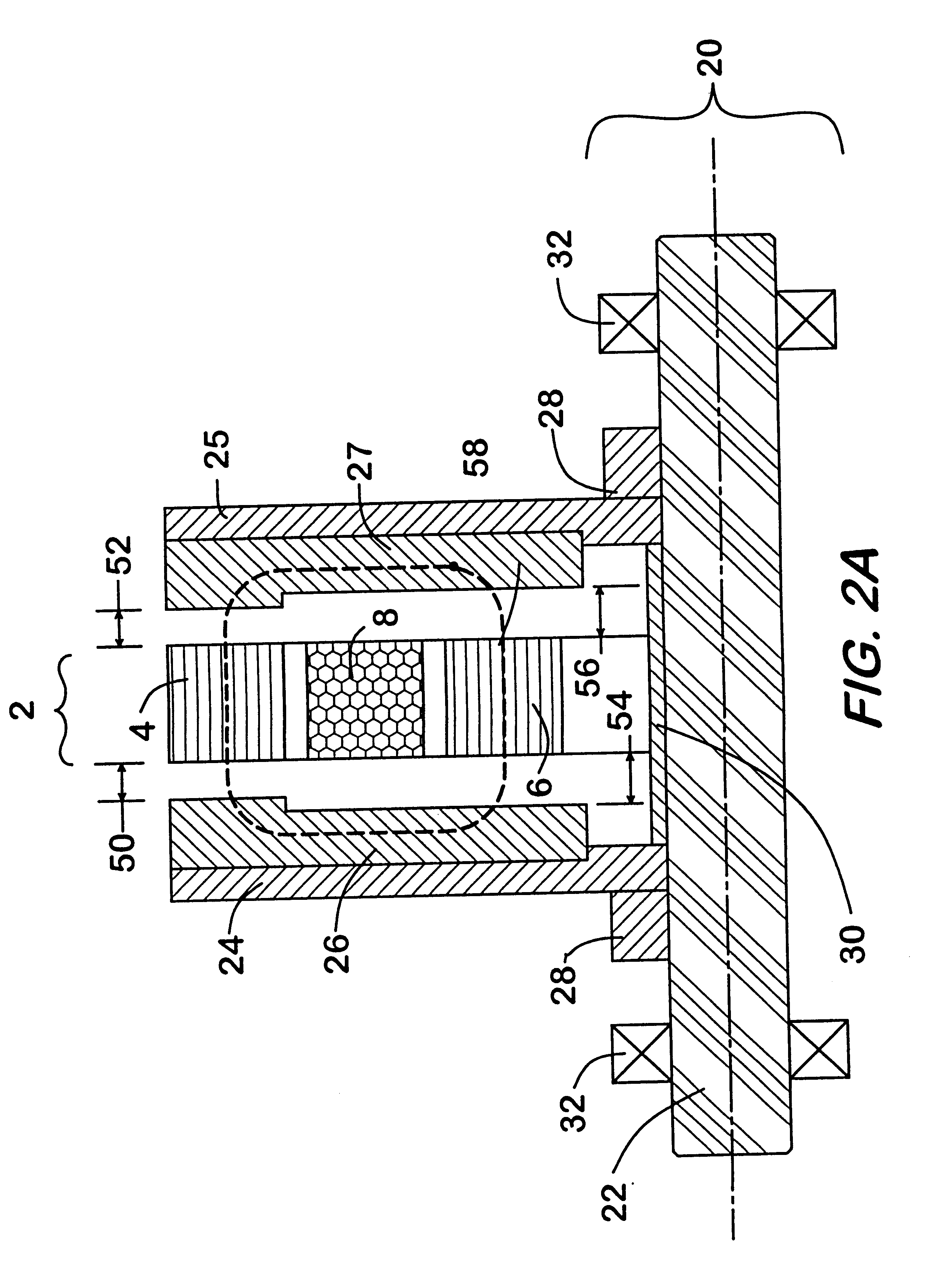

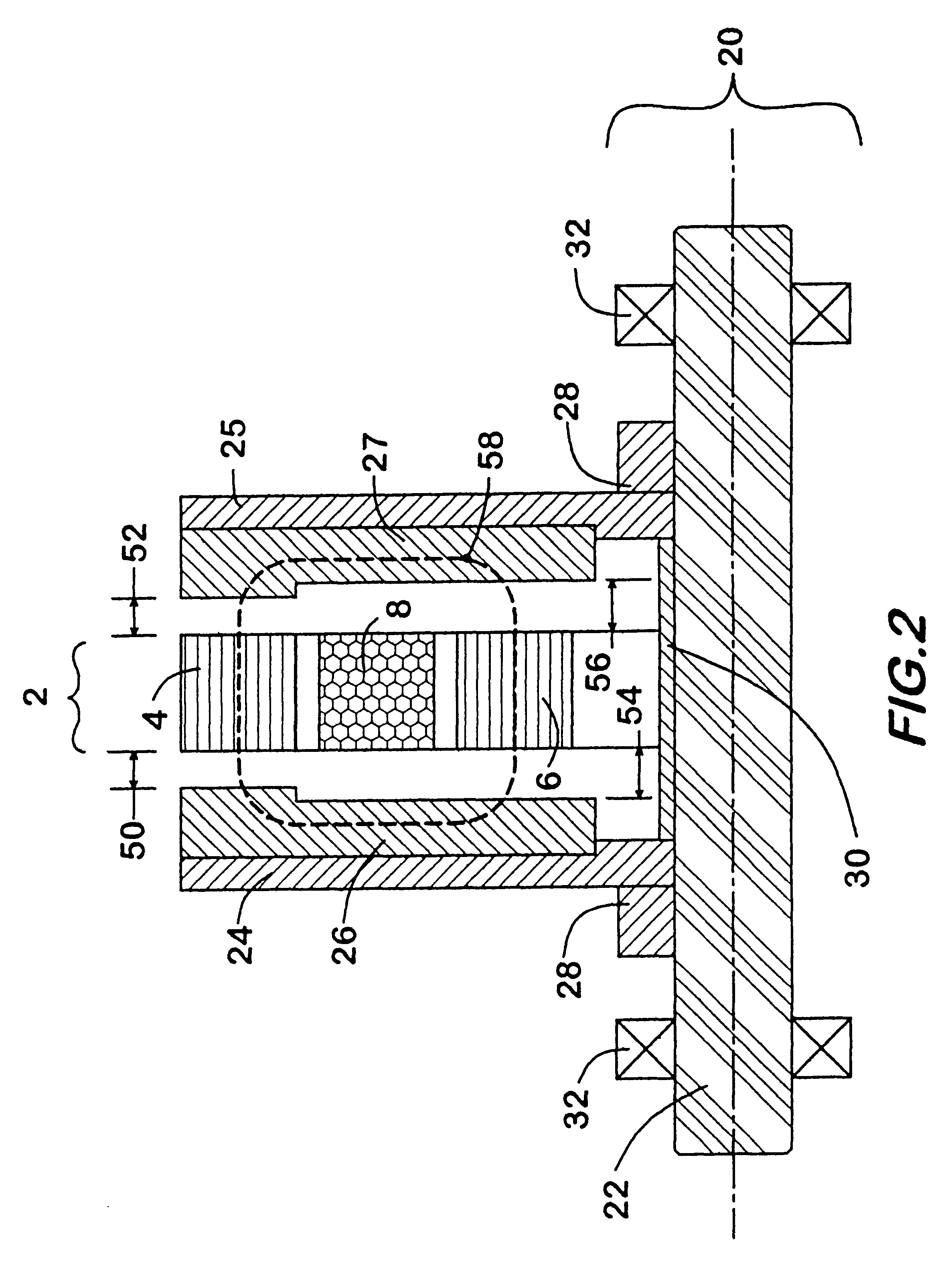

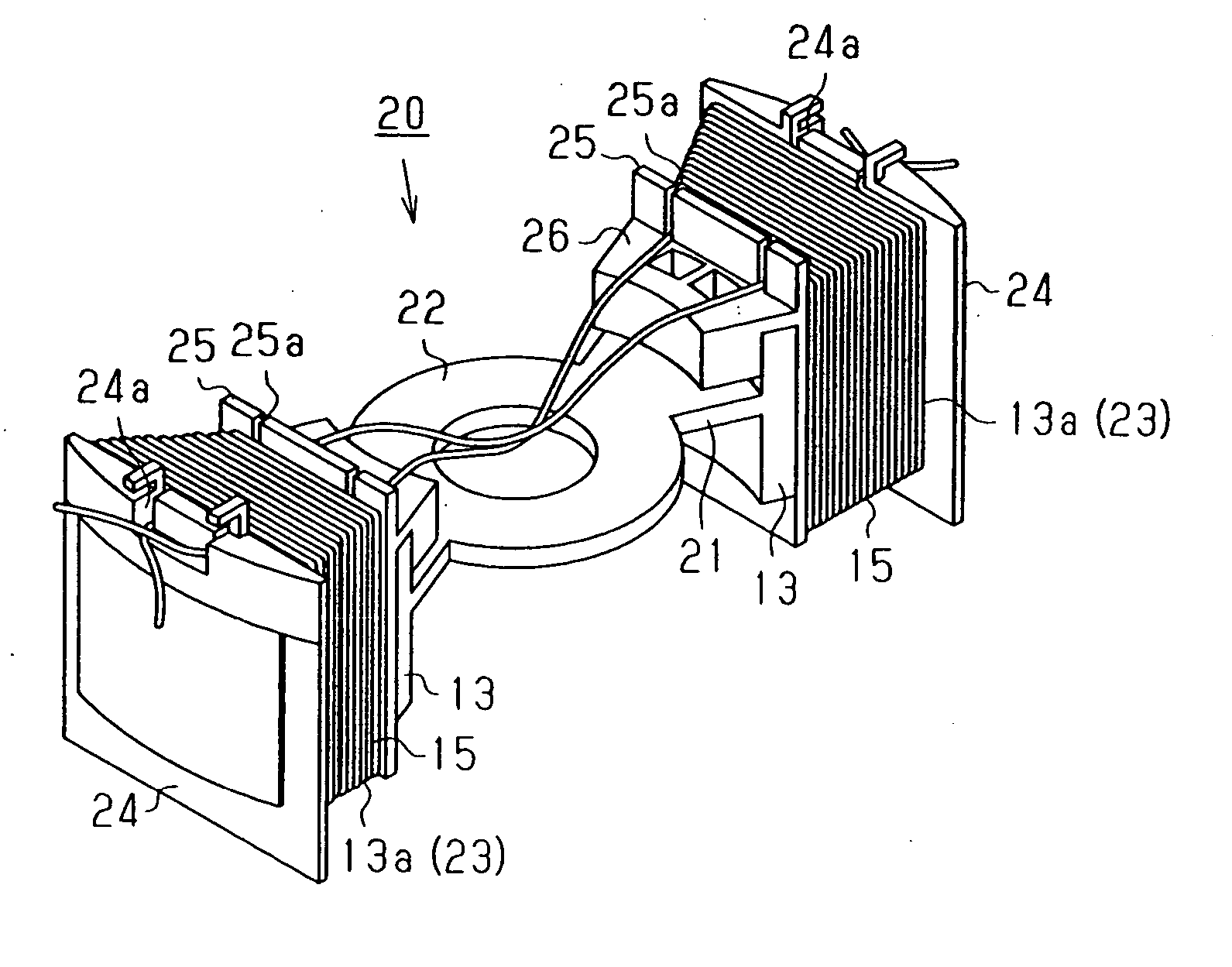

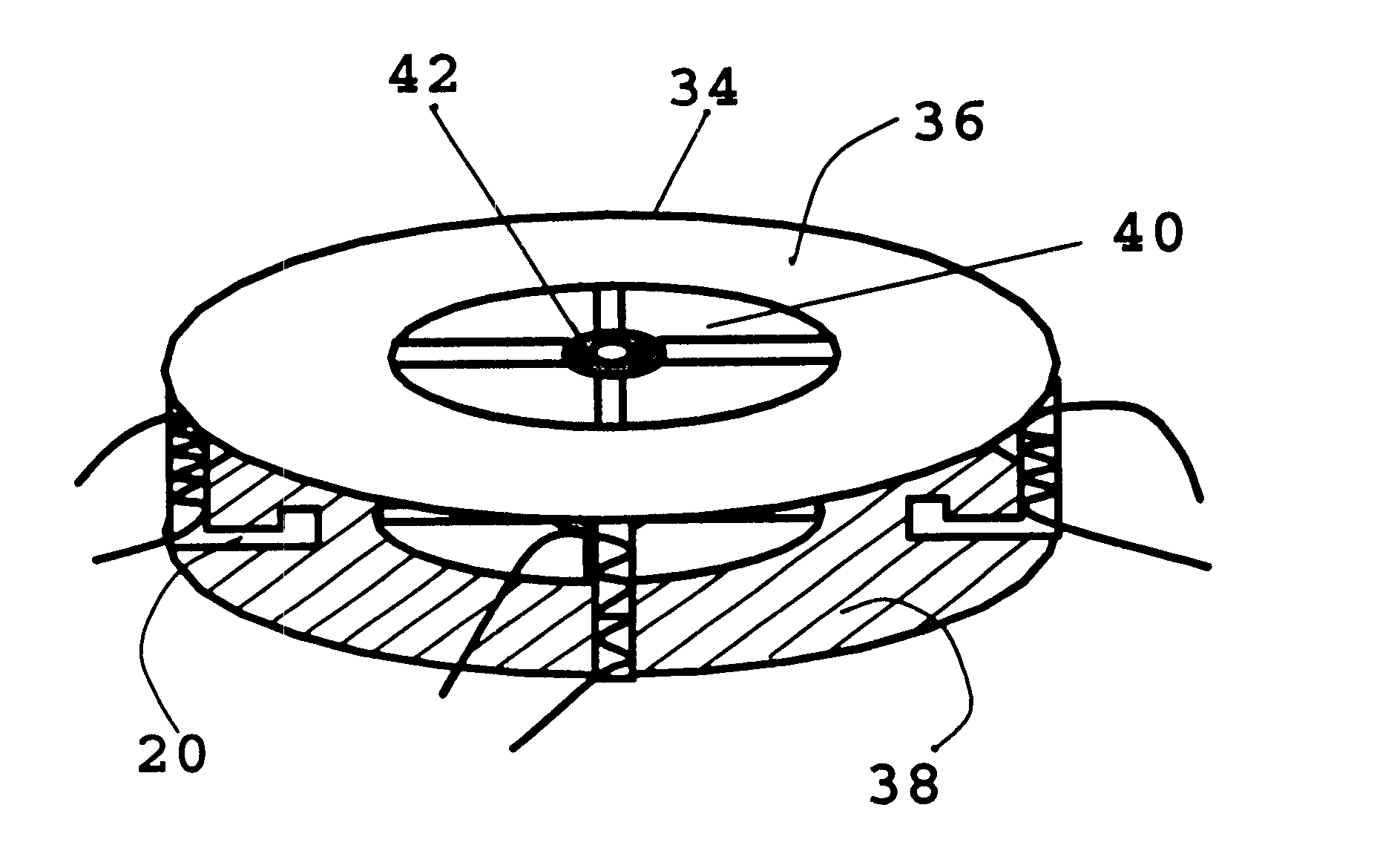

Low inductance electrical machine for flywheel energy storage

InactiveUS6175178B1Synchronous generatorsMagnetic circuit rotating partsBrushless motorsFlywheel energy storage

A low inductance electrical machine which may be used as an alternator or motor with low armature inductance is disclosed. Arrangements of complementary armature windings are presented in which the fluxes induced by currents in the armature windings effectively cancel leading to low magnetic energy storage within the machine. This leads to low net flux levels, low core losses, low inductance and reduced tendency toward magnetic saturation. Separately excited field arrangements are disclosed that allow rotor motion to effect brushless alternator or brushless motor operation. An exemplary geometry includes a stator including two toroidal rings and a concentric field coil together with a rotor structure separated from the stator by four air gaps. An alternate embodiment allows for counter-rotation of two rotor elements for use as a flywheel energy storage system in which the external gyroscopic effects cancel.

Owner:RAVEN TECH

High-power low-RPM DC motor

InactiveUS6194799B1Increase profitIncreasing motor torqueAsynchronous induction motorsPropulsion by batteries/cellsEngineeringConductor Coil

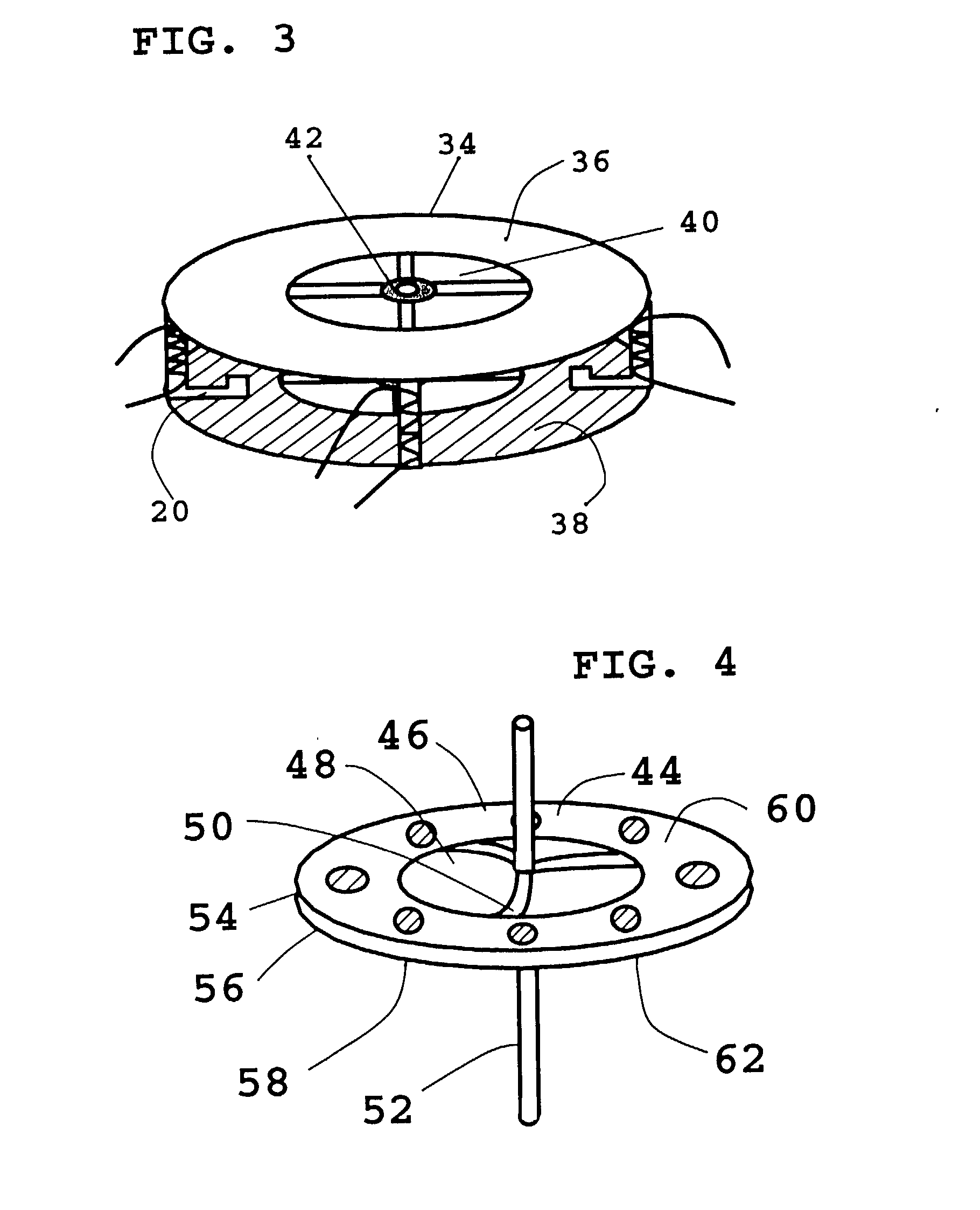

A high power low RPM direct current electric motor is disclosed whereby the high power output is achieved in one of two ways or both. In the first case, the need for cooling is reduced simultaneously along with an increase in the utilization of the magnetic field present in the motor permanent magnets. This is achieved by wrapping the electromagnet core with windings that are capable of demagnetizing the rotor permanent magnets under stall conditions. Interlocking motor circuitry is provided which prevents the full activation of these motor windings until motor RPM values reach a safe level. This increases motor power while decreasing resistive losses in electromagnet windings. In the second case, the rotary portion consists of a large diameter relatively flat rotor containing permanent magnets and having built in vanes for moving air over the electromagnet stator windings providing forced air cooling.

Owner:MAGNETIC MOTORS

High power low RPM D.C. motor

InactiveUS6037692AIncrease motor powerHigh strengthAC motor controlAsynchronous induction motorsEngineeringConductor Coil

A high power low RPM direct current electric motor is disclosed whereby the high power output is achieved in one of two ways or both. In the first case, the need for cooling is reduced simultaneously along with an increase in the utilization of the magnetic field present in the motor permanent magnets. This is achieved by wrapping the electromagnet core with windings that are capable of demagnetizing the rotor permanent magnets under stall conditions. Interlocking motor circuitry is provided which prevents the full activation of these motor windings until motor RPM values reach a safe level. This increases motor power while decreasing resistive losses in electromagnet windings. In the second case, the rotary portion consists of a large diameter relatively flat rotor containing permanent magnets and having built in vanes for moving air over the electromagnet stator windings providing forced air cooling.

Owner:MAGNETIC MOTORS

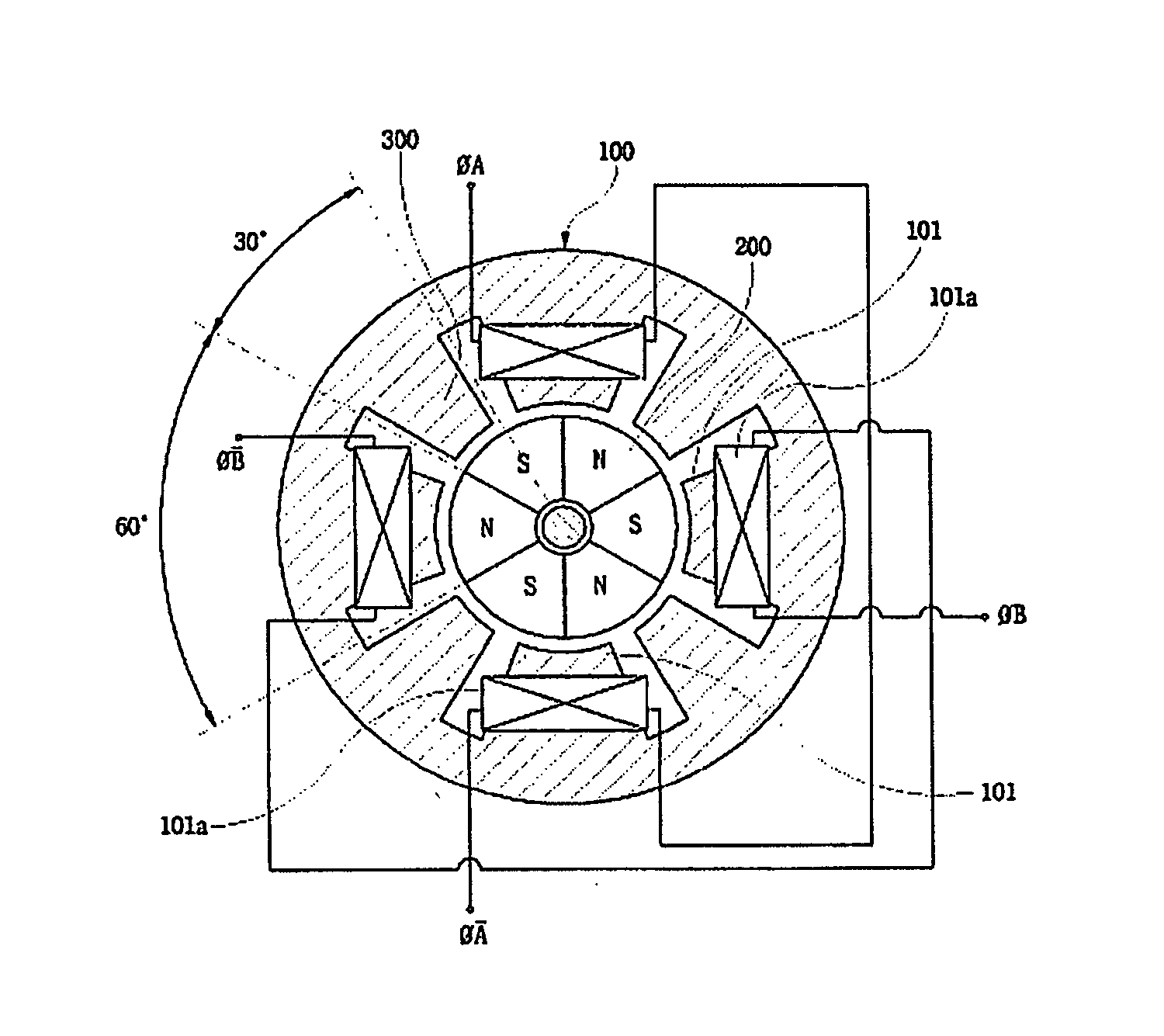

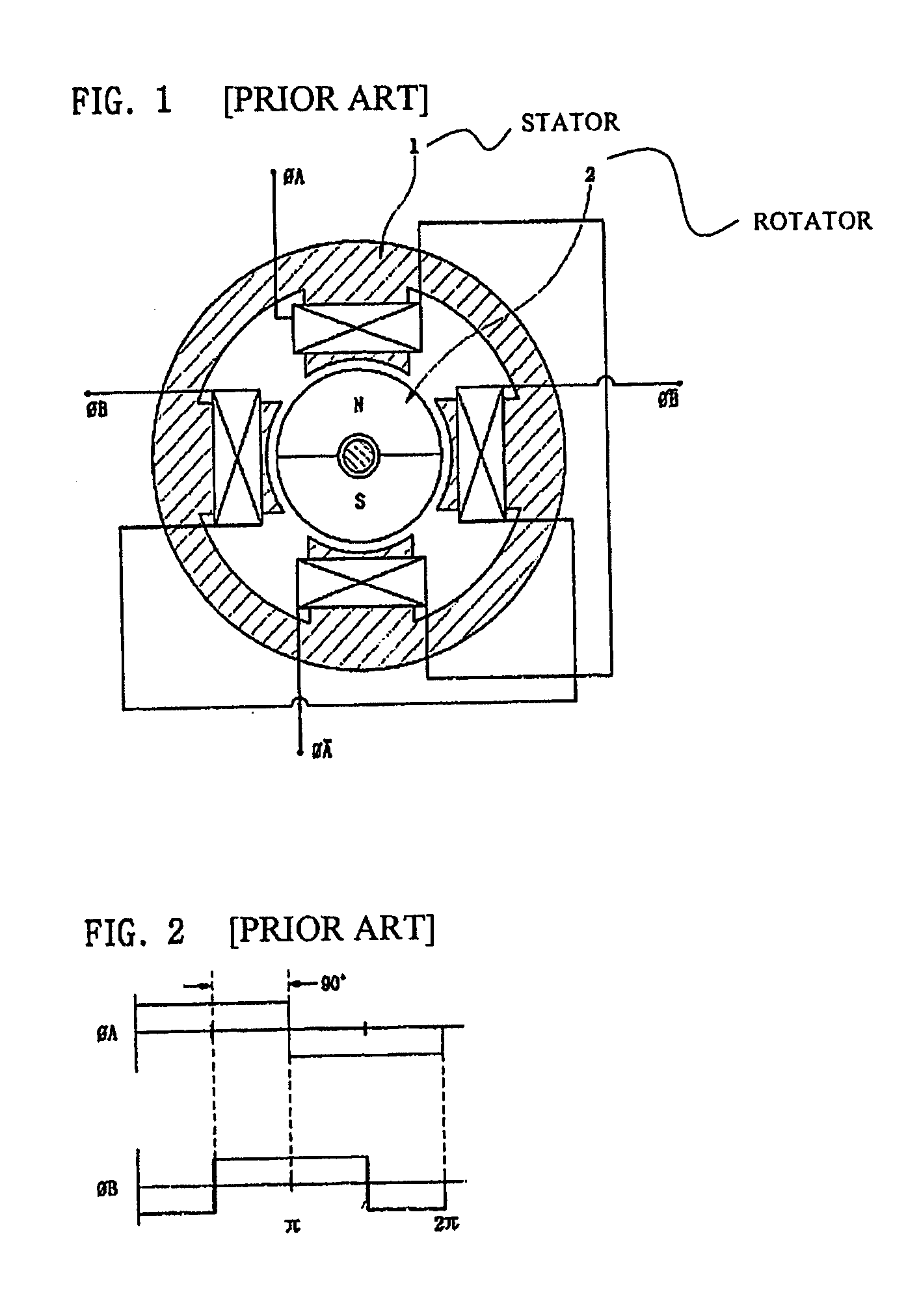

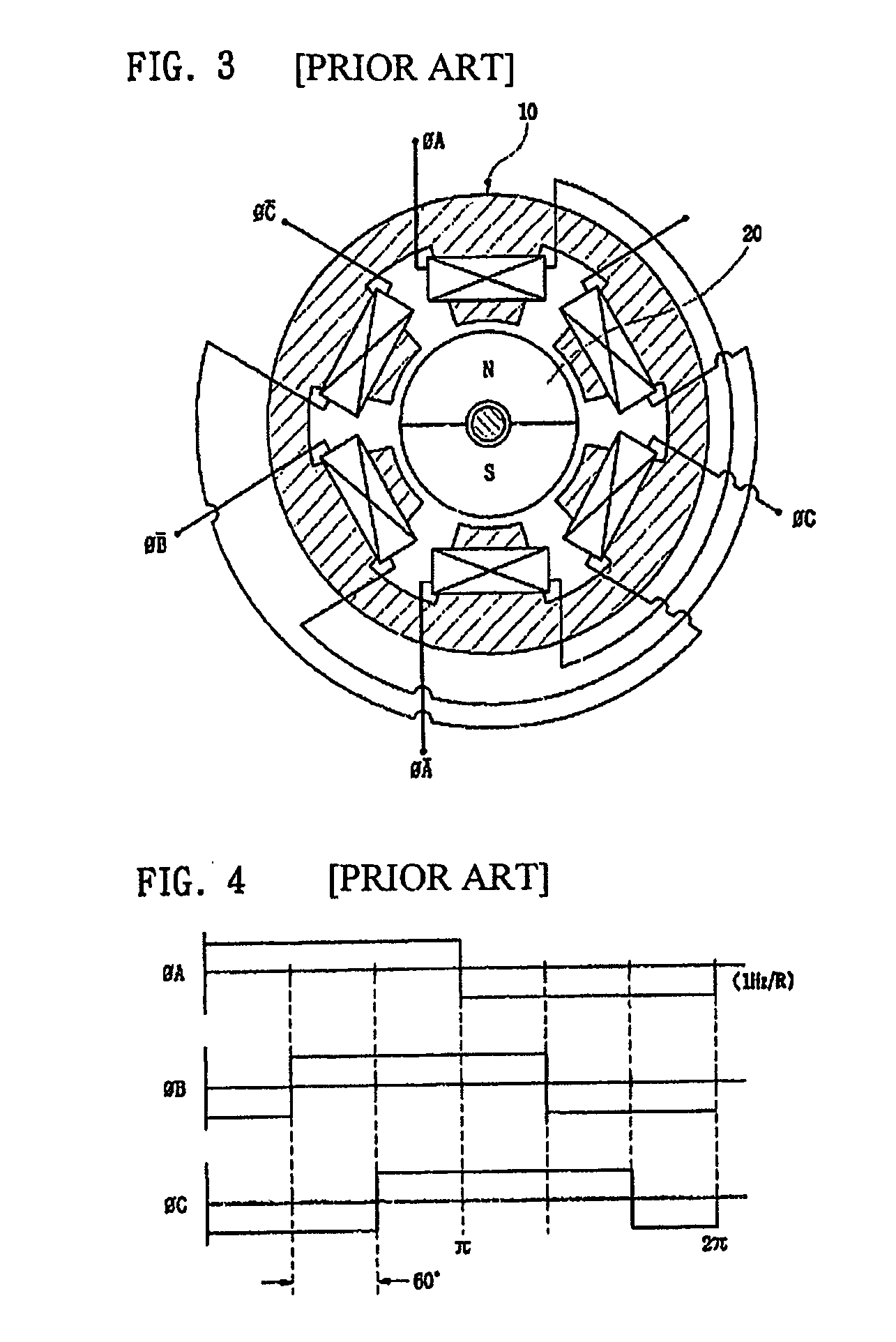

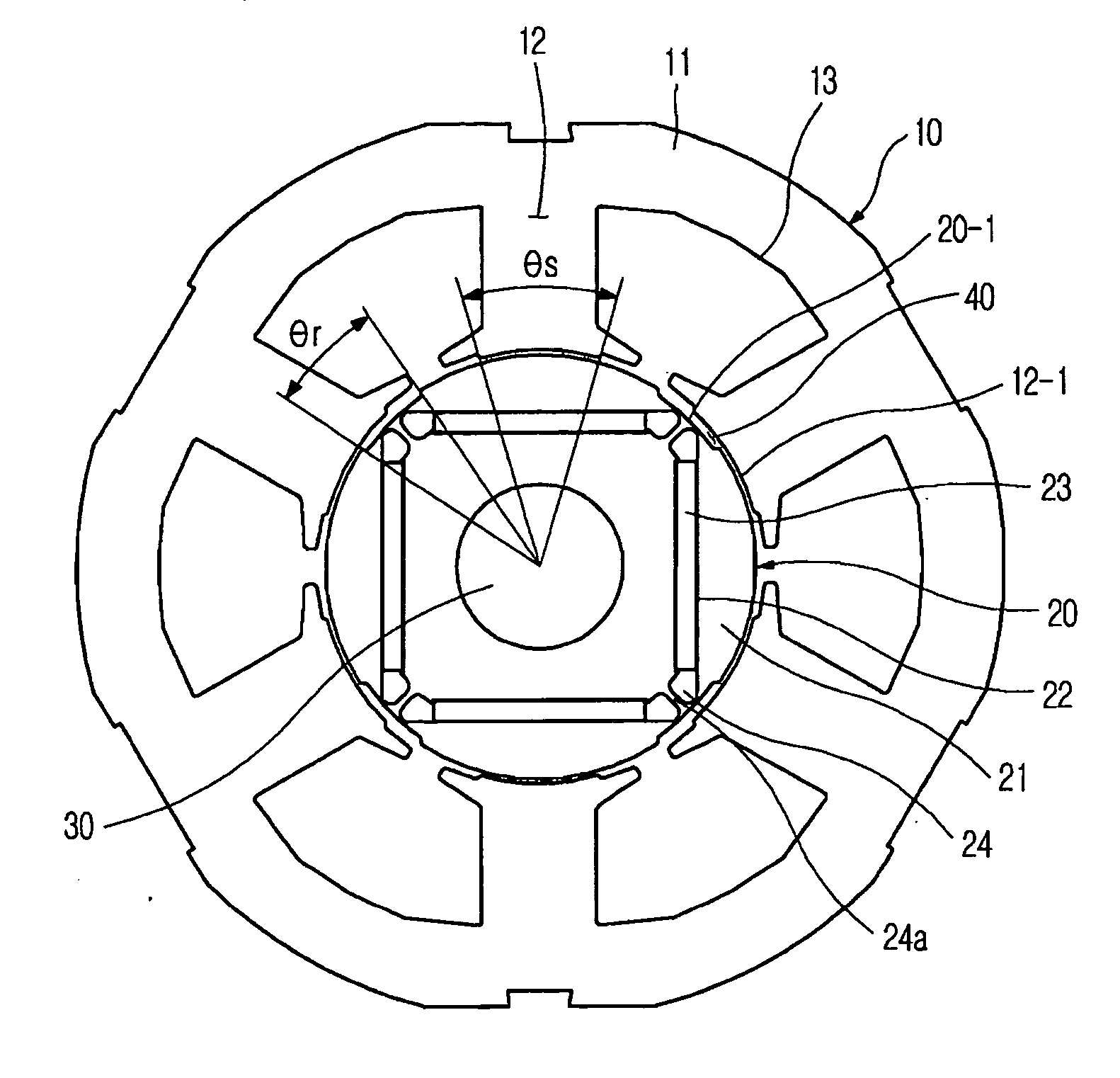

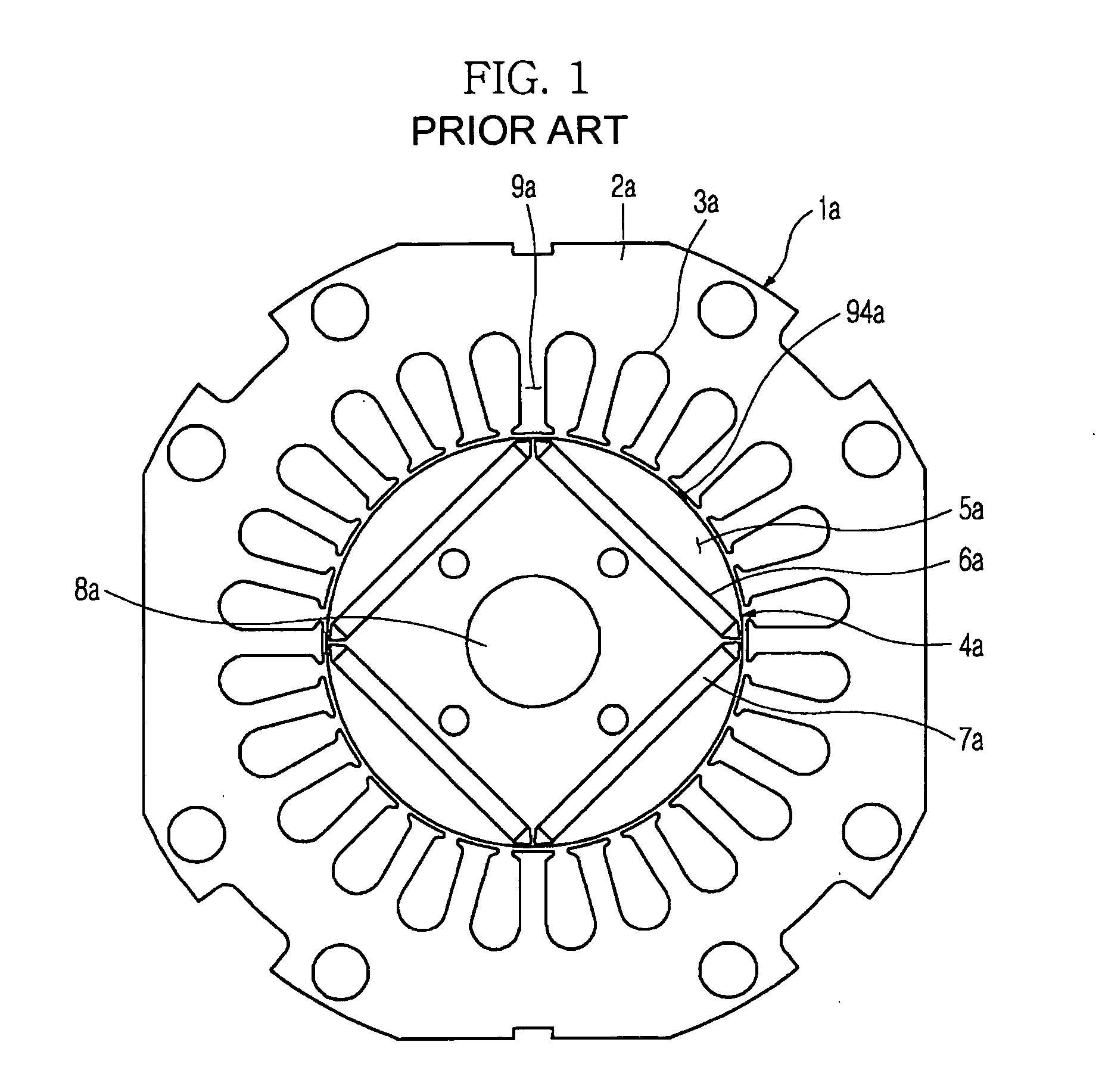

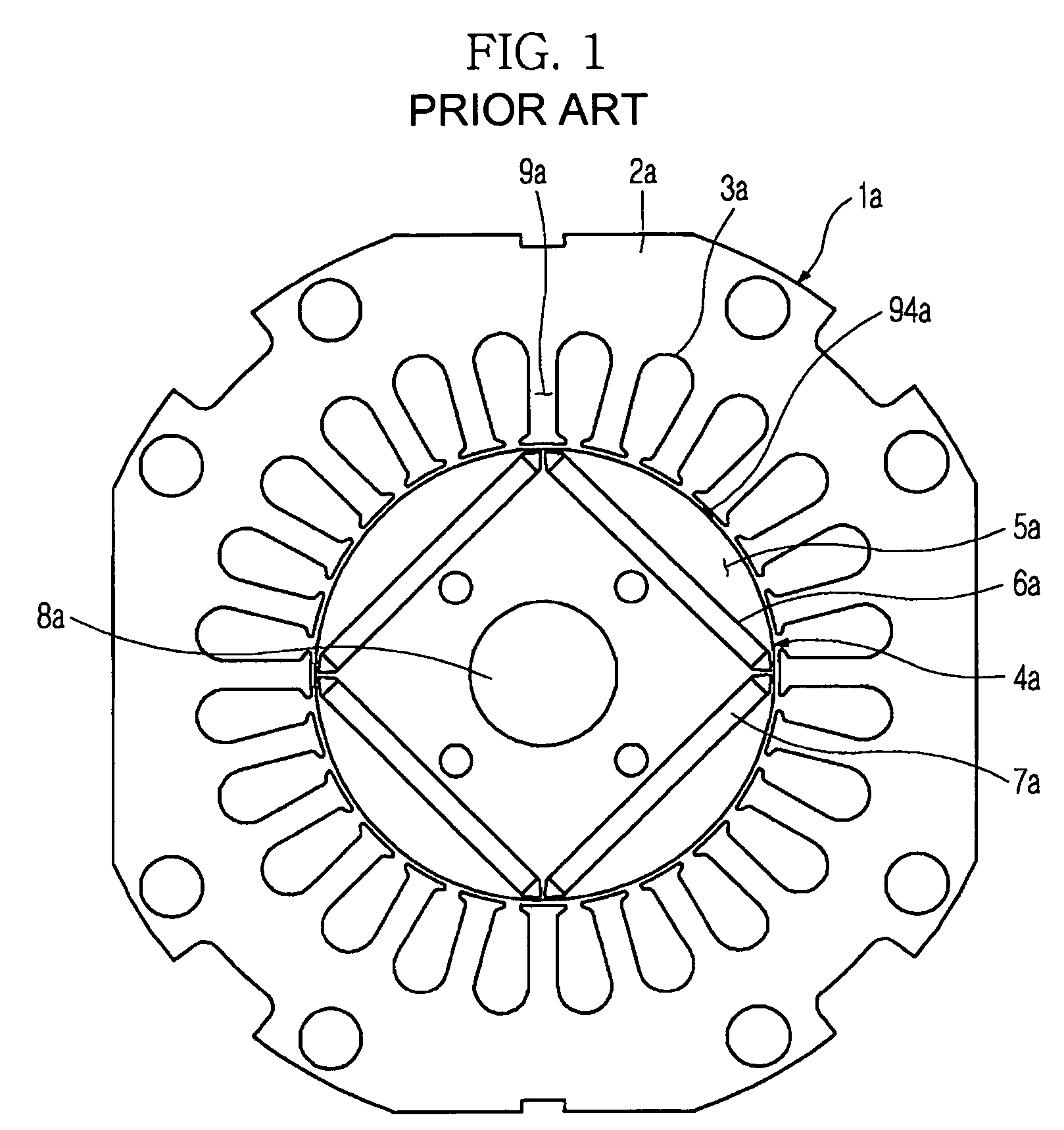

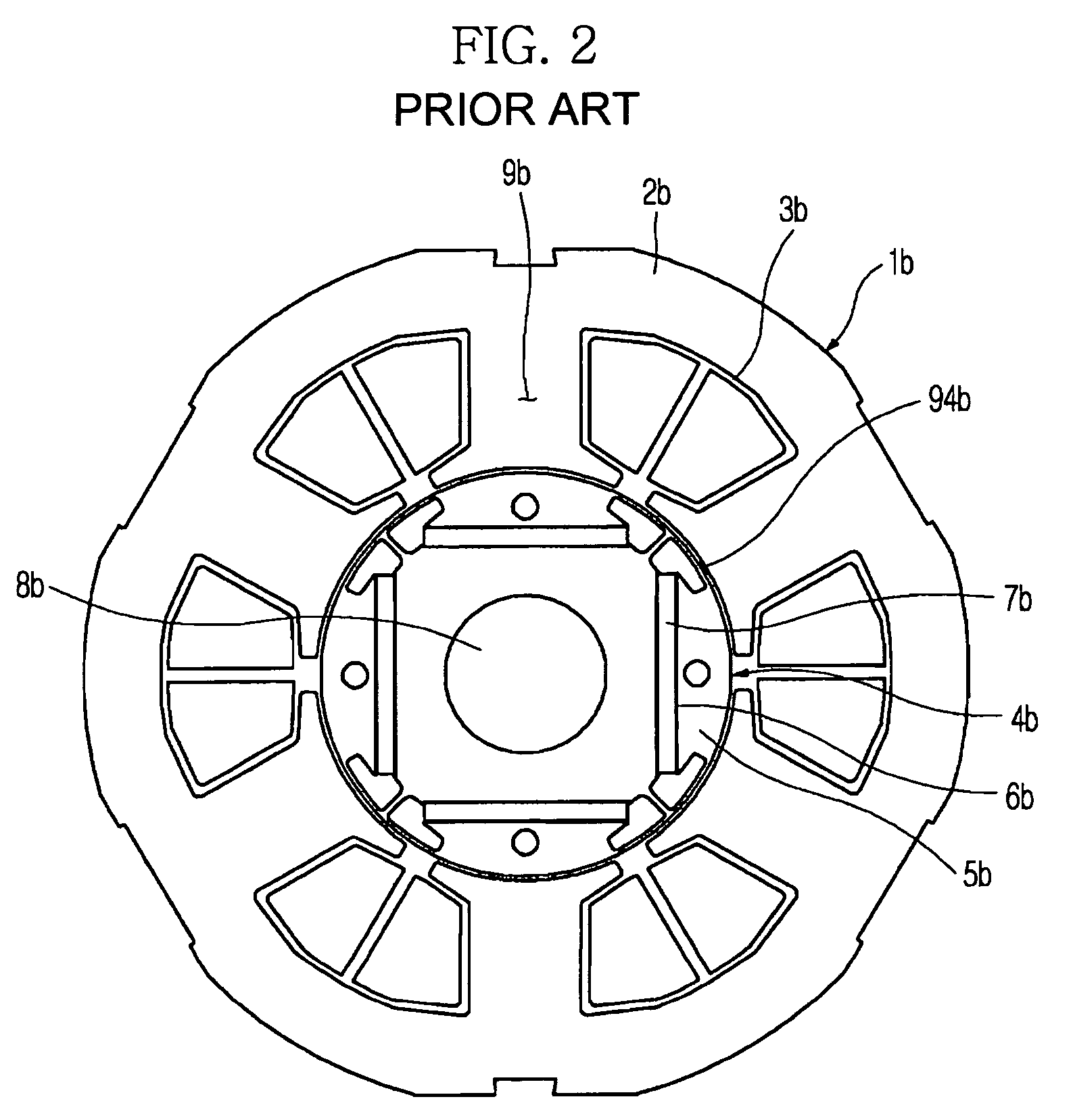

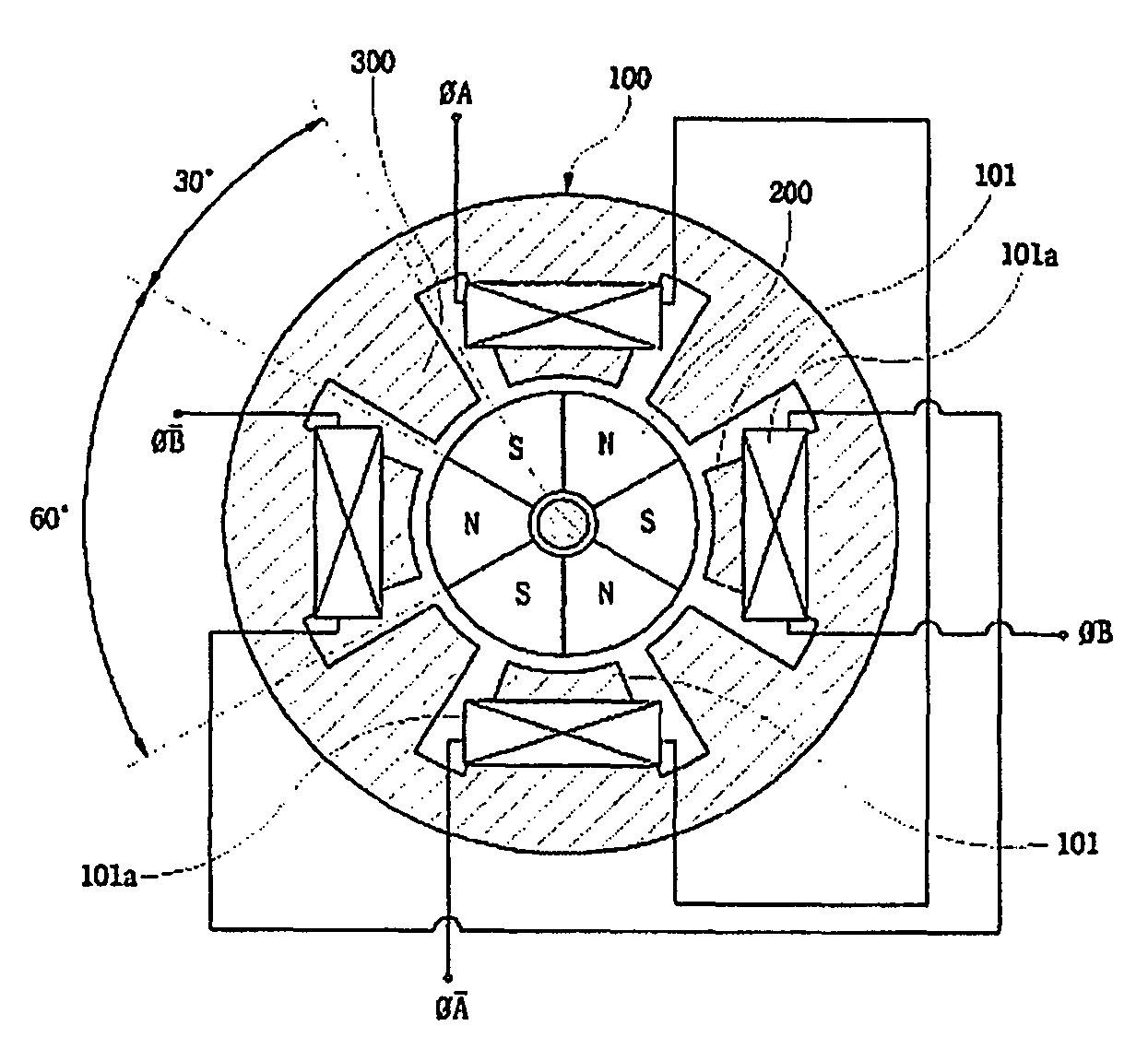

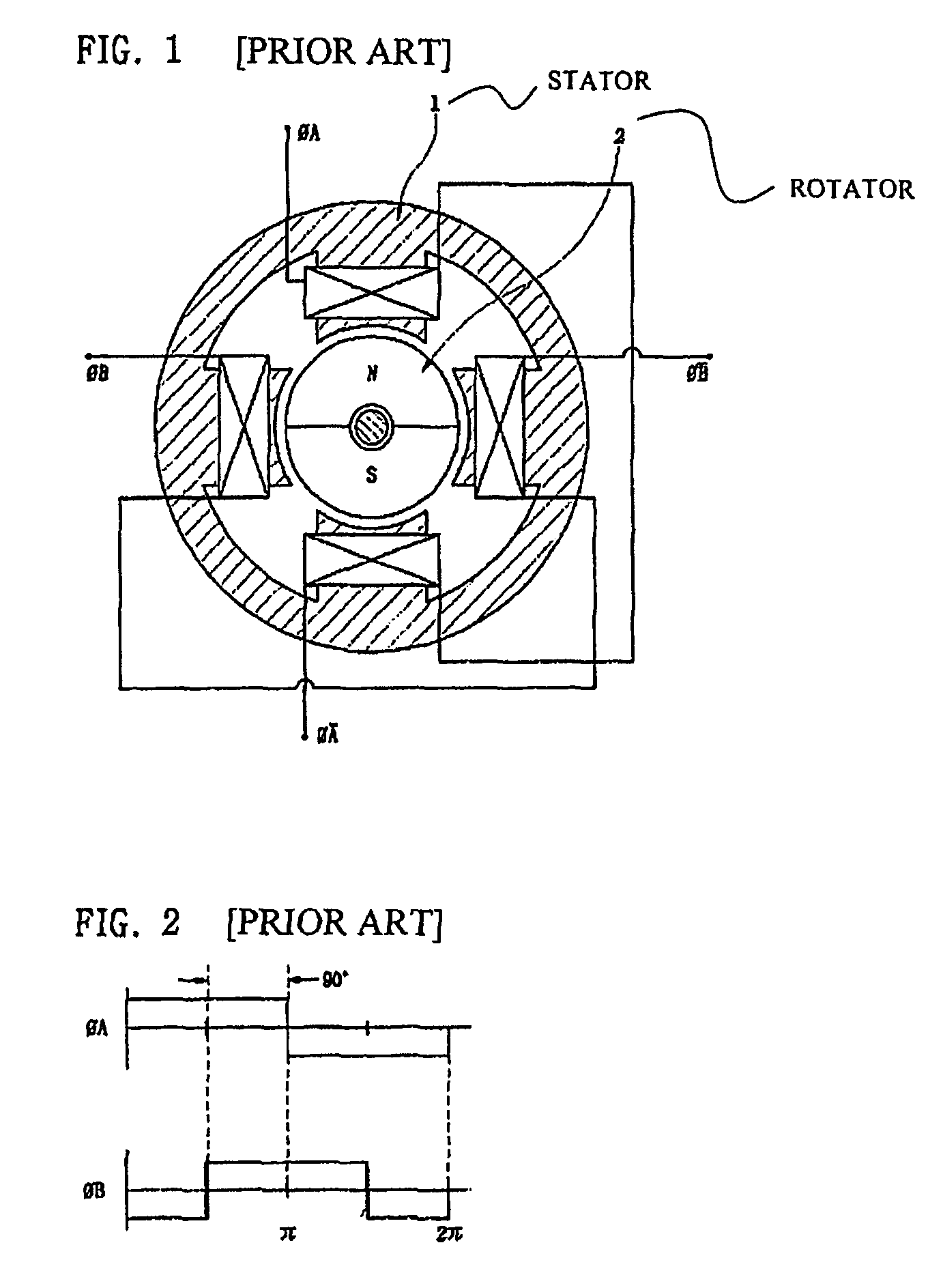

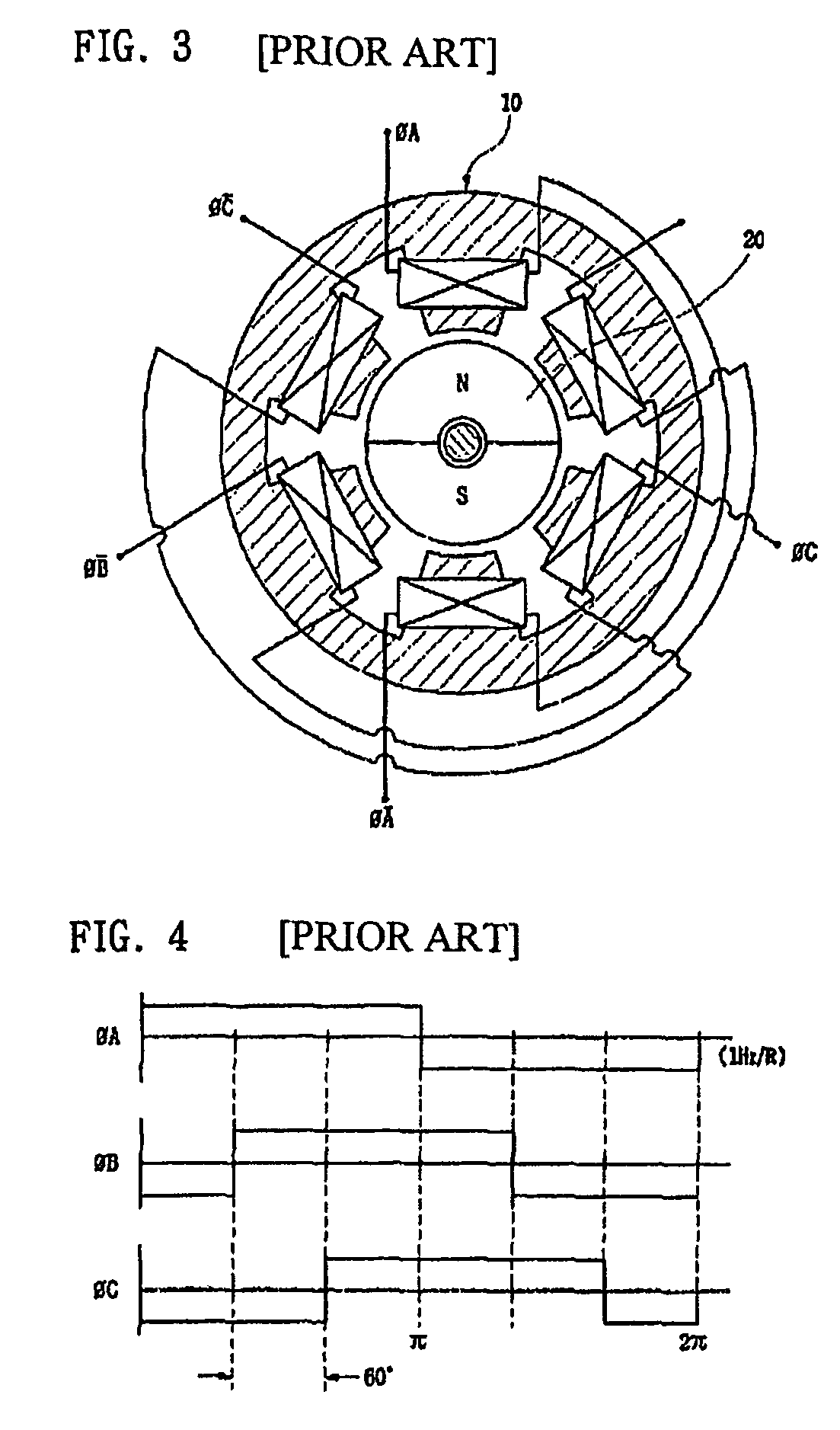

Two-phase brushless DC motor

ActiveUS20060244333A1Improve large rotation torque featureImprove efficiencyAC motor controlSynchronous motors startersBrushless motorsElectric machine

The present invention relates to a two-phase brushless DC motor which can increase a pemerance coefficient of a rotor to the maximum to thereby improve efficiency and starting feature of the motor, and to reduce torque ripple and noise thereof. The brushless motor of the present invention includes a two-phase winding stator having 4×n winding poles and auxiliary poles provided between the winding poles, and a rotor constituted by 6×n permanent magnet rotating poles having divided angle. Auxiliary poles between the stator poles can be provided. The two-phase brushless motor of the present invention can be driven by a control device for the two-phase motor which can transform electric power and rectify electronically.

Owner:BLUFFTON MOTOR WORKS

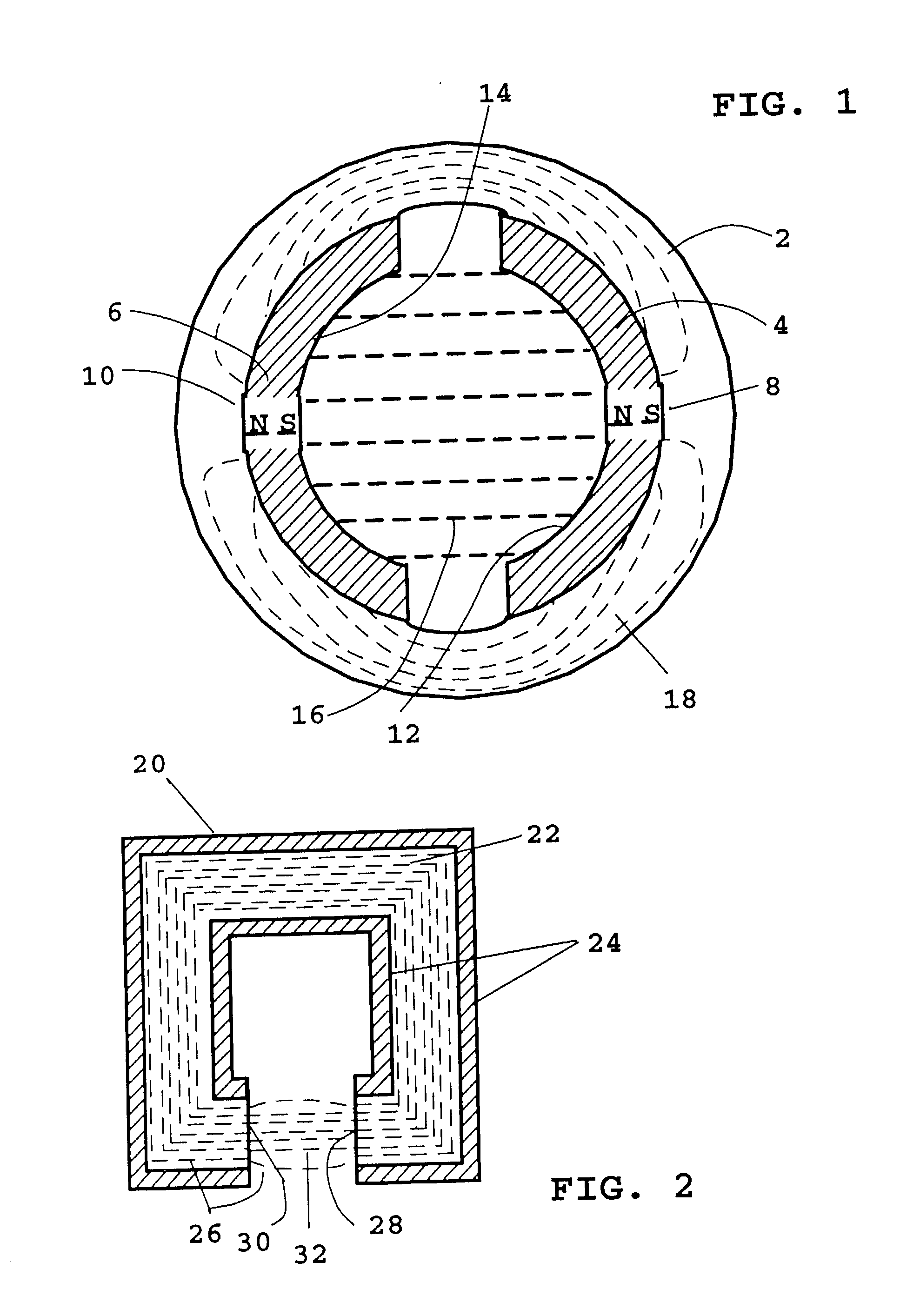

Permanent-magnet motor

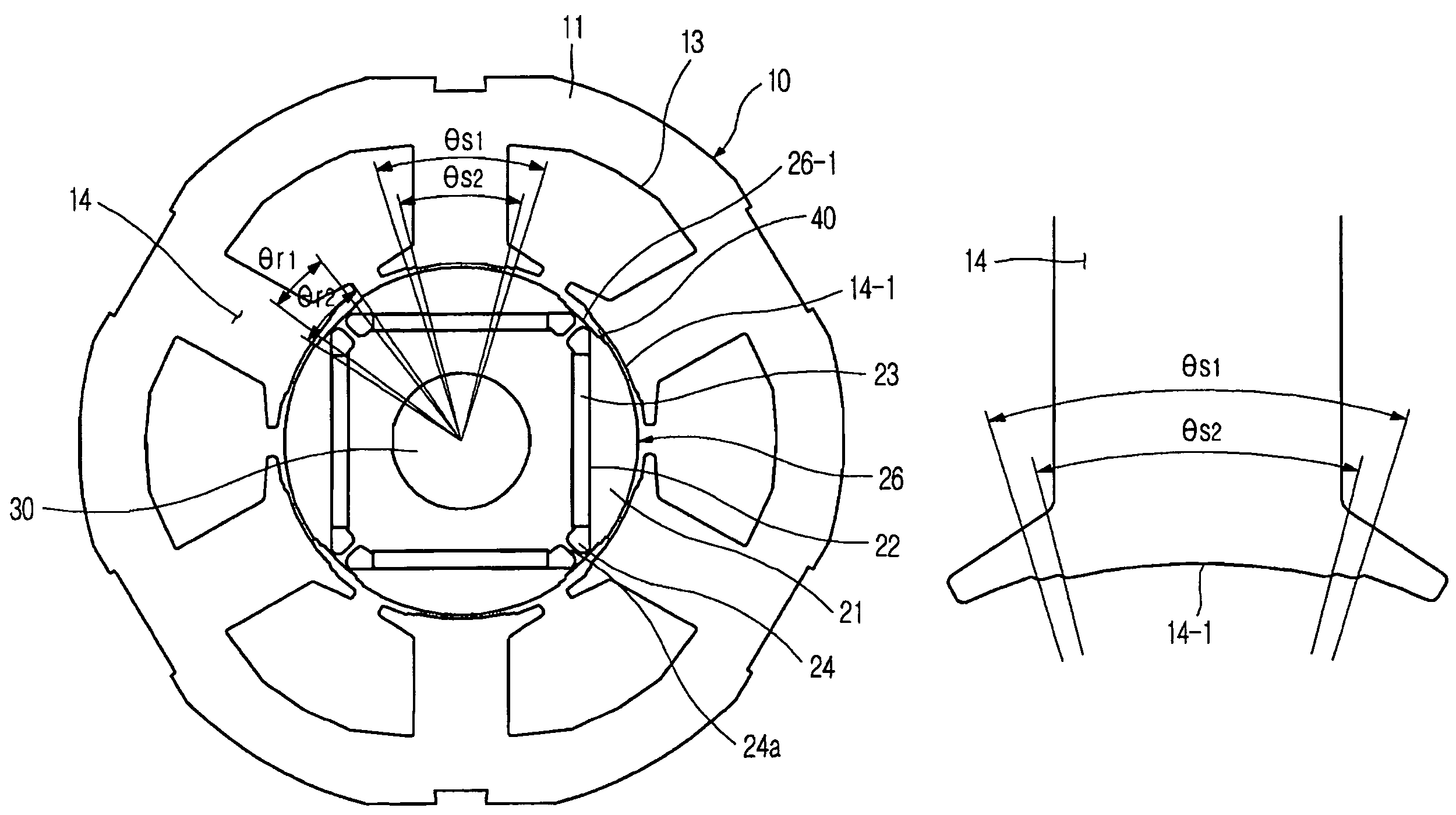

ActiveUS20060279158A1Magnetic circuit rotating partsSalient polesPermanent magnet motorMagnetic flux

A permanent-magnet motor including a rotor having permanent magnets disposed therein, and a stator, wherein an outer circumferential surface of the rotor is opposite to an inner circumferential surface of the stator, and one or both of the outer circumferential surface of the rotor and the inner circumferential surface of the stator are varied in a radial direction so as to provide a non-uniform gap between the two surfaces to approximate sinusoidal change in magnetic flux.

Owner:SAMSUNG ELECTRONICS CO LTD

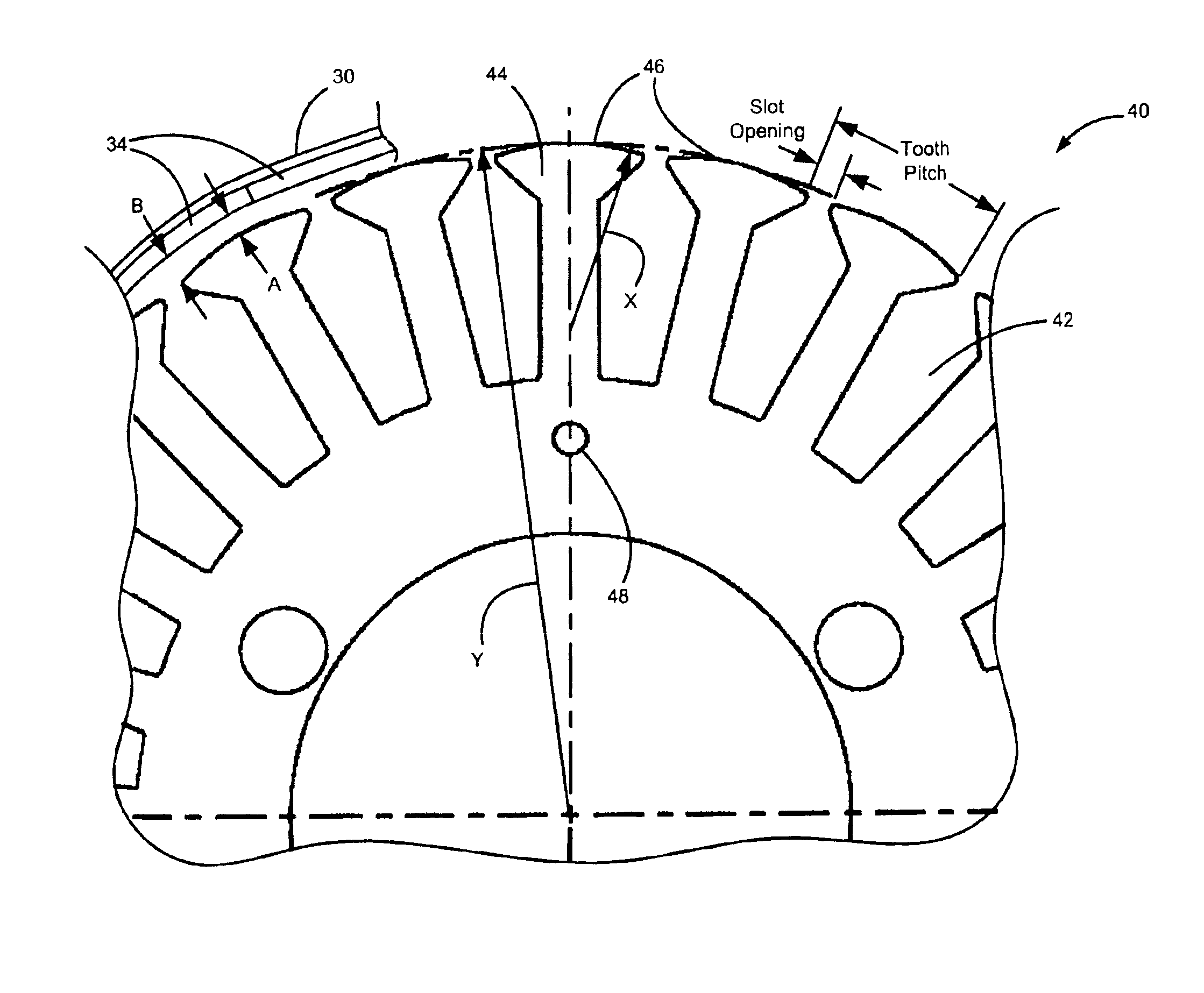

Reduced coil segmented stator

InactiveUS7122933B2Synchronous generatorsMagnetic circuit stationary partsElectric machineConductor Coil

A brushless permanent magnet (BPM) electric machine including a segmented stator having interconnected stator segment assemblies defining M stator teeth. Each of said M stator teeth having substantially the same axially facing size and shape. N coil windings are individually wound about the stator teeth. N<M.

Owner:NIDEC MOTOR CORP

High-speed electric system

ActiveUS20100251509A1Improve efficiencyConstant output powerSynchronous motors startersMultiple motor speed/torque controlElectric machineControl system

An electric system that includes a single-phase permanent-magnet electric machine and a control system for driving the electric machine under load at speeds in excess of 60 krpm. Additionally, a product that includes the electric system.

Owner:DYSON TECH LTD

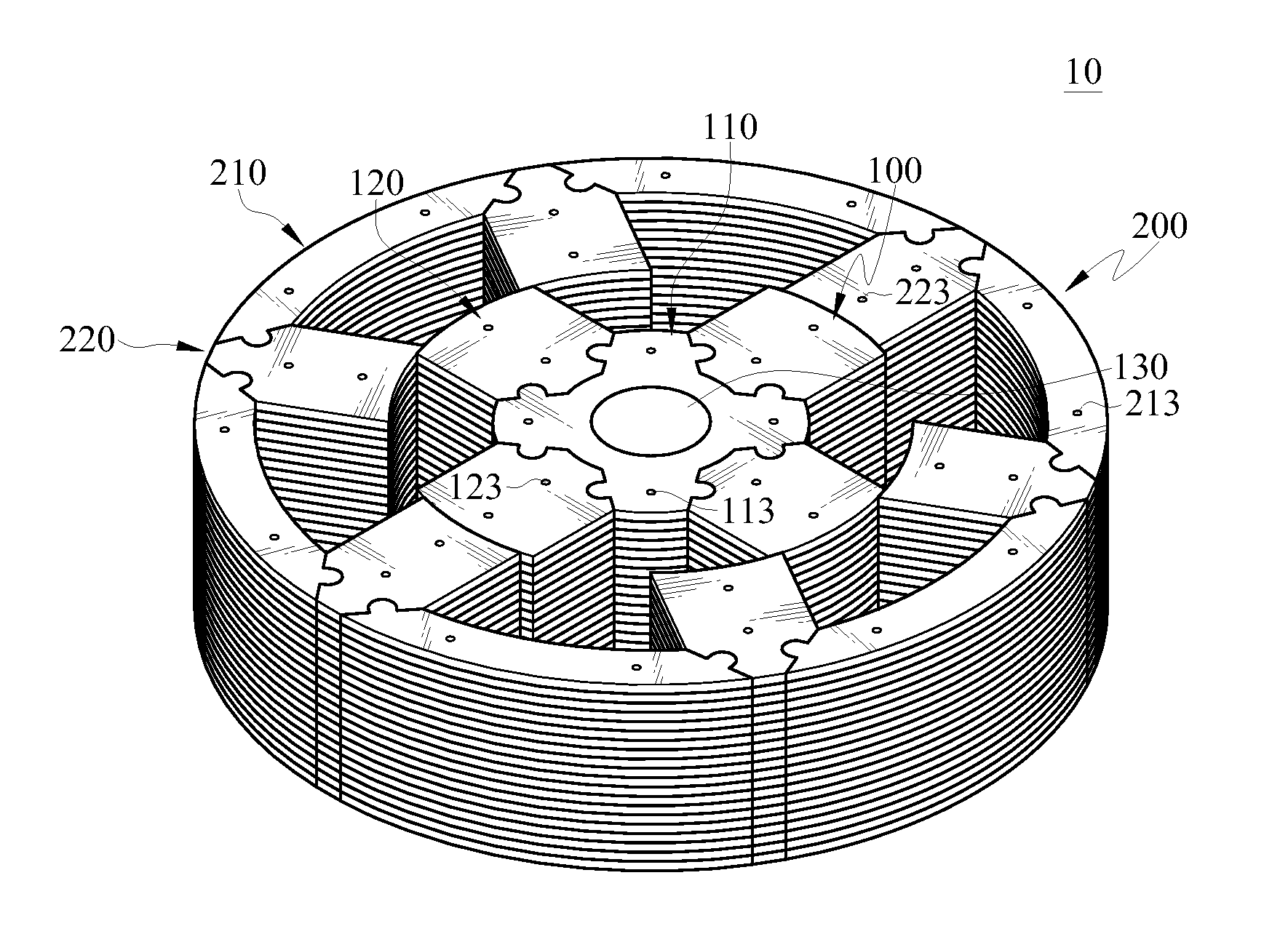

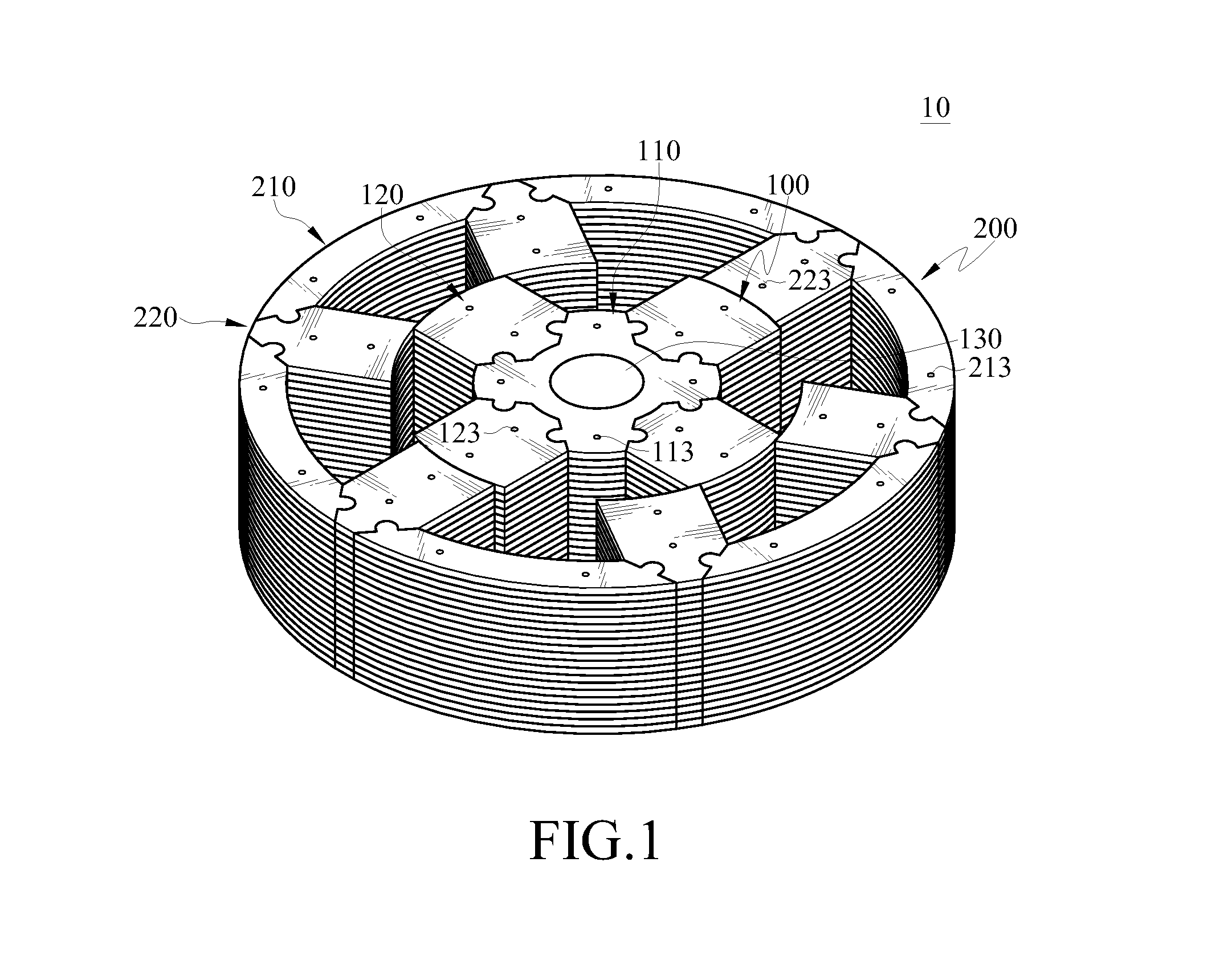

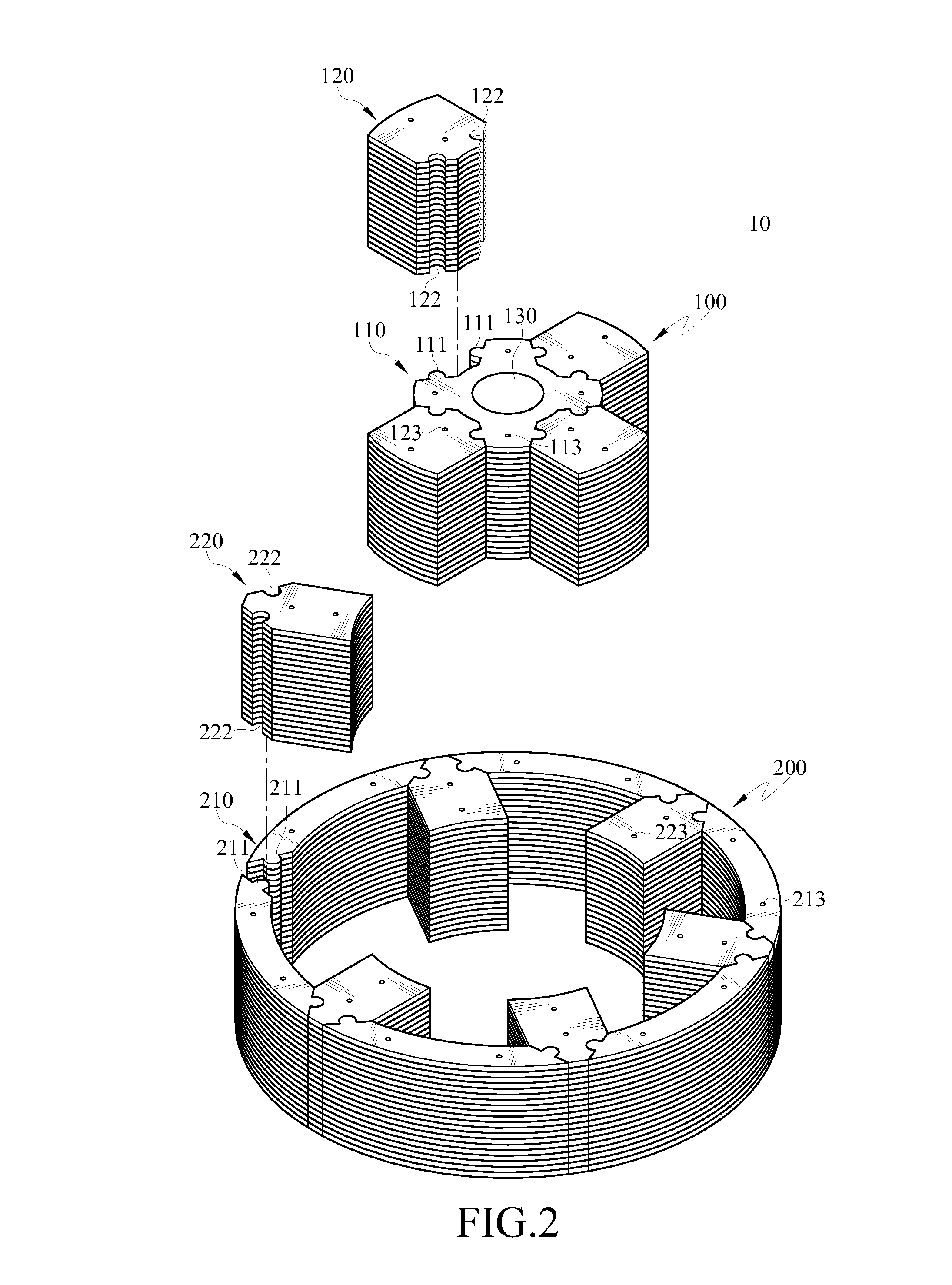

Segmented magneto-conductive structure applied in rotating machines

A segmented magneto-conductive structure applied in rotating machines comprises a rotor assembly and a stator assembly. The rotor assembly includes a rotor yoke component and a plurality of rotor teeth components. The rotor yoke component is made of non-oriented silicon steel. The rotor teeth components are made of grain-oriented silicon steel. The stator assembly includes a plurality of stator yoke components and a plurality of stator teeth components. The stator yoke components and the stator teeth components are made of grain-oriented silicon steel. Thereby, an operational efficiency of a motor applying the segmented magneto-conductive structure is enhanced.

Owner:IND TECH RES INST

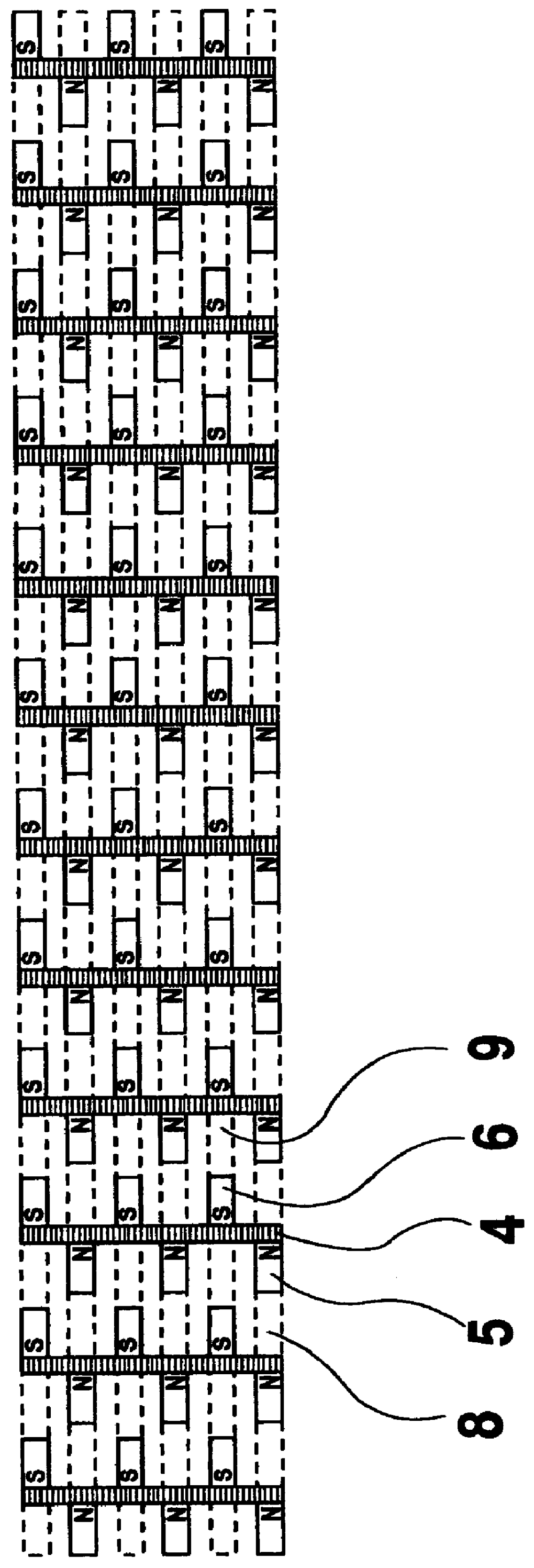

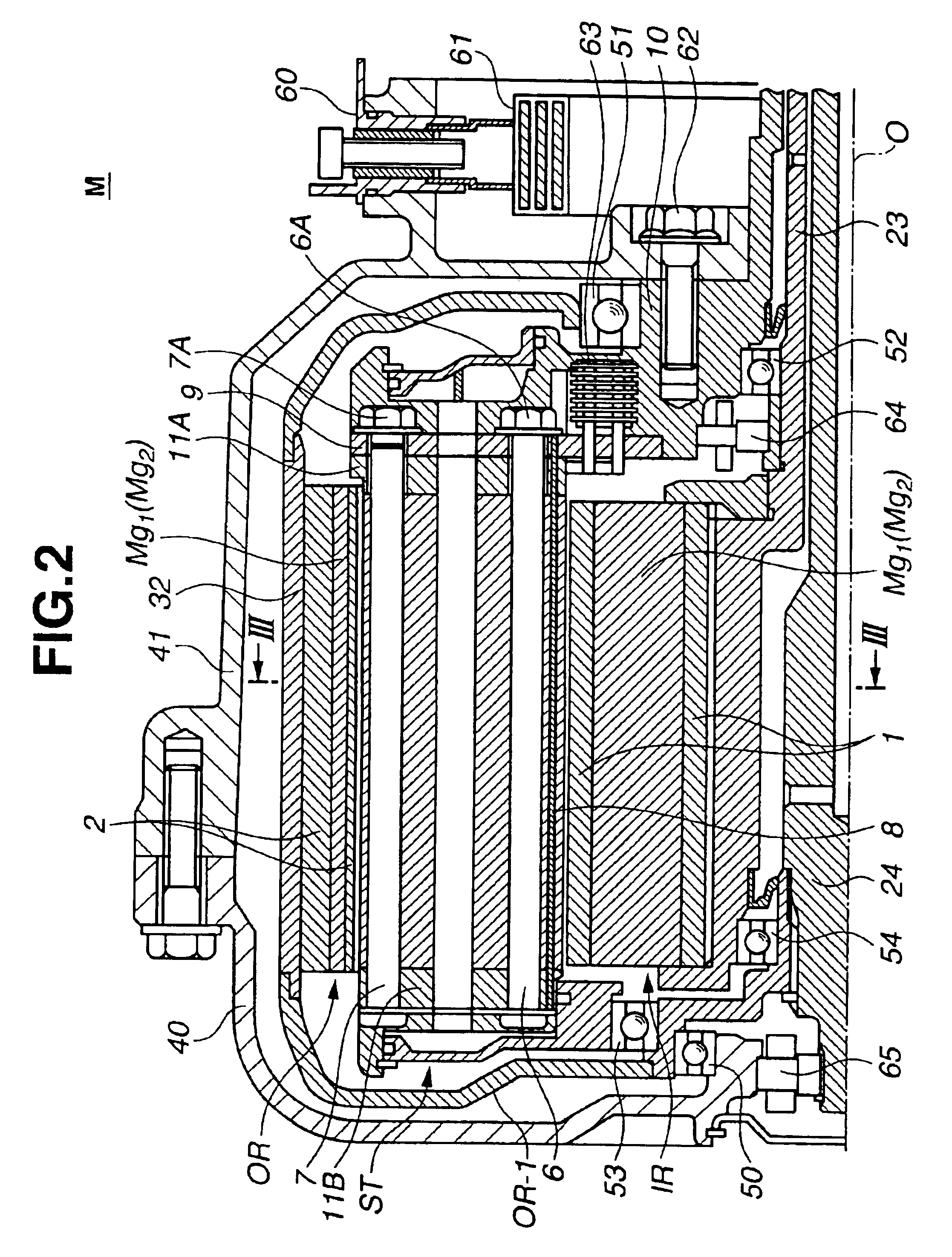

Synchronous motor with movable part having permanent magnets

The object of the present invention is to increase thrust generation of a linear motor, and to achieve miniaturization and the low price of a linear motor by improving a magnetic circuit. In order to achieve the object, the present invention provides a linear motor including a magnetic yoke for the north pole 8 which is commonly connected to the magnetic pole N of permanent magnets 4, a magnetic yoke for the south pole 9 which is commonly connected to the pole S of permanent magnets 4, a magnetic north pole 5 forming a part of magnetic yoke for the north pole 8 and being mounted on the surface of a slider 3, a magnetic south pole 6 forming a part of magnetic yoke for the south pole 9 and being mounted on the surface of a slider 3 so as to be alternately located in a traverse direction of the slider 3 with the magnetic north pole 5.

Owner:OKUMA CORP

Manufacturing method of armature, manufacturing method of motor, and armature

InactiveUS20050206264A1Improve productivitySmall sizeRotary current collectorWindingsProduction rateEngineering

The armature of a motor comprises a core constituted by assembling a plurality of split core members. Each split core member has at least two teeth. The method for manufacturing the armature comprises the steps of: winding a conductive wire on each tooth of each split core member to form a first coil on the teeth; spanning the conductive wire extending from a winding finishing end of the first coil from each tooth to the other tooth; winding the conductive wire on the tooth to which the conductive wire is spanned to form a second coil on the first coil; joining a winding starting end of the first coil and a winding finishing end of the second coil in each tooth to form a single coil; and mutually assembling the plurality of split core members each comprising the coils. As a result, productivity is improved, while reducing size.

Owner:ASMO CO LTD

Methods and apparatus for increasing power of permanent magnet motors

InactiveUS6472784B2Synchronous motors startersAsynchronous induction motorsMotor speedPermanent magnet motor

A method of increasing the power output of existing permanent magnet motors along with apparatus is disclosed. Increased power output is achieved by more completely utilizing the magnetic field of motor permanent magnets during running. The apparatus is external to the motor and therefore eliminates the need for modifications to the motor itself. The method involves providing a source of power to a permanent magnet motor which is capable of demagnetizing the motor permanent magnets at stall, and reducing the power at start up to a level sufficient to prevent demagnetization. Full power to the motor is provided when the motor speed reaches a level sufficient to prevent demagnetization of the permanent magnets.

Owner:MAGNETIC MOTORS

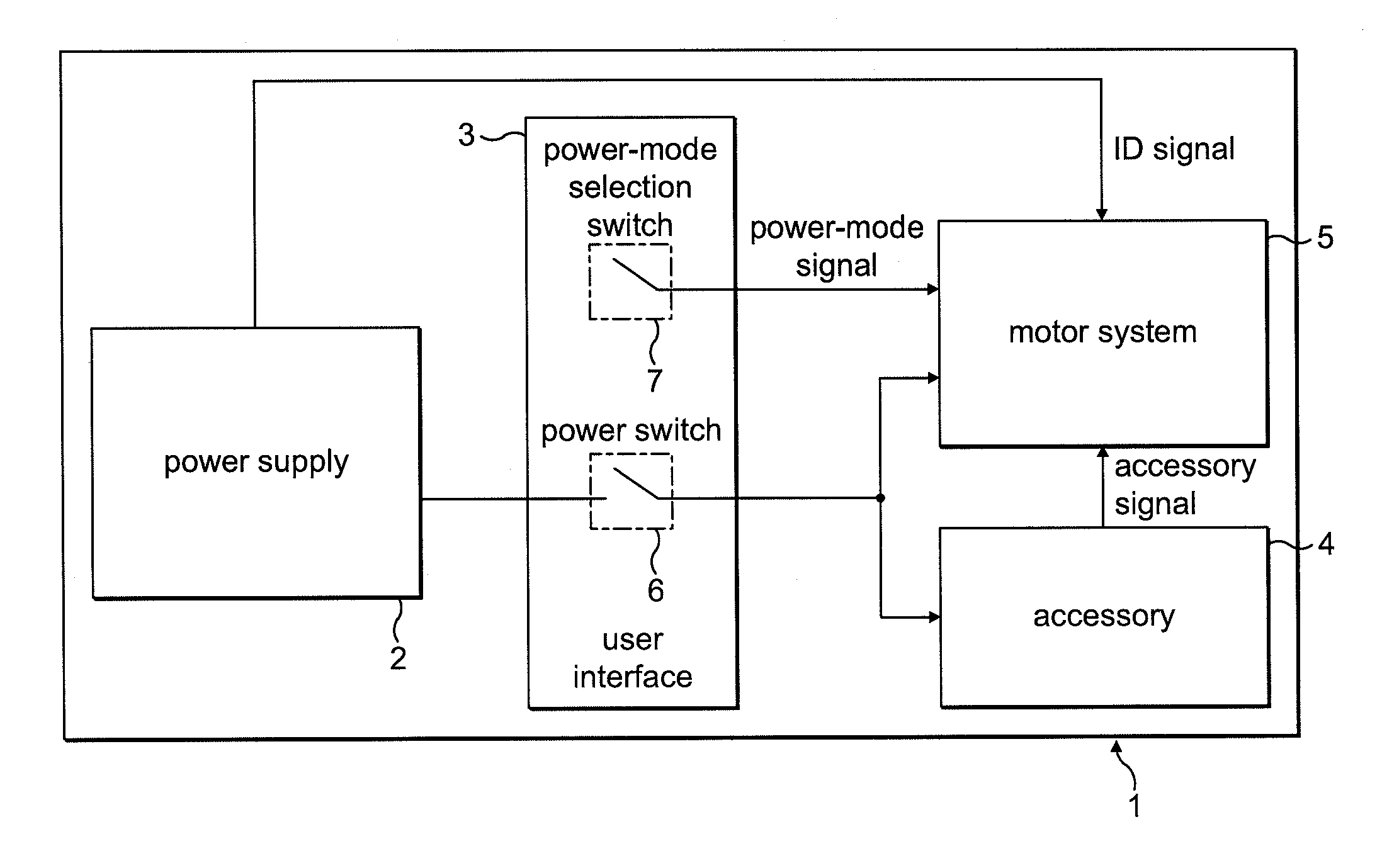

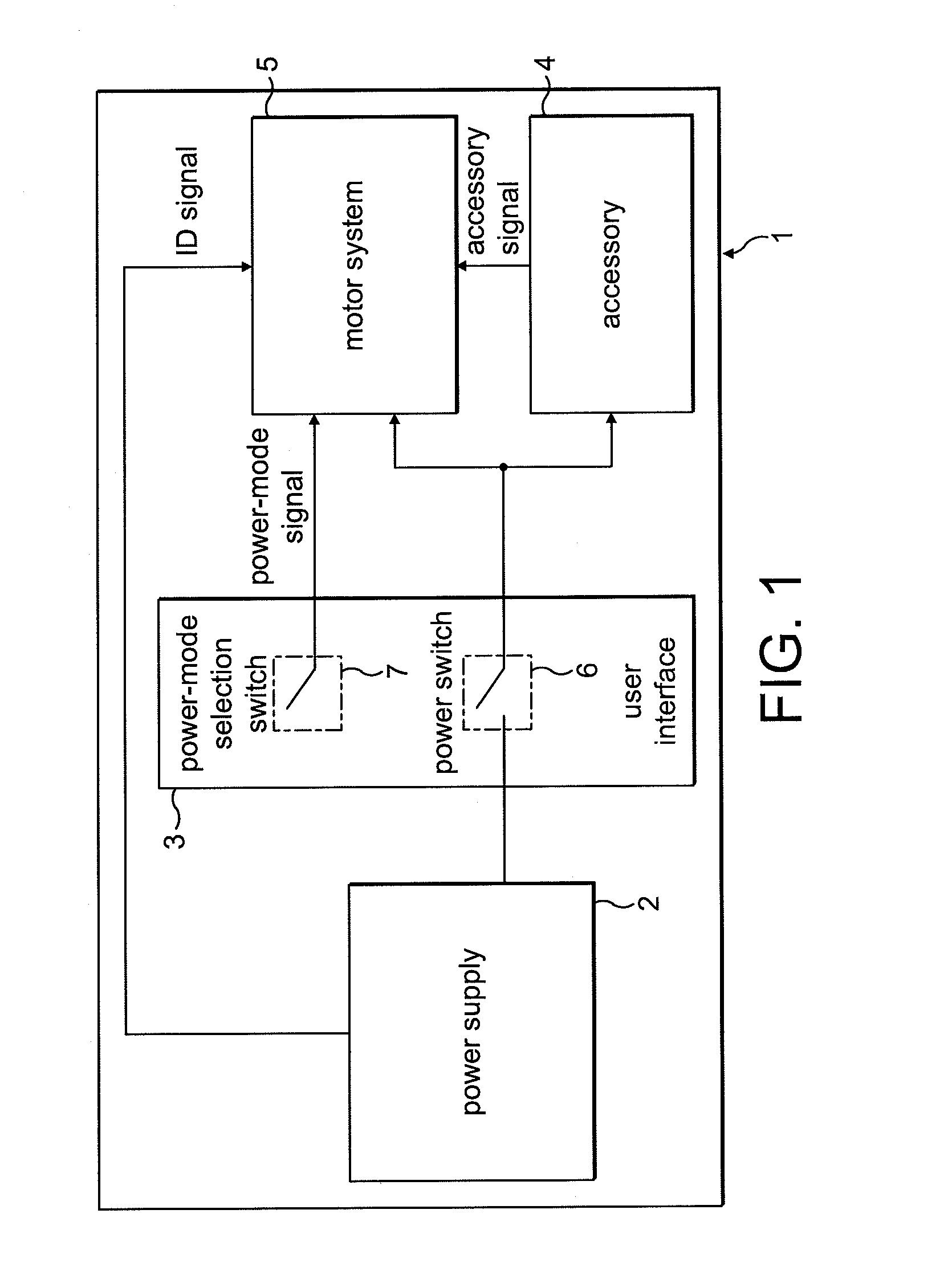

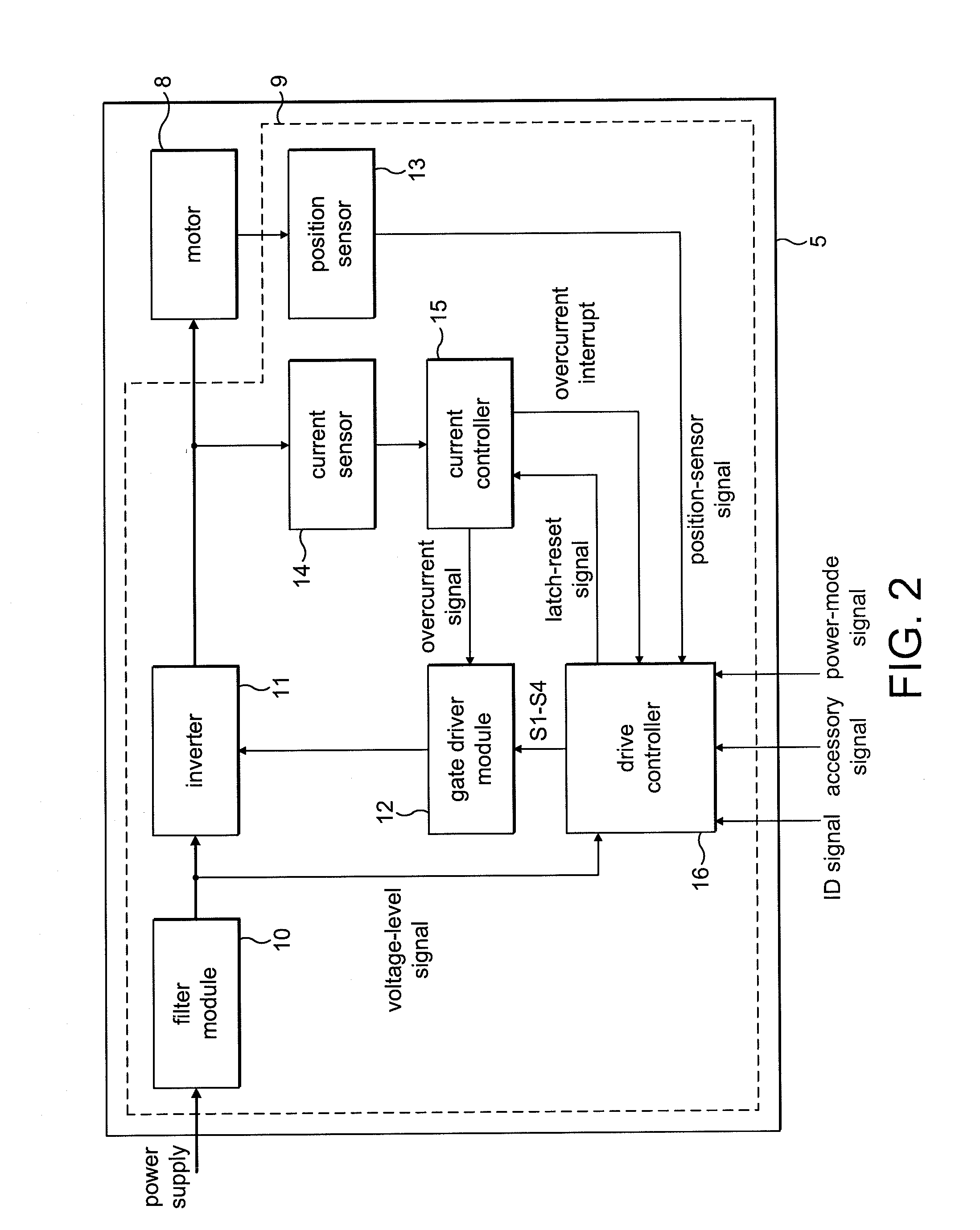

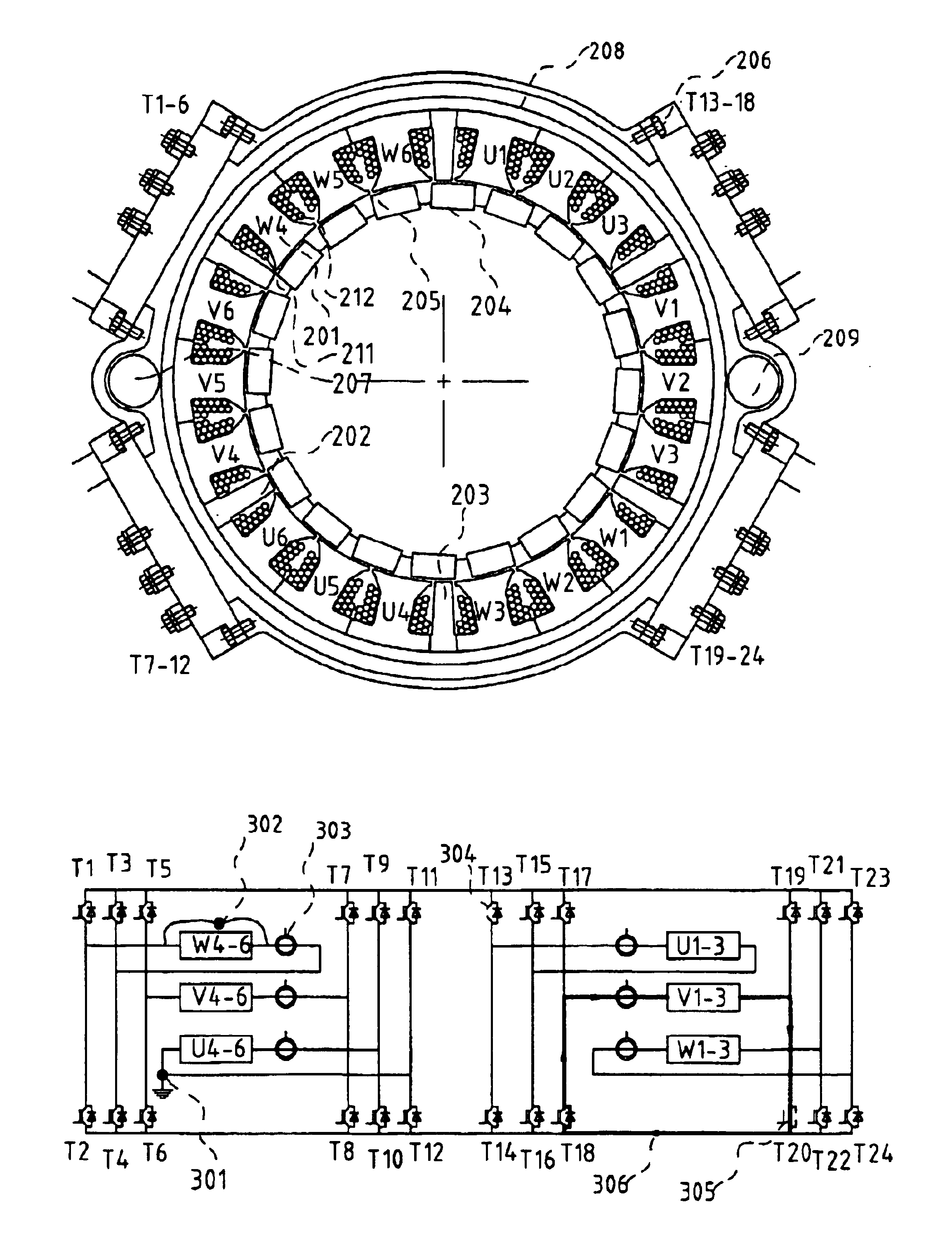

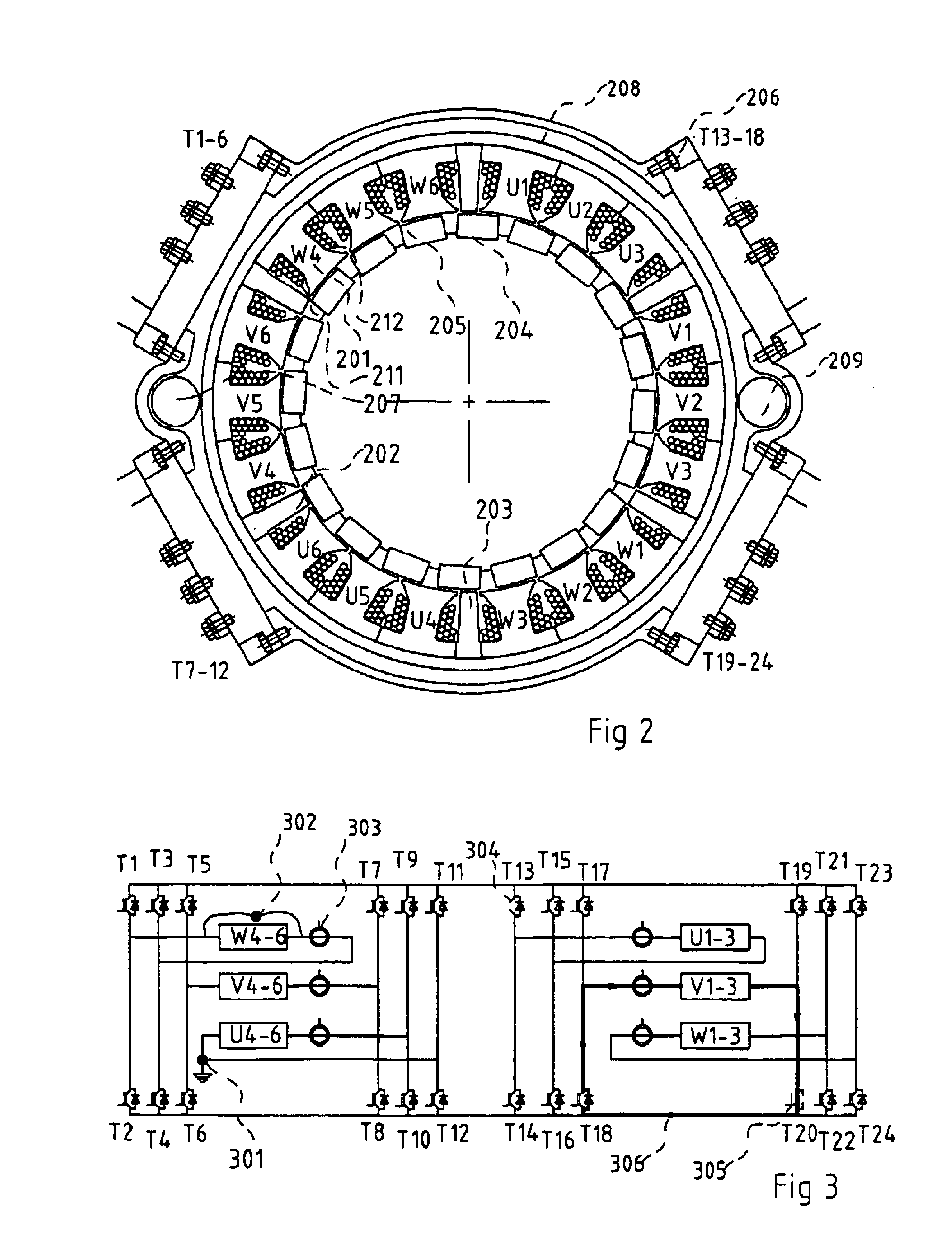

High reliability motor system

InactiveUS6885162B2Reduced risk of phase to phase shortageFull powerAC motor controlDC motor speed/torque controlElectrical conductorPower switching

A brushless electric motor system comprises a rotor and a stator comprising poles. Electrical phase windings have coils (U1-6, V1-6, W1-6) wound around the poles. Power switches (T1-24) controlled by a control device supply electric current the windings from positive and negative rails connected to power supply. For each phase at least one group of four power switches arranged in a H-bridge configuration is provided. The coils of each phase winding are preferably divided into winding group (U1-3, Ua-6, V1-3, V4-6, W1-3, W4-6) and the electric conductor of each winding group is then electrically conductor of the other winding groups. Then four power switches arranged in an H-configuration is provided for each winding group. The use of power switches in H-bridge configurations allows the faulty windings or winding groups to be disabled and that the rest of the windings or coils can be used for driving the rotor, this giving the motor system a high reliability. The current supplied to other windings or winding groups can then be increased to compensate for the faulty group. The coil groups can be separated from other coil groups by unwound stator poles. Current sensors (303) can sense the current in each winding group and be used to detect whether the currents are too high. The sensed currents can be used to identify fault conditions in the system so that then suitable switches can be disabled, disconnecting a faulty winding group.

Owner:STRIDSBERG LICENSING

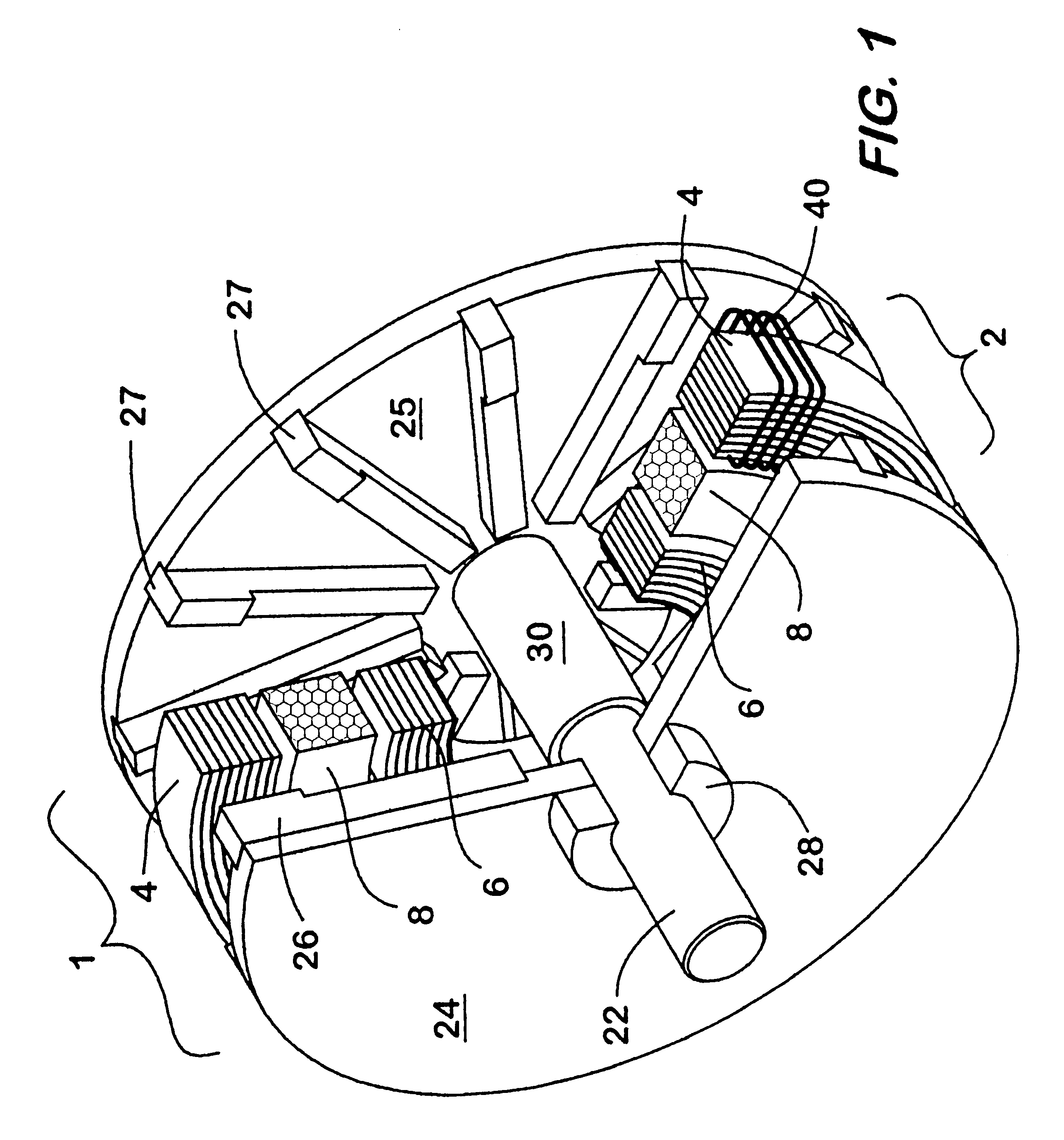

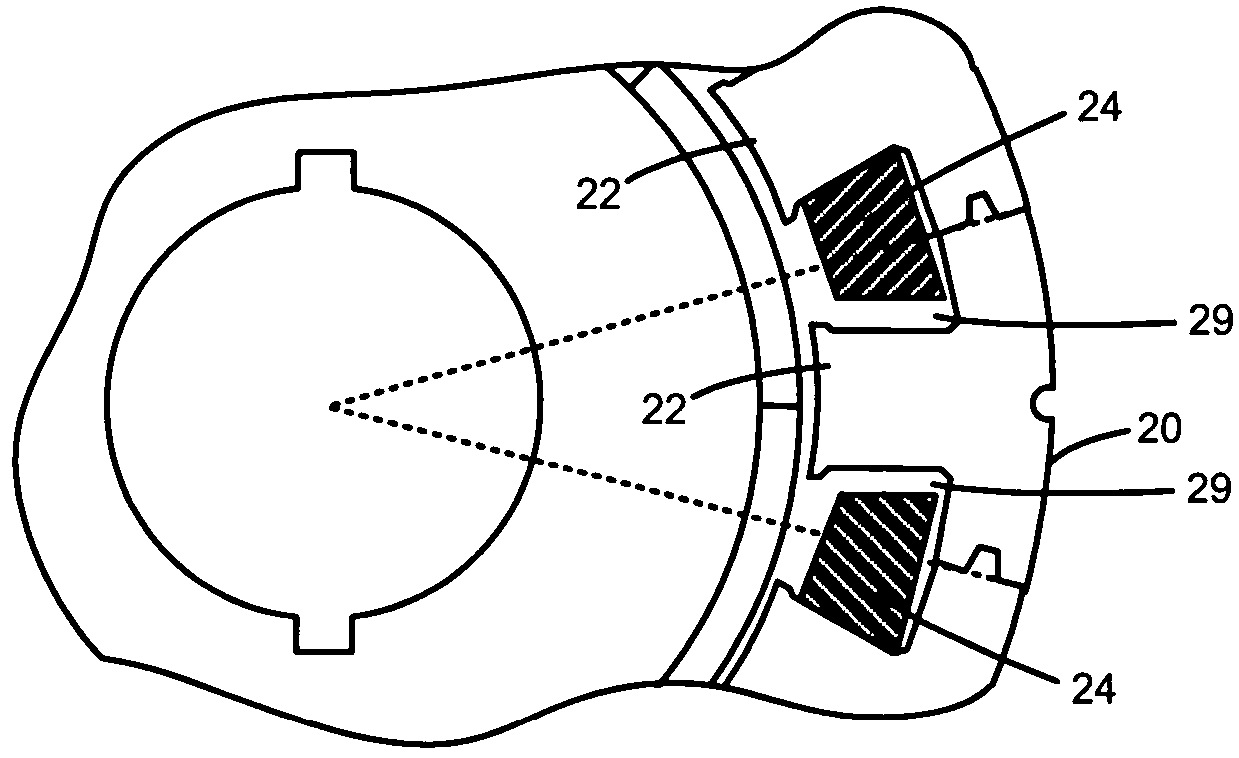

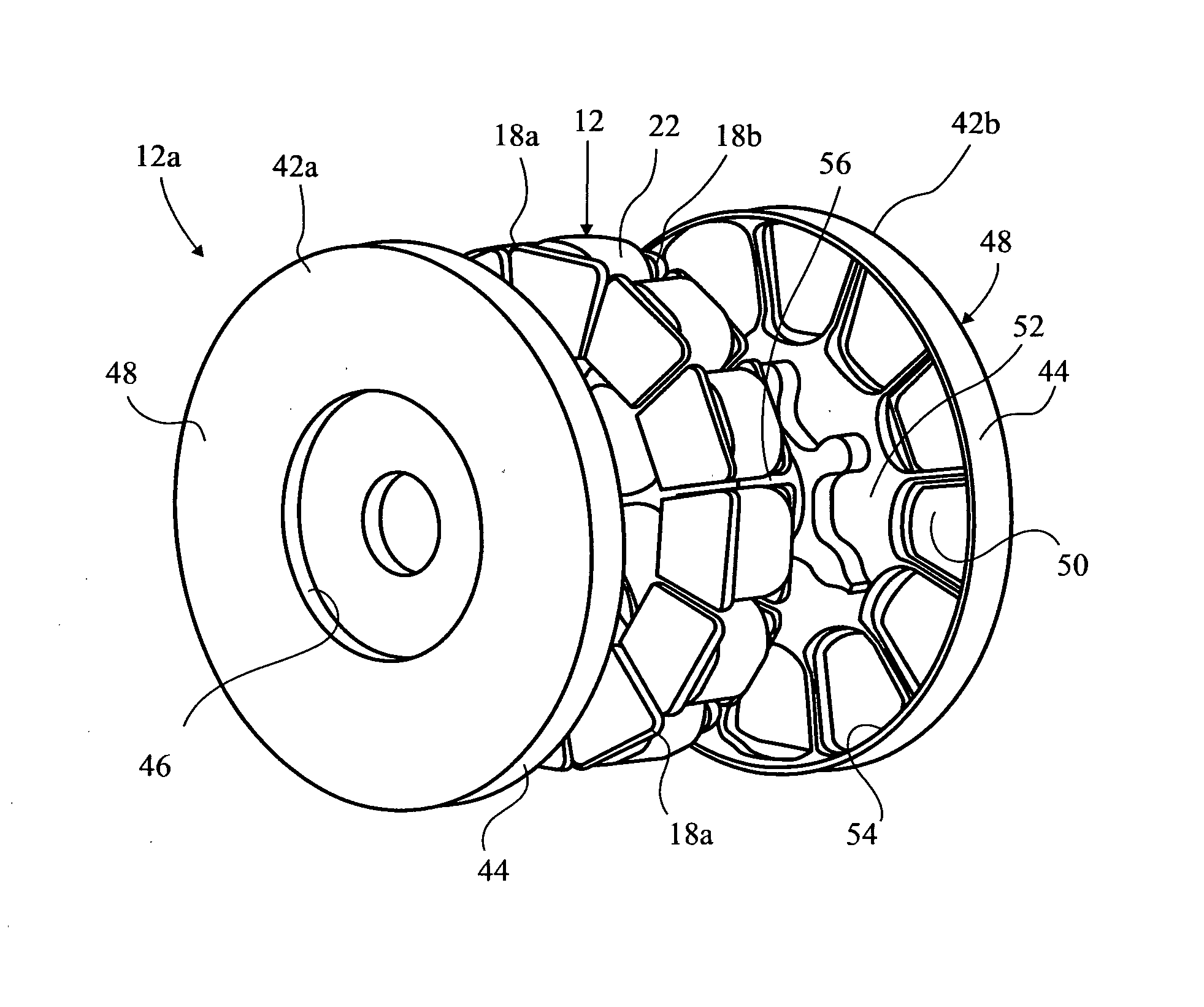

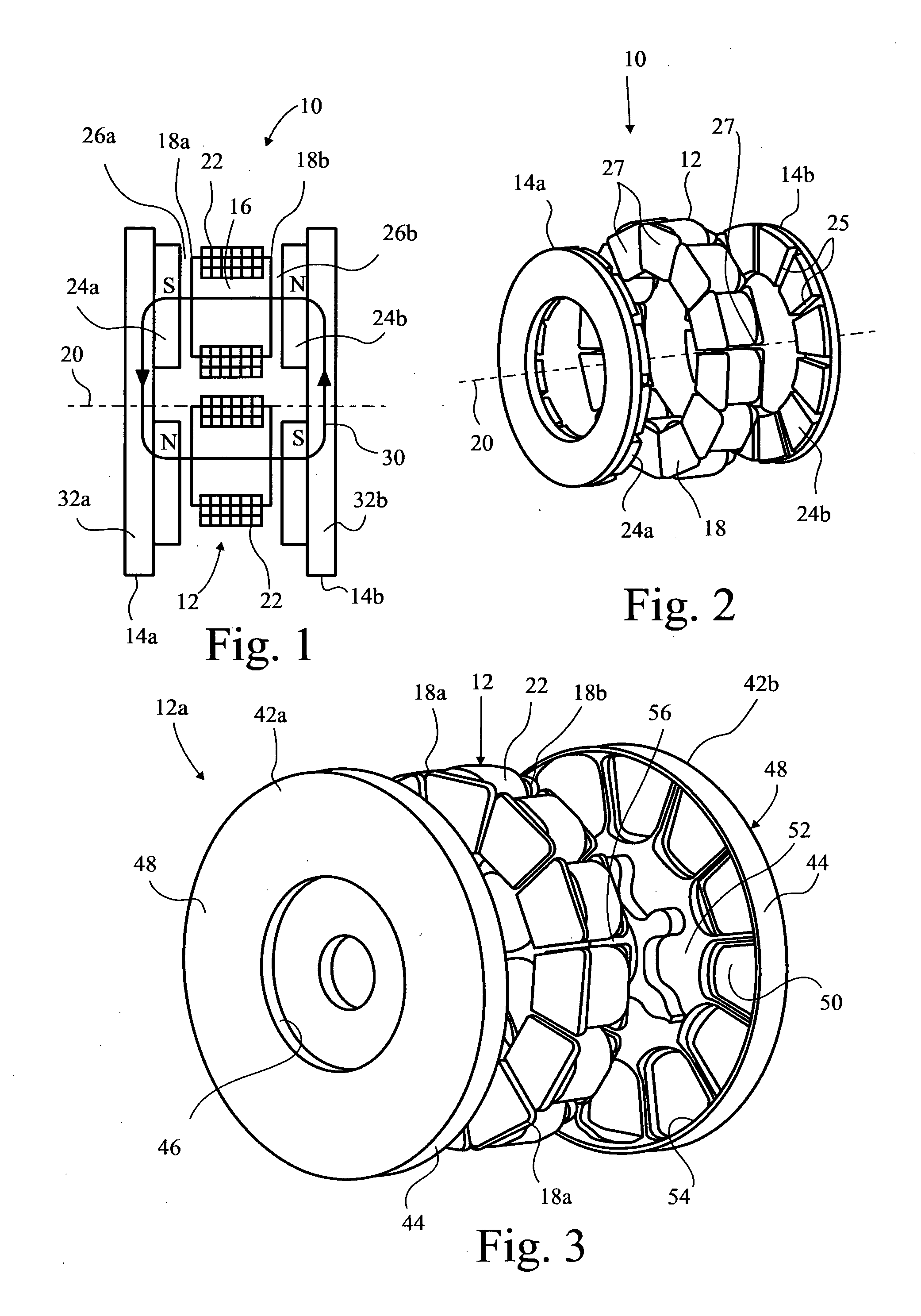

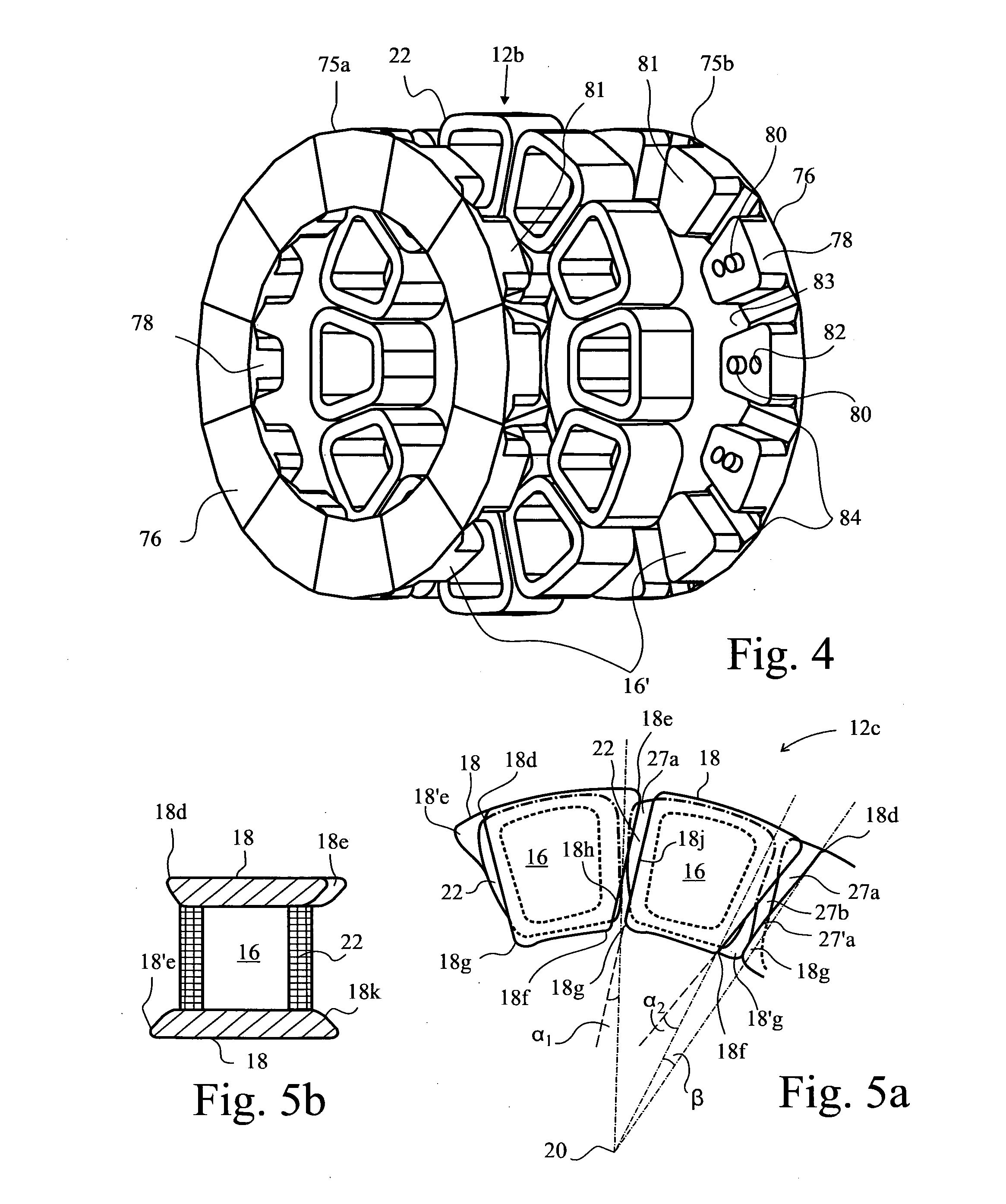

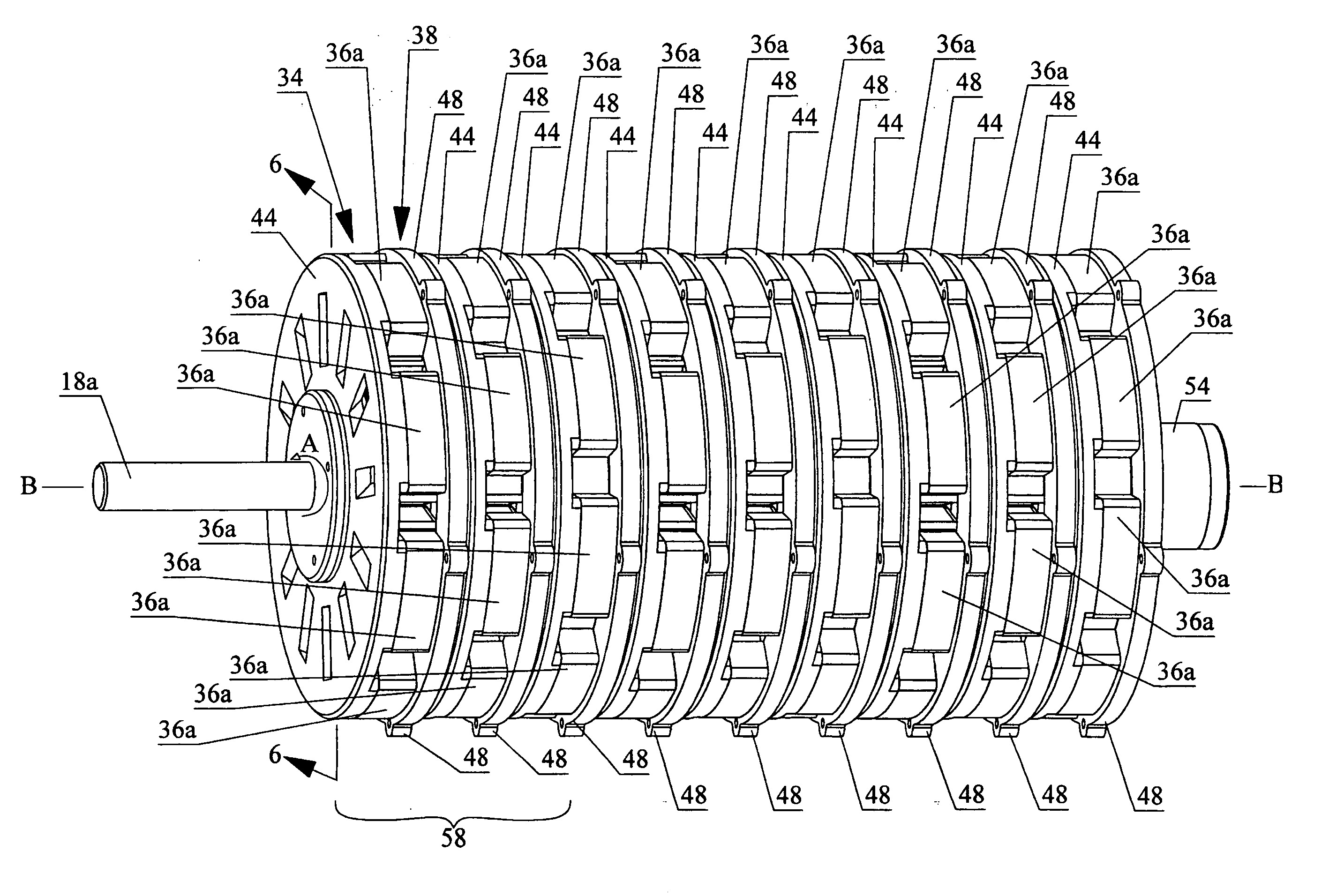

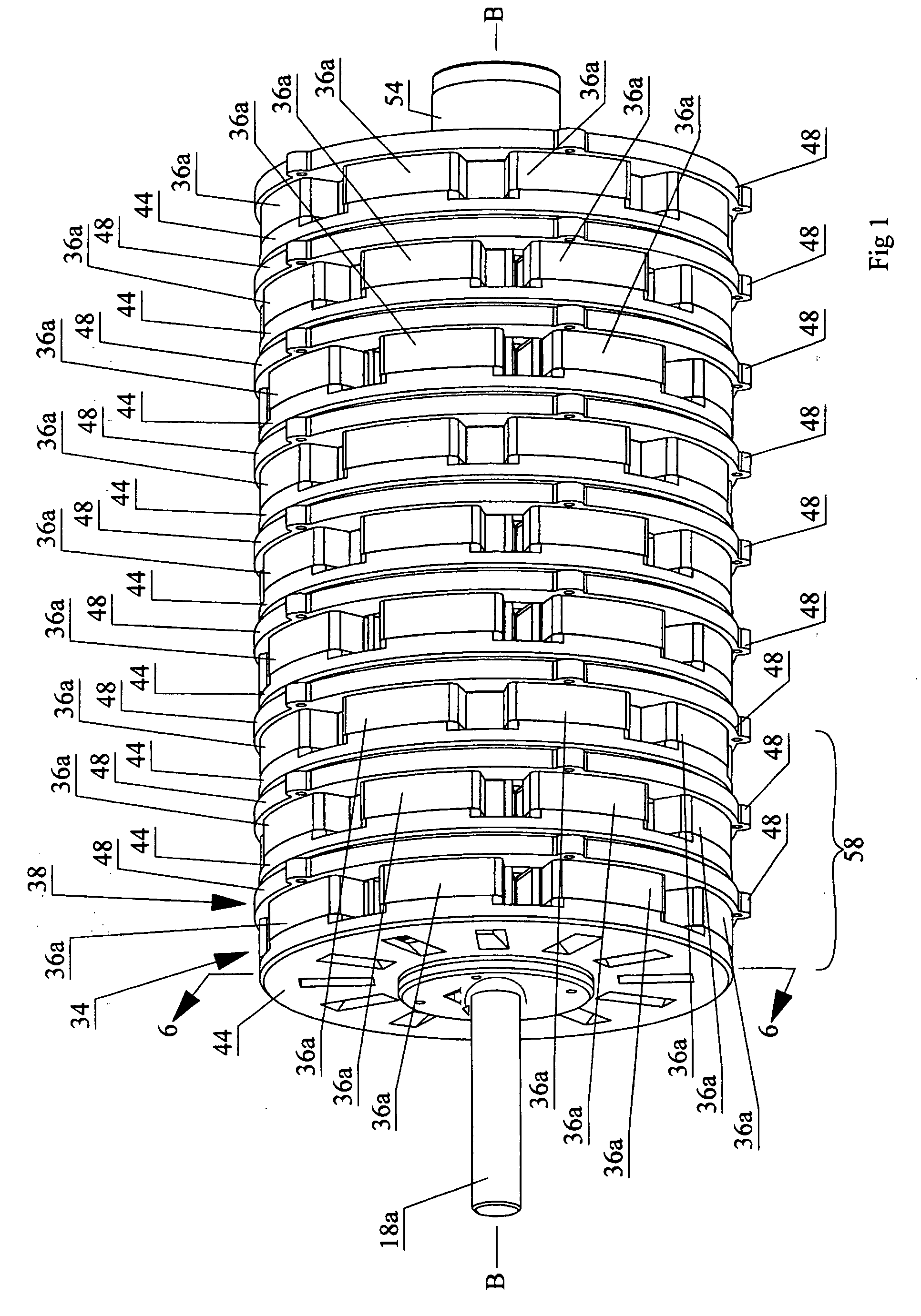

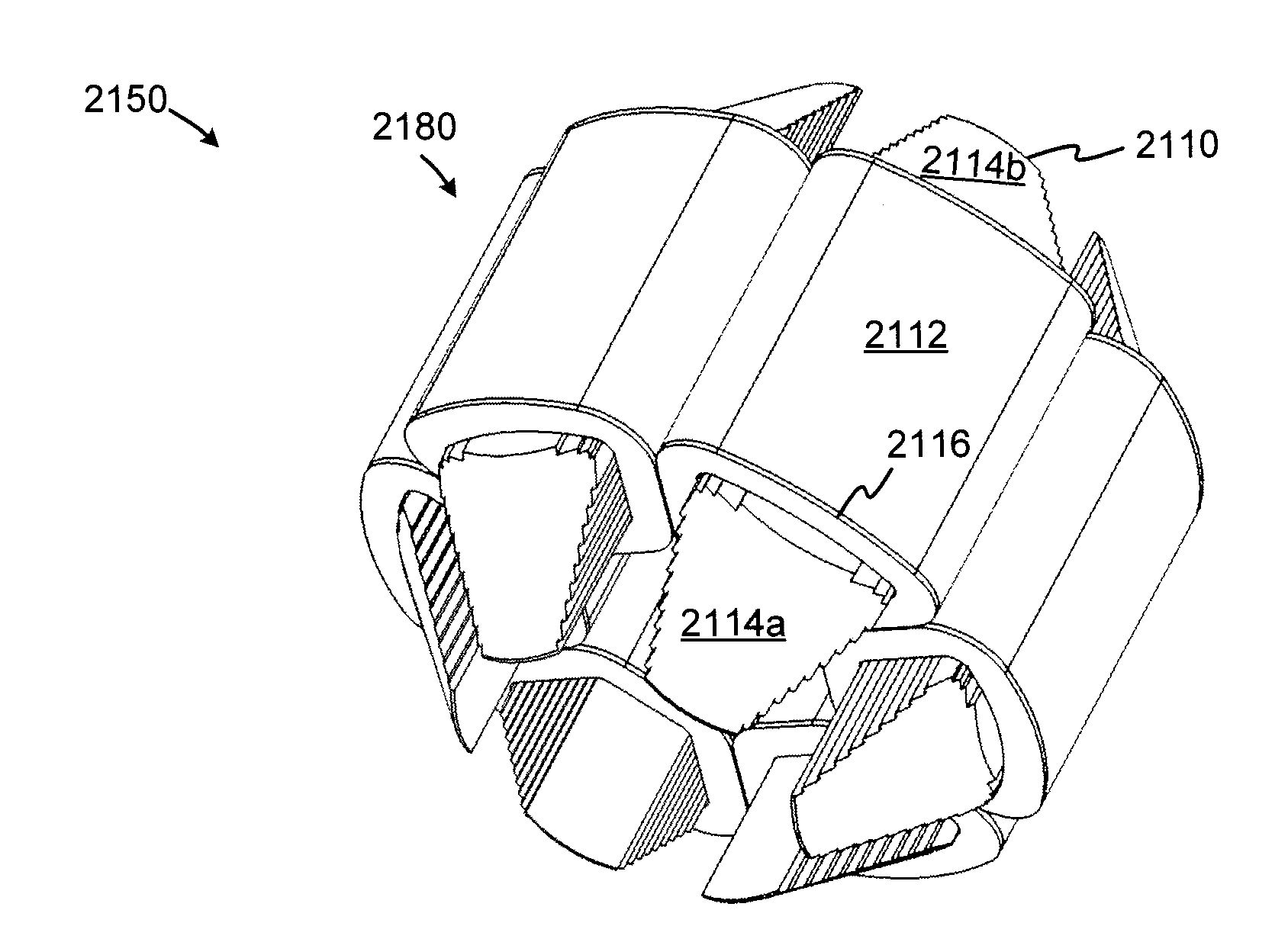

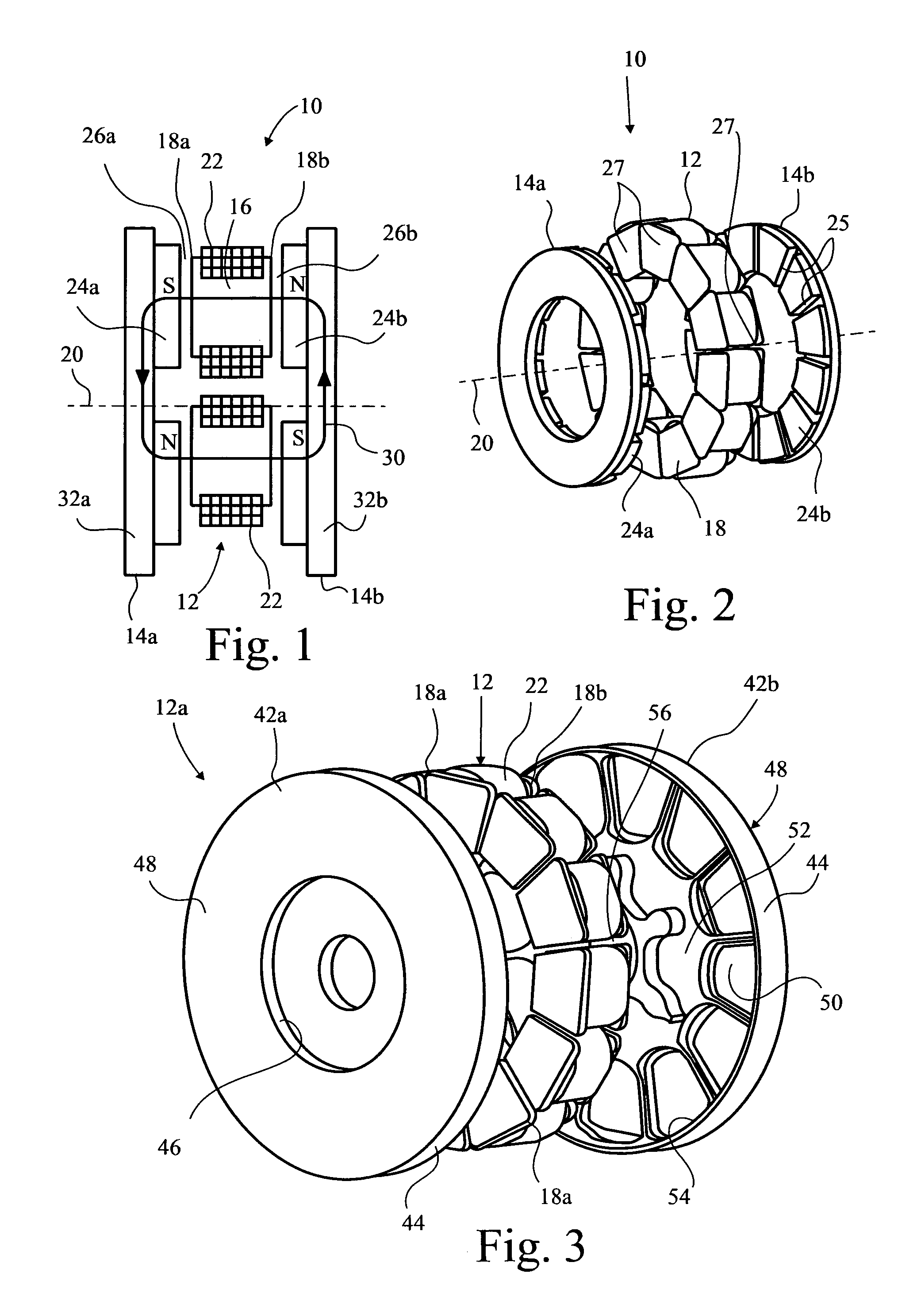

Electric machine- flux

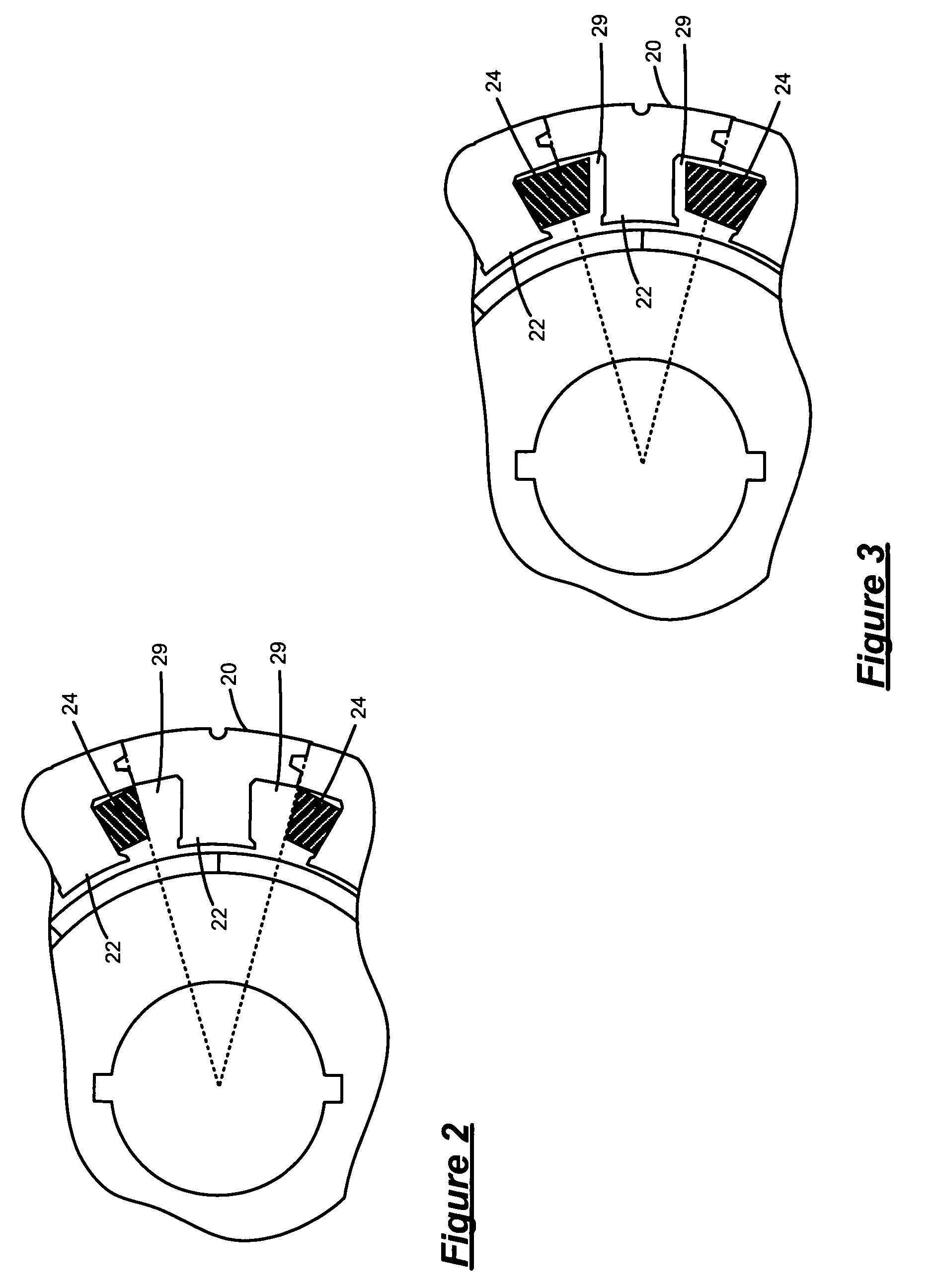

ActiveUS20110309694A1Gap minimizationIncrease the gapMagnetic circuit stationary partsSalient polesElectric machineMagnetic reluctance

An electric machine (10; 100) comprises a rotor (14) having permanent magnets (24) and a stator (12) having coils (22) wound on stator bars (16) for interaction with the magnets across an air gap (26a, b) defined between them. The rotor has two stages (14a, b) arranged one at either end of the bars. The bars have a shoe (18a, 8) at each end of each bar that links magnetic flux through the bars with said magnets on each stage. Adjacent shoes facing the same stage of the rotor have a high-reluctance shoe gap (27) between them; adjacent magnets on each stage of the rotor have a high-reluctance magnet gap (25) between them; and the shoe and magnet gaps (25, 27) are angled with respect to each other such that they engage progressively as the rotor rotates. Alternatively, the shoes facing each stage are in a ring of connected shoes such that the magnets experience a continuous reluctance that is at least 90% constant as a function of rotor position. The bars (16) and shoes (18) are formed separately from one another and at least a part of each is formed by moulding soft-iron particles so that the particles have a short dimension that is arranged transverse a reluctance-plane. The bars and shoes are assembled so that the reluctance-plane of the bar is parallel a longitudinal axis (16a) of the bar and said reluctance-plane of the shoe is transverse said longitudinal axis.

Owner:YASA LIMITED

Methods and apparatus for increasing power of permanent magnet motors

InactiveUS20030025408A1Propulsion by batteries/cellsVehicular energy storageMotor speedPermanent magnet motor

A method of increasing the power output of existing permanent magnet motors along with apparatus is disclosed. Increased power output is achieved by more completely utilizing the magnetic field of motor permanent magnets during running. The apparatus is external to the motor and therefore eliminates the need for modifications to the motor itself. The method involves providing a source of power to a permanent magnet motor which is capable of demagnetizing the motor permanent magnets at stall, and reducing the power at start up to a level sufficient to prevent demagnetization. Full power to the motor is provided when the motor speed reaches a level sufficient to prevent demagnetization of the permanent magnets.

Owner:MAGNETIC MOTORS

Constant-power electric system

ActiveUS20100251510A1Easy to controlKeep for a long timeSynchronous motors startersSingle motor speed/torque controlConstant powerControl system

An electric system that includes a single-phase permanent-magnet electric machine and a control system for driving the electric machine. The control system sequentially excites and freewheels a winding of the electric machine so as maintain substantially constant power over an operating speed range spanning at least 10 krpm and / or an excitation voltage range extending between a minimum voltage and a maximum voltage, the minimum voltage being less than 80% of the maximum voltage. Additionally, a product comprising the electric system.

Owner:DYSON TECH LTD

Permanent magnet motor having stator poles with stepped-end-surfaces and rotor with outer-circumferential-recessed surface

ActiveUS7550891B2Magnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesPermanent magnet motor

A permanent-magnet motor including a rotor having permanent magnets disposed therein, and a stator, wherein an outer circumferential surface of the rotor is opposite to an inner circumferential surface of the stator, and one or both of the outer circumferential surface of the rotor and the inner circumferential surface of the stator are varied in a radial direction so as to provide a non-uniform gap between the two surfaces to approximate sinusoidal change in magnetic flux.

Owner:SAMSUNG ELECTRONICS CO LTD

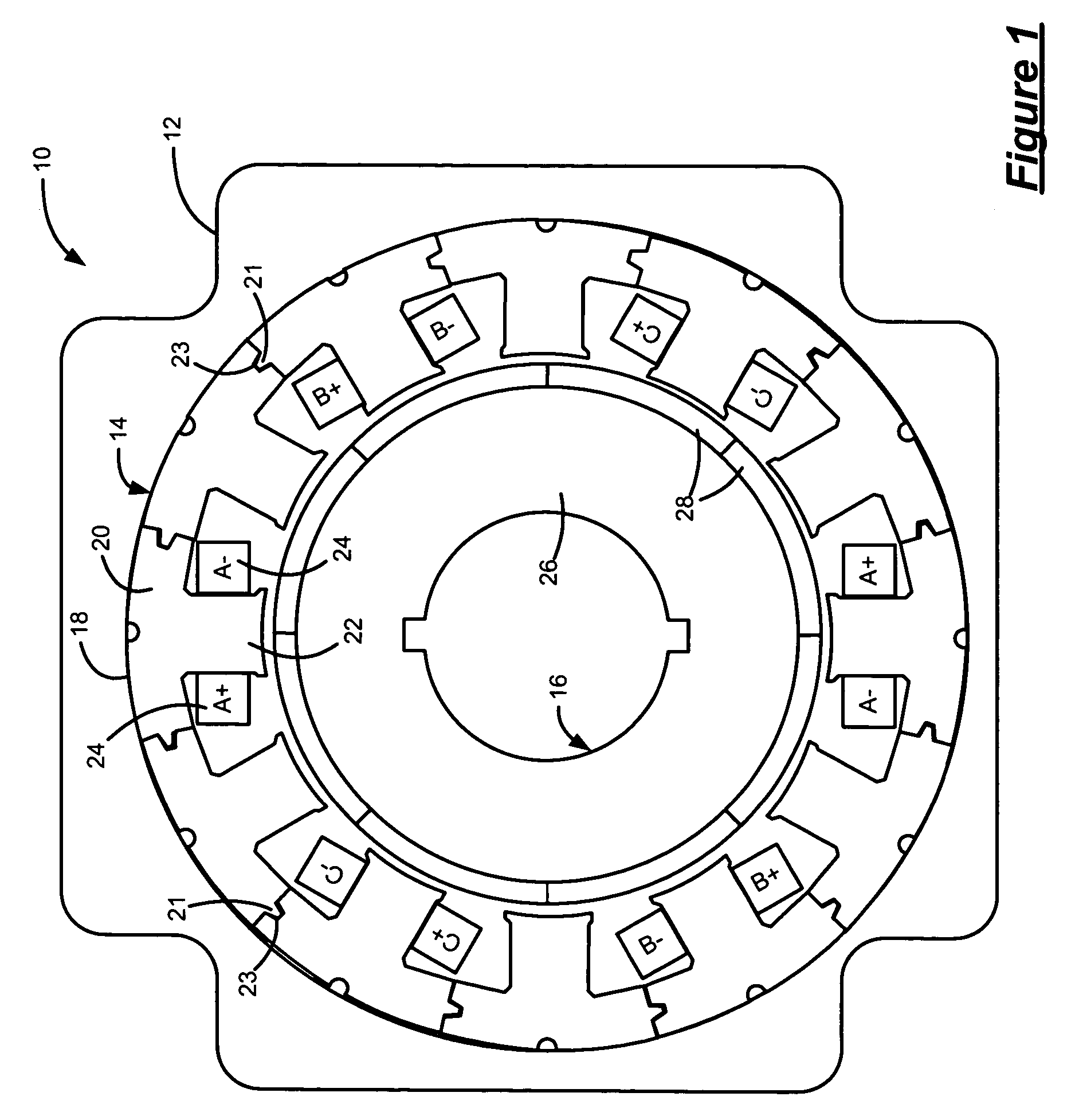

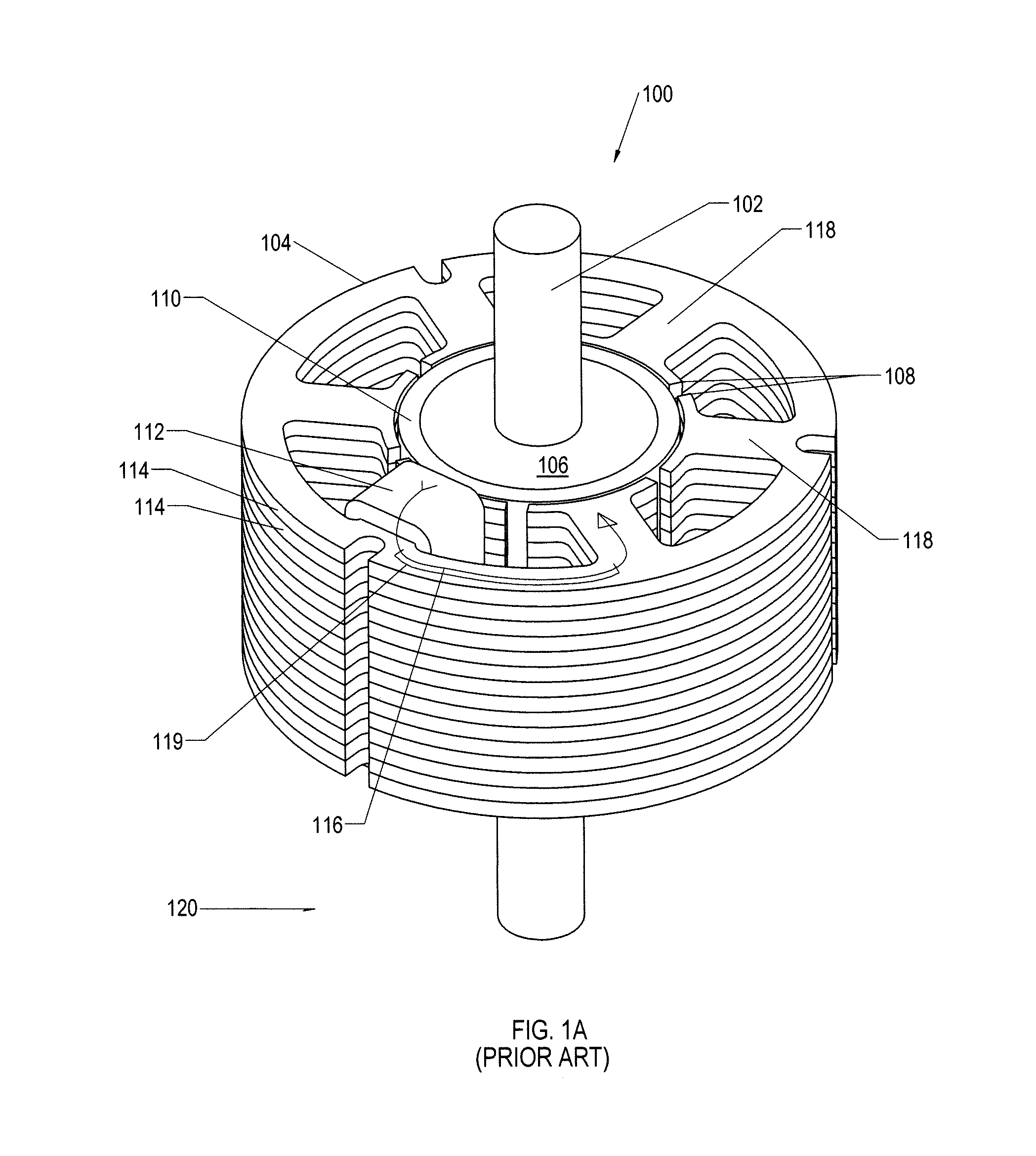

Brushless permanent magnet motor with high power density, low cogging and low vibration

InactiveUS6946760B2Other washing machinesRecord information storageElectric machinePermanent magnet motor

A brushless permanent magnet electric machine includes a stator assembly having a stator core that defines (12×n) slots and stator teeth having a generally “T”-shaped cross section. Winding wire is wound around the stator teeth, wherein a radially outer edge of the stator teeth define a crowned surface. A rotor includes permanent magnets defining (12±2)n poles, wherein n is an integer greater than zero.

Owner:NIDEC MOTOR CORP

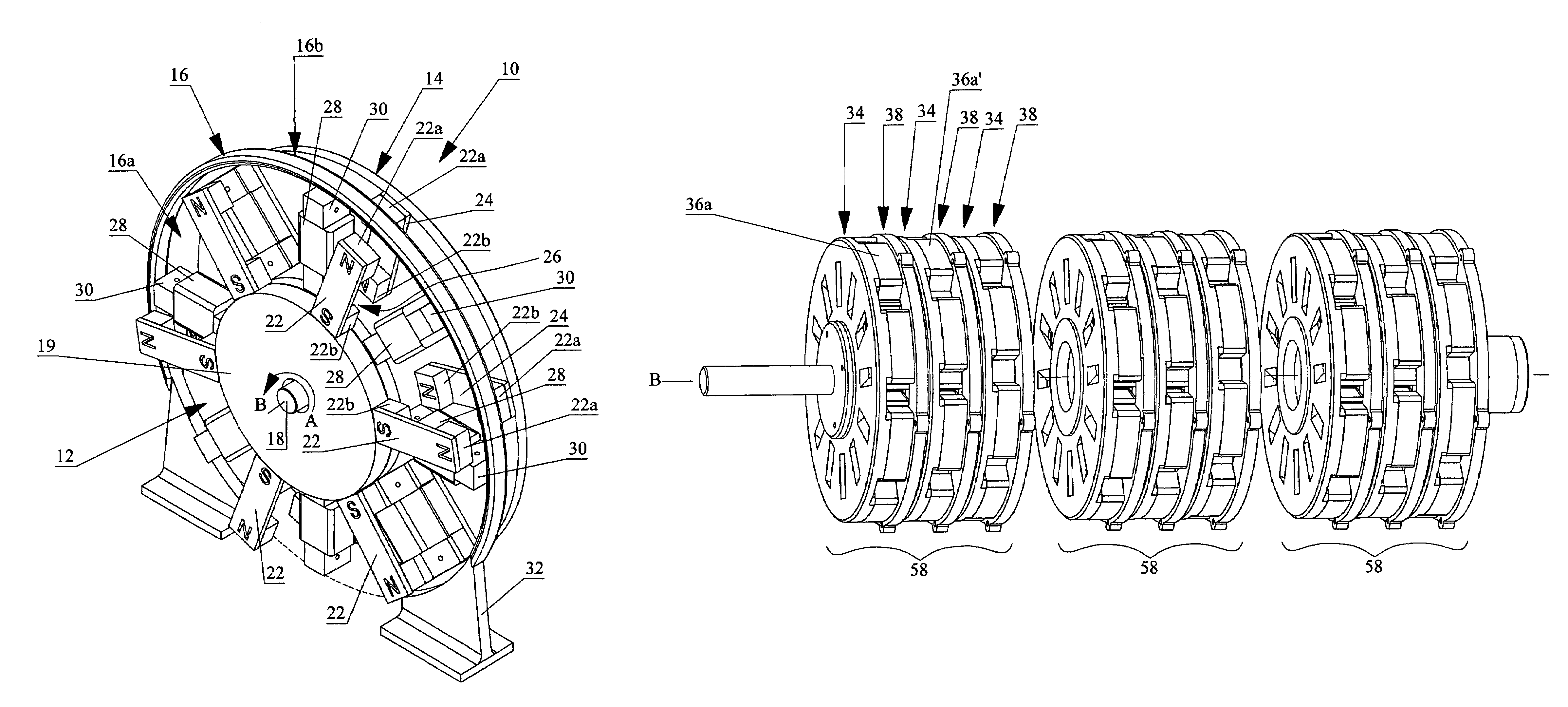

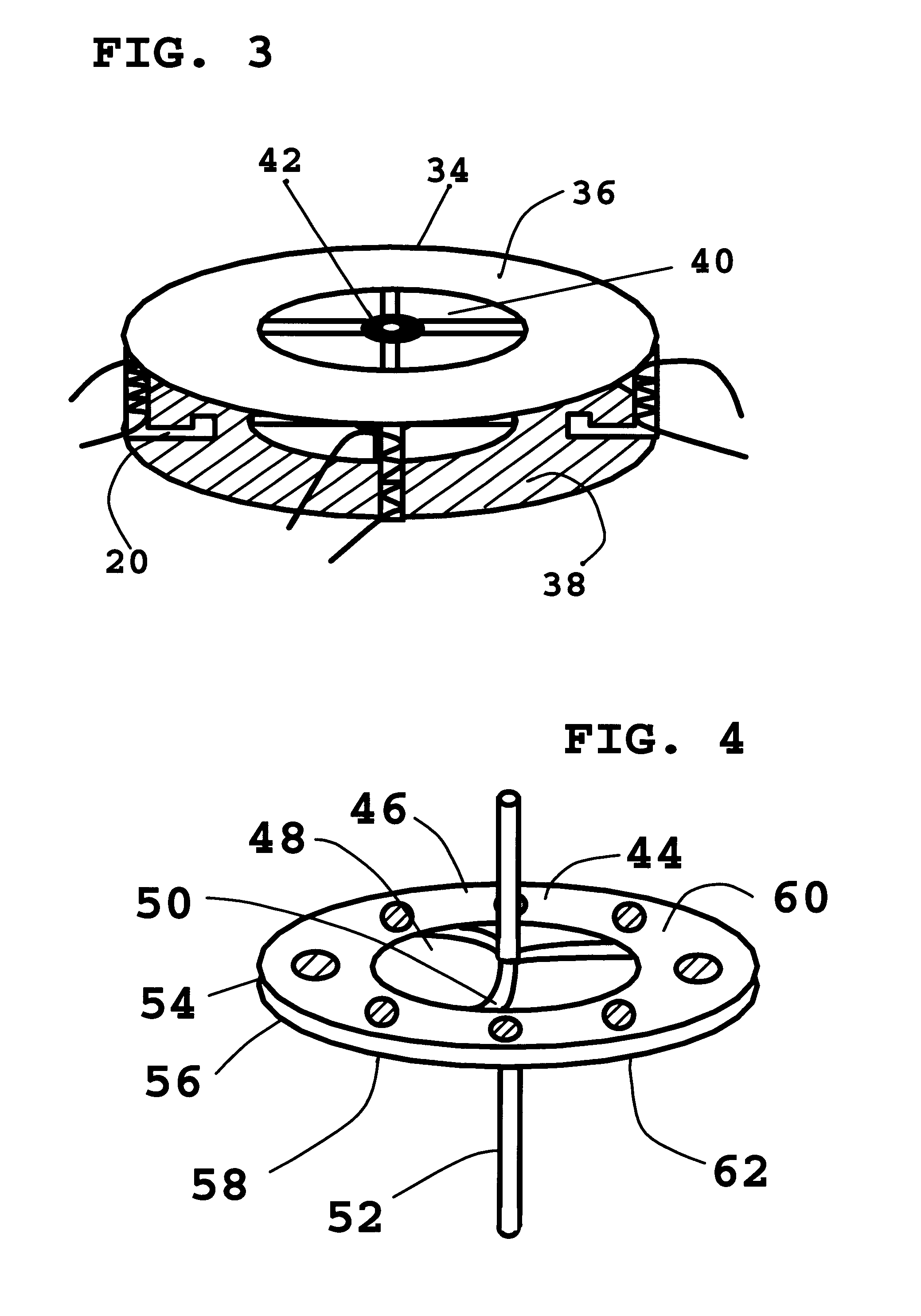

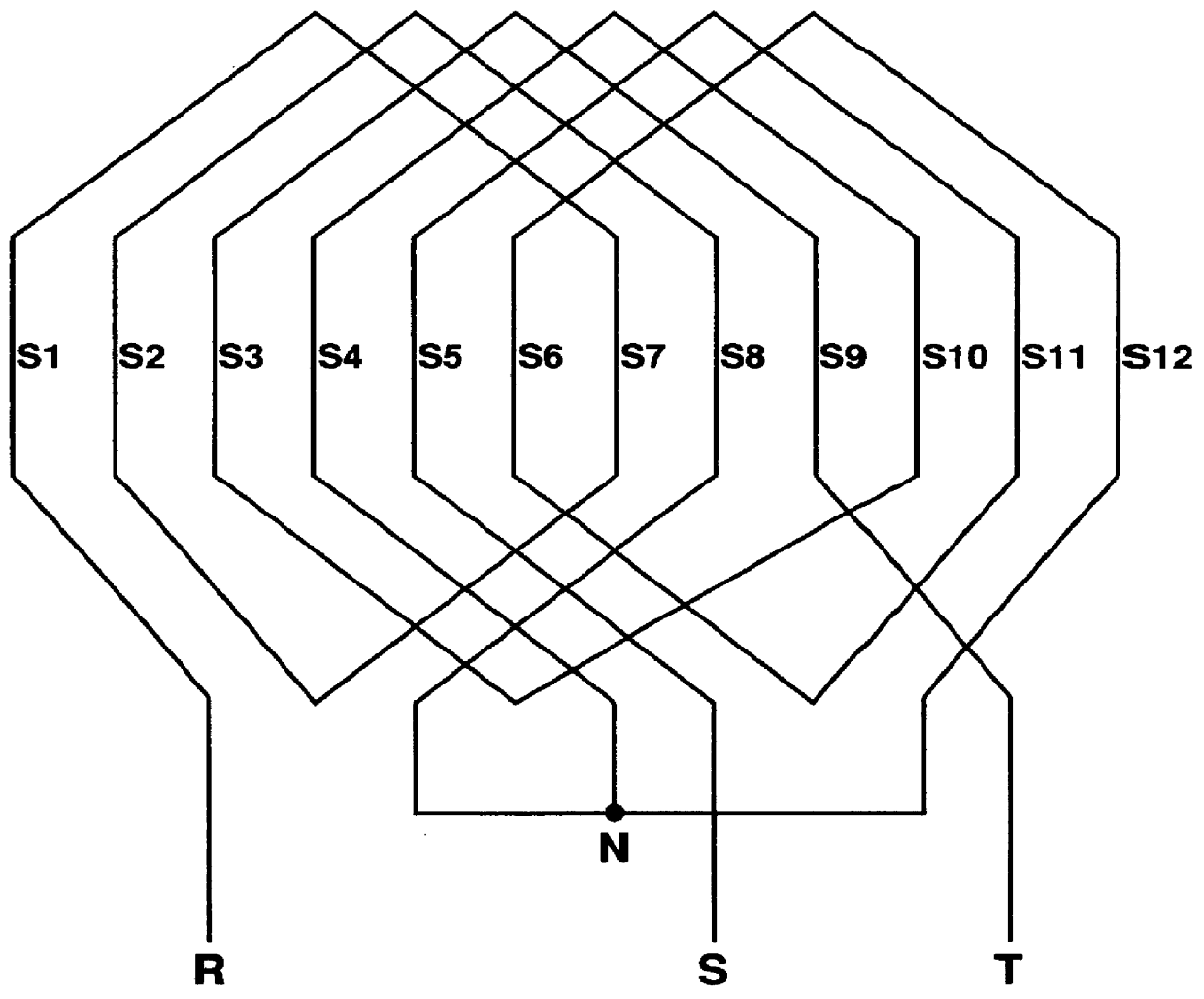

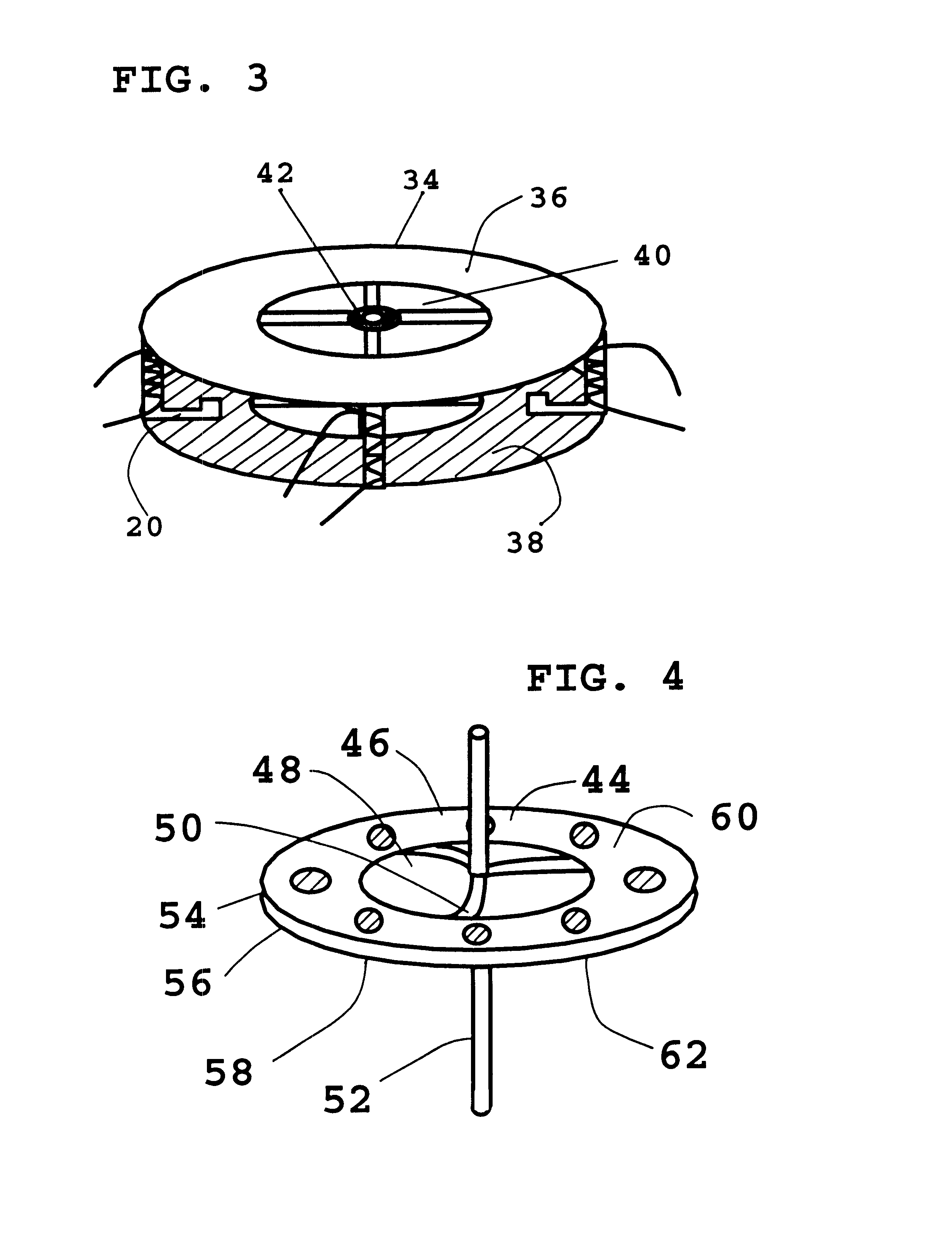

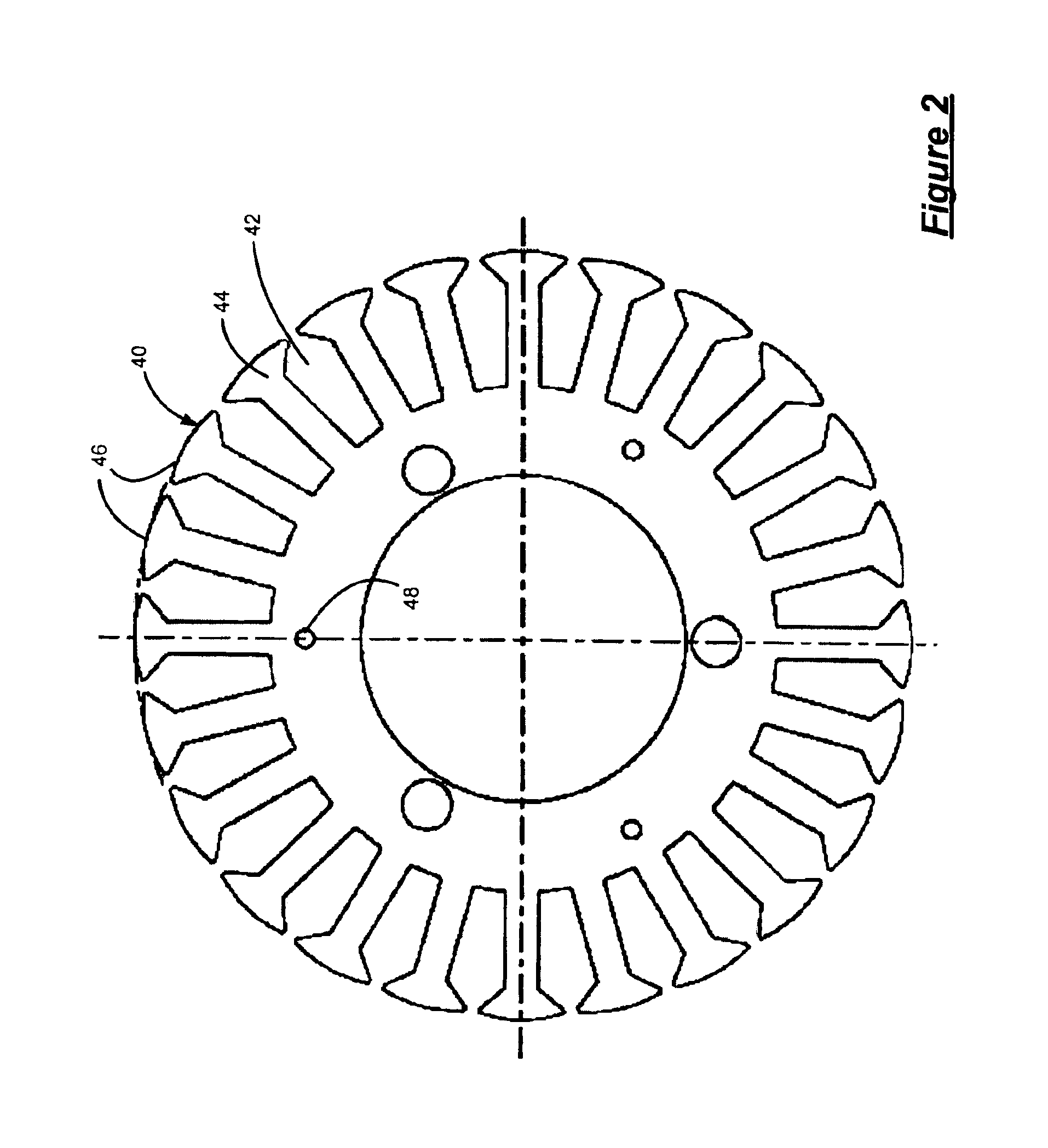

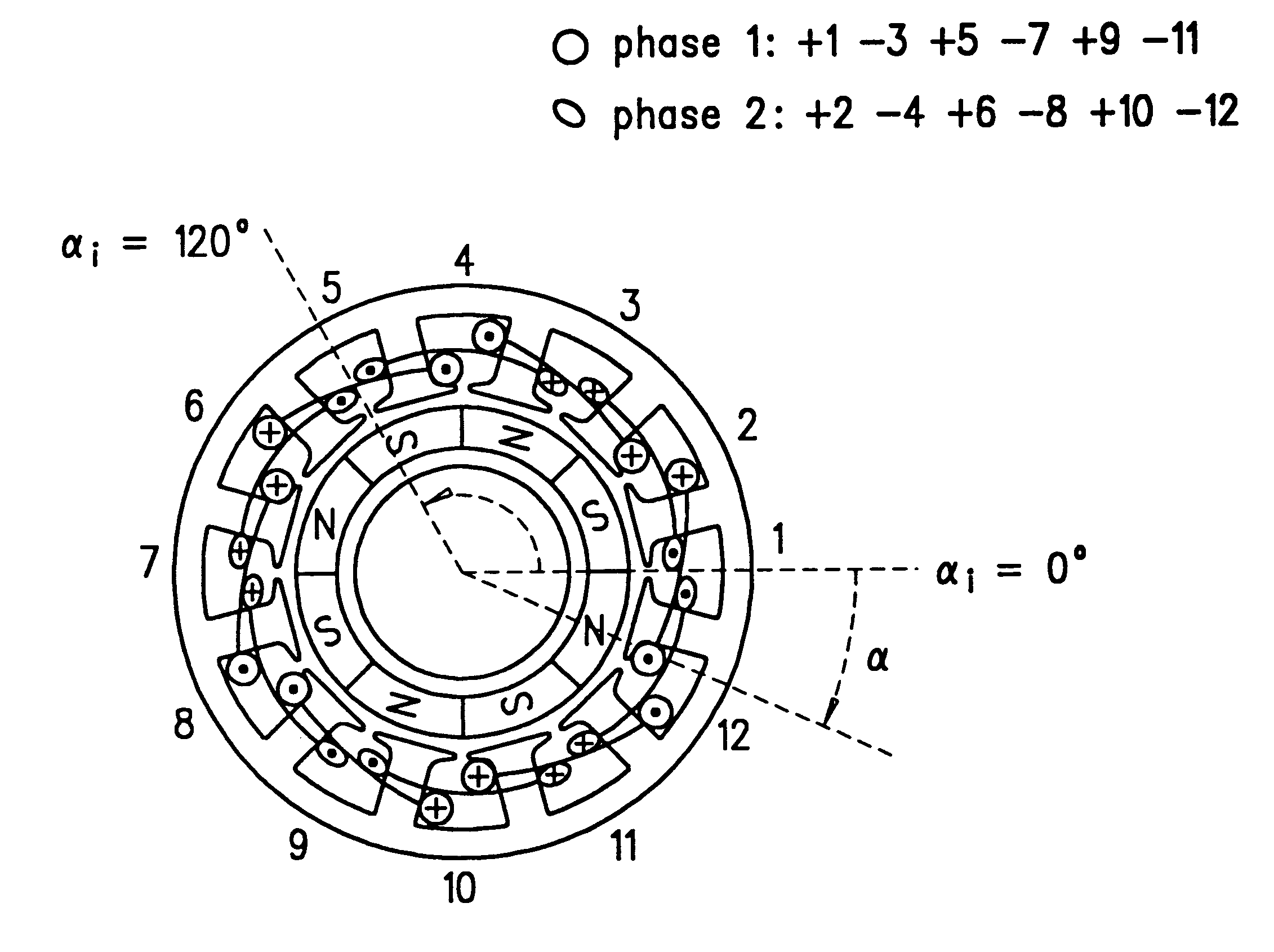

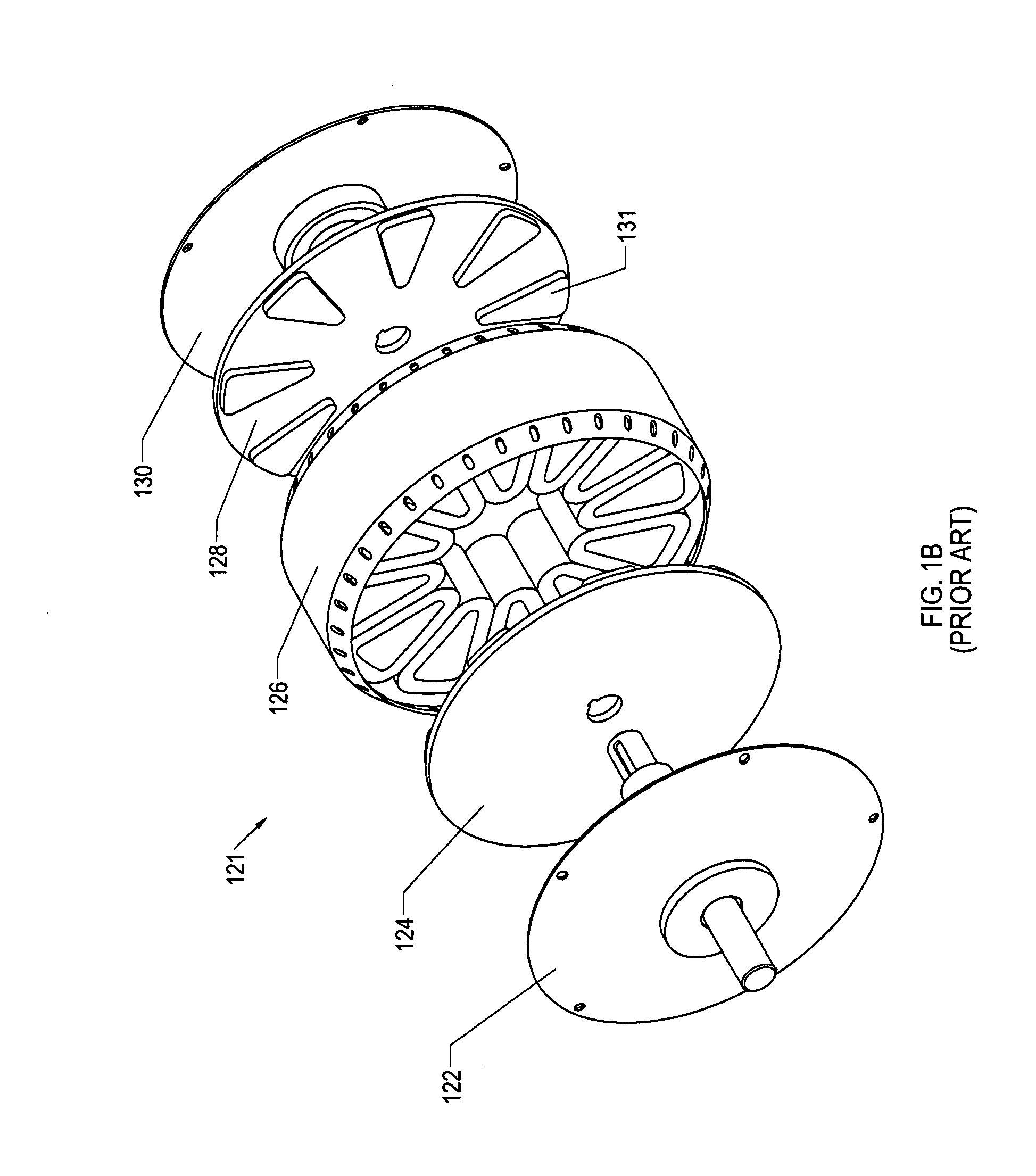

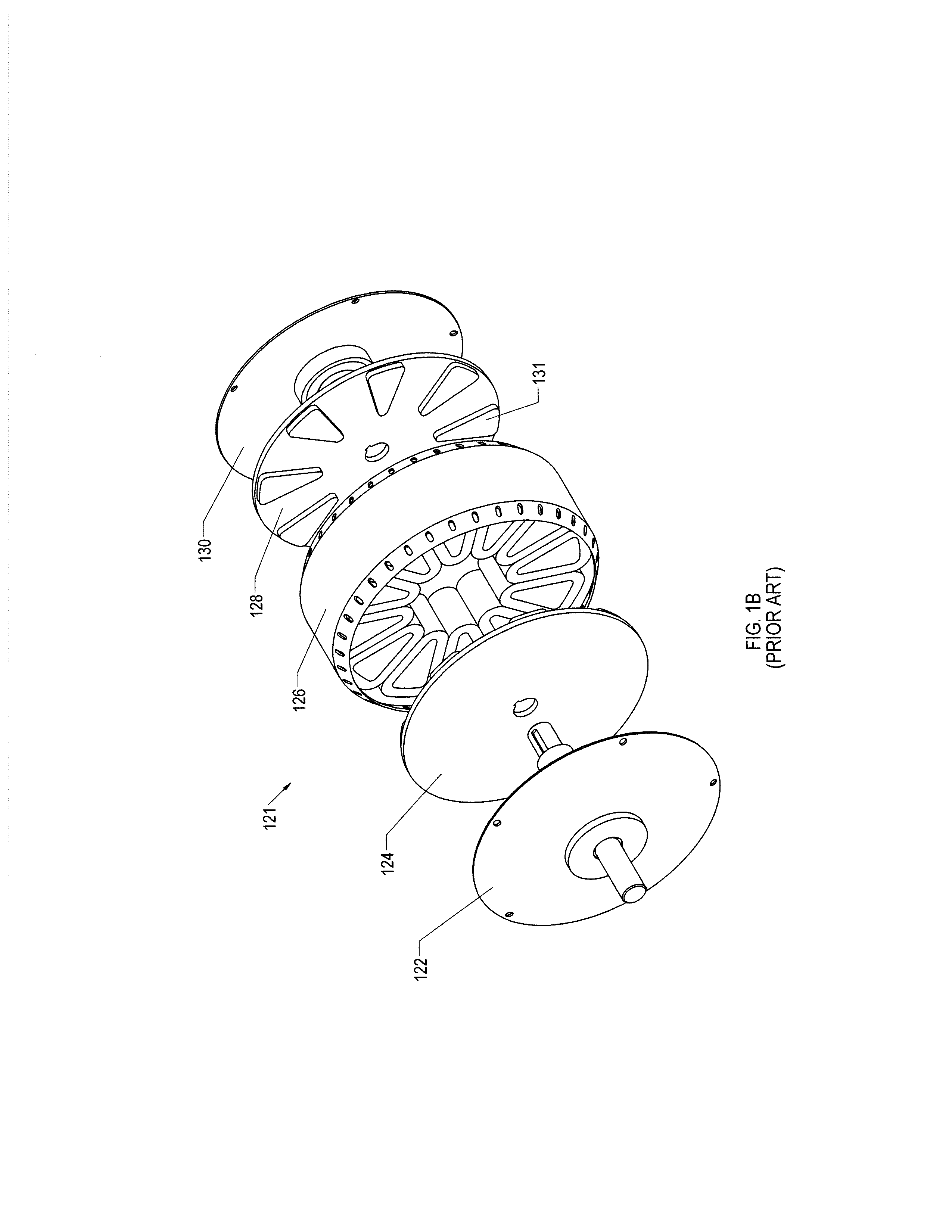

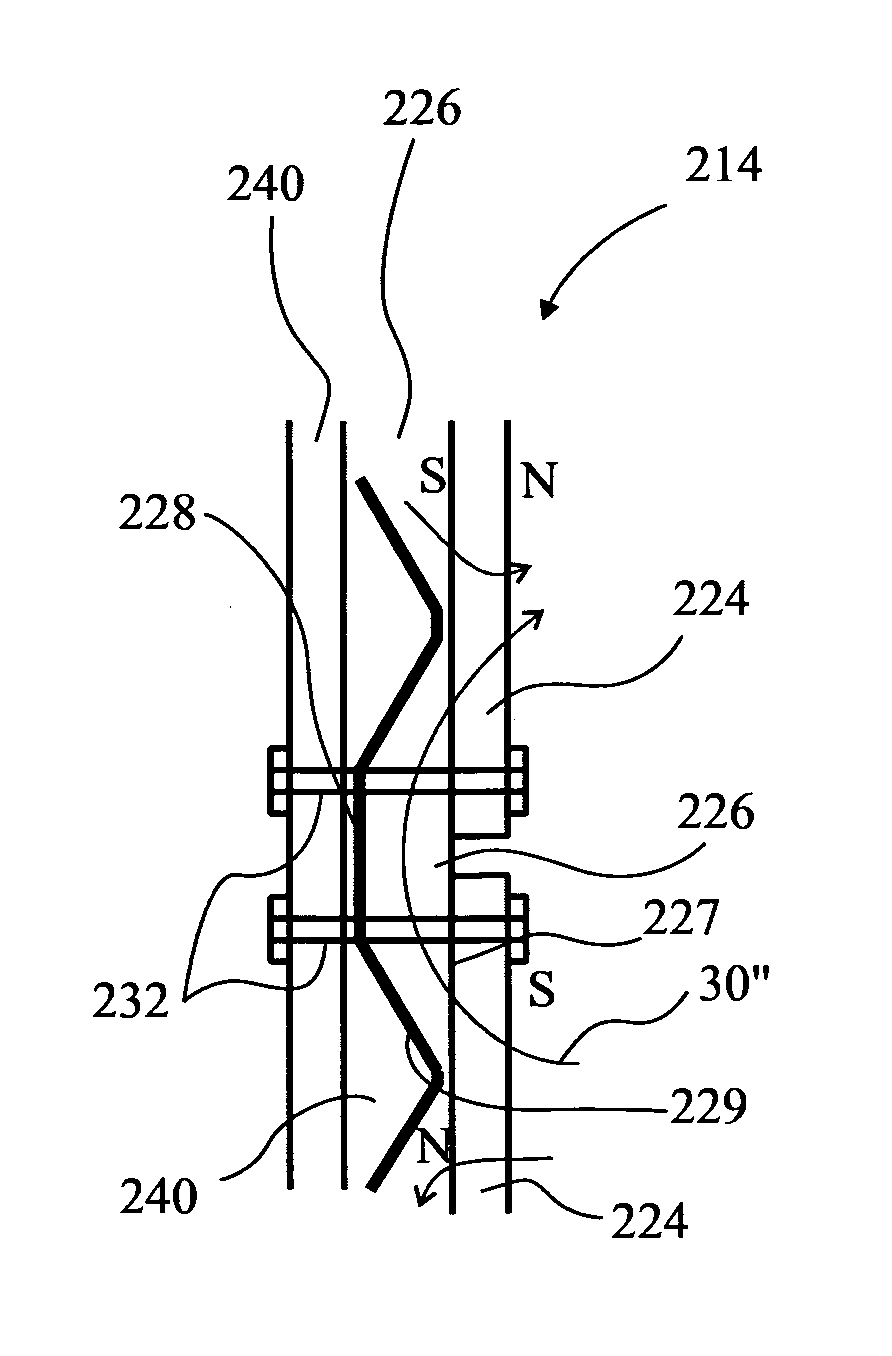

Polyphasic multi-coil generator

ActiveUS20060033393A1Reduce resistanceSynchronous generatorsMagnetic circuit rotating partsAngular orientationMulti coil

A polyphasic multi-coil generator includes a driveshaft, at least first and second rotors rigidly mounted on the driveshaft so as to simultaneously synchronously rotate with rotation of the driveshaft, and at least one stator sandwiched between the first and second rotors. The stator has an aperture through which the driveshaft is rotatably journalled. A stator array on the stator has an equally radially spaced-apart array of electrically conductive coils mounted to the stator in a first angular orientation about the driveshaft. The stator array is radially spaced apart about the driveshaft. The rotors and the stator lie in substantially parallel planes. The first and second rotors have, respectively, first and second rotor arrays. The first rotor array has a first equally radially spaced apart array of magnets radially spaced around the driveshaft at a first angular orientation relative to the driveshaft. The second rotor array having a second equally spaced apart array of magnets at a second angular orientation relative to the driveshaft. The first and second angular orientations are off-set by an angular offset so that the first and second rotor arrays are offset relative to one another.

Owner:DPM TECH INC +1

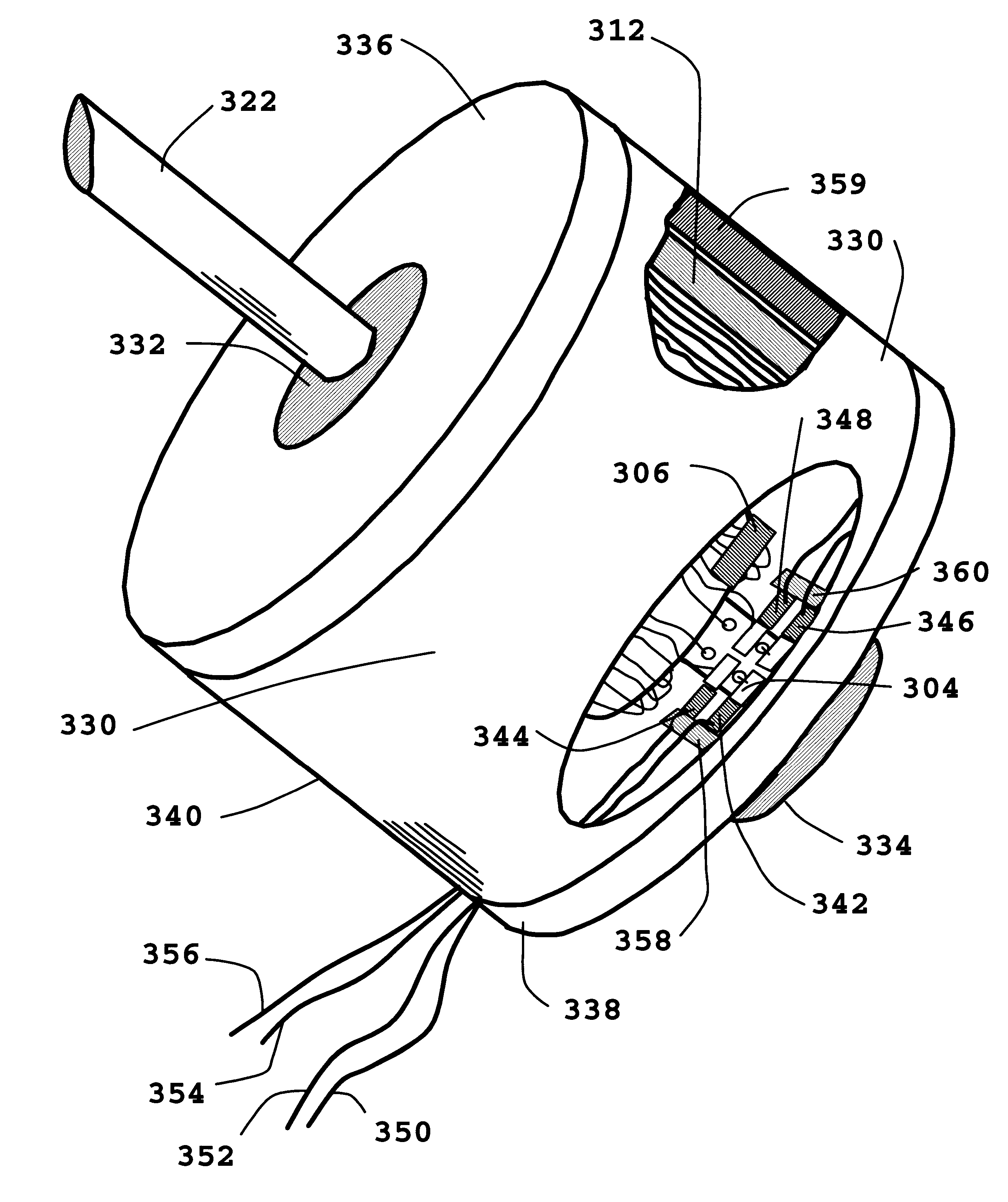

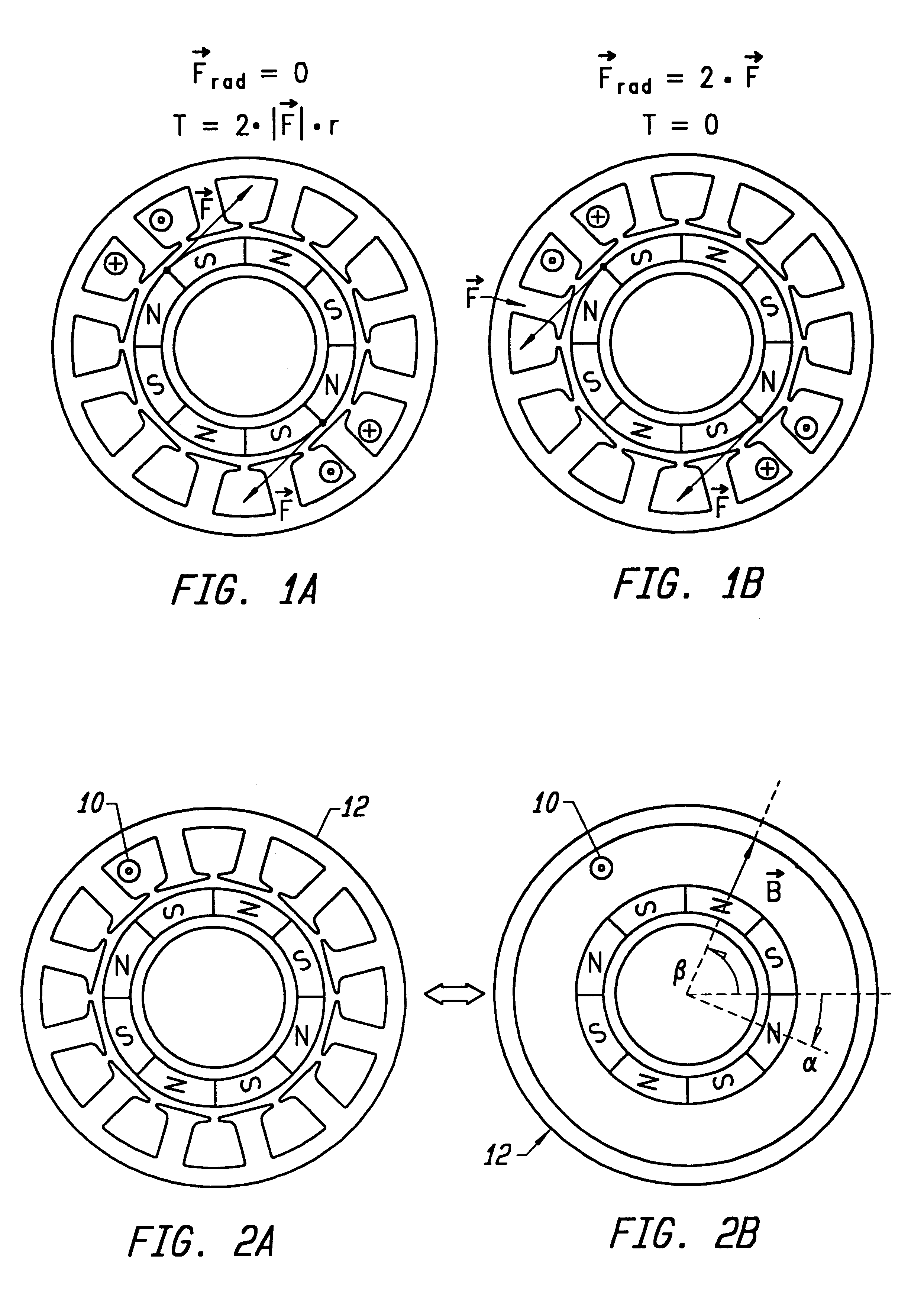

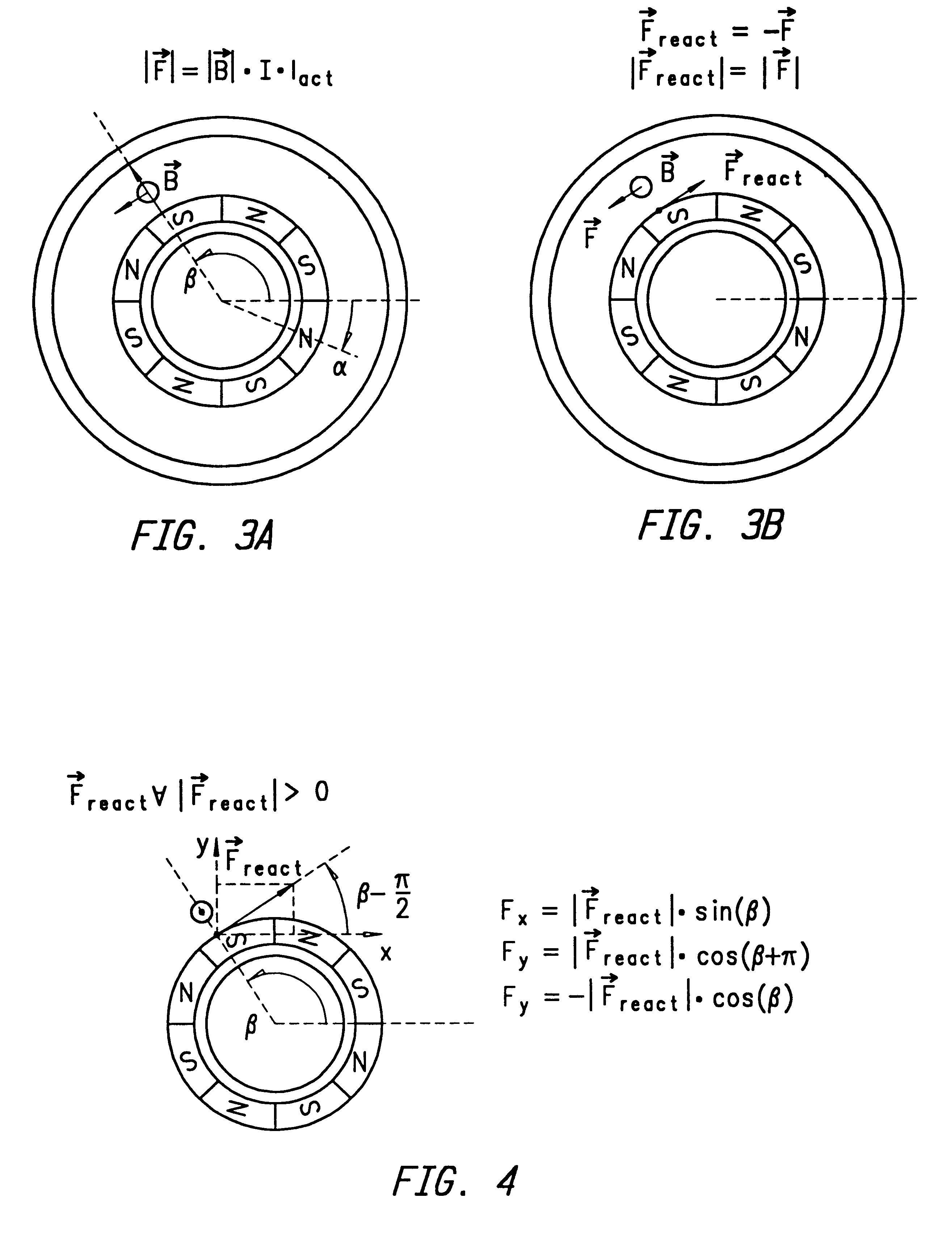

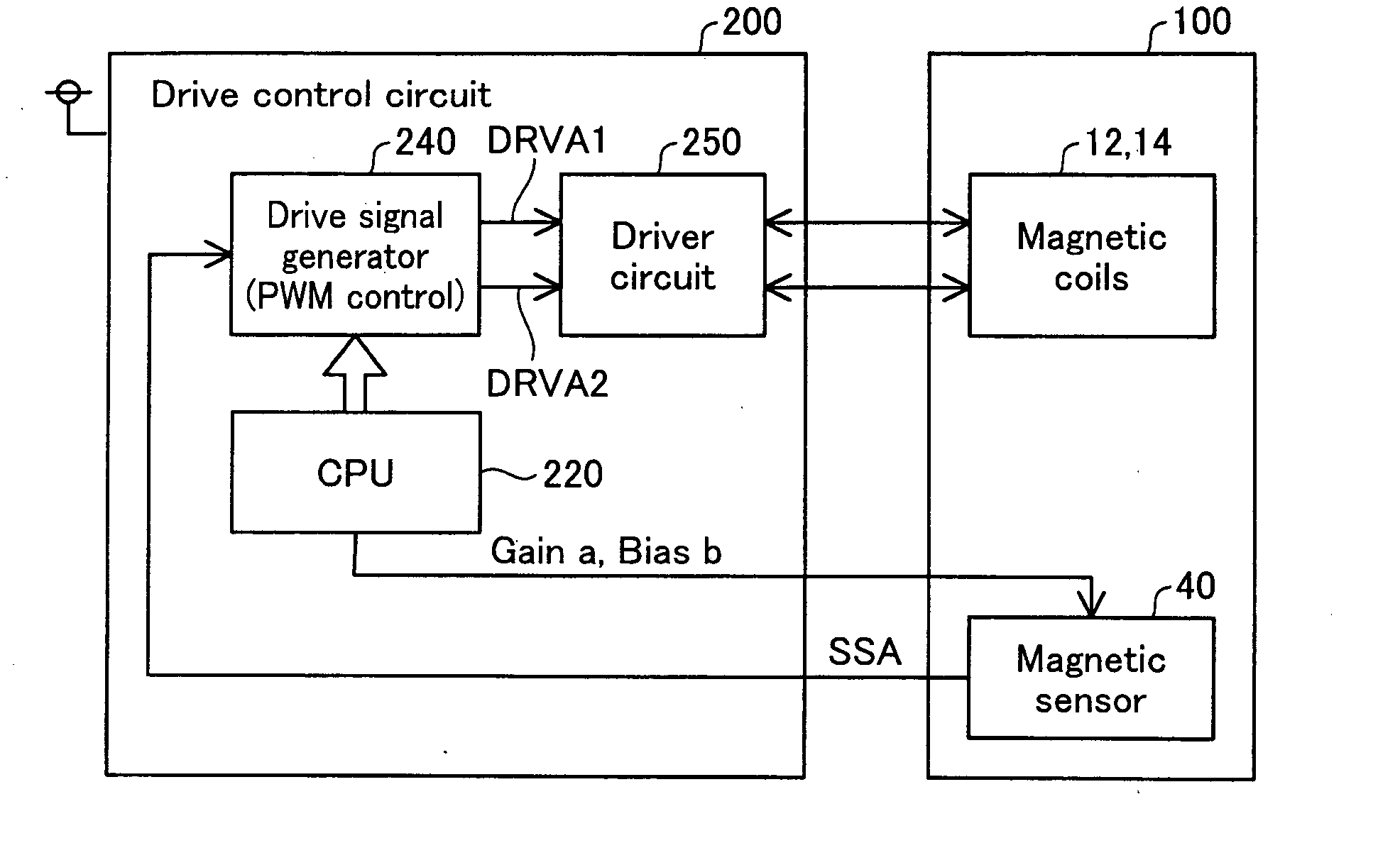

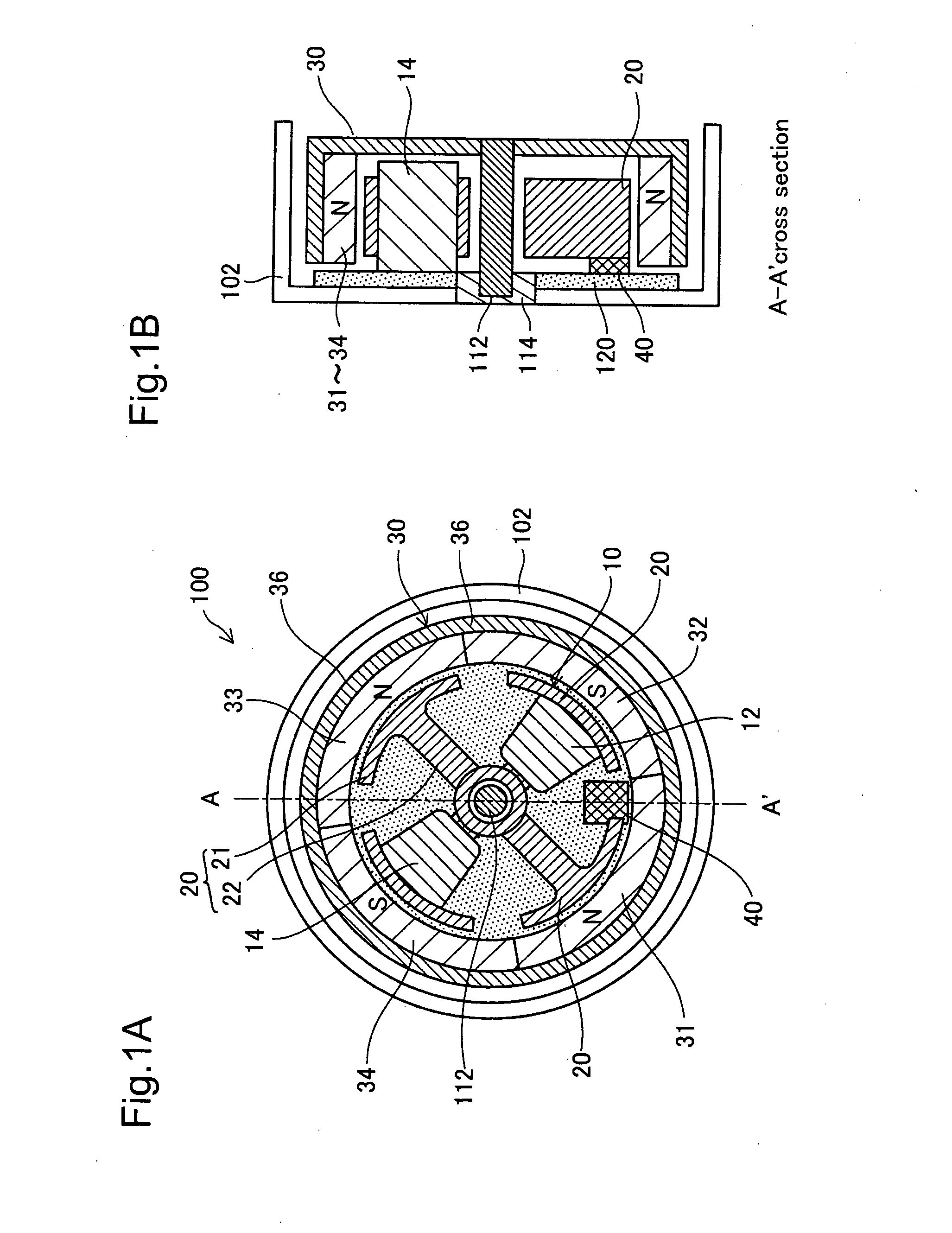

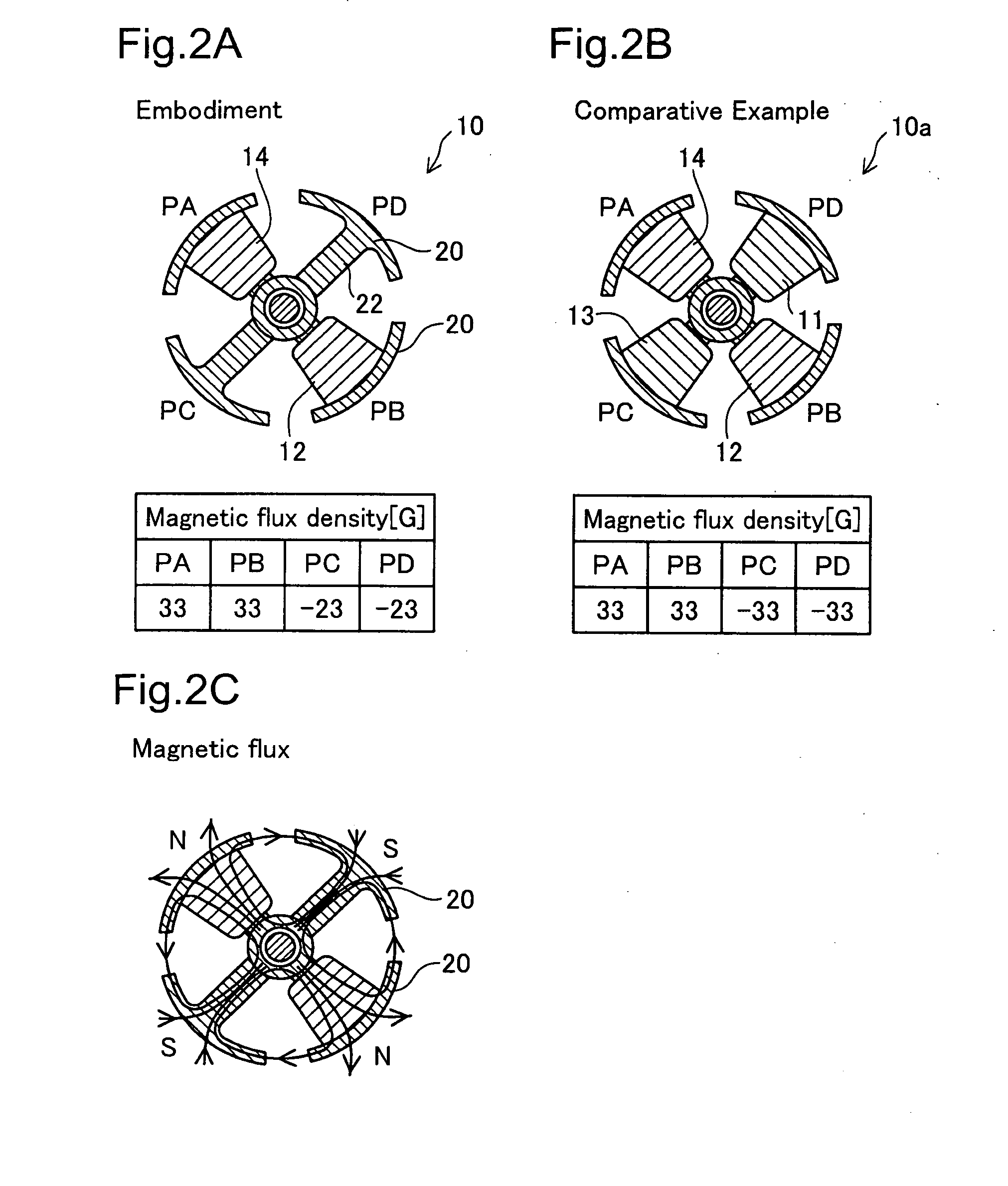

Brushless spindle DC motor used as an actuator to create radial force

An apparatus for stabilizing the spin axis of a rotating system, the rotating system having a rotor and motor means to cause rotation of the rotor about the spin axis and a magnet, windings, a source of drive current and an actuator combined with the motor means and forming a source of actuator current energizing the windings to generate a radial force which stabilizes the position of the spin axis and dampens other than rotational movements of the rotor.

Owner:SEAGATE TECH LLC

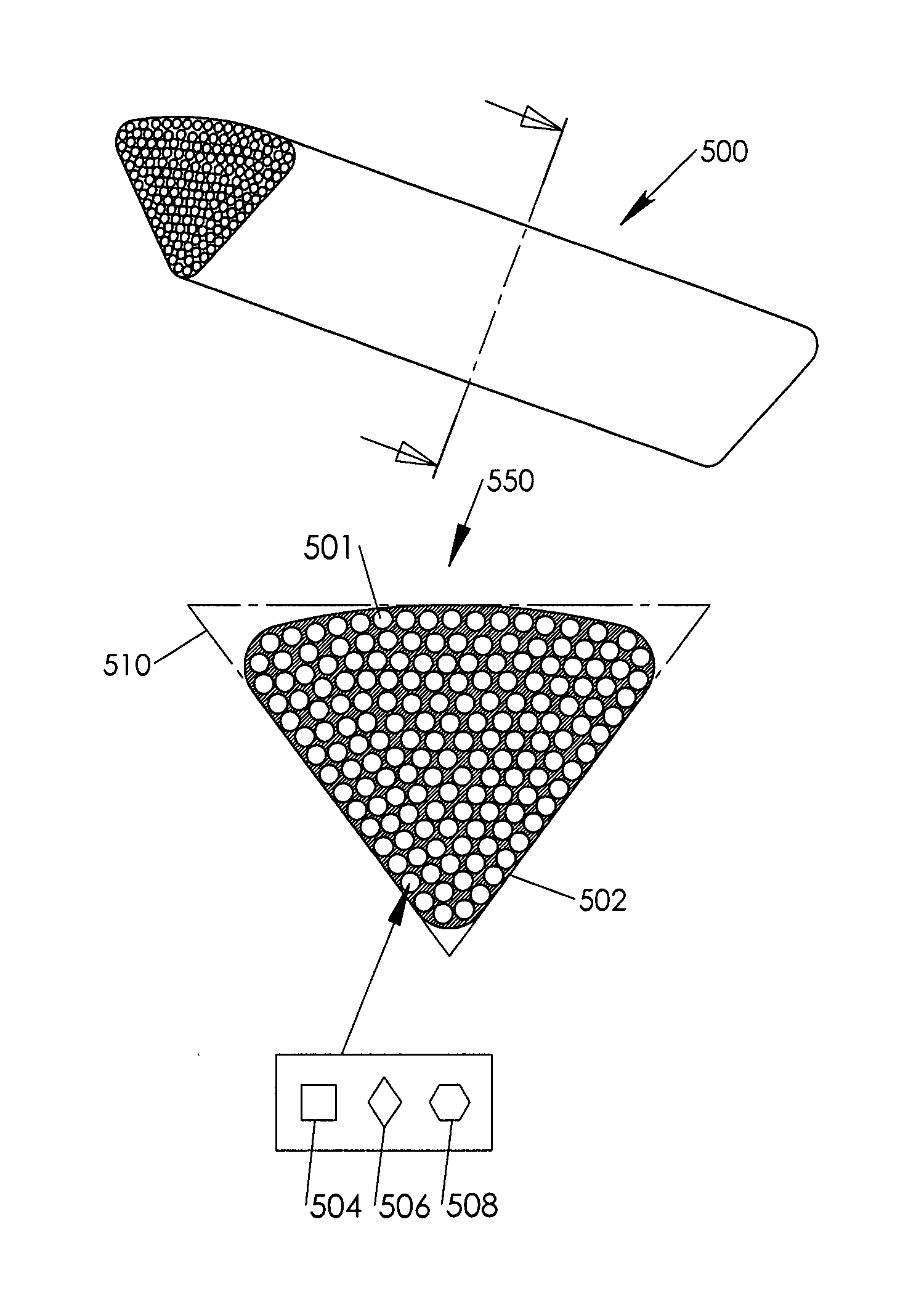

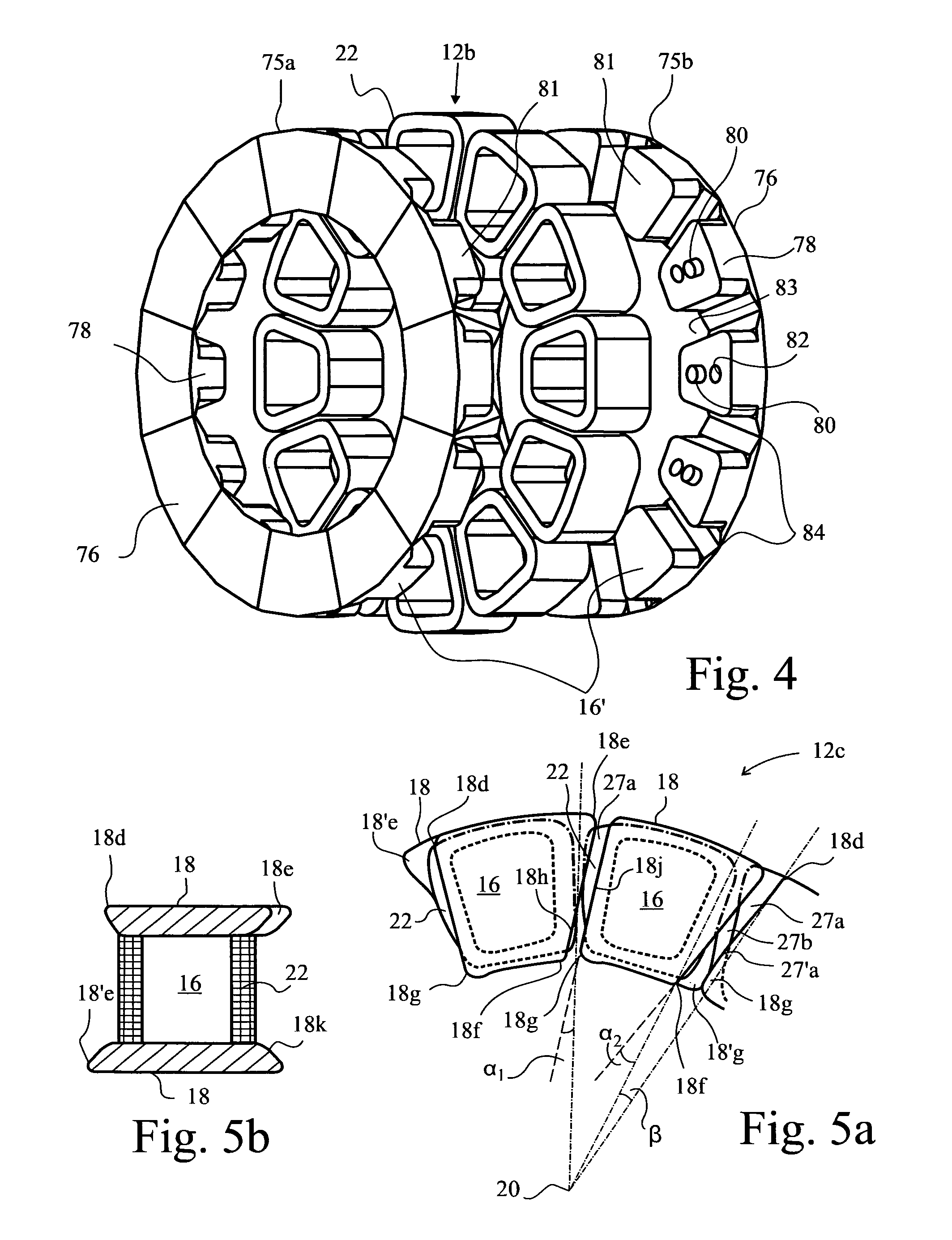

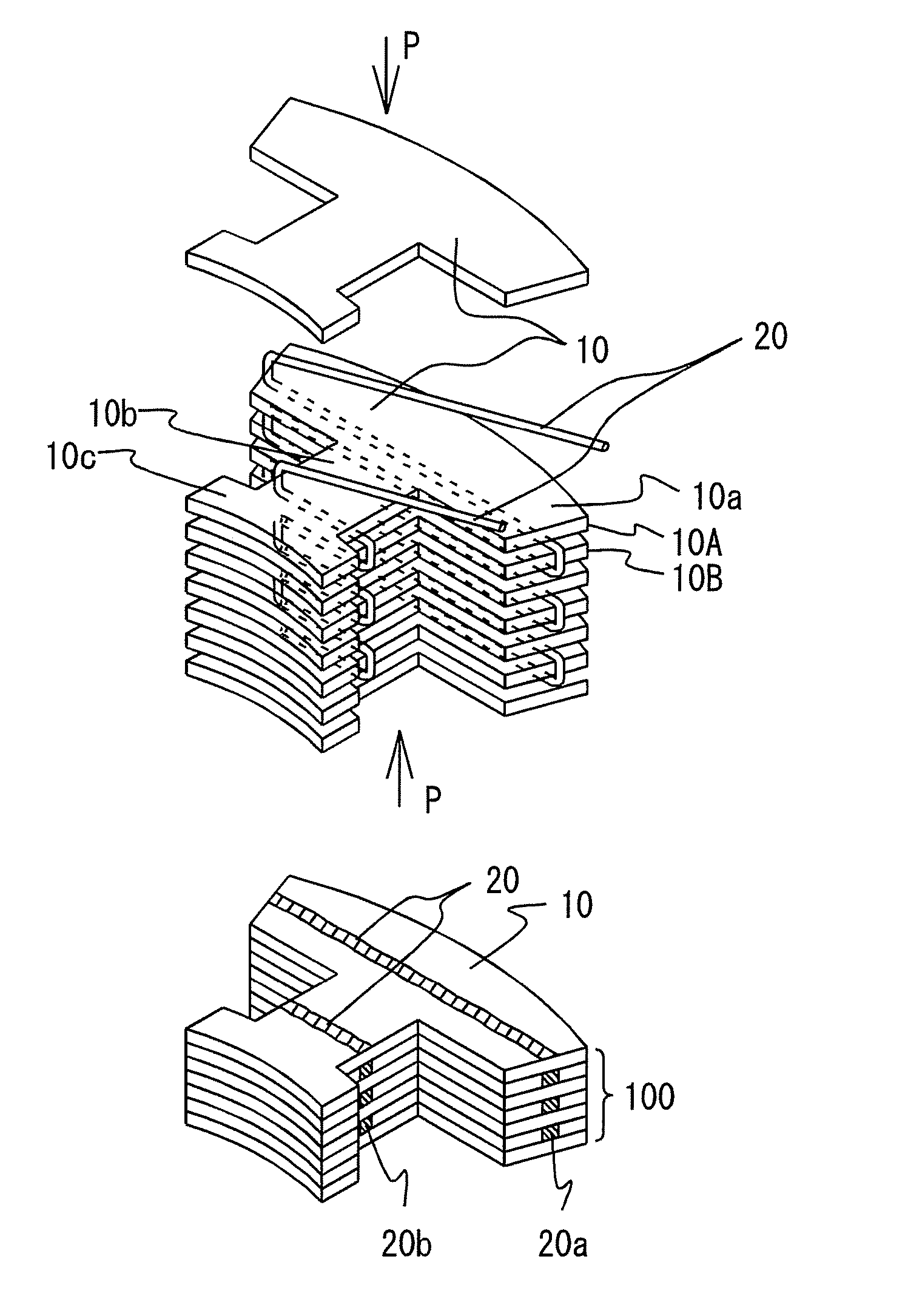

Field pole members and methods of forming same for electrodynamic machines

ActiveUS20070205675A1Increase torqueReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsUnit sizeManufacturing cost reduction

A method, apparatus, article of manufacture and system for producing a field pole member for electrodynamic machinery are disclosed to, among other things, reduce magnetic flux path lengths and to eliminate back-iron for increasing torque and / or efficiency per unit size (or unit weight) and for reducing manufacturing costs. For example, a field pole member structure can either reduce the length of magnetic flux paths or substantially straighten those paths through the field pole members, or both. In one embodiment, a method provides for the construction of field pole members for electrodynamic machines.

Owner:REGAL BELOIT AMERICA

Sculpted field pole members and methods of forming the same for electrodynamic machines

ActiveUS20130181565A1Increase torqueReduce manufacturing costMagnetic circuit stationary partsSalient polesUnit sizeManufacturing cost reduction

A method, apparatus, article of manufacture and system for producing a field pole member for electrodynamic machinery are disclosed to, among other things, reduce magnetic flux path lengths and to eliminate back-iron for increasing torque and / or efficiency per unit size (or unit weight) and for reducing manufacturing costs. For example, a field pole member structure can either reduce the length of magnetic flux paths or substantially straighten those paths through the field pole members, or both. In one embodiment, a method provides for the construction of field pole members for electrodynamic machines.

Owner:REGAL BELOIT AMERICA

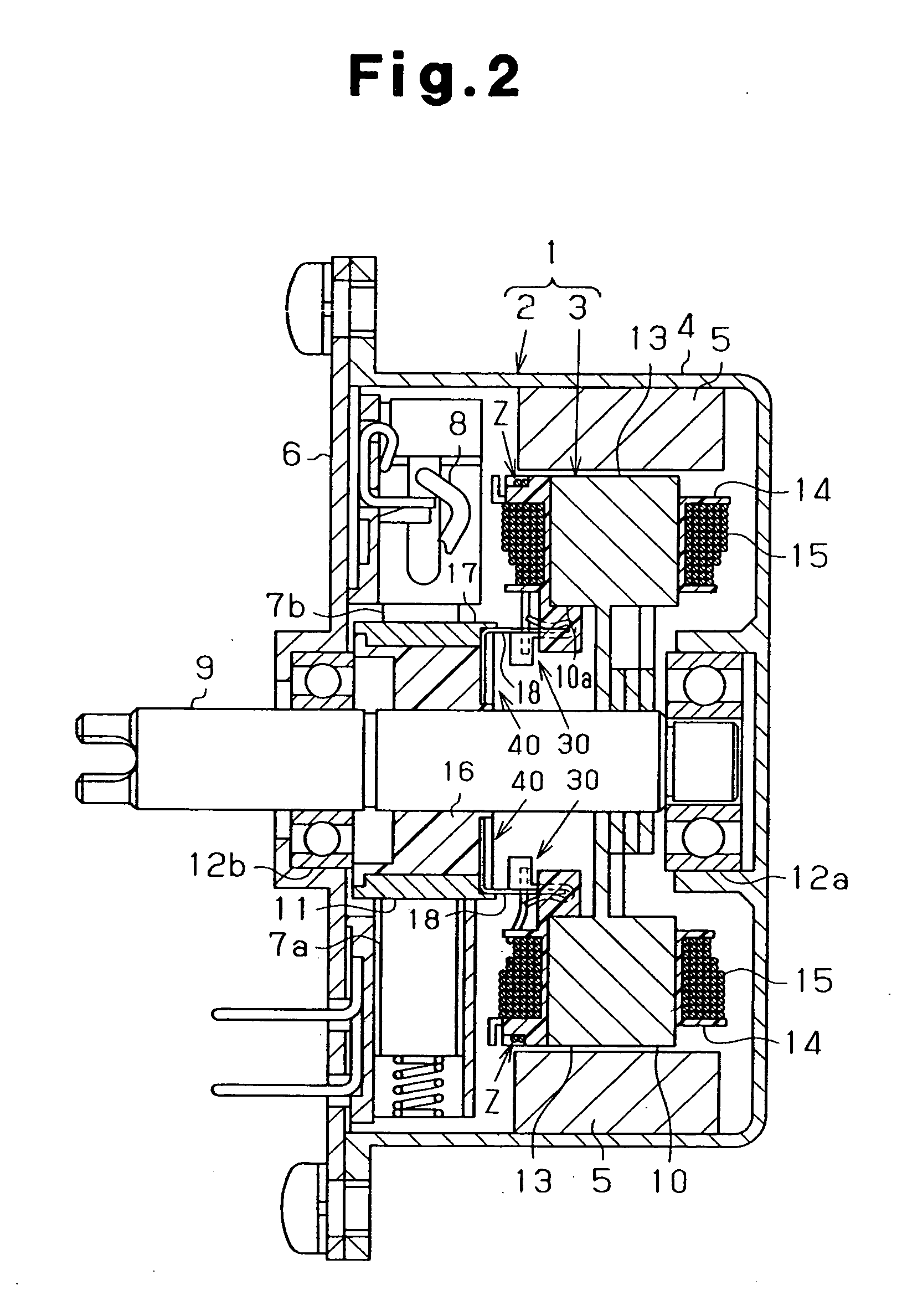

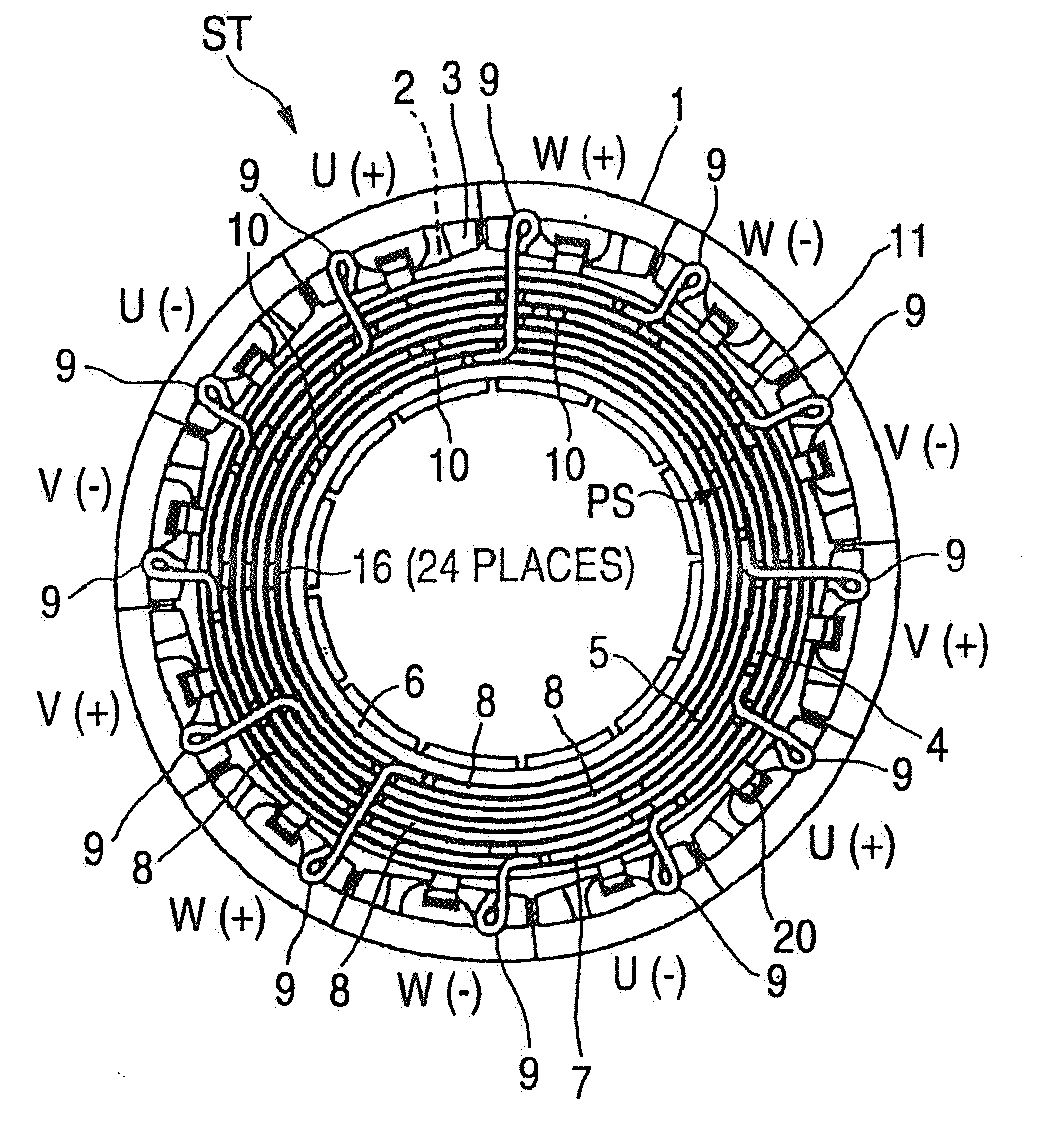

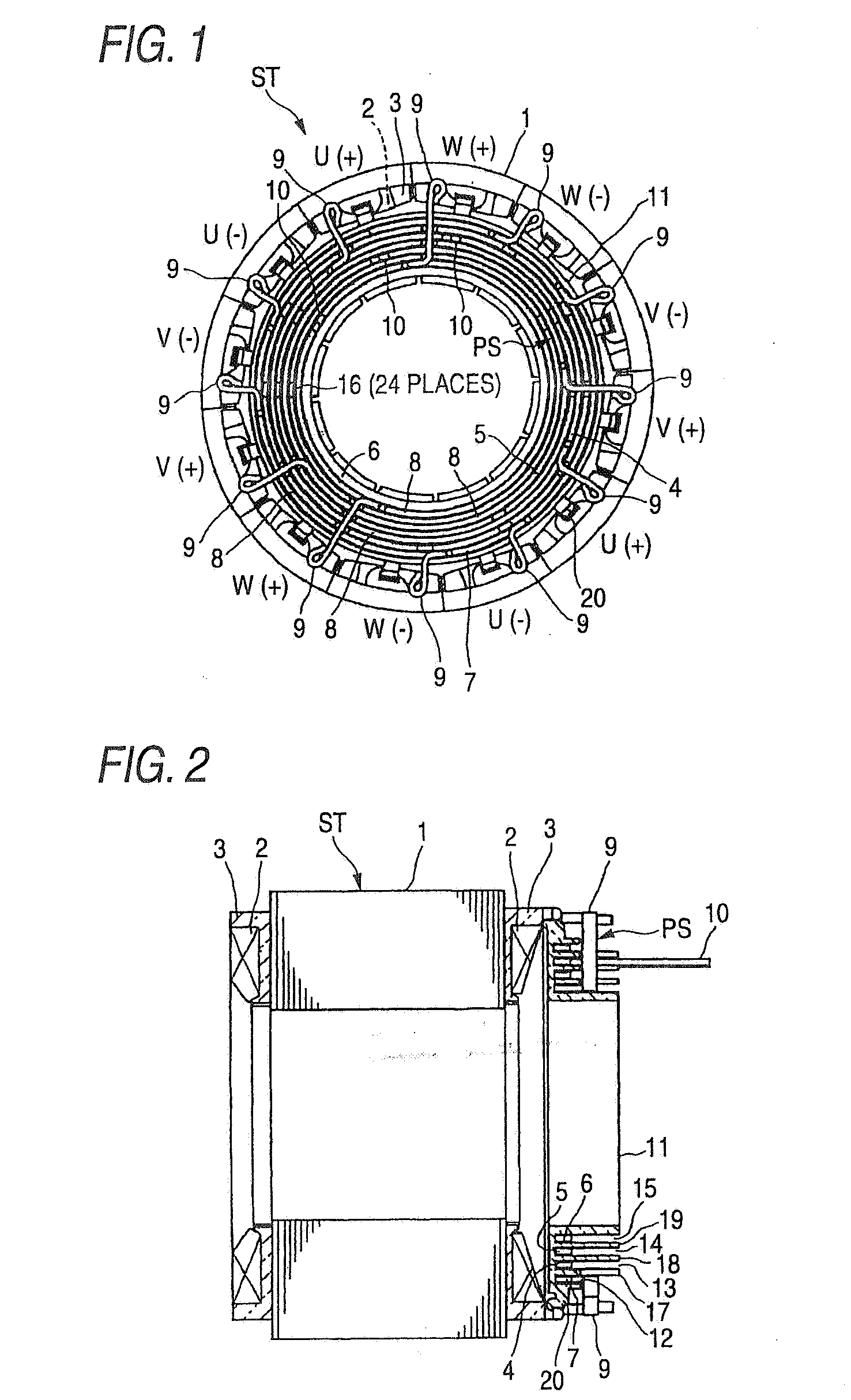

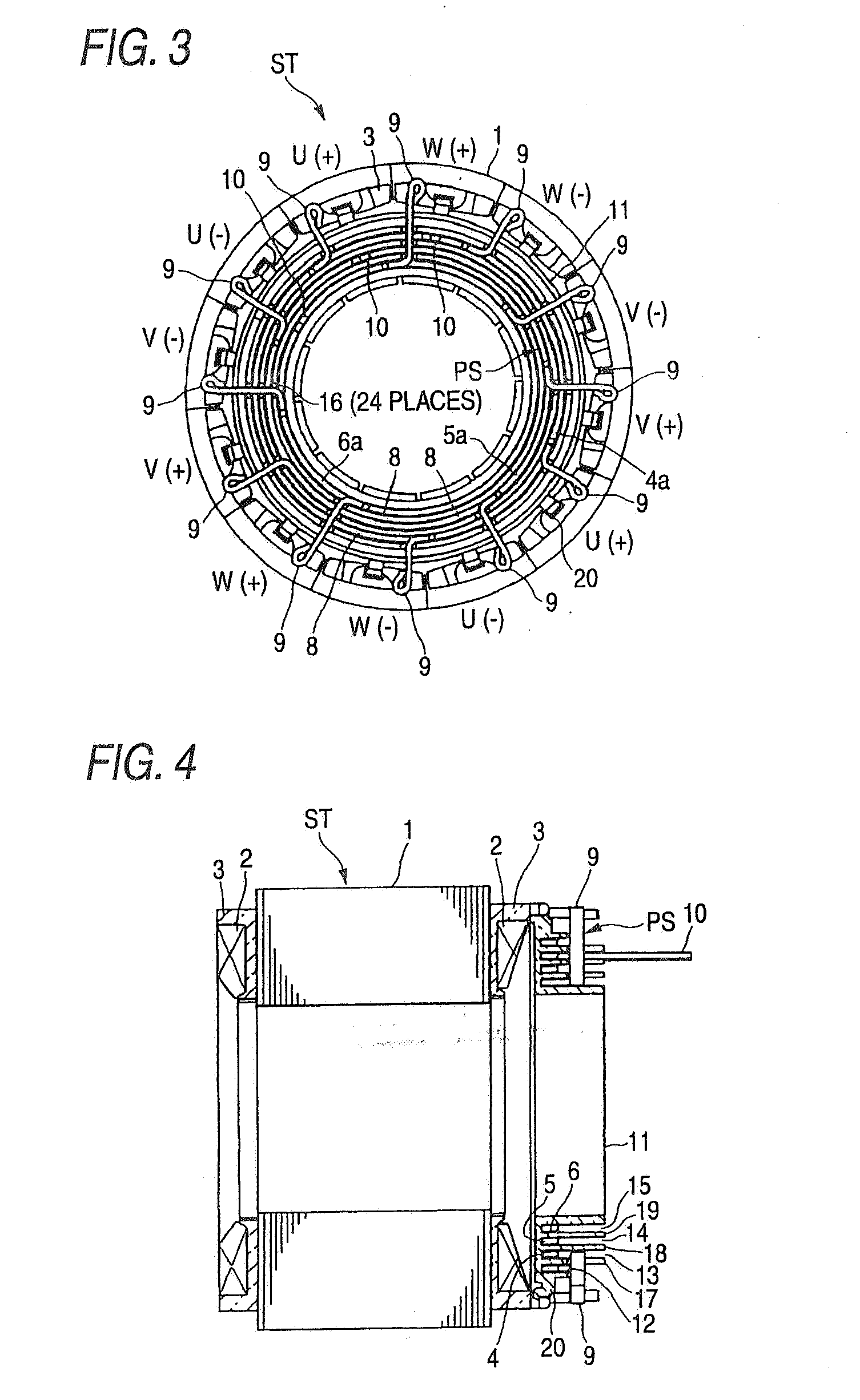

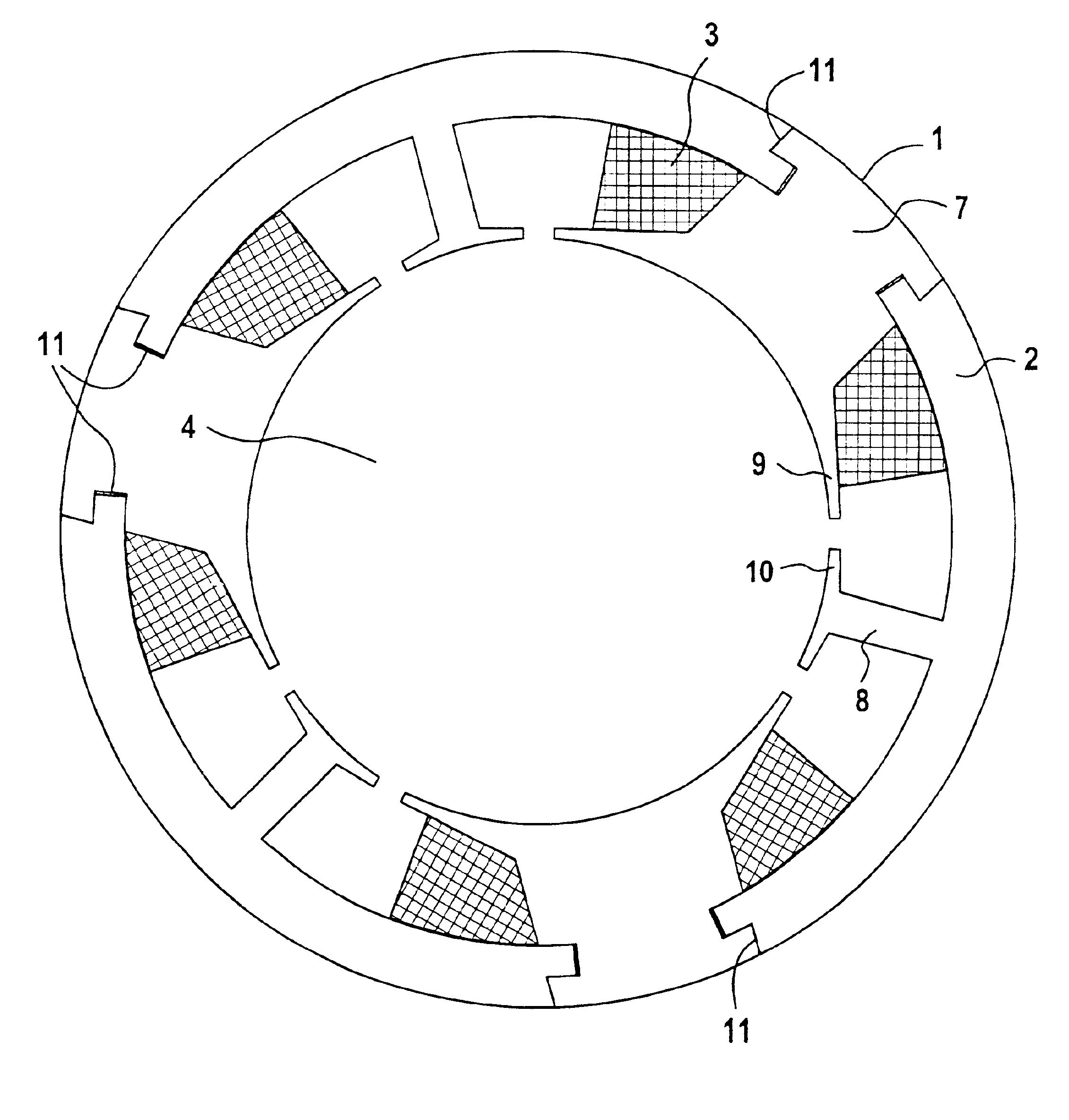

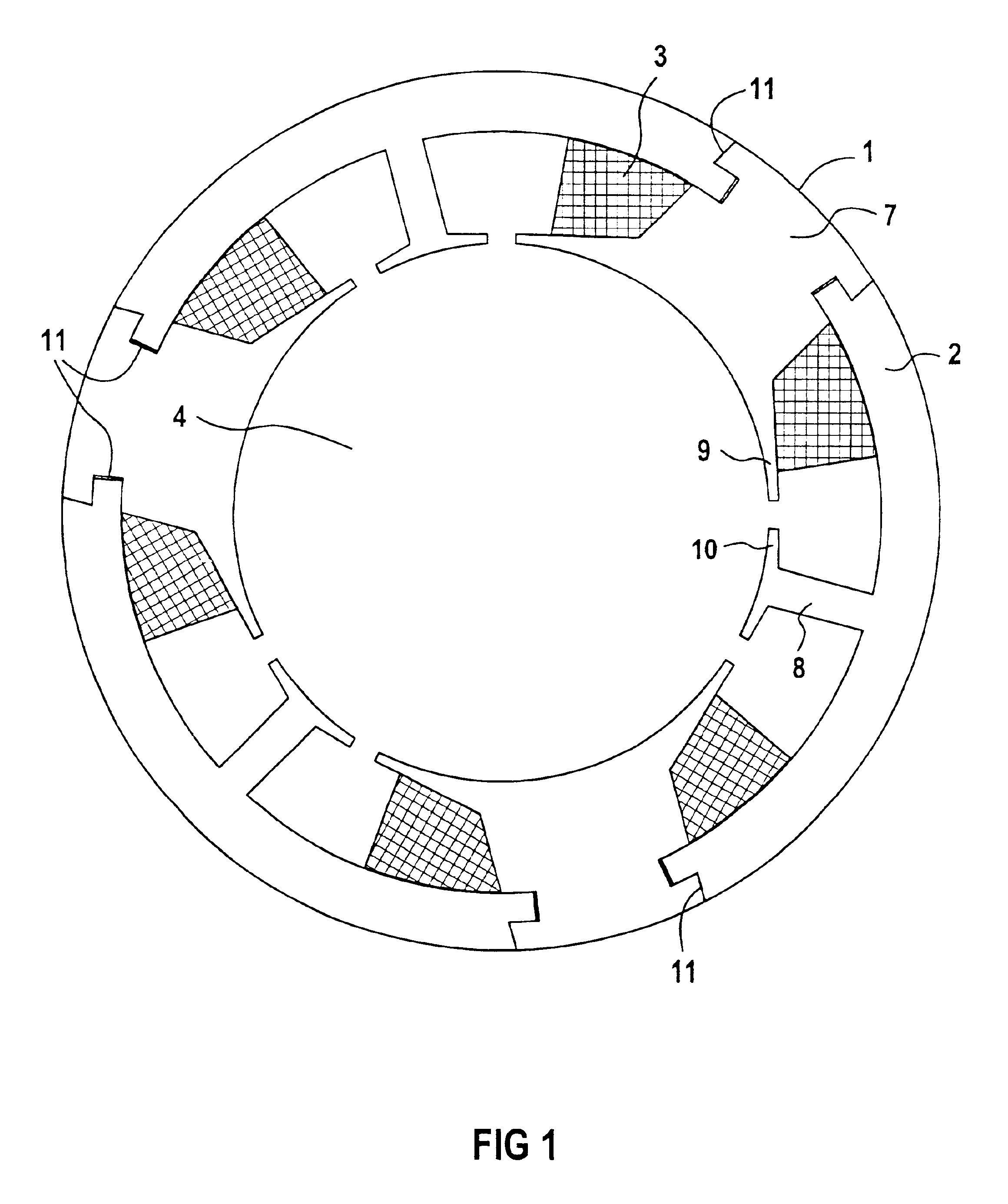

Rotary electric machine

InactiveUS20070205678A1Superior in pointSynchronous generatorsSalient polesElectric machineEngineering

A rotary electric machine comprising a stator body (ST in FIG. 1) which includes a winding configured of a plurality of coils (2), and a power supply section (PS) which includes conductive members (4, 5 and 6) for connecting the coils (2) to one another, and a holding member (11) for holding the conductive members (4, 5 and 6), wherein the power supply section (PS) is configured by employing the holding member (11) which is common to different connection structures such as a Y-connection and a delta connection. The rotary electric machine is advantageous in the points of the fabrication and supply of components owing to the common use of the components.

Owner:MITSUBISHI ELECTRIC CORP

Electric machine—flux

ActiveUS9071117B2Increase the gapGap minimizationMagnetic circuit stationary partsSalient polesElectric machineMagnetic reluctance

An electric machine (10; 100) comprises a rotor (14) having permanent magnets (24) and a stator (12) having coils (22) wound on stator bars (16) for interaction with the magnets across an air gap (26a, b) defined between them. The rotor has two stages (14a, b) arranged one at either end of the bars. The bars have a shoe (18a, 8) at each end of each bar that links magnetic flux through the bars with said magnets on each stage. Adjacent shoes facing the same stage of the rotor have a high-reluctance shoe gap (27) between them; adjacent magnets on each stage of the rotor have a high-reluctance magnet gap (25) between them; and the shoe and magnet gaps (25, 27) are angled with respect to each other such that they engage progressively as the rotor rotates. Alternatively, the shoes facing each stage are in a ring of connected shoes such that the magnets experience a continuous reluctance that is at least 90% constant as a function of rotor position. The bars (16) and shoes (18) are formed separately from one another and at least a part of each is formed by moulding soft-iron particles so that the particles have a short dimension that is arranged transverse a reluctance-plane. The bars and shoes are assembled so that the reluctance-plane of the bar is parallel a longitudinal axis (16a) of the bar and said reluctance-plane of the shoe is transverse said longitudinal axis.

Owner:YASA LIMITED

Brushless motor

InactiveUS20080246424A1Average power consumptionIncreased power consumptionAC motor controlSynchronous motors startersBrushless motorsEngineering

The brushless motor has a first and second drive member. The first drive member is equipped with M phase coil groups each having N electromagnetic coils where M is an integer of 1 or greater and N is an integer of 1 or greater. The second drive member has a plurality of permanent magnets, and is able to move relative to the first drive member. The first drive member has 2 (M×N) magnetic body cores. Each phase electromagnetic coil is coiled on a periodically selected magnetic body core at a ratio of 1 to 2M from among the arrangement of 2 (M×N) magnetic body cores.

Owner:GK BRIDGE 1

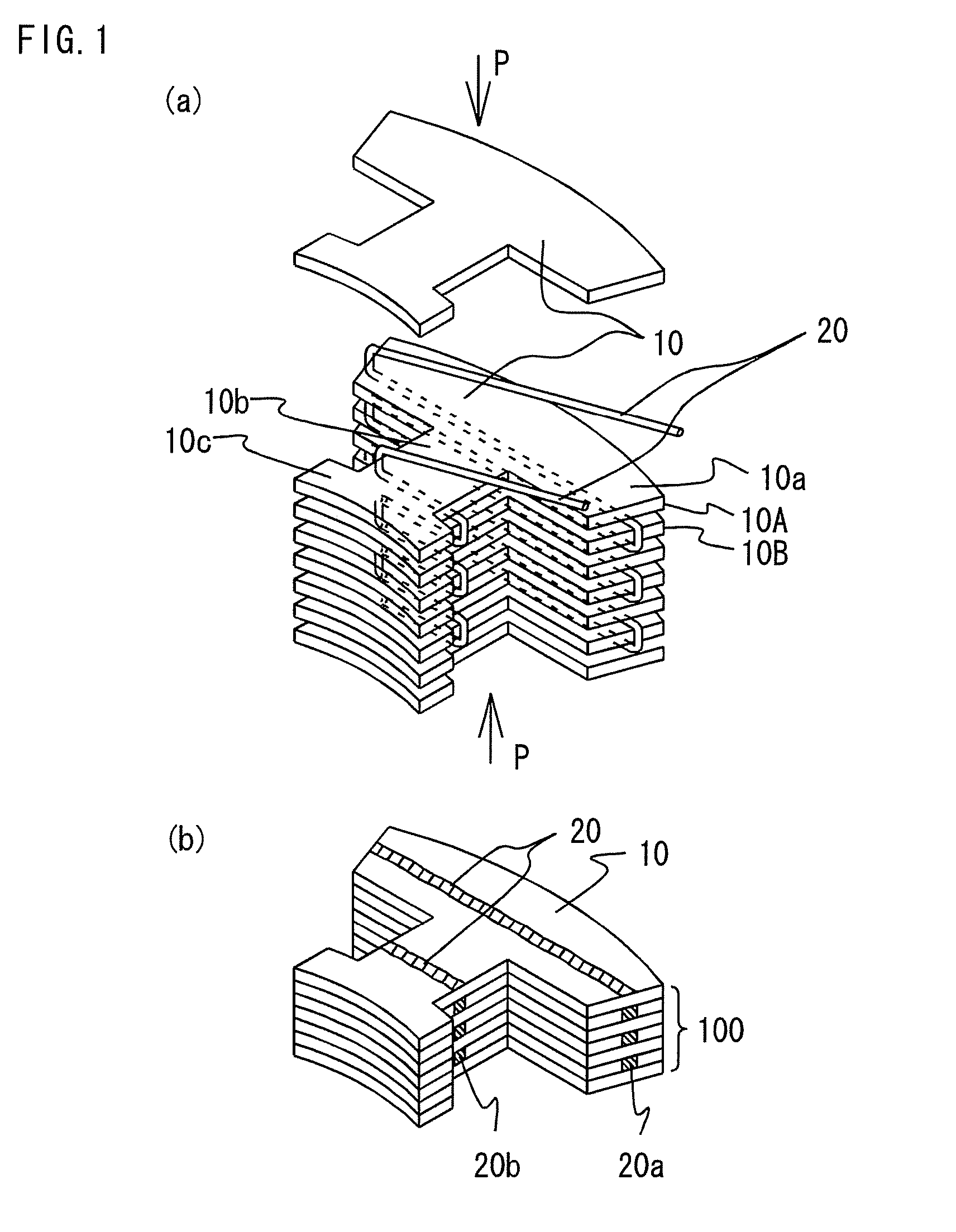

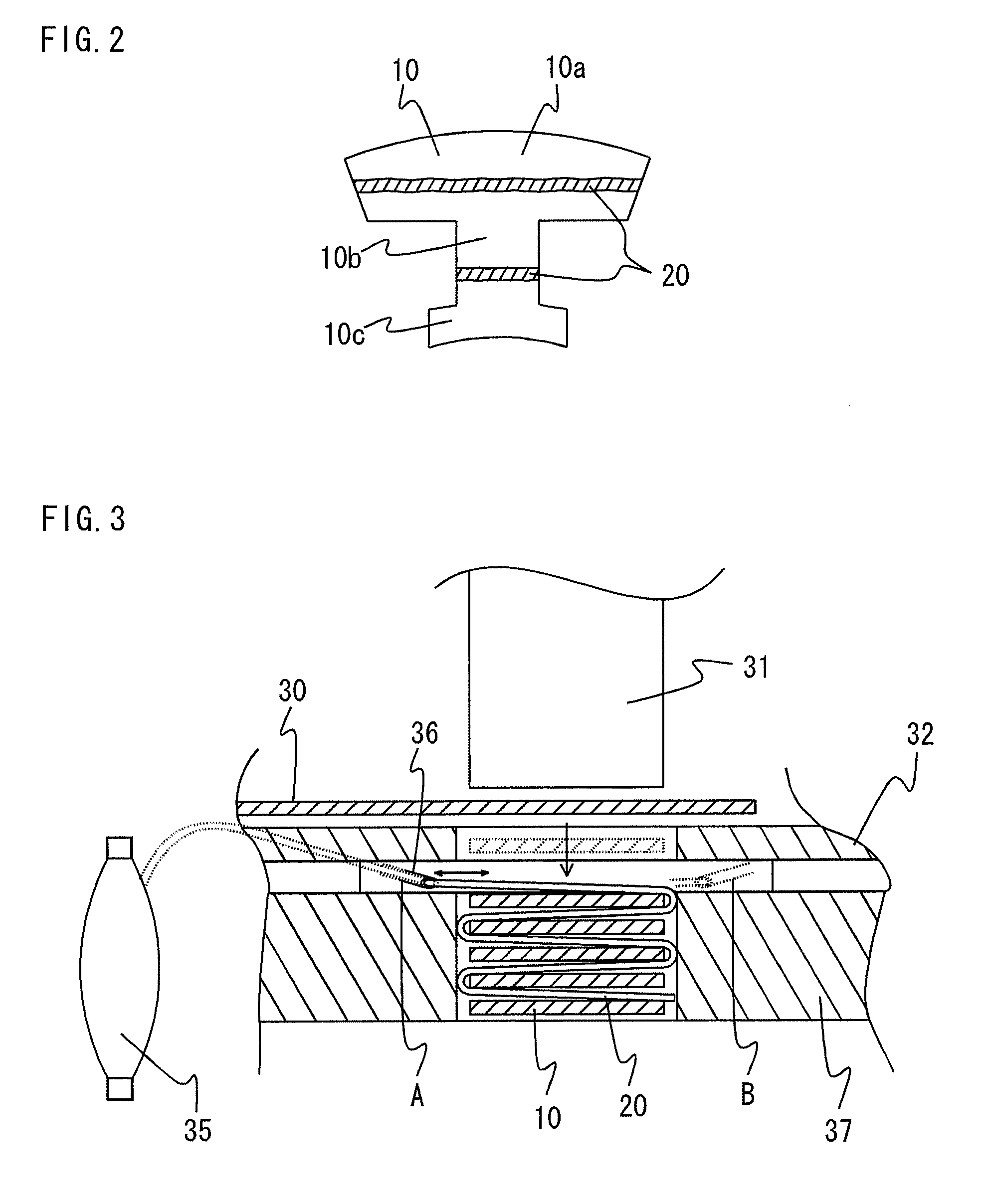

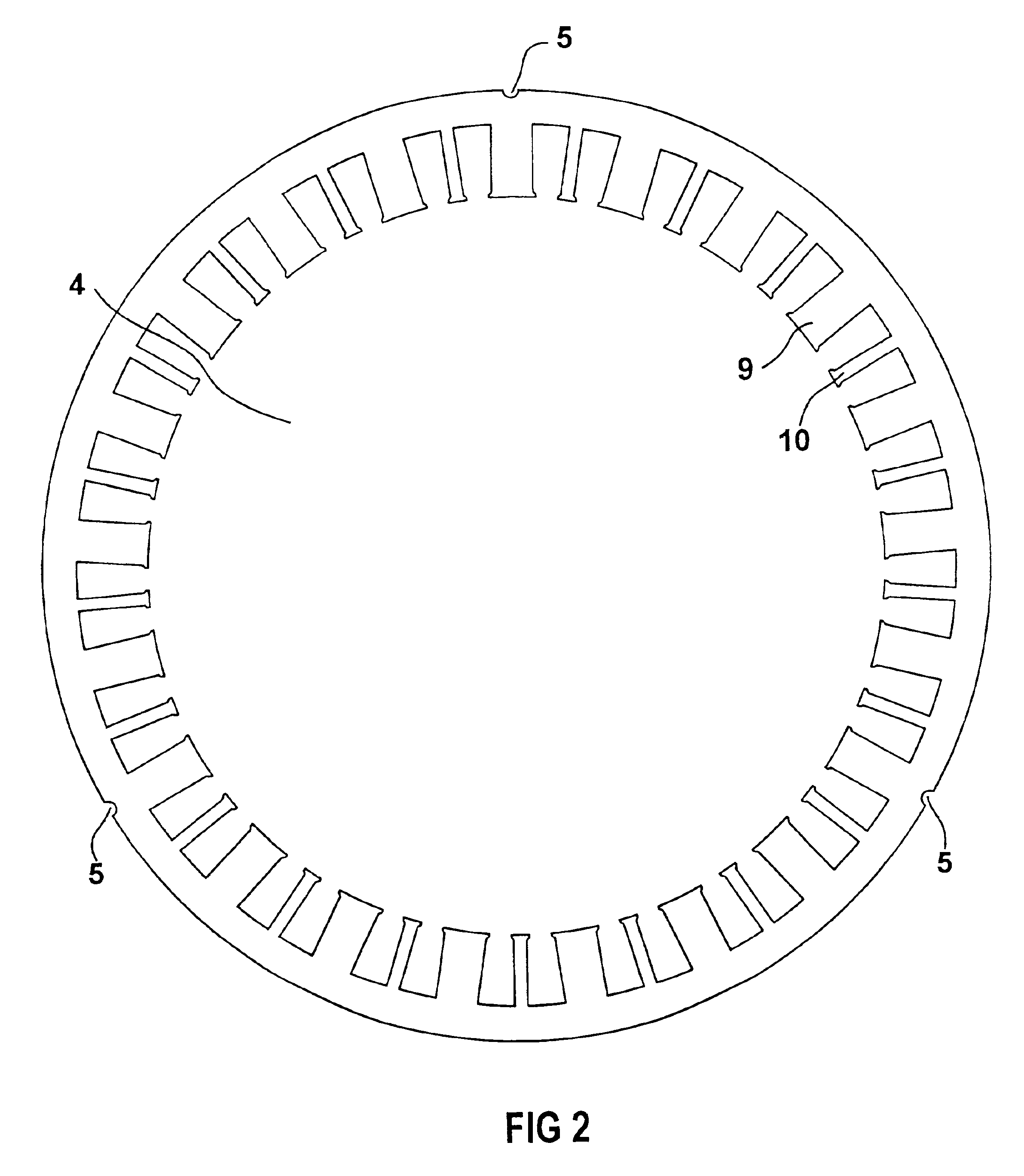

Laminated core, method and apparatus for manufacturing laminated core, and stator

ActiveUS20090195110A1Improve accuracyStable bonding strengthMagnetic circuit stationary partsSalient polesEngineeringMechanical engineering

A laminated core block includes a plurality of core members made of magnetic sheets stacked one on top of another, the plurality of core members including first and second core members which adjoin in a laminating direction, and a thermoplastic resin strand placed between the first and second core members. The thermoplastic resin strand is arranged to pass along one side surface of the first core member, between the first and second core members and along a side surface of the second core member on a side opposite to the aforementioned side surface of the first core member in this order. The first and second core members are bonded to each other by melting and curing the thermoplastic resin strand.

Owner:MITSUBISHI ELECTRIC CORP

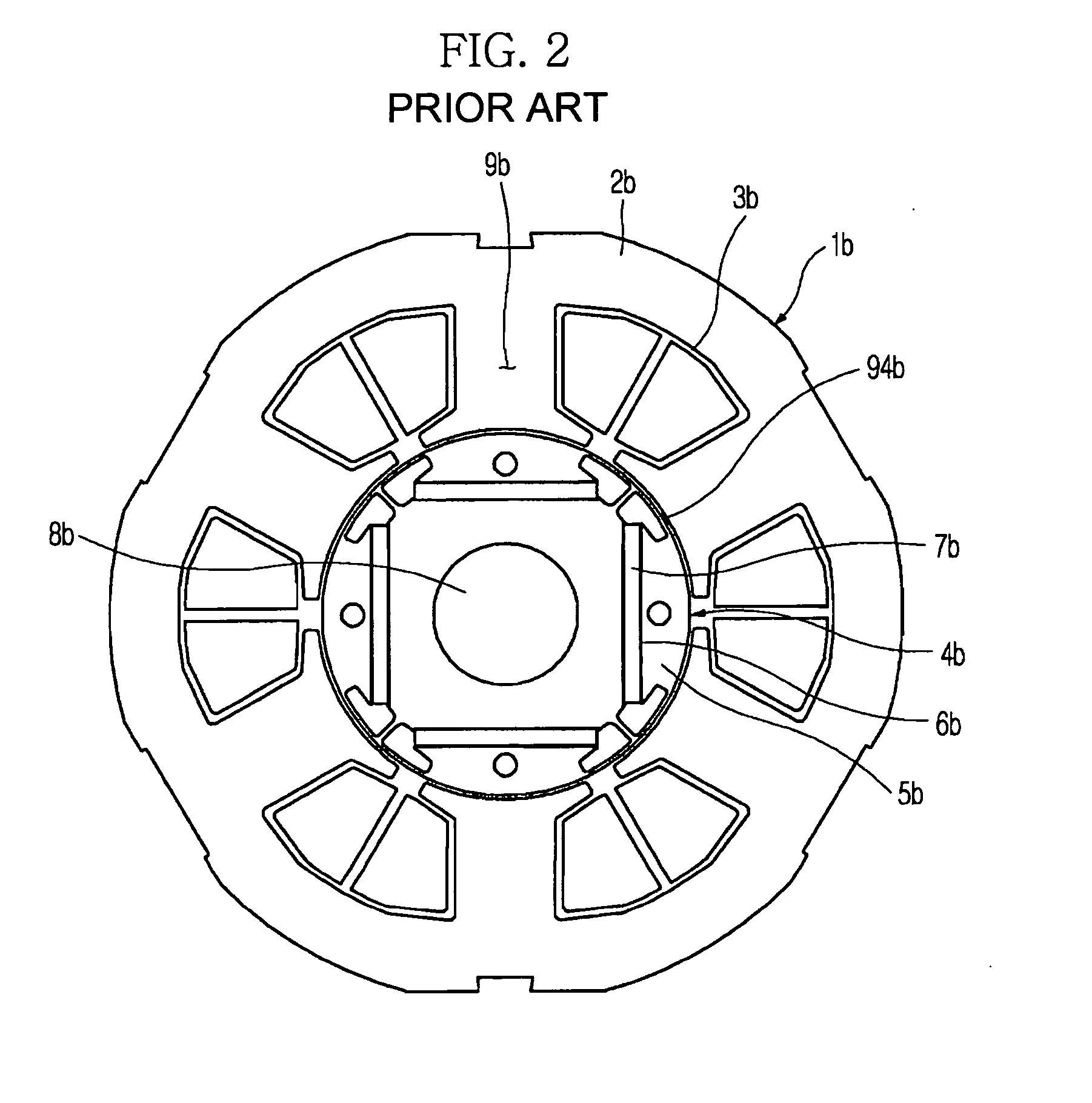

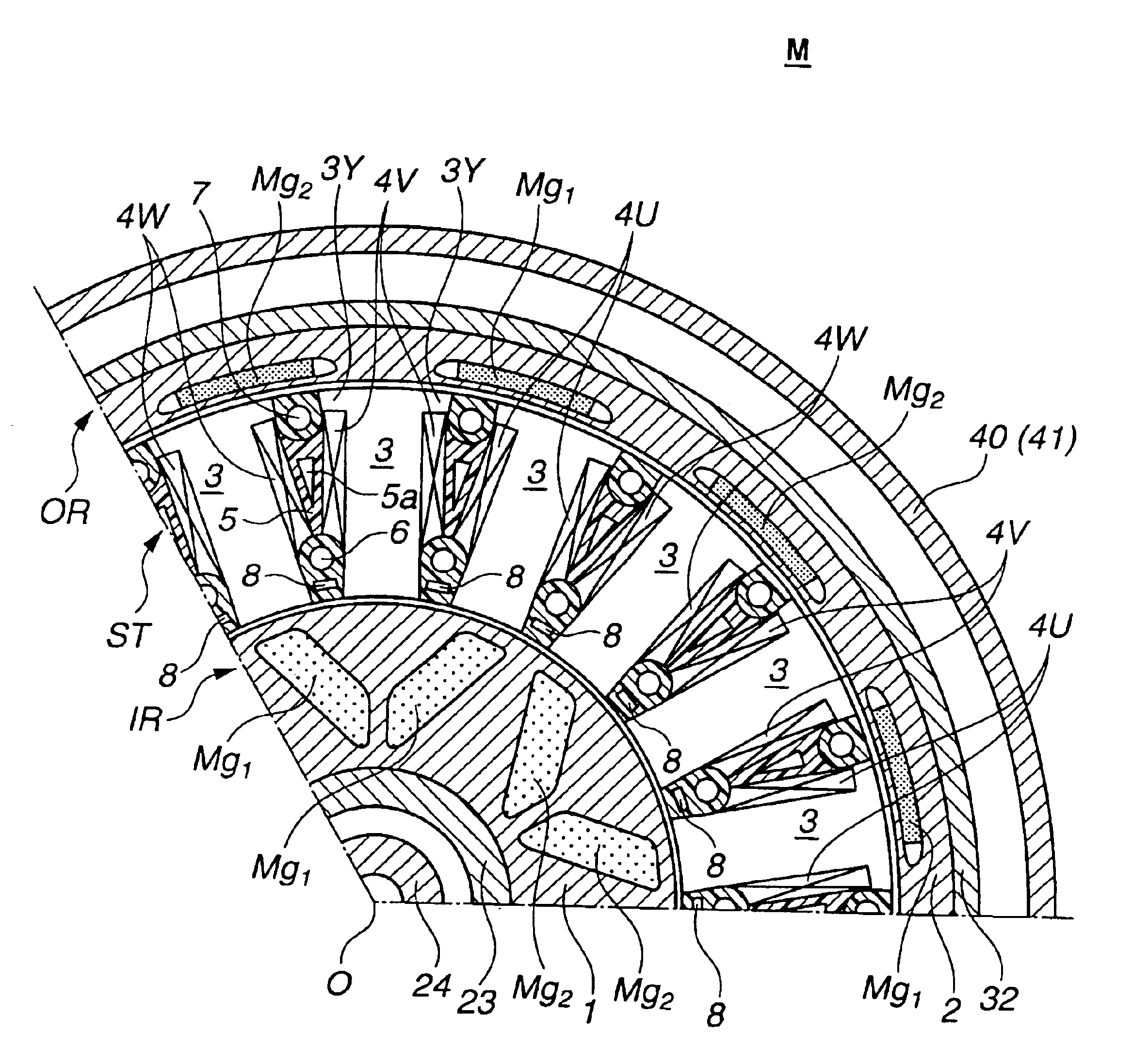

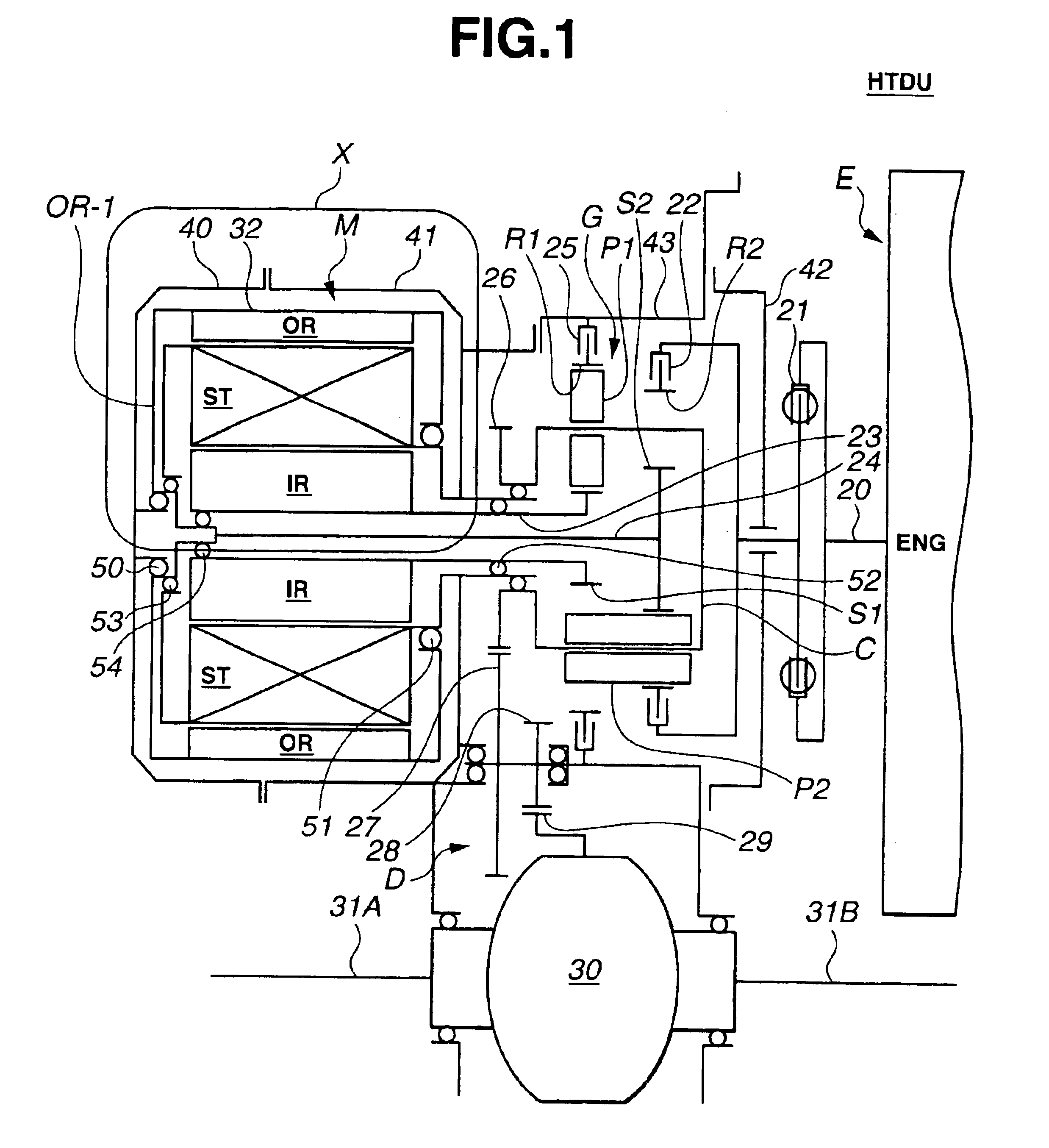

Stator of two rotor single stator type electric motor

InactiveUS6838790B2Sufficient motor performanceMagnetic circuit stationary partsSalient polesSteel platesPhysics

A stator for use in a two rotor single stator type electric motor includes a stator core including a plurality of stator teeth that are circumferentially arranged around a common axis leaving a plurality of identical spaces each being defined between adjacent two of the stator teeth. Each stator tooth includes a plurality of flat magnetic steel plates that are aligned along the common axis. A plurality of coils are put around the stator teeth respectively. Bolts extend through identical spaces of the stator core for combining the flat magnetic steel plates to have a fixed structure of the stator core. A molded plastic fills the identical spaces of the stator core. A plurality of elongate plate bars extend in the identical spaces through the molded plastic respectively. Each elongate plate bar extends in parallel with the common axis and is constructed of a magnetic material that has an electric resistance higher than the bolts.

Owner:NISSAN MOTOR CO LTD

Two-phase brushless DC motor

InactiveUS8004141B2Maximize Utilization EfficiencyMaximum efficiencySynchronous motors startersAC motor controlBrushless motorsStator voltage

Owner:BLUFFTON MOTOR WORKS

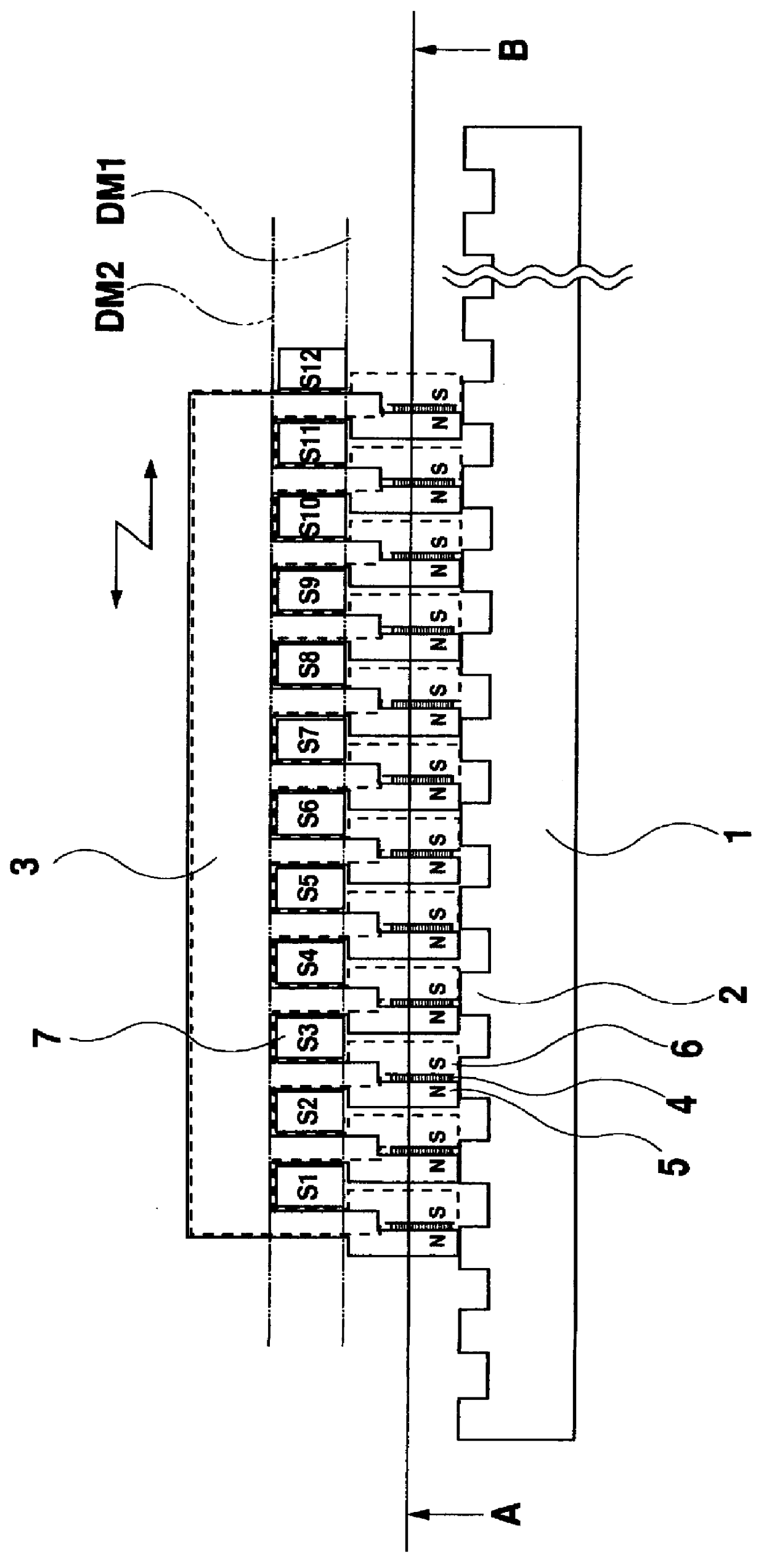

Permanent magnet rotor electrical synchronous machine with different alternatively arranged tooth pitch widths

InactiveUS6879079B2Low stator production costHigh machine utilizationSynchronous generatorsWindingsPermanent magnet rotorMachine utilization

In order to achieve high machine utilization with the magnetic fields having an approximately sinusoidal profile, an electrical synchronous machine is proposed having the following features:a stator and a rotor with the stator having a three-phase winding (3) and the rotor being fitted with permanent magnets,the three-phase winding (3) is arranged in slots in the stator,the slots in the stator are formed by essentially axially running teeth (7, 8) which have at least two different tooth pitch widths τzb and which are arranged alternately in the circumferential direction of the stator, with their number in each case being identical,only the teeth (7) with a tooth pitch width which is greater than other teeth (8) are at least partially surrounded by a winding (3).

Owner:SIEMENS AG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com