Patents

Literature

43results about How to "Increase motor power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

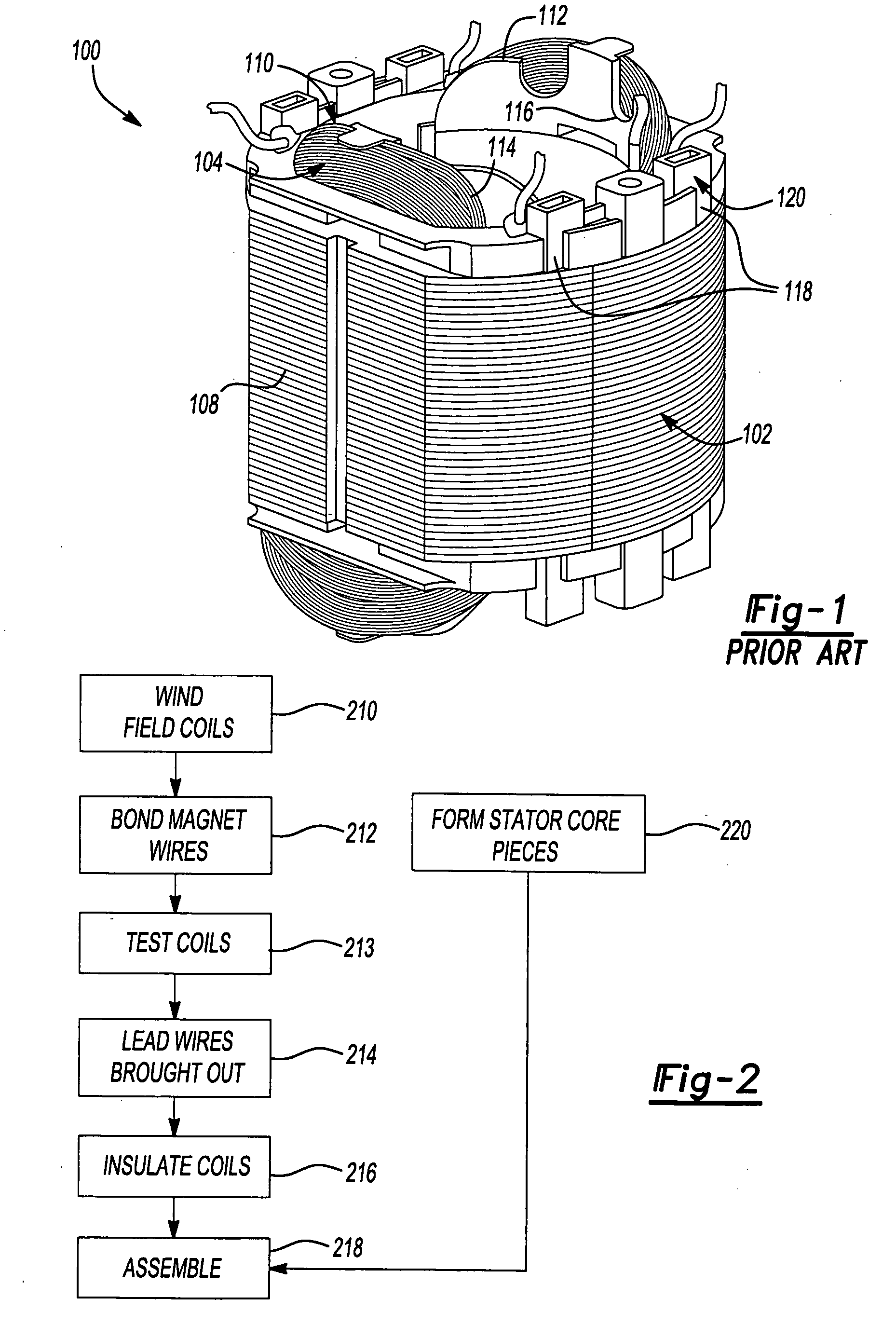

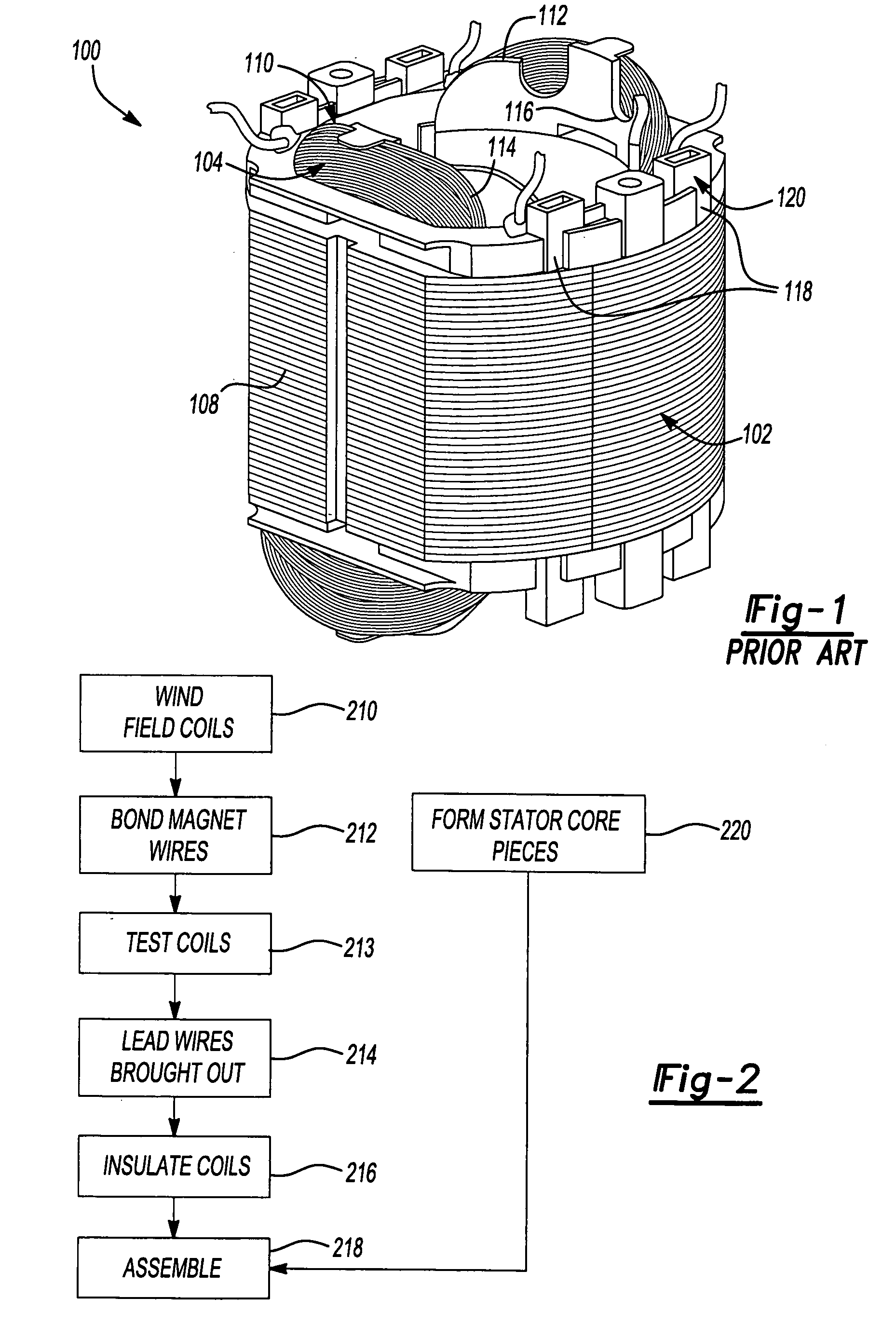

High power low RPM D.C. motor

InactiveUS6037692AIncrease motor powerHigh strengthAC motor controlAsynchronous induction motorsEngineeringConductor Coil

A high power low RPM direct current electric motor is disclosed whereby the high power output is achieved in one of two ways or both. In the first case, the need for cooling is reduced simultaneously along with an increase in the utilization of the magnetic field present in the motor permanent magnets. This is achieved by wrapping the electromagnet core with windings that are capable of demagnetizing the rotor permanent magnets under stall conditions. Interlocking motor circuitry is provided which prevents the full activation of these motor windings until motor RPM values reach a safe level. This increases motor power while decreasing resistive losses in electromagnet windings. In the second case, the rotary portion consists of a large diameter relatively flat rotor containing permanent magnets and having built in vanes for moving air over the electromagnet stator windings providing forced air cooling.

Owner:MAGNETIC MOTORS

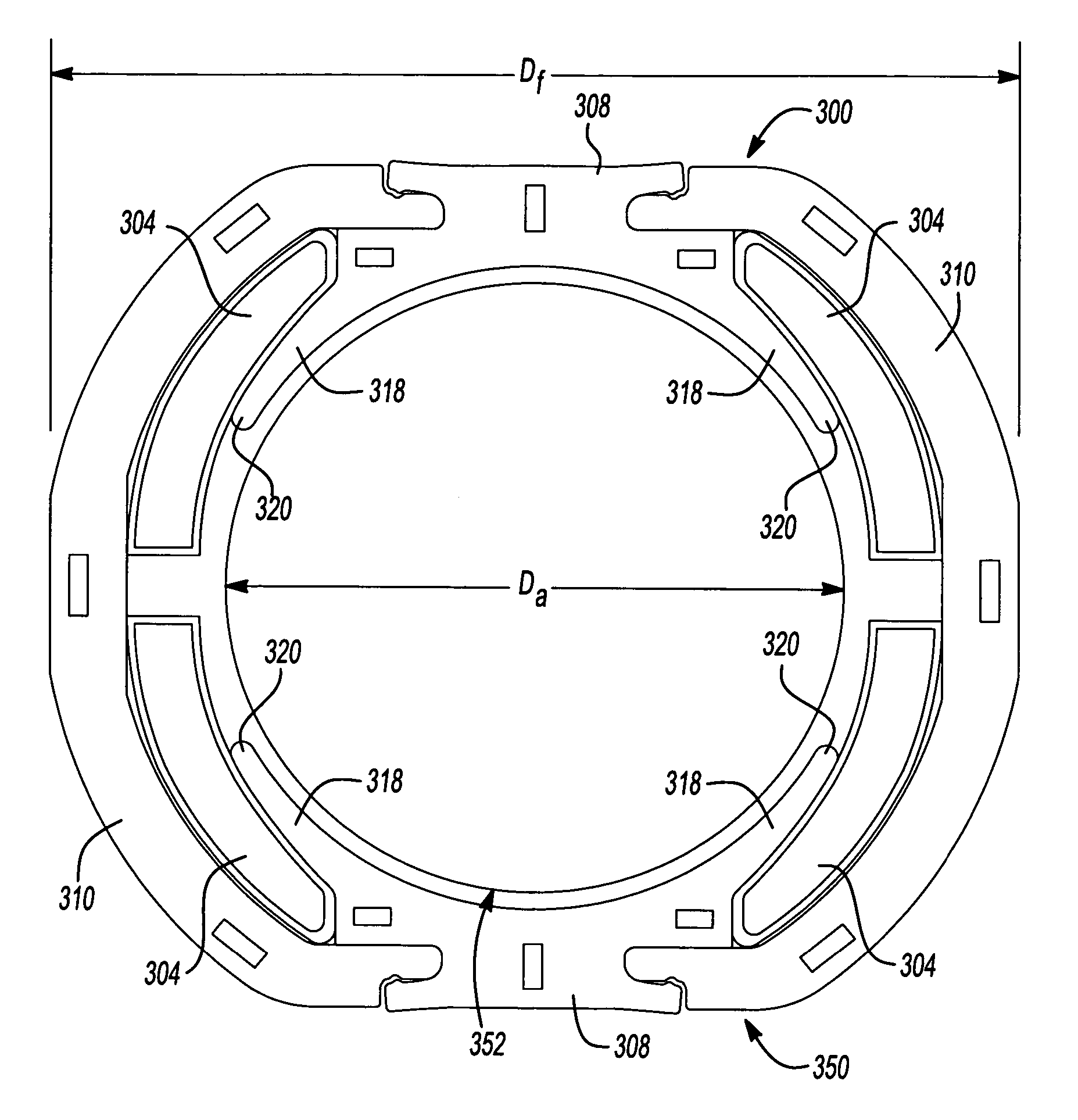

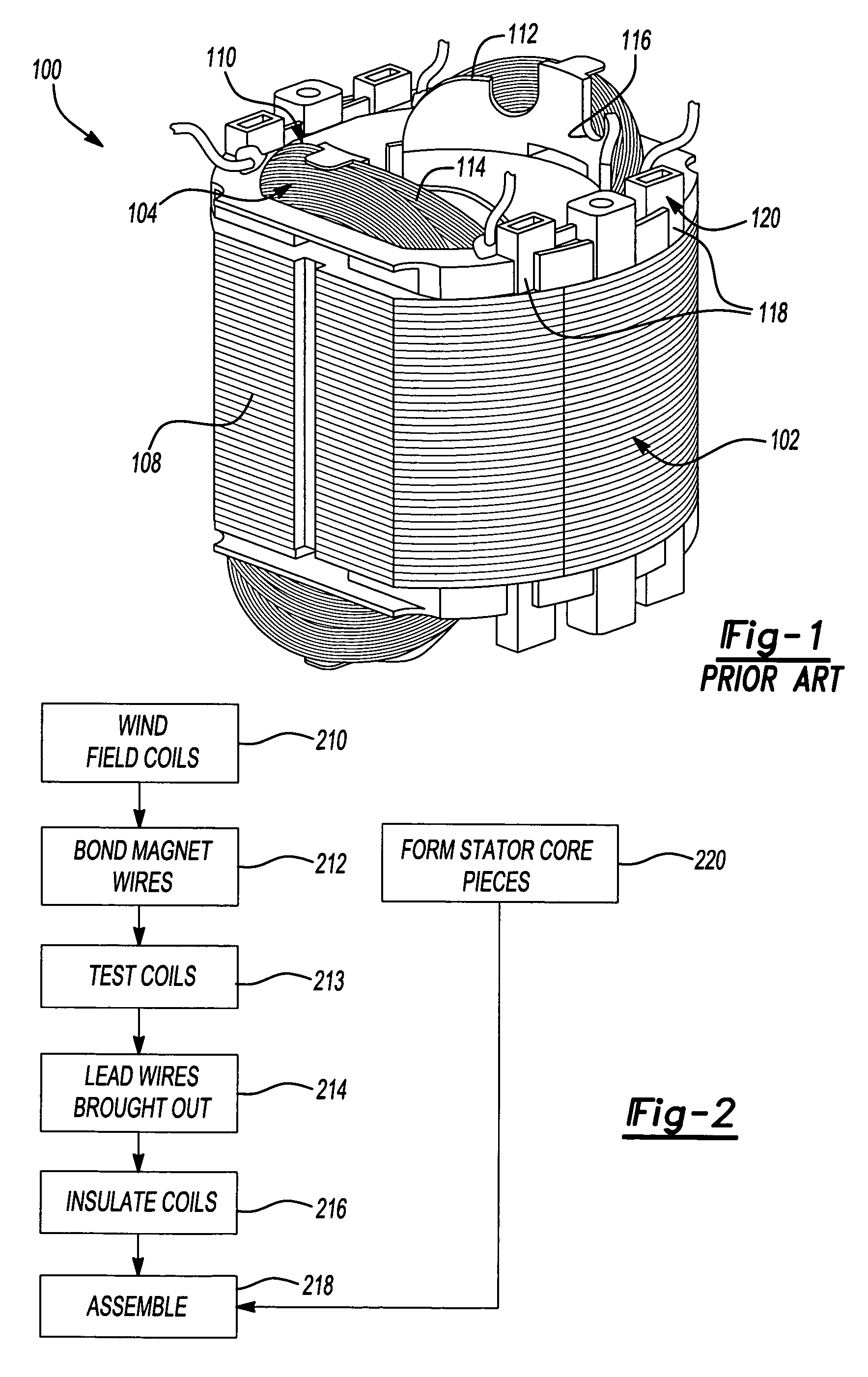

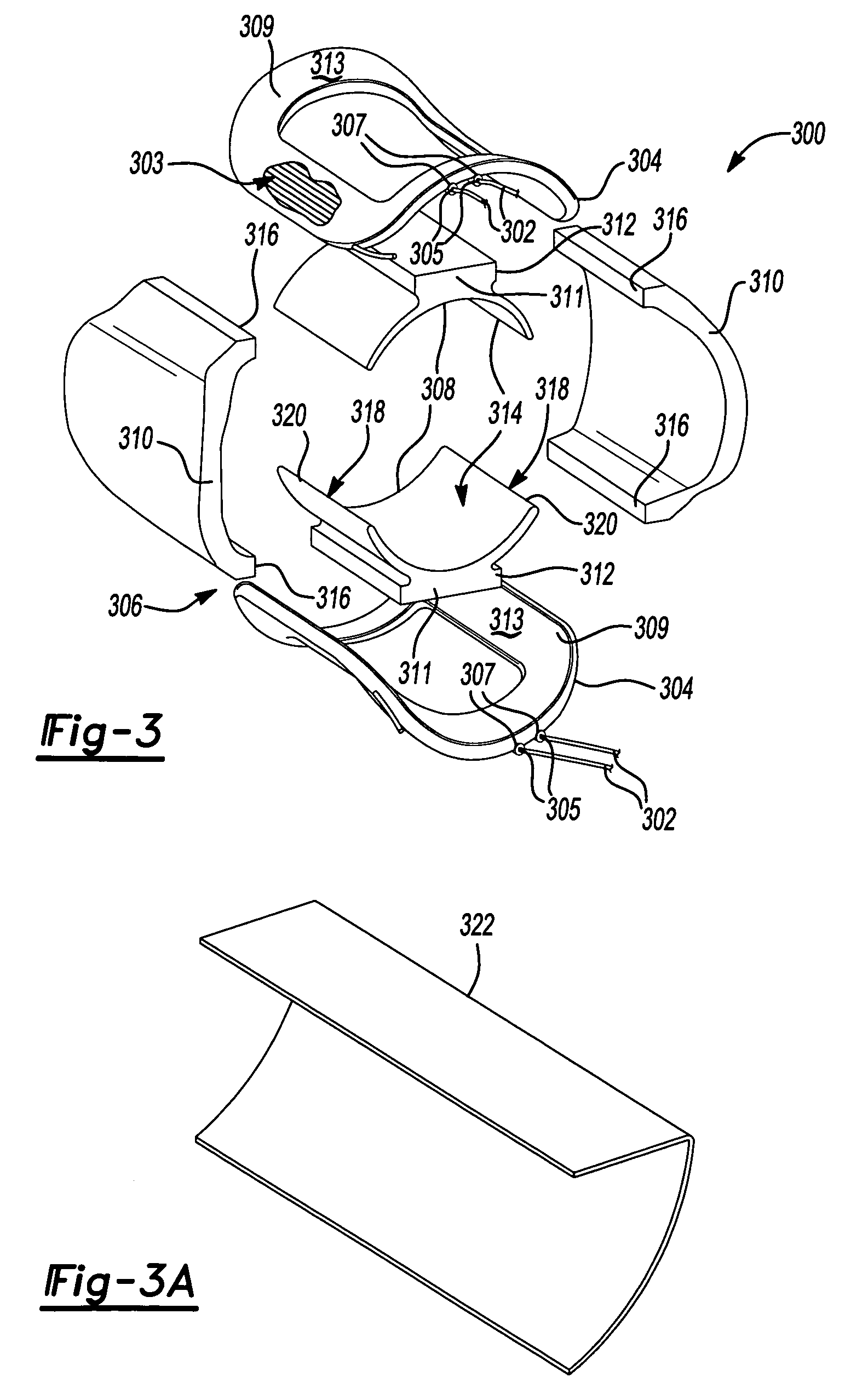

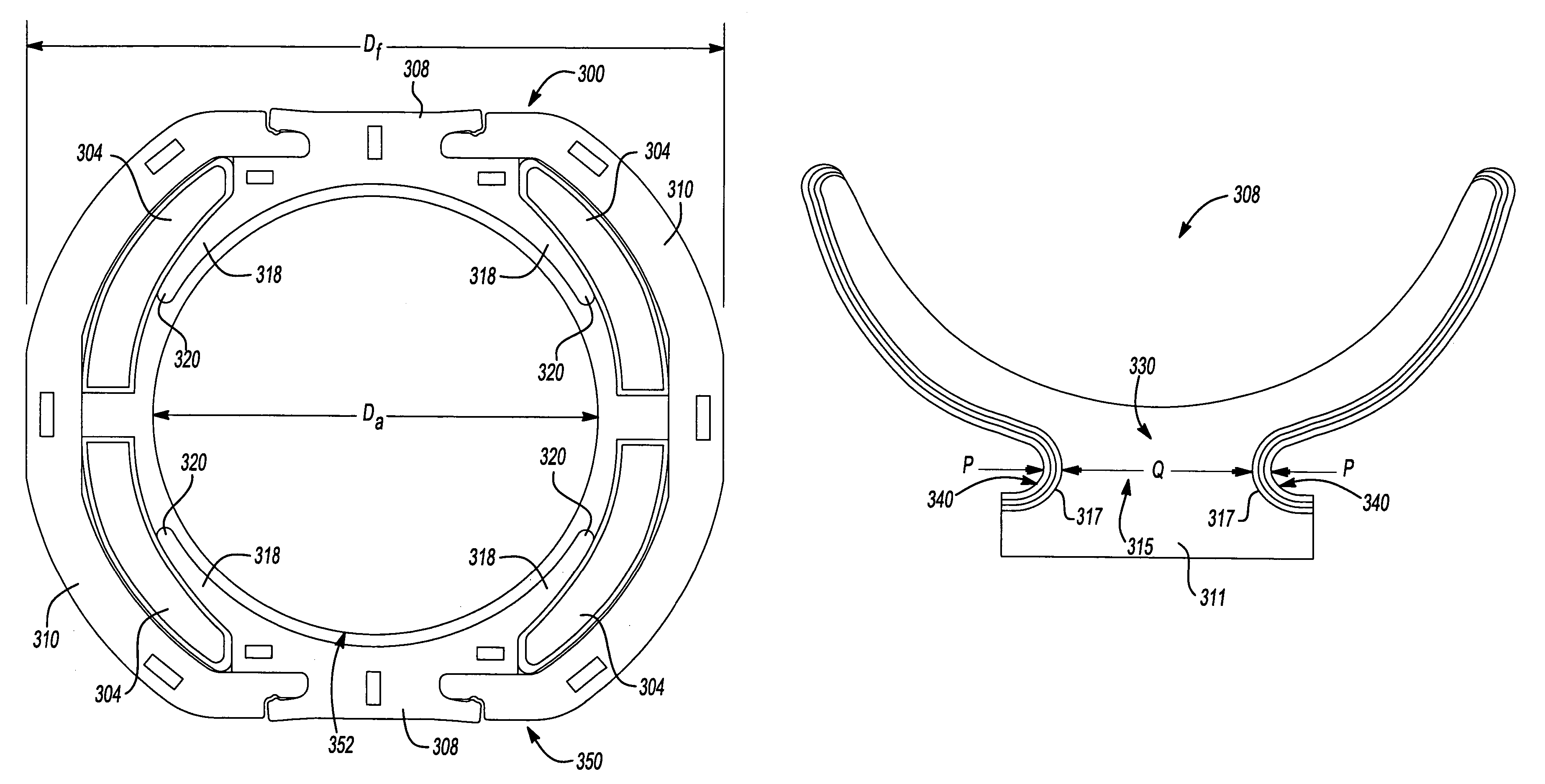

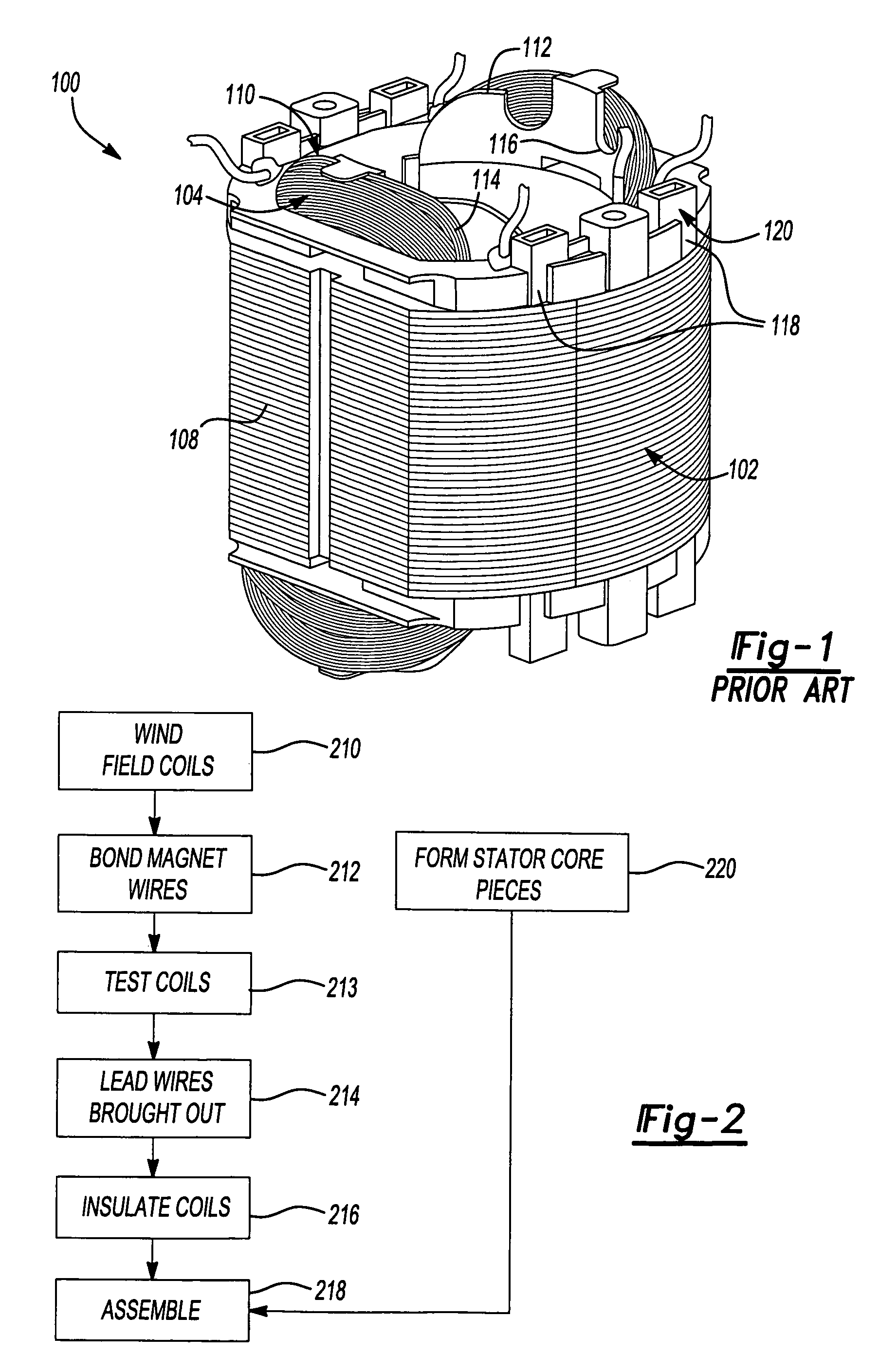

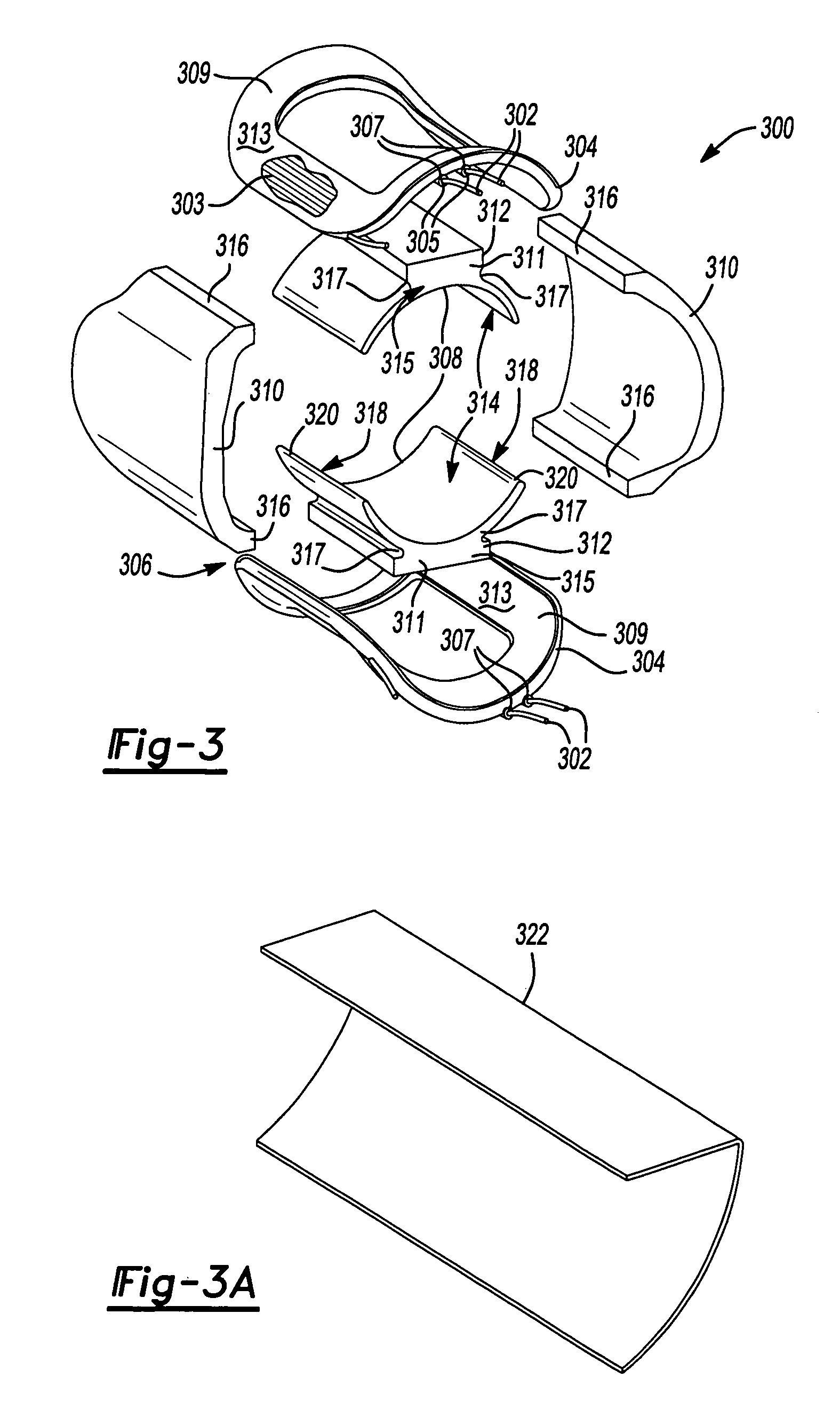

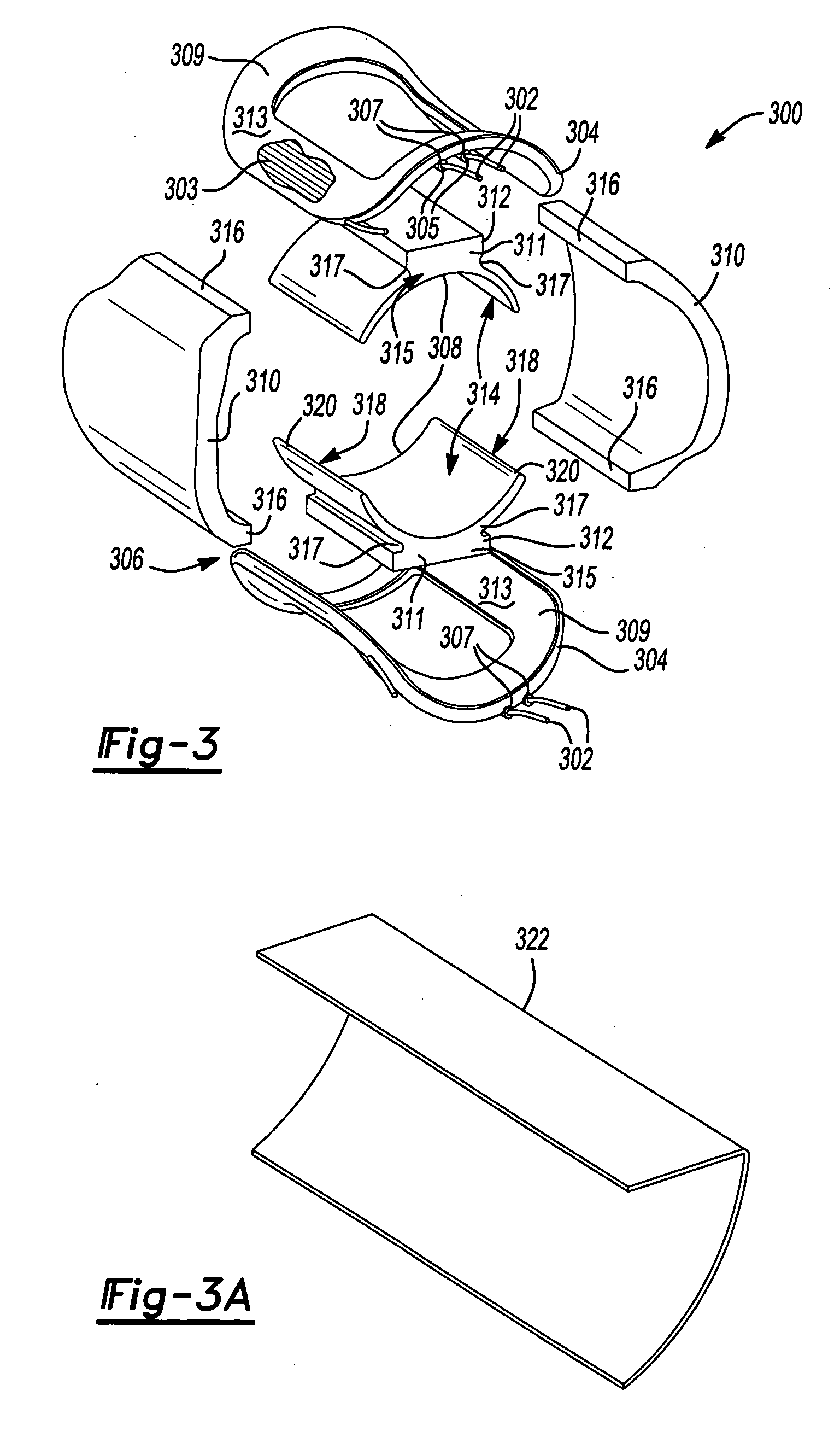

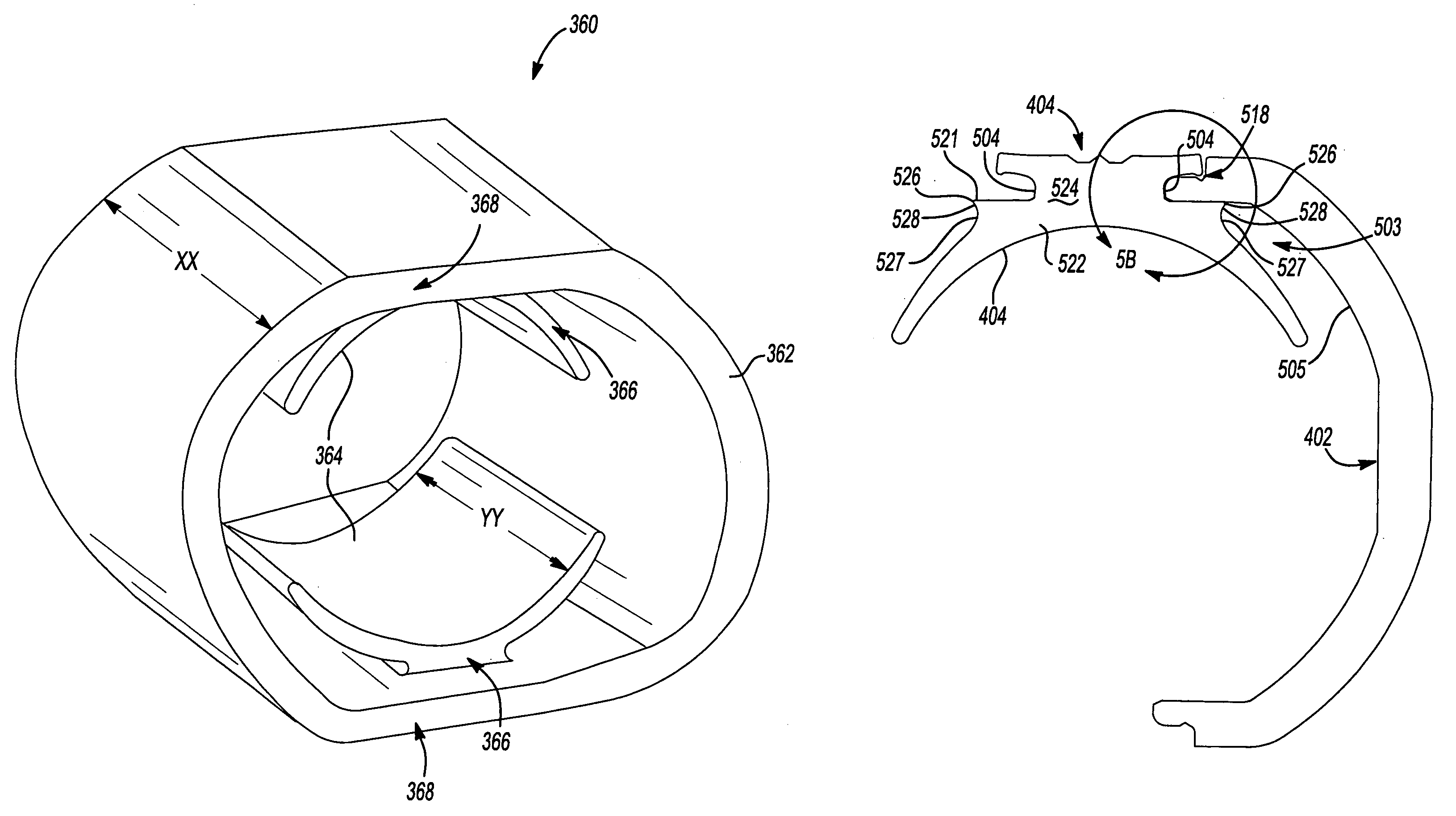

Field assemblies and methods of making same

InactiveUS7078843B2Increase powerReduce thicknessWindings insulation shape/form/constructionMagnetic circuit stationary partsPole piecePower tool

An electric motor, power tool using the electric motor, and method of making the electric motor includes making a stator by separately forming pole pieces, return path pieces and field coils. The field coils are placed over necks of the pole path pieces and the return path pieces are affixed to the pole pieces. An armature having an outside diameter of at least 0.625 the outside diameter of the stator is placed in the stator. In an aspect, the field coils are formed so that they extend beyond pole tips of the pole pieces.

Owner:BLACK & DECKER INC

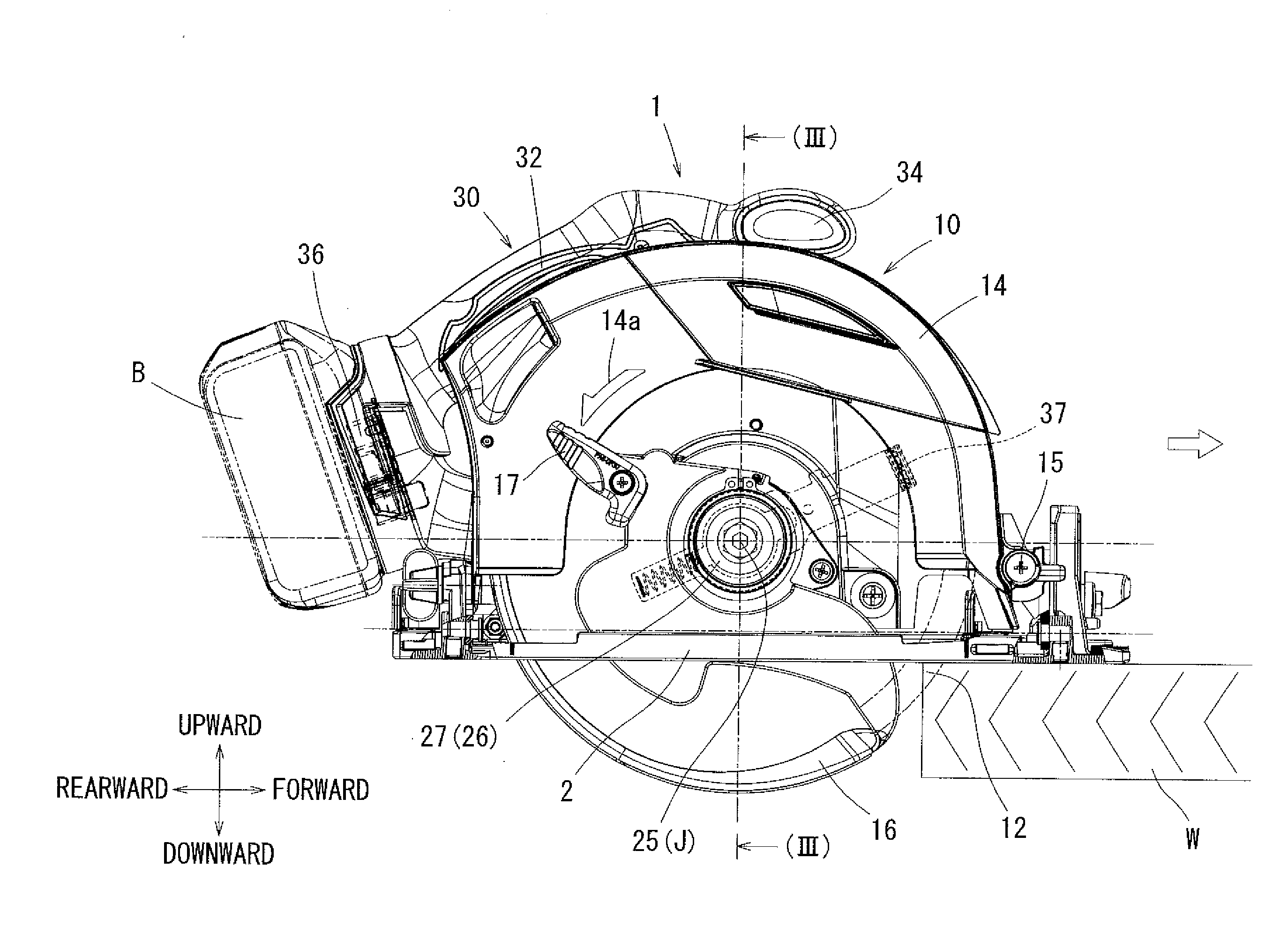

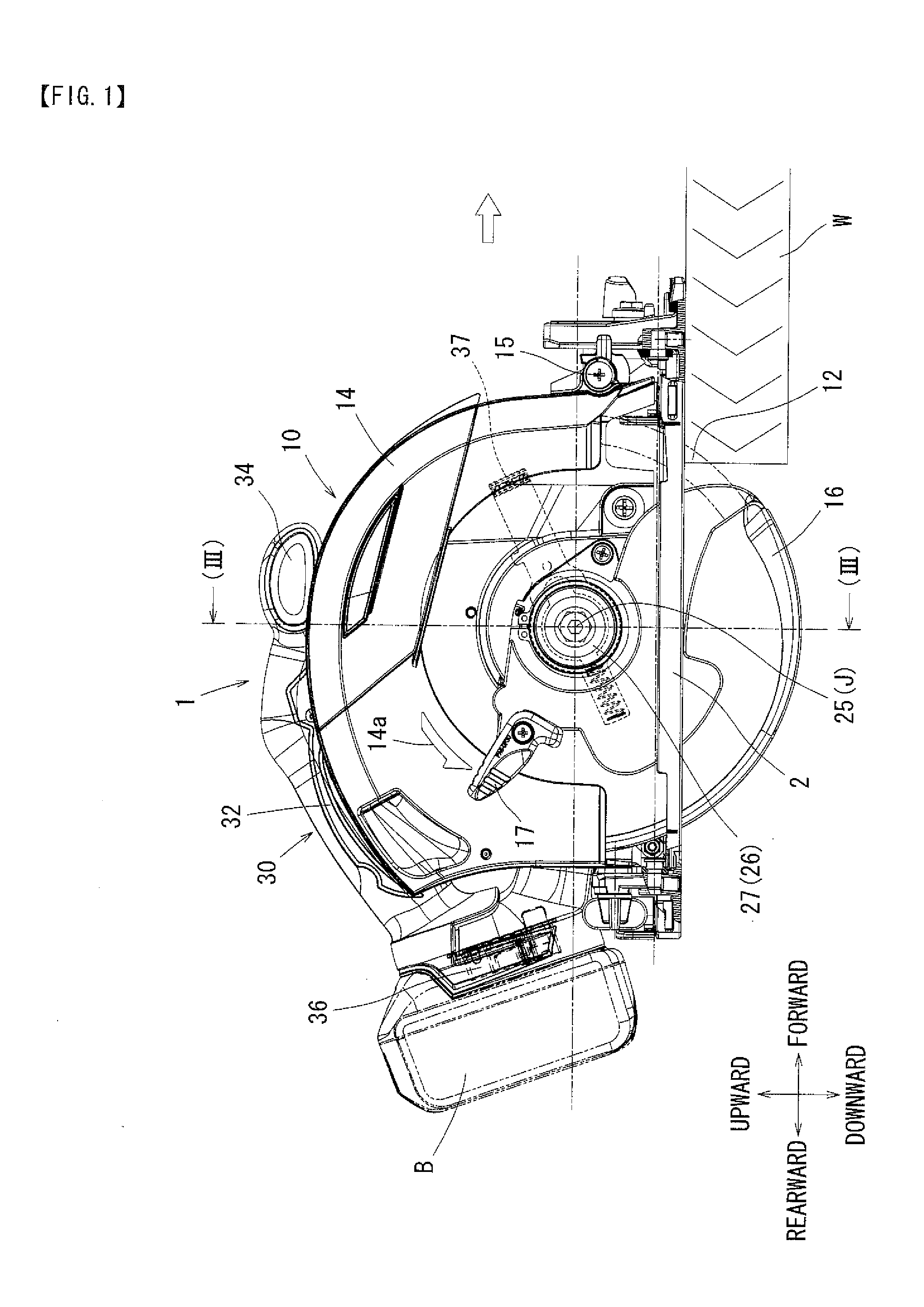

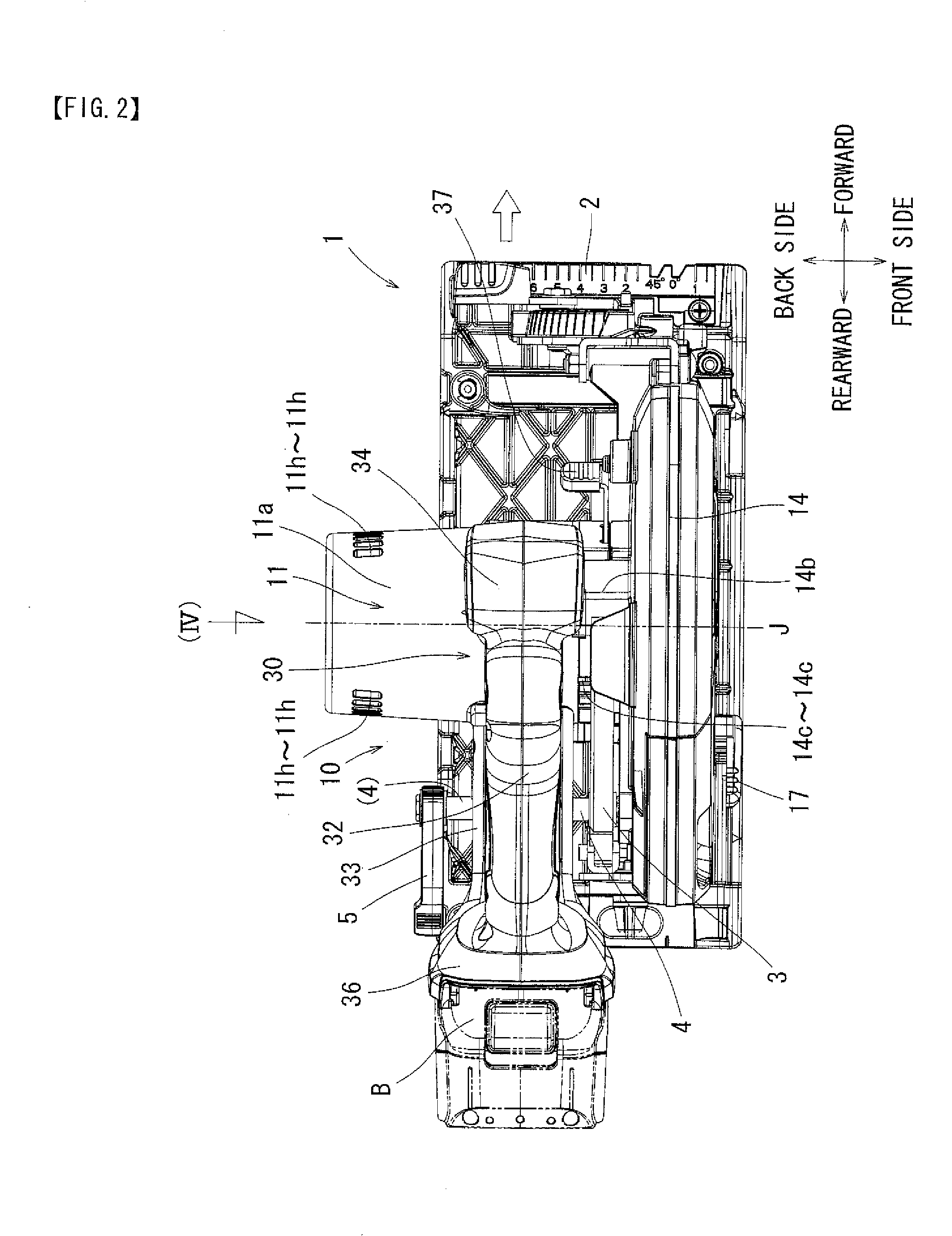

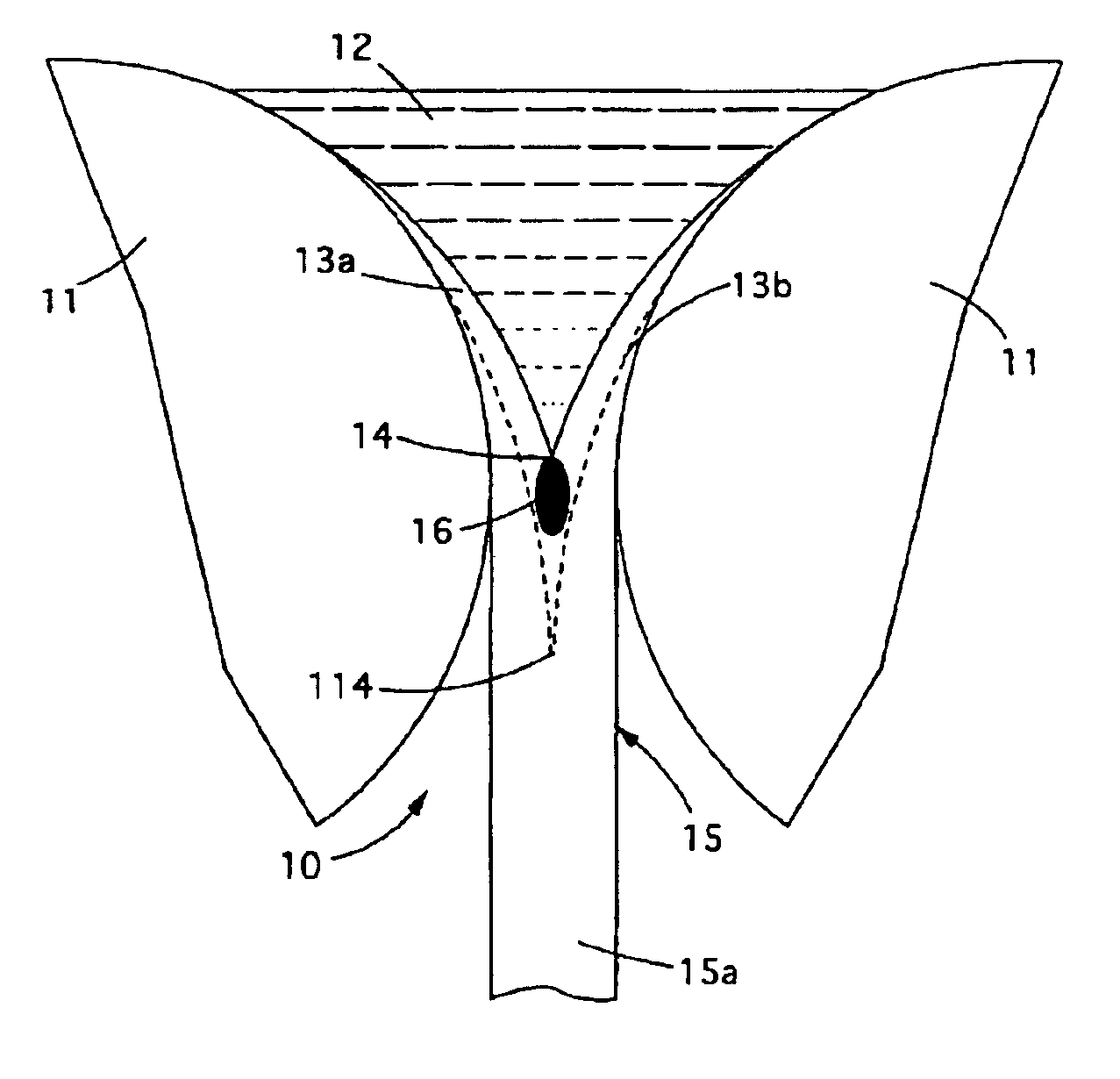

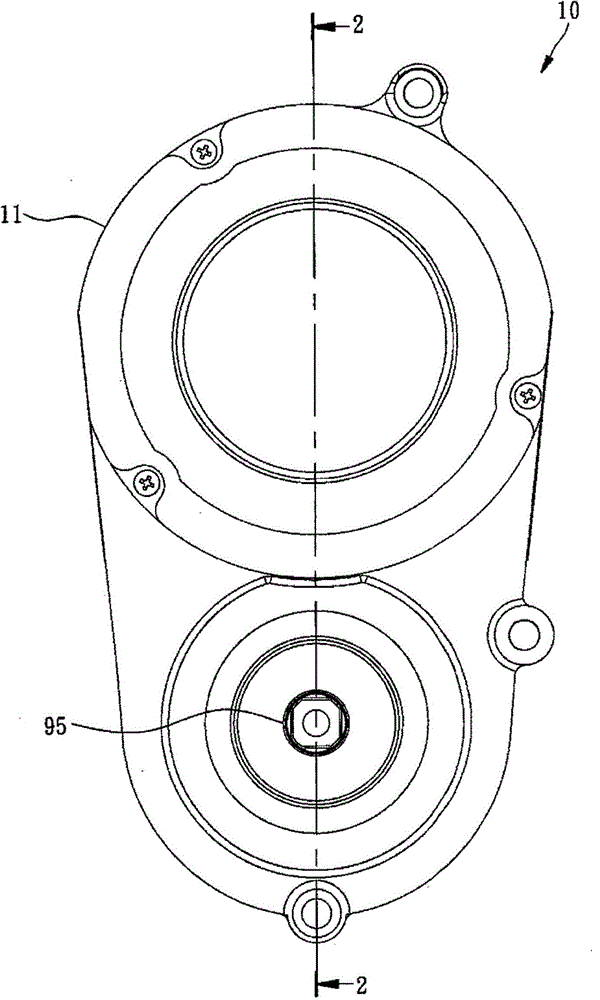

Cutting tool

InactiveUS20130333228A1Reduce vibrationReduce wind noiseMetal sawing devicesMetal working apparatusRotation velocityControl theory

In a portable cutting tool configured to perform a cutting operation through movement along the upper surface of a workpiece, when an ordinary inner rotor type motor is used as the drive source, the motor is rotated at high speed to obtain a high output, which is reduced in speed by a speed reduction device to thereby secure an appropriate rotational speed for a rotary cutter. Since the electric motor is rotated at high speed in this construction, there have been problems of noise, vibration, etc. The present invention aims to achieve a reduction in the noise and vibration of the cutting tool.A direct drive system is incorporated with an outer rotor type electric motor (11) used as the drive source and with a rotary cutter (12) directly mounted to an output shaft (11d) of the motor, and the electric motor (11) is rotated at an appropriate rotational speed for the rotary cutter (12), for example, at approximately 6,000 RPM, whereby it is possible to achieve a reduction in the noise and vibration of the cutting tool 1.

Owner:MAKITA CORP

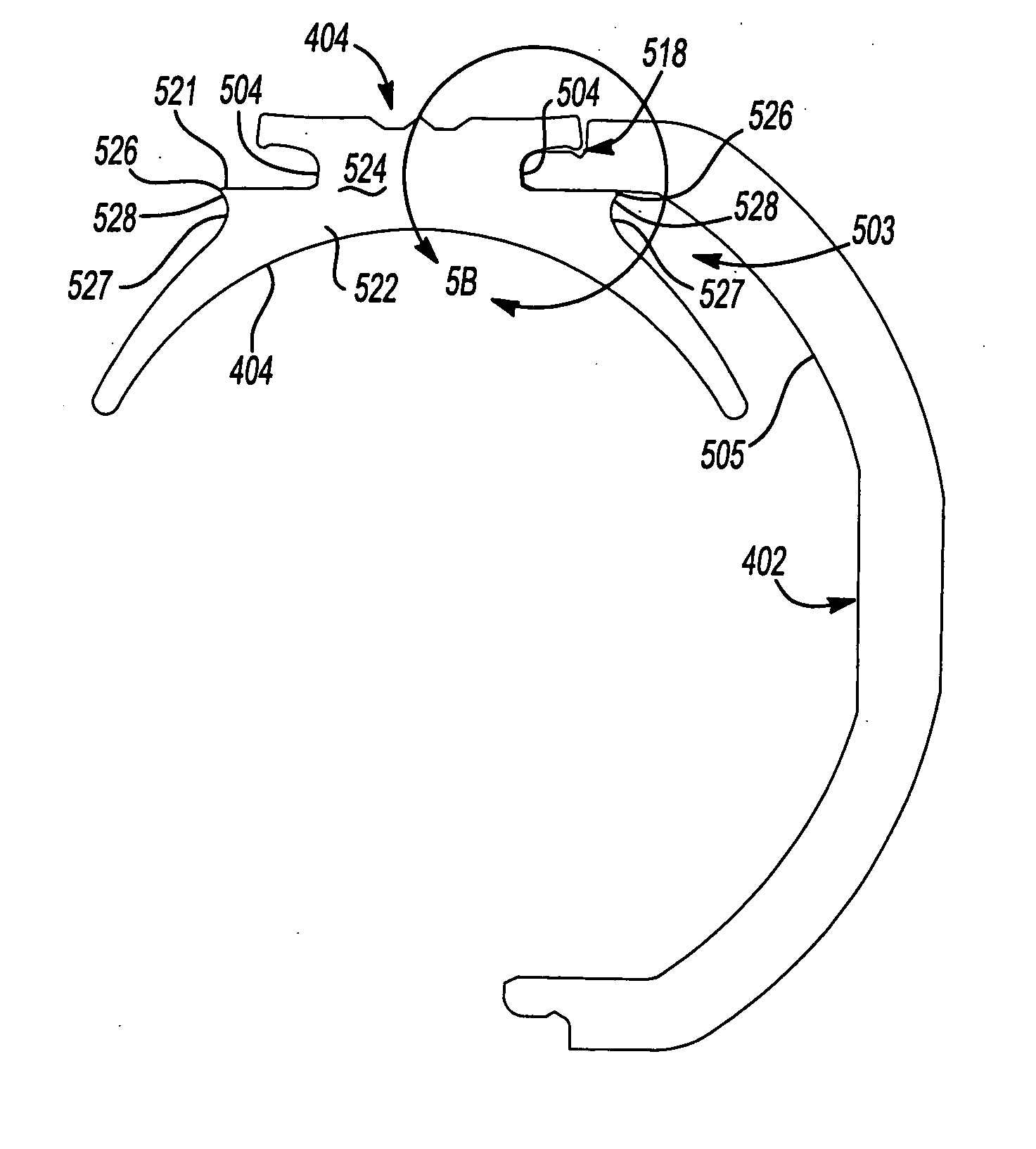

Field assemblies having pole pieces with ends that decrease in width, and methods of making same

InactiveUS7205696B2Increase powerReduce thicknessWindings insulation shape/form/constructionMagnetic circuit rotating partsEngineeringPole piece

An electric motor, power tool using the electric motor, and method of making the electric motor includes making a stator that includes pole portions that have axially opposed ends that gradually decrease in width. The pole portions may also have dovetail features that are received in corresponding recesses of the back iron portion.

Owner:BLACK & DECKER INC

Field assemblies having pole pieces with axial lengths less than an axial length of a back iron portion and methods of making same

InactiveUS20050189840A1Increase powerReduce thicknessWindings insulation shape/form/constructionMagnetic circuit rotating partsEngineeringPole piece

An electric motor, power tool using the electric motor, and method of making the electric motor includes making a stator that includes pole portions that have axial lengths less than an axial length of a back iron portion. Alternatively, or in addition, the pole portions have axially opposed ends that decrease in width. Alternatively, or in addition, the pole portions have dovetail features that are received in corresponding recesses of the back iron portion.

Owner:BLACK & DECKER INC

Method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates

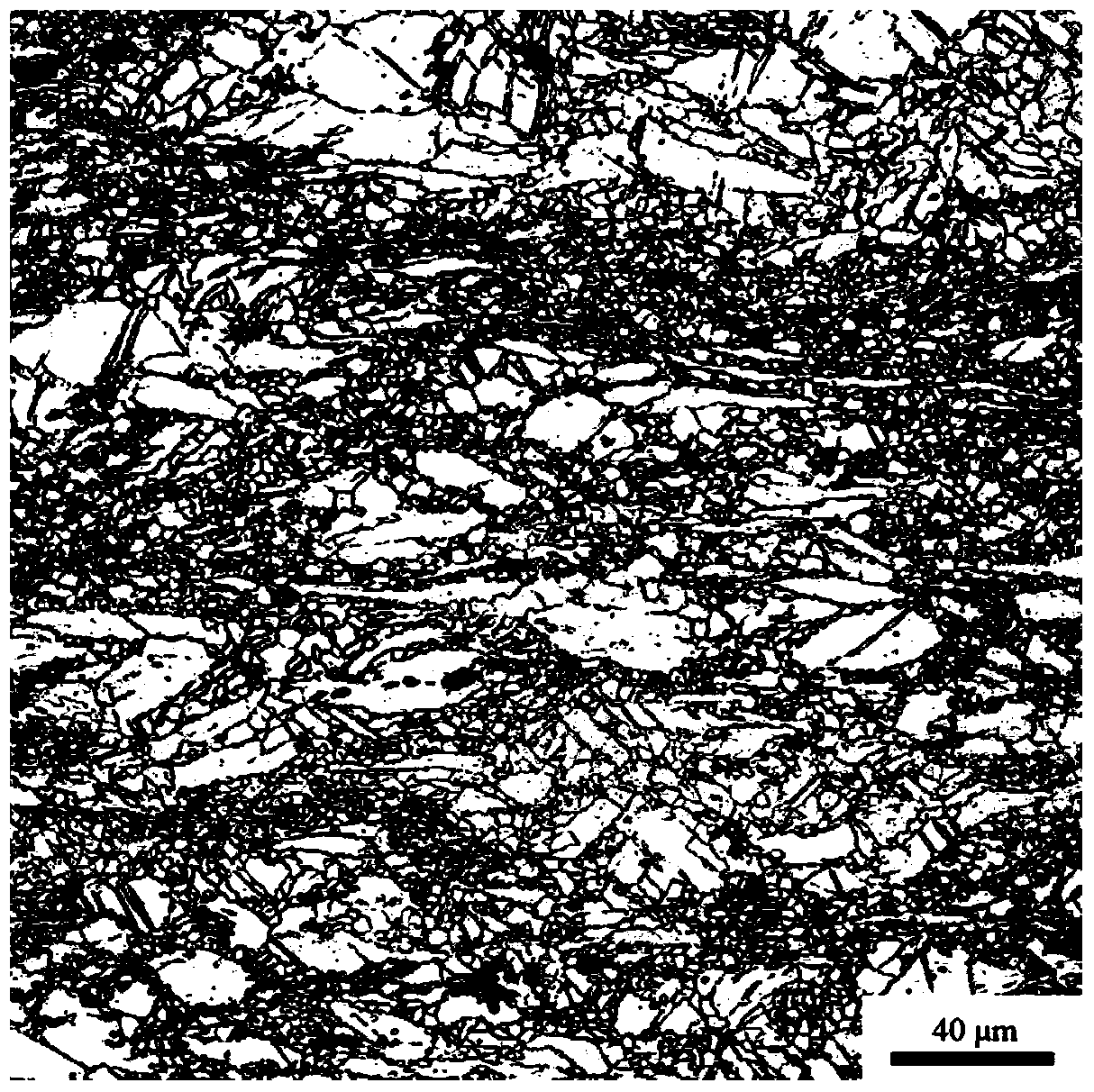

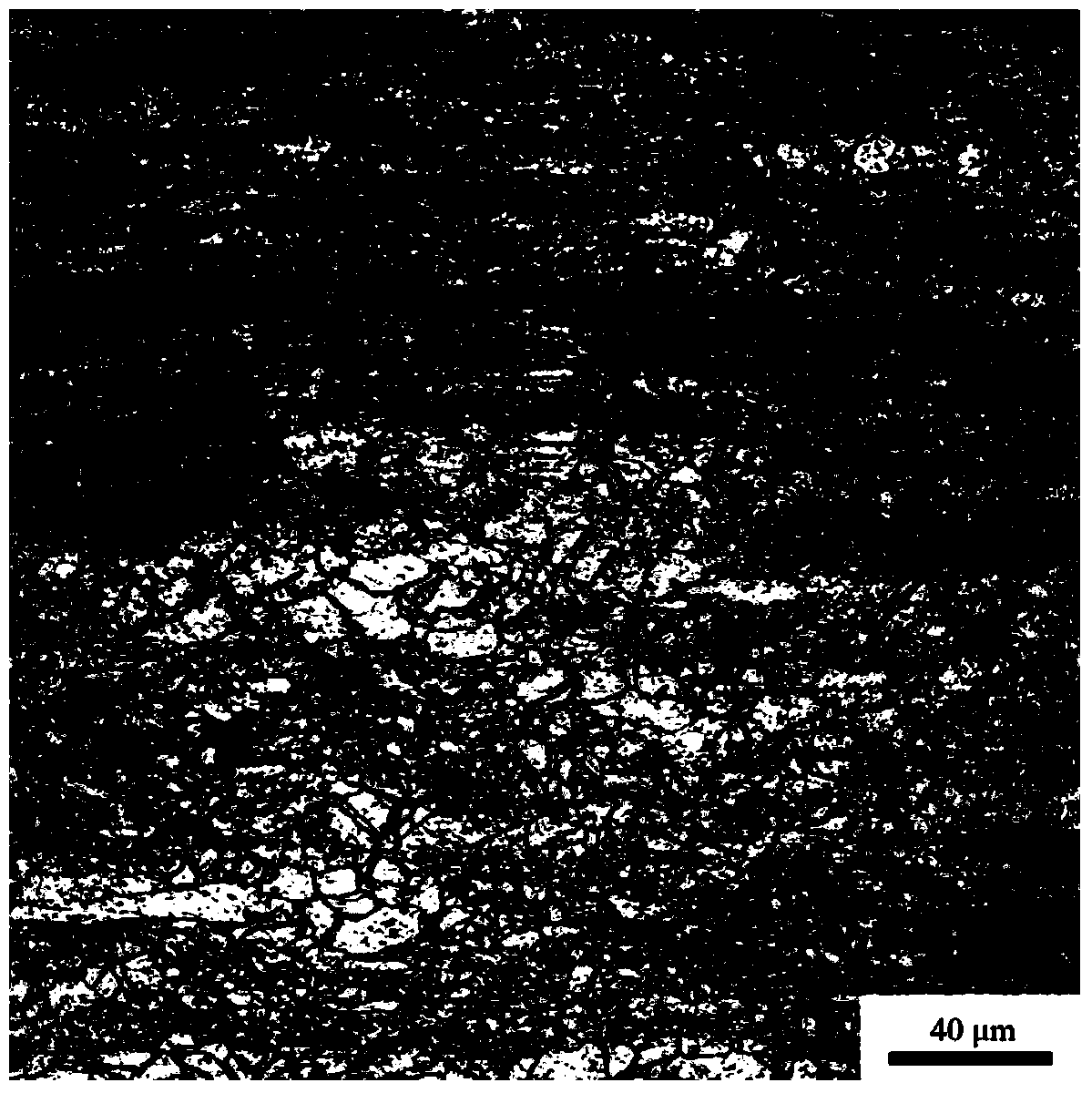

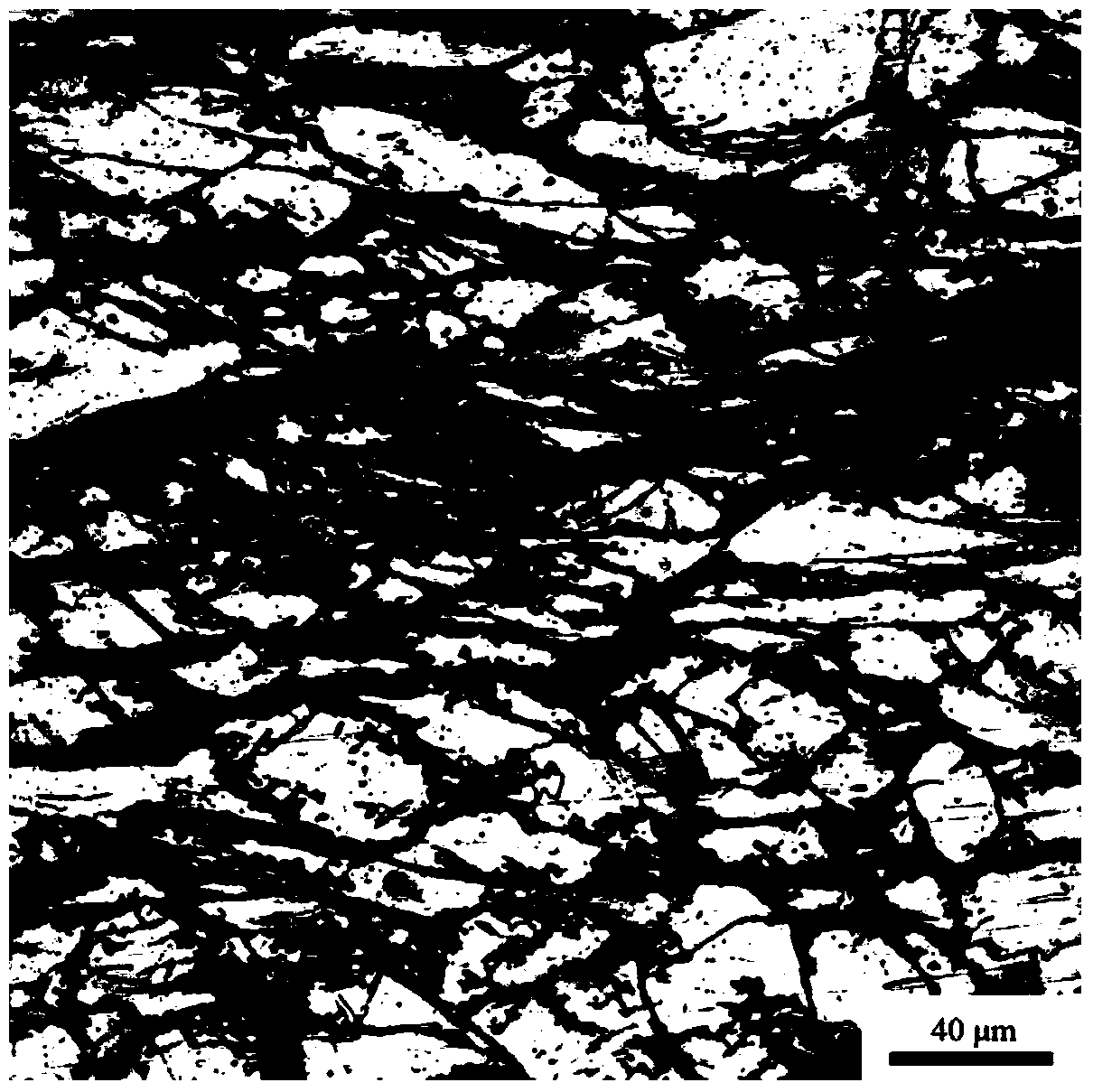

InactiveCN104259201AEnhanced ability to recover and recrystallizeImprove plasticityTemperature control deviceTension/compression control deviceDynamic recrystallizationSingle pass

The invention relates to a magnesium alloy processing method, in particular to a method for rolling high-ductility and high-scalability Mg-Al series magnesium alloy plates. The method comprises the steps of milling, heating and heat preservation of a plate, heating and heat preservation of a roller, rolling and cooling, wherein the rolling speed is 10-100 m / min; the rolling reduction of each time of rolling is 45%-80%. As the high-speed single-pass big-dependent-variable rolling is adopted for inducing obvious dynamic recrystallization, fully fine equiaxed grains are generated, and accordingly, the magnesium alloy plates of which the ductility and the scalability are greatly improved are acquired. Besides, as the annealing process is omitted, the manufacturing cost is greatly lowered, and the method is more suitable for large-scale industrial production.

Owner:CHONGQING UNIV

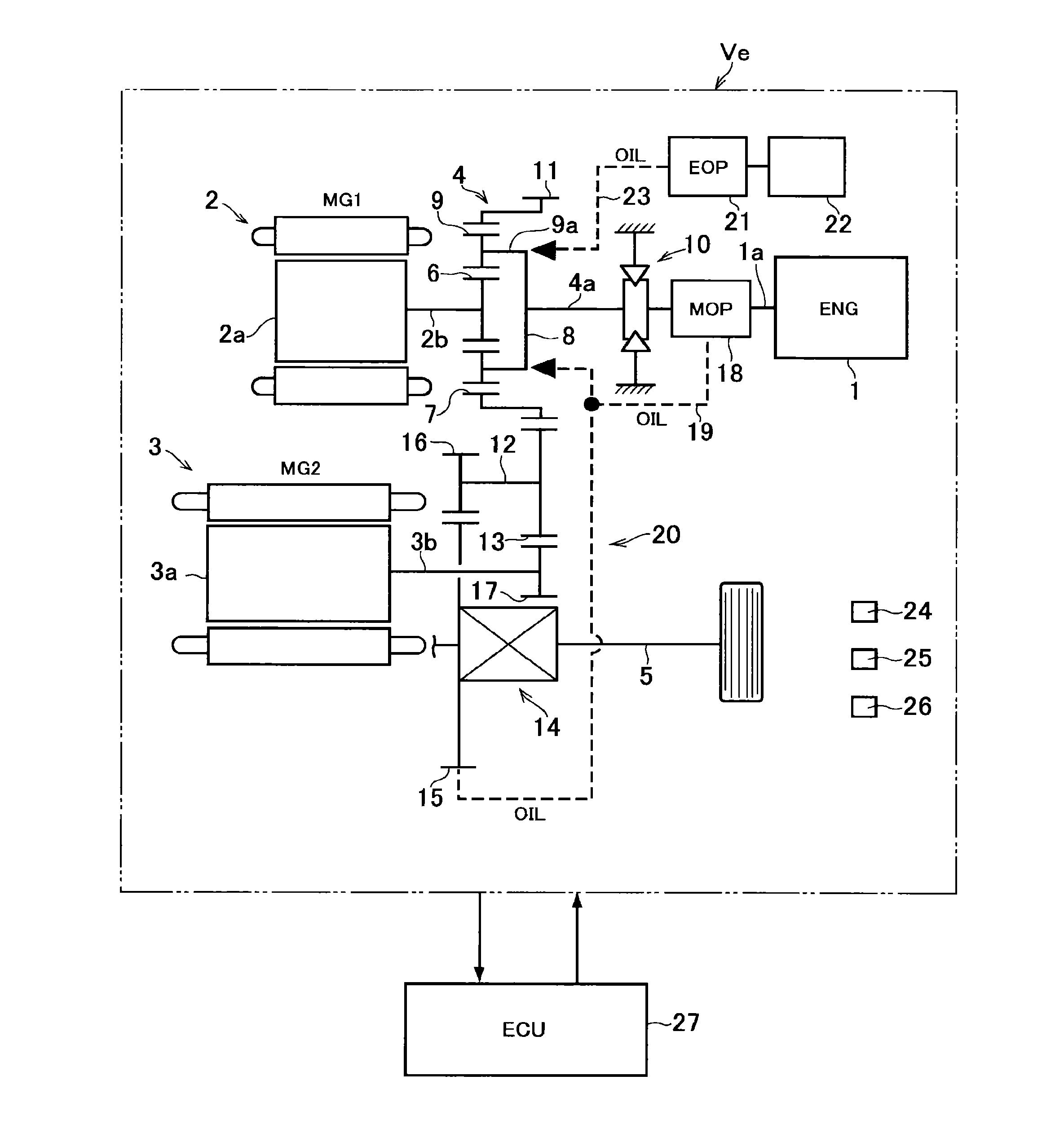

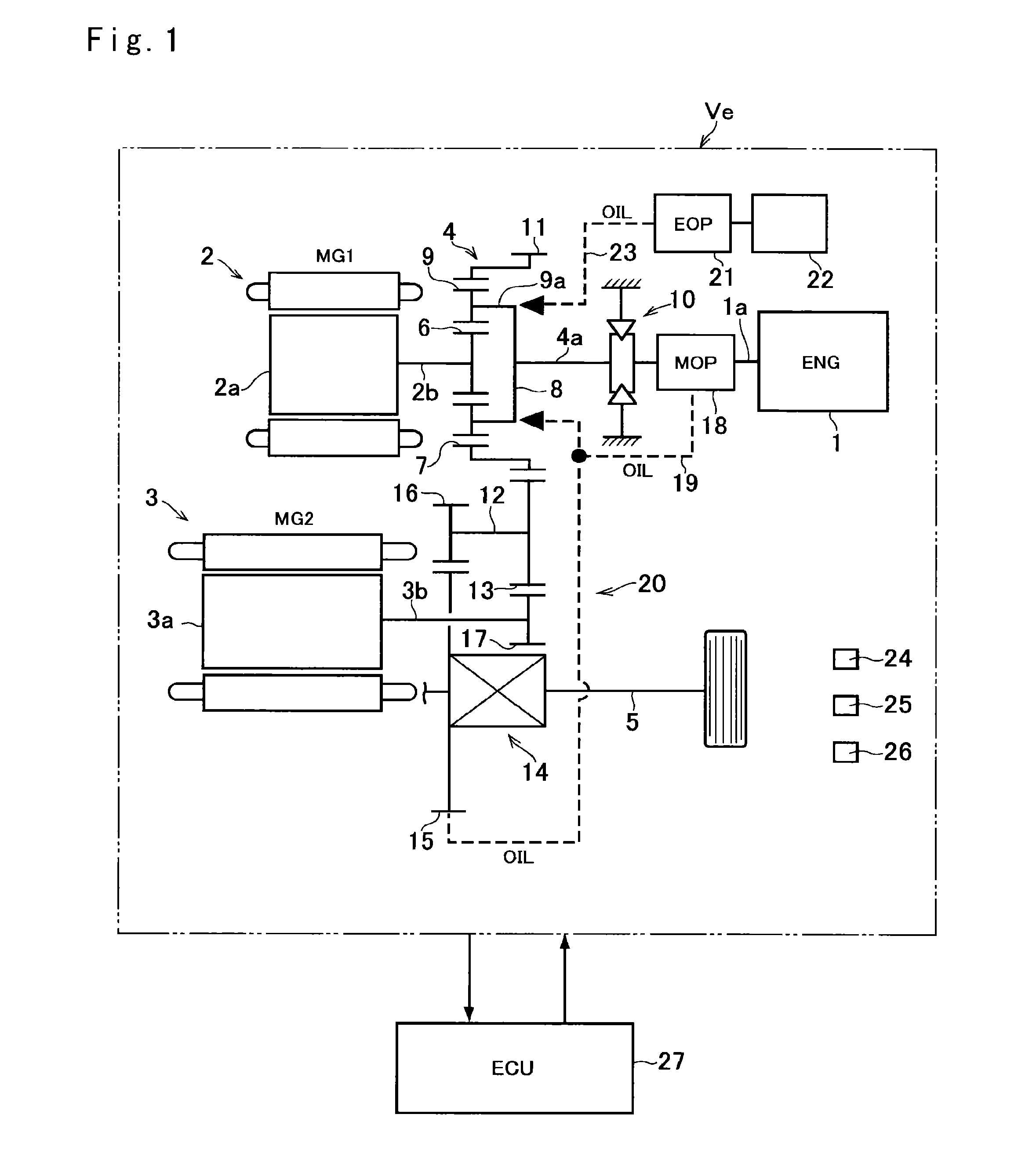

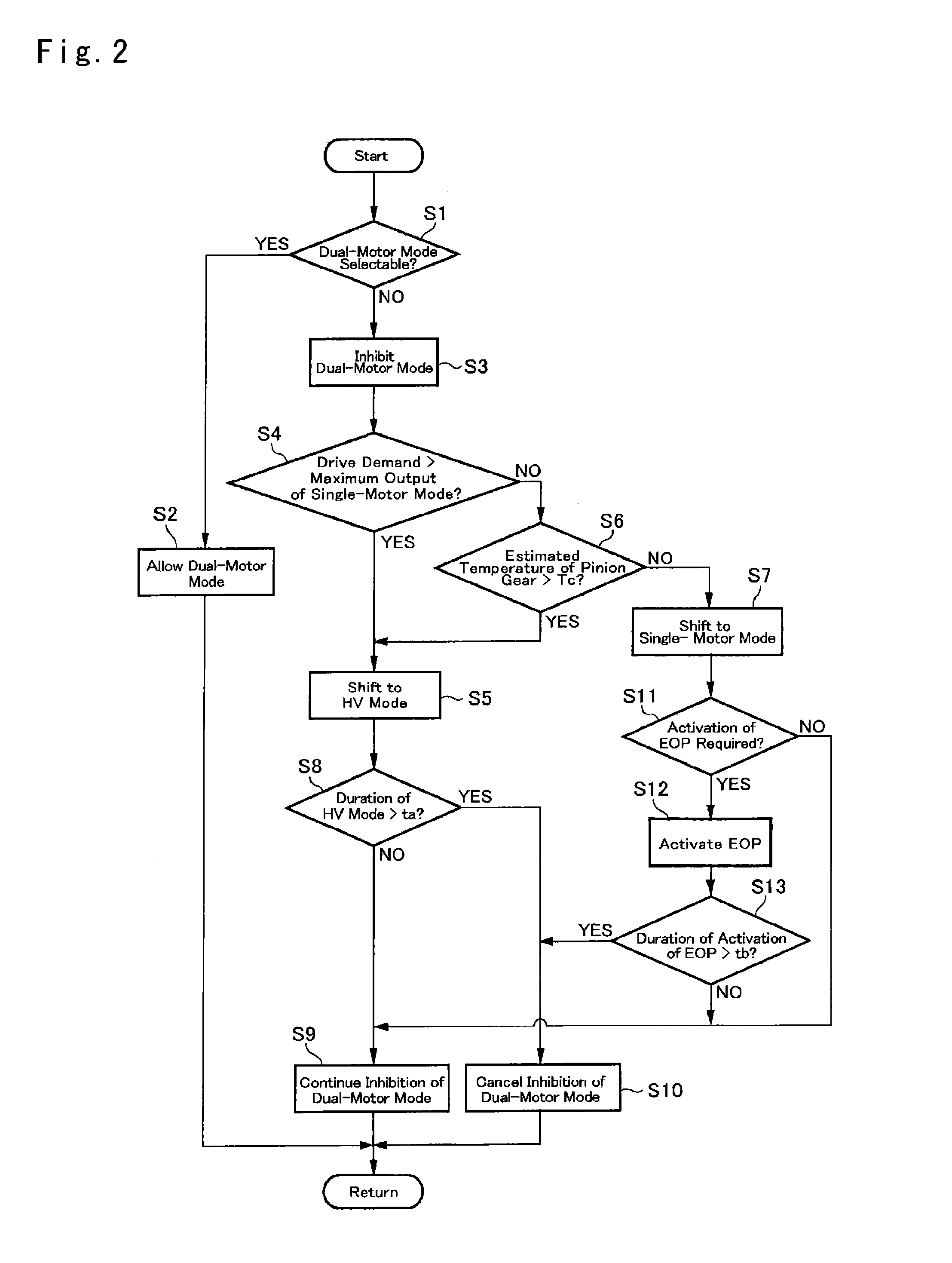

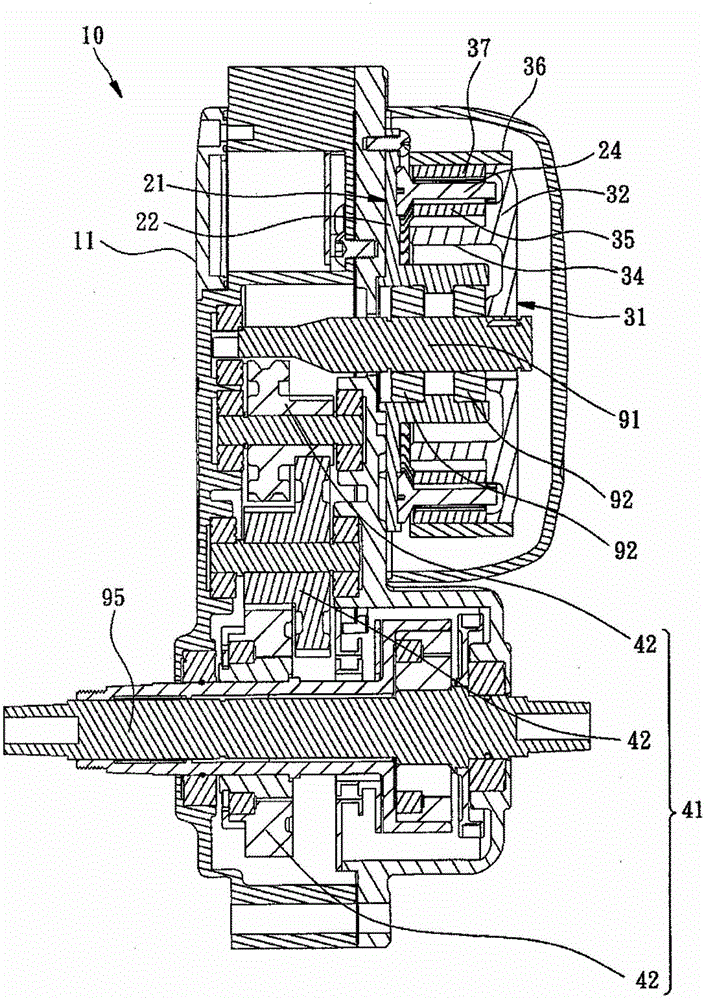

Control system for hybrid vehicle

ActiveUS20160280215A1Increase speedViscosity of oil is increasedHybrid vehiclesElectric propulsion mountingControl systemOperation mode

A control system for hybrid vehicles that ensures high motor power while limiting damage on a planetary gear unit is provided. In a planetary gear unit, a sun gear is connected to a first motor, a ring gear is connected to a second motor, and a carrier is connected to an engine. An operating mode of the hybrid vehicle can be selected from a hybrid mode, a single-motor mode, and a dual-motor mode. The control system is configured to shift the operating mode to the hybrid mode if an estimated temperature of the pinion gear is higher than a threshold temperature (step S5), and to the single-motor mode if the estimated temperature of the pinion gear is lower than a threshold temperature (step S7).

Owner:TOYOTA JIDOSHA KK

Field assemblies having pole pieces with axial lengths less than an axial length of a back iron portion and methods of making same

InactiveUS7211920B2Increase powerReduce thicknessWindings insulation shape/form/constructionMagnetic circuit stationary partsPole piecePower tool

An electric motor, power tool using the electric motor, and method of making the electric motor includes making a stator that includes pole portions that have axial lengths less than an axial length of a back iron portion. Alternatively, or in addition, the pole portions have axially opposed ends that decrease in width. Alternatively, or in addition, the pole portions have dovetail features that are received in corresponding recesses of the back iron portion.

Owner:BLACK & DECKER INC

Wireless battery snap

InactiveUS20060028175A1Eliminate inconvenienceEasy to useBatteries circuit arrangementsElectrically conductive connectionsEngineeringElectric wire

A wireless battery snap without any leading out electrical wires and which has at least one button with exposed metal for use in an electrical device for connecting the battery which is safer in use. The spring comprises an insulating support, conductive eyelets, cylindrical socket and plug electrode, spring, contact plate, insulating sheet and insulating cover. At least two electrode holes and protruded base, posts and side walls are provided in the insulating support for securing the contact plate, spring, conductive eyelets and insulating cover. The socket and plug electrodes are held by two conductive eyelets on the insulating support and fastened together with the spring and contact plate. Two button electrodes of the battery disposed on the socket and plug electrodes respectively are connected to the contact plate on the insulating support and spring or two contact poles. In use, it is necessary for the invention to have a set of displaceable electrodes of contact detrudes with two independent poles in the electrical device. The spring permanently contacts and depresses on one of the electrodes of the device, when the electrode is displaced, the contact plate connects with the other electrode or disconnects apart therefrom, causing electrical current to flow or stop.

Owner:TSIANG PUI HONG

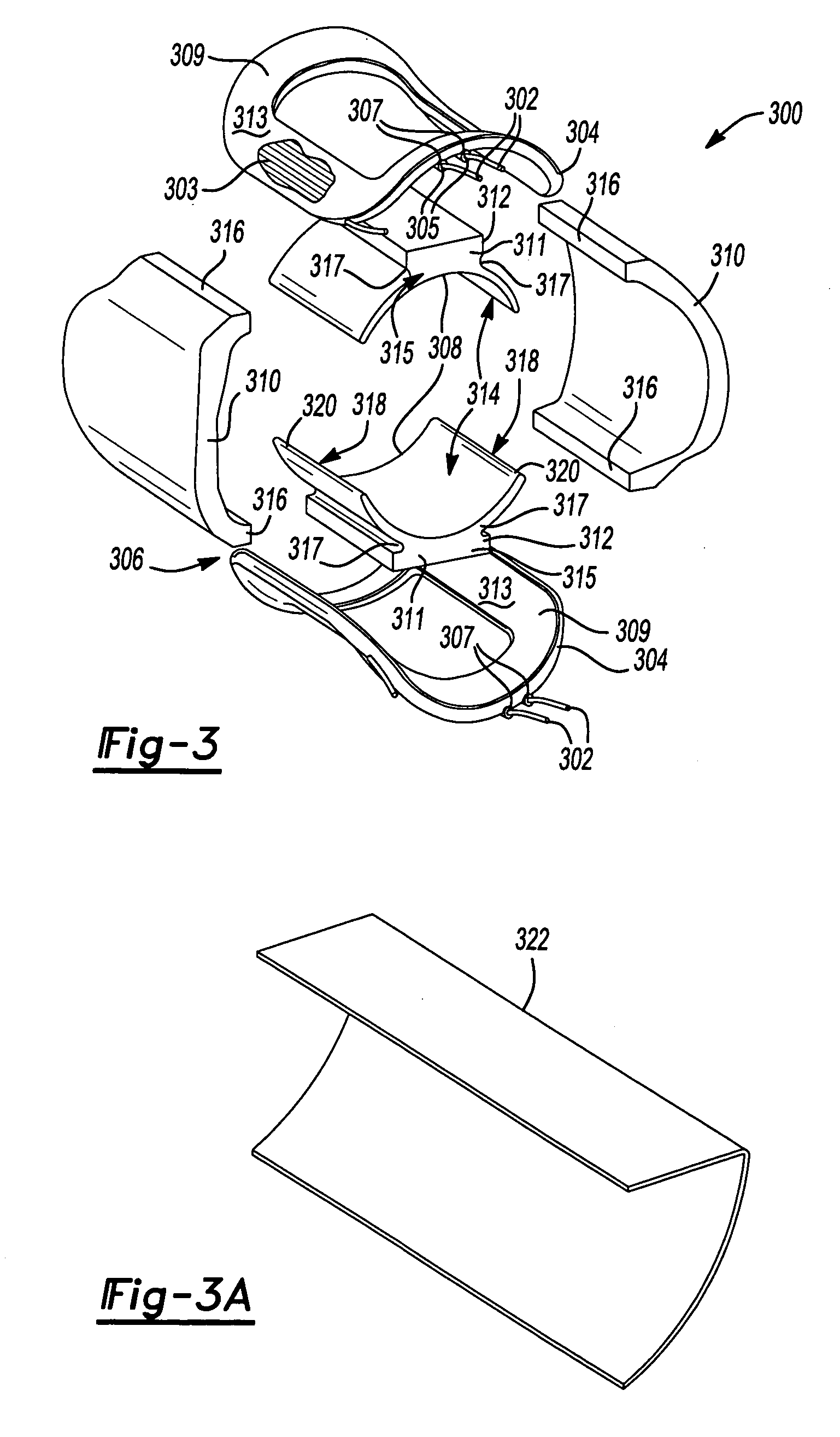

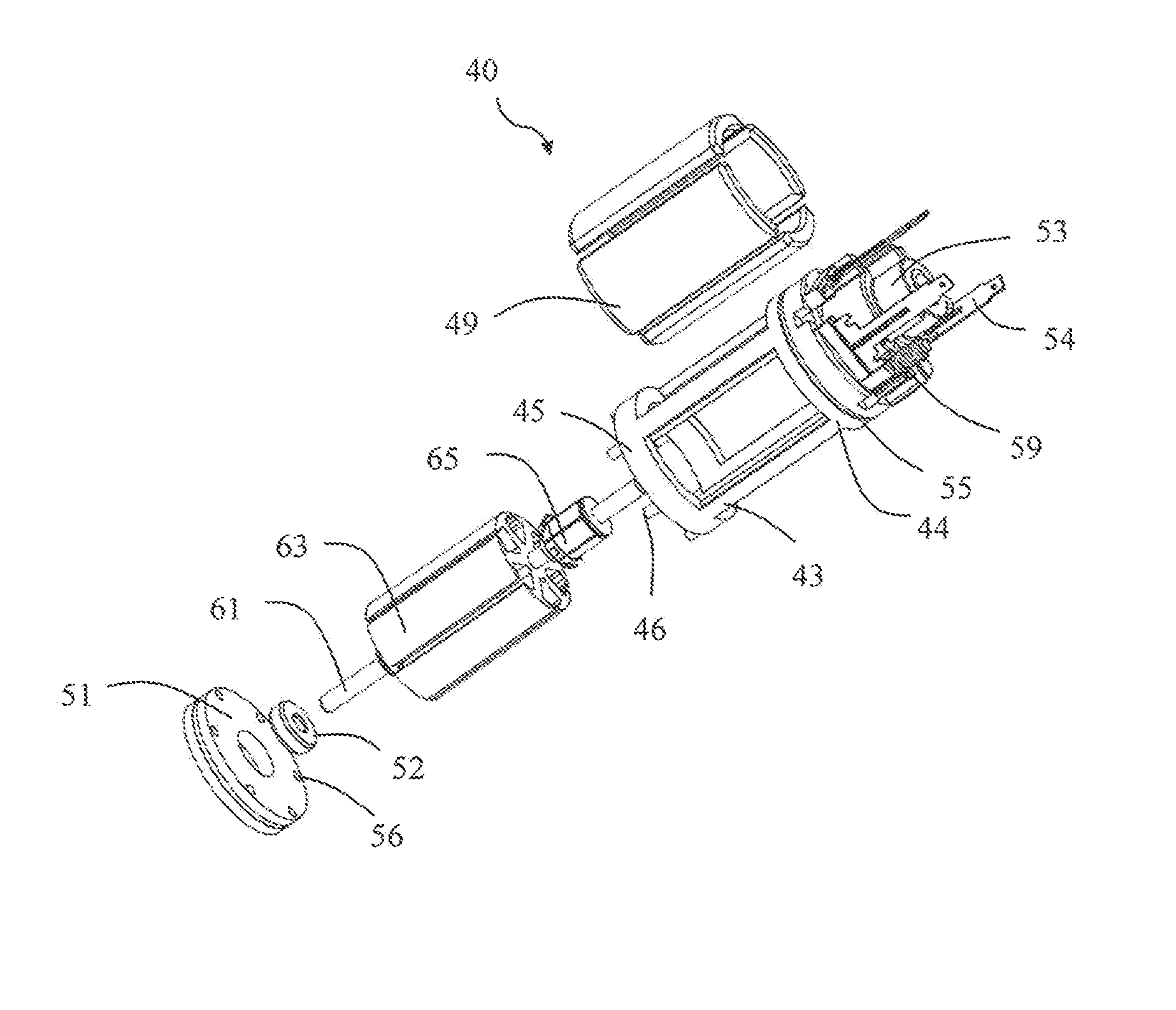

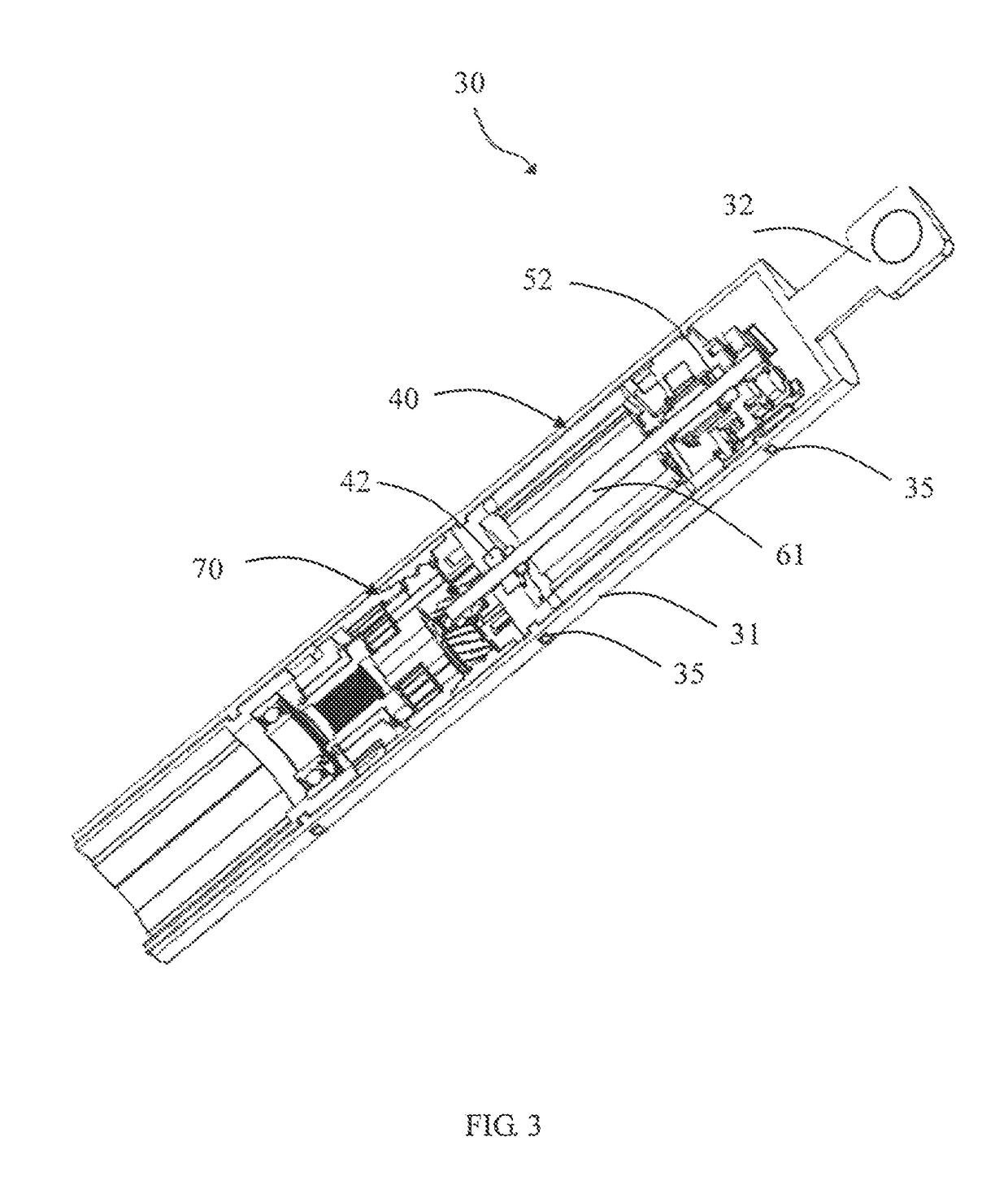

Power Strut

InactiveUS20150333591A1Prevent movementEliminates magnetically conductive outer housingMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringMagnet

A power strut for a vehicle lift gate, has a driver sleeve, a lead screw sleeve, a lead screw and a spring mounted in the lead screw sleeve. A gear reduction mechanism and a motor assembly are mounted in the driver sleeve for driving the lead screw. The motor assembly has a magnet mounting bracket fixed to the driver sleeve and a rotor disposed in the magnet mounting bracket. An end cover and multiple permanent magnets are fixed to the magnet mounting bracket. Each of the magnets is positioned between a corresponding pair of adjacent connecting portions and contacts an inner surface of the driver sleeve, thereby the driver sleeve provides a magnetic path between the magnets.

Owner:JOHNSON ELECTRIC SA

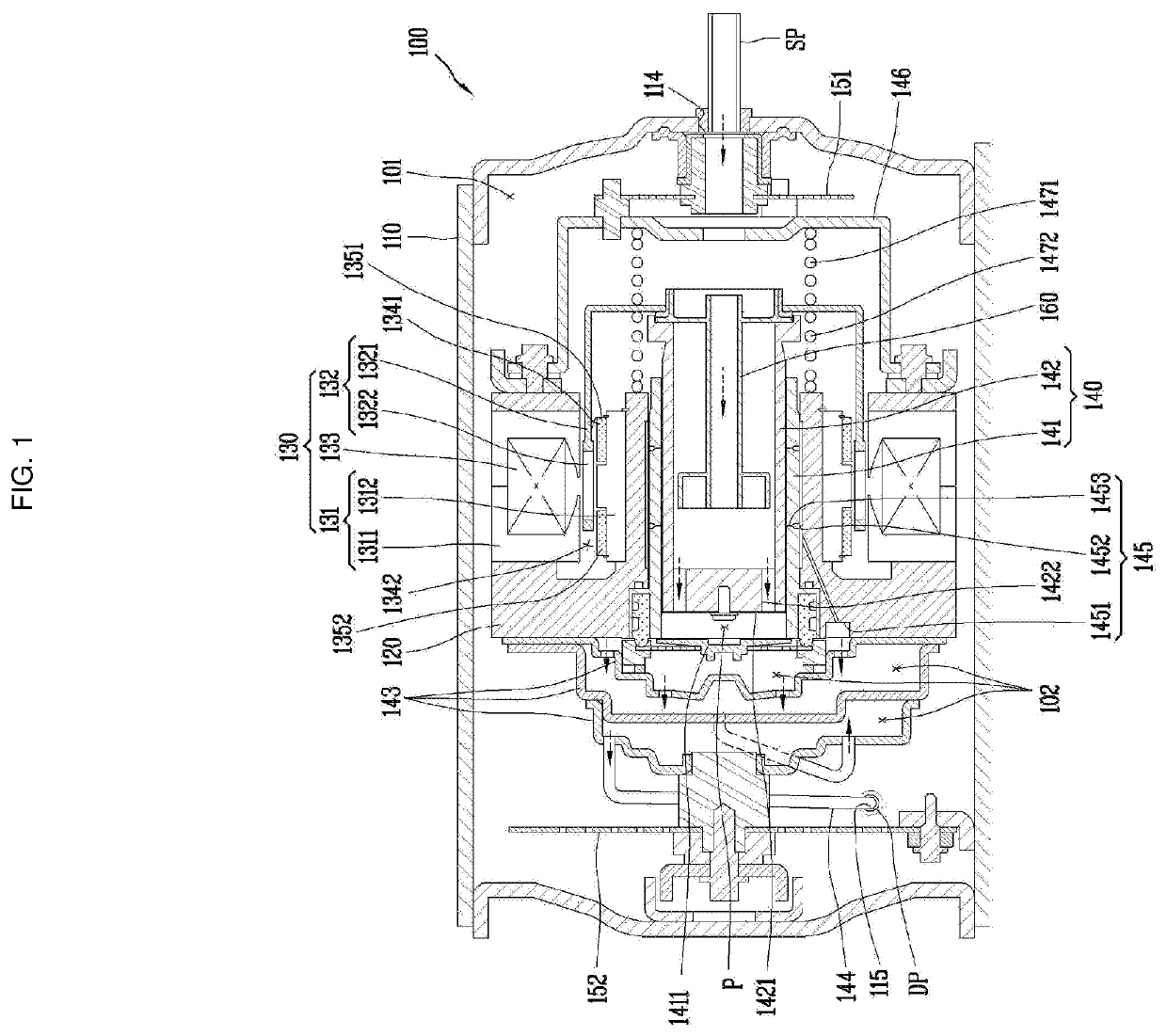

Linear compressor and control method thereof

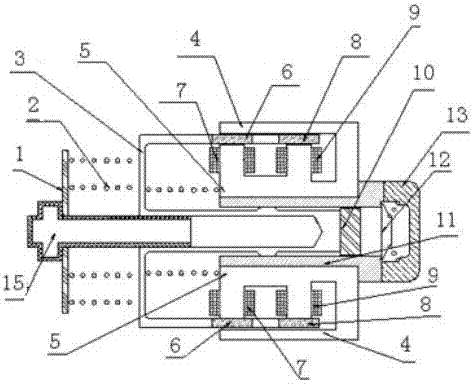

ActiveCN107013435AIncrease motor powerNo burn outPiston pumpsDynamo-electric machinesElectric machineLinear compressor

The invention discloses a linear compressor and a control method thereof. The linear compressor comprises a housing, as well as a compressor body structure and a motor structure which are arranged in the housing, wherein the compressor body structure comprises a cylinder, a piston, resonant springs and a discharge valve plate arranged on the cylinder; the motor structure comprises a rotor, an outer stator and an inner stator; a first permanent magnet and a second permanent magnet are arranged on the rotor at an interval; the inner stator is U-shaped; a first coil and a second coil are correspondingly arranged on the inner stator; the outer stator and the inner stator adopt an integral structure, form a surrounding structure on the side of the cylinder and form a rotor inserting gap on the side of the rotor; and the resonant springs are mounted between the inner stator and the rotor and also between the rotor and a rear baffle. According to the linear compressor, when one of the coils is electrified to work, the other coil can be either electrified or not, so that the problems of motor efficiency reduction, coil heating and permanent magnet demagnetization due to the reason that the current of a single-coil motor is improved to correspond to a high-load working condition are solved.

Owner:青岛中公联信息科技有限公司

Method and Apparatus for Controlling the Drive System for Mobile Equipment such as a Mobile Construction and/or Mining Machine

ActiveUS20120130578A1Minimize stress and oscillationAvoid fatigueDigital data processing detailsMotor depositionControl theoryMobile device

The present invention relates to a method and an apparatus for controlling the drive system for mobile equipment, when the operator's drive commander is kept constant, electric traction motors are controlled by a torque controller to provide uniform torque, deviations in speeds of the electric traction motors are determined and electric motor power of at least one is varied relatively to the electric motor power of the other in response to a determined deviation in speed to keep the torques uniform. The power control balancing compensates for the torque differences previously encountered when the speeds of the traction motors differ at equal power supplied to the traction motors.

Owner:LIEBHERR MINING EQUIP

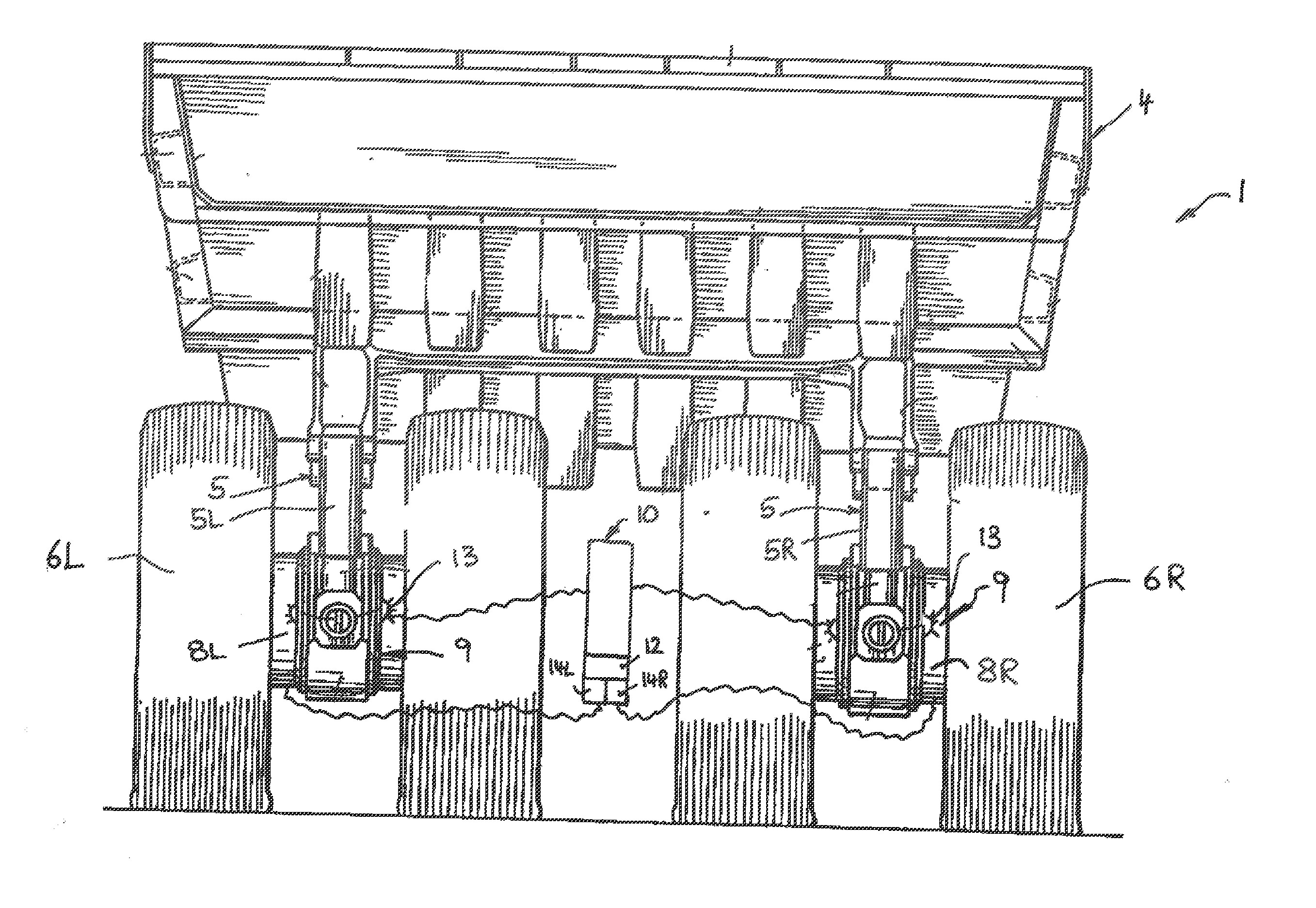

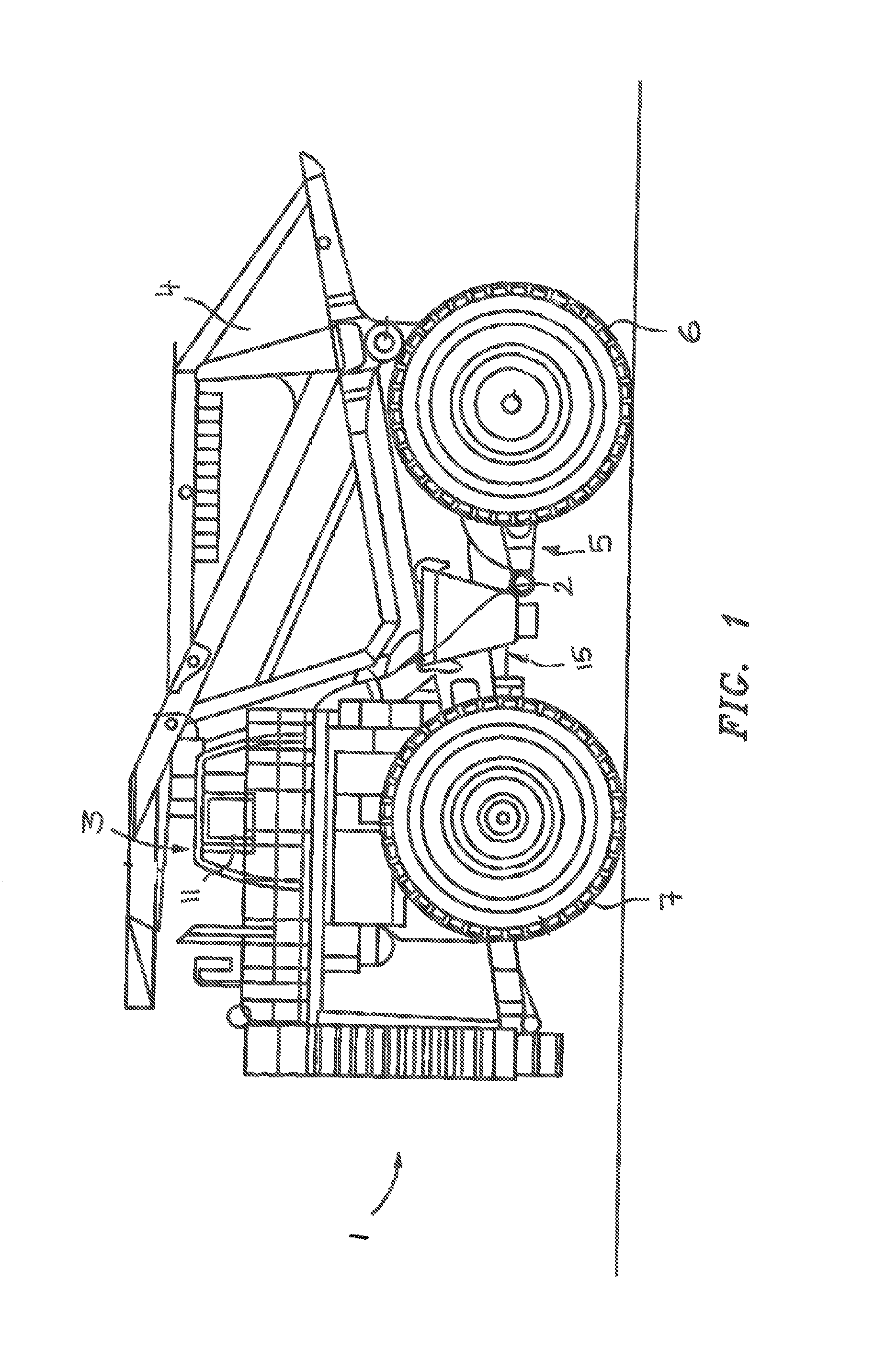

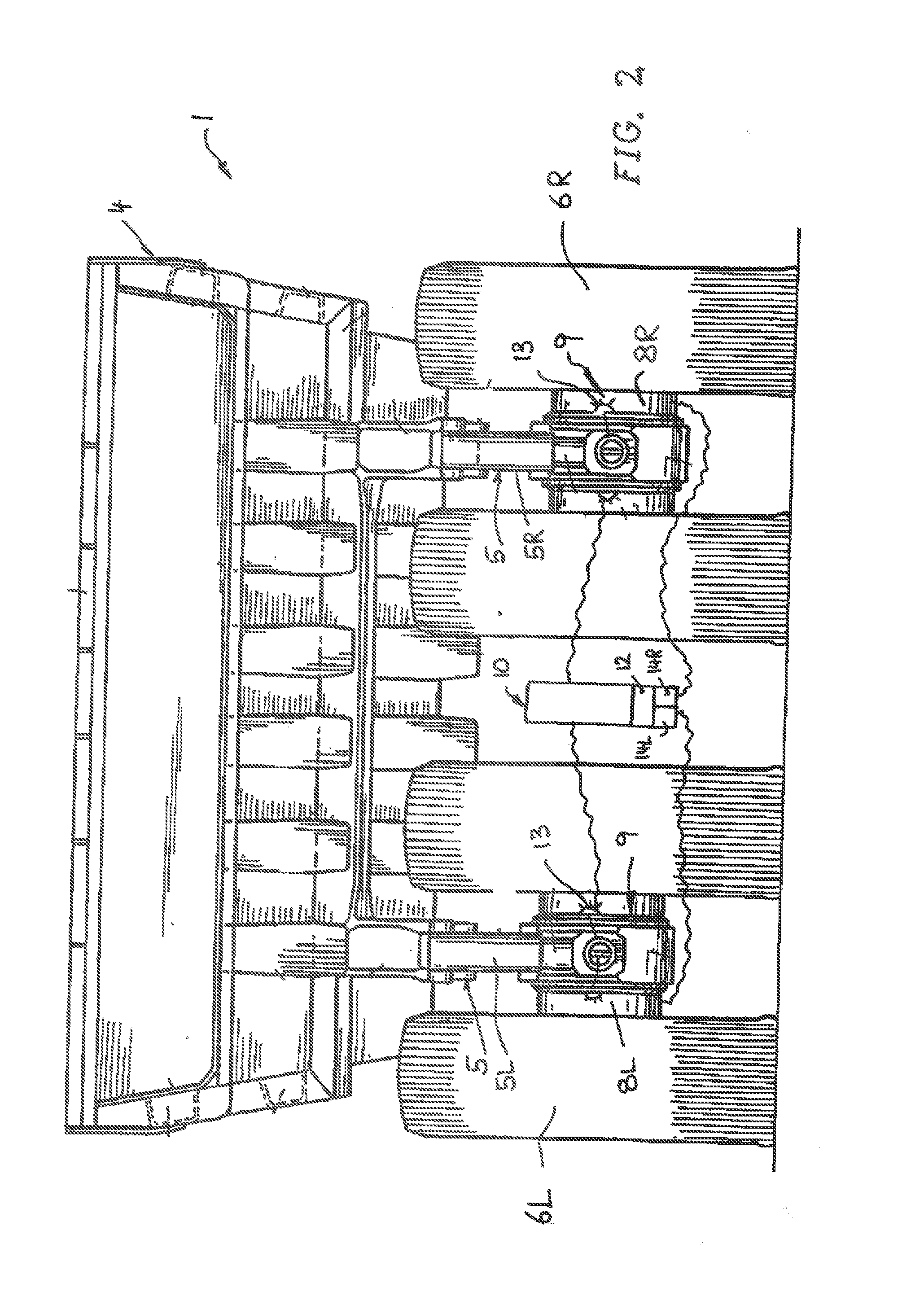

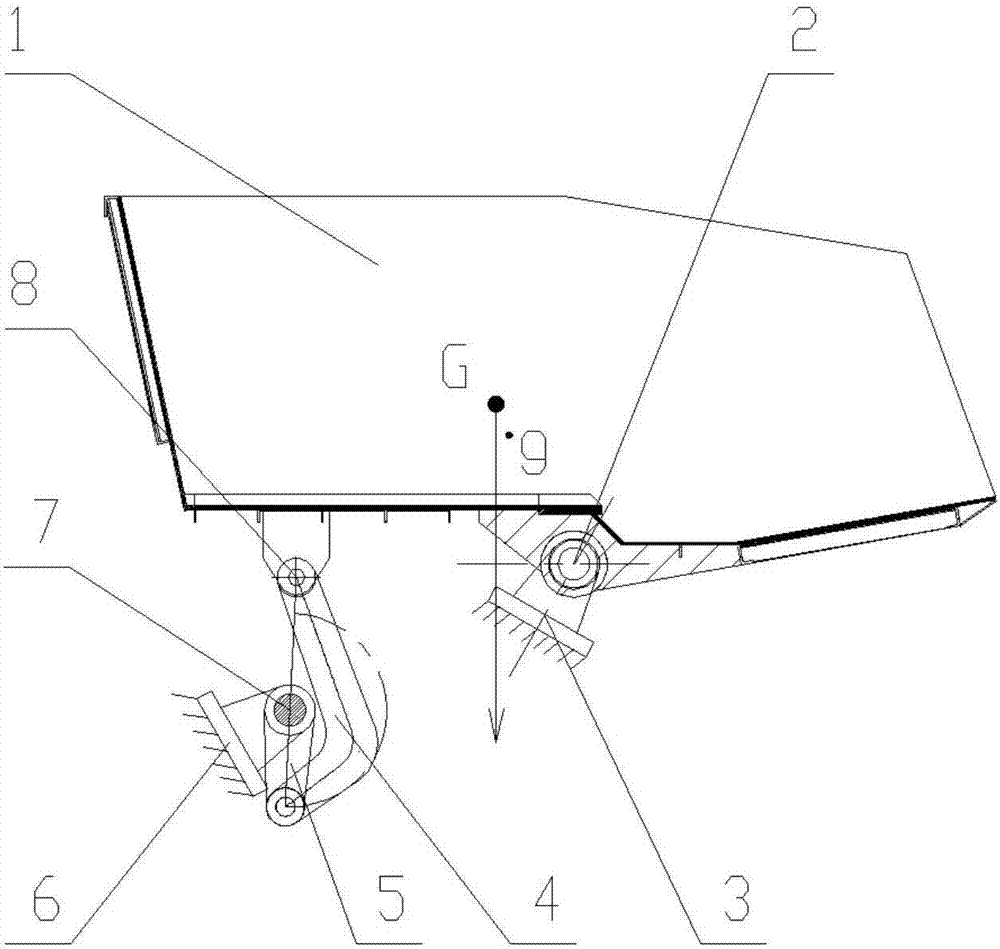

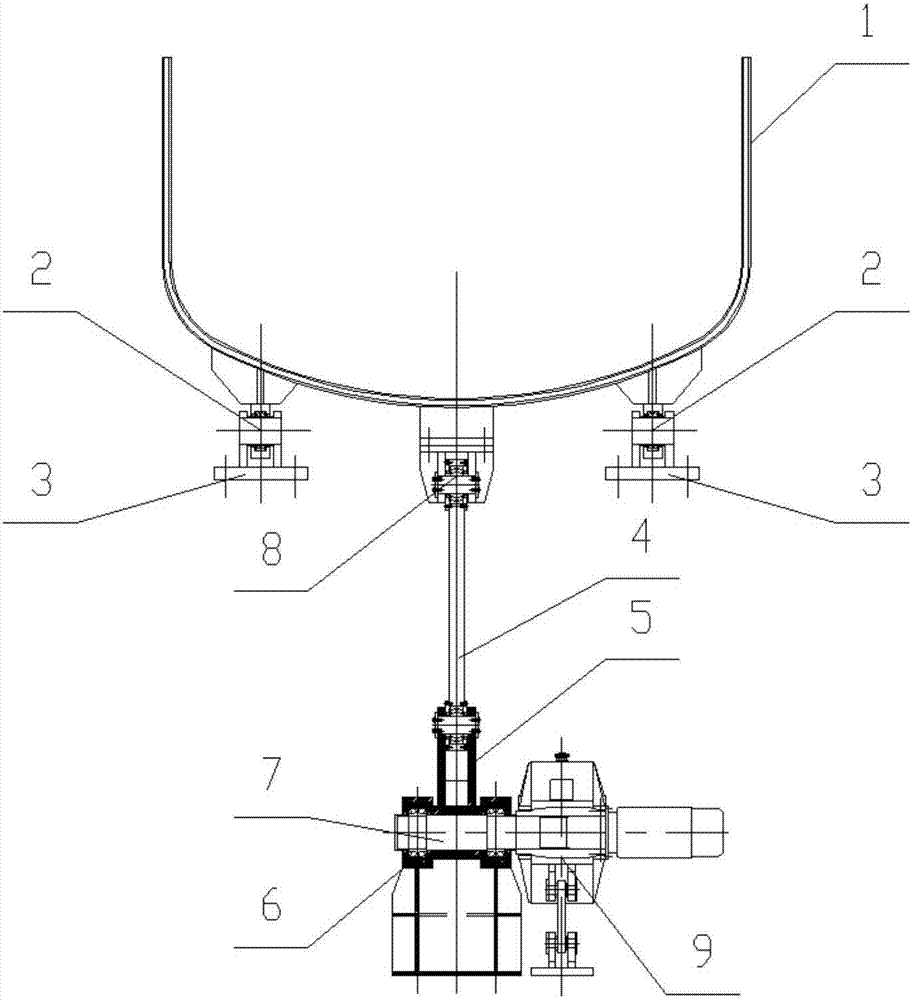

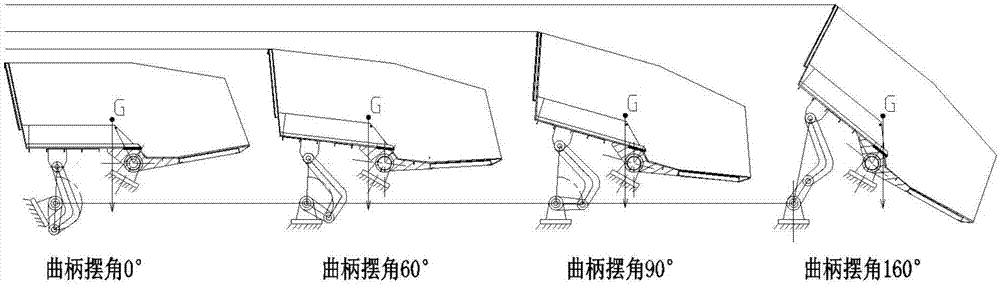

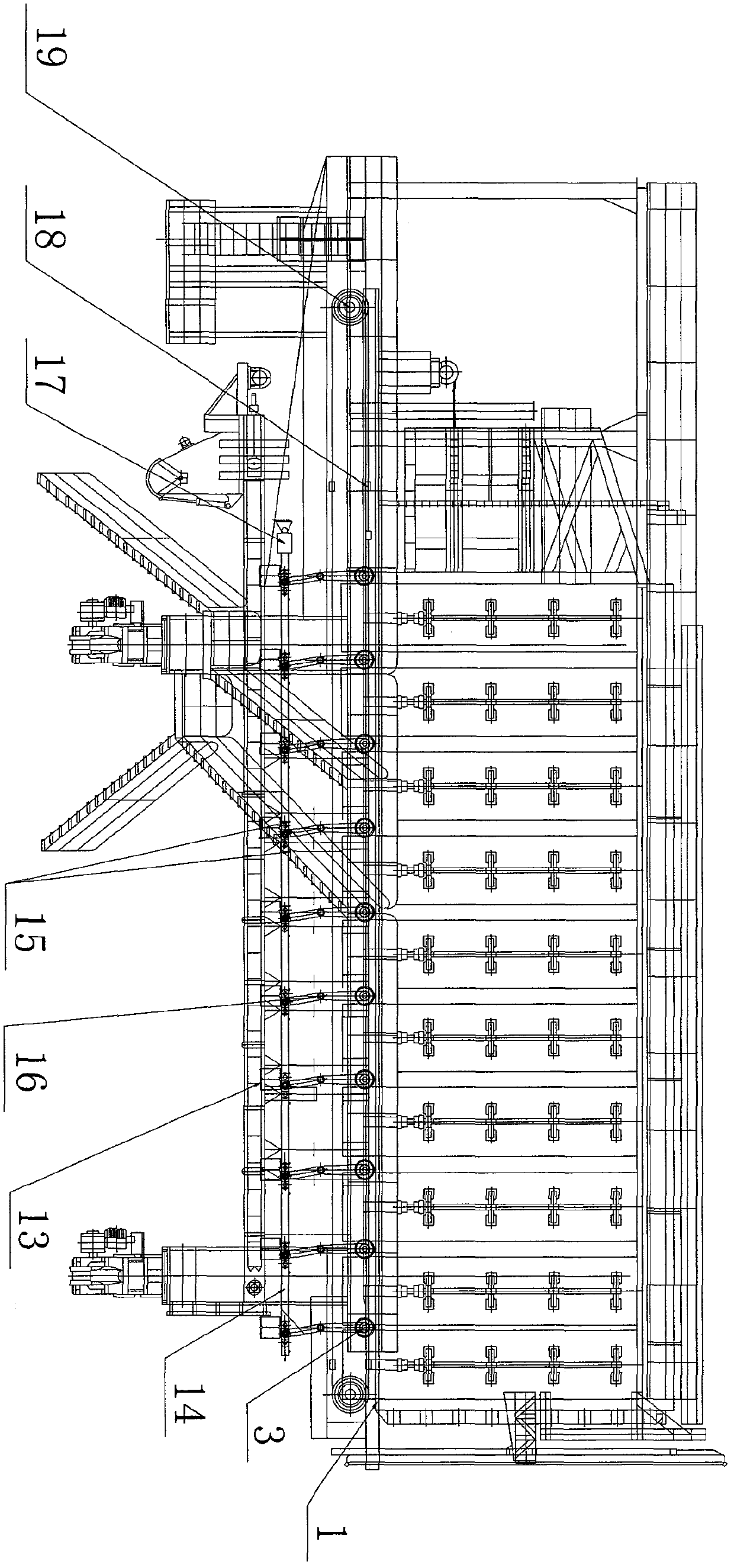

Overturning hopper and control method thereof

ActiveCN106927269AOptimize impact conditionsReduced output torque requirementsLarge containersBottle emptyingElectric machineryReducer

The invention discloses an overturning hopper. The overturning hopper comprises a hopper body, a hopper revolving support and an overturning mechanism, wherein the overturning mechanism comprises a link and a crank, one end of the link is hinged onto the hopper body, the other end of the link is hinged with the crank, and the other end of the crank is hinged onto a crank revolving support through a crank rotary shaft; and the receiving point and the unloading point of the hopper are both arranged at or close to the dead point of the overturning mechanism through optimizing the starting point and the ending point of the crank, so that the impacted force working condition of speed reducer equipment is optimized during the loading and the unloading of the overturning hopper. According to the mechanism, the centre-of-gravity position of the hopper body and the centre-of-gravity position of the hopper after the loading are further optimized, so that the centre of gravity of the hopper body is located between the revolving hinge point of the hopper and the supporting hinge point of the link and close to the revolving hinge point of the hopper; and requirements on the output torque of a speed reducer are greatly lowered by virtue of the force amplification effect of the link, so that the weight of the speed reducer equipment and the power of a tilting motor are greatly reduced, and the motor power and the energy consumption of the system are saved.

Owner:CISDI ENG CO LTD

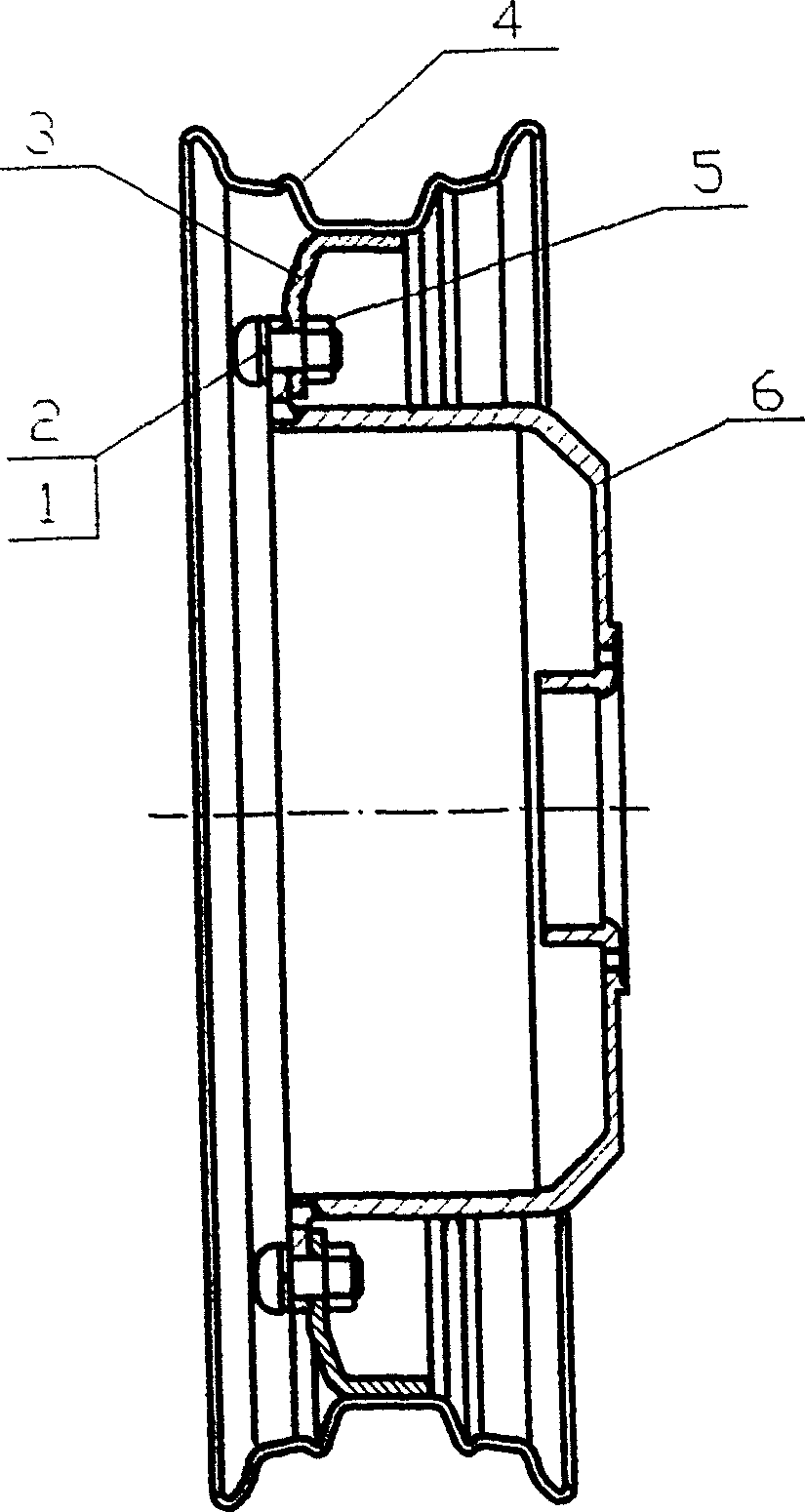

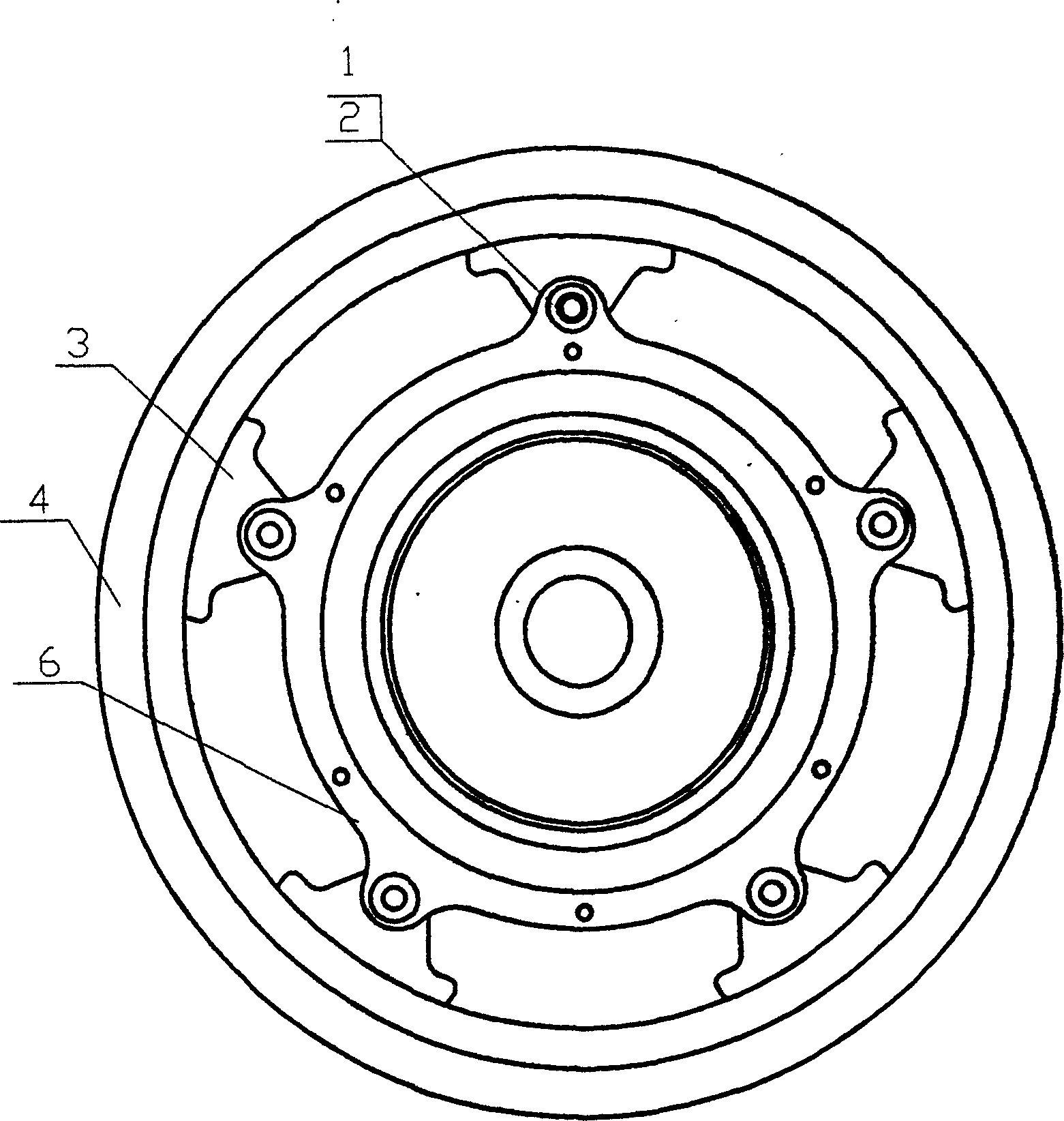

Electric motorcycle steel ring and motor casing unit assemblage and its manufacturing method

An assemblage of rim and motor casing for electric motorcycle is composed of steel rim and web consisting of several web units and fixed to the casing of motor. Its manufacture includes such steps as rolling steel plate to form steel rim, punching on steel plate to obtain web units, welding the web units to steel rim, and connecting the flange of motor casing with web via screw bolts.

Owner:朱吕国

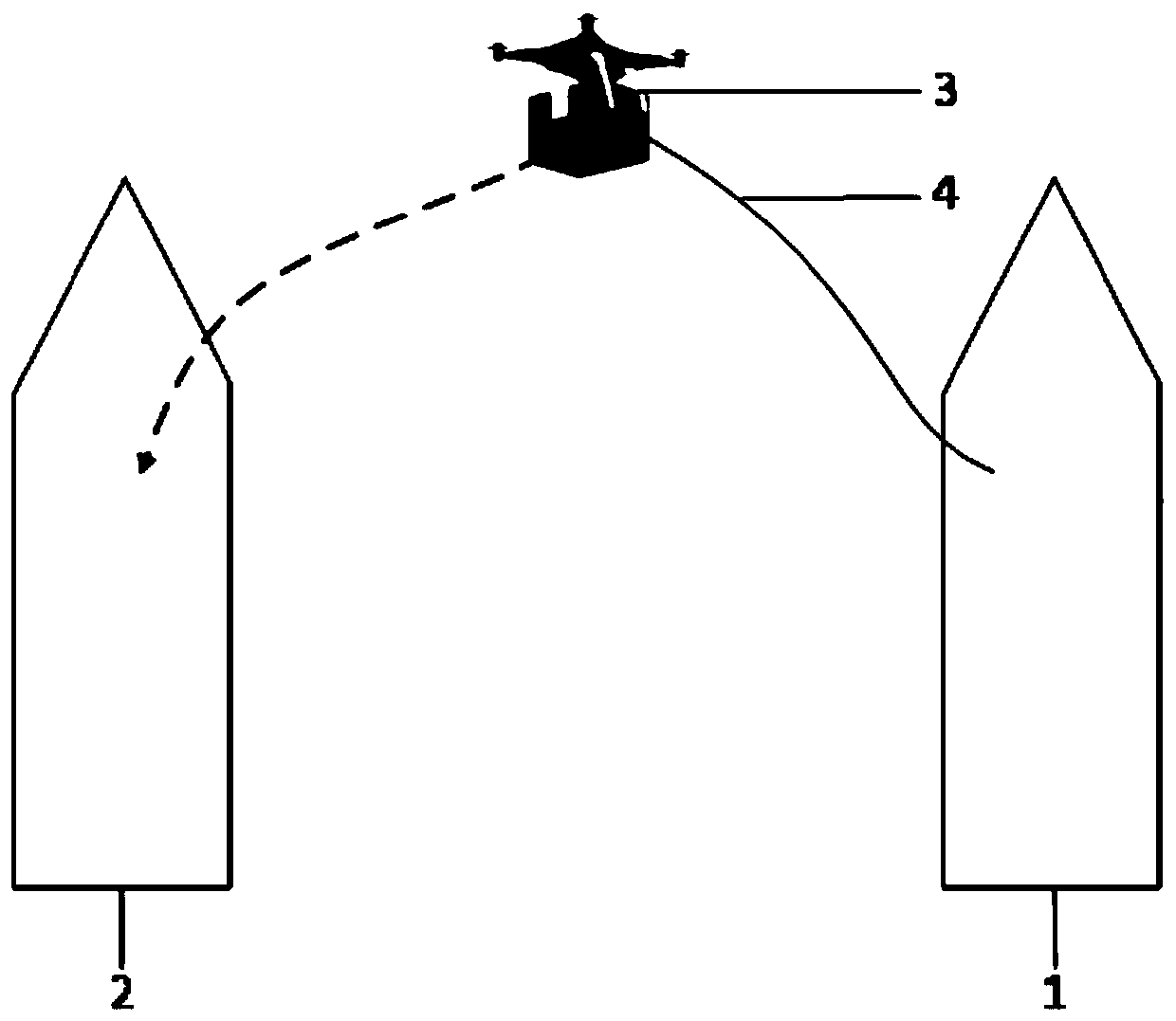

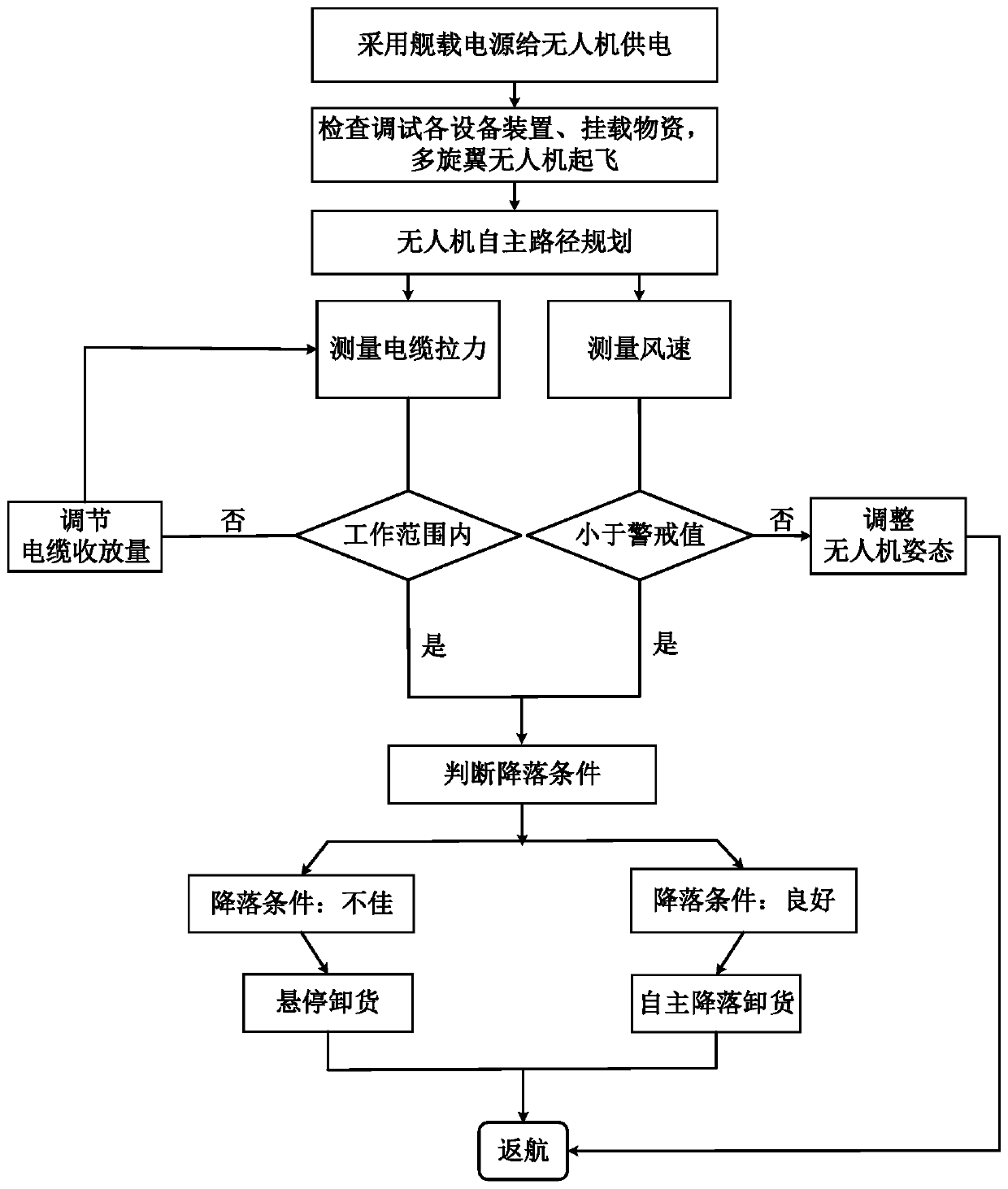

Offshore material supply method

InactiveCN110979568AUninterrupted transportIncrease motor powerCargo handling apparatusPassenger handling apparatusMarine engineeringUncrewed vehicle

The invention provides an offshore material supply method. The offshore material supply method is suitable for offshore supply of a multi-rotor unmanned aerial vehicle. Alternating current output by aship-borne power supply is converted into low-voltage direct current to be supplied to the unmanned aerial vehicle for use, so that the problems of limited onboard battery capacity, insufficient power, small carrying capacity, short endurance, poor wind resistance and the like of an existing multi-rotor unmanned aerial vehicle in the offshore supply process are overcome, and the transportation capacity and the wind resistance of the multi-rotor unmanned aerial vehicle during offshore ship material supply are improved.

Owner:SHANGHAI MARITIME UNIVERSITY

Power strut

InactiveUS10141813B2Prevent movementEliminates magnetically conductive outer housingMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringMagnet

A power strut for a vehicle lift gate, has a driver sleeve, a lead screw sleeve, a lead screw and a spring mounted in the lead screw sleeve. A gear reduction mechanism and a motor assembly are mounted in the driver sleeve for driving the lead screw. The motor assembly has a magnet mounting bracket fixed to the driver sleeve and a rotor disposed in the magnet mounting bracket. An end cover and multiple permanent magnets are fixed to the magnet mounting bracket. Each of the magnets is positioned between a corresponding pair of adjacent connecting portions and contacts an inner surface of the driver sleeve, thereby the driver sleeve provides a magnetic path between the magnets.

Owner:JOHNSON ELECTRIC SA

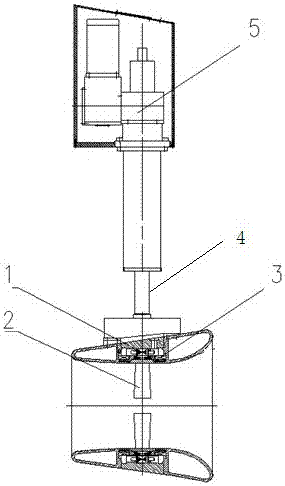

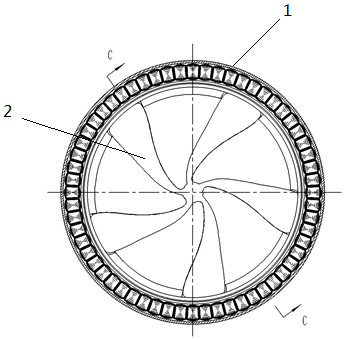

Full-rotation propeller driving device

InactiveCN107472492AEliminate the transmission linkImprove efficiencyRotary propellersPropulsion power plantsWater leakagePropulsive efficiency

The invention relates to a full-rotation propeller driving device comprising a wheel flange type motor, a propeller, a supporting device and a rotation device. The rotation device is fixed to a ship body, connected with the supporting device and the wheel flange type motor and used for driving the wheel flange type motor and the propeller to conduct rotation turning through the supporting device. According to the full-rotation propeller driving device, the propelling efficiency is high, noise and vibration are low, the structure is simple, the weight and size are small, the reliability is high, and the problem of water leakage of underwater mechanisms does not need to be worried.

Owner:GUANGZHOU HG MARINE CO LTD

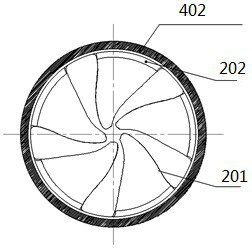

Contra rotating propeller driving device driven by magnetic bearing wheel flange type motor

InactiveCN107521646AEliminate sealing problemsImprove reliabilityMagnetic bearingsPropulsive elementsMagnetic bearingPropeller

The invention relates to a contra rotating propeller driving device driven by a magnetic bearing wheel flange type motor. The contra rotating propeller driving device mainly comprises a positive-rotating wheel flange type motor, a reverse-rotating wheel flange type motor, a positive-rotating propeller and a reverse-rotating propeller. The positive-rotating wheel flange type motor is connected with the positive-rotating propeller. The reverse-rotating wheel flange type motor is connected with the reverse-rotating propeller. The two wheel flange type motors are connected in series front and back, the rotating directions of the two propellers are opposite, and thrust of the same directions is generated. The propeller arranged at the back absorbs energy of a tailing vortex of the front propeller, and the overall propulsion efficiency and thrust are improved.

Owner:GUANGZHOU HG MARINE CO LTD

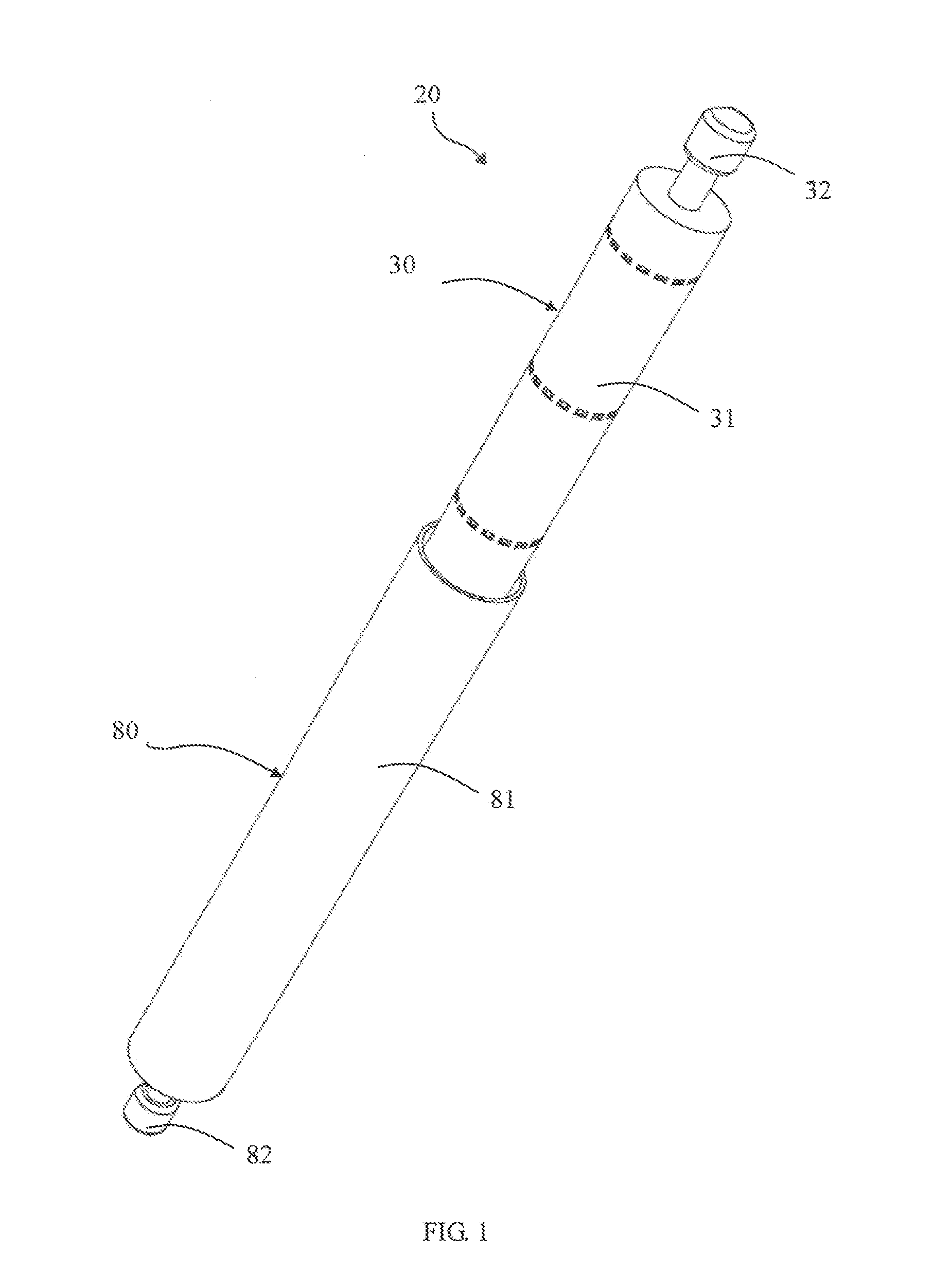

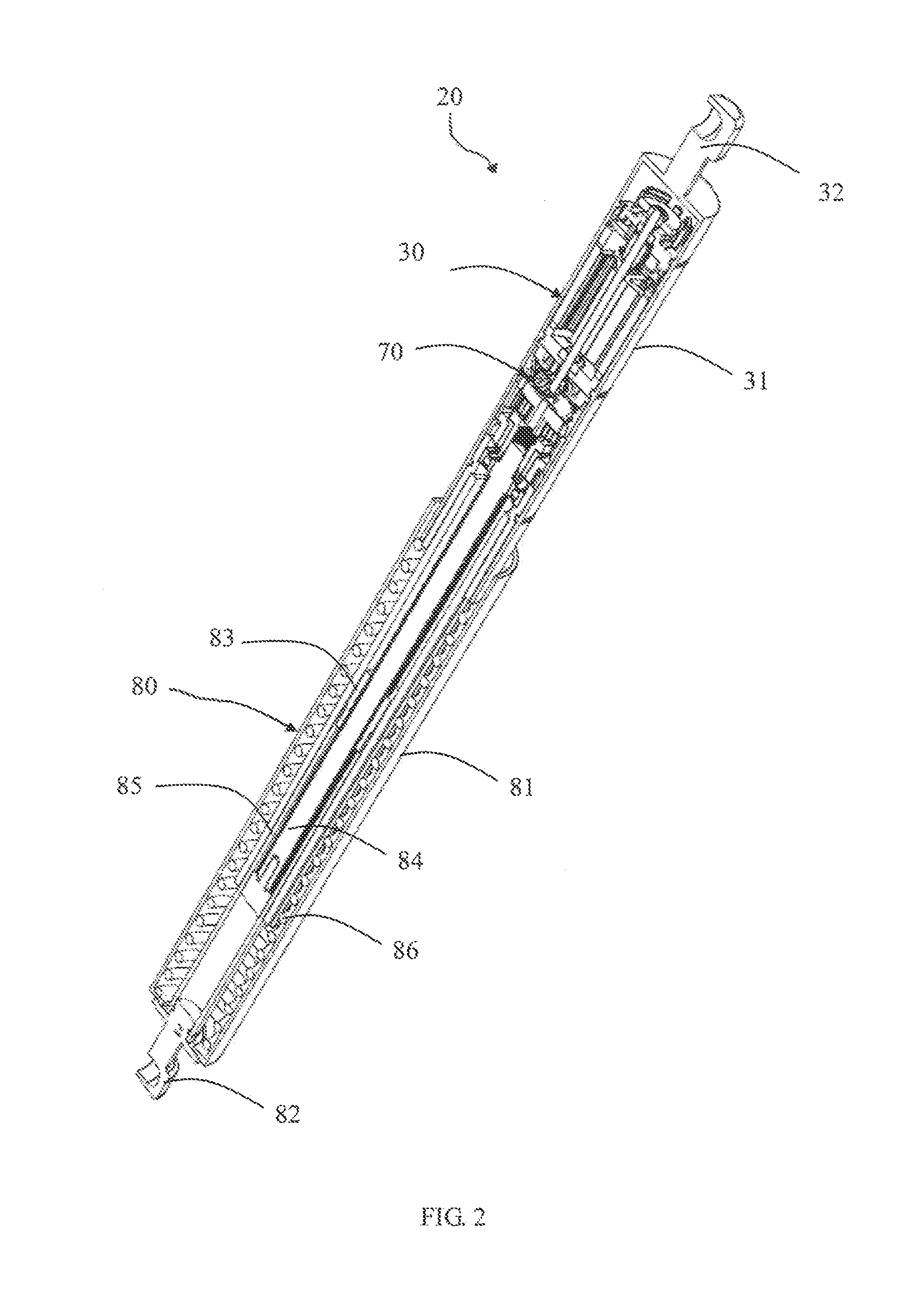

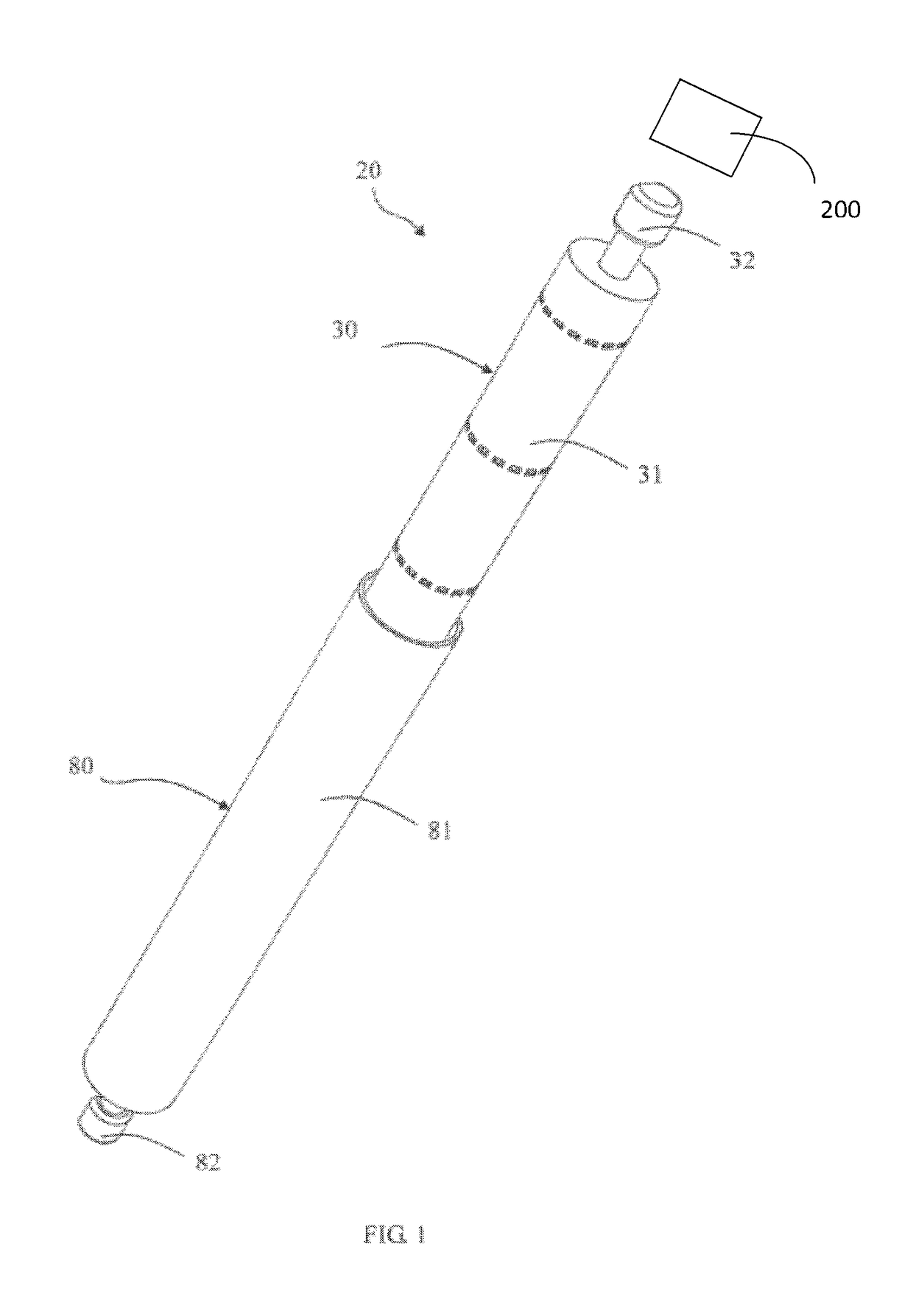

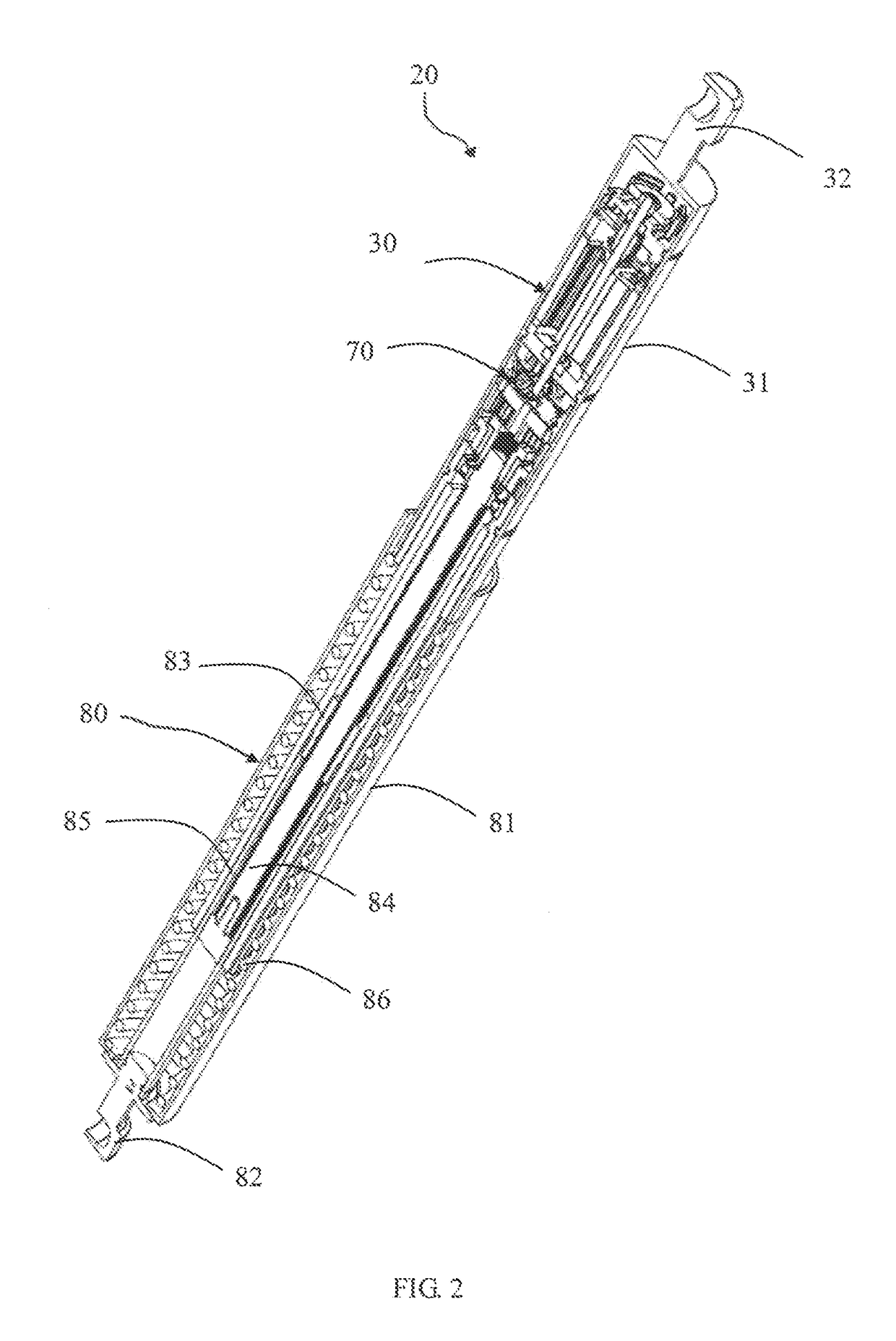

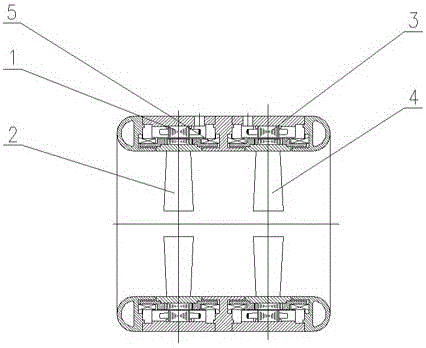

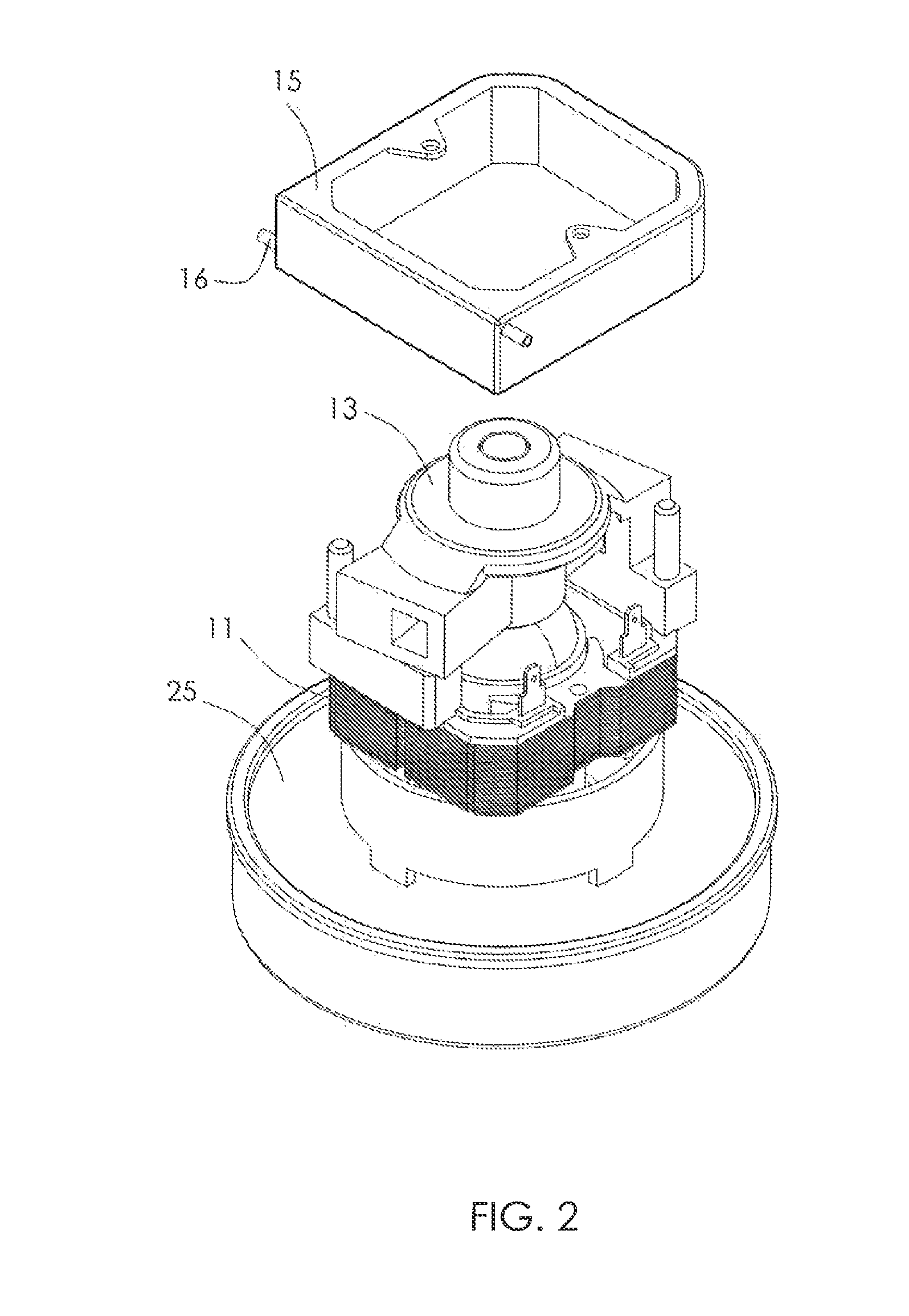

Awning adjustment device with variable speed and direction control

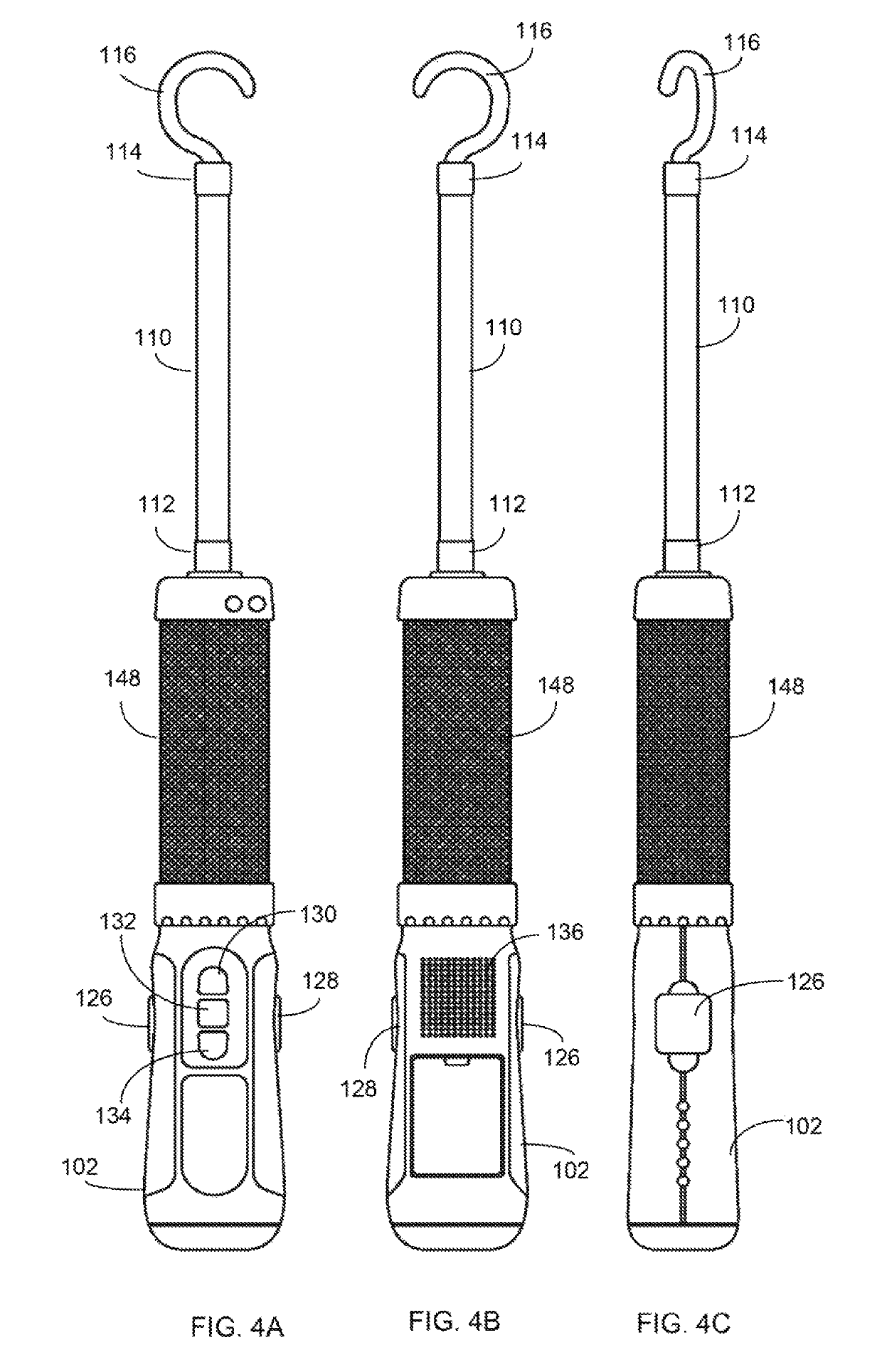

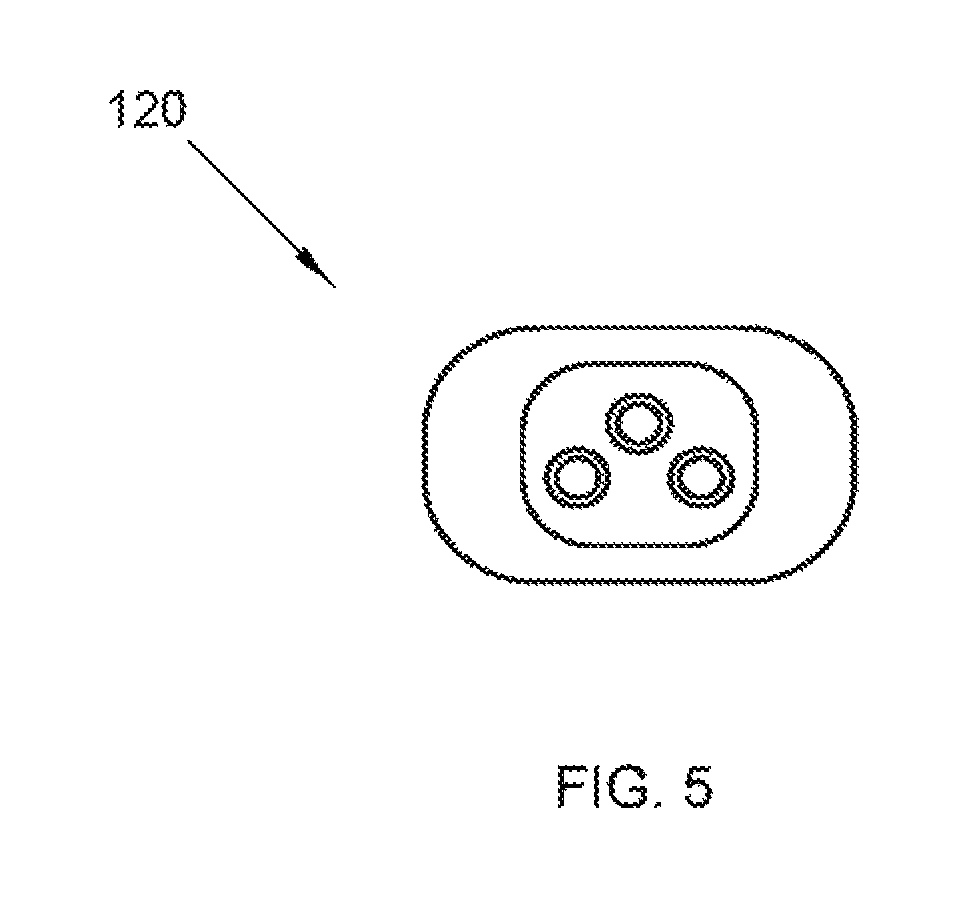

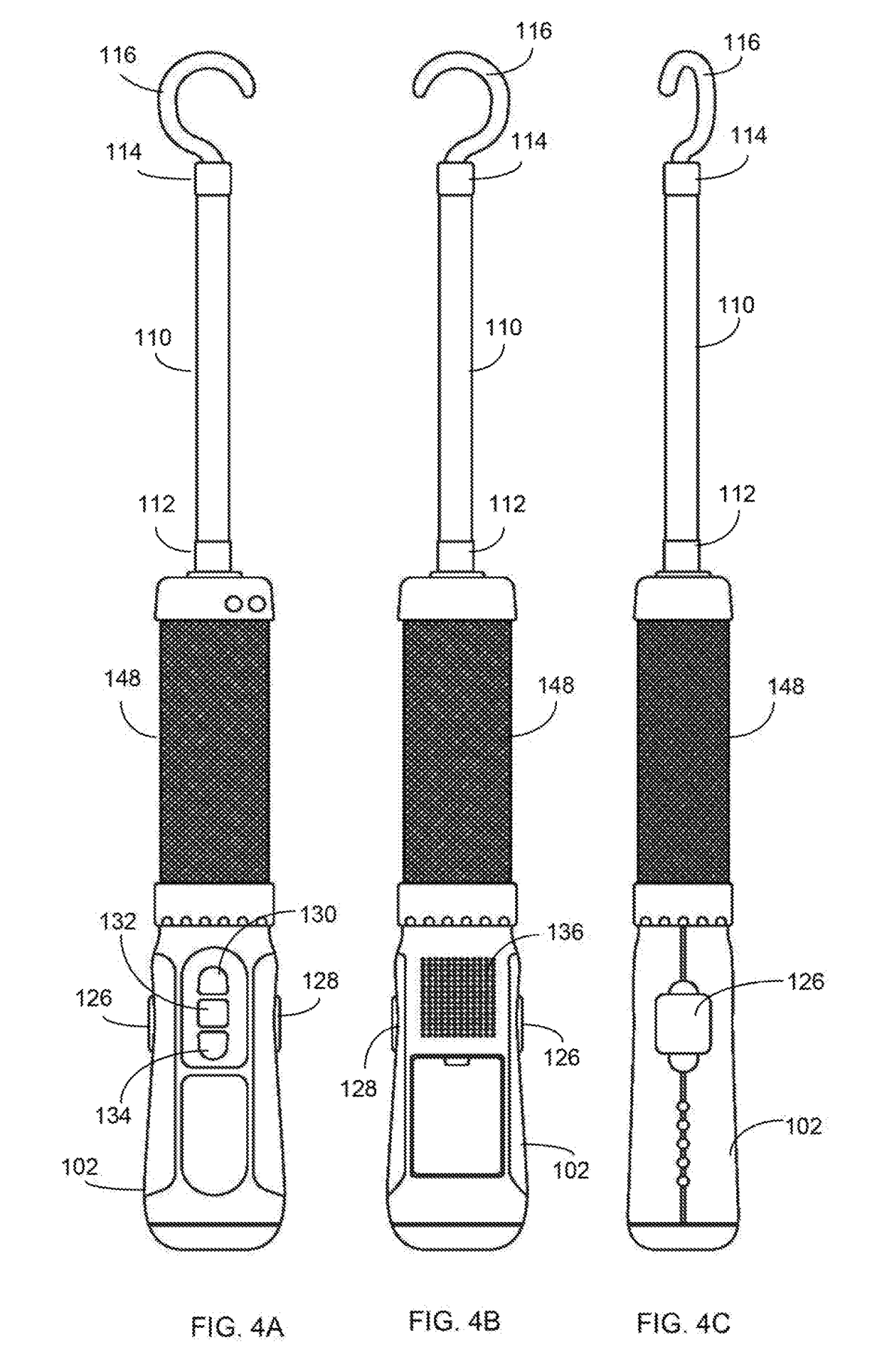

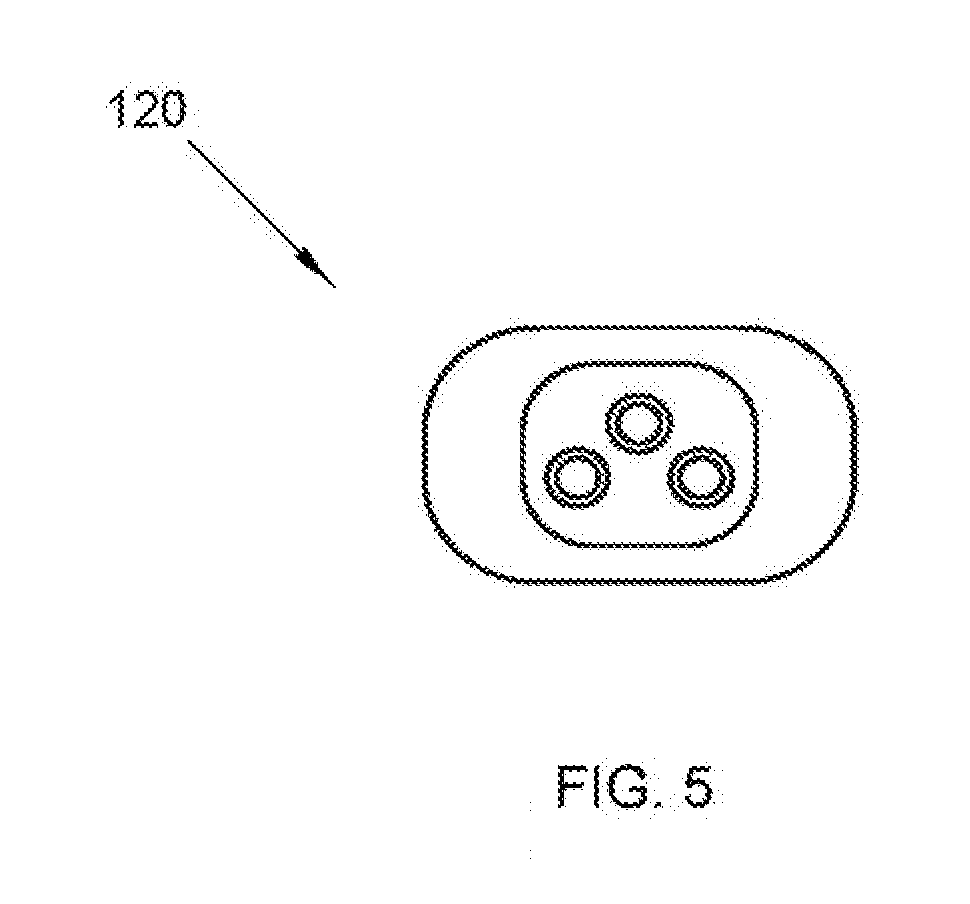

InactiveUS10323456B2Avoid damageIncrease motor powerSunshadesDoor/window protective devicesEngineeringMotor power

An awning adjustment device with variable speed and direction control serves to automatically open and close eclectic types of awnings by way of an elongated rod terminating at a hook. The hook detachably couples to an awning handle or crank mechanism. A motor powers the rod, so as to rotate the rod in variable speeds, directions, and durations. The rotational speed of the rod is either controlled by a user, or controlled by a rotation counter to variably increase or decrease the rotation of the rod, so as to prevent damaging the awning by rotating too fast. The control portion comprises a power on switch, a power off switch, a pause switch, a directional switch, and a speed switch. The motor operatively couples to at least one electrical power source through a power cord, or a battery to receive electrical power for operating the device.

Owner:AIRFLEX 5D LLC

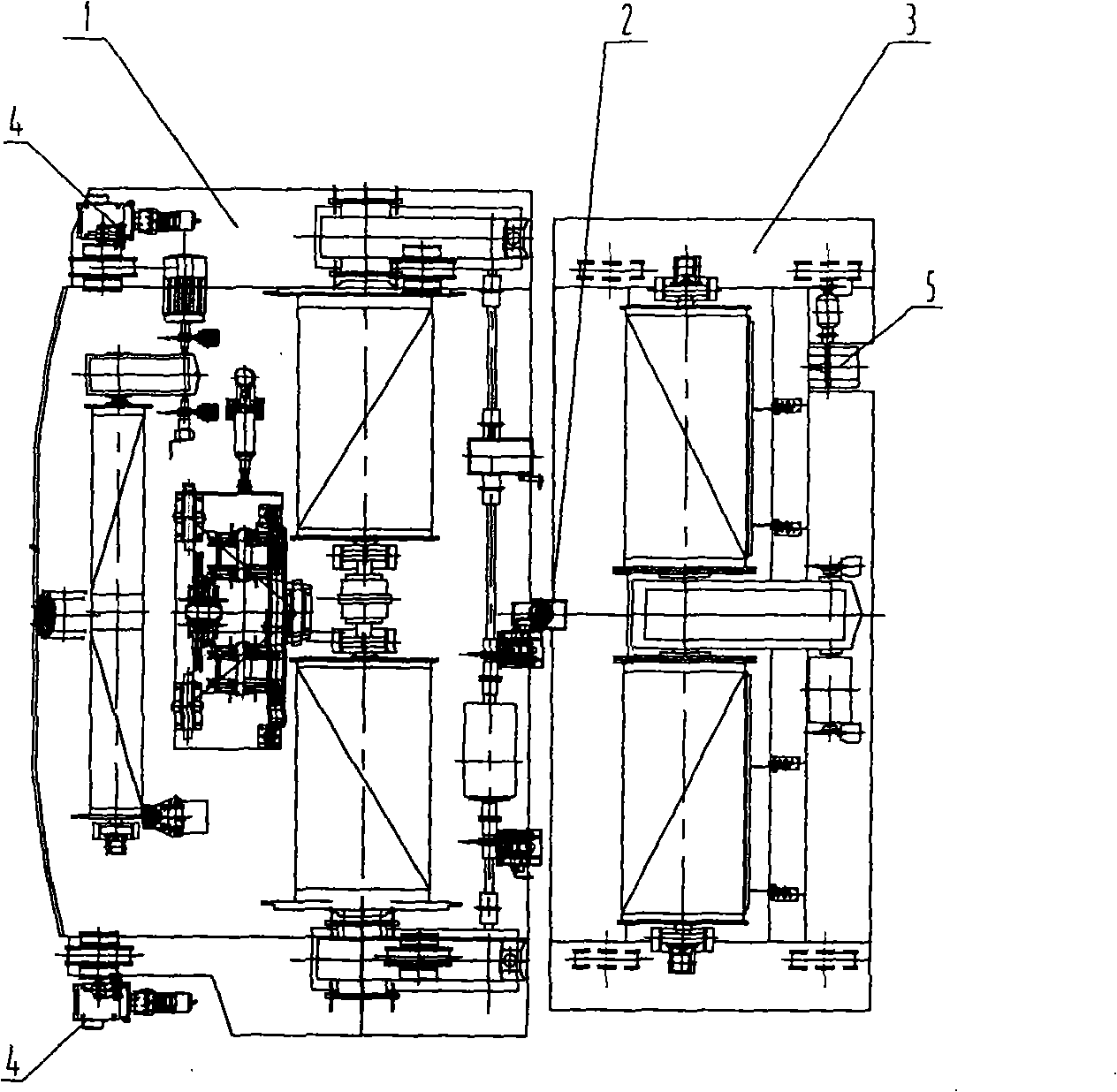

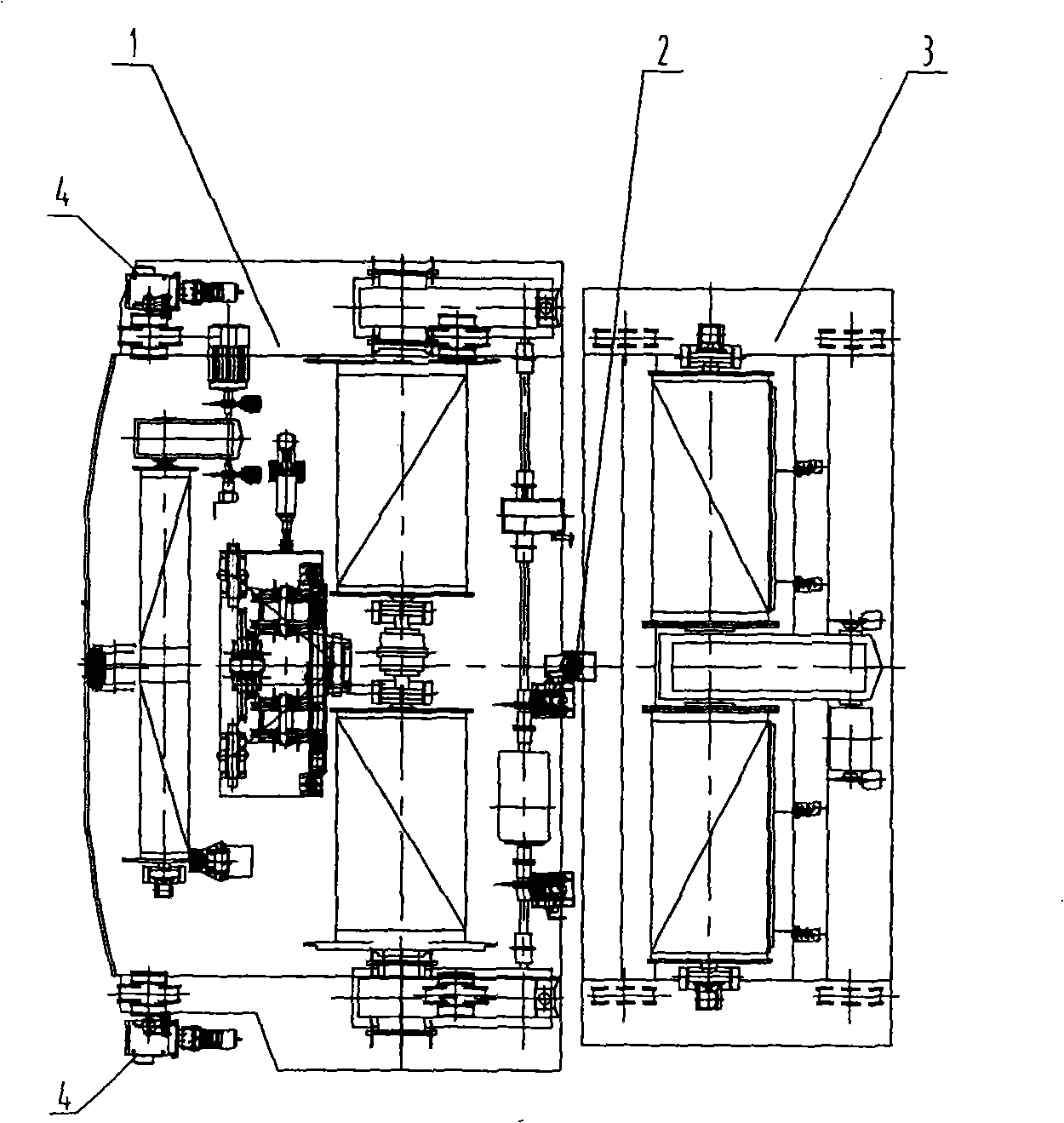

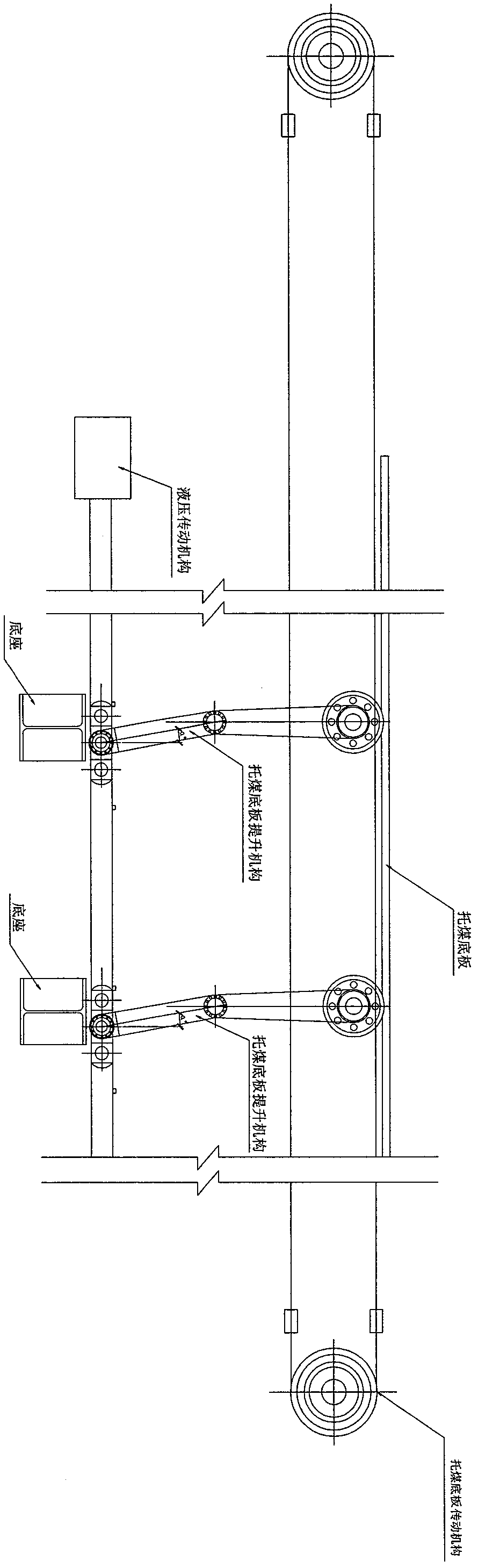

Synchronization equipment of ring-shaped crane double trolley

InactiveCN101537972ATroubleshoot out-of-sync issuesIncrease motor powerTravelling cranesNuclear powerEngineering

The invention relates to synchronization equipment of a ring-shaped crane double trolley and relates to a ring-shaped crane used in a nuclear power station. The synchronization equipment comprises a travelling trolley containing a driving mechanism, an installation trolley, and a joint operating device connecting the traveling trolley and the installation trolley, and is characterized in that the installation trolley is not provided with the driving mechanism. As only the travelling trolley of the synchronization equipment is provided with the driving mechanism, the driving mechanism of the installation trolley is canceled, the motor power running the driving mechanism is correspondingly added, and the traveling trolley drags the installation trolley by the joint operating device. In this way, the desynchronized problem during the parallel operation of the two trolleys is completely solved, and a set of running driving mechanism is reduced, thus reducing the cost of the product.

Owner:TAIYUAN HEAVY IND

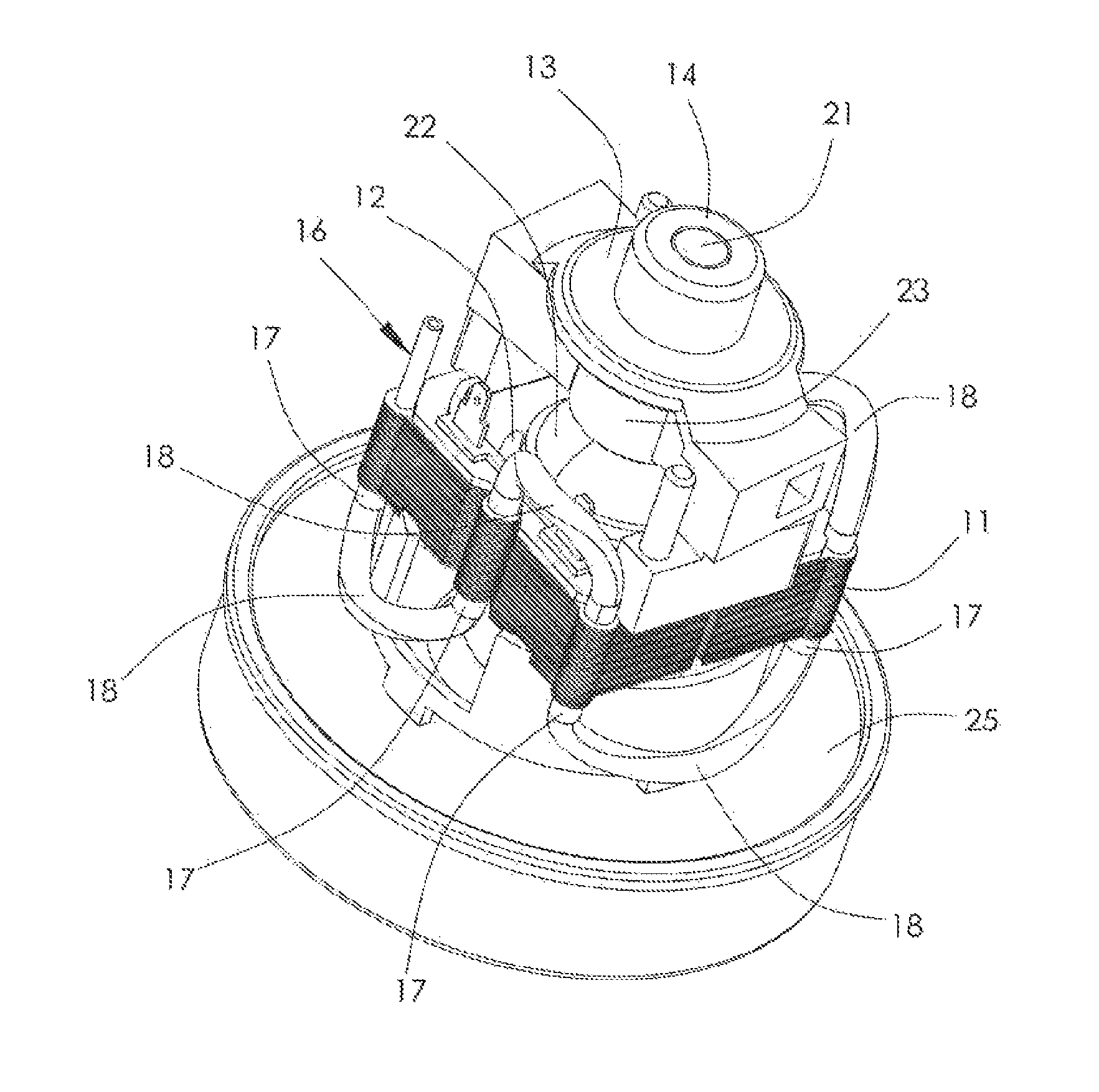

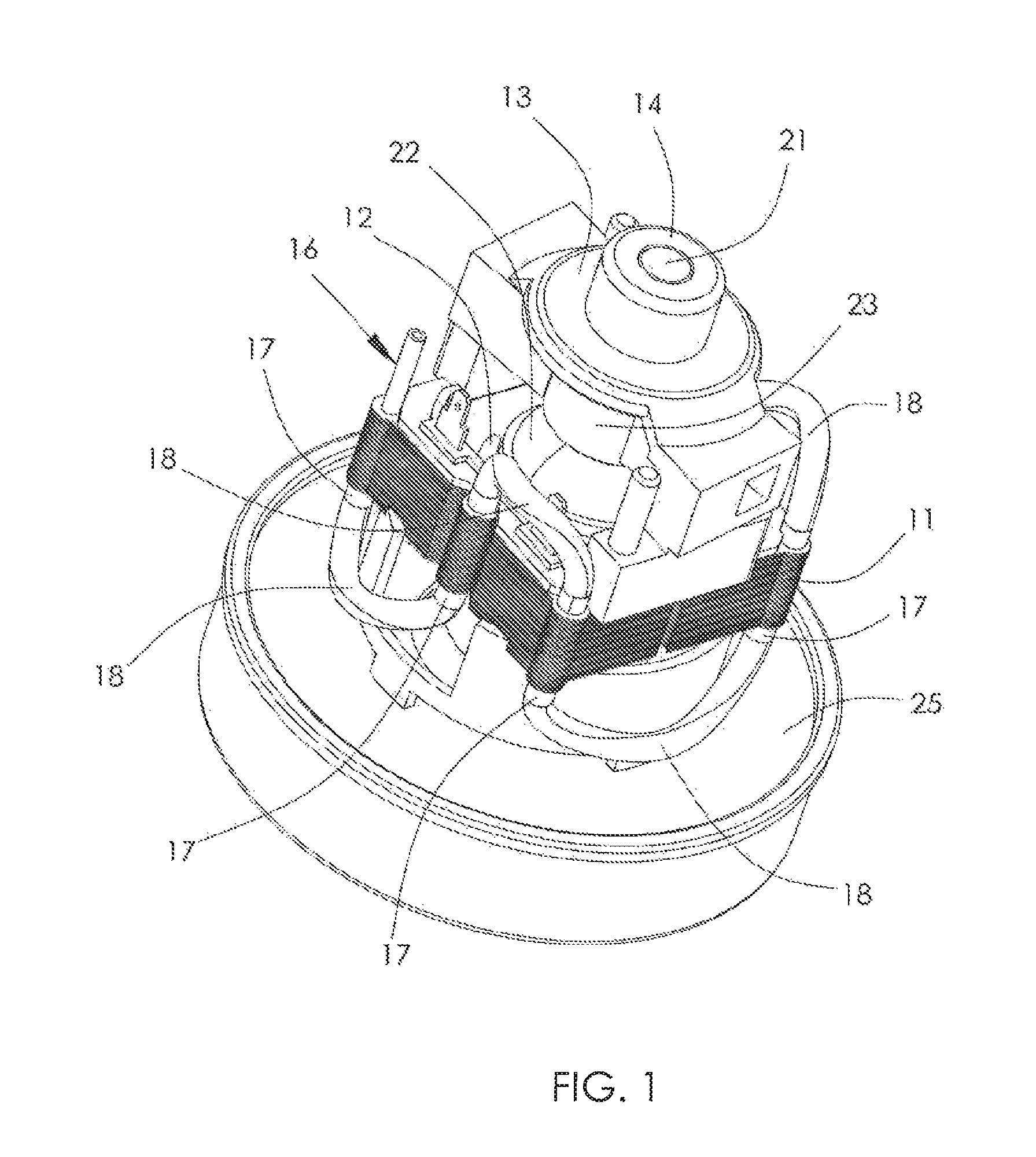

Cooling system of motor assembly for cleaner

InactiveUS8823222B2Reduce motor powerIncrease in sizeBrush bodiesMachine detailsEngineeringHome appliance

A motor assembly, especially for home appliances such as a cleaner, has an electric motor and a cooling system. The motor may be a fractional horsepower universal motor with a stator and a rotor. The cooling system has a cooling pipe thermally coupled to an element of the stator, such as a core of the stator and providing a flow path for a liquid to cool the motor.

Owner:JOHNSON ELECTRIC SA

Awning Adjustment Device with Variable Speed and Direction Control

InactiveUS20180355666A1Easy to extendEasy to retractSunshadesDoor/window protective devicesRotation velocityEngineering

An awning adjustment device with variable speed and direction control serves to automatically open and close eclectic types of awnings by way of an elongated rod terminating at a hook. The hook detachably couples to an awning handle or crank mechanism. A motor powers the rod, so as to rotate the rod in variable speeds, directions, and durations. The rotational speed of the rod is either controlled by a user, or controlled by a rotation counter to variably increase or decrease the rotation of the rod, so as to prevent damaging the awning by rotating too fast. The control portion comprises a power on switch, a power off switch, a pause switch, a directional switch, and a speed switch. The motor operatively couples to at least one electrical power source through a power cord, or a battery to receive electrical power for operating the device.

Owner:AIRFLEX 5D LLC

A new type of energy-saving tamping coke oven coal feeding device

InactiveCN102277178AReduce wearExtended service lifeCharging-discharging device combinationsCharging devicesNew energyActuator torque

The new energy-saving tamping coke oven coal charging car coal delivery device is composed of a coal bottom lifting mechanism, a hydraulic transmission mechanism, a limit mechanism, a coal bottom drag mechanism and a base, and a coal bottom lifting mechanism and a hydraulic transmission mechanism They are connected to each other, and the torque is transmitted to the lifting mechanism of the coal-supporting floor through the hydraulic transmission mechanism. The lifting mechanism deflects along the center of the load-bearing shaft. The lifting mechanism moves horizontally back and forth in the roller table groove. When the coal-supporting bottom plate is advancing or retreating, the coal-supporting bottom plate rises. When the coal charging box is ready to be loaded with coal and tamped, the coal-supporting bottom plate descends to the slideway; The lifting mechanism relies on the load-bearing shaft to connect with the load-bearing support, and the force of the supporting roller is transmitted to the load-bearing support; the load-bearing support and the hydraulic transmission mechanism are connected to the base, and the base bears the gravity and weight transmitted by the load-bearing support of the lifting mechanism for the coal bottom plate. The horizontal thrust transmitted by the hydraulic transmission rod, the transmission rod is constrained by the chain plate under the action of the hydraulic mechanism to move horizontally back and forth; the transmission mechanism of the coal support bottom plate is connected with the coal support bottom plate, and the position of the center line of the coal support bottom plate is fixed and adjusted by steel wire ropes at certain intervals The idler pulley ensures that the wire rope moves back and forth on the centerline. The invention has the advantages of rolling motion of the coal supporting bottom plate in the support roller groove, small frictional resistance, low power consumption, good coal cake stability, convenient operation and maintenance and energy saving.

Owner:李先才

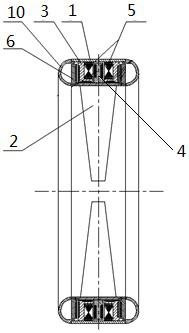

Annular electric propeller driven by axial magnetic flux motor

PendingCN111641308ACompact structureImprove efficiencyMagnetic circuit rotating partsRotary propellersElectric machineryEngineering

The invention relates to an annular electric propeller driven by an axial magnetic flux motor. The annular electric propeller comprises a shell, the axial magnetic flux motor, a propeller and a bearing assembly. According to the annular electric propeller, the axial magnetic flux motor arranged in water is adopted to directly drive the propeller to rotate, intermediate transmission equipment is eliminated, and the rotor and the propeller assembly are supported by the bearing arranged in water and transmit thrust to the motor and a ship body; intermediate transmission loss between the motor andthe propeller is reduced, efficiency is improved, the structure of a propulsion system is simplified, and noise, vibration and the like are reduced.

Owner:珠海市汉图达科技有限公司

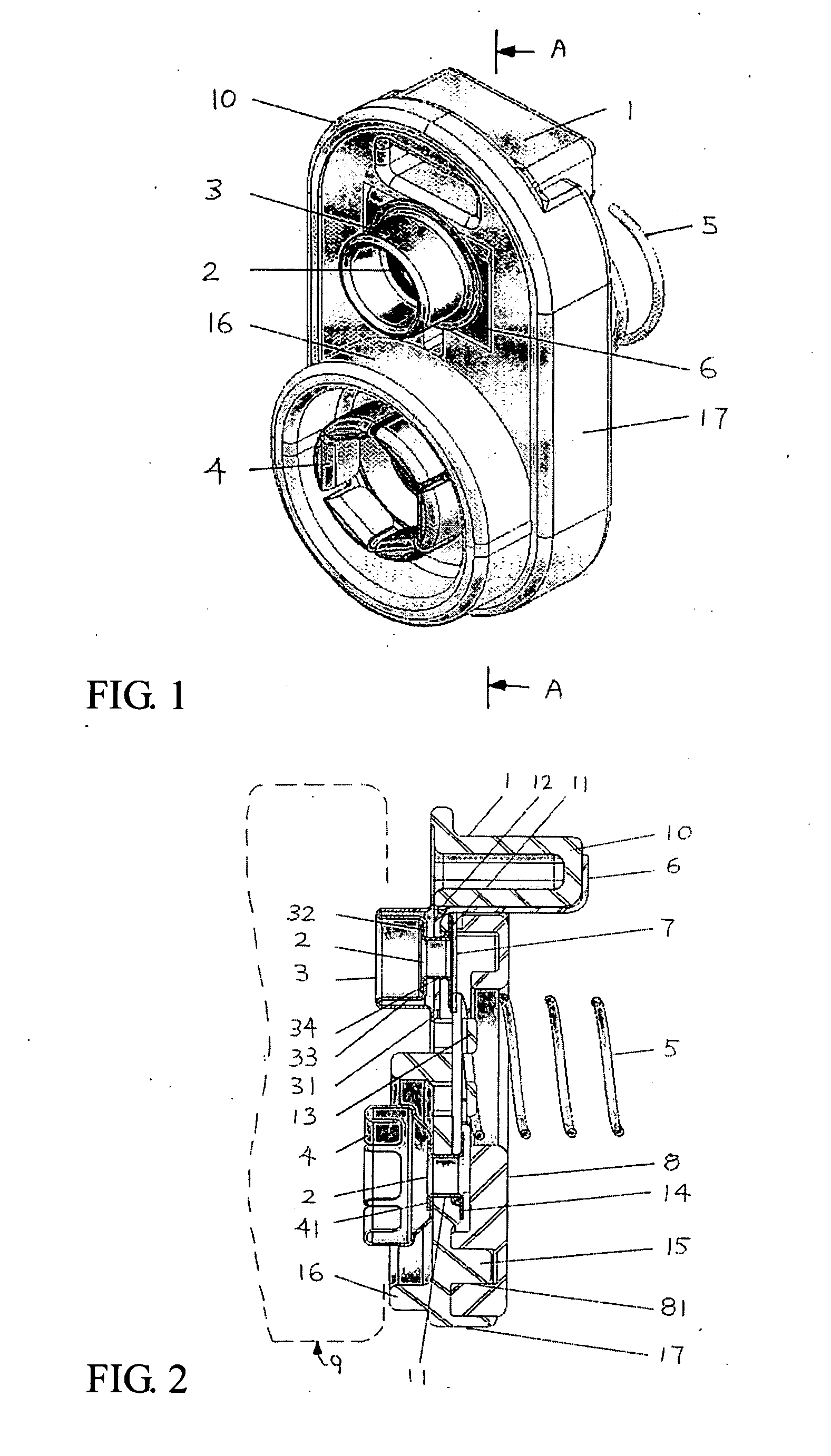

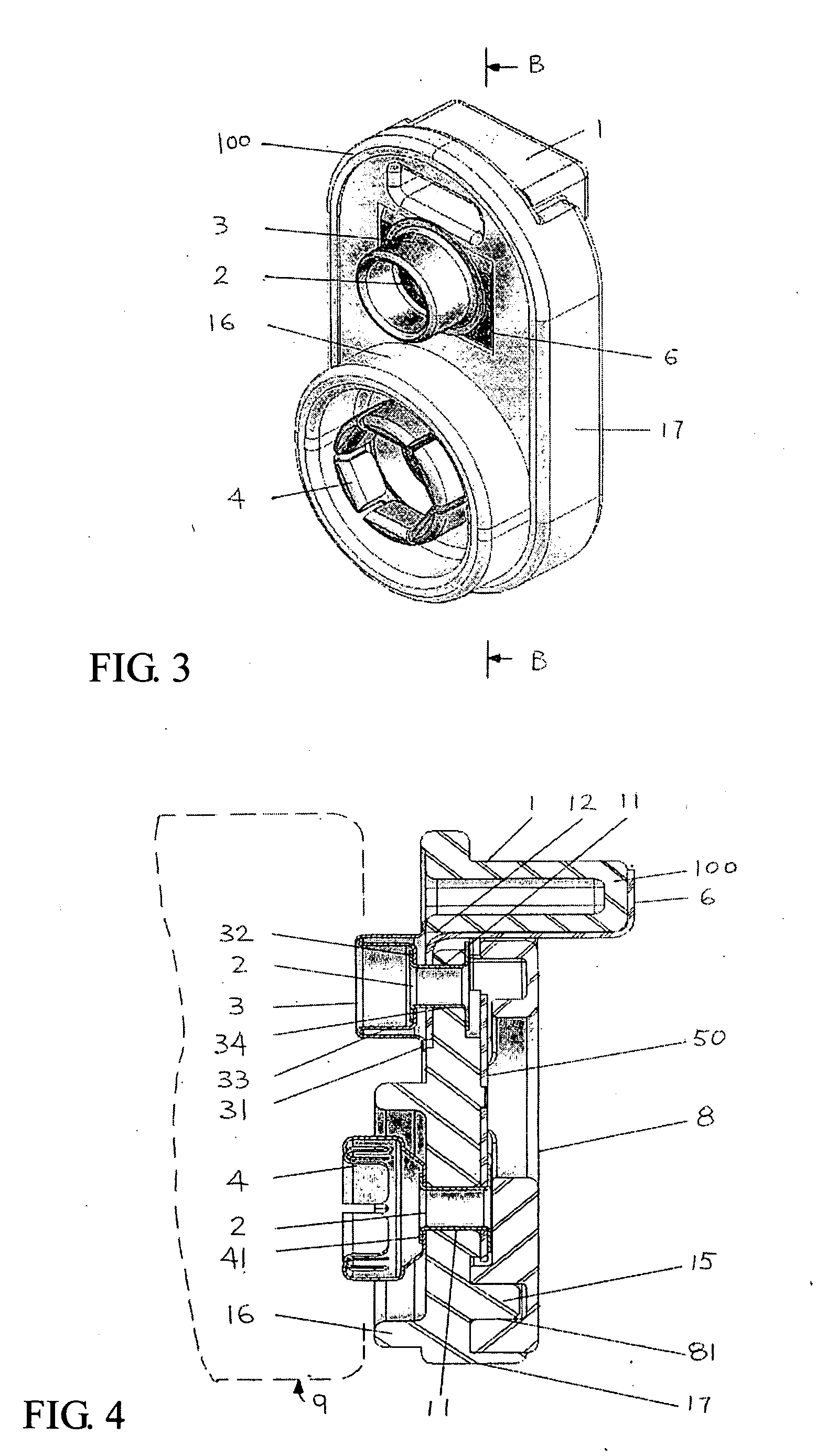

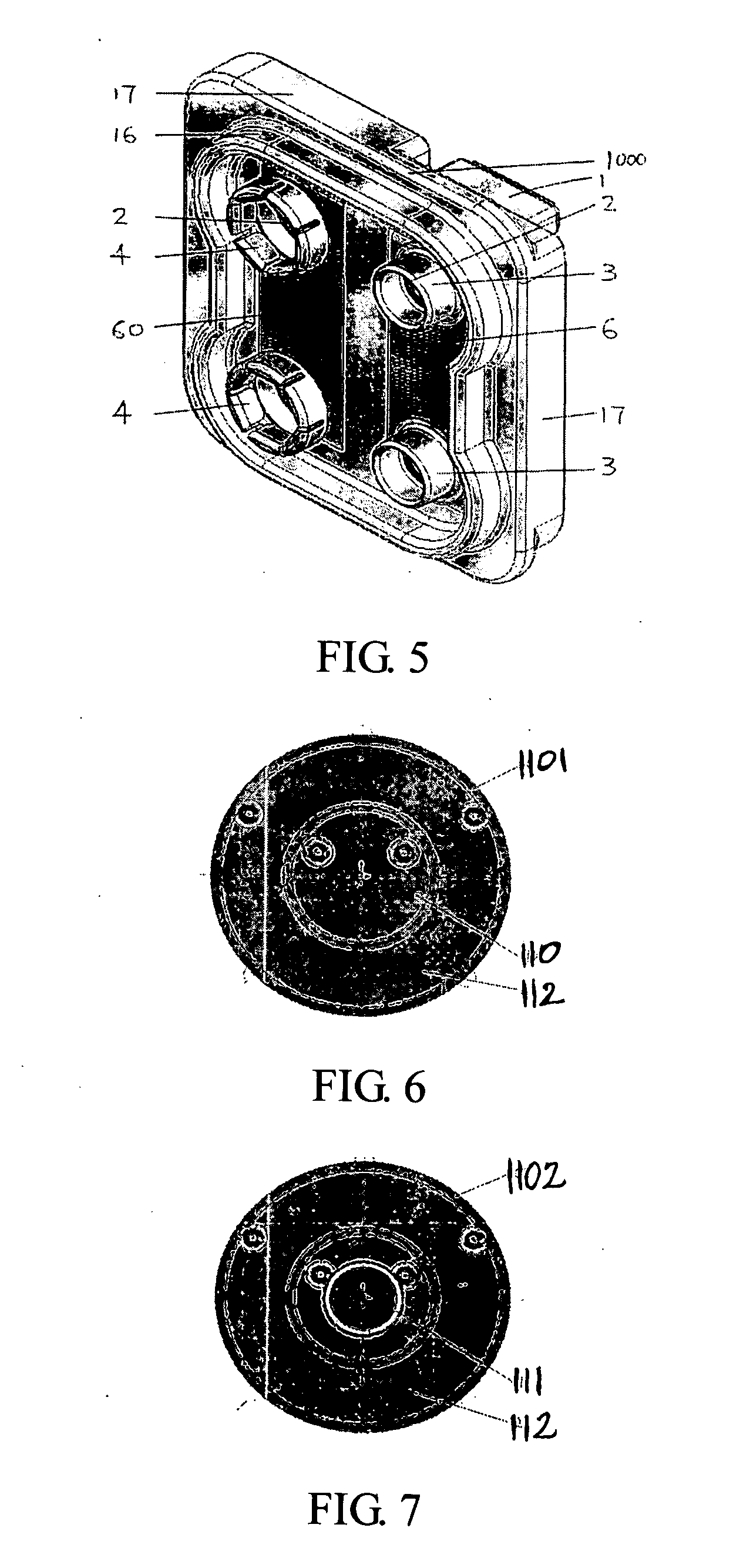

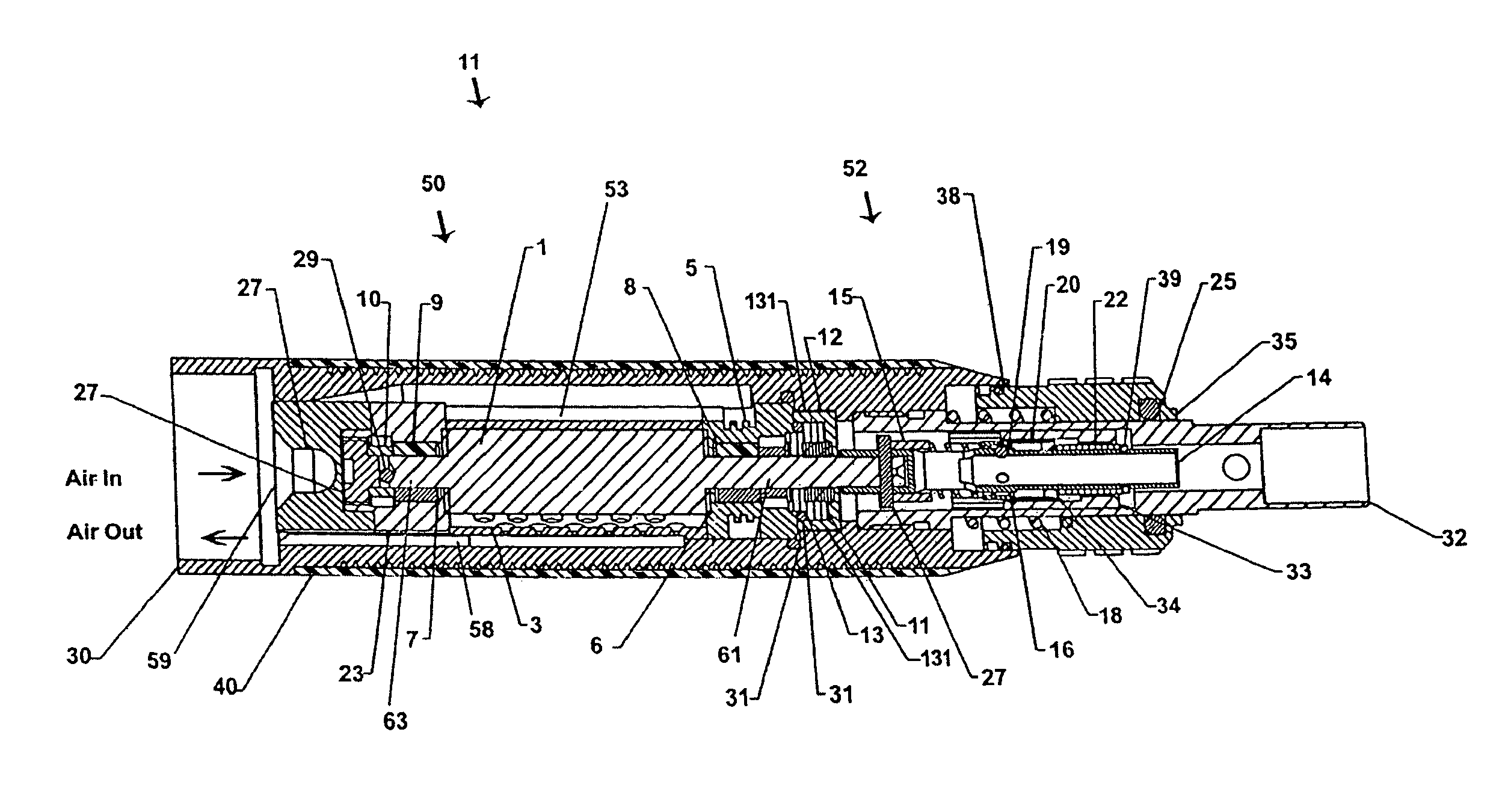

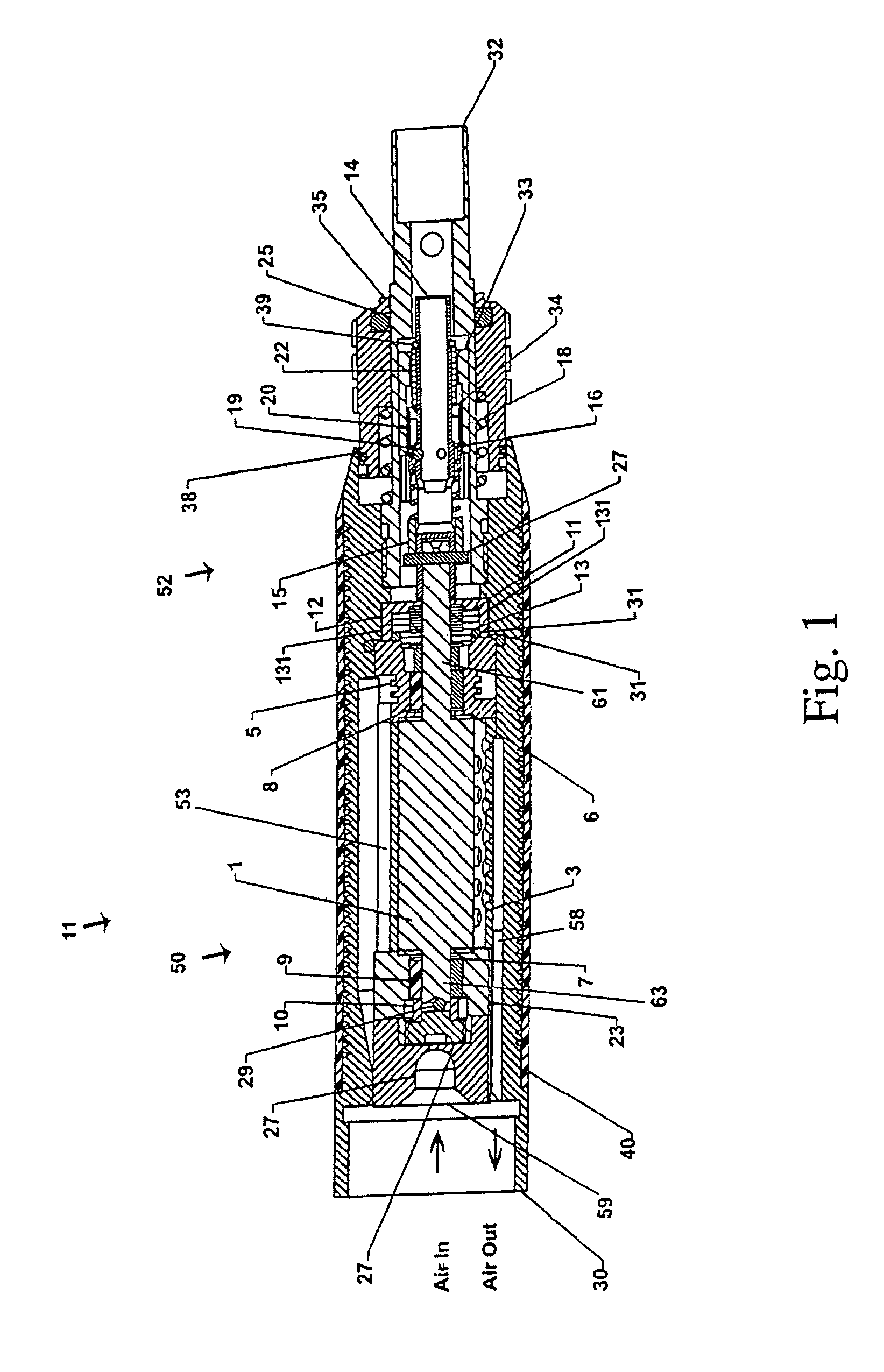

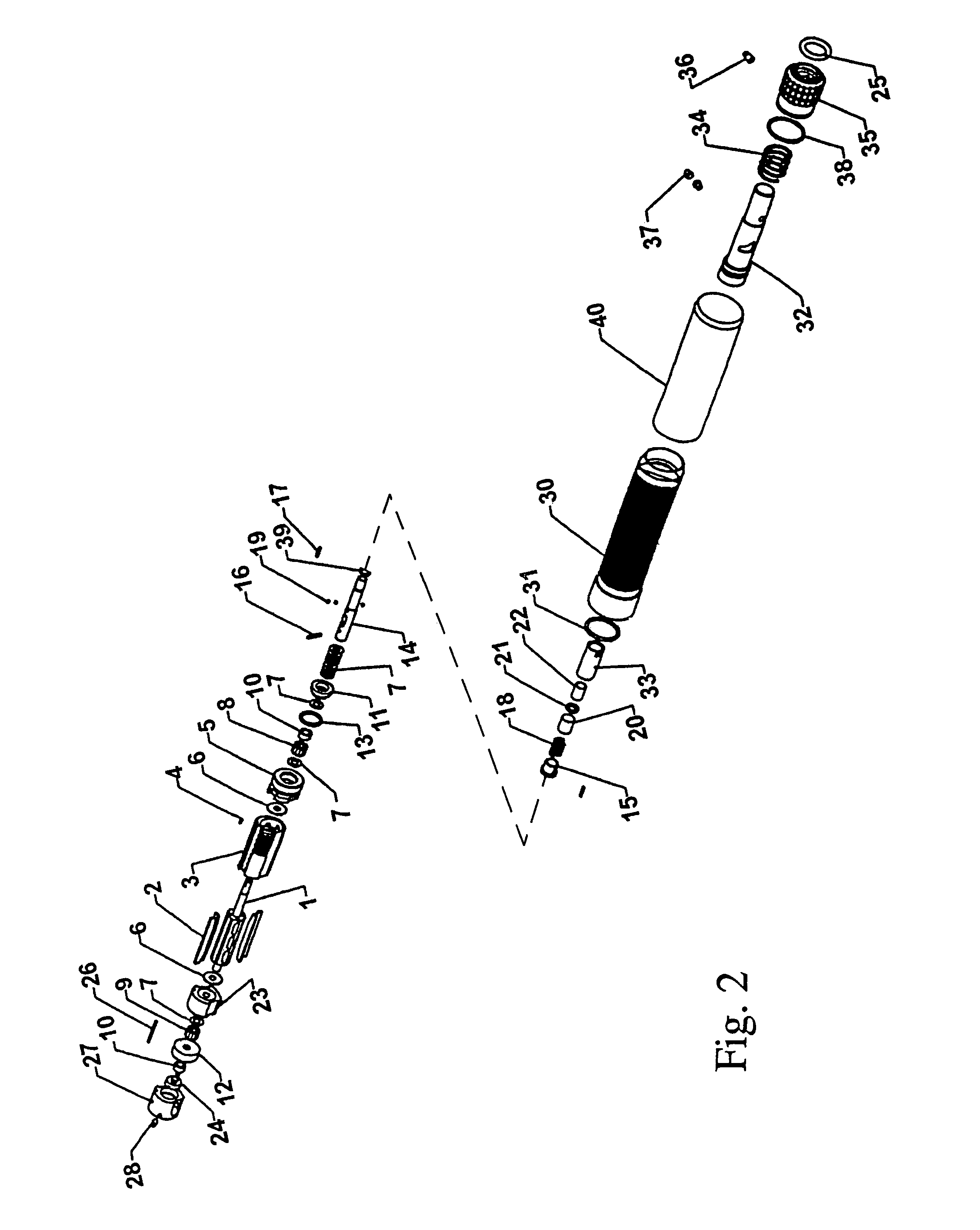

Surgical pneumatic motor for use with MRI

ActiveUS7527486B2Lower the heatReduce wearDiagnosticsRotary piston pumpsEngineeringMagnetic characteristic

A surgical pneumatic motor is designed to be used with or without an MRI machine without affecting or influencing the magnetic characteristic of the MRI machine. The motor includes an improved vane motor with undercuts in the spindle to increase the power faces of the vanes and spindle itself, the holes in the cylinder are modified to increase the sealing area between the spindle. The inlet cylindrical holes and the cylinder holes and grooves are arranged to enhance the life . Wear of the edge of the vanes is decreased by the judicious location of the discharge holes. The bearings are cooled by bypassing a portion of cylinder air before re-entering the air. The noise is attenuated by a cris-cross plug in the hose the temperature of the handle is reduced by a serrated sleeve. Slipping discs in the seal serves to enhance seal life.

Owner:ANSPACH EFFORT

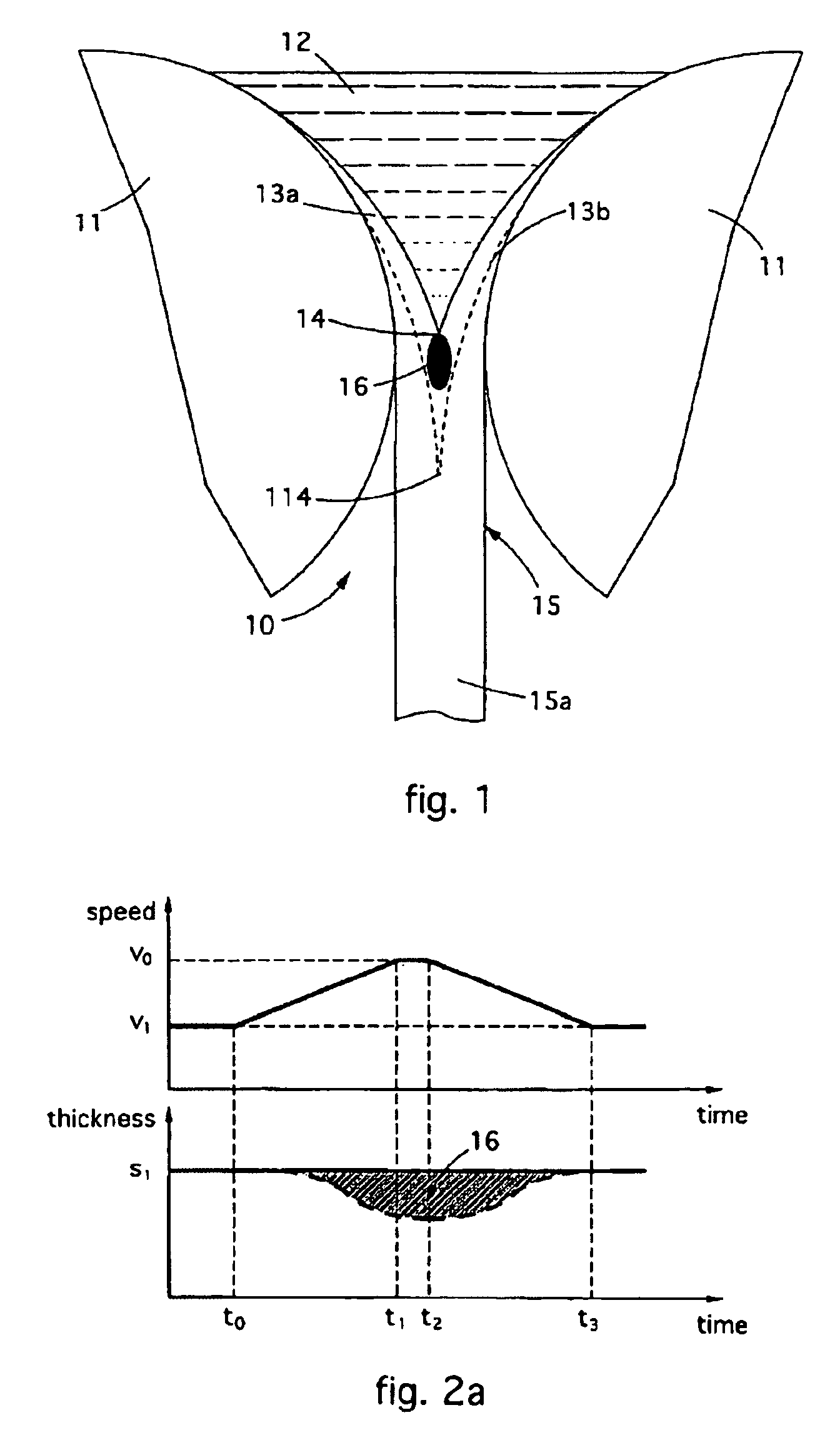

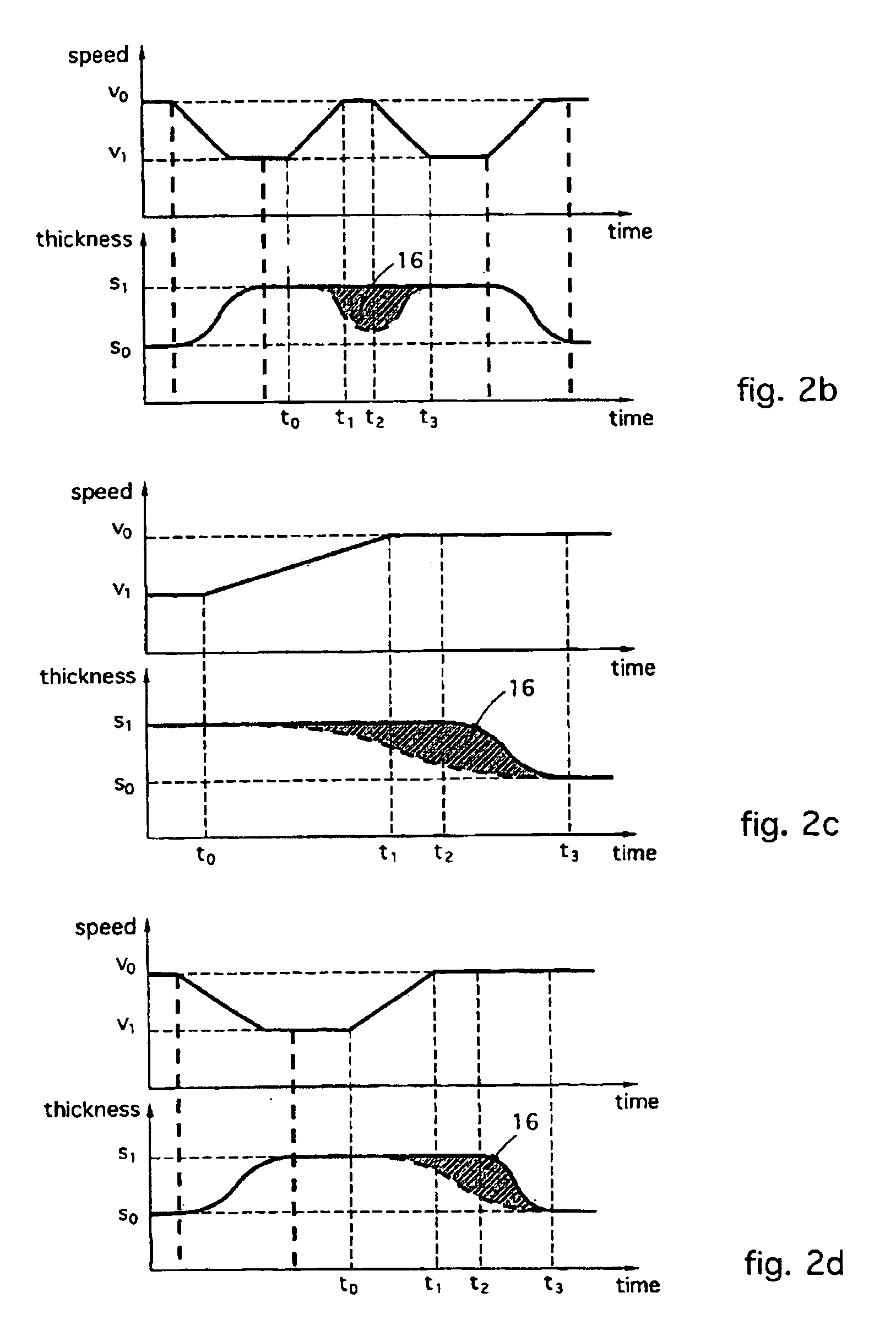

Method to shear a strip during the casting step

Method to shear a strip during the casting step, wherein the casting speed is increased, with respect to a speed of a stationary regime, maintaining the thickness of said cast strip constant to the value corresponding to the speed of a stationary regime, in order to determine the formation of a |liquid core which determines the re-melting of the adjacent skin and the breakage of the strip due to the weight of the part of the strip located under the liquid core.

Owner:DANIELI & C OFF MEC SPA

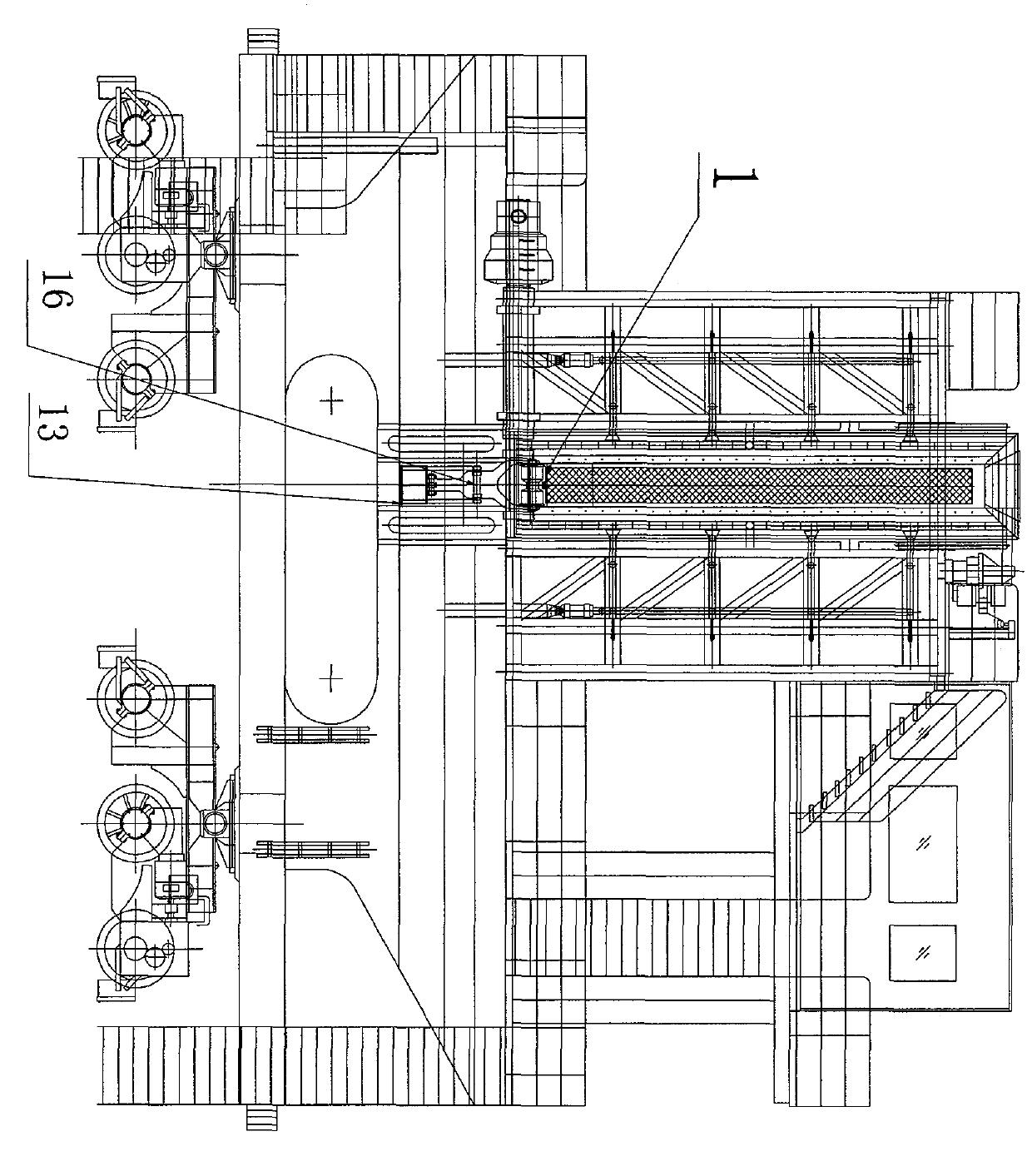

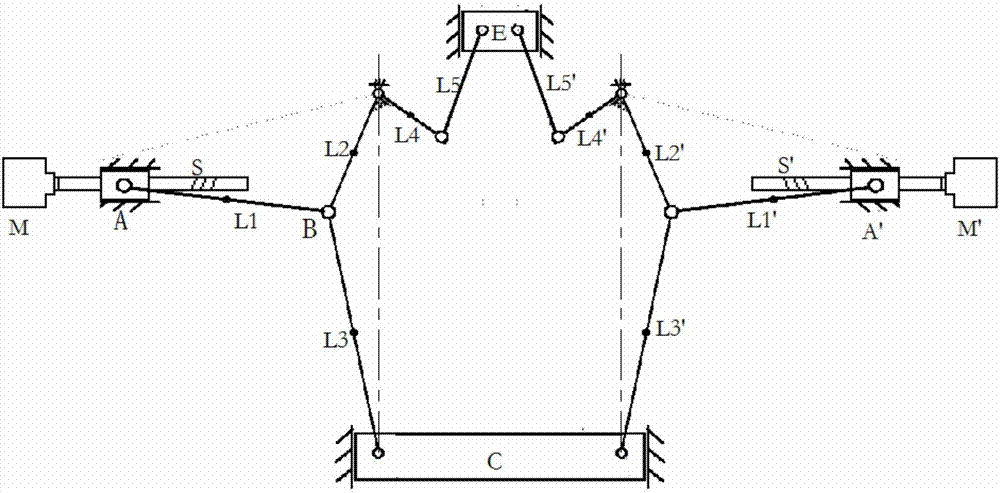

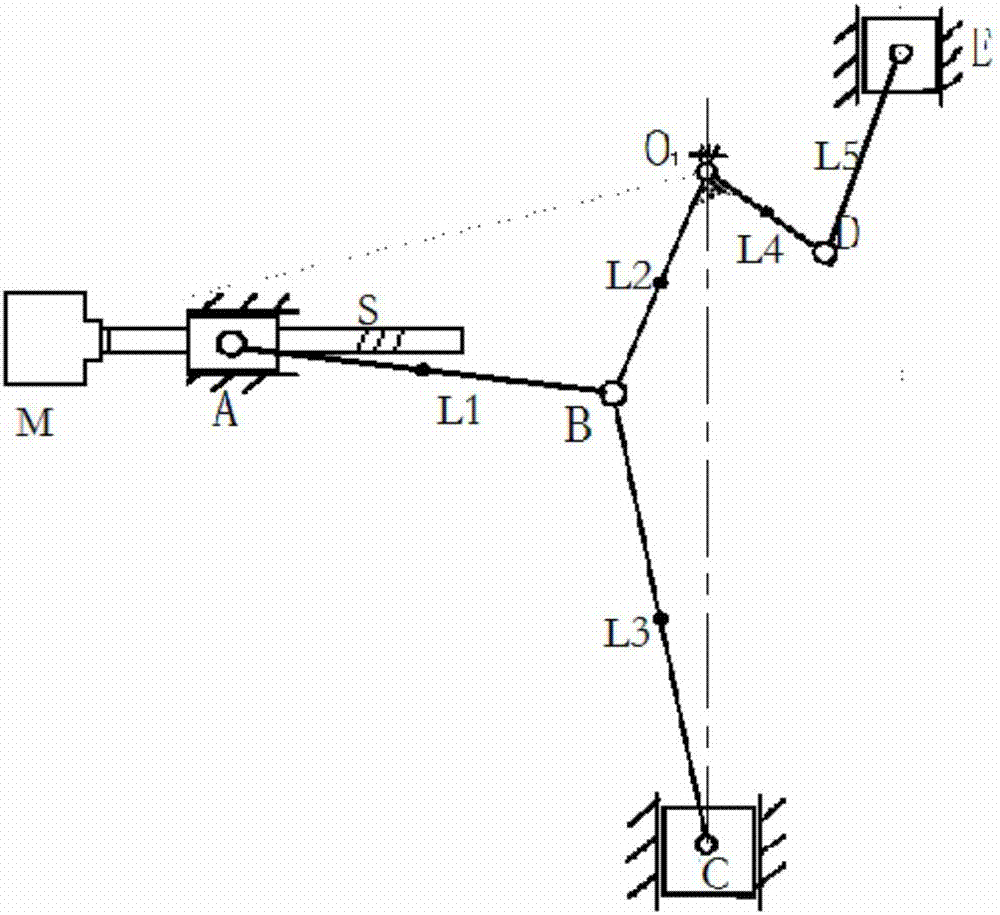

Mechanical servo main transmission device of large-tonnage high-speed fine blanking machine

The invention relates to a mechanical servo main transmission device of a large-tonnage high-speed fine blanking machine. The mechanical servo main transmission device comprises a main slide block, an auxiliary slide block and a drive mechanism, wherein the main slide block and the auxiliary slide block can only linearly move, and the drive mechanism can drive the main slide block and the auxiliary slide block to move at the same time. The drive mechanism comprises a servo motor, a lead screw connected with an output shaft of the servo motor, a slide block arranged on the lead screw in a sleeving manner and can only linearly move, a connection rod L1, a connection rod L2, a connection rod L3, a connection rod L4 and a connection rod L5. One end of the connection rod L1, one end of the connection rod L2 and one end of the connection rod L3 are hinged to the same point. The other end of the connection rod L1 and the other end of the connection rod L3 are hinged to the slide block and the main slide block correspondingly. The other end of the connection rod L2 is a fixed hinge point. One end of the connection rod L4 and the connection rod L2 are fixed into a whole, and the other end of the connection rod L4 is hinged to one end of the connection rod L5, and the other end of the connection rod L5 is hinged to the auxiliary slide block. The movement directions of the main slide block and the auxiliary slide block are opposite all the time. The device is good in dynamic characteristic, reasonable in arrangement, small in vibration, high in machining precision and capable of balancing inertia force.

Owner:WUHAN UNIV OF TECH

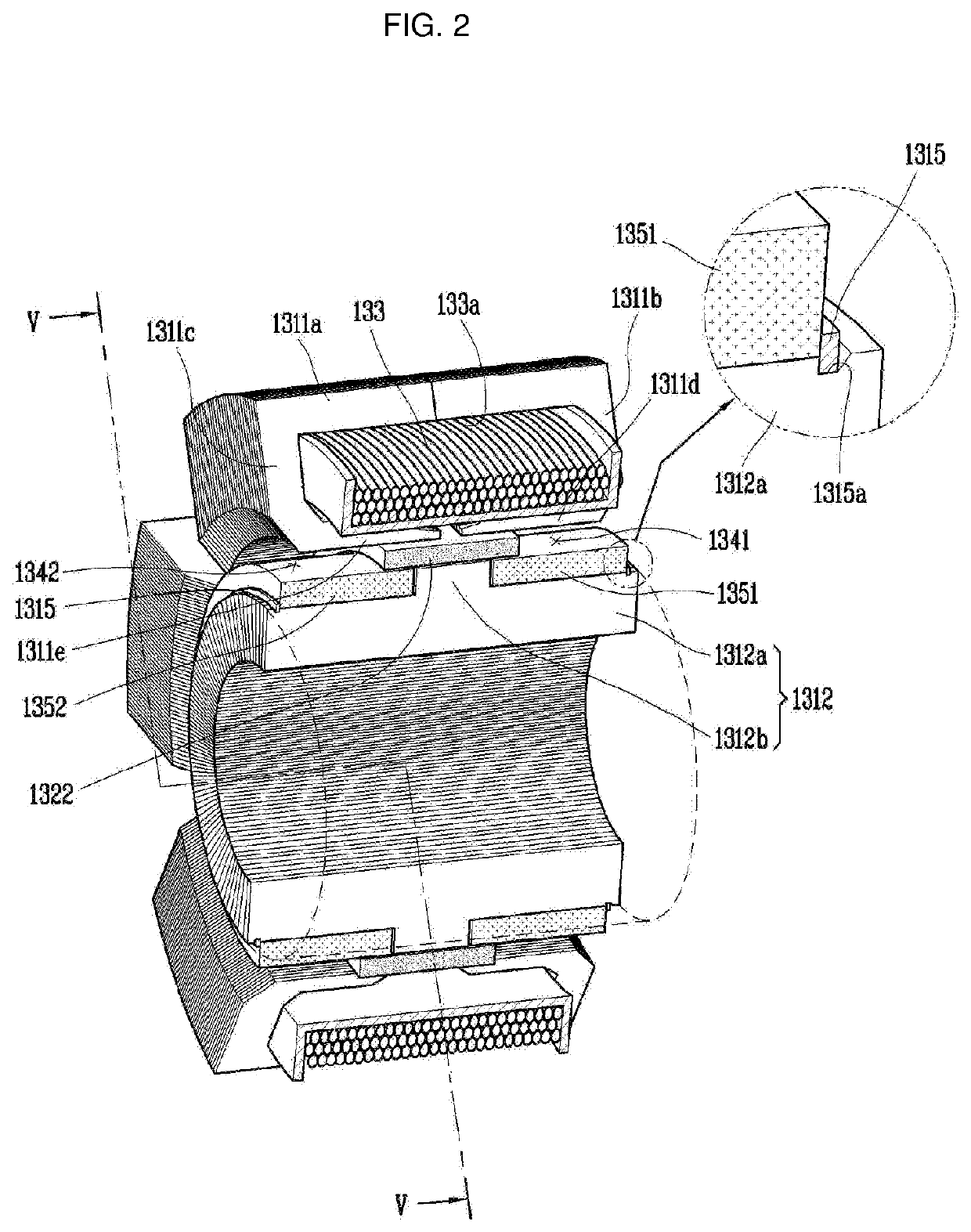

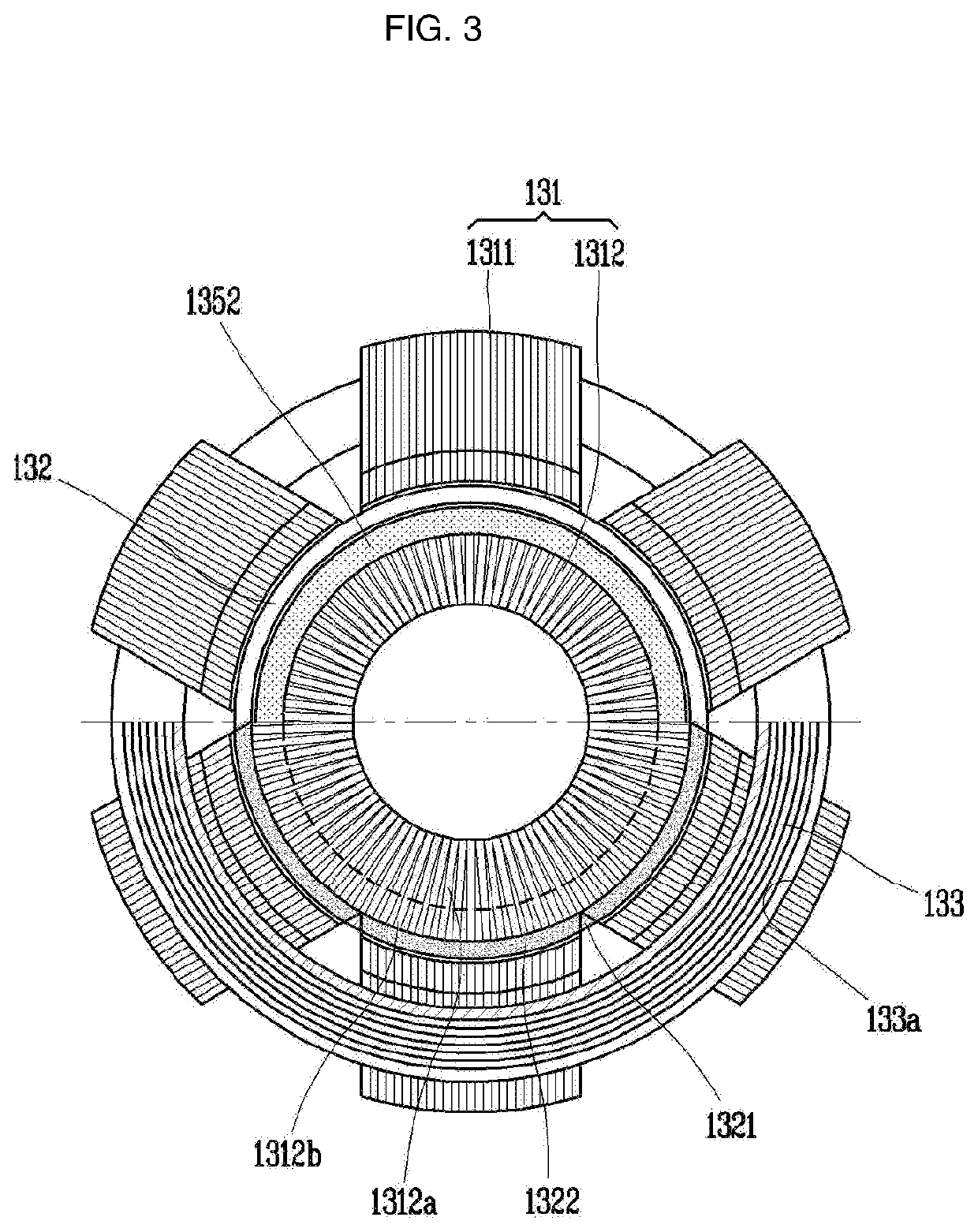

Linear motor and linear compressor having same

ActiveUS20200395836A1Increase thrustReducing centering forceReciprocating/oscillating/vibrating magnetic circuit partsPositive displacement pump componentsLinear compressorElectric machine

In a linear motor and the linear compressor having the same according to the present disclosure, a plurality of magnets are coupled to a stator equipped with a winding coil, and a mover core made of magnetic material instead of a permanent magnet is provided on the mover, and by the magnetizing plurality of magnets in the same direction, the motor output can increase by increasing thrust instead of decreasing the centering force for the mover core. In addition, as it is applied to a two-pore motor, it is possible to easily control the mover core and to easily perform an assembly operation and a magnetization operation for the magnet. In addition, as the stator is made of a grain-oriented core, core loss may be reduced and the motor efficiency may be improved.

Owner:LG ELECTRONICS INC

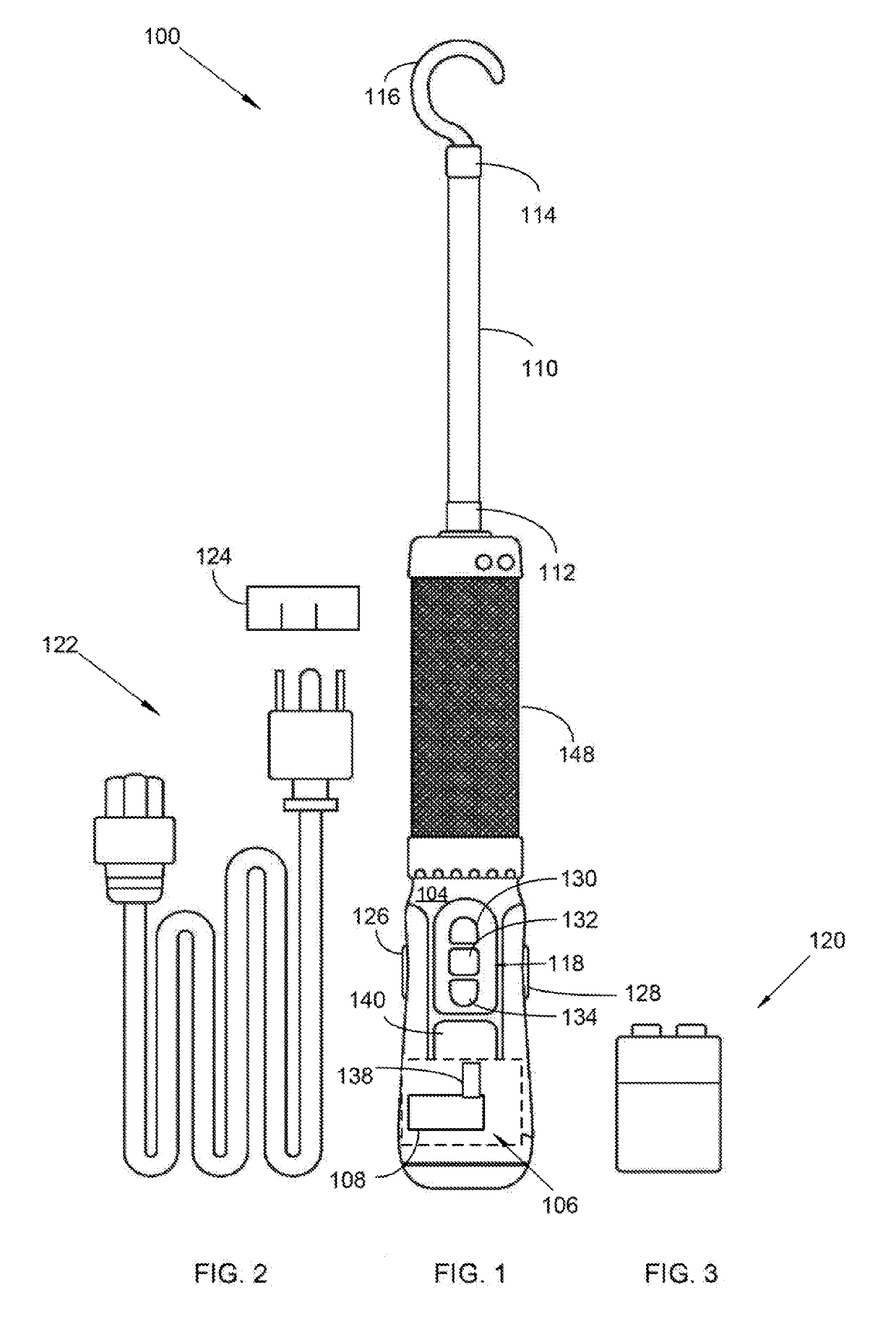

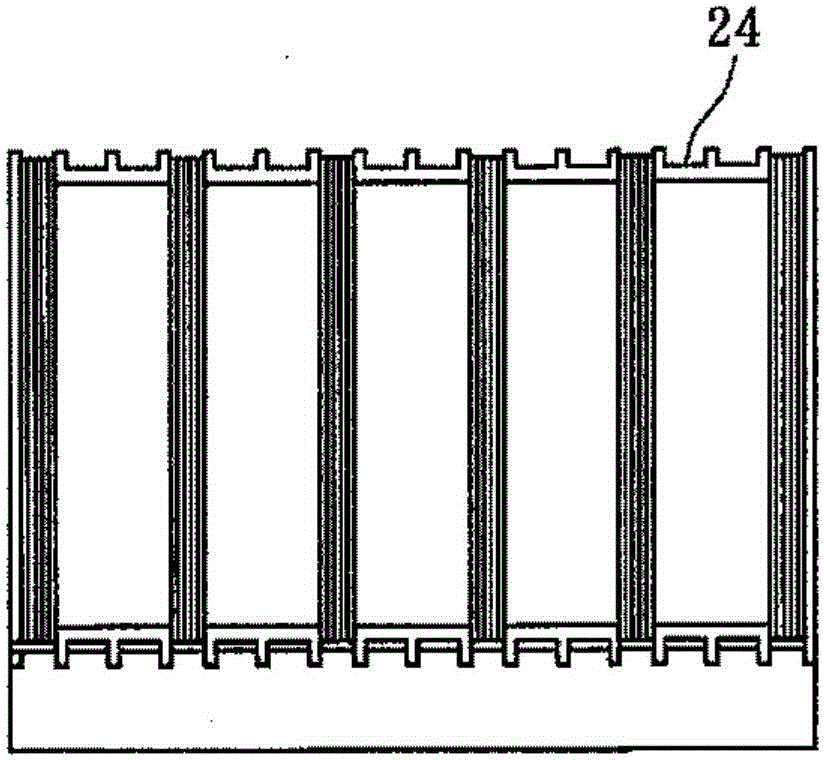

Dual-rotor motor for bike

InactiveCN104638856AReduce usageIncrease motor powerMagnetic circuit rotating partsMechanical energy handlingEngineeringMulti phase

The invention discloses a dual-rotor motor for a bike, which comprises a shell. the shell is internally provided with a stator assembly and a rotor assembly; the stator assembly is provided with a stator seat and a coil ring fixedly arranged on the stator seat; the coil ring is provided with a multi-phase winding distributed along the circumference; the rotor assembly is provided with a rotor fixing seat, an inner rotor and an outer rotor; the inner rotor and the outer rotor are ring-shaped and fixedly arranged on the rotor fixing seat and a preset distance is left between the inner rotor and the outer rotor; the opposite surfaces of the inner rotor and the outer rotor are respectively provided with multiple inner magnets and multiple outer magnets; the same poles of the inner magnets and the outer magnets are opposite to each other; and the coil ring and the multi-phase winding are located between the inner magnets and the outer magnets.

Owner:J D COMPONENTS CO LTD

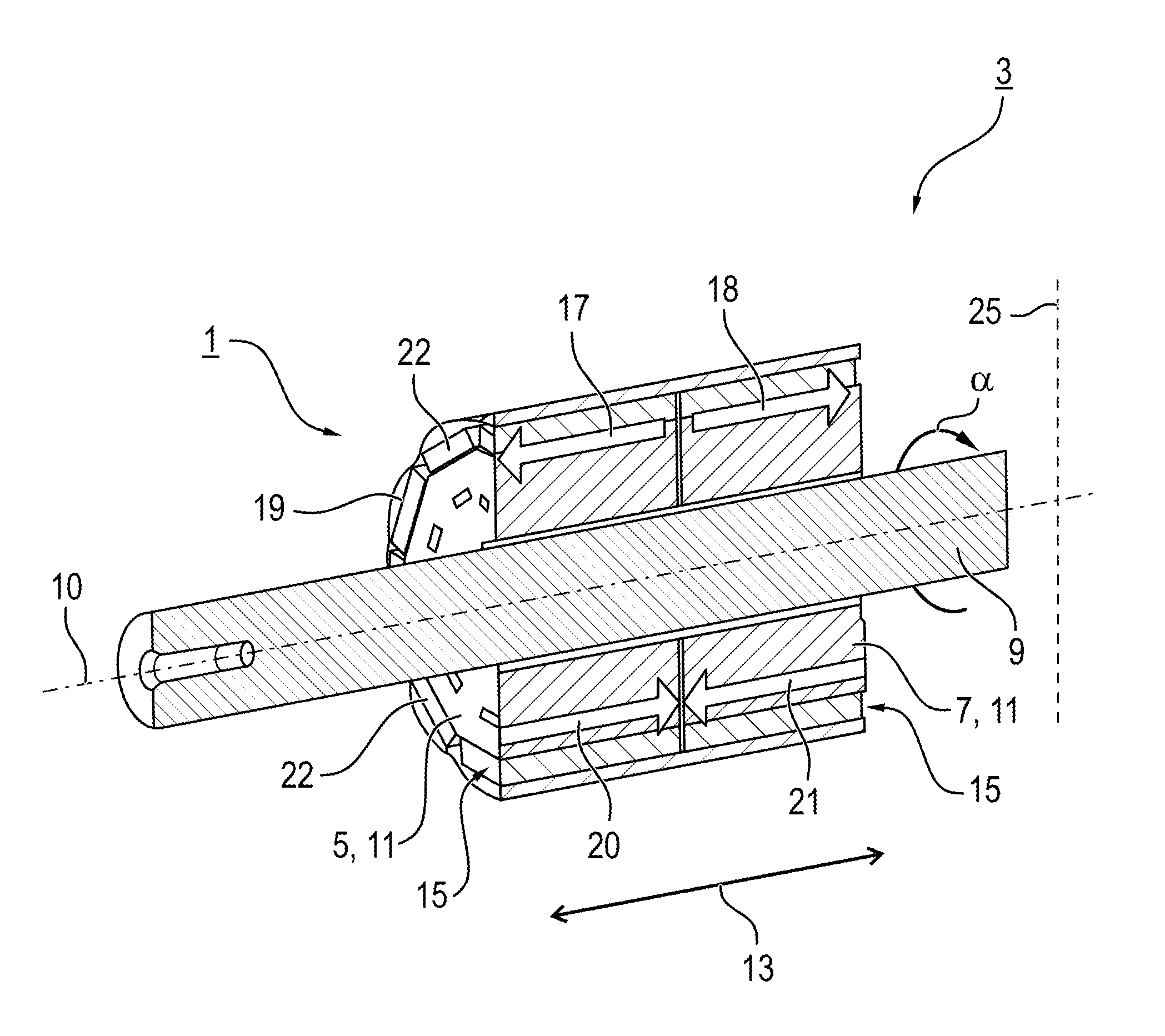

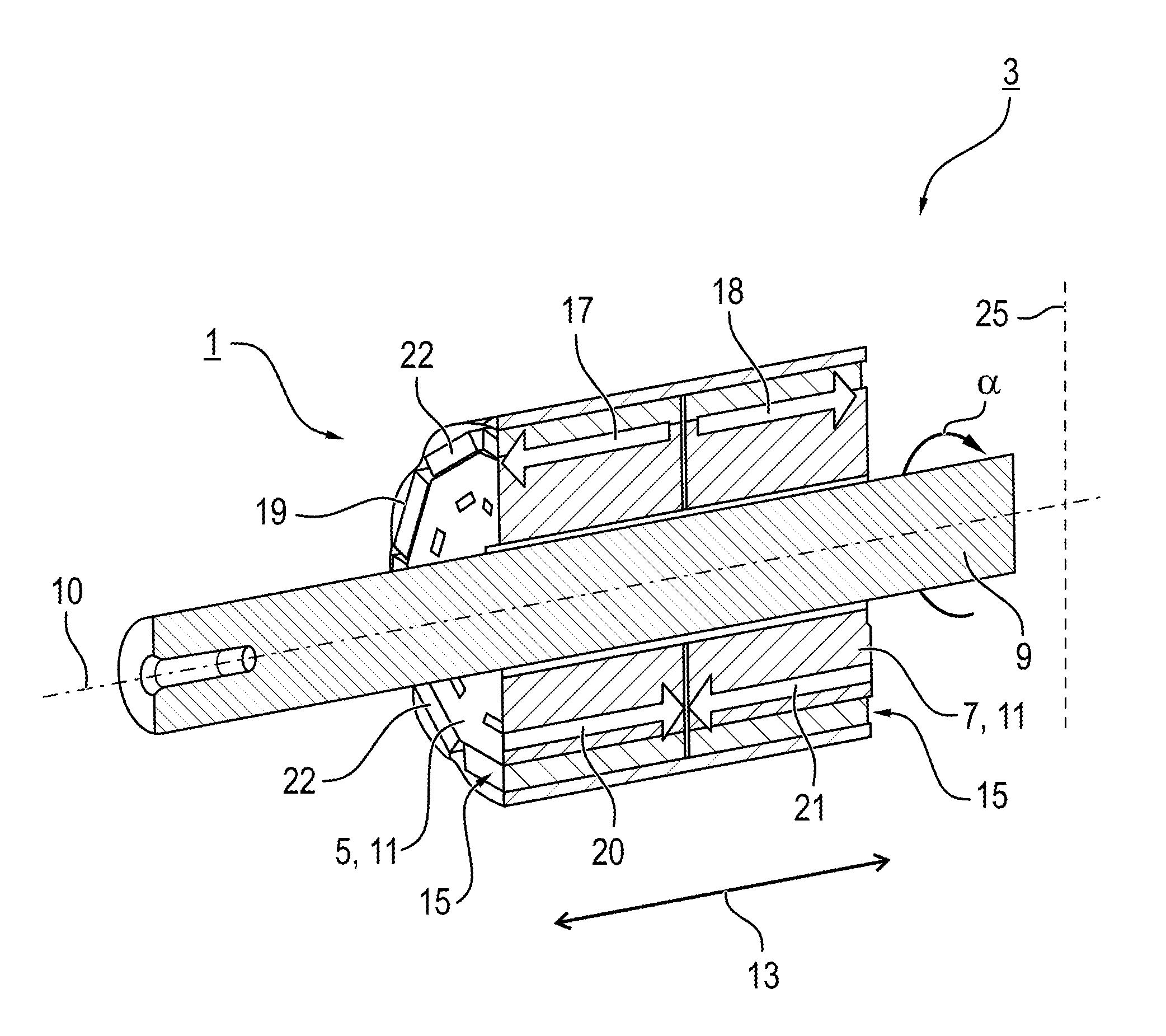

Method for producing a rotor and electric machine having a rotor

ActiveUS20150137649A1Low production costIncrease powerMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

A method produces a rotor which can rotate about a rotation axis, in particular for an electrical machine of a motor vehicle. At least two rotor body elements are each provided with a number of receiving pockets which are made in an axial direction. Magnet bodies are in each case pressed into the receiving pockets in the rotor body elements with an axial press-in direction. The rotor body elements are joined to one another in such a way that the press-in directions of the magnet bodies point away from one another. Additionally, an electrical machine has a rotor which is produced in this manner.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com