Patents

Literature

48 results about "Actuator torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Actuator torque is a quantitative expression of the amount of torque that an actuator is capable of producing.

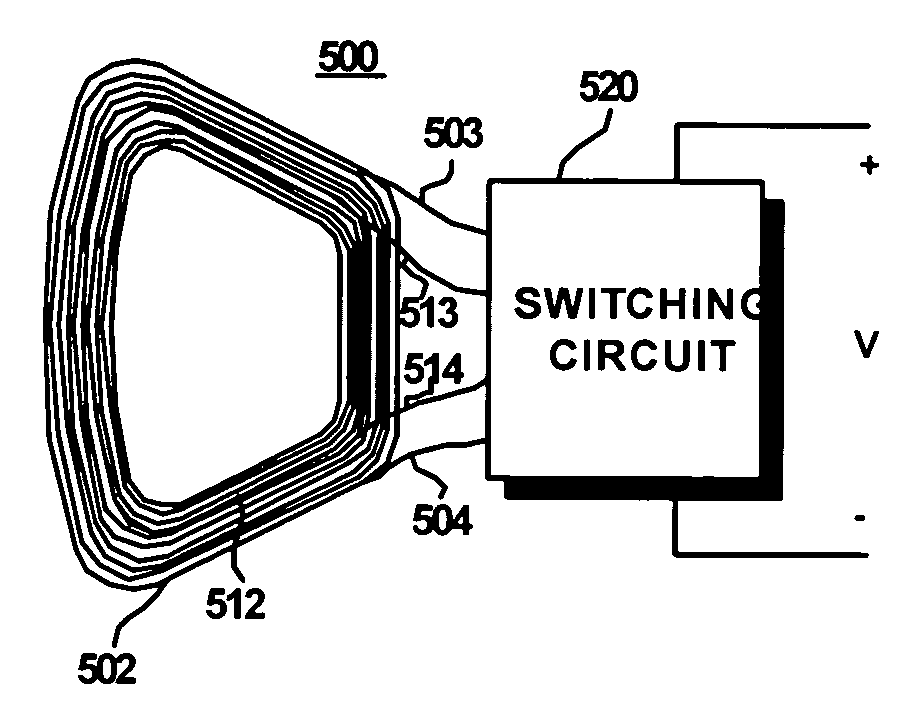

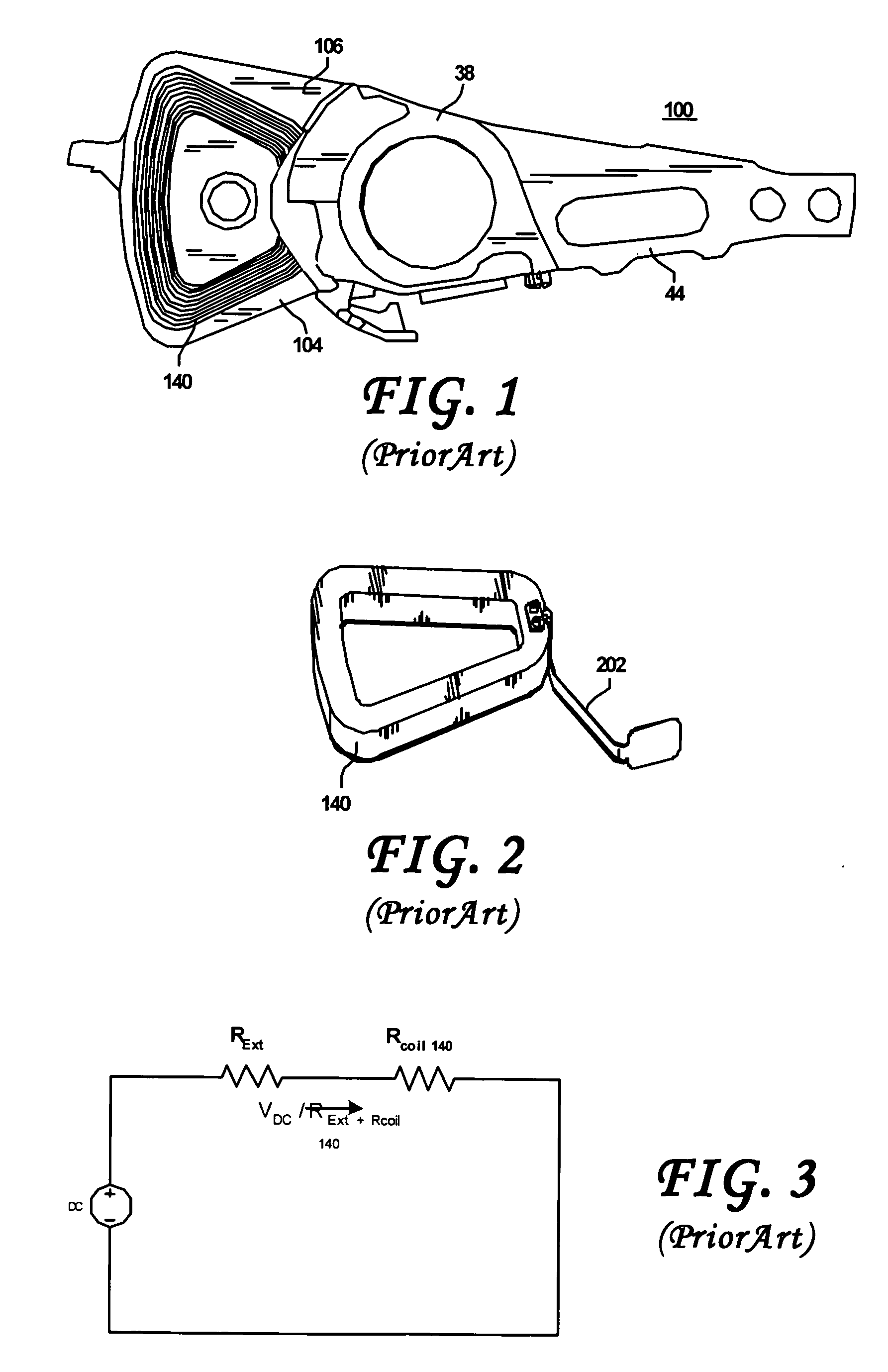

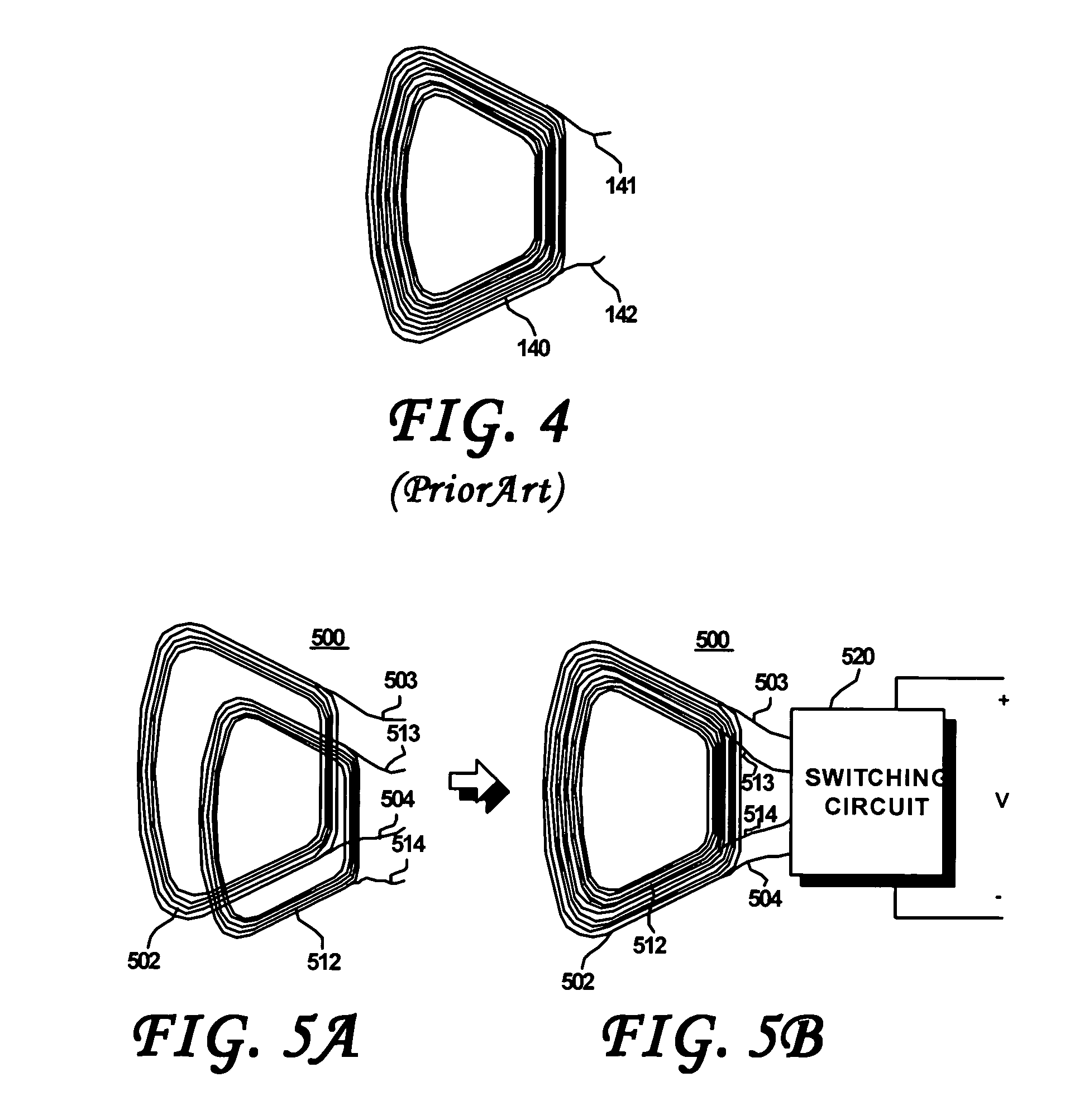

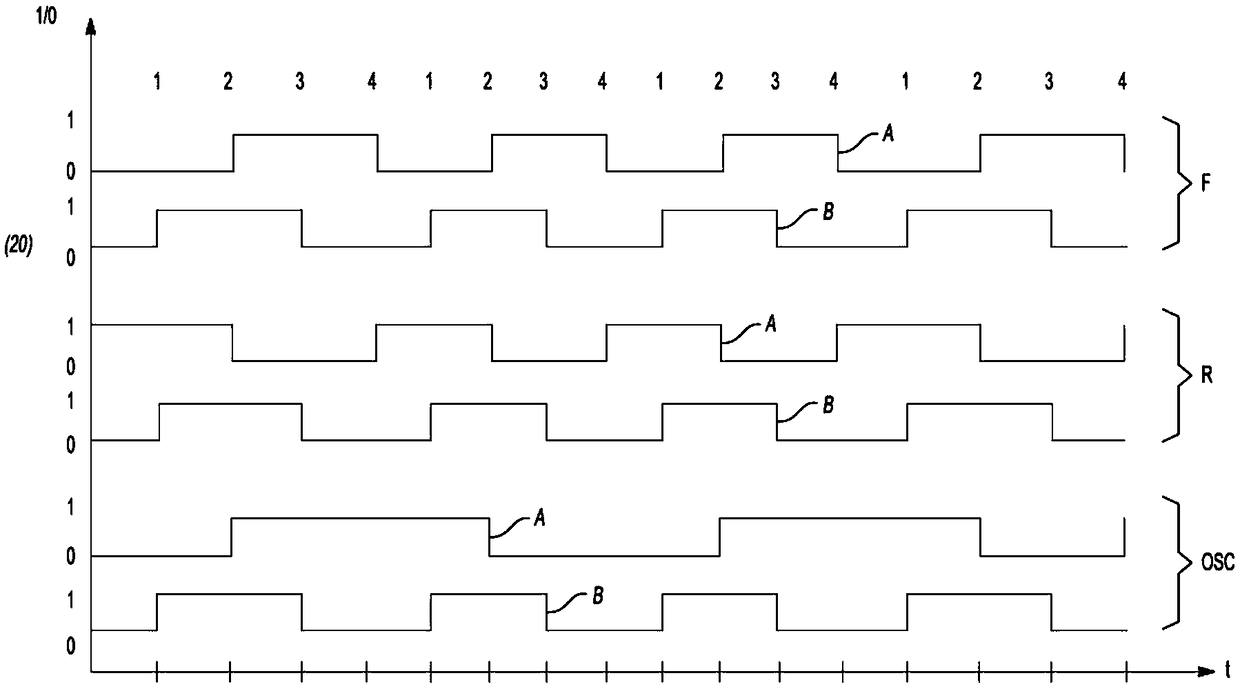

Disk drive having electrically parallel actuator coils for selectively boosting actuator torque

InactiveUS6947251B1Record information storageAlignment for track following on disksElectricityEngineering

A disk drive includes a disk, a voltage supply, a head stack assembly and a switching circuit. The head stack may include a coil portion that includes a coil assembly having first and second wound coils. The switching circuit is electrically coupled to the voltage supply and to the coil assembly, and is configured to selectively switch the first and second wound coils between a first configuration and a second different configuration in which the first wound coil is electrically in parallel with the second wound coil.

Owner:WESTERN DIGITAL TECH INC

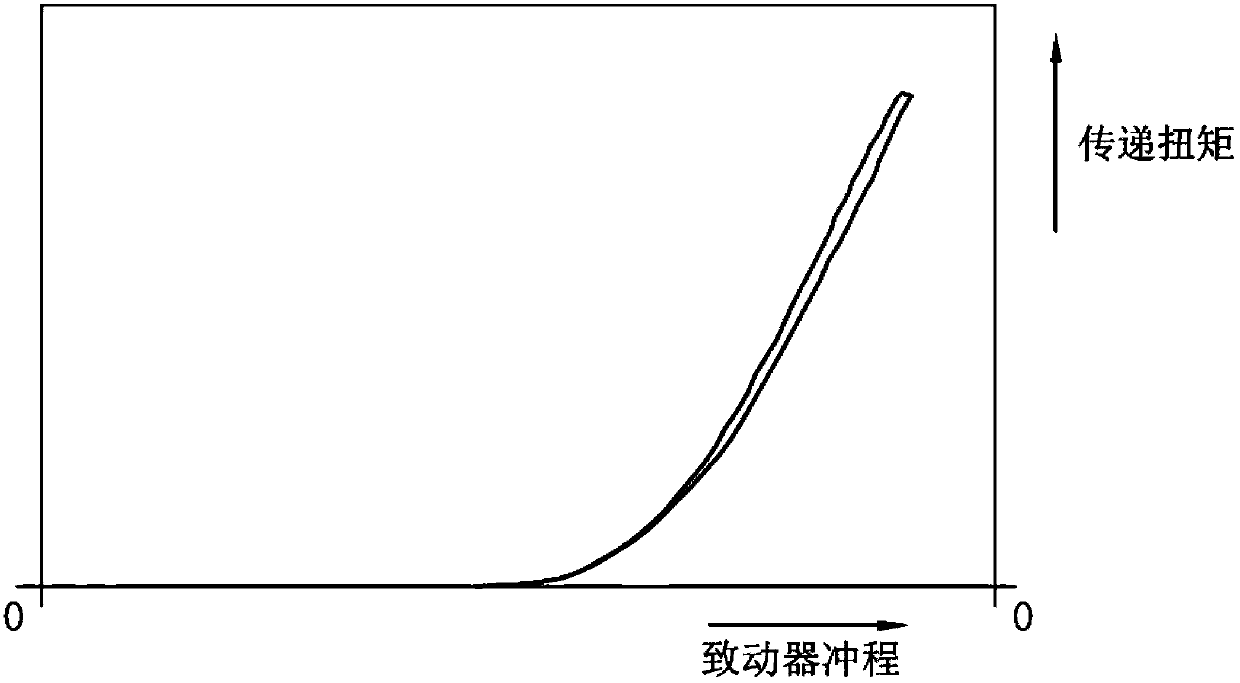

Estimating method for transmitting torque of dry type clutch in vehicle

Owner:HYUNDAI MOTOR CO LTD +1

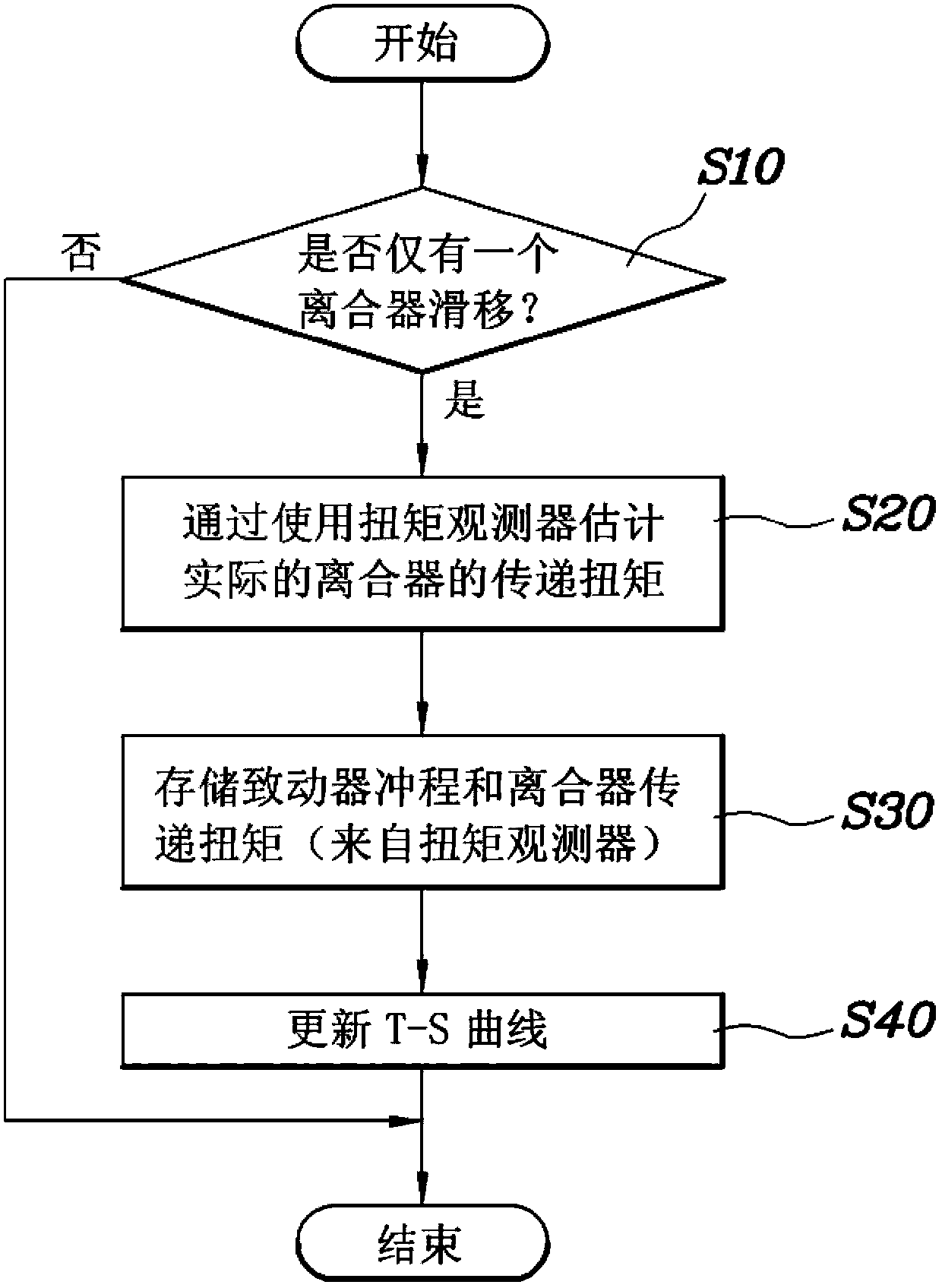

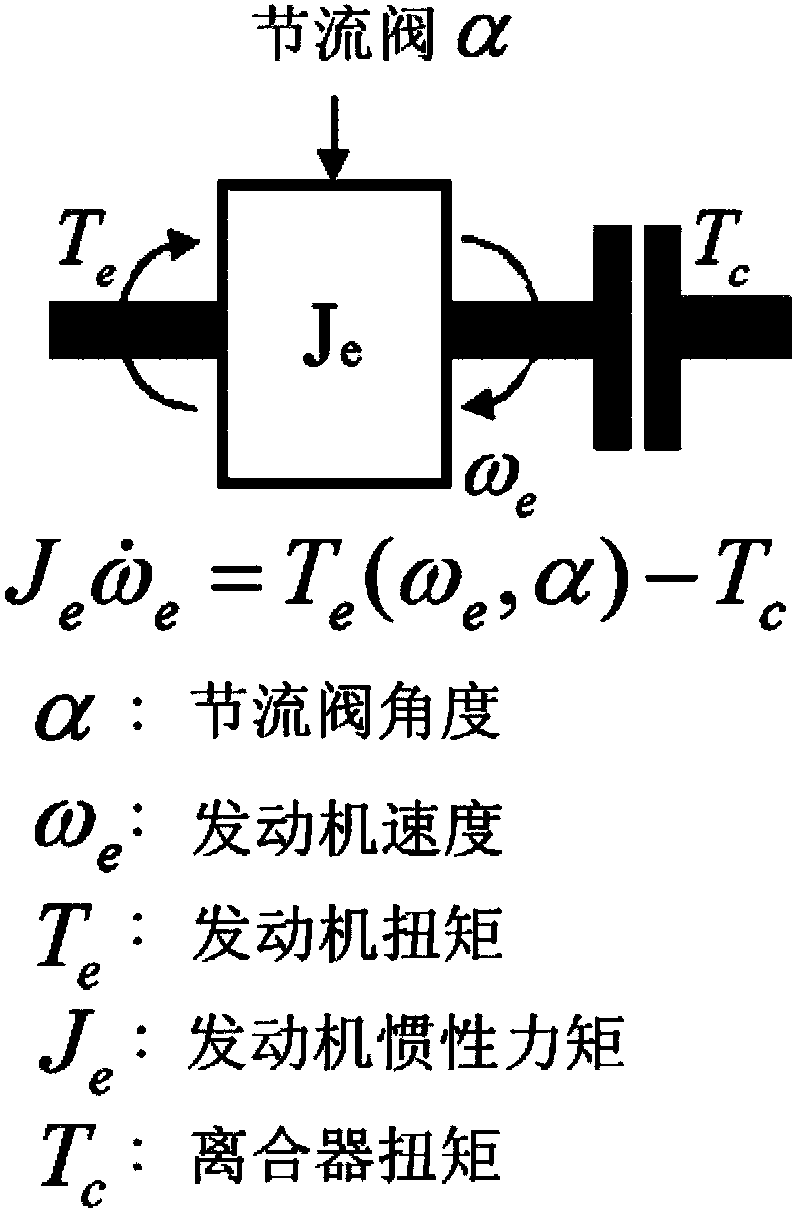

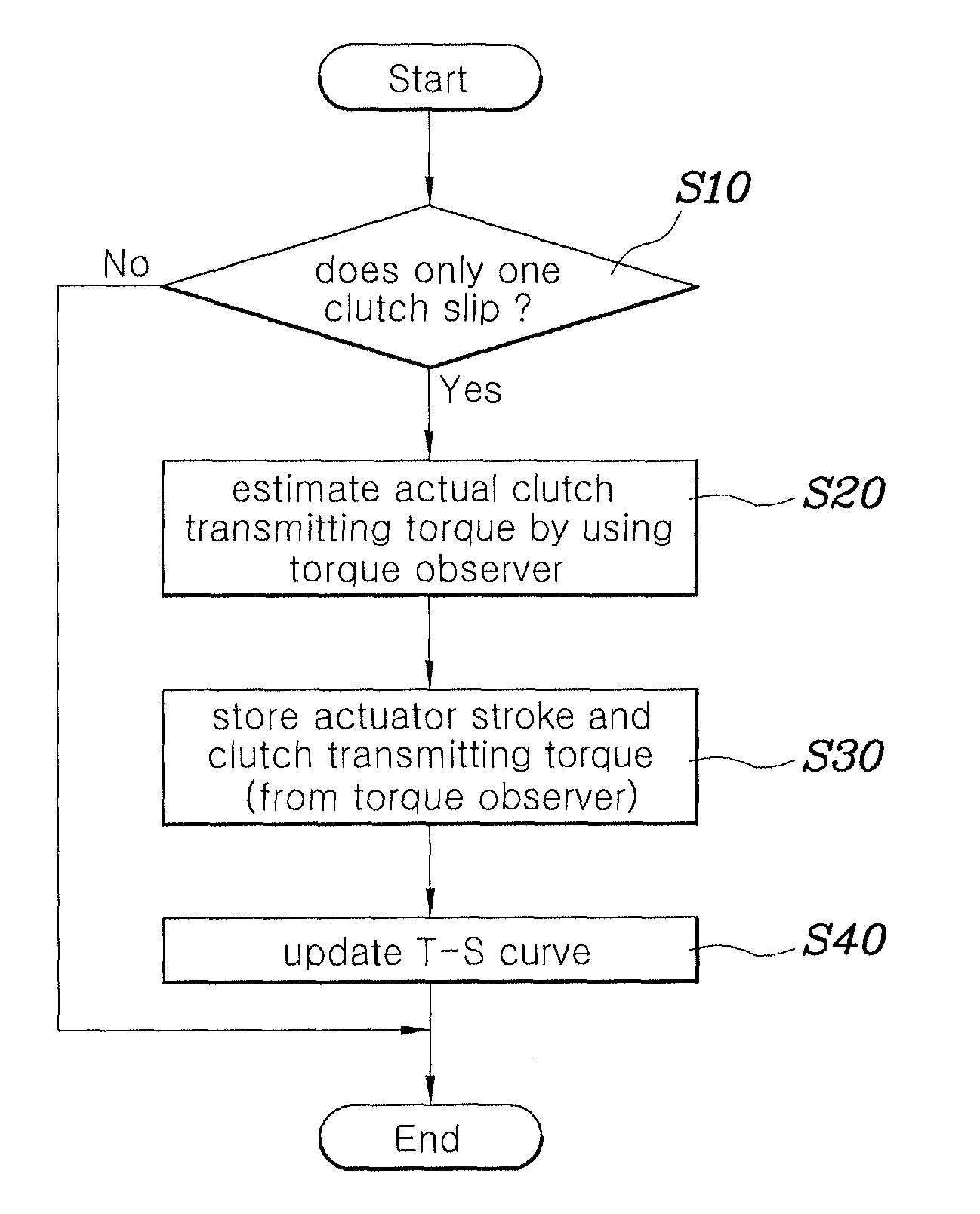

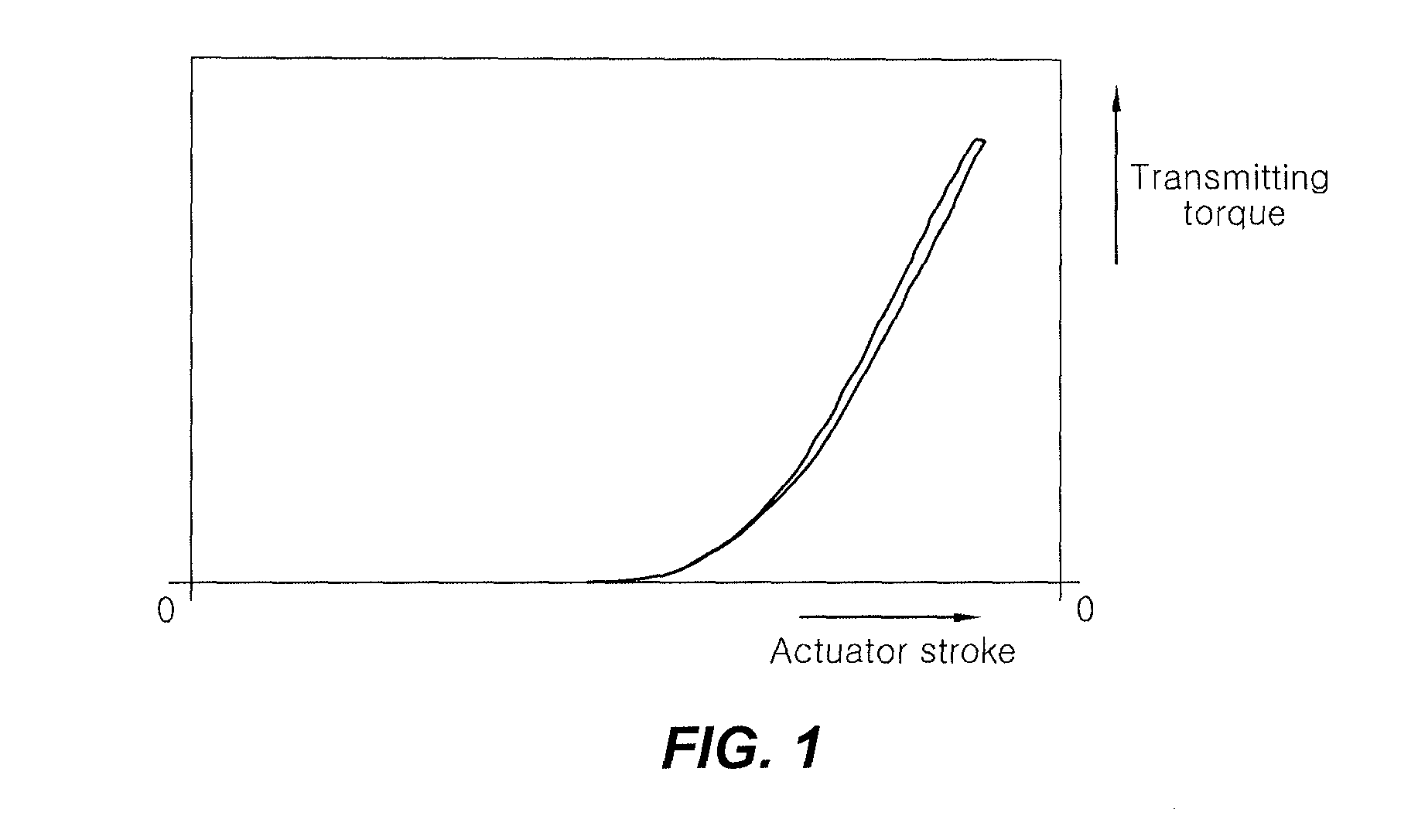

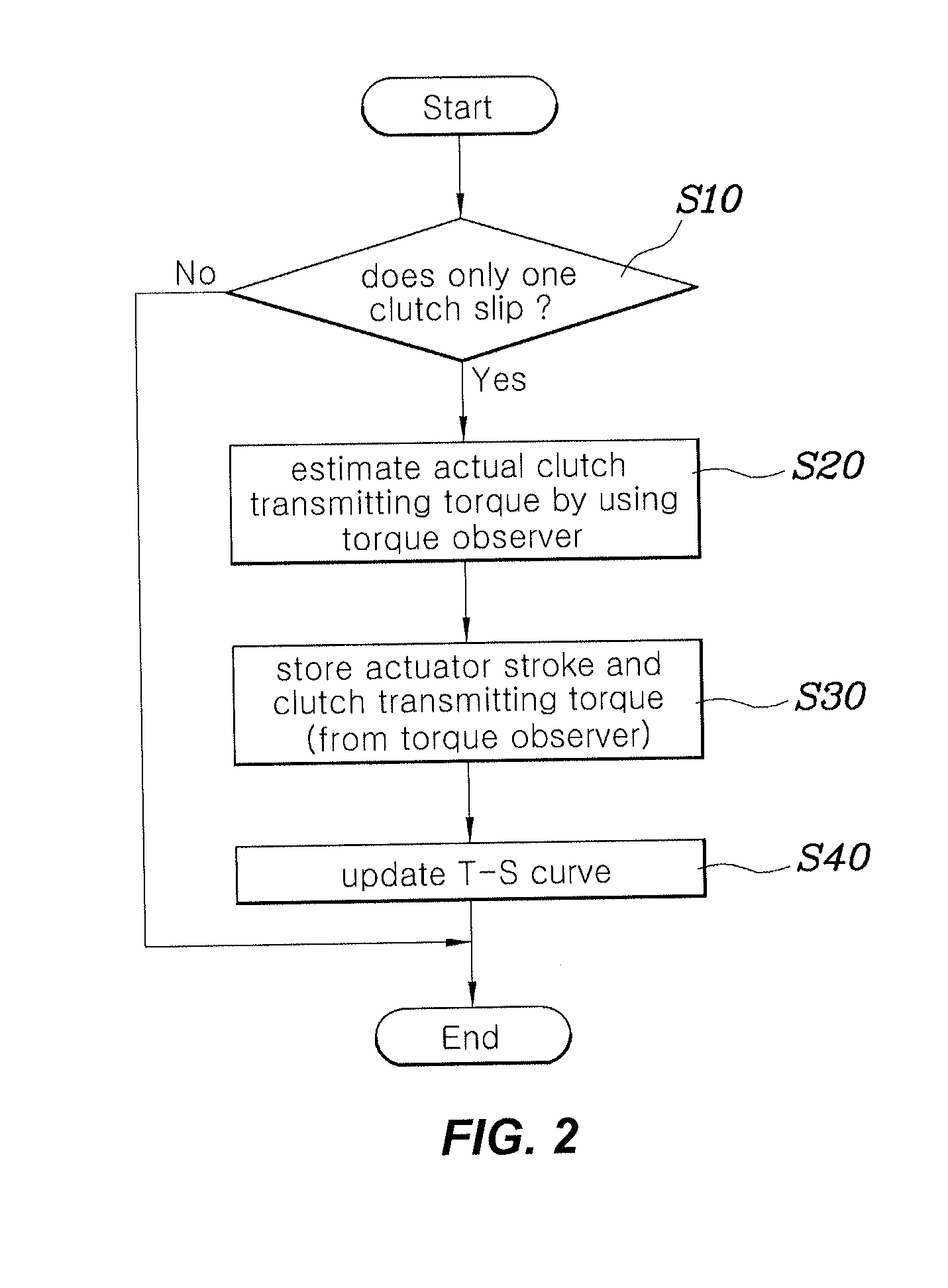

Estimating method for transmitting torque of dry type clutch in vehicle

InactiveUS8594901B1Securing durabilityDigital data processing detailsSlip couplingIn vehicleTorque observer

An estimating method for transmitting torque of a dry type clutch in a vehicle, may include a slip determining step of determining by a processor whether only one clutch slips between an engine and a transmission, a transmitting torque estimating step of estimating a current transmitting torque of the dry type clutch by using a torque observer when the only one clutch slips as a result of performing the slip determining step, and an updating step of reflecting the current transmitting torque of the dry type clutch estimated in the transmitting torque estimating step and an actuator torque in the transmitting torque estimating step to a T-S (Torque-Stroke) curve.

Owner:HYUNDAI MOTOR CO LTD +1

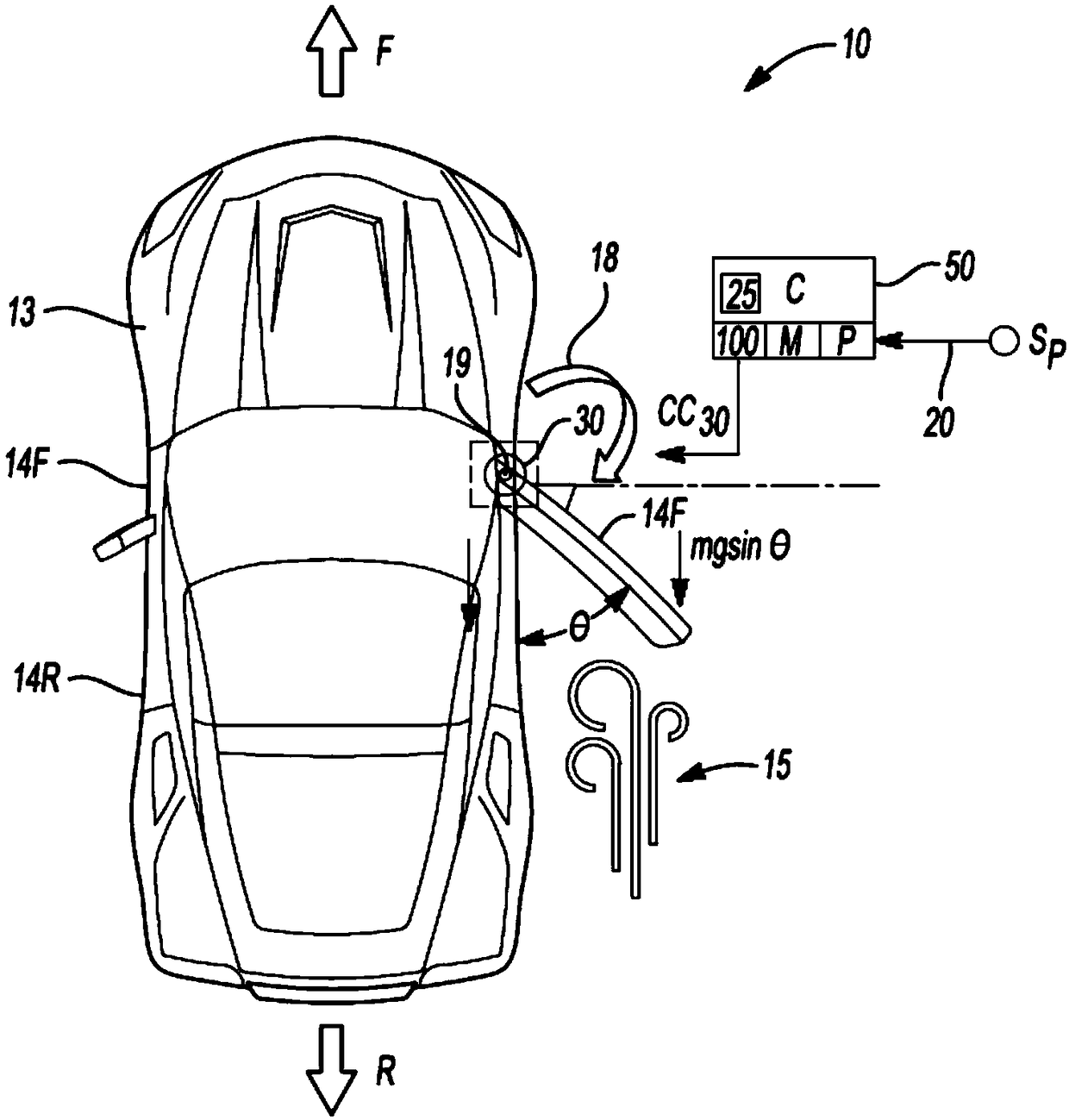

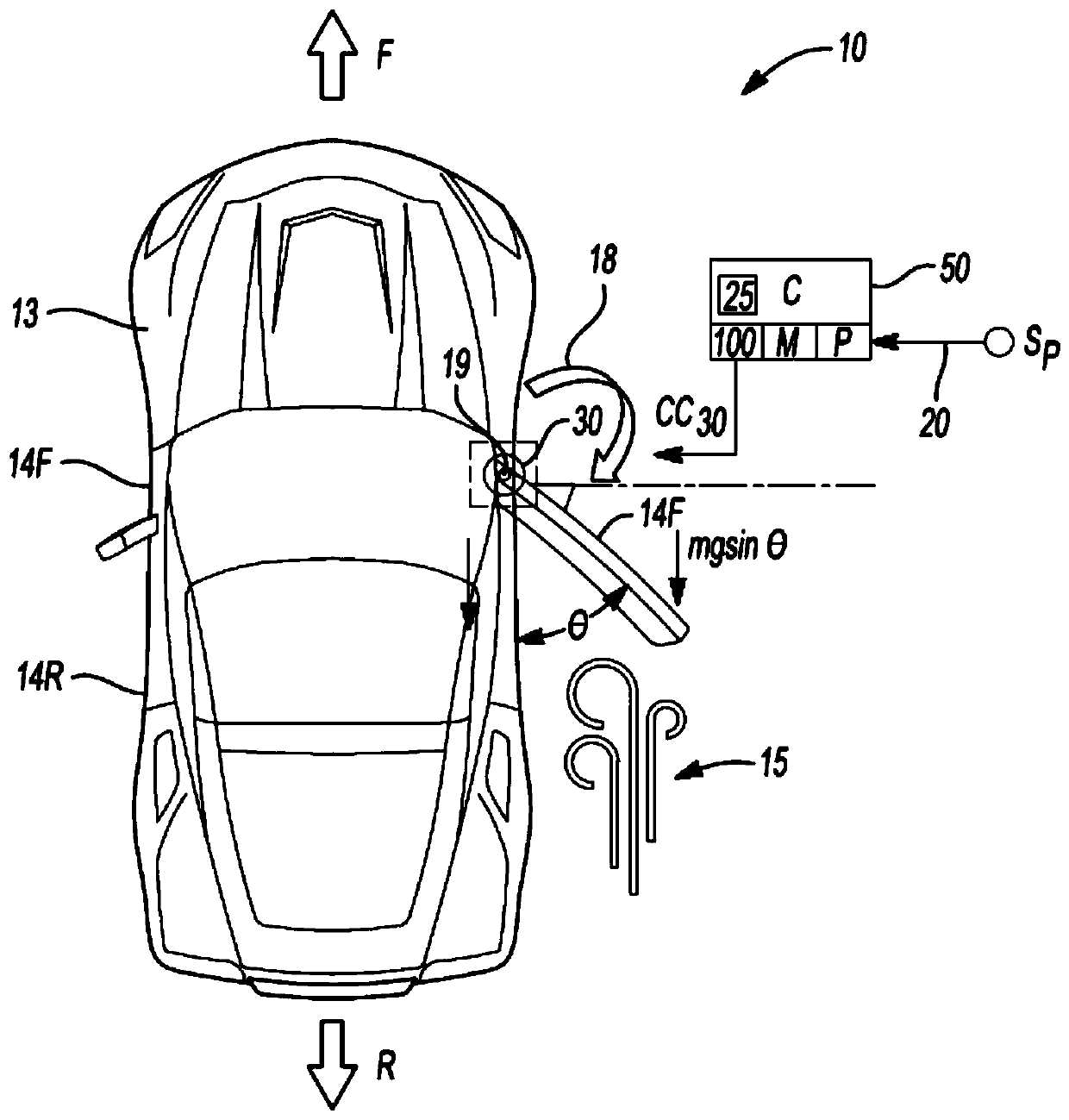

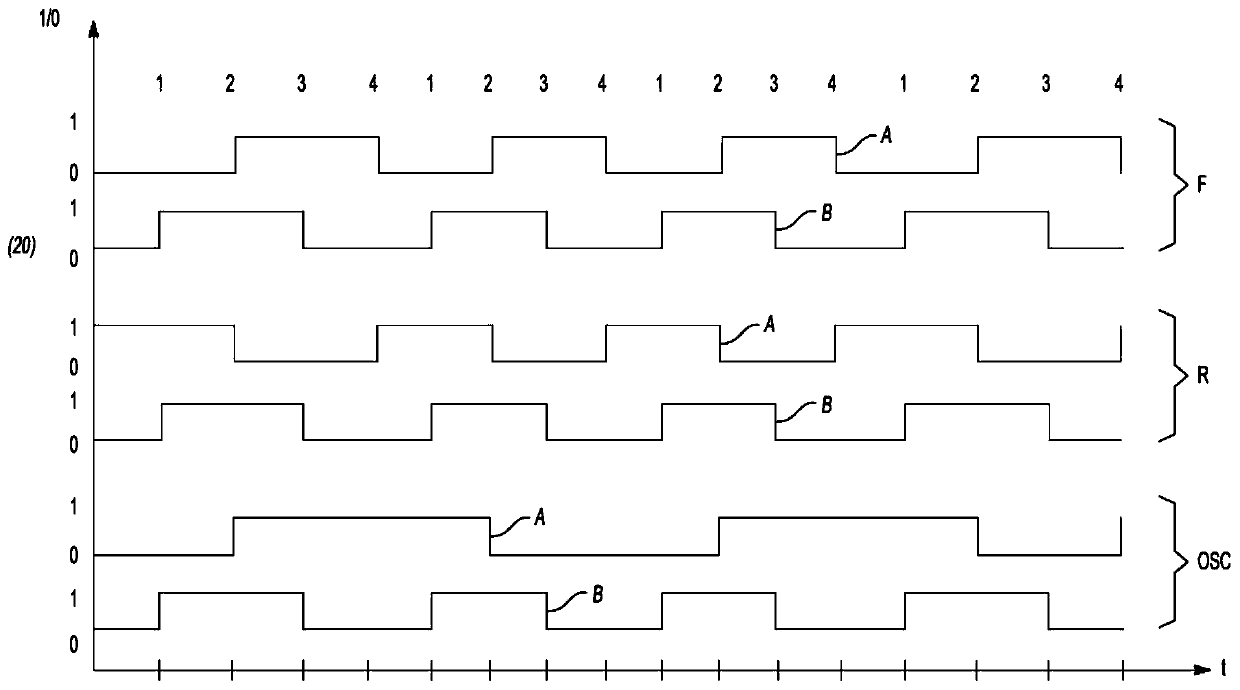

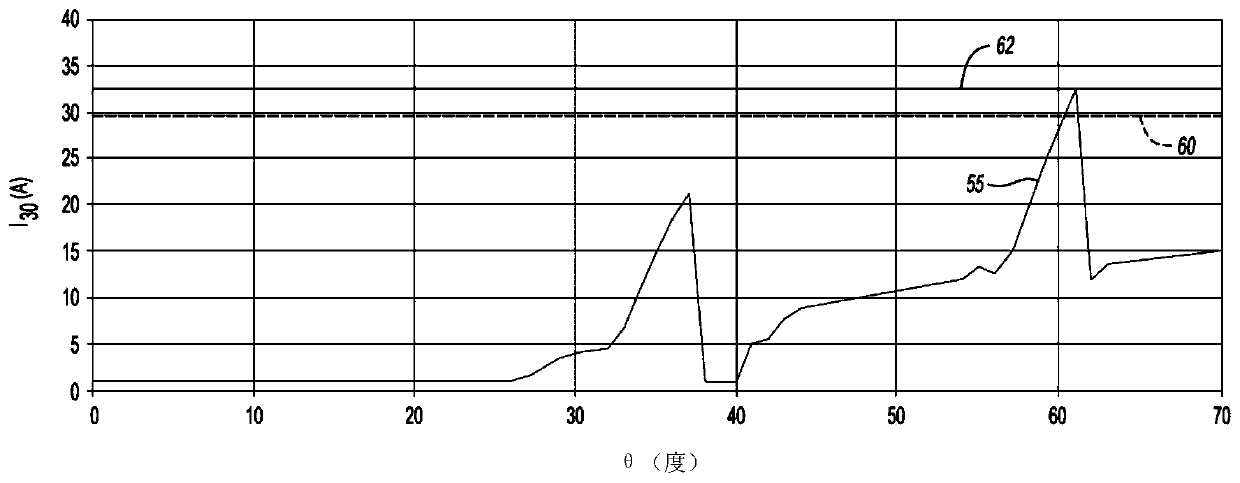

Vehicle with power swinging door and position-based torque compensation method

ActiveCN109138701AParameter calibration/settingPower-operated mechanismControl signalCurrent threshold

A system controls opening / closing of a power swinging door, e.g., in a vehicle, and includes a rotary actuator, position sensor, and controller. In a controller-executed method, the actuator applies torque to the door in response to control signals. The controller uses a measured raw angular position from the sensor to determine wind- or grade-based external forces acting on the door during opening or closing, and adjusts the actuator torque in response to the external forces. The sensor may be a rotary encoder, with the actuator being an electric motor. Lookup tables contain data relating oscillation to the external forces. The controller may induce door oscillation and to relate oscillation decay to the external forces. An obstacle-based current threshold may be adjusted in response to the external forces.

Owner:GM GLOBAL TECH OPERATIONS LLC

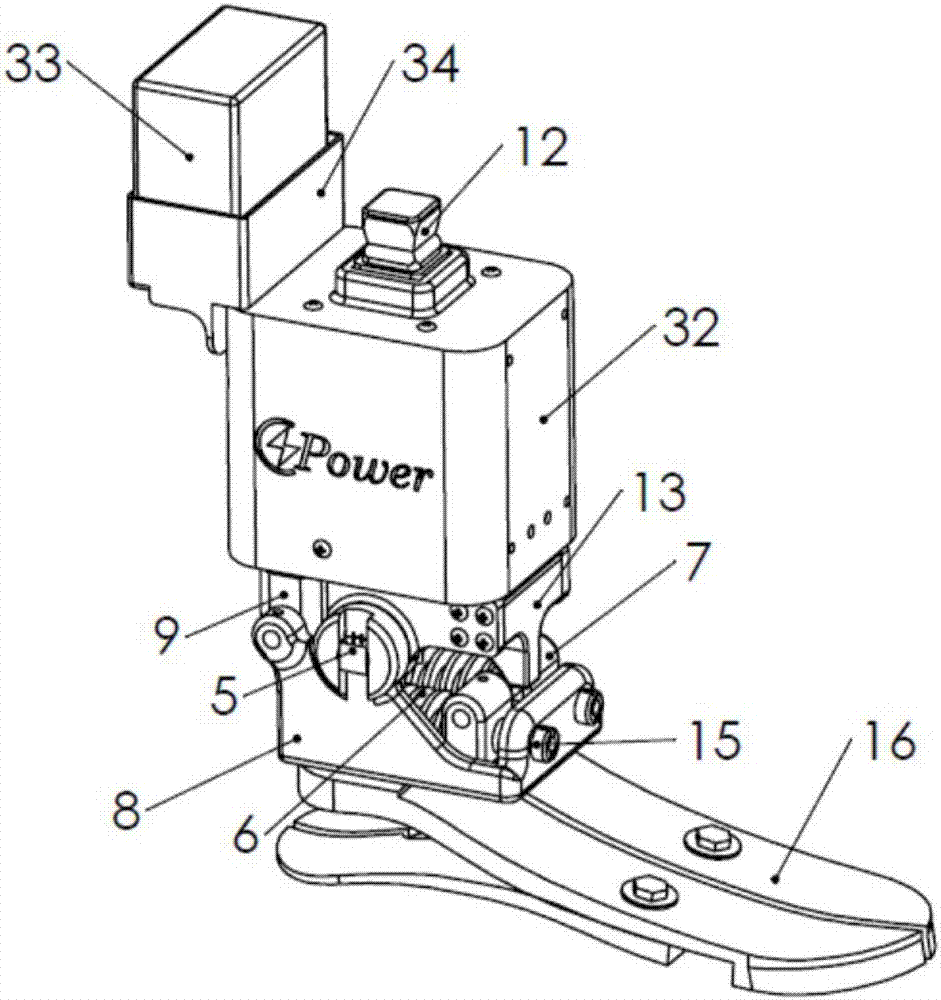

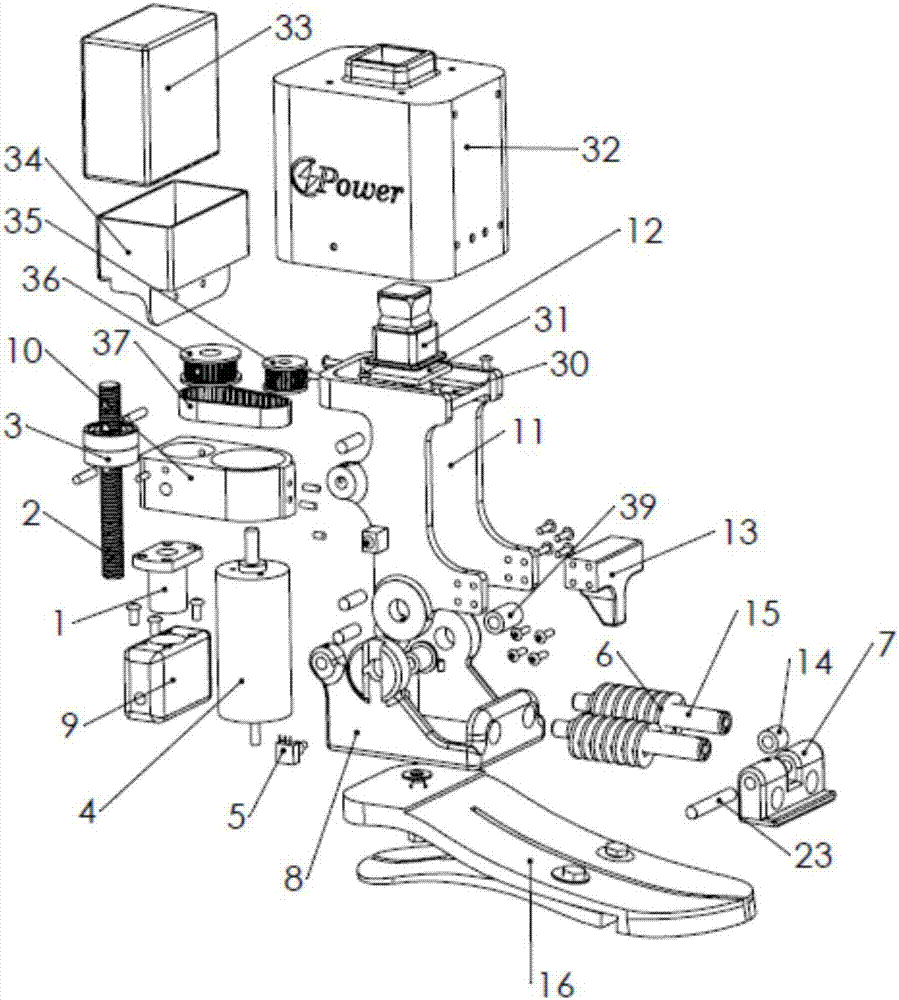

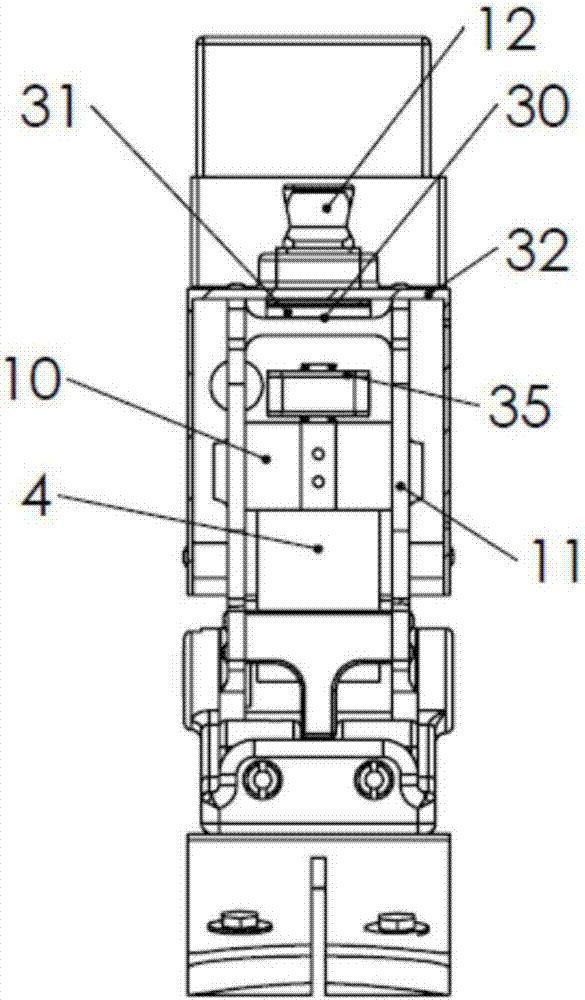

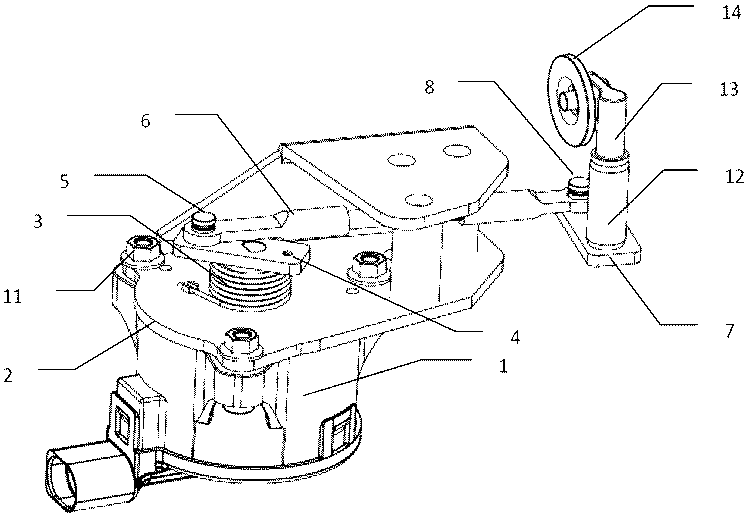

Ankle-foot prosthesis device

A powered ankle-foot prosthesis and associated methods of use are described herein. Such prostheses can employ an actuator and elastic components, the actuator being controlled to deliver net positivework to propel the wearing amputee forward and the elastic components being used to store and release negative energy to improve efficiency. Elastic components can be linear springs coupled with a cam and configured in parallel to the actuator. The cam profile can be designed to generate a desired spring torque versus angle curve rather than a spring stroke versus angle curve, thereby reproducinghuman ankle controlled dorsiflexion stiffness. Such configurations improve system energy efficiency and reduce both actuator torque and power requirements. Such prostheses can also operate in a passive mode, in which a nearly normal gait can be achieved even without powered assist.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

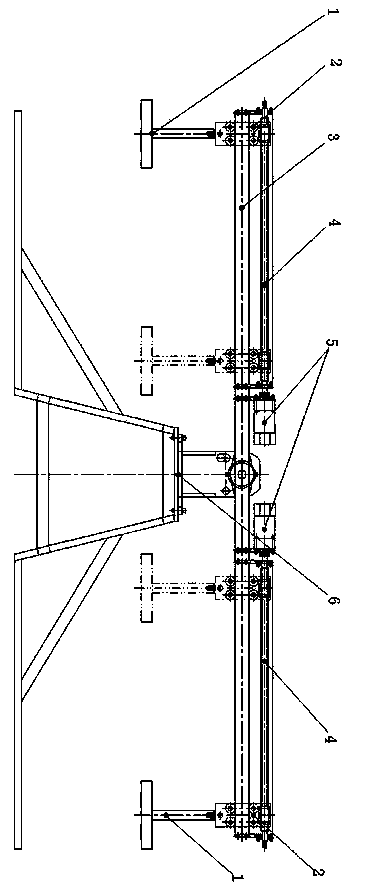

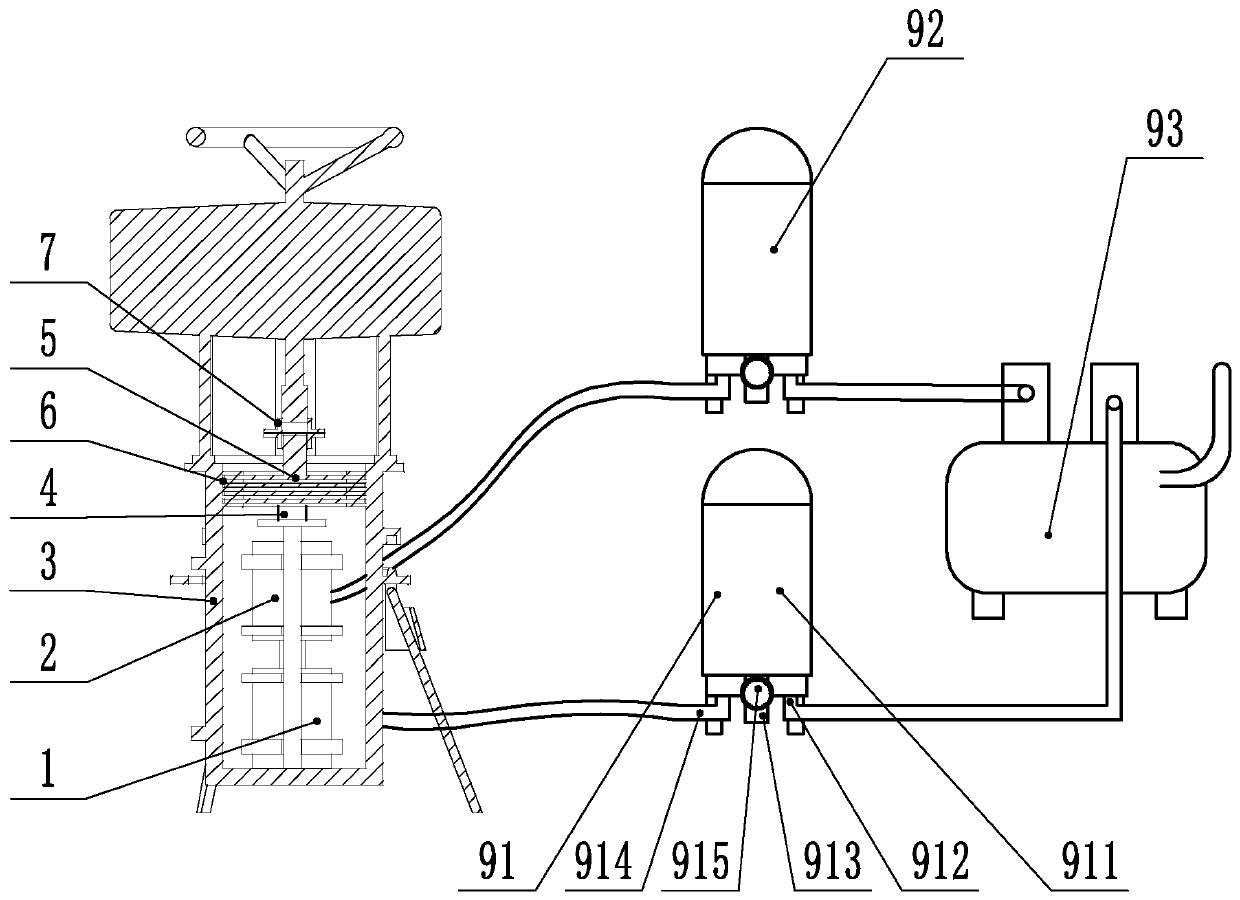

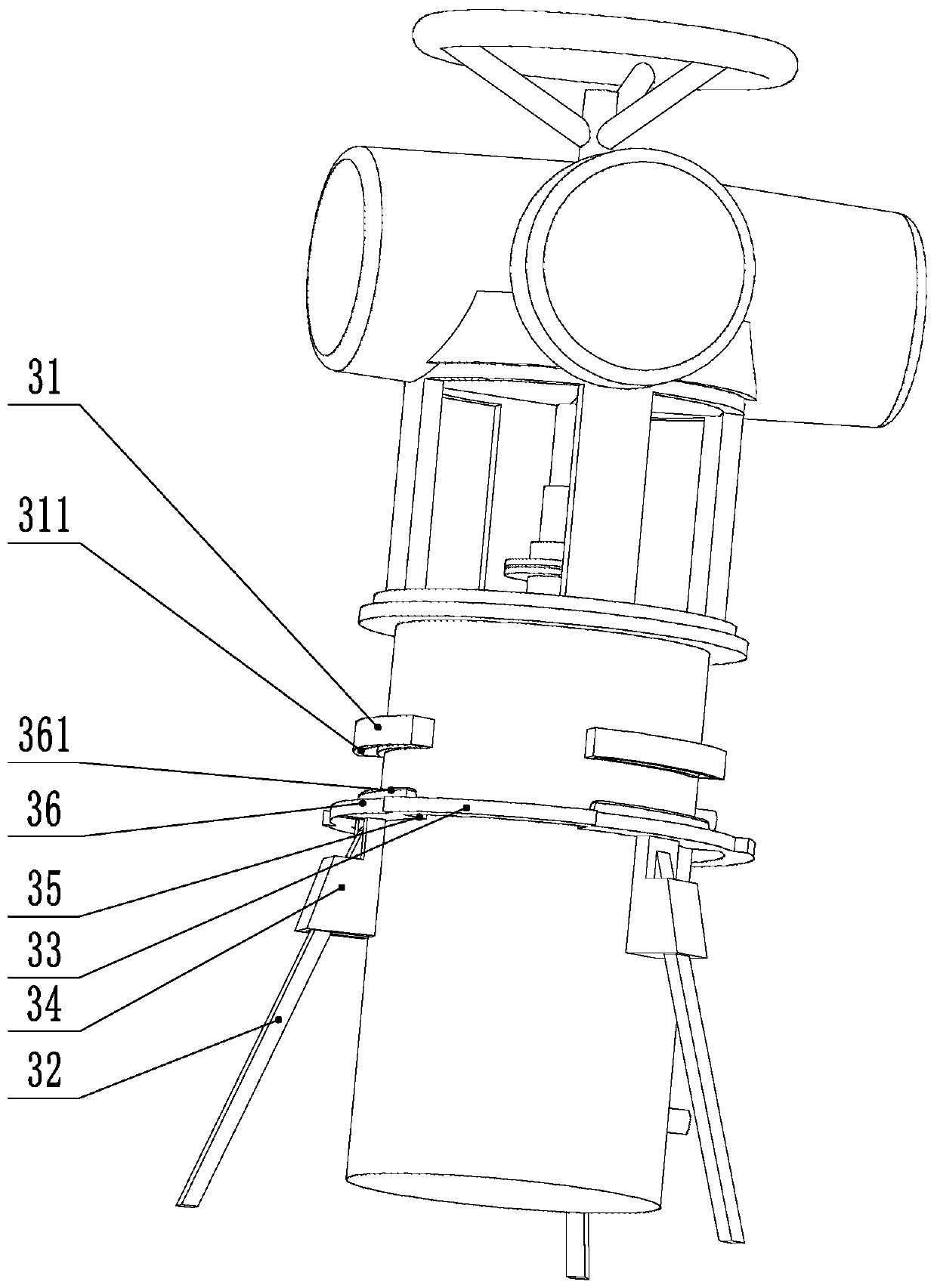

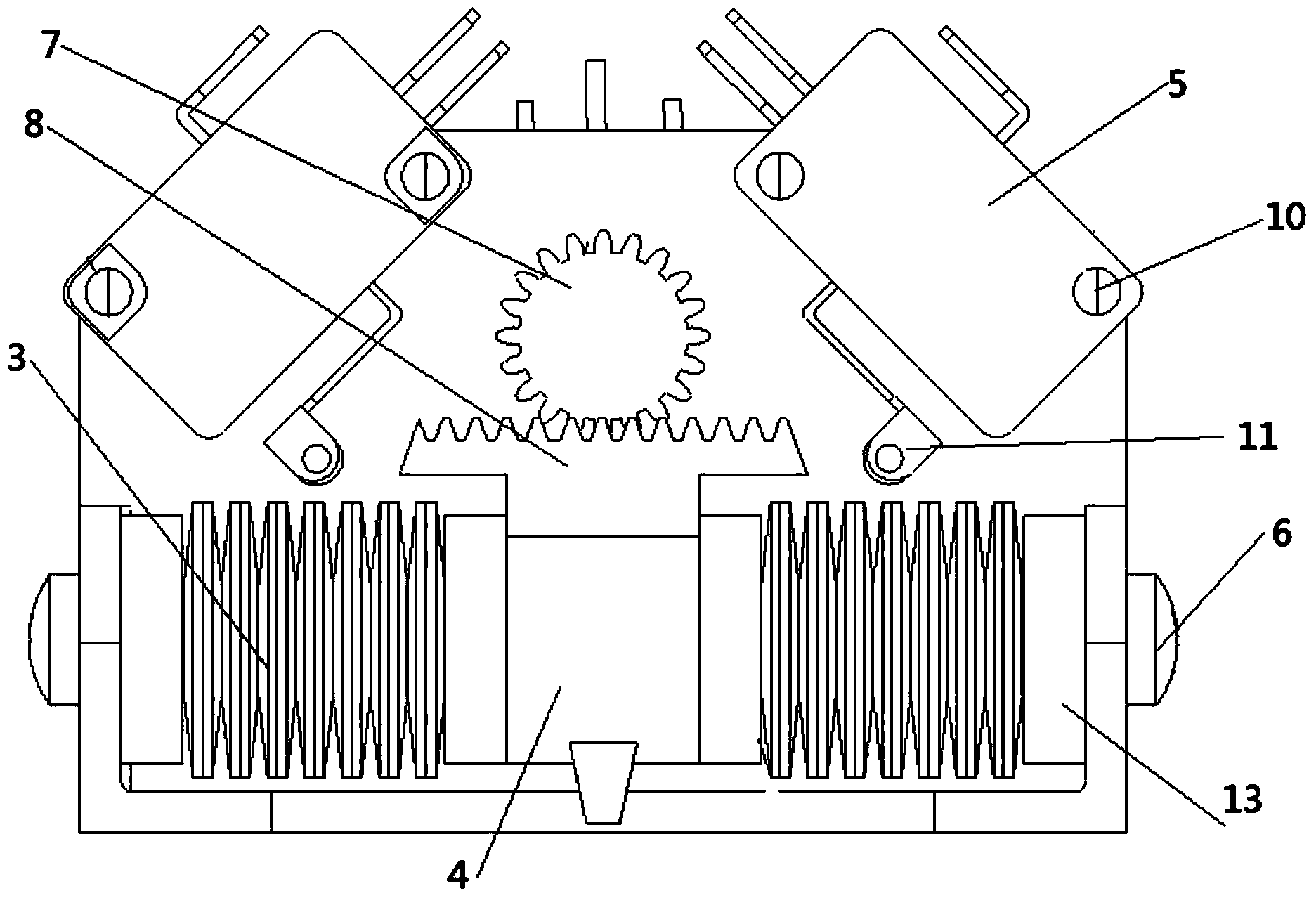

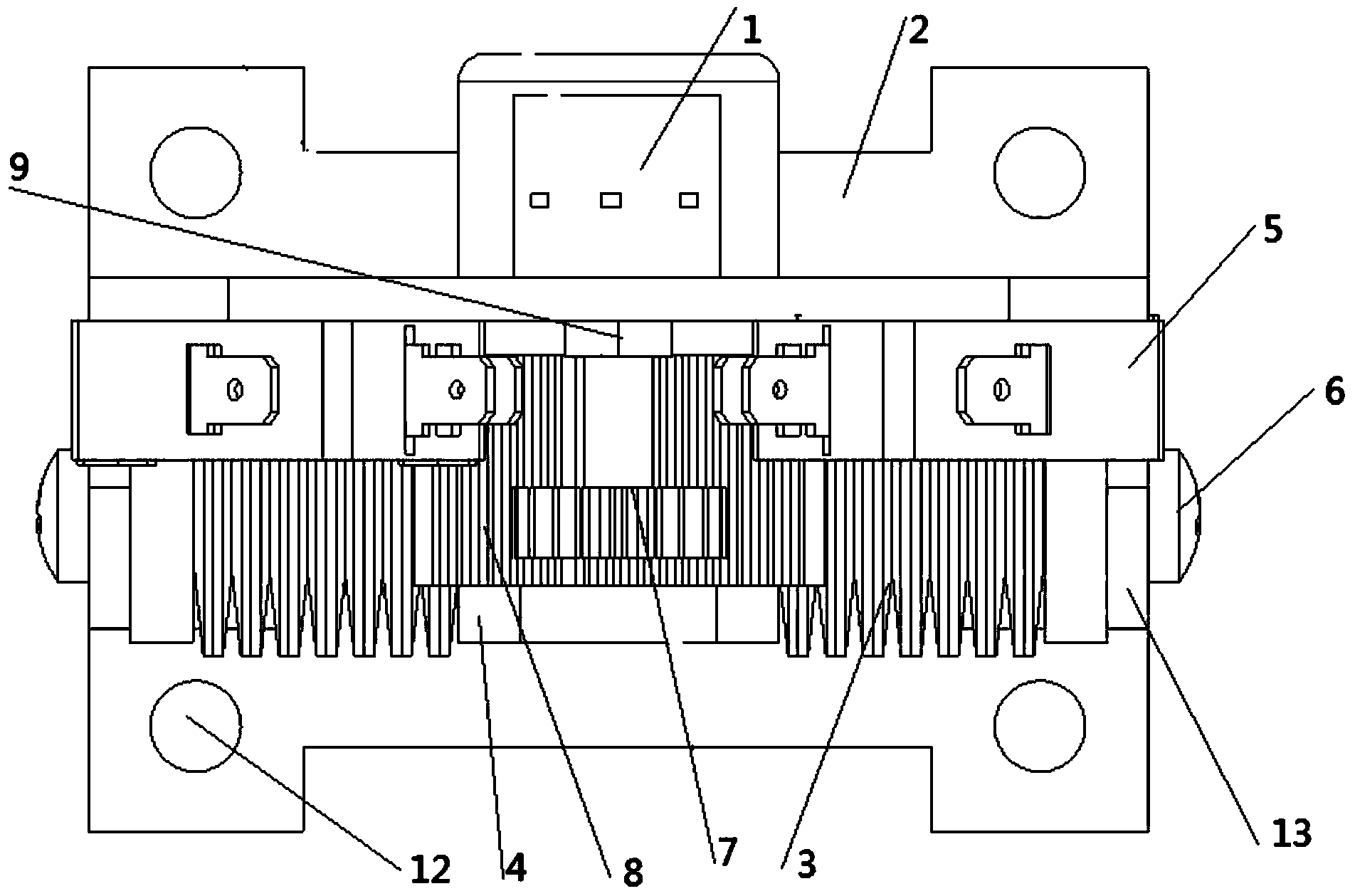

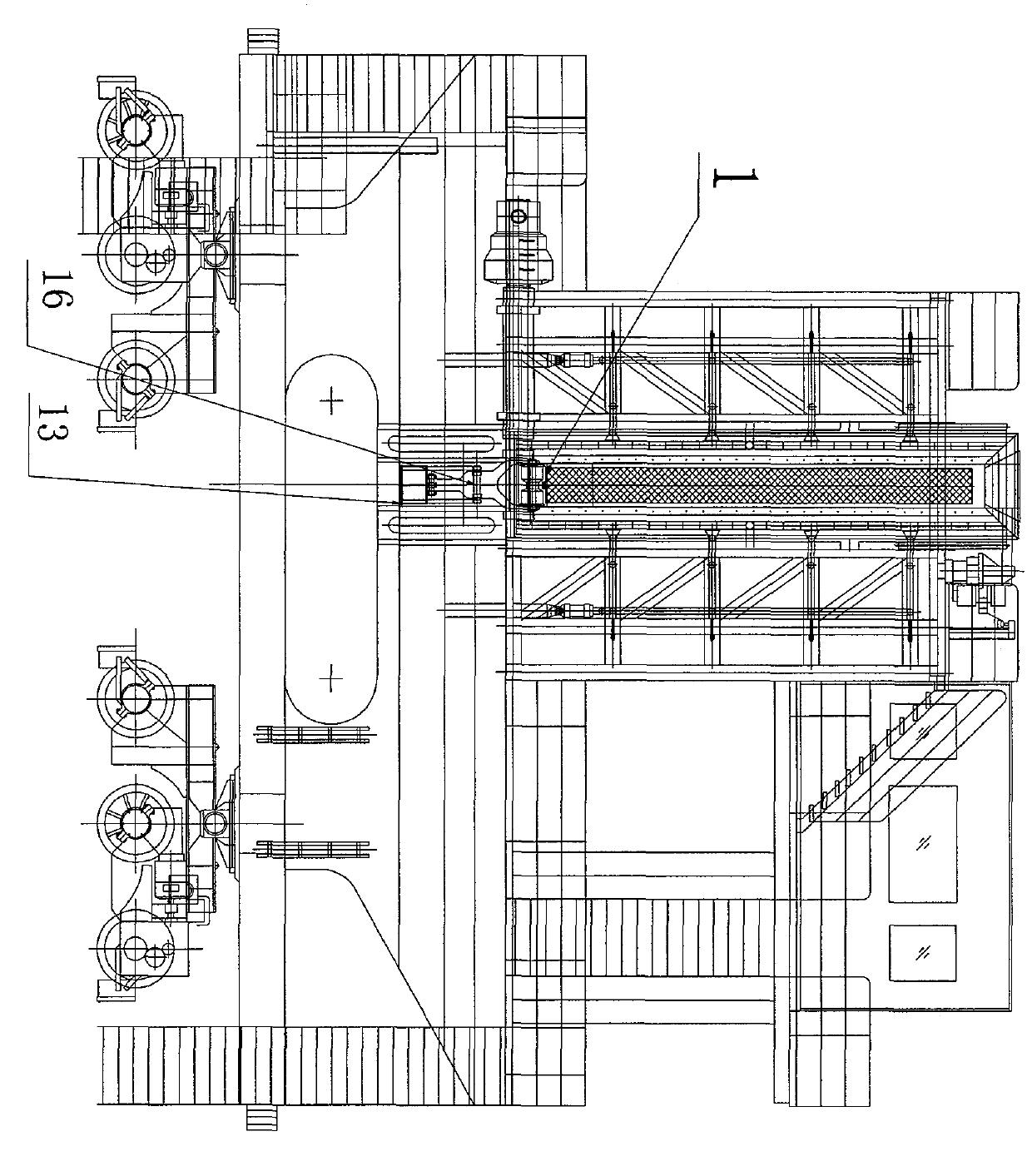

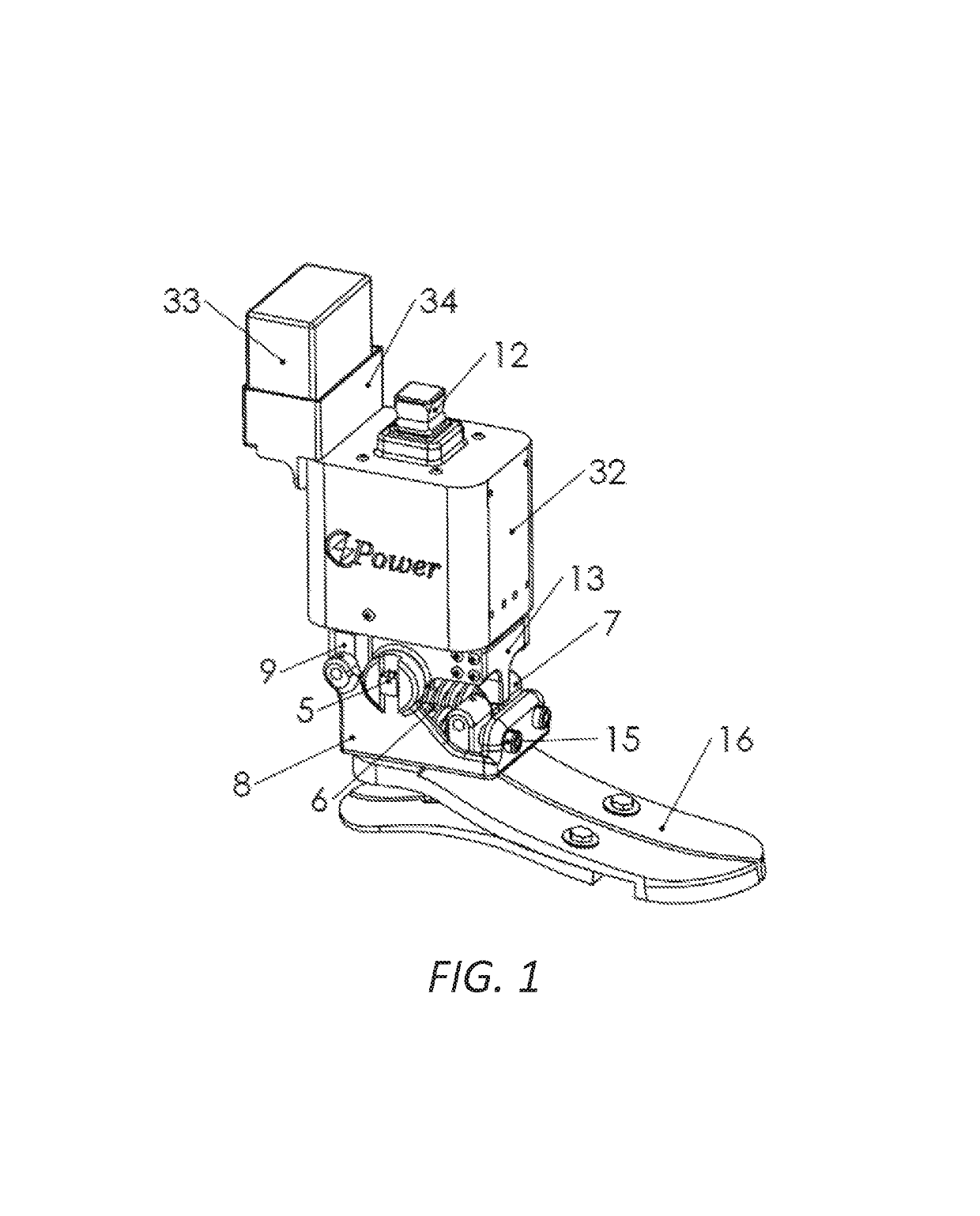

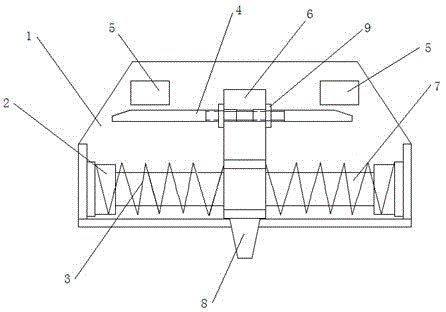

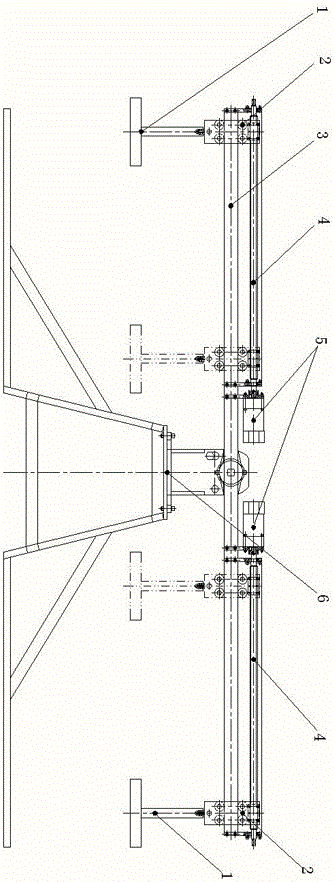

Torque calibration testing device for angular travel electric actuator

ActiveCN104006955ASave the trouble of adding and subtracting weightsImprove test efficiencyMachine part testingTest efficiencyElectric machine

The invention discloses a torque calibration testing device for an angular travel electric actuator. The torque calibration testing device comprises an overall support, motors, a force arm, pulley mechanisms, lead screws and weights. The angular travel electric actuator is connected with a driving hole in the middle of the force arm through an adapter driving sleeve, the lead screws and the motors are fixed to the force arm through the overall support, the force arm is connected with the overall support and can rotate by a certain angle around the center of the force arm, one ends of the pulley mechanisms are connected with the lead screws, the pulley mechanisms can move on the force arm under driving of the lead screws, and the other ends of the pulley mechanisms are connected with the weights. According to the torque calibration testing device, the lead screws can be driven by the motors to rotate to accordingly drive the weights to move on the force arm, the torque is accordingly adjusted, the trouble caused by the fact that the weights are continuously added or removed to adjust the torque is avoided, and therefore the testing efficiency is improved.

Owner:SUZHOU BONRAY MEASURE & CONTROL EQUIP

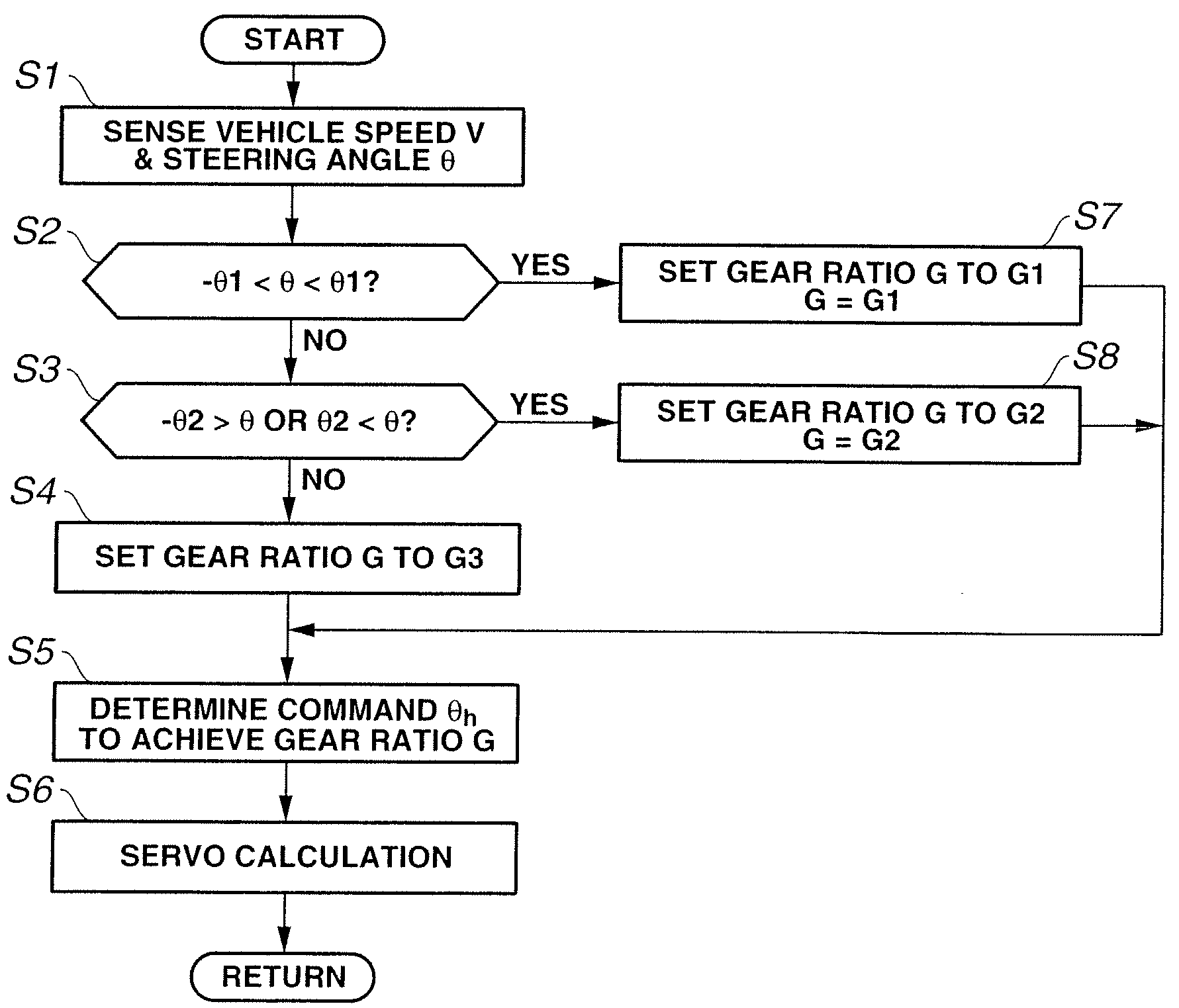

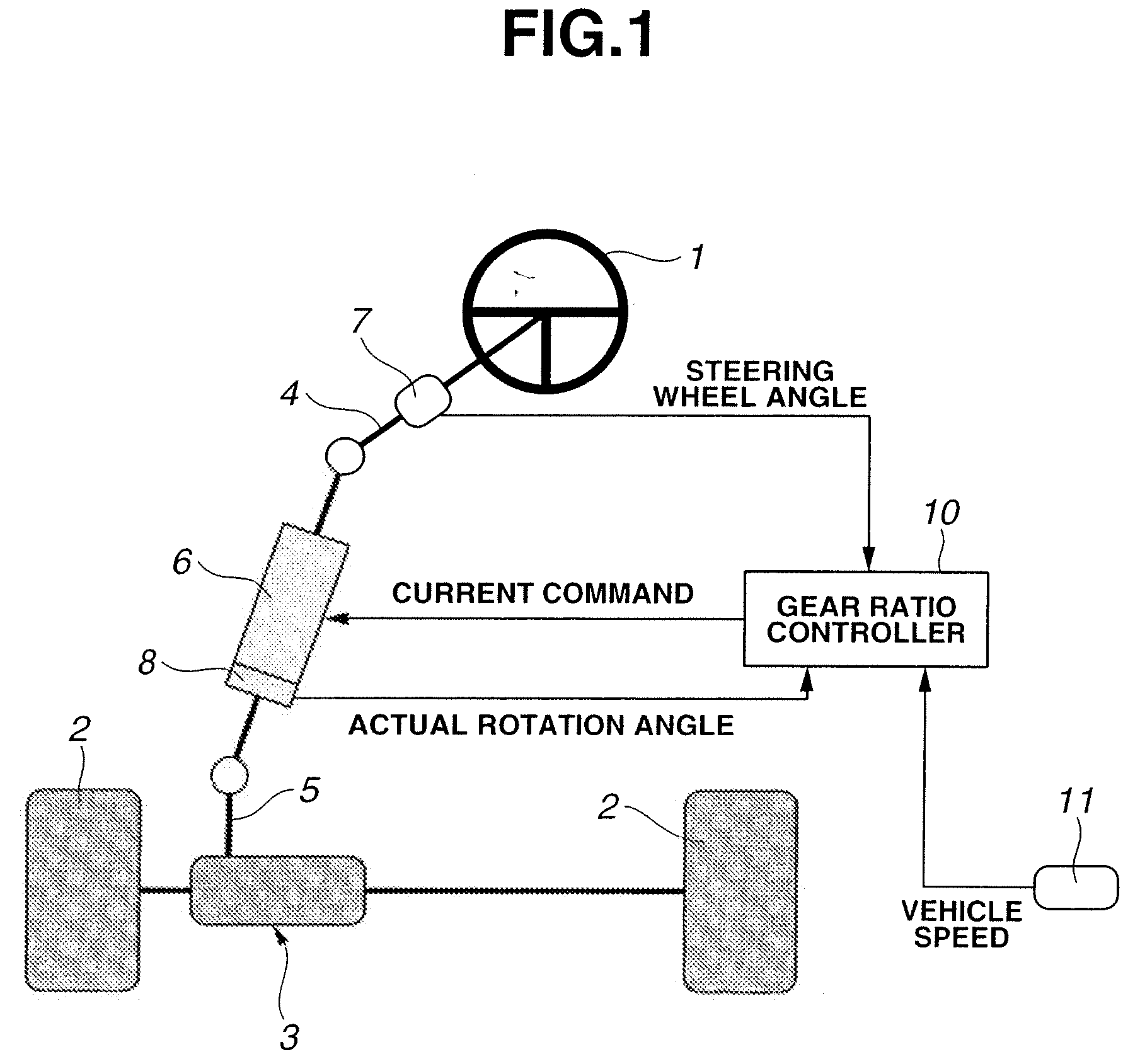

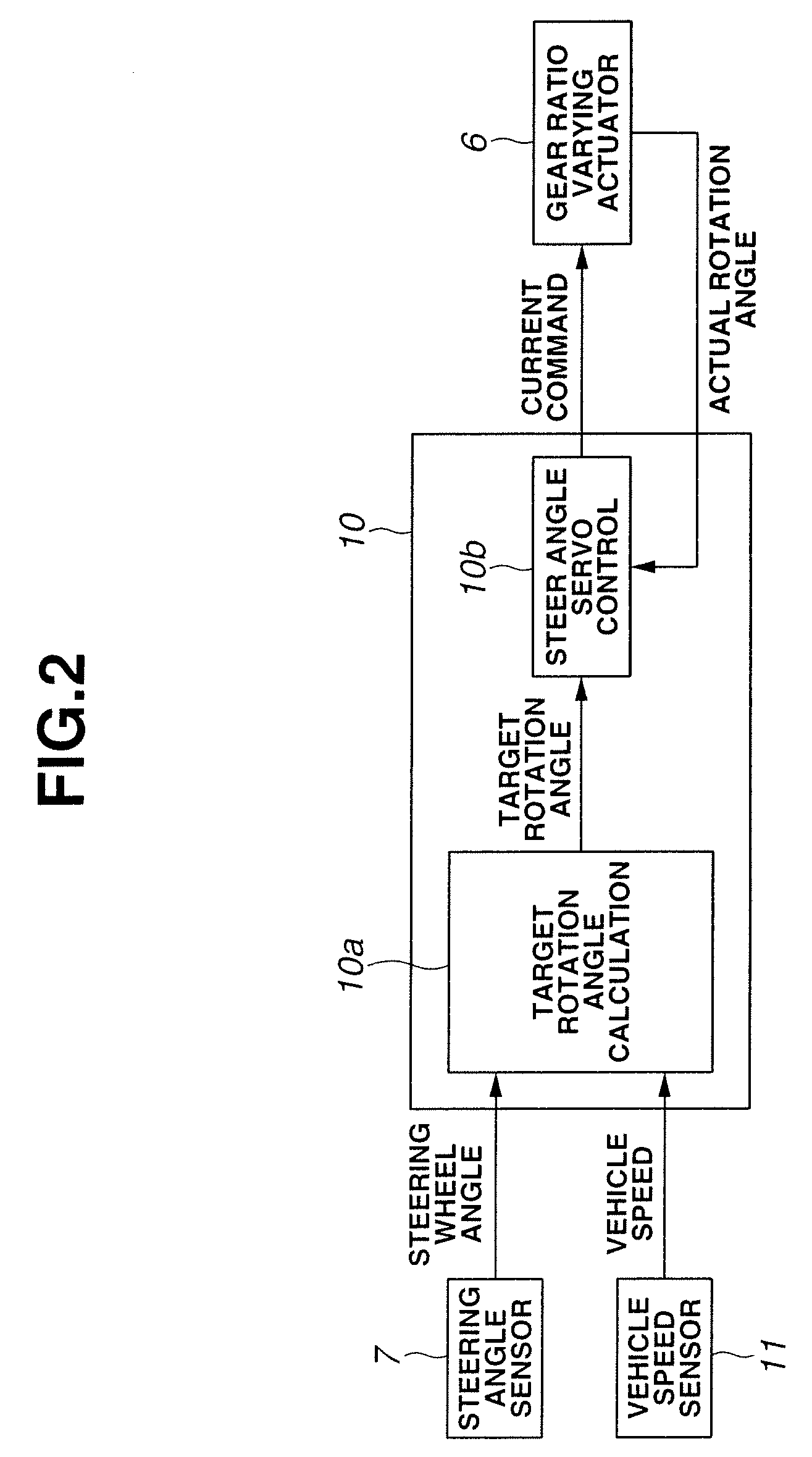

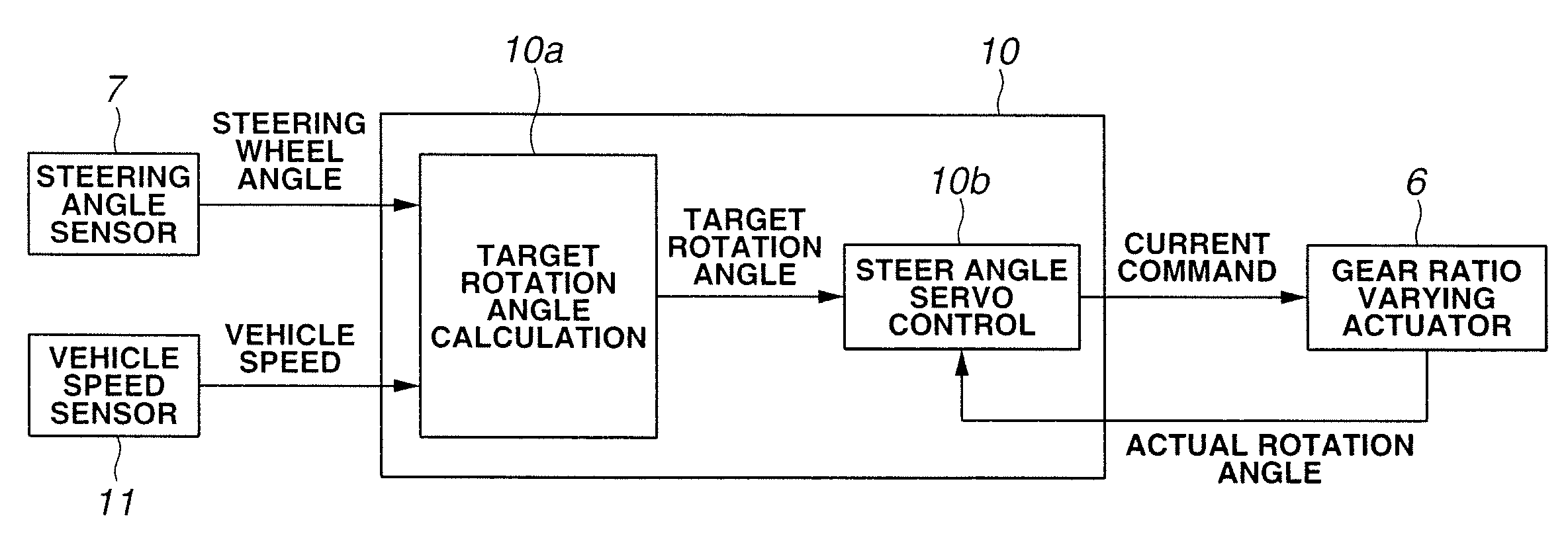

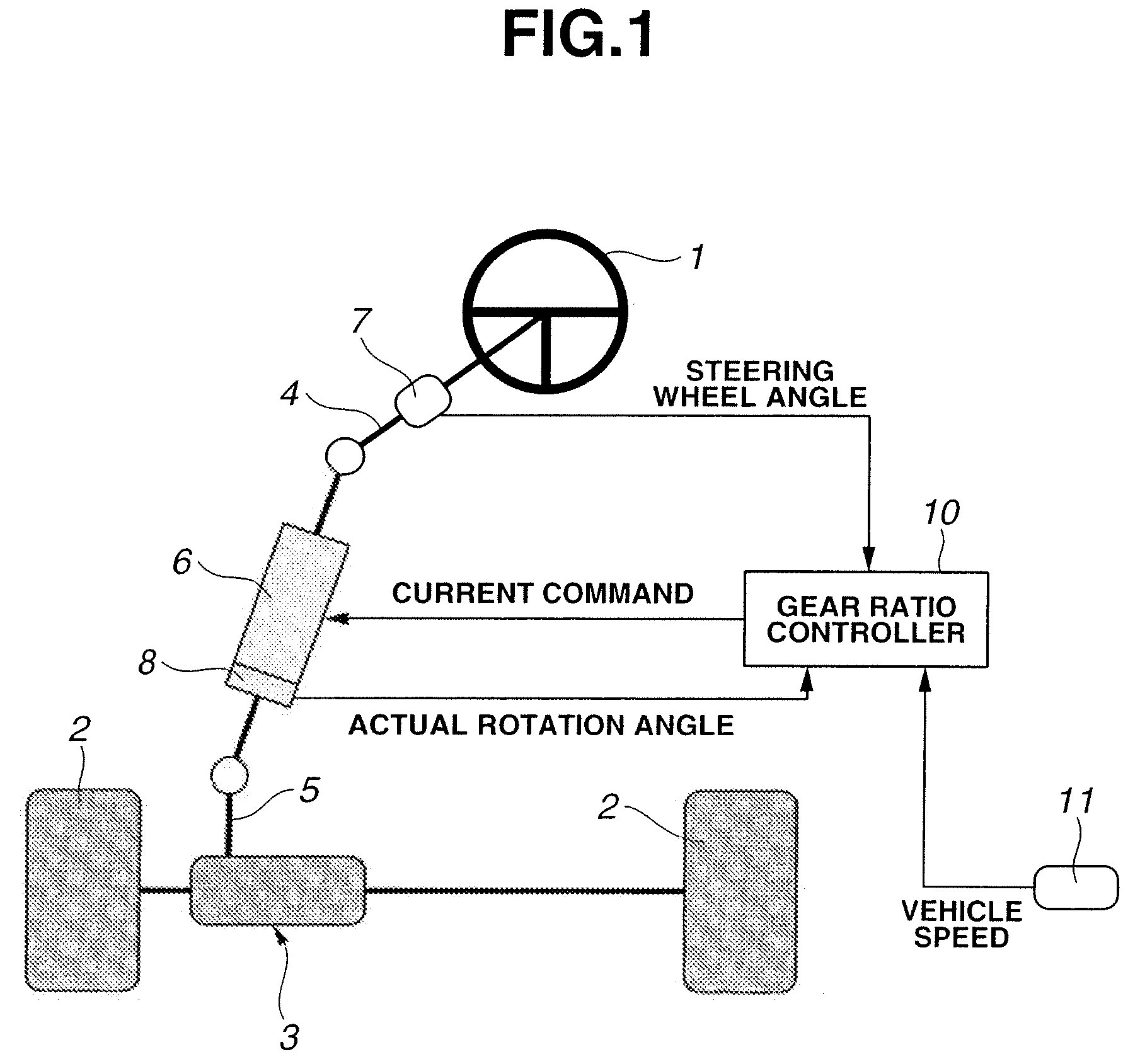

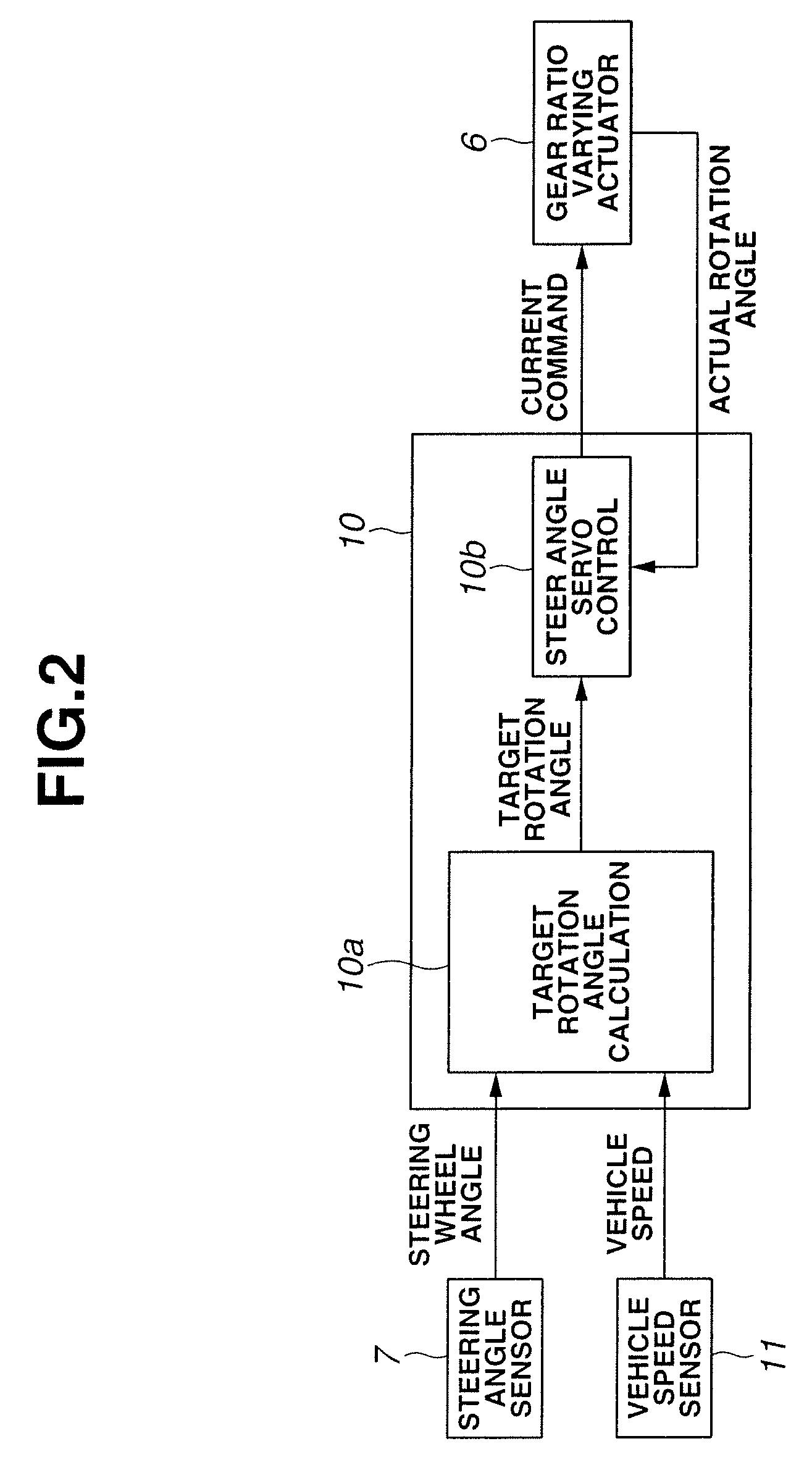

Vehicle steering control apparatus

ActiveUS20090037054A1Reduce reduction reactionObstruction is producedDigital data processing detailsSteering initiationsSteering wheelDriver/operator

A vehicle steering control apparatus includes an actuator to vary a steering gear ratio of a vehicle wheel steer angle of a steerable wheel to a steering wheel angle. A controller controls the actuator to produce an actuator torque in a steering direction at a start of a driver's steering operation.

Owner:NISSAN MOTOR CO LTD

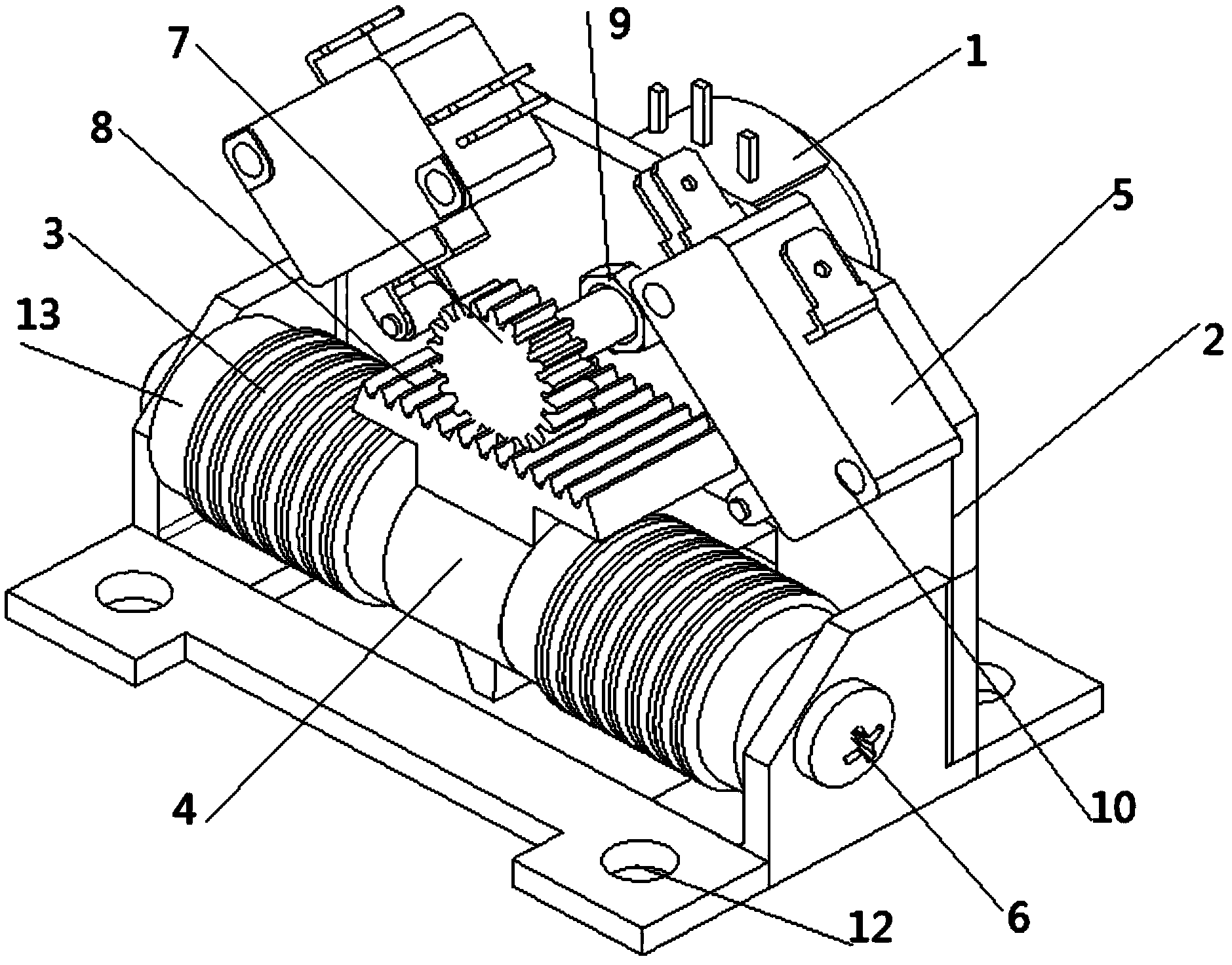

Comprehensive testing device for rotary valve electric actuator

The invention discloses a comprehensive testing device for a rotary valve electric actuator. The comprehensive testing device comprises a base, a first cylinder, a second cylinder, an encoder, a movable friction disc, a fixed friction disc, a torque sensor and a coupler, wherein a mounting cavity is formed in the base, a mounting station for mounting an actuator is arranged at the top end of the base, a main shaft is arranged on the movable friction disc, the torque sensor and the main shaft are connected with an external actuator by means of the coupler, and the encoder is mounted on the movable friction disc, and the first air cylinder and the second air cylinder output alternately to generate variable pressure, so that the fixed friction disc generates variable friction forces on the movable friction disc, and the actuator is subjected to different torque. In the test process, the torque sensor tests the torque changes of the actuator, the encoder tests the rotation angle changes ofthe actuator, and the test values are compared with standards, so as to test whether the actuator is qualified or not. Through the arrangement, three key values of a valve can be tested at one time,the operation is convenient, and the efficiency is high.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE

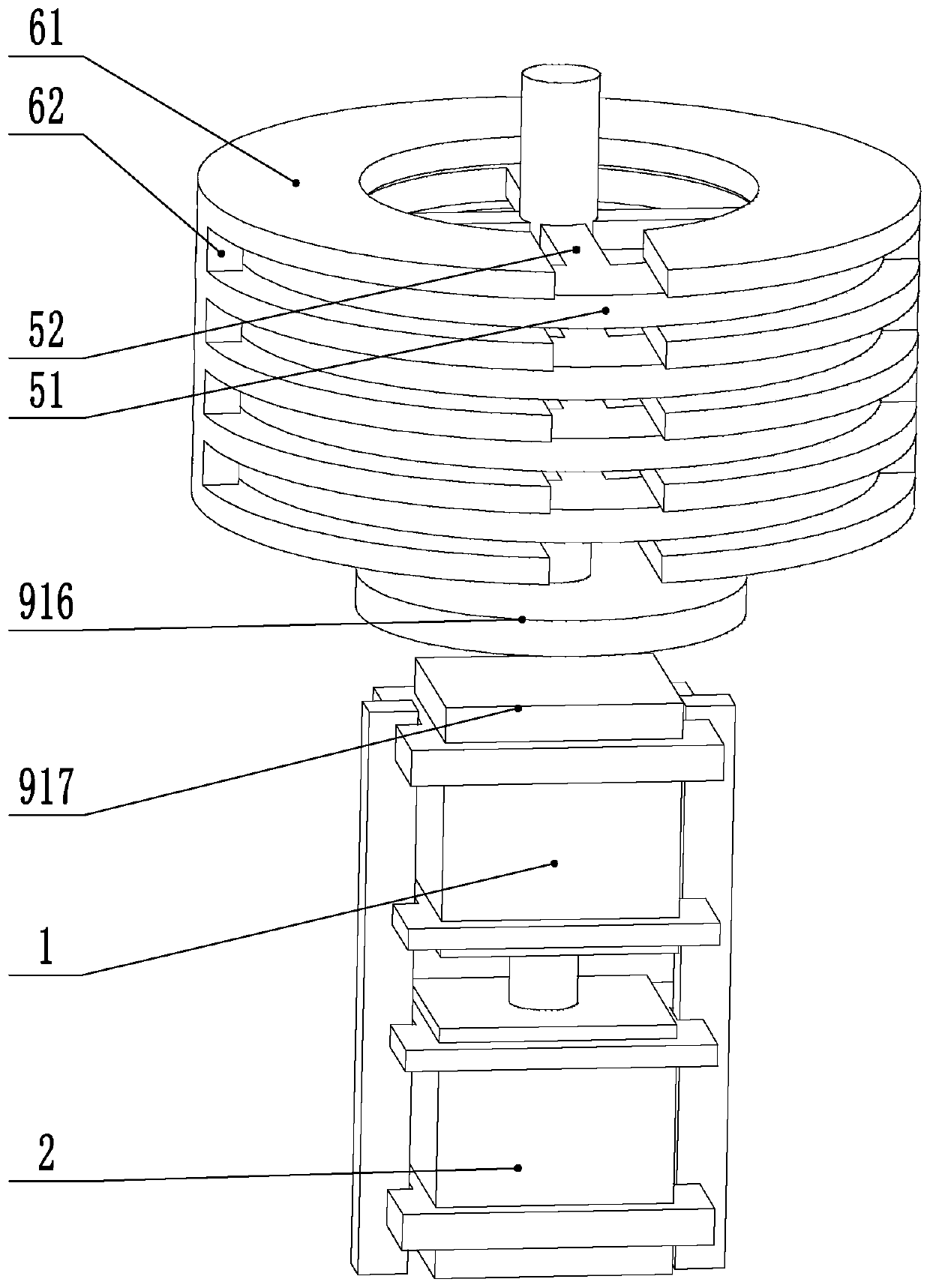

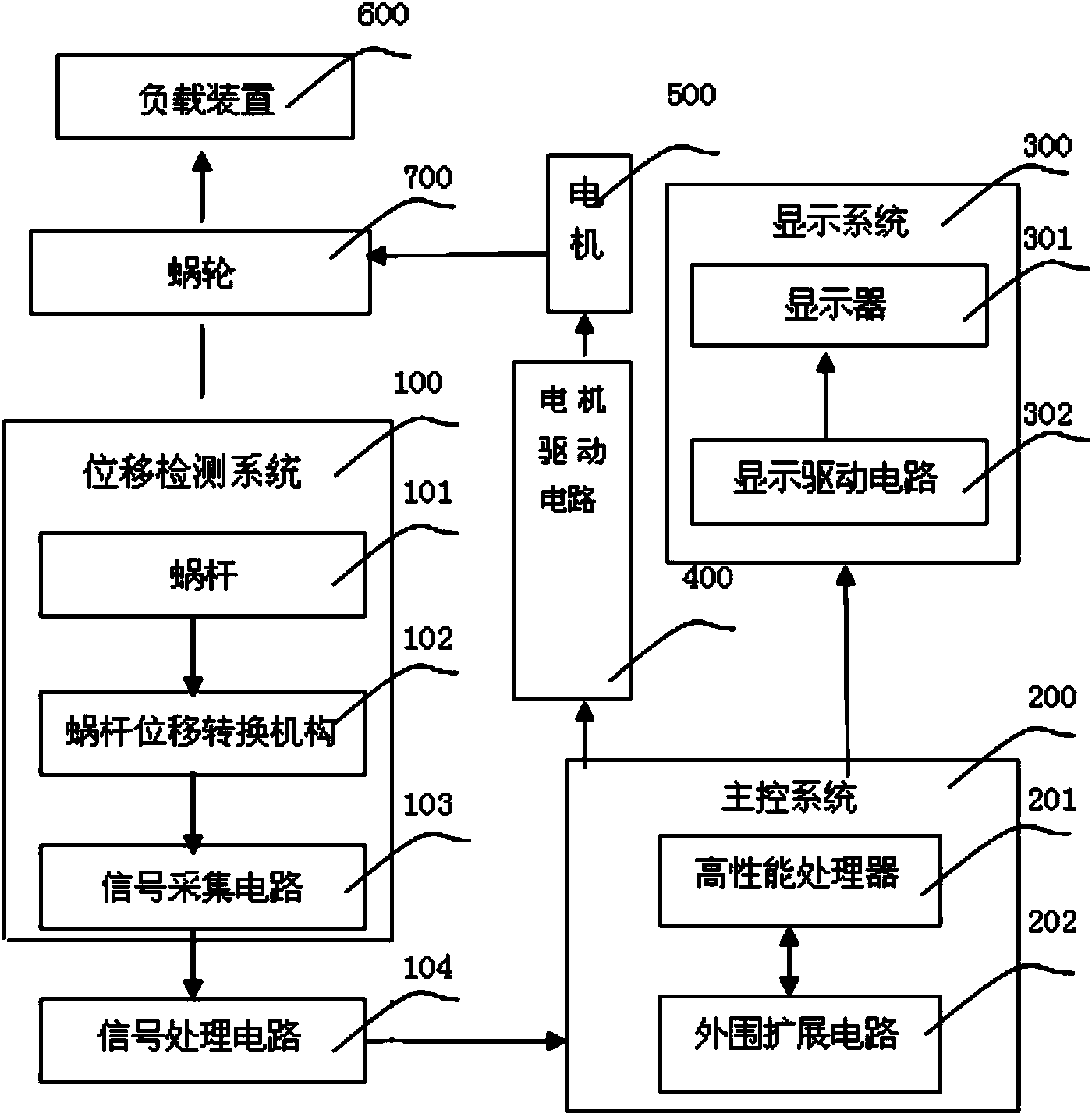

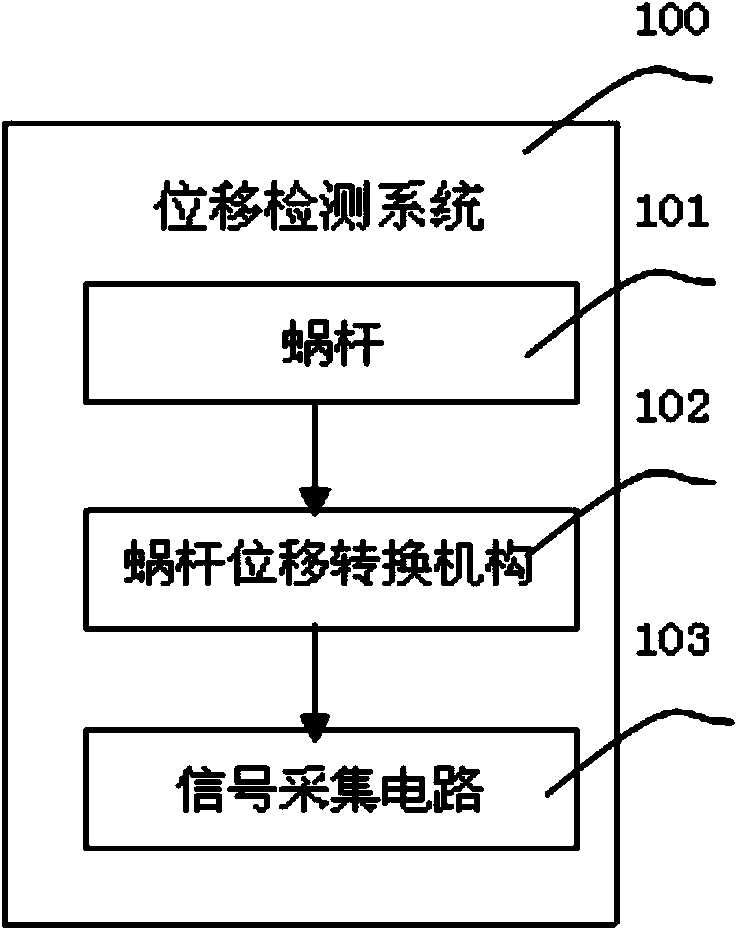

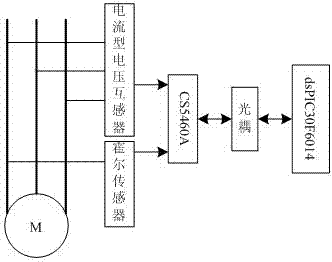

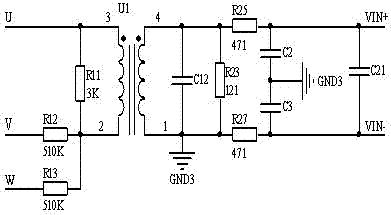

Torque control system and method of electric actuator

ActiveCN103672104AEasy to detectRealize monitoringOperating means/releasing devices for valvesSignal processing circuitsMotor drive

The invention discloses a torque control system and method of an electric actuator. The torque control system of the electric actuator comprises a main control system, a signal processing circuit connected with the main control system, and a displacement detecting system connected with the signal processing circuit, and further comprises a motor driving circuit, wherein the displacement detecting system comprise a signal collecting circuit; the signal collecting circuit transmits electric signal change parameters to the signal processing circuit after converting measurable physical displacement variation into the electric signal change parameters, and the signals are transmitted to the main control system after being amplified and shaped by the signal processing circuit; the motor driving circuit receives a control instruction of the main control system to adjust the rotation of a motor. By the utilization of the non-contact detection on the displacement, torque of the electric actuator is detected and controlled in real time. A convenience and efficient mode is provided for research, development and production of electric actuators and valve electric device control systems, and the technological level of the electric actuator industry is improved and developed.

Owner:上海国鼎数码科技有限公司

Vehicle steering control apparatus

ActiveUS8532876B2Reduce reduction reactionObstruction is producedSteering initiationsDigital data processing detailsSteering angleSteering wheel

A vehicle steering control apparatus includes an actuator to vary a steering gear ratio of a vehicle wheel steer angle of a steerable wheel to a steering wheel angle. A controller controls the actuator to produce an actuator torque in a steering direction at a start of a driver's steering operation.

Owner:NISSAN MOTOR CO LTD

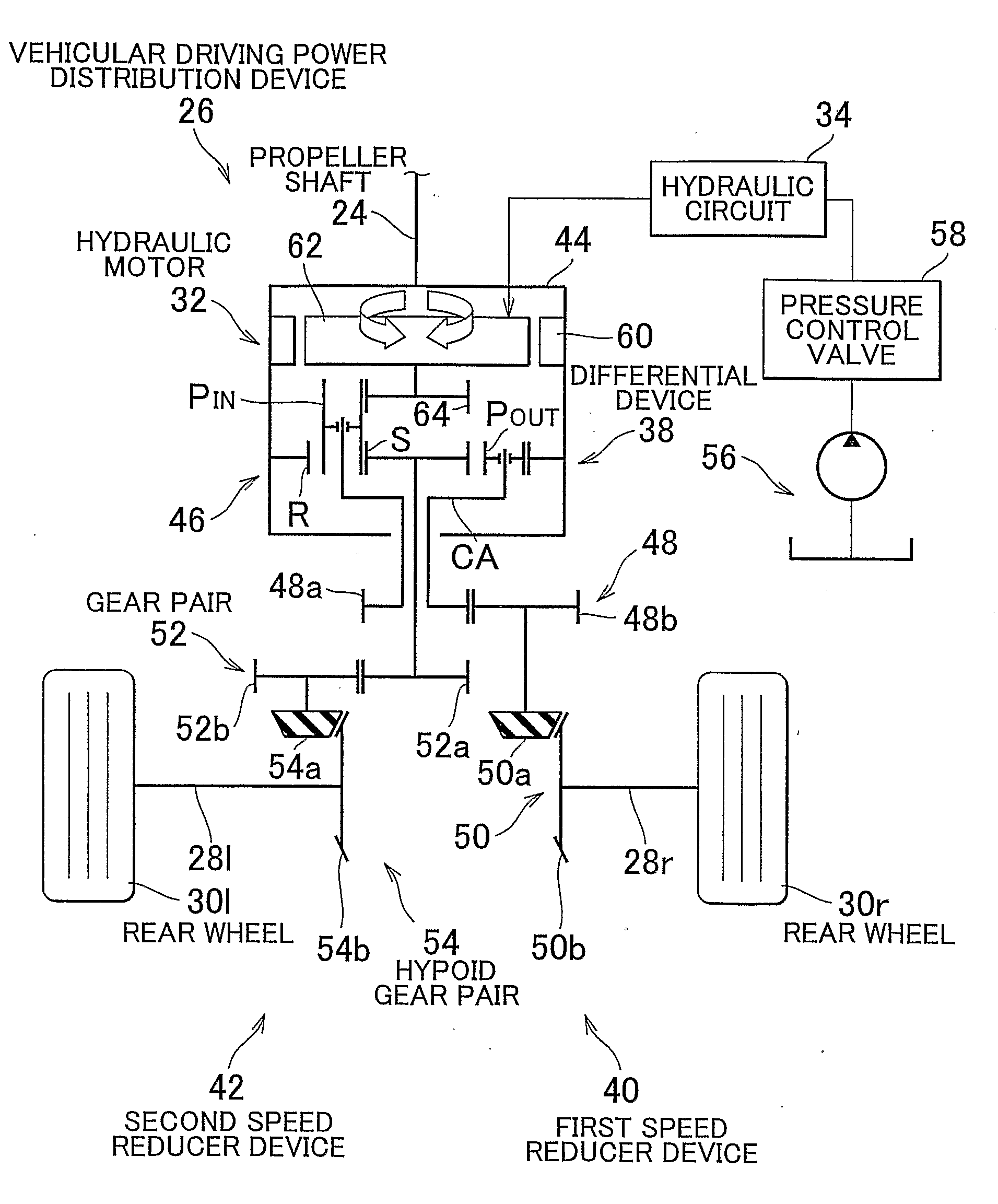

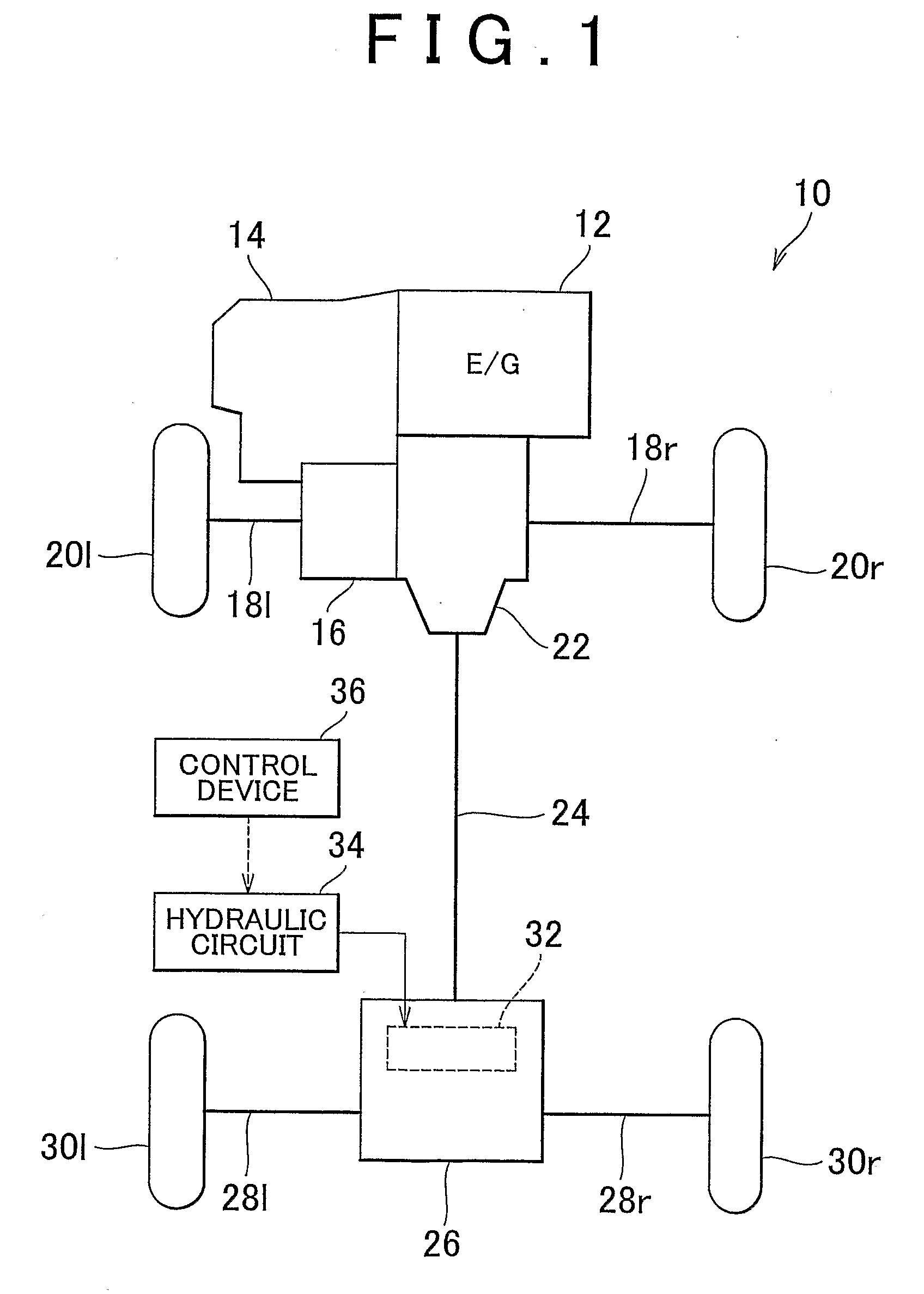

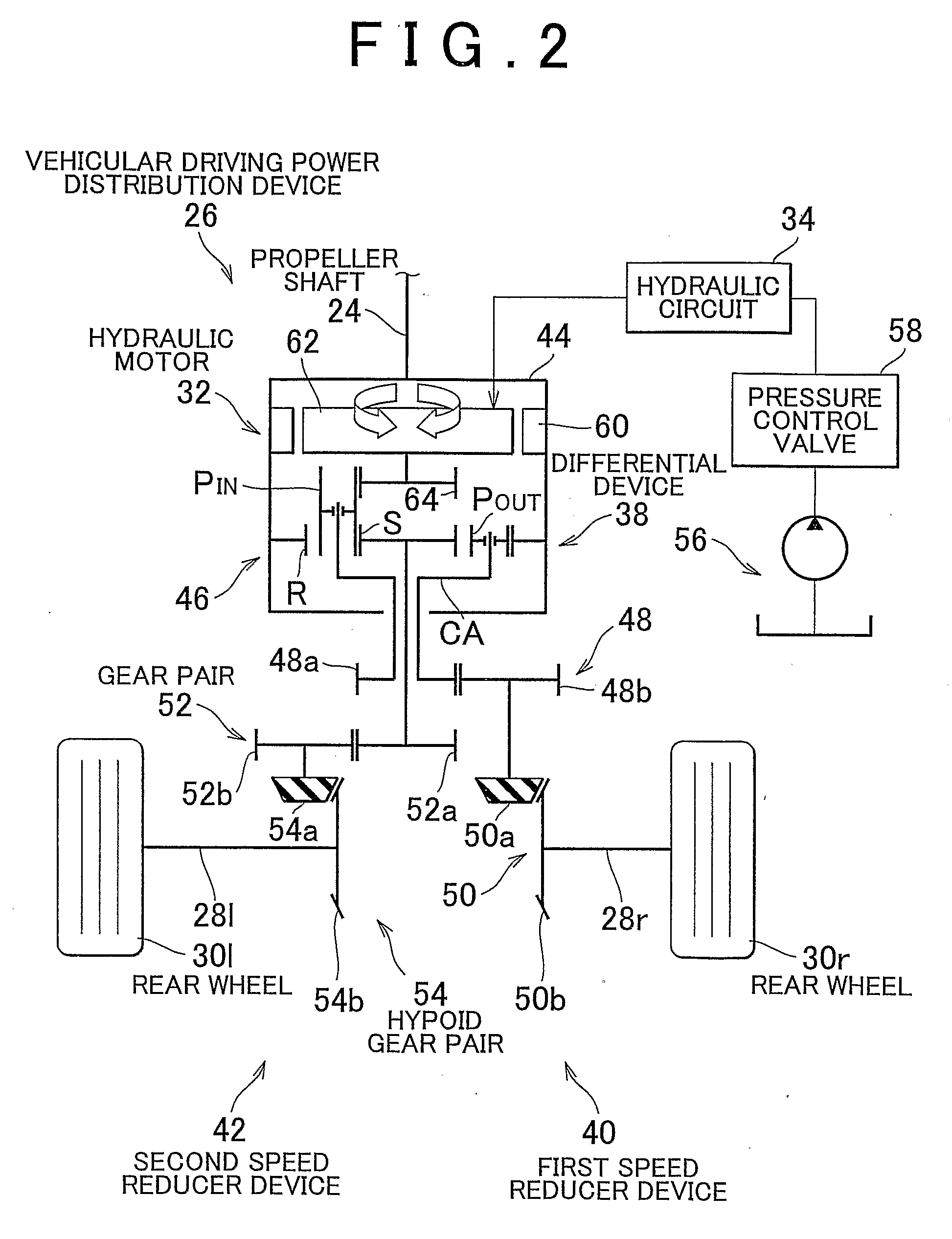

Vehicular driving power distribution device

InactiveUS20090082152A1Easy to controlSmall sizeToothed gearingsDifferential gearingsHydraulic motorDrive shaft

A driving power distribution device includes a propeller shaft that transmits the driving power generated by an engine, a differential device having a planetary gear device that is provided concentrically with the axial center of rotation of the propeller shaft, and a hydraulic motor fixed to the propeller shaft. The ring gear of the planetary gear device is coupled to the propeller shaft. The carrier is connected to a right rear wheel. The sun gear is connected to a left rear wheel. Inner pinions of the planetary gear device are driven by the hydraulic motor. Therefore, while the driving power generated by the engine is being distributed to the right and left rear wheels, a control of generating a desired torque difference or restricting the differential motion can be performed. Also, the actuator torque capacity can be reduced, so that size reduction of the device is made possible.

Owner:TOYOTA JIDOSHA KK

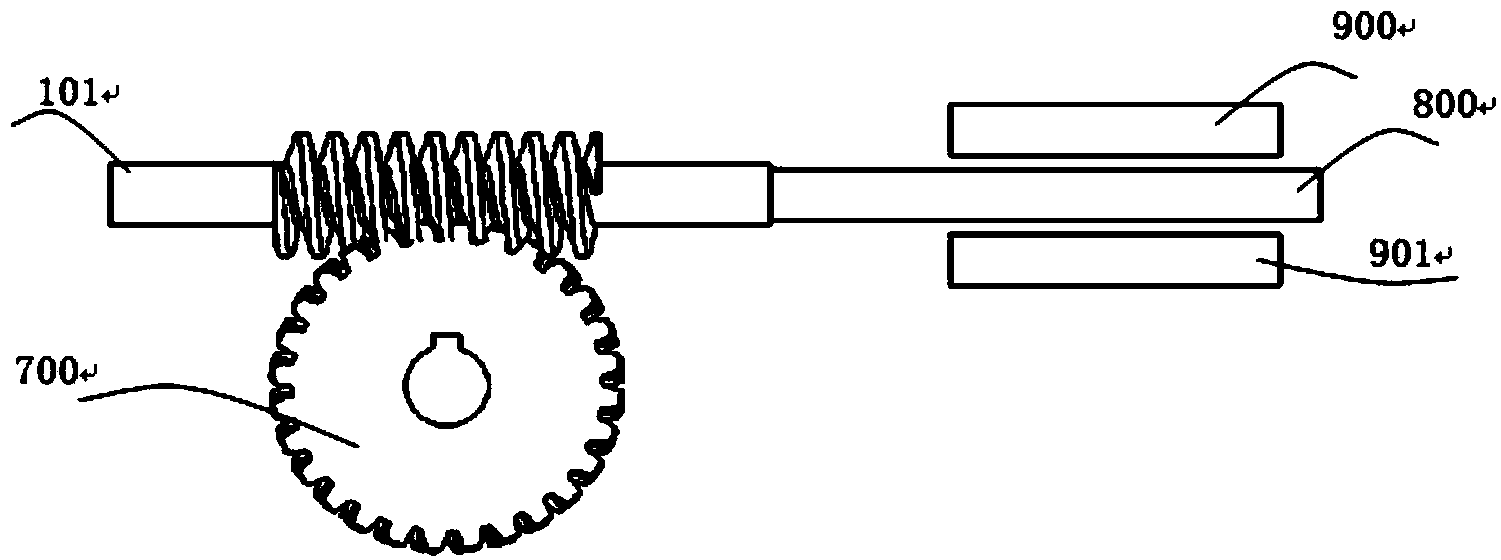

Electric actuator torque protection device

InactiveCN104332957AGuaranteed uptimeHigh movement precisionEmergency protective circuit arrangementsFriction gearingsRadial motionBlocked Connection

Discloses is an electric actuator torque protection device. The electric actuator torque protection device comprises a guide rod, two butterfly-shaped springs, a gear and a machine frame, wherein the two butterfly-shaped springs sleeve the guide rod, the two butterfly-shaped springs are separated through a connection block, a rack is further fixed on the connection block, the guide rod is fixed on the machine frame, radial motion of the two butterfly-shaped springs on the guide rod is limited by the machine frame, the gear is arranged on the rack in matching mode, travel switches are fixedly arranged in two moving directions of the rack, and the rack can touch a trigger of the travel switch when the rack moves in either direction. The electric actuator torque protection device is enabled to stably run due to the fact that common spiral springs are replaced with the butterfly-shaped springs, and simultaneously is high in moving accuracy due to the fact that an original slide block connection is replaced with a gear and rack motion transmission mode, and enables a person to directly observe numerical values on a display screen in torque running due to the fact that a potentiometer is added on the electric actuator torque protection device.

Owner:TIANJIN JINDA ACTUATOR CO LTD

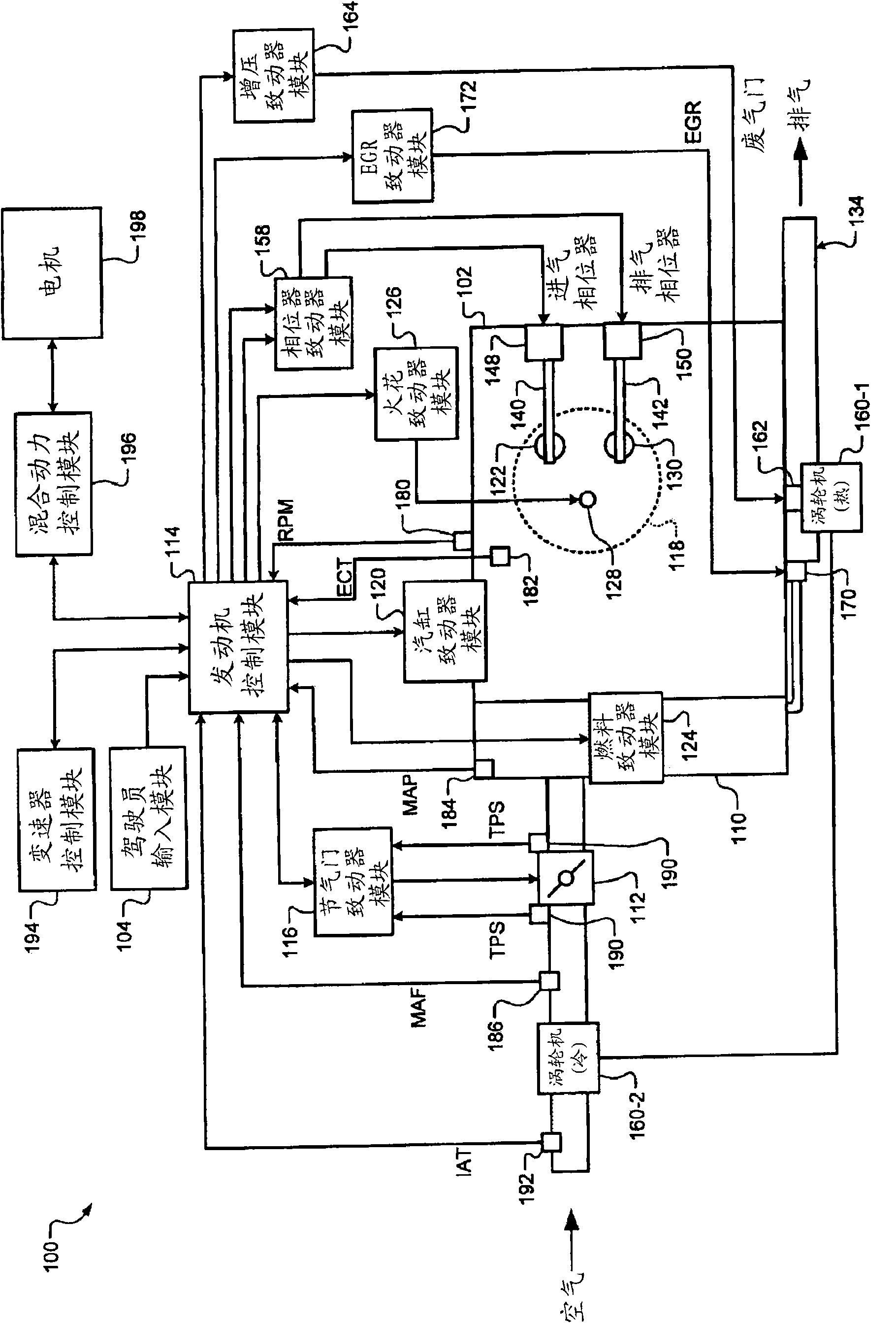

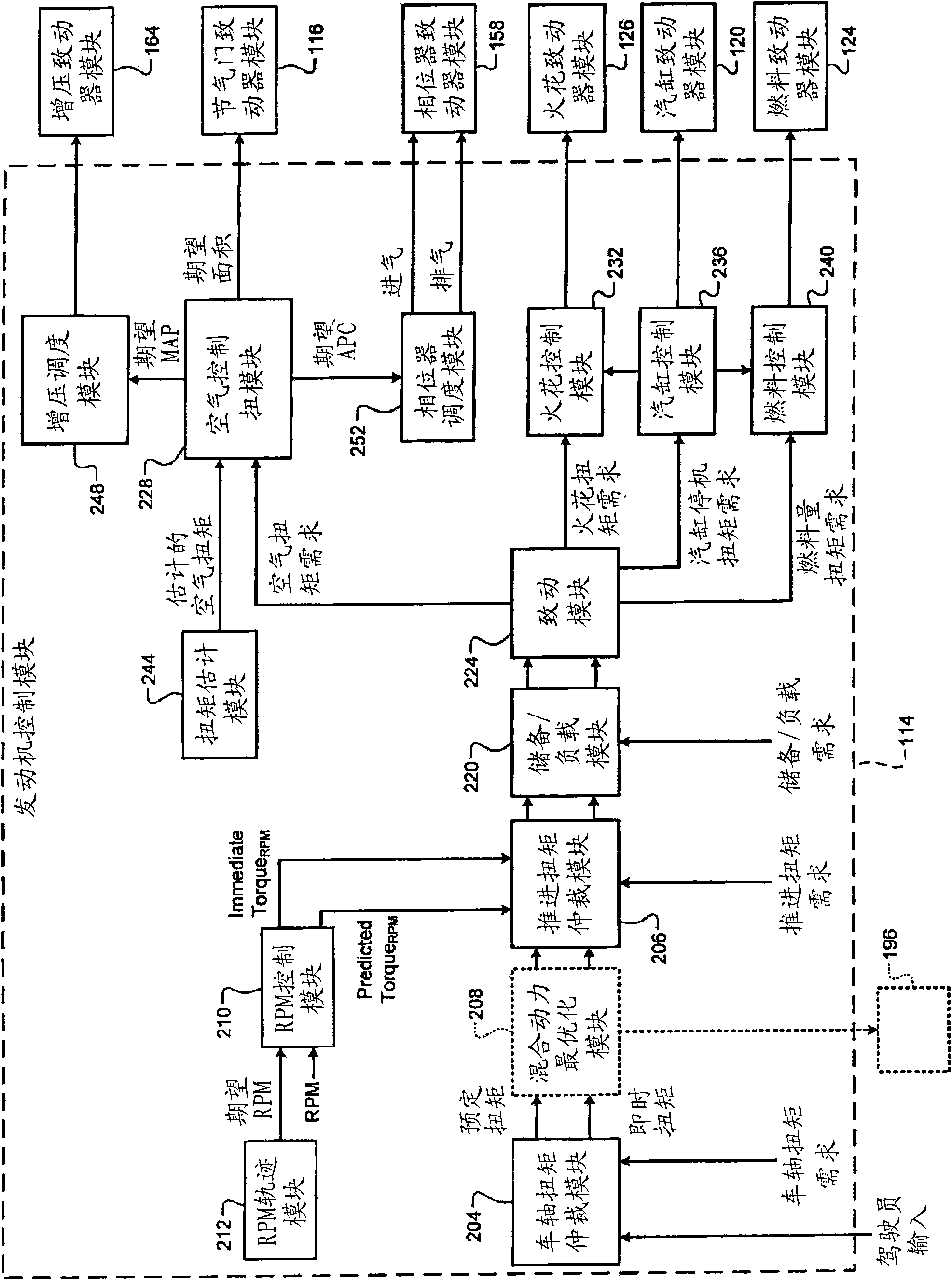

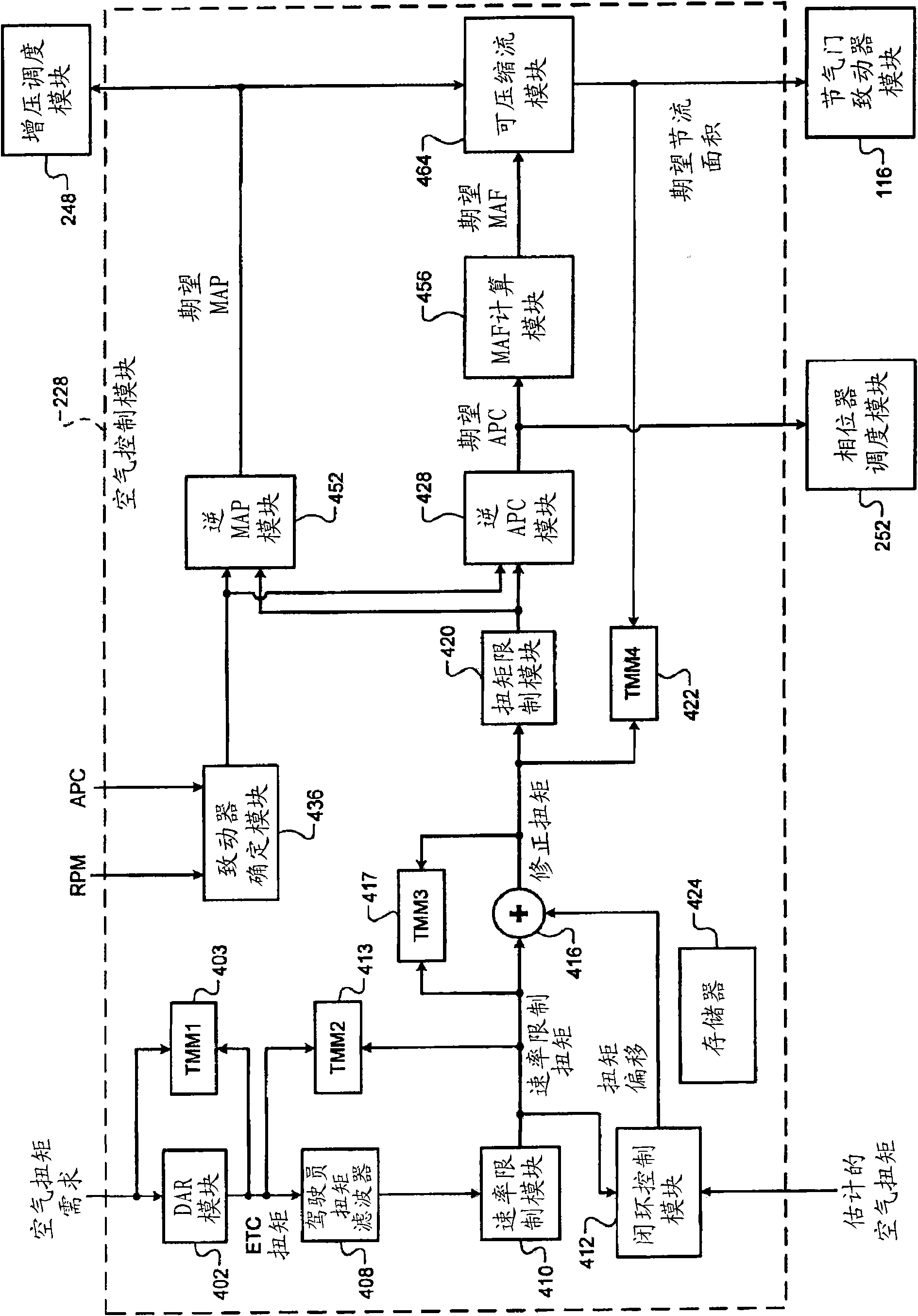

Securing throttle area in a coordinated torque control system

An engine system includes a throttle actuator module and a torque control module. The throttle actuator module controls a throttle actuator based on a desired throttle area. The torque control module determines an actuator torque. The torque control module determines a rate limited torque, a maximum torque, and a minimum torque based on the actuator torque and a predetermined rate of change. The torque control module determines the desired throttle area based on the actuator torque when the rate limited torque is greater than the maximum torque. The torque control module determines the desired throttle area based on the actuator torque when the rate limited torque is less than the minimum torque.

Owner:GM GLOBAL TECH OPERATIONS LLC

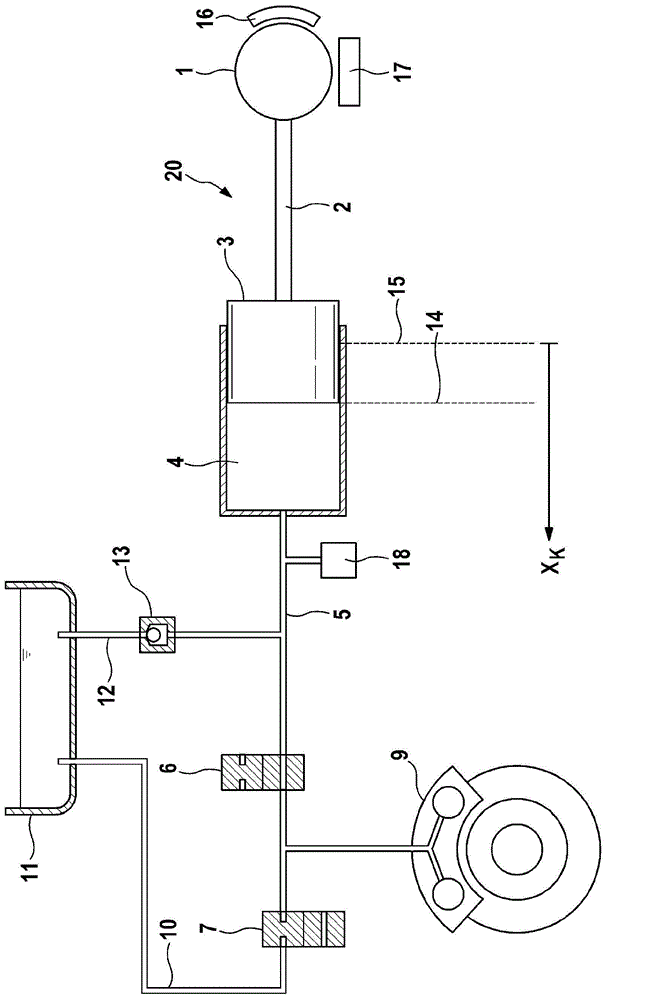

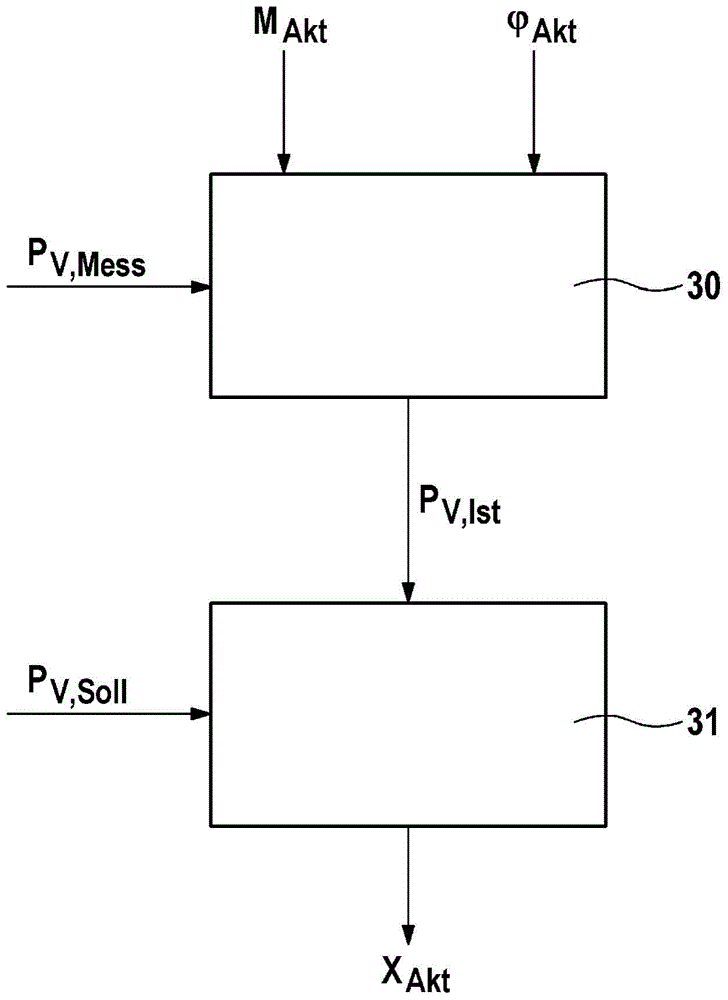

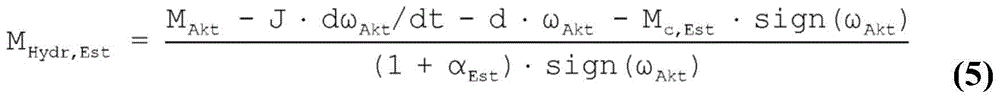

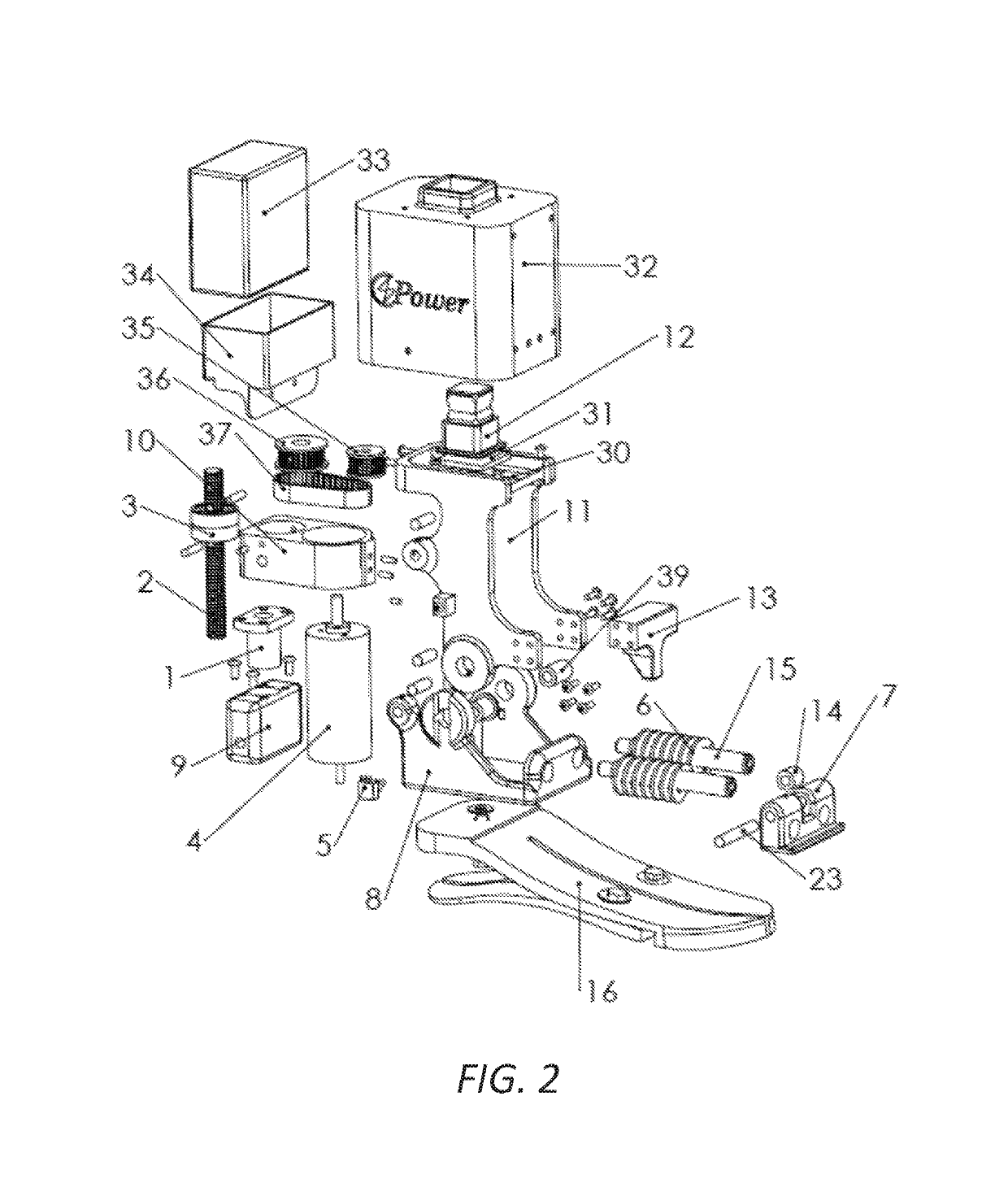

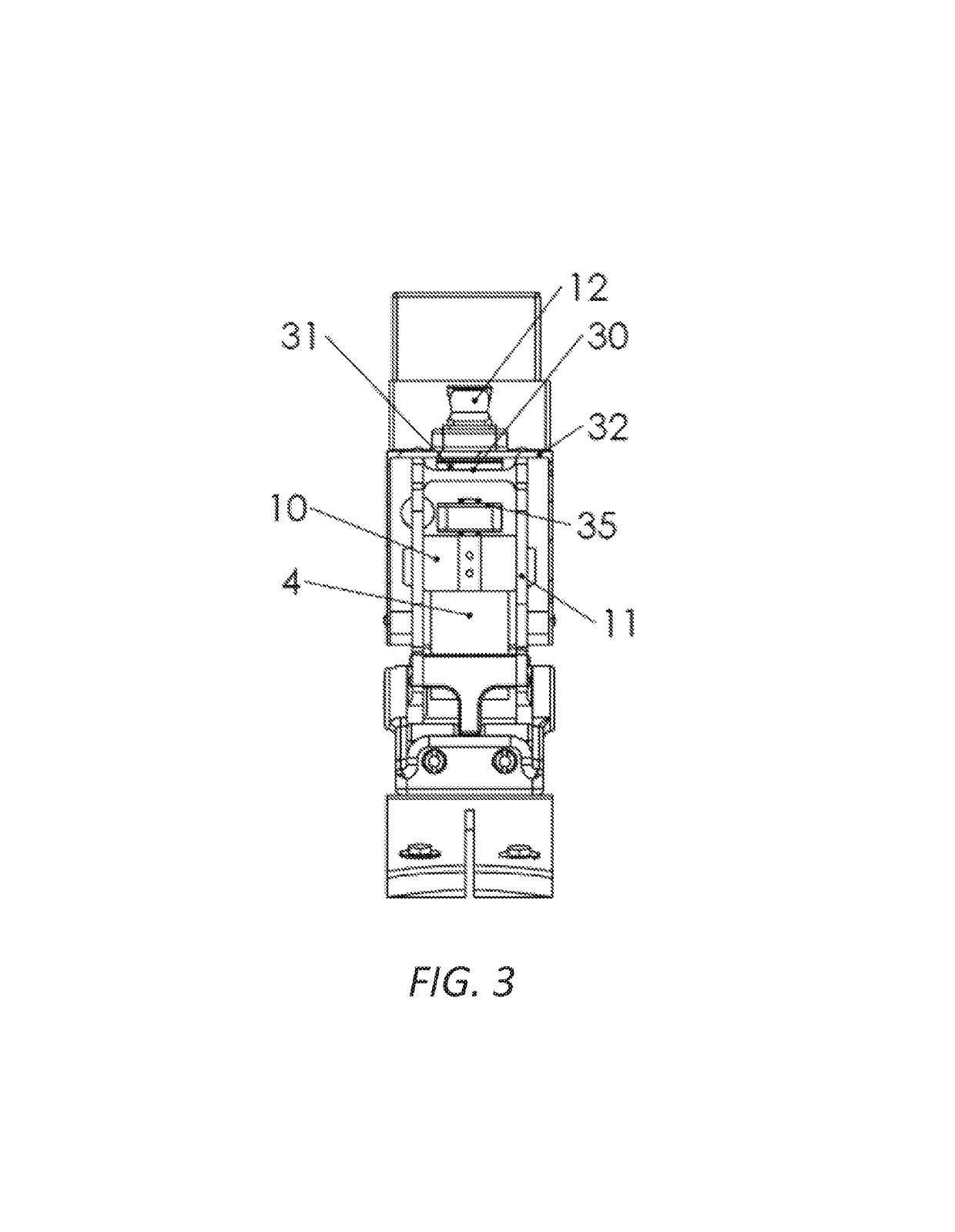

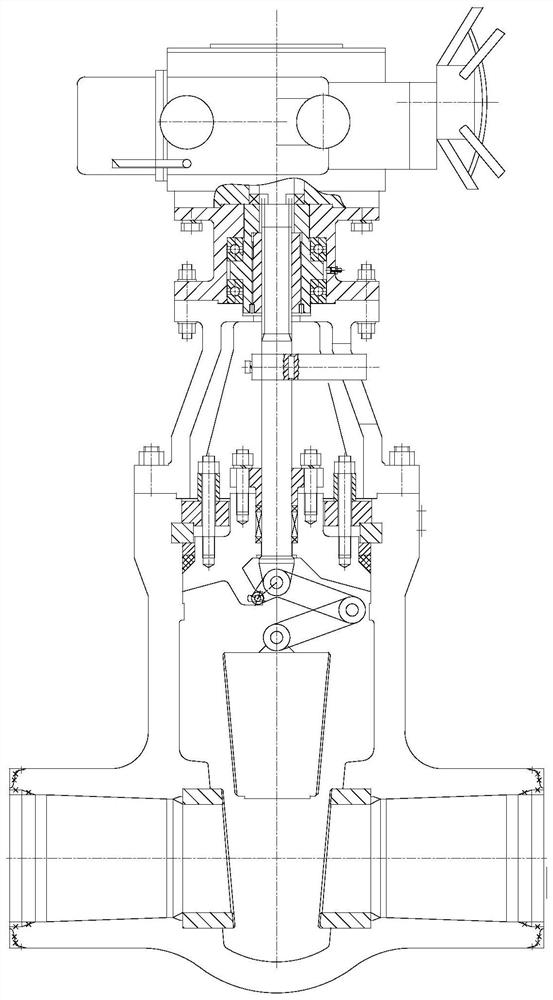

Method for operating a brake system, and brake system

ActiveCN103608226ALow costReduce conversionBraking action transmissionBrake-by-wireActuator torqueControl theory

The invention relates to a method for operating a brake system, in particular for motor vehicles, comprising an electrically controllable pressure supplying device (20) for hydraulically actuating at least one brake (9), in particular a wheel brake. The pressure supplying device (20) comprises a cylinder-piston arrangement with a hydraulic pressure chamber (4), the piston (3) of the cylinder-piston arrangement being movable by an electromechanical actuator (1, 2) in order to generate a specifiable target pressure (PV, Soll) in the hydraulic pressure chamber (4). An actuator torque (MAkt), in particular a motor torque, and an actuator position (fAkt), in particular a motor angular position, of the electromechanical actuator (1, 2) are ascertained, and a pressure value (PV, Est, PV, IstB, PV, IstC) for the pressure (PV) in the hydraulic pressure chamber (4) is determined (30) using the actuator torque (MAkt) and the actuator position (fAkt) taking into consideration a pressure model.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

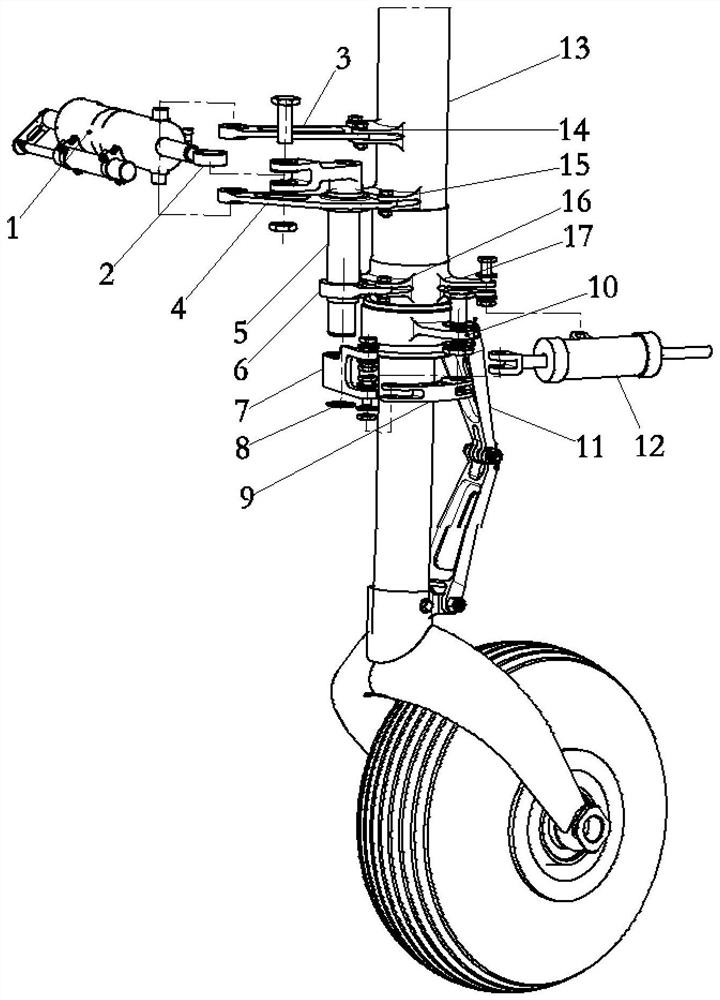

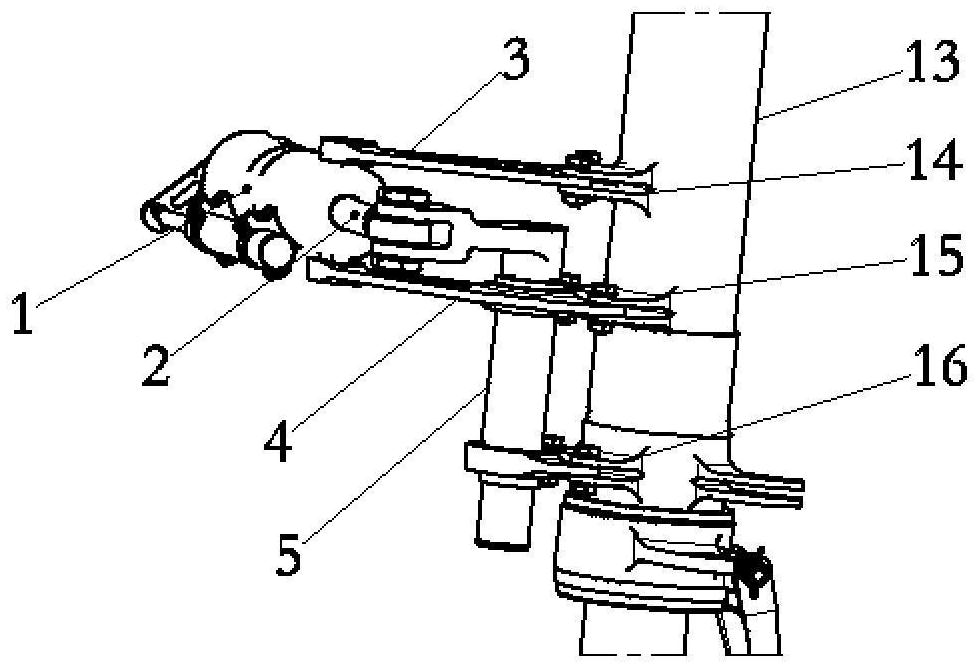

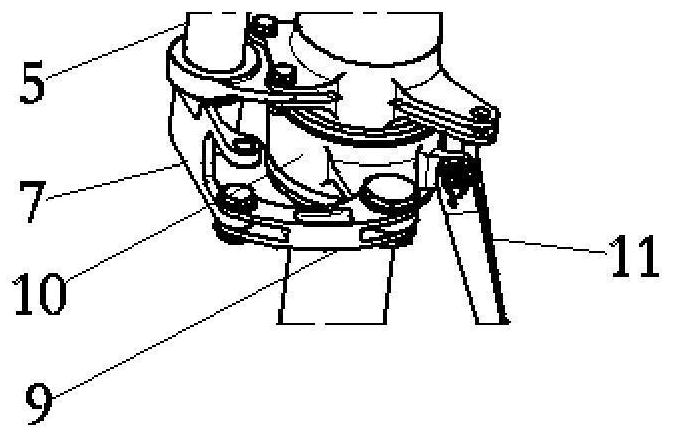

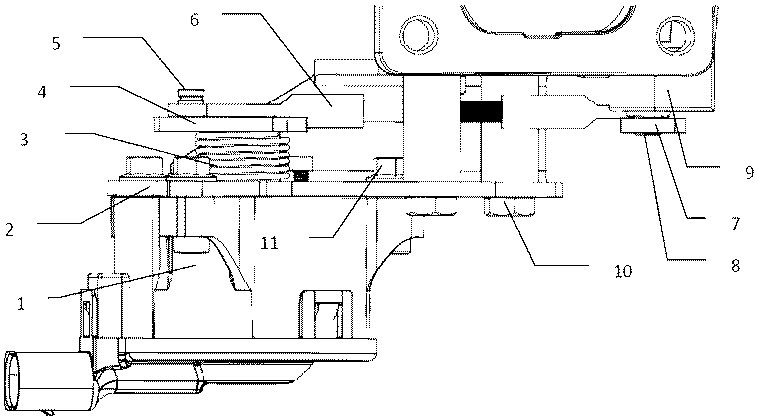

Connecting rod transmission type front wheel turning anti-swing mechanism

PendingCN112389641AChange the transmission ratioMeet the needs of use layoutWheel arrangementsActuator torqueReducer

The invention discloses a connecting rod transmission type front wheel turning anti-swing mechanism which comprises a turning actuator torque transmission mechanism, a planar connecting rod mechanismand a swing reducer. The turning actuator torque transmission mechanism comprises a turning actuator, a torsion bar, a second support and a first support, the turning actuator is connected with the front undercarriage outer cylinder through the second support and the first support, the piston rod of the turning actuator is movably connected with the rocker arm end of a torsion bar, and the bar body of the torsion bar is partially hinged to the second support and a third mounting connecting lug of the front undercarriage outer cylinder, and can rotate around the axis. The planar connecting rodmechanism comprises a double-lug connecting rod, a middle connecting rod, a front undercarriage ring body and a torsion arm, the double-lug connecting rod is connected with the bottom end of the torsion rod body part, an upper connecting lug of the double-lug connecting rod is hinged to the swing reducer, the lower connecting lug of the double-lug connecting rod is connected with one end of the middle connecting rod, and the other end of the middle connecting rod is connected with the front undercarriage ring body; the nfront undercarriage ring body is arranged on the front undercarriage outercylinder and can rotate around the outer cylinder, and one end of the torque arm is connected with the outer portion of the front undercarriage ring body.

Owner:HARBIN

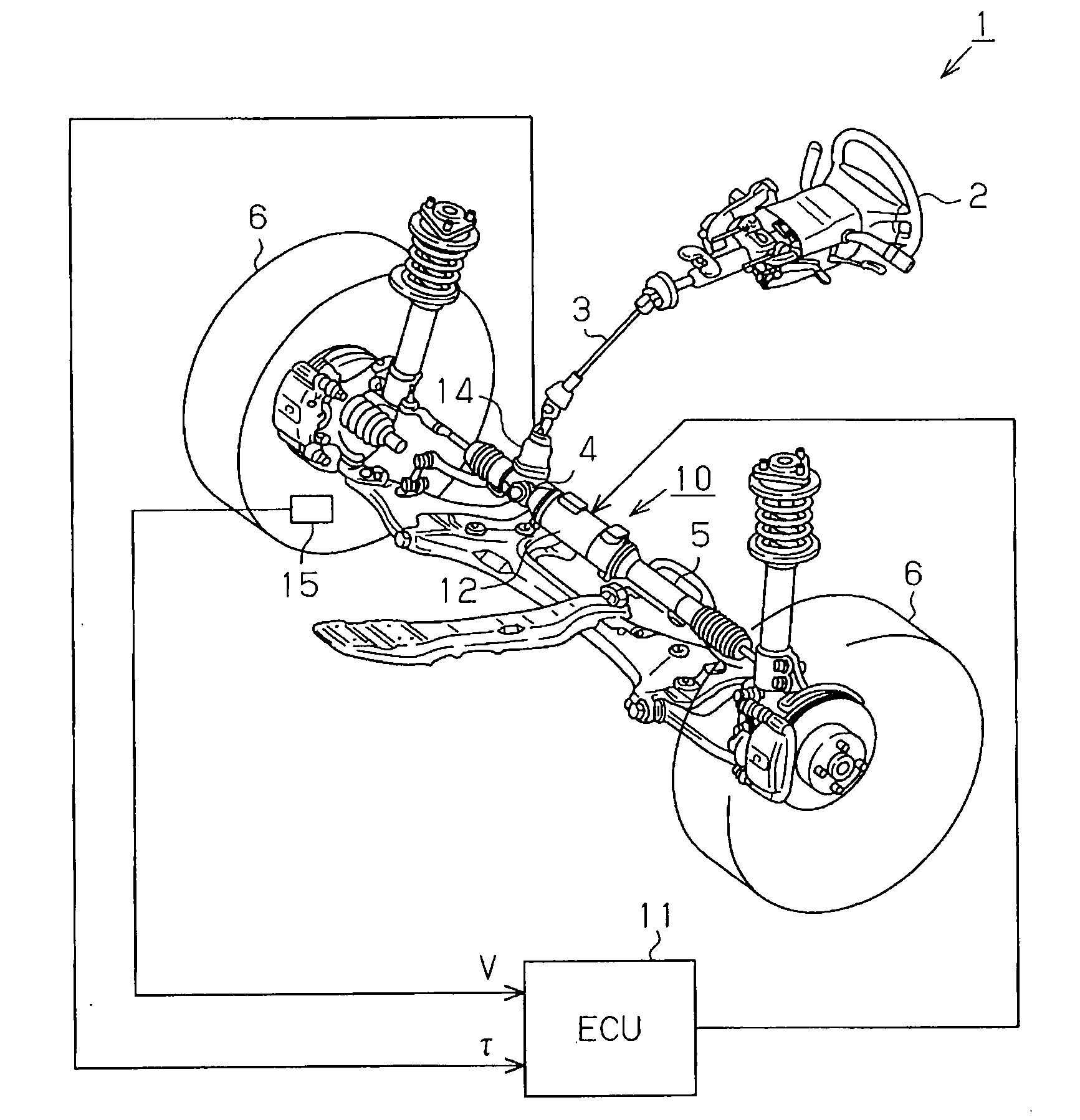

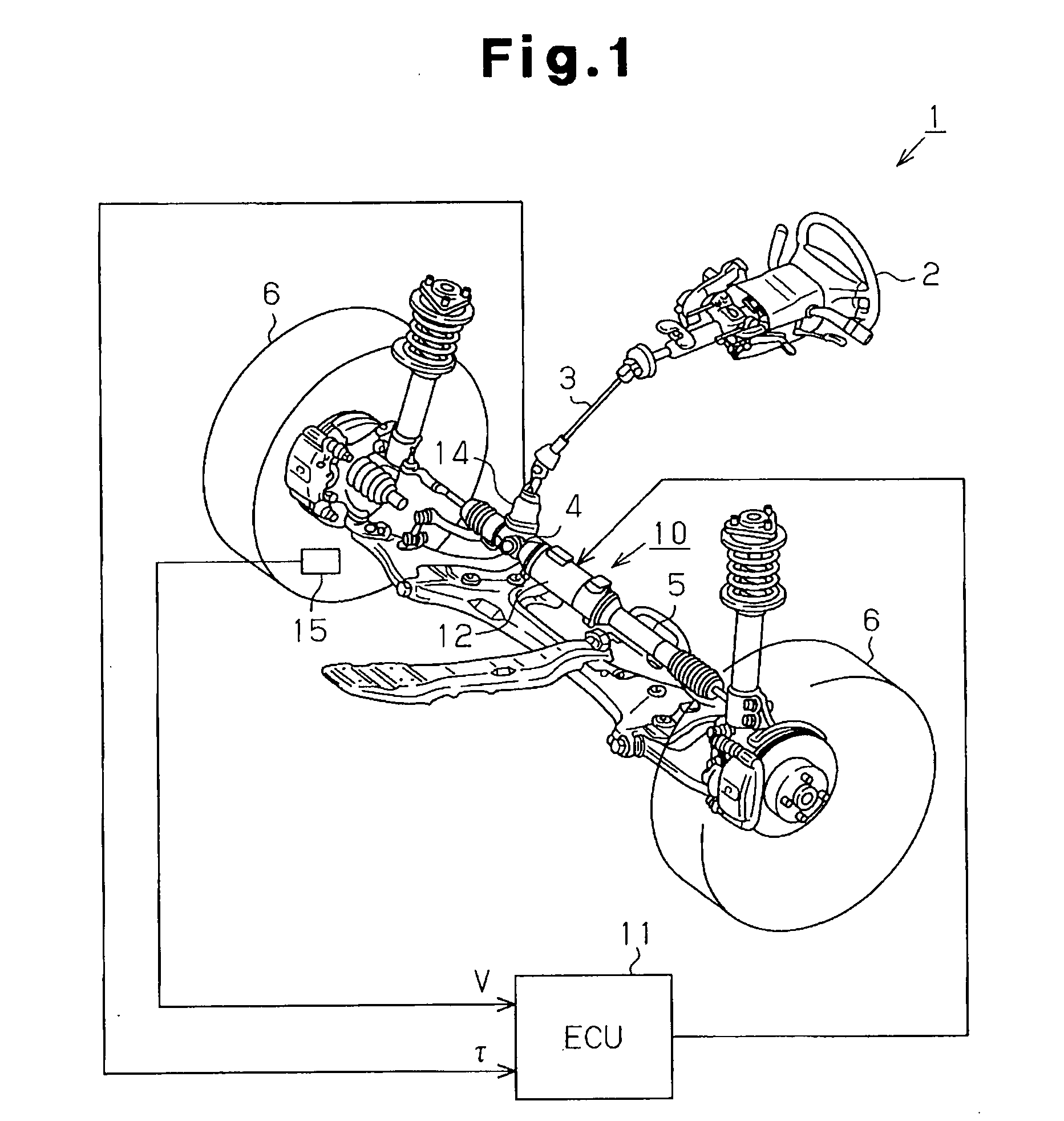

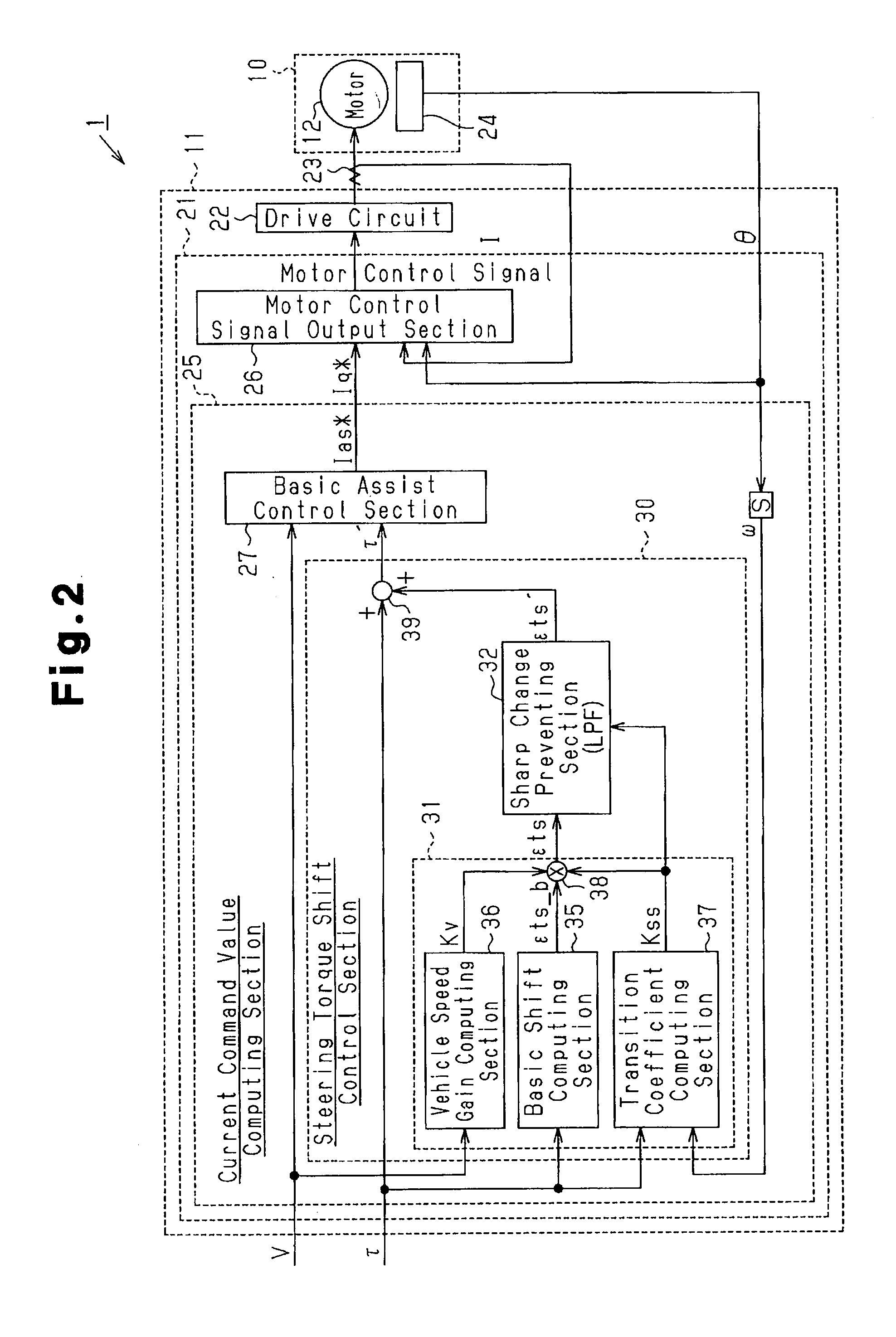

Electric power steering apparatus

ActiveUS20090299575A1Favorable steering feelingFavorable steering feelDC motor speed/torque controlDigital data processing detailsElectric power steeringElectric power system

An electric power steering (EPS) apparatus 1 includes a motor 12, an EPS actuator 10, a torque sensor 14, and an ECU 11. The EPS actuator 10 uses the motor 12 as a drive source to apply assist force to a steering system, thereby assisting a steering operation. The torque sensor 14 detects a steering torque τ of the steering system. The ECU 11 controls the operation of the EPS actuator 10. Based on the steering torque τ detected by the torque sensor 14, the ECU 11 computes a basic shift amount εts_b of the assist force applied to the steering system. The ECU 11 determines which one of returning, holding, and turning is the state of the steering operation. When the state of the steering operation is returning or holding, the ECU 11 executes compensation control for correcting the steering torque τ, which is used in the computation of the basic shift amount εts_b of the assist force, thereby increasing the assist force applied to the steering system. The ECU 11 subjects the steering torque shift control amount εts to a filtering process using a low pass filter, thereby inhibiting the steering torque shift control amount εts from sharply changing. When the state of the steering operation is turning, the ECU 11 changes a filter constant of the low pass filter so as to reduce the filtering effect.

Owner:JTEKT CORP

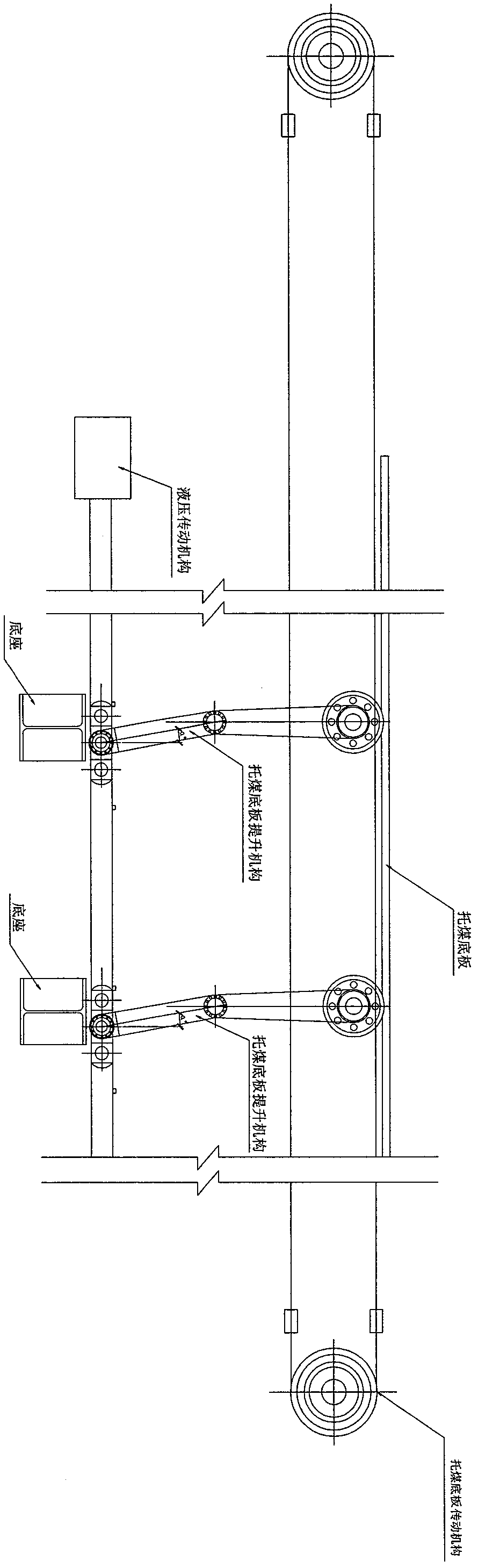

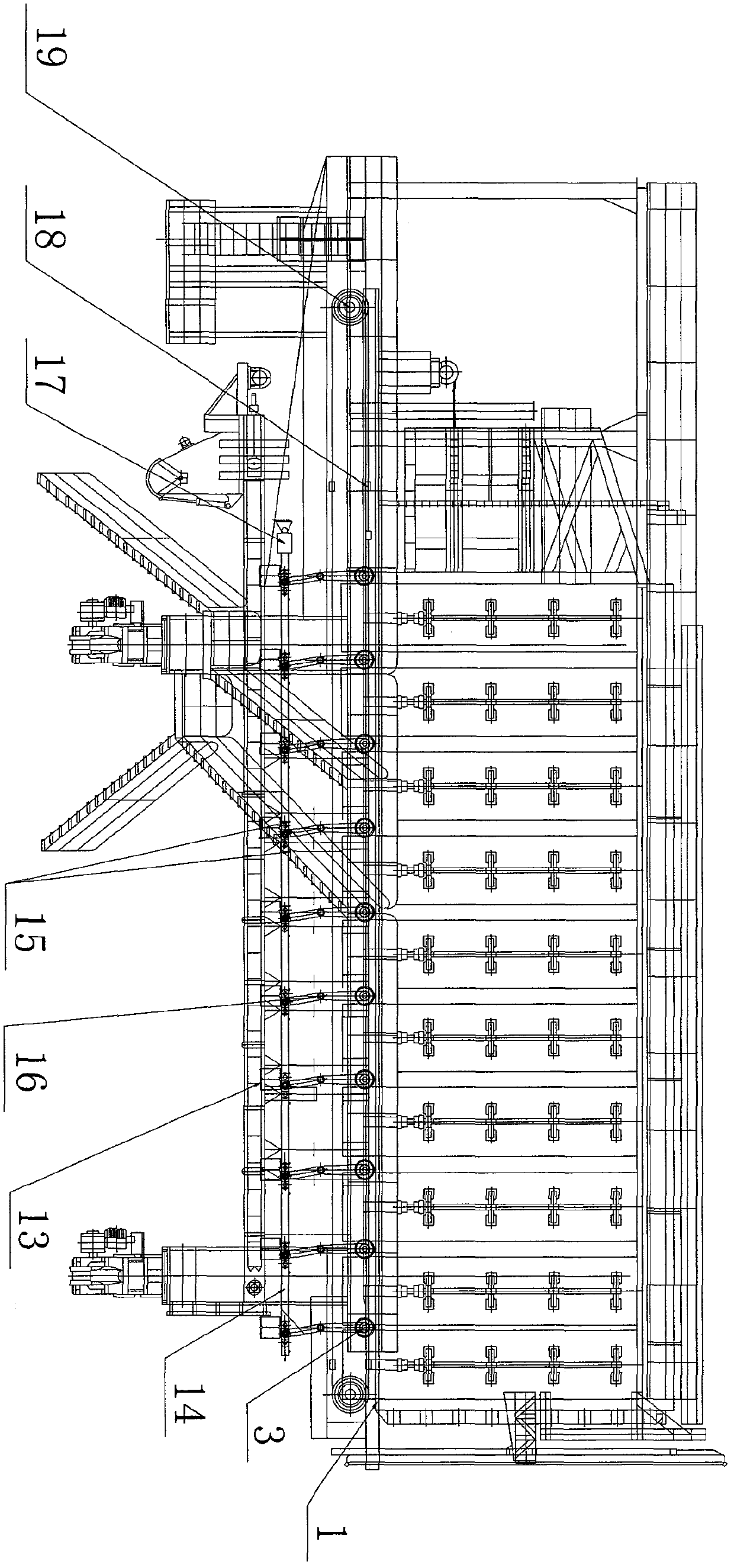

A new type of energy-saving tamping coke oven coal feeding device

InactiveCN102277178AReduce wearExtended service lifeCharging-discharging device combinationsCharging devicesNew energyActuator torque

The new energy-saving tamping coke oven coal charging car coal delivery device is composed of a coal bottom lifting mechanism, a hydraulic transmission mechanism, a limit mechanism, a coal bottom drag mechanism and a base, and a coal bottom lifting mechanism and a hydraulic transmission mechanism They are connected to each other, and the torque is transmitted to the lifting mechanism of the coal-supporting floor through the hydraulic transmission mechanism. The lifting mechanism deflects along the center of the load-bearing shaft. The lifting mechanism moves horizontally back and forth in the roller table groove. When the coal-supporting bottom plate is advancing or retreating, the coal-supporting bottom plate rises. When the coal charging box is ready to be loaded with coal and tamped, the coal-supporting bottom plate descends to the slideway; The lifting mechanism relies on the load-bearing shaft to connect with the load-bearing support, and the force of the supporting roller is transmitted to the load-bearing support; the load-bearing support and the hydraulic transmission mechanism are connected to the base, and the base bears the gravity and weight transmitted by the load-bearing support of the lifting mechanism for the coal bottom plate. The horizontal thrust transmitted by the hydraulic transmission rod, the transmission rod is constrained by the chain plate under the action of the hydraulic mechanism to move horizontally back and forth; the transmission mechanism of the coal support bottom plate is connected with the coal support bottom plate, and the position of the center line of the coal support bottom plate is fixed and adjusted by steel wire ropes at certain intervals The idler pulley ensures that the wire rope moves back and forth on the centerline. The invention has the advantages of rolling motion of the coal supporting bottom plate in the support roller groove, small frictional resistance, low power consumption, good coal cake stability, convenient operation and maintenance and energy saving.

Owner:李先才

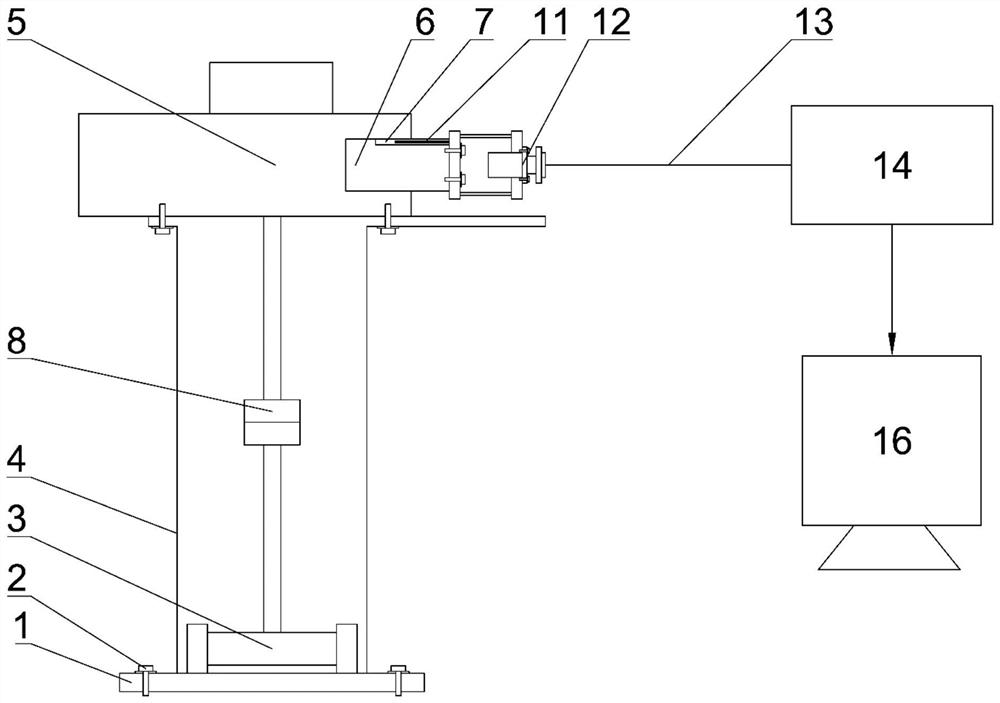

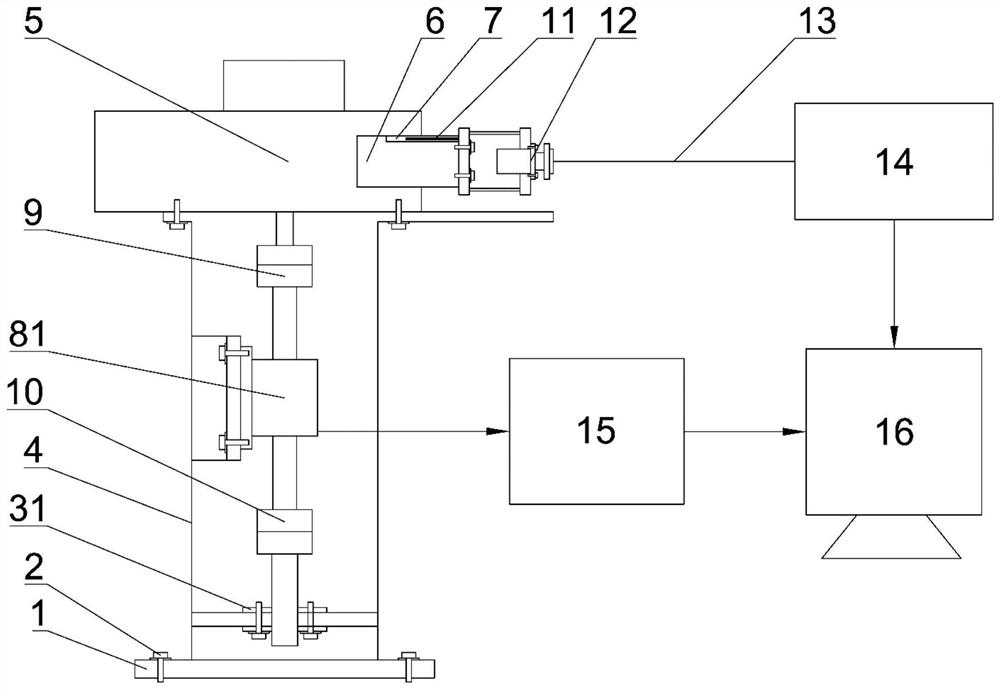

Torque and stroke measuring system and method for electric valve and actuator thereof

PendingCN112728195ARealize measurementWith anti-electromagnetic interferenceMachine part testingOperating means/releasing devices for valvesFiberValve actuator

Owner:EAST CHINA UNIV OF SCI & TECH

Turbocharging electric control bypass valve design

PendingCN108035794AEliminate mechanical playAvoid vibration noiseOperating means/releasing devices for valvesInternal combustion piston enginesTurbochargerTorque motor

The invention relates to a turbocharging electric control bypass valve structure design. The bypass valve structure comprises a bypass valve plate arranged on a turbocharger, an electric executer arranged on the turbocharger, a transmission mechanism connecting the electric executer with the bypass valve plate, and a spring generating pre-tightening force to the transmission mechanism. Due to thepre-tightening force generated through the spring, the bypass valve plate generates closing force. A brushless direct drive torque motor is preferably selected in the executer. By means of the turbocharging electric control bypass valve structure design, the mechanical gap of the bypass valve transmission mechanism can be effectively eliminated, and vibration abrasion, noise, lowering of reliability and shortening of the service life due to the gap are avoided. The executer torque and power requirements are lowered, and heat dissipation is reduced. Due to usage of the brushless direct drive torque motor, the reliability of the system can be greatly improved, and the service life of the system can be greatly prolonged.

Owner:SUZHOU FUGENA ELECTROMECHANICAL CO LTD

Ankle-foot prosthesis device

ActiveUS10406000B2Reduce energy consumptionReduce the required powerArtificial legsElastic componentProsthesis

A powered ankle-foot prosthesis and associated methods of use are described herein. Such prostheses can employ an actuator and elastic components, the actuator being controlled to deliver net positive work to propel the wearing amputee forward and the elastic components being used to store and release negative energy to improve efficiency. Elastic components can be linear springs coupled with a cam and configured in parallel to the actuator. The cam profile can be designed to generate a desired spring torque versus angle curve rather than a spring stroke versus angle curve, thereby reproducing human ankle controlled dorsiflexion stiffness. Such configurations improve system energy efficiency and reduce both actuator torque and power requirements. Such prostheses can also operate in a passive mode, in which a nearly normal gait can be achieved even without powered assist.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

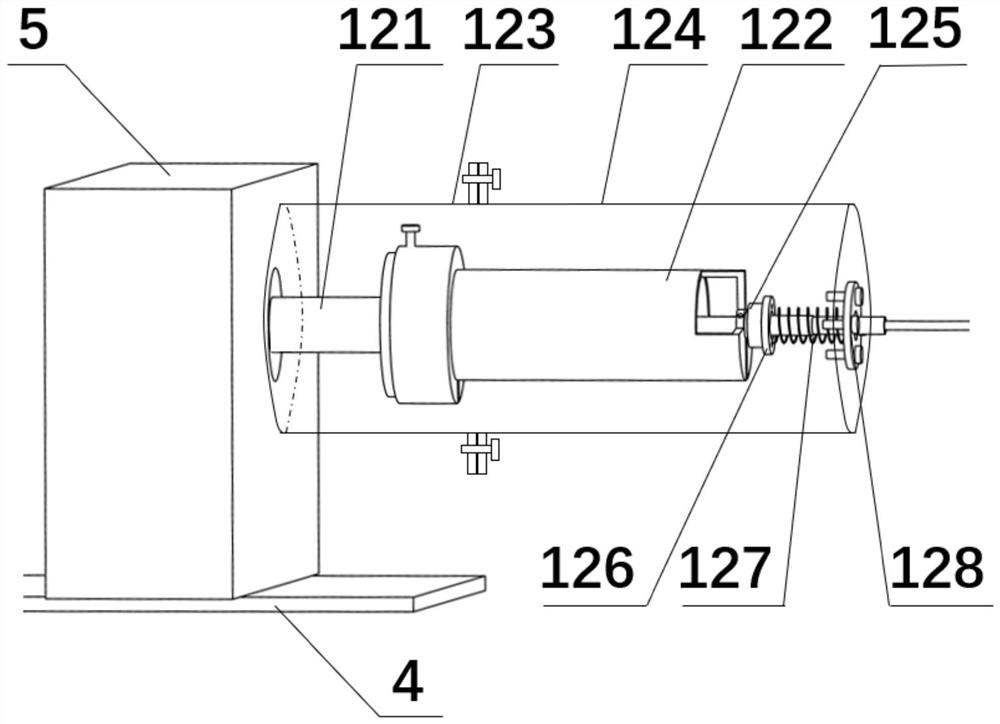

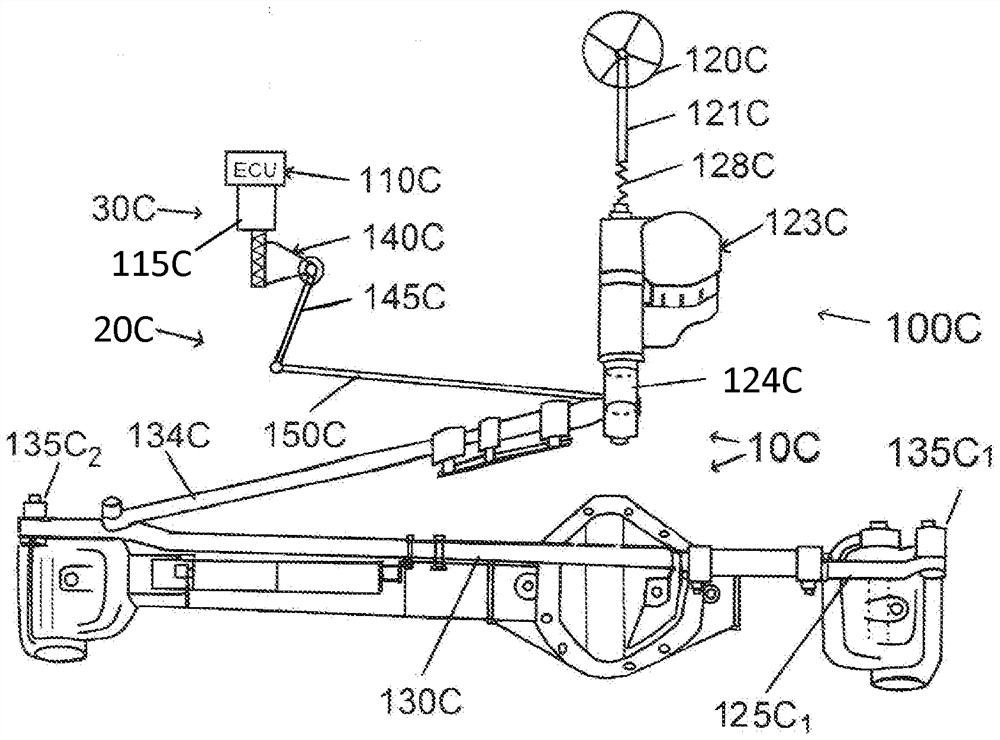

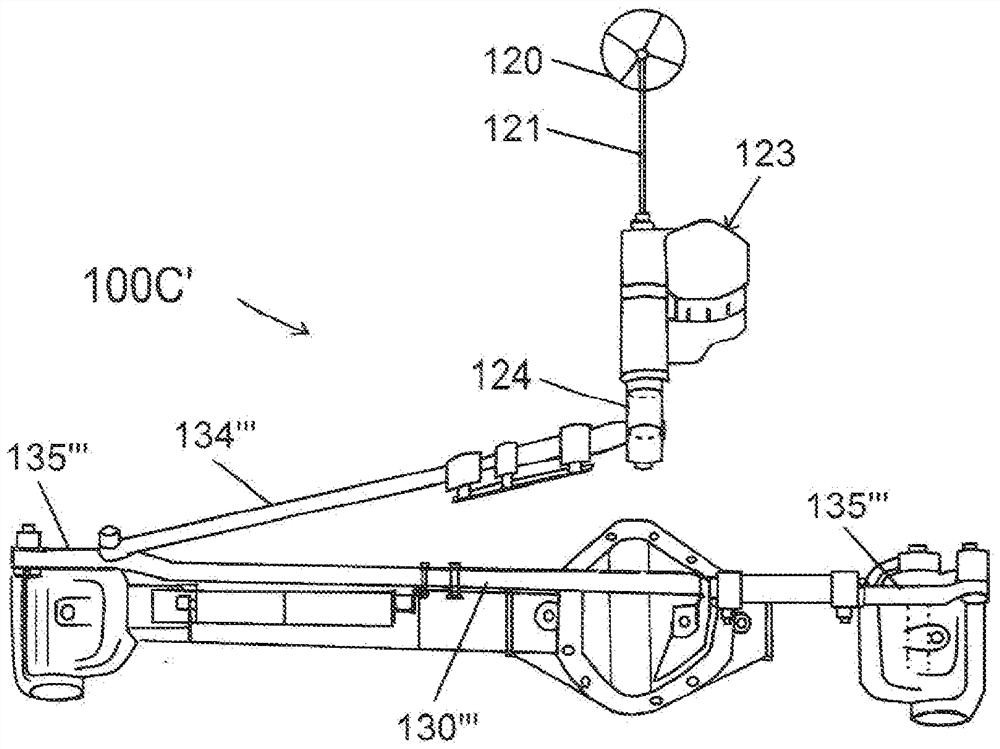

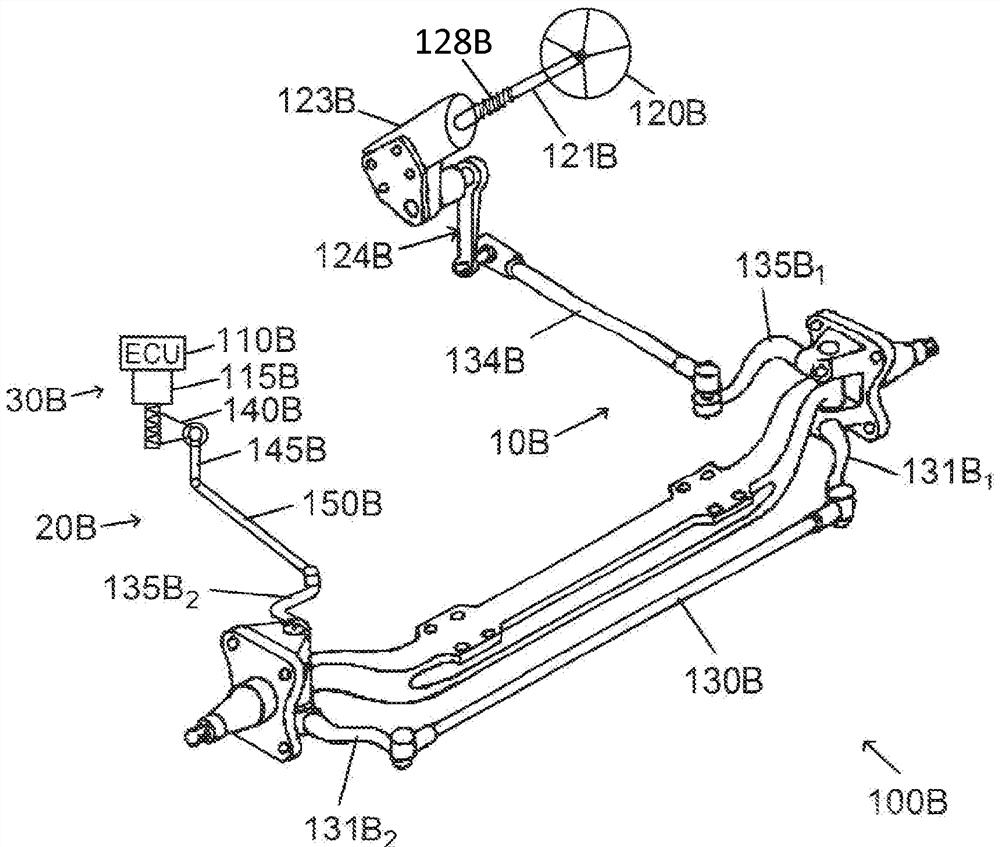

Power assisted steering system arrangement

PendingCN113365900AEnables Electric Power Assisted SteeringEfficient use ofMechanical steering gearsElectrical steeringDriver/operatorControl signal

The present invention relates to a power assisted steering system arrangement (100A) for a vehicle comprising a steering wheel (120A), and a first driver link arrangement (10A) which comprises a linkage between the steering wheel (120C) and front wheels (127,127) comprising a steering column (121A), a recirculating ball joint (RCB) (123A) arranged on a first side of the vehicle, a track rod arrangement for steering the front wheels (127,127), and a first lever arm (124A) arranged to transfer the torque applied by a driver via the steering wheel to the track rod arrangement and providing a connection between the RCB (123A) and the track rod arrangement. The system further comprises a torsion bar (128A) with a torsion-bar torque sensor associated with the steering column (121A); an assistance actuator (30A), arranged on a second side of the vehicle, opposite to the side of the vehicle where the RCB is arranged, the assistance actuator (30A) comprising at least an electric motor (115A) and an electronic control unit (ECU) (110A) controlling the electric motor depending on control signals received from the torsion-bar torque sensor; and an assistance actuator link arrangement (20A) connected to the track rod arrangement, so that a steering torque applied by the driver as well as an assistance actuator torque provided or applied by the assistance actuator (30A) is transferred to the track rod arrangement steering the front wheels of the vehicle.

Owner:感知知识产权有限公司

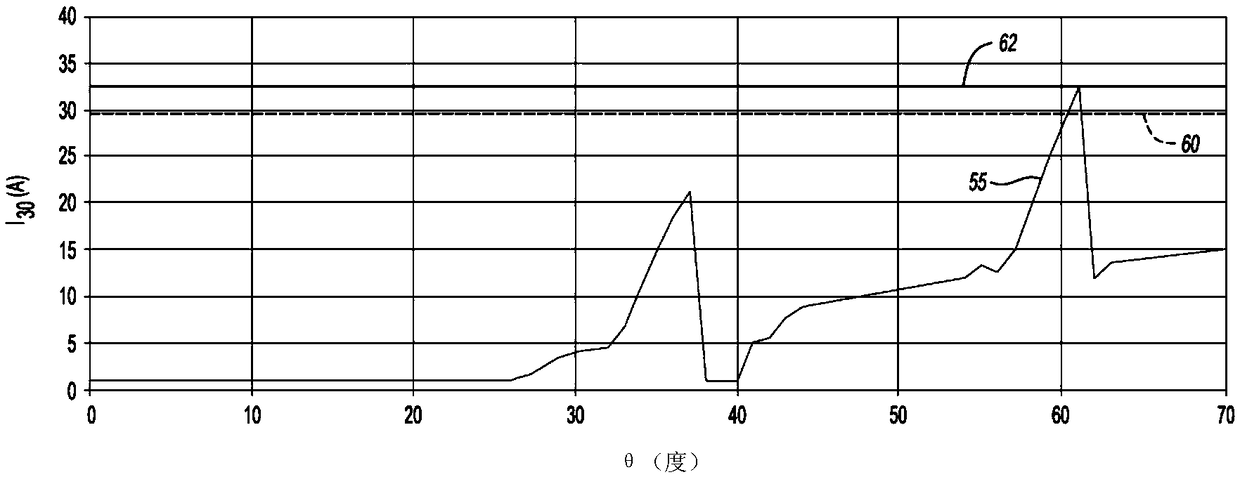

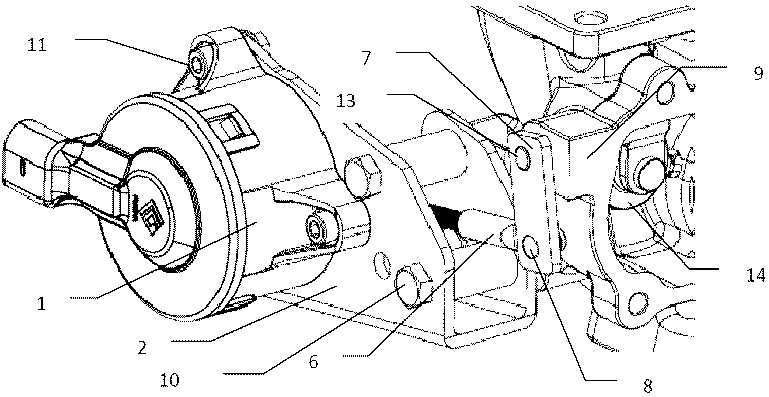

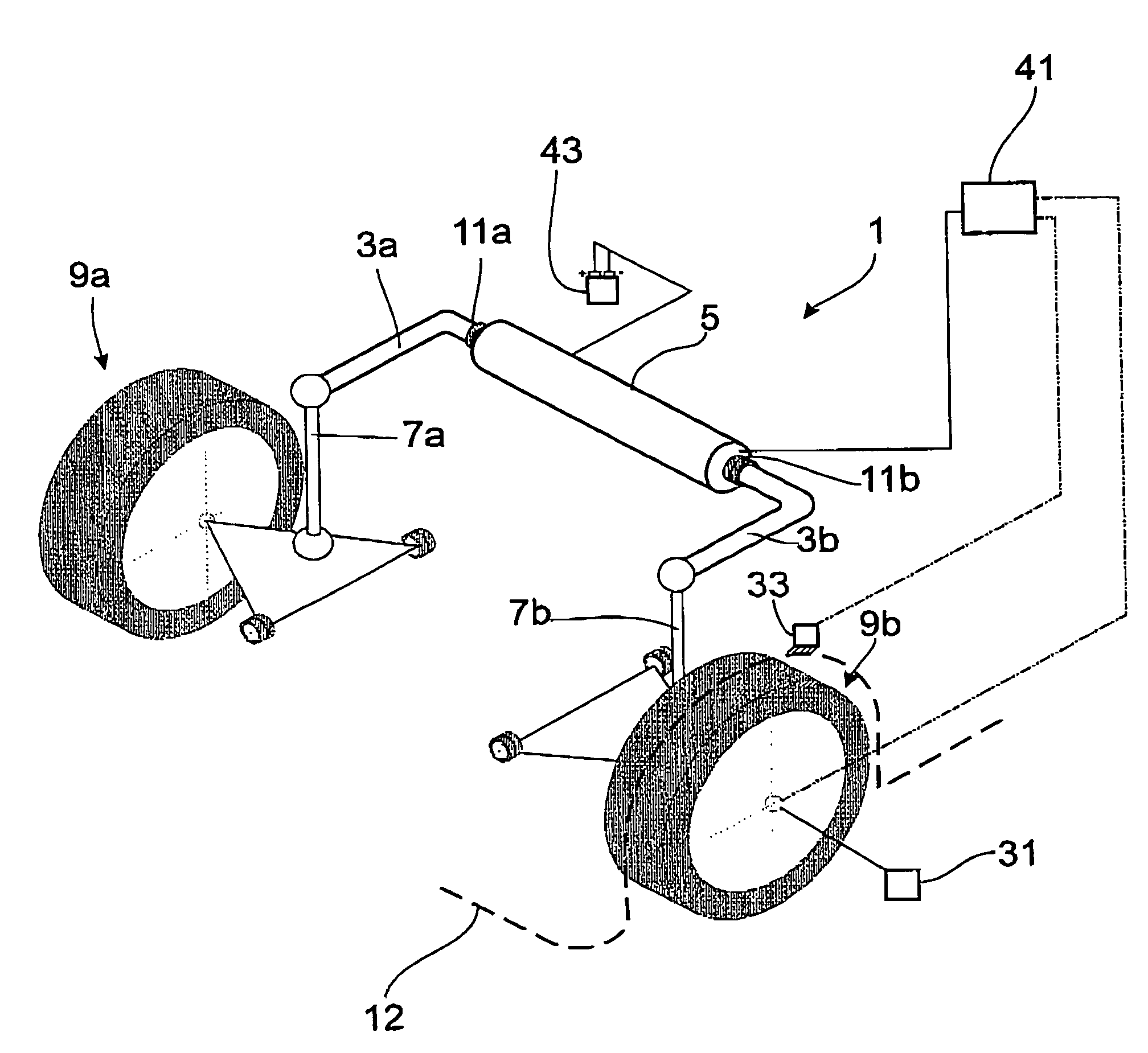

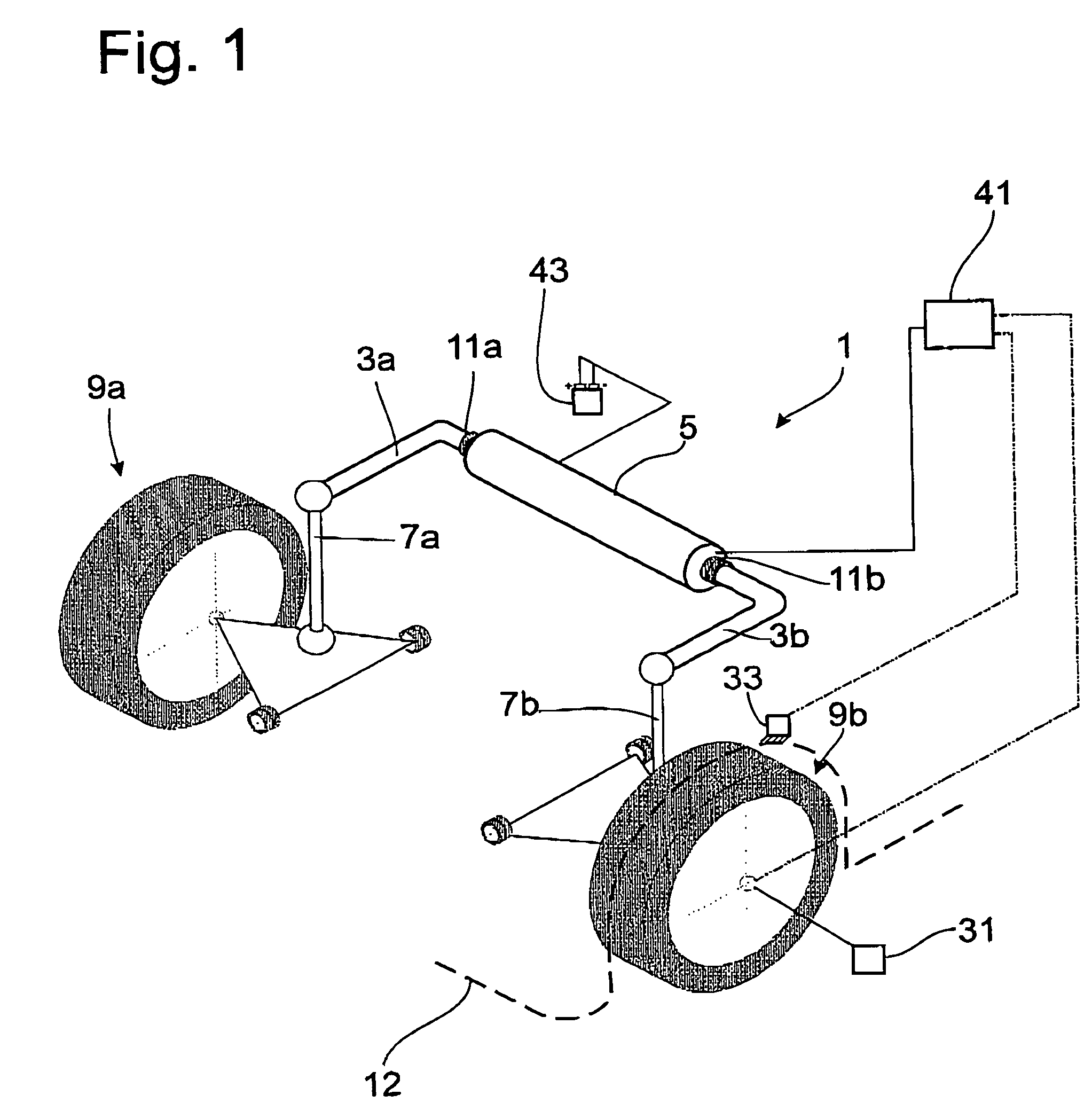

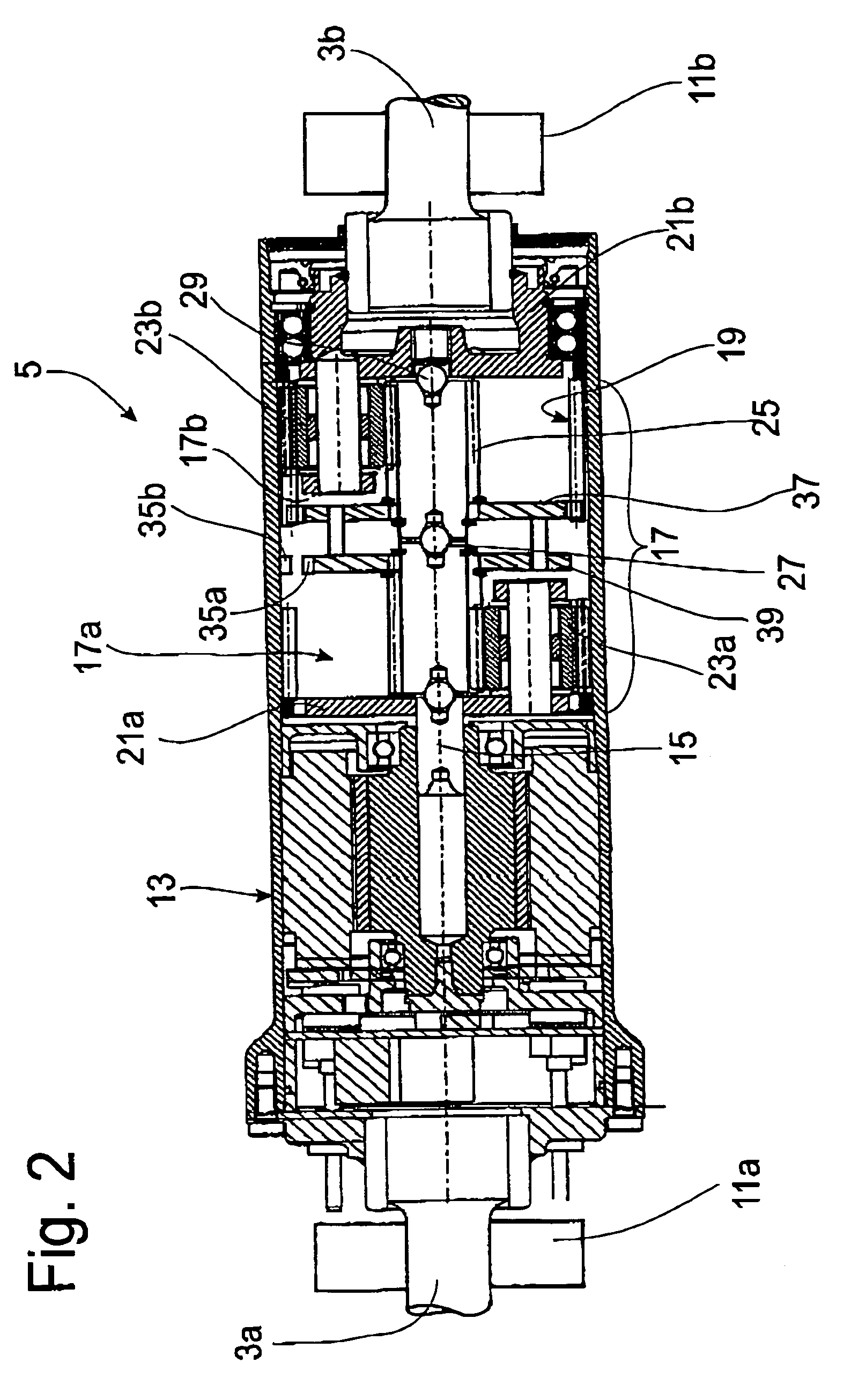

Method for operating an actuator, especially an electric actuator in a stabilizer arrangement

ActiveUS7983814B2Satisfactory suppressionEasy to moveDigital data processing detailsAnimal undercarriagesEngineeringActuator torque

Method for operating an adjustable stabilizer arrangement including an actuator, which applies actuator torque to stabilizer sections as a function of a command variable to influence the rolling movement of a motor vehicle body, where sensors are used to detect the movement of the motor vehicle body and the movements of the wheels. An operating condition of the actuator supplies a variable which can be used to determine the actuator torque, upon which is superimposed an adjustment signal for the actuator, and where the variable is modified by a weighting factor.

Owner:ZF FRIEDRICHSHAFEN AG

Over torque device of electric actuator

InactiveCN104358911AEnsure personal safetyImprove work efficiencyOperating means/releasing devices for valvesEmergency protective circuit arrangementsReciprocating motionActuator torque

The invention provides an over torque device of an electric actuator. The over torque device comprises a bracket, spring seats, springs, micro-switches, a cam and guide shafts, and further comprises a torque adjusting shaft, wherein the spring seats are symmetrically arranged on the two sides of the lower end of the bracket; the guide shaft sleeves into the middle lower end of the cam; the two ends of the guide shafts sleeve into the spring seats on the two sides respectively; the springs sleeve the guide shafts on the two sides of the cam; the corresponding spring seat sleeves one end of each spring and the lower end of the cam is convexly arranged at the lower end of the bracket; a thread end of the torque adjusting shaft is screwed into a bolt hole in the upper end of the cam; the two micro-switches are fixed on the two sides of the upper end of the bracket, are located above the torque adjusting shaft and are close to the two ends of the torque adjusting shaft; the cam is subjected to the force effect to do left and right reciprocating motion. The over torque device of the electric actuator has the beneficial effects that the over torque device can be used on a plurality of models of electric actuators by replacing the wire diameters of the springs; the aim that the power is cut off when the torque of the electric actuator is too great is realized by not moving the micro-switches and moving the torque adjusting shaft.

Owner:天津市津达执行器有限公司

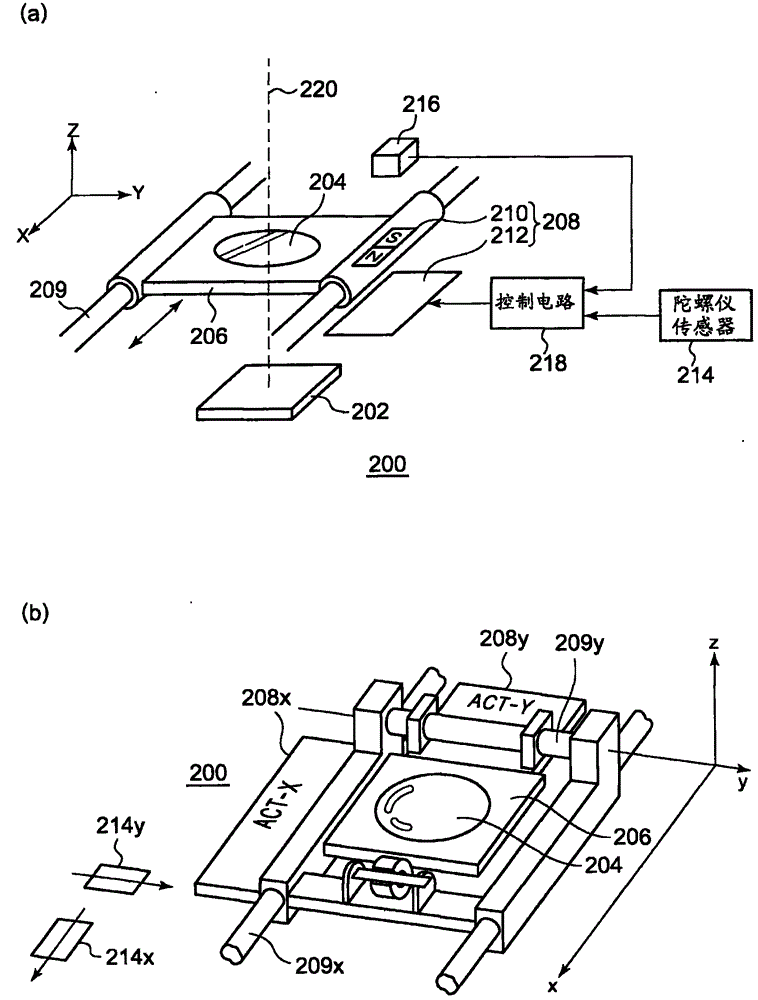

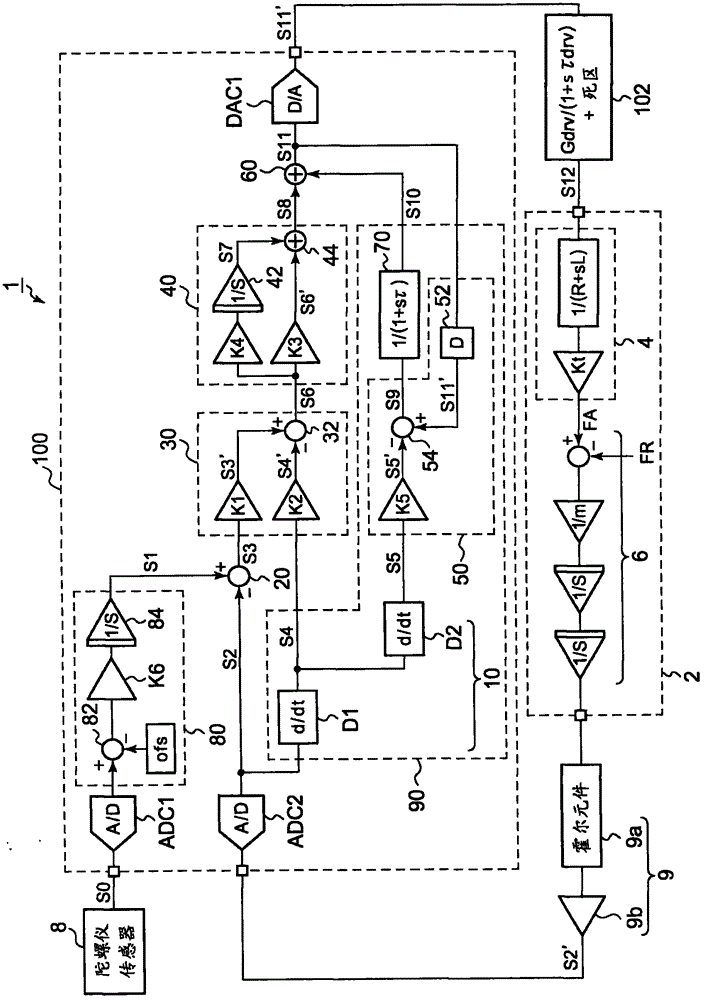

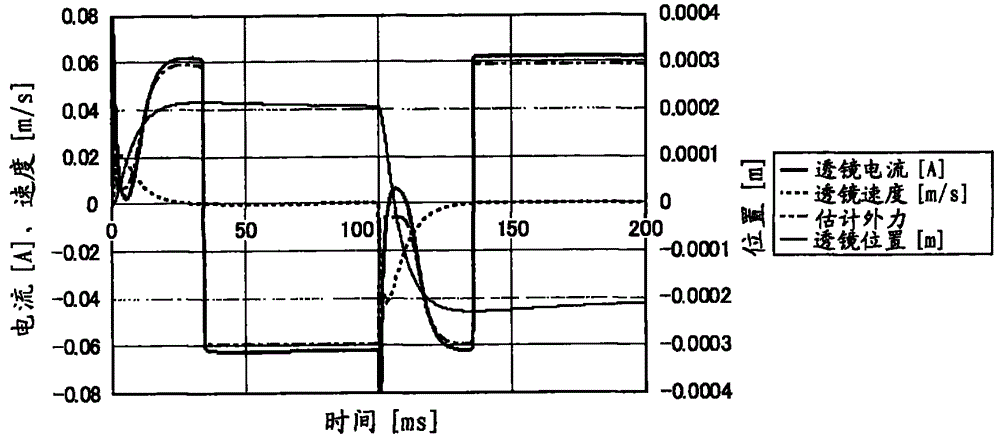

Motor control circuit, control method thereof and electronic device with imaging function

A control circuit generates a driving signal indicating an actuator torque. A first operation unit generates position, speed, and acceleration signals, based upon a detection signal indicating the actuator mover state. A second operation unit generates a first difference signal indicating the difference between a target signal and the position signal. A third operation unit generates a second difference signal indicating the difference between signals based on the first difference signal and the speed signal. A fourth operation unit generates a position control signal such that the second difference signal becomes zero. A fifth operation unit generates a third difference signal indicating the difference between signals based on a driving signal and the acceleration signal. A sixth operation unit generates a driving signal by summing a signal based on the position control signal and a disturbance estimation signal based on the third difference signal.

Owner:ROHM CO LTD

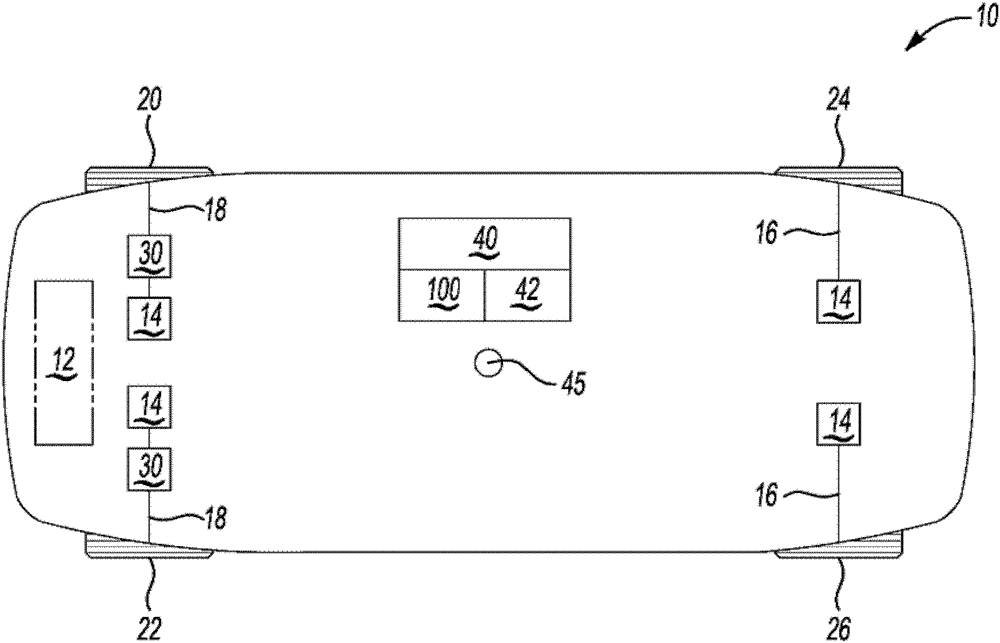

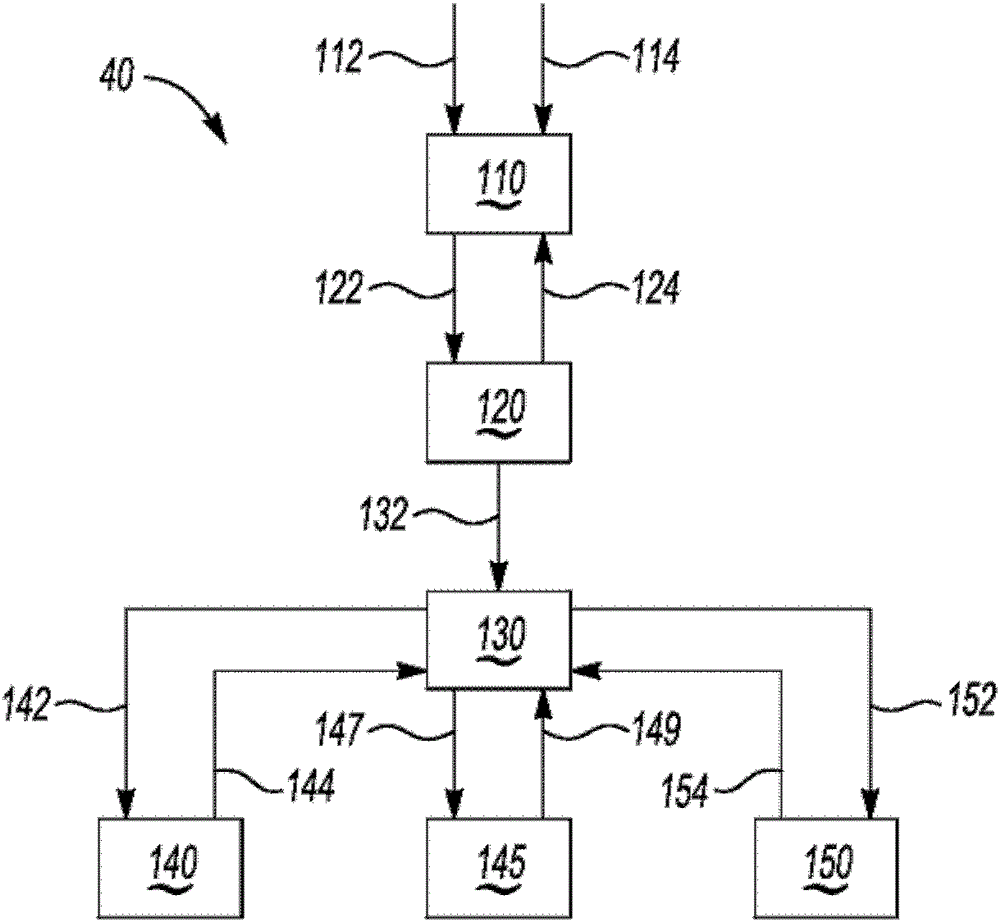

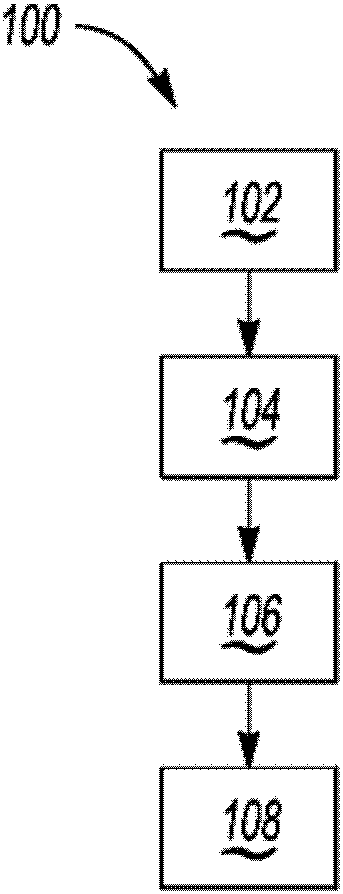

Vehicle with electric swing door and position-based torque compensation method

ActiveCN109138701BParameter calibration/settingPower-operated mechanismControl signalActuator torque

A system for controlling the opening and closing of a powered swing door, such as on a vehicle, includes a rotary actuator, a position sensor, and a controller. In a method performed by the controller, the actuator applies torque to the door in response to the control signal. Using the measured raw angular position from the sensor, the controller determines a wind or gradient based external force acting on the door during opening or closing, and adjusts the actuator torque in response to the external force. The sensor can be a rotary encoder and the actuator an electric motor. The lookup table contains data relating vibrations to external forces. The controller can cause vibration of the door and correlate the damping of the vibration to an external force. The obstacle-based current threshold can be adjusted in response to external forces.

Owner:GM GLOBAL TECH OPERATIONS LLC

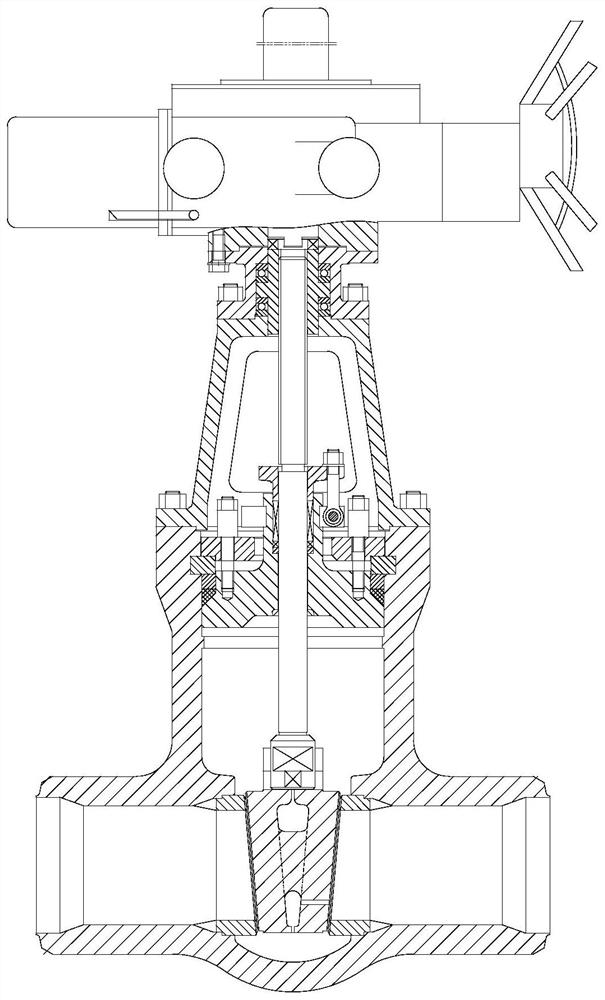

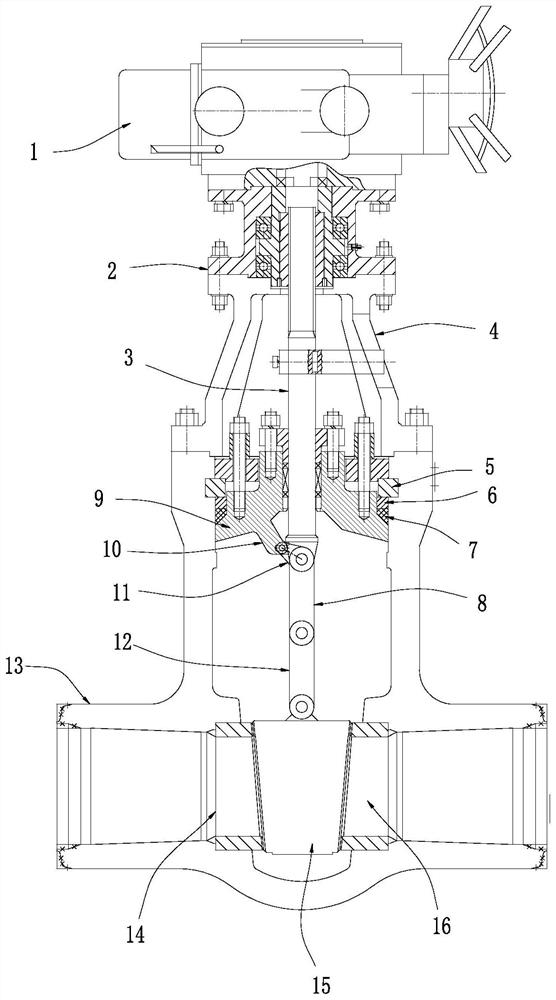

Quick opening and closing gate valve

PendingCN113007419AShort stem travelReduce the number of turnsOperating means/releasing devices for valvesGearingMaximum torqueLong arm

The invention discloses a quick opening and closing gate valve which comprises a valve body, a valve seat, a filler chamber seat, a valve cover, a transition mounting seat, an electric actuator, a valve rod, a valve clack, a circulation groove, a locking groove and a protruding part. A swing arm is hinged onto the protruding part and comprises a short arm and a long arm; the common end of the short arm and the long arm is hinged to the lower end of the valve rod; one end, away from the long arm, of the short arm is hinged with the protruding part; a hinge rod is hinged to the end, away from the valve rod, of the long arm; and the end, away from the long arm, of the hinge rod is hinged to the top of the valve clack. By means of the lever principle, when the maximum torque is needed at the moment of opening and closing, the force of the valve rod is completely used for opening and closing, after the valve clack is opened, a lever intervenes in work, the valve clack is pried to conduct the large stroke through the short stroke of the valve rod, and the purposes that under the condition that the torque of the actuator is not changed, the number of rotation turns is reduced, the stroke of the valve rod is shortened, and opening-closing time is saved are achieved.

Owner:黑龙江省穆棱市电站阀门有限责任公司

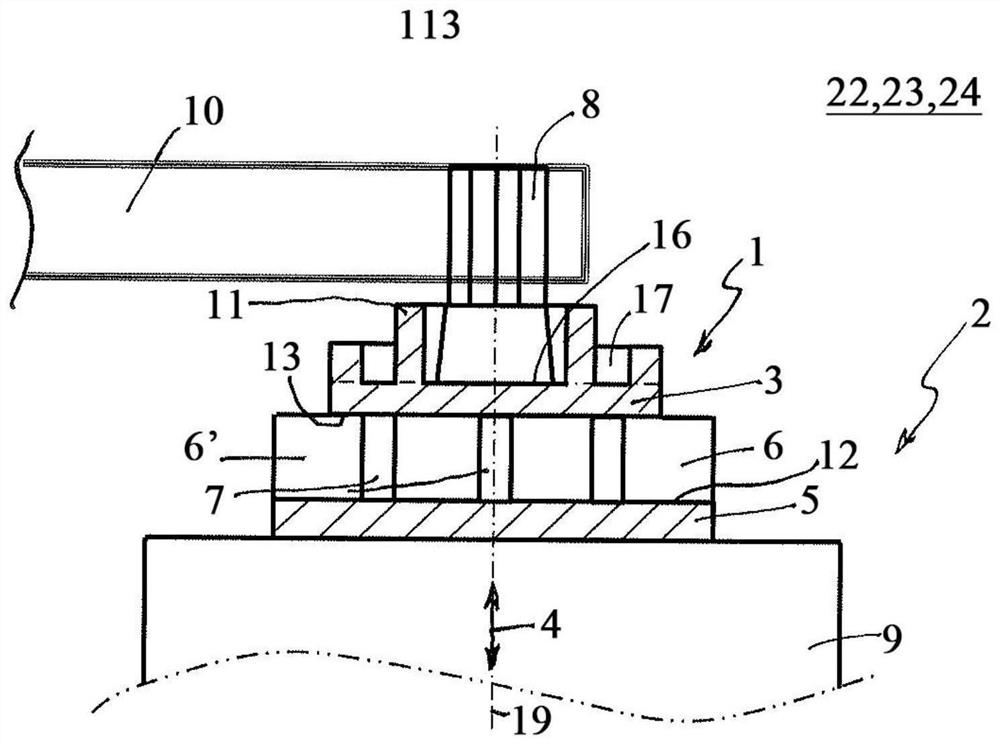

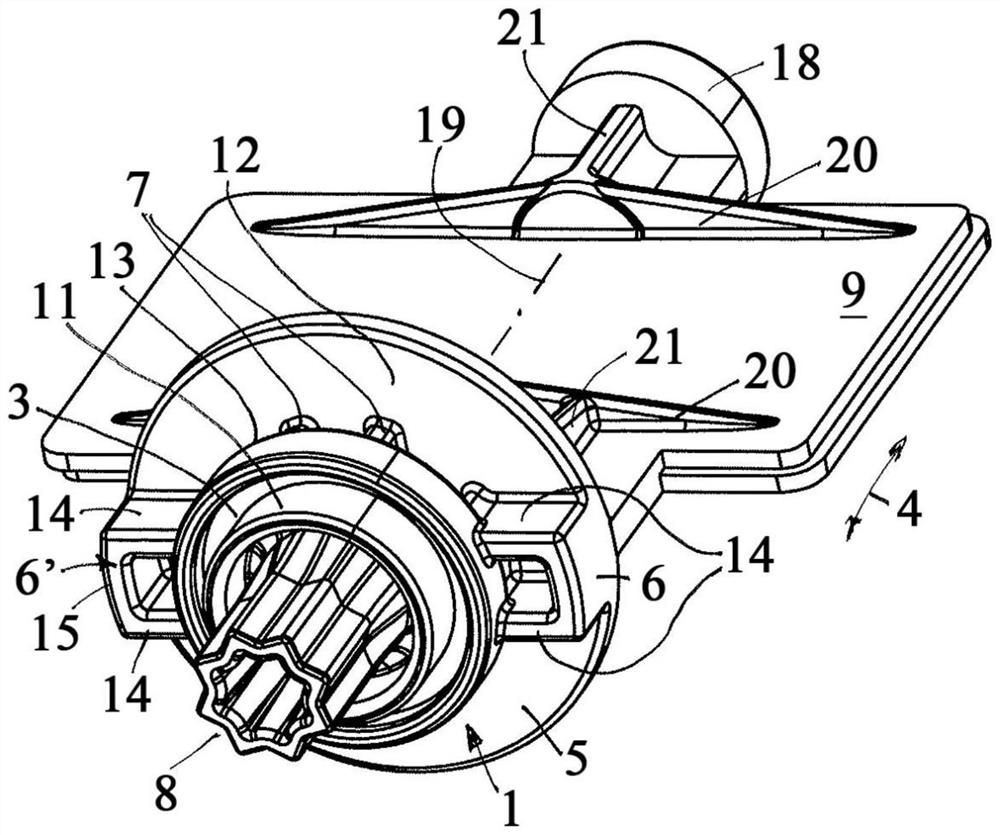

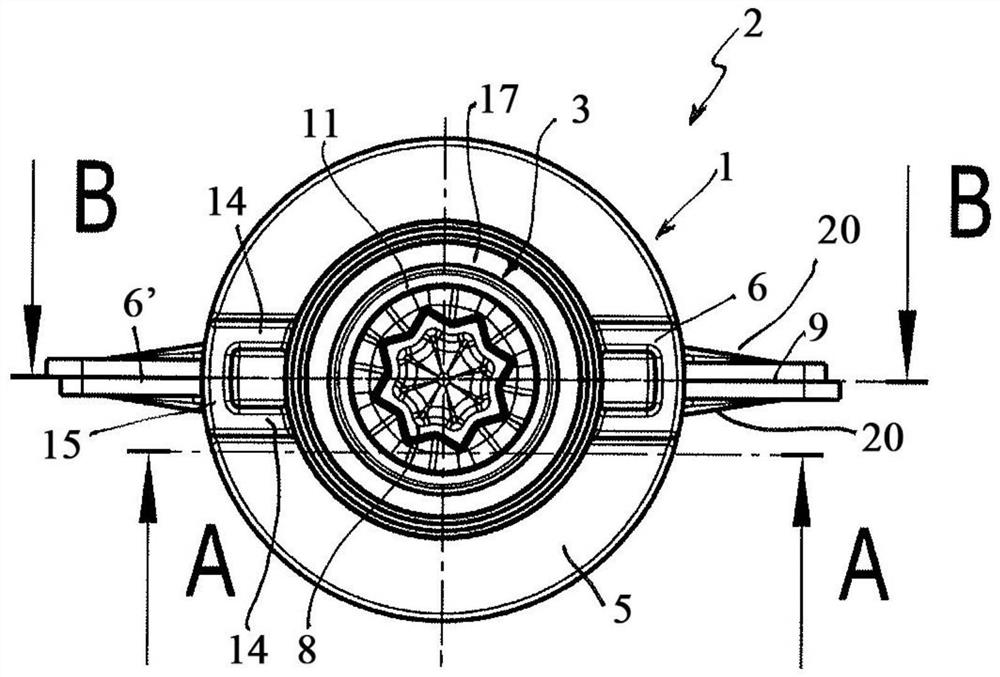

Flap stopper for a rotatable flap

ActiveCN113898743ASmall stop forceLow densityVehicle heating/cooling devicesLift valveShape changeEngineering

The invention relates to a flap stop (1) for a rotatable flap (2) for controlling an air flow. The flap stopper comprises a circular bearing support disc (3) and a circular stopper support disc (5) which is spaced apart therefrom in the axial direction (4), wherein stop elements (6, 6') are arranged on the stopper support disc (5), connecting ribs (7) are arranged between the bearing support disc (3) and the stopper support disc (5), and the bearing support disc (3), the stopper support disc (5), the stop elements (6, 6') and the connecting ribs (7) are formed as a one-piece plastic injection molded part. Under the influence of an actuator torque, the stress of a flap material can be distributed such that no residual (plastic) shape change is caused in the flap (2).

Owner:MAHLE INT GMBH

A quarter-stroke electric actuator torque calibration test device and test method thereof

ActiveCN104006955BSave the trouble of adding and subtracting weightsImprove test efficiencyMachine part testingTest efficiencyElectric machine

The invention discloses a torque calibration test device for an angular stroke electric actuator structure, which includes an integral support, a motor, a force arm, a pulley mechanism, a lead screw, and a weight. , lead screw, the motor is fixed on the force arm through the bracket, the force arm is connected with the overall support, the force arm can rotate a certain angle around the center, one end of the pulley mechanism is connected with the lead screw, driven by the lead screw, the pulley mechanism can be in the force arm Moving upward, the other end of the pulley mechanism is connected with the weight; the invention can drive the screw to rotate through the motor to drive the weight to move on the force arm, thereby adjusting the torque, eliminating the trouble of constantly adding and subtracting weights in order to adjust the torque , thus improving the test efficiency.

Owner:SUZHOU BONRAY MEASURE & CONTROL EQUIP

Instantaneous energy-based soft sensing method of electric actuator torque

InactiveCN102435364BGuaranteed real-timeGuaranteed accuracyWork measurementTorque measurementDigital signal processing24-bit

Owner:UNIV OF SHANGHAI FOR SCI & TECH

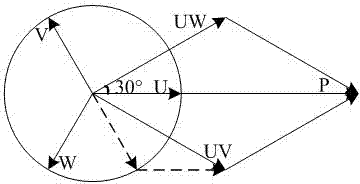

Real-time distribution of actuator torque in a vehicle

A method for allocating forces among corners of a vehicle having redundant sets of actuators includes determining a desired set of forces at the vehicle's center of gravity and utilizing a controller to allocate the desired set among the corners of the vehicle force as a virtual control command. The method also includes mapping virtual control instructions at the corner to actual or real control instructions at the corner, and using the actual or real control instructions to control a plurality of actuators at the corner. Actuators may include friction brakes and wheel motors. Mapping virtual control instructions may include using a least squares formula. Control of the actuators may be prioritized relative to each other using a weighting matrix. A vehicle includes a controller having an actuator configured to perform the method described above.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com