Quick opening and closing gate valve

A closed and fast technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of large cylinder diameter, unchanged stroke, waste, etc., to reduce the number of rotations, shorten the valve stem stroke, and save starting. closed time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

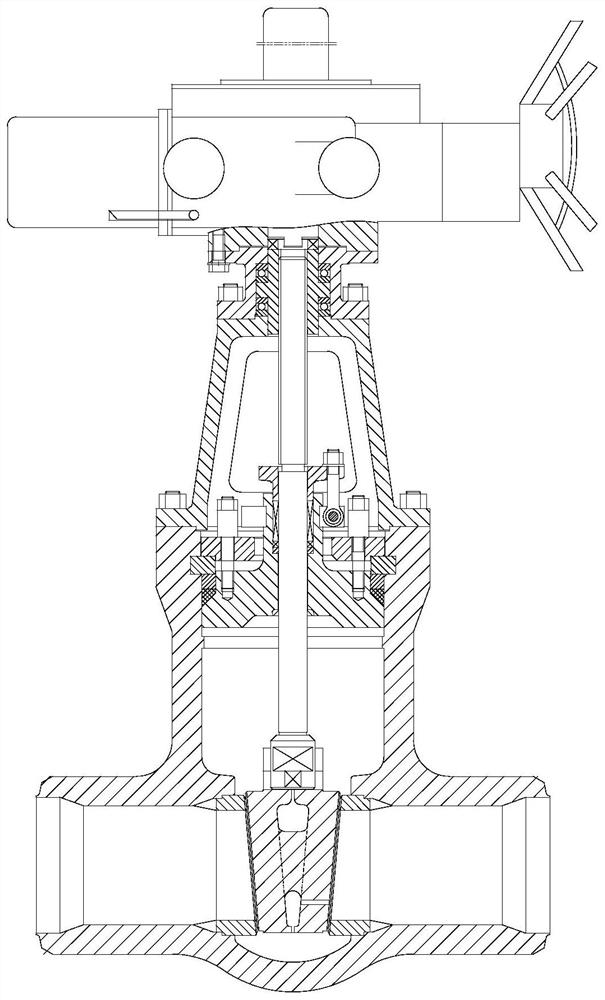

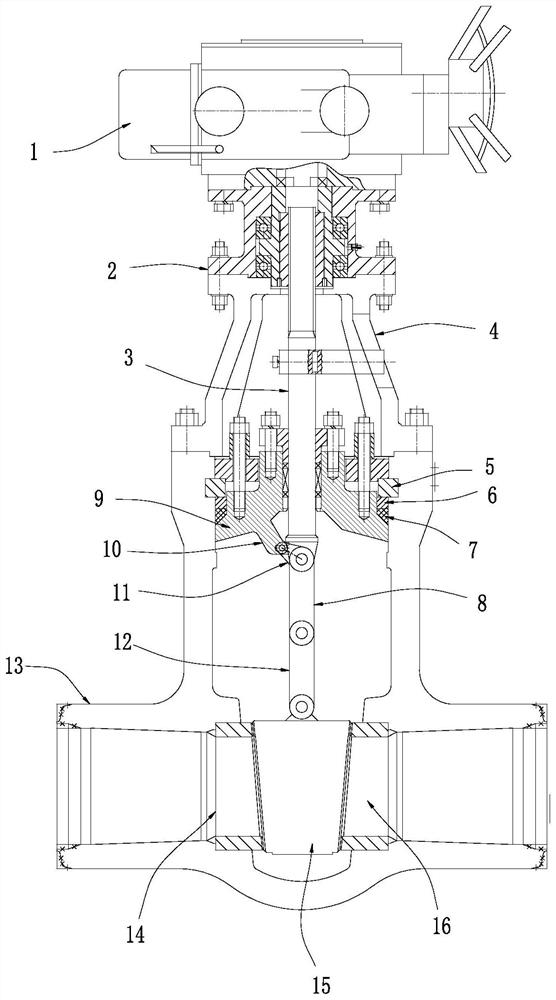

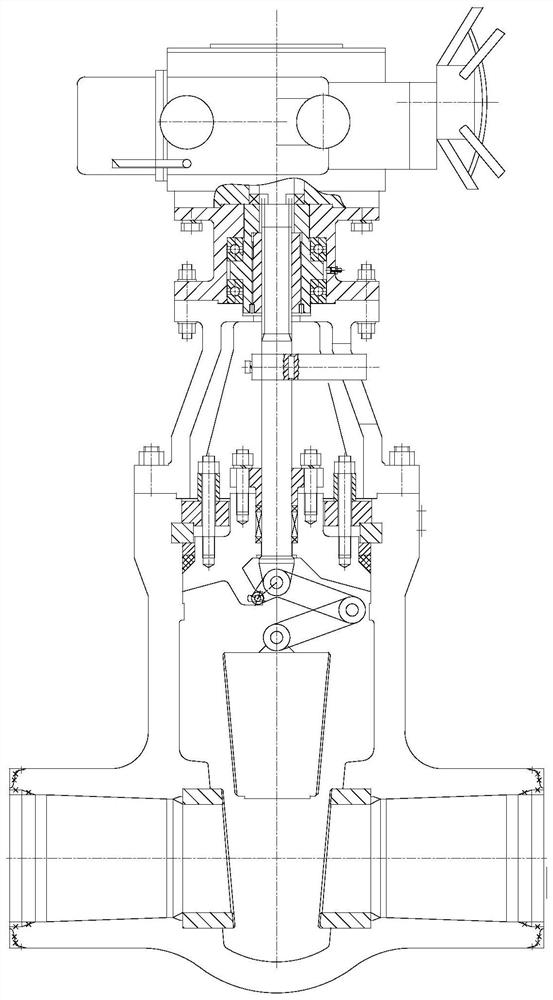

[0021] like Figure 2-3 As shown, a fast opening and closing gate valve includes a valve body 13, a valve seat 14, a packing chamber seat 9, a valve cover 4, a transition mounting seat 2, an electric actuator 1, a valve stem 3, and a valve disc 15. The valve seat 14 is located in the valve body 13, on which there is a flow groove 16 for medium circulation, the stuffing chamber seat 9 is detachably installed on the upper end of the valve body 13, the valve cover 4 is installed on the valve body 13, The transition mounting seat 2 is installed on the upper end of the valve cover 4, the electric actuator 1 is placed on the transition mounting seat 2, the valve stem 3 is drivingly connected with the electric actuator 1, and its sliding fit penetrates the stuffing chamber The seat 9 is connected with the valve disc 15. The electric actuator 1 drives the valve rod 3 to move up and down, and then drives the valve disc 15 to move up and down. The valve seat 14 is provided with a lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com