Patents

Literature

41results about How to "Short opening and closing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

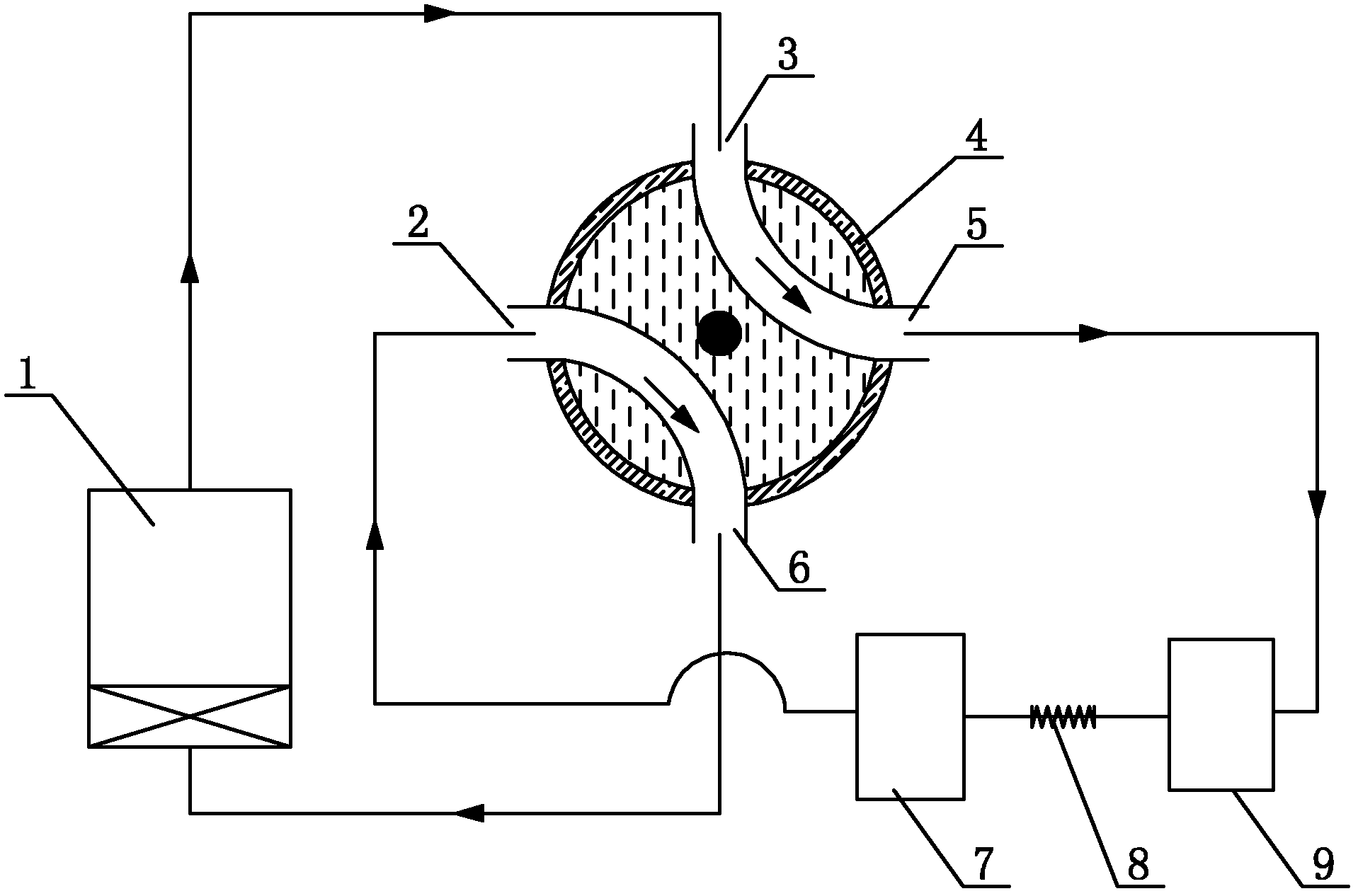

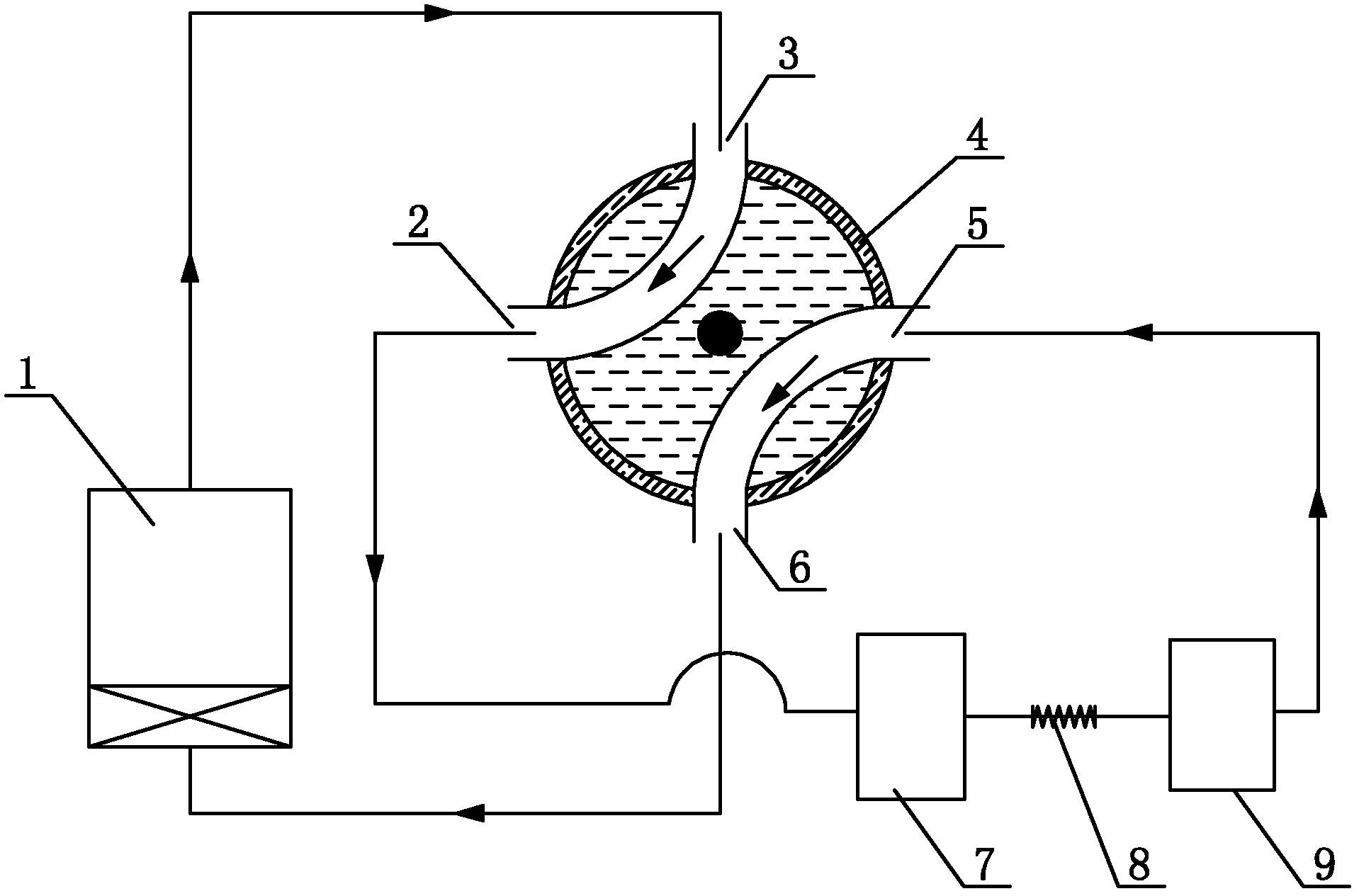

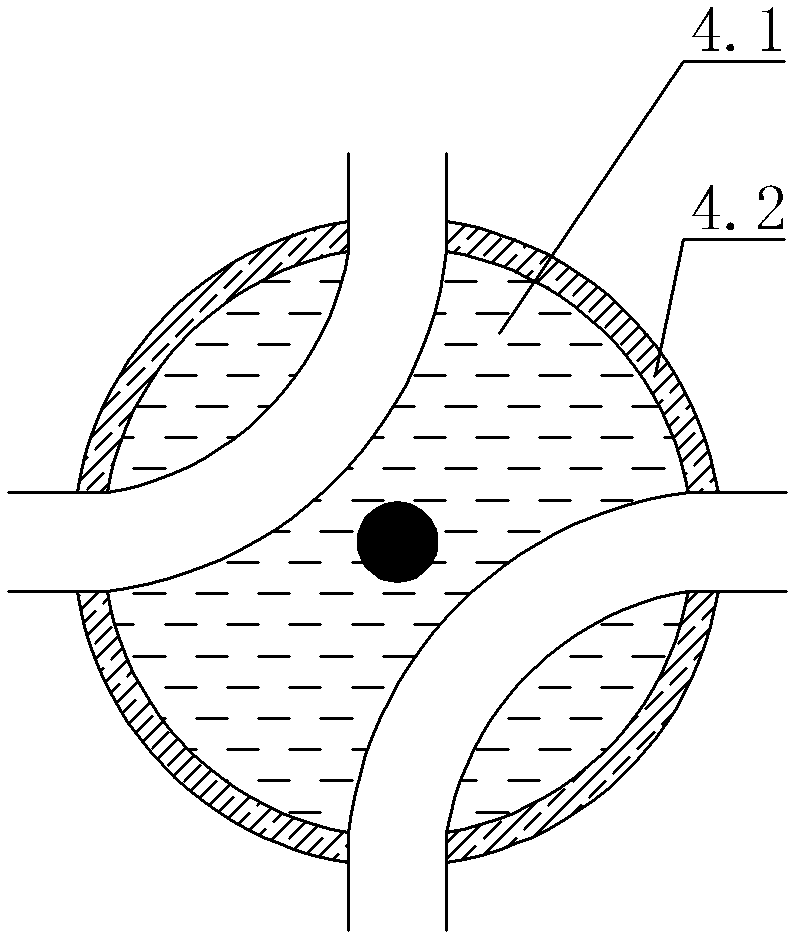

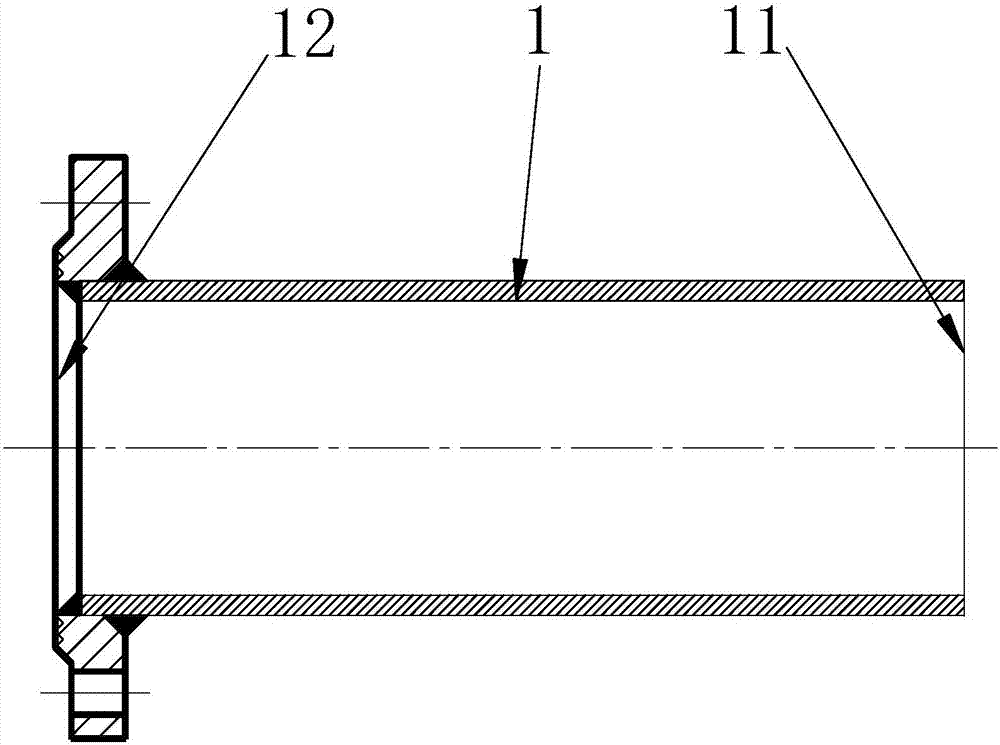

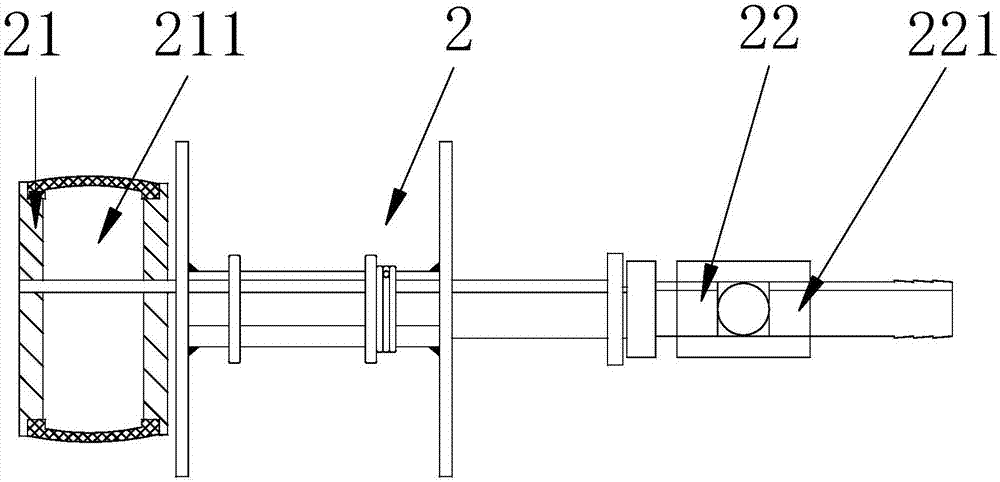

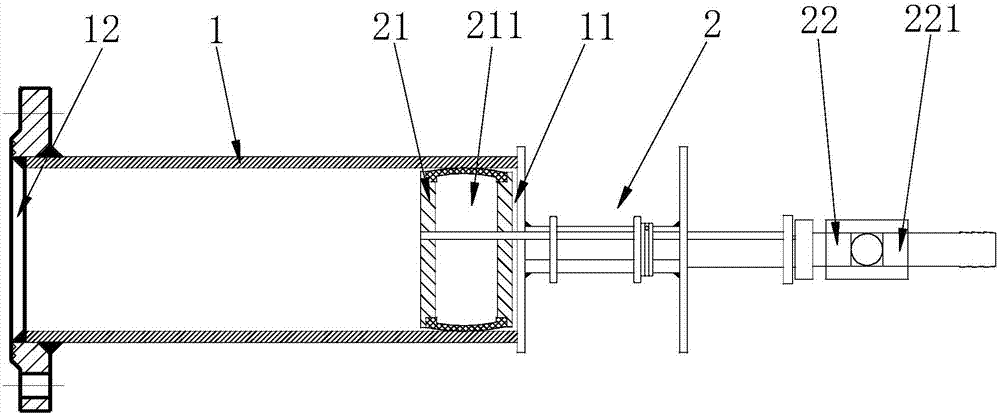

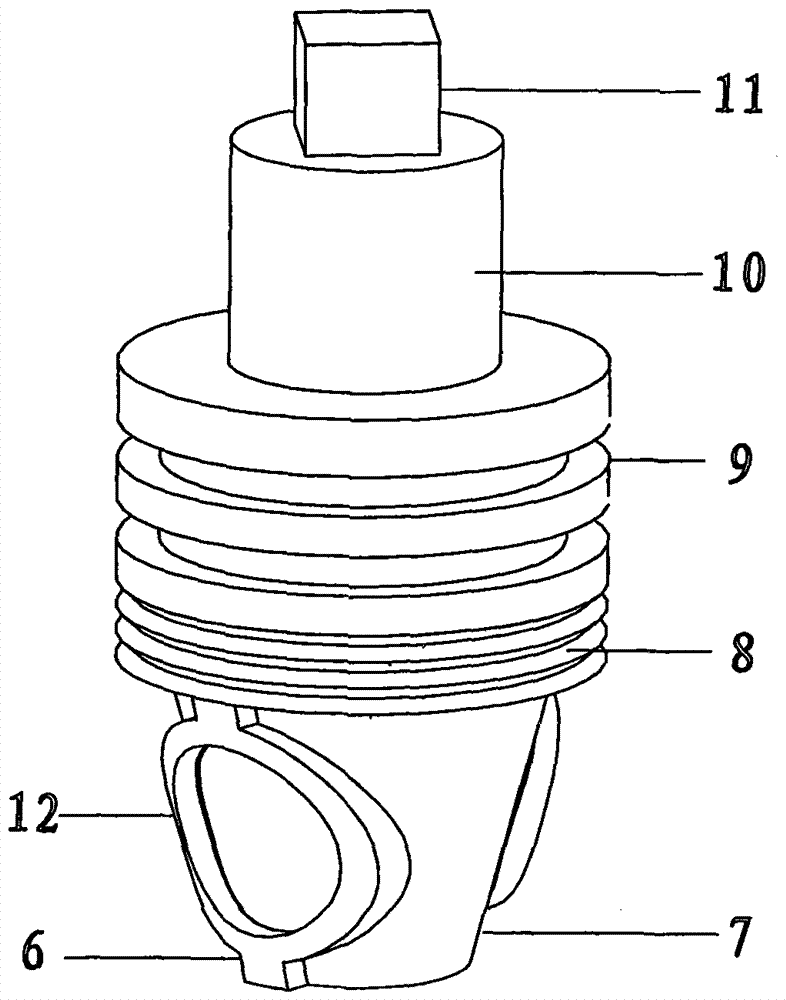

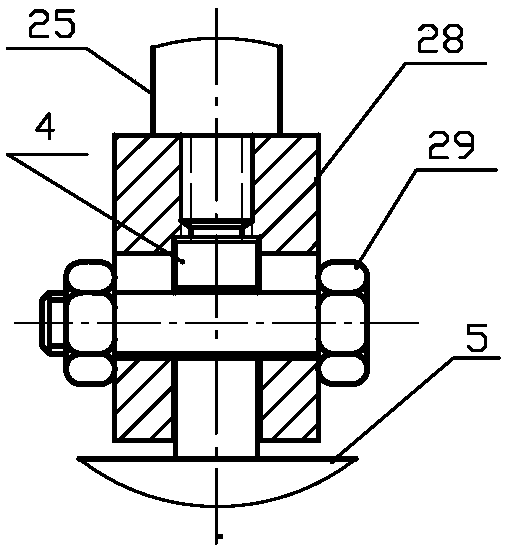

Four-way valve for Carnot cycle system

A four-way valve for a Carnot cycle system comprises a four-way valve body consisting of a valve body and a columnar valve spool. The four-way valve body is connected with an air conditioner through a pipeline, mutually symmetric channels are arranged inside the valve spool and penetrate through the surface of the valve spool, the valve body is provided with more than one through hole corresponding to the channels, and the diameter of each through hole is as same as that of an opening of each channel. A refrigerating state and a heating state are switched only by using a steeping motor for driving the valve spool and the valve body to be in running fit, modes can be switched by means of short-time electrification during running, and the valve can be kept continuing running in the original mode after power is cut off. Besides, the valve spool is hermetically connected with the inner surface of the valve body, so that tightness of the four-way valve is improved, and back flowing is prevented. The shortcomings of complicated structure, difficulty in manufacture, poor reliability and the like of a traditional four-way valve are overcome. The four-way valve has the advantages of simple and reasonable structure, high energy efficiency ratio, high control precision and short staring time, and is convenient for popularization and application.

Owner:MIDEA GRP CO LTD

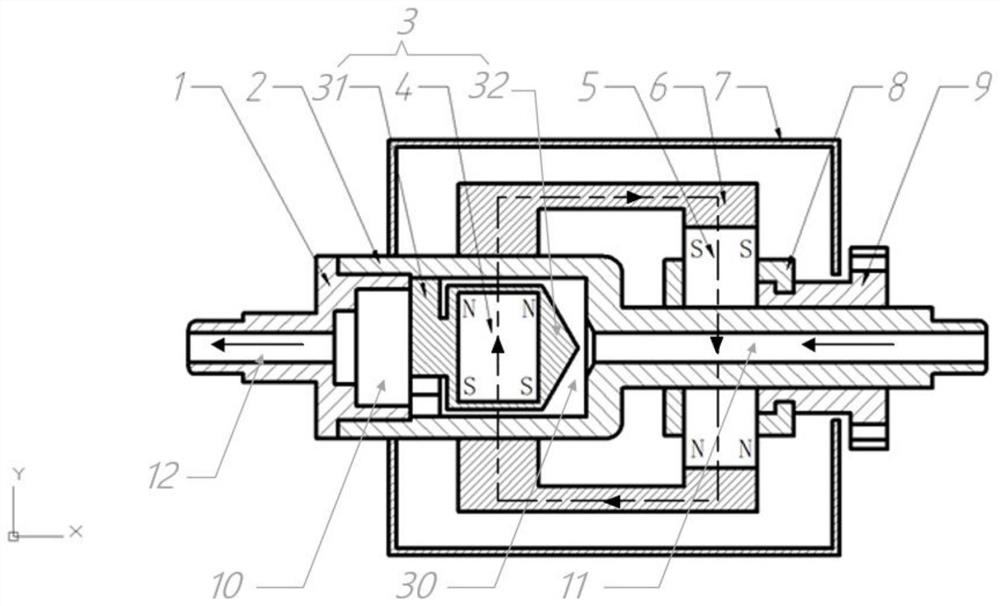

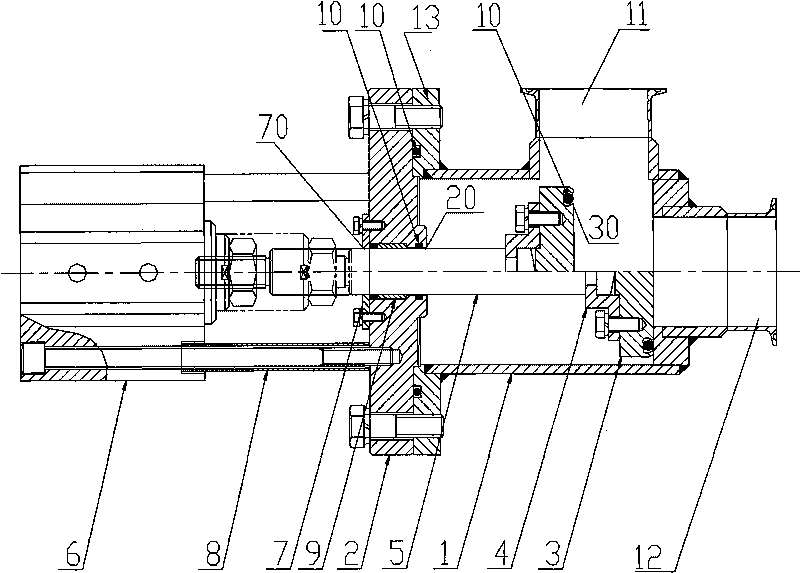

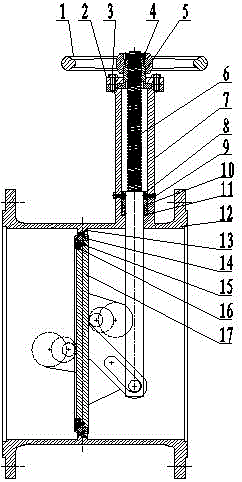

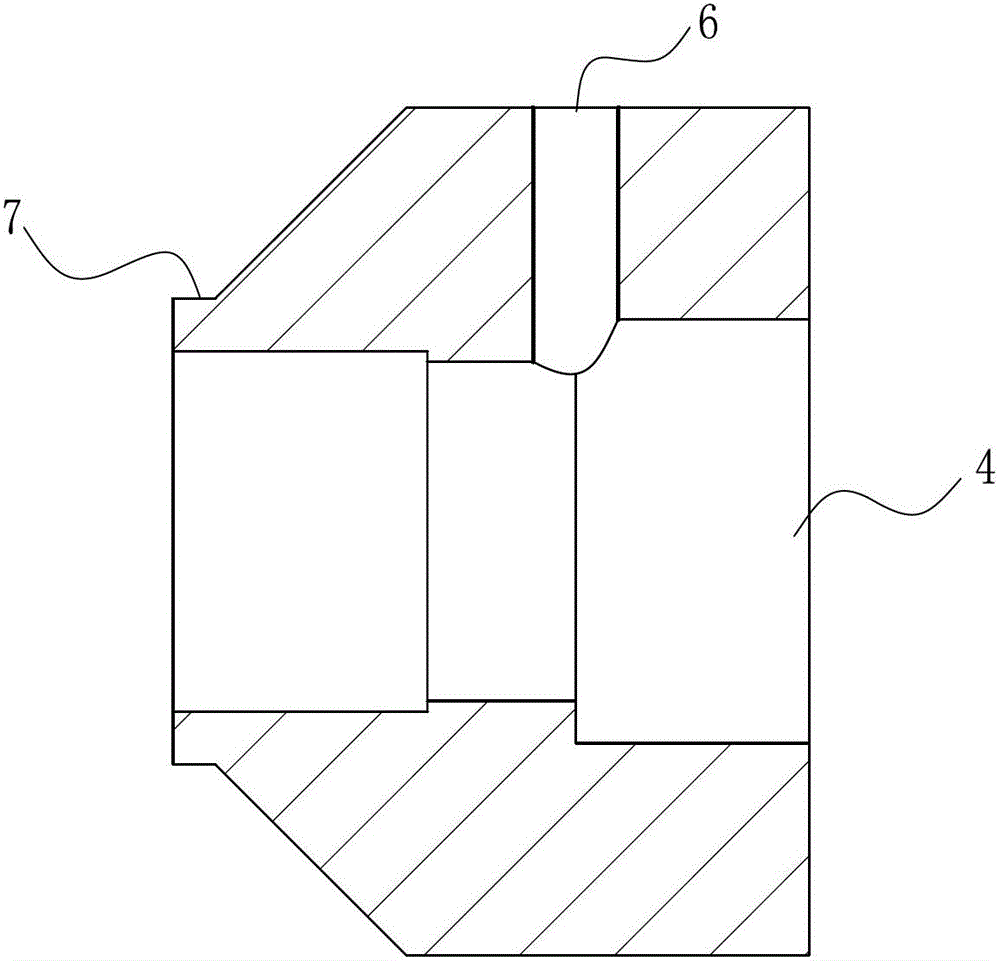

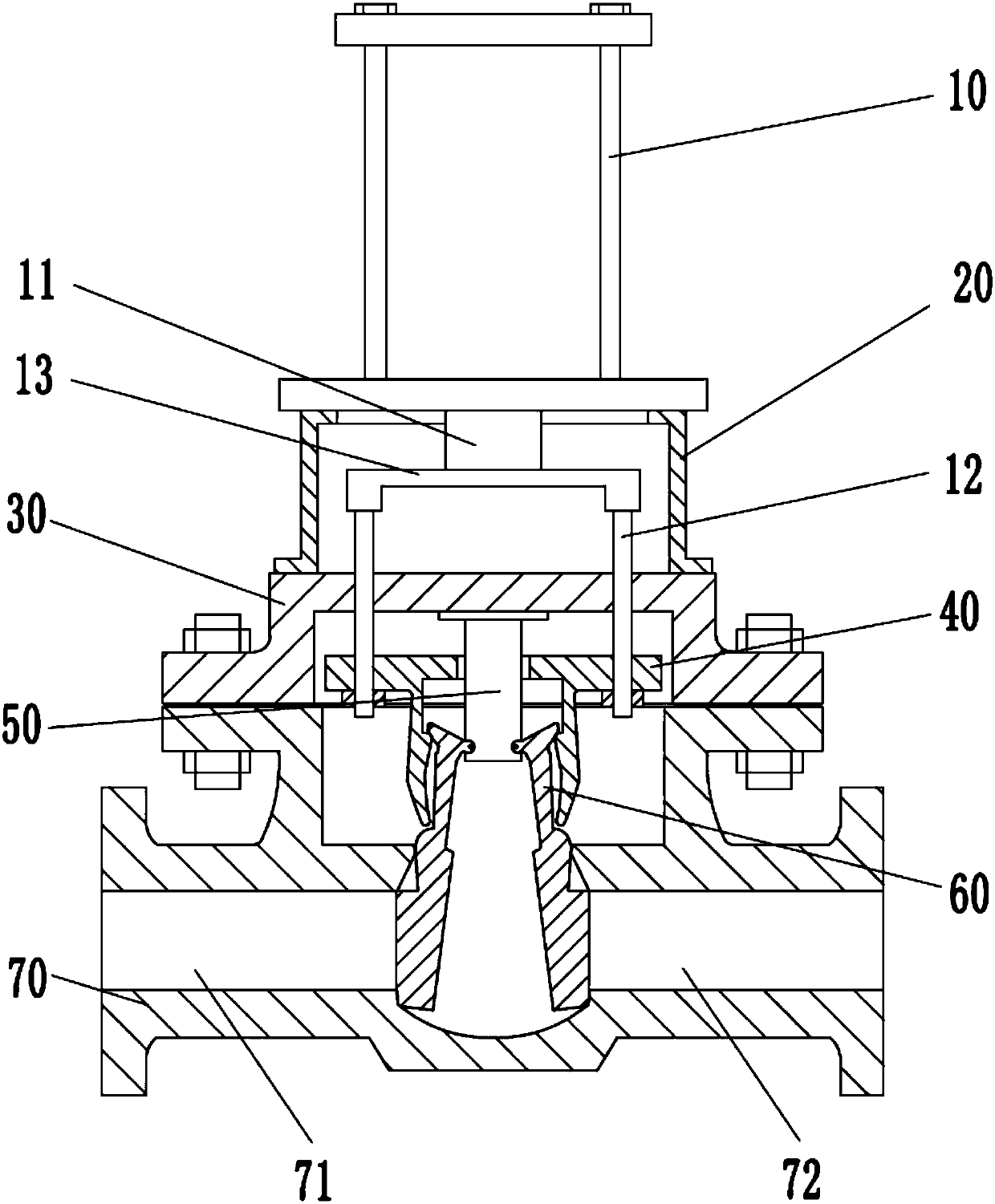

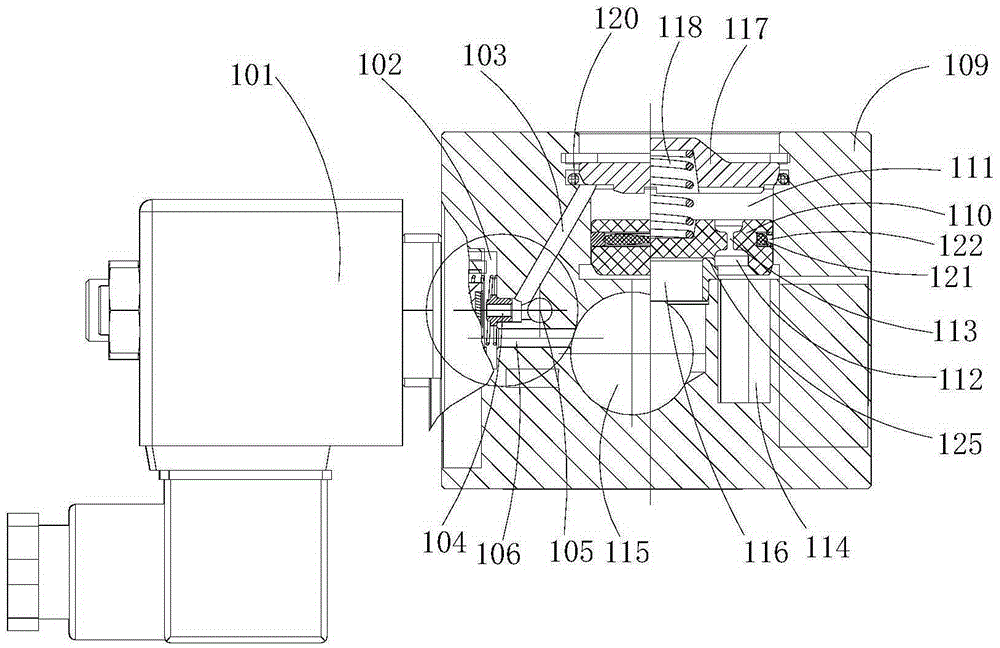

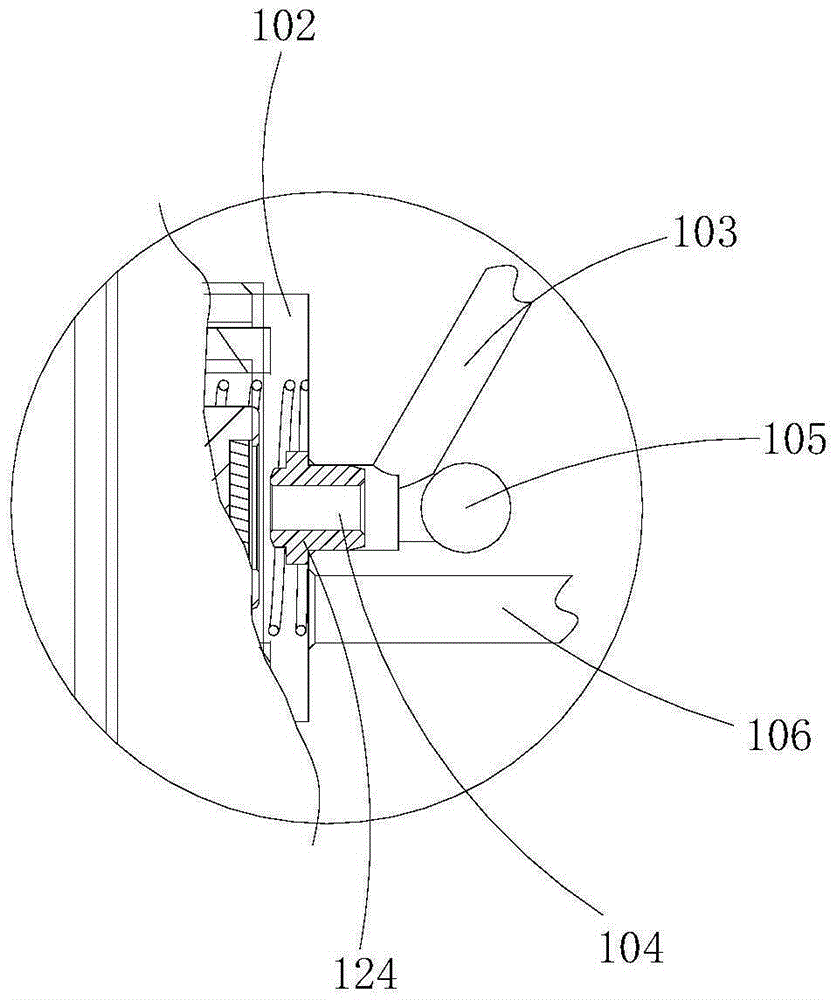

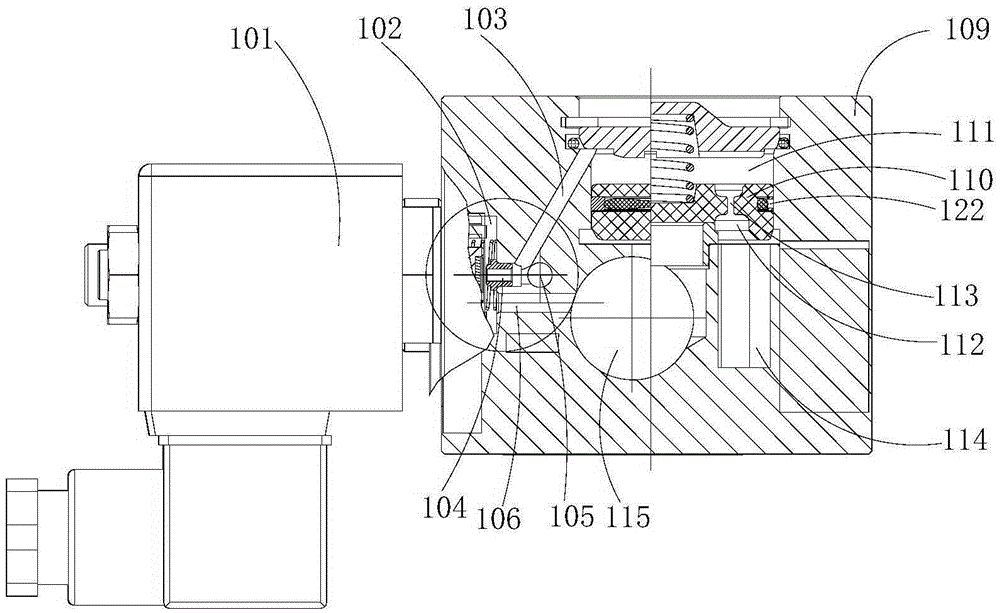

Ultra-clean proportional valve

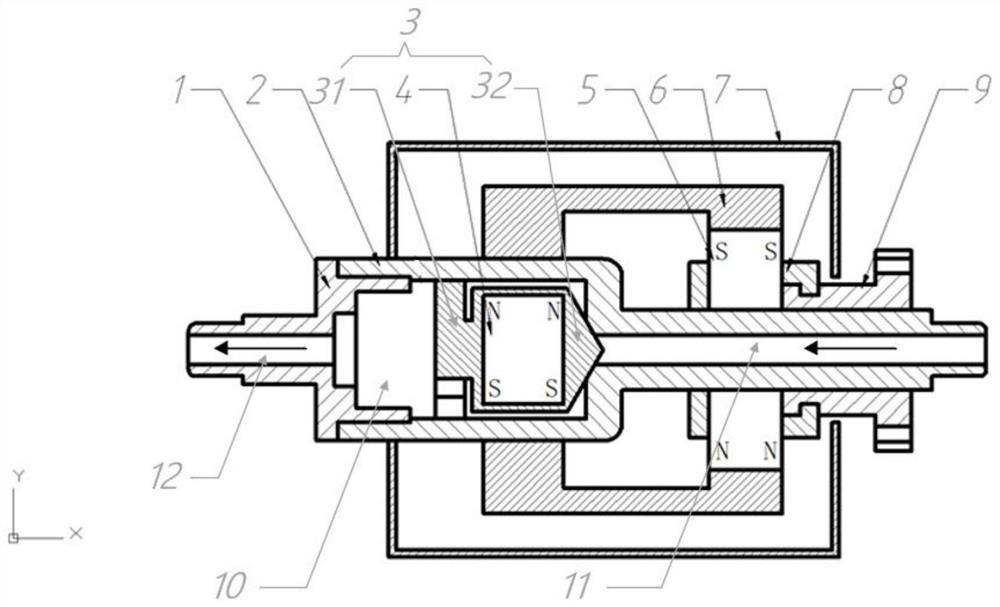

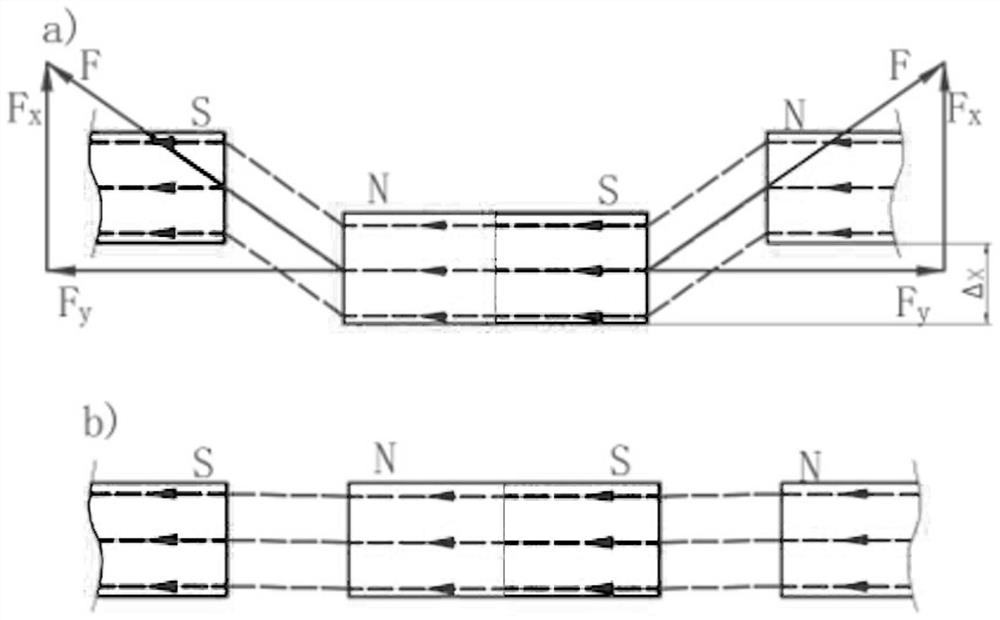

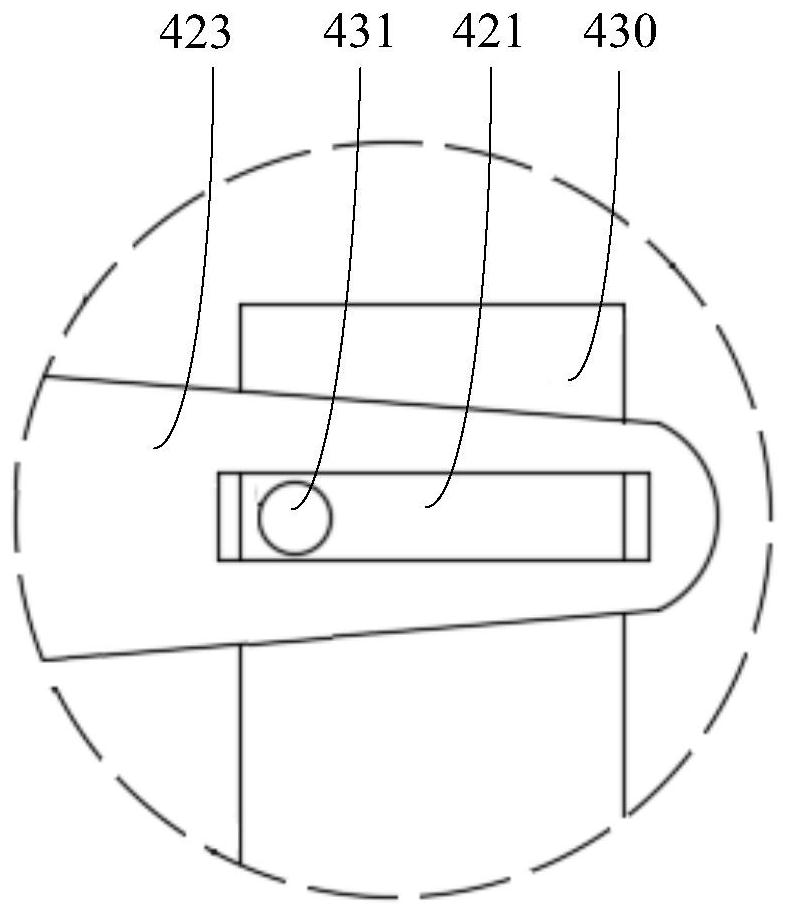

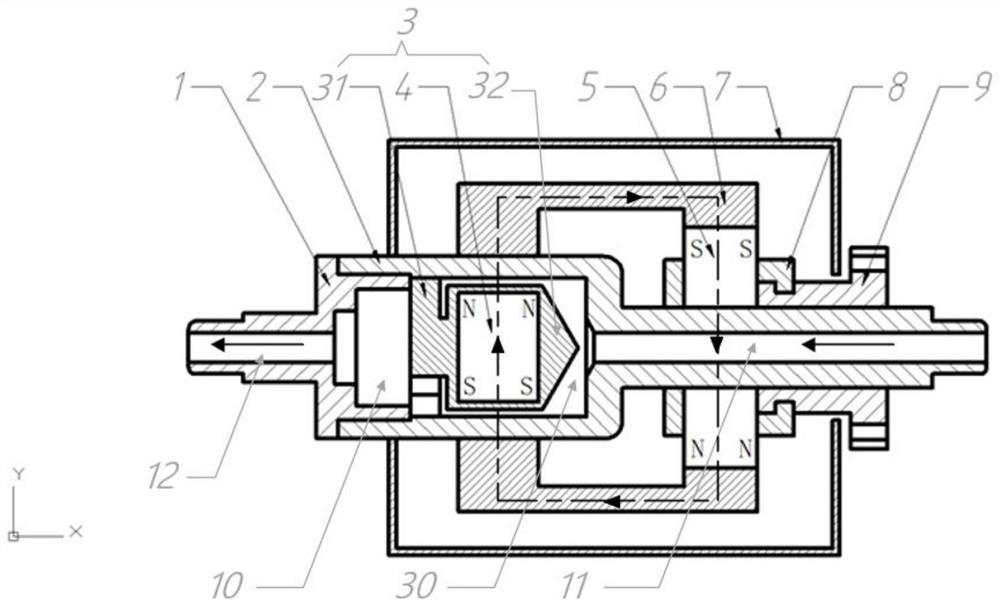

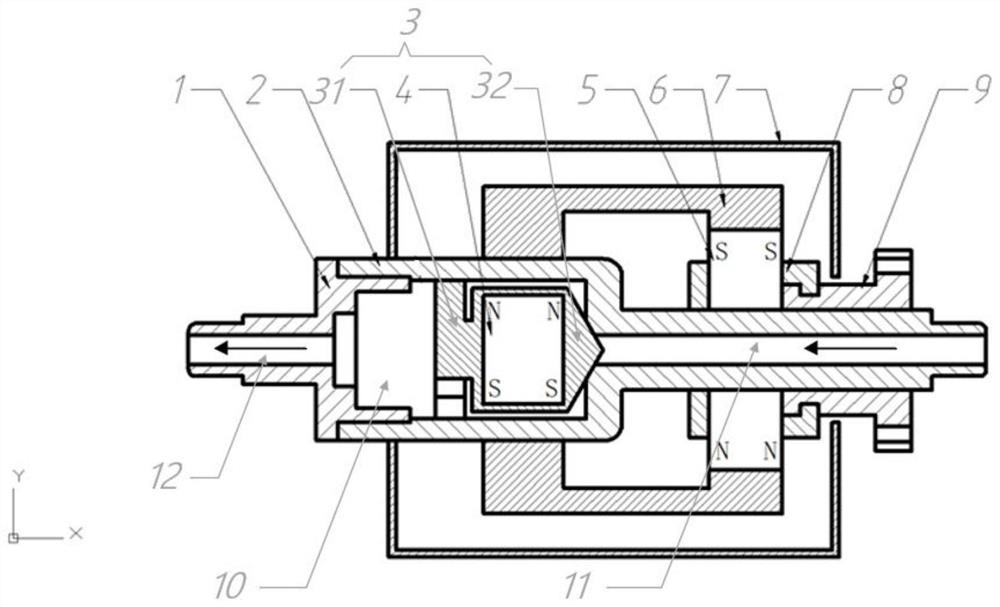

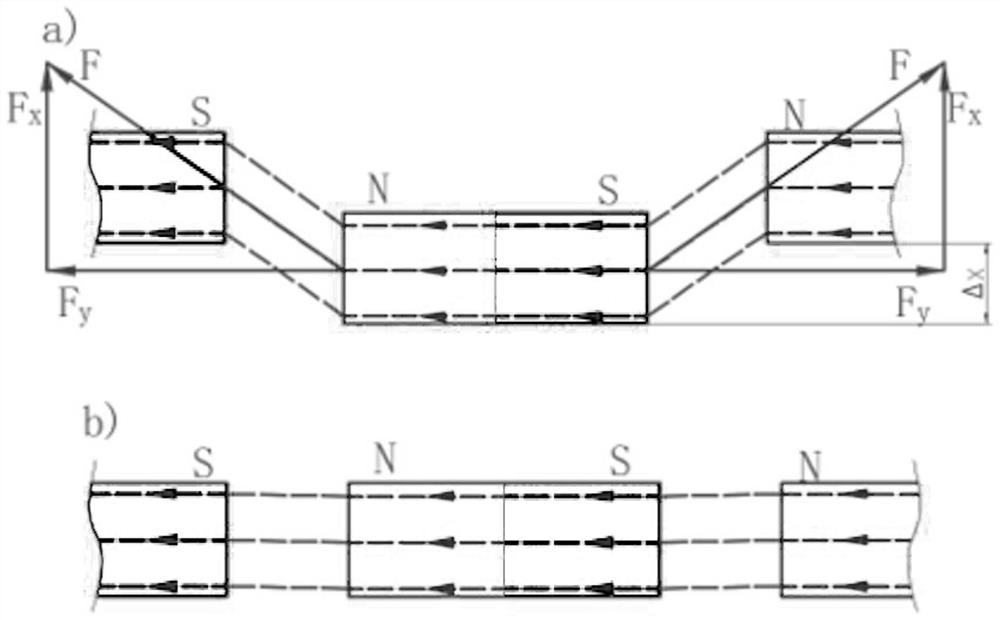

ActiveCN112303247ASmall operating distanceReduce distractionsOperating means/releasing devices for valvesLift valveMagnetic tension forceEngineering

The invention provides an ultra-clean proportional valve. The ultra-clean proportional valve is provided with an ultra-clean flow chamber, a magnetic driving assembly is arranged in the mode that an embedded permanent magnet and an external control permanent magnet are matched, a valve port is opened and closed based on the minimum magnetic resistance principle, and the position of the valve portcan be precisely controlled; the actuating distance of the magnetic driving assembly is small, the opening and closing time of the valve port is shortened, and the response speed is high; driving force in two directions can be applied to a valve element, and the problem that the reliability is poor when the valve element is opened depending on fluid impact force is solved; and magnetic induction lines of the magnetic field form a closed loop, the interference in the external space of the magnetic field is small, and the influence of magnets in the environment on the valve is avoided.

Owner:ZHEJIANG UNIV

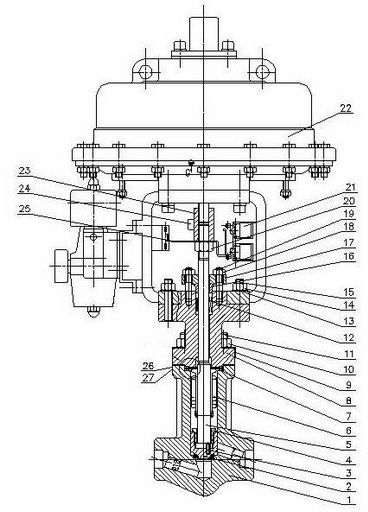

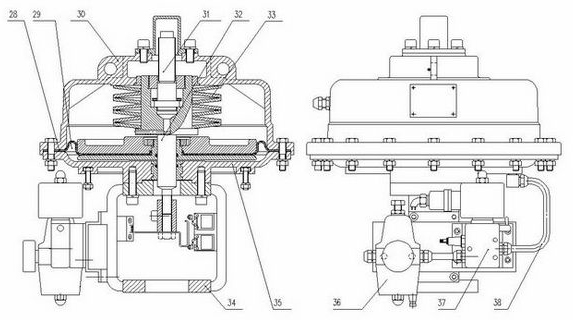

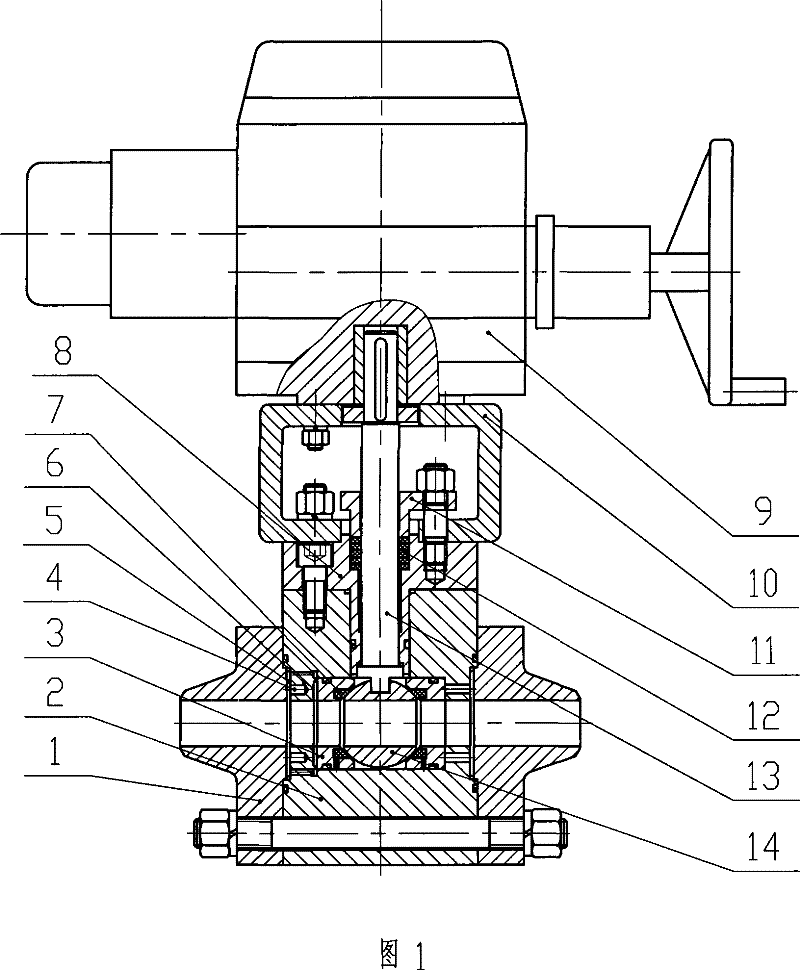

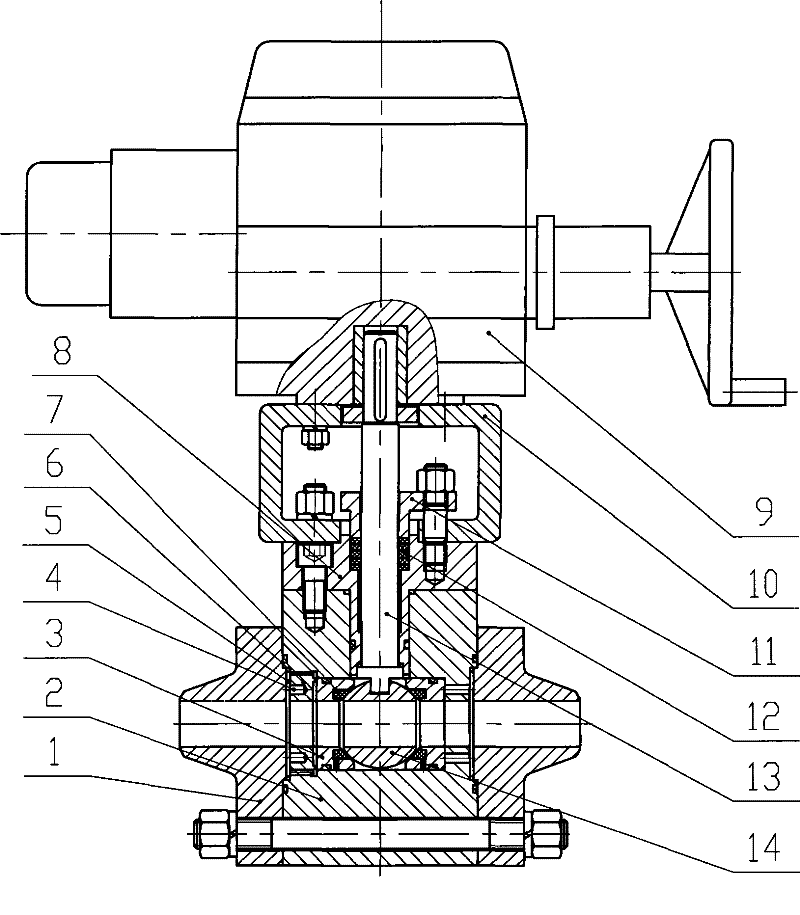

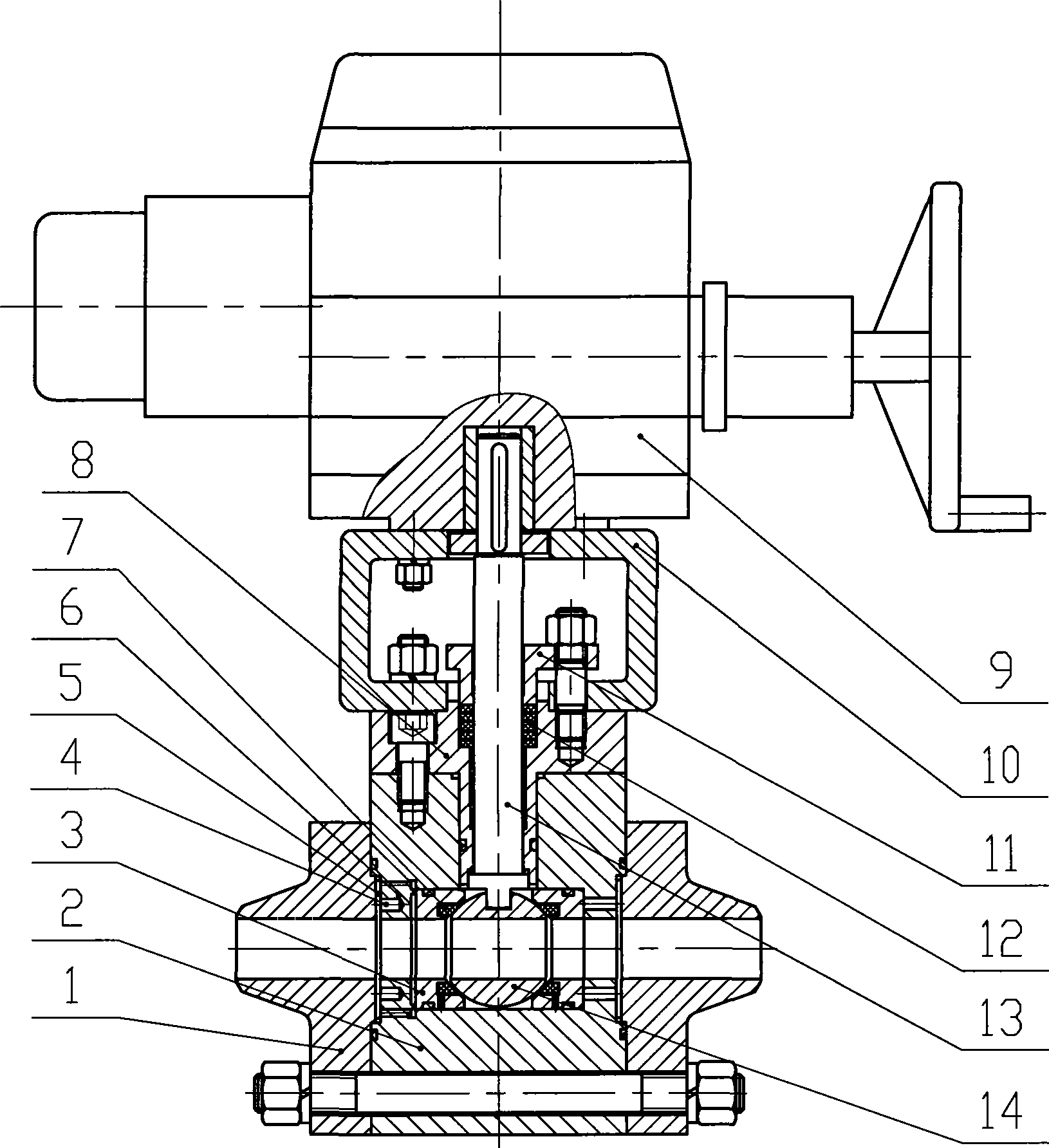

Nuclear class II film pneumatic bellows stop valve

InactiveCN102606748AHigh hardnessImprove sealingSpindle sealingsOperating means/releasing devices for valvesPressurized water reactorDiaphragm structure

A nuclear class II film pneumatic bellows stop valve belongs to the field of nuclear power valves used by large pressurized water reactor nuclear power station systems. Surfacing of hard alloy on both a valve seat and a valve clack enables sealing surfaces to be high in hardness, so that the valve is more wear-resistant and scour-resistant and is extremely resistant to corrosion. A Brinell hardness difference of 50 exists between the two sealing surfaces, so that excellent sealing property can be further guaranteed. A pneumatic device of a diaphragm structure is short in stroke, compact and flexible in structure, and a hand-operating mechanism can be mounted on the pneumatic device if needed. The pneumatic bellows stop valve is simple in structure, convenient in maintenance, short in opening and closing time by means of short operating stroke, and small in closing friction force, scour-resistant and reliable in sealing by means of conical surface sealing between the sealing surfaces of the valve clack and the valve seat.

Owner:DALIAN DAGAO VALVE

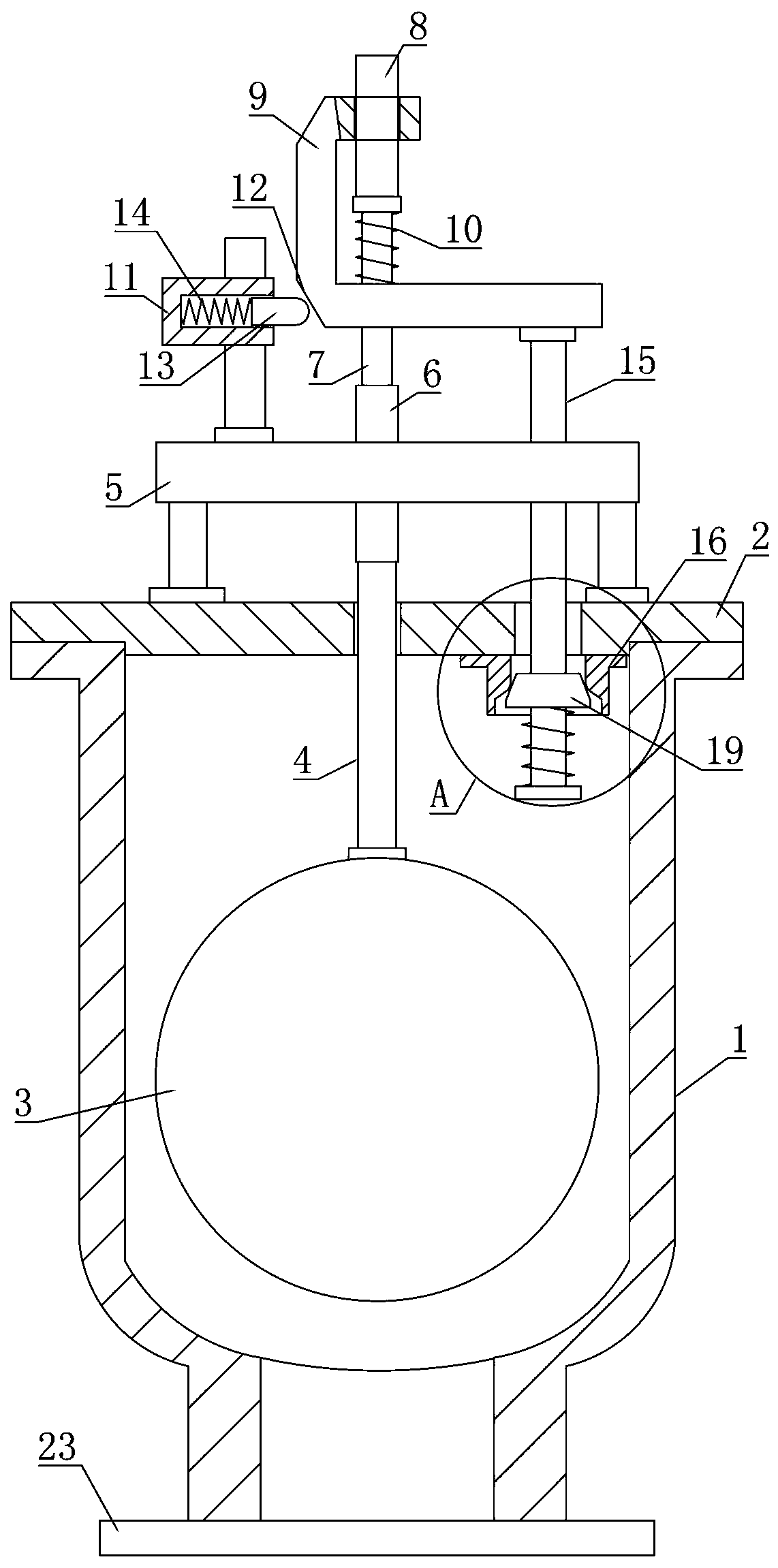

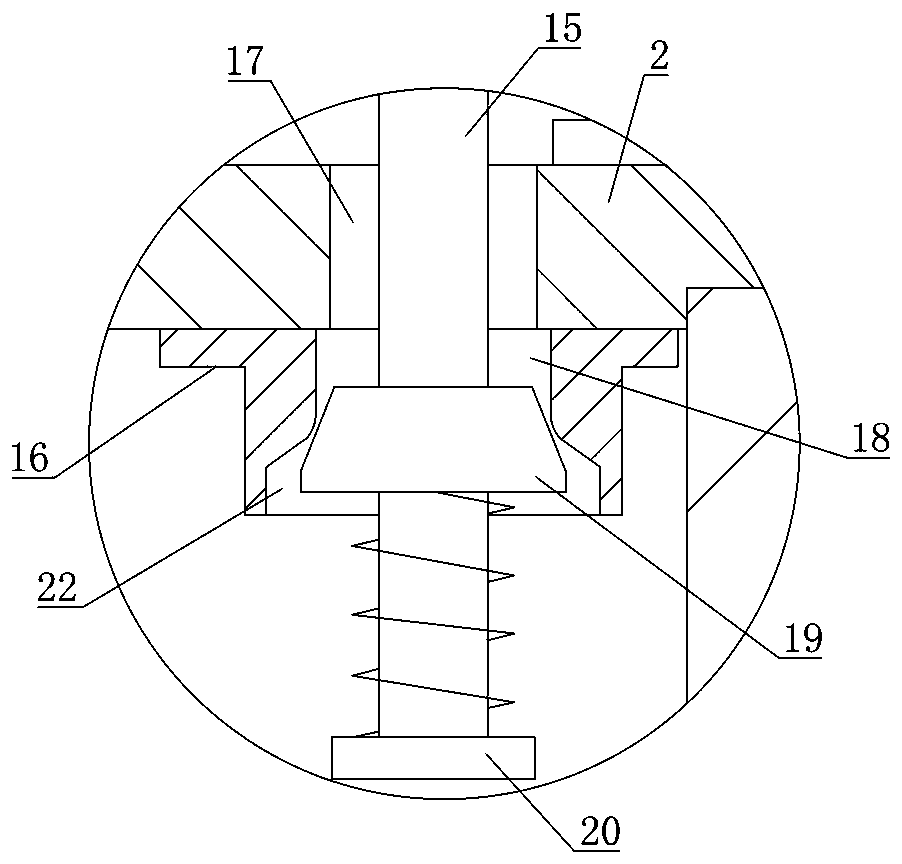

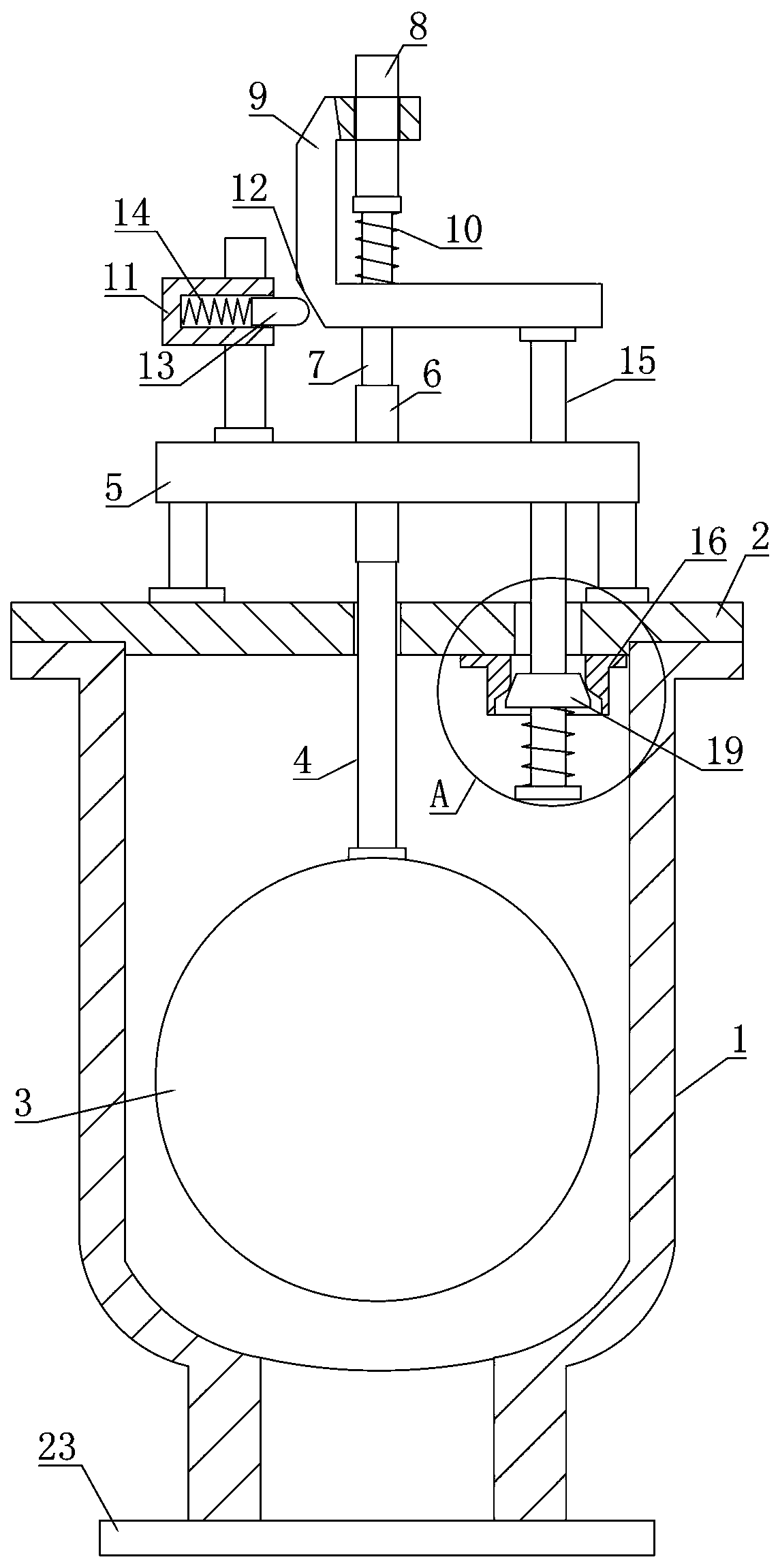

High efficiency and speed exhaust valve

ActiveCN109973699AShort opening and closing timeExtended service lifeOperating means/releasing devices for valvesVenting valvesEngineeringExhaust valve

The invention relates to a high efficiency and speed exhaust valve. A valve body is internally provided with a floating ball, and the upper part of the floating ball is fixedly provided with a guide rod; the guide rod extends out of a valve cover upwards, and is connected with the valve cover in an up-and-down sliding manner; a second rod is slidably connected with a U-shaped block; an auxiliary spring located between the two ends of the U-shaped block is fixed between the connection position between a first rod and the second rod, and the lower end of the U-shaped block, and a support frame is fixedly provided with a stop block located on the side, deviating from the opening of the U-shaped block; and the lower part of the side face, deviating from the opening, of the U-shaped block is provided with an inclined plane toward the opening direction of the U-shaped block downwards; the stop block is provided with a spacing hole with an opening facing the U-shaped block, and the interior of the spacing hole is slidably connected with a stop pin; the end, deviating from the U-shaped block, of the stop pin is in contact with the inclined plane, and the U-shaped block is provided with a control rod fixedly; and the upper inner wall of the valve cover is fixedly provided with a valve seat. The opening-closing time of the valve is shortened, and the service life of the valve is prolonged effectively; and the valve seat can be repaired or replaced when the valve seat is worn severely.

Owner:HENAN UNIVERSE VALVE CO LTD

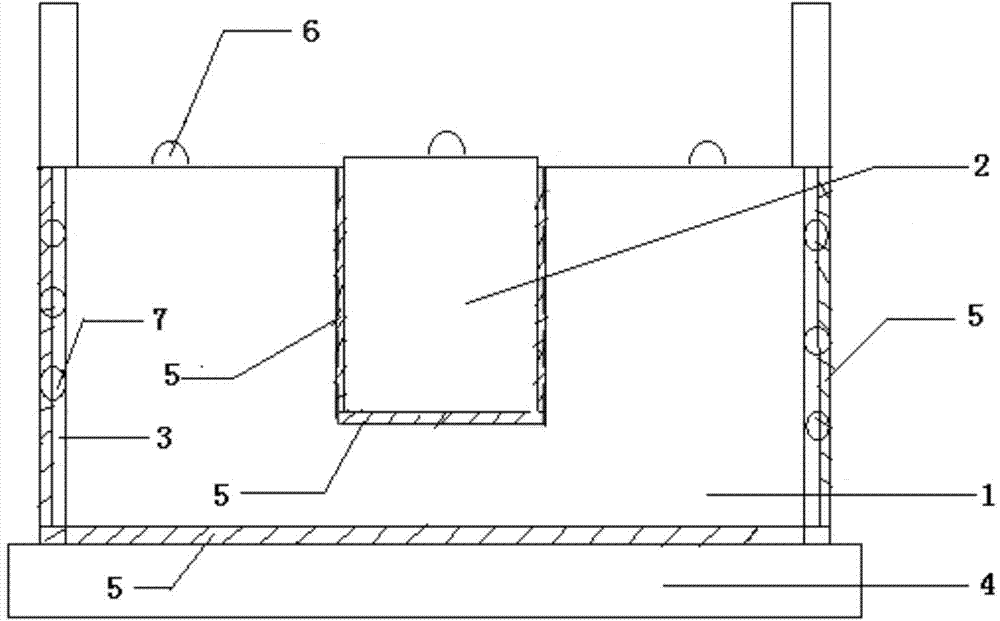

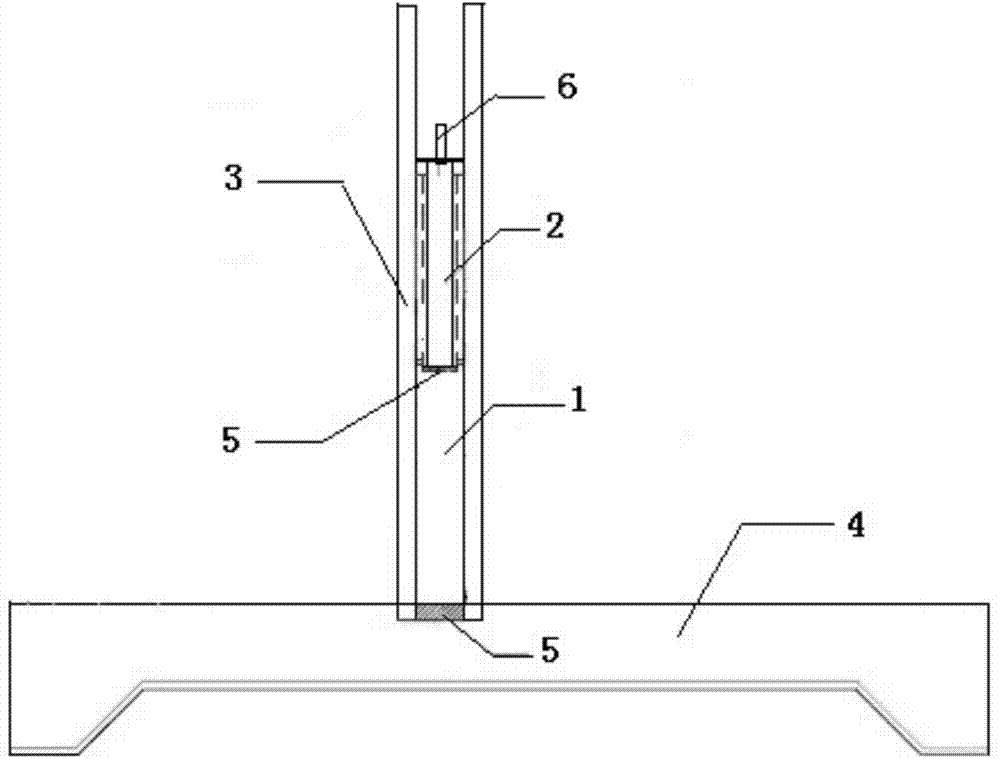

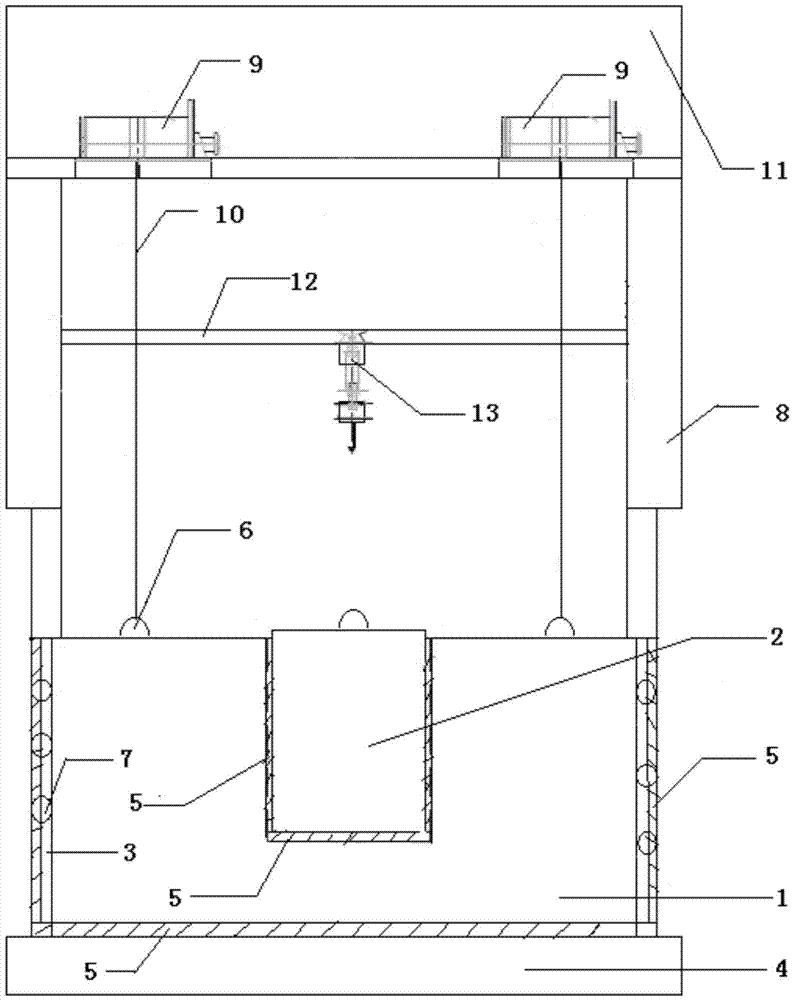

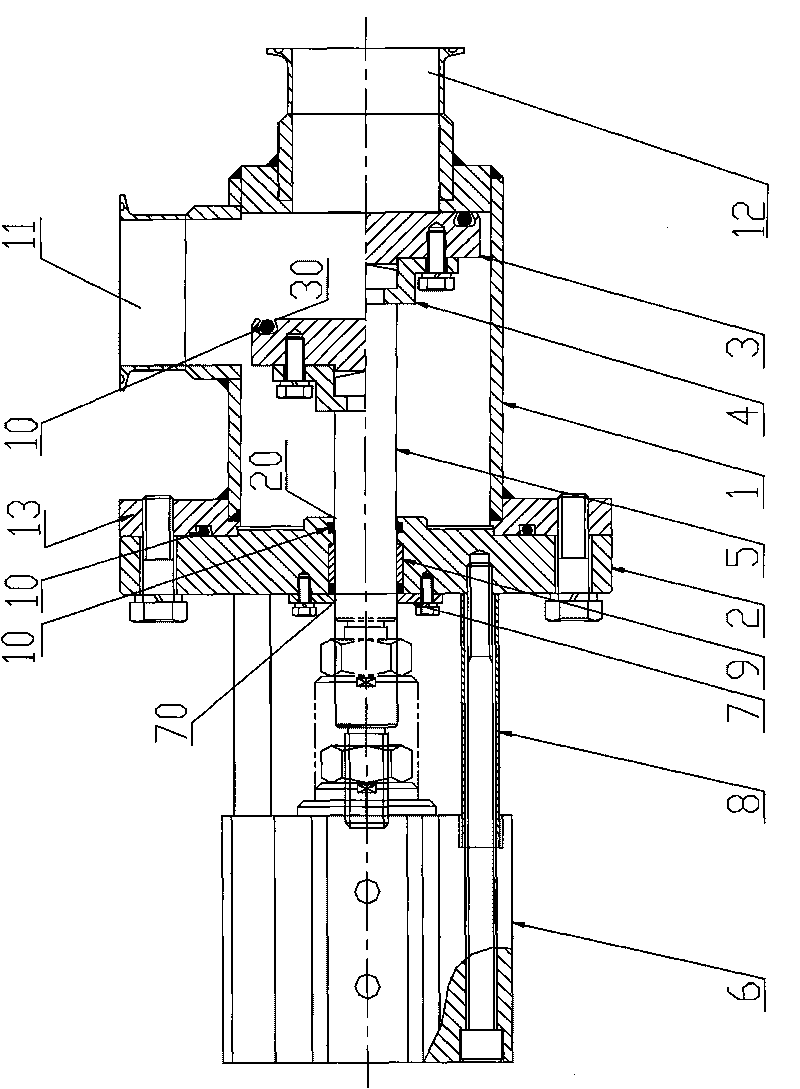

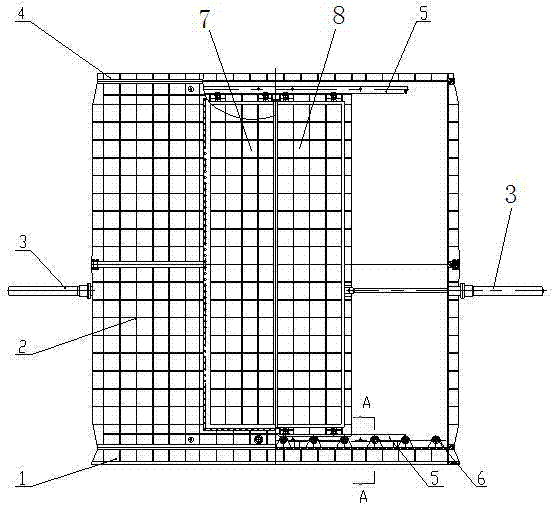

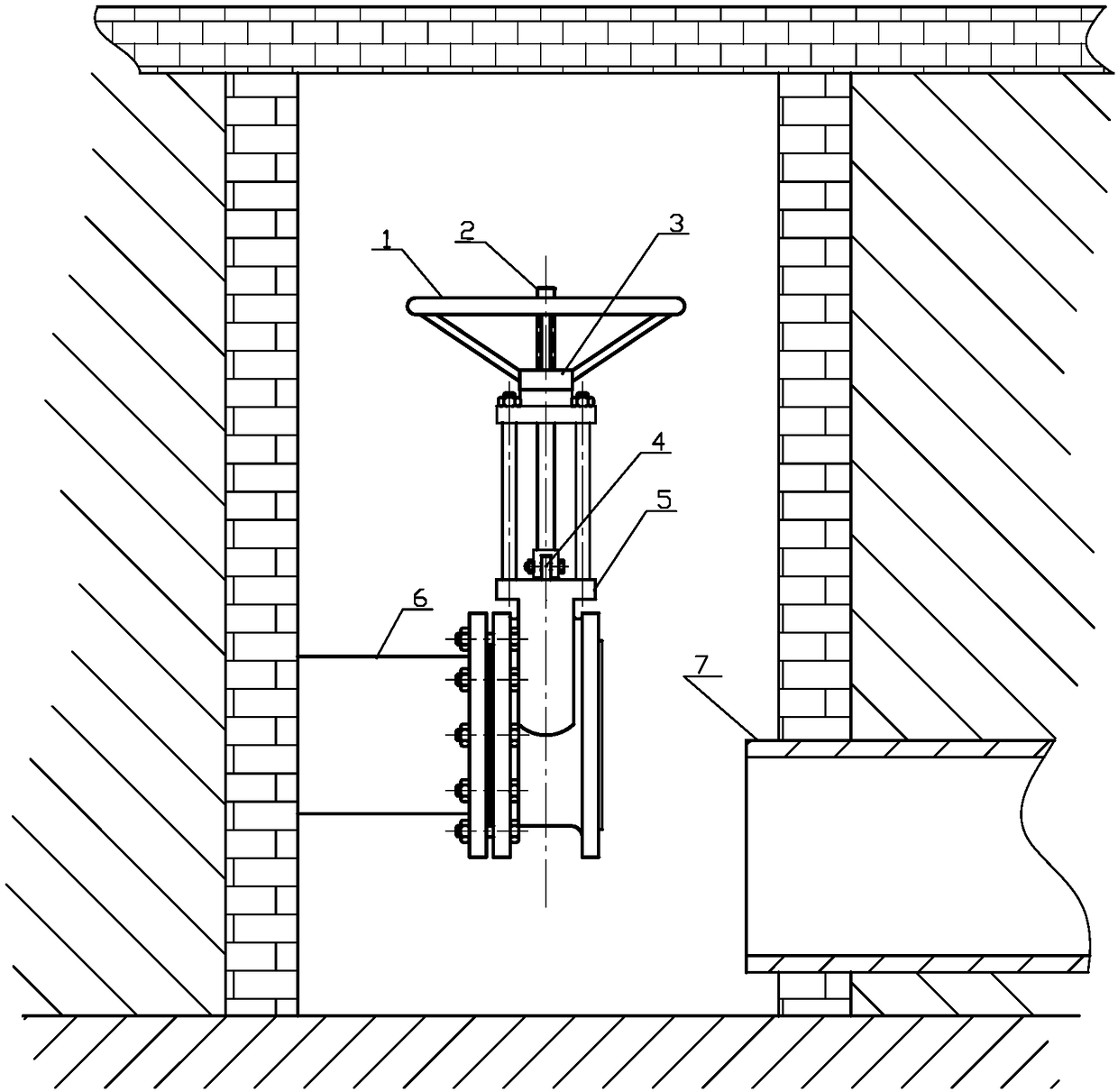

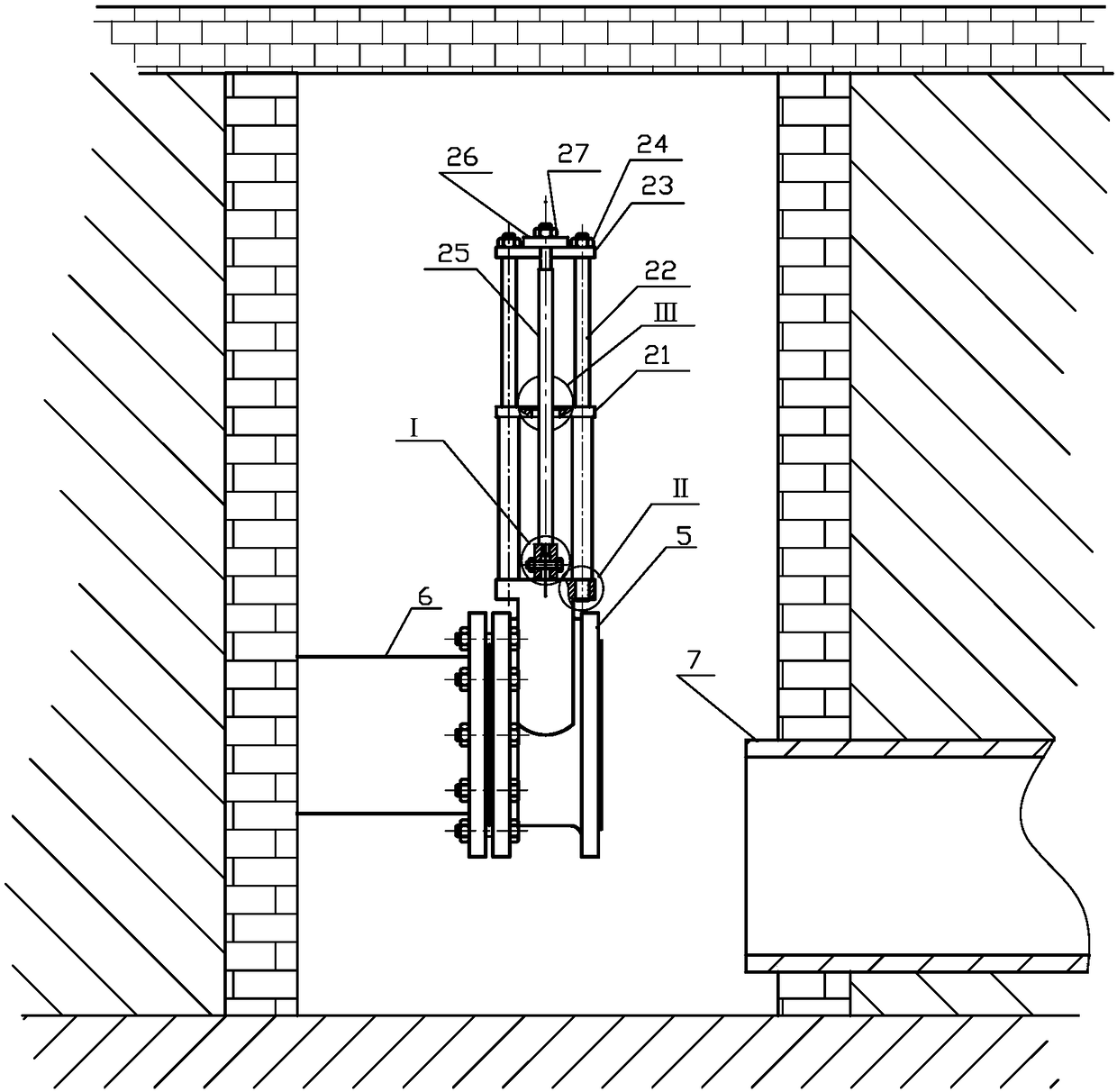

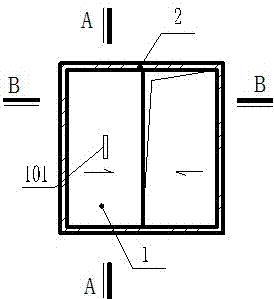

Double-lifting point embedded bulkhead gate system and application thereof

The invention relates to a double-lifting point embedded bulkhead gate system and application thereof. The system comprises a large bulkhead gate, a small bulkhead gate, a gate frame, a gate soleplate, water stop rubbers and lifting lugs, wherein the gate frame is a square frame provided with an opening at the upper end, and is fixed on the gate soleplate; the large bulkhead gate is a square plate arranged in the gate frame, and can vertically move in the gate frame; the water stop rubbers are arranged on the inner wall of the gate frame; a square gap is formed at the upper end of the large bulkhead gate; the small bulkhead gate is a square plate having the same size with the square gap, is embedded in the square gap of the large bulkhead gate, and can vertically move; the water stop rubbers are arranged on the inner wall of square gap of the large bulkhead gate; the lifting lugs are symmetrically fixed at the upper ends of two sides of the square gap of the large bulkhead gate; the lifting lugs are fixed in the middle position of the upper end of the small bulkhead gate. The double-lifting point embedded bulkhead gate system has the advantages of flexible opening, convenience in operation and short opening / closing time.

Owner:李煜科

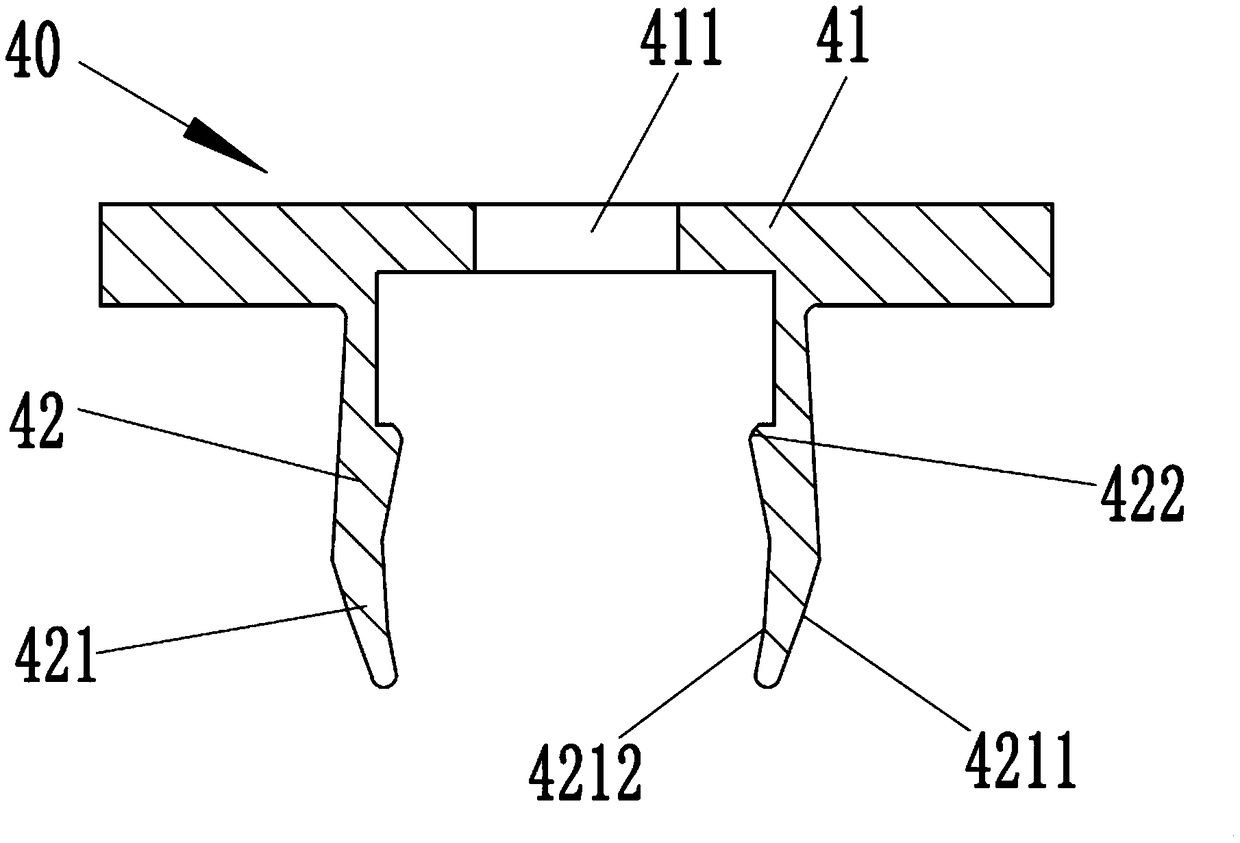

Pneumatic baffle valve for aseptic steam freeze dryer

InactiveCN101706009AMeet the requirements that need to be perpendicular to each otherMeet the requirements of perpendicularOperating means/releasing devices for valvesDrying solid materials without heatCouplingEngineering

The invention relates to a pneumatic baffle valve for an aseptic steam freeze dryer, which comprises an executing mechanism, a valve cap, a valve rod, a valve body, a valve plate and a coupling arranged in the inner cavity of the valve body, wherein the coupling is fixedly connected with one side end face of the valve plate; the valve body is provided with a first outlet and a second outlet; the first outlet is vertical to the second outlet; the valve cap is connected with a flange at the front end of the valve body; the central position of the end face of the valve cap is provided with a through hole; and the executing mechanism is an air cylinder and is fixedly connected with the valve cap. The pneumatic baffle valve for the aseptic steam freeze dyer has the advantages of small switch torque, small configured executing mechanism, stable work, compact structure, reliable seal, long service life, high promotion, great admittance, economic use and the like.

Owner:上海共和真空技术有限公司

Middle open type translation double-sealed rectangular gate valve

The invention relates to a middle open type translation double-sealed rectangular gate valve. A right valve plate and a left valve plate which are opened or closed through rectangular frames are installed in a rectangular valve body, and the right and left valve plates are driven to move by a driving device installed on the valve body, and limited by shifting forks at the tops and bottoms of the right and left valve plates and limit rollers; and flow channel compensation is performed by virtue of a flow channel compensation device installed on the edge of an inner cavity of the valve body and flow channel compensation pieces connected to the flow compensation device, while a front sealing ring and a rear sealing ring of the inner cavity of the valve body as well as the front and rear sealing rings in the closure position of the right and left valve plates constitute bidirectional sealing. The rectangular gate valve provided by the invention is a valve with large size and zero leakage, the flow channel clearance is smaller than 5 mm, and the valve is applicable for working conditions of high flow rate and strong vibration.

Owner:HUBEI HONGCHENG GENERAL MACHINERY

Method for pressure testing of overboard discharge pipe

InactiveCN107478399AIncrease working hoursCheck tightnessMeasurement of fluid loss/gain rateEngineeringFlange

The invention provides a method for pressure testing of an overboard discharge pipe, and the method comprises the following steps: installing a stopper at an opened end of the overboard discharge pipe, wherein the stopper is detachably connected with the overboard discharge pipe; injecting compressed air into the stopper, so as to block the opened end of the overboard discharge pipe; connecting a first pressure meter assembly at a flange end of the overboard discharge pipe; letting compressed air into the overboard discharge pipe through the first pressure meter assembly, and detecting the airtightness of the first pressure meter assembly. The method can achieve the quick testing of the airtightness of the overboard discharge pipe, is very simple in operation, is higher in efficiency, saves the materials, and is lower in cost.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

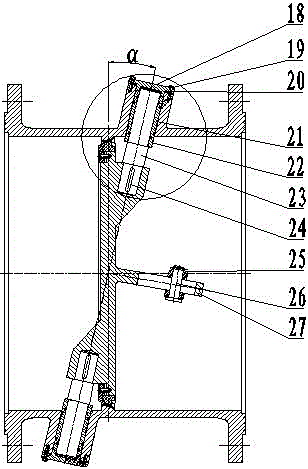

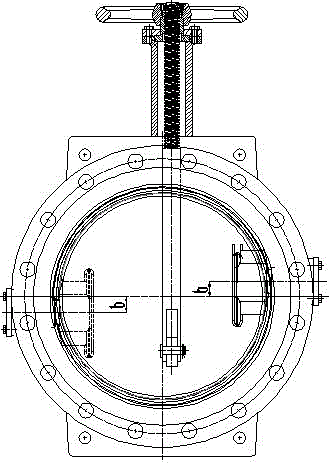

Bi-directional soft seal butterfly valve opened and closed through screw

ActiveCN104832660AShort opening and closing timeSmall opening and closing torqueLift valveValve housingsEngineeringButterfly valve

The invention discloses a bi-directional soft seal butterfly valve opened and closed through a screw. The butterfly valve comprises a hand wheel, a copper nut, the screw, a valve body bracket, a valve body, a valve body sealing seat, a valve plate sealing ring, a valve plate and valve shafts; when the valve plate is in a closed state, the plane, where the valve plate is positioned, and the screw are eccentric; a valve plate rocking handle is fixedly connected with the center of the valve plate; the screw and the valve plate rocking handle are connected through a pin shaft; the two valve shafts are respectively positioned on the two sides of the valve plate and form the angles alpha with the plane, where the valve plate is positioned when the valve plate is in the closed state; one valve shaft is positioned above the horizontal center axis of the valve plate; the other valve shaft is positioned below the horizontal center axis of the valve plate; and the eccentricity of the two valve shafts and the horizontal center axis of the valve plate in the closed state is b. The butterfly valve has the benefits as follows: the opening and closing are carried out through the screw, the opening and closing time is short, the opening and closing torque is less, and opening and closing are obvious; compared with worm gear case processing, the processing of the butterfly valve is simpler, the production cost is low, clamping during opening and closing does not occur and the valve plate can be opened fully.

Owner:ANHUI TONGDU FLOW TECH

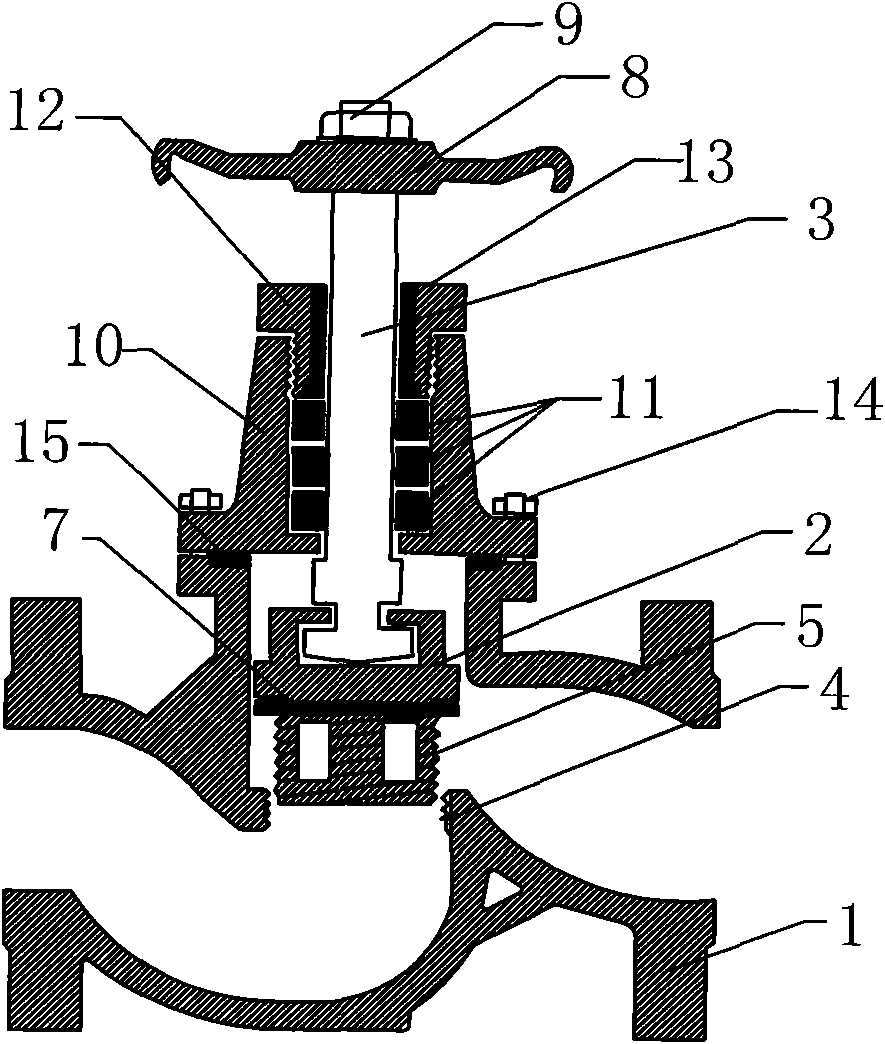

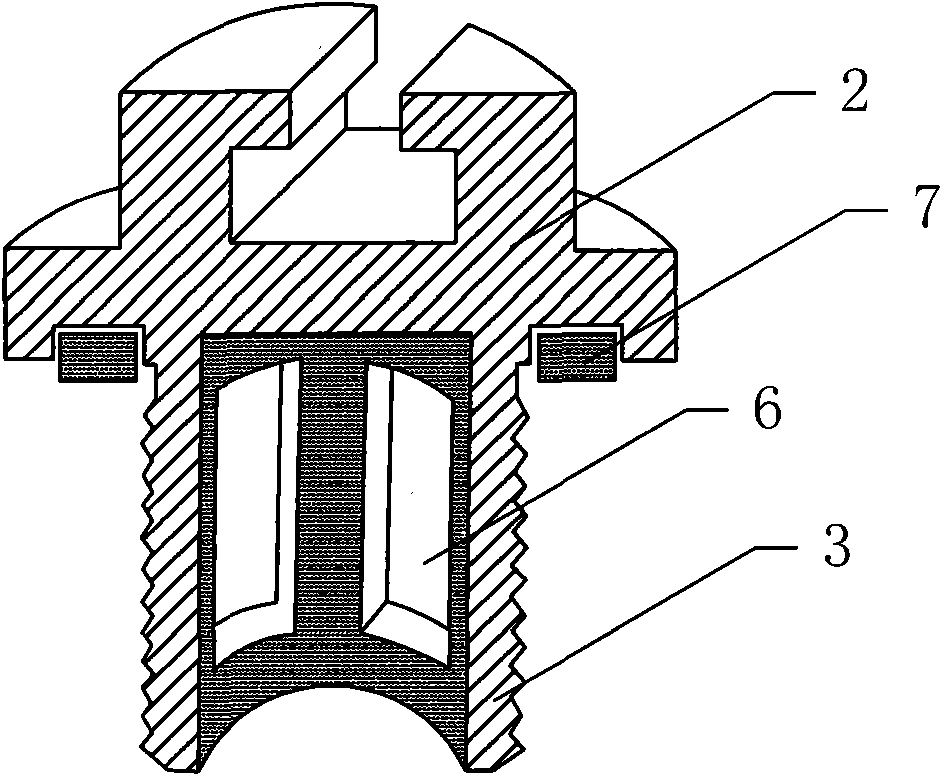

Threaded stop valve

InactiveCN101718345BReduce frictionSimple structureSpindle sealingsOperating means/releasing devices for valvesGraphiteFriction force

The invention relates to a threaded stop valve comprising a valve body, a valve clack and a valve rod. A through-hole nut at the bottom of the valve body is connected with a threaded valve clack at the bottom of the valve clack; the threaded valve clack is provided with a plurality of through holes; a layer of sealing rings is arranged in the middle of the valve clack; the valve clack is connected with the valve rod in a buckling way; the top end of the valve rod is provided with a hand wheel; the hand wheel is fixed on the top end of the valve rod through a hexagonal nut; a valve cover is arranged at the periphery of the valve rod; graphite filler is filled between the valve cover and the valve rod; the top end of the valve cover is provided with a graphite filler gland; a copper sleeve is arranged between the graphite filler gland and the valve rod; the valve body is fixedly connected with the valve cover through bolts; and a sealing gasket is arranged between the valve body and thevalve cover. The threaded stop valve has the advantages of simple structure, convenient manufacturing, maintaining and installing, short staring time during working, good sealing performance, small friction force of sealing surfaces, long service life and wide application range.

Owner:陈小珑

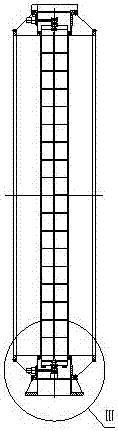

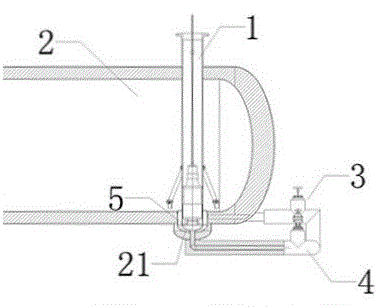

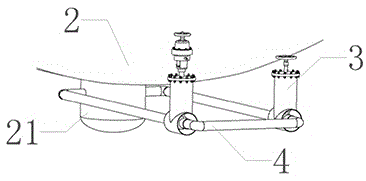

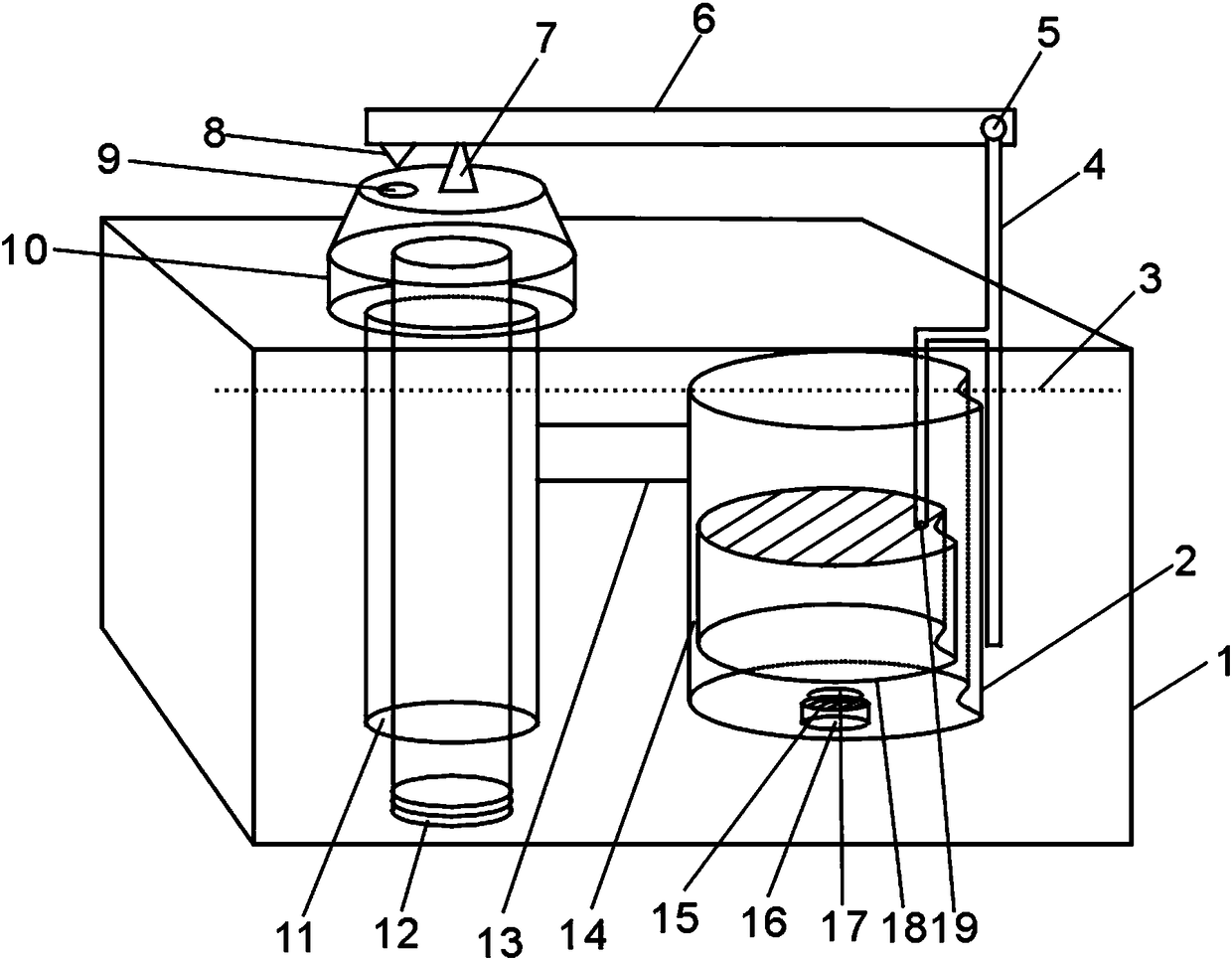

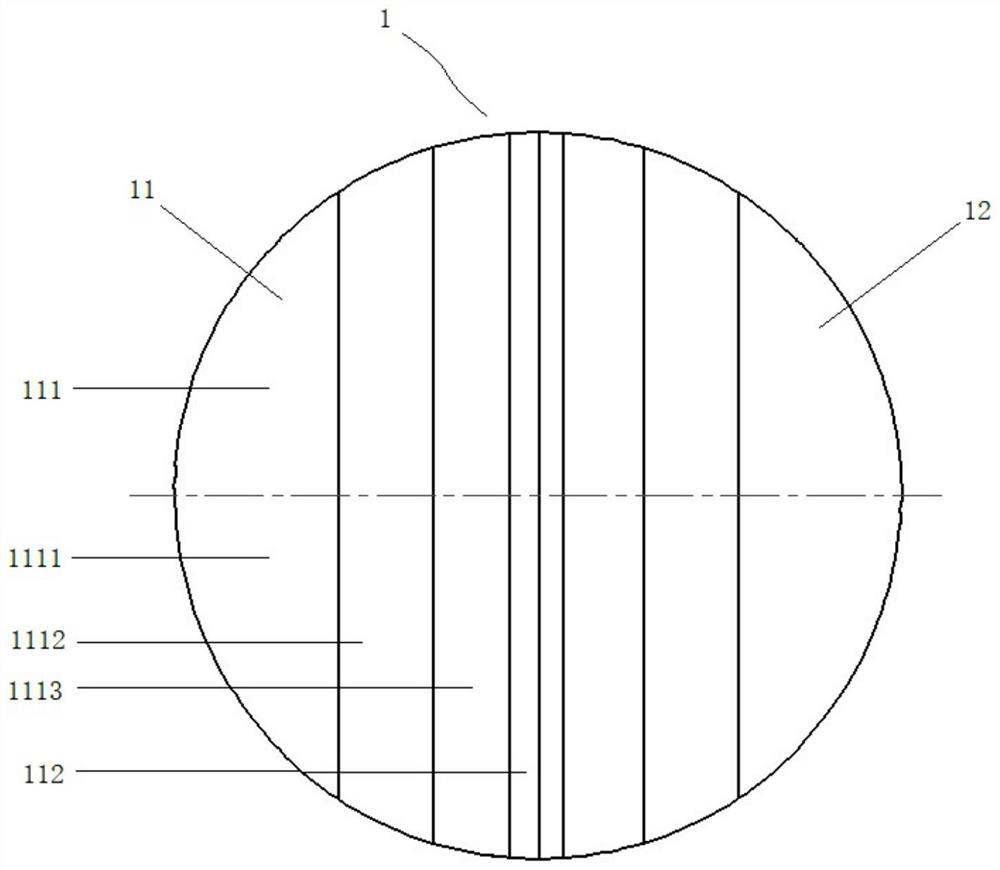

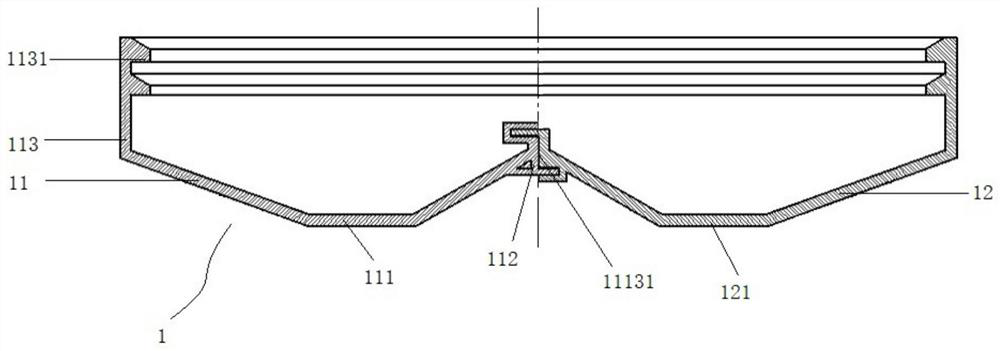

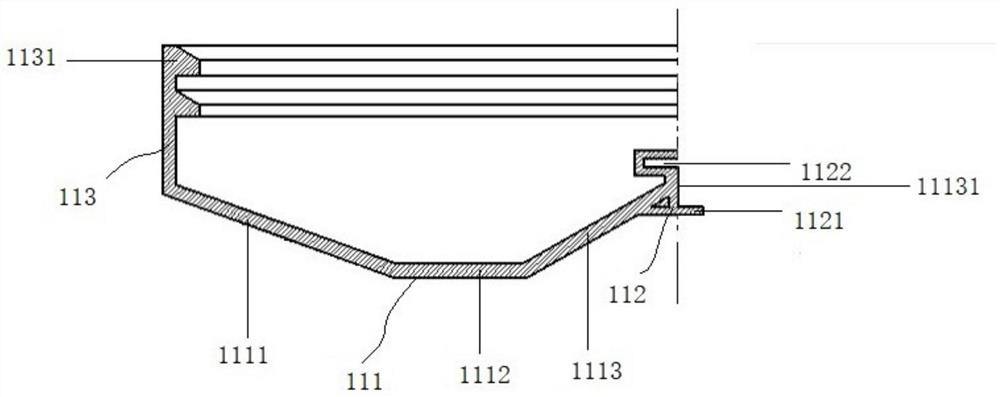

Built-in bottom-valve-free LNG pump well structure

ActiveCN105042328AShort work scheduleShort opening and closing timeContainer filling methodsContainer discharging methodsStorage tankGlobe valve

The invention discloses a built-in bottom-valve-free LNG pump well structure, and belongs to the field of LNG pump wells. The built-in bottom-valve-free LNG pump well structure comprises a pump well arranged in a storage tank. An immersed pump is arranged in the pump well, and a liquid inlet cavity is formed between the inlet end of the immersed pump and the bottom end of the pump well. A plurality of pipelines stretching out of the storage tank are arranged on the pump well. One end of each pipeline is communicated with the liquid inlet cavity, and the other end of each pipeline is communicated with the interior of the storage tank from the exterior of the storage tank. A plurality of stop valves are arranged on the parts, located on the outer portion of the storage tank, of the pipelines. The built-in bottom-valve-free LNG pump well structure has the beneficial effects that the structure is simple, and implementation and mounting are easy and convenient; the immersed pump can be maintained at any time, and the valves for controlling communication between the storage tank and the pump well can be maintained at any time; and LNG waste is greatly reduced, and no threat to the safety of maintenance personnel exists.

Owner:HOPE CLEAN ENERGY (GRP) CO LTD

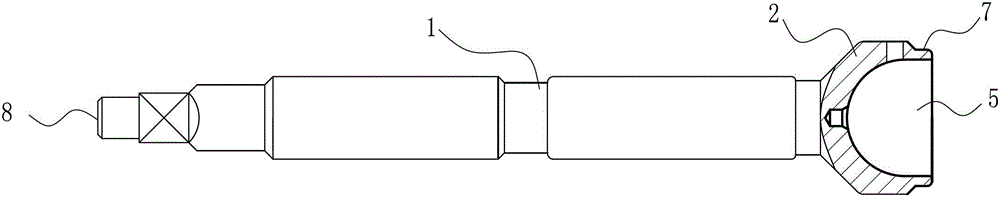

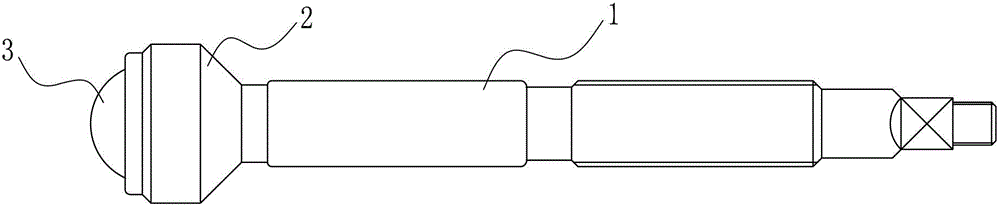

Valve rod for high-temperature high-pressure stop valve and machining method of valve rod

Owner:SUZHOU SAIHUA INSTR CONTROL CO LTD

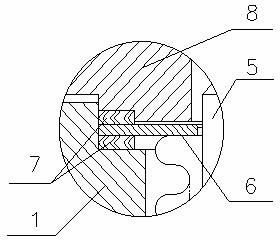

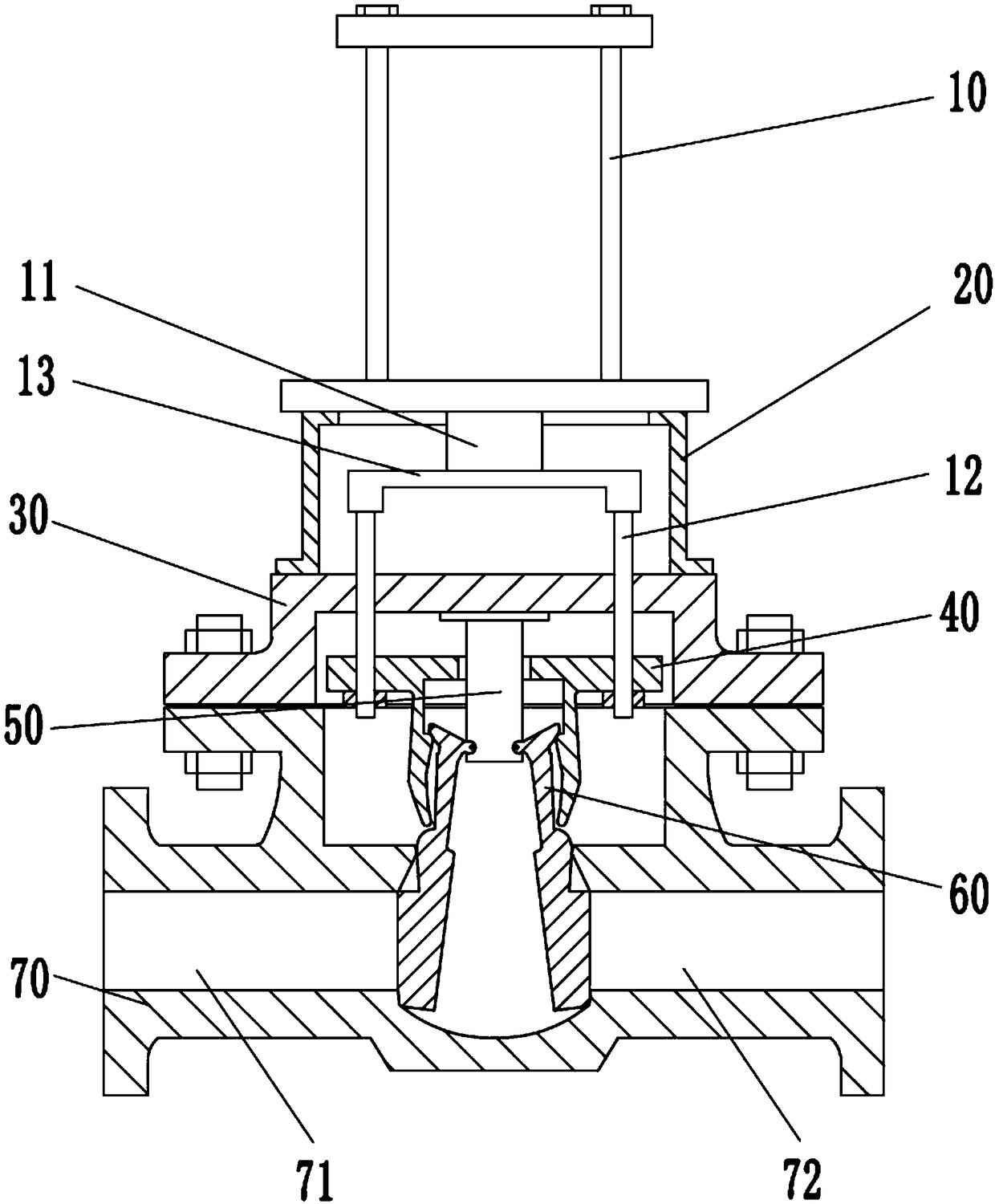

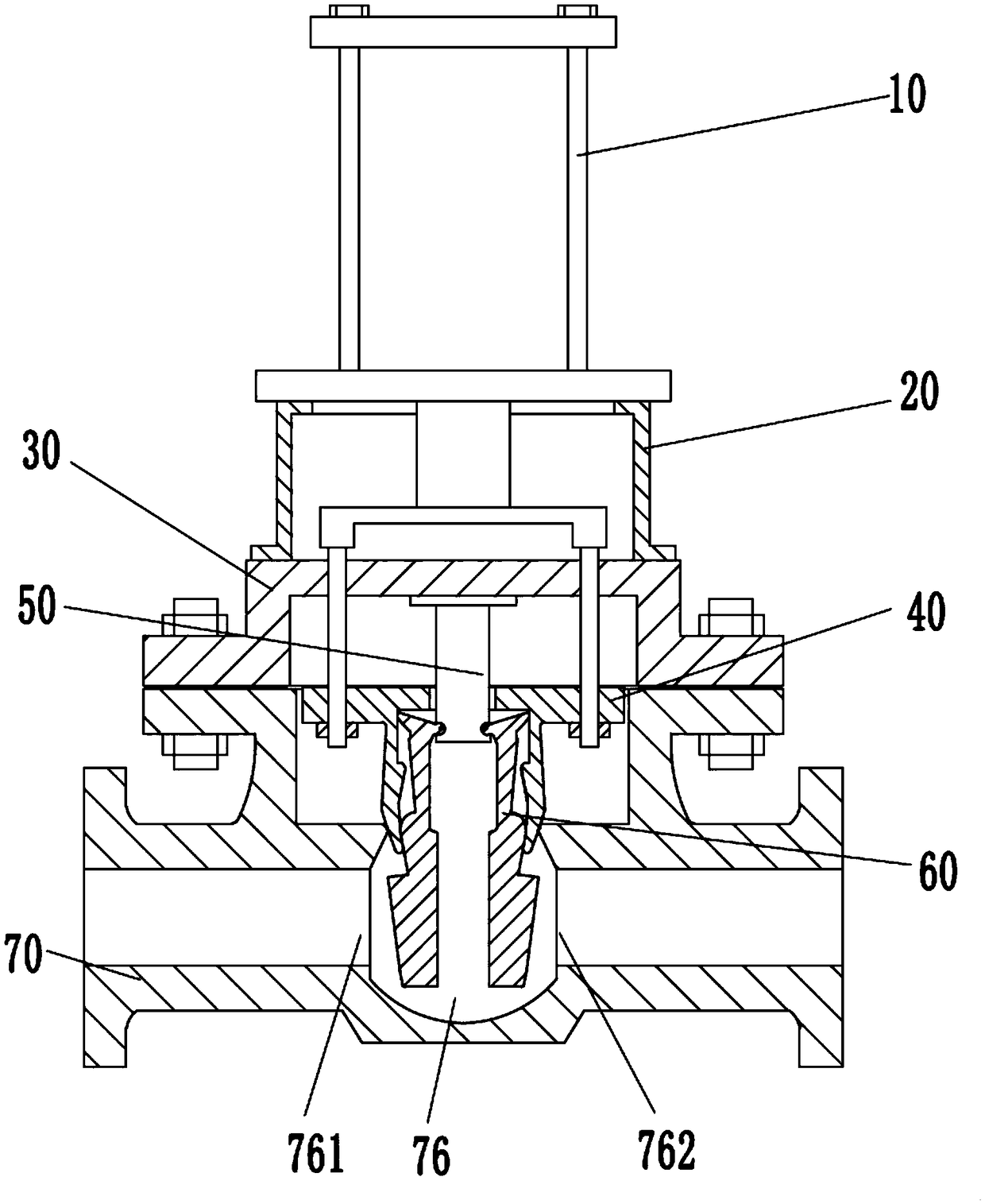

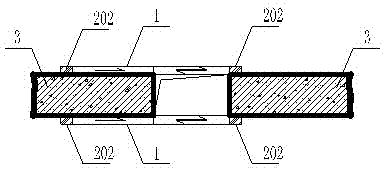

a valve

ActiveCN107559439BEasy to operateShort opening and closing timeOperating means/releasing devices for valvesSlide valveWater flowEngineering

The invention provides a valve. The valve comprises a valve body, a pair of valve plates, a driving mechanism and a moving piece, wherein the valve body is provided with a front channel, a rear channel and a valve cavity; the front channel communicates with the rear channel by the valve cavity; the pair of valve plates is positioned in the valve body and is pivotally connected to a fixing plate ofthe valve body; the driving mechanism comprises a cylinder and a pair of guide columns; the cylinder is fixed on the valve body; the pair of guide columns is movably arranged on a top cover of the valve body; the upper parts of the pair of guide columns are separately connected with an extension shaft of the cylinder; and the moving piece is fixedly mounted on the lower parts of the pair of guidecolumns and is in contact with the pair of valve plates. The valve is novel in structure; and during working, an operator enables the cylinder to work so as to drive the moving piece to move vertically, and then the valve plates are driven to rotate around a hinged shaft to open and close a valve opening. Therefore, the valve has the advantages of simplicity in operation, short opening and closing time, capability of controlling the amount of water flowing through the valve and long service life.

Owner:周常

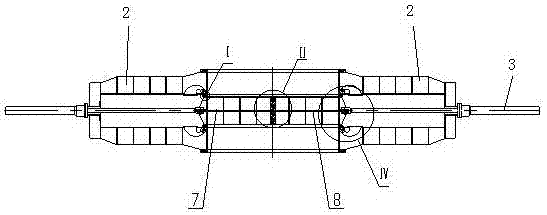

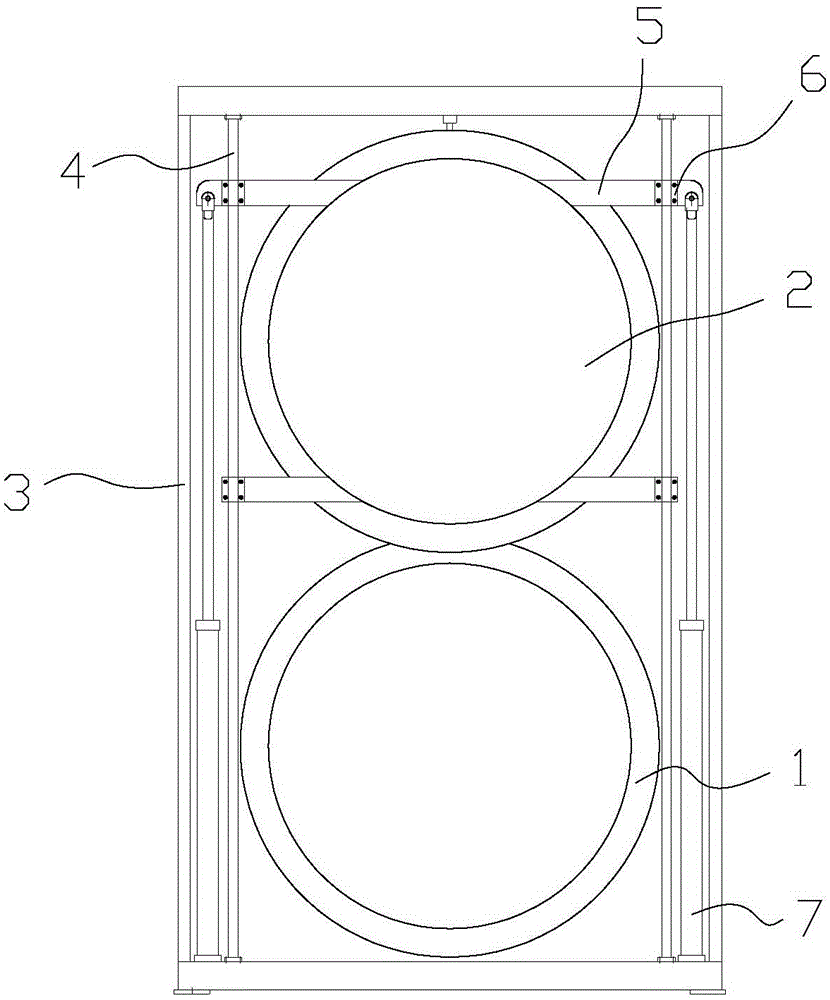

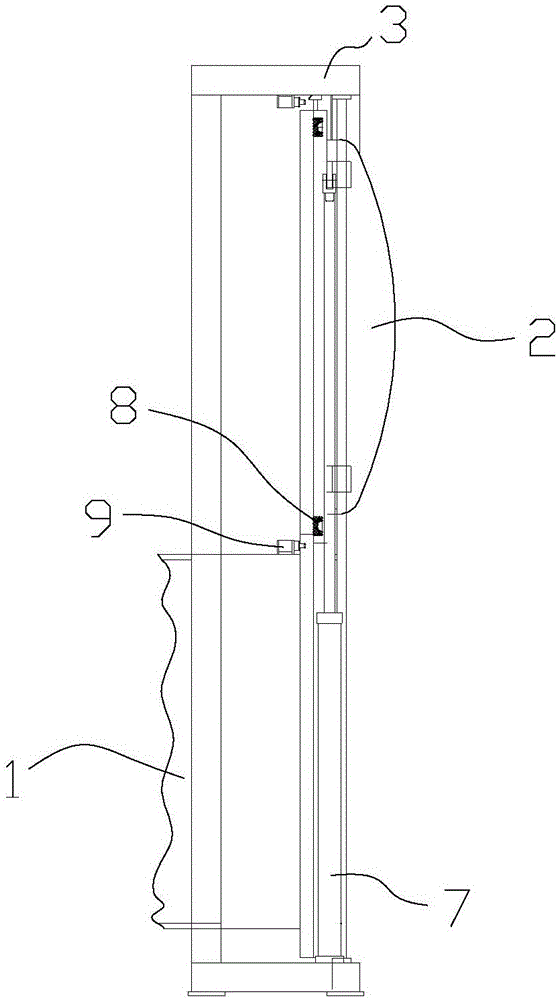

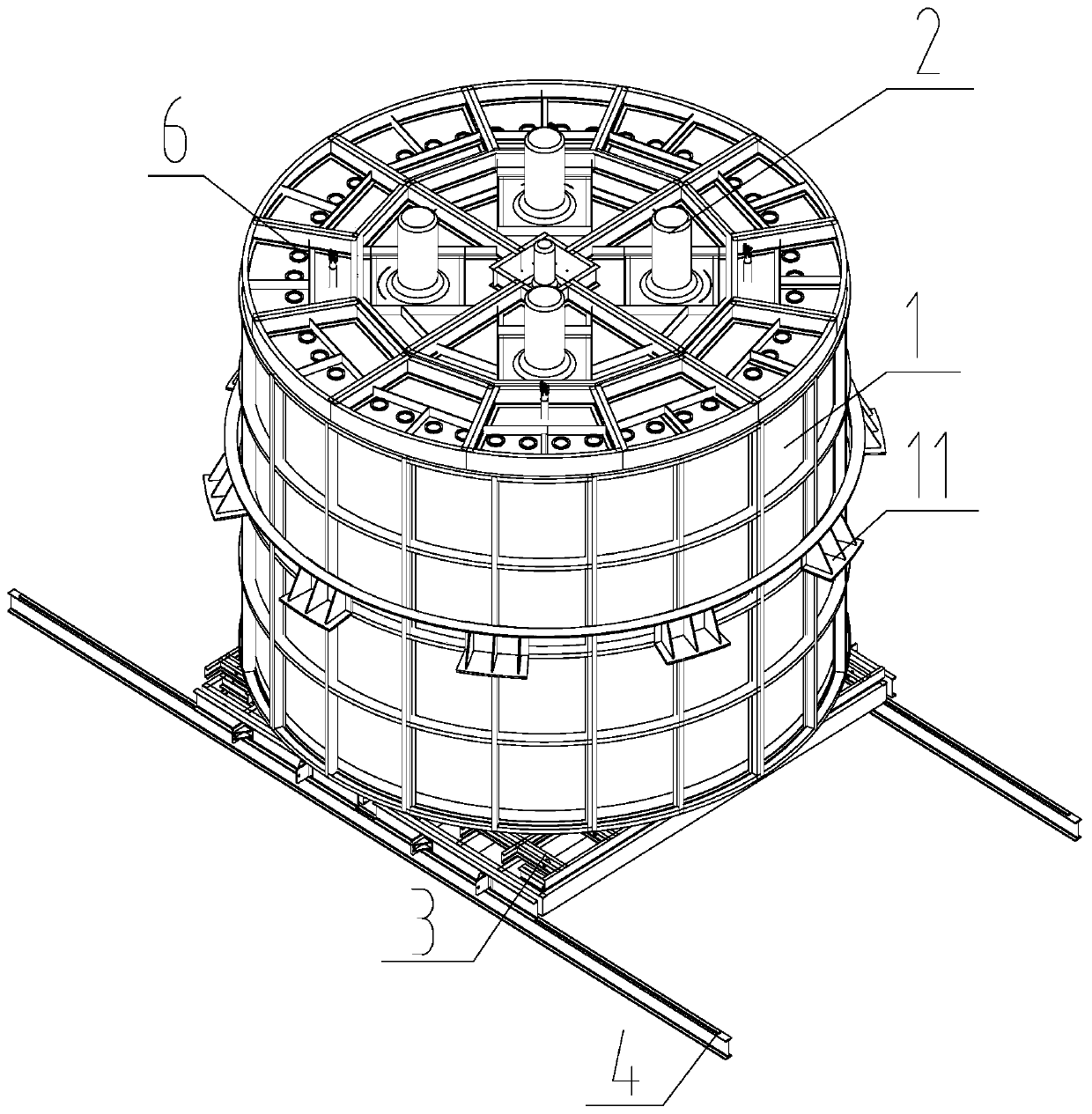

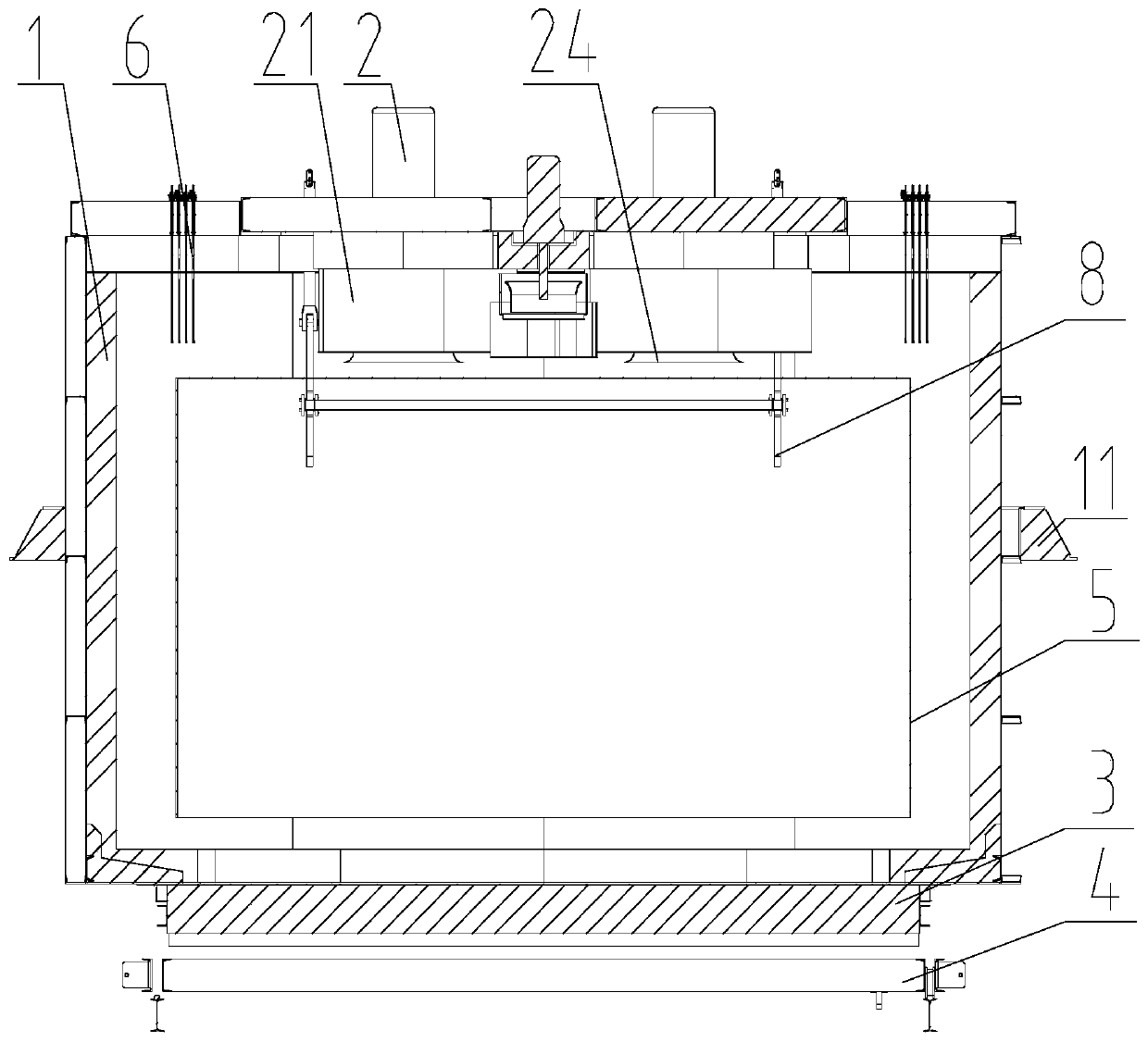

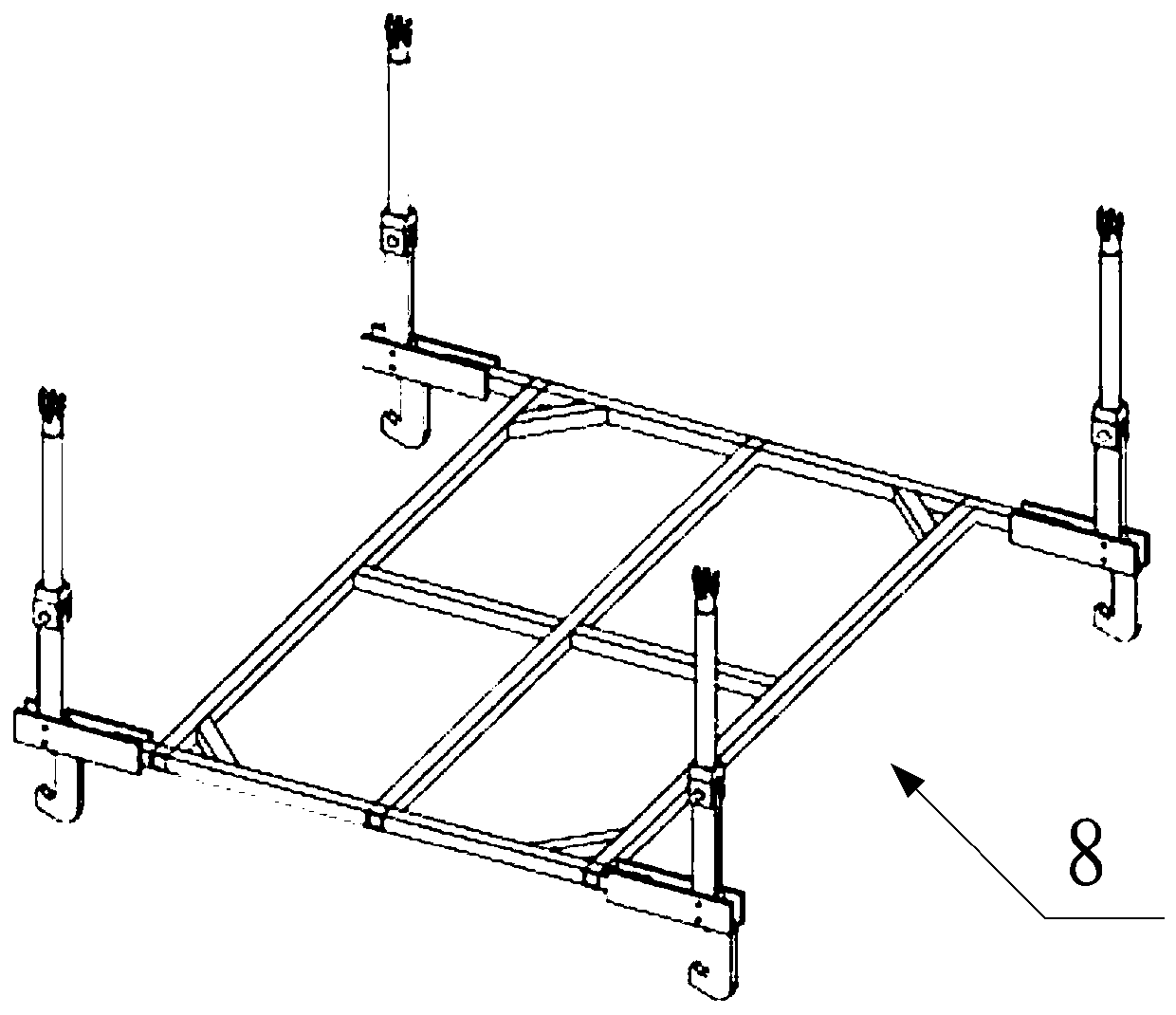

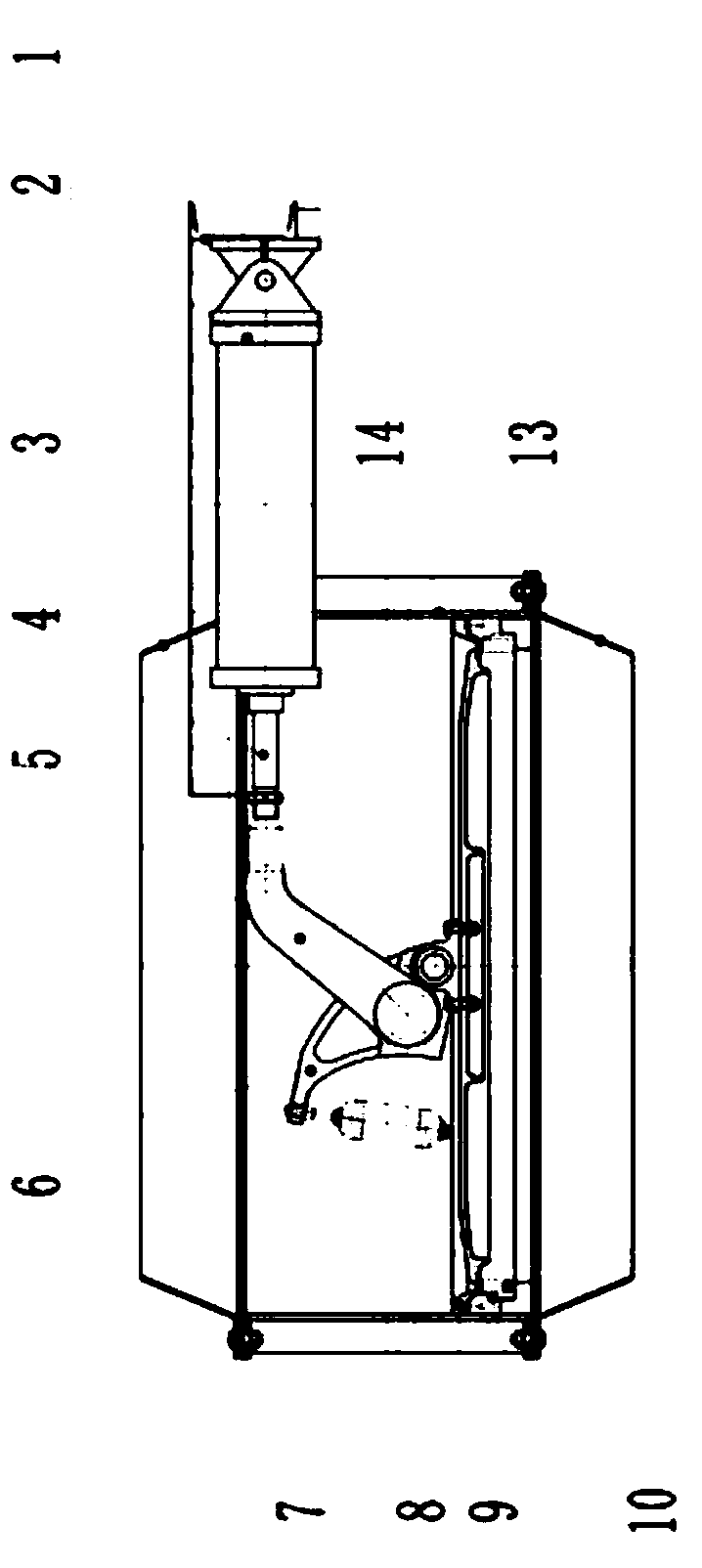

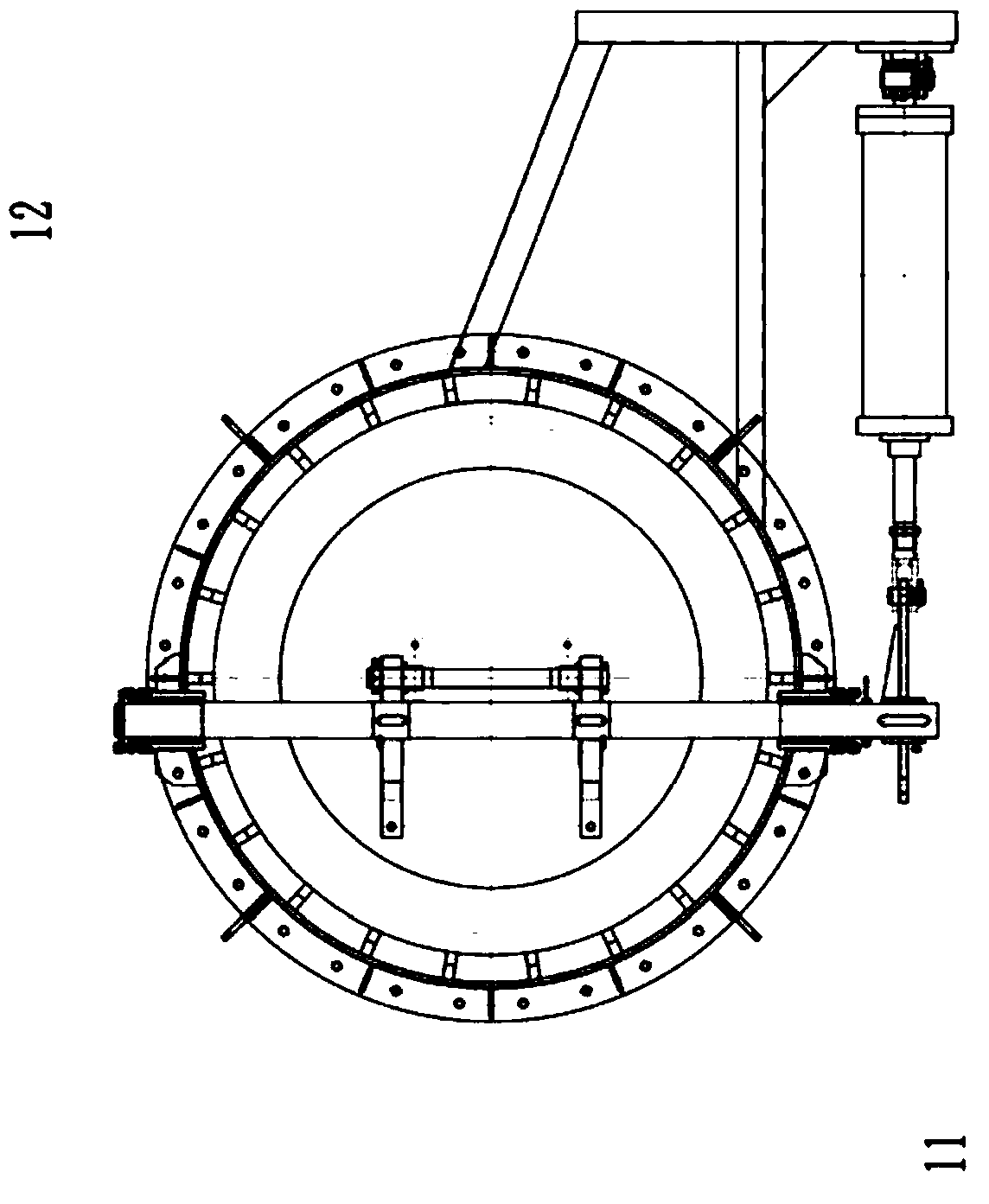

Horizontal type vulcanizing tank with vertical doubly-opened door panels being opened and closed in lifting mode

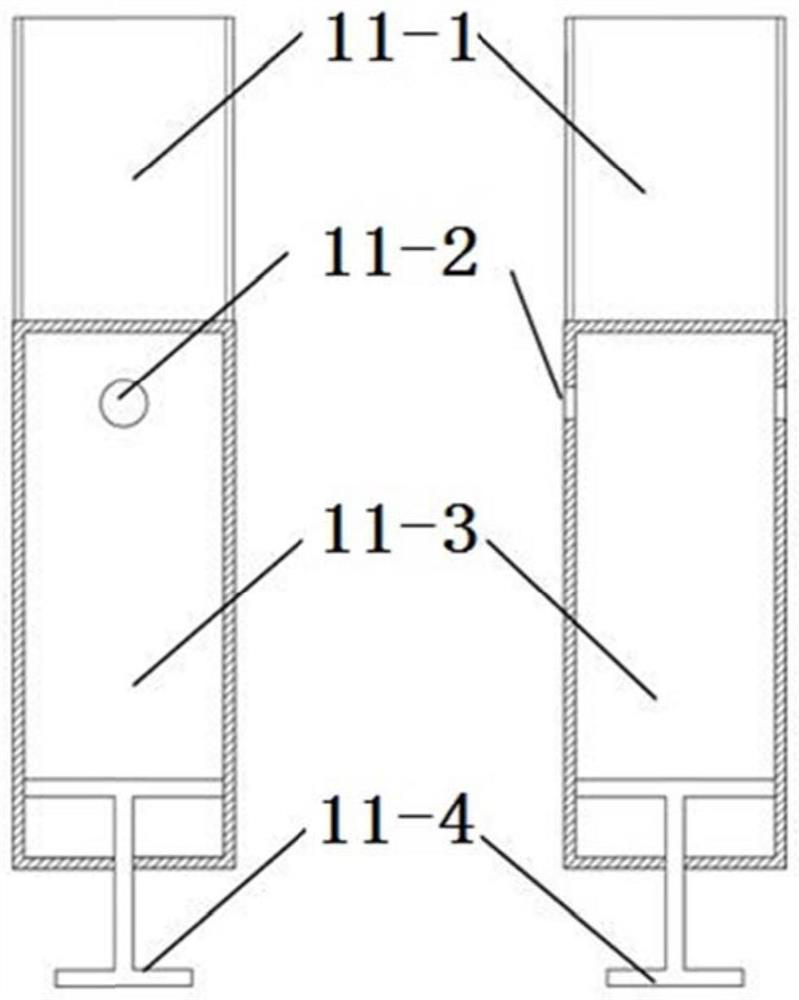

InactiveCN105014841AShort opening and closing timeOperational securityPower-operated mechanismSealing arrangementsEngineeringOperational safety

The invention discloses a horizontal type vulcanizing tank with vertical doubly-opened door panels being opened and closed in a lifting mode. The horizontal type vulcanizing tank comprises a horizontally placed barrel body and the door panels arranged at the two ends of the barrel body. Portal frames are arranged at the two ends of the barrel body. Lifting slide rods are arranged at the left side and the right side of each portal frame. Door panel supports transversely extending towards the lifting slide rods are arranged at the upper side and the lower side of each door panel respectively. The door panel supports are provided with slide rod bearings which are arranged on the lifting slide rods in sliding and sleeving modes. Hydraulic oil cylinders are vertically mounted at the left side and the right side of a bottom plate of each portal frame. The driving ends of the hydraulic oil cylinders and the door panel supports at the upper sides of the door panels are fixed. The door panels are opened and closed in the vertical lifting mode, the door opening and closing time is short, operation is safe and reliable, and the service cycle of sealing pieces can reach one or more years; the door panels move along the lifting slide rods and are driven by the hydraulic oil cylinders, in work, switching between opening and closing of doors can be achieved only by controlling actions of the hydraulic oil cylinders, the process can be intelligently controlled through a computer, and a high-end product is achieved.

Owner:WUHU HAILIAN MACHINERY INSTALLATION

High temperature plug valve

The characteristics of this high temperature plug valve: the primary seal and secondary seal of the valve are all metal seals. The metal special-shaped seal of the spool is on the surface of the inverted cone of the spool, the two parts that protrude around the orifices of the two fluid passages are integrated with the spool and made of the same metal material. Once sealed. The two-layer circular groove of the spool cooperates with the two-layer metal expansion ring to form a secondary seal. During the opening and closing process, this kind of high temperature plug valve has the characteristics of high temperature resistance, corrosion resistance, long life, fast speed, online maintenance, and the opening and closing torque is only 1 / 4~1 / 3 of similar products, and can be widely used in high temperature production.

Owner:石玉山

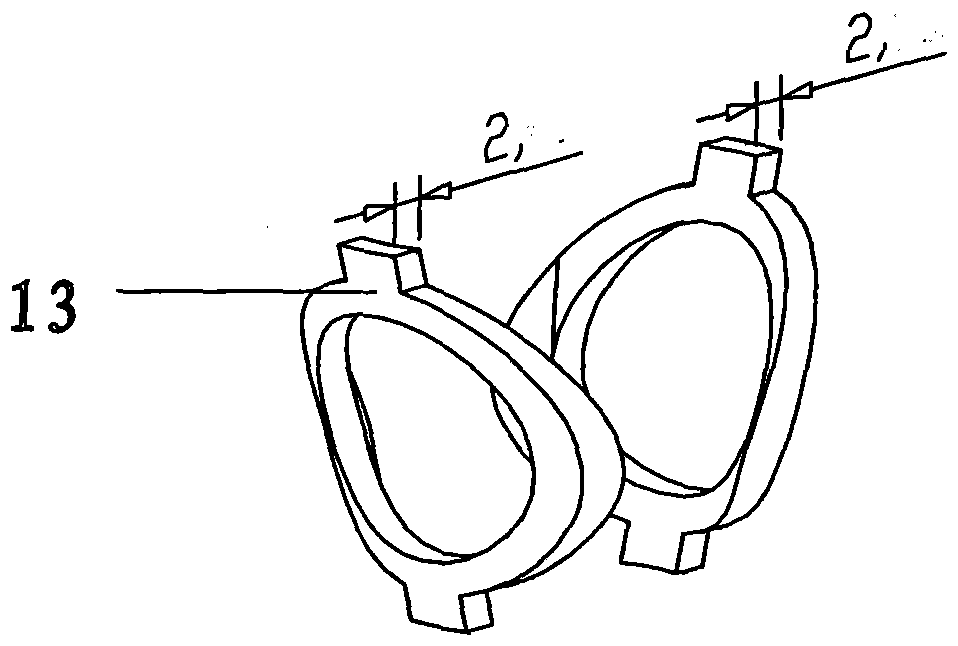

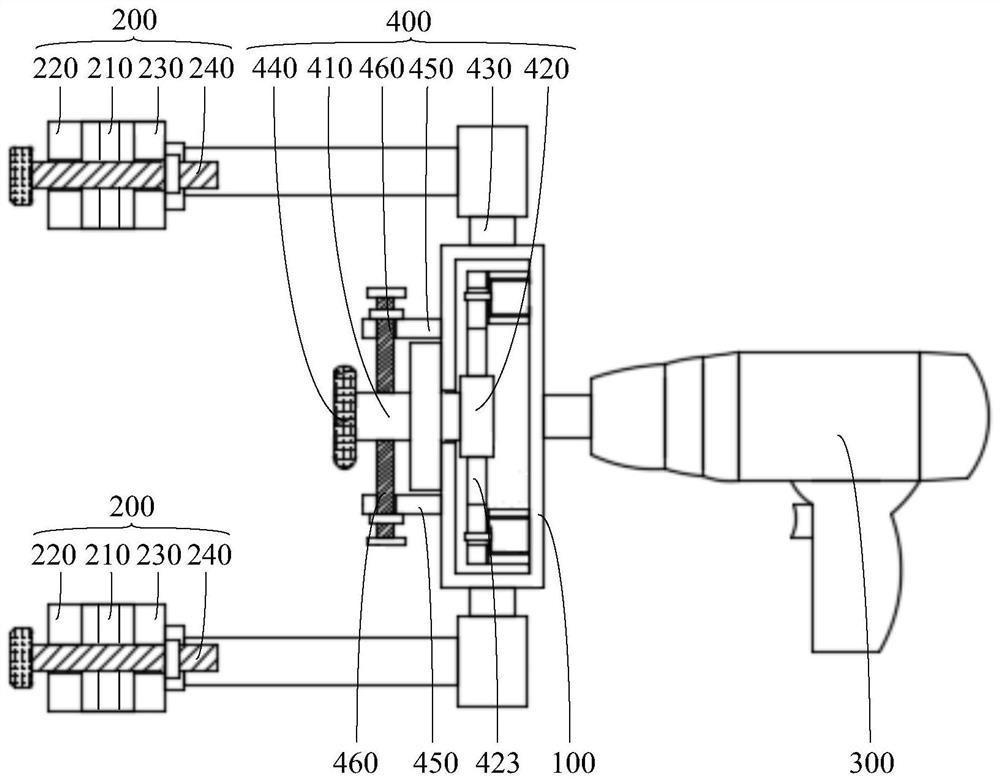

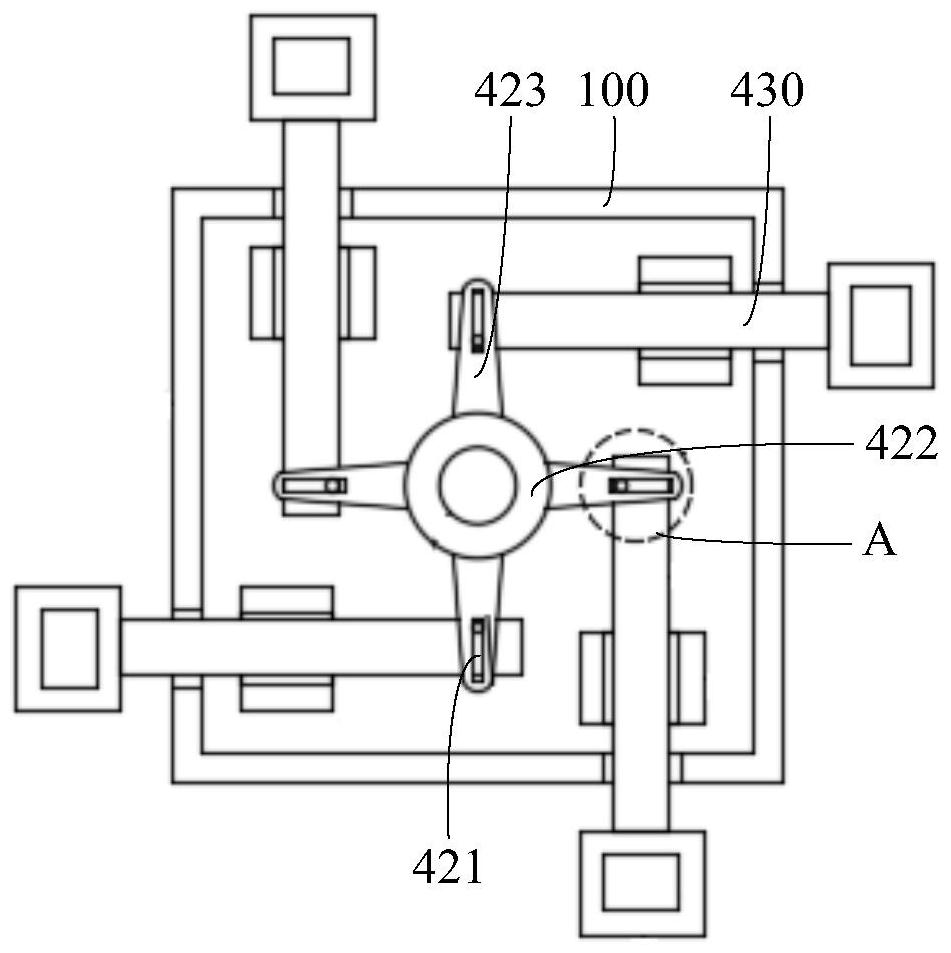

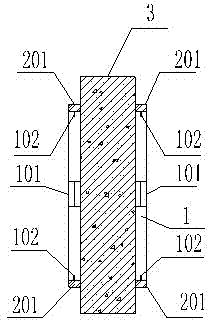

Valve wheel rotary device

InactiveCN111958553AAchieve rotationShort opening and closing timeMetal-working hand toolsControl mannerEngineering

The invention discloses a valve wheel rotary device and belongs to the technical field of valve control. The valve wheel rotary device comprises a rotary bracket (100), at least two clamping mechanisms (200) and an electric driving mechanism (300); one end of each of the clamping mechanisms (200) is connected with the rotary bracket (100); all clamping mechanisms (200) are distributed at intervalsin the circumferential direction of the rotary bracket (100) and can be fixed with a valve wheel; the electric driving mechanism (300) is connected with the rotary bracket (100) and drives the clamping mechanisms (200) to rotate through the rotary bracket (100). According to the scheme, the problem that the current valve on-off control manner wastes time and labor is solved.

Owner:SHENHUA SHENDONG POWER

An ultra-clean proportional valve

ActiveCN112303247BSmall operating distanceReduce distractionsOperating means/releasing devices for valvesLift valveMagnetic tension forceEngineering

Owner:ZHEJIANG UNIV

Large workpiece heating furnace

InactiveCN111551028ANo mutual interferenceAvoid mutual interferenceMaintainance of heating chambersFurnace typesEngineeringHearth

The invention discloses a large workpiece heating furnace which comprises multiple circulating fans. An air outlet at the furnace top is arranged to face the inner side of a furnace body. A gas circulating flow guide system is arranged between the furnace body and an inner hearth and comprises multiple arc flow guide plates, one end of each arc flow guide plate is arranged in an air outlet of thecorresponding circulating fan, and the other ends of the arc flow guide plates stretch out of the air outlets to be vertically arranged at intervals. The air outlets are divided by the arc flow guideplates into multiple branch air outlets, and the branch air outlets gradually become winder from the air outlet sides to the outside. Vertical first straight flow guide plates and second straight flowguide plates are connected with the two sides of the air outlets of the circulating fans respectively and meanwhile are connected with the inner side face of the furnace body and the outer side faceof the inner hearth, and multiple vertical air flues are formed by the inner side face of the furnace body, the outer side face of the inner hearth, the first straight flow guide plates and the secondstraight flow guide plates. Through the gas circulating flow guide system, gas in the furnace body is heated evenly, so that the temperature of gas entering the inner hearth is consistent, and workpieces are heated evenly.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Valve

ActiveCN107559439AEasy to operateShort opening and closing timeOperating means/releasing devices for valvesSlide valveWater flowEngineering

The invention provides a valve. The valve comprises a valve body, a pair of valve plates, a driving mechanism and a moving piece, wherein the valve body is provided with a front channel, a rear channel and a valve cavity; the front channel communicates with the rear channel by the valve cavity; the pair of valve plates is positioned in the valve body and is pivotally connected to a fixing plate ofthe valve body; the driving mechanism comprises a cylinder and a pair of guide columns; the cylinder is fixed on the valve body; the pair of guide columns is movably arranged on a top cover of the valve body; the upper parts of the pair of guide columns are separately connected with an extension shaft of the cylinder; and the moving piece is fixedly mounted on the lower parts of the pair of guidecolumns and is in contact with the pair of valve plates. The valve is novel in structure; and during working, an operator enables the cylinder to work so as to drive the moving piece to move vertically, and then the valve plates are driven to rotate around a hinged shaft to open and close a valve opening. Therefore, the valve has the advantages of simplicity in operation, short opening and closing time, capability of controlling the amount of water flowing through the valve and long service life.

Owner:周常

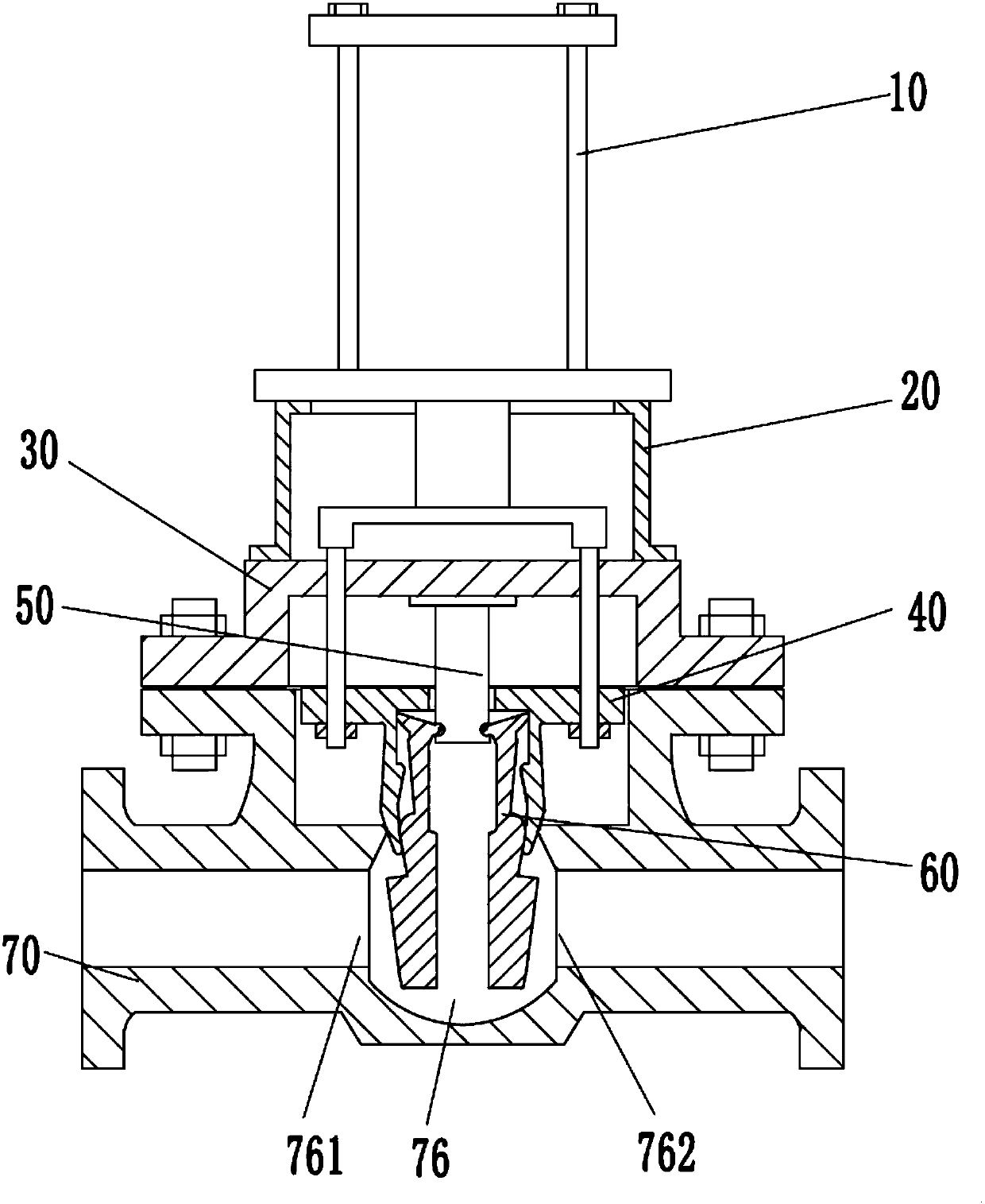

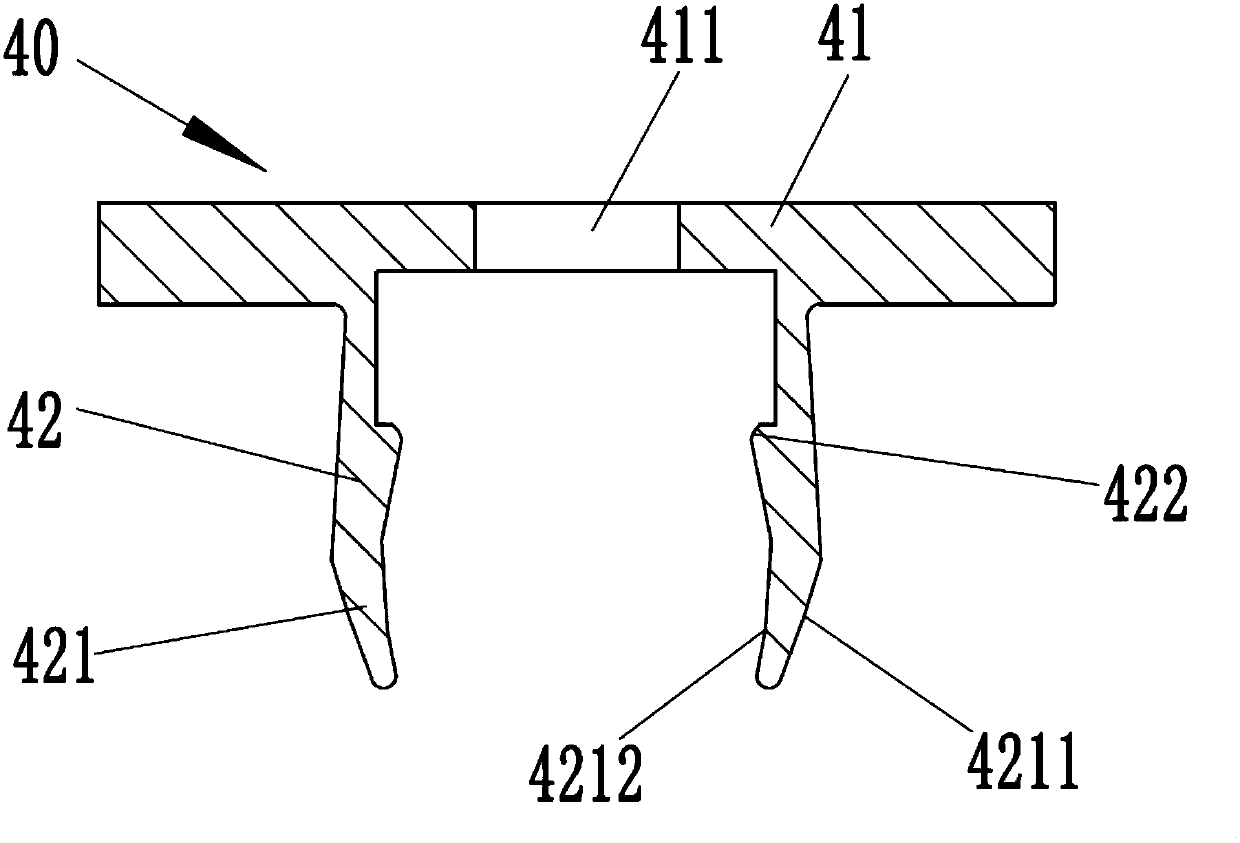

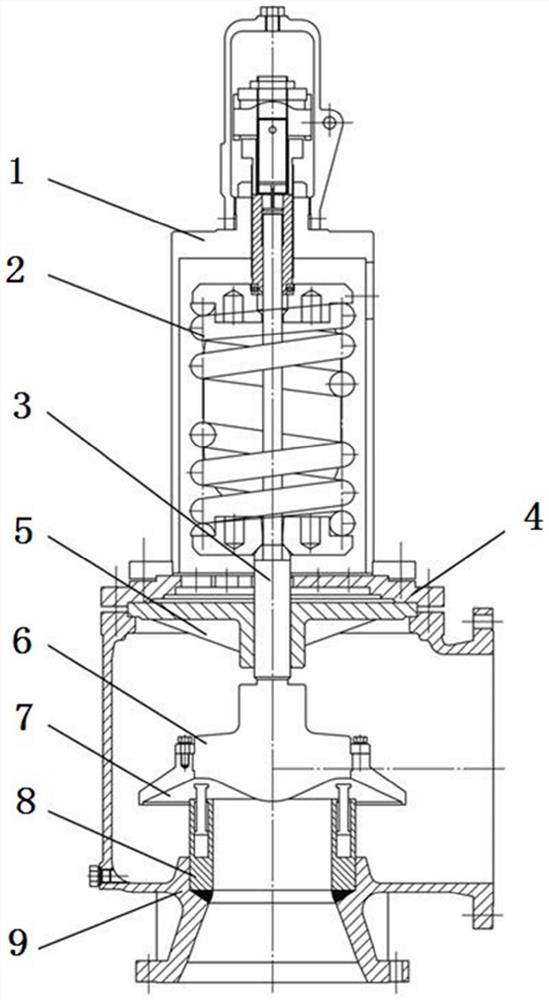

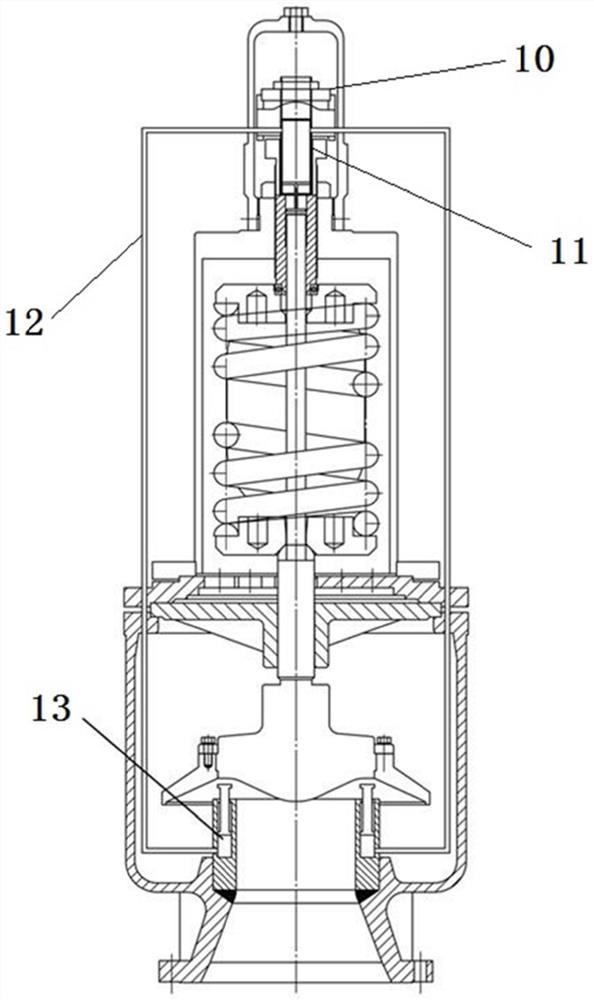

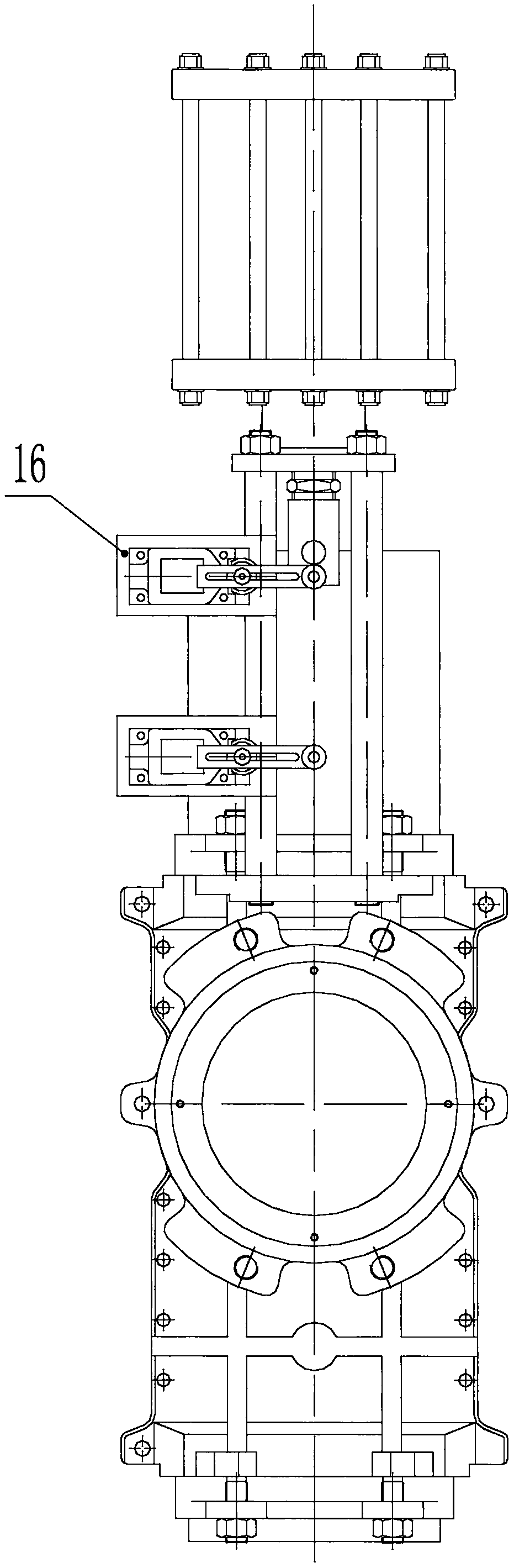

Safety valve structure capable of avoiding impact of valve clack during opening and closing and method thereof

InactiveCN113738921AShort opening and closing timeExtend your lifeValve members for absorbing fluid energyEqualizing valvesEngineeringSafety valve

The invention discloses a safety valve structure capable of avoiding impact of a valve clack during opening and closing and a method thereof. An upper buffer of the safety valve structure is fixed above a valve rod, a first piston is arranged at the bottom, and an inner cavity located above the first piston serves as a first oil cavity; a first oil conveying hole is formed in the side wall; and a lower buffer set comprises at least two lower buffers of the same structure, and all the lower buffers are located in a valve seat and evenly distributed. Second pistons are arranged at the tops of the lower buffers, and an inner cavity below the second pistons serves as a second oil cavity; and a second oil conveying hole is formed at the lower portion of the outer side wall, the first oil cavity, the oil conveying pipe and the second oil cavity jointly form a communicated buffering channel which is closed all the time, and the buffering channel is filled with buffering media. On the basis of ensuring that a safety valve is opened and closed in a short enough time, the impact of the valve clack to a guide sleeve in the opening stage and the impact of the valve clack to the valve seat in the closing stage are reduced, the service life of valve internals of the safety valve is prolonged, and impact damage in the opening and closing process of the safety valve is avoided.

Owner:ZHEJIANG UNIV

Time-delay water filling water intake rod

PendingCN108166583AIncrease water storage spaceScrub cleanFlushing devicesTime delaysDifferential pressure

The invention discloses a time-delay water filling water intake rod, which comprises a water tank, a head-on float cover, a remaining water over-flow level, a transmission rod, a loose joint, a lever,a pivot, a plug, a pressure relief hole, a differential pressure valve, a water filling outlet, a running water interface, a fixing bracket, an inter-float gap, a bottom-sealed sealing port, a bottom-sealed small float, a bottom-sealed water leaking port, an inverted float and a float connecting rod; the water intake rod is mainly characterized in that remaining water exists between the top of the inverted float and the remaining water over-flow level by a certain depth when the plug and the pressure relief hole are sealed, and the duration of a delayed water filling time of the water fillingwater outlet is determined by the amount of remained water, so that the problem of a sanitary appliance that kinetic energy becomes dispersed when flushing is conducted under the assistance of pressure of running water can be solved perfectly.

Owner:GUANGDONG HEGII SANITARY WARES CO LTD

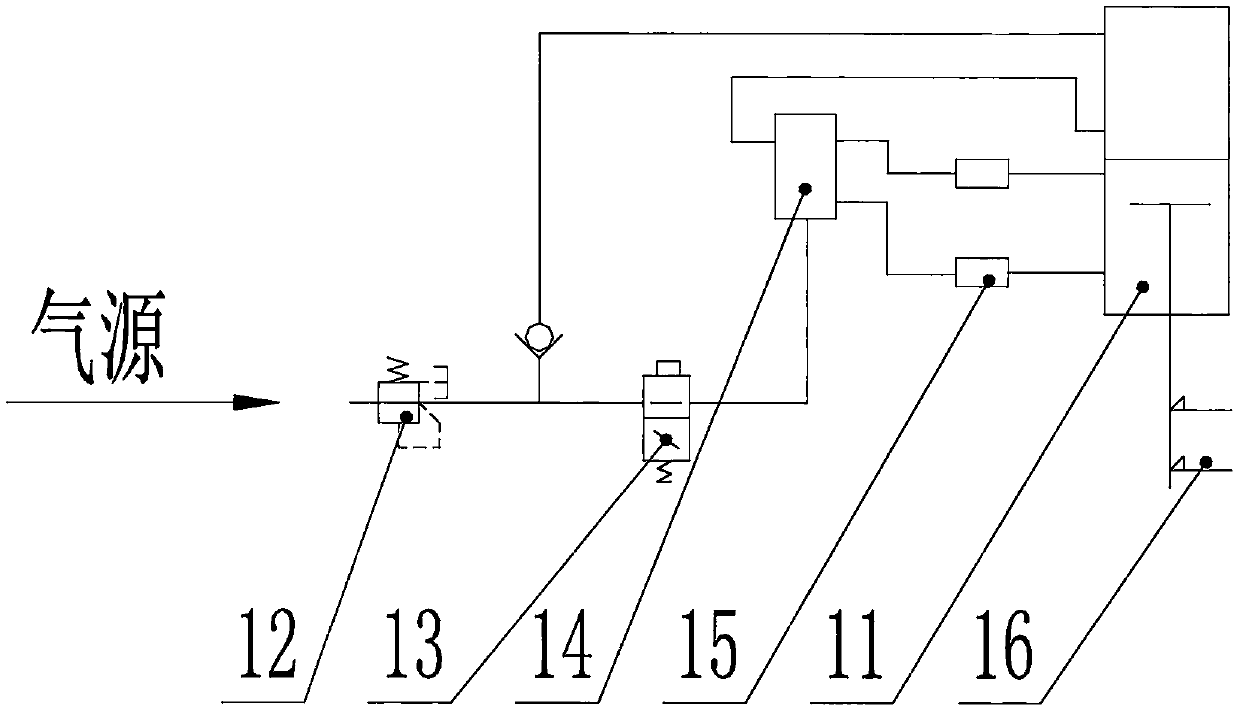

Quick cutting-off deslagging valve

InactiveCN109667949AEasy dischargeHigh strengthOperating means/releasing devices for valvesSlide valveExhaust valveHigh intensity

The invention discloses a quick cutting-off deslagging valve, belongs to the technical field of valves, and solves the problems that a conventional valve cannot cut off materials to lose self using effect of the valve. The quick cutting-off deslagging valve is characterized by comprising a valve body, knife switches, a flashboard and an air cylinder assembly, wherein the knife switches are mountedin the valve body; the two knife switches are symmetrically arranged on the outlet side of the valve body; the flashboard is arranged at an outlet surrounded with the knife switches; the knife switches have high intensity, the cutting properties are good, through cooperation with quick movement of the flashboard, favorable cutting-off functions can be realized, and mediums can be cut off at the knife switches; through air inlet and air exhaust of an electromagnetic valve, an air control valve is controlled to perform changes of an air path, and the valve opening and closing time is smaller than or equal to 1s; the valve opening and closing time is shortened to 1 / 3, and quick opening and closing are realized. Besides, an air cylinder assembly in an air storage tank is adopted, the air input quantity is increased by the air control valve, quick exhaust of the air in an air cylinder is realized through a quick exhaust valve, the operation time of the air cylinder is shortened, the cutting off speed is increased, and the sealing effect is good.

Owner:SHANDONG ZHONGLI HIGH PRESSURE VALVE CO LTD

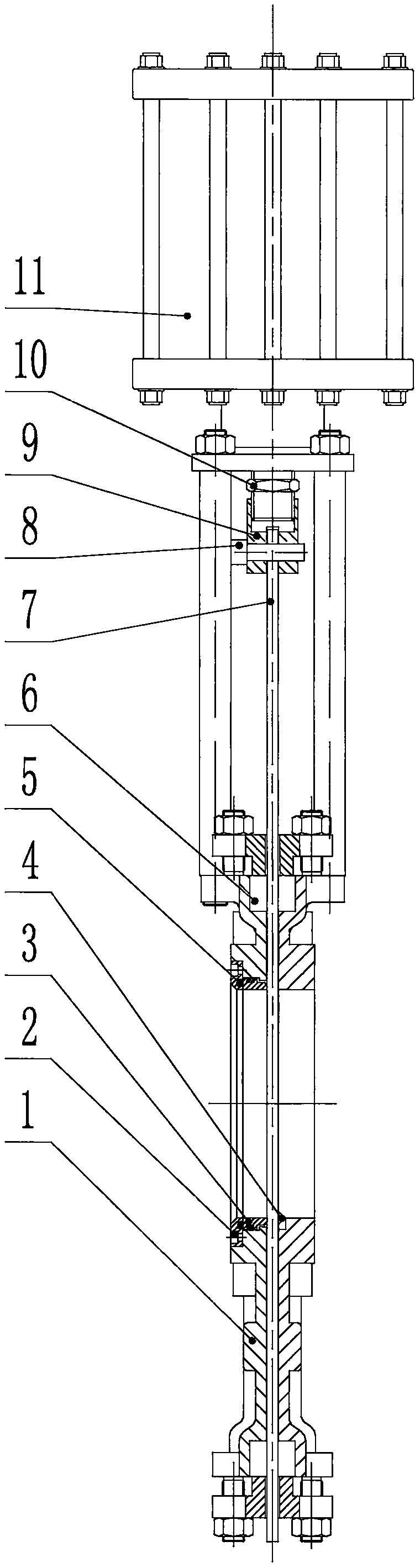

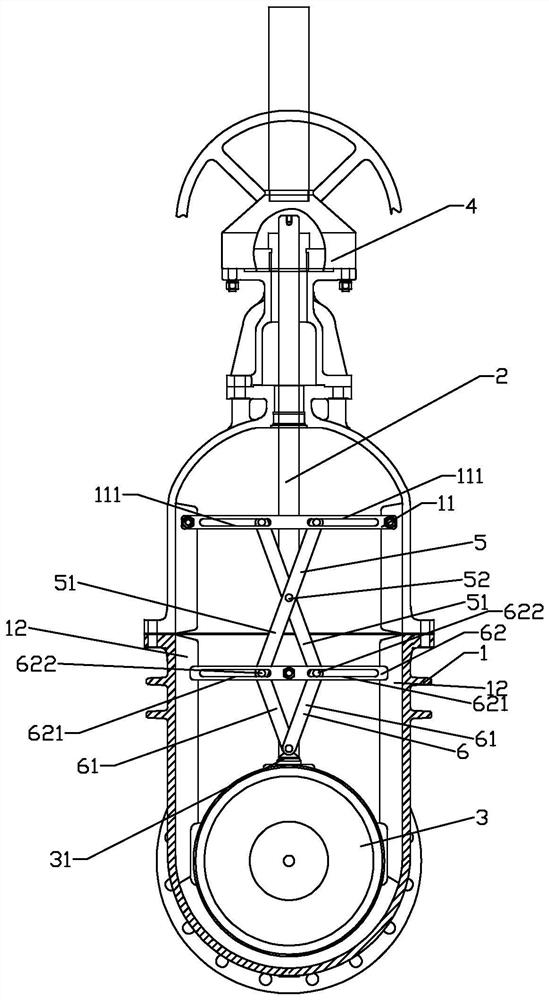

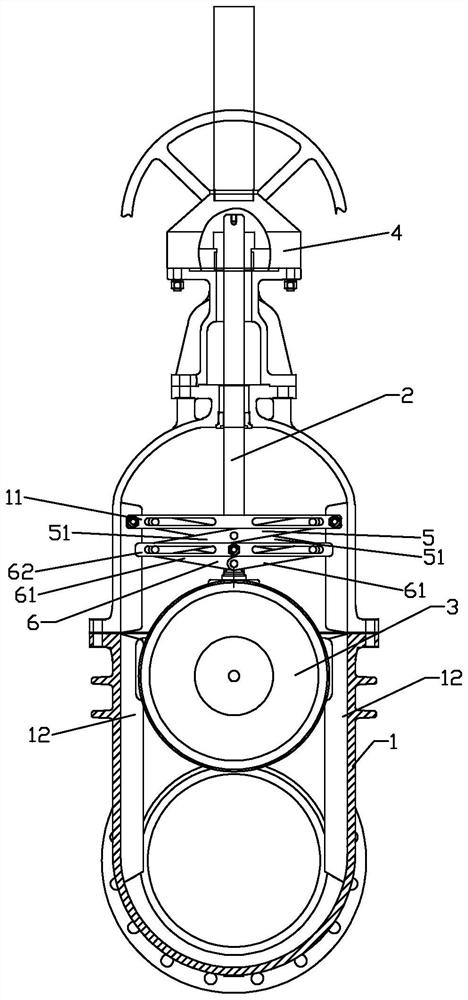

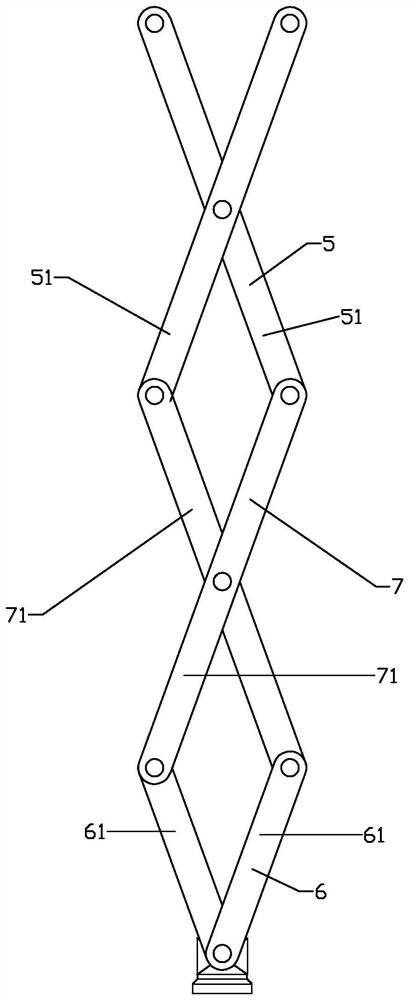

Quick opening and closing valve with scissor fork structure

PendingCN114542737AShort opening and closing timeOperating means/releasing devices for valvesSlide valveStructural engineeringVALVE PORT

The invention relates to a shear fork structure quick opening and closing valve which comprises a valve body, a valve rod arranged on the valve body, an opening and closing piece and a driving device, the driving device drives the valve rod to linearly ascend and descend, the shear fork structure quick opening and closing valve further comprises a first X-shaped transmission set located on the upper portion and a V-shaped transmission set located on the lower portion, and the first X-shaped transmission set comprises two first transmission rods arranged in an X shape; a first hinge shaft which ascends and descends synchronously with the valve rod and enables the two first transmission rods to be hinged is arranged at the crossed position of the two first transmission rods, the valve body is provided with a guide part for the upper ends of the first transmission rods to move transversely, the V-shaped transmission set is composed of two second transmission rods placed in a V shape, and the crossed position of the two second transmission rods is hinged to an opening and closing part. The upper ends of the second transmission rods and the lower ends of the first transmission rods are in one-to-one linkage arrangement and are opened and closed synchronously. By adopting the scheme, the invention provides the quick opening and closing valve with the scissor fork structure, which shortens the opening and closing time of the valve by shortening the stroke of the valve rod.

Owner:FANGZHENG VALVE GRP

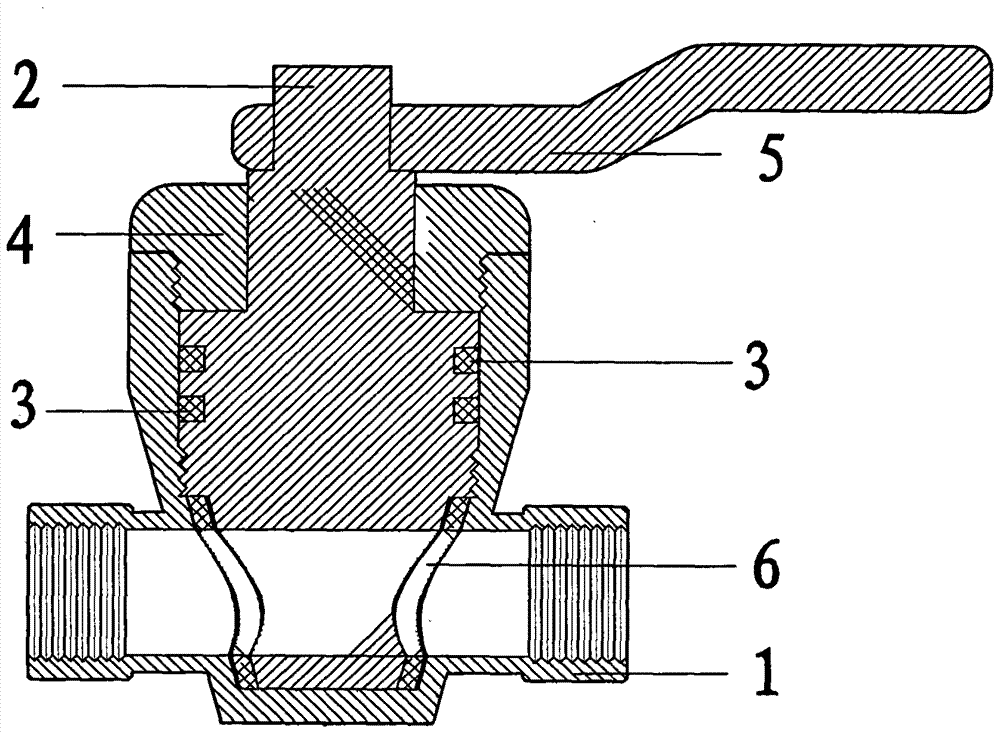

Safe level high-pressure ball valve

ActiveCN101435512BIncrease pressureShort opening and closing timePlug valvesValve housingsHigh pressureValve seat

The invention provides a safety high pressure ball valve. The safety high pressure ball valve comprises a valve body, valve covers, a valve seat, a ball body, a sealing ring, a valve rod, a packing box, filling material, a packing gland, a bracket and a driving device, wherein the left and right valve covers are fixed on both sides of the valve body by bolts, the sealing ring is arranged in the valve seat, the valve seat and the ball body are arranged in the valve body, the packing gland is sealed on the valve rod by the filling material, a channel at the left end of the valve body is provided with internal threads, the gland is provided with external threads matched with the internal threads, the gland is screwed in the valve body to tightly press the valve seat, a washer is arranged between the gland and the valve covers, the gland is symmetrically provided with two pierces, and the washer is made of pure nickel. The ball valve has the advantages of high pressure bearing of the product, short opening and closing time, reliable seal and convenient assembly and maintenance.

Owner:JIANGSU SHENTONG VALVE

valve well valve

ActiveCN106641299BAchieve closureMeet application needsOperating means/releasing devices for valvesSlide valveBlocked ConnectionBlowing down

Owner:JIANGMEN XINHUI DISTRICT LONGQUAN SEWAGE TREATMENT CO LTD

Safe level high-pressure ball valve

ActiveCN101435512AIncrease pressureShort opening and closing timePlug valvesValve housingsHigh pressureScrew thread

The invention provides a safety high pressure ball valve. The safety high pressure ball valve comprises a valve body, valve covers, a valve seat, a ball body, a sealing ring, a valve rod, a packing box, filling material, a packing gland, a bracket and a driving device, wherein the left and right valve covers are fixed on both sides of the valve body by bolts, the sealing ring is arranged in the valve seat, the valve seat and the ball body are arranged in the valve body, the packing gland is sealed on the valve rod by the filling material, a channel at the left end of the valve body is provided with internal threads, the gland is provided with external threads matched with the internal threads, the gland is screwed in the valve body to tightly press the valve seat, a washer is arranged between the gland and the valve covers, the gland is symmetrically provided with two pierces, and the washer is made of pure nickel. The ball valve has the advantages of high pressure bearing of the product, short opening and closing time, reliable seal and convenient assembly and maintenance.

Owner:JIANGSU SHENTONG VALVE

Pilot high-pressure valve

ActiveCN105422872AImprove integrityExtended service lifeOperating means/releasing devices for valvesLift valveEngineeringCylinder block

The invention provides a pilot high-pressure valve, and belongs to the field of high-pressure valves. The pilot high-pressure valve comprises a pilot valve and a main valve; the main valve includes a cylinder, a piston, a main valve intake port and a main valve exhaust port; a space in the cylinder is divided into an upper cavity and a lower cavity by the piston; a through hole is formed between the upper cavity and the lower cavity; the lower cavity is communicated with the main valve intake port; the main valve exhaust port is formed in the lower end surface of the piston; a pilot valve cavity and a valve element are arranged in the pilot valve; a pilot valve port is formed in the pilot valve cavity opposite to the valve element; the pilot valve is provided with a pilot valve intake port and a pilot valve channel; the pilot valve channel is communicated with the pilot valve port; and the pilot valve intake port is communicated with the upper cavity of the main valve. The pilot high-pressure valve is compact in structure, short in opening / closing time, high in stability and long in service life.

Owner:GUTANG MEASUREMENT & CONTROL TECH SHANGHAI CO LTD

Anti-flaming and anti-explosion sliding door device for down-hole refuge chamber

InactiveCN107130892ASolve the sealing problemShort opening and closing timeWing arrangementsWar-like protectionShock waveRolling resistance

The invention discloses an anti-flaming and anti-explosion sliding door device for a down-hole refuge chamber. The device comprises an anti-flaming and anti-explosion sliding door and a guide groove door frame which are arranged on the inner side and the outer side of a refuge chamber anti-explosion door wall. The anti-flaming and anti-explosion sliding door is embedded into the guide groove door frame, pulleys are embedded into the upper side and the lower side of the anti-flaming and anti-explosion sliding door, an upper guide groove and a lower guide groove of the guide groove door frame are attached to the pulleys, and absorption control valves are arranged on the left side and the right side of the guide groove door frame. The anti-flaming and anti-explosion sliding door is more easily opened and closed through rolling friction force. The problems that an anti-flaming and anti-explosion door deforms under explosive shock and is not easily opened and closed, and a handle of a common anti-explosion door is easily damaged are solved, when a down-hole accident happens, the anti-flaming and anti-explosion sliding door is easily opened and closed under the condition that no power supply or any external power source is needed, the two-layer sliding door can effectively separate explosive shock waves and toxic and hazardous gas generated by explosions, and people in the accident can rapidly enter the refuge chamber.

Owner:吕琳

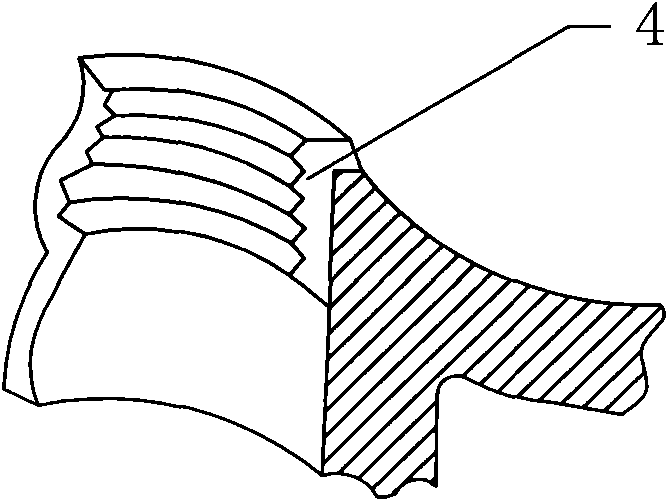

A high-safety horizontal explosion-proof tank door body and horizontal explosion-proof tank capable of realizing labyrinth sealing

ActiveCN111121568BRealize decompression and explosion ventingEffectively withstand axial shock wavesEngine sealsAmmunition storageEngineeringStructural engineering

A high-safety horizontal explosion-proof tank door body and a horizontal explosion-proof tank capable of realizing labyrinth sealing are provided between the left and right door leaves with a column-type tooth inlay structure capable of realizing the labyrinth sealing function, and the opening of the tank is provided with a The enclosing tooth insert structure of the enclosure plate corresponds to the tank mouth tooth insert structure, and the outer side of the enclosure plate is provided with a locking ring that locks and locks the door body, which can not only seal the high pressure gas generated by the explosion of explosives in the explosion-proof tank, It is also possible to use the labyrinth gap seal of the tooth claw structure and the explosion vent holes opened on the upper and lower walls of the explosion-proof tank to achieve safe pressure reduction and explosion venting, so that the tank body and the tank door form an integral structure that cannot be separated at the moment of explosion, realizing the indoor environment. Emergency safety explosion protection in small spaces.

Owner:梁荣

High temperature resistance hard sealing quickly-closed door

InactiveCN103851215AGuaranteed safe operationSimple structureOperating means/releasing devices for valvesSlide valveCold airPull force

The invention relates to a high temperature resistance hard sealing quickly-closed door. The high temperature resistance hard sealing quickly-closed door comprises a shell, an upper square round section, a lower square round section, an air cylinder, a main shaft, a crank, a rocker arm, a valve plate and a valve seat. According to the high temperature resistance hard sealing quickly-closed door, the transition of the upper square round section and the lower square round section is connected with a cold air pipeline or a warm air pipeline at the inlet of a coal mill, a pushing force or a pulling force of an air cylinder rod is used for quickly pushing the main shaft to rotate clockwise (in the closing direction) or counterclockwise (in the opening direction) by 90 degrees trough the crank; the rotation of the main shaft drives the valve plate to move through the rocker arm, so that the valve plate and the valve seat are tightly attached or separated so as to achieve the function of isolating a medium inside the pipeline or enabling the medium inside the pipeline to be circulated. The functions of simple structure, zero leakage, no accumulated dust and short opening and closing time are realized; after the high temperature resistance hard sealing quickly-closed door is quickly closed, the temperature inside the coal mill is below 40 DEG C, so that safe operation of a boiler is ensured, and the maintenance work of the coal mill is successfully completed.

Owner:洛阳广盈机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com